Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

3100

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations et

les adresses de nos centres de

service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-877-SKIL999 (1-877-754-5999) www.skil.com

For English Version Version française Versión en español

See page 2 Voir page 12 Ver la página 22

Page 2

General Safety Rules

READ ALL INSTRUCTIONS” Failure to follow the safety rules listed below and other basic safety precautions

!

WARNING

THINK SAFETY Safety is a combination of operator common sense and alertness at all times when the X-Bench is being used.

“

may result in serious personal injury.

Work Area

KEEP CHILDREN AWAY

Do not let visitors contact tool or extension cord. All visitors

hould be kept away from work area.

s

KEEP WORK AREAS CLEAN

Cluttered areas and benches invite accidents.

MAKE WORKSHOP CHILD-PROOF

With padlocks, master switches.

AVOID DANGEROUS ENVIRONMENTS

Don’t use power tools in damp or wet locations. Keep work

area well lit. Do not expose power tools to rain. Do not use

tool in presence of flammable liquids or gases.

Personal Safety

KNOW YOUR POWER TOOL

Read and understand the owner’s manual and labels affixed

to the tool. Learn its application and limitations as well as the

specific potential hazards peculiar to this tool.

DON’T OVERREACH

Keep proper footing and balance at all times.

STAY ALERT

Watch what you are doing. Use common sense. Do not operate tool when you are tired. Do not operate while under

medication or while using alcohol or other drug.

DRESS PROPERLY

To avoid being pulled into a blade, do not wear loose

clothing, loose fitting gloves, necktie or jewelry. Tie back long

hair or wear protective hair covering and roll long sleeves

above the elbow. Rubber gloves and non-skid footwear are

recommended when working outdoors.

USE SAFETY GOGGLES

Use safety goggles (head protection). Wear safety goggles

(must comply with ANSI Standard Z87.1) at all times. Wear

non-slip footwear and a hard hat, if appropriate. Also, use

face or dust mask if cutting operation is dusty, and ear

protectors (plugs or muffs) during extended periods of

operation.

GUARD AGAINST ELECTRIC SHOCK

Prevent body contact with grounded surfaces. For example:

pipes, radiators, ranges, refrigerator enclosures.

DISCONNECT TOOL FROM POWER SOURCE

When not in use, before servicing, when changing blades,

bits, cutters, etc.

KEEP GUARDS IN PLACE

In working order, and in proper adjustment and alignment.

REMOVE ADJUSTING KEYS AND WRENCHES

When not in use, before servicing, when changing blades,

bits, cutters, etc.

AVOID ACCIDENTAL STARTING

Make sure the switch is in the “OFF” (“O”) position before

plugging in tool.

NEVER STAND ON TOOL OR ITS STAND

Serious injury could occur if the tool is tipped or if the cutting

tool is accidentally contacted. Do not store materials on or

near the tool such that it is necessary to stand on the tool or

its stand to reach them.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that is

damaged should be carefully checked to ensure that it will

operate properly and perform its intended function. Check for

alignment of moving parts, mounting and any other conditions that may affect its operation. A guard or other part that

is damaged should be properly replaced.

ALL REPAIRS, ELECTRICAL OR MECHANICAL,

SHOULD BE ATTEMPTED ONLY BY TRAINED

REPAIRMEN.

Contact the nearest Skil Factory Service Center, Authorized

Service Station or other competent repair service.

USE ONLY SKIL REPLACEMENT PARTS;

Any others may create a hazard.

THE USE OF ANY OTHER ACCESSORIES NOT SPECIFIED IN THE CURRENT SKIL CATALOG MAY CREATE A

HAZARD.

Tool Use

DON’T FORCE TOOL

It will do the job better and safer at the rate for which it was

designed.

USE THE RIGHT TOOL

Don’t force small tool or attachment to do the job of a heavyduty tool. Don’t use tool for purpose not intended — for example; don’t use circular saw for cutting tree limbs or logs.

SECURE WORK

Use clamps or a vise to hold work. It’s safer than using your

hand and it frees both hands to operate the tool.

DIRECTION OF FEED

Feed work into a blade or cutter against the direction of

rotation of the blade or cutter only.

NEVER LEAVE TOOL RUNNING UNATTENDED

Turn power off. Don’t leave tool until it comes to a complete

stop. Be aware of the location and setting of the switch “ON"

position. Never leave the switch in the “ON” position. Be

aware of switch location and know how to shut off the tool in

emergency situations. Accidental start-ups could cause

injury.

DON’T ABUSE THE CORD

Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving

parts. Replace damaged cords immediately. Damaged cords

increase the risk of electric shock.

Tool Care

DO NOT ALTER OR MISUSE TOOL

These tools are precision built. Any alteration or modification not

specified is misuse and may result in dangerous conditions.

2.

Page 3

AVOID GASEOUS AREAS

o not operate electric tools in gaseous or explosive atmo-

D

pheres. Motors in these tools normally spark, and may re-

s

sult in a dangerous condition.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for better and safer performance.

ollow instructions for lubricating and changing accessories.

F

Inspect tool cords periodically and if damaged, have repaired

by authorized service facility. Inspect extension cords

periodically and replace if damaged. Keep handles dry, clean

and free from oil and grease.

CONNECTING THE TOOL

Before connecting the tool to a power source (receptacle,

outlet, etc.), be sure voltage supplied is the same as that

specified on the nameplate of the tool. A power source with

voltage greater than that specified for the tool can result in

serious injury to the user — as well as damage to the tool.

If in doubt, DO NOT PLUG IN THE TOOL. Using a power

source with voltage less than the nameplate rating is harmful

to the motor.

!

WARNING

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry

products, and

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

Some dust created by power sanding,

sawing, grinding, drilling, and other

!

ARNING

W

!

ARNING

W

stand and the power tool to be mounted.

the warnings and instructions may result in electric shock,

ire and /or serious injury.

f

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless_)

power tool.

Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments or changing accessories.

of the power tool is a cause of some accidents.

Properly assemble the working stand before the

mounting the tool.

risk of collapse.

Securely fasten the power tool the working stand before

use.

Power tool shifting on the working stand can cause

loss of control.

Place the working stand on a solid, flat and level

surface.

power tool or work piece cannot be steadily and safely

controlled.

Do not overload the working stand or use as ladder or

scaffolding.

cause the stand to be “top-heavy” and likely to tip over.

Use only Skil replacement parts. Any others may create a

hazard.

This product contains a chemical known to the

tate of California to cause cancer.

S

Read all safety warnings and all

instructions provided with the working

Failure to follow

Accidental starting

Proper assembly is important to prevent

When the working stand can shift or rock, the

Overloading or standing on the working stand

Specific Safety Instructions for X-Bench

Read and understand all instructions for use of XBench and insert plates with tools.

instructions listed below may result in serious personal

injury.

Use only with Skil accessory insert plates (jig saw,

drill press, belt sander and router).

The stamped rails or clamps may have sharp edges.

Be careful in handling the bench to prevent being cut.

Fully assemble and tighten all the fasteners required

for this stand.

stand and make sure it is still tight. A loose stand is

unstable and may shift in use and cause serious injury.

Turn tool switch and table switch control off and

disconnect power before mounting tools to the stand.

Unintended startup during assembly can cause injury.

Know how to shut off the power to the tool in an

emergency.

the switch control box while using the cut channel or the

tool attachments.

Before operating make sure the entire unit is placed

on a solid, flat, level surface.

if tool is unstable and tips.

Never stand on table or use as ladder or scaffolding.

Serious injury could occur if the table is tipped or the

Also remember to occasionally check the

Position yourself such that you can reach

Failure to follow all

Serious injury could occur

cutting tool is accidentally contacted. Do not store

materials on or near the table such that it is necessary to

stand on the table to reach them.

Do not load with more than 250 lbs. This table when

fully set and clamps are tightened is maximum rated to

250 lbs. Table could collapse under additional loads.

Do not use as storage shelf. This table is not intended

to be a storage shelf.

Do not store X-Bench in damp locations. Use only in

dry locations.

or the locks to become loose.

Use only Skil replacement parts. Any others may create

a hazard.

Don’t use with work pieces that cannot be properly

secured to the X-Bench, or that covers the table so

you cannot access accessory control box switch.

Oversized work pieces may cause instability while cutting

and you may not be able to shut off the power in an

emergency.

Insure wood/workpiece is properly positioned before

cutting. Incorrectly positioned workpiece may cause you to

inadvertently cut into the X-Bench top, clamps or frame.

Humidity will cause the table top to distort

3.

Page 4

X-Bench Accessory Control Box

Accessory Control Box

Only use the accessory control box for power tools designed

for use with accessory insert plates and suggested power

tools in this manual.

It is intended to be the mains switch for benchtop

applications if your Skil power tool is used in the insert plate.

t is also intended as a convenience outlet for use with your

I

kil Circular Saw and Miter Saw.

S

Double Insulated Tools

Double Insulation is a design concept used in electric

power tools which eliminates the need for the three wire

grounded power cord and grounded power supply system. It

is a recognized and approved system by Underwriter’s Laboratories, CSA and Federal OSHA authorities.

IMPORTANT: Servicing of a tool with double insulation

requires care and knowledge of the system and

should be performed only by a qualified service

technician.

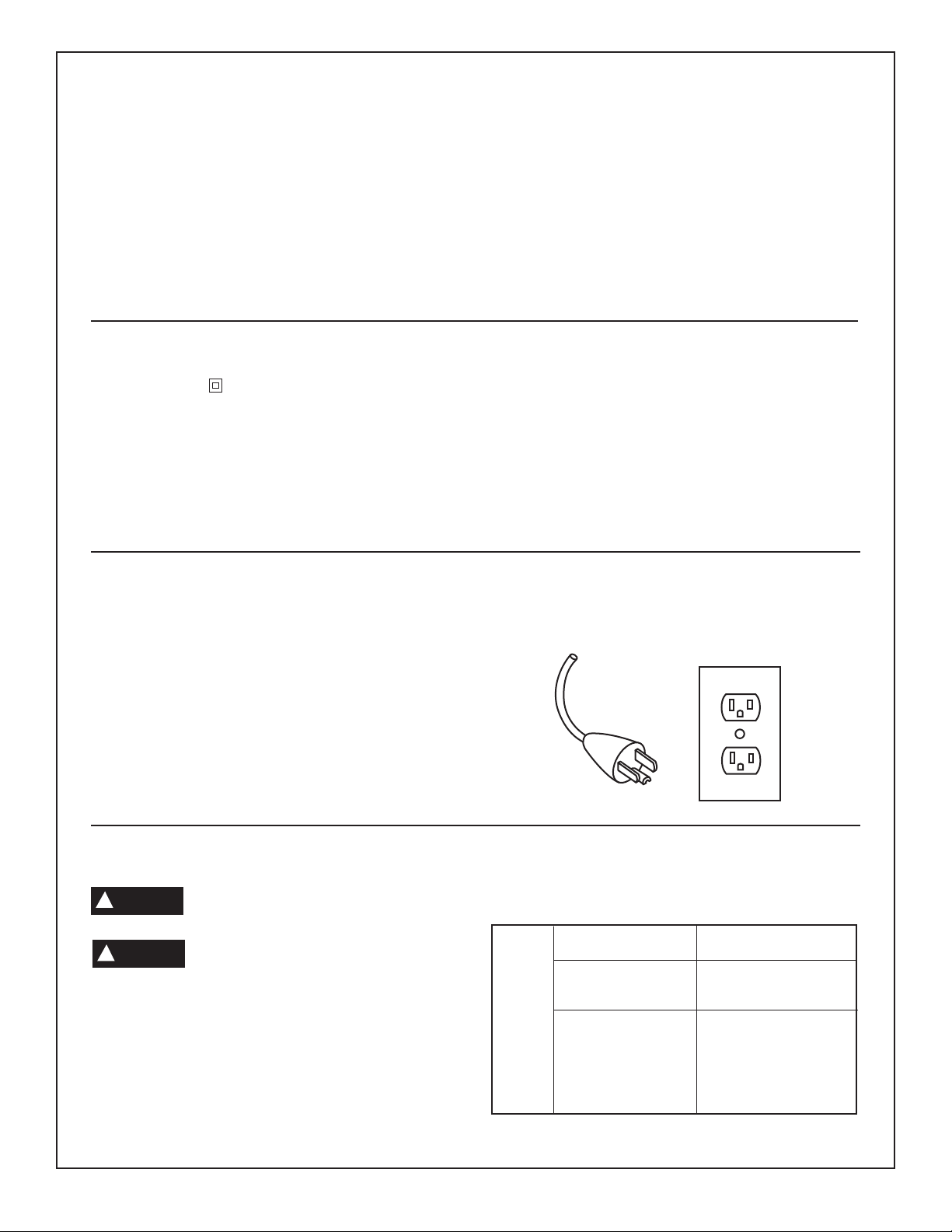

Grounded Tools

Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adaptor

plugs. Check with a qualified electrician if you are in

doubt as to whether the outlet is properly grounded.

If the tools should electrically malfunction or break down,

grounding provides a low resistance path to carry electricity

away from the user. Improper grounding can shock, burn or

electrocute. Grounded tools are equipped with three

conductor cord and three prong type plugs. Before plugging

in the tool be certain the outlet voltage supplied is within the

Accessory Switch

The accessory control box has an accessory On/Off switch

with lock off key. Be aware of your position while using the XBench for fast emergency shut off power. Remove lock off

key to disable switch when not in use.

WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS.

POLARIZED PLUGS. If your tool is equipped with a polarized plug (one blade is wider than the other), this plug will fit

in a polarized outlet only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. To reduce the

risk of electric shock, do not change the plug in any way.

voltage marked on the nameplate. Do not use “AC only”

rated tools with a DC power supply.

Extension Cords

!

WARNING

or electrocute.

!

WARNING

with adequate size conductors should be used to

prevent excessive voltage drop, loss of power or overheating. The table shows the correct size to use, depending on cord length and nameplate amperage

rating of tool. If in doubt, use the next heavier gauge.

Always use U.L. and CSA listed extension cords.

NOTE:

The smaller the gauge number, the heavier the cord.

Replace damaged cords immediately.

Use of damaged cords can shock, burn

Always use proper extension cord. If an

extension cord is necessary, a cord

“SAVE THESE INSTRUCTIONS!”

4.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

3-6

6-8

8-10

10-12

12-16

Cord Size in A.W.G.

Cord Length in Feet

25 50 100 150 15 30 60 120

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

16

18

16 16 14 12 1.0 2.5 4.0 —

12

14

12

14

—— ————

Wire Sizes in mm

Cord Length in Meters

1.0 2.5 4.0

.75

2

Page 5

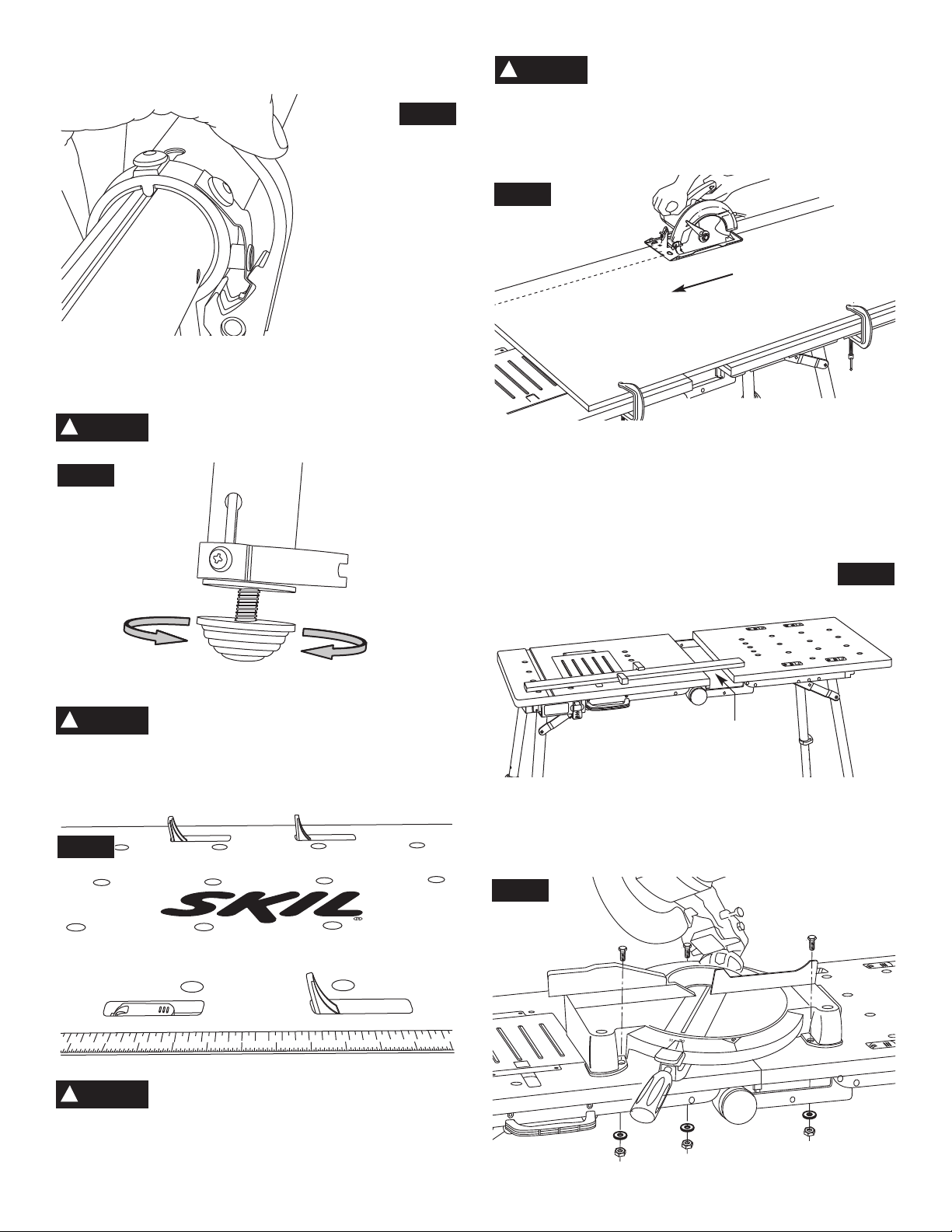

Using Your X-Bench Work Station – No Assembly Required

1. Opening the X-Bench

.

he X-Bench comes in the folded position and no assembly is

a

T

equired. In order to open the X-Bench, the user must pull and

r

twist the main knob, located by the handle, to the open position (Fig. 1a).

Fig. 1a

b. After the table has been opened, the knob must be turned back

into the locked position before extending the legs or placing the

table upright. To lock the table in place, twist the main knob back

into the closed position. Once the main knob is in the closed

position, the user can now safely extend the legs and then place

the table upright.

!

WARNING

(Fig. 1b).

Table lock must be in the locked position, the

bench may collapse in use if not fully locked.

Pins are not

engaged in

hole, unit is

n

ow open.

3. Adjusting Leg Height

.

ith the table still on its side or inverted, the user can adjust the

a

W

able height to his/her preference. In order to adjust the table

t

height the user must:

b. Fully open the leg locking lever. By positioning the lever in the

open position (Fig. 3), it will allow the user to adjust the leg to a

esired height marked on the leg. After the leg is positioned at a

d

desired height, the user must close the lever locking mechanism to

half way and allow the pin to snap into the lock position. You can

visually make sure the pin is depressed correctly and ensure the

leg cannot slide at this point. (Fig. 4).

If the pin is not depressed into the hole, the leg clamp will be very

difficult to close. Damage may occur to the leg clamp if too much

force is applied without the pin being in the correct location.

!

WARNING

collapse if leg locks are not secure..

Fig. 3

Each leg lock pin must be fully engaged and

clamped fully closed before use.

Table may

Fig. 1b

Pins are

engaged in

hole, the

table is now

locked.

2. Extending the Legs

a.

Once the table is opened and the main knob is in the locked

position, the user can now extend the legs of the work station.

While the table is on its side or inverted, extend the legs completely

and make sure the leg braces are straightened and locked. The

pin will lock in place to ensure that the leg brace is fully secured

(Fig. 2).

Pin is shown in the

locked position.

Fig. 2

Fig. 4

Pin is fully

depressed = leg

is locked in

position

!

WARNING

depress, this means the pin is not in the correct location. You

MUST adjust the leg to position the pin into the correct height

marking (Fig. 5). Close the clamp fully with pin in hole before use.

Table must be level and stable for use.

Table must be level and stable for use. If the

lever does not close completely or is difficult to

5.

Page 6

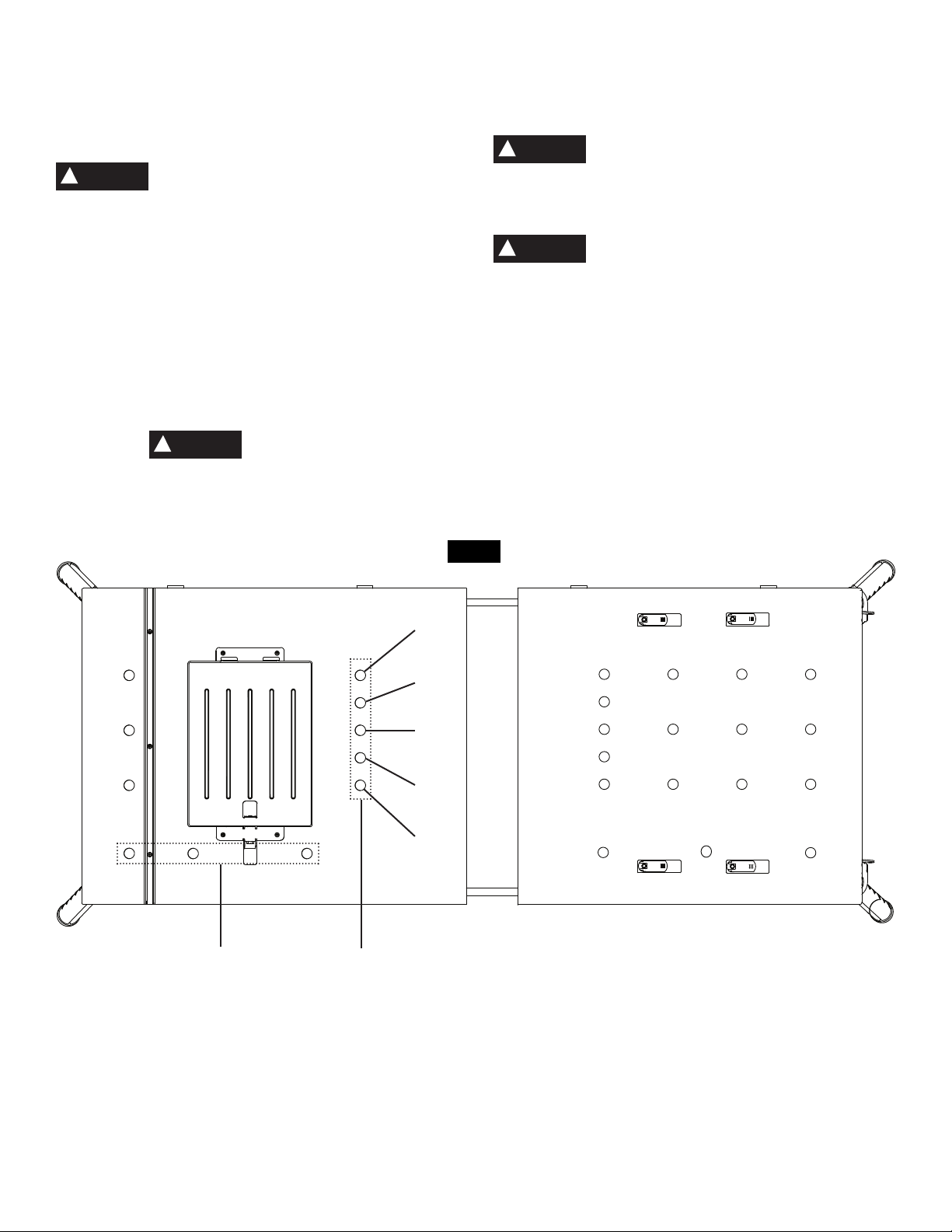

c. Once the user sets one leg at the desired height, follow the

10

11

9

8

12

13

14

15

16

17

17

18

21

20

22

23

24

25

26

27 28

29

30

31

32

33

34

35

36

37

38 39 40

41

42

43

44

45

46 47 48

same steps for the remaining three legs.

Fig. 5

Pin is not

depressed = leg

is not secured in

locked position

4. Adjustable Foot – for Leveling Bench

If you are working in an area that is not level, we have provided

a.

a solution. We have an adjustable foot that will extend 1.75”

inches to level your bench (Fig. 6).

!

WARNING

Before operating make sure the entire unit is

placed on a solid, flat, level surface.

Serious

injury could occur if tool is unstable and tips.

Fig. 6

!

WARNING

he cut channel is 2-3/4” deep and can be used with a

c.T

aximum 7 -1/4” Circular Saw. The cutting channel can be used

m

Use only with 7-1/4” or smaller circular saws.

Larger size saws may be able to cut thru brackets.

for cross cuts or rip cuts. The user must secure the work piece

with the wedge dogs provided or other clamping devices (Fig. 8).

Do not rip parallel to X-Bench dogs,.

Fig. 8

Direction

of Cut

6. Wedge Dogs

a.

Dog holes are throughout the table top surface and are meant to

hold work pieces in place while cutting (Fig. 9). Two wedge dogs

come with the X-Bench. These dogs are made specifically for the

X-Bench. Note feed direction while cutting in wedge dog position.

Blank insert plate must be in table top during top applications.

See

reference guide figure 28 for hole pattern identification of

wedge dogs.

5. Opening the Cut Channel

!

WARNING

. To open your cut channel there are four latches you need to

a

Cut channel must be fully open for sawing.

open first.

b. Unlock the four latches by pulling them upward and extend the

table outward (Fig. 7).

Fig. 7

Latch is now in the

locked position.

Latch is now in the

open position.

Fig. 9

Direction

of Cut

7. Miter Saw Mounting

There are three mounting holes that support most miter saw

a.

dimensions (Fig. 10). If you use a miter saw on this table, we

require you mount the miter saw to the X-Bench for safety. Note:

close cut channel for miter saw use.

Fig. 10

!

WARNING

Do not use the dog holes to pull the table

outward. Once the table is extended, the

latches MUST be locked in order to use the cut channel

correctly.

Failure to lock the latches while the table is in the open

position could cause the table top to move while cutting, which can

result in misaligned cuts or personal injury.

.

6

Page 7

ake sure X-Bench is not plugged in and

!

WARNING

8. Power Switch

a.

The female plug is located on the bottom of the switch and the

ale plug is located on the side of the switch box (Fig. 11).

m

onnect the switch box to an electrical outlet by using an

C

xtension cord. Plug the desired tool into the female plug and

e

turn the switch box for power on by raising the tab. Power is

now activated to the tool that is plugged into the switch box.

o deactivate the power, the user can push the bump off

b.T

witch located on the front of the switch box. When leaving the

s

workstation it is recommended that the user removes the lock off

key, to prevent unauthorized usage. (15 A maximum use for

switch box.)

Fig. 11

Extension

Cords

M

ain outlet is off.

m

Tools

he brace and leg can now be folded into the table. Follow this

T

tep for each of the legs.

s

!

WARNING

c. Once all the legs are inside the table, unlock the table by

turning the main knob to keep unlocked. See Section

more details. While the table is unlocked, this will allow the user

to fold the table in half.

!

WARNING

tep.

s

d. Once the table is folded in half, the knob must be turned back

o the locked position. See Section

t

step is not done, the table can open while the user is carrying

the product.

Keep hands clear of the pivot areas when folding

the legs inward as this can cause pinching.

1a for

Keep hands and other body parts from

folding area.

Pinch points may occur during this

or more details. If this

1bf

Accessory Installation

(Each Insert and Tool Sold separately)

10. Downdraft Table (Sold Separately)

Unlock the blank universal insert plate by releasing the latch

a.

in the front and remove the plate (Fig.14).

Fig. 14

9. Folding the Unit for Storage/Transportation

a.

Position the table on its side or inverted and compress all four

legs to the zero position (Fig. 12)

Fig. 12

b. To place the legs inside of the table, the user must press the

lock-pin located in the middle of the leg brace and pull on the

brace (Fig. 13).

Fig. 13

Push pin and pull on brace

to release.

b. Place downdraft table over the opening by placing the back

end into the open area first.

c. The downdraft table should be seated flush against the table

(Fig. 15).

d. Lock the latch of the downdraft table. If the latch cannot be

locked, the table is not seated correctly. Re-position and lock.

Fig. 15

.

7

Page 8

11. Tail Vise (Sold Separately)

a.

Locate the following parts:

(1) Clamp block (MDF), (2) Guide rods, (1) Threaded rod, (6)

Bolts and (6) Bolt covers.

b. Position clamp block (MDF) over guide rods, and threaded

od as shown in figure 16

r

c. Securely attach guide block to the rods with (6) washer and

bolts provided (Fig. 16).

d. Place one bolt cover over each screw head making sure it’s

flush to the table (Fig. 16).

Fig. 16

e. Locate the following parts:

(1) Threaded rod insert (2) Guide rod inserts, (3) Insert nuts, (2) Rod

blocks, (4) Screws, (4) Nuts and (1) Pin.

f. Insert rod inserts from the backside of frame completely into

the three holes provided (Fig. 17).

h. Place the rod block from backside of frame as shown, insert

two screws from the front side of frame into rod block and

secure with two nuts from backside of frame. Repeat this

procedure on other side of frame (Fig. 18).

i. Insert guide rods and threaded rod into nuts and rod insert

making sure guide rods go thru rod blocks on each side of frame

while slowly threading rod with the knob into the frame like a

vise (Fig. 19).

ig. 19

F

j. Once the tail vise has been threaded into rod inserts, attach

the pin provided onto the end of the threaded rod (Fig. 20).

Fig. 20

Fig. 17

g. Secure rod inserts to frame with the three large nuts provided

from the front side of frame (Fig. 18).

!

CAUTION

Make sure the orientations of the mating nuts

are as indicated in the figures.

Fig. 18

Rod Block

k. Place the selected object between the tail vise and table edge

and secure it by rotating the tail vise knob clockwise. Maximum

weight load is 40lbs.

!

CAUTION

of the vise (Fig. 21).

When clamping small work pieces, the tail vise

only works when the work piece is in the middle

Fig. 21

12. Clamping Kit (Sold Separately)

a.

Dog hole clamps are placed in the dog holes to hold the work

pieces in place during cutting (Fig. 22).

8.

Page 9

Fig. 22

Direction

of Cut

15. Shelf and Tool Bag (Sold Separately)

Shelf and tool bag come fully assembled.

a.

b. There are four hooks under the work bench (Fig. 23.)

c. Attach the Velcro straps located on the shelf to the hooks

under the table (Fig. 23).

Note: Unit can fold up with shelf and bag attached. Maximum

weight load is 20lbs.

Fig. 23

b. Secure both sides of tray using the (2) U-brackets and screws

(Fig 25).

Fig. 25

c. Remove the cup/tape dispenser by turning and matching the

shape (Fig. 26).

Fig. 26

13. Finishing Tray (Sold Separately)

a.

Locate the following parts:

(1) Knob, (1) Large washer, (2) U-brackets and (2) Screws.

Insert the tray into the three holes provided. From the back side

of frame thread large washer and knob into the middle hole in

tray until snug. (Fig. 24).

!

CAUTION

Do not over tighten the knob as it may damage

the plastic body.

Fig. 24

d. Remove and mount the paper towel dispenser into the vertical

slot Fig. 27. Maximum weight load is 10lbs.

Fig. 27

14. Wedge Dog Supports:

a.

Two wedge dog clamps are included with your X-Bench

product. These wedge dogs are placed into the dog holes on

the surface of the X-Bench to hold pieces of wood during cutting.

The wedge dogs are capable of holding 1x and 2x material.

.

9

Page 10

15. Universal Insert Plate:

a.

A blank insert plate is provided with the X-Bench. This area is

meant to be used only with the Skil insert plate technology which

is sold separately. The insert plates which can be purchased

separately are a jigsaw insert plate, sander insert plate, router

insert plate and a drill press insert plate.

!

ARNING

W

personal injury.

Use only X-Bench inserts and dedicated

ools.

t

ny others may cause loss of control and

A

Maintaining Your X-Bench

Maintenance

ertain cleaning agents and solvents can

!

CAUTION

gasoline, carbon tetrachloride, chlorinated cleaning solvents,

ammonia and household detergents which contain ammonia.

Avoiding use of these and other types of cleaning agents will

minimize the possibility of damage.

!

WARNING

Contact the nearest Factory Service Center or Authorized

Service Station or other competent repair service. Use only

identical replacement parts, any other may create a hazard.

C

amage plastic parts.

d

ll repairs, electrical or mechanical, should

A

be attempted only by trained repairmen.

ome of these are:

S

!

WARNING

Never place dogs on opposite sides of cut channel. Support must be on one side of table.

Cutting Suggestions

Fig. 28

2" x 10"

1" x 12"

2" x 8"

1" x 10"

2" x 6"

1" x 8"

2" x 4"

1" x 6"

1" x 4"

Wedge

Dog 1

Wedge

Dog 2

10

.

Page 11

Direction of Cut

Direction of Cut

.

11

Page 12

Consignes générales de sécurité

«

!

VERTISSEMENT

A

LA SÉCURITÉ AVANT TOUT – La sécurité est une combinaison de bon sens et de promptitude mentale de l’opérateur pendant tout le temps durant lequel

l

’outil X- Bench est utilisé.

NE LAISSEZ PAS LES ENFANTS S’APPROCHER

Ne laissez aucune personne entrer en contact avec l’outil ou le cordon de

rallonge. Tous les visiteurs doivent se tenir à une distance suffisante de la

zone de travail.

ASSUREZ-VOUS QUE VOTRE ZONE DE TRAVAIL EST BIEN DÉGAGÉE

Des lieux et des établis encombrés augmentent les risques d’accidents.

FAITES EN SORTE QUE VOTRE ATELIER NE PRÉSENTE AUCUN

DANGER POUR LES ENFANTS

Utilisez des cadenas et des interrupteurs généraux.

NE TRAVAILLEZ PAS DANS UN ENVIRONNEMENT DANGEREUX

Il ne faut jamais employer d’outils électriques dans des endroits humides

ou mouillés. Éclairez bien les lieux où vous travaillez. N’exposez pas vos

outils électriques à la pluie. Ne les utilisez pas en présence de liquides ou

de gaz inflammables.

Sécurité de l’utilisateur

FAMILIARISEZ-VOUS AVEC VOTRE OUTIL ÉLECTRIQUE

Lisez attentivement le manuel de l’utilisateur et les étiquettes collées sur

l’outil afin de bien les comprendre. Vous devez connaître les possibilités

et les limites de l’outil, ainsi que les dangers éventuels précis qu’il

présente.

GARDEZ TOUJOURS VOTRE ÉQUILIBRE

Assurez-vous que vous ne risquez jamais de perdre l’équilibre ou de

trébucher.

RESTEZ SUR VOS GARDES

Regardez toujours ce que vous êtes en train de faire. Faites preuve de

bon sens. N’utilisez pas l’outil lorsque vous êtes fatigué ou si vous êtes

sous l’effet d’un médicament, de l’alcool ou d’une autre drogue.

PORTEZ DES VÊTEMENTS APPROPRIÉS

Évitez de porter des vêtements flottants, des gants trop grands pour vous,

une cravate ou des bijoux, qui risqueraient d’être happés par la lame. Si

vous avez les cheveux long, attachez-les ou portez une coiffure de

protection, et remontez les manches longues au-dessus du coude. Le port

de gants en caoutchouc et de chaussures à semelles antidérapantes est

recommandé si vous travaillez à l’extérieur.

PORTEZ DES LUNETTES DE SÉCURITÉ

Utilisez des lunettes de sécurité (protection de la tête). Portez des

lunettes de sécurité (conformes à la norme ANSI Z87.1) pendant toute la

durée de votre travail. Portez des chaussures à semelles antidérapantes

et un casque si besoin est. Utilisez également un masque facial ou un

masque anti-poussière si l’opération de coupe produit de la poussière,

ainsi que des protège-oreilles (oreillères ou bouchons d’oreilles) si vous

utilisez un outil électrique pendant une durée prolongée.

PROTÉGEZ-VOUS CONTRE LES CHOCS ÉLECTRIQUES

Évitez d’entrer en contact avec les surfaces mises à la terre, telles que

tuyaux, radiateurs, cuisinières ou réfrigérateurs.

DÉBRANCHEZ LES OUTILS DE LEUR SOURCE DE TENSION SECTEUR

Débranchez-les quand ils ne sont pas utilisés, avant leur entretien, lors du

changement de lames, de forets, de couteaux, etc.

LAISSEZ LES CARTERS DE PROTECTION EN PLACE

Ils doivent être en bon état, bien réglés et bien alignés.

RETIREZ LES CLÉS DE RÉGLAGE ET DE SERRAGE

Lorsque les outils ne sont pas utilisés, avant leur entretien, lors du

changement de lames, de forets, de couteaux, etc.

ÉVITEZ LES MISES EN MARCHE ACCIDENTELLES

Assurez-vous que l’interrupteur est dans la position « ARRÊT » (« O »)

avant de brancher l’outil.

NE MONTEZ JAMAIS SUR L’OUTIL OU SUR SON SOCLE

L’utilisateur s’expose à de graves blessures s’il renverse l’outil ou s’il

LISEZ TOUTES LES INSTRUCTIONS » – Le non-respect des consignes de sécurité indiquées plus bas et des autres

précautions de sécurité essentielles risque de causer des blessures graves.

Zone de travail

entre accidentellement en contact avec l’outil de coupe. N’entreposez pas

d’objets quelconques sur l’outil ou à proximité de celui-ci de façon à ce

qu’il soit nécessaire de monter sur l’outil ou sur son socle pour les

atteindre.

ASSUREZ-VOUS QU’AUCUNE PIÈCE N’EST ENDOMMAGÉE

Avant de poursuivre votre travail, examinez soigneusement toute pièce

pouvant être endommagée (l’outil, un carter de protection ou toute autre

pièce) afin de vous assurer que cette pièce fonctionnera correctement et

remplit toujours la fonction prévue. Vérifiez l’alignement et

l’assujettissement des pièces mobiles, ainsi que toutes les autres

conditions qui peuvent affecter leur fonctionnement. Il faut remplacer

c

orrectement tout carter de sécurité ou tout autre composant endommagé.

TOUTES LES RÉPARATIONS – ÉLECTRIQUES OU MÉCANIQUES – NE

DOIVENT ÊTRE EFFECTUÉES QUE PAR DES TECHNICIENS QUALIFIÉS

Adressez-vous à votre Centre de service en usine Skil le plus proche, à un

point de service après-vente agréé par Skil ou à un autre service de

réparation compétent.

N’UTILISEZ QUE DES PIÈCES DE RECHANGE SKIL

Tout autre type de pièce risquerait de présenter un danger.

L’EMPLOI DE TOUT AUTRE ACCESSOIRE NON PRÉCONISÉ PAR LE

CATALOGUE SKIL PEUT PRÉSENTER UN DANGER.

Utilisation de l’outil

N’IMPOSEZ PAS DE CONTRAINTES EXCESSIVES À L’OUTIL

Il sera plus efficace et plus sûr si vous le faites fonctionner au régime

pour lequel il a été conçu.

EMPLOYEZ L’OUTIL QUI CONVIENT

N’employez pas un outil ou un accessoire de capacité réduite pour faire

un travail exigeant un outil de grande puissance. N’utilisez pas un outil

pour des travaux autres que ceux pour lesquels il a été conçu – par

exemple, n’utilisez pas une scie circulaire pour couper des branches

d’arbre ou des rondins.

ASSUJETTISSEZ BIEN LA PIÈCE SUR LAQUELLE VOUS TRAVAILLEZ

Maintenez-la en place avec des serre-joints ou un étau. Vous courrez

moins de risques qu’en la tenant à la main, et vous garderez ainsi les

deux mains libres pour faire fonctionner l’outil.

SENS DE LA COUPE

Faites avancer l’ouvrage contre une lame ou un autre outil de coupe

uniquement dans le sens opposé au sens de rotation de ces derniers.

NE VOUS ÉLOIGNEZ JAMAIS DE L’OUTIL SANS L’ARRÊTER

Mettez l’outil hors tension. Ne vous éloignez pas de l’outil avant qu’il ait

complètement cessé de fonctionner.Il est très important de toujours

savoir où se trouve l'interrupteur de l’outil quand il est dans sa position

de marche. Ne laissez jamais l’interrupteur dans la position de marche si

vous vous éloignez de l’outil. Sachez toujours où se trouve l’interrupteur

et comment éteindre l’outil pour les cas d’urgence. Une mise en marche

accidentelle risquerait de causer des blessures.

PRENEZ BIEN SOIN DU CORDON D’ALIMENTATION

Ne transportez jamais les outils par leur cordon d’alimentation et ne vous

servez pas de ce dernier pour les retirer de la prise de courant. Maintenez

le cordon d’alimentation à distance des sources de chaleur, d’huile, de

bords tranchants ou de pièces mobiles. Remplacez immédiatement les

cordons endommagés. Les cordons d’alimentation endommagés

augmentent le risque de chocs électriques.

Protection de l’outil

N’EMPLOYEZ PAS L’OUTIL DE FAÇON INCORRECTE ET NE LE

TRANSFORMEZ PAS

Ces outils sont construits avec une grande précision. Toute altération ou

modification non spécifiée est considérée comme une utilisation abusive

qui risque de créer des conditions d’emploi dangereuses.

12

.

Page 13

ÉVITEZ LES ENDROITS DANS LESQUELS L’ATMOSPHÈRE EST

CONTAMINÉE PAR DES GAZ

N

’utilisez pas d’outils électriques dans des atmosphères gazeuses ou

explosives. Les moteurs de ces outils produisent normalement des

étincelles qui risqueraient de présenter un danger.

P

RENEZ SOIN DE VOS OUTILS ET ENTRETENEZ-LES BIEN

Gardez vos outils affûtés et propres pour obtenir le rendement maximum

dans des conditions de sécurité optimales. Suivez les instructions pour le

graissage ou le remplacement des accessoires. Inspectez les cordons

d’alimentation à intervalles réguliers et, s’ils sont endommagés, faites-les

réparer dans un centre de service après-vente autorisé. Inspectez

périodiquement les cordons de rallonge et remplacez-les s’ils ont été

endommagés. Gardez les poignées des outils sèches, propres et

exemptes de toute trace d’huile ou de graisse.

RACCORDER VOTRE OUTIL

Avant de raccorder votre outil à une source de courant (prise de courant,

prise murale, etc.), assurez-vous que la tension est bien la même que celle

qui est indiquée sur la plaque signalétique de l’outil. Le branchement d’un

outil sur une source de courant ayant une tension supérieure à celle qui

est prescrite par le fabricant pour cet outil peut présenter des risques de

blessures graves pour l’utilisateur – ainsi que des risques

d’endommagement de l’outil. En cas de doute, NE BRANCHEZ PAS

L’OUTIL DANS UNE PRISE DE COURANT. L’utilisation d’une source de

courant ayant une tension inférieure à celle qui est indiquée sur la plaque

signalétique endommagera le moteur.

!

AVERTISSEMENT

ex., ponçage, sciage, meulage, perçage), notamment dans le cadre

d’activités de construction, contiennent des produits chimiques qui

sont des causes reconnues de cancers, de malformations

congénitales ou d’autres problèmes reproductifs. Voici quelques

exemples de tels produits chimiques :

• Le plomb provenant des peintures à base de plomb

• Les cristaux de silices provenant des briques et du ciment, ainsi que

d’autres produits de maçonnerie ; et

• L’arsenic et le chrome provenant des bois traités chimiquement.

Certaines poussières produites par des

travaux utilisant des outils électriques (p.

Le niveau de risque résultant d’une telle exposition varie en fonction de la

fréquence de ces types de travaux. Pour réduire l’exposition à ces

p

roduits chimiques, il faut travailler dans un lieu bien ventilé et porter un

équipement de protection approprié tel qu’un masque anti-poussière

conçu spécialement pour filtrer les particules microscopiques.

C

!

AVERTISSEMENT

!

AVERTISSEMENT

banc de travail et l'outil électrique à installer.

avertissements et consignes de sécurité risquerait de causer un choc

électrique, un incendie et/ou une blessure grave.

C

onservez tous les avertissements et toutes les consignes de sécurité

pour référence future.

Dans les avertissements, l'expression « outil électrique » fait référence à

votre outil électrique (à fil) à alimentation secteur ou à votre outil

électrique (sans fil) alimenté par pile(s).

Débranchez la fiche de la source d'alimentation électrique et/ou le

bloc-piles de l'outil électrique avant de réaliser des réglages ou de

changer des accessoires.

électrique est la cause de certains accidents.

Assemblez correctement le banc de travail avant d'y installer l'outil.

Un assemblage correct est important pour prévenir tout risque

d'effondrement du banc.

Assujettissez solidement l'outil électrique sur le banc de travail avant

de commencer à l'utiliser.

banc de travail peut entraîner la perte de contrôle.

Placez le banc de travail sur une surface solide, plate et horizontale.

Lorsque le banc de travail peut bouger ou se balancer, il est impossible

d'assurer la stabilité et le contrôle de l'outil électrique ou de l'ouvrage.

Ne surchargez pas le banc de travail et ne l'utilisez pas comme une

échelle ou un échafaudage.

monter dessus causera le déséquilibre du banc de travail, qui risquera

alors de basculer. N'utilisez que des pièces de rechange Skil. Toutes

autres pièces de rechange risqueraient de causer des dangers.

e produit contient un agent chimique

cancérigène selon l'État de Californie.

Lisez tous les avertissements et toutes les

c

onsignes de sécurité accompagnant le

Une mise en marche accidentelle de l'outil

Un changement de position de l'outil sur le

La surcharge du banc de travail ou le fait de

Le non-respect des

Consignes de sécurité spécifiques pour le poste de travail X-Bench

Lisez et comprenez toutes les consignes de sécurité et autres

instructions pour l'utilisation de la table X-Bench et des plaques

rapportées avec les outils.

sécurité et autres instructions indiquées plus bas peut causer des

blessures personnelles graves.

N'utilisez que des plaques rapportées d'accessoires Skil (scie à

chantourner, perceuse à colonne, ponceuse à courroie et toupie).

Les rails estampés et les brides de fixation peuvent avoir des bords

tranchants.

banc pour éviter de vous couper.

Assemblez complètement et serrez toutes les pièces de fixation

nécessaires pour ce banc.

occasionnellement le banc et de vous assurer qu'il est toujours

solidement assemblé. Un banc de travail dont certaines pièces de fixation

seraient desserrées sera instable et risquera de bouger pendant l'emploi

et de causer des blessures graves.

Désactivez les interrupteurs de l'outil et de la table, et mettez-les hors

tension avant de monter des outils sur le banc.

inadvertance pendant le montage risquerait de causer une blessure.

Sachez comment couper l'alimentation électrique de l'outil en cas

d'urgence.

boîte de commande de l'interrupteur pendant que vous utilisez la rainure

de coupe ou des dispositifs de fixation de l'outil.

Avant de mettre en service, assurez-vous que toute l'unité est placée

sur une surface solide, plate et horizontale.

de basculer et de causer une blessure grave à l'opérateur.

Prenez les précautions nécessaires lors de la manipulation du

Positionnez-vous de telle façon que vous puissiez atteindre la

Le non-respect de toutes les consignes de

Souvenez-vous également de vérifier

Une mise en marche par

Un outil instable risquerait

Ne montez jamais sur la table et ne l'utilisez pas comme une échelle

ou un échafaudage.

basculait ou en cas d'entrée en contact accidentel avec l'outil de coupe.

Ne rangez pas de matériel sur la table ou près de la table de telle sorte

qu'il serait nécessaire de monter sur la table pour l'atteindre.

Ne chargez pas avec plus de 250 li (110 kg). Cette table est conçue

pour supporter un poids maximum de 250 li (110 kg) quand elle est

complètement installée avec les brides de fixation serrées. La table

risquerait de s'effondrer sous des charges additionnelles.

N'utilisez pas comme étagère de rangement. Cette table n'est pas

conçue pour être utilisée comme une étagère de rangement.

Ne rangez pas la table X-Bench dans un endroit humide. Utilisez-la

seulement dans un endroit sec.

dessus de la table ou le desserrement des verrous.

Utilisez seulement des pièces de rechange Skil. Toutes autres pièces

de rechanges risqueraient de causer des dangers.

N'utilisez pas avec des ouvrages qui ne peuvent pas être assujettis

correctement sur la table X-Bench ou qui recouvrent la surface de la

table de telle façon que vous ne pouvez pas accéder à l'interrupteur de

la boîte de commande d'un accessoire.

risquent de causer de l'instabilité pendant la coupe, et vous risquez de ne

pas pouvoir couper l'alimentation électrique en cas d'urgence.

Assurez-vous que le matériau en bois/l'ouvrage est positionné

correctement avant de couper.

incorrecte risquerait de vous faire couper accidentellement la surface de

la table X-Bench, des brides de fixation ou le châssis de la table.

Une blessure grave pourrait être causée si la table

L'humidité entraînera la déformation du

Les ouvrages surdimensionnés

Un ouvrage positionné de façon

13

.

Page 14

Coffret de commande des accessoires de la toupie X-Bench

Coffret de commande des accessoires

N'utilisez le coffret de commande des accessoires que pour des

outils électriques conçus en vue d'un emploi avec des plaquettes

movibles et les outils électriques suggérés dans ce manuel.

a

Il est conçu pour servir d'interrupteur secteur lors des applications

sur établi si votre outil électrique Skil est utilisé dans la plaquette

amovible.

Il est également conçu comme interrupteur accessoire pour emploi

avec votre scie circulaire et votre scie à onglet Skil.

Outils à double isolation

La double isolation est un concept de design utilisé dans les outils

électriques pour éliminer les besoins de cordon d’alimentation à trois

fils, dont une prise de terre, et de dispositif d’alimentation à prise de

terre. Ce concept est reconnu et approuvé par Underwriter’s

Laboratories, l’ACNOR et l’OSHA aux États-Unis.

IMPORTANT : l’entretien d’un outil à double isolation exige la

connaissance du système et le recours à un technicien compétent en

la matière.

Outils mis à la terre

Les outils mis à la terre doivent être branchés dans une prise de

courant installée correctement et mise à la terre conformément à

tous les codes et à toutes les ordonnances. Ne retirez jamais la

broche de mise à la terre et ne modifiez la fiche en aucune façon.

N’utilisez pas d’adaptateurs. Consultez un électricien professionnel

si vous n’êtes pas certain que la prise de courant est mise à la

terre correctement.

Si les outils fonctionnent mal à cause d’un problème électrique ou ont

une défaillance d’origine électrique, la mise à la terre fournit un trajet

de moindre résistance pour éloigner l’électricité de l’opérateur. Une

mise à la terre incorrecte risque de causer un choc, une brûlure ou

même une électrocution. Les outils mis à la terre sont équipés d’un

cordon d’alimentation à trois conducteurs et de fiches du type à trois

broches. Avant de brancher l’outil, assurez-vous que la tension de

sortie fournie se trouve dans la plage de tensions indiquée sur la

plaque signalétique. N’utilisez pas d’outils comportant une restriction

« AC only » (courant alternatif seulement) avec une alimentation c.c.

Interrupteur des accessoires

Le coffret de commande des accessoires est muni d'un interrupteur

de mise sous tension/hors tension des accessoires avec clé de

verrouillage. Ayez toujours conscience de votre position lorsque

vous utilisez la toupie X-Bench afin d'être en mesure de mettre l'outil

rapidement hors tension en cas d'urgence. Retirez la clé de

errouillage pour désactiver l'interrupteur lorsque l'outil n'est pas

v

utilisé.

S’IL EST NÉCESSAIRE DE REMPLACER DES PIÈCES, N’UTILISEZ QUE

DES PIÈCES IDENTIQUES.

FICHES POLARISÉES : si votre outil est équipé d’une fiche polarisée (une

lame est plus large que l’autre), elle ne s’enfichera que d’une seule

manière dans une prise polarisée. Si la fiche n’entre pas à fond dans la

prise, réessayez en l’inversant. S’il n’est toujours pas possible de la faire

pénétrer totalement, demandez à un électricien professionnel d’installer

une prise appropriée. Pour réduire le risque de choc électrique, ne

modifiez la fiche en aucune façon.

Cordons de rallonge

!

AVERTISSEMENT

de cordons d’alimentation endommagés peut causer un choc

électrique, une brûlure ou même une électrocution.

!

AVERTISSEMENT

nécessaire, utilisez un cordon avec des conducteurs de calibre

adéquat pour éviter une chute de tension excessive, la perte de

courant ou une surchauffe. Le tableau ci-contre montre le calibre

recommandé pour les rallonges en fonction de la longueur du cordon

de rallonge et de l’intensité nominale de l’outil telle qu’elle figure sur

sa plaque signalétique. En cas de doute, optez pour le calibre

immédiatement supérieur. Utilisez toujours des cordons de rallonge

homologués par U. L. et l’ACNOR.

Remplacez immédiatement les cordons

d’alimentation endommagés. L’utilisation

Utilisez toujours un cordon de rallonge

approprié. Si un cordon de rallonge est

« CONSERVEZ CES INSTRUCTIONS »

DIMENSIONS RECOMMANDÉES POUR LES CORDONS DE RALLONGE

Intensité

nominale

de l’outil

REMARQUE :

cordon sera grand.

.

14

OUTILS À COURANT ALTERNATIF DE 120 VOLTS

Calibre A.W.G.

Longueur en pieds

25 50 100 150 15 30 60 120

3-6

6-8

8-10

10-12

12-16

16

18

18 16 14 12 .75 1.0 2.5 4.0

16

18

16

16

14 12 — — — — — —

plus le numéro du calibre est petit, plus le diamètre du

14

16

12

14

14 12 1.0 2.5 4.0 —

Calibre en mm

Longueur en mètres

.75

.75

.75 1.0 2.5 4.0

1.5

2

2.5

Page 15

Utilisation de votre poste de travail X-Bench – Aucun

assemblage n'est nécessaire

1. Ouverture du poste de travail X-Bench

a. Le poste de travail X-Bench est livré en position repliée et aucun assemblage

n'est nécessaire. Pour ouvrir le poste de travail X-Bench, l'utilisateur doit tirer et

tourner le bouton principal, situé près de la poignée, pour le mettre en position

d'ouverture (Fig. 1a)

Fig. 1a

b. Une fois que la table a été ouverte, il faut tourner à nouveau le bouton en

position de fermeture avant d'allonger les pieds ou de placer la table en position

verticale. Pour verrouiller la table en place, tournez à nouveau le bouton principal

en position de fermeture. Lorsque le bouton principal est en position de

fermeture, l'utilisateur peut allonger les pieds sans danger, puis mettre la table

en position verticale.

!

AVERTISSEMENT

s'il n'est pas verrouillé totalement. (Fig. 1b)

La table doit être en position verrouillée. Le banc

de travail risquerait de s'effondrer pendant l'emploi

Les chevilles ne

s

ont pas engagées

dans le trou ;

l'unité est ouverte

maintenant.

Fig. 1b

3. Réglage de la hauteur des pieds

La table étant toujours sur son côté ou renversée, l'utilisateur peut régler la

a.

hauteur de la table en fonction de ses préférences. Pour pouvoir régler la hauteur

de la table, l'utilisateur doit faire ce qui suit :

b. Ouverture complète du levier de verrouillage des pieds. En positionnant le

levier en position ouverte (Fig. 3), l'utilisateur pourra régler le pied à la hauteur

désirée indiquée sur le pied. Après que le pied aura été positionné à une hauteur

désirée, l'utilisateur devra fermer à moitié le mécanisme de verrouillage du levier

et laisser les chevilles se mettre en position verrouillée. Vous pouvez vérifier

visuellement que les chevilles sont enfoncées correctement et vous assurer que

le pied ne peut pas glisser. (Fig. 4)

Si les chevilles ne sont pas engagées dans le trou, il sera très difficile de fermer

l

a bride de fixation du pied. Cette bride de fixation pourrait être endommagée si

u

ne force excessive était appliquée alors que les chevilles ne sont pas dans la

position correcte.

!

AVERTISSEMENT

en position verrouillée avant l'emploi.

verrous des pieds n'étaient pas solidement fermés.

Chaque cheville de verrouillage du pied doit être

engagée complètement et fermée complètement

La table risquerait de s'effondrer si les

Fig. 3

Les chevilles sont

engagées dans le

trou ; la table est

verrouillée

maintenant.

2. Allongement des pieds

a.

Une fois que la table est ouverte et que le bouton principal est en position

verrouillée, l'utilisateur peut allonger les pieds du poste de travail. Placez la table

sur son côté ou renversez-la, puis allongez complètement les pieds et assurezvous que les pattes de renfort des pieds sont redressées et verrouillées en

position redressée. Les chevilles se verrouilleront en place pour assurer que la

patte de renfort est bien assujettie. (Fig. 2)

La cheville est

montrée en position

verrouillée.

Fig. 2

Fig. 4

La cheville est

complètement

enfoncée = le pied

est verrouillé en

position

!

AVERTISSEMENT

ou s'il est difficile à pousser, ceci signifie que la cheville n'est pas à l'endroit

correct. Vous DEVEZ régler le pied de façon à positionner la cheville au niveau du

repère de hauteur correct (Fig. 5). Fermez complètement la bride de fixation avec

la cheville dans le trou avant l'emploi. La table doit être stable et de niveau avant

l'emploi.

La table doit être stable et de niveau avant

l'emploi.

Si le levier ne se ferme pas complètement

15

.

Page 16

c. Après avoir réglé un pied à la hauteur désirée, l'utilisateur devra suivre la

10

11

9

8

12

13

14

15

16

17

17

18

21

20

22

23

24

25

26

27 28

29

30

31

32

33

34

35

36

37

38 39 40

41

42

43

44

45

46 47 48

même procédure pour régler la hauteur des trois autres pieds.

Fig. 5

La cheville n'est pas

enfoncée = le pied

n'est pas assujetti en

position verrouillée.

4

. Pied réglable – pour mettre le banc de travail de niveau

Si vous travaillez à un endroit où le sol n'est pas de niveau, nous avons une

a.

solution pour vous. Nous avons un pied réglable qui s'allongera jusqu'à 1,75 po

pour mettre votre banc de travail de niveau. (Fig. 6)

!

AVERTISSEMENT

sur une surface solide, plate et de niveau.

Avant de commencer à employer le poste de

travail, assurez-vous que toute l'unité est placée

Une blessure grave pourrait être

causée si l'outil était instable et basculait.

Fig. 6

!

AVERTISSEMENT

Utilisez seulement avec des scies circulaires de 7

1/4 po ou moins.

Des scies de plus grande taille

risqueraient de couper à travers les supports de fixation.

c. La rainure de coupe a une profondeur de 2 3/4 po et peut être utilisée avec

une scie circulaire de 7 1/4 po au maximum. La rainure de coupe peut être

utilisée pour des coupes longitudinales ou transversales. L'utilisateur doit

assujettir l'ouvrage avec les crampons fournis (brides à talon) ou avec d'autres

d

ispositifs de fixation (Fig. 8). Ne faites pas de coupes longitudinales

parallèlement aux crampons X-Bench.

ig. 8

F

Direction

de coupe

6. Crampons

Des trous de crampon existent sur toute la surface de la table afin de

a.

maintenir les ouvrages en place pendant la coupe (Fig. 9). Deux crampons sont

fournis avec le poste de travail X-Bench. Ces crampons sont fabriqués

spécialement pour le poste de travail X-Bench. Notez le sens de l'avance des

ouvrages lorsque vous coupez dans la position des crampons. Une plaque

rapportée doit être sur le dessus de la table pendant les applications l'utilisant.

Voir la

Figure 28 du Guide de référence pour identifier la configuration des

trous pour les crampons.

5. Ouverture de la rainure de coupe

!

AVERTISSEMENT

a.

Pour ouvrir votre rainure de coupe, vous devez d'abord ouvrir quatre verrous.

La rainure de coupe doit être complètement

ouverte pour pouvoir scier.

b. Déverrouillez les quatre verrous en les tirant vers le haut, et allongez la table

vers l'extérieur (Fig. 7).

Fig. 7

Le verrou est maintenant

dans la position verrouillée.

Le verrou est maintenant dans

la position ouverte.

Fig. 9

Direction

de coupe

7. Montage pour scie à onglet

a.

Il existe trois trous de montage qui supportent des scies à onglet de la plupart

des dimensions (Fig. 10). Si vous utilisez une scie à onglet sur cette table, vous

devez monter la scie à onglet sur le poste de travail X-Bench pour des raisons de

sécurité. Remarque : fermez la rainure de coupe en cas d'emploi d'une scie à

onglet.

Fig. 10

!

AVERTISSEMENT

N'utilisez pas les trous de crampon pour tirer la

table vers l'extérieur. Une fois que la table est

allongée, les verrous DOIVENT être verrouillés pour que la rainure de coupe

puisse être utilisée correctement.

Si vous ne verrouillez pas les verrous

pendant que la table est en position ouverte, vous risque de rendre possible un

mouvement du dessus de la table pendant la coupe, ce qui pourrait produire des

coupes mal alignées ou des blessures personnelles.

.

16

Page 17

!

AVERTISSEMENT

8. Interrupteur

a.

La fiche femelle est située sur le dessous de l'interrupteur et la fiche mâle est

située sur le côté du coffret de commutation (Fig. 11). Connectez le coffret de

commutation à une prise de courant en utilisant une rallonge. Branchez l'outil

désiré dans la fiche femelle et activez le coffret de commutation pour le mettre

s

ous tension en soulevant la languette. L'outil qui est branché dans le coffret de

commutation est maintenant sous tension.

b. Pour mettre l'outil hors tension, l'utilisateur peut appuyer sur l'interrupteur

situé sur le devant du coffret de commutation. Quand l'utilisateur s'éloigne du

poste de travail, il est recommandé qu'il retire la clé de déverrouillage afin

d'éviter tout risque d'utilisation non autorisée. (15 A maximum d'utilisation pour

le coffret de commutation)

Assurez-vous que le poste de travail n'est pas

branché et que la prise principale est hors tension.

Fig. 11

Fils de

rallonge

Outils

La patte de renfort et le pied peuvent maintenant être repliés à l'intérieur de la

table. Suivre la même procédure pour chacun des pieds.

!

AVERTISSEMENT

l'intérieur car elles risqueraient d'être pincées.

c. Une fois que tous les pieds seront à l'intérieur de la table, déverrouillez la table

e

n tournant le bouton principal pour la maintenir en position déverrouillée.

R

éférez-vous à la Section 1a pour plus de détails. L'utilisateur pourra replier la

table en deux pendant qu'elle est déverrouillée.

!

AVERTISSEMENT

replie.

Elles risqueraient d'être pincées pendant cette opération.

d. Après que la table aura été pliée en deux, il faudra tourner à nouveau le bouton

en position verrouillée. Référez-vous à la Section

opération n'est pas accomplie, la table risque de s'ouvrir pendant que l'utilisateur

l

a transporte.

Gardez les mains à une distance suffisante des

zones pivotantes lorsque vous repliez les pieds vers

Gardez vos mains et les autres parties de votre

corps à une distance suffisante de la zone qui se

b1 pour plus de détails. Si cette

Installation des accessoires

(Toutes les pièces rapportées et tous les outils sont vendus séparément.)

10. Table à ventilation verticale (vendue séparément)

a.

Déverrouillez la plaque rapportée universelle en relâchant le verrou à l'avant et

retirez alors la plaque (Fig. 14).

Fig. 14

9. Comment replier l'unité pour le rangement/transport

Positionnez la table sur son côté ou en position renversée et comprimez les

a.

quatre pieds pour les mettre en position zéro (Fig. 12).

Fig. 12

b. Pour placer les pieds à l'intérieur de la table, l'utilisateur doit appuyer sur la

cheville de verrouillage située au milieu de la patte de renfort du pied et tirer sur

cette patte de renfort (Fig. 13).

Fig. 13

Appuyez sur la cheville et tirez sur la

patte de renfort pour relâcher.

b. Placez la table à ventilation verticale au-dessus de l'ouverture en plaçant le

côté arrière dans la zone ouverte en premier.

c. La table à ventilation verticale doit reposer au ras de la table (Fig. 15).

d. Fermez le verrou sur la table à ventilation verticale. Si le verrou ne peut pas

être fermé, cela signifie que la table n'est pas dans la position correcte.

Repositionnez-la et verrouillez ensuite.

Fig. 15

17

.

Page 18

11. Étau à queue (vendu séparément)

a.

Localisez les composants suivants :

(1) bloc de fixation (MDF), (2) tiges de guidage, (1) tige filetée, (6) boulons et (6)

couvre-boulons.

b. Positionnez le bloc de fixation (MDF) au-dessus des tiges de guidage et des

t

iges filetées comme illustré à la Figure 16.

c. Attachez solidement le bloc de guidage sur les tiges avec les (6) boulons et

rondelles fournis (Fig. 16).

d. Placez un couvre-boulon sur chaque tête de vis en vous assurant qu'il est au

ras de la table (Fig. 16).

Fig. 16

h. Placez le bloc de guidage des tiges en position depuis le côté arrière du

châssis comme illustré, insérez deux vis depuis le côté avant du châssis à

l'intérieur du bloc de guidage des tiges et assujettissez-le au moyen de deux

écrous depuis le côté arrière du châssis. Recommencez cette procédure de

l'autre côté du châssis (Fig. 18).

i. Insérez les tiges de guidage et la tige filetée dans les écrous et la tige rapportée

en vous assurant que les tiges de guidage traversent les blocs de guidage de

c

haque côté du châssis tout en enfilant lentement la tige avec le bouton dans le

châssis comme un étau (Fig. 19).

Fig. 19

j. Une fois que l'étau à queue aura été enfilé dans les tiges rapportées, attachez la

cheville fournie à l'extrémité de la tige filetée (Fig. 20).

e. Localisez les composants suivants :

(1) tige filetée rapportée, (2) tiges de guidage rapportées, (3) écrous rapportés,

(2) blocs de guidage, (4) vis, (4) écrous et (1) cheville.

f. Insérez les tiges rapportées depuis le côté arrière du châssis complètement à

travers les trois trous prévus à cet effet (Fig. 17).

Fig. 17

g. Assujettissez les tiges rapportées sur le châssis au moyen des trois grands

écrous fournis depuis le côté avant du châssis (Fig. 18).

!

MISE EN GARDE

Assurez-vous que les orientations des écrous

assortis sont telles qu'indiquées sur les figures.

Fig. 18

Fig. 20

k. Placez l'objet sélectionné entre l'étau à queue et le bord de la table, et

assujettissez-le en faisant tourner le bouton de l'étau à queue dans le sens des

aiguilles d'une montre. La charge pondérale maximum est de 40 li (18 kg).

!

MISE EN GARDE

au milieu de l'étau (Fig. 21).

Lorsque vous attachez de petits ouvrages, l'étau à

queue ne fonctionnera que lorsque l'ouvrage sera

Fig. 21

Bloc de guidage des tiges

12. Kit de fixation par crampons (vendu séparément)

a.

Des crampons adaptés spécialement (brides à talon) sont placés dans les

trous prévus à cet effet pour maintenir les ouvrages en place pendant les

opérations de coupe (Fig. 22).

.

18

Page 19

Fig. 22

Direction

de coupe

15. Étagère et sac à outils (vendus séparément)

a

L

.

'étagère et le sac à outils sont livrés déjà assemblés.

b. Il existe quatre crochets au-dessous du banc de travail (Fig. 23).

c. Attachez les bandes Velcro situées sur l'étagère aux crochets au-dessous de la

table (Fig. 23).

Remarque : l'unité peut se replier avec l'étagère et le sac attachés. La charge

pondérale maximale est de 20 li (9 kg).

Fig. 23

b. Attachez les deux côtés du plateau en utilisant les (2) supports de montage en

forme de U et les vis assorties (Fig. 25).

ig. 25

F

c. Retirez le distributeur de coupes et de ruban en le faisant tourner et en

utilisant la forme correspondante (Fig. 26).

Fig. 26

13. Plateau de finition (vendu séparément)

a.

Localisez les composants suivants :

(1) bouton, (1) grande rondelle, (2) supports de montage en forme de U et

(2) vis.

Insérez le plateau dans les trois trous prévus à cet effet. Depuis le côté arrière du

châssis, enfilez la grande rondelle et le bouton dans le trou du milieu du plateau

jusqu'à ce qu'ils soient bien serrés (Fig. 24).

!

MISE EN GARDE

Ne serrez pas excessivement le bouton car cela

risquerait d'endommager le corps en plastique.

Fig. 24

d. Retirez et montez le distributeur de serviette en papier dans la fente verticale

(Fig. 27). La charge pondérale maximale est de 10 li (4,5 kg).

Fig. 27

14. Supports de crampons (brides à talon) :

a.

Deux crampons sont inclus avec le produit X-Bench que vous avez acheté.

Ces crampons sont placés dans les trous pour crampons sur la surface de la

table X-Bench pour maintenir en place des ouvrages en bois pendant les

opérations de coupe. Les crampons sont capables de maintenir en place 1x et 2x

matériau.

19

.

Page 20

15. Plaque rapportée universelle :

a.

Une plaque rapportée est fournie avec le poste de travail X-Bench. Cette

surface est conçue pour être utilisée exclusivement avec la technologie Skil

concernant les plaques rapportées, qui est vendue séparément. Les plaques

rapportées peuvent être achetées séparément pour des scies à chantourner, des

ponceuses, des toupies ou des perceuses à colonne.

!

VERTISSEMENT

A

quelconques autres équipements pourrait causer une perte de contrôle et des

blessures.

Utilisez seulement des plaques rapportées XB

ench et des outils spécialisés.

L

'utilisation de

Entretien de votre scie

de table X-Bench

Entretien

ertains solvants et produits de nettoyage

!

AVERTISSEMENT

u du tétrachlorure de carbone, solvants de nettoyage au chlore,

o

ammoniaque et détergents domestiques contenant de l’ammoniaque)

risquent d’endommager les composants en plastique.

produits et d’autres types de produits de nettoyage pour réduire le risque

d’endommagement.

!

MISE EN GARDE

ment par un réparateur ayant reçu la formation nécessaire.

entre de service en usine ou le point de service après-vente agréé le plus

c

proche, ou un autre service de réparation compétent. N’utilisez que des

pièces de rechange identiques aux pièces d’origine car l’emploi d’autres

pièces pourrait présenter des dangers.

C

(entre autres, produits contenant de l’essence

Évitez d’utiliser ces

Toutes les réparations, électriques comme

écaniques, doivent être effectuées seule-

m

Contactez le

!

AVERTISSEMENT

Ne placez jamais de crampons sur les côtés opposés de la rainure de coupe. Le support ne doit être

placé que d'un côté de la table.

Suggestions pour les opérations de coupe

Fig. 28

2 po x 10 po

1 po x 12 po

2 po x 8 po

1 po x 10 po

2 po x 6 po

1 po x 8 po

2 po x 4 po

1 po x 6 po

1 po x 4 po

Crampon

1

Crampon

2

20

.

Page 21

Direction de coupe

Direction de coupe

.

21

Page 22

Normas generales de seguridad

!

ADVERTENCIA

LA SEGURIDAD es una combinacion de sentido comun por parte del operador y de estar alerta en todo momento cuando se esta utilizando la X-Bench.

MANTENGA ALEJADOS A LOS NIÑOS

No permita que los visitantes toquen la herramienta o el cordón de extensión. Todos los visitantes deben mantenerse alejados del área de

trabajo.

MANTENGA LIMPIAS LAS AREAS DE TRABAJO

Las áreas y mesas desordenadas invitan a que se produzcan accidentes.

HAGA EL TALLER A PRUEBA DE NIÑOS

Con candados e interruptores maestros.

EVITE LOS ENTORNOS PELIGROSOS

No utilice herramientas mecánicas en lugares húmedos o mojados.

Mantenga el área de trabajo bien iluminada. No exponga las herramientas

mecánicas a la lluvia. No utilice la herramienta en presencia de líquidos o

gases inflamables.

CONOZCA SU HERRAMIENTA MECANICA

Lea y entienda el manual del usuario y las etiquetas puestas en la

herramienta. Aprenda las aplicaciones y los límites, así como los peligros

potenciales específicos que son propios de esta herramienta.

NO INTENTE ALCANZAR DEMASIADO LEJOS

Mantenga una posición y un equilibrio adecuados en todo momento.

MANTENGASE ALERTA

Fíjese en lo que está haciendo. Use el sentido común. No utilice la herramienta cuando esté cansado. No la use cuando se encuentre bajo la

influencia de medicamentos o al tomar alcohol u otras drogas.

VISTASE ADECUADAMENTE

Para evitar ser arrastrado hacia la hoja, no use ropa holgada, guantes

holgados, corbata ni alhajas. Sujétese el pelo largo detrás de la cabeza o

use una cubierta protectora para el pelo y súbase las mangas por encima

de los codos. Se recomiendan guantes de goma y calzado antideslizante

cuando se trabaje a la intemperie.

USE ANTEOJOS DE SEGURIDAD

Use anteojos de seguridad (protección de la cabeza). Use anteojos de

seguridad (deben cumplir con la norma ANSI Z87.1) en todo momento.

Use calzado antideslizante y casco, en caso de que sea apropiado.

Además, use una careta o una máscara antipolvo si la operación de corte

genera polvo, y protectores de oídos (tapones u orejeras) durante

períodos prolongados de utilización de la herramienta.

PROTEJASE CONTRA LAS SACUDIDAS ELECTRICAS

Evite el contacto del cuerpo con las superficies conectadas a tierra. Por

ejemplo: tuberías, radiadores, cocinas y refrigeradores.

DESCONECTE LAS HERRAMIENTAS DE LA FUENTE DE ENERGIA

Cuando no se estén utilizando, antes del servicio de ajustes y repa

raciones, al cambiar hojas, brocas, cortadores, etc.

MANTENGA PUESTOS LOS PROTECTORES

En buenas condiciones de funcionamiento y con el ajuste y la alineación

adecuados.

QUITE LAS LLAVES DE AJUSTE Y LAS LLAVES DE TUERCA

Cuando no se estén utilizando, antes del servicio de ajustes y reparaciones, al cambiar hojas, brocas, cortadores, etc.

EVITE EL ARRANQUE ACCIDENTAL

Asegúrese de que el interruptor esté en la posición “OFF” (“O”) (desconectado) antes de enchufar la herramienta.

NUNCA SE SUBA A LA HERRAMIENTA NI A SU SOPORTE

Se podrían producir lesiones graves si la herramienta se inclina o si se

toca accidentalmente la herramienta de corte. No guarde materiales

sobre la herramienta ni cerca de ésta de tal manera que sea necesario

“LEA TODAS LAS INSTRUCCIONES”. El incumplimiento de las normas de seguridad indicadas a continuación y otras

precauciones de seguridad básicas puede dar lugar a lesiones personales graves.

Area de trabajo

Seguridad personal

subirse a la herramienta o a su soporte para llegar a ellos.

R

EVISE LAS PIEZAS DAÑADAS

Antes de volver a utilizar la herramienta, una protección u otra pieza que

esté dañada deberá revisarse cuidadosamente para asegurarse de que

funcionará adecuadamente y de que realizará la función para la cual está

diseñada. Verifique la alineación de las piezas móviles, el montaje y

cualquier otra situación que pueda afectar su funcionamiento. Un

protector o cualquier otra pieza que presenta daños se debe sustituir

adecuadamente.

TODAS LAS REPARACIONES, ELÉCTRICAS O MECANICAS, DEBEN SER

R

EALIZADAS UNICAMENTE POR TÉCNICOS DE REPARACION

C

APACITADOS.

Póngase en contacto con el Centro de servicio de fábrica Skil, con la

Estación de servicio Skil autorizada o con otro servicio de reparaciones

competente más próximo.

UTILICE PIEZAS DE REPUESTO SKIL UNICAMENTE;

cualquier otra puede constituir un peligro.

LA UTILIZACION DE CUALQUIER OTRO ACCESORIO NO ESPECIFICADO

EN EL CATALOGO SKIL ACTUAL PUEDE CONSTITUIR UN PELIGRO.

Utilización de la herramienta

NO FUERCE LA HERRAMIENTA

La herramienta hará el trabajo mejor y con más seguridad a la capacidad

para la cual fue diseñada.

UTILICE LA HERRAMIENTA ADECUADA

No fuerce una herramienta pequeña o un accesorio pequeño a realizar el

trabajo de una herramienta pesada. No utilice la herramienta para

funciones para las cuales no fue diseñada — por ejemplo, no use una

sierra circular para cortar ramas o troncos de árboles.

FIJE LA PIEZA DE TRABAJO

Utilice abrazaderas o un tornillo de carpintero para sujetar la pieza de

trabajo cuando esto resulte práctico. Es más seguro que utilizar la mano

y deja libres ambas manos para manejar la herramienta.

DIRECCION DE AVANCE

Haga avanzar la pieza de trabajo por una hoja o cortador en contra del

sentido de rotación de la hoja o cortador únicamente.

NUNCA DEJE LA HERRAMIENTA FUNCIONANDO DESATENDIDA

Apague la herramienta. No deje la herramienta hasta que ésta se haya

detenido por completo. Conozca la ubicación y el ajuste de la posición de

ENCENDIDO del interruptor. No deje nunca el interruptor en la posición

de ENCENDIDO. Conozca la ubicación del interruptor y sepa cómo

apagar la herramienta en situaciones de emergencia. Los arranques

accidentales podrían causar lesiones.

NO ABUSE DEL CORDÓN

No use nunca el cordón para transportar las herramientas ni tire del

cordón para desenchufarlo de un tomacorriente. Mantenga el cordón

alejado del calor, el aceite y los bordes afilados o las piezas móviles.

Reemplace inmediatamente los cordones dañados. Los cordones

dañados aumentan el riesgo de que se produzcan sacudidas eléctricas.

Cuidado de la herramienta

NO ALTERE NI HAGA USO INCORRECTO DE LA HERRAMIENTA

Estas herramientas están fabricadas con precisión. Cualquier alteración o

modificación no especificada constituye un uso incorrecto y puede dar

lugar a situaciones peligrosas.

EVITE LAS AREAS DE GASES

No utilice herramientas eléctricas en una atmósfera gaseosa o explosiva.

Los motores de estas herramientas normalmente producen chispas y

pueden dar lugar una situación peligrosa.

22

.

Page 23

MANTENGA LAS HERRAMIENTAS CON CUIDADO

Conserve las herramientas afiladas y limpias para que funcionen mejor y

con más seguridad. Siga las instrucciones para lubricar y cambiar los

accesorios. Inspeccione periódicamente los cordones de las herramientas

y si están dañados hágalos reparar por un centro

de servicio autorizado. Inspeccione periódicamente los cordones de

e

xtensión y sustitúyalos si están dañados. Mantenga los mangos secos,

l

impios y libres de aceite y grasa.

ANTES DE CONECTAR LA HERRAMIENTA A UNA FUENTE DE ENERGIA