Page 1

Operating

Guide

SKIL

10"

Band

Saw

Model 3104

IMPORTANT=

Read

Before

Using

'~

SKIL

CORPORATION

O

SUBSIDIARY

OF

EMERSON

ELECTRIC

CO

.

Emerson

4801

W .

PETERSON

AVENUE*CHICAGO,IL60646

Page 2

AWARNING

"READ

ALL

INSTRUCTIONS"

Failuretofollow

the

SAFETY

RULES

listed

BELOW,

and

other

basic

safety

precautions,

may

resultinserious

personal

injury

.

General

Safety

Rules

Work

Area

"

KEEP

WORK

AREAS

CLEAN.Cluttered

areas

and

benches

invite

accidents

.

*AVOID

DANGEROUS

ENVIRONMENT

.

Don't

use

power

toolsindamporwet

locations.Keep

work

area

well

lit

.Donot

expose

power

toolstorain.Do

not

use

toolinpresence of

flammable

liquidsorgases

.

"

KEEP

CHILDREN

AWAY.Do

not

let

visitors

contact

toolorextension

cord

.

All

visitors

shouldbekept

away

from

work

area

.

"

MAKE

WORKSHOP

KID-PROOF-with

padlocks,

master

switches,

or by

removing

starter

keys

.

Personal

Safety

STAY

ALERT.Watch

what

you

are

doing.Use

common

sense.Do

not

operate

tool

when

you

are

tired

.

"

KEEP

GUARDS

IN

PLACE

in

working

order,

and

in

proper

adjustment

and

alignment

.

*DON'T

OVERREACH

.

Keep

proper

footing

and

balance

at

all

times

.

*DISCONNECTTOOLS.When

not

in

use;before

servicing;when

changing

blades,

bits,

cutters,

etc

.

*REMOVE

ADJUSTING

KEYS

AND

WRENCHES

.

Form

habit

of

checking

to see

that

keys and

adjusting

wrenches

are

removed

from

tool

before

turning

iton.

"

NEVER

STAND

ONTOOL

.

Serious

injury

could

occurifthe

tool

is

tippedorif

the

cutting

tool

is

accidentally

contacted

.

AVOID

ACCIDENTAL

STARTING.Be

sure switch

is

OFF

when

pluggedin.

"

USE

RECOMMENDED

ACCESSORIES

.

Consult

the

owner's

manual

for

recommended

accessories.Follow

the

instructions

that

accompany

the

accessories.The

use

of

improper

accessories

may

cause

hazards

.

*DRESS

PROPERLY

.Donot

wear

loose

clothing

or

jewelry.They

canbecaughtinmoving

parts.Rubber

gloves

and

non-skid

footwear

are

recommendedwhen

working

outdoors.Wear

protective

hair

covering to

contain

long

hair

.

"

ALWAYS

USE

SAFETY

GLASSES.Also

use

face

or

dust

maskifcutting

operationisdusty.Everyday

eye-

glasses

only have

impact

resistant

lenses,

they

are

NOT

safety

glasses

.

All

repairs

electricalormechanical

,,

shouldbeattempted

onlybytrain-

ed

repairmen.Contact

the

nearest

Skil

Factory

Service

Center,orAuthorized

Skil

Service Stationorother

competent

repair

service.Use

only

Skil

replacement

parts,

any

other

may

createahazard

.

AWARNING

"SAVE

THESE

INSTRUCTIONS"

Page

2

*CHECK

DAMAGED

PARTS.Before

further

use

of

the

tool, a

guardorother

part that

is

damaged

should

be

carefully

checked

to

determine

thatitwill

operate

properly

and

perform

its

intended

function

.

Check

for

alignmentofmoving

parts,

bindingofmoving

parts,

breakageofparts,

mounting,

and any

other

conditions

that

may

affect

its

operation.A

guard

or

other

part thatisdamaged

shouldbeproperly

re-

paired

or replaced.Have

defective

switches

replaced

.

Do

not

use

toolifswitch

does

not

turn

itonor

off

.

Tool

Use

"

DON'T

FORCE

TOOL.It

willdothe

job

better

and

safer at

the

rate for

whichitwas

designed

.

" USE

THE

RIGHT

TOOL.Don't

force small

tool

or

attachment

to

do

the

jobofa

heavy-duty

tool.Don't

use

tool

for

purpose

not

intended--for

example;don't

use

circular

saw

for

cutting

tree

limbs

or

logs

.

"

SECURE

WORK.Use clampsora

visetohold

work

.

It's

saferthan

using

your

hand and

it

frees

both

hands

to

operate

tool

.

"

DIRECTION

OF

FEED.Feed

work

intoablade

or

cutter

against

the

directionofrotationofthe

blade

or

cutter

only

.

"

NEVER

LEAVE

TOOL

RUNNING

UNATTENDED

.

Turn

power

off.Don't

leave

tool

untilitcomes

to a

complete

stop

.

Tool

Care

"

DONOT

ALTER

OR

MISUSE

TOOL

.

These

tools

are

precision

built.Any

alteration

or

modification

not

specifiedismisuse

and

may

resultina

dangerous

condition

.

"

AVOID

GASEOUS

AREAS.Do

not

operate

electric

toolsingaseous

or

explosive

atmospheres.Motors

in

these

tools

normally

spark,

and

the

sparks

might

ignite

fumes

.

"

MAINTAIN

TOOLS

WITH

CARE

.

Keep

tools

sharp

and

clean

for

better

and

safer

performance.Follow

instructions

for

lubricating

and

changing

accessories

.

Inspect

tool

cords

periodically

andifdamaged,

have

repairedbyauthorized

service

facility.Inspect

exten-

sion

cords

periodically

and

replaceifdamaged.Keep

handles

dry,

clean

and

free

from

oil

and

grease

.

Before

connecting

the

tool

to

a

power

source

(receptacle,

outlet,

etc.)be

sure

the

voltage

suppliedisthe

sameasthat

specifiedonthe

nameplate

of

the

tool.A

power

source

with

voltage greater

than

that

specified

for

the

tool

can

resultinSERIOUS

INJURY

to

the

user-as

wellasdamage

to

the

tool

.Ifin

doubt,

DO

NOT

PLUG

IN

THE

TOOL.Usingapower

source

with

voltage

less

than

the

nameplate

ratingisharmfu'

to

the

motor

.

AWARNING

Page 3

Tool

Safety

Rules

Foryour

own

safety,

do

not

attempt

to

operate

your

band

saw

untilitis

completely

assembled

and

installed

accordingtothe

instructions

. . .

and

until

you

read

and

understand

the

following

:

WARNING

"GENERAL

SAFETY

INSTRUCTIONS

.

..See

Page

2

"

TOOL

RULES

..... . ... .

. . ... . . ...

. .

See

Page

3

"

GETTING

TO

KNOW

YOUR

BAND

SAW

See

Page

6

"

OPERATIONS

... .

. .

. . . . . . .

. .

. . ...

See Page

9

"

ADJUSTMENTS

. . ... . . . . . ...

See

Pages12&13

"

MAINTENANCE

. .

.

.

. .

. .....

. . . ...

See

Page

10

Stability

of

Saw

"

YOUR

BAND

SAW

MUST

BE

BOLTED

SECURELY

TO

A

STAND

OR

WORK

BENCH

.Inaddition,

if

thereisany tendency

for

the

band saw

to

tip

over

or

move

during

certain

operations

suchascutting

long

heavy

boards,

bolt

your

band saw

standorwork-

benchtothe

floor

.

Location

"

This

band saw

is

intended

for

indoor

use

only

.

Protection

:

Eyes,

Hands,

Face,

Ears,

Body

"

Wear

safety

goggles

andaface

shieldifoperation

is

dusty.Wear

ear

plugsormuffs

during

extended

periodsofoperation.Do

not

wear

gloves...roll

long

sleeves

above

the

elbow

.

"

Do

not cut

piecesofmaterial

too

smalltohold

by

hand

.

"

Avoid

awkward

hand

positions

whereasudden

slip

could causeahandtomove

into

the

blade

.

"

Never

turn

your

band

saw

"ON"

before

clearing

the

table

of

all

Objects

(tools,

scrapsofwood,

etc

.)

except

for the

workpiece

and

related

feedorsupport

devices

for

the

operation

planned

.

"

Make

sure

the

blade

runs

downward

toward

the

table

.

Always

adjust

tracking

wheel

correctlysothat

the

blade

does

not run

off the

wheels

.

"

Always

adjust

blade

tension

correctly

.

"

ALWAYS

adjust

the

upper

blade guide

and

blade

guard

to

just

clear

the

workpiece

to

protect

the

operator,tokeep

blade

breakage

to

a

minimum,

and

to

provide

maximum

support

for

blade

.

Page

3

"

When

cutting

a large

pieceofmaterial,

make

sure

itissupported

at

table

height

.

"

Hold

the

work

firmly

against

the

table

.

"

Do

not

feed

the

material

too

fast

while

cutting.Only

feed

the

material

fast

enoughsothat

the

blade

will

cut.Keep

fingers

away

from

the

blade

.

"

Use

caution

when

cutting

off

material

whichisirreg-

ularincross section

which

could

pinch

the

blade

before

the

cutiscompleted.A

pieceofmolding

for

example

must

lay

flatonthe

table

and not be

permitted

to rock

while

being

cut

.

"

Use

caution

when

cutting

off

round

material

such

as

dowel

rods, or

tubing,

They

haveatendency

to

roll

while

being

cut

causing

the

blade

to "bite"

.

Always

usea"V"

block,orclamp

round

materialtoa

miter

gauge

.

"

When

backingupthe

workpiece,

the

blade

may

bind

in

the

cut

... . .

.

.

this

is

usually

causedbysawdust

clogging

up

the cutorbecause

the

blade

comes

out

of

the

guides.If

this

happens

:

Turn

off

the

band

saw

. . .

remove

plug

from

power

source

outlet

. . .

remove

cover

from

band

saw.Insert

a

screwdriver

or

wedge

in

the cut

...

rotate the

wheels

by

hand

while

backingupthe

workpiece

.

"

Never

leave

the

band

saw

work

area

with

the

power

on,

before

the

machine

has

come

to a

complete

stop,

or

without

removing

and

storing

the

switch

key

.

"

Never

operate

band

saw

with

cover

removed

.

"

Do

not

perform

layout,

assembly,orsetup

work

on

the

table

while

the

cutting

toolisrotating

.

"

Turn

saw

"off"

and

remove

plug

from power

supply

outlet

before

installing

or removing an

accessory

or

attachment

.

"

Should

any

part of

this

band

saw be

missing,

bent,

or

failinany way,orany

electrical

component

fail

to

perform

properly,

shut

off

power

switch

and remove

plug

from

power

supply

outlet.Replace

damaged,

missing,

and/or

failed

parts

before

resuming

opera-

tion

.

Think

Safety

"

Safetyisa

combinationofoperator

common

sense

and

alertness

whenever

the

band

saw

isinoperation

.

Do

not

allow

familiarity

(gained

On

1

from

frequent

use

of

your

band

saw)

to

become commonplace.Always

remember

thatacareless fractionofa

secondissufficient

to

inflict

severe

injury

.

AWARNING

Page 4

-

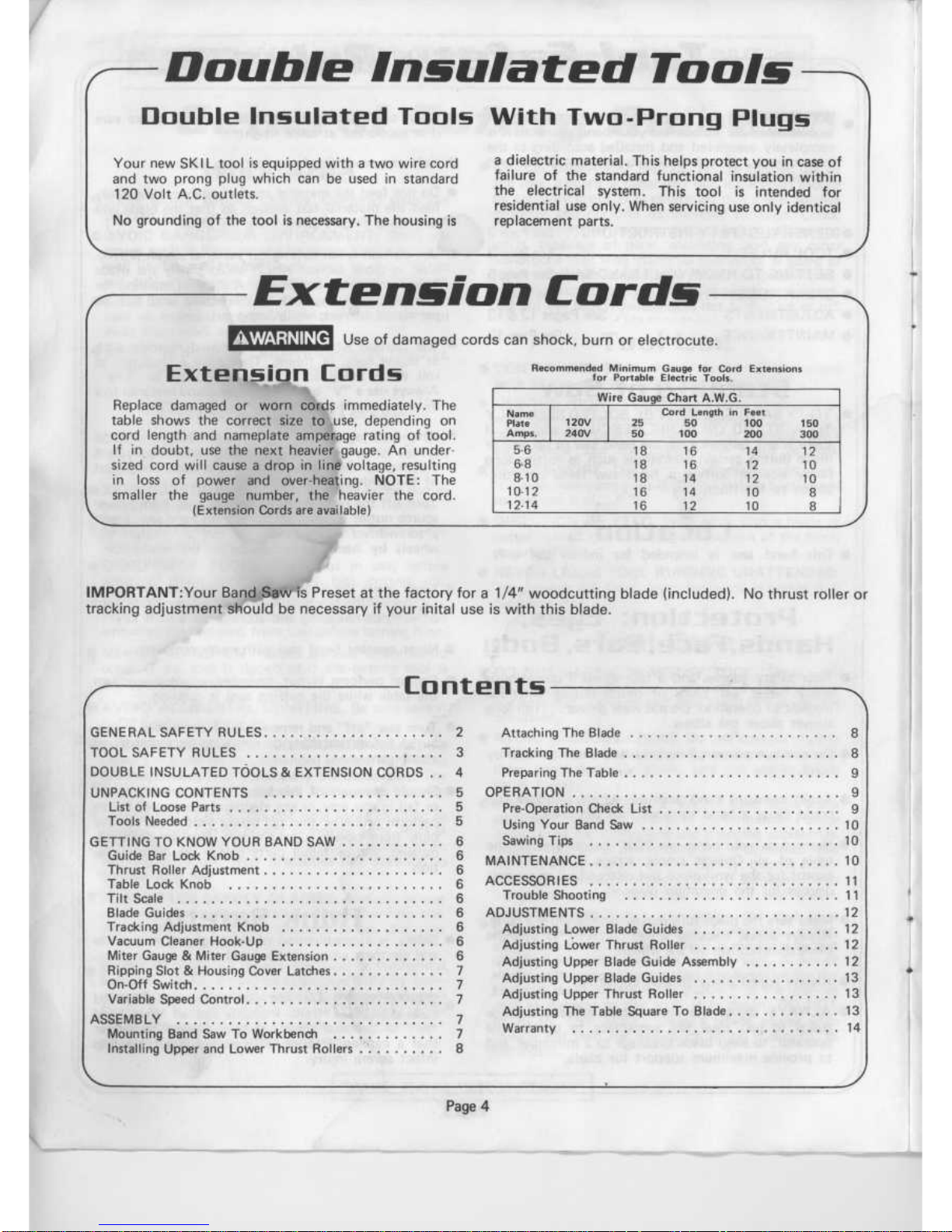

Double

Insulated

Tools

Double

Insulated

Tools

With

Two-Prong

Plugs

Your

new

SKI

L

tool

is

equipped

with a

two

wire

cord

andtwo

prong

plug

which

can

be usedinstandard

120

VoltA.C.outlets

.

No

grounding

of

the

toolisnecessary.The

housing

is

AWARNING

Replace

damaged

or

worn

cords

immediately.The

table

shows

the

correct

sizetouse,

depending

on

cord

length

and

nameplate

amperage

ratingoftool

.

It

in

doubt,

use the

next

heavier

gauge

.Anunder

sized

cord

will

causeadropinline

voltage,

resulting

in

loss

of

power

and

over-heating.NOTE

:

The

smaller

the

gauge

number,

the

heavier

the

cord

.

(Extension

Cords

are

available)

Contents

Page

4

a

dielectric

material.This

helps

protect

youincase of

failureofthe

standard

functional

insulation

within

the

electrical

system

.

This

tool

is

intended

for

residential

use

only.When

servicing

use

only

identical

replacement

parts

.

Extension Cords

Useofdamaged

cords

can

shock,

burn

or

electrocute

.

Recommended

Minimum

Gauge

for

Cord

Extensions

Extension

Cords

for

Portable

Electric

Tools

.

IMPORTANT

:Your

Band

Saw's

Presetatthe

factory

fora1/4"

woodcutting

blade

(included).No

thrust

roller

or

tracking

adjustment

shouldbe

necessaryifyour

inital

useiswith

this

blade

.

GENERAL

SAFETY

RULES

. . . . . . . . ...

. . . . . . . . ..2

Attaching

The

Blade

. . . . . . . . . . . . . . . . . . . . . . . .

8

TOOLSAFETY

RULES

. . . . . . . . . . ...

. . . . . . . . . .

3

Tracking

The

Blade

. . . ... ... . . . ... .

.

. . . . . . . .

8

DOUBLE

INSULATED

TOOLS&

EXTENSION

CORDS

. .

4

Preparing

The

Table

.

. . . . . . . . . . . . . . . . . .

.

. .

. .

.

9

UNPACKING

CONTENTS

.

. . . .

. ... . . . . . . . . . . .

.

5

OPERATION

... . . . . ...

. .

.

. .

... . ...

... . ... .

.

9

ListofLoose

Parts

. . . ... . . .

. ... . . . . . . . . . . . .

5

Pre-Operation

Check

List

. ...

. ... . ..... . . ... .

.

9

Tools

Needed

. . . . . . . . . . .

. . . . . . . . . . . . . . . . ..5

Using

Your

Band

Saw.. . . .

. .

. . . . . . ... . . . . ...

10

GETTING

TO

KNOWYOUR

BAND

SAW

. . . . . . . . . . . .

6

Sawing

Tips.. . . . . .

. . . .

. ...

. . . . . . . . .

. .

. . .

10

Guide

Bar

Lock

Knob

. ... ...

. ... . . . . . . . . . . . .

6

MAINTENANCE

.

. . . . . ... ... ...

. . . . . . . .

. ...

. .

10

Thrust

Roller

Adjustment

. . . . . . . . ...

. . . . . . . . . .

6

Table

Lock

Knob

. . . . . . ... ...

. ... . . . . . . . ..6

ACCESSORIES

...

. . . .

. . . . ..... . . . . . . . ..... .

11

Tilt

Scale

...

. . . . . . . . . . . . . . . .

. . . . . . . . . . ..6

Trouble

Shooting

. . .

. . . . . . ... ... . .

... .

. . . .

11

Blade Guides

. ... . . . . . . . . . ... .

. . . . . . . . . . . .

6

ADJUSTMENTS

. . . . . . ...

. . ...

. ...

. .

. ... . ... .

12

Tracking

Adjustment

Knob

. . . ...

. . . .

. ... . . . . .

6

Adjusting

Lower

Blade

Guides.. . . . . .

. . . . . . . . .

.

12

Vacuum

Cleaner

Hook-Up

. . .

. . . . . . . . . . . . . . . .

6

Adjusting

Lower

Thrust

Roller

. . . . . .

. . . . . . .

. .

. .

12

Miter

Gauge&Miter

Gauge

Extension

. . . . . . . . . . . . .

6

Adjusting

Upper

Blade

Guide

Assembly

. . . . . . . ... .

12

Ripping

Slot&Housing

Cover

Latches

. . . . . . . . . . . . .

7

Adjusting

Upper

Blade Guides

. . . . . . . . . . ...

. .

. .

13

On-Off

Switch

. . . . . . . ... ... ...

. . . . . . . . . . . . .

7

Variable

Speed

Control

. ...

. ... .

. .

. . . . . . . . . . . .

7

Adjusting

Upper

Thrust

Roller

. . . . . . . . . .

. . . . . ..13

Adjusting

The

Table

SquareToBlade..

. . .

. . . . . . .

.

13

ASSEMBLY

. . . . . . ... ...

. ... . ...

. ... .

. . . . . .

7

Mounting

Band

SawToWorkbench

. .

. ... .

. .....

7

Warranty

. ..... ... ... . . . . . . . . . . . .

. .

. ... .

14

Installing

Upper

and

Lower

Thrust

Rollers..

. .

. . . . . .

8

Wire

Gauge

ChartA.W

.G

Rams

Cord

LengthinFeet

plate

120V

25 50 100 150

Amps

.

240V

50 100 200

300

5-6

18 16 14 12

68

18 16 12

10

8-10

18

14

12

10

10-12

16

14 10

8

12-14

16

12

10

8

Page 5

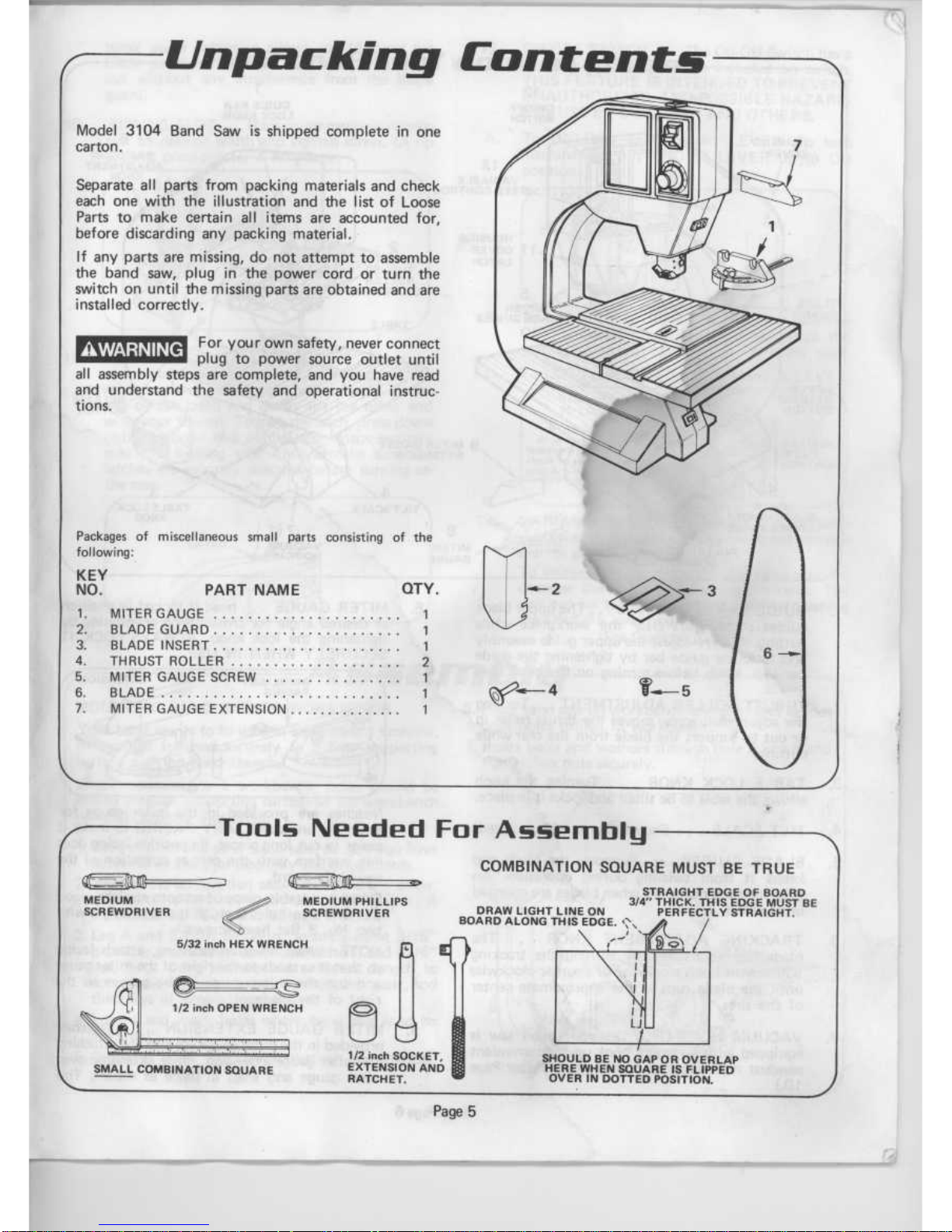

Unpacking

Contents

tents

Model

3104

Band

Saw

is

shipped

complete

in

one

carton

.

Separate

all

parts

from

packing

materials

and

check

each

one

with

the

illustration

and

the

listofLoose

Parts

to

make

certain

all

items

are

accounted

for,

before

discarding

any

packing

material

.

If

any

parts

are

missing,donot

attempttoassemble

the

band

saw, pluginthe

power

cordorturn

the

switchonuntil

the

missing

parts

are

obtained

and

are

installed

correctly

.

AWARNING

For

your

own

safety,

never

connect

plug

to

power

source

outlet

until

all

assembly

steps

are

complete,

and you

have

read

and

understand

the

safety

and

operational

instruc-

tions

.

Packagesofmiscellaneous

small

parts

consisting

of the

following

:

KEY

NO

.

PART

NAME

QTY

.

MEDIUM

_..-°."-MEDIUM

PHILLIPS

SCREWDRIVER

5/32

inch

HEX

WRENCH

1/2

inch

OPEN

WRENCH

SMALL

COMBINATION

SQUARE

Tools

Needed

For

Assembly

SCREWDRIVER

1/2

inch

SOCKET,

EXTENSION

AND

RATCHET

.

Page 5

SHOULD

BENOGAPOROVERLAP

HERE

WHEN

SQUARE

IS

FLIPPED

OVER

IN

DOTTED

POSITION

.

COMBINATION

SQUARE

MUST

BE

TRUE

STRAIGHT

EDGEOF

BOARD

3/4"

THICK.THIS

EDGE

MUST

BE

DRAW

LIGHT

LINE

ON

PERFECTLY

STRAIGHT

.

BOARD

ALONG

THIS

EDGE

.

1.MITER

GAUGE

...

. ... . . . . . . . . . . . .

. . .

1

2.BLADE

GUARD

. . . ...

. . . . . . . ... . .

. ...

1

3.BLADEINSERT

. . . ...

. . . . . . . . . ...

. ... 1

4.THRUST

ROLLER

. .

.

. . .

. . .

...

.

. ... .

. .

2

5.MITER

GAUGE

SCREW

. ... .....

. ... ...

1

6.BLADE

. ... ... . . . . . . . . . .....

. .

.

.

. . .

1

7.MITER

GAUGE

EXTENSION

. ... . . . . ..... . .

1

Page 6

HOUSI

No

COVER

6

LOWER

BLADE

GUIDES

UNDER

TABLE

2

LOWER

THRUST

ROLLER

ADJUSTMENT

UNDER

TABLE

Getting

to

Know

Your

Band

Saw

12

ON/OFF

SWITCH

1.GUIDE

BAR

LOCK

KNOB

. . .

The

upper

blade

guides

should

just

clear

the

workpiece

while

cutting.Always

adjust the

upper

guide

assembly

and

lock

the

guide

barbytightening

the

guide

bar

lock

knob

before

turningonthe

band

saw

.

2.THRUST

ROLLER

ADJUSTMENT

. . .

Turning

the

adjustment

screw

moves

the

thrust

roller

in

or

outtosupport

the

blade

from

the

rear

while

cutting

.

3.TABLE

LOCK

KNOB

..Turning

the

knob

allows

the

tabletobe

tilted

and

locks

it

in

place

.

4.TILT

SCALE

.

. .

Shows

degree

tableistilted

.

5.BLADE

GUIDES

..Supports

the

blade

and

keepsitfrom

twisting

during

operation.An

adjustmentisnecessary

when

blades are

changed

or

replaced

.

6.TRACKING

ADJUSTMENT

KNOB

. . .

The

blade

can be

trackedbyturning

the

tracking

adjustment

knob

clockwise

or counter-clockwise

until

the

blade

runsinthe

approximate

center

of

the

tires

.

7.VACUUM

HOOK-UP

.

.

your band saw

is

equipped

withavacuum

hook-up

for

convenient

sawdust

removal.(See

Maintenance/Motor

Page

10

.)

MITER

GAUGE

EXTENSION

4

TILT

SCALE

8.MITER

GAUGE

...

headislockedinposition

at

desired

angle

for

crosscuttingormitering

by

tightening

the

lock

knob.ALWAYS

LOCK

IT

SECURELY

WHEN

IN

USE

.

9

.

Page

6

7

VACUUM

HOOK-UP

GUIDE

BAR

LOCK

KNOB

Notches

are

providedinthe

miter

gauge

for

attachinganAUXILIARY

FACING

to

make

it

easiertocut

long

pieces.Be

positive

facing

does

not

interfere

with

the

proper

operationofthe

saw-blade

guard

.

Selectasuitable

piece

of

smooth

straight

wood

.

.

.

drill

two

holes

throughitand

attachitwith

twoNo.3flat

head

screws

.

NOTE:When

bevel

crosscutting,

attach

facing

so

thatitextends

to

the

rightofthe

miter

gauge

and

use the

miter

gaugeinthe

groove

to

the

rightofthe

blade

.

MITER

GAUGE

EXTENSION

.

.

Notches

providedinthe

miter

gauge

are

also

for

attaching

the

miter

gauge

extension.Place

extension

over

miter

gauge

and

snapinplaceasshown

.

The

Page 7

miter

gauge

extension

allows

youtolower

the

blade

guard

within

1/8" of the

material to

be

cut

without

any

interference

from

the

blade

guard

.

RIPPING

SLOT

. . .

Place

miter

gaugeinripping

slottodesired

width

and

tighten

screw.(A

rip

scaleisprovided

for

a

reference

.

HOUSING

COVER

LATCHES

..There

are

seven

latchestoremove

the

housing

cover

.

To

release

latches,

place

your

index

fingeratone

end

of

the

latch

and

gently

lift

the

other

end

with

your

thumb.To

lock

the

latch,

press

down

until

the

open

end

of

the

latch

snaps

securely

over

the

locking

tab

.

Always

make

sure

the

latches

are

securely

snapped

before

turning

on

the

saw

.

MOUNTING

BAND

SAWTO

WORKBENCH

5.Drill

(2)

3/8"

dia.holes

through

workbench

.

Assembly

Your

band

sawisto

be used

in

a

permanent

location,

it

must

be

fastened

securelytoa

firm

supporting

surface

such

as a

workbench

.

When

mounting

toaworkbench,

holes

should

be

drilled

through

supporting

surface

of

the

workbench

using

dimensions

illustrated

.

1

.

Before

mounting

your

band

saw,besure

you

have

access to

all

sides

for

assembly

and

adjustments

.

2.Release

the

latches

that

secure the

band

saw

cover

.

Loosen

table

lock

knob,

tilt

table

PRESS

COVER

t

RELEASE

BUTTON

and

REMOVE

COVER

.

3.LegAandB'must

be

bolted

securely using

5/16"

diameter

machine

screws,

lockwashers,

and

5/16"

hex

nuts.Bolts

must

be

of

sufficient

length to

accommodate

legsofsaw, washers,

hex

nuts,

and

thickness

of

supporting

surface

.

4.Locate

and

mark

holes

where

band

sawisto be

mounted

.

Page 7

12

.

ON-OFFSWITCH

. . .

The

On-Off

Switch

has

a

red

locking

lever

whichisincluded

on

switch

.

THIS

FEATURE

IS

INTENDED

TO

PREVENT

UNAUTHORIZED

AND

POSSIBLE

HAZARD-

OUS

USE

BY

CHILDREN

AND

OTHERS

.

A

.

To

UNLOCK

switch

insert

LEVER.To

turn

machine

ON

lift

END

of

LEVER

up

to

ON

position

.

LOCKING

LEVER

SWITCH

ON

B.To

turn

machine

OFF...PUSH

lever

down

to

OFF

position

.

Never

leave

the

saw

until

the

cutting

tool

has

come

to

a

complete

stop

.

C.To

LOCK

switchinoff

position

remove

LEVER

.

3/B"

DIA

.

REMOVE

LEVER

TO

LOCK

SWITCH

WARNING

:

After

removing

locking lever

awavs

check

to

see

that

the

N

switch

a

latched

in

OFF

position

.

13.VARIABLE

SPEED

CONTROL

. . .

The

band

sawisequipped

with

a

variable

speed

control

dial for

greater

versatility

.

To

increase

speed,

rotate

the

dial

clockwise

.

To

decrease

the

speed

turn

counter-clockwise.The

saw

can

be

turned

offatany

speedbypushing

the

ONiOFFlevertooff

position

.

(See

Chart

on page

10)

6.Place

band

saw

on

workbench

aligning

holesinfoot

with

holes

drilled

in

workbench

.

7.Insert

bolts

and

washers

through

holeAandBand

tighten

hex

nuts

securely

.

VARIABLE

SPEED

CONTROL

OAF

Page 8

1.Find

a

Thrust

Roller

among

loose parts

and

insert

in

upper

guide

assembly

.

UPPER

I IIB

LADE GUIDES

GUIDE

ASSEM.

PHILLIPS

SCREWS

ATTACHINGTHEBLADE

1.Remove

slotted

screwintable

.

2.Carefully

uncoil

the

blade

holdingitat

arms

length

.

NOTE:Your band

saw

can

be

used

witha1/8",

1/4",

3/8"or1/2"

wide

bIades,

62"

long

.

3.Turn

1/2"

tension

adjustment

nut

CLOCKWISE

until

the

blade

will

fit

over

all

three

wheels

.

4.Place

the

blade

through

the

slot

in

the

saw

table,

with

the

TEETH

POINTING

DOWNWARD

as

shown

.

NOTE:In

some

instances

the

blade

may

uncoil

"Inside

Out"

and

the

teeth

willbefacing

down,

but

away

from

the

operator.See

page

14

for

corrective

action

.

5.Place

the

blade

betwaan

upper

and

lower blade

guides

then

over

WHEEL

(1),

(2)

and

(3)

while

centering the

blade

approximately

on

all

three

wheels

.

6.Turn

1/2"

tension

adjustment

nut

COUNTER

CLOCKWISE

until

all

the

tensionison

the

blade

and

tension

adjustment

nutisloose

.

7.Turn

tension

adjustment

nut

CLOCKWISE

until

nutisfinger

tight

against

the

tracking

bracket,

then turn

tension

adjustment nut

CLOCKWISE

1/4

TURN

.

To

prevent

personal

injury,

NEVER

PLUG

IN

TOOL

with

the

housing

cover

off,

or

when

making

adjustments.Also

blades

are

SHARP

. . .

HANDLE

WITH

CARE

.

AWARNING

Turn

WHEEL

(2)

by

hand

CLOCKWISE

a

few

turns

and

noticeifthe

blade

remainsinthe

approximate

center

of

the

tires

.

If

the

blade

moves

away

from

the

centerofthe

wheels

while

you

are

turning

it,

the

bladeisnot

TRACKING

properly

.

If

the

TEETH

of

the

blade

move

TOWARD

you

:

a.Rotate

WHEEL

(2)

CLOCKWISE

by

hand,

while

turning

the

tracking

adjustment

knob

CLOCKWISE

just

enough

to

keep

the blade

in

the

approximate

centeroftires

.

TRACKING

THE

BLADE

If

the

TEETH

ofthe

blade

move

AWAY

from

you

:

b.Rotate

WHEEL

(2)

CLOCKWISE

by

hand, while

turning

the

tracking

adjustment

knob

COUNTER

CLOCKWISE

just

enough

to

keep

the

bladeinthe

approximate

center

of

tires

.

/J

Page 8

2

.

Find

a

Thrust

Roller

among

loose parts

and

insert

in

lower

guide

assembly

.

LOWER

BLADE

GUIDES

THRUST

ROLLER

J

Page 9

PREPARING

THE

TABLE

1,

Loosen

the

guide

bar

lock

knob,

and

lower

the

blade

guide

assembly

.

2.Attach

the

blade guardonthe

upper

guide

assem-

bly

and

secureitwith

two

screws

.

3.Locate

the

table

insert

and

placeitin

the

opening

in

the

table

.

4.Replace

3/16"

slotted

screw

flushorbelow

the

table

surface,

while holding

both

sides flush

.

5.The

blade

shouldbein

the

approximate

center

of

slotininsert

.

If

the

blade

runs

to

one

side

of table

insert

:

1.Loosen

table

lock

knob

and

tilt

table to

450 and

loosen

rear

1/2"

hex

screw

that

mounts

table

to

trunnion

.

2.Return

tableto900and

loosen

front

1/2"

hex

screw

that

mounts

tabletotrunnion

.

3

.

Shift table

leftorright

until

the

blade

is

in

the

approximate

centerofinsert

.

4.Securely tighten

front

screw,

tilt

table

to

450 and

securely

tighten

rear

screw

.

PRE-OPERATION

CHECK

LIST

Before

operating

your

Band

Saw,

check

the

items

listed

belowtobe

sure

your

sawisreadytocut

.

1.Band

Saw

firmly

mounted

to

workbench

.

2.Switch

OFF

.

3.Upper

blade

guard loweredtowithin

1/8"

of

material to

be

cut

.

4.Housing

cover

closed

and

locking

latches secure-

ly

snappedinplace

.

5.Blade

Tension

and

Tracking

properly adjusted

.

6.Saw

table

firmly

locked

in

position

.

7.Wear

safety

goggles

.

USING

YOUR

BAND

SAW

Your

Band

Sawiscapableofmaking

all

types

of

cuts

in

a

wide

variety of

materials.A

brief

description

of

cutting

methods

will

familiarize

you

with

the

basic

typesofcuts

.

CROSSCUTTING

Crosscuttingiscutting

across

the

grainofthe

wood

.

Page

9

FRONT

HEX

SCREW

REAR

HEX

SCREW

TABLE

LOCK

KNOB

Operation

MITER

CUTTING

BEVEL

CUTTING

SCROLLING

Suchacutisoften

usedtoshorten

lumber

such

as

2x4's

.

RIPPING

Ripping

is

cutting

along

the

grainofthe

wood.Such

a

cutisoften

usedtomake

lumber

suchasshelving

more

narrow

.

Miter

cuttingiseither

rippingorcrosscuttingatsome

angle

other

than

900.For

small

pieces

use the

miter

gauge.Miter

cuts

are

often

madeat450

for

use

in

picture

frames

and molding

work.The

miter

gauge

is

graduated

in

50

increments

from

00

to

600

.

Bevel

cuttingiseither

ripping

or

crosscutting

with

the

saw

table

tiltedatdesired

angle.Tilt

the

table

by

loosening

the

table

lock

knob.Set

the

table to

the

desired

angle

using

the quadrant

and

bevel

pointer

as

a

guide.Tighten

the

table

lock

knobtosecure

the

table

.

Scrollingisthe

cuttingofcurved

lines

.

With

the

1/8"

wide

scrolling

blade,avarietyofintricate

designs

are

possible

.

Page 10

METAL

CUTTING

Non-ferrous

metal

(without

iron

content)

can

be cut

withageneral

purpose

blade

.

Ferrous

sheet

metal

should be cut

usingametal

cutting

blade

.

SAWING

TIPS

1.Whenever

possible

makeafew

test

cutsinscrap

wood

to be

sure that

the

saw

is

properly

adjusted

.

2

.

When

making

finish

cuts,

position

the

wood

so

that

the

finished

sideisup.This

will

preventthe

finished

surface

from

splintering

.

3.Feed

wood

directly

into

the

saw

teeth

.

Don't

side

load

the

saw

blade.Thisisparticularly

important

when

scrolling

.

4.If

you

are

cuttingawarped

board,

position

it

with

the

concave

side

DOWN

.

5.Never

force

the

wood

into

the blade.Let the

saw

do

the

work

.

6

.

When

cutting

very

smallpieces,

useastick

to

push

the

wood

into

the

blade

.

7.Do

not

pull

material

being

cut

backward

to

prevent

the

blade

from

jumping

OFF

the

rollers

.

8

.

For

maximum

accuracy

when

using

miter

gauge,

"favor

one

sideofgrooveintable

.

SELECTION

CHART

The

following

chart

provides

recom

m

endations

for

blade

types,

and

speeds

basedonthe

type of

material

you

want

to

cut.These

speeds

are

recommended

starting

points.You

should

feel

free

to adjust

the

speed

up or

down

to

find

the

most

efficient

cutting

speed.The

adjusting

knob

is

conveniently

referenced

to

numbers

from

(1)

(low)

to

(6)

(high).After

you

have

determined

the

best

cutting

speed

foraspecific

material

you

can

record

the

reference

number

for

NOTE:Thick

non-ferrous

metals

may

require

oil

or

grease

on

lineofcut

.

Page10

Maintenance

For

your

own

safety,

turn

switch

"OFF"

and

remove

plug

from

power

source

outlet

before

maintainingorlubricating

your

saw

.

AWARNING

TIRES

Pitch

and

sawdust

that

accumulateonthe

tires

should

be

removed

withastiff

brush or scraped

off

with a

pieceofwood.Do

not

use a

sharp knifeorany

kind

of

solvent

.

When

the

tires

become

wom

they should be

replaced

.

When

replacing

the

tires,

stretch

them

around

the

wheels but

do

not

glue

themon.

GENERAL

Do

not

allow

pitchtoaccumulateonthe

table,

blade

insert,

blade

guides,orthrust

rollers.Clean

them

withaGum

and

Pitch

Remover

.

The

cord

and

the

tool

should be

wiped

withadry

clean cloth

to

prevent

deterioration

from

oil

and

grease

.

Certain

cleaning

agents

and

solvents

can

damage

plastic

parts.Some

of

these

are:gasoline,

carbon

tetrachloride,

chlorinated

cleaning

solvents,

ammonia

and

household

detergents

which

contain

ammonia.Avoiding

useofthese

and

other types

of

cleaning

agents

will

minimize

the

possibility

of

damage

.

A

CAUTION

Applyathin

coatofautomobile-type

wax

on

the

tablesothe

wood

slides easily

while

cutting.Also

apply

wax

to

the

inside

surfacesofthe

trunnion

.

MOTOR

Frequently

vacuum

or

blow

out any

sawdust

from

the

motor

.

A

vacuum

hook-up

openingisprovidedifyou

wish

to

remove

the

dust

and

chipsasthey

are

generated

.

Plug

the

vacuum

cleaner

hose

into

the

hole

provided

.

See

item7.onpage6.

All repairs, electricalormechanical,

shouldbeattempted

onlybytrained

repairmen.Corttact

the

nearest

Factory

Service

Cen-

terorAuthorwed

Service

Stationorother

competent

repair

service.Use

only

identical

replacement

parts,

any

other

may

create

a hazard

.

AWARNING

LUBRICATION

Allofthe

BALL

BEARINGS

are

packed

with

grease

at

the

factory.They

requirenofurther

lubrication

.

However,

after

six

months

to

one

year,

depending

upon

use,

its

wisetoreturn

your

tooltothe

nearest

Skil

Service

Center

for

the

following

:

"

Brushes

replaced

.

"

Parts

cleaned

and

inspected

.

"

Relubricated with

fresh

lubricant

.

*Electrical

system

tested

.

*All

repairs

.

future

use

.

BLADE

MATERIAL

SPEED

Wood

High

General Purpose

Plastic

Medium

Blade

Non-Ferrous

Medium

to

Metals

Medium-High

(Aluminum,

Zinc)

Wood

High

Scrolling

Blade

Plastic

Medium

Sheet Metal

LowtoMedium

Non-Ferrous

Metal

Cutting

Metals

B

lade

DONOTCUT

HARDENED

STEELS

J

Page 11

Accessories

it)e

useofany

other

accessories

not

specifiedinthis

manual

may

createahazard

.

J

Trouble

Shooting

Page

1

1

hill

IMPORTANT

:Your

Band

Saw

is

Presetatthe

factory

fora1/4"

woodcutting

blade

(included)

.

No

thrust

roller

or

tracking

adjustment

shouldbe

necessaryifyour

inital

useiswith

this

blade

.

WARNING

For

your

own

safety,

turn

switch

"OFF"

and

always

remove

plug

from

power

source

outlet

before

trouble

shooting

.

TROUBLE

PROBABLE

CAUSE

REMEDY

1.Defective

ON/OFF

switch

.

MOTOR

WILL

NOTRUN

2.Defective

cord

. 1

.

Return

unit to

you:nearest

Skil

Service

Center

.

3

.

Defective

Motor

.

4.Defective

speed

control

.

BLADE

DOES

NOT

RUN

1 .

Not

trackinggproperly

.

properly

.

1

.

Adjust

tracking,

See

Assembly

Section,

IN

THE

APPROXIMATE

"Tracking

the

Blade"

.

CENTEROF

THE

WHEELS

2.Check

for

proper

tension

.

BAND

SAW

SLOWS

1

.

Cutting

too

smallaradius

. 1.Stop

feeding,

and

backupto

the

material

DOWN

WHEN

CUTTING

slightly,

until

the

band

saw

speedsup.

2.Dull

blade

.

2.Replace

blade

.

1.Too

much

tension

.

1.Adjust

tension,

See

Assembly

Section,

"Installing

the Blade"

.

BLADESBREAKING

2.Kinkinblade

causedbycutting

2.Use

correct cutting

technique.See

too

smallaradiusorturning

the

"Operation"

Section,

material

too

fast

when

cutting

.

Cat

.

No

.

Description

Use

Cat

.

No

.

Description

Use

80038

1/8-x62-x14T.P.I.blade

Wood

scrolling

80047

1"x62"80

grit

Fast

stock

removal

(medium

sanding

(closed

coat)

80039

1/4"x62"x

6

T

.P.I.

blade(skip)

General

wood/plastic

belt)

80D40

3/8"x62"x

6T.P.I.blade

(skip

General

wood/plastic

800481"x62"

120

grit

Wood

finishing

(medium

fine

(closed

coat)

80041

1/2"x62"x

6T.P.I

.blade(skip)

General

wood/plastic

sanding

belt)

80042

1

/4"x62"xl8T.P.I.

blade

Ferrous

metal

under

80049

1

"x62"

220

grit

Ferrous

metal

1/4"

thick

(fine

sanding

belt)

(closed

coat)

80043

1/4"x62"x24

T.P.I.blade

Ferrous

metal

under

1/8"

thick

80080

Belt

sander

kit

To

convert

to1"belt

sander

80044

3/8"x62"x18T.P.I.

blade

Non-ferrous

metal

80090

Tool

stand

For

floor

mounting

saw

under

1/4"

thick

80046

318"x62"x24

T

P,1

.

blade

Non-ferrous

metal

under

1/8"

thick

Page 12

ADJUSTING

LOWER

THRUST

ROLLER

1.Tobesure

the

thrust

rollerisproperly

supporting

the

blade,

turn

the

thrust

roller

adjustment

screw

using

5/32"

hex

wrench

so

that

the

roller

moves

toward

the

blade

and

almost

touches

.

2.While

turning

the

upper wheel

clockwisebyhand,

adjust

the

thrust

roller until

it

barely

touches

the

blade

.

3.Run

the

lock

nut

down

finger

tight,

and

tighten

with

a

1/2"

socket

and

extension

.

4.Rotate

WHEEL

(2)

CLOCKWISE

a

few

times

by

hand

and

check

the

blade

guides

and

thrust

rollers

.

Make

readjustmentifnecessary

.

Adjustments

ADJUSTING

LOWER

BLADE

GUIDES

1.Loosen

the

two

Phillips

screws

that lock

the

lower

blade

guides

and

press

the

two

guides evenly

against

the

sidesofthe

blade

butdonot

pinch

the

blade.Release

the guides

and

rotate

the

upper

wheel

slightly

clockwise

moving

the

blade

down-

ward.Make

sure

one

guideisnot

farther

away

from

the

blade

than

the

other

and

securely

tighten

phillips

screws

.

Page

1

2

THRUST

ROLLER

INTERNAL

HEX

THRUST

ROLLER

ADJUSTMENT

SCREW

ADJUSTING

UPPER

BLADE

GUIDE

ASSEMBLY

NOTE:The

upper

and

lower blade guides

support

the

blade

and

keep

it

from

twisting

during

operation.An

adjustmentisnecessary

when

blades

are

changed

or

replaced

.

1.Loosen

two

hex

head

screwsinupper

blade guide

assembly and

slide

assembly forward

in

the

slots

until

the

front

edgeofthe

blade

guides

are

approxi-

mately

1/32"

from

the

GULLET

of

the

saw

blade

.

2.Tighten

two

hex

head

screws

while

keeping

the

blade guide

assembly

paralleltothe

table

.

NOTE:It

may

be

necessary

to

back

out

thrust

roller

adjustmenttoallow

thrust

roller

to

move

back from

bladetoget

1/32"

clearance

from

the

gullet

to edge

of

blade

guide

.

BLADE

GUIDE

LIP

SHOULD

AWAYS

FACE

THE

BLADE

GUIDE

ASSEMBLY

OAF

Page 13

ADJUSTING

UPPER

BLADE

GUIDES

1.Loosen

the

two

phillips

screws

that

lock

the

upper

blade guides

and

press

the

two

guides evenly

against

the

sides

of the blade butdonot

pinch

the

blade

.

Release

the

guides

and

rotate

WHEEL

(2)

slightly

CLOCKWISE

moving

the

blade

downward

.

Make

sure

one

guideisnot

farther

away

from

the

blade

than

the

other

and

securely

tighten

phillips

screws

.

Page13

ADJUSTING

UPPER

THRUST

ROLLER

NOTE:The

thrust

rollers

support

the

blade

from

the

rear

and

will

rotate

when

the

bladeispushed

against

them

while

you

are

cutting.As

soonasyou

stop

cut-

ting,

the

rollers

should

stop

rotating

.

1

.

To

be

sure

the

thrust

rollerisproperly

supporting

the

blade,

turn

the

thrust

roller

adjustment screw

using

5/32"

hex wrench

so

that

the

roller

moves

toward

the

blade

and

almost touches

.

2.While

turning

WHEEL

(2)

CLOCKWISE

by

hand,

adjust

the

thrust

roller

untilitbarely

touches

the

blade

'

%

.

3.Run

the

lock

nut

down

finger

tight,

and

tighten

witha1/2"

open

endwrench..

LOCK

NUT

INTERNAL

HEX

THRUST

ROLLER

ADJUSTMENT

SCREW

ADJUSTINGTHE

TABLE

SQUARE

TOBLADE

NOTE:The

combination

square

must

be

"true".See

"Tools

Needed"

section

for

Checking

Method

.

1.Loosen

table

lock

knob,

tilt

table,

REPLACE

COVER

be

sure

cover

release

button

snapsinslot,

and

SECURE

LY

SNAP

ALL

LATCHES

.

2.Loosen

guide

bar

lock

knob

and

raise

the

upper

blade guide

assembly

all

the

wayup.

Tighten

guide

bar

lock

knob

.

3.Placeasmall

squareontable

against

the

blade

as

shown

.

4

.

If

adjustment

is

required,

loosen

table

lock

knob,

tilt

table

and

adjust

3/8"

leveling

screw

inorout

while

returning

tableto90o

position

and

checking

with square.Repeat

procedure

until

tableissquare

.

Page 14

NOTE

:

It's

possible that

the

bladecould

be

inside

out.Hold

the

blade

as

shown,

with

the

saw

teeth

toward

you.Examine

the

teeth

in

your

RIGHT

HAND

.

The

teeth

should be

pointing

DOWN

for

proper

operation.If

they

are

pointing

up, the

blade

is

inside

out

.

To

reverse

it,

graspitwithyour

thumbs

and

finger

tips

and

twist

it

inside

out

.

AWARNING

Saw

bladeisvery

sharp.Use

care

when

handling

.

LIMITEDWARRANTYOFBENCHTOPTOOLS

Skd

Corporation

warrants

all

Skil

Bench

Top

Tools

which

do

not

perform

satisfactorily

duetodefects

in

workmanship

or

mate-

rials

from

the date of

purchaseto:

-One

year,ifthe

toolisused

for

personal

family

or

household

use

;

-Ninety

days,ifthe

fool

is

used

for

any

othr-

purpose,

such

as

commercialorrental,

Our

obligation

assumed

under

this

warranty

it

limited

to

the

repairorreplacement

of

parts,

without

charge,

which

are

defective

and

which

have

not

been

misused,

carelessly

handled,

or

defacedbyrepairs

made

or

attemptedbyothers

.

The

complete

fool

mustbe

returned,

transportation

prepaid,toany

Ski)

Factory

Service

Center

or

Authorized

Service

Station,

A

listing

of

Factory

Service

Centersispacked

with each

Skil

product,

This

warranty

does

not

applytoaccessories

.

This

warranty

gives

you

specific

legal

rights,

andyou

may

also

have ether

rights

which

vary

from

statetostate

.

This

warranty

applies only to

fools

sold

within

the

United

States

of

America

Canada

and

the

Commonwealth

of

Puerto

Rica

Page 15

0

Skil

Accessories

canbepurchased

at

your

local

Hardware/Home

Center

or

your

nearest

Skil

Factory

Service

Center listed

below

.

COLORADODM.r1,.6

x,1,

"

.

`

R1

s14

MCNONOil .ap

X11,110

EVra

11x.4c

400

-

;,'a'y

Ratio, 00

l

4

5V/4950

MINNESOTA

M,1nGpUb,,

2579

NI

tHeAwS644

.4

MISSOURIST

C,

:r,

4101

I

n

,

61110

MFWWLn'

;egar

1'1G

S

Al"',

941

ALABAMA

HvnMvife

.526192

ALASIFA

Anchorage

FA1N6rAG

1IANSAS

.,

,

SKIL

FACTORY

SERVICE

CENTERS

S]5N,17941

7'51

1,01

2500

5'61

43-7100

7191

797

1919

212,l6

762

715

411

411

-1

'9'

,r.

5191114

"

1

1513

~240244

121614470210

I,I1x91

51

:1

C

.I.~5562NHigh 51

43714

16141

6151070

OUAMOMA

DNAnOW

Op

600

N PIAn611Une

BIG

71107

t4%1236,0170

OREGON

PcvNM

623 5

tIMAn

97214

5113,

731

1414

r~lrlpANA

V6+a6IW

41O

YaoRl

AW

1910

x215146"

246

r16'Mwrrg

SLM

wbr

P2

17,12

17171

657

200

F'

.HIAeA

3171

L~

AN

15211

6

!4171

2610657

RMOE

"

LAND

Lot

Pra10sIF4

505

A1"n

146

07914

1411Im16W

SOUTH

CAROLINA

6renm111

1013

N

Flras4YRAeqa'79601

100312116161

TIMISSIE

A,2nrIV

7002

F

W

37917

'615'

1174

Ne-ov.,1956MRd

11114

'

901

mom

1.:-..r

'IS

MM5o 37703

.'!

350-q

"

naAf:1.a

:a:.45'

INMnM

Rkpe

75276

121,

741

5515

10,011G100MWegrEE

.fl1R101,TW

1711161L4m

UAW

7117

500

7942

IMM1

:47

917'

561AM..

.

.617MIrCnlb

.9hk2

71215

5g1

;NA1"

UTAH

San

LAW

Cny

7410

7155

SVAll15164115

5]

r,

111

,,'r

.

"um

NPM.4740

Irq1e,rINRO21511

617

.

.,a"

wgng

74146CNWh~Aw

IIIL

"13535117a

6.'

"

INGIN

-

tl1F74.

: .'nN

, 2 -

5161SM5010%

1a0Wna

-

W1.A

n1

"

S

.

Ilal

I7j

"

OIp1

1

1141%15

717,

"!10142

AI11AaU,IP

"

n/

44KIL

POWC4

TOOLS

AUTHORIZED

SERVICE

STATIONS

are

located

in

the

following

cities

.

For

addresses

and

phone

numbers,

see

your

phone

book

Yellow

Pagesunder

"Tools-

Electric"

.

LOUISIANA':nrevpdt.Vf641

Ma11rw

way"NO

.41142111

1112021

T

.4arr

F*p

1

~XvP

IM69551PM

.aI

CALIFORNIA

I,4A4

.pa,"

FIXING

Song,

Ieow~

M

"

r

.y4

Crw

Pae

112606

0

5210

Broea

Vv,Ja"16INaA6Al

5

.115

. .

.

ty

1w,

:7Di

I&aMSNA

a".

CO,CWAUOAr27arc1s

,

NEWYA

.1a..9

.V4A

AWARIAK

n " v"g11n

NEW

YORK

daEY

Grr"pe1

GMA6

El

Pie,

ILINA

HAWAIIPA

NORTH

CAFOLI

G1661epyD

A411MIle

VERMONT

5

v

.n01m

IDAHO

.,"

.

NercFNIf

OHIO

644x};v,.Hmlgeo00n

VIRGINIA

Roa-'

.

IOWA

.

OHLUgMA

rw

:e'

5'7

an

'='

MGM

iBXae.,cAAN

_

SOUTH

C~711A

Cu,11

.oe

TENNESSEE

ar,pr

,

~,'Ly

I

y

TEXAS

Ama,I",

A~m,ervAa6vn14

MIi110

.

WASHINGTON

vMn,4N.

.A

MST

~

wn"gvrS~

9u6AM

W9OIoo:Cs.

~

201!x0 n

"

F-328959

2/87

~

:,

PRINTED

INUS.A.

i

}d

.4_f

CONNECTICUT

RaMNo712:seas

Nai,

Mry

06067

PLWIDA

3A(Ayv1V,N

1626

Hendrchbe1721

" '

Nn--

Nat.ow

I,

N

5511

;1

i`55

'Pg4.51M"-

.a

6401K16At5717ha

: - . r " .

NANBp

b1

.w

3m

Lit,

:.

,

2U]1577

415

:1

19011

1910'26

-IDS,597

"

3"

BIb

S'7

a:"

14W147

119

:

1101am01

.14

I14N01S

;"

.1100INOIIN

S3D1

N LNNRAA

5

.

17121716

6701

9admn

106

A~*St

SPOT

13171

$41

f6~

,

INDIANA

,110:w

31175fe

SIGN

4227

13171

717

629'

OEM

DS

Nvr

.e

51L7UA'!

KANSAS

i

DR116M

Ma

7M45

f1m

F"

Nher

P

Zra

19411111 1663

prp7UCRr

hurlvlh

?5u1

Lrlielx,b4117

LOUISIANA NPw

0"l..,3501

1ch6uno"W2Sl70114

1

~YLNO

a4emaN

6434

IWN

.7Rd71714

',

I

ES,

:MN"hn9975A~HIVICA.4

ikill

A'I

;

W16AO11UM

60110

160466x.a

all

15

UPA6rlfe.~oro

2771

Gall

soH,q,

%Vmft

WIN

Yomm

PINwe

I'lot

YLOaw11ti4500

(2015194965'

per

MOM

f6MoA.6

4611

Cr1

NII7

16121

ria

115!

Meal

61,usNn1ea

Olm

wYW

LAHV0:0

1303

a "

arren2IM1

CMIFOMMIA

Mare.1790AGrowl,

WIDE

SanFM.Of(4

2216

PNrvAv.

01114

F

"eM151

N

NIN,

,

41

:0)

1501,171

-911

AA

rl~

A~Ow

WO

CMYNePN

f

1747

17141

610

V44

rte

rte

&A~

Y

aGnova

Dr-

14725

14151

205

0310

M.n6npnnSN6711

3P"C"X

Ia16611746

11091

251

7679

7411120

15775

MdXW

AWnu4

114

2

2113,

665

A'hll

MWIIHIAn

7S

Yank

SIHN

10013

1n5117

-

11,

.

t

521x..wtIN

MVARSI

E)S7

3rs

v,r

51'1

MOM

CAIIWM

CA6MN

400

4

Trpr

2113113

1

"

a

:vi',

.1-

RFNr06

~Mfwwe12no

' C"'

"

19.1

010_K~

1245

TwlestW

Rod

415129

5154W6nf

'"0012

.90001600S144125

q~RsAnApel

645

f

wasnmylw

6aaaNGO

IMU

T2

.

,

4RAVe

y

rr~('o15"

10191516

v-

h

:

'a7

C

:C"-

" -"1,

W

SIN

1

91"'

Loading...

Loading...