Page 1

A65R Refresh HIT 6E

Level 2.5e

Repair Documentation

Version Date Department Notes to change

V 1.00 01.08.2005 ICM MP CCQ GRM T New document

Service Repair Documentation

Level 2.5e – A65R

V 1.00

Page 1 of 47

Release 1.0

Page 2

Table of Contents:

1 List of available level 2,5e parts A65R 3

2 Required Equipment for Level 2,5e 5

3 Required Software for Level 2,5e A65R 5

4 Radio Part 6

4.1 BLOCK DIAGRAM RF PART 7

4.2 POWER SUPPLY RF-PART 7

4.3 FREQUENCY GENERATION 8

4.4 RECEIVER 11

4.5 TRANSMITTER 12

4.6 BRIGHT IC OVERVIEW 13

4.7 ANTENNA SWITCH (ELECTRICAL/MECHANICAL) 15

4.8 TRANSMITTER: POWER AMPLIFIER 17

5 Logic / Control 18

5.1 OVERVIEW OF HARDWARE STRUCTURE 18

5.2 EGOLD+ 19

6 Power Supply 23

6.1 POWER SUPPLY ASIC 23

6.2 BATTERY 33

6.3 CHARGING CONCEPT 34

7 Interfaces 38

7.1 VIBRA 38

7.2 EARPIECE 38

7.3 MICROPHONE 39

7.4 BATTERY 39

7.5 IO CONNECTOR WITH ESD PROTECTION 40

7.6 SIM 42

7.7 DISPLAY 42

8 Acoustic 43

8.1 MICROPHONE 43

8.2 EARPIECE/LOUDSPEAKER 44

9 Display and Illumination 45

9.1 DISPLAY 45

9.2 ILLUMINATION 46

10 Keyboard 47

Page 2 of 47

Service Repair Documentation

Level 2.5e – A65R

Release 1.0

Page 3

1 List of available level 2,5e parts A65R

Product RF Chipset ID Order Number Description CM

A65 HIT 6E C803 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT 6E C809 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT 6E C830 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT 6E C961 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT 6E C965 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT 6E D361 L50645-J4682-Y47 IC ASIC PMU 55-GENERATION

A65 HIT 6E D902 L50645-K280-Y303 IC FEM HITACHI GSM900 1800 1900 (Fem-Type5)

A65 HIT 6E D903 L50620-L6156-D670 IC TRANCEIVER HD155165BP

A65 HIT 6E N901 L50651-Z2002-A82 IC MODUL PA PF0814 (PA-Type2)

A65 HIT 6E R214 L36852-C-X RESISTOR 0R0 (Res-Type8)

A65 HIT 6E R215 L36852-C-X RESISTOR 0R0 (Res-Type8)

A65 HIT 6E R805 L36852-C-X RESISTOR 0R0 (Res-Type8)

A65 HIT 6E R902 L36852-C-X RESISTOR 0R0 (Res-Type8)

A65 HIT 6E R910 L36852-C-X RESISTOR 0R0 (Res-Type8)

A65 HIT 6E R958 L36852-C-X RESISTOR 0R0 (Res-Type8)

A65 HIT VE + 6E C165 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C200 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C201 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C202 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C207 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C209 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C220 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C283 L36377-F6105-K CAPACITOR 1U (Cap-Type6)

A65 HIT VE + 6E C284 L36377-F6105-K CAPACITOR 1U (Cap-Type6)

A65 HIT VE + 6E C285 L36377-F6105-K CAPACITOR 1U (Cap-Type6)

A65 HIT VE + 6E C286 L36377-F6105-K CAPACITOR 1U (Cap-Type6)

A65 HIT VE + 6E C287 L36377-F6225-M CAPACITOR 2U2 (Cap-Type4)

A65 HIT VE + 6E C288 L36377-F6225-M CAPACITOR 2U2 (Cap-Type4)

A65 HIT VE + 6E C289 L36377-F6225-M CAPACITOR 2U2 (Cap-Type4)

A65 HIT VE + 6E C362 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C363 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C364 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C365 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C366 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C367 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C369 L36377-F6225-M CAPACITOR 2U2 (Cap-Type4)

A65 HIT VE + 6E C370 L36377-F6225-M CAPACITOR 2U2 (Cap-Type4)

A65 HIT VE + 6E C371 L36377-F6225-M CAPACITOR 2U2 (Cap-Type4)

A65 HIT VE + 6E C372 L36377-F6105-K CAPACITOR 1U (Cap-Type6)

A65 HIT VE + 6E C373 L36377-F6225-M CAPACITOR 2U2 (Cap-Type4)

Service Repair Documentation

Level 2.5e – A65R

Page 3 of 47

Release 1.0

Page 4

A65 HIT VE + 6E C374 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C377 L36377-F6225-M CAPACITOR 2U2 (Cap-Type4)

A65 HIT VE + 6E C381 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C382 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C383 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C384 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C385 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C386 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C395 L36392-F1107-M CAPACITOR 100U (Cap-Type8)

A65 HIT VE + 6E C820 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C821 L36853-C9104-M4 CAPACITOR 100N (Cap-Type2)

A65 HIT VE + 6E C916 L36377-F6225-M CAPACITOR 2U2 (Cap-Type4)

A65 HIT VE + 6E D171 L36197-F5019-F415 IC EGOLD+ PMB7850 V3.1F M42

A65 HIT VE + 6E N280 L36810-C6098-D670 IC V-REG LM2794BLX (Vr-Type4)

A65 HIT VE + 6E R141 L36852-C-X RESISTOR 0R0 (Res-Type8)

A65 HIT VE + 6E R294 L36852-C-X RESISTOR 0R0 (Res-Type8)

A65 HIT VE + 6E R955 L36120-F422 3-H RESISTOR TEMP 22K (Res-Type7)

A65 HIT VE + 6E V151 L36840-D5062-D670 DIODE RB751S (Di-Type3)

A65 HIT VE + 6E V191 L36197-F5014-F98 DIODE SOT323 (Di-Type1)

A65 HIT VE + 6E V211 L36830-C1097-D670 TRANSISTOR FDG313N (Tra-Type1)

A65 HIT VE + 6E V220 L36851-Z9105-Z981 DIODE 1SS355 (Di-Type6)

A65 HIT VE + 6E V222 L36830-C1112-D670 TRANSISTOR SI1902 (Tra-Type4)

A65 HIT VE + 6E V361 L36830-C1110-D670 TRANSISTOR SI3911 (Tra-Type3)

A65 HIT VE + 6E Z171 L36 145-F102-Y10 QUARZ 32,768KHZ (Q-Type1)

A65 HIT VE + 6E Z211 L36 197-F5000-F116 FILTER EMI (Fi-Type2)

A65 HIT VE + 6E Z950 L36 145-F260-Y17 QUARZ 26MHZ (Q-Type4)

Service Repair Documentation

Level 2.5e – A65R

Page 4 of 47

Release 1.0

Page 5

2 Required Equipment for Level 2,5e

- GSM-Tester (CMU200 or 4400S incl. Options)

- PC-incl. Monitor, Keyboard and Mouse

- Bootadapter 2000/2002 (L36880-N9241-A200)

- Adapter cable for Bootadapter due to new Lumberg connector (F30032-P226-A1)

- Troubleshooting Frame A65 (F30032-Pxxx-A1)

- Power Supply NGMO1/NGMO2

- Spectrum Analyser

- Active RF-Probe incl. Power Supply

- Oscilloscope incl. Probe

- RF-Connector (N<>SMA(f))

- Power Supply Cables

- Dongle (F30032-P28-A1)

- BGA Soldering equipment

Reference: Equipment recommendation V1.6

(downloadable from the technical support page)

3 Required Software for Level 2,5e A65R

- Windows XP

- X-Focus version XX or higher

- GRT Version 3 or higher

- Internet unblocking solution (JPICS)

Service Repair Documentation

Level 2.5e – A65R

Page 5 of 47

Release 1.0

Page 6

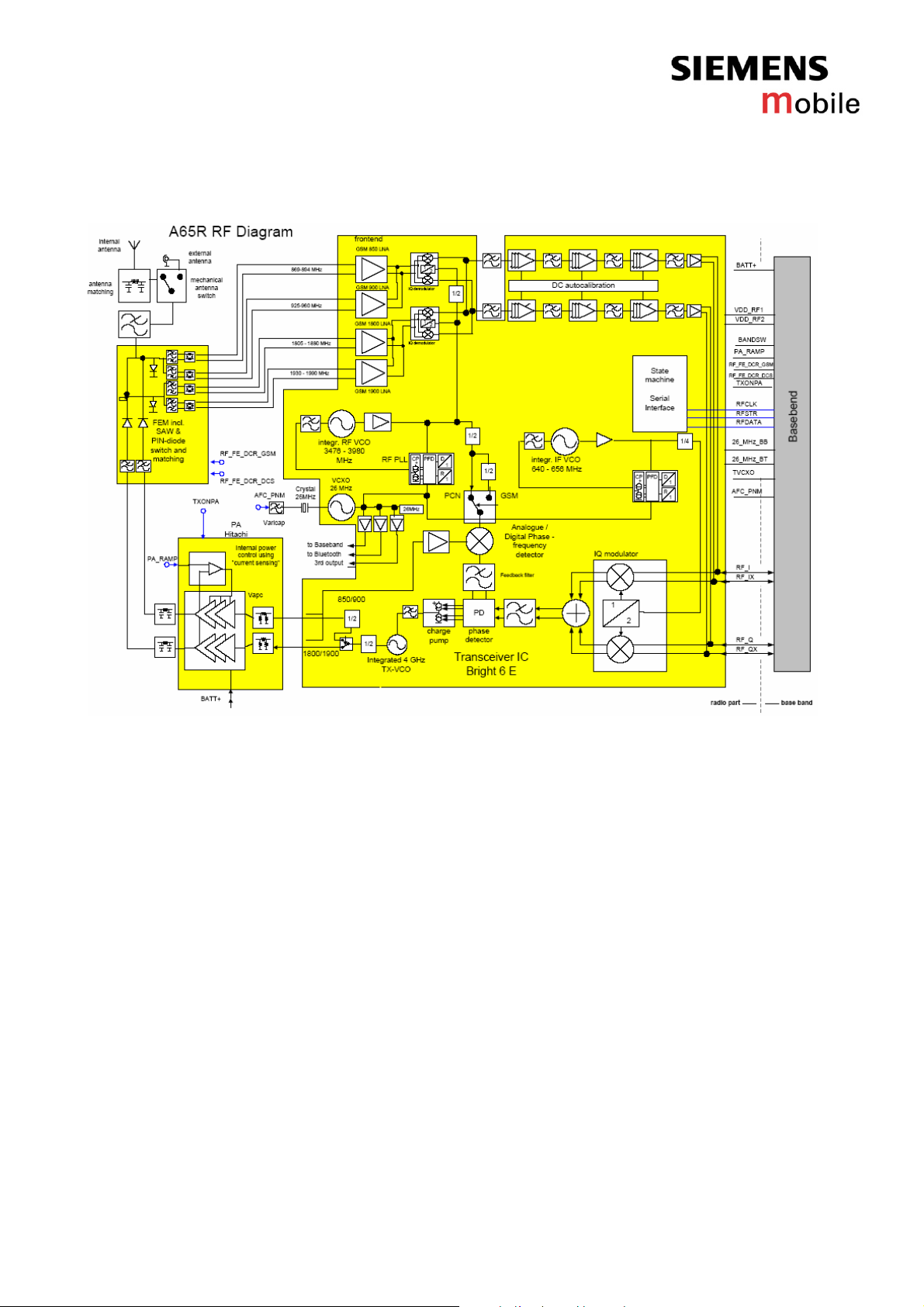

4 Radio Part

The radio part is realizes the conversion of the GMSK-HF-signals from the antenna to the

baseband and vice versa.

In the receiving direction, the signals are split in the I- and Q-component and led to the D/Aconverter of the logic part. In the transmission direction, the GMSK-signal is generated in an

Up Conversion Modulation Phase Locked Loop by modulation of the I- and Q-signals which

were generated in the logic part. After that the signals are amplified in the power amplifier.

Transmitter and Receiver are never active at the same time. Simultaneous receiving in the

EGSM900 and GSM1800 band is impossible. Simultaneous transmission in the EGSM900

and GSM1800 band is impossible, too. However the monitoring band (monitoring timeslot) in

the TDMA-frame can be chosen independently of the receiving respectively the transmitting

band (RX- and TX timeslot of the band).

The RF-part is dimensioned for triple band operation (EGSM900, DCS1800, PCS19000)

supporting GPRS functionality up to multiclass 10.

The RF-circuit consists of the following components:

• Hitachi Bright 6E chip set (HD155165BP) with the following functionality:

o PLL for local oscillator LO1 and LO2 and TxVCO

o Integrated local oscillators LO1, LO2

o Integrated TxVCO

o Direct conversion receiver including LNA, DC-mixer, channel filtering and

PGC-amplifier

o 26 MHz reference oscillator

• Transmitter power amplifier with integrated power control circuitry

• Frontend-Module including RX-/TX-switch and EGSM900 / DCS1800 / PCS 1900

receiver SAW-filters

• Quartz and passive circuitry of the 26MHz VCXO reference oscillator

Service Repair Documentation

Level 2.5e – A65R

Page 6 of 47

Release 1.0

Page 7

4.1 Block diagram RF part

4.2 Power Supply RF-Part

The voltage regulator for the RF-part is located inside the ASIC D361. It generates the

required 2,8V “RF-Voltages” named VCC_2.8V and VCC_SYN. VCC_2.8V is passed via a

0Ω resistor and renamed as VDD_BRIGHT as operating voltage for the BRIGHT The voltage

regulator is activated as well as deactivated via VCXOEN_UC

EGOLD+. The temporary deactivation is used to extend the stand by time.

Page 7 of 47

Service Repair Documentation

Level 2.5e – A65R

(Miscellaneous R6) provided by the

Release 1.0

Page 8

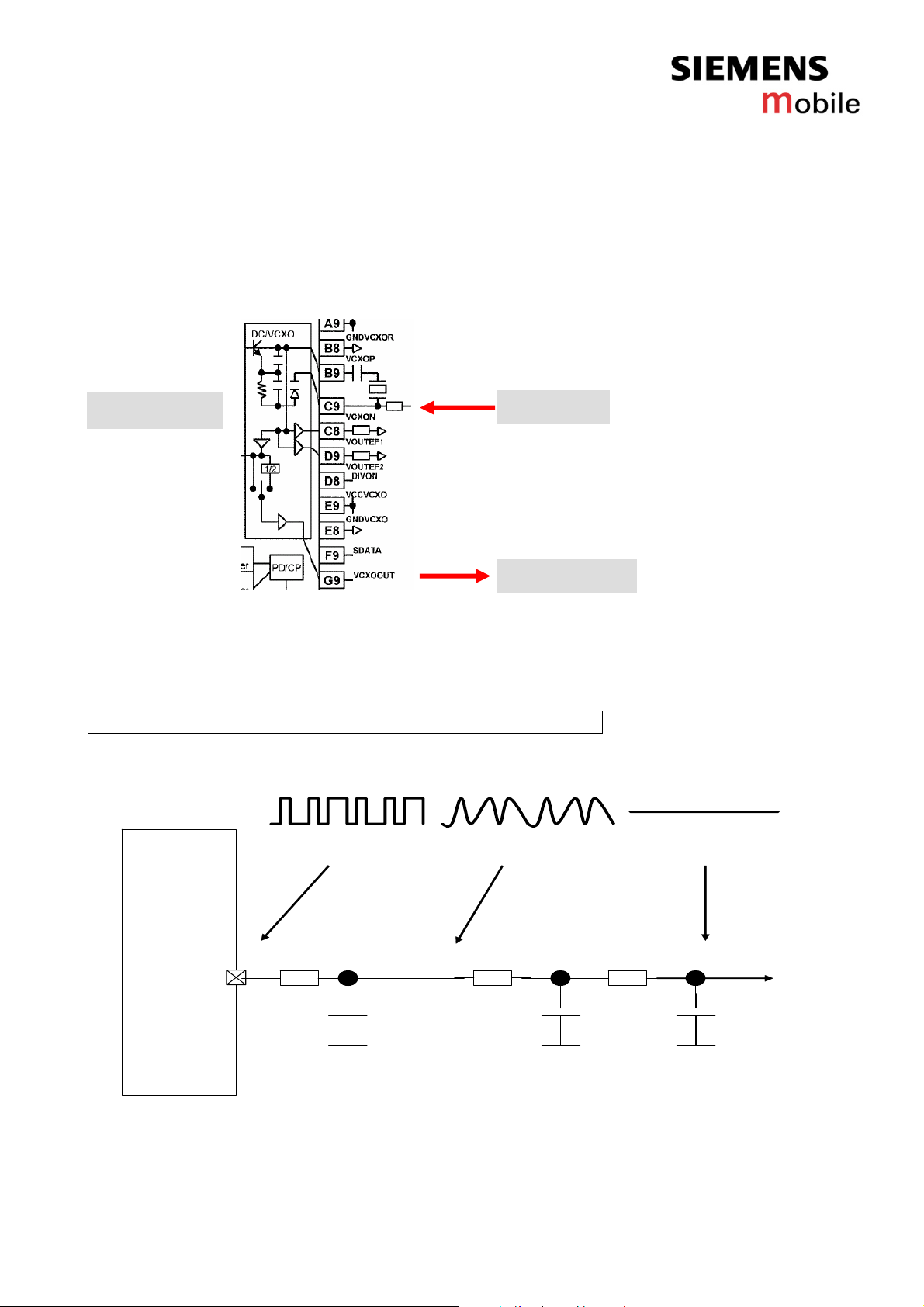

4.3 Frequency generation

The A65R mobile is using a reference frequency of 26MHz. The generation of the 26MHz

signal is done via a VCO (Z950). TP (test point) of the 26MHz signal is the TP 820

The oscillator output signal 26MHz_RF is directly connected to the BRIGHT IC

used as reference frequency inside the Bright (PLL). The signal leaves the Bright IC as

BB_SIN26M

Bright 6E

(ball G9) to be further used from the EGOLD+ (D171 (Functional T3)).

VCXO Out

SGOLDlite In

To compensate frequency drifts (e.g. caused by temperature) the oscillator frequency is

controlled by the (AFC) signal, generated through the internal EGOLD+ (D171

PLL. Reference for the “EGOLD-PLL” is the base station frequency received via the

Frequency Correction Burst.

The required voltage VCC_2.8V is provided by the ASCI D361

Waveform of the AFC_PNM signal from EGOLD+ to Oscillator

Signalform

(ball B9) to be

(Functional U5))

SGOL Dlite

RF_AFC

1

R1

C1

Service Repair Documentation

Level 2.5e – A65R

1 2 3

AFC_PNM

GND

2

R2

C2

GND

R3

3

C3

GND

Page 8 of 47

Release 1.0

Page 9

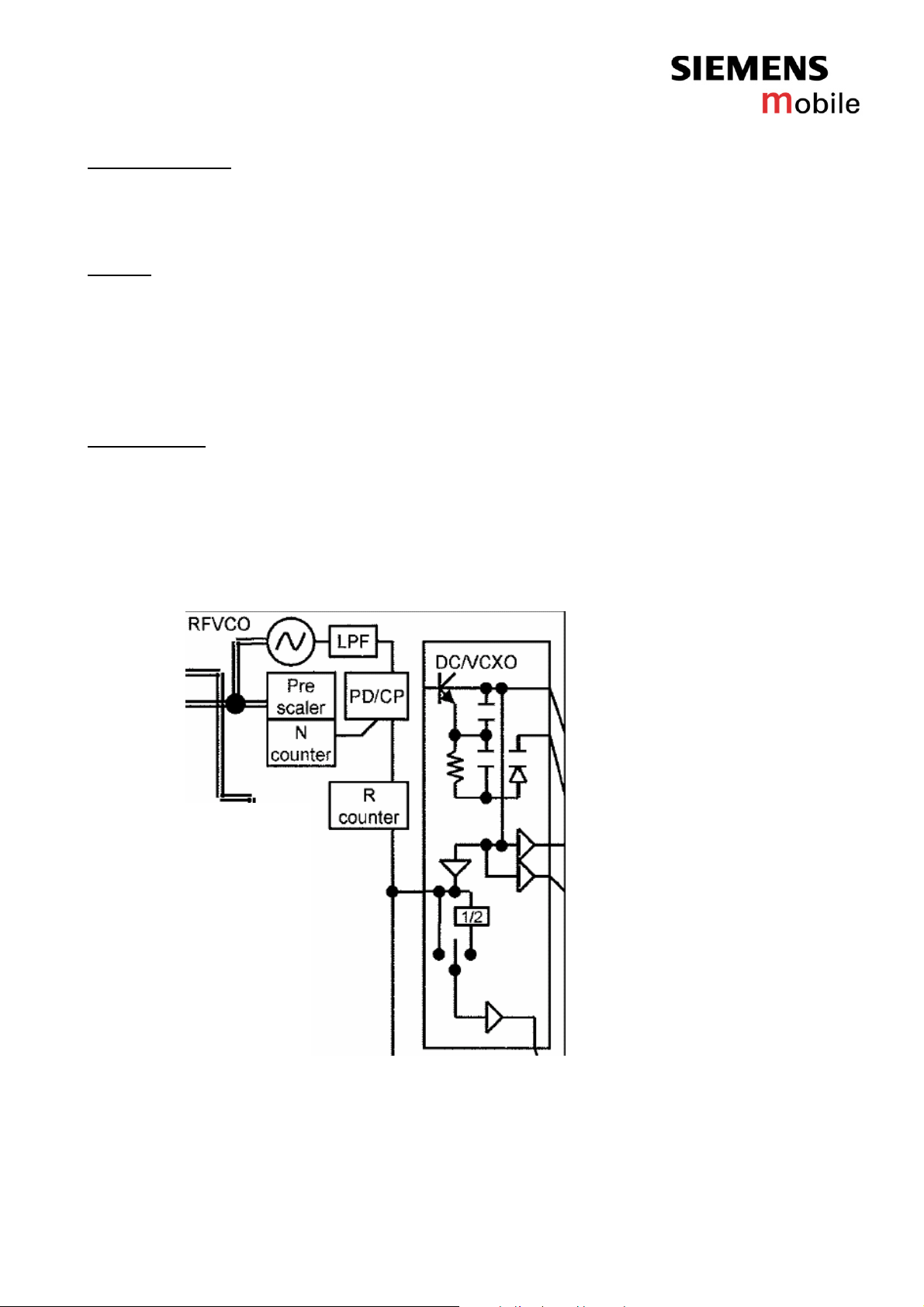

Synthesizer: LO1

First local oscillator (LO1) consists of a PLL and VCO inside Bright (D903) and an internal

loop filter

RF PLL

The frequency-step is 400 kHz in GSM1800 mode and 800kHz in EGSM900 mode due to the

internal divider by two for GSM1800 and divider by four for EGSM900. To achieve the

required settling-time in GPRS operation, the PLL can operate in fastlock-mode a certain

period after programming to ensure a fast settling. After this the loopfilter and currents are

switched into normal-mode to get the necessary phasenoise-performance. The PLL is

controlled via the tree-wire-bus of Bright VI E.

RFVCO (LO1)

The first local oscillator is needed to generate frequencies which enable the transceiver IC to

demodulate the receiver signal and to perform the channel selection in the TX part. The VCO

module is switched on with the signal PLLON. The full oscillation range is divided into 256

sub-bands To do so, a control voltage for the LO1 is used, gained by a comparator. This

control voltage is a result of the comparison of the divided LO1 and the 26MHz reference

Signal. The division ratio of the dividers is programmed by the EGOLD+, according to the

network channel requirements.

Service Repair Documentation

Level 2.5e – A65R

Page 9 of 47

Release 1.0

Page 10

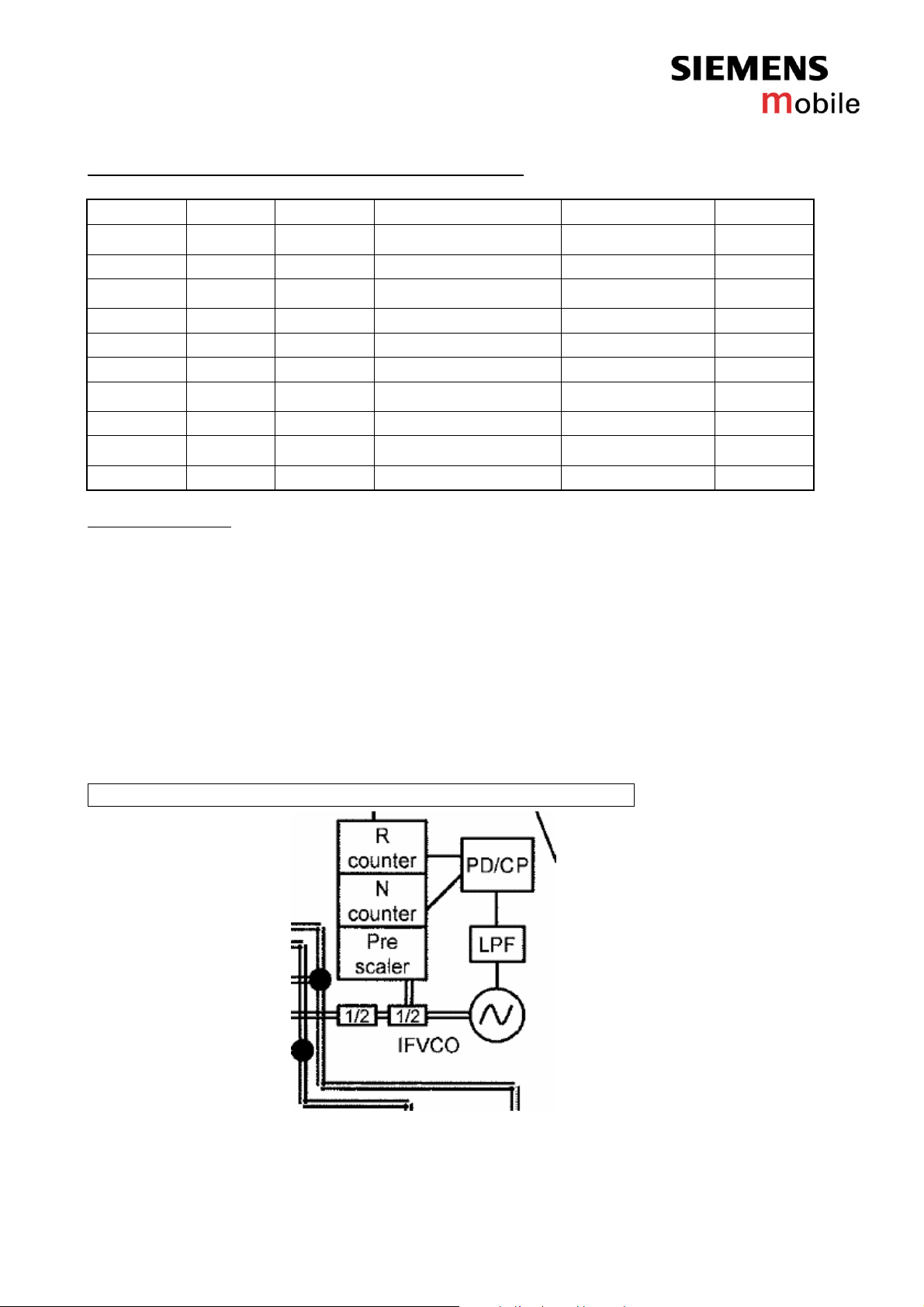

Matrix to calculate the TX and RX frequencies A65R:

Band RX / TX Channels RF frequencies LO1 frequency IF freq.

EGSM 900 Receive: 0..124 935,0 - 959,8 MHz LO1 = 4*RF

EGSM 900 Transmit: 0..124 890,0 - 914,8 MHz LO1 = 4*(RF+IF) 80,0 MHz

EGSM 900 Receive: 975..1023 925,2 - 934,8 MHz LO1 = 4*RF

EGSM 900 Transmit: 975..1023 880,2 - 889,8 MHz LO1 = 4*(RF+IF) 82,0 MHz

GSM 1800 Receive: 512..661 1805,2 - 1835,0 MHz LO1 = 2*RF

GSM 1800 Transmit: 512..661 1710,2 - 1740,0 MHz LO1 = 2*(RF+IF) 80,0 MHz

GSM 1800 Receive: 661..885 1835,0 - 1879,8 MHz LO1 = 2*RF

GSM 1800 Transmit: 661..885 1740,0 - 1784,8 MHz LO1 = 2*(RF+IF) 82,0 MHz

GSM 1900 Receive: 512..810 1930,2 - 1989,8 MHz LO1 = 2*RF

GSM 1900 Transmit: 512..810 1850,2 - 1909,8 MHz LO1 = 2*(RF+IF) 80,0 MHz

Synthesizer: LO2

The second local oscillator (LO2) consists of a PLL and VCO inside Bright (D903) and an

internal loop filter. Due to the direct conversion receiver architecture, the LO2 is only used for

transmit-operation. The LO2 covers a frequency range of at least 16 MHz (640MHz –

656MHz).

Before the LO2-signal gets to the modulator it is divided by 8. So the resulting TX-IF

frequencies are 80/82 MHz (dependent on the channel and band). The LO2 PLL and powerup of the VCO is controlled via the tree-wire-bus of Bright (EGOLD+ signals RF_DAT;

RF_CLK; RF_STR). To ensure the frequency stability, the 640MHz VCO signal is compared

by the phase detector of the 2

nd

PLL with the 26Mhz reference signal. The resulting control

signal passes the external loop filter and is used to control the 640/656MHz VCO.

The required voltage VDD_BRIGHT is provided by the ASIC D361

Service Repair Documentation

Level 2.5e – A65R

Page 10 of 47

Release 1.0

Page 11

4.4 Receiver

Receiver: Filter to Demodulator

The band filters are located inside the frontend module (D902). The filters are centred to the

band frequencies. The symmetrical filter output is matched to the LNA input of the Bright .The

Bright 6E incorporates three RF LNAs for GSM850/EGSM900, GSM1800 and GSM1900

operation. The LNA/mixer can be switched in High- and Low-mode to perform an

amplification of ~ 20dB. For the “High Gain“ state the mixers are optimised to conversion gain

and noise figure, in the “Low Gain“ state the mixers are optimised to large-signal behavior for

operation at a high input level. The Bright performs a direct conversion mixers which are IQdemodulators. For the demodulation of the received GSM signals the LO1 is required. The

channel depending LO1 frequencies for 1800MHz/1900MHz bands are divided by 2 and by 4

for 850MHG/900MHz band. Furthermore the IC includes a programmable gain baseband

amplifier PGA (90 dB range, 2dB steps) with automatic DC-offset calibration. LNA and PGA

are controlled via EGOLD+ signals RF_DAT; RF_CLK; RF_STR

channel-filtering is realized inside the chip with a three stage baseband filter for both IQ

chains. Only two capacitors which are part of the first passive RC-filters are external. The

second and third filters are active filters and are fully integrated. The IQ receive signals are

fed into the A/D converters in the EGAIM part of EGOLD+. The post-switched logic measures

the level of the demodulated baseband signal and regulates the level to a defined value by

varying the PGA amplification and switching the appropriate LNA gains.

From the antenna switch, up to the demodulator the received signal passes the following

blocks to get the demodulated baseband signals for the EGOLD+:

Filter

LNA

Demodulator

PGC

D903 Bright(D903)

The required voltage VDD_BRIGHT is provided by the ASIC D361

(RF CTRL J15, J16, J17). The

Service Repair Documentation

Level 2.5e – A65R

Page 11 of 47

Release 1.0

Page 12

4.5 Transmitter

Transmitter: Modulator and Up-conversion Loop

The generation of the GMSK-modulated signal in Bright (D903) is based on the principle of

up conversion modulation phase locked loop. The incoming IQ-signals from the baseband

are mixed with the divided LO2-signal. The modulator is followed by a lowpass filter (corner

frequency ~80 MHz) which is necessary to attenuate RF harmonics generated by the

modulator. A similar filter is used in the feedback-path of the down conversion mixer.

With help of an offset PLL the IF-signal becomes the modulated signal at the final transmit

frequency. Therefore the GMSK modulated rf-signal at the output of the TX-VCOs is mixed

with the divided LO1-signal to a IF-signal and sent to the phase detector. The I/Q modulated

signal with a center frequency of the intermediate frequency is send to the phase detector as

well.

The output signal of the phase detector controls the TxVCO and is processed by a loop filter

whose components are external to the Bright. The TxVCO which is realized inside the Bright

chip generates the GSMK modulated frequency.

Modulator

Filter

PD

Bright(D903)

The required voltage VDD_BRIGHT is provided by the ASIC D361

TxVCO

Service Repair Documentation

Level 2.5e – A65R

Page 12 of 47

Release 1.0

Page 13

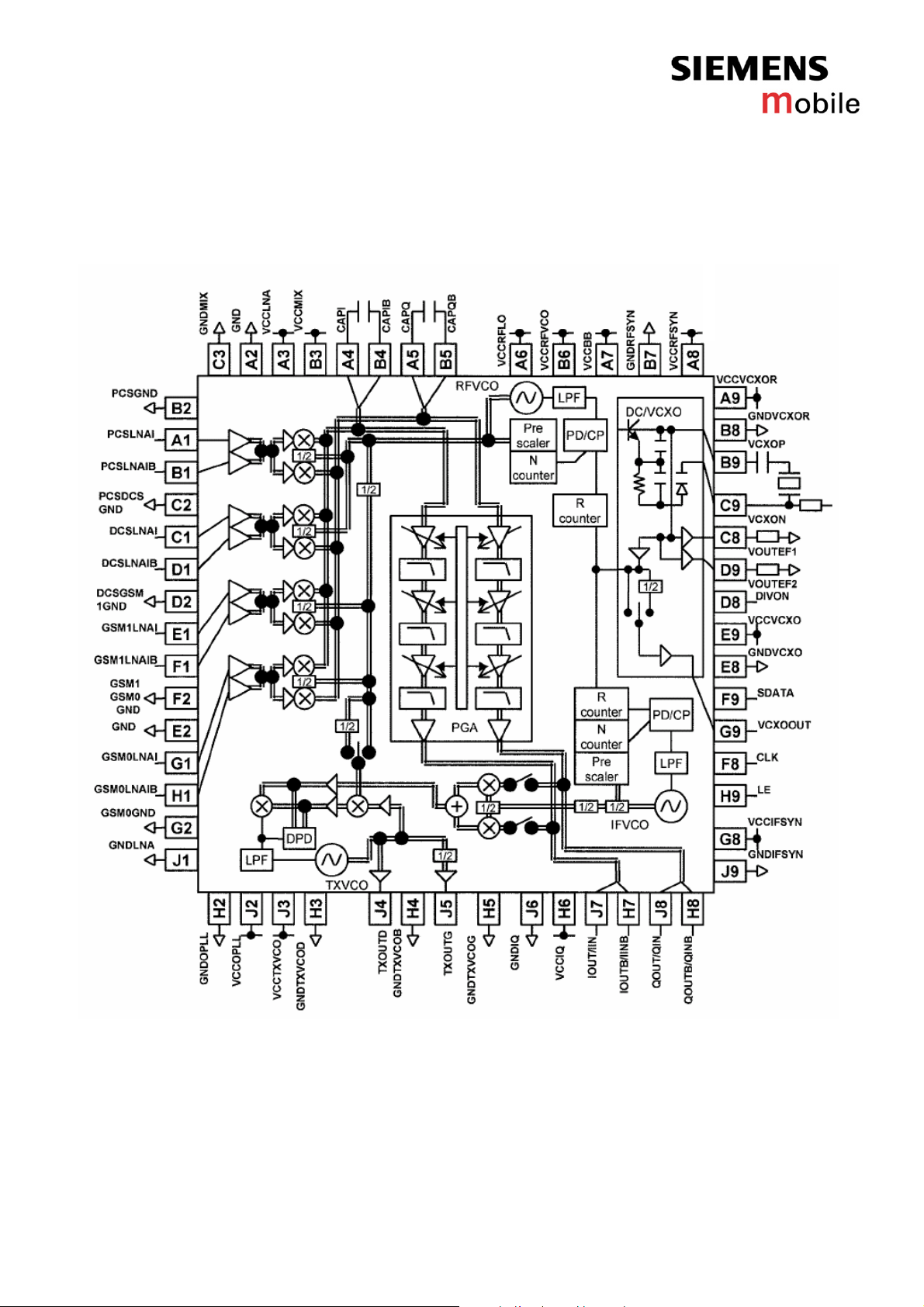

4.6 Bright IC Overview

BRIGHT 6E

IC Overview

Service Repair Documentation

Level 2.5e – A65R

Page 13 of 47

Release 1.0

Page 14

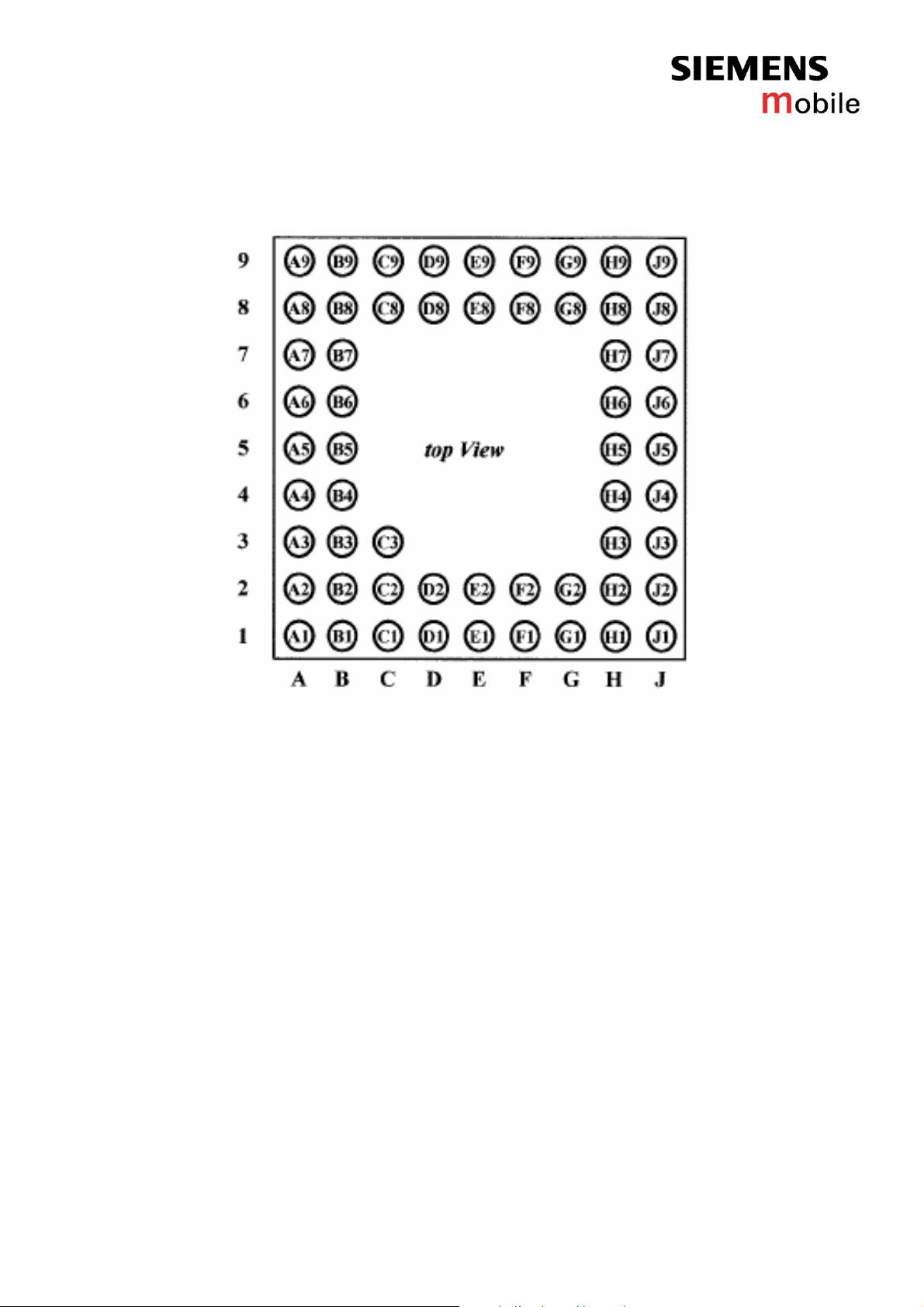

IC top view (ball overview)

Service Repair Documentation

Level 2.5e – A65R

Page 14 of 47

Release 1.0

Page 15

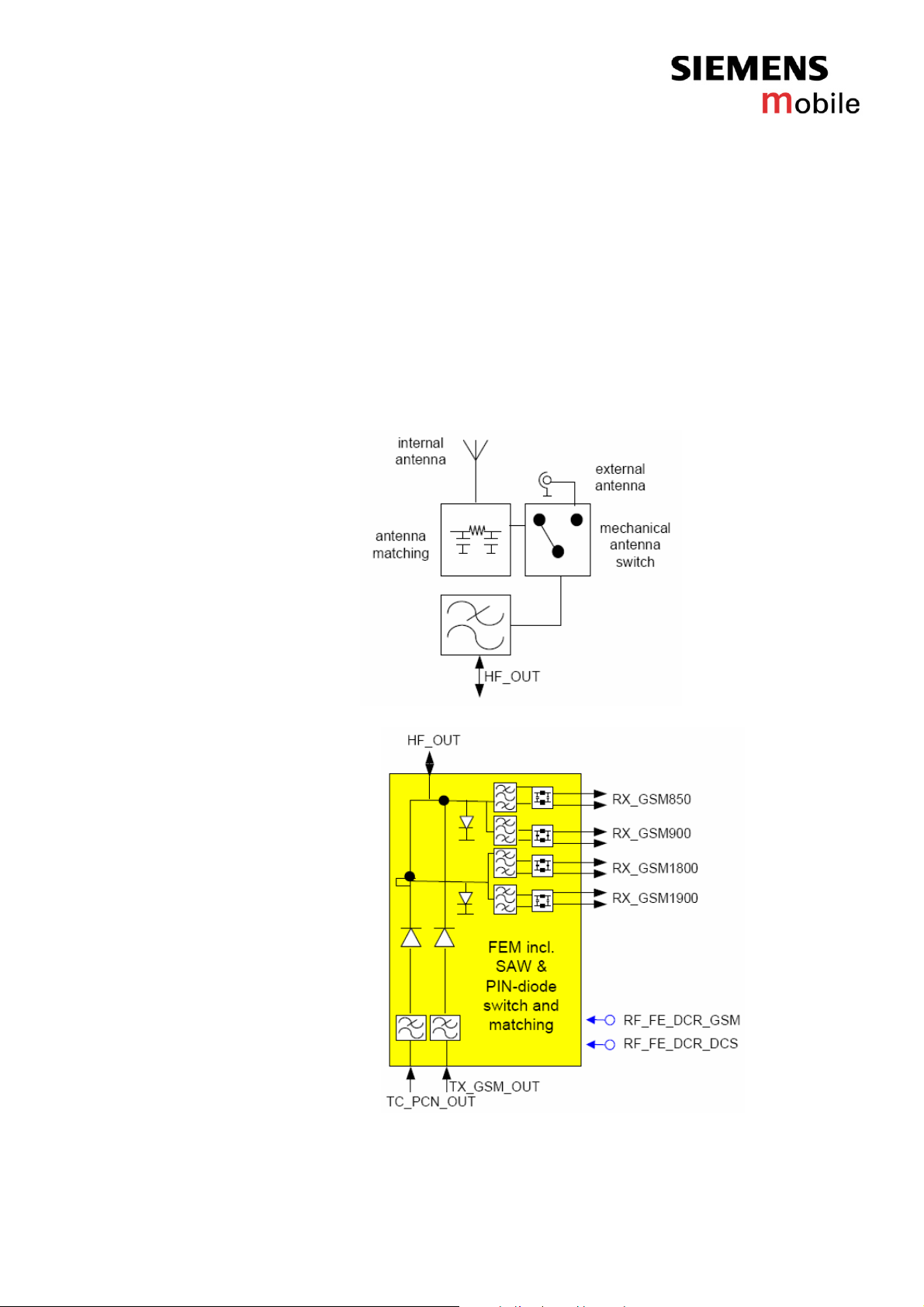

4.7 Antenna switch (electrical/mechanical)

Internal/External <> Receiver/Transmitter

The A65R mobile have two antenna switches.

a) The mechanical antenna switch for the differentiation between the internal and

external antenna.

b) The electrical antenna switch, for the differentiation between the receiving and

transmitting signals.

To activate the correct tx pathes of this diplexer, the EGOLD+ signals TXON_GSM and

RF_SW are required.

Internal/External antenna switch

The electrical antenna switch

Service Repair Documentation

Level 2.5e – A65R

Page 15 of 47

Release 1.0

Page 16

Top View :

Switching Matrix:

select mode Vsw 1 Vsw 2

GSM900/DCS1800/PCS1900 RX Low Low

EGSM TX high Low

DCS1800/PCS1900 TX Low High

Pin assignment:

1 Antenna 15 EGSM900 RX1

2 GND 16 EGSM900 RX2

3 Vsw2 (DCS1800/PCS1900 TX control) 17 DCS1800 RX1

4 GND 18 DCS1800 RX2

5 DCS1800/PCS1900 TX 19 PCS1900 RX1

6 GND 20 PCS1900 RX2

7 GND 21 GND

8 GND 22 GND

9 GND 23 GND

10 GND 24 GND

11 GND 25 GND

12 GND 26 Vsw1 (EGSM900 TX control)

13 GND 27 EGSM900 TX

14 28 GND

Service Repair Documentation

Level 2.5e – A65R

Page 16 of 47

Release 1.0

Page 17

4.8 Transmitter: Power Amplifier

The output signals (PCN_PA_IN , and GSM_PA_IN) from the TxVCO are led to the power

amplifier. The power amplifier is a PA-module N901 from Hitachi. It contains two separate 3stage amplifier chains GSM850/EGSM900 and GSM1800/GSM1900 operation. It is possible

to control the output-power of both bands via one VAPC-port. The appropriate amplifier chain

is activated by a logic signal

To ensure that the output power and burst-timing fulfills the GSM-specification, an internal

power control circuitry is use. The power detect circuit consists of a sensing transistor which

operates at the same current as the third RF-transistor. The current is a measure of the

output power of the PA. This signal is square-root converted and converted into a voltage by

means of a simple resistor. It is then compared with the PA_RAMP

The N901 is activated through the signal TXONPA

The required voltage BATT+ is provided by the battery.

RF_SW (TDMA Timer G16) which is provided by the EGOLD+.

(Analoq Interface J2) signal.

(GSM TDMA Timer F14).

Service Repair Documentation

Level 2.5e – A65R

Page 17 of 47

Release 1.0

Page 18

5 Logic / Control

5.1 Overview of Hardware Structure

5.1.1 Logic Block Diagram

Service Repair Documentation

Level 2.5e – A65R

Page 18 of 47

Release 1.0

Page 19

5.2 EGOLD+

Block Diagram EGOLD+

E-GOLD+ V3.0 Architecture

Single Chip Cellular Baseband Processor

Package: P-LFBGA-208

Viterbi

HW

Accelerator

Cipher Unit

A51/52

P ROM

60k x 16

P RAM

4k x 16

Y RAM

2k x 16

X RAM

15k x 16

X ROM

36k x 16

TAP Controller

Boundary Scan

GMSK

Modulator

Voiceband

Filters

RX and TX

Baseband

Filter/

Cordic-

Processor

JTAG

Interp./

Noise

Shaper

Interp./

Noise

Shaper

Σ∆

ADC

Σ∆

DAC

Σ∆

ADC

12 bit resolution

Σ∆

ADC

Switch Matrix

Battery & Temperature

Measurement

RF Output

Power Control

10 bit DAC

reference

voltage

confidential

DAC

R-String

2

DAC

R-String

2

2

MUX

2

2

2

2

2

Bandgap

Enable Signals to

X- and PD-Bus Peripherals

X-Bus

Boot

Block

Logic

Arranger

(LPA)

16 bit I/O Ports

DSP Timer1

78 MHz

x

Interleaving / De-Interlea ving

x

Speech Coding/Decoding

x

Level Measurement

x

Channel Coding/Decoding

x

Equalization

x

Encryption / Decryption

x

Voice Memo/Voice Dialing

x

GPRS support

OCEM

SEIB

TDMA Timer

8 3

4

3

I2S

OAK78 DSP

(FR, HR, EFR, AMR)

(FR, HR, EFR, AMR)

Interrupt Controller

Bus

Interface

Unit

GSM

DSP Serial

Comm. Interface /

DAI

DSP Timer2

6

Shared Memory

Dual Port 512 x 16

RF Control

8

8 16

21 24

16

3

Osc.

32.768 kHz

CAPCOM

2 x 8 bit

ID Register

6

Multicore

Debug Support

External

Bus & Port

Controller

CS(4:0)

AFC Unit

Pulse-Carry Mod.

Keypad

Interface

4

3

2

2

SSC

RTC

SPI

compatible

32 kHz

PD-Bus

MMCI

V5.4

5

SIM card

Interface

High Speed

(F=512, D=8/16)

2

6

ASC0

Autobaud

Detect

SRAM

256k x 8

GPT1/GPT2

Watchdog

80

I2C

ASC1

13/26/52 MHz / 32 kHz

READY#

NMI#

HOLD#

HLDA#

CLKOUT

RSTOUT#

Clock Generation

Peripheral Enable

Generator

Management

MCU

C166S

OCDS DPEC

Interrupt Controller

Dual Port RAM

1k x 16

LM-Bus

PROM

1k x 16

GPRS

Cipher Unit

Power

The EGOLD+ contains a 16-bit micro-controller (µC part), a GSM analog Interface (EGAIM), a DSP computing core (DSP part) and an interface for application-specific switch-functions.

The µC part consists of the following:

• Micro-controller

• System interfaces for internal and external peripheries

• On-chip peripheries and memory

The Controller Firmware carries out the following functions:

• Control of the Man Machine Interface (keypad, LCD, sensing element, control of the

illumination,...)

• GSM Layer 1,2,3 /GPRS

• Control of radio part (synthesizer, AGC, AFC, Transmitter, Receiver...),

• Control of base band processing (EGAIM)

• Central operating system functions (general functions, chip select logic, HW driver, control

of mobile phones and accessories...).

Service Repair Documentation

Level 2.5e – A65R

Page 19 of 47

Release 1.0

Page 20

The EGAIM part contains the interface between the digital and the analogue signal

processing:

• 2 Sigma Delta A/D converters for RX signal, and for the necessary signals for the charge

control and temperature measurement. For this, the converter inputs are switched over to

the various signals via the multiplexer.

• 2 D/A converters for the GMSK-modulated TX signal,

• 1 D/A converter for the Power Ramping Signal,

• 1 Sigma Delta A/D and D/A converter for the linguistic signal.

Measurement of Battery and Ambient Temperature

The battery temperature is measured via the voltage divider R1387, R138 by the EG OLD+

(Analog Interface P2). For this, the integrated Σ∆ converter of the RX-I base band branch is used.

This Σ∆ converter compares the voltage of TBAT and TENV internally. Through an analogue

multiplexer, either the RX-I base band signal, or the TBAT signal and the TENV signal is

switched to the input of the converter. The signal MEAS_ON from the EGOLD+

H15)

activates the battery voltage measurement The ambient temperature TENV is measured

directly at of the EGOLD

Measurement of the Battery Voltage

+(Analog Interface P3).

(GSM TDMA-TIMER

The measurement of the battery voltage is done in the Q-branch of the EGOLD+, for this

BATT+ is connected via a voltage divider R143, R146 to the EGOLD+

(Analog Interface P1). An

analogue multiplexer does the switching between the baseband signal processing and the

voltage measurement.

Service Repair Documentation

Level 2.5e – A65R

Page 20 of 47

Release 1.0

Page 21

A/D conversion of MIC-Path signals incl. coding

The Microphone signals (MICN2, MIP2, MICP1, MICN1) arrive at the voiceband part of the

EGOLG+. For further operations the signals will be converted into digital information, filtered,

coded and finally formed into the GMSK-Signal by the internal GMSK-Modulator. This so

generated signals (RF_I, RF_IX, RF_Q, RF_QX) are given to the Bright IC in the transmitter

path.

D/A conversion of EP-Path signals incl. decoding

Arriving at the baseband-Part the demodulated signals (RF_I, RF_IX, RF_Q, RF_QX) will be

filtered and A/D converted. In the voiceband part after decoding (with help of the µC part) and

filtering the signals will be D/A converted amplified and given as (EPP1_FIL, EPN1_FIL) to

the Power Supply ASIC.

Generation of the PA Control Signal (PA_RAMP)

The RF output power amplifier needs an analogue ramp up/down control voltage. For this the

system interface on EGOLD+ generates 2

serially to the power ramping path. After loading into an 10 bit latch the control value will be

converted into the corresponding analogue voltage with a maximum of ~2V

15

digital values which have to be transferred

Service Repair Documentation

Level 2.5e – A65R

Page 21 of 47

Release 1.0

Page 22

The DSP part contains:

• DSP signal processor

• Separate program/data memory

• a hardware block for processing the RX signal,

• a hardware block for “ciphers“,

• a hardware block for processing the linguistic signal,

• a hardware block for the “GMSK modulator“,

• De-/ interleaving memory,

• Communication memory

• a PLL for processing and reproducing the VCXO pulse signal.

In the DSP Firmware are implemented the following functions:

• scanning of channels, i.e., measurement of the field strengths of neighbouring base

stations

• detection and evaluation of Frequency Correction Bursts

• equalisation of Normal Bursts and Synchronisation Bursts

• channel encoding and soft-decision decoding for fullrate, enhanced-fullrate and

adaptive multirate speech, fullrate and halfrate data and control channels.

• channel encoding for GPRS coding

• fullrate, enhanced fullrate and adaptive multirate speech encoding and decoding

• mandatory sub-functions like

– discontinuous transmission, DTX

– voice activity detection

– background noise calculation

• generation of tone and side tone

• hands-free functions

• support for voice memo

• support for voice dialling

• loop-back to GSM functions

• GSM Transparent Data Services and Transparent Fax

• calculation of the Frame Check Sequence for a RLP frame used for GSM

NonTransparent Data Services

• support of the GSM ciphering algorithm

Real Time Clock (integrated in the EGOLD+):

The real time clock is powered via a separate voltage regulator inside the Power Supply

ASIC. Via a capacitor, data are kept in the internal RAM during a battery change for at least

30 seconds. An alarm function is also integrated with which it is possible to switch the phone

on and off.

Service Repair Documentation

Level 2.5e – A65R

Page 22 of 47

Release 1.0

Page 23

5.2.1 SRAM

Memory for volatile data

Memory Size: A65R - 8 Mbit

Data Bus: 16Bit

5.2.2 FLASH

Memory Size: A65R - 32 Mbit (4Mbyte)

Data Bus: 16 Bit

5.2.3 SIM

SIM cards with supply voltages of 1.8V and 3V are supported.

5.2.4 Vibration Motor

The vibration motor is mounted in the lower case. The electrical connection to the PCB is

realised with pressure contacts.

6 Power Supply

6.1 Power Supply ASIC

The power supply ASIC will contain the following functions:

• Powerdown-Mode

• Sleep Mode

• Trickle Charge Mode

• Power on Reset

• Digital state machine to control switch on and supervise the µC with a watchdog

• Voltage regulator

• Low power voltage regulator

• Additional output ports

• Voltage supervision

• Temperature supervision with external and internal sensor

• Battery charge control

• I2C interface

• Audio multiplexer

• Audio amplifier stereo/mono

• 16 bit Sigma/Delta DAC with Clock recovery and I2S

• Bandgap reference*

Service Repair Documentation

Level 2.5e – A65R

Page 23 of 47

Release 1.0

Page 24

Power Supply Diagram

Service Repair Documentation

Level 2.5e – A65R

Page 24 of 47

Release 1.0

Page 25

6.1.1 Power Supply Operating modes:

The ASIC can be used in different operating modes:

Mode

Power down

mode with

minimum activity

Start Up Mode ON_OFF

Full operating

mode

Active Mode

(submode of Full

operating mode)

Sleep Mode with

special low

current

operating mode

for the LDOs

(submode of Full

operating mode)

Pin

Requirements

ON/OFF

ON/OFF2

VDD_CHARGE

ON_OFF2

VDD_CHARGE

CHARGE_UC

In this mode, the µC(EGOLD+) controls the charging block and

SLEEP1_N

TC_ON

CHARGE_uC

Description

In power down mode the current consumption of the ASIC is very

low. The inputs for switch on conditions (ON/OFF-PinH2,

ON/OFF2-PinJ3 ,VDD_CHARGE-PinC3), the LPREG, Bandgap

reference and the POR cells are active. All other blocks are

switched off, so the battery is not discharged. This state is called

“phone off.

Start Up Mode can be initiated by ON_OFF(PinH2) or

ON_OFF2(PinC3). In this mode a sequential start-up of

references, oscillator, voltage supervision and regulators is

controlled by digital part. In failure case (under voltage, over

voltage or time out of the µC reaction)., the ASIC is shut down.

All blocks are active. Trickle charge is switched off. The blocks

fast charge and charge monitor can be active only in this mode.

These modes will be activated with VDD_CHARGE(PinC3) or

CHARGE_UC(PinH4). The name of this mode is “phone on” or

“active mode”. The border between the startup phase and the

active mode is the rising edge of the RESET2_N (PinG1) signal.

This will allow the µC(EGOLD+) to start working.

most of the failure cases. The ASIC can be controlled by the TWI

interface (I2CC-PinJ2, I2CD-PinG3, I2CI-PinE2), interrupts can

be sent by the ASIC. Further, the temperature and the voltages

are supervised (in case of failure, the uC will be informed). In

case of watchdog failure, over voltage or power on reset, the

ASIC will be switched off immediately. The mono and stereo

audio block can be switched on in active mode.

A low level at the signal VCOEN_UC (PinH1) will switch the

phone from the mode “PHONE ON” to sleep mode. This mode

can be activated out of the active mode. In sleep mode trickle

charge, fast charge, supply over voltage detection, supply under

voltage detection, audio function are switched off. LDO under

voltage detection, clock and all reference voltages are active.

LDOs are working in low current mode. The possibility to supply

the ASIC from VDD_CHARGE (Pi nC3) with the internal LDO is

switched off. Only the battery can be used for supply. This mode

is called “phone stand-by”.

Service Repair Documentation

Level 2.5e – A65R

Page 25 of 47

Release 1.0

Page 26

Mode

Trickle charge

mode to be able

to support

charging of the

battery

Pin

Requirements

VDD_CHARGE

EXT_PWR

Description

In case of a rising edge at VDD_CHARGE (PinC3) the ASIC

goes from power down to interim mode. In this mode, the

oscillator and the reference are started. The fuses are read in. If

the voltage is high enough (after a delay time of 1 ms to filter a

ringing), the internal signal EXT_PWR is going to H and the

power up continues. The ASIC shuts off if the voltage is below

threshold. In Trickle Charge Mode, first the charge unit starts and

charges the battery in case of under voltage. After reaching this

threshold voltage or if the battery has enough voltage from the

beginning, a start up similar to the regular startup mode is

initiated. In case of voltage drop under battery threshold, the first

trickle charging can be started again until the Active Mode is

entered. In this case, the internal VDDREF regulator, the

reference generator and oscillator are started and the ASIC is

supplied by VDDREF. If any failure is detected, the ASIC is

switched off.

Service Repair Documentation

Level 2.5e – A65R

Page 26 of 47

Release 1.0

Page 27

6.1.2 Power Supply Functions:

Functions

Switching on the

mobile phone

Watchdog

monitoring

Power-On-Reset

(POR)

Service Repair Documentation

Level 2.5e – A65R

Pin

Requirements

ON_OFF,

ON_OFF2,

VDD_CHARGE

WDOG As soon as the first WDOG (PinH3) pin rising is detected during

RESET_N

RESET2_N

Sequence

There are 3 different possibilities to switch on the phone by

external pins:

- VDD_CHARGE (PinC3) with rising edge after POR or high

- ON/OFF (PinH2) with falling edge

- ON/OFF2 (PinJ3) with rising edge

In order to guarantee a defined start-up behavior of the external

components, a sequential power up is used and the correct start

up of these blocks is supervised. In active mode, a continuous

signal at watchdog is needed to keep the system running. If the

signals fails, the ASIC will switch to power down mode. It must

be guaranteed that each start-up condition does not interfere and

block the other possible startup signals. In case of failure during

start-up, the device will go back to power down mode. To

guarantee that VDDCHARGE (PinC3) is always sensed we must

be able to detect whether the VDDCHARGE (PinC3) will have a

rising edge during POR (this can happen in case of an empty

battery). Therefore this signal is sensed as level sensitive at the

end of POR and edge sensitive after POR signal.

the TE4 timer, the device start the watchdog monitoring

procedure. Standard switch off of the phone is the watchdog.

The first edge of watchdog is rising. If a falling edge is detected

as the first transient the device will go to power down mode

again and the whole phone is switched off. Rising and falling

edges must be detected alternated. With any edge on WDOG

(PinH3) pin a counter will be loaded. The next - compared to the

previous edge - inverted edge must occur between end of T1,

and end of T2. If the signal occurs before end of T1 or is not

detected until end of T2, the device will go to power down mode

immediately after the violation of the watchdog criteria occurs.

T1 min. 0,327s/ typ. 0,360s/ max. 0,400s

T2 min. 2,600s/ typ. 2,860s/ max. 3,178s

To guarantee a correct start-up of the ASIC, a power on reset is

needed at first power supply ramping. Therefore a static/dynamic

power on reset circuit is added, which creates a reset each time

the power supply is connected. After POR the ASIC starts up the

reference and the oscillator, read in the fuse content and goes

back to power down mode. If the power supply will drop under

the POR threshold a synchronous reset is done and the ASIC

will go to power down mode independently of the previous

operating mode.

level at end of POR signal

Page 27 of 47

Release 1.0

Page 28

Functions

Voltage Supply

Logics

Voltage Supply

Logics

Voltage Supply

Logics

Voltage Supply

RF

Pin

Requirements

REG1

(2.9V)

REG2

(1,92V)

REG3

(2.65V)

VREGRF1,

RF_EN,

RESET_N

Sequence

The linear controller is designed for 2.9V(±2%) and a maximum

load current of 140 mA.

Voltage and current for the external Logic is supplied from the

internal 2.9V logic regulator. The operating voltage VREG1 is

kept constant up to the maximum rated load current. A reference

voltage for the regulator circuit is generated from a bandgap

reference

The linear controller is designed for 1.82V(±3%) and a maximum

load current of 300 mA.

The REG2 supplies the Baseband Processor. For a high power

application, the power has to be dissipated outside of the chip.

This is done with a series diode at the input of REG2, which will

force the regulator to a lower input voltage and therefore lower

power dissipation.

The linear controller is designed for 2.65V(±3%) and a maximum

load current of 220 mA.

It will consist basically of an internal operation amplifier, an

integrated p-channel output transistor as well as a capacitor (C =

2.2µF) for stabilizing the voltage. The required reference voltage

for the regulating circuit will be generated internally via a

bandgap. The negative feedback of the regulating circuit shall be

done via chip-internal resistances.

The linear controller is designed for 2.85V(min. 2.79V, max.

2.91V) and a maximum load current of 120 mA.

Voltage and current for RF-VCO and Transceiver is supplied

from the internal 2.85V LDO. The operating voltage RF12LDO is

kept constant up to the maximum rated load current. A reference

voltage for the regulator circuit is generated from a bandgap

reference. A low noise must be guaranteed.

RF1LDO is controlled by RF_EN. If it is set to high, the regulator

is enabled. The control method can be modified by TWI interface

between external and internal control mode. If internal control

mode is set, RF1LDO can only be enabled by TWI bit. In external

mode, RF1LDO can only be enabled by RF_EN.

RF1LDO is released with rising edge of RESET_N signal.

Service Repair Documentation

Level 2.5e – A65R

Page 28 of 47

Release 1.0

Page 29

Functions

Voltage Supply

RF

Voltage Supply

Audio

Voltage Supply

RTC

Voltage Supply

SIM

Pin

Requirements

VREGRF2,

SLEEP1_N,

SLEEP2_N,

POWER_ON

VREGA The linear controller is designed for 2.9V(min. 2.84V, max.

VLPREG The linear controller is designed for 2.00V(min. 1.9V, max. 2.1V)

VREGSIM The linear controller is designed for 2.9V(min. 2.84V, max.

Sequence

The linear controller is designed for 2.85V(min. 2.79V, max.

2.91V) and a maximum load current of 180 mA.

Voltage and current for RF-VCO and Transceiver is supplied

from the internal 2.85V LDO. The operating voltage RF2LDO is

kept constant up to the maximum rated load current. A reference

voltage for the regulator circuit is generated from a bandgap

reference. A low noise must be guaranteed.

RF2LDO is controlled by VCXO_EN (PinH1). If it is set to high,

the regulator is enabled. The control method can be modified by

TWI interface between external and internal control mode. If

internal control mode is set, RF2LDO can only be enabled by

TWI bit. In external mode, RF2LDO can only be enabled by

VCXO_EN (PinH1).

RF2LDO is released with rising edge of POWER_ON signal.

2.96V) and a maximum load current of 190 mA.

BATT+ (PinA9) is used for the whole stereo analog supply. The

DAC digital VDDDAC (PinC6), Low Noise Bandgap, Mono- and

Stereoamplifier supplies are connected to VREGA (PinB9). The

AUDIO performances are guaranteed only, if the VREGA

supplies all the stereo path.

VREGA is controlled with TWI registers directly by the µC.

and a maximum load current of 1 mA.

The output voltage can be adjusted to four different values with

TWI register by the µC. The selectable values are 2.00(default),

1.82, 1.92 and 2.07V. LP-LDO is always working and will switch

of only with POR signal.

2.96V) and a maximum load current of 60 mA. The output

voltage can be adjusted to a different value with TWI register by

the µC to 1.8V(min. 1.76V, max. 1.84V).

This regulator can be activated by TWI register , but only in

active mode. If the regulator is in power down, the output is

pulled down by a transistor to avoid electrostatic charging of

VREGSIM (PinB8)

Service Repair Documentation

Level 2.5e – A65R

Page 29 of 47

Release 1.0

Page 30

Functions

Charge Support CHARGE_UC,

Voltage

supervision

Supervision of

REG1 and

REG2

Powersupply

supervision

VDDA

supervision

Battery

temperature

supervision

Pin

Requirements

CHARGE,

VDDCHARGE,

AVDD,

SENSE_IN,

TBAT

The levels of regulator REG1 and REG2 and also the supply

REG1

REG2

VDD If the battery voltage BATT+ exceeds VDD high, everything is

VDDA To provide a short circuit protection at output of VDDA (PinA9)

Charging is stopped, when over temperature occurs. Within

Sequence

A charge support will be integrated for controlling the battery

charge function. It consists basically of a temperature sensor, an

external charge FET, an integrated High-side driver for the

external FET with an external resistor between the source and

the gate of the charge FET.

In the case of a rising edge at the CHARGE_UC(PinH4) the

power source will be switched on. In this way the charge FET

becomes conducting, provided that the integrated temperature

comparator does not give the signal for extreme temperature and

that no over voltage is present at the VDD. In the case of falling

slope at the CHARGE_UC(PinH4), the current source is

switched off and the pull-up resistor will make sure that the

charge FET is blocked after a definite time.

Temperature switchoff becomes effective at approx. T>60°C.

voltage BATT+ are supervised with comparators.

In active mode the regulators are supervised permanently. If the

voltage is under the threshold, the pin RESET_N2 (PinG1) stay

Low and the ASIC goes back to the power down mode. If the

voltage is longer than Tmin under threshold voltage, the

RESET_N2 (PinG1) is going to Low (Missing Watchdog signal ->

phone switched off). The level of regulator REG1 and REG2 will

be supervised permanently. If the voltage doesn’t reach the

threshold value at switch on, the RESET_N2 (PinG1) will stay

low and the ASIC will go back to power down mode. The

voltages are sensed continuously and digitally filtered with a time

constant Tmin. If the regulator voltage is under threshold longer

than Tmin, the RESET_N2 (PinG1) signal change to low and the

µC will go to RESET condition (Missing Watchdog signal ->

phone switched off).

switched off immediately within 1µs. Only the pull-up circuitry for

the external charge PMOS are active and will discharge the gate

of the external PMOS

and output of stereo buffer a voltage supervision is implemented.

If the VDDA output is less then this threshold, the VDDA will be

switched off for 128ms. After this time the VDDA will be started

again. The VDDA supervision starts 60ms after startup of VDDA.

128ms, 3 values are measured. When these 3 values are

identical status can be changed. The supervision is active in fast

charge or trickle charge mode. Voltage on pin TBAT (PinB3)

becomes smaller when temperature increases. If Vbat <

(Vref_exe - Vhyst) charging is disabled. Only when Vtbatt >

Vref_exe charging is enabled again.

Service Repair Documentation

Level 2.5e – A65R

Page 30 of 47

Release 1.0

Page 31

Functions

Device

temperature

supervision

Analog switch

Outport

TWI Interface TWI_CLK,

Audio mode

functions

Audio Mono

Mode

Pin

Requirements

To protect the ASIC, the temperature is supervised. The

The level can be defined by the bit out_port_high of the TWI

TWI_DATA,

TWI_INT

Four audio amplifiers are integrated to support these modes:

VREGA

MONO1

MONO2

VREFEX_M

Sequence

temperature is polled every 128ms and is filtered as in battery

temperature supervision. If over temperature is detected, a bit in

the STATUS register is set and an interrupt is generated.

Monitoring is started only in active mode.

register. The high level can be derived of VREG2 or VREG3.

Additional a pull down transistor is connected to this node.

The TWI interface (I2CC-PinJ2, I2CD-PinG3, I2CI-PinE2) is an

I2C compatible 2-wire interface with an additional interrupt pin to

inform the µC about special conditions.

The interface can handle clock rates up to 400 kHz.

1. Supply the speaker in the phone with audio signals including

the possibility of handsfree switch on and off. This is the

AUDIO MONO MODE.

2. Supply the s peaker in the phone with ringing signal (RINGER

MODE)

3. Transfer a key click, generated in digital part to the speaker.

(KEY-CLICK FUNCTION)

4. Supply of stereo head set with stereo signal with short circuit

protection. This is called the AUDIO STEREO MODE. These

different modes with gain and multiplexing can be controlled

via TWI. Also the output can be switched to TRI-STATE via

TWI interface.

This mode is the main function of the amplifier. The two

amplifiers are used as differential mono amplifier to drive the

speaker in the phone as external load. This differential approach

allows delivering an optimum of power to the speaker also in low

voltage mode. Both amplifier paths are inverting amplifiers with

external AC coupling at the input to compensate offset failures.

The gain can be adjusted with the TWI interface. The output

stage of the amplifiers must be able to drive a low impedance

load as an external speaker for the handsfree application.

General parameters: Gain can be adjusted for each channel

separately in steps of 1.5dB in the range of 21dB to –54 dB and

in steps of 3 dB in the range of –54dB to –75dB. The signals for

the amplifier are connected via an audio multiplexer with 3 pairs

of input signals.

Service Repair Documentation

Level 2.5e – A65R

Page 31 of 47

Release 1.0

Page 32

Functions

Ringer function RINGIN In ringer mo de the ringing signal is transferred via the amplifier to

Key click

function

Audio Multiplex

Matrix

I2S Interface CLO,

Pin

Requirements

Pushing a key of the phone can be combined with a key click.

AUDIOA1

AUDIOA2

AUDIOB1

AUDIOB2

AUDIOC1

AUDIOC2

WAO,

DAO

Sequence

the speaker to eliminate the additional buzzer. The speaker is

controlled with a rectangular signal RINGIN (PinG9). Input signal

is digital signal with variable frequency. Amplitude is adjusted by

TWI register.

For start-up a smaller time constant must be used to allow a fast

switch on behavior. Ringing function can be started at any time.

If the audio is off, the start-up is done with RINGER time

constant. If audio is starting with AUDIO start-up, the time

constant is switched to RINGER mode, too. If the audio amplifier

is already up and running, the RINGIN (PinG9) is connected to

the amplifier and audio signal is muted due to open multiplexer.

This function is also realized with the audio amplifier in pulsed

mode. The ASIC creates a digital PWM signal. Frequency of the

PWM signal is 3.5 kHz.

The start-up is similar to the ringer function. If the audio is off, the

start-up is done with KEYCLICK time constant. If audio is starting

with AUDIO start-up, the time constant is switched to KEYCLICK

mode, too. If the audio amplifier is already up and running, the

KEYCLICK is connected to the amplifier and audio signal is

muted due to open multiplexer.

Each of the three input sources should be switched to Mono and

Stereo outputs. Furthermore a conversion can be done.

Following sources:

- Mono differential

- Mono Single Ended (both channels parallel)

- Stereo

The DAC can be switched off for using the analog external

inputs. This principle will allow to do each combination and have

different modes for stereo and mono in parallel.

The I2S Interface is a three-wire connection that handles two

time multiplexed data channels. The three lines are the clock

(CLO), the serial data line (DAO) and the word select line

(WAO). The master I2S also generates the appropriate clock

frequency for CLO set to 32 times the sampling rate (FS)

Service Repair Documentation

Level 2.5e – A65R

Page 32 of 47

Release 1.0

Page 33

Functions

Audio DAC

PLL VDDPLL

Audio Stereo

Mode

Pin

Requirements

VDDDAC For digital to analog conversion a 16-bit sigma delta converter is

PLLOUT

VDDSTEREO

STEREO1

STEREO2

STEREOM

Sequence

used. Digital input signal is delivered with an I2S interface. The

I2S interface should be 16-bit format. To be able to work with all

possible operating modes, the sampling frequency can vary from

8kHz to 48kHz. The performance of the audio output signal must

be guaranteed over the full range the human ear is able to hear.

This means for FS=8kHz the noise at frequencies higher than

FS/2 must be suppressed. This is done by DSP and a single

ended 2

varied accordingly to the sampling frequency. Therefore a clock

recovery based on CLO signal of the I2S can be implemented.

This clock recovery must smooth any jitter of this clock to reduce

the noise of the DAC.

The PLL will have three frequency modes to produce a 32xCLO

clock for the DSP and the DAC. The loop filter is realized with an

external RC circuit. This PLL also contains a lock detector circuit.

For stereo mode 2 single ended buffers are used. These buffers

will be supplied by the additional regulator with 2.9 Volt to be

more stable against the GSM ripple on the battery voltage. Also

reference voltage for the buffers is generated by a high precision,

low noise bandgap reference for better performance. An external

capacitor is needed to filter this reference additionally. The gain

steps for the programmable gain amplifier is identical with the

mono amplifier. No keyclick and ringer needed for the stereo

part. Gain can be controlled with the TWI. The connected

speaker has an impedance of typical 16 Ohm. To guarantee an

ANTI-POP noise a digital startup is implemented. This will allow

a soft start of the VMID and creates a “clean” audio band during

the startup. For eliminating external coupling capacitors for the

speaker, an additional amplifier creates virtual ground (for both

speakers). Accordingly to this, the max current of the virtual

ground has to be the double of the normal output amplifier. Due

to the power amplifier offset a DC current appear in the headset.

Gain can be adjusted for each channel separately in steps of

1.5dB in the range of 21dB to –54 dB and in steps of 3 dB in the

range of –54dB to –75dB

nd

order Low Pass filter. The clock for the I2S will be

6.2 Battery

As a standard battery a LiIon battery with a nominal capacity of 3,7 Volt/700mAh is used.

Page 33 of 47

Service Repair Documentation

Level 2.5e – A65R

Release 1.0

Page 34

6.3 Charging Concept

Charging current

Charging control signal

6.3.1.1 Charging Concept

General

The battery is charged in the unit itself. The hardware and software is designed for LiIon with

4.2V technology.

Charging is started as soon as the phone is connected to an external charger. If the phone is

not switched on, then charging takes place in the background (the customer can see this via

the “Charge” symbol in the display). During normal use the phone is being charged

(restrictions: see below).

Charging is enabled via a PMOS switch in the phone. This PMOS switch closes the circuit for

the external charger to the battery. The EGOLD+ takes over the control of this switch

depending on the charge level of the battery, whereby a disable function in the POWER

SUPPLY ASIC hardware can override/interrupt the charging in the case of over voltage of the

battery (only for Manganese Chemistry Battery types e.g. NEC).

With the new slim Lumberg IO connector we lose the charger recognition via SB line. Now

we measure the charge current inside the POWER SUPPLY ASIC with a current monitor.

The charging software is able to charge the battery with an input current within the range of

350-600mA. If the Charge-Fet is switched off, then no charging current will flow into the

battery (exception is trickle charging, see below).

For controlling the charging process it is necessary to measure the ambient (phone)

temperature and the battery voltage. The temperature sensor will be an NTC resistor with a

nominal resistance of 22kΩ at 25°C. The determination of the temperature is achieved via a

voltage measurement on a voltage divider in which one component is the NTC. The NTC for

the ambient temperature will be on the PCB (13 MHz part).

Service Repair Documentation

Level 2.5e – A65R

Page 34 of 47

Release 1.0

Page 35

Measurement of Battery, Battery Type and Ambient Temperature

The voltage equivalent of the temperature and battery code on the voltage separator will be

calculated as the difference against a reference voltage of the EGOLD. For this, the

integrated Σ∆ converter in the EGOLD of the RX-I base band branch will be used. Via an

analogue multiplexer, either the RX-I base band signal, the battery code voltage or the

ambient temperature voltage can be switched over to the input of the converter. The 1-Bit

data stream of the converter will be subjected to a data reduction via the DSP circuit so that

the measured voltage (for battery and ambient temperature) will be available at the end as a

10-bit data word.

Measurement of the Battery Voltage

Analogue to the I-branch either the RX-Q base band signal or the battery voltage can be

measured in the Q-branch. Processing in the DSP circuit will be done analogue to the Ibranch. The EGOLD will be specified internally at voltage measurement input BATT+ for an

input voltage of 3V...4.5V.

Timing of the Battery Voltage Measurement

Unless the battery is charging, the measurement is made in the TX time slot. During charging

it will be done after the TX time slot. At the same time, either the battery temperature (in the Ibranch) and the battery voltage (in the Q-branch) or the ambient temperature in the I-branch

can be measured (the possibility of measurement in the Q-branch, the analogue evaluation of

the battery coding, is used for HW-Coding). Other combinations are not possible. For the

time of the measurement the multiplexer in the EGAIM must be programmed to the

corresponding measurement.

Recognition of the Battery Type

The battery code is a resistor with a resistance depending on the manufacturer.

Service Repair Documentation

Level 2.5e – A65R

Page 35 of 47

Release 1.0

Page 36

Charging Characteristic of Lithium-Ion Cells

LiIon batteries are charged with a U/I characteristic, i.e. the charging current is regulated in

relation to the battery voltage until a minimal charging current has been achieved. The

maximum charging current is approx. 600mA, minimum about 100mA. The battery voltage

may not exceed 4.2V ±50mV average. During the charging pulse current the voltage may

reach 4.3V. The temperature range in which charging of the phone may be started ranges

from 5...40°C, and the temperature at which charging takes place is from 0...45°C. Outside

this range no charging takes place, the battery only supplies current.

Trickle Charging

The POWER SUPPLY ASIC is able to charge the battery at voltages below 3.2V without any

support from the charge SW. The current will by measured indirectly via the voltage drop

over a shunt resistor and linearly regulated inside the POWER SUPPLY ASIC. The current

level during trickle charge for voltages <2.8V is in a range of 20-50mA and in a range of 50100mA for voltages up to 3.75V. To limit the power dissipation of the dual charge FET the

trickle charging is stopped in case the output voltage of the charger exceeds 10 Volt. The

maximum trickle time is limited to 1 hour. As soon as the battery voltage reaches 3.2 V the

POWER SUPPLY ASIC will switch on the phone automatically and normal charging will be

initiated by software (note the restrictions on this item as stated below).

Normal Charging

For battery voltages above 3.2 Volt and normal ambient temperature between 5 and 40°C the

battery can be charged with a charge current up to 1C*. This charging mode is SW controlled

and starts if an accessory (charger) is detected with a supply voltage above 6.4 Volt by the

POWER SUPPLY ASIC. The level of charge current is limited/controlled by the accessory or

charger.

INFO:

* C-rate

The charge and discharge current of a battery is measured in C-rate. Most portable batteries,

are discharge with 1C. A discharge of 1C draws a current equal to the battery capacity. For

example, a battery value of 1000mAh provides 1000mA for one hour if discharged at 1C. The

same battery discharged at 0.5C provides 500mAfor two hours. At 2C, the same battery

delivers 2000mA for 30 minutes. 1C is often referred to as a one-hour discharge; a 0.5 would

be a two-hour, and a 0.1C a 10 hour discharge.

Service Repair Documentation

Level 2.5e – A65R

Page 36 of 47

Release 1.0

Page 37

Restrictions

• A battery which has completely run down can not be re-charged quickly because the

battery voltage is less than 3.0V and the logic which implements the charge control cannot

be operated at this low voltage level. In this case the battery is recharged via tricklecharging. However, the charging symbol cannot be shown in the display because at this

time logic supply voltages are not operating. The charging time for this trickle-charging

(until the battery can be fast-charged from then on) is in the range of 1 hour. If, within this

time, the battery voltage exceeds 3.2V, then the POWER SUPPLY ASIC switches on the

mobile and charging continues in the Charge-Only Mode. In some circumstances it can

happen that after trickle-charging and the usually initiated switch-on procedure of the

mobile, the supply voltage collapses so much that the mobile phone switches off again. In

this case trickle charging starts again with a now raised threshold voltage of 3.75V instead

of 3.2V, at maximum for 20 minutes. The POWER SUPPLY ASIC will retry switching on

the phone up to 3 times (within 60 minutes overall).

• Charging the battery will not be fully supported in case of using old accessory (generation

‘45’ or earlier). It is not recommended to use any cables that adapt “old” to “new” Lumberg

connector. Using such adapters with Marlin will have at least the following impact:

1) half-sine wave chargers (e.g. P35 & home station) can not be used for trickle charging

2) normal charging might be aborted before the battery is fully charged

3) EMC compliance can not be guaranteed

• A phone with a fully charged LiIon battery will not be charged immediately after switch-on.

Any input current would cause an increase of the battery voltage above the maximum

permissible value. As soon as the battery has been discharged to a level of about 95%

(due to current consumption while use), it will be re-charged in normal charging mode.

• The phone cannot be operated without a battery.

• The phone will be destroyed if the battery is inserted with reversed polarity:

⇒ design-wise it is impossible to wrongly pole the phone. This is prevented by mechanical

means.

⇒ electrically, a correctly poled battery is presumed, i.e. correct polarity must be

guaranteed by suitable QA measures at the supplier

• The mobile phone might be destroyed by connecting an unsuitable charger:

⇒ a charger voltage >15V can destroy resistances or capacitors

⇒ a charger voltage >20V can destroy the switch transistor of the charging circuit

In case the transistor fails the ASIC will be destroyed. In the case of voltages lower than

15V and an improper current limitation the battery might be permanently damaged. A

protection against grossly negligent use by the customer (e.g. direct connection of the

charge contact to the electricity supply in a motor car) is not provided. Customer safety will

not be affected by this restriction.

Service Repair Documentation

Level 2.5e – A65R

Page 37 of 47

Release 1.0

Page 38

7 Interfaces

7.1 Vibra

XG227

Pin IN/OUT Remarks

1 I BATT+

2 O The FET V211, switching this signal, is controlled via

the EGOLD+ signal VIBRA_UC.

7.2 Earpiece

XG250

Pin Name IN/OUT Remarks

1 EPP1 O 1st connection to the internal earpiece. Earpiece can be

switched off in the case of accessory operation. EPP1

builds together with EPN1 the differential output to drive

the multifunctional “earpiece” (earpiece, ringer,

handsfree function).

2 EPN1 O 2nd connection to the internal earpiece. Earpiece can be

switched off in the case of accessory operation.

Page 38 of 47

Service Repair Documentation

Level 2.5e – A65R

Release 1.0

Page 39

7.3 Microphone

XG242

Pin Name IN/OUT Remarks

1 MICP1 O Microphone power supply. The same line carries the low

frequency speech signal.

2 MICN1 I Speech signal. The same line carries the microphone

power supply.

3 GND_MIC

7.4 Battery

Service Repair Documentation

Level 2.5e – A65R

XG181

Pin Name Level Remarks

1 GND - Ground

2 AKKU_TYP 0V...2.65V Recognition of

battery/supplier

3 BATT+ 3 V... 4.5V Positive battery pole

Page 39 of 47

Release 1.0

Page 40

7.5 IO Connector with ESD protection

7.5.1 IO Connector – New Slim Lumberg

Name IN/OUT Notes

Pin

1 POWER I/O POWER is needed for charging batteries and for supplying

the accessories. If accessories are supplied by mobile, talktime and standby-time from telephone are reduced.

Therefore it has to be respected on an as low as possible

power consumption in the accessories.

2 GND

3 TX O Serial interface

4 RX I Serial interface

5 DATA/CTS I/O Data-line for accessory-bus

Use as CTS in data operation.

6 RTS I/O Use as RTS in data-operation.

7 CLK/DCD I/O Clock-line for accessory-bus.

Use as DTC in data-operation.

8 AUDIO_L Analog O driving ext. left speaker

With mono-headset Audio_L and Audio_R differential mode

9 AUDIO_REF Analog O mid-voltage

in stereo mode reference to

AUDIO_L and AUDIO_R in mono mode not used

10 AUDIO_R Analog O driving ext. right speaker With mono-headset Audio_L and

Audio_R differential Signal

11 GND_MIC Analog I for ext. microphone

12 MICP2 Analog I External microphone

Service Repair Documentation

Level 2.5e – A65R

Page 40 of 47

Release 1.0

Page 41

7.5.2 ESD Protection with EMI filter

The Z211 is a 5-channel filter with over-voltage and ESD Protection array which is designed

to provide filtering of undesired RF signals in the 800-4000MHz frequency band Additionally

the Z211 contains diodes to protect downstream components from Electrostatic Discharge

(ESD) voltages up to 8 kV.

Pin configuration of the Z211

Z211 Circuit Configuration

Service Repair Documentation

Level 2.5e – A65R

Page 41 of 47

Release 1.0

Page 42

7.6 SIM

Pin Name IN/OUT Remarks

3 CCLK O Pulse for chipcard.

The chipcard is controlled directly from the EGOLD+.

2 CCRST O Reset for chipcard

I 7 CCIO

O

1 CCVCC - Switchable power supply for chipcard;

Data pin for chipcard;

10 kΩ pull up at the CCVCC pin

220 nF capacitors are situated close to the chipcard pins and are

necessary for buffering current spikes.

7.7 Display

Pin Name Remarks

1 2.9V Power supply display controller

2 LCD_CLK Clock

3 LCD_DAT Data line

4 LCD_RS Register select

5 LCD_CS Chip select

6 GND GND

7 VLCD Power supply display

8 LCD_RESET Reset

Page 42 of 47

Service Repair Documentation

Level 2.5e – A65R

Release 1.0

Page 43

8 Acoustic

The buzzer and the keypad clicks will be realized over the earpiece. At normal buzzer the

signaling will realized with swelling tones. At the same time a maximum sound pressure level

in the coupler of 135 +/- 5dB(A) is fixed.

The standard sounds will be generated by the EGOLD+, the advanced sounds will be

generated via firmware running on the DSP.

8.1 Microphone

8.1.1 Mechanical

The microphone is built in the Mounting Frame Lower Part and is mechanically fixed with a

rubber seal (gasket). The contact on the PCB is realized via spiral springs, which are

integrated in the gasket. Because of usage of Unidirectional Microphone, the gasket has a

front- and a back sound-inlet hole. The front sound-inlet is acoustically tighten connected with

a sound-inlet at the rear-side of the mounting frame lower part. The back sound-inlet is

acoustically tighten connected with a sound-inlet at the bottom-side of the mounting frame

lower part. The gasket of the microphone has a asymmetrical shape in order to provide nonrotating, guaranteed covering of the sound-inlets of mounting frame lower part to the

corresponding sound-inlets at microphone gasket.

8.1.2 Electrical

Both Microphones are directly connected to the EGOLD+.(Analog Interface G2, F1-G3, H2) via the

signals MICN1, MICP1

Microphone/Headset). Power supply for the Microphone is VMIC (EGOLD+

(Internal Microphone )and MICN2, MICP2 (External

.(Analog Interface G1))

Service Repair Documentation

Level 2.5e – A65R

Page 43 of 47

Release 1.0

Page 44

g

8.2 Earpiece/Loudspeaker

8.2.1 Mechanical

The speaker module is designed to provide optimal performance for mobile handsfree and

sound ringer. Plus independent from mobile leakage sound performance. Therefore speaker

module is a system that has a closed front volume with sound-outlets towards the ear of the

user. Back volume of Speaker module is using the unused air between the antenna and the

PCB. Back volume is just used for resonance, there is no sound output from back volume.

The speaker module is glued to the light guide and contacted via two bending springs to the

PCB. The light guide itself is screwed with six screws via the PCB to the mounting frame

lower part. Two of the six screws are located besides of the connection of speaker module

and light guide. Therefore a good and reliable connection between speaker module and PCB

should be provided.

8.2.2 Electrical

The internal and external Loudspeaker (Earpiece) is connected to the voiceband part of the

EGOLD+

EPP1_FIL. Output for external loudspeaker AUDIO_L - AUDIO_R, for internal Loudspeaker

EPP! – EPN1. The ringing tones are generated with the loudspeaker too. To activate the

ringer, the signal RINGIN from the EGOLD+

(Analog Interface B1, C1) via audio amplifier inside the ASIC (D361). Input EPN1_FIL -

(Miscellaneous,D16) is used

to ASIC

from

Bri

ht IC

EGOLD+

Page 44 of 47

Service Repair Documentation

Level 2.5e – A65R

Release 1.0

Page 45

9 Display and Illumination

9.1 Display

The display is provided with 2,65V from the ASIC (D361). The communication with the

EGOLD+ by the LCD-Signals, directly connected to the EGOLD+

Pin Name Remarks

1 LCD_CS Chip select

2 LCD_RESET Reset

3 LCD_RS Register select

4 LCD_CLK Clock

5 LCD_DAT Data line

6 2.9V Power supply display controller

7 GND GND

8 LCD_LED2_A Power supply display led 2

9 LIGHT_K Switched GND for display led 1 and led 2

10 LCD_LED1_A Power supply display led 1

Service Repair Documentation

Level 2.5e – A65R

Page 45 of 47

Release 1.0

Page 46

9.2 Illumination

The light is switched via switches inside the EGOLD+. With the signal LIGHT_KB (Miscellaneous

T17

) the illumination for the keyboard is controlled, with LIGHT_LCD. (GSM TDMA-Timer G15).

Required voltage for the display illumination is LCD_LED1_A and LCD_LED2_A.

The voltage regulator N280 with a nominal output voltage of 2.8V is used.

Required voltage for the keypad illumination is 2.9V from the Power Supply ASIC.

Service Repair Documentation

Level 2.5e – A65R

Page 46 of 47

Release 1.0

Page 47

10 Keyboard

The keyboard is connected via the lines KB0 – KB9 with the EGOLD+.

KB 7 is used for the ON/OFF switch. The lines KB0 – KB5 are used as output signals. In the matrix

KB6, KB8 and KB9 are used as input signals for the EGOLD+.

Service Repair Documentation

Level 2.5e – A65R

Page 47 of 47

Release 1.0

Loading...

Loading...