Page 1

XG-NV1E

XG-NV1EA

SHARP CORPORATION

SERVICE MANUAL

SERVICE-ANLEITUNG

SECAM/PAL/NTSC SYSTEM

LCD PROJECTOR

LCD PROJEKTOR

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

MODELS

MODELLE

XG-NV1E

XG-NV1EA

TENTATIVE

Page 2

XG-NV1E

XG-NV1EA

2

CONTENS

Page

INHALT

Page

• OVERALL WIRING DIAGRAM.........................45

• DESCRIPTION OF SCHEMATIC DIAGRAM ...49

• WAVEFORMS .................................................. 50

• SCHEMATIC DIAGRAM................................... 51

• PRINTED WIRING BOARD ASSEMBLIES......89

• PARTS LIST

ELECTRICAL PARTS ................................. 99

CABINET AND MECHANICAL PARTS.....126

ACCESSORIES PARTS ........................... 134

PACKING PARTS ..................................... 135

• PACKING OF THE SET .................................136

• NOTE TO SERVICE PERSONNEL....................3

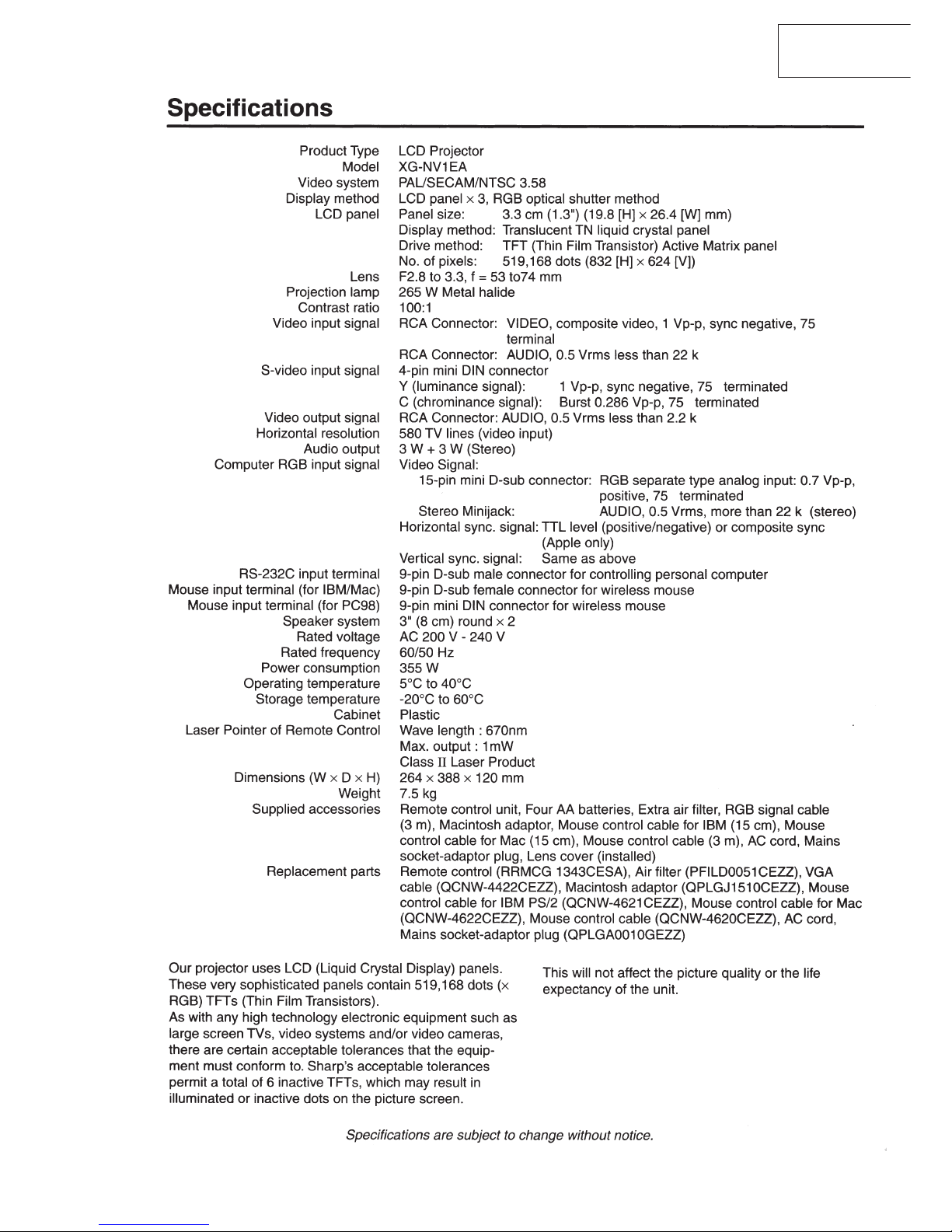

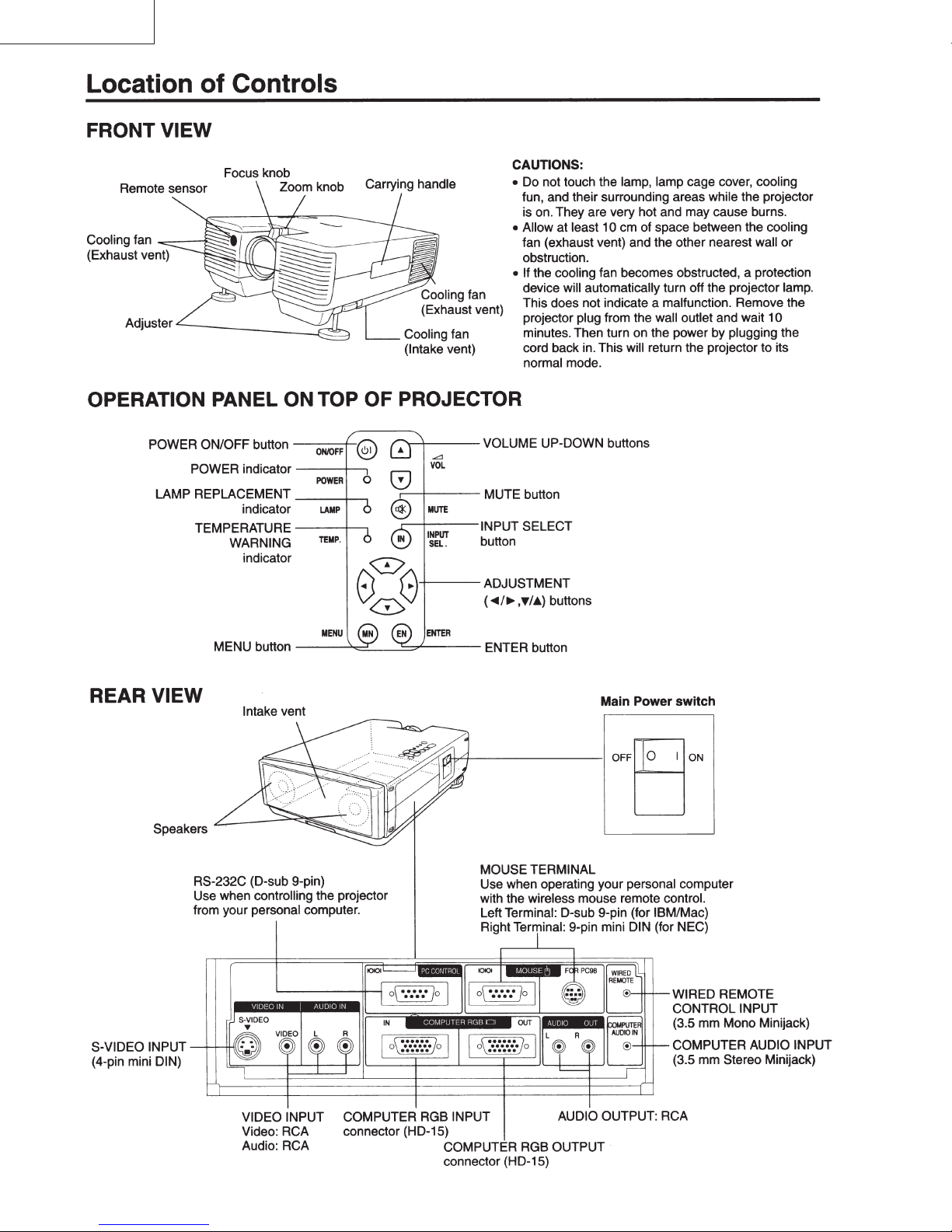

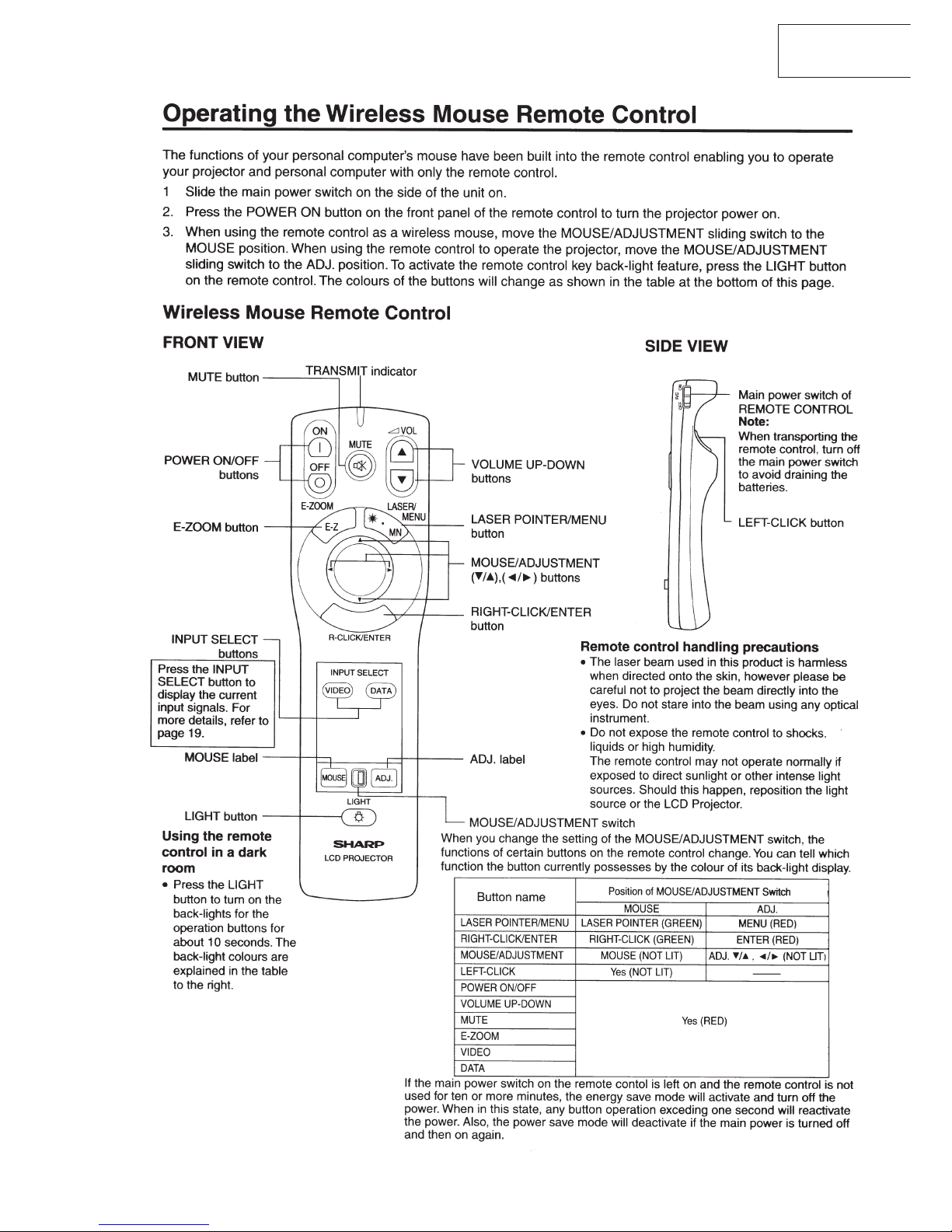

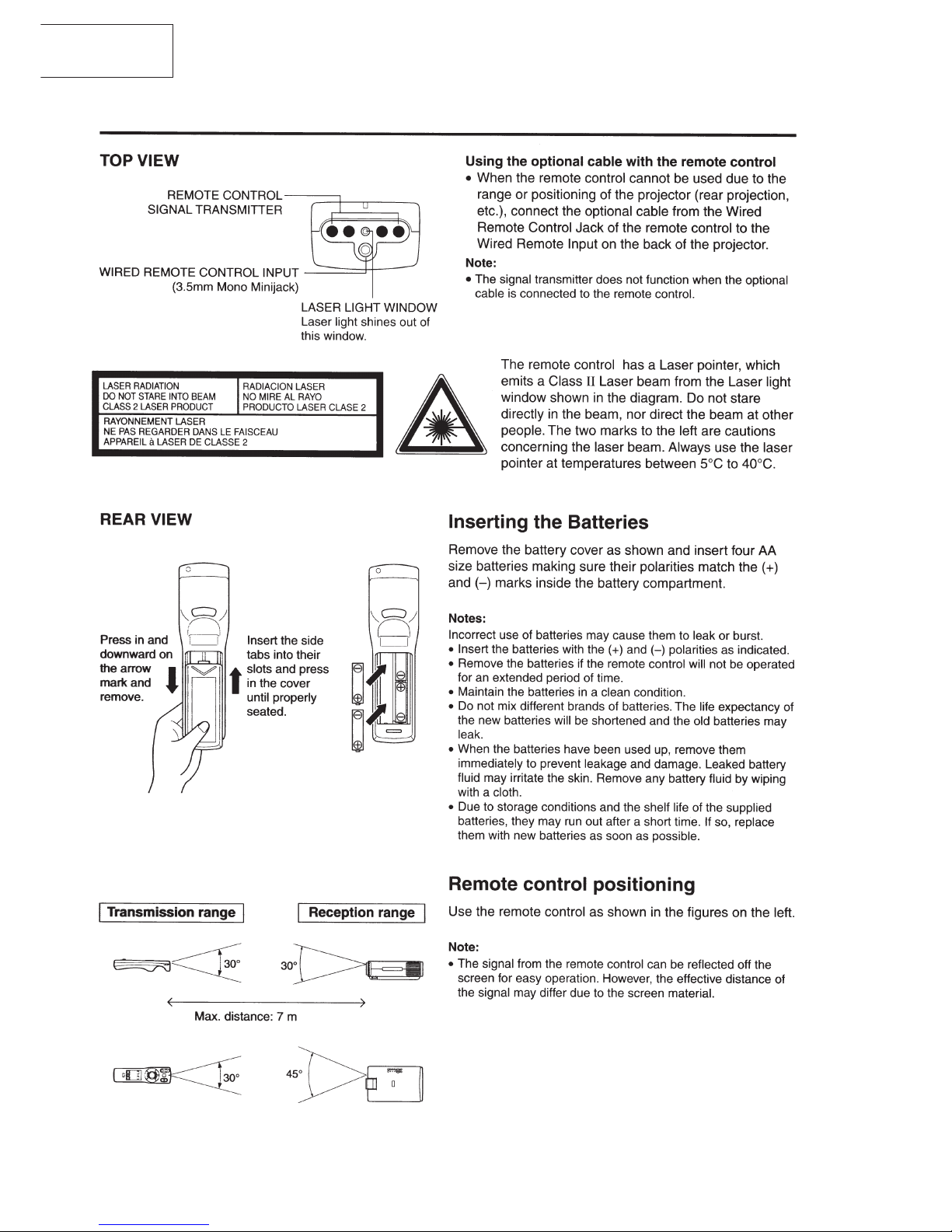

• SPECIFICATIONS.............................................. 4

• OPERATION MANUAL ...................................... 6

• REMOVAL OF MAJOR PARTS ........................ 11

• THE OPTICAL UNIT OUTLINE ........................ 16

• CONVERGENCE AND

FOCUS ADJUSTMENT.................................... 17

• ELECTRICAL ADJUSTMENT .......................... 21

• TROUBLESHOOTING T ABLE ......................... 22

• CHASSIS LAYOUT .......................................... 39

• BLOCK DIAGRAM ........................................... 41

• GESAMTSCHALTPLAN.......................................

• BESCHREIBUNG DES SCHEMATISCHEN

SCHALTPLANS....................................................

• WELLENFORMEN ...............................................

• SCHEMATISCHER SCHALTPLAN ......................

• LEITERPLATTENEINHEITEN..............................

• TEILELISTE

ELEKTRISCHE BAUTEILE ............................

CEHÄUSETEILE UND MECHANISCHE

TEILE..............................................................

ZUBEHÖRTEILE ............................................

VERPACKUNGSTEILE ..................................

• VERPACKEN DES GERÄTS ...............................

• HINWEISE FÜR DAS

WARTUNGSPERSONAL.....................................

• TECHNISCHE DATEN.........................................

• BEDIENUNGSANLEITUNG .................................

• ENTFERNEN DER WICHTIGSTEN TEILE..........

• ÜBERSICHT ÜBER DIE OPTIKEINHEIT.............

• ***** ......................................................................

• ELEKTRISCHE EINSTELLUNG...........................

• TABELLE FÜR STÖRUNGSSUCHE....................

• CHASSIS-ANORDNUNG.....................................

• BLOCKSCHALTBILD ...........................................

SeiteSeite

PagePage

• .............................................................................

• .............................................................................

• .............................................................................

• .............................................................................

• .............................................................................

•

........................................................................

........................................................................

........................................................................

........................................................................

• .........................................................................

• .............................................................................

• .............................................................................

• .............................................................................

• .............................................................................

• .............................................................................

• .............................................................................

• .............................................................................

• .............................................................................

•

• .............................................................................

Page 3

XG-NV1E

XG-NV1EA

3

NOTE TO SERVICE PERSONNEL

UV-RADIATION PRECAUTION

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

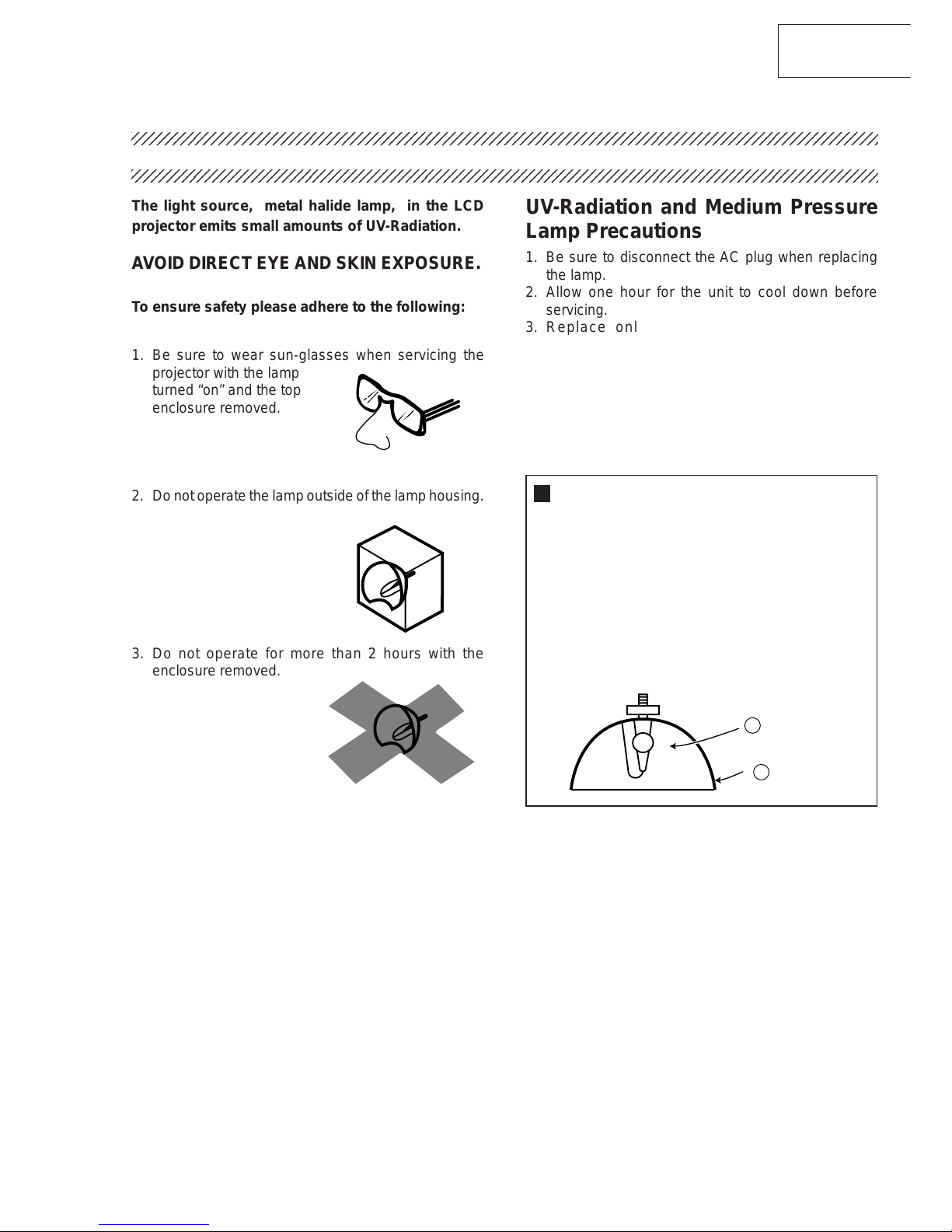

The light source, metal halide lamp, in the LCD

projector emits small amounts of UV-Radiation.

A VOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type

CLMPF0042DE01 rated V/265W.

4. The lamp emits small amounts of UV-Radiation,

avoid direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

DANGER ! –– Never turn the power on without

the lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp should

be done at least one hour after the power has been

turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

1

2

Lamp

Reflector

Page 4

XG-NV1E

XG-NV1EA

4

Page 5

XG-NV1E

XG-NV1EA

5

Page 6

XG-NV1E

XG-NV1EA

6

Page 7

XG-NV1E

XG-NV1EA

7

Page 8

XG-NV1E

XG-NV1EA

8

Page 9

XG-NV1E

XG-NV1EA

9

Page 10

XG-NV1E

XG-NV1EA

10

Page 11

XG-NV1E

XG-NV1EA

11

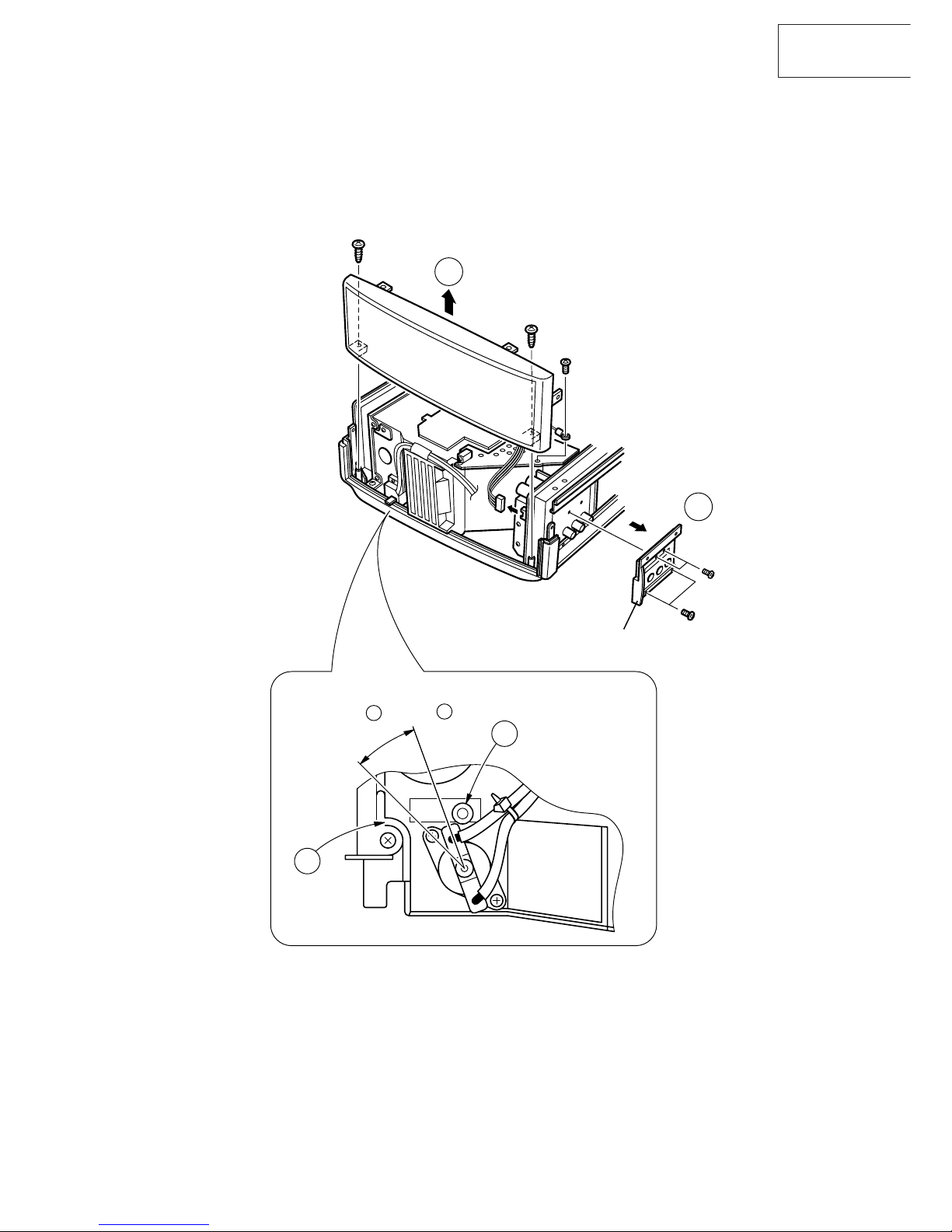

REMOVING OF MAJOR PARTS

Before starting this job, detach the lamp cage unit and the filter cover.

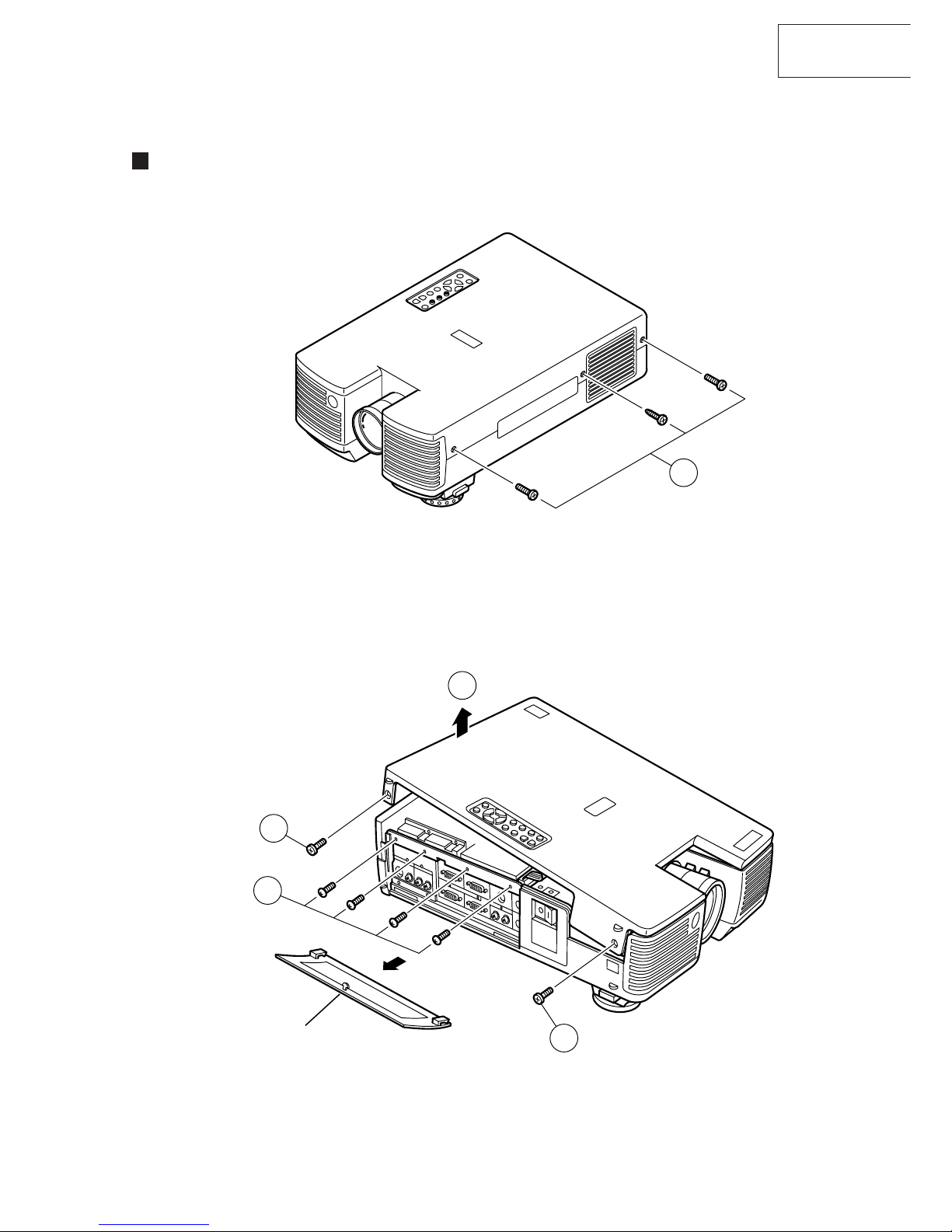

1.Removing the top cabinet

1-1. Remove the three screws at the carrying handle side.

1-2. Remove the two screws at the terminals side.

1-3. Detach the terminal door, and remove the four screws off the terminal cover.

1-4. Slowly lift the back of the top cabinet and disconnect the operation key unit connector (KY). Pull up and

away the top cabinet.

1-5. Place the top cabinet upside down. Remove the four screws off the operation key unit. Take out the

operation key unit.

(KY)

1-2

1-4

1-3

1-2

Top Cabinet

Terminal Door

1-1

Page 12

XG-NV1E

XG-NV1EA

12

2.Removing the front cabinets

2-1. Tilt the front-right cabinet forward. Pull it up out of position.

2-2. Tilt the front-left cabinet forward. Disconnect the infrared R/C receiver unit. Pull up the cabinet out of

position.

2-2

2-1

Front-right Cabinet

Infrared R/C Receiver Unit

Front-left Cabinet

Page 13

XG-NV1E

XG-NV1EA

13

3.Removing the rear cabinet and video terminal cover

3-1. Remove the two screws off the rear cabinet and the screw from the static ground lead. Pull up the cabinet

and disconnect the speaker connector (SP). Now the rear cabinet is free.

3-2. Remove the four screws off the video terminal cover. Detach the cover.

(SP)

3-1

3-2

a

b

Video Terminal Cover

Boss

Rib

Make sure the bimetal lead terminals are at the bottom

of the boss a and rib b .

Rear Cabinet

Page 14

XG-NV1E

XG-NV1EA

14

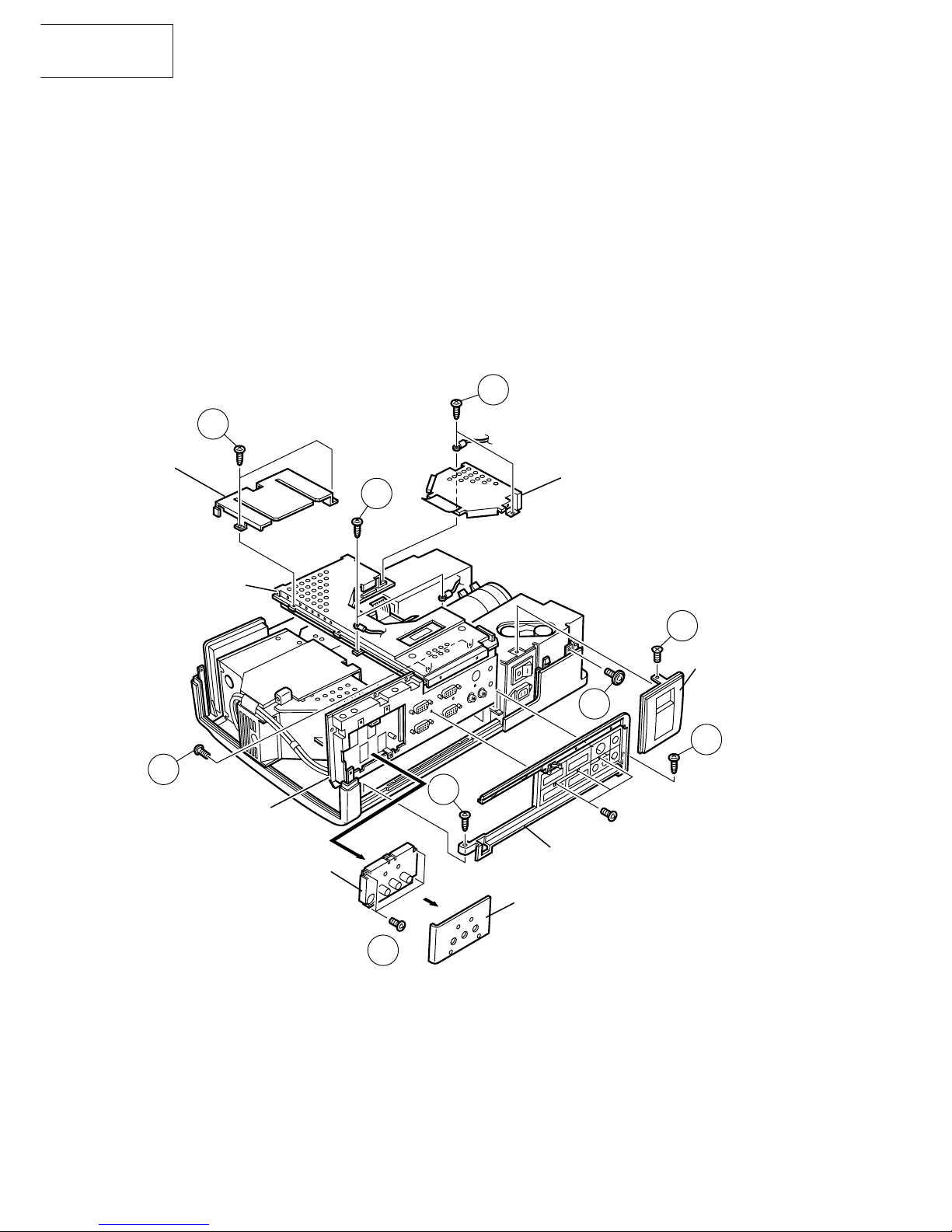

4.Removing the PWBs

4-1. Remove the two screws that fix the PC terminal cover to the bottom cabinet.

4-2. Remove the two screws off the output shield. Take out the output shield and disconnect the R-LCD, G-LCD

and B-LCD connectors (RP, GP, and BP).

4-3. Remove the four screws off the output unit. Disconnect the insulating barrier, the ground leads and the

connectors (FN, Q, LL, FF , LF, BL, RC and EA). Pull up and away the output unit and the signal/PC terminal/

video board unit.

4-4. Peel off the shield sheet. Remove the four screws off the video board unit. Pull the unit toward yourself to

take it out.

4-5. Remove the two screws off the back of the output unit. Separate this unit from the signal/PC terminal unit.

4-6. Remove the screw off the bottom cabinet and the screw off the power panel. Now take out the power panel.

4-1

4-1

4-3

4-3

4-2

4-5

4-4

4-6

4-6

Insulating

Barrier

Output Unit

Signal/PC Terminal

Unit

Output Shield

Power Panel

PC Terminal Cover

Shield Plate

Video Board

Unit

Page 15

XG-NV1E

XG-NV1EA

15

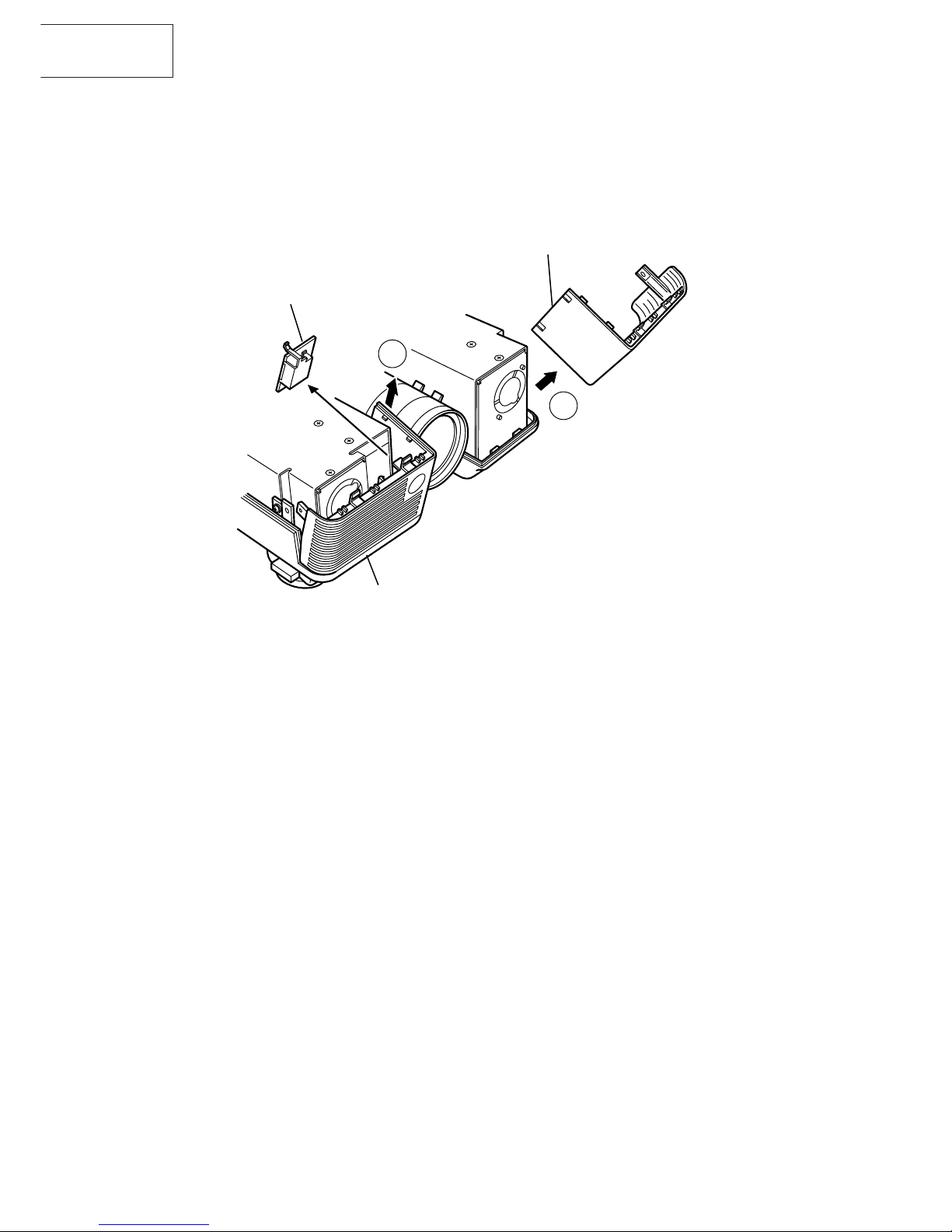

5.Removing the optics mechanism assembly

5-1. Remove the two screws off the angles A and B of the carrying handle. Detach the carrying handle.

5-2. Remove the two screws off the lamp socket holder. Take out the lamp socket.

5-3. Disconnect the bimetal connector (BA). Remove the four screws off the optics mechanism assembly, and

pull up and away this assembly.

5-4. Remove the two screws off the exhaust panel. Separate the panel from the bottom cabinet.

5-5. Remove the screw off the power/ballast unit assembly. Pull up and away the unit.

5-1

5-5

5-1

5-3

5-3 5-2 5-3

(BA)

5-3

5-4

Power/Ballast Unit

Carrying

Handle

Optics

Mechanism

Ass'y

Exhaust

Panel

Page 16

XG-NV1E

XG-NV1EA

16

B-LCD

G-LCD

GREEN

BLUE

BLUE

RED

R-LCD

Polarizer film

Dichroic coating

(B transmission)

Dichroic coating

(B reflection)

Incident polarizer plate R

Dichroic coating

(R transmission)

AL-coated mirror R

AL-deposited face

Polarizer film

Marking

AR-coated face

Marking

G reflector

Dichroic coating

B/G reflector

AL-coated mirror W

AL-deposited

face

Fly-eye lens (incoming light)

UV cut filter

Metal-halide lamp

(Light source)

Relay lens 1

AL-deposited face

AL-coated mirror B

Projection Lens

B reflector

Cross dichroic prism

Incident polarizer plate B

Relay lens 3

Relay lens 2

Incident polarizer plate G

Condenser lens G

Fly-eye lens (outgoing light)

Condenser lens R

* M3

M6

M4

M2

M5

M1

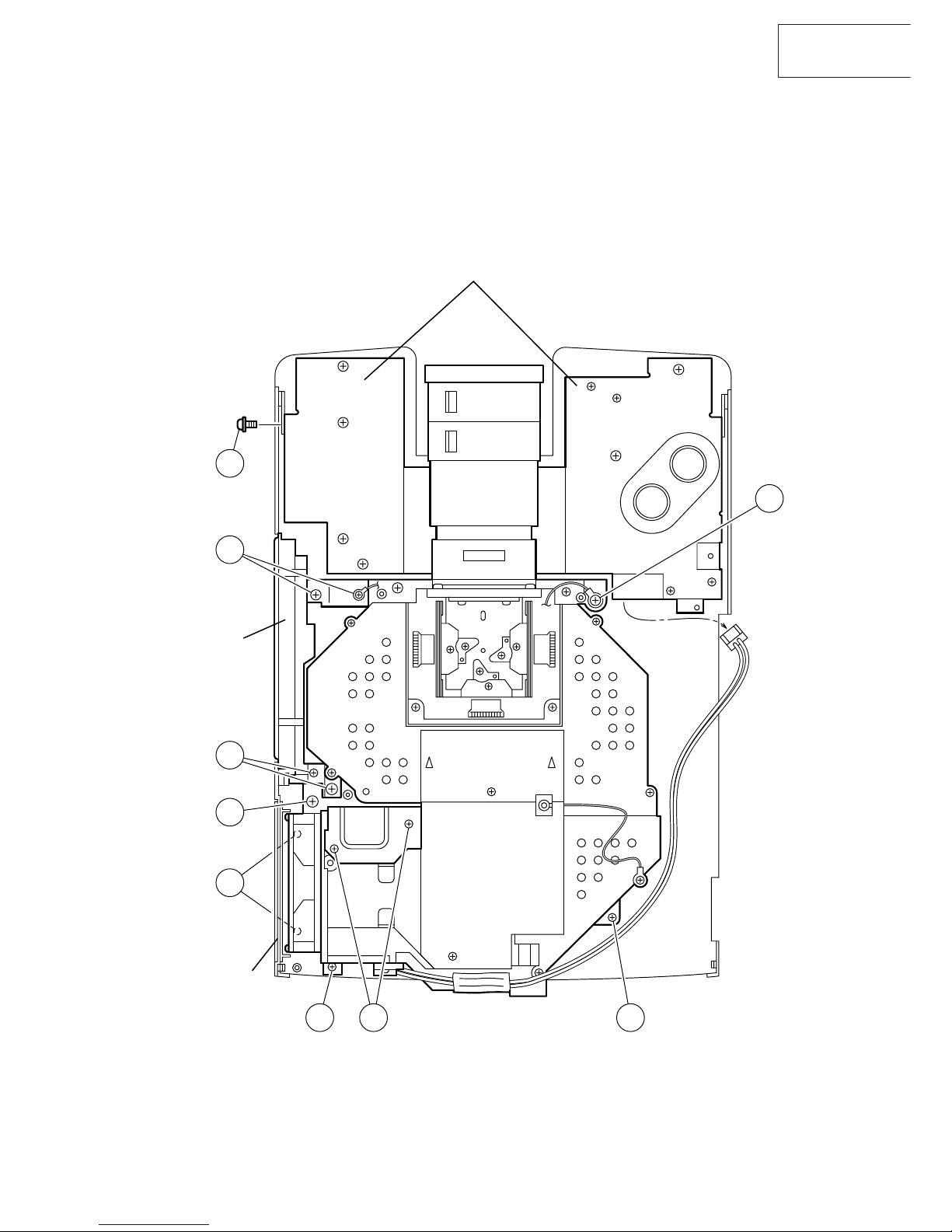

THE OPTICAL UNIT OUTLINE

* The M3 mirrors have a coating

wedge (for different film thickness). Set up these mirrors, with

their markings positioned as

shown above, so that their

coated faces and both sides be

in the correct directions.

Layout of the optical system

Note: Layout for positioning the optical system.

Page 17

XG-NV1E

XG-NV1EA

17

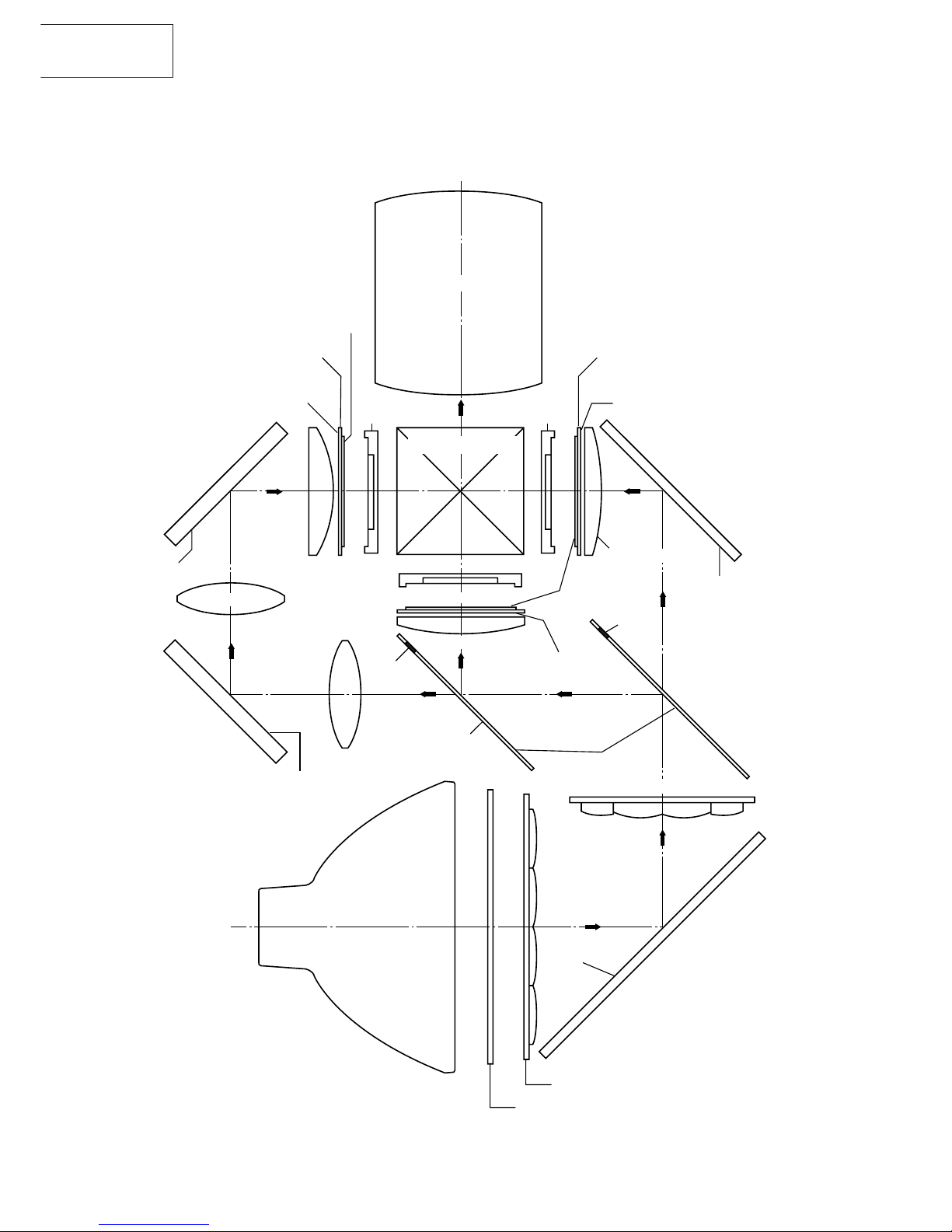

CONVERGENCE AND FOCUS ADJUSTMENT

» Start the convergence and focus adjustments with the top cabinet and the signal

shield removed but the power on. Use the remote control gun to adjust the image.

Take the following procedures.

1. Focusing the projection lens

(A) Replacing all the 3 LCD panels

1. Before replacing all the 3 LCD panels, project an image on the screen and bring it into focus.

2. Replace the panels with new ones. But until the focus has been completely readjusted, be careful not to

change the distance between the set and the screen, nor to move the projection lens focus and zoom

rings.

If the focus is readjusted with a different positional relation, the relation between the projection distance

and the screen size is affected. In other words, a short-distance image (40 WIDE, for example) may

get out of the focus range, or a long-distance image (300 WIDE, for example) may come out of focus.

(B) Replacing 1 or 2 of the 3 LCD panels

1. In adjusting the focus after replacement of one or two LCD panels, project an image on the screen and

turn the projection lens focus ring to get the non-replaced LCD panel into focus.

2. But until the focus has been completely adjusted for the new LCD panels, be careful not to change the

distance between the set and the screen, nor to move the projection lens focus and zoom rings.

(If the distance has been changed or the projection lens readjusted, repeat the above steps 1 and 2.)

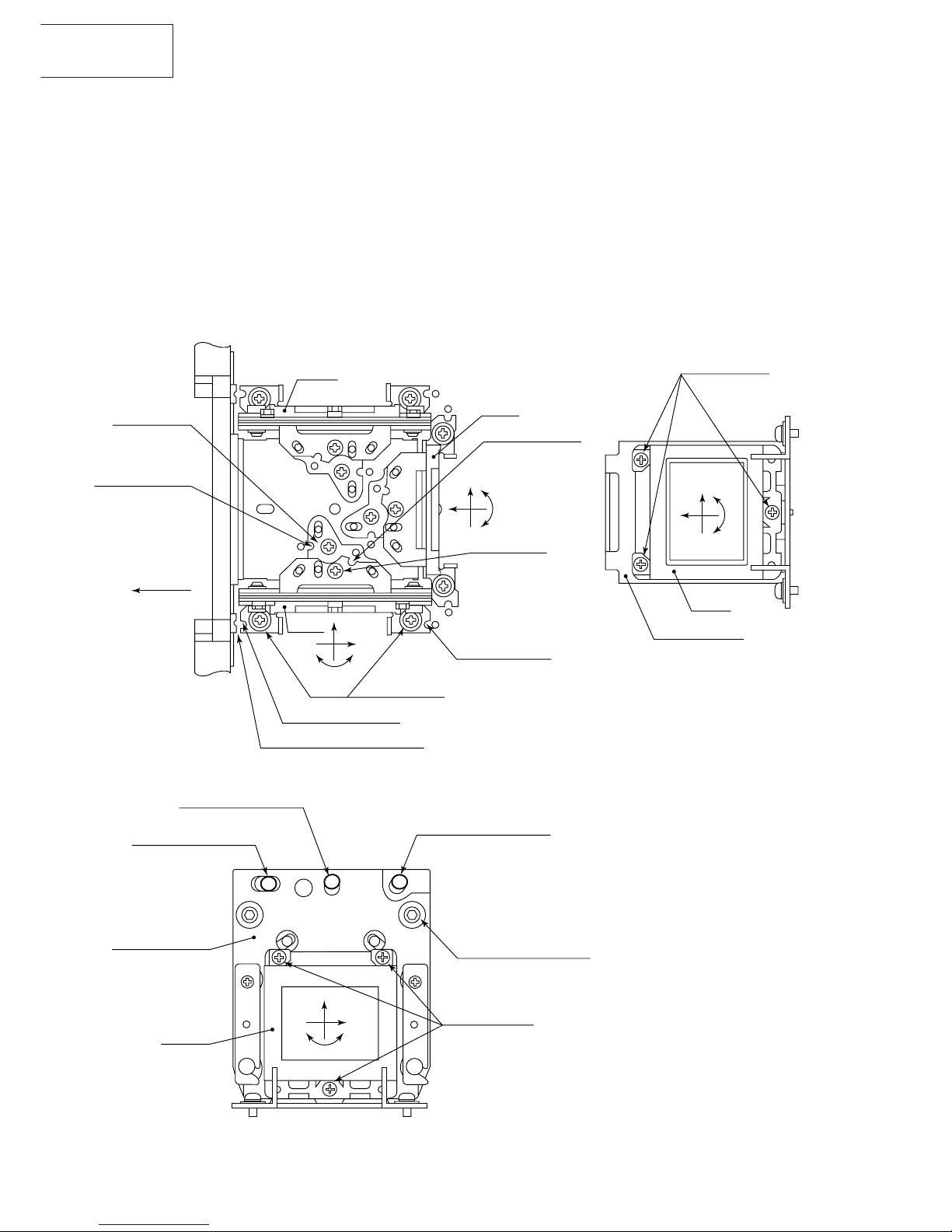

2. Adjusting the G-LCD panel

(A) Focus adjustment. (Make this adjustment on the white-only screen.)

1. Right-and-left focus adjustment (θY direction) . Loosen the lock screws "b" and "c" and insert the eccentric

screwdriver into the notch and hole "b". Turn the screwdriver until the right and left halves on the screen

get into focus.

First get the right and left halves in balance. Then improve the accuracy while making the adjustment

2 below.

2. T op-center-bottom focus adjustment (θX and Z directions). Loosen the lock screws "a" and "c" and insert

the eccentric screwdriver into the notch and hole "a" or "c".

Turn the screwdriver until the top, center and bottom on the screen get into focus. In adjusting this topto-bottom focus, temporarily tighten the lock screw "b" to fix the θY direction adjustment.

3. Repeat the above steps 1 and 2 to finely adjust the focus. Finally tighten up all the lock screws.

Note :

1 Carefully proceed with the focus adjustment because the adjusting directions are correlated.

2 In adjusting the convergence and focus, do not move the projection lens zoom and focus rings until the

end of all the adjustments.

(B) Convergence adjustment

» The G-LCD panel has no convergence adjustment mechanism. Use this panel as convergence adjustment

reference.

3. B-LCD panel adjustment (the same for the R-LCD panel)

(A) Focus adjustment

» Take the same procedure as for the G-LCD panel focus adjustment. Note that the adjustment range is

small in the Z direction. If the convergence is quite different between the B-LCD and G-LCD panels,

roughly adjust the convergence first and then the focus.

(B) Convergence adjustment

» Use a crosshatch pattern signal for this adjustment.

Make the adjustment just for the G-colour and the relevant colour.

(1) Loosen the convergence lock screw "d".

(2) With the G-LCD panel’s screen center as reference, adjust the B-LCD panel in the X, Y and θZ directions.

(3) Finally tighten up the convergence lock screw "d".

)

(

)

(

Page 18

XG-NV1E

XG-NV1EA

18

X

Z

θY

X

Y

θZ

X

Y

θZ

X

Z

θY

Notch and hole "a"

(Use an eccentric

screwdriver.)

Notch and hole "b"

(Use an eccentric

screwdriver.)

Lock screw "b"

(θY direction)

G-LCD panel

mounting screws

G adjusting plate

Notches and

holes "c"

(Use on eccentric

screwdriver.)

Notches and holes "c"

Lock screws "c"

(Use an bladed screwdriver.)

Eccentric cam

(Y direction adjustment)

Eccentric cam

(X direction adjustment)

Eccentric cam

(θZ direction adjustment)

Lock screw "d"

(convergence adjustment)

R•B adjusting plate

R•B-LCD

R•B-LCD panel

mounting screws

TOP VIEW

SIDE VIEW

SIDE VIEW

Lock screw "a"

FRONT

R-LCD

G-LCD

B-LCD

G-LCD

Convergence and Focus Adjustments Mechanism

Note :

1 The eccentric cam is used for convergence adjustment. This means that the cam’s turning and the linear

movement are not always uniform.

2 This model is not equipped with the LCD image adjustment mechanism. This is because the dichroic

prism is used for image formation. When the LCD panels all get into the best focus, the images are

almost completely converged.

Page 19

XG-NV1E

XG-NV1EA

19

X direction LCD right and left

Convergence Y direction LCD top and bottom

θZ direction Rotation around Z axis LCD turning axis

Z direction LCD optical axis

Focus θX direction Rotation around X axis LCD top-to-bottom flapping

θY direction Rotation around Y axis LCD right-to-left flapping

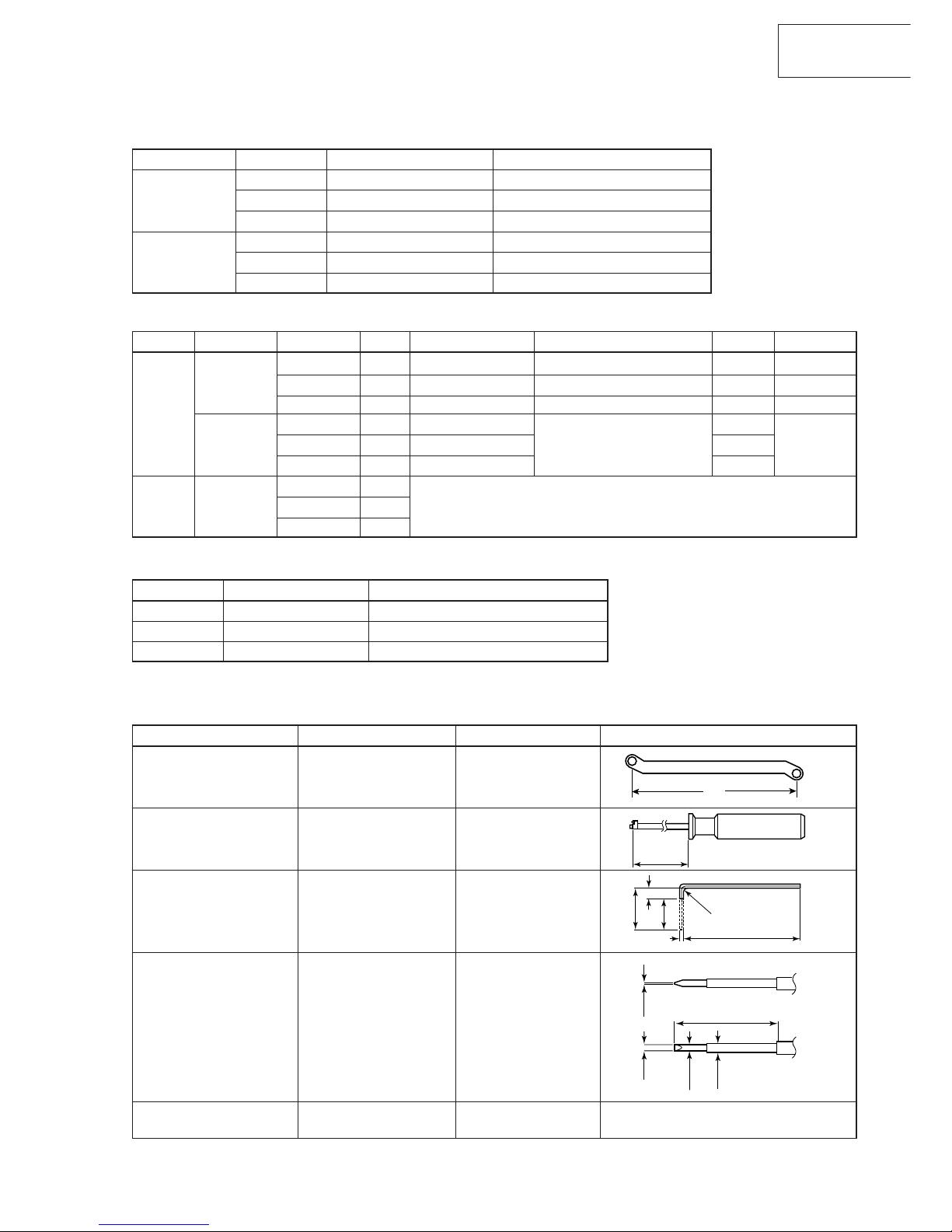

Tool Specific or General Tool code Configuration

Eccentric cam Specific 9DASPN-XGNV1U

adjusting wrench

Eccentric screwdriver Specific 9EQDRiVER-NV1A

Hex wrench General (redesigned) 9EQLNC-XGNV1U

Bladed screwdriver General 9EQDRiVER-NV1B

Phillips screwdriver General — For M2.6 pan-head machine screw

0.5

85min

ø5

(ø3.5)

3.5

2

5

(16)

(R2)

(50)

CUT

100

80

Focus Adjustments the Other Way

a Notch and hole "a" Z and θX directions

b Notch and hole "b" θY direction

c Notch and hole "c" Z, θX and θY directions

Convergence and Focus Adjusting and Tightening Tools

X direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

Convergence Y direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

R/B θZ direction ±1° Eccentric cam Eccentric cam adjusting wrench d Hex wrench

colours Z direction 0.8mm

Notch and hole "a" & "c"

Eccentric screwdriver, a, c Phillips

Focus θX direction ±1°

Notch and hole "a" & "c"

Bladed screwdriver a, c screwdriver

θY direction ±1°

Notch and hole "b" & "c"

b, c

Z direction ±0.2mm

G colour Focus θX direction ±1° Same as for R and B colours

θY direction ±1°

Colour Adjustment Direction

Movement

Position Adjusting tool

Lock screw

Tightening tool

Convergence and Focus Adjustments at a Glance

Adjustment directions

Lock screw Position Related direction

Adjustment Direction Definition Direction of LCD panel

Convergence and Focus Adjustment for the XG-NV1 Optical Mechanism

Page 20

XG-NV1E

XG-NV1EA

20

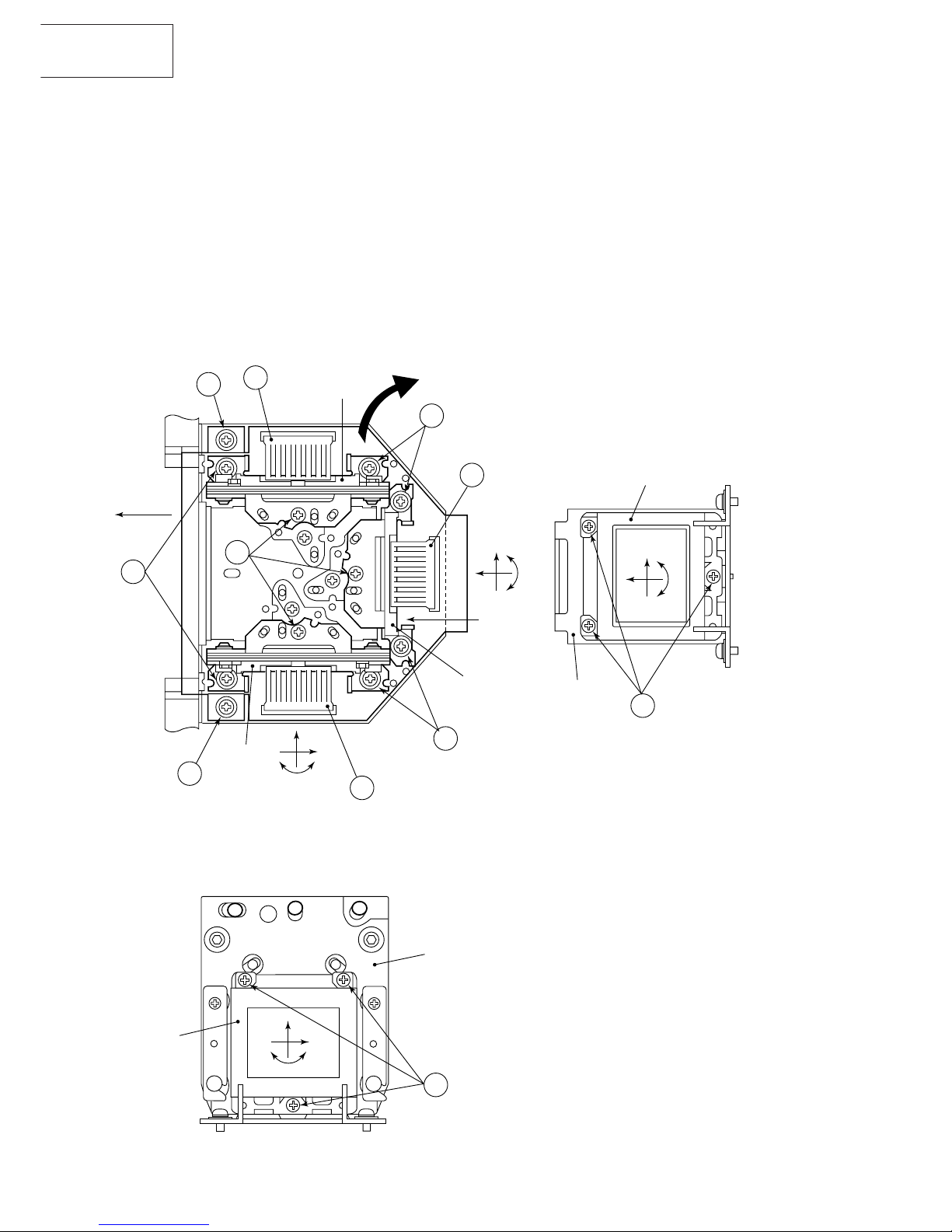

Replacing the LCDs

With the top cabinet removed

(1)Remove the output shield.

(2)Disconnect the LCD flat cable from the output PWB connector.

(3)Remove the lock screws "b" and "c". Detach the R/B adjusting plate or the G adjusting plate together with the

LCD panel.

(4)Separate the LCD panel from the adjusting plate.

(5)Mount a new LCD panel in the reverse order of the above steps (1), (2), (3) and (4).

~ Readjust the convergence and focus. Note that the G LCD panel needs no convergence adjustment and has

a small adjustment range in the Z direction.

X

Z

θY

TOP VIEW

SIDE VIEW

SIDE VIEW

X

Z

θY

X

Y

θZ

X

Y

θZ

G-LCD panel

mounting screws

G adjusting plate

Lock screws "c"

Lock screws "c"

Lock

screws "c"

Lock

screws "b"

R•B adjusting plate

R•B-LCD

R•B-LCD panel

mounting screws

FRONT

R-LCD

B-LCD

~

G-LCD

G-LCD

1

1

4

4

2

2

2

3

3

3

3

Page 21

XG-NV1E

XG-NV1EA

21

ELECTRICAL ADJUSTMENT

NOTE : The settings have been factory-adjusted to their best points. If any of them gets out of spec or after any

relevant part has been replaced, make the related adjustment.

Step

Adjustment Position

Adjustment Conditions Adjustment Method

Destinations Factory setting Setting on

remote control

Export S4 Set to 4 on shipment

Domestic S5 Set to 5 on shipment

1 Initialization of

EEPROM

2 Off-set for RGB

input

3 RGB gain

4 R-drive

5 B-drive

6 Rough-adjustment

of the voltage for

white

7 Rough-adjustment

of the voltage for

black

8 White balance

9 Common DC bias

1.Turn on the unit (Lighting

lamp) and burn-in for 15

minutes.

1. Supply the black signal.

(APL=100%)

2. Push S5013 then appearing ADJ-IN mode.

3. Select RGB1.

1. Supply the green (100%)

signal.

2. Select RGB1.

1. Supply the red (100%) signal

2. Select RGB1

1. Supply the blue (100%) signal.

2. Select RGB1.

1. Select RGB2.

1. Select RGB2.

1. Supply the gray scale signal1.

2. Select RGB2.

3. Items to be adjusted

· RW/RB

· GW/GB

· BW/BB

1. Supply each individual signal of R, G and B.

2. Select RGB2.

» Adjust ROS→128

GOS→128

BOS→128

» Adjust GAIN→62

» Adjust R-DRIVE→128

» Adjust B-DRIVE→128

» Adjust RW→60

GW→60

BW→60

» Adjust RB→196

GB→196

RB→196

» Should be adjusted to keep the following value.

RW+RB=256

GW+GB=256

BW+BB=256

» Adjust RC (Red), GC (Green) and BC (Blue) to obtain

the maximum contrast with each colour.

» Set as follows

Page 22

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

22

Checking the PWB performance

Use specified cable.

No

No

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

RGB input in trouble

Feed test pattern signal from PC.

Is supply voltage as specified?

Does image appear?

Is the image proper?

Does G picture appear?

Does R picture appear?

Is specified cable connected between

PC and projector?

Check control circuit (IC5001, IC5002,

IC5003 and IC5010).

Are D/A outputs of IC1007, IC1008

and IC1030 as specified?

Go to "Checking the B signal line of

output PWB".

Through-output in trouble

Power circuit in trouble.

Go to "Checking the through-output

circuit".

Are D/A outputs of IC1003, IC1004

and IC1028 as specified?

Go to "Checking the G signal line of

output PWB".

Are D/A outputs of IC1005, IC1006

and IC1029 as specified?

Go to "Checking the R signal line of

output PWB".

Go to "Checking the B signal line of

signal processing PWB".

Go to "Checking the remote control

circuit".

Go to "Checking the G signal line of

signal processing PWB".

Go to "Checking the R signal line of

signal processing PWB".

Remote control in trouble

TROUBLE SHOOTING TABLE

Page 23

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

23

Yes

Checking the G signal line of signal processing PWB

No

No

Yes

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

No

Yes

Yes

Yes

No

No

Yes

No

Yes

No

No

No

No

Yes

Yes

Yes

Go to "Checking synchronization".

Go to "Checking synchronization".

Check IC1002 and its peripheral parts.

IC1012, IC5002 or nearby circuit in

trouble.

IC1009 or nearby circuit in trouble.

IC1201 or nearby circuit in trouble.

Is there signal input at pin (11) of

IC1011?

Is there signal output at pin (35) of

IC1011?

Is there signal input at pin (7) of

IC1015?

Are there signal outputs at pins (197)

thru (204) of IC1201?

Is there clock output at pin (233) of

IC1001?

IC1003, IC1004, IC1028 or nearby

circuit in trouble.

Is there sync signal input at pins (15),

(216) or (217) of IC1201?

Are there signal inputs at pins (1),

(2), (3), (5) thru (8), (127) thru (130),

(132) thru (136), (138), (139), (145)

thru (149), (151) thru (154), (156)

thru (160) of IC1206?

Are there signal inputs at pins (143),

(144), (146), (147), (148), (152) and

(154) of IC1001?

Are there signal outputs at CH10 thru

CH17, CH20 thru CH27, CH30 thru

CH37, CH40 thru CH47, CH50 thru

CH57, and CH60 thru CH67 of

IC1001?

Check pin (4) line of connector TN.

Do voltages at pins (6), (18) and (19)

of IC1012 change?

Is there HSYNC signal input at pin

(23) of IC1011?

Is there clock input at pin (94) of

IC1001?

IC1011 or nearby circuit in trouble.

IC1015 or nearby circuit in trouble.

Is there clock output at pin (14) of

IC1201?

IC1001 or nearby circuit in trouble.

IC1206 or nearby circuit in trouble.

Is there clock input at pin (49) of

IC1201?

IC1001 or nearby circuit in trouble.

Are there clock inputs at pins (60),

(103) and (143) of IC1206?

Page 24

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

24

Yes

Checking the R signal line of signal processing PWB

No

No

Yes

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

No

Yes

Yes

Yes

No

No

Yes

No

Yes

No

No

No

No

Yes

Yes

Yes

Go to "Checking synchronization".

Go to "Checking synchronization".

Check IC1002 and its peripheral parts.

IC1012, IC5002 or nearby circuit in

trouble.

IC1009 or nearby circuit in trouble.

IC1201 or nearby circuit in trouble.

Is there signal input at pin (7) of

IC1011?

Is there signal output at pin (40) of

IC1011?

Is there signal input at pin (7) of

IC1014?

Are there signal inputs at pins (189)

thru (196) of IC1201?

Is there clock output at pin (233) of

IC1001?

IC1003, IC1004, IC1028 or nearby

circuit in trouble.

Is there sync signal input at pins (15),

(216) or (217) of IC1201?

Are there signal outputs at pins (1),

(2), (3), (5) thru (8), (127) thru

(130), (132) thru (136), (138), (139),

(145) thru (149), (151) thru (154),

(156) thru (160) of IC1206?

Are there signal outputs to pins

(129), (131), (132), (133), (136),

(137), (138) and (142) of IC1001?

Are there signal outputs at CH10 thru

CH17, CH20 thru CH27, CH30 thru

CH37, CH40 thru CH47, CH50 thru

CH57, and CH60 thru CH67 of

IC1001?

Check pin (4) line of connector TN.

Do voltages at pins (5), (18) and (19)

of IC1012 change?

Is there HSYNC signal input at pin

(23) of IC1011?

Is there clock input at pin (94) of

IC1001?

IC1011 or nearby circuit in trouble.

IC1015 or nearby circuit in trouble.

Is there clock output at pin (14) of

IC1201?

IC1001 or nearby circuit in trouble.

IC1206 or nearby circuit in trouble.

Is there clock input at pin (49) of

IC1201?

IC1001 or nearby circuit in trouble.

Are there clock inputs at pins (60),

(103) and (143) of IC1206?

Page 25

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

25

Yes

Checking the B signal line of signal processing PWB

No

No

Yes

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

No

Yes

Yes

Yes

No

No

Yes

No

Yes

No

No

No

No

Yes

Yes

Yes

Go to "Checking synchronization".

Go to "Checking synchronization".

Check IC1002 and its peripheral parts.

IC1012, IC5002 or nearby circuit in

trouble.

IC1009 or nearby circuit in trouble.

IC1201 or nearby circuit in trouble.

Is there signal input at pin (15) of

IC1011?

Is there signal output at pin (30) of

IC1011?

Is there signal input at pin (7) of

IC1016?

Are there signal outputs at pins (205)

thru (208), (212) thru (215) of IC1201?

Is there clock output at pin (233) of

IC1001?

IC1003, IC1004, IC1028 or nearby

circuit in trouble.

Is there sync signal input at pins (15),

(216) or (217) of IC1201?

Are there signal outputs at pins (1),

(2), (3), (5) thru (8), (127) thru (130),

(132) thru (136), (138), (139), (145)

thru (149), (151) thru (154), (156)

thru (160) of IC1206?

Are there signal outputs at pins

(156), (157), (158), (162), (163),

(164), (166) and (167) of IC1001?

Are there signal outputs at CH10 thru

CH17, CH20 thru CH27, CH30 thru

CH37, CH40 thru CH47, CH50 thru

CH57, and CH60 thru CH67 of

IC1001?

Check pin (4) line of connector TN.

Do voltages at pins (7), (18) and (19)

of IC1012 change?

Is there HSYNC signal input at pin

(23) of IC1011?

Is there clock input at pin (94) of

IC1001?

IC1011 or nearby circuit in trouble.

IC1015 or nearby circuit in trouble.

Is there clock output at pin (14) of

IC1201?

IC1001 or nearby circuit in trouble.

IC1206 or nearby circuit in trouble.

Is there clock input at pin (49) of

IC1201?

IC1001 or nearby circuit in trouble.

Are there clock inputs at pins (60),

(103) and (143) of IC1206?

Page 26

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

26

Checking the G signal line of output PWB

No

Yes

Connector CC poorly soldered or in

trouble.

Are outputs at pins (3), (4) and (5) of

IC4034 as specified?

Are there signal inputs at pins (1)

each of IC4038 thru IC4043?

Check connector CC. Do signals go

to pins (4), (5), (7), (8), (10) and (11)

of this connector?

IC4034, IC5002 or nearby circuit in

trouble.

Yes

Are there signal outputs at pins (7),

(8) and (14) of IC4044 and IC4045?

IC4038 thru IC4043, IC4044, IC4045

or nearby circuit in trouble.

Yes

Are signals fed from pins (2) thru (7)

of connector GP to the panel?

Connector GP poorly soldered or in

trouble.

Yes

Does flicker happen?

Go to "Checking the image for

shifting".

Yes

Is frame pulse fed to pin (1) of

connector GP?

Yes

Is common bias at pin (24) of

connector GP as specified?

Yes

Panel in trouble.

Yes

Yes

Q4024, Q4025, Q4026 or their signal

line in trouble.

Does frame pulse go out of IC4077?

Yes

Are FRP1 and FRP2 signals fed to

pins (9) and (12) of IC4077?

Any of IC4038 thru IC4043 faulty.

Checking the image for shifting

Yes Yes

IC1001 or nearby circuit in trouble.

Are signals fed via IC4074, IC4075

and IC4076 to the panel?

Panel in trouble.

Are signals fed to IC4074, IC4075

and IC4076?

IC4074, IC4075, IC4076 or nearby

circuit in trouble.

IC4077 or nearby

circuit in trouble.

No

IC1001 or nearby

circuit in trouble.

No

No

No

No

No

No No

No

No

Page 27

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

27

Checking the R signal line of output PWB

No

Yes

Connector CC poorly soldered or in

trouble.

Are outputs at pins (2), (18) and (19)

of IC4034 as specified?

Are there signal inputs at pins (1)

each of IC4401 thru IC4406?

Check connector CC. Do signals go

to pins (13), (14), (16), (17), (19) and

(20) of this connector?

IC4034, IC5002 or nearby circuit in

trouble.

Yes

Are there signal outputs at pins (7),

(8) and (14) of IC4036 and IC4407?

IC4401 thru IC4406, IC4436, IC4407

or nearby circuit in trouble.

Yes

Are signals fed from pins (2) thru (7)

of connector RP to the panel?

Connector RP poorly soldered or in

trouble.

Yes

Does flicker happen?

Go to "Checking the image for

shifting".

Yes

Is frame pulse fed to pin (1) of

connector RP?

Yes

Is common bias at pin (24) of

connector RP as specified?

Yes

Panel in trouble.

Yes

Yes

Q4024, Q4025, Q4026 or their signal

line in trouble.

Does frame pulse go out of IC4077?

Yes

Are FRP1 and FRP2 signals fed to

pins (9) and (12) of IC4077?

Any of IC4401 thru IC4406 faulty.

IC4077 or nearby

circuit in trouble.

No

IC1001 or nearby

circuit in trouble.

No

No

No

No

No

No

No

Page 28

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

28

Checking the B signal line of output PWB

No

Yes

Connector CC poorly soldered or in

trouble.

Are outputs at pins (6), (7) and (8) of

IC4034 as specified?

Are there signal inputs at pins (1)

each of IC4001 thru IC4006?

Check connector CC. Do signals go

to pins (22), (23), (25), (26), (28) and

(29) of this connector?

IC4034, IC5002 or nearby circuit in

trouble.

Yes

Are there signal outputs at pins (7),

(8) and (14) of IC4007 and IC4008?

IC4001 thru IC4006, IC4007, IC4008

or nearby circuit in trouble.

Yes

Are signals fed from pins (2) thru (7)

of connector BP to the panel?

Connector BP poorly soldered or in

trouble.

Yes

Does flicker happen?

Go to "Checking the image for

shifting".

Yes

Is frame pulse fed to pin (1) of

connector BP?

Yes

Is common bias at pin (24) of

connector BP as specified?

Yes

Panel in trouble.

Yes

Yes

Q4024, Q4025, Q4026 or their signal

line in trouble.

Does frame pulse go out of IC4077?

Yes

Are FRP1 and FRP2 signals fed to

pins (9) and (12) of IC4077?

Any of IC4001 thru IC4006 faulty.

IC4077 or nearby

circuit in trouble.

No

IC1001 or nearby

circuit in trouble.

No

No

No

No

No

No

No

Page 29

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

29

Checking synchronization

No

No

Yes

Yes

Yes

No

Are there signal outputs at pins

(3)(IN+) of IC2003 and IC2004?

Are there signal outputs at pins

(15)(H) and (217)(V) of IC1201?

Do horizontal and vertical sync

signals (at pins (13) and (14) of RGB

connector) come out of PC?

Are there signal outputs at pins

(6)(X1/EXT) and (22)(EXFBK) of

IC1013?

Connector or nearby circuit in trouble.

Go to "Checking the PLL circuit".

IC2003, IC2004 or nearby circuit in

trouble.

No

Yes

Yes

No

Is there signal output at pin (3)(IN+)

of IC2005?

Is there signal output at pin (216)(C)

of IC1201?

Connector or nearby circuit in trouble.

Go to "Checking the PLL circuit".

IC2005 or nearby circuit in trouble.

No

Yes

Yes

No

Is there signal output at pin

(15)(DOTCLK) of IC1013?

Check the sync circuit and its

peripheral parts.

IC1201 or nearby circuit in trouble.

IC1013, IC1201 or nearby circuit in

trouble.

Checking the PLL circuit

Page 30

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

30

Checking the remote control circuit

Yes

No

IC5001, IC5101, IC5102 or nearby

circuit in trouble.

Press the MENU key. Are there

signal outputs at pins (29) and (30) of

connector CA?

Remote control receiver or its nearby

circuit in trouble.

Checking the through-output circuit

Yes

No

Yes

No

Is specified cable connected between

LCP and monitor?

Yes

No

IC2003, IC2004, IC2005 or nearby

circuit in trouble.

Does analog output come from PC?

No digital output.

Use specified cable.

Are LCP and monitor in sync?

IC2001 or nearby circuit in trouble.

Page 31

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

31

No

X6001 or nearby circuit in trouble.

No

No

Lamp fails to light up.

Checking the video system

Are there signal inputs at pins (183),

(189) thru (204), (214) and (215) of

IC1201?

Yes

No picture

Is lamp on?

Is voltage applied to connector EA?

Is X6001 oscillating?

Yes

Yes

No

Are there signal inputs at pins (15),

(17) and (19) of IC6001?

Check signal line circuit.

Check power circuit and its parts.

No

Connector VS in trouble.

IC6003, IC6004 or IC6005 in trouble.

IC1201 or nearby circuit in trouble.

Yes

Yes

No

Are there signal inputs at IC6003,

IC6004 and IC6005?

Yes

Is pin (26) of connector VS at "L"

level?

Check IC6001 and its peripheral

circuits.

Input switching in trouble IC5002 or

nearby circuit in trouble.

No

No

Yes

Are there signal outputs at IC6003,

IC6004 and IC6005?

Yes

Page 32

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

32

No colour or unusual tint with NTSC signal

No

Yes

IC5001 or nearby circuit in trouble.

IC1201, IC1206 or nearby circuit in

trouble.

Set user control to standard value.

Check the video board.

Is colour mode judged properly?

Does user control work?

Video board in trouble.

Yes

Change process value for

adjustment.

Yes

No

No

No colour or unusual tint with PAL signal

No

Yes

IC5001 or nearby circuit in trouble.

IC1201, IC1206 or nearby circuit in

trouble.

Set user control to standard value.

Check the video board.

Is colour mode judged properly?

Does user control work?

Video board in trouble.

Yes

Change process value for

adjustment.

Replace the video board. Are colour

and tint as specified?

Yes

No

No

No colour or unusual tint with SECAM signal

No

Yes

IC5001 or nearby circuit in trouble.

IC1201, IC1206 or nearby circuit in

trouble.

Set user control to standard value.

Check the video board.

Is colour mode judged properly?

Does user control work?

Video board in trouble.

Yes

Change process value for

adjustment.

Replace the video board. Are colour

and tint as specified?

Yes

No

No

Replace the video board. Are colour

and tint as specified?

Page 33

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

33

Yes

Yes

No synchronization

No

Yes

Yes

No

No

No

Check the signal line from IC6005.

Is there video signal input at pins (15),

(17) or (19) of IC6001?

Are HSYNC and VSYNC signals from

pins (41) and (42) of IC6001 in sync

with input signal?

Check IC6001 and its peripheral

circuits.

Check the signal line from the

connector.

Which of vertical and horizontal

syncs fails?

Is there signal input from pin (22) of

connector VS to pin (214) of IC1201?

Is there signal input from pin (20) of

connector VS to pin (215) of IC1201?

Check IC102 and its peripheral

circuits.

Vertical

Horizontal

Page 34

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

34

Lamp failure to light up

No

No

Yes

Yes

Yes

Replace TGU1701. Check

connectors.

Is discharge noise heard?

No

Yes

Replace F701. Check and replace

Q1701.

Yes

Yes

Is F701 blown out?

No

Check DB701 and its peripheral parts.

No

Replace Q1702.

Yes

Is FET drive voltage applied from pin

(2) of IC1701?

No

IC1702 or nearby circuit in trouble.

Yes

No

Q1703 or nearby circuit in trouble.

Replace F704 or TF1701.

Is F704 or TF1701 blown out?

Yes

TGU1701 faulty.

Is voltage applied at TGU1701?

No

Is voltage applied to pin (16) of

IC1701?

Is voltage applied to pin (1) of

connector BL?

No

Check IC5001 and its peripheral

circuits.

Lamp faulty. Replace.

Does new lamp light up?

Is voltage applied across C1703?

Page 35

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

35

No sound

Yes

No

Check IC302 and its peripheral

circuits.

Yes

No

Does voltage at pin (9) of IC301

change with VOL UP/DOWN keys?

IC305 or nearby circuit in trouble.

Yes

No

Are there audio signal inputs at pins

(2) and (23) of IC301?

IC306, IC1022, IC1023 or nearby

circuit in trouble.

Yes

No

Are there audio signal inputs at pins

(1) and (9) of IC304?

Yes

No

Are there audio signal inputs at pins

(1) and (3) of connector SP?

Is sound heard with 3D SOUND off?

IC307 or nearby circuit in trouble.

IC304 or nearby circuit in trouble.

Replace speaker.

Checking IC302 and its peripheral circuits

Yes

No

Are there signal inputs at pins (27)

and (28) of IC302?

IC306, C320, C321, R334, or related

part in trouble.

Yes

No

Are there signal outputs at pins (17)

and (18) of IC302?

IC302 or nearby circuit in trouble.

IC306, C344, C345, R357, R358 or

related part in trouble.

Page 36

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

36

232C failure

Yes

No

Reconnect cable.

Yes

No

Is PC’s 232C setting as specified?

Make PC port setting.

Yes

No

Is there signal input at pin (11) of

IC2006?

Check cable, connector and their

peripheral parts.

Yes

No

Is there signal output at pin (12) of

IC2006?

Yes

No

Is there signal input at pin (47) of

IC5001?

Is cable connected?

IC2006 or nearby circuit in trouble.

Check signal line (connectors TH and

CA) and related parts.

IC5001 faulty.

Page 37

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

37

Yes

Switch off the PC, select the remote

mouse, reconnect the cable, and get

the PC restarted.

Mouse failure

Yes

No

Is cable connected both with serial

port and PC-98?

Is OSD system check remote mouse

properly set?

(Pin (13) of IC200: AT = "L", 98 ="H")

Double connection unacceptable.

Set to AT except for PC-98.

Is CF2001 oscillating?

IC2007 or CF2001 in trouble.

IC1025 in trouble.

IC2007 faulty.

IC2007 faulty.

IC2008 faulty.

No

Is voltage applied to pin (5) of IC2007

and pin (8) of IC2008?

Power is supplied from pin (8) of

J2005 for AT and from pin (1) of

J2006 for PC-98. Recheck the cable.

Yes

No

Yes

No

Yes

No

Is there remote control signal input at

pin (8) of IC2007?

Yes

No

Is communication made with DAT at

pin (15) of IC2007 and CLK at pin(16)

of IC2007?

Yes

No

Click the mouse. Is pin (18)(BUTTON)

of IC2007 set to "H" level?

Yes

No

Is there signal output at IC2008?

PS/2: DATA at pin (24), CLOCK at

pin (25)

MAC: ADB OUT at pin (27), ADB IN

at pin (11)

98: XA at pin (14), XB at pin (15),

YA at pin (16), YB at pin (17),

RIGHT at pin (1), LEFT at pin

(2)

Page 38

XG-NV1E

XG-NV1EA

TROUBLE SHOOTING TABLE (Continued)

38

Memo

Page 39

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

CHASSIS LAYOUT

Ref. No.17

**

POWER/BALLAST UNIT–C

REDENC0228CEZC

REDENC0240CEZC

POWER/BALLAST UNIT–A

REDENC0228CEZA

REDENC0240CEZA

POWER/BALLAST UNIT–D

REDENC0228CEZD

REDENC0240CEZD

POWER/BALLAST UNIT–B

REDENC0228CEZB

REDENC0240CEZB

PC TERMINAL UNIT

RUNTK0568CEZZ

VIDEO BOARD UNIT

RUNTK0567CEZZ

RUNTK0584CEZZ

OPERATION KEY UNIT

RUNTK0566CEZZ

OUTPUT UNIT

DUNTK9292DE02/03/05

OUTPUT SUB UNIT

DUNTK9293DE02/03/05

SIGNAL UNIT

DUNTK9291DE02/03/05

R/C RECEIVER UNIT

DUNTK9295DE02/03/05

39 40

Page 40

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

BLOCK DIAGRAM-1

BALLAST

UNIT

POWER

UNIT

OPERATION

KEY UNIT

OUTPUT SUB

UNIT

OUTPUT UNIT

41 42

Page 41

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

43

BLOCK DIAGRAM-2

SIGNAL UNIT

VIDEO BOARD

UNIT

PC TERMINAL

UNIT

44

Page 42

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

OVERALL WIRING DIAGRAM-1

SIGNAL UNIT

OUTPUT UNIT

VIDEO BOARD UNIT

PC TERMINAL UNIT

45 46

Page 43

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

47

OVERALL WIRING DIAGRAM-2

OU PUT UNIT

OUTPUT SUB UNIT

CONTROL KEY UNIT

POWER/BALLAST UNIT

R/C RECEIVER UNIT

DUNTK9295DE02

DUNTK9295DE03

DUNTK9295DE05

48

Page 44

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

SC4001 (RP1)

H: 20µsec/div

V: 2V/div

1

SC4001 (RP2)

H: 20µsec/div

V: 2V/div

2

SC4001 (RP13)

H: 10µsec/div

V: 1V/div

3

SC4001 (RP14)

H: 0.1µsec/div

V: 1V/div

4

SC4001 (RP15)

H: 0.1µsec/div

V: 1V/div

5

SC4001 (RP21)

H: 10µsec/div

V: 1V/div

6

SC4001 (RP18)

H: 10µsec/div

V: 1V/div

7

SC4002 (GP2)

H: 20µsec/div

V: 2V/div

8

SC4003 (BP2)

H: 20µsec/div

V: 2V/div

9

P1402 (VS9, Y7)

H: 20µsec/div

V: 1V/div

0

P1402 (VS20, H-sync)

H: 20µsec/div

V: 1V/div

q

P1402 (VS22, V-sync)

H: 5msec/div

V: 1V/div

w

IC1003

(TP1101, 27-pin)

H: 10µsec/div

V: 500mV/div

e

IC1005

(TP1105, 27-pin)

H: 10µsec/div

V: 500mV/div

r

IC1007

(TP1109, 27-pin)

H: 10µsec/div

V: 500mV/div

t

VOLTAGE MEASUREMENT CONDITION:

1. Voltages at test points are measured at the supply voltage of AC 220V. Signals

are fed by a colour bar signal generator for servicing purpose and the above

voltages are measured with a 20-kohm/V tester.

WAVEFORM MEASUREMENT CONDI-TION:

1. Waveforms at test points are observed at the supply voltage of AC 220V.

Signals are fed by a colour bar signal generator for servicing purpose.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/10W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise noted.

C : Solid W : Cement

S : Oxide Film T : Special

N : Metal Coating

DESCRIPTION OF SCHEMATIC DIAGRAM

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise noted.

(ML): Mylar (TA): Tantalum

(PF): Polypro Film (ST): Styrol

CAUTION:

This circuit diagram is original one, therefore there may be a slight difference from yours.

SAFETY NOTE:

1. DISCONNECT THE AC PLUG FROM THE AC OUTLET BEFORE

REPLACEING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE REGARDED AS

POTENTIAL SHOCK HAZARDS WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å”( )ARE IMPORTANT FOR MAINTAINING

THE SAFETY OF THE SET. BE SURE TO REPLACE THESE PARTS WITH

SPECIFIED ONES FOR MAINTAINING THE SAFETY AND PERFORMANCE

OF THE SET.

SPANNUNGSMESSUNGEN:

1. Spannungen an den Prüfpunkten werden bei einer Netzspannung von 220V

gemessen, Signale werden für die Wartung mit einem Farbbalken-Signal

generator zugeführt, und Spannungen werden mit einem Meßinstrument

(20 k /V) ermittelt.

SIGNALFORMMESSUNGEN:

1. Die Wellenformen an den Testpunkten werden bei einer Netzspannung von

220V verfolgt. Signale werden für die Wartung mit einem Farbbalken-Signal

generator zugeführt.

BEZEICHNUNG DES WIDERSTANDS UND

KONDENSATORS:

WIDERSTAND

1. Die Widerstandseinheit “Ω” wird weggelassen.

(K=kΩ=1000 Ω, M=MΩ).

2. Alle Widerstände haben ± 5%, sofern nicht anders angegeben.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. Alle Widerstände haben 1/10W, sofern nicht anders angegeben.

4. Alle Widerstände sind Kohletyp, sofern nicht anders angegeben.

C : Fest W : Zement

S : Oxidfilm T : Spezial

N : Metallüberzug

KONDENSATOR

1. Die Kapazitätseinheit ist µF, sofern nicht anders angegeben.

(P=pF=µµF).

2. Alle Kondensatoren haben 50V, sofern nicht anders angegeben.

3. Alle Kondensatoren sind Keramiktyp, sofern nicht anders angegeben.

(ML): Mylar (TA): Tantal

(PF): Polyprofilm (ST): Styrol

ACHTUNG:

bei diesem Schaltplan handelt es sich um den ursprünglichen. Esönnen

daher geringfügige Unterschiede zu dem lhrem bestehen.

SICHERHEITSANMERKUNGEN:

1. VOR DEM AUSWECHSELN VON TEILEN MUSS UNBEDINGT

NETZSTECKER AUS DER NETZSTECKDOSE GEZOGEN WERDEN.

2. DIE WARMEABLEITER DER HALBLEITER SOLLTEN BEIM BETRIEB

DES CHASSIS ALS MÖGLICHE URSACHEN VON GEFÄHRLICHEN

ELEKTRISCHEN SCHLÄGEN BETRACHTET WERDEN.

WICHTIGE SICHERHEITSANMERKUNGEN:

MIT “å”( )BEZEICHNETEN TEILE SIND BESONDERS WICHTIG

FÜR DIE AUFRECHTERHALTUNG DER SICHERHEIT . BEIM WECHDIESER

TEILE SOLLTEN DIE VORGESCHRIEBENEN TEILE IMMER VERWENDET

WERDEN, UM SOWOHL DIE SICHERHEIT ALS AUCH DIE LEISTUNG DES

GERÄTES AUFRECHTZUERHALTEN.

BESCHREIBUNG DES SCHEMATISCHEN SCHALTPLANS

WAVEFORMS

WELLENFORMEN

49 50

Page 45

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

SIGNAL UNIT-1/6

51 52

Page 46

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

SIGNAL UNIT-2/6

53 54

Page 47

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

55

SIGNAL UNIT-3/6

56

Page 48

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

SIGNAL UNIT-4/6

SIGNAL

SUB UNIT–A

57 58

Page 49

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

69 70

OUTPUT UNIT-3/5

Page 50

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

71 72

OUTPUT UNIT-4/5

Page 51

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

75 76

OUTPUT SUB and INFRARED R/C RECEIVER UNIT

Page 52

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

77 78

OPERATION KEY UNIT

Page 53

H

G

F

E

D

C

B

A

123456789101112

XG-NV1E

XG-NV1EA

XG-NV1E

XG-NV1EA

79 80

VIDEO BOARD UNIT

Page 54

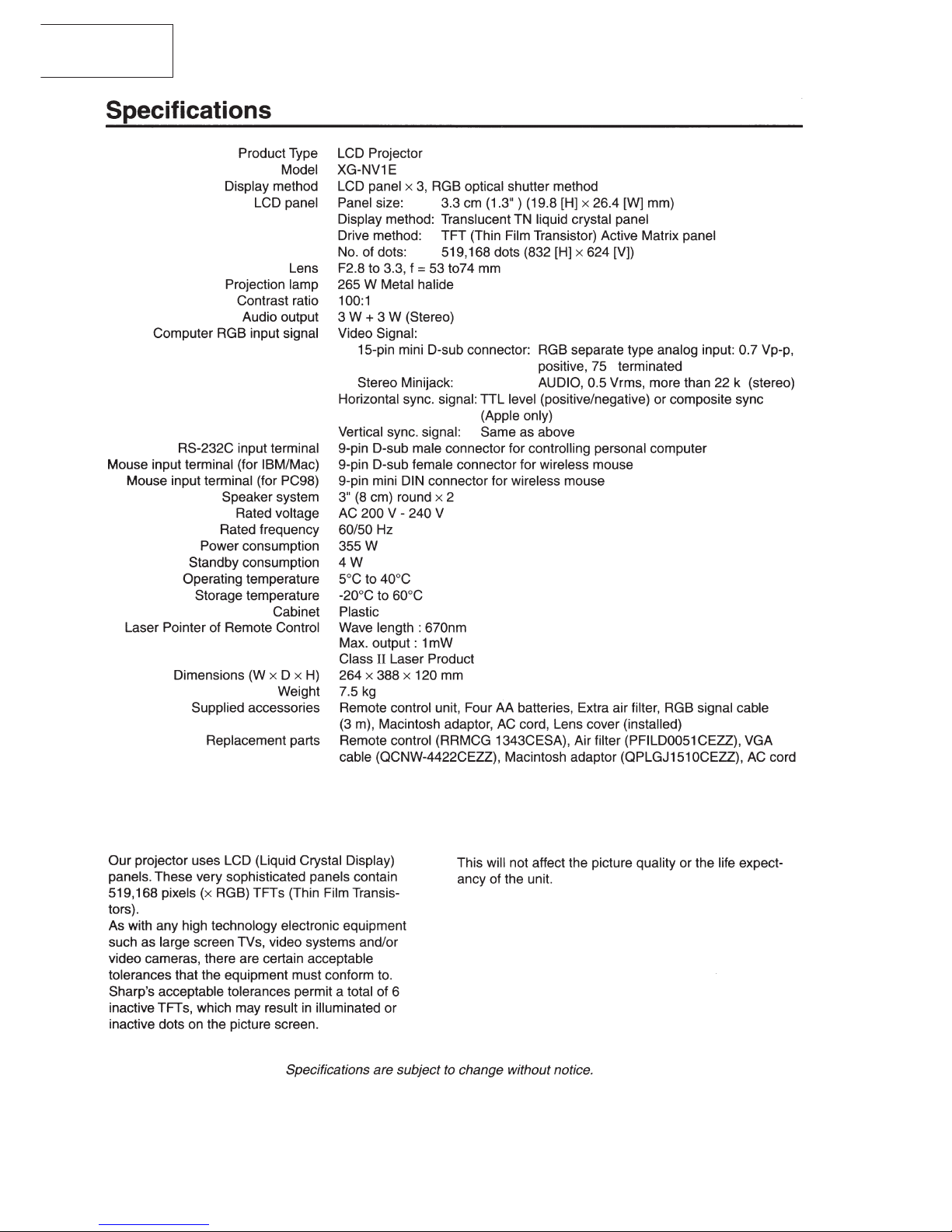

XG-NV2U/E/M

SUPPLEMENT

SERVICE MANUAL

SERVICE-ANLEITUNG

S70E3XG-NV2U/

SUPPLEMENT

PAL/SECAM/NTSC SYSTEM

LCD PROJECTOR

XG-NV2U

XG-NV2E

MODELS

MODELLE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

OUTLINE

This Service Manual Supplement covers the fan control PWB, output sub-PWB and output PWB, and their

combinations. These PWBs come in different versions depending on the production lots. Some types of PWBs

may be incompatible with each other. In replacing or repairing those PWBs, refer to this Supplement for proper

combinations.

ABRISS

Diese Ergänzung zum Wartungshandbuch behandelt die Ventilator-Zusatzplatine, die Ausgangs-Zusatzplatine

sowie die Ausgangsplatine und ihre Kombinationen. Diese Platinen werden in verschiedenen Ausführungen

geliefert, was wiederum von der jeweiligen Produktionsserie abhängt. Einige Platinentypen können miteinander

inkompatibel werden. Für das Auswechseln oder die Reparatur dieser Platinen beziehen Sie sich zwecks der

passenden Kombinationen bitte auf diese Ergänzung.

CONTENTS / INHALT

1.Interconnecting the Fan Control PWB and the

output sub-PWB ................................................. 2

2.Troubleshooting for the Fan Control PWB..........2

3.Repair procedure................................................ 3

4.Others ................................................................ 4

5.Connecting the QCNW-4979CEZZ cable leads

on the output sub-PWB ...................................... 8

6.Connecting the QCNW-4981CEZZ cable leads

on the output sub-PWB ...................................... 9

• PARTS LIST ..................................................... 10

Page Seite

1.Ausstellung eines technischen Berichts

hinsichtlich der Ventilator-Zusatzplatine .............5

2.Störungssuche für die Ventilator-Zusatzplatine..5

3.Reparaturverfahren ............................................ 6

4.Weiteres ............................................................. 7

5.Anschließen der QCNW-4979CEZZ-Kabel an

der Ausgangs-Zusatzplatine...............................8

6.Anschließen der QCNW-4981CEZZ-Kabel an

der Ausgangs-Zusatzplatine...............................9

• ERSATZTEILLISTE.......................................... 10

XG-NV2M

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 55

XG-NV2U/E/M

SUPPLEMENT

1.Interconnecting the Fan Control PWB and the output sub-PWB

Here are the three basic ways.

<1> Production lot in December 1997

Fan Control PWB (Display; K9661DE without √.)

QCNW-4978CEZZ QCNW-4979CEZZ

OUTPUT PWB √

1

QCNW-4982CEZZ QCNW-4983CEZZ

<2> Production lot in January 1998

Fan Control PWB (Display; S9661CE √.)

QCNW-4980CEZZ QCNW-4981CEZZ

<3> Production lot in February 1998 and on

Fan Control PWB (Display; S9661CE √,F0136AD √, √.)

QCNW-4980CEZZ QCNW-5001CEZZ

2. Troubleshooting for the Fan Control PWB

1

Checking the fan control PWB

2

Checking for a fan trouble

OUTPUT sub PWB √

1

Output sub PWB √

Output sub PWB √

102

3

Checking for a fan trouble

1

1

2

Turn on the projector power,

but the projector turns itself

off 2-3 seconds later.

Disconnect the relay connector

from the fan control PWB.

Fan

operated.

Fan control

PWB defective.

Fan

unoperated.

Other part

than the fan

Disconnect the lead from the

running fan.

Fan still

running

Fan control

Fan

interrupted

No problem.

PWB

defective.

Get the running fan locked.

Fan still

running

Fan control

Fan

interrupted

No problem.

PWB

defective.

control PWB

defective.

Precautions

* Some Fan Control PWBs are provided with a wire holder instead of the insulator lock. After repairing such a PWB,

remove the wire holder and bundle the wires with the insulator lock. If the insulator lock is cut off for repair purpose,

bundle the wires with a new insulator lock. (CE measures) Part code: LHLDW1033CEZZ

* If the output PWB has been replaced, readjustment is needed.

2

Page 56

3. Repair procedure

Fan Control PWB (Display; S9661CE √.)

QCNW-4980CEZZ QCNW-4981CEZZ

Output sub PWB √

1

1

Interconnecting 1:Production lot in December 1997

Fan Control PWB (Display; K9661DE without √.)

QCNW-4978CEZZ QCNW-4979CEZZ

OUTPUT PWB √

XG-NV2U/E/M

SUPPLEMENT

1

QCNW-4982CEZZ QCNW-4983CEZZ

Trouble spot Preparations Procedure

Fan Control PWB

Output sub-PWB

DUNTK9567DE

Fan Control PWB marked "A"

QCNW-4980CEZZ (with UL tape)

QCNW-4981CEZZ

When replace with the Output subPWB√:

2

Fan PWB marked "A"

QCNW-4980CEZZ (with UL tape)

QCNW-5001CEZZ

Disconnect the QCNW-4978CEZZ, -4979CEZZ, 4982CEZZ and -4983CEZZ cables, and connect the

QCNW-4980CEZZ and -4981CEZZ cables.

Disconnect the Output sub-PWB, Fan Control PWB,

QCNW-4978CEZZ, -4979CEZZ, -4983CEZZ cable,

and connect a new Output sub-PWB √, Fan Control

PWB marked "A", QCNW-4980CEZZ and QCNW5001CEZZ cable. Disconnect QCNW-4983CEZZ cable from Output PWB.

When replace with the Output sub-PWB√, disconnect the defective PWB from QCNW-

1

4979CEZZ cable, and connect the new PWB..

Output PWB

DUNTK5926DE

Both Output PWB √ and √ can be

1

2

used.

Disconnect QCNW-4983CEZZ cable from the defective PWB , and connect to the new PWB.

Interconnecting 2:Production lot in January 1998

OUTPUT sub PWB √

1

2

Trouble spot Preparations Procedure

Fan Control PWB

Output sub-PWB

DUNTK9567DE

Fan Control PWB marked "A"

When replace with the Output subPWB√:

QCNW-5001CEZZ cable

When replace with the Output sub-PWB√, disconnect the defective PWB from QCNW4981CEZZ cable, and connect the new PWB.

Output PWB

DUNTK5926DE

Both Output PWB √ and √ can be

used.

2

1

Replace Fan Control PWB marked "A".

Connect a new Output sub-PWB √ and QCNW-

2

5001CEZZ cable.

1

2

Replace the Output PWB as it is.

3

Page 57

XG-NV2U/E/M

SUPPLEMENT

Interconnecting 3:Production lot in February 1998 and on

Fan Control PWB (Display; S9661CE √,F0136AD √, √.)

QCNW-4980CEZZ QCNW-5001CEZZ

Trouble spot Preparations Procedure

Output sub PWB √

102

2

Fan Control PWB

Output sub-PWB

DUNTK9567DE

Fan Control PWB marked "A"

When replace with the Output subPWB√:

1

QCNW-4981CEZZ cable

When replace with the Output sub-PWB√, disconnect the defective PWB from QCNW-

Replace Fan Control PWB marked "A".

Disconnect Output sub PWB and QCNW-5001CEZZ

cable, and connect QCNW-4981CEZZ cable to a new

Output sub PWB√.

2

1

5001CEZZ cable, and connect the new PWB.

Output PWB

DUNTK9526DE

Both Output PWB √ and √ can be

1

2

used.

Replace the Output PWB as it is.

4. Others

1 The replacement fan control PWB is marked "A" on its back. PWBs of this type are manufactured as from

February 1998 (redesigned to upgrade the standby mode when the main power is turned on).

2 The replacement QCNW-4980CEZZ cable has UL tape attached.

The UL tape is applied to prevent the cable from getting caught by the side panel-to-top panel screw-down

bracket. See below for the tape position.

260 ± 5

Brown 1

Brown 2

Brown 3

Brown 4

Brown 5

1 Brown

2 Brown

3 Brown

4 Brown

5 Brown

PHR-5

(2-mm-pitch

50 ± 5

10

socket)

Fan Control PWB side

UL tape added here

4

SMP-05V-NC

(2.5-mm-pitch

relay connector)

Output sub-PWB side

Page 58

XG-NV2U/E/M

1 Überprüfung der Ventilator-

Zusatzplatine

Den Projektor einschalten; der

Projektor schaltet sich jedoch

2 bis 3 Sekunden später aus.

Den Relaisstecker von der

Ventilator-Steuerplatine

abtrennen.

Defekte

VentilatorSteuerplatine.

Ventilator

eingeschaltet

Anderes

Bauteil als die

VentilatorSteuerplatine

defekt.

Ventilator

ausgeschaltet

2 Überprüfung auf

Ventilatordefekt

Das Kabel vom laufenden

Ventilator abziehen.

Defekte

VentilatorSteuerplatine.

Ventilator

läuft noch.

Kein Problem.

Ventilator

gestoppt.

3 Überprüfung auf Ventilatordefekt

Den laufenden Ventilator

abstellen.

Defekte

VentilatorSteuerplatine.

Ventilator

läuft noch.

Kein Problem.

Ventilator

gestoppt.

SUPPLEMENT

1. Es bestehen drei grundsätzliche Möglichkeiten, die Ventilator-Steuerplatine und die

Ausgangs-Zusatzplatine anzuschließen.

<1> Produktionsserie im Dezember 1997

Ventilator-Steuerplatine (Display; K9661DE ohne √.)

QCNW-4978CEZZ QCNW-4979CEZZ

QCNW-4982CEZZ QCNW-4983CEZZ

<2> Produktionsserie im Januar 1998

Ventilator-Steuerplatine (Display; S9661CE √.)

QCNW-4980CEZZ QCNW-4981CEZZ

<3> Produktionsserie im Februar 1998 und danach

Ventilator-Steuerplatine (Display; S9661CE √,F0136AD √, √.)

QCNW-4980CEZZ QCNW-5001CEZZ

AUSGANGSPLATINE√

AUSGANGS-ZUSATZPLATINE √

1

AUSGANGS-ZUSATZ-

102

PLATINE √

1

AUSGANGS-ZUSATZPLATINE √

1

1

2

2.Störungssuche für die Ventilator-Steuerplatine

Vorsichtsmaßnahmen

* Einige Ventilator-Steuerplatinen sind mit einem Kabelhalter anstatt mit einem Kabelband zu versehen. Nach der

Reparatur einer solchen Platine ist der Kabelhalter zu entfernen und dann die einzelnen Kabel mit dem Kabelband

zu befestigen. Wenn das Kabelband wegen Reparaturarbeiten abgeschnitten wurde, sind die Kabel mit einem neuen

Kabelband zu befestigen. (CE-Maßnahmen) Teilecode: LHLDW1033CEZZ

* Wenn die Ausgangsplatine ausgewechselt wurde, ist eine Neueinstellung erforderlich.

5

Page 59

XG-NV2U/E/M

SUPPLEMENT

3. Reparaturverfahren

Anschluß 1: Produktionsserie im Dezember 1997

Ventilator-Steuerplatine (Display; K9661DE ohne √.)

QCNW-4978CEZZ QCNW-4979CEZZ

QCNW-4982CEZZ QCNW-4983CEZZ

Störungsstelle Vorbereitungen Verfahren

Ventilator-Steuerplatine

Ventilator-Steuerplatine (mit “A”

gekennzeichnet)

QCNW-4980CEZZ (mit UL-Band)

Die Kabel QCNW-4978CEZZ, -4979CEZZ, -4982CEZZ

und -4983CEZZ abtrennen, dann die Kabel QCNW4980CEZZ und QCNW-4981CEZZ anschließen.

QCNW-4981CEZZ

Ausgangs-Zusatzplatine

DUNTK9567DE

Für die Ausgangs-Zusatzplatine √

Ventilator-Steuerplatine (mit “A”

gekennzeichnet)

QCNW-4980CEZZ (mit UL-Band)

QCNW-5001CEZZ

Folgende Bauteile abtrennen: Ausgangs-Zusatzplatine

2

und Ventilator-Steuerplatine sowie die Kabel QCNW 4978CEZZ, -4979CEZZ, und -4983CEZZ. Danach die

Ausgangs-Zusatzplatine √, die Ventilator-Steuerplatine (mit “A” gekennzeichnet) und die Kabel QCNW4980CEZZ und -5001CEZZ an-schließen. Das Kabel

QCNW-4983CEZZ ebenfalls von der AusgangsZusatzplatine abtrennen.

Wenn die Ausgangs-Hilfsplatine √ ersetzt wird, ist das QCNW-4979CEZZ-Kabel von der

1

defekten. Platine abzutrennen und eine neue Platine anzuschließen.

AUSGANGSPLATINE√

AUSGANGS-ZUSATZPLATINE √

1

2

1

Ausgangsplatine

DUNTK5926DE

Ausgangsplatine √ oder √

1

2

Die defekte Ausgangsplatine vom Kabel QCNW4983CEZZ abtrennen und eine neue Ausgangsplatine anschließen.

Anschluß 2 : Produktionsserie im Januar 1998

Ventilator-Steuerplatine (Display; S9661CE √.)

QCNW-4980CEZZ QCNW-4981CEZZ

1

Störungsstelle Vorbereitungen Verfahren

Ventilator-Steuerplatine

Ventilator-Steuerplatine (mit “A”

gekennzeichnet)

Die Ventilator-Steuerplatine(mit “A” gekennzeichnet)

auswechseln.

DUNTK9661DE01

CFANR0084CE01

Ausgangs-Zusatzplatine

Für die Ausgangs-Zusatzplatine √

QCNW-5001CEZZ cable

Die Ausgangs-Zusatzplatine √ mit dem Kabel

22

QCNW-5001CEZZ verbinden.

DUNTK9567DE01

Wenn die Ausgangs-Hilfsplatine √ ersetzt wird, ist das QCNW-4981CEZZ-Kabel von der

1

defekten Platine abzutrennen und eine neue Platine anzuschließen.

AUSGANGS-ZUSATZPLATINE √

1

Ausgangsplatine

Ausgangs-Zusatzplatine √ oder √

DUNTK5926DE01

2

1

Die Ausgangsplatine auswechseln.

6

Page 60

Anschluß 3 : Produktionsserie im Februar 1998 und danach.

Ventilator-Steuerplatine (Display; S9661CE √,F0136AD √, √.)

QCNW-4980CEZZ QCNW-5001CEZZ

Störungsstelle Vorbereitungen Verfahren

AUSGANGS-ZUSATZ-

102

PLATINE √

2

XG-NV2U/E/M

SUPPLEMENT

Ventilator-Steuerplatine

Ausgangs-Zusatzplatine

DUNTK9567DE

Ventilator-Steuerplatine (mit “A”

gekennzeichnet)

Für die Ausgangs-Steuerplatine √

Ventilator-Zusatzplatine

QCNW-4981CEZZ cable

Die Ventilator-Steuerplatine(mit “A” gekennzeichnet)

auswechseln.

Die defekte Ausgangs-Zusatzplatine vom Kabel

1

QCNW-5001CEZZ abtrennen und eine neue

Ausgangs-Zusatzplatine √ am Kabel QCNW-

1

4981CEZZ anschließen.

Wenn die Ausgangs-Hilfsplatine √ ersetzt wird, ist das QCNW-5001CEZZ-Kabel von der

2

defekten Platine abzutrennen und eine neue Platine anzuschließen.

Ausgangsplatine

Ausgangs-Zusatzplatine √ oder √

1

Die Ausgangsplatine auswechseln.

2

DUNTK9526DE

4. Weiteres

1 Die Ersatzventilator-Steuerplatine ist an ihrer Rückseite mit “A” gekennzeichnet. Platinen dieses Typs wurden

von Februar 1998 an produziert (neu konstruiert, um den Bereitschaftsmodus zu aktualisieren, wenn der

Netzstrom zugeschaltet wird).

2 Am Ersatzkabel QCNW-4980CEZZ ist ein UL-Band angebracht.

Das UL-Band dient dazu, daß das Kabel nicht durch die Halterungsschraube der Seitenplatte und oberen Platte

eingeklemmt wird. Siehe die untere Abbildung hinsichtlich der Bandposition.

Braun 1

Braun 2

Braun 3

Braun 4

Braun 5

50 ± 5

PHR-5

(Steckverbindung,

2 mm Abstand)

10

260 ± 5

UL-Band hier angebracht

7

1 Braun

2 Braun

3 Braun

4 Braun

5 Braun

SMP-05V-NC

(Relaisanschluß,

Steigung 2,5 mm)

Ausgangs-ZusatzplatineVentilator-Steuerplatine

Page 61

XG-NV2U/E/M

SUPPLEMENT

5. Connecting the QCNW-4979CEZZ cable leads on the output sub-PWB (Production lot in

December 1997)

Anschließen der QCNW-4979CEZZ-Kabel an der Ausgangs-Zusatzplatine

(Produktionsserie im Dezember 1997)

Side A of output sub-PWB

Seite A der Ausgangs-Zusatzplatine

QCNW-4979CEZZ

1 Brown: PCON1 to R5510

Braun: PCON1 zu R5510

2 Red: 13V to R5506

Rot: 13 V to R5506

3 Orange: LOCK to C5558(+)

Orange: LOCK zu C5558(+)

4 Yellow: GND to GND on FL5505

Gelb: GND zu GND am FL5505

Side B of output sub-PWB

Seite B der Ausgangs-Zusatzplatine

3 Orange

2Red

Rot

4Yellow

Gelb

1Brown

Braun

8

Page 62

XG-NV2U/E/M

SUPPLEMENT

6. Connecting the QCNW-4981CEZZ cable leads on the output sub-PWB (Production lot in

January 1998)

Anschließen der QCNW-4981CEZZ-Kabel an der Ausgangs-Zusatzplatine

(Produktionsserie im Januar 1998)

Side A of output sub-PWB

Seite A der Ausgangs-Zusatzplatine

QCNW-4981CEZZ

1Brown: 16.5V to pin (1) of connector EA

Braun: 16,5 V zu Stift (1) von Anschluß EA

2Red: 13V to R5506

Rot: 13 V to R5506

3Orange: LOCK to C5558(+)

Orange: LOCK zu C5558(+)

4Yellow: PCON1 to R5510

Gelb: PCON1 zu R5510

5Green: GND to GND on FL5505

Grün: GND zu GND am FL5505

Side B of output sub-PWB

Seite B der Ausgangs-Zusatzplatine

3 Orange

2Red

Rot

5Green

Grün

1Brown

Braun

4Yellow

Gelb

9

Page 63

XG-NV2U/E/M

SUPPLEMENT

PARTS LIST

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics identified in this manual: electrical components having such features are

identified by "å" in the Replacement Parts Lists.

The use of a substitute replacement part which does not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual may create shock, fire or other hazards.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the

following informations.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

5. CODE 6. QUANTITY

★ MARK : SPARE PARTS-DELIVERY SECTION

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PRINTED WIRING BOARD ASSEMBLIES

ERSATZTEILLISTE

AUSTAUSCH VON TEILEN

Ersatzteile, die besondere Sicherheitseigenschften haben, sind in

dieser Anleitung markiert. Elektrische Komponenten mit solchen

Eigenshaften sind in den Ersatzteil durch "å" gekenn-zeichnet.

Der Gebrauch von Ersatzteilen, die nicht deselben Sicherheitseigenschaften haben wie die vom Hersteller empfohlenen ud in der

Bedienungsanleitung angegebenen, können zur Ursache von

Blitzeinschlägen, Bränden und anderen Gefahren werden.

"WIE MAN ERSATSTEILE BESTELLT"

Damit Ihre Bestellung promt und korrekt ausgeführt wird, geben Sie

bitte folgende Informationen.

1. MODELL NR. 2. REF. NR.

3. ERSATZTEIL NR. 4. BESCHREIBUNG

5. KODE 6. QUANTITÄT

★ MARKIERUNG : ERSATZTEILE-LIEFERUNG

SERVICE PARTS

(Not Replacement Item)

Servicing for Production lot in December 1997

CFANR0084CE01 - Fan Control Unit —

MODEL XG-NV2U

DUNTK9526DE01 - Output Unit —

DUNTK9567DE01 - Output Sub Unit —

MODEL XG-NV2E

CFANR0084CE01 - Fan Control Unit —

DUNTK9526DE02 - Output Unit —

DUNTK9567DE02 - Output Sub Unit —

MODEL XG-NV2M

CFANR0084CE01 - Fan Control Unit —

DUNTK9526DE03 - Output Unit —

DUNTK9567DE03 - Output Sub Unit —

Servicing for Production lot in February 1998 and on

QCNW-4978CEZZ J Connecting Code AG

QCNW-4979CEZZ J Connecting Code AF

QCNW-4980CEZZ J Connecting Code AH

QCNW-4981CEZZ J Connecting Code AG

QCNW-4982CEZZ J Connecting Code AE

QCNW-4983CEZZ J Connecting Code AE

QCNW-5001CEZZ J Connecting Code AG

Servicing for Production lot in January 1998

QCNW-4980CEZZ J Connecting Code AH

QCNW-4981CEZZ J Connecting Code AG

QCNW-5001CEZZ J Connecting Code AG

QCNW-4980CEZZ J Connecting Code AH

QCNW-4981CEZZ J Connecting Code AG

QCNW-5001CEZZ J Connecting Code AG

10

Page 64

XG-NV2U/E/M

SUPPLEMENT

11

Page 65

XG-NV2U/E/M

SUPPLEMENT

COPYRIGHT © 2000 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

TQ0966-S

Aug. 2000 Printed in Japan

In Japan gedruckt

SY. KY

SHARP CORPORATION

AV Systems Group

Quality & Reliability Control Center

Yaita, Tochigi 329-2193, Japan

12

Page 66

LV036

Sharp Electronics (UK) Ltd., Technical Services Group

1. Model

XGSV1E/XGNV1E

2. General

If the unit is used for a long period a double image may appear shifted six pixels to the left.

The OSD characters may also be observed

3. Servicing

Follow the procedure below if this is reported:

1. Check the IC5003 version, which is on top of the IC5003 and change to the improved

type as detailed in the table below.

Model IC5003 version seal Change to

CEN1 RH-IX3304CEN1

CEN2 RH-IX3304CEN2

XGSV1E

CEN3 RH-IX3304CEN3

VER 1.01 RH-IX3303CEN1

XGNV1E

CEN2 RH-IX3303CEN2

2. If the ghosting image does not diminish to the acceptable level with

the above step, change 6 capacitors to 10pF type as detailed in the

table below.

Model Capacitors Change to

XGSV1E C4311, C4312, C4320, C4321, C4323, C4324

XGNV1E C4310, C4311, C4312, C4313, C4314, C4315

VCCCCY1HH100D

GHOSTING IMAGE

TECHNICAL BULLETIN

Date: 19 November 2002

Model: XGNV1E

Ref.: 005

Colour: White

Page: 1 of 1

Loading...

Loading...