Snorkel AB46RT User Manual

Operator Manual

AB-46 RT

SERIAL NO. 1000 TO CURRENT

WARNING

All personnel shall carefully read, understand and follow all safety rules, operating instructions,

and the Scaffold Industry Associations MANUAL OF RESPONSIBILITIES (ANSI A92.5) before

operating or performing maintenance on any UpRight boom supported aerial work platform.

SAFETY RULES

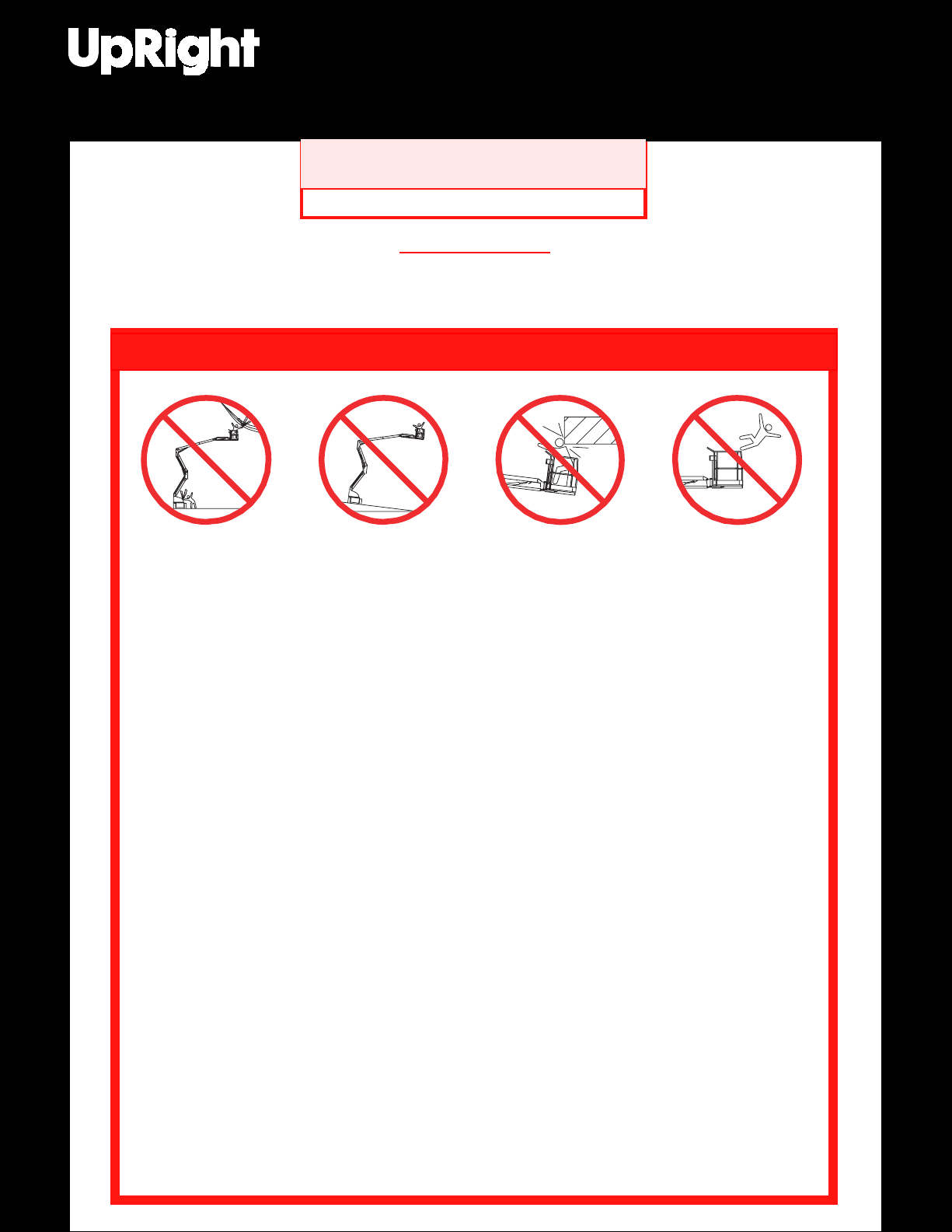

Electrocution Hazard Tip Over Hazard Collision Hazard Fall Hazard

Safety Rules and Operating Instructions

NEVER operate the

machine within ten (10)

feet of power lines. THIS

MACHINE IS NOT

INSULATED.

ALL occupants must wear an approved fall restraint properly attached to designated platform anchorage

point. Attach only one fall restraint to each anchorage point.

NEVER exceed maximum platform load of 500 lbs. (225 kg) and two (2) occupants.

NEVER exceed 45 lbs. (200 N) of side force per occupant.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-

offs, bumps, curbs, or debris; and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER elevate the machine when wind speeds exceed 28 mph (12.5 m/sec.).

IN CASE OF EMERGENCY push emergency stop button to cut power to all powered functions.

ALWAYS close and secure gate after entering platform.

NEVER exit or enter platform while elevated.

NEVER use ladders, scaffolding, or other items to gain height; work only from the platform floor.

NEVER climb down elevating assembly while platform is elevated.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose

wire connections, and damaged cables or hoses before using.

VERIFY that all labels are in place and legible before using. Refer to page 11 & 12 for label identification.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

IF ALARM SOUNDS while boom is elevated, STOP, carefully retract boom and lower platform without

rotating. Move machine to a firm, level surface.

NEVER attach overhanging loads or use boom as a crane.

NEVER alter operating or safety systems without manufacturers written consent.

NEVER charge battery near sparks or open flame. Charging batteries emit explosive hydrogen gas.

NEVER replace any component or part with anything other than original UpRight replacement parts

Safety Rules and Operating Instructions

without the manufacturer's written consent.

NEVER tow the machine. Transport by truck or trailer only.

AFTER USE, secure the work platform from unauthorized use by turn ing both keyswitches off and removing all keys.

Gasoline and diesel engine exhaust and some of their constituents are known to the State of California to cause

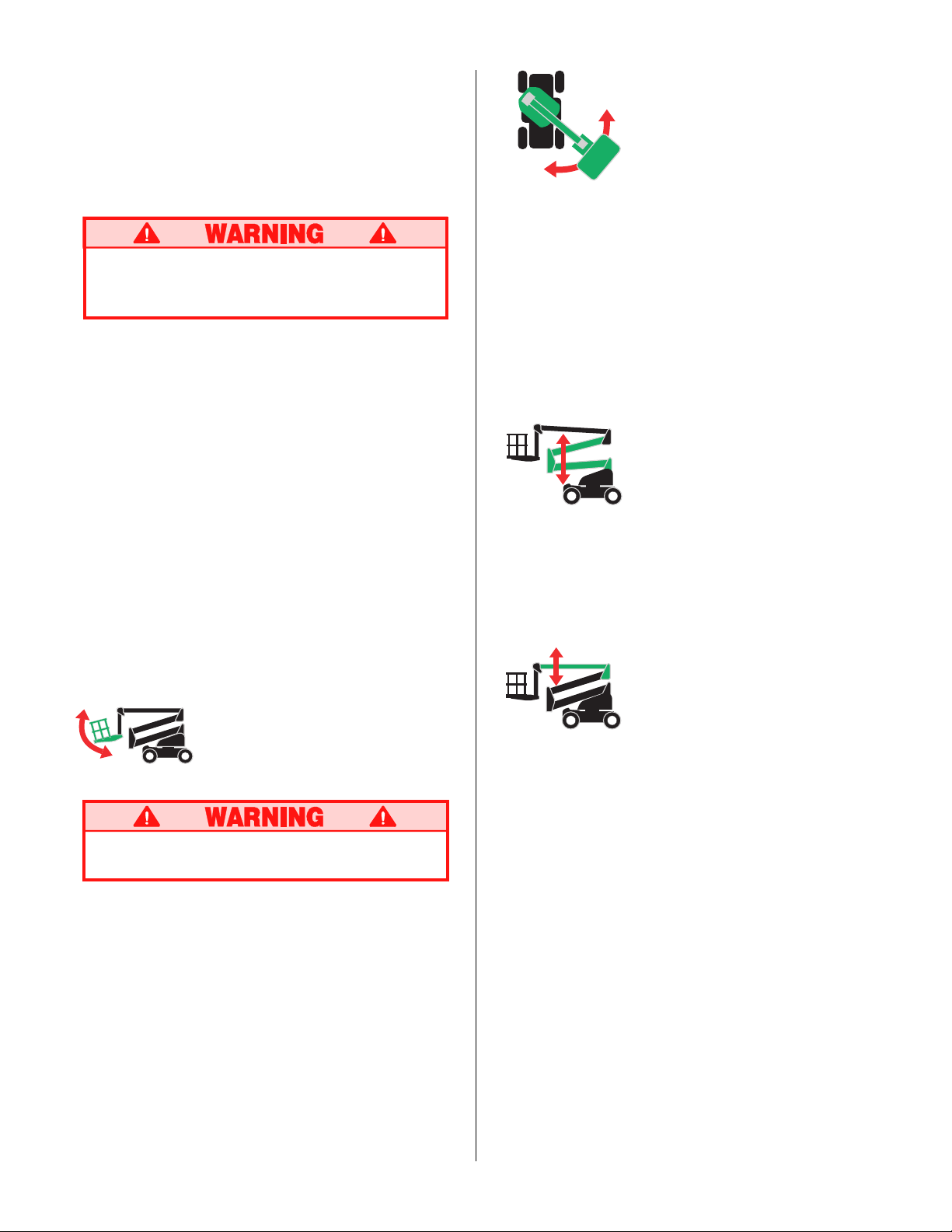

NEVER operate the

boom or drive with

platform elevated

unless on firm level

surface.

cancer, birth defects, and other reproductive harm.

NEVER position the

platform without first

checking for overhead

obstructions or other

hazards.

California Proposition 65 Warning

1

NEVER climb, stand or

sit on platform guardrails or midrail.

Introduction

This manual covers the operation of internal combustion powered models of the AB-46 RT Articulated

Boom. This manual must be stored on the machine

at all times.

Pre-Operation and Safety

Inspection

Carefully read, understand and follow all safety

rules, labels, and operating instructions, then

perform the following steps each day before use.

Perform a complete visual inspection of the entire

unit prior to operating. Check the following areas for

discrepancies:

1. Open panels and check hydraulic components / hoses

for damage or leaks. Check electrical components /

wiring for damage or loose connections.

2. Inspect chassis, axles, hubs, and steering linkage

for damage, deformation, buckled paint, loose or

missing hardware, and cracked welds.

3. Check tires for damage, punctures, and inflation;

tire pressure must be 55 psi.

4. Check all hoses / cables for wear.

5. Inspect elevating assembly for damage, deformation, buckled paint, loose or missing hardware,

and cracked welds.

6. Inspect platform and guardrails for damage,

deformation, buckled paint, loose or missing

hardware, and cracked welds. Insure that gate

operates freely and latches securely.

7. Check Hydraulic fluid level with platform fully

lowered.

8. Check battery fluid level (see battery maintenance, page 9).

9. Check fuel level, add fuel if necessary (see

fueling, page 9).

10.Ensure that radiator is cold, check coolant level.

Add if necessary.

NEVER remove the cap from a hot radiator.

Hot coolant can cause severe burns.

2. Turn chassis key switch to chassis, and turn on

(rotate clockwise) emergency stop switches at the

chassis control panel and at the platform control

panel.

3. Press the engine start button to crank the engine;

release when engine starts. If engine is cold:

press the preheat button and hold for six seconds

prior to starting diesel models.

4. Push in the chassis emergency stop button

engine should stop. Repeat for platform emergency stop button. Return both emergency stop

buttons to the on position, and start engine.

5. Operate each function switch to raise / lower,

extend / retract, rotate left / right, each section of

the elevating assembly and observe the operation

of the machine. All functions should operate

through full cycle smoothly.

6. Turn chassis key switch to platform.

7. Mount the platform, close and latch the gate, and

attach approved fall restraint to designated platform

anchorage point. Attach only one fall restraint to

each point.

8. Start the engine.

9. Without depressing the foot switch, move the drive

control handle, machine should not function.

10.Depress the foot switch and move the drive

control handle forward and reverse. Observe that

proportional functions operate smoothly, and that

brakes apply quickly after control is released.

11.While depressing foot switch, operate steer

switch to left and right. Observe that steering

wheels turn properly.

12.While depressing foot switch, turn function speed

control knob to desired setting, and operate boom

controls. Observe that boom operates smoothly,

and that upper boom, jib, turret rotation, platform

level, and platform rotation controls operate

proportionally in conjunction with function speed

control knob. Observe that platform maintains

level when boom is elevated.

13.With the upper boom elevated one foot, operate

drive control handle. Observe that drive speed is

limited to creep approximately (1 foot [.3m] per

second). Lower upper boom to stowed position.

14.Press the service horn button. Observe that horn

is audible.

SYSTEM FUNCTION INSPECTION

Note: Refer to figures 1 and 2 for chassis and

platform control locations.

1. Before performing the following tests, check area

around machine and overhead for obstructions,

holes, drop-offs, and debris.

DO NOT use a machine that is damaged or

malfunctioning. Tag and remove the unit

from service until it is repaired.

2

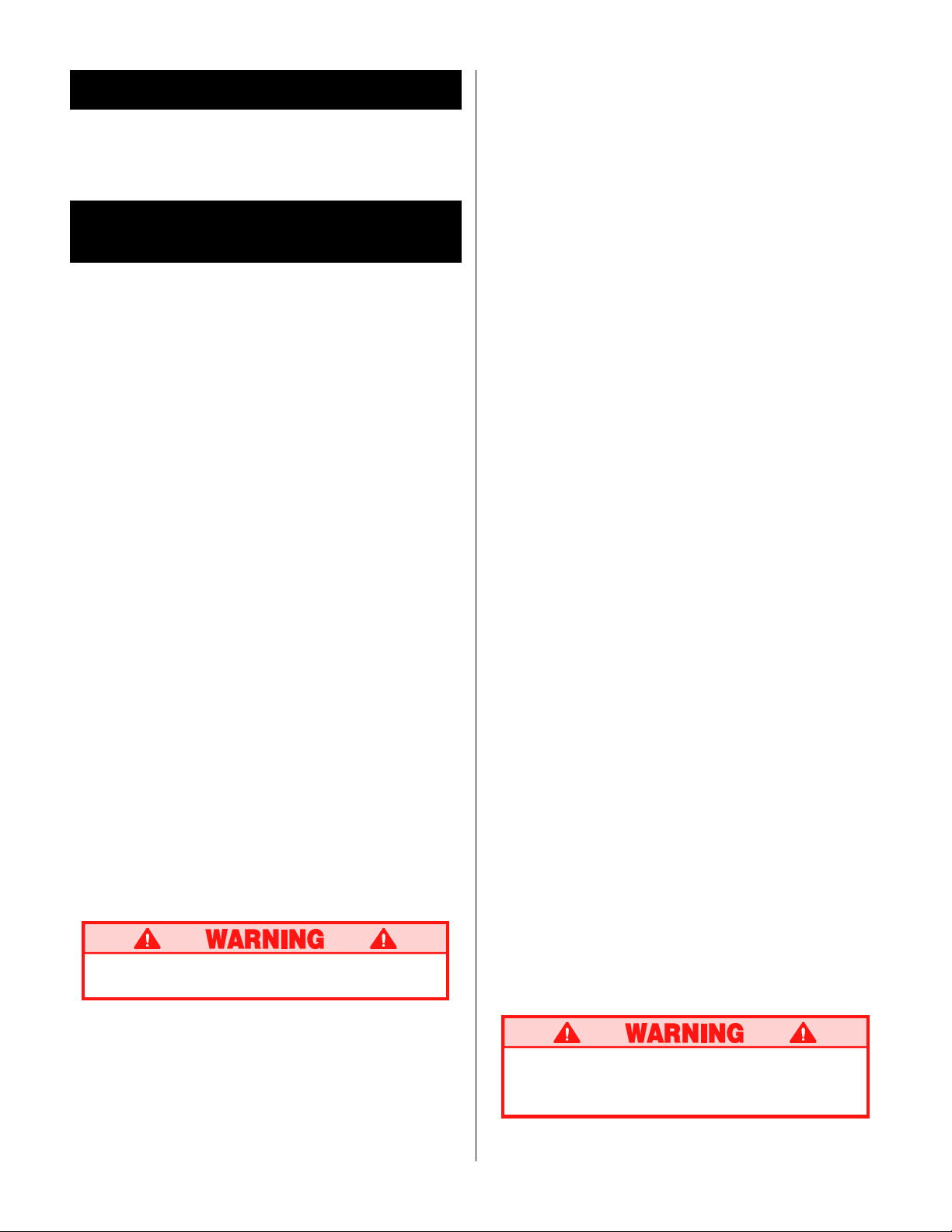

Controls and Indicators

Operation

2

1

6

7

10

Figure 1: Chassis Controls

Note: The following list corresponds to the

numbered items in figures one and two.

1. Emergency stop.

2. Engine start.

3. Speed Selector.

4. Keyswitch.

5. Control fuses.

6. Riser control.

7. Upper boom control.

8. Boom extension control.

9. Jib control.

10.Turret rotation control.

11.Platform rotation control.

12.Platform level control.

13.Hourmeter.

14.Service horn button.

15.Drive control handle.

16.Function speed control.

17.Fuel selector (dual fuel).

18.Foot switch (located on platform floor).

19.Out of level indicator.

20.Preheat button (diesel).

20

13

4

11

5

8

12

Before operating work platform insure that:

Pre-operation and safety inspection has been

completed, and any discrepancies have been

corrected.

The operator has been thoroughly trained on the

operation of the machine.

9

The work area is clear of all obstructions, holes,

drop-offs, or persons in the route of travel.

The surface is capable of supporting wheel loads.

Refer to figures one and two for control locations.

Emergency Stop

At any time during operation, press the emergency

stop button to stop all functions in an emergency.

Service Horn

At any time during operation, press the service horn

button to sound an audible warning if necessary.

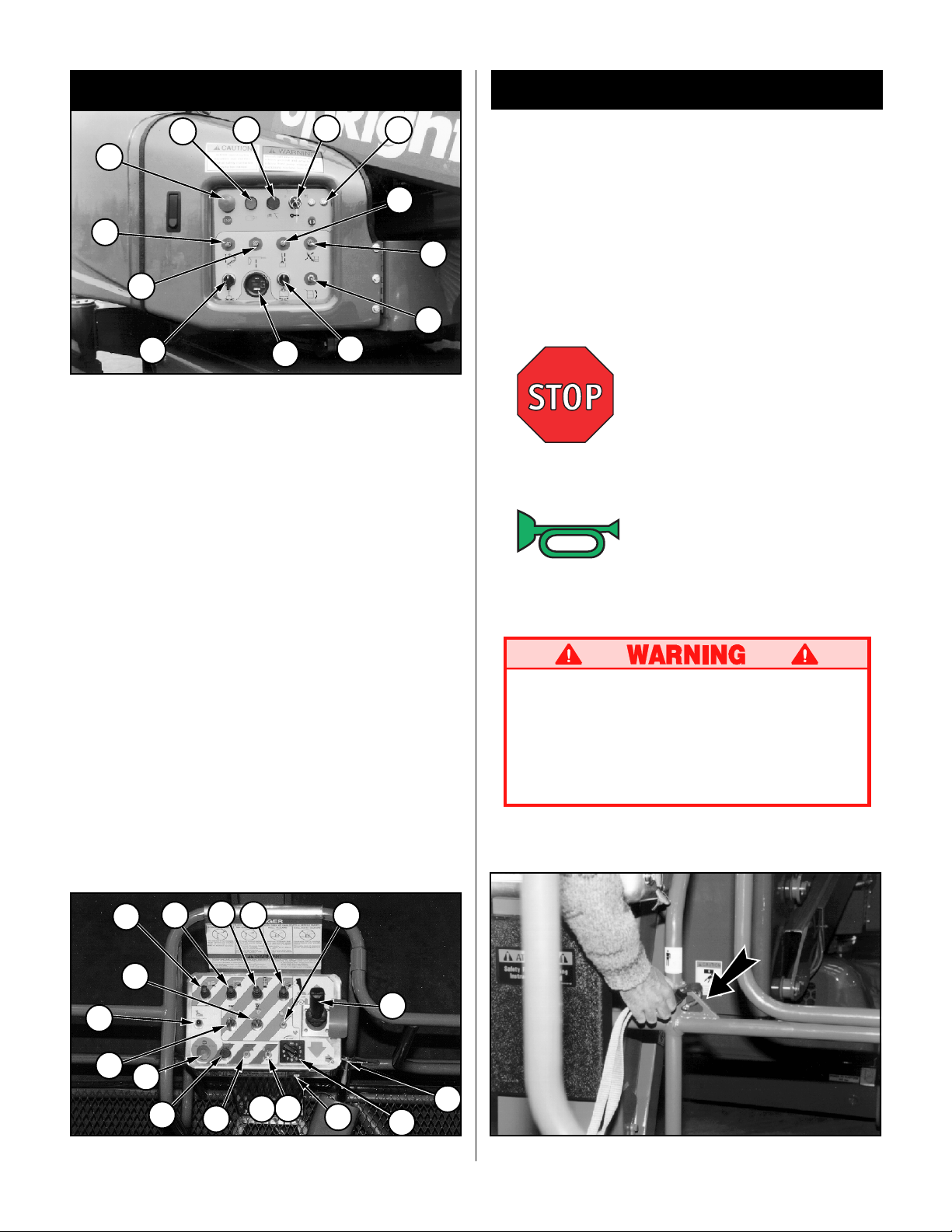

Always wear an approved fall restraint

properly attached to designated platform

anchorage point when driving or elevating the

machine (see figure 3).

Attach only one fall restraint to each anchorage point.

19

10

8

6

7

11

1

14

Figure 2: Platform Controls

9

20

17

3

12

5

15

4

16

Figure 3: Typical Fall Restraint Anchorage Point

3

Starting the engine

From the lower controls

1. Turn the chassis key switch to chassis position.

2. Press the start button to crank the engine. Release when the engine starts.

3. When the engine is cold: press and hold the

preheat button while starting the diesel engine.

Note: Do not depress the foot switch when

cranking engine, as this may flood engine.

From the platform controls

1. Turn the chassis key switch to platform controls.

2. Turn the platform keyswitch fully clockwise to

crank the engine. Release when engine starts.

3. When the engine is cold: Press and hold the

preheat button while starting the diesel engine.

Note: Do not depress the foot switch when

cranking engine, as this may flood engine.

3. Attach approved fall restraint to designated

platform anchorage point. Attach only one fall

restraint to each point.

4. Start engine.

5. Check that the area around and above the work

platform is clear of obstructions, holes, drop-offs,

persons in the route of travel, and the surface is

capable of supporting wheel loads.

6. Examine the terrain and place the speed selector

switch in the appropriate position (Hi or Lo).

7. Depress the foot switch and move the drive

control handle forward to travel forward and

reverse to travel in the reverse direction.

8. While driving in HI speed, pressing the button,

located on the front of the drive control handle,

will shift momentarily into LO for improved torque.

Note: When the boom is rotated to the front of

the chassis (steering wheels aft) directions of

travel and steering will be reversed. Observe the

color coded arrows on the control panel near the

drive control handle, and on the chassis. They

will indicate the direction of travel when the drive

control handle is moved.

Driving

With Boom Lowered

The AB-46 RT has two drive speeds when the

boom is lowered to efficiently accommodate varying

terrain.

Lo Speed: The Lo speed capability allows the

machine to be easily maneuvered

through rougher terrain and negotiate

steeper slopes.

Hi Speed: The Hi speed capability is convenient

for maneuvering in areas that are

relatively smooth and where the

machine will not be driven over rough

or sloping tereain.

Turn chassis key switch to platform, and turn on (turn

1.

clockwise) the chassis emergency stop switch.

2. Mount the platform, close and latch the gate.

The front axle will oscillate freely through a

limited range when driving for greater ease of

negotiating irregular terrain.

With Boom Elevated

Travel with boom elevated is restricted to firm

level surfaces only. When the articulating front

axle is not level, it will lock into position and

disable the drive function.

When driving elevated, the machine will travel at

creep speed (1 foot [.3 m] per second).

Steering

1. While depressing the foot switch, push the steering

switch (located on top of the control handle) to the

left to turn left, and right to turn right.

Note: Steering is not self centering. Wheels

must be returned to the straight ahead position

by operating the steering switch.

POSITIONING THE PLATFORM

Positioning the platform as close as possible to the

work area requires some planning. First, you must

survey the work site to find a suitable place to park

the machine. This must be a firm level area as close

as possible to the work area. Take into consideration all obstructions on the ground and overhead

and avoid them.

4

Once you have moved the machine to a firm level

surface as near as possible to the work area, follow

the instructions on page five to position the platform

as close to the work area as possible.

Always, before operating any function, check the

area around and overhead for any obstructions or

electrical conductors.

NEVER exit the platform while the boom is

elevated. Keep both feet firmly planted on

the platform floor at all times.

Multifunction Controls

The UpRight AB-46 RT employs the use of

multifunction controls. This means that riser or boom

extension will function at full speed while

simultaneously operating upper boom, jib, turret, or

rotating the platform.

The turret may be rotated while driving when boom is

lowered if necessary to make turns in tight areas.

No other boom functions will operate while driving.

Rotating the Turret

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase

speed, counterclockwise to decrease. If you are

not sure what speed to use, start out slow; the

speed can be varied while operating the function.

2. While depressing the foot switch, turn the turret

rotation control switch counterclockwise to rotate

left, clockwise to rotate right. Release the switch

to stop rotation. Observe the area around the

boom when rotating the turret to avoid any obstructions.

Elevating the Riser

Lower Control Operation

All boom functions will operate at fixed speed. Those

which are adjustable will operate at the speed set on

the platform control.

1. Turn chassis keyswitch to chassis controls.

2. With engine running, operate boom control

switches to position the platform.

Leveling the Platform

DO NOT operate the machine if the platform

does not maintain level when elevated.

Note: Platform leveling can be performed only

with the boom stowed and should be done only

to calibrate the automatic leveling system.

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase

speed, counterclockwise to decrease. If you are

not sure what speed to use, start out slow; the

speed can be varied while operating the function.

2. While depressing the foot switch, push the

platform level control switch forward to swing the

platform upward, rearward to swing the platform

downward. Release the switch to stop leveling.

1. While depressing the foot switch, push the riser

control lever forward to elevate the riser, rearward

to lower the riser. Release the control lever to

stop elevating / lowering. The riser will function at

a constant speed, function speed control setting

is not necessary.

Elevating the Upper Boom

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase

speed, counterclockwise to decrease. If you are

not sure what speed to use, start out slow; the

speed can be varied while operating the function.

2.

While depressing the foot switch, push the upper

boom control lever forward to elevate the upper

boom, rearward to lower the upper boom. Release

the control lever to stop elevating / lowering.

5