Page 1

SM 2610957105 05-08 6/5/08 7:39 AM Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes d’utilisation/de sécurité

Instrucciones de funcionamiento y seguridad

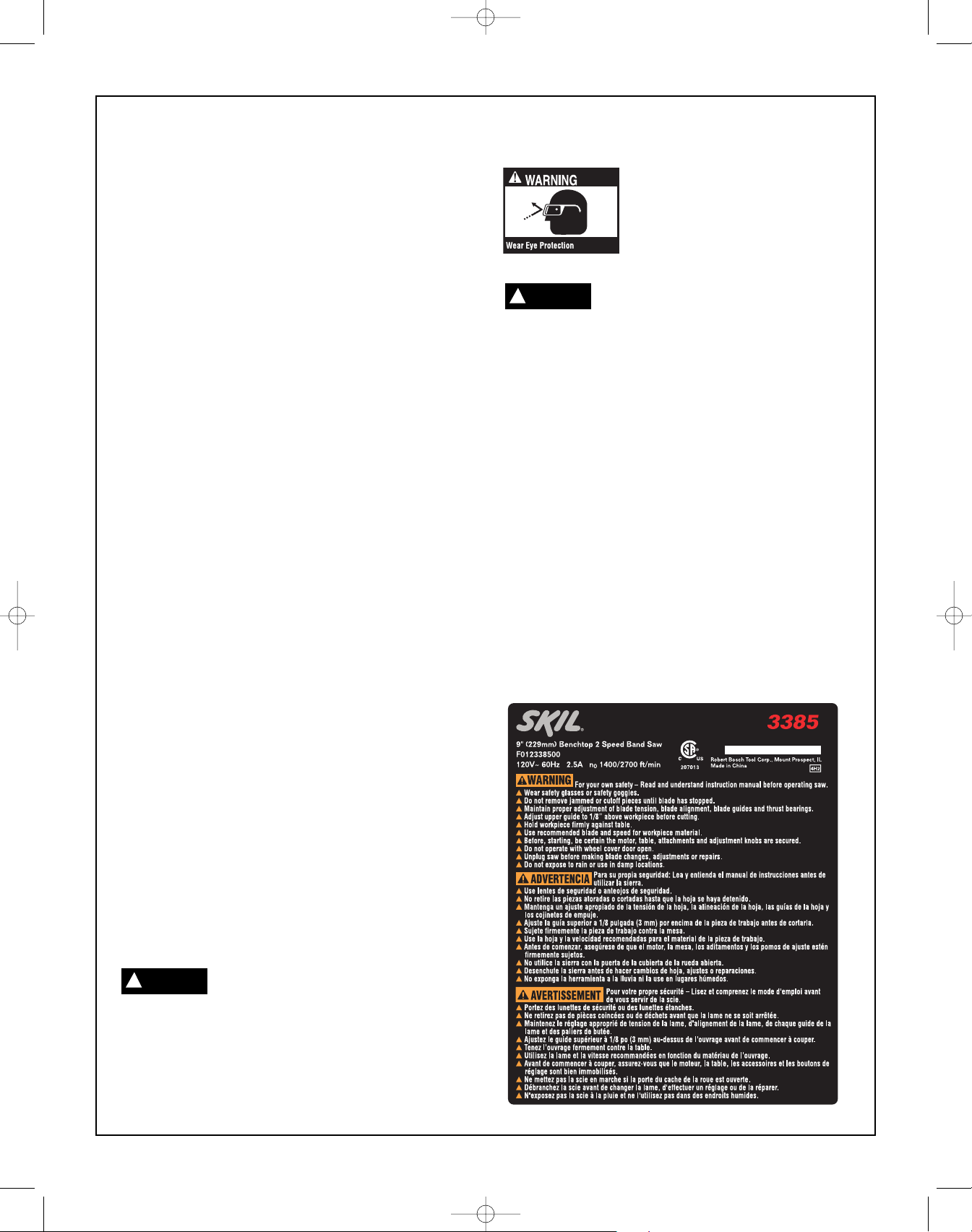

3385-01

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations et

les adresses de nos centres de

service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-877-SKIL999 (1-877-754-5999) www.skil.com

For English Version Version française Versión en español

See page 2 Voir page 19 Ver la página 36

Page 2

SM 2610957105 05-08 6/5/08 7:39 AM Page 2

General Safety Rules

!

WARNING

“READ ALL INSTRUCTIONS” Failure to follow the safety rules listed below and other basic safety

precautions may result in serious personal injury.

Work Area

KEEP CHILDREN AWAY

Do not let visitors contact tool or extension cord. All

visitors should be kept safe distance from work area.

KEEP WORK AREAS CLEAN

Cluttered areas and benches invite accidents.

MAKE WORKSHOP KID-PROOF

With padlocks, master switches, or by removing

starter keys.

AVOID DANGEROUS ENVIRONMENTS

Don’t use power tools in damp or wet locations. Keep

work area well lit. Do not expose power tools to rain.

Do not use the tool in the presence of flammable

liquids or gases.

Personal Safety

KNOW YOUR POWER TOOL

Read and understand the owner’s manual and labels

affixed to the tool. Learn its application and

limitations as well as the specific potential hazards

peculiar to this tool.

DON’T OVERREACH

Keep proper footing and balance at all times.

STAY ALERT

Watch what you are doing. Use common sense. Do

not operate tool when you are tired. Do not operate

while under medication or while using alcohol or

other drugs.

WEAR PROPER APPAREL

Do not wear lose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get caught in

moving parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long hair.

ALWAYS USE SAFETY GLASSES

Also use face or dust mask if cutting operation is dusty,

and ear plugs during extended periods of operation.

Everyday eyeglasses have only impact resistant

lenses, they are NOT safety glasses.

GUARD AGAINST ELECTRIC SHOCK

Prevent body contact with grounded surfaces. For

example: pipes, radiators, ranges, refrigerator

enclosures.

DISCONNECT TOOLS FROM POWER SOURCE

When not in use, before servicing, when changing

blades, bits, cutters, etc.

KEEP GUARDS IN PLACE

In working order, and in proper adjustment and

alignment.

REMOVE ADJUSTING KEYS AND WRENCHES

When not in use, before servicing, when changing

blades, bits, cutters, etc.

REDUCE THE RISK OF UNINTENTIONAL STARTING

Make sure the switch is in the “OFF” position before

plugging in tool.

GROUND ALL TOOLS

This tool is equipped with an approved 3-conductor

cord and a 3 prong grounding type plug to fit the

proper grounding type receptacle. The green

conductor in the cord is the grounding wire. Never

connect the green wire to a live terminal.

NEVER STAND ON TOOL OR ITS STAND

Serious injury could occur if the tool is tipped or if the

cutting tool is accidentally contacted. Do not store

materials on or near the tool such that it is necessary

to stand on the tool or its stand to reach them.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

ensure that it will operate properly and perform its

intended function. Check for alignment of moving

parts, mounting, and any other conditions that may

affect its operation. A guard or other part that is

damaged should be properly replaced.

!

WARNING

repairmen. Contact the nearest Skil Factory Service

Center, Authorized Service Station or other

competent repair service.

!

WARNING

!

WARNING

may create a hazard.

All repairs, electrical or mechanical,

should be attempted only by trained

Use only Skil replacement parts; any

others may create a hazard.

The use of any other accessories not

specified in the current Skil catalog,

“SAVE THESE INSTRUCTIONS”

2.

Page 3

SM 2610957105 05-08 6/5/08 7:39 AM Page 3

Additional Safety Rules

Tool Use

DON’T FORCE TOOL

It will do the job better and safer at the rate for which

t was designed.

i

SE THE RIGHT TOOL

U

on’t force a small tool or attachment to do the job of

D

a heavy duty tool. Don’t used tool for purpose not

intended—for example, don’t use a circular saw for

cutting tree limbs or logs.

SECURE WORK

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate

the tool.

NEVER LEAVE TOOL RUNNING UNATTENDED

Turn power off. Don’t leave tool until it comes to a

complete stop.

Tool Care

DO NOT ALTER OR MISUSE TOOL

These tools are precision built. Any alteration or

modification not specified is misuse and may result in

dangerous conditions.

AVOID GASEOUS AREAS

Do not operate electric tools in a gaseous or

explosive atmosphere. Motors in these tools normally

spark, and may result in a dangerous condition.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically

and if damaged, have repaired by authorized service

facility. Inspect extension cords periodically and

replace if damaged. Keep handles dry, clean and

free from oil and grease.

Before connecting the tool to a power source

(receptacle, outlet, etc.), be sure voltage supplied is

the same as that specified on the nameplate of the

tool. A power source with a voltage greater than that

specified for the tool can result in serious injury to the

user, as well as damage to the tool. If in doubt, DO

NOT PLUG IN THE TOOL. Using a power source with

a voltage less than the nameplate rating is harmful to

the motor

.

The operation of any power tool can

esult in foreign objects being

r

hrown into the eyes, which can

t

result in severe eye damage.

Always wear safety goggles that

comply with ANSI Z87.1 (shown on

Package) before commencing power tool operation.

!

WARNING

and other construction activities contains

chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other

masonry products, and

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter

out microscopic particles.

NOTE AND FOLLOW THE SAFETY WARNINGS

AND INSTRUCTIONS THAT APPEAR ON THE

Some dust created by power

sanding, sawing, grinding, drilling,

BAND SAW PRESS:

!

WARNING

OPERATOR COMMON SENSE AND ALERTNESS AT

ALL TIMES WHEN THE BAND SAW IS BEING USED.

Do not allow familiarity (gained from frequent use of your

band saw) to become commonplace. Always remember

that a careless fraction of a second is sufficient to inflict

severe injury.

THINK SAFETY

SAFETY IS A COMBINATION OF

.

3

Page 4

SM 2610957105 05-08 6/5/08 7:39 AM Page 4

!

WARNING

1. Do not stare directly at the laser beam. Eye damage

may occur if you deliberately stare into the beam.

2. The laser light beam used in this system is Class II

with maximum 1 mW and 650 nm wavelengths. AVOID

DIRECT EYE EXPOSURE.

3. The laser must be used and maintained in

accordance with the manufacturer’s instructions:

• Never aim the beam at any person or an object other

than the workpiece.

• Do not project the laser beam into the eyes of others.

• Always ensure the laser beam is aimed at a workpiece

without reflective surfaces as the laser beam could be

projected into your eyes or the eyes of others.

To reduce the risk of injury:

Laser safety

!

CAUTION

performance of procedures other

than those specified herein may

esult in hazardous radiation

r

xposure.

e

Use of controls or

adjustments or

Specific safety rules for band saws

1. To avoid injury from unexpected movement, make

sure the saw is on a firm, level surface, properly

secured to prevent rocking. Make sure there is

adequate space for operations. Bolt the saw to a

support surface to prevent slipping or sliding during

operation.

2. Turn off and unplug the saw before moving it.

3. Use the correct size and style of blade.

4. Make sure the blade teeth point down and toward the

table.

5. Blade guide, supports, bearings, and blade tension

must be properly adjusted to avoid accidental blade

contact and to minimize blade breakage. To maximize

blade support, always adjust the upper blade guide and

blade guard so that it barely clears the workpiece.

6. The table tilt lock handle should be tight.

7. Use extra caution with very large, very small, or

awkward workpieces.

8. Use extra supports to prevent workpieces from sliding

off the table top.

9. Workpieces should be secured so they don’t twist,

rock, or slip while being cut.

10. Plan intricate or small work carefully to avoid

pinching the blade. Avoid awkward operations and hand

positions to prevent accidental contact with the blade.

11. Small pieces should be secured with clamps or

fixtures. Do not hold small pieces with your hand

because your fingers might go under the blade guard.

12. Support round work properly (use a V block or press

it against the miter gauge) to prevent it from rolling and

the blade from biting.

13. Cut only one workpiece at a time. Make sure the

table is clear of everything except the workpiece and its

guides before you turn the saw on.

14. Always watch the saw run before each use. If there

is excessive vibration, saw blade stuttering, or unusual

noise, stop immediately. Turn the saw off. Unplug it

immediately. Do not start the saw again until the

problem has been located and corrected.

15. To free any jammed material, turn the switch off.

Remove the switch key and unplug the saw.

Wait for all moving parts to stop before removing the

jammed material.

16. Do not leave the work area until all moving parts

have stopped. Shut off the power to master switches.

Remove the switch key from the band saw and store it

in a safe place, away from children. Childproof the

workshop!

17. Maintain proper adjustment of blade tension, blade

alignment, blade guides and thrust bearings.

18. Adjust upper guide to 1/8” above workpiece before

cutting.

19. Hold workpiece firmly against table.

20. Use recommended blade and speed for workpiece

material.

21. Before, starting, be certain the motor, table,

attachments and adjustment knobs are secured.

22. Do not operate with wheel cover door open.

23. Unplug saw before making blade changes,

adjustments or repairs.

24. Do not expose to rain or use in damp locations.

.

4

Page 5

SM 2610957105 05-08 6/5/08 7:39 AM Page 5

Motor Specifications and Electrical Requirements

General Specifications

Voltage Rating . . . . . . . . . . . . . . . . . . .120 V, 60 Hz

mperage Rating . . . . . . . . . . . . . . . . . . . . . . .2.5 A

A

No Load Speed . . . . . . .N

Throat . . . . . . . . . . . . . . . . . . . . . . . . . .9" (22.9 cm)

Blade . . . . . . . . . . . . . . . . . . . . . . .59 1/2” (151 cm)

Cutting Capacity . . . . . . . . . . . . . . . .3 1/2" (8.9 cm)

Table size . . . . . . . . . 11 3/4 x 11 3/4" (30 x 30 cm)

1400 / 2700 min (SFPM)

o

Motor Specifications

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped with

an electric cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged into a

matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

This Band Saw is designed to use a 1700 RPM motor. It

is wired for operation on 110-120 volts, 60 Hz. alternating

current. Before connecting the motor cord to power

source, make certain the switch is in the “OFF” position

and be sure the electric current is of the same

characteristics as stamped on the band saw nameplate.

Connection To A Power Source

This machine must be grounded while in use to protect

the operator from electric shock.

Plug power cord into a 110-120V properly grounded type

outlet protected by a 15-amp dual element time delay fuse

or circuit breaker.

Not all outlets are properly grounded. If you are not sure

that your outlet, as pictured in Fig. 1, is properly

grounded; have it checked by a qualified electrician.

!

DANGER

installing or removing the plug to or from the outlet.

!

DANGER

serious shock, particularly when used near metal

plumbing or other metal objects. If shocked, your

reaction could cause your hands to hit the tool.

!

WARNING

immediately to avoid shock or fire hazard.

To avoid electric shock, do not touch

the metal prongs on the plug when

Failure to properly ground this power

tool can cause electrocution or

If power cord is worn, cut or damaged

in any way, have it replaced

Your unit is for use on 120 volts; it has a plug that looks

like the one in Figure 1.

FIG. 1

This power tool is equipped with a 3-conductor cord and

grounding type plug, approved by Underwriters

Laboratories and the Canadian Standards Association.

The ground conductor has a green jacket and is

attached to the tool housing at one end and to the

ground prong in the attachment plug at the other end.

If the outlet you are planning to use for this power tool is

of the two-prong type, DO NOT REMOVE OR ALTER

THE GROUNDING PRONG IN ANY MANNER. Have a

qualified electrician replace the TWO-prong outlet with a

properly grounded THREE-prong outlet.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface that is

green with or without yellow stripes is the equipmentconductor. If repair or replacement of the electric cord or

plug is necessary, do not connect the equipmentgrounding conductor to a live terminal.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely

understood, or if in doubt as to whether the tool is

properly grounded.

Always use proper extension cord. The use of any

extension cord will cause some loss of power. To keep

this to a minimum and to prevent overheating and motor

burn-out, use the table below to determine the minimum

wire size (A.W.G.) extension cord. Use only 3-wire

extension cords which have 3-prong grounding type

plugs and 3-pole receptacles which accept the tool’s

plug. Make sure your extension cord is in good

condition.

Extension Cord Length Wire Size A.W.G.

0-25 feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

26-50 feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

51-100 feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

“SAVE THESE INSTRUCTIONS”

.

5

Page 6

SM 2610957105 05-08 6/5/08 7:39 AM Page 6

Table of Contents

Page

General Safety Rules .................................................. 2

Additional Safety Rules........................................... 3– 4

Motor Specifications and Electrical Requirements ..... 5

npacking and Checking Contents............................. 7

U

able of Loose Parts ................................................... 7

T

Page

Getting To Know Your Band Saw........................... 8–9

Assembly and Adjustments .................................9-14

Basic Band Saw Operation................................15-17

Maintaining Your Band Saw....................................18

Troubleshooting ......................................................53

.

6

Page 7

SM 2610957105 05-08 6/5/08 7:39 AM Page 7

Unpacking and Checking Contents

!

ARNING

W

ntil all assembly steps are complete and until you

u

ave read and understood the entire owner’s

h

manual.

Model 3385-01 Motorized Band Saw is shipped

complete in one box.

1. Unpacking and Checking Contents, separate all parts

from packing materials. Check each one with the “Table

of Loose Parts” to make sure all items are accounted for

before discarding any packing material.

!

WARNING

in power cord or turn the switch on until the

missing parts are obtained and are installed

correctly.

2. Remove the protective oil that is applied to table and

base. Use any ordinary household type grease and spot

remover.

!

WARNING

volatile solvents.

3. Apply a coat of paste wax to the table and machined

surfaces of base to prevent rust. Wipe all parts

thoroughly with a clean dry cloth.

To reduce the risk of injury, never

connect plug to power source outlet

If any parts are missing, do not attempt to assemble the band saw, plug

To avoid fire or toxic reaction, never

use gasoline, naptha or similar highly

A

B

C

D

Table of Loose Parts

ITEM DESCRIPTION QTY.

A

B Table 1

C Table insert 1

D Fence 1

E

F 3 mm allen wrench 1

G

H Table bolt, washer, lock washer 4

I

Band Saw

Miter gauge assembly 1

10 and 13 mm combination wrench 1

Operating Guide 1

I

1

H

E

G

F

.

7

Page 8

SM 2610957105 05-08 6/5/08 7:39 AM Page 8

Getting To Know Your Band Saw

1 Blade tension knob

2 Blade tension quick release handle

ED work light

3 L

4 Blade

able support assembly

5 T

6 Lower blade guide

7 Drive belt

8 Lower wheel

oor

9 D

10 Reset button

11 Upper wheel

12 Blade tracking lock knob

13 Blade tracking knob

14 Motor assembly

15 Base

16 Dust port

17 Table tilt adjustment lock knob

18 Table tilt adjustment knob

1

1

10

2

11

9

3

4

5

8

6

29

28

27

15

26

19 Table

20 Upper blade guide

21 Upper blade guide lock knob

22 Upper blade guide adjustment knob

23 Upper viewing port

24 Upper door latch

25 Laser line adjustment knob

26 Lower door latch

27 ON/OFF switch with safety key

28 Laser switch

29 Work light switch

25

23

24

2

7

1

2

19

23

22

12

13

21

20

19

18

14

17

16

15

8.

Page 9

SM 2610957105 05-08 6/5/08 7:39 AM Page 9

Assembly and adjustments

efore assembling the band saw, turn

!

WARNING

unplug the power cord from the electrical outlet.

The power cord must remain unplugged whenever

you are working on the saw.

1. Loosen the locking knob (1) and rotate the blade

guard knob (2) to raise the upper blade guard (3) to

the highest position.

2. Place the table on the table support by sliding the slot

(4) in the table over the blade (5), taking care not to

damage the blade.

3. Align the four holes on the bottom of the table over

the four holes in the table support

4. Place a washer and locking washer on each bolt (7)

and secure the bolt through the table support and into

the table.

5. Tighten all four bolts to make sure the table is

fastened securely.

6. Align the slit in the plastic table insert (8) with the slit

in the table and the blade. Press the inset into the

square opening in the middle of the table.

Note: The table must be properly adjusted before

operating the saw. See Table tilt adjustment (page 10).

B

off the saw, remove the safety key and

Install the table (Figs. 3–6)

(6).

FIG. 3

2

1

3

5

FIG. 4

4

FIG. 6

6

FIG. 5

7

8

9.

Page 10

SM 2610957105 05-08 6/5/08 7:39 AM Page 10

Assembly and adjustments

Install the fence (Fig. 7)

1. Raise the clamp (1) on the fence assembly to the up

position.

2. Place the fence on the table so that the clamp is at the

front of the table.

3. Lower the fence clamp to lock the fence in position on

the table. Rotate clamp to adjust tightness.

To move the fence, raise the clamp and slide the fence

to the desired location. Lower the clamp to lock the fence

in position.

Mount the band saw to a work

surface (Fig. 8)

Secure the saw to a suitable work surface by inserting

the appropriate mounting hardware through the four predrilled holes

(2) in the base of the saw.

Adjustments

!

WARNING

and unplug the power cord from the electrical outlet.

The power cord must remain unplugged whenever

you are working on the saw.

Before adjusting the band saw, turn

off the saw, remove the safety key,

FIG. 7

1

FIG. 8

2

2

Table tilt adjustment (Fig. 9)

to 45° to the right.

The table tilts from 0

1. Turn the table tilt lock knob

2. Turn the table tilt adjustment knob (4) until the pointer

is at the desired angle on the table tilt gauge (5).

3. Tighten the table lock knob (3) to secure the table.

°

(3) counterclockwise.

Connect to a dust collection

system (Fig. 10)

A 1 1/2" (3.8 cm) dust port (6) is located on the motor

side of the band saw. This port can be connected to a

dust collection system directly by connecting the pickup

end of the dust collection hose to the dust port.

FIG. 9

FIG. 10

4

6

5

3

10.

Page 11

SM 2610957105 05-08 6/5/08 7:39 AM Page 11

Assembly and adjustments

Blade tension adjustment (Fig. 11)

A change in blade width or type of material being cut will

affect the blade tension. If the blade tension is too loose,

the blade may slip on the wheels. If the blade is too

tight, the blade may break.

1. Turn the blade tension knob

the upper blade wheel (2) and increase the tension

on the blade. The blade should be tight on the wheel,

but do not overtighten the blade.

2. Turn the blade tension knob

lower the upper blade wheel (2) and reduce the

tension on the blade.

(1) clockwise, to raise

(1) counterclockwise to

Blade tracking adjustment (Fig. 11 and 12)

Check for proper blade tension before making any

blade tracking adjustments.

1. Rotate the upper blade wheel

check the position of the blade on the wheel. The

blade should remain in the center of the wheel.

a. If the blade moves toward the front of the wheel,

loosen the blade tracking lock knob (4) and turn the

blade tracking knob (3) slightly clockwise. At the

same time, turn the upper wheel (2) until the blade is

centered.

b. If the blade moves toward the back edge of the

wheel, turn the blade tracking knob (3) slightly

counterclockwise. At the same time, turn the upper

wheel (2) until the blade is centered.

Tighten the blade tracking lock knob

2.

finished making adjustments.

3. Check the position of the blade on the lower wheel. If

the tracking is off, continue adjusting the blade until it

sits properly on both wheels.

(2) clockwise and

(4) when you are

FIG. 11

FIG. 12

1

2

4

3

11.

Page 12

SM 2610957105 05-08 6/5/08 7:39 AM Page 12

Assembly and adjustments

Replace the blade (Fig. 13)

!

WARNING

t is possible to replace the blade with the table in place,

I

owever, it may be easier to remove the table before

h

eplacing the blade. If you do not remove the table,

r

remove the plastic table inset and pull the table

extension out so that it does not block the slot in the

table before removing or installing the blade.

1. Loosen the fence clamp and remove the fence from

the table.

2. Pull on the upper and lower door latches to open the

wheel cover door.

3. Move the blade tension adjustment quick release

handle

reduce tension on the blade.

4. Remove the old blade

away from the upper and lower blade guides (3) (and

through the slot in the table if you did not remove it).

5. Put the new blade in position around the upper and

lower wheels and between the upper and lower blade

guides

6. Center the blade on the upper and lower wheels.

Turn the upper wheel slowly to check the position of

the blade.

7. Move the blade tension adjustment quick release

handle

on the blade.

8. Make sure the blade is still centered on the upper and

Blade teeth are sharp. Use care when

handling a band saw blade.

(1) clockwise to lower the upper wheel and

(2). Slide the blade out and

(3).

(1) counterclockwise to increase the tension

FIG. 13

1

2

3

3

lower wheels and that it moves freely through the

blade guides.

9. The blade must be adjusted properly before operating

the saw:

a. See Blade tension adjustment (page 11).

b. See Blade tracking adjustment (page 11).

c. See Blade guide adjustment (page 12).

Blade guide adjustment

The upper and lower blade guides and support bearings

(located above and below the table) keep the blade

moving in a straight line during operation. These guides

must be checked and adjusted before each use and

after changing the blade.

Note: Make sure the blade tension and tracking are

properly adjusted before adjusting the upper and lower

blade guides.

Adjust the upper blade guide (Fig. 14–16)

Make sure the upper blade guide assembly

1.

right-angles to the blade (2). If not:

a. Loosen the screw (3) and rotate the assembly until it

is perpendicular to the blade.

b. Tighten the screw (3).

2. Loosen the support bearing screw (4) and move the

support bearing (5) forward or backward until the

(1) is at

bearing is 1/32" (0.8 mm) behind the blade. Tighten

the screw (4).

3. Loosen the left and right blade guide screws

move the guides (7) as close to the blade as possible

without pinching it. Using a feeler gauge (not

provided), make sure the space between each guide

and the blade measures 0.02" (0.5 mm). Tighten the

screws (6).

FIG. 14

3

1

2

12.

(6) and

Page 13

SM 2610957105 05-08 6/5/08 7:39 AM Page 13

Assembly and adjustments

Adjust the lower blade guides (Fig. 17)

1. Remove the table (see page 12).

2. Loosen the lower support bearing screw (1). Move

the support bearing (2) forward or backward until the

earing is 1/32" (0.8 mm) behind the blade (3)

b

3. Loosen the lower blade guide screws (4) and move

he left and right blade guides (5)as close to the

t

blades as possible without pinching it. Using a feeler

gauge (not provided), make sure the space between

each guide and the blade measures 0.02" (0.5 mm).

Tighten both screws

4. Install the table, taking care not to bump the table

against the blade.

(4).

.

Set blade guide assembly height (Fig. 18)

The blade guide assembly should be set approximately

1/8" (3.2 mm) above the workpiece.

1. Loosen the blade guide lock knob (1).

2. Rotate the blade guide adjustment knob (2) to lower

the blade guide assembly (3).

3. Tighten the blade guide lock knob (1).

FIG. 15

FIG. 16

5

4

2

7

7

6

6

FIG. 17

FIG. 18

3

1

2

5

5

6

1

2

3

6

13.

Page 14

SM 2610957105 05-08 6/5/08 7:39 AM Page 14

Assembly and adjustments

Miter gauge adjustment (Fig. 19)

lace the miter gauge in the right groove on the table.

P

he miter gauge can be adjusted 0° to 60° right and left

T

to maintain an accurate angle on your workpiece. To

adjust the angle on the miter gauge:

1. Turn the miter gauge knob

loosen.

2. Rotate the base of the gauge to align the pointer

with the desired angle.

3. Tighten the miter gauge knob

(1) counterclockwise to

(2)

(1).

Change speeds (Figs. 20 and 21)

Change the speed by moving the drive belt to the

adjacent pulleys.

1. Open the door.

2. Loosen, but do not remove, the two bolts

the motor assembly to the housing.

3. Pull the motor assembly (2) up (counterclockwise) to

reduce the tension on the belt (3).

4. Move the belt to the adjacent pulleys. Make sure the

belt is positioned properly on the pulleys.

5. Push the motor assembly down (clockwise) to

increase tension on the belt.

6. Tighten the two bolts that hold the motor to the

housing.

(1) that hold

FIG. 19

1

2

FIG. 20

1

2

Wheel brush adjustment (Fig. 21)

The wheel brush is located against the lower blade

wheel and helps keep the blade clean of sawdust and

wood chips.

1. Loosen the screw (4) that secures the wheel brush

(5).

2. Position the wheel brush against the blade.

3. Tighten the screw.

FIG. 21

3

1

4

5

14.

Page 15

SM 2610957105 05-08 6/5/08 7:39 AM Page 15

Operation

ON/OFF switch (Fig. 22)

. To turn the saw ON, move the switch (1)to the up

1

(ON) position.

2. To turn the saw OFF, move the switch to the down

(OFF) position.

3. To lock the switch in the OFF position:

a. Wait until the band saw has come to a complete stop.

b. Remove the safety key

Store the safety key in a safe place.

4. To unlock the switch and turn the saw ON, insert the

safety key into the switch, and move the switch to the

ON position.

(2) from the switch housing.

Reset button (Fig. 22)

In the event of an overload, the band saw has an

overload circuit. During an overload, the saw will stop

operating even though the switch is in the ON position.

To recover from an overload:

1. Turn the ON/OFF switch

2. Unplug the power cord from the power source.

3. Remove the workpiece, if needed.

4. Plug the power cord back into the power source.

5. Open the door and press the reset button (5).

6. Close the door and turn the ON/OFF switch to the ON

position.

(1) to the OFF position.

FIG. 22

FIG. 23

5

3

1

2

7

4

6

LED work lamp (Figs. 22 and 23)

The LED work lamp (6) has an adjustable gooseneck

for precision control when aiming the

light. The work lamp switch (4) is independent and may

be turned ON or OFF separately from

the band saw switch.

Laser line (Figs. 22 and 23)

1. Set the workpiece in place on the table.

2. Turn ON the laser light switch (3).

3. Rotate the laser line adjustment knob (7) to move the

laser line to the desired position on the workpiece.

15.

Page 16

76.2

SM 2610957105 05-08 6/5/08 7:39 AM Page 16

Assembly and adjustments

se scrap lumber to check the settings and to get the feel of operating the band saw

!

WARNING

Do not turn the power on before all adjustments have been made. Check to make sure the upper guide is in

•

place. Always keep the upper blade guide close to your work, approximately 1/8" (3.2 mm) above the

workpiece.

• Do not force the workpiece against the blade. Light contact permits easier cutting and prevents unwanted

friction and heating of the blade.

• Sharp saw blades need little pressure for cutting. Steadily move the workpiece against the blade without

forcing it.

U

before attempting regular work.

General cutting

Use the band saw for straight line operations such as

cross-cutting, ripping, miter cutting, beveling, compound

cutting, and resawing.

To avoid twisting the blade, do not turn sharp corners;

instead, saw around corners.

Cutting curves

When cutting curves, carefully turn the workpiece so the

blade follows without twisting. If the curve

is so sharp that you repeatedly back up and cut new

kerf, use a narrower blade, or a blade with more set

(teeth further apart). When a blade has more set, the

workpiece turns easier but the cut is rougher.

When changing a cut, do not withdraw the workpiece

from the blade. The blade may get drawn off the

wheels. To change a cut, turn the workpiece and saw

out through the scrap material area.

When cutting long curves, make relief cuts as you go

along.

Circle cutting (Fig. 24)

1. Adjust the upper blade guard to 1/8" (3.2 mm) above

the workpiece.

A band saw is basically a “curve-cutting” saw. It is not

capable of doing intricate inside cutting as can be done

with a scroll saw.

!

WARNING

2. Use both hands while feeding the work into the blade.

Hold the workpiece firmly against the table.

Use gentle pressure. Do not force the work, allow the

blade to cut.

3. The smallest diameter circle that can be cut is

determined by the width of the blade. For example, a

1/4" (6.4 mm) wide blade will cut a minimum diameter of

approximately 1 1/2" (38.1 mm).

Do not use this band saw to cut

ferrous metals.

FIG. 24

Minimum Circle Diameter Minimum Radius Blade Width

1 1/2” (12.7 mm) 1/4” (6.4 mm) 1/8” (3 mm)

2 1” (25.4 mm) 1/2” (12.7 mm) 3/16” (4.7 mm)

3 1-1/2” (38.1 mm) 3/4” (19.05 mm) 1/4” (6.4 mm)

4 3” (76.2 mm) 1-1/2” (38.1 mm) 3/8” (9.5 mm)

16.

Page 17

Operation

Recommended Blade Width

sretemilliMsehcnI

5.9,4.68/3,4/1gnittuCssorC

5.9,4.68/3,4/1gnittuCretiM

5.9,4.68/3,4/1gnileveB

5.9,4.68/3,4/1gnittuCdnuopmoC

42.giFeeS42.giFeeSgnittuCelcriC

4.6,2.34/1,8/1gnittuCevruC

SM 2610957105 05-08 6/5/08 7:39 AM Page 17

Operation (continued)

Blade selection

!

ARNING

W

For longest wear and best cutting results, use the

correct blade thickness, width, and temper for the type

of material you will cut.

When sawing small curves and delicate work, use

narrow blades. Otherwise, use the widest blade

possible. For cutting wood and similar materials with this

band saw, purchase blades in widths up to 3/8" (9.5

mm), and a length of 59 1/4 or 59 1/2" (150.5 or 151

mm).

Do not cut ferrous metals with this band saw.

Blade teeth are sharp. Use care when

handling a band saw blade.

Common causes of blade breakage:

Poor guide alignment and adjustment.

•

• Forcing or twisting a wide blade around a short

radius.

• Feeding too fast.

• Dull teeth or not enough set.

• Too much blade tension.

• Setting top guide assembly too high above the

workpiece.

Lumpy or improperly finished braze or weld on the

•

blade.

• Continuous running of blade when not cutting.

17.

Page 18

SM 2610957105 05-08 6/5/08 7:39 AM Page 18

Maintaining Your Band Saw

Maintenance

o reduce the risk of injury, turn

!

ARNING

W

lug from the power source outlet before

p

maintaining or lubricating your band saw.

Frequently blow out any dust that may accumulate

inside of the housing and motor.

Clean off pitch which accumulates on the table, blade

guides, and bearings.

Remove pitch and dust from the upper and lower

wheels using a stiff brush. Do not use solvents.

An occasional coat of paste wax on the work table

will allow the wood being cut to glide smoothly across

the work surface.

!

CAUTION

Including: gasoline, carbon tetrachloride, chlorinated

cleaning solvents, ammonia and household

detergents that contain ammonia. Avoiding use of

these and other types of cleaning agents minimizes

the probability of damage.

T

ower switch “OFF” and remove

p

GENERAL

Certain cleaning agents and

solvents damage plastic parts.

9. Place the blade over the lower blade wheel (2). Move

the quick release handle (1) counterclockwise to raise

he upper wheel and increase the tension on the

t

blade.

0. Adjust the blade tension, tracking, and upper and

1

ower blade guides. See pages 11 - 13.

l

11. Check the deflection of the drive belt in the center

between the two pulleys on the opposite side from

the belt tension wheel. The belt should deflect 1/2"

(12 mm) deflection when pressing on the drive belt

in the center between the two pulleys. To adjust the

belt tension, see page 11.

Use only recommended accessories. Follow

instructions that accompany accessories. Use of

improper accessories may cause hazards.

FIG. 25

2

To avoid shock or fire hazard, if the power cord is worn,

cut or damaged in any way, have it replaced

immediately.

!

WARNING

repairmen.

Center, Authorized Skil Service Station or other competent repair service. Use only Skil replacement parts;

any other may create a hazard.

All repairs, electrical or mechanical,

should be attempted only by trained

Contact the nearest Skil Factory Service

Drive belt replacement (Figs. 25 and 26)

1. Move the blade tension adjustment quick release

handle (1) clockwise to lower the upper wheel and

reduce tension on the blade.

2. Pull on both the upper and lower door latches to open

the wheel cover door.

3. Remove the blade from the lower blade wheel.

4. Remove the snap ring (3) from the lower wheel shaft.

5. Pull the lower blade wheel (2) from the band saw.

6. Remove the drive belt (4).

7. Position a new drive belt on the lower blade wheel

pulley and put the wheel back into the band saw.

Loop the drive belt over the motor pulley

8. Secure the lower blade wheel in position with the

snap ring

(3).

(5).

FIG. 26

4

2

3

5

18.

Page 19

SM 2610957105 05-08 6/5/08 7:39 AM Page 19

Consignes générales de sécurité

!

AVERTISSEMENT

LISEZ TOUTES LES CONSIGNES. Le non-respect des consignes de sécurité indiquées ci-dessous et d’autres

précautions de sécurité de base peut entraîner des blessures corporelles graves.

Lieu de travail

GARDEZ LES ENFANTS À UNE DISTANCE APPROPRIÉE

Ne laissez pas les visiteurs entrer en contact avec un outil ou un fil

de rallonge. Tous les visiteurs doivent être gardés à une distance

suffisante du lieu de travail pour garantir leur sécurité.

MAINTENEZ LE LIEU DE TRAVAIL PROPRE

Les zones et tables encombrées augmentent les risques

d’accidents.

ASSUREZ LA SÉCURITÉ DES ENFANTS DANS L’ATELIER

Utilisez des cadenas et/ou des coupe-circuits, ou retirez les clés de

mise en marche.

ÉVITEZ LES ENVIRONNEMENTS DANGEREUX

N’utilisez pas les outils dans des endroits humides. Gardez la zone

de travail bien éclairée. N’exposez pas les outils électriques à la

pluie. N’utilisez pas l’outil en présence de liquides ou de gaz

inflammables.

Sécurité personnelle

CONNAISSEZ VOTRE OUTIL ÉLECTRIQUE

Lisez et comprenez le mode d’emploi et les étiquettes apposées

sur l’outil. Apprenez son application et ses limitations, ainsi que

les risques spécifiques possibles associés à l’emploi de cet outil.

NE VOUS PENCHEZ PAS EXCESSIVEMENT

Maintenez toujours une bonne assise pour ne pas risquer de

perdre l’équilibre.

RESTEZ ALERTE

Faites attention à ce que vous faites. Faites preuve de bon sens.

N’utilisez pas cet outil lorsque vous êtes fatigué. Ne vous en servez

pas après avoir consommé de l’alcool ou lorsque vous prenez des

médicaments altérant votre état mental.

PORTEZ DES VÊTEMENTS APPROPRIÉS

Ne portez pas de vêtements lâches, de gants, de cravate, de

bagues, de bracelets ou d’autres bijoux qui risqueraient d’être

attrapés dans des pièces en mouvement. Il est recommandé de

porter des chaussures à semelle antidérapante. Couvrez-vous les

cheveux si vous avez les cheveux longs.

UTILISEZ TOUJOURS DES LUNETTES DE SÉCURITÉ

Utilisez aussi un masque facial ou un masque antipoussières si

l’opération de coupe produit de la sciure, et portez des boucheoreilles en cas d’utilisation prolongée. Les lunettes ordinaires

n’ont que des lentilles à l’épreuve des chocs – elles NE sauraient

remplacer des lunettes de sécurité.

PROTECTION CONTRE LES CHOCS ÉLECTRIQUES

Empêchez tout contact de quelconques parties de votre corps

avec des surfaces mises à la terre – par exemple : tuyaux,

radiateurs, cuisinière électrique, enceinte de réfrigérateur.

DÉBRANCHEZ LES OUTILS DE LA SOURCE

D’ALIMENTATION ÉLECTRIQUE

Quand vous ne vous en servez pas, avant de les réparer, avant de

changer des lames, mèches, couteaux, etc.

AISSEZ LES DISPOSITIFS DE PROTECTION À LEUR PLACE

L

En bon ordre de fonctionnement, et bien ajustés et alignés

RETIREZ LES CLÉS ET CLAVETTES DE RÉGLAGE

Lorsque l’outil n’est pas utilisé, avant une opération d’entretien,

lors du changement de lames, de mèches, de couteaux, etc.

DIMINUEZ LE RISQUE DE MISE EN MARCHE ACCIDENTELLE

Assurez-vous que l’interrupteur est dans la position hors tension

(« OFF ») avant de brancher l’outil.

METTEZ TOUS LES OUTILS À LA TERRE

Cet outil est muni d’un cordon à trois conducteurs agréé et d’une

fiche de mise à la terre de type à trois broches qui sont

compatibles avec la prise de mise à la terre du type approprié. Le

conducteur vert du cordon est le fil de mise à la terre. Ne con

nectez jamais le fil vert à une borne sous tension.

NE MONTEZ JAMAIS SUR L’OUTIL OU SUR SON SUPPORT

Vous risqueriez une blessure grave si l’outil basculait ou en cas de

contact accidentel avec l’outil. Ne placez pas de matériaux sur

l’outil ou à proximité de celui-ci de telle manière qu’il pourrait être

nécessaire de monter sur l’outil ou sur son support pour les

atteindre.

INSPECTEZ LES PIÈCES ENDOMMAGÉES LE CAS ÉCHÉANT

Avant de continuer à utiliser l’outil, inspectez attentivement tout

dispositif de protection ou autre élément endommagé pour vous

assurer qu’il fonctionne correctement et joue le rôle qu’il est censé

jouer. Vérifiez l’alignement des pièces mobiles, les mécanismes de

montage et tous les autres problèmes éventuels qui pourraient

affecter le fonctionnement. Il faut remplacer tout dispositif de

protection ou autre élément endommagé comme il se doit.

!

AVERTISSEMENT

d’effectuer des réparations, qu’elles soient électriques ou

mécaniques. Contactez le Centre de service usine Skil, un

Centre de service après-vente agréé ou un autre service de

réparation qualifié.

!

AVERTISSEMENT

risquerait d’être dangereux.

!

AVERTISSEMENT

actuel risquerait d’être dangereuse.

Il ne faut demander qu’à des réparateurs

ayant reçu la formation nécessaire

N’utilisez que des pièces de rechange

Skil ; l’emploi de pièces différentes

L’utilisation d’accessoires quelconques

qui ne figurent pas dans le catalogue Skil

-

« CONSERVEZ CES CONSIGNES D’UTILISATION/DE SÉCURITÉ »

19.

Page 20

SM 2610957105 05-08 6/5/08 7:39 AM Page 20

Consignes de sécurité additionnelles

Emploi de l’outil

NE FORCEZ PAS L’OUTIL

L’outil fonctionnera mieux et de façon moins dangereuse à la

vitesse pour laquelle il a été conçu.

UTILISEZ L’OUTIL QUI CONVIENT

Ne forcez pas un petit outil ou accessoire pour faire le travail d’un

outil plus robuste. N’utilisez pas d’outils à des fins pour lesquelles

ils n’ont pas été conçus – par exemple, n’utilisez pas de scie

circulaire pour couper des branches d’arbres ou des bûches.

ASSUJETTISSEZ L’OUVRAGE

Utilisez des brides ou des étaux pour maintenir l’ouvrage en place.

C’est plus sûr que d’utiliser vos mains, et cela vous permet de

vous servir de vos deux mains pour utiliser l’outil.

NE LAISSEZ JAMAIS UN OUTIL EN MARCHE SANS

SURVEILLANCE

Mettez l’outil hors tension. Ne vous en éloignez pas avant qu’il se

soit complètement arrêté.

Entretien de l’outil

N’ALTÉREZ PAS L’OUTIL ET UTILISEZ-LE CONFORMÉMENT

AUX INSTRUCTIONS

Ces outils sont construits avec une grande précision. Toute

altération ou modification non spécifiée constitue une utilisation

non conforme qui risquerait de causer des conditions

dangereuses.

ÉVITEZ D’UTILISER DANS UN ENVIRONNEMENT GAZEUX

N’utilisez pas d’outils électriques dans une atmosphère gazeuse

ou explosive. Les moteurs associés à ces outils produisent

généralement des étincelles qui risqueraient de causer des

conditions dangereuses.

ENTRETENEZ SOIGNEUSEMENT LES OUTILS

Gardez les outils bien aiguisés et propres pour obtenir le meilleur

rendement et réduire les dangers. Suivez les instructions pour

lubrifier et changer les accessoires. Inspectez périodiquement les

cordons électriques des outils et, s’ils sont endommagés, faitesles réparer par un service de réparation agréé. Inspectez

périodiquement les fils de rallonge et remplacez-les s’ils sont

endommagés. Maintenez les poignées sèches et propres, et

assurez-vous qu’il n’y a pas de taches d’huile ou de graisse.

Avant de brancher l’outil dans une source d’alimentation électrique

(prise de courant, connecteur de prolongation, etc.), assurez-vous

que la tension fournie est la même que celle qui est indiquée sur la

plaque signalétique de l’outil. Une source d’alimentation électrique

ayant une tension supérieure à celle qui est spécifiée pour l’outil

pourrait causer des blessures graves à l’utilisateur, ainsi que des

dommages à l’outil. Si vous avez le moindre doute, NE BRANCHEZ

PAS L’OUTIL. L’utilisation d’une source d’alimentation électrique

ayant une tension inférieure à celle de la plaque signalétique est

mauvaise pour le moteur.

!

AVERTISSEMENT

DE BON SENS DE L’OPÉRATEUR ET DE VIVACITÉ D’ESPRIT À

TOUT MOMENT PENDANT QUE LA SCIE EST EN TRAIN DE

FONCTIONNER.

Il faut toujours rester vigilant, même si, au bout d’un certain

temps, le fait d’avoir utilisé souvent votre scie à ruban risque de

LA SÉCURITÉ AVANT TOUT

LA SÉCURITÉ EST UNE COMBINAISON

vous faire croire qu’il n’existe aucun danger. Souvenez-vous

toujours qu’une seconde d’inattention est suffisante pour causer

une blessure grave.

Le fonctionnement de tout outil électrique

risque de causer la projection de corps

étrangers dans les yeux, ce qui peut

e

ntraîner des lésions graves des yeux.

Portez toujours des lunettes de sécurité

conformes à la norme ANSI Z87.1 (illustrée

sur l’emballage) avant de commencer à travailler avec l’outil.

!

AVERTISSEMENT

rectification, de perçage et d’autres activités de construction

avec des outils électriques contiennent des produits chimiques

qui sont connus comme causant des cancers, des malformations

congénitales et d’autres problèmes affectant la reproduction.

Voici quelques exemples de tels produits chimiques :

• Le plomb de peintures à base de plomb,

• La silice cristalline de briques et de ciment, ainsi que d’autres

produits de maçonnerie, et

• L’arsenic et le chrome de bois d’œuvre ayant subi un traitement

chimique.

Votre risque résultant de telles expositions est variable, selon la

fréquence de votre exposition. Pour réduire votre exposition à de

tels produits chimiques : travaillez dans un endroit bien ventilé et

en portant un matériel de sécurité agréé, comme un masque

antipoussières qui est conçu spécialement pour filtrer les

particules microscopiques.

Certaines poussières créées par des

opérations de ponçage, de sciage, de

NOTEZ ET RESPECTEZ LES AVERTISSEMENTS ET LES

INSTRUCTIONS CONCERNANT LA SÉCURITÉ QUI FIGURENT

SUR LA PRESSE DE SCIE À RUBAN :

20

.

Page 21

SM 2610957105 05-08 6/5/08 7:39 AM Page 21

Consignes de sécurité relatives aux rayons laser

!

AVERTISSEMENT

1. Ne regardez pas directement la source du rayon laser. Vous

risquez de subir des dommages aux yeux si vous regardez

délibérément la source du rayon laser.

2. Le rayon laser utilisé dans ce système est un laser de Classe II

de 1 mW avec des longueurs d’ondes maximales de 650 nm.

ÉVITEZ TOUTE EXPOSITION DIRECTE DES YEUX.

3. Le laser doit être utilisé et entretenu conformément aux instructions du fabricant :

• Ne pointez jamais le rayon laser en direction d’une personne ou

d’un objet autre que l’ouvrage.

• Ne projetez pas le rayon laser dans les yeux de quelqu’un

d’autre.

• Assurez-vous toujours que le rayon laser est dirigé vers un

ouvrage sans surfaces réfléchissantes, parce que le rayon laser

risquerait alors d’être projeté dans vos yeux ou dans les yeux

de quelqu’un d’autre.

Pour réduire le risque de blessures :

!

ATTENTION

réglages, ou l’exécution de procédures

autres que ce qui est indiqué ici

risquerait de causer une exposition à des

rayonnements dangereux.

L’utilisation de

commandes ou de

Consignes de sécurité particulières pour les scies à ruban

1. Pour éviter tout risque de blessure à la suite d’un mouvement

inattendu, assurez-vous que la scie est sur une surface ferme et de

niveau, et qu’elle est correctement assujettie pour éviter qu’elle ne

se balance. Vérifiez qu’il y a assez de place pour l’opération prévue.

Boulonnez la scie sur une surface de support pour empêcher tout

glissement ou dérapage pendant l’opération de coupe.

2. Éteignez et débranchez la scie avant de la déplacer.

3. Utilisez des lames de la taille et du style appropriés.

4. Assurez-vous que les dents de la lame sont orientées vers le bas

et en direction de la table.

5. Le guide de la lame, les supports, les paliers et la tension de la

lame doivent être ajustés correctement pour éviter tout risque de

contact accidentel avec la lame et pour réduire au minimum le

risque de bris de lame. Pour maximiser le support de la lame,

ajustez toujours le guide supérieur de la lame et le dispositif de

protection de la lame afin que ce dernier soit bien serré mais ne

fasse pas obstacle au mouvement de l’ouvrage.

6. La poignée de verrouillage de l’inclinaison de la table doit être

bien serrée.

7. Faites extrêmement attention avec les ouvrages très grands, très

petits ou ayant des formes compliquées.

8. Utilisez des supports supplémentaires pour empêcher l’ouvrage

de glisser et de tomber du dessus de la table.

9. Les ouvrages doivent être assujettis de façon à ce qu’ils ne

risquent pas de se tordre, de se balancer ou de glisser pendant

l’opération de coupe.

10. Planifiez soigneusement les opérations de coupe complexes ou

sur des ouvrages de petite taille afin de ne pas risquer un

pincement de la lame. Évitez toutes opérations risquant de vous

faire perdre l’équilibre ou nécessitant des positions inconfortables

des mains pour ne pas risquer d’entrer en contact accidentellement

avec la lame.

11. Les petits ouvrages doivent être assujettis au moyen de brides

ou d’autres attaches. Ne tenez pas les ouvrages de petite taille avec

votre main parce que vos doigts risqueraient de pénétrer audessous du dispositif de protection de la lame.

12. Supportez adéquatement les ouvrages cylindriques (utilisez un

bloc en V ou appuyez-les contre le guide d’onglet) pour éviter qu’ils

ne roulent et pour que la lame ne risque pas de mordre.

13. Coupez seulement un ouvrage à la fois. Assurez-vous qu’il n’y

a rien sur la table en dehors de l’ouvrage et de ses guides avant

d’allumer la scie.

14. Inspectez toujours la scie en mouvement avant chaque

opération. Si vous notez des vibrations excessives, des hésitations

de la lame de la scie ou des bruits inhabituels, arrêtez

immédiatement et éteignez la scie. Débranchez-la tout de suite. Ne

remettez pas la scie en marche jusqu’à ce que le problème ait été

localisé et corrigé.

15. Pour libérer tout matériau coincé, mettez d’abord l’interrupteur

dans la position d’arrêt (OFF). Retirez la clé de l’interrupteur et

débranchez la scie.

Attendez que toutes les pièces mobiles soient à l’arrêt avant de

retirer le matériau coincé.

16. Ne quittez pas le lieu de travail avant que toutes les pièces

mobiles soient à l’arrêt. Mettez les coupe-circuit hors tension.

Retirez la clé de l’interrupteur de la scie à ruban et rangez-la en lieu

sûr, hors de portée des enfants. Assurez-vous qu’il n’y ait aucun

danger pour des enfants dans l’atelier !

17. Maintenez un réglage correct de la tension et de l’alignement de

la lame, des guides de lame et des paliers de butée.

18. Ajustez le guide supérieur à 1/8 po au-dessus de l’ouvrage

avant de commencer à couper.

19. Maintenez l’ouvrage fermement contre la table.

20. Utilisez la lame recommandée à la vitesse indiquée en fonction

du matériau de l’ouvrage.

21. Avant de commencer, assurez-vous que le moteur, la table, les

accessoires et les boutons de réglage sont bien dans les positions

désirées.

22. N’utilisez pas la scie avec la porte de l’enjoliveur de roue

ouverte.

23. Débranchez la scie avant de procéder à des changements,

réglages ou réparations de lames.

24. N’exposez pas à la pluie et n’utilisez pas dans des endroits

humides.

21

.

Page 22

SM 2610957105 05-08 6/5/08 7:39 AM Page 22

Spécifications du moteur et spécifications électriques

Spécifications générales

Tension nominale . . . . . . . . . . . . . . . . . . . . . . . . . . .120 V, 60 Hz

Débit nominal en ampères . . . . . . . . . . . . . . . . . . . . . . . . . . .2,5 A

Vitesse à vide . . . . . . . . . . . . . . . .No 1 400 / 2 700 tr/mn (c/mn)

Col . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 po (22,9 cm)

Lame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59 1/2 po (151 cm)

Capacité de coupe . . . . . . . . . . . . . . . . . . . . . . .3 1/2 po (8,9 cm)

Dimensions de la table . . . . . . .11 3/4 x 11 3/4 po (30 x 30 cm)

Spécifications du moteur

En cas de dysfonctionnement ou de panne de fonctionnement, la

mise à la terre fournit un trajet de moindre résistance pour le

courant électrique afin de réduire le risque de choc électrique. Cet

outil est équipé d’un cordon électrique muni d’un conducteur de

mise à la terre de l’équipement et d’une fiche de mise à la terre. La

fiche doit être branchée dans une prise appropriée qui est installée

correctement et mise à la terre conformément à tous les codes et

à toutes les ordonnances applicables.

Cette scie à ruban est conçue pour utiliser un moteur de

1 700 tr/mn. Elle est câblée pour un fonctionnement avec

alimentation en courant alternatif de 110-120 volts, 60 Hz. Avant de

connecter le cordon du moteur à la source d’alimentation

électrique, assurez-vous que l’interrupteur est dans la position hors

tension (« OFF ») et vérifiez que le courant électrique a les mêmes

caractéristiques que celles qui sont estampées sur la plaque

signalétique de la scie à ruban.

Raccordement à une source d’alimentation

Cette machine doit être mise à la terre pendant son emploi afin de

protéger l’opérateur contre les risques de chocs électriques.

Branchez le cordon d’alimentation électrique dans une prise de

courant de 110-120 V du type correctement mis à la terre protégée

par un disjoncteur ou un fusible à temporisation double de 15

ampères.

Toutes les prises de courant ne sont pas obligatoirement mises à

la terre correctement. Si vous n’êtes pas certain que votre prise de

courant, telle qu’illustrée à la Fig. 1, est bien mise à la terre,

demandez à un électricien professionnel de l’inspecter.

!

DANGER

lorsque vous installez la fiche dans la prise de courant ou

lorsque vous l’en retirez.

!

DANGER

ou un choc électrique grave, en particulier en cas d’utilisation

à proximité de canalisations en métal ou d’autres objets en

métal. En cas de choc électrique, votre réaction pourrait causer

un contact accidentel entre vos mains et l’outil.

!

AVERTISSEMENT

que ce soit, faites-le remplacer immédiatement pour éviter tout

risque de choc électrique ou d’incendie.

Votre appareil est conçu pour une alimentation électrique de 120

volts ; il a des fiches qui ressemblent à celle de la Figure 1.

Pour éviter tout risque de choc électrique, ne

touchez pas les broches en métal de la fiche

L’absence de mise à la terre correcte de cet

outil électrique peut causer une électrocution

Si le cordon d’alimentation est usé,

coupé ou endommagé de quelque façon

Cet outil électrique est muni d’un cordon à trois conducteurs et

d’une fiche mise à la terre agréés par Underwriters Laboratories et

FIG. 1

par l’Association Canadienne de Normalisation. Le conducteur de

mise à la terre a une gaine verte et est attaché au bâti de l’outil à

un bout et à la broche de mise à la terre de la fiche de raccordement à l’autre bout.

Si la prise de courant que vous avez l’intention d’utiliser pour cet

outil électrique est du type à deux broches, IL NE FAUT PAS

RETIRER LA BROCHE DE MISE À LA TERRE OU L’ALTÉRER DE

QUELQUE FAÇON QUE CE SOIT. Demandez à un électricien

professionnel de remplacer la prise de courant à DEUX trous par

une prise de courant à TROIS trous mise à la terre correctement.

Une connexion incorrecte du conducteur de mise à la terre de

l’équipement peut créer un risque de choc électrique. Le

conducteur avec une isolation dont la surface extérieure est verte,

avec ou sans bandes jaunes, est le conducteur prévu pour

l’équipement. S’il s’avère nécessaire de réparer ou de remplacer le

cordon électrique ou la fiche, ne connectez pas le conducteur de

mise à la terre de l’équipement à une borne sous tension.

Consultez un électricien professionnel ou un technicien qualifié si

les instructions de mise à la terre ne sont pas complètement

comprises ou si vous n’êtes pas certain que l’outil est mis à la

terre correctement.

Utilisez toujours un cordon de rallonge approprié. L’emploi de

quelque cordon de rallonge que ce soit causera une certaine perte

de puissance. Pour réduire cette perte au minimum possible et

pour empêcher la surchauffe et le claquage du moteur, utilisez le

tableau ci-dessous afin de déterminer le diamètre minimum des

fils (A.W.G.) du cordon de rallonge. Utilisez seulement des

cordons de rallonge à trois fils ayant des fiches du type de mise à

la terre à trois broches et des prises de courant à trois trous

compatibles avec la fiche de l’outil. Assurez-vous que votre

cordon de rallonge est en bon état.

Longueur du cordon de rallonge

0-25 pi (0-7,5 m) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

26-50 pi (7,8-15 m) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

51-100 pi (15,3-30 m) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Diamètres des fils A.W.G.

« CONSERVEZ CES CONSIGNES

D’UTILISATION/DE SÉCURITÉ »

22

.

Page 23

SM 2610957105 05-08 6/5/08 7:39 AM Page 23

Table des matières

Page

Consignes générales de sécurité . . . . . . . . . . . . . . . . . . . . . . . 19

Consignes de sécurité additionnelles . . . . . . . . . . . . . . . . . 20-21

Spécifications du moteur et spécifications électriques . . . . . . 22

Déballage et inspection du contenu . . . . . . . . . . . . . . . . . . . .24

Tableau des pièces en vrac . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Page

Connaissance élémentaire de votre scie à ruban . . . . . . . . . . .25

Assemblage et réglages ......................................................26-31

Opérations de base avec la perceuse à colonne ..............32-34

Entretien de votre perceuse à colonne ....................................35

Guide de diagnostic ....................................................................53

23

.

Page 24

SM 2610957105 05-08 6/5/08 7:39 AM Page 24

Déballage et inspection du contenu

!

AVERTISSEMENT

de courant avant que toutes les étapes de la procédure

d’assemblage ne soient terminées et avant d’avoir lu et

compris la totalité du mode d’emploi.

La scie à ruban motorisée modèle 3385-01 est expédiée complète

dans une seule boîte.

1. Déballez et inspectez le contenu, puis séparez toutes les pièces

des matériaux d’emballage. Comparez chaque pièce avec le «

Tableau des pièces en vrac » pour vous assurer que toutes les

pièces sont présentes avant de mettre au rebut de quelconques

matériaux d’emballage.

!

AVERTISSEMENT

la scie à ruban, de brancher son cordon d’alimentation ou de

mettre l’interrupteur dans la position de marche avant de vous

être procuré toutes les pièces manquantes et de les avoir

installées correctement.

2. Éliminez la couche d’huile de protection qui est appliquée sur la

table et sur la base. Utilisez n’importe quelle graisse domestique

ordinaire et un produit détachant.

!

AVERTISSEMENT

d’essence, de naphte ou de solvants très volatils similaires.

3. Appliquez une couche de cire sur la table et sur les surfaces

usinées de la base pour empêcher la formation de rouille.

Essuyez soigneusement toutes les pièces avec un tissu sec et

propre.

Pour réduire le risque de blessure, ne

branchez jamais la fiche dans une prise

Si de quelconques pièces sont

manquantes, ne tentez pas d’assembler

Pour éviter tout risque d’incendie ou de

réaction toxique, n’utilisez jamais

A

B

C

D

Tableau des pièces en vrac

ARTICLE DESCRIPTION QTÉ

A Scie à ruban 1

B Table 1

C

D Guide longitudinal 1

E

F Clé hexagonale de 3 mm 1

G Clé combinée de 10 et 13 mm 1

H

I Guide d’utilisation 1

Plaque amovible de table

Ensemble de guide d’onglet

Boulon, rondelle et rondelle de

blocage de la table

I

1

1

4

24

H

E

G

F

.

Page 25

SM 2610957105 05-08 6/5/08 7:39 AM Page 25

Connaissance élémentaire de votre scie à ruban

1 Bouton de réglage de la tension de la lame

oignée à relâchement rapide de la tension de la lame

2 P

3 Lumière de travail à DEL

ame

4 L

5 Ensemble de support de la table

6 Guide inférieur de la lame

7 Courroie d’entraînement

oue inférieure

8 R

9 Porte

outon de réinitialisation

10B

11 Roue supérieure

12 Bouton de verrouillage du mécanisme

de contrôle de la lame

13 Bouton du mécanisme de contrôle de la lame

14 Ensemble de moteur

15 Base

16 Orifice de dépoussiérage

17 Bouton de verrouillage du réglage

de l’inclinaison de la table

18 Bouton de réglage de

l’inclinaison de la table

1

1

10

2

11

9

3

4

5

8

6

2

23

29

24

25

28

27

15

19 Table

20 Guide supérieur de la lame

21 Bouton de verrouillage du

guide supérieur de la lame

22 Bouton de réglage du dispositif du guide supérieur de la lame

23 Hublot supérieur

24 Verrou du haut de la porte

25 Bouton de réglage du rayon laser

26 Verrou du bas de la porte

27 Interrupteur de marche/arrêt (ON/OFF) avec clé de sécurité

28 Interrupteur du laser

29 Interrupteur de la lumière de travail

26

19

19

18

23

22

21

20

7

1

2

12

13

14

17

16

15

25.

Page 26

SM 2610957105 05-08 6/5/08 7:39 AM Page 26

Assemblage et réglages

!

AVERTISSEMENT

sécurité et débranchez le cordon d’alimentation de la prise de

courant. Le cordon d’alimentation doit rester débranché à

chaque fois que vous travaillez sur la scie.

Avant de commencer à assembler la scie

à ruban, éteignez la scie, retirez la clé de

Installation de la table (Fig. 3-6)

1. Desserrez le bouton de verrouillage (1) et tournez le bouton du

dispositif de protection de la lame

de protection supérieur de la lame

élevée.

2. Placez la table sur le support de la table en faisant glisser la

(4) dans la table au-dessus de la lame (5), en faisant

fente

attention de ne pas endommager la lame.

3. Alignez les quatre trous au bas de la table au-dessus des quatre

trous dans le support de la table

4. Placez une rondelle et une rondelle de blocage sur chaque

(7), et assujettissez le boulon à travers le support de la

boulon

table et dans la table même.

5. Serrez tous les quatre boulons pour faire en sorte que la table

soit fermement assujettie.

6. Alignez la fente dans la plaque amovible de table en plastique

(8) avec la fente dans la table et la lame. Appuyez sur la plaque

amovible pour la faire entrer dans l’orifice carré au milieu de la

table.

(2) pour soulever le dispositif

(3) jusqu’à la position la plus

(6).

FIG. 3

2

1

3

5

Assembly and adjustments

FIG. 4

4

Remarque : la table doit être ajustée correctement avant que la

scie ne soit mise en marche. Voir la rubrique consacrée au réglage

de l’inclinaison de la table (page 27).

FIG. 6

6

FIG. 5

7

8

26.

Page 27

SM 2610957105 05-08 6/5/08 7:39 AM Page 27

Assemblage et réglages

Installation du guide longitudinal (Fig. 7)

1. Soulevez la bride (1) sur l’ensemble de guide longitudinal dans

la position élevée.

2. Placez le guide longitudinal sur la table de façon que la bride

soit à l’avant de la table.

3. Abaissez la bride de fixation du guide longitudinal de façon à

verrouiller le guide longitudinal en position sur la table. Faites

tourner la bride pour serrer ou desserrer.

Pour déplacer le guide longitudinal, soulevez la bride et faites

glisser le guide jusqu’à la position désirée. Abaissez la bride pour

verrouiller le guide en place.

Montage de la scie à ruban sur une surface

de travail (Fig. 8)

Assujettissez la scie à une surface de travail appropriée en insérant

la quincaillerie de montage nécessaire dans les quatre trous

percés en usine

(2) dans la base de la scie.

Réglages

!

AVERTISSEMENT

de sécurité et débranchez le cordon d’alimentation électrique

de la prise de courant. Le cordon d’alimentation doit rester

débranché à chaque fois que vous travaillez sur la scie.

Avant de procéder au réglage de la scie à

ruban, éteignez la scie, retirez-en la clé

FIG. 7

1

FIG. 8

2

2

Réglage de l’inclinaison de la table (Fig. 9)

La table s’incline de 0° à 45° vers la droite.

1. Tournez le bouton de verrouillage du réglage de l’inclinaison de

la table

(3) dans le sens contraire des aiguilles d’une montre.

2. Tournez le bouton de réglage de l’inclinaison de la table

jusqu’à ce que la flèche indicatrice corresponde à l’angle désiré

sur l’indicateur d’inclinaison de la table

3. Serrez le bouton de verrouillage de l’inclinaison de la table

pour assujettir la table.

Raccor

dement à un système de collecte

(5).

(4)

(3)

de la poussière (Fig. 10)

Un orifice de dépoussiérage de 1 1/2 po (3,8 cm) (6) est situé sur

le côté moteur de la scie à ruban. Cet orifice peut être raccordé

directement à un système de collecte de la poussière en

connectant le bout de ramassage du tuyau de collecte de la

poussière à l’orifice de dépoussiérage.

FIG. 9

FIG. 10

4

5

3

6

27.

Page 28

SM 2610957105 05-08 6/5/08 7:39 AM Page 28

Assemblage et réglages

Réglage de la tension de la lame (Fig. 11)

Un changement de la largeur de la lame ou du type de matériau

qui est coupé affectera la tension de la lame. Si la tension de la

lame est insuffisante, la lame risquera de glisser sur les roues. Si

la tension de la lame est excessive, il existe un risque de bris de la

lame.

1. Tournez le bouton de réglage de la tension de la lame

le sens des aiguilles d’une montre pour élever la roue

supérieure de la lame

La lame devrait alors être serrée contre la roue ; il ne faut pas

serrer excessivement le bouton de réglage de la tension de la

lame.

2. Tournez le bouton de réglage de la tension de la lame

le sens contraire des aiguilles d’une montre pour abaisser la

roue supérieure de la lame (2) et réduire la tension sur la lame.

(2) et augmenter la tension sur la lame.

(1) dans

(1) dans

Réglage du mécanisme de contrôle

de la lame (Fig. 11 et 12)

Vérifiez la tension de la lame avant de procéder à des réglages du

mécanisme de contrôle de la lame.

1. Tournez la roue supérieure de la lame

aiguilles d’une montre et vérifiez la position de la lame par

rapport à la roue. La lame doit rester au centre de la roue.

a. Si la lame se déplace vers l’avant de la roue, desserrez le

bouton de verrouillage du mécanisme de contrôle de la lame

(4) et tournez légèrement dans le sens des aiguilles d’une

montre le bouton du mécanisme de contrôle de la lame

En même temps, tournez la roue supérieure

que la lame soit centrée.

b. Si la lame se déplace vers le bord arrière de la roue, tournez

légèrement dans le sens contraire des aiguilles d’une montre

le bouton du mécanisme de contrôle de la lame

même temps, tournez la roue supérieure

la lame soit centrée.

2. Serrez le bouton de verrouillage du mécanisme de contrôle de

la lame

(4) après avoir fini tous les réglages.

3. Vérifiez la position de la lame sur la roue inférieure. Si le

contrôle de la lame est inadéquat, continuez à effectuer des

réglages de la lame jusqu’à ce qu’elle repose correctement sur

les deux roues.

(2) dans le sens des

(3).

(2) jusqu’à ce

(3). En

(2) jusqu’à ce que

FIG. 11

FIG. 12

1

2

4

3

28.

Page 29

SM 2610957105 05-08 6/5/08 7:39 AM Page 29

Assemblage et réglages

Remplacement de la lame (Fig. 13)

!

AVERTISSEMENT

lation d’une lame de scie à ruban.

Il est possible de remplacer la lame avec la table en place, mais il

peut être plus facile de retirer la table avant de remplacer la lame.

Si vous ne retirez pas la table, retirez la plaque amovible de table en

plastique et tirez sur la rallonge de la table pour qu’elle ne bloque

pas la fente dans la table avant de retirer ou d’installer la lame.

1. Desserrez la bride de fixation du guide longitudinal et retirez le

guide de la table.

2. Tirez sur les verrous du haut et du bas de la porte pour ouvrir

la porte de l’enjoliveur de la roue.

3. Déplacez la poignée à relâchement rapide du dispositif de

réglage de la tension de la lame

d’une montre pour abaisser la roue supérieure et réduire la

tension sur la lame.

4.

Retirez la lame qui se trouve dans la scie

lame vers l’extérieur et dans le sens opposé aux guides

supérieur et inférieur de la lame

la table si vous ne l’avez pas déjà retirée).

5. Mettez la nouvelle lame en position autour des roues

supérieure et inférieure, et entre les guides supérieurs et

inférieurs de la lame

6. Centrez la lame sur les roues supérieure et inférieure. Tournez

lentement la roue supérieure afin de vérifier la position de la

lame.

7. Faites tourner la poignée de relâchement rapide du dispositif de

réglage de la tension de la lame

aiguilles d’une montre pour augmenter la tension sur la lame.

8. Assurez-vous que la lame est toujours centrée sur les roues

supérieure et inférieure, et qu’elle se déplace librement entre les

guides de la lame.

Les dents de la lame sont très pointues.

Faites très attention lors de la manipu-

(1) dans le sens des aiguilles

(3) (et à travers la fente dans

(3).

(1) dans le sens contraire des

(2). Faites glisser la

FIG. 13

1

2

3

3

9. La lame doit être ajustée correctement avant de mettre la scie

en marche :

a. Voir la rubrique consacrée au réglage de la tension de la lame

(page 28).

b. Voir la rubrique consacrée au réglage du contrôle de la lame

(page 28).

c. Voir la rubrique consacrée au réglage des guides de la lame

(page 29).

Réglage des guides de la lame

Les guides supérieurs et inférieurs de la lame et les paliers de

support (situés au-dessus et au-dessous de la table) permettent à

la lame de se déplacer en ligne droite pendant le fonctionnement.

Ces guides doivent être inspectés et ajustés avant chaque emploi

et après avoir changé de lame.

Remarque : assurez-vous que les systèmes de réglage de la

tension et du contrôle de la lame sont ajustés correctement avant

de procéder au réglage des guides supérieur et inférieur de la

lame.

Réglage des guides supérieurs de la lame

(Fig. 14-16)

1. Assurez-vous que l’ensemble des guides supérieurs de la lame