Page 1

AB50JRT

Operator Manual

Page 2

Page 3

Please Note:

The UpRight AB50JRT is sold in some regions as the

Snorkel AB50J.

Therefore any reference to the Snokel AB50J also applies to the

UpRight AB50JRT

UpRight Powered Access HQ

Vigo Centre

Birtley Road

Washington

Tyne & Wear

NE38 9DA

UK.

Europe

TEL: +44 (0) 845 1550 058

FAX: +44 (0) 195 2299 948

USA

TEL: +1 (785) 989 3000

FAX: +1 (785) 989 3070

www.upright.com

Page 4

Page 5

LIMITED WARRANTY

Snorkel warrants eachnew machine manufactured and sold by it to be free from defects in material and workmanship for a

periodofone(1)year fromdateofdeliveryto aCustomeror forone yearafter themachinehas beenplacedinfirstservicein a

Dealerrentalfleet, whichevercomes first.Anypart orpartswhich,upon examinationbythe SnorkelServiceDepartment,are

foundtobedefective, will be replaced or repaired, at the solediscretion of Snorkel, through its local Authorized Dealer at no

charge.

Snorkelfurther warrantsthestructuralcomponents; specifically, themainframechassis,turntable,booms and scissor arms,

of each newmachinemanufacturedby it to be free from defects in material and workmanship for an additional period of four

(4) years.Any such par t or parts which, upon examination by the Snorkel Ser vice Department, are found to be defective will

bereplaced orrepairedby Snorkelthroughits localAuthorizedDealeratno charge;however,anylabor chargesincurredas a

result of such replacement or repair will be the responsibility of the Customer or Dealer.

The Snorkel Service Department must be notified within forty-eight (48) hours of any possiblewarrantysituation during the

applicable warranty period. Personnel performing warranty repair or replacement must obtain specific approval by Snorkel

Service Department prior to performing any warranty repair or replacement.

Customer and Dealer shall not be entitled to the benefits of this warranty and Snorkel shall have no obligations hereunder

unless the “Pre-Delivery and Inspection Report” has been properly completed and returned to the Snorkel Service

Department within ten (10) days after delivery of the Snorkelproduct to Customer or Dealer’s rental fleet. Snorkel must be

notified, in writing, within ten (10) days, of any machine sold to a Customer from a Dealer’s rental fleet dur ing the warranty

period.

At the direction of the Snorkel Service Department, any component par t(s) of Snorkel products to be replaced or repaired

underthiswarrantyprogram mustbereturnedfreightprepaid to the SnorkelService Department forinspection. All warranty

replacement parts will be shipped freight prepaid (standard ground) from the Snorkel Ser vice Department or from Snorkel’s

Vendor to Dealer or Customer.

REPLACEMENT PARTS WARRANTY

Any replacement or service part made or sold by Snor kel is not subject to the preceding Limited Warranty beyond the

normal warranty period of the machine upon which the par t was installed.

THIS WARRANTY EXCLUDES AND SNORKEL DOES NOT WARRANT:

1. Engines, motors, tires and batteries which are manufactured by suppliers to Snorkel, who furnish their own warranty.

Snorkelwill, however,to theextentpermitted,passthrough anysuch warrantyprotection totheCustomerorDealer.

2. AnySnorkelproduct whichhasbeenmodified oralteredoutsideSnorkel’sfactorywithout Snorkel’swritten approval,if

suchmodification or alteration,inthesolejudgmentofSnorkel’sEngineering and/or Service Departments, adversely

affects the stability, reliability or service life of the Snorkel product or any component thereof.

3. AnySnorkel productwhich hasbeensubject tomisuse, impropermaintenanceoraccident.“Misuse”includesbutisnot

limited to operation beyond the factory-rated load capacity and speeds. “Improper maintenance” includes but is not

limited to failure to follow the recommendations contained in the Snorkel Operation, Maintenance, Repair Parts

Manuals.Snorkelis not responsiblefor normal maintenance,serviceadjustmentsand replacements,includingbutnot

limited to hydraulic fluid, filters and lubrication.

4. Normalwearof anySnorkelcomponentpart(s).Normal wearofcomponent parts mayvarywith the typeapplicationor

type of environment in which the machine may be used;such as, but not limited to sandblasting applications.

5. Any Snorkel product that has come in direct contact with any chemical or abrasive material.

6. Incidental or consequential expenses, losses, or damages related to any part or equipment failure, including but not

limited to freight cost to transport the machine to a repair facility, downtime of the machine, lost time for workers, lost

orders, lost rental revenue, lost profits or increased cost.

This warrantyisexpresslyin lieu of all other warranties,representations or liabilities of Snorkel, either expressedorimplied,

unless otherwise amended in writing by Snorkel’s President, Vice President-Engineer ing, Vice President-Sales or Vice

President-Marketing.

SNORKEL MAKES NO WARRANTIES WHICH EXTEND BEYONDTHE DESCRIPTION OF THIS LIMITED WARRANTY.

SNORKEL MAKES NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULARPURPOSE

AND DISCLAIMS ALL LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT

LIMITED TO INJURY TO PERSONS OR PROPERTY.

The Customer shall make all warrantyclaims through its local AuthorizedDealer and should contact the Dealer from whom

the Snorkel product was purchased for warranty service. Or, if unable to contact the Dealer, contact the Snorkel Service

Department for further assistance.

Effective July 1995

© Snorkel – all rights reserved

Printed in USA

Page 6

Electrical Hazard

■

Electrical Hazard Warning

DANGER

THE SNORKELIFT AERIAL WORK PLATFORM

IS NOT ELECTRICALLY INSULATED.

If the platform, booms, or any other conductive part of a Snorkelift contacts a high-voltage electr ical

conductor, the result can be SERIOUS INJURY or DEATH for persons on or near the machine.

GO NO CLOSER THAN THE MINIMUM SAFE APPROACH DISTANCES

(M.S.A.D) - AS OUTLINED IN TABLE 1 AND FIGURE 3

ON THE NEXT PAGE.

Be sure to allow for sag and sway in the wires and the work platform.

If a Snorkelift comes in contact with a live electrical conductor, the entire machine can be charged.

If that happens, you should remain on the machine and not contact any other structure or object within

reach. That includes the ground, adjacent buildings, poles, and any object not a part of the Snorkelift.

Such contact could make your body a conductor to the other object creating an electrical shock hazard

resulting in SERIOUS INJURY or DEATH.

DO NOT attempt to enter or leave the Snorkelift until you are sure the electricity has been turned off.

If a Snorkelift is in contact with a live conductor, the platform operator MUST warn others on the ground

in the vicinity of the Snorkelift to STA Y AWAY from the machine, since their bodies can also form a

path for electricity to ground thus creating an electrical shock hazard with possible ELECTROCUTION

and DEATH.

DO NOT attempt to operate the Snorkelift ground controls when the platform, booms, or any other

conducting part of a Snorkelift is in contact with electrical wires or if there is an immediate danger of

such contact.

Regard all conductors as energized.

Personnel working on or near a Snorkelift must be continuously aware of electrical hazards,

recognizing that SERIOUS INJURY or DEATH can result if contact with an electrical wire does occur.

AB50J – 0163189 page - i

Page 7

Electrical Hazard

■

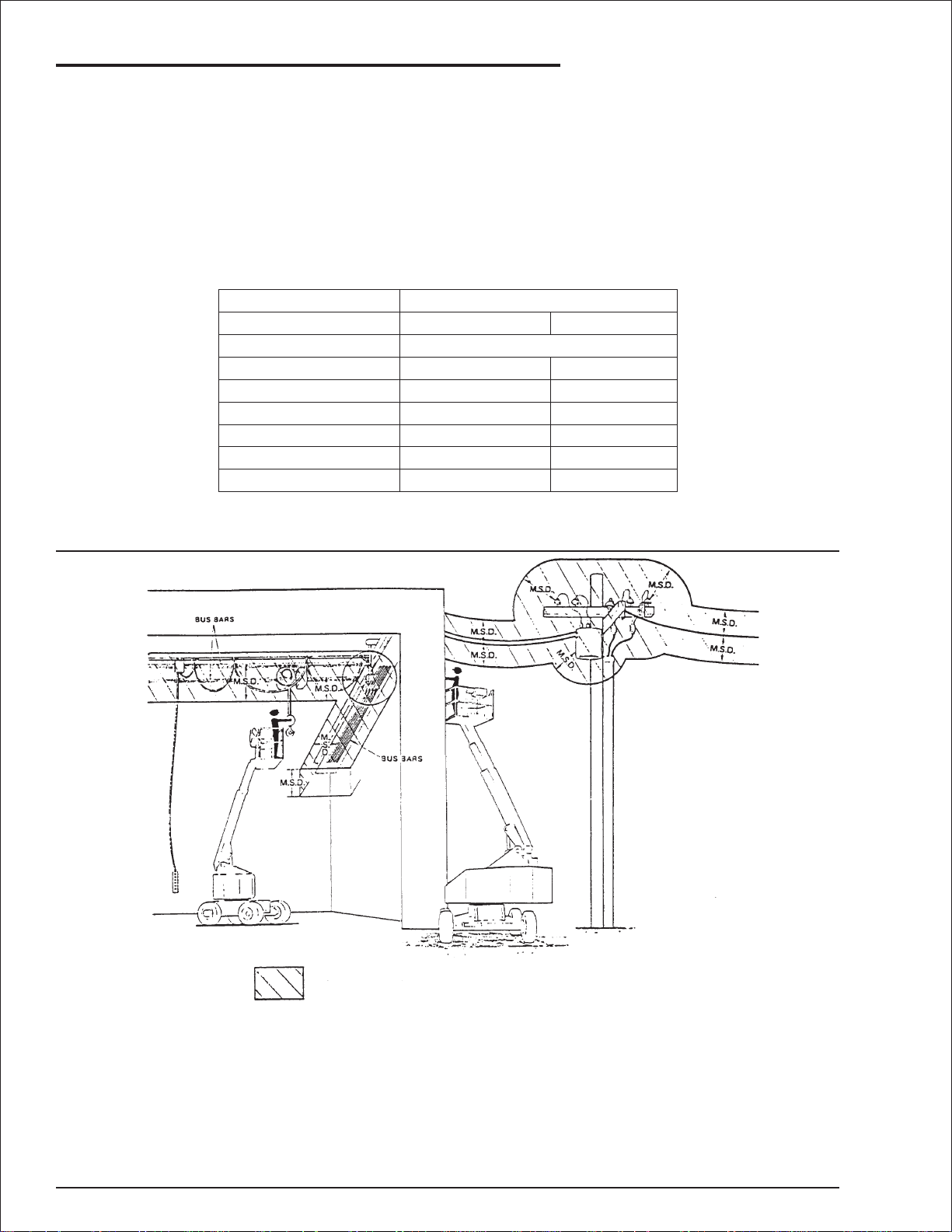

Minimum Safe Approach Distance

The Snorkelift is an all metal boom, NOT ELECTRICALLY INSULATED, aerial work platform.DO NOT

operate it near ELECTRICAL conductors.Regard all conductors as being energized. Use the table and

illustration below to determine safe clearance from electrical conductors. Table 1 and Figure 3 are

reprinted courtesy of Scaffold Industry Association, ANSI/SIA A92.5, page 23.

Table 1 - (M.S.A.D.)

❑

Minimum Safe Approach Distance

to energized (exposed or insulated power lines)

Voltage range Minimum safe approach distance

(phase to phase)

0 to 300V

over 300v to 50kv

over 50kv to 200kv

over 200kv to 350kv

over 350kv to 500kv

over 500kv to 750kv

over 750kv to 1000kv

(Feet) (Meters)

Avoid contact

10

15

20

25

35

45

3.05

4.60

6.10

7.62

10.67

13.72

Figure 3 - (M.S.A.D.)

❑

Denotes prohibited zone

Danger: - Do not allow machine personnel or conductive

materials inside prohibited zone.

- Maintain M.S.A.D. from all energized lines and parts

as well as those shown.

- Assume all electrical parts and wires are energized

unless known otherwise.

Caution:

page - ii AB50J – 0163189

- Diagrams shown are only for purposes of illustrating

M.S.A.D. work positions, not all work positions.

Page 8

Introduction

The most important chapter in this manual is

"Safety" chapter 1. Take time, now, to study it

closely.The information in chapter 1, might save

your life or prevent serious injur y.

■

Signs

The following three conventions are used

throughout this manual.

1. Danger sign

DANGER

means: Attention! Become alert! Your safety is

involved.

2. Caution sign

CAUTION

means one of two things: (1) an action, about

to be performed, is potentially hazardous and

might result in minor personal injur y if not

done correctly, or (2) an action, about to be

performed, can harm the Snorkelift if not done

correctly.

3. Note sign

■

Operation Rules

The following rules will help ensure the safety of

personnel and help prevent needless downtime

because of damaged equipment.

1. Only TRAINED and AUTHORIZED operators

shall be permitted to operate the equipment.

2. All manufacturer’s operating instructions and

safety rules and all employers’ safety rules

and all OSHA and other government safety

rules must be strictly adhered to.

3. Repairs and adjustments shall be made only

by QUALIFIED TRAINED maintenance

personnel.

4. No modification shall be made to the

equipment without prior written consent of

the Snorkel Engineering Department.

5. You must make a pre-start inspection of the

Snorkelift at the beginning of each shift.A

malfunctioning machine must not be used.

6. You must make an inspection of the work

place to locate possible hazards before

operating the Snorkelift.

DANGER

means: The information following is to assist

you in either the proper steps to take for an

action or as additional information concer ning

your present situation, but does not indicate a

dangerous condition to either you or the

Snorkelift.

■

Qualified Operators

The Snorkelift aerial platform has built in safety

features and has been factory tested for

compliance with Snorkel specifications and

industry standards.However, any personnel lifting

device can be potentially dangerous in the hands

of untrained or careless operators.

Training is essential and must be performed by a

QUALIFIED person. Become proficient in

knowledge and actual operation before using the

machine on the job. You must be TRAINED and

AUTHORIZED to perform and functions of the

Snorkelift. Operation of the Snorkelift must be

within the scope of the machine specifications.

Before operation of the Snorkelift you must read

and understand the operating instructions in this

manual as well as the decals, warnings, and

instructions on the machine itself.

DO NOT operate this equipment unless you

are TRAINED and AUTHORIZED and have

read and thoroughly understand all of the

information given in this Operator’s Manual

and on all DANGER and CAUTION signs on

the machine. Misuse of this machine can

result in DEATH or SERIOUS INJURY.

■

Maintenance

Every person who maintains, inspects, tests, or

repairs these machines, and every person

supervising any of these functions, MUST be

properly trained.

This Operator’s Manual provides a daily

inspection procedure that will help you keep your

Snorkelift in good operating condition. DO NOT

perform other maintenance unless you are a

TRAINED mechanic, QUALIFIED to work on the

Snorkelift. Call QUALIFIED maintenance

personnel if you find problems or malfunctions.

DO NOT modify this machine without written

approval from the Engineering Department of

Snorkel.

AB50J – 0163189 page - iii

Page 9

Introduction

■

Responsibilities of Parties

It is imperative that all owners and users of the

Snorkelift read, understand, and conform to all

applicable regulations. Ultimate compliance to

OSHA regulations is the responsibility of the

employer using the equipment.

ANSI Standard A92.5 identifies requirements of

all parties who might be involved with

Boom-Supported Elevating Work Platforms.

A reprint of the “Manual of Responsibilities for

Dealers, Owners, Users, Operators, Lessors and

Lessees of ANSI/SIA A92.5-1992 Boom

Supported Elevating Work Platforms” is available

from Snorkel dealers or from the factory upon

request.

Copies are also available from:

Scaffold Industry Association

20335 Ventura Blvd. Suite 310

Woodland Hills, CA 91364-2471 USA

■

OSHA, ANSI and CSA Standards

The Snorkelift is a boom-supported elevating

work platform built to conform to the following

standards:

OSHA Paragraph1910.67 Title 29, C.F.R.

Vehicle-Mounted Elevating and Rotating

Work Platforms - Labor.

OSHA Paragraph1926.556 Title 29, C.F.R.

Aerial Lifts - Construction.

ANSI Standard A92.5-1992

Boom-Supported Elevating Work Platforms.

■

Options

The use of optional equipment is discussed in the

“Options” chapter 11.

The options you will find discussed there are:

1. AC generator.

2. Air line to platform.

3. Motion warning alarms.

4. Battery (extra).

5. Cold weather start kit.

6. Dual fuel.

7. Operator horn.

8. Flashing lights.

9. Platform work lights.

10. LPS rating.

11. Sandblast protection kit.

12. Spark arrestor.

13. Platform swinging gate.

14. Optional tires.

15. Tow kit.

16. 4-wheel drive functions.

CSA Standard CAN 3-B354.4-M82

Boom-type Elevating Work Platforms.

■

California Proposition 65 Warning

The state of California requires that all equipment

used within its boundaries shall have the

following warnings noted in the Operator’s

Manual.

page - iv AB50J – 0163189

■

Additional Information

For additional information contact your local

dealer or Snorkel at:

Snorkel Inter national, Inc.

P.O.Box 1160

St. Joseph, MO 64502-1160 USA

816-364-0317

http://www.snorkelusa.com

Page 10

Table of Contents

Electrical Hazard

Electrical Hazard Warning . . . . . . . . . . . . . . . . . . i

Minimum Safe Approach Distance . . . . . . . . . . . ii

Table 1 - (M.S.A.D.). . . . . . . . . . . . . . . . . . . . . . ii

Figure 3 - (M.S.A.D.). . . . . . . . . . . . . . . . . . . . . ii

Introduction

Signs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Qualified Operators . . . . . . . . . . . . . . . . . . . . . . iii

Operation Rules . . . . . . . . . . . . . . . . . . . . . . . . . iii

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Responsibilities of Parties . . . . . . . . . . . . . . . . . iv

OSHA, ANSI and CSA Standards . . . . . . . . . . . iv

California Proposition 65 Warning . . . . . . . . . . . iv

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Additional Information . . . . . . . . . . . . . . . . . . . . iv

1. Safety

Safe Operation. . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . 1-1

Work Place Inspection and Practices . . . . . . 1-1

Electrocution . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Tipover and Falling Hazards . . . . . . . . . . . . . 1-2

Crushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

General Safety Precautions. . . . . . . . . . . . . . . 1-2

Personnel Precautions . . . . . . . . . . . . . . . . . 1-2

Operator General Precautions . . . . . . . . . . . 1-2

Mounting and Dismounting Precautions . . . . 1-3

Starting and Stopping Precautions . . . . . . . . 1-3

Operating Precautions . . . . . . . . . . . . . . . . . 1-3

Operator Maintenance Precautions . . . . . . . 1-3

Fuel Handling Precautions . . . . . . . . . . . . . . 1-3

Safety Placards and Decals . . . . . . . . . . . . . . 1-3

Safety Placards and Decals Location . . . . . . . 1-4

2. Safety Devices

Safety Device Information . . . . . . . . . . . . . . . . 2-1

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start-Up Alarm . . . . . . . . . . . . . . . . . . . . . . . 2-1

Engine Shut-Off Alarm . . . . . . . . . . . . . . . . . 2-2

Alternator Not Charging Alarm . . . . . . . . . . . 2-2

Axle Unlocked Alarm. . . . . . . . . . . . . . . . . . . 2-2

Tilt Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

All Motion Alarm . . . . . . . . . . . . . . . . . . . . . . 2-3

Descending Boom Alarm . . . . . . . . . . . . . . . 2-3

Drive Motion Alarm . . . . . . . . . . . . . . . . . . . . 2-3

Other Safety Devices. . . . . . . . . . . . . . . . . . . . 2-3

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Emergency Stop Switches . . . . . . . . . . . . . . 2-4

At Ground Control Box . . . . . . . . . . . . . . . . . 2-4

At Platform Control Box. . . . . . . . . . . . . . . . . 2-4

Flashing Lights . . . . . . . . . . . . . . . . . . . . . . . 2-4

Foam Filled Tires. . . . . . . . . . . . . . . . . . . . . . 2-5

Platform Foot Switch . . . . . . . . . . . . . . . . . . . 2-5

Lanyard Anchor Points . . . . . . . . . . . . . . . . . 2-5

Platform Guardrails . . . . . . . . . . . . . . . . . . . . 2-5

Ground Fault Circuit Interrupt . . . . . . . . . . . . 2-6

Platform Gravity Gate . . . . . . . . . . . . . . . . . . 2-6

Ground Operation Switch . . . . . . . . . . . . . . . 2-7

Operator Horn. . . . . . . . . . . . . . . . . . . . . . . . 2-7

Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Platform Swinging Gate . . . . . . . . . . . . . . . . 2-7

Platform Work Lights. . . . . . . . . . . . . . . . . . . 2-8

Tipover Hazard Light. . . . . . . . . . . . . . . . . . . 2-8

3. Specifications

General Specifications. . . . . . . . . . . . . . . . . . . 3-1

Engine Oil Charts . . . . . . . . . . . . . . . . . . . . . . 3-2

Engine Data. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Overall Dimensions . . . . . . . . . . . . . . . . . . . . . 3-3

Working Envelope . . . . . . . . . . . . . . . . . . . . . . 3-4

Nomenclature and Serial Numbers . . . . . . . . . 3-5

Right Side View Of Machine . . . . . . . . . . . . . 3-5

Booms Identification . . . . . . . . . . . . . . . . . . . 3-5

Left Side View Of Machine . . . . . . . . . . . . . . 3-6

Serial Number Location. . . . . . . . . . . . . . . . . 3-6

AB50J – 0163189 page - v

Page 11

Table of Contents

4. Gauges

Ammeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Engine Coolant . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Gas Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Engine Oil Dipstick . . . . . . . . . . . . . . . . . . . . 4-2

Filter Minder. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Filter Minder Indicators . . . . . . . . . . . . . . . . . 4-2

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

LPG (Liquefied Petroleum Gas) . . . . . . . . . . . 4-3

Hour Meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Hydraulic Oil Filter. . . . . . . . . . . . . . . . . . . . . . 4-3

Hydraulic Oil Level. . . . . . . . . . . . . . . . . . . . . . 4-4

Hydraulic Oil Temperature. . . . . . . . . . . . . . . . 4-4

Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5. Automatic Shut-Offs and Circuit Breakers

Automatic Shut-Offs . . . . . . . . . . . . . . . . . . . . 5-1

Engine Temperature . . . . . . . . . . . . . . . . . . . 5-1

Engine Oil Pressure . . . . . . . . . . . . . . . . . . . 5-1

Circuit Breakers. . . . . . . . . . . . . . . . . . . . . . . . 5-2

6. Controls

Controls Description . . . . . . . . . . . . . . . . . . . . 6-1

Controls and Controls Decals Locations. . . . . 6-1

Ground Control Box. . . . . . . . . . . . . . . . . . . . . 6-2

Ground Control Box Controls . . . . . . . . . . . . 6-3

Platform Control Box . . . . . . . . . . . . . . . . . . . . 6-4

Platform Control Box Controls. . . . . . . . . . . . 6-5

Platform Foot Switch . . . . . . . . . . . . . . . . . . . . 6-6

Battery Switch . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

7. Daily Inspection and Maintenance

Daily Inspection and Maintenance Table. . . . . 7-1

Engine Fuel Level . . . . . . . . . . . . . . . . . . . . . . 7-2

Fuel Tank Cap . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Engine Oil Level. . . . . . . . . . . . . . . . . . . . . . . . 7-2

Gasoline Engine . . . . . . . . . . . . . . . . . . . . . . 7-2

Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Fuel Leaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Gasoline Engine . . . . . . . . . . . . . . . . . . . . . . 7-3

Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Engine Coolant Level. . . . . . . . . . . . . . . . . . . . 7-3

Wiring Harnesses . . . . . . . . . . . . . . . . . . . . . . 7-4

Battery Terminals. . . . . . . . . . . . . . . . . . . . . . . 7-4

Battery Fluid Level. . . . . . . . . . . . . . . . . . . . . . 7-5

Hydraulic Oil Level. . . . . . . . . . . . . . . . . . . . . . 7-5

Hydraulic Oil Leaks . . . . . . . . . . . . . . . . . . . . . 7-5

Tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Bolts and Fasteners. . . . . . . . . . . . . . . . . . . . . 7-6

Structural Damage and Welds. . . . . . . . . . . . . 7-7

Lanyard Anchor Points . . . . . . . . . . . . . . . . . . 7-8

Platform Gravity Gate . . . . . . . . . . . . . . . . . . . 7-8

Swinging Gate . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Platform Guardrails . . . . . . . . . . . . . . . . . . . . . 7-8

Flashing Lights . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Charging System. . . . . . . . . . . . . . . . . . . . . . . 7-9

Ground Control Switches and Alarms . . . . . . 7-9

Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Emergency Power . . . . . . . . . . . . . . . . . . . . . 7-10

Platform Box Switches and Alarms . . . . . . . . 7-11

Operator Horn . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Motion Warning Alarm. . . . . . . . . . . . . . . . . . 7-11

Ground Fault Circuit Interrupt . . . . . . . . . . . . 7-11

Platform Work Lights. . . . . . . . . . . . . . . . . . . 7-12

Slide Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Axle Unlocked Alarm. . . . . . . . . . . . . . . . . . . 7-13

Placards and Decals . . . . . . . . . . . . . . . . . . . 7-14

Standard Placards and Decals . . . . . . . . . . 7-14

Optional Placards and Decals. . . . . . . . . . . 7-14

Inspection Drawing . . . . . . . . . . . . . . . . . . . 7-15

page - vi AB50J – 0163189

Page 12

Table of Contents

8. Operation

Operating Procedures . . . . . . . . . . . . . . . . . . . 8-1

Control Stations. . . . . . . . . . . . . . . . . . . . . . . . 8-1

Emergency Stopping . . . . . . . . . . . . . . . . . . . . 8-1

Operation Considerations . . . . . . . . . . . . . . . . 8-2

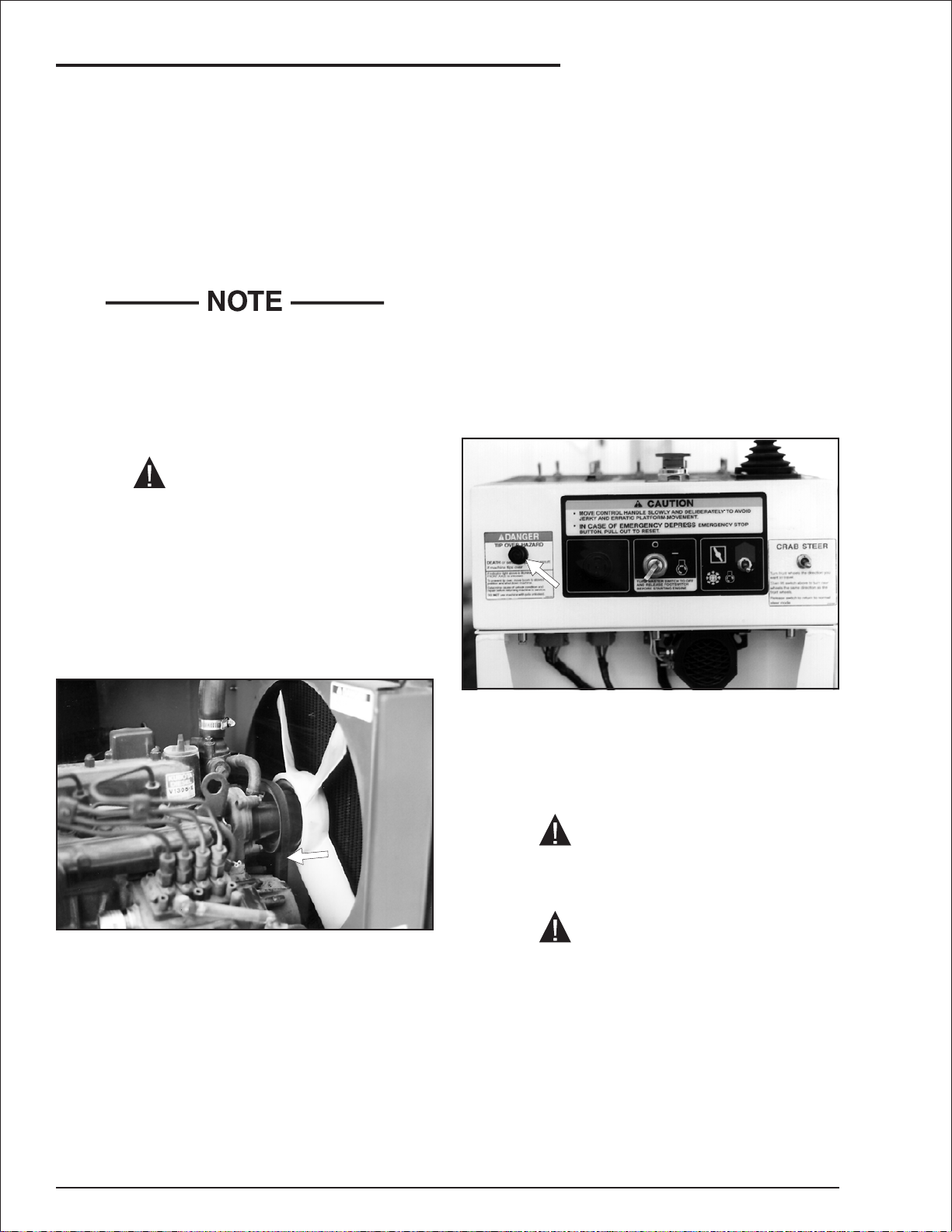

Starting From Ground Control Box . . . . . . . . . 8-2

Starting From Platform Control Box. . . . . . . . . 8-4

Moving The Platform . . . . . . . . . . . . . . . . . . . . 8-5

From Ground Control Box. . . . . . . . . . . . . . . 8-6

From Platform Control Box . . . . . . . . . . . . . . 8-6

Driving the AB50J . . . . . . . . . . . . . . . . . . . . . . 8-7

Forward and Reverse Drive. . . . . . . . . . . . . . 8-7

Steering the AB50J . . . . . . . . . . . . . . . . . . . . . 8-7

Steer Left and Right . . . . . . . . . . . . . . . . . . . 8-7

4-Wheel Steer . . . . . . . . . . . . . . . . . . . . . . . . 8-7

4-Wheel Steer With Crab Steer. . . . . . . . . . . 8-8

Electrical Outlets (GFCI) at Platform . . . . . . . 8-8

AC Generator . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Securing for Day . . . . . . . . . . . . . . . . . . . . . . . 8-9

9. Emergency Operation

Emergency Operation Procedures . . . . . . . . . 9-1

Operation From Platform Control Box. . . . . . 9-1

Operation From Ground Control Box . . . . . . 9-2

11. Options

AC Generator. . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Air Line To Platform . . . . . . . . . . . . . . . . . . . . 11-1

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Extra Battery . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Cold Weather Start Kit. . . . . . . . . . . . . . . . . . 11-2

Dual Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Operator Horn . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

LPS Rating . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Sandblast Protection Kit . . . . . . . . . . . . . . . . 11-2

Spark Arrestor . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Platform Swinging Gate. . . . . . . . . . . . . . . . . 11-3

Tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Highway or Bar Lug. . . . . . . . . . . . . . . . . . . 11-3

Flotation Tires . . . . . . . . . . . . . . . . . . . . . . . 11-3

Foam Filled Tires. . . . . . . . . . . . . . . . . . . . . 11-4

Large Tires . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Tow Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Towing Procedures . . . . . . . . . . . . . . . . . . . 11-4

4-Wheel Functions. . . . . . . . . . . . . . . . . . . . . 11-5

4-Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . 11-5

4-Wheel Steer . . . . . . . . . . . . . . . . . . . . . . . 11-5

4-Wheel Steer With Crab Steer. . . . . . . . . . 11-5

10. Stowing and Transporting

Stowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

To Lock the AB50J: . . . . . . . . . . . . . . . . . . . 10-1

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Trailering . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Securing to a Transport Vehicle . . . . . . . . . 10-2

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Lifting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Chapter 12. Troubleshooting

Troubleshooting Chart . . . . . . . . . . . . . . . . . . 12-1

AB50J – 0163189 page - vii

Page 13

■

Safe Operation

The following safety information is vitally

important for safe operation of the AB50J. Failure

to follow these instructions can result in personal

injury or DEATH.

Pre-Start Inspection

❑

At the start of each work shift, the AB50J shall be

given a visual inspection and function test. See

the “Daily Inspection and Maintenance” chapter

7, in this manual for a list of items to inspect and

test.

1. Safety

When moving the platform, check the clearance

around the AB50J to avoid contact with

structures or other hazards. Always look in the

direction of motion.

Keep ground personnel from under the platform

when the platform is raised.

Secure all accessories, containers, tools, and

other materials in the platform to prevent them

from accidentally falling or being kicked off the

platform.

DO NOT engage in any form of “horseplay”or

“stunt driving” while operating the AB50J.

CAUTION

DO NOT operate the AB50J unless you are

trained and authorized, understand the

operation characteristics of the AB50J, and

have inspected and tested all functions to be

sure they are in proper working order.

Work Place Inspection and Practices

❑

Do not use the AB50J as a ground for welding.

Ground to the work piece.

Before the AB50J is used, and dur ing use, check

the area in which the AB50J is to be used for

possible hazards such as, but not limited to:

1. Drop-offs or holes.

2. Side slopes.

3. Bumps and floor obstructions.

4. Debris.

5. Overhead obstructions and electrical

conductors.

6. Hazardous locations.

7. Inadequate surface and support to withstand

all load forces imposed by the aerial platform

in all operating configurations.

8. Wind and weather conditions.

9. Presence of unauthorized persons.

10. Other possible unsafe conditions.

Before using the aerial platform in any hazardous

(classified) location, make certain it is approved

and of the type required by ANSI/NFP A 505 for

use in that particular location.

DO NOT permit riders on the machine anyplace

other than on the platform.

Remove all loose objects stored in or on the

machine, par ticularly in the platform. Remove all

objects which do not belong in or on the machine.

When other moving equipment is in the area,

take special precautions to comply with local

regulations regarding warnings.

Never steady the platform by positioning it

against another platform.

DO NOT operate an AB50J that is not functioning

properly, or has been damaged, until the machine

has been repaired by a qualified maintenance

person.

DO NOT operate an AB50J that does not have all

its decals and placards attached and legible.

Drive the machine with care and at speeds

compatible with conditions. Use extra caution

when driving over rough ground, on slopes, and

when turning.

Know and understand the job site traffic flow

patterns and obey the flagmen, road signs, and

signals.

Watch for bystanders and never allow anyone to

be under, or to reach through, the machine and

its equipment while operating.

Use the recommended transport device when

loading the machine.

A recommended safety practice is to have

personnel that are trained in the operation of the

emergency controls working in the immediate

area of the AB50J to assist the platform operator

in the event of an emergency.

AB50J – 0163189 page 1 - 1

Page 14

1. Safety

Electrocution

❑

The AB50J is an all metal boom,

NON-INSULATED, aerial work platform. DO NOT

operate it near ELECTRICAL conductors.Regard

all conductors as being energized.

DO NOT operate outside during a thunderstorm.

Tipover and Falling Hazards

❑

DO NOT operate the AB50J from a position on

trucks, trailers, railway cars, floating vessels,

scaffolds, or similar equipment unless the

application is approved in writing by Snorkel.

If the platform or elevating assembly becomes

caught, snagged, or otherwise prevented from

normal motion by an adjacent structure or other

obstacles such that control reversal does not free

the platform, remove all personnel from the

platform before attempts are made to free the

platform using ground controls.

It is best not to transfer from the platform to

another structure or from the structure to the

platform, unless that is the safest way to do the

job.Judge each situation separately taking the

work environment into account. If it is necessary

to transfer from the platform to another structure

the following guidelines apply:

1. Where possible, place the work platform over

a roof or walking structure to do the transfer.

2. Transfer your anchorage from one structure

to another before you step across.

3. Remember, you might be departing the work

platform to a structure where

arrest

4. Use the platform entrance, do not climb over

the guard rails.

All platform occupants MUST wear a fall restraint

device connected to a lanyard anchor point.

DO NOT exceed the unrestricted platform

capacity as indicated on the capacity placard at

the entrance to the platform.

DO NOT raise the boom if the AB50J is on soft

ground.Operate the boom only on a firm surface

capable of withstanding all load forces imposed

by the aerial platform in all operating conditions.

Do Not carry loads that extend beyond the

platform guardrails without prior written consent

from Snorkel.

is required.

personal fall

Raise the platform only when the AB50J is on

level ground.

Maintain a firm footing on the platform floor.

Climbing on the guardrails is prohibited.

DO NOT use ladders, planks, or other devices to

extend or increase your work position from the

platform.

DO NOT jerk the controls. Move the controls

slowly and deliberately to avoid jerky and erratic

operation.Always stop the controls in the neutral,

off, position before going in the opposite

direction.

DO NOT use the boom for any purpose other

than to position personnel, their tools, and

materials.

DO NOT use the AB50J as a crane, hoist, or

jack.

DO NOT operate the AB50J in winds, or wind

gusts, of 28 mph (45 km/h) or more.

DO NOT add anything to the AB50J that will

increase the wind loading (banners, flags, etc.).

Crushing

❑

Always look in the direction of travel.Avoid

overhead obstructions.

Never cover the floor grating or otherwise

obstruct your view below.

Make sure the area below the platform is free of

personnel before lowering.

■

General Safety Precautions

❑

Personnel Precautions

If you encounter any suspected malfunction of

the aerial platform, or any hazard or potentially

unsafe condition relating to capacity, intended

use, or safe operation, cease operation and seek

assistance from management.

❑

Operator General Precautions

Make sure that all protective guards, cowlings,

and doors are in place and secure.

Be sure the guardrail system, including the gate,

is in place and secure.

Care shall be taken to prevent rope, electrical

cords, and hoses, etc., from becoming entangled

in the aerial platform.

page 1 - 2 AB50J – 0163189

Page 15

1. Safety

Mounting and Dismounting Precautions

❑

Use three points of support when getting on or off

the platform (two hands and one foot or a similar

set of points). Keep the platform clean.

DO NOT jump off the machine.

DO NOT dismount while the machine is in

motion.

Starting and Stopping Precautions

❑

DO NOT start until all personnel are clearly away

from the machine.

Before leaving the operator’s station, place the

machine in the stowed position.

When leaving the machine parked or unattended,

remove the starter key from the Master Key

Switch, set the Battery switch to OFF, then lock

the Battery switch.

Operating Precautions

❑

DO NOT modify the AB50J in any way.

When parts or components are replaced, they

shall be identical or equivalent to or iginal Snorkel

parts or components.

DO NOT override any of the safety features of the

AB50J.

Limit travel speeds according to conditions. Take

into account: grade, surface, congestion, visibility,

side slope, location of personnel, and other

hazards.

❑

Operator Maintenance Precautions

Use extreme caution when removing radiator

caps.Park the machine and let it cool down

before opening a pressurized compartment.

CAUTION

DO NOT use your hand to search for hydraulic

oil leaks. High pressure hydraulic oil can easily

cut and penetrate your skin — a very serious

injury that requires immediate attention by a

medical specialist trained in that type of injury.

Use a piece of cardboard or wood to search

for hydraulic oil leaks.

DO NOT attempt repairs unless you are

trained.Refer to manuals and experienced

repair personnel for help.

Fuel Handling Precautions

❑

DO NOT smoke or permit open flames while

fueling or near fueling operations.

Never remove the fuel cap or refuel a gasoline

engine while the engine is running or hot. Never

allow fuel to spill on hot machine components.

Maintain control of the fuel filler nozzle when

filling the tank.

DO NOT fill the fuel tank to capacity.Allow room

for expansion.

Clean up spilled fuel immediately.

Tighten the fuel tank cap securely. If the fuel cap

is lost, replace it with an approved cap from

Snorkel. Use of a non-approved cap without

proper venting may result in pressurization of the

tank.

Never use fuel for cleaning purposes.

For diesel engines, use the correct fuel grade for

the operating season.

■

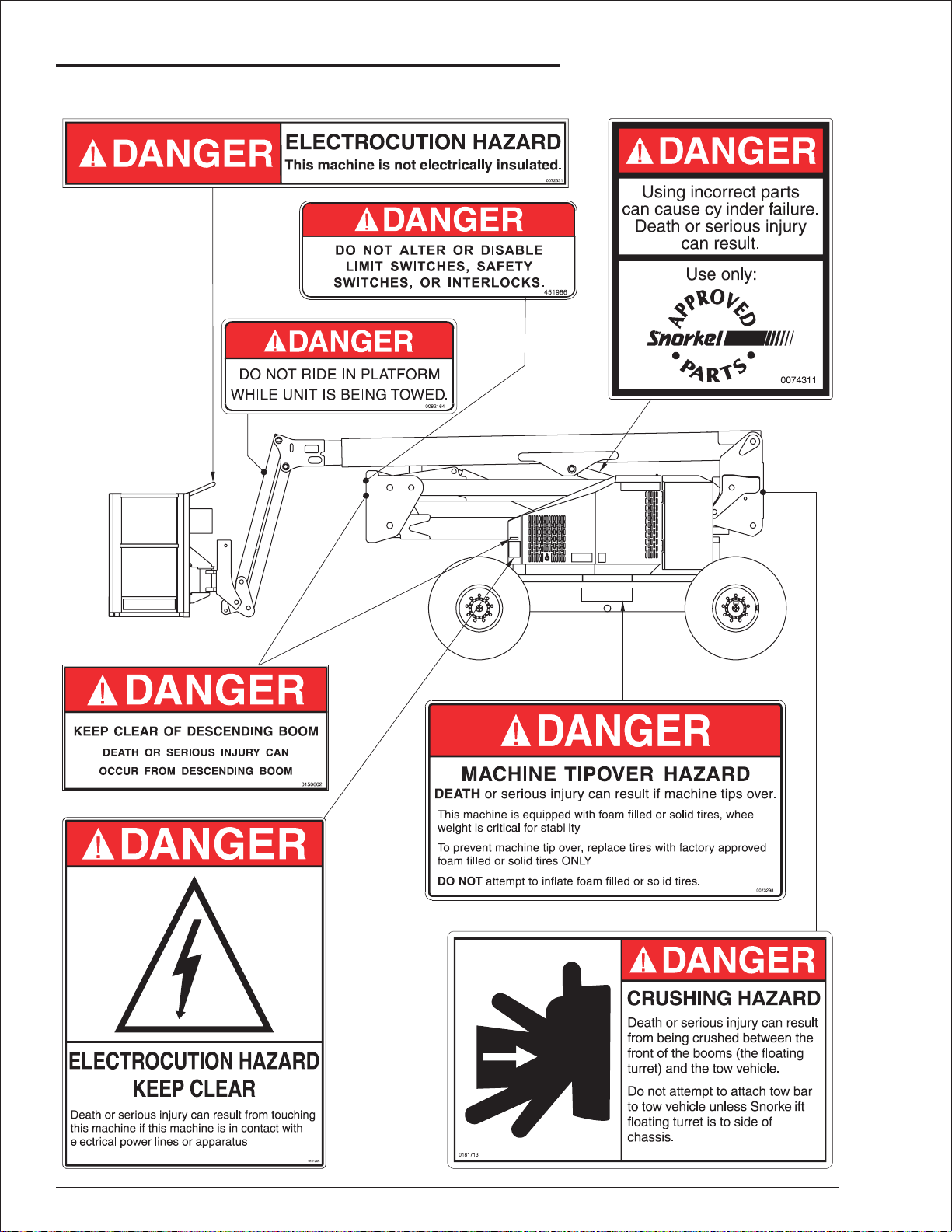

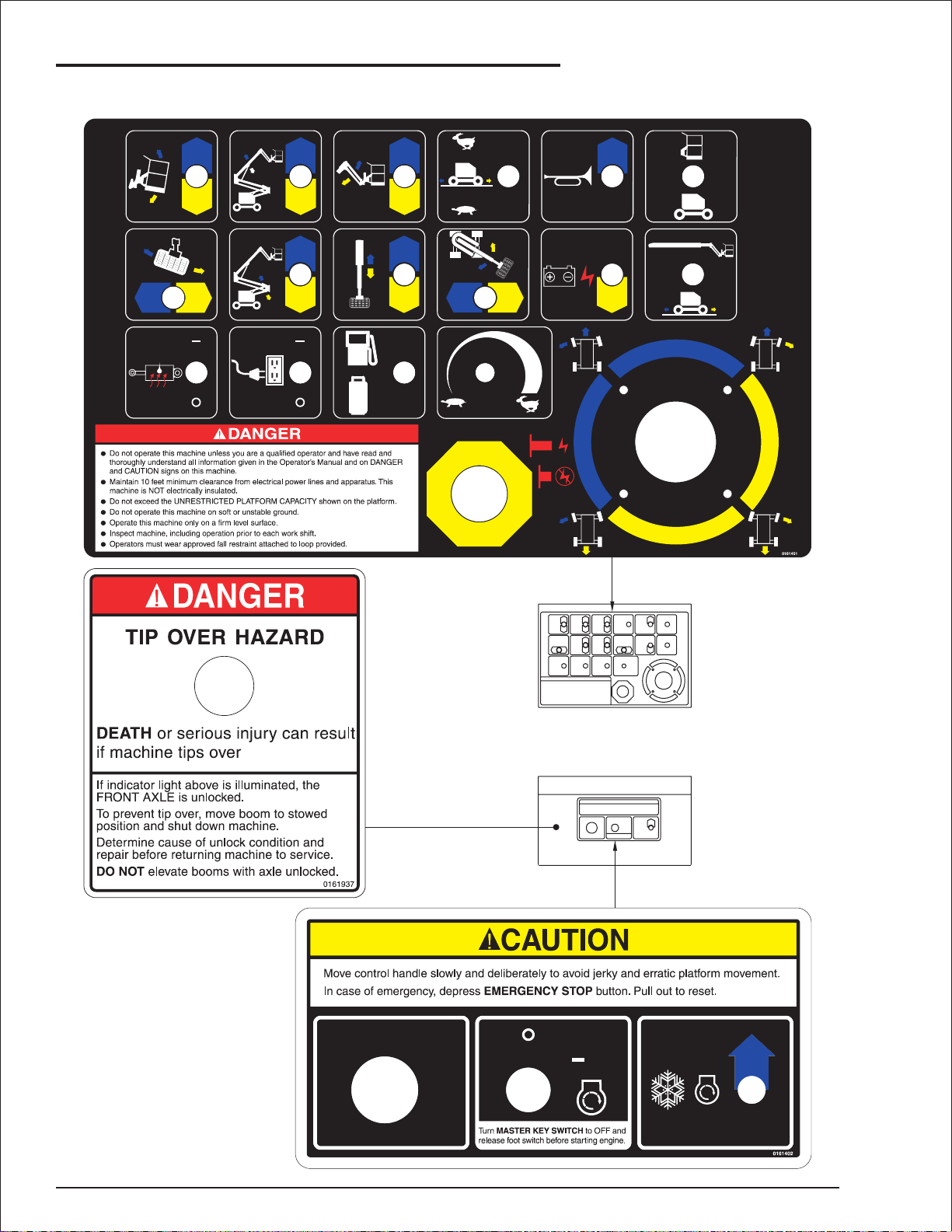

Safety Placards and Decals

There are several safety placards and decals on

the AB50J. Their locations and descriptions are

shown in this section. Take time to study them.

CAUTION

Be sure that all the safety placards and decals

on the AB50J are legible.Clean or replace

them if you cannot read the words or see the

pictures.Clean with soap & water and a soft

cloth. Do not use solvents.

You MUST replace a placard or decal if it is

damaged, missing, or cannot be read. If it is

on a part that is replaced, make sure a new

decal or placard is installed on the replaced

part. See your Snorkel dealer for new decals

and placards.

Refer to Placards and Decals in the “Daily

Inspection and Maintenance” chapter 7, for

part numbers, location, and required quantities

of all placards and decals.

AB50J – 0163189 page 1 - 3

Page 16

1. Safety

■

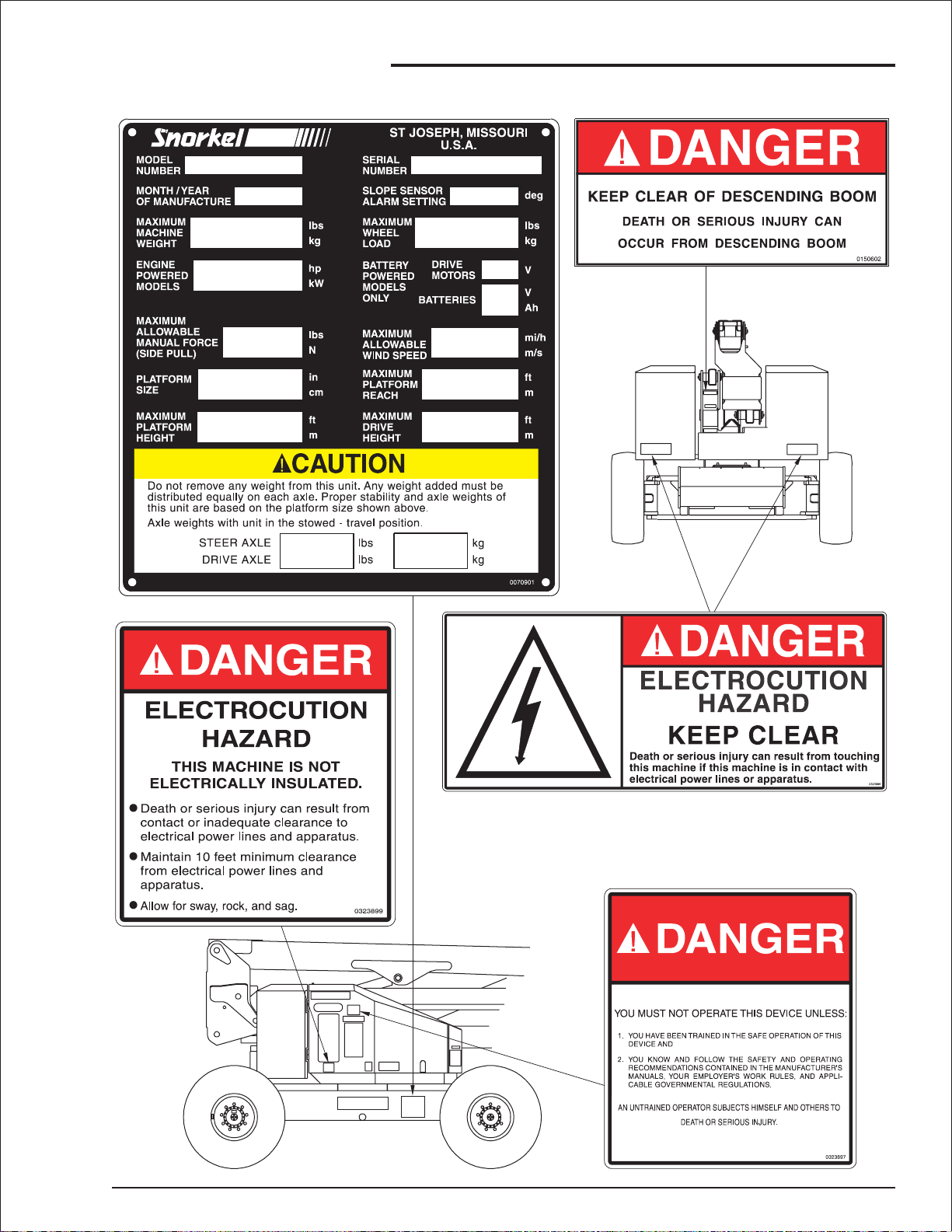

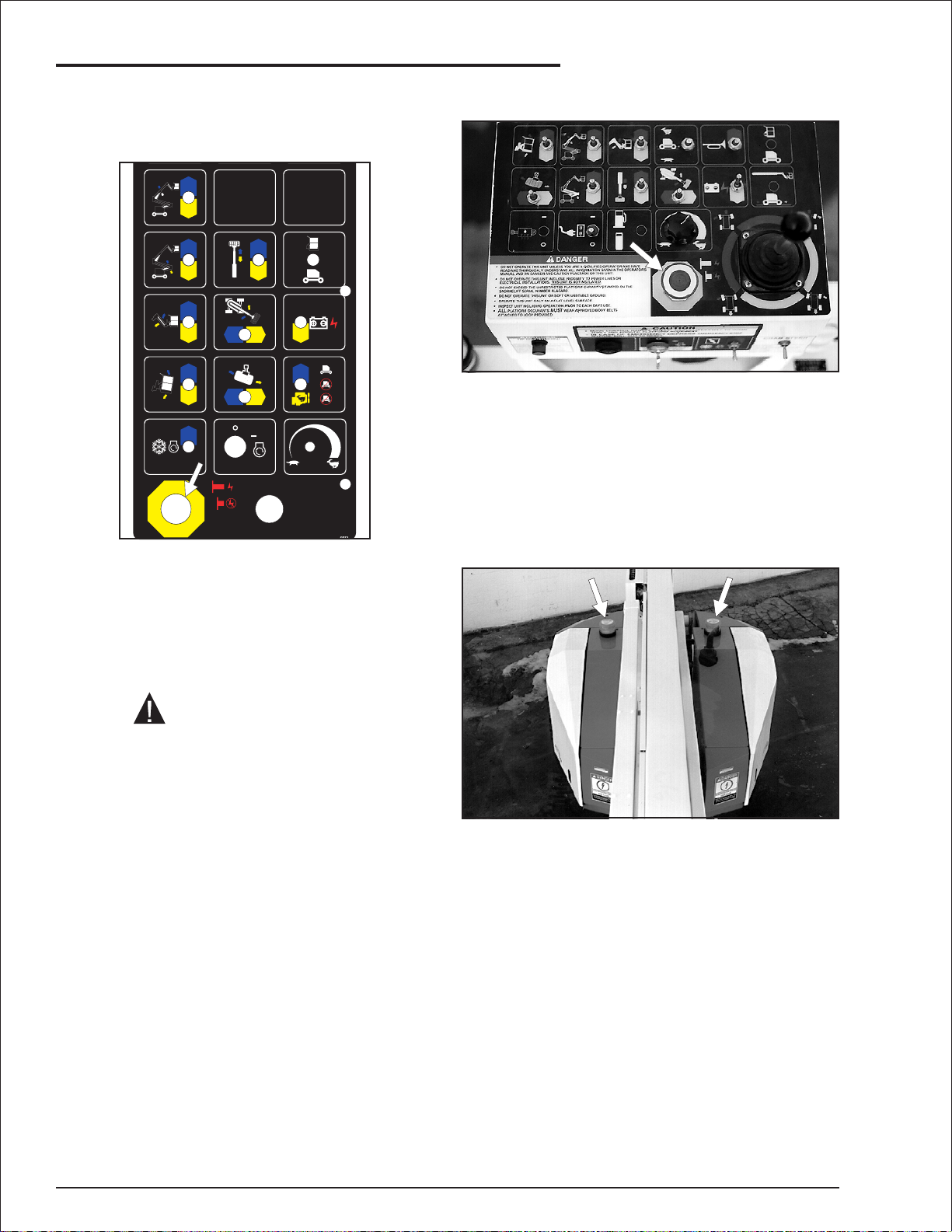

Safety Placards and Decals Location

(Tow option only)

(Tow option only)

page 1 - 4 AB50J – 0163189

Page 17

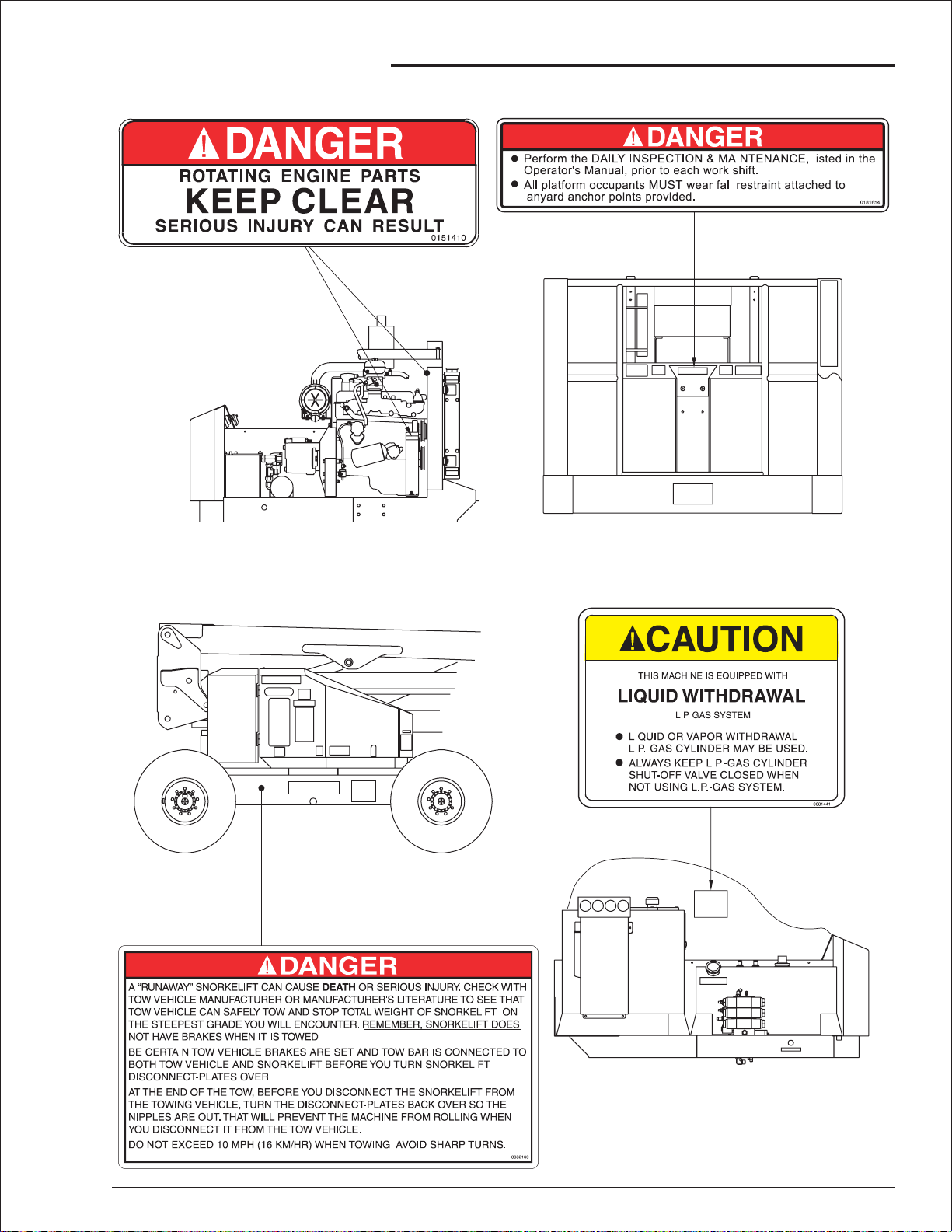

1. Safety

(Tow option only)

PLATFORM

(LPG option only)

AB50J – 0163189 page 1 - 5

Page 18

1. Safety

PLATFORM CONTROL BOX

page 1 - 6 AB50J – 0163189

Page 19

1. Safety

AB50J – 0163189 page 1 - 7

Page 20

■

Safety Device Information

For emergency operation controls and procedures,

see the “Emergency Operation” chapter 9.

The devices listed in this chapter are safety

devices.

They are on the AB50J to increase safety in the

work place for both the operator and other people

near the AB50J.

CAUTION

DO NOT by pass, disable, modify, or ignore

any of these devices.Check them carefully at

the start of each work shift to see that they are

in working order (see “Daily Inspection and

Maintenance” chapter 7). If any is found to be

defective, remove the AB50J from service

immediately until a qualified service technician

can make repairs.

■

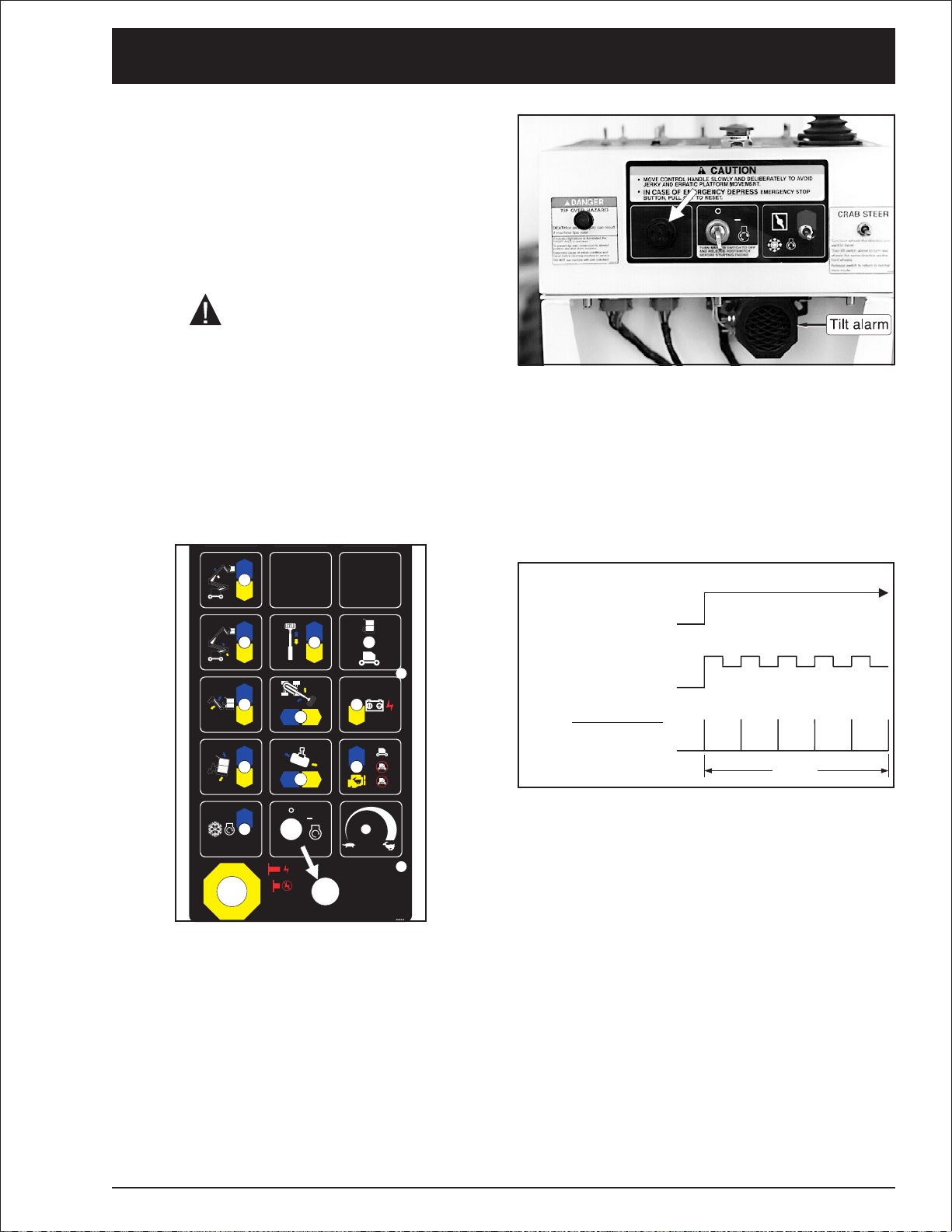

Alarms

2. Safety Devices

the other is located on the platform control box.

The buzzers are connected in parallel, they both

emit the same pattern of sound at the same time.

The tilt alarm is also located on the platform

control box.

The different alarm sound patterns these three

devices make are shown in the table immediately

below and discussed below the table.

There are two buzzers on the AB50J. One is

located on the ground control box,

Engine start-up

Overheating

Low oil pressure

Alternator not charging

Axle unlocked

Tilt alarm

Optional alarms:

All motion

Descending boom

Drive motion

❑

Start-Up Alarm

When the Master Key Switch or Anti-Restart

switch is turned ON, just prior to starting, the

buzzers emit a loud continuous tone to alert

others in the area that the AB50J is about to

start. The tone will continue until the AB50J starts

or the switch is turned OFF.

off

off

off

5 sec.

AB50J – 0163189 page 2 - 1

Page 21

2. Safety Devices

Engine Shut-Off Alarm

❑

The engine shut-off alarm comes on when the

engine is overheating or the oil pressure is low.

When the alarm sounds you should immediately

lower the platform completely down then turn the

engine off until the condition that caused the

alarm has been corrected.See “Automatic

Shut-Offs and Circuit Breakers” chapter 5 for

more information.

If the engine has automatically shut off, and

will not restart, go to the “Emergency

Operation” chapter 9, and use emergency

operation procedures to lower the platform.

Alternator Not Charging Alarm

❑

CAUTION

DO NOT continue to operate the AB50J while

the alternator alarm sounds. Without charging

current, the battery will discharge to the point

it cannot operate Emergency Power.

Axle Unlocked Alarm

❑

The front axle of the AB50J pivots so that all four

wheels remain on the ground when the machine

is driven with the main boom elevated less than

5° and the riser booms down. This improves

traction for 4-wheel drive machines and reduces

the ground pressure for all machines while they

are driven between work sites.

The main boom (more than 5°) and/or riser

booms should only be raised when the AB50J is

on a smooth level surface.When the main boom

is raised more than 5° or the riser booms are

raised slightly the front axle is automatically

forced to lock into position parallel to the rear axle

so that the bottoms of all four tires are in the

same plane. This maximizes stability of the

chassis while the booms are up.

If the engine alternator quits (usually because of

a broken fan belt), a continuous tone alarm will

automatically sound. The alarm warns you that

the battery is discharging.

Check the alternator drive belt to see if it is

broken or loose before you try to restart the

engine.If the engine will not restart, refer the

problem to a qualified service technician.

If the front axle is not locked parallel to the rear

axle when the main boom is raised more than 5°

or riser booms are raised, the TIP OVER

HAZARD light will come on and the “axle

unlocked”alarm will sound.

DANGER

DO NOT raise the main boom or riser booms

while the “axle unlocked” alarm is sounding.

CAUTION

When the alarm sounds you should

IMMEDIATELY lower the booms completely

down.Drive to a slightly different position, then

raise the booms again. If the alarm comes on

again, take the machine out of service

immediately and refer the problem to a

qualified service technician.

page 2 - 2 AB50J – 0163189

Page 22

Tilt Alarm

❑

The tilt alarm warns the AB50J operator that the

AB50J is over 5° out of level.If the tilt continues

to increase, the AB50J will eventually tip over.

DANGER

To prevent Death or Serious Injury, when you

hear the loud two toned (high-low-high-low...)

alarm, immediately retract and lower the

platform. When the platform is completely

down, determine and correct the cause of the

tilt before raising the platform again.

All Motion Alarm

❑

The optional all motion alarm emits a loud

beeping sound anytime a platform moving switch

is used or anytime the DRIVE/STEER controller

is used. The alarm alerts people near the AB50J

that some part of the AB50J is moving.

Descending Boom Alarm

❑

The optional descending boom alarm emits a

loud beeping sound anytime the jib boom, main

boom, or riser booms come DOWN. The alarm

also sounds when the tip boom RETRACTS.The

alarm alerts people near the AB50J that a boom

is lowering.

2. Safety Devices

■

Other Safety Devices

Battery

❑

The battery in the AB50J is a safety device

because it powers the emergency operating

circuits.If the platform is aloft and the engine

dies, battery power is the only way to lower the

platform, there is no manual bleed down

procedure.Thus, battery maintenance is very

important. The battery should always be kept at

full charge and the battery terminals kept free of

corrosion.

❑

Drive Motion Alarm

The optional drive motion alarm emits a loud

beeping sound anytime the Drive/Steer controller

is in FORWARD or REVERSE. This alarm alerts

people on the ground that the AB50J is traveling

along the ground.

If an optional extra battery is installed, at rear of

turntable, it too is a safety device.The extra

battery is not connected to the standard battery.

The batteries alternate use: only one battery is

connected to the electrical system at a time. Each

time the starter motor is activated the battery

used changes.

AB50J – 0163189 page 2 - 3

Page 23

2. Safety Devices

Emergency Stop Switches

❑

At Ground Control Box

❑

Press the large red Emergency Stop switch in,

at any time, under any conditions, and the entire

machine stops, the engine turns off, the brakes

automatically set, and nothing moves.

At Platform Control Box

❑

Press the large red Emergency Stop switch

down (off) and the entire machine stops, the

engine turns off, the brakes automatically set,

and nothing moves.

This switch must be pulled to its up (on) position

to control the AB50J from the platform.

Flashing Lights

❑

This switch must be pulled out (on) for anything

on the AB50J to work.

CAUTION

The ground control box is designed to override

the platform control box.

If the platform control box Emergency Stop

switch is down (off) the ground control box can

still be used to start and operate the AB50J.

The optional flashing lights alert people that the

AB50J is present. The lights flash at about one

flash per second any time the Battery,

Emergency Stop (at the ground), and Master

Key Switch are all ON.

There is no ON/OFF switch for the flashing lights.

page 2 - 4 AB50J – 0163189

Page 24

2. Safety Devices

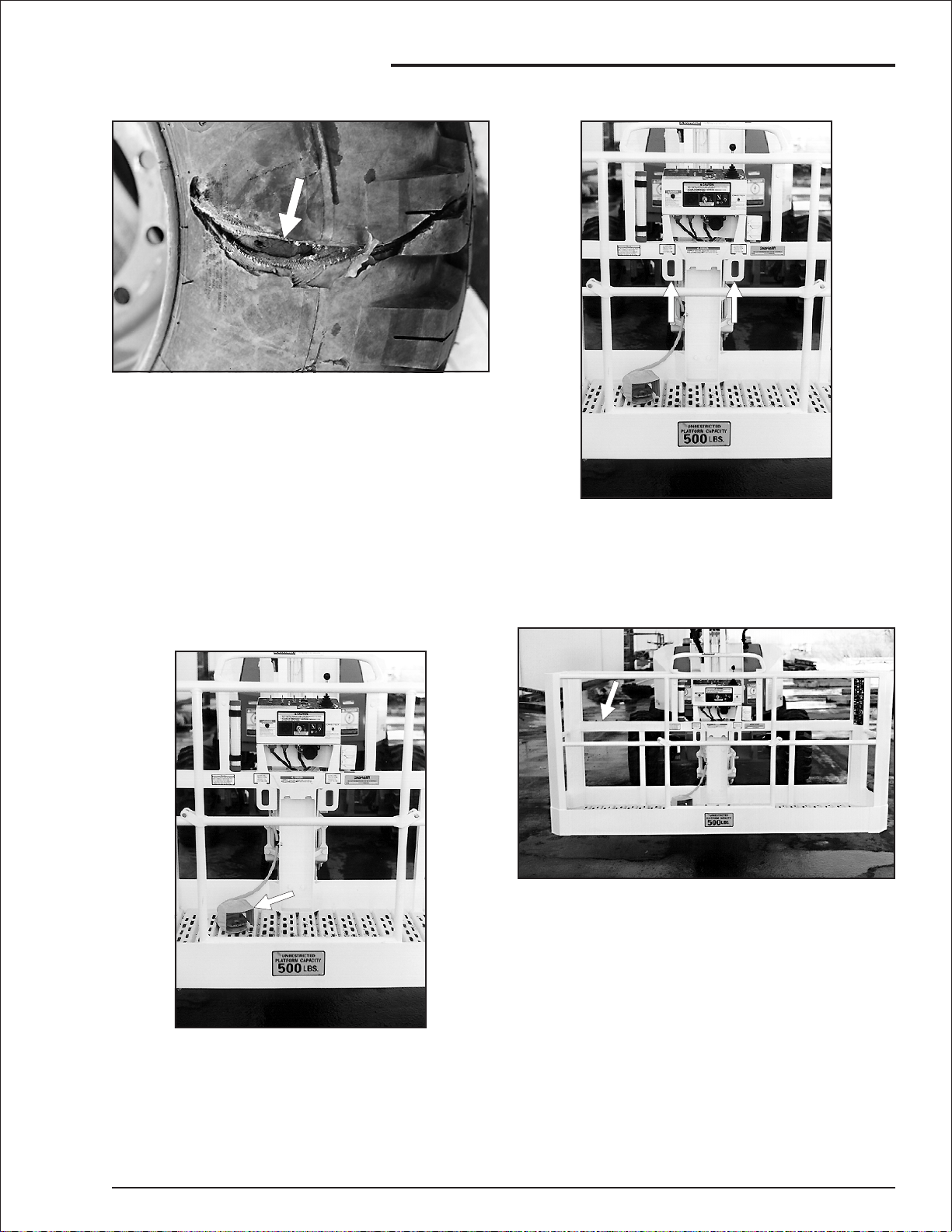

Foam Filled Tires

❑

Optional foam filled tires eliminate the possibility

of air leaks or blowouts which might cause a

tipover. Foam filled tires are therefore a safety

device.

Inspect them at the start of each work shift

according to the procedures in the “Daily

Inspection and Maintenance” chapter 7.

The foam filled tire shown here, shows signs of

damage and therefore is not acceptable for

service.

❑

Platform Foot Switch

Lanyard Anchor Points

❑

All personnel on the platform shall attach their fall

restraint lanyards to one of the lanyard anchor

points.

❑ Platform Guardrails

The guardrails help protect you from falling off the

platform. Be sure the guardrails are properly

installed and that the gravity gate or swinging

gate is in place.

The platform foot switch prevents the platform

from moving if something accidentally pushes

one of the platform moving controls on the

platform control box.To make the platform move

you must step on the foot switch at the same time

you use a platform moving control.

AB50J – 0163189 page 2 - 5

Page 25

2. Safety Devices

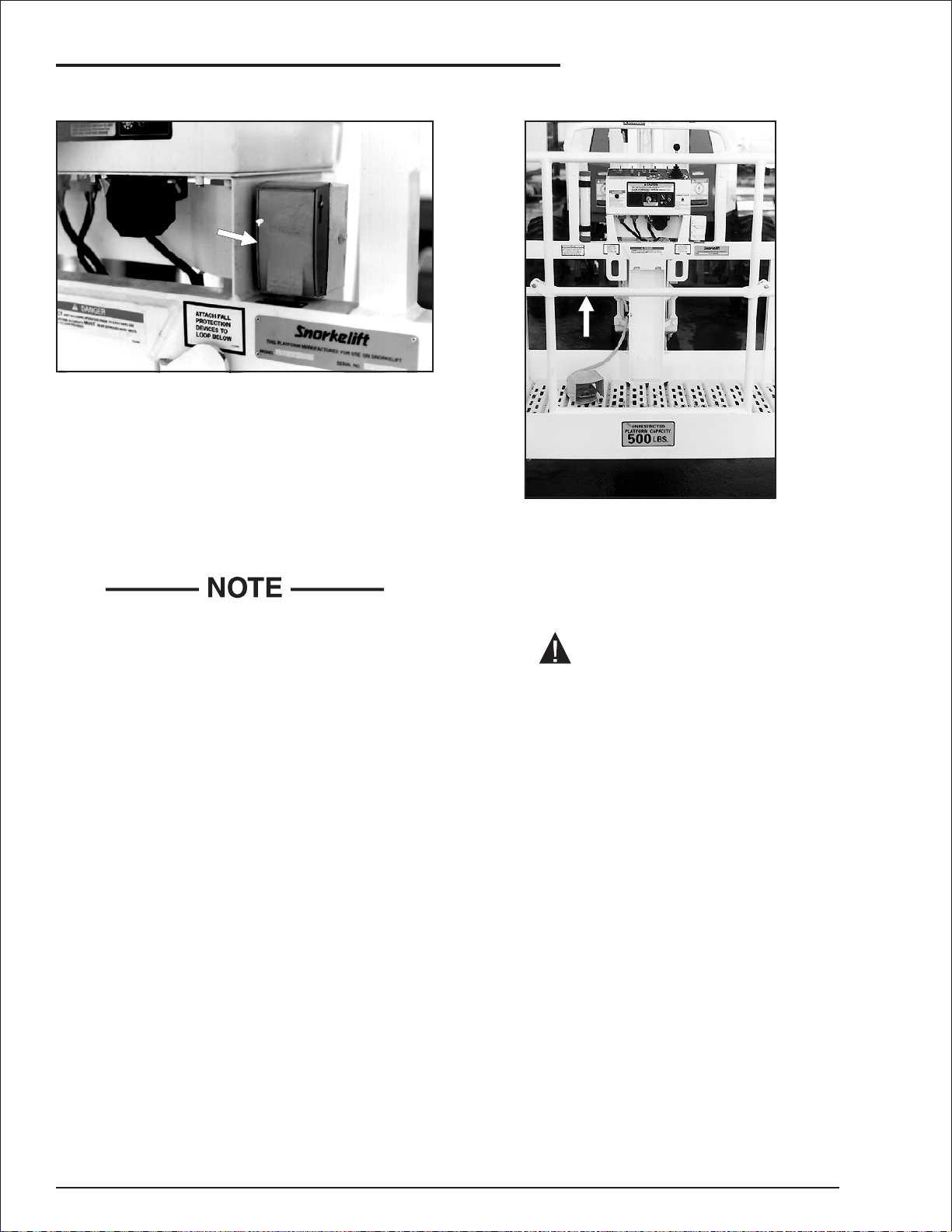

Ground Fault Circuit Interrupt

❑

The ground fault circuit interrupt (GFCI) is located

near the platform control box.

The GFCI protects against short circuits to

ground.When there is a short to ground the GFCI

shuts off power to the electrical outlets.

To use the outlet, connect the power input

connector, at the rear of the turntable, to a source

of 125 V AC, 15 A electrical power.

Platform Gravity Gate

❑

The platform gravity gate is the place in the

platform guardrail system where you should enter

and leave the platform.

If the AB50J has the optional AC Generator,

plug the power input connector into the

generator.Then, set the AC Generator switch,

on the platform control box, to ON.

See “electrical Outlet at the Platform” in the

“Operation” chapter 8, for more information

about how to use the GFCI.

Raise the gate and step under it onto the

platform.

CAUTION

Once you have entered the platform and

attached your fall restraint lanyard to an

anchor point, check to see that the gravity

gate has fallen back into place.

page 2 - 6 AB50J – 0163189

Page 26

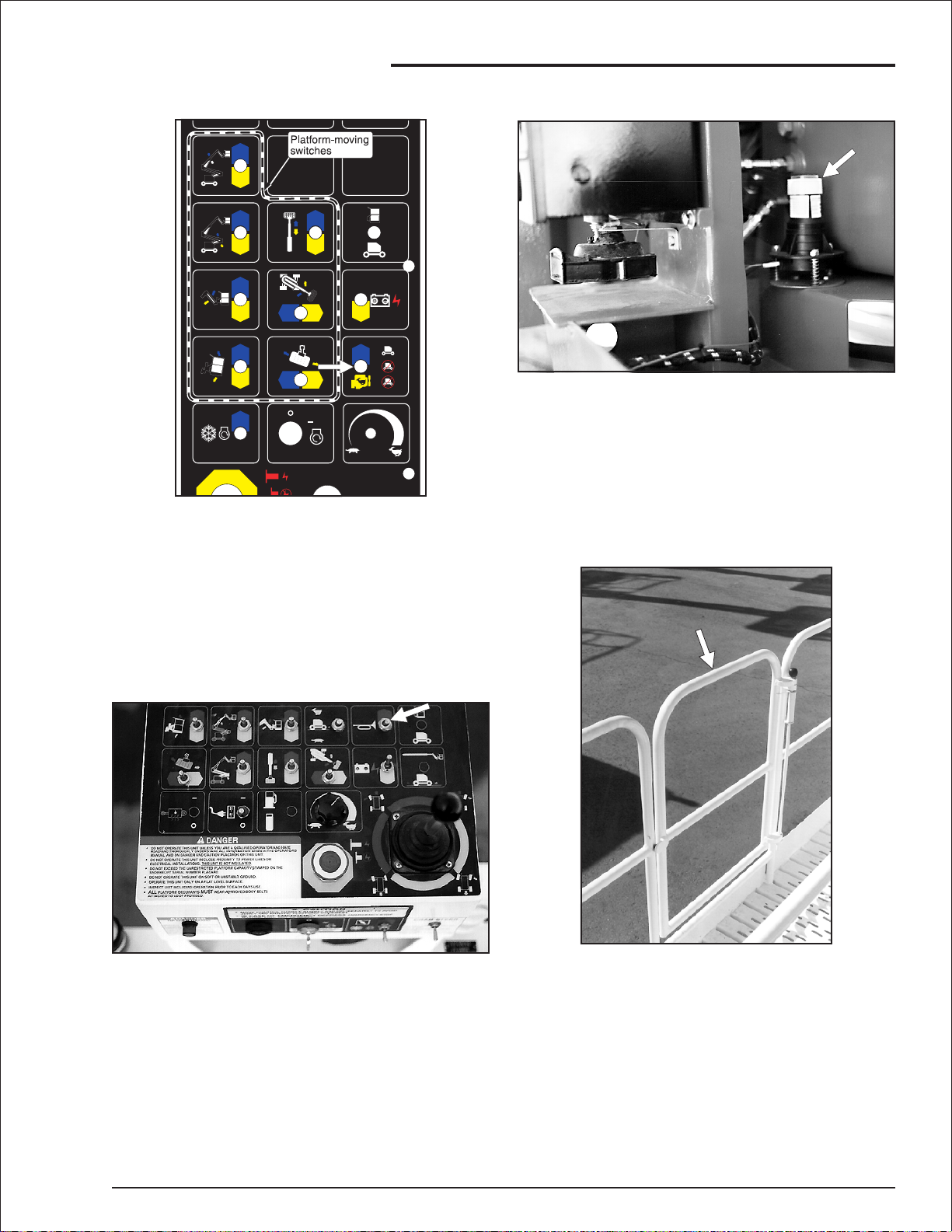

Ground Operation Switch

❑

The Ground Operation switch prevents the

platform from moving if something accidentally

pushes one of the platform moving switches at

the ground control box. To make the platform

move you must push and hold the Ground

Operation switch up at the same time you use a

platform moving switch.

2. Safety Devices

Level Sensor

❑

The level sensor, located behind the ground

control box, detects how far out of level the

turntable is.

If the turntable gets over 5° out of level and the

booms are raised, the level sensor activates the

tilt alarm.

Platform Swinging Gate

❑

❑

Operator Horn

The optional operator Horn is used primarily to

get the attention of people on the ground when

you are wor king aloft. For the horn to work the

Battery switch must be ON and the following

switches, on the ground control box, must be set

as indicated:

Platform/Ground Selector . . . . . . PLATFORM

Emergency Stop. . . . . . . . . . . Pulled Out (ON)

Master Key Switch . . . . . . . . . . . . . . . . . . . ON

The optional platform swinging gate is designed

to automatically close after you enter or leave the

platform. It helps prevent people from falling off

the platform.

AB50J – 0163189 page 2 - 7

Page 27

2. Safety Devices

Platform Work Lights

❑

The optional platform work lights are located on

top the platform guardrail. For the lights to work,

the Battery switch must be ON and the following

switches, on the ground control box, must be set

as indicated:

Tipover Hazard Light

❑

This light will come on when the front axle should

be locked but is not. The axle unlocked alarm will

sound when this light is on. When this light

comes on you should immediately completely

lower the booms.

Drive to a slightly different position then raise the

booms again. If the alarm comes on, take the

machine out of service IMMEDIATELY and refer

the problem to a qualified service technician. For

more information about the axle lock, see “Axle

Unlocked Alarm” at the star t of this chapter.

Platform/Ground Selector . . . . . . PLATFORM

Emergency Stop. . . . . . . . . . . Pulled Out (ON)

Master Key Switch . . . . . . . . . . . . . . . . . . . ON

The toggle switch on the back of a light turns it on.

CAUTION

Incandescent lights draw three amperes (35

watts) each. Halogen lights draw four amperes

(50 watts) each.

If you wor k with the lights turned on and the

engine turned off, the battery can discharge to

the point it will not start the engine nor run the

Emergency Power hydraulic pump.

If you cannot leave the engine running while

the lights are on, start and run the engine at

least 15 minutes in each hour to keep the

battery charged.

page 2 - 8 AB50J – 0163189

Page 28

3. Specifications

The Snorkelift AB50J is a boom supported

elevating work platform built to conform to all

applicable OSHA, ANSI or CSA standards as

previously outlined.

■

General Specifications

Working height, nominal . . . . . . . . 56.0 ft (17.07 m)

Platform height, maximum . . . . . . 50.2 ft (15.30 m)

Platform reach, max . . . . . . . . . . . . 28.0 ft (8.53 m)

Length, stowed. . . . . . . . . . . . . . . . 21.0 ft (6.40 m)

Width, overall . . . . . . . . . . . . . . . . . . 90 in (2.29 m)

Height

(booms down & retracted). . . . . . . 83 in (2.11 m)

Wheelbase. . . . . . . . . . . . . . . . . . . . 96 in (2.44 m)

Ground clearance . . . . . . . . . . . . . . . 7 in (17.8 cm)

Tailswing, stowed . . . . . . . . . . . . . . . 15 in (0.38 m)

Weight,approximate. . . . . . . . 15,280 lbs (6,930 kg)

Wheel loading, single - max. . . 7,890 lbs (3,580 kg)

Ground pressure, standard tires . . 77 psi (529 kPa)

Gradeability

2-wheel drive . . . . . . . . . . . . . . . . . . . . . . . . 25%

4-wheel drive . . . . . . . . . . . . . . . . . . . . . . . . 40%

Platform size:

Standard . . . . . . . . . . . . 30 x 72 in (76 x 183 cm)

Optional. . . . . . . . . . . . . 30 x 96 in (76 x 244 cm)

Unrestricted rated work load

(total weight of personnel, tools, and equipment

that platform is designed to carry abov e its floor):

Load weight. . . . . . . . . . . . . . . 500 lbs (227 kg)

Occupants . . . . . . . . . . . . . . . . . . . . . 2 people

Travel speeds

Booms down and retracted. . . 3.5 mph (5.6 km/h)

Booms up and/or extended. . . 0.5 mph (0.8 km/h)

Turning radius

2-wheel steer, inside . . . . . . . . . . . 89 in (2.26 m)

2-wheel steer, outside . . . . . . . . . 205 in (5.21 m)

4-wheel steer, inside . . . . . . . . . . . 45 in (1.14 m)

4-wheel steer, outside . . . . . . . . . 124 in (3.15 m)

Tires . . . . . . . . . . . . . . . 12 x 16.5 (30.5 x 42), 8 ply

Electrical system . . . 12 V dc (neg. chassis ground)

Environmental operating ranges:

ambient air temperature

Fahrenheit . . . . . . . . . . . . . . . . . 0°F to +110°F

Centigrade . . . . . . . . . . . . . . . . -18°Cto+43°C

Wind speed

(maximum gust or steady) . . 28 mph (45 km/hr)

Fuel tank capacity

Gas or diesel. . . . . . . . . . 15 gal USA (56.8 liters)

Optional LPG . . . . . . . . . . . 43.5 lbs USA (20 kg)

Hydraulic oil

Pressure, maximum . . . . . 3,500 psi (24,150 kPa)

Tank capacity . . . . . . . . 16.5 gal USA (62.5 liters)

Maximum temperature at tank . . . . 200°F(93°C)

Type and grade recommended

Above 10°F (-13°C) Mobil DTE-13M ISO VG32

Below 10°F (-13°C) . Mobil DTE-11M ISO VG15

Boom times, (complete range of movement):

Turntable Swing, 360°

CW or CCW . . . . . . . . . . . . . . 60 - 70 seconds

Platform Rotation, 180°

CW or CCW . . . . . . . . . . . . . . 15 - 20 seconds

Main Boom Elevation, +75°/-1° to horizontal

UP: . . . . . . . . . . . . . . . . . . . . . 30 - 35 seconds

DOWN: . . . . . . . . . . . . . . . . . . 20 - 25 seconds

Riser Boom Elevation

UP: . . . . . . . . . . . . . . . . . . . . . 55 - 60 seconds

DOWN: . . . . . . . . . . . . . . . . . . 55 - 60 seconds

Jib Boom, +45°/-75° to horizontal

UP:. . . . . . . . . . . . . . . . . . . . . 25 - 30 seconds

DOWN:. . . . . . . . . . . . . . . . . . 15 - 20 seconds

AB50J – 0163189 page 3 - 1

Page 29

3. Specifications

■

Engine Data

Engine Make Ford (gasoline) Ford (LPG) Kubota (diesel)

Model VSG 411 or VSG 413 V1305

Fuel gasoline LPG (liquefied petroleum

gas)

Fuel Grade Unleaded 87 octane

(motor method)

Do not use gasoline

blended with methyl

alcohol.

Coolant 50% water + 50% ethylene glycol

Operating

Temperature

Oil Capacity 3.5 qt USA

Oil Grade API: SG, SG/CC, or SG/CD API: CD/CE

Oil Weight see chart below

Running Time

(one tank fuel)

160°F - 190°F

(71°C-88°C)

(3.25 liters)

A full tank of gasoline, or diesel, will last an entire eight hour shift, under

normal working conditions. It normally takes two tanks of LPG per eight hour shift.

HD5

Gas Processors

Association Standard

2140.

Category: special duty

propane

diesel

Diesel fuel No.2-D

(ASTM D975)

180°F - 205°F

(82°C-96°C)

1.59 gal USA

(6.0 liters)

■

Engine Oil Charts

page 3 - 2 AB50J – 0163189

Page 30

■

Overall Dimensions

3. Specifications

8'-11"

(2.7m)

15.9"

(40cm)

6'-10"

(2.1m)

14.4"

(36.5cm)

21'-0"

(6.4m)

7'-6"

(2.3m)

4'-9"

(1.4m)

6'-11"

(2.1m)

2'-10"

(86cm)

3'-11"

(1.1m)

4'-0"

(1.2m)

8'-0"

(2.4m)

6'-0"

(1.8m)

Center of gravity

in stowed position

2'-10"

(86cm)

3'-8"

(114cm)

7'-6"

(2.3m)

AB50J – 0163189 page 3 - 3

Page 31

3. Specifications

■

Working Envelope

(METERS)

FEET

(16.8)

55

(15.2)

(13.7)

(12.2)

(10.7)

(9.1)

(7.6)

50

45

40

35

30

25

(6.1)

20

(4.6)

15

(3.0)

10

(1.5)

page 3 - 4 AB50J – 0163189

(0)

5

0

30

(9.1)

25

(7.6)

20

(6.1)

15

(4.6)

10

(3.0)

5

(1.5)

0

(0)

5

(1.5)

Page 32

■

Nomenclature and Serial Numbers

Right Side View Of Machine

❑

3. Specifications

Platform controls

Platform

Main boom

Rear

drive wheels

Turntable

Serial

number

Front lifting

tie down lugs

Chassis

Front

steering wheels

❑

Booms Identification

ATB 50 Main boom = Tip boom + Ba se boom

Tip boom

AB50J – 0163189 page 3 - 5

Base boom

Page 33

3. Specifications

Left Side View Of Machine

❑

Turntable

Front

steering wheels

Ground

controls

Chassis

Upper riser boom

Rear

drive wheels

Lower riser boom

Rear lifting

tiedownlugs

Jib boom

Serial

number

Platform

❑

Serial Number Location

Front

steering wheels

Serial number stamped

on left side of chassis

Chassis

Rear

drive wheels

Serial number stamped

on top of chassis tube

page 3 - 6 AB50J – 0163189

Page 34

4. Gauges

■

Ammeter

The ammeter gauge shows the electric current

from the alternator to the battery. When the

engine is running, the needle in the ammeter

gauge should not be to the left of “0.” Under

normal operating conditions, after the engine has

been running for a few minutes, this gauge

should read “0.”

■

Engine Oil

Gas Engine

❑

Diesel Engine

❑

■

Engine Coolant

The engine coolant reservoir is in front of the

radiator.When the engine is at operating

temperature the coolant level should be at the

HOT line.When the engine is cold there should

be about one inch (2.5 cm) of coolant in the

bottom of the reservoir.

Engine oil level is measured with a dipstick. Oil

capacities given in “Specifications” chapter 3,are

approximate.

True values may vary from machine to machine

due to slight variations or modifications during

production.

The oil dipstick is the only way to accurately

gauge if the engine oil level is correct.

AB50J – 0163189 page 4 - 1

Page 35

4. Gauges

Engine Oil Dipstick

❑

Gasoline engine Diesel engine

Engine oil level should always be between the

lines on the dipstick, never above or below them.

The AB50J should be on level ground when you

check the dipstick.

Check the oil level after the engine has been

turned off a few minutes so that oil can run down

out of the engine into the sump.

Filter Minder Indicators

❑

As the filter clogs, the vacuum increases

(pressure drops). As the vacuum increases, the

yellow indicator (1) raises toward the red area (2)

of the sight glass. When the yellow indicator

reaches the red, it’s time to change the air filter.

The yellow indicator (1) stays at its highest

setting. It does not go to the bottom of the sight

glass when the engine is tur ned off.After the filter

is changed, press the small RESET button (3) to

reset the yellow indicator to the bottom of the

sight glass.

■

Fuel

■

Filter Minder

The air filter gauge, filter minder, is located just

above the ground control box.

The gauge measures the vacuum (air pressure)

between the intake manifold and the air filter.

The fuel gauge is located on top of the gasoline

or diesel fuel tank. Read the fuel gauge at the line

in the clear plastic window. The gauge reads in

fractions-of-a-full-tank.

CAUTION

DO NOT run a diesel fuel tank empty. Air in the

fuel line makes a diesel engine hard to start.

page 4 - 2 AB50J – 0163189

Page 36

4. Gauges

■

LPG (Liquefied Petroleum Gas)

Optional LPG tanks have two fuel gauges (1) and

(2) on top.One measures correctly when the tank

is standing on end (vertical), the other measures

correctly when the tank is laying down

(horizontal).

Both read in fractions-of-a-full-tank. Standard

AB50J tanks are mounted vertically, therefore,

you should read the vertical scale (1).

The Hour Meter also accumulates time when:

Battery Switch . . . . . . . . . . . . . . . . . . . . . . ON

Platform/Ground Selector . . . . . . PLATFORM

Emergency Stop

(at ground control box) . . . . . Pulled Out (ON)

Emergency Stop

(at platform control box) . . . . Pulled Out (ON)

Master Key Switch . . . . . . . . . . . . . . . . . . . ON

Anti-Restart Switch . . . . . . . . . . . . . . . . . . ON

The hour meter gauge cannot be reset.use it

to tell when it is time to perform the periodic

maintenance listed in the Maintenance and

Repair Parts Manual.

■

Hydraulic Oil Filter

Optional second LPG tanks are mounted

horizontally.Read the horizontal gauge on

them.

■

Hour Meter

The hour meter gauge is basically an electric

clock.It accumulates time when:

Battery Switch . . . . . . . . . . . . . . . . . . . . . . ON

Platform/Ground Selector . . . . . . . . GROUND

Emergency Stop

(at ground control box) . . . . . Pulled Out (ON)

Master Key Switch . . . . . . . . . . . . . . . . . . . ON

The hydraulic oil filter gauge (1) is located above

the hydraulic oil filter (2). The gauge measures

pressure into the filter.As the filter clogs, the

pressure goes up.

CAUTION

The hydraulic oil filter gauge should only be

read by qualified trained maintenance

personnel. An accurate reading requires very

special conditions and should not be

attempted by operators.

AB50J – 0163189 page 4 - 3

Page 37

4. Gauges

■

Hydraulic Oil Level

The hydraulic oil level gauge (1) is on the side of

the hydraulic oil tank (2).

■

Hydraulic Oil Temperature

The hydraulic oil temperature gauge measures

the temperature of the oil in the tank. The

temperature should not exceed 200°F (93°C). If it

does, reduce your driving speed or stop the

engine and let the hydraulic oil cool.

The gauge shows the actual level of oil inside the

hydraulic oil tank.

Read it only when the booms are completely

down and completely retracted. Otherwise, the

boom hydraulic cylinders become large

reservoirs for hydraulic oil and the oil level in

the tank will be low.

The oil level (3) should be between the HIGH

mark and LOW mark.

■

Temperature

The temperature gauge shows the temperature of

the water antifreeze mixture as the mixture enters

the engine block.

The typical operating temperature range for

FORD engines is 160°Fto190°F (71°Cto88°C).

The typical range for Kubota engines is 180°Fto

205°F (82°Cto96°C).

page 4 - 4 AB50J – 0163189

Page 38

5. Automatic Shut-Offs and Circuit Breakers

■

Automatic Shut-Offs

The AB50J engine will automatically shut off if:

1. The engine temperature gets too high.

2. The engine oil pressure gets too low.

3. The main circuit breaker trips.

A continuous tone alarm will sound as the engine

begins to overheat or if the oil pressure is low.For

circuit breaker problems there is no audible alarm.

The subsections below explain the shut-offs in

more detail.

See the “Safety Devices” chapter 2, for an alarm

timing diagram.

DANGER

If you are aloft in the platform when a

continuous tone alarm sounds, IMMEDIATELY

lower the platform to ground by using normal

operating procedures or emergency operating

procedures if the engine will not run. Then,

check the AB50J as described below.Failure to

do so might result in harm to the AB50J or

might result in stranding you aloft, in some

cases, with no EMERGENCY POWER.

Engine Oil Pressure

❑

If the engine oil pressure drops to an unsafe level

the engine automatically shuts off and an alarm

sounds.If you are aloft in the platform and the

engine automatically shuts off and will not restart,

use EMERGENCY POWER to lower the platform

(see “Emergency Operation” chapter 9).

Check the engine oil level (see “Daily Inspection

and Maintenance” chapter 7), before you try to

restart the engine.If the engine oil is low, replenish

it then check for leaks. Check the engine oil filter

(with the engine turned off) to be sure it is in place

and tight. If the engine will not restart, or if it

automatically shuts off a second time, refer the

problem to a qualified service technician.

❑

Engine Temperature

If the temperature of either a gasoline or diesel

engine reaches 220°F (104°C) a warning alarm

will sound. If the temperature continues to climb

to 230°F (110°C) the engine will automatically

shut off and cannot be restarted until it cools.

Check engine coolant level (see “Daily Inspection

and Maintenance” chapter 7), before you try to

restart the engine. If the coolant is low, replenish

it then start the engine and visually check the

radiator, radiator hoses, and engine head gasket

for leaks. If the engine will not restart, or if it

automatically shuts off a second time, refer the

problem to a qualified service technician.

The oil filter (1) on a Ford engine is easy to reach.

The oil filter (2) on a Kubota engine is on the

back side of the engine, approximately where the

fuel filter (3) is on the front side.

AB50J – 0163189 page 5 - 1

Page 39

5. Automatic Shut-Offs and Circuit Breakers

If the cause of the problem is not immediately

obvious, refer the problem to a qualified

service technician.

There are two ways to get to the oil filter on a

Kubota engine.

1. One way is to rotate the turntable (4) about

30° clockwise with respect to the chassis (5)

then reach through the hole (6) in the bottom

of the turntable (4).

If the 15 A circuit breaker on the side of the outlet

CAUTION

Use caution to avoid burns as the engine and

exhaust manifold might be hot.

trips, disconnect whatever you plugged into the

outlet, wait one minute, then press the circuit

breaker button back in.

CAUTION

2. The second way is to reach over the engine.

■

Circuit Breakers

With the exception of the GFCI outlet at the

platform, there are no circuit breakers on the

AB50J that are accessible to an operator.

Circuit breakers on the AB50J automatically reset

themselves about one minute after tripping.

When a circuit breaker trips that will not reset, or

if it resets automatically but trips again,

immediately attempt to lower the platform to the

ground by using normal operating procedures.

If normal procedures do not work, use

EMERGENCY procedures (see “Emergency

Operation” chapter 9) to lower the platform.

page 5 - 2 AB50J – 0163189

If the ground fault circuit breaker in the GFCI

outlet trips, disconnect whatever you plugged into

the outlet, wait one minute, then press the

RESET button back in.

If a circuit breaker trips two times in a row, refer

the problem to a qualified service technician.

Page 40

■

Controls Description

This chapter shows the controls at the ground

control box and the platform control box, and

explains what each control does.

6. Controls

“Operation” chapter 8, covers the proper use of

controls.

See the “Emergency Operation” chapter 9, for

correct emergency operation procedures.

See the “Options” chapter 11, for correct

operation procedures of any optional equipment.

This chapter DOES NOT explain how to use

the controls to produce useful work.

■

Controls and Controls Decals Locations

Platform Control Box Front

The main operating functions of an AB50J can be

controlled from the ground control box or from the

platform control box.

Platform Controls Box Top

Steer

Ground Controls

AB50J – 0163189 page 6 - 1

Drive

Page 41

6. Controls

■

Ground Control Box

Controls for operating the AB50J from the

ground, are located on the left side of the

turntable.

The number of each control below corresponds to

the control’s call out on the control box illustration.

1.

Emergency Stop: Press the red button in, at

any time, under any conditions, and the

entire machine stops - the engine turns off,

the brakes automatically set, and nothing

moves.This switch must be out for anything

on the machine to work.

2.

Platform/Ground Selector : Must be in the

GROUND position (down) for the ground

control box to work. The switch MUST be in

the PLATFORM position (up) for the platform

control box to work.

3.

Choke/Cold Star t: This switch only works for

diesel engines. Gasoline engines have

automatic chokes. Hold the switch UP for 10

seconds then release it just before you start

an engine that is at ambient air temperature

(a “cold” engine). That will cause the glow

plugs to warm the inside top of each cylinder,

thus aiding combustion.

4.

Master Key Switch: This switch works like

an automobile ignition switch. Hold it at

START until the engine starts, then release it

to ON. Turn the Master Key Switch to OFF if

the platform is to stay in one position for a

long time, that will turn the engine off and

save fuel.

5.

Boom Speed: This control determines how

fast the booms move.Set it to SLOW (turtle)

until you are very familiar with the way the

machine works or if the platform is working in

dangerous or cramped surroundings.

6.

Ground Operation: You must manually hold

this switch up any time you use one of the

seven platform moving switches, (switches 7

through 13), to move the platform.

Control switches 7 through 13 are the platform

moving switches.Each is a three position,

momentary contact, normally OFF switch.

See Nomenclature and Serial Numbers in the

“Specifications” chapter 3, for boom

identification.

7.

Main Boom Lift: UP raises the main boom.

DOWN lowers the base boom.

8.

Extend/Retract: EXTEND extends the tip

boom out of the base boom. RETRACT

retracts the tip boom into the base boom.

9.

Riser Lift: Up raises the upper and lower

riser booms. DOWN lowers them.

10.

Jib: UP raises the jib boom. DOWN lowers

the jib boom.

11.

Swing: CW (left) rotates the entire turntable

clockwise (as seen from above). CCW (right)

rotates the turntable counterclockwise.

12.

Platform Level: UP rotates the platform up

relative to the end of the jib boom. DOWN

rotates the platform down.

13.

Platform Rotate: CW (left) rotates the

platform clockwise (as seen from above)

relative to the end of the jib boom. CCW

(right) rotates the platform counterclockwise.

14.

Emergency Power:If the engine stops and

cannot be restarted, continuously holding this

switch down activates a small, battery

powered hydraulic pump that supplies

emergency hydraulic power for the machine.

Boom movements will be slow and have long

lag times under EMERGENCY POWER.

DO NOT use this switch for normal operation.

Holding the switch up increases the engine

speed and activates the platform moving

switches in preparation to do work. Set the

switch to FAST IDLE (down position) only

when you need to quickly warm the engine.

Return to IDLE (center position) after engine

warm up.

page 6 - 2 AB50J – 0163189

Page 42

Ground Control Box Controls

❑

7

6. Controls

8

11

10

13

12

9

3

2

14

6

1

4 5

AB50J – 0163189 page 6 - 3

Page 43

6. Controls

■

Platform Control Box

Controls for operating the AB50J from the

platform are located on the platform control box,

with the exception of the foot switch which is on

the platform floor.

The number of each control below corresponds to

the control’s call out on the control box illustration.

1.

Emergency Stop: Press the large red button

down at any time, under any conditions, and

the entire machine stops - the engine turns

off, the brakes automatically set, and nothing

moves.This switch must be pulled to its up

(or out) position if the AB50J is to be

controlled from the platform.

2.

Choke/Cold Star t: This switch only works for

diesel engines. Gasoline engines have

automatic chokes. Hold the switch UP for 10