Page 1

Page 2

Page 3

SL26/30SL Series

Serial Numbers 50001 – Current

ENGLISH

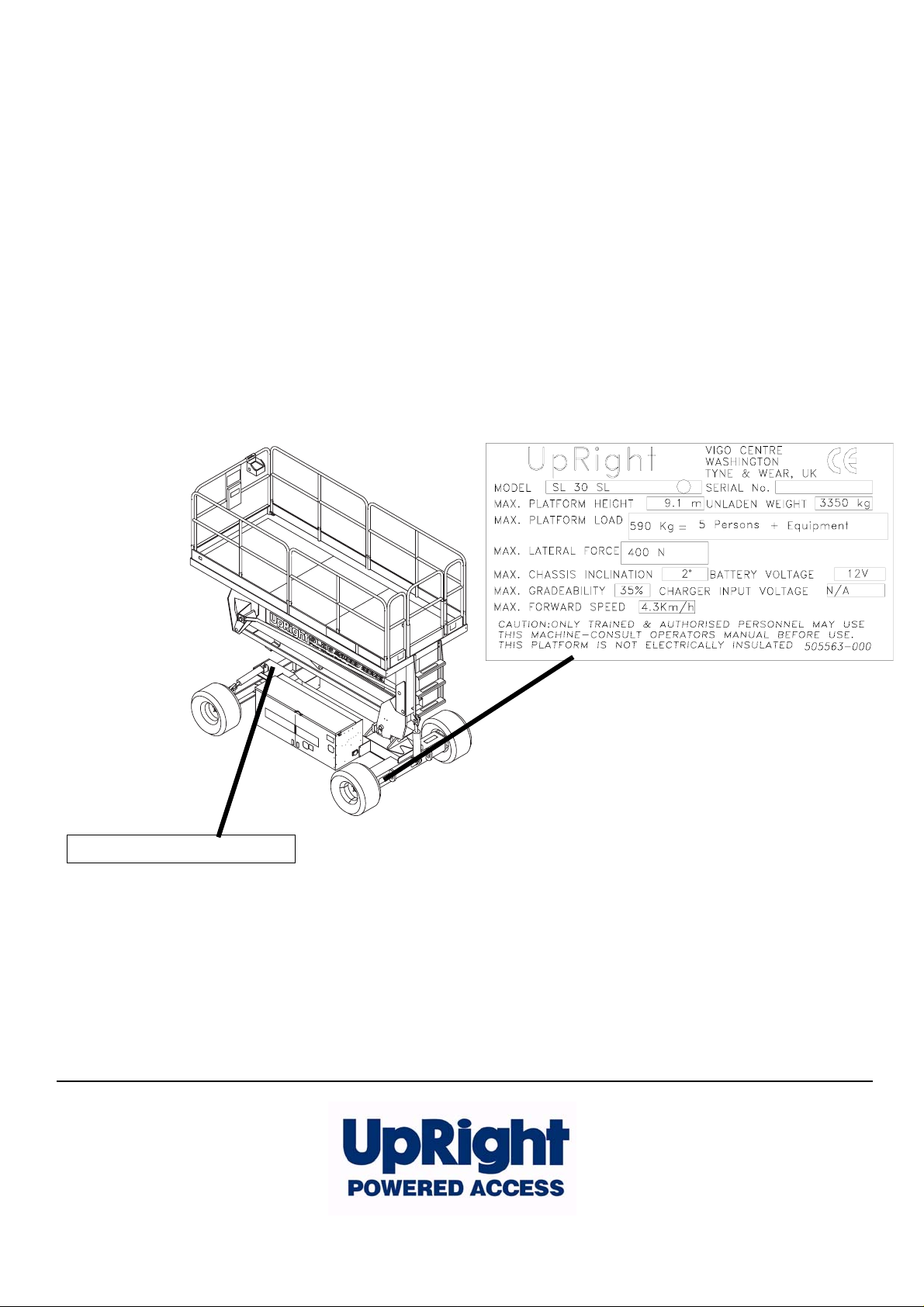

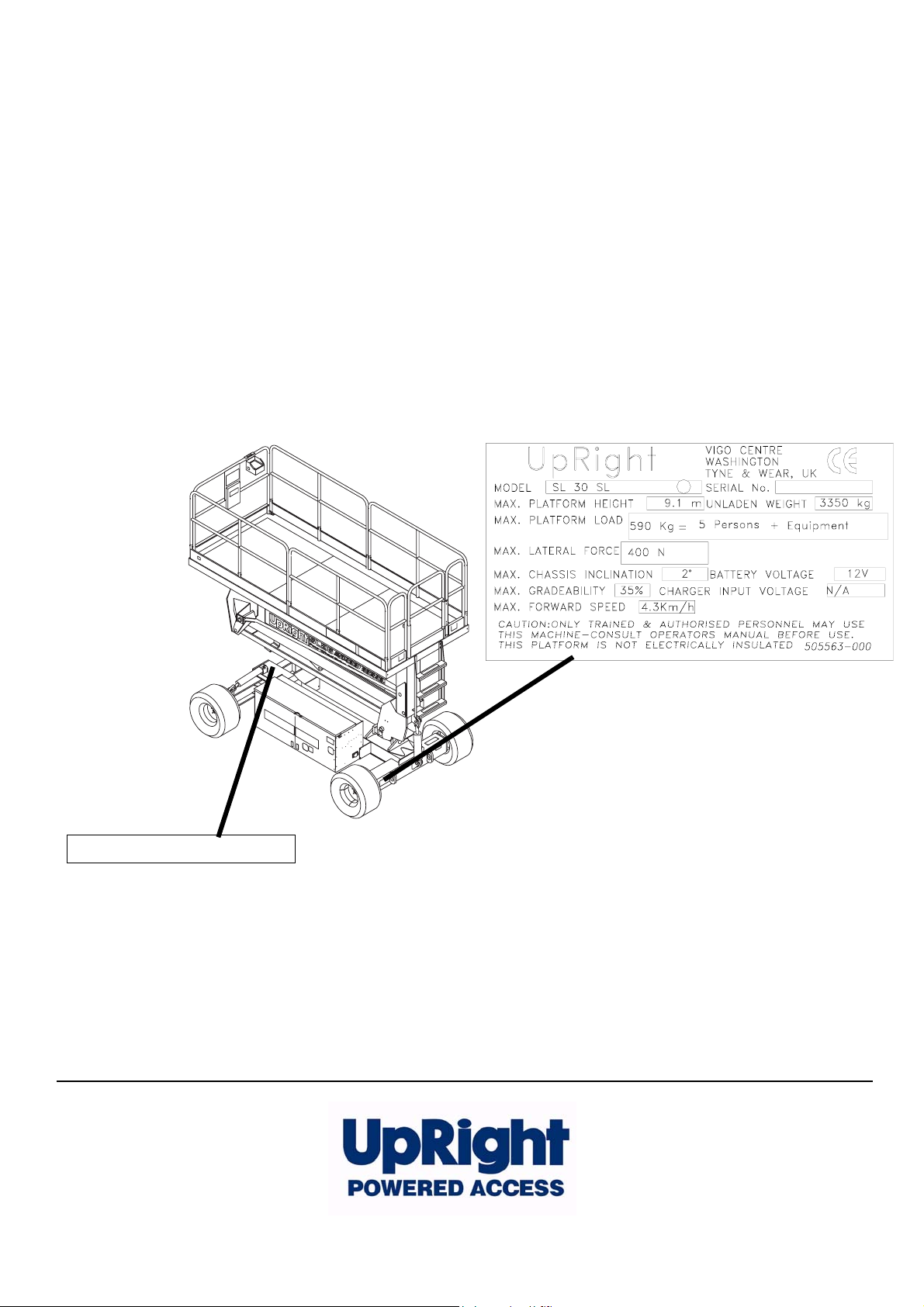

When contacting UpRight for service or parts information, be sure to include the MODEL and SERIAL NUMBERS from t he

equipment nameplate. Should the namepla te be missing, the SERIAL NUMBER is also stamped on top of the chassis

above the front axle pivot.

Stamped Serial Number

USA

TEXT FOR ILLUSTRATION PURPOSE ONLY

Europe

TEL: +1 (559) 443 6600

FAX: +1 (559) 268 2433

TEL: +44 (0) 1952 200

FAX: +44 (0) 1952 229

www.upright.com

Page 4

Page 5

OPERATION MANUAL

C

WARNING

All personnel shall carefully read, understand and follow all safety rules and operating

instructions before operating or performing maintenance on any UpRight aerial work platform.

Safety Rules

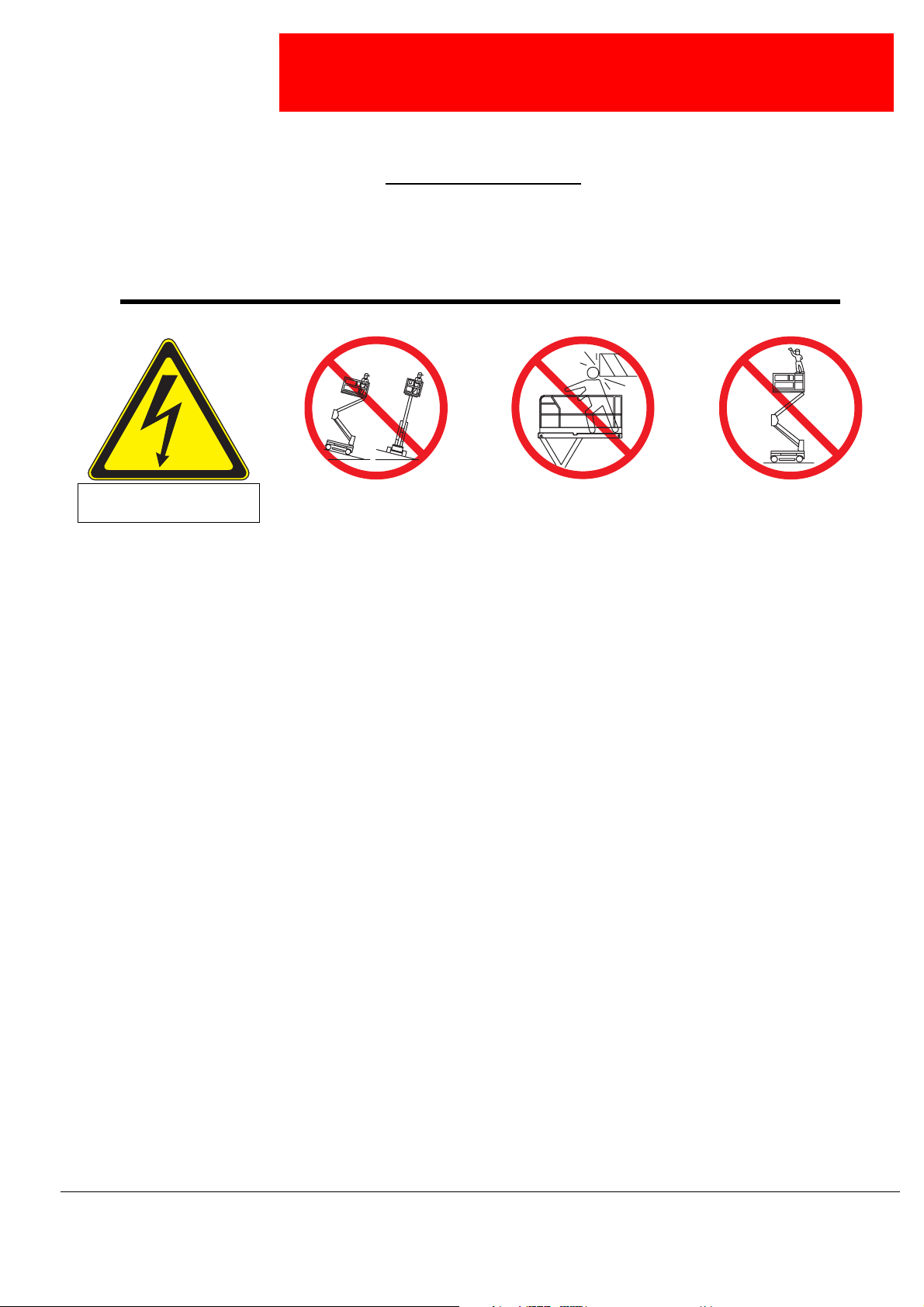

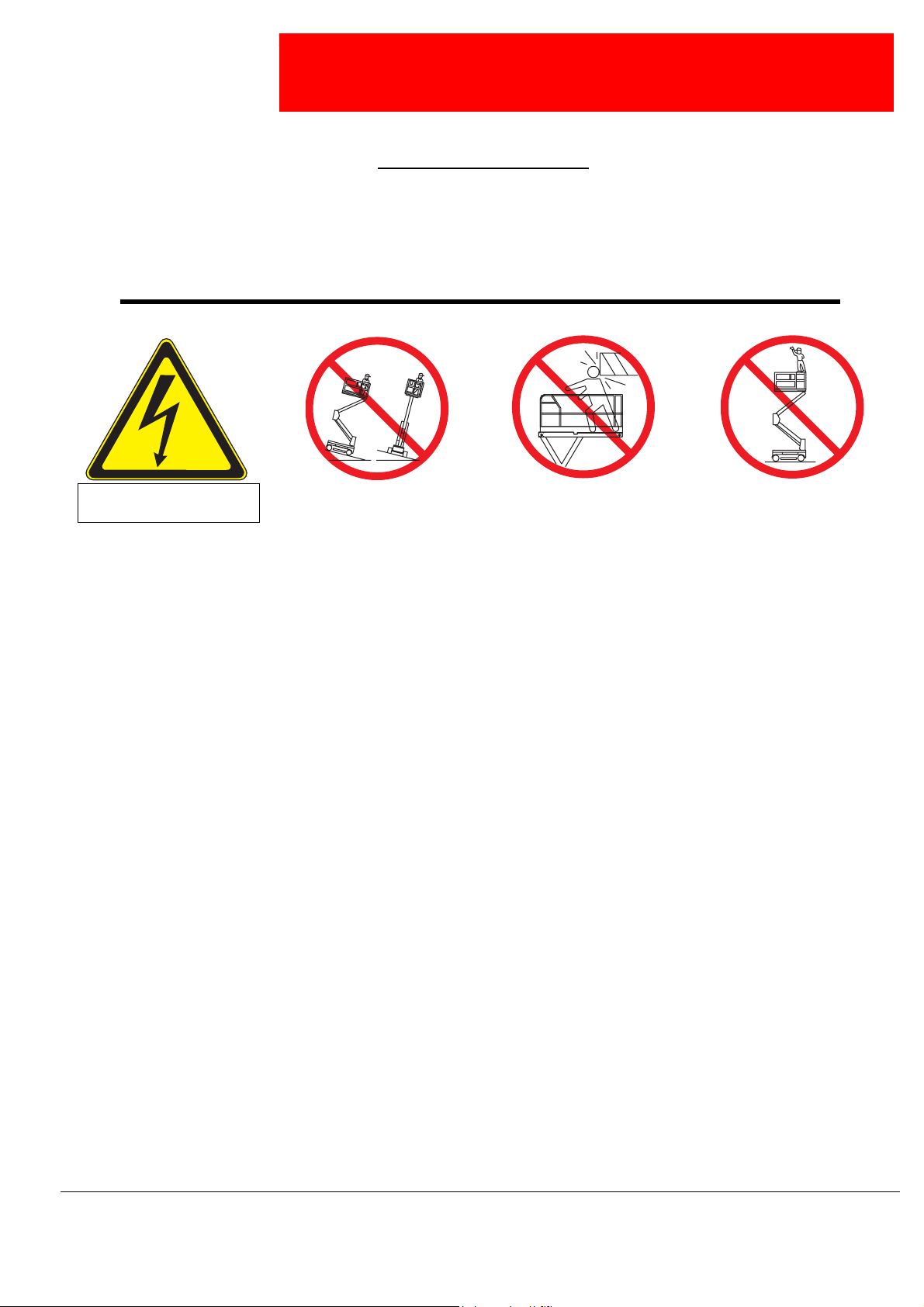

Electrocution Hazard Tip Over Hazard

THIS MACHINE IS NOT

INSULATED!

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material

used for the job. It is designed for repair and assemb ly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures,

buildings etc.). All other uses of the aerial work platform are prohibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live parts of electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See “Special Limitations” on page 4 for details.

The use and operation of the aerial work platform as a lifting tool or a crane (lifting of loads from below upwards or from up high on

down) is prohibited!

NEVER exceed the manual force allowed for this machine. See “Special Limitations” on page 4 for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris;

and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 4 for details.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures, etc.,

is prohibited!

Dismantling the swing gate or other railing components is prohibited! Always make certain that the swing gate is closed and securely

locked!

It is prohibited to keep the swing gate in an open position (held open with tie-straps) when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohib ited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged

cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To by pa ss any safety equipmen t is prohibited and presents a danger for the persons on the aerial work platform and in its working

range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas.

Modifications to the aerial work platform are prohibited or permissible only at the approval by

AFTER USE, secure the work platform from unauthorized use by turning both keyswitches off and removing key.

NEVER elevate the platform or drive

the machine while elevated unless the

machine is on a firm, level surface.

ollision Hazard Fall Hazard

NEVER position the platform

without first checking for overhead

obstructions or other hazards.

UpRight.

NEVER climb, stand, or sit on

platform guardrails or midrail.

Page 1

Page 6

C

ONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Special Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Platform Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Manual Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Beaufort Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lift Overload Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pre-Operation Safety Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

System Function Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Platform Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Travel With the Platform Lowered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Elevating the Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Travel With the Platform Elevated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lowering the Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Levelling the Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Emergency Lowering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fold Down guardrails, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fold Down Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Erection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Towing or Winching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Parking Brake Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

After Use Each Day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hour Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Transporting the Work Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Preparation for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lifting By Crane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

By Forklift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Driving or Winching onto a Truck or Trailer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Blocking The Elevating Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Scissor Brace Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Scissor Brace Stowage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Battery Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inspection and Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Daily Preventative Maintenance Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page 2 Operation Manual

Page 7

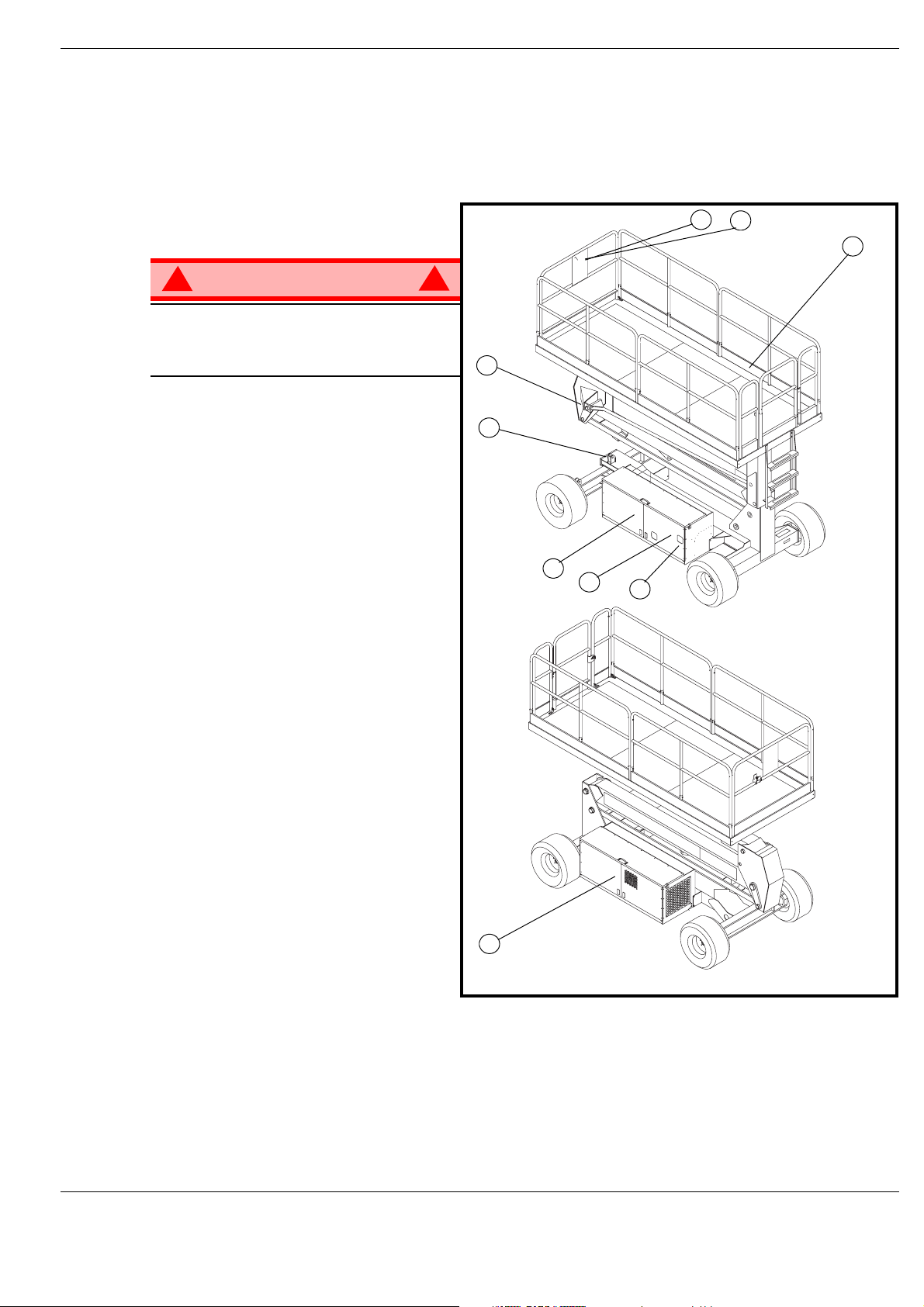

Introduction

I

NTRODUCTION

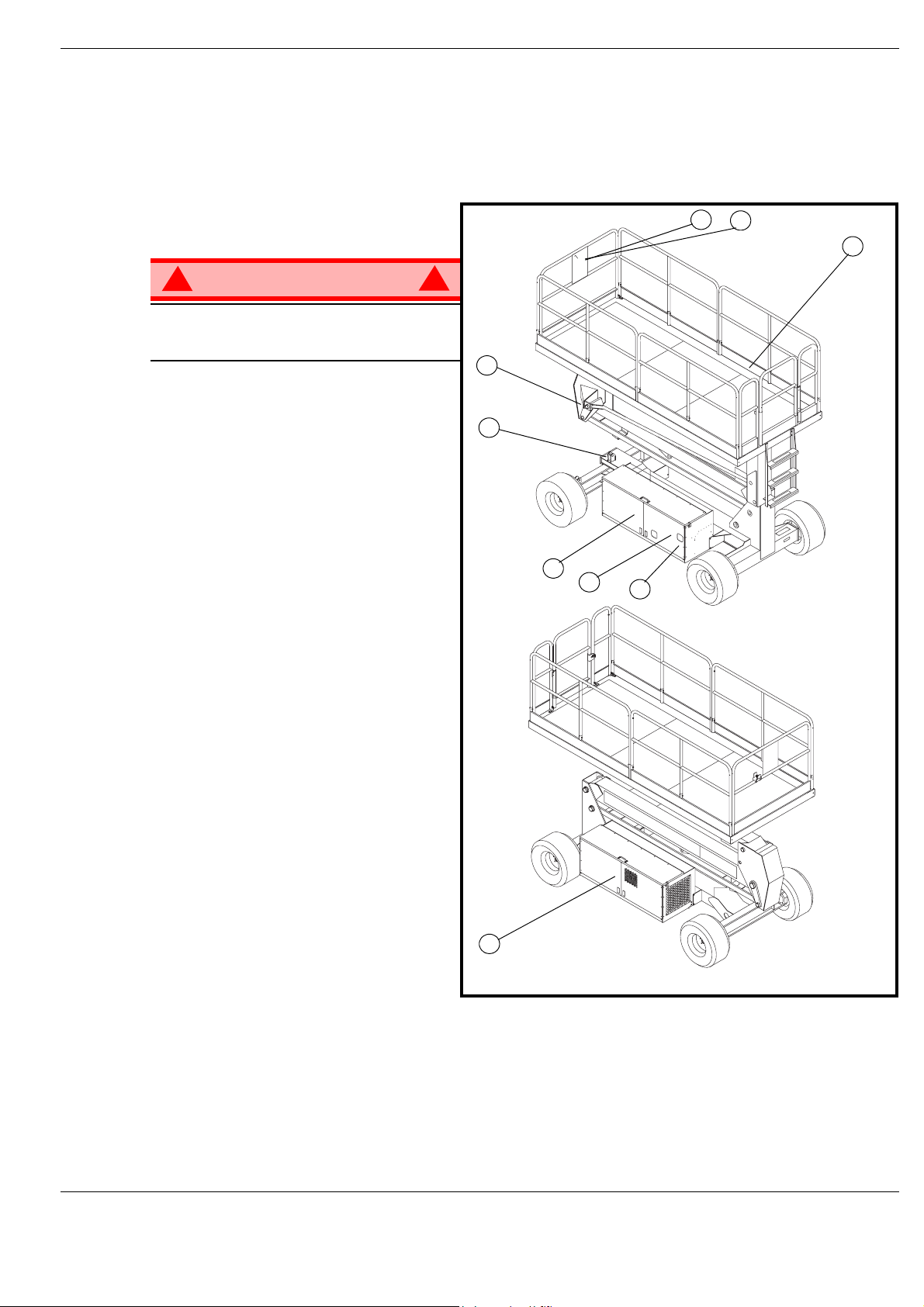

This manual covers operation of the SL26 & SL26/30 Speed Level Series Self-Propelled Work Platforms.

This manual must be stored on the machine at all times.

G

ENERAL

1. Platform

D

ESCRIPTION

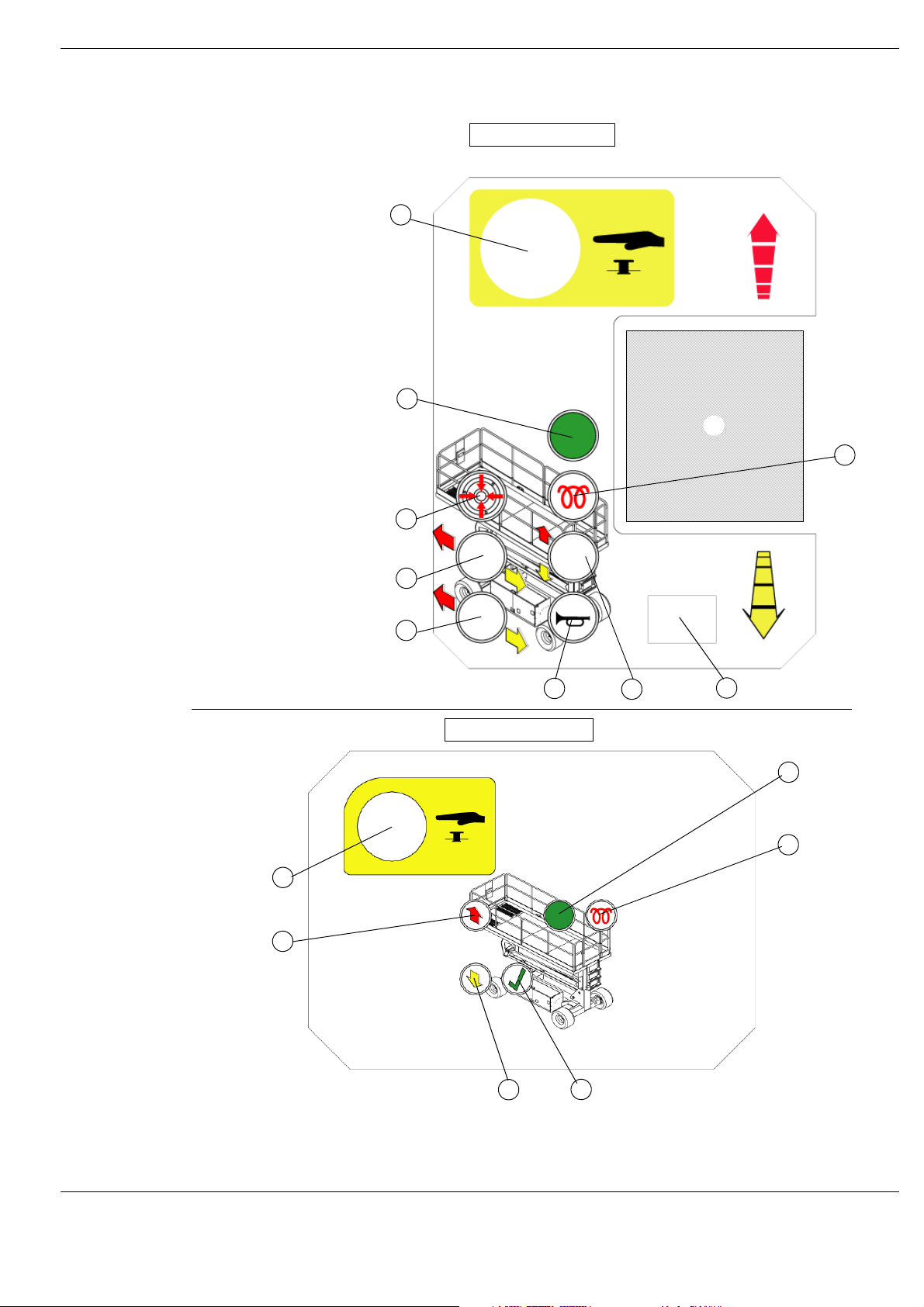

Figure 1: SL26/30 SL Series

7

6

1

!

WARNING

DO NOT use the maintenance platform

without guardrails properly assembled

and in place

2. Elevating Assembly

3. Chassis

4. Power Module

5. Control Module

6. Platform Controls

7. Manual Case

8. Chassis Controls

9. Hydraulic Fluid Reservoir

!

2

3

5

8

9

4

Operation Manual Page 3

Page 8

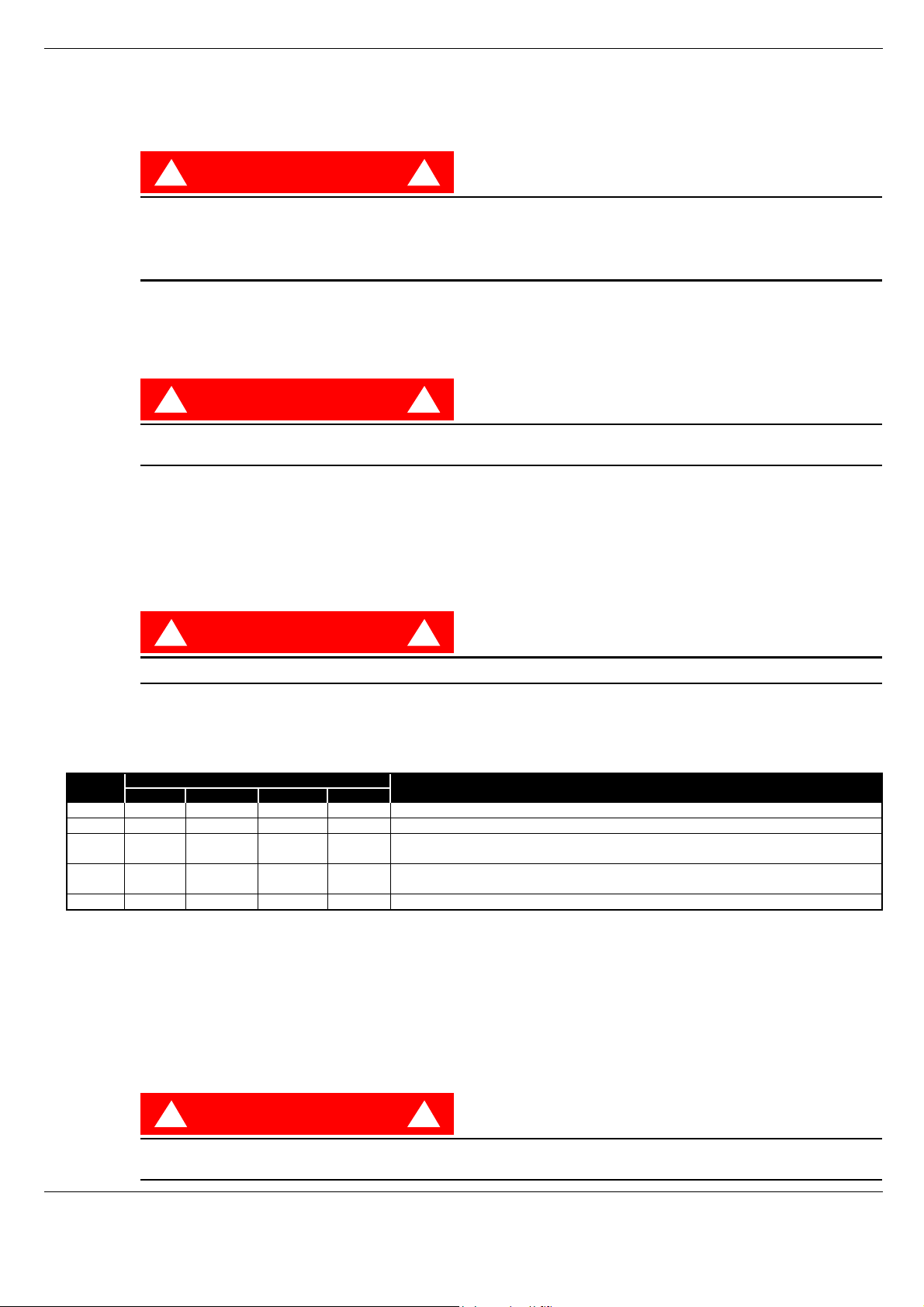

Special Limitations

S

PECIAL

P

M

L

IMITATIONS

Travel with the platform raised is limited to creep speed range.

Elevating the Work Platform is limited to firm, level surfaces only.

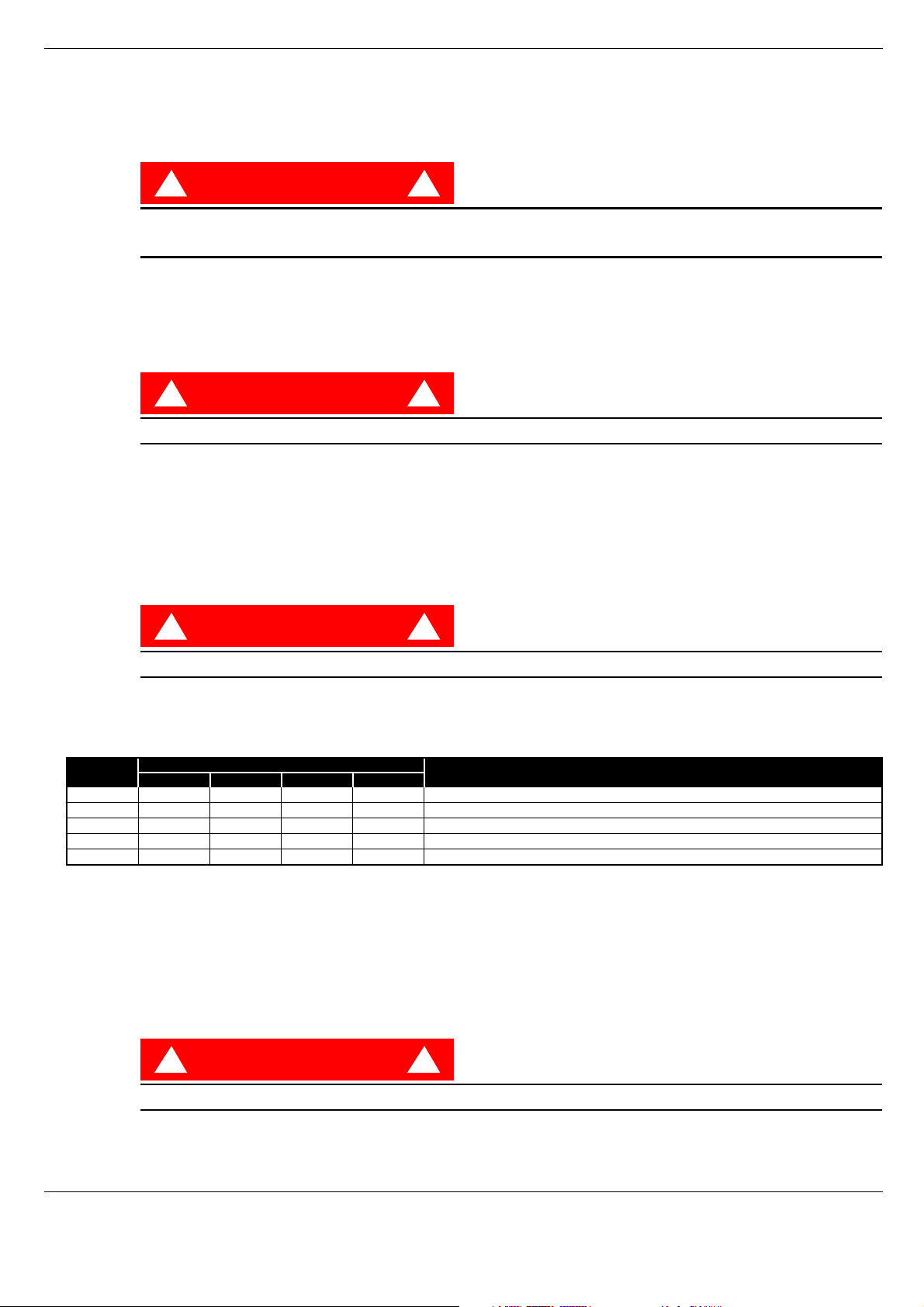

DANGER

! !

The elevating function shall ONLY be used when the work platform is leveled and on a firm surface.

The work platform is NOT intended to be driven over uneven, rough, or soft terrain.

LATFORM

The maximum capacity for the MACHINE, including occupants is determined by model and options, and

is listed in “Specifications” on page 18.

DANGER

! !

DO NOT exceed the maximum platform capacity or the platform occupancy limits for this machine.

ANUAL

Manual force is t he force applied by the occu pants to objects such a s w alls or o ther structures out side the

work platform.

F

C

APACITY

ORCE

The maximum allowable manual f orce is limited to 200 N ( 45 lbs.) of force per occupa nt , wit h a maximum

of 400 N (90 lbs.) for two or more occupants.

DANGER

! !

DO NOT exceed the maximum amount of manual force for this machine.

B

EAUFORT

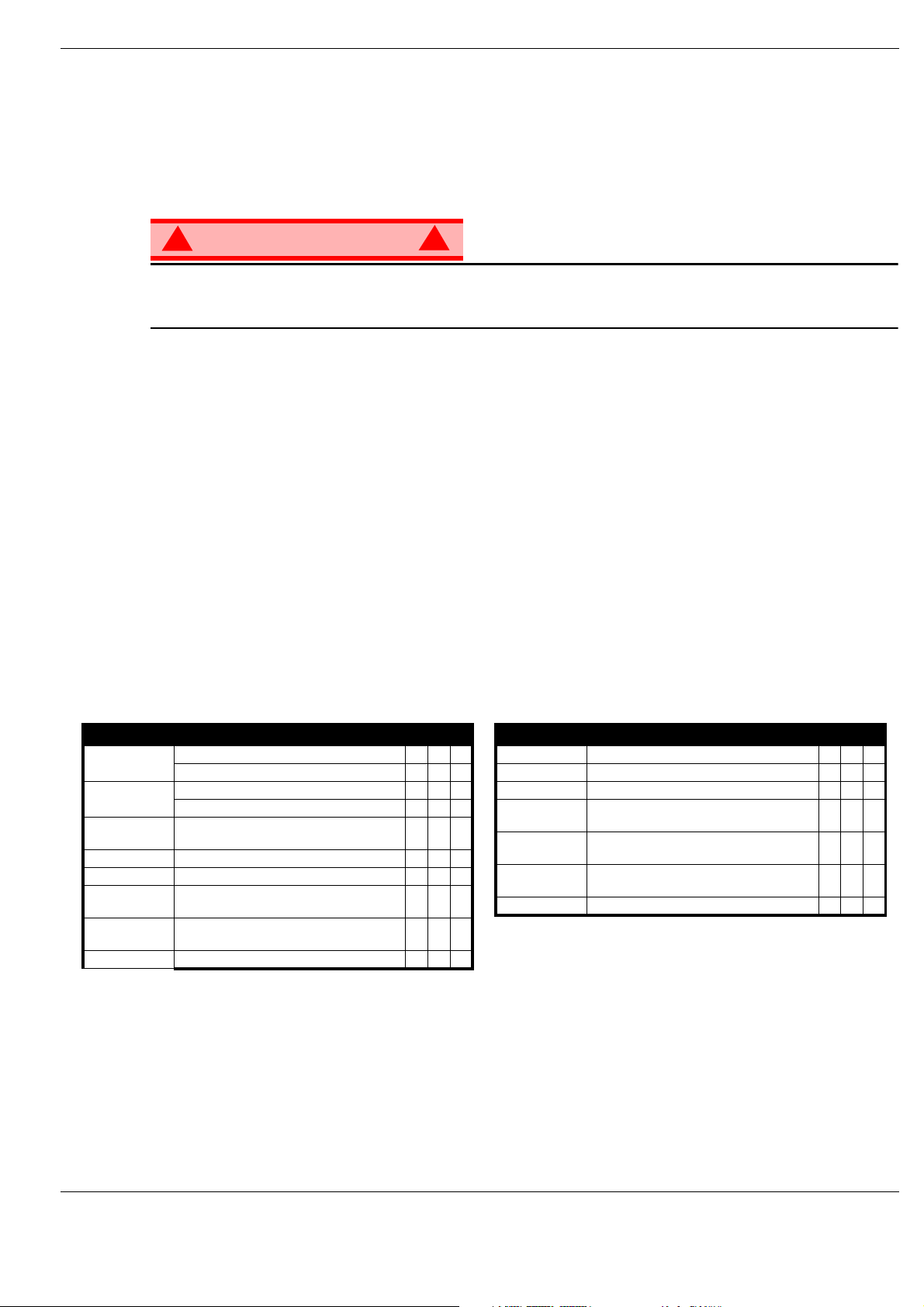

Never operate the machine when wind speeds exceed 12.5m/s (28 mph) [Beaufort scale 6].

BEAUFORT

RATING

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0 Papers and thin branches move, flags wave.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18 Dust is raised, paper whirls up, and small branches sway.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25 Shrubs with leaves start swaying. Wave crests are apparent in ponds or swamps.

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31 Tree branches move. Power lines whistle. It is difficult to open an umbrella.

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5 Whole trees sway. It is difficult to walk against the wind.

m/s km/h ft/s mph

L

IFT

O

If a load equivelent to 90% of safe working load is lifted a fault code “03” will be displayed on the digital

display on the platform control box. If a load which is greater than the safe working load is present in the

basket all machine functions will cease to operate and an acoustic warning will sound. In order to return to

normal operation a load equal to or less than the saf e working load m ust be present in th e bask et and th e

power must be re-cycled, power can be re-cycled by pushing the emergency stop button and releasing it

again.

WIND SPEED

VER L OA D

S

CALE

A

LARM

GROUND CONDITIONS

DANGER

! !

Never operate the machine with a platform load greater than the rated capacity.

Page 4 Operation Manual

Page 9

Controls and Indicators

C

ONTROLS

AND

I

NDICATORS

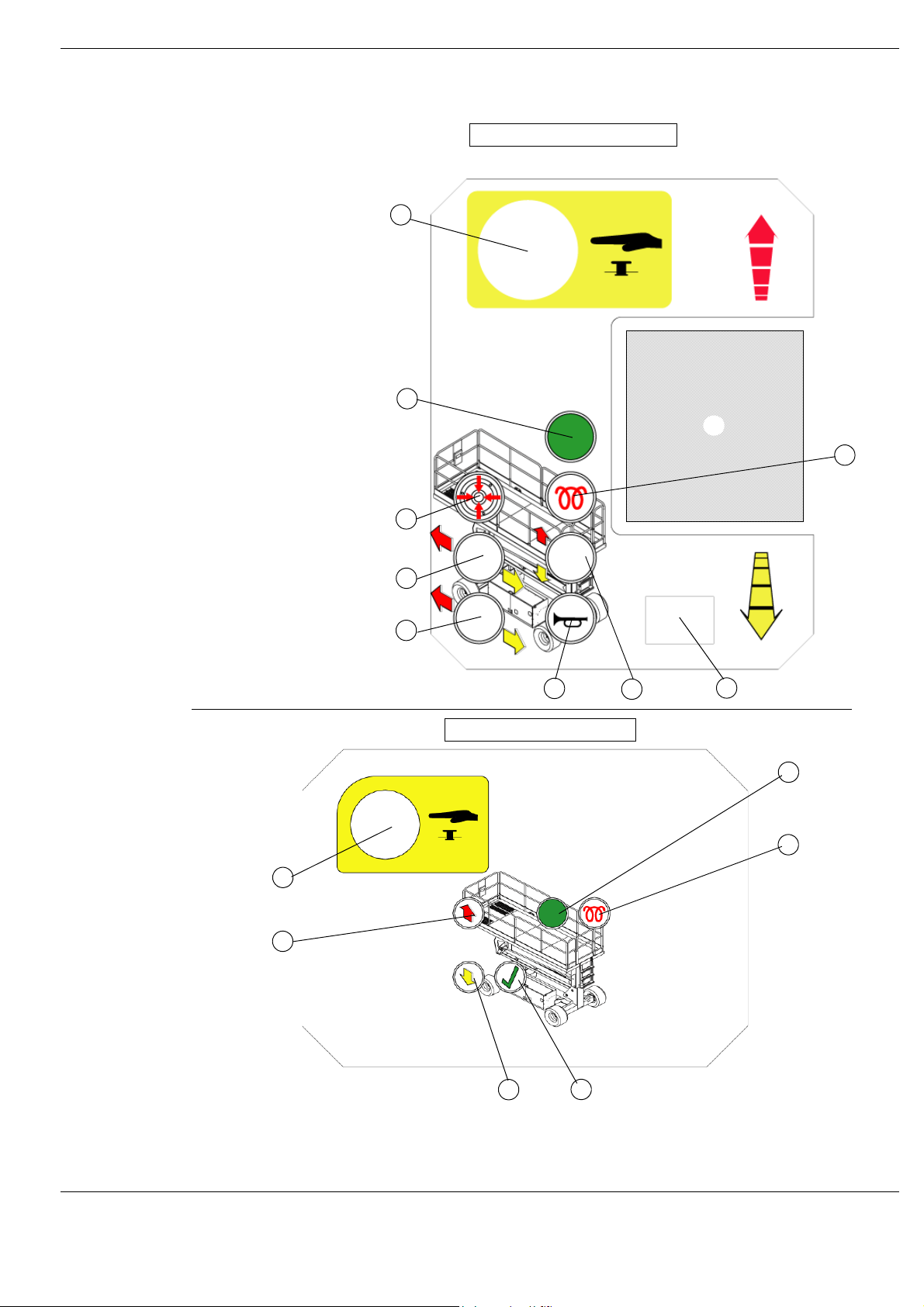

Figure 2: Controls and Indicators

Platform Controls

8

7

10

6

1 Drive (Hi Speed)

2. Drive (Low Speed)

3. Level

4. Horn Button

5. Lift/Lower Button

6. Glow Plug

7. Engine Start

8. Emergency Stop Button

9. Display

10. Joystick

1

2

3

2

1

4

Chassis Controls

5

9

6

5

1. Emergency Stop

2. Elevate

3. Descend

4. Enable

5. Glow Plug

6. Start

3

4

Operation Manual Page 5

Page 10

Pre-Operation Safety Inspection

P

RE

-O

PERATION

NOTE: Carefully read, understand and follow all safety rules, operating instructions, labels and

National Safety Instructions/Requirements. Perform the following steps each day before use.

1. Open modules and inspect for damage, fluid leaks or missing parts.

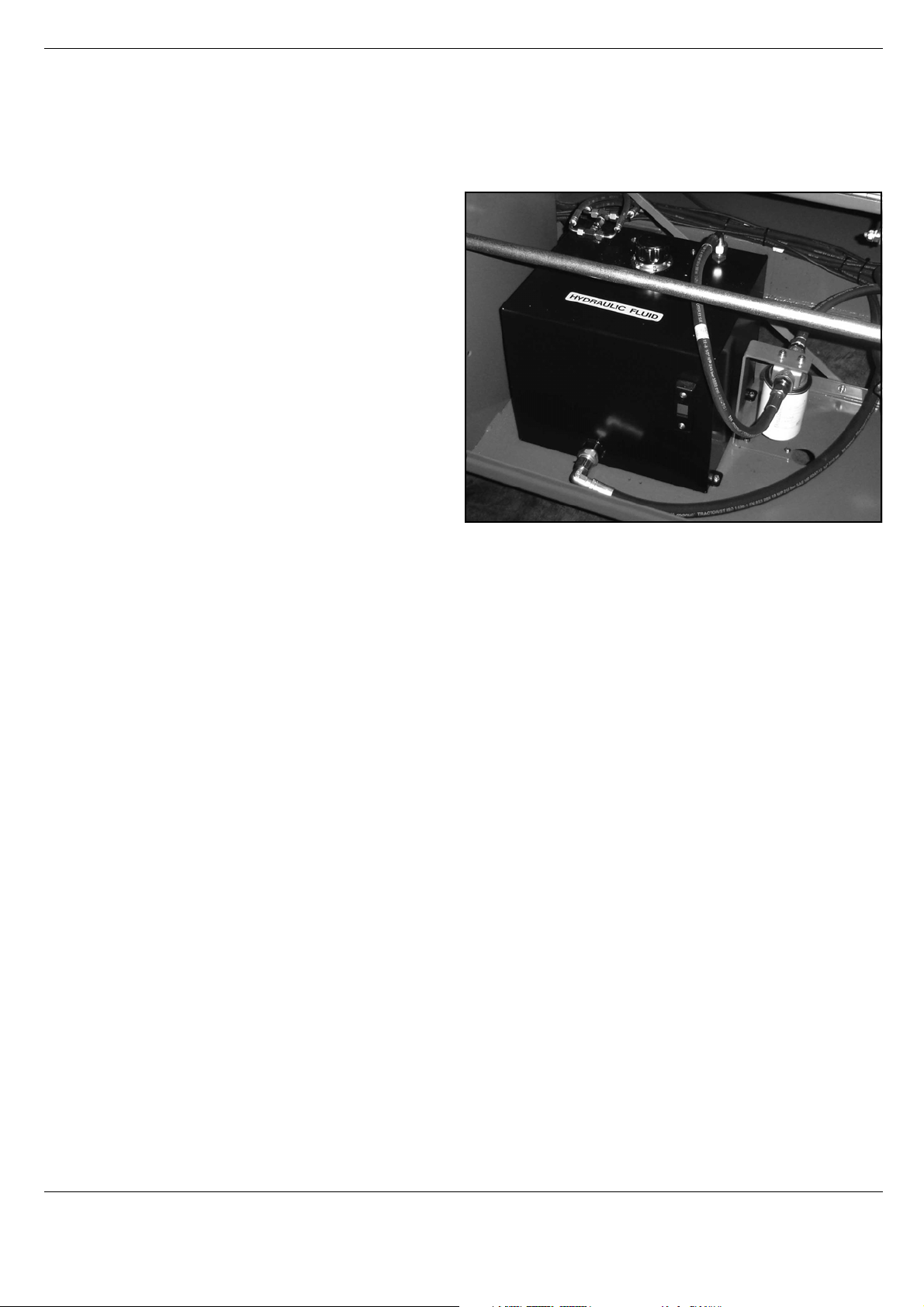

2. Check the leve l of the h ydraulic fluid with

the platform fully lowered. The hydraulic

reservoir is located in the Control Module Door. The fluid level must be

between the MIN and MAX lines. Add

hydraulic fluid if necessary.

3. Check that fluid level in the starter battery is correct.

4. Check the level of the Diesel fuel with

the engine switched off. The fuel tank is

located in the Power Module. Add fuel

as required.

5. Check that all guardrails are in place

and all fasteners are properly tightened.

6. Inspect the machine thoroughly for

cracked w elds and structural damage,

loose or missing hardware, hydraulic

leaks, damaged control cable, loose wire connections and wheel bolts.

S

AFETY

I

NSPECTION

Figure 3: Hydraulic Tank

Page 6 Operation Manual

Page 11

System Function Inspection

S

YSTEM

F

UNCTION

Refer to Figure 2 (Page 5) for the locations of various controls and indicators.

I

NSPECTION

!

WARNING

STAND CLEAR of the work platform while performing the following checks.

Before operating the work platform, survey the work area for surface hazards such as holes, drop-offs,

bumps and debris.

Check in ALL directions, including above the work platform, for obstructions and electrical cond u cto rs.

Protect the control console cable from possible damage while performing checks.

1. Move the machine, if necessary, to an unobstructed area to allow for full elevation.

2. Twist Chassis Emergency Stop Switch to the ON position.

3. Twist Platform Emergency Stop Switch t o the ON position.

4. Turn the Key Switch to the ON position.

5. Visually inspect the elevating assembly, lift cylinder, cables, and hoses for cracked welds and structural

damage, loose hardware, hydraulic leaks, loose wire connections, and erratic operation. Check for missing or loose parts.

6. Push the Chassis ELEVATE and ENABLE buttons and fully elevate the platform.

7. Partially lower the platform by pushing Chassis DESCEND and ENABLE buttons, and check for proper

operation of the audible lowering alarm.

8. Open the Emergency Lowering Valve (see Figure 4) by pulling the knob out to check for proper operation. When the platform is lowered, release the knob.

9. Push the Chassis Emergency Stop Switch to check for proper operation. All machine functions should

be disabled. Twist the Chassis Emergency Stop Switch to resume.

10. Check that the route is clear of obstacles (persons, obstructions, holes, and drop-offs, bumps and

debris), is level, and is capable of supporting the wheel loads.

11. Mount the platform and properly close the entrance.

12. Select DRIVE mode.

!

NOTE: Use both HI and LOW drive (if applicable) when performing the following step.

13. While engaging the Safety Interlock Trigger, move the Joystick to FORWARD, then REVERSE, to check

for speed control.

14. Push the Steering Switch RIGHT, then LEFT, to check for steering control.

15. Select LIFT mode. Grasp the Joystick, engaging the Safety Interlock Trigger, and push it forward to

check platform lift controls. Raise the platform to full elevation.

16. Pull back on the Joystick. The platform should descend and the audible lowering alarm should sound.

17. Push the Platform Emergency Stop Switch to check for proper operation. All machine functions should

be disabled. Pull out the Platform Emergency Stop Switch to resume.

Operation Manual Page 7

Page 12

Operation

O

PERATION

Before operating t he wo rk platform, ensure that the Pre-Operation Saf et y Inspecti on has been co mpleted

and that any deficiencies ha v e been cor rected. Ne ver opera te a dama ged or malfunctioning mac hine.

The operator must be thoroughly trained on this machine.

S

TARTING THE

1. Mount the platform and properly close the entrance.

2. Depress and hold the GLOW PLUG button for approximately 5 seconds.

3. Press green START button.

T

RAVEL

1. Check that the route is clear of obstacles (persons, obstructions, holes, drop-offs, bumps, and debris),

is level, and is capable of supporting the wheel loads.

2. Verify that the Engine is started and the Chassis Emergency Stop Switch is ON (pulled out).

3. Mount the platform and properly close the entrance.

4. Check clearances above, below, and to the sides of platform.

5. Twist the Platform Emergency Stop Switch out to the ON position.

6. Select DRIVE mode.

W

ITH THE

E

NGINE

P

LATFORM

L

OWERED

NOTE: Choose between standard drive and extra torque depending on the gradient.

7. Engage the Safety Interlock Trigger and move the Joystick to FORWARD or REVERSE to travel in the

desired direction. The speed of the machine will vary depending on how far from center the Joystick is

moved.

S

TEERING

1. Turn the Drive/Lift Switch to DRIVE.

2. While engaging the Safety Interlock Trigger, push the Steering Switch to RIGHT or LEFT to turn the

wheels in the desired direction. Observe the tires while maneuvering the work platform to ensure proper

direction.

NOTE: Steering is not self-centering. Wheels must be returned to the straight ahead position by

operating the Steering Switch.

E

LEVATING

1. Select a firm, level surface.

2. Select LIFT mode.

3. While engaging the Safety Interlock Trigger, push the Joystick forward.

4. If the machine is not level the tilt alarm will sound and the machine will not lift or drive.

5. If the tilt alarm sounds the platform must first be fully lowered, then elevate the platform approximately

600mm (2ft), stop, press and hold the LEVEL button until the tilt alarm is silenc ed . On ly then ca n you

elevate fully. If the platform is not levelled correctly the tilt alarm will continue to sound and lift functions

will be cut at a height of approximately 2m (6ft).

THE

P

LATFORM

Page 8 Operation Manual

Page 13

Operation

T

RAVEL

NOTE: The machine will travel at reduced speed when the platform is elevated.

1. Check that the route is clear of obstacles (persons , obstructions , holes , drop-offs , b umps, and debris), is

level, and is capable of supporting the wheel loads.

2. Check clearances above, below, and to the sides of platform.

3. Select DRIVE mode.

4. Engage the Safety Interlock Trigger on the Joystick and move to FORWARD or REVERSE to travel in

the desired direction. The speed of the machine will vary depending on how far from center the Jo ystick

is moved.

5. If the machine is not level the tilt alarm will sound and the machine will not lift or drive. If the tilt alarm

sounds the platform must be lowered and the machine moved to a firm, level surface before attempting

to re-elevate the platform.

L

OWER ING THE

1. Select LIFT mode.

2. Check around the base of the platform to ensure that no one is in contact wit h the machine. Engage the

Safety Interlock Trigger and pull back on the Joystick to lower the platform.

3. The platform will stop when it reaches the PPE cutout height. Inspect around the machine to ensure no

one is in contact with the machine. After a four-second time delay, lower the platform as in step 2.

W

ITH THE

P

P

LATFORM

LATFORM

E

LEVATED

L

EVELLING

The AUTO LEVEL feature is designed to level the platform in a situation where the ground has no more

than a 13 degree slope side to side and 9 degr ees f o re and aft , if the slop e is gr eater than 1 3 degr ees side

to side and 9 degrees fore and aft the AUTO LEVEL feature will not function.

The tilt alarm will continue to sound until the platform is level

1. Check that the route is clear of obstacles (persons , obstructions , holes , drop-offs , b umps, and debris), is

level, and is capable of supporting the wheel loads.

2. Check clearances above, below, and to the sides of platform.

3. Elevate the platform approximately 600mm (2ft).

4. Press and hold the AUTO LEVEL and Engage the Safety Interlock Trigger until the platform is level and

the tilt alarm is silenced.

5. In this condition only the ELEVATE and DESCEND functions will work.

6. If you need to drive you must descend and return the platform to it’s normal inclanation.

THE

P

LATFORM

Operation Manual Page 9

Page 14

Operation

E

MERGENCY

L

OWER ING

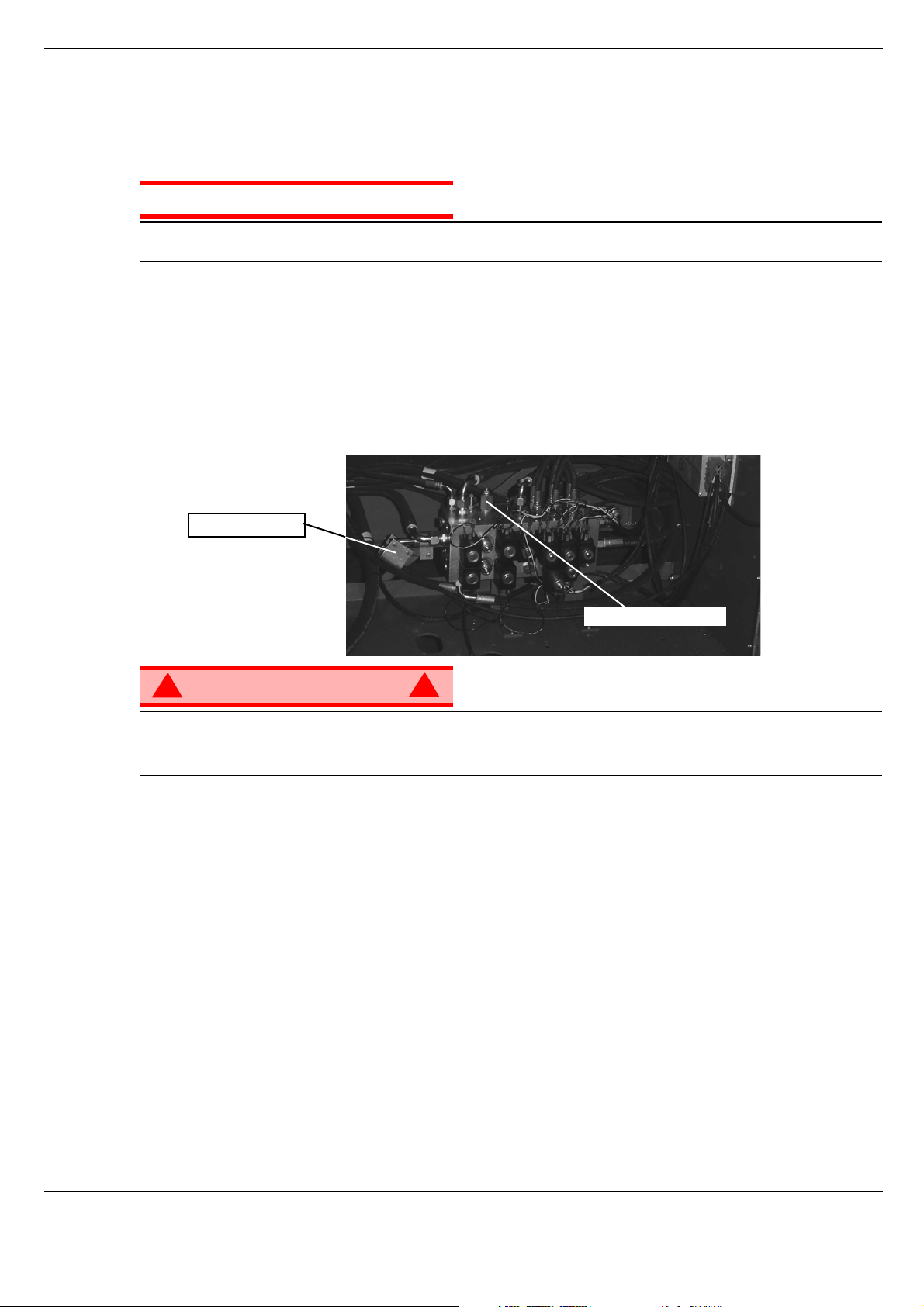

Figure 4: Emergency Lowering Valve

!

WARNING

If the platform should fail to lower, NEVER

climb down the elevating assembly.

Stand clear of the elevating assembly while

operating the Emergency Lowering Valve

Knob.

SL26-30 S

The Emergency Lowering Valve for the

SL26-30 is located in the control module of

the machine and is accessable through an

opening in the control module door.

1. Open the Emergency Lowering Valve by pulling and holding the handle.

2. To close, release the knob. The platform will not elev ate if the Emergency Lowering Valve is open.

PEED

L

EVEL

!

Emergency Lowering Knob

Page 10 Operation Manual

Page 15

Operation

F

OLD

This procedure applies only to the SL26-30 Speed Level model for the purpose of passing through a standard double doorway. Guardrails must be returned to proper position before using the machine.

F

OLD

1. Unhook the controller from the side guardrail and place it on the floor of the platform.

2. Starting at the front of the platform, remove nuts, bolts and washers from the top of the front guardrail.

Fold the front guardrail down onto the platform.

3. Close and latch gate.

4. Remove nuts, bolts and washers from the top of the rear guardrail. Fold the rear guardrail do wn onto the

platform being careful to keep latched at all times.

5. Remove nuts, bolts and w ashers from the to p of the side guardr ails. Li ft up and f old one sid e guardrail in

E

RECTION PROCEDURE

D

OWN GUARDRAILS

D

OWN PROCEDURE

so it rests on the deck. Repeat with other side guardrails.

1. Raise side guardrails, making sure each is pushed down to secure the guardrail in the vertical

position.

2. Install bolts, washers and nuts betw een the side guardrails, tighten securely.

3. Raise rear guardrail assembly, aligning holes and install bolts, washers and nuts. Tighten securely.

DANGER

! !

Before entering platform, guardrails

must be securely fastened in their

proper position.

Operation Manual Page 11

Page 16

Towing or Winching

T

OWIN G OR

Perform the following only when the machine will not operate under its own power and it is necessary to

move the machine or when winching onto a transport vehicle (see “Transporting the Work Platform” on

page 13).

W

INCHING

CAUTION

DO NOT tow or winch the machine faster than 0,3 m/s (1 ft./s). Faster speeds will damage drive

components and void the warranty.

B

RAKE

Perform the following only when the machine will not operate under it’s own power and it is necessary to move the machine or when towing the machine up a grade or onto a trailer to transport.

1. Close the needle valve by turning the allen screw clockwise.

2. Pump the Brake Release Pump until the Parking Brake Cylinder Rod clears the wheel rotor.

3. The machine will now roll when pushed or pulled.

4. Be sure to open needle valve and verify that the cylinder rod has extended before the machine

is operated.

R

ELEASE

P

UMP

Hand Pump

Needle Valve

!

WARNING

Never tow faster than 0,3 m/sec. (1 ft./sec.).

Never op erate the work platform with the parking brakes released. Serious injury or damage could

result.

A

FTER

1. Ensure that the platform is fully lowered.

2. Park the machine on a firm level surface, preferably under cover, secure against vandals, children and

unauthorized operation.

3. Turn the Chassis Key Switch to OFF and remove the key to prevent unauthorized ope ration.

H

OUR

To access the hour meter function perform the following steps.

U

M

SE

ETER

E

ACH

!

D

AY

1. Climb into the basket (with the machine powered up)

2. Push the platform emergency stop button.

3. Hold down the following buttons, Horn & Lift.

4. While holding the buttons twist the emergency stop button to return power to the machine.

5. “hr” will now be displayed on the readout, Pressing the right turn button will scroll through the accumulated hours two digits at a time. For example, if pressing the right turn butto n once displays “20”, pressing

it a 2nd time displays “58”, and pressing it a 3rd time displays “hr”, the elapsed time of operation is 2058

hours.

Page 12 Operation Manual

Page 17

Transporting the Work Platform

T

RANSPORTING

P

REPARATION FOR

1. Fully lower the platform.

2. Disconnect the battery negative (-) lead from the battery terminal.

3. Band the controller to the front guardrail.

4. Band the elevating linkage to the frame.

L

IFTING

1. Secure straps to chassis tie down/lifting lugs only.

2. Place the platform onto the transport vehicle in transport position.

3. Chock the wheels.

4. Secure the work platform to the transport vehicle with chains or straps of adequate load capacity

attached to the chassis tie down/lifting lugs.

B

Y

THE

C

W

RANE

ORK

S

HIPMENT

P

LATFORM

BY F

! !

Forklifting is for transport only.

See specifications for weight of work platform and be certain that forklift is of adequate capacity to lift

the work platform.

Forklift from the side by lifting under the Chassis Modules.

D

RIVING OR

ONTO

RAILER

T

NOTE: Do not winch faster than 0,3 m/s (1 ft/s).

1. Move the machine onto the truck or trailer;

A. To Drive the machine onto the transport vehicle:

B. To Winch the machine onto the transport vehicle:

2. Secure the work platform to the transport vehicle with chains or straps of adequate load capacity

ORKLIFT

DANGER

W

INCHING

A T

a. Move the work platform up the ramp and into

transport position.

b. Set the wheels straight and turn off the machine.

c. Chock the wheels.

a. Move the work platform up to the ramp.

b. Attach the winch cable to the tie down/lifting lugs.

c. Release the parking brakes (refer to “Towing or

Winching” on page 12).

d. Winch the platform into transport position

e. Chock the wheels.

attached to the chassis tie down/lifting lugs.

RUCK OR

Front Tie

Down and

Lifting Lugs

Figure 5: Transporting the Work Platform

Forklift

Rear Tie Down/Lift

CAUTION

Overtightening of the chains or straps attached to the Tie Down/Lifting Lugs may result in damage to

work platform.

Operation Manual Page 13

Page 18

Maintenance

M

AINTENANCE

!

WARNING

Never pe rform service while the platform is elevated without first blocking the elevating assembly.

DO NOT stand in the elevating assembly area while deploying or storing the brace.

B

LOCKING

LEVATING

E

T

HE

A

SSEMBLY

!

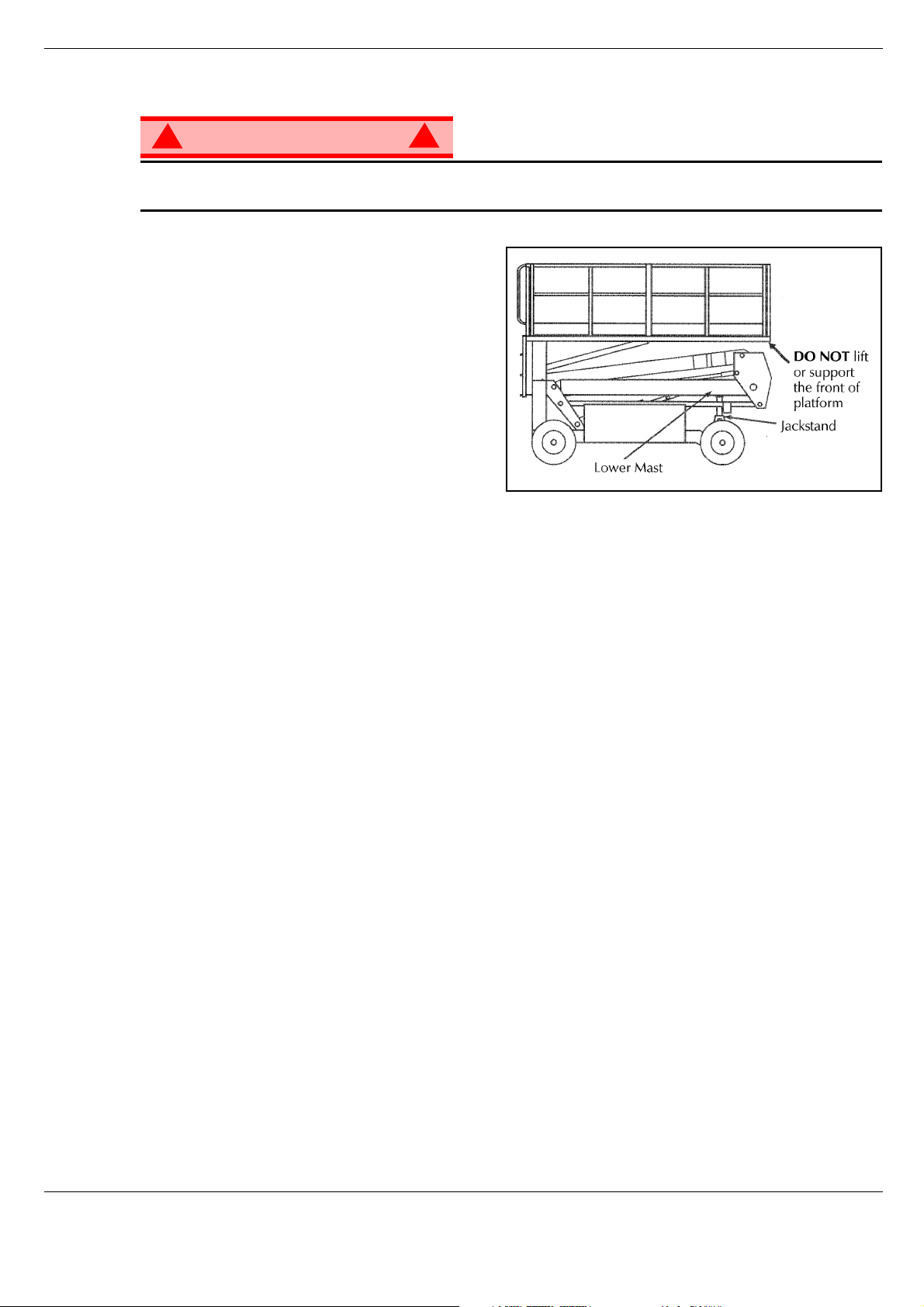

Figure 6: Scissor Brace

INSTALLATION

1. P ark the work platform on firm, level ground and

leave the engine running.

2. Ensure the Chassis Emergency Stop Button is

twisted to the ON position.

3. Press and hold the Chassis LIFT and ENABLE

buttons to elevate the platform approximately

305 mm (12 inches).

4. Place a jackstand with a minimum rating of

1814 kg (4000 lbs.) betw een the lower ma st and

chassis, just behind the front axle.

5. Press and hold the Chassis DESCEND and ENABLE buttons to lower the platform until jackstand is

secured tightly between lower mast and Chassis.

REMOVAL

1. Press and hold the Chassis LIFT and ENABLE buttons to elevate the platform until the jackstand can

be removed.

2. Remove jackstand.

3. Press and hold the Chassis DESCEND and ENABLE buttons to completely lower the platform.

Page 14 Operation Manual

Page 19

Maintenance

B

ATTERY

M

AINTENANCE

!

WARNING

Hazard of explosive gas mixture. Keep sparks, flame, and smoking material away from batteries.

Always wear safety glasses when working near batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with clean water.

Always replace batteries with UpRight batteries or manufacturer approved replacements.

• Check the battery fluid level daily, especially if the work platform is being used in a warm, dry climate.

• If electrolyte level is lower than 10 mm

tap water with high mineral content, as it will shorten battery life.

• Keep the terminals and tops of the batteries clean.

• Refer to the Service Manual to extend battery life and for complete service instructions.

B

ATTERY CHARGING

The battery is charged while the engine is running.

!

3

(

/

in.) above the plates add distilled water only. DO NOT use

8

Operation Manual Page 15

Page 20

Maintenance

F

AULT

01 - SYSTEM INIT ERROR

02 - SYSTEM PLATFORM COM ERROR

03 - PLATFORM OVERLOAD

04 - SYSTEM LOWER PANEL COM ERROR

05 - OIL PRESSURE LOW

06 - COOLANT TEMP HOT

21 - PLATFORM START ON

22 - PLATFORM LEFT TURN SW ON

23 - PLATFORM RIGHT TURN SW ON

24 - PLATFORM LIFT SW ON

25 - PLATFORM HISPEEDDRIVE SW ON

26 - PLATFORM GLOWLP SW ON

27 - PLATFORM LOSPEEDDRIVE SW ON

28 - PLATFORM AUTOLEVEL SW ON

29 - PLATFORM JOYSTICK ENABLE SW ON

C

ODES

31 - PLATFORM JOYSTICK NOT NEUTRAL

34 - GROUND PANEL ENABLE SW ON

37 - GROUND PANEL DOWN SW ON

38 - GROUND PANEL UP SW ON

43 - GROUND PANEL START SW ON

45 - GROUND PANEL GLOWLP SW ON

51 - Coil Fault HiSpeed1

52 - Coil Fault HiSpeed2

55 - Coil Fault LiftUp

56 - Coil Fault LiftDown

57 - Coil Fault TiltLeft

58 - Coil Fault TiltRight

59 - Coil Fault SteerRight

61 - Coil Fault SteerLeft

62 - Coil Fault TiltRear

63 - Coil Fault TiltForward

66 - Coil Fault Forward

67 - Coil Fault Reverse

71 - Coil Fault CushionValve

72 - Coil Fault AxleFloat

73 - Coil Fault SteerDump

68 – LOW BATTERY FAULT

Page 16 Operation Manual

Page 21

Inspection and Maintenance Schedule

I

NSPECTION

The Complete Inspection consists of periodic visual and operational checks, along with periodic minor

adjustments that assure proper performance. Daily inspection will prevent abnormal wear and prolong the

life of all systems. The inspection and maintenance schedule should be performed at the specified intervals. Inspection and maintenance shall be performed by personnel who are trained and familiar with

mechanical and electrical proc edu re s.

AND

M

AINTENANCE

S

CHEDULE

D

AILY

M

AINTENANCE

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

!

WARNING

Before performing preventative maintenance, familiarize yourself with the operation of the machine.

Always block the elevating assembly whenever it is necessary to perform maintenance while the

platform is elevated.

The daily preventative maintenance checklist has been designed for machine service and maintenance.

Please photocopy this page and use the checklist when inspecting the machine.

P

REVENTATIVE

T

ABLE KEY

!

M

AINTENANCE

P

Date:_______________________________________

Owner: _____________________________________

Model No:___________________________________

Serial No: ___________________________________

REVENTATIVE

C

M

AINTENANCE

HECKLIST

R

EPORT

COMPONENT INSPECTION OR SERVICES Y N R

Battery

Chassis

Control Cable

Controller Check switch operation.

Drive Motors Check for operation and leaks.

Elevating

Assembly

Emergency

Lowering System

Entire Unit Check for and repair collision damage.

Check electrolyte level.

Check battery cable condition.

Check hoses for pinch or rubbing points.

Check welds for cracks.

Check the exterior of the cable for pinching,

binding or wear.

Inspect for structural cracks.

Operate the emergency lowering valve and check

for serviceability.

Serviced By:_________________________________

COMPONENT INSPECTION OR SERVICES Y N R

Hydraulic Fluid Check fluid level.

Hydraulic Pump Check for hose fitting leaks.

Hydraulic System Check for leaks.

Labels

Platform Deck

and Rails

Platform Deck

and Rails

Tires and Wheels Check for damage.

Check for peeling, missing, or unreadable labels

& replace.

Check welds for cracks.

Check condition of deck.

Operation Manual Page 17

Page 22

505562-000 Specifications

S

PECIFICATIONS

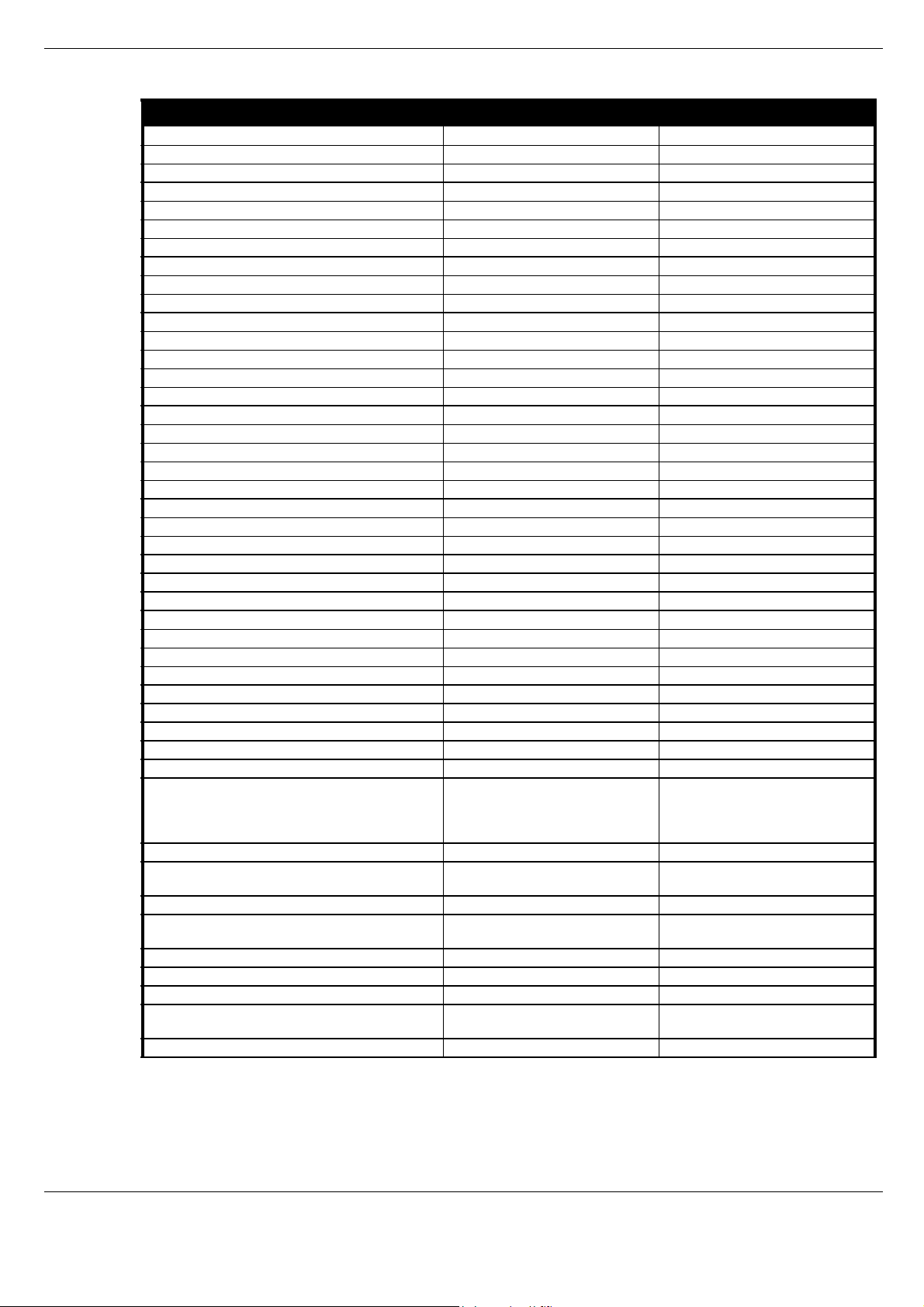

ITEM SL26SL SL30SL

Platform Size (Inside Toeboards)

Standard 1,71 m x 4,22 m [67.5 in. x 166.5 in.] 1,71 m x 4,22 m [67.5 in. x 166.5 in.]

Slide Out Deck Extended 1,71 m x 4,61 m [67.5 in. x 181.5 in.] N/A

Max. Platform Capacity

Standard 680kg [1,500 lbs.] 590 kg [1,300 lbs.]

w/ Extension 680kg [1,500 lbs.] N/A

On Extension 227g [500 lbs.] N/A

Max. No. of occupants

Standard 5 people 5 people

on Extension 2 people N/A

Height

Working Height 9.75 m [32 ft.] 10.97 m [36 ft.]

Max. Platform Height 7.93m [26 ft.] 9,14 m [30 ft.]

Min. Platform Height 1.5 m [59 in.] 1.5 m [59 in.]

Max. Drive Height 7.93 m [26 ft.] 9.14 m [30 ft.]

Dimensions

Weight Diesel: 3,216 kg [7,090 lbs.] Diesel: 3.216 kg [7,090 lbs.]

Overall Width, Standard 2,13 m [84 in.] 2,13 m [84 in.]

Overall Height 2,6 m [102.5 in.] 2,6 m [102.5 in.]

Overall Length, Standard 3.79 m [149 in.] 4,39 m [173 in.]

Surface Speed

Platform Lowered 0 to 5.0 km/h [0 to 3.1 m.p.h.] 0 to 5.0 km/h [0 to 3.1 m.p.h.]

Platform Raised 0 to 0.8 km/h [0 to 0.5 m.p.h.] 0 to 0.8 km/h [0 to 0.5 m.p.h.]

System Voltage 12 Volt DC 12 Volt DC

Hydraulic Tank Capacity 74 l [19.5 US Gallons] 74 l [19.5 US Gallons]

Maximum Hydraulic System Pressure 210 bar [3000 psi] 210 bar [3000 psi]

Hydraulic Fluid

Above 32° f [0° c]) ISO #46 ISO #46

Normal use, below 32° f [0° c]) ISO #32 ISO #32

Below 0° f [-17° c] ISO #15 ISO #15

Lift System One Single Stage Lift Cylinders One Single Stage Lift Cylinders

Lift Speed Raise, 48 sec./Lower, 40 sec. Raise, 48 sec./Lower, 40 sec.

Platform Leveling 13° side to side, 9° Fore and Aft 13° side to side, 9° Fore and Aft

Power Source 20 HP (Diesel) 20 HP (Diesel)

Drive Control Proportional Proportional

Control System Joystick Controller with Safety

Interlock Trigger and Thumb Rocker

Steering, Toggle Selector and

Emergency Stop Switches

Horizontal Drive Four Wheel, Hydraulic Motors Four Wheel, Hydraulic Motors

Tyres (Standard) 26 x 12.00 - 12 NHs Super Terra-grip

with Trac Seal

ANSI Spec. Pneumatic Tire Pressure Do Not Exceed 57 PSI Do Not Exceed 57 PSI

Parking Brakes Dual Spring Applied, Hydraulic

Release, multi-disc

Turning Radius (inside) 3,96 m [13 ft.] 3,96 m [13 ft.]

Maximum Gradeability 35% [19°] 35% [19°]

Wheel Base 2,54 m [100 in.] 2,54 m [100 in.]

Guardrails 1,11 m [43.5 in.] high, Fold Down with

gate.

Toe board 152 mm [6 in.] High 152 mm [6 in.] High

Joystick Controller with Safety

Interlock Trigger and Thumb Rocker

Steering, Toggle Selector and

Emergency Stop Switches

26 x 12.00 - 12 NHs Super Terra-grip

with Trac Seal

Dual Spring Applied, Hydraulic

Release, multi-disc

1,11 m [43.5 in.] high, Fold Down with

gate.

*Specifications are subject to change without no tice. Hot weather or he avy use may affect performance.

Refer to the Service Manual for complete parts and service information.

This machine meets or exceeds all applicable requirements of OSHA and ANSI A92.6-1999.

Page 18 Operation Manual

Page 23

Serie SL26/30SL

Seriennummern 50001 – aktuell

DEUTSCH

Stellen Sie sicher , dass Sie die MODEL L- und SERIENNUMMERN auf dem G erätetype nschild angeben, w enn Sie sich mit

UpRight bezüglich Wartungs- oder Ersatzteilinformationen in Verbindung setzen. Sollte das Typenschild fehlen, finden Sie

die SERIENNUMMER auch auf dem Fahrwerk über der vorderen Schwenkachse.

Eingestanzte Seriennummer

USA

TEL: +1 (559) 443 6600

FAX: +1 (559) 268 2433

Europa

TEL: +44 (0) 1952 200

FAX: +44 (0) 1952 229

www.upright.com

Page 24

Page 25

BETRIEBSANLEITUNG

S

WARNUNG

Alle Bediener müssen die Sicherheitsregeln und Betriebsanleitungen gründlich durchlesen,

verstehen und befolgen, bevor sie an irgendeiner UpRight-Hocharbeitsbühne Wartungsarbeiten

ausführen oder die Arbeitsbühne in Betrieb nehmen.

Sicherheitsregeln

Elektroschockgefahr Kippgefahr Kollisionsgefahr

DIESE MASCHINE IST NICHT

ISOLIERT!

EINSATZ DER HOCHARBEITSBÜHNE: Diese Hocharbeitsbühne dient dazu, Personen und Werkzeuge sowie die für die j eweilige Arbeit

erforderlichen Materialien zu transportieren. Sie wurde speziell für Reparatur- und Montagearbei ten sowie für Einsatzbereiche konzipiert, die

sich oberhalb der Mitarbeiter befinden, sodass die Mitarbeiter nach oben gerichtet arbeiten müssen (z. B. Decken, Kräne, Dachstrukturen,

Gebäude etc.). Jede andere Verwendung der Hocharbeitsbühne ist strikt verboten!

DIESE HOCHARBEITSBÜHNE IST NICHT ISOLIERT! Aus diesem Grund muss zwingend ein Sicherheitsabstand zu allen leitfähigen Teilen

der elektrischen Ausrüstung eingehalten werden!

Die angegebene zulässige Höchstlast darf nicht überschritten werden! Nähere Informationen hierzu finden Sie im Abschnitt

“Beschränkungen” auf Seite 4.

Es ist streng verboten, die Hocharbeitsbüh ne als Hubwerkzeug oder Kran einzusetzen (d. h. um Lasten von unten nach oben oder von oben

nach unten zu befördern).

Die für diese Maschine zuläss i ge m anuelle Kraft NIEMALS überschreiten. Nähere Informationen hierzu finden Sie im Abschnitt

“Beschränkungen” auf Seite 4.

Lasten immer gleichmäßig auf der Plattform VERTEILEN.

Vor Inbetriebnahme der Maschine IMMER ZUERST die Aufstellfläche im Arbeitsbereich auf Gefahren wie Bodenlöcher, ausgelaufene

Flüssigkeiten, Bodenerhebungen, Kanten oder Schutt untersuchen und diese umgehen bzw. beseitigen.

Maschine nur auf Oberflächen IN BETRIEB NEHMEN, die die zulässigen Radlasten aufnehmen können.

Maschine NIEMALS in Betrieb nehmen, wenn di e tatsächliche Windgeschwindigkeit höher ist als die Windgeschwindigkeit, für die die

Maschine ausgelegt ist. Nähere Informationen hierzu finden Sie im Abschnitt “Beaufort-Skala” auf Seite 4.

IM NOTFALL NOT-AUS-Schalter drücken, um alle strombetriebenen Funktionen zu deaktivieren.

WENN EIN ALARM ERTÖNT, während die Plattform ausgefahren wird, Plattform ANHALTEN und vorsichtig einfahren (absenken). Maschine

auf feste, ebene Oberfläche fahren.

Es ist verboten, auf das Schutzgeländer der Plattform zu klettern, darauf zu stehen oder von der Plattform aus auf Gebäude, Stahl- oder

vorgefertigten Betonstrukturen zu zu klettern!

Das Schwingtor oder andere Komponenten des Schutzgeländers zu demontieren ist verboten! Vergewissern Sie sich immer, dass das

Schwingtor geschlossen und sicher verriegelt ist!

Es ist verboten, das Schwingtor geöffnet zu halten (z. B. mit Befestigungsgurten), wenn die Plattform ausgefahre n wird!

Die Höhe oder Reichweite der Plattform durch Anbringen von Leitern, Gerüsten oder ähnlichen Vorrichtungen zu vergrößern ist verboten!

IMMER ZUERST die Hubvorrichtung blockieren, bevor bei ausgefahrener Plattform Wartungs- oder Instandhaltungsarbeiten an der Maschine

durchgeführt werden.

Maschine vor jedem Gebrauch sorgfältig auf Risse an Schweißstellen, lose oder fehlende Beschläge, Leckagen in der Hydraulikvorrichtung,

gelöste Kabelverbindungen und beschädigte Kabel oder Schläuche UNTERSUCHEN.

Vor Gebrauch SICHERSTELLEN, dass alle Bezeichnungsschilder ordnungsgemäß angebracht und vollständig lesbar sind.

NIEMALS eine Maschine benutzen, die beschädigt ist, nicht ordnungsgemäß funktioniert oder deren Bezeichnungsschilder Beschädigungen

aufweisen oder sogar ganz fe hlen.

Sicherheitseinrichtungen zu umgehen ist verboten und stellt eine Gef ahr für alle Personen dar, die sich auf der Hocharbeit sbühne und in deren

Arbeitsbereich befinden.

Batterien NIEMALS in der Nähe von Funkenquellen oder offenen Flammen aufladen. Beim Aufladen von Batterien wird explosives

Wasserstoffgas freigesetzt.

Änderungen an der Hocharbeitsbühne sind verboten bzw. nur mit ausdrücklicher Zustimmung von UpRight zulässig.

NACH GEBRAUCH ist die Hocharbeit sb ühne gegen unbefug ten Gebr auch du rch Dritte zu s ichern. Hierzu müs sen beide Schlü sselschalt er auf

“Aus” gestellt und die Schlüssel abgezogen werden.

NIEMALS die Plattform ausfahren oder die

Maschine mit ausgefahrener Plattform

fortbewegen, wenn sich die Maschine nicht

auf einer festen, ebenen Fläche befindet.

Plattform NIEMALS in Position bringen,

ohne vorher sicherzustellen, dass der

Bereich über der Plattform frei von

Hindernissen und anderen Gefahren ist.

Plattformgeländers klettern und au ch

turzgefahr

NIEMALS auf das obere oder

mittlere Gestänge des

nicht darauf stehen oder sitzen.

Seite 1

Page 26

I

NHALT

Einführung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Allgemeine Beschreibung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Beschränkungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Tragfähigkeit der Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Manuelle Kraft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Beaufort-Skala . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Überlastalarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Bedienelemente und Anzeigen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sicherheitsprüfung vor Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Überprüfung der Systemfunktionen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Bedienung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Starten des Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fahren mit eingefahrener Plattform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lenken. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ausfahren der Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fahren mit ausgefahrener Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Einfahren der Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Nivellieren der Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Notfallabsenkung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Einklappen des Schutzgeländers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Einklappen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ausklappen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Schleppen oder Anheben . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Manuelles Lösen der Feststellbremsen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Nach dem täglichen Gebrauch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Betriebsstundenzähler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Transport der Arbeitsbühne . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Vorbereitung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Anheben per Kran. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Per Gabelstapler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Fahren oder Heben auf einen LKW oder Anhänger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Instandhaltung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Blockieren der Hubvorrichtung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation der Hubvorrichtung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Entfernung der Hubvorrichtung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Instandhaltung der Batterie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Aufladen der Batterie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Fehlercodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inspektions- und Instandhaltungsplan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Checkliste der täglichen präventiven Instandhaltungsmaßnahmen . . . . . . . . . . . . . . . . . . . . . . . . . .17

Technische Daten. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Seite 2 Betriebsanleitung

Page 27

Einführung

E

INFÜHRUNG

Dieses Handbuch beschreibt Einsatz und Bedienung der selbstfahrenden Arbeitsbühnen der Serie

SL26/30 Speed Level. Das Handbuch muss immer bei der Maschine aufbewahrt werden.

A

LLGEMEINE

1. Plattform

B

ESCHREIBUNG

Figure 1: Serie SL26/30 SL

7

6

1

!

WARNUNG

Hocharbeitsbühne NICHT ohne korrekt

montiertes und angebrachtes

Schutzgeländer verwenden.

2. Hubvorrichtung

3. Fahrwerk

4. Antriebsmodul

5. Steuermodul

6. Plattform-Bedienelemente

7. Handbuchfach

8. Fahrwerk-Bedienelemente

9. Behälter für Hydraulikflüssigkeit

!

2

3

5

8

9

4

Betriebsanleitung Seite 3

Page 28

Beschränkungen

B

ESCHRÄNKUNGEN

Bei ausgefahrener Plattform kann die Maschine nur im Schleichgang gefahren werden.

Die Arbeitsbühne kann nur auf festen, ebenen Oberflächen ausgefahren werden.

GEFAHR

! !

Die Hubfunktion darf NUR verwendet werden, wenn die Arbeitsbühne nivelliert ist und auf einer festen

Oberfläche steht.

Die Arbeitsbühne ist NICHT daf ür ausgelegt, auf unebenem, grobem oder w eichem Gelände gef ahren

zu werden.

T

RAGFÄHIGKEIT DER

Die maximale Tragfähigkeit der MASCHINE, einschließlich P ersonen , hängt vom Modell und verschieden en

Optionen ab; Sie finden eine entsprechende Liste im Abschnitt “Technische Daten” auf Seite 18.

GEFAHR

! !

Maximale Tr agfähig keit der Platt form oder maximal zulässige Personenzahl für diese Maschine NICHT

überschreiten.

P

LATTFORM

M

ANUELLE

Unter manueller Kraft versteht man die Kraft, die die Personen auf der Plattform auf Objekte wie Wände

oder andere Strukturen außerhalb der Arbeitsbühne ausüben.

Die maximal zulässige manuelle Kraft ist auf 200 N pro Person beschränkt, d. h. maximal 400 N, wenn

sich zwei oder mehr Personen auf der Plattform befinden.

GEFAHR

! !

Die für diese Maschine maximal zulässige manuelle Kraft NICHT überschreiten.

B

EAUFORT

Niemals die Maschine in Betrieb nehmen, wenn die Windgeschwindigkeit mehr als 12,5 km/h [BeaufortSkala 6] beträgt.

BEAUFORT-

WERT

3 3,4~5,4 12,25~19,4 11,5~17,75 7,5~12,0 Papier und dünne Zweige bewegen sich, Fahnen wehen.

4 5,4~8,0 19,4~28,8 17,75~26,25 12,0~18 Staub und Papier wird aufgewirbelt und kleine Zweige schaukeln.

5 8,0~10,8 28,8~38,9 26,25~35,5 18~24,25

6 10,8~13,9 38,9~50,0 35,5~45,5 24,5~31

7 13,9~17,2 50,0~61,9 45,5~56,5 31~38,5 Ganze Bäume schwanken. Das Gehen bei Gegenwind ist schwierig.

m/s km/h ft/s mph

Ü

WINDGESCHWINDIGKEIT

BERLASTALARM

Wenn eine Last angehoben wird, die 90 % der Nennlast ausmacht, erscheint im digitalen Display des

Bedienpultes an der Plattform der Fehlercode “03”. Befindet sich im Fahrkorb eine Last , die höh er als die

Nennlast ist, werden alle Maschinenfunktionen blockiert und eine akustische Warnung ertönt. Damit der

normale Betrieb wieder aufgenommen werden kann, muss die Last im Fahrkorb verringert werden,

sodass sie gleich oder niedriger als die Nennlast ist, und die Stromzufuhr zur Maschine muss aus- und

wieder eingeschaltet werden. Das Aus- und wieder Einschalten der Stromversorgung kann durch

Drücken und anschließendes Lösen des Not-Aus-Tasters erfolgen.

K

-S

RAFT

KALA

BODEN-/UMGEBUNGSBEDINGUNGEN

Sträucher mit Blättern beginnen zu schaukeln. In Teichen, Sümpfen oder anderen Gewässern erscheinen

Wellenkämme.

Zweige und Äste von Bäumen bewegen sich. Stromleitungen pfeifen. Regenschirme können nur mit Mühe

geöffnet werden.

GEFAHR

! !

Niemals die Maschine in Betrieb nehmen, wenn sich auf der Plattform eine Last befindet, die die

angegebene Tragfähigkeit überschreitet.

Seite 4 Betriebsanleitung

Page 29

Bedienelemente und Anzeigen

B

EDIENELEMENTE

UND

A

NZEIGEN

Plattform-Bedienelemente

Figure 2: Bedienelemente und Anzeigen

8

7

10

6

1 Antrieb (schnell)

2. Antrieb (langsam)

3. Nivellieren

4. Taste für die Hupe

5. Taste zum Aus-/Einfahren

6. Taste für Vorglühen

7. Start des Motors

8. Not-Aus-Taster

9. Display

10. Steuerknüppel

1

2

3

2

1

4

Fahrwerk-Bedienelemente

5

9

6

5

1. Not-Aus

2. Ausfahren

3. Einfahren

4. Freigabe

5. Taste für Vorglühen

6. Start

3

4

Betriebsanleitung Seite 5

Page 30

Sicherheitsprüfung vor Inbetriebnahme

S

ICHERHEITSPRÜFUNG

NOTE: Lesen Sie sich alle Sicherheitsregeln, Betriebsanleitungen, Bezeichnungsschilder und

nationalen Sicherheitsanweisungen/-anforderungen sorgfältig durch, stellen Sie sicher,

dass Sie sie vollständig verstanden haben und halten Sie sie ein. Gehen Sie jeden Tag vor

Inbetriebnahme der Maschine wie folgt vor.

1. Öffnen Sie die Module, und untersuchen Sie sie auf Beschädigungen, Leckagen oder fehlende Teile.

2. Überprüfen Sie bei vollständig

abgesenkter Plattform die

Füllstandshöhe der Hydraulikflüssigkeit.

Der Hydraulikbehälter befindet sich in

der Tür des Steuermoduls. Die

Füllstandshöhe der Flüssigkeit muss

zwischen den Strichen für MIN und MAX

liegen. Füllen Sie bei Bedarf

Hydraulikflüssigkeit nach.

3. Stellen Sie sicher, dass die Flüssigkeit

in der Starterb a tte rie die korrekte

Füllstandshöhe aufweist.

4. Überprüfen Sie bei ausgeschaltetem

Motor die Füllstandshöhe des

Dieselkraftstoffs. Der Kraftstofftank

befindet sich in der Tür des

Antriebsmoduls. Füllen Sie bei Bedarf

Kraftstoff nach.

5. Überprüfen Sie, ob alle Komponenten der Schutzgeländer angebracht und sämtliche

Befestigungselemente ordnungsgemäß festgezogen sind.

6. Untersuchen Sie die Maschine sorgfältig auf Risse an Schweißstellen und Schäden an der Struktur,

lose oder fehlende Beschläge , Lec kagen in der Hyd raulikv orrichtung, Beschädi gungen am Steuerkabel

sowie lose Kabelverbindungen und Radbolzen.

VOR

I

NBETRIEBNAHME

Figure 3: Hydraulikbehälter

Seite 6 Betriebsanleitung

Page 31

Überprüfung der Systemfunktionen

Ü

BERPR ÜFUNG

Die Positionen der verschiedenen Bedienelemente und Anzeigen sehen Sie in Figure 2 (Seite 5).

DER

S

YSTEMFUNKTIONEN

!

WARNUNG

HALTEN SIE AUSREICHENDEN ABSTAND zur Arbeitsbühne, während Sie die nachfolgenden

Überprüfu ngen durchführen.

Untersuchen Sie vor Inbetriebnahme der Hocharbeitsbühne die Aufstellfläche im Arbeitsbereich auf

Gefahren wie Bodenlöcher, ausgelaufene Flüssigkeiten, Bodenerhebungen und Schutt.

Prüfen Sie in ALLE Richtungen, einschließlich im Bereich über der Platt f orm, ob irgendwelche Hindernisse

und elektrische Leitungen vorhanden sind.

Schützen Sie das Kabel des Bedienpultes vor möglichen Beschädigungen, während Sie diese

Prüfungen durchführen.

1. Fahren Sie die Maschine ggf. in einen Bereich ohne Hindernisse, um die Hubvorrichtung vollständig

auszufahren.

2. Drehen Sie den Not-Aus-Schalter des Fahrwerks auf EIN.

3. Drehen Sie den Not-Aus-Schalter der Plattform auf EIN.

4. Stellen Sie den Schlüsselschalter auf EIN.

5. Führen Sie eine Sichtprüfung an Hubvorrichtung, Hubzylinder, Kabeln und Schläuchen durch. Stellen

Sie sicher, dass keine Risse an Schweißstellen und Schäden an der Struktur, lose Beschläge, Leckagen

in der Hydraulikvorrichtung oder gelösten Kabelv erbindungen v orliegen und dass die Maschine f ehlerfr ei

arbeitet. Vergewissern Sie sich, dass keinerlei Teile fehlen oder gelöst sind.

6. Drücken Sie die Fahrwerkschalter für AUSFAHREN und FREIGABE, und fahren Sie die Plattform

vollständig aus.

7. Fahren Sie die Plattform anschließend teilweise wieder ein, indem Sie die Fahrwerkschalter für

EINFAHREN und FREIGABE drücken, und überprüfen Sie, ob der akustische Absenkalarm korrekt

arbeitet.

!

8. Überprüfen Sie, ob das Ventil zur Notfallabsen kung korrekt arbeitet, indem Sie es durch Herausziehen

des Knopfes öffnen (siehe Figure 4). Wenn die Plattform eingefahren wird, lassen Sie den Knopf los.

9. Drücken Sie den Not-Aus-Schalter des Fahrwerks, um zu überprüfen, ob er korrekt arbeitet. Alle

Maschinenfunktionen sollten jetzt deaktiviert sein. Drehen Sie den Not-Aus-Schalter des Fahrwerks,

um den Betrieb wieder aufzunehmen.

10. Prüfen Sie, ob der Verfahrweg frei von Hindernissen (Personen, sonstige Hindernisse, Bodenlöcher

und ausgelaufene Flüssigkeiten, Bodenerhebungen und Schutt) und eben ist und die Radlasten tragen

kann.

11. Besteigen Sie die Plattform, und schließen Sie die Eingangspforte ordnungsgemäß.

12. Wählen Sie den Modus FAHREN.

NOTE: Verwenden Sie ggf. beide Antriebe (SCHNELL und LANGSAM), wenn Sie die folgenden Schritte

ausführen.

13. Rasten Sie den V erriegelungsa uslöser ein und bew egen Sie den Steue rknüppel dabei VORWÄR TS und

dann RÜCKWÄRTS, um die Geschwindigkeitssteuerung zu überprüfen.

14. Drücken Sie den Lenkschalter nach RECHTS und dan n nach LINKS, um zu überprüfen, ob die Len kung

ordnungsgemäß funktioniert.

15. Wählen Sie den Modus AUSFAHREN. Greife n Sie den Steuerknüppel, während Sie dabei den

Verriegelungsauslöser einrasten, und schieben Sie ihn nach vorn, um die Bedienelemente zum

Ausfahren der Plattform zu überprüfen. Fahren Sie die Plattform vollständig aus.

16. Ziehen Sie den Steuerknüppel nach hinten. Die Plattform sollte nun einfahren und der akustische

Absenkalarm ertönen.

17. Drücken Sie den Not-Aus-Schalter der Plattform, um zu überprüfen, ob er korrekt arbeitet. Alle

Maschinenfunktionen sollten jetzt deaktiviert sein. Ziehen Sie den Not-Aus-Schalter der Plattform

heraus, um den Betrieb wieder aufzunehmen.

Betriebsanleitung Seite 7

Page 32

Bedienung

B

EDIENUNG

Vor Inbetriebnahme der Hocharbeitsbühne müssen Sie sicherstellen, dass sämtliche vorbereitenden

Sicherheitsprüfungen durchgeführt und eventuelle Defekte behoben wurden. Nehmen Sie niemals eine

beschädigte oder nicht ordnungsgemäß arbeitende Maschine in Betrieb. Der Bediener muss

umfassend auf dieser Maschine geschult worden sein.

S

TARTEN DES

1. Besteigen Sie die Plattform und schließen Sie die Eingangspforte ordnungsgemäß.

2. Drücken Sie die Taste für VORGLÜHEN herunter, und halten Sie sie rund 5 Sekunden lang gedrückt.

3. Drücken Sie die grüne START-Taste.

F

AHREN

1. Prüfen Sie, ob der Verfahrweg frei von Hindernissen (Personen, sonstige Hindernisse, Bodenlöcher,

ausgelaufene Flüssigkeiten, Bodenerhebungen und Schutt) und eben ist und die Radlasten tragen

kann.

2. Vergewissern Sie sich, dass der Motor gestartet ist und dass sich der Not-Aus- Sch alter de s Fahrwerks

in der Position EIN befindet (d. h. herausgezogen ist).

3. Besteigen Sie die Plattform und schließen Sie die Eingangspforte ordnungsgemäß.

4. Überprüfen Sie den Bereich über, unter und an den Seiten der Plattform.

5. Ziehen Sie den Not-Aus-Schalter der Plattform in die Position EIN.

6. Wählen Sie den Modus FAHREN.

MIT EINGEFAHRENER

M

OTORS

P

LATTFORM

NOTE: Wählen Sie - je nach Steigung - zwischen dem Standardantrieb und einem zusätzlichen

Drehmoment.

7. Rasten Sie den Verriegelungsauslöser ein und bewegen Sie den Steuerknüppel VORWÄRTS oder

RÜCKWÄRTS, um in die gewünschte Richtung zu fahren. Die Geschwindigkeit der Maschine hängt

davon ab, wie weit der Steuerknüppel von der Mittelstellung wegbewegt wird.

L

ENKEN

1. Drehen Sie den Schalter für Fahren/Ausfahren in die Stellung für FAHREN.

2. Drücken Sie bei eingerastetem Verriegelungsauslöser den Schalter für die Lenkung nach RECHTS

oder LINKS, um die Räder in die gewünschte Richtung zu lenken. Beobachten Sie beim Manövrieren

der Arbeitsbühne die Räder, um sicherzustellen, dass sie in die korrekte Richtung zeigen.

NOTE: Die Lenkung ist nicht selbstzentrierend. Die Räder müssen mithilfe des Schalters für die

Lenkung wieder geradeaus gestellt werden.

A

USFAHREN

1. Wählen Sie eine feste, ebene Oberfläche.

2. Wählen Sie den Modus AUSFAHREN.

3. Schieben Sie bei eingerastetem Verriegelungsauslöser den Bedienhebel nach vorne.

4. Wenn die Maschine nicht nivelliert ist, ertönt der Kippalarm; in diesem Fall fährt die Maschine weder

die Plattform aus noch lässt sie sich selbst fahren.

5. Wenn der Kippalarm ertönt, müssen Sie die Plattform zuerst vollständig absenken, dann ca. 600 mm

ausfahren, anschließend stoppen und schließlich die Taste für NIVELLIEREN herunterdrücken und

gedrückt halten, bis der Kippalarm verstummt. Er st danach können Sie die Plattform vollständig

ausfahren. Wenn die Plattform nicht korrekt nivelliert ist, ertönt der Kippalarm weiter und alle

Funktionen zum Ausfahren werden bei Erreichen einer Höhe von ca. 2 m blockiert.

DER

P

LATTFORM

Seite 8 Betriebsanleitung

Page 33

Bedienung

F

AHREN

NOTE: Wenn die Plattform ausgefahren ist, fährt die Maschine mit gedrosselter Geschwindigkeit.

1. Prüfen Sie, ob der Verfahrweg frei von Hinde rnissen (Personen, sonstige Hindernisse, Bodenlöcher,

ausgelaufene Flüssigkeiten, Bodenerhebungen und Schutt) und eben ist und die Radlasten tragen

kann.

2. Überprüfen Sie den Bereich über, unter und an den Seiten der Plattform.

3. Wählen Sie den Modus FAHREN.

4. Rasten Sie den Verriegelungsauslöser ein und bewegen Sie den Steuerknüppel VORWÄRTS oder

RÜCKWÄRTS, um in die gewünschte Richtung zu fahren. Die Geschwindigkeit der Maschine hängt

davon ab, wie weit der Steuerknüppel von der Mittelstellung wegbewegt wird.

5. Wenn die Maschine nicht nivelliert ist, ertönt der Kippalarm; in diesem Fall fährt die Maschine weder

die Plattform aus noch lässt sie sich selbst fahren. Wenn der Kippalarm ertönt, muss die Plattform

eingefahren (abgesenkt) und die Maschine auf eine feste, ebene Oberfläche gefahren werden, bevor

Sie erneut versuchen können, die Plattform auszufahren.

E

INFAHREN

1. Wählen Sie den Modus AUSFAHREN.

2. Überprüfen Sie den Bereich rund um den Plattformsockel, um sicherzustellen, dass keine Personen

oder Hindernisse mit der Maschine in Kontakt sind. Rasten Sie den Verriegelungsauslöser ein und

ziehen Sie den Steuerknüppel zurück, um die Plattform einzufahren (abzusenken).

3. Die Plattform stoppt, sobald sie die Höhe des persönlichen Schutzausschnitts erreicht hat.

Vergewissern Sie sich, dass rund um die Maschine keine Personen oder Hindernisse mit der Maschine

in Kontakt sind. Fahren Sie dann nach einer zeitlichen Verzögerung v on vier Sekunden die

Arbeitsplattform wie in Schritt 2 beschrieben ein.

MIT AUSGEFAHRENER

DER

P

LATTFORM

P

LATTFORM

N

IVELLIEREN

Die Funktion AUTOMATISCHE NIVELLIERUNG wurde für das Nivellieren der Plattform in Situationen

entwickelt, in denen das Gelände ein seitliches Gefälle von maximal 13 Grad und ein Längsgefälle von

max. 9 Grad aufweist. Ist das Gefälle größer als 13 Grad (seitlich) bzw. 9 Grad (Längsrichtung), dann

arbeitet die Funktion zur AUTOMATISCHEN NIVELLIERUNG nicht.

Der Kippalarm ertönt solange, bis die Plattform nivelliert ist.

1. Prüfen Sie, ob der Verfahrweg frei von Hinde rnissen (Personen, sonstige Hindernisse, Bodenlöcher,

ausgelaufene Flüssigkeiten, Bodenerhebungen und Schutt) und eben ist und die Radlasten tragen

kann.

2. Überprüfen Sie den Bereich über, unter und an den Seiten der Plattform.

3. Fahren Sie die Plattform um rund 600 mm aus.

4. Drücken Sie die Taste für die automatische Nivellierung, und halten Sie sie gedrückt. Rasten Sie dann

den Verriegelungsauslöser ein bis die Plattform nivelliert ist und der Kippalarm verstummt.

5. In dieser Situation arbeiten nur die Funktionen AUSFAHREN und EINFAHREN.

6. Soll die Maschine gefahren werden, dann müssen Sie die Plattform zuerst einfahren und wieder in ihre

normale Neigung bringen.

DER

P

LATTFORM

Betriebsanleitung Seite 9

Page 34

Bedienung

N

OTFALLABSENKUNG

Figure 4: Ventil zur Notfallabsenkung

!

WARNUNG

Falls sich die Plat tform nicht einfahren

lassen sollte, AUF KEINEN FALL an

der Hubvorrichtung herunterklettern.

Halten Sie Abstand zur Hubvorrichtung,

und betätigen Sie den Knopf für das Ventil

zur Notfallabsenkung.

SL26/30 S

Auf der SL26/30 befin det sich das V entil zu r

Notfallabsenkung im Steuermodul der

Maschine und ist über eine Öffnung in der

Tür zum Steuermodul zugänglich.

1. Öffnen Sie das Ventil zur Notfallabsenkung, indem Sie den Griff herausziehen und gezogen halten.

2. Zum Schließen lassen Sie den Knopf einfach los. Die Plattform fährt nicht aus, wenn das Ventil zur

Notfallabsenkung geöffnet ist.

PEED

L

EVEL

!

Knopf zur Notfallabsenkung

Seite 10 Betriebsanleitung

Page 35

Bedienung

E

INKLAPPEN

Die hier beschriebene Vorgehensweise gilt nur für das Modell SL26/30 Speed Level und ist für Fälle

gedacht, in denen durch ei n zweiflügeliges Tor mit Standardmaßen gefahren wer de n m u ss. Vor Inbetrieb-

nahme der Maschine muss das Schutzgeländer zuerst wieder in seine korrekte Position gebracht

werden.

E

INKLAPPEN

1. Hängen Sie die Steuerung aus dem Seitengeländer aus, und legen Sie sie auf dem Boden de r Plattf orm

ab.

2. Beginnen Sie auf der Frontseite der Plattform, und entfernen Sie Muttern, Bolzen und Unterlegscheiben

aus der Oberseite des vorderen Geländers. Klappen Sie das vordere Geländer ein, sodass es auf der

Plattform aufliegt.

3. Schließen und verriegeln Sie das Tor.

4. Entfernen Sie die Muttern, Bolzen und Unterlegscheiben aus der Obe rseite d es rüc kwärtigen Geländers.

Klappen Sie das rückwärtige Geländer ein, sodass es auf der Pla ttform aufliegt. Achten Sie dabei darauf,

dass es die gesamte Zeit über verriegelt bleibt.

5. Entfernen Sie die Muttern, Bolzen und Unterlegscheiben aus der Oberseite des Seitengeländers.

Heben Sie ein Seitengeländer an, und klappen Sie es ein, sodass es auf dem Deck aufliegt.

Wiederholen Sie den Vorgang mit den anderen Seitengeländern.

A

USKLAPPEN

1. Heben Sie die Seitengeländer an, und vergewissern Sie sich dabei, dass alle heruntergedrückt werden,

um das Geländer in vertikaler Position zu sichern.

2. Bringen Sie Bolzen, Unterlegscheiben und Muttern zwischen den Seitengeländern an, und ziehen Sie sie

fest.

3. Heben Sie das rückwärtige Geländer an, richten Sie die Öffnungen aufeinander aus, und bringen Sie

Bolzen, Unterlegscheiben und Muttern an. Ziehen Sie sie fest.

DES

S

CHUTZGELÄNDERS

GEFAHR

! !

Vor Betreten der Plattform müssen

sich alle Geländer wieder in ihrer

korrekten Position befinden und

sicher befestigt sein.

Betriebsanleitung Seite 11

Page 36

Schleppen oder Anheben

S

CHLEPPEN

Führen Sie die folgenden Schritte nur durch, wenn die Maschine nicht aus eigener Kraft fährt, aber

bewegt werden muss, oder wenn sie auf ein Transportfahrzeug gehoben werden soll (siehe

“Transportieren der Arbeitsplattform” auf Seite 13).

ODER

A

NHEBEN

VORSICHT

Maschine NIEMALS mit einer Geschwindigkeit von mehr als 0,3 m/s schleppen oder anheben. Bei

höheren Geschwindigkeiten w erden die Antriebskomponenten beschädigt, und die Garantie erlöscht.

M

ANUELLES

Führen Sie die folgenden Schritte nur durch, wenn die Maschine nicht aus eigener Kr aft f ährt, aber

bewegt werden muss oder wenn sie eine Steigung hinaufgeschleppt oder für den Transport auf

einen LKW gehoben werden soll.

1. Schließen Sie das Nadelventil, indem Sie die Inbusschraube im Uhrzeigersinn drehen.

2. Betätigen Sie Pumpe zum Lösen der Bremsen, bis die Bremsen gelöst sind.

3. Die Maschine rollt jetzt, sobald sie geschoben oder gezogen wird.

4. Vor Inbetriebnahme der Maschine müssen Sie dar auf achten , das Nadelv entil wieder zu öffnen

und überprüfen, ob die Zylinderstange ausgefahren ist.

L

ÖSEN

DER

F

ESTSTELLBREMSEN

Handpumpe

Nadelventil

!

WARNUNG

Maschine niemals mit einer höheren Geschwindigkeit als 0,3 m/s schleppen.

Arbeitsbühne niemals in Betrieb nehmen, we nn die Feststellbremsen gelöst sind. Andernfalls kann es

zu schweren Körperverletzungen oder Sachschäden kommen.

N

ACH DEM

1. Vergewissern Sie sich, dass die Plattform vollständig eingefahren (abgesenkt) ist.

2. Parken Sie die Maschine auf einer festen, ebenen Fläche, vorzugsweise abgedeckt und gesichert

gegen Vandalismus und unbefugten Betrieb sowie unzugänglich für Kinder.

3. Stellen Sie den Schlüsselschalter am Fahrwerk auf AUS, und ziehen Sie den Schlüssel ab, um ein en

Betrieb durch unbefugte Dritte zu verhindern.

B

ETRIEBSSTUNDENZÄHLER

Gehen Sie wie folgt vor, um die Betriebsstundenzählerfunktion aufzurufen.

1. Steigen Sie in den Fahrkorb (bei eingeschalteter Maschine)

2. Drücken Sie den Not-Aus-Taster der Plattform.

3. Halten Sie folgende Tasten heruntergedrückt: Tasten für Hupe & Ausfahren.

4. Während Sie diese Tasten heruntergedrückt halten, drehen Sie nun den Not-Aus-Taster, um die

Maschine wieder einzuschalten.

5. In der Anzeige erscheint je tzt “hr”. Durch Drüc k en der Taste zum Drehen nach rechts werden Ihnen die

aufgelaufenen Stunden in zw ei Schritten angez eigt. Ein Bei spiel: Sie drüc ken die Taste zum Drehen nach

rechts einmal, und es erscheint die Zahl “20”; Sie drücken die Taste ein zweites Mal, und die Zahl “58”

wird angezeigt. W enn Sie die Taste ein drittes Mal herunterdrücken, erscheint “hr” (f ür “hours” = Stunde n).

Das bedeutet, das 2058 Betriebsstunden vergangen sind.

TÄGLICHEN

!

G

EBRAUCH

Seite 12 Betriebsanleitung

Page 37

Transport der Arbeitsbühne

T

RANSPORT DER

V

ORBEREITUNG

1. Fahren Sie die Plattform vollständig ein.

2. Ziehen Sie das negative (-) Batteriekabel von der Batterieklemme ab.

3. Binden Sie die Steuerung am vorderen Geländer fest.

4. Binden Sie die Hubverbindungen am Rahmen fest.

A

NHEBEN

1. Befestigen Sie die Gurte nur an den Hebe-/Befestigungsösen des Fahrwerks.

2. Platzieren Sie die Plattform auf dem Transportfahrzeug in Transportposition.

3. Blockieren Sie die Räder mit Bremsklötzen.

4. Sichern Sie die Arbeitsbühne mit Ketten oder Gurten von geeigneter Belastbarkeit am

Transportfahrzeug, indem Sie sie an den Hebe-/Befestigungsösen des Fahrwerks anbringen.

P

ER

G

ABELSTAPLER

GEFAHR

! !

Das Anheben per Gabelstapler darf nur zu Transportzwecken erfolgen.

Bitte lesen Sie in den technischen Daten das Gewicht der Hocharbeitsbühne nach, und stellen Sie

sicher, dass der Gabelstapler entsprechend ausgelegt ist, um diese Maschine anzuheben.

PER

A

RBEITSBÜHNE

K

RAN

Das Anheben per Gabelstapler erfolgt von der Seite, wobei die Arme des Gabelstaplers unter den

Modulen des Fahrwerks ansetzen.

Figure 5: Transport der Arbeitsbühne

F

AHREN

AUF EINEN

NHÄNGER

A

NOTE: Maschine niemals schneller als 0,3 m/s

anheben.

1. Bewegen Sie die Maschine auf den LKW oder

Anhänger.

A. So fahren Sie die Maschine auf das

Transportfahrzeug:

a. Bringen Sie die Arbeitsbühne die Rampe hinauf

und in die Transportposition.

b. Richten Sie die Räder gerade aus, und schalten

Sie die Maschine aus.

c. Blockieren Sie die Räder mit Bremsklötzen.

B. So heben Sie die Maschine auf das

Transportfahrzeug:

a. Bewegen Sie die Arbeitsbühne auf die Rampe.

b. Bringen Sie das Seil der Hebevorrichtung an den Befestigungs-/Hebeösen an.