Page 1

j

UX-27OOCMUKMC

FO-255OCMUKMC

I

SHARP’

\

CHAPTER 1, GENERAL DESCRIPTION

[I] Specifications

[2] Operation panel

[3] Transmittable documents

[4] installation

[5] Quick reference guide

CHAPTER 2. ADJUSTMENTS

[I] Adjustments

[2] Diagnostics and service soft switch

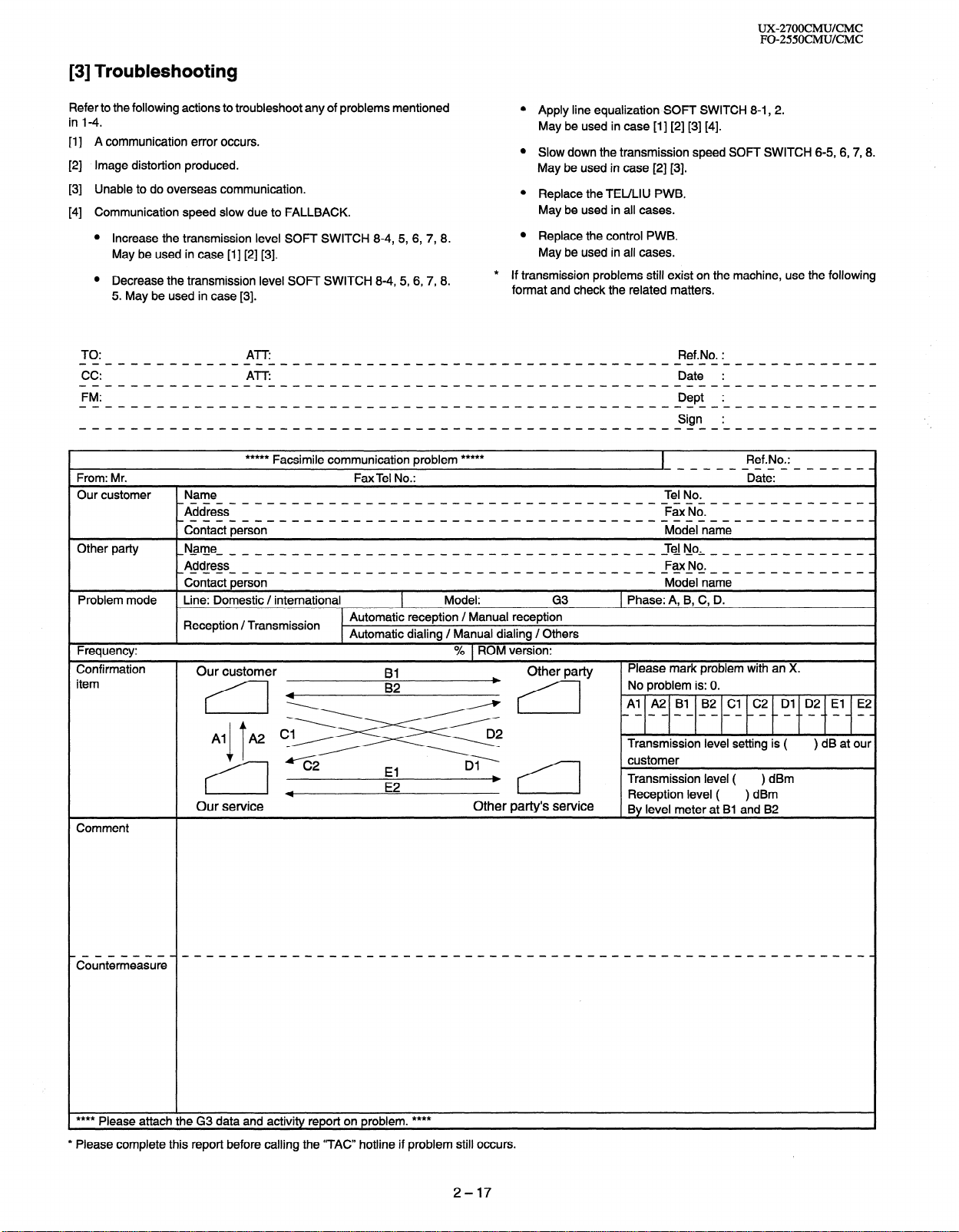

[3] Troubleshooting

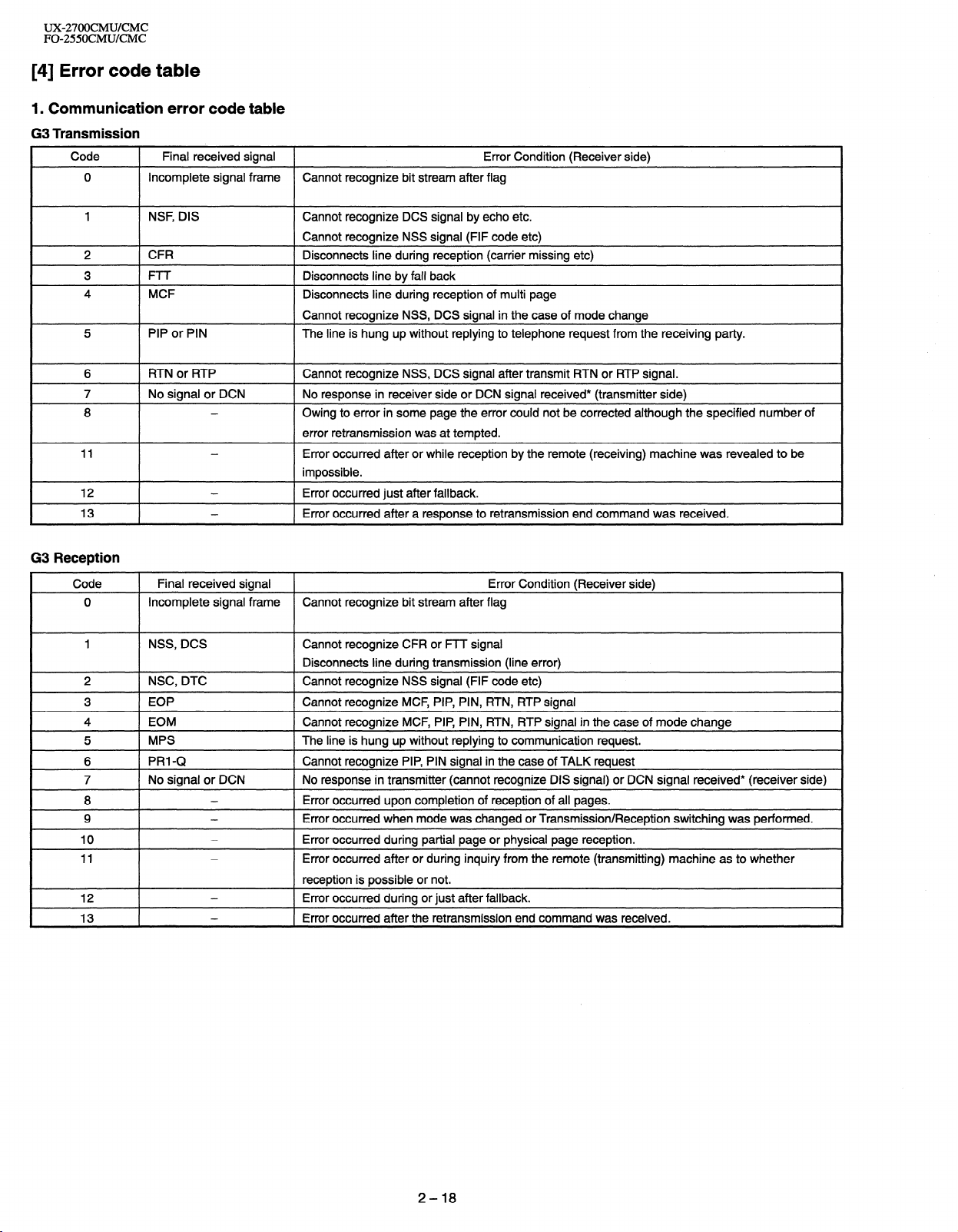

[4] Error code table

CHAPTER 3. MECHANISM BLOCKS

[I] General description

[2] Disassembly and assembly

procedures

............................................ 1-I

......................................... I-2

................................................. I-4

............................................... 2-I

...................................... 2-l 7

....................................... 2-I 8

.................................. 3-I

....................................... 3-4

-

..........................

...............................

..........

SERVICEMANUAL ,,

._

No. OOZU27OCMUSME

FACSIMILE

UX-2700CM

MODEL FO-2550CM

CONTENTS

CHAPTER 6. CIRCUIT SCHEMATICS AND

PARTS LAYOUT

61

6-13

6-I 7

6-24

7-I

8-I

I-3

I-9

2-2

[I] Control PWB circuit

[2] TEULIU PWB circuit

[3] Ink sensor PWB circuit

[4] Printer PWB circuit

[5] Operation panel PWB circuit . ..D.Om . . . . . . . . . _. 6-23

[6] IrDA PWB circuit ..,..D.....,......~,,..,...,..~,...~~.

[7] Power supply PWB circuit . . .m . . . . ._... .._.D . . . 6-25

CHAPTER 7. OPERATION FLOWCHART

[I] Protocol .....................................................

[2] Power on sequence

CHAPTER 6. OTHERS

[ I] Service tools . ..D..........~.D~.~........*...~.....*...~...

[2] IC signal name

. . . . . . . . . . . . . . . . . . . ..m....m....m...

. . . . . . . . . . . . ..ma..m......m...m.

a.....*....Dm....*......... 6-15

. . . . . . . . . ..*...0.....lJ......li......

.................................. 7-2

. . . . . . . . . . . . . . . ..~0~.~..~...~....~.....~.. 8-6

CHAPTER 4. DIAGRAMS

[I] Block diagram

[2] Wiring diagram

[3] Point-to-point diagram

CHAPTER 5. CIRCUIT DESCRIPTION

[I] Circuit description ..................................

[2] Circuit description of control PWB. 512

[3] Circuit description of TEULIU PWB ......... 5-11

[4] Circuit description of

power supply PWB

[5] Circuit description of CIS PWB ............... 5-I 5

[6] Color scanner block ................................ 5-I 6

[7] Basis of color ............................................ 5-I 8

Parts marked with “&’ is important for maintaining the safety of the set. Be sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

............................................ 4-I

.......................................... 4-2

............................... 4-3

51

.................

............................ 5-14

SHARP CORPORATION

CHAPTER 9. INK JET PRINTER

Engine specifications

[II

Abbreviations

PI

Diagnostic information . . . . . . . . . . ..D...DO.O..e......m.

PI

Circuit description

WI

Overall troubleshooting of printer PWB .._ 9-7

PI

How to decide the number of the wrong

PI

nozzle . . . . . . . . ..~........D~...~..~..~~...........~..~ 9-10

Waveforms

VI

Service checks

PI

IC signal name

PI

PARTS GUIDE

. . . . . . . ..~..0#...~......~.~.~................ 9-I

.,............*~......~.~...~.“~.~.~~..~.....0 9-12

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

.~~..........D........~..~.~.~‘. 9-I

. . . . . . . . . . . . . . ..~..D...~....~......~.. 9-2

. . . . . . . . . . . . ..D.*...m..*......mm0.mm....

. . . ..~...D....0.~..0..~~.~~~~.~.~..~~~~~ 9-I 9

9-I

9-l 5

Page 2

UX-27OOCMUKMC

FO-255OCMUKMC

- CAUTION FOR BAlTERY REPLACEMENT -

(Danish)

Lithiumbatteri-Eksplosionsfare ved fejlagtig handtering.

Udskiftning ma kun ske med batteri af samme fabrikat og type.

Lever det brugte batteri tilbage til Ieverandoren.

(English)

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the equipment manufacturer.

Discard used batteries according to manufacturer’s

(Finnish) VAROITUS

Paristo voi rajahtaa, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Havita kaytetty paristo valmistajan ohjeiden

(French)

II y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

meme type ou d’un type recommande par le constructeur.

Wlettre au rebut les batteries usagees conformement aux

(Swedish)

Explosionsfare vid felaktigt batteri byte.

Anvand samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera anvant batteri enligt fabrikantens

(German)

Explosionsgefahr bei Vetwendung inkorrekter Batterien.

Als Ersatzbatterien durfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anweisungen.

ADVARSEL !

Caution !

instructions.

mukaisesti.

ATTENTION

instructions du fabricant.

VARNING

instruktion.

Achtung

Page 3

CHAPTER 1 n GENERAL DESCRIPTION

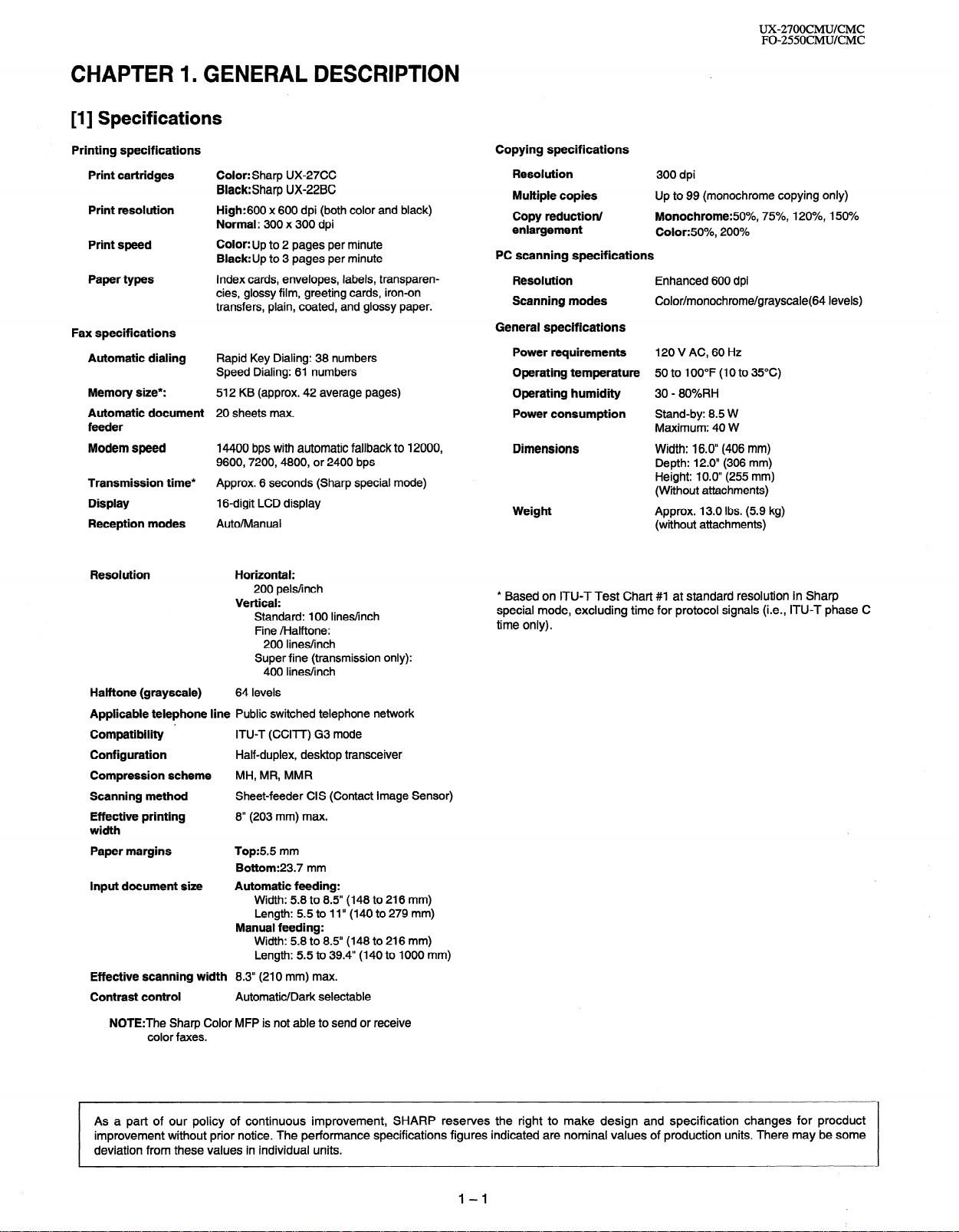

[I] Specifications

UX-27OOCMUKMC

FO-255OCMUKMC

Printing specifications

Print cartridges

Print resolution

Print speed

Paper types

Fax specifications

Automatic dialing

Memory size*:

Automatic document

feeder

Modem speed

Transmission time*

Display

Reception modes

Halftone (grayscale)

Applicable telephone line Public switched telephone network

Compatibility ’ ITU-T (CCITT) G3 mode

Configuration

Compression scheme MH, MR, MMR

Scanning method Sheet-feeder CIS (Contact Image Sensor)

Effective printing 8” (203 mm) max.

width

Paper margins Top:55 mm

Input document size Automatic feeding:

Effective scanning width 8.3” (210 mm) max.

Contrast control

NOTE:The Sharp Color MFP is not able to send or receive

color faxes.

Color: Sharp UX-27CC

Black:Sharp UX-22BC

High:600 x 600 dpi (both color and black)

Normal: 300 x 300 dpi

Color: Up to 2 pages per minute

Black:Up to 3 pages per minute

Index cards, envelopes, labels, transparencies, glossy film, greeting cards, iron-on

transfers, plain, coated, and glossy paper.

Rapid Key Dialing: 38 numbers

Speed Dialing: 61 numbers

512 KB (approx. 42 average pages)

20 sheets max.

14400 bps with automatic fallback to 12000,

9600,7200,4800, or 2400 bps

Approx. 6 seconds (Sharp special mode)

1 B-digit LCD display

Auto/Manual

Horizontal:

200 pels/inch

Vertical:

Standard: 100 lines/inch

Fine /Halftone:

200 lines/inch

Super fine (transmission only):

400 lines/inch

64 levels

Half-duplex, desktop transceiver

Bottom:23.7 mm

Width: 5.8 to 8.5” (148 to 216 mm)

Length: 5.5 to 1 I” (140 to 279 mm)

Manual feeding:

Width: 5.8 to 8.5” (148 to 216 mm)

Length: 5.5 to 39.4” (140 to 1000 mm)

Automatic/Dark selectable

Copying specifications

Resolution

Multiple copies

Copy reduction/

enlargement

PC scanning specifications

Resolution

Scanning modes

General specifications

Power requirements 120 V AC, 60 Hz

Operating temperature 50 to 100°F (10 to 35°C)

Operating humidity 30 - 80%RH

Power consumption Stand-by: 8.5 W

Dimensions Width: 16.0” (406 mm)

Weight Approx. 13.0 Ibs. (5.9 kg)

* Based on ITU-T Test Chart #I at standard resolution in Sharp

special mode, excluding time for protocol signals (i.e., ITU-T phase C

time only).

300 dpi

Up to 99 (monochrome copying only)

Monochrome:fiO%, 75%, 120%, 150%

Color:50%, 200%

Enhanced 600 dpi

Color/monochrome/grayscale(64 levels)

Maximum: 40 W

Depth: 12.0” (306 mm)

Height: 10.0” (255 mm)

(Without attachments)

(without attachments)

As a part of our policy of continuous improvement, SHARP reserves the right to make design and specification changes for procduct

improvement without prior notice. The performance specifications figures indicated are nominal values of production units. There may be some

deviation from these values in individual units.

1-I

Page 4

UX-27OOCMUKMC

FO-255OCMUKMC

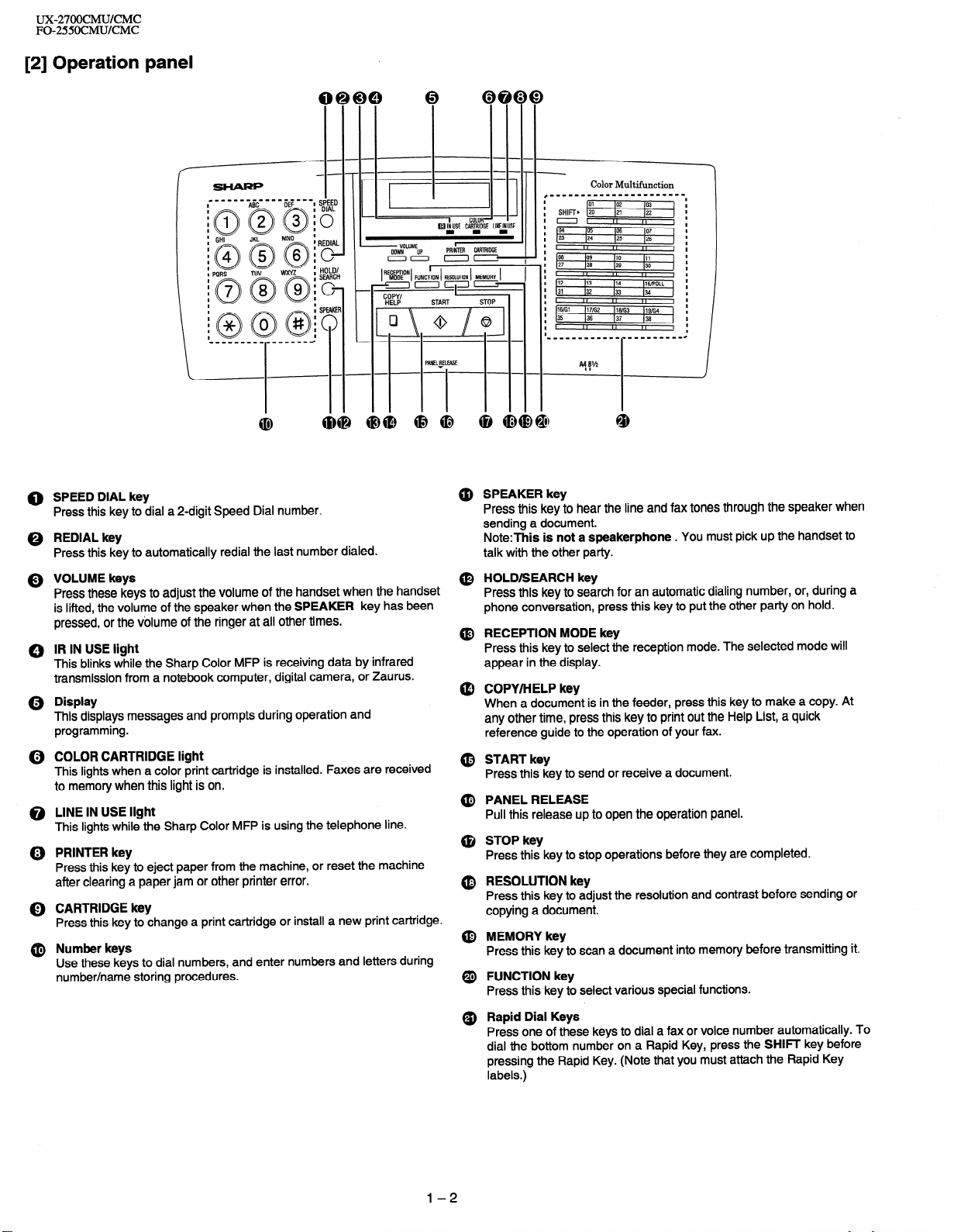

[2] Operation panel

I

I

SHIFT, [vi

I

I

==I

I

04 165 lo6 107

I

23 124

I

I

I

p8

I

I

27 I26

I

I

I

#12 113

I

31 132

I

I

I

16ffil )17/G2 116ffi3 )lgffi4

I

35

I

I

I

(25 126

II

,,

lo9 110 111

129 130

II

I,

114 IlS/POLL

133 (34

II I, ,,

136 137 136

II I, ,,

I

,,

I

I

,,

I

I

I

0 SPEED DIAL key

Press this key to dial a 2-digit Speed Dial number.

0 REDIAL key

Press this key to automatically redial the last number dialed.

Q VOLUME keys

Press these keys to adjust the volume of the handset when the handset

is lifted, the volume of the speaker when the SPEAKER key has been

pressed, or the volume of the ringer at all other times.

0 IR IN USE light

This blinks while the Sharp Color MFP is receiving data by infrared

transmission from a notebook computer, digital camera, or Zaurus.

Q Display

This displays messages and prompts during operation and

programming.

(i) COLOR CARTRIDGE light

This lights when a color print cartridge is installed. Faxes are received

to memory when this light is on.

@ LINE IN USE light

This lights while the Sharp Color MFP is using the telephone line.

@) PRINTER key

Press this key to eject paper from the machine, or reset the machine

after clearing a paper jam or other printer error.

0 CARTRIDGE key

Press this key to change a print cartridge or install a new print cartridge.

@ Number keys

Use these keys to dial numbers, and enter numbers and letters during

number/name storing procedures.

@ SPEAKER key

Press this key to hear the line and fax tones through the speaker when

sending a document.

Note:This is not a speakerphone . You must pick up the handset to

talk with the other party.

(0 HOLD/SEARCH key

Press this key to search for an automatic dialing number, or, during a

phone conversation, press this key to put the other party on hold.

@ RECEPTION MODE key

Press this key to select the reception mode. The selected mode will

appear in the display.

@ COPY/HELP key

When a document is in the feeder, press this key to make a copy. At

any other time, press this key to print out the Help List, a quick

reference guide to the operation of your fax.

@ START key

Press this key to send or receive a document.

@ PANEL RELEASE

Pull this release up to open the operation panel.

@ STOP key

Press this key to stop operations before they are completed.

@ RESOLUTION key

Press this key to adjust the resolution and contrast before sending or

copying a document.

@ MEMORY key

Press this key to scan a document into memory before transmitting it.

@ FUNCTION key

Press this key to select various special functions.

Q) Rapid Dial Keys

Press one of these keys to dial a fax or voice number automatically. To

dial the bottom number on a Rapid Key, press the SHIFT key before

pressing the Rapid Key. (Note that you must attach the Rapid Key

labels.)

l-2

Page 5

UX-27OOCMUKMC

FO-255OCMUKMC

. [3] Transmittable documents

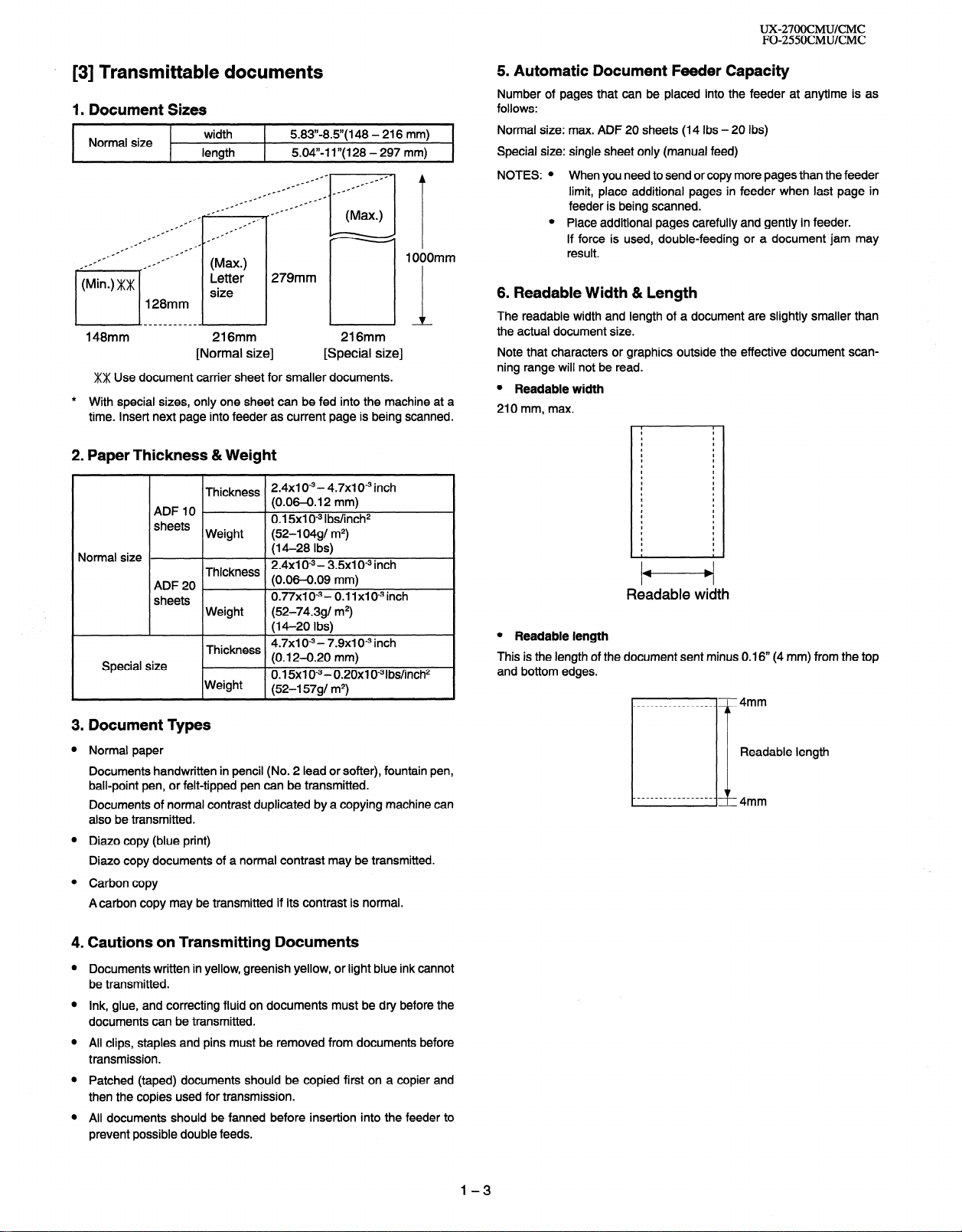

1. Document Sizes

Normal size

--

-

_-- _--

.-

.-

length

.-

_f1° .--

c

c-- ---

--

--

.-

c-

.-

.-

.--

128mm

width

.-

.-

--

--

(Max.)

Letter

size

c-

c-

_.--

5.83”.8.5”( 148 - 216 mm)

5.04,)-l I”( 128 - 297 mm)

c-

1 OOOmm

279mm

L-h

148mm

216mm

[Normal size]

XX Use document carrier sheet for smaller documents.

* With special sizes, only one sheet can be fed into the machine at a

time. Insert next page into feeder as current page is being scanned.

2. Paper Thickness &Weight

2.4x1 0w3- 4.7x1 0m3 inch

(0.06-0.12 mm)

0.15x1 O-3 Ibs/inch2

(52-l 04gl m2)

(14-28 Ibs)

2.4x1 O-3- 3.5x1 0” inch

(0.06-0.09 mm)

0.77x1 o-3(52-74.391 m2)

(M-20 Ibs)

4.7x1 o-3 - 7.9x1 O9 inch

(0.12-0.20 mm)

0.15x1 O-3 - 0.20x1 0-31bs/inch2

(52-l 5791 m2)

Normal size

Special size

ADF IO

sheets

ADF20 _

sheets

Thickness

Weight

Thickness

Weight

Thickness

Weight

216mm

[Special size]

0.11x10-3inch

5. Automatic Document Feeder Capacity Number of pages that can be placed into the feeder at anytime is as

follows:

Normal size: max. ADF 20 sheets (14 Ibs - 20 Ibs)

Special size: single sheet only (manual feed)

NOTES: l When you need to send or copy more pages than the feeder

limit, place additional pages in feeder when last page in

feeder is being scanned.

l Place additional pages carefully and gently in feeder.

If force is used, double-feeding or a document jam may

result.

6. Readable Width & Length

The readable width and length of a document are slightly smaller than

the actual document size.

Note that characters or graphics outside the effective document scanning range will not be read.

l Readable width

210 mm, max.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

t

/t---t/

Readable width

l Readable length

This is the length of the document sent minus 0.16” (4 mm) from the top

and bottom edges.

3. Document Types

Normal paper

Documents handwritten in pencil (No. 2 lead or softer), fountain pen,

ball-point pen, or felt-tipped pen can be transmitted.

Documents of normal contrast duplicated by a copying machine can

also be transmitted.

Diazo copy (blue print)

Diazo copy documents of a normal contrast may be transmitted.

Carbon copy

Acarbon copy may be transmitted if its contrast is normal.

4. Cautions on Transmitting Documents

Documents written in yellow, greenish yellow, or light blue ink cannot

be transmitted.

Ink, glue, and correcting fluid on documents must be dry before the

documents can be transmitted.

All clips, staples and pins must be removed from documents before

transmission.

Patched (taped) documents should be copied first on a copier and

then the copies used for transmission.

All documents should be fanned before insertion into the feeder to

prevent possible double feeds.

1-3

Page 6

UX-27OOCMUKMC

FO-255OCMUKMC

7. Use of Document Carrier Sheet

A document carrier sheet must be used for the following documents.

Those with tears.

Those smaller than size 583”(W) x 504”(L) (148 mm (W) x 128

Make print straight

across paper

E.G.

Place the document

carrier in the document

feeder with the clear film

side down

Direction

NOTE: To transmit a carbon-backed document, insert a white sheet of

l

NOTES: l When using the document carrier, carefully read the in-

of insertion

paper between the carbon back of the document and the document carrier.

Those containing an easily separable writing substance (e.g., trac-

ing paper written on with a soft, heavy lead pencil).

structions written on the back.

l If the document carrier is dirty, clean it with a soft, moist

cloth, and then dry it before using for transmission.

l Do not place more than one document in the carrier at a

time.

TELEPHONE JACK

near the machine.

A standard RJII C telephone jack must be

This is the telephone jack commonly used

0 Plugging the fax machine into a jack which is not an RJI 1 C jack may

result in damage to the machine or your telephone system. If you do

not know what kind of jack you have, or needed to have one installed,

contact the telephone company.

located

in most homes and offices.

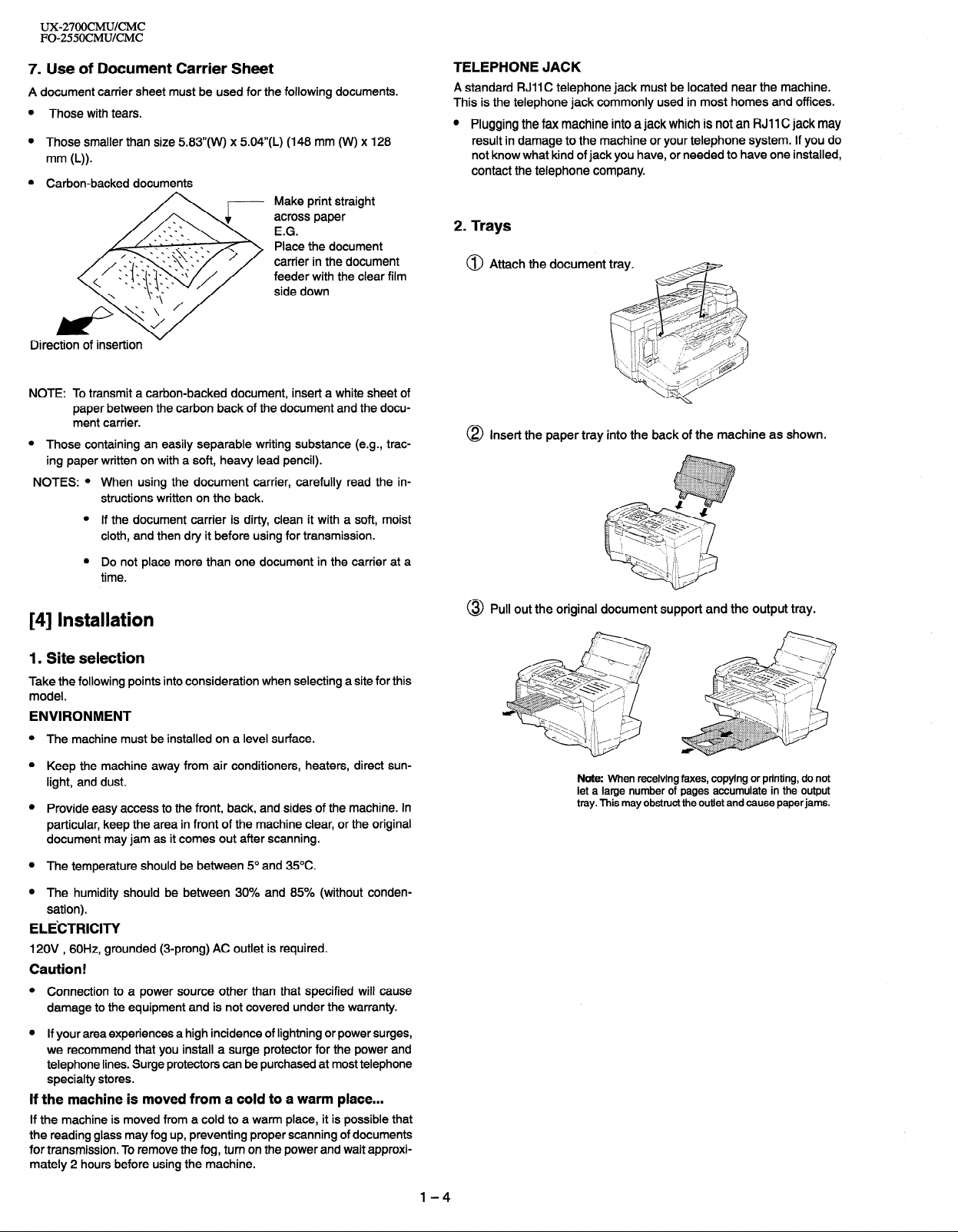

2. Trays

@ Attach the document

@ Insert the paper tray into the back of the machine as shown.

[4] Installation

1. Site selection

Take the following points into consideration when selecting a site for this

model.

ENVIRONMENT

The machine must be installed on a level surface.

Keep the machine away from air conditioners, heaters, direct sunlight, and dust.

Provide easy access to the front, back, and sides of the machine. In

particular, keep the area in front of the machine clear, or the original

document may jam as it comes out after scanning.

The temperature should be between 5” and 35OC.

The humidity should be between 30% and 85% (without conden-

sation).

ELE’CTRICITY

120V , 60H2, grounded (3-prong) AC outlet is required.

Caution!

Connection to a power source other than that specified will cause

damage to the equipment and is not covered under the warranty.

If your area experiences a high incidence of lightning or power surges,

we recommend that you install a surge protector for the power and

telephone lines. Surge protectors can be purchased at most telephone

specialty stores.

If the machine is moved from a cold to a warm place...

If the machine is moved from a cold to a warm place, it is possible that

the reading glass may fog up, preventing proper scanning of documents

for transmission. To remove the fog, turn on the power and wait approximately 2 hours before using the machine.

@ Pull out the original document support and the output tray.

Note: When receiving faxes, copying or printing, do not

let a large number of pages accumulate in the output

tray. This may obstruct the outlet and cause paper jams.

l-4

Page 7

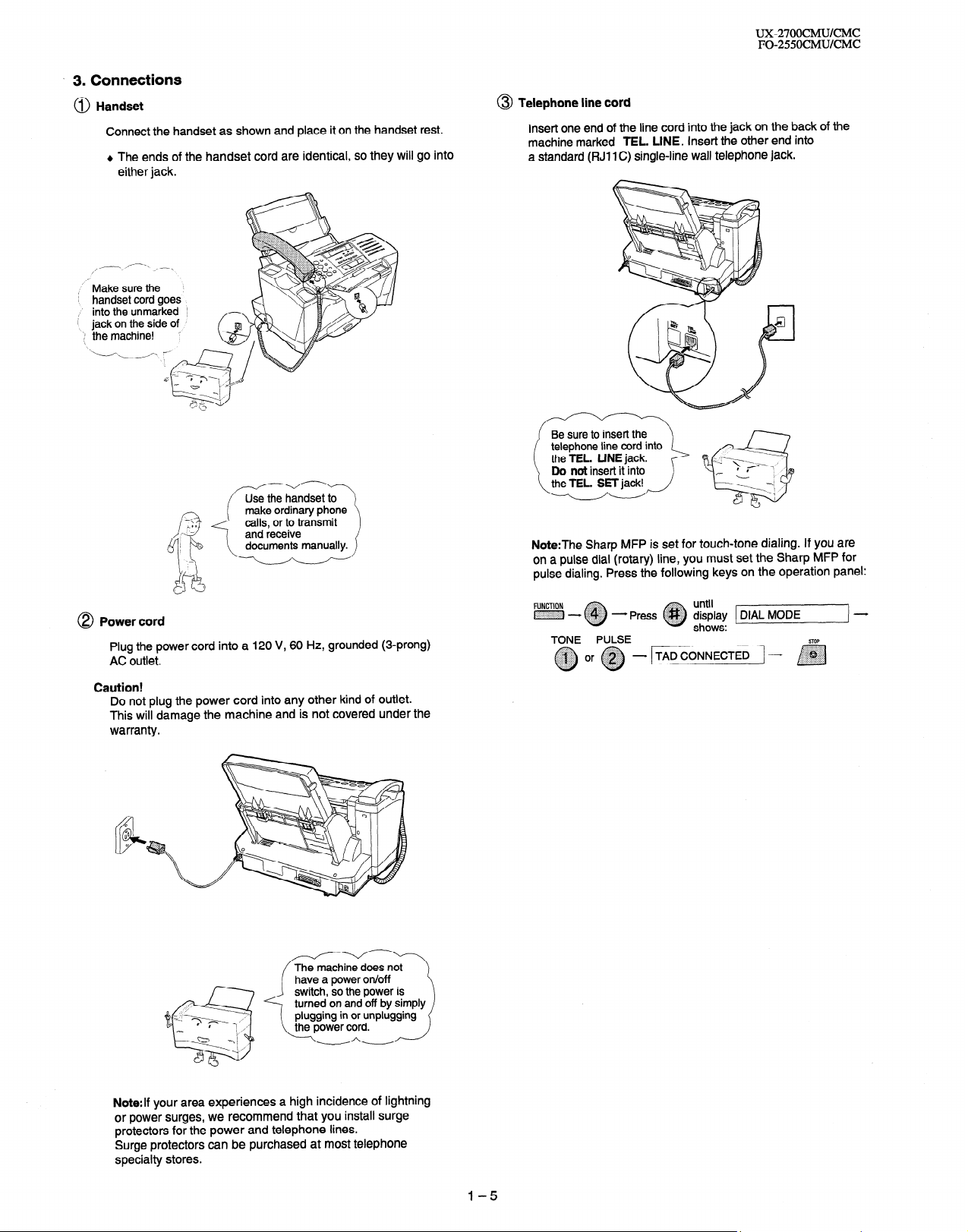

* 3. Connections

@ Handset

Connect the handset as shown and place it on the handset rest.

+ The ends of the handset cord are identical, so they will go into

either jack.

,.-. /----.- ,_-,

I

,“- Make sure the

i handset cord goes

,’ into the unmarked

i

jack on the side of ’

‘:I the machine! ‘:

1

1

‘.-i-N

UX-27OOCMUKMC

FO-255OCMUKMC

@ Telephone line cord

Insert one end of the line cord into the jack on the back of the

machine marked TEL. LINE. Insert the other end into

a standard (FIJI 1 C) single-line wall telephone jack.

Be sure to insert the

telephone line cord into

the TEL. LINE jack.

Do not insert it into

8 Power cord

Plug the power cord into a 120 V, 60 Hz, grounded (3-prong)

AC outlet.

Caution!

Do not plug the power cord into any other kind of outlet.

This will damage the machine and is not covered under the

warranty.

Note:The Sharp MFP is set for touch-tone dialing. If you are

on a pulse dial (rotary) line, you must set the Sharp MFP for

pulse dialing. Press the following keys on the operation panel:

..:.:;~:::>,

- Press @#/$~ display

TONE PULSE

until

0

shows:

TADCONNECTED -

Di

STOP

Note:If your area experiences a high incidence of lightning

or power surges, we recommend that you install surge

protectors for the power and telephone lines.

Surge protectors can be purchased at most telephone

specialty stores.

1-5

Page 8

ux-27OocMU/cMc

FO-2550CMU/CMC

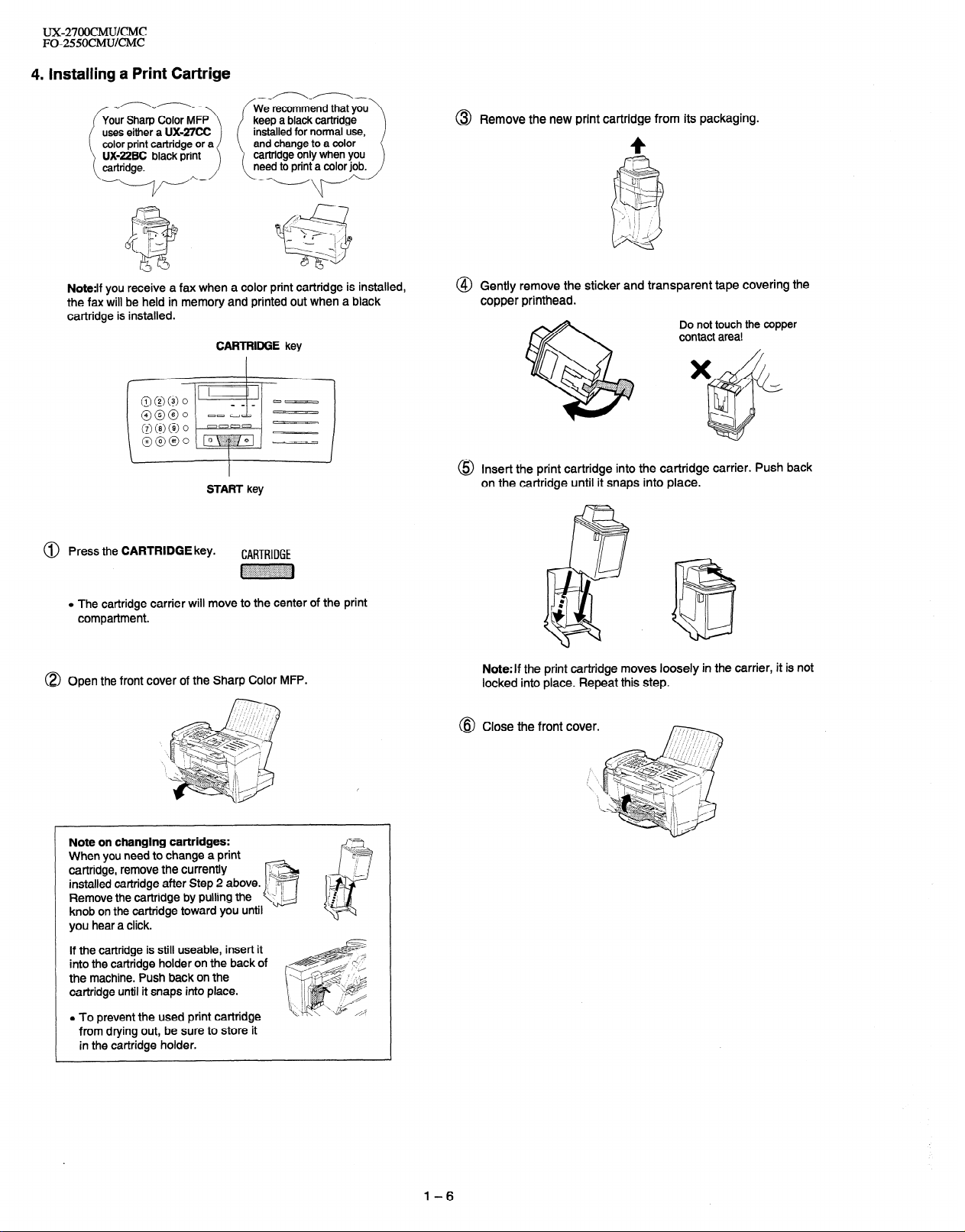

4. Installing a Print Cartrige

@ Remove the new print cartridge from its packaging.

4

Note:lf you receive a fax when a color print cartridge is installed,

the fax will be held in memory and printed out when a black

cartridge is installed.

CARTRIDGE key

START key

@ Press the CARTRIDGE key.

CARTRIDGE

~~~

o The cartridge carrier will move to the center of the print

compartment.

@) Open the front cover of the Sharp Color MFP.

@ Gently remove the sticker and transparent tape covering the

copper printhead.

Insert the print cartridge into the cartridge carrier. Push back

on the cartridge until it snaps into place.

Note:If the print cartridge moves loosely in the carrier, it is not

locked into place. Repeat this step.

Close the front

cover.

Note on changing cartridges:

When you need to change a print

cartridge, remove the currently

installed cartridge after Step 2 above.

Remove the cartridge by pulling the

knob on the cartridge toward you

hear a click.

you

If the cartridge is still useable, insert it

into the cartridge holder on the back of

the machine. Push back on the

cartridge until it snaps into place.

l To prevent the used print cartridge

from drying out, be sure to store it

in the cartridge holder.

until

1-6

Page 9

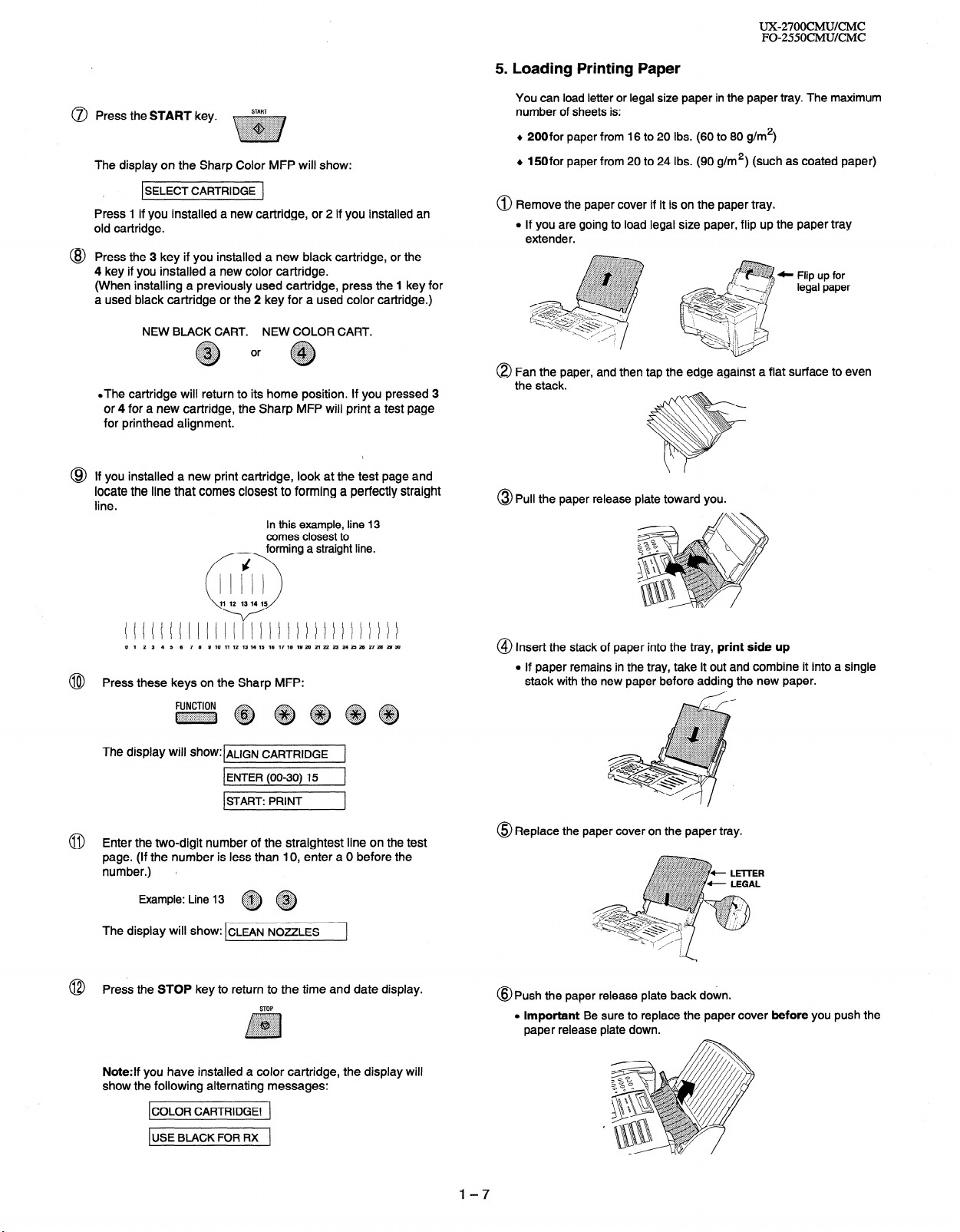

5 . Loading Printing Paper

UX2700CMU/CMC

FO-255OCMUKMC

@ Press the START key.

START

~~

The display on the Sharp Color MFP will show:

SELECT CARTRIDGE

I

Press 1 if you installed a new cartridge, or 2 if you installed an

old cartridge.

@ Press the 3 key if you installed a new black cartridge, or the

4 key if you installed a new color cartridge.

(When installing a previously used cartridge, press the 1 key for

a used black cartridge or the 2 key for a used color cartridge.)

NEW BLACK CART.

NEW COLOR CART.

.The cartridge will return to its home position. If you pressed 3

or 4 for a new cartridge, the Sharp MFP will print a test page

for printhead alignment.

@ If you installed a new print cartridge, look at the test page and

locate the line that comes closest to forming a perfectly straight

line.

In this example, line 13

comes closest to

~ forming a straight line.

You can load letter or legal size paper in the paper tray. The maximum

number of sheets is:

+ 200for paper from 16 to 20 Ibs. (60 to 80 g/m*)

+ 150for paper from 20 to 24 Ibs. (90 g/m*) (such as coated paper)

@ Remove the paper cover if it is on the paper tray.

l If you are going to load legal size paper, flip up the paper tray

extender.

,:~::a:,,;:.~:r...,..~...~,.,..~~.~~~~~

.Y..... ../: ..,. :.+:..

::;::::::::::::)y:. ,ii~~i~~~:~i:~i:?~~,~i:

..i:i:i:~:w:~~.~W:i.::::a:i:::::?~:~?::~~~:!~:~.

~. .,...,...,.,.,.,.,..... < . . . . . . .

~ ~ legal paper

..,........%...h

. .:~.+:qy II Flip “p for

8 Fan the paper, and then tap the edge against a flat surface to even

the stack.

@ Pull the paper release plate toward you.

0 1 2 3 4 5 6 7 6 9 10 11 12 13 14 15 16 17 16 19 26 21 22 23 24 23 26 27 26 26 36

Press these keys on the Sharp MFP:

@

The display Will show:lALfGN CARTRIDGE 1

1 ENTER (00-30) 15

ISTART: PRINT 1

1

@ Enter the two-digit number of the straightest line on the test

page. (If the number is less than IO, enter a 0 before the

number.) l

::qiij::.

Example: Line 13

~~

The display will show: CLEAN NOZZLES

Press the STOP key to return to the time and date display.

@

STOP

Note:If you have installed a color cartridge, the display will

show the following alternating messages:

ICOLOR CARTRIDGE! 1

1 USE BLACK FOR RX

1

@ Insert the stack of paper into the tray, print side up

l If paper remains in the tray, take it out and combine it into a single

stack with the new paper before adding the new paper.

@ Replace the paper cover on the paper tray.

@Push the paper release plate back down.

l Important Be sure to replace the paper cover before you push the

paper release plate down.

l-7

Page 10

UX-27OOCMWCMC

FO-255OCMUKMC

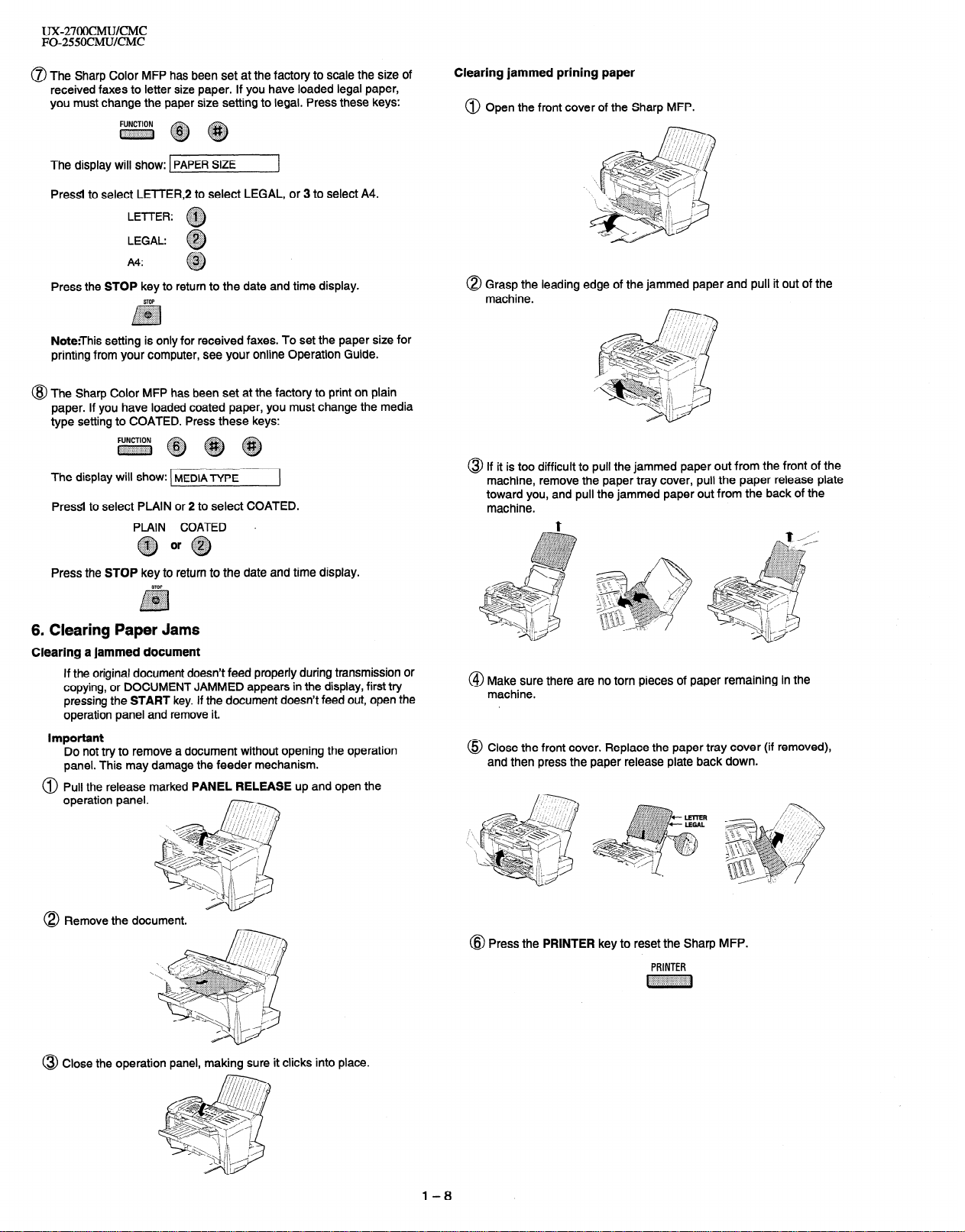

0 The Sharp Color MFP has been set at the factory to scale the size of

received faxes to letter size paper. If you have loaded legal paper,

you must change the paper size setting to legal. Press these keys:

~~~

The display will show: PAPER SIZE

Pressl to select LETTER,2 to select LEGAL, or 3 to select A4.

LE-f-l-ER: ~

LEGAL: ,,,, .

A4:

. .

.@#

0

.$&@

. . . . . . . .

0

Press the STOP key to return to the date and time display.

STOP

~~~

:iiiiiiiijiiiii:i:i:::::::::

/

Note:This setting is only for received faxes. To set the paper size for

printing from your computer, see your online Operation Guide.

@ The Sharp Color MFP has been set at the factory to print on plain

paper. If you have loaded coated paper, you must change the media

type setting to COATED. Press these keys:

~~~~

The display will show: MEDIA -ryp~

PressI to select PLAIN or 2 to select COATED.

PLAIN COATED s

:&qg or $y;:;

Q @

Clearing jammed prining paper

@ Open the front cover of the Sharp MFP.

0 Grasp the leading edge of the jammed paper and pull it out of the

machine.

@ If it is too difficult to pull the jammed paper out from the front of the

machine, remove the paper tray cover, pull the paper release plate

toward you, and pull the jammed paper out from the back of the

machine.

t

/

,

Press the STOP key to return to the date and time display.

STOP

:::::::,:y::::::::::

$ggpg

.,.,.,.,.,., ..:::::::

. .,. (...,.,.,.,._..

:.:.:+: . . . . . . . ..+........

/7

6. Clearing Paper Jams

Clearing a jammed document

If the original document doesn’t feed properly during transmission or

copying, or DOCUMENT JAMMED appears in the display, first try

pressing the START key. If the document doesn’t feed out, open the

operation panel and remove it.

Important

Do not try to remove a document without opening the operation

panel. This may damage the feeder mechanism.

@ Pull the release marked PANEL RELEASE up and open the

operation panel.

0 Remove the document.

\

@ Make sure there are no torn pieces of paper remaining in the

machine.

@ Close the front cover. Replace the paper tray cover (if removed),

and then press the paper release plate back down.

@ Press the PRINTER key to reset the Sharp MFP.

PRINTER

~

@ Close the operation panel, making sure it clicks into place.

l-8

Page 11

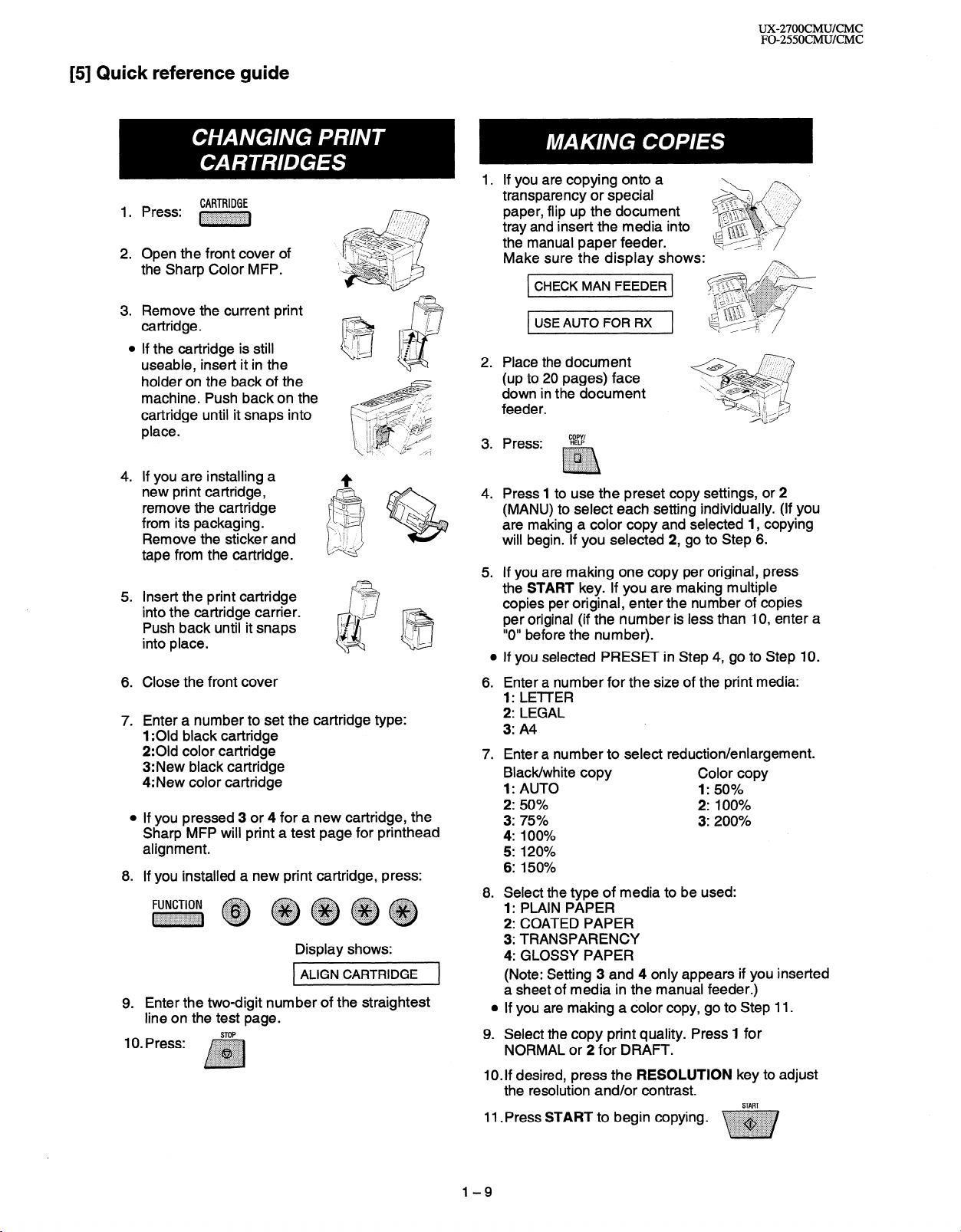

[5] Quick reference guide

Press: ~

2.

Open the front cover of

the Sharp Color MFP.

3. Remove the current print I-?

cartridge.

0

If the cartridge is still

useable, insert it in the

holder on the back of the

machine. Push backon the

cartridge until it snaps into

place.

4. If you are installing a

new print cartridge,

remove the cartridge

from its packaging.

Remove the sticker and

tape from the cartridge.

5. Insert the print cartridge

into the cartridge carrier.

Push back until it snaps

into place.

Close the front cover

6.

7.

Enter a number to set the cartridge type:

1 :Old black cartridge

2:Old color cartridge

3: New black cartridge

4: New color cartridge

a

If you pressed 3 or 4 for a new cartridge, the

Sharp MFP will print a test page for printhead

alignment.

8.

If you installed a new print cartridge, press:

~ ~ ~~~~

Enter the two-digit number of the straightest

9.

line on the test page.

I(). press: ,~~~~

CARTRIDGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

:.:.:.~:.:.:.:,:.:.:.:.~~~:,:.:,~:.:.:,:.:.:.:

I

.:.:.:., :::::::.

.:.>:.:.:.: ..,:::$$:

.i:i:i:i:{:$, . ,;i;g$$

.:.:+:.:.:.>:.. ,.,.,.,.....,...

. . . . . ..(. . . . . . . . . . . . . . . . . . . .

,i:i:j:~:::::::::::::::::::::::::f’.:

i

Display shows:

1 ALIGN CARTRIDGE

P&&&-

7

]

UX-27OOCMUKMC

FO-2550CMUKMC

If you are copying onto a

transparency or special

paper, flip up the document

tray and insert the media into

the manual paper feeder.

Make sure the display shows:

CHECK MAN FEEDER

t USE AUTO FOR RX

Place the document

2.

(up to 20 pages) face

down in the document

feeder.

3.

Press:

?Z?

. . . . . . . . . . . ..‘.‘.‘.‘.~......

foci,

.A,. ..,.. .,.;.......... . . . . . . . . . .

..,. ,.,.,., .:.......... . . . . . . . . . . .

. . .,.,.,...,............... ,.,., . .

.

i

4. Press 1 to use the preset copy settings, or 2

(MANU) to select each setting individually. (If you

are making a color copy and selected 1, copying

will begin. If you selected 2, go to Step 6.

If you are making one copy per original, press

5.

the START key. If you are making multiple

copies per original, enter the number of copies

per original (if the number is less than IO, enter a

“0” before the number).

0

If you selected PRESET in Step 4, go to Step IO.

Enter a number for the size of the print media:

6.

1: LETTER

2: LEGAL

3: A4

7.

Enter a number to select reduction/enlargement.

Black/white copy

Color copy

1: AUTO 1: 50%

2: 50%

2: 100%

3: 75% 3: 200%

4: 100%

5: 120%

6: 150%

8. Select the type of media to be used:

1: PLAIN PAPER

2: COATED PAPER

3: TRANSPARENCY

4: GLOSSY PAPER

(Note: Setting 3 and 4 only appears if you inserted

a sheet of media in the manual feeder.)

l If you are making a color copy, go to Step 11.

9. Select the copy print quality. Press 1 for

NORMAL or 2 for DRAFT.

IO. If desired, press the RESOLUTION key to adjust

the resolution and/or contrast.

11 .Press START to begin copying.

START

1-9

Page 12

ux2700cMu/CMc

FO-255OCMUKMC

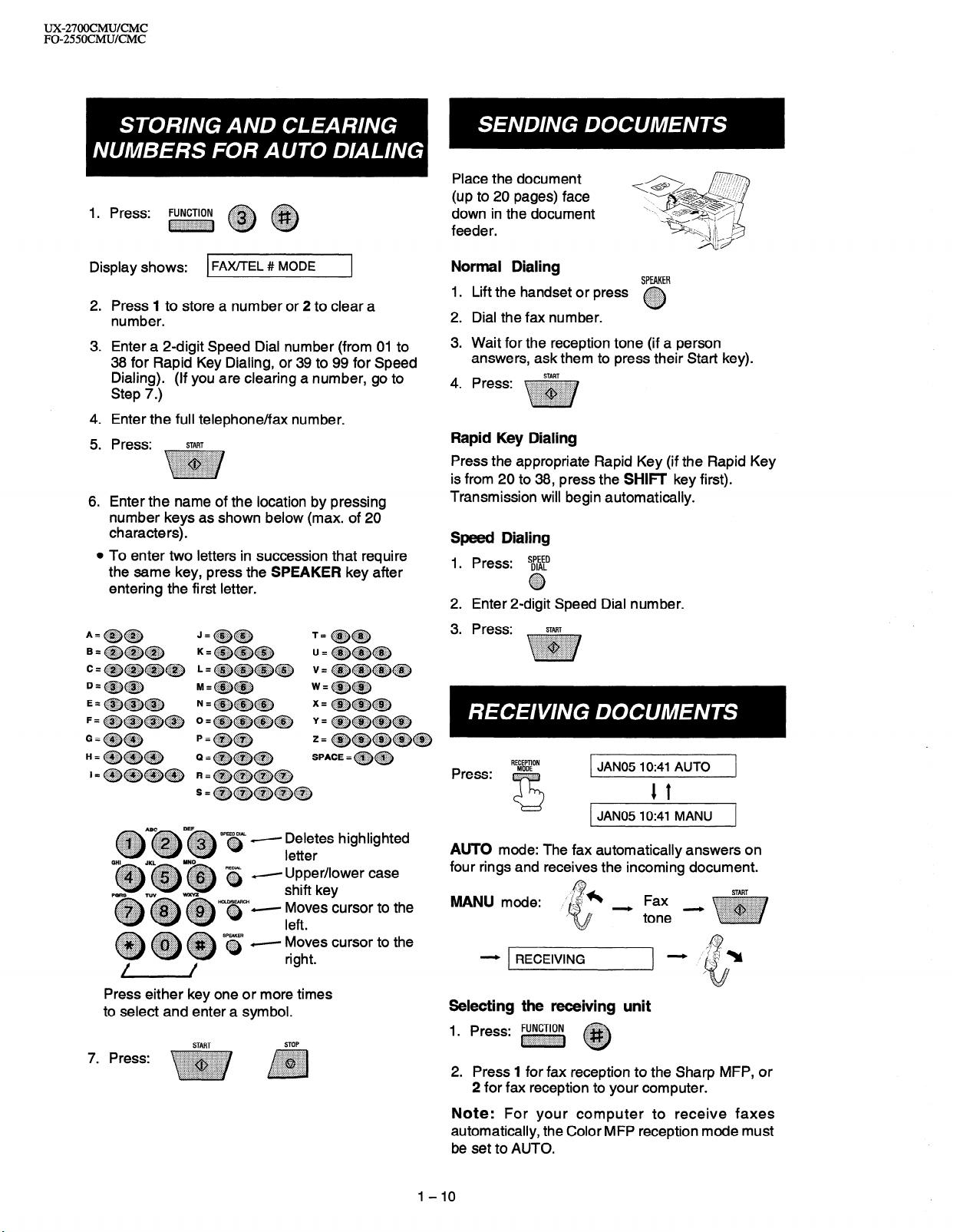

1. Press: FUNCTION

~~~ ~ ~

Place the document

(up to 20 pages) face

down in the document

feeder.

Display shows:

2.

Press I to store a number or 2 to clear a

FAX/TEL # MODE

F

8

number.

Enter a 2-digit Speed Dial number (from 01 to

3.

38 for Rapid Key Dialing, or 39 to 99 for Speed

Dialing). (If you are clearing a number, go to

Step 7.)

4.

Enter the full telephone/fax number.

5.

Press:

6.

Enter the name of the location by pressing

START

number keys as shown below (max. of 20

characters).

0

To enter two letters in succession that require

the same key, press the SPEAKER key after

entering the first letter.

Normal Dialing

1.

Lift the handset or press

2.

Dial the fax number.

3.

Wait for the reception tone (if a person

-

SPEAKER

answers, ask them to press their Start key).

4.

Press:

START

Rapid Key Dialing

Press the appropriate Rapid Key (if the Rapid Key

is from 20 to 38, press the SHIF key first).

Transmission will begin automatically.

Speed Dialing

1. Press:

2. Enter 2-digit Speed Dial number.

Press: START

3.

s$$tD

0 ::::::::::::: ..:::::::..

‘.::i$;::.’

~A~~D~ S’s - E;Ts highlighted

Y Upper/lower case

Press either key one or more times

to select and enter a symbol.

START

STOP

RECEPTION

JAN05 lo:41 AUTO

1 t

JAN05 IO:41 MANU

AUTO mode: The fax automatically answers on

four rings and receives the incoming document.

WljJU mode:

- RECEIVING

Selecting the receiving unit

1. Press: FUNCTloN

2. Press 1 for fax reception to the Sharp MFP, or

2 for fax reception to your computer.

~ ~

Note: For your computer to receive faxes

automatically, the Color MFP reception mode must

be set to AUTO.

I-IO

START

Page 13

UX-27OOCMUKMC

FO-255OCMUKMC

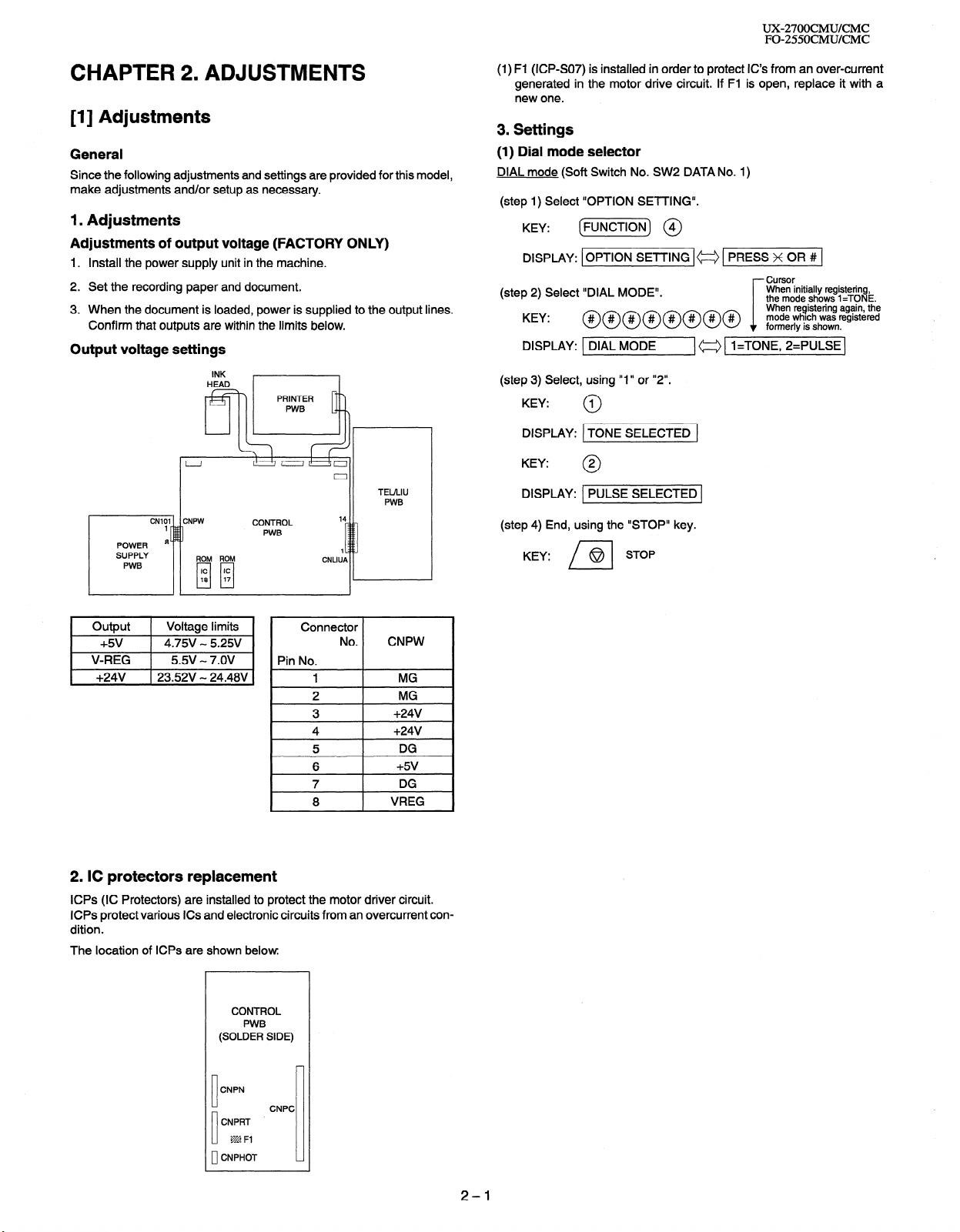

CHAPTER 2. ADJUSTMENTS

[l] Adjustments

General

Since the following adjustments and settings are provided for this model,

make adjustments and/or setup as necessary.

1. Adjustments

Adjustments of output voltage (FACTORY ONLY)

1. Install the power supply unit in the machine.

2. Set the recording paper and document.

3. When the document is loaded, power is supplied to the output lines.

Confirm that outputs are within the limits below.

Output voltage settings

INK

HEAD

811

TEULIU

PWB

CNLIUP

14

1

CONTROL

PWB

(1) Fl (ICPSO7) is installed in order to protect IC’s from an over-current

generated in the motor drive circuit. If Fl is open, replace it with a

new one.

3. Settings

(1) Dial mode selector

DIAL mode (Soft Switch No. SW2 DATA No. 1)

(step 1) Select “OPTION SETTING”.

KEY: (m) @I

DISPLAY: [OPTION SETTING I= 1 PRESS x 0R # ]

Cursor

(step 2) Select “DIAL MODE”.

KEY: @@@@@@@@ %?~$/;;~%%

DISPLAY: 1 DIAL MODE

(step 3) Select, using “1” or “2”.

KEY:

DISPLAY: 1 TONE SELECTED 1

KEY:

(step 4) End, using the “STOP” key.

KEY:

1

0

2

0

PULSE SELECTED (

STOP

@

n

(a [ l=TONE, 2=PULSE]

When initially registering,

the mode shows 1 =TONE.

i

1 Output 1 Voltage limits

+5v 4.75V - 5.25V

V-REG 5.5v - 7.OV

+24v j 23.52V - 24.48V

I

Connector

Pin No.

No.

1

2

3

4

5

6

7

8

CNPW

MG

MG

+24V

+24v

DG

+5v

DG

VREG

2. IC protectors replacement

ICPs (IC Protectors) are installed to protect the motor driver circuit.

ICPs protect various ICs and electronic circuits from an overcurrent condition.

The location of ICPs are shown below.

CONTROL

PWB

(SOLDER SIDE)

CNPN

CNPRT

CNPHOT

10

CNPC

m Fl

2-l

Page 14

UX27OOCMUKMC

FO-255OCMUKMC

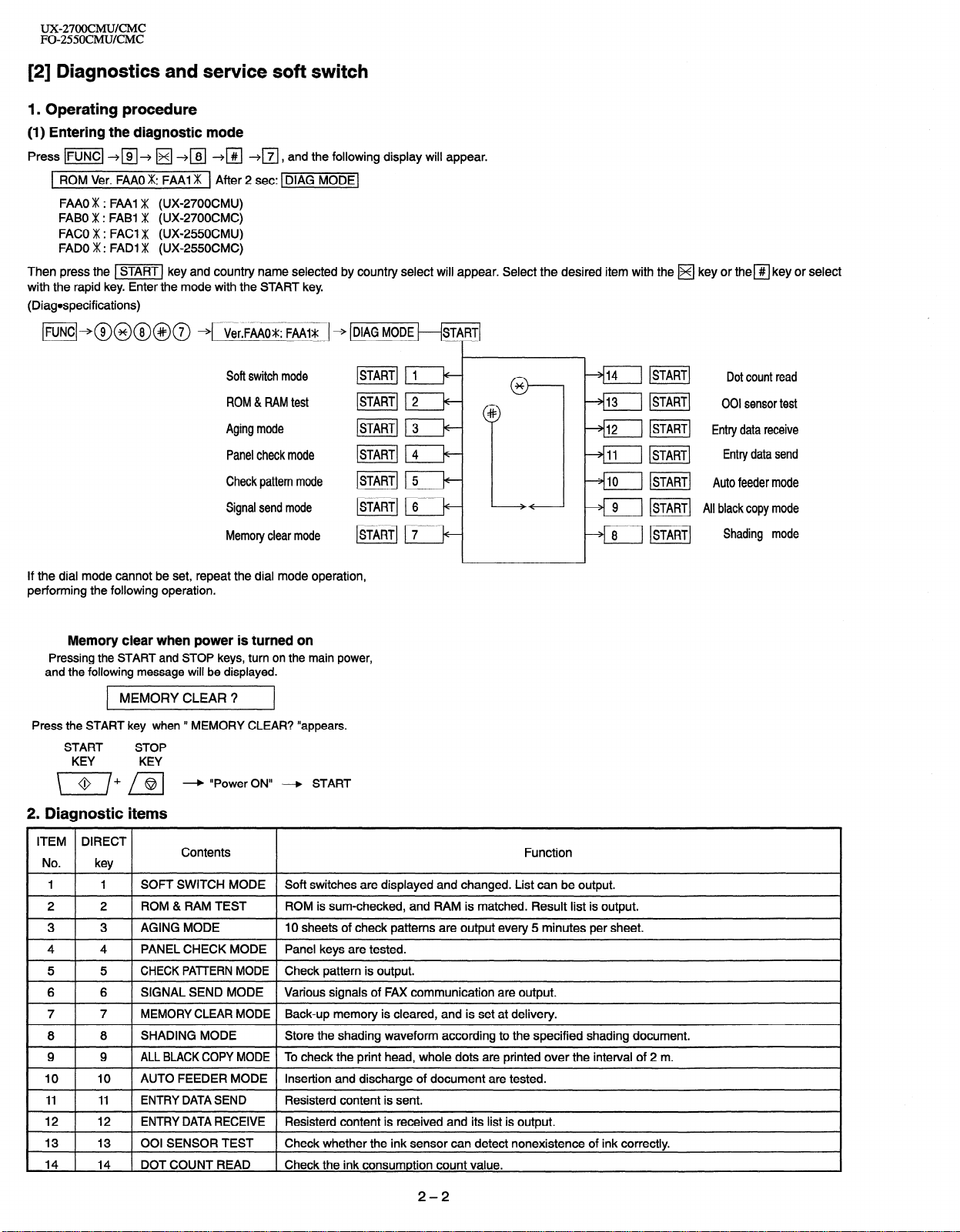

[2] Diagnostics and service soft switch

1. Operating procedure

(1) Entering the diagnostic mode

Press v] --+a+ q +m +I#I $j,

1 ROM Ver. FAA0 m: FAA1 m ] After 2 set: vMODE(

FAA0 m : FAA1 m (UX-2700CMU)

FABO m : FABI m (UX-2700CMC)

FACO m : FACI m (UX-2550CMU)

FAD0 m : FAD1 m (UX-2550CMC)

Then press the vj key and country name selected by country select will appear. Select the desired item with the H key or them key or select

with the rapid key. Enter the mode with the START key.

(Diagospecifications)

w]+@@@@@ + Ver.FAAOV: FAAIS _ + DIAG MODE

Soft switch mode

ROM & RAM test

and the following display will appear.

*

Aging mode

Panel check mode

Check pattern mode

Signal send mode

Memory clear mode

START 4 t+START 5 k

~START~ 6 t+--

ISTART] 1 7 t+-

bfl ]STARTI Entry data receive

/-+fiil mi Entry data send

v%--l m] Auto feeder mode

p 9 1 ISTART] All blackcopy mode

8 mi Shading mode

P

If the dial mode cannot be set, repeat the dial mode operation,

performing the following operation.

Memory clear when power is turned on

Pressing the START and STOP keys, turn on the main power,

and the following message will be displayed.

MEMORY CLEAR ?

Press the START key when ’ MEMORY CLEAR? “appears.

START

KEY

2. Diagnostic items

ITEM DIRECT

No.

I I

1

I

2

I

3 I 3

4

I

5

I

6

I

7

I

8

I

9

I

I0 I

” I

‘2 I

13 1 13 1 001 SENSOR TEST 1 Check whether the ink sensor can detect nonexistence of ink correctly.

14 1 14 1 DOTCOUNTREAD 1 Check the ink consumption count value.

STOP

KEY

* “Power ON” + START

key

1 1 SOFT SWITCH MODE 1 Soft switches are displayed and changed. List can be output.

2

I

1 AGING MODE I IO sheets of check patterns are output every 5 minutes per sheet.

4 1 PANEL CHECK MODE 1 Panel keys are tested.

5 I CHECK PATTERN MODE 1 Check pattern is output.

6 1 SIGNAL SEND MODE 1 Various signals of FAX communication are output.

7 1 MEMORY CLEAR MODE 1 Back-up memory is cleared, and is set at delivery.

8 1 SHADING MODE I Store the shading waveform according to the specified shading document.

I ALL BLACK COPY MODE I To check the print head, whole dots are printed over the interval of 2 m.

9

10 I AUTO FEEDER MODE I Insertion and discharge of document are tested.

11 I ENTRY DATA SEND

12 I ENTRY DATA RECEIVE I Resisterd content is received and its list is output.

Contents

ROM & RAM TEST

] ROM is sum-checked, and RAM is matched. Result list is output.

Resisterd content is sent.

I

Function

2-2

Page 15

UX-27OOCMUKMC

FO-255OCMUKMC

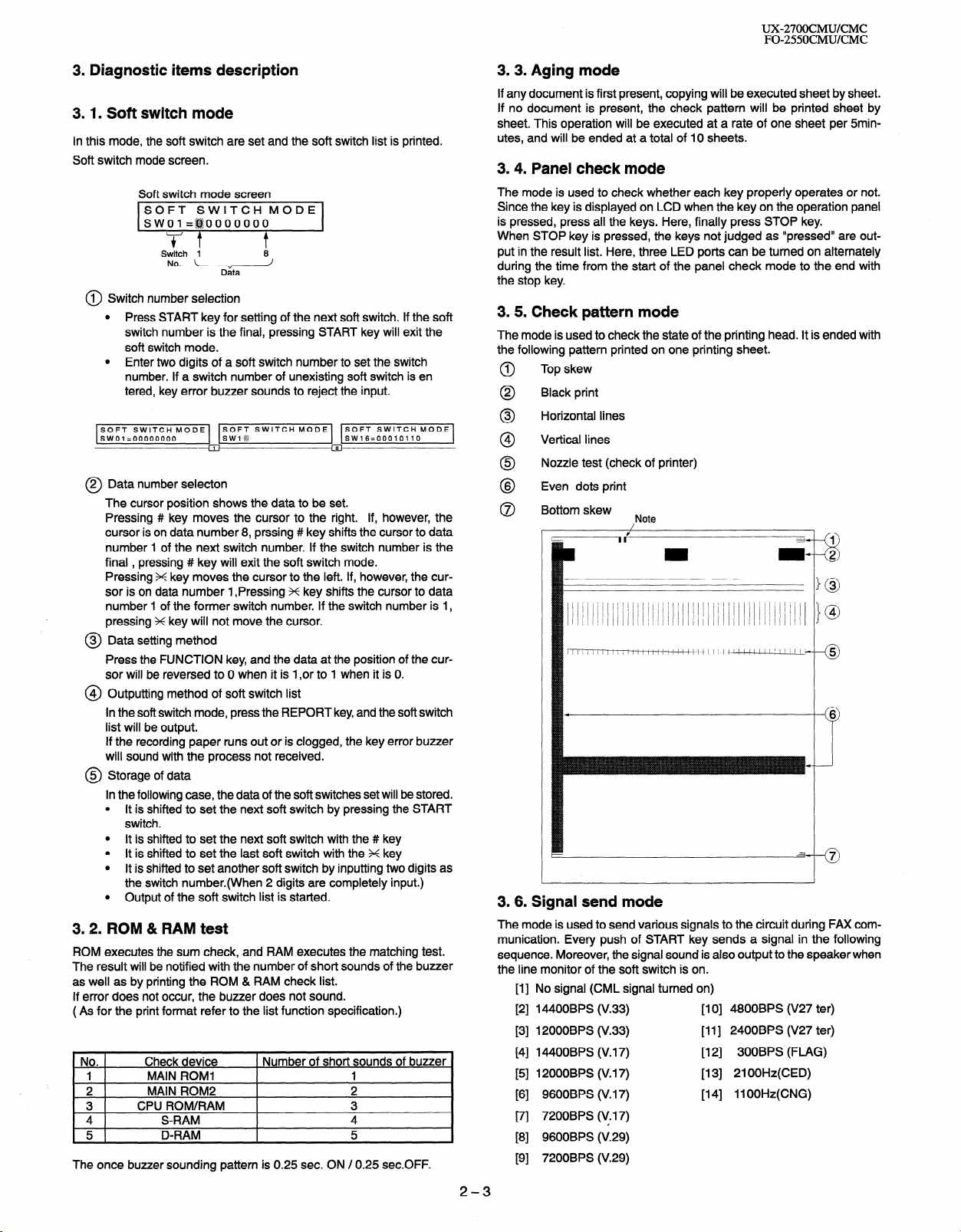

3. Diagnostic items description

3.1. Soft switch mode

In this mode, the soft switch are set and the soft switch list is printed.

Soft switch mode screen.

Soft switch mode screen

31

Switch 1

No. \-“8J

1 Switch number selection

0

l Press START key for setting of the next soft switch. If the soft

Data

switch number is the final, pressing START key will exit the

soft switch mode.

l Enter two digits of a soft switch number to set the switch

number. If a switch number of unexisting soft switch is en

tered, key error buzzer sounds to reject the input.

SOFT SWITCH MODE

sw01=00000000

2 Data number selecton

0

SOFT SWITCH MODE

SW1 g

1

SOFT SWITCH MODE

SW16=00010110

--*

The cursor position shows the data to be set.

Pressing # key moves the cursor to the right. If, however, the

cursor is on data number 8, prssing # key shifts the cursor to data

number 1 of the next switch number. If the switch number is the

final , pressing # key will exit the soft switch mode.

Pressing X key moves the cursor to the left. If, however, the cursor is on data number 1 ,Pressing X key shifts the cursor to data

number 1 of the former switch number. If the switch number is I,

pressing X key will not move the cursor.

@ Data setting method

Press the FUNCTION key, and the data at the position of the cursor will be reversed to 0 when it is 1 ,or to 1 when it is 0.

@ Outputting method of soft switch list

In the soft switch mode, press the REPORT key, and the soft switch

list will be output.

If the recording paper runs out or is clogged, the key error buzzer

will sound with the process not received.

@ Storage of data

In the following case, the data of the soft switches set will be stored.

l It is shifted to set the next soft switch by pressing the START

switch.

l It is shifted to set the next soft switch with the # key

l It is shifted to set the last soft switch with the X key

l It is shifted to set another soft switch by inputting two digits as

the switch number.(When 2 digits are completely input.)

l Output of the soft switch list is started.

3.2. ROM 81 RAM test

ROM executes the sum check, and RAM executes the matching test.

The result will be notified with the number of short sounds of the buzzer

as well as by printing the ROM & RAM check list.

If error does not occur, the buzzer does not sound.

( As for the print format refer to the list function specification.)

No. Check device

1 MAIN ROM1 1

. 2 MAIN ROM2

3 CPU ROM/RAM

4 S-RAM

5 D-RAM

The once buzzer sounding pattern is 0.25 sec. ON / 0.25 sec.OFF.

Number of short sounds of buzzer

2

3

4

5

3.3. Aging mode

If any document is first present, copying will be executed sheet by sheet.

If no document is present, the check pattern will be printed sheet by

sheet. This operation will be executed at a rate of one sheet per 5minutes, and will be ended at a total of IO sheets.

3.4. Panel check mode

The mode is used to check whether each key properly operates or not.

Since the key is displayed on LCD when the key on the operation panel

is pressed, press all the keys. Here, finally press STOP key.

When STOP key is pressed, the keys not judged as “pressed” are output in the result list. Here, three LED ports can be turned on alternately

during the time from the start of the panel check mode to the end with

the stop key.

3.5. Check pattern mode

The mode is used to check the state of the printing head. It is ended with

the following pattern printed on one printing sheet.

Top skew

0

Black print

0

Horizontal lines

0

4

Vertical lines

@

Nozzle test (check of printer)

0

Even dots print

8

Bottom skew

0

Note

3.6. Signal send mode

The mode is used to send various signals to the circuit during FAX communication. Every push of START key sends a signal in the following

sequence. Moreover, the signal sound is also output to the speaker when

the line monitor of the soft switch is on.

No signal (CML signal turned on)

[II

14400BPS (V.33)

PI

12000BPS (V.33)

PI

14400BPS (V. 17)

E41

12000BPS (V. 17)

PI

9600BPS (V. 17)

Fl

7200BPS (V. 17)

171

9600BPS (V.29)

PI

7200BPS (V.29)

PI

[I 0] 4800BPS (V27 ter)

[II] 2400BPS (V27 ter)

[12] 300BPS (FLAG)

[I 31 21 OOHz(CED)

[14] llOOHz(CNG)

2-3

Page 16

UZ27OOCMUKMC

FO-255OCMUKMC

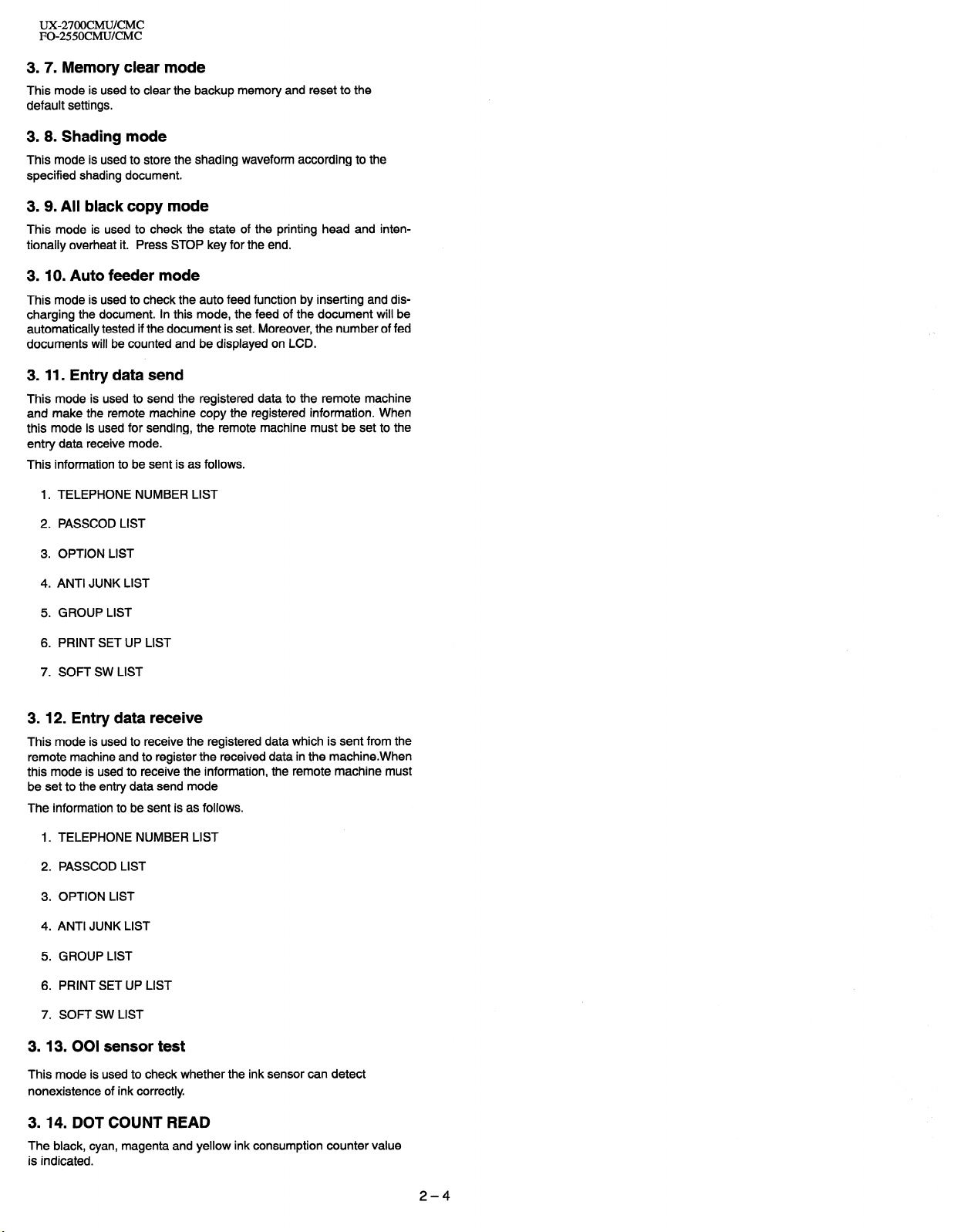

3.7. Memory clear mode

This mode is used

default settings.

to

clear

the backup

memory and reset to the

3.8. Shading mode

This mode is used to store the

specified shading document.

shading waveform according to the

3. 9. All black copy mode

This mode is used to check the state of the printing head and intentionally overheat it. Press STOP key for the end.

3.10. Auto feeder mode

This mode is used to check the auto feed function by inserting and discharging the document. In this mode, the feed of the document will be

automatically tested if the document is set. Moreover, the number of fed

documents will be counted and be displayed on LCD.

3. 11. Entry data send

This mode is used to send the registered data to the remote machine

and make the remote machine copy the registered information. When

this mode is used for sending, the remote machine must be set to the

entry data receive mode.

This information to be sent is as follows.

1. TELEPHONE NUMBER LIST

2. PASSCOD LIST

3. OPTION LIST

4. ANTI JUNK LIST

5. GROUP LIST

6. PRINT SET UP LIST

7. SOFT SW LIST

3. 12. Entry data receive

This mode is used to receive the registered data which is sent from the

remote machine and to register the received data in the machine.When

this mode is used to receive the information, the remote machine must

be set to the entry data send mode

The information to be sent is as follows.

1. TELEPHONE NUMBER LIST

2. PASSCOD LIST

3. OPTION LIST

4. ANTI JUNK LIST

5. GROUP LIST

6. PRINT SET UP LIST

7. SOFT SW LIST

3.13.001 sensor test

This mode is used to check whether

nonexistence of ink correctly

the ink sensor can detect

3.14. DOT COUNT READ

The black, cyan, magenta and yellow ink consumption counter value

is indicated.

2-4

Page 17

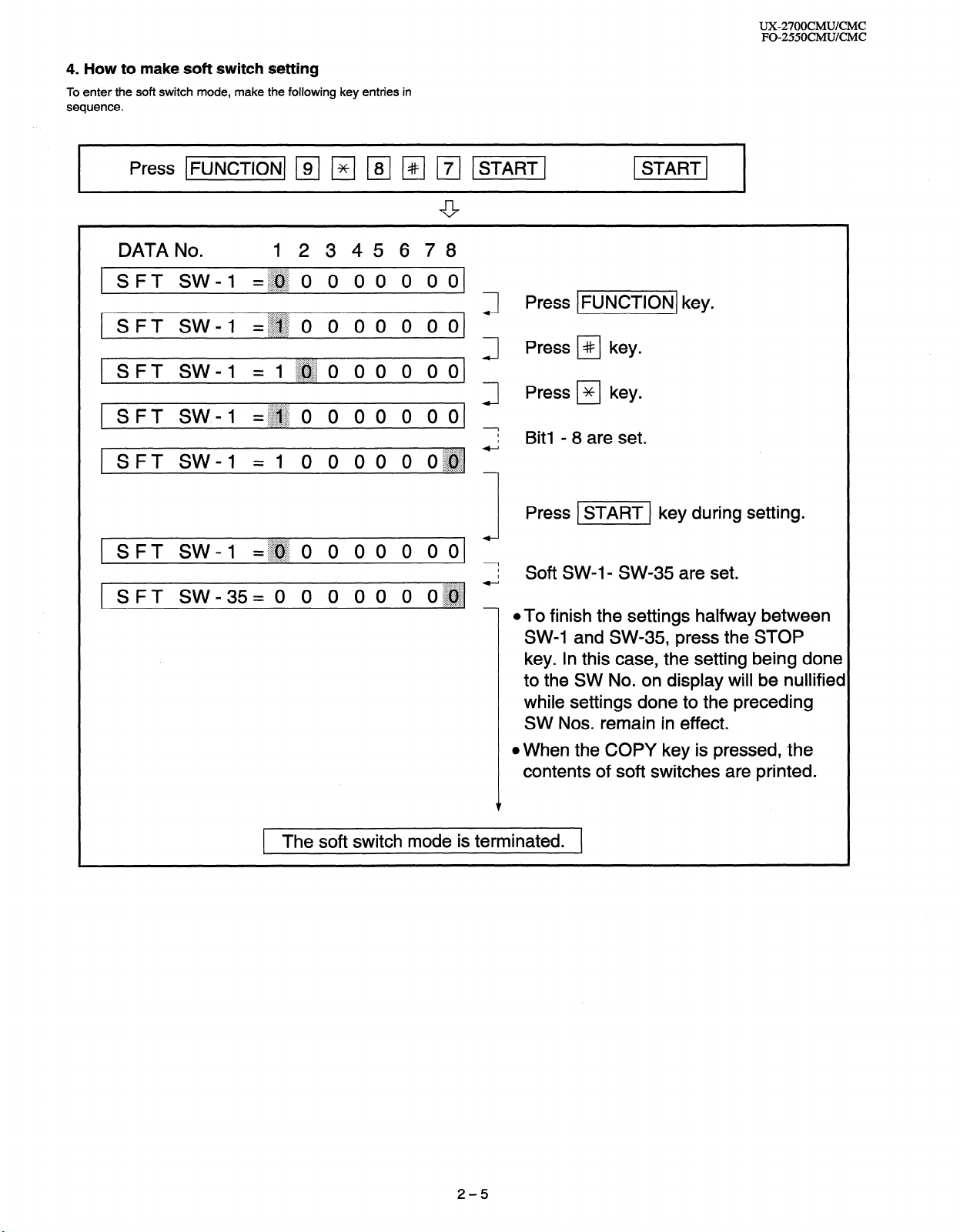

4. How to make soft switch setting

To enter the soft switch mode, make the following key entries in

sequence.

DATA No. 12345678

1 SFT SW-1

1 SFT SW-1 =~~

[SFT SW-1 =

SFT SW.4

I-

SFT SW-1

=~~ () 0 0 0 0 () o(

0 0 () 0 0 0 01

:.>x.::::.....:.:,..

l~~o 00 O ool

=~~o 0 00 () 00

=I () () 00 0 0~~~ -

Press IFUNCTIONJ key.

Press PI key.

Press ) * 1 key.

J

1

I

I

. . . . . . . .

~.L.+:.:.>:+:.:.

Bit1 - 8 are set.

. . . . . . . . . .

UX-27OOCMUKMC

FO-255OCMUICMC

.:.:.:.I:.::::::::::::

SFT SW-1

SPT SW_35= () 0 0 0 0 () 0~~ -

=~~o 0 00 0 ()()

. . ,.... ~_.............

. . . . . . . . . . . . . . . ._

1 The soft switch mode is terminated. 1

Press v] key during setting.

I

7 Soft SW-l- SW-35 are set.

@To finish the settings halfway between

SW-1 and SW-35, press the STOP

key. In this case, the setting being done

to the SW No. on display will be nullified

while settings done to the preceding

SW Nos. remain in effect.

l When the COPY key is pressed, the

contents of soft switches are printed.

2-5

Page 18

UX27OOCMUKMC

FO-255OCMUKMC

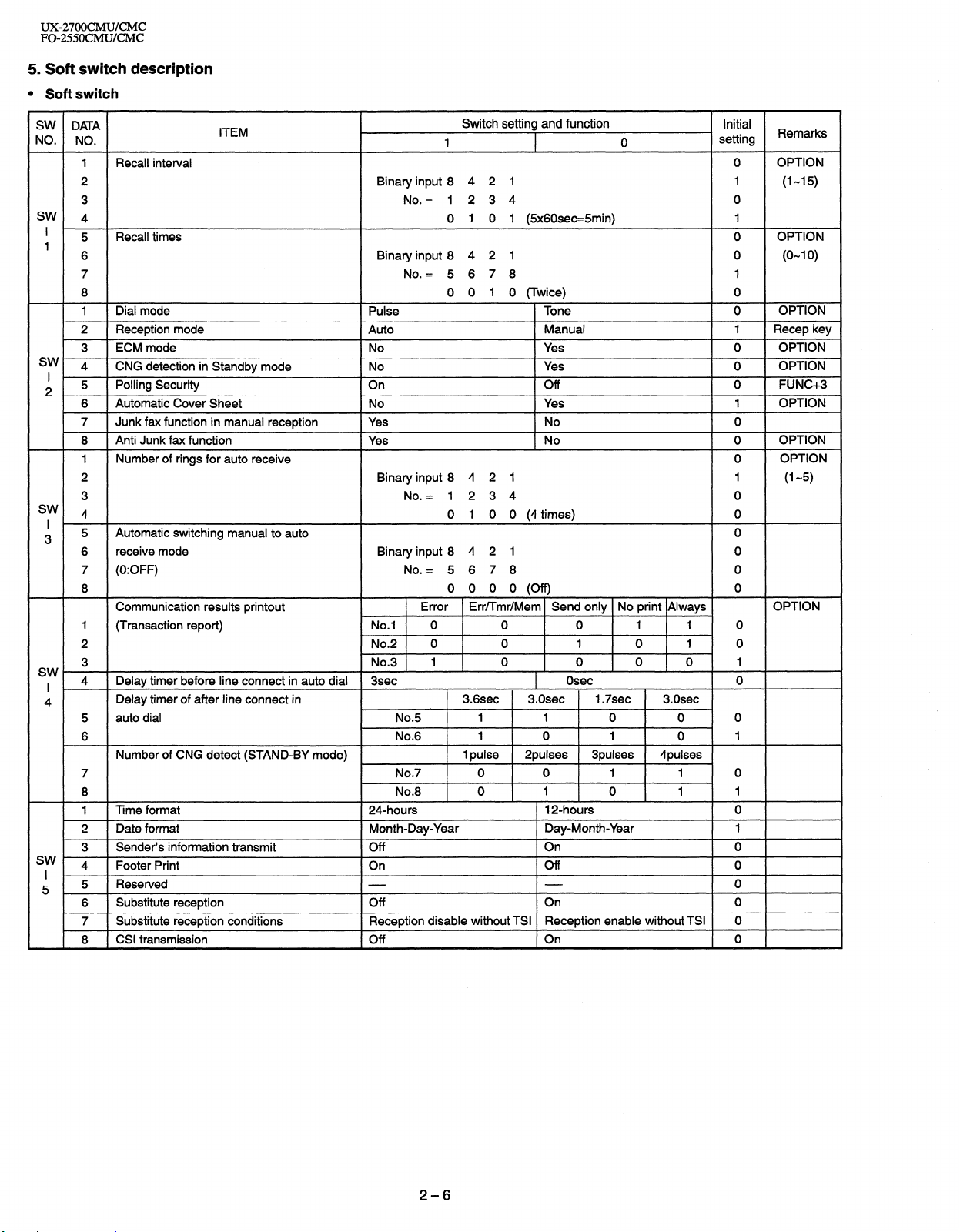

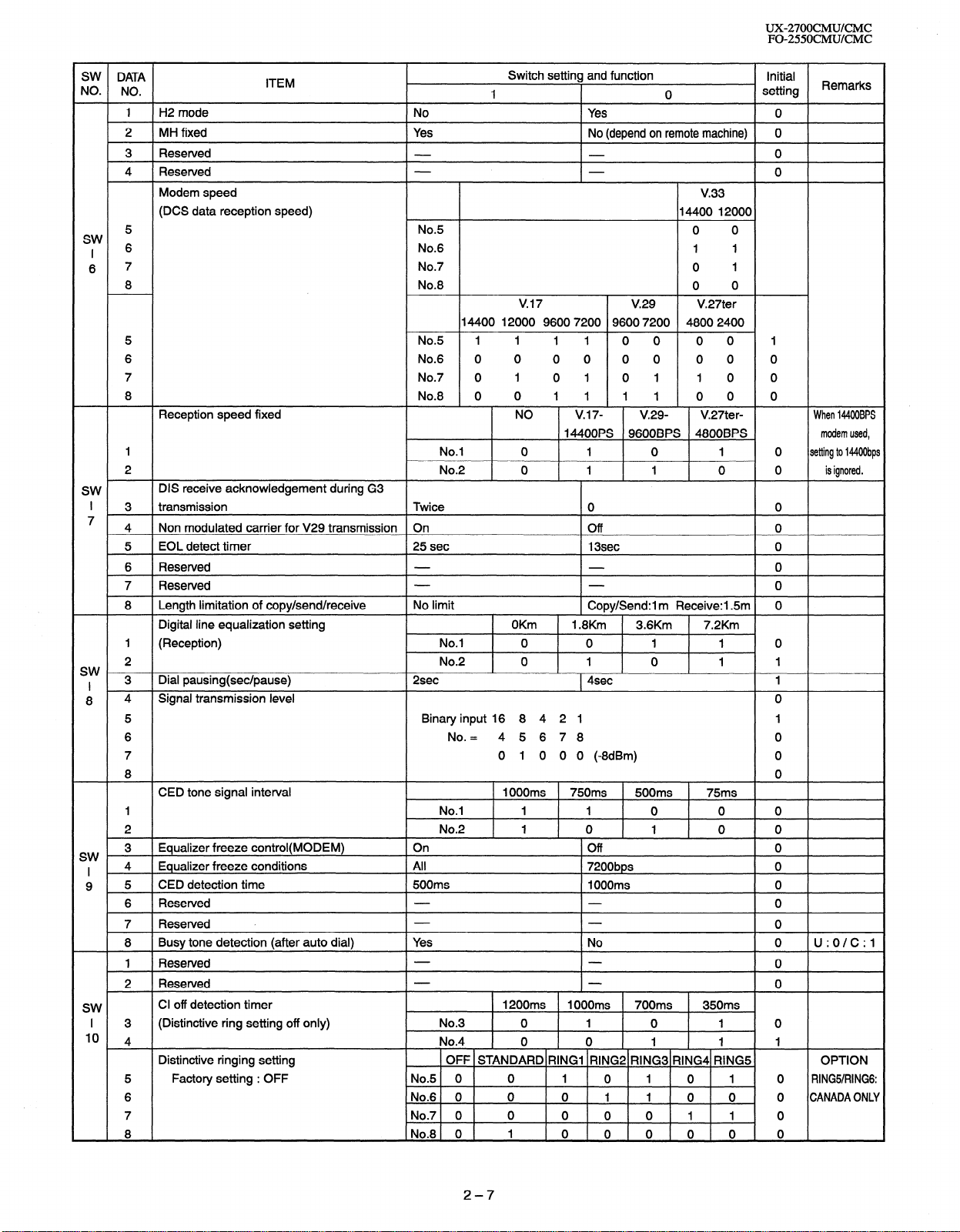

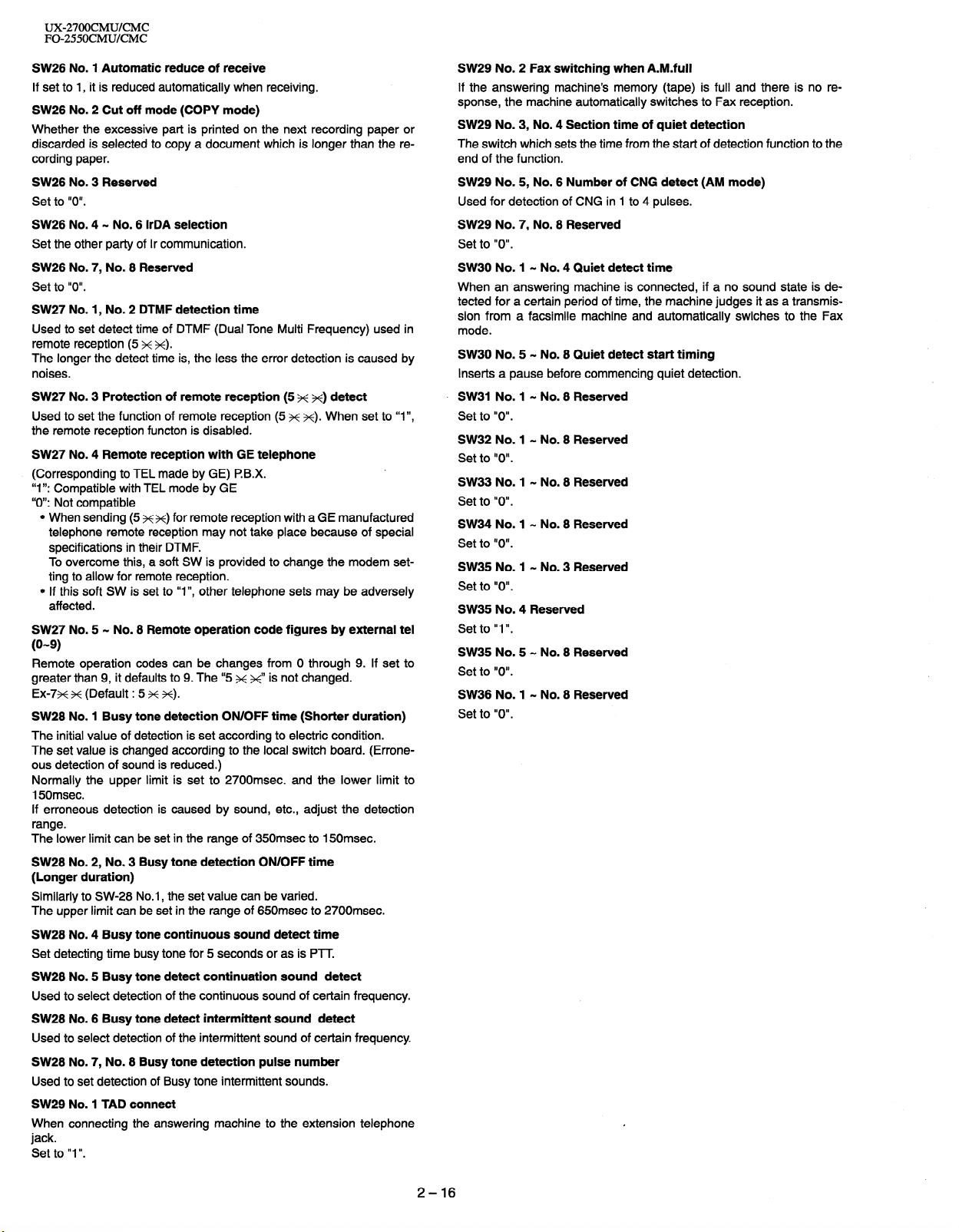

5. Soft switch description

l Soft switch

SW DATA

NO. NO.

1 Recall interval 0 OPTION

2 Binary input 8 4 2 1 1 (I-15)

3 No. = 1234 0

SW

4 0 0 1 1 @x60sec=5min)

5 Recall times 0 OPTION

’

1

6 Binary input 8 4 2 1 0 (O-l 0)

7 No. = 5 6 7 8 1

8 0 0 1 0 (Twice) 0

1 Dial mode Pulse Tone 0 OPTION

2 Reception mode

3 ECM mode No Yes 0 OPTION

sw 4

I

2 5 Polling Security On Off 0 FUNC+3

sw 4 0 1 0 0 (4 times) 0

I ’

3 5 Automatic switching manual to auto 0

sw I 4 Delay timer before line connect in auto dial 3sec

4

sw

I 1

5 5 Reserved 0

CNG detection in Standby mode No Yes

6 Automatic Cover Sheet No Yes

7 Junk fax function in manual reception

8 Anti Junk fax function

1 Number of rings for auto receive 0

2 Binary input 8 4 2 1 1 (l-5)

3 No. = 1234 0

6 receive mode Binary input 8 4 2 1 0

7 (0:OFF) No. = 5 6 7 8 0

8 0 0 0 0 (Off) 0

Communication results printout

I (Transaction report) No.1 0 0 0 1 1 0

2 No.2 0 0 1 0 1 0

3 No.3 1 0 0 0 0 1

Delay timer of after line connect in

5 auto dial No.5 1 1 0 0 0

6 No.6 1 0 1 0 1

Number of CNG detect (STAND-BY mode)

7 No.7 0 0 1 1 0

8 No.8 0 1 0 1 1

1 Time format 24.hours 12-hours 0

2 Date format Month-Day-Year Day-Month-Year 1

3 Sender’s information transmit Off On 0

4 Footer Print On Off 0

6 Substitute reception Off On 0

7 Substitute reception conditions

8 CSI transmission Off On 0

ITEM

Auto

Yes

Yes

Reception disable without TSI Reception enable without TSI 0

Switch setting and function

1 0 setting

Manual 1 Recep key

No 0

No 0

Error Err/Tmr/Mem Send only No print Always

Osec 0

3.6sec 3.Osec 1.7sec 3.0sec

1 pulse 2pulses 3pulses

4pulses

Initial

Remarks

1

OPTION

0

1 OPTION

OPTION

OPTION

OPTION

2-6

Page 19

UX-2700CMUKMC

FO-255OCMUKMC

SW DATA

NO. NO.

1 H2 mode No Yes 0

2 MH fixed

3 Reserved 0

4 Reserved 0

Modem speed

(DCS data reception speed) 14400 12000

5 No.5

sw

I 6 No.6 1 1

6 7 No.7 0 1

8 No.8 0 0

5 No.5 1 1 1 1 0 0 0 0 1

6 No.6 0 0 0 0 0 0 0 0 0

7 No.7 0 1 0 1 0 1 1 0 0

8 No.8 0 0 1 1 1 1 0 0 0

Reception speed fixed

1 No.1 0 1 0 1 0 setting to 1440Obps

2 No.2 0 1 1 0 0 is ignored.

SW

DIS receive acknowledgement during G3

ITEM

Yes

14400 12000 9600 7200 9600 7200 4800 2400

Switch setting and function

1

No (depend on remote machine) 0

v.17 V.29

NO

v.17-

14400PS 9600BPS 4800BPS modem used,

0

v.33

0 0

V.27ter

V.29- V.27ter- When 144OOBPS

Initial

setting

I 3 transmission Twice 0 0

7

4 Non modulated carrier for V29 transmission On Off 0

5 EOL detect timer 25 set 13sec 0

6 Reserved 0

7 Reserved 0

Length limitation of copy/send/receive No limit

8

Digital line equalization setting OKm

1 (Reception) No.1 0 0 1 1 0

2 No.2 0 1 0 1 1

sw I 3 Dial pausing(sec/pause) 2sec 1 4sec 1

8 4 Signal transmission level 0

5 Binary input 16 8 4 2 1 1

6 No. = 4 5678 0

7 0 1 0 0 0 (-8dBm) 0

8 0

CED tone signal interval

1 No.1 1 1 0 0 0

2 No.2 1 0 1 0 0

3 Equalizer freeze control(MODEM) On

SW

I 4

9 5 CED detection time 500ms I OOOms 0

,

SW

I 3 (Distinctive ring setting off only) No.3 0 1 0 1 0

I0 4 No.4 0 0 1 1 1

Equalizer freeze conditions

6 Reserved 0

7 Reserved 0

8 Busy tone detection (after auto dial) Yes

1 Reserved 0

2 Reserved 0

Cl off detection timer 1200ms

Distinctive ringing setting

5 Factory setting : OFF No.5 0 0 1 0 1 0 1 0 RING51RING6:

6 No.6 0 0 0 I 1 0 0.0 CANADA ONLY

7 No.7 0 0 0 0 0 1 1 0

8 No.8 0 1 0 0 0 0 0 0

All

OFF STANDARD RING1 RING2 RING3 RING4 RING5, OPTION

1 OOOms

Copy/Send:1 m Receive:l.Sm 0

1.8Km 3.6Km 7.2Km

750ms 500ms 75ms

Off 0

7200bps 0

No 0 U:O/C:l

1 OOOms 700ms 350ms

Remarks

2-7

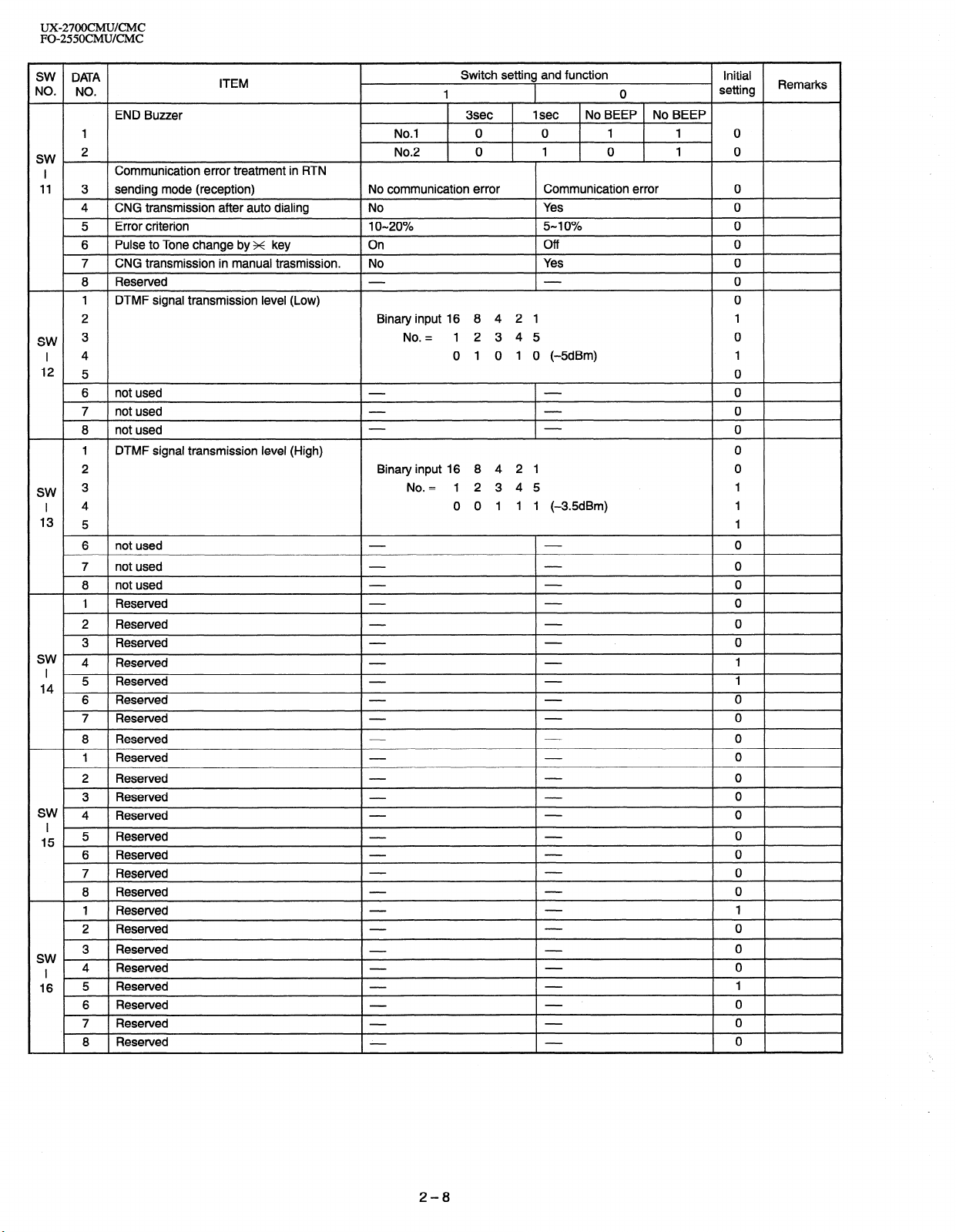

Page 20

UX-27OOCMUKMC

FO-2550CMUKMC

SW DATA

NO. NO.

END Buzzer

1

SW. *

I

11 3 sending mode (reception) No communication error

SW 3

I 4

12

SW 3

I 4

13

sw

I

14 ; Reserved 1

SW 4

I

15 5 Reserved

SW

I 4 Reserved

16 5 Reserved

Communication error treatment in RTN

4 CNG transmission after auto dialing

5 Error criterion 1 O-20%

6 Pulse to Tone change by x key On Off 0

7

CNG transmission in manual trasmission. No Yes 0

8 Reserved

1 DTMF signal transmission level (Low)

2

5

6 not used

7 not used

8 not used

1 DTMF signal transmission

2

5 1

6 not used

7 not used

8 not used

1 Reserved

2 Reserved

3 Reserved

4 Reserved

Reserved

7 Reserved

8 Reserved

1 Reserved

2 Reserved

3 Reserved

Reserved 0

6 Reserved

7 Reserved

8 Reserved

1 Reserved

2 Reserved

3 Reserved

6 Reserved

7 Reserved

8 Reserved

ITEM

No.1 0 0 1

No.2 0 1 0

No Yes 0

Binary input 16 8 4 2 1

No. = 12345 0

level (High)

Binary input 16 8 4 2 1

No. = 12 3 45

Switch setting and function

1

3sec

0 1 0 1 0 (-SdBm)

0 0 1 1 1 (-3.5dBm) 1

1 set No BEEP No BEEP

Communication error 0

5-I 0% 0

0

1 0

1 0

setting

Initial

0

0

1

1

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

1

0

0

0

1

0

0

0

Remarks

2-8

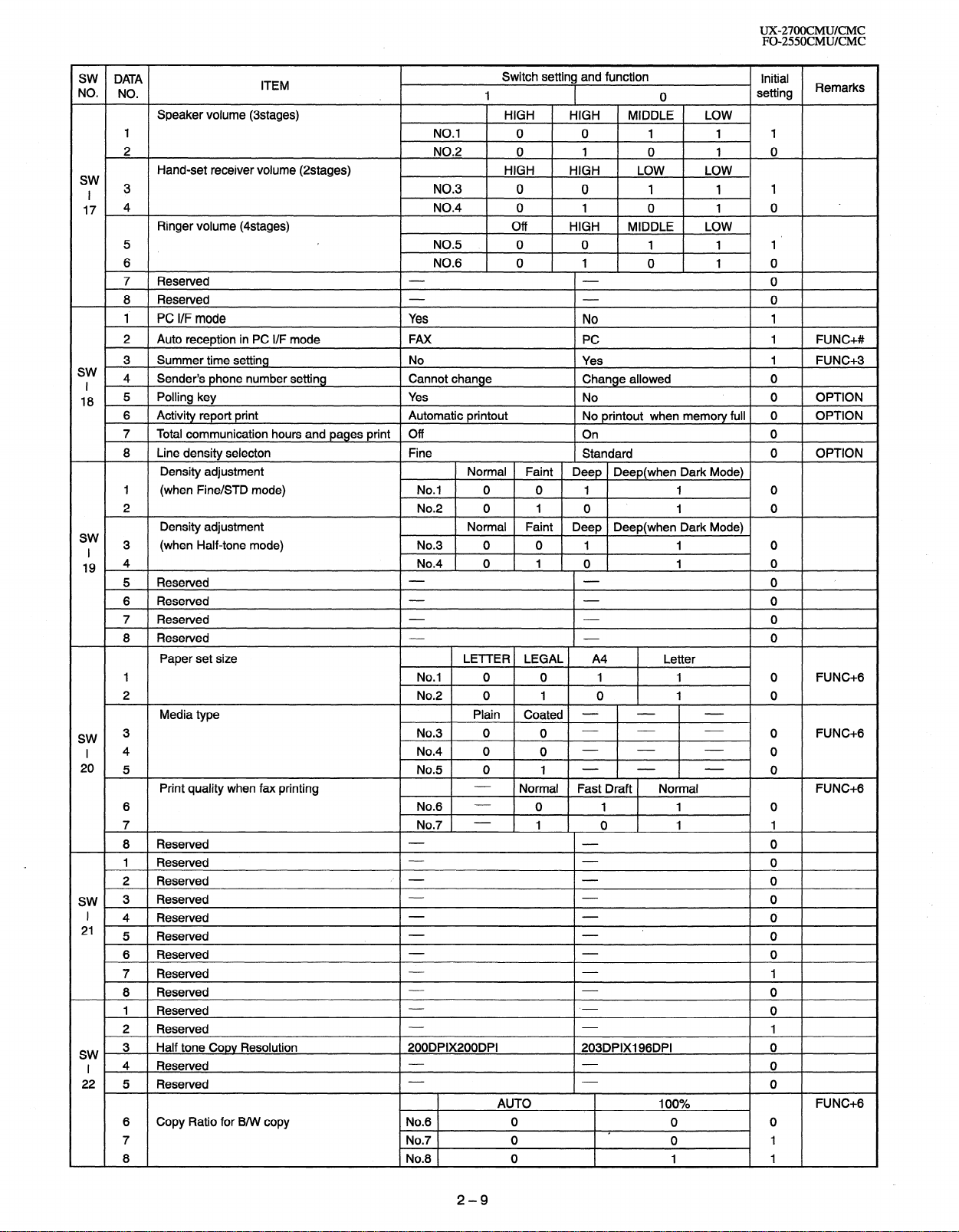

Page 21

UX-27OOCMUKMC

FO-255OCMUKMC

SW DATA

NO. NO.

Speaker volume (3stages)

1 NO.1 0 0 1 1 1

2 NO.2 0 1 0 1 0

Hand-set receiver volume (2stages)

sw

I 3 NO.3 0 0 1 1 1

17 4 NO.4 0 1 0 1 0

Ringer volume (4stages)

5 NO.5 0 0 1 1 1’

6 NO.6 0 1 0 1 0

7 Reserved 0

8 Resewed 0

1 PC I/F mode Yes No 1

2 Auto reception in PC I/F mode

3 Summer time setting

sw

4 Sender’s phone number setting

I

18 5 Polling key Yes No 0 OPTION

6 Activity report print

7 Total communication hours and pages print

8

Line density selecton Fine

Density adjustment Normal Faint

1 (when Fine/STD mode) No.1 0 0 1 1 0

2 No.2 0 1 0 1 0

Density adjustment Normal Faint

sw 3

I (when Half-tone mode) No.3 0 0 1 1 0

19 4 1 _ 0 1 0

ITEM

FAX

No

Cannot change Change allowed 0

Automatic printout

Off

Switch setting and function

1

HIGH HIGH

HIGH

Off

HIGH LOW LOW

HIGH MIDDLE LOW

PC

Yes

No printout when memory full 0

On

Standard

Deep Deep(when Dark Mode)

Deep Deep(when Dark Mode)

0 setting

MIDDLE LOW

Initial

Remarks

1 FUNC+#

1

FUNC+S

OPTION

0

0 OPTION

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved

Paper set size LE-ITER LEGAL A4

1 No.1 0 0 1 1 0 FUNC+6

2 No.2 0 1 0 1 0

Media type

SW 3 No.3 0 0

I 4 No.4 0 0 - - - 0

20 5 No.5 0 1 - - _ 0

Print quality when fax printing Normal

6 No.6 - 0 1 1 0

7 No.7 - 1 0 1 1

8 Reserved 0

1 Reserved 0

2 Reserved /’ - 0

SW, 3 Reserved 0

Plain Coated - - -

I-

Letter

- - -

Fast Draft Normal

O

0 FUNC+G

FUNC+6

I 4 Reserved 0

21 5 Reserved 0

6 Reserved 0

7 Reserved 1

8 Reserved 0

1 Reserved 0

2 Reserved 1

SW 3

I 4 Reserved 0

22 5 Reserved 0

Half tone Copy Resolution 200DPIX200DPI

AUTO 100%

6 Copy Ratio for B/W

7 No.7 0 0 1

8 No.8 0 1 1

copy

No.6 0 0 0

203DPIX196DPI 0

FUNC+6

.

2-9

Page 22

UX-27OOCMUKMC

FO-2550CMUKMC

SW DATA

NO. NO.

1 Reserved 0

2 Reserved 0

SW. 3 Reserved 0

I 4 Reserved 0

_

23 5 Reserved 0

6 Reserved 0

7 Resewed 1

8 Reserved 0

1 Align cartridge (I-30) for color cartridge

2 Binary input 16 8 4 2 1 1

3 No. = 12345 1

sw I 4 0 1 1 1 1 (15) 1

24 5 1

6 FAX printing with paper from manual feeder Yes

7 FAX printing with color cartridge Yes No

8 FAX printing when low ink detected Yes No

1

Align cartridge (I-30) for black cartridge

2 Binary input 16 8 4 2 1 1

3 No. = 12345 1

SW 4 0 1 1 1 1 (15) 1

5 1

I

6 Cartridge alarm Off On 0

25

7 Low ink detection in black cartridge Yes No

Low ink detection in color cartridge Yes No 0

8

1

Automatic Reduce of receive

2

Cut off mode (COPY mode)

3 Reserved 0

I rDA selection

sw 4 No.4 0 0 0 0 1 0

5 No.5 0 0 1 1 0 0

I

26

6 No.6 0 1 0 1 0 0

7 Reserved 0

8 Reserved 0

DTMF detection time

1 No.1 0 0 1 1 0

2 No.2 0 1 . 0 1 0

3 Protection of remote reception (5 x x ) detect Yes

sw 4 Remote reception with GE telephone

I *

27 5 Remote operation code figures by external 0 OPTION

6 tel (O-9) Binary input 8 4 2 1 1

7 No. = 5 6 7 8 (Data No.) 0

8 Ex 0 1 0 1 1

1 Busy tone detection ON/OFF time (Shorter duration) 350ms

Busy tone detection ON/OFF time (Longer duration)

2 No.2 0 0 1 1 0

3 No.3 0 1 0 1 I

SW, 4

I 5

28

Busy tone continuous sound detect time 5sec

Busy tone detect continuation sound detect No

6 Busy tone detect intermittent sound detect No Yes 0

Busy tone detection pulse number

7 No.7 0 0 1 1 0

8 No.8 0 1 0 1 1

ITEM

Auto 100%

Continue Cut-off 0

PCprint ZAURUS print File Transfer DG camera Off OPTION

Compatible Not compatible 1

Switch setting and function

1 0

No 0

50ms 80ms

No 0

1 OOms 120ms

1 150ms 0

650ms 900ms 2700ms 900ms

1 Osec

Yes 0

2pulses 4pulses

Gpulses

1 Opulses

Initial

setting

Remarks

FUNC+G

0

0

0

FUNC+G

0

1

1 FUNC+G

FUNC+G

OPTION

1

2-10

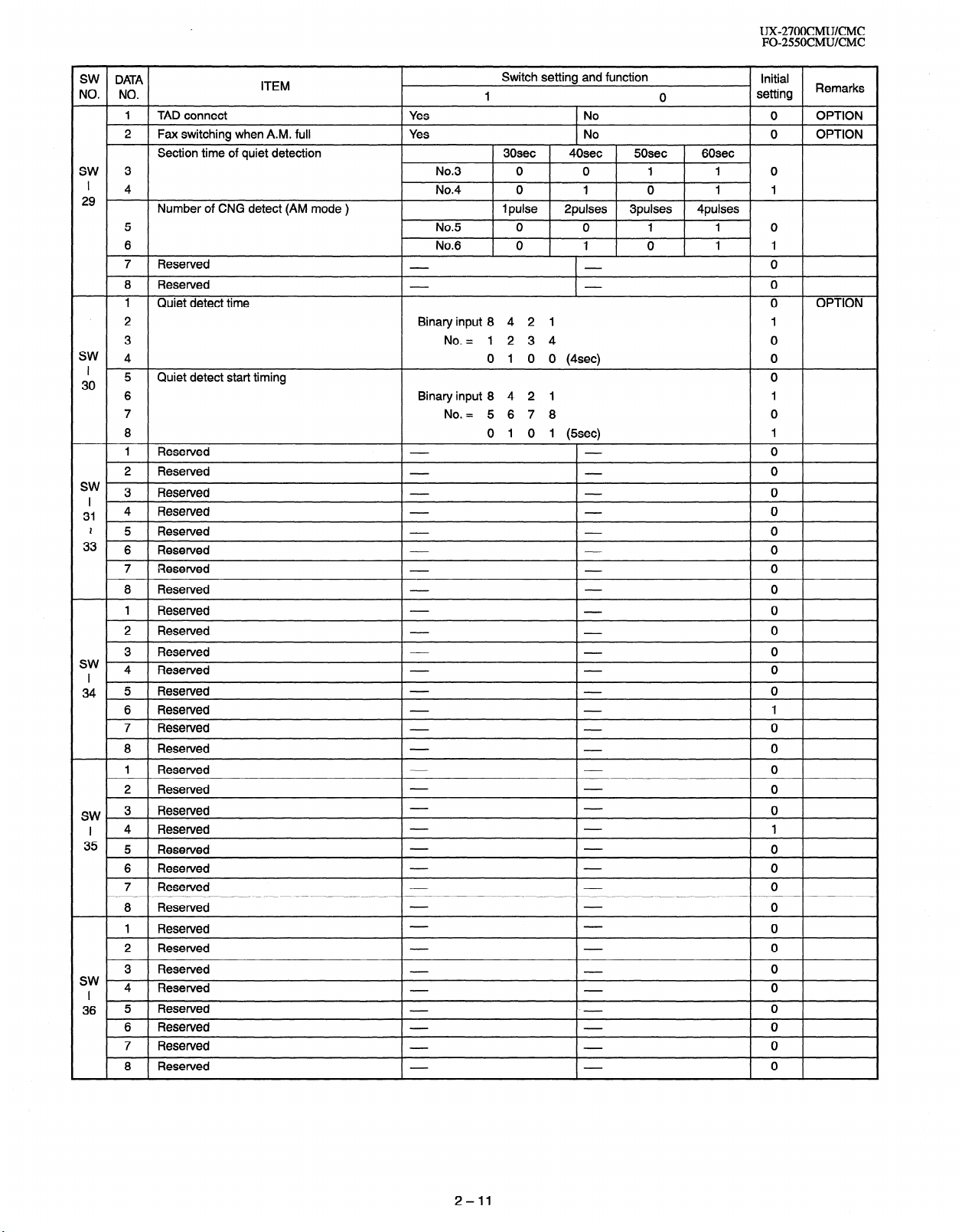

Page 23

UX-27OOCMUKMC

FO-255OCMWCMC

SW DATA

NO. NO.

1 TAD connect Yes No 0 OPTION

2 Fax switching when A.M. full

Section time of quiet detection

SW 3 No.3 0 0 1 1 0

’

4 No.4 0 1 0 1 1

29

Number of CNG detect (AM mode ) 1 pulse

5 No.5 0 0 1 1 0

6 No.6 0 1 0 1 1

7 Reserved 0

8 Reserved 0

1 Quiet detect time 0 OPTION

ITEM

Yes No 0 OPTION

Switch setting and function

1 0

30sec 40sec 5Osec 60sec

2pulses 3pulses 4pulses

Initial

setting Remarks

2 Binary input 8 4 2 1 1

3 No. = 1 2 3 4 0

SW

4 0 1 0 0 (4sec) 0

I 30

sw 3

I ’

31 4 Reserved 0

,

Quiet

5

6 Binary input 8 4 2 1 1

7 No. = 5 6 7 8 0

8 0 1 0 1 (5sec) 1

1 Reserved 0

2 Reserved 0

detect start

Reserved 0

timing

2 5 Resetved 0

33 6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

sw

4 Reserved 0

I

34 5 Reserved 0

6 Resetved 1

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

SW 3 Reserved 0

I 4 Resewed 1

35 5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Resetved 0

sw I 4 Reserved 0

36 5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Resetved 0

0

2-11

Page 24

UX-27OOCMUKMC

FO-2550CMUKMC

l Soft switch function description

SW1 No. 1 w No. 4 Recall interval

Choice is made for a recall interval for speed and rapid dial-numbers.

Use a binary number to program this. If set to 0 accidentally, 1 will be

assumed.

SW1 No. 5 - No. 8 Recall times

Choice is made as to how many recall attempts should be made. Use

a binary number to program this.

SW2 No. 1 Dial mode

Switch the type according to the telephone circuit connected to the

facsimile.

1 : PULSE DIAL

0 : TONE DIAL

SW2 No. 2 Reception mode

Auto/manual receiving mode is set.

SW2 No. 3 ECM mode

Used to determine ECM mode function. Refer to the following table.

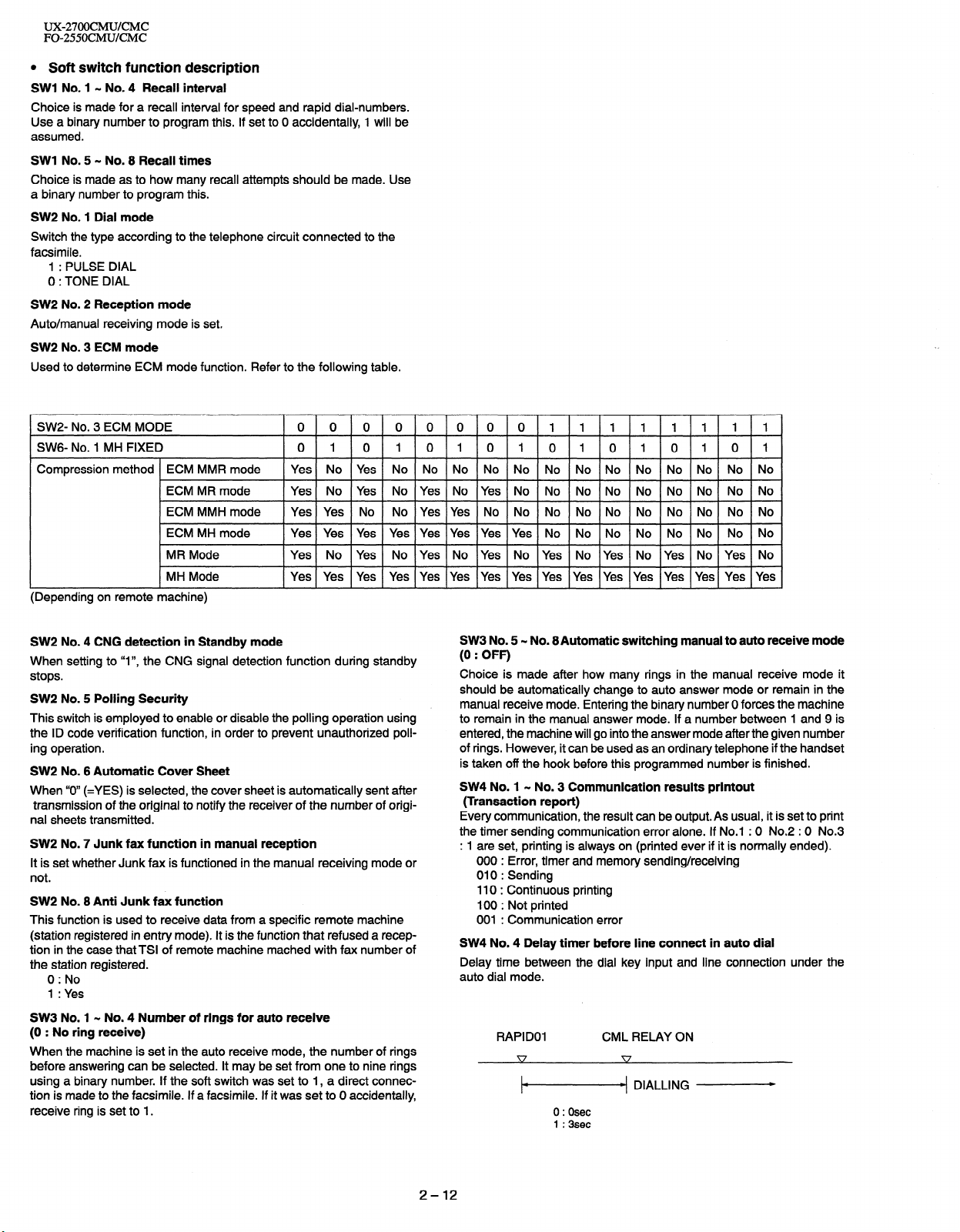

SWZ- No. 3 ECM MODE

0 0 0 0 0 0 0 0 11111 11 1

SWG- No. 1 MH FIXED 0 1 0 10 10 10 10 IO 10 1

Compression method ECM MMR mode

ECM MR mode

ECM MMH mode

ECM MH mode

MR Mode

MH Mode

Yes No Yes No NO NO NO NO NO NO NO NO NO No No No

Yes No Yes No Yes No Yes No No No NO No NO NO No No

Yes Yes No No Yes Yes NO No No NO NO NO NO No No No

Yes Yes Yes Yes Yes Yes Yes Yes No No No No NO NO No No

Yes No Yes No Yes No Yes No Yes No Yes No Yes NO Yes No

Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

(Depending on remote machine)

SW2 No. 4 CNG detection in Standby mode

When setting to “I”, the CNG signal detection function during standby

stops.

SW2 No. 5 Polling Security

This switch is employed to enable or disable the polling operation using

the ID code verification function, in order to prevent unauthorized polling operation.

SW2 No. 6 Automatic Cover Sheet

When “0” (=YES) is selected, the cover sheet is automatically sent after

transmission of the original to notify the receiver of the number of origi-

nal sheets transmitted.

SW2 No. 7 Junk fax function in manual reception

It is set whether Junk fax is functioned in the manual receiving mode or

not.

SW2 No. 8 Anti Junk fax function

This function is used to receive data from a specific remote machine

(station registered in entry mode). It is the function that refused a reception in the case that TSI of remote machine mached with fax number of

the station registered.

0 : No

SW3 No. 5 - No. 8Automatic switching manual to auto receive mode

(0 : OFF)

Choice is made after how many rings in the manual receive mode it

should be automatically change to auto answer mode or remain in the

manual receive mode. Entering the binary number 0 forces the machine

to remain in the manual answer mode. If a number between 1 and 9 is

entered, the machine will go into the answer mode after the given number

of rings. However, it can be used as an ordinary telephone if the handset

is taken off the hook before this programmed number is finished.

SW4 No. 1 - No. 3 Communication results printout

(Transaction report)

Every communication, the result can be output. As usual, it is set to print

the timer sending communication error alone. If No.1 : 0 No.2 : 0 No.3

: 1 are set, printing is always on (printed ever if it is normally ended).

000 : Error, timer and memory sending/receiving

010 : Sending

110 : Continuous printing

100 : Not printed

001 : Communication error

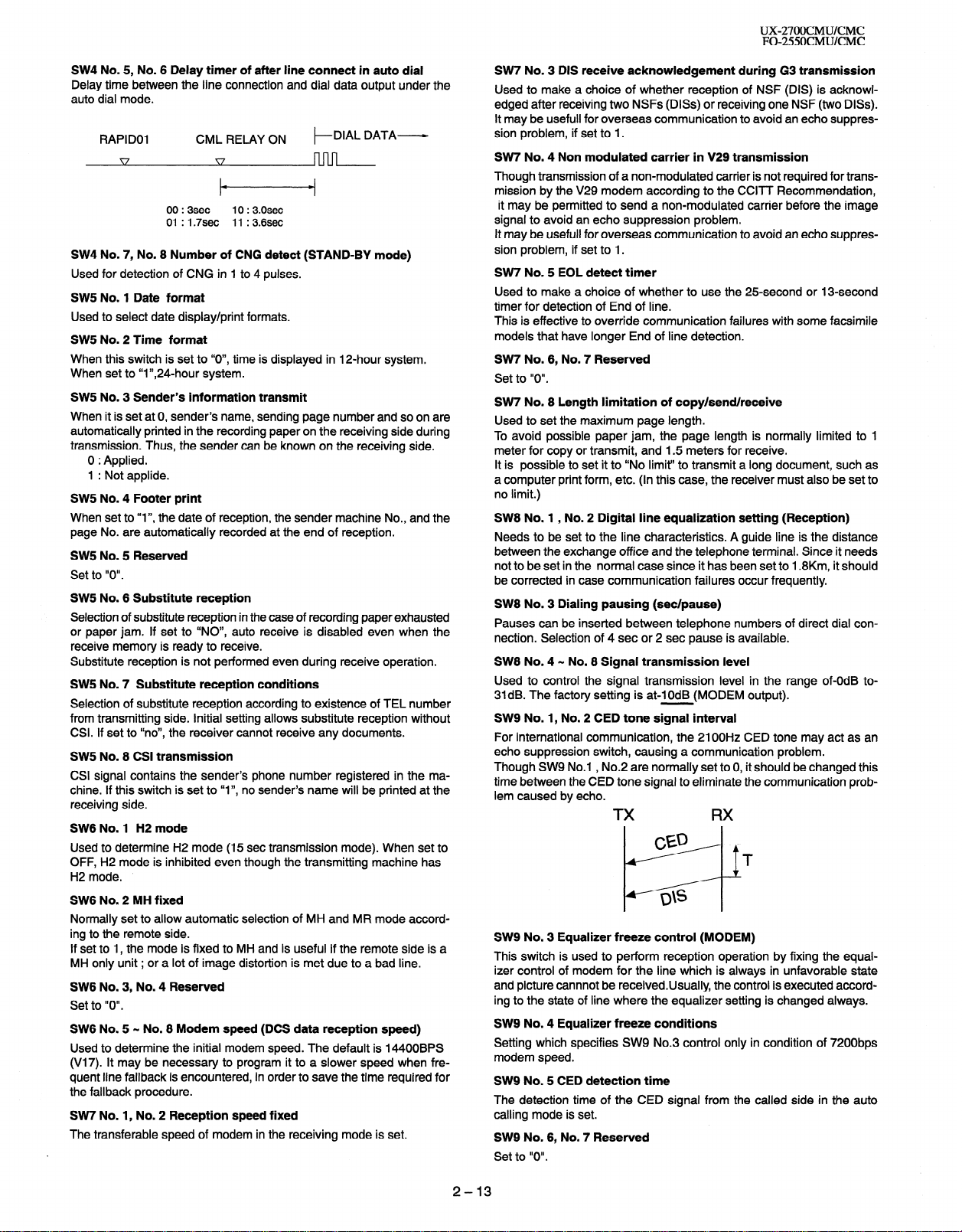

SW4 No. 4 Delay timer before line connect in auto dial

Delay time between the dial key input and line connection under the

auto dial mode.

1 : Yes

SW3 No. 1 N No. 4 Number of rings for auto receive

(0 : No ring receive)

RAPID01 CML RELAY ON

When the machine is set in the auto receive mode, the number of rings

before answering can be selected. It may be set from one to nine rings

using a binary number. If the soft switch was set to 1, a direct connection is made to the facsimile. If a facsimile. If it was set to 0 accidentally,

receive ring is set to 1.

1-4 DIALLING

0:Osec

1 :3sec

2-12

Page 25

UX-27OOCMUKMC

FO-255OCMUKMC

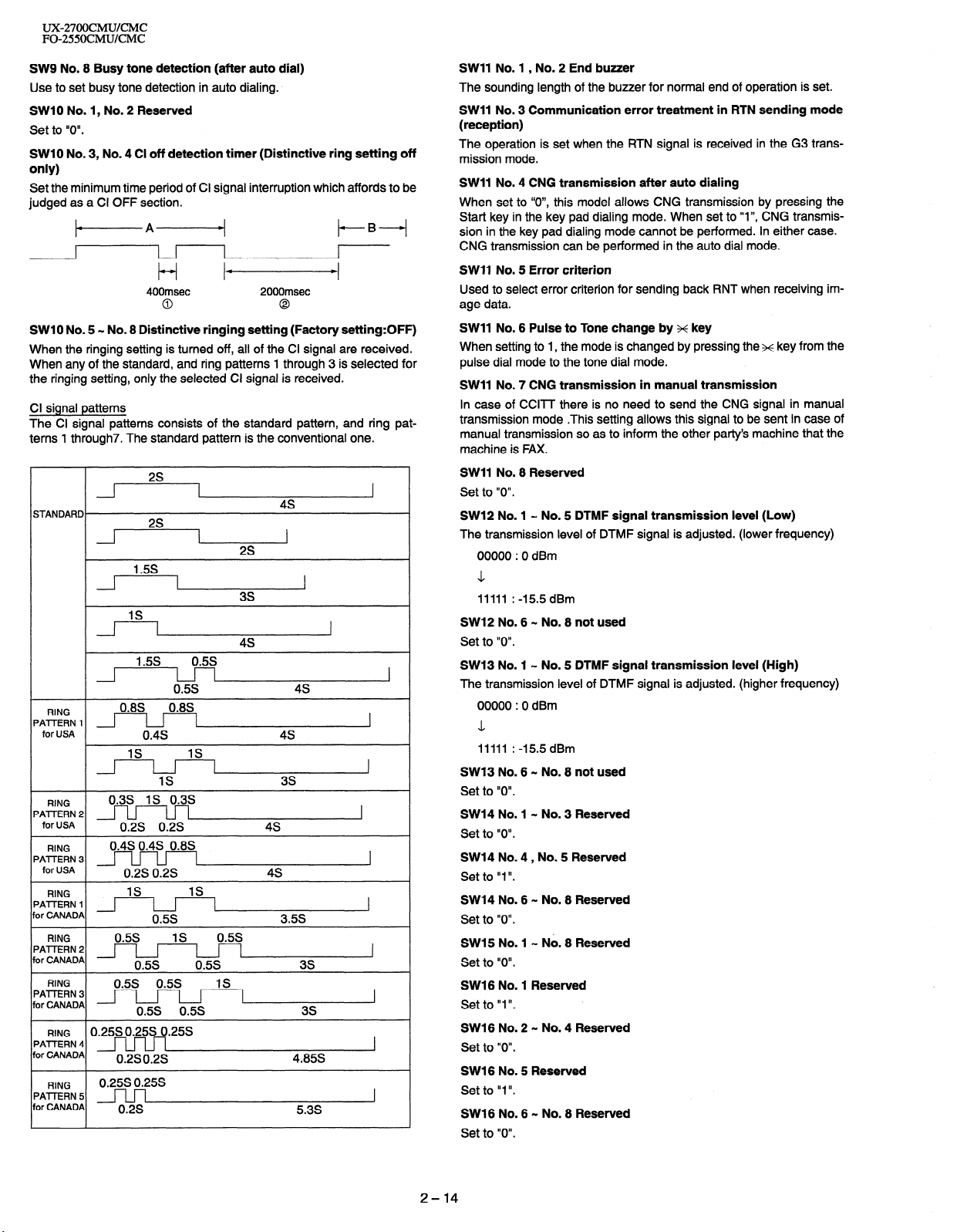

SW4 No. 5, No. 6 Delay timer of after line connect in auto dial

Delay time between the line connection and dial data output under the

auto dial mode.

RAPID01

CML RELAY ON t-

00 : 3sec

01 : 1.7sec

10 : 3.0sec

11 : 3.6sec

DIAL DATA-

SW4 No. 7, No. 8 Number of CNG detect (STAND-BY mode)

Used for detection of CNG in 1 to 4 pulses.

SW5 No. 1 Date format

Used to select date display/print formats.

SW5 No. 2 Time format

When this switch is set to “O”, time

is displayed in 12-hour system.

When set to “I”,24-hour system.

SW5 No. 3 Sender’s information transmit

When it is set at 0, sender’s name, sending page number and so on are

automatically printed in the recording paper on the receiving side during

transmission. Thus, the sender can be known on the receiving side.

0 : Applied.

1 : Not applide.

SW5 No. 4 Footer print

When set to “

page No. are automatically

I”, the date of reception , the sender machine No., and the

recorded at the end of reception.

SW5 No. 5 Reserved

Set to “0”.

SW5 No. 6 Substitute reception

Selection of substitute reception in the case of recording paper exhausted

or paper jam. If set to “NO”, auto receive is disabled even when the

receive memory is ready to receive.

Substitute reception is not performed even during receive operation.

SW5 No. 7 Substitute reception conditions

Selection of substitute reception according to existence of TEL number

from transmitting side. Initial setting allows substitute reception without

CSI. If set to “no”, the receiver cannot receive any documents.

SW5 No. 8 CSI transmission

CSI signal contains the sender’s phone number registered in the machine. If this switch is set to “I”, no sender’s name will be printed at the

receiving side.

SW6 No. 1 H2 mode

Used to determine H2 mode (15 set transmission mode). When set to

OFF, H2 mode is inhibited even though the transmitting machine has

H2 mode.

SW6 No. 2 MH fixed

Normally set to allow automatic selection of MH and MR mode according to the remote side.

If set to 1, the mode is fixed to MH and is useful if the remote side is a

MH only unit ; or a lot of image distortion is met due to a bad line.

SW6 No. 3, No. 4 Reserved

Set to “0”.

SW6 No. 5 - No. 8 Modem speed (DCS data reception speed)

Used to determine the initial modem speed. The default is 14400BPS

(V17). It may be necessary to program it to a slower speed when frequent line fallback is encountered, in order to save the time required for

the fallback procedure.

SW7 No. 1, No. 2 Reception speed fixed

The transferable speed of modem in the receiving mode is set.

SW7 No. 3 DIS receive acknowledgement during G3 transmission

Used to make a choice of whether reception of NSF (DIS) is acknowl-

edged after receiving two NSFs (DISs) or receiving one NSF (two DISs).

It may be usefull for overseas communication to avoid an echo suppres-

sion problem, if set to 1.

SW7 No. 4 Non modulated carrier in V29 transmission

Though transmission of a non-modulated carrier is not required for trans-

mission by the V29 modem according to the CCITT Recommendation,

it may be permitted to send a non-modulated carrier before the image

signal to avoid an echo suppression problem.

It may be usefull for overseas communication to avoid an echo suppression problem, if set to 1.

SW7 No. 5 EOL detect timer

Used to make a choice of whether to use the 25.second or 13-second

timer for detection of End of line.

This is effective to override communication failures with some facsimile

models that have longer End of line detection.

SW7 No. 6, No. 7 Reserved

Set to “0”.

SW7 No. 8 Length limitation of copy/send/receive

Used to set the maximum page length.

To avoid possible paper jam, the page length is normally limited to 1

meter for copy or transmit, and 1.5 meters for receive.

It is possible to set it to “No limit” to transmit a long document, such as

a computer print form, etc. (In this case, the receiver must also be set to

no limit.)

SW8 No. 1 , No. 2 Digital line equalization setting (Reception)

Needs to be set to the line characteristics. A guide line is the distance

between the exchange office and the telephone terminal. Since it needs

not to be set in the normal case since it has been set to 1.8Km, it should

be corrected in case communication failures occur frequently.

SW8 No. 3 Dialing pausing (set/pause)

Pauses can be inserted between telephone numbers of

direct dial con-

nection. Selection of 4 set or 2 set pause is available.

SW8 No. 4 - No. 8 Signal transmission level

Used to control the signal transmission level in the range of-OdB to31dB. The factory setting is at-IOdB (MODEM output).

SW9 No. 1, No. 2 CED tone signal interval

For international communication, the 2100Hz CED tone may act as an

echo suppression switch, causing a communication problem.

Though SW9 No.1 , No.2 are normally set to 0, it should be changed this

time between the CED tone signal to eliminate the communication problem caused by echo.

SW9 No. 3 Equalizer freeze control (MODEM)

This switch is used to perform reception operation by fixing the equal-

izer control of modem for the line which is always in unfavorable state

and picture cannnot be receivedUsually, the control is executed according to the state of line where the equalizer setting is changed always.

SW9 No. 4 Equalizer freeze conditions

Setting which specifies SW9 No.3 control only in condition of 7200bps

modem speed.

SW9 No. 5 CED detection time

The detection time of the CED signal from the called side in the auto

calling mode is set.

SW9 No. 6, No. 7 Reserved

Set to “0”.

2-13

Page 26

UX-27OOCMUKMC

FO-255OCMUKMC

SW9 No. 8 Busy tone detection (after auto dial)

Use to set busy tone detection in auto dialing.

SW10 No. 1, No. 2 Reserved

Set to “0”.

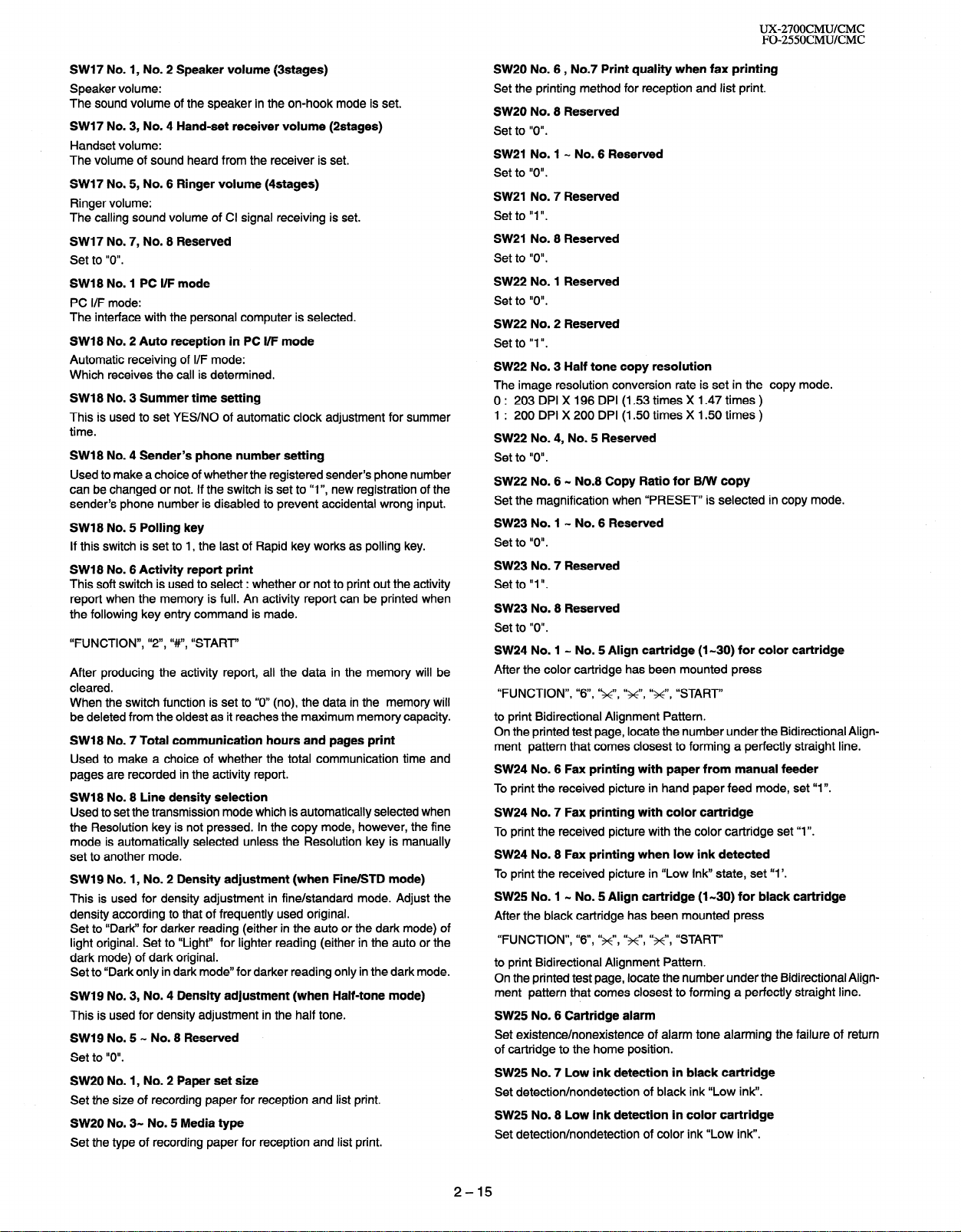

SW10 No. 3, No. 4 Cl off detection timer (Distinctive ring setting off

only)

Set the minimum time period of Cl signal interruption which affords to be

judged as a Cl OFF section.

+A+

I I

t-i Id

400msec 2000msec

0

0

t-B-i

LI

SW1 0 No. 5 - No. 8 Distinctive ringing setting (Factory setting:OFF)

When the ringing setting is turned off, all of the Cl signal are received.

When any of the standard, and ring patterns 1 through 3 is selected for

the ringing setting, only the selected Cl signal is received.

Cl signal patterns

The Cl signal patterns consists of the standard pattern, and ring patterns 1 through7. The standard pattern is the conventional one.

2s

1

STANDARD.

1

4s

2s

1.5s

3s

IS

I

4s

/i -l--I

RING

‘AlTERN 1 1

‘AlTERN 2

‘AlTERN 3

‘AlTERN 2

or CANADA

‘AlTERN 3

or CANADA

‘AlTERN 4

or CANADA

‘AlTERN 5

or CANADA

I

for USA

RING

for USA

RING

for USA

RING

RING

RING

RING

1.5s 0.5s

0.5s

0.8S, , , 0.8S,

I-l I

0.4s 4s

IS

IS

IS

0.3s IS 0.3s

0.2s 0.2s

0.4s 0.4s 0.8s

0.2s 0.2s 4s

IS

IS

0.5s 3.5s

0.25s 0.25s 0.25s

0.2s 0.2s

0.25SO.25S

0.2s

4s

3s

4s

4.85s

5.3s

1

I

I

I

I

SW11 No. 1 , No. 2 End buzzer

The sounding length of the buzzer for normal end of operation is set.

SW11 No. 3 Communication error treatment in RTN sending mode

(reception)

The operation is set when the RTN signal is received in the G3 trans-

mission mode.

SW11 No. 4 CNG transmission after auto dialing

When set to ‘IO”, this model allows CNG transmission by pressing the

Start key in the key pad dialing mode. When set to “I”, CNG transmission in the key pad dialing mode cannot be performed. In either case.

CNG transmission can be performed in the auto dial mode.

SW11 No. 5 Error criterion

Used to select error criterion for sending back RNT when receiving image data.

SW11 No. 6 Pulse to Tone change by x key

When setting to 1, the mode is changed by pressing the x key from the

pulse dial mode to the tone dial mode.

SW11 No. 7 CNG transmission in manual transmission

In case of CCITT there is no need to send the CNG signal in manual

transmission mode .This setting allows this signal to be sent in case of

manual transmission so as to inform the other party’s machine that the

machine is FAX.

SW11 No. 8 Reserved

Set to “0”.

SW12 No. 1 - No. 5 DTMF signal transmission level (Low)

The transmission level of DTMF signal is adjusted. (lower frequency)

00000 : 0 dBm

\1

11111 : -15.5 dBm

SW12 No. 6 - No. 8 not used

Set to “0”.

SW13 No. 1 - No. 5 DTMF signal transmission level (High)

The transmission level of DTMF signal is adjusted. (higher frequency)

00000 : 0 dBm

L

11111 : -15.5 dBm

SW13 No. 6 w No. 8 not used

Set to “0”.

SW14 No. 1 - No. 3 Reserved

Set to “0”.

SW14 No. 4, No. 5 Reserved

Set to “1”.

SW14 No. 6 - No. 8 Reserved

Set to “0”.

SW15 No. 1 - No. 8 Reserved

Set to “0”.

SW16 No. 1 Reserved

Set to “1”.

SW16 No. 2 - No. 4 Reserved

Set to “0”.

SW16 No. 5 Reserved

Set to “I “.

SW16 No. 6 - No. 8 Reserved

Set to “0”.

2-14

Page 27

UX-27OOCMUKMC

FO-255OCMUKMC

SW17 No. 1, No. 2 Speaker volume (3stages)

Speaker volume:

The sound volume of the speaker in the on-hook mode is set.

SW17 No. 3, No. 4 Hand-set receiver volume (2stages)

Handset volume:

The volume of sound heard from the receiver is set.

SW17 No. 5, No. 6 Ringer volume (4stages)

Ringer volume:

The calling sound volume of Cl signal receiving is set.

SW17 No. 7, No. 8 Reserved

Set to “0”.

SW18 No. 1 PC I/F mode

PC I/F mode:

The interface with the personal computer is selected.

SW18 No. 2 Auto reception in PC I/F mode

Automatic receiving of I/F mode:

Which receives the call is determined.

SW18 No. 3 Summer time setting

This is used to set YES/NO of automatic clock adjustment for summer

time.

SW18 No. 4 Sender’s phone number setting

Used to make a choice of whether the registered sender’s phone number

can be changed or not. If the switch is set to “I”, new registration of the

sender’s phone number is disabled to prevent accidental wrong input.

SW18 No. 5 Polling key

If this switch is set to 1, the last of Rapid key works as polling key.

SW18 No. 6 Activity report print

This soft switch is used to select : whether or not to print out the activity

report when the memory is full. An activity report can be printed when

the following key entry command is made.

“FUNCTION”, “Z”, “#“, “START’

After producing the activity report, all the data in the memory will be

cleared.

When the switch function is set to “0” (no), the data in the memory will

be deleted from the oldest as it reaches the maximum memory capacity.

SW18 No. 7 Total communication hours and pages print

Used to make a choice of whether the total communication time and

pages are recorded in the activity report.

SW18 No. 8 Line density selection

Used to set the transmission mode which is automatically selected when

the Resolution key is not pressed. In the copy mode, however, the fine

mode is automatically selected unless the Resolution key is manually

set to another mode.

SW19 No. 1, No. 2 Density adjustment (when Fine/STD mode)

This is used for density adjustment in fine/standard mode. Adjust the

density according to that of frequently used original.

Set to “Dark” for darker reading (either in the auto or the dark mode) of

light original. Set to “Light” for lighter reading (either in the auto or the

dark mode) of dark original.

Set to “Dark only in dark mode” for darker reading only in the dark mode.

SW19 No. 3, No. 4 Density adjustment (when Half-tone mode)

This is used for density adjustment in the half tone.

SW19 No. 5 w No. 8 Reserved

Set to “0”.

SW20 No. 1, No. 2 Paper set size

Set the size of recording paper for reception and list print.

SW20 No. 3- No. 5 Media type

Set the type of recording paper for reception and list print.