Page 1

MAMMOMAT 1000/3000/3000 Nova - Opdimar

Service

Service Instructions

© Siemens AG 2001

The reproduction, transmission or

use of this docu men t or its con tent s

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 5 English

Print No .: SPB7-230.061.08.03.02 Doc . Gen. Date: 03.01

Replaces: SPB7-230.061.08.02.02 and SPB7-230.061.06.02. 02 65 69 334

Page 2

0 - 2 Revision

Chapter Page Revision

All All 03

Opdimar Register 5 SPB7-230.061.08 Page 2 of 6 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 3

Contents 0 - 3

Page

1 _______Prerequisites __________________________________________________1 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Traini ng of customer support engineers. . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Documents required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Ultra 10 CD-ROMs required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Ultra 1 CD-ROMs required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Meters and appliances required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

2 _______Functional description __________________________________________2 - 1

Ultra 10 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Ultra 1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

Biopsy controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Biopsy unit control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

RS-232 switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

CCD camera power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Application software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

CCD camera communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Control of MAMMOMAT and biopsy unit . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Power supply workstation main unit. . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

CCD camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Biopsy unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

3 _______Protective measures for CCD camera______________________________3 - 1

4 _______Protective measures ____________________________________________4 - 1

5 _______Service mode__________________________________________________5 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Advanced service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Selection of mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Calibration of the biopsy unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Setting up needles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Editing needle values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7

Backup of temporary storage media . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 8

Use of Advanced service functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 9

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 9

Main menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 9

Country settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 11

Test of units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 12

Software upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 13

New software version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 14

Enabling the DICOM option . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 15

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 3 of 6 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 4

0 - 4 Contents

Page

Instruction for obtaining the systems host ID and hostname . . . . . . . . . . . .5 - 15

Network settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 17

Miscellaneous. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 18

Restoring data from MO disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 20

CCD camera calibration and maintenance . . . . . . . . . . . . . . . . . . . . . .5 - 21

Grid table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 21

Non grid table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 22

Disk cache settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 23

Use of printer setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 24

Stand alone Opdima system . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 24

Networked Opdima system. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 25

Log administration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 27

Log inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 28

6 ______ Removal and replacement of sub-assemblies _______________________6 - 1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

MO unit (no CD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Removing the MO unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Installing the MO unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Tests and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

CD/MO unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Removing the CD/MO unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Installing the CD/MO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Tests and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Biopsy controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Removal of biopsy controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Removal of biopsy controller cover . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Replacement of components in the biopsy control ler. . . . . . . . . . . . . . . . 6 - 6

Ultra 10 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Ultra 1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

Biopsy unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 10

Ultra 10 Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 11

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 11

Ultra 1 Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 12

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 12

CCD camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 13

Exchange of workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 14

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 14

Reinstallation of software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

Ultra 10 Pre installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

Ultra 1 Pre installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 20

Ultra 10/Ultra 1 Installation of Op dima ASW 2.1 ( part No. 65 27 639) . . . . . . .6 - 22

Restore hostname and data . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 24

Final procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 24

7 ______ Messages _____________________________________________________7 - 1

Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Opdimar Register 5 SPB7-230.061.08 Page 4 of 6 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 5

Contents 0 - 5

Page

8 _______Fault isolation chart ____________________________________________8 - 1

Fault isolation chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

Explanations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

9 _______Troubleshooting guide __________________________________________9 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Biopsy unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 2

Biopsy unit not responding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 2

Problem with calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 2

Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

Camera not responding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

Cannot use camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 4

If “Bogus file system” appears. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 4

Problem with date in database mode . . . . . . . . . . . . . . . . . . . . . . . . 9 - 4

No images displayed on monitor . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 4

Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 4

Ultra 1 If the workstation does not start after an unplanned power cut off. . . . . . 9 - 4

Image Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 5

Problems during calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 5

Quadrant difference on patient images . . . . . . . . . . . . . . . . . . . . . . . 9 - 5

Quadrant missing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 5

White line/dot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 5

MAMMOMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 6

Cannot use MAMMOMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 6

Network problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 7

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 8

Printer connected directly to Opdima . . . . . . . . . . . . . . . . . . . . . . . .9 - 8

Printer connected to network . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 8

MO unit / CD drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 9

All problems with MO disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 9

If the message “Failed to store on MO disk” appears . . . . . . . . . . . . . . . . 9 - 9

If the message “Cannot read disk Prepare disk?” appears . . . . . . . . . . . . . 9 - 9

Cannot communicate with MO unit . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 9

10 ______Measures after service _________________________________________10 - 1

Verifying the calibration of the biopsy unit. . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Check of Opdima AEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Performance Criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

Check of resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

Performance Criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

Protective earth measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 5

Biopsy unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 5

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 5 of 6 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 6

0 - 6 Contents

Biopsy controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 5

CCD camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 5

Biopsy controller cable duct . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 6

11 _____ Changes to previous version ____________________________________11 - 1

12 _____ Appendix 1 __________________________________________________ A1 - 1

Ultra 1 Installation of CD drive, part no 65 38 180 . . . . . . . . . . . . . . . . . . A1 - 1

Ultra 1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1 - 2

13 _____ Appendix 2 __________________________________________________ A2 - 1

Database log file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2 - 1

14 _____ Appendix 3 __________________________________________________ A3 - 1

Customer specific data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3 - 1

Test protocol repetitiveness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3 - 1

Biopsy calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3 - 1

Test protocol CCD camera calibrati on . . . . . . . . . . . . . . . . . . . . . . . . A3 - 2

Test protocol image quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3 - 3

AEC function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3 - 3

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3 - 5

Test protocol protective earth measurement . . . . . . . . . . . . . . . . . . . . . A3 - 6

Biopsy unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3 - 6

Biopsy controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3 - 6

CCD camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3 - 6

Biopsy controller cable duct . . . . . . . . . . . . . . . . . . . . . . . . . . . A3 - 6

Opdimar Register 5 SPB7-230.061.08 Page 6 of 6 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 7

Prerequisites 1

General 1

Valid for Opdimar system ASW 2.1 on SUN workstation, part No. 64 30 453.

This document is valid for both Ultra 10 (SUN workstation with seri al No.W1201) and Ultra

1 (SUN workstation with serial No. <1201) when not sta ted di fferently.

Training of customer support engineers 1

Due to the technology used in this equipment, setup, servi ce and maintenance may only

be carried out by a customer support engineer who has attended a training workshop or

has participated in at least one install ation.

Documents required 1

• Supplement to the Instructions for Use MAMMOMAT 3000 - Opdimar

(included in the Opdimar delivery)

• MAMMOMAT 1000/3000/3000 Nova - Opdimar Maintenance I nstructions

(included in the Opdimar delivery)

• MAMMOMAT 3000 - Opdimar Wiring Diagram

(included in the Opdimar delivery)

1 - 1

• MAMMOMAT 1000/3000 Nova Wiring Diagram

• Technical Information TI 219

• For Ultra 1 only: MAMMOMAT 3000 Opdimar Service Instructions

Workstation (Ultra 1) SPB7-230.061. 02.02.02

Ultra 10 CD-ROMs required 1

• Ultra 10 Service Manual, part No. 65 27 670 (included in the Opdimar delivery)

Reading Ultra 10 Service Manual CD-ROM:

You may view the HTML document and watch the video clips on a PC with a CD dri ve

running Windows 95 or later by using Netsca pe Navigator

Internet Explorer, version 4.0 or later. Refer to the browser documentati on about

configuring your browser to view MPEG-1 files.

• Operating environment installation CD 02/00, part No. 65 27 704 or

Operating environment installa tion CD 05/99, part No. 65 27 696

(for Solaris 2.5.1 HW 11/97, included i n the Opdimar delivery)

• Solaris 2.5.1 HW 11/97 CD-ROM and

CDE/Desktop 1.1 CD-ROM

(both are included in a separate packag e called Media kit Solaris 2.5.1 HW 11/97,

part No. 65 01 956, included in the workst ation delivery)

TM

, version 4.0 or later, or

• Opdimar ASW 2.1, part No. 65 27 639

Ultra 1 CD-ROMs required 1

• Opdimar ASW 1.3, part No. 64 32 665 (i ncludes operating system)

• Opdimar ASW 2.1, part No. 65 27 639

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 1 of 2 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 8

1 - 2 Prerequisites

Meters and appliances required 1

• Protective ground wire tester (44 15 899 RV090)

• Stereo calibration phantom (included in the Opdimar deliver y) (part No. 64 30 701)

• Acrylic plastic (PMMA) plates, three plates measuring 15 0 mm x 150 mm x 20 mm and

one plate measuring 150 mm x 150 mm x 10 mm, part No. 85 49 438 and 97 88 423

respectively

• Resolution phantom with at least 10 line pairs per mm

• 4,5 cm PMMA

• For Ultra 10 only: PC with a CD drive running Windows 95 or later by using Nets cape

TM

Navigator

read Ultra 10 Service Manual)

, version 4.0 or later, or I nternet Explorer, version 4.0 or l ater (to be able to

• If software upgrade: External CD drive for Ultra 1 ( part No. 64 30 453

serial No. 1109-1146)

Tools required 1

• Standard service tools

• PROM extractor for PLCC 32

Opdimar Register 5 SPB7-230.061.08 Page 2 of 2 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 9

Functional description 2

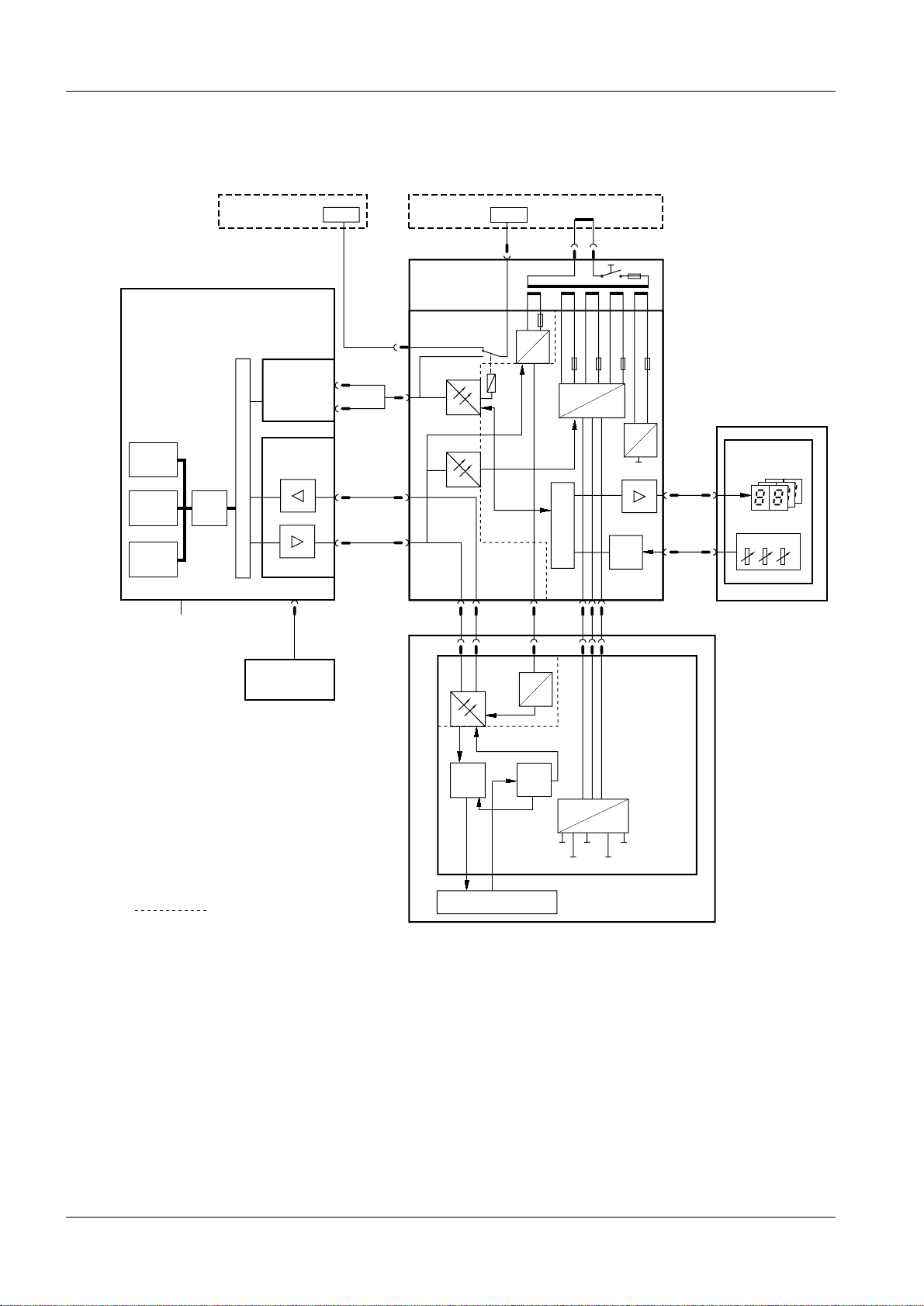

Ultra 10 Block diagram 2

The block diagram below shows the function of the Opdimar system.

2 - 1

M3000 printer /

service PC

Workstation

System

monitor

Graphics

acc.

RAM

Incoming mains 100 - 120V AC

or 220 - 240V AC

CPU

Switch selectable

2 x RS-232

D101 Camera

interface board

PCI BUS

PCI BUS

Printer

(option)

RS-232

A

exp. sync.

B

biopsy data

X101

12-bit image

data

RS-422

X101

control data

M3000 stand

Biopsy

controller

D200 Biopsy

control board

X205

X204

X203

X203

X206

DTR

POW_ON

X202

X111 X111 X112X110,X111

X202

RS-232

AC

DC

5V_COM

230V AC

Mains

cable

DC

AC

7V_COM

POW_ON

X202 X201

DC

CPU

DC

7V

20V

AC

30V

DC

5V

ADC

CCD camera

D110 CCD

camera board

X207

X207

X885

X885

M3000

Biopsy unit

X Y Z

Fig. 1 Block diagram

= Galvanic separation

CCD

control

logic

CCD sandwich

ADC

DC

DC

5V

C_CL

A_CL

CCD_R

SRC_CL

OPD00465

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 1 of 6 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 10

2 - 2 Functional description

Ultra 1 Block diagram 2

The block diagram below shows the function of the Opdimar system.

M3000 printer /

service PC

Workstation

System

monitor

Graphics

acc.

RAM

Incoming mains 100 - 240V AC

CPU

2 x RS-232

D100 Camera

interface board

SBUS

SBUS

Printer

(option)

RS-232

A

exp. sync.

B

biopsy data

X101

12-bit image

data

RS-422

X101

control data

M3000 stand

Biopsy

controller

D200 Biopsy

control board

X205

X204

X203

X203

X206

DTR

POW_ON

X202

X111 X111 X112X110,X111

X202

RS-232

AC

5V_COM

230V AC

Mains

cable

DC

AC

7V_COM

POW_ON

CPU

X202 X201

DC

DC

DC

7V

20V

30V

AC

DC

5V

ADC

CCD camera

D110 CCD

camera board

X207

X207

X885

X885

M3000

Biopsy unit

X Y Z

= Galvanic separation

Fig. 2 Block diagram

CCD

control

logic

CCD sandwich

ADC

DC

DC

C_CL

CCD_R

SRC_CL

OPD00178

5V

A_CL

Opdimar Register 5 SPB7-230.061.08 Page 2 of 6 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 11

Functional description 2 - 3

Biopsy controller 2

The biopsy controller has three main functions:

• Biopsy unit control

• Switching of RS-232 from MAMMOMAT to either MAMMOMAT printer/service PC or

workstation

• CCD camera power supply

Biopsy unit control 2

The biopsy functions are controlled by the mic ro controller. In the biopsy unit there are

three potentiometers indicating the current needle position.

The values from the potentiomet ers are A/D con verted and sent to the micro cont roller. To

check the converted values from the A/D converter, the potentiometer values are

converted in parallel by the micro controller.

RS-232 switching 2

To enable RS-232 communication between MAMMOMAT and either MAMMOMAT print er/

service PC or workstation, a relay is used. The relay is controlled by the workstation.

CCD camera power supply 2

The biopsy controller converts the mains AC voltage to DC voltages. The DC voltages are

used by the CCD camera.

LEDs 2

On the biopsy controller printed circuit boar d, D200, there are a number of LEDs with the

following meaning:

• Indication of RAM error

• Indication of PROM error

• Indication of analog/digital converter

• Indication of NVM error

• Indication of TxD error

• Selection of RS-232 communication to MAMMOMAT printer/service PC or workstatio n

(SELECT_WS)

• Supply voltages (e.g. 5V_COM, 30V_CC)

For more information on LEDs, see MAMMOMAT 1000/3000/3000 Nova - Opdimar

Wiring Diagram.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 3 of 6 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 12

2 - 4 Functional description

Workstation 2

The workstation includes the following parts:

• Main unit, including temporary storage media i.e. hard di sk

• Monitor

• Keyboard and mouse

• CD drive

For Ultra 1 only: External CD drive

For Ultra 10 only: Internal CD driv e

• Solaris operating system

For Ultra 1 only: Included on the ASW 1.3 CD-ROM

For Ultra 10 only: Included in Media kit Sol aris 2.5.1 HW 11/97

• External MO unit i.e. magneto-optical drive, used for t he permanent storage media and

backup

• Printer (option)

The workstation is used for:

• Running application software

• Communication with the CCD camera

• Control of MAMMOMAT and biopsy unit

Application software 2

The application software run by the workstati on is the main communication interface with

the user and units of the Opdimar system.

Start-up and login

Mode selection

Stereo examination

mode

Spot examination

mode

Database

mode

Service mode

Error handlingHelpData storage

OPD00179

Fig. 3 Application software logic flow

Opdimar Register 5 SPB7-230.061.08 Page 4 of 6 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 13

Functional description 2 - 5

NOTICE

NOTICE

CCD camera communication 2

The camera interface in the workstation main uni t sends commands to the CCD camera

from the workstation and receives the image from the camera. The interface adapts the

workstation data bus to RS-422.

The camera interface also supplies the CCD camera opto couplers with power.

Control of MAMMOMAT and biopsy unit 2

The workstation controls the MAMMOMAT via RS-232 communication.

Biopsy calculations are performed by the workstation and target coordinates are sent to

the biopsy unit.

Monitor 2

,ID´PRQLWRULVLQVWDOOHGEHVXUHQRWWRFKDQJHWKHSURSRUWLRQV

EHWZHHQOHQJWKDQGZLGWK,IWKLVKDVEHHQGRQHDQ\ZD\SUHVV

WKHDXWRVL]LQJDQGFHQWULQJEXWWRQPDUNHGZLWKDV\PERO

)LJWRUHVWRUHWKHSUHYLRXVVHWWLQJV

Fig. 4 Symbol

Power supply workstation main unit 2

When setting the main voltage on the contact, relate to local main

voltage.

CCD camera 2

The CCD camera consists of a printed circuit board, CCD sandwich and RS-422

interface. When the x-ray beams reach the CCD sandwich, electric energy proport ional to

the x-ray energy is produced. The produced electrical current is A/D converted to digital

information and sent to the workstation RAM via an RS-422 inter face.

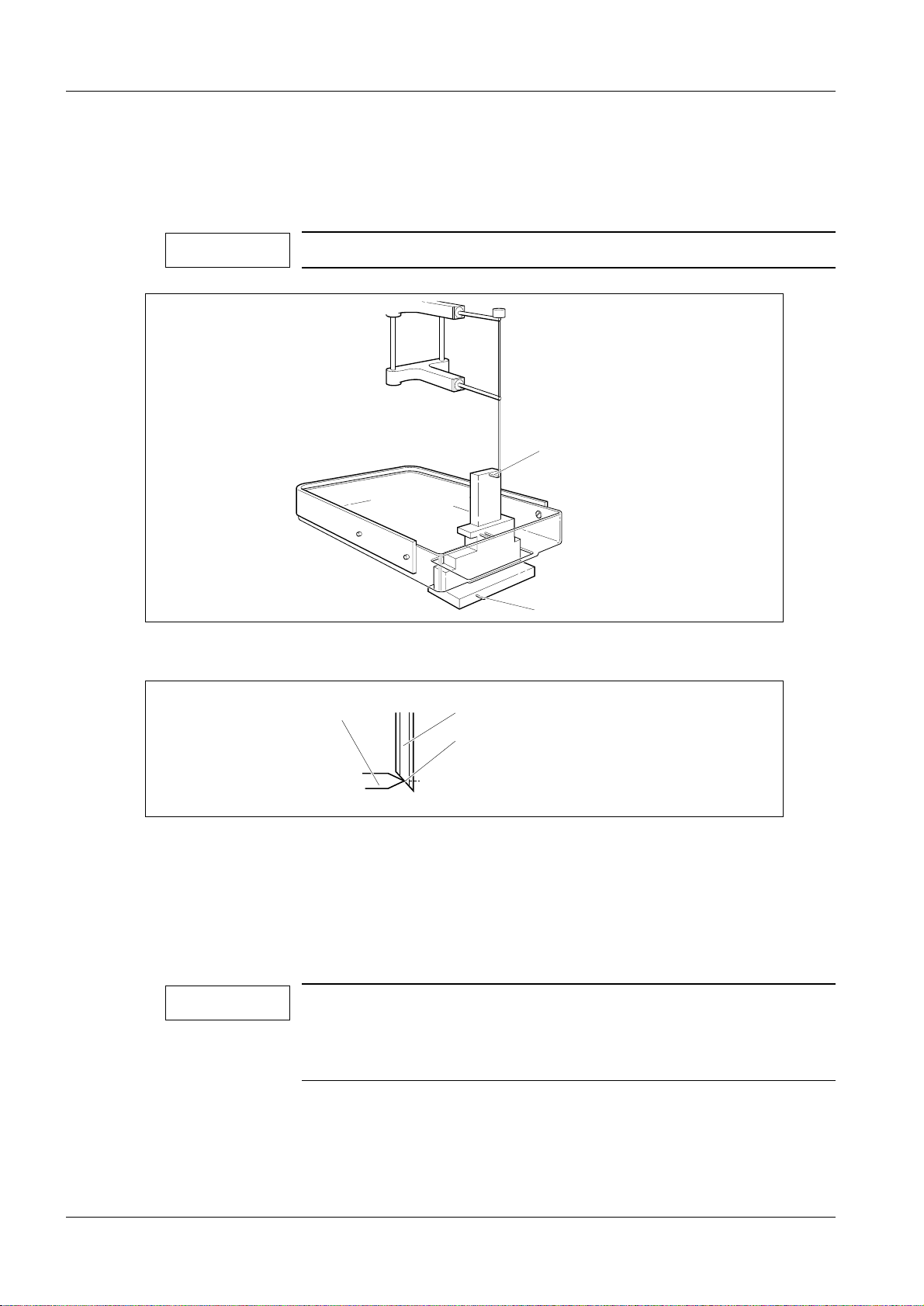

Biopsy unit 2

The biopsy unit is used for performing biopsy examinations.

The biopsy unit consists of a needle positioning device which is firmly attached to an

18 cm x 24 cm object table with a cut-out contour that is superim posed on the CCD.

External stereo diaphragm, needle supp ort and compression plate are also i ncluded in the

biopsy unit. The biopsy unit can easily be attached to the swivel arm of the MAMMOMAT.

There are three displays on the biopsy unit front. The displays show spatial deviation of

needle tip from the suspect point in x-, y- and z-axis calculated by the workstation.

Three potentiometers monitors the actual position of the needle tip.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 5 of 6 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 14

2 - 6 Functional description

This page intentionally left blank.

Opdimar Register 5 SPB7-230.061.08 Page 6 of 6 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 15

Protective measures for CCD camera 3

CAUTION

CAUTION

The CCD camera has to be handled with extreme care, it is very

sensitive to mechanical shocks and temperature. When not connected do not touch the pins in the camera contacts. Shock and

temperature sensors are integrated in the camera.

The CCD camera is sensitive to mechanical shock and shall

always be stored in the attaché case, delivered with the system,

when disconnected from the biopsy controller.

The camera shall be used within 10230i C.

The camera shall be transported or stored within 0240i C.

3 - 1

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 1 of 2 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 16

3 - 2 Protective measures for CCD camera

This page intentionally left blank.

Opdimar Register 5 SPB7-230.061.08 Page 2 of 2 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 17

Protective measures 4

CAUTION

WARNING

WARNING

CAUTION

It is very important that any intervention in the equipment shall start with disconnecting it

from the power supply with the main circuit breaker. To prevent accidental triggering of

high voltage and radiation, set the switch S2 (SS) on board D702 to OFF (lower position,

no triggering of the SS relay).

Before switching off the power for the workstation it is important

to first shut down the application software (see Logout and turning off the workstation in Supplement to the Instructions for Use

MAMMOMAT 3000 - Opdimar).

If the system is only switched off at the control panel or with S2/

D711 in the MAMMOMAT generator, line voltage will still be

present at the generator line connection, line filter Z1, Z2, transformer T1, transformer T10 and board D711 (see MAMMOMAT

1000/3000 Nova Wiring Diagram). The Opdimar is switched off

separately.

4 - 1

After shut-down of the system, there may still be about 380 V DC

present on the intermediate circuit of the MAMMOMAT generator.

This will be indicated by LED V24 on board D710. The voltage will

drop to less than 30 V within about 3 minutes, the LED goes out at

about 30 V.

The boards contain electrostatic highly sensitive components

requiring particular care in their handling (ground before making

contact and place only on a conductive surface, see Technical

Information TI 219). After completed hardware service, a protective earth measurement shall be performed.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 1 of 2 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 18

4 - 2 Protective measures

This page intentionally left blank.

Opdimar Register 5 SPB7-230.061.08 Page 2 of 2 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 19

Service mode 5

NOTICE

General 5

There are three different user levels in the Opdimar software.

• Regular user

• Administration user

• Service user

Administration users use the Service mode to perform the following tasks:

• Calibration of the biopsy unit

• Setting up needles

• User administration

• Network setup, DICOM nodes

• Backup functions

Advanced service 5

Service users can additi onally access advanced service functions. To get access you

have to log in with the user name “service”. The password is obtained from Siemens

Service Centre .

5 - 1

The following advanced service functions are included:

• Country settings

• Unit tests

• Software upgrade

• Restore disk

• Camera calibration/maintenance

• Disk cache

• Printer setup

• Log administration

• View log

The Opdimar external diaphragm must be used for tests and calibrations involving radiation.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 1 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 20

5 - 2 Service mode

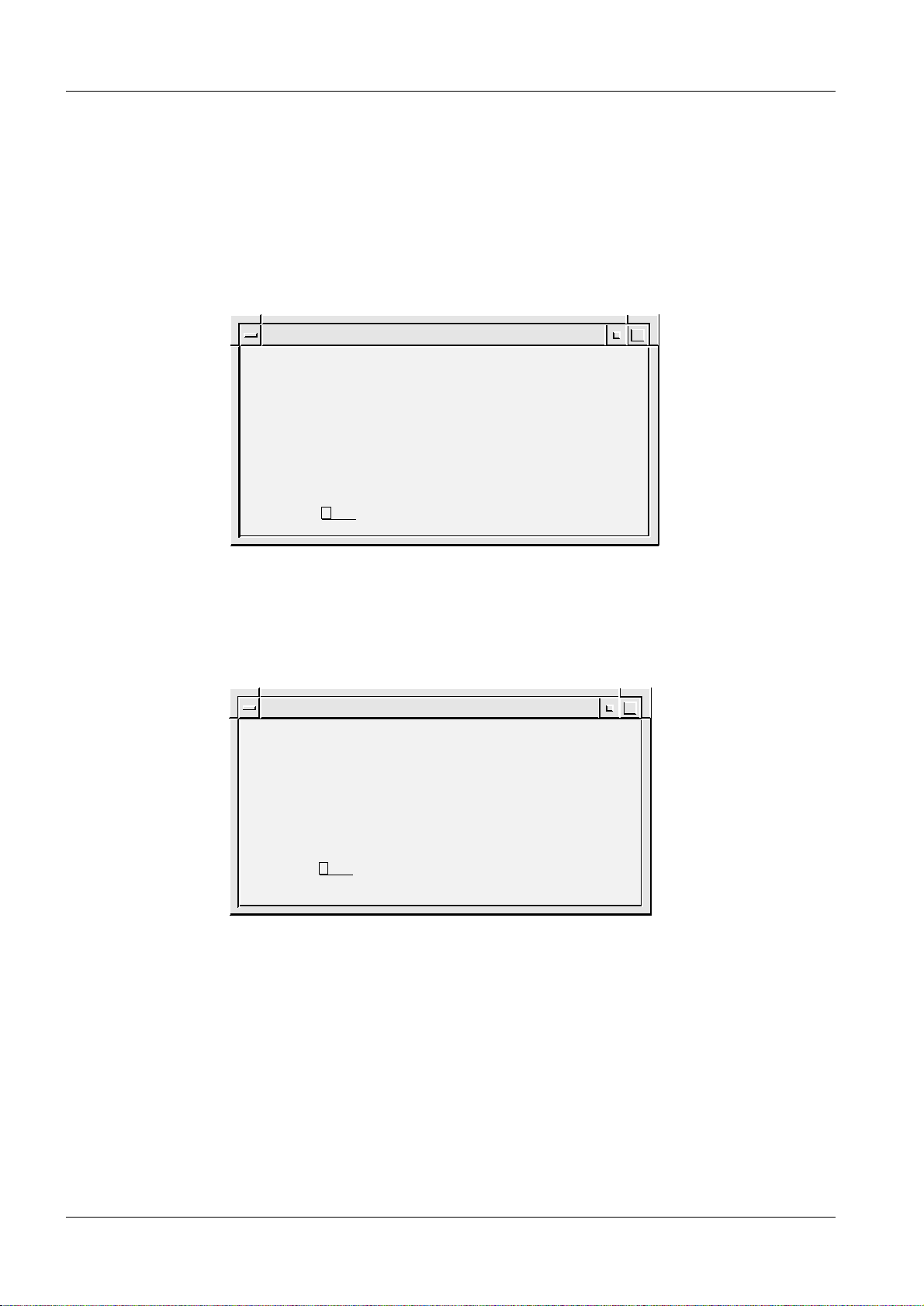

Selection of mode 5

After a successful login, the mode selection dialog is displayed.

1. Press the Service but ton.

Press Logout to cancel.

Mode Selection

Press a button to enter a user mode.

Stereo Spot

Database Service

Logout

Fig. 1 Mode selection dialog

Help

OPD00063

2. Select desired ser vice function from the service dia log.

Service

Biopsy Calibration Needle Setup

User Administration

Advanced Service

Network Setup

Change Password

Backup

Close Help

OPD00433

Fig. 2 Service dialog

Opdimar Register 5 SPB7-230.061.08 Page 2 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 21

Service mode 5 - 3

Calibration of the biopsy unit 5

Calibration of the biopsy unit is carried out by usi ng a stereo calibration phantom with

targets at fixed positions. By releasing two stereo pair exposures with a fine needle

adjusted to different targets, the s ystem is automat ically ca librated. Foll ow the instr uctions

given on the screen during the calibration procedu re.

1. Press the Biopsy Cali bration button in the service dial og.

The following is shown on the scre en:

Pixel x 138 value 1139 Gray scale center 1000 width 400y 152

123-45-6789

03/26/97

Help >>

i

Z

Z

Fig. 3 Dialogs during calibration

2. Place the stereo cal ibration phantom on the biopsy table and compress.

With the targets facing the pati ent side, the phantom fits in the openi ng of the

stereo compression plate, see Fig. 4. Target 2 shall be positioned 25228 mm in

negative x-axis direction an d 12 mm from the object table side.

1.00x

Message

1) Place and compress the stereo

calibration phantom and insert

a fine needle of suitable length.

2) Move the needle holder to the first

calibration position. 3) Remove the

needle. 4) Acquire a stereo pair of images.

Help

Default Needle

Num. X Y Z

Close Help

Targets

Display a stereo pair!

Core 100

Control

Control

Windows

Image Tools

Pointer

Magnify

[mm]

[mm]

Delete

Transmit

Ruler

Delete

Histogram

Filters

2

Layout

Invert

Zoom

Pan

Restore

Print

Help

Acquire

Single

Double

Targets

Exit

OPD00085

3. Select a fine needl e to be used and measure the length.

Measuring the needle length is described on Pag e 5 - 7.

4. Choose Other in the Needle opt ion menu and enter the selected needle length

(minimum 90 mm).

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 3 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 22

5 - 4 Service mode

NOTICE

NOTICE

5. Insert needle guides corresponding with the needle diameter.

6. Insert the fine needle into the needle guides.

7. Move the needle to Target 1 of the stereo calibration phantom, see Fig. 4, by using

the adjustment knobs. Position t he needle according to Fig. 5.

Make sure the needle is moved to Target 1.

Target 1

OPD00512

OPD00175

Fig. 4 Stereo calibration phantom

Target

Fig. 5 Position of needle

Target 2

Fine needle

Needle channel center

8. Remove the needle.

9. Acquire and release a stereo pair of images.

Set the exposure parameters to 25 kV and 28 mAs in manual mode.

10. Check the reference marks and adjust if necessary, mark Target 1 and press

Transmit.

When performing the biopsy calibration set the magnification to

0.7 and change Contrast/brightness in order to find all targets in

the phantom. Be sure to mark the target at which the needle tip

was positioned.

11. Insert the fine needle into the needle support of the biopsy uni t.

12. Move the needle to Target 2 of the stereo calibration phantom by using the

adjustment knobs.

Opdimar Register 5 SPB7-230.061.08 Page 4 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 23

Service mode 5 - 5

13. Remove the needle.

14. Acquire and release a stereo pair of images.

Set the exposure parameters to 25 kV and 28 mAs in manual mode.

15. Check the reference marks and adjust if necessary, mark Target 2 and press

Transmit.

When the calibration is successfu lly calibrated, the followi ng message is

displayed:

Message

The biopsy unit has now been

calibrated. Press EXIT!

OK

Fig. 6 Information message

Help

OPD00176

16. Perform a final check according to Verifying the calibrat ion of the biopsy unit on

Page 10 - 1 to make sure that the biopsy unit wor ks properly.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 5 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 24

5 - 6 Service mode

Setting up needles 5

1. Press the Needle Setup button in the service dialog.

Needle Setup

Type

Fine

Core

Close Help

Fig. 7 Setting up needles dialog

L1 (mm) L2 (mm)

90.5 -

110.0 5

2. Press Add... .

You can only add needles which match the needle gui des with the fixed

diameters: 0.7, 0.9, 1.2, 1.65, or 2.1 mm.

Add...

Edit...

Delete

OPD00087

Needles

Enter needle values.

L1

L2

OK Help

Fig. 8 Needle values dialog

Cancel

3. Select needle type (fine or core) from the option menu and enter needle l ength in

the text field.

L1 shall be 30 to 175 mm when selecting fine needle, L2 is not applicable for fine

needle. When selecting core, L1 shall be set to <170 mm.

CoreType

(mm)

(mm)

OPD00088

Opdimar Register 5 SPB7-230.061.08 Page 6 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 25

Service mode 5 - 7

CAUTION

NOTICE

Ensure by measuring the length of the specified needle or core

gun with needle that the right values are entered.

If the stroke length of the core gun is changed, a new needle has

to be selected from the Targets dialog. The core needle length L1

shall be measured with the core needle in outer position and

mounted in the core gun.

Fine needle

L1

L1

Needle channel center

Fig. 9 Measuring of needle length

When using core gun, the system safety margin to avoid hitting

the biopsy table is 5 mm.

Core gun

L1

L2

L1L2

Core gun

with coax

L1

L2

OPD00089

Editing needle values 5

1. Select a needle from the needle setup dialog.

2. Press Edit... .

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 7 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 26

5 - 8 Service mode

WARNING

NOTICE

Backup of temporary storage media 5

As a service user it is possible to make a complete backup of all folders existing on the

temporary storage media (the hard disk).

1. Press the Backup button in the service dialog.

Backup

Backup / restore

Backup to MO

Setup for backup

Backup enabled

OK Help

Fig. 10 Backup dialog

Restore from MO

2. In the setup for backup section disable the backup.

3. Press the Backup to MO button.

4. Follow the instruction given in the message dialogs.

5. Enable the backup in the backup dialog.

Backup of temporary storage media cannot replace the regular

use of backup described in Using the Backup function in Supplement to the Instructions for Use MAMMOMAT 3000 - Opdimar.

OPD00326

Backup of temporary storage media only saves the content

present on the hard disk at the actual moment. Images may have

been erased by the disk cache system (see Page 5 - 23) or software reinstallation.

This backup might take a long time and require several MO disks

since all folders on hard disk will be copied to backup MO.

Opdimar Register 5 SPB7-230.061.08 Page 8 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 27

Service mode 5 - 9

Use of Advanced service functions 5

General 5

To get access to the advanced service menu you have to log in with the user name

“service”. The password is obtained from Sieme ns Servi ce Centre.

The advanced service is carried out by using a number of text dialogs. Selection of an

item in a dialog can be done in three different ways:

• Use the up/down arrows of the keyboard to step through the field s (underlined)

• Use the space bar to step through the fields

• Type the corresponding number or letter of the item

Press Enter to execute.

Main menu 5

The main menu is used to access all the advanced service functio ns.

1. Press the Advanced service button in the service dialog.

2. Select a function from the menu.

Advanced Service

SERVICES

1.

Country Settings

2.

Unit Tests

3.

Software Upgrade

4.

Restore Disk

5.

Camera Calibration/Maintenance

6.

Disk Cache

7.

Printer Setup

8.

Log Administration

9.

View Log

Close

Help

Select: Close

Fig. 11 A dvanced ser vice dialog

Country Settings Function for selection of country of installation (your country).

Unit Tests Function for performing tests of subassemblies.

OPD00409

Software Upgrade Function for performing upgrade of software and for

modifications of software.

Restore Disk Function for restoring data from MO disk.

Camera Calibration/

Maintenance

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 9 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Function for performing installation and maintenance of CCD camera.

Page 28

5 - 10 Service mode

Disk Cache Function for disk cache settin gs .

Printer Setup Function for setup of printer.

Log Administration Function for log settings.

View Log Function for inspection of logs.

Close Function for leaving the advanced service mode.

Opdimar Register 5 SPB7-230.061.08 Page 10 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 29

Service mode 5 - 11

Country settings 5

National parameters are set in the country settings dialog. On delivery it contains default

settings.

Advanced Service

COUNTRY SETTINGS

Language: English

Time Zone: MET

Time Settings: Year: 2000 Month: 10 Day: 24 Hour: 09 Minute: 21

Id Pattern: 111-11-1111

Date Pattern: m/d/y

Service Center: Undefined

Institution Name: Undefined

Department Name: Undefined

Action: Close Close/Help/Apply

OPD00513

Fig. 12 Country settings dialog

Available Languages Shows the languages currently available by the system.

Language Selection of language in the dialogs. Select with space bar. If language

is changed, log out and log in to make the change take effect.

Time Zone A selection of the time zone used by the system. Select with space bar.

For faster selection, type the first letter of the desired time zone name.

Time Settings Value of system clock. If changed, Apply will reboot.

NOTICE! The database is updated every time an examination is

performed or when an image is loaded from a MO disk. The sys-

tem clock cannot be set to a point earlier than the last update.

ID Pattern Selection of ID-number structure. Type pattern with the keyboard: “1”

for digit, “a” for letter and an arbitrary character for punctuation mark.

For example: 111-11-1111.

Date Pattern Selection of date structure. Type pattern with the keyboard: “y” for year,

“m” for month, “d” for day and an arbitrary character for punctuation

mark.

For example: m/d/y or y-m-d (do not type mm/dd/yy or yy-mm-dd).

Service Center Type the appropriate service center.

Institution Name Type the appropriate name for the institution.

Department Name Type the appropriate name for the department.

1. Select Country Settings in the advanced service dialo g.

2. Set the values for Language, Time Zone, ID Pattern, Date Pattern, Service

Center, Institution Name and Departmen t Name in each respective fields.

3. Select Apply and press Enter to execute the changes.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 11 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 30

5 - 12 Service mode

NOTICE

Test of units 5

Advanced Service

UNIT TESTS

Unit

Test

Mammomat

Yes

Camera

Yes

Biopsy Controller

Yes

Modem

Yes

MO-Disk

Yes

Database

Yes

Action: Run Close/Help/Run

Fig. 13 Un it tests dialog

Status

OK

OK

OK

N/A

N/A

OK

OPD00171

Before performing unit tests, the biopsy unit needs to be

mounted to the MAMMOMAT. Otherwise the biopsy controller test

will fail.

1. Select Unit Tests in the advanced service dialog.

2. Select Yes or No to select/deselect the parts to be included in the test.

3. Select Run and press Enter.

Each unit that passes the test wil l be indicat ed with an OK messag e. If i t does not pass , a

Failed message will appear. Units that have not been tested are indicated with an

Untested message.

The units are tested according to the following:

• MAMMOMAT - test if there is a connection and if the power is on

• CCD camera - test if there is a connection and if the power is on

• Biopsy controller - test if there is a connect ion and if the power is on

• Database - reading and writing in the database

Opdimar Register 5 SPB7-230.061.08 Page 12 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 31

Service mode 5 - 13

Software upgrade 5

The software upgrade dialog is used to upgrade the current software version with a new

version from CD-ROM and to do modifications of the software.

Advanced Service

SOFTWARE UPGRADE

1. New software version

2. DICOM option

3. Network settings

4. Restore hostname

5. Update eeprom

6. Miscellaneous

Close

Help

Select: Close

OPD00514

Fig. 14 Software upgrade dialog

New software version Upgrade with new version from CD-ROM.

DICOM option Enabling the DICOM option.

NOTICE! A license key is necessary to install DICOM.

Network settings Function for defining the network settings for the Opdimar sys-

tem.

Restore hostname The hostname of the original workstation can be restored to a

new workstation.

Restore hostname from most recently used local/backup MO disk.

Update eeprom For Ultra 1 only: Save system specific information to NVRAM.

Miscellaneous Database and MO disk utilities.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 13 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 32

5 - 14 Service mode

NOTICE

CAUTION

New software version 5

This menu will be used when installing the next version of

software.

Make sure that all examinations are stored on the

MO disk before upgrading. The examinations are stored when

exiting an examination or database session, see Storing data on

MO disk in Supplement to the Instructions for Use MAMMOMAT

3000 - Opdimar.

1. Select Advanced service in the Service mode.

2. Insert the CD-ROM for the new ASW software version.

3. Select Software upgrade and New software version.

Advanced Service

NEW SOFTWARE VERSION

Current Release: opdima.2.1_6527639

CD-ROM Release: opdima.xxxx

Action: Close Close/Help/Install

Fig. 15 New software version, advanced service dialog

4. Select Install.

OPD00515

Opdimar Register 5 SPB7-230.061.08 Page 14 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 33

Service mode 5 - 15

NOTICE

NOTICE

Enabling the DICOM option 5

To enable the DICOM option you need the DICOM license key that is received when

purchasing the DICOM option.

The DICOM licence is written on the invoice and the dispatch note. If not, please contact

Siemens-Elema AB mammography logistics department in Solna, Sweden for further

information. The mammography logistics department will ask for serial No. and host ID of

the workstation in question.

Instruction for obtaining the systems host ID and hostname 5

1. Switch on the workstation.

2. Log in as service user.

3. Press the Control, Alt, Shift and ! keys at the keyboard simultaneous ly.

4. Switch to default behavior?

Press OK. The screen will flash for a second.

5. Place the mouse pointer on the screen background and press the rightmost

mouse button.

6. Select New window.

7. Type “

8. Type “

9. Type “

10. Press the Control, Alt, Shift and ! keys at the keyboard simult aneously.

11. Switch to custom behavior?

Press OK. The screen will flash for a second.

12. Done!

hostname” and press Enter.

Note the hostname (opdxxxx) shown on the screen.

hostid” and press Enter .

Note the host id (xxxxxxxx) shown on the screen.

exit” and press Enter.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 15 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 34

5 - 16 Service mode

DICOM option

1. Select Advanced service in the Service mode.

2. Select Software Upgrade.

3. Select DICOM option.

Advanced Service

DICOM OPTION

Enabled License key

No Undefined

Action: Close Close/Help/Apply

OPD00437

Fig. 16 DICOM option, advanced service dialog

4. Select Yes.

5. Enter License key and Apply.

6. Select y to reboot.

7. Configure DICOM nodes according to Network Setup in Supplement to the

Instructions for Use MAMMOMAT 3000 - Opdimar.

Opdimar Register 5 SPB7-230.061.08 Page 16 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 35

Service mode 5 - 17

NOTICE

Network settings 5

Enable network

1. Select Advanced service in the Service mode.

2. Select Software upgrade and Network settings.

3. Supply appropriate values for the network settings into the fi elds and apply.

(The values shall be supplied by the network administrator at the hospita l.)

Advanced Service

NETWORK SETTINGS

Network enabled for this host, opd1190: Yes

IP address: 123.123.123.11

Netmask: 255.255.255.0

Default router: 123.123.123.22

Action: Close Close/Help/Apply/Pingtest

OPD00518

Fig. 17 Network settings

IP address Address for the system in the network, written as four decimal

numbers separated by periods, e.g. 123.123.123.11.

No initial 0, e.g. 10.10.10.10 is OK but 010.01 0.010.01 is

not OK.

Netmask Netmask used in the network if IP standard subnetting is used.

Default router The IP address of the default router, if this is used in the network.

No initial 0, e.g. 10.10.10.10 is OK but 010.01 0.010.01 is

not OK.

4. Select y to enable the network. The workstation will be turned off.

5. Connect the network cable.

6. Switch on the workstation.

Pingtest

A pingtest checks that the default router is alive, it can be performed when the network is

enabled.

1. Select Pingtest in the Network settings dialog.

Some alive routers do not reply to pingtest, check with network

administrator.

To test if a host is alive or not, write the IP address temporarily in the field for Default

router and perform a pingtest.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 17 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 36

5 - 18 Service mode

Miscellaneous 5

1. Select Advanced service in the Service mode.

2. Select Miscellaneous.

Advanced Service

MISCELLANEOUS

Options

1. Check database

2. Inspect database contents

3. MO disk utilities

Close

Help

Select: Close

OPD00516

Fig. 18 M iscellaneous , advance d service dialog

Check database

This will check and adjust invalid folder names that may have been introduced in earlier

software versions.

1. Select check database.

Advanced Service

CHECK DATABASE

Check:

Yes MO Disk

Yes Local Database

Action: Close Close/Help/Run

OPD00441

Fig. 19 C heck datab ase, advan ced service dialog

2. Select the database to check, MO Disk and/or Local Database.

3. Select Run.

Opdimar Register 5 SPB7-230.061.08 Page 18 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 37

Service mode 5 - 19

NOTICE

Inspect database contents

1. Select Inspect database contents.

A Text Editor window with a log file will appear on the screen, see example in

Appendix 2.

The log file is only a print-out of the data in the database.

Changes in the log file will NOT affect the database.

2. When done, close the Text Editor window.

MO disk util it ie s

Advanced Service

MO DISK UTILITIES

Options:

1. Check MO disk

2. Repair MO disk

3. View output from latest "Repair MO disk" execution

4. Identify MO disk

5. List MO directories and files

6. Create clean MO disk

Close

Help

Select: Close

Fig. 20 MO disk utilities, advanced service dialog

OPD00517

Check MO disk Check MO disk file system integrity.

Repair MO disk Repair MO disk file system.

NOTICE! Run only if Check MO disk shows that something

has to be done.

View output Lists output from latest “Repair MO disk” execution.

Identify MO disk Shows the kind of disk (local storage/backup/transfer...).

List MO directories and files View contents of MO disk.

Create a clean MO disk Format a new disk or erase contents of a formerly used disk.

WARNING! Use with extreme caution. Erases all content on

MO disk.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 19 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 38

5 - 20 Service mode

WARNING

NOTICE

Restoring data from MO disk 5

Copies the database from the MO disk to the hard disk. It is possible to use a local

storage MO disk or a backup MO disk.

Advanced Service

RESTORE DISK

MO-Disk: /opdxxxx/3

Last Backup: 990908

Action: Restore Close/Help/Restore

OPD00460

Fig. 21 Restore disk dialog

MO disk Name of the inserted MO disk.

Last backup Last date for storing on the MO disk.

1. Insert the most recently used MO disk in the MO unit.

2. Select Restore Disk in the advanced service dialog.

3. Select Restore and press Enter to copy the data to the hard disk.

When restoring data, be sure to insert the MO disk that was used

most recently before the reinstallation of software.

Date for last update of MO disk is displayed on the monitor before

confirmation of restore.

If the system is restored from an older MO disk, the most recent

folders will be lost from the dat a b ase and the new M O di s k nu m bering can be incorrect. Please contact HSC for more informat ion.

Set up the printer once again after software reinstallation.

Printer info can not be restored.

Opdimar Register 5 SPB7-230.061.08 Page 20 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 39

Service mode 5 - 21

NOTICE

NOTICE

CCD camera calibration and maintenance 5

Advanced Service

CAMERA CALIBRATION/MAINTENANCE

Action: Run Close/Help/Run

OPD00411

Fig. 22 Camera calibration/maintenance

This calibration shall be performed with the object table (grid or

non grid) that the customer is going to use in most cases.

Do not use the stereo table when calibrating.

Fill in your values in the test protocol for CCD camera calibration (see Appendix 3).

Grid table 5

1. To avoid grid lines in the calibration images, temporary incr ease the grid speed

during calibration as foll ows:

Change the grid fast speed time to 1500 ms , the grid fast speed to 99% of max

and the grid slow speed to 40% of max (Fig. 23) us ing the service PC.

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

AEC

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Grid

Grid fast speed time 1500

Grid fast speed 99

Grid slow speed 40

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

ms (2.5 s max)

% of max

% of max

OPD00491

Fig. 23

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 21 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 40

5 - 22 Service mode

2. Place 40 mm acrylic plastic (PMMA) on the table, covering the CCD.

3. Select Camera Calibration/Maintenance in the advanced service dial og.

4. Select Run and set 27 kV, Mo/Mo and AEC mode, on the generator.

Follow the instructions displ ayed on the screen.

Between each exposure the acrylic plasti c shall be moved slightly (the reason

being that impurities in th e plastic shall not influence the calibration).

After the exposure series, corr ection tables will be calculat ed. This will take 10

minutes at most.

After a successful calibrat ion (10 exposures in each mode - normal resolu tion and

high) the message “Camera successfully cal ibrated” will appear on the screen.

5. Change the grid speed back to original values.

6. Perform check of Opdimar AEC and check of resolution. See Check of Opdima

AEC on Page 10 - 2 and Check of resolution on Page 10 - 4.

Non grid table 5

1. Place 30 mm acrylic plastic (PMMA) on the table, covering the CCD.

2. Select Camera Calibration/Maintenance in the advanced service dial og.

3. Select Run and set 26 kV, Mo/Mo and AEC mode, on the generator.

Follow the instructions displ ayed on the screen.

Between each exposure the acrylic plasti c shall be moved slightly (the reason

being that impurities in th e plastic shall not influence the calibration).

After the exposure series, corr ection tables will be calculat ed. This will take 10

minutes at most.

After a successful calibrat ion (10 exposures in each mode - normal resolu tion and

high) the message “Camera successfully cal ibrated” will appear on the screen.

4. Perform check of Opdimar AEC and check of resolution. See Check of Opdima

AEC on Page 10 - 2 and Check of resolution on Page 10 - 4.

Opdimar Register 5 SPB7-230.061.08 Page 22 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 41

Service mode 5 - 23

Disk cache settings 5

Storage parameters can be set in the disk cache dialog:

Advanced Service

DISK CACHE

Clean cache trigger: 75 %

Number of images to clean: 50

Action: Apply Close/Help/Apply

OPD00461

Fig. 24 Disk cache dialog

Clean cache trigger Cleans a number of images from the cache memory (the temporary

storage media i.e. hard disk) when it has been filled up to a percentage

of the capacity. Normally set to 75%.

Number of images to

clean

The number of images to erase once the trigger level has been

reached. Normally set to 50.

1. Select Disk Cache in the advanced service dialog.

2. Set the values.

3. Select Apply and press Enter.

Every time an examination is performed a folder contain ing the image file, the image icons

and the image header file is created. When an examina tion is f inished th e complete fol der

is copied to the MO disk. If a folder has been copied to a MO disk, its images will be

erased from the hard disk if the cache limit is reached.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 23 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 42

5 - 24 Service mode

NOTICE

NOTICE

Use of printer setup 5

Stand alone Opdima system 5

Connection of stand alone printer.

Advanced Service

PRINTER SETUP

Printer Alternatives:

none

ps_net PostScript network printer

ps_par PostScript parallel printer

scaled Codonics NP-1600 scaled

Selection: none

Action: Apply Close/Help/Apply

Fig. 25 Printer setup dialog

1. Select printer by pressing the Space button.

1.1 ps_net: PostScript network printer, for post script printer connected to the

network connector of the workstation se e 7/Fig. 10 on Page 6 - 11. The

printer IP address has to be set to 10. 10.10.2.

1.2 ps_par: PostScript parallel printer, for post script printer connected t o the

parallel port of the workstati on see 8/Fig. 10. on Page 6 - 11.

1.3 scaled: Codonics NP-1660 or NP-1600 scaled, for a Codonics printer

connected to the network connector of t he workstation see 7/Fig. 10 on

Page 6 - 11. The printer IP address has to be se t to 10.10.10.2.

2. Select Apply and press Enter.

3. Connect your selected printer after turning off th e system.

OPD00412

If no printer is connected select none, apply and restart the system.

Opdimar Register 5 SPB7-230.061.08 Page 24 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 43

Service mode 5 - 25

NOTICE

Networked Opdima sy stem 5

Connection of networked printer.

Advanced Service

PRINTER SETUP

1. Add access to network printer

2. Remove access to network printer

3. Select printer

Close

Help

Select: Close

OPD00428

Fig. 26 P rinter setup dialog when connected to a network

When the Opdimar system is connected to a network (see Page 5 - 17) it can be

configured to print on a printer connected to the network. Supported printer types are

postscript printers and printers that can handle XWD files (X Window Dump).

Add access to network printer

Advanced Service

ADD NETWORK PRINTER

Printer name: mammo_printer

Description: Codonics_mammo_dept

Address: 123.123.123.33

(Remote name: scaled )

Printer type: XWD

Action: Close Close/Help/Apply

OPD00527

Fig. 27 Add network printer dialog

Printer name: Logical name presented when selecting printer in Advanced

service. No space characters are allowed. E.g. mammo_printer.

Description: Textual description, for example the location of the printer. E.g.

Codonics_mammo_dept.

Address: IP address for printer, e.g. 123.123.123.33.

No initial 0, e.g. 10.10.10.10 is OK but 010.010.010.01 is not OK.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 25 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 44

5 - 26 Service mode

Remote name: Name of printer at remote system. No space characters are

allowed.

NOTICE! The remote name “scaled” must be used when

using a Codonics printer.

Printer type: PS or XWD. Use PS for all postscript printers.

NOTICE! XWD shall be used with Codonics printers.

Select printer

Advanced Service

SELECT PRINTER

Printer Alternatives:

none

ps_par PostScript parallel printer

mammo_printer Codonics_mammo_dept

Selection: mammo_printer

Action: Close Close/Help/Apply

OPD00528

Fig. 28 Select printer dialog, example

Note that only ps-par and network printers that have been added can be selected when

the network has been enabled for the system.

Remove access to network printer

Advanced Service

REMOVE NETWORK PRINTER

Printers:

mammo_printer XWD 123.123.123.33 Codonics_mammo_dept

Selection: mammo_printer

Action: Close Close/Help/Apply

OPD00529

Fig. 29 Remove network printer dialog, example

Previously defined printers can be removed from the l ist of printers. Note that the pri nter

that is currently selected cannot be remov ed.

Opdimar Register 5 SPB7-230.061.08 Page 26 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 45

Service mode 5 - 27

Log administration 5

Log files are stored on the temporary storage media and on the MO disks. In the log

administration dialog, the l ogging can be turned on/off.

Advanced Service

LOG ADMINISTRATION

Log

System Log

Error Log

Activity Log

Maintenance Log

Action: Apply Close/Help/Apply

Fig. 30 Log administration dialog

1. Select Log Administration in the advanced service dialog.

2. Select Yes/No to turn on/off each respective log.

3. Select Apply and press Enter.

Enabled

Yes

Yes

Yes

Yes

Size

N/A

N/A

N/A

N/A

OPD00184

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 27 of 28 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 46

5 - 28 Service mode

Log inspection 5

Through the view log dialog, the log files can be inspected.

Advanced Service

VIEW LOG

1. Message Log

2. Error Log

3. Activity Log

4. Service Log

5. Backup Log

C. Close

H. Help

Select: Close

OPD00414

Fig. 31 View log dialog

Message Log Log for messages presented to the user.

Error Log Log for Opdimar related errors.

Activity Log Log for all user activities.

Service Log Log for activities in service mode.

Backup Log Log for activities made in backup mode.

Close Function for leaving the view log dialog.

1. Select View Log in the advanced service dialog.

2. Select a log from the menu in the view log dialog.

Opdimar Register 5 SPB7-230.061.08 Page 28 of 28 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 47

Removal and replacement of sub-assemblies 6

WARNING

CAUTION

NOTICE

General 6

After performing hardware service, protecti ve earth measurement has to be performed,

see Protective earth measurement on Page 10 - 5.

Switch off the power to the system at the main circuit breaker

after complete power off.

If the workstation shall be powered off, use the “poweroff” command and make sure that the system has completed the process

before switching off any main power. If power to the workstation

is disabled during the pow er off sequence or without using the

“poweroff” command, data could be lost.

For Ultra 10 only: After the “poweroff” command has been started the OK prompt will

appear. To switch off the power completely press Control + power on key si multaneously.

MO unit (no CD) 6

6 - 1

HEWLETT

PACKARD

Fig. 1 The MO unit, front view

Removing the MO unit 6

,I02XQLWLVGHIHFWLYHWKHFRPSOHWHXQLWPXVWEHUHSODFHG

1. Disconnect the power supply cable (AC in) and SCSI cable from the back of the

unit (Fig. 2).

2. Unplug the SCSI terminator from the back of the unit (Fig. 2).

3. Remove the unit.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 1 of 24 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 48

6 - 2 Removal and replacement of sub-assemblies

NOTICE

Installing the MO unit 6

Make sure that the SCSI cables are properly connected and fixed

to the units and that the cable is not bent to much just behind the

MO unit. Also, check that the MO unit is terminated correctly. If

not, this might generate a lot of problems e.g. failure to write

images to MO disk, corrupted MO disk or corrupted hard disk.

SCSI ID Disk drive type Disk drive function

1 Magneto-optical drive Permanent storage and backup m edia

(MO disk)

Connector for

SCSI ID switch

Device Mode switch

incoming SCSI cable

1

3

Fan AC in

Fig. 2 MO unit, back view

On/off switch

SCSI terminator

OPD00522

1. Set SCSI ID switch to 1 (SCSI address).

2. Set Device mode switch to 3 (Direct access/verify on).

3. Connect the power supply cable, the SCSI terminator and the SCSI cabl e to the

unit.

Tests and Adjustments 6

1. Switch on the system.

2. Ensure that the system is operating properly.

Opdimar Register 5 SPB7-230.061.08 Page 2 of 24 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 49

Removal and replacement of sub-assemblies 6 - 3

NOTICE

CD/MO unit 6

CD-ROM drive

Magneto-optical drive

B

A

NEWS

SYSTEM

Fig. 3 CD/MO unit

Removing the CD/MO unit 6

OPD00098

,IWKH&'GULYHRU02XQLWLVGHIHFWLYHWKHFRPSOHWHXQLWPXVWEH

UHSODFHG

1. Disconnect the power supply cable (AC in) and SCSI cable from the back of the

unit (Fig. 4).

2. Unplug the SCSI terminator from the back of the unit (Fig. 4).

3. Remove the unit.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 3 of 24 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 50

6 - 4 Removal and replacement of sub-assemblies

NOTICE

NOTICE

Installing the CD/MO 6

Make sure that the SCSI cables are properly connected and fixed

to the units and that the cable is not bent to much just behind the

MO unit. Also, check that the MO unit is terminated correctly. If

not, this might generate a lot of problems e.g. failure to write

images to MO disk, corrupted MO disk or corrupted hard disk.

SCSI ID Disk drive type Disk drive function

1 Magneto-optical drive Permanent storage and backup media

(MO disk)

6 CD-ROM disk drive Software distribution

Fan

On/off switch

AC in

Fig. 4 CD/MO unit, back view

,IWKH02XQLWKDVQRVZLWFKHVWKH6&6,,'VDUHVHWLQWHUQDOO\

1. Set CD SCSI ID switch to 6.

2. Set MO SCSI ID switch to 1.

CD SCSI ID switch

6

1

MO SCSI ID switch

Connector for

incoming SCSI

cable

SCSI terminator

3. Connect the power supply cable, the SCSI terminator and the SCSI cabl e to the

unit.

Tests and Adjustments 6

1. Switch on the system.

2. Ensure that the system is operating properly.

Opdimar Register 5 SPB7-230.061.08 Page 4 of 24 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 51

Removal and replacement of sub-assemblies 6 - 5

CAUTION

WARNING

Biopsy controller 6

Removal of biopsy controller 6

The biopsy controller is attached to the stand rear side. T o remove the unit proceed as

follows:

1. Remove the CCD camera and store it in its attaché case.

Do not touch the pins in the contacts of the camera.

The CCD camera is sensitive to mechanical shock and shall

always be stored in the attaché case when disconnected fro m the

biopsy controller.

2. Remove the biopsy controller cable duct.

3. Disconnect all cables.

4. Lift off the biopsy controller (1/Fig. 5) from the holder s of the stand (2/Fig. 5).

If the MAMMOMAT power is switched on, there is mains voltage

present at the biopsy controller mains cord connector.

2

1

OPD00152

Fig. 5 Biopsy controller

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 5 of 24 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 52

6 - 6 Removal and replacement of sub-assemblies

NOTICE

Removal of biopsy controller cover 6

To remove the cover of the biopsy controller, proceed as follows:

1. Remove the 13 screws (4/Fig. 6) on the back side of the biopsy controller .

2. Remove the seven countersunk screws (2/Fig. 6) on the sides of the biop sy

controller.

3. Lift off the cover, starting at the top.

1243 5

7

Fig. 6 Removal of cover

6

OPD00186

Replacement of components in the biopsy controller 6

Replacement of board D200

To replace the board D200 in the biopsy controller, proceed as follows:

1. Remove the screws (3/Fig. 6) holding the connectors X201, X202, X206, X207,

X208.

2. Loosen the four screws (1/Fig. 6) on the back side of the biopsy con troller.

3. Loosen the four screws (7/Fig. 6) on the side of the biopsy control ler.

4. Remove the screws (6/Fig. 6) holding the board.

5. Remove the board and install the new board. If necessary, loosen the transf ormer.

Make sure to replace the isolation fi lm at the connectors X203, X204 and X205.

When installing the board, pry the boar d holders carefully in posit ion by using a

screwdriver at the slots (5/Fi g. 6) on the back side of the biopsy control ler.

6. With an ohm meter verify that the isolation film at connector s X203, X204 and

X205 is functioning properly. The res istance shall be in excess of 10 Mc, when

measuring between the back side of the biop sy controller and the shielded

housing surrounding the pins of the connect ors X203, X204 and X205. If the

resistance is less than 10 Mc, the isol ation film has to be replaced.

Led V2 NVM error “Biopsy unit not responding” will appear after

replacement of D200, see Biopsy unit not responding on Page 9 -

2.

Opdimar Register 5 SPB7-230.061.08 Page 6 of 24 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 53

Removal and replacement of sub-assemblies 6 - 7

CAUTION

Replacement of fuse in mains filter

The mains filter (3/Fig. 7) contains a fuse. To change fuse, proceed as follows:

1. Remove the fuse holder (1/Fig. 7) from the filter using a screwdriv er and remove

the old fuse (2/Fig. 7).

2. Install a new fuse in the fuse holder.

3. Insert the fuse holder into the filter according to Fi g. 7.

The new fuse must be placed in the same position as the old one

and the marks on the fuse holder and the mains filter must coincide, see Fig. 7.

Fig. 7 Fuse in mains filter

220-240V

1

0

1

3

2

OPD00187

Replacement of fuses on printed circuit board, D200

Fuses on the board D200 in the biopsy controller can be exchanged. The location of the

fuses is shown in MAMMOMAT 1000/3000 Nova - Opdimar Wiring Diagram.

Replacement of EPROMs

To replace the EPROMs of the board D200 in the biopsy unit, proceed as follows:

1. Use PROM extractor to remove the EPROM.

2. Install the new EPROM.

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 7 of 24 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 54

6 - 8 Removal and replacement of sub-assemblies

Ultra 10 Cables 6

The biopsy controller is the central unit for the cable connections. The cables are

connected to the biopsy controller accordi ng to the figure below:

CCD camera

D110

X112

X110

X111

Workstation

Printer

(option)

Fig. 8 Connection of cables

D101/X101

A

B

M3000 printer/

Service PC

M3000 generator

X201

X202

X203

X204

X205

Biopsy controller

Mains cable

X207

X206

Z801

X2 X885

Biopsy unit

(M3000 stand)

Protective

earth cable

X880

M3000 stand

OPD00464

Opdimar Register 5 SPB7-230.061.08 Page 8 of 24 Siemens-Elema AB

Service Rev. 03 03.01 SPS-UD Solna, Sweden

Page 55

Removal and replacement of sub-assemblies 6 - 9

Ultra 1 Cables 6

The biopsy controller is the central unit for the cable connections. The cables are

connected to the biopsy controller according to the figure below:

CCD camera

D110

X112

X110

X111

Workstation

Printer

(option)

Fig. 9 Connection of cables

D100/X101

A

B

M3000 printer/

Service PC

M3000 generator

X201

X202

X203

X204

Biopsy controller

X205

X206

X2 X885

X207

Mains cable

Z801

M3000 stand

Biopsy unit

(M3000 stand)

OPD00188

Siemens-Elema AB Register 5 SPB7-230.061.08 Page 9 of 24 Opdimar

Solna, Sweden Rev . 03 03.01 SPS-UD Service

Page 56

6 - 10 Removal and replacement of sub-assemblies

Biopsy unit 6

After any repair on the biopsy unit the accuracy has to be tested with the stereo calibrat ion