Page 1

s

Introduction

INSTRUCTIONS

ENGLISH

SITRANS F M MAGFLO

Electromagnetic flowmeter

type MAG 5100 W

Siemens Flow Instruments SITRANS F M MAGFLO

sensor and a transmitter. These instructions only describe the sensor installation. For further

information on the transmitter installation, please refer to the SITRANS F M MAGFLO

electromagnetic flowmeters consist of a

handbook.

083R9166

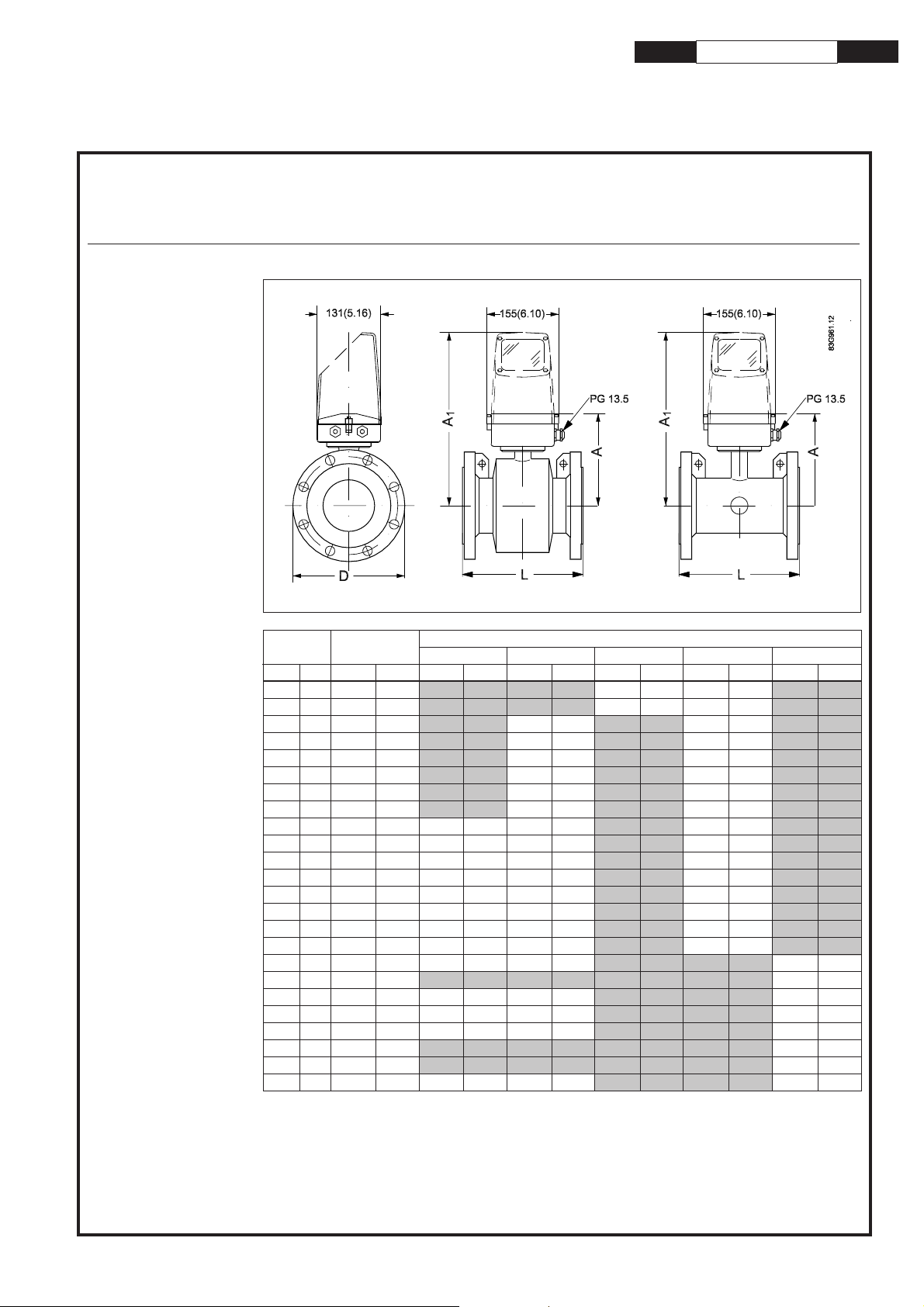

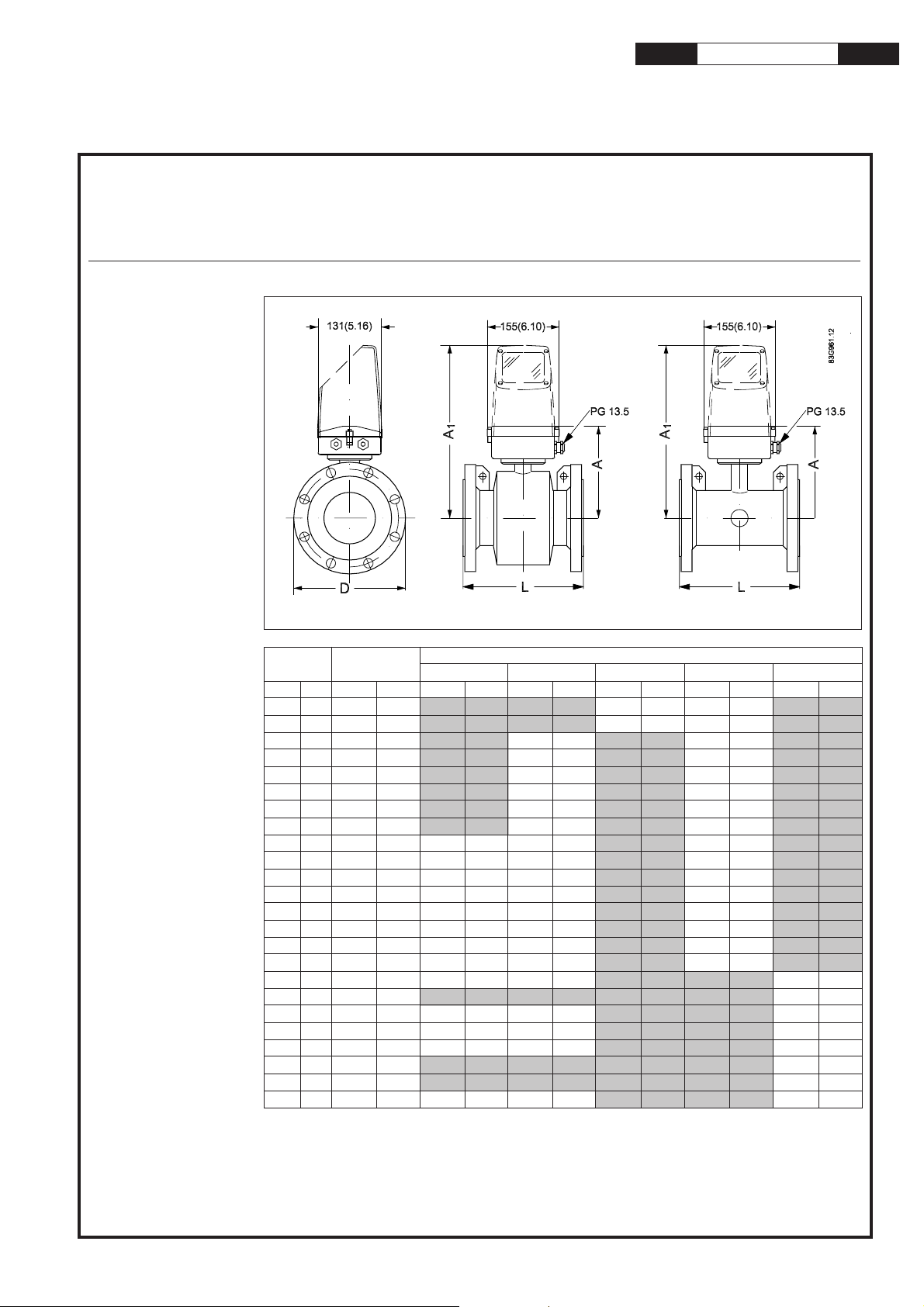

Dimensions and

weight

Dimensions

MAG 5100 W, compact/separate

Nominal

size

mm inch mm inch mm inch mm inch mm inch mm inch mm inch

25 1" 187 7.4 N/A N/A N/A N/A 200 7.9 200 7.9 N/A N/A

40 1½” 197 7.8 N/A N/A N/A N/A 200 7.9 200 7.9 N/A N/A

50 2" 188 7.4 N/A N/A 200 7.9 N/A N/A 200 7.9 N/A N/A

65 2½” 194 7.6 N/A N/A 200 7.9 N/A N/A 200 7.9 N/A N/A

80 3" 200 7.9 N/A N/A 200 7.9 N/A N/A 200 7.9 N/A N/A

100 4" 207 8.1 N/A N/A 250 9.8 N/A N/A 250 9.8 N/A N/A

125 5" 217 8.5 N/A N/A 250 9.8 N/A N/A 250 9.8 N/A N/A

150 6" 232 9.1 N/A N/A 300 11.8 N/A N/A 300 11.8 N/A N/A

200 8" 257 10.1 350 13.8 350 13.8 N/A N/A 350 13.8 N/A N/A

250 10" 284 11.2 450 17.7 450 17.7 N/A N/A 450 17.7 N/A N/A

300 12" 310 12.2 500 19.7 500 19.7 N/A N/A 500 19.7 N/A N/A

350 14" 362 14.3 550 21.7 550 21.7 N/A N/A 550 21.7 N/A N/A

400 16" 387 15.2 600 23.6 600 23.6 N/A N/A 600 23.6 N/A N/A

450 18" 418 16.5 600 23.6 600 23.6 N/A N/A 600 23.6 N/A N/A

500 20" 443 17.4 625 24.6 625 24.6 N/A N/A 680 26.8 N/A N/A

600 24" 494 19.4 750 29.5 750 29.5 N/A N/A 820 32.3 N/A N/A

700 28" 544 21.4 875 34.4 875 34.4 N/A N/A N/A N/A 875 34.4

750 30" 571 22.5 N/A N/A N/A N/A N/A N/A N/A N/A 937 36.9

800 32" 606 23.9 1000 39.4 1000 39.4 N/A N/A N/A N/A 1000 39.4

900 36" 653 25.7 1125 44.3 1125 44.3 N/A N/A N/A N/A 1125 44.3

1000 40" 704 27.7 1250 49.2 1250 49.2 N/A N/A N/A N/A 1250 49.2

42" 704 27.7 N/A N/A N/A N/A N/A N/A N/A N/A 1250 49.2

1100 44" 755 29.7 N/A N/A N/A N/A N/A N/A N/A N/A 1375 54.1

1200 48" 810 31.9 1500 59.1 1500 59.1 N/A N/A N/A N/A 1500 59.1

A

PN 10

PN 16 PN 40 Class 150

L

AWWA

Order no.: FDK:521H1190

SFIDK.PI.026.V1.52

Page 2

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

Weight

Nominal size

mm inch kgs lbs kgs lbs kgs lbs kgs lbs kgs lbs

25 1" N/A N/A N/A N/A 4 9 4 9 N/A N/A

40 1½" N/A N/A N/A N/A 7 15 6 13 N/A N/A

50 2" N/A N/A 9 20 N/A N/A 8 20 N/A N/A

65 2½" N/A N/A 10.7 24 N/A N/A 11 24 N/A N/A

80 3" N/A N/A 11.6 26 N/A N/A 13 28 N/A N/A

100 4" N/A N/A 15.2 33 N/A N/A 19 41 N/A N/A

125 5" N/A N/A 20.4 45 N/A N/A 24 52 N/A N/A

150 6" N/A N/A 26 57 N/A N/A 29 64 N/A N/A

200 8" 48 106 48 106 N/A N/A 56 124 N/A N/A

250 10" 64 141 69 152 N/A N/A 79 174 N/A N/A

300 12" 76 167 86 189 N/A N/A 110 243 N/A N/A

350 14" 100 220 116 255 N/A N/A 131 289 N/A N/A

400 16" 127 280 144 317 N/A N/A 165 364 N/A N/A

450 18" 152 335 178 393 N/A N/A 176 388 N/A N/A

500 20" 184 405 232 512 N/A N/A 235 518 N/A N/A

600 24" 258 568 343 736 N/A N/A 345 761 N/A N/A

700 28" 315 693 350 772 N/A N/A N/A N/A 309 681

750 30" N/A N/A N/A N/A N/A N/A N/A N/A 480 1058

800 32" 410 904 442 975 N/A N/A N/A N/A 421 928

900 36" 512 1129 550 1213 N/A N/A N/A N/A 539 1188

1000 40" 650 1433 732 1614 N/A N/A N/A N/A 670 1477

42" N/A N/A N/A N/A N/A N/A N/A N/A 700 1544

1100 44" N/A N/A N/A N/A N/A N/A N/A N/A 1100 2426

1200 48" 990 2183 1106 2439 N/A N/A N/A N/A 1030 2271

PN 10 PN 16 PN 40 Class 150

AWWA

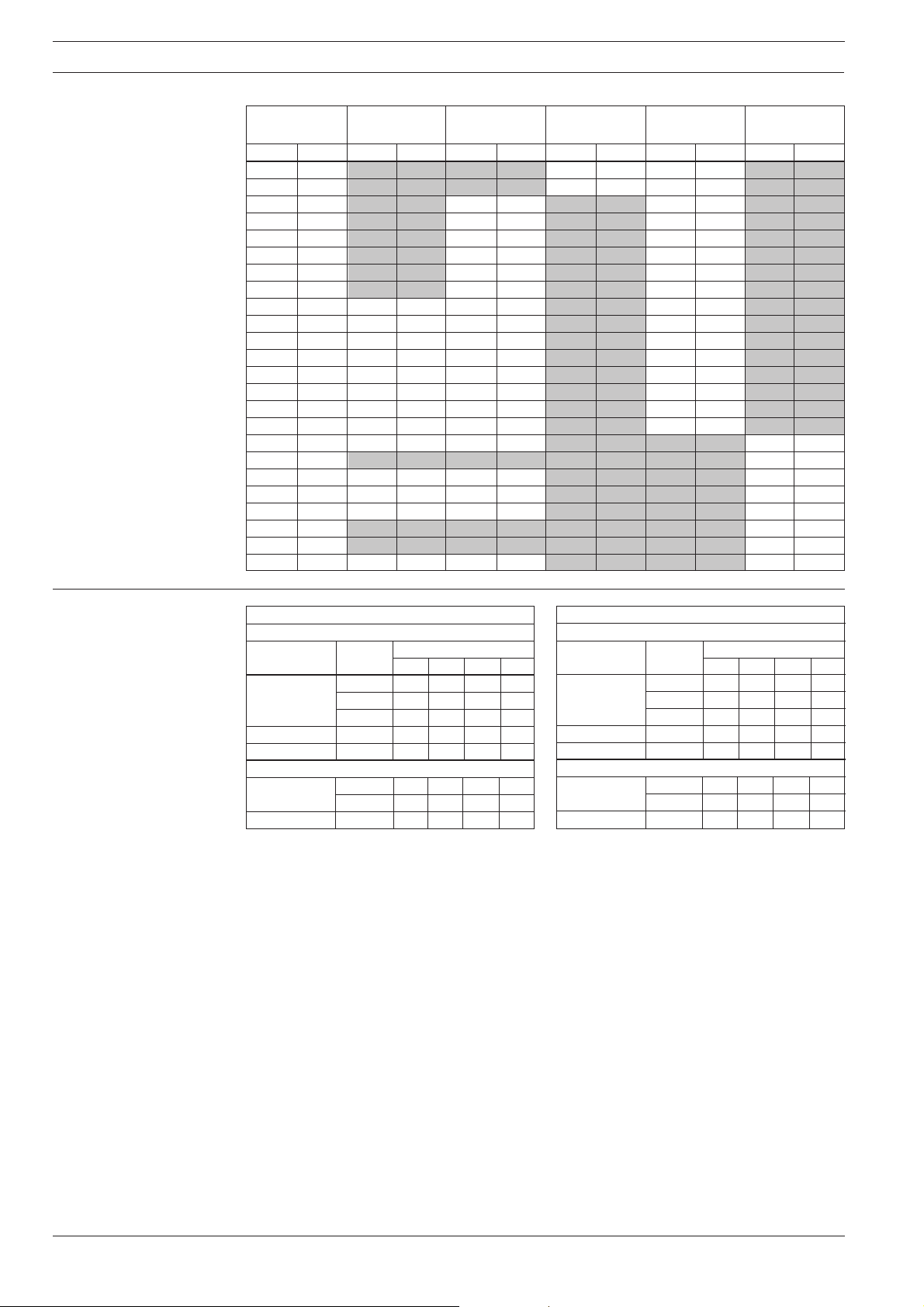

The effect of temperature

on working pressure

Metric (Pressures in bar)

Sizes 25 mm, 40 mm & > 300 mm

Flange spec. Flange Temperature

rating −5105090

EN 1092-1 PN 10 10.0 10.0 9.7 9.4

PN 16 16.0 16.0 15.5 15.1

PN 40 40.0 40.0 38.7 37.7

ANSI B16.45 150 lb 19.7 19.7 19.3 18.0

AWWA C-207 Class D 10.3 10.3 10.3 10.3

Sizes 50 mm to 300 mm

EN 1092-1 PN 10 10.0 10.0 10.0 8.2

PN 16 10.0 16.0 16.0 13.2

ANSI B16.45 150 lb 10.0 19.7 19.7 16.2

°°

°C

°°

Imperial (Pressures in Psi)

Sizes 1", 1½", & > 12"

Flange spec. Flange Temperature

rating 23 50 120 200

EN 1092-1 PN 10 145 145 141 136

PN 16 232 232 225 219

PN 40 580 580 561 547

ANSI B16.45 150 lb 286 286 280 261

AWWA C-207 Class D 150 150 150 150

Sizes 2" to 12"

EN 1092-1 PN 10 145 145 145 119

PN 16 145 232 232 191

ANSI B16.45 150 lb 145 286 286 235

°°

°F

°°

2

Page 3

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

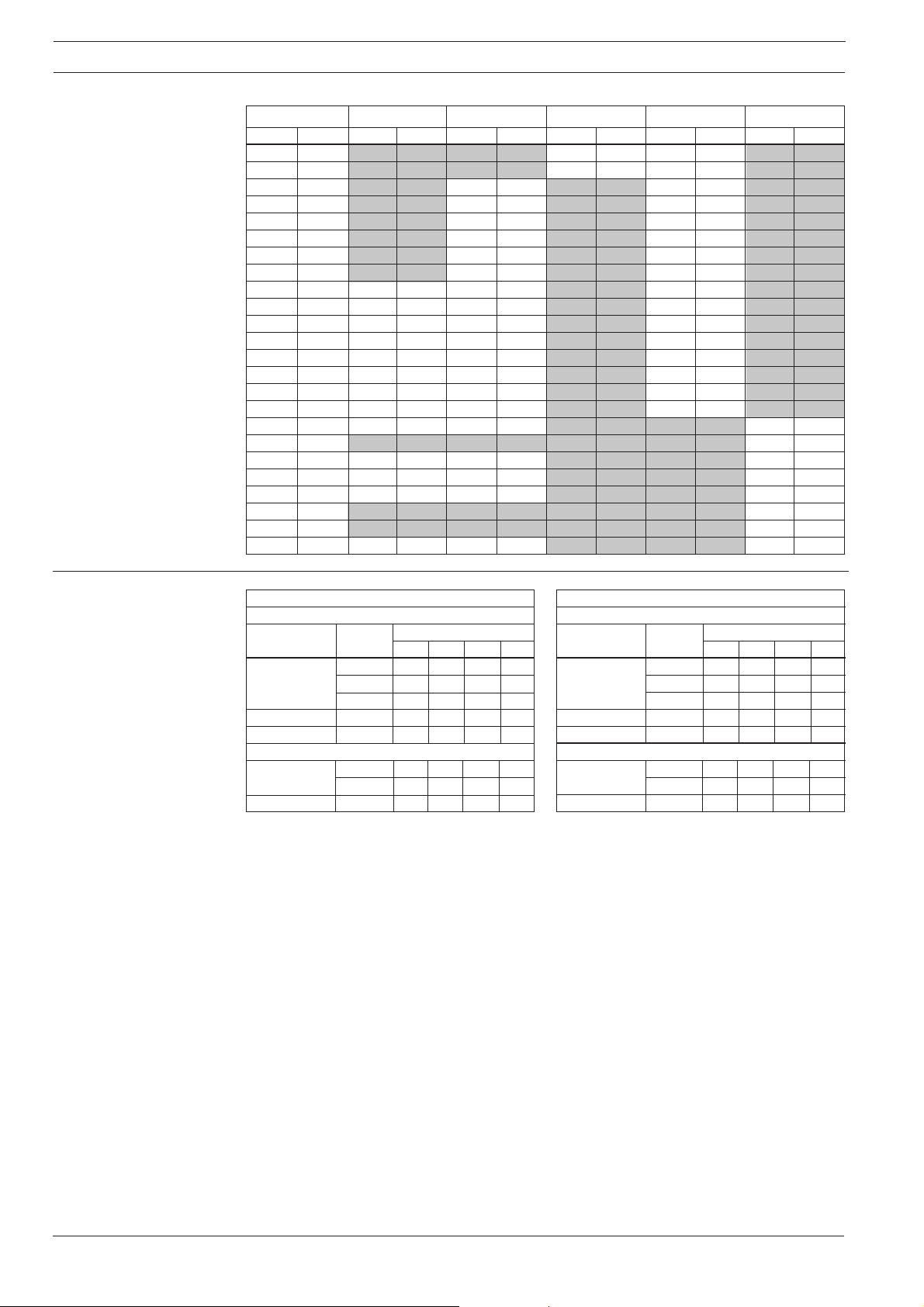

Installation, general

Reading and operating the flowmeter is possible under almost any installation conditions

because the display can be oriented in relation

to the sensor. To ensure optimum flow measurement attention should be paid to the following:

The sensor must always be completely full with

liquid.

Therefore avoid:

• Installation at the highest point in the pipe

system

• Installation in vertical pipes with free outlet

For partially filled pipes or pipes with downward

flow and free outlet the flowmeter should be

located in a U-tube.

Installation in vertical pipes

Recommended flow direction: upwards. This

minimizes the effect on the measurement of

any gas/air bubbles in the liquid.

3

Page 4

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

Installation, general

(continued)

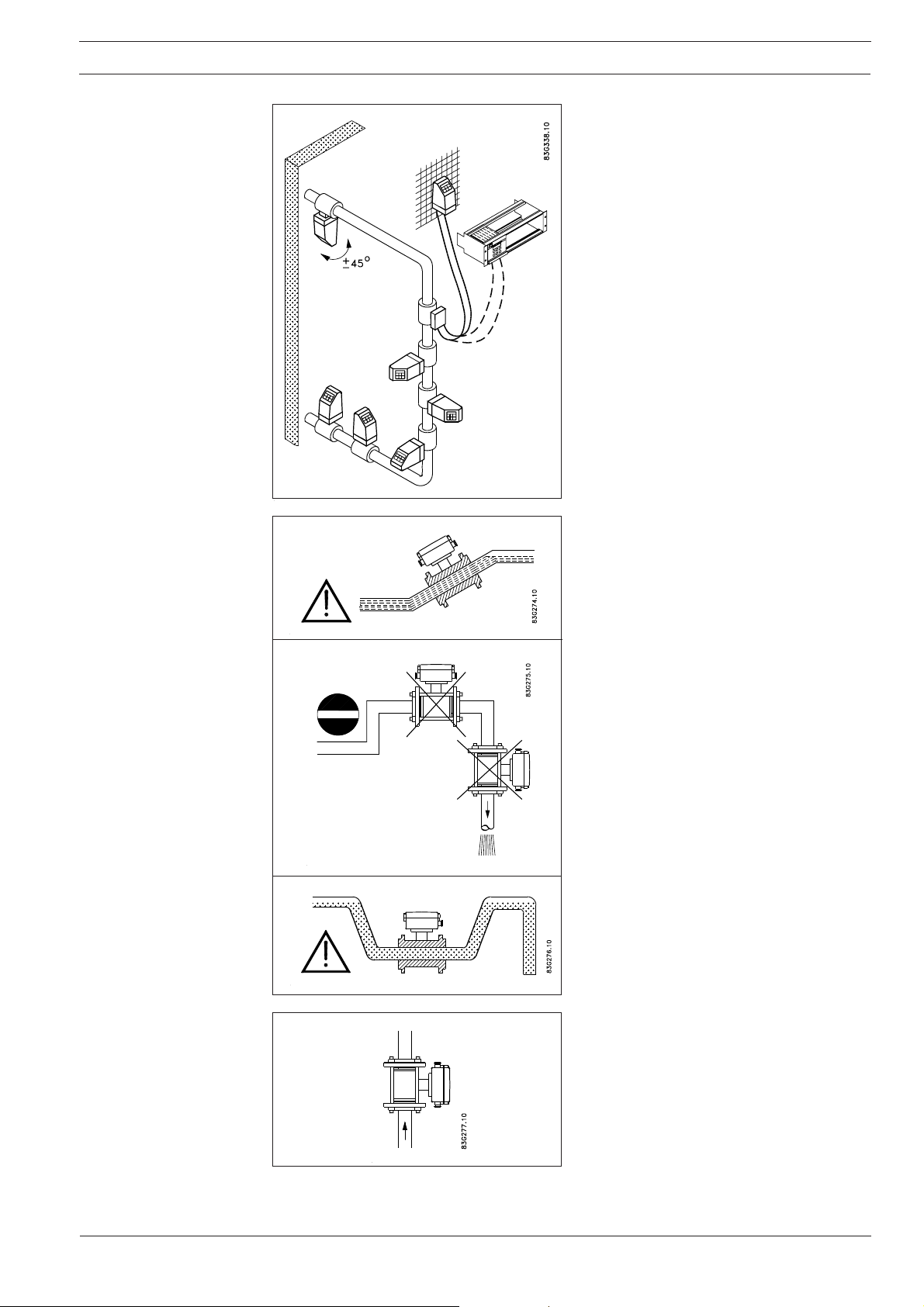

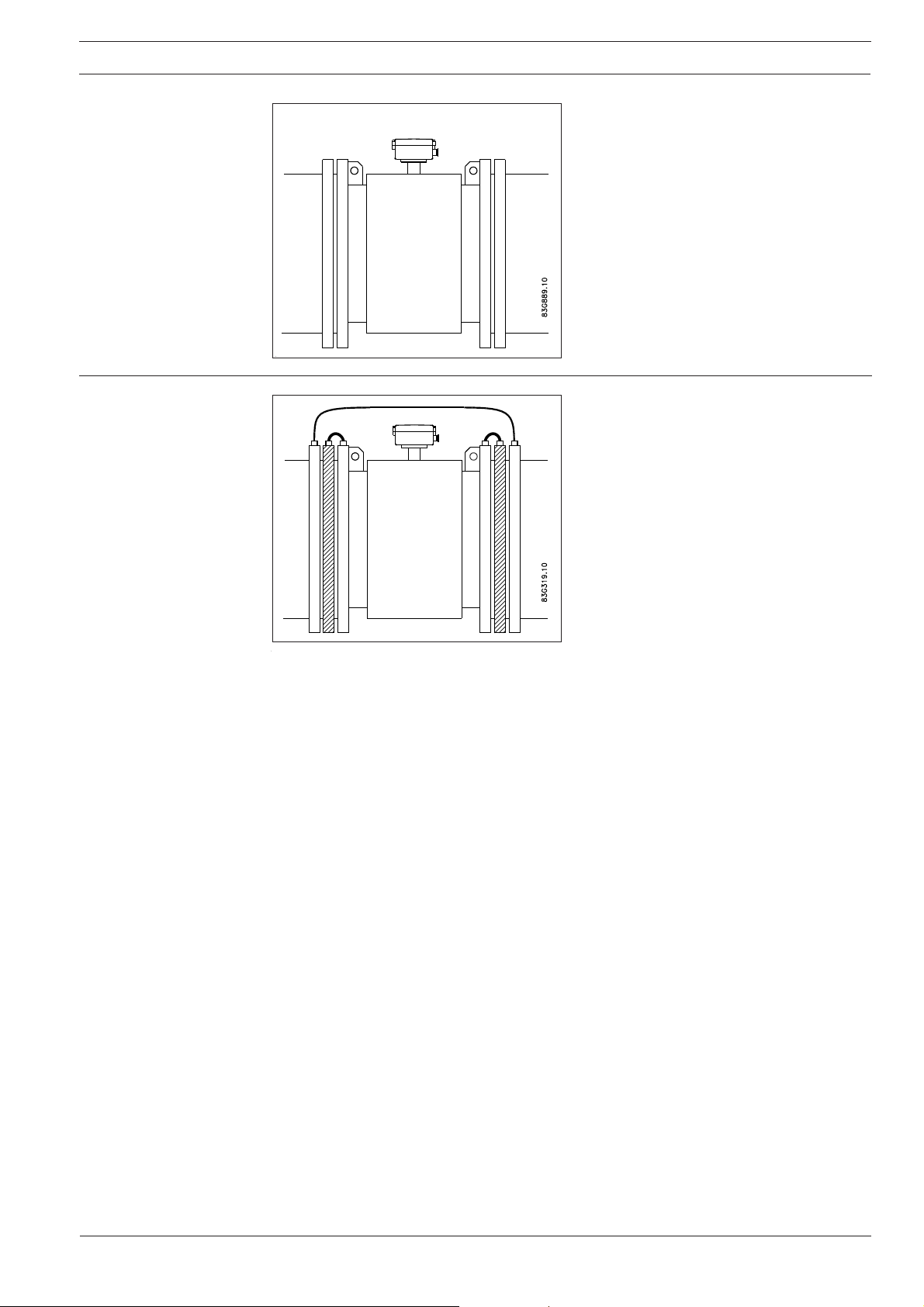

Installation in horizontal pipes

The sensor must be mounted as shown in the

upper figure. Do not mount the sensor as shown

in the lower figure. This will position the electrodes at the top where there is possibility for air

bubbles and at the bottom where there is possibility for mud, sludge, sand etc.

If using empty pipe detection the sensor can be

tilted 45°, as shown in the upper figure.

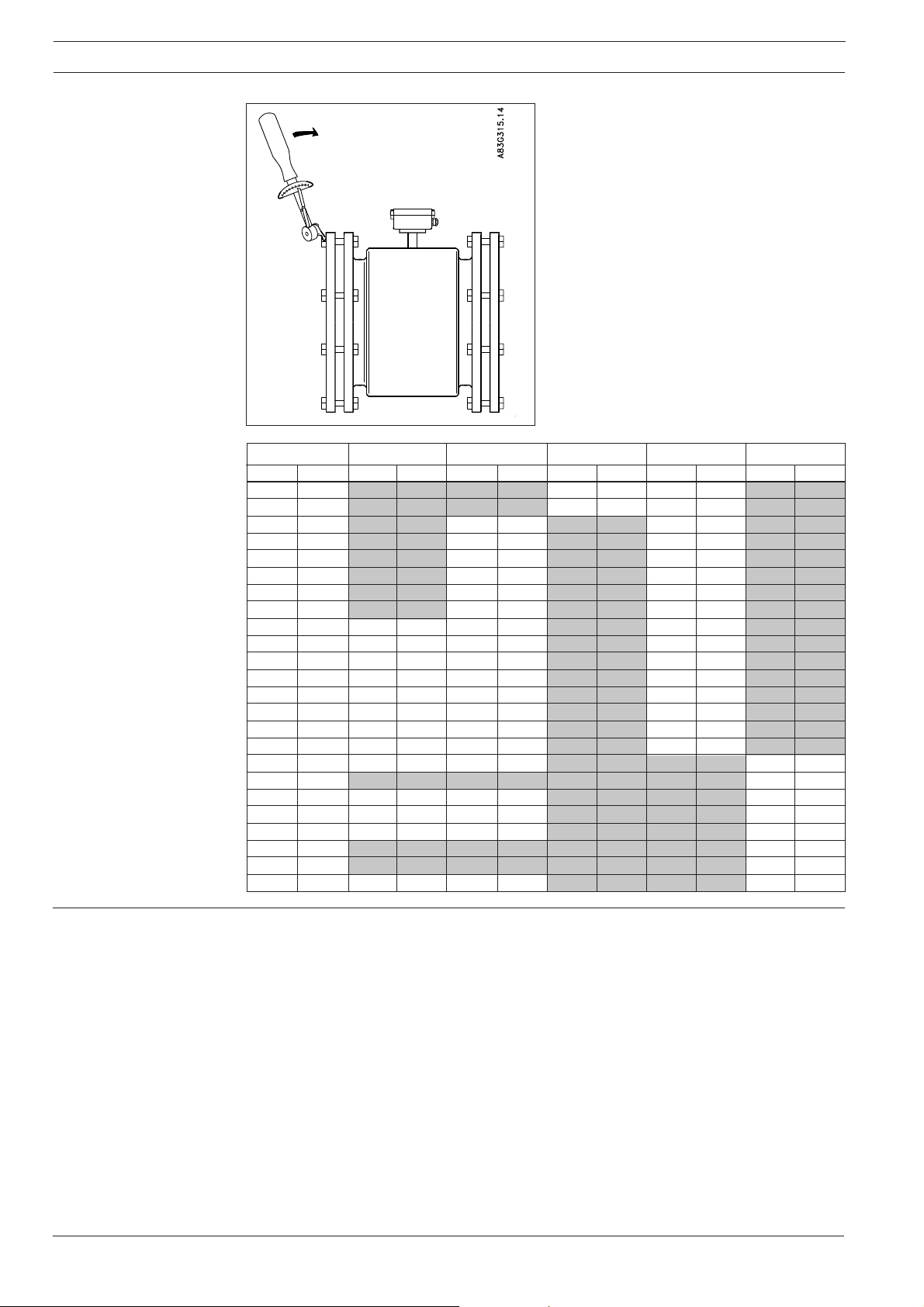

Measuring abrasive liquids and liquids containing particles

Recommended installation is in a vertical/inclined pipe to minimize the wear and deposits

in the sensor.

Inlet and outlet conditions

To achieve accurate flow measurement it is

essential to have straight lengths of inlet and

outlet pipes and a certain distance between

pumps and valves.

It is also important to centre the flowmeter in

relation to pipe flanges and gaskets.

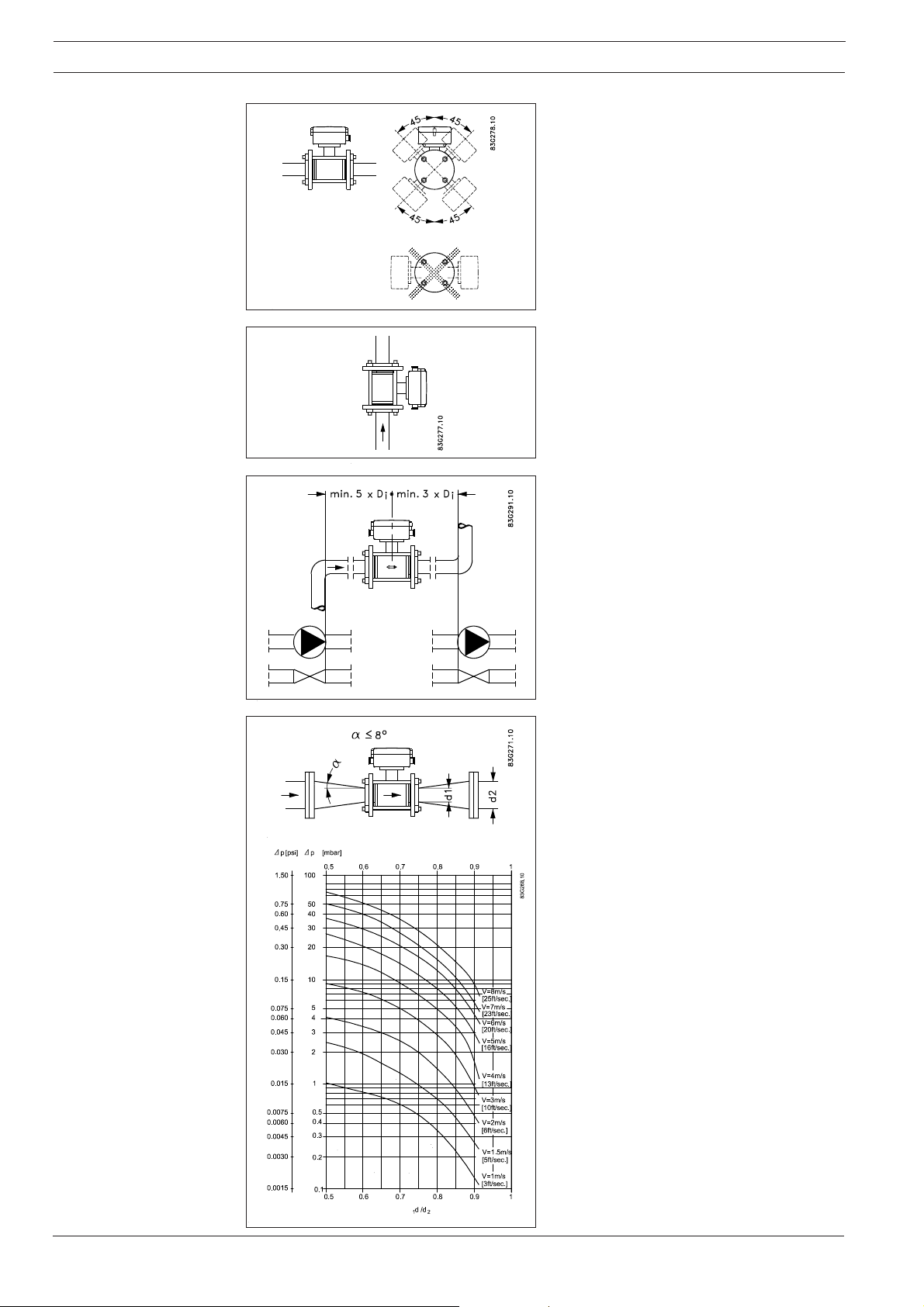

Installation in large pipes

The flowmeter can be installed between two

reducers (e.g. DIN 28545). Assuming that at 8°

the following pressure drop curve applies. The

curves are applicable to water.

Example:

A flow velocity of 3 m/s (V) in a sensor with a

diameter reduction from DN 100 to DN 80

= 0.8) gives a pressure drop of 2.9 mbar.

(d

1/d2

4

Page 5

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

Potential equalisation Potential equalisation is carried out with the

Cathodic protected

piping

With earthing electrodes

built-in earthing electrodes.

Special attention must be given to systems with

cathodic protection.

By compact mounting:

The transmitter must be supplied through an

isolation transformer. The terminal "PE" must

never be connected.

By remote mounting:

The screen must only be connected at the

sensor end via a 1.5 µF condensator. The

screen must never be connected at both ends.

By isolated sensor:

If above mentioned connections are unacceptable the sensor must be isolated from the pipe

work.

5

Page 6

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

Maximum allowable

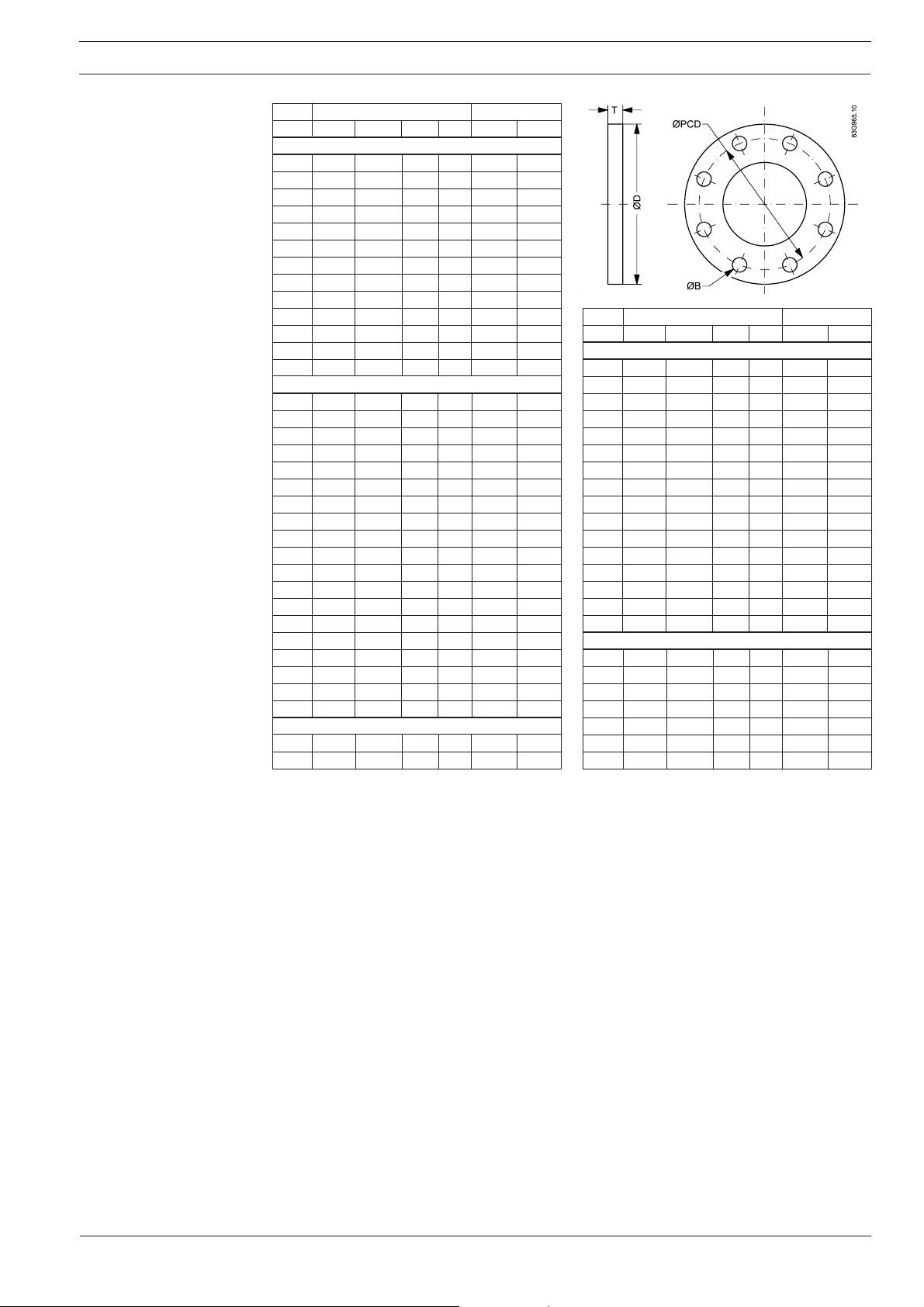

torques

Standard bolts must be well lubricated and tightened evenly around the gasket. Leakage/damage to the flowmeter or piping may arise if bolts

are overtightened.

Nominal size

mm inch Nm f/lbs Nm f/lbs Nm f/lbs Nm f/lbs Nm f/lbs

25 1" N/A N/A N/A N/A 10 7 7 5 N/A N/A

40 1½" N/A N/A N/A N/A 16 12 9 7 N/A N/A

50 2" N/A N/A 25 18 N/A N/A 25 18 N/A N/A

65 2½" N/A N/A 25 18 N/A N/A 25 18 N/A N/A

80 3" N/A N/A 25 18 N/A N/A 34 25 N/A N/A

100 4" N/A N/A 25 18 N/A N/A 26 19 N/A N/A

125 5" N/A N/A 29 21 N/A N/A 42 31 N/A N/A

150 6" N/A N/A 50 37 N/A N/A 57 42 N/A N/A

200 8" 50 37 50 37 N/A N/A 88 65 N/A N/A

250 10" 50 37 82 61 N/A N/A 99 73 N/A N/A

300 12" 57 42 111 82 N/A N/A 132 97 N/A N/A

350 14" 60 44 120 89 N/A N/A 225 166 N/A N/A

400 16" 88 65 170 125 N/A N/A 210 155 N/A N/A

450 18" 92 68 170 125 N/A N/A 220 162 N/A N/A

500 20" 103 76 230 170 N/A N/A 200 148 N/A N/A

600 24" 161 119 350 258 N/A N/A 280 207 N/A N/A

700 28" 200 148 304 224 N/A N/A N/A N/A 200 148

750 30" N/A N/A N/A N/A N/A N/A N/A N/A 240 177

800 32" 274 202 386 285 N/A N/A N/A N/A 260 192

900 36" 288 213 408 301 N/A N/A N/A N/A 240 177

1000 40" 382 282 546 403 N/A N/A N/A N/A 280 207

42" N/A N/A N/A N/A N/A N/A N/A N/A 280 207

1100 44" N/A N/A N/A N/A N/A N/A N/A N/A 290 214

1200 48" 395 292 731 539 N/A N/A N/A N/A 310 229

PN 10

PN 16 PN 40 Class 150

AWWA

Torque calculations

6

All values are theoretical and are calculated making the following assumptions:

1) All bolts are new and material selection is according to EN 1515-1 table 2

2) Gasket material not exceeding 75 shore A durometer is used between the flowmeter and

mating flanges

3) All bolts are galvanized and adequately lubricated

4) The values are calculated for use with carbon steel flanges

5) Flowmeter and mating flanges are correctly aligned

Page 7

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

Flange mating dimensions (Metric)

Dimensions mm Bolting

mm OD PCD T B Holes Bolts

PN 10

200 340 295 24 22 8 M20

250 395 350 26 22 12 M20

300 445 400 26 22 12 M20

350 505 460 28 22 16 M20

400 565 515 32 26 16 M24

450 615 565 36 26 20 M24

500 670 620 38 26 20 M24

600 780 725 42 30 20 M27

700 895 840 30 30 24 M27

800 1015 950 32 33 24 M30

900 1115 1050 34 33 28 M30

1000 1230 1160 34 36 28 M33

1200 1455 1380 38 39 32 M36

PN 16

50 165 125 19 18 4 M16

65 185 145 20 18 8 M16

80 200 160 20 18 8 M16

100 220 180 22 18 8 M16

125 250 210 22 18 8 M16

150 285 240 24 22 8 M20

200 340 295 26 22 12 M20

250 405 355 29 26 12 M24

300 460 410 32 26 12 M24

350 520 470 35 26 16 M24

400 580 525 38 30 16 M27

450 640 585 42 30 20 M27

500 715 650 46 33 20 M30

600 840 770 52 36 20 M33

700 910 840 36 36 24 M33

800 1025 950 38 39 24 M36

900 1125 1050 40 39 28 M36

1000 1255 1170 42 42 28 M39

1200 1485 1390 48 48 32 M45

PN 40

25 115 85 16 14 4 M12

40 150 110 18 18 4 M16

Dimensions mm Bolting

mm OD PCD T B Holes Bolts

150 lb

25 108 79 14 16 4 M14

40 127 98 18 16 4 M14

50 152 121 19 19 4 M16

65 178 140 22 19 4 M16

80 190 152 24 19 4 M16

100 229 191 24 19 8 M16

125 254 216 24 22 8 M20

150 279 241 25 22 8 M20

200 343 298 29 22 8 M20

250 406 362 30 25 12 M24

300 483 432 32 25 12 M24

350 533 476 35 28 12 M27

400 597 540 36.5 28 16 M27

450 635 578 40 32 16 M30

500 699 635 43 32 20 M30

600 813 749 48 35 20 M33

AWWA

700 927 864 33 35 28 M33

750 984 914 35 35 28 M33

800 1060 978 38 41 28 M39

900 1168 1086 41 41 32 M39

1000 1289 1200 41 41 36 M39

1050 1346 1257 44 41 36 M39

1200 1511 1422 48 41 44 M39

7

Page 8

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

Manufacturer’s design

and safety statement

1. Responsibility for the choice of lining and electrode materials with regard to their abrasion and

corrosion resistance lies with the purchaser; the effect of any change in process medium during

the operating life of the flowmeter should be taken into account. Incorrect selection of lining

and/or electrode materials could lead to a failure of the flowmeter.

2. Stresses and loading caused by earthquakes, traffic, high winds and fire damage not taken

into account during flowmeter design.

3. Do not install flowmeter such that it acts as a focus for pipeline stresses. External loadings not

taken into account during flowmeter design.

4. During operation do not exceed the pressure and/or temperature ratings indicated on the data

label or in the installation instructions.

5. It is recommended that all installations should include an appropriate safety valve and

adequate means for draining/venting.

6. Under the Pressure Equipment Directive this product is a pressure accessory, and not

approved for use as a safety accessory, as defined by the Pressure Equipment Directive.

7. Removal of the terminal box except by Siemens Flow Instruments or their approved agents will

invalidate the PED conformity of the product.

In accordance with the Pressure Equipment Directive (97/23/EC).

We have checked the contents of this manual for agreement with the hardware and

software described. Since deviations cannot be precluded entirely, we cannot guarantee

full agreement. However, the data in this manual are reviewed regularly and any

necessary corrections included in subsequent editions. Suggestions for improvement

are always welcomed.

Technical data subject to change without prior notice.

Siemens Flow Instruments A/S

Nordborgvej 81

8

DK-6430 Nordborg

The reproduction, transmission or use of this document or its contents is not permitted without

express written authority.

Offenders will be liable for damages. All rights, including rights created by patent grant or

registration of a utility model or design, are reserved.

Copyright © Siemens AG 05.2004 All Rights Reserved

Order no.: FDK:521H1190-01

Printed in: Denmark

Page 9

s

Einführung

INSTRUCTIONS

DEUTSCH

SITRANS F M MAGFLO

Magnetisch-induktiver Durchflussmesser

Typ MAG 5100 W

Siemens Flow Instruments SITRANS F M MAGFLO

bestehen aus einem Messaufnehmer und einem Messumformer. Diese Instruktion beschreibt nur

die Montage des Messaufnehmers. Für weitere Informationen über die Montage des Messumformers,

siehe bitte das SITRANS F M MAGFLO

magnetisch-induktive Durchflussmesser

Produkthandbuch.

083R9166

Abmessungen und

Gewichte

Abmessungen

MAG 5100 W, kompakte/getrennte Montage

Nennweite A

mm Zoll mm Zoll mm Zoll mm Zoll mm Zoll mm Zoll mm Zoll

25 1" 187 7,4 - - - - 200 7,9 200 7,9 - 40 1½” 197 7,8 - - - - 200 7,9 200 7,9 - 50 2" 188 7,4 - - 200 7,9 - - 200 7,9 - 65 2½” 194 7,6 - - 200 7,9 - - 200 7,9 - 80 3" 200 7,9 - - 200 7,9 - - 200 7,9 - 100 4" 207 8,1 - - 250 9,8 - - 250 9,8 - 125 5" 217 8,5 - - 250 9,8 - - 250 9,8 - 150 6" 232 9,1 - - 300 11,8 - - 300 11,8 - 200 8" 257 10,1 350 13,8 350 13,8 - - 350 13,8 - 250 10" 284 11,2 450 17,7 450 17,7 - - 450 17,7 - 300 12" 310 12,2 500 19,7 500 19,7 - - 500 19,7 - 350 14" 362 14,3 550 21,7 550 21,7 - - 550 21,7 - 400 16" 387 15,2 600 23,6 600 23,6 - - 600 23,6 - 450 18" 418 16,5 600 23,6 600 23,6 - - 600 23,6 - 500 20" 443 17,4 625 24,6 625 24,6 - - 680 26,8 - 600 24" 494 19,4 750 29,5 750 29,5 - - 820 32,3 - 700 28" 544 21,4 875 34,4 875 34,4 - - - - 875 34,4

750 30" 571 22,5 - - - - - - - - 937 36,9

800 32" 606 23,9 1000 39,4 1000 39,4 - - - - 1000 39,4

900 36" 653 25,7 1125 44,3 1125 44,3 - - - - 1125 44,3

1000 40" 704 27,7 1250 49,2 1250 49,2 - - - - 1250 49,2

42" 704 27,7 - - - - - - - - 1250 49,2

1100 44" 755 29,7 - - - - - - - - 1375 54,1

1200 48" 810 31,9 1500 59,1 1500 59,1 - - - - 1500 59,1

PN 10 PN 16 PN 40 Klasse 150

L

AWWA

Order no.: FDK:521H1190

SFIDK.PI.026.V1.52

Page 10

SITRANS F M MAGFLO

Magnetisch-induktiver Durchflussmesser Typ MAG 5100 W

Gewicht

Nennweite

mmZollkglbkg lbkg lbkg lbkg lb

251"----49 49-40 1½" - - - - 7 15 6 13 - 50 2" - - 9 20 - - 8 20 - 65 2½" - - 10,7 24 - - 11 24 - 80 3" - - 11,6 26 - - 13 28 - 100 4" - - 15,2 33 - - 19 41 - 125 5" - - 20,4 45 - - 24 52 - 150 6" - - 26 57 - - 29 64 - 200 8" 48 106 48 106 - - 56 124 - 250 10" 64 141 69 152 - - 79 174 - 300 12" 76 167 86 189 - - 110 243 - 350 14" 100 220 116 255 - - 131 289 - 400 16" 127 280 144 317 - - 165 364 - 450 18" 152 335 178 393 - - 176 388 - 500 20" 184 405 232 512 - - 235 518 - 600 24" 258 568 343 736 - - 345 761 - 700 28" 315 693 350 772 - - - - 309 681

750 30" - - - - - - - - 480 1058

800 32" 410 904 442 975 - - - - 421 928

900 36" 512 1129 550 1213 - - - - 539 1188

1000 40" 650 1433 732 1614 - - - - 670 1477

42" - - - - - - - - 700 1544

1100 44" - - - - - - - - 1100 2426

1200 48" 990 2183 1106 2439 - - - - 1030 2271

PN 10 PN 16 PN 40 Klasse 150

AWWA

Auswirkung der

Temperatur auf den

Arbeitsdruck

Metrisch (Drücke in bar)

Nennweite 25 mm, 40 mm und > 300 mm

Flansch- Druck- Temperatur

Spez. stufe −5105090

EN 1092-1 PN 10 10,0 10,0 9,7 9,4

PN 16 16,0 16,0 15,5 15,1

PN 40 40,0 40,0 38,7 37,7

ANSI B16.45 150 lb 19,7 19,7 19,3 18,0

AWWA C-207 Class D 10,3 10,3 10,3 10,3

Nennweite 50 mm bis 300 mm

EN 1092-1 PN 10 10,0 10,0 10,0 8,2

PN 16 10,0 16,0 16,0 13,2

ANSI B16.45 150 lb 10,0 19,7 19,7 16,2

°°

°C

°°

Zollsystem (Drücke in psi)

Nennweite 1", 1½", und > 12"

Flansch- Druck- Temperatur

Spez. stufe 23 50 120 200

EN 1092-1 PN 10 145 145 141 136

PN 16 232 232 225 219

PN 40 580 580 561 547

ANSI B16.45 150 lb 286 286 280 261

AWWA C-207 Class D 150 150 150 150

Nennweite 2" bis 12"

EN 1092-1 PN 10 145 145 145 119

PN 16 145 232 232 191

ANSI B16.45 150 lb 145 286 286 235

°°

°F

°°

10

Page 11

SITRANS F M MAGFLO

Magnetisch-induktiver Durchflussmesser Typ MAG 5100 W

Einbau, allgemein Der Durchflussmesser kann in jeder Einbau-

lage abgelesen werden, da die Anzeige drehbar ist und in jeder beliebigen Position im

Verhältnis zum Messaufnehmer eingebaut werden kann. Die endgültige Position sollte vor der

Montage festgelegt werden. Um optimale Messergebnisse zu sichern, sind folgende Hinweise

zu beachten:

Der Messaufnehmer muss immer vollständig

gefüllt sein.

Vermeiden Sie:

• Einbau an höchster Stelle des Rohrsystems

• Einbau in einer senkrechten Rohrleitung mit

freiem Ablauf.

Ist eine nur teilweise gefüllte Rohrleitung oder

der freie Ablauf nicht zu vermeiden, sollte der

Durchflussmesser gedükert werden.

Einbau in einer senkrechten Rohrleitung

Empfohlene Strömungsrichtung: von unten

nach oben. Dadurch werden ungenaue Messergebnisse, verursacht durch Gas- bzw. Luftblasen im Medium, vermieden.

11

Page 12

SITRANS F M MAGFLO

Magnetisch-induktiver Durchflussmesser Typ MAG 5100 W

Einbau, allgemein

(Fortsetzung)

Einbau in einer waagerechten Rohrleitung

Der Messaufnehmer ist wie nebenstehend in

der oberen Abbildung gezeigt zu montieren.

Wegen der Lage der Elektroden oben (hier

können Luftblasen entstehen) und unten (eventuelle Ansammlung von Schlamm, Sand usw.)

darf die Montage nicht wie in der unteren Abbildung gezeigt erfolgen. Wird die Leerlaufüberwachung aktiviert, um einen leeren Messaufnehmer zu melden, dürfen Messaufnehmer

und Messumformer nicht mehr als 45 bis 60°

gedreht werden, siehe obere Abbildung.

Messen von verunreinigten bzw. abrasiven

Medien

In diesem Fall wird der Einbau in einer senkrechten bzw. schrägen Rohrleitung empfohlen, um Verschleiß bzw. Ablagerungen so weit

wie möglich zu vermeiden.

Ein- und Auslauf

Genaue Messwerte können nur dann erzielt

werden, wenn ausreichend große gerade Einund Auslaufstrecken sowie genügender Abstand nach Pumpen, Ventilen o. ä. eingehalten

werden.

Außerdem muss der Durchflussmesser mittig

zu den Flanschen und Dichtungen des Rohrsystems eingebaut werden.

Einbau in einer Rohrleitung mit großem

Durchmesser

Falls notwendig, kann der Durchflussmesser

auch zwischen zwei Reduzierstücken, z. B.

nach DIN 28545 eingebaut werden. Unter der

Voraussetzung, dass α

< 8° gilt nebenstehen-

des Druckverlustdiagramm (Medium: Wasser).

Beispiel:

Eine Durchflussgeschwindigkeit von V = 3 m/s

in einem Messaufnehmer mit einer Durchmesserreduktion von DN 100 auf DN 80

= 0,8) verursacht einen Druckabfall von

(d

1/d2

2,9 mbar.

12

Page 13

SITRANS F M MAGFLO

Magnetisch-induktiver Durchflussmesser Typ MAG 5100 W

Potentialausgleich Potentialausgleich erfolgt mit den eingebauten

Kathodischer

Rohrleitungsschutz

Mit Erdungselektroden

Erdungselektroden.

Bei Rohrleitungen mit katodischem Schutz ist

besondere Sorgfalt geboten.

Bei kompaktem Einbau:

Der Messumformer muss über einen Trenntransformator gespeist werden. Der Anschluss

"PE" darf niemals angeschlossen werden.

Bei getrenntem Einbau:

Die Abschirmung muss man über einen 1,5 µF

Kondensator mit dem Messaufnehmerende

verbinden. Die Abschirmung darf nie an beide

Enden angeschlossen werden.

Bei isoliertem Einbau:

Falls die obengenannten Anschlüsse nicht

akzeptierbar sind, muss der Messaufnehmer

von der Rohrleitung isoliert werden.

13

Page 14

SITRANS F M MAGFLO

Magnetisch-induktiver Durchflussmesser Typ MAG 5100 W

Maximal zulässige

Drehmomente

Flanschenbolzen gut einfetten und gleichmäßig

um die Dichtungsfläche anziehen. Ein zu hohes

oder "schiefes" Anziehen kann Undichtigkeiten

bzw. Schäden am Durchflussmesser und an

der Rohrleitung verursachen.

Nennweite

mm Zoll Nm f/lb Nm f/lb Nm f/lb Nm f/lb Nm f/lb

25 1" - - - - 10 7 7 5 - 40 1½" - - - - 16 12 9 7 - 50 2" - - 25 18 - - 25 18 - 652½"- -2518- -2518- 80 3" - - 25 18 - - 34 25 - 100 4" - - 25 18 - - 26 19 - 125 5" - - 29 21 - - 42 31 - 150 6" - - 50 37 - - 57 42 - 200 8" 50 37 50 37 - - 88 65 - 250 10" 50 37 82 61 - - 99 73 - 300 12" 57 42 111 82 - - 132 97 - 350 14" 60 44 120 89 - - 225 166 - 400 16" 88 65 170 125 - - 210 155 - 450 18" 92 68 170 125 - - 220 162 - 500 20" 103 76 230 170 - - 200 148 - 600 24" 161 119 350 258 - - 280 207 - 700 28" 200 148 304 224 - - - - 200 148

750 30" - - - - - - - - 240 177

800 32" 274 202 386 285 - - - - 260 192

900 36" 288 213 408 301 - - - - 240 177

1000 40" 382 282 546 403 - - - - 280 207

42"----- ---280207

1100 44" - - - - - - - - 290 214

1200 48" 395 292 731 539 - - - - 310 229

PN 10 PN 16 PN 40 Klasse 150

AWWA

DrehmomentBerechnungen

14

Alle Werte sind theoretisch und werden unter folgenden Annahmen berechnet:

1) Alle Bolzen sind neu und die Werkstoffauswahl entspricht EN 1515-1 Tabelle 2

2) Dichtungswerkstoff von höchstens 75 Shore A Härte wird zwischen dem Durchflussmesser

und den zugehörigen Flanschen verwendet

3) Alle Bolzen sind verzinkt und entsprechend eingefettet

4) Die Werte sind für den Einsatz mit Kohlenstoffstahl-Flanschen berechnet

5) Durchflussmesser und zugehörige Flansche sind einwandfrei ausgerichtet

Page 15

SITRANS F M MAGFLO

Magnetisch-induktiver Durchflussmesser Typ MAG 5100 W

FlanschAnpassungsmaße

(Metrisch)

Abmessungen mm Verschraubung

mm OD PCD T B Löcher Bolzen

PN 10

200 340 295 24 22 8 M20

250 395 350 26 22 12 M20

300 445 400 26 22 12 M20

350 505 460 28 22 16 M20

400 565 515 32 26 16 M24

450 615 565 36 26 20 M24

500 670 620 38 26 20 M24

600 780 725 42 30 20 M27

700 895 840 30 30 24 M27

800 1015 950 32 33 24 M30

900 1115 1050 34 33 28 M30

1000 1230 1160 34 36 28 M33

1200 1455 1380 38 39 32 M36

PN 16

50 165 125 19 18 4 M16

65 185 145 20 18 8 M16

80 200 160 20 18 8 M16

100 220 180 22 18 8 M16

125 250 210 22 18 8 M16

150 285 240 24 22 8 M20

200 340 295 26 22 12 M20

250 405 355 29 26 12 M24

300 460 410 32 26 12 M24

350 520 470 35 26 16 M24

400 580 525 38 30 16 M27

450 640 585 42 30 20 M27

500 715 650 46 33 20 M30

600 840 770 52 36 20 M33

700 910 840 36 36 24 M33

800 1025 950 38 39 24 M36

900 1125 1050 40 39 28 M36

1000 1255 1170 42 42 28 M39

1200 1485 1390 48 48 32 M45

PN 40

25 115 85 16 14 4 M12

40 150 110 18 18 4 M16

Abmessungen mm Verschraubung

mm OD PCD T B Löcher Bolzen

150 lb

25 108 79 14 16 4 M14

40 127 98 18 16 4 M14

50 152 121 19 19 4 M16

65 178 140 22 19 4 M16

80 190 152 24 19 4 M16

100 229 191 24 19 8 M16

125 254 216 24 22 8 M20

150 279 241 25 22 8 M20

200 343 298 29 22 8 M20

250 406 362 30 25 12 M24

300 483 432 32 25 12 M24

350 533 476 35 28 12 M27

400 597 540 36.5 28 16 M27

450 635 578 40 32 16 M30

500 699 635 43 32 20 M30

600 813 749 48 35 20 M33

AWWA

700 927 864 33 35 28 M33

750 984 914 35 35 28 M33

800 1060 978 38 41 28 M39

900 1168 1086 41 41 32 M39

1000 1289 1200 41 41 36 M39

1050 1346 1257 44 41 36 M39

1200 1511 1422 48 41 44 M39

15

Page 16

SITRANS F M MAGFLO

Magnetisch-induktiver Durchflussmesser Typ MAG 5100 W

Stellungnahme des

Herstellers hinsichtlich

Aufbau und Sicherheit

1. Die Verantwortung für die Wahl der Auskleidungs- und Elektrodenwerkstoffe hinsichtich ihrer

Abrieb- und Korrosionsfestigkeit trägt der Käufer; die Auswirkung jeglicher Änderung im

Prozessmedium während der Betriebs-Lebensdauer des Durchflussmessers sollte man

berücksichtigen. Unsachgemäße Wahl der Auskleidungs- und/oder Elektrodenwerkstoffe

könnte zu einem Ausfall des Durchflussmessers führen.

2. Anspannungen und Belastung durch Erdbeben, Verkehr, starke Winde und Brandschäden

werden bei der Auslegung des Messers nicht berücksichtigt.

3. Den Durchflussmesser nicht so installieren, dass er im Zentrum von RohrleitungsVerformungen steht. Externe Belastungen werden bei der Auslegung des Durchflussmesser

nicht berücksichtigt.

4. Während des Betriebs nicht die Druck- und/oder Temperaturwerte überschreiten, die auf dem

Typenschild oder in den Einbauanweisungen angegeben sind.

5. Es empfiehlt sich, dass alle Installationen ein geeignetes Sicherheitsventil und entsprechende

Vorrichtungen zum Entleeren/Entlüften enthalten.

6. Unter der Druckbehälter-Richtlinie ist dieses Produkt ein Druckzubehör und nicht zur

Verwendung als Sicherheitszubehör zugelassen, wie in der Druckbehälter-Richtlinie

festgelegt.

7. Der Abbau der Anschlussdose, außer durch Siemens Flow Instruments oder deren zugelassene

Vertreter, macht die PED-Konformität des Produkts ungültig.

Gemäß der Druckbehälter-Richtlinie (97/23/EG).

Wir haben den Inhalt dieser Druckschrift auf Übereinstimmung mit der beschriebenen Hardund Software geprüft. Dennoch können Abweichungen nicht ausgeschlossen werden, so

dass wir für die vollständige Übereinstimmung keine Gewähr übernehmen. Die Angaben in

dieser Druckschrift werden jedoch regelmäßig überprüft und notwendige Korrekturen sind in

der nachfolgenden Auflage enthalten. Für Verbesserungsvorschläge sind wir dankbar.

Änderungen, die dem technischen Fortschritt dienen, sind ohne vorherige Ankündigung

möglich.

Siemens Flow Instruments A/S

Nordborgvej 81

16

DK-6430 Nordborg

Weitergabe sowie Vervielfältigung dieser Unterlage, Verwertung und Mitteilung ihres Inhalts

nicht gestattet, soweit nicht ausdrücklich zugestanden. Zuwiderhandlungen verpflichten zu

Schadenersatz. Alle Rechte vorbehalten, insbesondere für den Fall der Patenterteilung oder

GM-Eintragung.

Copyright © Siemens AG 09.2004 All Rights Reserved

Bestell-Nr.: FDK:521H1190-01

Gedruckt in : Denmark

Page 17

s

Présentation

INSTRUCTIONS

FRANÇAIS

SITRANS F M MAGFLO

Débitmètre à induction magnétique

type MAG 5100 W

Le débitmètre à induction magnétique SITRANS FM MAGFLO

compose d'une tête de mesure et d'un convertisseur de signaux. Cette instruction concerne le

montage de la tête de mesure. Pour plus d'informations sur le montage du convertisseur de signaux,

voir le Manuel.

de Siemens Flow Instruments se

083R9166

Dimensions et poids

Dimensions

MAG 5100 W, montage compact/séparé

Dimensions

nominales

mm Pouce mm Pouce mm Pouce mm Pouce mm Pouce mm Pouce mm Pouce

25 1" 187 7,4 - - - - 200 7,9 200 7,9 - 40 1½” 197 7,8 - - - - 200 7,9 200 7,9 - 50 2" 188 7,4 - - 200 7,9 - - 200 7,9 - 65 2½” 194 7,6 - - 200 7,9 - - 200 7,9 - 80 3" 200 7,9 - - 200 7,9 - - 200 7,9 - 100 4" 207 8,1 - - 250 9,8 - - 250 9,8 - 125 5" 217 8,5 - - 250 9,8 - - 250 9,8 - 150 6" 232 9,1 - - 300 11,8 - - 300 11,8 - 200 8" 257 10,1 350 13,8 350 13,8 - - 350 13,8 - 250 10" 284 11,2 450 17,7 450 17,7 - - 450 17,7 - 300 12" 310 12,2 500 19,7 500 19,7 - - 500 19,7 - 350 14" 362 14,3 550 21,7 550 21,7 - - 550 21,7 - 400 16" 387 15,2 600 23,6 600 23,6 - - 600 23,6 - 450 18" 418 16,5 600 23,6 600 23,6 - - 600 23,6 - 500 20" 443 17,4 625 24,6 625 24,6 - - 680 26,8 - 600 24" 494 19,4 750 29,5 750 29,5 - - 820 32,3 - 700 28" 544 21,4 875 34,4 875 34,4 - - - - 875 34,4

750 30" 571 22,5 - - - - - - - - 937 36,9

800 32" 606 23,9 1000 39,4 1000 39,4 - - - - 1000 39,4

900 36" 653 25,7 1125 44,3 1125 44,3 - - - - 1125 44,3

1000 40" 704 27,7 1250 49,2 1250 49,2 - - - - 1250 49,2

42" 704 27,7 - - - - - - - - 1250 49,2

1100 44" 755 29,7 - - - - - - - - 1375 54,1

1200 48" 810 31,9 1500 59,1 1500 59,1 - - - - 1500 59,1

A

PN 10

PN 16 PN 40 Classe 150

L

AWWA

Order no.: FDK:521H1190

SFIDK.PI.026.V1.52

Page 18

SITRANS F M MAGFLO

Débitmètre à induction magnétique type MAG 5100 W

Poids

Dimensions

nominales

mm Pouce kg lb kg lb kg lb kg lb kg lb

25 1" - - - - 4 9 4 9 - 40 1½" - - - - 7 15 6 13 - 50 2" - - 9 20 - - 8 20 - 652½"- -10,724- -1124- 80 3" - -11,626- -1328- 1004" - -15,233- -1941- 1255" - -20,445- -2452- 150 6" - - 26 57 - - 29 64 - 200 8" 48 106 48 106 - - 56 124 - 250 10" 64 141 69 152 - - 79 174 - 300 12" 76 167 86 189 - - 110 243 - 350 14" 100 220 116 255 - - 131 289 - 400 16" 127 280 144 317 - - 165 364 - 450 18" 152 335 178 393 - - 176 388 - 500 20" 184 405 232 512 - - 235 518 - 600 24" 258 568 343 736 - - 345 761 - 700 28" 315 693 350 772 - - - - 309 681

750 30" - - - - - - - - 480 1058

800 32" 410 904 442 975 - - - - 421 928

900 36" 512 1129 550 1213 - - - - 539 1188

1000 40" 650 1433 732 1614 - - - - 670 1477

42" - - - - - - - - 700 1544

1100 44" - - - - - - - - 1100 2426

1200 48" 990 2183 1106 2439 - - - - 1030 2271

PN 10 PN 16 PN 40 Classe 150

AWWA

Effet de la température

sur la pression de

service

Métrique (Pressions en bar)

Dimensions 25 mm, 40 mm et > 300 mm

Spécific. Pression Température

brides brides −5105090

EN 1092-1 PN 10 10,0 10,0 9,7 9,4

PN 16 16,0 16,0 15,5 15,1

PN 40 40,0 40,0 38,7 37,7

ANSI B16.45 150 lb 19,7 19,7 19,3 18,0

AWWA C-207 Class D 10,3 10,3 10,3 10,3

Dimensions 50 mm à 300 mm

EN 1092-1 PN 10 10,0 10,0 10,0 8,2

PN 16 10,0 16,0 16,0 13,2

ANSI B16.45 150 lb 10,0 19,7 19,7 16,2

°°

°C

°°

Impérial (Pressions en psi)

Dimensions 1", 1½" et > 12"

Spécific. Pression Température

brides brides 23 50 120 200

EN 1092-1 PN 10 145 145 141 136

PN 16 232 232 225 219

PN 40 580 580 561 547

ANSI B16.45 150 lb 286 286 280 261

AWWA C-207 Class D 150 150 150 150

Dimensions 2" à 12"

EN 1092-1 PN 10 145 145 145 119

PN 16 145 232 232 191

ANSI B16.45 150 lb 145 286 286 235

°°

°F

°°

18

Page 19

SITRANS F M MAGFLO

Débitmètre à induction magnétique type MAG 5100 W

Installation générales Il est possible de lire et d’utiliser le débitmètre

dans la plupart des conditions d’installation

l’afficheur pouvant être orienté par rapport à la

tête de mesure. Pour obtenir des mesures de

débit optimales, respecter les recommandations suivantes:

La tête de mesure doit toujours être totalement

remplie de liquide.

Pour cela, éviter:

• le montage au point le plus haut de la

tuyauterie,

• le montage sur tubes verticaux à sortie libre.

Dans le cas de tubes en partie vides ou à

écoulement vers le bas et sortie libre, le

débitmètre doit être installé dans un tube en U.

Installation sur conduites verticales

Sens d'écoulement recommandé: vers le haut,

afin de minimiser l'effet des bulles d'air ou de

gaz pouvant se trouver dans le liquide sur la

précision de mesure.

19

Page 20

SITRANS F M MAGFLO

Débitmètre à induction magnétique type MAG 5100 W

Installation générales

(suite)

Montage sur conduites horizontales

La tête de mesure doit être montée conformément à la figure du haut. Eviter le montage de la

figure du bas les électrodes étant situées dans

la partie supérieure, où des bulles d’air peuvent

se former, et dans la partie inférieure, où peuvent

se trouver de la boue, du sable, etc.

Pour une surveillance optimale des conduites

vides, la tête de mesure doit être orientée selon

un angle de 45°, comme indiqué par la figure du

haut.

Mesure de fluides abrasifs ou contenant des

particules en suspension

Dans ce cas, nous recommandons un montage sur conduites verticales/inclinées pour

réduire l'usure et les dépôts dans la tête de

mesure.

Conditions amont et aval

Pouir garantir la précision de mesure, prévoir

des sections droites en amont et en aval de la

tête de mesure pour maintenir une distance

suffisante entre le débitmètre et de possibles

perturbations hydrauliques.

Le centrage du débitmètre par rapport aux brides

et aux joints de la tuyauterie joue aussi un rôle

important.

Installation sur conduites de grand diamètre

Le débitmètre peut aussi être installé entre

deux raccords réducteurs (par ex. DIN 28545).

On suppose que, à 8°, on obtient la courbe de

perte de charge ci-dessous. Ces courbes sont

valables pour l'eau.

Exemple:

Pour une vitesse d'écoulement de 3 m/s (V)

dans la tête de mesure et une réduction de

diamètre de DN 100 à DN 80 (d

obtient une perte de charge de 2,9 mbar.

= 0,8), on

1/d2

20

Page 21

SITRANS F M MAGFLO

Débitmètre à induction magnétique type MAG 5100 W

Compensation de

potentiel

Tuyauterie à protection

cathodique

Avec les électrodes de terre

L'égalisation de potentiel se fait par les électrodes de mise à la terre intégrées.

Les tuyauteries à protection cathodique font

l’objet de dispositions particulières.

Montage compact:

Le convertisseur de signaux doit être alimenté

par un transformateur d’isolement. La borne

PE ne doit pas être raccordée.

Montage séparé:

Le blindage doit seulement être raccordé à

l’extrémité du convertisseur de signaux par un

condensateur 1,5 µF. Il ne doit jamais être

raccordé par ses deux extrémités.

Isolation de la tête de mesure:

Si les raccordements ci-dessus ne sont pas

envisageables, la tête de mesure doit être

isolée du réseau de canalisations.

21

Page 22

SITRANS F M MAGFLO

Débitmètre à induction magnétique type MAG 5100 W

Couples maxima

admissibles

Utiliser des boulons standards: les graisser

convenablement et les serrer de facon égale

tout autour des faces de contact des joints. Les

boulons trop serrés ou serrés de faςon inégale

risquent d'occasionner des fuites ou de

détériorer le débitmètre ou la tuyauterie.

Dimensions

nominales

mm Pouce Nm f/lb Nm f/lb Nm f/lb Nm f/lb Nm f/lb

25 1" - - - - 10 7 7 5 - 40 1½" - - - - 16 12 9 7 - 50 2" - - 25 18 - - 25 18 - 65 2½"- - 2518 - - 2518 - 80 3" - - 25 18 - - 34 25 - 100 4" - - 25 18 - - 26 19 - 125 5" - - 29 21 - - 42 31 - 150 6" - - 50 37 - - 57 42 - 200 8" 50 37 50 37 - - 88 65 - 250 10" 50 37 82 61 - - 99 73 - 300 12" 57 42 111 82 - - 132 97 - 350 14" 60 44 120 89 - - 225 166 - 400 16" 88 65 170 125 - - 210 155 - 450 18" 92 68 170 125 - - 220 162 - 500 20" 103 76 230 170 - - 200 148 - 600 24" 161 119 350 258 - - 280 207 - 700 28" 200 148 304 224 - - - - 200 148

750 30" - - - - - - - - 240 177

800 32" 274 202 386 285 - - - - 260 192

900 36" 288 213 408 301 - - - - 240 177

1000 40" 382 282 546 403 - - - - 280 207

42"----- ---280207

1100 44" - - - - - - - - 290 214

1200 48" 395 292 731 539 - - - - 310 229

PN 10

PN 16 PN 40 Klasse 150

AWWA

Calculs du couple Toutes les valeurs sont théoriques et calculées d’après les suppositions suivantes:

1) Tous les boulons sont neufs et le choix des matériaux correspond à EN 1515-1 Tableau 2

2) Le matériau d’étanchéité, avec tout au plus 75 Shore A sur le duromètre, est inséré entre le

débitmètre et les brides respectives

3) Tous les boulons sont galvanisés et lubrifiés de façon adéquate

4) Les valeurs sont calculées pour l’utilisation avec des brides en acier au carbone

5) Le débitmètre et les brides associées sont correctement alignés

22

Page 23

SITRANS F M MAGFLO

Débitmètre à induction magnétique type MAG 5100 W

Dimensions

correspondant aux

brides (Métriques)

Dimensions mm Boulonnage

mm OD PCD T B Trous Boulons

PN 10

200 340 295 24 22 8 M20

250 395 350 26 22 12 M20

300 445 400 26 22 12 M20

350 505 460 28 22 16 M20

400 565 515 32 26 16 M24

450 615 565 36 26 20 M24

500 670 620 38 26 20 M24

600 780 725 42 30 20 M27

700 895 840 30 30 24 M27

800 1015 950 32 33 24 M30

900 1115 1050 34 33 28 M30

1000 1230 1160 34 36 28 M33

1200 1455 1380 38 39 32 M36

PN 16

50 165 125 19 18 4 M16

65 185 145 20 18 8 M16

80 200 160 20 18 8 M16

100 220 180 22 18 8 M16

125 250 210 22 18 8 M16

150 285 240 24 22 8 M20

200 340 295 26 22 12 M20

250 405 355 29 26 12 M24

300 460 410 32 26 12 M24

350 520 470 35 26 16 M24

400 580 525 38 30 16 M27

450 640 585 42 30 20 M27

500 715 650 46 33 20 M30

600 840 770 52 36 20 M33

700 910 840 36 36 24 M33

800 1025 950 38 39 24 M36

900 1125 1050 40 39 28 M36

1000 1255 1170 42 42 28 M39

1200 1485 1390 48 48 32 M45

PN 40

25 115 85 16 14 4 M12

40 150 110 18 18 4 M16

Dimensions mm Boulonnage

mm OD PCD T B Trous Boulons

150 lb

25 108 79 14 16 4 M14

40 127 98 18 16 4 M14

50 152 121 19 19 4 M16

65 178 140 22 19 4 M16

80 190 152 24 19 4 M16

100 229 191 24 19 8 M16

125 254 216 24 22 8 M20

150 279 241 25 22 8 M20

200 343 298 29 22 8 M20

250 406 362 30 25 12 M24

300 483 432 32 25 12 M24

350 533 476 35 28 12 M27

400 597 540 36.5 28 16 M27

450 635 578 40 32 16 M30

500 699 635 43 32 20 M30

600 813 749 48 35 20 M33

AWWA

700 927 864 33 35 28 M33

750 984 914 35 35 28 M33

800 1060 978 38 41 28 M39

900 1168 1086 41 41 32 M39

1000 1289 1200 41 41 36 M39

1050 1346 1257 44 41 36 M39

1200 1511 1422 48 41 44 M39

23

Page 24

SITRANS F M MAGFLO

Débitmètre à induction magnétique type MAG 5100 W

Déclaration du fabricant

à l’égard de la construction et de la sécurité

1. L’acheteur est responsable pour le choix des matériaux de revêtement et d‘électrode à l’égard

de leur résistance à l’usure et à la corrosion; il faut tenir compte de l’effet de tout changement

dans le fluide de procès pendant la durée de service du débitmètre. Le choix inopportun des

matériaux de revêtement et/ou d‘électrode pourrait causer une défaillance du débitmètre.

2. Les contraintes et charges dues à un séisme, circulation, vents forts et aux dégâts du feu ne

sont pas prises en compte pour la conception du débitmètre.

3. Ne pas installer le débitmètre de sorte qu’il se trouve au centre des déformations de la

conduite. Les contraintes externes ne sont pas prises en compte pour la conception du

débitmètre.

4. Pendant le fonctionnement, ne pas dépasser les valeurs de pression et/ou de température,

indiquées sur la plaque d’identification ou dans les instructions d‘installation.

5. Il est recommandé, que toutes les installations soient équipées d’une soupape de surpression

appropriée et de dispositifs adéquats pour la vidange/purge d‘air.

6. Sous la Directive Équipements de Pression, ce produit est un accessoire de pression et ne

pas agréé pour l’utilisation comme accessoire de sécurité, comme fixé dans la Directive

Équipements de Pression.

7. Le démontage de la boîte de connexion, sauf si effectué par Siemens Flow Instruments ou

leurs représentants autorisés, annule la conformité PED du produit.

Selon la Directive Équipements de Pression (97/23/CE).

Nous avons vérifié la conformité du contenu du présent manuel avec le matériel et le

logiciel qui y sont décrits. Or, des divergences n’étant pas exclues, nous ne pouvons

pas nous porter garants pour la conformité intégrale. Si l’usage du manuel devait

révéler des erreurs, nous en tiendrons compte et apporterons les corrections

nécessaires dès la prochaine édition. Veuillez nous faire part de vos suggestions.

Nous nous réservons le droit de modifier les caractéristiques techniques.

Siemens Flow Instruments A/S

24

Nordborgvej 81

DK-6430 Nordborg

Toute communication ou reproduction de ce support d’informations, toute exploitation ou

communication de son contenu sont interdites, sauf autorisation expresse. Tout manquement à

cette règle est illicite et expose son auteur au versement de dommages et intérêts. Tous nos

droits sont réservés, notamment pour le cas de la délivrance d’un brevet ou celui de

l’enregistrement d’un modèle d’utilité.

Copyright © Siemens AG 09.2004 All Rights Reserved

Réf. de cde.: FDK:521H1190-01

Imprimé en: Denmark

Page 25

s

Indledning

INSTRUCTIONS

DANSK

SITRANS F M MAGFLO

Magnetisk induktiv flowmåler

type MAG 5100 W

Siemens Flow Instruments SITRANS F M MAGFLO

målehoved og en transmitter. Denne instruktion omhandler installation af målehovedet. For

yderligere vejledning om installation af målehoved og transmitter se SITRANS F M MAGFLO

håndbog.

magnetisk induktive flowmålere består af et

083R9166

Mål & vægt

Mål

MAG 5100 W, kompakt/separat

Nominel

størrelse

mm inch mm inch mm inch mm inch mm inch mm inch mm inch

25 1" 187 7,4 - - - - 200 7,9 200 7,9 - 40 1½” 197 7,8 - - - - 200 7,9 200 7,9 - 50 2" 188 7,4 - - 200 7,9 - - 200 7,9 - 65 2½” 194 7,6 - - 200 7,9 - - 200 7,9 - 80 3" 200 7,9 - - 200 7,9 - - 200 7,9 - 100 4" 207 8,1 - - 250 9,8 - - 250 9,8 - 125 5" 217 8,5 - - 250 9,8 - - 250 9,8 - 150 6" 232 9,1 - - 300 11,8 - - 300 11,8 - 200 8" 257 10,1 350 13,8 350 13,8 - - 350 13,8 - 250 10" 284 11,2 450 17,7 450 17,7 - - 450 17,7 - 300 12" 310 12,2 500 19,7 500 19,7 - - 500 19,7 - 350 14" 362 14,3 550 21,7 550 21,7 - - 550 21,7 - 400 16" 387 15,2 600 23,6 600 23,6 - - 600 23,6 - 450 18" 418 16,5 600 23,6 600 23,6 - - 600 23,6 - 500 20" 443 17,4 625 24,6 625 24,6 - - 680 26,8 - 600 24" 494 19,4 750 29,5 750 29,5 - - 820 32,3 - 700 28" 544 21,4 875 34,4 875 34,4 - - - - 875 34,4

750 30" 571 22,5 - - - - - - - - 937 36,9

800 32" 606 23,9 1000 39,4 1000 39,4 - - - - 1000 39,4

900 36" 653 25,7 1125 44,3 1125 44,3 - - - - 1125 44,3

1000 40" 704 27,7 1250 49,2 1250 49,2 - - - - 1250 49,2

42" 704 27,7 - - - - - - - - 1250 49,2

1100 44" 755 29,7 - - - - - - - - 1375 54,1

1200 48" 810 31,9 1500 59,1 1500 59,1 - - - - 1500 59,1

A

PN 10 PN 16 PN 40 Klasse 150

L

AWWA

Order no.: FDK:521H1190

SFIDK.PI.026.V1.52

Page 26

SITRANS F M MAGFLO

Magnetisk flowmåler type MAG 5100 W

Vægt

Nominel

størrelse

mm inch kgs lbs kgs lbs kgs lbs kgs lbs kgs lbs

251"----49 49-40 1½" - - - - 7 15 6 13 - 50 2" - - 9 20 - - 8 20 - 65 2½" - - 10,7 24 - - 11 24 - 80 3" - - 11,6 26 - - 13 28 - 100 4" - - 15,2 33 - - 19 41 - 125 5" - - 20,4 45 - - 24 52 - 150 6" - - 26 57 - - 29 64 - 200 8" 48 106 48 106 - - 56 124 - 250 10" 64 141 69 152 - - 79 174 - 300 12" 76 167 86 189 - - 110 243 - 350 14" 100 220 116 255 - - 131 289 - 400 16" 127 280 144 317 - - 165 364 - 450 18" 152 335 178 393 - - 176 388 - 500 20" 184 405 232 512 - - 235 518 - 600 24" 258 568 343 736 - - 345 761 - 700 28" 315 693 350 772 - - - - 309 681

750 30" - - - - - - - - 480 1058

800 32" 410 904 442 975 - - - - 421 928

900 36" 512 1129 550 1213 - - - - 539 1188

1000 40" 650 1433 732 1614 - - - - 670 1477

42" - - - - - - - - 700 1544

1100 44" - - - - - - - - 1100 2426

1200 48" 990 2183 1106 2439 - - - - 1030 2271

PN 10

PN 16 PN 40 Klasse 150

AWWA

Sammenhæng mellem

temperatur og

arbejdstryk

Metrisk (Tryk angivet i bar)

Dimension 25 mm, 40 mm & > 300 mm

Flange Flange Temperatur

specifikation tryk −510 5090

EN 1092-1 PN 10 10,0 10,0 9,7 9,4

PN 16 16,0 16,0 15,5 15,1

PN 40 40,0 40,0 38,7 37,7

ANSI B16.45 150 lb 19,7 19,7 19,3 18,0

AWWA C-207 Klasse D 10,3 10,3 10,3 10,3

Dimension 50 mm til 300 mm

EN 1092-1 PN 10 10,0 10,0 10,0 8,2

PN 16 10,0 16,0 16,0 13,2

ANSI B16.45 150 lb 10,0 19,7 19,7 16,2

°°

°C

°°

Imperial (Tryk angivet i Psi)

Dimension 1", 1½", & > 12"

Flange Flange Temperatur

specifikation tryk 23 50 120 200

EN 1092-1 PN 10 145 145 141 136

PN 16 232 232 225 219

PN 40 580 580 561 547

ANSI B16.45 150 lb 286 286 280 261

AWWA C-207 Klasse D 150 150 150 150

Dimension 2" til 12"

EN 1092-1 PN 10 145 145 145 119

PN 16 145 232 232 191

ANSI B16.45 150 lb 145 286 286 235

°°

°F

°°

26

Page 27

SITRANS F M MAGFLO

Magnetisk flowmåler type MAG 5100 W

Installation, generelt

Flowmåleren kan aflæses og betjenes under

så at sige alle indbygningsforhold, idet displayet kan drejes i forhold til målehovedet.

For at sikre optimal flowmåling bør man være

opmærksom på følgende:

Målehovedet skal altid være fuldstændig fyldt

med væske.

Derfor bør man undgå:

• Installation på det højeste sted i rørsystemet.

• Installation i lodrette rør med frit udløb.

Ved delvist fyldte rør eller rør med nedadgående flowretning og frie udløb bør flowmåleren

placeres i et U-rør.

Montage i lodrette rør

Anbefalet flowretning: opad. Dette minimerer

indflydelse på målingen fra evt. gas-/luftbobler

i væsken.

27

Page 28

SITRANS F M MAGFLO

Magnetisk flowmåler type MAG 5100 W

Installation, generelt

(fortsættelse)

Montage i vandrette rør

Målehovedet monteres som vist på den øverste figur. Målehovedet må ikke monteres som

vist på den nederste figur af hensyn til

elektrodernes placering øverst, hvor der er

mulighed for luftbobler, og nederst, hvor der er

mulighed for mudder, slam, sand osv.

Med henblik på detektering af tomt målerør

vippes målehovedet 45-60° som vist på den

øverste figur.

Måling på slibende væsker og væsker med

partikler

Her anbefales indbygning i lodrette/skrå rør, for

at mindske slitage og aflejringer i målehovedet.

Ind- og udløbsforhold

For at opnå en nøjagtig flowmåling er det nødvendigt at have lige indløbs- og udløbsstrækninger og en vis afstand til pumper og

ventiler.

Det er ligeledes vigtigt, at flowmåleren er centreret i forhold til rørsystemets flanger og pakninger.

Montage i store rør

Flowmåleren kan også monteres imellem to

reduktionsstykker (f. eks. DIN 28545). Ved 8°

gælder nedenstående tryktagskurve.

Kurverne er gældende for vand.

Eksempel:

En flowhastighed på 3 m/s (V) i et målehoved

med en diameterreduktion fra DN 100 til DN 80

= 0,8) forårsager et trykfald på 2,9 mbar.

(d

1/d2

28

Page 29

SITRANS F M MAGFLO

Magnetisk flowmåler type MAG 5100 W

Potentialeudligning Potentialeudligning udføres med indbyggede

Katodisk beskyttet

rørsystem

Med jordingselektroder

jordingselektroder.

Ved rørsystemer med katodisk beskyttelse skal

der tages særlige hensyn.

Kompakt montering:

Transmitteren skal strømforsynes via en skilletransformator. "PE"-klemmen må ikke være

tilsluttet.

Separat montering:

Afskærmnigen må kun tilsluttes transmitterens

ende via en 1,5 µF kondensator.

Afskærmningen må aldrig tilsluttes i begge

ender.

Isoleret målehoved:

Hvis de ovenstående tilslutningsmuligheder ikke

kan accepteres, skal målehovedet isoleres fra

rørsystemet.

29

Page 30

SITRANS F M MAGFLO

Magnetisk flowmåler type MAG 5100 W

Tilspænding Standardbolte skal være velsmurte og spændes

jævnt rundt omkring pakfladen. For stor eller

"skæv" tilspænding kan forårsage utætheder/

skader på flowmåler og rørsystem.

Nominel

størrelse

mm inch Nm f/lbs Nm f/lbs Nm f/lbs Nm f/lbs Nm f/lbs

25 1" - - - - 10 7 7 5 - 40 1½" - - - - 16 12 9 7 - 50 2" - - 25 18 - - 25 18 - 652½"- -2518- -2518- 80 3" - - 25 18 - - 34 25 - 100 4" - - 25 18 - - 26 19 - 125 5" - - 29 21 - - 42 31 - 150 6" - - 50 37 - - 57 42 - 200 8" 50 37 50 37 - - 88 65 - 250 10" 50 37 82 61 - - 99 73 - 300 12" 57 42 111 82 - - 132 97 - 350 14" 60 44 120 89 - - 225 166 - 400 16" 88 65 170 125 - - 210 155 - 450 18" 92 68 170 125 - - 220 162 - 500 20" 103 76 230 170 - - 200 148 - 600 24" 161 119 350 258 - - 280 207 - 700 28" 200 148 304 224 - - - - 200 148

750 30" - - - - - - - - 240 177

800 32" 274 202 386 285 - - - - 260 192

900 36" 288 213 408 301 - - - - 240 177

1000 40" 382 282 546 403 - - - - 280 207

42"----- ---280207

1100 44" - - - - - - - - 290 214

1200 48" 395 292 731 539 - - - - 310 229

PN 10

PN 16 PN 40 Klasse 150

AWWA

Moment beregning Alle værdier er teoretiske og beregnet ud fra følgende forudsætninger:

1) Alle bolte er nye og boltematerialet er valgt i henhold til EN 1515-1 tabel 2

2) Pakningsmaterialet, som anvendes mellem flowmåler og modflange må ikke overstige

hårdhed 75 shore A

3) Alle bolte er galvaniserede og velsmurte

4) De beregnede værdier er gældende for flanger af kulstofstål (St. 37.2)

5) Flowmåleren og modflangen flugter korrekt på linie

30

Page 31

SITRANS F M MAGFLO

Magnetisk flowmåler type MAG 5100 W

Flange dimensioner

(metrisk)

Mål mm Bolte

mm OD PCD T B Hul Dia.

PN 10

200 340 295 24 22 8 M20

250 395 350 26 22 12 M20

300 445 400 26 22 12 M20

350 505 460 28 22 16 M20

400 565 515 32 26 16 M24

450 615 565 36 26 20 M24

500 670 620 38 26 20 M24

600 780 725 42 30 20 M27

700 895 840 30 30 24 M27

800 1015 950 32 33 24 M30

900 1115 1050 34 33 28 M30

1000 1230 1160 34 36 28 M33

1200 1455 1380 38 39 32 M36

PN 16

50 165 125 19 18 4 M16

65 185 145 20 18 8 M16

80 200 160 20 18 8 M16

100 220 180 22 18 8 M16

125 250 210 22 18 8 M16

150 285 240 24 22 8 M20

200 340 295 26 22 12 M20

250 405 355 29 26 12 M24

300 460 410 32 26 12 M24

350 520 470 35 26 16 M24

400 580 525 38 30 16 M27

450 640 585 42 30 20 M27

500 715 650 46 33 20 M30

600 840 770 52 36 20 M33

700 910 840 36 36 24 M33

800 1025 950 38 39 24 M36

900 1125 1050 40 39 28 M36

1000 1255 1170 42 42 28 M39

1200 1485 1390 48 48 32 M45

PN 40

25 115 85 16 14 4 M12

40 150 110 18 18 4 M16

Mål mm Bolte

mm OD PCD T B Hul Dia.

150 lb

25 108 79 14 16 4 M14

40 127 98 18 16 4 M14

50 152 121 19 19 4 M16

65 178 140 22 19 4 M16

80 190 152 24 19 4 M16

100 229 191 24 19 8 M16

125 254 216 24 22 8 M20

150 279 241 25 22 8 M20

200 343 298 29 22 8 M20

250 406 362 30 25 12 M24

300 483 432 32 25 12 M24

350 533 476 35 28 12 M27

400 597 540 36,5 28 16 M27

450 635 578 40 32 16 M30

500 699 635 43 32 20 M30

600 813 749 48 35 20 M33

AWWA

700 927 864 33 35 28 M33

750 984 914 35 35 28 M33

800 1060 978 38 41 28 M39

900 1168 1086 41 41 32 M39

1000 1289 1200 41 41 36 M39

1050 1346 1257 44 41 36 M39

1200 1511 1422 48 41 44 M39

31

Page 32

SITRANS F M MAGFLO

Magnetisk flowmåler type MAG 5100 W

Producentens udsagn

omkring udseende og

sikkerhed

1. Ansvaret for den valgte lining og elektrode materiales holdbarhed overfor slitage og korrossion

påhviler køber; indflydelse fra evt. ændring i mediesammensætning på et vilkårligt tidspunkt

i produktets levetid skal herunder tages i betragtning. Forkert valg af lining og/eller elektrode

materiale kan medføre udfald af flowmåleren.

2. Påvirkninger kommende fra jordskælv, trafik, kraftige vindforhold og ildløs er ikke taget i

betragtning ved udformning af flowmåleren.

3. Flowmåleren må ikke installeres, således at den mekanisk belaster omkringliggende rørføring.

Udvendig belastning er ikke medregnet ved udformning af flowmåleren.

4. Ved anvendelse skal de, på skilte eller i instruktionen, angivne tryk og/eller temperatur

grænser overholdes og må ikke overskrides.

5. Det anbefales at alle installationer inkluderer en sikkerhedsventil for mulig udluftning/

dræning.

6. I henhold til trykdirektivet PED er denne flowmåler et tryktilbehør og som sådant ikke godkendt

som sikkerheds tilbehør i henhold til PED.

7. Afmontering af klemkasse fra flowmåler, medfører bortfald af PED overensstemmelse for

produktet; medmindre afmontering udføres af Siemens Flow Instruments eller en af dem

godkendt person.

I overensstemmelse med trykdirektivet Pressure Equipment Directive (97/23/EC)

We have checked the contents of this manual for agreement with the hardware and

software described. Since deviations cannot be precluded entirely, we cannot guarantee

full agreement. However, the data in this manual are reviewed regularly and any

necessary corrections included in subsequent editions. Suggestions for improvement

are always welcomed.

Technical data subject to change without prior notice.

Siemens Flow Instruments A/S

Nordborgvej 81

32

DK-6430 Nordborg

The reproduction, transmission or use of this document or its contents is not permitted without

express written authority.

Offenders will be liable for damages. All rights, including rights created by patent grant or

registration of a utility model or design, are reserved.

Copyright © Siemens AG 09.2004 All Rights Reserved

Order no.: FDK:521H1190-01

Printed in: Denmark

Loading...

Loading...