Page 1

SMA Solar Technology AG

Solar Inverters

MLX Series

Installation Guide / Guía de instalacíon / Guide d’installation /

Installationsanleitung

www.SMA.de

Page 2

Choice of Language - Selección de idioma - Choix de la langue - Sprachauswahl

Page 5

Página 40

Page 78

Seite 116

English UK

Español

Français

Deutsch

L00410644-01_2q / Rev. date: 2014-06-02 1

Page 3

IMPORTANT SAFETY INSTRUCTIO...

IMPORTANT SAFETY INSTRUCTIONS - SAVE THESE INSTRUCTIONS

Safety Message Types

The following symbols are used in this document:

DANGER

Indicates a potentially hazardous situation which will

result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which could

result in minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTICE

Indicates important information, including situations

which may result in damage to equipment or property.

General Safety

CAUTION

This manual contains important instructions that shall be

followed during installation and maintenance of the MLX

inverter.

NOTICE

BEFORE INSTALLATION

Check for damage to equipment and packaging. If in

doubt, contact the supplier before commencing installation.

WARNING

INSTALLATION

For optimum safety, follow the steps described in this

document. Keep in mind that the inverter has 2 voltagecarrying sides; the PV input and the AC grid.

DANGER

DISCONNECTING THE INVERTER

Before starting work on the inverter, switch off AC at the

mains switch and PV using the PV load switch. Ensure

that the inverter cannot be unintentionally reconnected.

Use a voltage tester to ensure that the unit is disconnected and voltage free. The inverter can still be charged

with very high voltage at hazardous levels even when it

is disconnected from AC grid and solar modules. Wait at

least 5 minutes following disconnection from grid and

PV panels before proceeding.

L00410644-01_2q / Rev. date: 2014-06-02

Page 4

IMPORTANT SAFETY INSTRUCTIO...

WARNING

RISK OF ELECTRIC SHOCK

These servicing instructions are for use by qualified

personnel only. To reduce the risk of electric shock, do

not perform any servicing other than that specified in

the operating instructions unless you are qualified to do

so.

WARNING

The inverter is not equipped with an isolation

transformer and is intended to be installed according to

NFPA 70, 690.35 with an ungrounded (floating) PV array.

WARNING

Input and output circuits are isolated from the enclosure.

System grounding, when required by the Canadian

Electrical Code, Part I, is the responsibility of the

installer.

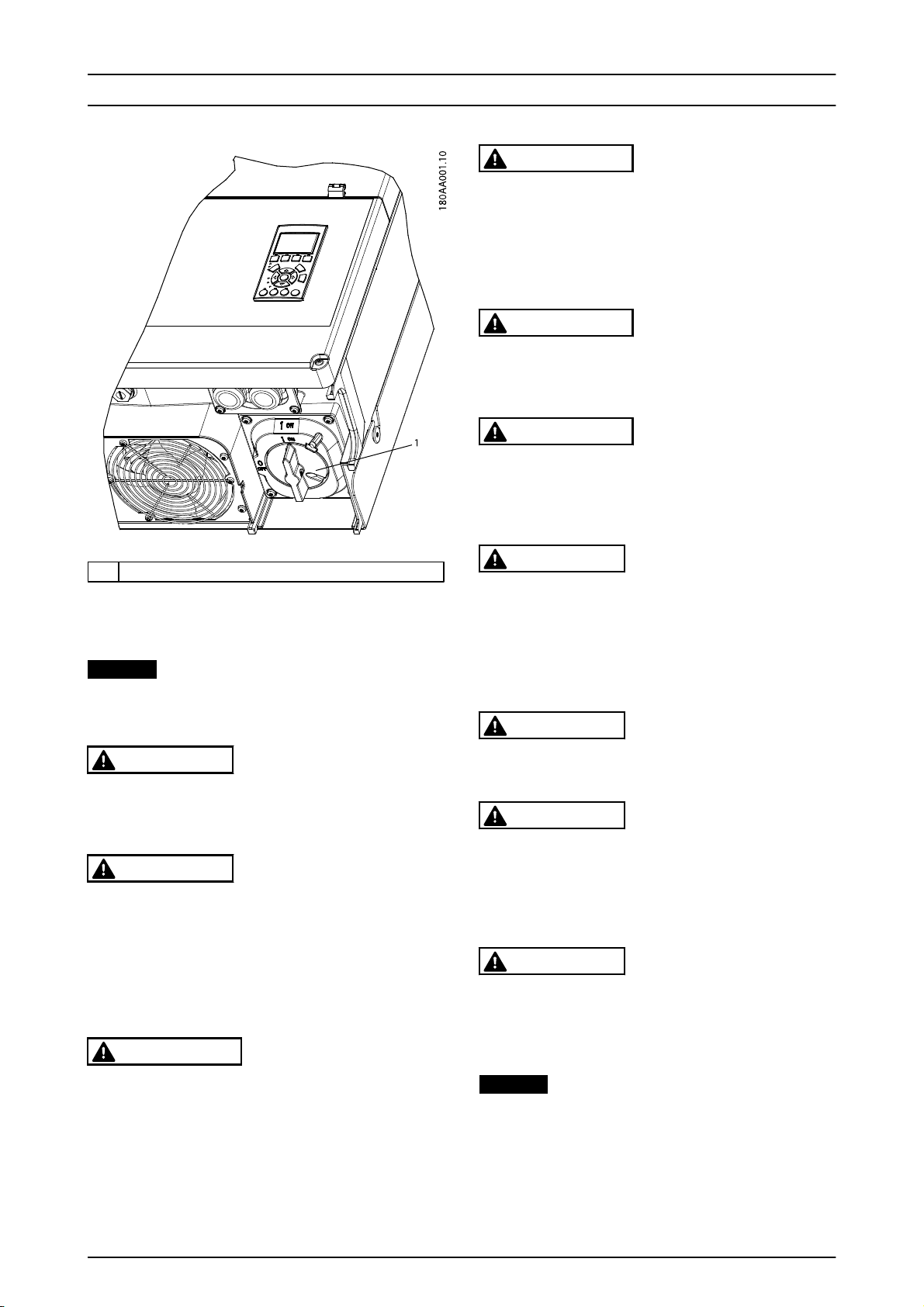

1 PV load switch (optional)

Illustration 1.1

NOTICE

The PV load switch can be secured in the ‘Off’ position

using a padlock.

CAUTION

DC voltages up to 1000 V are present in a PV system

even when the inverter is disconnected from the AC grid.

Faults or inappropriate use may lead to electric arcing.

CAUTION

MAINTENANCE AND MODIFICATION

Only authorised personnel are permitted to modify the

inverter. To ensure personal safety, use only original

spare parts available from the supplier. If non-original

spare parts are used, compliance with CE/UL guidelines

in respect of electrical safety, EMC, and machine safety is

not guaranteed.

WARNING

INSTALLER

Observe the National Electric Code, ANSI/NFPA 70.

Input and output circuits are isolated from the enclosure.

System grounding is the responsibility of the installer.

CAUTION

All persons installing and servicing inverters must be:

Trained and authorised in general safety rules

•

for work on electrical equipment.

Familiar with local requirements, rules, and

•

regulations for the installation.

CAUTION

The inverter does not provide overcurrent protection.

This must be provided by the installer. See Table 5.8.

CAUTION

The temperature of the cooling racks and components

inside the inverter can exceed 70 °C/158 °F. Observe the

danger of burn injury.

The inverter is to be installed so that it is not expected

to be contacted by persons.

CAUTION

To reduce the risk of fire, connect only to a circuit

provided with 125 A maximum branch-circuit

overcurrent protection in accordance with the National

Electrical Code, ANSI/NFPA 70.

NOTICE

Use 75 °C or 90 °C wire, either AWG copper or AWG

aluminium. See 2.7 Cable Entry.

L00410644-01_2q / Rev. date: 2014-06-02

Page 5

IMPORTANT SAFETY INSTRUCTIO...

NOTICE

The symbol for protective earth used in this manual is

identified in Illustration 2.18.

The on/off symbol is identified in 3.2.2 Turn PV Load

Switch On.

NOTICE

For information about ambient temperature rating, see

5.4 Installation Conditions.

NOTICE

This manual contains information about field wiring

connections and torque specifications. See 5.5 Torque

Specifications.

NOTICE

This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio

or television reception, which can be determined by

turning the equipment off and on, the user is

encouraged to try to correct the interference by 1 or

more of the following measures:

Reorient or relocate the receiving antenna.

•

Increase the distance between the equipment

•

and receiver.

Connect the equipment into an outlet on a

•

circuit different from that to which the receiver

is connected.

Consult the dealer or an experienced radio/TV

•

technician for help.

Conformity

Go to the download area at www.sma.de for information.

See also 5 Technical Data.

L00410644-01_2q / Rev. date: 2014-06-02

Page 6

Contents

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Unpacking

1.3 Identification of Inverter

1.4 Installation Sequence

1.5 Overview of Installation Area

2 Installation

2.1 Environment and Clearances

2.2 Mounting the Mounting Plate

2.3 Mounting the Inverter

2.4 Removing the Inverter

2.5 Access to the Installation Area

2.6 AC Grid Connection

2.7 Cable Entry

2.8 Ethernet Connections

2.9 PV Connection

2.9.1 External String Combiners 18

7

8

10

10

10

11

12

12

13

14

15

15

16

17

17

18

2.10 Closure

3 Initial Setup and Start

3.1 User Interface

3.1.1 Operation Modes 20

3.2 Display

3.2.1 Initial Setup via LCS Tool 21

3.2.2 Turn PV Load Switch On 21

3.2.3 Start-up

3.3 LCS Tool

3.3.1 Getting Started 22

4 Service

4.1 Troubleshooting

4.2 Maintenance

5 Technical Data

5.1 Specifications

5.2 Trip Settings

19

20

20

20

21

22

28

28

30

31

31

32

5.3 Conformity

5.4 Installation Conditions

5.5 Torque Specifications

L00410644-01_2q / Rev. date: 2014-06-02 5

33

34

34

Page 7

Contents

5.6 Mains Circuit Specifications

5.7 Auxiliary Interface Specifications

5.8 Ethernet Connections

35

35

36

6 L00410644-01_2q / Rev. date: 2014-06-02

Page 8

Introduction

1Introduction

The MLX inverters are designed to act exclusively as gridtied inverters for photovoltaic (PV) systems. The inverter

converts DC voltage generated by a solar array into

electrical AC power. The unit must be tied to the utility

grid and a photovoltaic system in order to operate

properly. It is not suitable for any other applications (such

as a battery back-up or wind-powered systems).

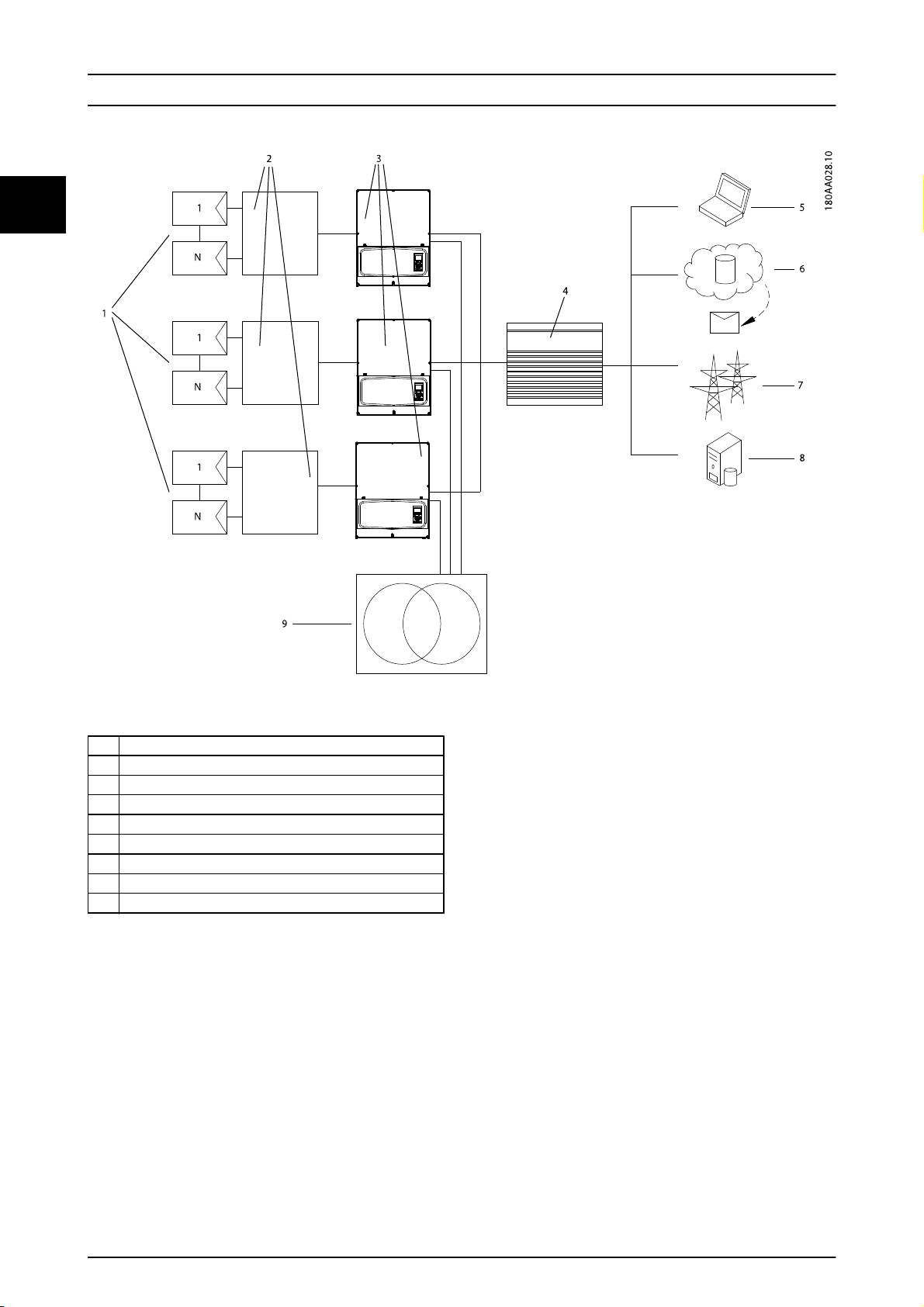

The MLX system consists of 4 main components (see also

Illustration 1.1):

MLX inverter.

•

DC combiner.

•

The DC combiner makes it possible to combine

the needed number of PV strings for the MLX

inverter. A DC combiner is needed for each MLX

inverter.

MLX Inverter Manager.

•

The MLX Inverter Manager is required for

operating the MLX inverters. Each Inverter

Manager can handle up to 42 inverters. The

Inverter Manager handles all communication to

the inverters. It forms a single point of interface

for data accusation systems, upload to cloud

services and power-plant control.

LCS Tool.

•

The LCS Tool is required for commissioning and

servicing MLX inverters, via the Inverter Manager.

The LCS Tool acts as the primary user interface

for the MLX system.

1 1

L00410644-01_2q / Rev. date: 2014-06-02 7

Page 9

1

Introduction

Illustration 1.1 System Overview

1PV array

2DC combiner

3MLX inverter

4MLX Inverter Manager

5LCS Tool

6CLX portal or third party

7 Utility control

8 SCADA system

9Transformer

Table 1.1 System Overview

1.1 Purpose of the Manual

The Installation Guide provides information required to

install and commission the MLX series inverter.

Additional resources available:

Inverter Manager Installation Poster, for

•

information required to commission the MLX

inverter as well as setup of inverter communication (EU).

Inverter Manager Assembly Installation Guide, for

•

information required to commission the MLX

inverter as well as setup of inverter communication (US).

Design Guide, for information required for detailed

•

inverter layout planning in a diversity of solar

energy applications.

Fan Installation Instruction, for information

•

required to replace a fan.

SPD Installation Instruction, for information

•

required to replace surge protection devices.

These documents are available from the download area at

www.sma.de, or from the supplier of the solar inverter.

8 L00410644-01_2q / Rev. date: 2014-06-02

Page 10

Introduction

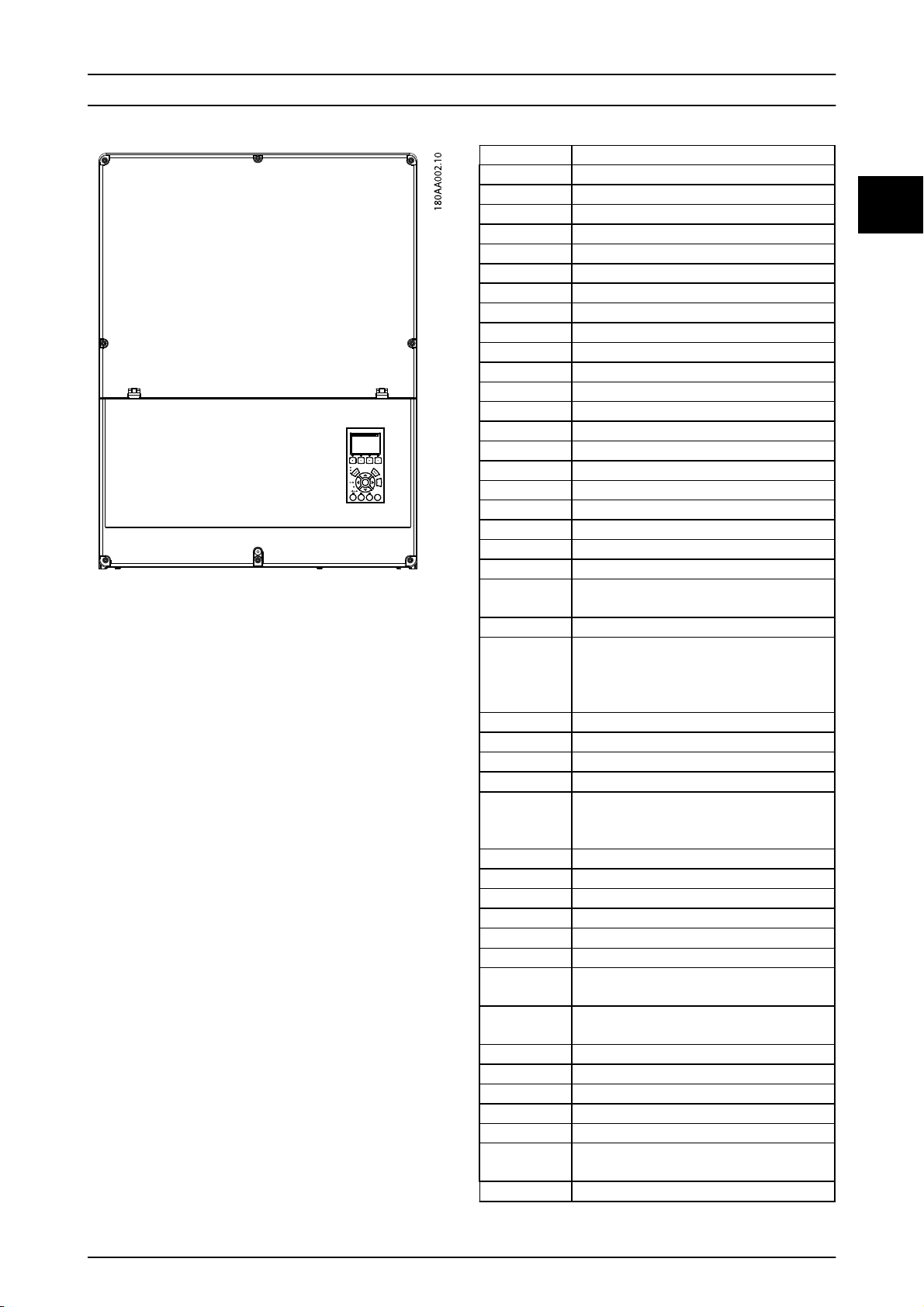

Illustration 1.2 MLX Inverter

Abbreviation Description

ANSI American National Standards Institute

AWG American Wire Gauge

cat5e Category 5 twisted pair cable (enhanced)

DHCP Dynamic Host Configuration Protocol

DNO Distribution Network Operator

DSL Digital Subscriber Line

EMC (Directive) Electromagnetic Compatibility Directive

ESD Electrostatic Discharge

FCC Federal Communications Commission

FRT Fault Ride Through

GSM Global System for Mobile Communications

HDD Hard Disk Drive

IEC International Electrotechnical Commission

IT Isolated Terra

LCS Local Commissioning and Service

LED Light-Emitting Diode

LVD (Directive) Low Voltage Directive

MCB Miniature Circuit Breaker

MPP Maximum Power Point

MPPT Maximum Power Point Tracking

NFPA National Fire Protection Association

P P is the symbol for active power and is

measured in Watts (W).

PCB Printed Circuit Board

PCC Point of Common Coupling

The point on the public electricity network to

which other customers are, or could be,

connected.

PE Protective Earth

PELV Protected Extra-Low Voltage

PLA Power Level Adjustment

P

NOM

POC Point of Connection

P

STC

PV Photovoltaic, photovoltaic cells

RCD Residual-Current Device

RCMU Residual Current Monitoring Unit

R

ISO

ROCOF Rate Of Change Of Frequency

Q Q is the symbol for reactive power and is

S S is the symbol for apparent power and is

STC Standard Test Conditions

SW Software

THD Total Harmonic Distortion

TN-S Terra Neutral - Separate. AC Network

TN-C Terra Neutral - Combined. AC Network

TN-C-S Terra Neutral - Combined - Separate. AC

TT Terra Terra. AC Network

Power, Nominal conditions

The point at which the PV system is connected

to the public electricity grid.

Power, Standard Test Conditions

Insulation Resistance

measured in reactive volt-amperes (VAr).

measured in volt-amperes (VA).

Network

1 1

Table 1.2 Abbreviations

L00410644-01_2q / Rev. date: 2014-06-02 9

Page 11

Introduction

1

1.2 Unpacking

Contents:

Inverter

•

Mounting plate

•

Accessories bag, containing:

•

6 wall plugs 8 x 50 mm

•

6 mounting screws 6 x 60 mm

•

1 M25 cable gland with sealing

•

grummet for Ethernet cables

2 x conduit bracket (2 in)

•

1 equipment grounding bolt M6 x 12

•

mm

Installation guide, booklet format

•

Quick guide, poster format

•

1.3 Identification of Inverter

1.4 Installation Sequence

1. Pay special attention to the important safety

instructions at the beginning of this manual.

2. Install the inverter according to 2.1 Environment

and Clearances, 2.2 Mounting the Mounting Plate,

and 2.3 Mounting the Inverter.

3. Open the inverter according to 2.5 Access to the

Installation Area.

4. Install AC according to 2.6 AC Grid Connection.

5. Install Ethernet according to 2.8.1 Ethernet

Connections.

6. Install PV according to 2.9 PV Connection.

7. Close the inverter according to 2.5 Access to the

Installation Area.

8. Turn on AC.

9. Finalise commissioning by using the Local

Commissioning and Service Tool (LCS Tool). The

tool is available from the download area at

www.sma.de. The hardware requirements for the

LCS Tool are:

PC running WindowsTM 7 and onwards

•

150 Mb HDD

•

2 Gb RAM

•

For setup via the LCS Tool, refer to 3.3 LCS Tool.

10. Turn on PV by turning on the PV load switch.

Refer to 2.9.2 Connection of PV.

11. Verify the installation by:

Inverter display: LED ‘On’ is solid green.

•

LCS Tool: In inverter view status is ‘On

•

grid’.

12. The inverter is now in operation.

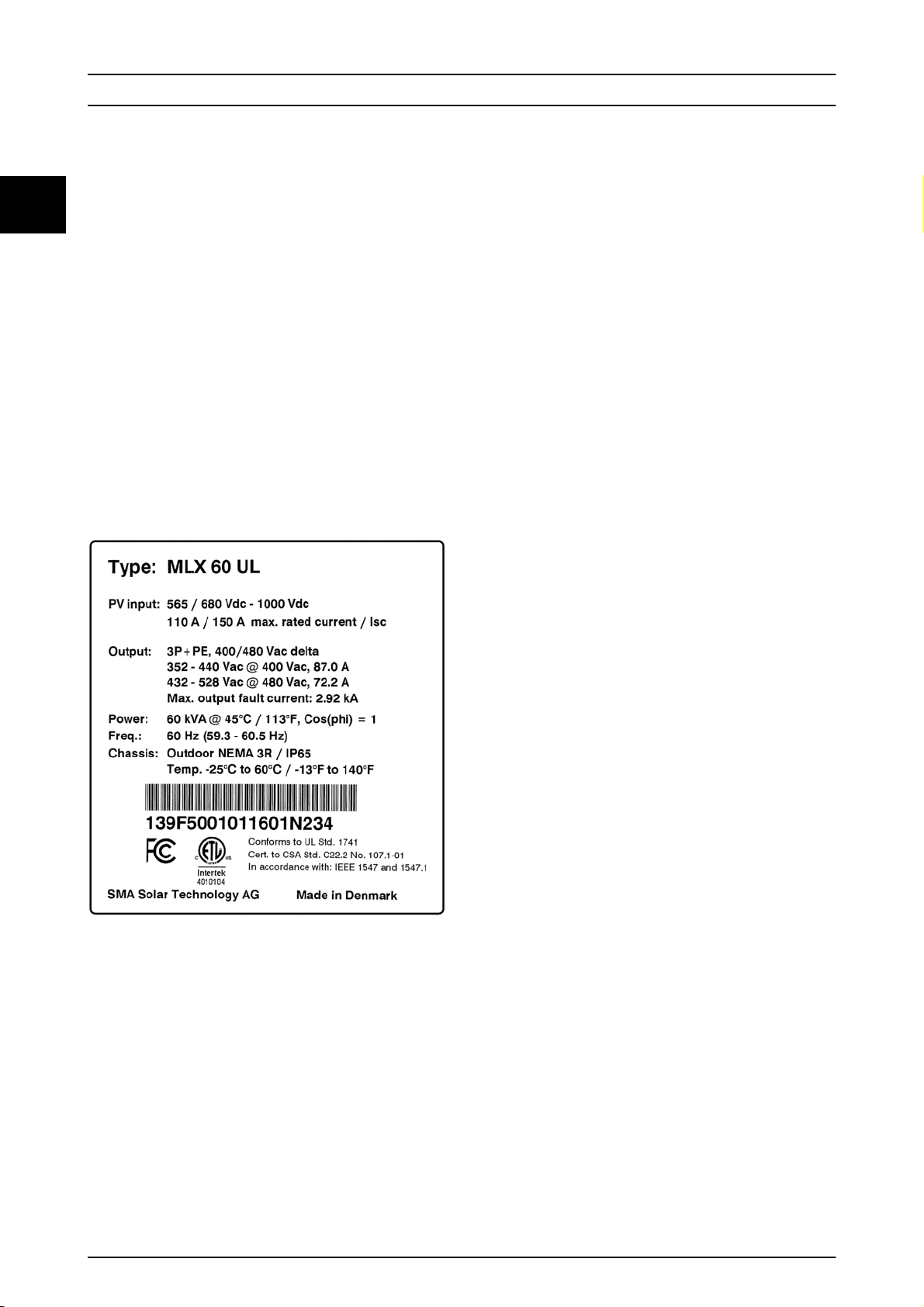

Illustration 1.3 Product Label, Example

The product label on the side of the inverter shows:

Inverter type.

•

Important specifications.

•

Serial number, located under the bar code, for

•

inverter identification.

10 L00410644-01_2q / Rev. date: 2014-06-02

Page 12

Introduction

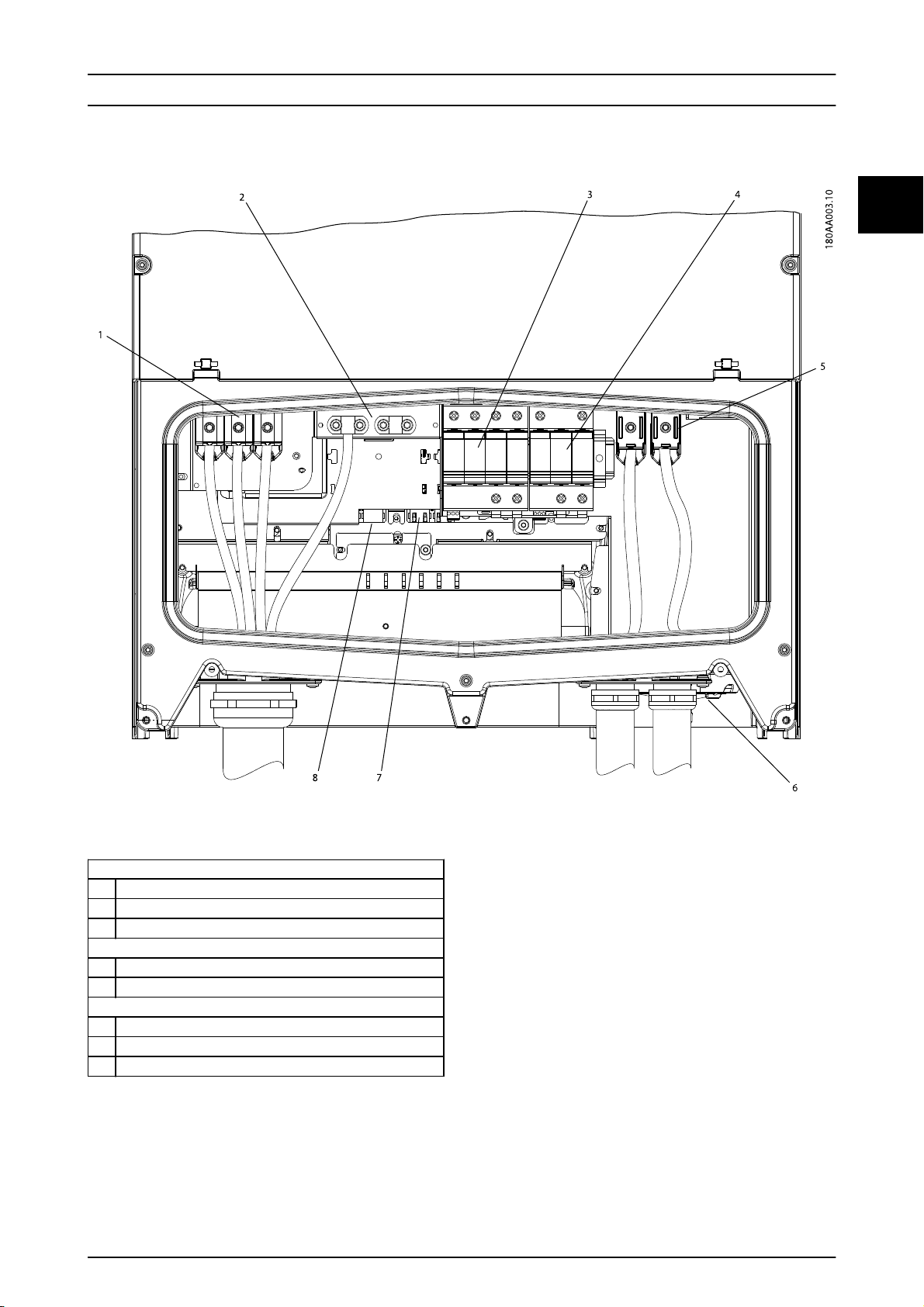

1.5 Overview of Installation Area

1 1

Illustration 1.4 Overview of Installation Area

PELV (Safe to touch)

2 Equipment grounding

7 Ethernet interface x 2

8 RS-485 interface (not in use)

Live Part

1 AC connection terminals

5 PV connection terminals

Other

3Surge Protection AC

4Surge Protection DC

6 PV load switch (optional)

Table 1.3 Overview of Installation Area

L00410644-01_2q / Rev. date: 2014-06-02 11

Page 13

2

Installation

2 Installation

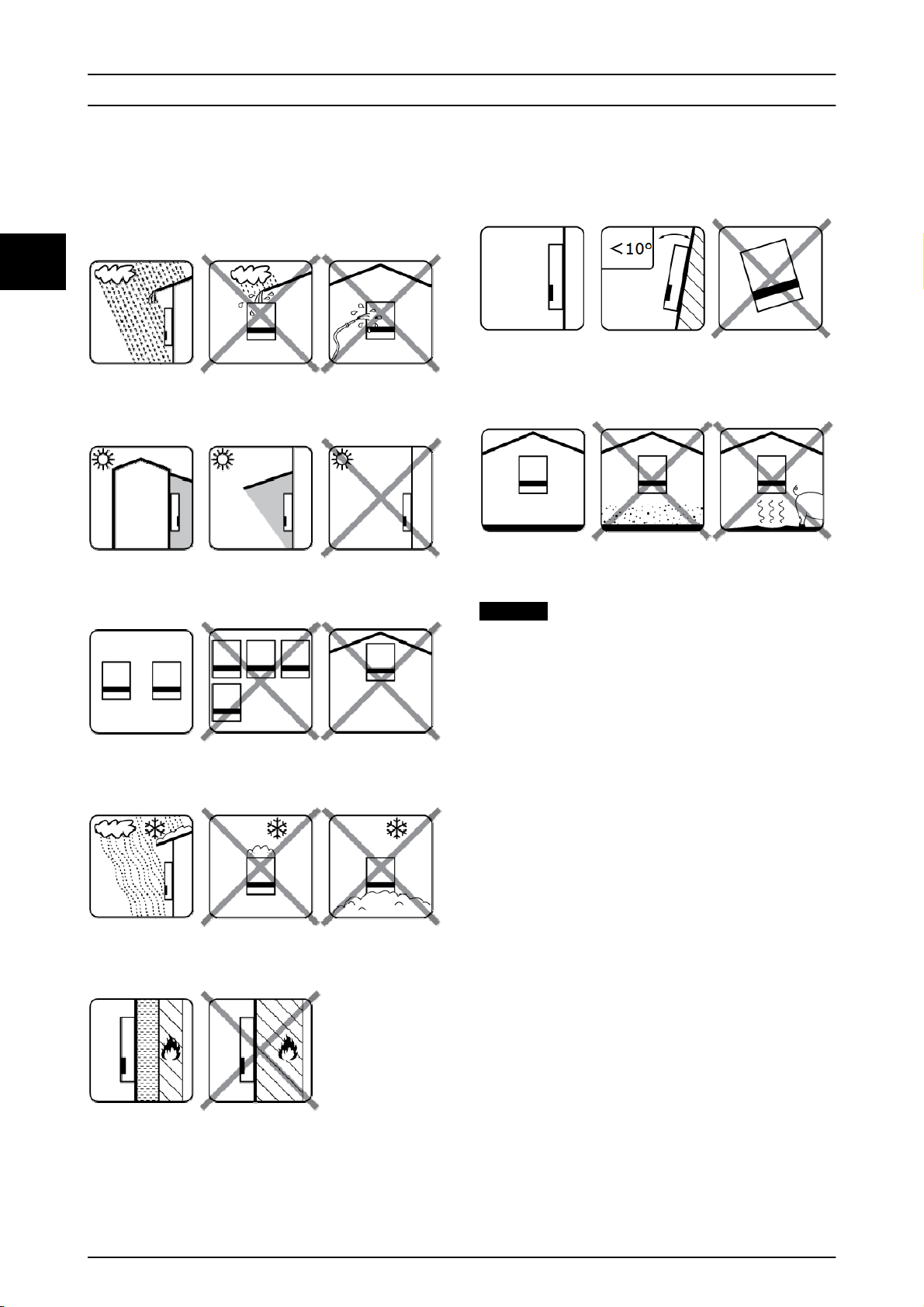

2.1 Environment and Clearances

Illustration 2.6 Mount Upright on Vertical Surface. Backwards

tilt of up to 10 degrees is permitted

Illustration 2.1 Avoid Constant Stream of Water

Illustration 2.2 Avoid Direct Sunlight

Illustration 2.3 Ensure Adequate Air Flow

Illustration 2.4 Ensure Adequate Air Flow

Illustration 2.7 Prevent Dust and Ammonia Gases

NOTICE

When planning the installation site, ensure that the

inverter product label and warning labels remain visible.

For details, refer to 5 Technical Data.

Illustration 2.5 Mount on Non-flammable Surface

12 L00410644-01_2q / Rev. date: 2014-06-02

Page 14

Installation

2

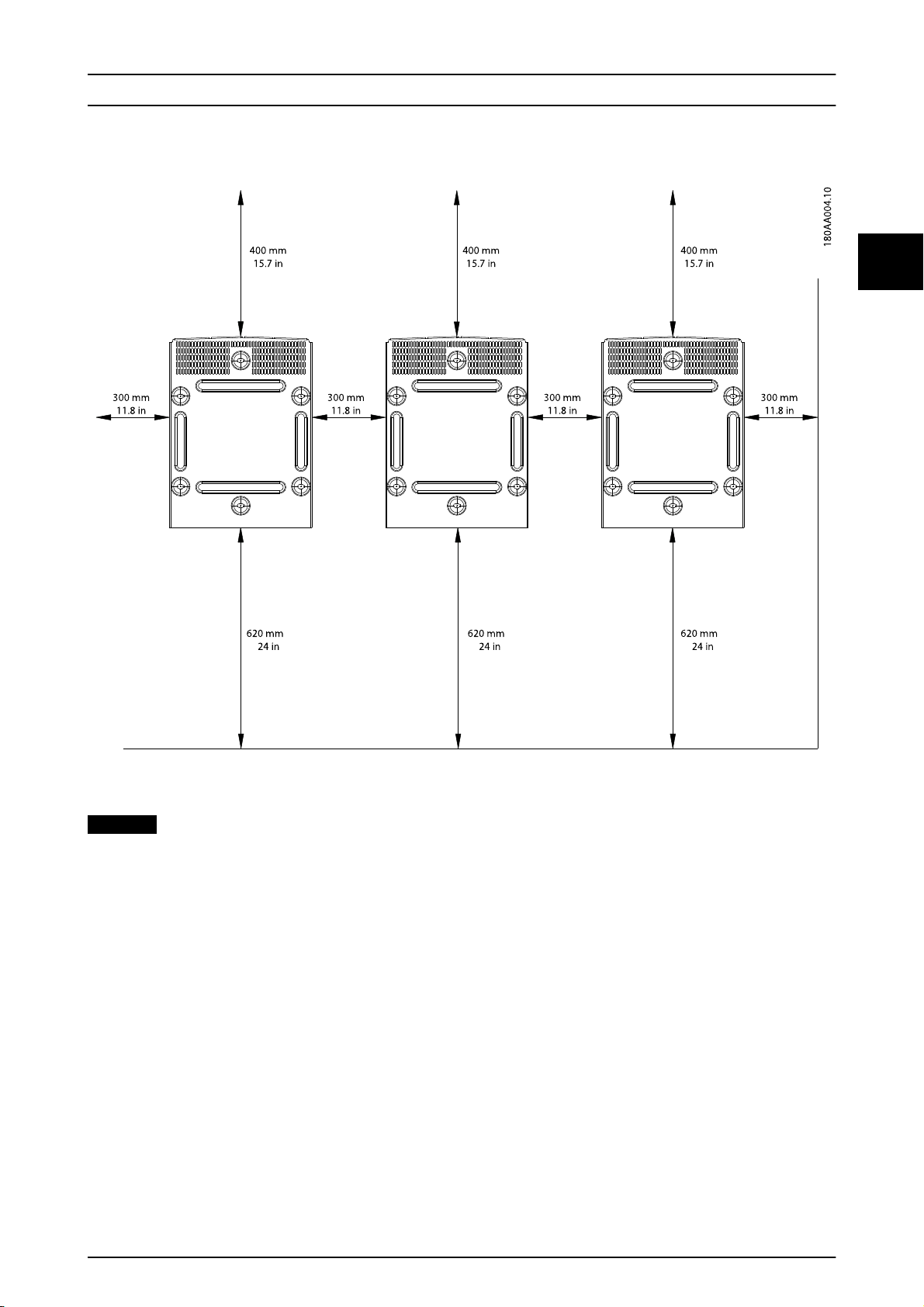

2.2 Mounting the Mounting Plate

2

Illustration 2.8 Safe Clearances

NOTICE

Ensure 620 mm / 24 in base clearance for adequate

airflow.

L00410644-01_2q / Rev. date: 2014-06-02 13

Page 15

2

Installation

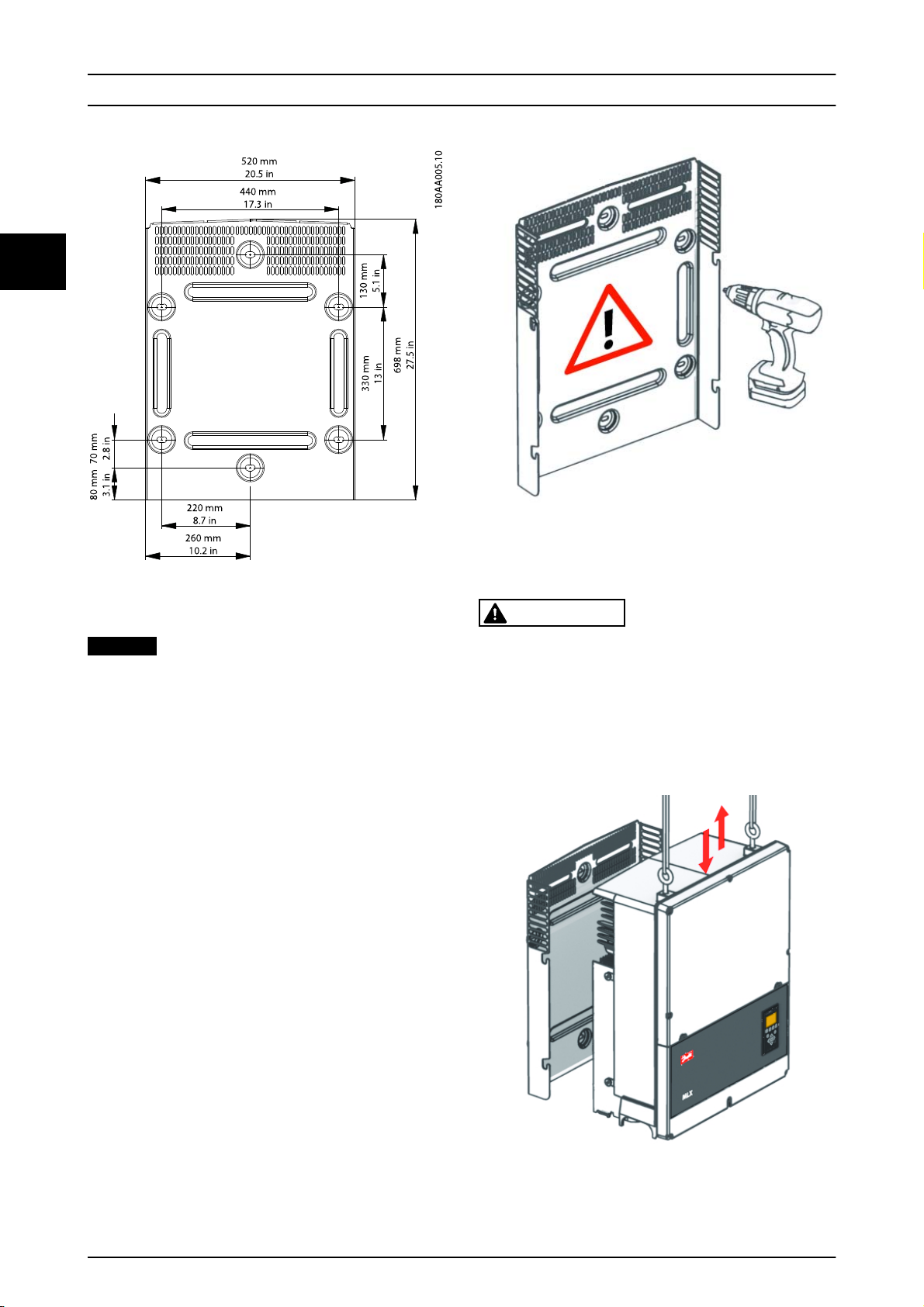

Illustration 2.10 Mounting the Mounting Plate

Illustration 2.9 Mounting Plate

NOTICE

Use of the mounting plate delivered with the inverter is

mandatory. If the inverter is mounted without the

mounting plate, the guarantee becomes void.

It is highly recommended to use all 6 mounting holes.

Mount the mounting plate:

Install in the defined environment.

•

Use screws and wall plugs that can safely carry

•

the weight of the inverter.

Ensure that the mounting plate is correctly

•

aligned.

Observe safe clearances when installing 1 or

•

more inverters, to ensure adequate airflow.

Clearances are specified in Illustration 2.8 and on

the mounting plate label.

Mounting multiple inverters in a single row is

•

recommended. Contact the supplier for

guidelines when mounting inverters in more than

1 row.

Ensure adequate clearance at the front, for safe

•

installation and service access to the inverter.

.

2.3 Mounting the Inverter

CAUTION

Refer to local health and safety regulations when

handling the inverter.

Procedure:

1. Lift the inverter. Locate the slots on the side of

the mounting plate. Use M12 or ½ in lifting bolts

and matching nuts (not part of delivery).

Illustration 2.11 Position the inverter

14 L00410644-01_2q / Rev. date: 2014-06-02

Page 16

Installation

2

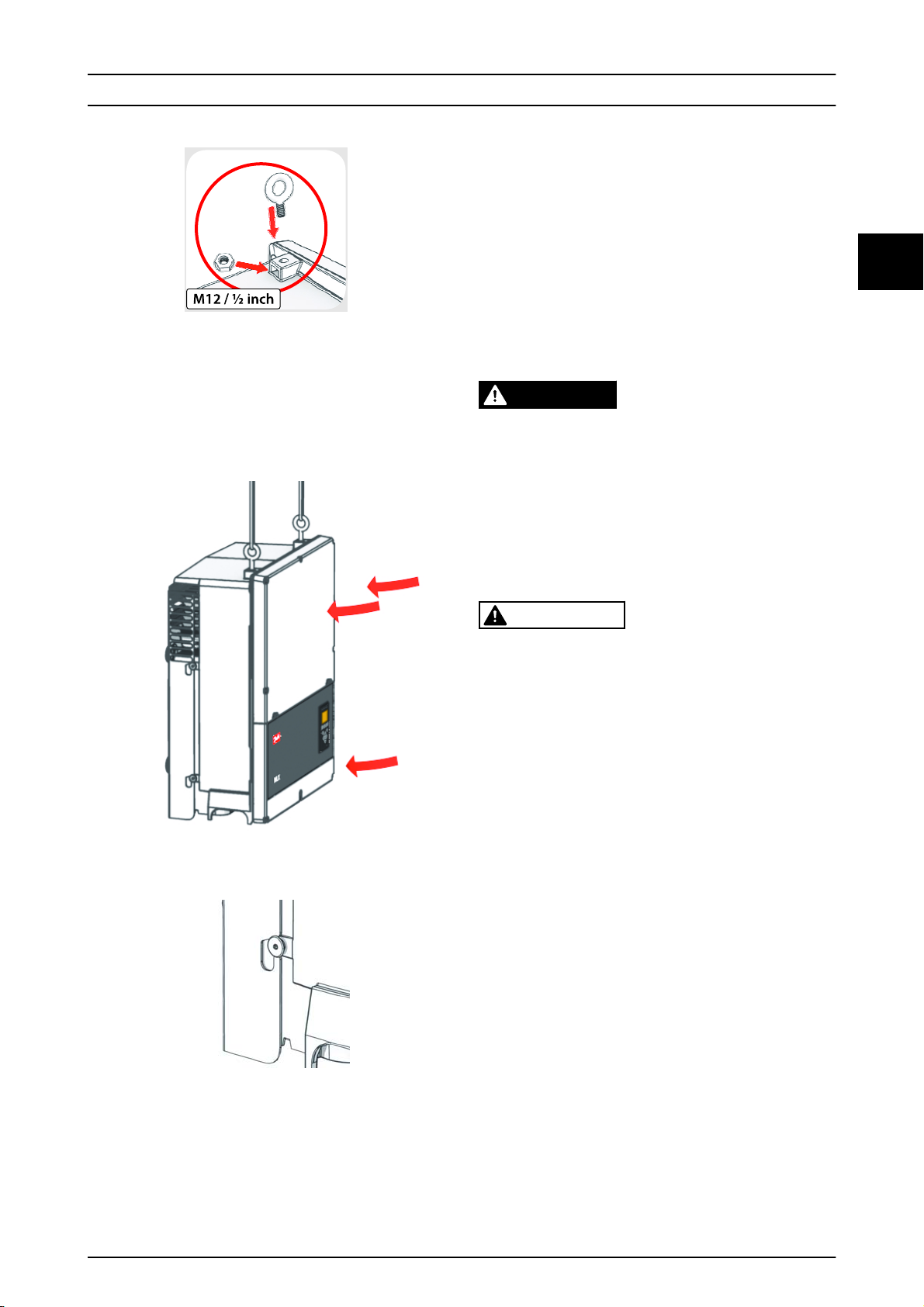

Illustration 2.12 Lifting Bolts

2. On the inverter, position the side screws against

the mounting plate slots.

3. Push the inverter as shown so the side screws

slide into the 2 lower slots and the 2 upper slots.

See Illustration 2.13 and Illustration 2.14.

2.4 Removing the Inverter

Procedure:

1. Perform removal in the reverse order of

mounting.

2. Lift the inverter.

3. Lift and slide the inverter out of the mounting

plate slots.

4. Lift the inverter free of the mounting plate.

2.5 Access to the Installation Area

DANGER

Before starting work on the inverter, switch off AC at the

mains switch and PV using the PV load switch. Ensure

that the inverter cannot be unintentionally reconnected.

Use a voltage tester to ensure that the unit is disconnected and voltage free. The inverter can still be charged

with very high voltage at hazardous levels even when it

is disconnected from AC grid and solar modules. Wait at

least 5 minutes following disconnection from grid and

PV panels before proceeding.

2

Illustration 2.13 Slide into Slots

CAUTION

Observe ESD safety regulations. Discharge any electrostatic charge by touching the grounded enclosure,

before handling any electronic component.

Procedure:

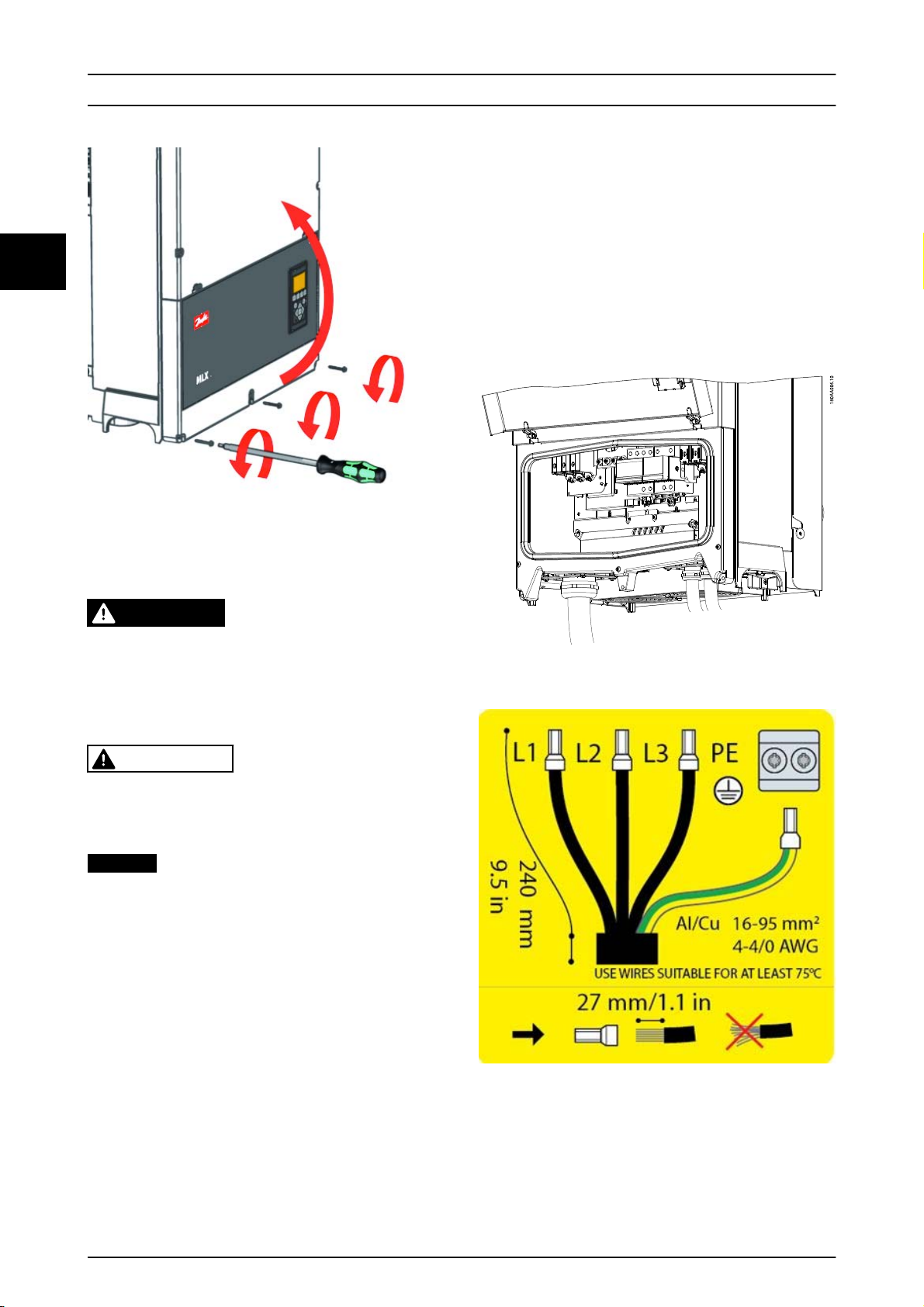

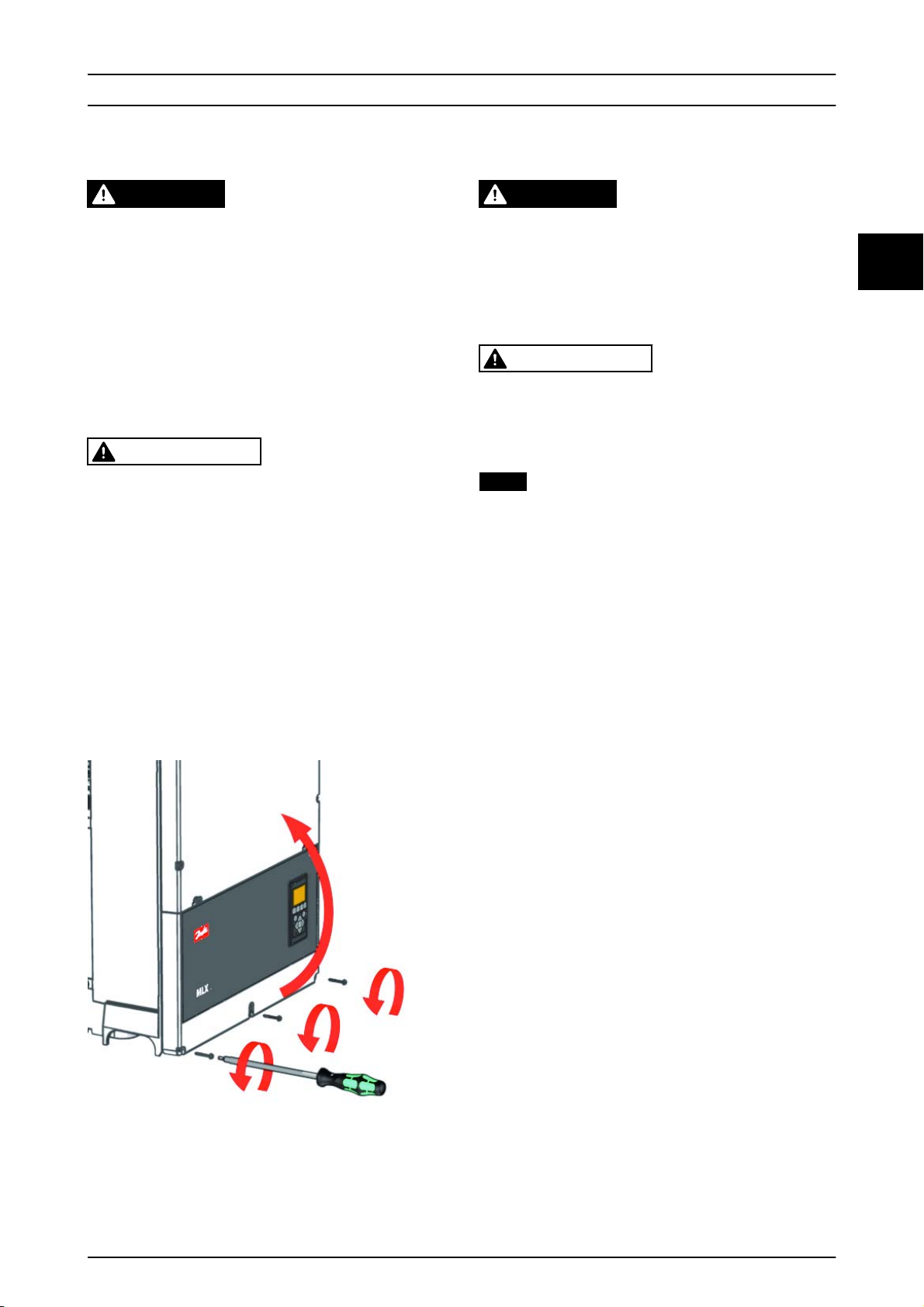

1. To open the cover, loosen the 3 lower front

screws using a TX 30 screwdriver. The screws are

captive screws and cannot fall out.

2.

Lift the cover 180°. A magnet holds the cover

open.

3. To close the cover, lower it into place and fasten

the 3 front screws.

Illustration 2.14 Detail of Sliding into Slot

4. Check that the 4 side screws sit securely in the

mounting plate slots.

5. Release the inverter.

L00410644-01_2q / Rev. date: 2014-06-02 15

Page 17

2

Installation

Insulation Resistance Detection

The inverter has a built-in Insulation Resistance Detection /

ISO circuit, which is certified according to the UL 1741 for

Non-Isolated EPS Interactive PV Inverters. The Insulation

Resistance Detector performs a measurement of the

connected PV system resistance to ground before the

inverter connects to the grid. If the resistance is below the

grid code set value, the inverter will wait and re-measure

the resistance after a short while. When the resistance is

above the grid code set value, the inverter performs a selftest and connects to the grid.

Illustration 2.15 Loosen Front Screws and Lift Cover

2.6 AC Grid Connection

DANGER

These instructions for AC grid connection are for

qualified personnel only. To reduce the risk of electric

shock, do not perform any servicing other than that

specified in the operating instructions unless you are

qualified to do so.

CAUTION

For fuse and RCD information, refer to 5 Technical Data.

AC fuse rating must not exceed the ampacity of the

conductors used.

NOTICE

Wiring methods used shall be in accordance with the

National Electric Code, ANSI/NFPA 70, and the Canadian

Electrical Code, Part I.

Always observe local regulations.

All installers must observe the relevant wiring methods.

IMI Detection

The inverter has built-in IMI/RCMU (Insulation Monitoring

Interrupter / Residual Current Monitoring Unit). Certification is according to the UL 1741 for Non-Isolated EPS

Interactive PV Inverters. The IMI/RCMU circuit is 100%

single fault immune. It acts on a continuous ground fault

current and a sudden change in the ground fault current.

This functionality is running during normal operation.

Illustration 2.16 Installation Area

Illustration 2.17 AC Cable Wire Strip

The MLX inverter must only be connected to a 3-phase

grid.

16 L00410644-01_2q / Rev. date: 2014-06-02

Page 18

Installation

2

On the AC cable, strip insulation on all 4 wires. The

protective earth wire (PE) must be longer than the mains

wires. See Illustration 2.17.

1. Verify that the inverter rating matches the grid.

2. Ensure that main circuit breaker is released, and

take precautions to prevent connection.

3. Open the front cover.

4. Insert the cable through the AC gland to the

terminal blocks.

5. Connect the 3 mains wires (L1, L2, L3) and the PE

wire to the terminal block with the respective

markings. The PE wire is marked with the symbol

shown in Illustration 2.18.

6. Optional: Make an extra PE connection at the

secondary PE earthing points using the external

equipment grounding bolt delivered with the

inverter. See Illustration 5.2.

7. All wires must be properly fastened with the

correct torque. See 5.5 Torque Specifications.

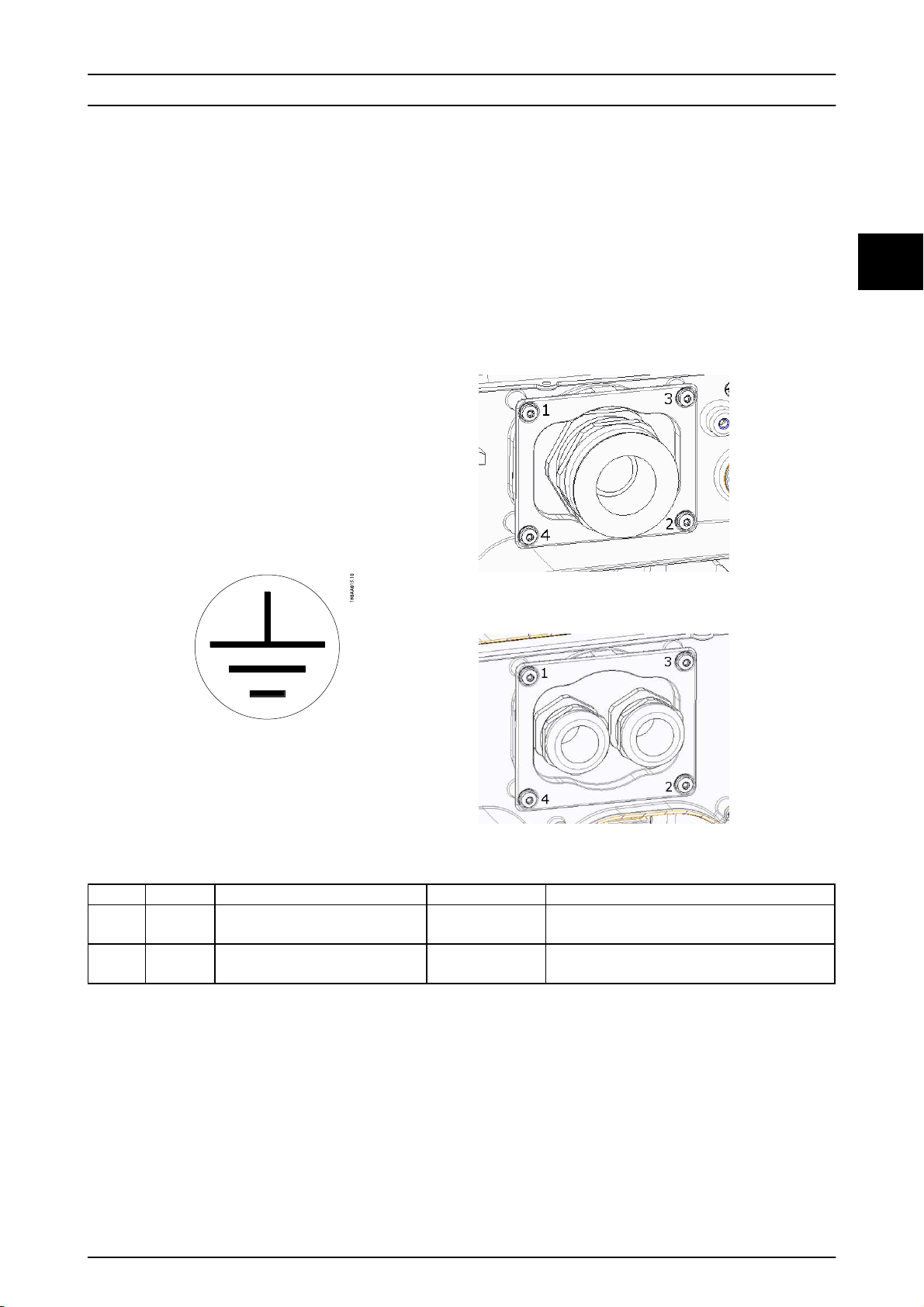

2.7 Cable Entry

Options for cable entry

Cable glands (premounted), or

•

2-inch conduit adapters (supplied in accessories

•

bag)

If changing to the 2-inch conduit adapters, ensure to

tighten the screws in the order shown in Illustration 2.19

and Illustration 2.20. First tighten all screws with 0.75 Nm

(6.5 in-lbf) and then 1.5 Nm (13 in-lbf).

Illustration 2.19 AC Mounting Bracket

2

Illustration 2.18 Protective Earth Symbol

Terminal

AC

PV

Table 2.1 Acceptable Conductor Sizes

1)

Always observe current capacity of cables used.

1)

Range

16-95 mm

6-4/0 AWG

16-95 mm

6-4/0 AWG

Max. conductor temperature rating Conductor material Cable jacket diameter with supplied cable gland

2

90 ºC Al/Cu 37-44 mm

2

90 ºC Al/Cu 14-21 mm

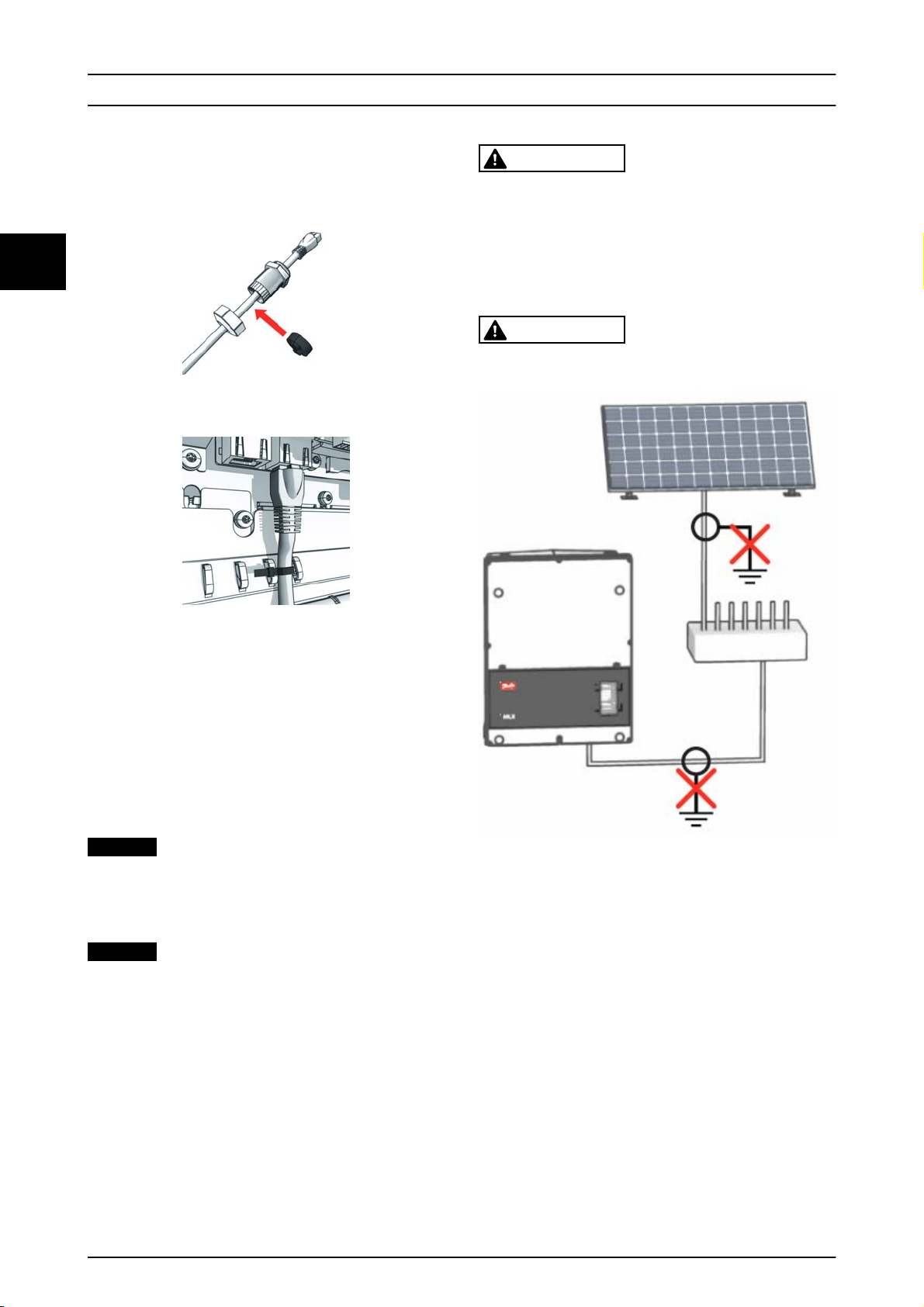

2.8 Ethernet Connections

Before connecting Ethernet cables, refer to the

requirements in 5.8 Ethernet Connections.

Illustration 2.20 DC Mounting Bracket

Procedure:

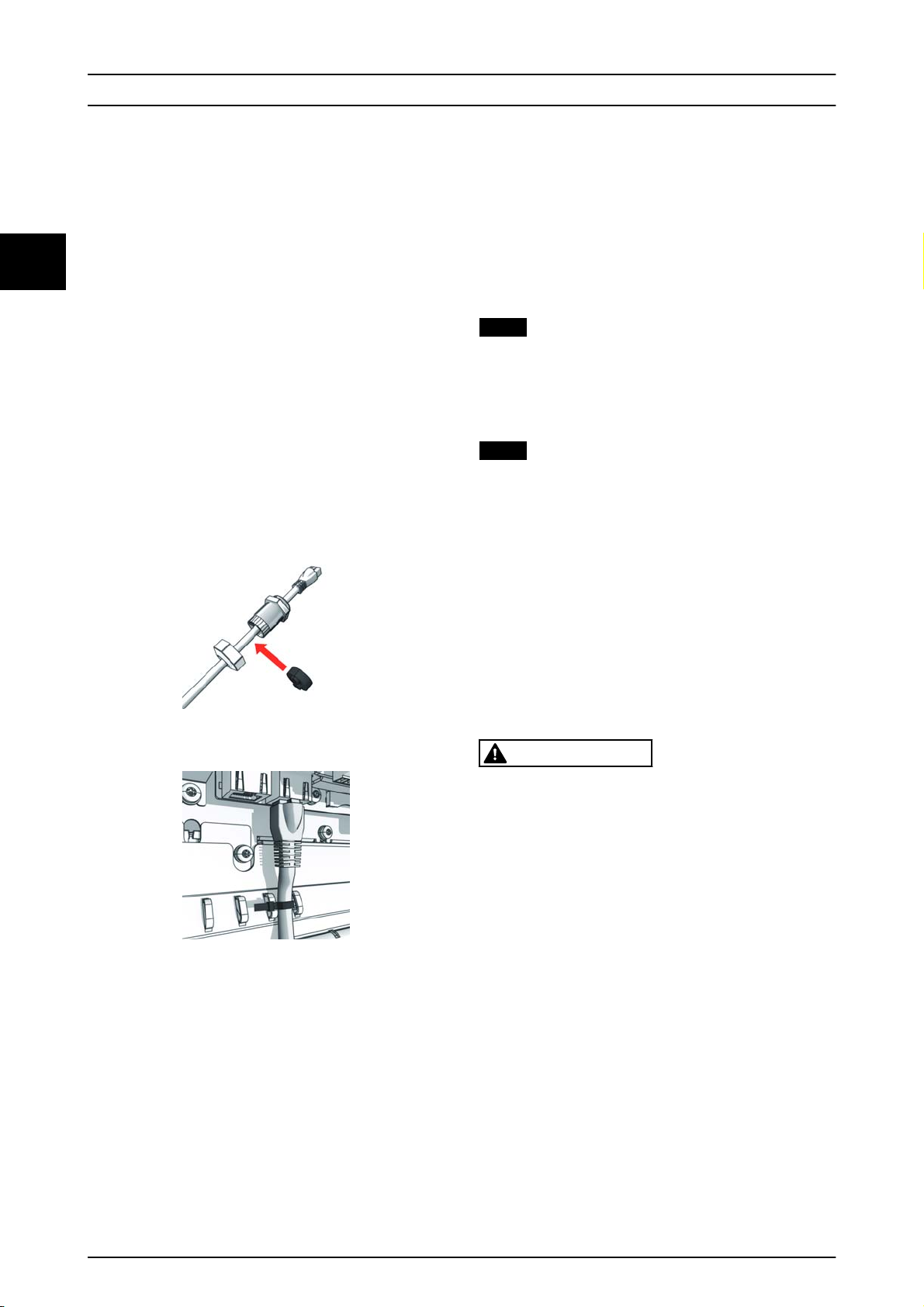

1. Do not remove the RJ-45 connector on the

Ethernet cable.

2. Run the cables through the base of the inverter

via cable glands. See Illustration 2.21.

3. Cut slice in rubber grummet. Place the grummet

in the gland to ensure proper seal.

4. Plug into the Ethernet connector.

L00410644-01_2q / Rev. date: 2014-06-02 17

Page 19

Installation

2

5. Fasten cables with cable ties to ensure a durable

connection over time. See Illustration 2.22.

Illustration 2.21 Run Cables Through Cable Glands

CAUTION

PV array is floating, with both the (+) and (-) conductors

connected to the inverters' PV inputs. Neither conductor

is to be connected to earth.

A DC load switch on either the DC combiner or inverter

(optional) for safe disconnect of DC power to inverter is

required.

CAUTION

Do NOT connect PV to earth!

Illustration 2.22 Fasten with Cable Ties

2.9 PV Connection

2.9.1 External String Combiners

PV strings must be connected to the DC input via an

external string combiner. The purpose of the string

combiner is to combine the PV strings from the PV array

and secure the individual strings against overcurrent.

NOTICE

It is essential that all PV strings connected to the DC

combiner are even in number and type of modules and

tilt and orientation.

NOTICE

Observe correct fuse rating. Consult module manufacturers' manuals for information on correct string fuse

rating.

Use a suitable voltmeter that can measure up to 1000 V

DC. Verify the polarity and maximum voltage of the PV

arrays by measuring the PV open-circuit voltage. The

inverter is protected against reversed polarity and will not

generate power until the polarity is correct.

Illustration 2.23 Do Not Connect PV to Earth

The combined output from the DC combiner must be

connected to the DC input of the MLX inverter.

18 L00410644-01_2q / Rev. date: 2014-06-02

Page 20

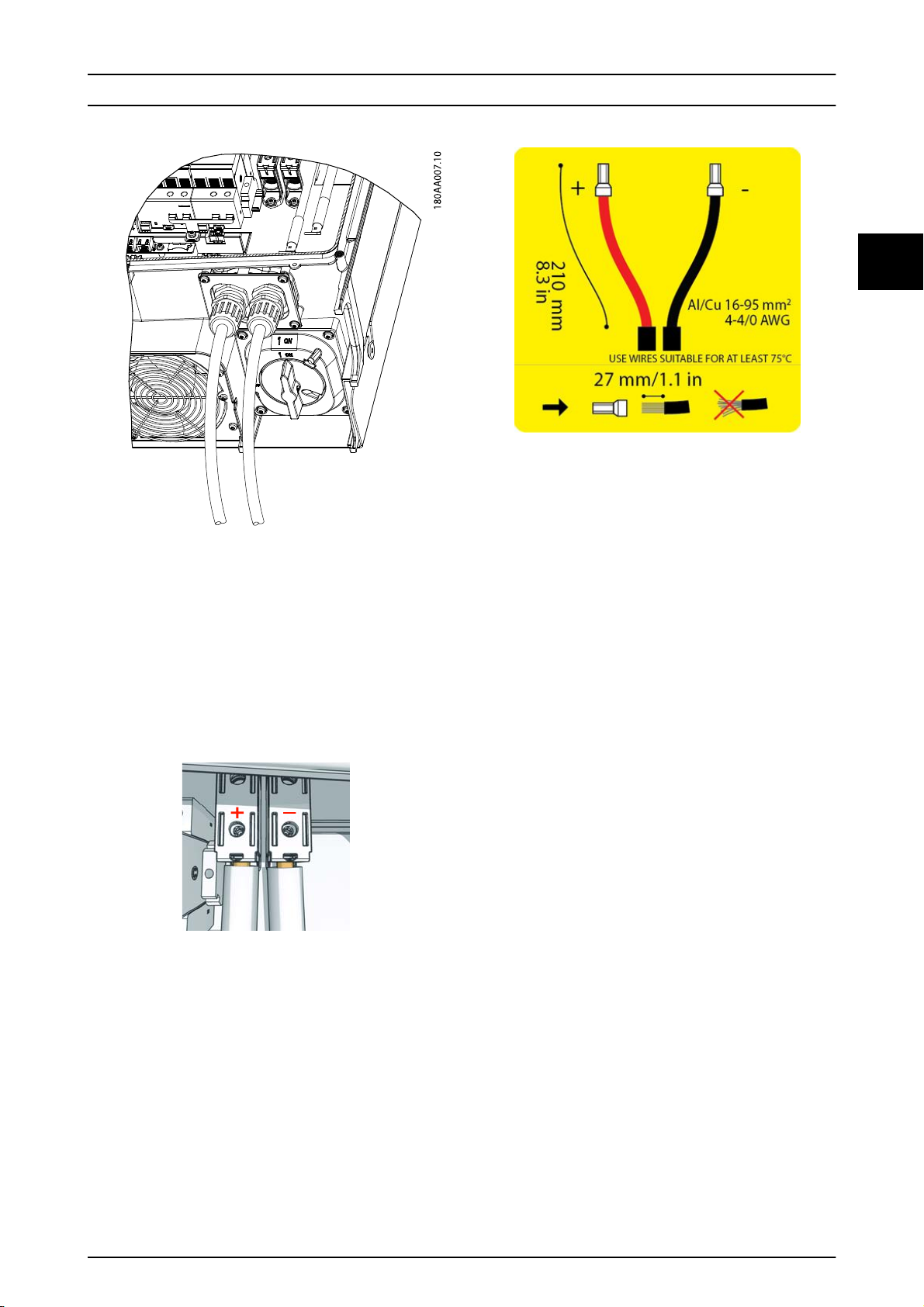

Installation

2

2

Illustration 2.26 DC Label

2.10 Closure

Illustration 2.24 DC Connection Area

1. On the inverter or string combiner turn the PV

load switch into off position.

2. Connect the PV cables from the external string

combiner to the inverter. Ensure correct polarity,

see Illustration 2.25.

3. All wires must be properly fastened with the

correct torque. See 5.5 Torque Specifications.

Illustration 2.25 Connect to PV Input

1. Close the cover of the inverter installation area.

Fasten the 3 front screws. See 5.5 Torque Specifi-

cations.

2. Turn on AC power.

L00410644-01_2q / Rev. date: 2014-06-02 19

Page 21

Initial Setup and Start

3 Initial Setup and Start

3

3.1 User Interface

The user interface comprises:

Local display, for all inverter variants. The local

•

display enables read-only status information of

the inverter. It is not possible to configure or set

up the MLX inverter via the display. The ‘#’ in the

display explains the operation modes.

Local Commissioning and Service Tool (LCS Tool).

•

The LCS Tool enables configuration of 1 or

multiple MLX inverters.

3.1.1 Operation Modes

The inverter has 5 operation modes, indicated by LEDs.

Status LEDs

Green

Off grid

Connecting

On grid

Internal inverter event

Fail safe

- - - - - - - - - - - - - - - - -

Red

- - - - - - - - - - - - - - - - -

Green

▬██▬██▬██▬██▬██▬

Red

- - - - - - - - - - - - - - - - -

Green

Red

Green

Red

Green

Red

██████████████████

▬

- - - - - - - - - - - - - - - - -

▬██▬██▬██▬██▬██▬

- - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - -

▬██▬██▬██▬██▬██▬

▬

On grid (Green LED on)

#60.

The inverter is connected to the grid and energises the

grid. The inverter disconnects when:

it detects abnormal grid conditions (dependent

•

on grid code), or

an internal event occurs, or

•

PV power is insufficient (no power is supplied to

•

the grid for 10 minutes).

The inverter then enters connecting mode or off grid

mode.

Internal Inverter Event (Green LED flashing)

#54.

The inverter is waiting for an internal condition to be

within limits (for example a too high temperature) before

it will go back on grid.

Fail Safe (Red LED flashing)

#70.

If the inverter detects an error in its circuits during the selftest (in connecting mode) or during operation, the inverter

goes into fail safe mode, disconnecting from grid. The

inverter will remain in fail safe mode until power has been

absent for a minimum of 10 minutes, or the inverter has

been shut down completely (AC+PV).

3.2 Display

Table 3.1 Operation Modes

Off grid (standby) (LEDs off)

#0-51.

When no power has been delivered to the AC grid for

more than 10 minutes, the inverter disconnects from the

grid and shuts down. User and communication interfaces

remain powered for communication purposes.

Connecting (Green LED flashing)

#52-53.

The inverter starts up when the PV input voltage reaches

the minimum DC feed-in voltage. The inverter performs a

series of internal self-tests, including measurement of the

resistance between the PV arrays and earth. Meanwhile, it

also monitors the grid parameters. When the grid

parameters have been within the specifications for the

required amount of time (depends on grid code), the

inverter starts to energise the grid.

NOTICE

It can take up to 10 sec. until the display activates, after

power up.

The integrated display on the inverter front gives the user

access to information about the PV system and the

inverter.

20 L00410644-01_2q / Rev. date: 2014-06-02

Page 22

Initial Setup and Start

3

Illustration 3.1 Overview of Display Buttons and Functionality

Key Function

Adjust contrast level of display. Use

F1

F2

F3

F4

Home

OK

Arrow Up

Arrow Down

Arrow Right

Arrow Left

Back

On - Green LED

Alarm - Red LED

arrow up/down button while holding

down the F1 button.

Not in use

Return to main screen

Not in use

A step up

A step down

Toggles screen right

Toggles screen left

Return to main screen

IP address

•

Inverter Manager MAC address

•

Inverter software version

•

3.

Actual values. This section contains:

PV voltage and current

•

Phase-to-phase voltages

•

Phase currents

•

Grid frequency

•

3.2.1 Initial Setup via LCS Tool

The LCS Tool makes it possible to chose from a list of

predefined settings for different grids. All grid-specific

limits must be configured using the LCS Tool.

After installation, check all cables and close the inverter.

Turn on AC power.

WARNING

Correct selection of grid code is essential to comply with

local and national standards.

3.2.2 Turn PV Load Switch On

3

Table 3.2 Overview of Display Buttons and Functionality

The screen structure is divided into 3 sections:

1.

Main screen. Current and daily production. This

section contains:

Actual power output (kW)

•

Energy counter current day (kWh)

•

Total energy counter (kWh)

•

Current date

•

Current time

•

Operation mode (#)

•

2.

Inverter information. This section contains:

Inverter type

•

Inverter name

•

Serial no.

•

L00410644-01_2q / Rev. date: 2014-06-02 21

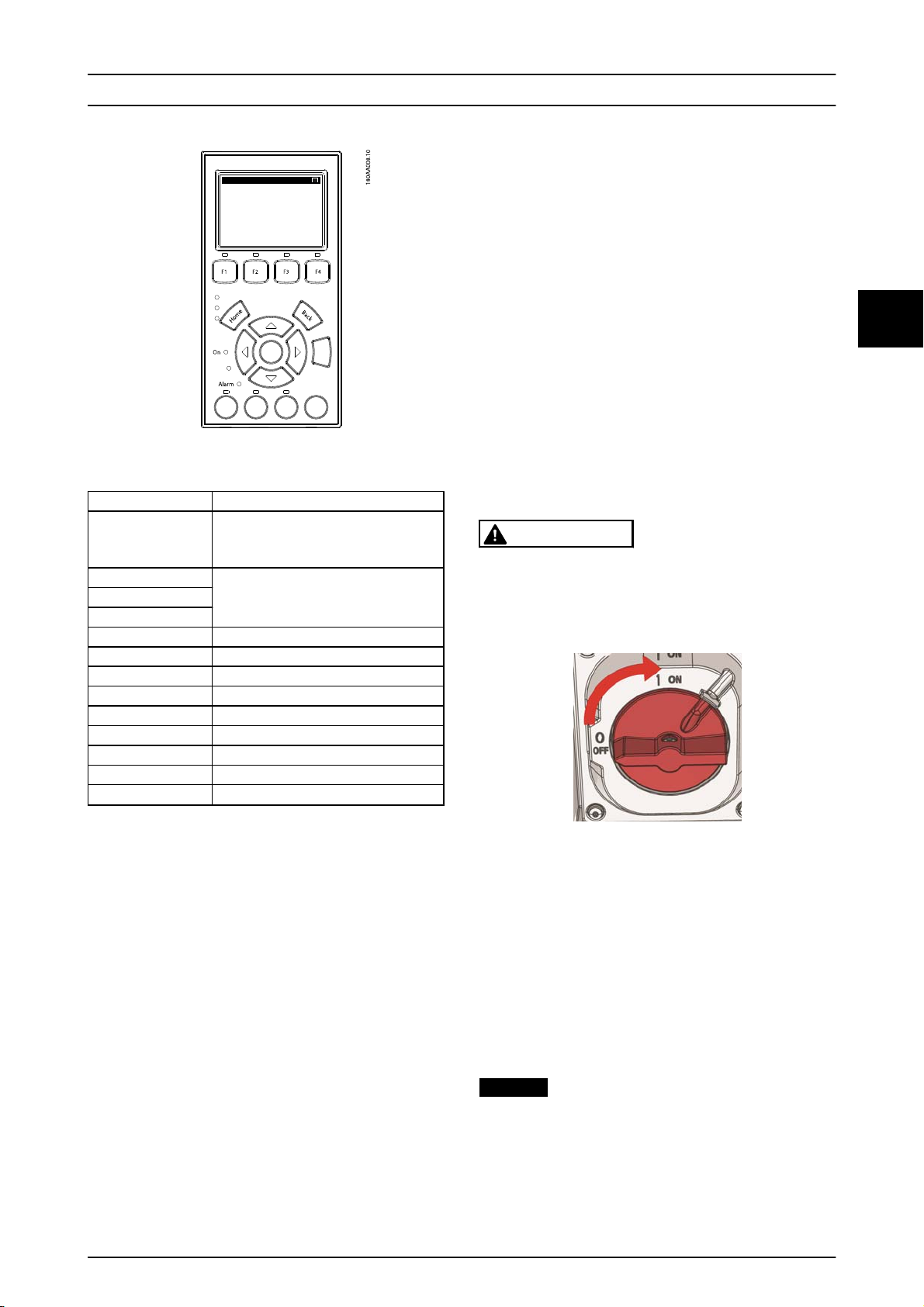

Illustration 3.2 PV Load Switch

Turn PV load switch on, either via inverter or string

combiner.

3.2.3 Start-up

The inverter starts automatically if sufficient solar

irradiation is available. The start-up takes a few minutes.

During this period, the inverter performs a self-test

procedure.

NOTICE

The inverter is protected against reversed polarity. The

inverter does not generate power until any reversed

polarity is corrected.

Page 23

3

Initial Setup and Start

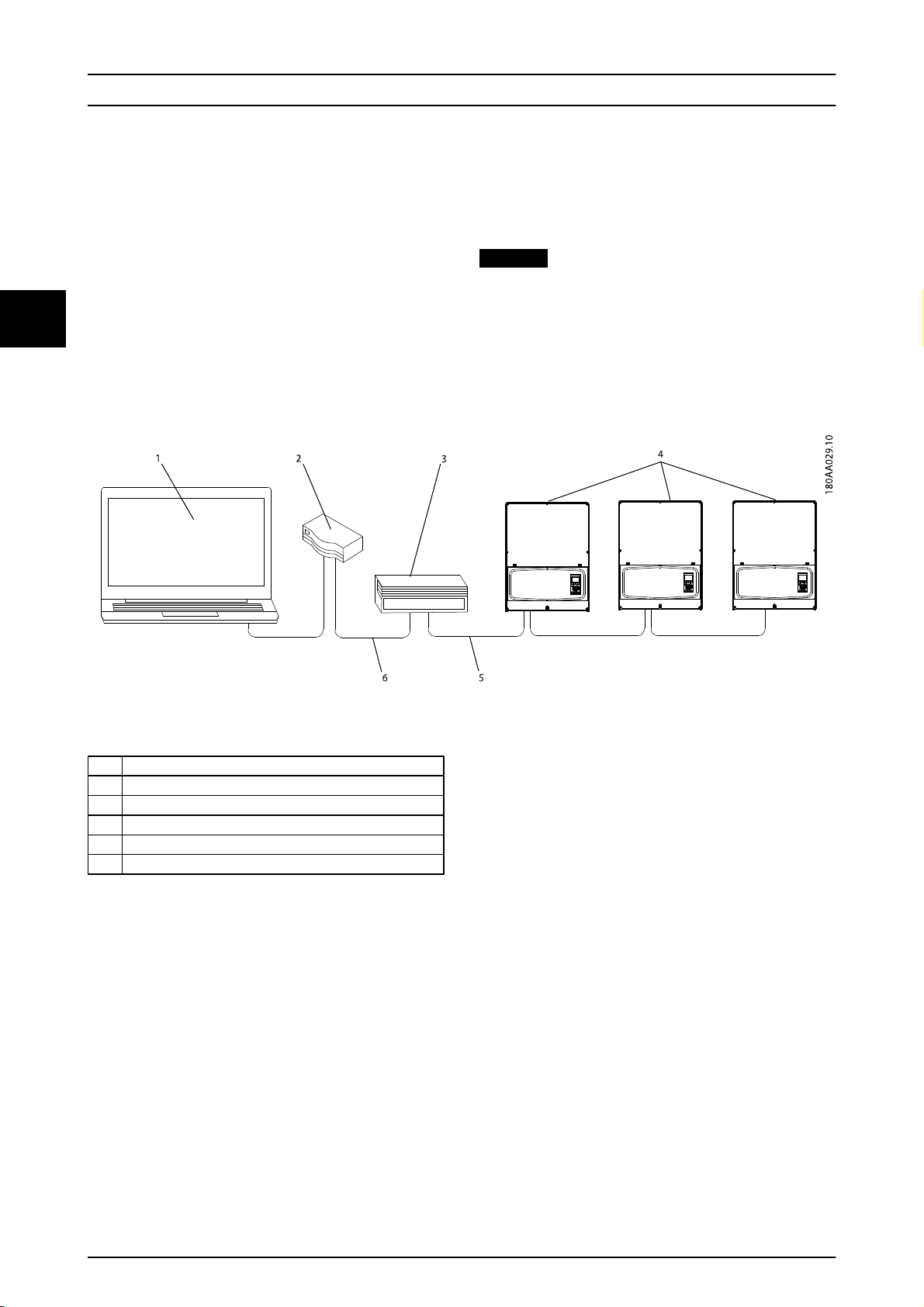

3.3 LCS Tool

The MLX inverters and Inverter Managers must be commissioned via the Local Commissioning and Service Tool (LCS

Tool). Commissioning is required before the MLX inverters

can connect to the AC grid and start to convert power.

The LCS Tool is available from the download area at

www.sma.de.

The hardware requirements for the LCS Tool are:

PC running WindowsTM 7 and onwards

•

150 Mb HDD

•

2 Gb RAM

•

The LCS Tool must be installed on a local PC drive. The PC

must be connected to the Inverter Manager’s LAN 1 port

via Ethernet.

NOTICE

The Inverter Manager must have an IP address assigned

by a DHCP server on the LAN 1 port.

It is important that the PC running the LCS Tool is

connected to the same IP subnet as the Inverter

Manager.

Port LAN 2 is intended for MLX inverters exclusively.

Illustration 3.3 Commissioning of Inverters Using LCS Tool

1 LCS Tool

2Router/DHCP

3MLX Inverter Manager

4MLX inverter

5LAN 2

6LAN 1

3.3.1 Getting Started

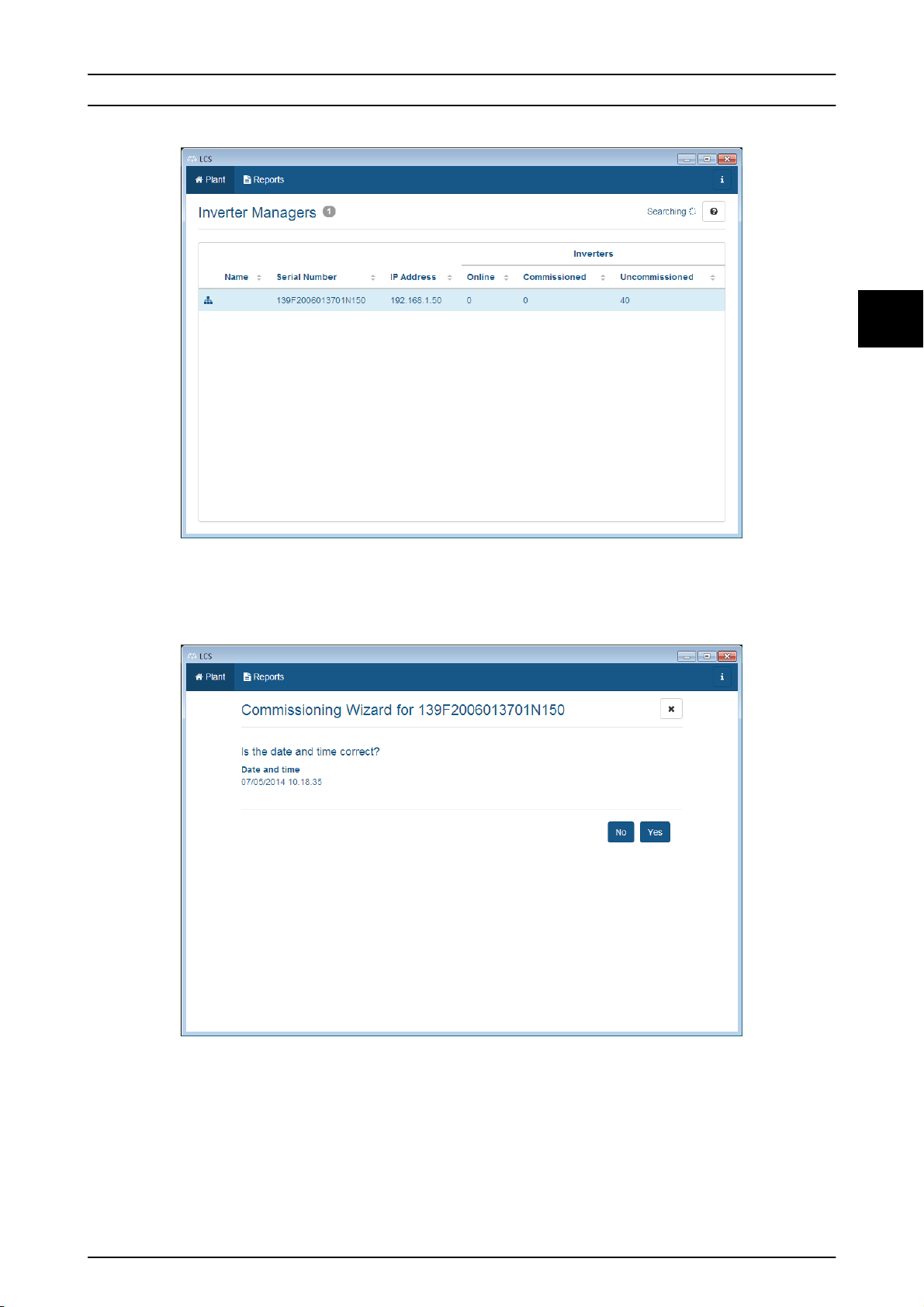

1. Start up the LCS Tool. The tool displays a list of

all identified Inverter Managers. It can take

several minutes before the LCS Tool has

identified all Inverter Managers.

2. The screen now shows a list of all Inverter

Managers (see Illustration 3.4). To start the wizard,

click the Inverter Manager to be configured. By

clicking the Inverter Manager, the inverter(s)

discovered by the Inverter Manager are displayed.

Uncommissioned inverters (no grid code

assigned) are presented with a blue square

together with their software version.

22 L00410644-01_2q / Rev. date: 2014-06-02

Page 24

Initial Setup and Start

3

3

Illustration 3.4 LCS Tool - Initial Screen

3. Verify that date and time are correct. If not, set

date and time and continue. See Illustration 3.5.

Illustration 3.5 LCS Tool - Verify Date and Time

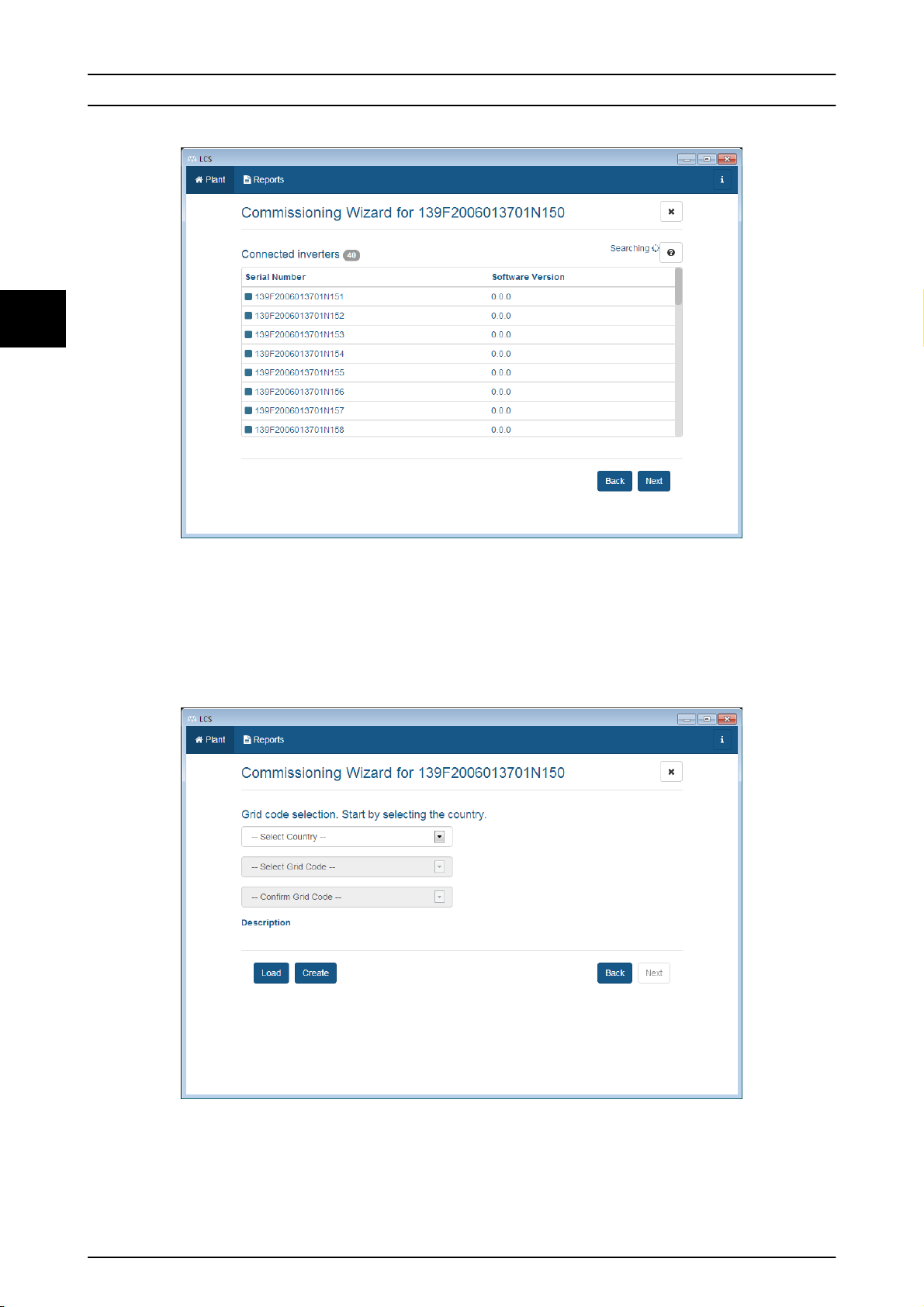

4. A list of inverters identified by the selected

Inverter Manager is shown. See Illustration 3.6.

Verify that the list of inverters is complete.

Verify that all inverters are present. It is possible

to continue the configuration of the listed

L00410644-01_2q / Rev. date: 2014-06-02 23

inverters even if not all inverters are discovered.

The undiscovered inverters can always be

configured later.

Page 25

3

Initial Setup and Start

Illustration 3.6 LCS Tool - List of Connected Inverters

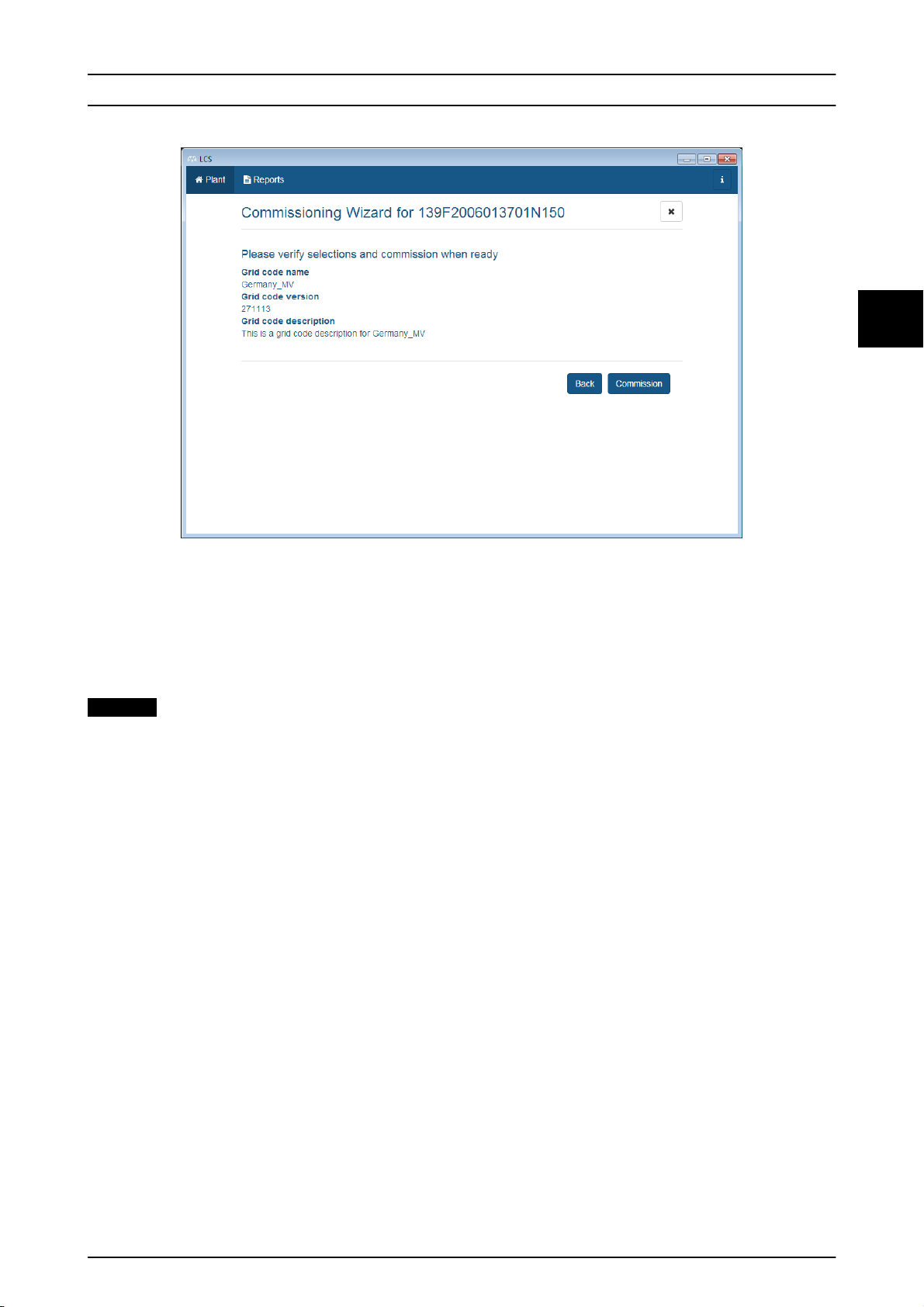

5. Select the desired country from the list of options

available for the inverters in the network. See

Illustration 3.7.

6. Select the desired grid code from the list of

options available for the selected country. If

needed, load a custom grid code by clicking the

‘Load’ button. See Illustration 3.7. The ‘Create’

button is inactive and cannot be used.

Illustration 3.7 LCS Tool - Select Country and Grid Code

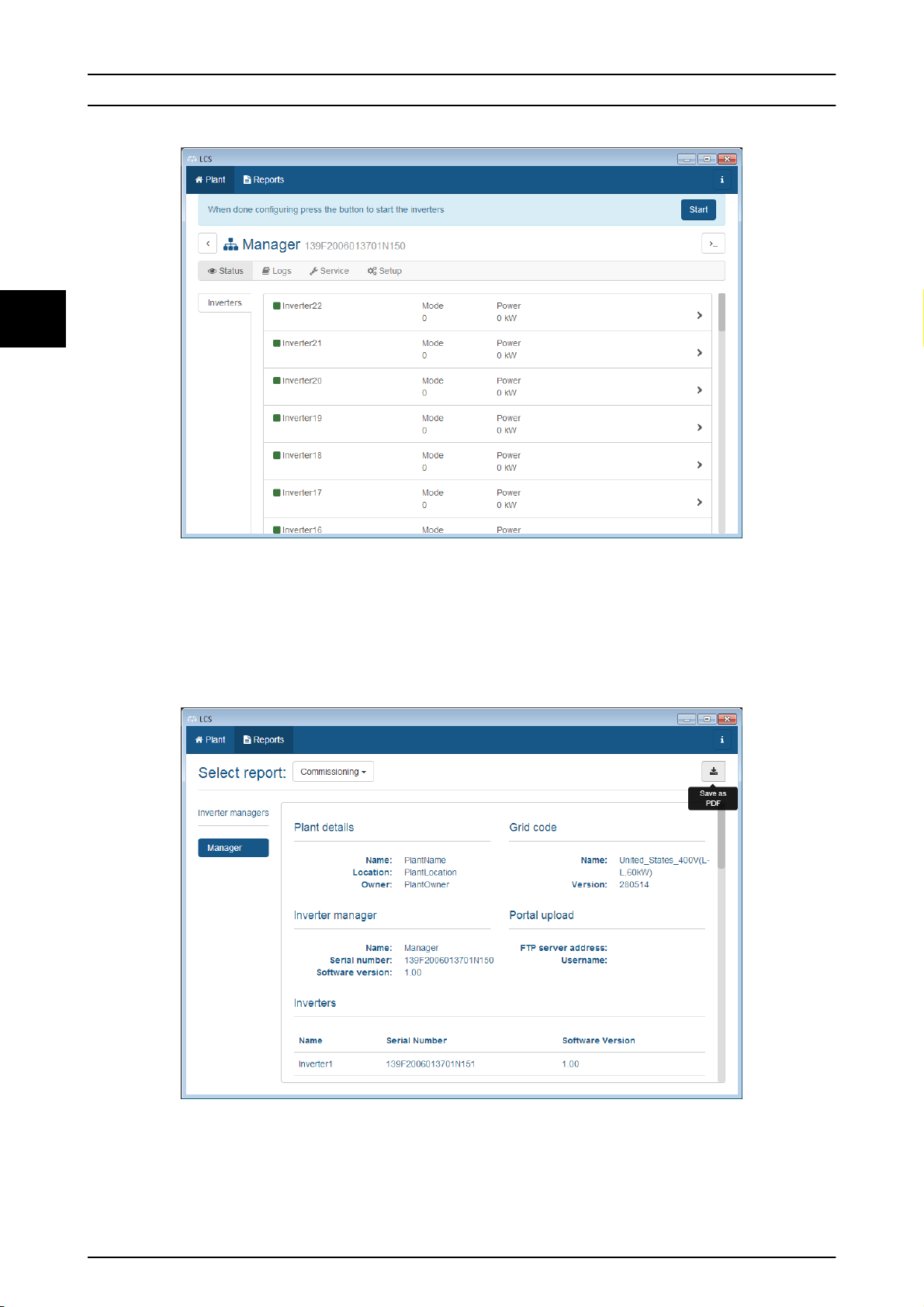

7. The LCS Tool prompts for a confirmation of the

selected country and grid code. See

24 L00410644-01_2q / Rev. date: 2014-06-02

Illustration 3.8. Incorrect configuration can be

changed using the ‘Back’ button and changing

the settings in the previous windows.

Page 26

Initial Setup and Start

3

3

Illustration 3.8 LCS Tool - Verification of Country and Grid Code

8. The system now applies the selected grid code to

the Inverter Manager and the discovered

inverters. Any inverter added at a later stage

automatically inherits the same grid code. Only 1

grid code per Inverter Manager is possible.

NOTICE

It is essential to choose the correct grid code. The grid

code cannot be changed afterwards without contacting

SMA.

9. A green square identifies the commissioned

inverters. However, the inverters do not connect

to grid before a ‘Start’ command is issued from

the bar below the top menu. See Illustration 3.9.

L00410644-01_2q / Rev. date: 2014-06-02 25

Page 27

3

Initial Setup and Start

Illustration 3.9 LCS Tool - List of all Inverters Connected to the Inverter Manager

10. If sufficient PV power is present and the grid

code conditions are met, the inverters connect to

the grid.

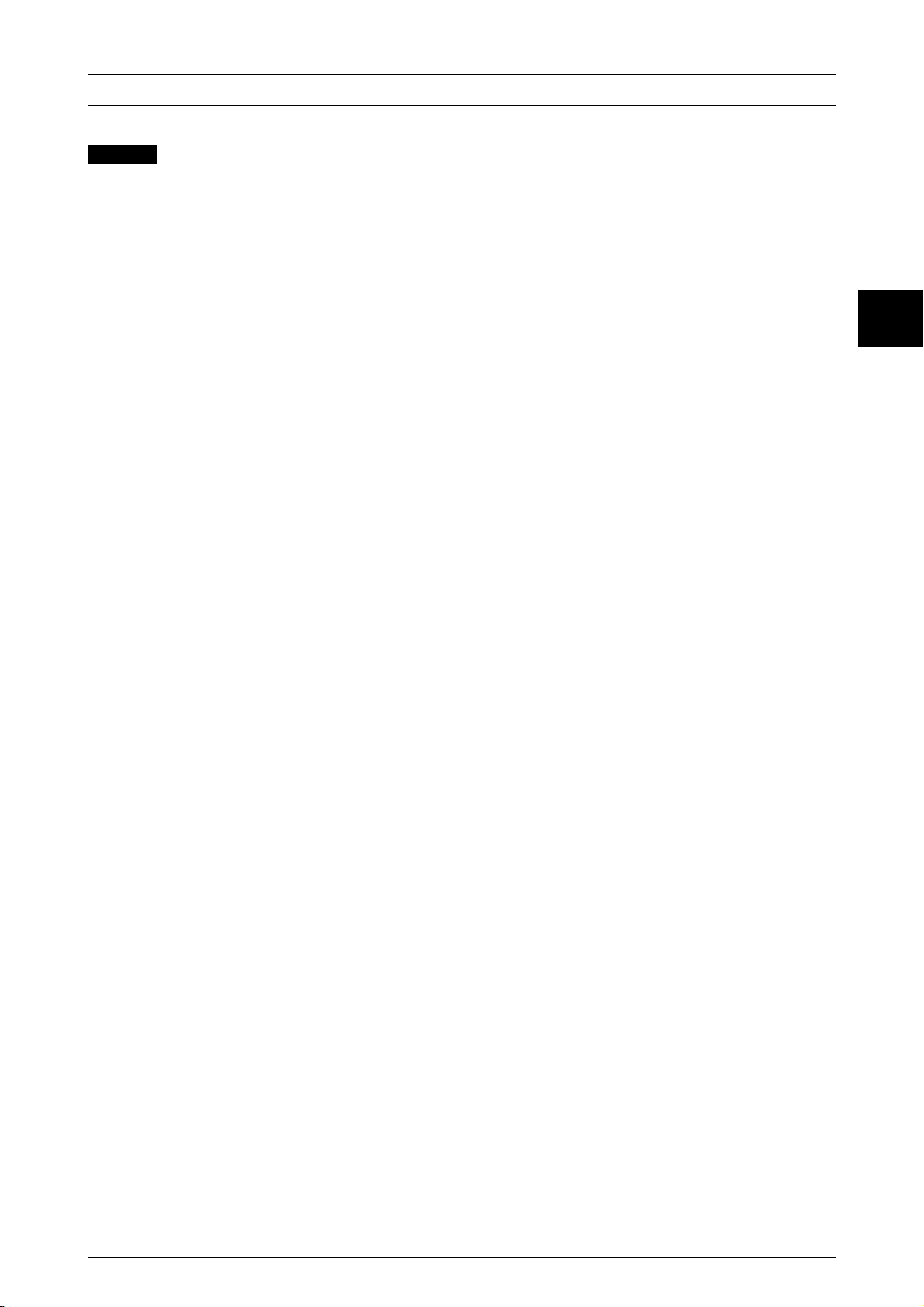

11. Upon commissioning, it is possible to download a

commissioning report under the menu ‘Reports’.

The report contains all information about inverter

settings, including actual disconnect values for

each inverter. See Illustration 3.10.

Illustration 3.10 LCS Tool - Commissioning Report

26 L00410644-01_2q / Rev. date: 2014-06-02

Page 28

Initial Setup and Start

3

NOTICE

If the desired grid code is not available, or if the LCS

Tool warns about incompatible software versions, the

grid code and software library must be updated on the

LCS Tool.

For utility-interactive inverters, field adjustable trip limits

and trip times can be altered from default settings. See

5.2 Trip Settings. After user registration and authorisation,

authorised service personnel can generate new grid code

settings at www.sma.de. The new grid code settings can be

downloaded as a file and applied to the MLX inverters via

the LCS Tool. These grid code files are encoded and can

only be used for the particular installation.

3

L00410644-01_2q / Rev. date: 2014-06-02 27

Page 29

Service

4Service

4.1 Troubleshooting

The information is organised in tables showing messages

appearing in the LCS Tool, known as events. The tables

contain descriptions of events as well as explanations of

which actions to take when an event occurs.

4

Event Type

ID

Display

Description

Action

DNO

Hotline

PV

Indicates whether the event relates to grid, PV, internal or fail safe issues.

The specific event ID.

Text shown in display.

Description of the event.

Description of which action to take prior to contacting any other parties.

If the prescribed action has not identified the malfunction, contact the DNO for further assistance.

If the prescribed action has not identified the malfunction, contact the inverter hotline for further assistance.

If the prescribed action has not identified the malfunction, contact the PV supplier for further assistance.

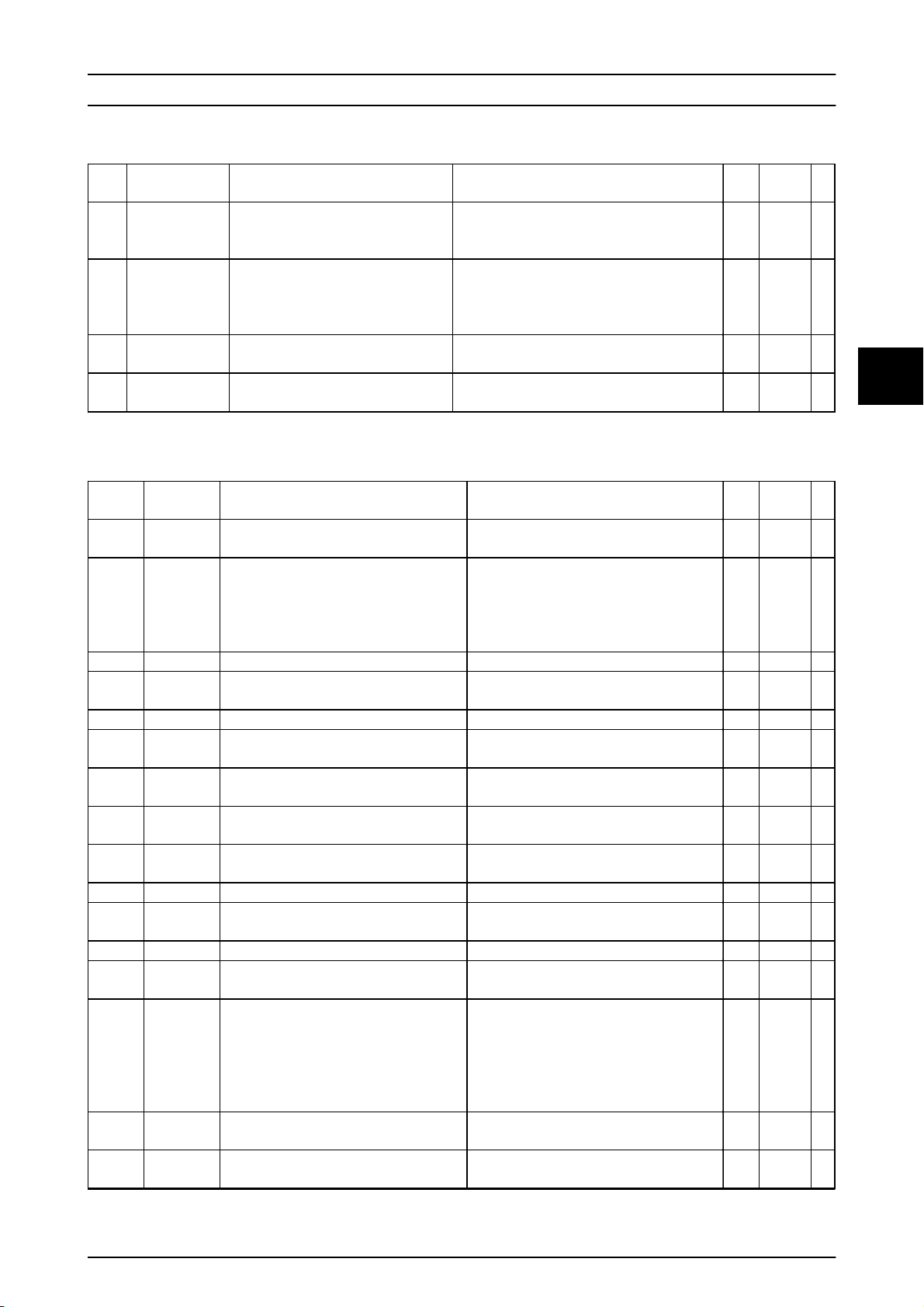

Grid-related Events

ID Status

Description Action DNO Hotline PV

message

1–6 Grid voltage too low. Check voltage and AC installation. If the voltage is

zero, check the fuses.

7–9 Grid voltage average over 10 minutes

too high.

10–15 Grid voltage too high. Check voltage and AC installation. x - 16–18 The inverter has detected a voltage peak

on the grid.

19, 22 Grid frequency too low or too high. Check grid frequency. x - 31–33 DC grid current too high. For repeated daily occurrences, perform onsite grid

34–37 Residual Current Monitoring Unit (RCMU)

has measured an excessive current.

40 AC grid notOKThe AC grid has been out of range for

more than 10 minutes (frequency and/or

voltage).

41–43 Fault ride through. The inverter has

detected that grid voltage was below or

above a certain level.

48, 51 Grid frequency too low or too high. Check grid frequency and AC installation. x - 54–56 DC grid current too high (stage 2). For repeated daily occurrences, perform onsite grid

61 Loss of mains, open phase detected. If the event reoccurs several times each day, contact

62 Loss of mains. If the event reoccurs several times each day, contact

Check that the installation is correct according to

the installation guide. If so, increase the mean

voltage limit according to 3.3.1 Getting Started.

Check voltage and AC installation. x - -

analysis.

Turn both DC and AC off and wait until the display

turns off. Then turn on DC and AC and observe if

the event reoccurs.

Visual inspection of all PV cables and modules.

Check grid frequency, grid voltage, SW version, and

grid code setting.

If this event is reported several times each day,

perform onsite grid analysis.

analysis.

the DNO.

the DNO.

x- -

x- -

-x -

-x -

x- -

x- -

x- -

x- -

Table 4.1 Grid-related Events

28 L00410644-01_2q / Rev. date: 2014-06-02

Page 30

Service

4

PV-related Events

ID Status

Description Action DNO Hotline PV

message

103 PV current is too

high/waiting

115,

PV ISO too low The resistance between ground and PV

260

258 PV voltage too

high/waiting

278 DC voltage high warning. Check that PV installation and layout correspond

Table 4.2 PV-related Events

Too many PV modules connected in

parallel. Should only appear on newly

installed systems.

is too low for the inverter to start up.

This will force the inverter to make a

new measurement after 10 minutes.

DC voltage is too high. Check that PV installation and layout correspond

Check number of strings in parallel and current

ratings. Has the current limit been exceeded?

Reconnect strings in parallel.

Make a visual inspection of all PV cables and

modules for correct installation according to the

installation guide. The event could indicate that

the PE connection is missing.

to recommendations in the manuals.

to recommendations in the manuals.

-x x

-x x

-x x

-x x

Internal Events

ID Status

Description Action DNO Hotline PV

message

201–208 The internal temperature of the inverter is

too high.

209, 210 Voltage on DC bus is too high. If event persists, reset the inverter by discon-

211 Fan rpm low Fan speed is too low. Check if the inverter fan is blocked. - x 213–215 Internal error. Voltage measured before and

after the relay differs too much.

216–218 Current measured on AC side is too high. Call service. - x 219–221 Internal error. Voltage measured before and

after the relay differs too much.

225–240,

275

241, 242,

245, 249

248 Internal CPU error. Restart the inverter. If event persists, call

252–254 Current measured on AC side is too high. If the event is repeated, call service. - x 243, 263 Internal error. Restart the inverter. If event persists, call

279 Temperature sensor error. If the event is repeated, call service. - x 280 Self-test 24-hour timeout. Self-test must run

281 Too many RCMU events during the past 24

282 Grid code settings invalid. Restart the inverter. If event persists,

283 Gatedrive error. Restart the inverter. If event persists, call

Failure in memory/EEPROM. Restart the inverter. If event persists, call

Internal communication error. Restart the inverter. If event persists, call

at least once per 24 hours.

hours.

Only 4 automatic reconnect attempts after

event 34 is allowed during a 24-hour period.

The inverter will automatically try to

reconnect after a certain period.

Check that the inverter is not covered and

that the ventilation duct is not blocked.

necting DC and AC, using the switches. If the

event is repeated, check the maximum PV

voltage using the display to see if it is above

the limits.

Call service. - x -

Call service. - x -

service.

service.

service.

service.

None. - - -

Wait up to 24 hours. If event 34 also occurs,

follow the action for event 34.

reconfigure the grid code settings.

service.

-x -

-x -

-x -

-x -

-x -

-x -

-x -

-x -

-x -

4

L00410644-01_2q / Rev. date: 2014-06-02 29

Page 31

Service

4

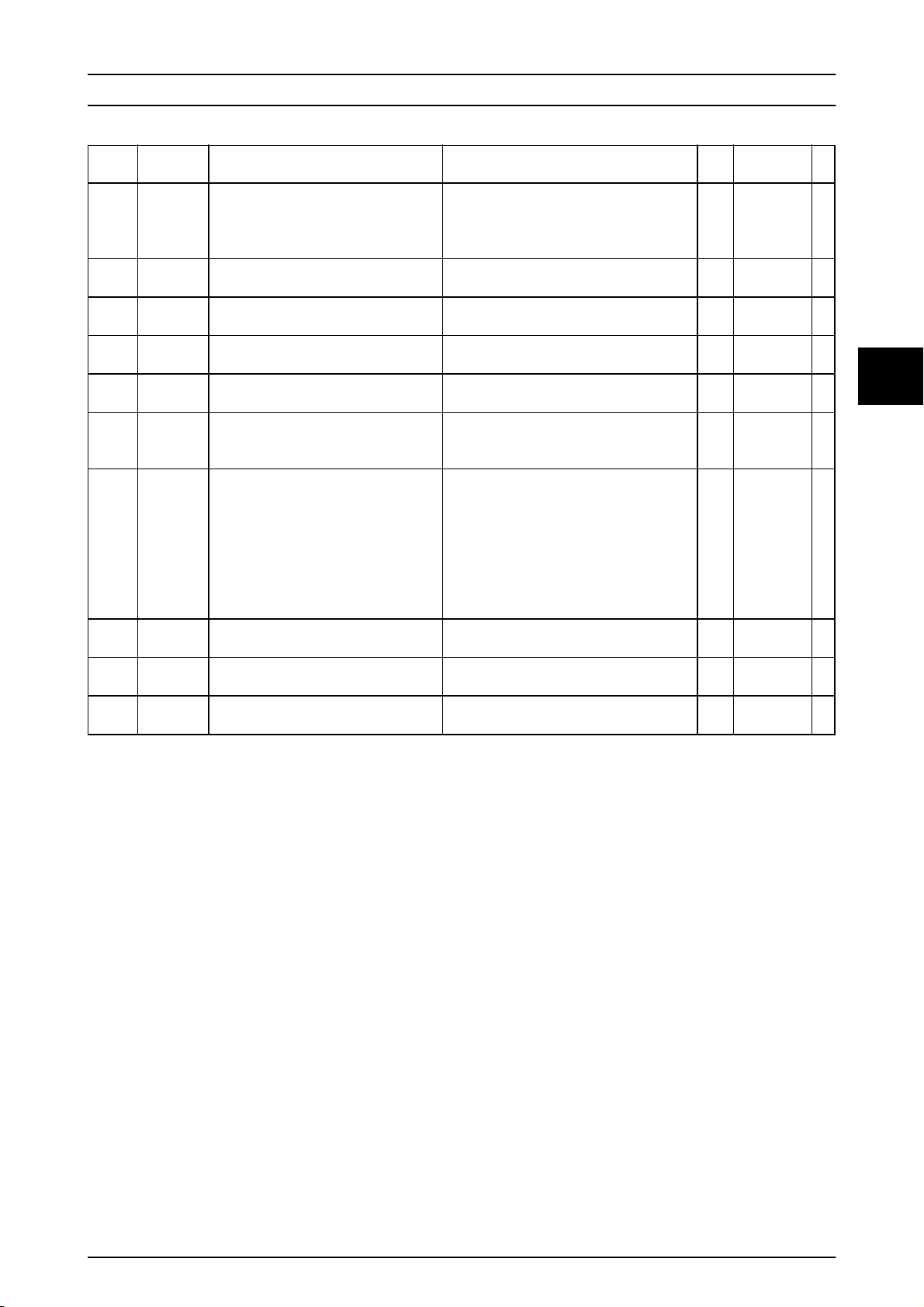

ID Status

message

323 Internal fan error. Maximum output power

Table 4.3 Internal Events

Events Caused by the Self-test

ID Description Action DNO Hotline PV

100 PV input current is negative.

Sensor error.

264, 266 Measurement circuit test failed. Restart the inverter. If event persists, call

272 PV surge protection device error. Inverter will continue

operation without surge protection.

273 Grid surge protection device error. Inverter will continue

operation without surge protection.

274 Surge protection device status unknown. Restart the inverter. If event persists, call

350–352 RCMU self-test failed. Call service. - x 353 Current sensor test failed. Call service. - x 356–361 Transistor and relay test failed or inverter relay has failed

(contact assumed welded).

366 RCMU self-test failed. Call service. - x -

Description Action DNO Hotline PV

If the event is repeated, call service. - x -

has been reduced.

Check polarity of PV installation, if correct,

call service.

service.

Service: Replace PV surge protection device. - x -

Service: Replace grid surge protection

device.

service.

Call service. - x -

-x -

-x -

-x -

-x -

Table 4.4 Events Caused by the Self-test

4.2 Maintenance

Ensure that the heat sink at the rear of the inverter is not

covered.

Clean the contacts of the PV load switch once per year.

Clean by cycling the switch to on and off positions 10

times. The PV load switch is located at the base of the

inverter.

For correct operation and long service life, ensure free air

circulation

around the heat sink at the top and side of the

•

inverter where the air exhausts, and

to the fan at the inverter base.

•

To clear obstructions, clean using pressurised air, a soft

cloth, or a brush.

WARNING

Temperature of the heat sink can exceed 70 °C.

30 L00410644-01_2q / Rev. date: 2014-06-02

Page 32

Technical Data

5

5 Technical Data

5.1 Specifications

Parameter MLX 60

AC

Rated apparent power

Rated active power

Reactive power range

Rated grid voltage (voltage range) 3P + PE (delta or WYE) / 400-480 V (+/- 10%)

Grounding schemes supported TT, TN

Rated current AC 3 x 87 A

Max. current AC 3 x 87 A

AC current distortion (THD at nominal output power) < 5%

Power factor default > 0.99 at rated power

Power factor - regulated 0.8 over-excited, 0.8 under-excited

Stand-by power consumption (comm. only) 3 W

Rated grid frequency (frequency range) 50/60 Hz (+/- 10%)

DC

Input voltage range 565–1000 V @ 400 V

Rated voltage DC 630 V @ 400 V

MPPT voltage range - rated power 570–800 V @ 400 V

Max. voltage DC 1000 V

Min. on grid power 100 W

Max. MPPT current DC 110 A

Max. short-circuit current DC 150 A

MPP tracker / Input per MPPT 1 / 1 (external string combining)

Efficiency

Max. efficiency 98.6% (preliminary value)

EU / CEC efficiency at V

MPPT efficiency static 99.9% (preliminary value)

Enclosure

Dimensions (H x W x D) 740 × 570 × 300 mm (29 × 22.5 × 12 in)

Weight

Acoustic noise level 55 dB(A) (preliminary value)

1)

2)

1)

dc,r

98.0% / 98.0% (preliminary value)

60 kVA

60 kW

0–36 kVAr

680–1000 V @ 480 V

ac

710 V @ 480 V

685–800 V @ 480 V

75 kg (165 lbs)

ac

3)

ac

ac

ac

ac

5

Table 5.1 Specifications

1)

At rated grid voltage.

2)

At rated grid voltage, Cos(phi)=1.

3)

Depending on installed options.

L00410644-01_2q / Rev. date: 2014-06-02 31

Page 33

5

Technical Data

Parameter MLX series

Electrical

Electrical Safety

PELV on the communication and control card Class II

Functional

Functional Safety

Islanding detection - loss of mains

RCD compatibility

1)

IEC 62109-1/IEC 62109-2 (Class I, grounded – communication part

•

Class II, PELV)

UL 1741 with non-Isolated EPS Interactive PV Inverters

•

IEEE 1547

•

Voltage and frequency surveillance

•

DC content of AC current surveillance

•

Insulation resistance surveillance

•

Residual current monitoring

•

UL1998

•

Active frequency shift

•

Disconnection

•

3-phase monitoring

•

ROCOF/SFS

•

Type B, 600 mA

Table 5.2 Safety Specifications

1)

Depending on local regulations.

5.2 Trip Settings

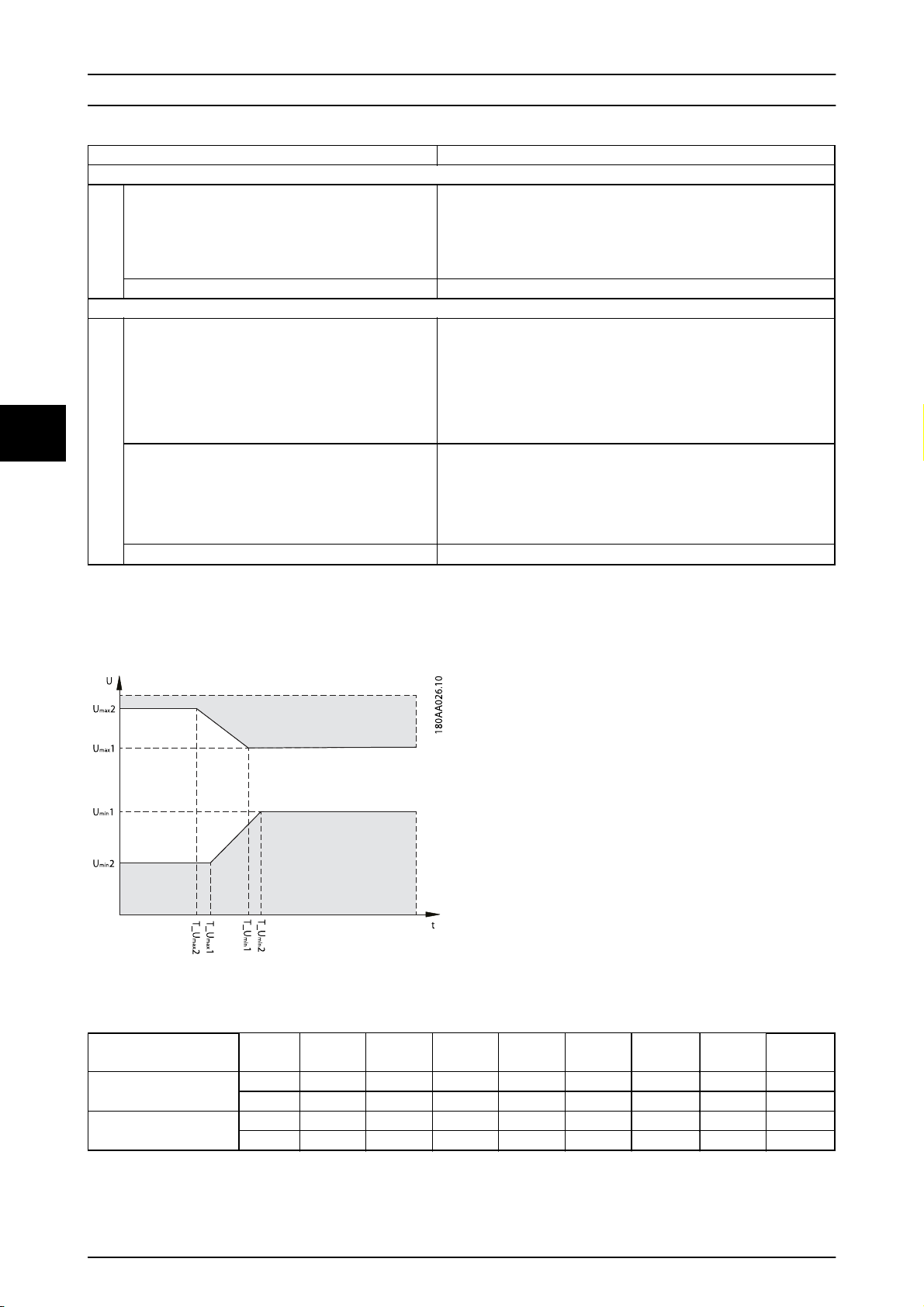

Illustration 5.1 Over-voltage and Under-voltage Disconnect

Nom. grid

Nom. voltage 400 V Default 200.00 0.16 352.00 2.00 440.00 1.00 480.00 0.16

Nom. voltage 480 V Default 240.00 0.16 423.00 2.00 528.00 1.00 576.00 0.16

Table 5.3 Default Voltage Trip Levels and Trip Times

32 L00410644-01_2q / Rev. date: 2014-06-02

Range 160-240 0.1-3.0 300-380 0.5-3.0 420-480 0.5-3.0 440-520 0.1-3.0

Range 192-288 0.1-3.0 360-456 0.5-3.0 504-576 0.5-3.0 528-624 0.1-3.0

U

[V]

min

2

T_U

2

U

1

T_U

1

U

1

T_U

1

U

2

T_U

[s]

[s]

min

[V]

min

[s]

min

[V]

max

[s]

max

max

[V]

max

2

Page 34

Technical Data

5

F

Default 57.00 0.16 59.30 10.00 60.50 0.16 - Range 56.5-57.5 0.1-3.0 57.0-59.8 0.16-300 60.1-60.9 0.16-3.0 60.1-61.0 0.1-3.0

Table 5.4 Default Frequency Trip Levels and Trip Times

min

[Hz]

2

T_F

[s]

min

2

F

min

[Hz]

1

T_F

[s]

min

1

F

max

[Hz]

1

T_F

[s]

max

1

F

max

[Hz]

2

T_F

[s]

NOTICE

The values apply only to IEEE 1547.

5.3 Conformity

International standards MLX series

Directive LVD 2006/95/EC

Directive EMC 2004/108/EC

IEC 62109-1/IEC 62109-2

Safety

Functional safety

EMC, immunity

EMC, emission

Utility interference EN 61000-3-12

CE Yes

Utility characteristics

UL 1741

UL 508i

IEC 62109-2

UL 1741/IEEE 1547

EN 61000-6-1

EN 61000-6-2

EN 61000-6-3

EN 61000-6-4

CISPR 11 Class B

FCC Part 15

IEC 61727

EN 50160

IEEE 1547 UI

max

2

5

Table 5.5 International Standards Compliance

Approvals and certificates are available from the download

area at www.sma.de.

L00410644-01_2q / Rev. date: 2014-06-02 33

Page 35

5

Technical Data

5.4 Installation Conditions

Parameter Specification

Operational temperature range -25 °C – 60 °C (possible power derating above 45 °C)

(-13 °F – 140 °F) (possible power derating above 113 °F)

Storage temperature -40 °C – 60 °C (-40°F – 140 °F)

Relative humidity 95% (non-condensing)

Environmental class according to IEC 60721-3-4 4K4H/4Z4/4B2/4S3/4M2/4C2

Cooling concept Forced

Air quality - general ISA S71.04-1985

Level G3 (at 75% RH)

Air quality - coastal, heavy industrial and agricultural zones Must be measured and classified acc. to ISA S71.04-1985: G3 (at 75% RH)

Vibration < 1G

Enclosure rating ingress protection class IP65

UL 50E enclosure type NEMA 3R

Max. operating altitude 2000 m (6562 ft) above sea level

Installation Avoid constant stream of water.

Avoid direct sunlight.

Ensure adequate air flow.

Mount on non-flammable surface.

Mount upright on vertical surface.

Prevent dust and ammonia gases.

Table 5.6 Conditions for Installation

5.5 Torque Specifications

Illustration 5.2 Overview of Inverter with Torque Indications

Parameter Tool Tightening Torque

1M63 cable gland

body

2Terminals on AC

terminal block

3 PE TX 30 3.9 Nm (35 in-lbf)

4 Terminal on DC TX 30 14 Nm (124 in-lbf)

5M32 cable gland

body

6M32 cable gland

compression nut

7M25 cable gland

body

8M25 cable gland

compression nut

9M6 equipment

grounding

Front screw (not

shown)

Table 5.7 Tightening Torque Specifications

Wrench

65/68 mm

TX 30 14 Nm (124 in-lbf)

Wrench 36 mm 6 Nm (53 in-lbf)

Wrench 36 mm 1.8 Nm (16 in-lbf)

Wrench 33 mm 10 Nm (89 in-lbf)

Wrench 33 mm 1.8 Nm (16 in-lbf)

TX 20 3.9 Nm (35 in-lbf)

TX 30 1.5 Nm (13 in-lbf)

6 Nm (53 in-lbf)

CAUTION

If the blind plugs are removed (see (7) in Illustration 5.2),

use fittings with type rating: 3, 3S, 4, 4X, 6, 6P.

34 L00410644-01_2q / Rev. date: 2014-06-02

Page 36

Technical Data

5

5.6 Mains Circuit Specifications

Parameter Specification

Maximum inverter current, I

Recommended blow fuse type gL/gG (IEC

60269-1)

Recommended blow fuse Class T (UL/USA) 125 A

Recommended MCB type B or C 125 A

Table 5.8 Mains Circuit Specifications

acmax

87 A

100-125 A

NOTICE

Observe local regulations.

5.7 Auxiliary Interface Specifications

Interface Parameter Parameter Details Specification

Ethernet Cable

RJ-45 connectors:

2 pcs RJ-45 for Ethernet

Galvanic interface insulation Yes, 500 Vrms

Direct contact protection Double/Reinforced insulation Yes

Short-circuit protection Yes

Communication Network topology Star and daisy chain

Cable Max. cable length between

Max. number of inverters

Cable jacket diameter (

Cable type Shielded Twisted Pair (STP CAT 5e or

Cable characteristic impedance

Wire gauge 24-26 AWG (depending on mating

Cable shield termination Via metallic RJ-45 plug

inverters

⌀

)

2 x 5-7 mm

SFTP CAT 5e)

100

Ω

– 120

metallic RJ-45 plug)

100 m (328 ft)

1)

42

2)

Ω

5

Table 5.9 Auxiliary Interface Specifications

1)

Max. number of inverters are 42 per Inverter Manager.

Illustration 5.3 Auxiliary Interfaces

2)

For outdoor use, we recommend outdoor burial type cable (if

buried in the ground) for Ethernet.

L00410644-01_2q / Rev. date: 2014-06-02 35

Page 37

5

Technical Data

5.8 Ethernet Connections

Illustration 5.4 RJ-45 Pinout Detail for Ethernet

Colour Standard

Pinout

Ethernet

1. RX+ Green/white Orange/white

2. RX Green Orange

3. TX+ Orange/white Green/white

4. Blue Blue

5. Blue/white Blue/white

6. TX- Orange Green

7. Brown/white Brown/white

8. Brown Brown

Table 5.10 RJ-45 Pinout Detail for Ethernet

Cat 5

T-568A

Cat 5

T-568B

5.8.1 Network Topology

The inverter has 2 Ethernet RJ-45 connectors enabling the

connection of several inverters in a line topology as an

alternative to the typical star topology. The 2 ports are

similar and can be used interchangeably.

Illustration 5.5 Network Topology

A Linear daisy chain

B Star topology

C Ring topology (only if spanning tree is used)

1MLX inverter

2Ethernet switch

Table 5.11 Network Topology

Status of the LEDs next to the Ethernet port is explained in

Table 5.12. There are 2 LEDs per port.

Status Yellow LED Green LED

Off Link speed 10 Mbit No link

On Link speed 100 Mbit Link

Flashing - Activity

Table 5.12 LED Status

NOTICE

Ring topology is only permitted if realised with Ethernet

switch supporting spanning tree.

36 L00410644-01_2q / Rev. date: 2014-06-02

Page 38

INSTRUCCIONES DE SEGURIDAD ...

INSTRUCCIONES DE SEGURIDAD IMPORTANTES: GUARDAR ESTAS

INSTRUCCIONES

Tipos de mensajes de seguridad

En este documento se utilizan los símbolos descritos a

continuación:

PELIGRO

Indica una situación potencialmente peligrosa que

provocaría lesiones graves o la muerte.

ADVERTENCIA

Indica una situación potencialmente peligrosa que

podría provocar lesiones graves o la muerte.

PRECAUCIÓN

Indica una situación potencialmente peligrosa que

podría provocar lesiones leves o moderadas. También se

utiliza para alertar contra aquellas prácticas que puedan

resultar inseguras.

AVISO!

Indica información importante, incluidas aquellas

situaciones que podrían provocar daños a propiedades o

al equipo.

Seguridad general

PRECAUCIÓN

Este manual contiene instrucciones importantes que se

deben seguir durante la instalación y el mantenimiento

del inversor MLX.

AVISO!

ANTES DE LA INSTALACIÓN

Compruebe que no se hayan producido daños en el

equipo ni en el embalaje. En caso de duda, póngase en

contacto con el proveedor antes de comenzar la

instalación.

ADVERTENCIA

INSTALACIÓN

Para conseguir unas condiciones de seguridad óptimas,

siga los pasos que se describen en este documento.

Recuerde que el inversor tiene dos lados con tensión: la

entrada FV y la red de CA.

PELIGRO

DESCONEXIÓN DEL INVERSOR

Antes de comenzar a trabajar con el inversor, desconecte

la CA en el interruptor de red eléctrica y el interruptor

FV girando el seccionador FV. Asegúrese de que no se

puede volver a conectar el inversor de manera

involuntaria. Utilice un voltímetro para asegurarse de

que la unidad está desconectada y sin tensión. Aunque

esté desconectado de la red de CA y los módulos solares,

el inversor puede estar cargado con una tensión alta a

niveles peligrosos. Espere al menos 5 minutos tras la

desconexión de la red y de los paneles FV antes de

proceder.

L00410644-01_2q / Rev. date: 2014-06-02

Page 39

INSTRUCCIONES DE SEGURIDAD ...

1 Interruptor de carga FV (opcional)

ADVERTENCIA

RIESGO DE ELECTROCUCIÓN

Estas instrucciones de mantenimiento solo deben ser

utilizadas por personal cualificado. Para reducir el riesgo

de electrocución, no realice más tareas de mantenimiento que las especificadas en las instrucciones de

funcionamiento a menos que esté cualificado para ello.

ADVERTENCIA

El inversor no está equipado con un transformador de

aislamiento y está destinado a instalarse según la

normativa NFPA 70, 690.35 con el campo FV en configuración flotante (sin ninguno de los dos polos puesto a

tierra).

ADVERTENCIA

Los circuitos de entrada y salida están aislados de la

carcasa.

El sistema de conexión a tierra, cuando lo exija el Código

Eléctrico Canadiense, Parte I, será responsabilidad del

instalador.

Ilustración 1.1

AVISO!

El interruptor de carga FV se puede proteger en la

posición «Off» (apagado) con un candado.

PRECAUCIÓN

El sistema FV presenta tensiones de CC de hasta 1000 V,

incluso cuando la red de CA está desconectada. Las

averías o el uso inadecuado pueden dar lugar a la

formación de un arco eléctrico.

PRECAUCIÓN

MANTENIMIENTO Y MODIFICACIÓN

Solo se permite efectuar modificaciones en el inversor al

personal autorizado para ello. Para garantizar la

seguridad del usuario, utilice únicamente recambios

originales suministrados por el proveedor. Si se utilizan

recambios no originales, no habrá ninguna garantía de

que se cumplan las directrices CE/UL de seguridad

eléctrica, compatibilidad electromagnética (CEM) y

seguridad de la máquina.

PRECAUCIÓN

Todas las personas que efectúen tareas de instalación y

mantenimiento de inversores deberán:

tener formación y autorización sobre las normas

•

generales de seguridad para trabajar con

equipos eléctricos;

estar familiarizadas con los requisitos,

•

reglamentos y normas locales para la

instalación.

PRECAUCIÓN

El inversor no proporciona protección contra sobrecorriente. Esta la debe suministrar el instalador. Consulte

Tabla 5.8.

PRECAUCIÓN

La temperatura de las rejillas de refrigeración y de los

componentes internos del inversor puede superar los

70 °C/158 °F. Tenga en cuenta el peligro de lesiones por

quemaduras.

El inversor debe instalarse de manera que el personal no

pueda entrar en contacto con él.

ADVERTENCIA

INSTALADOR

Cumpla con el código eléctrico nacional, ANSI/NFPA 70.

Los circuitos de entrada y salida están aislados de la

carcasa. El sistema de conexión a tierra es responsabilidad del instalador.

L00410644-01_2q / Rev. date: 2014-06-02

PRECAUCIÓN

Para reducir el riesgo de incendio, conecte únicamente a

un circuito que disponga de protección contra sobrecorriente de 125 A, de acuerdo con el Código Eléctrico

Nacional, ANSI/NFPA 70.

Page 40

INSTRUCCIONES DE SEGURIDAD ...

AVISO!

Utilice un cable para 75 °C o 90 °C de cobre o aluminio,

de tipo AWG en ambos casos. Consulte 2.7 Cable Entry.

AVISO!

El símbolo de protección de conexión a tierra empleado

en este manual está identificado en Ilustración 2.18.

El símbolo de encendido/apagado está identificado en

3.2.2 Turn PV Load Switch On.

AVISO!

Para obtener información sobre el valor nominal de

temperatura ambiente, consulte 5.4 Installation

Conditions.

AVISO!

Este manual contiene información sobre las conexiones

de cableado de campo y las especificaciones del par.

Consulte 5.5 Torque Specifications.

AVISO!

Tras realizar las pruebas pertinentes con este equipo, se

ha determinado que cumple con los límites de un

dispositivo digital clase B, de conformidad con el

apartado 15 de la normativa FCC. Estos límites se han

diseñado para proporcionar una protección razonable

contra interferencias nocivas en una instalación

residencial. Este equipo genera, utiliza y puede radiar

energía de radiofrecuencia por lo que, si no se instala y

utiliza de acuerdo con las instrucciones, puede causar

interferencias nocivas a las comunicaciones por radio. Sin

embargo, no hay garantía de que no se produzcan

interferencias en una instalación concreta. Si este equipo

causa interferencias nocivas en la recepción de radio o

televisión que puedan determinarse mediante el

encendido y apagado del equipo, recomendamos que el

usuario intente corregir las interferencias aplicando una

o más de estas medidas:

Reorientar o reubicar la antena receptora.

•

Aumentar la distancia entre el equipo y el

•

receptor.

Conectar el equipo a la salida de un circuito

•

diferente al que esté conectado el receptor.

Consultar al distribuidor o a un técnico de

•

radio/TV experimentado para obtener ayuda.

Conformidad

Para obtener más información, vaya a la zona de descargas

en www.sma.de.

Consulte también 5 Technical Data.

L00410644-01_2q / Rev. date: 2014-06-02

Page 41

Índice

Índice

1 Introducción

1.1 Objetivo de este manual

1.2 Desembalaje

1.3 Identificación del inversor

1.4 Secuencia de instalación

1.5 Información general sobre el área de instalación

2 Instalación

2.1 Entorno y espacios libres

2.2 Instalación de la placa de montaje

2.3 Montaje del inversor

2.4 Desmontaje del inversor

2.5 Acceso al área de instalación

2.6 Conexión de red de CA

2.7 Entrada de cable

2.8 Conexiones Ethernet

2.9 Conexión FV

2.9.1 String combiners externos 53

42

43

45

45

45

46

47

47

48

49

50

50

51

52

53

53

2.10 Cierre

3 Configuración inicial y arranque

3.1 Interfaz de usuario

3.1.1 Modos de funcionamiento 55

3.2 Display

3.2.1 Ajuste inicial mediante herramienta LCS 56

3.2.2 Ponga el seccionador FV en posición ON 57

3.2.3 Arranque

3.3 Herramienta LCS

3.3.1 Inicio 58

4 Mantenimiento

4.1 Resolución de problemas

4.2 Mantenimiento

5 Datos técnicos

5.1 Especificaciones

5.2 Ajustes de desconexión

54

55

55

56

57

57

65

65

68

69

69

70

5.3 Conformidad

5.4 Condiciones de la instalación

5.5 Especificaciones del par de apriete

40 L00410644-01_2q / Rev. date: 2014-06-02

71

72

72

Page 42

Índice

5.6 Especificaciones del circuito de la red eléctrica

5.7 Especificaciones de la interfaz auxiliar

5.8 Conexiones Ethernet

73

73

74

L00410644-01_2q / Rev. date: 2014-06-02 41

Page 43

Introducción

1Introducción

1

Los inversores MLX están diseñados para actuar exclusivamente como inversores de conexión a red para sistemas

fotovoltaicos (FV). El inversor convierte la corriente

continua generada por un campo solar en corriente

alterna. La unidad deberá conectarse a la red eléctrica y a

un sistema fotovoltaico para funcionar correctamente. No

es adecuada para otras aplicaciones (como, por ejemplo,

una batería de reserva o sistemas eólicos).

El sistema MLX está formado por cuatro componentes

principales (consulte también Ilustración 1.1):

Inversor MLX.

•

String combiner

•

El string combiner permite conectar en paralelo

el número necesario de strings FV para el inversor

MLX. Se requiere un string combiner para cada

inversor MLX.

Inverter Manager MLX

•

El Inverter Manager MLX es necesario para

gestionar los inversores MLX. Cada Inverter

Manager admite hasta 42 inversores. El Inverter

Manager se ocupa de todas las comunicaciones

con los inversores. Supone una interfaz única

para sistemas de adquisición de datos, carga a

servicios en la nube y gestión de red.

Herramienta LCS

•

La herramienta LCS es necesaria para la puesta en

servicio y el mantenimiento de los inversores MLX

mediante el Inverter Manager. La herramienta LCS

actúa como interfaz de usuario principal del

sistema MLX.

42 L00410644-01_2q / Rev. date: 2014-06-02

Page 44

Introducción

1 1

Ilustración 1.1 Vista general del sistema

1Campo FV

2String Combiner

3Inversor MLX

4 Inverter Manager MLX

5Herramienta LCS

6 CLX Portal o de terceros

7Gestión de Red

8Sistema SCADA

9 Transformador

Tabla 1.1 Vista general del sistema

1.1 Objetivo de este manual

La Guía de instalación proporciona la información necesaria

para instalar y poner en marcha el inversor de la serie

MLX.

Recursos adicionales disponibles:

Póster de instalación del Inverter Manager, ofrece

•

información necesaria para la puesta en marcha

del inversor MLX y la configuración de la comunicación del inversor (UE).

Guía de instalación del cuadro que integra el

•

Inverter Manager, ofrece información necesaria

para poner en marcha el inversor MLX y

configurar la comunicación del inversor (EE. UU.).

Guía de diseño, contiene la información necesaria

•

para el diseño de aplicaciones de energía solar

con este inversor.

Instrucciones de instalación de ventiladores,

•

contiene la información necesaria para la

sustitución de ventiladores.

L00410644-01_2q / Rev. date: 2014-06-02 43

Page 45

Introducción

1

Instrucciones de instalación de los descargadores

•

contra sobretensión, contiene la información

necesaria para la sustitución de los descargadores

contra sobretensión.

Estos documentos se encuentran a su disposición en la

zona de descarga www.sma.de, o a través del proveedor

del inversor solar.

Ilustración 1.2 Inversor MLX

Abreviatura Descripción

ANSI Instituto Nacional Estadounidense de

Estándares

AWG Calibre de cable estadounidense

cat5e Cable trenzado categoría 5 (mejorado)

DHCP Protocolo de configuración dinámica de hosts

DNO Operador de redes de distribución

DSL Línea de abonado digital

CEM (directiva) Directiva sobre compatibilidad electromag-

nética

ESD Descarga electrostática

FCC Comisión Federal de Comunicaciones

FRT Fault Ride Through

GSM Sistema global de comunicaciones móviles

HDD Unidad de disco duro

IEC Comisión Electrotécnica Internacional

IT Sistema de tierras aislado

LCS Puesta en marcha y mantenimiento local

LED Diodo emisor de luz

LVD (directiva) Directiva de baja tensión

MCB Disyuntor en miniatura

MPP Punto de máxima potencia

MPPT Seguimiento del punto de máxima potencia

NFPA Asociación Nacional Estadounidense para la

Protección contra Incendios

P P es el símbolo de la potencia activa y se mide

en vatios (W).

PCB Placa de circuito impreso

PCC Punto de conexión

Es el punto en la red eléctrica pública en el

que varios clientes están, o podrían estar,

conectados.

PE Conexión a tierra

PELV Protección por tensión extrabaja

PLA Ajuste del nivel de potencia

P

NOM

POC Punto de conexión

P

STC

FV Fotovoltaico, células fotovoltaicas

RCD Dispositivo de corriente residual

RCMU Unidad de control de la corriente residual

R

ISO

ROCOF Tasa de variación de la frecuencia

Q Q es el símbolo de la potencia reactiva y se

S S es el símbolo de la potencia aparente y se

STC Condiciones de prueba estándar

SW Software

THD Tasa de distorsión armónica total

TN-S Conexión a tierra con neutro separado. Red de

TN-C Conexión a tierra con neutro combinado. Red

TN-C-S Conexión a tierra con neutro separado y

TT Conexión tierra a tierra. Red de CA.

Tabla 1.2 Abreviaturas

Potencia nominal

Es el punto en el que el sistema FV se conecta

a la red eléctrica pública.

Potencia en condiciones de prueba estándar

Resistencia de aislamiento

mide en voltamperios reactivos (VAr).

mide en voltamperios (VA).

CA.

de CA.

combinado. Red de CA.

44 L00410644-01_2q / Rev. date: 2014-06-02

Page 46

Introducción

1.2 Desembalaje

Índice:

Inversor

•

Placa de montaje

•

Bolsa de accesorios, que incluye:

•

6 tacos para tornillos de 8 x 50 mm

•

6 tornillos de montaje de 6 x 60 mm

•

1 prensaestopas M25 con anillo aislante

•

para cables Ethernet

2 soportes de conducto (2 entradas)

•

1 perno de conexión a tierra del equipo,

•

M6 x 12 mm

Guía de instalación (folleto)

•

Guía rápida (póster)

•

1.3 Identificación del inversor

1.4 Secuencia de instalación

1. Preste especial atención a las instrucciones de

seguridad importantes que se encuentran al

inicio de este manual.

2. Instale el inversor según los apartados

2.1 Environment and Clearances, 2.2 Mounting the

Mounting Plate y 2.3 Mounting the Inverter.

3. Abra el inversor de acuerdo con 2.5 Access to the

Installation Area.

4. Instale la CA según 2.6 AC Grid Connection.

5.

Instale Ethernet según 2.8.1 Ethernet Connections.

6. Conecte la corriente continua según 2.9 PV

Connection.

7.

Cierre el inversor según 2.5 Access to the

Installation Area.

8. Active la CA.

9. Para finalizar la puesta en marcha, utilice la

herramienta de puesta en marcha y mantenimiento locales (herramienta LCS). La herramienta

está disponible en la zona de descargas de

www.sma.de. Los requisitos de hardware para la

herramienta LCS son los siguientes:

1 1

Ilustración 1.3 Etiqueta del producto, ejemplo

La etiqueta del producto, situada en el lateral del inversor,

indica:

Tipo de inversor.

•

Especificaciones importantes.

•

Número de serie, ubicado bajo el código de

•

barras, para identificación del inversor.

PC con WindowsTM 7 o superior

•

HDD de 150 Mb

•

2 Gb de RAM

•

Si desea realizar la configuración mediante la

herramienta LCS, consulte 3.3 LCS Tool.

10. Utilice el seccionador FV para conectar la

corriente continua. Consulte 2.9.2 Connection of

PV.

11. Compruebe los siguientes elementos de la

instalación:

El display del inversor: el LED de

•

encendido está en verde.

Herramienta LCS: el estado del inversor

•

es «Conectado a la red».

12. El inversor está listo para funcionar.

L00410644-01_2q / Rev. date: 2014-06-02 45

Page 47

1

Introducción

1.5 Información general sobre el área de

instalación

Ilustración 1.4 Información general sobre el área de instalación

PELV (contacto seguro)

2 Conexión a tierra del equipo

7Interfaz Ethernet (x2)

8 Interfaz RS 485 (no está en uso)

Pieza en tensión

1 Terminales de conexión de CA

5 Terminales de conexión FV

Otros

3 Descargador contra sobretensiones, lado CA

4 Descargador contra sobretensiones, lado CC

6 Interruptor de carga FV (opcional)

Tabla 1.3 Información general sobre el área de instalación

46 L00410644-01_2q / Rev. date: 2014-06-02

Page 48

Instalación

2

2Instalación

2.1 Entorno y espacios libres

Ilustración 2.1 Evite el flujo constante de agua

2

Ilustración 2.6 Móntelo recto en una superficie vertical. Se

permite una inclinación hacia atrás de hasta 10º

Ilustración 2.2 Evite la radiación solar directa

Ilustración 2.3 Asegúrese de que exista suficiente ventilación

Ilustración 2.4 Asegúrese de que exista suficiente ventilación

Ilustración 2.7 Evite la exposición a polvo y gases de

amoniaco

AVISO!

A la hora de elegir el emplazamiento para la instalación,

asegúrese de que la etiqueta de producto del inversor y

las etiquetas de advertencia permanecen visibles. Si

desea más información, consulte 5 Technical Data.

Ilustración 2.5 Móntelo en una superficie ignífuga

L00410644-01_2q / Rev. date: 2014-06-02 47

Page 49

2

Instalación

2.2 Instalación de la placa de montaje

Ilustración 2.8 Espacios de seguridad

AVISO!

Deje un espacio libre de 620 mm (24 pulg.) en la base

para que el aire fluya adecuadamente.

48 L00410644-01_2q / Rev. date: 2014-06-02

Page 50

Instalación

2

2

Ilustración 2.10 Instalación de la placa de montaje

Ilustración 2.9 Placa de montaje

AVISO!

Es obligatorio utilizar la placa de montaje suministrada

con el inversor. Si el inversor se monta sin la placa de

montaje, la garantía no tiene validez.

Es altamente recomendable utilizar los seis orificios de

montaje.

Instalación de la placa de montaje:

Instálela en el entorno definido.

•

Utilice tornillos y tomas de pared que puedan

•