Page 1

SB66JRT

Operator Manual

(EN) Manual part number 508372-001 for serial numbers 10000 to 10031.

June 08

Page 2

Page 3

Table of Contents

Declaration of Conformity ...........................................2

Safety Rules ............................................................... 3

Introduction ................................................................. 4

Component Identifi cation ............................................ 4

Special Limitations......................................................5

Platform Capacity ....................................................5

Manual Force ..........................................................5

Platform Overload Sensing System ........................5

Beaufort Scale .........................................................5

Controls and Indicators...............................................6

Battery Disconnect Switch ......................................6

Lower Controls and Indicators ................................6

Upper Controls and Indicators ................................6

Pre-Operation Safety Inspection ................................7

System Function Inspection .......................................8

Operation .................................................................... 9

Cold Weather Start-Up ............................................9

Hydraulic System Cold Weather Warm-Up .............9

Preparing for Operation ...........................................9

Lower Controls ........................................................9

Upper Controls ......................................................10

Boom Operation ....................................................10

Driving and Steering ..............................................10

Drive Speeds ......................................................... 11

Motion Warning Alarm ........................................... 11

AC Generator ........................................................ 11

Air Line .................................................................. 11

Driving Lights ........................................................12

Platform Work Lights .............................................12

Emergency Lowering ............................................12

After Use Each Day ...............................................12

Table of Contents

Transporting the Machine .........................................13

Preparing for Transportation .................................13

By Crane ...............................................................13

By Truck ................................................................13

Maintenance ............................................................. 14

Hydraulic Fluid ......................................................14

Check Hydraulic Fluid ...........................................14

Engine ...................................................................14

Oil Level ................................................................14

Battery Maintenance .............................................14

Inspection and Maintenance Schedule.....................15

Daily Preventative Maintenance Checklist ...............16

Preventative Maintenance Report ......................... 16

Decal Location ..........................................................17

Specifi cations ...........................................................19

Aerial Platform .......................................................19

Platform ................................................................. 19

Function Speed .....................................................19

Drive System .........................................................19

Tyres ......................................................................19

Electrical System ...................................................19

Hydraulic System ..................................................19

Engine ...................................................................19

Fuel Tank Capacity ................................................ 19

Ambient Air Temperature Operating Range ..........19

Maximum Wind Speed ..........................................19

Working Envelope .................................................19

SB66JRT 1

Page 4

EC DECLARATION OF CONFORMITY

FOR MACHINERY

MACHINERY:

Powered Aerial Platform known as:

Type: Upright SB66JRT

Serial Number:

The machine specified above conforms to the following provisions:

Machinery directive 98/37/EC (using document EC Community Legislation on Machinery and taking

guidance from EN280:2001 + Amendment A1:2004)

Council Directive 89/336/EEC on Electromagnetic Compatibility as amended by 93/68/EEC and 92/31/EC

Council Directive 73/23/EEC on Low Voltage Equipment Safety as amended by 93/68/EE

Council Directive 2000/14/EC on Noise Emission in the Environment by Equipment for use Outdoors

As performed in accordance with EN 3744:1995

Measured sound power level

Guaranteed sound power level 100dB

E. C. Type Examination Certificate No:

91 dB Min

100dB Max

Note: Modification of the specified unit renders this declaration invalid

2 SB66JRT

Page 5

SAFETY RULES

AWarning

All personnel shall carefully read, understand and follow all safety rules and operating instructions

before operating or performing maintenance on any UpRight aerial work platform.

Electrocution Hazard Tip Over Hazard Collision Hazard Fall Hazard

8

3

B

A

t

h

g

i

R

p

U

THIS MACHINE IS

NOT INSULATED!

NEVER elevate the platform

or drive the machine while

elevated unless the machine

is on a firm, level surface

NEVER position the platform

without first checking for

overhead obstructions or

other hazards.

NEVER climb, stand, or sit

on platform guardrails or

midrail.

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the

material used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings,

cranes, roof structures, buildings etc.). Uses or alterations to the aerial work platform must be approved by UpRight.

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live

parts of electrical equipment!

Exceeding the specifi ed permissible maximum load is prohibited! See “Platform Capacity” on page 5 for details.

The use and operation of the aerial work platform as a lifting tool or a crane is prohibited!

NEVER exceed the manual force allowed for this machine. See “Manual Force” on page 5 for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without fi rst surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs,

or debris; and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 5 for details.

Do not operate the aerial platform in windy or gusty conditions. Do not add anything to the aerial platform that will increase the

wind loading such as billboards, banners, flags, etc.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a fi rm, level surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete

structures, etc., is prohibited!

Dismantling the entry gate or other railing components is prohibited! Always make certain that the entry gate is closed!

It is prohibited to keep the entry gate in an open position when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and

damaged cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its

working range.

NEVER charge batteries near sparks or open fl ame. Charging batteries emit explosive hydrogen gas.

Modifi cations to the aerial work platform are prohibited or permissible only at the approval by UpRight.

AFTER USE, secure the work platform from unauthorized use by turning the keyswitch off and removing key.

The driving of MEWP’s on the public highway is subject to national traffi c regulations.

Certain inherent risks remain in the operation of this machine despite utilizing proper design practices and safeguarding.

Harness attachment points are provided in the platform and the manufacturer recommends the usage of a fall restraint

harness, especially where required by national safety regulations.

Care must be taken to ensure that the machines meets the requirements of stability during use, transportation, assembly,

dismantling when out of service, testing, or foreseeable breakdowns.

In the event of an accident or breakdown see “Emergency Lowering” on page 12, do not operate the aerial platform if it is

damaged or not functioning properly. Qualifi ed maintenance personnel must correct the problem before putting the aerial

platform back into service.

SB66JRT 3

Page 6

Introduction

Introduction

This manual covers the SB66JRT Aerial Work Platform.

This manual must be stored on the machine at all

times.

Read, Understand and follow all safety rules and operating instructions before attempting to operate the

machine.

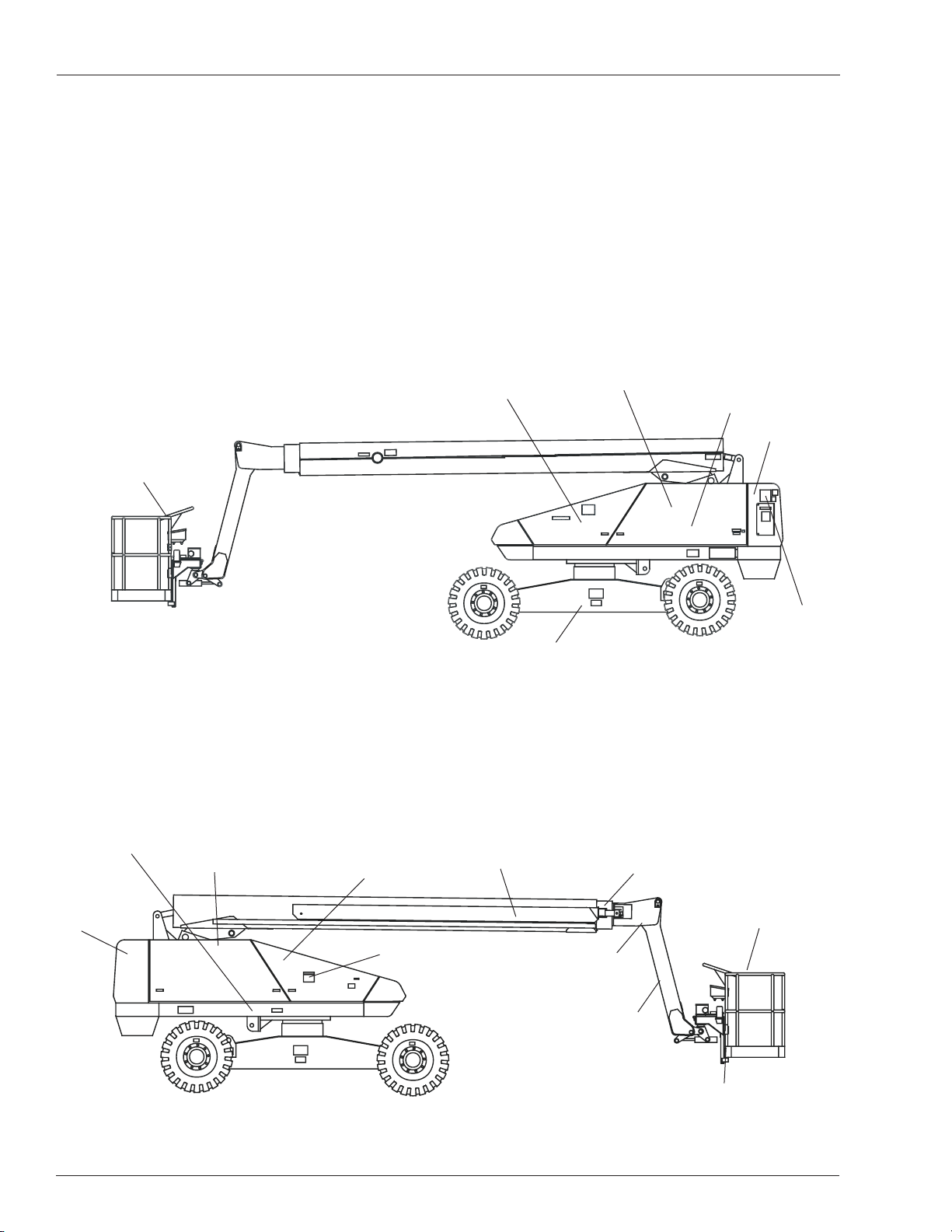

Component Identifi cation

Upper Controls

When contacting UpRight for service or parts information,

be sure to include the MODEL and SERIAL NUMBERS

from the equipment nameplate. Should the nameplate

be missing, the SERIAL NUMBER is also stamped at the

top front of the chassis.

Operator’s

Fuel Tank

Manual

Wiring Box

Lower Controls

Emergency

Lowering

Valve

Engine

Hydraulic Fluid Tank

And Filter

Right Side

Battery Disconnect Switch

Batteries

Main Boom

Chassis

Tip Boom

Nameplate

Location

Steer Wheels

Intermediate

Boom

Platform

Jib

Platform

Steer Wheels

Foot Switch

Left Side

4 SB66JRT

Page 7

Special Limitations

Special Limitations

Travel with the platform raised is limited to creep speed

range. Elevating the platform is limited to firm, level

surfaces only.

ADanger

The elevating function shall ONLY be used when the

work platform is level and on a firm surface.

The work platform is NOT intended to be driven over

uneven, rough, or soft terrain.

Platform Capacity

Two people and tools may occupy the platform. The maximum platform capacity for the aerial platform is stated in

the “Specifications” on page 19.

ADanger

DO NOT exceed the maximum platform capacity or

the platform occupancy limits for this machine.

Manual Force

Manual force is the force applied by the occupants to

objects such as walls or other structures outside the

work platform.

The maximum allowable manual force is limited to 200N

(45 lbs) of force per occupant, with a maximum of 400 N

(90 lbs) for two occupants.

ADanger

DO NOT exceed the maximum amount of manual

force for this machine.

The system will remain in error mode until the excess

load is removed from the platform and the emergency

stop button or start switch is cycled off and back on,

resetting the system. At that time, the machine functions

are operational.

ACaution

The emergency power system is for emergency lowering and stowing only. The length of time the pump

can be operated depends on the capacity of the battery. Do not use this system for normal operation.

If the platform overload sensing system is tripped while

operating the machine or if the system is in error mode

and can not be reset, the emergency power system may

still be used for emergency machine operation.

ADanger

The aerial platform can tip over if it becomes unstable.

Death or serious injury will result from a tip-over accident. Do not exceed the capacity values indicated

on the platform rating placard.

The overload sensing system is not active when the

machine is being driven with the booms in the stowed

position. This allows the machine to be driven without

the system sensing an overload due to rough ground

conditions.

To eliminate repeated tripping of the system during machine operation, there is a five second delay in machine

functions following:

starting the engine.

•

Platform Overload Sensing System

All functions are stopped from the upper and lower controls, when the platform overload limit is exceeded. The

horn will sound intermittently and the platform overload

light will blink until the excess load is removed from the

platform. At that time, the machine functions are again

operational.

If the platform becomes significantly overloaded, or if an

upward force on the platform exceeds approximately 2225

N (500 lb), the system will enter into error mode, stopping

all functions from the upper and lower controls. The horn

will then sound constantly and the overload light will stay

illuminated at the upper and lower controls.

BEAUFORT

RATING

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0 Papers and thin branches move, fl ags wave.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18 Dust is raised, paper whirls up, and small branches sway.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5 Whole trees sway. It is diffi cult to walk against the wind.

SB66JRT 5

m/s km/h ft/s mph

WIND SPEED

Figure 1 – Beaufort Scale

placing the drive/boom selector switch in the boom

•

position when the main boom is below horizontal and

fully retracted.

removing excess load from the platform.

•

Beaufort Scale

Never operate the machine when wind speeds exceed

12.5 m/s (28mph) [Beaufort scale 6]. Refer to Figure 1.

GROUND CONDITIONS

Shrubs with leaves start swaying. Wave crests are apparent in ponds

or swamps.

Tree branches move. Power lines whistle. It is diffi cult to open an

umbrella.

Page 8

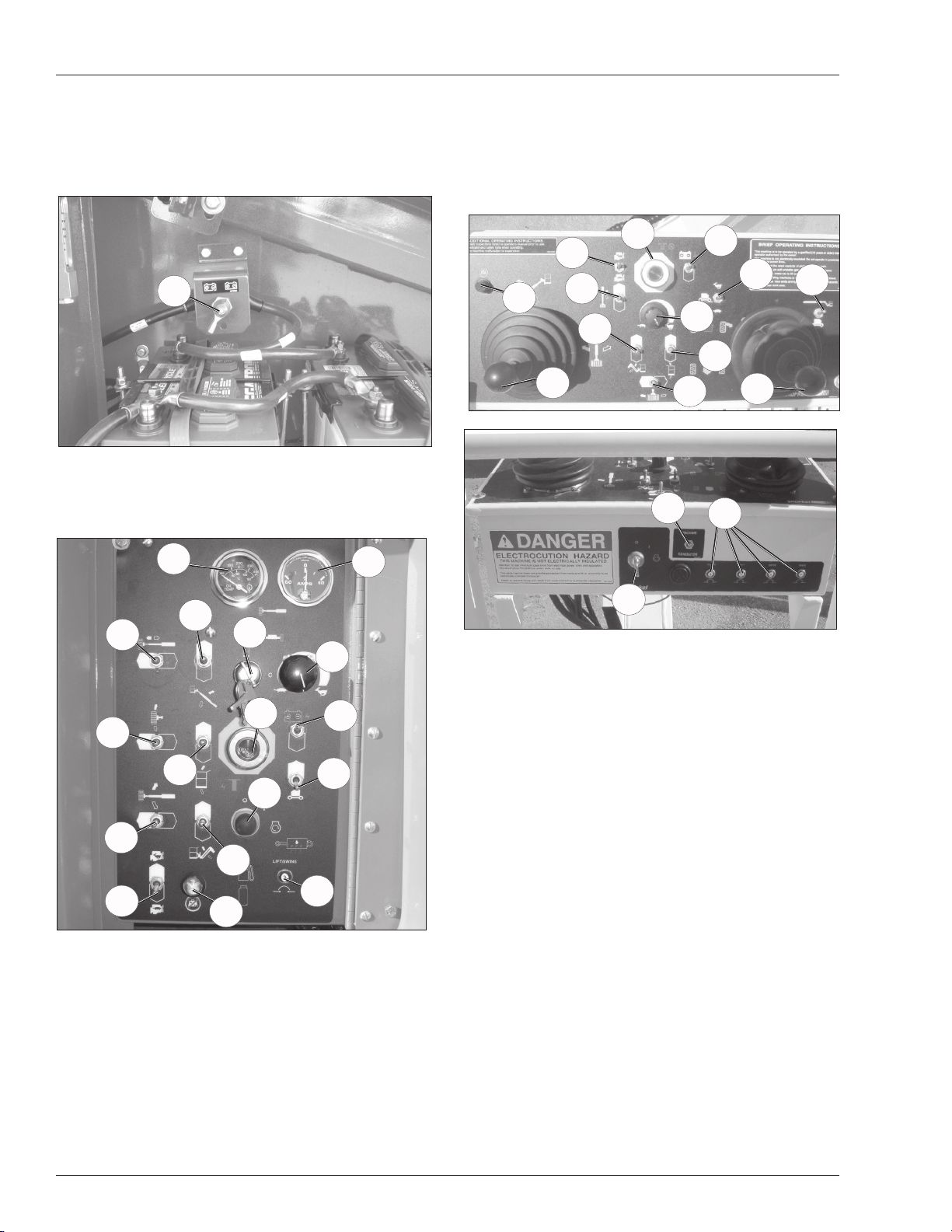

Controls and Indicators

Controls and Indicators

The operator shall know the location of each control and

indicator and have a thorough knowledge of the function

and operation of each before attempting to operate the

machine.

1

Figure 2 –Battery Disconnect Switch

1. Battery Disconnect Switch

13. Ground operation switch

14. Engine throttle switch

15. Boom rotate switch

16. Platform overload light

17. Engine temperature gauge

18. Ammeter

21

28

33

27

26

32

34

25

22

24

20

23

29

31

30

17

11

10

8

7

15

14

Figure 3 – Lower Controls and Indicators

2. Start button

3. Engine/emergency power switch

4. Emergency stop button

5. Boom speed knob

6. Circuit breaker reset button

7. Platform level switch

8. Platform rotate switch

9. Jib articulation switch

10. Boom extend/ retract switch

11. Boom elevation switch

12. Control selector switch

12

4

2

9

16

18

19

5

3

13

6

Figure 4 – Upper Controls and Indicators

19. Start switch

20. Engine/emergency power switch

21. Emergency stop button

22. Boom speed knob

23. Circuit breaker reset buttons

24. Platform level switch

25. Platform rotate switch

26. Jib articulation switch

27. Boom extend/ retract switch

28. Engine throttle switch

29. Drive range switch

30. Drive/ boom selector switch

31. Drive joystick

32. Boom joystick

33. Platform overload light

34. Machine/generator switch

6 SB66JRT

Page 9

Pre-Operation Safety Inspection

Pre-Operation Safety Inspection

Note

Carefully read, understand and follow all safety rules,

operating instructions, labels and National Safety Instructions/Requirements. Perform the following steps each

day before use.

1. Open the turntable covers and inspect for damage,

fluid leaks or missing parts.

2. Check the level of the hydraulic fluid with the platform fully lowered. The fluid level must be between

the full and add marks as viewed on the sight glass.

Add recommended hydraulic fluid if necessary. See

“Specifications” on page 19.

3. Check that the fluid level in the batteries is correct.

See “Battery Maintenance” on page 14.

4. Check that all guardrails are in place and all fasteners

are properly tightened.

5. Inspect the machine thoroughly for cracked welds

and structural damage, loose or missing hardware,

hydraulic leaks, damaged control cable and loose

wire connections.

SB66JRT 7

Page 10

System Function Inspection

System Function Inspection

Refer to “Controls and Indicators” on page 6 for the locations of various controls and indicators.

AWarning

STAND CLEAR of the work platform while performing

the following checks.

Before operating the machine, survey the work area

for surface hazards such as holes, drop-offs, bumps

and debris.

Check in ALL directions, including above the work

platform, for obstructions and electrical conductors.

1. Move the machine, if necessary, to an unobstructed

area to allow for full elevation.

2. Pull the Lower Control Emergency Stop Switch to the

ON position.

3. Pull the Upper Control Emergency Stop Switch to the

ON position.

4. Visually inspect the elevating assembly, lift cylinder,

cables, and hoses for cracked welds and structural

damage, loose hardware, hydraulic leaks, loose wire

connections, and erratic operation. Check for missing

or loose parts.

5. Test each machine function (Lift, Slew, Telescope)

from the lower control station by holding the ground

operation switch up while operating the control toggle

switches (ref: Figure 3 on page 6).

6. Test the engine/emergency power switch for proper

operation.

7. Push the Lower Control Emergency Stop Button to

check for proper operation. All machine functions

should be disabled. Pull the Lower Control Emergency Stop Button outward to resume.

8. Enter the platform and close the gate.

9. Check that the route is clear of obstacles (persons,

obstructions, debris), is level, and is capable of supporting the wheel loads.

10. Test each machine function (Drive, Lift, Slew, Telescope, Platform Rotate, Platform Level) from the

upper control station by stepping on the platform foot

switch and operating the function controls (ref: Figure

4 on page 6).

11. Push the Upper Control Emergency Stop Button to

check for proper operation. All machine functions

should be disabled. Pull the Upper Control Emergency Stop Button outward to resume.

8 SB66JRT

Page 11

Operation

Operation

The aerial platform may be operated from either the lower

or upper controls.

ADanger

The aerial platform is not electrically insulated. Death

or serious injury will result from contact with, or inadequate clearance from, an energized conductor.

Do not go closer than the minimum safe approach

distance as defined by national safety regulations.

Pinch points may exist between moving components.

Death or serious injury will result from becoming

trapped between components, buildings, structures

or other obstacles. Make sure there is sufficient clearance around the machine before moving the chassis,

booms, or platform. Allow sufficient room and time

to stop movement to avoid contact with structures

or other hazards.

The aerial platform can tip over if it becomes unstable.

Death or serious injury will result from a tip-over accident. Operate the aerial platform on a firm, flat, level

surface. Avoid travel speeds and/or rough terrain that

could cause sudden changes in platform position. Do

not drive or position the aerial platform for elevated

use near any drop-off, hole, slope, soft or uneven

ground, or other tip-over hazard.

At the lower controls, hold the manifold heater switch on

for about a minute before turning the master switch to

start the engine. A glow plug in the manifold preheats the

air to help start the engine. Continue to hold the switch

while starting the engine. Do not release the switch until

the engine starts.

If the engine does not start within 20 seconds, continue

to hold the manifold heater switch and turn the master

switch off. Wait for one minute before trying to start the

engine again.

Hydraulic System Cold Weather Warm-Up

The hydraulic oil may be warmed by bottoming out the

boom extension cylinder. Raise the main boom so it is

horizontal and operate the boom retract function while the

machine is stowed. With the cylinder bottomed out the oil

flow will produce heat to warm the hydraulic oil.

ACaution

Not all hydraulic fluid is suitable to use in the hydraulic system. Some have poor lubricating characteristics and can increase component wear. Only use

hydraulic fluid as recommended.

Use cold weather hydraulic oil as recommended in the

machine General Specifications in temperatures of

-12°C (10°F) or below.

The platform rated work load is the total weight of the personnel and equipment that may be lifted in the platform.

The work loads are stated on the platform rating placard

mounted at the rear of the platform.

ADanger

The aerial platform can tip over if it becomes unstable.

Death or serious injury will result from a tip-over accident. Do not exceed the capacity values indicated

on the platform rating placard.

Capacity values indicate the rated lifting capacity and do

not indicate aerial platform stability.

The operator bears ultimate responsibility for ensuring

that the aerial platform is properly set up for the particular

conditions encountered.

Cold Weather Start-Up

If the ambient temperature is 0°C (32°F) or below, the

engine and hydraulic system oil may need to be warmed

before operation. Do not operate the engine at more than

a fast idle until the engine and hydraulic oil has had a

chance to warm. The engine may be equipped with an

optional cold weather start kit.

Cold, thick hydraulic oil does not flow well and may cause

delay in response to control movement and improper voltage output of the AC generator. Cold oil may also cause

cavitation and pump damage. The hydraulic system may

be equipped with an optional cold weather warm-up kit.

Preparing for Operation

Use the following procedure to prepare the aerial platform

for operation.

1. Perform a prestart inspection as described in the

“Daily Preventative Maintenance Checklist” on page

16.

2. Place the battery disconnect switch in the on position.

3. Close and latch the doors.

4. Before painting or sandblasting make sure the sandblast protection kit and the platform control cover are

properly installed. These options, when used properly

will protect the control placards and cylinder rods from

paint overspray and abrasion while sandblasting.

Lower Controls

The lower controls override the upper controls. This

means that the lower controls can always be used to

operate the platform regardless of the position of the

upper control emergency stop button.

Boom, turntable, and platform functions may be operated

from the lower controls. The lower controls may be used

for initial set up of the aerial platform, and for testing and

inspection.

Use the following procedure to operate boom, turntable,

or platform functions using the lower controls (ref: Figure

3 on page 6).

SB66JRT 9

Page 12

Operation

1. Pull the emergency stop button outward. Insert the

key in the control selector and turn the switch to the

lower control position.

2. Press the start button until the engine starts, then

release. The engine will not start if the control selector switch is left in the lower control position for 30

seconds or longer before starting the engine. The

control selector switch must be turned back to off

before the engine will start.

3. Let the engine warm to operating temperature.

4. Turn the boom speed knob to slow.

5. Hold the ground operation switch up while operating

the control toggle switches.

6. Hold the appropriate toggle switch in the desired

direction.

7. Release the function toggle switch to stop movement.

8. Place the ground operation switch in the off position

when no functions are being operated.

Upper Controls

The upper controls may be used for driving the aerial

platform and positioning the booms and platform while

on the job.

2. Step down on the platform foot switch. This switch

must be held down to operate the upper controls.

3. Hold the appropriate control in the desired direction.

Always look in the direction of movement.

4. Gradually turn the boom speed knob to control

the boom extend, jib and platform rotate function

speed.

5. Releasing the control to its neutral position, or releasing the foot switch will stop movement.

Driving and Steering

ADanger

The aerial platform can tip over if it becomes unstable.

Death or serious injury will result from a tip-over accident. Do not drive an elevated aerial platform on

soft, uneven, or sloping surfaces. Do not drive the

machine on grades that exceed 25 percent.

For operation on grades up to 30 percent, it is recommended that the main boom be near horizontal and the

jib on the aerial platform elevated just enough to provide

adequate ground clearance. A 30 percent grade is a 0.91

m (36″) vertical rise in 3.05 m (10″) horizontal length.

Avoid driving with the platform over the front (steer) end

of the chassis. In this position the machine is difficult to

control because:

Use the following procedure to operate machine functions

using the upper controls.

1. At the lower controls, pull the emergency stop button

outward. Insert the key in the control selector and turn

the switch to the upper control position.

2. Enter the platform and securely close the gate.

3. Attach the fall restraint lanyard to one of the anchor

points.

4. Pull the emergency stop outward.

5. Turn the anti-restart master switch to on and pause

a few seconds while the alarm sounds to alert others

that the machine is about to start. Turn the switch to

start, then release it to on. The engine will not start if

the switch is left in the on position for 30 seconds or

longer before turning it to start. The switch must be

turned back to off before the engine will start.

6. Let the engine warm to operating temperature.

Boom Operation

Use the following procedure to operate the turntable,

boom, or platform functions.

1. Turn the boom speed knob to slow.

drive and steer control movements and their result-

•

ing machine movements are reversed.

when driving fast, sudden turns or stops produce

•

more severe reactions to platform occupants.

more turning space is required to prevent the

•

platform from colliding with obstacles several feet

beyond the path of the tyres.

AWarning

Death or serious injury can result from improperly

driving or steering the aerial platform. Read and understand the information in this manual and on the

placards and decals on the machine before operating

the aerial platform on the job.

The blue and yellow arrows on the chassis indicate the

direction the chassis will move when the drive or steer

control is moved toward the corresponding color.

When the machine is in the stowed position, with the

booms centered between the rear wheels, the direction

of drive and steer control movement corresponds with

the direction of chassis movement.

When the turntable is rotated from the stowed position,

with the booms to either side of or in front of the chassis,

the direction of control movement does not correspond

with the direction of chassis movement.

10 SB66JRT

Page 13

Operation

To avoid confusion, always drive to the work area or

move between work areas with the turntable and booms

in the stowed position. After arriving at the work area, the

booms may be positioned to the side or the front of the

chassis for final positioning. Always look in the direction

of movement as indicated by the directional arrows on

the chassis.

Use the following procedure to operate the drive and

steer functions.

1. Determine the desired drive range for the specific

driving conditions.

Use high range when traveling across fi rm, fl at,

•

level surfaces. High range can only be activated

when the booms are stowed. High range is for high

speed, low torque operation.

Use low range for driving on loading ramps or

•

other steep grades and when safety considerations

demand slow deliberate machine movement. Low

range is for low speed, high torque operation.

2. Place the drive/boom selector switch in the drive

position.

3. Step down on the platform foot switch.

4. Push the drive joystick forward to move the chassis forward, the direction of the blue arrow. Pull the

joystick backward to move the chassis backward,

the direction of the yellow arrow. The drive speed is

proportional to the joystick position.

5. To stop drive motion, return the joystick to neutral.

6. Push the drive joystick to the right to steer to the right,

the direction of the yellow arrow. Push the joystick

to the left to steer to the left, the direction of the blue

arrow.

Note

The steering wheels are not self-centering. Set the steering wheels straight ahead after completing a turn.

7. After driving to the desired location, release the foot

switch, or push the emergency stop button to apply

the parking brakes.

AWarning

The potential for an accident increases when safety

devices do not function properly. Death or serious

injury can result from such accidents. Do not alter,

disable or override any safety device.

Do not use the aerial platform if it drives faster than 0.96

km/h (0.6 miles per hour) [7.9 m (26 feet) in 30 seconds]

when the booms are elevated from the stowed position.

Motion Warning Alarm

The optional motion warning alarm sounds loud intermittent beeps when the drive joystick is in the forward or

reverse position.

AC Generator

The optional generator supplies power to the electrical

outlet only when the engine is running and the machine

is stationary. The machine functions will not operate when

the machine/generator selector switch is in the generator

position.

ACaution

Cold hydraulic oil does not flow well and may produce

improper generator output voltage. Improper outlet

voltage can damage some electrical power tools and

equipment. Warm the hydraulic oil before operating

the generator.

Do not operate the generator unless the hydraulic oil temperature is at least 38°C (100°F). Refer to Cold Weather

Start-Up for a hydraulic oil warm-up procedure.

Start the engine and place the machine/generator selector switch in the generator position (ref: Figure 4 on

page 6).

The engine will run at high idle while the generator is

operating. The generator will continue to operate as long

as the engine is running and the switch is in the generator position.

Air Line

The optional air line may be used to conduct air for tool

operation at the platform. The input connector is at the

rear of the chassis and the output connector is at the

platform on the rotator guard. The maximum working

pressure of the line is 1,723 kPa (250 psi).

Drive Speeds

The drive speed is proportional to the joystick position.

The farther the joystick is moved, the faster the travel

speed.

Always slow down and shift the drive system to low

range before traveling over rough terrain or any sloped

surface.

Drive speed ranges are interlocked through a limit switch

that senses the main boom position. When the boom is

elevated, only the slowest drive speed will work regardless of the drive range switch position.

SB66JRT 11

The air line may be used to conduct fluids such as water

or antifreeze. Contact your local distriburor or UpRight

for compatibility information before using the air line to

conduct other fluids.

ACaution

Fluid in the air line can damage some air tools or

freeze and damage the line. Drain and blow out the

air line after using it to conduct fluids.

Page 14

Operation

Use the following procedure to drain the air line.

1. Close the input connector on the chassis.

2. Open the output connector at the platform.

3. Raise the boom slightly above horizontal.

4. Open the input connector on the chassis.

5. Allow the fluid to drain from the line.

6. Lower the boom and close both connections.

Driving Lights

The optional driving lights are for use in dimly lit areas

and are not intended for driving on public roadways.

There are two headlights at the front of the chassis and

two blinking taillights at the rear of the chassis. The lights

are operational when the battery disconnect switch and

the master switch are turned on.

Note

Working with the driving or platform work lights on, while

the engine is off, can discharge the batteries enough that

the engine will not start or the emergency power system

will not operate. If the engine cannot be left running while

the lights are on, start and run the engine for at least 15

minutes each hour.

Figure 5 – Emergency Lowering Valve

After Use Each Day

1. Ensure that the platform is fully lowered.

2. Park the machine on a firm level surface, preferably

under cover, secure against vandals, children and

unauthorized operation.

3. Turn the Chassis Key Switch to OFF and remove the

key to prevent unauthorized operation.

Platform Work Lights

The optional platform work lights are located on the top

rail of the platform. The direction a light points can be

adjusted by using two 1/2″ wrenches to loosen the clamp

below the light.

The lights are operational when the upper controls emergency stop button is pulled up and the anti-restart master

switch is turned on. The engine speed increases to high

idle when the platform work lights are turned on.

Emergency Lowering

AWarning

If the platform should fail to lower, NEVER climb down

the elevating assembly.

Stand clear of the elevating assembly while operating

the Emergency Lowering Valve Knob.

Ask a person on the ground to open the Emergency Lowering Valve to lower the platform. The Emergency Lowering Valve is located on the base of the lift cylinder.

1. Slowly turn the knob to open the bleed down valve.

Control the rate of descent by turning the knob.

2. To close, turn the knob.

Note

The platform will not elevate if the Emergency Lowering

Valve is open.

12 SB66JRT

Page 15

Transporting the Machine

Transporting the Machine

Preparing for Transportation

Use the following procedure to prepare the aerial platform

for transportation.

1. Remove any unnecessary tools, materials, or other

loose objects from the platform.

2. Close and latch all cowling doors.

By Crane

Secure the straps to chassis lifting/lugs only.

Know the approximate location of the center of gravity

before lifting the machine off the ground. Refer to Figure

6.

ADanger

Lifting by Crane is for transport purposes only.

See Specifications for weight of machine and be

certain that the crane is of adequate capacity to lift

the machine.

By Truck

1. Maneuver the machine into transport position and

chock wheels.

2. Place a wood block under the tip end of the jib foot.

Lower the platform so the foot rests on the wood

block.

ACaution

Ratchets, winches, and come-alongs can produce

enough force to damage machine components. Do

not over tighten the straps or chains when securing

the aerial platform to the transport vehicle.

3. Use a nylon strap to securely fasten the platform

against the wood block. Thread the strap over the

toeboard. Refer to Figure 7.

Figure 7 – Platform

4. Secure the machine to the transport vehicle with

chains or straps of adequate load capacity attached

to the chassis lifting/tie down points.

0080650

Lifting Lug

Center of Gravity

in Stowed Position

0083426

Tie-Down Lug

1.2

m

(51 )

"

approximate

Tie-Down Lug

0083426

0083432

Figure 6 – Center of Gravity

SB66JRT 13

Page 16

Maintenance

Maintenance

AWarning

Never perform service while the platform is elevated.

Hydraulic Fluid

The hydraulic fluid reservoir is located in the chassis door.

Refer to Figure 8.

Figure 8 – Hydraulic Fluid Reservoir

Battery Maintenance

AWarning

Hazard of explosive gas mixture. Keep sparks, flame,

and smoking material away from batteries.

Always wear safety glasses when working near batteries.

Battery fluid is highly corrosive. Thoroughly rinse

away any spilled fluid with clean water.

Always replace batteries with UpRight batteries or

manufacturer approved replacements weighing 26,3

kg (58 lbs) each.

Check the battery fl uid level daily, especially if the

•

machine is being used in a warm, dry climate.

If electrolyte level is lower than 10 mm (3/8″) above the

plates add distilled water only. DO NOT use tap water with

high mineral content, as it will shorten battery life.

Keep the terminals and tops of the batteries clean.

•

Refer to the Service Manual to extend battery life and

•

for complete service instructions.

Note

Never add fluid if the platform is elevated.

Check Hydraulic Fluid

1. Make sure that the platform is fully lowered.

2. Open the left front cowling door.

3. Check the fluid level on the gauge on the end of the

reservior.

4. Add the appropriate fluid to bring the level to the FULL

mark. See “Specifications” on page 19.

Engine

Open the engine compartment doors on both sides of the

machine and visually inspect the engine and its components with the engine off.

Oil Level

Check the engine oil level before starting the engine

so the oil has drained to the pan. The proper oil level is

between the add and full marks on the dipstick.

The distance between the top and bottom dipstick marks

corresponds to about 1 l (1 quart US). Add oil, if necessary, before starting the engine.

14 SB66JRT

Page 17

Inspection and Maintenance Schedule

Inspection and Maintenance Schedule

The Complete Inspection consists of periodic visual and

operational checks, along with periodic minor adjustments

that assure proper performance. Daily inspection will prevent abnormal wear and prolong the life of all systems.

The inspection and maintenance schedule should be

performed at the specified intervals and after prolonged

periods of storage before returning the machine to service. Inspection and maintenance shall be performed by

personnel who are trained and familiar with mechanical

and electrical procedures.

AWarning

Before performing preventative maintenance, familiarize yourself with the operation of the machine.

Always block the elevating assembly whenever it is

necessary to perform maintenance while the platform

is elevated.

The daily preventative maintenance checklist has been

designed for machine service and maintenance. Please

photocopy the Daily Preventative Maintenance Checklist

and use the checklist when inspecting the machine.

SB66JRT 15

Page 18

Daily Preventative Maintenance Checklist

Daily Preventative Maintenance Checklist

Preventative Maintenance Report

Date:

Owner:

Serial No:

Serviced By:

Model No:

ITEM INSPECTION OR SERVICES Y N R

Operator’s Manual In place, all pages readable and intact

Engine

Oil level Between full and add marks

Coolant Air intake and fan free of obstructions, belt in good condition

Radiator Cap tight, good condition and clean

Fuel tank and line Tank full, cap in place and tight/ no leaks

Air filter Clear indicator

Charging system Proper operation

Cold weather start kit No damage or deformation

Electrical System

Emergency power battery Condition and charged for proper operation

Battery fluid level and terminals Proper level/clean, connectors tight

Cables and wiring harness No wear or physical damage

Hydraulic System

Fluid level Between full and add marks

Fluid filter Verify operation in the green zone

Hose, tubes and fittings No leaks

Cold weather warm-up kit Proper operation

Foam Filled Tyres and Wheels Good condition

Lower Control Station

Operating controls Proper operation

Emergency stop and emergency power Shuts off lower controls/proper operation

Emergency Lowering Proper operation

Level Sensor Sounds tilt alarm

Flashing Light Proper operation

Sandblast Protection Kit In place and proper operation

Bumpguard In place, no damage or deformation

Structures

Weldments Welds intact, no damage or deformation

Slide pads In place, no damage or deformation

Fasteners In place and tight.

Wire ropes No deformation or broken strands

Upper Control Station

Guardrail system and lanyard anchors Welds intact, no damage or deformation

Operating controls Proper operation

Emergency stop and emergency power Shuts off upper controls/proper operation

Horn Sounds when activated.

Electrical power outlet Proper operation of outlet

Drive motion alarm Sounds when aerial platform moves

Driving and work lights Proper operation

Platform control cover In place and proper operation

Placards and Decals In place and readable

Maintenance Table Key: Y = Yes/Acceptable, N = No/Not Accetable, R = Repaired/Acceptable

16 SB66JRT

Page 19

Decal Location

Decal Location

SB66JRT 17

Page 20

Decal Location

ITEM PART NO. QTY. DESCRIPTION

1 0073298 2 Placard, danger foam filled

tyres

2 0323896 5 Decal, danger electrical haz-

ard

3 0070420 1 Placard, emergency bleed

down valve

4 508234-003 2 Decal, UpRight brand logo

5 0323897 1 Decal, danger you must not

operate

6 0074209 1 Placard, pre-start instructions

7 1 Placard, platform capacity -

(consult factory)

8 0323899 1 Decal, danger electrical haz-

ard

9 0070540 3 Decal, yellow arrow

10 0070541 3 Decal, blue arrow

11 0070901 1 Placard, caution serial num-

ber

12 5560655 12 Pop rivet #AD32-ABS

13 0071425 1 Placard, platform identifica-

tion

14 0071927 1 Decal, hydraulic oil

16 562386 1 Record box

17 0073491 1 Decal, safe operation infor-

mation

18 508228-001 2 Decal, SB66JRT logo

19 0073224 1 Decal, notice manual reorder

20 0072276 2 Placard, lug nut torque

0072277 2 Placard, lug nut torque

21 5560080 8 Bumper

22 970009 2 Capscrew 1/4-20 x 1/2 inch

long hex head grade 5

23 0072531 1 Decal, danger electrical haz-

ard

24 7030003 1 Decal, lube recommenda-

tions

25 0070921 1 Placard, 125 volts 15 amps

26 0073043 1 Decal, operating manual en-

closed

27 0073139 1 Crankcase oil tag - (used for

shipping only)

28 0074311 5 Decal, danger cylinder failure

- (1 per cylinder)

29 9980021 2 Plug 3-1/2 inch diameter

30 5569012 4 Rubber bumper

31 0150448 1 Decal, attach fall restraint

32 0073492 1 Decal, rotate while greasing

33 9980022 1 Plug 4 inch diameter

34 0074372 1 Placard, engine rpm

35 0073667 2 Decal, inspect wire ropes

ITEM PART NO. QTY. DESCRIPTION

36 0074210 1 Decal, danger electrical/tipping

hazard

37 5560004 2 Nut 1/4-20 self locking

38 0074921 2 Decal, 4 inch stripe

39 0190989 1 Decal, danger do not reach

40 9980013 2 Cap

41 0181562 1 Placard, ANSI standard

42 0083232 1 Decal, lift/tie down

43 0083426 4 Decal, tie down symbol

44 0080650 4 Decal, lift

45 0071925 1 Decal, gasoline fuel

0071926 1 Decal, diesel fuel

46 0151410 3 Decal, danger rotating engine

parts

47 0074316 1 Decal, caution governor dam-

age

48 0112092 1 Decal, engine control module

49 508235-001 2 Decal, 4 x 4 logo

50 0081441 1 Placard, caution liquid with-

drawal - LP only

51 0081377 1 Decal, LPS logo - (LP fuel

only)

52 0090493 1 Decal, dual fuel instructions

53 0071793 1 Decal, hydraulic warm-up

instructions

54 508229-001 1 Decal, UpRight brand logo

18 SB66JRT

Page 21

Specifi cations

Specifi cations

Aerial Platform

Working height 21.9 m (72′)

Maximum platform height 20.1 m (66′)

Horizontal reach 17.1 m (56′)

Main boom

Articulation -1° to +72°

Extension 0 to 8.33 m (0 to 328″)

Turntable rotation 360° continuous

Turning radius, inside 4.7m (15′ 5″)

Wheelbase 3 m (10′)

Ground clearance 33 cm (13″)

Maximum wheel load 5,900 kg (13,000 lbs)

Maximum ground pressure 11.3 kPa (78 psi)

Weight, GVW

Approximate 11,916 kg (26,220 lbs)

Stowed width 2.4 m (7′ 11.5″)

Stowed length 10 m (33′)

Stowed height 2.7 m (8′ 9″)

Platform

Dimensions

Standard steel 76 cm x 152 cm (30″ x 60″)

Rated work load 227 kg (500 lb)

Optional aluminum 76 cm x 244 cm (30″ x 96″)

Rated work load 227 kg (500 lb)

Rotation 90° CW to 80° CCW

Maximum number of occupants 2 people

Optional AC generator 220 VAC

Maximum operating temperature 93°C (200°F)

Hydraulic fluid recommended

Above -12°C (10°F) Mobil DTE-13M (ISO VG32)

Below -12°C (10°F) Mobil DTE-11M (ISO VG15)

Engine

Diesel Deutz F4L-2011F

Fuel Tank Capacity

Diesel 151 l (40 US gal)

Ambient Air Temperature Operating Range

Celsius -18°C to 43°C

Fahrenheit 0°F to 110°F

Maximum Wind Speed

Gust or steady 45 km/h (28 mph)

Vibration less than 2.5 m/sec

Sound Threshold below 100 dB(A)

Working Envelope

Meters

(Feet)

21.3

(70)

2

Function Speed

Turntable rotation, 360 degrees 165 to 175 seconds

Main boom

Up 64 to 75 seconds

Down 64 to 75 seconds

Extend 65 to 75 seconds

Retract 35 to 45 seconds

Jib

Up 7 to 13 seconds

Down 7 to 13 seconds

Platform rotation, 170 degrees 16 to 20 seconds

Drive

High, booms stowed 4.8 km/h (3.0 mph)

Low, booms elevated 0.96 km/h (0.6 mph)

Drive System

Standard Four wheel drive

Optional Two wheel drive

Gradeability – theoretical 4x4 65%

Tyres

Foam Filled, 12 ply 38 cm x 50 cm (15″ x 19.5″)

Electrical System

Voltage 12 V DC negative chassis ground

Source Two - 12 V 550 CCA batteries

Fluid recommended distilled water

18.3

(60)

15.2

(50)

12.2

(40)

9.1

(30)

6.1

(20)

3.0

(10)

0

12.2

6.1

(20)

9.1

(30)

(40)

15.2

(50)

18.3

(60)

3.0

0

(10)

Hydraulic System

Maximum pressure 17,250 kPa (2,500 psi)

Reservoir capacity 99 l (26.1 US gal)

System capacity 132 l (35 US gal)

SB66JRT 19

Page 22

Page 23

Page 24

Local Distributor:

Lokaler Vertiebshändler:

Distributeur local:

El Distribuidor local:

Il Distributore locale:

USA

TEL: +1 (559) 443 6600

FAX: +1 (559) 268 2433

Europe

TEL: +44 (0) 845 1550 058

www.upright.com PN- 508372-001-(EN)

Loading...

Loading...