Page 1

Urdaneta

MAMMOMAT Novation

Troubleshooting Guide

System

SP

Mammomat Novation DR

08380490

Print No.:

Replaces: n.a.

SPB7-250.840.01.01.02

© Siemens AG

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 10.05

2005

Page 2

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service procedures.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 2 of 100

Medical Solutions

Page 3

Table of Contents 3

1- 0Table of Contents

1 _______ General Information______________________________________________ 5

Protective measures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Printed circuit boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measurements with the oscilloscope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 _______ Error messages _________________________________________________ 6

Error messages of the master Err 0XX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Error messages of the panel Err 1XX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Error messages of the filament Err 3XX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Error messages of the AEC Err 4XX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Error messages of the FFDM DR System Er 5XX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Error messages of the power pack Err 6XX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Error messages of the OPDIMA Err 7XX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Error messages of the stand Err 8XX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3 _______ Log and error files ______________________________________________ 36

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

SW Version VA10x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Copy MPxxxx files (detector files), dump files and syngo logs . . . . . . . . . . . . . . . . . 37

Copy Array and Brick log files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Windows Eventlog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SW Version VA11x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Copy MPxxxx files (detector files), dump files and syngo logs . . . . . . . . . . . . . . . . . 46

Copy Array and Brick log files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Windows Eventlog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Copy SaveLogs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4 _______ Generator checks ______________________________________________ 56

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Documents required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Troubleshooting tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Signals on D750 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Tube high voltage, current and mAs values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Filament circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5 _______ Image quality __________________________________________________ 74

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Gain calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Bad pixel mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Qualify log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Image examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 3 of 100

Page 4

4 Table of Contents

6 _______ Compression Unit ______________________________________________ 94

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Documents required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Check the adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Check the potentiometer R863 (position transducer) . . . . . . . . . . . . . . . . . . . . . . . . 95

Check the potentiometer R861 (compression force) . . . . . . . . . . . . . . . . . . . . . . . . . 95

Check the movements (up/down) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Check the detection of compression paddle.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7 _______ Changes to the previous version _________________________________ 100

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 4 of 100

Medical Solutions

Page 5

General Information 5

1General Information

2-

Protective measures 0

System power supply 0

Before you begin working on equipment, it is very important that you disconnect it from

the power supply at the main circuit breaker. Before removing or inserting any of the

printed circuit boards, switch off the equipment.

WARNING

If the system is only switched off at the control panel, the line voltage will still be present at the generator line connection (see wiring

diagram).

¹ A life-threatening hazard of electric shock exists.

WARNING

After the system shuts down, there may still be 380 V DC present

on the intermediate circuit.

¹ A life-threatening hazard of electric shock exists

Printed circuit boards 0

CAUTION

The printed circuit boards contain highly electrostatically-sensitive components.

If disregarded, the components could be damaged.

¹ Use ESD equipment, ground prior to making contact, and

place the components on a conductive surface.

Measurements with the oscilloscope 0

WARNING

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

Under no circumstances should the existing ground conductor in

the mains cable be disconnected when operating the oscilloscope.

There is a life-threatening hazard of electric shock.

¹ For measurements in which a resulting ground loop may

affect the measuring result, use the differential amplifier

(difference measurement).

Page 5 of 100

10.05 CS SD 24

Page 6

6 Error messages

2Error messages

3-

Error messages of the master Err 0XX 0

A malfunction detected by the system is indicated by " Err" followed by a three-digit error

code on the kV and mAs displays of the control panel. This can be acknowledged by the

operator pressing the limit button. Exceeded limits are also deleted with the limit button.

Err 004

“Communication master - AEC disturbed or AEC not ready”

Description

If the master processor (D750) can no longer activate the AEC processor via the serial

interface or if any important data from the control deck is missing, the above error message is displayed.

Fault elimination

First check if PC board D750 is plugged in correctly and if the connections to the power

supply and the serial interface (see wiring diagram) are functioning correctly.

If no fault can be found, PC board D750 should be replaced.

Err 005

“Flash in AEC is defective or not correctly initiated”

Description

During initialization, the AEC processor (D750) checks the data stored in its E

2

means of stored checksums. If this data is incorrect or if the E

PROM fails, the AEC pro-

2

PROM by

cessor informs the master processor via the serial interface and the above error message

is displayed.

The master also generates this error if communication has not been established with the

AEC during exposure release.

NOTE

In contrast, error 004 appears if communication started with the

master disturbed.

Fault elimination

Reprogram E2PROM or replace E2PROM or PC board D750. Reprogram using the service PC "Backup" menu.

Err 008

“Communication master - stand disturbed or stand not ready”

Description

This error means that communication between the master processor and unit processor

via the serial interface is faulty or interrupted.

Fault elimination

Check whether the power supply and the serial interface (see wiring diagram) to the unit

are functioning correctly.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 6 of 100

Medical Solutions

Page 7

Error messages 7

Err 011

“Exposure aborted by user”

Description

If the exposure buttons are released prematurely, exposure is aborted immediately. On

the control deck, the LIMIT LED (→0←) lights up, an acoustic signal sounds and the

above error message is displayed.

Fault elimination

This error indication is purely informational and does not require further action. Should it

appear frequently, however, check the contacts of the exposure release buttons. Replace

the exposure release button(s), if necessary.

Err 012

“Time limit reached”

Description

In order to prevent the tube assembly from overloading, a timer runs during exposure.

This is set to the time limit prior to exposure. If this timer runs down, the exposure is

aborted immediately, and the above error message is displayed. Depending on the mode

of operation, the time limit is calculated as follows:

AEC mode

The time limit is the power-dependent load time plus a tolerance value (approx. 400 ms).

mAs mode

The time limit is the calculated exposure time plus a certain reserve. If this period is

shorter than 2 s, 2 s are assumed. If it exceeds 2 s, a reserve time of 400 ms is added.

The time limit can be read off in ms with the service PC in “normal mode” under item “AEC

data”. The value shown here does not include the extra 400 ms.

Fault elimination

The tube current and the filament current must be measured again with the oscilloscope

(test points MA_ACT and FIL_CURR_ACT on D750). The nominal and actual value of the

tube current can be read off with the service PC in normal mode. If the actual tube current

is too low, you must first ensure that the dynamic learn filament current (DLF switch) is

switched on. The tube must be readjusted in any case. Should difficulties still occur, the

tube current actual value acquisition must be checked (see wiring diagram).

Err 013

“mAs limit reached in AEC exposure”

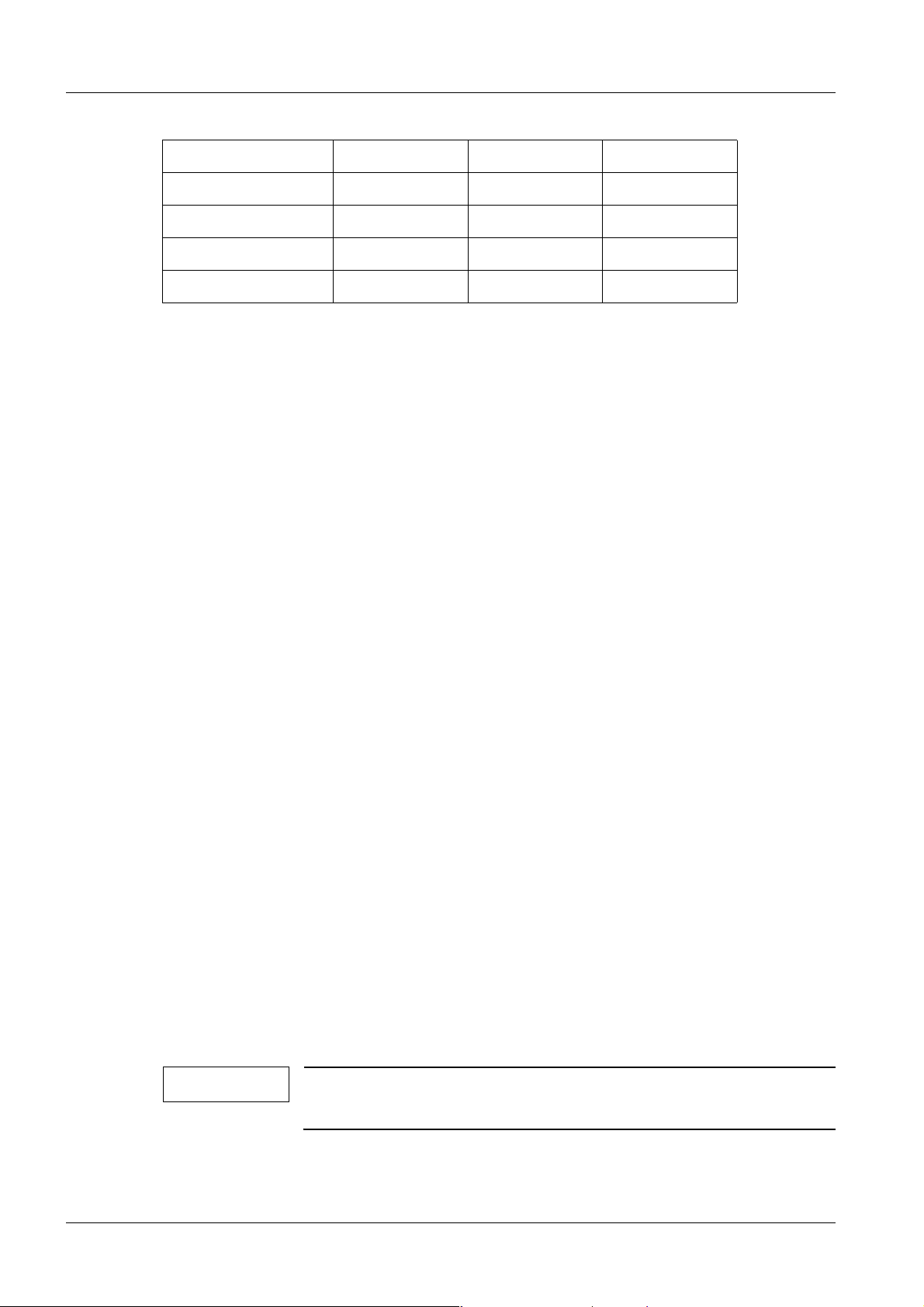

Description

For safety reasons, the accumulated mAs is integrated via the timer independently of the

AEC during AEC exposures. If a focus, tube assembly and kV-dependent time limit (see

table) is obtained without the AEC being switched off, the exposure is aborted and the

above error message is displayed.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 7 of 100

Page 8

8 Error messages

Tube assembly 25 kV 30 kV 35 kV

P40 MoW-100G F1 196 mAs 163 mAs 140 mAs

P40 MoW-100G F2 600 mAs 500 mAs 428 mAs

P40 MoW-100G F3 238 mAs 198 mAs 170 mAs

P40 MoW-100G F4 752 mAs 627 mAs 537 mAs

Fault elimination

The dose signal from the detector or the chamber to the hardware of the AEC (see wiring

diagram) must be checked.

If no error can be detected, PC board D750 or D801 must be replaced.

Err 014

“kV, corrected for dose calculation, is out of range”

Description

The kV value used for glandular dose calculations is the "set kV" adjusted for the actual

HVL value of the tube. This corrected kV value is outside the limits of the lookup tables

used for glandular dose calculations.

Fault elimination

Reload the tube-specific HVL values using the "dose calculation configuration program".

Err 020

“PC message had bad length”

Description

The length of the message sent from the service PC to the MAMMOMAT Novation

DR

is

too long.

Fault elimination

Check that the correct version of the service program is being used.

Err 022

“Receive message from external unit failed”

Description

An error occurred when the MAMMOMAT Novation

DR

was receiving data from the PC or

printer.

NOTE

May occur if the printer is switched on/off while the rest of the system is on.

Fault elimination

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 8 of 100

Medical Solutions

Page 9

Error messages 9

Check the cables and connectors to the PC or printer. Board 750 defective. PC/printer

defective.

Err 024

“PC, ID camera or workstation has not sent ACK/NAK within two seconds. Three

tries are made”

Description

The service PC did not answer.

Fault elimination

Check the cables and connectors to the PC. PC defective.

Err 025

“PC, ID camera or workstation sends NAK three times as response to one and the

same message”

Description

The service PC did not receive information from the master. Timeout occurred and the

service PC responds with NAK.

Fault elimination

1. Reset error on panel and try again.

2. Reset MAMMOMAT Novation

DR

and PC.

Err 030

“Master PLD requests interruption of tube voltage”

Description

The master PLD logic has detected a type of error that is considered fatal and must terminate the exposure.

Fault elimination

1. Reset error on panel and try again.

Err 040

“The radiation protection door is open”

Description

The radiation protection door switch is not active while exposure is being released.

Fault elimination

1. Check the door switch.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 9 of 100

Page 10

10 Error messages

Error messages of the panel Err 1XX 0

Err 105

“Checksum error in installation data stored in panel EEPROM”

Description

Each time the MAMMOMAT Novation

2

PROM on the control deck is checked with a shadow area also stored in the E2PROM.

E

If any discrepancy is detected, the above error message is displayed.

Fault elimination

The installation data can be corrected via the service PC. If this error appears more frequently, exchange the deck PC board D740 and reinstall the parameters in the control

panel; see Service SW Backup/Restore. The opdose parameters have to be programmed

manually via the control deck. For the remaining parameters, use the service PC

"Backup" menu.

Err 106

2

“E

PROM program area error”

DR

is switched on, the installation area in the

Description

When data is stored in the E

2

PROM of the control panel during programming of the

opdose parameters, this is read back once more to check whether it has been stored correctly. If any differences occur, the above error message is displayed.

Fault elimination

2

The E

PROM in the panel must be replaced. If the error still occurs, the whole D740 must

be replaced. In both cases the parameters in the control panel have to be reinstalled. The

opdose parameters have to be programmed manually via the control deck. For the

remaining parameters, use the service PC, backup menu.

Err 107

“No communication panel - master”

Description

If no data transmission takes place between the deck and the master during the first 20 s

after power on, the control deck switches to the so-called “standalone” mode. The keyboard can be operated normally. If the exposure release button is operated in this mode,

the above error message is displayed.

Fault elimination

The cause of this error can be an interruption on the serial interface to the master. For this

reason, this connection must be checked carefully.

Err 121

“The version number of EEPROM and PROM are not the same”

Description

This error applies to the panel.

Fault elimination

Check EEPROM and PROM.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 10 of 100

Medical Solutions

Page 11

Error messages 11

Error messages of the filament Err 3XX 0

Err 303

“Filament current outside limits”

Description

During “Stand-by”, the master checks whether there is any filament current. If the filament

current is not within 10% from nominal of a predetermined value, the above error message is displayed.

Fault elimination

Check fuse F2 (see wiring diagram).

Check filament wires.

Filament of tube assembly defective.

PC board D750 defective.

Err 304

“Filament current over limit”

Description

During “Stand-by”, the master checks whether there is any filament current. If the filament

current does not reach a predetermined value or the filament current exceeds 8.5 A, the

above error message is displayed.

Fault elimination

Check fuse F2 (see wiring diagram).

Check filament wires.

Filament of tube assembly defective.

PC board D750 defective.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 11 of 100

Page 12

12 Error messages

Error messages of the AEC Err 4XX 0

Err 401

“Error during configuration of PLD.”

Description

Configuration of PLD device in AEC failed.

Fault elimination

Check whether Proms are inserted properly

Switch off the MAMMOMAT Novation

DR

MAT Novation

. If the error recurs, replace the D750 circuit board.

Err 402

“Self-test of PLD failed.”

Description

DR

. Wait approx. one minute. Start up the MAMMO-

Gain test of circuit board D750 failed.

Fault elimination

Switch off the MAMMOMAT Novation

DR

MAT Novation

. If the error recurs, replace the D750 circuit board.

DR

. Wait approx. one minute. Start up the MAMMO-

Err 403

“Self-test timeout. Fatal error in PLD’s internal program.”

Description

Timeout occurred in the PLD device in the AEC during gain test of circuit board D750.

Fault elimination

Switch off the MAMMOMAT Novation

DR

MAT Novation

. If the error recurs, replace the D750 circuit board.

DR

. Wait approx. one minute. Turn on the MAMMO-

Err 404

“AEC CPU requests interruption of tube voltage”

Description

The processor in the AEC part of the master board requests termination of high voltage

generation.

Fault elimination

Check the tube power module and the HV inverter module.

Err 405

“AEC PLD cannot perform requested operation because it is busy self- testing”

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 12 of 100

Medical Solutions

Page 13

Error messages 13

The PLD in the AEC part of the master board requests termination of high voltage generation.

Fault elimination

Check the tube power module and the HV inverter module.

Err 406

“PLD cannot perform requested operation because it is busy self-testing.”

Description

The PLD in the AEC cannot perform requested operation because it is performing a

self-test.

Fault elimination

Acknowledge the displayed error and wait approx. one minute.

Err 407

“Time-out error while erasing AEC flash memory”

Description

The D750 contains a memory device called “flash memory”. This memory is used for storing AEC parameters and correction tables. Before writing data into the memory, it is necessary to erase the sector in which data is to be stored. The erasing procedure is

controlled by a timer. If anything goes wrong while erasing the AEC flash memory and a

timeout occurs, an error results.

Fault elimination

Switch off the MAMMOMAT Novation

MAT Novation

DR

. If the error recurs, replace the D750 circuit board.

DR

. Wait approx. one minute. Start up the MAMMO-

Err 408

“Time-out error while writing to AEC flash memory (time-out in waiting for ok indication)”

Description

The D750 contains a memory device called “flash memory”. This memory is used for storing AEC parameters and correction tables. The procedure of writing this data is controlled

by a timer. If anything goes wrong while writing to the AEC flash memory and a timeout

occurs, an error results.

Fault elimination

Switch off the MAMMOMAT Novation

DR

MAT Novation

. If the error recurs, replace the D750 circuit board.

DR

. Wait approx. one minute. Start up the MAMMO-

Err 409

“AEC flash test has locked up (time-out of 15 seconds exceeded)”

Description

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 13 of 100

Page 14

14 Error messages

During start-up of the unit, the AEC performs a number of tests, e.g. testing of the flash

memory device on D750. This testing is controlled by a timer and if something is wrong, a

timeout occurs.

Fault elimination

DR

Switch off the MAMMOMAT Novation

DR

MAT Novation

. If the error recurs, replace the D750 circuit board.

Err 410

“Attempt to start an exposure before AEC flash memory has delivered correction

values”

Description

Before an AEC exposure is released and based on the exposure settings on the panel,

the AEC fetches an estimated dose from a correction table stored in the flash memory. If

the exposure buttons are pressed during a reading operation from the flash memory, an

error occurs.

Fault elimination

. Wait approx. one minute. Start up the MAMMO-

Acknowledge the displayed error. Wait 15 seconds. Try to perform an exposure.

Err 412

“Attempt made to start an exposure while self-testing of the PLD in AEC was in

progress”

Description

Attempt made to start an exposure while a self-test of the PLD in the AEC was in

progress.

Fault elimination

Acknowledge the displayed error. Wait 15 seconds. Try to perform an exposure.

Err 413

“Exposure too short, correction value could not be loaded in time”

Description

An estimated dose is calculated before an exposure is released. The minimum estimated

dose is defined for a minimum object thickness. For a normal object thickness (> 5 mm),

the AEC will calculate a necessary correction value to add to the estimated dose during

exposure. This procedure takes a while, and in the case of particularly thin objects, the

AEC may not be able to determine within the time limit whether a correction is necessary.

An error results due to the small object thickness.

Fault elimination

Acknowledge the displayed error. Change the exposure parameters (e.g. lower kV).

Err 414

“Attempt to release an exposure after the PLD in AEC has failed self-test/ configuration”

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 14 of 100

Medical Solutions

Page 15

Error messages 15

Description

Caused by previously generated errors 401, 402, 403, 409 and not restarting

MAMMOMAT Novation

Fault elimination

Switch off the MAMMOMAT Novation

MAMMOMAT Novation

Err 416

“Estimated dose out of range”

Description

Estimated dose out of range, which can be caused by

- an extreme sensitivity setting

- an extreme sensitivity correction setting

- an extreme density correction setting.

DR

.

DR

. Wait approx. one minute. Start up the

DR

. If the error recurs, replace the D750 circuit board.

This means that the exposure will be terminated by the max. mAs limit.

Fault elimination

Acknowledge the displayed error. Make sure that the correct AEC correction tables are

installed. Check settings for sensitivity, sensitivity correction and density correction.

Err 418

“Attempt to make offset compensation test while in AEC mode”

Description

During an offset compensation test, the AEC board is set to a special test mode and cannot perform an AEC exposure. Because of this, test exposures have to be performed in

the mAs mode during this test.

Fault elimination

Acknowledge the displayed error. Change to mAs and follow the instructions for an offset

compensation test.

Err 419

“Attempt to write to registers of PLD not available during exposure”

Description

This is an internal error that does not interfere with an exposure and is not shown on the

control panel.

Fault elimination

If this error is discovered when reading the error buffer via the service PC, please report it

immediately.

Err 420

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 15 of 100

Page 16

16 Error messages

“Dose or time monitor overflow in PLD”

Description

This is an internal error that does not interfere with an exposure and is not shown on the

control panel. The time and dose values reported by the service PC are not valid.

Fault elimination

If this error is discovered when reading the error buffer via the service PC, please report it

immediately.

Err 421

“Wrong test mode request received by PLD”

Description

This is an internal error that does not interfere with an exposure and is not shown on the

control panel.

Fault elimination

If this error is discovered when reading the error buffer via the service PC, please report it

immediately.

Err 422

“Attempt to read registers of PLD not available during exposure”

Description

This is an internal error that does not interfere with an exposure and is not shown on the

control panel.

Fault elimination

If this error is discovered when reading the error buffer via the service PC, please report it

immediately.

Err 423

“Counters for estimated doses in PLD not initialized in time”

Description

If mAs mode: Internal error that does not interfere with an exposure and is not shown on

the control panel. If AEC mode: Internal error that interferes with an exposure and is

shown on the control panel.

Fault elimination

If mAs mode: If this error is discovered when reading the error buffer via the service PC,

please report it immediately.

If AEC mode: Acknowledge the displayed error. Wait 15 seconds. Try to perform an

exposure.

Err 450

“Exposure aborted by dose monitoring”

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 16 of 100

Medical Solutions

Page 17

Error messages 17

Description

An AEC exposure could not be performed due to insufficient dose rate.

Fault elimination

Acknowledge the displayed error. Change the exposure parameter settings (e.g. higher

kV).

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 17 of 100

Page 18

18 Error messages

Error messages of the FFDM DR System Er 5XX 0

Err 501

“DR detector request interruption of tube voltage”

Description

The HW signal DR_DET_RDY_FOR_EXP has become inactive during exposure.

Fault elimination

Check the plugs and connections at board D750.

Err 502

“DR system request interruption of tube voltage”

Description

If the exposure buttons are released prematurely, exposure is aborted immediately.

The HW signal DR_SYST_RDY has become inactive during exposure.

Fault elimination

Check the plugs and connections at board D750.

Err 503

“Master does not sense DR signal level change within specified times”

Description

At exposure start, the HW signal DR_DET_RDY_FOR_EXP is not activated within the

specified time.

Fault elimination

Check the plugs and connections at board D750.

Err 504

“Master senses an error within the DR system”

Description

The HW signal DR_DET_ERR has been activated.

Fault elimination

Check the plugs and connections at board D750.

Check the switch S1 on grid drive.

Err 506

“Master senses a tube arc during the AEC pre exposure when in DR mode”

Description

A tube arc has occurred during the AEC pre-exposure. No tube arc is allowed during the

AEC pre-exposure.

Fault elimination

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 18 of 100

Medical Solutions

Page 19

Error messages 19

N/A

Err 578

“mAs exceeds maximum”

Description

The calculated AEC main exposure mAs value returned from the DR system exceeds the

maximum mAs value that the MAMMOMAT Novation

Fault elimination

Check AEC functioning

Err 579

“Master is not updated with the mAs value for the main exposure in AEC mode”

Description

The mAs value for the main exposure has not been calculated/transmitted by the DR system or received by the MAMMOMAT Novation

DR

Fault elimination

DR

can handle.

within the specified time.

Check the plugs and connections at board D750.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 19 of 100

Page 20

20 Error messages

Error messages of the power pack Err 6XX 0

Err 601

“Rotation speed not reached within 3s”

Description

During starting of the rotating anode, the master counts the control pulses and compares

them with a ‘tube assembly and intermediate circuit voltage’-dependent table value. If this

is not reached within 3 s, err 601 is displayed.

Fault elimination

Check oscillation current (see wiring diagram). Rotating anode cable or stator defective.

Err 602

“kV

Displayed on PC: kV

- minimum tube voltage 17 kV not reached”

min

-minimum tube voltage 17kV not reached

min

Description

If 17 kV is not reached within 250 ms after the KVE signal, the above error message is

displayed.

Fault elimination

Intermediate circuit voltage too low (see wiring diagram).

Tube current or power too high. See also (Tube high voltage, current and mAs

values / p. 63)

Check oscillation current (see wiring diagram).

SS relay not pulled up (see wiring diagram).

“kV

” too low.

nom

Board D750 defective.

Err 603

“kV

- tube voltage greater than 50 kV”

max

Description

During exposure, a threshold switch in the kV controller monitors whether the high voltage

exceeds 50 kV. If this is the case, the exposure is aborted immediately via the KVA lead.

Fault elimination

Check the kV nominal value. Check tube current and power, see also (Tube high voltage,

current and mAs values / p. 63). Actual value acquisition defective (see wiring diagram).

Replace PC board D750.

Err 604

“WR Austast - inverter short circuit blanking signal remains”

Description

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 20 of 100

Medical Solutions

Page 21

Error messages 21

When I

(Overcurrent) in the inverter is exceeded, the control is interrupted for 200 ms.

max

The software then checks whether the blanking signal is still applied. If this is the case,

the above error message is displayed.

Fault elimination

Transistor module in HV inverter defective. Check tube current and power, see also (Tube

high voltage, current and mAs values / p. 63). Check fuse (F2) . Stator short circuit. Board

D750 defective.

Err 606

“Inverter short circuit during radiation”

Description

HV-Inverter overcurrent during exposure sequence.

Fault elimination

Transistor module in HV inverter defective. Check fuse (F2).Check tube current and

power, see also (Tube high voltage, current and mAs values / p. 63)

Stator short circuit.

Board D750 defective.

Err 607

“Inverter short circuit during brake cycle”

Description

Actual tube voltage deviates by more than 5% from nominal value at the start of the exposure.

Fault elimination

Transistor module in HV inverter defective. Check fuse (F2).Check tube current and

power, see also (Tube high voltage, current and mAs values / p. 63). Stator short circuit.

Err 608

“Tube current is outside limits”

Description

Actual tube current deviates by more than 10% from nominal at the start of exposure.

Fault elimination

Transistor module in HV inverter defective. Check fuse (F2).

Stator short circuit.

Err 611

“KVA signal disabled during radiation”

Description

During exposure, KVA becomes “H” and the inverter is thus enabled. If this enabling fails,

the above error message is displayed.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 21 of 100

Page 22

22 Error messages

Fault elimination

Check KVA lead (see wiring diagram). Board D750 defective.

Err 620

“U

+15V to control inverter not present”

anst

Displayed on PC: U

+15V to control inverter not present

anst

Description

The DC bus voltage used for powering the modules of the generator assembly is too low

or too high.

Fault elimination

Check the power supply and fuses.

Err 630

“PH1 pressure switch on the HV tank activated”

Description

the HV actual value does not correspond to the HV set value. The above error message is

displayed.

Fault elimination

Overload of the tube assembly or of HV inverter.

Line interruption (see wiring diagram).

Board D750 defective (monitoring).

Err 631

“Open connector in the generator”

Description

At least one connector between modules of the generator assembly or between the master board and the modules of the generator assembly is not connected.

Fault elimination

Line interruption (see wiring diagram).

Board D750 defective (monitoring).

Err 632

“Bias voltage error”

Description

Active bias voltage for large focus or inactive bias voltage for small focus.

Fault elimination

Check power supplies and fuses on D750.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 22 of 100

Medical Solutions

Page 23

Error messages 23

Err 633

“The high voltage is detected during stand by”

Description

If any or both of the signals HV_ON and EN_HV_ON are active during standby (no exposure being performed), this error is issued. Displayed when the tube is arcing.

Fault elimination

Press the "Lim" button to clear the error message.

Check the HV inverter module.

Err 634

“Voltage outside limits for 15V supplies”

Description

This error is issued if the +15V supply voltage goes below 10.6V or if the -15V supply voltage goes above -10.75V.

Fault elimination

Check the power supplies at the mains converter module and the fuses.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 23 of 100

Page 24

24 Error messages

Error messages of the OPDIMA Err 7XX 0

Err 777

“Exposure sequence is aborted by OPDIMA”

Description

The time between pressing acquire from the workstation and releasing the exposure from

the MAMMOMAT generator has exceeded 60 seconds.

The selected exposure parameters (kV, mAs) will yield an excessively hard beam quality

for the object.

The cancel button was pressed while "Expose at MAMMOMAT" or "Exposure preparation

started" was displayed.

Fault elimination

Press the limit button on the MAMMOMAT generator control panel to continue.

Err 778

“No communication present between MAMMOMAT and OPDIMA”

Description

Communication problem.

Fault elimination

Press "Retry" at the workstation or press the limit button on the MAMMOMAT generator

control panel to continue. Check the plugs and cables.

Err 779

“The mAs value for main exposure in OPDIMA AEC mode has not been received in

time”

Description

Communication problem.

Fault elimination

Press the limit button on the MAMMOMAT generator control panel to continue.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 24 of 100

Medical Solutions

Page 25

Error messages 25

Error messages of the stand Err 8XX 0

Err 801

“Time out of AR signal”

Description

The grid has not reached its start position within 2 seconds.

Fault elimination

Board D750 defective.

Check grid functioning.

Err 802

“OKT 2 pressure switch on tube housing or beam form anode or door switch”

Description

The oil pressure in the tube has exceeded the limit.

Fault elimination

Allow the tube to cool down. Close door/switches.

Err 803

“Stand requests interruption of tube voltage”

Description

The processor on stand CPU board D801 requests termination of high voltage generation.

Fault elimination

Switch off the equipment and then switch it on again.

Err 811

“Stand not ready for exposure”

Description

Normally, the panel does not allow start of exposure if any of the following errors is

present: No object table installed, no film cassette inserted, film cassette not changed

after exposure, improper diaphragm mounted. Nor will it allow exposure, if the tube

assembly is at a distance from the floor that could result in collision. These operator errors

are indicated on the control panel (the LED at the corresponding symbol lights up). Should

the control panel nevertheless allow start of exposure, this might be due to a bit error during the transmission of data between the stand and the control panel. As a precautionary

measure, the stand also checks whether the conditions are fulfilled. If this is not the case,

error message 811 is generated.

Fault elimination

Switch off the equipment and then switch it on again.

Err 812

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 25 of 100

Page 26

26 Error messages

“Compression protect switch not OK in stand”

Description

This signal is used to check for proper operation of the compression protect relay (Kl) on

the motor board (D802). The CPU (D801) reads the signal after a short delay after releasing the compression pedal in order to check that the relay has opened and disabled motor

operation in the compression direction. Note that the test point on D802 is protected with

4.75k.

Fault elimination, troubleshooting

Check the fuses on board D802. Normal active level 9V (test point COMP_PROT on

D802). If the level is OV check 14V and Kl on the motor board or look for a short circuit on

the ribbon cable between D801 and D802. If the cable is OK, D802 should be replaced.

If the voltage is 18V at the test point, the ribbon cable is open or D801 is faulty.

If the voltage is OK, replace D801.

Err 813

“Compression Motor controller, or motor, error in stand”

Description

This signal indicates an overcurrent or lack of voltage (5V or 15V) in the compression

motor drive. In the case of an overcurrent, the signal appears after about 2 s and disappears after about 0.5 s. The signal causes D801 to stop sending pulses to the compression drive and thus disables the compression motor. The red LED “comp error”, V2 lights

when error (comp_ok signal low) except if 5V is missing. There is no test point.

Fault elimination, troubleshooting

If V2 is lit steadily, check fuses F3 (24V) and F2 (24VF & l5V). l5V is indicated by LED

V49 and can be measured at test point l5V on D802. Test point 24VF should measure

about 30V in an unloaded state. 5V is indicated by LED V7 and test point 5V on D802. If

5V and 14V (normally about 18V unloaded) are missing, check Fl on D801. Missing voltages can also be caused by an open connection in emergency stop switch S880.

Overcurrent is most likely caused by a faulty motor, mechanical overloading of motorized

movement, short-circuited wiring of D805 or a faulty D802.

Err 815

“Compression speed too high, error suspected in stand”

Description

The CPU (D801) has detected a compression speed greater than 13 cm/s. The software

causes the compression motor to reverse direction.

Fault elimination, troubleshooting

This error can be caused by play in the compression unit, defective compression measurement hardware, or a short-circuited power stage on the motor board. In the first two

cases, replace the compression unit and recalibrate the compression values with the service PC program. In the third case, the compression motor will run at a max. speed

upwards except when a compression pedal is pressed. It is not certain that error 815 will

appear. Replace D802.

Err 816

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 26 of 100

Medical Solutions

Page 27

Error messages 27

“Collimator fails to reach correct position in time”

Description

Time out for filter lamella positioning during startup.

Fault elimination, troubleshooting

Check whether the collimator plates move at all.

If the collimator plates do not move:

- Check whether the CPU is sending out pulses, COLL_ST test point on D801, if not,

replace D801.

- Check whether the wing board (D805) is receiving pulses, test point COLL_ST on

D805; if not, check the cables and connectors between D801 and D805.

- Check voltages on the wing board.

- Check STEP_ENABLE test point on D805. It should be low (0V) when pulses are output to the motor.

If the collimator plates do move:

- Check whether the collimator position light switch is functioning as in the description

above.

- Check whether it moves for the entire 8 s. If it does but apparently does not reach the

other position in time, something may be in the way and slowing the speed, or the

motor may be faulty. In the latter case, try replacing the motor.

- If the motor stops after just a short time, either the motor or the wing board (D805) is

faulty. Try replacing one of them.

- Check collimator calibration (lamp and/or X-ray field).

If not successful, replace collimator and/or D814.

Err 817

“Filter self-test failure”

Description

The zero position for the filter wheel is not found during start-up.

Fault elimination, troubleshooting

Switch between the three anode/filter combinations on the control panel and check if the

filter disk moves.

- Check whether the filter position light switch works.

- If it only moves slowly, something may be in the way and slowing the speed, or the

motor may be faulty. In the latter case, try replacing the motor.

- If the motor stops after just a short time, either the motor or the wing board (D805) is

faulty. Try replacing one of them.

If not successful, replace collimator and/or D814.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 27 of 100

Page 28

28 Error messages

Err 818

“Filter positioning failure”

Description

The zero position for the filter wheel is not found after exposure.

Fault elimination

Switch between the three anode/filter combinations on the control panel and check if the

filter disk moves.

- Check whether the filter position light switch works.

- If it only moves slowly, something may be in the way and slowing the speed, or the

motor may be faulty. In the latter case, try replacing the motor.

- If the motor stops after a short time, either the motor or the wing board (D805) is

faulty. Try replacing one of them.

If not successful, replace collimator and/or D814.

Err 819

“Drive protect switch not OK (lift and rotation), in stand”

Description

This signal is used to check for proper operation of the drive protect relay (K6) on the

motor board (D802). The CPU (D801) reads the signal after a short delay after releasing

the activated lift or rotation button in order to check that the relay has opened and disabled motor operation.

Fault elimination, troubleshooting

Normal active level 5V (test point DRIVE_PROT on D802). If the level is 0V, check 24VF

and K3 on the motor board or look for a short circuit on the ribbon cable between D801

and D802. If the cable is OK, D802 should be replaced.

If the voltage is 30V at the test point, the ribbon cable is open or D801 is faulty.

If the voltage is OK, replace D801.

NOTE

There is no error for the lift & rotation drive corresponding to the

compression OK error. If this fault occurs, D801 stops sending

pulses to D802 and the selected motor stops. The LED V12,

DRIVE_ERROR functions in the same manner as COMP_ERROR.

Note that the current limit is lower when the lift motor is moving

downward. If there are problems with lift or rotation operation indicating an overload, look at the DRIVE_ERROR LED to determine

if the motor is overloaded.

Overloading is possible due to improper balancing (adjustment of the spring or improper

loading of the lifting carriage) or improper adjustment of the rotation brake. Faulty motor,

short-circuited wiring or faulty D802 are other possible causes.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 28 of 100

Medical Solutions

Page 29

Error messages 29

Err 820

“Write/read back failure with EEPROM in stand”

Description

If data is stored in the E

to verify that it has been stored correctly. In the event of differences, the above error message is displayed.

Fault elimination

Repeat the attempt to write in the E

of repeated attempts, board D801 must be replaced. All stand parameters must be reinstalled. Use the service PC to reinstall the stand parameters from floppy or disk.

Err 821

“Stand EEPROM has wrong version nbr (=old or corrupt)”

Description

The version number of the PROM stand is also stored in the E

starting up the equipment, the version number stored in the E

version number of the PROM. If they do not correspond, the above error message code is

displayed on the control panel. This occurs after changing the software version to indicate

that a new version has been installed.

2

PROM (D801.I34) stand during adjustment, a check is performed

2

PROM. If this not does not yield any results, in spite

2

PROM (D801.I34). When

2

PROM is compared to the

Fault elimination

The version number of the new software is automatically written into the E

2

PROM. Switch

off the equipment and then switch it on again. The error should not recur.

Err 822

“Grid failed to move properly”

Description

The grid has to move properly from the start. This is supervised by the CPU. The CPU

measures the time from start till the grid has reached one of the end positions and then is

able to leave it. To check that the grid is functioning properly and does not jam, the time

the grid requires to move between the two end positions is also measured the first time. If

the time for start or run check exceeds 2 sec., this error appears.

Fault elimination, troubleshooting

Check programming of the grid fast speed (normally 80%) and the grid fast speed time

(normally 500 ms).

Check the bucky board. First try another board. Make sure the grid moves freely along its

entire travel path in both directions.

Check the output voltage at test point GRID_M on D802. At 80% speed and nominally

30V on 24VF, GRID_M should be 30 - 0.8*30 = 6V during fast grid movement. Check for

possible short circuits if the signal remains at about 30V. This voltage goes to the bucky

via board D805 and its relay Kl. Test point GRID_SP on D802 is the control signal from

D801. It is a 5V, 20 kHz PWM signal. At 80% speed, the signal should be low at about 40

µs and high at about 10 µs per period. Replace D802 if the correct output is not achieved

despite proper input, cabling and bucky.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 29 of 100

Page 30

30 Error messages

Err 824

“Stand motor voltage drops unnaturally”

Description

The CPU (D801) measures voltage 24VF from the motor board (D802). If this value is

below about 16V, this error is reported.

Fault elimination, troubleshooting

Check that the stand has voltage (generator - X14 connected, F4 OK). The stand display

should be on.

Check that the emergency stop is not activated and that its wiring is OK.

Check that LED V49, 15V, is lit. If not, check fuses F2 and F3 on D802 in the stand.

Check voltage 24VF (measure with reference to test point 0V on D802).

Check the ribbon cable between D802 and D801.

Replace D801.

Err 825

“One or more potentiometers seem to have lost contact with stand”

Description

The four potentiometers, R803-tube angle, R871-preset angle, R861-preset force and

R863-thickness, have their return current through signal pot_return. This is done to

assure that no potentiometer is missing or partly disconnected so that it can yield a value

leading to improper stand operation. During stand configuration or after replacing a potentiometer or the compression unit, the correct value for the signal potentiometer check

must be read and stored in the stand’s E

2

PROM with the service PC program. This error

is reported if the measured value is more than 32 bits less than the programmed value.

Fault elimination, troubleshooting

Check that all potentiometers are functioning properly. An error can be caused by an open

connection, connector or potentiometer. If all four potentiometers are functioning properly,

check the programming of the potentiometer check and correct it. The need for such an

adjustment may indicate a potentiometer is about to fail.

Err 826

“There is a short circuit somewhere among potentiometers in stand”

Description

The same circuitry as Err 825 is used. In this case the error indicates that the value is

more than 32 bits greater than the programmed value.

Fault elimination, troubleshooting

Check the actual and programmed pot. check values with the service PC program. If the

value is only slightly too high, check all potentiometers for mechanical damage or sensitivity. A short circuit (pot. or wiring) should yield the max. value for pot_check (3FF).

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 30 of 100

Medical Solutions

Page 31

Error messages 31

Err 829

“Collimator motor communication error”

Description

Communication between the stand and collimator control board D814 is erroneous or disrupted.

Fault elimination, troubleshooting

Check cables and plugs. Replace D814.

Err 830

“Filter motor communication error”

Description

Communication between the stand and collimator control board D814 is erroneous or disrupted.

Fault elimination, troubleshooting

Check cables and plugs. Replace D814.

Err 831

“Paddle decoder communication error”

Description

Identification of compression paddle fails.

Fault elimination, troubleshooting

Clean the sensor at the paddle. Check whether the paddle code is working with another

paddle.

Err 850

“Write/read back failure for table 1 in stand EEPROM”

Description

Each time the MAMMOMAT Novation

DR

R is switched on, the adjustment data in the

stand EEPROM (D801.I34) is checked with a checksum. Each menu under “Stand config”

has its own checksum. If a discrepancy is detected in the stand installation menu, the

above error message is displayed.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 851

“Write/read back failure for table 2 in stand EEPROM”

Description

Each time the MAMMOMAT Novation

DR

is switched on, the adjustment data in the stand

EEPROM (D801.I34) is checked with a checksum. Each menu under “Stand config” has

its own checksum. If a discrepancy is detected in the calibrate compression menu, the

above error message is displayed.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 31 of 100

Page 32

32 Error messages

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 852

“Write/read back failure for table 3 in stand EEPROM”

Description

Each time the MAMMOMAT Novation

EEPROM (D801.I34) is checked with a checksum. Each menu under “Stand config” has

its own checksum. If a discrepancy is detected in the rotation calibration menu, the above

error message is displayed.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 853

“Write/read back failure for table 4 in stand EEPROM”

DR

is switched on, the adjustment data in the stand

Description

Each time the MAMMOMAT Novation

DR

is switched on, the adjustment data in the stand

EEPROM (D801.I34) is checked with a checksum. Each menu under “Stand config” has

its own checksum. If a discrepancy is detected in the rotation calibration menu, the above

error message is displayed.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 854

“Write/read back failure for table 5 in stand EEPROM”

Description

Each time the MAMMOMAT Novation

DR

is switched on, the adjustment data in the stand

EEPROM (D801.I34) is checked with a checksum. Each menu under “Stand config” has

its own checksum. If a discrepancy is detected in the lift parameters menu, the above

error message is displayed.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 855

“Write/read back failure for table 6 in stand EEPROM”

Description

Each time the MAMMOMAT Novation

DR

is switched on, the adjustment data in the stand

EEPROM (D801.I34) is checked with a checksum. Each menu under “Stand config” has

its own checksum. If a discrepancy is detected in the best compression menu, the above

error message is displayed.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 32 of 100

Medical Solutions

Page 33

Error messages 33

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 856

“Write/read back failure for table 7 in stand EEPROM”

Description

Each time the MAMMOMAT Novation

EEPROM (D801.I34) is checked with a checksum. Each menu under “Stand config” has

its own checksum. If a discrepancy is detected in the rotation parameters menu, the

above error message is displayed.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 857

“Write/read back failure for table 8 in stand EEPROM”

DR

is switched on, the adjustment data in the stand

Description

Each time the MAMMOMAT Novation

DR

is switched on, the adjustment data in the stand

EEPROM (D801.I34) is checked with a checksum. Each menu under “Stand config” has

its own checksum. If a discrepancy is detected in the beam limiting device menu, the

above error message is displayed.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 858

“Write/read back failure for table 9 in stand EEPROM”

Description

Each time the MAMMOMAT Novation

DR

is switched on, the adjustment data in the stand

EEPROM (D801.I34) is checked with a checksum. Each menu under “Stand config” has

its own checksum. If a discrepancy is detected in the rotation parameters menu, the

above error message is displayed.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 859

“Write/read back failure for table 10 in stand EEPROM”

Description

Each time the MAMMOMAT Novation

DR

is switched on, the adjustment data in the stand

EEPROM (D801.I34) is checked with a checksum. Each menu under “Stand config” has

its own checksum. If a discrepancy is detected in the rotation calibration menu, the above

error message is displayed.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 33 of 100

Page 34

34 Error messages

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 860

“Write/read back failure for table 11 in stand EEPROM”

Description

Incorrect checksum for collimator calibration parameters for small focus Mo in EEPROM.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 861

“Write/read back failure for table 12 in stand EEPROM”

Description

Incorrect checksum for collimator calibration parameters for large focus Mo in EEPROM.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 862

“Write/read back failure for table 13 in stand EEPROM”

Description

Incorrect checksum for collimator calibration parameters for small focus W in EEPROM.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 863

“Write/read back failure for table 14 in stand EEPROM”

Description

Incorrect checksum for collimator calibration parameters for large focus W in EEPROM.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 864

“Write/read back failure for table 15 in stand EEPROM”

Description

Incorrect checksum for collimator calibration parameters for the light field focus in

EEPROM.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 34 of 100

Medical Solutions

Page 35

Error messages 35

Err 865

“Write/read back failure for table 16 in stand EEPROM”

Description

Incorrect checksum for the calibration parameters for wing differences in EEPROM.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 866

“Write/read back failure for table 17 in stand EEPROM”

Description

Incorrect checksum for the calibration parameters for the filter in EEPROM.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 867

“Write/read back failure for table 18 in stand EEPROM”

Description

Incorrect checksum for the calibration parameters for the optimum compression function

in EEPROM.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Err 868

“Write/read back failure for table 19 in stand EEPROM”

Description

Incorrect checksum for the calibration parameters for the optimum compression function

in EEPROM.

Fault elimination

Install all stand parameters using the service PC “Back-up” menu.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 35 of 100

Page 36

36 Log and error files

3Log and error files

4-

General 0

Some files on Mammomat Novation system contain information about processes on the

system. This information could be helpful for determination of failure, detector artifacts,

communications problems, blue screen and automatic reboot of the WH AWS.The analysis of the files requires specific knowledge. For this reason, if support is required, the files

have to be sent to USC/HSC.

If support by USC/HSC is requested, groups of files have to be sent for explicit analysis:

• MPxxxx.smj, MPxxxx.map, qualify.log,MPxxxx.cfg and drapi.log: They are locat-

ed under WH AWS in folder C:\AWS\drul\data\.

• Brick files: These files can be shown by using the PCMX Web software.

• Savelog files: a feature on the syngo SW is implemented for extracting the files and

burning them onto CD (only as of SW VA11x).

• Windows Event log.

• syngo logs. They are located under WH AWS in folder C:\AWS\log\*.*

• Dump files (if available). They are located under WH AWS in folder C:\winnt\

minidump\*.dmp.

• brickspy.tar.gz file.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 36 of 100

Medical Solutions

Page 37

Log and error files 37

SW Version VA10x 0

These instructions describe extracting log files for WH AWS with SW VA10x.

Copy MPxxxx files (detector files), dump files and syngo logs 0

These files have to be copied to a defined folder to ensure a correct copy.

Work steps

• The syngo AWS application is running.

• Select Service and Local Service in the menu bar under Options

Fig. 1:

• Enter the service key and press OK. The Home menu appears.

• Select Utilities

• Select Escape to OS

• Enter start explorer under parameters.

Command: NT command Interpreter

Parameters: start explorer

• Press the enter key.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 37 of 100

Page 38

38 Log and error files

• Windows Explorer opens.

Fig. 2: Detector files

• Under C:\AWS\drul\data, select the files Drapi.log, MPxxxx.cfg, qualify.log,

MPxxxx.map and MPxxxx.smj,(1/Fig.2/p.38)click the right mouse button and copy

and paste to folder C:\AWS\Service\extract.

• Select C:\winnt\minidump\*.dmp (if available), right-click, and copy and paste to fold-

er C:\AWS\Service\extract.

• Under C:\AWS\log , select all files (*.*), right-click them and copy and paste them to

folder C:\AWS\Service\extract.

• Close Explorer.

• Close Explorer.

• Select Home

• Close the Service software window

Copy Array and Brick log files 0

Use the Web Brick window to display these files.

Work steps

Array files

• The syngo AWS application is running.

• Select Service and Local Service in the menu bar under Options

• Enter the service key and press OK. The Home menu appears.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 38 of 100

Medical Solutions

Page 39

Log and error files 39

• Enter http:brick under address.

Fig. 3: PXCM Web Control Interface

• Select array(1/Fig.3/p.39)

• Select Log File(s)

Fig. 4:

• The user name and appropriate password have to be entered (Fig.4/p.39)

Login: root

Password: *****

• Press OK

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 39 of 100

Page 40

40 Log and error files

• Select All Log Files

Fig. 5:

• Right-click syslog and select Save Target As (Fig.5/p.40)

• Save the file as array_syslog in the directory C:\AWS\Service\extract.

• Right-click syslog.0 and select Save Target As .

• Save the file as array_syslog.0 in the directory C:\AWS\Service\extract.

• Brick files

• Select Brick(2/Fig.3/p.39)

• Select Log File(s)

• Select All Log Files

• Right-click syslog and select Save Target As

• Save the file as brick_syslog in the directory C:\AWS\Service\extract.

• Right-click syslog.0 and select Save Target As

• Save the file as brick_syslog.0 in the directory C:\AWS\Service\extract.

• Close the Web Brick window.

• Close the Service software,

Windows Eventlog 0

Work steps

• The syngo AWS application is running.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 40 of 100

Medical Solutions

Page 41

Log and error files 41

• Select Service and Local Service in the menu bar under Options

Fig. 6:

• Enter the service key and press OK. The Home menu appears.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 41 of 100

Page 42

42 Log and error files

• Select EventLog on the right upper edge of the menu bar.

Fig. 7: EventLog_System

• Select the following parameters as shown in (Fig.7/p.42) .

Domain: System(1/Fig.7/p.42)

Severity: All(2/Fig.7/p.42)

Extended: selected(3/Fig.7/p.42)

NT-Message: selected(3/Fig.7/p.42)

Message limit: empty(4/Fig.7/p.42)

Extract to file: System.txt ((5/Fig.7/p.42)

Time range: last month (e.g.: from dd_mm_yyyy to dd_mm_yyyy (actual

date)).(6/Fig.7/p.42)

Select GO.(7/Fig.7/p.42)

• The log file appears.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 42 of 100

Medical Solutions

Page 43

Log and error files 43

Fig. 8: EventLog_Application

• Select the following parameters as shown in (Fig.8/p.43) .

Domain: Application(1/Fig.8/p.43)

Severity: All(2/Fig.8/p.43)

Facility: Developer(3/Fig.8/p.43)

Extended: selected(4/Fig.8/p.43)

NT Message: selected(4/Fig.8/p.43)

Message limit: empty(5/Fig.8/p.43)

Extract to file:Application.txt(6/Fig.8/p.43)

Time range: last month (e.g.: from dd_mm_yyyy to dd_mm_yyyy (actual

date))(7/Fig.8/p.43)

Select GO.(8/Fig.8/p.43)

• The log file appears.

Brickspy.tar.gz file

Use telnet to start a script.

• Select Service and Local Service in the menu bar under Options

• Select Utilities

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 43 of 100

Page 44

44 Log and error files

• Select Escape to OS

• Enter start telnet brick under parameters

Login: root (and press enter)

Password: brick (and press enter)

• From the brick# command prompt, execute the following command:

brickspy all (use lowercase letters and press enter)

• Wait until the script is finished and enter Exit (and press enter)

Use ftp to get the saved file.

• Select Service and Local Service in the menu bar under Options

• Select Utilities

• Select Escape to OS

• Enter start cmd under parameters

• At the DOS prompt, enter cd C:\AWS\Service\extract (and press enter)

• At c:\temp, enter ftp brick (and press enter)

• User: ftp (and press enter)

• Password: a random e-mail address, e.g.. test@siemens.com

• At the ftp prompt, enter bin (and press enter)

• Enter prompt (and press enter)

• Enter cd tmp (and press enter)

• Enter dir (and press enter)

The file brickspy.tar.gz will be displayed

• Enter mget brick* (and press enter)

• After the file has been transferred, enter quit to exit ftp.

• The file brickspy.tar.gz can be found on WH AWS under C:\Temp.

The log files are now stored in the folder C:\AWS\Service\extract and can be copied to

an external storage medium, e.g., USB stick. If no external drive is available, the log files

should be saved to CD. For this procedure, do the following:

Creating a new backup package

• Select Local Service/Configuration/(Backup/Restore)

• Enter a new package name(e.g.:ServiceLogFiles) in the blank line below

Package(1/Fig.9/p.45)

• Click add(2/Fig.9/p.45)

• In the blank line “file &dir”, enter the name: C:\AWS\Service\extract(3/Fig.9/p.45)

• Click add after each entry(4/Fig.9/p.45).

The new file or path selection is now visible in the files & directories list box.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 44 of 100

Medical Solutions

Page 45

Log and error files 45

Fig. 9: Backup Package

• Click save(5/Fig.9/p.45).

Back up your created package to CD.

• Select Local Service/Backup & Restore.

• Under Command: select Backup.

• Select the CD-R drive.

• Select your own created backup package: ServiceLogFiles.

• Click Go.

The backup process to CD will be started!

• After you have completed the backup, check your CD with the stored log files.

The configured ServiceLogFiles package is stored on CD compressed as file type “*.ar”.

You can use the syngo arviewer.exe to read or extract these files. For more information,

contact CS HSC 24 or your local USC.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 45 of 100

Page 46

46 Log and error files

SW Version VA11x 0

These instructions describe extracting log files for WH AWS with SW VA11x.

Copy MPxxxx files (detector files), dump files and syngo logs 0

These files have to be copied to a defined folder to ensure a correct copy on the CD.

Work steps

• The syngo AWS application is running.

• Select Service and Local Service in the menu bar under Options

Fig. 10:

• Enter the service key and press OK. The Home menu appears.

• Select Utilities

• Select Escape to OS

• Enter start explorer under parameters

Command: NT command Interpreter

Parameters: start explorer

• Press the enter key.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 46 of 100

Medical Solutions

Page 47

Log and error files 47

• Windows Explorer opens.

Fig. 11: Detector files

• Under C:\AWS\drul\data, select the files Drapi.log, MPxxxx.cfg, qualify.log,

MPxxxx.map and MPxxxx.smj,(1/Fig. 11 / p. 47)right-click, and copy and paste to

folder C:\AWS\service\html\whaws\extract.

• Select C:\winnt\minidump\*.dmp (if available), right-click, and copy and paste to fold-

er C:\AWS\Service\html\whaws\extract.

• Under C:\AWS\log , select all files (*.*), right-click them and copy and paste them to

folder C:\AWS\Service\html\whaws\extract.

• Close Explorer.

• Select Home

• Close the Service software window

The storage files will be written onto CD by burning the SaveLogs files.

Copy Array and Brick log files 0

Use the Brick Configuration feature to display these files.

Work steps

Array files

• The syngo AWS application is running.

• Select Service and Local Service in the menu bar under Options

• Enter the service key and press OK. The Home menu appears.

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 47 of 100

Page 48

48 Log and error files

• Select the Acquisition System button.

Fig. 12: PXCM Web Control Interface

• Select Brick Configuration(1/Fig. 18 / p. 54)

• Select array(1/Fig. 12 / p. 48)

• Select Log File(s)

Fig. 13:

• The user name and appropriate password have to be entered(Fig. 13 / p. 48)

Login: root

Password: *****

• Press OK

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 48 of 100

Medical Solutions

Page 49

Log and error files 49

• Select All Log Files

Fig. 14:

• Right-click syslog and select Save Target As (Fig. 14 / p. 49)

• Save the file as array_syslog in the directory C:\AWS\Service\html\whaws\extract.

• Right-click syslog.0 and select Save Target As .

• Save the file as array_syslog.0 in the directory C:\AWS\Service\html\whaws\extract.

• Brick files

• Select Brick

• Select Log File(s)

• The user name and appropriate password have to be entered

Login: root

Password: *****

• Press OK

• Select All Log Files

• Right-click syslog and select Save Target As

• Save the file as brick_syslog in the directory C:\AWS\Service\html\whaws\extract.

• Right-click syslog.0 and select Save Target As

• Save the file as brick_syslog.0 in the directory C:\AWS\Service\html\whaws\extract.

• Close the Web Brick window.

• Select Home in the Service software

Siemens AG SPB7-250.840.01.01.02 MAMMOMAT Novation

Medical Solutions

10.05 CS SD 24

Page 49 of 100

Page 50

50 Log and error files

• Copied files will be written by burning the SaveLogs to CD

Windows Eventlog 0

Work steps

• The syngo AWS application is running.

• Select Service and Local Service in the menu bar under Options

Fig. 15:

• Enter the service key and press OK. The Home menu appears.

MAMMOMAT Novation SPB7-250.840.01.01.02 Siemens AG

10.05 CS SD 24

Page 50 of 100

Medical Solutions

Page 51

Log and error files 51