Page 1

SINUMERIK

This document was produced for training purposes.

Siemens assumes no responsibility for its contents.

SINUMERIK

Measure Kinematics

With CYCLE9960

Training Manual

Edition 2022.03

Page 2

Page 3

SINUMERIK

Measure Kinematics

With CYCLE9960

Manual

Valid for:

SINUMERIK ONE SW6.15

Page 4

Page 5

Sinumerik

Measure kinematics with CYCLE9960

Module objective:

Module Description:

Content:

SINUMERIK ONE V6.15 Page 1 A650

This document was produced for training purposes.

Siemens assumes no responsibility for its contents.

A650

SINUMERIK

ONE

Objective: Geometric sample calculation

System prerequisites

Machine data

Programming

Program example: Machine with kinematics type "M"

Program example: Machine with kinematics type "P"

Program example: Machine with kinematics type "T"

Term definitions

The modul contains the basic functions of CYCLE9960 which is used to measure the kinematics of a

machine to use transformations like TRAORI or CYCLE800 for examle.

The reader should be able to handle the CYCLE9960 for machines with kinematic transformations.

Page 6

A650 Page 2 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

Page 7

Notes:

SINUMERIK ONE Page 3 A650

Measure kinematics with CYCLE9960

A650

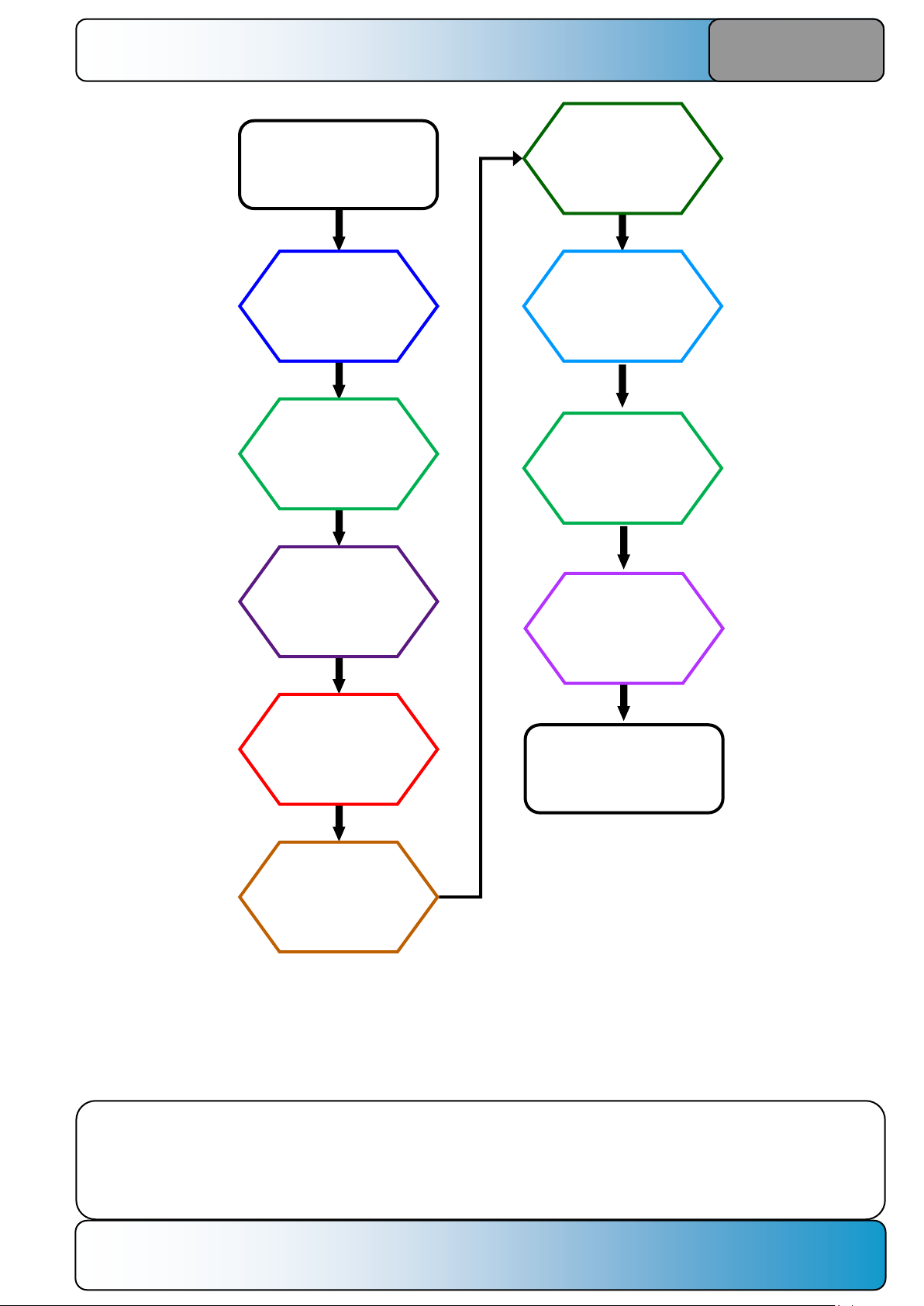

Objective:

Geometric

sample

calculation

System

prerequisites

Machine

data

Programming

Program

example:

Machine with

kinematics type

"M"

Program

example:

Machine with

kinematics type

"P"

Program

example:

Machine with

kinematics type

"T"

Term

definitions

Program

example:

Machine with

table-C-axis

Measure kinematics with

CYCLE9960

END

Measure kinematics with

CYCLE9960

START

Page 8

Notes:

A650 Page 4 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

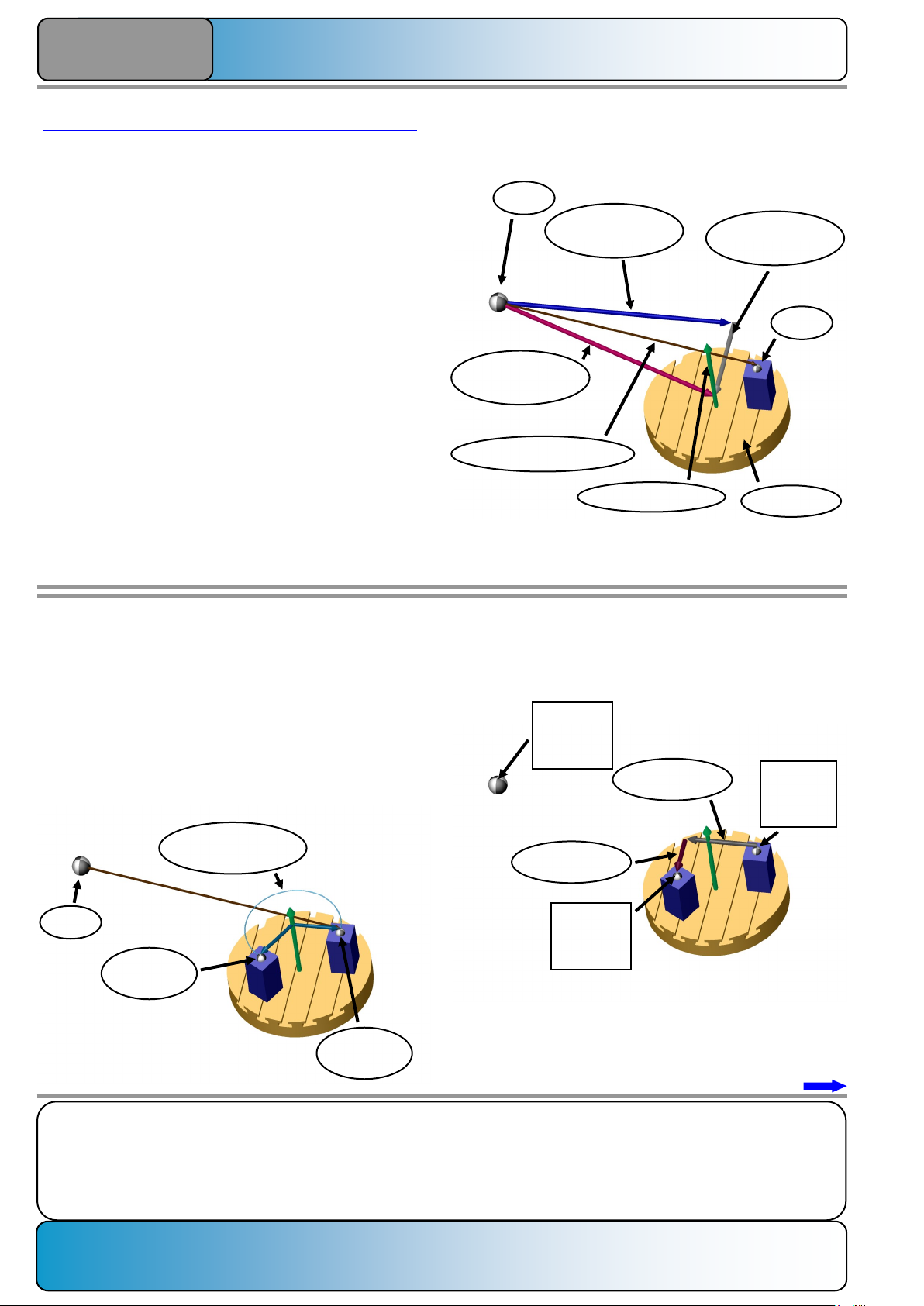

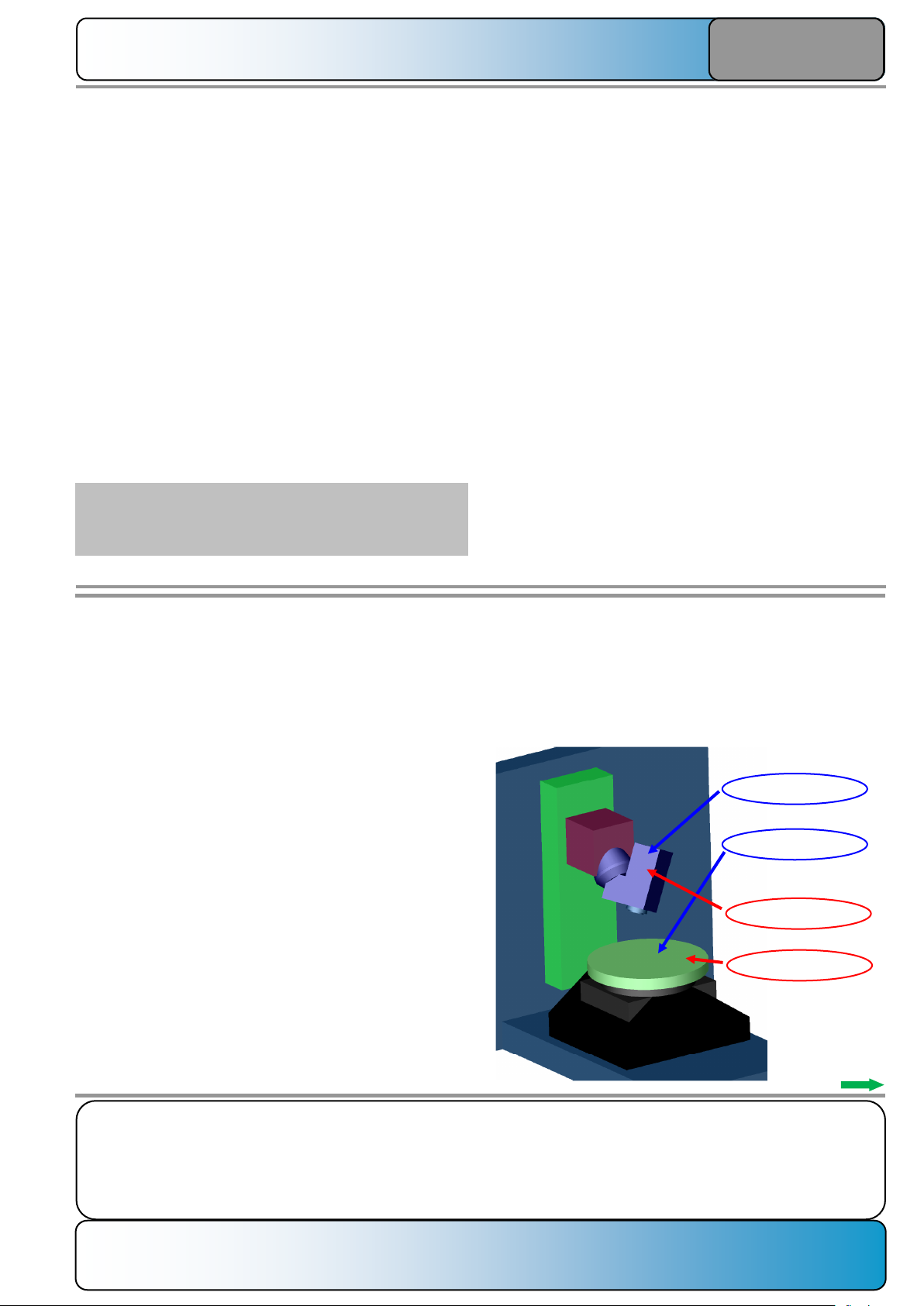

Use of the "Measure kinematics" function and objective:

The "Measure kinematics" function determines for machine

tools with at least one rotary axis the exact position of the

fulcrum (= offset vector) and the exact path of the spin axis (=

direction vector or rotary axis vector).

This information is required when using the orientation

transformations (e.g. CYCLE800, TRAORI) and the movement transformations (e.g. TRANSMIT, TRACYL) so that the

dimensional stability of the performed machining can be

optimized.

The effect of an offset vector on the precision of a machining

is illustrated with a graphical example.

The following data is assumed:

4x machine with C axis in the table

Offset vector for the C axis: X500 Y-200 mm

Zero offset to the workpiece: X600 Y-200 Z150 mm

The C axis should be turned by 240°.

MCS

WCS

Direction vector C

Offset vector C

(total)

Offset vector C

X component

Offset vector C

Y component

C axis

Zero offset

Overview of the complete design:

In the controller, the distance between the spin axis and WCS

is calculated from the known data (zero offset and C offset

vector):

∆X=NPVX - OFFSETX = 600 mm - 500 mm = 100 mm

∆Y=NPVY - OFFSETY = -200 mm - (-200 mm) = 0 mm

The effective distance between WCS and the rotary axis is

therefore 100 mm.

If the rotary axis is turned by 240°, the workpiece reference

point (WCS) at the C direction vector rotates:

Arc

R = 100 mm

WCS at

C = 0°

WCS at

C = 240°

When the difference between both workpiece zero points is

considered (before the rotation and after the rotation), the

difference values for X and Y result:

∆X = -150 mm

∆Y = -86.6 mm

MCS:

X=600 mm

Y=-200 mm

Z=150 mm

MCS:

X=450 mm

Y=-286.6 mm

Z=150 mm

MCS:

X=0 mm

Y=0 mm

Z=0 mm

MCS

Page 9

Notes:

SINUMERIK ONE Page 5 A650

Measure kinematics with CYCLE9960

A650

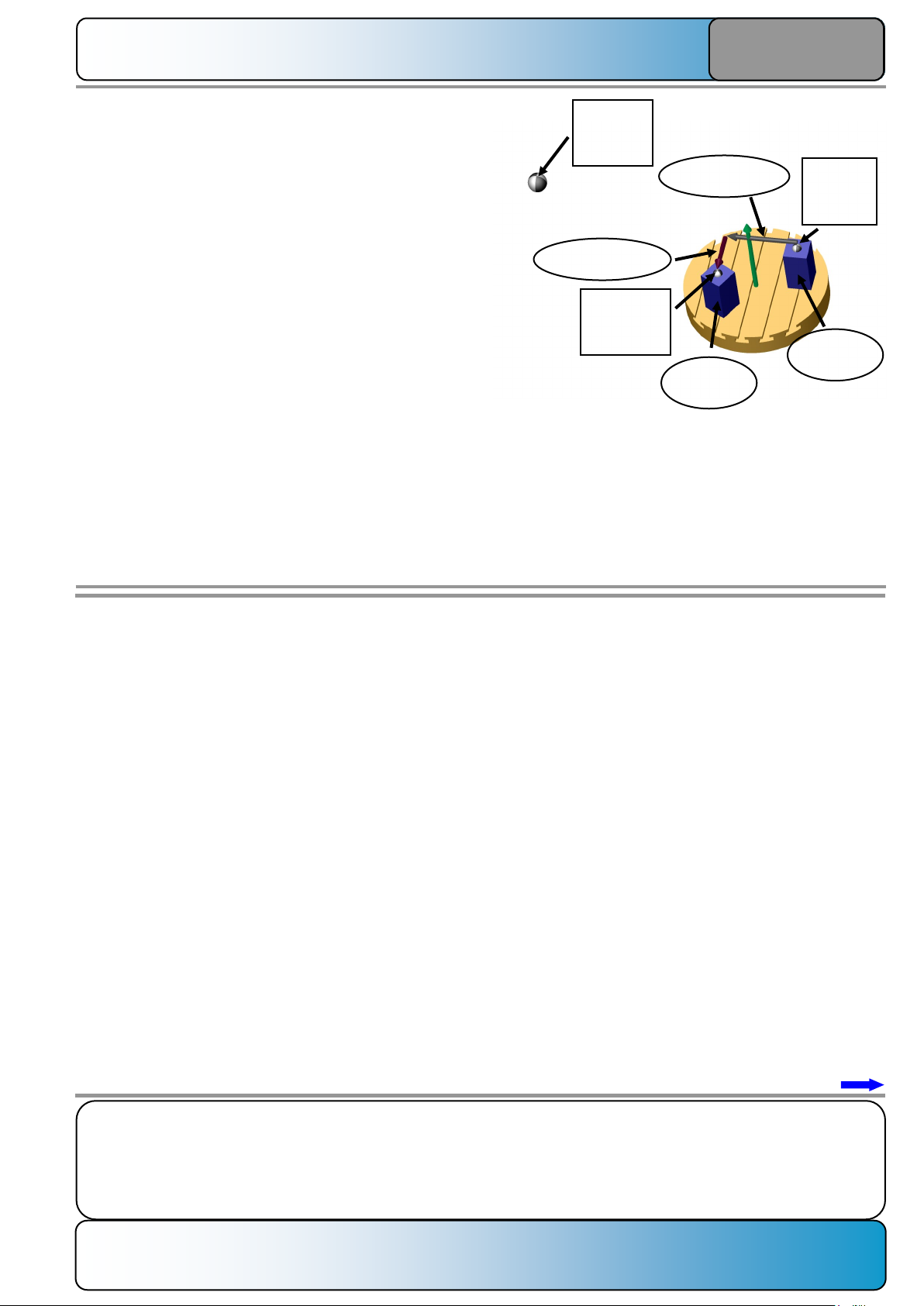

If, because of a measurement error during the measurement

of the kinematics or, for example, after replacement of a

measurement system of the X/Y axis, the actual values of the

offset vector do not match the position stored in the controller,

differences result between the calculated zero point position

after the C rotation and the actual position of the new

workpiece reference point.

Assumption:

The position of the C rotary axis in the MCS is actually X 500

mm and Y -200 mm.

The position of the C rotary axis stored in the controller is

X 499.9 mm and Y -200.15 mm.

The zero offset is X 600 mm, Y -200 mm, Z 150 mm.

This corresponds to the previously used constellation, only

the rotary axis is implicitly "moved" to another position.

The following differences between the entered C rotary axis

position and the WCS result:

∆X=NPVX - OFFSETX = 600 mm - 499.9 mm=100.1 mm

∆Y=NPVY - OFFSETY = -200 mm - (-200.15 mm) =0.15 mm

The effective distance (total radius) between WCS and the

rotary axis is therefore 100.100 mm.

Calculation:

Radius=SQRT(POT(100.1)+POT(0.15))=100.1001123 mm

∆X = -150.15

∆Y = -86.689 mm

MCS:

X=600 mm

Y=-200 mm

Z=150 mm

MCS:

X=449.85 mm

Y=-286.839 mm

Z=150 mm

MCS:

X=0 mm

Y=0 mm

Z=0 mm

No change has been made to the mechanical design of the

machine, but only to the position data of the C rotary axis in

the controller. The following differences (difference of the

MCS positions for C = 240°) result between the now

calculated MCS positions after rotating the C axis and the

"correctly" determined position data:

∆X= 450 mm - 499.85 mm=0.15 mm

∆Y=-286.6 mm - (-286.839 mm) =0.239 mm

This calculated example shows why the machine kinematics

must be measured precisely:

The position of rotary axes and the travel direction of the rotary

axes must be known exactly so that precise results can be

achieved when machining with rotary axis movements.

The above sample calculation shows a deviation of the

rotation axis position of 0.1 mm that leads later to an almost

three-fold deviation of 0.282 mm!

These necessary measurements can be performed with

CYCLE9960.

CYCLE9960 can perform the required corrections and store

the measurement results in log files.

WCS at

C = 0°

WCS at

C = 240°

Page 10

Notes:

A650 Page 6 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

Fundamentals for measuring the kinematics with CYCLE9960:

System prerequisites:

The function must be enabled via a system license:

To use the function, an operational transformation must be

configured on the machine. This includes:

• TOOLCARRIER, defined classically.

• TOOLCARRIER, defined based on a kinematic chain.

• TRAORI transformation, defined based on a kinematic

chain.

Other constraints are:

• The machine must be designed perpendicular with a

right-handed coordinate system, see DIN 66217.

• The tool spindle must be perpendicular to the work

plane.

• The axis directions of all linear and rotary axes must

conform with DIN 66217.

• The deployed 3D probe must be calibrated.

• The deployed measuring sphere must be perfectly

spherical and permanently mounted.

The entry-level softkey for the program editor must also be

enabled:

Machine data

The following machine and setting data is relevant for the

measurement:

SD 54760 $SNS_MEA_FUNCTION_MASK_PIECE

Bit 27:

The selection field: "Tolerance" for limiting the correction of

linear vectors can be hidden from the programming screen for

CYCLE9960:

Bit 27 = 0:

The tolerance can be defined in the programming screen.

Bit 27 = 1:

The tolerance cannot be defined in the programming screen;

the selection field is not shown.

werden, das Auswahlfeld wird nicht aufgeblendet.

Page 11

Notes:

SINUMERIK ONE Page 7 A650

Measure kinematics with CYCLE9960

A650

Meaning of the ones-digit:

x0: Calculation of all components from CYCLE9960

x1: X component of the offset vector from

$SCS_MEA_KIN_VALUE[n] n=0,1

x2: Y component of the offset vector from

$SCS_MEA_KIN_VALUE[n] n=0,1

x3: Z component of the offset vector from

$SCS_MEA_KIN_VALUE[n] n=0,1

x4: X component of the offset vector from the active

transformation retain

x5: Y component of the offset vector from the active

transformation retain

x6: Z component of the offset vector from the active

transformation retain

Meaning of the tens-digit for tool carrier:

0x: Selection for a closed vector chain

1x: Selection for an opened vector chain

The free component may need to be defined via a specified

normalization so that no unwanted displacement of the

collision bodies occurs in the kinematic chain!

For the index n of the setting data item, check whether the

swivel data set selected for correction is a classic defined tool

carrier or a tool carrier based on a kinematic chain.

The assignment of the first and second rotary axes always

applies:

SD 55645 $SCS_MEA_KIN_MODE[0] - first rotary axis

SD 55645 $SCS_MEA_KIN_MODE[1] - second rotary axis

The "first rotary axis" and "second rotary axis" assignment

depends on the base type of the kinematics for kinematics

with 2 rotary axes.

The exact assignment is shown in the next figures for classic

tool carriers and tool carriers based on a kinematic chain.

For dynamic transformations (e.g. TRAORI_DYN) with the

"alternative call" setting, the same conditions as for a classic

tool carrier or a tool carrier based on a kinematic chain.

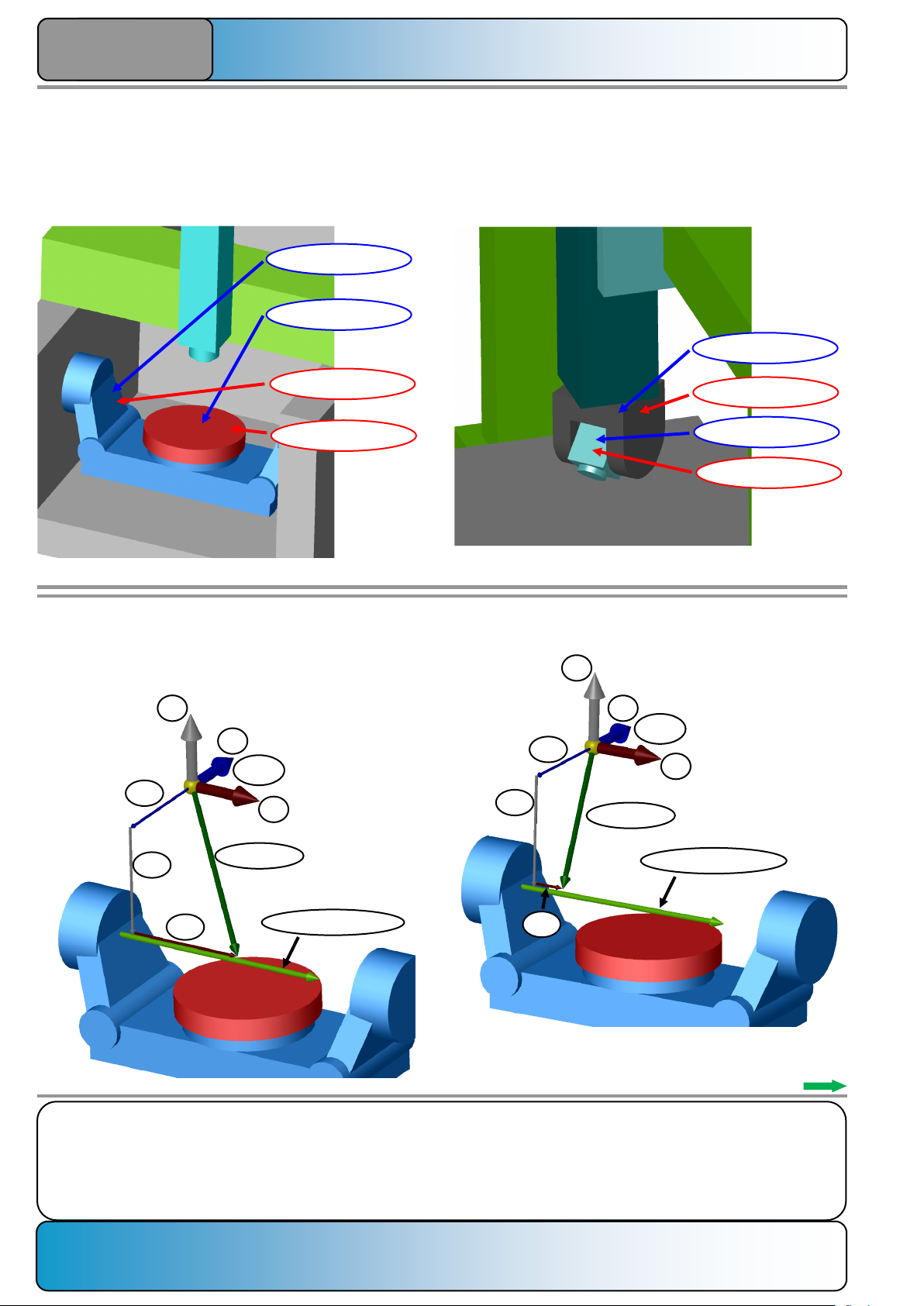

Machine type "M"

A. Classic tool carrier

B. Tool carrier based on a kinematic chain

(Direction of rotation: from the end of the workpiece

chain to the end of the tool chain.)

1st rotary axis

2nd rotary axis

1st rotary axis

2nd rotary axis

SD 55644 $SCS_MEA_KIN_TOL

For each approached rotary axis position, a measurement is

performed at the sphere, whereby the radius of the sphere is

calculated. The tolerance range within which the calculated

sphere diameter may fluctuate can be set with this SD.

SD 55645 $SCS_MEA_KIN_MODE[n] n=0,1

Correction behavior for a component of an offset vector parallel to the rotary axis (example: X component of an A axis or Z

component of a C axis).

The components parallel to the rotary axis can be influenced

by this SD so that after measurement either existing values

are retained or the values can be specified.

Components of offset vectors for rotary axes can also be

specified that do not run parallel to one of the machine axes,

such as a 45° head axis with the vector (0,1,1). For example,

the Y or Z component can be specified for this axis.

Page 12

Notes:

A650 Page 8 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

Z

X

Y

I2

Y

I2

Z

I2

X

I2 Total

Rotary axis vector V1

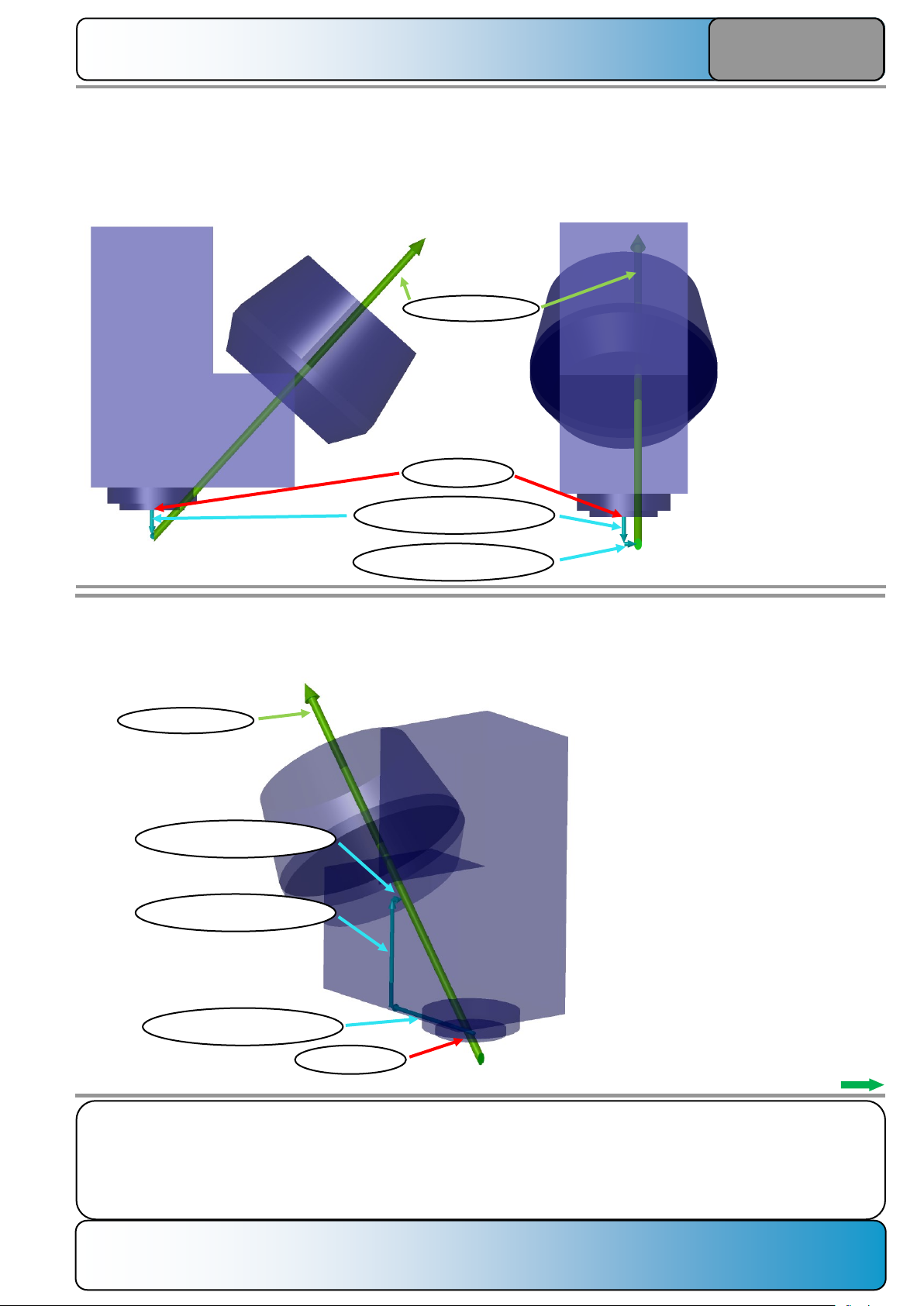

Example for different ways of defining the offset vector I2

(distance from the MCS to rotary axis 1):

The attack point of offset vector I2 in the X axis of the MCS

can take any values.

Possibility 1:

MCS

Z

Y

MKS

X

I2

Y

I2

Z

I2

X

I2 Total

Rotary axis vector V1

Possibility 2:

I2X=100 mm

I2Y=400 mm

I2Z=400 mm

I2

Total

=574.456 mm

I2X=400 mm

I2Y=400 mm

I2Z=400 mm

I2

Total

=692.820 mm

Any value for I2x leads to a correct kinematic solution while

changing the offset vector component I3x (X distance from the

1st RA to the 2nd RA).

Machine type "P"

A. Classic tool carrier

B. Tool carrier based on a kinematic chain

(Direction of rotation: from the end of the workpiece

chain to the end of the tool chain.)

1st rotary axis

2nd rotary axis

1st rotary axis

2nd rotary axis

Machine type "T"

A. Classic tool carrier

B. Tool carrier based on a kinematic chain

(Direction of rotation: from the end of the workpiece

chain to the end of the tool chain.)

1st rotary axis

2nd rotary axis

1st rotary axis

2nd rotary axis

Page 13

Notes:

SINUMERIK ONE Page 9 A650

Measure kinematics with CYCLE9960

A650

A normalization would make sense on the Y axis or Z axis.

Example: The value for the Y axis should be normalized to 100 mm.

Rotary axis vector V

Offset vector VZ = 80.025 mm

Tool reference

Offset vector VX = 5.691 mm

Offset vector VY = 100.000 mm

The original offset vector with the values I=

(5.691, 0, -19.975) is lengthened along the

rotary axis vector V=(0, 1, 1). This means: if

the offset vector is lengthened by 1 mm in

the Y direction, the Z component also grows

by 1 mm. The X component does not

change.

If the attack point of the offset vector at the

rotary axis vector should be moved by Y +

100 mm, the Z value is moved by 100 mm.

The new components of the offset vector

yield:

I=(5.691, 100, 80.025).

Example for a 45° B axis in the head:

In this case, the tool reference point is the reference for the offset vector. In the example, the direction vector has the

configuration (0,1,1). Because of mechanical manufacturing tolerances, the direction vector also always has an offset in

the X direction to the tool reference point (center of the milling spindle).

The offset vector has the values (5.691, 0, -19.975).

Rotary axis vector V

Offset vector VZ = -19.975 mm

Tool reference

Offset vector VX = 5.691 mm

Page 14

Notes:

A650 Page 10 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

SD 55646 $SCS_MEA_KIN_VALUE[n] n=0,1

Setpoint for the component of the offset vector specified in

SD 55645[n] if SD 55645[n] = 1,2 or 3.

Meaning of index n:

n=0: Setpoint for rotary axis 1

n=1: Setpoint for rotary axis 2

SD 55647 $SCS_MEA_KIN_MIN_ANG_TRIANGLE

Valid value range: 2° to 60°.

This SD is relevant when a measurement is defined over

three individual sphere measurement points per rotary axis.

An arc is calculated from these three points.

If the three points are connected with straight lines, this

produces a triangle. The SD defines the minimum angle that

may exist within the triangle.

If two points lie too closely together, a small position deviation

for one of the two points causes a large change of the

calculated center point and of the calculated radius. In the

ideal case, all three angles are 60° within the triangle. In this

case, a measurement uncertainty has only a minimal effect

on the result.

Example 1:

The three measurement points differ in the position of the

rotary axis by 120°, all angles within the triangle are 60°.

This case is very favorable for the calculation and smaller

measurement deviations have only a limited effect on the

calculation result.

Example 2:

The three measurement points differ in the position of the

rotary axis by 30°; the angles within the triangle are unequal.

This case is unfavorable for the calculation, because smaller

measurement deviations have a large effect on the

calculation result.

Calculation of the triangle:

The sphere center is 200 mm distant from the spin axis.

Each rotary axis turns by 30°.

This produces the angles in the gray triangle:

Angle at the center sphere: 150°

Angle at the outer spheres: 15°

Example with concrete numbers:

Case 1:

The red-highlighted sphere is moved by –1 mm in the Y axis.

The rotation center calculated from the 3 sphere centers has

the following deviations to the actual rotation center:

∆X=0.000 mm

∆Y=0.667 mm

Y-1 mm

Page 15

Notes:

SINUMERIK ONE Page 11 A650

Measure kinematics with CYCLE9960

A650

SD 55648 $SCS_MEA_KIN_MIN_ANG_POS

Valid value range: 10° to 180°.

Minimum total angle of a rotary axis traversed to perform the

rotary axis measurement.

In the ideal case, all measurement points are distributed over

360°. Kinematic conditions mean that this cannot always be

implemented for all rotary axes, for example, when

restrictions in the traversal area exist.

If the measurement points on an arc lie very close to each

other, a small position deviation of an individual measurement

point causes a large deviation in the result. Consequently, it is

desirable to keep the distance between the measurement

points as large as possible and to perform the measurement

with the maximum possible traversal area for the rotary axis.

Case 2:

The red-highlighted sphere is moved by –1 mm in the Y axis.

The rotation center calculated from the 3 sphere centers has

the following deviations to the actual rotation center:

∆X=0.848 mm

∆Y=3.164 mm

Y-1 mm

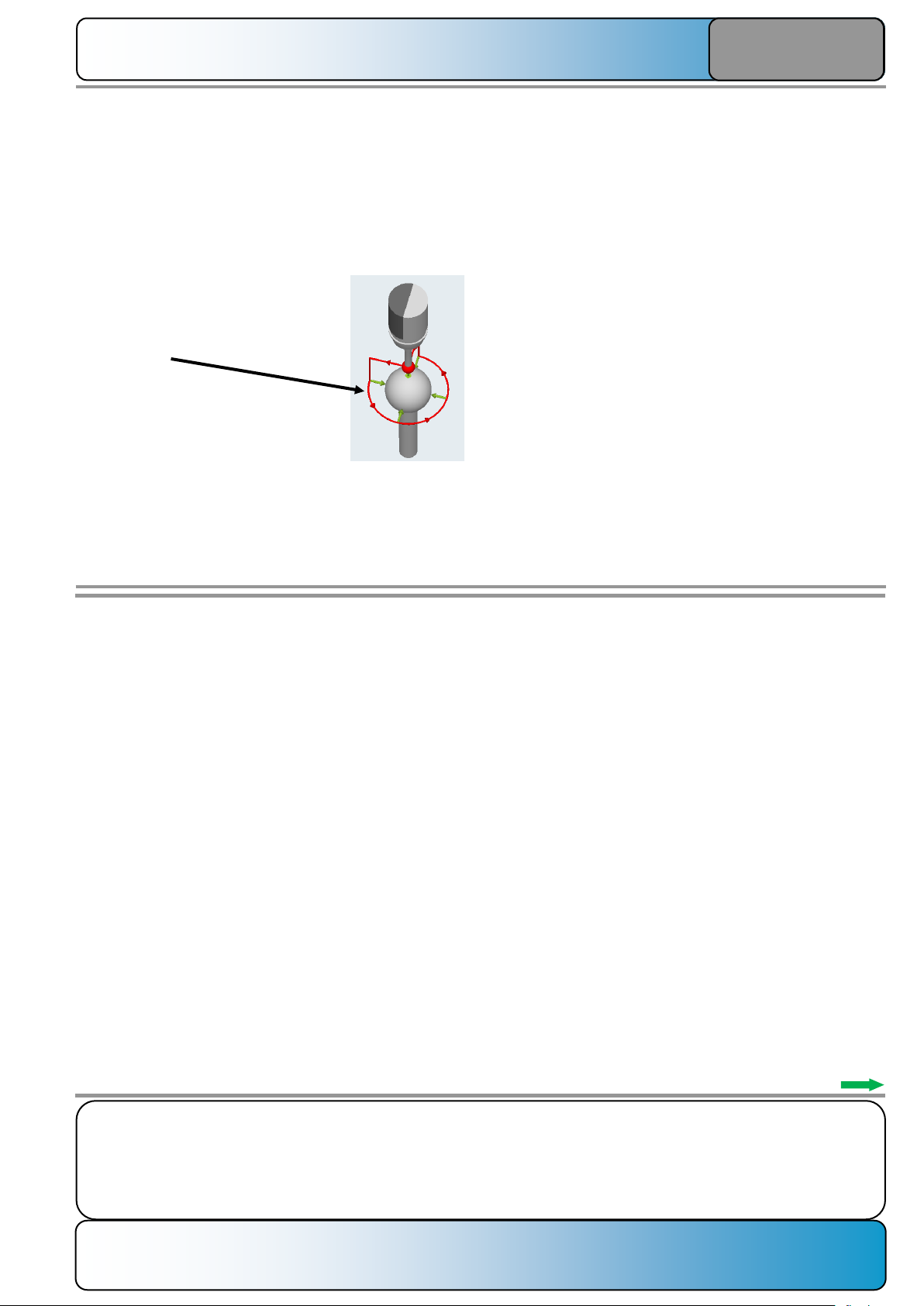

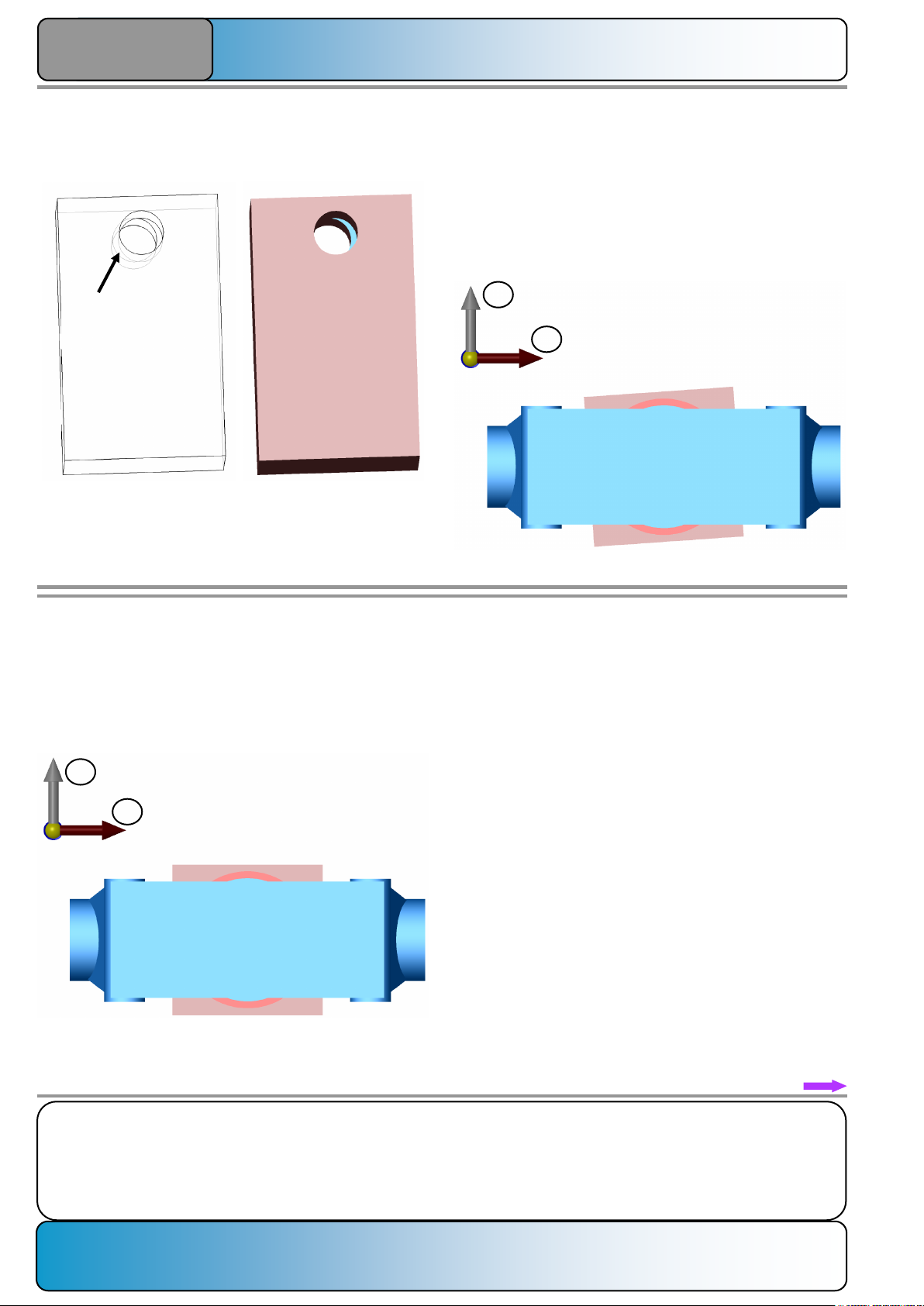

SD 55649 $SCS_MEA_KIN_BALL_VEC[n] n=0,1,2

Vector for the alignment of the sphere shaft at initial setting of

the kinematic. This specification is required so that no collision

of the probe with the sphere shaft occurs during a sphere

measurement. The vector direction runs from the sphere

center starting at the sphere shaft.

The vector must not be normalized.

$SCS_MEA_KIN_BALL_VEC[0]

X component of the shaft vector

$SCS_MEA_KIN_BALL_VEC[1]

Y component of the shaft vector

$SCS_MEA_KIN_BALL_VEC[2]

Z component of the shaft vector

Example:

For this case, the following apply:

$SCS_MEA_KIN_BALL_VEC[0]=0

$SCS_MEA_KIN_BALL_VEC[1]=-1

$SCS_MEA_KIN_BALL_VEC[2]=-1

Z

Y

X

X

Y

Z

Vector = (0, -1, -1)

Page 16

Notes:

A650 Page 12 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

Bit9:

Bit 9 is not evaluated for CYCLE9960.

Bit 9 is evaluated only for CYCLE996.

Bit10:

Enable the "Measurement with reference" selection field in the

programming screen:

Bit10=0:

The selection field for a reference measurement is not

displayed.

Bit10=1:

The selection field for a reference measurement is displayed.

This means it is possible to compare replaceable kinematic

units (e.g. attachment heads on milling machines or also on

turret lathes) with each other (determination of the "open"

offset component).

Bit 11:

Number of measurement points when measuring the sphere:

Bit 11 = 0:

When "Measure on circular path" measurement mode is used,

10 measurement points are approached: 4x on the circular

circumference and 1x at the top of the sphere.

This operation is performed 2x.

Bit 11 = 1:

When "Measure on circular path" measurement mode is used,

8 measurement points are approached: 3x on the circular

circumference and 1x at the top of the sphere.

This operation is performed 2x.

Bit12:

Behavior for the "Tolerance monitoring" alarm case:

Bit12=0:

Behavior for the "Tolerance monitoring" alarm case:

Bit 12 = 0:

A CANCEL alarm is issued in the event of a tolerance

violation. The alarm can be acknowledged and the kinematics

can be rewritten despite the alarm.

Bit 12 = 1:

A RESET alarm is issued in the event of a tolerance violation.

The alarm cannot be acknowledged and the program must be

canceled with RESET.

Bit 13:

Mode for normalization with kinematic type "P" or table

kinematics with 2 rotary axes:

Bit 13 = 0:

The normalization is performed with the two I2 vectors

(distance from the machine zero to the 1st rotary axis) and I3

(distance from the 1st rotary axis to the 2nd rotary axis).

Bit 13 = 1:

The normalization for rotary axis 2 is performed in the I4 vector (distance from the 2nd rotary axis to the machine zero).

SD 55740 $SCS_MEA_FUNCTION_MASK

Bit 7:

Bit 7 is not evaluated for CYCLE9960. All normalizations are

performed based on the active vectors.

Bit 7 is evaluated for CYCLE996.

Bit 8:

Kinematic measurement with active tool carrier (CYCLE800)

or TRAORI permitted.

Behavior for Bit 8 = 0:

An active transformation before beginning the measurement

is deactivated and reactivated after the end of the

measurement.

Behavior for Bit 8 = 1:

If Bit 8=1, a transformation must be active before beginning

the measurement. Permitted are:

• Tool carrier in classic form with $TC_CARR

• Tool carrier based on kinematic chain $NT

• TRAORI_DYN based on a kinematic chain

Page 17

Notes:

SINUMERIK ONE Page 13 A650

Measure kinematics with CYCLE9960

A650

SD 55637 $SCS_MEA_FEED_POS_DEG

Positioning feed for repositioning the rotary axes during the

measurement in degrees/min.

As standard, the value is set to 360°/min.

SD 55640 $SCS_MEA_FEED_CIRCLE

Feed for circumventing the measuring

sphere on a circular path.

"Position on circular path" must be

selected in the programming screen.

Page 18

Notes:

A650 Page 14 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

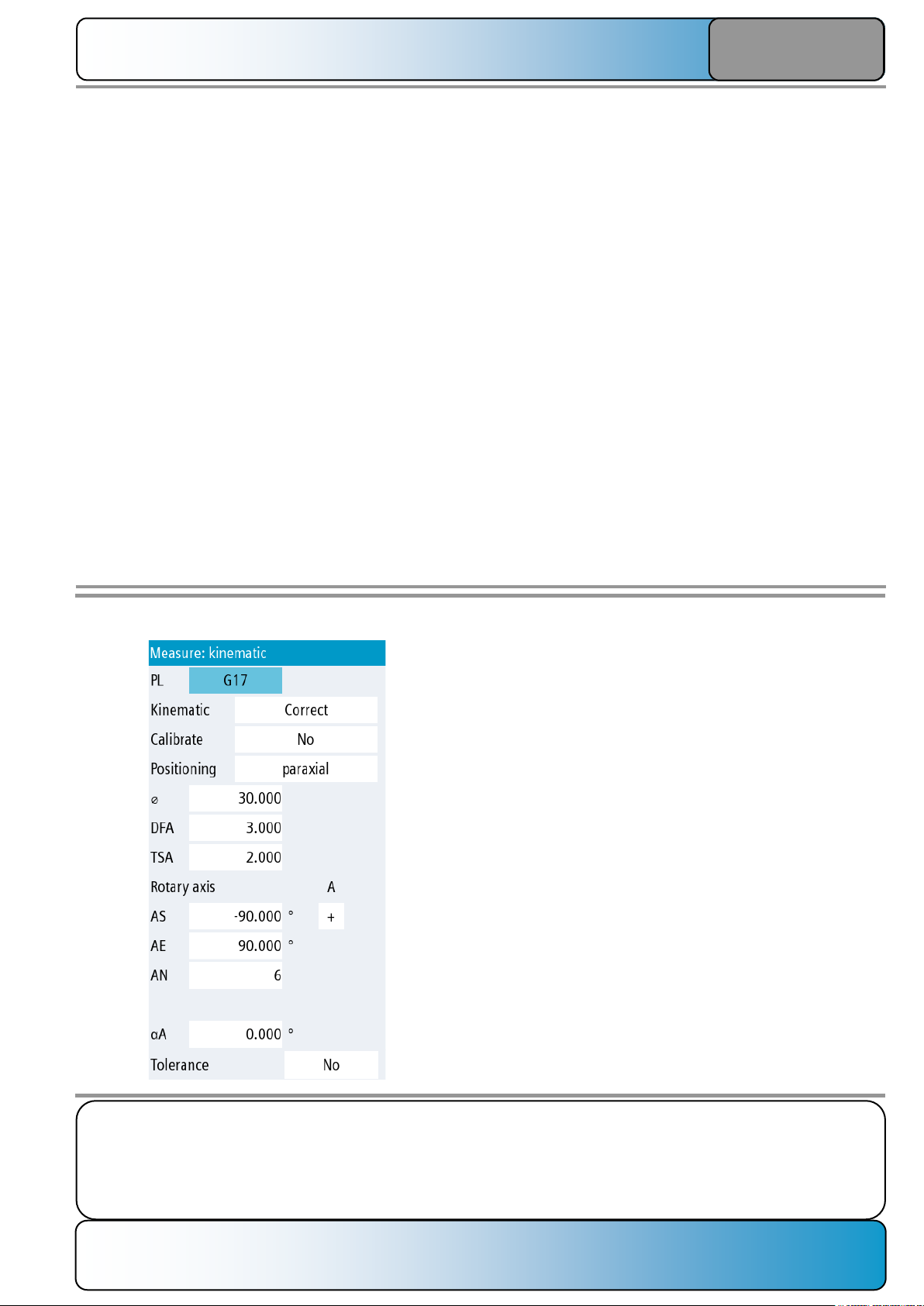

Programming:

Call from a DIN-ISO part program:

The input screen of CYCLE9960 can be called from an

opened program editor.

The appearance of the screen depends on various system

data items:

Explanation of the individual input fields:

1.

Selection of the work plane in which the measurement should

be performed:

Setting options:

G17 XY plane

G18 ZX plane

G19 YZ plane

No selection: The measurement is performed in the

active plane.

2.

Name of the transformation agreement for which the

correction should be performed.

The following can be used:

Tool carrier, defined classic

Tool carrier based on a kinematic chain

Dynamic transformation of the TRAORI_DYN type

Static transformation of the TRAORI_STAT type

1

14

13

12

11

10

2

3

4

5

6

7

8

9

MD 52005

$MCS_DISP_PLANE_MILL

SD 55740

$SCS_MEA_FUNCTION_MASK Bit 10

Die verwendete Rundachse wird aus der

angewählten Transformation automatisch

vorbelegt.

16

15

Second part of the input mask:

Please see the next page…..

Page 19

Notes:

SINUMERIK ONE Page 15 A650

Measure kinematics with CYCLE9960

A650

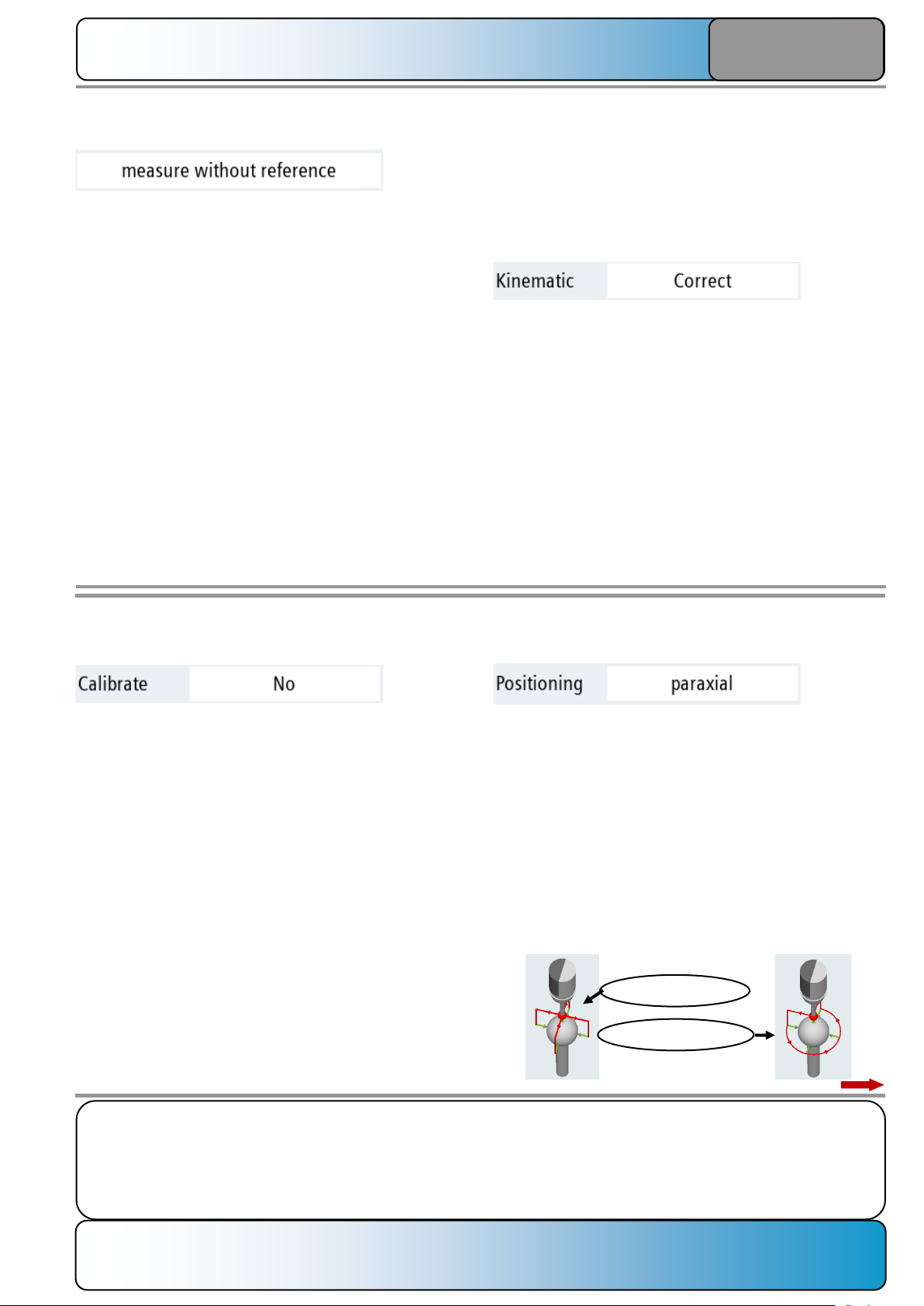

4.

Measuring mode:

Setting options:

Correct

Only correct

Measure only

Correct:

After the measurement, the results are entered into the

machine data.

The measurement results can also be displayed or stored in a

log file.

Only correct:

Calculate with the last stored values.

Measure only:

After the measurement, the results are displayed or a log file

can be created.

Setting options:

Yes

No

Yes:

The probe on the sphere is calibrated before beginning the

actual measurement. The calibration is performed in the

active work plane. The calibrated length of the probe is not

changed.

Because the length of the probe is relevant for calculating the

kinematics, the length of the probe must be calibrated exactly

before beginning the measurement with CYCLE9960.

No:

The deployed probe is not calibrated before beginning the

measurement.

5.

Calibrate the probe:

6.

Positioning:

Setting options:

Paraxial

On circular path

Paraxial:

The probe approaches each individual measurement point

from a point above the sphere center and returns to this point

after the measurement.

On circular path:

The probe positions from the first measurement point at the

height of the sphere equator on a circular path to the next

measurement point. Because of the few positioning

movements, this method is faster than the axis-parallel method.

Axis parallel

On circular path

For several attachment heads, machining must begin with the

reference head in "Measure reference" mode. A check is

made whether for all subsequent measurements in "Adapt to

reference" mode, the same zero offset is active as for

measuring the reference.

3.

Settings for reference measurements:

Setting options:

Measure reference

Adapt to reference

Measure without reference

Measure reference:

If a machine with replaceable kinematic modules (e.g. attachment heads) should be measured, a kinematic module must

serve as reference for the measurement of the other

modules.

Adapt to reference:

Measurement of a further kinematic module that should

receive a reference to the reference kinematics.

Measure without reference:

Measurement without replaceable modules. This method is

the standard method for 5x machines without replaceable

kinematic modules.

Page 20

Notes:

A650 Page 16 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

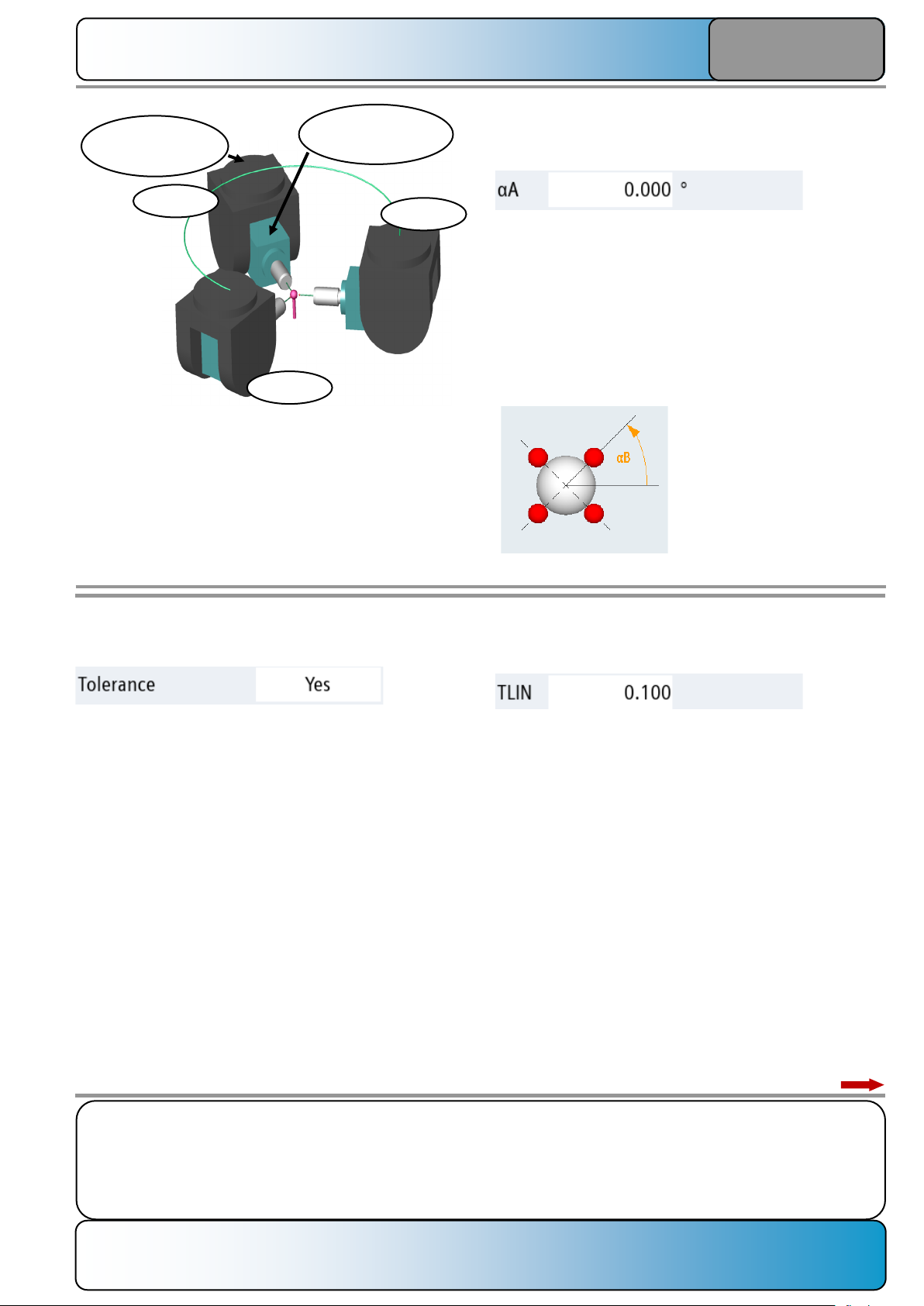

9.

Confidence range:

The confi-

dence range

specifies the maximum permissible deviation for each individual measuring sphere operation. An alarm is issued if the

measured center point of the sphere (= actual value) deviates

from the calculated center point of the sphere (= setpoint) by

more than the programmed TSA value. The measurement

must then be terminated with RESET.

Data for definition of the measurement configuration of a

rotary axis:

To define the measurement of a rotary axis, the following

parameters are defined for each rotary axis:

• Position of the rotary axis in degrees for the first

measurement

• Position of the rotary axis in degrees for the last

measurement

• Number of measurement points for this rotary axis

(3-12)

• Position of the rotary axis that should currently not be

measured (if two rotary axes are available)

• Offset angle for the touch points

The measuring sphere must be constructed so that a measurement is possible at the initial setting of the kinematics.

The first measurement is performed at the initial setting of the

kinematics, even when it is not contained in the definitions of

the two individual measuring ranges for the two rotary axes.

10.

Start angle for the rotary axis measurement:

For the definition of the measuring range, the start and end

values must be selected so that the start value is smaller than

the end value. The measuring range is divided into uniform

sections by the definition of the number of measurement

points.

The start angle must lie within the valid traversal area of the

rotary axis.

11.

End angle for the rotary axis measurement:

The end angle must be larger than the start angle and must

lie within the valid traversal area of the rotary axis.

For the measurement of a rotary axis, an angle range as large

as possible should lie between the start angle and the end

angle.

12:

Number of measurement points:

The number of measurement points can be selected in the

range 3 to 12. The larger the number of measurement points,

the more precise the kinematics can be calculated.

13.

Position of the rotary axis not moved during the measuring

operation:

If two rotary axes are present on the machine, the axis not

involved with the measurement can leave its initial setting.

This can avoid collisions or the calibration of the kinematics

can be adapted to a specific machining situation.

In particular for head kinematics, it is desirable to position the

second rotary axis from the initial setting while the first rotary

axis is being measured:

7.

Diameter of the measuring sphere:

The diameter of the measuring sphere must be entered

precisely. A certified calibration sphere should be deployed as

measuring sphere.

8.

Measurement path:

The measurement path serves as a measurement section

traversed before and after the expected switching point.

Consequently, the maximum measurement stroke is always

twice the input value.

If for relatively large input values the probe is prepositioned at

long distance from the measuring sphere, there may be a risk

of collision and the measurement takes longer.

Page 21

Notes:

SINUMERIK ONE Page 17 A650

Measure kinematics with CYCLE9960

A650

15:

Tolerance mode for linear vectors:

Setting options:

Yes

No

Yes:

The tolerance for the maximum change of the linear vectors

can be programmed. Consequently, among other things, the

specification is important for machines with the "Collision

Avoidance" function so that the collision bodies are not

moved too far by an unwanted excessive change of the offset

vectors.

For the normalization of "free vector components", such as

the X component for a vector (-1,0,0), SD 55645 must be

observed!

No:

The tolerance for the maximum change of the linear vectors

cannot be programmed in the cycle.

16:

Tolerance value for linear vectors:

The maximum permissible change value with which a linear

vector or offset vector may be adapted.

If the programmed tolerance is exceeded, an alarm is issued

after calculation and the program must be terminated with

RESET.

14:

Start angle for the measurement at the sphere:

If the orientation of the shaft is specified in the SD 55649

$SCS_MEA_KIN_BALL_VEC, the start angle for each

measurement of the sphere is calculated automatically so that

no collision occurs between the probes.

If no vector direction of the sphere shaft is specified, the start

angle can be specified manually, but must be adapted to the

kinematics of the machine and the associated measuring

range (start and end angles of the rotary axes).

1st rotary axis:

C

2nd rotary axis:

A=-90°

If for this kinematic, the A axis remains at a position of 0°

during the measurement of the C axis, the machine does not

significantly change its position in X/Y/Z during the

measurement. Because the measurement points from which

the turning center is calculated lie very close together, large

deviations can occur during the calculation.

A setting of the A axis at -90° causes a very significant

positioning movement in X/Y/Z that allows the turning point of

the C axis to be calculated more precisely.

C=120°

C=240°

C=0°

Page 22

Notes:

A650 Page 18 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

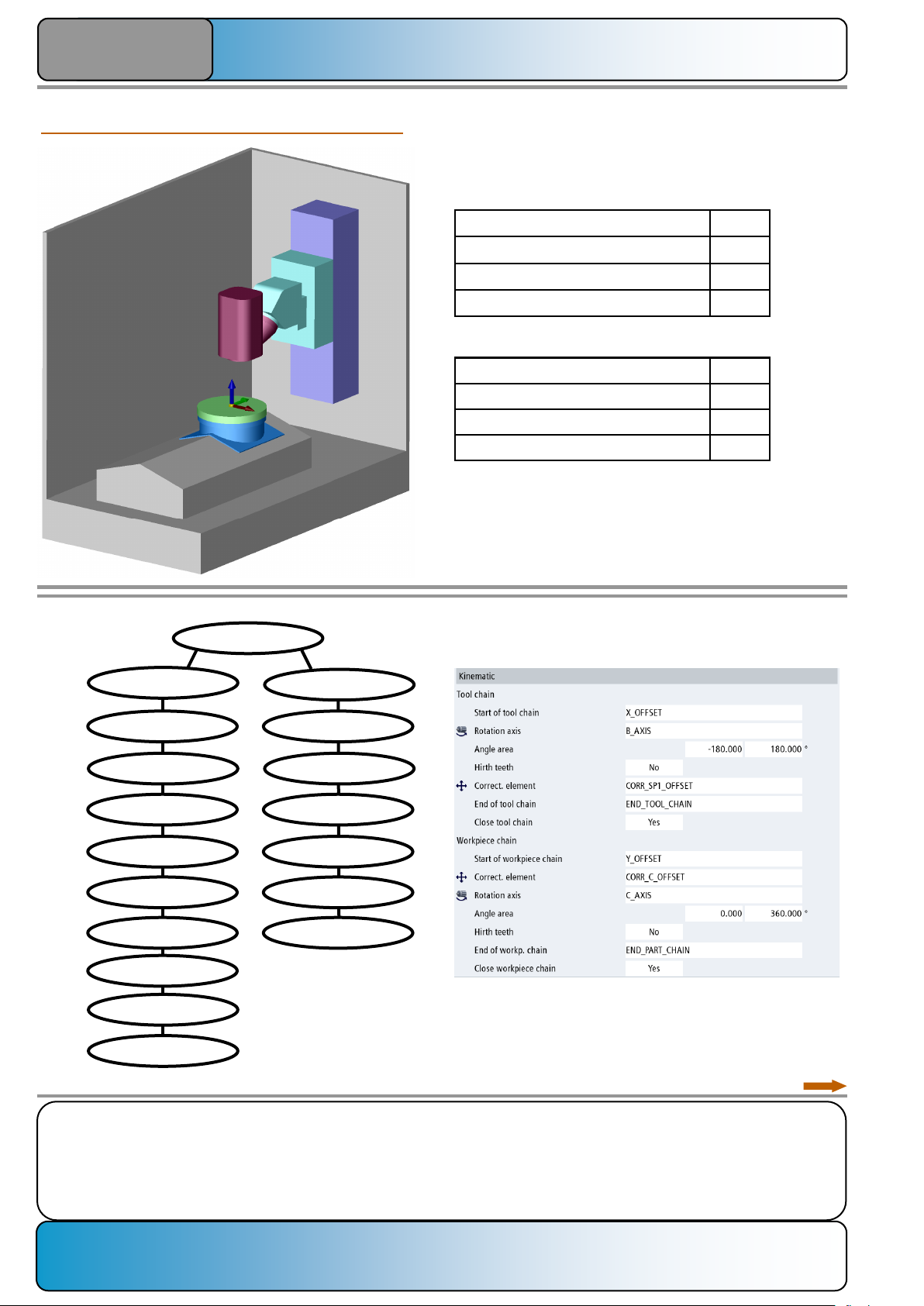

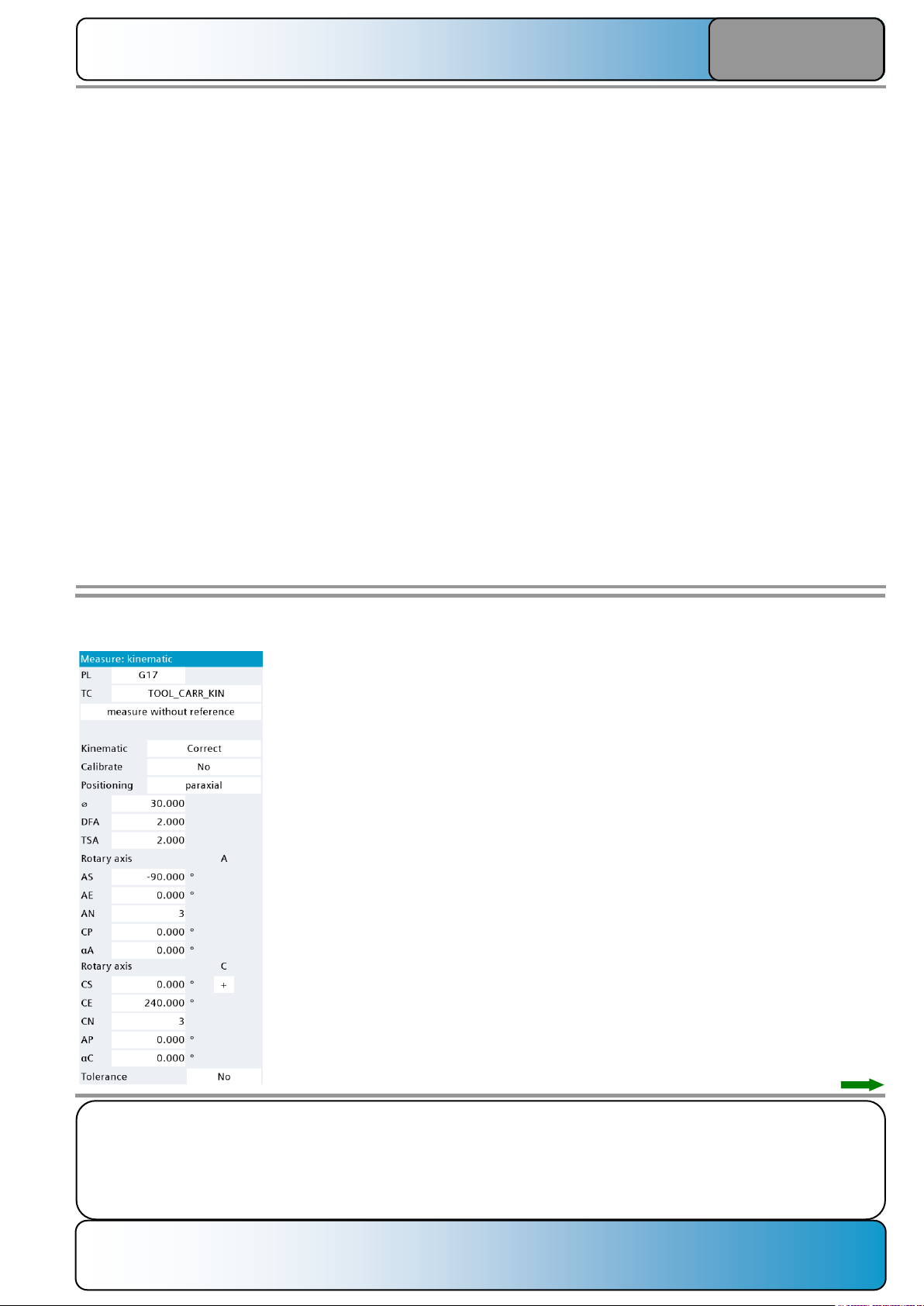

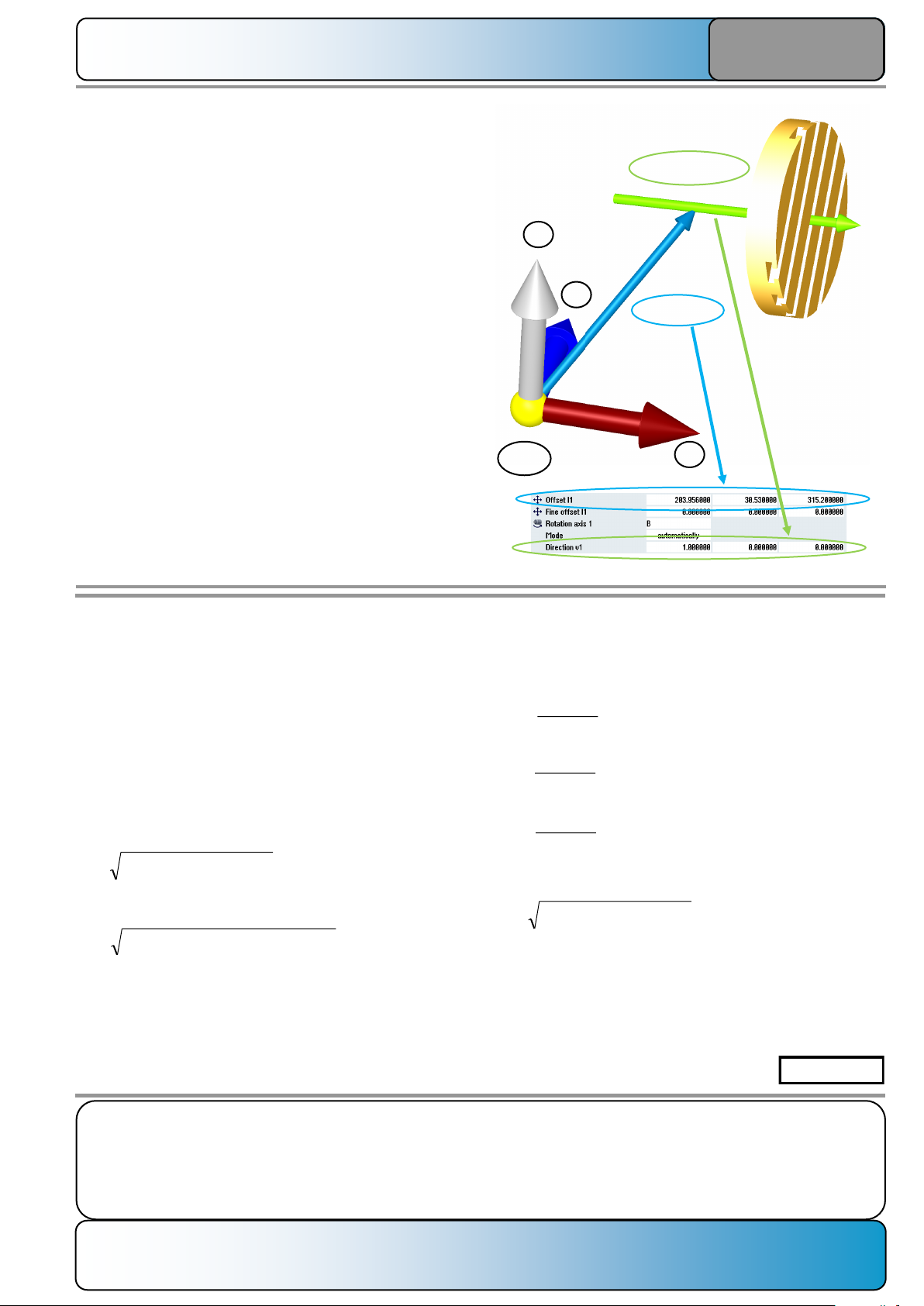

Sample program for a machine with mixed kinematics:

Name of the rotary axis B

Direction vector of the rotary axis 0, 1, 1

Software limit switch minus MD 36100 -180°

Software limit switch plus MD 36110 180°

Name of the rotary axis C

Direction vector of the rotary axis 0, 0, -1

Software limit switch minus MD 36100 -

Software limit switch plus MD 36110 -

Kinematic chain of

the machine:

ROOT

Y_OFFSET

X_AXIS

CORR_SP1_OFFSET

Y_AXIS

X_OFFSET

Z_OFFSET

Z_AXIS

SP1_OFFSET

SP1_AXIS

B_OFFSET

C_OFFSET

CORR_C_OFFSET

B_AXIS

C_AXIS

TABLE_OFFSET

END_PART_CHAIN

END_TOOL_CHAIN

Configuration of the "TOOL_CARR_KIN" tool carrier

(kinematically relevant part):

A sample program is created to measure mixed kinematics

with tool carrier based on a kinematic chain.

The machine has the following data:

Head axis:

The software limit switches of table axis C are not relevant,

because it is defined as modulo rotary axis.

Table axis:

Page 23

Notes:

SINUMERIK ONE Page 19 A650

Measure kinematics with CYCLE9960

A650

Sample program

N1000 TRAFOOF

N1010 CYCLE800

N1020 $P_UIFR[1]=CTRANS(X,150,Y,0,Z,200)

N1030 T="3D_PROBE"

N1040 M6

N1050 $SCS_MEA_KIN_BALL_VEC[0]=0

N1060 $SCS_MEA_KIN_BALL_VEC[1]=0

N1070 $SCS_MEA_KIN_BALL_VEC[2]=-1

N1080 $SCS_MEA_KIN_MODE[0]=6 ;C AXIS AT KIN. CHAIN, RETAIN Z VALUE

N1090 $SCS_MEA_KIN_MODE[1]=6 ;B AXIS AT KIN. CHAIN, RETAIN Z VALUE

N1100 STOPRE

N1110 G54 G17

N1120 CYCLE800(1,"TOOL_CARR_KIN",200000,57,0,0,0,0,0,0,0,0,0,1,100,1)

N1130 G0 X0 Y0 Z20

N1140 CYCLE150(30,10002,"//NC:/MPF.DIR/PROTOCOL_9960.TXT")

N1150 CYCLE9960(11400,"TOOL_CARR_KIN",1,30,0,0,180,3,0,0,0,240,3,0,0.001,2,2,1,1,0,1)

N1160 CYCLE800(1,"0",200000,57,0,0,0,0,0,0,0,0,0,1,100,1)

N1170 CYCLE150(30,10000,"")

N1180 M30

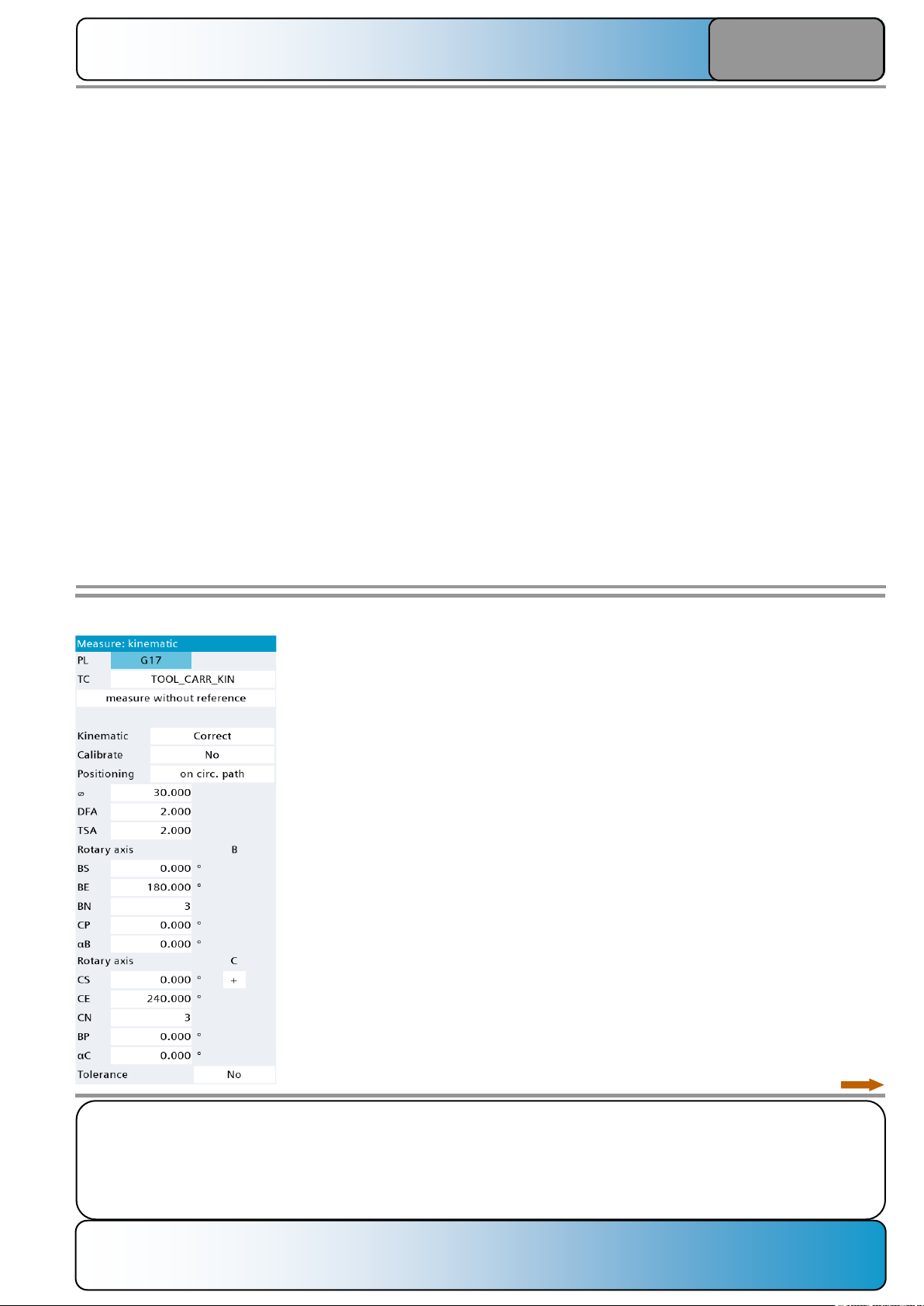

Assignment of the CYCLE9960 input screen:

Image of the protocol file:

***************************************************************

Date : 2019-07-11 Time: 12:22:33

Protocol: //NC:/MPF.DIR/PROTOCOL_9960.TXT

Program : /_N_WKS_DIR/_N_EXAMPLE_5X_M_BC_WPD/_N_KINEMATIK_9960_

DOKU_M_MPF

Machine :

***************************************************************

--------------------------------------------------------------1 : Time: 12:22:33

Results measure: Kinematic measure complete /CYCLE9960

Variant : S_MVAR=11400

Measuring plane: G17

Name / number : TOOL_CARR_KIN / 2

Rotary axis 1 : B start: 0.000 final: 180.000 no.: 3

Position of rotary axis 2 : 0.000

Rotary axis 2 : C start: 0.000 final: 240.000 no.: 3

Position of rotary axis 1 : 0.000

--------------------------------------------------------------Difference of measure: X [mm] Y [mm] Z [mm]

max Value 0.00940 0.00945 0.05073

min Value -0.36203 -0.28886 -0.28886

B [deg] C [deg] X [mm] Y [mm] Z [mm]

0.00000 0.00000 0.00000 0.00000 0.00000

90.00000 0.00000 -0.36203 -0.25174 -0.21111

180.00000 0.00000 -0.00002 -0.28886 0.05073

0.00000 0.00000 0.00000 0.00000 0.00000

0.00000 120.00000 0.00940 -0.01503 -0.28885

0.00000 240.00000 -0.01505 0.00945 -0.28886

Difference of vector before: X [mm] Y [mm] Z [mm]

CORR_SP1_OFFSET 0.00000 0.00000 15.00000

CORR_C_OFFSET 0.00000 0.00000 0.00000

Results:

Difference of vector: X [mm] Y [mm] Z [mm]

CORR_SP1_OFFSET 0.24197 0.16979 15.00000

CORR_C_OFFSET 0.00808 -0.00427 0.00000

Page 24

Notes:

A650 Page 20 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

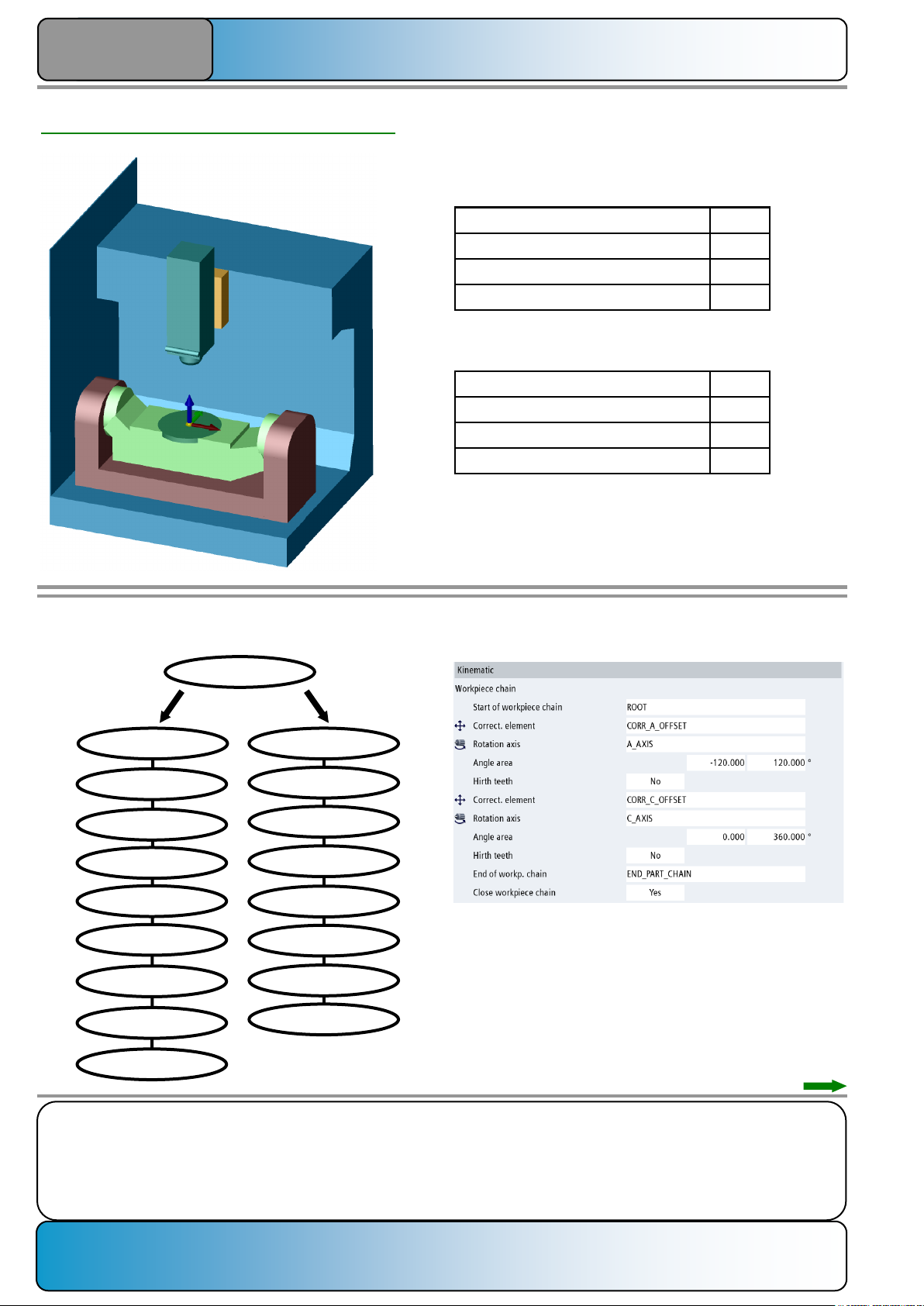

Sample program for a machine with table kinematics:

Name of the rotary axis A

Direction vector of the rotary axis -1, 0, 0

Software limit switch minus MD 36100 -120°

Software limit switch plus MD 36110 120°

Name of the rotary axis C

Direction vector of the rotary axis 0, 0, -1

Software limit switch minus MD 36100 -

Software limit switch plus MD 36110 -

Kinematic chain of

the machine:

Configuration of the "TOOL_CARR_KIN" tool carrier

(kinematically relevant part):

A sample program is created to measure the table

kinematics with a tool carrier based on a kinematic chain.

The machine has the following data:

First rotary axis:

Second rotary axis:

The software limit switches of table axis C are not relevant,

because it is defined as modulo rotary axis.

ROOT

Y_OFFSET

Y_AXIS

X_OFFSET

X_AXIS

Z_OFFSET

Z_AXIS

SP1_OFFSET

SP1_AXIS

END_TOOL_CHAIN

END_PART_CHAIN

TABLE_OFFSET

C_AXIS

CORR_C_OFFSET

C_OFFSET

A_AXIS

CORR_A_OFFSET

A_OFFSET

Page 25

Notes:

SINUMERIK ONE Page 21 A650

Measure kinematics with CYCLE9960

A650

Sample program:

N1000 TRAFOOF

N1010 CYCLE800

N1020 $P_UIFR[1]=CTRANS(X,200,Y,0,Z,150)

N1030 T="3D_PROBE"

N1040 M6

N1050 $SCS_MEA_KIN_BALL_VEC[0]=0

N1060 $SCS_MEA_KIN_BALL_VEC[1]=0

N1070 $SCS_MEA_KIN_BALL_VEC[2]=-1

N1080 $SCS_MEA_KIN_MODE[0]=6 ;C AXIS AT KIN. CHAIN, RETAIN Z VALUE

N1090 $SCS_MEA_KIN_MODE[1]=4 ;A AXIS AT KIN. CHAIN, RETAIN X VALUE

N1100 STOPRE

N1110 G54 G17

N1120 CYCLE800(1,"TOOL_CARR_KIN",200000,57,0,0,0,0,0,0,0,0,0,1,100,1)

N1130 G0 X0 Y0 Z20

N1140 CYCLE150(30,10002,"//NC:/MPF.DIR/PROTOCOL_9960.TXT")

N1150 CYCLE9960(11400,"TOOL_CARR_KIN",1,30,0,-90,0,3,0,0,0,240,3,0,0.001,2,2,1,1,0,1)

N1160 CYCLE800(1,"0",200000,57,0,0,0,0,0,0,0,0,0,1,100,1)

N1170 CYCLE150(30,10000,"")

N1180 M30

Assignment of the CYCLE9960 input screen:

Image of the protocol file:

***************************************************************

Date : 2019-07-10 Time: 14:06:19

Protocol: //NC:/MPF.DIR/PROTOCOL_9960.TXT

Program : /_N_WKS_DIR/_N_KINEMATIK_9960_WPD/_N_KINEMATIK_9960_D

OKU_MPF

Machine :

***************************************************************

--------------------------------------------------------------1 : Time: 14:06:19

Results measure: Kinematic measure complete /CYCLE9960

Variant : S_MVAR=11400

Measuring plane: G17

Name / number : TOOL_CARR_KIN / 2

Rotary axis 1 : A start: -90.000 final: 0.000 no.: 3

Position of rotary axis 2 : 0.000

Rotary axis 2 : C start: 0.000 final: 240.000 no.: 3

Position of rotary axis 1 : 0.000

--------------------------------------------------------------Difference of measure: X [mm] Y [mm] Z [mm]

max Value 0.03119 0.03118 0.00000

min Value -0.02522 -0.02522 -0.29568

A [deg] C [deg] X [mm] Y [mm] Z [mm]

0.00000 0.00000 0.00000 0.00000 0.00000

-90.00000 0.00000 0.00887 0.01775 -0.29568

-45.00000 0.00000 0.00887 0.01775 -0.29568

0.00000 0.00000 0.00000 0.00000 0.00000

0.00000 120.00000 0.03119 -0.02522 -0.29567

0.00000 240.00000 -0.02522 0.03118 -0.29568

Difference of vector before: X [mm] Y [mm] Z [mm]

CORR_A_OFFSET 0.00000 0.00000 0.00000

CORR_C_OFFSET 0.00000 0.00000 0.00000

Results:

Difference of vector: X [mm] Y [mm] Z [mm]

CORR_A_OFFSET 0.00000 -0.51895 0.50309

CORR_C_OFFSET 0.01534 0.49967 0.00000

Page 26

Notes:

A650 Page 22 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

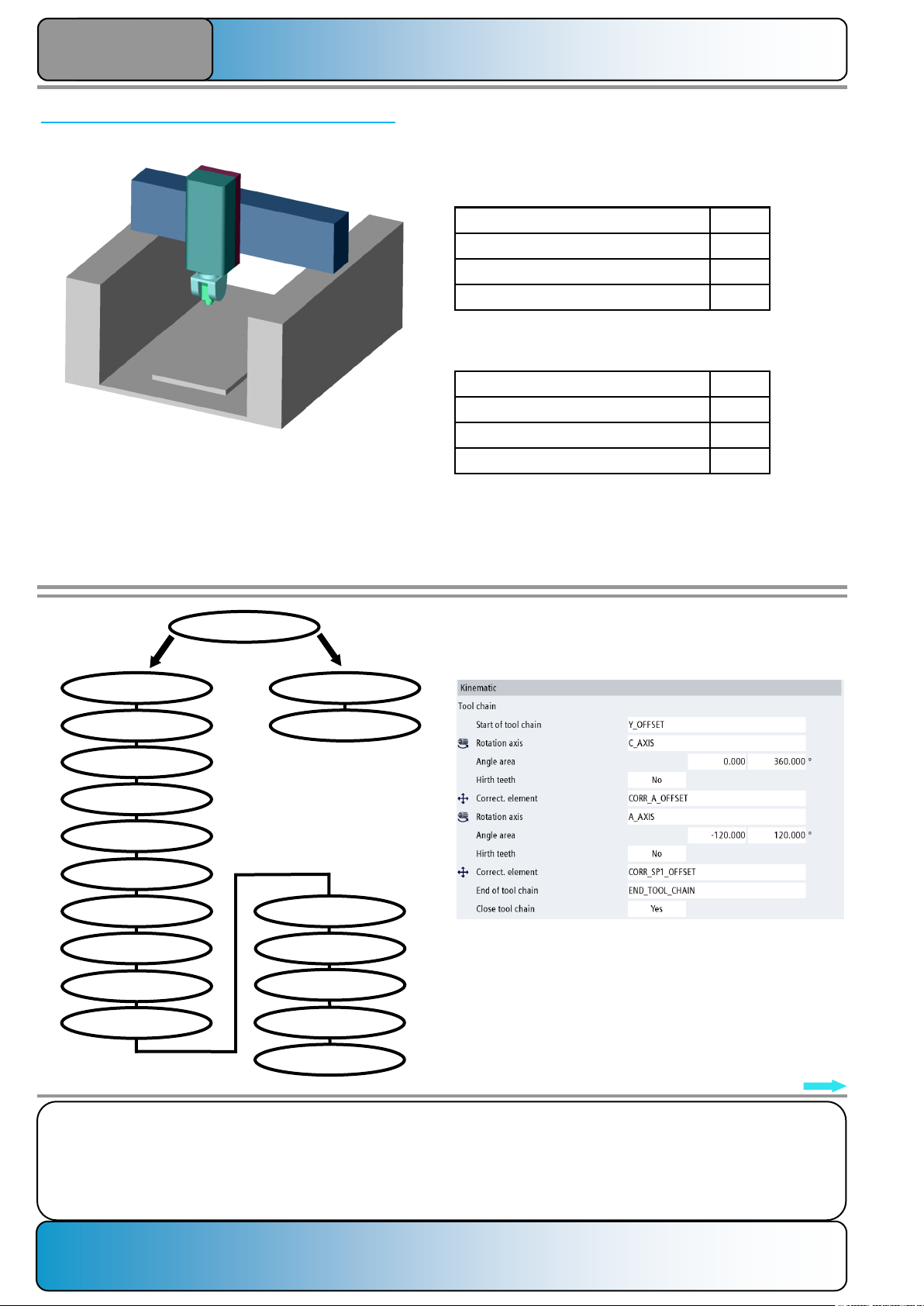

Sample program for a machine with head kinematics:

Name of the rotary axis C

Direction vector of the rotary axis 0, 0, 1

Software limit switch minus MD 36100 -1°

Software limit switch plus MD 36110 360°

Name of the rotary axis A

Direction vector of the rotary axis 1, 0, 0

Software limit switch minus MD 36100 -100°

Software limit switch plus MD 36110 100°

Kinematic chain

of the machine:

Configuration of the "TOOL_CARR_KIN" tool carrier

(kinematically relevant part):

A sample program is created to measure the head

kinematics with a tool carrier based on a kinematic chain.

The machine has the following data:

First rotary axis:

Second rotary axis:

ROOT

Y_OFFSET

CORR_SP1_OFFSET

Y_AXIS

X_OFFSET

X_AXIS

Z_OFFSET

Z_AXIS

SP1_OFFSET

SP1_AXIS

A_OFFSET

CORR_A_OFFSET

C_OFFSET A_AXIS

C_AXIS

TABLE_OFFSET

END_PART_CHAIN

END_TOOL_CHAIN

Page 27

Notes:

SINUMERIK ONE Page 23 A650

Measure kinematics with CYCLE9960

A650

Sample program:

N1000 TRAFOOF

N1010 CYCLE800

N1020 $P_UIFR[1]=CTRANS(X,200,Y,0,Z,250)

N1030 T="3D_PROBE"

N1040 M6

N1050 $SCS_MEA_KIN_BALL_VEC[0]=0

N1060 $SCS_MEA_KIN_BALL_VEC[1]=0

N1070 $SCS_MEA_KIN_BALL_VEC[2]=-1

N1080 $SCS_MEA_KIN_MODE[0]=6 ;DISTANCE C-A AXIS AT KIN. CHAIN

N1090 $SCS_MEA_KIN_MODE[1]=4 ;DISTANCE A-SP1 AT KIN. CHAIN

;BEI C-A: RETAIN Z VALUE

;BEI A-SP1: RETAIN X VALUE

N1100 STOPRE

N1110 G54 G17

N1120 CYCLE150(30,10002,"//NC:/MPF.DIR/PROTOCOL_9960.TXT")

N1130 CYCLE800(1,"TOOL_CARR_KIN",200000,57,0,0,0,0,0,0,0,0,0,1,100,1)

N1140 G0 X0 Y0 Z20

N1150 CYCLE9960(11400,"TOOL_CARR_KIN",1,30,0,0,240,3,90,0,-90,90,3,0,0.001,2,2,1,1,0,1)

N1160 CYCLE800(1,"0",200000,57,0,0,0,0,0,0,0,0,0,1,100,1)

N1170 CYCLE150(30,10000,"")

N1180 M30

Assignment of the CYCLE9960 input screen:

Image of the protocol file:

***************************************************************

Date : 2019-07-10 Time: 16:45:38

Protocol: //NC:/MPF.DIR/PROTOCOL_9960.TXT

Program : /_N_WKS_DIR/_N_EXAMPLE_5X_T_AC_WPD/_N_KINEMATIK_9960_

DOKU_T_MPF

Machine :

***************************************************************

--------------------------------------------------------------1 : Time: 16:45:38

Results measure: Kinematic measure complete /CYCLE9960

Variant : S_MVAR=11400

Measuring plane: G17

Name / number : TOOL_CARR_KIN / 2

Rotary axis 1 : C start: 0.000 final: 240.000 no.: 3

Position of rotary axis 2 : 90.000

Rotary axis 2 : A start: -90.000 final: 90.000 no.: 3

Position of rotary axis 1 : 0.000

---------------------------------------------------------------

Difference of measure: X [mm] Y [mm] Z [mm]

max Value 0.93802 0.58650 0.10699

min Value -0.79923 -0.58230 -0.14093

C [deg] A [deg] X [mm] Y [mm] Z [mm]

0.00000 90.00000 -0.02830 0.58650 0.07917

120.00000 90.00000 -0.79923 -0.58230 0.06834

240.00000 90.00000 0.93802 -0.34191 -0.14093

0.00000 0.00000 0.00000 0.00000 0.00000

0.00000 -90.00000 0.00049 -0.45370 0.10699

0.00000 90.00000 -0.02832 0.58650 0.07916

Difference of vector before: X [mm] Y [mm] Z [mm]

CORR_A_OFFSET 0.00000 0.00000 0.00000

CORR_SP1_OFFSET 0.00000 0.00000 0.00000

Results:

Difference of vector: X [mm] Y [mm] Z [mm]

CORR_A_OFFSET -0.01408 0.33105 0.00000

CORR_SP1_OFFSET 0.00000 -0.06642 -0.52038

Page 28

Notes:

A650 Page 24 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

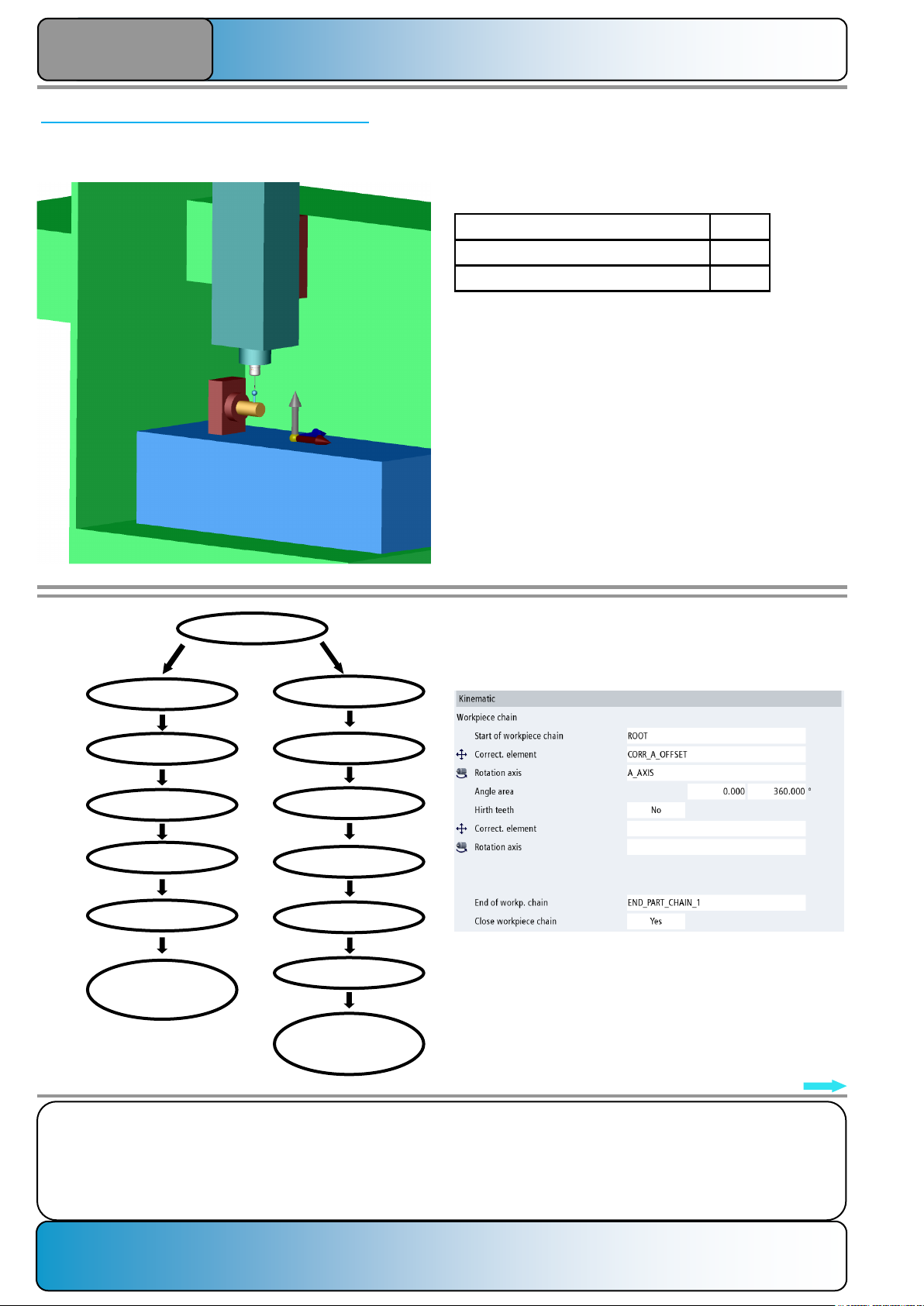

Second rotary axis:

Not installed

ROOT

Y_OFFSET

CORR_A_OFFSET

Y_AXIS

X_OFFSET

X_AXIS

Z_OFFSET

Z_AXIS

SP1_OFFSET

SP1_AXIS

A_OFFSET

A_AXIS

END_

PART_CHAIN

END_

TOOL_CHAIN

Note:

Because of the collision data of the A-Axis there should be

not correction of the X-Offset in the element A_CORR.

$SCS_MEA_KIN_MODE[0]=4

With this setup the value of the X-Offset will be kept after

the measuring is finished.

Configuration of the "TOOL_CARR_KIN" tool carrier

(kinematically relevant part):

Kinematic chain

of the machine:

Sample program for a machine with dividing unit:

Name of the rotary axis A

Direction vector of the rotary axis -1, 0, 0

$MA_ROT_IS_MODULO[A] 1

A sample program is created to measure the table

kinematics with only one rotary axis with a tool carrier based

on a kinematic chain.

The machine has the following data:

First rotary axis:

Page 29

Notes:

SINUMERIK ONE Page 25 A650

Measure kinematics with CYCLE9960

A650

N1000 CYCLE800

N1010 TRAFOOF

N1040 $P_UIFR[1]=CTRANS(X,-200,Y,0,Z,230)

N1050 G54

N1060 T="3D_PROBE"

N1070 M6

N1080 D1

N1090 G17 G54 G90

N1100 $SCS_MEA_KIN_BALL_VEC[0]=0

N1110 $SCS_MEA_KIN_BALL_VEC[1]=0

N1120 $SCS_MEA_KIN_BALL_VEC[2]=-1

N1130 $SCS_MEA_KIN_MODE[0]=4

N1140 $SCS_MEA_FEED_POS_DEG=5000

N1150 CYCLE800(1,"TOOL_CARR_KIN",200000,57,0,0,0,0,0,0,0,0,0,1,100,101)

N1160 G0 Z300

N1170 G0 X0 Y0

N1180 G0 Z20

N1190 CYCLE150(30,10001,"//NC:/MPF.DIR/PROTOCOL_9960.TXT")

N1200 CYCLE9960(11400,"TOOL_CARR_KIN",1,30,0,-90,90,6,0,0,0,0,3,0,0.1,3,2,1,1,10,1)

N1210 CYCLE150(30,10000,"")

N1220 CYCLE800

N1230 M30

***************************************************************

Date : 2021-03-04 Time: 18:17:05

Protocol: //NC:/MPF.DIR/PROTOCOL_9960.TXT

Program : /_N_WKS_DIR/_N_VERMESSEN_9960_WPD/_N_VERMESSEN_9960_M

PF

Machine :

***************************************************************

--------------------------------------------------------------1 : Time: 17:17:05

Results measure: Kinematic measure complete /CYCLE9960

Variant : S_MVAR=11400

Measuring plane: G17

Name / number : TOOL_CARR_KIN / 1

Rotary axis A: start: -90.000 final: 90.000 no.: 3

--------------------------------------------------------------Difference of measure: X [mm] Y [mm] Z [mm]

max Value 0.00000 0.03398 0.00000

min Value -0.00368 0.00000 -0.29567

A [deg] -- [deg] X [mm] Y [mm] Z [mm]

0.00000 0.00000 0.00000 0.00000 0.00000

270.00000 0.00000 -0.00105 0.03140 -0.29567

90.00000 0.00000 -0.00368 0.03398 -0.29567

Results:

Difference of vector: X [mm] Y [mm] Z [mm]

A_CORR 0.00000 -0.03266 -0.44553

Assignment of the CYCLE9960 input screen:

Image of the protocol file:

Sample program:

Page 30

Notes:

A650 Page 26 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

Term definition: ideal and real vector

An ideal vector always corresponds to the details on the

technical drawing or the CAD data model, namely the ideal

status. In practice, manufacturing tolerances that result from

physical effects, such as temperature and bending, cause

deviations from this ideal status. The actual status, such as

the exact spin axis where a machine component turns, is

designated as real vector and must be determined with an

appropriate measuring procedure.

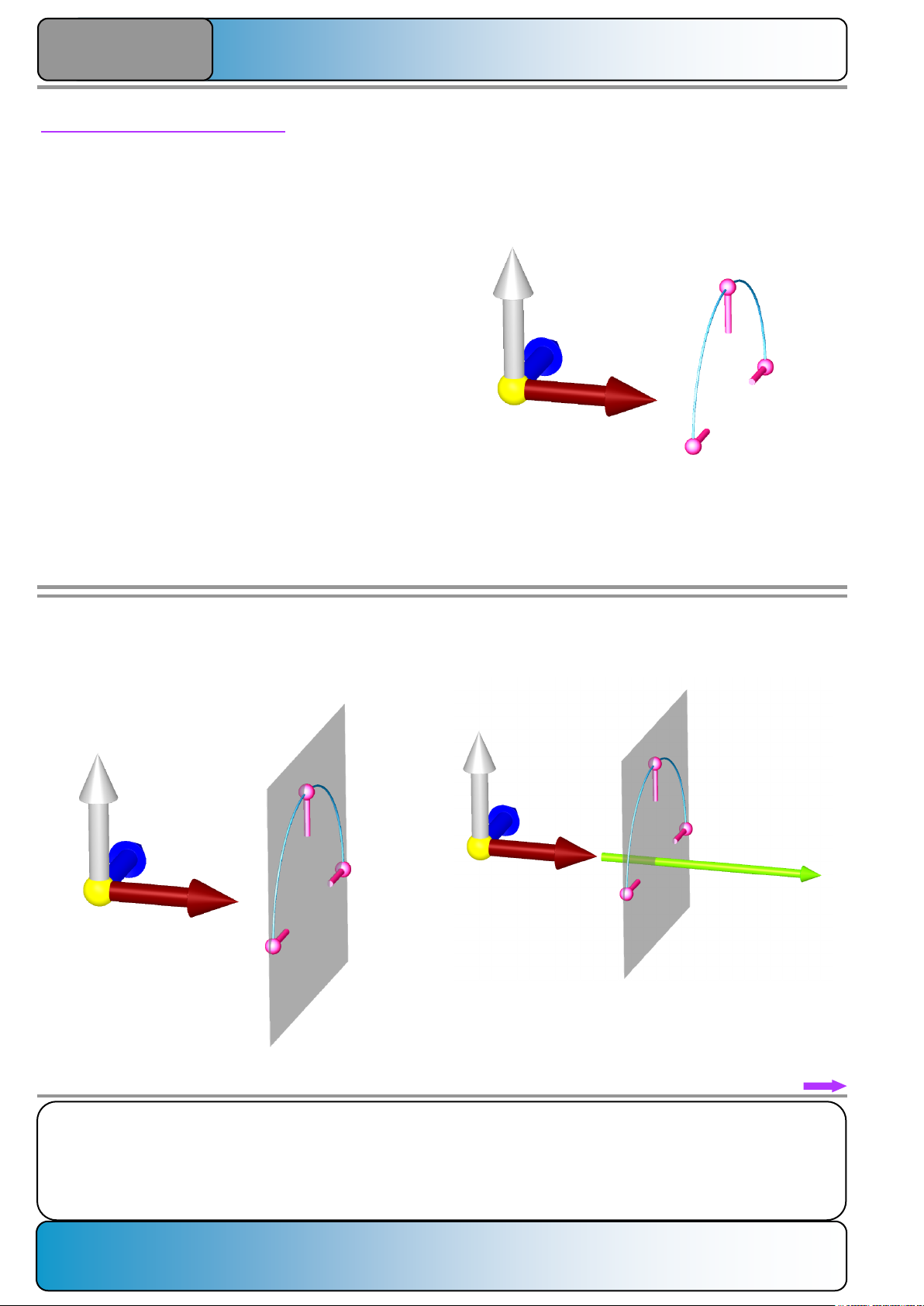

The direction vector of a rotary axis is calculated in 3 steps:

Step 1:

Measurement of the axis (here, an A axis in the table with 3

measurement points).

Step 2:

Calculation of a plane through the three measurement points.

Step 3:

Calculation of a vector perpendicular to this plane.

Because this calculated vector describes the actual path of

the rotary axis, it is a "real" vector.

In addition to an X component, this vector also has a Y

component and a Z component.

Page 31

Notes:

SINUMERIK ONE Page 27 A650

Measure kinematics with CYCLE9960

A650

In practice, a spin axis from the table of a machine that turns

at the X axis of the machine (A axis) does not run exactly

parallel to the X axis of the MCS.

The deviation is apparent in the top view (shown

exaggerated):

X

Y

Real rotary axis vector

of the A axis

The vector has not only an "X component", but also a major

"Y component". Ideally, the misalignment should be

compensated with a mechanical correction of the bearing

positions.

If a workpiece is clamped, it can be aligned with the "Measure

2 points with correction of the rotary axis" measuring cycle.

The edges of the workpiece then lie parallel to the MCS:

X

Y

Workpiece

C axis

Z

Z

If the A axis is turned by 90°, the actual position of the workpiece relative to the machine coordinate system can be

determined easily:

X

Y

Z

Machining with reversal (e.g. a spindled drill hole from two

sides) at the upper edge of the workpiece would cause an

offset of both cylinders.

The Y and Z components can be measured only after the

machine has been assembled so that a statement concerning

the angularity of the machine geometry can be made.

Example for a measured real vector:

A=(-0.9999999994 , 0.000025383 , 0.000023745)

Consequently, the rotary axis vector is specified as ideal

vector during the commissioning (and normally also in the

subsequent operation):

A=(-1,0,0)

To evaluate the quality of the machine, the assumption can

be made: the measured real vector is multiplied by the factor

1000:

A=(-999.9999994 , 0.025383 , 0.023745)

This means: when travel is made along the rotary axis vector,

the deviation is Y = 0.025 mm and Z = 0.023 mm for an X

path of –999.999 mm.

Travel is so obviously in the measureable area.

Recommendation: Ensure that the components of both

"subdirections" are set to non-zero values only in the fifth decimal place after the decimal point. For larger values, a mechanical correction of the axis should be considered.

Page 32

Notes:

A650 Page 28 SINUMERIK ONE

Measure kinematics with CYCLE9960

A650

To illustrate the relation:

Vector (-0.999,-0.046,0) means:

For a length of –0.999 mm in X, the deviation in

Y is –0.046 mm.

For a length of –99.9 mm in X, the deviation in

Y is already -4.6 mm!

Note:

The use of real vectors, in conjunction with orientation

transformations (CYCLE800, TRAORI), sometimes leads to

changed axis positions compared with kinematics with purely

ideal vectors. There may be a risk of collision.

Consequently, the real vectors are not written for CYCLE9960.

If necessary, they can be activated from the log file.

When the "VCS-ECO" function is used, the real vectors can

be written to a file that can then be used for VCS together with

a classic defined tool carrier.

Initial situation 2:

A real vector of the A axis (-0.999,-0.046,0) is entered in the

machine constants.

If the WCS is turned by 90° at the X axis, in addition to the

movement of the A axis, the C axis also moves. This means

the side surface of the workpiece is parallel to the X axis of

the machine.

X

Z

Because the C axis must compensate for the distortion, it is

no longer at position 0° in the WCS.

Initial situation 1:

An ideal vector of the A axis (-1,0,0) is entered in the machine

constants.

If the WCS is turned by 90° at the X axis, the A axis is forced

to move at the real spin axis. Whereby, the C axis is not

moved; this means the side surface of the workpiece is no

longer parallel to the X axis of the machine.

X

Z

In this machining situation, the A axis is defined as ideal

vector (-1,0,0) in the machine data.

Offset in X

Page 33

Notes:

SINUMERIK ONE Page 29 A650

Measure kinematics with CYCLE9960

A650

Term definition: Offset vector and direction vector

To describe a straight line running in space, two details are

required:

1. Direction of the straight line based on the machine

coordinate system (direction vector).

A direction vector specifies the movement direction of linear

axes or the path of the rotation axis for rotary axes.

2. Distance of the machine coordinate system to any point on

the direction vector (= offset vector).

These two details allow any point that lies on the straight line

to be described precisely.

In conjunction with the kinematic description of a machine for

SINUMERIK 840D, the letter "V" represents rotary axis

vectors or direction vectors, whereas the letter "I" represents

offset vectors.

Both vectors are described by individual components in X, Y

and Z in the valid machine coordinate system.

X

Y

Z

Offset vector

Direction vector

MCS

Term definition: Normalized vector

A "normalized vector" is considered to be a vector whose

length has the value "1". The unit of measurement is

interpreted by the NC in the valid unit of measurement

system.

The offset vector of the 45° B head is used as example for

performing a calculation:

I=(5.691, 100, 80.025)

The total length of a vector can be calculated as follows:

( ) ( ) ( )

222

ZYx

IIIL ++=

The values used by the example vector give:

( ) ( ) ( )

222

025.80100691.5 ++=L

The total length (or the magnitude) of the vector is calculated

as:

204.128=L

The vector should have a length of 1 mm, but is currently

128.204 mm long.

The individual components of the vector must be divided by

this total length:

04439.0

204.128

691.5

==

X

I

78000.0

204.128

100

==

Y

I

As check, these values can be used again in the formula.

( ) ( ) ( )

222

ZYx

IIIL ++=

The formula must supply the result value "1".

The vector is so "normalized".

The accuracy of the calculations performed with the vector

also depends on the number of decimal places after the

decimal point; a specification with 5-6 places after the

decimal point is recommended.

62420.0

204.128

025.80

==

Z

I

A650: END

Page 34

Measure kinematics with CYCLE9960

A650 END

A650 Page 30 SINUMERIK ONE

Notes:

Loading...

Loading...