SMA Inverter Manager,I/O Box Installation Manual

IMVIOBOX-IA-xx-16 | 111684-00.01 | Version 1.6 ENGLISH / DEUTSCH / ESPAÑOL /

FRANÇAIS / 日本語

Installation Manual / Installationsanleitung / Instrucciones de

instalación / Instructions d’installation / 設置説明書

SMA INVERTER MANAGER / SMA DIGITAL I/O BOX /

LCS-TOOL

SMA Solar Technology AG

2 IMVIOBOX-IA-xx-16

IMVIOBOX-IA-xx-16 | Version 1.6 ENGLISH

1 Information on this Document

1.1 Validity

This document is valid for the SMA Inverter Manager, the

SMA Digital I/O Box, and for the LCS-Tool.

1.2 Target Group

The activities described in this document must only be

performed by qualified persons. Qualified persons must

have the following skills:

• Training in the installation and commissioning of

electrical devices

• Training in how to deal with the dangers and risks

associated with installing and using electrical devices

and installations

• Training in the installation and configuration of IT

systems

• Knowledge of how an inverter works and is operated

• Knowledge of all applicable laws, standards and

directives

• Knowledge of and compliance with this document and

all safety information and warning messages

1.3 Symbols

1.4 Nomenclature

Symbol Explanation

Indicates a hazardous situation

which, if not avoided, will result

in death or serious injury

Indicates a hazardous situation

which, if not avoided, can result

in death or serious injury

Indicates a hazardous situation

which, if not avoided, can result

in minor or moderate injury

Indicates a situation which,

if not avoided, can result in

property damage

Information that is important for

a specific topic or goal, but is

not safety-relevant

☐ Indicates a requirement for

meeting a specific goal

☑ Desired result

✖ A problem that might occur

Complete designation Designation in this

document

SMA Inverter Manager Inverter Manager

SMA Digital I/O Box I/O Box

Local commissioning and

service tool (LCS-Tool)

LCS tool

Sunny Tripower 60,

Sunny Highpower Peak1,

Sunny Tripower Storage

60

Inverters

SMA Solar Technology AG SMA

SMA Solar Technology

America LLC

SMA Solar Technology

Canada Inc.

Symbol Explanation

Installation Manual

SMA INVERTER MANAGER /

SMA DIGITAL I/O BOX /

LCS-TOOL

2 Safety SMA Solar Technology AG

4 IMVIOBOX-IA-xx-16 Installation Manual

2 Safety

2.1 Intended Use

The Inverter Manager is a device for monitoring and

controlling up to 42 Sunny Tripower 60 or

Sunny Highpower 75 or up to 20

Sunny Tripower Storage 60 with battery storage system in

decentralized PV system.

The I/O Box is a function interface for one Inverter

Manager. The I/O Box receives commands for grid

management services via digital signals and sends these

specifications to the Inverter Manager.

The Inverter Manager receives the specifications from the I/

O Box and controls all inverters in the PV system

accordingly. The Inverter Manager and the I/O Box must

only be used indoors and must only be operated with the

Sunny Tripower 60, Sunny Tripower Storage 60 and

Sunny Highpower Peak1.

The LCS-Tool is required for commissioning and servicing

the inverters via the Inverter Manager. The LCS-Tool is the

primary user interface for th e PV system and battery storage

system.

Use this product only in accordance with the information

provided in the enclosed documentation and with the

locally applicable standards and directives. Any other

application may cause personal injury or property damage.

For safety reasons, it is not permitted to modify the product

or install components that are not explicitly recommended

or distributed by SMA for the product. Unauthorized

changes and modifications will void all warranty claims and

the operating permission. Any use of the product other than

that described in the Intended Use section does not qualify

as appropriate.

The type label must remain permanently attached to the

product. The enclosed documentation is an integral part of

this product.

3 Inverter Manager

3.1 Scope of Delivery

Check the scope of delivery of each product for

completeness and any externally visible damage. Contact

your distributor if the scope of delivery is incomplete or

damaged.

The delivery may contain parts that are not required for the

installation.

Figure 1: Components included in the scope of delivery of the

Inverter Manager

Item Quantity Designation

A 1 Inverter Manager

B 2 Wall mounting brackets

C 1 Bracket for mounting on top-hat rail

(35 mm DIN rail)

D 1 Connection for electricity supply

E 2 Bootlace ferrules

F 1 Connecting terminal plate for

electricity supply

G 2 Connecting terminal plates for

serial port

H 4 Screws for wall and top-hat rail

mounting

I 1 Installation Manual

SMA Solar Technology AG 3 Inverter Manager

Installation Manual IMVIOBOX-IA-xx-16 5

3.2 Mounting the

Inverter

Manager

3.2.1 Option 1: Wall Mounting

3.2.2 Option 2: Mounting on Top-Hat

Rail

Damage to the products and cables due to moisture

The Inverter Manager and the I/O Box are not protected

against splash water. Consequently, moisture can

penetrate the device and damage the products and

cables.

• The Inverter Manager and the I/O Box must be

installed in a dry environment, e.g. indoors or in a

splash-proof enclosure (d egree of protec tio n: a t least

IP54 (NEMA 3R)).

3 Inverter Manager SMA Solar Technology AG

6 IMVIOBOX-IA-xx-16 Installation Manual

3.3 Connection to the

Inverter

Manager

3.3.1 Safety Information

3.3.2 Circuitry Overview of

Sunny

Tripower 60 /

Sunny

Highpower 75

Figure 2: Circuitry Overview of Sunny Tripower 60 /

Sunny Highpower 75

Danger to life due to electric shock

Lethal voltages are present at the connection point of the

utility grid.

• Disconnect the connection point from voltage sources

and ensure that the connection point is voltage-free.

Item Designation

A Sunny Tripower 60 /

Sunny Highpower 75

BPC with LCS-Tool

CRouter

D SunSpec Alliance compatible weather

station (optional)

E I/O Box (optional)

FInverter Manager

Item Designation

SMA Solar Technology AG 3 Inverter Manager

Installation Manual IMVIOBOX-IA-xx-16 7

3.3.3 Circuitry Overview of

Sunny

Tripower Storage 60

Figure 3: Circuitry Overview of Sunny Tripower Storage 60

3.3.4 Connecting the Inverter and

Router via Ethernet

Pin assignment of network ports (LAN 1 and LAN 2):

Figure 4: Pin assignment of network ports

Item Designation

A Battery

B Sunny Tripower Storage 60

CPC with LCS-Tool

D Power Analyser UMG 604-PRO from

Janitza electronics GmbH

ERouter

F SunSpec Alliance compatible weather

station (optional)

G I/O Box (optional)

H Inverter Manager

Pin Assignment for

10/100 Mbps

Assignment for

1000 Mbps

1ETx+ TRD(0)+

2ETx- TRD(0)3 ERx+ TRD(1)+

4 --- TRD(2)+

5 --- TRD(2)6 ERx- TRD(1)-

81

81

3 Inverter Manager SMA Solar Technology AG

8 IMVIOBOX-IA-xx-16 Installation Manual

3.3.5 Connecting the I/O Box and

Weather Station (Optional)

Pin assignment of the serial interface (RS485) at the Inverter

Manager:

Figure 5: Pin assignment of the serial interface

The I/O Box must be connected to port 2 of the Inverter

Manager. Termination for the RS485 interface is not

necessary.

Interfaces and Data of the Weather Station

Only one weather station can be connected to each Inverter

Manager. The weather station must be connected to port 1

of the Inverter Manager. A maximum of two temperature

sensors are supported.

The following data of the weather station are provided by

the Inverter Manager:

3.3.6 Connecting the

Inverter

Manager to the Voltage

Supply

Procedure:

To connect the Inverter Manager to the voltage supply,

perform the following actions in the specified order.

• Connect the grounding conductor to the

Inverter Manager.

• Connect the power supply unit.

Connecting the Grounding Conductor to the

Inverter Manager

Shielded ground: The shielded ground (also called

"protected ground") is located at the pin connector for the

electrical connection in the displayed view.

Procedure:

• Ground the Inverter Manager. For this purpose,

connect the grounding conductor to the grounding

screw of the Inverter Manager. Proper grounding and

the correct cable route help limit possible interference

emissions due to electromagnetic interferences (EMI).

7--- TRD(3)+

8--- TRD(3)-

Do not connect during operation

Do not connect the I/O Box or the weather station to

the Inverter Manager during operation. Errors might

occur that cannot be detected immediately.

• Disconnect the Inverter Manager from voltage

sources.

Pin Assignment

1 --2 --3 DataB(+)

4 DataA(-)

5GND

6 --7 --8 ---

Pin Assignment for

10/100 Mbps

Assignment for

1000 Mbps

3

2

1

4

5

9

8

7

6

Meteorological

data

SunSpec

Modbus

TCP

LCS-Tool /

FTP Push

Sunny

Portal

Ambient

temperature and

PV temperature

yes yes yes

Wind direction

and wind speed

yes yes yes

Horizontal

irradiation

yes yes If inclined

irradiation is

not

available

Inclined

irradiation

no yes yes

Danger to life due to electric shock from touching

an ungrounded product

Touching an ungrounded product can cause a lethal

electric shock.

• Ensure that the product is integrated into the existing

overvoltage protection.

• Ground the enclosure of the product.

SMA Solar Technology AG 3 Inverter Manager

Installation Manual IMVIOBOX-IA-xx-16 9

Connecting the Power Supply Unit

SMA recommends using the top-hat rail power supply

available as an accessory (order number:

CLCON-PWRSUPPLY)* .

Procedure:

1. Mount the power supply unit (see the manufacturer

manual).

2. Connect the connection cable to the power supply unit

(see the manufacturer manual). Trim the unused

insulated conductors up to the cable sheath and write

down the conductor colors.

3. Connect the connection cable to the terminal block for

the voltage supply (9 VDC to 36 VDC). Make sure that

the shielded grounding conductor is connected with the

grounding terminal.

4. Plug the terminal block for the voltage supply with

connected power supply unit in the pin connector

"Power Input" of the Inverter Manager.

5. Connect the AC connection cable to the power supply

unit (see the manufacturer manual).

7. Connect the other end of the AC connection cable to

the voltage supply.

8. Connect the connection point to the utility grid.

☑ Once the Power LED is glowing green, the

Inverter Manager is ready for operation.

3.4 Ethernet Connection of the

Inverter Manager

LAN 1 (system network)

The IP address and the subnet mask are assigned to the

LAN 1 port of the Inverter Manager by an external DHCP

server.

An IP address can be manually assigned to LAN 1 Port of

the Inverter Manager.

LAN 2 (inverter network)

The IP address is assigned to the inverter by the Inverter

Manager.

Resetting the Inverter Manager to DHCP

• Press the power button three times in succession within

one second to reset the Inverter Manager to DHCP.

3.5 LED Signals of the

Inverter Manager

* Not available in all countries.

6.

Danger to life due to electric shock

Lethal voltages are present at the connection point of

the utility grid.

• Disconnect the connection point from voltage

sources and make sure it cannot be

reconnected.

GND

9 to 36 VDC

LED State Explanation

Power Glowing

green

The Inverter Manager is in

operation.

Off The Inverter Manager is not

in operation.

LAN Glowing

green

100 Mbps Ethernet mode

Glowing

yellow

1000 Mbps (gigabyte)

Ethernet mode

Off No activity or

10 Mbps Ethernet

Tx1, Tx2

(P1-P2)

Flashing

green

Data transmission via serial

ports P1-P2

Off No data transmission via

serial ports P1-P2

Rx1, Rx2

(P1-P2)

Flashing

green

Data reception via serial

ports P1-P2

Off No data reception via serial

ports P1-P2

4 I/O Box SMA Solar Technology AG

10 IMVIOBOX-IA-xx-16 Installation Manual

3.6 Technical data

4 I/O Box

4.1 Scope of Delivery

Check the scope of delivery of each product for

completeness and any externally visible damage.

Contact your distributor if the scope of delivery is

incomplete or damaged.

The delivery may contain parts that are not required for the

installation.

Figure 6: Components included in scope of delivery of the I/O Box

Voltage supply

Input voltage 9 Vdc to 36 Vdc

Power consumption < 20 W

Maximum conductor

cross-section

1.3 mm² (16 AWG)

General data

Dimensions

(width x height x depth)

160 mm x 125 mm x

49 mm

(6.3 in x 4.9 in x 1.9 in)

Weight 940 g (2 lbs)

Mounting type Wall mounting or top-hat

rail

Operating temperature

range

-40°C to +75°C

-40°F to +167°F

Relative humidity,

non-condensing

5% to 95%

Approvals UL 508, UL 60950-1,

CSA C22.2 No.

60950-1-07, EN 60950-1,

CCC (GB9254,

GB17625.1), EN 55022,

Class A, EN 61000-3-2,

Class D, EN 61000-3-3,

EN 55024, FCC Part 15,

Subpart B, Class A

Interfaces

User interface LCS-Tool for PC via Ethernet

Interface to inverter LAN 2, Ethernet interface

(RJ45)

Interface to external

network

LAN 1, Ethernet interface

(RJ45)

Interface to I/O box

(optional)

RS485 (D-sub 9) /

SunSpec mode

Sensor interface for

SunSpec compatible

weather stations (optional)

RS485 (D-sub 9) /

SunSpec mode

Maximum cable length for

Ethernet connection

100 m (328 ft)

Maximum cable length for

RS485 cabling

1200 m (4000 ft)

System monitoring Sunny Portal, SunSpec

Modbus TCP

Active/reactive power

setpoint

Constant value, curve or

remotely controlled via

SunSpec Modbus TCP with

I/O Box

Supported baud rate for

operation of a weather

station

9600, 19200, 57600,

115200

Power supply unit (recommended)

Type designation CLCON-PWRSUPPLY*

Input 100 Vac to 240 Vac

Output 24 Vdc; 2.5 A

Ambient temperature -25°C to +70°C

Approvals CE, UL

* Not available in all countries.

Item Quantity Designation

A1 I/O Box

B1 CD

Interfaces

A

B

C

SMA Solar Technology AG 4 I/O Box

Installation Manual IMVIOBOX-IA-xx-16 11

4.2 Mounting the I/O Box

4.2.1 Option 1: Wall Mounting

4.2.2 Option 2: Mounting on Top-Hat

Rail

4.3 Connection to the I/O Box

4.3.1 Overview

Figure 7: Overview of the connection to the I/O Box

4.3.2 Connecting the

Inverter

Manager

Pin assignment of the RS485 terminal

(see Section 3.3.5, page 8):

C 1 Quick reference guide for

installation

Damage to the products and cables due to moisture

The Inverter Manager and the I/O Box are not protected

against splash water. Consequently, moisture can

penetrate the device and damage the products and

cables.

• The Inverter Manager and the I/O Box must be

installed in a dry environment, e.g. indoors or in a

splash-proof enclosure (d egree of protec tio n: a t least

IP54 (NEMA 3R)).

Item Quantity Designation

1

2

1

2

3

Item Designation

A Digital inputs for connecting a signal source

(inputs DI0 to DI5 can be assigned; all

other inputs have no function)

B Maintain the default setting: X1 = 1,

X10 = 0

C Connection of the Inverter Manager

D Connection of the electricity supply

E Maintain the default setting: 1 = Dual,

2 = Initial

Do not connect during operation

Do not connect the I/O Box to the Inverter Manager

during operation. Errors might occur that cannot be

detected immediately.

• Disconnect the Inverter Manager from voltage

sources.

• Connect the I/O Box with the Inverter Manager.

• Reconnect the Inverter Manager to the voltage

supply.

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

D1+

D1-

GND

D2+

D2-

P1

P2

V+

V-

X10

X1

Dual

Run

Rep

Initial

COM0

DI0

DI1

DI2

DI3

DI4

DI5

DI6

DI7

COM1

DIO0

DIO1

DIO2

DIO3

GND

DIO4

DIO5

DIO6

DIO7

GND

A

C

D

COM0

DI0

DI1

DI2

DI3

DI4

DI5

GND

B

E

4 I/O Box SMA Solar Technology AG

12 IMVIOBOX-IA-xx-16 Installation Manual

4.3.3 Connecting the Signal Source

Connection of a Signal Source with

Potential-Free Relay Contact

Connection of a Signal Source (10 V to 30 V)

with Digital Output Signals

4.3.4 Connecting the I/O Box to the

Voltage Supply

Connect the 12 Vdc to 36 Vdc connection line with the

terminal for the voltage supply. Connect the grounding of

the connection line to the "V" terminal and connect the

grounding pin (GND) if grounding is present.

4.3.5 LED Signals of the I/O Box

Pin Assignment

D2- --D2+ --GND GND

D1- DataA(-)

D1+ DataB(+)

(5) GND

(3) Data B (+)D1+

(4) Data A (−)/D1−

COM0

DI0

DI1

DI2

DI3

DI4

DI5

DI6

DI7

COM1

DIO0

DIO1

DIO2

DIO3

GND

DIO4

DIO5

DIO6

DIO7

GND

COM0

DI0

DI1

DI2

DI3

DI4

DI5

GND

Dry Contact:

closed: DI0 = on

open: DI0 = off

COM0

DI0

DI1

DI2

DI3

DI4

DI5

DI6

DI7

COM1

DIO0

DIO1

DIO2

DIO3

GND

DIO4

DIO5

DIO6

DIO7

GND

COM0

DI0

DI1

DI2

DI3

DI4

DI5

GND

Wet Contact:

0Vto3V=off

10Vto30V=on

U

U

10Vto30V

Pin Assignment

V- / V+ Voltage supply 24 Vdc (12 Vdc to 36 Vdc)

Diameter of the leads

For safety reasons, the leads for the electricity

supply must have a diameter of at least 2 mm².

LED State Explanation

Power Glowing

yellow

The I/O Box is in operation.

Off The I/O Box is not in operation.

Ready Glowing

green

The system is ready for

operation.

Green is

flashing once

per second

The "detect" function was

triggered.

Flashing

green every

0.5 seconds

Firmware is being updated.

Flashing

green

When the green LED is on for

five seconds and then goes off

for five seconds, it means that

the system is in "Safe Mode".

Off The system is not ready for

operation.

Port 1 Flashing

green

Data is being sent or received.

Port 2 Flashing

yellow

Data is being sent or received.

SMA Solar Technology AG 4 I/O Box

Installation Manual IMVIOBOX-IA-xx-16 13

4.4 Technical data

System data

Electricity supply 24 Vdc nominal,

12 Vdc to 36 Vdc

Cabling I/O cable max. 25 mm²

(4 AWG)

Dimensions 27.8 mm x 124 mm x 84 mm

(1.09 in x 4.88 in x 3.31 in)

Weight < 200 g

Operating temperature

range

Standard module:

-10°C to +75°C

(14°F to 167°F)

Storage temperature -40°C to +85°C

(-40°F to 185°F)

Relative humidity,

non-condensing

5% to 95%

Operating altitude < 2000 m

Industry standards and

certifications

UL 508, CE, FCC Class A

Digital input

Sensor type Potential-free contact

(NPN or PNP); wet contact

I/O mode DI or event counter

Potential-free contact On = ground fault

Off = open

Wet contact (DI to COM) On = 10 Vdc to 30 Vdc

Off = 0 Vdc to 3 Vdc

Insulation voltage 3000 Vdc or 2000 Veff

Counter/Frequency 250 Hz, memory in off-state

5 LCS tool SMA Solar Technology AG

14 IMVIOBOX-IA-xx-16 Installation Manual

5 LCS tool

The inverters and the Inverter Manager must be

commissioned via the local commissioning and service tool

(LCS-Tool). Commissioning is required before the inverters

are connected to the utility grid and start to feed-in power.

It is recommended to use the latest version of the LCS-Tool.

The LCS-Tool is available in the download area at

www.SMA-Solar.com.

The hardware requirements for the LCS-Tool are:

• PC with Windows

TM

7 and later

•1 GB HDD

• 2 GB RAM

The LCS-Tool must be installed on a local PC drive. The PC

must be connected to the LAN 1 port of the Inverter

Manager via a router (DHCP recommended).

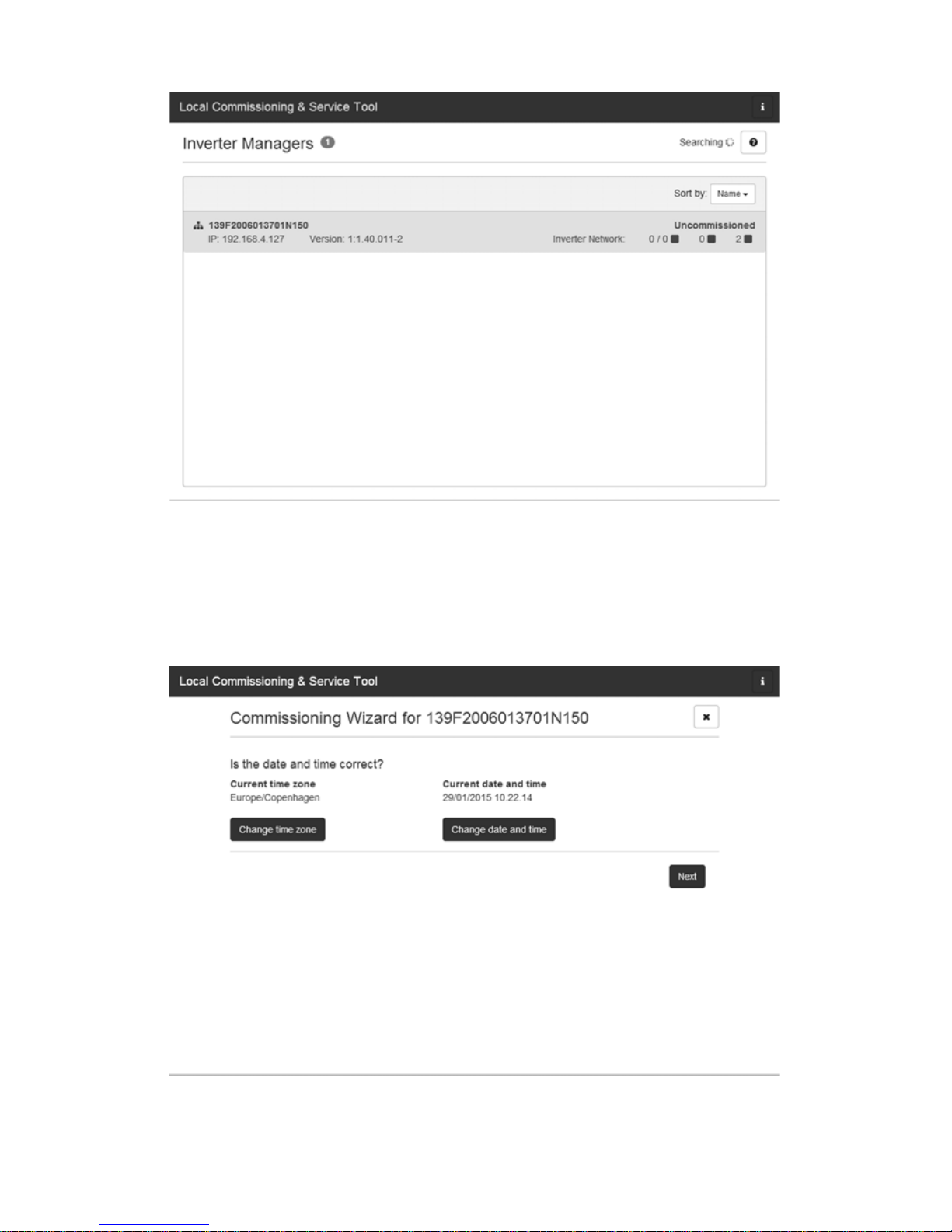

Figure 8: Commissioning inverters via the LCS-Tool

5.1 Commissioning

1. Start up the LCS-Tool. The tool shows a list of all

identified Inverter Managers. It can take several

minutes until the LCS-Tool has identified all Inverter

Managers.

2. The screen now shows a list of all Inverter Managers

(see figure 9). To start the assistant, click on the Inverter

Manager to be configured. By clicking on the Inverter

Manager, the inverters found by the Inverter Manager

are displayed. Inverters that have not been

commissioned (no grid code assigned) are presented

with a blue square together with their software version.

INFORMATION

The LAN 1 port of the Inverter Manager must have

an IP address assigned by a DHCP server that is

connected to the LAN 1 port.

An IP address can be manually assigned to the

Inverter Manager.

It is important that the computer (on which the

LCS-Tool runs) is connected to the same IP subnet as

the Inverter Manager.

The Inverter Manager may not be assigned an IP

from the system network range 192.168.4.0/24.

The LAN 2 port is only intended for inverters and

battery storage systems.

ALCS tool

B Router (DHCP recommended)

C Inverter Manager

D Sunny Tripower 60 / Sunny Highpower 75

ELAN 1

FLAN 2

G Power Analyser UMG 604-PRO from Janitza

electronics GmbH

H Sunny Tripower Storage 60

I Battery

SMA Solar Technology AG 5 LCS tool

Installation Manual IMVIOBOX-IA-xx-16 15

Figure 9: LCS-Tool - start screen

3. Assign a password for your user group when first

registering. The security status of your password is

displayed.

4. Verify that date and time are correct. If not, set date

and time and continue (see figure 10).

Figure 10: LCS-Tool - checking date and time

5 LCS tool SMA Solar Technology AG

16 IMVIOBOX-IA-xx-16 Installation Manual

5. In case of battery storage systems, enter the battery

details. The details under Pre-Set Battery Limits serve as

additional safety limit for battery charging and

discharging (see the battery manufacturer's manual).

Figure 11: LCS-Tool - Battery details

6. Optionally, you can assign a name, location and

owner of the Inverter Manager (see figure 11).

Figure 12: LCS-Tool - PV system details

SMA Solar Technology AG 5 LCS tool

Installation Manual IMVIOBOX-IA-xx-16 17

7. A list of the identified inverters of the selected Inverter

Manager is displayed.

Make sure that all inverters are present. It is possible to

continue the configuration of the listed inverters even if not

all inverters are detected. The undetected inverters can

always be configured later.

8. Select the desired country from the list of options

available for the inverters in the network (see figure

13).

9. Select the desired grid code from the list of options

available for the selected country. If necessary, load a

customer specific grid code by clicking the button

[Load] (see figure 13). The button [Create] is inactive

and cannot be used.

Figure 13: LCS-Tool - selecting the country and grid code

5 LCS tool SMA Solar Technology AG

18 IMVIOBOX-IA-xx-16 Installation Manual

10. The LCS-Tool prompts for a confirmation of the selected

country and grid code. In case of battery storage

systems, the battery details are additionally shown.

A wrong configuration can be changed by clicking the

[Back] button and by changing the settings in the

previous window.

11. The system then applies the grid code selected on the

Inverter Manager to the detected inverters. Any

inverter added at a later stage automatically inherits

the same grid code. The application of only one grid

code is possible per Inverter Manager.

12. A green square identifies the commissioned inverters.

The inverters are only connected to the utility grid when

the [Start] command has been carried out from the bar

below the start menu (see figure 14).

Figure 14: LCS-Tool - list of all inverters connected to the Inverter

Manager

INFORMATION

It is essential to choose the correct grid code.

A modification after the first ten operating hours have

passed is only possible with a personal SMA Grid

Guard code.

The grid code parameters can be changed

subsequently with the LCS-Tool (see

section 5.2.7, page 28). Prerequisite is the use of the

latest version of the LCS-Tool.

SMA Solar Technology AG 5 LCS tool

Installation Manual IMVIOBOX-IA-xx-16 19

13. If sufficient PV power is present and the grid code

conditions are met, the inverter starts the operation. For

battery storage systems, a successful battery start and

the fulfillment of the Grid-Code requirements is

necessary.

14. During commissioning it is possible to download a

commissioning report in the Reports menu. The report

contains information about inverter settings, including

actual disconnection values for each inverter. By

clicking the folder icon in the menu Reports, it is

possible to open a folder for commissioning reports

(incl. grid code information) (see 15).

Figure 15: LCS-Tool - commissioning report

5 LCS tool SMA Solar Technology AG

20 IMVIOBOX-IA-xx-16 Installation Manual

5.2 Operation

5.2.1 Forgot Password

Figure 16: LCS-Tool - forgotten password?

If you have forgotten the password for the user interface,

you can log in with a Personal Unlocking Key (PUK). Each

user group has its own PUK.

Procedure:

1. Request a PUK (see "Application for ordering a PUK" at

www.SMA-Solar.com).

2. Open the LCS-Tool.

3. Select the user group User or Installer.

4. Enter the PUK instead of the password.

5. Call up the menu Setup.

6. Change the password of the desired user group under

Password.

7. Select [Save] to save the changes.

SMA Solar Technology AG 5 LCS tool

Installation Manual IMVIOBOX-IA-xx-16 21

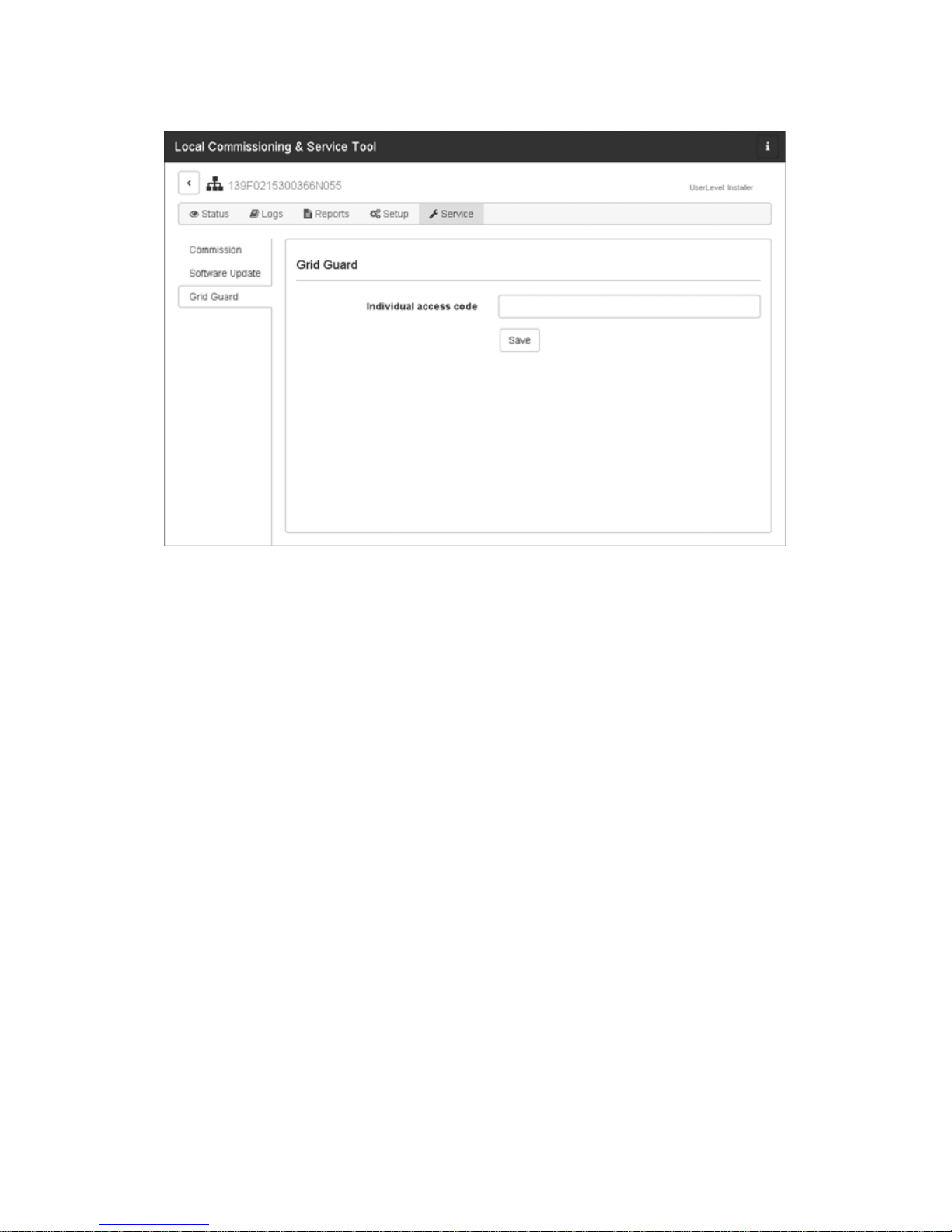

5.2.2 Changing the Grid Code

Figure 17: LCS-Tool - entering the SMA Grid Guard code

To reset the Inverter Manager after the first ten operating

hours and to select a new country data set, use your

SMA Grid Guard code under the user group Installer (see

certificate "Order form for the SMA Grid Guard code" at

www.SMA-Solar.com).

Procedure:

1. Open the LCS-Tool.

2. Log in as an Installer.

3. Call up the menu Service.

4. Enter your SMA Grid Guard code in the field

Individual access code under Grid Guard.

5. Select [Save] to save the changes.

☑ A new menu item General is available under the

menu Setup.

5 LCS tool SMA Solar Technology AG

22 IMVIOBOX-IA-xx-16 Installation Manual

5.2.3 Updating the Firmware

Figure 18: LCS-Tool - manual firmware update

You can carry out the firmware update of the Inverter

Manager manually. It is recommended to use the latest

version of the LCS-Tool. The LCS-Tool is available in the

download area at www.SMA-Solar.com.

Procedure:

1. Open the LCS-Tool.

2. Log in as User or Installer.

3. Call up the menu Service.

4. Select the tab Inverter Manager under Software

Update.

5. Select [Start update] to carry out the update.

☑ The update is carried out now.

Damage to the products due to disruption of the

update procedure

If the connection between the Inverter Manager and the

computer is disrupted, a damage to the device may occur.

• Do not disconnect the connection between the

Inverter Manager and the computer.

• Do not disconnect the computer and

Inverter Manager from the electricity supply.

• Do not switch the computer to energy-saving mode.

SMA Solar Technology AG 5 LCS tool

Installation Manual IMVIOBOX-IA-xx-16 23

5.2.4 Setting the System Fallback

Figure 19: LCS-Tool - setting the fallback parameter

A system fallback can be configured in the event of a

communication failure between the Inverter Manager and a

superior control unit (e.g. SCADA system or

Power Plant Controller). The superordinate system fallback

can only be configured via the LCS-Tool. To set the values

for a superordinate fallback, use your SMA Grid Guard

code under the user group Installer (see

section 5.2.2, page 21).

Procedure:

1. Open the LCS-Tool.

2. Log in as an Installer.

3. Call up the menu Setup.

4. Enter the respective values under Plant fallback.

5. Select [Save] to save the changes.

5 LCS tool SMA Solar Technology AG

24 IMVIOBOX-IA-xx-16 Installation Manual

5.2.5 Setting Limited Export

Figure 20: LCS-Tool - setting Limited Export

With the Limited Export feature in connection with a

Modbus-capable energy meter, a maximum defined AC

output power can be made available at the grid-connection

point (see figure 22). The total nominal power of all

inverters connected to the Inverter Manager is taken into

account. At the grid-connection point, the inverter's

maximum output power is increased or decreased by the

amount of self-consumption.

The limitation at the grid-connection point is complied with,

while all connected loads can still be supplied with energy

from the inverters.

The maximum setpoint of the nominal PV system power can

be assigned with static or dynamic attributes:

• Assignment of static attributes:

Set the parameter Active Power (P_ref) for the active

power limitation in menu Inverter Parameter under

Protection settings > Support settings >

Immediate controls (see Section 5.2.7 “Changing of

Inverter Parameters”, page 28).

• Assignment of dynamic attributes:

In addition, the setpoint of the nominal PV system

power can be limited dynamically via I/O Box,

Modbus and direct marketer interface. If the value is set

dynamically, the parameter Active Power (P_ref) is

overwritten in the LCS-Tool. This applies to both the

regular feed-in operation and to the activated Limited

Export function. A load-dependent control is not

possible without an activated Limited Export function.

The inverters are then directly limited to the setpoint

(see figure 23).

Procedure:

1. Open the LCS-Tool.

2. Log in as an Installer.

3. Call up the menu Setup.

4. Enter the respective values under Limited Export.

5. Select [Save] to save the changes.

The parameters Meter IP-Address, Meter Modbus Port,

Meter Modbus Unit ID and the register Meter Power

Modbus are used for the configuration of the energy meter.

With zero export as a special case of Limited Export, the

feed-in operation into the utility grid can be completely

prevented. The parameter Safety Offset indicated as

percentage of nominal PV system power is a safety margin

to the maximum value of the output power set at the

grid-connection point.

This safety value is preset for safety reasons and due to

sudden load changes. Thus, a safety margin to the setpoint

is ensured. With the activation process, the setpoint is

reduced to the safety value. Thus, the feed-in power is

always less than the actual setpoint.

SMA Solar Technology AG 5 LCS tool

Installation Manual IMVIOBOX-IA-xx-16 25

The parameter Meter Connection Timeout is the time in

seconds that is required to adjust the nominal PV system

power to 0 W when communication to the energy meter is

interrupted.

To acquire an overview of the current system values, open

the menu Status and select Overview (see figure 21).

Figure 21: LCS-Tool - Overview of current system values

Modbus control

To make this limitation permanent, set the desired

value in the Modbus register 40349.

To disconnect the inverter immediately from the utility

grid while the Limited Export function is running, set

the value "0" in the Modbus register 40348.

For further information on the Modbus interface see

technical information "SUNNY TRIPOWER 60 /

SUNNY HIGHPOWER PEAK1 - SunSpec®

Modbus® Interface" at www.SMA-Solar.com.

5 LCS tool SMA Solar Technology AG

26 IMVIOBOX-IA-xx-16 Installation Manual

Figure 22: Feeding-in operation with Limited Export / Peak Load

Shaving

Figure 23: Feeding-in operation without Limited Export

A Inverters

B Inverter Manager

CLoads

D Utility grid

E Grid-connection point

F Sunny Tripower 60 / Sunny Highpower 75:

Energy meter

Sunny Tripower Storage 60:

Power analyzer UMG 604-PRO von Janitza

electronics GmbH

G Modbus TCP

HAC

SMA Solar Technology AG 5 LCS tool

Installation Manual IMVIOBOX-IA-xx-16 27

5.2.6 Setting the Peak Load Shaving

Function

Figure 24: LCS-Tool - Setting the Peak Load Shaving function

With the Peak Load Shaving function in combination with

the Power Analyser UMG 604-PRO from Janitza electronics

GmbH, the behavior of the Sunny Tripower Storage 60 on

the power exchange at the grid-connection point can be

optimized (see Figure 22). With the "Peak Load Shaving"

function, certain grid-exchange power outputs to which the

Sunny Tripower Storage 60 is adjusted depending on its

power and battery capacity available can be set. The

acquisition of active power at the grid-connection point is

systematically limited to a maximum value (Discharge

Setpoint/Consumption Limit). This maximum value is

given as upper limit for the grid reference power in the

LCS-Tool. The battery is discharged above this maximum

value in a controlled manner. Thus, the maximum value is

retained as long as the battery capacity allows it.

The battery is charged when the value is below the minimum

value set in the LCS-Tool (Charge Setpoint/Feed-in

Limit). In conjunction with a PV system, this value specifies

the threshold for increased self-consumption.

Procedure:

1. Open the LCS-Tool.

2. Log in as an Installer.

3. Call up the menu Setup.

4. In the menu Limited Export, the function Peak Load

Shaving is activated.

5. Under Peak Load Shaving, enter the respective

values for Discharge Setpoint/Consumption Limit

and Charge Setpoint/Feed-in Limit in kW.

6. Select [Save] to save the changes.

5 LCS tool SMA Solar Technology AG

28 IMVIOBOX-IA-xx-16 Installation Manual

5.2.7 Changing of Inverter

Parameters

Figure 25: LCS-Tool - changing of inverter parameters

All inverter parameter are Grid Guard protected and

require the Grid Guard code for changes. To change the

inverter settings, use your SMA Grid Guard code under the

user group Installer (see section 5.2.2, page 21).

Procedure:

1. Open the LCS-Tool.

2. Log in as an Installer.

3. Call up the menu Setup.

4. Enter the respective values under Inverter

Parameter.

5. Select [Save] to save the changes.

Input values for Peak Load Shaving

The input value for Discharge Setpoint/

Consumption Limit is interpreted by the Inverter

Manager as a positive value and the one for Charge

Setpoint/Feed-in Limit as a negative value. If the

Inverter Manager, for example, has to limit the grid

reference power to +50 kW and charge the battery

below a grid reference power of +10 kW, the value

50 must be entered for Discharge Setpoint/

Consumption Limit and the value -10 for Charge

Setpoint/Feed-in Limit.

If the value for Discharge Setpoint/Consumption

Limit and the value for Charge Setpoint/Feed-in

Limit is set to 0, this corresponds to the classical

increased self-consumption of PV power without the

shaving of peak loads.

FNN note

In Germany, according to FNN note "Connecting

and operating storage units in low voltage networks"

(October 2016), systems eligible under the FIT

scheme in accordance with EEG and KWKG are not

allowed to feed energy from storage units into the

utility grid. To ensure this, the input value for

Discharge Setpoint/Consumption Limit is not

allowed to be negative.

SMA Solar Technology AG 5 LCS tool

Installation Manual IMVIOBOX-IA-xx-16 29

Deactivating/Activating the inverter

parameters

To activate and deactivate a parameter, double-click on the

parameter using the left mouse button.

When the parameters are activated, the input fields and

buttons are enabled. Inactive parameters are marked with

disable.

Fi gure 26: LC S-T ool - dea cti vating/ act ivating the inverte r pa rameters

5 LCS tool SMA Solar Technology AG

30 IMVIOBOX-IA-xx-16 Installation Manual

Changing signs on power factor parameters

To change signs on power factor parameters, click on the

sign using the left mouse button.

Figure 27: LCS-Tool - changing signs

Setting the I/O Box Parameters

To enter the parameters in the sub-menu I/O Box, click on

the input fields using the right mouse buttons.

Figure 28: LCS-Tool - setting the I/O Box parameter

Loading...

Loading...