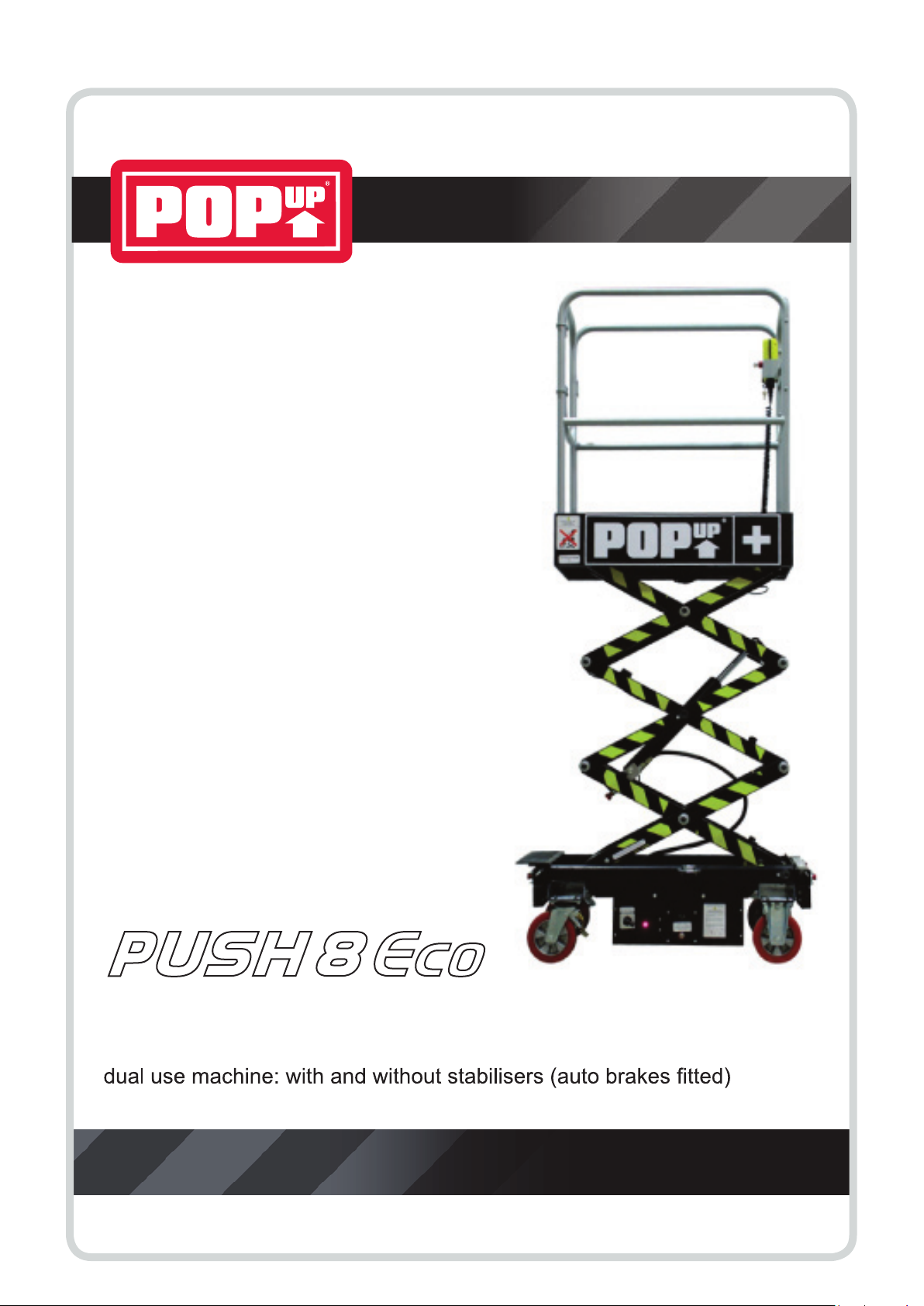

Page 1

Elevating Work Platform

Operators Safety and Maintenance Handbook

PN 510844-000-EN

JULY 2011 sn:0796+

Page 2

At Pop-Up Products we welcome

any feedback and suggested

improvements for our products.

Please email us at

feedback@popupproducts.co.uk

You can also download a copy of this

handbook online at

www.popupproducts.co.uk

Page 3

POP-UP PUSH 8 ECO

Operator’s Safety and

Contents

Section 1 Page

DESCRIPTION

Introduction 3

Description 3

Intended use 3

Training 3

Modifications 4

Terminology 5

Section 2

SPECIFICATION

Technical data 6

Operating site 7

Noise and vibration 7

Limitations 7

Section 3

SAFETY RULES

Safety Rules 8

Section 4

OPERATING INSTRUCTIONS

Daily checks 9

Manoeuvring the platform 9

Engaging the brakes 10

Auto brakes 10

Deploying the stabilisers 10

Stowing the stabilisers 10

Battery isolation switch 11

Entering and leaving the platform 12

Control pendant 12

Emergency stop 13

Emergency lowering 13

Emergency plunger valve 14

Battery charging 14

Section 5 Page

MAINTENANCE

Safety during maintenance 15

Periodical maintenance and checks 15/16

Storage 16

Lubrication 16

Hydraulic oil 17

Electrical schematic 18

Hydraulic schematic 19

Troubleshooting 20

Section 6

TRANSPORT INSTRUCTIONS

Lifting 21

Preparation for transport 21

Loading and unloading 22

Section 7

MAINTENANCE AND

REPAIR RECORD

Maintenance and repair record 23

Notes 24

Daily checks – operator checklist 25

Page 2 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 4

Introduction

This handbook provides information on the safe operation of this work

platform. Operators should read and understand all of the information

contained within this manual prior to operating the work platform.

The handbook contains several warnings, these indicate situations which if not

avoided could result in serious injury or death to persons, or damage to the

machine or property.

Additional copies of this handbook are available from the manufacturer at the

address below. Information contained in this handbook is based on the latest

product information at time of publication.

Pop-Up Products Ltd operate a policy of continuous improvement and therefore

reserve the right to make product changes at any time without obligation.

Description

The POP-UP PUSH 8 ECO is a scissor lift type work platform, which is

manoeuvred manually into work positions and elevated and lowered using an

electro-hydraulic control system.

Section 1

DESCRIPTION

The standard machine includes the following standard features:

• 240kg safe working load

• 4.5 metre working height

• 1.72 metre stowed height

• Easily manoeuvrable

• Pass through standard doors

• Simple operation

• Steel guard rails

• Non-slip platform

• Steerable wheels

• Manual brakes on rear swivel wheels

• Auto brakes on front xed wheels

• Anti-crushing lowering delay

• Integral battery charger

• Emergency lowering facility

• Easily transportable

• Low maintenance

• Complies with EN280:2001

• Stabilisers (optional if auto brakes tted)

Intended use

The machine has been designed to comply with the safety requirements of the

Machinery Directive 2006/42/EC taking guidance from the European Standard BS

EN280:2001 + A2:2009 Mobile Elevating Work Platforms.

The machine is intended to be used to lift persons, plus essential tools and

materials, to enable work to be undertaken at height. Typical applications will

include maintenance, cleaning, painting, etc. at varying heights above ground level.

WARNING

THE MACHINE MUST NOT BE USED IN APPLICATIONS OR FOR USES

OUTSIDE OF THE SCOPE OF THIS HANDBOOK. SHOULD A CERTAIN

APPLICATION NOT BE COVERED, THEN THE MANUFACTURER SHOULD

BE CONTACTED

Page 3 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 5

Training

It is essential that persons operating this POP-UP PUSH 8 ECO are fully trained

in the setting up, safe use and inspection of the machine. Please download a copy

of our free Pop-Up & POP-UP PUSH 8 ECO Familiarisation Guide from www.

popupproducts.co.uk The guide has been designed to assist competent people in

safely operating our range of low-level push around scissor lifts.

WARNING

OPERATION OF THIS MACHINE BY UNTRAINED OPERATORS MAY RESULT IN

SERIOUS INJURY OR DEATH

Modications

No modifications must be made to this machine unless the manufacturer has given

full written approval. If in doubt contact the manufacturer for advice.

Manufacturer’s address:

Pop-Up Products Limited

2 Deeside Point

Tenth Avenue

Deeside Industrial Park

Deeside

CH5 2UA

UK

Tel +44 (0)1244 833 933

Fax +44 (0)1244 833 934

Email feedback@popupproducts.co.uk

www.popupproducts.co.uk

Section 1

DESCRIPTION

Page 4 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 6

Terminology

Section 1

DESCRIPTION

1. Control pendant

2. Emergency stop button & key

3. Gate

4. Guard rail

5. Handbook

6. Platform

7. 110V and 240V charger leads

8. Scissor pack

9. Main lift cylinder

10. Emergency plunger valve

11. Maintenance props

12. Bubble spirit level

13. Stabilisers

14. Forklift pocket (1 of 4)

15. Chassis

16. Auto front brakes

17. Manual brake (1 of 2)

18. Hydraulic tank

19. Battery

20. Hydraulic pack

21. Battery charger

22. Chassis plate

23. Battery condition meter

24. Battery charging indicator

25. Battery charger socket

26. Power selector

27. Emergency lowering valve

Page 5 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 7

Technical data

Safe working load (SWL) 240kg

equivalent to 1 person + 160kg tools and materials

Maximum platform height 2.5 metres

Maximum working height 4.5 metres

Platform length 1.01 metres

Platform width 0.52 metres

Platform guard rail height 1.10 metres

Toe board height 0.15 metres

Maximum allowable manual force 200 Newtons

Maximum allowable wind speed 0 metres/sec*

Maximum allowable chassis inclination 0 degrees

Electrical system 12 volt DC

Motor 0.7 kW

Batteries 1 x 80 Ah

Battery charger Universal 90V to 240V AC

Section 2

SPECIFICATION

Hydraulic system

Maximum pressure 13 MPa

Reservoir capacity 1.22 litre

Function speeds (approx.)

Raise 24 seconds

Lower 25 seconds

Approx. no. of lifts (fully charged with SWL) 120

Overall length 1.26 metres

Overall height (stowed) 1.72 metres

Overall width (with stabilisers deployed) 1.30 metres

Overall width (without stabilisers) 0.70 metres

Overall mass (GVW) without stabilisers 343kg

Overall mass (GVW) with stabilisers 365kg

Weight (without stabilisers) 343kg

Maximum wheel load 350kg

*For use in indoor exposed areas up to 12.5m/sec wind speed – pack available on request

Page 6 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 8

Operating site

Select a site for the machine from which the platform will be able to reach the

required work area. A visual inspection of the operating site should be made before

setting up the machine. Particular attention should be given to the following items:

1. Ground conditions

Ensure that the ground on which the POP-UP PUSH 8 ECO is to operate is capable of supporting the weight of the machine (including the weight of the operator

plus tools and materials). Be aware of floors or coverings (e.g. manhole covers)

that may not withstand point loadings exerted by the castor wheels.

An interlock system ensures that the stabiliser beams and legs are fully deployed

before the work platform can be raised. It is essential that each of the four stabiliser

feet are located on firm, solid ground. The POP-UP PUSH 8 ECO auto brake kit

enables the removal of stabilisers for use in 0m/sec wind conditions.

2. Ground flatness

The POP-UP PUSH 8 ECO must only be operated on flat (0º chassis inclination)

and level surfaces. The allowable chassis inclination is indicated when the spirit

level bubble is within the marked limits. All castor wheels must be in full contact

with the ground.

Section 2

SPECIFICATION

In indoor exposed wind speeds up to 12.5m/sec the POP-UP PUSH 8 ECO can be

used with a stabiliser pack.

3. Obstructions

When manoeuvring, raising and lowering, ensure that there are no obstructions or

persons that may be struck by the platform.

Noise and vibration

Noise levels emitted from this machine do not exceed 70 dB(A). Hand and arm

vibration experienced on this machine does not exceed 0.5 m/s2.

Limitations

The POP-UP PUSH 8 ECO is limited to operation indoors. The machine must not

be used outdoors. Please consult the manufacturer if you are unsure of any application for which the machine is to be used.

This machine has been tested for Electromagnetic Compatibility (EMC) however,

operation near to high powered radio transmission apparatus (e.g. radar, antennae)

or within strong electrical and/or magnetic fields may affect some features of this

product

WARNING

THIS MACHINE HAS NOT BEEN DESIGNED FOR OPERATION WITHIN

POTENTIALLY EXPLOSIVE ATMOSPHERES

WARNING

THIS MACHINE IS NOT ELECTRICALLY INSULATED AND MUST NEVER BE

USED FOR LIVE LINE WORKING. DEATH OR SERIOUS INJURY CAN RESULT

FROM CONTACT WITH, OR INADEQUATE CLEARANCE FROM, ELECTRICAL

CONDUCTORS

Page 7 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 9

Section 3

SAFETY RULES

Safety Rules

NEVER Exceed the rated capacity (Safe Working Load or SWL) of the platform (240kgs).

NEVER Use the POP-UP PUSH 8 ECO as a ‘crane’ (e.g. by suspending loads from beneath the platform).

NEVER Make any attempt to increase the working height or outreach of the platform (e.g. by use of

stepladders in the platform).

NEVER Operate the POP-UP PUSH 8 ECO if the bubble spirit level is outside the marked limits.

NEVER Manoeuvre the POP-UP PUSH 8 ECO on an inclined surface otherwise it may become

uncontrollable.

NEVER Manoeuvre the POP-UP PUSH 8 ECO whilst in its elevated position, as this may cause instability.

NEVER Manoeuvre the POP-UP PUSH 8 ECO with a person or materials in the platform.

NEVER Enter or exit the platform unless the platform is in the lowered and transport position.

NEVER Apply external side loads to the platform or scissor structure.

NEVER Allow persons at ground level to operate the controls whilst the platform is occupied (unless in an

emergency situation).

NEVER Operate the POP-UP PUSH 8 ECO outdoors.

NEVER Attempt to overreach.

NEVER Interfere with, wedge or attempt to override hydraulic, electrical or mechanical safety devices.

ALWAYS Check that there are no obstructions or persons that may be struck by the platform before and

during the raising and lowering of the platform.

ALWAYS Ensure that the access gate is closed once the operator has entered the work platform.

ALWAYS Ensure that another responsible person on site knows how to use the emergency controls.

ALWAYS Undertake the daily checks recommended in this handbook prior to operation of the machine.

ALWAYS Ensure that all instructions, warning and Safe Working Load decals are clean and legible.

ALWAYS Ensure the POP-UP PUSH 8 ECO is positioned on adequate ground to support the weight of the

machine.

ALWAYS Ensure that sufficient clearance is given if working near to live conductors.

ALWAYS Ensure the manual rear brakes have been engaged before elevating the work platform.

ALWAYS Ensure that auto front brakes are functioning correctly before attempting to use the machine.

ALWAYS Ensure that the platform does not come into contact with fixed objects (e.g. buildings, etc.) or

moving objects (e.g. vehicles, other plant equipment, etc.).

ALWAYS Replace any removable guard rails (e.g. close and lock access gate) to enable full edge protection

to be maintained.

ALWAYS Ensure that the load is evenly distributed within the platform.

ALWAYS Ensure the safety of persons that may enter the area around the platform (e.g. cordon off the area

to prevent persons entering the danger area).

ALWAYS Ensure hands are kept within the confines of the guard rails whilst elevating the work platform.

Page 8 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 10

OPERATING INSTRUCTIONS

Daily checks

Prior to operating the POP-UP PUSH 8 ECO, the following items must be checked:

Section 4

• Structure (e.g. damage, cracks,

corrosion, abrasion, welds,

connections)

• Platform (floor, rails)

• Castors (smooth movement, damage)

• Rear manual brakes

• Auto front brakes

• Hydraulic oil

• Oil leaks

* The raise and lower functions can be tested by removing the upper control box

from its holder in the work platform and using the controls whilst at ground level.

(NOTE: unless in an emergency situation, this practice must not be employed

when a person is in the work platform).

If the above checks reveal malfunctions or damage on the POP-UP PUSH 8 ECO,

then the machine must not be used until the problem is rectified. If in doubt, seek

further assistance from the manufacturer.

If safety decals are no longer legible or missing, please contact the manufacturer

for replacements.

The Daily Checks page in Section 7 of this handbook may be photocopied to

provide an aide memoir for operators when undertaking these important checks.

• Battery condition

• Raise and lower functions (including

descent delay) *

• Emergency stop and lowering

functions

• Limit switch

• Safety decals

• Stabilisers (optional if POP-UP PUSH

8 ECO is tted with auto brakes)

WARNING

BEFORE OPERATING YOUR POP-UP PUSH 8 ECO, YOU MUST ENSURE THAT

YOU HAVE BEEN ADEQUATELY TRAINED IN ITS USE AND HAVE FULLY READ

AND UNDERSTOOD THIS OPERATOR’S HANDBOOK, PAYING PARTICULAR

ATTENTION TO SECTION 3 - SAFETY RULES

Manoeuvring the platform

Manoeuvre the platform into position using both hands on the platform rails

as shown. Take care to avoid trapping hands or feet whilst manoeuvring the

platform.

Never manoeuvre the POP-UP PUSH 8 ECO whilst it is elevated or with a

person, tools or materials in the platform.

Page 9 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 11

Section 4

OPERATING INSTRUCTIONS

Engaging the brakes

Always ensure that both rear manual castor brakes are engaged before elevating the work platform to prevent

any inadvertent movement. The brakes are engaged by pushing down on the lever as shown. Releasing the

brake is simply a reversal of the engaging procedure. Before operating please ensure that both of the manual

rear brakes are engaged.

Engage Release Auto brakes

Auto brakes

On the latest models POP-UP PUSH 8 ECO is fitted with a secondary automatic brake system acting on the

front fixed wheels. POP-UP PUSH 8 ECO does not require stabilisers if these auto brakes are fitted. An auto

brake kit is available to purchase. This system should be checked for functionality before attempting to use the

machine. To check, leave the rear manual brakes ‘OFF’ and elevate the machine approximately 150mm. Hold

the handrail on both sides at the gate end and attempt to push the machine. It should be difficult to push the

machine if the auto brakes are functioning correctly. Please consult the manufacturer if the machine is easily

pushed. Before operating please ensure the manual rear brakes are engaged. An auto brake kit is available for

POP-UP PUSH 8 ECO for the safe removal of stabilisers.

Stabilisers

Deploying the stabilisers

Models of POP-UP PUSH 8 ECO, without auto brakes, are fitted with

four stabilisers, one at each corner. All four stabilisers must be fully

deployed before the platform can be raised, as follows:

1. Pull out the red knob on the stabiliser beam housing

2. Extend the beam until it locks into position

3. Pull out the blue plunger on the stabiliser leg so that the foot

drops to the ground

4. Ensure that the plunger pin engages into the radial slot at the top

of the leg

5. Wind the handle clockwise until it is hand-tight

6. Ensure that the yellow stabiliser indicator lamp is lit

Once the stabilisers are in position, the platform can be raised to the

desired height.

Retracting and stowing the stabilisers

When work is finished on the POP-UP PUSH 8 ECO, the platform

should be lowered into its resting position and the worker should exit

the platform. Only then should the stabilisers be retracted and stowed.

To do so:

1. Turn the handle anti-clockwise to loosen the stabiliser foot

2. Pull out and hold the blue plunger

3. Lift the stabiliser leg until it is in the raised position

4. Release the blue plunger until it is seated in the radial ring around the bottom of the stabiliser leg

5. Pull the red knob on the stabiliser beam outwards

6. Push the beam back into its housing until it locks into the ‘transport’ position

Page 10 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 12

OPERATING INSTRUCTIONS

Battery isolation switch

The POP-UP PUSH 8 ECO is provided with a key operated switch which is used

to isolate the battery and therefore the electrical system, preventing unauthorised

use. To enable the electrical system, insert the key and turn clockwise, as shown

below, making sure the emergency stop button is fully released.

Ensure that when the machine is not in use, the emergency stop button is depressed and the key removed. Further electrical isolation can be achieved by

selecting ‘0’ on the power selector switch. Position ‘1’ is for normal operation and

Section 4

Page 11 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 13

OPERATING INSTRUCTIONS

position ‘2’ is for charging the machine.

Entering and leaving the work

platform

Always use three points of contact when entering or exiting the platform, using the

handholds provided. For example, use two hands and one foot, as shown below.

Section 4

Use the step provided on the base of the machine.

On entering the platform, ensure that the gate is closed behind you.

Control pendant

The control pendant houses the platform raise and lower controls.

Pressing the ‘UP’ button raises the platform.

Pressing the ‘DOWN’ button lowers the platform.

To avoid crushing and shearing hazards, a delay feature is fitted which

actuates when the platform is lowered to the transport position. The platform

will momentarily stop to enable the operator to look around the machine to

determine whether any persons are adjacent to the scissor mechanism. After

a time delay, the lowering control will be enabled once more to permit the

operator to continue to lower to the transport position.

Page 12 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 14

OPERATING INSTRUCTIONS

Take care to avoid repeated jerky movements which could cause unnecessary

impact loads on the structure.

Emergency stop

An emergency stop button is provided on the control pendant. Once depressed,

this isolates power to the raise and lower functions.

To restore functionality, twist the emergency stop button clockwise to release the

button, as shown below.

Section 4

Turning the Power Selector to the ‘0’ position also has the effect of isolating power

to the raise and lower functions.

Emergency lowering

1. Pull out Plunger ‘A’ and rotate through 90 degrees.

2. Turn valve ‘B’ anticlockwise until platform starts to lower. To stop the platform at

any time, turn valve clockwise until platform stops descending.

3. Once platform has descended fully, please ensure valve ‘B’ is closed off by

Plunger ‘A’ Valve ‘B’

Page 13 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 15

OPERATING INSTRUCTIONS

turning clockwise.

4. Also ensure that the plunger valve is reset before operating, see instructions for

plunger valve resetting.

Emergency plunger valve

The plunger valve must be reset to enable the machine to operate correctly. To

reset the valve firstly ensure Valve’B’ has been fully closed. Depress the raise

button on the pendant control and raise the platform until the maintenance stands

Section 4

can be deployed. Once the stands have been deployed simply pull Plunger

‘A’ and turn through 90 degrees. Push the plunger back into the slot as

shown left.

Depress the raise button once again and reset the maintenance stands. The

machine is now able to operate correctly.

Battery charging

A battery condition meter is fitted to the POP-UP PUSH 8 ECO as shown.

To accurately check the battery condition, a load must be applied across

the battery, elevating the machine from ground level will achieve this. Stand

away from the machine with the control pendant and press the UP button

whilst observing the bars on the metre. This metre displays the amount

of charge in the battery. All bars illuminated shows that the battery is fully

charged.

If less than four bars are on the display, the battery requires charging.

The POP-UP PUSH 8 ECO is supplied with a dedicated battery charger,

which is separate to the machine. Do not use any other type of battery

charger to charge your POP-UP PUSH 8 ECO machine.

To charge the battery, follow these steps:

1. Turn the power selector switch to ‘0’ (OFF) position.

2. Connect either the 240V or 110V lead (depending on mains supply) to the

POP-UP PUSH 8 ECO at the point shown.

Page 14 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 16

3. Connect the mains lead to a suitable power supply (either 110V or 240V)

4. Turn the power selector to ‘2’ (CHARGE) position and leave the charger to complete

the charging cycle. It will shut off automatically once finished. The battery should

be fully recharged after a period of 12 hours, which is indicated by the 95% light

illuminating on the battery charging indicator panel as shown.

Section 5

MAINTENANCE

Safety during maintenance

When performing maintenance on the POP-UP PUSH 8 ECO with the platform elevated, always ensure that the

maintenance props are engaged as shown.

WARNING

FAILURE TO ENGAGE THE MAINTENANCE PROPS MAY RESULT

IN THE PLATFORM LOWERING WITHOUT WARNING

Periodical maintenance and checks

The following checks should be undertaken at the recommended intervals shown:

Daily/Pre-use Monthly 6 Monthly 12 Monthly

Inspect structure

Inspect platform

Check castors

Check manual rear brakes function

Check auto brakes function

Inspect for oil leaks

Check battery condition

Check raise/lower functions

Check emergency stop

Check emergency lower

Check stabilisers and lights function

Inspect training card and safety decals

Check hydraulic oil level

Inspect limit switches

Inspect wiring

Check electrical connectors

Lubricate roller guides

Lubricate grease nipples

Lubricate pivot pins

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • •

• • •

• • •

• • •

• • •

• • •

• •

Page 15 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 17

Periodical maintenance and checks

(continued)

Prior to first use of the POP-UP PUSH 8 ECO, all daily/pre-use checks must be

undertaken. If the machine has been in storage for a long period of time, it may

be necessary to undertake additional checks and tests as per the table on the

preceding page (e.g. lubrication, hydraulic oil, battery condition).

The Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) require

that lifting equipment for lifting persons must be THOROUGHLY EXAMINED every

six months.

Following any maintenance on the POP-UP PUSH 8 ECO, a full function test

should be undertaken to ensure correct operation of the machine.

It is essential that only manufacturer’s approved replacement parts are used when

maintaining and servicing the POP-UP PUSH 8 ECO. Failure to do so may result in

an unsafe or unstable machine.

Section 5

MAINTENANCE

Storage

The electrical components of this POP-UP PUSH 8 ECO are not protected from external weather conditions and the machine should therefore not be stored outdoors.

Storage in a clean, dry indoor environment is recommended.

Frequent checks on the condition of the machine should be made to ensure no

excessive deterioration occurs due to the environment in which the machine is

housed.

Lubrication

The required lubrication points are shown opposite.

Lubrication points are to be found on the end of the scissor pack at both

ends of the machine.

The lubricant recommended for use with this POP-UP PUSH 8 ECO is:

standard machine grease

Page 16 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 18

Hydraulic oil

The hydraulic oil level can be checked by removing the filler cap. The correct

amount of oil is in the tank when the tip of the level rod has hydraulic oil on it. This

check must be carried out on a level surface.

The hydraulic oil can be topped up by adding oil to the filler as shown below. Take

care not to spill hydraulic fluid over any of the surrounding machine components.

The hydraulic oil can be drained by removing the tank. Remove the bolts as shown

above and separate the tank from the pump body. The hydraulic fluid can then be

correctly disposed of.

Reassembly is the reverse of above.

Section 5

MAINTENANCE

Filler cap Bolts

The hydraulic oil recommended for use with this POP-UP PUSH 8 ECO is: mineral

basis hydraulic oil with lubricating, antifoaming, anti-corrosive, antioxidant HLHLP (ISO and UNI HM)-HV-HLPD performances according to DIN51524 part 1-2

standards

Minimum viscosity 15cts (23oE / 77, 39 SSU at 100oF)

Max. viscosity at starting up 800cts (105,6oE / 3708 SSU at 100oF)

Max. working viscosity 100cts (13,2 E / 463,5 SSU at 100oF)

Suggested viscosity range 25 ÷ 40 cts = (3,47 ÷ 5,35o E / 119,3 ÷ 186,3 SSU a 100oF)

Allowed temperature Max 80oC (176oF)

Recommended temperature 30 ÷ 60oC (86 ÷ 140oF)

Page 17 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 19

Electrical schematic

Section 5

MAINTENANCE

Page 18 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 20

Hydraulic schematic

CYLINDER

Section 5

MAINTENANCE

ELECTROMAGNETIC VALVE

VALVE 512728-000

ELECTROMAGNETIC

VALVE

CHECK VALVE

MOTOR

FILTER

RELIEF VALVE

THROTTE VALVE

PUMP

FILTER

RESERVOIR

Page 19 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 21

Troubleshooting

Problem Cause Repair

Section 5

MAINTENANCE

Platform does not raise

(motor not running)

Platform does not raise

(motor running)

Platform creeps

(uncontrolled lowering)

Oil leakage from cylinder Faulty sealing Replace sealing

Oil leakage from piping or joint Insufficient tightening or seal

Oil leakage from air breather Excessive quantity of oil Reduce oil quantity

1. Faulty wiring 1. Check the wiring referring to the

electrical schematic

2. Battery is disconnected 2. Reconnect the battery

3. Battery charge is insufficient 3. Charge the battery

1. Faulty adjustment of relief

valve

2. Faulty hydraulic pump 2. Replace power pack

3. Insufficient hydraulic oil 3. Add hydraulic oil

1. Oil leakage in power pack 1. Replace lowering valve

2. Oil leakage from hydraulic

circuit

invalid

1. Adjust relief valve

2. Check hydraulic circuit and repair

Tighten joint again or replace seal

Page 20 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 22

TRANSPORT INSTRUCTIONS

Lifting

No lifting attachment points are provided on the POP-UP PUSH 8 ECO and therefore lifting of the machine (e.g. with a crane or straps) is prohibited.

Preparation for transport

Prior to transporting the POP-UP PUSH 8 ECO on a vehicle, ensure that the following precautions are taken in order to avoid damage to the machine or damage

to the transporting vehicle.

1. Ensure that the platform is fully lowered to its rest position.

2. Ensure that loose items (e.g. control pendant, battery charger) are secured to

the platform.

3. Ensure brakes are engaged on both rear castor wheels.

4. Secure the POP-UP PUSH 8 ECO to the transport vehicle using straps across

the platform as shown below.

Section 6

Page 21 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 23

TRANSPORT INSTRUCTIONS

Loading and unloading

When loading or unloading the POP-UP PUSH 8 ECO, use one of the methods

shown.

Forklift Tail lift

Section 6

When using a forklift to lift the POP-UP PUSH 8 ECO, ensure the forks are

sufficiently inserted into the forklift pockets in the base of the machine. Safety decals applied to the POP-UP PUSH 8 ECO show the location of the forklift pockets.

When using a tail lift to load or unload the POP-UP PUSH 8 ECO ensure that the

manual brakes are applied to both rear castor wheels. Ensure that the capacity of

the tail lift is sufficient to handle the POP-UP PUSH 8 ECO. Take care when ma-

noeuvring the machine on the tail lift.

WARNING

NEVER ATTEMPT TO LOAD OR UNLOAD THE POP-UP PUSH 8 ECO BY

MANUAL EFFORT ONLY, SERIOUS INJURY, MACHINE OR PROPERTY

DAMAGE COULD RESULT

Page 22 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 24

MAINTENANCE AND

REPAIR RECORD

Maintenance

Date Scheduled maintenance undertaken By

Repairs

Section 7

Date Repairs undertaken By

Examinations/tests

Date Examinations/tests undertaken By

PLEASE PHOTOCOPY THIS PAGE FOR YOUR OWN USE, AS REQUIRED.

Page 23 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 25

Notes

Section 7

MAINTENANCE AND

REPAIR RECORD

Page 24 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 26

Daily checks – operator checklist

The following checklist has been provided to enable daily checks to be

undertaken prior to use of this POP-UP PUSH 8 ECO. These checks should

be carried out each working day or at the beginning of each shift. The

purpose of the checks is to identify any wear and tear or malfunction of the

machine’s components and systems.

WARNING

FAILURE TO UNDERTAKE THESE CHECKS MAY RESULT IN DEFECTS ON, OR

DETERIORATION OF THIS POP-UP PUSH 8 ECO GOING UNDETECTED AND

POSSIBLY RESULTING IN AN UNSAFE MACHINE

Note that Regulation 8 of the Lifting Operations and Lifting Equipment

Regulations 1998 (LOLER) require that persons using lifting equipment have

appropriate training and instructions to enable them to identify whether

lifting equipment is safe to use.

Section 7

MAINTENANCE AND

REPAIR RECORD

Machine number

1. Prior to operating the platform, the following items must be checked:

OK? (please tick) OK? (please tick)

Structure Battery condition

Platform Raise and lower

Castors Emergency stop

Rear manual brakes Emergency lower

Front auto brakes Limit switch

Hydraulic oil Safety decals

Stabilisers (optional if POP-UP PUSH 8 ECO is fitted with auto

Oil leaks

Date

brakes)

Checked by

2. Use raise, lower and emergency stop functions to ensure correct operation.

Should any defects be identified in any of the above areas, these should be reported to your employer. It may be necessary to further seek assistance from the

supplier of the machine, this may be the hire company or the manufacturer. You

should only rectify any defects if you are authorised and competent to do so.

Do not use the machine unless each of the items above is checked and

stated OK.

Page 25 of 25Pop-Up PUSH 8 ECO Operator’s Safety and Maintenance Handbook ( rev.0.0.1.0210)

Page 27

At Pop-Up Products we welcome

any feedback and suggested

improvements for our products.

Please email us at

feedback@popupproducts.co.uk

You can also download a copy of

this handbook online at

www.popupproducts.co.uk

Page 28

Pop-Up Products Limited

Pop-Up Products Limited

Call +44 (0) 1244 833933

Email contact@popupproducts.co.uk

www.popupproducts.co.uk

IPS Service, Parts & Warranty

Service +44 (0)1952 671 400

Parts & Warranty +44 (0) 1952 607 660

www.ips-ltd.biz

www.popupproducts.co.uk

Pop-Up Products Limited

2 Deeside Point, Tenth Avenue, Deeside Industrial Park, Deeside CH5 2UA

Tel +44 (0) 1244 833 933 Fax +44 (0) 1244 833 934 Email contact@popupproducts.co.uk

Loading...

Loading...