Page 1

ENVELOPE MANAGEMENT

SYSTEM (

EMS

)

CALIBRATION MANUAL

MODELS

TB 120, PRO 100 & PRO 126

Use this manual to calibrate all PRO 100, PRO 126 and TB 120

machines.

See table of contents for section that is for your machine.

DO NOT attempt to calibrate the

read and completely understanding the procedures described in this

manual.

ONLY qualified personnel, trained on the

calibration procedures.

Should there be any question concerning anything covered in this

manual, contact the Snorkel Customer Service Department, telephone

816-364-0317 or for additional information.

Snorkel

P O Box 1160

St Joseph Mo 64502-1160

Phone: 816-364-0317

EMS

system without having first

EMS

, should perform

EMS

P/N 0191401

April 1997 - revised September 2000

Printed in the USA

Page 2

IMPORTANT INFORMATION

Before performing

we recommend that you have the following tools at

your disposal:

1. Fluke 88 or equivalent.

2. Calibration harness - Snorkel part no. 0191008

3. Three prong test plug - Snorkel part no. 0191025

4. Two prong test plug - Snorkel part no. 0191024

5. EZ Cal (when available)

EMS

trouble shooting or calibration,

Page 3

TABLE OF CONTENTS

SECTION I

CALIBRATION TB 120 machines manufactured before September 1994

and have not been updated to three point computers.

Joystick calibration – (lift and extend) . . . . . . . . . . . . . . . . . . . 1 - 1

Sensor calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Ramp calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Full speed/half speed calibration . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Half speed calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Valve calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Backup

SECTION II

CALIBRATION TB 120 machines manufactured before September 1994

EMS

calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

and have been updated to three point computers.

To determine if machine has been updated, look

inside turntable under base boom on right side for angle

indicator arm.

1-3

1-4

Joystick calibration – (lift and extend) . . . . . . . . . . . . . . . . . . . 2 - 1

Sensor calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Three point calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Ramp calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Full speed/half speed calibration . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Half speed calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Valve calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

Backup

SECTION III

CALIBRATION All PRO 100 and PRO 126 machines

Joystick calibration – (lift and extend) . . . . . . . . . . . . . . . . . . . 3 - 1

Sensor calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Ramp calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 5

Speed calibration table (factory settings) . . . . . . . . . . . . . . . . . 3 - 6

Full speed calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Half speed calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Valve calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

EMS

calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

and TB 120 machines manufactured after September 1994

3-2

3-4

3-6

Page 4

TABLE OF CONTENTS

SECTION IV

GENERAL CALIBRATION NOTES

Primary and backup

Common mistakes in the calibration . . . . . . . . . . . . . . . . . . . . 4 - 2

Calibration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Primary joystick and sensor calibration overview . . . . . . . . . . . . 4 - 2

Ramp calibration overview . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Full/Half speed calibration overview . . . . . . . . . . . . . . . . . . . . 4 - 4

Valve calibration overview . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

EMS

SECTION V

TROUBLE SHOOTING FOR ENVELOPE MANAGEMENT SYSTEM

Trouble shooting description index. . . . . . . . . . . . . . . . . . . . . 5 - 1

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Primary and backup set location illustration . . . . . . . . . . . . . . . 5 - 2

Primary set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Backup set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Primary

Primary

Primary

Backup

Trouble shooting for system calibration errors . . . . . . . . . . . . . . 5 - 13

calibration modes & tables . . . . . . . . . . . . . . . . . . . . . . 4 - 6

EMS

EMS

EMS

EMS

errors during power-up . . . . . . . . . . . . . . . . . . . 5 - 3

errors when joystick is at center . . . . . . . . . . . . . . 5 - 6

errors during normal operation . . . . . . . . . . . . . . . 5 - 8

errors (TB 120 and PRO 126 only) . . . . . . . . . . . . . 5 - 11

EMS

system . . . . . . . . . . . . . . . . . . . . . 4 - 1

4-3

5-4

5-5

5-7

5-8

5-9

5-10

5-11

5-12

Page 5

SECTION I

CALIBRATION

Use this section to calibrate - TB 120 machines manufactured before

September 1994 and have not been updated to three point computers.

Before performing the sensor calibration make sure the unit is on a flat, firm

and level surface with the turntable in the stowed position, boom over rear

axle, counter weight over the steer axle.

Primary and backup

EMS

may be calibrated individually or simultaneously.

WARNING

During sensor calibration, the envelope management

system DOES NOT limit the position of the platform. The

operator should follow the calibration instructions carefully

to prevent positioning the platform outside of the working

envelope.

JOYSTICK CALIBRATION - (LIFT AND EXTEND):

1. Turn platform Master switch “OFF”, pull Emergency Stop switch button “OUT”.

2. At ground control, set Platform/Ground Selector switch to “PLATFORM”, pull

Emergency Stop button “OUT” and turn Master switch “ON”.

Note: Engine and all EMS status lights should be “OFF”.

3. At platform, move the Drive Controller to full “ON” forward while pressing and

holding the CALIBRATE and ERROR RESET buttons and starting the engine.

Note: Wait for approximately, two (2) seconds until SYSTEM NORMAL

light remains on. Also note that the CAL MODE light will flash

four (4) times and then remain on.

4. Let go of controller and buttons.

5.

DO NOT ACTIVATE THE FOOT SWITCH. Fully deflect each of the following

controllers, (full “ON” each direction). Extend\Retract\Up\Down. Make sure you

hold each controller “ON” for a few seconds in each direction. Push the

CALIBRATE button.

Note: If the calibration is accepted - two (2) short beeps will be heard.

The system will then go into the sensor calibration. If a long beep

sounds - TURN OFF the machine and start the controller and

sensor calibration again.

6. Continue on to sensor calibration without shutting engine “OFF”.

Page no. 1 - 1

Page 6

SENSOR CALIBRATION:

1. Open junction box on left side of turntable and install calibration harness to all

matching numbered terminals.

Note: Disconnect

EMS

harness leads labeled 14, 15, 21 and 22 from

proportional control valve. Match numbers and connect the

remaining calibration harness leads to proportional control valve.

2. Make sure boom is fully lowered and fully retracted before proceeding.

3. At ground control station, perform the following boom operations:

1. Set Platform/Ground Selector switch to “GROUND”.

2. Fully retract boom.

3. Lower boom fully.

4. Raise boom until it stops.

5. Keep boom raised, extend boom fully.

6. Raise boom fully.

7. Press CALIBRATE button.

If the data is accepted, there will be two (2) short beeps. One (1) long beep

indicates incorrect data has been entered. If one (1) long beep is heard, turn

“OFF” the machine and repeat the joystick and sensor calibrations again.

If the backup

EMS

has been calibrated and is currently effective, the boom will

stop at the backup envelope during step 4 above, causing continuous repeating

beeps, indicating the backup envelope has been reached.

After the two (2) calibration data sets are accepted, (joystick and sensor), the

system may error out right away. This will indicate that other calibration data

has not been done or more data need to be calibrated.

If other data is calibrated and is acceptable, the system will go to normal

operation. Turn engine “OFF”. Remove calibration harness and reconnect

EMS

to proportional control valve. Retract and lower boom.

RAMP CALIBRATION - (FACTORY SET AT FOUR (4) CLICKS:

(At ground control, perform the following).

1. Press and hold both the CALIBRATE and ERROR RESET buttons firmly.

Turn “ON” the power - (DO NOT start engine). Wait for approximately two (2)

seconds until SYSTEM NORMAL, AUTO MODE and CAL MODE lights remain

on. Note that the CAL MODE light will flash two (2) times.

Let go of the two buttons.

2. One (1) short beep will be heard, indicating that the ramp speed for extend is to

be set. To set the ramp speed for extend, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished, press the CALIBRATE button. (0 essentially skips calibration for this

function, leaving the previous calibration value intact).

Page no. 1 - 2

Page 7

RAMP CALIBRATION (Continued):

3. Two (2) short beeps will be heard, indicating that the ramp speed for retract is to

be set. To set ramp speed for retract, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished press the CALIBRATE button.

4. Three (3) short beeps will be heard, indicating that the ramp speed for lift is to

be set. To set the ramp speed for lift, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished press the CALIBRATE button.

5. Four (4) short beeps will be heard, indicating that the ramp speed for lower is to

be set. To set the ramp speed for lower, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished press the CALIBRATE button.

Note: If the system has a calibration error or has never been calibrated,

MAKE SURE to press the ERROR RESET button at least once for

each ramp speed, otherwise the pre-programmed data will not

change (calibrate).

Upon completion of steps 2 through 5, the system will beep twice, indicating

the calibration has been completed for ramp. There will not be an error in this

calibration because the system will always accept the change (calibration), if

any. If the system errors out immediately after ramp calibration, other data has

not been calibrated. Turn “OFF” machine and proceed to the FULL Speed/Half

Speed calibration procedure.

FULL SPEED/HALF SPEED CALIBRATION - (Factory set at 1 click):

1. Deflect the Drive joystick forward while pressing and holding the CALIBRATE

button firmly. Then turn the power “ON”, (DO NOT start the engine). Wait for

approximately two (2) seconds until the SYSTEM NORMAL, CAL MODE and

AUTO MODE lights are “ON”. Note, the CAL MODE light will flash three (3)

times. Release the CALIBRATE button and joystick.

2. One (1) beep will be heard, indicating that the extend speed is to be set. To set

the extend speed, press the ERROR RESET button the number of times for the

desired speed with one (1) being the fastest and eight (8) being the slowest.

When finished press the CALIBRATE button. (0 essentially skips calibration for

this function, leaving the previous calibration value intact).

3. Two (2) beeps will be heard, indicating that the retract speed is to be set. To set

the retract speed, press the ERROR RESET button the number of times for the

desired full speed, with one (1) being the fastest and eight (8) being the slowest.

When finished press the CALIBRATE button.

4. Three (3) beeps will be heard, indicating that the full lift speed is to be set. To

set the full lift speed, press the ERROR RESET button the number of times for

the desired full speed, with one (1) being the fastest and eight (8) being the

slowest. When finished press the CALIBRATE button.

Page no. 1 - 3

Page 8

FULL SPEED/HALF SPEED CALIBRATION (Continued):

5. Four (4) beeps will be heard, indicating that the full lower speed is to be set. To

set the full lower speed, press the ERROR RESET button the number of times

for the desired full speed, with one (1) being the fastest and eight (8) being the

slowest. When finished press the CALIBRATE button.

The system bill beep twice, indicating that calibration has been completed for

full speed. There will not be an error in this calibration because the system will

always accept the change (calibration) if any.

HALF SPEED CALIBRATION - (Factory set at 4 clicks):

6. The system will immediately go to half lift speed calibration, three (3) beeps will

be heard. Set the half lift speed by pressing the ERROR RESET button the

number of times corresponding to the desired speed with one (1) being the

fastest and eight (8) being the slowest speed. Then press the CALIBRATE

button.

7. Four (4) beeps will be heard, indicating that the half lower speed is to be set. To

set the half speed for lower, press the ERROR RESET button the number of

times for the desired speed, with one (1) being the fastest and eight (8) being

the slowest. When finished press the CALIBRATE button.

Note: If the system has a calibration error or has never been calibrated,

MAKE SURE to press the ERROR RESET button at least once for

each Full/Half speed, otherwise the pre-programmed data will not

change (calibrate).

Upon completion of steps 2 through 7, the system will beep twice, indicating

the calibration has been completed for Full/half speed. There will not be an

error in this calibration because the system will always accept the change

(calibration), if any. If the system errors out immediately after Full/Half speed

calibration, other data has not been calibrated. Turn “OFF” machine and

proceed to the valve calibration procedure.

If other data is calibrated and acceptable, the system will go to normal

operation.

Page no. 1 - 4

Page 9

VALVE CALIBRATION:

Note: MAKE SURE the hydraulic oil is at operating temperature (80° F.),

before calibration.

1. At the ground control, raise the boom to approximately horizontal height with

boom partially extended, (two to three feet), to allow for valve calibration.

Turn engine “OFF”.

2. Press and hold the CALIBRATE button firmly, then start the engine, wait for

approximately two (2) seconds until the SYSTEM NORMAL, AUTO MODE and

CAL MODE lights are “ON”. Note that the CAL MODE light will flash once. Let

go of the CALIBRATE button.

3. Operate the Extend control switch and Ground Operation switch allowing the

boom to extend at full speed. It takes more than a few seconds before the boom

starts to move. Continue to hold the Extend control switch until the boom stops.

Operate the Retract control switch and Ground Operation switch to retract the

boom at full speed until the boom comes to a full stop. Then do the same for Lift

and Lower, releasing the Ground Operation switch after each function.

MAKE SURE that when performing the valve calibration that you hold the

function switch for Extend, Retract, Lift and Lower on long enough or at the end

of the valve calibration procedure it will error out.

4. Observe the motion of the boom carefully, especially in cold oil conditions. If the

boom fails to move for more than 120 seconds or two minutes, turn “OFF” the

machine and start the valve calibration again.

5. If the data is accepted for all four functions, two (2) short beeps will be heard;

otherwise a long beep will sound. If a long beep sounds, turn “OFF” the machine

and start the valve calibration again.

6. If the system accepts the calibration data and then errors out immediately after

calibration, return to the joystick and sensor calibration and repeat all of the

above procedures.

7. At this stage, all data should have been calibrated. The system goes to normal

operation and SYSTEM NORMAL and AUTO MODE lights should stay “ON”.

Page no. 1 - 5

Page 10

BACKUP

EMS

CALIBRATION:

1. Before calibration, power up the machine. If the calibration data stored in the

EMS

controller has been calibrated before and is currently within acceptable

limits, the system will go to normal operation with SYSTEM NORMAL on.

2. If the system errors out with ERROR and CAL MODE lights on, then the data

stored in the

EMS

controller is not correct or has not been calibrated.

3. It is required to calibrate the sensor when it is initially installed into the

TB 120 machine.

4. Install Cal harness.

Sensor Calibration:

(Make sure boom is fully lowered and fully retracted before proceeding).

1. Press and hold back-up CALIBRATE and ERROR RESET buttons while starting

the engine, (requires two persons). Wait for approximately two (2) seconds until

SYSTEM NORMAL and CAL MODE lights are on. Note that CAL MODE light

will flash four (4) times. Let go of the two buttons.

2. To calibrate sensors, length and angle sensors are moved through the full

extremes of boom lift and extend movements.

3. Using The ground controls, move the boom in the following sequence:

1. Retract boom fully.

2. Lower boom fully.

3. Raise boom until it stops.

4. Keeping boom raised, extend boom fully.

5. Raise boom fully.

6. Press CALIBRATE button.

If the calibration data is accepted, there will be two (2) short beeps; else, a

long beep (2 seconds). If a long beep should sound, turn “OFF” machine and

start sensor calibration again.

Note: When the calibration data is accepted, the system will go to normal

operation.

Page no. 1 - 6

Page 11

SECTION II

CALIBRATION

Use this section to calibrate - TB 120 machines manufactured before

September 1994 and have updated to three point computers. To determine if

machine has been updated, look inside turntable under base boom on right

side for angle indicator arm.

Before performing the sensor calibration make sure the unit is on a flat, firm

and level surface with the turntable in the stowed position, boom over rear

axle, counter weight over the steer axle.

Primary and backup

EMS

may be calibrated individually or simultaneously.

WARNING

During sensor calibration, the envelope management

system DOES NOT limit the position of the platform. The

operator should follow the calibration instructions carefully

to prevent positioning the platform outside of the working

envelope.

JOYSTICK CALIBRATION - (LIFT AND EXTEND):

1. Turn platform Master switch “OFF”, pull Emergency Stop switch button “OUT”.

2. At ground control, set Platform/Ground Selector switch to “PLATFORM”, pull

Emergency Stop button “OUT” and turn Master switch “ON”.

Note: Engine and all EMS status lights should be “OFF”.

3. At platform, move the Drive Controller to full “ON” forward while pressing and

holding the CALIBRATE and ERROR RESET buttons and starting the engine.

Note: Wait for approximately, two (2) seconds until SYSTEM NORMAL

light remains on. Also note that the CAL MODE light will flash

four (4) times and then remain on.

4. Let go of controller and buttons.

5.

DO NOT ACTIVATE THE FOOT SWITCH. Fully deflect each of the following

controllers, (full “ON” each direction). Extend\Retract\Up\Down. Make sure you

hold each controller “ON” for a few seconds in each direction. Push the

CALIBRATE button.

Note: If the calibration is accepted - two (2) short beeps will be heard.

The system will then go into the sensor calibration. If a long beep

sounds - TURN OFF the machine and start the controller and

sensor calibration again.

6. Continue on to sensor calibration without shutting engine “OFF”.

Page no. 2 - 1

Page 12

SENSOR CALIBRATION:

1. Open junction box on left side of turntable and install calibration harness to all

matching numbered terminals.

Note: Disconnect

EMS

harness leads labeled 14, 15, 21 and 22 from

proportional control valve. Match numbers and connect the

remaining calibration harness leads to proportional control valve.

2. At ground control station, perform the following boom operations:

1. Set Platform/Ground Selector switch to “GROUND”.

2. Fully retract boom.

3. Lower boom fully.

4. Raise boom until it stops.

5. Keep boom raised, extend boom fully.

6. Raise boom fully.

7. Press CALIBRATE button.

If the data is accepted, there will be two (2) short beeps. One (1) long beep

indicates incorrect data has been entered. If one (1) long beep is heard, turn

“OFF” the machine and repeat the joystick and sensor calibrations again.

If the backup

EMS

has been calibrated and is currently effective, the boom will

stop at the backup envelope during step 4 above, causing continuous repeating

beeps, indicating the backup envelope has been reached.

THREE POINT CALIBRATION:

The following addition to the sensor calibration procedure is required for the

TB 120 machines with

EMS

electronic control units identified by Apitech part

number MC21320019 for the primary system and part number MC21320020 for

the backup system. These units require a “third point” or step to complete the

calibration of the boom angle software. This added step to the calibration

procedure verifies the angle at which the

EMS

system begins coordinate

movement of the boom down and retract functions. The “third point” indicator

arm is located on the inside of the right side of the turntable.

1. Once the Joystick and Sensor Calibration is successfully completed, the

EMS

now goes directly into the third point calibration mode.

2. The operator must retract the boom then lower the boom until the pin contacts

the boom at the mark stamped on the boom. Care must be taken to align the pin

and the mark as close as possible. It is recommended that the contact be

inspected up close as opposed to from ground level.

3. In this position the operator must depress the CALIBRATE button. Should the

data be acceptable, the audible alarm will sound two (2) short beeps. If the data

is bad, the ERROR indicator will be illuminated and the audible alarm will sound

one long beep. Turn “OFF” the machine and repeat the joystick. sensor and

three point calibration again. The

EMS

will only allow 2° ± for this calibration.

Once and audible acknowledgment has been given, the SYSTEM NORMAL

indicator will be illuminated signifying that the vehicle is ready for operation.

This procedure must be also REPEATED at the end of the BACKUP SYSTEM

calibration as outlined on page2-7ofthis manual.

Page no. 2 - 2

Page 13

THINGS THE PRIMARY LOOKS FOR AND THAT THE BACKUP LOOKS FOR

PRIMARY LOOKS FOR BACKUP LOOKS FOR

1. JOYSTICK CALIBRATION

2. SENSOR CALIBRATION

3. THREE POINT CALIBRATION (IF EQUIPPED WITH)

1. SENSOR CALIBRATION

2. THREE POINT CALIBRATION

After the three (3) calibration data sets are accepted, (joystick, sensor and

three point), the system may error out right away. This will indicate that other

calibration data has not been done or more data need to be calibrated.

If other data is calibrated and is acceptable, the system will go to normal

operation. Turn engine “OFF”. Remove calibration harness and reconnect

EMS

to proportional control valve. Retract and lower boom.

RAMP CALIBRATION - (FACTORY SET AT FOUR (4) CLICKS:

1. Press and hold both the CALIBRATE and ERROR RESET buttons firmly.

Turn “ON” the power - (DO NOT start engine). Wait for approximately two (2)

seconds until SYSTEM NORMAL, AUTO MODE and CAL MODE lights remain

on. Note that the CAL MODE light will flash two (2) times. Let go of the buttons.

2. One (1) short beep will be heard, indicating that the ramp speed for extend is to

be set. To set the ramp speed for extend, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished, press the CALIBRATE button. (0 essentially skips calibration for this

function, leaving the previous calibration value intact).

3. Two (2) short beeps will be heard, indicating that the ramp speed for retract is to

be set. To set ramp speed for retract, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished press the CALIBRATE button.

4. Three (3) short beeps will be heard, indicating that the ramp speed for lift is to

be set. To set the ramp speed for lift, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished press the CALIBRATE button.

5. Four (4) short beeps will be heard, indicating that the ramp speed for lower is to

be set. To set the ramp speed for lower, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished press the CALIBRATE button.

Note: If the system has a calibration error or has never been calibrated, MAKE

SURE to press the ERROR RESET button at least once for each ramp

speed, otherwise the pre-programmed data will not change (calibrate).

Upon completion of steps 2 through 5, the system will beep twice, indicating

the calibration has been completed for ramp. There will not be an error in this

calibration because the system will always accept the change (calibration), if

any. If the system errors out immediately after ramp calibration, other data has

not been calibrated. Turn “OFF” machine and proceed to the FULL Speed/Half

Speed calibration procedure.

Page no. 2 - 3

Page 14

FULL SPEED/HALF SPEED CALIBRATION - (Factory set at 1 click):

1. Deflect the Drive joystick forward while pressing and holding the CALIBRATE

button firmly. Then turn the power “ON”, (DO NOT start the engine). Wait for

approximately two (2) seconds until the SYSTEM NORMAL, CAL MODE and

AUTO MODE lights are “ON”. Note, the CAL MODE light will flash three (3)

times. Release the CALIBRATE button and joystick.

2. One (1) beep will be heard, indicating that the extend speed is to be set. To set

the extend speed, press the ERROR RESET button the number of times for the

desired speed with one (1) being the fastest and eight (8) being the slowest.

When finished press the CALIBRATE button. (0 essentially skips calibration for

this function, leaving the previous calibration value intact).

3. Two (2) beeps will be heard, indicating that the retract speed is to be set. To set

the retract speed, press the ERROR RESET button the number of times for the

desired full speed, with one (1) being the fastest and eight (8) being the slowest.

When finished press the CALIBRATE button.

4. Three (3) beeps will be heard, indicating that the full lift speed is to be set. To

set the full lift speed, press the ERROR RESET button the number of times for

the desired full speed, with one (1) being the fastest and eight (8) being the

slowest. When finished press the CALIBRATE button.

5. Four (4) beeps will be heard, indicating that the full lower speed is to be set. To

set the full lower speed, press the ERROR RESET button the number of times

for the desired full speed, with one (1) being the fastest and eight (8) being the

slowest. When finished press the CALIBRATE button.

The system bill beep twice, indicating that calibration has been completed for

full speed. There will not be an error in this calibration because the system will

always accept the change (calibration) if any.

Page no. 2 - 4

Page 15

HALF SPEED CALIBRATION - (Factory set at 4 clicks):

6. The system will immediately go to half lift speed calibration, three (3) beeps will

be heard. Set the half lift speed by pressing the ERROR RESET button the

number of times corresponding to the desired speed with one (1) being the

fastest and eight (8) being the slowest speed. Then press the CALIBRATE

button.

7. Four (4) beeps will be heard, indicating that the half lower speed is to be set. To

set the half speed for lower, press the ERROR RESET button the number of

times for the desired speed, with one (1) being the fastest and eight (8) being

the slowest. When finished press the CALIBRATE button.

Note: If the system has a calibration error or has never been calibrated,

MAKE SURE to press the ERROR RESET button at least once for

each Full/Half speed, otherwise the pre-programmed data will not

change (calibrate).

Upon completion of steps 2 through 7, the system will beep twice, indicating

the calibration has been completed for Full/half speed. There will not be an

error in this calibration because the system will always accept the change

(calibration), if any. If the system errors out immediately after Full/Half speed

calibration, other data has not been calibrated. Turn “OFF” machine and

proceed to the valve calibration procedure.

If other data is calibrated and acceptable, the system will go to normal

operation.

Page no. 2 - 5

Page 16

VALVE CALIBRATION:

Note: MAKE SURE the hydraulic oil is at operating temperature (80° F.)

before calibration.

1. At the ground control, raise the boom to approximately horizontal height with

boom partially extended, (two to three feet), to allow for valve calibration.

Turn engine “OFF”.

2. Press and hold the CALIBRATE button firmly, then start the engine, wait for

approximately two (2) seconds until the SYSTEM NORMAL, AUTO MODE and

CAL MODE lights are “ON”. Note that the CAL MODE light will flash once. Let

go of the CALIBRATE button.

3. Operate the Extend control switch and Ground Operation switch allowing the

boom to extend at full speed. It takes more than a few seconds before the boom

starts to move. Continue to hold the Extend control switch until the boom stops.

Operate the Retract control switch and Ground Operation switch to retract the

boom at full speed until the boom comes to a full stop. Then do the same for Lift

and Lower, releasing the Ground Operation switch after each function.

MAKE SURE that when performing the valve calibration that you hold the

function switch for Extend, Retract, Lift and Lower on long enough or at the end

of the valve calibration procedure it will error out.

4. Observe the motion of the boom carefully, especially in cold oil conditions. If the

boom fails to move for more than 120 seconds or two minutes, turn “OFF” the

machine and start the valve calibration again.

5. If the data is accepted for all four functions, two (2) short beeps will be heard;

otherwise a long beep will sound. If a long beep sounds, turn “OFF” the machine

and start the valve calibration again.

6. If the system accepts the calibration data and then errors out immediately after

calibration, return to the joystick and sensor calibration and repeat all of the

above procedures.

7. At this stage, all data should have been calibrated. The system goes to normal

operation and SYSTEM NORMAL and AUTO MODE lights should stay “ON”.

Page no. 2 - 6

Page 17

BACKUP

EMS

CALIBRATION:

1. Before calibration, power up the machine. If the calibration data stored in the

EMS

controller has been calibrated before and is currently within acceptable

limits, the system will go to normal operation with SYSTEM NORMAL on.

2. If the system errors out with ERROR and CAL MODE lights on, then the data

stored in the

EMS

controller is not correct or has not been calibrated.

3. It is required to calibrate the sensor when it is initially installed into the

TB 120 machine.

Sensor Calibration:

1. Press and hold back-up CALIBRATE and ERROR RESET buttons while starting

the engine, (requires two persons). Wait for approximately two (2) seconds until

SYSTEM NORMAL and CAL MODE lights are on. Note that CAL MODE light

will flash four (4) times. Let go of the two buttons.

2. To calibrate sensors, length and angle sensors are moved through the full

extremes of boom lift and extend movements.

3. Using The ground controls, move the boom in the following sequence:

1. Retract boom fully.

2. Lower boom fully.

3. Raise boom until it stops.

4. Keeping boom raised, extend boom fully.

5. Raise boom fully.

6. Press CALIBRATE button.

If the calibration data is accepted, there will be two (2) short beeps; else, a

long beep (2 seconds). If a long beep should sound, turn “OFF” machine and

start sensor calibration again.

Note: When the calibration data is accepted, the system will go to normal

operation.

Page no. 2 - 7

Page 18

SECTION III

CALIBRATION

Use this section to calibrate - all PRO 100 and PRO 126 machines and

TB 120 machines manufactured after September 1994.

Before performing the sensor calibration make sure the unit is on a flat, firm

and level surface with the turntable in the stowed position, boom over rear

axle, counter weight over the steer axle.

Primary and backup

EMS

may be calibrated individually or simultaneously.

WARNING

During sensor calibration, the envelope management

system DOES NOT limit the position of the platform. The

operator should follow the calibration instructions carefully

to prevent positioning the platform outside of the working

envelope.

PRIMARY JOYSTICK AND SENSOR CALIBRATION (TB 120, PRO 100, PRO 126)

BACKUP SENSOR CALIBRATION (TB 120, PRO 126)

JOYSTICK CALIBRATION — (LIFT AND EXTEND):

1. Turn platform Master switch ON, pull Emergency Stop switch button OUT.

2. At ground control, set Platform/Ground Selector switch to GROUND, pull

Emergency Stop button OUT and turn Master switch ON but do not start engine.

3. Turn the battery disconnect switch on the left side of the turntable to the OFF

position. Open junction box located below the battery disconnect switch.

4. The primary and backup BDU's (Basic Display Units) [PRO 100 has a primary

BDU only], are located on the inside of the junction box lid. With your left hand,

press and hold the CALIBRATE and ERROR RESET buttons located on the

primary BDU (the left one) and activate the toggle switch located between

(below) the BDU's.

5. With your right hand, turn the battery disconnect switch to the ON position.

Note: The SYSTEM NORMAL and the AUTO MODE lights on the primary

BDU should illuminate and remain on. The CAL MODE light should

flash four times and then remain on.

6. With your right hand, press and hold the CALIBRATE and ERROR RESET

buttons located on the backup BDU (the right one) [TB 120 & PRO 126 only].

7. Release the primary CALIBRATE and ERROR RESET buttons and the toggle

switch located between the BDU's with your left hand.

Note: The SYSTEM NORMAL and the AUTO MODE lights on the backup

BDU should illuminate and remain on. The CAL MODE light on the

backup BDU should flash three times and then remain on.

Page no. 3 - 1

Page 19

JOYSTICK CALIBRATION — (LIFT AND EXTEND) (Continued):

8. Release the backup CALIBRATE and ERROR RESET buttons with your right

hand [TB 120 & PRO 126 only].

9. IMMEDIATELY proceed to the ground station and start the engine. Do not turn

the master switch off first.

Note: You have 30 seconds to start the engine from the time the battery

disconnect switch is turned on. If the engine will not start, repeat

this procedure from step 2.

If 30 seconds in not long enough disconnect wire number one (1) to

anti-restart relay in lower control box. Reconnect wire after you

start engine.

10. At the ground control station, set the Platform/Ground Control switch to

PLATFORM.

11. Proceed to the platform. DO NOT ACTIVATE THE FOOT SWITCH. Fully deflect

each of the following controller, (full “ON” each direction).

Extend\Retract\Up\Down. Make sure you hold each controller on for a few

seconds in each direction.

12.

At the junction box, push the CALIBRATE button on the PRIMARY BDU ONLY.

Note: If the calibration is accepted – two (2) short beeps will be heard.

The system will then go into the sensor calibration. If a long beep

sounds – TURN OFF the machine and start the controller and

sensor calibration again.

If the joysticks only are being calibrated, stop here and shut the engine off with

out pressing any more buttons. If the sensors are also being calibrated

continue on to sensor calibration without shutting engine OFF.

Page no. 3 - 2

Page 20

SENSOR CALIBRATION:

Note: Sensor calibration cannot be performed with out performing a

joystick calibration.

OPTIONAL STEP:

Follow this optional step to reduce the time it takes to perform the sensor

calibration. Open the ground control wiring box and locate the 175 terminal

post on the wiring box panel. Locate the PWM module on the right side of the

wiring box. Remove the purple PWM module wire from the 175 terminal and

position it so it won't make contact with any wires. Connect the orange wire

from the PWM module to the 175 terminal. After calibration is complete return

wiring to original configuration.

WARNING

FAILURE TO RETURN WIRING TO ORIGINAL

CONFIGURATION WILL RESULT IN EXCESS SWING

SPEED FROM GROUND CONTROL OR DAMAGE TO THE

PWM MODULE.

1. Disconnect

control valve. Install the Calibration Harness by matching numbers and

connecting the calibration harness leads to proportional control valve. Finish

installation by matching all of the numbers of the remaining harness leads and

connecting them to the corresponding terminals in the junction box.

2. At ground control station, perform the following boom operations:

1. Set Platform/Ground Selector switch to “GROUND”.

2. Fully retract boom.

3. Lower jib boom fully [PRO 100 & PRO 126 only].

4. Lower main boom.

TB 120 – Lower main boom completely.

PRO 100 & PRO 126 only – Lower main boom so that

bottom of platform mount frame is approximately 6 inches

above the ground.

1. Raise boom until it stops.

EMS

harness leads labeled 14, 15, 21 and 22 from proportional

2. Keep boom raised, extend boom fully.

3. Raise and extend booms fully (hold switch on for 30 seconds).

4. Press primary CALIBRATE button.

If the data is accepted, there will be two (2) short beeps.

One (1) long beep indicates incorrect data has been entered.

If one (1) long beep is heard, turn “OFF” the machine and

repeat the joystick and sensor calibrations again.

Page no. 3 - 3

Page 21

SENSOR CALIBRATION (Continued):

5. Press backup CALIBRATE button.

[TB 120 & PRO 126 only]

If the data is accepted, there will be two (2) short beeps.

One (1) long beep indicates incorrect data has been entered.

If one (1) long beep is heard, turn “OFF” the machine and

repeat the joystick and sensor calibrations again.

6. Retract the boom fully.

7. Locate the third point indicator arm inside of the turntable on

the right near the boom pivot pin. Raise the arm so that the

indicator pin touches the bottom of the main boom side plate.

8. Lower the boom until the indicator pin is aligned with the mark

on the main boom side plate.

9. Press backup CALIBRATE button.

[TB 120 & PRO 126 only]

If the data is accepted, there will be two (2) short beeps. One (1) long beep

indicates incorrect data has been entered. If one (1) long beep is heard,

turn “OFF” the machine and repeat the joystick and sensor calibrations

again.

10. Press primary CALIBRATE button.

If the data is accepted, there will be two (2) short beeps. One (1) long beep

indicates incorrect data has been entered. If one (1) long beep is heard,

turn “OFF” the machine and repeat the joystick and sensor calibrations

again.

After the three (3) calibration data sets are accepted, (joystick and sensor), the

primary system may error out right away. This will indicate that other

calibration data has not been done or more data needs to be calibrated.

If other data is calibrated and is acceptable, the system will go to normal

operation. Turn engine OFF. Remove calibration harness and reconnect the

EMS

harness to the proportional control valve. Retract and lower boom.

Page no. 3 - 4

Page 22

RAMP CALIBRATION – ( FACTORY SET AT FOUR (4) CLICKS):

1. At ground control, set Platform/Ground Selector switch to GROUND, pull

Emergency stop button OUT and turn Master switch ON but do not start engine.

2. Turn the battery disconnect switch on the left side of the turntable to the OFF

position. Open junction box located below the battery disconnect switch.

3. The primary and backup BDU's (Basis Display Units) [PRO 100 has a primary

BDU only] are located on the inside of the junction box lid. With your left hand,

press and hold the CALIBRATE and ERROR RESET buttons located on the

primary BDU (the left one only).

4. With your right hand, turn the battery disconnect switch to the ON position.

Note: The SYSTEM NORMAL and the AUTO MODE lights on the primary

BDU should illuminate and remain on. The CAL MODE light should

flash two times and then remain on.

5. Release the primary CALIBRATE and ERROR RESET buttons with your left

hand.

6. One (1) short beep will be heard, indicating that the ramp speed for extend is to

be set. To set the ramp speed for extend, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished, press the CALIBRATE button. (0 essentially skips calibration for this

function, leaving the previous calibration value intact).

7. Two (2) short beeps will be heard, indicating that the ramp speed for retract is to

be set. To set ramp speed for retract, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished press the CALIBRATE button.

8. Three (3) short beeps will be heard, indicating that the ramp speed for lift is to

be set. To set the ramp speed for lift, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished press the CALIBRATE button.

Page no. 3 - 5

Page 23

RAMP CALIBRATION (Continued):

9. Four (4) short beeps will be heard, indicating that the ramp speed for lower is to

be set. To set the ramp speed for lower, press the ERROR RESET button the

number of times for the desired ramp speed, with one (1) being the minimum

ramp or fastest and eight (8) being the maximum ramp or slowest. When

finished press the CALIBRATE button.

Note: If the system has a calibration error or has never been calibrated,

MAKE SURE to press the ERROR RESET button at least once for

each ramp speed, otherwise the pre-programmed data will not

change (calibrate).

Upon completion of steps 5 through 9, the system will beep twice, indicating

the calibration has been completed for ramp. There will not be an error is this

calibration because the system will always accept the change (calibration), if

any. If the system errors out immediately after ramp calibration, other data has

not been calibrated. Turn OFF machine and proceed to the FULL Speed/Half

Speed calibration procedure.

SPEED CALIBRATION TABLE – (Factory Settings):

The table below lists the settings of the

EMS

functions for full speed and half

speed when your unit was shipped from the factory. Should adjustment of

these speeds be required, follow the procedures listed under (SPEED

CALIBRATIONS) on pages3-7and3-8ofthis manual to reset the desired

function speed.

EMS

FUNCTION SPEED CALIBRATION TABLE - FACTORY SETTINGS

FULL SPEED HALF SPEED

MODEL EXTEND RETRACT LIFT LOWER LIFT LOWER

TB 120 1 CLICK 1 CLICK 1 CLICK 1 CLICK 2 CLICKS 2 CLICKS

PRO 100 4 CLICKS 1 CLICK 8 CLICKS 4 CLICKS 7 CLICKS 5 CLICKS

PRO 126 1 CLICK 1 CLICK 1 CLICK 1 CLICK 2 CLICKS 2 CLICKS

Page no. 3 - 6

Page 24

SPEED CALIBRATIONS:

FULL SPEED CALIBRATION:

1. At ground control, set Platform/Ground Selector switch to GROUND, pull

Emergency Stop button OUT and turn Master switch ON but do not start the

engine.

2. Turn the battery disconnect switch on the left side of the turntable to the OFF

position. Open junction box located below the battery disconnect switch.

3. The primary and backup BDU's (Basis Display Units) [PRO 100 has a primary

BDU only] are located on the inside of the junction box lid. With your left hand,

press and hold the CALIBRATE button located on the primary BDU (the left one)

and activate the toggle switch located between (below) the two BDU's.

4. With your right hand, turn the battery disconnect switch to the ON position.

Note: The SYSTEM NORMAL and the AUTO MODE lights on the primary

BDU should illuminate and remain on. The CAL MODE light should

flash three times and then remain on.

5. Release the primary CALIBRATE button and the toggle switch with your left

hand.

6. One (1) beep will be heard, indicating that extend speed is to be set. To set the

extend speed, press the ERROR RESET button the number of times for the

desired speed with one (1) being the fastest and eight (8) being the slowest.

When finished press the CALIBRATE button. (0 essentially skips calibration for

this function, leaving the previous calibration value intact).

7. Two (2) beeps will be heard, indicating that the retract speed is to be set. To set

the retract speed, press the ERROR RESET button the number of times for the

desired full speed, with one (1) being the fastest and eight (8) being the slowest.

When finished press the CALIBRATE button.

8. Three (3) beeps will be heard, indicating that the full lift speed is to be set. To

set the full lift speed, press the ERROR RESET button the number of times for

the desired full speed, with one (1) being the fastest and eight (8) being the

slowest. When finished press the CALIBRATE Button.

9. Four (4) beeps will be heard, indicating the full lower speed is to be set. To set

the full lower speed, press the ERROR RESET button the number of times for

the desired full speed, with one (1) being the fastest and eight (8) being the

slowest. When finished press the CALIBRATE button.

The system will beep twice, indicating that calibration has been completed for

full speed. There will not be an error in this calibration because the system will

always accept the changed (calibration) if any.

Page no. 3 - 7

Page 25

HALF SPEED CALIBRATION:

10. The system will immediately go to half lift speed calibration, three (3) beeps will

be heard. Set the half lift speed by pressing the ERROR RESET button the

number of times corresponding to the desired speed with one (1) being the

fastest and eight (8) being the slowest speed. Then press the CALIBRATE

button.

11. Four (4) beeps will be heard, indicating that the half lower speed is to be set. To

set the half speed for lower, press the ERROR RESET button the number of

times for the desired speed, with one (1) being the fastest and eight (8) being

the slowest. When finished press the CALIBRATE button.

Note: If the system has a calibration error or has never been calibrated,

MAKE SURE to press the ERROR RESET button at least once for

each Full/Half speed, otherwise the pre-programmed data will not

change (calibrate).

Upon completion of steps 6 through 11, the system will beep twice, indicating

the calibration has been completed for Full/Half speed. There will not be an

error in this calibration because the system will always accept the change

(calibration), if any. If the system errors out immediately after Full/Half speed

calibration, other data has not been calibrated. Turn OFF machine and proceed

to the valve calibration procedure.

If other data is calibrated and acceptable, the system will go to normal

operation.

Page no. 3 - 8

Page 26

VALVE CALIBRATION:

Note: MAKE SURE the hydraulic oil is at operating temperature before calibration.

1. At the ground control, raise the boom to within 30 degrees above horizontal with

boom partially extended, (two to three feet), to allow for valve calibration. Turn

engine OFF.

2. At ground control, set Platform/Ground Selector switch to GROUND, pull

Emergency Stop button OUT and turn Master switch ON but do not start the engine.

3. Turn the battery disconnect switch on the left side of the turntable to the OFF

position. Open junction box located below the battery disconnect switch.

4. The primary and backup BDU's (Basic Display Units) [PRO 100 has a primary

BDU only] are located on the inside of the junction box lid. With your left hand,

press and hold the CALIBRATE button located on the primary BDU (the left

one).

5. With your right hand, turn the battery disconnect switch to the ON position.

Note: The SYSTEM NORMAL and the AUTO MODE lights on the primary

BDU should illuminate and remain on. The CAL MODE light should

flash once and then remain on.

6. Release the primary CALIBRATE button with your left hand.

7. IMMEDIATELY proceed to the ground control station and start the engine. Do

not turn the master switch off first.

Note: You have 30 seconds to start the engine from the time the battery

disconnect switch is turned on. If the engine will not start, repeat

this procedure from step 1.

8. Operate the Extend control switch and Ground operation switch allowing the

boom to extend. It can take a few minutes before the boom starts to move.

Continue to hold the Extend control switch until the boom stops. Operate the

Retract control switch and Ground operation switch to retract the boom until the

boom comes to a full stop. Then do the same for Lift and Lower, releasing the

Ground Operation switch after each function. MAKE SURE that when

performing the valve calibration that you hold the function switch for Extend,

Retract, Lift and Lower on long enough for the boom to move and come to a

stop or at the end of the valve calibration procedure it will error out.

Observe the motion of the boom carefully, especially in cold oil conditions. If

the boom fails to move within three minutes or moves for more than a minute,

turn OFF the machine and start the valve calibration again.

If the data is accepted for all four functions, two (2) short beeps will be heard;

otherwise a long been will sound. If a long beep sounds, turn OFF the machine

and start the valve calibration again.

If the system accepts the calibration data and then errors out immediately after

calibration, return to the joystick and sensor calibration and repeat all of the

above procedures.

At this stage, all data should have been calibrated. The system should go to

normal operation and SYSTEM NORMAL and AUTO MODE lights should stay ON.

Page no. 3 - 9

Page 27

SECTION IV

GENERAL CALIBRATION NOTES

PRIMARY AND BACKUP

Note: The exact calibration sequence should be followed for any new

EMS

1. If the system does not allow a requested calibration procedure, the operator

should try to calibrate the previous functions. For example, if the system does

not allow Full/Half speed calibration, then start the Ramp speed calibration. If

the Ramp speed calibration is not allowed either, then start with Joystick and

Sensor calibration.

2. Once the initial calibration is done and accepted, the operator can calibrate any

of the four calibration functions in any order.

3. Primary and backup

4. Note: [PRO 100 has a primary

COMMON MISTAKES IN THE CALIBRATION:

1. The operator does not count number of light flash when entering calibration

mode.

controller.

EMS

SYSTEMS:

EMS

may be calibrated individually or simultaneously.

EMS

only]

2. The operator does not hold the buttons or joystick long enough(2 seconds) when

entering calibration mode.

3. Valve calibration is not done within the high speed zone and less than 30°

above horizontal.

4. In Joystick and Sensor calibration, the operator does not exercise the joystick

and boom to their full extremes.

5. In Valve calibration, the operator does not wait for boom to move and stop or

change direction before the system completes the calibration.

6. In Sensor calibration, the operator does not hold boom Lift on long enough for

boom to travel through the hydraulic cushion and reach its maximum boom

angle.

Page no. 4 - 1

Page 28

CALIBRATION OVERVIEW:

The calibration mode is utilized to initialize the complete system or to optimize

the vehicle's performance. Complete system calibration is required whenever a

system has been installed onto a vehicle. Each individual system calibration

routine can be used in the event a component has been replaced or if vehicle

application conditions change. (See Sections I, II and III for specific calibration

instructions.

Calibration routines must be conducted in the following sequence:

1. Joystick, Sensor and Third Point calibration.

2. Ramp Speed Calibration.

3. Full/Half Speed Calibration.

4. Valve Calibration.

PRIMARY JOYSTICK AND SENSOR CALIBRATION OVERVIEW:

The joystick and sensor calibration routine can be entered by starting the

vehicle under the following conditions:

1. Drive controller deflected forward.

2. Reset button activated.

3. Calibrate button activated.

If this criteria is detected during power up, the Electronic Control Unit (ECU)

will illuminate the CAL MODE, AUTO MODE and SYSTEM NORMAL indicators,

(the CAL MODE light fill flash four (4) times before remaining lit). The operator

can execute the joystick calibration procedure. To calibrate the joystick, the

operator needs only to move the extend/retract joystick and lift/lower joystick to

its extreme positions. While the operator is doing this, the ECU is learning the

usable voltage range of the joysticks. The upper and lower limits will then be

auto scaled for maximum resolution.

Upon completion of the joystick calibration procedure, the operator must

depress the CALIBRATE button to continue. Depressing the CALIBRATE

button will acknowledge the ECU that the joystick calibration is complete. The

data obtained will then be evaluated. Should the data be acceptable, the

audible alarm will sound two (2) short beeps. If the data is bad, the ERROR

indicator will be illuminated and the audible alarm will sound one (1) long beep.

Once an audible acknowledgment has been given the CAL MODE, AUTO

MODE and SYSTEM NORMAL indicators will be illuminated. The sensor

calibration may now be executed. The joysticks control switches for boom

functions will not move the boom in this procedure.

To calibrate the sensors, the operator needs to manually exercise the boom to

it's extreme operating positions using a calibration harness and the procedure

that follows. While the operator is doing this, the ECU is learning the usable

range of the sensors. The upper and lower limits will then be auto scaled for

maximum resolution. It is important that when calibrating the sensors that they

are exercised through their extreme operating range. Upon completion of the

sensor calibration procedure, the operator must depress the CALIBRATE

button to continue.

Page no. 4 - 2

Page 29

PRIMARY JOYSTICK AND SENSOR CALIBRATION OVERVIEW (Continued):

WARNING

During sensor calibration, the envelope management system in the primary

EMS

should be careful not to operate the platform outside of the working envelope.

Depressing the CALIBRATE button will acknowledge the ECU that the sensor

calibration is complete. Upon completion of this, the data obtained will be

evaluated. Should the data be acceptable, the audible alarm will sound two (2)

short beeps. If the data is bad, the ERROR indicator will be illuminated and the

audible alarm will sound one (1) long beep.

To calibrate the third point calibration, fully retract the boom. Locate the third

point indicator arm inside of the turntable on the right near the boom pivot pin.

Raise the arm so that the indicator pin touches the bottom of the main boom

side plate. Lower the boom until the indicator pin is aligned with the mark on

the main boom side plate.

Depressing the CALIBRATE button will acknowledge the ECU that the

calibration is complete. Upon completion of this, the data obtained will be

evaluated. Should the data be acceptable, the audible alarm will sound two (2)

short beeps. If the data is bad, the ERROR indicator will be illuminated and the

audible alarm will sound one (1) long beep.

controller DOES NOT limit the position of the platform. The operator

Once an audible acknowledgment has been given, the SYSTEM NORMAL

indicator will be illuminated signifying that the vehicle is ready for normal

operation.

The joystick and sensor calibration error can not be reset by pressing the reset

button in the display unit. The operator has to recalibrate again.

RAMP CALIBRATION OVERVIEW:

To enter the Ramp Calibration mode, the operator must depress the

CALIBRATE and ERROR RESET buttons on power-up. When this is done, the

CAL MODE, AUTO MODE and SYSTEM NORMAL indicators will be

illuminated, (the CAL MODE indicator will flash two (2) times before remaining

lit). At this point, one (1) short beep will be heard to indicate that the Extend

ramp speed should be selected. Depress the ERROR RESET button zero (0) to

eight (8) times in succession, the number of times corresponding to the desired

ramp with one (1) being minimum ramp and eight (8) being maximum ramp,

(the CAL MODE indicator will go off with each depression of the ERROR

RESET button), and then depress the CALIBRATE button. This enters the ramp

scaling factor into the ECU for the Extend function, (0 essentially skips

calibration for this function, leaving the previously calibrated value intact). At

this point, two (2) short beeps will be heard and the procedure should be

repeated for the retract function. Similarly, the lift (3 beeps) and lower

(4 beeps) functions should be calibrated. Upon completion of this, the audible

alarm will sound two (2) short beeps and the SYSTEM NORMAL indicator will

be illuminated signifying that the vehicle is ready for operation.

Page no. 4 - 3

Page 30

FULL/HALF SPEED CALIBRATION OVERVIEW:

To enter Full/Half Speed Calibration mode, the operator must depress the

CALIBRATE button and deflect the drive controller forward on power-up. When

this is done, the CAL MODE, AUTO MODE and SYSTEM NORMAL indicators

will be illuminated, (the CAL MODE indicator will flash three (3) times before

remaining lit). At this point, one (1) short beep will be heard to indicate that the

Extend speed should be selected. Depress the ERROR RESET button zero (0)

to eight (8) times in succession, the number of times corresponding to the

desired speed with one (1) being maximum speed and eight (8) being minimum

speed, (the CAL MODE indicator will go off with each depression of the

ERROR RESET button), and then depress the CALIBRATE button.

This enters the max speed scaling factor into the ECU for the Extend function,

(0 essentially skips calibration for this function, leaving the previously

calibrated value intact). At this point, two (2) short beeps will be heard and the

procedure should be repeated for the retract function. Similarly, the lift

(3 beeps) and lower (4 beeps) functions should be calibrated. Upon completion

of this, the audible alarm will sound two (2) short beeps, pause, three (3) beeps

and SYSTEM NORMAL, AUTO MODE and CAL MODE indicators will be

illuminated.

Upon completion of the Full Speed calibration, the

EMS

will automatically go

into the Half Speed calibration, with lift having (3 beeps) and lower (4 beeps).

Upon completion of this, the audible alarm will sound two (2) short beeps and

the SYSTEM NORMAL indicator will be illuminated signifying that the vehicle is

ready for operation.

Page no. 4 - 4

Page 31

VALVE CALIBRATION OVERVIEW:

The boom must be retracted well within the high speed operating range and the

angle must be less than 30 degrees for this procedure to work, or else the

error light will illuminate immediately. It is important to calibrate all functions

when in the valve calibration mode. The following is recommended for proper

valve calibration. To enter the Valve calibration mode, the operator must

depress the calibrate switch “ON” while powering-up. When this is done the

CAL MODE, AUTO MODE and SYSTEM NORMAL indicators will be

illuminated, (the CAL MODE light will flash once before remaining lit). The

valve calibration may now be executed. To calibrate the valve the operator

must activate each function being controlled by the ECU, in this case the four

(4) boom motions. As the operator moves the joystick off center, a command is

generated and sent to the valve. This command is continually increased by the

electronic control unit until motion is detected. The ECU will allow the specific

boom function to move for about two (2) seconds to assure successful

calibration.

1. Calibrate one function at a time.

2. Allow sufficient cylinder travel for the function chosen.

3. Hold the joystick in the desired direction until the cylinder

has traveled for two (2) seconds, and stopped.

4. Calibrate all functions each time the valve calibration

mode is entered.

5. Vehicle oil temperature should be at normal operating

temperature.

Upon completion of this, the data obtained will be evaluated. Should the data

be acceptable, the audio alarm will sound two (2) short beeps. If the data is

bad, the ERROR indicator will be illuminated and the audible alarm will sound

one (1) long beep. Once an audible acknowledgment had been given, the

SYSTEM NORMAL indicator will be illuminated signifying that the vehicle is

ready for operation.

Page no. 4 - 5

Page 32

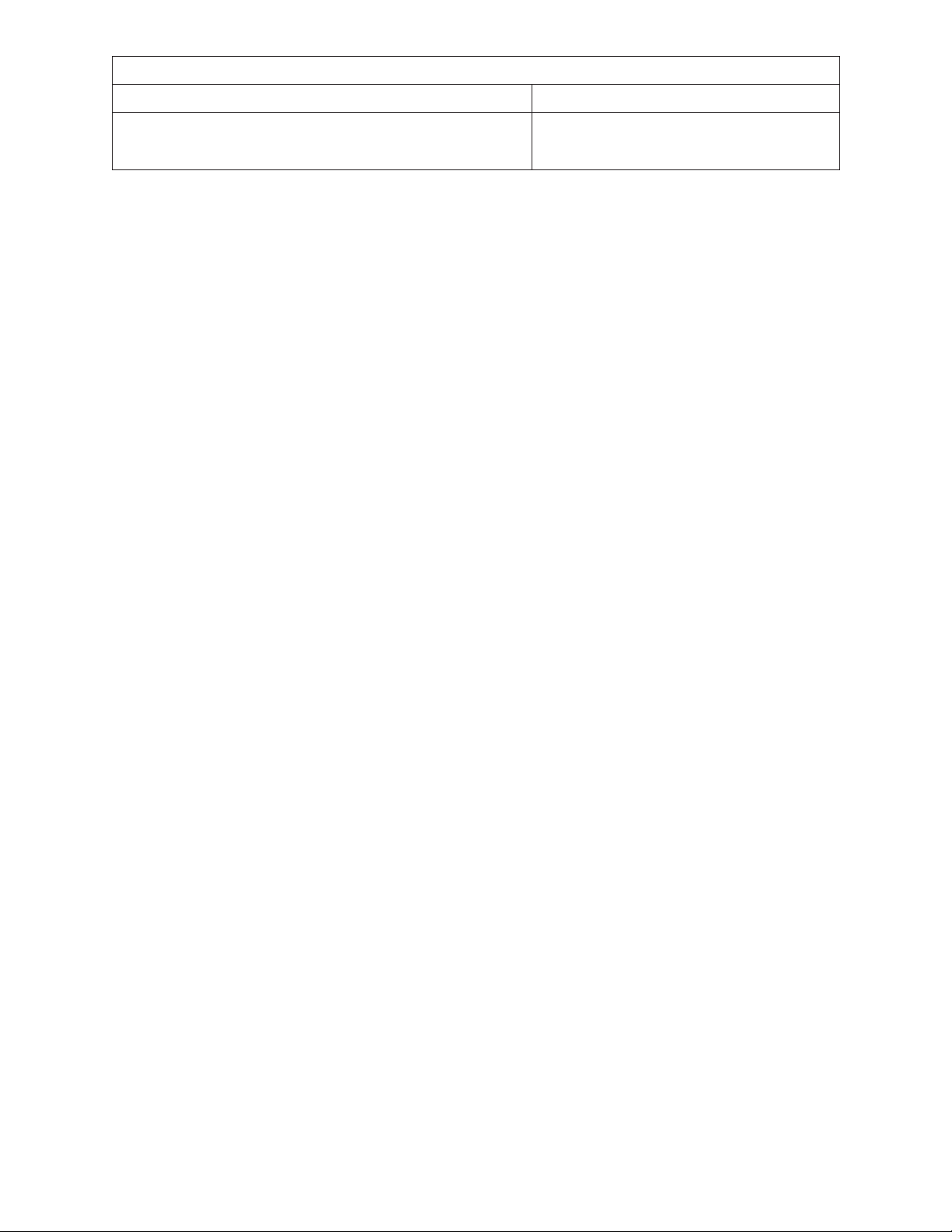

EMS

CALIBRATION MODES:

EMS

The

up of the system, the

with the self-check the

EMS

is powered up each time the ignition switch is turned on. Upon power

EMS

conducts a self-diagnostic check. In conjunction

EMS

monitors the status of three switch inputs. The

checks the status of each switch to determine if a calibration mode is

being requested by the operator. The following table will describe the switch

combinations and the resulting power up mode.

TB 120 BEFORE SEPTEMBER 1994

SWITCH CONDITION UPON POWER UP

ERROR RESET

BUTTON

POWER UP MODE PRESSED PRESSED

NORMAL CONDITION

SYSTEM WAITING

JOYSTICK AND SENSOR

CALIBRATION

RAMP

CALIBRATION

SPEED

CALIBRATION

VALVE CALIBRATION NO YES NO

NO NO NO

YES YES YES

YES YES NO

NO YES YES

CALIBRATE

BUTTON

GROUND OPERATION SWITCH “UP”

OR

DRIVE CONTROLLER FULL FORWARD

PRO 100, PRO 126 & TB 120 AFTER SEPTEMBER 1994

SWITCH CONDITION UPON POWER UP

ERROR RESET

BUTTON

POWER UP MODE PRESSED PRESSED

NORMAL CONDITION

SYSTEM WAITING

JOYSTICK AND SENSOR

CALIBRATION

RAMP

CALIBRATION

SPEED

CALIBRATION

VALVE CALIBRATION NO YES NO

NO NO NO

YES YES YES

YES YES NO

NO YES YES

CALIBRATE

BUTTON

CENTER TOGGLE SWITCH

BETWEEN BDU'S

Page no. 4 - 6

Page 33

TROUBLESHOOTING DESCRIPTION INDEX

0.0 General Description

EMS

1.0 Primary

errors during power-up

1.1 All lights, except error light, and alarm flash on, but then error light

and alarm remain on - self test fails

1.2 ERROR and CAL MODE light on after self test

1.3 ERROR light on after self test

1.4 All lights flash and error on but no alarm

1.5 Lights and alarm never turn on

1.6 All lights except ERROR on - system dead

1.7 Light and alarm pulse on and off

EMS

2.0 Primary

errors that occur when joystick is at center

2.1 ERROR light on and the boom can not be operated

2.2 ERROR and AUTO MODE lights on and the boom retract/lower only

2.3 Undesired motion and system error out

2.4 Errors caused by a backup system error

EMS

3.0 Primary

errors during normal operation

3.1 Envelope control issues

3.2 No motion error

3.3 Slow motion in manual mode

3.4 Intermittent errors

EMS

4.0 Backup

errors

4.1 Power-up and normal operation errors

4.2 Wake-up check and warning

5.0 Troubleshooting for calibration errors

Page no. 5 - 1

Page 34

0.0 General Description

The envelope management system consists of a primary and a backup set.

[PRO 100 has a primary

EMS

set only]. Each set has its own controller

(electronic unit or ECU) and its own boom length and boom angle sensors.

BACKUP

SET

PRIMARY

SET

Primary and backup set location illustration

PRIMARY SET:

The primary set receives input from the joysticks its boom sensors and

controls the proportional valve for the lift/lower and extend/retract functions

to keep the platform within the primary working envelope. When the

operator moves a joystick to request motion, the primary controller

compares that request with the booms current position with respect to the

primary envelope. If the requested motion would not cause the platform to

go beyond the primary envelope the controller sends a pulse width

modulated signal to the proportional valve to move the boom in the

requested fashion. When the platform nears the primary envelope, the

controller slows the platform to a stop at the envelope.

Upon power-up (key switch on) - sequence of operation

ECU (Primary) Looks For:

1. Power on wire #E-32 must be above 9 volts - (from ECU 3 amp fuse)

2. Chassis ground on C-32

3. Ground on E-18 (ground signal for CAL MODE)

4. Checks center position on Extend controller wire E-14 (minimum 2.352 to maximum 2.666)

5. Checks center position on Lift controller wire E-16 (minimum 2.352 to maximum 2.666)

6. Checks voltage from length sensor wire E-2

7. Checks voltage from angle sensor wire A-2

8. Checks power from backup ECU wire A-16-B (12 volts)

Page no. 5 - 2

Page 35

BACKUP SET:

The TB 120 and the PRO 126 have a backup

EMS

set. This backup set is

active at all times and receives input only from its boom sensors and

controls the blocking valves for the lift/lower and extend/retract functions to

keep the platform within the backup working envelope. If the backup

controller determines that the platform is at the backup envelope, it closes

the blocking valves to stop motion in the directions that would cause the

platform to go beyond the backup envelope.

Upon power-up (key switch on) - sequence of operation

ECU (Backup) Looks For:

1. Power on wire #E-32-B must be above 9 volts - (from ECU 3 amp fuse)

2. Chassis ground on C-32-B

3. Checks voltage from length sensor wire E-2-B

4. Checks voltage from angle sensor wire A-2-B

The PRO 100 has a limit switch back up system that requires no calibration.

EMS

1.0 Primary

errors during power-up

Power up the system by starting the engine on the vehicle. Observe what

the display lights and the audible alarm do for the first couple of seconds.

During the system's internal self test, the lights should all flash on and the

alarm should beep once, the SYSTEM NORMAL and AUTO MODE lights

should be left on. The control system goes to normal operation mode.

Note: NEVER Deflect any joystick or press any button during power-up,

unless a calibration procedure is to be performed.

1.1 All lights, except error light, and alarm flash ON first. The error

light, and alarm remain on. System appears dead and can not be

reset. The self-test fails. Replace the

EMS

controller.

1.2 All lights are on first. System normal light is on but off shortly. Then

ERROR and CAL MODE lights remain on. This indicates to the

operator that some data has not been properly calibrated and

stored into the permanent memory of the

SYSTEM NORMAL ERROR AUTO MODE CAL MODE ALARM

ON ON ON

EMS

controller.

Page no. 5 - 3

Page 36

Primary

EMS

errors during power-up (Continued):

The following steps should be followed in order to ensure proper system

performance, but the operator has the ability to enter normal system operation

using default values.

1.2.1 Press the ERROR RESET button. If the ERROR light is off and

the system is operable after releasing the button, then some of

stored data is not correct and default data will be used for normal

operation.

SYSTEM NORMAL ERROR AUTO MODE CAL MODE ALARM

ON ON ON

The CAL MODE indicates that a calibration procedure is required.

1.2.2 If the error can not be reset by pressing ERROR RESET button,

then perform joystick and sensor calibrations. If the system does

not enter the joystick and sensor calibration mode, check wires

A-18, A-20, and E-18 for continuity to wire.

Refer to section 5.0 for trouble shooting on system calibrations.

1.3 All lights, except error light, and alarm flash on first. System normal

light is on but, about 0.5 second later, off again. Then only the

ERROR light remains on and the alarm continues to sound.

SYSTEM NORMAL ERROR AUTO MODE CAL MODE ALARM

ON ON

First thing to do is press the reset button.

1.3.1 The

EMS

does not respond to the reset button, i.e., the alarm still

sounds when the reset button is being pressed.

1.3.1.1 Check both BDU's (Basic Display Unit) to see if the reset button

is functioning properly and connected to the

EMS

properly.

1.3.1.2 Check wire A-20 for continuity to ground.

(Should have continuity when not pushed)

If Calibration and Error Reset button is stuck in,

will go into CAL MODE. If Error Reset button is stuck in,

EMS

system

EMS

system will error out on power-up.

1.3.1.3 Replace the

EMS

controller.

1.3.2 If the system goes to normal, operation mode and the error is

cleared, then the error is an intermittent error. Intermittent errors

may occur during power-up. If intermittent errors occur frequently,

the system components such as sensors, joysticks, battery and

harness should be checked. Replace them if necessary.

Page no. 5 - 4

Page 37

Primary

EMS

errors during power-up (Continued):

1.3.3 The error is cleared by pressing the error reset button, but the

system errors out again after releasing the reset button. Refer to

section 2.0 for trouble shooting.

1.4 All lights, except error light, and alarm flash on first. Then the

ERROR light remains on with no alarm.

SYSTEM NORMAL ERROR AUTO MODE CAL MODE

ON

ALARM

1.4.1 Check the alarm and its connection, replace the alarm or harness.

1.4.2 Check the reset button. A stuck ERROR RESET button will

continue resetting the system and the alarm will sound a short

beep in every second. Replace the BDU (Basic Display Unit).

1.5 Display lights never on and alarm never turns on.

1.5.1 Check the power and ground connection to the

EMS

controller.

1.5.2 Check E-32 for above 9 volts, check C-32 for ground.

1.5.3 If power is getting to the

EMS

controller, then check for power

going to the display unit on wire A-32 (9-12 volts). If correct

power is not going to the display, then replace the harness. If

correct power is going to the display, then replace the display

unit.

1.5.4 If problem is still not fixed at this point, then replace the

EMS

controller and perform full calibration on the system.

1.6 Alarm and all display light except ERROR turn on and stay on.

System otherwise seems dead.

1.6.1 Check and/or replace the

EMS

1.6.2 If condition still exists after checking or replacing

controller harness.

EMS

controller

harness, then replace the controller.

1.7 Lights and alarm keep turning on and off at the rate of once every

1/2 to 1 second. Replace

EMS

controller.

Page no. 5 - 5

Page 38

2.0 Primary

EMS

errors that occur when joystick is at center

This section provides troubleshooting information for the primary

EMS

errors

that occur when the operator is not operating the boom, i.e., the joysticks are

not deflected.

2.1 Errors that stop the control system. Error light and alarm will be on.

Operator will not be able to move the boom. This can be verified by

deflecting the joystick to see if the boom is moving.

SYSTEM NORMAL ERROR AUTO MODE CAL MODE ALARM

ON ON

Example: Premature boom bleed down or retraction of boom

(caused by cylinder packing or holding valve.