Siemens MAG 1100 F, MAG 1100, MAG 3100, MAG 3100 P, MAG 5000 Operating Instructions Manual

...Page 1

&MFDUSPNBHOFUJDGMPXNFUFST

."(."('."(."(1."(8

."(."(

0QFSBUJOH*OTUSVDUJPOTp

4*53"/4'

Page 2

SFIDK.PS.027.W6.02

SITRANS F M

Siemens Flow Instruments

range of electromagnetic

flowmeters

2

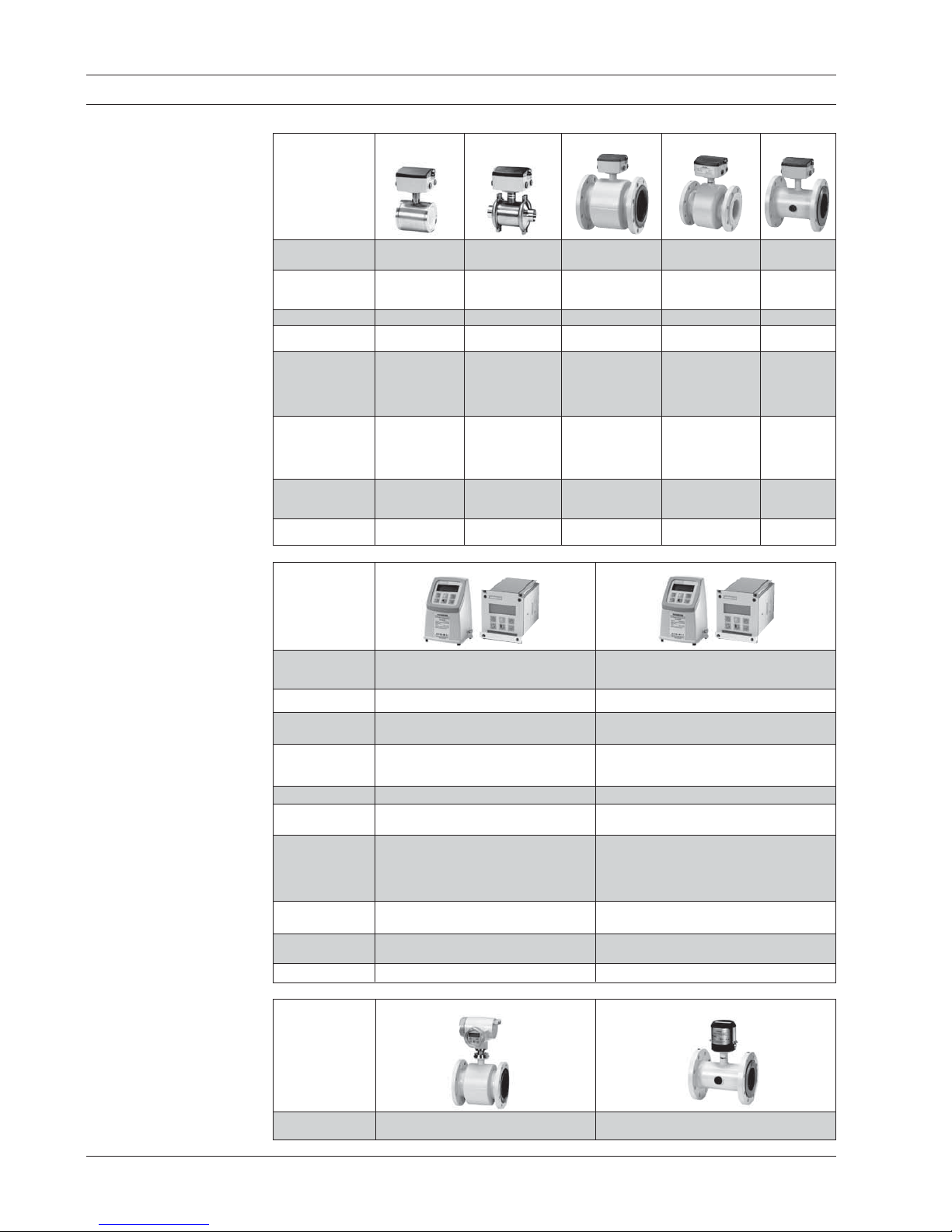

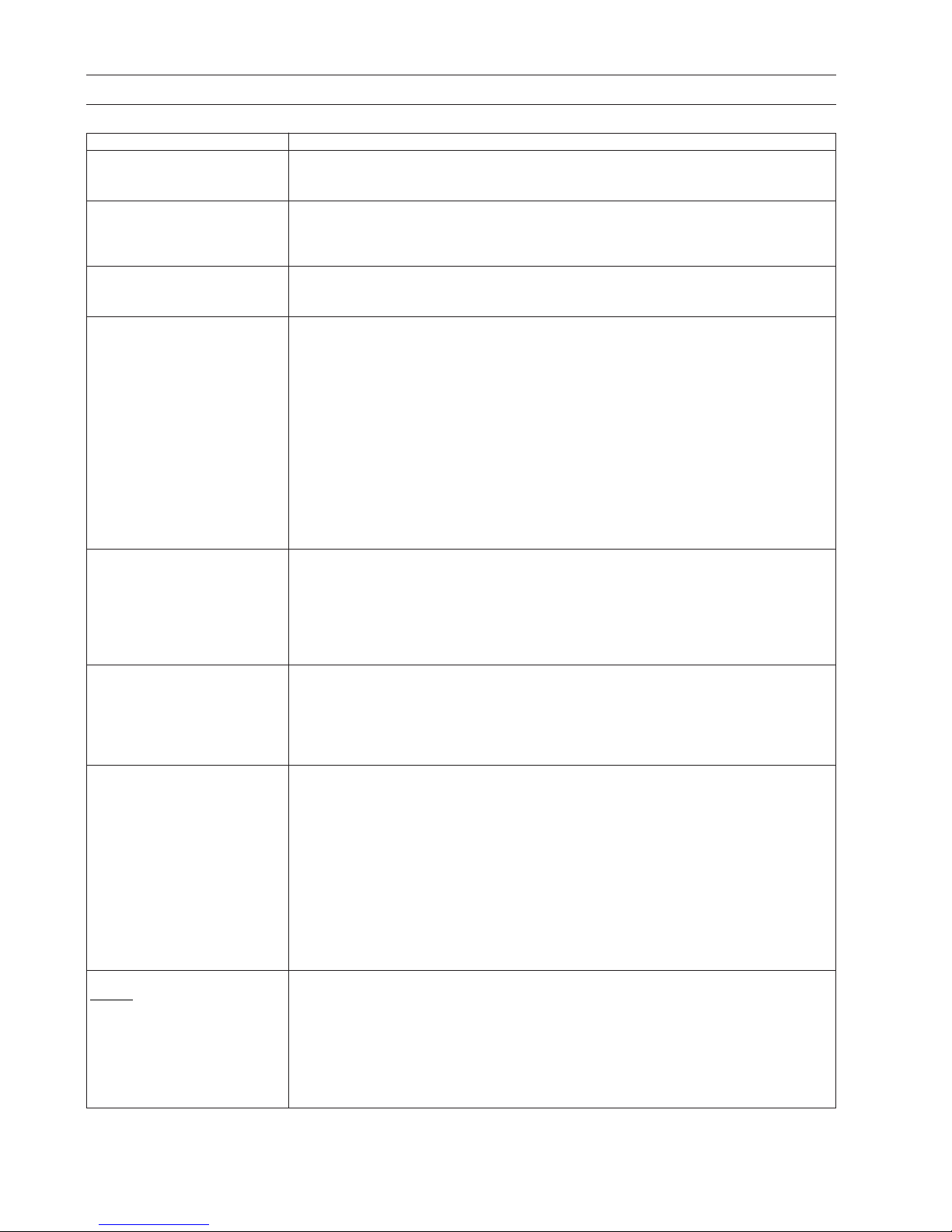

MAG 1100 MAG 1100 F MAG 3100 MAG 3100 P MAG 5100 W

Size [mm/inch] DN 2 ... 100/ DN 10 ... 100/ DN 15 ... 2000/ DN 15 ... 300/ DN 25 ... 2000/

1

/12" ... 4"

3

/8" ... 4"

1

/2" ... 78"

1

/2" ... 12"

1

" ... 78"

Connection Flangeless Weld-in adapter, Flange Flange Flange

(Sandwich design) clamp adapter,

thread adapter

Pressure [bar/psi] Max. 40/600 Max. 40/600 Max. 100/1450 Max. 50/725 Max. 40/600

Temperature [°C/°F] −30 ... +200/ −30 ... +150/ −40 ... +180/ −20 ... +150/ −10 ... +70/

−20 ... 400 −20 ... 300 −40 ... 350 −4 ... 300 −14 ... 160

Liner Zirconium oxide Ceramic (Al

2O3

), Neoprene, EPDM, PTFE, PFA EPDM, NBR,

(Zr0

2

) PFA Teflon (PTFE), Ebonite

Ceramic (Al

2O3

), Ebonite,

PFA Linatex

®

PFA

Electrodes Platinum Platinum AISI 316 Ti, Hastelloy C Hastelloy C,

Hastelloy C Hastelloy C Hastelloy C, Grounding

Platinum/iridium, electrodes

Titanium, Tantalum,

Grounding electrodes

Enclosure IP67/NEMA 4X IP67/NEMA 4X IP67/IP68 IP67/IP68 IP67/IP68

NEMA 4X/6 / NEMA 4X/6 / NEMA 4X/6 /

NEMA 6P NEMA 6P NEMA 6P

Ex-version ATEX 2G D ATEX 2G D ATEX 2G D ATEX 2G D FM Class 1,

FM Class 1, Div 2 FM Class 1, Div 2

FM/CSA Class 1, Div 2 FM/CSA Class 1, Div 2

Div 2

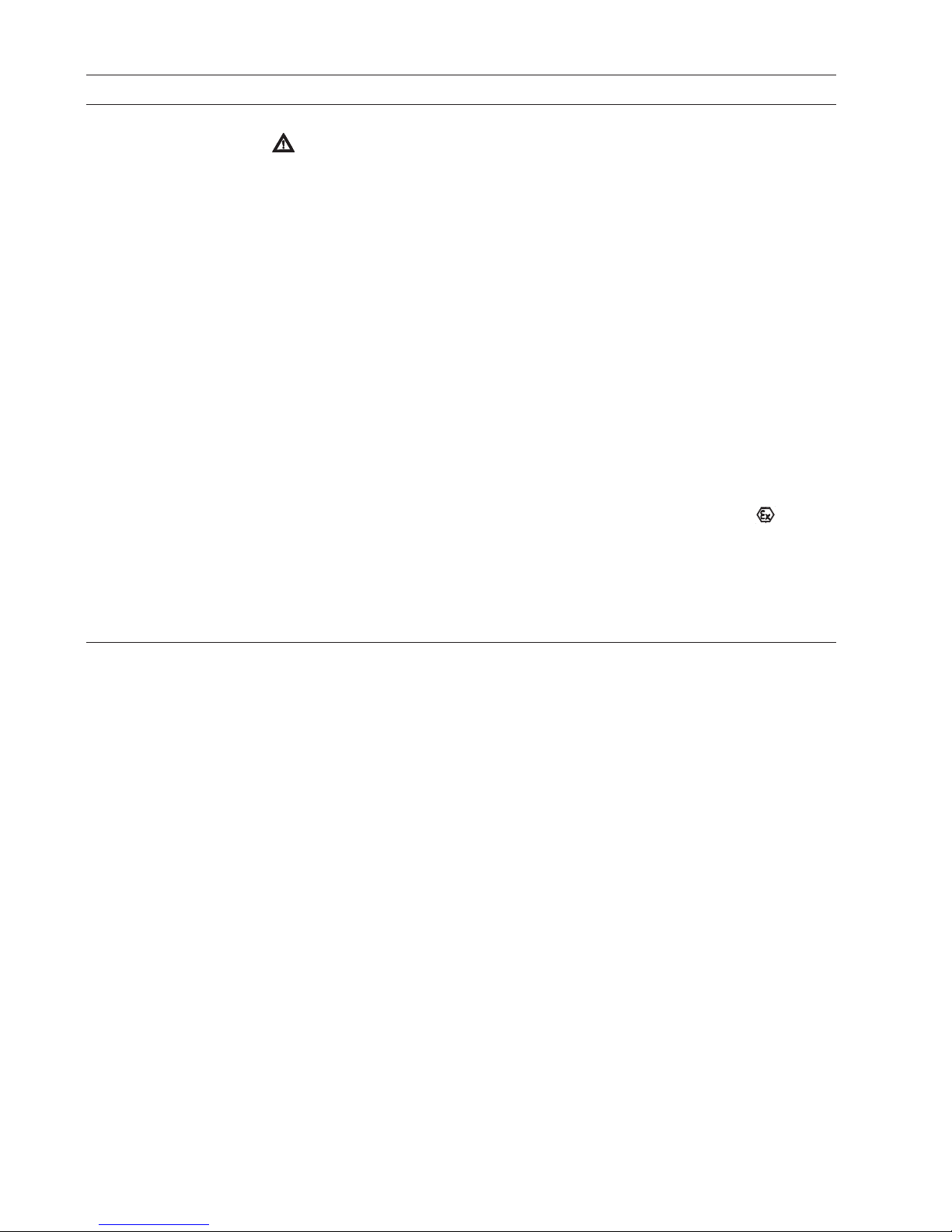

MAG 5000 MAG 6000

Outputs 1 current output 1 current output

1 digital output 1 digital output

1 relay output 1 relay output

Flow direction Uni/bidirectional Uni/bidirectional

Communication Optional HART

®

Add-on modules, HART, Profibus PA & DP,

MODBUS RTU, DeviceNet, Foundation Fieldbus H1

Display 3 lines 3 lines

20 characters 20 characters

(optional without display) (optional without display)

Meter uncertainty ±0.4% o.r. ±0.20% o.r.

Enclosure IP67, IP20 IP67, IP20

NEMA 6 (NEMA 4X), NEMA 2 NEMA 6 (NEMA 4X), NEMA 2

Custody transfer MI-001 MI-001

approval PTB PTB (hot and cold water)

OIML R 49 OIML R 49

OIML R 75

OIML R 117

Approvals ATEX 2G D ATEX 2G D

FM/CSA Class 1, Div 2 FM/CSA Class 1, Div 2

Power supply 12 ... 24 V AC/DC 12 ... 24 V AC/DC

115 ... 230 V AC 115 ... 230 V AC

Batch No Yes

MAG 6000 Industry MAG 8000

Refer to Operating manual Operating manual

A5E02083319 083R9174

Page 3

3

SITRANS F M

1.1 Product introduction................................................................................................................................................. 5

1.2 Mode of operation .................................................................................................................................................... 6

1.3 Pressure Equipment Directive 97/23ECs ................................................................................................................. 7

1.3.1 Exclusions ............................................................................................................................................................... 8

1.3.2 Product marking ....................................................................................................................................................... 8

2.1 Sensor MAG 1100 .................................................................................................................................................... 9

2.2 Sensor MAG 1100 F............................................................................................................................................... 11

2.3 Sensor MAG 3100 .................................................................................................................................................. 13

2.4 Sensor MAG 5100 W ............................................................................................................................................. 16

2.5.1 Transmitter MAG 5000 ........................................................................................................................................... 17

2.5.2 Transmitter MAG 6000 ........................................................................................................................................... 14

2.5.4 Safety barrier (e ia) ................................................................................................................................................ 19

2.5.5 Cleaning unit .......................................................................................................................................................... 19

2.6 Meter uncertainty ................................................................................................................................................... 20

2.7 Output characteristics MAG 5000 and MAG 6000 ................................................................................................. 21

2.8.1 Conductivity of medium and sensor cables ........................................................................................................... 22

2.8.2 Cable requirements ................................................................................................................................................ 22

2.9 Cable data (Supplied by Siemens Flow Instruments) ............................................................................................ 22

3.1.1 Sizing table (DN 2 to DN 2000) .............................................................................................................................. 23

3.1.2 Sizing table (

1

/12 ... 78").......................................................................................................................................... 24

3.2.1 Minimum conductivity ............................................................................................................................................. 25

3.2.2 Liner selection guide .............................................................................................................................................. 25

3.2.3 Electrode selection guide ...................................................................................................................................... 25

3.3 Installation conditions ............................................................................................................................................ 25

3.4 Cleaning unit .......................................................................................................................................................... 29

3.5 Custody transfer approval ..................................................................................................................................... 30

3.6 Transmitter MAG 5000 CT, MAG 6000 CT Sealing .................................................................................................. 30

3.7 Ex survey according to Directive 94/9/EC (ATEX) ................................................................................................. 31

3.8 Approvals ............................................................................................................................................................... 32

4.1 Sensor MAG 1100 .................................................................................................................................................. 33

4.2 Sensor MAG 1100 F ............................................................................................................................................... 34

4.3 Sensor MAG 5100 W ............................................................................................................................................. 37

4.4 Sensor MAG 3100 .................................................................................................................................................. 39

4.4.1 Sensor MAG 3100 .................................................................................................................................................. 39

4.5 Transmitter ............................................................................................................................................................. 41

5.1 Potential equalization ............................................................................................................................................. 44

5.2 Inlet protection MAG 3100 ..................................................................................................................................... 45

5.3 Cathodic protected piping ...................................................................................................................................... 45

6.1 Compact installation MAG 5000 and MAG 6000 .................................................................................................... 46

6.2.1 Add-on modules MAG 6000 only ............................................................................................................................ 48

6.2.2 Remote installation. At the sensor ......................................................................................................................... 49

6.2.3 Remote installation. Wall mounting ......................................................................................................................... 50

6.2.4 Remote installation. Transmitter in 19" insert ......................................................................................................... 51

6.2.5 Add-on modules MAG 6000 only ............................................................................................................................ 52

6.2.6 Installation in IP 66 wall mounting enclosure ......................................................................................................... 53

6.2.7 Installation in IP 65 panel mounting enclosure (front of panel) .............................................................................. 54

6.2.8 Installation into the back of a panel ...................................................................................................................... 55

6.3 Transmitter Safety barrier ...................................................................................................................................... 56

6.4 Transmitter Cleaning unit ........................................................................................................................................ 57

7.1 Transmitter MAG 5000 and MAG 6000 connection diagram ................................................................................... 58

7.2 Wiring diagram for transmitter and sensor ............................................................................................................. 59

8.1 Keypad and display layout..................................................................................................................................... 62

8.2 Menu build-up ......................................................................................................................................................... 63

8.2.1

Password ............................................................................................................................................................... 63

8.3.1 MAG 5000 and MAG 6000 - Menu overview .......................................................................................................... 64

8.3.2 MAG 5000 CT and MAG 6000 CT - Menu overview................................................................................................ 65

8.4.1 Basic settings ........................................................................................................................................................ 66

8.4.2 Outputs ...................................................................................................................

............................................... 67

8.4.3 Digital and relay outputs ........................................................................................................................................ 67

8.4.4 Relay outputs ......................................................................................................................................................... 68

8.4.5 External input ......................................................................................................................................................... 68

8.4.6 Sensor characteristics ........................................................................................................................................... 69

8.4.7 Reset mode ............................................................................................................................................................ 69

8.4.8 Service mode ......................................................................................................................................................... 70

8.4.9 Operator menu setup ............................................................................................................................................. 71

8.4.10 Product identity ..................................................................................................................................................... 72

8.4.11 Change password .................................................................................................................................................. 72

8.4.12 Language mode ..................................................................................................................................................... 73

8.4.13 HART

®

co mmu nic ati on M AG 500 0 HA RT o r as add-on module .............................................................................. 73

8.5.1 Flow rate ................................................................................................................................................................ 74

8.5.2 Totalizer ................................................................................................................................................................. 74

8.5.3 Batch ..................................................................................................................................................................... 74

8.6.1 Settings available .................................................................................................................................................. 75

8.6.2 Dimension dependent factory settings .................................................................................................................. 76

8.6.3 Dimension dependent batch and pulse output settings ......................................................................................... 76

8.6.4 MAG 5000 CT and MAG 6000 CT settings ............................................................................................................. 80

8.7.1 Error handling......................................................................................................................................................... 81

8.7.2 List of error numbers ............................................................................................................................................. 82

9.1 Transmitter check list ............................................................................................................................................. 83

9.2 Trouble shooting MAG transmitter .......................................................................................................................... 84

9.3 Check list MAG sensor .......................................................................................................................................... 85

9.4 Coil resistance table .............................................................................................................................................. 86

10. Ordering ................................................................................................................................................................. 87

2. Technical data

1. Product introduction

3. Project guidance

4. Dimensions and weight

6. Installation of transmitter

5. Installation of sensor

7. Electrical connection

8. Commissioning

10. Ordering

9. Service

Page 4

4

SITRANS F M

For safety reasons it is important that the following points, especially the points marked with

a warning sign, are read and understood before the system is being installed:

• Installation, connection, commissioning, and service must be carried out by personnel

who are qualified and authorized to do so.

• It is very important that the same people have read and understood the instructions and

directions provided in this manual and that they follow the instructions and directions

before putting the equipment into use!

• People who are authorized and trained by the owner of the equipment may operate the

equipment.

• The installer must ensure that the measuring system is correctly connected and is in

accordance with the connection diagram. The transmitter has to be earthed by means

of a 4 mm

2

potential equalising conductor.

• In applications where the operating pressure or media can be hazardous in the event

of a pipe failure, we recommend that special precautions are taken during the installation

of the sensor, such as sensor location, guarding or the use of a pressure relief valve.

• Siemens Flow Instruments can provide assistance with the selection of sensor parts in

contact with the media. However, the full responsibility for the selection rests with the

customer and Siemens Flow Instruments can take no responsibility for any failure due

to material incompatibility.

• Equipment used in hazardous areas must be Ex-approved and marked

.

It is required that the "Special Conditions for Safe Use" provided in the manual and in

the Ex certificate are followed!

• Installation of the equipment must comply with national regulations.

Example EN 60079-14 for the European Community.

• Repair and service can be done by approved Siemens Flow Instruments personnel only.

1. Introduction

1. Responsibility for the choice of lining and electrode materials with regard to their abrasion

and corrosion resistance lies with the purchaser; the effect of any change in process medium

during the operating life of the flowmeter should be taken into account. Incorrect selection

of lining and/or electrode materials could lead to a failure of the flowmeter.

2. It is the responsibility of the user to ensure that stresses and loading caused by earthquakes,

traffic, high winds and fire damage are taken into account during installation, when

appropriate. These forces are not taken into account during flowmeter design.

3. It is the responsibility of the user to ensure that the flowmeter is installed such that it does not

act as a focus for pipeline stresses. External loading are not taken into account during

flowmeter design.

4. During operation do not exceed the pressure and/or temperature ratings indicated on the

data label or in the installation instructions.

5. It is the responsibility of the user to ensure that all installations include over pressure

protection, means for draining/venting, and that adequate protection is provided to minimize

any risk of contact with hot surfaces.

6. Under the Pressure Equipment Directive this product is a pressure accessory, and not

approved for use as a safety accessory, as defined by the Pressure Equipment Directive.

7. Removal of the terminal box except by Siemens Flow Instruments or their approved agents

will invalidate the PED conformity of the product.

In accordance with the Pressure Equipment Directive (97/23/EC)

Manufacturer's design

and safety statement

Page 5

5

SITRANS F M

All SITRAN S F M electromagnetic flowmeters feature a unique SENSORPROM® memory unit

which stores sensor calibration data and transmitter settings for the lifetime of the product.

At commissioning the flowmeter commences measurement without any initial programming.

The factory settings matching the sensor are stored in the SENSORPROM

®

unit. Also customer-

1.1

Product introduction

1. Product introduction

SITRANS F M electromagnetic flowmeters are characterised by simplicity:

⇒ Simple to install

⇒ Simple to commission

⇒ Simple to operate

⇒ Simple to maintain

SITRANS F M electromagnetic flowmeters are manufactured by Siemens Flow Instruments A/S

- one of the world's leading manufacturers of flowmeters.

specified settings are downloaded to the

SENSORPROM

®

unit. Should the transmitter be

replaced, the new transmitter will upload all

previous settings and resume measurement without

any need for re-programming.

Furthermore, the "fingerprint" used in connection

with the Siemens Flow Instruments Verificator is

stored during the sensor calibration.

USM II "Plug & Play" add-on communicati on

modules.

USM II - the Universal Signal Module with "Plug &

Play" simplicity makes it easy to access and integrate

the flow measurement with almost any system. It

ensures the flowmeter will be easy to upgrade to new

communication platforms in the future, too.

Electromagnetic flowmeters are suitable for measuring the flow of almost all electrically

conducting liquids, pastes and slurries.

A prerequisite is that the medium must have a minimum conductivity of 5

µS/cm and a solid content

of maximum 40%. The temperature, pressure, density, and viscosity have no influence on the result.

The main applications of the electromagnetic flowmeters can be found in the following sectors:

• Water and wastewater

• Chemical and pharmaceutical industries

• Food and beverage industry

• Mining, aggregates and cements industries

• Pulp and paper industry

• Steel industry

• Power; utility and chilled water industry

The wide variety of combinations and versions from the modular system means that ideal

adaptation is possible to each measuring task.

Page 6

6

SITRANS F M

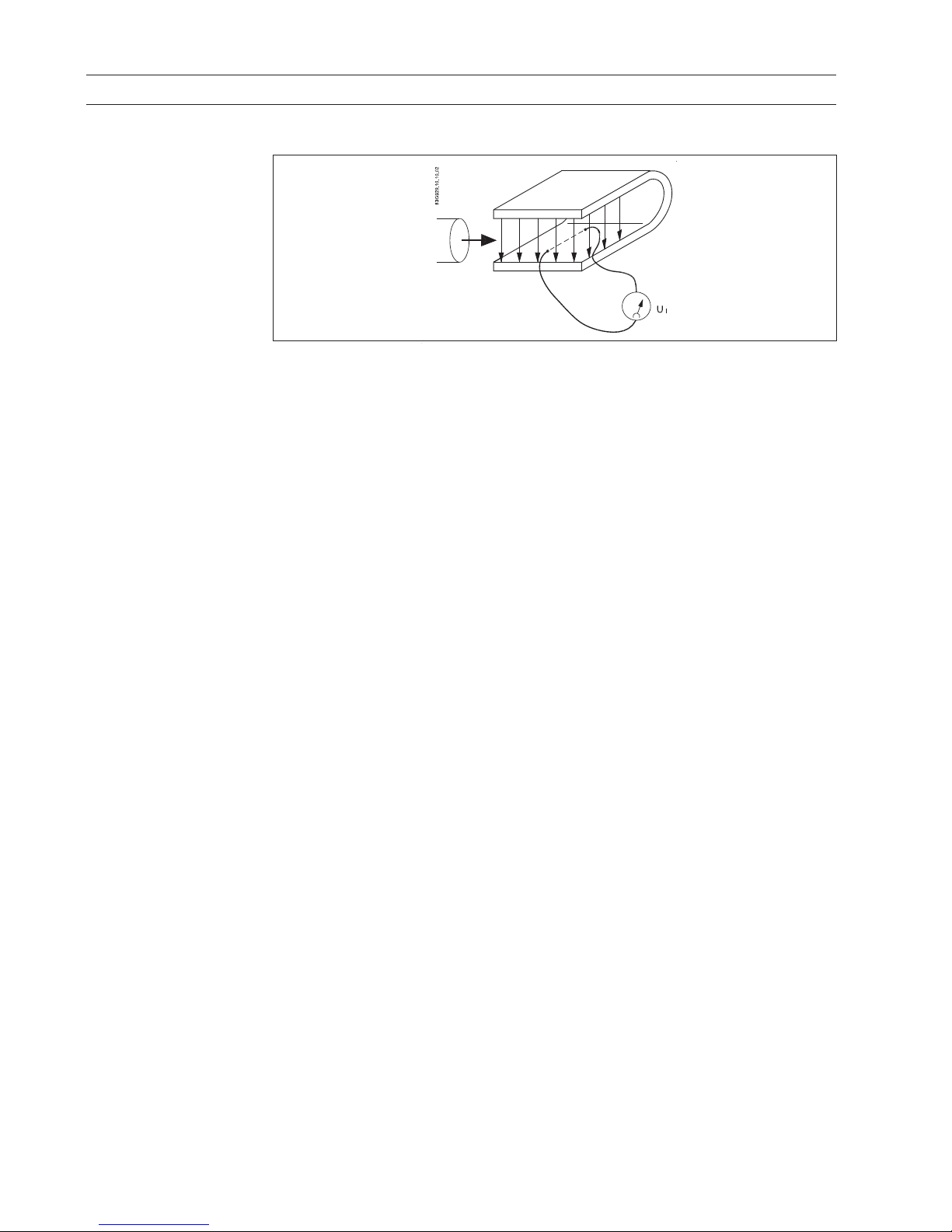

0DJQHWLF)LHOG

)ORZ

1. Product introduction

U

i

= When an electrical conductor of length L is moved at velocity v, perpendicular to the lines of

flux through a magnetic field of strength B, the voltage Ui is induced at the ends of the conductor

Ui = L x B x v

Ui=Induced voltage

L=Conductor length = Inner pipe diameter = k

1

B = Magnetic field strength = k

2

v = Velocity of conductor (media)

k=k1 x k

2

Ui = k x v, the electrode signal is directly proportional to the fluid velocity

A flowmeter

consists of a sensor (MAG 1100, MAG 1100 F, MAG 3100, MAG 3100 P or MAG 5100 W)

and a transmitter (MAG 5000 or 6000).

SENSOR

The sensor converts the flow into an electrical voltage (U

i

) proportional to the velocity of the flow.

The sensor is built up of a stainless steel pipe, 2 coils, electrodes, an isolating liner, housing and,

where applicable, connecting flanges.

TRANSMITTER

The transmitter consists of a number of function blocks which convert the sensor voltage into flow

readings.

Power supply

Two different types of power supply are available. A 12 ... 24 V AC/DC and a 115 ... 230 V AC switch

mode type.

Coil current module generates a pulsating magnetizing current that drives the coils in the sensor.

The current is permanently monitored and corrected. Errors or cable faults are registered by the selfmonitoring circuit.

Input circuit amplifies the flow proportional signal from the electrodes. The input impedance is

extremely high: >10

14

Ω which allows flow measurements on fluids with conductivities as low as

5

µS/cm. Measuring errors due to cable capacitance are eliminated due to active cable screening.

Digital signal processor converts the analog flow signal to a digital signal and suppresses

electrode noise through a digital filter. Inaccuracies in the transmitter as a result of long-term drift

and temperature drift are monitored and continuously compensated for via the self-monitoring

circuit. The analog to digital conversion takes place in an ultra low noise ASIC with 23 bit signal

resolution. This has eliminated the need for range switching. The dynamic range of the transmitter

is therefore unsurpassed with a turn down ratio of minimum 3000:1.

CAN communication

The transmitter operates internally via an internal CAN communication bus. Signals are transferred

through a signal conditioner to the display module, and to/from internal/external option modules

and the dialog module.

Dialog module

The display unit consists of a 3-line display and a 6-key keypad. The display shows a flow rate or

a totalizer value as primary reading.

Output module converts flow data to an analog, a digital and a relay output. The outputs are

galvanically isolated and can be individually set to suit a particular application.

1.2

Mode of operation

The flow measuring principle is based on Faraday’s law of electromagnetic induction.

Page 7

7

SITRANS F M

1. Product introduction

1.3

Pressure Equipment

Directive 97/23EC

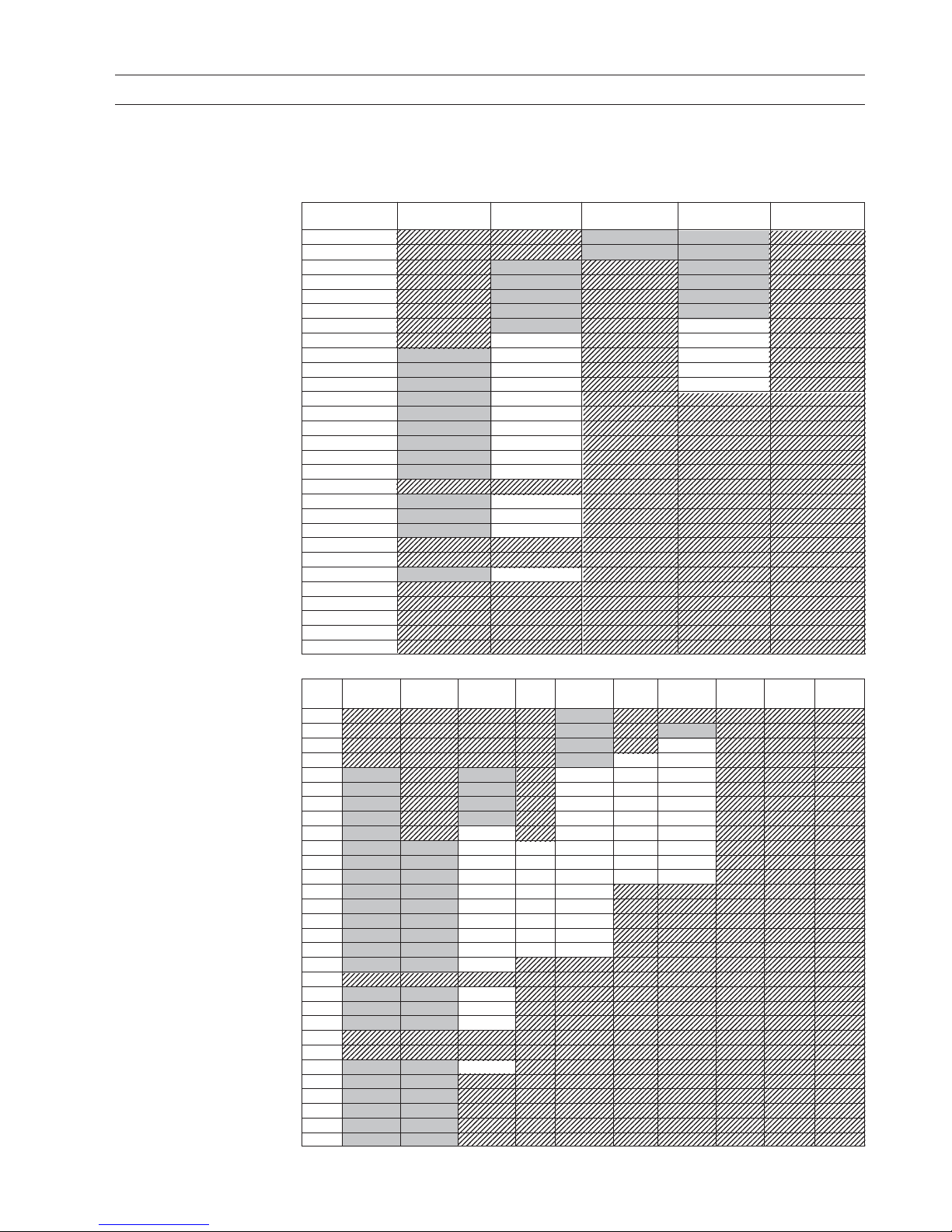

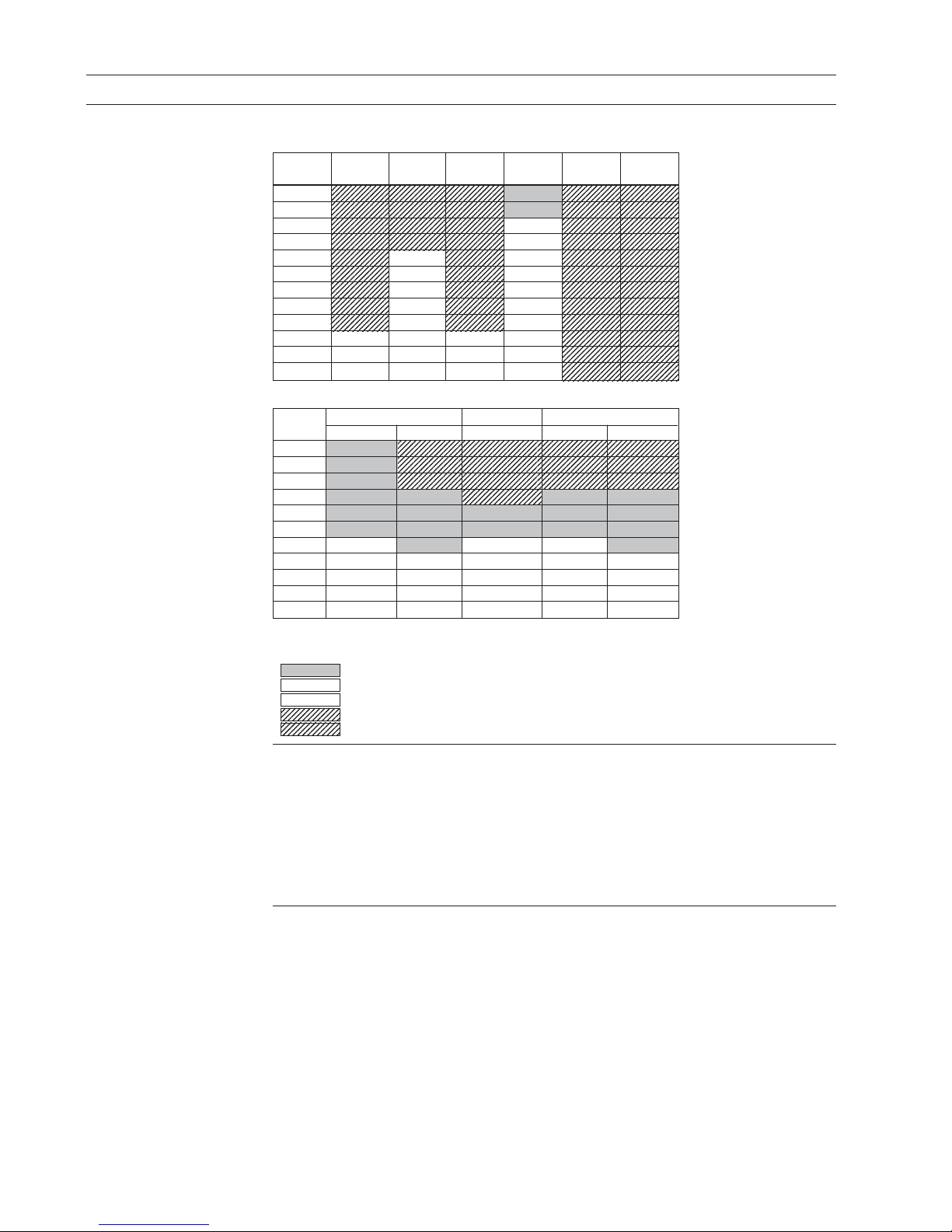

Flange PN 6 PN 10 PN 16 PN 25 PN 40 PN 63 PN 100 150 lb 300 lb AWWA

mm

15 N/A N/A N/A N/A EXC.PED N/A N/A N/A N/A N/A

25 N/A N/A N/A N/A EXC.PED N/A EXC.PED N/A N/A N/A

40 N/A N/A N/A N/A EXC.PED N/A PED N/A N/A N/A

50 N/A N/A N/A N/A EXC.PED PED PED N/A N/A N/A

65 EXC.PED N/A EXC.PED N/A PED PED PED N/A N/A N/A

80 EXC.PED N/A EXC.PED N/A PED PED PED N/A N/A N/A

100 EXC.PED N/A EXC.PED N/A PED PED PED N/A N/A N/A

125 EXC.PED N/A EXC.PED N/A PED PED PED N/A N/A N/A

150 EXC.PED N/A PED N/A PED PED PED N/A N/A N/A

200 EXC.PED EXC.PED PED PED PED PED PED N/A N/A N/A

250 EXC.PED EXC.PED PED PED PED PED PED N/A N/A N/A

300 EXC.PED EXC.PED PED PED PED PED PED N/A N/A N/A

350 EXC.PED EXC.PED PED PED PED N/A N/A N/A N/A N/A

400 EXC.PED EXC.PED PED PED PED N/A N/A N/A N/A N/A

450 EXC.PED EXC.PED PED PED PED N/A N/A N/A N/A N/A

500 EXC.PED EXC.PED PED PED PED N/A N/A N/A N/A N/A

600 EXC.PED EXC.PED PED PED PED N/A N/A N/A N/A N/A

700 EXC.PED EXC.PED PED* N /A N/A N/ A N/A N/A N/A N/A

750 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

800 EXC.PED EXC.PED PED* N /A N/A N/ A N/A N/A N/A N/A

900 EXC.PED EXC.PED PED* N /A N/A N/ A N/A N/A N/A N/A

1000 EXC.PED EXC.PED PED* N/A N/ A N /A N/ A N/A N/A N/A

1050 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

1100 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

1200 EXC.PED EXC.PED PED* N/A N/ A N /A N/ A N/A N/A N/A

1400 EXC.PED EXC.PED N/A* N/A N/ A N/A N/A N/A N/A N /A

1500 EXC.PED EXC.PED N/A* N/A N/ A N/A N/A N/A N/A N /A

1600 EXC.PED EXC.PED N/A* N/A N/ A N/A N/A N/A N/A N /A

1800 EXC.PED EXC.PED N/A* N/A N/ A N/A N/A N/A N/A N /A

2000 EXC.PED EXC.PED N/A* N/A N/ A N/A N/A N/A N/A N /A

MAG 3100

Since 30 May 2002 the "Pressure Equipment Directive" is mandatory for all pressure equipment

sold within the EU and EFTA.

Siemens Flow Instruments products confirms to PED by following the tables below.

Flange

mm PN 10 PN 16 PN 40 CL 150 AWWA

25 N/A N/A EXC.PED EXC.PED N/A

40 N/A N/A EXC.PED EXC.PED N/A

50 N/A EXC.PED N/A EXC.PED N/A

65 N/A EXC.PED N/A EXC.PED N/A

80 N/A EXC.PED N/A EXC.PED N/A

100 N/A EXC.PED N/A EXC.PED N/A

125 N/A EXC.PED N/A PED N/A

150 N/A PED N/A PED N/A

200 EXC.PED PED N/A PED N/A

250 EXC.PED PED N/A PED N/A

300 EXC.PED PED N/A PED N/A

350 EXC.PED PED N/A N/A N/A

400 EXC.PED PED N/A N/A N/A

450 EXC.PED PED N/A N/A N/A

500 EXC.PED PED N/A N/A N/A

600 EXC.PED PED N/A N/A N/A

700 EXC.PED PED* N/A N/A N/A

750 N/A N/A N/A N/A N/A

800 EXC.PED PED* N/A N/A N/A

900 EXC.PED PED* N/A N/A N/A

1000 EXC.PED PED* N/A N/A N/A

1050 N/A N/A N/A N/A N/A

1100 N/A N/A N/A N/A N/A

1200 EXC.PED PED* N/A N/A N/A

1400 N/A N/A* N/A N/A N/A

1500 N/A N/A* N/A N/A N/A

1600 N/A N/A* N/A N/A N/A

1800 N/A N/A* N/A N/A N/A

2000 N/A N/A* N/A N/A N/A

MAG 5100 W (7ME6580 only < DN600 (< 24"))

Page 8

8

SITRANS F M

MAG 3100 high temperature and 3100 P

Flange PN 10 PN 16 PN 25 PN 40 CL 150 CL 300

mm

15 N/A N/A N/A EXC.PED N/A N/A

25 N/A N/A N/A EXC.PED N/A N/A

40 N/A N/A N/A PED N/A N/A

50 N/A N/A N/A PED N/A N/A

65 N/A PED N/A PED N/A N/A

80 N/A PED N/A PED N/A N/A

100 N/A PED N/A PED N/A N/A

125 N/A PED N/A PED N/A N/A

150 N/A PED N/A PED N/A N/A

200 PED PED PED PED N/A N/A

250 PED PED PED PED N/A N/A

300 PED PED PED PED N/A N/A

1. Product introduction

MAG 1100 and MAG 1100 F

1.3.1

Exclusions

All products sold outside of EU and EFTA are excluded from the directive, also products sold into

certain market sectors are excluded. These include

1) Meters used in networks for the supply, distribution and discharge of water.

2) Meters used in pipelines for the conveyance of any fluid from offshore to onshore.

3) Meters used in the extraction of petroleum or gas, including christmas tree and manifold

equipment.

4) Any meter mounted on a ship or mobile offshore platform.

1.3.2

Product marking example

All meters will now carry either a CE mark or a CE mark followed by for example 0086

CE

0086: This indicates that the product conforms to PED 97/23/EC, LVD 2006/95/EC, &

EMC 2004/108/EC

CE: This indicates that the product conforms to LVD 2006/95/EC & EMC 2004/108/EC

Flange MAG 1100 MAG 1100 HT MAG 1100 F

mm Ceramic PFA Ceramic Ceramic PFA

2EXC.PEDN/A N/A N/A N/A

3EXC.PEDN/A N/A N/A N/A

6EXC.PEDN/A N/A N/A N/A

10 EXC.PED EXC.PED N/A EXC.PED EXC.PED

15 EXC.PED EXC.PED EXC.PED EXC.PED EXC.PED

25 EXC.PED EXC.PED EXC.PED EXC.PED EXC.PED

40 PED EXC.PED PED PED EXC.PED

50 PED PED PED PED PED

65 PED PED PED PED PED

80 PED PED PED PED PED

100 PED PED PED PED PED

Siemens Flow Instruments products confirms to PED by following the tables below.

The key to the tables is as follows.

EXC. PED

Excluded from PED under SEP or LVD

PED Product covered by PED

PED* Product covered by PED but available conforming or non conforming to PED

NA Size/pressure outside of PED scope or not available in the size range

NA* DN1400-2000 only available non conforming to PED

Page 9

9

SITRANS F M

2. Technical data

2. Technical data

2.1 Sensor MAG 1100 and MAG 1100 HT (High temperature)

MAG 1100 and MAG 1100 Ex

Type MAG 1100 MAG 1100 HT (High temperature)

Measuring principle Electromagnetic induction

Excitation frequency DN 2 ... 65 (1/12" … 2½"): 12.5 Hz / 15 Hz DN 15 ... 50 (½" … 2"): 12.5 Hz / 15 Hz

(Main supply: 50 Hz / 60 Hz) DN 80, 100 (3", 4"): 6.25 Hz / 7.5 Hz DN 80, 100 (3", 4"): 6.25 Hz / 7.5 Hz

Process connection

Nominal size

• MAG 1100 (Ceramic) DN 2 … DN 100 (

1

/12" … 4") DN 15 … DN 100 (½" … 4")

• MAG 1100 (PFA) DN 10 … DN 100 (

3

/8" ... 4")

Mating flanges EN 1092-1 (DIN 2501), ANSI B 16.5 class 150 EN 1092-1 (DIN 2501), ANSI B 16.5 class 150

and 300 or equivalent and 300 or equivalent

Option:

DN 2 ... 10 (

1

/12" ... 3/8"):

G½" / NPT ½" pipe connection adapters

Rated operating conditions

Ambient conditions

Ambient temperature

1)

• Sensor -40 … +100 °C (-40 … +212 °F) -40 … +100 °C (-40 … +212 °F)

• Sensor ATEX -20 … +60 °C (-4 … +140 °F) -20 … +50 °C (-4 … +122 °F)

• Compact transmitter

MAG 5000/6000 -20 … +50 °C (-4 … +122 °F)

Temperature of medium

• MAG 1100 (Ceramic) -20 … +150 °C (-4 … +302 °F) -20 … +200 °C (-4 … +392 °F)

• MAG 1100 ATEX (Ceramic) -20 … +150 °C (-4 … +302 °F) -20 … +180 °C (-4 … +356 °F)

• MAG 1100 (PFA) -30 … +130 °C (-20 … +266 °F)

Suitable for steam sterilization at 150 °C (302 °F)

Temperature shock

• MAG 1100 (Ceramic)

- Duration

≤ 1 min, followed

by 10 min rest • DN 2, 3 (

1

/12", 1/8") No limitations

•DN 6, 10, 15, 25: Max. ∆T ≤ 80 °C/min • DN 15, 25: Max. ∆T ≤ 80 °C/min

(¼",

3

/8", ½", 1": Max. ∆T ≤ 80 K/min) (½", 1": Max. ∆T ≤ 80 K/min)

•DN 40, 50: Max.

∆T ≤ 70 °C/min • DN 40, 50, 65: Max. ∆T ≤ 70 °C/min

(1½", 2", 2½": Max. ∆T ≤ 70 K/min) (1½", 2": Max. ∆T ≤ 70 K/min)

•DN 80, 100: Max.

∆T ≤ 60 °C/min • DN 80, 100: Max. ∆T ≤ 60 °C/min

(3", 4": Max.

∆T ≤ 60 K/min) (3", 4": Max. ∆T ≤ 60 K/min)

• MAG 1100 (PFA) Max. ±100 °C (210 °F) momentarily

Operating pressure

• MAG 1100 (Ceramic) • DN 2 ... 65: 40 bar (

1

/12" … 2½": 580 psi) • DN 15 ... 50: 40 bar (½" … 2”: 580 psi)

•DN 80: 37.5 bar (3": 540 psi) •DN 80: 37.5 bar (3": 540 psi)

•DN 100: 30 bar (4": 435 psi) •DN 100: 30 bar (4": 435 psi)

Vacuum: 1 x 10

-6

bar

abs

(1.5 x 10-5 psi

abs

)Vacuum: 1 x 10

-6

bar

abs

(1.5 x 10-5 psi

abs

)

• MAG 1100 (PFA) 20 bar (290 psi)

Vacuum: 0.02 bar

abs

(0.3 psi

abs

)

DN 80 ... DN 100: CO2 pressure max. 7 bar (101.5 psi)

Mechanical load • 18 ... 1000 Hz random in x, y, z, directions for • 18 ... 1000 Hz random in x, y, z, directions for

2 hours according to EN 60068-2-36 2 hours according to EN 60068-2-36

•Sensor: 3.17 grms •Sensor: 3.17 grms

•Sensor with compact MAG 5000/ 6000 mounted

transmitter: 3.17 grms

Page 10

10

2. Technical data

SITRANS F M

Type MAG 1100 MAG 1100 HT (High temperature)

Enclosure rating IP67 to EN 60529 (NEMA 4X), 1 mH2O for 30 min

EMC 89/336 EEC

Design

Weight See dimensional drawings See dimensional drawings

Material

•Enclosure

- MAG 1100 Stainless steel AISI 316L (1.4404) Stainless steel AISI 316L (1.4404)

•Terminal box

- Standard Fibre glass reinforced polyamide (no ATEX) Stainless steel AISI 316 (1.4436)

- Option Stainless steel AISI 316 (1.4436) (ATEX)

•Fixing studs Stainless steel AISI 304 (1.4301), Stainless steel AISI 304 (1.4301),

Number and size to EN 1092-1:2001 Number and size to EN 1092-1:2001

• Gaskets

- Standard EPDM (max. 150 °C, PN 40 (max. 300 °F, 600 psi)) Graphite (max. 200 °C, PN 40 (max. 390 °F, 600 psi))

- Option • Graphite (max. 200 °C, PN 40 (max. 390 °F, 600 psi))

• PTFE (max. 130 °C, PN 25 (max. 270 °F, 300 psi))

•Pipe connection adapters:

DN 2, 3, 6 and 10 (

1

/

12

",

1

/

8", ¼" and

3

/

8")• Stainless steel, AISI 316

• Hastelloy C22

• PVDF

Liner

•MAG 1100 (Ceramic) • DN 2, 3 (

1

/12"

,

1

/8"

): Zirconium oxide (ZrO2)DN 15 ... 100 (½

"

... 4"): Aluminium oxide Al2O

3

•DN 6 ... 100 (¼" ... 4"): Aluminium oxide Al2O

3

•Reinforced PFA (no ATEX)

Electrodes

•MAG 1100 (Ceramic) • DN10 ... 100 (

3

/

8

" ... 4") : Platinum with gold / Platinum with gold / Titanium brazing alloy

Titanium brazing alloy

•DN 2 ... 6 (

1

/12"

... ¼"): Platinium

• MAG 1100 (PFA) • DN 10 ... 15 (

3

/

8

" ... ½"): Hastelloy C276

•DN 25 ... 100 (1" ... 4"): Hastelloy C22

Cable entries •Remote installation 2 x M20 or 2 x½ NPT Remote installation 2 x M20 or 2 x ½" NPT

•Compact installation

- MAG 5000/MAG 6000: 4 x M20 or 4 x ½" NPT

Certificates and approvals

Conforms to PED – 97/23 EC and CRN (PFA) PED – 97/23 EC and CRN (PFA)

Custody Transfer

(MAG 5000/6000 CT) Cold water pattern approval PTB (Germany) Heat meter pattern approval - OIML R 75 (Denmark)

Heat meter pattern approval - OIML R 75 (Denmark) Hot water pattern approval - PTB (Germany)

Hot water pattern approval - PTB (Germany)

Other media than water pattern approval -

OIML R 117 (Denmark)

Ex approvals

MAG 1100 (Ceramic)

•ATEX sensor ATEX 2G D sensor Ex d e ia IIB T3 - T6 ATEX 2G D sensor Ex d e ia IIB T3 - T6

• Sensor with/without FM Class 1 div 2 FM Class 1 div 2

MAG 5000/6000

MAG 1100 (PFA)

•Sensor with/without

MAG 5000/6000 FM Class 1 div 2

1)

Conditions are also dependent on liner characteristics

For technical specifications for transmitter - please see transmitter pages.

Page 11

11

SITRANS F M

2. Technical data

Type MAG 1100 F

Measuring principle Electromagnetic induction

Excitation frequency DN 10 ... 65 (¼" … 2½"): 12.5 Hz / 15 Hz

(Main supply: 50 Hz / 60 Hz) DN 80 ... 100 (3”, 4”): 6.25 Hz / 7.5 Hz

Process connection

Nominal size DN 10 … DN 100 (

3

/8" … 4")

Process connection Hygienic adapters available for:

•Direct welding onto pipe

•Clamp fitting

•Threaded fitting

Rated operating conditions

Ambient conditions

Ambient temperature

1)

•Sensor -40 … +100 °C (-40 … +212 °F)

•Sensor ATEX -20 … +60 °C (-4 … +140 °F)

•Compact transmitter

MAG 5000/6000 -20 … +50 °C (-4 … +122 °F)

Temperature of medium

MAG 1100 F (Ceramic) -20 … +150 °C (-4 … +300 °F) Suitable for steam sterilization

MAG 1100 F (PFA) -30 … +130 °C (-20 … +270 °F) Suitable for steam steralization at 150 °C (300 °F)

Temperature shock

MAG 1100 F

•Duration

≤ 1 min, followed by

10 min rest • DN 10, 15, 25: Max. ∆T ≤ 80 °C/min

(

3

/8", ½", 1": Max. ∆T ≤ 80 °C/min)

•DN 40, 50, 65: Max. ∆T ≤ 70 °C/min

(1½", 2", 2½": Max. ∆T ≤ 70 °C/min)

•DN 80, 100: Max.

∆T ≤ 60 °C/min

(3", 4": Max.

∆T ≤ 60 °C/min)

MAG 1100 F (PFA) Max. ± 100 °C (210 °F) momentarily

Operating pressure

MAG 1100 F (Ceramic) DN 10 ... 65: 40 bar (3/8" … 2½": 580 psi)

DN 80: 37.5 bar (3": 540 psi)

DN 100: 30 bar (4": 435 psi)

Vacuum: 1 x 10

-6

bar

abs

(1.5 x 10-5 psi

abs

)

MAG 1100 F (PFA) 20 bar (290 psi)

Vacuum: 0.02 bar

abs

(0.3 psi

abs

)

DN 80 ... 100: CO2 pressure max. 7 bar (101.5 psi)

Mechanical load 18 ... 1000 Hz random in x, y z, directions for 2 hours according to EN 60068-2-36

Sensor: 3.17 grms

Sensor with compact MAG 5000/6000 mounted transmitter: 3.17 grms

Enclosure rating IP67 to EN 60529 (NEMA 4X), 1 mH2O for 30 min

EMC 86/336 EEC

Design

Weight See dimensional drawings

Material

Enclosure

•MAG 1100 F Stainless steel AISI 316L (1.4404)

Terminal box (remote version only)

•Standard Fibre glass reinforced polyamide

•Option Stainless steel AISI 316 (1.4436)

•Ex ATEX (remote version only) Stainless steel AISI 316 (1.4436)

2.2 Sensor MAG 1100 F

Page 12

12

2. Technical data

SITRANS F M

Type MAG 1100 F

Liner

MAG 1100 F (Ceramic) Aluminium oxide Al

2O3

(ceramics)

MAG 1100 F (PFA) Reinforced PFA (teflon) (no ATEX)

Electrodes

MAG 1100 F (Ceramic) Platinum with gold / Titanium brazing alloy

MAG 1100 F (PFA) • DN 10 ... 15 (

3

/8" ... ½"): Hastelloy C276

•DN 25 ... 100 (1" ... 4"): Hastelloy C22

Cable entries •Remote installation 2 x M20 or 2 x ½ NPT

•Compact installation

- MAG 5000/MAG 6000: 4 x M20 or 4 x ½"NPT

Certificates and approvals

MAG 1100 F (Ceramic) 3A (sensor with Polyamid terminal box ), transmitter not part of the approval

•Ex ATEX approvals for sensor ATEX 2G D sensor EEx d e ia IIB T3 - T6

• Sensor with/without

MAG 5000/6000 FM Class 1 div 2

MAG 1100 F (PFA) 3A (sensor with Polyamid terminal box ), transmitter not part of the approval

FM Class 1 div 2

Conforms to PED – 97/23/EC and CRN (PFA)

Custody Transfer

(MAG 5000/6000 CT) Cold water pattern approval PTB (Germany)

Heat meter pattern approval - OIML R 75 (Denmark)

Hot water pattern approval - PTB (Germany)

Other media than water pattern approval - OIML R 117 (Denmark)

Weld-in adapter

Adapter for welding onto dairy pipe

Tri-Clover, ISO 2037, DIN 11850,

SMS 3008, BS 4825-1

•DN 10, 15, 25, 40, 50, 65 and 80

(

3

/

8

"

, ½", 1", 1½", 2", 2½" and 3")PN 40 (600 psi)

•DN 100 (4”) PN 25 (350 psi)

Clamp adapter

Tri-Clamp, ISO 2852, DIN 32676,

SMS 3016, BS 4825-3

•DN 10, 15, 25, 40 and 50

(

3

/

8

"

, ½", 1", 1½", and 2")PN 16 (200 psi)

•DN 65, 80 and 100 (2½", 3" and 4")PN 10 (150 psi)

Thread adapter

DIN 11851

•DN 10, 15, 25, and 40

(

3

/8", ½"”, 1", and 1½")PN 40 (600 psi)

•DN 50, 65, 80 and 100

(2

"

, 2½", 3" and 4")PN 25 (350 psi)

ISO 2853, BS 4825-4

• DN 10, 15, 25, 40, 50, 65 and 80

(

3

/

8

"

, ½", 1", 1½", 2", 2½ and 3")PN 16 (200 psi)

SMS 1145

•DN 25, 40, 50, 65 and 80

(1", 1½", 2", 2½" and 3")PN 6 (80 psi)

Design

Material

Adapter Stainless steel AISI 316/Stainless steel AISI 304 (ISO 2852)

Gasket

• MAG 1100 F (Ceramic) FKM/FPM with stainless steel insert (AISI 304) (-20 ... +150 °C (-4 ... +302 °F))

EPDM (-20 ... +150 °C (-4 ... +302 °F))

• MAG 1100 F (PFA) EPDM (-20 ... +150 °C (-4 ... +302 °F))

NBR (-20 ... +100 °C (-4 ... +212 °F))

Note:

When combined sensor and adapter, the operating pressure is the lower rated of the two.

Page 13

13

SITRANS F M

2. Technical data

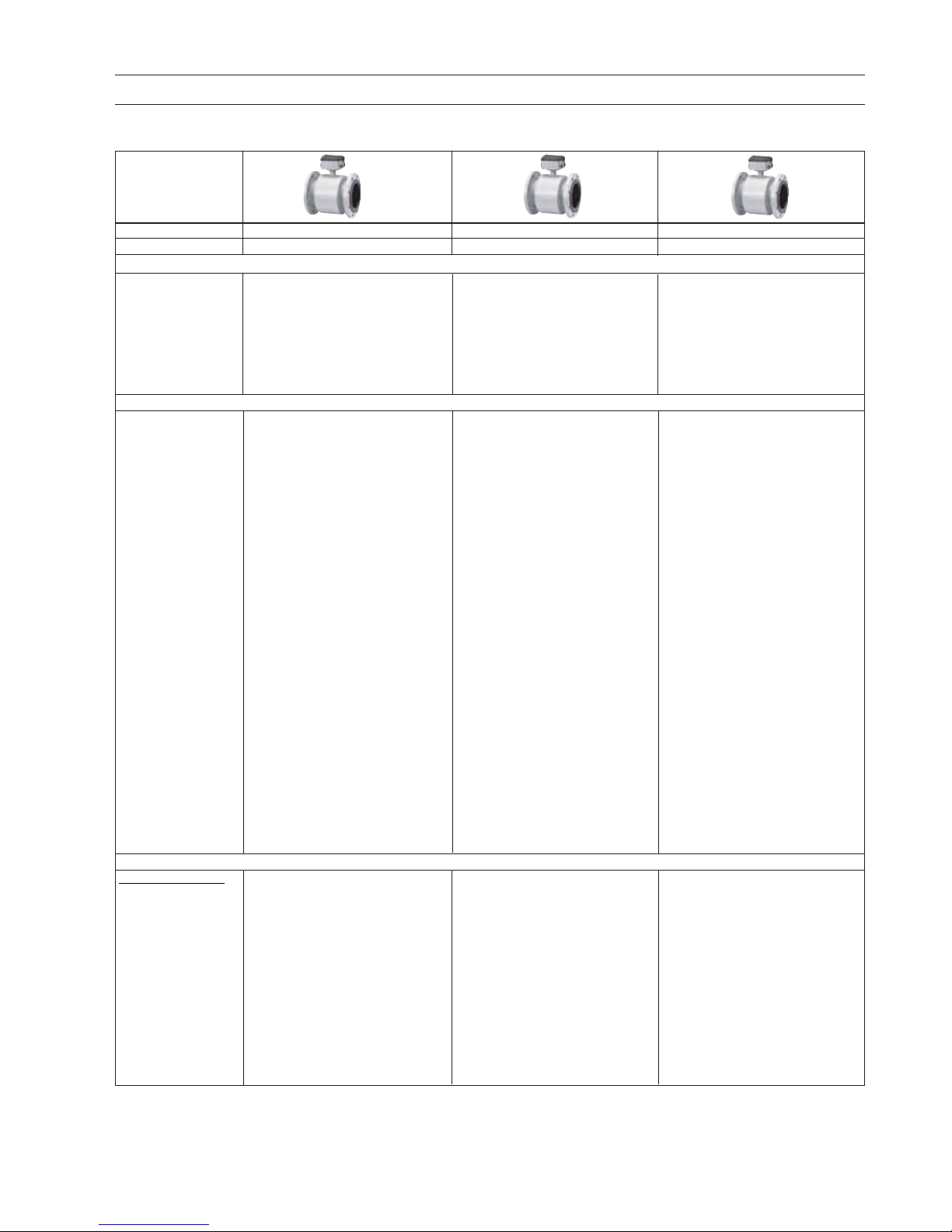

Type MAG 3100 MAG 3100 HT (High Temperature) MAG 3100 P

Nominal size DN 15 ... DN 2000 (½" ... 78") DN 15 ... DN 300 (½" ... 12") DN 15 ... DN 300 (½" ... 12")

Measuring principle Electromagnetic induction

Excitation frequency • DN 15 ... 65 (½" … 2½"): • DN 15 ... 65 (½" … 2½"): • DN 15 ... 65 (½" … 2½"):

(Main supply: 12.5 Hz / 15 Hz 12.5 Hz / 15 Hz 12.5 Hz / 7.5 Hz

50 Hz / 60 Hz) • DN 80 ... 150 (3" ... 6"): • DN 80 ... 150 (3" ... 6"): • DN 80 ... 150 (3" ... 6"):

6.25 Hz / 7.5 Hz 6.25 Hz / 7.5 Hz 6.25 Hz / 7.5 Hz

•DN 200 ... 1200 (8" ... 48"): • DN 200 ... 300 (8" ... 12"): • DN 200 ... 300 (8" ... 12"):

3.125 Hz / 3.75 Hz 3.125 Hz / 3.75 Hz 3.125 Hz / 3.75 Hz

•DN 1400 ... 2000 (54" ... 78"):

1.5625 Hz / 1.875 Hz

Process connection

Flanges EN 1092-1, raised face EN 1092-1, raised face EN 1092-1, raised face

(EN 1092-1, DIN 2501 & BS 4504 (EN 1092-1, DIN 2501 & BS 4504 (EN 1092-1, DIN 2501 & BS 4504

have the same mating dimensions) have the same mating dimensions) have the same mating dimensions)

•DN 65 ... 2000 (2½" … 78"): • DN 15 ... 300 (½" … 12"): • DN 15 ... 50 (½" … 2"):

PN 6 (87 psi) PN 40 (580 psi) PN 40 (580 psi)

•DN 200 ... 2000 (8" … 78"): • DN 65 ... 300 (2½" … 12"): • DN 65 ... 300 (2½" … 12"):

PN 10 (145 psi) PN 16 (232 psi) PN 16 (232 psi)

•DN 65 ... 2000 (2½" … 78"): • DN 200 ... 300 (8" … 12"): • DN 200 ... 300 (8" … 12"):

PN 16 (232 psi) PN 10 (145 psi) PN 10 (145 psi)

•DN 200 ... 600 (8" … 24"): • DN 200 ... 300 (8" … 12"):

PN 25 (362 psi) PN 25 (362 psi) ANSI B16.5 (~BS 1560), raised face

•DN 15 ... 600 (½" … 24"): • ½" ... 12":

PN 40 (580 psi) ANSI B16.5 (~BS 1560), raised face: Class 150 (20 bar (290 psi))

•DN 50 ... 300 (2" … 12"): • ½” ... 12":

PN 63 (913 psi) Class 150 (20 bar (290 psi))

•DN 25 ... 300 (1" … 12"): • ½” ... 12":

PN 100 (1450 psi) Class 300 (50 bar (725 psi))

ANSI B16.5 (~BS 1560), raised face

•½” ... 24”: Class 150 (20 bar (290 psi)) AS 2129, raised face ½" ... 12":

•½” ... 24”: Class 300 (50 bar (725 psi)) Table E

AWWA C-207, flat face 28" ... 78":Other flanges and pressure ratings

Class D (10 bar) on request

AS 2129, raised face ½" ... 48

"

:

Table E

AS 4087, raised face:

•PN 16 (DN 50 ... 1200, 16 bar (232 psi))

•PN 21 (DN 50 ... 600, 21 bar (304 psi))

•PN 35 (DN 50 ... 600, 35 bar (508 psi))

Other flanges and pressure ratings

on request

Rated operation conditions

Ambient temperature

(conditions also

dependent on liner

characteristiques)

• Sensor -40 … +100 °C (-40 … +212 °F) -40 … +100 °C (-40 … +212 °F) -40 … +100 °C (-40 … +212 °F)

• Sensor ATEX -20 … +60 °C (-4 … +140 °F) For medium temperature up

to 150 °C (302 °F)

-20 … +60 °C (-4 … +140 °F)

For medium temperature

150 ... 180 °C (302 ... 356 °F):

-20 … +50 °C (-4 … +122 °F)

•Compact transmitter

MAG 5000/6000 -20 … +50 °C (-4 … +122 °F) -20 … +50 °C (-4 … +122 °F) -20 … +50 °C (-4 … +122 °F)

2.3 Sensor MAG 3100, MAG 3100 HT and MAG 3100 P

MAG 3100, MAG 3100 HT and MAG 3100 P

Page 14

14

2. Technical data

SITRANS F M

MAG 3100, MAG 3100 HT and MAG 3100 P

Type MAG 3100 MAG 3100 HT (High Temperature) MAG 3100 P

Operating pressure

Operating pressure •Neoprene 0.01 ... 100 bar •PTFE Teflon •PTFE Teflon

[abs. bar] (maximum (0.15 ... 1450 psi) - DN 15 ... 300 (½" … 12") - DN 15 ... 300 (½" … 12") :

operating pressure • EPDM 0.01 ... 40 bar (0.15 ... 580 psi) (130/180 °C (266/356°F)): 0.3 ... 40 bar (4 ... 580 psi)

decreases with • Linatex

®

0.01 ... 40 bar 0.6 ... 50 bar (9 ... 725 psi) • PFA

increasing operating (0.15 ... 580 psi) (180 °C (356 °F) - DN 25 ... 100 (1" … 4"):

temperature and with • Ebonite 0.01 ... 100 bar PTFE has factory-mounted grounding 0.01 ... 50 bar (0.15 ... 725 psi)

stainless steel flanges) (0.15 ... 1450 psi) SS rings type E & SS terminal box)

• PTFE • PFA

DN

≤ 300 (≤ 12"): - DN 25 ... 100 (1" … 4"):

0.3 ... 50 bar (4 ... 725 psi) 0.01 ... 50 bar (0.15 ... 725 psi)

350 ≤ DN ≤ 600

(14“ ≤ DN ≤ 24"):

0.3 ... 40 bar (4 ... 580 psi)

•PFA

- DN 25 ... 100 (1" … 4"):

0.01 ... 50 bar (0.15 ... 725 psi)

Enclosure rating IP67/NEMA 4X/6 to EN 60529, 1 m H

2

O for 30 min

Option: IP68/NEMA 6P to EN 60529, 10 mH2O cont. (no ATEX)

Pressure drop at 3 m/s As straigth pipe

Test pressure 1.5 x PN (where applicable)

Mechanical load • 18 ... 1000 Hz random in x, y, z, directions for 2 hours according to EN 60068-2-36

•Sensor: 3.17 grms

•Sensor with compact MAG 5000/6000 mounted transmitter: 3.17 grms

Temperature of medium • Neoprene 0 … +70 °C (32 … 158 °F) • PTFE -20 … +130 °C (-4 … +266 °F) • PTFE -20 … +130 °C (-4 … +266 °F)

•EPDM -10 … +70 °C (14 … 158 °F) •PTFE -20 … +180 °C (-4 ... +356 °F) • PFA -20 … +150 °C (-4 … +300 °F)

•Linatex® (rubber) -40 … +70 °C Factory-mounted grounding rings

(-40 … +158 °F) (for temperatures type E and SS terminal box. Can only

below -20 °C (-4 °F) AISI 304 or 316 be used with remote transmitter.

flanges must be used) • PFA -20 … +150 °C (-4 … +300 °F)

•Ebonite 0 … 95 °C (32 … 203 °F)

•PTFE -20 … +100 °C (-4 … +212 °F)

•PFA -20 … +100 °C (-4 … +212°F)

EMC 89/336 ECC

Design

Weight See dimensional drawings

Flange and housing Carbon steel ASTM A 105, with material corrosion-resistant two-component epoxycoating (min. 150 µm)

or

AISI 304 (1.4301) flanges and carbon steel housing, with corrosion-resistant two-component epoxy coating (min. 150 µm)

or

AISI 316 L (1.4404) flanges and housing, polished

Measuring pipe material AISI 304 (1.4301)

2.3 Sensor MAG 3100, MAG 3100 HT and MAG 3100 P (continued)

Page 15

15

SITRANS F M

2. Technical data

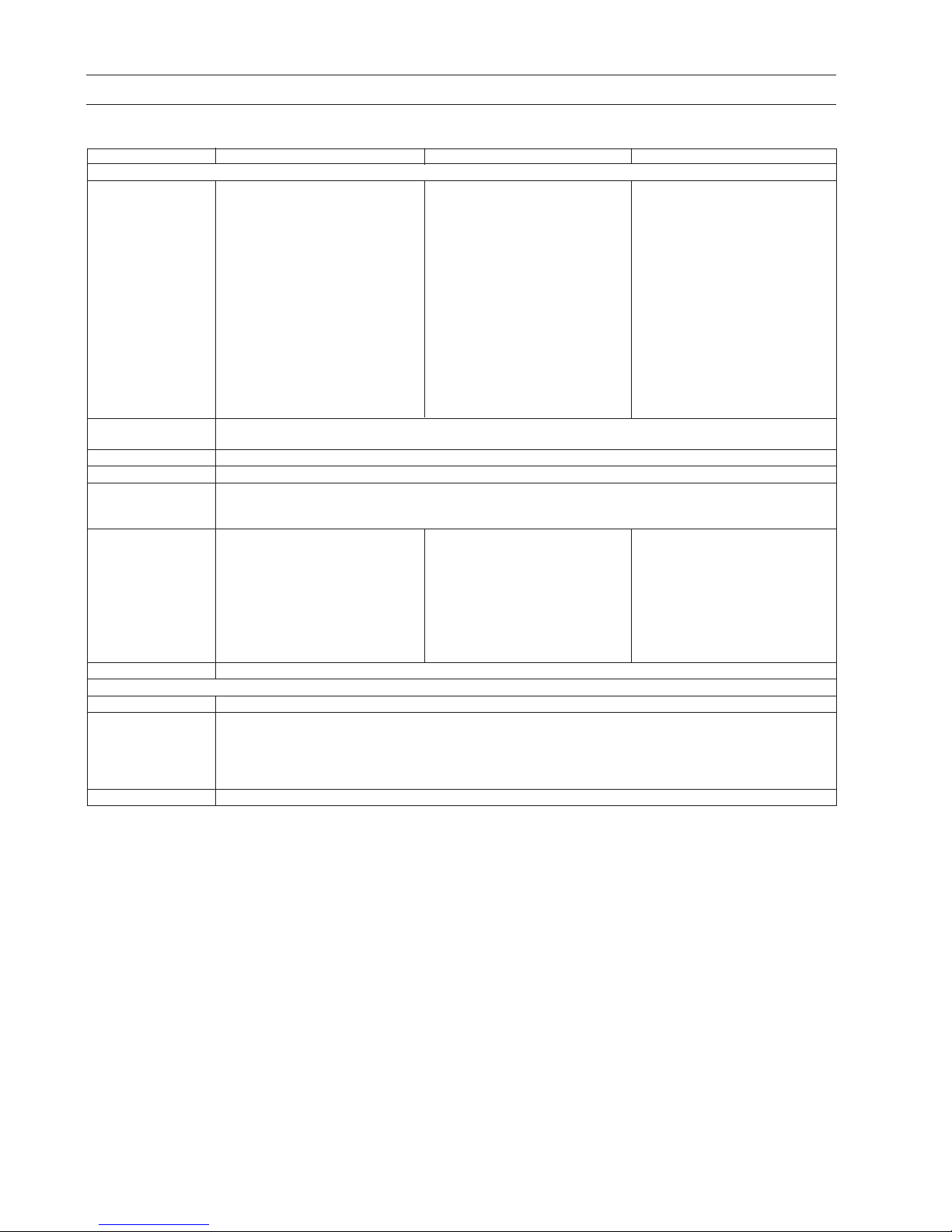

MAG 3100, MAG 3100 HT and MAG 3100 P

Design (continued)

Type MAG 3100 MAG 3100 HT (High Temperature) MAG 3100 P

Electrode material • AISI 316 Ti (1.4571) • AISI 316 Ti (1.4571) Hastelloy C276 (PFA: Hastelloy C22)

•Hastelloy C276 (PFA: Hastelloy C22) •Hastelloy C276 (PFA: Hastelloy C22)

•Platinum/iridium, •Platinum/iridium,

•Titanium •Titanium

•Tantalum •Tantalum

Grounding electrode Material as measuring electrodes: No grounding electrodes No grounding electrodes

material Exceptions - see ordering data

Terminal box (remote • Standard: Fibre glass reinforced • Stainless steel AISI 316 (1.4436) • Standard: Fibre glass reinforced

version only) polyamide • Ex ATEX (remote version only) polyamide

•Option: Stainless steel AISI 316 Stainless steel AISI 316 (1.4436) •Option: Stainless steel AISI 316

(1.4436) (1.4436)

•Ex ATEX (remote version only): •Ex ATEX (remote version only)

Stainless steel AISI 316 (1.4436) Stainless steel AISI 316 (1.4436)

Cable entries • Remote installation:

2 x M20 or 2 x ½ NPT

•Compact installation

-MAG 5000/MAG 6000: 4 x M20 or 4 x ½"NPT

Certificates and approvals

Conforms to PED – 97/23 EC, CRN

Material certificate On request On request Pipe and flange certificate available

EN 10204 3.1 as option

Ex approvals ATEX 2G D sensor ATEX 2G D sensor ATEX 2G D sensor

•DN 15 ... 300/(½" ... 12"): •DN 15 ... 300/(½" ... 12"): •DN 15 ... 300/(½" ... 12"):

EEx d e ia IIC T4 - T6 EEx d e ia IIC T3 - T6 EEx d e ia IIC T3 - T6

•DN 350 ... 2000/(14" ... 78"): Non-ATEX sensors Non-ATEX sensors

EEx e ia IIC T4 - T6 • FM Class 1, Div 2 • FM Class 1, Div 2

Non-ATEX sensors • CSA Class 1, Div 2 • CSA Class 1, Div 2

•FM Class 1, Div 2

•CSA Class 1, Div 2

Drinking water approvals EPDM lining:

•WRAS (WRc, BS6920 cold water, UK)

•ACS listed (F)

•DVGW W270 (D)

NSF/ANSI Standard 61 (Cold water, US)

•Belgaqua (B)

Mcerts (EPDM or PTFE lining with

AISI 316 Ti or Hastelloy C276 electrodes)

Custody transfer (CT) Cold water - DANAK TS 22.36.001 Heat meter pattern approval - OIML R 75 Cold water - DANAK TS 22.36.001

(

≤

DN2000) Cold water pattern approval PTB (Denmark) Cold water pattern approval PTB

(MAG 5000/6000 CT) (Germany) Hot water pattern approval - PTB (Germany)

Heat meter pattern approval - OIML R 75 (Germany) Heat meter pattern approval - OIML R 75

(Denmark) (Denmark)

Hot water pattern approval - PTB Hot water pattern approval - PTB

(Germany) (Germany)

Other media than water pattern approval - Other media than water pattern approval -

OIML R 117 (Denmark) OIML R 117 (Denmark)

2.3 Sensor MAG 3100, MAG 3100 HT and MAG 3100 P (continued)

Page 16

16

2. Technical data

SITRANS F M

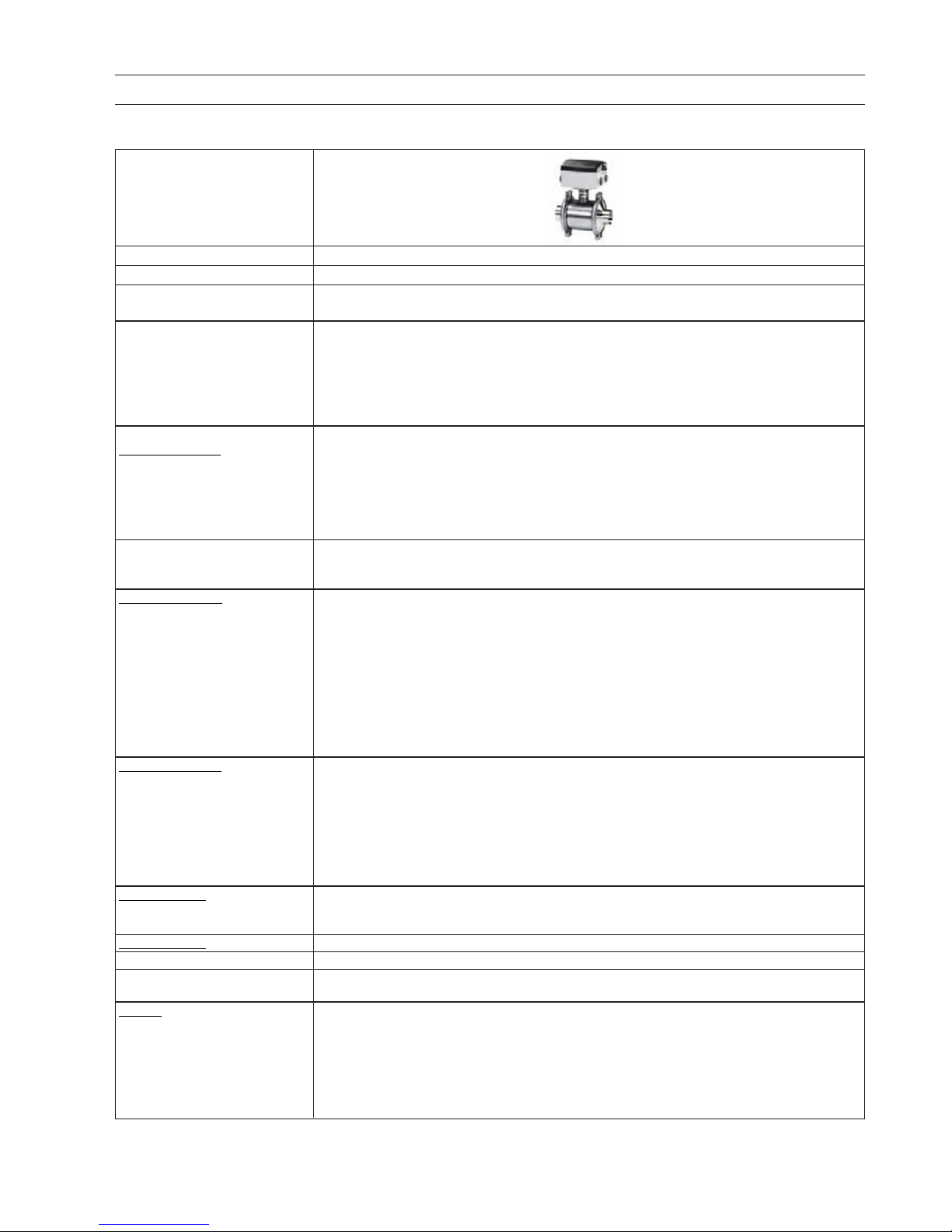

MAG 5100 W

2.4 Sensor MAG 5100 W

1)

For sizes larger than 600 mm (24”) in PN 16, PED conformity is available as a cost-added option. The basic unit will carry the LVD (Low Voltage Directive) and

EMC approvals.

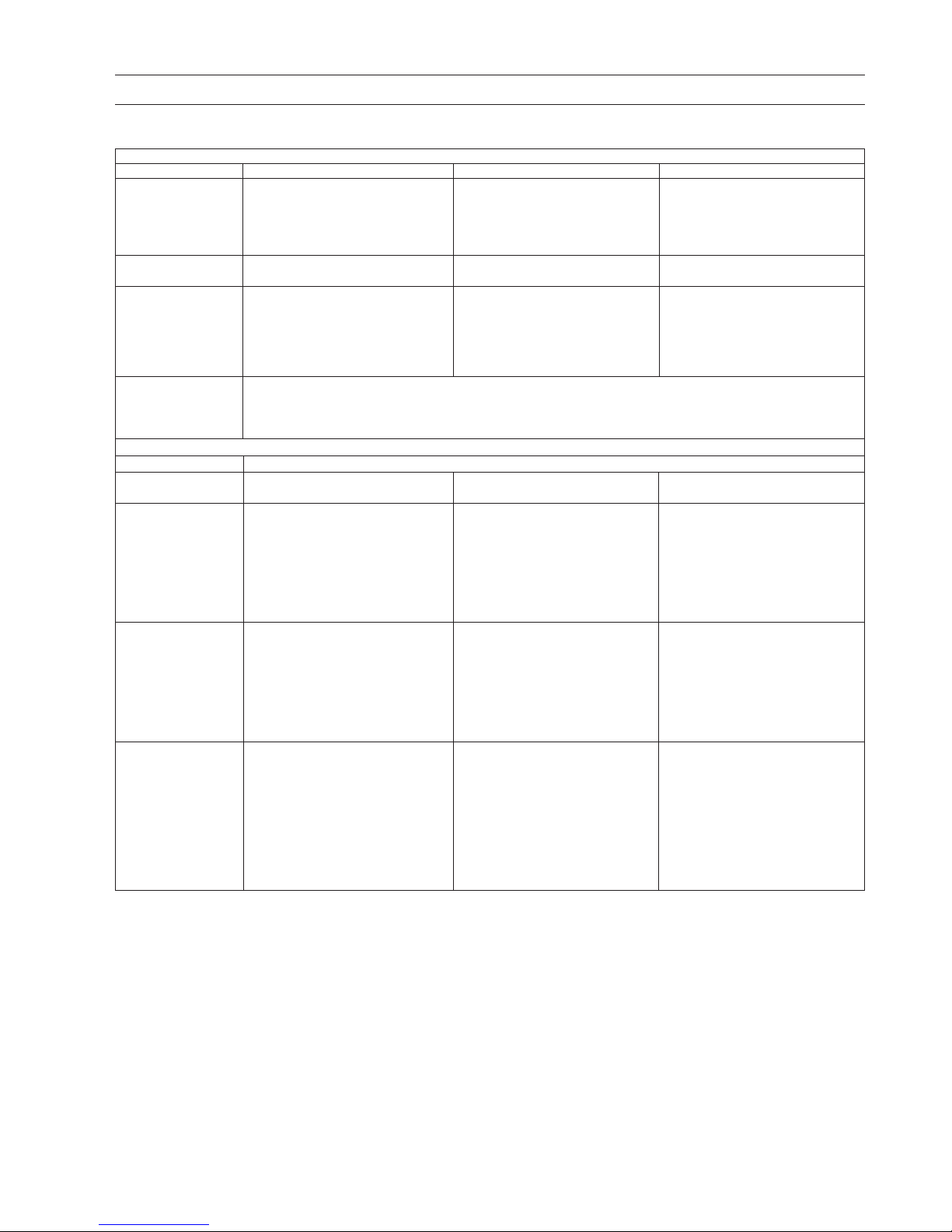

Technical specifications EPDM or NBR lining (Order No. 7ME6520) Ebonite lining (Order No. 7ME6580)

Product characteristic: Targeted towards the EU water markets and Targeted towards the Non EU water markets

low flow applications:

Design and nominal size Full bore sensor: DN 25 ... 40 (1" ... 1

½

")Full bore sensor: DN 25 ... 2000 (1" ... 78")

Coned sensor: DN 50 ... 300 (2" ... 12")

Full bore sensor: DN 350 ... 1200 (14" ... 48")

Measuring principle Electromagnetic induction Electromagnetic induction

Excitation frequency DN 25 ... 65 (1" ... 2½"): 12.5 Hz /15 Hz DN 25 ... 65 (1" ... 2½"): 12.5 Hz /15 Hz

(Mains supply: 50 Hz/60 Hz) DN 80 ... 150 (3" ... 6"): 6.25 Hz /7.5 Hz DN 80 ... 150 (3" ... 6"): 6.25 Hz /7.5 Hz

DN 200 ... 300 (8" ... 12"): 3.125 Hz / 3.75 Hz DN 200 ... 1200 (8" ... 48"): 3.125 Hz / 3.75 Hz

DN 350 ... 1200 (14" ... 48"): 1.5625 Hz /1.875 Hz DN 1400 ... 2000 (54" ... 78"): 1.5625 Hz /1.875 Hz

Process connection

Flanges

•

EN 1092-1 PN 10 (145 psi): DN 200 ... 300 (8" ... 12"): Raised face (EN 1092-1, DIN 2501 and BS 4504

Flat face flanges have the same mating dimensions)

PN 10 (145 psi): DN 350 ... 1200 (14" ... 48"): PN 6 (87 psi): DN 1400 ... 2000 (54" ... 78")

Raised face flanges PN 10 (145 psi): DN 200 ... 2000 (8" ... 78")

PN 16 (232 psi): DN 50 ... 300 (2" ... 12"): PN 16 (232 psi): DN 65 ... 600 (2" ... 24")

Flat face flanges PN 40 (580 psi): DN 25 ... 50 (1" ... 2

“

)

PN 16 (232 psi): DN 350 ... 1200 (14" ... 48“):

Raised face flanges

PN 40 (580 psi): DN 25 ... 40 (1" ... 1½"):

Raised face flanges

•

ANSI B16.5 Class 150 lb: 1" ... 24":1" ... 24

“

: Class 150 lb

•

AWWA C-207 Class D: 28” ... 48", Flat face Class D: 28" ... 78"h, Flat face

•

AS4087 PN 16 (DN 50 ... 1200), (2" ... 48") PN 16 (DN 50 ... 1200), (2" ... 48")

16 bar (232 psi) 16 bar (232 psi)

•

JIS B 2220:2004 - K10 (1" ... 24")

Rated Operation conditions

Ambient temperature

•

Sensor -40 ... +70 °C (-40 ... +158 °F) -20 ... +70 °C (-4 ... +158 °F)

•

With compact transmitter -20 ... +50 °C (-4 ... +122 °F) -20 ... +50 °C (-4 ... +122 °F)

MAG 5000/6000

•

With compact transmitter MAG 6000 I -20 ... +60 °C (-4 ... +140 °F) -20 ... +60 °C (-4 ... +140 °F)

Operating pressure (Abs) DN 25 ... 40 (1" ... 1½"): DN 25 ... 50 (1" ... 2"):

[abs. bar] (maximum operating 0.01 ... 40 bar (0.15 ... 580 psi) 0.01 ... 40 bar (0.15 ... 580 psi)

pressure decreases with increasing DN 50 ... 300 (2" ... 12"): DN 65 ... 1200 (2½" ... 48"):

operating temperature) 0.03 ... 20 bar (0.44 ... 290 psi) 0.01 ... 16 bar (0.15 ... 232 psi)

DN 350 ... 1200 (14" ... 48"): DN 1400 ... 2000 (54" ... 78"):

0.01 ... 16 bar (0.15 ... 232 psi) 0.01 ... 10 bar (0.15 ... 145 psi)

Enclosure rating

•

Standard IP67 to EN 60529 / NEMA 4X/6 IP67 to EN 60529 / NEMA 4X/6

(1 mH2O for 30 min) (1 mH2O for 30 min)

•

Option IP68 to EN 60529 / NEMA 6P IP68 to EN 60529 / NEMA 6P

(10 mH2O continuously) (10 mH2O continuously)

Pressure drop at 3 m/s (10 ft/s) DN 25 ... 40 (1" ... 1½"): As straight pipe As straight pipe

DN 50 ... 300 (2" ... 12"): Max. 25 mbar (0.36 psi)

DN 350 ... 1200 (14" ... 48"): As straight pipe

Test pressure 1.5 x PN (where applicable) 1.5 x PN (where applicable)

Mechanical load 18 ... 1000 Hz random in x, y, z, directions for 2 18 ... 1000 Hz random in x, y, z, directions for

hours according to EN 60068-2-36 2 hours according to EN 60068-2-36

Sensor: 3.17 grms Sensor: 3.17 grms

Sensor with compact MAG 5000/6000 mounted Sensor with compact MAG 5000/6000 mounted

transmitter: 3.17 grms transmitter: 3.17 grms

Sensor with compact MAG 6000 I mounted Sensor with compact MAG 6000 I mounted

transmitter: 1.14 grms transmitter: 1.14 grms

Medium conditions

Temperature of medium

•

NBR - 10 ... +70 °C (14 ... 158 °F) -

•

EPDM - 10 ... +70 °C (14 ... 158 °F) -

•

Ebonite - - 10 ... +70 °C (14 ... 158 °F)

EMC 89/336 EEC 89/336 EEC

Page 17

17

SITRANS F M

2. Technical data MAG 5000 and MAG 6000

2.4 Sensor MAG 5100 W

(continued)

Technical specifications EPDM or NBR lining (Order No. 7ME6520) Ebonite lining (Order No. 7ME6580)

Product characteristic: Targeted towards the EU water markets and Targeted towards the Non EU water markets

low flow applications:

Design

Material

• Housing and flanges Carbon steel, with corrosionresistant Carbon steel ASTM A 105, with corrosionresistant

two-component epoxy coating two-component epoxy coating

(min. 150 µm) (min. 150 µm)

• Corrosivity category Corrosivity category C4, according to ISO 12944-2 Corrosivity category C4, according to ISO 12944-2

• Measuring pipe AISI 304 (1.4301) (DN 50 ... DN 300 (2" ... 12") AISI 304 (1.4301)

Carbon steel)

• Electrode Hastelloy Hastelloy

• Grounding electrode Hastelloy Hastelloy

• Terminal box Fibre glass reinforced polyamide Fibre glass reinforced polyamide

Certificates and approvals

Certificates Custody Transfer (only together with MAG

5000/6000 CT)

OIML R 49 pattern approval cold water (Denmark

and Germany): DN 50 ... 300 (2" ... 12")

(For further details see approval :

08-3412 TS 22.36 005 or PTB 6.221/05.21)

MI 001 cold water (EU): DN 50 ... 300 (2" ... 12")

(For further details see approval : DK-0200-MI001-001)

Drinking water approvals EPDM: NSF/ANSI Standard 61 (Cold water, US) (pending)

NSF/ANSI Standard 61 (Cold water, US) WRAS (WRc, BS6920 cold water, GB)

WRAS (WRc, BS6920 cold water, GB)

ACS listed (F),

DVGW W270 (D)

Belgaqua (B)

MCert

NBR:

NSF/ANSI Standard 61 (Cold water, US, only

ANSI B16.5 flanges)

MCert

Approvals PED – 97/23 EC1), CRN PED – 97/23 EC (only < DN 600 (< 24"))

FM Class 1, Div 2 FM Class 1, Div 2 (pending)

1)

For sizes larger than 600 mm (24”) in PN 16, PED conformity is available as a cost-added option. The basic unit will carry the LVD (Low Voltage Directive) and

EMC approvals.

Page 18

18

2. Technical data

SITRANS F M

MAG 5000 and MAG 6000

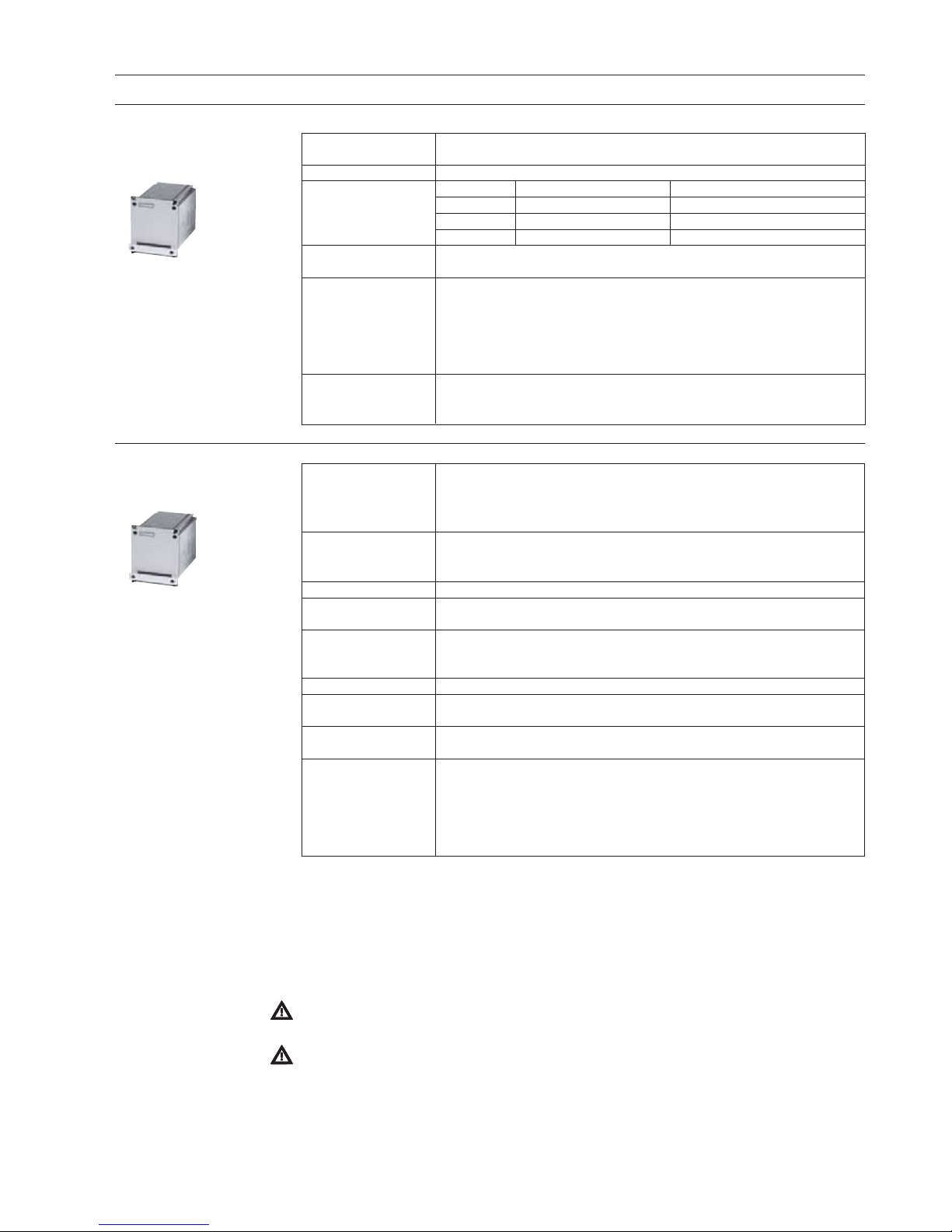

2.5.1 Transmitter MAG 5000 / MAG 6000

Mode of operation and design

Measuring principle Electromagnetic with pulsed constant field

Empty pipe Detection of empty pipe (special cable required in remote mounted installation)

Excitation frequency Depends on sensor size

Electrode input impedance > 1 x 1014

Ω

Input

Digital input 11 ... 30 V DC, R

i

= 4.4 K

Ω

•Activation time 50 ms

•Current IDC

11 V

= 2.5 mA, I

DC 30 V

= 7 mA

Output

Current output

•Signal range 0 ... 20 mA or 4 ... 20 mA

•Load < 800

Ω

•Time constant 0.1 … 30 s, adjustable

Digital output

Frequency 0 ... 10 kHz, 50% duty cycle (uni/bidirectional)

Pulse (active) DC 24 V, 30 mA, 1 K

Ω

≤ R

i

≤

10 K

Ω

, short-circuit protected (power supplied from flowmeter)

Pulse (passive) DC 3 … 30 V, max. 110 mA, 200 Ω ≤ R

i

≤

10 K

Ω

(powered from connected equipment)

Time constant 0.1 … 30 s, adjustable (for batch fixed at 0.1 s)

Relay output

Time constant Changeover relay, same as current output

Load 42 V AC/2 A, 24 V DC/1 A

Low flow cut off 0 ... 9.9% of maximum flow

Galvanic isolation All inputs and outputs are galvanically isolated

Max. measuring error

MAG 5000 0.2% of rate

MAG 6000 0.22% of rate

Rated operation conditions

Ambient temperature

•Operation •Display version:

-20 ... +50 °C (-4 ... +122 °F)

•Storage -40 ... +70 °C (-40 ... +158 °F)

Mechanical load

Compact version 18 ... 1000 Hz, 3,17 G rms, sinusoidal in all directions to IEC 68-2-36

19“ insert 1 ... 800 Hz, 1 G, sinusoidal in all directions to IEC 68-2-36

Degree of protection

Compact version IP67/NEMA 4X/6 to IEC 529 and DIN 40050 (1 m H2O 30 min.)

19“ insert IP20/NEMA 1 to IEC 529 and DIN 40050

EMC performance

EN 61326-1 (industrial environments)

CISPR II Group 1 Class A

EN 61326-2-5

Display and keypad

Totalizer Two eight-digit counters for forward, net or reverse flow

Display Background illumination with alphanumeric text, 3 x 20 characters to indicate flow rate, totalized

values, settings and faults

Reverse flow indicated by negative sign

Time constant Time constant as current output time constant

Design

Enclosure material

•Compact version Fiber glass reinforced polyamide; optional (IP67 only): AISI 316 stainless steel

•19“ insert Standard 19“ insert of aluminium/steel (DIN 41494), width: 21 TE, height: 3 HE

•Back of panel IP20/NEMA 1; Aluminium

•Panel mounting IP20/Nema 1 (Prepared for IP65/NEMA 2 display side) ABS plastic

•Wall mounting IP66/NEMA 4X; ABS plastic

Dimensional drawings

Compact version See dimensional drawings

19“ insert See dimensional drawings

Weight

Compact version 0.75 kg (2 lb)

19“ insert See dimensional drawings

Power supply

115 ... 230 V AC +10% -15%, 50 ... 60 Hz, 17 VA; Fuse: 500 mA T

11 ... 30 V DC or 11 ... 24 V AC; Fuse 2 A T

Power consumption • 115....230 V AC: 17 VA

• 24 V AC : 9W, I

N

= 380 mA, IST = 8 A (30 ms)

• 12 V DC : 11 W, IN = 920 mA, IST = 4 A (250 ms)

Certificates and approvals CE, ULc general purpose, C-tick; CSA/FM Class 1, div 2

Custody transfer approval Mcerts

(MAG 5000/6000 CT) Cold water: MI-001, PTB/OIML R49 (Pattern approval DE/DK)

Hot water: PTB and DANAK OIML R 75 (hot water pattern approval) (MAG 6000 CT)

Other media than water (milk, beer etc.) PTB and DANAK OIML R 117 (pattern approval) (MAG 6000 CT)

Communication •MAG 5000: Without serial communication or HART as option

•MAG 6000: Prepared for client mounted add-on modules:

HART, Profibus PA/DP, MODBUS RTU, DeviceNet, Foundation Fieldbus H1

•MAG 5000/6000 CT: No communication moduls approved

Page 19

19

SITRANS F M

2. Technical data

Safety barrier & cleaning unit

Application For use with MAG 5000/6000 19" and MAG 1100 1100 F and 3100, 3100 P, in

ATEX 2 GD version

Ex approval [EEx e ia] IIC

Cable parameter Group Capacity in µFInductance in mH

Electrode IIC ≤ 4.1 ≤ 1.5

IIB ≤ 45 ≤ 87

IIA ≤ 45 ≤ 87

Ambient temperature During operation: −20 ... +60°C

During storage: −20 ... +70°C

Enclosure

Material Standard 19" insert in aluminium/steel (DIN 41494)

Width: 21 TE

Height 3 HE

Enclosure rating IP 20 to EN 60529 and DIN 40050

Mechanical load 1 G, 1-800 Hz sinusoidal in all directions to EN 60068-2-36

EMC performance

Emission EN 50081-1 (Light industry)

Immunity EN 50082-2 (Industry)

2.5.4

Safety barrier (e ia)

Application For use together with MAG 5000 and 6000 19" insert to clean the measuring

electrodes on sensors MAG 1100, MAG 1100F or MAG 3100.

NB: Must not be used with intrinsically safe ATEX sensors

NB: Not be used with sensors with Hastelloy and Tantalum electrodes

NB: Only for measuring electrodes

Cleaning voltage

AC cleaning 60 V AC

DC cleaning 30 V DC

Cleaning period 60 sec. + 60 sec. pause

Relay Switch relay activated when cleaning is in progress

Load 42 V/2 A

Operation Switch relay activated when cleaning is in progress

Automatic Yes

Manual No

Indicator lamps LEDs: "ON" and "CLEANING"

Supply voltage and 115 ... 230 V AC +10% ... −15%, 50 ... 60 Hz, 7 VA cleaning, 5 VA stand by

power consumption 11 ... 30 V DC /11 ... 24 V AC, 50 ... 60 Hz, 7 VA cleaning, 5 VA stand by

Ambient temperature During operation: −20 ... +50°C (−4 ... +122 °F)

During storage: −20 ... +70°C (−4 ... +158 °F)

Enclosure

Material Standard 19" insert in aluminium/steel (DIN 41494)

Width: 21 TE

Height: 3 HE

Rating IP 20 to EN 60529 and DIN 40050

Mechanical load 1 G, 1 ... 800 Hz sinusoidal in all directions to EN 60068-2-3 6

2.5.5

Cleaning unit

Cleaning unit

The Siemens Flow Instruments cleaning unit can be used with MAG 5000 or 6000 in 19" insert nonCT version.

The cleaning unit can be used in applications where the liner material and subsequently the

electrodes may be coated with deposits. If the coating is electrically insulating, the electrode signal

will be reduced. If the coating is electrically conductive, the electrode signal will be partly shortcircuited and in both cases the accuracy of the meter will decrease (dependent on the type and

thickness of the coating).

Note:

The cleaning unit cannot be used for flammable or explosive media!

Note:

The cleaning unit cannot be used with sensors with Hastelloy and Tantalum electrodes!

Page 20

20

2. Technical data

SITRANS F M

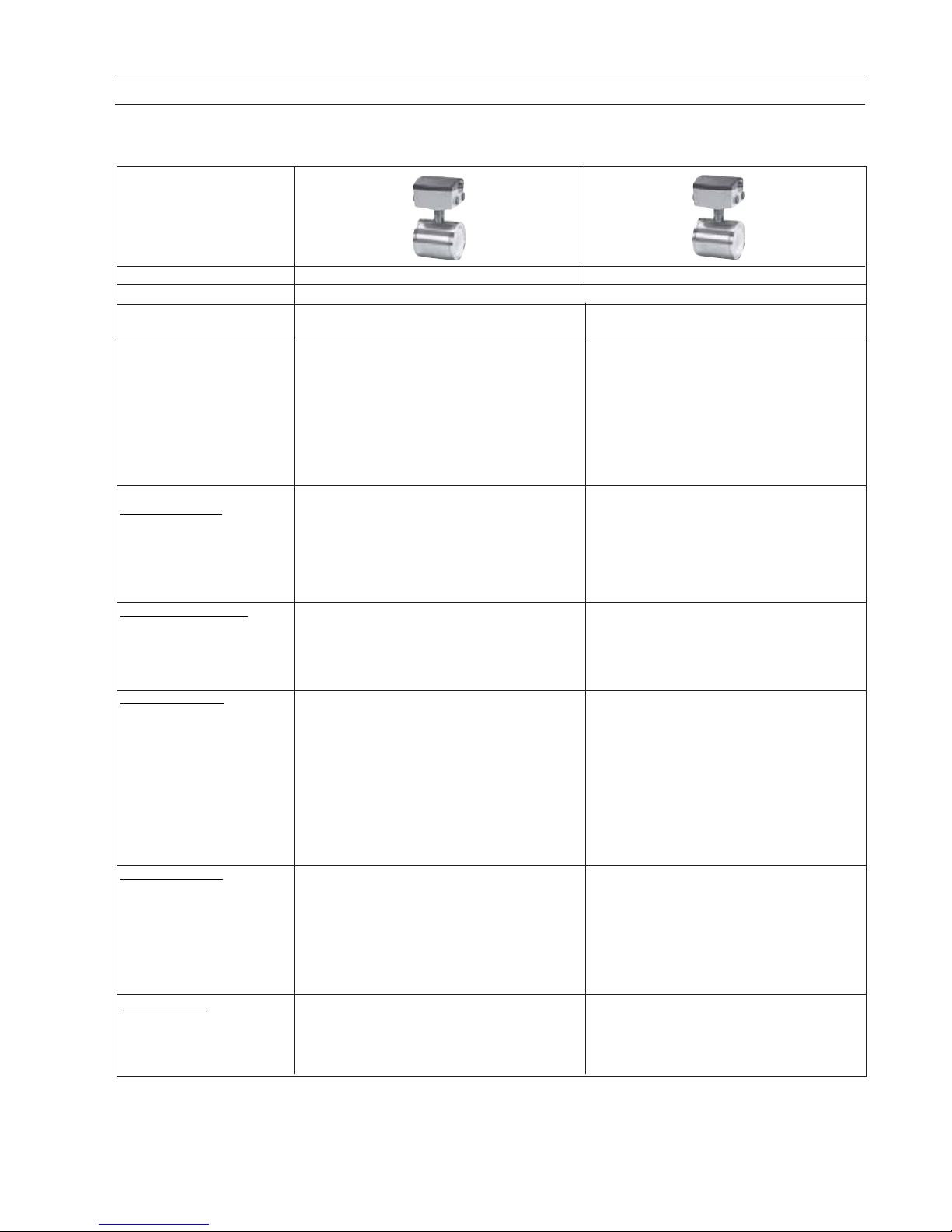

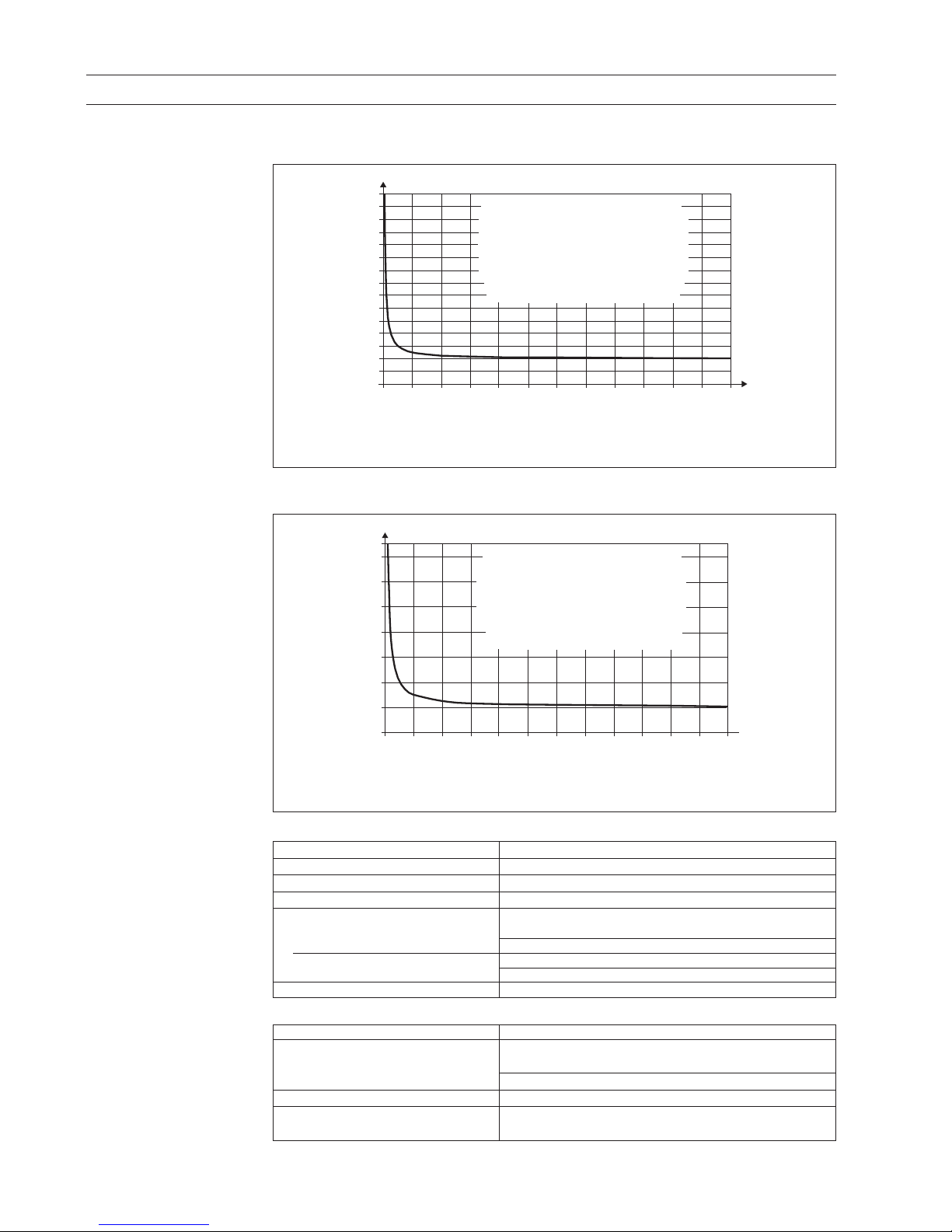

MAG 5000 with MAG 1100, MAG 1100F, MAG 5100W, MAG 3100 and MAG 3100P and

MAG 6000/6000I with MAG 1100/1100F with PFA

2.6

Flowmeter accuracy

*)±1.25 mm/s zero-point for MAG 5100 W DN 350 ... DN 1200

V: Actual flow velocity [m/s]

E: Meter uncertainty as a percentage of actual flow

MAG 6000 and MAG 6000I with MAG 1100 (ceramic), MAG 1100F (ceramic), MAG 5100W,

MAG 3100 and MAG 3100P

*)±1.25 mm/s zero-point for MAG 5100 W DN 350 ... DN 1200

V: Actual flow velocity [m/s]

E: Meter uncertainty as a percentage of actual flow

Reference conditions (ISO 9104 and DIN/EN 29104)

Medium temperature 20°C ±5°C (68°F ±9°F)

Ambient temperature 20°C ±5°C (68°F ±9°F)

Supply voltage Un ±1%

Warming-up time 30 minutes

Incorporation in conductive pipe section

• Inlet section 10×DN (DN ≤ 1200/48")

5×DN (DN > 1200/48")

•

Outlet section 5×DN (DN ≤ 1200/48"),

3×DN (DN > 1200/48")

Flow conditions Fully developed flow profile

Additions in the event of deviations from reference conditions

Current output As pulse output ±(0.1% of actual flow +0.05% FSO)

Effect of ambient temperature

•

Display/frequency/pulse output: < ±0.003% / °C act.

• Current output: < ±0.005% / °C act.

Effect of supply voltage < 0.005% of measuring value on 1% change

Repeatability ±0.1% of actual flow for V ≥ 0.5 m/s (1.5 ft/s) and

conductivity ≥ 10 µS/cm

3

)ORZPHWHUXQFHU WDLQW\

* MAG 5100 W (Order No. 7ME652...) with DN 350 ... 1200

v ≥ 0.1 m/s (0.3 ft/s) --> E: ±0.4 ± 2 mm/s

v < 0.1 m/s (0.3 ft/s) --> E: ±(0.25/v) % of measured value

V: Flow velocity

E: Meter uncertainty as a percentage of measured value

v ≥ 0.1 m/s (0.3 ft/s) --> E: ±0.4 ± 1 mm/s *

v < 0.1 m/s (0.3 ft/s) --> E: ±(0.25/v) % of measured value

10

0,2

0,0

0,6

0,4

1,0

0,8

1,4

1,2

1,8

1,6

2,2

2,0

2,6

2,4

3,0

2,8

23456789101112

3.306.69.9131620232630333639

[m/s]

[ft/s]

[±% E]

)ORZPHWHUXQFHU WDLQW\

V: Flow velocity

E: Meter uncertainty as a percentage of measured value

v ≥ 0.1 m/s (0.3 ft/s) --> E: ±0.2 ± 1 mm/s *

v < 0.1 m/s (0.3 ft/s) --> E: ±(0.125/v) % of measured value *

* MAG 5100 W (Order No. 7ME652...) with DN 350 ... 1200

v ≥ 0.1 m/s (0.3 ft/s) --> E: ±0.2 ± 2.5 mm/s

v < 0.1 m/s (0.3 ft/s) --> E: ±(0.25/v) % of measured value

MAG 1100 / 1100 F

10 2 3 4 5 6 7 8 9 10 11 12 [m/s]

[ft/s]

[±% E]

0,0

0,2

0,4

0,6

0,8

1,0

1,2

1,4

3.306.69.9131620232630333639

Page 21

21

SITRANS F M

2. Technical data

&XW

RII

4

P$

&XW

RII

4

P$

P$

4

&XW

RII

&XW

RII

P$

4

)>+]@

)PD[

&XW

RII

4

&XW

RII

)>+]@

)PD[

4

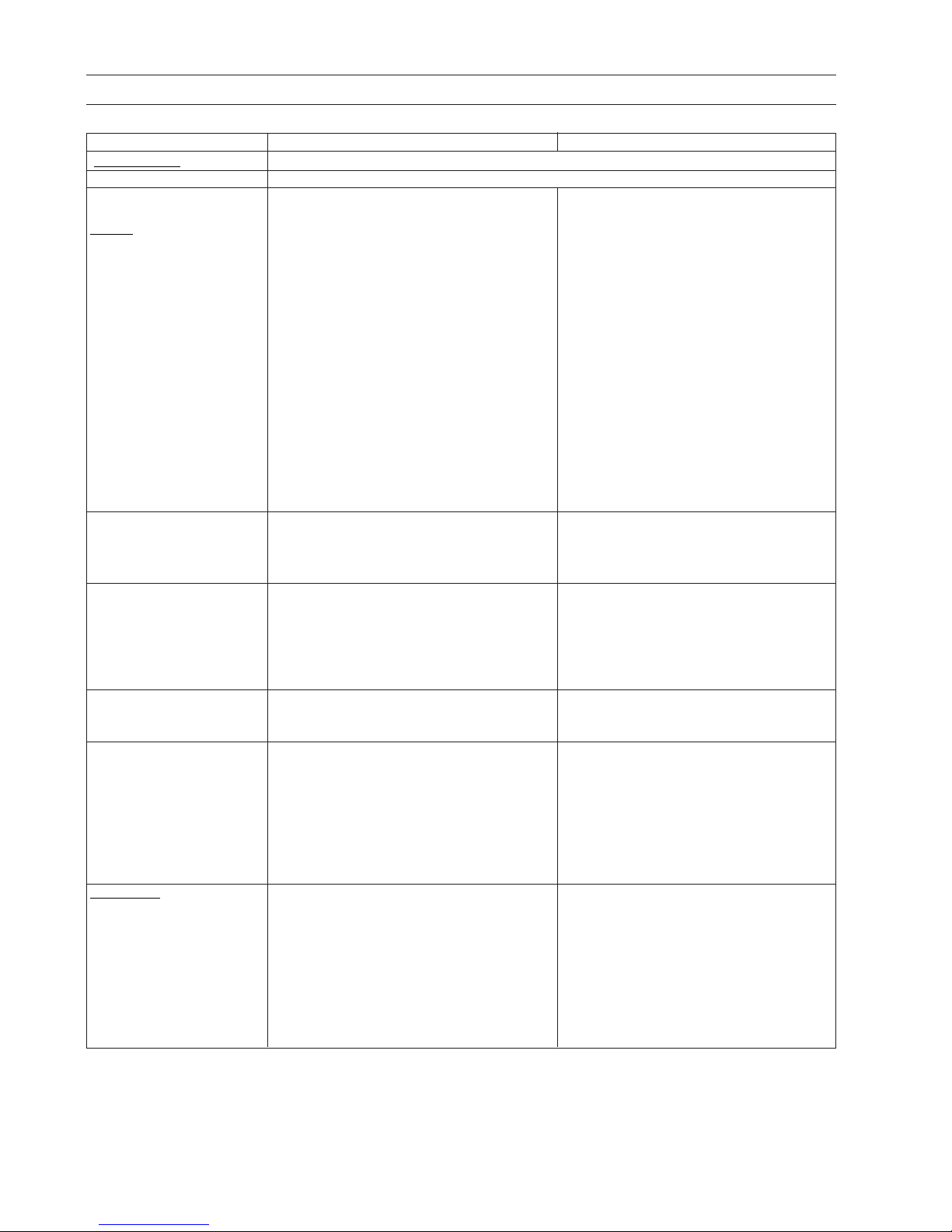

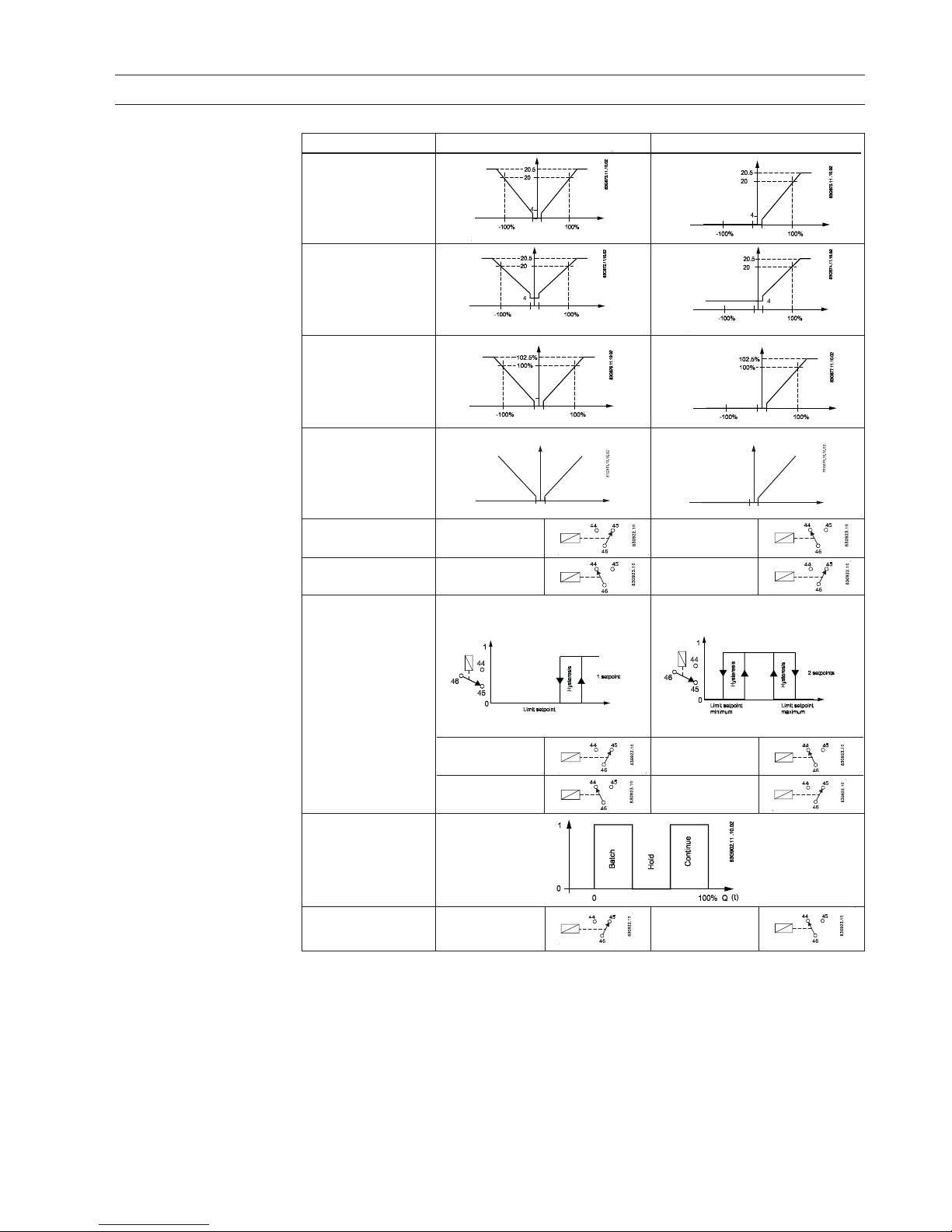

2.7

Output characteristics

MAG 5000 and MAG 6000

([WHUQDO

FRXQWHU

&XW

RII

4

&RXQWHU

&XW

4

Output characteristics Bidirectional mode Unidirectional mode

0 ... 20 mA

4 ... 20 mA

Frequency

Pulse output

Relay

Power down Active

Error relay No error Error

Limit switch or

direction switch

Low flow Intermediate flow

(Reverse flow)

High flow High flow/

(Forward flow) Low flow

Batch on digital

output

Batch on relay Hold Batch

83G1082a.10.10.02

83G1082b.10.10.02

Page 22

22

2. Technical data

SITRANS F M

Coil cable Electrode cable

Basic data No. of conductors 2 3

Min. sqr. area 0.5 mm2/20 gage 0.2 mm2/22 gage

Screen Yes Yes

Max. capacitance N.A. 350 pF/m / 107 pF/ft.

Max. cable loop Media temperature:

resistance < 100°C/< 210°F40 Ω N/A

< 200°C/< 390°F6 Ω N/A

Cable glands on sensor M20x1.5 gland - Cable ø 5-13 mm (0.20 - 0.51 Inch)

and transmitter: ½"NPT gland - Cable ø 5-9 mm (0.20 - 0.35 Inch)

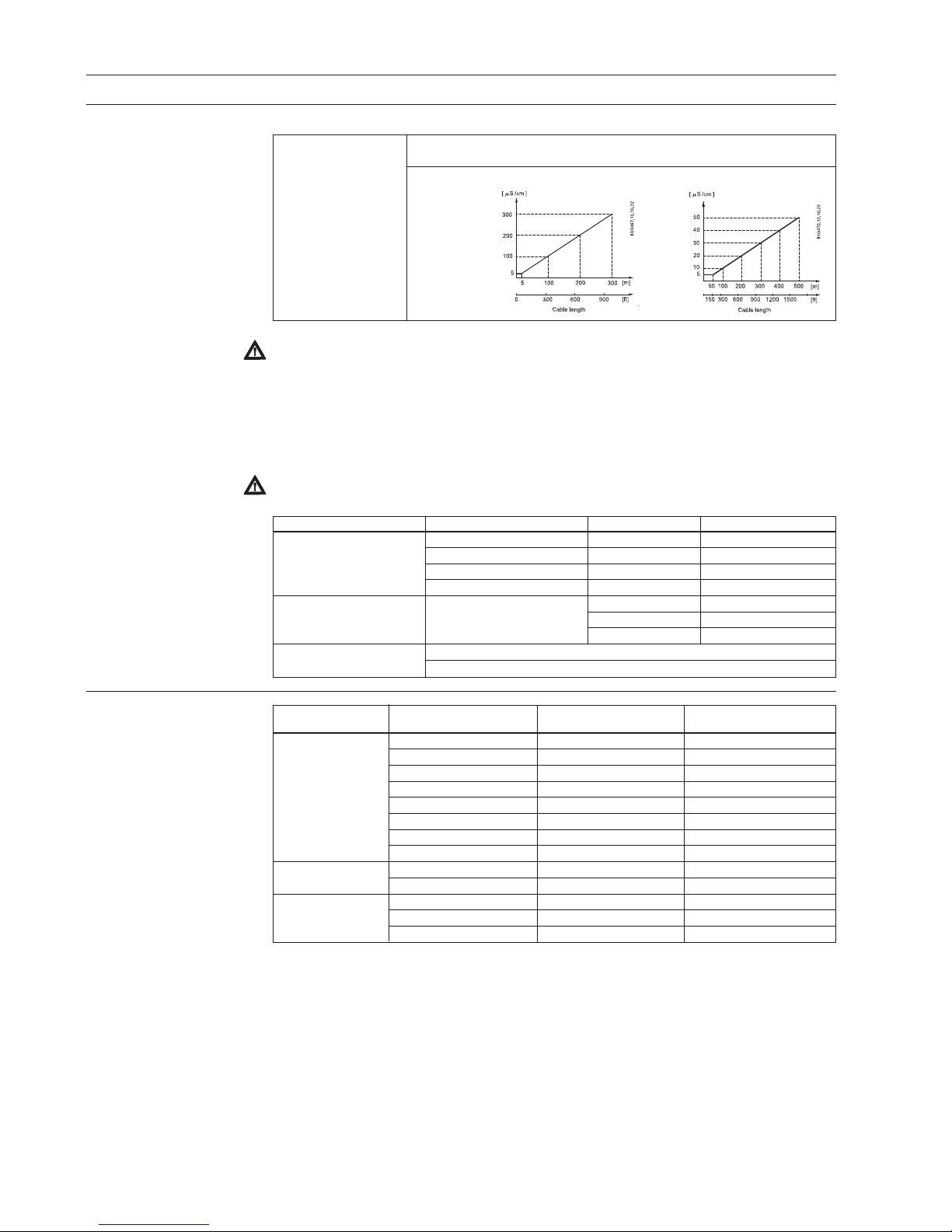

2.8.1

Conductivity of medium

and sensor cables

Conductivity of Compact installation:

medium Liquids with an electrical conductivity ≥ 5 µS/cm.

Remote

installation:

Standard cable

2.8.2

Cable requirements

2.9

Cable data

(Supplied by Siemens

Flow Instruments)

Standard cable Special cable

(electrode/coil) (electrode)

Basic data No. of conductors 3 3

Sqr. area 1.5 mm2/18 gage 0.25 mm2/22 gage

Screen Yes Double

Color code Brown, blue, black Brown, blue, black

Outside color Grey Grey

Ext. diameter 7.8 mm/0,3" 8.1 mm/0,32"

Conductor Flexible CU Flexible CU

Isolation material PVC PVC

Amb. temperature Flexible installation −5 ... 70°C/−23 ... 160°F −5 ... 70°C/−23 ... 160°F

Non-flexible installation −30 ... 70°C/−20 ... 160°F −30 ... 70°C/−20 ... 160°F

Cable parameter Capacity 161.50 pF/m / 49.24 pF/ft. N/A

Inductance 0.583 µH/m / 0.178 µH/ft. N/A

L/R 43.83 µH/Ω N/A

Special cable

Note

For detection of empty sensor the min. conductivity must always be >50 µS/cm a nd t h e m a x. l e ng t h

of the electrode cable when remote mounted is 50 meters (164 ft). Special cable must be used!

For 19" Ex applications with safety barriers special cable cannot be used and the empty pipe

function can therefore not be used. For these applications 25 meters (82 ft) of cable can be used

in order to obtain 0.25% and 50 meters (164 ft) to obtain 0.5%.

For remote MID installations the max. cable length is 3 meters (9.8 ft). For other CT application

standard requirements are applicable.

Note

Empty sensor detection is not available with DN 2, 3 (1/12, 1/8 inch) sizes.

Page 23

2 3

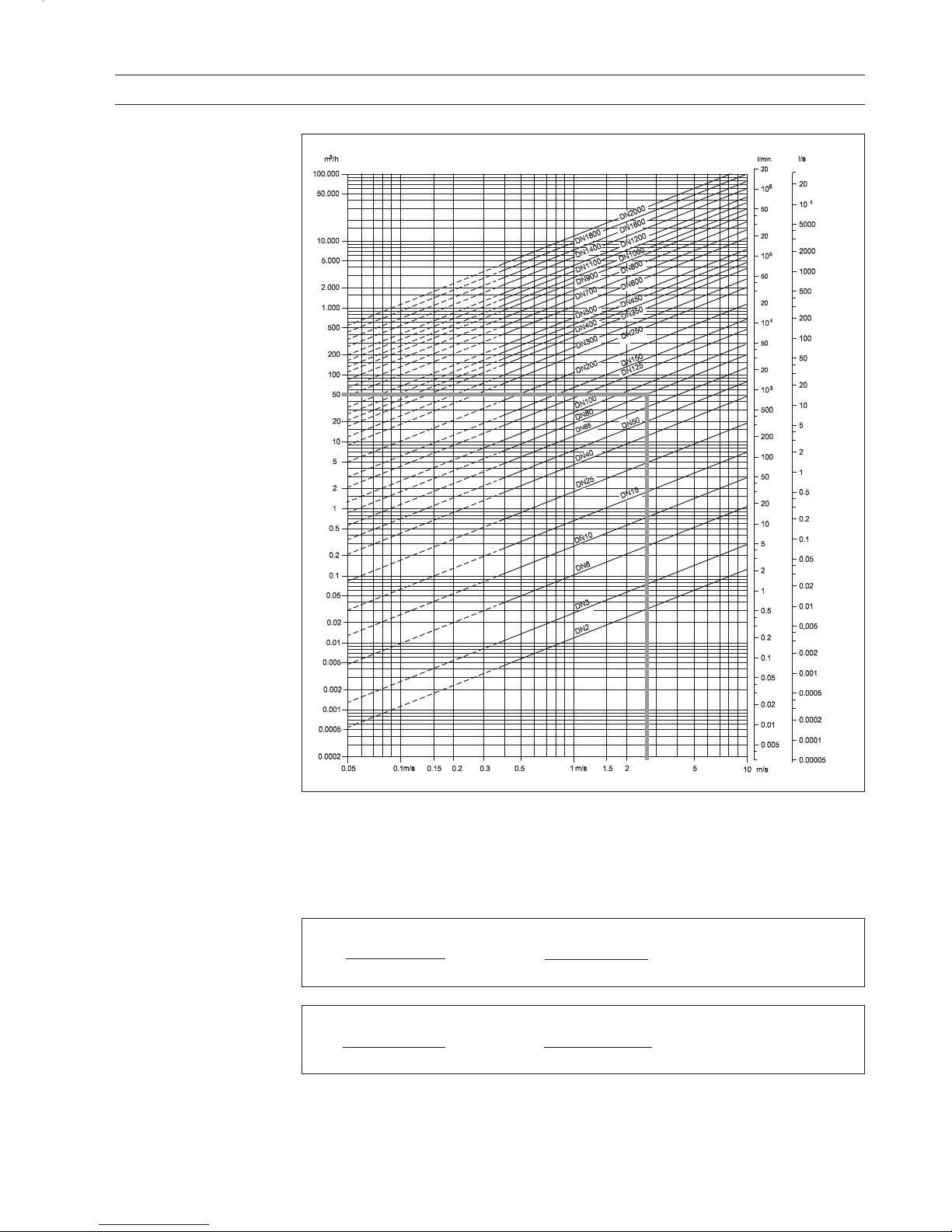

SITRANS F M

3. Project guidance

3. Project guidance

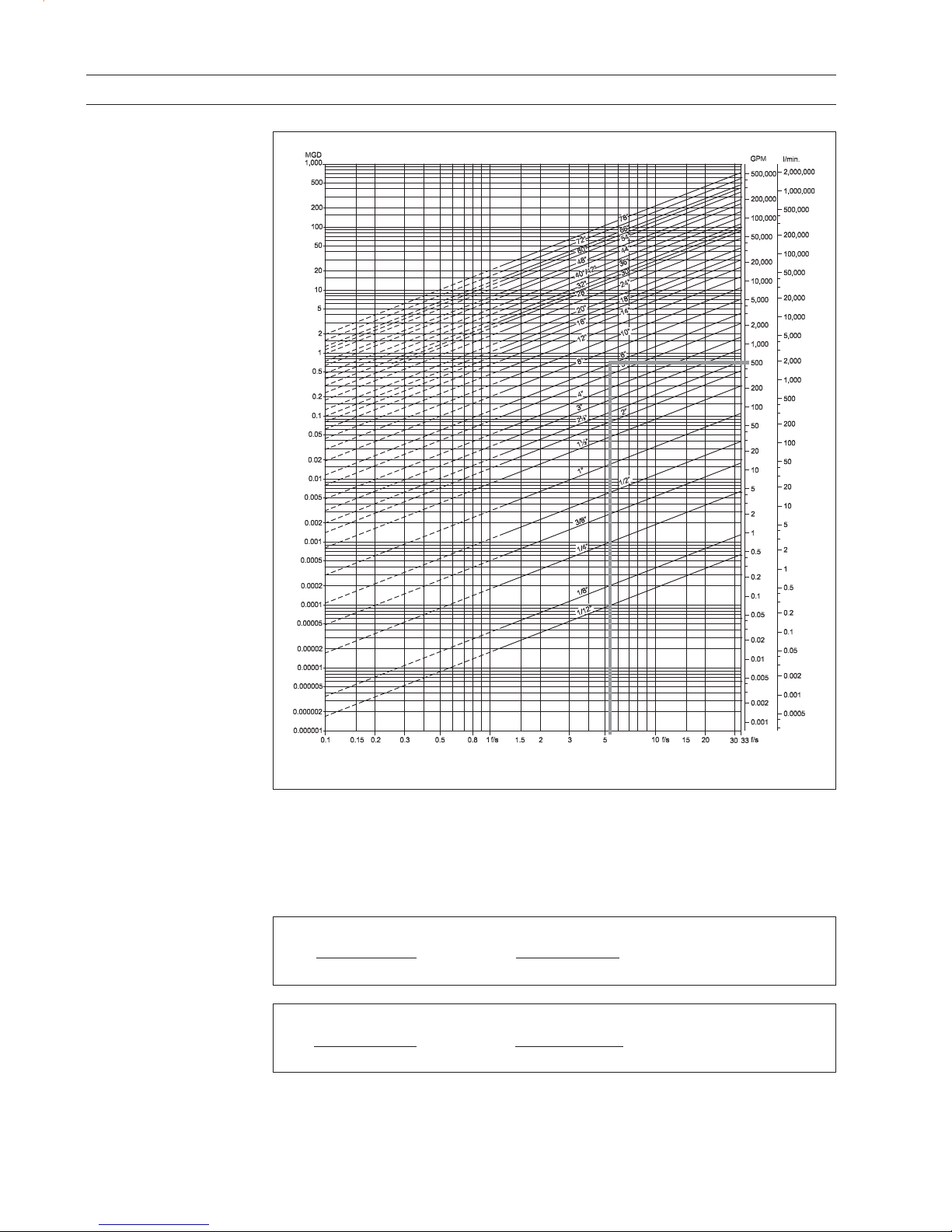

3.1.1.

Sizing table

(DN 2 to DN 2000)

The table shows the relationship between flow velocity v, flow quantity Q and sensor dimension DN.

Guidelines for selection of sensor

Min. measuring range: 0 ... 0.25 m/s

Max. measuring range: 0 ... 10 m/s

Normally the sensor size is selected so that the nominal flow velocity v lies within the measuring

range 1 ... 3 m/s.

Flow velocity calculation formula:

V =

1273.24 x Q [l/s]

[m/s] or

DN

2

[mm]

Flow velocity calculation formula:

V =

0.408 x Q [GPM]

[ft/s] or

(Pipe ID)

2

[inch]

V =

283.67 x Q [MGD]

[ft/s]

(Pipe ID)

2

[inch]

V =

353.68 x Q [m

3

/h]

[m/s]

DN

2

[mm]

Page 24

24

SITRANS F M

3. Project guidance

Flow velocity

3. Project guidance

3.1.2.

Sizing table

(

1

/12 ... 78 ")

The table shows the relationship between flow velocity v, flow quantity Q and sensor dimension DN.

Guidelines for selection of sensor

Min. measuring range: (0 ... 0.8 ft./sec)

Max. measuring range: (0 ... 33 ft./sec)

Normally the sensor size is selected so that the nominal flow velocity v lies within the measuring

range (1 ... 15 ft./sec.)

Flow velocity calculation formula:

V =

1273.24 x Q [l/s]

[m/s] or

DN

2

[mm]

Flow velocity calculation formula:

V =

0.408 x Q [GPM]

[ft/s] or

(Pipe ID)2 [inch]

V =

283.67 x Q [MGD]

[ft/s]

(Pipe ID)2 [inch]

V =

353.68 x Q [m3/h]

[m/s]

DN

2

[mm]

Page 25

2 5

SITRANS F M

3. Project guidance

3.2.1

Minimum conductivity

Applications Min. conductivity

Compact/remote

DN 2 & 3 (DN ≥ 1/12 & 1/8 inch) 30 µS/cm

DN ≥ 6 (DN ≥ ¼ inch) 5 µS/cm

With empty pipe detection 50 µS/cm

Ex-installations

(Remote mounted only)

30 µS/cm

District heating systems

(Without DC cleaning unit)

250 µS/cm max. 150 ft

3.2.2

Liner selection guide

Liner Applications

Zirconium oxide ZrO2 General purpose, agressive chemicals

Ceramics Al2O3 General purpose, food and beverage, agressive chemicals

PFA General purpose, food and beverage, pulp and paper, chemicals,

high temperature and chemical resistance

Neoprene Water and wastewater and some chemical applications

EPDM Drinking water applications, (not hydrocarbons)

PTFE Chemical and general process industries, high temperature and

chemical resistance

Linatex

®®

®®

®

Abrasive media and mining slurries

Ebonite Drinking water applications, wastewater applications and certain

chemical applications

NBR: General purpose, Drinking water, sea water

3.2.3

Electrode selection guide

Electrodes Applications

AISI 316 Ti General purpose, water, sewage and district heating

Hastelloy C The preferred choice for water and wastewater, chemicals, food

and beverage, and pharmaceutical industries

Titanium Process and chemical industry which require a high corrosion

resistance

Tantalum Chemical industry with aggressive media

Platinum and platinum/irridium The ultimate electrode material unaffected by most liquids

3.3

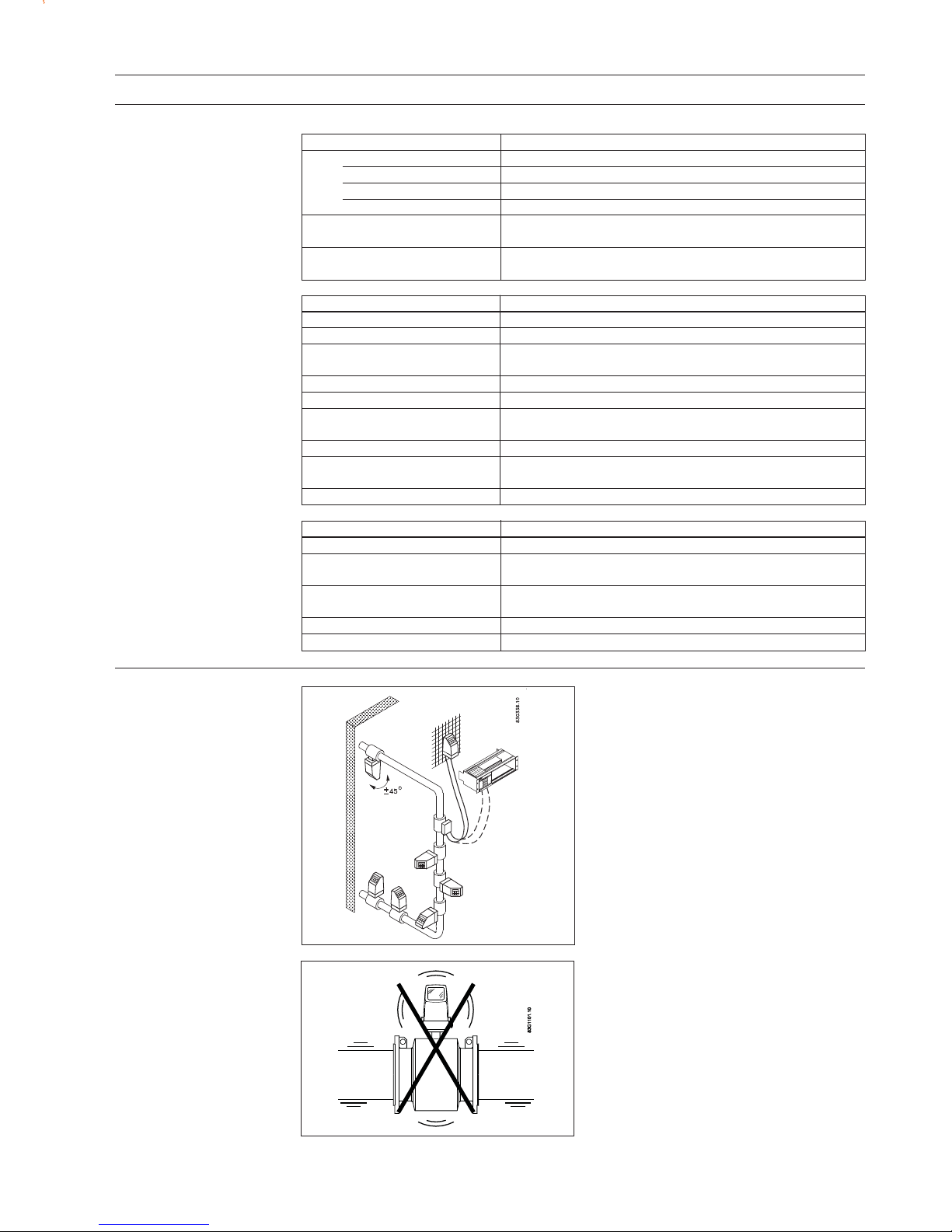

Installation conditions

Reading and operating the flowmeter is possible under almost any installation conditions

because the display can be oriented in relation

to the sensor. To ensure optimum flow measurement, attention should be paid to the following:

Page 26

26

SITRANS F M

3. Project guidance

The sensor must be mounted as shown in the

upper figure. Do not mount the sensor as shown

in the lower figure. This will position the

electrodes at the top where there is possibility

for air bubbles and at the bottom where there is

possibility for mud, sludge, sand etc.

If using empty pipe detection, the sensor can be

tilted 45°, as shown in the upper figure.

Recommended installation is in a vertical/inclined pipe to minimize the wear and deposits in

the sensor.

Installation in horizontal

pipes

Measuring abrasive

liquids and liquids

containing particles

The sensor must always be completely full with

liquid.

Therefore avoid:

• Installation at the highest point in the pipe

system

• Installation in vertical pipes with free outlet

For partially filled pipes or pipes with downward

flow and free outlet the flowmeter should be

located in a U-tube.

Recommended flow direction: upwards. This

minimizes the effect on the measurement of

any gas/air bubbles in the liquid.

Installation in vertical pipes

3.3

Installation conditions

(continued)

Transmitter can be mounted compact or remote.

Page 27

2 7

SITRANS F M

3. Project guidance

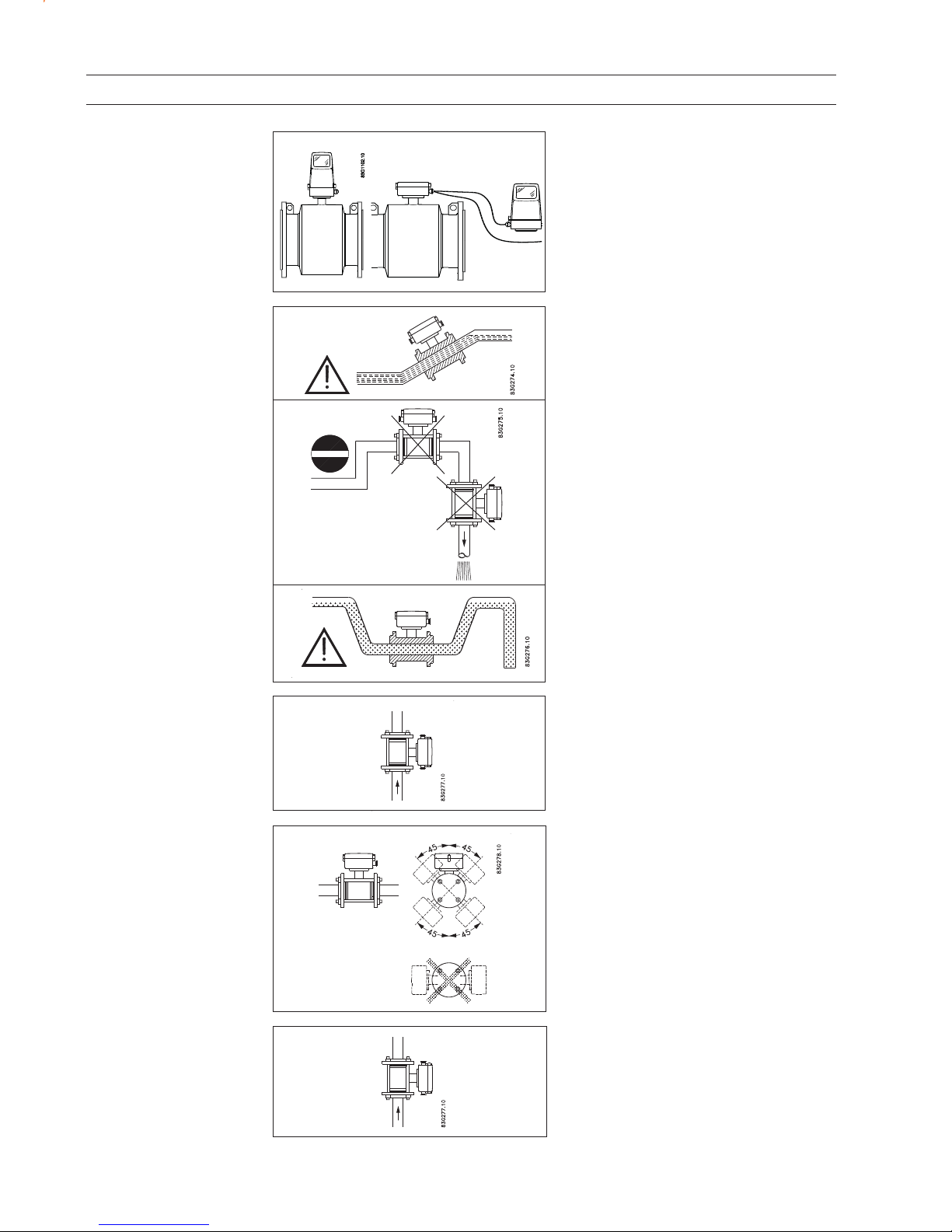

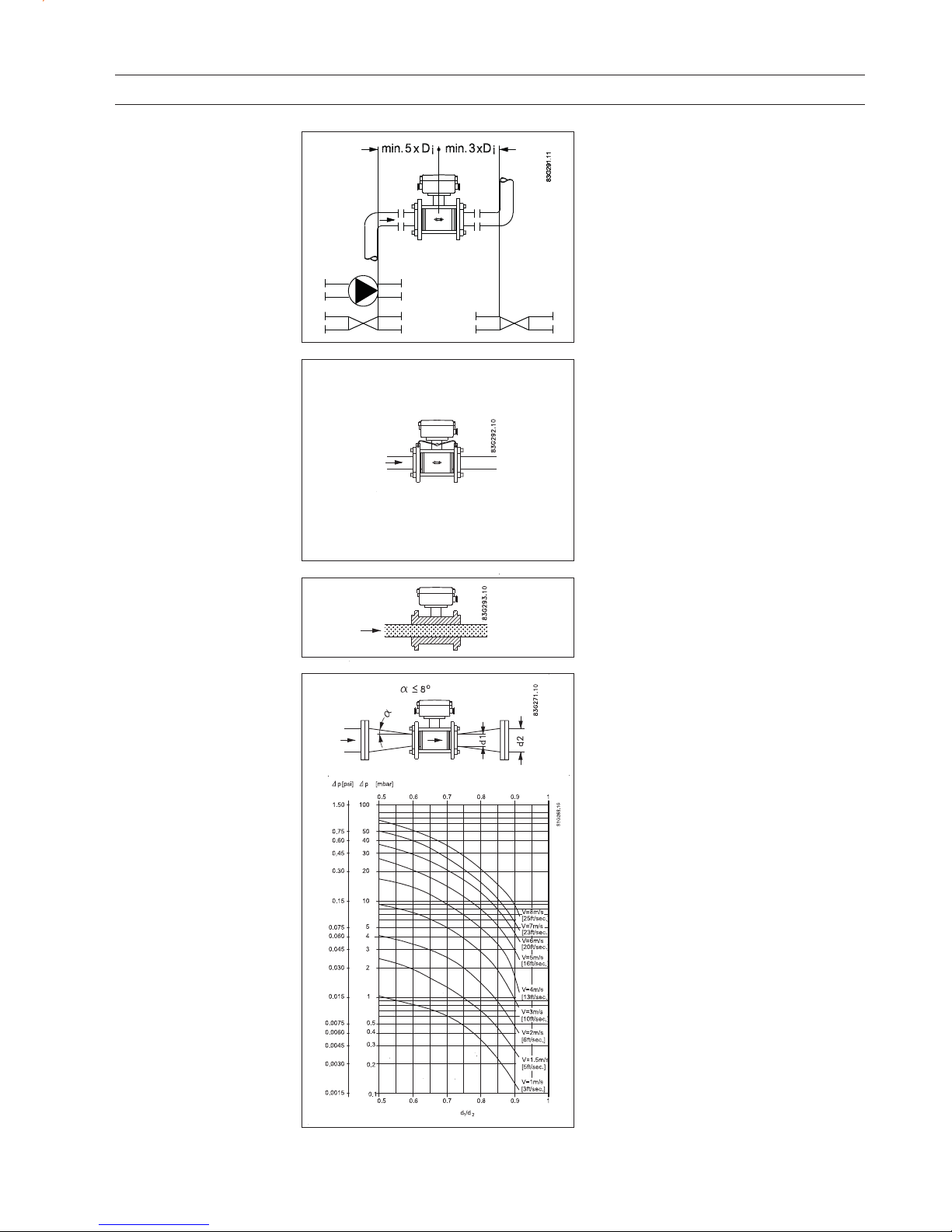

To achieve accurate flow measurement it is

essential to have straight lengths of inlet and

outlet pipes and a certain distance between

pumps and valves.

It is also important to centre the flowmeter in

relation to pipe flanges and gaskets.

The electrical potential of the liquid must always

be equal to the electrical potential of the sensor.

This can be achieved in different ways depending on the application:

A. W ire jum per bet ween se nsor an d ad jace nt

flanges. (MAG 1100 and MAG 3100).