Siemens 9510, 9610 Installation Manual

9510 / 9610 Power Meter

Installation Guide

DANGER

DANGER

ElectricaI equipment contains hazardous voltages and high speed moving parts.

ElectricaI equipment contains hazardous voltages and high speed moving parts.

Can cause death, serious injury or property damage.

Can cause death, serious injury or property damage.

See safety instruction contained herein. Restrict use to qualified personnel.

See safety instruction contained herein. Restrict use to qualified personnel.

The use of unauthorized parts in the repair of the equipment or tampering by unqualified personnel will

The use of unauthorized parts in the repair of the equipment or tampering by unqualified personnel will

result in dangerous conditions that can cause death, serious injury or property damage.

result in dangerous conditions that can cause death, serious injury or property damage.

IMPORTANT

IMPORTANT

The information contained herein is general in nature and not intended for specific application

The information contained herein is general in nature and not intended for specific application

purposes. It does not relieve the user of responsibility to use sound practices in application, installation,

purposes. It does not relieve the user of responsibility to use sound practices in application, installation,

operation, and maintenance of the equipment purchased. Siemens reserves the right to make changes

operation, and maintenance of the equipment purchased. Siemens reserves the right to make changes

at any time without notice or obligations. Should a conflict arise between the general information

at any time without notice or obligations. Should a conflict arise between the general information

contained in this publication and the contents of drawings or supplementary material or both, the latter

contained in this publication and the contents of drawings or supplementary material or both, the latter

shall take precedence.

shall take precedence.

QUALIFIED PERSONNEL

QUALIFIED PERSONNEL

For the purposes of this manual and product labels, "qualified personnel" is one who is familiar

For the purposes of this manual and product labels, "qualified personnel" is one who is familiar

with the installation, construction, or operation of the equipment and the hazards involved. In

with the installation, construction, or operation of the equipment and the hazards involved. In

addition, s/he has the following qualifications:

addition, s/he has the following qualifications:

(a) is trained and authorized to energize, de-energize, clear, ground, and tag circuits and

(a) is trained and authorized to energize, de-energize, clear, ground, and tag circuits and

equipment in accordance with established safety practices.

equipment in accordance with established safety practices.

(b) is trained in the proper care and use of protective gear equipment such as rubber gloves, hard

(b) is trained in the proper care and use of protective gear equipment such as rubber gloves, hard

hat, safety glasses or face shields, flash clothing, etc., in accordance with established safety

hat, safety glasses or face shields, flash clothing, etc., in accordance with established safety

procedures.

procedures.

(c) is trained in rendering first aid.

(c) is trained in rendering first aid.

SUMMARY

SUMMARY

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met in connection with installation, operation, or maintenance. Should further

possible contingency to be met in connection with installation, operation, or maintenance. Should further

information be desired or should particular problems arise which are not covered sufficiently for the pur-

information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the local the sales office.

chaser’s purposes, the matter should be referred to the local the sales office.

THE CONTENTS OF THIS INSTRUCTION MANUAL SHALL NOT BECOME PART OF OR MODIFY ANY PRIOR

THE CONTENTS OF THIS INSTRUCTION MANUAL SHALL NOT BECOME PART OF OR MODIFY ANY PRIOR

OR EXISTING AGREEMENT, COMMITMENT OR RELATIONSHIP. THE SALES CONTRACT CONTAINS ALL

OR EXISTING AGREEMENT, COMMITMENT OR RELATIONSHIP. THE SALES CONTRACT CONTAINS ALL

OBLIGATIONS OF SIEMENS ENERGY & AUTOMATION, INC. THE WARRANTY CONTAINED IN THE

OBLIGATIONS OF SIEMENS ENERGY & AUTOMATION, INC. THE WARRANTY CONTAINED IN THE

CONTRACT BETWEEN THE PARTIES IS THE SOLE WARRANTY OF SIEMENS ENERGY & AUTOMATION, INC.

CONTRACT BETWEEN THE PARTIES IS THE SOLE WARRANTY OF SIEMENS ENERGY & AUTOMATION, INC.

ACCESS, ISGS, Isolated Multi-Drop, S7-I/O, SBwin, SAMMS-LV, SAMMS-MV,SEAbus,SIEServe, Static

ACCESS, ISGS, Isolated Multi-Drop, S7-I/O, SBwin, SAMMS-LV, SAMMS-MV,SEAbus,SIEServe, Static

Trip III, Wisdom, and WinPM are trademark, Sensitrip and Sentron are registered trademarks of Siemens

Trip III, Wisdom, and WinPM are trademark, Sensitrip and Sentron are registered trademarks of Siemens

Energy & Automation, Inc. SIEMENS is a registered trademark and Windows is a trademark of Microsoft

Energy & Automation, Inc. SIEMENS is a registered trademark and Windows is a trademark of Microsoft

Corporation. ION is a registered trademark of Power Measurement Ltd. All other product names men-

Corporation. ION is a registered trademark of Power Measurement Ltd. All other product names mentioned herein are used for identification purposes only and may be the trademarks or registered trade-

tioned herein are used for identification purposes only and may be the trademarks or registered trademarks of their respective companies.

marks of their respective companies.

Standards Compliance

CSA: Certified to CAN/

CSA C22.2 No.1010-1

Certified to

UL 3111

3

Installation Considerations

Installation and maintenance of the 9510/9610 meter should only be performed by qualified, competent personnel

that have appropriate training and experience with high voltage and current devices. The meter must be installed in

accordance with all Local and National Electrical Codes.

DANGER

Failure to observe the following instructions may result in severe injury or death.

◆ During normal operation of the 9510/9610 meter, hazardous voltages are present on its terminal strips,

and throughout the connected potential transformer (PT), current transformer (CT), digital (status) input,

control power and external I/O circuits. PT and CT secondary circuits are capable of generating lethal

voltages and currents with their primary circuit energized. Follow standard safety precautions while performing any installation or service work (i.e. removing PT fuses, shorting CT secondaries, etc).

◆ The terminal strips on the meter base should not be user-accessible after installation.

◆ Do not use digital output devices for primary protection functions. These include applications where the

devices perform energy limiting functions or provide protection of people from injury. Do not use the

9510/9610 in situations where failure of the devices can cause injury or death, or cause sufficient energy

to be released that can start a fire. The meter can be used for secondary protection functions.

◆ Do not HIPOT/Dielectric test the digital (status) inputs, digital outputs, or communications terminals. Refer

to the label on the 9510/9610 meter for the maximum voltage level the device can withstand.

CAUTION

Observe the following instructions, or permanent damage to the meter may occur.

◆ The 9510/9610 meter offers a range of hardware options that affect input ratings. The 9510/9610

meter’s serial number label lists all equipped options. Applying current levels incompatible with the current

inputs will permanently damage the meter. This document provides installation instructions applicable to

each hardware option.

◆ The 9510/9610 meter’s chassis ground must be properly connected to the switchgear earth ground for

the noise and surge protection circuitry to function correctly. Failure to do so will void the warranty.

◆ Terminal screw torque: Barrier-type (current, voltage, and relay terminal screws: 1.35 Nm (1.00 ft-lbf)

max. Captured-wire type (

digital inputs/outputs, communications, power supply: 0.90 Nm (0.66

ft.lbf) max.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense. The Ringer

Equivalence Number (REN) for the 9510/9610 optional internal modem is 0.6. Connection to the 9510/9610

internal modem should be made via an FCC Part 68 compliant telephone cord (not supplied). The 9510/9610

cannot be used on a public coin phone service or party line services.

Network Compatibility Notice for the Internal Modem

The internal modem in meters equipped with this option is compatible with the telephone systems of most countries

in the world, with the exception of Australia and New Zealand. Use in some countries may require modification of the

internal modem’s initialization strings. If problems using the modem on your phone system occur, please contact

Siemens Customer Service

4

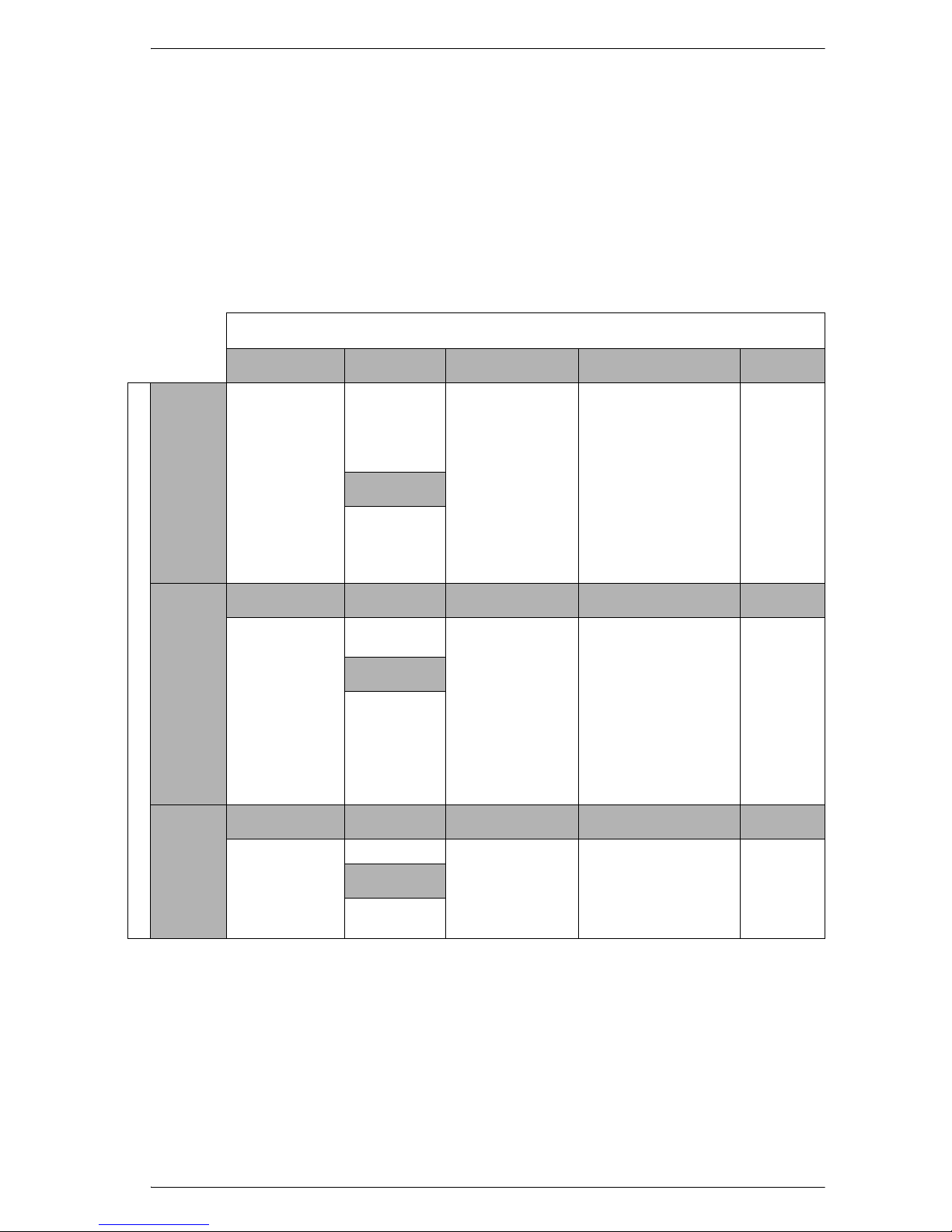

9510 / 9610 Models

Integrated Display Model

Comes with front optical port.

TRAN (transducer) Model

The TRAN model has no display.

Remote Terminal Unit (RTU)

The RTU (9510 only) has no power metering capability.

Available Options

Form Factor Current Inputs COM I/O Security

Option

9510

Model

9610

Integ. Display

TRAN

5 MB memory

10 MB memory

Up to 256

sampling rate

Standard

(5 Amp)

1 Amp

Current

probes

Power Supply

Standard

Low Voltage

DC

Standard (RS-232,

RS-485, optical)

Ethernet RJ45

Ethernet Fiber

Modem

Standard (8 digital

inputs, 3 Form C relays,

4 Form A outputs)

Extra 8 digital inputs

Four 0-1mA analog

inputs

Four 0-20 mA analog

inputs

Four -1 to 1mA analog

outputs

Four 0-20 mA analog

outputs

Standard

RMANSI

Form Factor Current Inputs COM I/O Security

Integ. Display

TRAN

5 MB memory

10 MB memory

Up to 512

sampling rate

(standard)

1024 sampling

rate (optional)

EN50160

compliance

Same as

9510

Power Supply

Same as

9510

Same as

9510

Same as 9510 Same as

Form Factor Current Inputs COM I/O Security

1

2

9510

9510

RTU

Integ. Display

TRAN

5 MB memory

10 MB memory

Notes

1

Standard = password protected, no locking or sealing.

2

RMANSI = ANSI C12.16 approved; meets ANSI C12.20 class 0.2

accuracy standards.

N/A Same as

9510

Power Supply

Same as

9510

Same as 9510 Standard

only

5

Before You Begin

Before installing the meter, familiarize yourself with the steps in this guide and

read the safety precautions presented on the “Installation Considerations”

page.

DANGER

Do not power up the meter until the current and voltage wiring is completed.

Recommended Tools

Phillips screwdriver

Precision flat-head screwdriver

Wire cutters / stripper

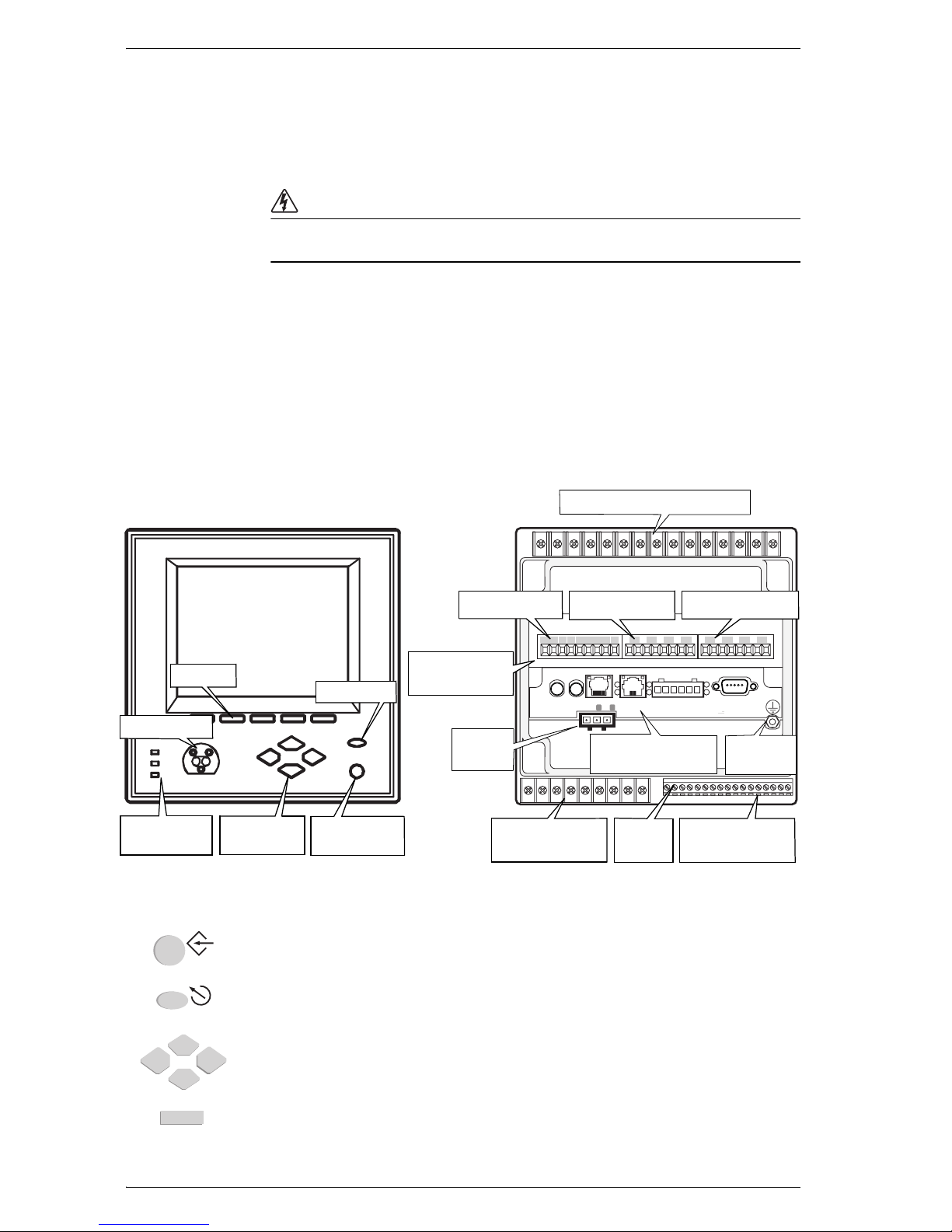

Meter Overview

Softkeys

Optical Port

Operational

LEDs

Meter Front

ESC Button

Navigation

Buttons

PROG/SELECT

Button

Front Panel Button Functions

Digital Inputs Analog Inputs Analog Outputs

I/O Expansion

Card

Power

Supply

Voltage and Current Inputs

DICOM

DI7

DI8

G

Form C

Digital Outputs

Meter Back

AI4

DI1

DI3DI4DI5DI6

DI2

DCD

_

+

L

N

AI1 AO1

AI2 A02

AI3 A03

RXD

Communications

Card

Digital

Inputs

Form A

Digital Outputs

AO4

TXDTXD

CCOM ARD

Ground

Te rm in al

PROG/SELECT: Press the PROG/SELECT (program or select) button to enter Setup

PROG

mode. In Setup mode, press the

ESC: Press the ESC (Escape) button to return to a higher menu or discontinue a

ESC

configuration change.

NAVIGATION: Press the UP / DOWN arrow buttons to highlight menu items, or

increment / decrement numbers.

Press the

SOFTKEY: Press a SOFTKEY button to select the parameter that you want to

configure from the sub-menus.

6

PROG/SELECT button to accept changes.

LEFT or RIGHT arrow buttons to move to an adjacent digit.

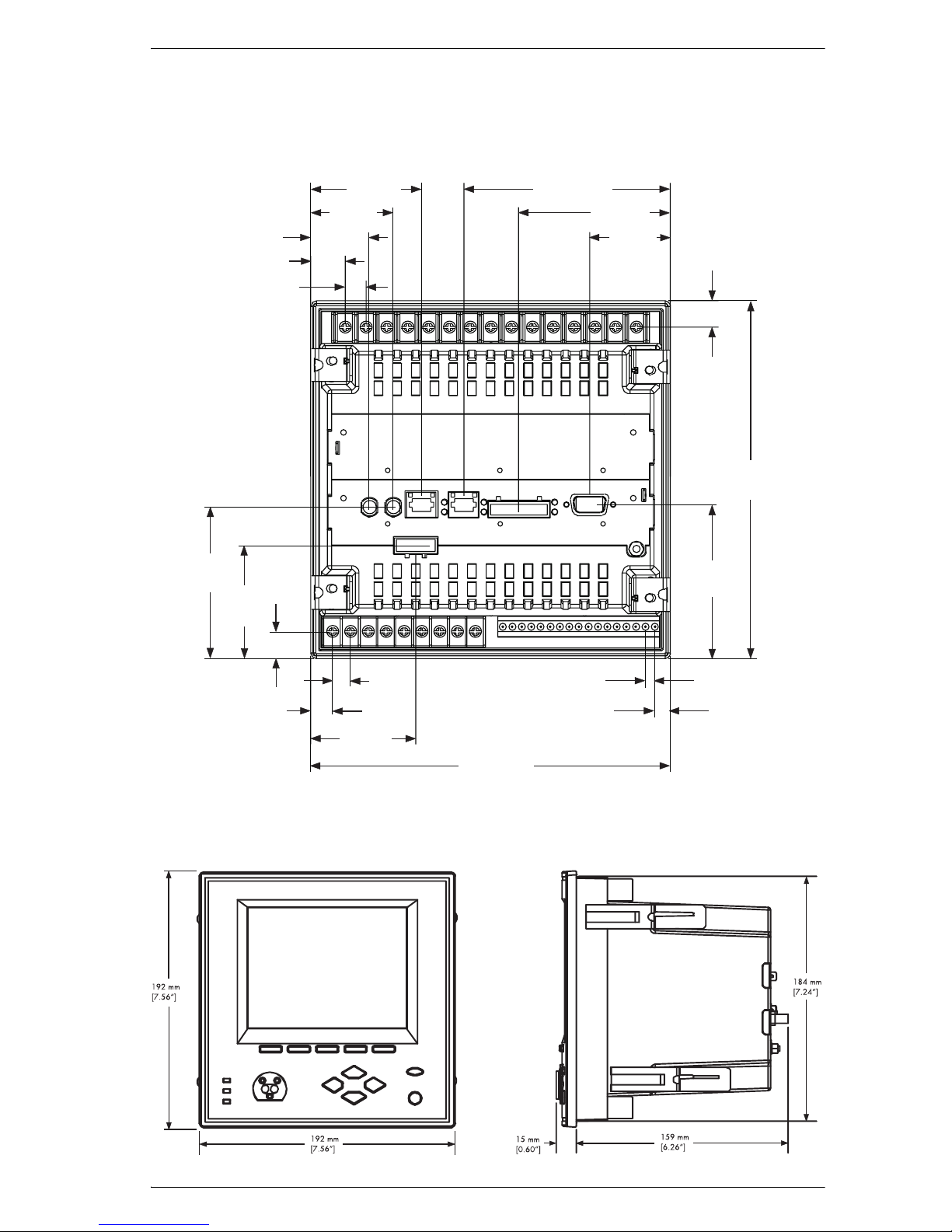

Unit Dimensions

Basic Model — Rear View

81.1mm

[3.19“]

31.9 mm

[1.23“]

18.3 mm

[0.72“]

11.1 mm

[0.44“]

60.7 mm

[2.39“]

14.2 mm

[0.56“]

59.0 mm

[2.322“]

43.9 mm

[1.73“]

56.1 mm

[2.21“]

9.5 mm

[0.38“]

11.5 mm

[0.45“]

192.0 mm

[7.56“]

110.4 mm

[4.35“]

5.1 mm

[0.20“]

8.48 mm

[0.33“]

80.9 mm

[3.19“]

43.3 mm

[1.71“]

14.2 mm

[0.56“]

192.0 mm

[7.56“]

82.5 mm

[3.25“]

Basic Model — Front View

Basic Model — Side View

7

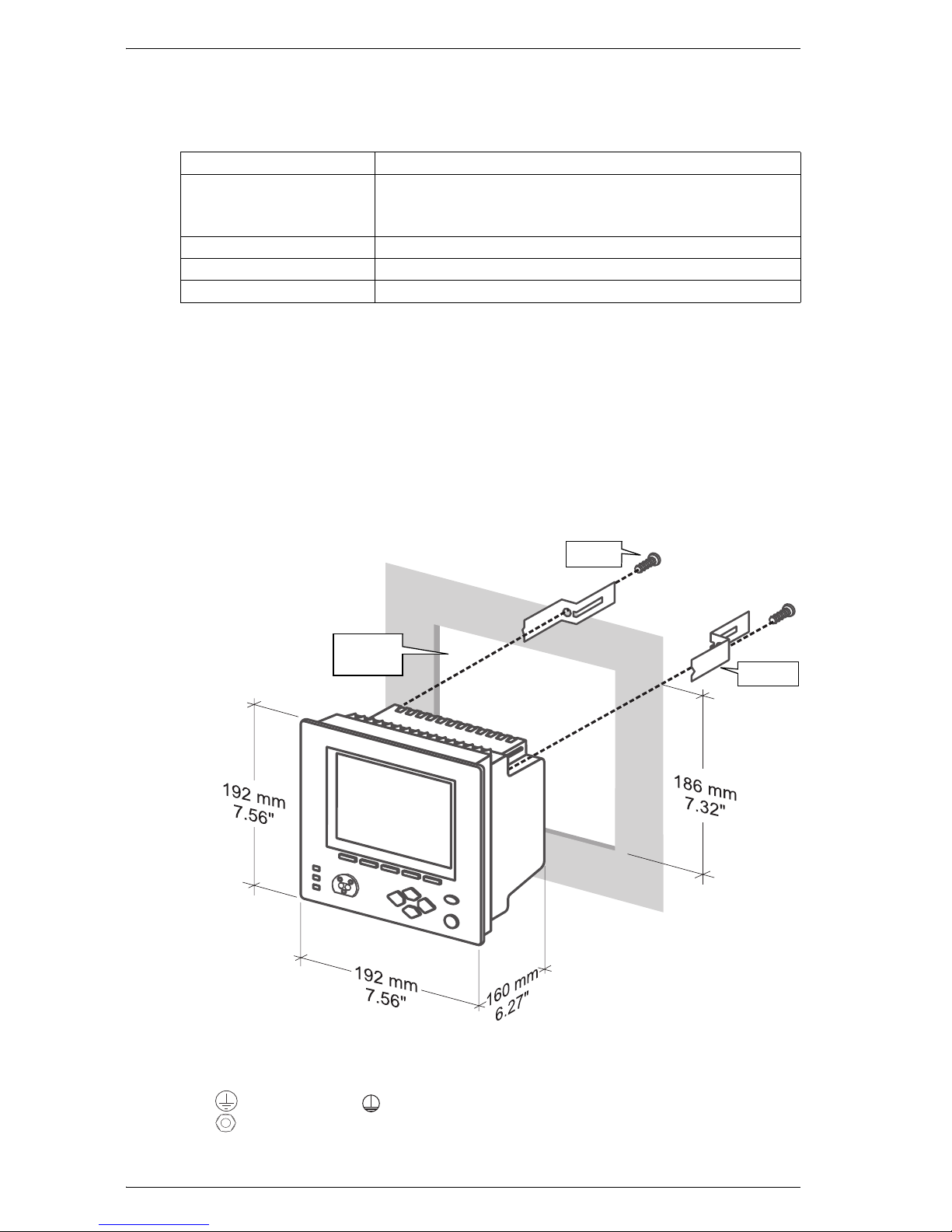

Step 1: Mount the Meter

Environmental Specifications

Mounting Location Indoor use

-20 to +70ºC (-4 to +158ºF) Standard Power Supply

Operating Range

Display Operating Range -20 to +70ºC (-4 to +158ºF)

Storage Range -40 to +85ºC (-40 to +185ºF)

Relative Humidity Range 5 to 95% non-condensing

Meter Battery Considerations

The meter’s battery life expectancy depends on both temperature and the

amount of time the meter is without power. For typical installations, the

battery should last 20 years or more. If the meter is not powered, the battery

will last a minimum of 7 years at room temperature.

Integrated Display Model

1. Fit the meter into the DIN standard 192 cutout (186 mm by 186 mm).

2. Slide the four brackets into their slots on the back of the meter and secure

using the four Phillips head screws. Do not overtighten.

-20 to +50ºC (-4 to +122ºF) Low Voltage DC Power Supply

No formation of ice

DIN 192

Cutout

Screw

Bracket

Step 2: Wire the Ground Terminal

Connect the terminal to a good earth ground with a 2.1 mm2 (14 AWG)

wire. Ensure that the terminal nut is tightened down securely onto the ground

wire. Do not use metal door hinges as a grounding point.

8

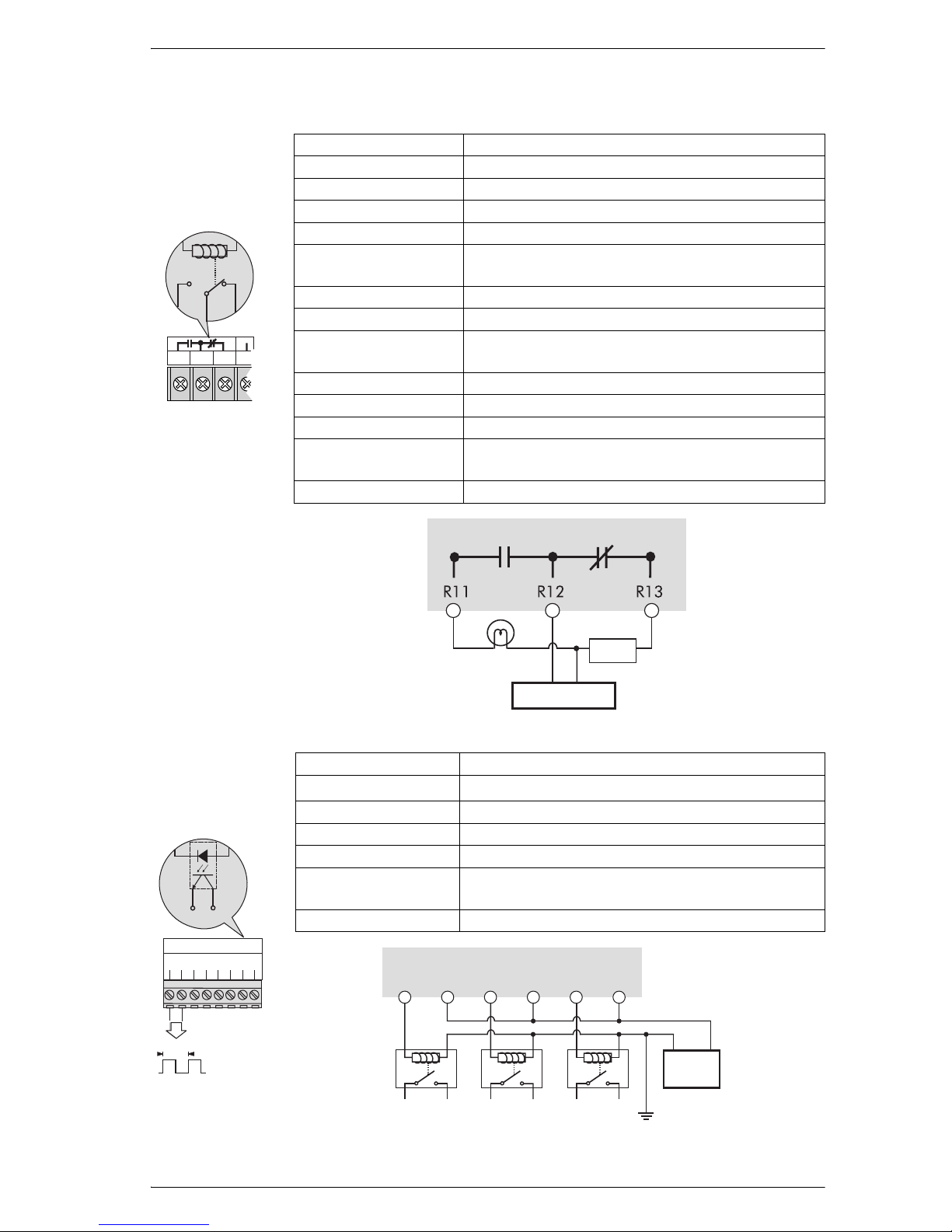

Step 3: Wire the Digital I/O and Analog I/O

Form C Digital Outputs: Mechanical Relays R1 - R3

Type Form C (R1, R2, R3)

Internal Form C

Mechanical

Relay

R11

R11 R12

R12

R13

R13

R21

Contacts NO, K, NC

Wire Use wiring that is appropriate for the application

Connector Ring or split ring connector

Voltage Rating 250 VAC / 30 VDC

Rated Load @

Rated Voltage

Resistive: 10 A (AC/DC)

Inductive (PF=0.4): 7.5 A (AC) / 5 A (DC)

Max. Voltage 380 VAC / 125 VDC between K and NO/NC

MOV Protection 300 V max. between NO and NC

Max. Load @

Max. Voltage

3 A (AC) / 0.2 A (DC)

Turn-On Time 15 ms max.

Isolation 5,000 VAC for 60 s

Turn-Off Time 5 ms max.

Lifetime

No load = 10,000,000 operations

Rated voltage and load = 100,000 operations

Update time ½ cycle or 1 s

K

Meter

Alarm Lamp

External Supply

Form A Digital Outputs: Solid State Relays D1 - D4

Typ e Fo r m A (D1, D2, D3, D4)

Internal Form A

Solid State Relay

+

_

D1

DIGITAL OUTPUTS

D3

D4

-

D2

-

+

D1

+

-

+

-

Wire

1.3 to 0.1 mm

Signal Type Continuous or pulse

Max. Load Voltage 30 VDC

Max. Load Current 80 mA per channel

Isolation

Optically isolated; max. 5,000 V RMS isolation

(UL-E91231)

Scan Time ½ cycle or 1 s

+

_

D3

+

Meter

_

D2

2

(16 to 28 AWG)

+

_

NCNO

Mechanical

relays should

always be

protected by

external fuses

Load

+

D1

1.8 Wh

D4 output is factory-configured to pulse once every 1.8 Wh for Class 20 meters,

or once every 0.18Wh for Class 2 meters (for calibration testing purposes).

External

Relays

+

+

_ _

+

_

+

_

External Supply

30VDC max

9

Loading...

Loading...