Page 1

This catalog is out of date, see note on page 3

2002

·

teleperm m

Catalog PLT 112

AS 488/TM

automation systems

Page 2

This catalog is out of date, see note on page 3

Related catalogs

TELEPERM M

AS 235, AS 235 H and AS 235 K Automation Systems

Order No.:

E86060-K3811-A100-A3-7600

TELEPERM M

Operation and Monitoring with WinCC/TM

Order No.:

E86060-K3823-A100-A1-7600

TELEPERM M

CS 275 Bus System

Order No.:

E86060-K3813-A100-A1-7600

SIMATIC PCS 7

SIMATIC PCS 7 Process Control System

Order No.:

E86060-K4678-A111-A5-7600

SIMATIC

Components for

Totally Integrated Automation

Order No.:

E86060-K4670-A111-A7-7600

PLT 111

PLT 123

PLT 130

ST PCS 7

ST 70

SIMATIC NET

Industrial Communication & Field Devices

Order No.:

E86060-K6710-A101-B2-7600

SITRAIN

Information and Training for

Automation and Drives

Order No.: E86060-K6850-A101-B3 (only in German)

on CD-ROM: E86060-D6850-A100-B7-7400 (only in German)

Automation and Drives

The Entire Product Range on CD-ROM

Order No.:

E86060-D4001-A100-B7

Trademarks Internet

All names in this catalog identified by ® are

registered trademarks of the Siemens AG.

All other product and system names are (registered) trademarks

of their respective owners and must be treated accordingly.

IK PI

ITC

CA 01

Visit our Automation and Drives

Technology Site in the Internet!

Our address is

www.siemens.com/automation

Page 3

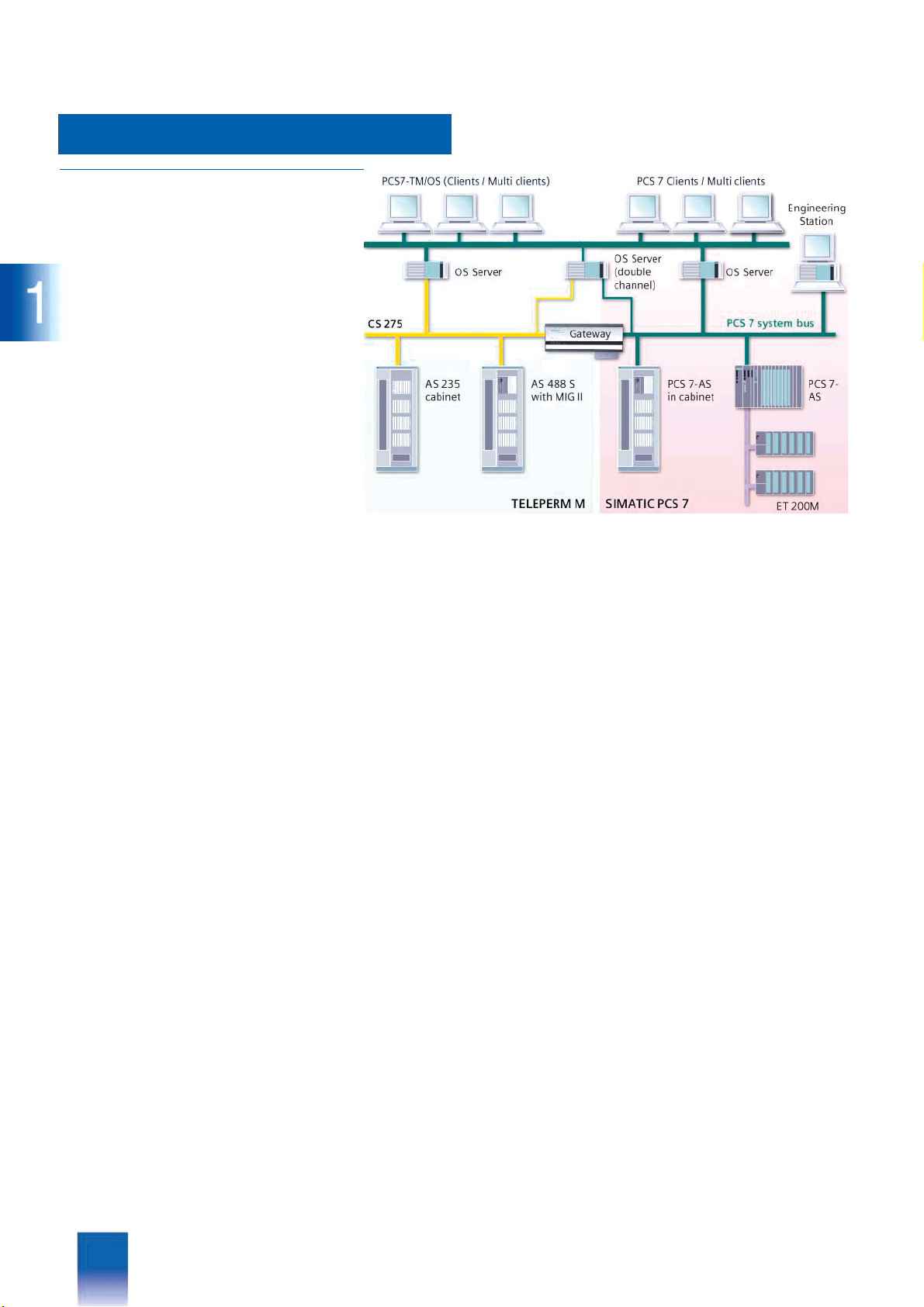

AS 488/TM

automation systems

Catalog PLT 112 · 2002

Introduction

System architecture

AS 488 S

cabinet system

System properties

System software

Commissioning

Engineering

1

2

3

The products in this catalog are also included in

the CD-ROM Catalog CA 01

Order No.:

E86060-D4001-A100-B7-7600

Please contact your local Siemens office

or representative.

This catalog is no longer available in printed

form. However, it can still be used to obtain

information and for ordering spare parts.

Certain products from this catalog are no

longer available. Your Siemens partner will

offer appropriate substitutes wherever

possible.

AS 488 K

compact system

4

AS 488 in

SIMATIC design

5

SIMATIC PCS 7

cabinet design

6

Migration of

existing systems

7

Process I/Os

8

Bus communication

9

Data couplings with

other systems

Appendix

Indexes

Internet, Training

Terms and Conditions of

Sales and Delivery

10

11

Page 4

This catalog is out of date, see note on page 3

Introduction

TELEPERM M Process Control System

1/2 Overview

1/2 Automation systems

1/2 Operator systems

1/3 Engineering

1/3 System bus

1/3 Migration strategy

AS 488/TM

1/4 Overview

1/5 Highlights - Classification in the

TELEPERM M system environment

1/6 Area of application

1/6 Functions - Highlights

Siemens PLT 112 · 2002

6/1

Page 5

Introduction

This catalog is out of date, see note on page 3

TELEPERM M Process Control System

■

Overview

The TELEPERM M process control system provides all functions required for process automation. It is highly suitable for the complete

automation of continuous or discontinuous

(batch) processes.

The TELEPERM M systems are divided into

functional units optimized for different task encountered with process automation:

• Automation systems

• Operator systems

• Bus systems.

Automation systems

The TELEPERM M automation system of type AS 488/TM based

on the SIMATIC M7-400 hardware platform is available with two

performance levels and four different design versions for program-controlled processing of process signals.

The system software functions of the AS 488/TM are compatible

with the system software version G of the previous AS 235 system. Existing application software of the AS 230 / AS 235 automation systems can be used further, application software of

AS 220 automation systems only following conversion.

The AS 488/TM can be operated on both the CS 275 and

PROFIBUS-TM system buses. As a result of its variable configuration, it is equally suitable for TELEPERM M migration, for the

expansion of existing systems, or the design of new systems.

Application details:

• Replacement of existing AS 220 / AS 230 / AS 235 automation

systems during migration by replacement of the existing basic

rack by a preassembled rack with the AS 488/TM system

• Expansion of existing systems on the CS 275 system bus

• Expansion of existing systems by PROFIBUS-TM system components using the CS-L2 bridge

• New systems

In the case of new systems, the PROFIBUS-TM based on the

standardized PROFIBUS is preferably used as the system bus.

Using TELEPERM M-specific communication, automation systems connected on the PROFIBUS-TM can communicate with

one another and also with TELEPERM M components on the

CS 275 system bus coupled via the CS-L2 bridge.

A wide range of TELEPERM M input/output modules is available

for the AS 488/TM, some of which have their own processing

functions or are configurable specific to the application. Via one

or two PROFIBUS-DP interfaces it is additionally possible to connect SIMATIC ET 200B, ET 200M, ET 200S, ET 200X and

ET 200U distributed I/O systems with a comprehensive selection

of I/O modules. Within this range, the I/O modules of the

ET 200M distributed I/O system which have been specially tailored to process engineering are particularly recommendable.

Introduction

A large number of devices possessing a DP interface can be additionally operated on the PROFIBUS-DP of the AS 488/TM. For

example, DP interfaces integrated in the CPU modules of the

SIMATIC S7-300 permit a simple slave connection to the

AS 488/TM. Gateway modules on the PROFIBUS-DP

(DP/PA link, DP/AS-i link, DP/DP coupler) additionally permit

access to the PROFIBUS-PA and AS-Interface fieldbuses and to

the I/O buses of SIMATIC PCS 7, S7-300, S7-400 or systems

from other vendors.

Operator systems

The bus-based PCS7/TM-OS operator system is used for process communication. The PCS7/TM-OS is suitable as a

HMI component for the AS 488/TM and the TELEPERM M

AS 220 S / AS 220 H, AS 215, AS 230 / AS 230 K, AS 235 /

AS 235 K / AS 235 H and AS 388/TM automation systems which

are no longer actively marketed. It communicates with the

subordinate TELEPERM M automation systems and with

SIMATIC S5-155U via one of the CS 275 or PROFIBUS-TM field

buses.

The variable configuration of the PCS7/TM-OS operator system

from a single-user to multi-user system with single-client or multiclient functionality covers the complete bandwidth of the application spectrum from low-end to high-end performance.

The wide variety of operator-accessible automation systems together with the variability for communication and expansion

mean that the PCS7/TM-OS is well qualified as a replacement for

older TELEPERM M operator systems, for system extensions or

for new systems.

1/2

Siemens PLT 112 · 2002

Page 6

This catalog is out of date, see note on page 3

TELEPERM M Process Control System

Introduction

Engineering

The PROGRAF AS+/NT configuring software which can be installed on personal computers with the Windows NT or

Windows 2000 operating system is predestined for the engineering of TELEPERM M automation systems. An engineering

PC with PROGRAF AS+/NT can be connected to one of the two

TELEPERM M system buses using a bus-specific interface module. It can then be used to configure an AS 488/TM or equally

well to configure the AS 230 / AS 230 K, AS 235 / AS 235 K /

AS 235 H and AS 388/TM automation systems which are no

longer actively marketed.

PROGRAF AS+/NT can be used to graphically configure,

test, optimize and document the application software of the

TELEPERM M automation systems. The configurations of previously installed automation systems can also be read in, recompiled and subsequently processed further or documented in

graphic form. Any PCS7/TM-OS-Single single-user system with

RC license (Runtime+Configuration) is suitable for configuring

PCS7/TM-OS operator systems. It is alternatively possible to use

a server equipped with an RC license and additional operator

terminal for OS configuring. The PCS7/TM-OCX (NORA) display

blocks (if used) and the PCS7/TM coupling package dependent

on the types of AS used must be installed on both configuring

systems.

System bus

The system bus is the central communication component of every distributed process control system. Two different bus systems are available for the TELEPERM M process control system,

and can also be combined together within a plant:

• CS 275

• PROFIBUS-TM

The CS 275 bus system which has been proven in many automation plants functions according to the token passing principle

and can also have a redundant configuration. Several buses can

be combined together using bus couplers such that bus networks are produced corresponding to the plant structure. The

bus system is provided with distributed control. The bus interface of each subsystem may take over the master function according to specific criteria.

The PROFIBUS-TM bus system also operates according to the

token passing principle. It can be designed as an electrical or

optical network. The two network structures can also be mixed

together. A characteristic of the PROFIBUS-TM bus system is

that it corresponds to the modern PROFIBUS communications

standards according to EN 50170, but also uses the

TELEPERM M dialog mechanisms of the CS 275 (AKS, BKS,

MKS and PL/PS telegrams) at the application level (interface between bus interface module and application).

PROFIBUS-TM is preferably used for new systems, or also for

the expansion of existing systems. When extending systems, existing components with CS 275 communication can be combined with new components using a CS-L2 bridge.

All automation systems and operator systems of the

TELEPERM M process control system can be operated on the

CS 275 system bus, but only the current AS 488/TM and

PCS7/TM-OS systems as well as the AS 388/TM and OS 525

systems which are no longer actively marketed on the

PROFIBUS-TM system bus.

Migration strategy

The purpose of migration of the proven TELEPERM M process

control system into the new, future-oriented generation of the

SIMATIC PCS 7 system within the Siemens automation concept

"Totally Integrated Automation" is to retain customer investments

made in hardware and software and to provide them with a graded, economical transition to newer, more productive technologies with minimum technical and financial risks.

Migration is divided into the following steps:

• Innovation

- Migration of the TELEPERM M process control system by renewal of components close to the process (automation systems) and of system-internal communication with hardware of

the SIMATIC M7 and PROFIBUS systems

- Expansion of the process I/Os for the innovative automation

systems by integration of the ET 200M, ET 200S, ET 200U

and ET 200X distributed I/Os and of the PROFIBUS-PA and

AS-Interface fieldbuses via PROFIBUS-DP

- Linking of the existing CS 275 system bus to the new

PROFIBUS-TM system bus via a CS-L2 bridge

- Integration of SIMATIC S5, SIMATIC S7 and SIMATIC PCS 7

systems with data coupling via PROFIBUS-AG/AG independent of the system bus

• Combination

Standardization of the HMI components of the TELEPERM M

and SIMATIC PCS 7 systems on the basis of the SIMATIC

PCS 7 operator station, as well as combination of partial

TELEPERM M and SIMATIC PCS 7 systems with these common HMI components

• Homogenization

Replacement of the TELEPERM M automation systems by

SIMATIC PCS 7 automation systems with further use of existing

TELEPERM M I/Os

Siemens PLT 112 · 2002

1/3

Page 7

This catalog is out of date, see note on page 3

Introduction

AS 488/TM

■

Overview

The AS 488/TM automation system based on the

SIMATIC M7-400 hardware platform combines the advantages

of a modern hardware generation with the AS 235 functionality of

the TELEPERM M process control system proven in numerous

applications. It is suitable for automation of continuous processes or also of recipe-based batch processes.

The functions of the AS 488/TM system software are compatible

with the G system software of the previous AS 235 system. Thus

you can continue to use existing application software of the

AS 220 / AS 230 / AS 235 automation systems with its standard

function blocks, user function blocks, TML programs and

STEP M programs. AS 220 application software, however, must

first be converted (service is part of migration offer).

The AS 488/TM automation system is available in four different

versions:

• AS 488 with modular, standard packaging system for connection at the rear according to the SIMATIC guidelines

• AS 488 S cabinet system for installation in TELEPERM M cabinets with 19" packaging system (cabinets not included in

scope of delivery of AS 488 S, they must be ordered as options

if required from Catalog PLT 111)

• AS 488, installed in SIMATIC PCS 7 cabinets (only with exclusive use of distributed SIMATIC I/Os; see Catalog ST PCS7.A,

Add-ons for the SIMATIC PCS 7 process control system)

• AS 488 K compact system for installation in TELEPERM M wall

housings or cabinets

The AS 488 K compact system and the AS 488 S cabinet system

provide numerous possibilities for system expansion and modernization by replacement of TELEPERM M automation systems

which are no longer available or marketed, with a simultaneous

increase in the AS performance. The completely equipped

AS 488 K / AS 488 S basic systems which have been pretested

by means of a switch-on test can be individually adapted by numerous options, and ideally integrated into an existing system

environment. System integration is carried out using so-called

migration racks (MIG I / MIG II with AS 488 S and MIG K with

AS 488 K). The migration rack is simultaneously the interface to

the TELEPERM M I/Os in the extension units of the TELEPERM M

cabinets and in the ES 100 K extension systems. Up to five

I/O modules can be directly inserted into the MIG II and MIG K

migration racks just like in the basic unit of an AS 235 or

AS 235 K.

As with the AS 230 / AS 235, up to three extension units can be

operated in the basic cabinet on I/O bus A of an AS 488 S as

well as an external ES 100 K. Up to four extension units of an

AS 230 / AS 235 extension cabinet can be connected to an

AS 488 S via I/O bus B if the ribbon cable for the I/O bus is replaced. During migration off the AS 488/TM it is therefore possible to add a fourth extension unit to a maximally configured

AS 235 extension cabinet. Limitation of the number of migratable

I/O modules does not therefore exist for an AS 230 / AS 235 configured with the maximum number of TELEPERM M I/O modules.

The AS 488 K with its MIG K migration rack offers the same

packaging system as an AS 235 K. The MIG K migration rack

has five slots for TELEPERM M I/O modules. The serial coupling

known from the AS 235 K permits connection of 2 x 4 ES 100 K

compact extension systems. These can be positioned up to

500 m away from the AS 488 K automation system, and are

therefore highly suitable for a distributed configuration.

In addition to the migration of existing TELEPERM M I/Os, all versions of the AS 488/TM automation system can also be extended

by distributed I/Os on the PROFIBUS-DP. In addition to the

ET 200M system with a comprehensive range of I/O modules

specially designed for process engineering, it is also possible to

use the SIMATIC ET 200B, ET 200S, ET 200iS, ET 200X and

ET 200U I/O systems (the latter is no longer actively marketed).

It is additionally possible to operate a wide range of devices

possessing a DP interface on the PROFIBUS-DP of the

AS 488/TM. For example, DP interfaces integrated in the

CPU modules of the SIMATIC S7-300 permit a simple slave connection to the AS 488/TM. Using gateway modules on the

PROFIBUS-DP (DP/PA link, DP/AS-i link, DP/DP coupler), it is

also possible to access the PROFIBUS-PA and AS-Interface

fieldbuses and the I/O buses of SIMATIC PCS 7, S7-300, S7-400

or systems from other vendors.

The homogeneous interfacing of the distributed SIMATIC I/Os

forces distribution close to the process. Significant cost savings

are therefore achieved for the process I/Os as well as for field

wiring and routing.

The AS 488 S is optimized for installation in TELEPERM M cabinets with 19" packaging system, and therefore particularly suitable for the migration or expansion of existing TELEPERM M

systems. The system is mounted on the front cabinet members.

The TELEPERM M installation guidelines are applicable with respect to the CE marking wherever TELEPERM M I/O modules

are operated in an AS 488 S. On the other hand, the SIMATIC

S7/M7 guidelines apply to an AS 488 S exclusively operating

with distributed I/Os on the PROFIBUS-DP.

1/4

Siemens PLT 112 · 2002

Page 8

This catalog is out of date, see note on page 3

Introduction

AS 488/TM

AS 488/TM systems for new plants exclusively with distributed

I/Os on the PROFIBUS-DP can also be installed in

SIMATIC PCS 7 cabinets. The SIMATIC S7/M7 installation

guidelines also apply to this version (see Catalog ST PCS7.A,

add-ons for the SIMATIC PCS 7 process control system).

Customers can select between two CPUs with different performance levels for all design versions of the AS 488/TM:

• SIMATIC M7 CPU 486-3 with approx. 150% of the performance

of an AS 235

• SIMATIC M7 CPU 488-3 with approx. 270 - 300% of the performance of an AS 235

A commissioning terminal based on PC/programming device

can be used for commissioning of the AS 488/TM. The terminal

is connected via a serial interface to the respective AS 488/TM

and offers the user the same GUI and syntax as known from the

AS 235. Because of the serial interface, not all HMI requirements

can be fulfilled. Furthermore, the commissioning terminal is not

suitable for operation/configuring of another AS using the

AS bus configuration channel.

PROGRAF AS+/NT is a convenient configuring tool for the

AS 488/TM automation systems. It is compatible with all AS 23x

systems. PROGRAF AS+/NT executes on an appropriate

PC/programming device with Windows NT/2000/XP operating

system and connection to the CS 275/PROFIBUS-TM system

bus. PROGRAF AS+/NT permits the creation of an online configuring station for AS 488/TM on the TELEPERM M system bus. On

the CS 275 system bus, PROGRAF AS+/NT additionally offers

HMI facilities corresponding to local operation of an AS 235.

■

Highlights

Classification in the TELEPERM M system environment

Note:

Some of the communications partners/systems referred to below

are no longer available or no longer marketed. Reference to the

systems in the context "Classification in the TELEPERM M system environment" does not permit any conclusions to be made

on their availability.

• Communications capability with existing systems and

I/O modules

All automation systems and operator systems of the

TELEPERM M process control system can be operated on the

CS 275 system bus. Only the current AS 488/TM and

PCS7/TM-OS systems as well as the AS 388/TM and OS 525

systems which are no longer actively marketed can be operated on the PROFIBUS-TM system bus. Communication specific

to TELEPERM M between bus stations on different system buses is possible via a CS-L2 bridge. The AS 388/TM and

AS 488/TM systems respond on the system bus like an AS 235

system with compatible functions compared to the

PCS7/TM-OS or OS 525 system. The AS 488/TM automation

system can communicate with the following TELEPERM M systems:

- AS 388/TM or AS 488/TM automation systems on the

PROFIBUS-TM system bus, or AS 215, AS 220 S/K/H,

AS 230, AS 230 K, AS 235, AS 235 H, AS 235 K, AS 488/TM

on the CS 275 system bus

- OS 525, OS 525 Local or PCS7/TM-OS operation and moni-

toring systems on the PROFIBUS-TM system bus, or CS 275,

OS 252, OS 262, OS 265, OS 520 on the CS 275 system bus

- Engineering systems: personal computer with the

PROGRAF AS+/NT program package, personal computer or

ES 500 with the PROGRAF AS+ program package, on the

CS 275 or PROFIBUS-TM system bus

- Other systems

SIMATIC PCS 7, SIMATIC S7, SIMATIC S5 and systems from

other vendors via the DP bus PROFIBUS-DP, the coupling

bus PROFIBUS-AG/AG, or via a 3964R serial coupling with

TM module 6DS1 333-8AB.

• Limitations in communication

- The response of the AS 488/TM and AS 388/TM systems in a

homogeneous network with approved TELEPERM M stations

on the CS 275 or PROFIBUS-TM system bus (AS 235,

OS 525, PCS7/TM-OS etc.) maps the AS 235 system with the

exception of CD mode (e.g. for data formats and block

names on the bus). CD couplings (without acknowledgment)

for AKx/BKx blocks are not implemented in the AS 388/TM

and AS 488/TM systems. When carrying out migration or

when importing user structures, the CD couplings must therefore be removed prior to loading into the automation system.

:

Note

When communicating with other stations (e.g. systems from

other vendors) via the N-AT interface module on the CS 275,

not all functions of the AS 388/TM and AS 488/TM react identically to those in an AS 235 system. In individual cases, it

must be checked from the viewpoint of the other systems prior to connection of an automation system to the system bus

whether the required communications functions can be implemented with the AS 388/TM or AS 488/TM systems.

- Use of the STRUK-AS 220 EA program via the system bus is

not released for the AS 388/TM and AS 488/TM systems.

- Use of the AS bus configuring channel for operation/configuring of another AS using a commissioning terminal is not released because of the serial communications mode of the

commissioning terminal.

- Communication to the process I/Os is carried out via serial

PROFIBUS-DP interfaces. These are operated according to

the standard protocol. If devices from other vendors are connected, these must comply with the PROFIBUS-DP standard,

and their data interfaces must be completely described.

AS 388/TM and AS 488/TM automation systems each have

two PROFIBUS-DP interfaces.

- The AS 488/TM communicates with existing I/O modules from

the TELEPERM M range via a special interface module and

the parallel I/O bus interface (ribbon cable) in the

TELEPERM M cabinets.

- The process image is automatically generated by the interface module, and this module must therefore recognize the

connected I/O modules. Only those modules and systems

listed in the Section "Migration of existing systems" or published on the Internet "AS 488/TM configuration list" can be

used.

• Non-migratable systems

The AS 488/TM automation system does not offer a compatible

replacement for the fault-tolerant AS 235 H automation system;

migration would only be possible with relinquishing of the redundancy. Furthermore, the FM 100 field multiplexer must continue to be operated on existing AS 230 / AS 235 automation

systems.

Siemens PLT 112 · 2002

1/5

Page 9

This catalog is out of date, see note on page 3

Introduction

AS 488/TM

■

Area of application

The main applications of the AS 488/TM are:

• Replacement of existing AS 220, AS 230/230 K and

AS 235/235 K automation systems

With an AS 220 / AS 230 / AS 235, the subrack with the central

processing units in the TELEPERM M cabinet is replaced by an

AS 488 S with compatible functions. Existing extension units

with installed TELEPERM M I/Os can be used further. With an

AS 230 K / AS 235 K, migration is carried out by replacing the

complete basic system in the TELEPERM M housing, rack or

cabinet by an AS 488 K compact system with compatible functions. TELEPERM M I/O modules previously inserted in the

AS 230 K / AS 235 K basic system can be used further following conversion and rewiring in the migration rack of the

AS 488 K.

When replacing existing automation systems, the AS 488 S

and AS 488 K migration systems are preferably connected to

the existing CS 275 system bus. Alternatively possible is connection to the PROFIBUS-TM system bus.

• Expansion of existing TELEPERM M systems on the

CS 275 system bus

Expansions on the CS 275 system bus are mainly the result of

modernization by migration with AS 488/TM. Existing systems

with TELEPERM M I/Os can also be expanded by SIMATIC distributed I/Os on the PROFIBUS-DP. In addition to the ET 200M

with a comprehensive range of standard I/O modules for process engineering applications, it is also possible to use the

complete range released for AS 488/TM.

• Expansion of existing TELEPERM M systems by

PROFIBUS-TM system components with use of the

CS-L2 bridge

Existing and new system components can be connected together using a CS-L2 bridge. The bridge couples the two

CS 275 and PROFIBUS-TM buses, and converts the different

parts of the TM protocol. The AS 235 and AS 488/TM systems

on the CS 275 bus can then also be controlled by OS 525 operator systems or PCS7/TM-OS on the PROFIBUS-TM. Analog

and binary values can be exchanged between automation systems on the two buses.

Distributed SIMATIC I/Os on the PROFIBUS-DP are primarily

used for acquisition and output of process signals on the

PROFIBUS-TM components used for the system expansion. In

addition to the ET 200M with a comprehensive range of standard I/O modules for process engineering applications, it is

also possible to use the complete range released for

AS 488/TM.

• New systems with the AS 488/T M automation system

In the case of new systems, it is recommendable to use the

PROFIBUS-TM based on the standardized PROFIBUS as the

system bus. The AS 488/TM automation systems are operated

centrally using bus-coupled PCS7/TM-OS operator systems,

and configured via bus using the PROGRAF AS+/NT program

package. The SIMATIC distributed I/Os from the ET 200 range

are preferred as the process I/Os. Interfacing to the automation

systems is carried out via the PROFIBUS-DP fieldbus.

The favorite standard within the ET 200 range is the ET 200M

I/O system with a comprehensive range of I/O modules of

SIMATIC S7-300 design, including special modules for process engineering. In addition, the complete range of distributed I/Os released for AS 488/TM can of course also be used.

■

Functions

Highlights

• Functions compatible with the proven AS 235 automation systems: existing application software and installed process I/Os

can be used further

• Future-oriented system basis:

continuous evolution to new technologies with the modern

hardware platform of the SIMATIC M7 systems

• Two performance ranges:

selectable CPU performance corresponding to 150% or 270 to

300% of the performance of an AS 235

• Four design systems:

- AS 488 in modular standard packaging system according to

SIMATIC guidelines

- AS 488 S cabinet system for installation in TELEPERM M cab-

inets

- AS 488, installed in SIMATIC PCS 7 cabinets

- AS 488 K compact system for installation in TELEPERM M

wall housing or cabinets

• Can be used for modernization and expansion of existing systems and also for new systems

• Flexible adaptation of automation system to the respective

task:

- Comprehensive range of distributed I/Os

- ET 200M I/Os especially suitable for process engineering

- Compact modules in adapter casings, operation without fans

- Adaptable packaging system

- Migration of existing TELEPERM M systems

• Modern communication standards:

- PROFIBUS-TM system bus for connection of components

close to the process or remote from the process, also with optical design (redundant media)

- PROFIBUS-DP fieldbus for interfacing of distributed process

I/Os and of systems from other vendors with a smaller data interface

• PROFIBUS-AG/AG coupling bus for interfacing of SIMATIC S5,

SIMATIC S7, SIMATIC PCS 7 and systems from other vendors

with data coupling (independent of system bus)

• Bridge for connection of CS 275 and PROFIBUS-TM system

buses

1/6

Siemens PLT 112 · 2002

Page 10

This catalog is out of date, see note on page 3

System architecture

2/2 System properties

2/4 System software

2/5 Data blocks

2/5 Blocks for analog and digital processing

2/5 Blocks for binary processing

2/6 Blocks for processing with standardized

operation and monitoring

2/6 Blocks for signal exchange via the CS 275 or

PROFIBUS-TM system bus

2/7 Blocks for distributed process I/Os on the

PROFIBUS-DP fieldbus

2/7 Blocks for PLC/PLC coupling with

PROFIBUS-AG/AG

2/8 Driver blocks for I/O modules of the

TELEPERM M system via the

TPM 478 communications module

2/9 Blocks for I/O modules with standardized

display

2/9 Organization blocks

2/9 Test blocks

2/10 Commissioning

2/11 Engineering with PROGRAF AS+/NT

Siemens PLT 112 · 2002

6/1

Page 11

System architecture

This catalog is out of date, see note on page 3

System properties

■

Overview

The AS 488/TM automation system consists of standard hardware components from the SIMATIC M7 systems, supplementary components for applications in TELEPERM M, and a memory

card with system software whose functions are compatible with

the AS 235 automation system.

All system programs are saved permanently on the memory

card of the AS 488/TM automation system. The user configurations are also saved permanently on the same medium.

The main characteristic of the AS 488/TM system software is the

complete simulation of the AS 235 functions on the basis of an

RMOS32 real-time operating system on a SIMATIC M7 central

processing unit CPU 486-3 or CPU 488-3.

The system software permits configuring of the automation functions as with the AS 235 system (using dedicated function

blocks, TML and STEP M programs) as well as communication

via a system bus.

The AS 488/TM automation systems are available in four different versions to permit optimum adaptation to different customer

requirements:

• As AS 488 with the modular SIMATIC M7-400 packaging system for connection at the rear according to the SIMATIC guidelines

• As AS 488 S cabinet system: SIMATIC M7-400 packaging system optimized for installation in TELEPERM M cabinets with

19" packaging system

• As AS 488 with SIMATIC M7-400 packaging system, installed

in SIMATIC PCS 7 cabinets (only with exclusive use of

SIMATIC distributed I/Os; see Catalog ST PCS7.A, add-ons

for the SIMATIC PCS 7 process control system).

• As AS 488 K compact system: SIMATIC M7-400 packaging

system, migrated in TELEPERM M compact system and suitable for installation in TELEPERM M wall housings or cabinets.

The AS 488/TM system with the CPU 486-3 provides 150% automation performance (in the sense of computing performance) of

an AS 235 system, and with the CPU 488-3 it provides 270% to

300% automation performance of an AS 235 system with an

equivalent uniform communication performance on the system

bus.

Exceptional features of the automation systems are their universal functions for automation tasks, compatibility with the AS 235

systems, as well as the communication capability with the

PROGRAF AS+/NT configuring tool, the PCS7/TM-OS operator

systems and other automation systems on the CS 275 and on

the PROFIBUS-TM (incl. CS-L2 bridge communication with stations on the other system bus in each case).

Both continuous processes and comprehensive batch processes (production procedure repeated in same or modified form)

can be automated by the AS 488/TM system.

The automation systems have a minimum cycle time of 125 ms

for closed-loop and open-loop controls. The individually configured functions can be processed in a basic cycle (125 ms, 1 s

and background level) or in a multiple thereof. An acyclic alarm

processing level is present in addition.

System architec ture

■

Functions

• Automation system with graded performance and communication via system bus

• PROFIBUS-TM system bus, or CS 275 as alternative

• Central operation and monitoring with the PCS7/TM-OS operator system

• Configuring with graphical user interface using the

PROGRAF AS+/NT engineering tool on PC/programming device

• Commissioning support with commissioning terminal based on

PC/programming device with known TELEPERM M syntax

• SIMATIC S7/M7 packaging system; integration in

TELEPERM M cabinets/housing with MIG I, MIG II or MIG K

migration racks

• Distributed I/Os with the modular ET 200M I/O stations (including Ex(i) modules), ET 200B, ET 200U, ET 200S, ET 200iS

(available soon) and ET 200X

• TELEPERM M I/O modules in standard TELEPERM M cabinets

with AS 488 S / AS 488 K migration packages

• The PROFIBUS-DP of the AS 488/TM is open for interfacing of

certified PROFIBUS-DP devices

• System programs on memory card plus user area for archiving

• 4 Mbyte user memory

• 32-bit processing of analog values, identical to the AS 235 system

• Complete range of standard function blocks, identical to the

AS 235 system

• User function blocks with convenient TML programming language, or also the STEP M programming language for openloop controls

• Online configuring/programming with graphic support by

PROGRAF AS+/NT

• Compatible with preconfigured SIGRID TM V5 (GF/GFE),

BATCH X-TM and FUZZY TM program packages

• Reloadable software packages with couplings and I/O links:

- PROFIBUS-AG/AG coupling

- PROFIBUS-PA I/Os

- AS-I I/Os

- SIWAREX M PROFIBUS-DP I/Os

- PROFIBUS-DP I/Os with extended analog formats

- PROFIBUS-DP I/Os: panels based on Windows CE

- PROFIBUS-DP I/Os: IP 262 closed-loop control module of

ET 200U; reloadable driver block as standard on the memory

card of the AS 488/TM

- Options: special driver blocks for use of SIMOVERT,

MICRODRIVES, SIPART DR, FM 350, CEAG devices, etc.

2/2

Siemens PLT 112 · 2002

Page 12

This catalog is out of date, see note on page 3

■

Technical Specifications

Quantity breakdown

The AS 488/TM automation systems have the following quantity

breakdowns:

AS 488/TM CPU 486-3 CPU 488-3

Control loops *) 45 to 120 90 to approx. 216

Additional analog value

monitoring

Sequential controls *) 8 to 20 16 to approx. 36

Logic controls *) 150 to 370 300 to approx. 666

User memory 4 Mbyte 4 Mbyte

Computing performance

compared to AS 235

*) The values identified by an asterisk apply as alternatives and

are not for addition.

45 to 180 90 to approx. 324

150 % 270 to 300 %

System architecture

System properties

Siemens PLT 112 · 2002

2/3

Page 13

System architecture

System software

This catalog is out of date, see note on page 3

■

Overview

A separate memory card with system software is required for

each automation system. The system software of the AS 488/TM

is completely present on this memory card, and only executes

there. The software is reloaded each time the system is switched

on or reset. The memory card is divided into a system memory

and a user memory. The system memory is read-only, and contains the system software in the form of basic programs and

standard function blocks.

The memory card is inserted into a special slot in the automation

system’s CPU. It must not be removed during operation, it must

remain permanently inserted in the CPU.

Standard function blocks

Dedicated function blocks, the so-called standard function

blocks, are available in the automation systems for solving control engineering tasks. The AS 488/TM system contains the same

standardized function blocks as the AS 235 automation system

for measured-value acquisition, closed-loop control, open-loop

control, calculation and monitoring.

Supported by the powerful PROGRAF AS graphic configuring

tool, the standard function blocks present in the system software

are activated by means of configuring instructions and linked

into an automation structure which is partially processed cyclically by the automation system’s CPU, and partially also acyclically.

The standard function blocks of the AS 488/TM system are listed

in the tables under "Configuring". Blocks have been omitted

which are still in the system software for compatibility reasons

but have no significance any longer for applications with the

AS 488/TM.

Optional function blocks

Various preconfigured standard software packages are available which can be subsequently loaded and executed on the

AS 488/TM. Compatibility with the AS 488/TM system software is

guaranteed for the following packages:

AG/AG coupling Standard data coupling of SIMATIC S5/S7,

SIWAREX M

(driver)

ZEIT Utilization measuring program for all AS

FENS Reloadable window block for diagnostics of

Special blocks On request; including optional special driver

Note:

The following software packages can also be used, but are no

longer actively marketed:

• SIGRID TM V5 (basic process engineering functions and basic

function elements)

• BATCH X-TM (program system for automation of recipe-controlled batch processes)

• FUZZY TM (configuration of fuzzy controls)

The SIGRID TM V5, BATCH X-TM and FUZZY TM function

blocks belong to software class C.

SIMATIC PCS 7 as well as devices from other

vendors via the PROFIBUS-AG/AG bus system

Standard driver for the SIWAREX M weighing/dosing unit as distributed I/O on

PROFIBUS-DP

cycles

module data on PROFIBUS-DP

blocks for use with SIMOVERT, MICRODRIVES, SIPART DR, FM 350, CEAG devices

User function blocks

If the standard function blocks are insufficient to fulfil the control,

operation, monitoring and communication tasks, the TML process language (TELEPERM M Language) can be used for analog and binary processing operations, and the STEP M control

language for binary logic operations. TML and STEP M can be

used to define new function blocks optimally tailored to the respective automation task.

Functions which can only be solved with difficulty using standard function blocks, e.g. optimization, startup and shutdown, or

open-loop controls, can be solved more simply using these optimized function blocks.

TML language

TML is used to produce more complex blocks for comprehensive analog, binary and character processing functions with individual test and processing algorithms. TML is particularly

suitable if many functions of the same type are to be linked with

different signals, addresses or parameters (multiplex system).

STEP M language

Binary functions such as linking, saving and time delays are required for sequential and logic controls. The main component of

STEP M is the logic operation with which scanning, linking, setting, resetting and assignment instructions can be formulated.

Parts of the program which are used repeatedly can be transferred into subroutines.

2/4

Siemens PLT 112 · 2002

Page 14

This catalog is out of date, see note on page 3

System architecture

System software

■

Configuration

Listing of TELEPERM M standard function blocks

Data blocks

Typ e Na me Function

GA Data block for glo-

bal analog values

GB Data block for glo-

bal binary values

GM Data block for glo-

bal flags

GT Data block for glo-

bal times (timer)

FA Data field block for

analog values

FSA Data field block for

analog values

FB Data field block for

binary data

FC Data field block for

characters

Blocks for analog and digital processing

Typ e Na me

SUM Adder

MUL Multiplier

DIV Divider

RAD Square root extrac-

tor

LN Logarithm extractor

EXP Exponential value

ABS Absolute value X = | X |

INT Integrator

DIF Differentiator

PT Delay

TOZ Dead time

MIN Minimum-value

selection

MAX Maximum-value

selection

TOB Dead band

PLG Progression block

GW Limit monitor

ASL Analog-value switch

SPEI Analog-value moni-

tor

Storage of 256 analog values with error

-9

;

10

storage of process image, historical values etc.

Saving, scanning and linking of

256 binary values;

preferably for binary process inputs and

outputs

Saving, scanning and linking of 256 internal binary statuses

Saving and generation of times/timers for

execution of time-dependent functions

Saving of internal/external analog values

with error 10

results;

extension of GA block

Saving of internal/external analog values

with error 10

results

Saving of internal/external binary values;

extension of GB/GM blocks

Saving of alphanumeric characters

(texts)

Function

Y = X1 + X2 - X3 - X4

Y = X1 ⋅ X2

Y = X1/X2

Y= sqrt (X) or

Y = K

Y = KF ⋅ In | X |

Y = e

Y = K ⋅ integral (X) dt, K = 1/T

Y(s)/X(s) = (T ⋅ s)/(1 + (T ⋅ s/v))

Y(s)/X(s) = 1/(1 + T ⋅ s)

Y(s)/X(s) = e

Y = minimum of X1, X2, X3

Y = maximum of X1, X2, X3

Y = X - TOBU for X < TOBU

Y = 0 for TOBU

Y = X - TOBU for X > TOBO

Linear interpolation between 6 pairs of

turning points

Limit check between 2 switching points

Y = X1 for S = "0"

Y = X2 for S = "1"

Saving of max. 256 analog values

-9

; preferably for internal

-4

; preferably for internal

⋅ sqrt (X)

x

-s ⋅ T

≤ X ≤ TOBO

Blocks for binary processing

Typ e Na me Function

VU AND

VO OR

VN Negation

VM Flag

VZ Time delay

VS +

STEP M block

STEP

MPX Multiplexer

BW Binary selection

INKU Increment converter

BCE BCD input

BCA BCD output

KA Sequence start

KAK Sequence start

KB Sequence

KBK Sequence

KS Sequence step

KV Sequence branch

KE Sequence end

KEK Sequence end

HA Auxiliary oil

EAR Single analog-value

marshalling

EBR Single bit marshal-

ling

UBR Universal binary

marshalling

A = E1 AND E2 AND E3

A = E1 OR E2 OR E3

A = NOT E

Flag of binary input signals (flip-flop)

Delay for switching on and off

Freely programmable in STEP M

To supply the STEP commands in the following VS/KS block

Selection of status combination from

max. 3 binary signals

Converts analog values into opening or

closing pulses

Conversion of a BCD signal into an analog value

Conversion of an analog value into a

BCD signal

Marks the beginning of an ON/OFF

branch of a subgroup control

As KA, with additional functions

Conditions of a control step, for power

plant systems

As KB, with additional functions

As KB, for process engineering systems

Branching of a sequence into max. 6

branches, with process engineering systems

Last block in a sequence

As KE, with additional functions

Controls electric auxiliary oil pumps for

supply of bearing oil to aggregates

Allocates analog values from block outputs in GA blocks

Links individual binary outputs to GB/GM

data blocks

Links 16 binary blocks to GB/GM data

blocks

Siemens PLT 112 · 2002

2/5

Page 15

System architecture

System software

This catalog is out of date, see note on page 3

Blocks for processing with standardized operation and

monitoring

Typ e Na me Function

R Controller

RN Controller

M Data monitoring

VRatio

B Operator communi-

cation

S Control circuit

G Subgroup control

GK Group control

A Output for binary

data

F Window block

FN Window block

TTrend

SR Recorder

C Switchover

PKM Message recording

PKF Message sequence

display

PID controller, e.g. for disturbance variable feedforward; tracking of setpoint

and manipulated variable; limit generation

As R, with additional functions

• Monitors a measured value for 3 pairs of

limits

• Extension of controller block for limit

monitoring

• Limiting of measured value to error limits

• Generation of a ratio, e.g. with ratio control

• Proportional adjuster, e.g. with synchronization control or for influencing the

command variable of a cascade

• Display of analog values (e.g. internal

results)

• Modification of analog and binary values (e.g. input of constants)

Operation and monitoring of a sequence

in process engineering systems

Operation and monitoring of sequences

in power plant systems

As G, with additional functions

Display and modification of a binary

value

Display of 5 measured values; each of

the 5 values is monitored for a pair of limits

• Display and limit monitoring of 5 measured values

• Input of 5 pairs of limits with associated

hysteresis and of 5 measuring ranges

for the display

• Display of the trend of two measured

values as a bargraph; timebase between 1.625 s and 36 h

• Display on commissioning terminal or in

PROGRAF AS+/NT engineering tool

• Summary of max. 4 series of measurements displayed as dashed curves on

screen; 4 pairs of limits for monitoring

the measured values

• Display on commissioning terminal or in

PROGRAF AS+/NT engineering tool

For switching over of binary signals, e.g.

manual/automatic mode

Records configured messages from

binary input module/GB block

• Output of PKM messages; new messages of PKM blocks

• Display on commissioning terminal or in

PROGRAF AS+/NT engineering tool

Blocks for signal exchange via the CS 275 or PROFIBUS-TM

system bus

Typ e Na me Function

AKS Analog coupling

and transmitter

block

AKE Analog coupling

and receiver block

BKS Binary coupling and

transmitter block

BKE Binary coupling and

receiver block

ZKS Character coupling

and transmitter

block

ZKE Character coupling

and receiver block

MKS Signal coupling and

transmitter block

MEL Signalling

SKS Status coupling and

transmitter block

PLPS Read and write

parameters

Transmission of max. 28 analog values

and abbreviated time (minutes and seconds) from an automation system to

max. 6 or 32 receivers (AKE blocks)

Reception of max. 28 analog values via

the system bus from the data set of an

AKS block of another bus station

Transmission of max. 128 binary signals

and abbreviated time from an automation

system to max. 6 or 32 receivers (BKE

blocks)

Reception of max. 128 binary values via

the system bus from the data set of a

BKS block of another bus station

Transmission of max. four S16 strings

from an automation system to max. 6 or

32 receivers (ZKE blocks)

Reception of max. four S16 strings from

another automation system

Transmission of 32 binary signals as

messages (with time of signal change

→ "1“ or "1“ → "0“) to other bus

from "0“

stations

Output of configured plain text messages

with time (resolution 1 s)

Transmission of status information to

higher-level systems (operation and monitoring systems, computers)

Read or write up to 20 parameters with a

bus-coupled AS 388/TM or AS 488/TM

system

2/6

Siemens PLT 112 · 2002

Page 16

This catalog is out of date, see note on page 3

Blocks for distributed process I/Os on the PROFIBUS-DP

fieldbus

Typ e Na me Function

DPAE Analog input DP

DPAA Analog output DP

DPBE Binary input DP

DPBA Binary output DP

SIWA SIWAREX M

DP4E 4-byte analog-value input

DP4A 4-byte analog-value output

HMI HMI server block

PAAI Analog input for PROFIBUS-PA

PAAO Analog output for PROFIBUS-PA

PADI Discrete-value input for PROFIBUS-PA

PADO Discrete-value output for PROFIBUS-PA

KRIP, RIP IP 262 driver block

Acquisition of analog signals via the distributed process

I/O modules

Output of analog signals via the distributed process

I/O modules

Acquisition of binary signals via the distributed process

I/O modules

Output of binary signals via the distributed process

I/O modules

Reloadable driver block for integration of SIWAREX M

weighing and dosing electronics for custody transfer

into the TELEPERM M process control system

Recording of analog values of type IEEE/S7 floatingpoint numbers, S5 floating-point numbers and 4-byte

integers from S7, S5 and external stations

Output of analog values of type IEEE/S7 floating-point

numbers, S5 floating-point numbers and 4-byte integers

to S7, S5 and external stations

Block for interfacing of panels based on Windows CE

(e.g. OP170B/MP270/MP370)

Recording of analog and status values of a

PROFIBUS-PA field device (transmitter)

Output of analog and status values as well as readback

of analog and binary statuses of a PROFIBUS-PA field

device (representative for actuators, drives, controllers,

etc.)

Recording of discrete values including the status value

of a PROFIBUS-PA field device

Output of discrete and status values as well as readback

of binary statuses of a PROFIBUS-PA field device (representative for actuators, drives, controllers etc.)

Interfacing of IP 262 closed-loop control module via

PROFIBUS-DP

System architecture

System software

Blocks for PLC/PLC coupling with PROFIBUS-AG/AG

Typ e Na me Function Interface

S5KS

[AGAG]

S5KE

[AGAG]

Transmitter and coupling block for connection of

SIMATIC S5/S7 automation systems

Receiver and coupling block for connection of

SIMATIC S5/S7 automation systems

Data transfer to PLC/AS via PROFIBUS-AG/AG,

standard driver with extended functions for PLC/PLC

coupling

Data reception from PLC/AS via PROFIBUS-AG/AG,

standard driver with extended functions for PLC/PLC

coupling

IF 964-DP

IF 964-DP

Siemens PLT 112 · 2002

2/7

Page 17

This catalog is out of date, see note on page 3

System architecture

System software

Driver blocks for I/O modules of the TELEPERM M system

via the TPM 478 communications module

Typ e Na me Function For modules with

AE Analog input

Suitable for PROFIBUS-DP

process image

Not with SIMATIC S7 I/O modules

AR Analog input marshalling

AA Analog output

Suitable for PROFIBUS-DP

process image

BEI Binary input

BRA Binary marshalling

Suitable for PROFIBUS-DP

process image

BAU Binary output

RZ Input block for dual-channel

controllers

RZA Output block for dual-channel

controllers

BU8 Binary transmitter monitoring

block

BU16 Binary transmitter monitoring

block

ZE Metered pulse input

E110 Binary input for SIMATIC S5 input

modules

Suitable for PROFIBUS-DP pro-

cess image

A110 Binary output for SIMATIC S5

output modules

Suitable for PROFIBUS-DP pro-

cess image

S5KE Coupling to SIMATIC S5/

S7 programmable controllers

- receive -

S5KS Coupling to SIMATIC S5/

S7 programmable controllers

- transmit -

MSB Motor/valve and actuator control

TVB Preselection and subloop control

BRBK Organization and binary input

and output block

ABR Analog input and output

Acquisition of an analog signal via a channel of an analog input module

(0 to 20 mA, 4 to 20 mA, 0 to

couples) or an analog input module of the SIMATIC S5 programmable controller

systems (series U)

Acquisition of 8 analog process values, conversion into physical variables;

saving in GA blocks or direct linking

Output of an analog signal via a channel of an analog output module or an

analog output module of the SIMATIC S5 programmable controller systems

(series U)

Acquisition of binary signals via a binary input module; saving of binary signals

in the GB block

Acquisition of 8 binary signals via a binary input module; allocation of signals

to defined linking addresses

Output of max. 32 binary signals to a binary output module 6DS1 603-...

Acquisition of analog and binary signals from a channel of a dual-channel

controller module

Transfer of positioning increment DY or setpoint increment DW coming from a

controller block R or RN to a channel of a controller module

Acquisition and monitoring of 8 binary signals via a binary input module 6DS1 620-8AA

Acquisition and monitoring of 16 binary signals via a binary input module 6DS1 600-8AA

Acquisition of a channel of a metered pulse input module 6DS1 607-8AB

Reading in of 16 binary values from an interface module for input modules of the

SIMATIC S5 programmable controllers S5-110 or for input modules of the

SIMATIC S5 programmable controller systems (series U) or for standard binary

input modules

Output of 16 binary values from an interface module for output modules of the

SIMATIC S5 programmable controllers S5-110 or for output modules of the

SIMATIC S5 programmable controller systems (series U) or for standard binary

output modules

Acquisition of signals from the interface module via telegrams with point-to-point

connection, standard driver

Transmission of signals to the interface module via telegram with point-to-point

connection, standard driver

Acquisition and transfer of binary signals to the binary calculation module 6DS1 717-8AA/-8RR

Acquisition and transfer of binary signals to the binary calculation module for

operation and monitoring of a preselection or subloop control

Acquisition of binary signals from the flag area of the binary calculation module,

coordination together with ABR, MSB or TVB

Acquisition and transfer of analog signals via the binary calculation module to

the analog extension module

±10 V; Pt 100 resistance thermometers, thermo-

Order No.

6DS1 701-8AA, -8AB

6DS1 730-8AA

6DS1 731-8AA/

-8BA/-8EA/-8FA/-8RR

6DS1 703-8AB, -8RR

6DS1 321-8AA

coupling module

6DS1 700-...

6DS1 701-8AA, -8AB

6DS1 730-8AA

6DS1 731-8AA/

-8BA/-8EA/-8FA/-8RR

6DS1 703-8AB, -8RR

6DS1 321-8AA

coupling module

6DS1 700-...

6DS1 702-8AA, -8RR

6DS1 321-8AA

coupling module

6DS1 601-...

6DS1 602-...

6DS1 615-8AA

6DS1 601-...

6DS1 602-...

6DS1 615-8AA

6DS1 604-8AA

6DS1 605-8BA

6DS1 402-...

6DS1 403-...

6DS1 402-...

6DS1 403-...

6DS1 621-8AA

6DS1 310-8AA/-8AB

coupling module

6DS1 321-8AA

coupling module

6DS1 600-8AA

6DS1 601-8BA

6DS1 602-8BA

6DS1 615-8AA

6DS1 310-8AA/-8AB

coupling module

6DS1 321-8AA

coupling module

6DS1 603-8BA

6DS1 604-8AA

6DS1 605-8BA

6DS1 333-8AB

coupling module

6DS1 333-8AB

coupling module

6DS1 719-8AA/-8RR

6DS1 717-8AA/-8RR

6DS1 717-8AA/-8RR

6DS1 717-8AA/-8RR

6DS1 720-8AA

2/8

Siemens PLT 112 · 2002

Page 18

This catalog is out of date, see note on page 3

System architecture

System software

Blocks for I/O modules with standardized display

Typ e Nam e Function For modules with Order No.

RE Controller, single-channel

RK Controller, single-channel

EM Individual control drive, motor

EU Individual control drive, motor

EV Individual control drive, valve

EK Individual control drive, valve

DZ Proportional counter

EG Individual control drive modules

(4 to 8 channels)

Acquisition of signals from single-channel controller modules;

transfer of commands and standardized increments to the controller modules

As RE, with additional functions 6DS1 400-8BA

Acquisition of signals from the individual control drive modules

and passing on of signals to the binary outputs, e.g. for a subgroup control; transfer of commands to the individual control drive

modules

As EM, with additional functions 6DS1 500-8BA

As EM, for the corresponding modules 6DS1 501-8BA/

As EV, with additional functions 6DS1 501-8BA/-8BB

Acquisition of signals from proportional counter modules

(2/4 channels), connection of these signals to the block outputs;

transfer of commands and standardized analog values

Acquisition of signals from modules, connection of these signals

to the binary outputs; transfer of commands

6DS1 400-8BA

(S controller)

6DS1 401-8BA

(K controller)

(S controller)

6DS1 401-8BA

(K controller)

6DS1 500-8BA

6DS1 502-8BA

6DS1 502-8BA

-8BB

6DS1 503-8BA

6DS1 503-8BA

6DS1 613-8BB

6DS1 504-8AA

6DS1 505-8AA

Organization blocks

Typ e Na me Function

XB Processing, cyclic

XA Processing, acyclic

XZ Time start

FUTA Function keys

RNAM Name change

APRO

+

PROB

Test blocks

Typ e Na me Function

TANZ Test display

TUEB Test monitoring

WART Test and maintenance

TML connection (connection

of PROBLEM blocks)

For disabling/enabling a group of function blocks and for

enabling each n-th cycle

For disabling/single enabling a sequence of function blocks.

When installed in the alarm level (ZYK 1) as an ALARM block:

1 x processing of subsequent block sequence

For time-dependent switching on/off of blocks and block

sequences

For switching on/off of blocks and block sequences using operator input

Modification of type or block name

For "insertion" of an application-specific TML program into the

sequence list

Monitoring of binary and analog variables;

selective modification of variables possible

(max. 16 analog variables and 16 binary variables within a standard display)

For sequence monitoring of TML programs:

• Cyclic sequence monitoring

• Single monitoring of a program cycle

(up to 248 TML programs can be monitored)

Menu-based calling of maintenance subroutines (switchover of

XB, status of coupling block, activate error message, TML)

Siemens PLT 112 · 2002

2/9

Page 19

This catalog is out of date, see note on page 3

System architecture

Commissioning

■

Overview

A commissioning terminal is required for commissioning and

system configuring of the AS 488/TM or the CS-L2 bridge. A personal computer/programming device with the commissioning

terminal software ASBEDIEN belonging to the system software

can be used as the commissioning terminal. The commissioning

terminal software is delivered in two versions for MS-DOS and

Windows NT operating systems.

Commissioning terminal

The commissioning terminal is required for the following tasks:

• System configuring for bus communication and I/Os

• To edit initialization files on the memory card, e.g. to set the bus

and station addresses

• To describe hardware configurations, e.g. I/O stations on the

PROFIBUS-DP fieldbus and their configuration (see Section

"Process I/Os").

• Archiving of user software on the memory card

• Commissioning

• Downloading of initialization and driver software onto the memory card, e.g. for the 2nd PROFIBUS-DP line, for SIWAREX M

or PLC/PLC coupling, and for the IP 262 in ET 200U.

Together with the commissioning terminal software belonging to

the system software, any personal computer/programming device can be used as the commissioning terminal if it satisfies the

following requirements:

DOS version of commissioning terminal software

• CPU with 80386, 80486 or Pentium processor

• Vacant main memory min. 320 Kbyte

• VGA graphics (min. resolution 640 x 480)

• One vacant serial COM port

• MS-DOS operating system version 5.0 or later for commissioning terminal software

• Microsoft Windows 3.1 or Windows for Workgroups 3.11 operating system for the COM PROFIBUS configuring software

(if required, see Section "Process I/Os").

NT version of commissioning terminal software

• CPU with Pentium processor

• Vacant hard disk capacity approx. 5.1 Mbyte

• One vacant serial COM port

• MS-DOS operating system version 5.0 or later for commissioning terminal software

• Microsoft Windows NT (V 4.0 or later) or Windows 2000 operating system.

Both versions are included in the delivery of the system software.

■

Design

Cable for connection of the commissioning terminal

The commissioning terminal for the AS 488/TM automation

systems and the CS-L2 bridge is connected via a cable

6ES7 902-... to the IF 962-COM serial interface module in the

CPU.

IF 962-COM serial interface module

The IF 962-COM serial interface module is required to connect a

commissioning terminal to an AS 488/TM automation system

and to the CS-L2 bridge. It is inserted into the system CPU.

Notes on operation of the commissioning terminal

The commissioning terminal supports use of the known operation and monitoring interface of the automation system for commissioning and servicing purposes, but without offering the

quality of an operation and monitoring system.

The commissioning terminal can be permanently connected to

the automation system. The serial data transmission rate is

19.2 kbit/s.

Communication between the AS and the commissioning terminal is automatically resynchronized following an interruption,

e.g. as a result of message interferences.

For diagnostics purposes or for setting parameters, AS operations according to AS 235 conventions are also possible using

the commissioning terminal. However, the operation/configuration of another automation system using the AS bus configuring

channel is not permissible. As a result of the serial interface, the

commissioning terminal is certainly not an adequate substitute

for an operator system or engineering system.

The AS and PC systems must be electrically isolated from one

another if the distances between the earth potentials are greater

than 10 m.

■

Ordering Data

Connecting cable for commissioning terminal

SIMATIC S7/M7 cable for point-topoint connections RS 323 C RS 232 C, in each case with

9-contact Sub-D socket

•5m long

• 10 m long

IF 962-COM serial interface

module

for commissioning terminal,

with two RS 232 interfaces

Order No.

6ES7 902-1AB00-0AA0

6ES7 902-1AC00-0AA0

6ES7 962-3AA00-0AC0

2/10

Siemens PLT 112 · 2002

Page 20

This catalog is out of date, see note on page 3

■

Overview

PROGRAF AS+/NT is a powerful PC-based engineering tool for

the TELEPERM M AS 230/230 K and AS 235/235 K/235 H as

well as AS 388/TM and AS 488/TM automation systems (including the AS 488 S and AS 488 K versions with a varying design).

It is equipped with a convenient graphical user interface based

on Microsoft Windows NT 4.0/2000/XP. This tool permits significant simplification, acceleration and rationalization of engineering, testing and commissioning, software updating and

documentation, as well as training.

PROGRAF AS+/NT can be used to graphically configure, test,

optimize and document the application software of the

TELEPERM M automation systems. In contrast to comparable

products from other vendors, PROGRAF AS+/NT also permits

reading, recompilation and subsequent further graphical processing or documentation of the structures of already installed

automation systems. Features such as the function diagram editor with online testing and curve display, the libraries for elements for repeated use, and the import functions make

PROGRAF AS+/NT an indispensable aid for AS engineering.

PROGRAF AS+/NT also offers operation and monitoring facilities

on the CS 275 system bus, corresponding to local operation of

an AS 235.

PROGRAF AS+/NT supersedes the proven PROGRAF AS+ engineering tool which only executes on the Microsoft Windows 3.1

operating system. The new tool has complete function and data

compatibility with the previous product. User data generated

with PROGRAF AS+ can be processed further with

PROGRAF AS+/NT, and vice versa.

As a result of its versatile functions as well as supporting of testing, commissioning and optimization, PROGRAF AS+/NT is particularly suitable

• for TELEPERM M customers carrying out self-configuring,

• for consultants specialized in TELEPERM M configuring, and

• for Siemens-internal configuring, testing and commissioning

departments.

Bus connection

PROGRAF AS+/NT supports the new N-PCI (for CS 275 system

bus) and CP 5613 (for PROFIBUS-TM system bus) bus interface

modules envisaged for PCI slots. The DP-5613/Windows NT 4.0,

2000 PRO/V2.1 software, Order No. 6GK1 713-5DB21-3AA0, is

additionally required for the PROFIBUS-TM connection using

CP 5613.

Just like PROGRAF AS+, the PROGRAF AS+/NT can also be

used together with the N-AT (for CS 275 system bus) and

CP 5412(A2) (for PROFIBUS-TM system bus) bus interface

modules designed for ISA slots.

Note:

The CP 5412(A2) communications processor is still available under Order No. 6GK1 541-2BA00. You additionally require the

DP-5412/NT 4.0 software, Order No. 6GK1 702-5DW52-3AA0.

System architecture

Engineering with PROGRAF AS+

■

Functions

The PROGRAF AS+/NT program features the following functions:

Powerful graphic function diagram editor

The function diagram editor provides a hierarchical breakdown,

zoom functions, and fully-automatic generation of connection

lines, connectors and margins.

All standard function blocks are available as well as user function blocks generated using PROGRAF AS+/NT or read out of an

automation system.

PROGRAF AS+/NT provides a breakdown into function areas,

function groups and function diagrams for individual process

functions in order to map hierarchical identification systems. The

window system permits two pages to be displayed on the

screen, e.g. in order to link function blocks from different groups.

One of the most important functions is the autorouter which rapidly and automatically draws the links between function blocks.

If a block is shifted - even onto another page - the autorouter automatically updates the connection lines, connectors and also

the contents of the margins.

Closed data cycle

All entered user data are immediately checked by the integral

database, and saved centrally. Subsequent modifications can

always be read into PROGRAF AS+/NT and updated there automatically. The data thus remain consistent in both systems.

The database uses this information to automatically generate a

loading sequence with instructions for the automation system.

This loading sequence is transmitted to the automation system

via the system bus.

It is also possible to load an AS-RAM dump read using

PROGRAF AS+/NT into an AS 488/TM using the commissioning

terminal, or, in the opposite direction, to read an AS-RAM dump

using the commissioning terminal and to transfer this to

PROGRAF AS+/NT.

Siemens PLT 112 · 2002

2/11

Page 21

System architecture

Engineering with PROGRAF AS+

This catalog is out of date, see note on page 3

Configuration of customer-specific and branch-specific libraries

PROGRAF AS+/NT can be used to generate customer-specific

or branch-specific libraries with elements which are used repeatedly when configuring. This is also possible for several

workstations with PC network support.

These library elements include process functions, user function

blocks and programs.

When storing on a server, central libraries can be produced for

networked PCs, thus permitting several engineers to access the

current library objects.

Special library elements in PROGRAF AS+/NT are the so-called

standard diagrams with which identical or similar AS functions

can be rapidly generated.

Standard diagrams are generated by transferring an individual

function diagram into a library. They are automatically assigned

general diagram variables. The configuring engineer can also

define his own variables. The desired standard diagrams can be

called from the library and assigned the respectively required

data for the variables.

Complete, automatically generated documentation

Complete documentation includes the following individual documents:

• List of contents

• Graphic documentation of block configurations (function diagrams)

• Graphic function diagrams of the STEP programs

• Structograms of the TML programs for user function blocks

• Documentation of TML and STEP programs and process display instructions in the form of lists

• Documentation of the block sequence, the blocks not inserted

into the processing sequence, as well as the driver and coupling blocks in the form of lists

• Various cross-reference lists.

The documentation is independent of whether

PROGRAF AS+/NT was used for configuring or whether the data

have been read out of an automation system and decompiled.

Documentation of individual parts of the AS configuration is also

possible.

Central workstation for control engineer

Complete configurations, delta loading lists (only changes in

configuration) and partial configurations (for test purposes) can

be loaded by PROGRAF AS+/NT into the automation systems.

PROGRAF AS+/NT also permits the central exchange of

AS-RAM dumps with the PC. The user data can then be read

from the automation system into PROGRAF AS+/NT, stored

there centrally as a file, and reloaded back into the automation

system.

During the commissioning phase, PROGRAF AS+/NT is the central engineering workstation for the control engineer. A local

AS configuration desktop is emulated on his monitor like with the

AS 235 system (AS terminal emulation). The process variables

are updated cyclically.

Central online commissioning

with AS terminal emulation and display of dynamic values and

curves directly in the function diagram editor, e.g. for optimization of control loops. Up to four process values can be displayed

as curves. Parameters modified in this online mode can also be

written into the database of PROGRAF AS+/NT in order to guarantee data consistency.

Data import and export

There are external interfaces from the database: data from external planning tools can be imported into PROGRAF AS+/NT.

Cross-reference data can be generated and exported in the process for the configuring tools of the OS 265-3, OS 520, OS 525

and PCS7/TM-OS operator systems.

■

Technical Specifications

Hardware requirements

• Graphics card resolution min. 1024 x 768, min. 32768 colors

• High-resolution color monitor; for ergonomic reasons we recommend a screen diagonal of at least 19 inches (49 cm)

• 3.5" diskette drive as well as a 5.25" drive for reading the AS

diskettes

• PostScript laser printer.

Software requirements

• MS Windows NT 4.0 or MS Windows 2000 or Windows XP operating system

Note: no operating system software is included in the delivery

of PROGRAF AS+/NT.

Automation systems released for PROGRAF AS+/NT:

• AS 230, AS 230 K, AS 235, AS 235 K, AS 235 H as well as

AS 388/TM and AS 488/TM automation systems

• The system software release F3.02 is required for unlimited use

of PROGRAF AS+/NT with the above-mentioned AS 23x automation systems.

The following limitations otherwise apply:

• With AS 230, version B, C or D, the AS diskette format must first

be converted to the format of the AS 230, version E.

• Bus-coupled operation of PROGRAF AS+/NT is not possible

with AS 230/230 K, version B, C, D or E.

2/12

Siemens PLT 112 · 2002

Page 22

This catalog is out of date, see note on page 3

System architecture

Engineering with PROGRAF AS+

■

Ordering Data

PROGRAF AS+/NT

comprising:

• 1 software CD with program

package in German and English

• Software protection (dongle)

PROGRAF AS+/NT upgrade

for PROGRAF AS+, comprising

software CD with program package in German and English as

well as software protection (dongle)

• From version V2.x/V3.x to version V4.x

• From version V4.0 to version

V4.x

PROGRAF AS+ Instructions

(German)

PROGRAF AS+ Instructions

(English)

Order No.

6DL5 255-1CX

6DL5 255-1CX00-4XX4

6DL5 255-1CX00-4XX3

C79000-G8000-C450

C79000-G8076-C450

Accessories

PC components (ISA) for connection to

TELEPERM M system bus

CP 5412 (A2) communications

processor for connection to the

PROFIBUS-TM bus system

comprising:

• CP 5412 (A2)

• Firmware on 3.5" diskette

Order No.

6GK1541-2BA00

Obsolescent product

DP-5412/NT 4.0

Configuring software for CP 5412

(A2) on CD-ROM, executes with

Windows 98 and NT 4.0

Obsolescent product

6GK1702-5DW52-3AA0

PC components (PCI) for connection to

TELEPERM M system bus

CP 5613 communications processor for connection to the

PROFIBUS-TM bus system

comprising:

• CP 5613 (PCI card)

• CD-ROM with driver for Windows NT 4.0 / Windows 2000,

configuration software and electronic manual

DP-5613/NT 4.0

Configuring software for CP 5613

on CD-ROM, executes with

Windows NT 4.0 / Windows 2000

Order No.

6GK1 561-3AA00

6GK1 713-5DB60-3AA0

Siemens PLT 112 · 2002

2/13

Page 23

System architecture

This catalog is out of date, see note on page 3

2/14

Siemens PLT 112 · 2002

Page 24

This catalog is out of date, see note on page 3

AS 488 S Cabinet system