Page 1

XG-C40XU(1

XG-C40XE(1

SERVICE MANUAL

SERVICE-ANLEITUNG

S22F7XGC40XU1

LCD PROJECTOR

LCD PROJEKTOR

)

)

XG-C40XU(1

)

MODELS

MODELLE

In the interests of user-safety (Required by saf ety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. A ußerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

OUTLINE

Based on the existing models XG-C40XU/XE, these models have their LCD panels redesigned.

This Service Manual covers only the modifications that are different from the base models. For the

unchanged service information, refer also to the Service Manual (S01B4XG-C40XU) for the base

models (XG-C40XU/XE).

BESCHREIBUNG

Die LCD-Bildschirme dieser Modelle wurden gemäß den vorhandenen Modellen XG-C40XU/XE

neu konstruiert. Diese Service-Anleitung beinhaltet die Veränderungen, welche sich von den

Grundmodellen unterscheiden.

Beziehen Sie sich für die unveränderten Service-Informationen der Grundmodelle (XG-C40XU/

XE) auf die Service-Anleitung (S01B4XG-C40XU).

XG-C40XE(1

)

CONTENTS INHALT

Page

» LIST OF CHANGED PARTS....................................... 2

» ELECTRICAL ADJUSTMENT .................................... 4

» BLOCK DIAGRAM.................................................... 16

» OVERALL WIRING DIAGRAM ................................. 18

» SCHEMATIC DIAGRAM: OUTPUT UNIT ................. 20

» PARTS LIST.............................................................. 30

SHARP CORPORATION

Seite

» LISTE VON VERÄNDERTEN TEILEN........................ 9

» ELEKTRISCHE EINSTELLUNG............................... 11

» BLOCKSCHALTBILD................................................ 16

» GESAMTSCHALTPLAN ........................................... 18

» SCHEMATISCHER SCHALTPLAN

AUSGABEEINHEIT .................................................. 20

» ERSATZTEILLISTE .................................................. 30

1

Page 2

XG-C40XU(1

XG-C40XE(1

)

)

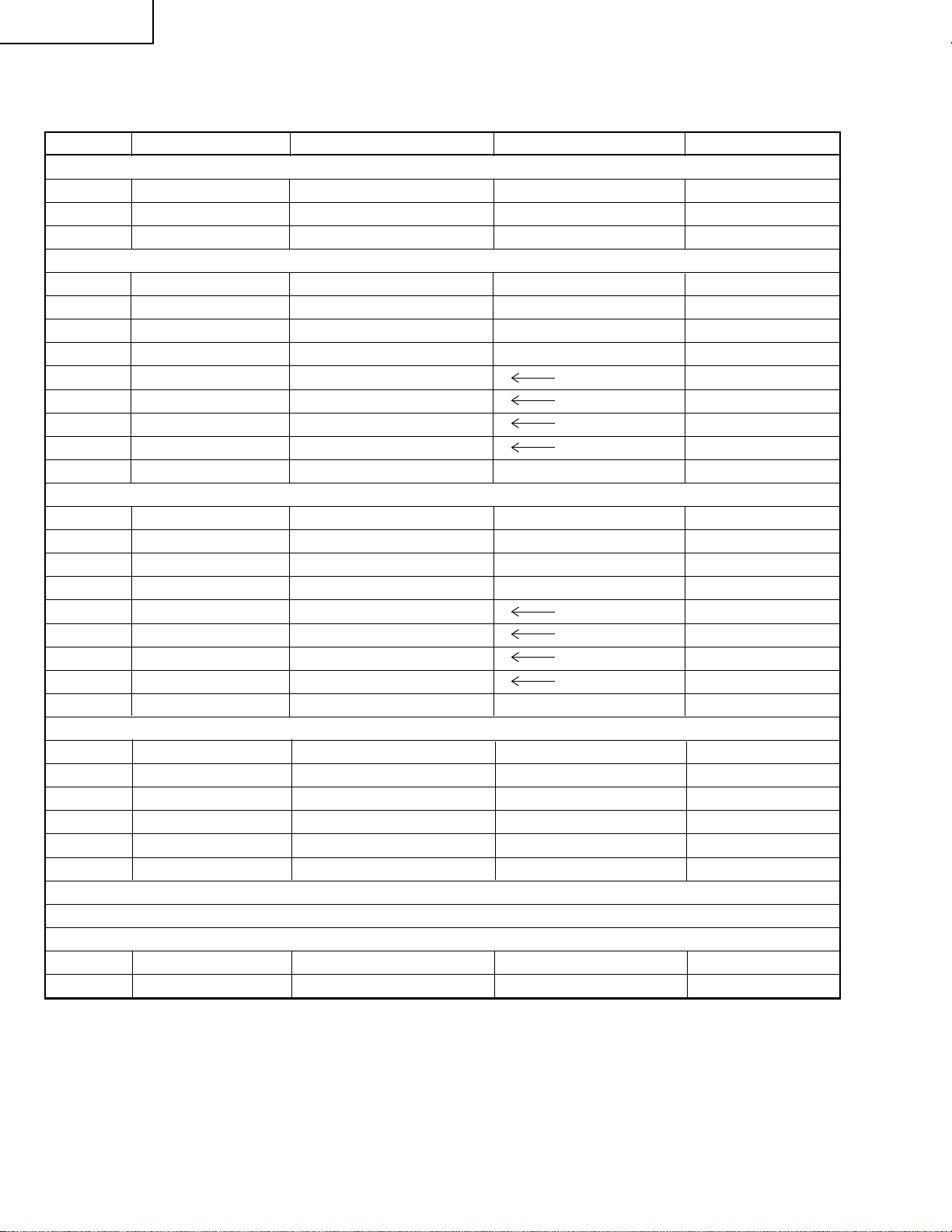

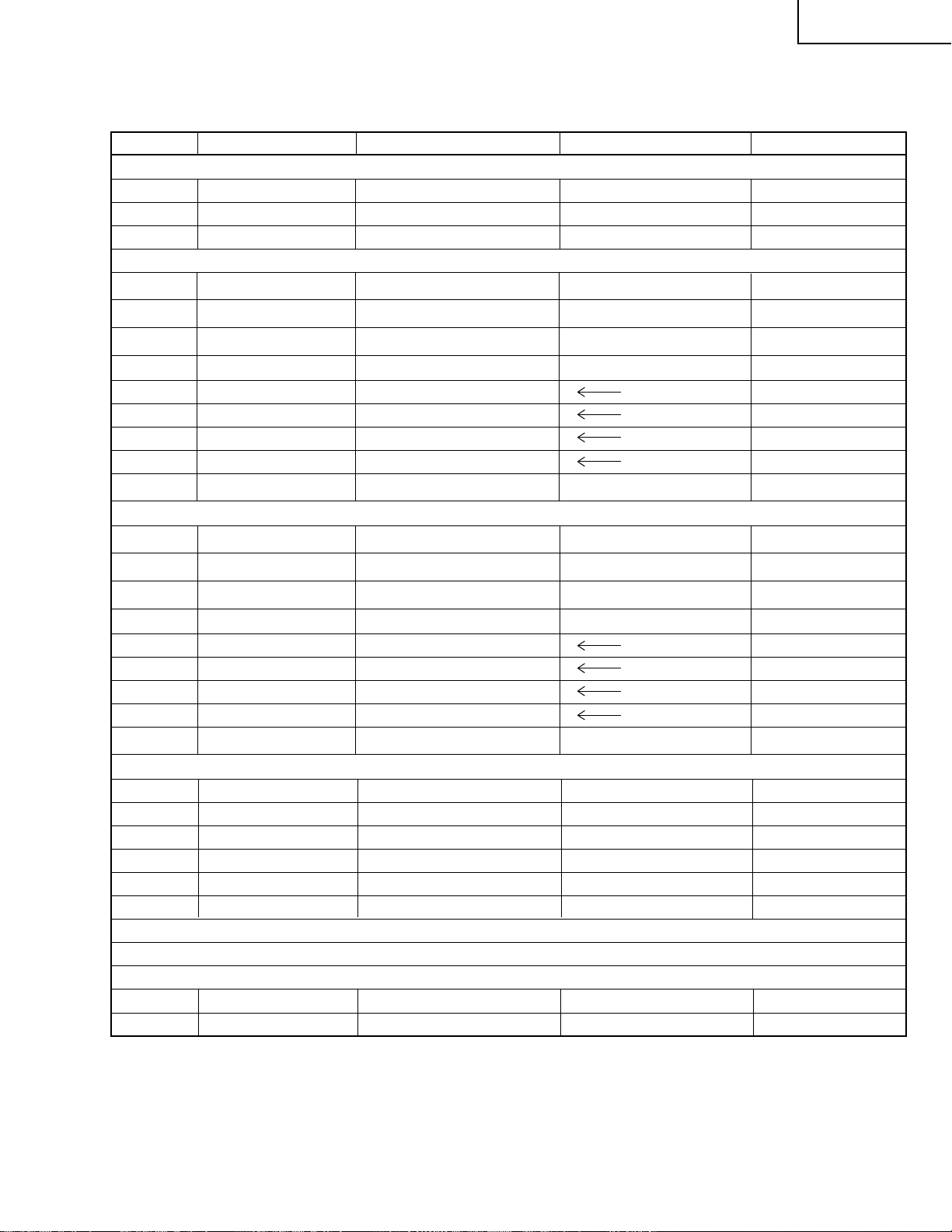

LIST OF CHANGED PARTS

Ref.No. Description Current New Note

LCD PANELS XG-C40XU(1) / XG-C40XE(1

LCD Module Unit Red

LCD Module Unit Green

LCD Module Unit Blue

PWB ASSEMBLIES XG-C40XU(1

RLCDP141CEZZ RLCDPA004WJZZ

RLCDP142CEZZ RLCDPA005WJZZ

RLCDP143CEZZ RLCDPA006WJZZ

)

Signal Unit DUNTKA211DE11 DUNTKB116DE04 Six parts changed

PC Terminal Unit DUNTKA212DE11 DUNTKB117DE04 No parts changed

S-Out/Regulater Unit

DUNTKA693FE01 DUNTKA693FE04 No parts changed

Output Unit DUNTKA694FE01 DUNTKB181FE01

Video Unit DUNTK9769DE24

AC Inlet Unit RUNTK0677CEZZ

Power Unit RDENC0334CEZZ

Ballast Unit RDENC0333CEZZ

PC I/F Unit CPCi-0047CE15 CPCi-0047CE18 No parts changed

PWB ASSEMBLIES XG-C40XE(1

)

Signal Unit DUNTKB116DE02 DUNTKB116DE05 No parts changed

PC Terminal Unit DUNTKB117DE02 DUNTKB117DE05 No parts changed

S-Out/Regulater Unit

DUNTKA693FE02 DUNTKA693FE05 No parts changed

Output Unit DUNTKA694FE02 DUNTKB181FE02

Video Unit DUNTK9769DE25

AC Inlet Unit DUNTK0677CEZZ

Power Unit RDENC0334CEZZ

Ballast Unit RDENC0333CEZZ

PC I/F Unit CPCi-0047CE16 CPCi-0047CE19 No parts changed

SIGNAL UNIT XG-C40XU(1

C886

C887

R1010

R1011

R1013

R1814

Capacitor 22 16V EL.

Capacitor 10 16V EL.

Resistor 0 1/16W M-Ox

Resistor 0 1/16W M-Ox

Resistor 0 1/16W M-Ox

Resistor 0 1/16W M-Ox

.

.

.

.

— VCEAPF1CW226M

— VCEAPF1CW106M

— VRS-CY1JF000J

— VRS-CY1JF000J

— VRS-CY1JF000J

— VRS-CY1JF000J

OUTPUT UNIT XG-C40XU(1

)

)

/ XG-C40XE

Refer to Parts List

CABINET AND MECHANICAL PARTS XG-C40XU(1

3-2

3-2

Bottom Cabinet Ass’y

Bottom Cabinet Ass’y

DBDYU1140CEK1 DBDYU1140CEK2 XG-C40XU1

DBDYU1141CEK1 DBDYU1141CEK3 XG-C40XE1

)

/ XG-C40XE

)

(1)

(1)

2

Page 3

Ref.No. Description Current New Note

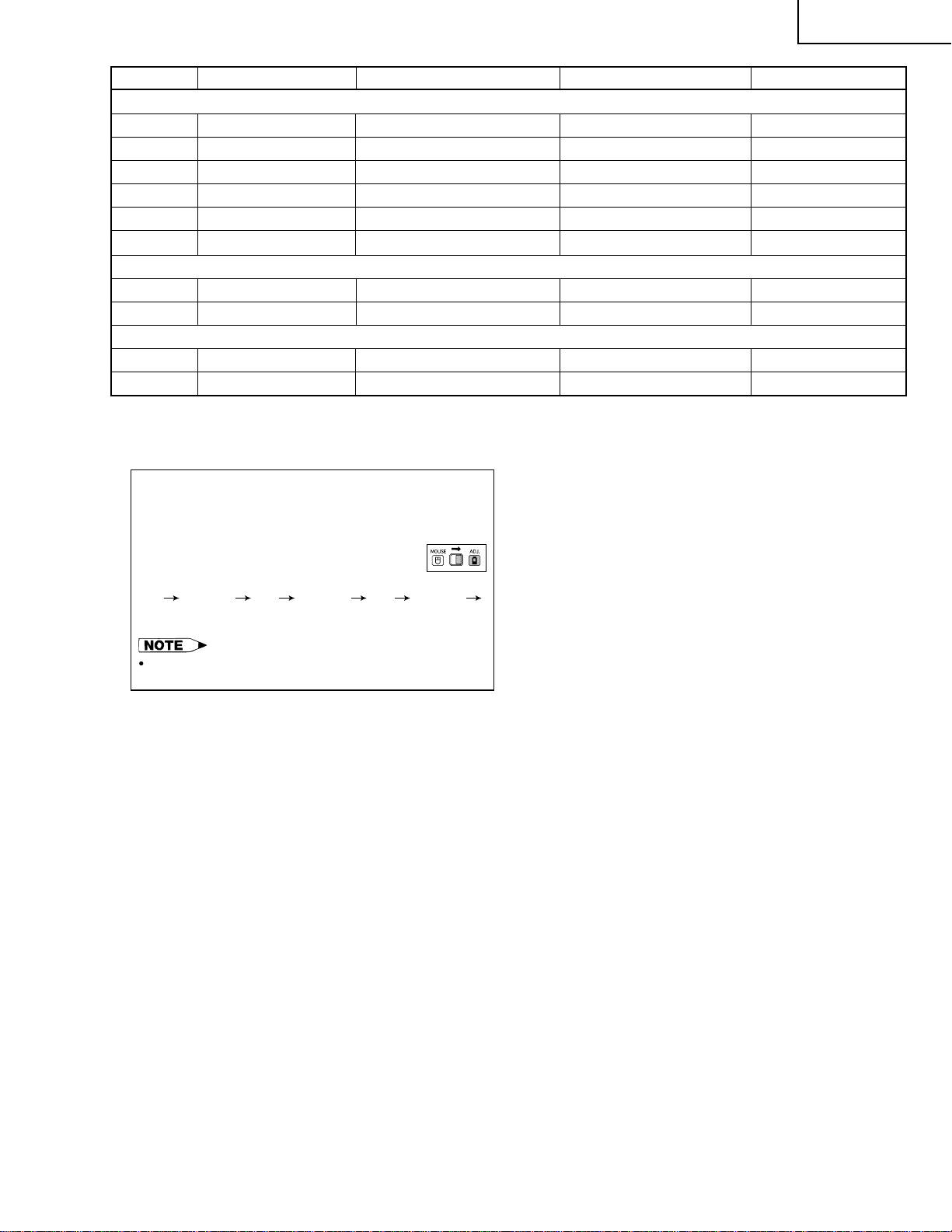

OPTICS MECHANISM PARTS XG-C40XU(1

6-37

6-38

6-39

6-47

6-83

6-91

LCD Module Unit Red

LCD Module Unit Green

LCD Module Unit Blue

Screw M2.6-8, x12

Emergent Polarizer B

Flyeye Lens Aperture

RLCDP0141CEZZ RLCDPA004WJZZ

RLCDP0142CEZZ RLCDPA005WJZZ

RLCDP0143CEZZ RLCDPA006WJZZ

XASSF26P06000 XASSF26P08000

PFiLW0295CEZZ PFiLW0300CEZZ

PSLDP3078CEFW — Delete

SUPPLIED ACCESSORIES XG-C40XU(1

)

/ XG-C40XE

)

/ XG-C40XE

(1)

(1)

CD-ROM UDSKA0053CEN1 UDSKA0059CEN1

CD-ROM UDSKA0057CEN1 UDSKA0059CEN1

SERVICE JIGS XG-C40XU(1

Extension Cable 20-pin

Extension Cable 32-pin

QCNW-5058CEZZ QCNW-5419CEZZ

QCNW-5688CEZZ QCNW-4852CEZZ

)

XG-C40XE(1

)

XG-C40XU(1

XG-C40XE(1

)

)

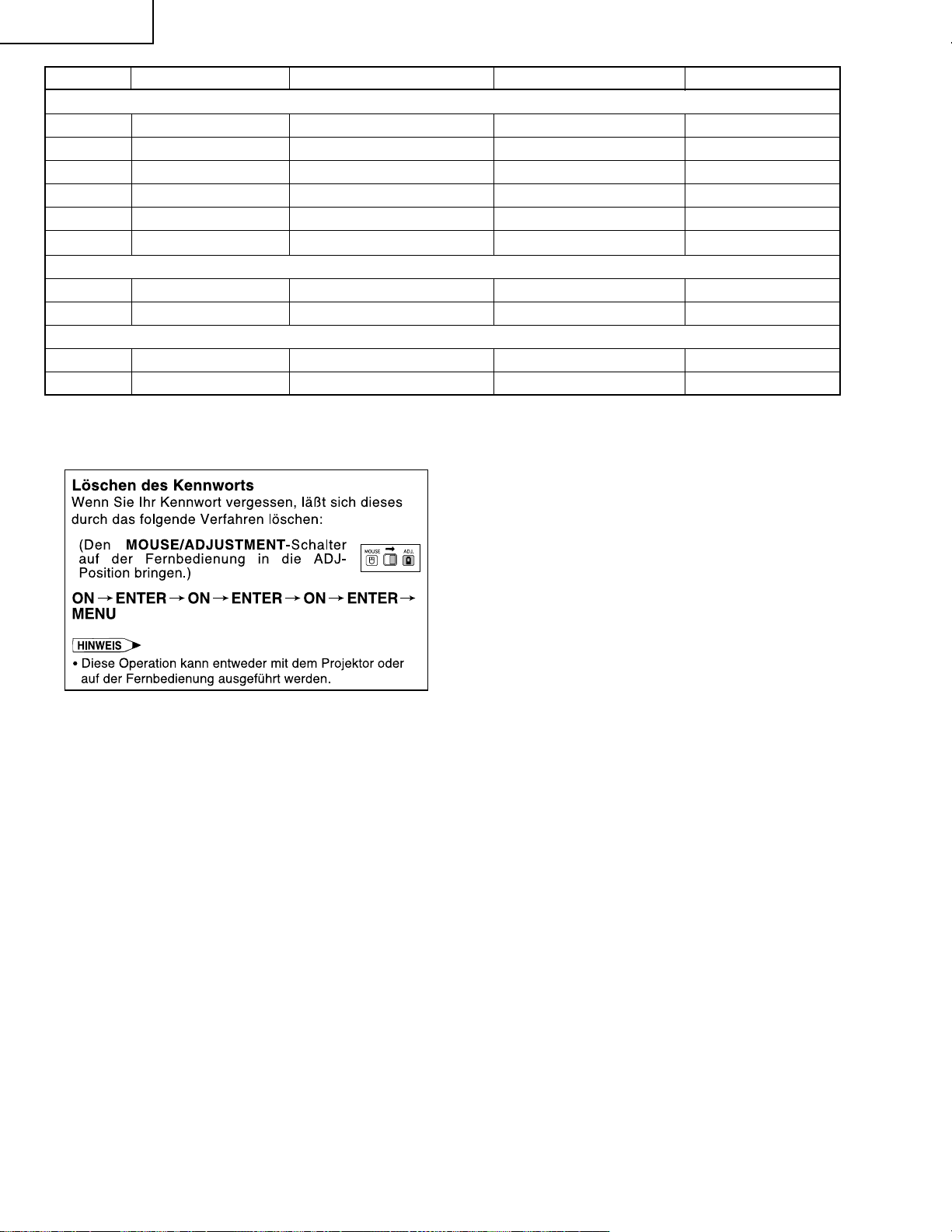

Clearing the Password

If you forget your password, you can use the following

procedure to clear the password.

(Slide the MOUSE/ADJUSTMENT switch

on the remote control to the ADJ.position.)

ON ENTER ON ENTER ON ENTER

MENU

This procedure can be performed either from the projector

or with the remote control.

3

Page 4

XG-C40XU(1

XG-C40XE(1

)

)

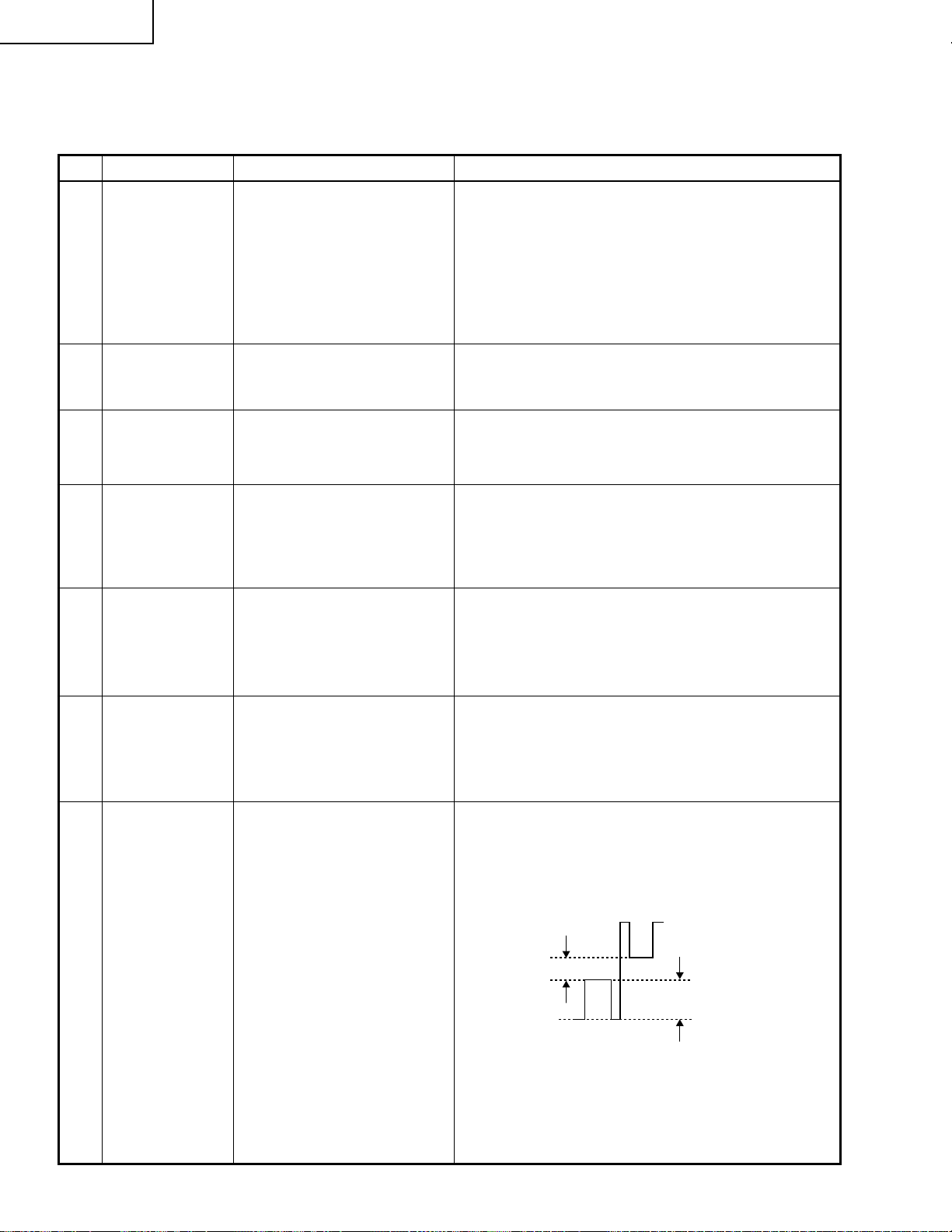

ELECTRICAL ADJUSTMENT

Hook up a signal generator, or a DOSV or Mac personal computer to the projector in order to feed the

signals specified in the Adjusting conditions.

No. Adjusting point Adjusting conditions Adjusting procedure

1 EEPROM

initialization

1. Turn on the power (make

sure the lamp lights up) and

warm up the unit for 15 minutes.

» Make the following settings:

Press SW5101 to call up the process mode and

execute S2 in the SSS menu. Now the system, with

the PC board not included, is initialized. Do not

execute S1 because otherwise the PC board will

be initialized.

To adjust the PC board, follow the instruction in

"Adjusting the PC board".

2 3.3V power

supply

adjustment

3 2.5V power

supply

adjustment

4 R drive » Using the control switches or the remote controller

1. Turn on the power.

2. Connect the digital voltmeter to TP1446.

1. Turn on the power.

2. Connect the digital voltmeter to TP1447.

1. Feed the 100% red-only signal. Make the following

choice.

» Adjust R1649 so that the voltmeter should read

3.43 ±0.03 Vp-p.

» Adjust R1652 so that the voltmeter should read

2.60 ±0.05 Vp-p.

buttons, adjust the data so that the signal be-

comes bit-less (noise).

Group : A/D

Subject : R-D

5 B drive 1. Feed the 100% blue-only

signal. Make the following

choice.

» Using the control switches or the remote controller

buttons, adjust the data so that the signal be-

comes bit-less (noise).

Group : A/D

Subject : B-D

6 G drive 1. Feed the 100% green-only

signal. Make the following

choice.

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes

bit-less (noise).

Group : A/D

Subject : G-D

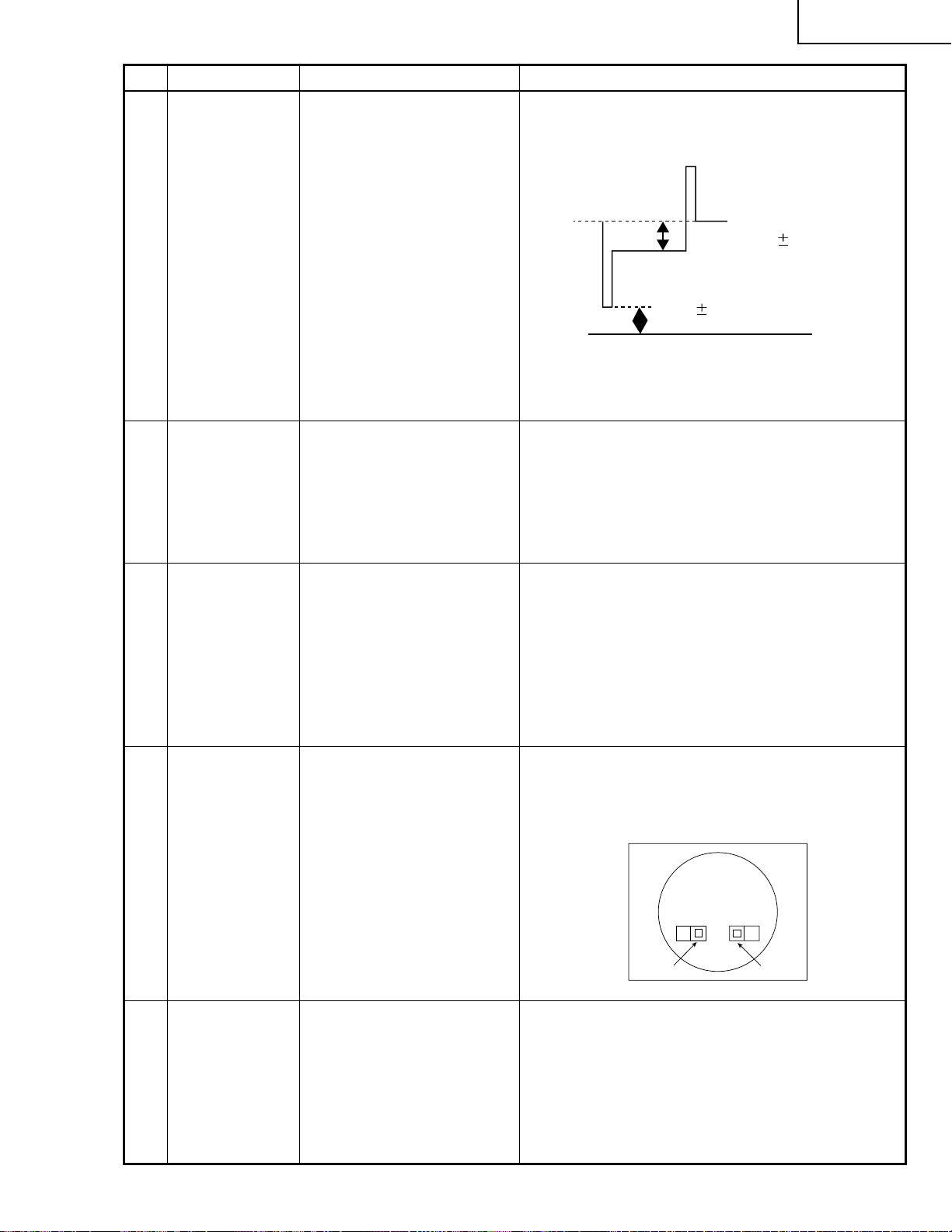

7 RGB 1 system

black level

signal amplitude

(odd-numbered)

1. Make the following choice:

Group : OUTPUT 1

Subject : G1-BLK

G1-GAIN

For red, choose the sub-

jects R1-BLK and R1-GAIN.

For blue, choose the subjects B1-BLK and B1-GAIN.

2. Connect the oscilloscope to

TP1101 for red.

TP1201 for green.

TP1301 for blue.

» Choose the subject G1-GAIN and adjust the sig-

nal amplitude to 3.6 ±0.1 Vp-p using the control

switches or the remote controller buttons.

» Next,choose the subject G1-BLK and adjust the

white to white level to 2.5 ±0.1V DC.

(Adjust to 2.5V

DC for red and

blue.)

2.5V

3.6Vp-p

(Adjust to 3.6Vp-p

for green and blue.)

» Adjust the signal's amplitude and white to white

level to 2.5 ± 0.1 DC and 3.6 ± 0.1V Vp-p, respectively, for red and blue.

4

Page 5

No. Adjusting point Adjusting conditions Adjusting procedure

1

2

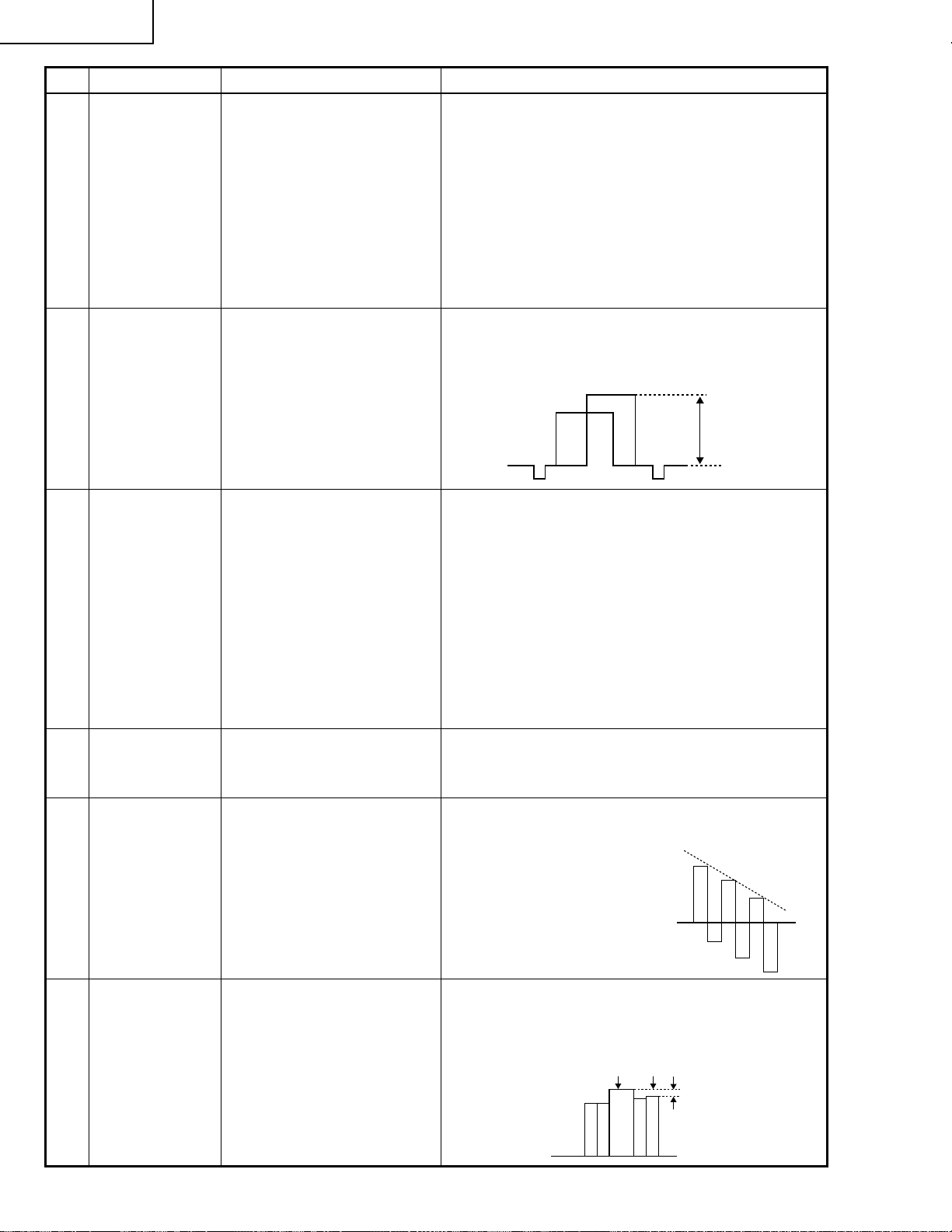

8 P SIGNAL 1. Connect the oscilloscope to

TP1102 for red.

TP1202 for green.

» Adjust the PSIG waveform as shown below.

(With XGA signal input)

TP1302 for blue.

XG-C40XU(1

XG-C40XE(1

)

)

9 Sample and

hold pulse

phase checking

10 RGB counter-

voltage

adjustment

2. Make the following choice:

Group : OUTPUT 2

Subject : PSIG-H

PSIG-L

3. Using the horizontal 10-step

signal, make sure no vertical

stripes appear every 12 dots.

(If any white or black v ertical

stripes appear, finely adjust

the PSIG-L setting.)

1. Feed the XGA-mode 75-Hz

black signal.

2. Select the following group

and subjects.

Group : OUTPUT3

Subject: SH-PHASE,

GCK-PHASE

1. Feed the black-and-red

(25%) stripe signal (XGA).

2. Make the following choice:

Group : OUTPUT 3

Subject : RC (R)

Adjust the PSIG-L setting.

3.7V 0.1V

Adjust the PSIG-H setting.

2.3V 0.1V

GND

» Make sure that the (G) and (B) wav eforms are similar

to that of (R).

» Make sure that the SH-PHASE and GCK-PHASE

settings are 11 and 6, respectively.

» Using the control switches or the remote controller

buttons, adjust the data in order to minimize the

flicker.

» Make the same adjustment for BC (B), GC (G).

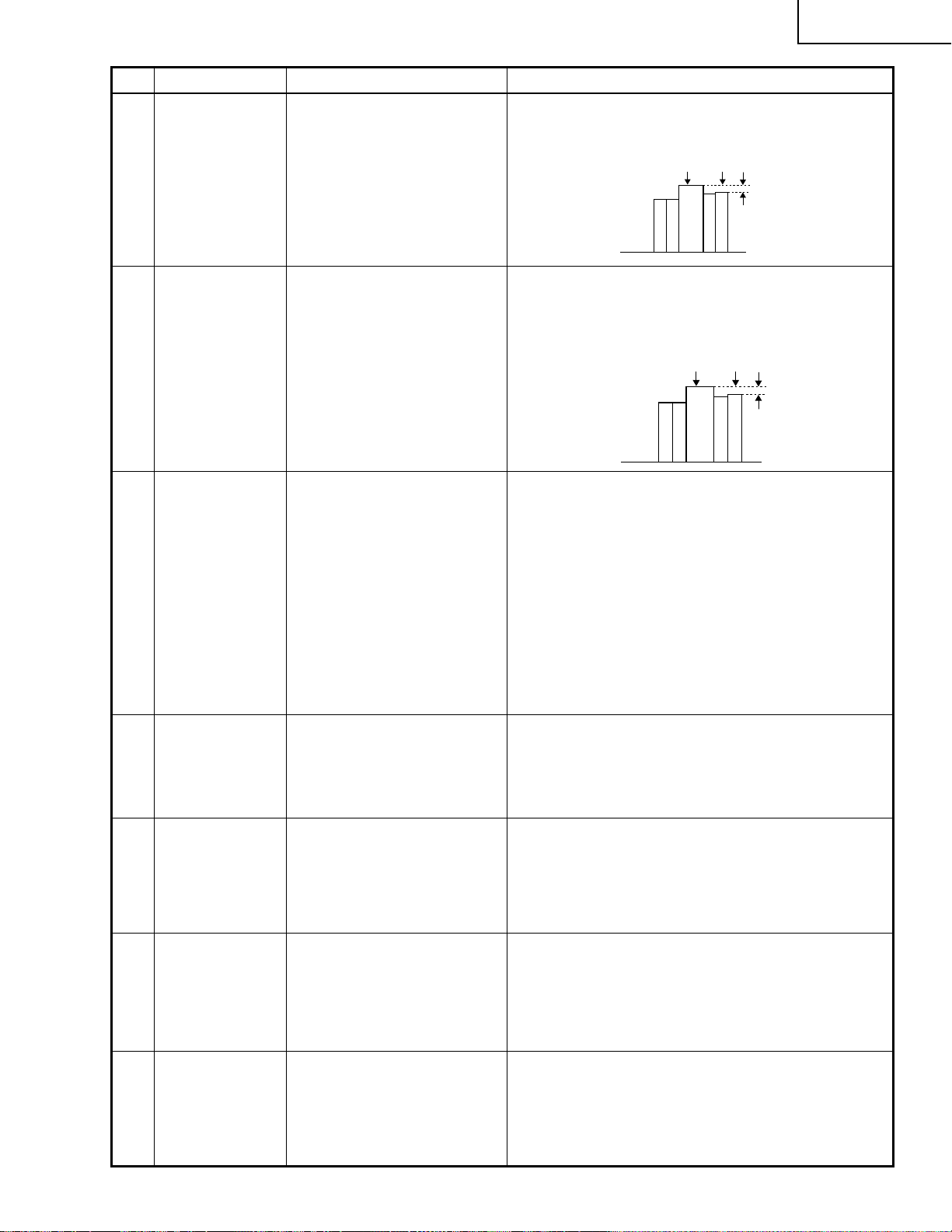

11 RGB gradation

regeneration

adjustment

12 RGB white

balance

1. F eed the green-only SMPTE

pattern signal (XGA).

Group : OUTPUT 1

Subject : G1-BLK

1. Feed the 32-step gray scale

signal (XGA).

Group : OUTPUT 1

Subject : R1-BLK (R)

B1-BLK (B)

» See if the image is equally adjusted at the center

and both sides of the screen. If not, readjust the

setting to have the image equal at right and left.

» Adjust the G-BLK data until the gradation of the

portion 1 (95% and 100% white) shown below

can be slightly recognized. Make sure also that the

gradation of the portion 2 (0% and 5% black) is

visible.

» Choose the subjects R1-BLK and B1-BLK and

adjust the black balance of the gradation.

5

Page 6

XG-C40XU(1

100% White Red

XG-C40XE(1

)

)

No. Adjusting point Adjusting conditions Adjusting procedure

13 Horizontal

center

14 Video picture

adjustment

15 Video

brightness

adjustment

1. Feed the NTSC monoscope

pattern signal.

2. Group : VIDEO 2

Subject : N358-DLY (4)

N443-DLY (0)

PAL-DLY (3)

SECAM-DLY (0)

Make sure the settings are

as above.

3. Group : VIDEO 1

Subject : NTSC-H

1. Feed the split colour bar signal.

Group : VIDEO 1

Subject : PICTURE

2. Connect the oscilloscope

between pin (2) of P801 and

GND.

1. Feed the baseband (split

colour bar) signal. (The ONAIR signal is not accepted

because of its too much

noise.)

Group : VIDEO 2

Subject :

VROS/VGOS/VBOS

2. Press the control switch or

the remote control’s mute

button (to set the gamma

correction to the process

setting).

» Using the control switches or the remote controller

buttons, adjust the data to have the same overscan

in Reft and Right.

» Using the control switches or the remote controller

buttons, adjust the black-to-white (100%) level

difference to 2.0 ±0.06 Vp-p.

2.0Vp-p

» Using the control switches or the remote controller

buttons, adjust the setting until the black signal

becomes bit-less.

16 Video AGC 1.

Feed the split colour bar signal.

Group : VIDEO 1

Subject : AGC

17 Tint 1. Feed the split colour bar

signal.

Group : VIDEO 1

Subject : TINT

2. Connect the oscilloscope to

pin (4) of P801.

18 NTSC colour

saturation level

1. Feed the split colour bar signal.

Group : VIDEO 1

Subject : N-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

» Using the control switches or the remote controller

buttons, adjust the setting until the white signal

becomes bit-less.

» Using the control switches or the remote controller

buttons, adjust the data to have the -(B-Y) waveform downhill straight.

» After adjusting, adjust the

value of TINT up 3 point.

» Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.00 ±0.05 Vp-p .

(same as 100% white)

6

Page 7

No. Adjusting point Adjusting conditions Adjusting procedure

XG-C40XU(1

XG-C40XE(1

)

)

19 PAL colour

saturation level

20 SECAM colour

saturation level

21 Video input

panel signal

amplitude

adjustment

1. Feed the P AL colour bar signal.

Group : VIDEO 1

Subject : P-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

1. Feed the SECAM colour bar

signal.

Group : VIDEO 1

Subject : S-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

1. Feed the NTSC 10-step sig-

nal.

2. Select the following group

and subject.

Group : VIDEO2

Subject: R1-GAIN

B1-GAIN

3. Connect the oscilloscope to

TP1101 (R) and TP1201 (G).

4. For the blue colour, connect

the oscilloscope to TP1301

(B) and TP1201 (G).

» Using the control switches or the remote controller

buttons, adjust the diff erence between the 100%

white portion and the red portion to 0.2 ±0.05 Vp-p .

100% White Red

» Using the control switches or the remote controller

buttons, adjust the data to have a level difference

of 0.2 ±0.05 Vp-p between the 100% white portion

and the red portion.

100% White Red

» Select R1-GAIN and adjust the setting so that the

R and G signals have the same amplitude.

» For the blue colour, adjust the setting the same

way.

22 Video white

balance

1. Feed the NTSC monoscope

pattern signal

Group : VIDEO 2

Subject : R1-BLK

B1-BLK

23 DTV white

balance

1. Feed the monoscope pattern

signal.

2. Group : DTV

Subject: CR-OFFSET

CB-OFFSET

24 Setup 1. Group : VIDEO1

Subject: SET UP B

SET UP C

25 Automatic

colour

errugularity

correction

1. Using the colour errugularity

correction system (ccdc),

apply automatic colour

correction.

» Using the control switches or the remote controller

buttons, adjust so that the entire screen looks

evenly colourless.

» Using the control switches or the remote controller

buttons, adjust so that the entire screen looks

evenly colourless.

» Make sure the settings are 11 for SET UP B and 2

for SET UP C.

» Make sure there is no noticeable colour irregularity

left on the screen.

7

Page 8

XG-C40XU(1

XG-C40XE(1

)

)

No. Adjusting point Adjusting conditions Adjusting procedure

26 Colour system

performance

check

27 Video system

performance

check

28 Audio system

performance

check

29 RGB

performance

check

30 Off-timer

performance

check

31 Thermistor

performance

check

1. Receive the colour bar signal.

1. Receive the monoscope pattern signal.

» In the process mode and select L1. Check the col-

our and tint.

» In the process mode and select L2. Check the pic-

ture, brightness and sharpness.

» In the process mode nad select L3. Check the bass,

treble.

1. Receive the RGB signal. » In the process mode and select L4. Check the pic-

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

» In the process mode and select OFF. Make sure that

the off-timer starts with “5” (minutes), counts down each

minute in 1 second, and turns off the set at “0”.

1. Heat the ther mistor using a

» Make sure the “TEMP” is displayed.

dryer.

32 Automatic

synchronization

1. Receive the PHASE check

pattern signal.

» Call the VGA/SVGA/XGA/SXGA mode and make

sure that the clock, phase, horizontal and vertical

positions can be automatically adjusted.

33 Keystone

» Make sure the keystone correction functions well.

correction

performance

check

34 Factory settings » Make the following settings.

Process

adjustment

S3 “Factory setting 3”(XG-C40XE1)

S4 “Factory setting 4”(XG-C40XU1)

Remote controller setting

8

Page 9

LISTE V ON VERÄNDERTEN TEILEN

Ref.Nr. Beschreibung Bestehend Neu Bemerkung

LCD PANELS XG-C40XU(1) / XG-C40XE(1

LCD Module Unit Red

LCD Module Unit Green

LCD Module Unit Blue

PWB ASSEMBLIES XG-C40XU(1

RLCDP141CEZZ RLCDPA004WJZZ

RLCDP142CEZZ RLCDPA005WJZZ

RLCDP143CEZZ RLCDPA006WJZZ

)

)

XG-C40XU(1

XG-C40XE(1

)

)

Signal Unit DUNTKA211DE11 DUNTKB116DE04

PC Terminal Unit DUNTKA212DE11 DUNTKB117DE04

S-Out/Regulater Unit

DUNTKA693FE01 DUNTKA693FE04

Output Unit DUNTKA694FE01 DUNTKB181FE01

Video Unit DUNTK9769DE24

AC Inlet Unit RUNTK0677CEZZ

Power Unit RDENC0334CEZZ

Ballast Unit RDENC0333CEZZ

PC I/F Unit CPCi-0047CE15 CPCi-0047CE18

PWB ASSEMBLIES XG-C40XE(1

Signal Unit DUNTKB116DE02 DUNTKB116DE05

PC Terminal Unit DUNTKB117DE02 DUNTKB117DE05

S-Out/Regulater Unit

DUNTKA693FE02 DUNTKA693FE05

Output Unit DUNTKA694FE02 DUNTKB181FE02

Video Unit DUNTK9769DE25

AC Inlet Unit DUNTK0677CEZZ

Power Unit RDENC0334CEZZ

Ballast Unit RDENC0333CEZZ

Sechs Teile verändert

Keine Teile verändert

Keine Teile verändert

Keine Teile verändert

)

Keine Teile verändert

Keine Teile verändert

Keine Teile verändert

PC I/F Unit CPCi-0047CE16 CPCi-0047CE19

SIGNAL UNIT XG-C40XU(1

C886

C887

R1010

R1011

R1013

R1814

Capacitor 22 16V EL.

Capacitor 10 16V EL.

Resistor 0 1/16W M-Ox

Resistor 0 1/16W M-Ox

Resistor 0 1/16W M-Ox

Resistor 0 1/16W M-Ox

.

.

.

.

— VCEAPF1CW226M

— VCEAPF1CW106M

— VRS-CY1JF000J

— VRS-CY1JF000J

— VRS-CY1JF000J

— VRS-CY1JF000J

OUTPUT UNIT XG-C40XU(1

Beziehen Sie sich auf die Teilliste

CABINET AND MECHANICAL PARTS XG-C40XU(1

3-2

3-2

Bottom Cabinet Ass’y

Bottom Cabinet Ass’y

DBDYU1140CEK1 DBDYU1140CEK2 XG-C40XU1

DBDYU1141CEK1 DBDYU1141CEK3 XG-C40XE1

)

)

/ XG-C40XE

)

/ XG-C40XE

Keine Teile verändert

(1)

(1)

9

Page 10

XG-C40XU(1

XG-C40XE(1

Ref.Nr. Beschreibung Bestehend Neu Bemerkung

OPTICS MECHANISM PARTS XG-C40XU(1

6-37

6-38

6-39

6-47

6-83

6-91

SUPPLIED ACCESSORIES XG-C40XU(1

SERVICE JIGS XG-C40XU(1

)

)

)

/ XG-C40XE

LCD Module Unit Red

LCD Module Unit Green

LCD Module Unit Blue

Screw M2.6-8, x12

Emergent Polarizer B

Flyeye Lens Aperture

CD-ROM UDSKA0053CEN1 UDSKA0059CEN1

CD-ROM UDSKA0057CEN1 UDSKA0059CEN1

Extension Cable 20-pin

Extension Cable 32-pin

RLCDP0141CEZZ RLCDPA004WJZZ

RLCDP0142CEZZ RLCDPA005WJZZ

RLCDP0143CEZZ RLCDPA006WJZZ

XASSF26P06000 XASSF26P08000

PFiLW0295CEZZ PFiLW0300CEZZ

PSLDP3078CEFW — Streichen

)

/ XG-C40XE

)

XG-C40XE(1

QCNW-5058CEZZ QCNW-5419CEZZ

QCNW-5688CEZZ QCNW-4852CEZZ

(1)

(1)

)

10

Page 11

ELEKTRISCHE EINSTELLUNG

3,6Vs-s

(F r Rot und Blau auf

2,5 V einstellen.)

(F r Grn und Blau

auf 3,6 Vs-s einstellen.)

2.5V

Einen Signalgenerator, PC oder Macintosh-Computer am Projektor anschließen, um die in den

Einstellbedingungen spezifizierten Signale zuzuführen.

Nr. Einstellposition Einstellbedingung Einstellverfahren

1 EEPROM-

Initialisierung

1. Den Netzschalter

einschalten und das Gerät

für ca. 15 Minuten

vorwärmen lassen.

(Sicherstellen, daß die

Kontrollampe aufleuchtet.)

» Folgende Einstellungen vornehmen:

SW5101 drücken, um den Verarbeitungsmodus

abzurufen, und um S2 im SSS-Menü auszuführen.

Das System ist nun initialisiert (PC-Platine nicht

miteingeschlossen). S1 darf nicht ausgeführt

werden, da die PC-Platine sonst initialisiert wird.

Um die Platine einzustellen, die Vorschriften in

"Einstellung der Platine" folgen.

XG-C40XU(1

XG-C40XE(1

)

)

2 3,3 V -

StromversorgungsEinstellung

3 2,5 V -

StromversorgungsEinstellung

4 R-Antrieb

5 B-Antrieb

6 G-Antrieb

1. Den Netzschalter

einschalten.

2. Den Digitalvoltmeter an

TP1446 anschließen.

1. Den Netzschalter

einschalten.

2. Den Digitalvoltmeter an

TP1447 anschließen.

1. Das Rotsignal (100%)

zuführen und die folgende

Wahl treffen.

Gruppe : Analog/Digital

Gegenstand: R-D

1. Das Blausignal (100%)

zuführen und die folgende

Wahl treffen.

Gruppe : Analog/Digital

Gegenstand : B-D

1. Das Grünsignal (100%)

zuführen und die folgende

Wahl treffen.

Gruppe : Analog/Digital

Gegenstand : G-D

» R1649 einstellen, bis der Voltmeter 3,43 V ±0.03

Vs-s zeigt.

» R1652 einstellen, bis der Voltmeter 2,60 V ±0.05

Vs-s zeigt.

» Die Regelschalter oder die Tasten auf der

Fernbedienung betätigen und die Daten so

einstellen, daß das Signal "bitlos" (Störung) wird.

» UDie Regelschalter oder die Tasten auf der

Fernbedienung betätigen und die Daten so

einstellen, daß das Signal "bitlos" (Störung) wird.

» Die Regelschalter oder die Tasten auf der

Fernbedienung betätigen und die Daten so

einstellen, daß das Signal "bitlos" (Störung) wird.

7 Schwarzpegel-

Signalamplitude

für RGB 1System

(ungeradzahlig)

1. Die folgende Wahl treffen.

Gruppe : OUTPUT 1

Gegenstand : G1-BLK

G1-GAIN

Für Rot sind die

Gegenstände R1-BLK und

R1-GAIN zu wählen.

Für Blau sind die

Gegenstände B1-BLK und

B1-GAIN zu wählen.

2. Das Oszilloskop

anschließen an

TP1101 für Rot.

TP1201 für Grün.

TP1301 für Blau.

» Den Gegenstand G1-GAIN wählen und den

Schwarz-Spitzenpegel auf 3,6 ±0,1 Vs-s

Gleichspannung einstellen. Hierfür die

Regelschalter oder die Tasten auf der

Fernbedienung betätigen.

» Danach den Gegenstand G1-BLK wählen und die

Weiß-zu-Weiß Pegeldifferenz auf 2,5 ±0,1 VGleichstrom einstellen.

» Die Signalamplitude auf 2,5 ±0,1 V-Gleichstrom

und die Weiß-zu-Weiß Pegeldifferenz auf

3,6 ±0,1Vs-s für das Rot und Blau einstellen.

11

Page 12

XG-C40XU(1

XG-C40XE(1

)

)

Nr. Einstellposition Einstellbedingung Einstellverfahren

8 P-SIGNAL

9 Uberprufung der

Muster- und

Halteimpulsphasen

1. Das Oszilloskop

anschließen an

TP1102 für Rot.

TP1202 für Grün.

TP1302 für Blau.

2. Die folgende Wahl treffen.

Gruppe : OUTPUT 2

Gegenstand : PSIG-H

PSIG-L

3. Mittels des horizontalen

10-Stufensignals,

sicherstellen, daß die

horizontalen Nadelstreifen

aller 12 Punkte nicht

erscheinen. (Wenn weiße

oder schwarze vertikale

Nadelstreifen erscheinen,

ist die PSIG-L-Einstellung

fein vorzunehmen.)

1. Das XGA-Modus Schwarzsignal (75 Hz)

zuführen.

2. Folgende Wahl vornehmen:

Gruppe : OUTPUT 3

Gegenstand: SH-PHASE,

GCK-PHASE

» Die P-SIG-Wellenform auf die nachstehende Form

einstellen.

(Mit XGA-Signaleingang)

Die PSIG-L-Einstellung vornehmen.

3.7V 0.1V

Die PSIG-H-Einstellung vornehmen.

2.3V 0.1V

GND

» Sicherstellen, daß die Wellenformen für (G) und (B)

ähnlich wie die Wellenform für (R) sind.

» Sicherstellen, daß die SH-PHASE- und GCK-

PHASE-Einstellungen 11 bzw 6 sind.

10 Einstellung der

RGBGegenspannung

11 Regenerierung-

seinstellung für

RGB-Abstufung

12 RGB-

Weißbalance

1. Das 25%-Schwarz/RotStreifensignal (XGA)

zuführen.

2. Folgende Wahl vornehmen:

Gruppe : OUTPUT 3

Gegenstand : RC (R)

1. Das SMPTESignalmustersignal (nur

Grün) zuführen (XGA).

Gruppe : OUTPUT 1

Gegenstand : G1-BLK

1. Das Grauskalensignal (32

Abstufungen) zuführen

(XGA).

Gruppe : OUTPUT 1

Gegenstand : R1-BLK (R)

B1-BLK (B)

» Die Daten einstellen, um das Bildflimmern zu

reduzieren. Hierfür die Regelschalter oder die

Tasten auf der Fernbedienung betätigen.

» Die gleichen Einstellungen für BC (B), GC (G).

» Sicherstellen, daß beide Seiten rechts und links

am Bildschirm mittig ausgerichtet sind. Falls dies

nicht der Fall ist, muß der Bildschirm so eingestellt

werden, daß das Bild rechts und links identisch ist.

» Die G-BLK-Daten einstellen, bis die erste

Abstufung 1(95% und 100% weiß; nachfolgend

aufgeführt) geringfügig erkannt werden kann.

Sicherstellen, daß die zweite Abstufung 2(0%

und 5% schwarz) sichtbar ist.

2

1

» Die Posten R1-BLK und B1-BLK wählen und die

Schwarzbalance der Abstufung einstellen.

12

Page 13

Nr. Einstellposition Einstellbedingung Einstellverfahren

XG-C40XU(1

XG-C40XE(1

)

)

Horizotalregelung

13

14 Einstellung des

Videobilds

15 Einstellung der

Bildhelligkeit

1. Das NTSCMonoskopsignal zuführen.

2. Gruppe : VIDEO 2

Gegenstand : N358-DLY (4)

N443-DLY (0)

PAL-DLY (3)

SECAM-DLY (0)

Sicherstellen, daß die

Einstellungen

richtigeingestellt sind.

3. Gruppe : VIDEO 1

Gegenstand : NTSC-H

1. Das T rennfarbbalk ensignal

zuführen.

Gruppe : VIDEO 1

Gegenstand : PICTURE

2. Ein Oszilloskop zwischen

Stift (2) von P801 und GND

anschließen.

1. Das Grundfrequenzsignal

(Trennfarbbalkensignal)

zuführen. (Das ON-AIRSignal ist nicht zulässig, da

es zu viele Störungen

erzeugt.)

Gruppe : VIDEO2

Gegenstand :VROS/VGOS/VBOS

2. Den Regelschalter oder die

Stummschalttaste auf der

Fernbedienung drücken,

um die Gammakorrektur

auf die

Verarbeitungseinstellung

einzustellen.

» Die Daten einstellen, um den gleichen Überscan-

Wert rechts und links zu erzielen. Hierfür die

Regelschalter oder die Tasten auf der

Fernbedienung betätigen.

» Die Schwarz-zu-Weiß Signalpegeldifferenz (100%)

auf 2,0 ±0,06 Vs-s einstellen. Hierfür die

Regelschalter oder die Tasten auf der

Fernbedienung betätigen.

2.0Vs-s

» Mit den Regelschaltern am Gerät oder über die

Fernbedienung die Daten so einstellen, daß das

Schwarzsignal “bitlos” wird.

16 Video-AGC

17 Farbton

1. Das getrennte

Farbbalkensignal zuführen.

Gruppe: VIDEO 1

Gegenstand: AGC

1. Das T rennfarb balkensignal

zuführen.

Gruppe : VIDEO 1

Gegenstand : TINT

2. Das Oszilloskop am Stift(4)

von P801 anschließen.

13

» Unter Verwendung der Steuerschalter oder der

Fernbedienungstasten die Einstellung so

vornehmen, daß das Weißsignal bitlos wird.

» Die Daten so einstellen, daß die -(B-Y)-Welle

geradlinig abfällt. Hierfür die Regelschalter oder

die Tasten auf der Fernbedienung betätigen.

» Nach der Einstellung den

Wert von TINT um 3

Punkte erhöhen.

Page 14

XG-C40XU(1

100% Weiß Rot

100% Weiß Rot

XG-C40XE(1

)

)

Nr. Einstellposition Einstellbedingung Einstellverfahren

18 NTSC-

Farbsättigungspegel

19 PAL-

Farbsättigungspegel

20 SECAM-

Farbsättigungspegel

1. Das T rennfarbbalk ensignal

zuführen.

Gruppe : VIDEO 1

Gegenstand : N-COLOR

2. Das Oszilloskop am Stift(1)

von P801 anschließen.

1. Das P AL-Farbbalkensignal

zuführen.

Gruppe : VIDEO 1

Gegenstand : P-COLOR

2. Das Oszilloskop am Stift(1)

von P801 anschließen.

1. Das SECAMFarbbalkensignal zuführen.

Gruppe : VIDEO 1

Gegenstand : S-COLOR

2. Das Oszilloskop am Stift(1)

von P801 anschließen.

» Die Differenz (100%) des Weiß- und Rotanteils auf

0,00 ±0,05 Vs-s einstellen. Hierfür die

Regelschalter oder die Tasten auf der

Fernbedienung betätigen.

(wie bei 100% Weißpegel)

» Die Differenz (100%) des Weiß- und Rotanteils auf

0,2 ±0,05 Vs-s einstellen. Hierfür die Regelschalter

oder die Tasten auf der Fernbedienung betätigen.

100% Weiß Rot

» Die Daten-Differenz (100%) des Weiß- und

Rotanteils auf 0,2 ±0,05 Vs-s einstellen. Hierfür die

Regelschalter oder die Tasten auf der

Fernbedienung betätigen.

21 Einstellung der

Signal-Amplitude

des

Video-Eingabefelds

22 Video-

Welßbalance

23 Einstellung des

DTV-Weißabgleichs

1. Das NTSC-10-Stufensignal

zuführen.

2. Die Gruppe und den

Gegenstand wählen:

Gruppe: VIDEO2

Gegenstand: R1-GAIN

B1-GAIN

3. Das Oszilloskop mit

TP1101 (R) und TP1201

(G) verbinden.

4. Für Blau das Oszilloskop

mit TP1301 (B) und

TP1201 (G) verbinden.

1. Das NTSCMonoskopsignal zuführen.

Gruppe : VIDEO 2

Gegenstand : R1-BLK

B1-BLK

1. Das

Monoskopmuster-Signal

zuführen.

2. Gruppe: DTV

Gegenstand: CR-OFFSET

CB-OFFSET

» R1-GAIN wählen, dann die Amplitude des

R-Signals und die Amplitude des G-Signals auf

den gleichen Wert einstellen.

» Die gleiche Einstellung für das blaue Signal

vornehmen.

» Mit den Regelschaltern am Gerät oder über die

Fernbedienung die Einstellung so vornehmen, daß

die gesamte Bildschirmfläche gleichmäßig unbunt

erscheint.

» Mit den Regelschaltern am Gerät oder über die

Fernbedienung die Einstellung so vornehmen, daß

die gesamte Bildschirmfläche gleichmäßig unbunt

erscheint.

14

Page 15

Nr. Einstellposition Einstellbedingung Einstellverfahren

24 Setup

25 Automatische

Farbabweichungskorrektur

1. Gruppe: VIDEO1

Gegenstand: SET UP B

SET UP C

1. Unter Verwendung des

automatischen

Farbabweichungskorrektur

» Sich vergewissern, daß die Einstellungen wie folgt

vorgenommen wurden: 11 für SET UP B, und 2 für

SET UP C.

» Sich vergewissern, daß am Bildschirm keine

Farbabweichungen auftreten.

-Systems (ccdc) die

automatische

Farbabweichungskorrektur

vornehmen.

XG-C40XU(1

XG-C40XE(1

)

)

26

Leistungsprüfung

des

Farbsystems

27

Leistungsprüfung

des

Videosystems

28

Leistungsprüfung

des

Audiosystems

29 RGB-

Leistungsprüfung

30

Leistungsprüfung

Off-Timer

31 Thermistor-

Leistungsprüfung

1. Das Farbbalkensignal

empfangen.

1. Das Monoskopsignal

empfangen.

1. Das RGB-Signal

empfangen.

1. Den Thermistor mit einem

Fön erwärmen.

» Im V erarbeitungsmodus L1 anwählen. Die Farbe und

die Tönung überprüfen.

» Im V erarbeitungsmodus L2 anwählen. Die Farbe und

die Tönung überprüfen.

» Im Verarbeitungsmodus L3 anwählen. Baß, Höhen

und Balance überprüfen.

» Im V erarbeitungsmodus L4 anwählen. Bild, Helligkeit,

Rot, Blau, Takt, Phase, Horizontal- und

Vertikalposition überprüfen.

» Im Verarbeitungsmodus OFF anwählen.

Sicherstellen, daß der Off-Timer bei "5" (Minuten)

beginnt, jede Minute in 1 sec Intervallen

herunterzählt und das Gerät bei "0" ausschaltet.

» Sicherstellen, daß "TEMP" angezeigt wird.

32 Automatische

Synchronisierung

33

Leistungsprüfung

für

KeystoneKorrektur

34

Werkseinstellungen

1. Das PHASE-

Prüfmustersignal

empfangen.

» Den VGA/SVGA/XGA/SXGA-Modus einschalten

und sicherstellen, daß Taktung und Phase sowie

Horizontal- und Vertikalposition automatisch

einstellbar sind.

» Sicherstellen, daß die Keystone-Korrektur gut

funktioniert.

» Folgende Einstellungen durchführen:

Verarbeitung

seinstellung

S3

S4

Fernbedienungseinstellung

"Werkseinstellung 3"(

"Werkseinstellung 4"(

XG-C40XE1

XG-C40XU1

15

)

)

Page 16

BLOCK DIAGRAM / BLOCKSCHALTBILD

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

16~17

Page 17

OVERALL WIRING DIAGRAM / GESAMTSCHALTPLAN

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

18~19

Page 18

OUTPUT UNIT-1/5 / AUSGABEEINHEIT-1/5

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

20~21

Page 19

OUTPUT UNIT-2/5 / AUSGABEEINHEIT-2/5

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

22~23

Page 20

OUTPUT UNIT-3/5 / AUSGABEEINHEIT-3/5

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

24~25

Page 21

OUTPUT UNIT-4/5 / AUSGABEEINHEIT-4/5

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

26~27

Page 22

OUTPUT UNIT-5/5 / AUSGABEEINHEIT-5/5

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

28~29

Page 23

XG-C40XU(1

XG-C40XE(1

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

)

)

PARTS LIST

ERSATZTEILLISTE

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics

identified in this manual: electrical components having such f eatures

are identified by "å" in the Replacement Parts Lists.

The use of a substitute replacement part which does not have the

same safety characteristics as the factory recommended replacement parts shown in this service manual may create shock, fire or

other hazards.

Ersatzteile, die besondere Sicherheitseigenschften haben, sind in

dieser Anleitung markiert. Elektrische Komponenten mit solchen

Eigenshaften sind in den Ersatzteil durch "å" gekenn-zeichnet.

Der Gebrauch von Ersatzteilen, die nicht deselben Sicherheitseigenschaften haben wie die vom Hersteller empfohlenen ud in der

Bedienungsanleitung angegebenen, können zur Ursache von

Blitzeinschlägen, Bränden und anderen Gefahren werden.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the

following informations.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

5. CODE 6. QUANTITY

★ MARK : SPARE PARTS-DELIVERY SECTION

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

Damit Ihre Bestellung promt und korrekt ausgeführt wird, geben Sie

bitte folgende Informationen.

LCD PANELS

AUST A USCH VON TEILEN

"WIE MAN ERSATSTEILE BESTELLT"

1. MODELL NR. 2. REF. NR.

3. ERSATZTEIL NR. 4. BESCHREIBUNG

5. KODE 6. QUANTITÄT

★ MARKIERUNG : ERSATZTEILE-LIEFERUNG

DUNTKB116DE04

SIGNAL UNIT

NOTE: THE PARTS HERE SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

RLCDPA004WJZZ J LCD Module Unit, Red CQ

RLCDPA005WJZZ J LCD Module Unit, Green CQ

RLCDPA006WJZZ J LCD Module Unit, Blue CQ

C886 VCEAPF1CW226M J 22 16V Electrolytic AB

C887 VCEAPF1CW106M J 10 16V Electrolytic AB

R1010 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1011 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1013 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1814 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

CAPACITORS

RESISTORS

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

DUNTKB116DE04 – Signal Unit —

XG-C40XU(1

DUNTKB117DE04 – PC Terminal Unit —

DUNTKA693FE04 – S-Out/Regulater Unit —

DUNTKB181FE01 – Output Unit —

DUNTK9769DE24 – Video Unit —

RUNTK0677CEZZ – AC Inlet Unit —

RDENC0334CEZZ – Power Unit —

CPCi-0047CE18 – PC I/F Unit —

RDENC0333CEZZ J Ballast Unit CB

XG-C40XE(1

DUNTKB116DE05 – Signal Unit —

DUNTKB117DE05 – PC Terminal Unit —

DUNTKA693FE05 – S-Out/Regulater Unit —

DUNTKB181FE02 – Output Unit —

DUNTK9769DE25 – Video Unit —

RUNTK0677CEZZ – AC Inlet Unit —

RDENC0334CEZZ – Power Unit —

CPCi-0047CE19 – PC I/F Unit —

RDENC0333CEZZ J Ballast Unit CB

)

(Unit Replacement Item)

)

(Unit Replacement Item)

30

Page 24

XG-C40XU(1

XG-C40XE(1

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

)

)

DUNTKB181FE01/02

OUTPUT UNIT

INTEGRATED CIRCUITS

IC1004 RH-iX2204CEZZ J PQ12TZ11 AG

IC1101 VHiCXA3512R-1 J CXA3512R-T6 BB

IC1102 VHiCXA3512R-1 J CXA3512R-T6 BB

IC1201 VHiCXA3512R-1 J CXA3512R-T6 BB

IC1202 VHiCXA3512R-1 J CXA3512R-T6 BB

IC1204 VHiNJM2902V-1 J NJM2902V AD

IC1301 VHiCXA3512R-1 J CXA3512R-T6 BB

IC1302 VHiCXA3512R-1 J CXA3512R-T6 BB

IC1307 VHiLM2663M+-1 J LM2663MX AS

IC1401 VHiCXA2111R-1 J CXA2111R BB

IC1403 VHiNJM2060V-1 J NJM2060V AF

IC1404 VHiM62352GP-1 J M62352Gp AQ

IC1409 VHiPQ20VZ11-1 J PQ20VZ11 AH

IC1410 VHiPQ05TZ11-1 J PQ05TZ11 AH

IC1411 VHiTA8184F/-1 J TA8184F AN

IC1412 VHiM62352GP-1 J M62352GP AQ

IC1501 VHiLV4053AT-1 J SN74LV4053APWR AE

IC1502 VHiNJM2902V-1 J NJM2902V AD

IC1504 VHiLV123AT+-1 J SN74LV123APWR AF

IC1505 VHiAHC2G241-1 J SN74AHC2G241HD AF

IC1506 VHiAHC2G241-1 J SN74AHC2G241HD AF

IC1507 VHiPQ05TZ11-1 J PQ05TZ11 AH

IC1508 VHiAHC2G241-1 J SN74AHC2G241HD AF

IC1603 VHiPQ20VZ11-1 J PQ20VZ11 AH

IC1611 VHiHCT541AF-1 J TC74HCT541AF AG

IC1612 VHiHCT541AF-1 J TC74HCT541AF AG

IC1613 RH-iX1952CEZZ J 74F86SJ AD

IC1615 VHi74HCT125-1 J HD74HCT125T AF

IC5003 VHiM62352GP-1 J M62352GP AQ

IC5004 VHiM62320FP-1 J M62320FP AK

IC5005 VHiM62320FP-1 J M62320FP AK

IC5006 VHiSNHC00T/-1 J SN74HC00PW AG

IC5007 VHiM62320FP-1 J M62320FP AK

IC5008 VHiM24C64WN-1 J M24C64-WMN6T AL

IC5009 VHiSNHC08T/-1 J SN74HC08PW AG

IC5010 VHiPST600iM-1 J IC-PST600IMT AE

IC5021 VHiBA033SFP-1 J BA033SFP-E2 AG

IC5101 RH-iX3393CEZZ J MB89P538-101PF AR

IC5102 VHiAHC2G241-1 J SN74AHC2G241HD AF

IC5503 VHiPQ05SZ51-1 J PQ05SZ51 AG

IC5504 VHiBA00ASFP-1 J BA00ASFP-E2 AG

IC5505 VHiBA00ASFP-1 J BA00ASFP-E2 AG

IC5506 VHiSN1G66DC-1 J SN74AHC1G66HDC AD

IC5507 VHiBA00ASFP-1 J BA00ASFP-E2 AG

IC5508 VHiBA00ASFP-1 J BA00ASFP-E2 AG

TRANSISTORS

Q1105 VS2SC2411KR-1 J 2SC2411KR AC

Q1106 VS2SA1036KR-1 J 2SA1036KR AC

Q1107 VS2SC2411KR-1 J 2SC2411KR AC

Q1108 VS2SA1036KR-1 J 2SA1036KR AC

Q1109 VS2SA1530AR-1 J 2SA1530AR AB

Q1110 VS2SC2411KR-1 J 2SC2411KR AC

Q1112 VS2SA1036KR-1 J 2SA1036KR AC

Q1113 VS2SC2411KR-1 J 2SC2411KR AC

Q1114 VS2SA1036KR-1 J 2SA1036KR AC

Q1205 VS2SC2411KR-1 J 2SC2411KR AC

Q1206 VS2SA1036KR-1 J 2SA1036KR AC

Q1207 VS2SC2411KR-1 J 2SC2411KR AC

Q1208 VS2SA1036KR-1 J 2SA1036KR AC

Q1210 VS2SC2411KR-1 J 2SC2411KR AC

Q1211 VS2SC2411KR-1 J 2SC2411KR AC

Q1212 VS2SA1036KR-1 J 2SA1036KR AC

Q1213 VS2SA1036KR-1 J 2SA1036KR AC

Q1301 VS2SA1530AR-1 J 2SA1530AR AB

Q1305 VS2SC2411KR-1 J 2SC2411KR AC

Q1306 VS2SA1036KR-1 J 2SA1036KR AC

Q1307 VS2SC2411KR-1 J 2SC2411KR AC

Q1308 VS2SA1036KR-1 J 2SA1036KR AC

Q1310 VS2SC2411KR-1 J 2SC2411KR AC

Q1311 VS2SC2411KR-1 J 2SC2411KR AC

Q1312 VS2SA1036KR-1 J 2SA1036KR AC

Q1313 VS2SA1036KR-1 J 2SA1036KR AC

Q1401 VS2SC2735//-1 J 2SC2735 AB

Q1402 VS2SC2735//-1 J 2SC2735 AB

Q1403 VS2SC2735//-1 J 2SC2735 AB

Q1501 VSHN1B04FU/-1 J HN1B04FU AC

Q1502 VSHN1B04FU/-1 J HN1B04FU AC

Q1503 VSHN1B04FU/-1 J HN1B04FU AC

Q1505 VSHN1B04FU/-1 J HN1B04FU AC

Q1506 VSHN1B04FU/-1 J HN1B04FU AC

Q1507 VSHN1B04FU/-1 J HN1B04FU AC

Q1601 VS2SC3928AR-1 J 2SC3928AR AB

Q1602 VS2SC3928AR-1 J 2SC3928AR AB

Q1603 VS2SC3928AR-1 J 2SC3928AR AB

Q1604 VS2SC3928AR-1 J 2SC3928AR AB

Q1605 VSDTC144EUA-1 J DTC144EUA AB

Q1606 VSDTC144EUA-1 J DTC144EUA AB

Q1607 VSDTC144EUA-1 J DTC144EUA AB

Q1608 VSDTC144EUA-1 J DTC144EUA AB

Q1609 VSDTC144EUA-1 J DTC144EUA AB

Q1610 VSDTC144EUA-1 J DTC144EUA AB

Q1611 VSDTC144EUA-1 J DTC144EUA AB

Q1612 VSDTC144EUA-1 J DTC144EUA AB

Q1613 VSDTC144EUA-1 J DTC144EUA AB

Q1614 VSDTC144EUA-1 J DTC144EUA AB

Q1615 VSDTC144EUA-1 J DTC144EUA AB

Q1616 VSDTC144EUA-1 J DTC144EUA AB

Q1617 VSDTC144EUA-1 J DTC144EUA AB

Q1618 VSDTC144EUA-1 J DTC144EUA AB

Q1619 VSDTC114EU/-1 J DTC114EU AB

Q1620 VSDTC114EU/-1 J DTC114EU AB

Q5002 VS2SC3928AR-1 J 2SC3928AR AB

Q5003 VS2SC3928AR-1 J 2SC3928AR AB

Q5004 VS2SC3928AR-1 J 2SC3928AR AB

Q5005 VS2SC3928AR-1 J 2SC3928AR AB

Q5007 VS2SC3928AR-1 J 2SC3928AR AB

Q5008 VSDTC144EUA-1 J DTC144EUA AB

Q5201 VS2SA1036KR-1 J 2SA1036KR AC

Q5202 VS2SA1036KR-1 J 2SA1036KR AC

Q5304 VS2SC2735//-1 J 2SC2735 AB

Q5305 VS2SC2735//-1 J 2SC2735 AB

Q5306 VS2SC2735//-1 J 2SC2735 AB

Q5307 VS2SC2735//-1 J 2SC2735 AB

Q5514 VS2SC3928AR-1 J 2SC3928AR AB

Q5516 VS2SC3928AR-1 J 2SC3928AR AB

Q5517 VS2SC3928AR-1 J 2SC3928AR AB

Q5518 VS2SC3928AR-1 J 2SC3928AR AB

Q5519 VSDTC114EU/-1 J DTC114EU AB

Q5520 VS2SA1530AR-1 J 2SA1530AR AB

Q5526 VSDTC114EU/-1 J DTC114EU AB

Q5536 VS2SC3928AR-1 J 2SC3928AR AB

DIODES

D1003 VHDDAN202K/-1 J Diode AB

D1401 VHDDAN202K/-1 J Diode AB

D1402 VHDDAN202K/-1 J Diode AB

D1502 VHDDAN202K/-1 J Diode AB

D1602 VHDDAN202K/-1 J Diode AB

D5001 VHDHRW0702A-1 J Diode AE

D5002 VHDHRW0702A-1 J Diode AE

D5003 VHDHRW0702A-1 J Diode AE

D5004 VHDHRW0702A-1 J Diode AE

D5005 VHDMA153///-1 J Diode AB

D5006 VHDMA153///-1 J Diode AB

D5007 VHDMA153///-1 J Diode AB

D5008 VHDMA153///-1 J Diode AB

D5009 VHDHRW0702A-1 J Diode AE

D5010 VHDHRW0702A-1 J Diode AE

D5011 VHDHRW0702A-1 J Diode AE

D5012 VHDHRW0702A-1 J Diode AE

D5013 VHDMA153///-1 J Diode AB

D5014 VHDMA153///-1 J Diode AB

D5015 VHDMA153///-1 J Diode AB

D5016 VHDMA153///-1 J Diode AB

31

Page 25

XG-C40XU(1

XG-C40XE(1

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

)

)

DUNTKB181FE01/02

OUTPUT UNIT (Continued)

D5017 VHDHRW0702A-1 J Diode AE

D5018 VHDMA153///-1 J Diode AB

D5023 VHDDAN202K/-1 J Diode AB

D5024 RH-EX0858CEZZ J Zener Diode, 6.3V AC

D5025 VHDDAN202K/-1 J Diode AB

D5503 VHDDAN202K/-1 J Diode AB

D5504 VHDDAN202K/-1 J Diode AB

D5505 VHDDAN202K/-1 J Diode AB

D5513 VHDDAN202K/-1 J Diode AB

D5514 RH-EX0516CEZZ J Zener Diode, 5.1V AB

D5520 VHDDAN202K/-1 J Diode AB

D5521 VHDDAN202K/-1 J Diode AB

D5523 VHDDAN202K/-1 J Diode AB

PACKAGED CIRCUIT

X5101 RCRSB0286CEZZ J Crystal AH

COILS

L1101 VP-1M100J1R6N J Peaking 10µHAC

L1102 VP-1M100J1R6N J Peaking 10µHAC

L1201 VP-1M100J1R6N J Peaking 10µHAC

L1202 VP-1M100J1R6N J Peaking 10µHAC

L1301 VP-1M100J1R6N J Peaking 10µHAC

L1302 VP-NM100KR42N J Peaking 10µHAB

L1303 VP-1M100J1R6N J Peaking 10µHAC

L1304 VP-NM100KR42N J Peaking 10µHAB

CONTROLS

R1649 RVR-M4846GEZZ J 220k (B) AC

R1652 RVR-M4846GEZZ J 220k (B) AC

CAPACITORS

C1010 VCEAPF1EW336M J 33 25V Electrolytic AB

C1013 VCAAPC1CJ276M J 27 16V Electrolytic

C1101 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1102 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1103 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1104 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1105 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1106 VCCCCY1HH220J J 22p 50V Ceramic AA

C1108 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1109 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1110 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1112 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1113 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1114 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1115 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1116 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1117 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1118 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1123 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1126 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1127 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1128 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1147 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1201 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1202 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1203 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1204 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1206 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1207 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1208 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1209 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1210 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1212 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1213 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1214 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1215 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1216 VCCCCY1HH220J J 22p 50V Ceramic AA

C1219 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1220 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1223 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1225 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1226 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1227 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1228 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1229 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1234 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1247 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1253 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1301 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1302 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1303 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1304 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1305 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1306 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1307 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1308 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1309 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1310 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1312 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1313 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1314 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1315 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1316 VCCCCY1HH220J J 22p 50V Ceramic AA

C1322 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1323 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1325 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1326 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1327 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1328 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1347 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1348 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1349 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1350 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1353 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1354 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1357 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1358 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1401 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1402 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1403 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1404 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1405 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1406 VCCCCY1HH270J J 27p 50V Ceramic AA

C1407 VCCCCY1HH390J J 39p 50V Ceramic AA

C1408 VCCCCY1HH270J J 27p 50V Ceramic AA

C1420 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1421 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C1422 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1423 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1424 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1425 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1426 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1428 VCKYCY1AF105Z J 1.0 10V Ceramic AC

C1429 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1430 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1431 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1432 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1433 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1434 VCEAPF1EW226M J 22 25V Electrolytic AB

C1435 VCEAPF1EW226M J 22 25V Electrolytic AB

C1436 VCEAPF1CW106M J 10 16V Electrolytic AB

C1437 VCEAPF0JW107M J 100 6.3V Electrolytic AC

C1438 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1439 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1460 VCKYCY1HB102K J 1000p 50V Ceramic AA

C1461 VCEAPF1CW476M J 47 16V Electrolytic AC

C1462 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1463 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1464 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1465 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1466 VCKYTV1CF105Z J 1.0 16V Ceramic AB

C1467 VCKYTV1CF105Z J 1.0 16V Ceramic AB

C1468 VCFRED1HM822J J 8200p 50V Mylar AD

32

Page 26

XG-C40XU(1

XG-C40XE(1

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

)

)

DUNTKB181FE01/02

OUTPUT UNIT (Continued)

C1469 VCFYEC1CM334J J 0.33 16V Mylar AE

C1470 VCEAPF1CW106M J 10 16V Electrolytic AB

C1471 VCKYCY1CF154Z J 0.15 16V Ceramic AB

C1472 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1473 VCE9PF1CW106M J 10 16V Elect.(N.P) AC

C1474 VCEAPF1CW106M J 10 16V Electrolytic AB

C1475 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1476 VCEAPF1CW107M J 100 16V Electrolytic AD

C1477 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1478 VCEAPX1EW107M J 100 25V Electrolytic AD

C1479 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1480 VCEAPF1CW107M J 100 16V Electrolytic AD

C1481 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1482 VCEAPF1EW336M J 33 25V Electrolytic AB

C1483 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1484 VCEAPF1CW106M J 10 16V Electrolytic AB

C1493 VCCCCY1HH5R0C J 5.0p 50V Ceramic AA

C1494 VCCCCY1HH5R0C J 5.0p 50V Ceramic AA

C1495 VCCCCY1HH5R0C J 5.0p 50V Ceramic AA

C1501 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1502 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1503 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1504 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1505 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1506 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1507 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1508 RC-KZ0416CEZZ J 10 25V Ceramic AE

C1510 VCCCCY1EH102J J 1000p 25V Ceramic AB

C1511 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1541 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1542 VCEAPF0JW107M J 100 6.3V Electrolytic AC

C1543 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1544 VCEAPX1EW107M J 100 25V Electrolytic AD

C1606 VCEAPF1EW226M J 22 25V Electrolytic AB

C1607 VCEAPF1EW226M J 22 25V Electrolytic AB

C1619 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1620 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1621 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1623 VCCCCY1HH100D J 10p 50V Ceramic AA

C1625 VCCCCY1HH100D J 10p 50V Ceramic AA

C1626 VCCCCY1HH100D J 10p 50V Ceramic AA

C1627 VCCCCY1HH100D J 10p 50V Ceramic AA

C1628 VCCCCY1HH100D J 10p 50V Ceramic AA

C1629 VCCCCY1HH100D J 10p 50V Ceramic AA

C1630 VCCCCY1HH100D J 10p 50V Ceramic AA

C1631 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C5001 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5007 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5012 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5015 VCCCCY1HH101J J 100p 50V Ceramic AA

C5016 VCCCCY1HH101J J 100p 50V Ceramic AA

C5017 VCCCCY1HH101J J 100p 50V Ceramic AA

C5033 VCEAPF0JW476M J 47 6.3V Electrolytic AB

C5041 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5045 VCEAPF0JW107M J 100 6.3V Electrolytic AC

C5046 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5055 VCEAPF0JW226M J 22 6.3V Electrolytic AB

C5056 VCEAPF0JW476M J 47 6.3V Electrolytic AB

C5057 VCKYCY1HB103K J 0.01 50V Ceramic AA

C5058 VCEAPF0JW107M J 100 6.3V Electrolytic AC

C5063 VCEAPF1CW107M J 100 16V Electrolytic AD

C5064 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5065 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5164 VCCCCY1HH221J J 220p 50V Ceramic AA

C5165 VCKYCY1HB102K J 1000p 50V Ceramic AA

C5167 VCKYCY1HB102K J 1000p 50V Ceramic AA

C5170 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5171 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5174 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5175 RC-KZ0074TAZZ J 10 6.3V Ceramic AF

C5176 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5177 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5178 VCCCCY1HH220J J 22p 50V Ceramic AA

C5179 VCCCCY1HH220J J 22p 50V Ceramic AA

C5507 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5508 VCEAPF1CW476M J 47 16V Electrolytic AC

C5509 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5510 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C5511 VCEAPF1EW336M J 33 25V Electrolytic AB

C5512 VCEAPF1CW107M J 100 16V Electrolytic AD

C5513 VCEAPF0JW107M J 100 6.3V Electrolytic AC

C5514 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5515 VCEAPF1CW107M J 100 16V Electrolytic AD

C5516 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5530 VCEAPF1CW226M J 22 16V Electrolytic AB

C5531 VCE9PF1CW336M J 33 16V Elect.(N.P) AD

C5534 VCEAPF1CW226M J 22 16V Electrolytic AB

C5535 VCEAPF1CW226M J 22 16V Electrolytic AB

C5553 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5554 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5555 VCKYCY1HB103K J 0.01 50V Ceramic AA

C5556 VCKYCY1HB103K J 0.01 50V Ceramic AA

C5562 VCKYCY1HB103K J 0.01 50V Ceramic AA

C5564 VCEAPF1CW226M J 22 16V Electrolytic AB

C5565 VCEAPF1EW336M J 33 25V Electrolytic AB

C5566 VCEAPF1CW107M J 100 16V Electrolytic AD

C5568 VCEAPF1EW336M J 33 25V Electrolytic AB

C5569 VCEAPF1CW107M J 100 16V Electrolytic AD

C5570 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5572 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5574 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5575 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C5576 VCKYTV1CF105Z J 1.0 16V Ceramic AB

RESISTORS

R1003 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1015 VRS-TX2HF000J J 0 1/2W Metal Oxide AA

R1016 VRS-TX2HF000J J 0 1/2W Metal Oxide AA

R1018 QFS-L5015CEZZ J Fuse Resistor AD

R1065 VRS-CY1JF153F J 15k 1/16W Metal Oxide AA

R1066 VRS-CY1JF682F J 6.8k 1/16W Metal Oxide AA

R1067 VRS-CY1JF682F J 6.8k 1/16W Metal Oxide AA

R1071 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1081 VRS-CY1JF203F J 20k 1/16W Metal Oxide AA

R1082 VRS-CY1JF103F J 10k 1/16W Metal Oxide AA

R1083 VRS-CY1JF103F J 10k 1/16W Metal Oxide AA

R1084 VRS-CY1JF203F J 20k 1/16W Metal Oxide AA

R1085 VRS-CY1JF153F J 15k 1/16W Metal Oxide AA

R1086 VRS-CY1JF682F J 6.8k 1/16W Metal Oxide AA

R1087 VRS-CY1JF682F J 6.8k 1/16W Metal Oxide AA

R1088 VRS-CY1JF682F J 6.8k 1/16W Metal Oxide AA

R1089 VRS-CY1JF682F J 6.8k 1/16W Metal Oxide AA

R1090 VRS-CY1JF153F J 15k 1/16W Metal Oxide AA

R1093 VRS-CY1JF103F J 10k 1/16W Metal Oxide AA

R1094 VRS-CY1JF203F J 20k 1/16W Metal Oxide AA

R1095 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1101 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1102 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1103 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1105 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1109 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1110 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1111 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1112 VRS-CY1JF470J J 47 1/16W Metal Oxide AA

R1113 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1114 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1115 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1116 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1117 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1118 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1119 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1120 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1122 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1123 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1124 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1131 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

33

Page 27

XG-C40XU(1

XG-C40XE(1

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

)

)

DUNTKB181FE01/02

OUTPUT UNIT (Continued)

R1132 VRS-CY1JF560J J 56 1/16W Metal Oxide AA

R1133 VRS-CY1JF560J J 56 1/16W Metal Oxide AA

R1134 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1135 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1137 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1138 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1139 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1140 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1141 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1142 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1150 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1152 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1158 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1160 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1166 VRS-TV1JD270J J 27 1/16W Metal Oxide AA

R1167 VRS-CY1JF272J J 2.7k 1/16W Metal Oxide AA

R1168 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1171 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1172 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1173 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1174 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1175 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1180 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1181 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1184 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1185 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1186 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1188 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1189 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1190 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1191 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1192 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1202 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1204 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1206 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1207 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1208 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1209 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1210 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1211 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1212 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1214 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1215 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1216 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1217 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1218 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1219 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1220 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1221 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1223 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1224 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1231 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1234 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1235 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1236 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1237 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1240 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1241 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1242 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1249 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1251 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1252 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1253 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1256 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1259 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1260 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1261 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1262 VRS-CY1JF470J J 47 1/16W Metal Oxide AA

R1271 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1272 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1273 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1274 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1275 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1280 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1284 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1285 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1286 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1288 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1289 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1290 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1291 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1292 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1302 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1303 VRS-CY1JF470J J 47 1/16W Metal Oxide AA

R1306 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1309 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1310 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1313 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1314 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1315 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1316 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1317 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1318 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1319 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1320 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1321 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1322 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1323 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1324 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1331 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1332 VRS-CY1JF560J J 56 1/16W Metal Oxide AA

R1333 VRS-CY1JF560J J 56 1/16W Metal Oxide AA

R1335 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1336 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1337 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1338 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1340 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1341 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1342 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1349 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1350 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1353 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1356 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1357 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1358 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1359 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1360 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1366 VRS-TV1JD270J J 27 1/16W Metal Oxide AA

R1367 VRS-CY1JF272J J 2.7k 1/16W Metal Oxide AA

R1368 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1371 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1372 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1373 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1374 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1375 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1380 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1384 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1385 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1386 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1388 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1389 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1390 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1391 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1392 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1401 VRN-CY1JF560D J 56 1/16W Metal Film AA

R1402 VRN-CY1JF560D J 56 1/16W Metal Film AA

R1403 VRN-CY1JF560D J 56 1/16W Metal Film AA

R1404 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1405 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1406 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1407 VRS-CY1JF181J J 180 1/16W Metal Oxide AA

R1408 VRS-CY1JF181J J 180 1/16W Metal Oxide AA

R1409 VRS-CY1JF181J J 180 1/16W Metal Oxide AA

R1410 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1411 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1412 VRS-CY1JF332J J 3.3k 1/16W Metal Oxide AA

34

Page 28

XG-C40XU(1

XG-C40XE(1

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

)

)

DUNTKB181FE01/02

OUTPUT UNIT (Continued)

R1413 VRS-CY1JF332J J 3.3k 1/16W Metal Oxide AA

R1414 VRS-CY1JF332J J 3.3k 1/16W Metal Oxide AA

R1415 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1416 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1417 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1418 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1419 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1420 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1421 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1422 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1423 VRS-CY1JF272J J 2.7k 1/16W Metal Oxide AA

R1425 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1426 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1427 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1428 VRS-CY1JF470J J 47 1/16W Metal Oxide AA

R1429 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1430 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1431 VRS-CY1JF470J J 47 1/16W Metal Oxide AA

R1432 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1433 VRS-CY1JF470J J 47 1/16W Metal Oxide AA

R1434 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1435 VRS-CY1JF470J J 47 1/16W Metal Oxide AA

R1442 VRS-CY1JF220F J 22 1/16W Metal Oxide AA

R1443 VRS-CY1JF220F J 22 1/16W Metal Oxide AA

R1447 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1448 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1449 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1450 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1451 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1454 VRS-CY1JF202J J 2.0k 1/16W Metal Oxide AA

R1455 VRS-CY1JF302J J 3.0k 1/16W Metal Oxide AA

R1456 VRS-CY1JF752F J 7.5k 1/16W Metal Oxide AA

R1457 VRS-CY1JF152F J 1.5k 1/16W Metal Oxide AA

R1458 VRS-CY1JF183F J 18k 1/16W Metal Oxide AA

R1460 VRS-CY1JF392J J 3.9k 1/16W Metal Oxide AA

R1464 VRS-CY1JF392J J 3.9k 1/16W Metal Oxide AA

R1466 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1467 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1468 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1469 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1470 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1471 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1472 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1473 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1474 VRS-CY1JF123F J 12k 1/16W Metal Oxide AA

R1475 VRS-CY1JF102F J 1.0k 1/16W Metal Oxide AA

R1476 VRS-CY1JF510F J 51 1/16W Metal Oxide AA

R1477 VRS-TX2HF000J J 0 1/2W Metal Oxide AA

R1480 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1486 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1490 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1491 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1492 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1493 VRS-TX2HF5R6J J 5.6 1/2W Metal Oxide AA

R1494 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R1495 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R1496 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1497 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1498 VRS-CY1JF473J J 47k 1/16W Metal Oxide AA

R1499 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1501 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1502 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1503 VRS-CY1JF561J J 560 1/16W Metal Oxide AA

R1504 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1505 VRS-CY1JF471J J 470 1/16W Metal Oxide AA

R1506 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1507 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1508 VRS-CY1JF561J J 560 1/16W Metal Oxide AA

R1509 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1510 VRS-CY1JF471J J 470 1/16W Metal Oxide AA

R1511 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1515 VRS-TX2HF100J J 10 1/2W Metal Oxide AA

R1517 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1518 VRS-CY1JF272J J 2.7k 1/16W Metal Oxide AA

R1522 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1523 VRS-CY1JF561J J 560 1/16W Metal Oxide AA

R1524 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1525 VRS-CY1JF471J J 470 1/16W Metal Oxide AA

R1526 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1527 VRS-CY1JF821J J 820 1/16W Metal Oxide AA

R1528 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1532 VRS-CY1JF821J J 820 1/16W Metal Oxide AA

R1533 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1534 VRS-CY1JF152J J 1.5k 1/16W Metal Oxide AA

R1535 VRS-CY1JF822J J 8.2k 1/16W Metal Oxide AA

R1536 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1537 VRS-CY1JF821J J 820 1/16W Metal Oxide AA

R1538 VRS-CY1JF221J J 220 1/16W Metal Oxide AA

R1539 VRS-CY1JF471J J 470 1/16W Metal Oxide AA

R1540 VRS-CY1JF681J J 680 1/16W Metal Oxide AA

R1541 VRS-CY1JF221J J 220 1/16W Metal Oxide AA

R1542 VRS-CY1JF681J J 680 1/16W Metal Oxide AA

R1543 VRS-CY1JF471J J 470 1/16W Metal Oxide AA

R1544 VRS-CY1JF221J J 220 1/16W Metal Oxide AA

R1545 VRS-CY1JF471J J 470 1/16W Metal Oxide AA

R1546 VRS-CY1JF681J J 680 1/16W Metal Oxide AA

R1557 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1558 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1559 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1561 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1562 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1563 VRS-CY1JF682J J 6.8k 1/16W Metal Oxide AA

R1565 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R1566 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R1567 VRN-CY1JF562D J 5.6k 1/16W Metal Film AB

R1568 VRS-CY1JF470J J 47 1/16W Metal Oxide AA

R1575 VRS-CY1JF470J J 47 1/16W Metal Oxide AA

R1576 VRS-CY1JF470J J 47 1/16W Metal Oxide AA

R1586 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1587 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1589 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1601 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1602 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1603 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1606 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1607 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1608 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1609 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1610 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1611 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1612 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1613 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R1616 VRS-CY1JF123F J 12k 1/16W Metal Oxide AA

R1617 VRS-CY1JF102F J 1.0k 1/16W Metal Oxide AA

R1618 VRS-CY1JF221J J 220 1/16W Metal Oxide AA

R1619 VRS-TV1JD4R7J J 4.7 1/16W Metal Oxide AA

R1626 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1627 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1628 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1629 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1630 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1632 VRS-CY1JF332J J 3.3k 1/16W Metal Oxide AA

R1633 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1634 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1635 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1636 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1637 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1648 VRS-TV1JD000J J 0 1/16W Metal Oxide AA

R1650 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1651 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1653 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1654 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1657 VRS-CY1JF393J J 39k 1/16W Metal Oxide AA

R1658 VRS-CY1JF393J J 39k 1/16W Metal Oxide AA

R1676 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1678 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

35

Page 29

XG-C40XU(1

XG-C40XE(1

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

)

)

DUNTKB181FE01/02

OUTPUT UNIT (Continued)

R1680 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1681 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1682 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R1683 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R1684 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R1685 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R1686 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R1740 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1741 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1742 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1743 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1744 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1745 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1746 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1747 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1748 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1749 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1750 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1751 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1752 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1753 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1754 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1755 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1756 VRS-CY1JF3R3J J 3.3 1/16W Metal Oxide AA

R1757 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R1771 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1772 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1773 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1781 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1782 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1786 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1827 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1837 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1846 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R5003 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R5004 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R5005 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R5006 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5008 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5010 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R5011 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5012 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R5013 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5016 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R5017 VRS-TX2HF3R9J J 3.9 1/2W Metal Oxide AB

R5018 VRS-TX2HF3R9J J 3.9 1/2W Metal Oxide AB

R5022 VRS-TX2HF3R9J J 3.9 1/2W Metal Oxide AB

R5023 VRS-CY1JF102J J 1.0k 1/16W Metal Oxide AA

R5024 VRS-TX2HF3R9J J 3.9 1/2W Metal Oxide AB

R5031 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R5032 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5035 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5036 VRS-TW2ED470J J 47 1/4W Metal Oxide AA

R5037 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5038 VRS-TW2ED101J J 100 1/4W Metal Oxide AA

R5039 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5040 VRS-TW2ED221J J 220 1/4W Metal Oxide AA

R5041 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5042 VRS-TW2ED221J J 220 1/4W Metal Oxide AA

R5043 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5044 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5045 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5046 VRS-TW2ED221J J 220 1/4W Metal Oxide AA

R5047 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R5048 VRS-TX2HF220J J 22 1/2W Metal Oxide AB

R5053 VRS-CA1JF101J J 100 1/16W Metal Oxide AA