Page 1

SUNNY ISL

AND

NA-BOX-12-3-20-BE-en-12 | Version 1.2ENGLISH

Operating manual

NA-BOX 12

Page 2

Legal Provisions

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-122

Legal Provisions

The information contained in these documents is the property of SMA Solar Technology AG. No part of this document

may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, be it electronic,

mechanical, photographic, magnetic or otherwise, without the prior written permission of SMA Solar Technology AG.

Internal reproduction used solely for the purpose of product evaluation or other proper use is allowed and does not

require prior approval.

SMA Solar Technology AG makes no representations or warranties, express or implied, with respect to this

documentation or any of the equipment and/or software it may describe, including (with no limitation) any implied

warranties of utility, merchantability, or fitness for any particular purpose. All such representations or warranties are

expressly disclaimed. Neither SMA Solar Technology AG nor its distributors or dealers shall be liable for any indirect,

incidental, or consequential damages under any circumstances.

The exclusion of implied warranties may not apply in all cases under some statutes, and thus the above exclusion may

not apply.

Specifications are subject to change without notice. Every attempt has been made to make this document complete,

accurate and up-to-date. Readers are cautioned, however, that product improvements and field usage experience may

cause SMA Solar Technology AG to make changes to these specifications without advance notice, or per contract

provisions in those cases where a supply agreement requires advance notice. SMA Solar Technology AG shall not be

responsible for any damages, including indirect, incidental or consequential damages, caused by reliance on the

material presented, including, but not limited to, omissions, typographical errors, arithmetical errors or listing errors in

the content material.

SMA Warranty

You can download the current warranty conditions from the Internet at www.SMA-Solar.com.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. Missing designations do not mean that a

product or brand is not a registered trademark.

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

Email: info@SMA.de

Status: 2/13/2019

Copyright © 2019 SMA Solar Technology AG. All rights reserved.

Page 3

Table of Contents

SMA Solar Technology AG

Operating manual 3NA-BOX-12-3-20-BE-en-12

Table of Contents

1 Information on this Document..................................................................................................... 5

1.1 Validity ............................................................................................................................................................. 5

1.2 Target Group ................................................................................................................................................... 5

1.3 Levels of warning messages............................................................................................................................ 5

1.4 Symbols in the Document................................................................................................................................ 5

1.5 Typographies in the document ....................................................................................................................... 6

1.6 Designation in the document .......................................................................................................................... 6

1.7 Additional Information..................................................................................................................................... 6

2 Safety ............................................................................................................................................ 7

2.1 Intended Use.................................................................................................................................................... 7

2.2 IMPORTANT SAFETY INSTRUCTIONS......................................................................................................... 7

3 Scope of Delivery ......................................................................................................................... 10

4 Product Overview ........................................................................................................................ 11

4.1 Product Description.......................................................................................................................................... 11

4.2 Symbols on the Product................................................................................................................................... 12

4.3 System Structure............................................................................................................................................... 13

5 Mounting....................................................................................................................................... 14

5.1 Requirements for Mounting............................................................................................................................. 14

5.2 Preparing the Mounting Location ................................................................................................................... 15

5.3 Transporting and Mounting the Product ........................................................................................................ 16

6 Electrical Connection .................................................................................................................... 18

6.1 Overview of the Connection Area.................................................................................................................. 18

6.1.1 Interior View ..................................................................................................................................................... 18

6.1.2 View from Below.............................................................................................................................................. 19

6.2 Connecting the Multicluster-Box ..................................................................................................................... 19

6.3 Connecting the Utility Grid ............................................................................................................................. 19

6.4 Connecting Control and Measuring Cables of the Multicluster-Box............................................................ 20

6.5 Mounting the Kick Plates................................................................................................................................. 21

7 Preparing for Commissioning ..................................................................................................... 22

8 Disconnect from voltage sources ................................................................................................ 23

9 Periodic Actions ............................................................................................................................ 24

9.1 Removing the Protective Cover....................................................................................................................... 24

9.2 Inserting Power and Control Cables .............................................................................................................. 25

9.3 Connecting Power Cables to Spring-Cage Terminals................................................................................... 26

9.4 Connecting Control Cables to Spring-Cage Terminals ................................................................................. 27

9.5 Mounting the Protective Cover ....................................................................................................................... 28

10 Maintenance ................................................................................................................................. 29

10.1 Inspection of Residual-Current Devices .......................................................................................................... 29

10.2 Checking the Surge Arresters ......................................................................................................................... 30

10.3 Testing the Tie Switch Tripping Function Every 6 Months ............................................................................. 30

10.4 General Maintenance Work .......................................................................................................................... 32

11 Decommissioning the Product ..................................................................................................... 34

Page 4

Table of Contents

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-124

12 Technical Data .............................................................................................................................. 35

13 Contact .......................................................................................................................................... 38

Page 5

1 Information on this Document

SMA Solar Technology AG

Operating manual 5NA-BOX-12-3-20-BE-en-12

1 Information on this Document

1.1 Validity

This document is valid for:

• NA-BOX-12.3-20 (NA-Box 12)

1.2 Target Group

The tasks described in this document must only be performed by qualified persons. Qualified persons must have the

following skills:

• Training in how to deal with the dangers and risks associated with installing, repairing and using electrical

devices, batteries and installations

• Training in the installation and commissioning of electrical devices and installations

• Knowledge of all applicable laws, standards and directives

• Knowledge of and compliance with this document and all safety information

1.3 Levels of warning messages

The following levels of warning messages may occur when handling the product.

DANGER

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

Indicates a situation which, if not avoided, can result in property damage.

1.4 Symbols in the Document

Symbol Explanation

Information that is important for a specific topic or goal, but is not safety-relevant

☐

Indicates a requirement for meeting a specific goal

☑

Desired result

✖

A problem that might occur

Example

Page 6

1 Information on this Document

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-126

1.5 Typographies in the document

Typography Use Example

bold

• Messages

• Terminals

• Elements on a user interface

• Elements to be selected

• Elements to be entered

• Connect the insulated conductors

to the terminals X703:1 to

X703:6.

• Enter 10 in the field Minutes.

>

• Connects several elements to be

selected

• Select Settings > Date.

[Button]

[Key]

• Button or key to be selected or pressed

• Select [Enter].

1.6 Designation in the document

Complete designation Designation in this document

Multicluster-Box 12 Multicluster-Box

NA-Box 12 NA-Box

SunnyIsland 6.0H / 8.0H Sunny Island, battery inverter

1.7 Additional Information

For more information, please go to www.SMA-Solar.com.

Title and information content Type of information

MULTICLUSTER-BOX 12 Installation – circuitry overview

MULTICLUSTER-BOX 12 Operating manual

Page 7

2 Safety

SMA Solar Technology AG

Operating manual 7NA-BOX-12-3-20-BE-en-12

2 Safety

2.1 Intended Use

The NA-Box is an automatic transfer switch and enables the operation of an SMA multicluster system on a utility grid in

accordance with the VDE-AR-N4105 application regulations.

Do not exceed the maximum AC connection power of the NA-Box. Cables with copper conductors must be used for

the installation.

When using an NA-Box in Germany, the following additional connection conditions must be observed:

• Maximum output power of the PV system: 100kW

• Maximum feed-in power into the utility grid: 100kW

The NA-Box may only be commissioned in conjunction with the Multicluster-Box.

In terms of interference immunity, the product is suitable for EMC environment A, and in terms of EMC emissions, it is

suitable for EMC environment B (as per IEC 61439-1:2011).

The product is designed for indoor use only.

Only operate the product at temperatures between −-25°C and +60°C.

The NA-Box is designed for use at altitudes of up to 2000 m above Mean Sea Level. If you would like to use the NA-

Box at altitudes above 2000 m, contact Service (see Section13, page38).

Use this product only in accordance with the information provided in the enclosed documentation and with the locally

applicable laws, regulations, standards and directives. Any other application may cause personal injury or property

damage.

Alterations to the product, e.g. changes or modifications, are only permitted with the express written permission of

SMA Solar Technology AG. Unauthorized alterations will void guarantee and warranty claims and in most cases

terminate the operating license. SMA Solar Technology AG shall not be held liable for any damage caused by such

changes.

Any use of the product other than that described in the Intended Use section does not qualify as the intended use.

The enclosed documentation is an integral part of this product. Keep the documentation in a convenient, dry place for

future reference and observe all instructions contained therein.

This document does not replace and is not intended to replace any local, state, provincial, federal or national laws,

regulations or codes applicable to the installation, electrical safety and use of the product. SMA Solar Technology AG

assumes no responsibility for the compliance or non-compliance with such laws or codes in connection with the

installation of the product.

The type label must remain permanently attached to the product.

2.2 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This section contains safety information that must be observed at all times when working on or with the product.

The product has been designed and tested in accordance with international safety requirements. As with all electrical

or electronical devices, there are residual risks despite careful construction. To prevent personal injury and property

damage and to ensure long-term operation of the product, read this section carefully and observe all safety

information at all times.

Page 8

2 Safety

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-128

DANGER

Danger to life due to electric shock when live components or cables are touched

High voltages are present in the conductive components or cables of the product. Touching live parts and cables

results in death or lethal injuries due to electric shock.

• Do not touch non-insulated parts or cables.

• Disconnect the product from voltage sources and make sure it cannot be reconnected before working on the

device.

• Only disassemble the protective covers, if the product is disconnected from all voltage sources.

• Wear suitable personal protective equipment for all work on the product.

CAUTION

Risk of injury if the product tips over

The product is heavy and may tip over if not properly fastened to the support surface. This can result in crushing

injuries.

• Upon installation, attach the product to the support surface.

CAUTION

Risk of burns due to hot components

Some components and terminals inside the product can become hot during operation. Touching hot components or

terminals can result in burn injuries.

• Wear suitable personal protective equipment for all work on the product.

• Only operate the product with its protective cover mounted.

• Prior to removing the protective cover, let the product cool down.

CAUTION

Injury to persons or property damage due to unauthorized access to the grid and PV system

protection of the NA-Box

Unauthorized access or incorrect settings on the grid and PV system protection device in the NA-Box can cause grid

failures, yield losses, damage to the multicluster system or the NA-Box and injuries to persons. Furthermore, the

operating licence may also be revoked.

• Prior to commissioning the NA-Box, secure the grid and PV system protection device against unauthorized

access. The password protection must be activated on the grid and PV system protection device (see grid and

PV system protection documentation).

• Only operate the NA-Box when the grid and PV system protection device is secured against unauthorized

access.

Page 9

2 Safety

SMA Solar Technology AG

Operating manual 9NA-BOX-12-3-20-BE-en-12

NOTICE

Damage to the product due to sand, dust and moisture ingress

Sand, dust and moisture penetration can damage the product and impair its functionality.

• Do not open the product during a dust storm or precipitation.

• Close the product in case of interruption of work or after finishing work.

• The product must only be closed during operation.

• Store the product in a dry and covered location when closed. Observe storage conditions.

Effects of an emergency disconnection

Emergency disconnection on the battery inverter triggers the uncontrolled shutdown of the system and unsaved

data is lost.

• Only trip the emergency disconnection to avoid danger or consequential damage.

• In the event of an emergency disconnection, always check whether any fuse elements in the product, such as

circuit breakers, have tripped.

• If any fuse elements have tripped, reactivate these fuse elements.

Page 10

3 Scope of Delivery

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1210

3 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your distributor if the scope

of delivery is incomplete or damaged.

B D

C

E

A

Figure 1: Components included in the scope of delivery

Position Quantity Designation

A 1 NA-Box

B 10 Strain relief with counter sleeve (22mmto28mm)

C 2 Fuse link 6A, tripping characteristics: gG

D 2 Fuse link 1A, tripping characteristics: gG

E 1 Operating manual and documentation for the grid and PV system protection de-

vice

Page 11

4 Product Overview

SMA Solar Technology AG

Operating manual 11NA-BOX-12-3-20-BE-en-12

4 Product Overview

4.1 Product Description

The NA-Box is an automatic transfer switch. It enables the operation of an SMA multicluster system on a utility grid in

accordance with the VDE-AR-N4105 application regulations. In the event of a grid failure, the NA-Box disconnects

the SMA multicluster system from the utility grid via a redundant tie switch.

A

C

D F

G

E

GB

Figure 2: NA-Box with cabinet door open

Position Designation

A Protective cover

Prevents inadvertent contact with live components during operation and thus protects

from electric shocks. When the product is in operation, the protective covers must always be mounted.

B Type label

The type label clearly identifies the product. The type label must remain permanently attached to the product. You will find the following information on the type label:

• Device type (Model)

• Serial number (Serial No. or S/N)

• Date of manufacture

• Device-specific characteristics

C Fuse holder 6A

Used as receptacles for cylindrical thermal fuses (6A, tripping characteristic gG). The

thermal fuses protect the connected conductors from excessive heat build-up due to

overload or short circuits.

D External grid and PV system protection device which interrupts the connection between

the power generation system and the electricity grid in the event of voltage- or frequency disturbances via the control of a redundant tie switch.

The grid and PV system protection device monitors the utility grid voltage and frequency for disturbances. If the values fall below the lower limits or exceed the upper

limits, the grid and PV system protection device disconnects the power generation system from the utility grid by opening the redundant tie switch.

The NA-Box is fitted with the grid and PV system protection device manufactured by

BenderGmbH&Co.KG.

Page 12

4 Product Overview

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1212

Position Designation

E Test button for the tie switch

The tripping mechanism of the tie switch must be tested regularly for correct operation

(see Section10.3, page30).

F Fuse holder 1A

Used as receptacles for cylindrical thermal fuses (1A, tripping characteristic gG). The

thermal fuses protect the connected conductors from excessive heat build-up due to

overload or short circuits.

4.2 Symbols on the Product

Symbol Explanation

Beware of electrical voltage

The product operates at high voltages.

Beware of hot surface

The product can get hot during operation.

Observe the documentation

Observe all documentation supplied with the product.

Grounding conductor

This symbol indicates the position for connecting a grounding conductor.

WEEE designation

Do not dispose of the product together with the household waste but in accordance with the

disposal regulations for electronic waste applicable at the installation site.

Degree of protectionIP55

The product is protected against interior dust deposits and water that is directed as a jet

against the enclosure from all directions.

CE marking

The product complies with the requirements of the applicable EU directives.

Page 13

4 Product Overview

SMA Solar Technology AG

Operating manual 13NA-BOX-12-3-20-BE-en-12

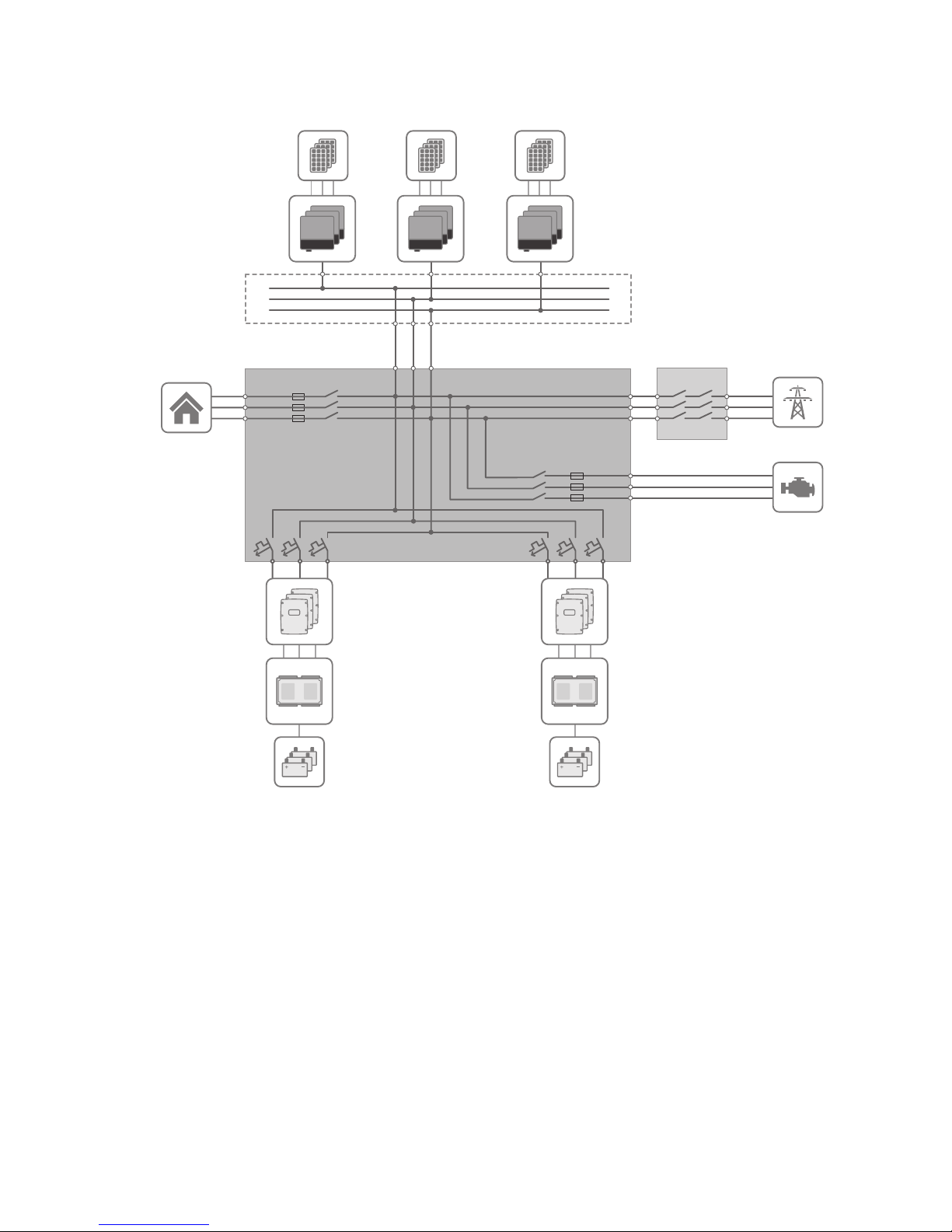

4.3 System Structure

BATFUSE

SUNNY ISLAND

NA-BOX

Load contactor

MULTICLUSTER BOX

(Main AC distribution board)

PV main

distribution box

(not included in the

delivery)

BATTERY

Generator contactor

GENERATOR

LOAD

PV MODULES

PV INVERTERS

UTILITY GRID

Figure 3: Circuitry principle of a multicluster system – example with NA-Box

Page 14

5 Mounting

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1214

5 Mounting

5.1 Requirements for Mounting

WARNING

Danger to life due to fire or explosion

Despite careful construction, electrical devices can cause fires.

• Do not mount the product in areas containing highly flammable materials or gases.

• Do not mount the product in potentially explosive atmospheres.

Mounting location:

☐ A solid, flat support surface must be available for mounting.

☐ The mounting location must be suitable for the weight and dimensions of the product (see Section12 "Technical

Data", page35).

☐ The mounting location should be freely and safely accessible at all times without the need for any auxiliary

equipment (such as scaffolding or lifting platforms). Non-fulfillment of these criteria may restrict servicing.

☐ The mounting location must not hinder access to disconnection devices.

☐ All local requirements concerning minimum passage widths and escape routes must be observed.

☐ All ambient conditions must be met (see Section12, page35).

☐ The mounting location must be less than 2000 m above Mean Sea Level. If you would like to use the NA-Box at

altitudes above 2000 m, contact Service (see Section13, page38).

☐ The product may only be mounted in a permitted mounting position.

Permitted und prohibited mounting position:

Figure 4: Permitted and prohibited mounting positions

Page 15

5 Mounting

SMA Solar Technology AG

Operating manual 15NA-BOX-12-3-20-BE-en-12

Recommended clearances:

200200200 200 200

300

Figure 5: Recommended clearances (dimensions in mm)

☐ There must be sufficient space at the mounting location to ensure compliance with the recommended clearances.

☐ There must be a distance of at least 300mm between the NA-Box and the Multicluster-Box. This will ensure

adequate heat dissipation for each product.

Dimensions for mounting:

598

380

475

62.5

26560

298

Ø 13

Figure 6: Outside base measurements and dimensions of the drill holes (dimensions in mm)

5.2 Preparing the Mounting Location

WARNING

Danger to life due to fire or explosion if mounted at an unsuitable location

Mounting the product in areas with a high fire hazard can result in fire. This can result in death or serious injury.

• Do not install the product on flammable construction materials.

• Do not mount the product in areas containing highly flammable materials.

• Do not mount the product in potentially explosive atmospheres.

Additionally required mounting material (not included in the scope of delivery):

☐ 4 suitable screw anchors for attaching the product

Procedure:

1. On the support surface, mark the positions of the four drill holes for attaching the base (see Section5.1,

page14).

2. Drill holes at the marked positions.

3. Use screw anchors that are suitable for the support surface.

Page 16

5 Mounting

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1216

5.3 Transporting and Mounting the Product

WARNING

Danger to life if raised or suspended loads tip over, fall or sway

Vibrations or careless or hasty lifting and transportation may cause the product to tip over or fall. This can result in

death or serious injury.

• Always transport the product as close to the floor as possible.

• All means of transport and auxiliary equipment used must be designed for the weight of the product. Weight:

109kg.

• Always transport and lift the product upright.

• Always maintain a sufficient safety distance from the product during transport.

• Take into account the center of gravity of the product. The center of gravity is approximately in the center of the

cabinet.

• Wear suitable personal protective equipment for all work on the product.

NOTICE

Damage to the product due to sand, dust and moisture ingress after setting down on

unsuitable surface

Setting the product down on an unsecured or uneven surface may cause the product to warp and allow sand, dust

and moisture to enter the product. Sand, dust and moisture penetration can damage the product and impair its

functionality.

• Never set the product down on an unsecured or uneven surface.

Overview of transport options:

The product is delivered on a Euro pallet. You can use the following means of transport to lift the product off the Euro

pallet:

• Forklift

• Crane with suitable fork

Additionally required mounting material (not included in the scope of delivery):

☐ 4 suitable screws to attach the product to the support surface

Procedure:

1. Remove all fastening screws from the kick plates at the front and rear (TX30).

2. Remove kick plates.

3. Retain the kick plates and the fastening screws for later use.

4. Slide a suitable means of transport under the product.

5. Transport the product to the mounting location using a suitable transport lock.

Page 17

5 Mounting

SMA Solar Technology AG

Operating manual 17NA-BOX-12-3-20-BE-en-12

6.

CAUTION

Risk of injury if the Multicluster-Box tips over

The Multicluster-Box is heavy and may tip over if not properly fastened to the support surface. This can result in

crushing injuries.

• Attach the product to the support surface using four suitable screws.

Page 18

6 Electrical Connection

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1218

6 Electrical Connection

6.1 Overview of the Connection Area

6.1.1 Interior View

A

C

H

D

E

G

F

B

Figure 7: Overview of the connection area

Position Designation

A

Terminal X210, X211 with spring-cage terminals to connect the control cables

B De-energized surge arrester

C

Terminal X201:7-9 with spring-cage terminals L1, L2 and L3 to connect the line conductors of the Multicluster-Box

D

Terminal X201:6 with spring-cage terminals PE to connect the grounding conductor of

the Multicluster-Box

E

Terminal X201:10 with spring-cage terminals N to connect the neutral conductor of

the Multicluster-Box

F

Terminal X201:4 with spring-cage terminals N to connect the neutral conductor of the

utility grid

G

Terminal X201:5 with spring-cage terminals PE to connect the grounding conductor of

the utility grid

H

Terminal X201:1-3 with spring-cage terminals L1, L2 and L3 to connect the line conductors of the utility grid

Page 19

6 Electrical Connection

SMA Solar Technology AG

Operating manual 19NA-BOX-12-3-20-BE-en-12

6.1.2 View from Below

BC

A

Figure 8: Position of the enclosure openings

Position Designation

A Enclosure openings for the control cables

B Enclosure openings for the power cables of the Multicluster-Box

C Enclosure openings for the power cables of the utility grid

6.2 Connecting the Multicluster-Box

Cable requirements:

☐ Conductor material: copper

☐ Conductor cross-section: 50mm²to150mm²

☐ The power cables must be ground-fault and short-circuit protected.

☐ Line conductors, the neutral conductor and grounding conductor must have the same cross-section.

☐ The AC conductors and DC conductors must always be routed in separate cables.

Procedure:

1. Insert the power cables into the product (see Section9.2, page25).

2. Connect the grounding conductor to the spring-cage terminal PE at terminal X201:6 (see Section9.3,

page26).

3. Connect the neutral conductor to the spring-cage terminal N at terminal X201:10.

4. Connect the line conductors to the spring-cage terminals L1, L2 and L3 at the terminals X201:7-9.

5. Ensure that a right-hand rotating magnetic field is present at the connection point of the Multicluster-Box.

6. Provide for strain relief of the power cables in the spring-cage terminal by attaching them to the appropriate cable

support rail. Use the strain reliefs and counter-sleeves provided.

6.3 Connecting the Utility Grid

Cable requirements:

☐ Conductor material: copper

☐ Conductor cross-section: 50mm²to150mm²

☐ The power cables must be ground-fault and short-circuit protected.

☐ Line conductors, the neutral conductor and grounding conductor must have the same cross-section.

☐ The AC conductors and DC conductors must always be routed in separate cables.

Procedure:

1. Insert the power cables into the product (see Section9.2, page25).

Page 20

6 Electrical Connection

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1220

2. Connect the grounding conductor to the spring-cage terminal PE at terminal X201:5 (see Section9.3,

page26).

3. Connect the neutral conductor to the spring-cage terminal N at terminal X201:4 .

4. Connect the line conductors to the spring-cage terminals L1, L2, and L3 at the terminals X201:1-3.

5. Ensure that a right-hand rotating magnetic field is present at the connection point of the Multicluster-Box.

6. Provide for strain relief of the power cables in the spring-cage terminal by attaching them to the appropriate cable

support rail. Use the strain reliefs and counter-sleeves provided.

6.4 Connecting Control and Measuring Cables of the Multicluster-Box

Assignment of spring-cage terminals with the control cables:

1

2

5

4

6

3 3

4

7

6

5

1

2

8910

11

12

13

PE

X210 X210

PE PEPEPE

A

B

C

D E F

Figure 9: Overview of the spring-cage terminals

Position Designation

A Multicluster-Box grounding contactor interlock (DC)

B NA-Box AC contactor feedback (DC)

C NA-Box voltage measurement (AC)

D Multicluster-Box generator contactor interlock (AC)

E NA-Box AC contactor2 interlock (AC)

F NA-Box AC contactor1 interlock (AC)

Cable requirements:

☐ Conductor material: copper

☐ Conductor cross-section: 0.75mm²to2.5mm²

☐ The AC conductors and DC conductors must always be routed in separate cables.

Ground connection at terminals X210 and X211

If the control cable between the Multicluster-Box and NA-Box contains a grounding conductor, the grounding

conductor terminal must not be connected on both sides.

Procedure:

1. Insert the control cables into the product (see Section9.2, page25).

2. Connect the control cables to the spring-cage terminals (see Section9.4, page27).

Page 21

6 Electrical Connection

SMA Solar Technology AG

Operating manual 21NA-BOX-12-3-20-BE-en-12

• X210:1,2: Multicluster-Box grounding contactor interlock

• X210:4,5: NA-Box AC contactor feedback

• X211:1-4: NA-Box voltage measurement

• X211:6,7: Multicluster-Box generator contactor interlock

• X211:8,9: NA-Box AC contactor2 interlock

• X211:11,12: NA-Box AC contactor1 interlock

6.5 Mounting the Kick Plates

Requirements:

☐ All installation work must be completed.

Procedure:

1. Ensure that the power cables are secured with a strain relief.

2. Insert the kick plates and attach with the fastening screws (TX30, torque:12Nm).

Page 22

7 Preparing for Commissioning

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1222

7 Preparing for Commissioning

CAUTION

Injury to persons or property damage due to unauthorized access to the grid and PV system

protection of the NA-Box

Unauthorized access or incorrect settings on the grid and PV system protection device in the NA-Box can cause grid

failures, yield losses, damage to the multicluster system or the NA-Box and injuries to persons. Furthermore, the

operating licence may also be revoked.

• Prior to commissioning the NA-Box, secure the grid and PV system protection device against unauthorized

access. The password protection must be activated on the grid and PV system protection device (see grid and

PV system protection documentation).

• Only operate the NA-Box when the grid and PV system protection device is secured against unauthorized

access.

Requirements:

☐ The NA-Box must be correctly mounted (see Section5, page14).

☐ All cables must be correctly connected (see Section6, page18).

☐ All cables must be tightly enclosed by a membrane or cable feed-through in the floor of the NA-Box.

☐ All power cables must be secured inside or outside the NA-Box.

☐ The floor of the NA-Box must be closed with the base plates (see Section9.2, page25). All seals at the base

plates must be correctly positioned.

Procedure:

1. Ensure that the power cables are secured with a strain relief.

2. Insert the kick plates and attach with the fastening screws (TX30, torque:12Nm).

3. Mount the protective cover (see Section9.5, page28).

4. Close NA-Box.

5. Ensure that the requirements for commissioning the Multicluster-Box are fulfilled (see Multicluster-Box operating

manual).

Page 23

8 Disconnect from voltage sources

SMA Solar Technology AG

Operating manual 23NA-BOX-12-3-20-BE-en-12

8 Disconnect from voltage sources

CAUTION

Risk of burns due to hot components

Some components and terminals inside the product can become hot during operation. Touching hot components or

terminals can result in burn injuries.

• Wear suitable personal protective equipment for all work on the product.

• Only operate the product with its protective cover mounted.

• Prior to removing the protective cover, let the product cool down.

1. Switch off all loads.

2. Stop the multicluster system on the master of the main cluster (see operating manual of the Sunny Island).

3. Switch off all SunnyIsland inverters (see the SunnyIsland operating manual).

4. Disconnect the PV main distribution board from voltage sources and secure against reconnection.

5. Shut down the generator and secure against reconnection.

6. Disconnect the utility grid from the multicluster system at the grid-connection point and secure against

reconnection.

7. Open NA-Box.

8. Remove the protective cover (see Section9.1, page24).

9. Ensure that no voltage is present at all terminals of the NA-Box.

10. Cover and isolate any adjacent live components.

Page 24

9 Periodic Actions

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1224

9 Periodic Actions

9.1 Removing the Protective Cover

DANGER

Danger to life due to electric shock when live components or cables are touched

High voltages are present in the conductive components or cables of the product. Touching live parts and cables

results in death or lethal injuries due to electric shock.

• Do not touch non-insulated parts or cables.

• Disconnect the product from voltage sources and make sure it cannot be reconnected before working on the

device.

• Only disassemble the protective covers, if the product is disconnected from all voltage sources.

• Wear suitable personal protective equipment for all work on the product.

CAUTION

Risk of burns due to hot components

Some components and terminals inside the product can become hot during operation. Touching hot components or

terminals can result in burn injuries.

• Wear suitable personal protective equipment for all work on the product.

• Only operate the product with its protective cover mounted.

• Prior to removing the protective cover, let the product cool down.

Procedure:

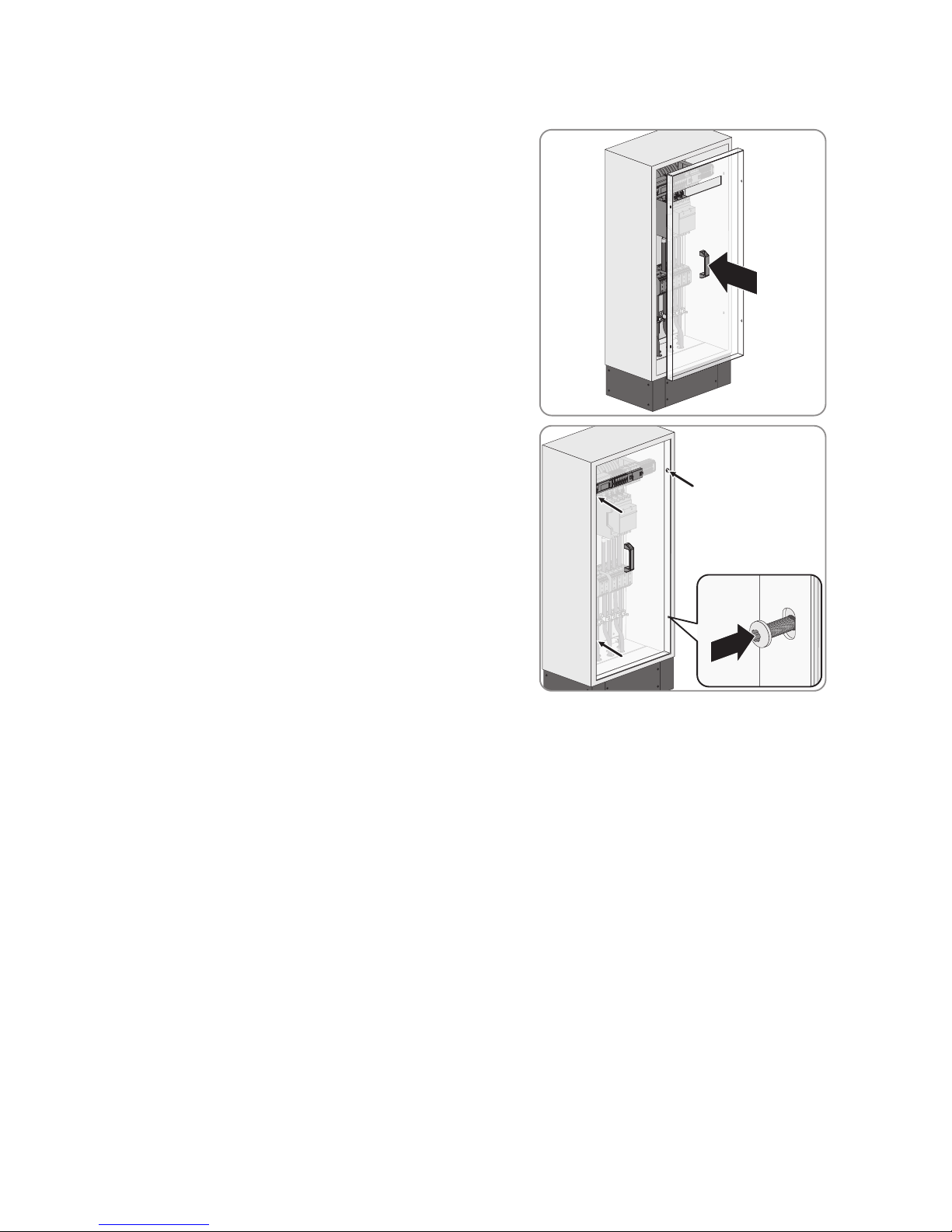

1. Release all fastening screws in the protective cover (TX30).

Page 25

9 Periodic Actions

SMA Solar Technology AG

Operating manual 25NA-BOX-12-3-20-BE-en-12

2. Remove the protective cover forwards.

3. Retain the protective cover and the fastening screws for later use. In this way, the protective cover can be mounted

at a later time and thus the NA-Box recommissioned.

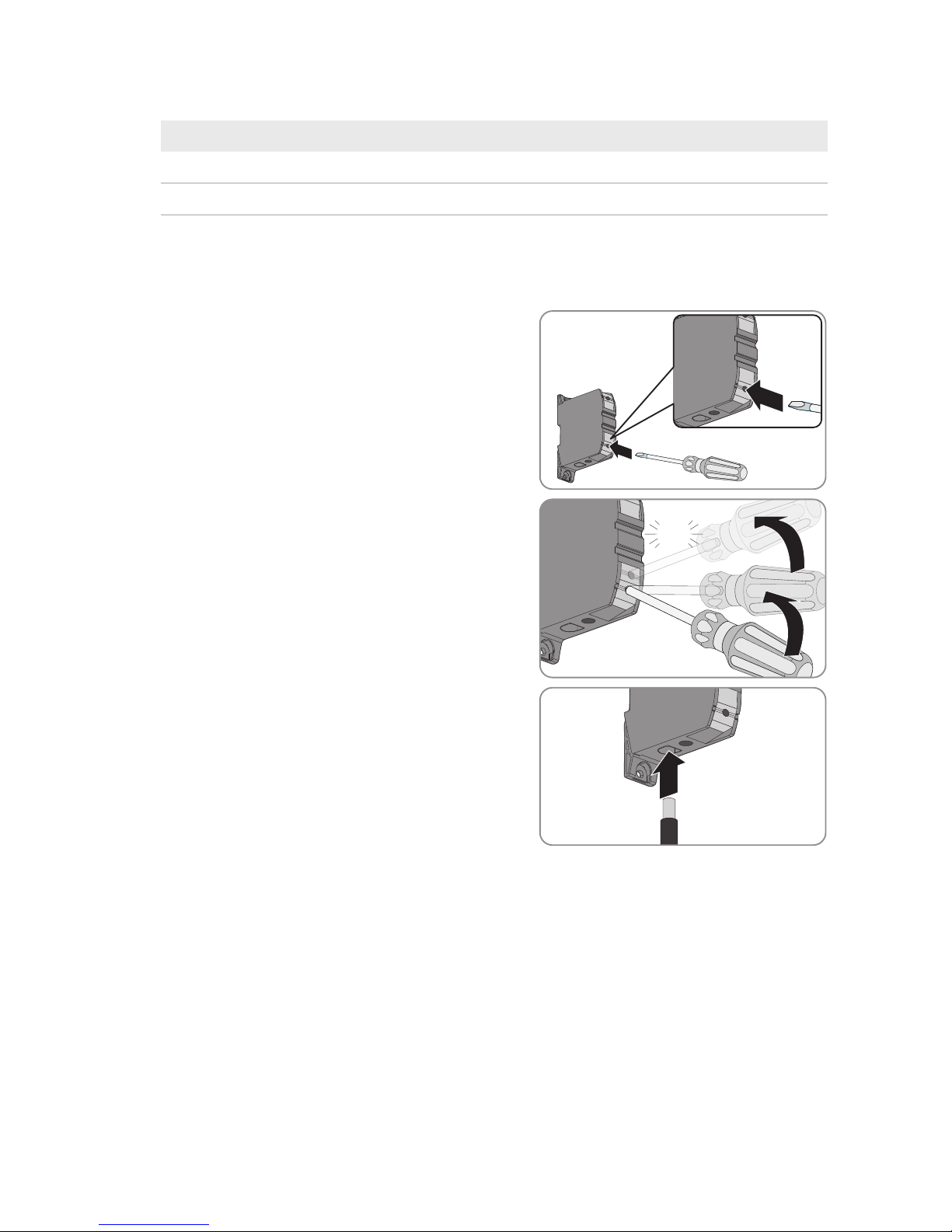

9.2 Inserting Power and Control Cables

NOTICE

Damage to the product due to sand, dust and moisture because of leaky membranes

By piercing unnecessary or oversized holes, the membranes in the cable feed-through plate become leaky. Sand,

dust and moisture penetration can damage the product and impair its functionality.

• Select membranes that match the cable diameter.

• Only pierce as many holes in the membranes of the cable feed-through plate as you need for the cables.

• The hole in the membrane must be smaller than the diameter of the cable to be led through.

• Only insert one cable in each membrane.

Requirement:

☐ The kick plates must be dismantled (see Section5.3, page16).

Procedure:

1. Remove the protective cover (see Section9.1, page24).

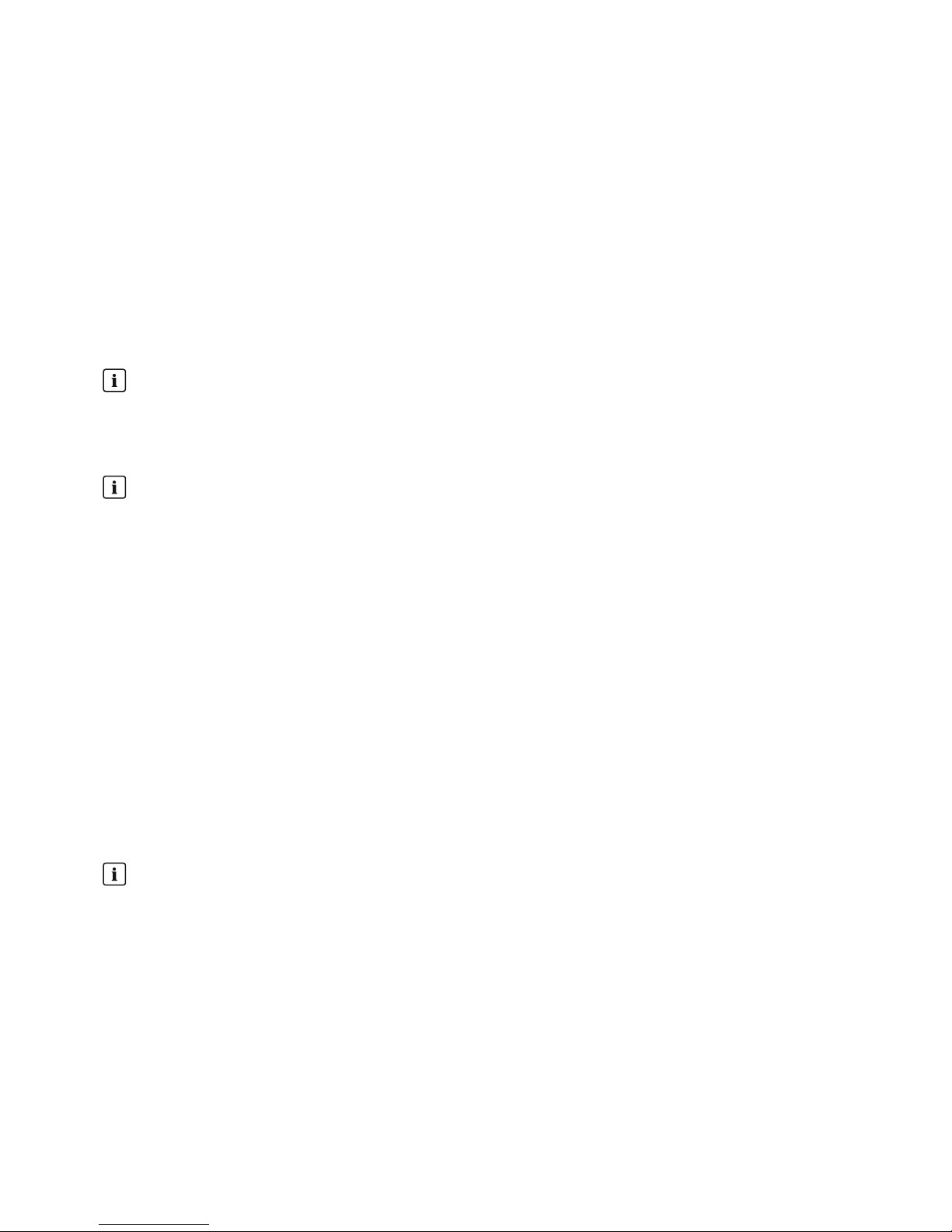

2. Remove all screws of the front and rear base plates (TX25) and

remove the base plates.

3. Insert all cables into the product in accordance with the following procedure:

• Select a suitable enclosure opening for the given cable.

• Pierce the membrane of the selected enclosure opening with a pointed object. Make sure that the opening is

not too large.

• Insert each cable through the membrane of the selected enclosure opening into the Multicluster-Box. Ensure

that the cable is tightly enclosed by the membrane.

Page 26

9 Periodic Actions

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1226

• Strip the insulation of each cable .

Cable typ Stripping length

Power cable 40mm

Control cable 20mm

4. Ensure that the seal at the edge of the base plate is firmly attached.

5. Insert the base plates and tighten all screws of the base plate (TX25 screwdriver, torque: 9Nm).

9.3 Connecting Power Cables to Spring-Cage Terminals

1. Insert the screwdriver into the clamping contact of the spring-cage

terminal.

2. In the clamping contact, press the screwdriver upwards in two

stages as far as the stop. This pretensions the spring of the springcage terminal. The spring-cage terminal emits an audible click

when the clamping contact is sufficiently pretensioned.

click

3. Insert the stripped insulated conductor into the spring-cage

terminal until it reaches the stop. Ensure that no insulation is

trapped in the terminal.

Page 27

9 Periodic Actions

SMA Solar Technology AG

Operating manual 27NA-BOX-12-3-20-BE-en-12

4. Press down the screwdriver in the clamping contact and pull it out

of the contact.

click

5. Make sure that the insulated conductor is securely attached and that no insulation is trapped.

9.4 Connecting Control Cables to Spring-Cage Terminals

1. Insert the screwdriver into the clamping contact of the spring-cage

terminal.

2. Insert the stripped insulated conductor into the spring-cage

terminal until it reaches the stop. Ensure that no insulation is

trapped in the terminal.

3. Pull the screwdriver out of the clamping contact.

4. Make sure that the insulated conductor is securely attached and that no insulation is trapped.

Page 28

9 Periodic Actions

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1228

9.5 Mounting the Protective Cover

1. Insert the protective cover into the product.

2. Tighten all fastening screws (TX30, torque: 4Nm).

Page 29

10 Maintenance

SMA Solar Technology AG

Operating manual 29NA-BOX-12-3-20-BE-en-12

10 Maintenance

10.1 Inspection of Residual-Current Devices

Inspection interval for residual-current devices

The inspection interval for residual-current devices depends on the prevailing operating temperature.

• At prevailing operating temperatures of up to 40°C: inspect every 6 months.

• At prevailing operating temperatures of above 40°C: inspect every 3 months.

Instruction of end users

Because the protective cover remains in place during this test, testing is not hazardous and can be performed by

the end user. However, if the residual-current device does not trip, the NA-Box and the multicluster system must be

disconnected from voltage sources by a qualified person.

• Instruct the end user on the necessary procedure.

• Inform the end user that the inspection interval must always be complied with.

• Point out to the end user that if a defect is detected, a qualified person is required to perform the next steps.

Supply of loads temporarily disconnected during testing

During testing of the residual-current devices, the connection to the utility grid is temporarily disconnected. When

grid feed-in from a generator is discontinued, the supply of the loads is also interrupted.

• If the utility grid is connected, switch off sensitive loads prior to the test.

A

B

Overview of the residual-current device

Position Designation

A Test button

B Switch lever

Top position: residual-current device is switched on.

Bottom position: residual-current device has tripped or is switched off.

Requirements:

☐ The utility grid must be connected to the multicluster system.

Procedure:

1. Stop the multicluster system at the master of the main cluster (see Sunny Island operating manual).

2. On the residual-current device F228 press the [TEST] button.

3. If the residual-current device does not trip after pressing the button, perform the following steps:

Page 30

10 Maintenance

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1230

• Disconnect the NA-Box and multicluster system from voltage sources (see Section8, page23)

• Contact the Service (see Section13, page38). This will trigger the requisite spare parts order.

4. If the residual-current device has tripped, wait at least five seconds.

5. Reactivate the residual-current device after at least five minutes. To do this, move the switch lever of the residualcurrent device into the top position.

6. In the NA-Box also test the residual-current device F229. Use the same procedure as described for the residualcurrent device F228.

7. Start the multicluster system at the master of the main cluster (see Sunny Island operating manual).

8. Document the test result in accordance with the locally applicable standards and directives. This is your proof that

regular inspection has taken place.

10.2 Checking the Surge Arresters

Inspection interval for surge arresters

The inspection interval for surge arresters depends on the prevailing operating temperature.

• At prevailing operating temperatures of up to 40°C: inspect every 6 months.

• At prevailing operating temperatures of above 40°C: inspect every 3 months.

Instruction of end users

Because the protective cover remains in place during this test, testing is not hazardous and can be performed by

the end user. However, if the residual-current device does not trip, the NA-Box and the multicluster system must be

disconnected from voltage sources by a qualified person.

• Instruct the end user on the necessary procedure.

• Inform the end user that the inspection interval must always be complied with.

• Point out to the end user that if a defect is detected, a qualified person is required to perform the next steps.

Procedure:

1. Check whether the signal light on the surge arrester F230 is green or red.

If the signal light on the surge arrester shows green, the surge arrester is in proper working order.

If the signal light on the surge arrester shows red, the surge arrester is defective.

2. If the surge arrester is defective, contact Service (see Section13, page38). This will trigger the requisite spare

parts order.

3. Document the test result in accordance with the locally applicable standards and directives. This is your proof that

regular inspection has taken place.

10.3 Testing the Tie Switch Tripping Function Every 6 Months

Instruction of end users

Because the protective cover remains in place during this test, testing is not hazardous and can be performed by

the end user. However, if the residual-current device does not trip, the NA-Box and the multicluster system must be

disconnected from voltage sources by a qualified person.

• Instruct the end user on the necessary procedure.

• Inform the end user that the inspection interval must always be complied with.

• Point out to the end user that if a defect is detected, a qualified person is required to perform the next steps.

Page 31

10 Maintenance

SMA Solar Technology AG

Operating manual 31NA-BOX-12-3-20-BE-en-12

To test the functionality of the tie switch and therefore to ensure that islanding detection is functioning, the tripping

function of the tie switch must tested every six months. Both impact chains must be tested since the islanding detection

function is redundant. Opening the NA-Box tie switch Q202 simulates a stand-alone grid, resulting in the Sunny Island

detecting an undesired stand-alone grid, switching to the "stand-alone grid" operating state and opening the NA-Box

tie switch Q201.

INFO

TEST

RESET

MENU

ESC

A

B

Figure 10: Test buttons for tripping the tie switches

Position Designation

A

Test button on the grid and PV system protection device

B

Test button S220

Requirement:

☐ The LEDs ALARM1 and ALARM2 on the grid and PV system protection device must be off (see grid and PV

system protection device documentation).

Procedure:

1. Press and hold the Test button for at least five seconds.

☑ The NA-Box tie switch Q202 opens. The SunnyIsland inverter detects a stand-alone grid within five seconds

and switches to the operating state "stand-alone grid" and opens the NA-Box tie switch Q201.

✖ The tie switch Q202 does not open or the SunnyIsland inverter does not react?

• Disconnect the NA-Box and multicluster system from voltage sources (see Section8, page23).

• Contact the Service (see Section13, page38). This will trigger the requisite spare parts order.

2. Release the Test button and wait for at least 30 seconds.

☑ The NA-Box tie switch Q201 closes, the SunnyIsland inverter switches to the operating state "grid feed-in"

and closes the NA-Box tie switch Q202.

✖ The tie switch Q201 does not close?

• Disconnect the NA-Box and multicluster system from voltage sources (see Section8, page23).

• Contact the Service (see Section13, page38). This will trigger the requisite spare parts order.

3. Repeat the test for the impact chain using test button S220. To do so, use the same procedure as described for

the Test button.

4. Document the test result in accordance with the locally applicable standards and directives. This is your proof that

regular inspection has taken place.

Page 32

10 Maintenance

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1232

10.4 General Maintenance Work

The general maintenance work must be performed every twelve months.

DANGER

Danger to life due to electric shock when live components or cables are touched

High voltages are present in the conductive components or cables of the product. Touching live parts and cables

results in death or lethal injuries due to electric shock.

• Do not touch non-insulated parts or cables.

• Disconnect the product from voltage sources and make sure it cannot be reconnected before working on the

device.

• Only disassemble the protective covers, if the product is disconnected from all voltage sources.

• Wear suitable personal protective equipment for all work on the product.

NOTICE

Damage due to cleaning agents

The use of cleaning agents may cause damage to the product and its components.

• Clean the product and all its components only with a cloth moistened with clear water.

Adverse ambient conditions reduce maintenance intervals

Location and ambient conditions influence the maintenance intervals. Note that cleaning and corrosion protection

may be required more frequently depending on the conditions at the installation site.

• If the product is subject to adverse ambient conditions, a reduction of the maintenance intervals is

recommended. Above all, the intervals between cleaning work and corrosion protection should be reduced.

• SMA recommends a monthly optical inspection to determine the maintenance requirement.

Required maintenance materials and tools

Only those consumables and maintenance materials not normally included in the standard equipment of an electrically

qualified person are listed. It is taken for granted that standard tools and materials such as torque wrenches, onecontact voltage testers and wrenches will be available for all maintenance operations.

☐ To repair minor surface corrosion damage: touch-up sticks, paint brushes, spray paint or, alternatively, 2K-PUR

acrylic paint (RAL-Farbe: 7035)

☐ To repair large-surface corrosion damage: touch-up sticks or, alternatively, 2K-PUR acrylic paint (RAL color: 7035)

☐ Abrasive cloth

☐ Degreaser

☐ For maintaining the seals: talcum, petroleum jelly or wax

Procedure:

1. Check whether the inside of the product is soiled or moist.

2. If the interior of the product is dirty, clean the product.

3. If the interior of the product is moist or water has accumulated, dry the product out.

4. Check whether all connections have been tightened with the correct torque (see Section12, page35)

5. If any connections are not tightened with the correct torque, tighten with a suitable torque wrench.

6. Check all power cables on the product for discoloration or changes in the appearance of the insulation.

7. If any power cables are discolored or the appearance of the insulation has changed, replace these power cables.

Page 33

10 Maintenance

SMA Solar Technology AG

Operating manual 33NA-BOX-12-3-20-BE-en-12

8. Check all insulated conductors, terminals and fuse elements in the product for discoloration or changes in the

appearance of the insulation.

9. If any insulated conductors, terminals or fuse elements in the product are discolored or have changed in

appearance, contact Service (see Section13, page38).

10. Check whether the product is free of corrosion damage.

11. If the product displays minor corrosion damage, treat the affected area as follows:

• Sand the area.

• Clean the area with degreaser.

• Paint the area.

12. If the product displays large-scale corrosion damage, treat the entire surface as follows:

• Sand the surface.

• Clean the entire surface with degreaser.

• Paint the entire surface.

13. Check whether all seals on the cabinet door are undamaged.

14. If a seal is damaged, replace the seal.

15. Apply talcum, petroleum jelly or wax to seals. This will prevent frost damage.

Page 34

11 Decommissioning the Product

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1234

11 Decommissioning the Product

DANGER

Danger to life due to electric shock when live components or cables are touched

High voltages are present in the conductive components or cables of the product. Touching live parts and cables

results in death or lethal injuries due to electric shock.

• Do not touch non-insulated parts or cables.

• Disconnect the product from voltage sources and make sure it cannot be reconnected before working on the

device.

• Only disassemble the protective covers, if the product is disconnected from all voltage sources.

• Wear suitable personal protective equipment for all work on the product.

Procedure:

1. Make sure that the product and entire multicluster system have been disconnected from all voltage sources.

2. Remove all fastening screws from the kick plates at the front and rear (TX30). Retain the kick plates and the

fastening screws for later use.

3. Disassemble the protective covers and base plates.

4. Remove all cables from the product.

5. Release and remove the fastening screws on the bottom of the product.

6. Mount the protective covers and base plates.

7. Close the cabinet doors.

8.

WARNING

Danger of crushing if raised or suspended loads tip over or fall

Vibrations or careless or hasty lifting and transportation may cause the product to tip over or fall. This can result

in death or serious injury.

• Always transport the product as close to the floor as possible.

• All means of transport and auxiliary equipment used must be designed for the weight of the product.

Weight: 109kg.

• Always transport and lift the product upright.

• Always maintain a sufficient safety distance from the product during transport.

• Take into account the center of gravity of the product. The center of gravity of the product is

approximately in the center of the cabinet and is marked on the packaging with the center of gravity

symbol.

9. Remount the kick plates on the product.

10. Dispose of the product in accordance with the locally applicable disposal regulations for electronic waste.

Page 35

12 Technical Data

SMA Solar Technology AG

Operating manual 35NA-BOX-12-3-20-BE-en-12

12 Technical Data

Connection to utility grid

Number of terminals 1 x three-phase

Rated grid input power 138 kW

Rated operating voltage between L and N 230V

Rated operating voltage between L1 and L2 400V

Rated current / AC input current 3 x 200 A

Terminals for connection N, PE, L1, L2, L3 Spring-cage terminals

Minimum connectable conductor cross-section 50mm²

Maximum connectable conductor cross-section 150mm²

Unaffected short-circuit current / relative rated short-circuit current at the terminals ≤17kA

Maximum permitted rated current of the back-up fuse 200 A gG

Short-circuit current breaking capacity of the back-up fuse ≥25kA

Forward current of the back-up fuse ≤17kA

Multicluster-Box connection

Number of terminals 1 x three-phase

Rated grid input power 138 kW

Rated operating voltage between L and N 230V

Rated operating voltage between L1 and L2 400V

Rated current / AC input current 3 x 200 A

Terminals for connection N, PE, L1, L2, L3 Spring-cage terminals

Minimum connectable conductor cross-section 50mm²

Maximum connectable conductor cross-section 150mm²

Unaffected short-circuit current / relative rated short-circuit current at the terminals ≤17kA

Maximum permitted rated current of the back-up fuse 200 A gG

Short-circuit current breaking capacity of the back-up fuse ≥25kA

Forward current of the back-up fuse ≤17kA

Connection of grounding

Terminal for grounding conductor connection Spring-cage terminals

Minimum connectable conductor cross-section 50mm²

Maximum connectable conductor cross-section 150mm²

Page 36

12 Technical Data

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1236

Auxiliary electric circuits

Rated operating voltage of the AC auxiliary circuits 230V

Rated operating voltage of the DC auxiliary circuits 48V

Fuse 10x38cylinder fuse

Maximum permitted fuse rating for F223 to F227

1 A gG

Maximum permitted fuse rating for F220 to F222

6 A gG

Terminals for connecting the control cables Spring-cage terminal

Minimum connectable conductor cross-section 0.75mm²

Maximum connectable conductor cross-section 2.5mm²

General Data

Number of line conductors 3

Permitted grid configuration TN-S, TN-C-S and TT

Rated frequency 50 Hz

Frequency range 45Hz to 52Hz

Rated impulse withstand voltage 4kV (2000m)

Width x height x depth (with base) 600mmx 1400mmx435mm

(incl.200mmbase)

Weight 109kg

Maximum operating altitude above mean sea level 2000 m

Inner subdivision Form 1 (no subdivision)

Exterior design closed type

Installation only fixed interior installation

permitted

Construction type fixed components

Suitable for use by electrically qualified persons or unqualified persons Installation of the system and

replacement of equipment by

electrically qualified persons

only / actuation of test buttons

and read-off of information by

unqualified persons permitted

Measures for protection against electric shock Basic protection through

insulation materials and covers /

fault protection through

grounding conductors and short-

circuit protection devices /

personal protection through

residual-current devices

Page 37

12 Technical Data

SMA Solar Technology AG

Operating manual 37NA-BOX-12-3-20-BE-en-12

Enclosure degree of protection (as per IEC60529) IP55

Degree of protection with open enclosure door (as per IEC 60529) IP20B

Pollution degree at the mounting location (as per IEC 61439-1:2011) 3

Pollution degree in the enclosure (micro-environment) 2

Protection class (as per IEC417) 1

Overvoltage category (as per IEC60664) Overvoltage category3

EMC environment, emission (as per IEC 61439-1:2011) Electromagnetic interference,

environment B (EMC directive,

Article 5 – Annex I.1.b)

EMC environment, interference immunity (as per IEC 61439-1:2011) Interference immunity,

environment A (EMC Directive

Article 5 – Annex I.1.b)

EC Declaration of Conformity Yes

Operating temperature range* -20°C to +50°C

Humidity (non-condensing) 10% to 90%

* At operating temperatures of over 40°C the SunnyIsland inverters reduce their output power (derating).

Derating

Output power / rated power up to 40°C 138 kW

Output power / rated power at 40°C to 50°C Derating according to power-

temperature curve (see

Multicluster-Box operating

manual)

Rated voltage / rated insulation voltage

Switch cabinet wiring L to N 250VAC

Switch cabinet wiring L1 to L2 433VAC

Auxiliary AC circuits 250VAC

Auxiliary DC circuits 70VDC

Page 38

13 Contact

SMA Solar Technology AG

Operating manualNA-BOX-12-3-20-BE-en-1238

13 Contact

If you have technical problems with our products, please contact the SMAServiceLine. The following data is required

in order to provide you with the necessary assistance:

• Box

– Device type

– Serial number

• Battery inverter:

– Device type

– Quantity

• PV inverter:

– Device type

– Quantity

• Electrical loads:

– Device type

– Quantity

• Type, power and maximum current for the generator (if present)

• Multicluster Box (if available)

– Device type

– Serial number

• Batteries:

– Type

– Nominal capacity and nominal voltage (with lead-acid batteries)

Deutschland

Österreich

Schweiz

SMA Solar Technology AG

Niestetal

Sunny Boy, Sunny Mini Central,

SunnyTripower: +495619522‑1499

Monitoring Systems

(Kommunikationsprodukte):

+495619522‑2499

Hybrid Controller

(PV-Diesel-Hybridsysteme):

+495619522-3199

Sunny Island, Sunny Boy Storage,

Sunny Backup:

+495619522-399

Sunny Central, Sunny Central Storage:

+495619522-299

SMA Online Service Center:

www.SMA-Service.com

Belgien

Belgique

België

Luxemburg

Luxembourg

Nederland

SMA Benelux BVBA/SPRL

Mechelen

+3215286 730

SMA Online Service Center:

www.SMA-Service.com

Česko

Magyarország

Slovensko

SMA Service Partner TERMS a.s.

+4203876 85 111

SMA Online Service Center:

www.SMA-Service.com

Türkiye SMA Service Partner DEKOM Ltd. Şti.

+90 24 22430605

SMA Online Service Center:

www.SMA-Service.com

Page 39

13 Contact

SMA Solar Technology AG

Operating manual 39NA-BOX-12-3-20-BE-en-12

France SMA France S.A.S.

Lyon

+33 472 22 97 00

SMA Online Service Center :

www.SMA-Service.com

Ελλάδα

Κύπρος

SMA Service Partner AKTOR FM.

Αθήνα

+30 210 8184550

SMA Online Service Center:

www.SMA-Service.com

España

Portugal

SMA Ibérica Tecnología Solar, S.L.U.

Barcelona

+34935635099

SMA Online Service Center:

www.SMA-Service.com

United Kingdom SMA Solar UK Ltd.

Milton Keynes

+441908304899

SMA Online Service Center:

www.SMA-Service.com

Italia SMA Italia S.r.l.

Milano

+39028934-7299

SMA Online Service Center:

www.SMA-Service.com

Australia SMA Australia Pty Ltd.

Sydney

Toll free for Australia:

1800SMAAUS

(1800762287)

International: +61294914200

United Arab

Emirates

SMA Middle East LLC

Abu Dhabi

+9712234 6177

SMA Online Service Center:

www.SMA-Service.com

India SMA Solar India Pvt. Ltd.

Mumbai

+912261713888

ไทย SMA Solar (Thailand) Co., Ltd.

กรุงเทพฯ

+6626706999

대한민국 SMA Technology Korea Co., Ltd.

서울

+82-2-520-2666

South Africa SMA Solar Technology South Africa

Pty Ltd.

Cape Town

08600SUNNY (08600 78669)

International: +27 (0)21 826 0699

SMA Online Service Center:

www.SMA-Service.com

Argentina

Brasil

Chile

Perú

SMA South America SPA

Santiago de Chile

+562 2820 2101

Other countries

International SMA Service Line

Niestetal

00800SMASERVICE

(+8007627378423)

SMA Online Service Center:

www.SMA-Service.com

Page 40

www.SMA-Solar.com

Loading...

Loading...