Page 1

I

XG-NV3XB

($1 S HARP

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

SERVICE MANUAL

S88W4XG-NV3XB

PAL/SECAM/NTSC SYSTEM

LCD PROJECTOR

MODEL

XG-NV3XB

- \.

CONTENTS

Page

SPECIFICATIONS ..............................................

IMPORTANT SERVICE SAFETY NOTES.. ....... .3

NOTE TO SERVICE PERSONNEL.. ................. .4

OPERATION MANUAL ......................................

REMOVING OF MAJOR PARTS . ...................... 13

,>’

RESETTING THE TOTAL LAMP TIMER.. ........ 18

THE OPTICAL UNIT OUTLINE ........................ 19

CONVERGENCE AND

FOCUS ADJUSTMENT ...................................

ELECTRICAL ADJUSTMENT

ADJUSTING THE PC BOARD ......................... 30

TROUBLE SHOOTING TABLE ........................ 31

CHASSIS LAYOUT ..........................................

..........................

2

l BLOCK DIAGRAM ........................................... 49

. OVERALL WIRING DIAGRAM ......................... 53

l DESCRIPTION OF SCHEMATIC DIAGRAM -55

8 l WAVEFORMS ..................................................

SCHEMATIC DIAGRAM ...................................

l PRINTED WIRING BOARD ASSEMBLIES.. . .I07

l PARTS LIST

............................... 123

.................................. 165

20

25

47

n ELECTRICAL PARTS

111 CABINET AND MECHANICAL PARTS.. . .157

n ACCESSORIES PARTS ........................... 164

n PACKING PARTS .....................................

l PACKING OF THE SET

Page

56

57

164

SHARP CORPORA’[ON

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

XG-NV3XB

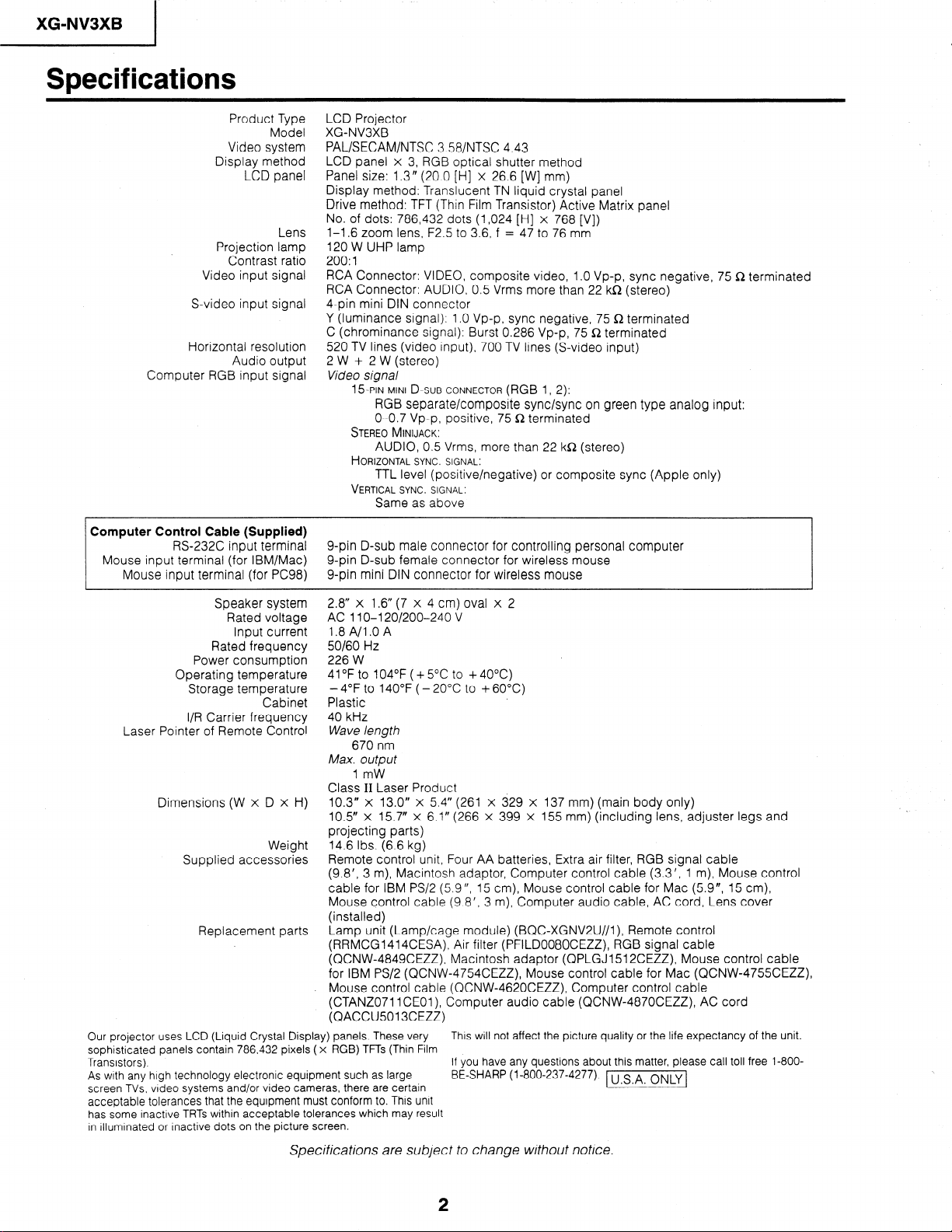

Specifications

Product Type

Model

Video system

Display method

LCD panel

Lens

Projection lamp

Contrast ratio

Video input signal

S-video input signal

Horizontal resolution

Audio output

Computer RGB input signal

Computer Control Cable (Supplied)

RS-232C input terminal

Mouse input terminal (for IBM/Mac)

Mouse input terminal (for PC98)

LCD Projector

XG-NV3XB

PAL/SECAM/NTSC 358/NTSC 4.43

LCD panel x 3, RGB optical shutter method

Panel size: 1.3 fl (20.0 [H] x 26.6 [W] mm)

Display method: Translucent TN liquid crystal panel

Drive method: TFT (Thin Film Transistor) Active Matrix panel

No. of dots: 786,432 dots (1,024 [H] x 768 [V])

I-1.6 zoom lens, F2.5 to 3.6, f = 47 to 76 mm

120 W UHP lamp

200: 1

RCA Connector: VIDEO, composite video, 1 .O Vp-p, sync negative, 75 R terminated

RCA Connector: AUDIO, 0.5 Vrms more than 22 kS2 (stereo)

4-pin mini DIN connector

Y (luminance signal): 1 .O Vp-p, sync negative, 75 Q terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 Q terminated

520 TV lines (video input), 700 TV lines (S-video input)

2 W + 2 W (stereo)

Video signal

1 ~-PIN MINI D-SUB CONNECTOR (RGB 1, 2):

RGB separate/composite sync/sync on green type analog input:

O-O.7 Vp-p, positive, 75 R terminated

STEREO MINIJACK:

AUDIO, 0.5 Vrms, more than 22 kR (stereo)

HORIZONTAL SYNC. SIGNAL:

TTL level (positive/negative) or composite sync (Apple only)

VERTICAL SYNC. SIGNAL:

Same as above

g-pin D-sub male connector for controlling personal computer

g-pin D-sub female connector for wireless mouse

g-pin mini DIN connector for wireless mouse

Speaker system

Rated voltage

Input current

Rated frequency

Power consumption

Operating temperature

Storage temperature

Laser Pointer of Remote Control

Our projector uses LCD (Liquid Crystal Display) panels. These very

sophisticated panels contain 786,432 pixels ( x RGB) TFTs (Thin Film

Transistors).

As with any high technology electronic equipment such as large

screen TVs, video systems and/or video cameras, there are certain

acceptable tolerances that the equipment must conform to. This unit

has some inactive TRTs within acceptable tolerances which may result

in illuminated or inactive dots on the picture screen.

I/R Carrier frequency

Dimensions (W x D x H)

Supplied accessories

Replacement parts

Cabinet

Weight

2.8” x 1.6” (7 x 4 cm) oval x 2

AC 110-l 20/200-240 V

1.8 A/1 .O A

50/60 Hz

226 W

41 OF to 104°F ( + 5OC to + 40°C)

- 4OF to 140°F ( - 20°C to + 60°C)

Plastic

40 kHz

Wave length

670 nm

Max. output

1 mW

Class II Laser Product

10.3” x 13.0” x 5.4” (261 x 329 x 137 mm) (main body only)

10.5” x 15.7” x 6.1” (266 x 399 x 155 mm) (including lens, adjuster legs and

projecting parts)

14.6 Ibs. (6.6 kg)

Remote control unit, Four AA batteries, Extra air filter, RGB signal cable

(9.8’, 3 m), Macintosh adaptor, Computer control cable (3.3’, 1 m), Mouse control

cable for IBM PS/2 (5.9 ‘I, 15 cm), Mouse control cable for Mac (5.9”, 15 cm),

Mouse control cable (9.8’, 3 m), Computer audio cable, AC cord, Lens cover

(installed)

Lamp unit (Lamp/cage module) (BQC-XGNV2U//I), Remote control

(RRMCG1414CESA) Air filter (PFILD0080CEZZ) RGB signal cable

(QCNW-4849CEZZ) Macintosh adaptor (QPLGJ1512CEZZ), Mouse control cable

for IBM PS/2 (QCNW-4754CEZZ), Mouse control cable for Mac (QCNW-4755CEZZ)

Mouse control cable (QCNW-4620CEZZ), Computer control cable

(CTANZ071 lCEOI), Computer audio cable (QCNW-4870CEZZ) AC cord

(QACCUSOI 3CEZZ)

Specifications are subject to change without notice.

This will not affect the picture quality or the life expectancy of the unit.

If you have any questions about this matter, please call toll free 1-800-

BE-SHARP (I-800-237-4277).

[U.S.A.1

2

Page 3

XG-NV3XB

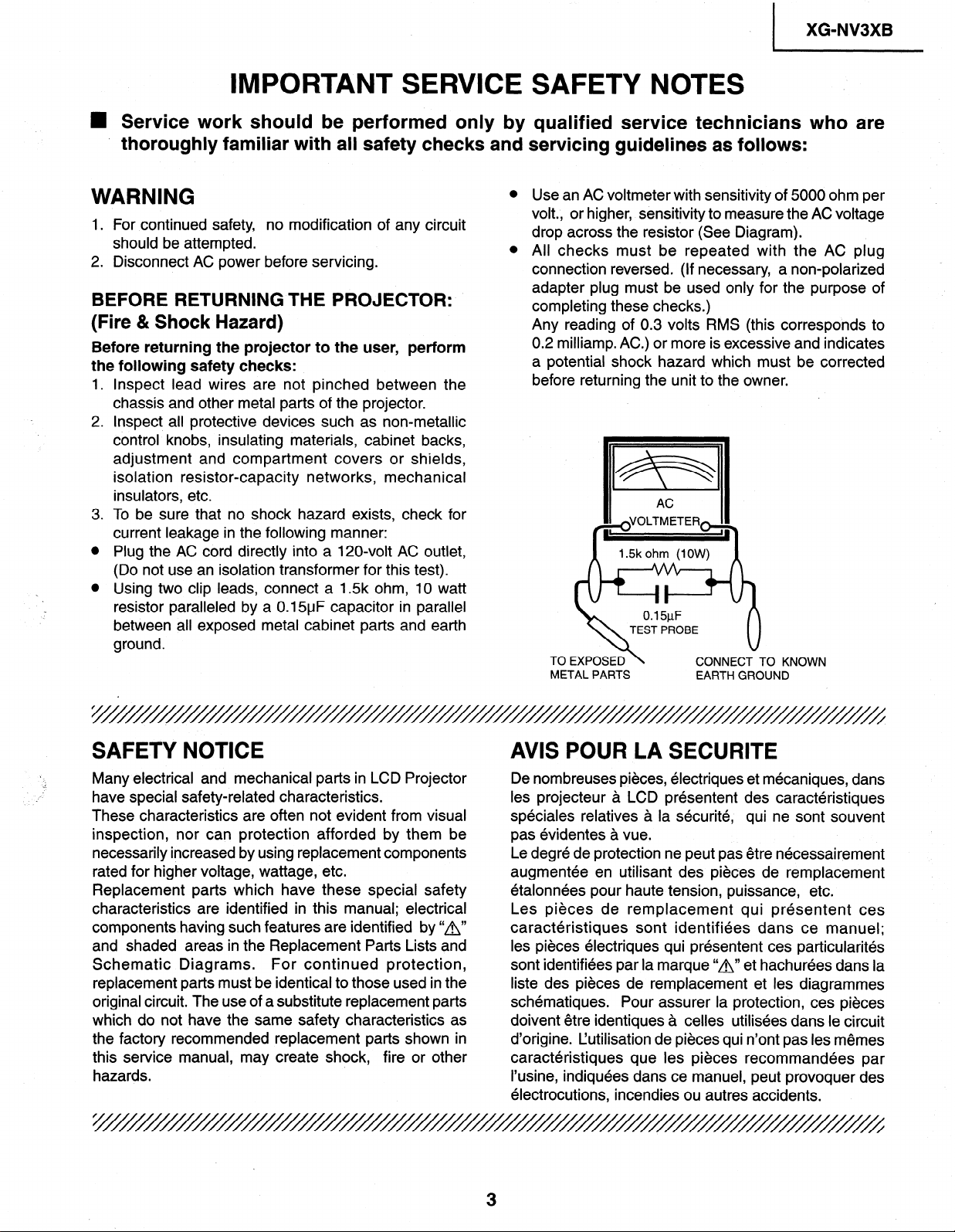

IMPORTANT SERVICE SAFETY NOTES

n Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

I .

.

. .

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

l Plug the AC cord directly into a 120~volt AC outlet,

(Do not use an isolation transformer for this test).

l Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15uF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor (See Diagram).

All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

TEST PROBE

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

~ .

.

_’

“‘.

SAFETY NOTICE

Many electrical and mechanical parts in LCD Projector

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “A”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

replacement parts must be identical to those used in the

original circuit. The use of a substitute replacement parts

which do not have the same safety characteristics as

the factory recommended replacement parts shown in

this service manual, may create shock, fire or other

hazards.

For continued protection,

AVIS POUR LA SECURITE

De nombreuses pieces, electriques et mecaniques, dans

les projecteur a LCD presentent des caracteristiques

speciales relatives a la securite, qui ne sont souvent

pas evidentes a vue.

Le degre de protection ne peut pas etre necessairement

augmentee en utilisant des pieces de remplacement

etalonnees pour haute tension, puissance, etc.

Les pieces de remplacement qui presentent ces

caracteristiques sont identifiees dans ce manuel;

les pieces electriques qui presentent ces particularites

sont identifiees par la marque “A” et hachurees dans la

liste des pieces de remplacement et les diagrammes

schematiques. Pour assurer la protection, ces pieces

doivent etre identiques a celles utilisees dans le circuit

d’origine. Cutilisation de pieces qui n’ont pas les memes

caracteristiques que les pieces recommandees par

I’usine, indiquees dans ce manuel, peut provoquer des

electrocutions, incendies ou autres accidents.

Page 4

XG-NV3XB

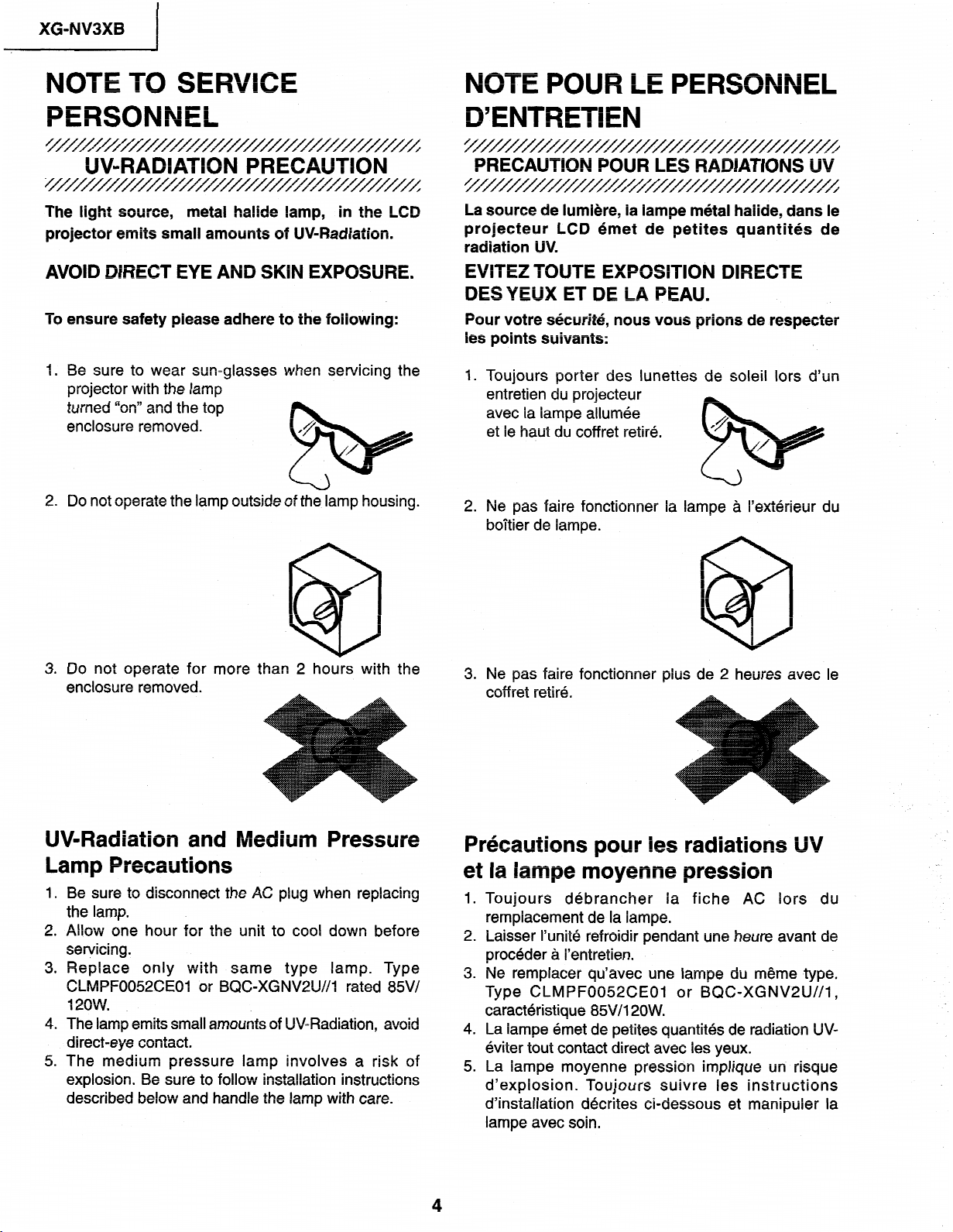

NOTE TO

SERVICE

PERSONNEL

c

UV-RADIATION

;///////////////////

The light source,

projector emits small amounts

AVOID

To ensure safety

1. Be

2. Do not operate the lamp outside of the lamp housing.

DIRECT

sure to wear sun-glasses when servicing the

projector

turned “on” and the top

enclosure removed.

with

metal

EYE AND SKIN

please adhere

the

lamp

PRECAUTION

halide

lamp, in the LCD

of

UV-Radiation.

EXPOSURE.

to the

following:

b

PRECAUTION POUR LES RADIATIONS UV

////////////////////

La source de lumibe,

projecteur LCD 6met de petites quantitQs de

radiation UV.

EVITEZ TOUTE

DESYEUX ET DE LA

Pour votre sburite,

les points

1. Toujours porter des lunettes de soleil

entretien du projecteur

avec la lampe allumee

et le haut du coffret

2. Ne pas faire fonctionner la lampe a I’exterieur du

bo7tier de lampe.

suivants:

la lampe

m&al halide, dans le

EXPOSITION DIRECTE

PEAU.

nous vous prions

retire.

de respecter

lors

d’un

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1

.

Be sure to disconnect the AC plug when replacing

the lamp.

.

Allow one hour for the unit to cool down before

2

servicing.

3 .

Replace only with same type lamp. Type

CLMPF0052CEOl or BQCXGNV2U//l rated 85V/

120w.

.

The lamp emits small amounts of UV-Radiation, avoid

4

direct-eye contact.

.

The medium pressure lamp involves a risk of

5

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le

coff ret retire.

Prhautions pour les radiations UV

et la lampe moyenne pression

1

.

Toujours debrancher la fiche AC lors du

remplacement de la lampe.

2

.

Laisser I’unite refroidir pendant une heure avant de

proceder a I’entretien.

.

Ne remplacer qu’avec une lampe du meme type.

3

Type CLMPF0052CEOl or BQC=XGNV2U//l,

caracteristique 85V/12OW.

4

.

La lampe emet de petites quantites de radiation UVeviter tout contact direct avec les yeux.

.

La lampe moyenne pression implique un risque

5

d’explosion. Toujours suivre les instructions

d’installation d&rites ci-dessous et manipuler la

lampe avec soin.

4

Page 5

/ XG-NV3XB

c

UV-RADIATION PRECAUTION (Continued)

3

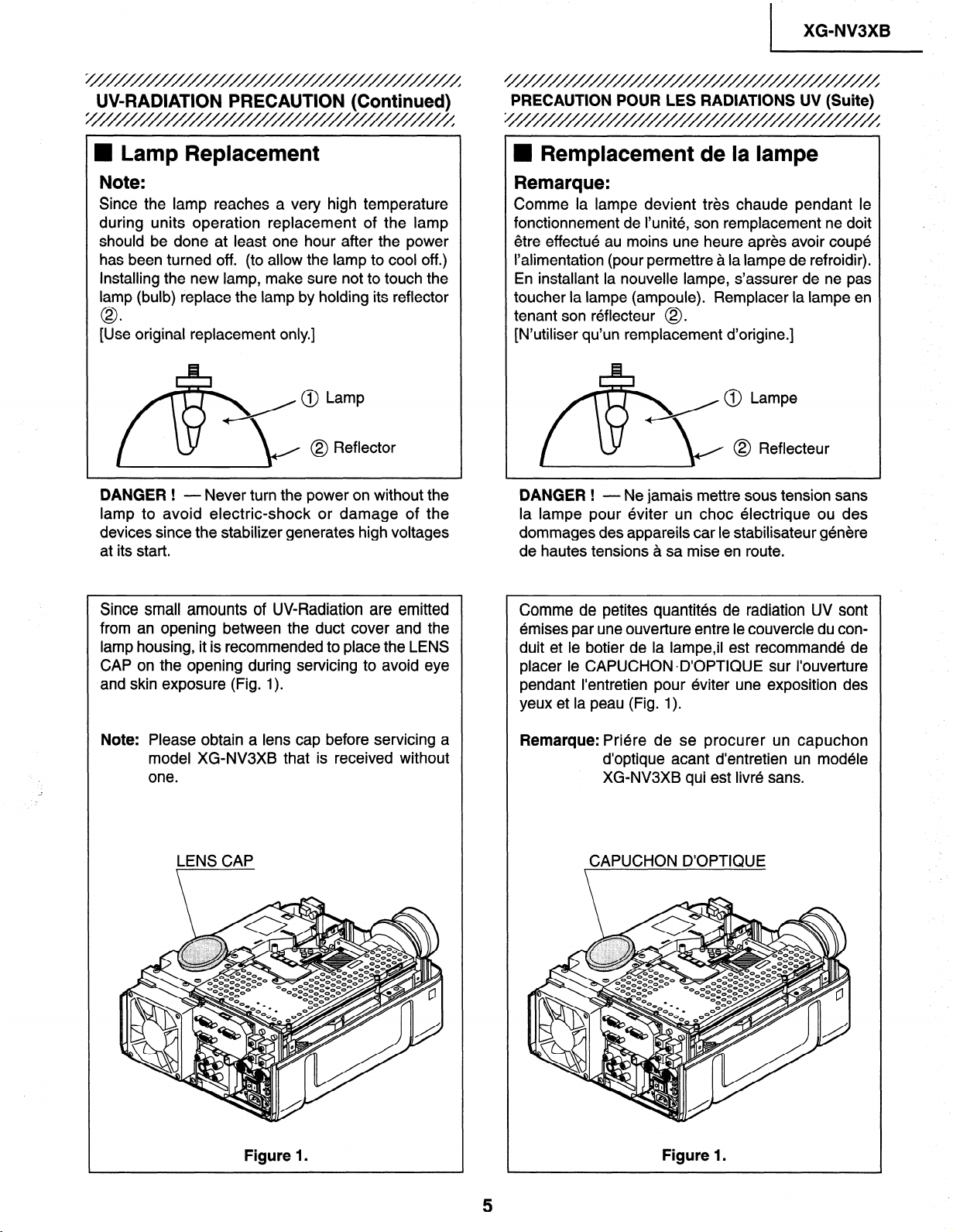

n Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

.

0

[Use original replacement only.]

/@ Lamp

A \J

DANGER ! - Never turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

@ Reflector

I

PRECAUTION POUR LES RADIATIONS UV (Suite)

<

n Remplacement de la lampe

Remarque:

Comme la lampe devient tres chaude pendant le

fonctionnement de I’unite, son remplacement ne doit

etre effectue au moins une heure apres avoir coupe

I’alimentation (pour permettre a la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son reflecteur 0.

[N’utiliser qu’un remplacement d’origine.]

/@ Lampe

d

DANGER !

la lampe pour eviter un choc electrique ou des

dommages des appareils car le stabilisateur g&We

de hautes tensions a sa mise en route.

- Ne jamais mettre sous tension sans

@ Reflecteur

Since small amounts of UV-Radiation are emitted

from an opening between the duct cover and the

lamp housing, it is recommended to place the LENS

CAP on the opening during servicing to avoid eye

and skin exposure (Fig. 1).

Note: Please obtain a lens cap before servicing a

model XG-NV3XB that is received without

one.

LENS CAP

Comme de petites quantites de radiation UV sont

emises par une ouverture entre le couvercle du conduit et le botier de la lampe,il est recommande de

placer le CAPUCHON D’OPTIQUE sur l’ouverture

pendant I’entretien pour eviter une exposition des

yeux et la peau (Fig. 1).

Remarque: Priere de se procurer un capuchon

d’optique acant d’entretien un modele

XG-NV3XB qui est livre sans.

CAPUCHON D’OPTIQUE

Figure 1.

Figure 1.

Page 6

XG-NV3XB

Cautions Concerning the Laser Pointer

Le pointeur laser de la telecommande

emet un rayon laser depuis I’ouverture

montree sur I’illustration ci-contre. Le laser

emis est un laser de classe II; toutefois,

evitez de regarder dans I’ouverture d’ou

sort le rayon ou de diriger le rayon laser

sur vous ou sur d’autres personnes. Les

trois marques a la gauche representent les

etiquettes de precaution pour le rayon

laser.

Toujours utiliser le pointeur laser a une

temperature entre 41°F et 104OF (entre

+ 5°C et +4O”C).

Attention:

l L’utilisation de commandes, de reglages ou

d’execution de procedures differentes de

celles mentionnees dans ce guide peuvent

entraber une exposition dangereuse aux

radiations.

DO NOT STARE INTO BEAM REMOTE CONTROL

r

AVOID EXPOSURE-

LASER RADIATION IS

EMITTED FROM THIS

APERTURE.

EVITER TOUTE

EXPOSITION

UN RAYONNEMENT

LASER EST iMlS

DEPUIS CETTE

OUVERTURE.

“COMPLIES WITH 21 CFR SUBCHAPTER J”

A

Sortie du faisceau laser

Prkautions touchant le pointeur laser

“COMPLIES WITH 21 CFR SUBCHAPTER J”

SHARP ELECTRONICS CORPORATION

SHARP PLAZA, MAHWAH, NEW JERSEY 07430

1 CLASS II LASER PRODUCT 1 FABRIQUt AU JAPON

AVOID EXPOSURE-

LASER RADIATION IS

EMITTED FROM THIS

APERTURE.

I I

A

The laser pointer on the remote control

emits a laser beam from the laser light

window shown in the figure to the left. The

laser emitted is a class II laser; therefore,

do not look into the laser window or shine

the laser beam on yourself or other people.

The three marks to the left are the caution

labels for the laser beam.

Always use the laser pointer at temperatures between 41 “F and 104°F ( + 5°C and

+ 40°C).

Caution:

0

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

LASER LIGHT WINDOW

WARNING: The bimetallic component has the primary conductive side exposed. Be very careful in

handling this component when the power is on.

,

AVERTISSEMENT: La composante bimetallique dispose du conducteur primaire d6nud6. Faire attention

lors de la manipulation de cette composante sous tension.

Page 7

XG-NV3XB

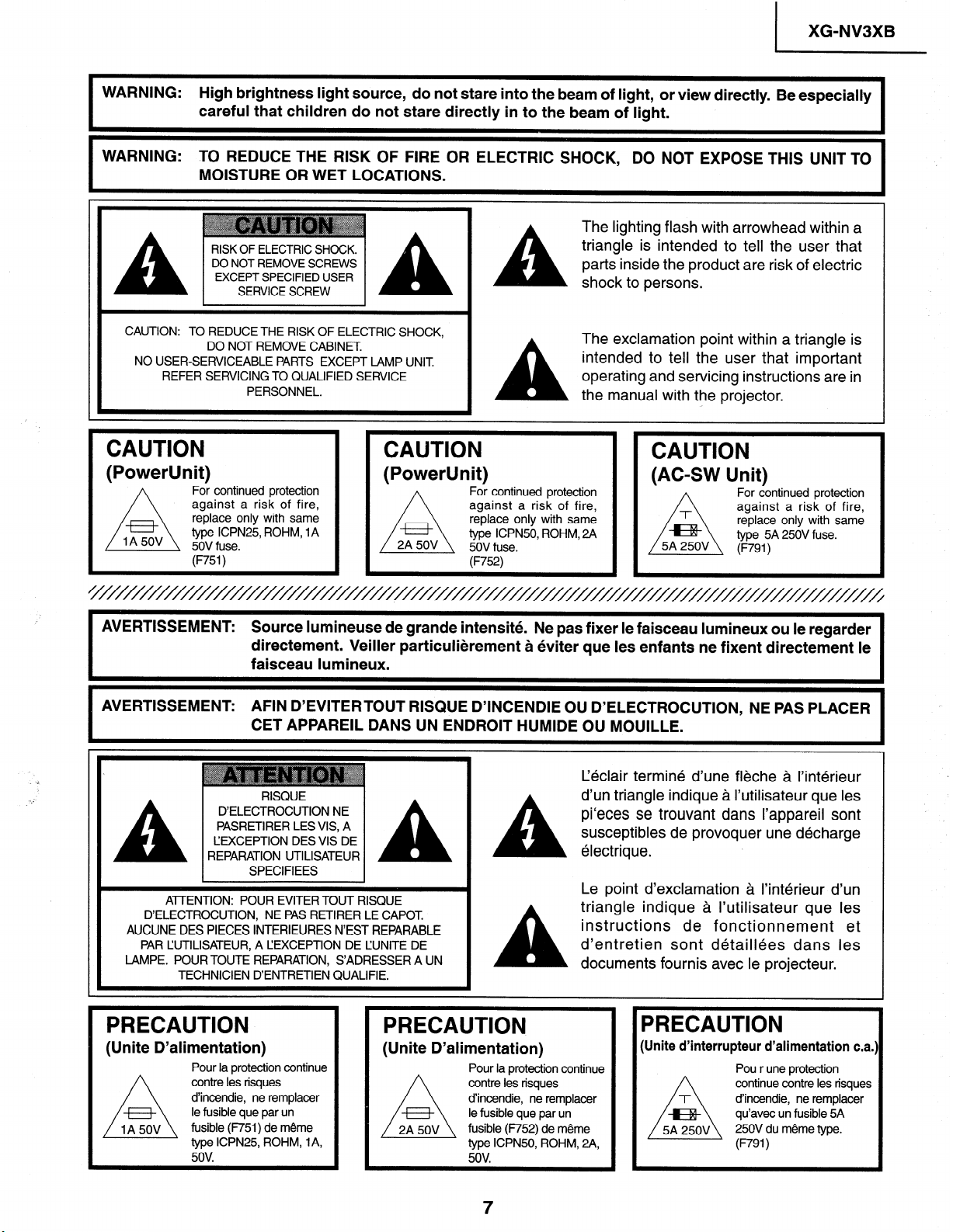

WARNING:

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT

CAUTION

(PowerUnit)

High brightness light source, do not stare into the beam of light, or view directly. Be especially

careful that children do not stare directly in to the beam of light.

MOISTURE OR WET LOCATIONS.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

DO NOT REMOVE CABINET

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

CAUTION

(PowerUnit)

For continued protection

against a risk of fire,

replace only with same

type ICPN25, ROHM, IA

50V fuse.

(F751)

A

A

For continued protection

against a risk of fire,

replace only with same

type ICPNSO, ROHM, 2A

50V fuse.

(F752)

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

(AC-SW Unit)

For continued protection

against a risk of fire,

replace only with same

type 5A 250V fuse.

(F791)

,

AVERTISSEMENT:

AVERTISSEMENT: AFIN D’EVITERTOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

A

AUENTION: POUR EVITER TOUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR WTILISATEUR, A CEXCEPTION DE LUNITE DE

LAMPE. POUR TOUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

PRECAUTION

(Unite D’alimentation)

Pour la protection continue

contre les risques

d’incendie, ne remplacer

le fusible que par un

fusible (F751) de meme

type ICPN25, ROHM, IA,

5oV.

Source lumineuse de grande intensite. Ne pas fixer le faisceau lumineux ou le regarder

directement. Veiller particulierement a eviter que les enfants ne fixent directement le

faisceau lumineux.

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

C&lair termine d’une fleche a I’interieur

RISQUE

D’ELECTROCUTION NE

PASRETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REPARATION UTILISATEUR

SPECIFIEES

A

I

PRECAUTION

(Unite D’alimentation)

Pour la protection continue

contre les risques

d’incendie, ne remplacer

le fusible que par un

fusible (F752) de meme

type ICPN50, ROHM, 2A,

5ov.

A

A

d’un triangle indique a I’utilisateur que les

pi‘eces se trouvant dans I’appareil sont

susceptibles de provoquer une decharge

electrique.

Le point d’exclamation a I’interieur d’un

triangle indique a I’utilisateur que les

instructions de fonctionnement et

d’entretien sont detaillees dans les

documents fournis avec le projecteur.

PRECAUTION

(Unite d’interrupteur d’alimentation c.a.]

Pou r une protection

continue contre les risques

d’incendie, ne remplacer

qu’avec un fusible 5A

250V du meme type.

(F791)

7

Page 8

XG-NV3XB

/

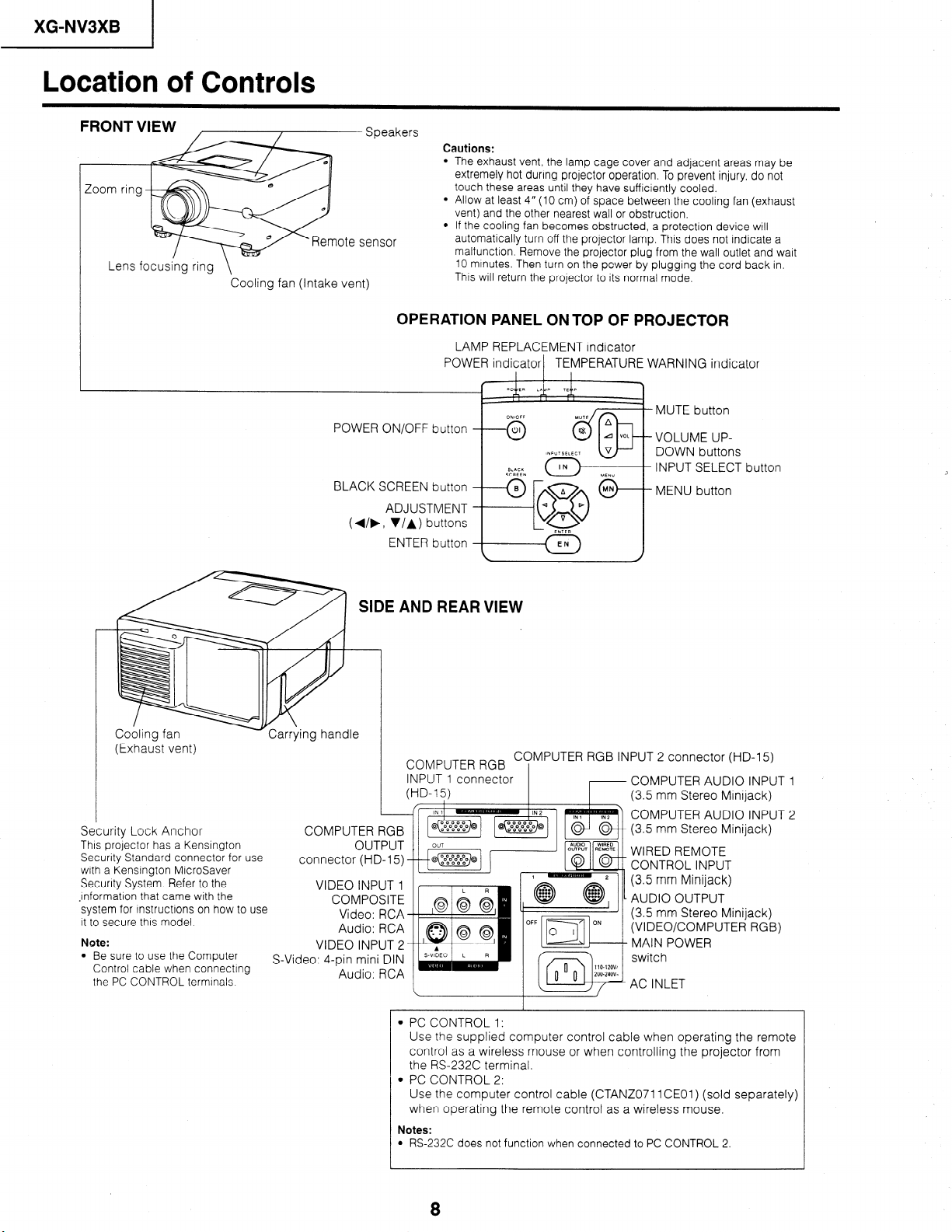

Location of Controls

FRONT VIEW

Zoom ring

Lens focusing ring

,

/

\

Cooling fan (Intake vent)

Speak .ers

Cautions:

l The exhaust vent, the lamp cage cover and adjacent areas may be

l Allow at least 4” (10 cm) of space between the cooling fan (exhaust

* If the cooling fan becomes obstructed, a protection device will

Tote s

ensor

OPERATION PANEL ON TOP OF PROJECTOR

POWER indicator1 TEMPERATURE WARNING indicator

POWER ON/OFF button

BLACK SCREEN button

ADJUSTMENT

(d/b, WA) buttons

ENTER button

extremely hot during projector operation. To prevent injury, do not

touch these areas until they have sufficiently cooled.

vent) and the other nearest wall or obstruction.

automatically turn off the projector lamp. This does not indicate a

malfunction. Remove the projector plug from the wall outlet and wait

10 minutes. Then turn on the power by plugging the cord back i

This will return the projector to its normal mode.

n.

LAMP REPLACEMENT indicator

MUTE button

VOLUME UPDOWN buttons

INPUT SELECT

button

MENU button

(Exhaust vent)

Security Lock Anchor

This projector has a Kensington

Security Standard connector for use

with a Kensington MicroSaver

Security System. Refer to the

-information that came with the

system for instructions on how to use

it to secure this model.

Note:

l Be sure to use the Computer

Control cable when connecting

the PC CONTROL terminals.

SIDE AND REAR VIEW

I

COMPUTER RGB

OUTPUT

connector (HD-15)

VIDEO INPUT 1

COMPOSITE

Video: RCA

Audio: RCA

VIDEO INPUT 2

S-Video: 4-pin mini DIN

Audio: RCA

COMPUTER RGB I

INPUT 1 connector

(HD-15)

/ I

COMPUTER RGB INPUT 2 connector (HD-15)

COMPUTER AUDIO INPUT 1

(3.5 mm Stereo Minijack)

COMPUTER AUDIO INPUT 2

(3.5 mm Stereo Minijack)

WIRED REMOTE

CONTROL INPUT

(3.5 mm Minijack)

AUDIO OUTPUT

(3.5 mm Stereo Minijack)

(VIDEO/COMPUTER RGB)

MAIN POWER

switch

l PC CONTROL 1:

I vu --+-

U

AC INLET

Use the supplied computer control cable when operating the remote

control as a wireless mouse or when controlling the projector from

the RS-232C terminal.

l PC CONTROL 2:

Use the computer control cable (CTANZ071 ICEOI) (sold separately)

when operating the remote control as a wireless mouse.

Notes:

l RS-232C does not function when connected to PC CONTROL 2.

Page 9

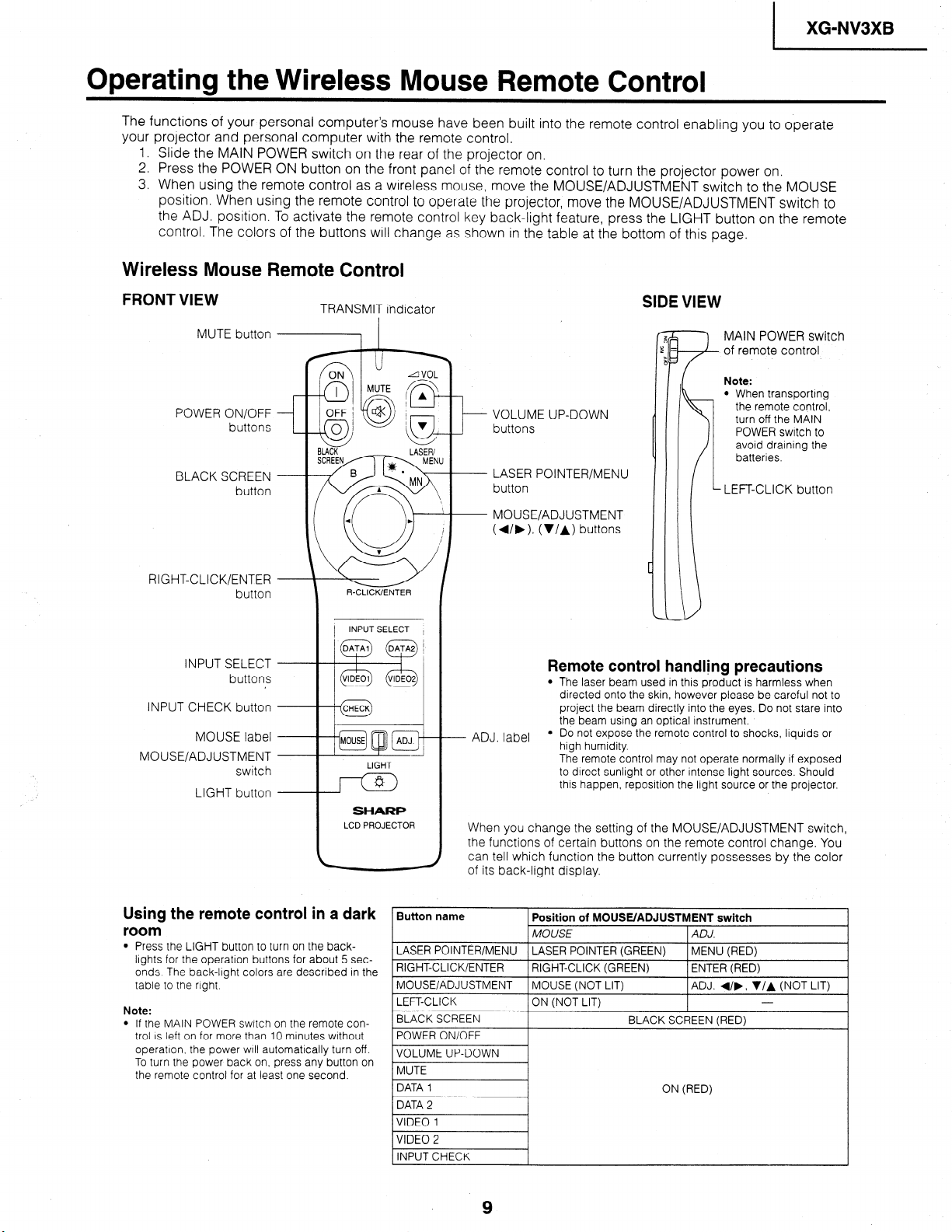

Operating the Wireless Mouse Remote Control

The functions of your personal computer’s mouse have been built into the remote control enabling you to operate

your projector and personal computer with the remote control.

1. Slide the MAIN POWER switch on the rear of the projector on.

2. Press the POWER ON button on the front panel of the remote control to turn the projector power on.

3. When using the remote control as a wireless mouse, move the MOUSE/ADJUSTMENT switch to the MOUSE

position. When using the remote control to operate the projector, move the MOUSE/ADJUSTMENT switch to

the ADJ. position. To activate the remote control key back-light feature, press the LIGHT button on the remote

control. The colors of the buttons will change as shown in the table at the bottom of this page.

Wireless Mouse Remote Control

XG-NV3XB

FRONT VIEW

MUTE button

POWER ON/OFF

BLACK SCREEN

RIGHT-CLICK/ENTER

INPUT SELECT

INPUT CHECK button

MOUSE label

MOUSE/ADJUSTMENT

LIGHT button

buttons

button

button

buttons

switch

TRANSMIT indicator

R-CLICK/ENTER

LIGHT

SHARP

LCD PROJECTOR

SIDE VIEW

MAIN POWER switch

zw-

VOLUME UP-DOWN

buttons

LASER POINTER/MENU

button

MOUSE/ADJUSTMENT

of remote control

Note:

0 When transporting

the remote control,

turn off the MAIN

POWER switch to

avoid draining the

batteries.

- LEFT-CLICK button

(4/b), (V/A> buttons

Remote control handl/ng precautions

l The laser beam used in this product is harmless when

directed onto the skin, however please be careful not to

project the beam directly into the eyes. Do not stare into

the beam using an optical instrument.

- ADJ. label

When you change the setting of the MOUSE/ADJUSTMENT switch,

the functions of certain buttons on the remote control change. You

can tell which function the button currently possesses by the color

of its back-light display.

l Do not expose the remote control to shocks, liquids or

high humidity.

The remote control may not operate normally if exposed

to direct sunlight or other intense light sources. Should

this happen, reposition the light source or the projector.

Using the remote control in a dark

room

l Press the LIGHT button to turn on the back-

lights for the operation buttons for about 5 seconds. The back-light colors are described in the

table to the right.

Note:

l If the MAIN POWER switch on the remote con-

trol IS left on for more than IO minutes without

operation, the power will automatically turn off.

To turn the power back on, press any button on

the remote control for at least one second.

Button name

LASER POINTER/MENU

RIGHT-CLICK/ENTER

1 MOUSE/ADJUSTMENT

LEFT-CLICK

BLACK SCREEN

1 POWER ON/OFF

1 VOLUME UP-DOWN 1

1 MUTE

1 DATA 1

i DATA 2

1 VIDEO 1

1 VIDEO 2

1 INPUT CHECK

9

Position of MOUSE/ADJUSTMENT switch

MOUSE 1 ADJ.

LASER POINTER (GREEN)

RIGHT-CLICK (GREEN) ENTER (RED)

1 MOUSE (NOT LIT)

ON (NOT LIT)

BLACK SCREEN (RED)

MENU (RED)

1 ADJ. 4/,, ‘I/A (NOT LIT)

1

I

I

I

ON (RED)

I

I

I

-

1

Page 10

XG-NV3XB

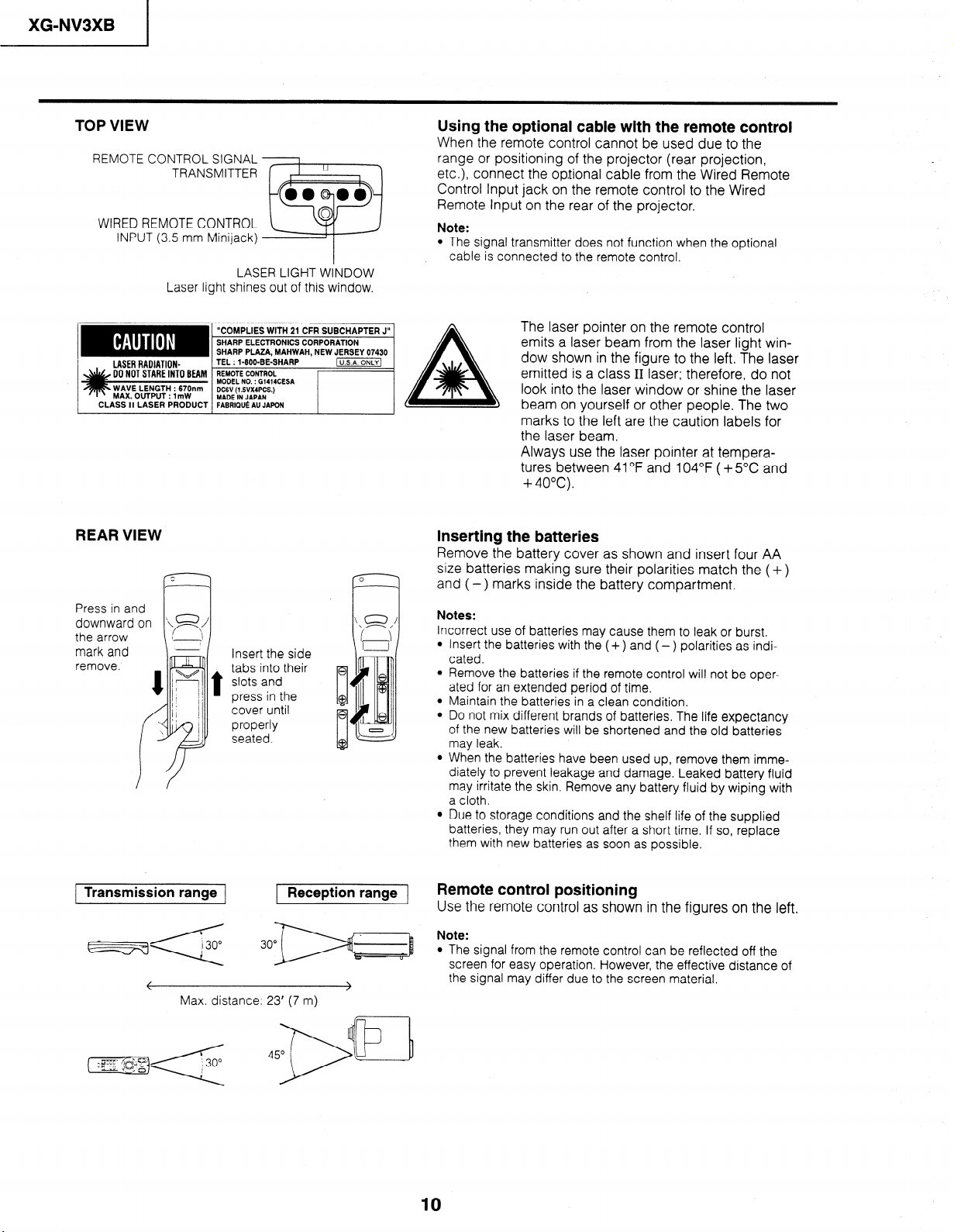

TOP VIEW

REMOTE CONTROL SIGNAL

TRANSMITTER

WIRED REMOTE CONTROL

INPUT (3.5 mm Minijack)

Laser light shines out of this window.

CLASS II LASER PRODUCT

REAR VIEW

E----T

Press in and

the arrow

mark and

remove.

i

em 00

0

~

LASER LIGHT WINDOW

“COMPLIES WITH 21 CFR SUBCHAPTER J”

SHARP ELECTRONICS CORPORATION

SHARP PLAZA, MAHWAH, NEW JERSEY 07430

Insert the side

tabs into their

slots and

press in the

cover until

properly

seated.

Using the optional cable with the remote control

When the remote control cannot be used due to the

range or positioning of the projector (rear projection,

etc.), connect the optional cable from the Wired Remote

Control Input jack on the remote control to the Wired

Remote Input on the rear of the projector.

Note:

l The signal transmitter does not function when the optional

cable is connected to the remote control.

The laser pointer on the remote control

emits a laser beam from the laser light window shown in the figure to the left. The laser

emitted is a class II laser; therefore, do not

A

look into the laser window or shine the laser

beam on yourself or other people. The two

marks to the left are the caution labels for

the laser beam.

Always use the laser pointer at temperatures between 41 OF and 104°F ( + 5°C and

+ 40°C).

Inserting the batteries

Remove the battery cover as shown and insert four AA

size batteries making sure their polarities match the ( + )

and ( -) marks inside the battery compartment.

Notes:

Incorrect use of batteries may cause them to leak or burst.

0

Insert the batteries with the (+) and (-) polarities as indicated.

Remove the batteries if the remote control will not be operated for an extended period of time.

Maintain the batteries in a clean condition.

Do not mix different brands of batteries. The life expectancy

of the new batteries will be shortened and the old batteries

may leak.

0

When the batteries have been used up, remove them immediately to prevent leakage -and damage. Leaked battery fluid

may irritate the skin. Remove any battery fluid by wiping with

a cloth.

Due to storage conditions and the shelf life of the supplied

batteries, they may run out after a short time. If so, replace

them with new batteries as soon as possible.

Transmission range

L_e 300mEh Note:

I

\

Max. distance: 23’ (7 m)

Reception range

/

Remote control positioning

Use the remote control as shown in the figures on the left.

l The signal from the remote control can be reflected off the

screen for easy operation. However, the effective distance of

the signal may differ due to the screen material.

10

Page 11

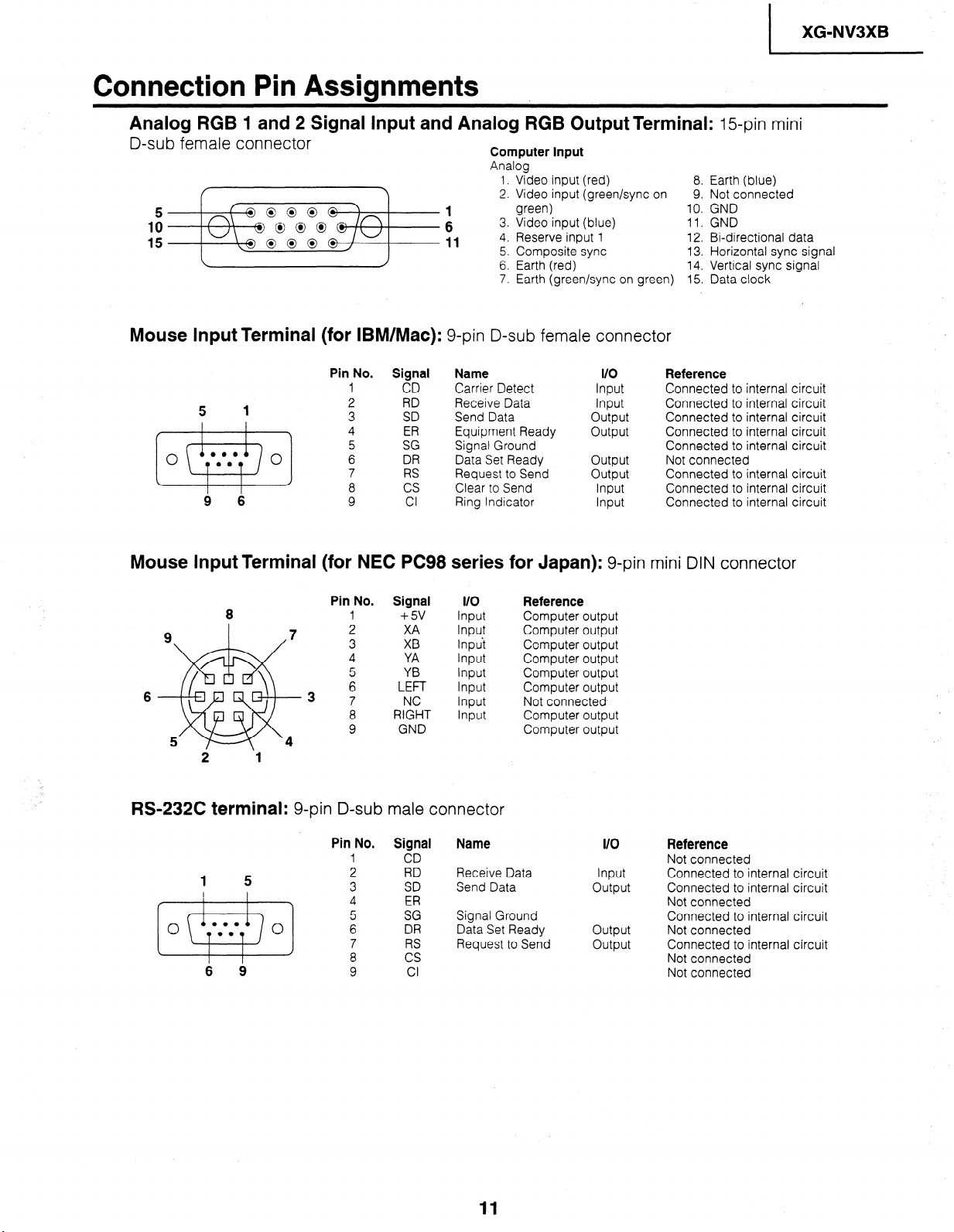

Connection Pin Assignments

Analog RGB 1 and 2 Signal Input and Analog RGB Output Terminal: %-pin mini

D-sub female connector

\

5 1

10 6

15 11

Mouse Input Terminal (for IBM/Mac): g-pin D-sub female connector

Computer Input

Analog

1. Video input (red)

2. Video input (green/sync on

green)

3. Video input (blue)

4. Reserve input 1

5. Composite sync

6. Earth (red)

7. Earth (green/sync on green)

8. Earth (blue)

9. Not connected

10.

GND

11.

GND

12. Bi-directional data

Horizontal sync signal

13.

14. Vertical sync signal

15. Data clock

XG-NV3XB

9 6

Pin No. Signal

1 CD

2 RD

3 SD

4 ER

5 SG

6 DR

7 RS

8 cs

9 Cl

Name

Carrier Detect

Receive Data

Send Data

Equipment Ready

Signal Ground

Data Set Ready

Request to Send

Clear to Send

Ring Indicator

I/O

Input

Input

output

output

output

output

Input

Input

Reference

Connected to internal circuit

Connected to internal circuit

Connected to internal circuit

Connected to internal circuit

Connected to internal circuit

Not connected

Connected to internal circuit

Connected to internal circuit

Connected to internal circuit

Mouse Input Terminal (for NEC PC98 series for Japan): g-pin mini DIN connector

6

Pin No. Signal

+5v

XA

XB

YA

YB

LEFT

NC

RIGHT

GND

I/O

Input

Input

Input

Input

Input

Input

Input

Input

Reference

Computer output

Computer output

Computer output

Computer output

Computer output

Computer output

Not connected,

Computer output

Computer output

RS-232C terminal: g-pin D-sub male connector

Pin No.

1

1 5

0 0 0

0

GzQ

.a

6 9

0

Signal

CD

RD

SD

ER

SG

DR

RS

cs

Cl

Name

Receive Data

Send Data

Signal Ground

Data Set Ready

Request to Send

11

I/O

Input

output

output

output

Reference

Not connected

Connected to internal circuit

Connected to internal circuit

Not connected

Connected to internal circuit

Not connected

Connected to internal circuit

Not connected

Not connected

Page 12

XG-NV3XB

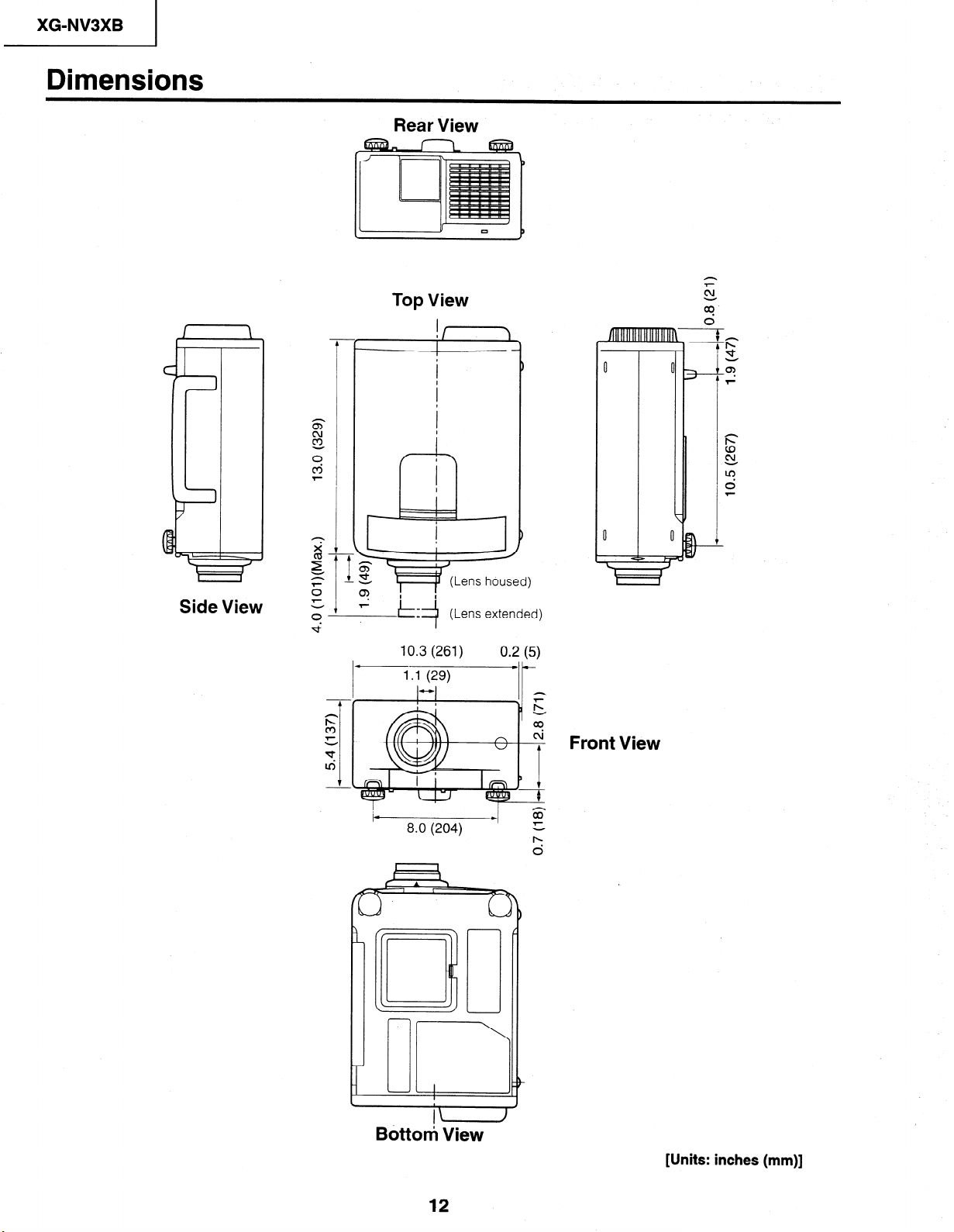

Dimensions

Rear View

Top View

I/

I

I

Side View z

-7

4

v kZ!j (Lens extended)

d

10.3 (261)

1.1 (29)

I

I-

8.0 (204)

0.2 (5)

It-

s

=

b

d

Front View

Bbttoh View

12

[Units: inches (mm)]

Page 13

XG-NV3XB

REMOVING OF MAJOR PARTS

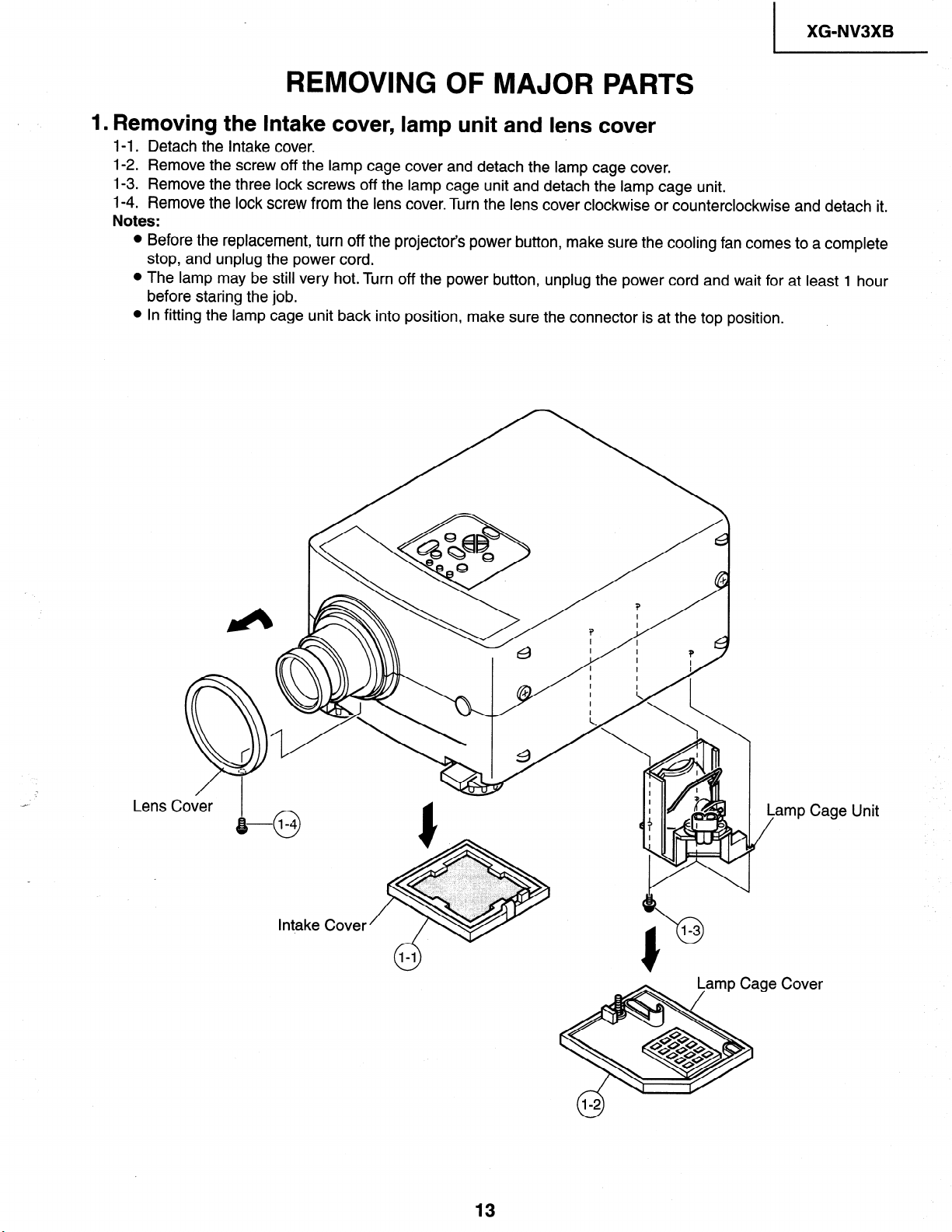

1. Removing the Intake cover, lamp unit and lens cover

l-l. Detach the Intake cover.

1-2. Remove the screw off the lamp cage cover and detach the lamp cage cover.

1-3. Remove the three lock screws off the lamp cage unit and detach the lamp cage unit.

l-4. Remove the lock screw from the lens cover. Turn the lens cover clockwise or counterclockwise and detach it.

Notes:

Before the replacement, turn off the projector’s power button, make sure the cooling fan comes to a complete

stop, and unplug the power cord.

The lamp may be still very hot. Turn off the power button, unplug the power cord and wait for at least 1 hour

before staring the job.

In fitting the lamp cage unit back into position, make sure the connector is at the top position.

Lens

Lamp Cage Unit

/

-ge Cover

13

Page 14

XG-NV3XB 1

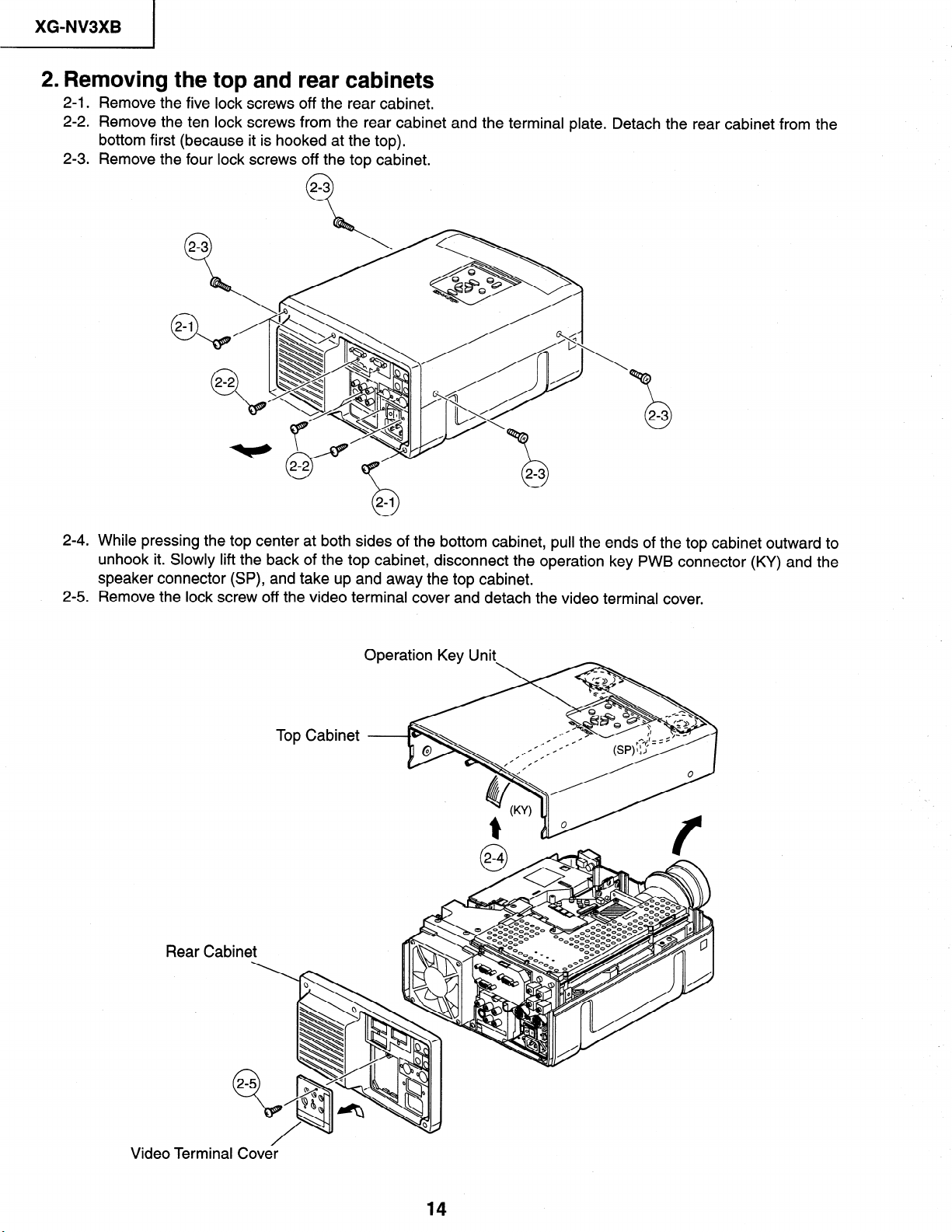

2. Removing the top and rear cabinets

2-1 .

Remove the five lock screws off the rear cabinet.

2-2 .

Remove the ten lock screws from the rear cabinet and the terminal plate.

bottom first (because it is hooked at the top).

2-3 *

Remove the four lock screws off the top cabinet.

Detach th

\

+

2-3

h

e rear cabinet from the

2-4 .

While pressing the top center at both sides of the bottom cabinet, pull the ends of the top cabinet outward to

unhook it. Slowly lift the back of the top cabinet, disconnect the operation key PWB connector (KY) and the

speaker connector (SP), and take up and away the top cabinet.

.

Remove the lock screw off the video terminal cover and detach the video terminal cover.

2-5

Rear Ca

Video Terminal Cover

Page 15

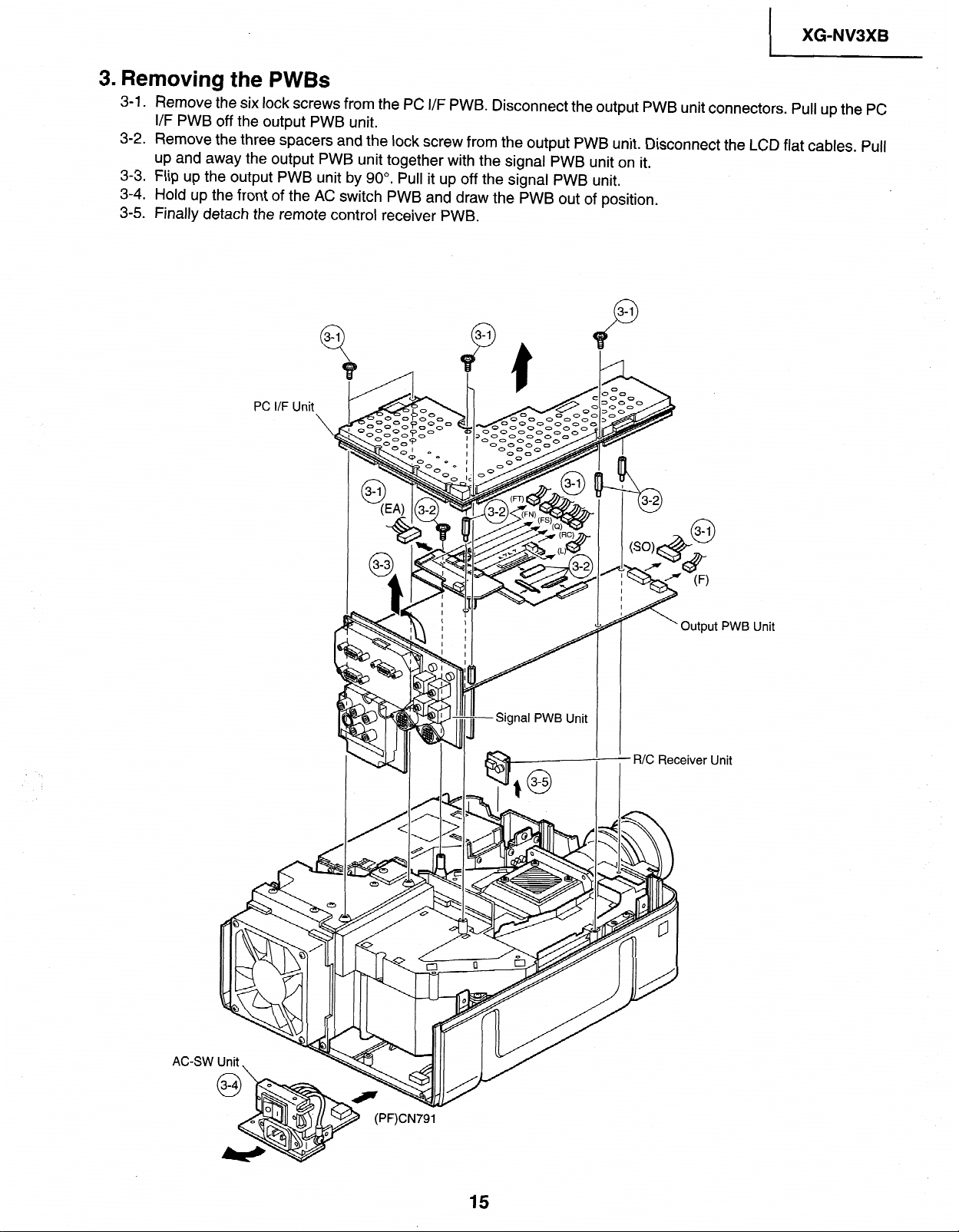

3. Removing the PWBs

3-1 .

Remove the

I/F PWB off the output PWB unit.

3-2

.

Remove the three spacers and

up and away the output PWB unit together with the signal PWB unit on it.

3-3 .

Flip up the output PWB unit by 90°. Pull it up

3-4

Hold up the front of the AC switch PWB and draw the PWB out of position.

.

3-5 .

Finally detach the remote control receiver PWB.

six lock screws

I/F Unit

PC

\

1 XG-NV3XB

from the PC I/F PWB. Disconnect the output PWB unit connectors. Pull up the PC

the lock screw from the

off

c

output PWB unit. Disconnect the LCD flat cables. Pull

the signal PWB unit.

AC-SW

PWB Unit

a R/C Receiver Unit

Page 16

XG-NV3XB

I

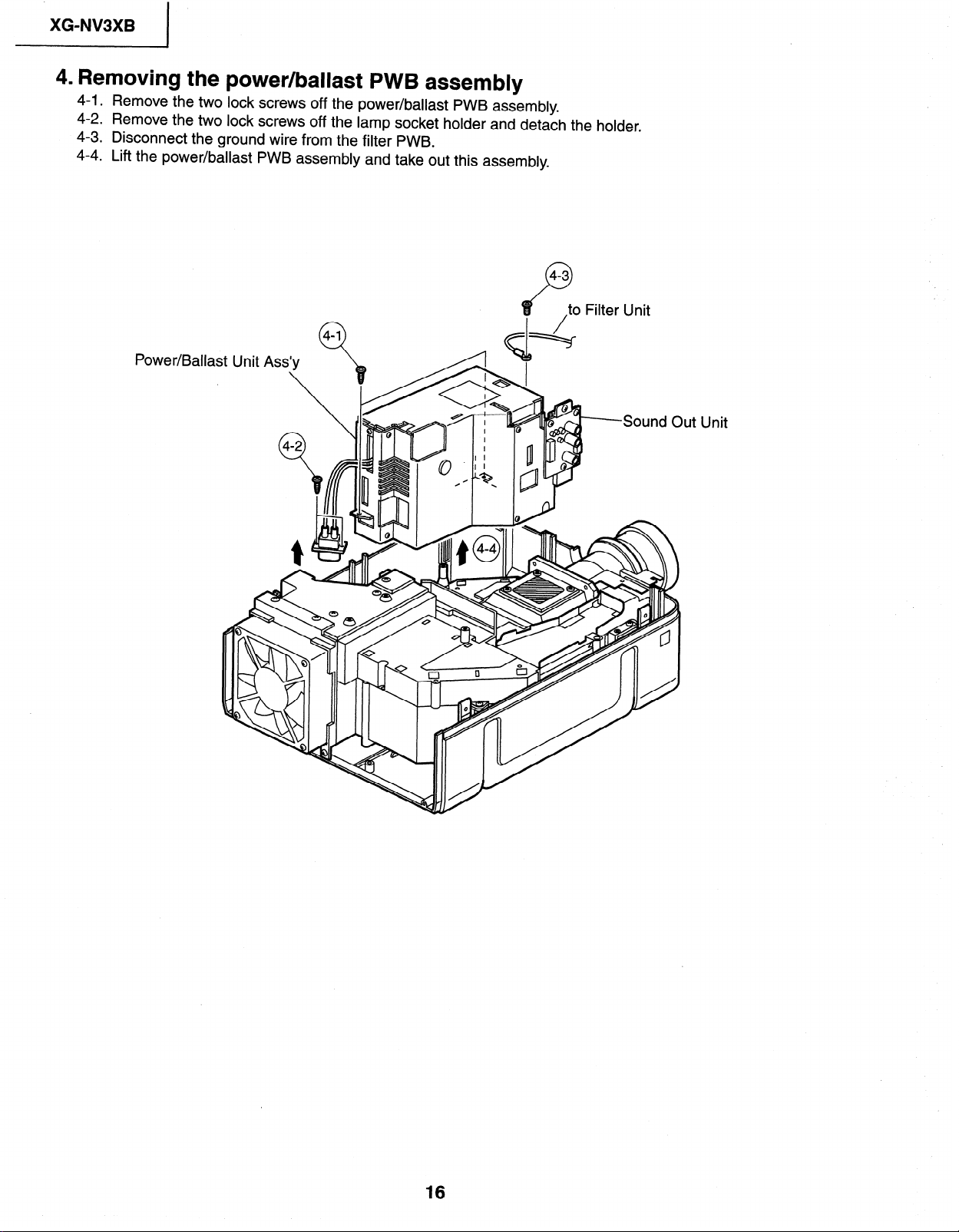

4. Removing the power/ballast PWB assembly

4-1. Remove the two lock screws off the power/ballast PWB assembly.

4-2. Remove the two lock screws off the lamp socket holder and detach the holder.

4-3. Disconnect the ground wire from the filter PWB.

4-4. Lift the power/ballast PWB assembly and take out this assembly.

Power/Balls

iut Unit

16

Page 17

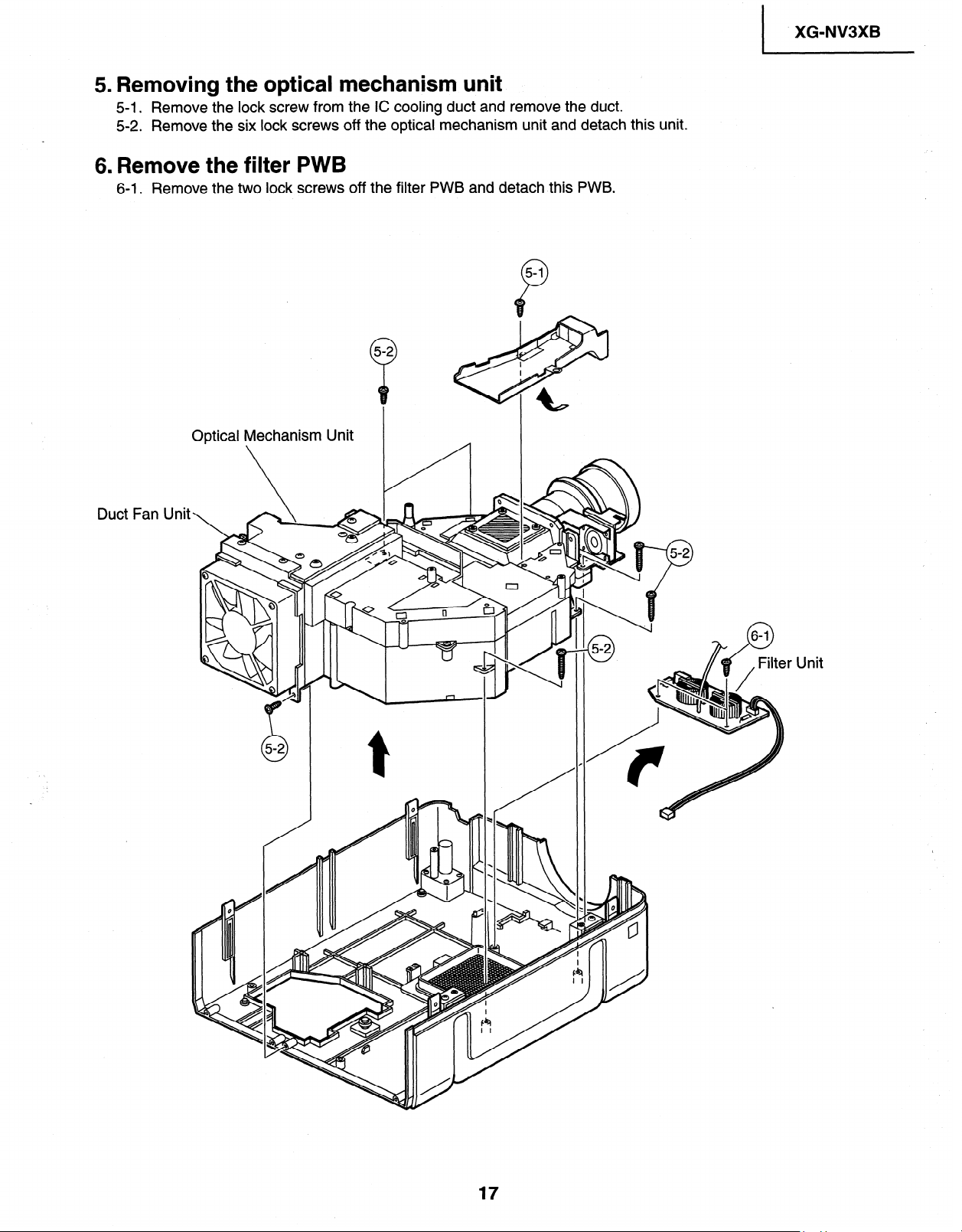

5. Removing the optical mechanism unit 5-I. Remove the lock screw from the IC cooling duct and remove the duct.

5-2. Remove the six lock screws off the optical mechanism unit and detach this unit.

6. Remove the filter PWB

6-1. Remove the two lock screws off the filter PWB and detach this PWB.

Optical Mechanism Unit

’ XG-NV3XB

Duct Fan Unit

5-2

0

Unit

Page 18

j XG-NV3XB

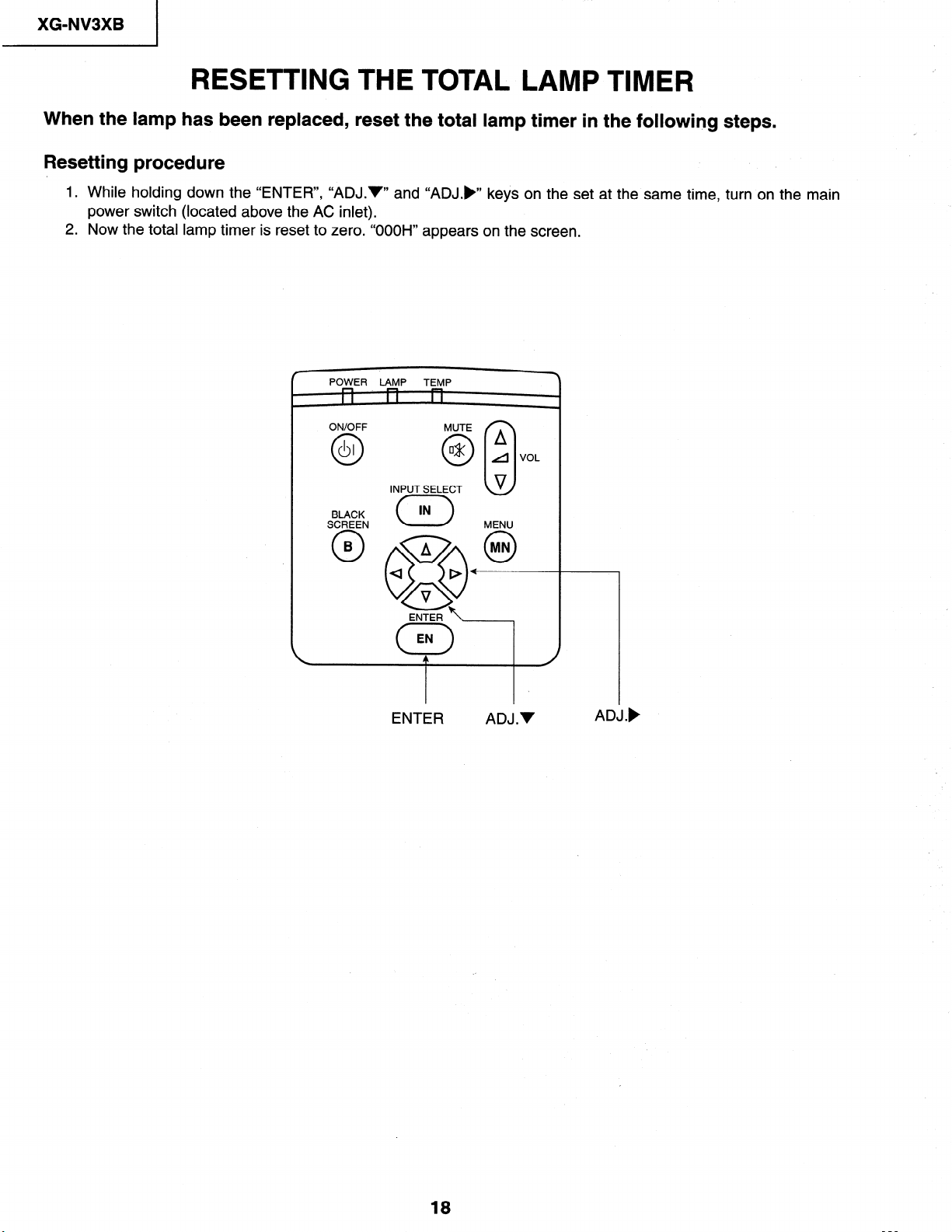

RESETTING THE TOTAL LAMP TIMER

When the lamp has been replaced, reset the total lamp timer in the following steps.

Resetting procedure

1. While holding down the “ENTER”, “ADJF” and “ADJ.)” keys on the set at the same time, turn on the main

power switch (located above the AC inlet).

2. Now the total lamp timer is reset to zero. “OOOH” appears on the screen.

r - POfiER L/44’ TZP

ON/OFF

I

01

0

BLACK

SCREEN

INPUT SELECT

= MENU

ENTER

w

ADJ.V

ADJ.)

18

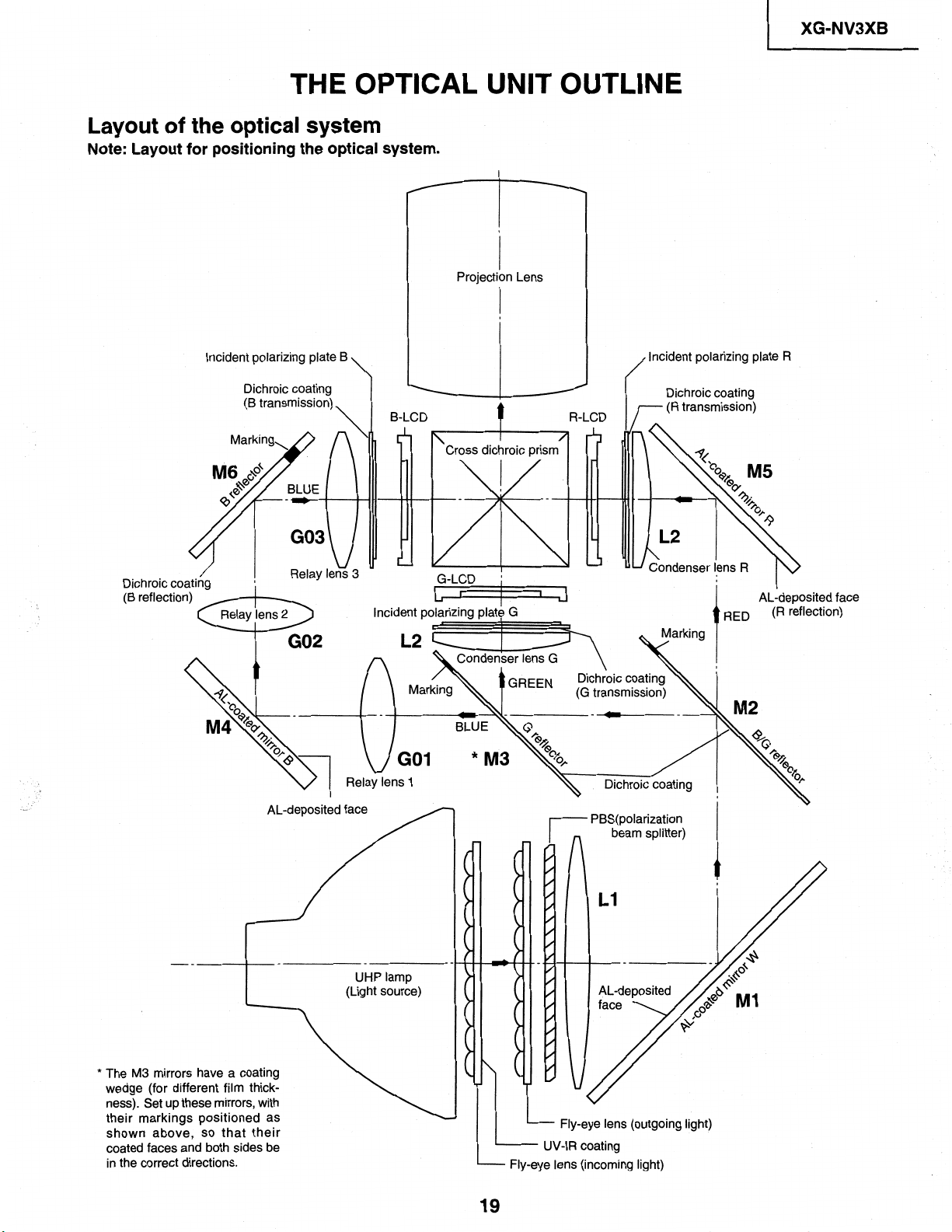

Page 19

Page 20

XG-NV3XB 1

’

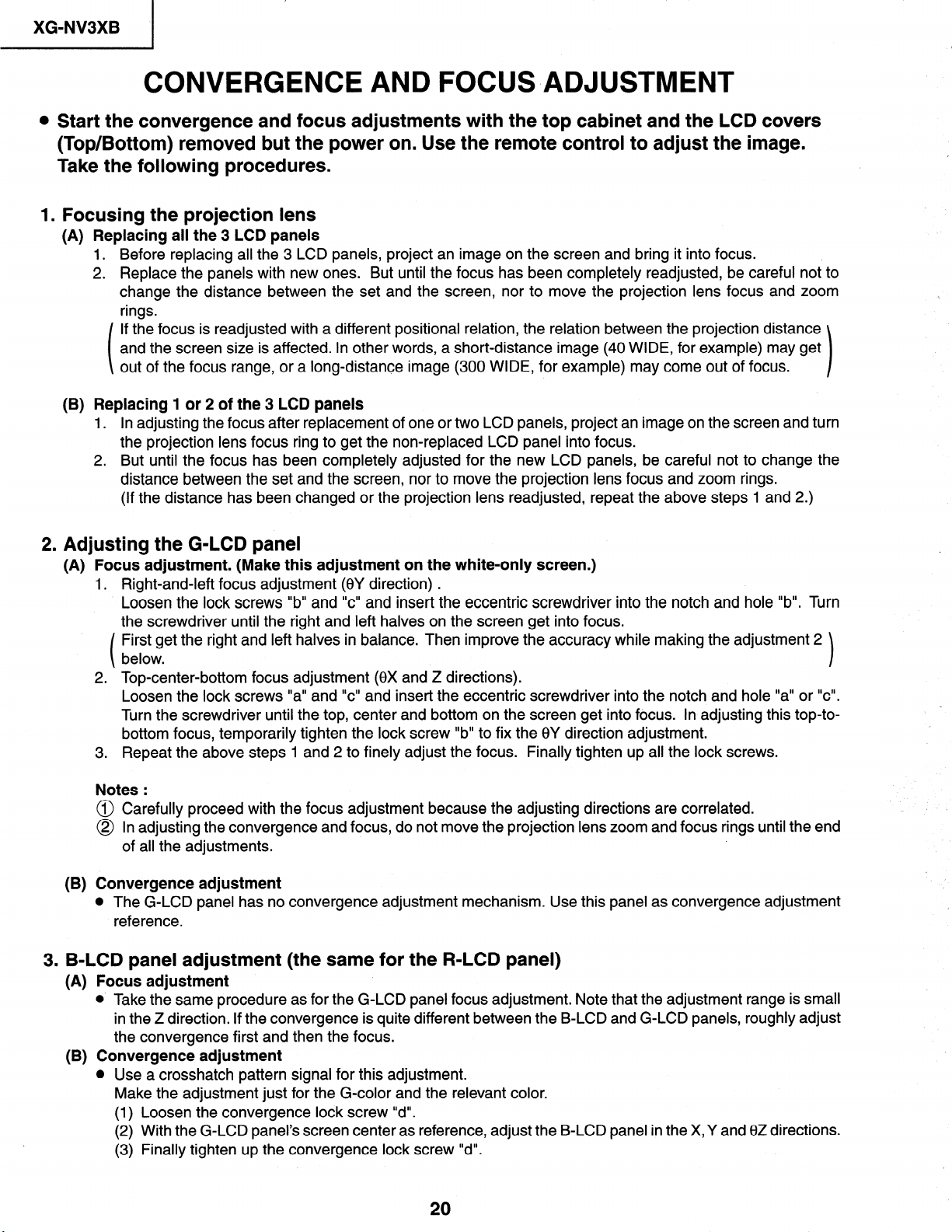

CONVERGENCE AND FOCUS,ADJUSTMENT

l Start the convergence and focus adjustments with the top cabinet and the LCD covers

(Top/bottom) removed but the power on. Use the remote control to adjust the image.

Take the following procedures.

1. Focusing the projection lens

(A) Replacing all the 3 LCD panels

1. Before replacing all the 3 LCD panels, project an image on the screen and bring it into focus.

2. Replace the panels with new ones. But until the focus has been completely readjusted, be careful not to

change the distance between the set and the screen, nor to move the projection lens focus and zoom

rings.

If the focus is readjusted with a different positional relation, the relation between the projection distance

and the screen size is affected. In other words, a short-distance image (40 WIDE, for example) may get

out of the focus range, or a long-distance image (300 WIDE, for example) may come out of focus.

(B) Replacing 1 or 2 of the 3 LCD panels

1. In adjusting the focus after replacement of one or two LCD panels, project an image on the screen and turn

the projection lens focus ring to get the non-replaced LCD panel into focus.

2. But until the focus has been completely adjusted for the new LCD panels, be careful not to change the

distance between the set and the screen, nor to move the projection lens focus and zoom rings.

(If the distance has been changed or the projection lens readjusted, repeat the above steps 1 and 2.)

2. Adjusting the G-LCD panel

Focus adjustment. (Make this adjustment on the white-only screen.)

(4

1. Right-and-left focus adjustment @Y direction) .

Loosen the lock screws “b” and “c” and insert the eccentric screwdriver into the notch and hole ‘lb”. Turn

the screwdriver until the right and left halves on the screen get into focus.

First get the right and left halves in balance. Then improve the accuracy while making the adjustment 2

below.

Top-center-bottom focus adjustment (0X and Z directions).

2 .

Loosen the lock screws “a” and “c” and insert the eccentric screwdriver into the notch and hole “a” or “c”.

Turn the screwdriver until the top, center and bottom on the screen get into focus. In adjusting this top-tobottom focus, temporarily tighten the lock screw “b” to fix the 8Y direction adjustment.

Repeat the above steps 1 and 2 to finely adjust the focus. Finally tighten up all the lock screws.

.

3

Notes :

@ Carefully proceed with the focus adjustment because the adjusting directions are correlated.

@ In adjusting the convergence and focus, do not move the projection lens zoom and focus rings until the end

of all the adjustments.

Convergence adjustment

l The G-LCD panel has no convergence adjustment mechanism. Use this panel as convergence adjustment

reference.

3. B-LCD panel adjustment (the same for the R-LCD panel)

(A) Focus adjustment

0‘ Take the same procedure as for the G-LCD panel focus adjustment. Note that the adjustment range is small

in the Z direction. If the convergence is quite different between the B-LCD and G-LCD panels, roughly adjust

the convergence first and then the focus.

(B) Convergence adjustment

l Use a crosshatch pattern signal for this adjustment.

Make the adjustment just for the G-color and the relevant color.

(1) Loosen the convergence lock screw “d”.

(2) With the G-LCD panel’s screen center as reference, adjust the B-LCD panel in the X, Y and 8Z directions.

(3) Finally tighten up the convergence lock screw “d”.

Page 21

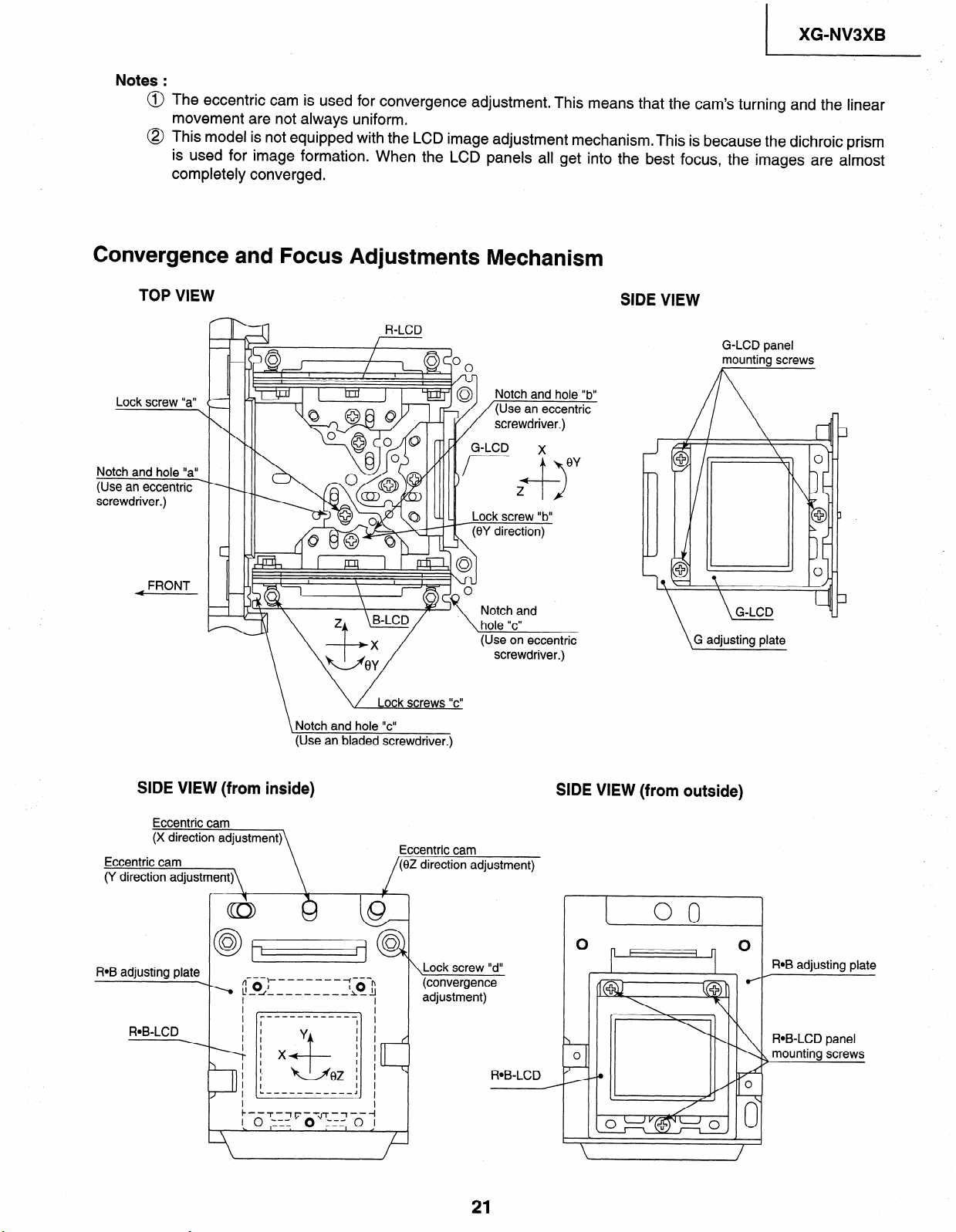

Notes :

@ The eccentric cam is used for convergence adjustment. This means that the cam’s turning and the linear

movement are not always uniform.

@ This model is not equipped with the LCD image adjustment mechanism.This is because the dichroic prism

is used for image formation. When the LCD panels all get into the best focus, the images are almost

completely converged.

Convergence and Focus Adjustments Mechanism

XG-NV3XB

TOP VIEW

Lock screw “a”

Notch and hole “a”

(Use an eccentric .

screwdriver.)

FRONT

SIDE VIEW

R-LCD

/

\

\ Nogk screws “c” screwdriver*)

(Use an bladed sd’rewdriver.)

G-LCD panel

mounting screws

\G adjusting plate

SIDE VIEW (from inside)

Eccentric cam

(X direction adjustment)\

Eccentric cam

(Y direction adjustment)\

ROB adjusting plate

ROB-LCD

\

h

b

\ /

_

r

\

c

c--

S ?!!I/‘-----

---------

I-

I

I

I

I

I x

I

I

1

I

I

I---T-~~--~T-~----I

1 0 ,z_, 0 z,:, 0

Eccentric cam

(0Z direction adjustment)

I

I

I

I

I

I

I

I

I

I

I

1

21

SIDE VIEW (from outside)

Of 1-1 ,’ 1R.B adjusting plate

ROB-LCD panel

mounting screws

ROB-LCD

Page 22

XG-NV3XB ]

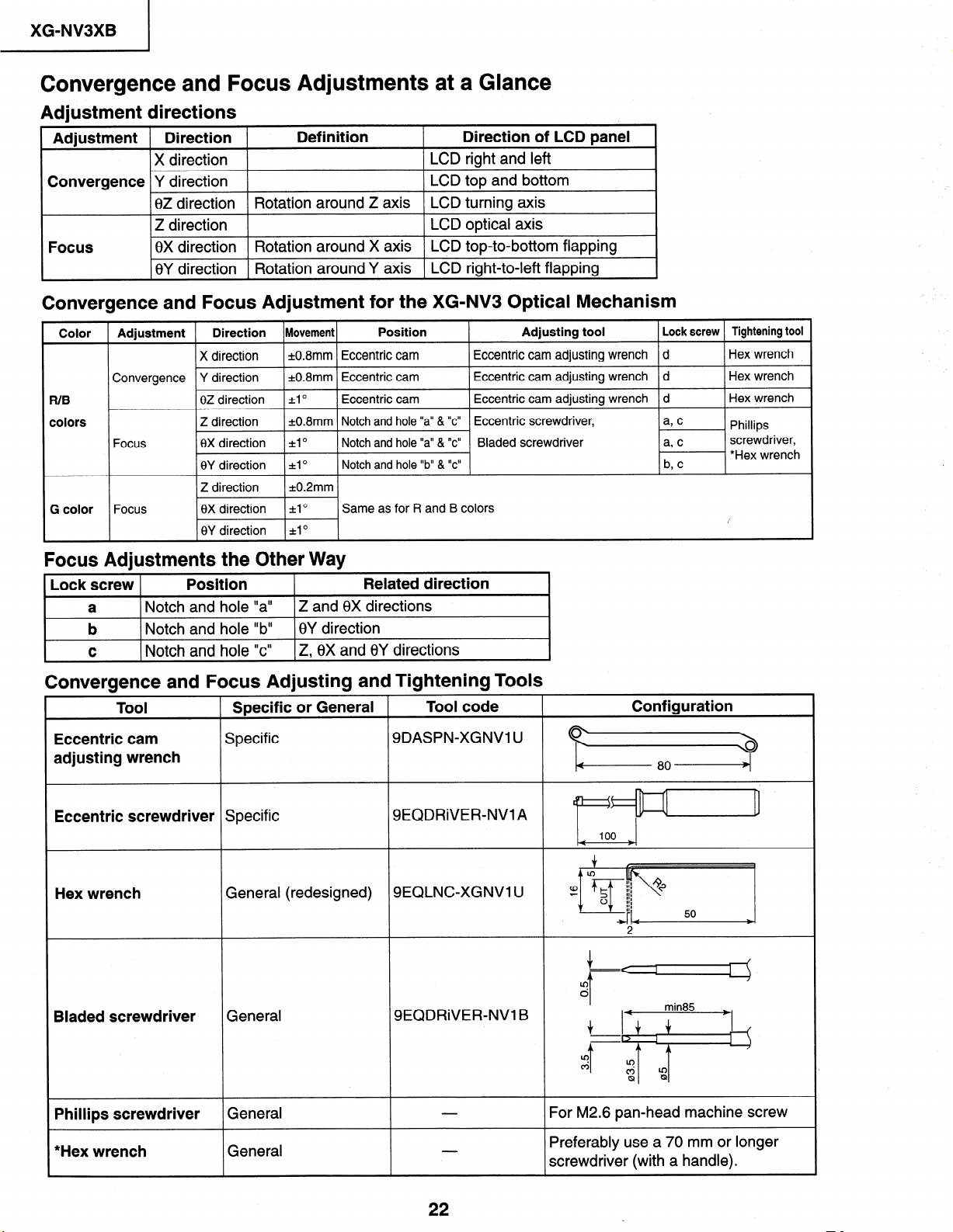

Convergence and Focus Adjustments at a Glance

Adjustment directions

Adjustment Direction

X direction

Convergence Y direction

Definition Direction of LCD panel

LCD right and left

LCD top and bottom

I

0Z direction Rotation around Z axis LCD turning axis

Z direction LCD optical axis

Focus

0X direction Rotation around X axis

8Y direction

Rotation around Y axis LCD right-to-left flapping

LCD top-to-bottom flapping

\

Convergence and Focus Adjustment for the XG-NV3 Optical Mechanism

Color 1 Adjustment

Convergence

R/B

colors

Focus

G color Focus

Direction IMovement 1

X direction

Y direction

8Z direction 1~1”

Z direction

0X direction *I”

8Y direction *I”

Z direction I *0.2mm I

*0.8mm Eccentric cam

[*0.8mm 1 Eccentric cam ) Eccentric cam adjusting wrench 1 d -wrench

+0.8mm Notch and hole “a” & “c”

Position

I

I

I

Adjusting tool

Eccentric cam adjusting wrench

1 Eccentric cam 1 Eccentric cam adjusting wrench 1 d

Eccentric screwdriver,

Notch and hole “a” & “c”

Notch and hole “b” & “c”

Same as for R and B colors

Bladed screwdriver

1

1 Lock screw I Tightening tool

1 d -wrench

Focus Adjustments the Other Way

Lock screw

Position

a Notch and hole “a”

b

C

Notch and hole “b”

Notch and hole “c”

Z and 8X directions

0Y direction

Z, 0X and 0Y directions

Related direction

1 Hex wrench

Phillips

screwdriver,

*Hex wrench

Convergence and Focus Adjusting and Tightening Tools

Eccentric cam

-

Tool

Specific or General

Specific

- -

Tool code

9DASPN-XGNVl U

adjusting wrench

Eccentric screwdriver Specific

Hex wrench

Bladed screwdriver

Phillips screwdriver

General (redesigned) 9EQLNCXGNVl U

General SEQDRiVER-NV1 B

General

SEQDRiVER-NV1 A

Configuration

3

2

Ad A

q

z

80+

min85

2

qL

+--

Ln

0

t ~

+ It t

Ilr!

c9

t

For M2.6 pan-head machine screw

*Hex wrench

General

Preferably use a 70 mm or longer

screwdriver (with a handle).

Page 23

XG-NV3XB

Ils

5

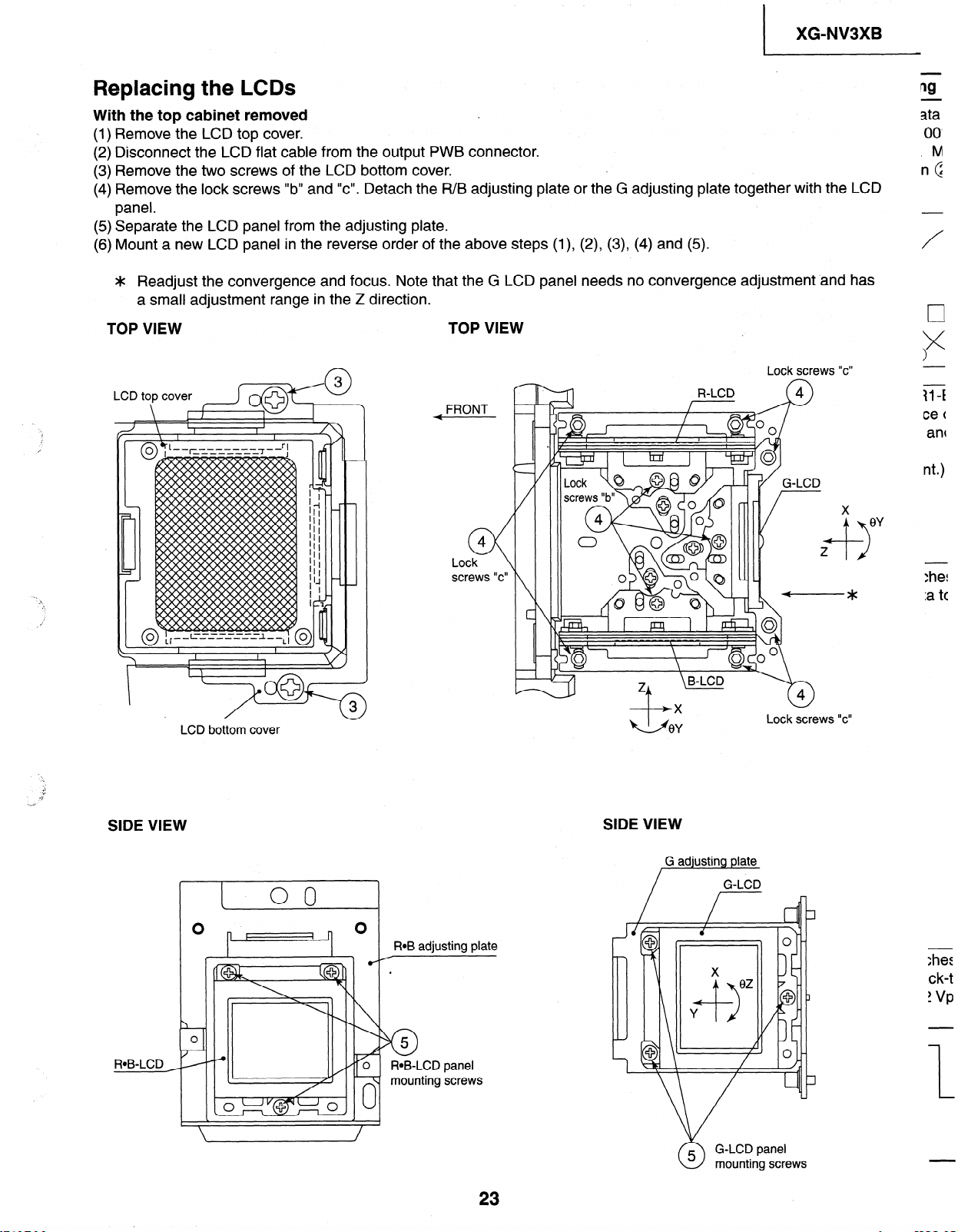

Replacing the LCDs

With the top cabinet removed

(1) Remove the LCD top cover.

(2) Disconnect the LCD flat cable from the output PWB connector.

(3) Remove the two screws of the LCD bottom cover.

(4) Remove the lock screws “b” and “c”. Detach the R/B adjusting plate or the G adjusting plate together with the LCD

panel.

(5) Separate the LCD panel from the adjusting plate.

(6) Mount a new LCD panel in the reverse order of the above steps (1) (2), (3), (4) and (5).

* Readjust the convergence and focus. Note that the G LCD panel needs no convergence adjustment ‘and has

a small adjustment range in the Z direction.

TOP VIEW

LCD top cover

\ /

TOP VIEW

FRONT

r-P-II

Lock screws “c”

R-LCD (7 4

iii

00’

, M

nc

/

cl

X

>

31-E

ce (

ant

nt.)

*

he t / I

-.

.A

SIDE VIEW

/==yiJ

LCD bottom cover

R43 adjusting plate

/

.

SIDE VIEW

Lock screws “c”

:a tc

%

he

/

ck-t

!Vp

5

0

ROB-LCD panel

mounting screws

mounting screws

Page 24

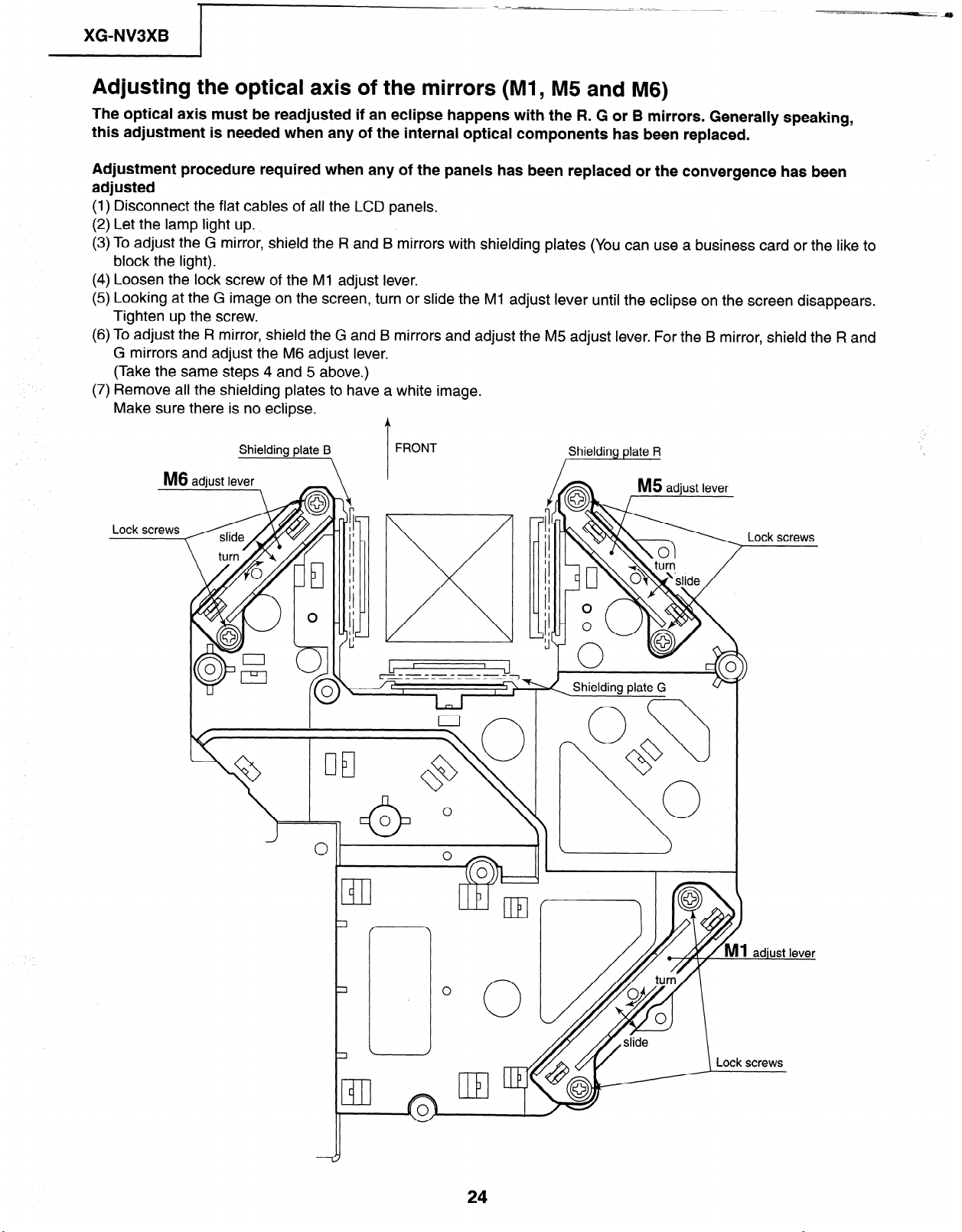

Adjusting the optical axis of the mirrors (Ml9 M5 and M6)

The optical axis must be readjusted if an eclipse happens with, the R. G or B mirrors. Generally speaking,

this adjustment is needed when any of the internal optical components has been replaced.

Adjustment procedure required when any of the panels has been replaced or the convergence has been

adjusted

(1) Disconnect the flat cables of all the LCD panels.

(2) Let the lamp light up.

(3) To adjust the G mirror, shield the R and B mirrors with shielding plates (You can use a business card or the like to

block the light).

(4) Loosen the lock screw of the Ml adjust lever.

(5) Looking at the G image on the screen, turn or slide the Ml adjust lever until the eclipse on the screen disappears.

Tighten up the screw.

(6) To adjust the R mirror, shield the G and B mirrors and adjust the M5 adjust lever. For the B mirror, shield the R and

G mirrors and adjust the M6 adjust lever.

(Take the same steps 4 and 5 above.)

(7) Remove all the shielding plates to have a white

Make sure there is no eclipse.

imaae.

Lock

Shielding plate B

FRONT

I

Shielding plate R

,

24

Page 25

1

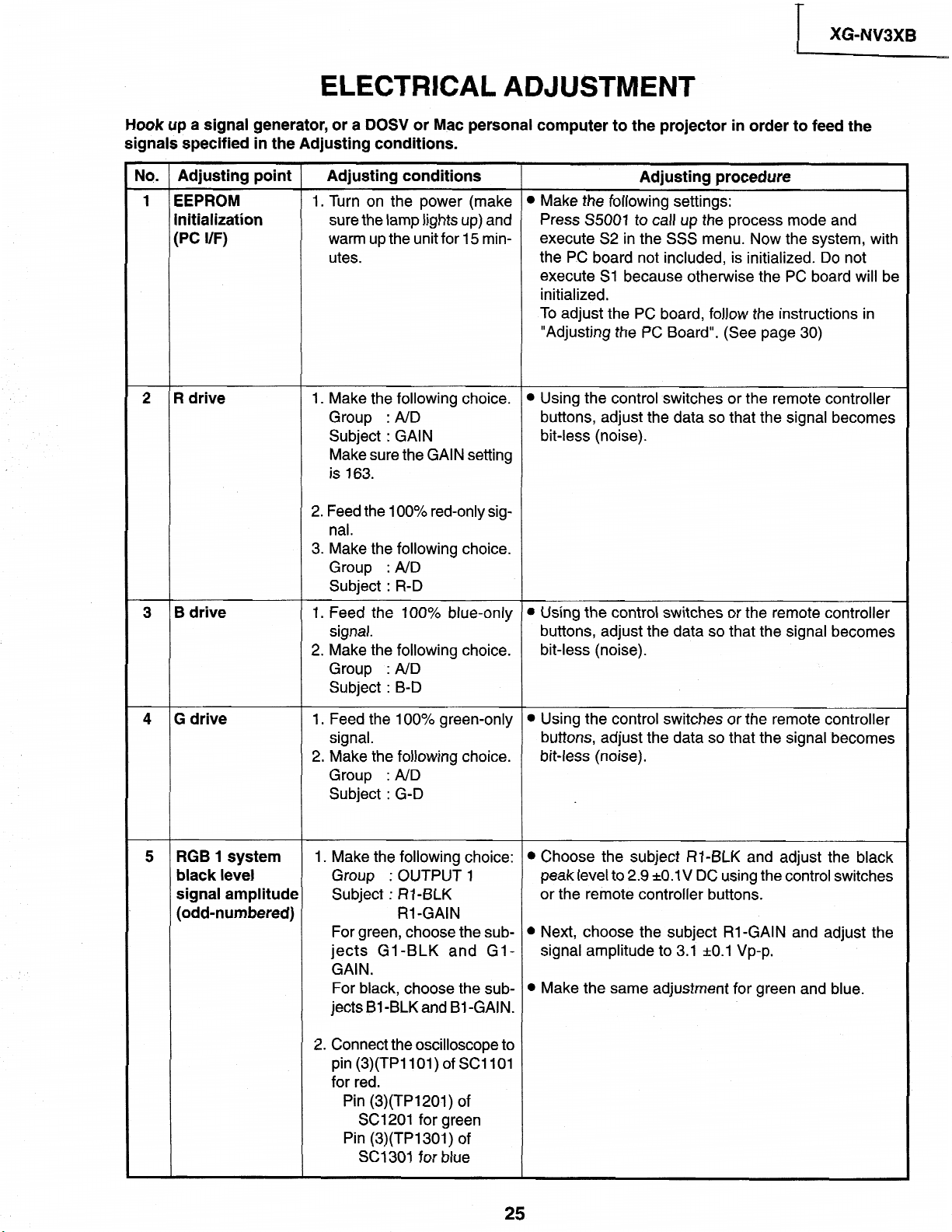

Hook

signals

.

NQ

1

2

up a signal

generator, or a DOSV or Mac personal computer

specified in the

Adjusting point

EEPROM

initialization

(PC I/F)

R drive

ELECTRICAL ADJUSTMENT

to the

Adjusting

Adjusting

1.

1. Make

conditions.

conditions

Turn

on the power

sure

the lamp

warm up

utes.

the

Group : AID

Subject : GAIN

Make sure the GAIN setting

is 163.

lights up)

the unit for

following choice.

(make

15

min-

and

l Make

l

the

following settings:

Press

S5001

execute

the PC

execute Sl

initialized.

To

“Adjusting the

Using the control

buttons,

bit-less (noise).

S2

board not

adjust the PC

adjust

XG-NV3XB

projector in order to feed

the

Adjusting procedure

to call up

in the SSS

because otherwise the PC board will be

PC Board”. (See page

the

the process mode

menu.

included, is initialized.

board, follow

switches

data so that

Now the system, with

the

instructions in

or the remote

the

signal becomes

Do

30)

and

not

controller

3 B drive

4

G

drive

5

RGB 1 system

black level

signal amplitude

(odd-numbered)

2. Feed the 100% red-only sig-

nal.

3. Make the following choice.

Group : A/D

Subject : R-D

I. Feed the 100% blue-only

signal.

2.

Make the following choice.

Group : A/D

Subject : B-D

1. Feed the 100% green-only

signal.

2. Make the following choice.

Group : AID

Subject : G-D

I. Make the following choice:

Group : OUTPUT 1

Subject : RI-BLK

RI -GAIN

For green, choose the sub-

jects Gl-BLK and Gl-

GAIN.

For black, choose the sub-

jects Bl -BLK and Bl-GAIN.

l

Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes

bit-less (noise).

l

Using the control

buttons, adjust the data so

bit-less

l

Choose the subject RI-BLK and adjust the black

peak level to 2.9 kO.1 V DC using the control switches

or the remote controller buttons.

@ Next, choose the subject RI-GAIN and adjust the

signal amplitude to 3.1 +O.l Vp-p.

l

Make the same adjustment for green and blue.

(noise).

.

switches or

that the

the remote controller

signal

becomes

2. Connect the oscilloscope to

pin (3)(TPllOl) of SC1 101

for red.

Pin (3)(TPl201) of

SC1201 for green

Pin (3)(TPl301) of

SC1301 for blue

25

Page 26

XG-NV3XB

I

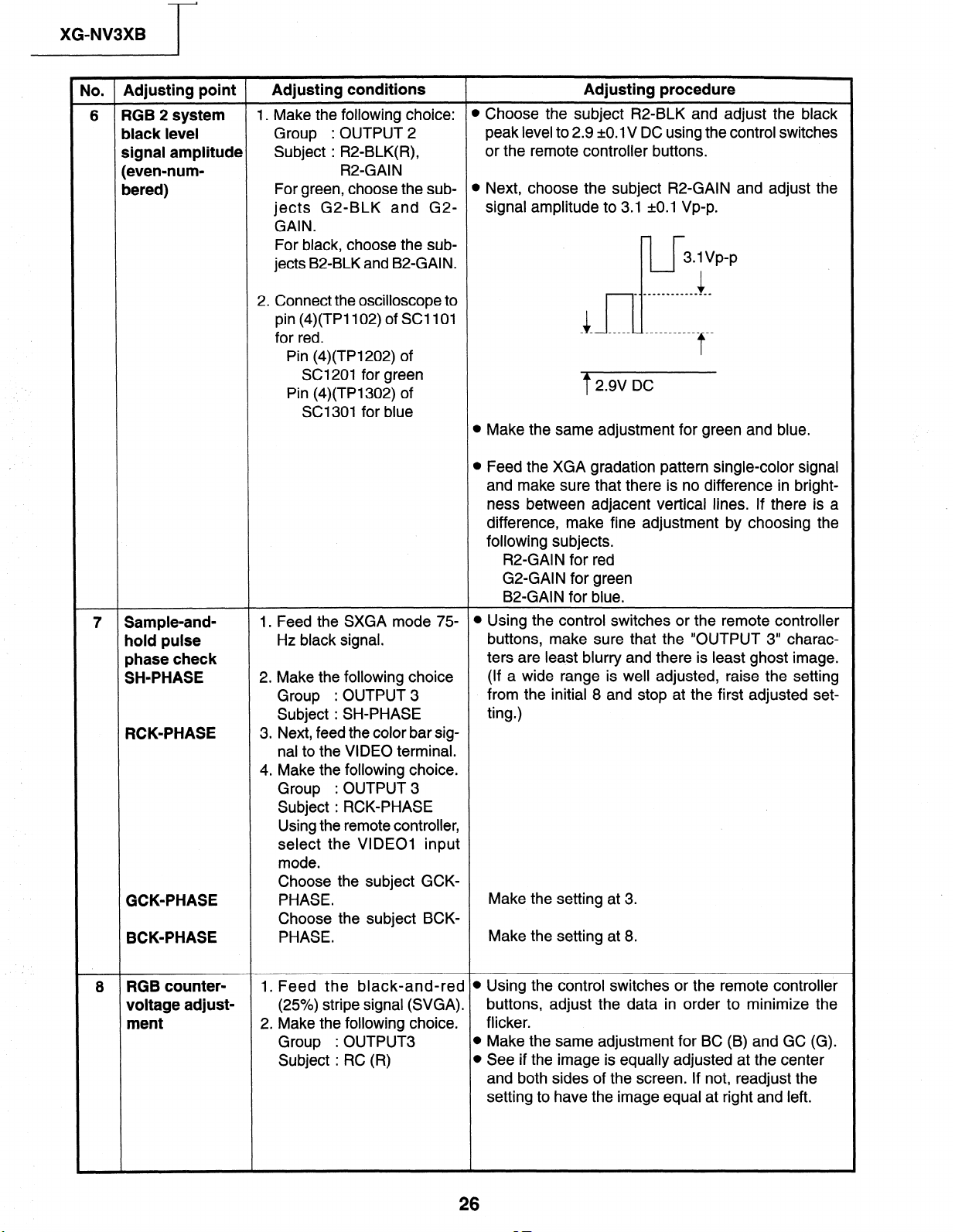

No. Adjusting point

6 RGB 2 system

blat k level

signal amplitude

(even-numbered)

7 Sample-and-

hold pulse

phasecheck

SH-PHASE

RCK-PHASE

GCK-PHASE

BCK-PHASE

Adjusting conditions

1. Make the following choice:

Group : OUTPUT 2

Subject : R2-BLK(R),

R2-GAI N

For green, choose the subjects G2-BLK and G2GAIN.

For black, choose the subjects B2-BLK and B2-GAIN.

2. Connect the oscilloscope to

pin (4)(TP1102) of SC1 101

for red.

Pin (4)(TPI202) of

SC1201 for green

Pin (4)(TP1302) of

SC1301 for blue

1. Feed the SXGA mode 75

Hz black signal.

2. Make the following choice

Group : OUTPUT 3

Subject : SH-PHASE

3. Next, feed the color bar sig-

nal to the VIDEO terminal.

4. Make the following choice.

Group : OUTPUT 3

Subject : RCK-PHASE

Using the remote controller,

select the VIDEO1 input

mode.

Choose the subject GCKPHASE.

Choose the subject BCKPHASE.

Adjusting procedure

l Choose the subject R2BLK and adjust the black

peak level to 2.9 kO.1 V DC using the control switches

or the remote controller buttons.

@ Next, choose the subject R2-GAIN and adjust the

signal amplitude to 3.1 -i-O.1 Vp-p.

3.1 vp-p

f

t 2.9V DC

l Make the same adjustment for green and blue.

l Feed the XGA gradation pattern single-color signal

and make sure that there is no difference in bright-

ness between adjacent vertical lines. If there is a

difference, make fine adjustment by choosing the

following subjects.

R2-GAIN for red

G2-GAIN for green

B2-GAIN for blue.

l Using the control switches or the remote controller

buttons, make sure that the “OUTPUT 3” characters are least blurry and there is least ghost image.

(If a wide range is well adjusted, raise the setting

from the initial 8 and stop at the first adjusted set-

ting.)

Make the setting at 3.

Make the setting at 8.

8 RGB counter-

1. Feed the black-and-red 0 Using the control switches or the remote controller

voltage adjust- (25%) stripe signal (SVGA).

ment

2. Make the following choice.

Group : OUTPUT3

Subject : RC (R)

buttons, adjust the data in order to minimize the

flicker.

0 Make the same adjustment for BC (B) and GC (G).

l See if the image is equally adjusted at the center

and both sides of the screen. If not, readjust the

setting to have the image equal at right and left.

Page 27

I XG-NV3XB

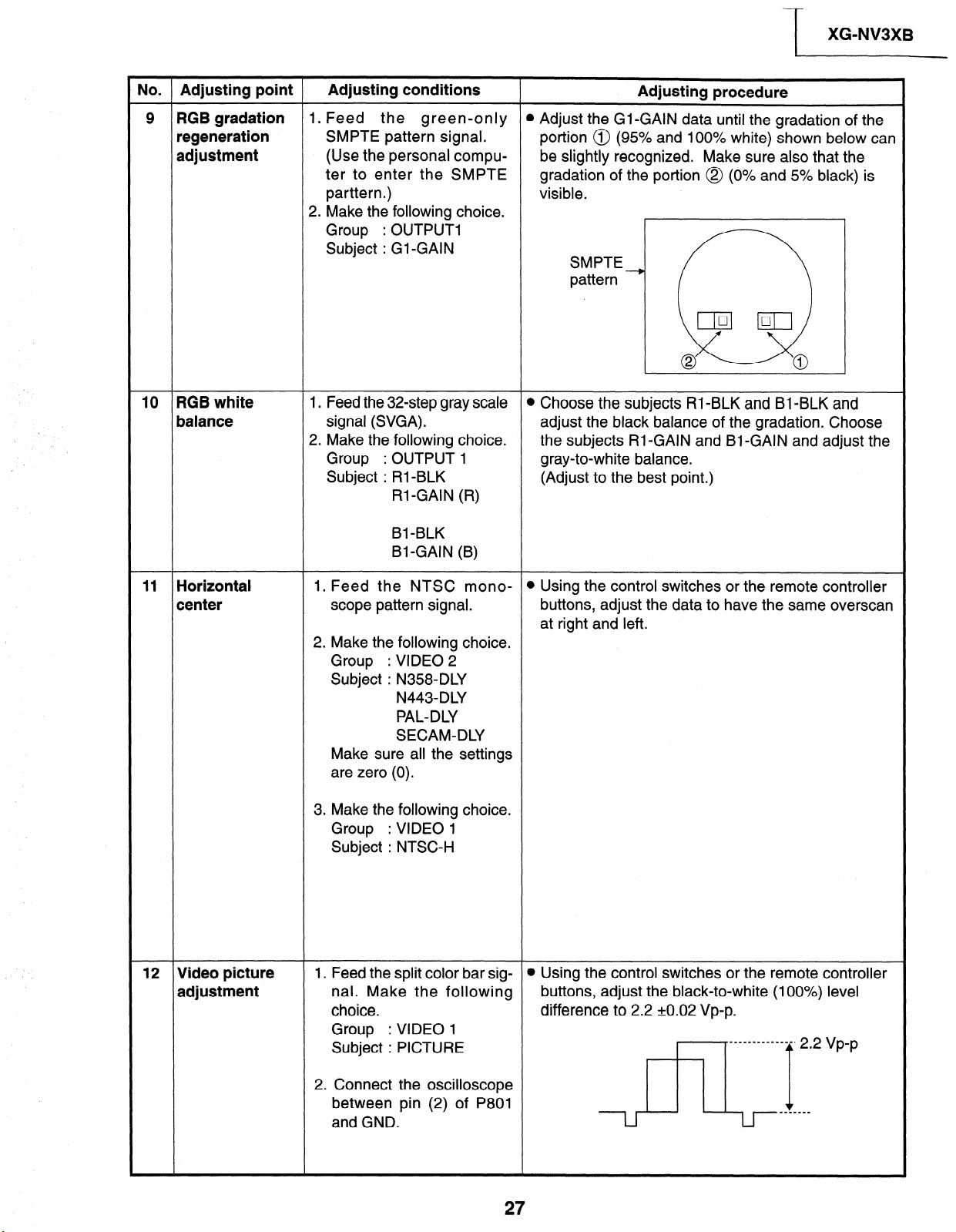

No. Adjusting point

9 RGB gradation

regeneration

adjustment

10 RGB white

balance

Adjusting conditions

1. Feed the green-only

SMPTE pattern signal.

(Use the personal computer to enter the SMPTE

parttern .) visible.

2. Make the following choice.

Group : OUTPUT1

Subject : G&GAIN

1. Feed the 32-step gray scale l Choose the subjects Rl-BLK and Bl-BLK and

signal (SVGA). adjust the black balance of the gradation. Choose

2. Make the following choice.

Group : OUTPUT 1 gray-to-white balance.

Subject : Rl-BLK

RI -GAIN (R)

Bl -BLK

Bl-GAIN (B)

l Adjust the Gl-GAIN data until the gradation of the

portion @ (95% and 100% white) shown below can

be slightly recognized. Make sure also that the

gradation of the portion @ (0% and 5% black) is

SMPTE

pattern +

the subjects W-GAIN and Bl-GAIN and adjust the

(Adjust to the best point.)

Adjusting procedure

11 Horizontal

center

12 Video picture

adjustment

1. Feed the NTSC monoscope pattern signal.

2. Make the following choice.

Group : VIDEO 2

Subject : N358-DLY

N443-DLY

PAL-DLY

SECAM-DLY

Make sure all the settings

are zero (0).

3. Make the following choice.

Group : VIDEO 1

Subject : NTSC-H

1. Feed the split color bar sig-

nal. Make the following

choice.

Group

Subject : PICTURE

: VIDEO 1

* Using the control switches or the remote controller

buttons, adjust the data to have the same overscan

at right and left.

l Using the control switches or the remote controller

buttons, adjust the black-to-white (100%) level

difference to 2.2 kO.02 Vp-p.

2. Connect the oscilloscope

between pin (2) of P801

and GND.

27

Page 28

/ XG-NV3XB

No. Adjusting point Adjusting conditions

13 Video AGC 1. Feed the split color bar sig-

nal. Make the following

choice.

: VIDEO 1

: VIDEO 1

: VIDEO 1

14 Video

brightness

adjustment

15 Tint

Group

Subject : AGC

2. Connect the oscilloscope

between pin (2) of P801

and GND.

1. Feed the baseband color l Using the control switches or the remote controller

bar signal. (The ON-AIR

signal is not accepted because of its too much

noise.)

2. Make the following choice.

Group

Subject : BRIGHT

3. Press the control switch or

the remote controller’s

mute button (to set the

gamma correction to the

process setting).

1. Feed the color bar signal.

Make the following choice.

Group

Subject : TINT

2. Connect the oscilloscope to

pin (5) of P801.

Adjusting procedure

l Using the control switches or the remote controller

buttons, adjust the black-to-white (100%) level

difference to 1.65 kO.02 Vp-p.

buttons, decrease 2 points from the level where the

black signal becomes bit-less.

l Using the control switches or the remote controller

buttons, adjust the data to have the -(B-Y) waveform downhill straight.

. .

. .

. .

l .

. .

. .

. . .

. .

l .

. . .

. .

. .

. .

16 NTSC color 1. Feed the color bar signal.

saturation level 2. Make the following choice.

Group

Subject : N-COLOR

3. Connect the oscilloscope to

pin (1) of P801.

: VIDEO 1

l Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.2 kO.02 Vp-p.

100% White Red

Page 29

.

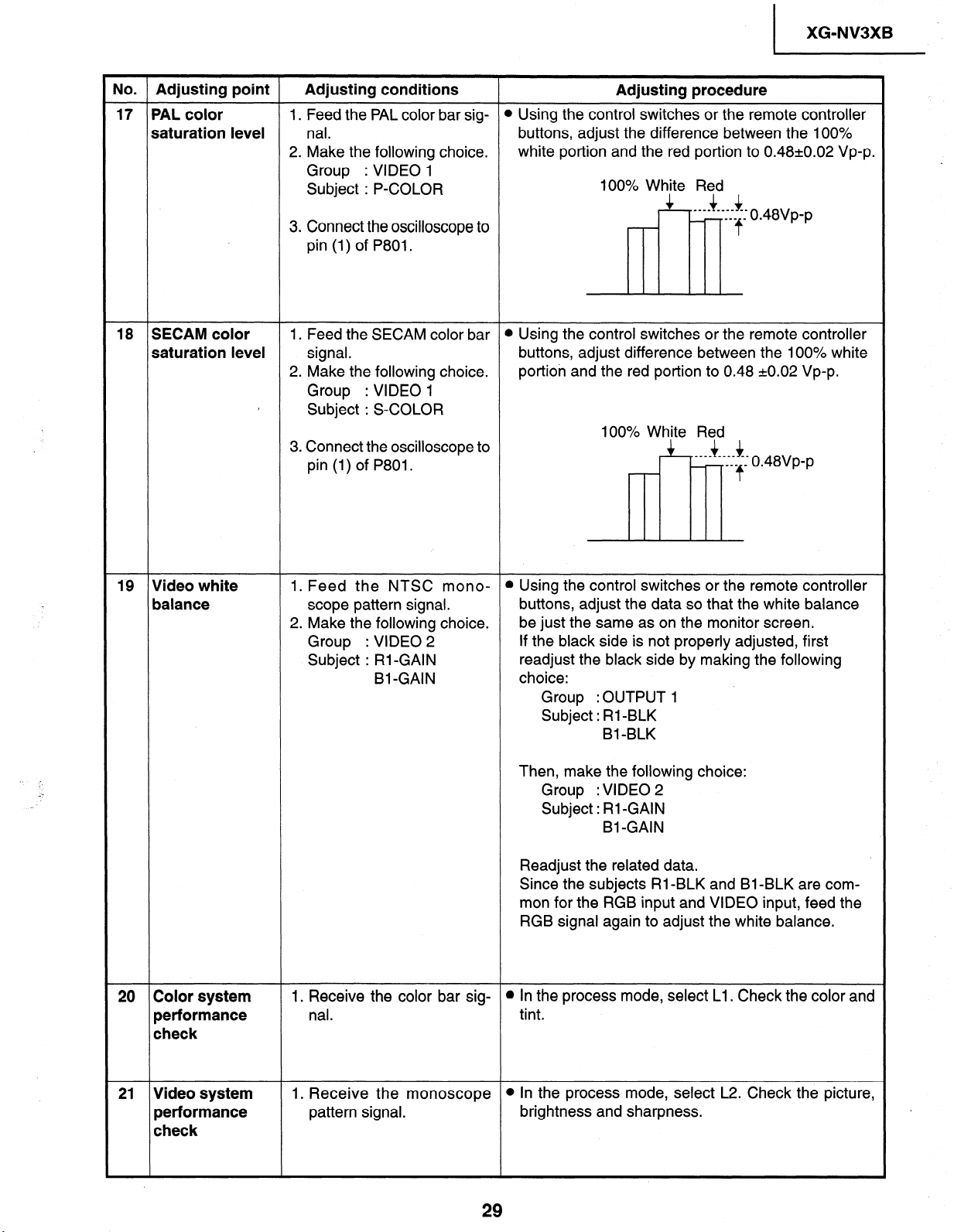

No

Adjusting point

PAL color

saturation level

18

SECAM color

saturation level

Adjusting conditions

1. Feed the PAL color bar signal.

2. Make the following choice.

Group

Subject : P-COLOR

3. Connect the oscilloscope to

pin (1) of P801.

1. Feed the SECAM color bar

signal.

2. Make the following choice.

Group : VIDEO 1

Subject : S-COLOR

3. Connect the oscilloscope to

pin (1) of P801.

: VIDEO 1

XG-NV3XB

Adjusting procedure

Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.48kO.02 Vp-p.

100% White Red

0.48Vp-p

l Using the control switches or the remote controller

buttons, adjust difference between the 100% white

portion and the red portion to 0.48 ~0.02 Vp-p.

100% White Red

0.48Vp-p

Video white

balance

Color system

performance

check

1. Feed the NTSC monoscope pattern signal.

2. Make the following choice.

Group

Subject : RI-GAIN

1. Receive the color bar signal.

: VIDEO 2

BI-GAIN

l Using the control switches or the remote controller

buttons, adjust the data so that the white balance

be just the same as on the monitor screen.

If the black side is not properly adjusted, first

readjust the black side by making the following

choice:

Group :OUTPUT 1

Subject : RI -BLK

Bl -BLK

Then, make the following choice:

Group : VIDEO 2

Subject: Rl-GAIN

Bl -GAIN

Readjust the related data.

Since the subjects Rl -BLK and Bl -BLK are common for the RGB input and VIDEO input, feed the

RGB signal again to adjust the white balance.

l In the process mode, select Ll. Check the color and

tint.

Video system

performance

check

1. Receive the monoscope

pattern signal.

l In the process mode, select L2. Check the picture,

brightness and sharpness.

Page 30

XG-NV3XB

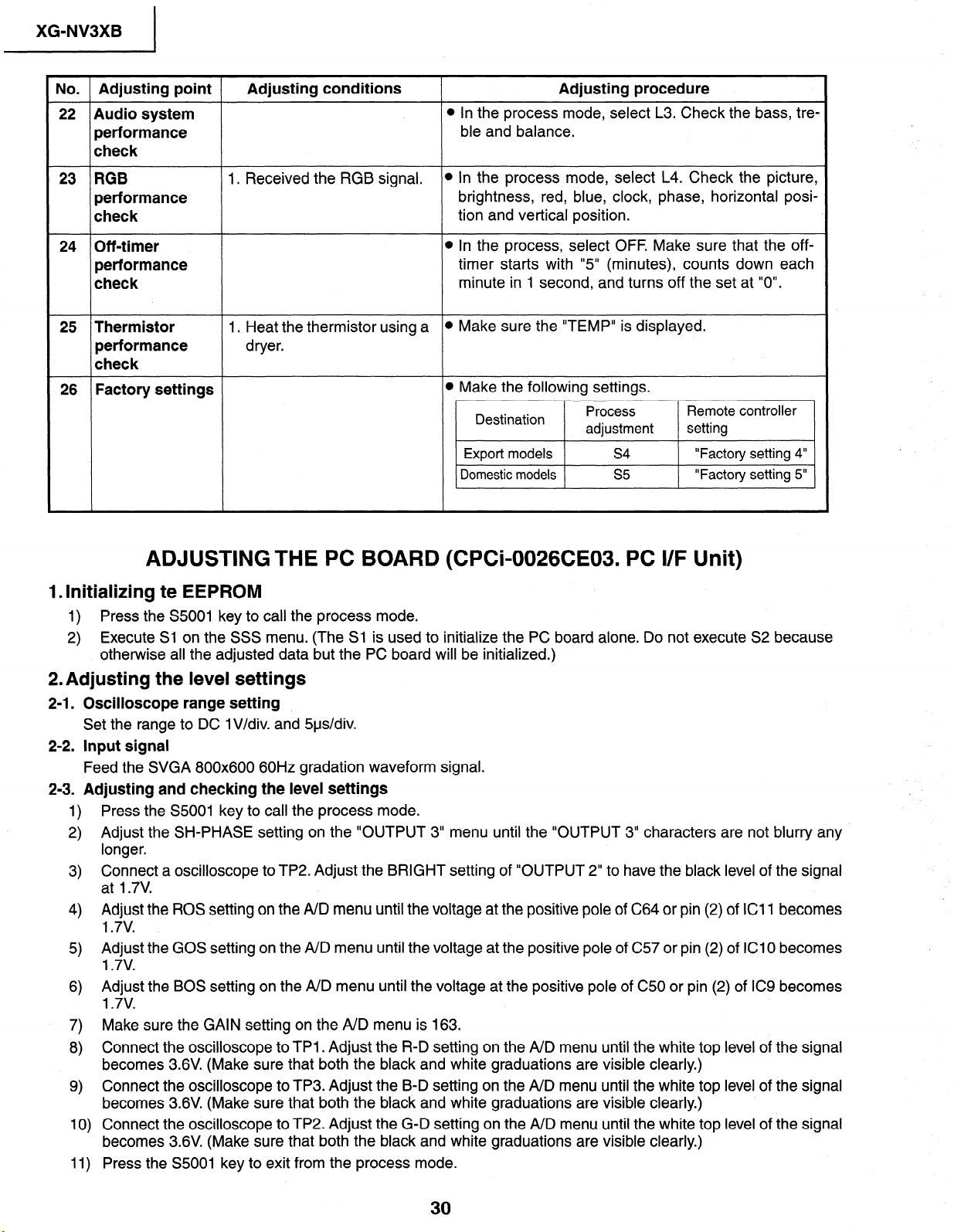

No. Adjusting point

22 Audio system

performance

check

23 RGB

performance

check

24 Off-timer

performance

check

25 Thermistor

performance dryer.

check

26 Factory settings

Adjusting conditions

1. Received the RGB signal.

1. Heat the thermistor using a

Adjusting procedure

l In the process mode, select L3. Check the bass, tre-

ble and balance.

l In the process mode, select L4. Check the picture,

brightness, red, blue, clock, phase, horizontal posi-

tion and vertical position.

l In the process, select OFF Make sure that the off-

timer starts with “5” (minutes), counts down each

minute in 1 second, and turns off the set at “0”.

l Make sure the “TEMP” is displayed.

l Make the following settings.

Destination

Export models s4

Domestic models s5

Process

adjustment

Remote controller

setting

“Factory setting 4”

“Factory setting 5”

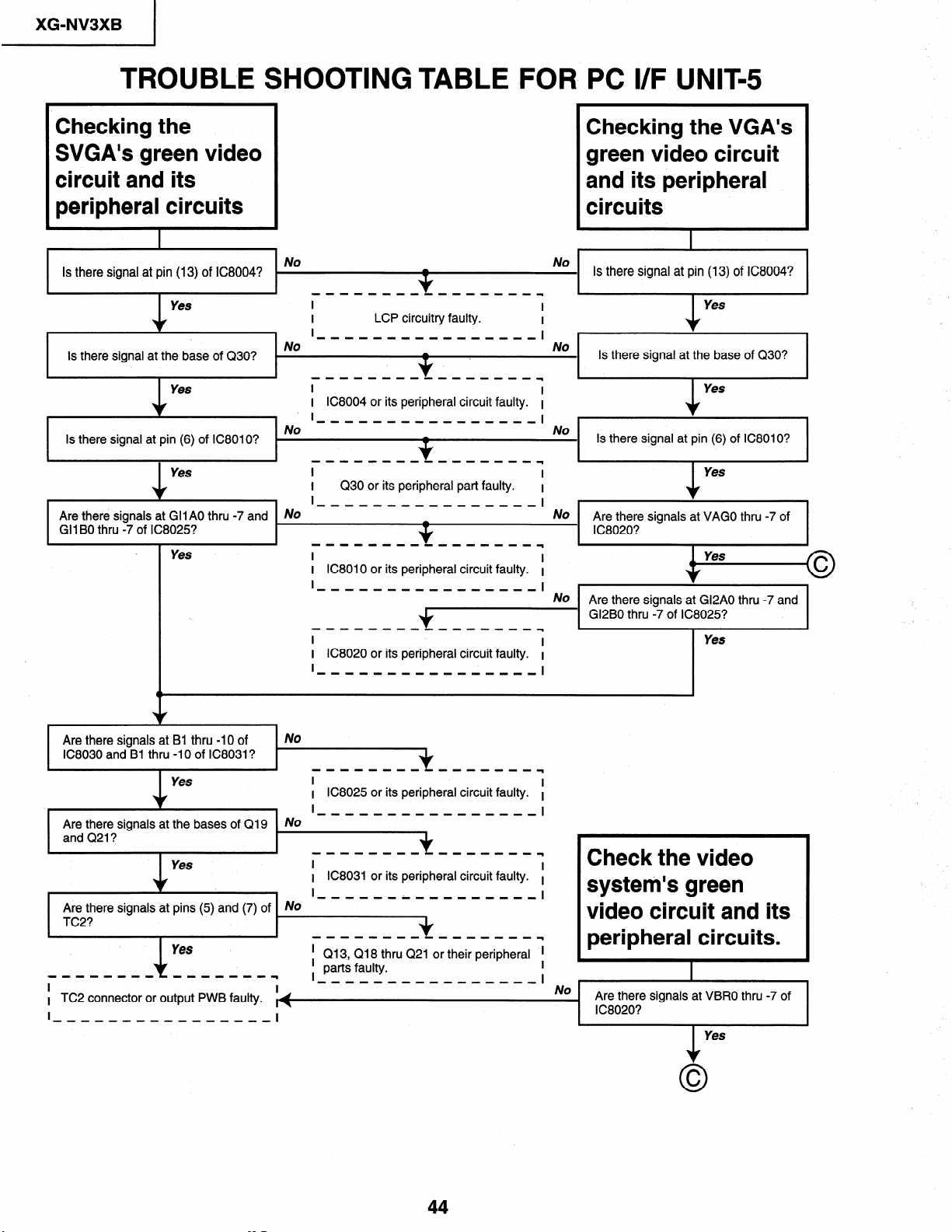

ADJUSTINGTHE PC BOARD (CPCi-0026CE03. PC I/F Unit)

1. Initializing te EEPROM

1) Press the S5001 key to call the process mode.

2) Execute Sl on the SSS menu. (The Sl is used to initialize the PC board alone. Do not execute S2 because

otherwise all the adjusted data but the PC board will be initialized.)

2. Adjusting the level settings

2-l. Oscilloscope range setting

Set the range to DC lV/div. and 5us/div.

2-2. input signal

Feed the SVGA 800x600 60Hz gradation waveform signal.

2-3. Adjusting and checking the level settings

Press the S5001 key to call the process mode.

1)

Adjust the SH-PHASE setting on the “OUTPUT 3” menu until the “OUTPUT 3” characters are not blurry any

2)

longer.

Connect a oscilloscope to TP2. Adjust the BRIGHT setting of “OUTPUT 2” to have the black level of the signal

3)

at 1.7V.

Adjust the ROS setting on the A/D menu until the voltage at the positive pole of C64 or pin (2) of ICl 1 becomes

4)

1.7v.

Adjust the GOS setting on the A/D menu until the voltage at the positive pole of C57 or pin (2) of IClO becomes

5)

1.7v.

Adjust the BOS setting on the A/D menu until the voltage at the positive pole of C50 or pin (2) of IC9 becomes

6)

1.7v.

Make sure the GAIN setting on the A/D menu is 163.

7)

Connect the oscilloscope to TPl . Adjust the R-D setting on the A/D menu until the white top level of the signal

8)

becomes 3.6V. (Make sure that both the black and white graduations are visible clearly.)

Connect the oscilloscope to TP3. Adjust the B-D setting on the A/D menu until the white top level of the signal

9)

becomes 3.6V. (Make sure that both the black and white graduations are visible clearly.)

Connect the oscilloscope to TP2. Adjust the G-D setting on the A/D menu until the white top level of the signal

lo)

becomes 3.6V. (Make sure that both the black and white graduations are visible clearly.)

Press the S5001 key to exit from the process mode.

11)

Page 31

TROUBLE SHOOTING TABLE

/ XG-NV3XB

Checking the PWB performance

I

Video input in trouble

I

p--I--

I Go to “Checking the video unit )

I circuit”.

I I-I-------I--

Y ----I-q

I

RGB input in trouble

I

,., ,_----~-__-_-~ ,-_____Y______~

1 IP~dtestpa~signalfrom 1 i _Th;~““l”“_‘rc_“i;n_ _ _j i _;;~;“k;g_t~~~~~

,

Is specified cable connected

between PC and projector?

I

Yes

I

&

Is supply voltage as specified?

I

4

Does image appear?

Yes

l for PC I/F unit ‘I.

Through-output in trouble

I

No

-I--I-I-I-I

.

I

Use specified cable.

I

L------------l

I -----II-------

No

-------I-q

r Checkthe connectors, starting I

from the PC input circuit.

I

I

II---------III

I

---a

Remote control in trouble

I

I

‘I

l

I

l

31

Page 32

XG-NV3XB

TROUBLE SHOOTING TABLE (Continued)

Checking the video system

Is the lamp on?

Yes

Is specified voltage fed to EA

cnnnectnrs7

11”. ;_____-A_--_--_;

Are there signal inputs at pins (1) and

(9) of IC816?

Yes

Are there signal outputs at pins (3)

and (6) of IC816?

I

Yes

------------ ----------

I

I Go to “Checking IC801

l (RGB signal output circuit)“. ! I

I

L-l-l---

----

l

I 1 Check IC816 their

I I peripheral circuits as well ;

J

L---------

No

as switching circuit

No

No

NO

.

--

-- J

__I

I

I

I

-----

1 Check the power circuit and its parts. I

-----

l__--_~______l__--_r-_____

I Check the video unit circuit

__I -------

Go to “Lamp fails to light-up”.

----------- I

-------

Are there signals at pin (4) of IC401

and pin (4) of IC402?

Yes

----

I I Check the oscillation circuit I

I (IC6004 and its peripheral I I of IC401 and IC402, and

I

.

l circuits).

L-----

------

I I their peripheral circuits.

J

L-----

--q

------

No

I

I

I

J

Checking the video unit circuit

Is there video signal output at pin (7)

of IC6001?

Yes

Is there video signal input at IC6004?

Yes

Are there signal outputs at pins (6)

and (8) of IC6004?

Yes

1

Check the low-pass and buffer circuits

of Q6002 thru Q6008. Is the signal as

specified?

Yes

1

1 : Go to “Checking IC801 (RGB signal I

output circuit)“.

----------

------

No

I

I Check the IC6001 selector switch,

I terminal voltage and input circuit.

No ------I---------

-------

I

Check the low-pis-a;d&iey

I

circuits of Q6009 thru Q6014.

I

- - - - - - - - - - - - - - - -

NO

-------

l

Check IC6004 and ii FeipLeil

I

circuits (bias).

I

----------

No

-----I

.

I Check Q6002 thru Q6008 and their

I peripheral circuits.

I

I

I

-----I

I-----

----

I

I

-9

I

1

I

-9

I

I

l

I

;

I

32

Page 33

TROUBLE SHOOTING TABLE (Continued)

Checking IC801 (RGB signal output circuit)

----

l

t Go to “No color or unusual tone”, “No I

Y signal” or “Out of sync”.

I

--- ---

-------

-----I--

---

I

NO 1 Are there RGB output waveforms at 1 NO

pins (31), (32) and’(33) of IC801?

Yes

I

Are there output waveforms at the

1 emitters of Q1501, Ql502 and

Ql503?

I

Yes

Are A/D outputs of IC1504, ICI505

and ICI506 as specified?

XG-NV3XB

1 Check the data transfer and other I

l performance, at pins (17) and (18) of I

I video IC801.

Nfi - - - - - - - - - - - - - - - -I

#WV

; Check Q801 thru Q803 (buffer), I

I ICI501 (amplifier), ICI502 (RGB I

l offset) and their peripheral circuits.

NO - - - - - - - - - - - - - - - -I

I

I Go to “Trouble shooting table for PC I

I I/F unit”.

--I-- ---

-- ---

Checking the chroma and Y signals of IC801 (RGB signal output)

Are there signal inputs at pins (29)

(Y signal) and (3)(chroma signal) of

P402?

Yes

Are there output waveforms at pins

(3)(chroma signal) and (6)

(Y signal) of IC816?

Yes

Are there signal inputs at pins (20)

(chroma signal) and (21) (Y signal)

1 of IC801?

Yes

; -0 -t; YCLeikin, ;c-oy ;,, 7

I signal output circuit)“.

---I

1

-I---- ------

NO

----

I

I

I

----I

~~

4

rCTheck_he k: s switching andtheiy I

I peripheral circuits. If there is no signal

I at pins (8) and (16), check 3-D noise

I reduction circuit (IC806).

,,,o

L - - - - - - - - - - - - - - -

I

I

I

I

- - - - - - - - I - - - - - - - I

I

I

---

Go to “Checking the video unit

circuit”.

----

---

I

Check IC801 and its peripheral

circuits.

--

--

-----

I

I

---

--‘I

1

I

I

/-yxII____

I Check IC806 (3-D noise reducti&;

I

I circuit) and its peripheral circuits.

---

---- --------I

I

I

i

I

33

Page 34

XG-NV3XB

TROUBLE SHOOTING TABLE (Continued)

Checking IC806 (3-D noise reduction circuit) and its peripheral circuits

Are there signal inputs at pins (40)

(Y signal) and (45)(chroma signal) of

IC806?

Yes

Are there signal outputs at pins (55)

(Y signal) and (5l)(chroma signal) of

IC806?

Yes

Are there signal outputs at the

emitters of Q817 (Y signal) and Q910

(chroma signal)?

Yes

I

I _Leck ;;I 6a~d~c801

,,,&;I 1

I output circuit).

No

,_______-___--__7

1 Check the buffer circuit of Q814 thru

1 Q816 as well as Q903 thru Q905.

II--

No

r

l-___-__-_-__-__7

1 Check IC806, IC807 (memory) and

1 their peripheral circuits.

------

No

I Q817, Q907 and Q910.

9

-----I

I

I

No color or unusual tone (NTSC,

Is there chroma signal input at pin

(20) of IC801?

Yes

Are there signal outputs at pins

(46)(R-Y) and (45)(B-Y) of IC801?

1 -II--I.--m&

Yes

-----------

l

l

Check IC803, IC814 1

peripheral circuits.

I

and-their --9 ------ ------- --- I

NO

l__________-____7

1 Go back to the signal processing

I block.

----

No

I

Check the oscillat~~o~X~0~ id 7

I

X802, and their peripheral circuits. 1

I

I

I

--------

-------

----------

----------

PAL)1

-----

I

I

-II--

l

I

I

l

I

I

No color or unusual tone (SECAM)

Is there chroma signal input at pin

(20) of IC802?

Are there signal outputs at pins

(ll)(R-Y) and (12)(8-Y) of IC802?

Yes

III

I

ChecklC80;, I& idtheir

I

peripheral circuits.

I

I--

--

i

----I

-----I

-q

No

No

-I--II-~

I

I

I

II---- ---------

1

I

I

Check the X802 oiciaioi, ;iOP 7

and their peripheral circuits.

34

--

I

I

Page 35

XG-NVSXB

TROUBLE

No or unusual Y signal

I

I

Is there Y signal input at pin (21) of

IC801?

I

I

Yes

1

Is there Y signal output at pin (40) of

IC801?

I Yes

b

Is there Y signal output at pin (17) of

IC81 I?

I

-----‘I

Check IC803 and its peripheral

I

circuits.

I

SHOOTING TABLE (Continued)

I

1

NO

-I--

l

Go back to the signal processing

I

block.

I

--

NO

INo ________;__--___I

I

I

___I

Check IC801 and its peripheral

;

circuits.

I

circuits as well as IC805 (AGC).

- - - - - - - - - - - - - - - -

I

__I

A- --

___I

--

--l

--- I

III

l

I

1

I

1

I

No or unusual horizontal sync

I

Is there horizontal sync pulse output

at pin (56) of IC801?

Yes

Is there horizontal sync pulse output

at pin (9) of IC603?

Yes

l circuits, and go to “Trouble shooting

I table for PC I/F unit”.

No or unusual vertical sync

I

Is there vertical sync pulse output at

pin (4) of IC801?

Yes

I circuits, and go to “Trouble shooting

I table for PC I/F unit”.

NO

I

I

I

I--

NO

I_

I

I

I

I_

I

IV0

I

I

I

--

I

I

circuits.

--- --_I

Check t;e-pis, shaping ~ir~u~o~

IC602 and IC603.

_I_I

_I_ --

_I-

---

I_

---

1

circuits.

----

---

_I

I_

_I-

I

I

q

1

I

I

I

35

Page 36

XG-NV3XB

Go to “Checking the PWB

performance”.

TROUBLE SHOOTING TABLE (Continued)

Checking the output PWB unit

I

Are there signal inputs at

IV0 Pl404, PI405 and SCl501? No

Are voltages applied to EA and

l I

Go to “Checking the clock I

I I

circuit and its peripheral

l I

circuits”.

EB connectors?

l

I

Yes

PI----

I

I Check the power unit circuit. I

I ----II-I-----I

I

I

Are there signal outputs at pins

(30) and (40) of ICI 109,

ICI 209 and ICI 309?

Yes

Are there signal inputs at pin No

(16) of ICllll, ICIIIO,

ICl210, ICI21 I, ICI 310 and

Are there signal outputs at pins

(23), (2% (271, (33), (35) and

(37) of ICI 1 IO, ICI 111,

ICl210, ICl211, ICI310 and

ICI31 I?

I

Yes

, 1 ,i

Are there signal inputs at No

SCIIOI, SC1201 and

I If there is no signal input at : 1 Yes

I pins (1) and (3-i) of SCIIOI, ;

I SCll02and SCl103, check

I the switching circuit and

l amplifier circuit of ICI 112,

I l

I I Check the R, G and B panels. I

I ICll13, ICl212, ICI213 and I I

I ICl313, and their peripheral’ I - - - - - - - - - - - I circuits.

------------- J

No

; check l;l;O; ;;2;9

l ICI309 and their peripheral

I circuits.

1 II-I- III-----

-----Iv--I-III

r

I Check the switching circuit of f

I and their peripheral circuits.

- - - - - - - - - - - - -

No

II______

Check the input and output I

1 I

signals at ICI 106, ICI206 and I

I

ICI306 Check also ICI 1 IO,

Icllll, ICl210, ICl211,

ICl310, ICl311, and their

peripheral circuits.

-II----I---- J I

I

-I--I

I

l If there is no signal input at I

Y l---l-

I pins (15) and (30) of

I SCIIOI, SCll02and I

I SCl.103, check lC5509, I

I

I lC5514, and their

I peripheral circuits.

-I

I-I I--II-I--

1

__I_

I

i

l

;

I

I

I

l

36

yr3--____

Check ICl406, ICl407, I

I

ICI408 and their

I

peripheral circuits.

I

LB-I---II---- J

I

I

Page 37

TROUBLE SHOOTING TABLE (Continued)

No audio output

,

I

Are there audio signal outputs at pins NO

(5) and (27) of SC6001?

I

Are there audio signal outputs at pins

No

-III--I

I

I Check the input, the switching circuit I

I of IC6001 and IC6002, and their

I peripheral circuits.

I-II-

II-I--I-I--

c

/ XG-NV3XB

III-I-

I_

I

I

l

Yes

I

IC303 and IC304 and their peripheral ,

.

Are there audio signal outputs at pins

(4) and (6) of IC7301?

III-III

l

l If the voltage at pin (7) of IC7301 is

1 not as specified, check Q5501,

1 Q5502 and their peripheral circuits.

--------I)-

-,

----I---

------

1

No

Yes

----I-I

I

1 Check IC7301 and its peripheral

I

I

l circuits, and the SP connectors and

1 speakers.

I

I

I---

.

------

---

-----I

I circuits, the IC1409 control voltage,

I the PI501 connectors, etc.

--l--l-l

III-I

I

l Check IC7301 and its peripheral

1 circuits.

-----I)

I

)

I

-I --II----~

--I--IIII-

I-l----l

I

,

I

I

I

37

Page 38

XG-NV3XB

Which output voltage line fails?

----

( ReplaceF751.

------I J ’

TROUBLE SHOOTING TABLE (Continued)

-7 4.5V

-7 ------m-q

1 ’

Replace F752. I

--- ---- J

Checkig the Power Unit

I

yes Is there any other output

voltage failure?

No

Is EA connector disconnected

or loose?

No

I

Yes

r

I Reconnect the EA connector.

L -----I- ----- J

-----I

I

-----I

I Replace IC701, IC702, T701 or I

I R724.

----- ----I --- J

Is AC voltage (85-264V)

applied across the PA

connector?

Yes

No

-II---- -----

;

L ---I- ----- -- J

ReplaclF&.

I

Yes ’

Is R724 open?

No

1

I

Is there short-circuit between

collector and emitter of Q702?

Yes

l I-------1

I- Replace i’ki

----I -- J ’ ----I

1

Replace PC702.

No

-- J

I

38

Page 39