Snorkel AB46RT User Manual [en, de, es, fr]

AB46RT

Operator Manual

This first section of the Operator manual is the English language version.

Betriebsanleitung

Der zweite Abschnitt von dieser Betriebsanleitung ist die Deutsche version.

Guide d’opérateur

La troisième section de ce manuel d'opérateurs est la version de langue Française.

Manual de los Usuario

La cuarta sección de este manual del usuario corresponde a la versión en Española.

English Language Section

SAFETY RULES

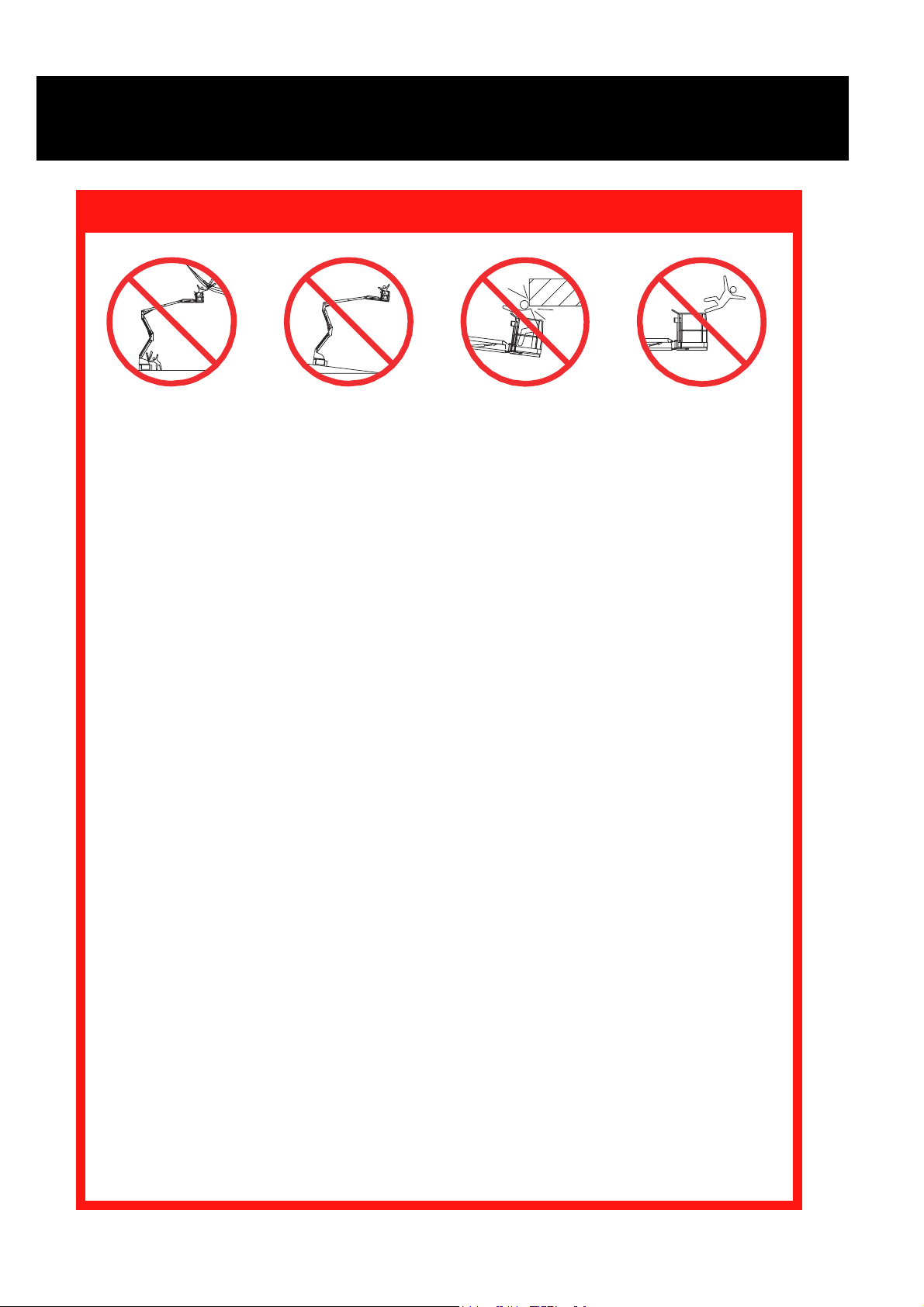

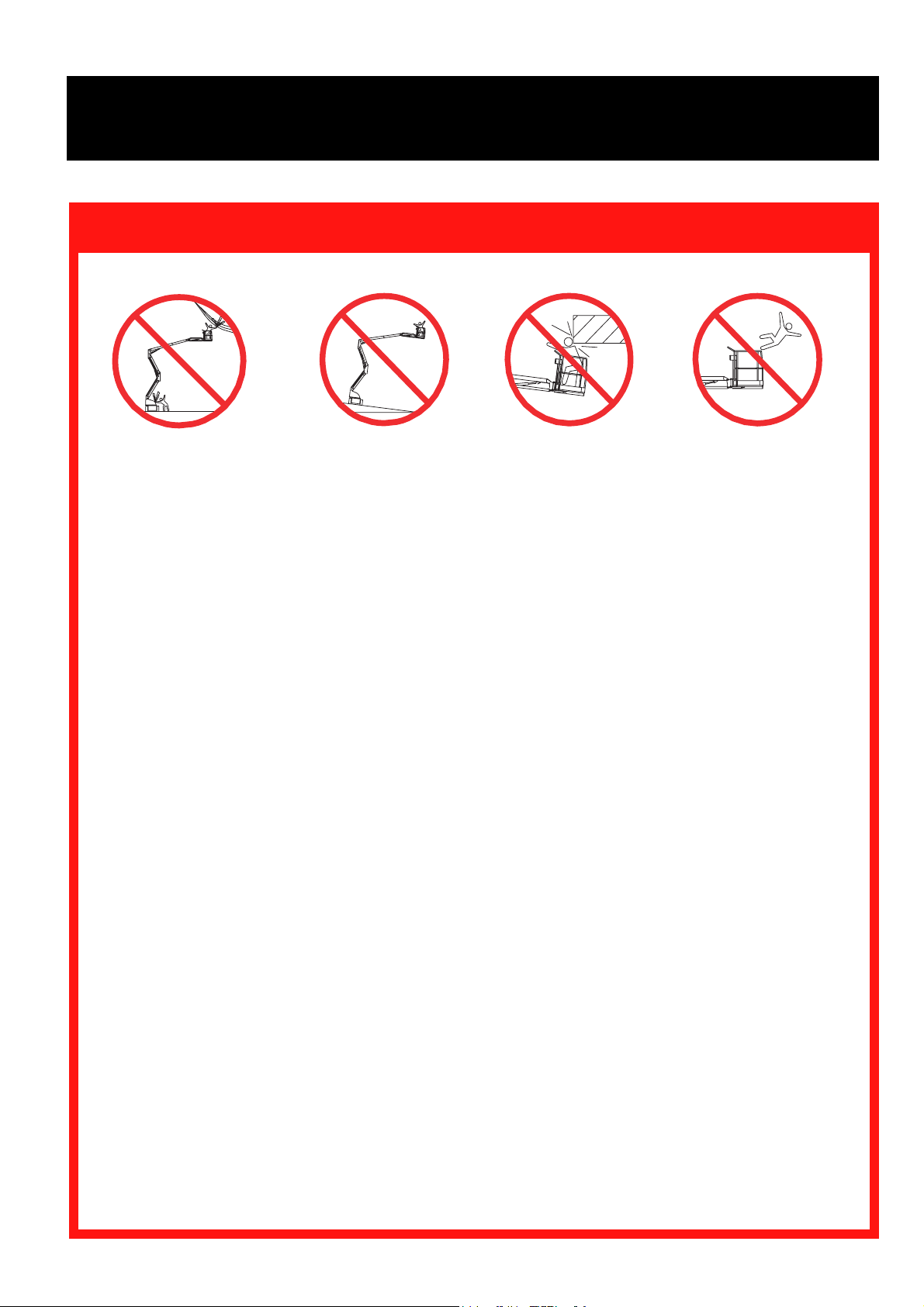

Electrocution Hazard Tip Over Hazard Collision Hazard Fall Hazard

NEVER operate the

machine within ten (10)

feet of power lines. THIS

MACHINE IS NOT

INSULATED.

ALL occupants must wear an approved fall restraint properly attached to designated platform anchor-

age point. Attach only one fall restraint to each anchorage point.

NEVER exceed maximum platform load of 225 kg (500 lbs.) and two (2) occupants.

NEVER exceed 200 N (45 lbs.) of side force per occupant.

NEVER Operate the machine when noise levels exceed 80 dB.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes,

drop-offs, bumps, curbs, or debris; and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER elevate the machine when wind speeds exceed 12.5 m/sec. (28 mph).

IN CASE OF EMERGENCY push emergency stop button to cut power to all machine functions.

ALWAYS close and secure gate after entering platform.

NEVER exit or enter platform while elevated.

NEVER use ladders, scaffolding, or other items to gain height; work only from the platform floor.

NEVER climb down elevating assembly while platform is elevated.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose

wire connections, and damaged cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

IF ALARM SOUNDS while boom is elevated, STOP, carefully retract boom and lower platform without

rotating. Move machine to a firm, level surface.

NEVER attach overhanging loads or use boom as a crane.

NEVER alter operating or safety systems without manufacturers written consent.

NEVER charge battery near sparks or open flame. Charging batteries emit explosive hydrogen gas.

NEVER replace any component or part with anything other than original UpRight replacement parts

without the manufacturer's written consent.

NEVER tow the machine. Transport by truck or trailer only.

AFTER USE, secure the work platform from unauthorized use by turning both keyswitches off and

removing all keys.

NEVER operate the

boom or drive with

platform elevated

unless on firm level

surface.

NEVER position the

platform without first

checking for overhead

obstructions or other

hazards.

NEVER climb, stand or

sit on platform guardrails or midrail.

California Proposition 65 Warning

Gasoline and diesel engine exhaust and some of their constituents are known to the State of California

to cause cancer, birth defects, and other reproductive harm.

2

Introduction

This manual covers the operation of internal combustion

powered models of the AB-46 RT Articulated Boom. This

manual must be stored on the machine at all times.

Pre-Operation and Safety

Inspection

Carefully read, understand and follow all safety rules,

labels, and operating instructions, then perform the

following steps each day before use.

Perform a complete visual inspection of the entire unit

prior to operating. Check the following areas for discrepancies:

1. Open panels and check hydraulic components / hoses

for damage or leaks. Check electrical components /

wiring for damage or loose connections.

2. Inspect chassis, axles, hubs, and steering linkage for

damage, deformation, buckled paint, loose or missing

hardware, and cracked welds.

3. Check tires for damage, punctures, and inflation; tire

pressure must be 3,8 bar (55 psi).

4. Check all hoses / cables for wear.

5. Inspect elevating assembly for damage, deformation,

buckled paint, loose or missing hardware, and

cracked welds.

6. Inspect platform and guardrails for damage, deformation, buckled paint, loose or missing hardware, and

cracked welds. Insure that gate operates freely and

latches securely.

7. Check Hydraulic fluid level with platform fully lowered.

8. Check battery fluid level (see battery maintenance,

page 10).

9. Check fuel level, add fuel if necessary (see fueling,

page 10).

10.Ensure that radiator is cold, check coolant level. Add

if necessary.

NEVER remove the cap from a hot radiator. Hot

coolant can cause severe burns.

chassis control panel and at the platform control

panel.

3. Press the engine start button to crank the engine;

release when engine starts. If engine is cold: press

the preheat button and hold for six seconds prior to

starting diesel models.

4. Push in the chassis emergency stop button engine

should stop. Repeat for platform emergency stop

button. Return both emergency stop buttons to the

on position, and start engine.

5. Operate each function switch to raise / lower, extend

/ retract, rotate left / right, each section of the

elevating assembly and observe the operation of the

machine. All functions should operate through full

cycle smoothly.

6. Turn chassis key switch to platform.

7. Mount the platform, close and latch the gate, and

attach approved fall restraint to designated platform

anchorage point. Attach only one fall restraint to

each point.

8. Start the engine.

9. Without depressing the foot switch, move the drive

control handle, machine should not function.

10.Depress the foot switch and move the drive control

handle forward and reverse. Observe that proportional functions operate smoothly, and that brakes

apply quickly after control is released.

11.While depressing foot switch, operate steer switch to

left and right. Observe that steering wheels turn

properly.

12.While depressing foot switch, turn function speed

control knob to desired setting, and operate boom

controls. Observe that boom operates smoothly,

and that upper boom, jib, turret rotation, platform

level, and platform rotation controls operate proportionally in conjunction with function speed control

knob. Observe that platform maintains level when

boom is elevated.

13.With the upper boom elevated one foot, operate

drive control handle. Observe that drive speed is

limited to creep approximately (1 foot [.3m] per

second). Lower upper boom to stowed position.

14.Press the service horn button. Observe that horn is

audible.

SYSTEM FUNCTION INSPECTION

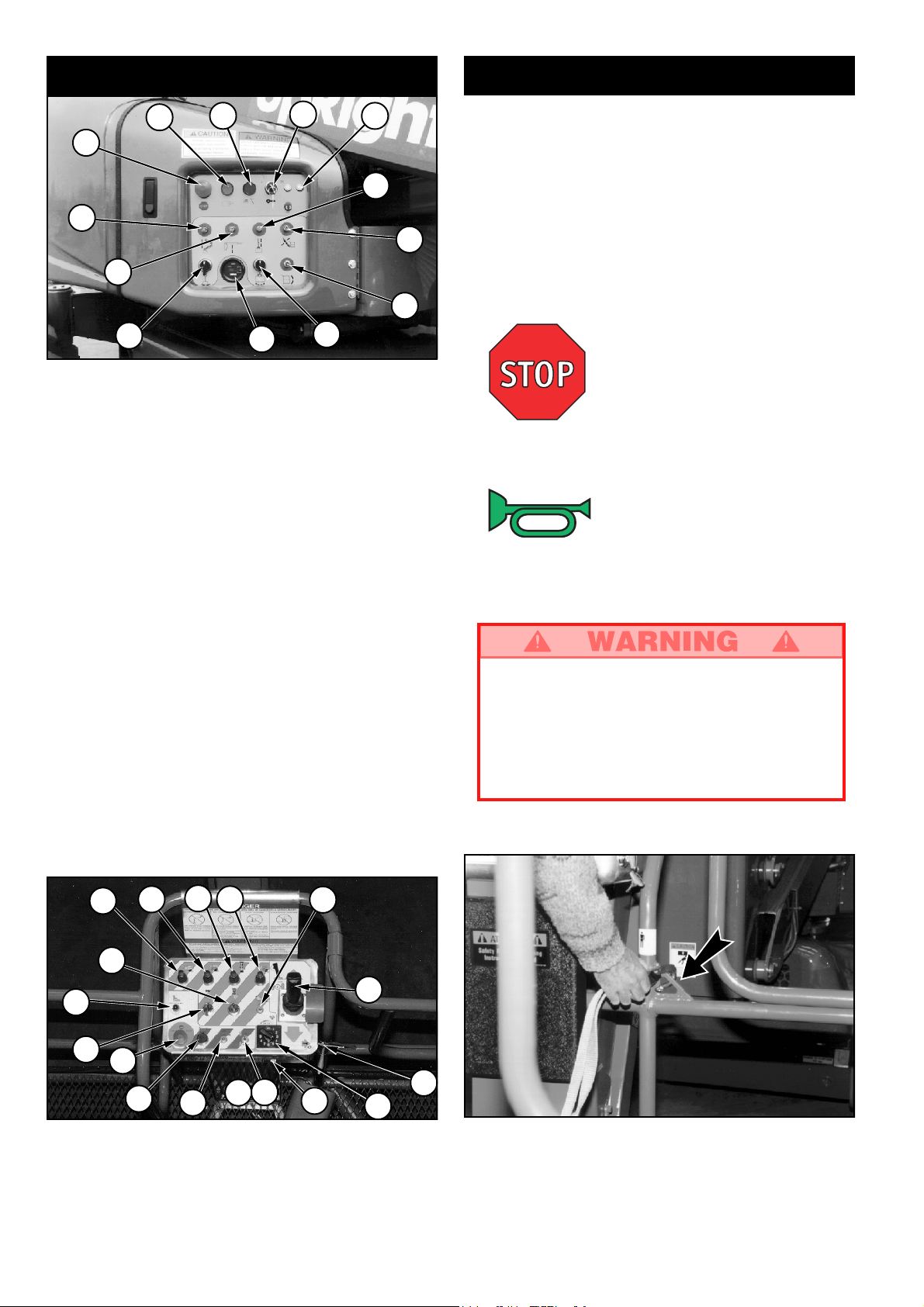

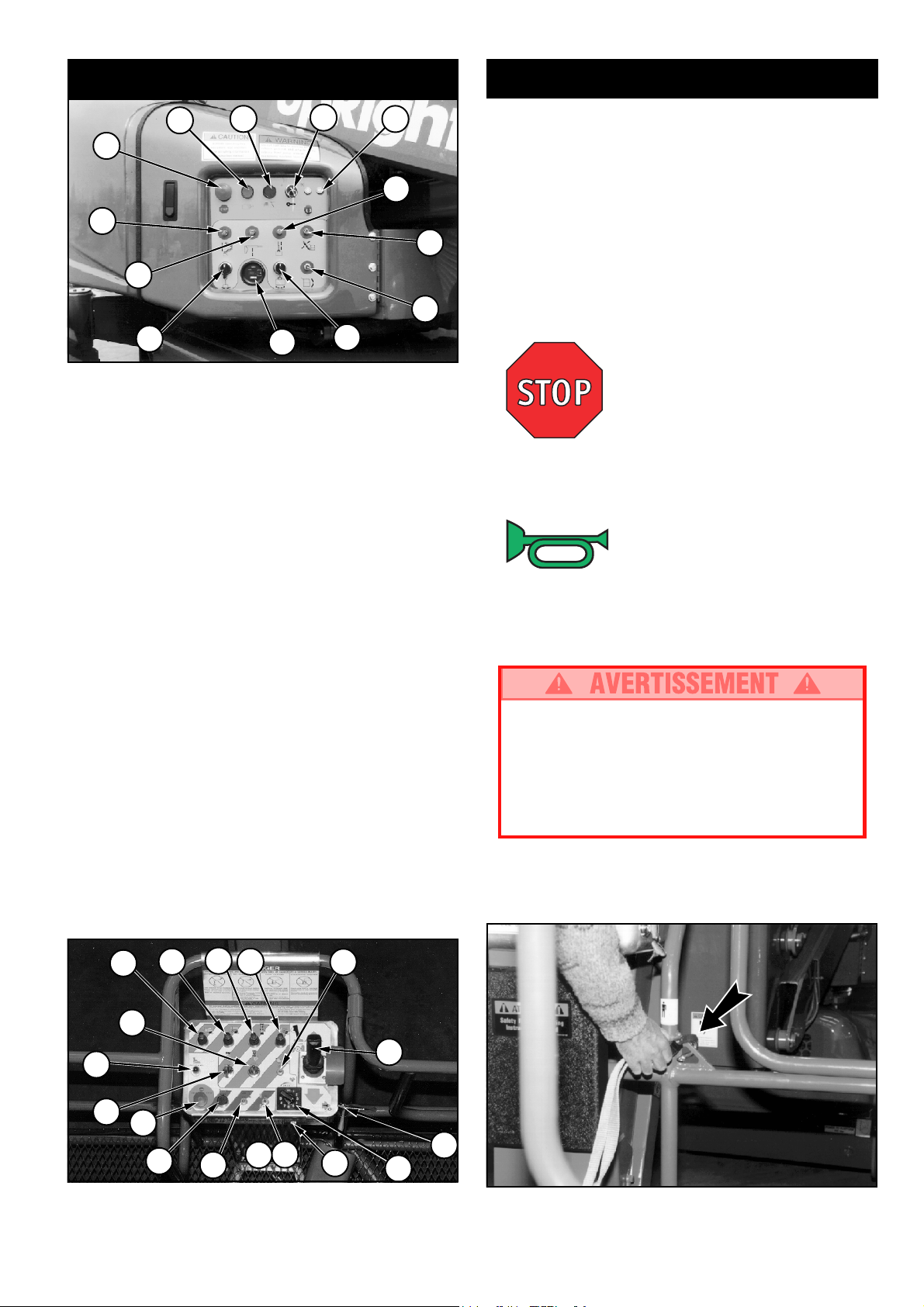

Note: Refer to figures 1 and 2 for chassis and

platform control locations.

1. Before performing the following tests, check area

around machine and overhead for obstructions,

holes, drop-offs, and debris.

2. Turn chassis key switch to chassis, and turn on

(rotate clockwise) emergency stop switches at the

DO NOT use a machine that is damaged or

malfunctioning. Tag and remove the unit from

service until it is repaired.

3

Controls and Indicators

Operation

2

20

4

5

1

8

6

7

12

10

Figure 1: Chassis Controls

Note: The following list corresponds to the numbered items in figures one and two.

1. Emergency stop.

2. Engine start.

3. Speed Selector.

4. Keyswitch.

5. Control fuses.

6. Riser control.

7. Upper boom control.

8. Boom extension control.

9. Jib control.

10.Turret rotation control.

11.Platform rotation control.

12.Platform level control.

13.Hourmeter.

14.Service horn button.

15.Drive control handle.

16.Function speed control.

17.Fuel selector (dual fuel).

18.Foot switch (located on platform floor).

19.Out of level indicator.

20.Preheat button (diesel).

13

11

Before operating work platform insure that:

Pre-operation and safety inspection has been

completed, and any discrepancies have been

corrected.

The operator has been thoroughly trained on the

operation of the machine.

9

The work area is clear of all obstructions, holes,

drop-offs, or persons in the route of travel.

The surface is capable of supporting wheel loads.

Refer to figures one and two for control locations.

Emergency Stop

At any time during operation, press the emergency stop

button to stop all functions in an emergency.

Service Horn

At any time during operation, press the service horn

button to sound an audible warning if necessary.

Always wear an approved fall restraint properly

attached to designated platform anchorage point

when driving or elevating the machine (see

figure 3).

Attach only one fall restraint to each anchorage

point.

19

10

8

6

7

9

11

1

14

Figure 2: Platform Controls

17

3

20

12

5

15

4

16

Figure 3: Typical Fall Restraint Anchorage Point

4

Starting the engine

3. Attach approved fall restraint to designated platform

anchorage point. Attach only one fall restraint to

each point.

From the lower controls

1. Turn the chassis key switch to chassis position.

2. Press the start button to crank the engine. Release

when the engine starts.

3. When the engine is cold: press and hold the preheat

button while starting the diesel engine.

Note: Do not depress the foot switch when cranking

engine, as this may flood engine.

From the platform controls

1. Turn the chassis key switch to platform controls.

2. Turn the platform keyswitch fully clockwise to crank

the engine. Release when engine starts.

3. When the engine is cold: Press and hold the preheat

button while starting the diesel engine.

Note: Do not depress the foot switch when cranking

engine, as this may flood engine.

Driving

4. Start engine.

5. Check that the area around and above the work

platform is clear of obstructions, holes, drop-offs,

persons in the route of travel, and the surface is

capable of supporting wheel loads.

6. Examine the terrain and place the speed selector

switch in the appropriate position (Hi or Lo).

7. Depress the foot switch and move the drive control

handle forward to travel forward and reverse to travel

in the reverse direction.

8. While driving in HI speed, pressing the button,

located on the front of the drive control handle, will

shift momentarily into LO for improved torque.

Note: When the boom is rotated to the front of the

chassis (steering wheels aft) directions of travel and

steering will be reversed. Observe the color coded

arrows on the control panel near the drive control

handle, and on the chassis. They will indicate the

direction of travel when the drive control handle is

moved.

The front axle will oscillate freely through a limited

range when driving for greater ease of negotiating

irregular terrain.

With Boom Lowered

The AB-46 RT has two drive speeds when the boom is

lowered to efficiently accommodate varying terrain.

Lo Speed: The Lo speed capability allows the machine

to be easily maneuvered through rougher

terrain and negotiate steeper slopes.

Hi Speed: The Hi speed capability is convenient for

maneuvering in areas that are relatively

smooth and where the machine will not be

driven over rough or sloping terrain.

1. Turn chassis key switch to platform, and turn on

(turn clockwise) the chassis emergency stop switch.

2. Mount the platform, close and latch the gate.

With Boom Elevated

Travel with boom elevated is restricted to firm level

surfaces only. When the articulating front axle is not

level, it will lock into position and disable the drive

function. Drive is disabled above 8m (26ft).

When driving elevated, the machine will travel at creep

speed (1 foot [.3 m] per second).

Steering

1. While depressing the foot switch, push the steering

switch (located on top of the control handle) to the left

to turn left, and right to turn right.

Note: Steering is not self centering. Wheels must

be returned to the straight ahead position by

operating the steering switch.

POSITIONING THE PLATFORM

Positioning the platform as close as possible to the work

area requires some planning. First, you must survey the

work site to find a suitable place to park the machine.

This must be a firm level area as close as possible to

the work area. Take into consideration all obstructions

on the ground and overhead and avoid them.

5

Once you have moved the machine to a firm level

surface as near as possible to the work area, follow the

instructions on page five to position the platform as

close to the work area as possible.

Always, before operating any function, check the area

around and overhead for any obstructions or electrical

conductors.

NEVER exit the platform while the boom is

elevated. Keep both feet firmly planted on the

platform floor at all times.

Multifunction Controls

The UpRight AB-46 RT employs the use of multifunction

controls. This means that riser or boom extension will

function at full speed while simultaneously operating

upper boom, jib, turret, or rotating the platform.

The turret may be rotated while driving when boom is

lowered if necessary to make turns in tight areas. No

other boom functions will operate while driving.

Lower Control Operation

All boom functions will operate at fixed speed. Those

which are adjustable will operate at the speed set on the

platform control.

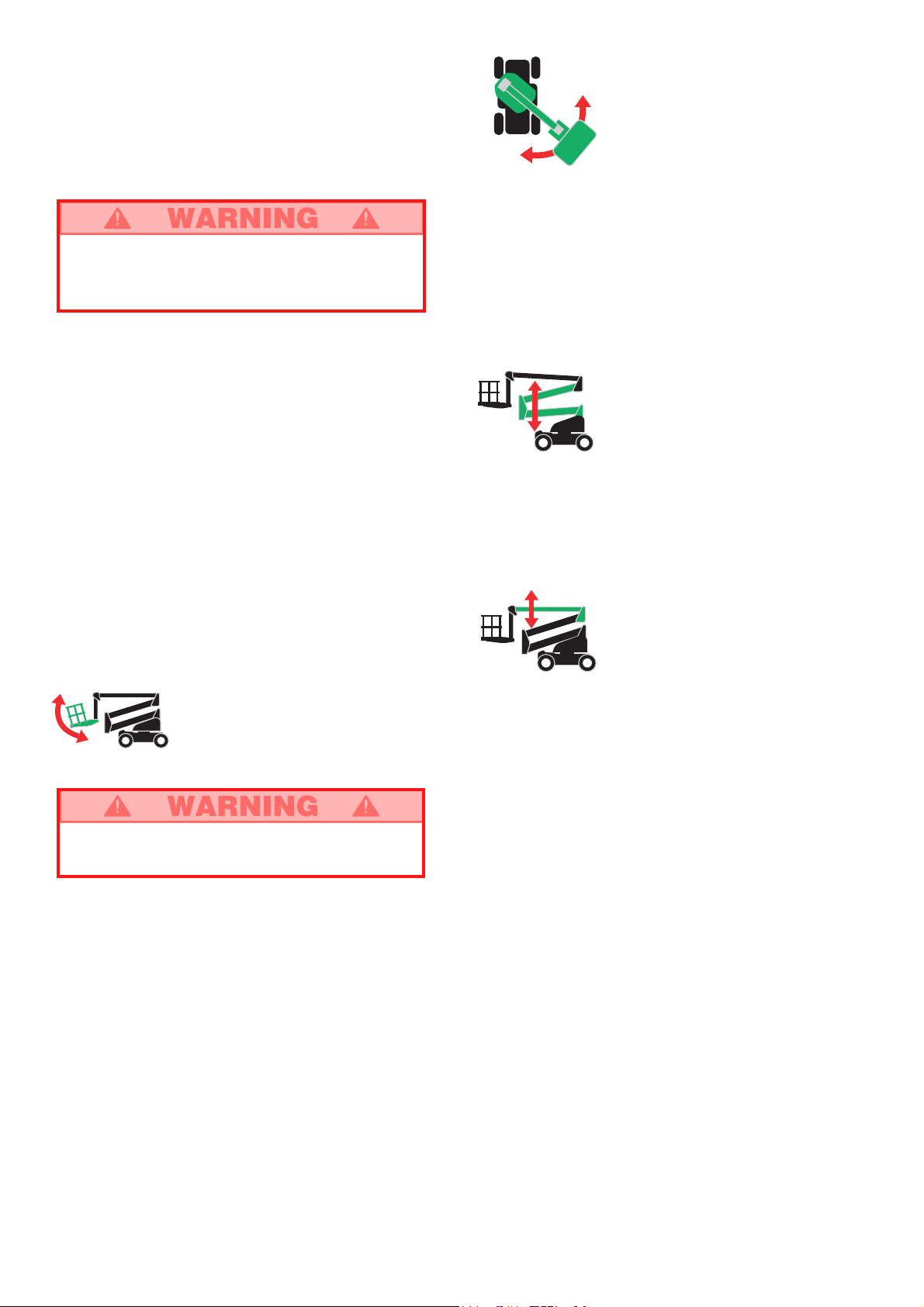

Rotating the Turret

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease. If you are not sure

what speed to use, start out slow; the speed can be

varied while operating the function.

2. While depressing the foot switch, turn the turret

rotation control switch counterclockwise to rotate left,

clockwise to rotate right. Release the switch to stop

rotation. Observe the area around the boom when

rotating the turret to avoid any obstructions.

Elevating the Riser

1. While depressing the foot switch, push the riser

control lever forward to elevate the riser, rearward to

lower the riser. Release the control lever to stop

elevating / lowering. The riser will function at a

constant speed, function speed control setting is not

necessary.

1. Turn chassis keyswitch to chassis controls.

2. With engine running, operate boom control switches

to position the platform.

Leveling the Platform

DO NOT operate the machine if the platform does

not maintain level when elevated.

Note: Platform leveling can be performed only with

the boom stowed and should be done only to calibrate the automatic leveling system.

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease. If you are not sure

what speed to use, start out slow; the speed can be

varied while operating the function.

2. While depressing the foot switch, push the platform

level control switch forward to swing the platform

upward, rearward to swing the platform downward.

Release the switch to stop leveling.

Elevating the Upper

Boom

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease. If you are not sure

what speed to use, start out slow; the speed can be

varied while operating the function.

2. While depressing the foot switch, push the upper

boom control lever forward to elevate the upper

boom, rearward to lower the upper boom. Release

the control lever to stop elevating / lowering.

6

Lowering Elevating Assembly

Extending the Upper

Boom

1. While depressing the foot switch, push the boom

extension control lever rearward to extend the boom,

forward to retract the boom. Release the control

lever to stop extending / retracting. The boom

extension will function at a constant speed, function

speed control setting is not necessary.

Elevating the Jib

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease. If you are not sure

what speed to use, start out slow; the speed can be

varied while operating the function.

2. While depressing the foot switch, push the jib control

lever forward to elevate the jib, rearward to lower the

jib. Release the control lever to stop elevating /

lowering.

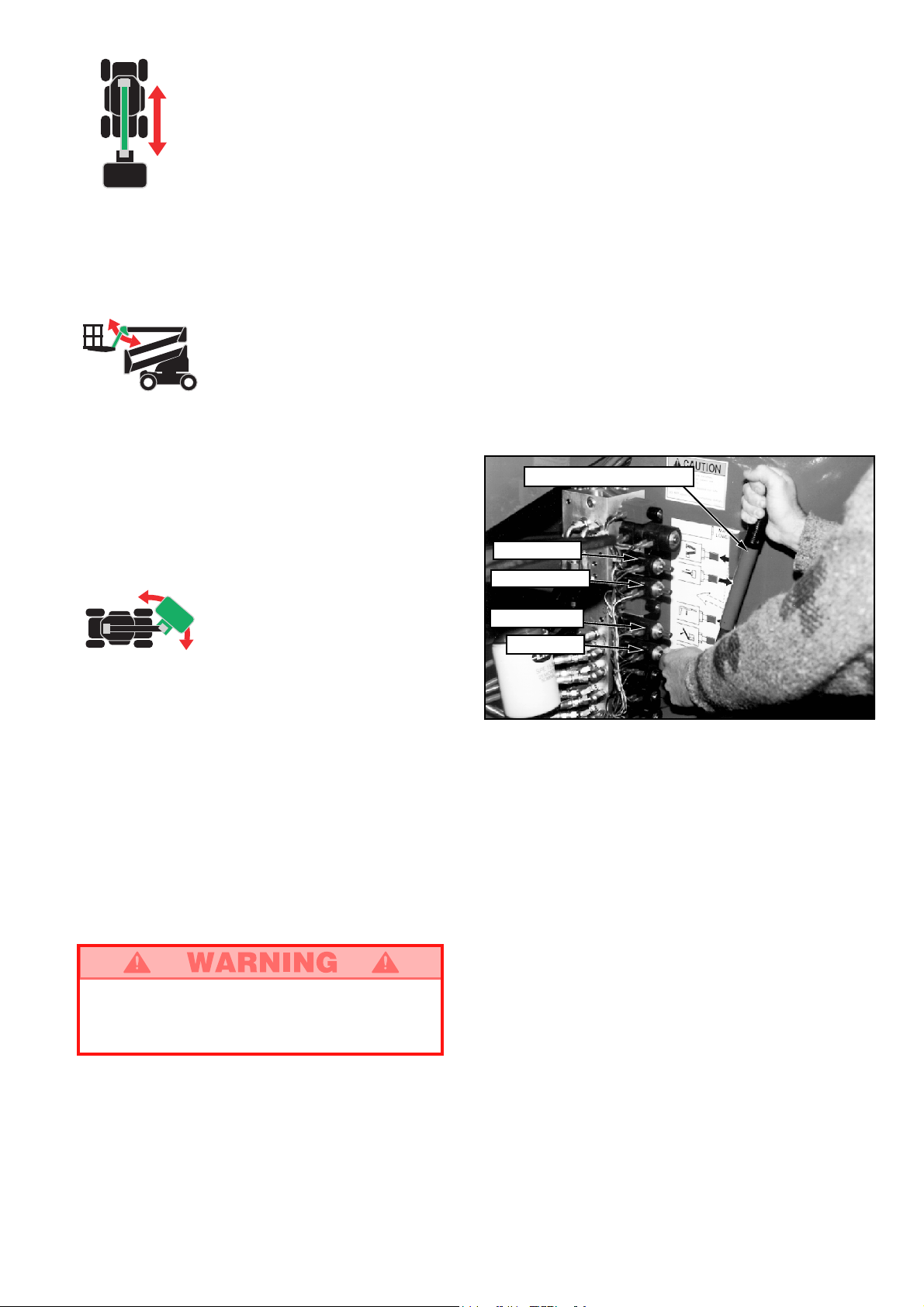

1. Open the cover on the hydraulic module (opposite side

of t he t urr e t fr om the chassis control panel).

2. Remove the wire loop retainer from the hand pump

lever, and extend the handle upward to gain

leverage.

3. Operate the manual override (knurled knob) on the

appropriate valve (see fig. 4). Push in to lower /

extend, pull out to raise / retract as required.

4. While holding the appropriate valve in position, pump

the handle in and out until that section of the elevating assembly is lowered / retracted.

5. Repeat as necessary operating each valve until the

elevating assembly is fully lowered.

Note: Use of the hand pump causes a diverter valve

to open disabling normal controls. The valve will

remain open until pressure is bled off. After operating any function with the hand pump, cycle the jib

valve in and out 6 times to bleed off pressure.

Emergency control pump

Riser Valve

Extend Valve

Rotating the Platform

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease. If you are not sure

what speed to use, start out slow; the speed can be

varied while operating the function.

2. While depressing the foot switch, turn the platform

rotation control switch counterclockwise to rotate left,

clockwise to rotate right. Release the switch to stop

rotation.

EMERGENCY OPERATION

In the event of powered function failure, the elevating

assembly may be lowered manually by the following

procedure.

NEVER climb down the elevating assembly. If

controls do not respond, ask someone on the

ground to lower the boom manually.

Boom Valve

Jib Valve

Figure 4: Emergency Control Operation

Rotating Turret

1. To manually rotate the turret, remove the manual

turret crank from inside of the control side turret

cover.

2. Set ratchet direction on turret crank.

3. Place the socket of the crank onto the hex shaft stub

of the turret rotation gearbox.

4. Turn the crank clockwise to rotate the turret counterclockwise, turn counterclockwise to rotate the turret

clockwise.

7

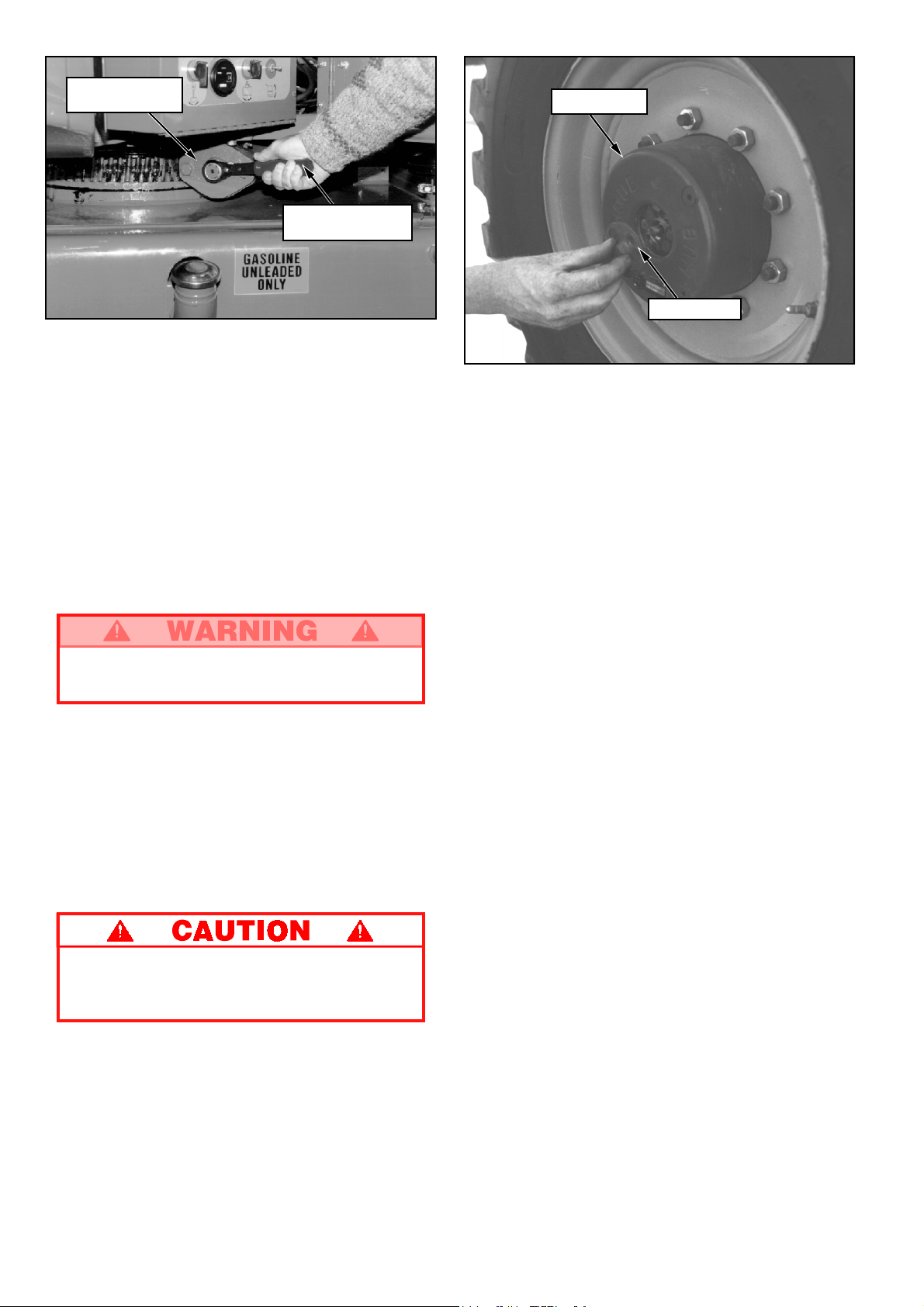

Turret Rotation

Gear Box

Figure 5: Manual Turret Rotation

EMERGENCY TOWING

7

/8 in. Ratcheting

Wrench

Drive Hub

Center Cap

Figure 6: Disengaging Drive Hub

Perform the following only when the machine will not

operate under its own power and it is necessary to move

the machine or when winching onto a trailer for transportation.

1. Insure that the platform is fully lowered, and that the

turret is rotated so that the platform is to the rear of

the machine.

2. Attach chain / cable of sufficient strength for towing

the machine to front or rear tie down lugs.

Chock wheels before disengaging hubs. Machine may roll.

3. Refer to figure 6 and disengage all four drive hubs.

Remove two screws and center cap. Reinstall

center cap in the opposite direction.

4. When ready to move the machine, remove the

chocks. Toe or winch into position and replace

chocks.

5. Engage all four drive hubs by returning the center

caps to their original orientation.

AFTER USE EACH DAY

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably under

cover, secure against vandals, children or unauthorized operation.

3. Turn the upper key switch to OFF, the lower key

switch to platform and remove all keys to prevent

unauthorized operation.

DO NOT move the machine faster than 3 mph.

Faster speeds will damage drive components

and void warranty.

8

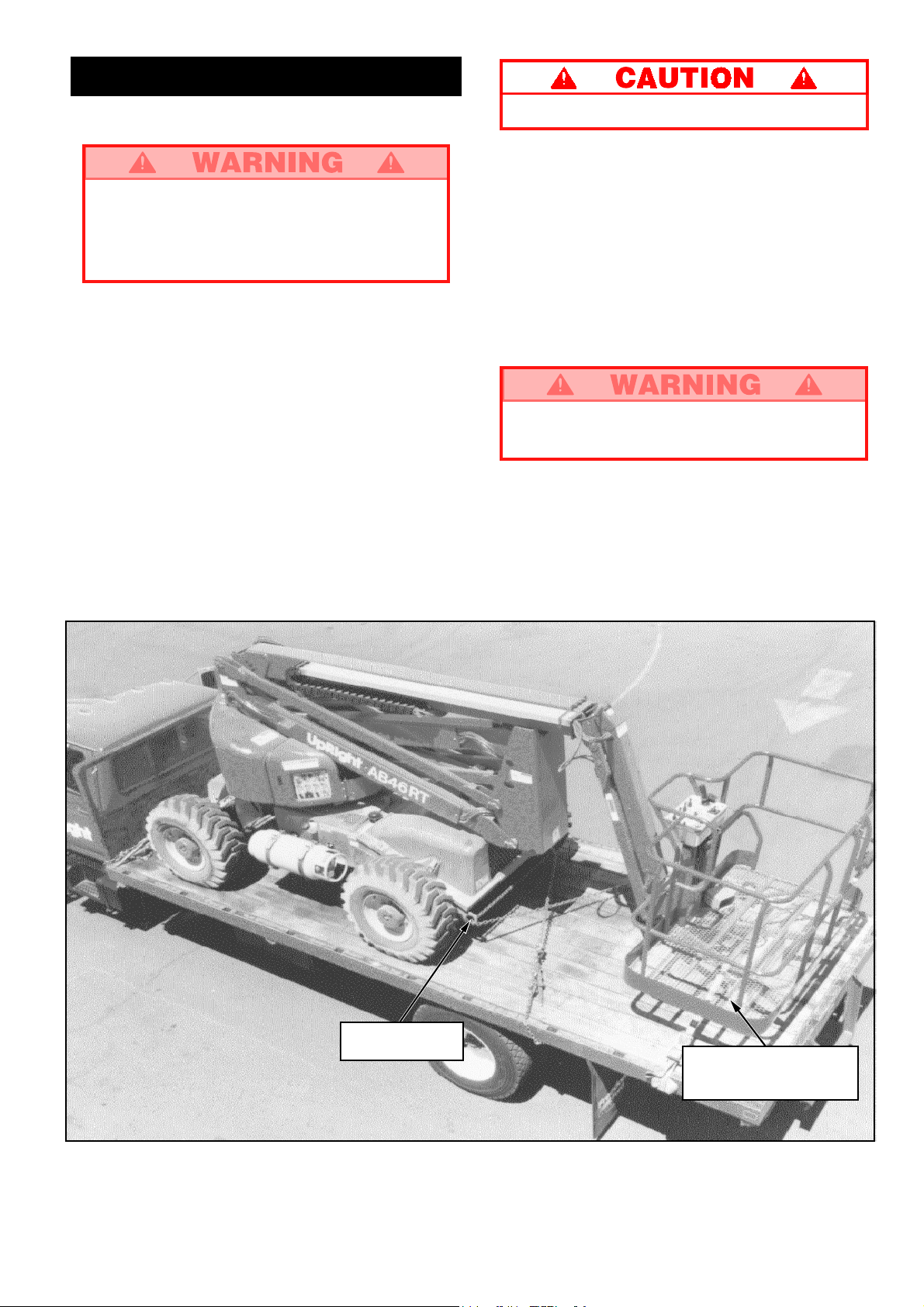

Transportation

BY CRANE

Stand clear of machine when lifting.

Check specifications on back page, insure that

crane and slings are of correct capacity to lift

weight of unit.

1. Insure that boom is fully lowered and retracted.

2. Attach straps to chassis lifting lugs only. Insure that

straps are adjusted properly to keep unit level when

lifting.

BY TRUCK OR TRAILER

1. Insure that boom is fully lowered and retracted.

2. Maneuver the machine onto bed of truck / trailer.

3. When winching, follow instructions for emergency

towing on page 8. Attach winch cable to front tie

down lugs.

Do not winch machine faster than 3 mph.

4. After winching, insure that brakes are set.

5. Secure the machine to the transport vehicle using

chains / straps of adequate load capacity (refer to

specifications, back page) attached to chassis tie

down lugs (see figure 7).

6. Place a wooden block (10.5" x 6" x 35"

[27 cm x 15 cm x 89 cm]

braces as shown (see figure 7).

7. Attach ratchet strap; under platform floor grating, over

support braces (see figure 7). Tighten securely, do

not overtighten.

NEVER elevate the machine while on a truck or

trailer.

) under platform support

Chassis Tie Down

Lifting Lug (typ.)

Figure 7: Securing the Machine for Transportation

9

Wooden Block

10.5" x 6" x 35"

[27 cm x 15 cm x 89 cm]

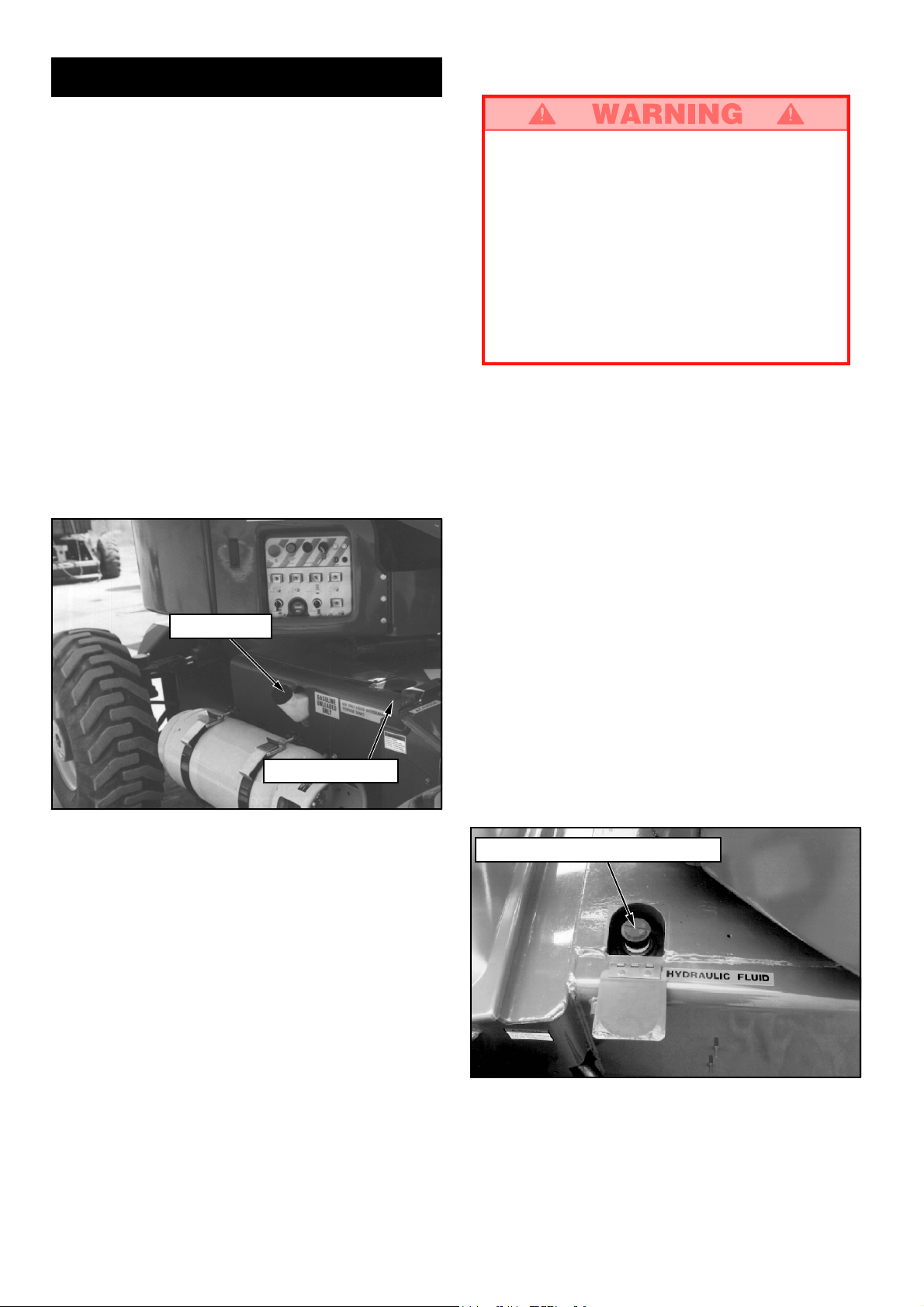

FUELING

Maintenance

BATTERY MAINTENANCE

Gasoline

1. Open fill pipe cap located on chassis left side (see

figure 8).

2. Fill to capacity with unleaded motor fuel only.

3. Check fuel level by lifting flap located on top of

chassis left side (see figure 8). Fuel tank full capacity

is 25 US gallons.

Diesel

1. Open fill pipe cap located on chassis left side (see

figure 8).

2. Fill to capacity with diesel motor fuel only, grade #1-D,

or #2-D. Use distillate fuel only, do not use residual or

blend.

3. Check fuel level by lifting flap located on top of

chassis left side (see figure 8). Fuel tank full capacity

is 25 US gallons.

Hazard of explosive gas mixture. Keep sparks,

flame and smoking materials away from

batteries.

Always wear safety glasses when working with

batteries.

Battery fluid is highly corrosive. Rinse away any

spilled fluid thoroughly with clean water.

Always replace batteries with UpRight batteries

or manufacturer approved replacements

weighing 62 lbs. (28 kg) each.

Check battery fluid level daily, especially if work platform

is being used in a warm, dry climate.

If electrolyte level is lower than 3/8 in. (10 mm) above

plates add distilled water only. DO NOT use tap water it

will shorten battery life.

Keep terminals and top of battery clean.

TIRES

Tire selection can affect the stability of the machine.

Use only tires supplied by UpRight unless approved by

the manufacturer in writing.

Fuel Fill Pipe

Fuel Level Gauge

Figure 8: Fuel Fill Pipe and Level Gauge

HYDRAULIC OIL

1. Check oil level at sight gauge inside engine compartment right hand side with the platform fully lowered.

2. If necessary, fill to capacity with clean ISO 46

compatible hydraulic oil.

3. Lift flap located on top of chassis right side (see

figure 9).

4. Open filler / breather cap to add hydraulic oil.

5. Replace cap.

Hydraulic Oil Filler / Breather Cap

LUBRICATION

Refer to service manual for lubrication chart and

guidelines.

Figure 9: Hydraulic Oil Filler / Breather Cap

10

ROUTINE SERVICE

Use the following table as a guide for routine maintenance. Inspection and maintenance shall be

performed by personnel who are trained and familiar

with mechanical and electrical procedures. Refer to

the Service Manual for complete service instructions.

Please copy this page and use the Routine Service Table

as a checklist when inspecting a machine for service.

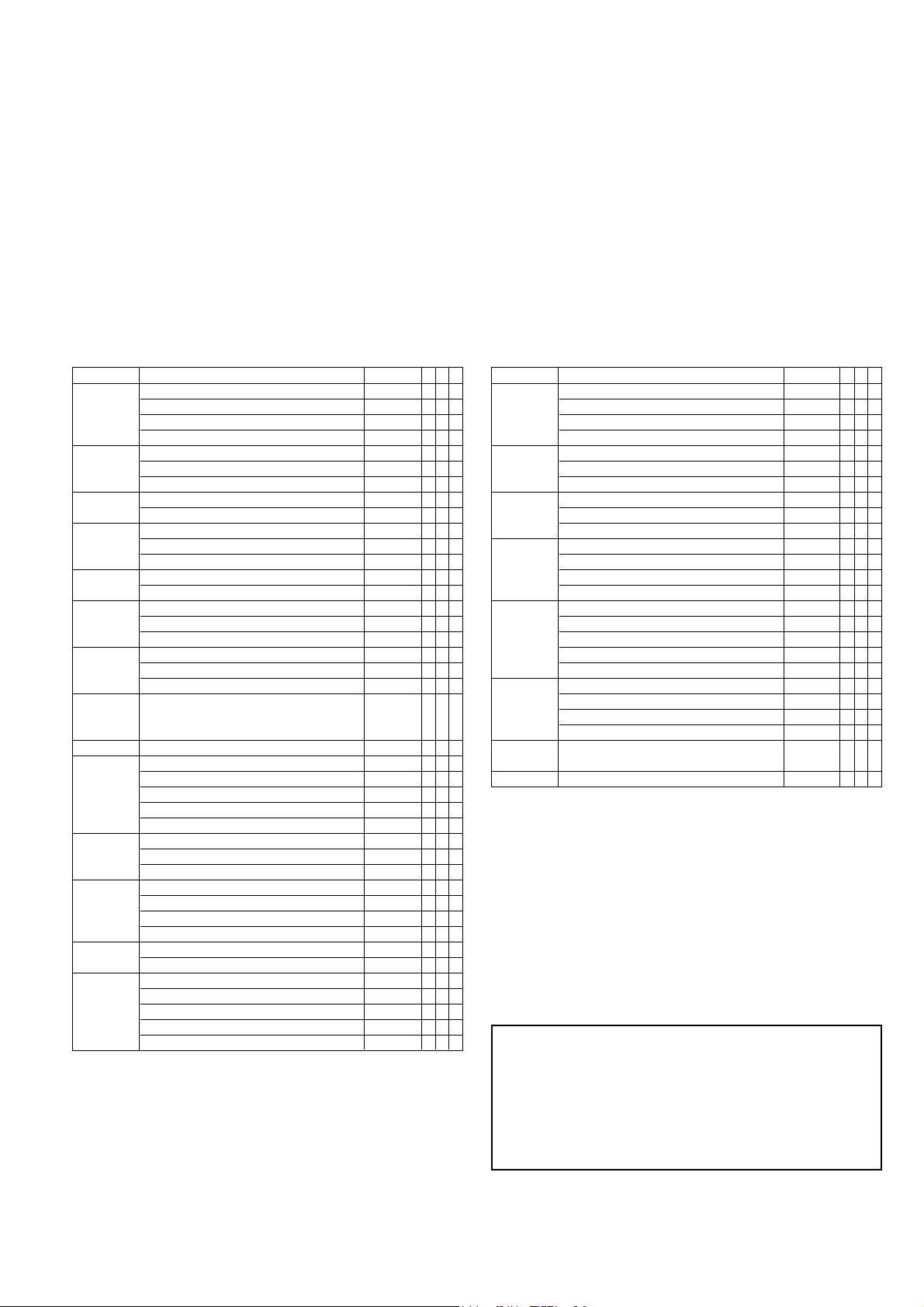

Routine Service Table

Routine Service Table Key

Interval

Daily=each shift (every day) or every eight hours

30D=every month (30 days) or every 50 hours

3M=every 3 months or 125 hours

6M=every 6 months or 250 hours

1Y=every year or 500 hours

2Y=every 2 years or 1000 hours

Y=Yes/Acceptable

N=No/Not Acceptable

R=Repaired/Acceptable

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Engine Oil Check level and condition Daily

Check for leaks Dai l y

*Change oil & filter (Dual Fuel) 100HOURS

*Change oil & filter (Diesel) 200HOURS

Engine Fuel Check fuel level Dai ly

System Check for leaks Dai l y

Replace fuel filter 6M

Engine Air Replace air cleaner 6M

Cleaner Check air cleaner Daily

Battery Check electrolyte level Dail y

Clean exterior 3M

Clean terminals 3M

Engine Check coolant level (with engine cold) Daily

Coolant Replace coolant 3M

Hydraulic Check oil level Dai ly

Oil Change filter 6M

Drain and replace with ISO 46 compatible oil 2Y

Hydraulic Check for leaks Dai ly

System Check hose connections 30D

Check hoses for exterior wear 30D

Emergency Check operation of emergency override

Hydraulic valves and hand pump Daily

System

Controller Check operation of all controls Dai l y

Platform Check fasteners for proper torque Daily

Floor and Check welds for cracks Dail y

Rails Check condition of platform Daily

Check condition of anchorage points Daily

Check condition of operators manual Daily

Tires Check for damage Daily

Check air pressure (3,8 bar [55 psi]) Daily

Check lug nuts (torque to 90 ft. lbs. [123 Nm]) 30D

Hydraulic Wipe clean 30D

Pump Check for leaks at mating surfaces 30D

Check for hose fitting leaks Dai l y

Check mounting bolts for proper torque 30D

Hydraulic Check hydraulic drive motor operation Daily

Drive System Check hoses, fittings, and valve block for leaks Dai ly

Steering Check fittings for proper torque 6M

System Oil all pivot points 30D

Check steering cylinder for leaks 30D

Check linkage for wear areas 30D

Check for missing / loose retainers Daily

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Elevating Inspect for structural cracks Dai ly

Assembly Check pivot points for wear 30D

Chassis Check hoses for pinch or rubbing points Daily

Turret Check ring gear for proper lubrication and wear Daily

Drive Check for leaks Dai l y

Hubs Check oil level 250H/6M

Lift Check the cylinder rods for wear 30D

Cylinders

Entire Unit Check for and repair collision damage Dai ly

Labels Check for peeling, missing, or unreadable

Slew Ring Check fasteners for proper torque 30D

*First oil change after 50 hours.

Check pivot pin retaining bolts for proper torque 30D

Check members for deformation Dai ly

Check component mounting for proper torque 6M

Check welds for cracks Dai ly

Lubricate worm gear bearings 150H/3M

Lubricate ring gear (MoS

Change oil after break-in period 50H/30D

Change oil (SAE 90 wt. gear oil) 2000H/2Y

Check pivot pin retaining bolts

Check seals for leaks 30D

Inspect pivot points for wear 30D

Check fittings for proper torque 30D

Check fasteners for proper torque 3M

Check for corrosion, remove and repaint 3M

Lubricate 30D

labels & replace

grease) 150H/3M

2

for proper torque

Daily

30D

Service Report

Date:_______________________________________

Owner: _____________________________________

Model No: ____________ Serial No: ____________

Serviced By: ________________________________

Service Interval: _____________________________

11

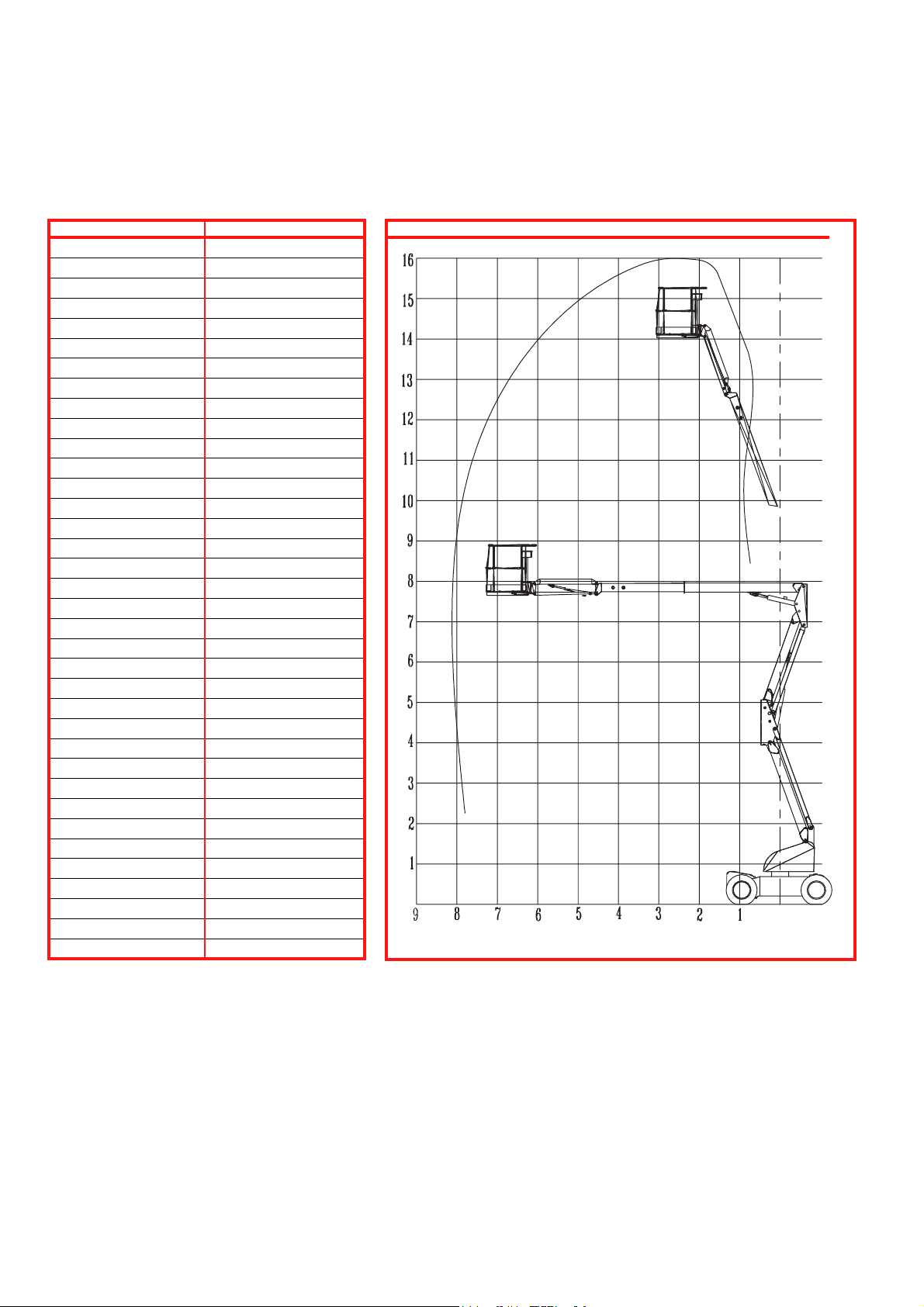

Specifications*

ITEM SPECIFICATION

Height

Working height maximum 16.1 m [52 ft. 10 in.]

Platform height maximum 14.3 m [46 ft. 10 in.]

Platform step in height 0.48 m [19 in.]

Up and over height 7.8 m [25 ft. 8 in.]

Drivable height 14.3 m [46 ft. 10 in.]

Horizontal outreach 7.5 m [24 ft. 6 in.]

Turret rotation 360 deg. noncontinuous

Platform rotation 160 deg.

Tail swing None

Jib length 1.5 m [5 ft.]

Jib arc 140 deg.

Inside turning radius 0.9 m [3 ft.]

Outside turning radius 3,7 m [12 ft.]

Drive speed (lowered) 7.2 km/h [4.5 mph]

Drive speed (elevated) 1 km/h[.6 mph]

Gradability 40%

Platform Size 1.75 m x 1 m [69 in. x 39 in.]

Guardrail height 1.1 m [43 1/2 in.]

Toeboards 152 mm [6 in.]

Maximum platform capacity 227 kg [500 lbs]

Maximum no. of occupants 2

Weight (Gas Model) 6558 kg [14,460 lbs.]

Weight (Diesel Model) 6649 kg [14,660 lbs.]

Overall height 2.2 m [7 ft. 4 in.]

Overall length 5.6 m [18 ft. 4 in.]

Overall width 2 m [6 ft. 7 in.]

Wheel base 2.2 m [7 ft. 2 in.]

Wheel track 1.7 m [5 ft. 5 in.]

Ground Clearance 330 mm [13 in.]

Power source (Gas Model) Ford VSG 413

Power source (Diesel Model) John Deere 3015DF

System voltage 12VDC

Maximum Hyd. Pressure 345 bar [5000 psi]

Controls Electric Proportional

Tires 14x17.5 10 ply lug tread

REACH ENVELOPE DIAGRAM

DIMENSIONS IN METERS

*

Specifications subject to change without notice.

Refer to Service Manual for complete parts and service information.

12

Section française

CONSIGNES DE SÉCURITÉ

Danger d’électrocution

NE JAMAIS utiliser la machine

à moins de 3 m (10 pi) de

lignes d’énergie électrique.

CETTE MACHINE N’EST PAS

ISOLÉE.

TOUS les occupants doivent porter un dispositif antichute d’un modèle approuvé, correctement fixé au point de fixation désigné à cet

effet de la plate-forme. Ne fixer qu’un dispositif antichute par point de fixation.

NE JAMAIS dépasser la charge maximale de la plate-forme, établie à 225 kg (500 lb) et à deux (2) occupants.

NE JAMAIS dépasser une force latérale par occupant de 200 N (45 lb).

NE JAMAIS utiliser la machine dans un environnement où le niveau de bruit dépasse 80 dB.

RÉPARTIR également toutes les charges sur la plate-forme.

NE JAMAIS utiliser la machine sans avoir d’abord vérifié si la surface de la zone de travail ne présente pas de dangers tels que

des trous, des dénivellations, des bosses, des bordures ou des débris et sans s’être assuré qu’on peut les éviter.

NE faire fonctionner la machine QUE sur des surfaces pouvant supporter la charge des roues.

NE JAMAIS élever la plate-forme lorsque la vitesse du vent dépasse 12,5 m/s (28 mi/h).

EN CAS D’URGENCE, appuyer sur le bouton d’arrêt d’urgence pour couper toute alimentation aux fonctions de la marche.

TOUJOURS fermer au loquet le portillon après être monté sur la plate-forme.

NE JAMAIS tenter de descendre de la plate-forme ni tenter d’y monter lorsqu’elle est élevée.

NE JAMAIS dresser d’échelle, d’échafaudage ni d’autres objets permettant de prendre de la hauteur; toujours travailler à partir du

plancher de la plate-forme.

NE JAMAIS descendre par le dispositif d’élévation lorsque la plate-forme est élevée.

VÉRIFIER la machine à fond, avant de l’utiliser, afin d’y déceler toute soudure fissurée, toute pièce de fixation ayant du jeu ou qui

manquerait, toute fuite du circuit hydraulique, toute connexion lâche et tout câble ou tuyau qui serait endommagé.

S’ASSURER que toutes les étiquettes sont en place et bien lisibles avant d’utiliser la machine.

NE JAMAIS utiliser une machine qui est endommagée, qui ne fonctionne pas correctement, ou dont les étiquettes sont endomma-

gées ou manquantes.

SI L’ALARME RETENTIT alors que la flèche est élevée, ARRÊTER, rentrer la flèche avec précaution, et abaisser la plate-forme

sans faire pivoter la machine. Amener la machine jusque sur une surface horizontale solide.

NE JAMAIS fixer une charge qui déborde ni utiliser la flèche comme une grue.

NE JAMAIS modifier les dispositifs d’exploitation ou de sécurité de la machine sans le consentement écrit préalable du fabricant.

NE JAMAIS charger la batterie d’accumulateurs près d’une flamme ou d’une source d’étincelles : les batteries dégagent de

l’hydrogène gazeux explosif lorsqu’elles rechargent.

NE JAMAIS remplacer quelque élément ou quelque pièce que ce soit par autre chose qu’une pièce d’origine UpRight sans le

consentement écrit du fabricant.

NE JAMAIS remorquer la machine : ne la transporter qu’à bord d’un camion ou d’une remorque.

APRÈS AVOIR UTILISÉ la plate-forme élévatrice, tourner les deux clés de l’interrupteur à la position d’arrêt (« OFF »), puis les

retirer afin de prévenir l’utilisation de la plate-forme par toute personne non autorisée.

Danger de basculement

NE JAMAIS utiliser le bras

articulé à flèche ni conduire plate-forme élevée

sans que la machine ne

soit sur une surface horizontale solide.

Danger de collision

NE JAMAIS positionner la

plate-forme sans s’être

d’abord assuré qu’il n’y a

pas d’obstacles ou autres

sources de danger aux

alentours.

Danger de chute

NE JAMAIS monter, s’as-

seoir ou se tenir debout

sur les rampes du garde-

Avertissement concernant la Proposition 65 (Californie)

À la connaissance de l’État de Californie, les fumées d’échappement des moteurs à essence et des moteurs diesel,

ainsi que certains de leurs éléments constituants, peuvent provoquer le cancer, des anomalies congénitales

et autres effets nocifs sur la reproduction.

13

Introduction

Ce manuel se rapporte à l’utilisation des modèles à moteur à

combustion interne de bras articulé à flèche AB-46. On

veillera à le garder sur la machine en tout temps.

Vérification préliminaire de

sécurité et d’utilisation

Lire d’abord attentivement toutes les règles de sécurité, les

étiquettes et le mode d’emploi, en s’assurant de les comprendre et de s’y conformer. Chaque jour avant d’utiliser la

machine, exécuter les tâches suivantes :

Effectuer une inspection visuelle complète de la machine

avant de l’utiliser. Porter une attention particulière aux

points suivants :

1. Ouvrir les panneaux, et vérifier que les composants

des circuits hydrauliques/les tuyaux ne présentent pas

de fuites ni de dommages. Vérifier qu’aucun composant/filage électrique ne présente de dommages ni de

connexions ayant du jeu.

2. Vérifier à fond le châssis, les essieux, les moyeux et la

timonerie de direction pour s’assurer qu’ils ne présentent pas de dommages, de déformations, de peinture

gondolée, de pièces de fixation ayant du jeu ou qui

manquent, ni de soudures fissurées.

3. Vérifier si les pneus sont endommagés, perforés o u mal

gonflés; la pression de gonflage doit être de 3,8 bar (55

2

).

lb/po

4. Vérifier tous les tuyaux/les câbles pour s’assurer qu’ils

ne sont pas usés.

5. Vérifier à fond le dispositif d’élévation pour s’assurer

qu’il ne présente pas de dommages, de déformations,

de peinture gondolée, de pièces de fixation ayant du

jeu ou qui manquent, ni de soudures fissurées.

6. Vérifier à fond la plate-forme et les garde-corps pour

s’assurer qu’ils ne présentent pas de dommages, de

déformations, de peinture gondolée, de pièces de fixation ayant du jeu ou qui manquent, ni de soudures

fissurées. S’assurer que le portillon fonctionne librement et se ferme au loquet fermement.

7. La plate-forme étant abaissée complètement, vérifier le

niveau d’huile hydraulique.

8. Vérifier le niveau d’électrolyte de la batterie. (Voir En-

tretien des batteries, à la page 21.)

9. Vérifier le niveau de carburant; faire l’appoint de carburant si

nécessaire. (Voir Faire le plein, à la page 21.)

10. S’assurer que le radiateur est froid, et vérifier le niveau de

liquide de refroidissement. Faire l’appoint au besoin.

NE JAMAIS ôter le bouchon d’un radiateur chaud.

Le liquide de refroidissement chaud peut causer

de graves brûlures.

ESSAI DE FONCTIONNEMENT

DES ÉLÉMENTS

Nota : Se reporter aux figures 1 et 2 pour obtenir les

emplacements du pupitre de commande sur le châssis

et sur la plate-forme.

1. Avant d’effectuer les essais suivants, vérifier d’abord que

l’aire qui entoure la machine ne présente pas de dangers

tels que des obstacles en surplomb, des trous, des dénivellations et des débris.

2. Tourner l’interrupteur à clé du boîtier de commande à la

position de châssis (« CHASSIS »), puis faire tourner

dans le sens horaire les interrupteurs d’arrêt d’urgence

au tableau de commande monté sur le châssis ainsi

qu’au tableau de commande monté sur la plate-forme.

3. Enfoncer le bouton de démarrage du moteur pour lancer

le moteur; relâcher le bouton de démarrage lorsque le

moteur a démarré. Si le moteur est froid : appuyer sur le

bouton d’étrangleur et le maintenir enfoncé tout en démarrant, dans le cas des modèles à essence/gaz

propane; appuyer sur le bouton de préchauffage et le

maintenir enfoncé pendant six (6) secondes avant de

démarrer, dans le cas des modèles à moteur diesel.

4. Enfoncer le bouton d’arrêt d’urgence du châssis; le moteur devrait s’arrêter. Répéter l’essai avec le bouton d’arrêt d’urgence de la plate-forme. Ramener les deux boutons d’arrêt d’urgence à la position « ON », puis démarrer

le moteur.

5. Mettre en marche chaque interrupteur de fonction pour

élever/abaisser, déployer/rentrer, faire pivoter à gauche/à

droite, chaque section du dispositif d’élévation, et observer

le fonctionnement de la machine. Toutes les fonctions

devraient effectuer le cycle complet en douceur.

6. Tourner l’interrupteur à clé du châssis à la position de

plate-forme (« PLATFORM »).

7. Monter sur la plate-forme, fermer le portillon au loquet et

fixer le dispositif antichute approuvé au point de fixation

désigné de la plate-forme. Ne fixer qu’un seul dispositif

antichute par point de fixation.

8. Démarrer le moteur.

9. Sans enfoncer l’interrupteur à pédale, déplacer le levier

de direction : la machine devrait rester immobile.

10. Enfoncer l’interrupteur à pédale, et déplacer le levier de

direction en avant, puis en arrière. Noter si les fonctions

proportionnelles se déroulent en douceur et si les freins

s’appliquent rapidement une fois la commande relâchée.

11. Tout en enfonçant l’interrupteur à pédale, actionner le

bouton de commande de direction vers la gauche et vers

la droite. Noter si les roues directrices braquent correctement.

12. Tout en enfonçant l’interrupteur à pédale, tourner le bouton de commande de vitesse des fonctions au réglage

voulu, et faire fonctionner les commandes du bras articulé à flèche. Noter si le bras articulé à flèche fonctionne

en douceur et si les commandes de la flèche, du bras en

porte-à-faux, de rotation du revolver, du positionnement

horizontal de la plate-forme et de la rotation de la plateforme fonctionnent de façon proportionnelle, conjointement avec la manoeuvre du bouton de commande de

vitesse des fonctions. Noter si la plate-forme se maintient

de niveau lorsque le bras articulé à flèche est élevé.

13. La flèche étant élevée de 0,3 m (1 pi), manoeuvrer le

levier de direction. Noter si la vitesse d’avance est limitée

à la marche extra-lente (0,3 m [1 pi] à la seconde). Abaisser la flèche en position escamotée.

14. Appuyer sur le bouton de la sirène d’appel. Noter si le

timbre retentit.

NE PAS utiliser la machine si elle est endommagée

ou en mauvais état de fonctionnement. Apposer une

étiquette volante sur la machine et la retirer du

service jusqu’à ce qu’elle ait été réparée.

14

Commandes et indicateurs

Mode d’emploi

2

20

4

5

1

8

6

9

7

12

10

Figure 1 : Emplacement des commandes

sur le châssis

Nota : La liste suivante correspond aux accessoires

indiqués par un numéro dans les figures 1 et 2.

1. Bouton d’arrêt d’urgence

2. Bouton de démarrage du moteur

3. Sélecteur de vitesse

4. Interrupteur à clé

5. Fusibles des circuits de commande

6. Commande du bras articulé de soulèvement

7. Commande de la flèche

8. Commande de la rallonge de flèche

9. Commande du bras en porte-à-faux

10. Commande de rotation du revolver

11. Commande de rotation de la plate-forme

12. Commande de positionnement horizontal

de la plate-forme

13. Horomètre

14. Bouton de la sirène d’appel

15. Levier de direction

16. Commande de v

17. Sélecteur de combustible (alimentation jumelée)

18. Interrupteur à pédale (situé sur le plancher

de la plate-forme)

19. Voyant d’inclinaison

20. Bouton de préchauffage (diesel)

itesse des fonctions

13

11

Avant d’utiliser la plate-forme élévatrice, s’assurer :

Que la vérification préliminaire de sécurité et

d’utilisation a été effectuée, et que tout écart noté

est corrigé.

Que l’opérateur a reçu une formation pratique qui lui a

permis de bien connaître l’utilisation de la machine.

Que l’aire de travail est exempte de tout obstacle, de

tout trou/dénivellation et de toute personne qui se

trouverait sur la voie de passage.

Que la surface peut supporter la charge des roues.

Voir les emplacements des commandes aux figures 1 et 2.

Arrêt d’urgence

En tout temps pendant l’utilisation, lorsqu’une situation

d’urgence se présente, appuyer sur le bouton d’arrêt

d’urgence pour arrêter toutes les fonctions.

Sirène d’appel

En tout temps pendant l’utilisation, appuyer sur le bouton

de sirène d’appel pour faire retentir une alarme sonore, si

nécessaire.

Toujours porter un dispositif antichute approuvé, fixé correctement au point de fixation

désigné de la plate-forme, pendant la conduite

ou l’élévation de la machine (voir figure 3).

Ne fixer qu’un seul dispositif antichute par point

de fixation.

8

6

7

9

12

11

19

10

1

20

14

Figure 2 : Emplacement des commandes

sur la plate-forme

17

3

5

15

4

16

Figure 3 : Point de fixation type

pour dispositif antichute

15

Loading...

Loading...