Page 1

TopPage

SERVICE MANUAL

CODE: 00ZMXLCX4/S1E

DIGITAL MULTIFUNCTIONAL SYSTEM

OPTION

LARGE CAPACITY THREE TRAYS

CONTENTS

[1] SPECIFICATIONS . . . . . . . . . . . . . 1-1

[2] MAINTENANCE

1. Maintenance table . . . . . . . . . . 2-1

[3] REPLACEMENT AND ADJUSTMENT

1. Front door and covers . . . . . . . 3-1

2. Inner cover, paper feed unit . . . 3-1

3. Paper feed roller . . . . . . . . . . . . 3-1

4. LCT motors. . . . . . . . . . . . . . . . 3-2

5. Image position sensor board,

exit sensor . . . . . . . . . . . . . . . . 3-4

6. Paper height sensors,

paper size sensors . . . . . . . . . . 3-4

7. Main control board . . . . . . . . . . 3-4

8. Side registration adjustment . . . 3-5

9. Dehumidifier heater

installing procedures

(0PQC4150431//) . . . . . . . . . . . 3-5

MODEL

[4] DETAILED DESCRIPTIONS

1. Paper feed . . . . . . . . . . . . . . . . 4-1

2. Paper lift . . . . . . . . . . . . . . . . . . 4-2

3. Paper size detection. . . . . . . . . 4-2

4. Remaining paper detectiion . . . 4-3

5. Paper end detection . . . . . . . . . 4-3

[5] OVERALL MECHANICAL

INFORMATION

1. Mechanical component

layout . . . . . . . . . . . . . . . . . . . . 5-1

2. Drive layout . . . . . . . . . . . . . . . 5-1

3. Electrical components . . . . . . . 5-2

4. A4/LT LCT MX-LCX4 layout

(with bypass) . . . . . . . . . . . . . . 5-3

5. Electrical component

summary . . . . . . . . . . . . . . . . . 5-3

MX-LCX4

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

MX-LCX4

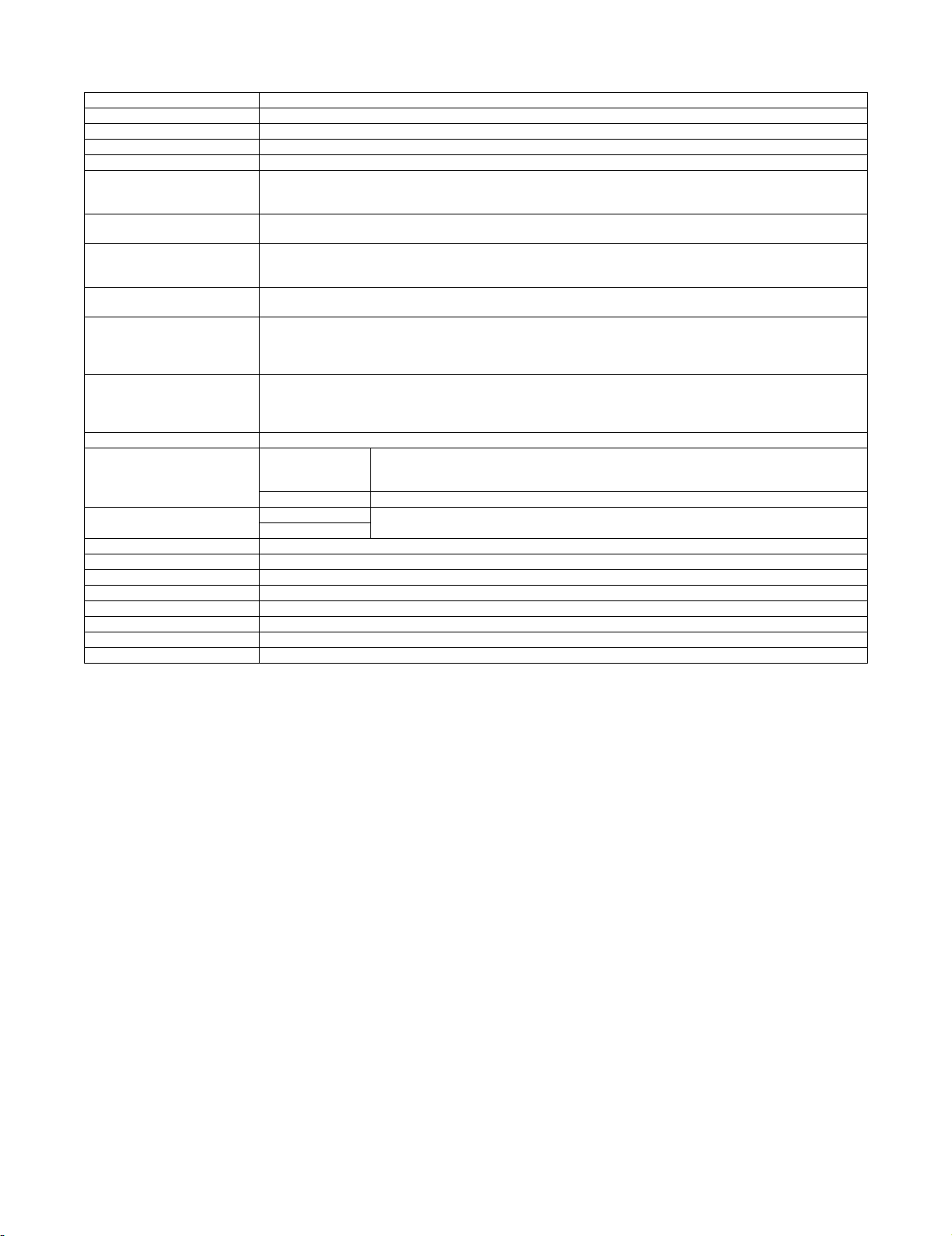

[1] SPECIFICATIONS

Form Large Capacity Trays (3 Trays)

Transport speed 85 – 110 sheets/minute to be supported

Transport standard Center alignment

Paper size A4, A5R, B5, 8.5 x 11, 5.5 x 8.5R, 9 x 12 (A4W)

Paper size label Available

Paper size setting Upper tray: User setting (Size setting by guide at Interior side of tray)

Paper size setting for shipment Inch: 8.5 x 11

Feedable paper size/weight Upper tray: 52 – 205 g/m

Paper type Plain paper, Heavy paper, Recycled paper, Thin paper, Pre-printed paper, letter head, Punched paper, Transparency paper,

Paper capacity Standard Paper

Detection of remaining paper Available level detection (5 levels)

Paper supply Paper supply from the upper section by the front loading method

Tray rising/falling time Rising Upper tray / Middle tray: 10 seconds or less

Reliability MCBJ in compliance with the main unit

Life 5 years or 24,000K

Power consumption 150W or less

Power source DC24V (Supplied by the main unit)

Dimensions W526 x D728 x H980 mm

Occupied dimension 540 x 730 mm

Weight Approximately 95 kg

Installation/Maintenance By service person

Heater AC 18W x 2 36W (Service parts: 0PQC4150431//)

Middle tray: User setting (Size setting by guide at Interior side of tray)

Lower tray: Service setting (Size setting by operation panel)

AB: A4

Middle tray: 52 – 205 g/m

Lower tray: 52 – 163 g/m

Colored paper, Tab paper (Not available for the Saddle tray), Label paper (Available only for the Offset tray)

Upper tray / Middle tray: 1000 sheets

Lower tray: 2550 sheets

2

(80 g/m

)

Upper tray / Middle tray: 100%, 75%, 50%, 25%, Empty

Lower tray: 100%, 75%, 50%, 25%, Empty

* Detection error 3%

Falling Self-weight falling

MCBF

2

/ 16 lbs Bond – 110 lbs Index

2

/ 16 lbs Bond – 110 lbs Index

2

/ 16 lbs Bond – 90 lbs Index

Lower tray : 15 seconds or less

Time required from tray insertion to empty detection without paper

Service Manual

MX-LCX4 SPECIFICATIONS 1 – 1

Page 3

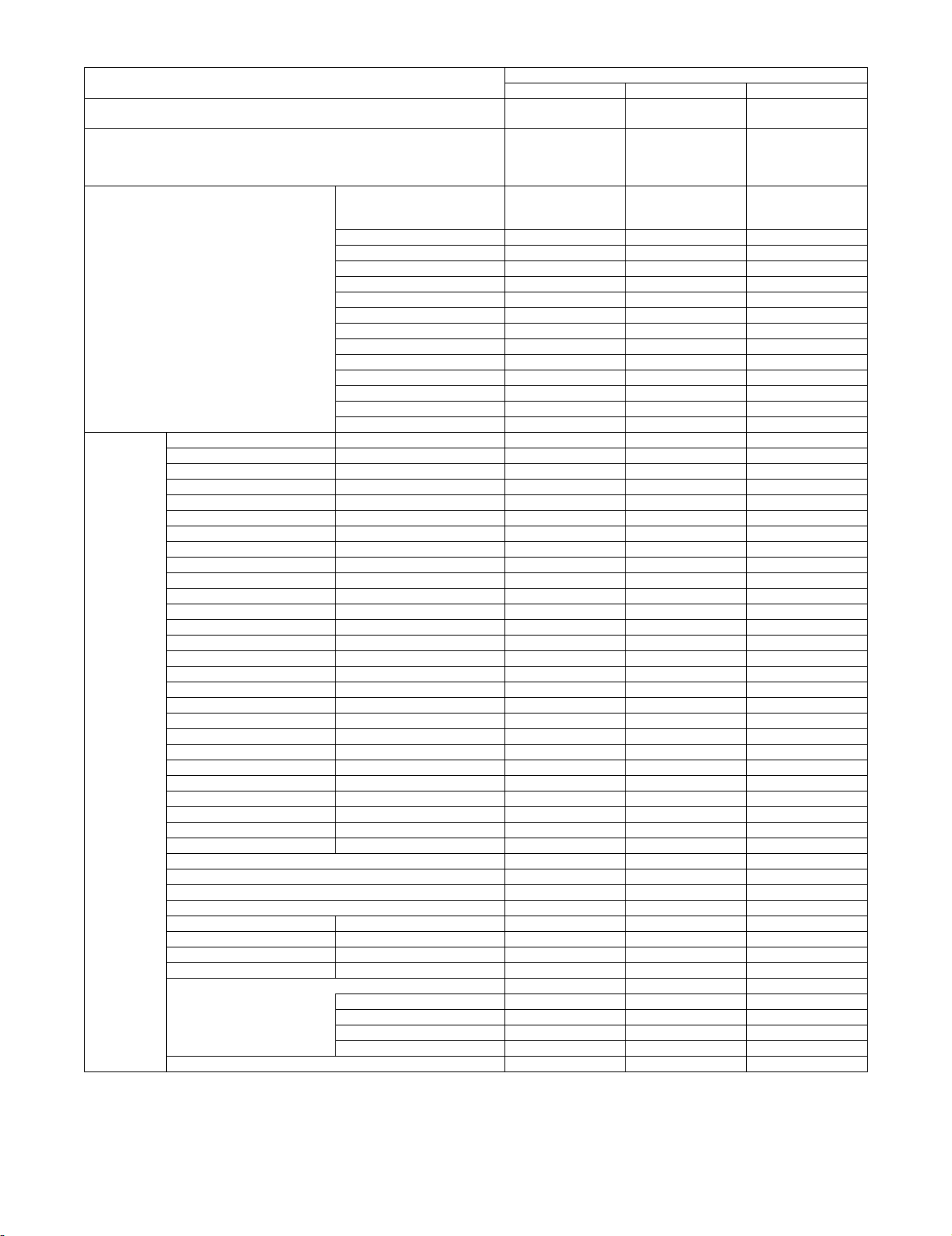

Paper Size/Type/Weight

LCT(A4)

Uppe r Tr ay Mi dd le Tr ay Lo wer Tra y

Minimum paper weight 52 g/m

2

(14 lbs bond)

Maximum paper weight 205 g/m

2

(40 lbs bond)

(110 lbs index)

(65 lbs cover)

Paper type Thin paper Yes

(Even 52 g/m

2

(110 lbs index)

(65 lbs cover)

(Even 52 g/m

is possible)

Plain paper Yes Yes Yes

Recycled paper Yes Yes Yes

Colored paper Yes Yes Yes

Letter head Yes Yes Yes

Pre-printed paper Yes Yes Yes

Pre-punched paper Yes Yes Yes

Heavy paper 1 (106 – 128 g/m

Heavy paper 2 (129 – 176 g/m

Heavy paper 3 (177 – 205 g/m

Heavy paper 4 (206 – 300 g/m

2

) Yes Yes Yes

2

) Yes Yes Yes

2

)Yes Yes No

2

)NoNoNo

Tab paper Yes Yes No

Transparency paper Yes Yes Yes

Label paper No Yes No

Paper size 12" x 18" (A3W) 305 x 457 — — —

Ledger (11" x 17") 279 x 432 — — —

Ledger (11" x 17") Z folding 279 x 216 — — —

Legal (8.5" x 14") 216 x 356 — — —

Legal (8.5" x 14") Z folding 216 x 178 — — —

Mexican Legal (8.5" x 13.4") 216 x 340 — — —

Foolscap (8.5" x 13") 216 x 330 — — —

Letter (8.5" x 11") 279 x 216 Yes Yes Yes

Letter R (8.5" x 11" R) 216 x 279 — — —

Letter R (8.5" x 11" R) Z folding 216 x 140 — — —

Invoice (5.5" x 8.5") 216 x 140 — — —

Invoice R (5.5" x 8.5" R) 140 x 216 Yes Yes Yes

Exective R (7.25" x 10.5") 184 x 266 — — —

9 x 12 (A4W) 305 x 229 Yes Yes Yes

A3 297 x 420 — — —

A3 Z folding 297 x 210 — — —

B4 257 x 364 — — —

B4 Z folding 257 x 182 — — —

A4 297 x 210 Yes Yes Yes

A4-R 210 x 297 — — —

A4-R Z folding 210 x 148 — — —

B5 257 x 182 Yes Yes Yes

B5-R 182 x 257 — — —

A5 210 x 148 — — —

A5-R 148 x 210 Yes Yes Yes

SRA3 320 x 450 mm — — —

SRA4 320 x 225 mm — — —

318 x 234.75 mm — — —

312.5 x 220 mm — — —

318 x 469.5 mm — — —

312.5 x 440 mm — — —

8K 270 x 390 — — —

16K 270 x 195 — — —

16K-R 195 x 270 — — —

Postcard 100 x 148 — — —

Special – Custom size

Custom Range

min Main — — —

No No No

max Main — — —

min Sub — — —

max Sub — — —

Special – Size uncertain — — —

2

52 g/m

(14 lbs bond)

2

205 g/m

(40 lbs bond)

Ye s

is possible)

(14 lbs bond)

163 g/m

(90 lbs Index)

2

(Even 52 g/m

is possible)

52 g/m

Yes

2

2

2

MX-LCX4 SPECIFICATIONS 1 – 2

Page 4

MX-LCX4

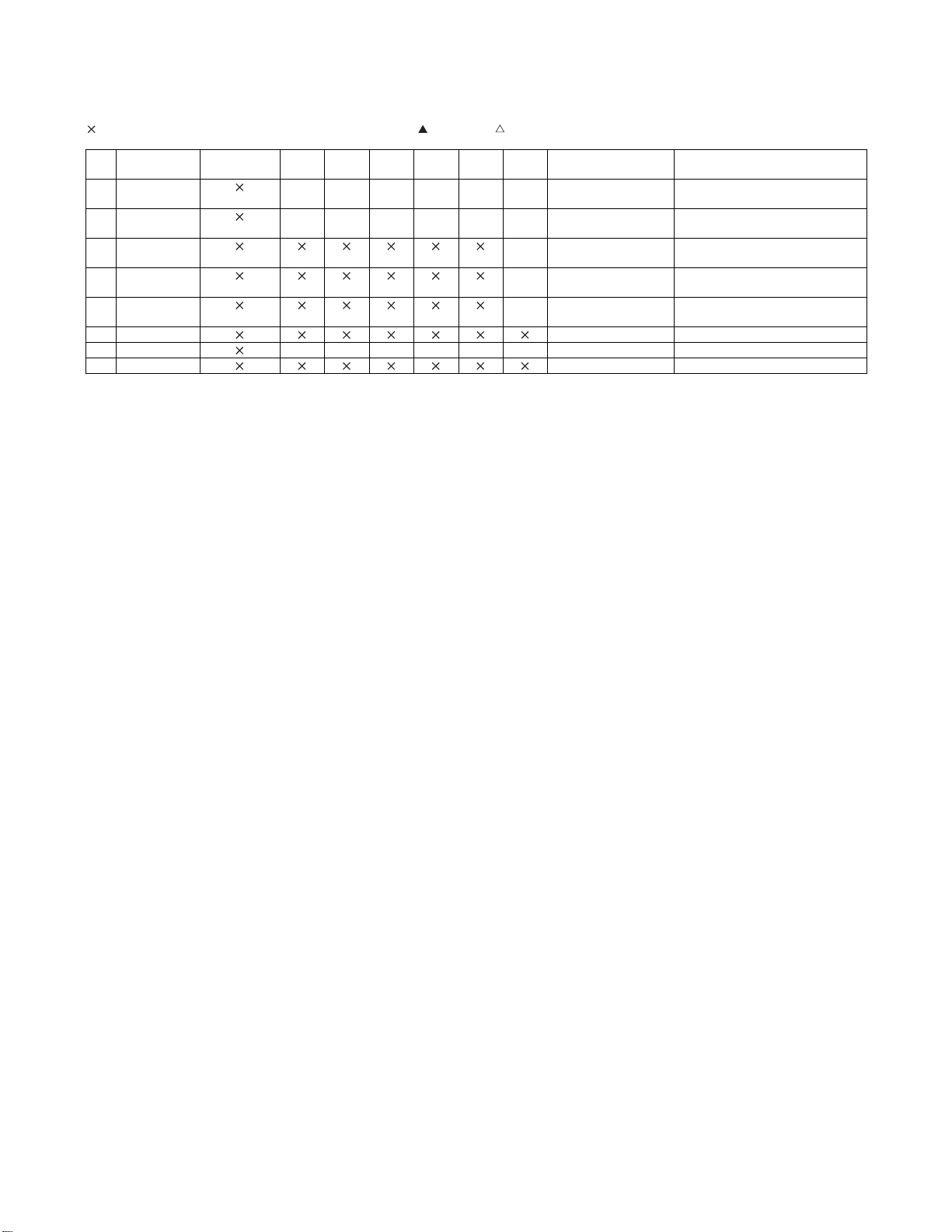

[2] MAINTENANCE

Service Manual

1. Maintenance table

: Check (Clean, replace or adjust as needed) {: Clean : Replace : Adjust ✩: Lubricate : Shift position

No. Parts name

1 Transport

guide plate

2 Grip roller

drive/follower

3 Pick-up roller

(1 – 3 step)

4 Feed roller

(1 - 3 step)

5 Separate roller

(1 – 3 step)

6 Torque limiter

7 Sensor {{{{{{

8Gear UKOG-0307FCZZ

Occasionally

When calling

500K 1000K 1500K 2000K 2500K 3000K

{{{{{{ When there is dirt, wipe with dry

{{{{{{ When there is dirt, wipe with cloth

Life judgement

(Reference)

[Note 1] Roller life 200K When there is dirt, wipe with cloth

[Note 1] Roller life 200K When there is dirt, wipe with cloth

[Note 1] Roller life 200K When there is dirt, wipe with cloth

Tool, oil, chemicals Procedure

Treatment after procedure

cloth.

and water.

and water.

and water.

and water.

[Note 1] Replacement reference: Replace according to each paper feed counter value.

MX-LCX4 Paper feed tray 1, 2, 3: 200K or 1 year Torque limiter: 800K

(NOTE) Paper feed section roller life

Each roller life is as shown on the left. When, therefore, a certain paper feed unit is excessively used, its life may be expired before the maintenance timing.

Actually, however, different sizes of paper are used with different paper feed trays, and it is quite rare that the roller replacement must be made

before the maintenance timing.

If a certain size of paper must be heavily used, set different paper feed trays for that paper size. This information must be explained to the user.

When servicing, check the use frequency of each paper feed tray, and replace the rollers as needed.

When cleaning the roller, it is advisable to use a cloth with a small quantity of water.

The friction level is smaller in the order of the paper pick-up roller, the paper feed roller, and the separation roller.

MX-LCX4 MAINTENANCE 2 – 1

Page 5

MX-LCX4

[3] REPLACEMENT AND

ADJUSTMENT

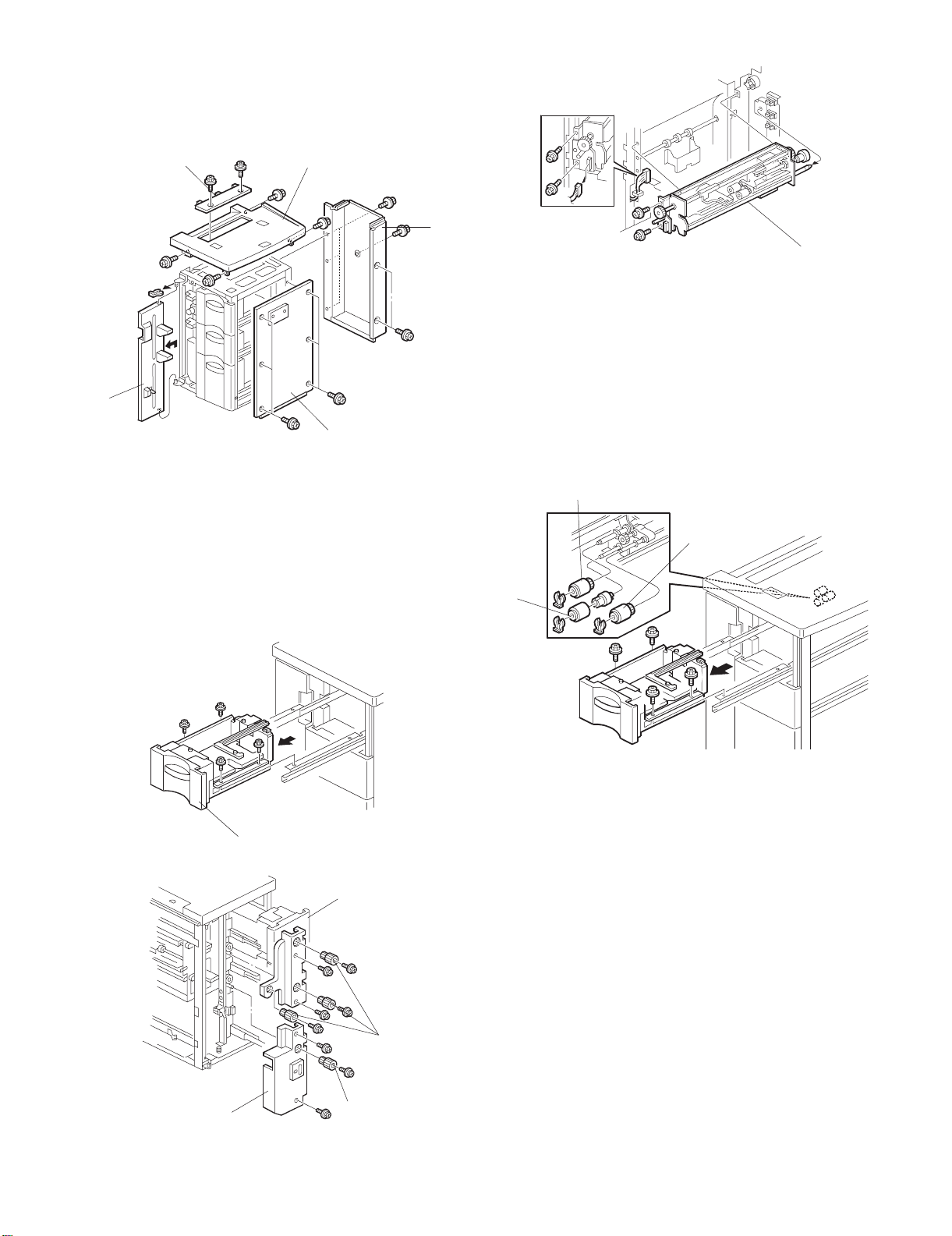

1. Front door and covers

Service Manual

[E]

[B]

[A] Top cover (screw x 4).

[B] Front door (stopper x 1).

NOTE: While lifting the top cover, remove the snap ring and front

door.

[C] Rear cover (screw x 6).

[D] Right cover (screw x 6).

[E] Paper slot cover (screw x 2).

[A]

[C]

[D]

2. Inner cover, paper feed unit

[F]

• Open the front door.

• Remove right cover (see 1.)

Remove:

[A] Pull out tray and remove it (screw x 4)

[B] Knobs (x 3) (screw x 1 each)

[C] Upper inner cover (screw x 2)

[D] Knob (screw x 1)

[E] Lower inner cover (screw x 1)

[F] Paper feed unit (connector x 1, screw x 2)

3. Paper feed roller

[B]

[A]

[C]

[E]

[A]

Remove:

• Remove the right cover (see 1.)

• Remove the paper trays. (see 2.)

[A] Pick-up roller (stopper x 1).

[B] Feed roller (stopper x 1).

[C] Separation roller (stopper x 1).

[C]

[B]

[D]

MX-LCX4 REPLACEMENT AND ADJUSTMENT 3 – 1

NOTE: 1) The LCT pick-up and separation rollers are the same

as pick-up and separation rollers of the main machine.

These rollers are interchangeable.

2) The feed rollers of the LCT and main machine are different because they are designed to rotate in opposite

directions. The feed rollers of the LCT and main

machine are not interchangeable.

3) Never touch the surface of the rollers with bare hands.

• Clear the PM counters for the new rollers (see Section "2. Preventive Maintenance).

Page 6

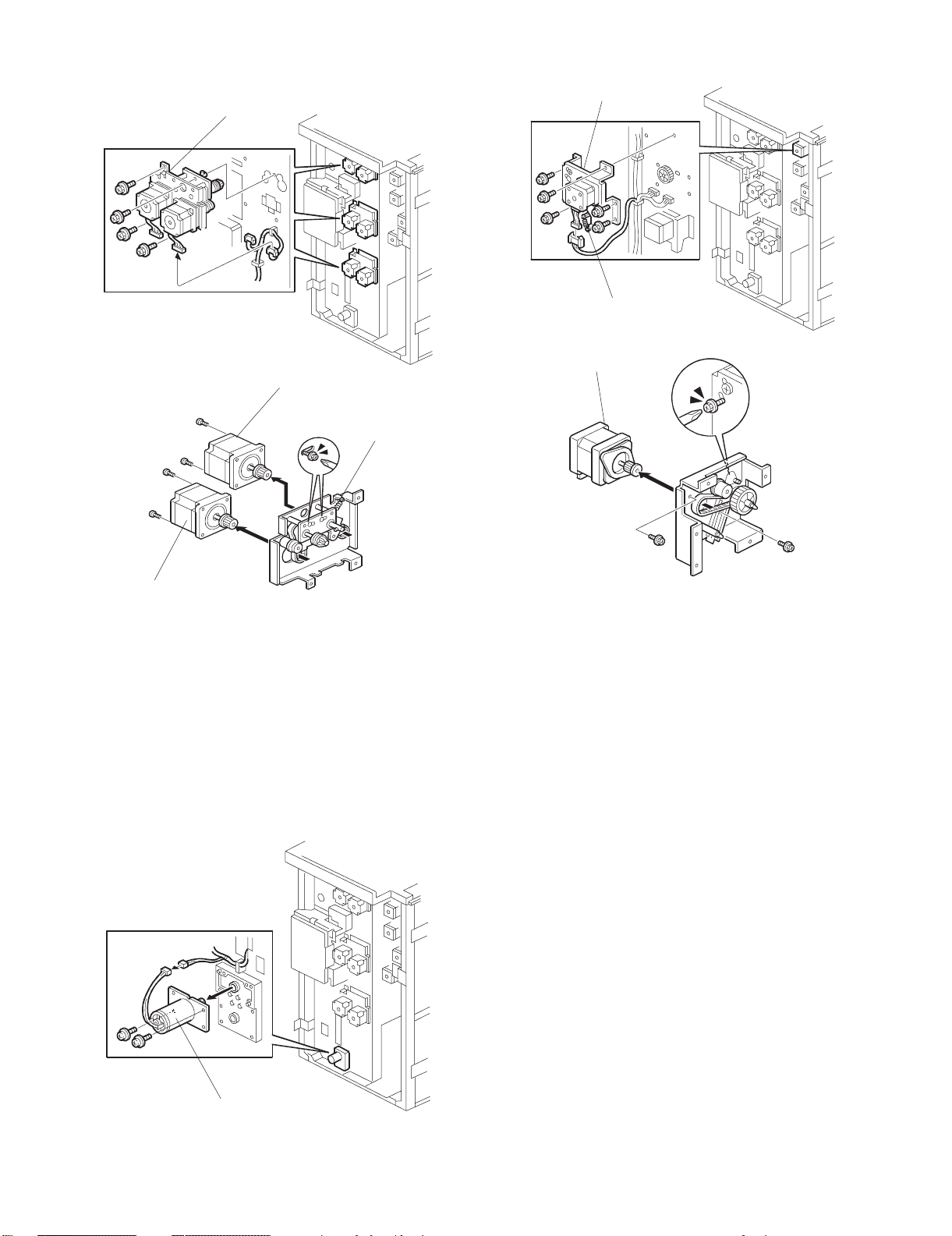

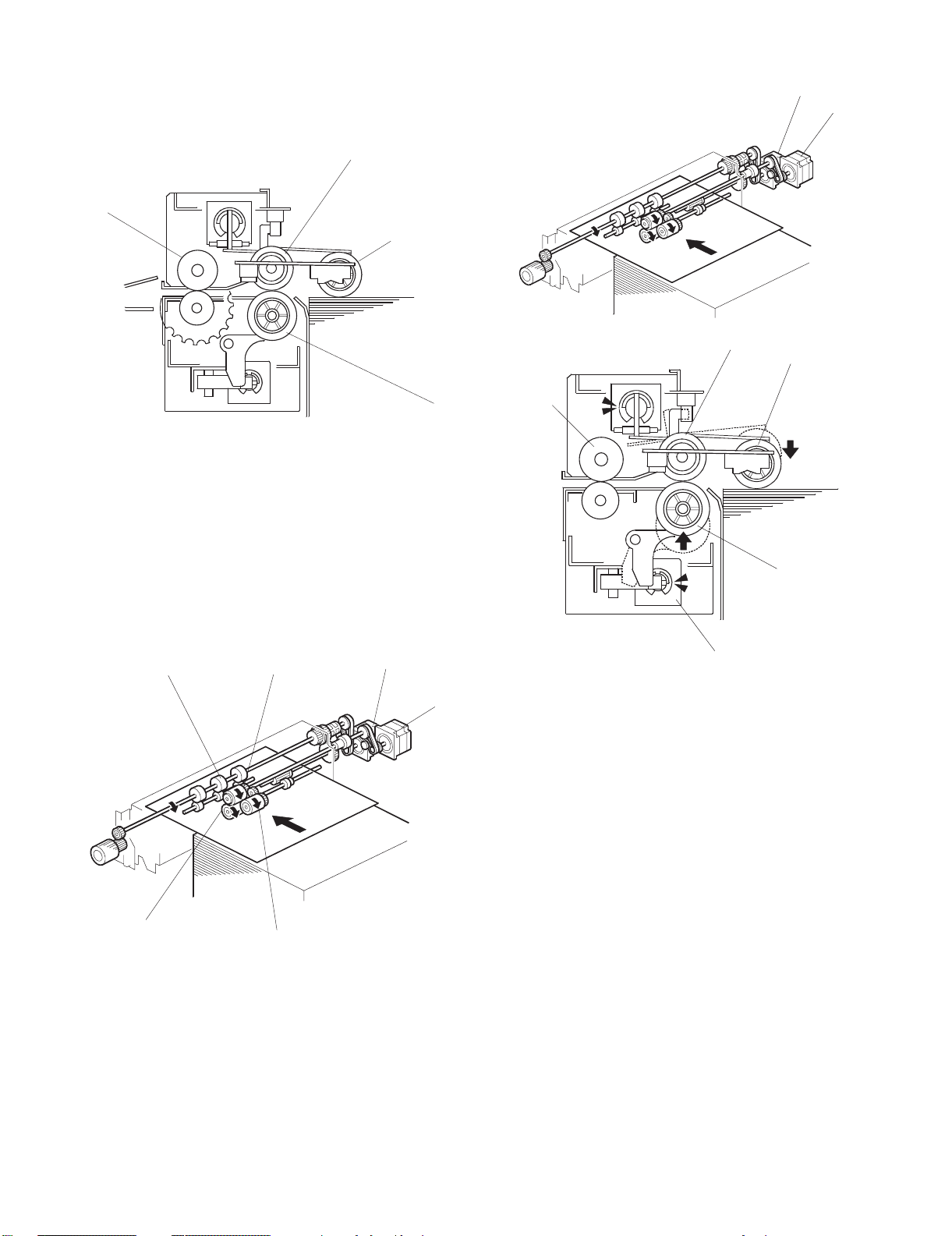

4. LCT motors

C. 4th transport motor

A. Paper feed, grip motors

[A]

(1)

(2)

[C]

(3)

[B]

[C]

[A]

[B]

(1)

[D]

Each paper feed unit has a paper feed motor (1) and a grip motor

(2). The removal procedure is the same for each feed tray.

Remove:

• Rear cover (see 1.)

[A] Motor unit (screw x 4, connector x 2)

[B] Springs (x 2). First, loosen the screws (x 2) (3).

[C] Paper feed motor (screw x 2)

[D] Grip motor (screw x 2)

Reinstallation

• Attach the tension spring, then tighten the screws (3) to tighten

the belts.

B. 6th lift motor

Remove:

• Rear cover. (see 1.)

[A] 4th Transport motor unit (screw x 5, connector x 1).

[B] Spring (x 1). First, loosen screw (1) (screw x 1).

[C] 4th transport motor (screw x 2, Timing belt x 1)

Reinstallation

• Be sure that the tension spring is connected, then tighten the

screw (1).

[A]

Remove:

• Rear cover (see 1.)

[A] 6th lift motor (screw x 2, connector x 1)

MX-LCX4 REPLACEMENT AND ADJUSTMENT 3 – 2

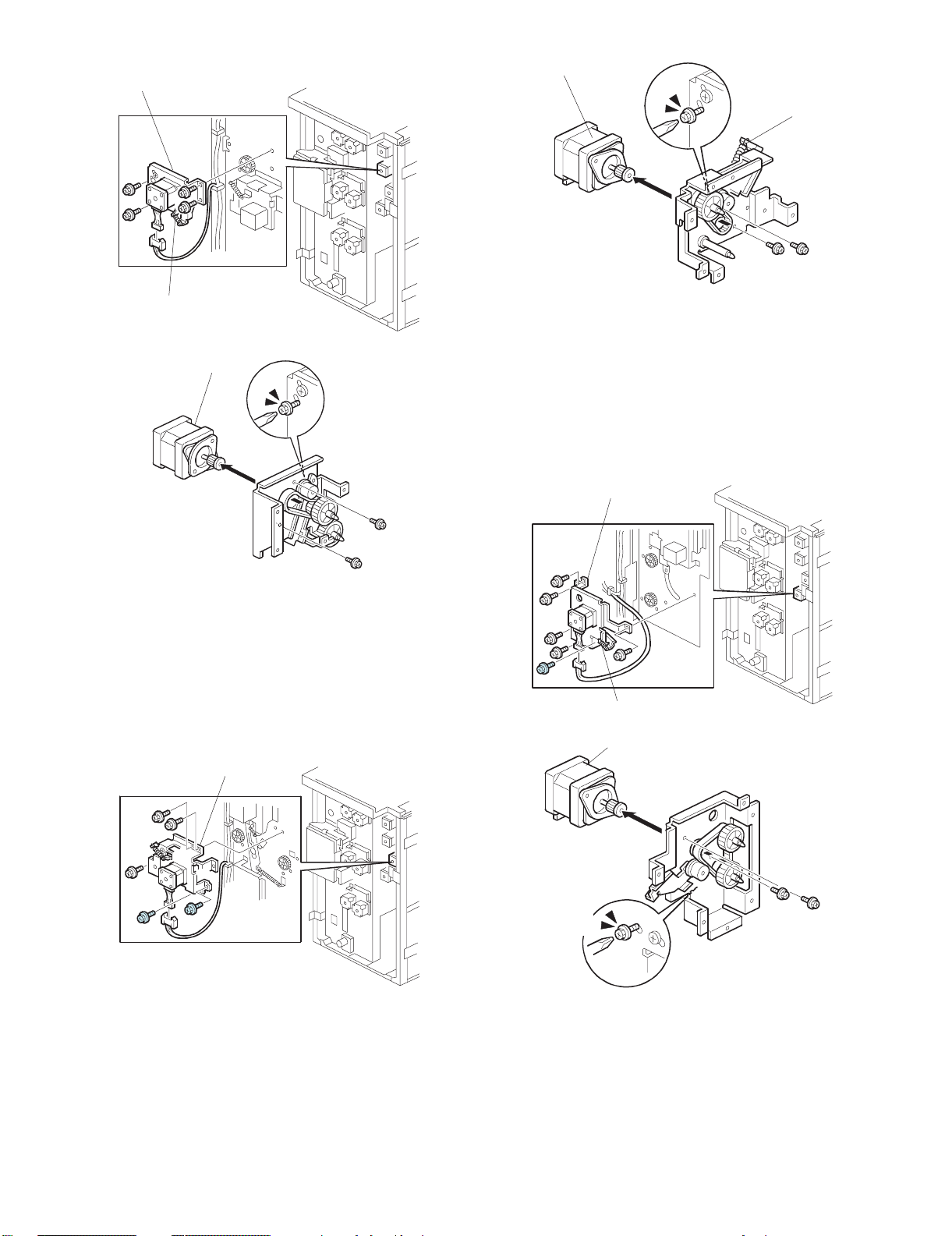

Page 7

D. 5th transport motor

[A]

[C]

(1)

[B]

[B]

[C]

Remove:

• Rear cover. (see 1.)

[A] Motor unit (screw x 4, connector x 1).

[B] Spring (x 1). First, loosen screw (1) (screw x 1).

[C] 5th Transport motor (screw x 2, Timing belt x 1)

Reinstallation

• Be sure that the tension spring is connected, then tighten the

screw (1).

(1)

E. LCT exit motor

Remove:

• Remove the rear cover. (see 1.)

[A] Motor unit (screw x 6, connector x 1).

[B] Spring (x 1). First, loosen screw (1) (screw x 1).

[C] LCT exit motor (screw x 2, Timing belt x 1)

Reinstallation

• Be sure that the tension spring is connected, then tighten the

screw (1).

F. 6th transport motor

[A]

[B]

[C]

[A]

(1)

Remove:

• Rear cover. (see 1.)

[A] Motor unit (screw x 6, connector x 1).

[B] Spring (x1). First, loosen screw (1) (screw x 1).

[C] LCT exit motor (screw x 2, Timing belt x 1)

Reinstallation

• Be sure that the tension spring is connected, then tighten the

screw (1).

MX-LCX4 REPLACEMENT AND ADJUSTMENT 3 – 3

Page 8

G. 4th, 5th lift motors

[A]

B. Image position sensor board

[E] Image position sensor board (screw x 2, clamp x 1, connector x

2)

C. Exit sensor

[F] Exit sensor unit (screw x 1, connector x 1, clamp x 1)

[G] Exit sensor

6. Paper height sensors, paper size

sensors

[B]

[C]

Remove:

• Rear cover. (see 1.)

[A] Main control board bracket (screw x 5, connector x All)

[B] 4th lift motor (screw x 3, connector x 1)

[C] 5th lift motor (screw x 3, connector x 1)

5. Image position sensor board, exit sensor

[E]

[A]

[C]

[A]

[C]

[A]

[B]

[B]

4th/5th Tray

6th Tray

Remove:

• Rear cover. (see 1.)

• Right cover. (see 1.)

[A] Paper height sensor unit (clamp x 2, screw x 1, connector x 4).

[B] Paper height sensors (Hooks x 4 each)

[C] Paper size sensors (connector x 1 each)

7. Main control board

[A]

[B]

[D]

[G]

[F]

A. Image position sensor

Disconnect the LCT from the copier.

[A] Harness cover (screw x 1, clamp x 1)

[B] Image position sensor unit (screw x 1, clamp x 1, connector x 1)

[C] Stopper (screw x 1)

[D] Image position sensor

• After replacing the image position sensor, do the procedure for

image position sensor adjustment. (see 9.)

MX-LCX4 REPLACEMENT AND ADJUSTMENT 3 – 4

Remove:

• Rear cover. (see 1.)

[A] Main control board (screw x 6, Standoffs x 2, connector x All)

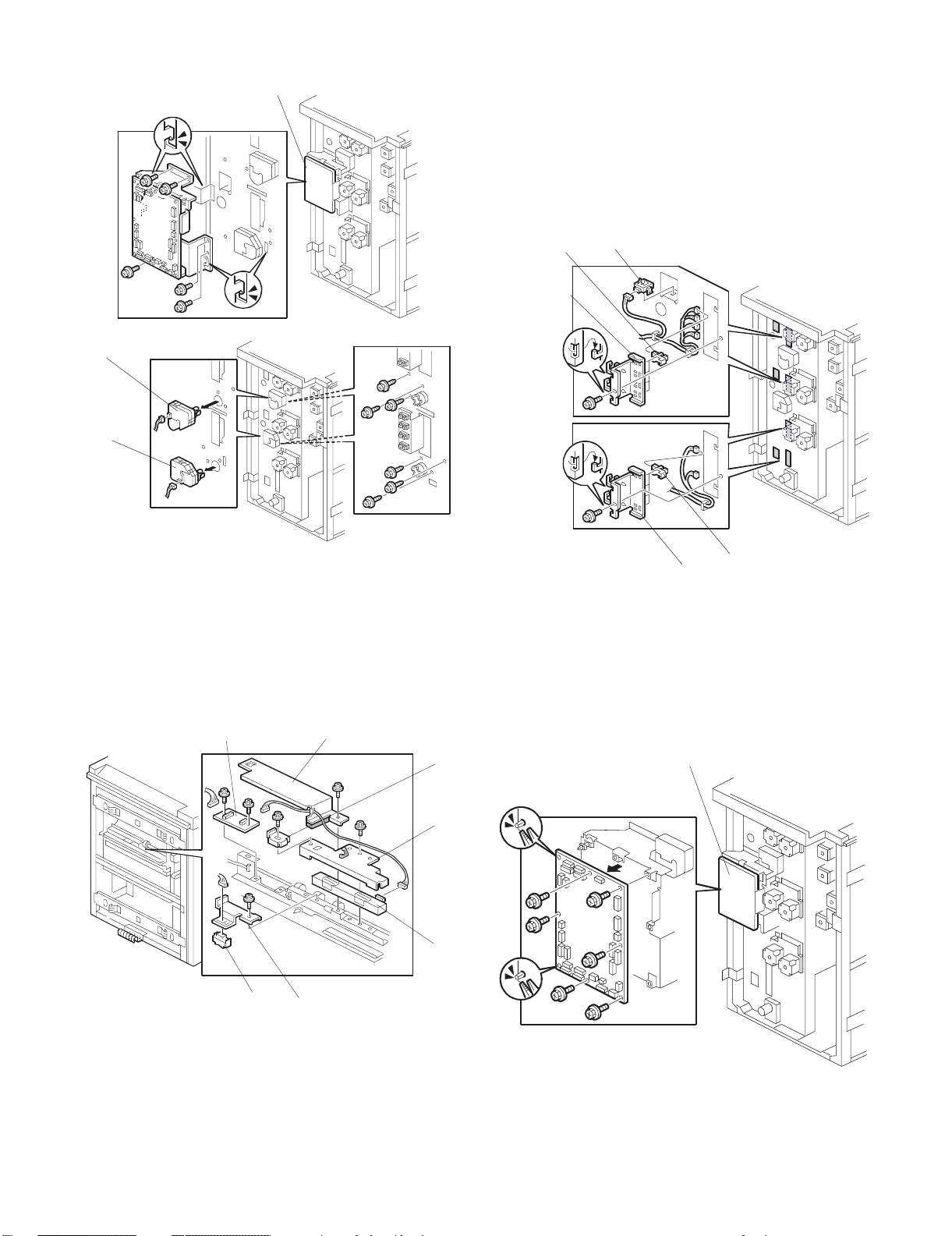

Page 9

8. Side registration adjustment

[A]

Normally the side registration of the image can be adjusted in the

SP mode.

If the punch hole positions are not aligned from a particular feed

station, however, you can manually adjust the side registration by

changing the tray cover position for that tray, and then adjust the

side registration of the image.

1) Pull out the tray.

2) Change the screw positions [A] at both the right and left sides

as shown.

NOTE: Adjustment range: 0 ± 2.0 mm adjustment step: 1.0 mm/

step

B. Installing procedures

1) Remove the lower-stage cassette (4 screws).

2) Remove the rear cabinet. (5 screws)

9. Dehumidifier heater installing procedures (0PQC4150431//)

A. Component parts

Heater cover

Heater

(x 2)

M4 washer screw (x 1)

Interface harness

(with heater line)

M4 screw (x 7)

Remove the earth plate. (2 screws)

MX-LCX4 REPLACEMENT AND ADJUSTMENT 3 – 5

Page 10

3) Remove the interface harness plate (2 screws), and remove

the harness.

Screw (x 2)

Interface harness

4) Install a new interface harness, and insert the connector into

the PWB.

Fix the earth wire of the heater harness with the accessory

washer screw.

6) Install the heater cover. (3 screws)

Install the rear cabinet and fix it with the screw.

Interface harness

Heater harness

section

Snap band fixing

Earth fixing screw

5) Fix the two heaters with two screws for each of them, and fix

the harness with the snap band.

Snap band fixing

(3 positions)

MX-LCX4 REPLACEMENT AND ADJUSTMENT 3 – 6

Page 11

MX-LCX4

[4] DETAILED DESCRIPTIONS

1. Paper feed

A. Paper feed rollers

[B]

[D]

[A]

C. Pick-up and feed

Service Manual

[D]

[C]

[C]

This LCT has three paper tray feed stations:

The 4th and 5th tray each hold 1,000 sheets of paper. The 6th tray

holds 2,550 sheets of paper. Total: 4,550 sheets

Each tray contains four rollers:

[A] Pick-up roller

[B] Paper feed roller

[C] Separation roller

[D] Grip roller

NOTE: The pick-up roller, paper feed roller, and separation roller

are a standard FRR paper feed system.

B. Paper feed motors

[E]

[F]

Two stepper motors control the paper feed drive:

[A] Paper feed motor

[B] Grip motor

The paper feed motor drives the pick-up roller [C] and the paper

feed roller [D].

The grip motor drives the grip roller [E] that feeds the paper out of

the tray, and the separation roller [F].

[D]

[C]

[B]

[A]

[E]

[F]

[G]

[B]

[A]

When a paper feed station is not selected:

• Separation roller solenoid [A] is de-activated

• Separation roller [B] turns freely.

When the paper feed station is selected for a job:

• Paper feed motor [C] and grip motor [D] turn on.

When the feed motor [C] turns on, it drives the feed roller [E]. It also

drives the pick-up roller [F] because the pick-up roller is linked to

the feed roller by an idle gear.

When the separation solenoid [A] turns on, the separation roller [B]

contacts the paper feed roller [E] and turns with the feed roller,

unless more than one sheet of paper is fed. The three trays of the

LCT unit use the standard FRR mechanism.

When the paper feed motor turns on, the pick-up solenoid turns on

and the pick-up roller [F] lowers until it contacts the top sheet of the

paper stack and then sends it to the paper feed and separation rollers.

When the paper feed sensor detects the leading edge of the paper,

the paper feed motor switches off, the pick-up roller lifts, and the

grip rollers [G] feed the paper out of the tray.

MX-LCX4 DETAILED DESCRIPTIONS 4 – 1

Page 12

2. Paper lift

A. Tray detection

When a tray is set in the machine, the tray detection method used

depends on the tray:

• The upper tray and middle tray are detected when any one of the

paper size switch signals is low.

• The lower tray is detected when the switch 1 signal of the paper

size switch is low.

[E]

[F]

[E]

C. Lift sensor

[D]

[A]

[E]

[C]

[B]

[J]

[G]

[D]

[C]

When the lift motor turns on, the pick-up solenoid [A] activates to

lower the pick-up roller [B]. When the top sheet of paper reaches

the proper paper feed level, the paper pushes up the pick-up roller

and the actuator [C] on the pick-up roller supporter [D] de-activates

[A]

[B]

H]

[

the lift sensor [E] to stop the lift motor.

After several paper feeds, the paper level gradually lowers, then

the lift sensor is activated and the lift motor turns on again until the

lift sensor is de-activated again.

3. Paper size detection

[A]

[I]

B. Lift mechanism

When the machine detects that the paper tray is set in the machine,

the tray lift motor [A] rotates and the coupling gear [B] on the tray lift

motor engages the pin [C] of the lift drive shaft [D]. The tray drive

belts [E] are connected to the tray bottom plate [F] and are driven

by the tray lift motor via the lift drive shaft [D] and tray drive pulleys

[G]. When the lift motor turns counterclockwise, the tray bottom

plate [F] moves up. The tray goes up until the top of the paper stack

pushes up the pick-up roller and the lift sensor in the feed unit is

de-activated.

When the actuator [H] on the rear end of the bottom plate activates

the paper height sensors [I], the remaining paper capacity is

detected. (see 4.)

When pulling out the tray, the coupling gear [B] separates from the

pin [C], so that the tray bottom plate moves downward. In the bottom tray, the damper [J] lets the tray bottom plate drop slowly.

MX-LCX4 DETAILED DESCRIPTIONS 4 – 2

[B] 21 3

A4-

B5-

SW10100011

LEF

SW21010001

SW31101000

LEF

A5LEF

A5-

SEF

LT-

LEF

HLTLEF

1: HI 0: LOW

HTL-

SEF

A. Top tray (tray 4) and middle tray (tray 5)

For the top and middle trays, the paper size switch [A] detects the

paper size. The paper size switch contains three microswitches.

The paper size switch is actuated by an actuator plate [B] at the

rear of the tray. Each paper size has its own unique combination as

shown in the table and the CPU determines the paper size by the

combination.

B. Bottom tray (tray 6)

The bottom tray has the same switch as the top and middle trays.

However, it is only used for detecting when the tray is pushed in.

For the bottom tray, the paper size must be selected in the SP5019007:

Page 13

4. Remaining paper detectiion

[E]

[A]

[D]

[C]

[B]

The amount of paper remaining in the tray is detected by the three

paper height photo-interrupter sensors on the left rail as the bottom

plate rises. Five states, determined by the position of the actuator

are possible.

1) With the actuator [A] below paper height sensor 1 [B], no sen-

sor is actuated and the display indicates 100%.

2) When the actuator passes paper height sensor 1 [B] , the dis-

play indicates 75% of the paper supply remaining.

3) When the actuator passes paper height sensor 2 [C], the dis-

play indicates 50% of the paper supply remaining.

4) When the actuator passes paper height sensor 3 [D], the dis-

play indicates 25% of the paper supply remaining.

NOTE: When the actuator enters the gap of the near end sensor

[E], the machine signals near end.

Finally, when the last sheet feeds, the paper end sensor signals

that the tray is empty. (see 5.)

5. Paper end detection

[A]

[B]

The paper end sensor [A] detects the top sheet of the paper in the

tray by monitoring the reflected light. When the paper tray runs out

of paper, the paper end sensor does not receive the reflected light

due to the cutout [B]. Then, the tray lift motor rotates backwards 2

seconds to drop the tray bottom plate.

MX-LCX4 DETAILED DESCRIPTIONS 4 – 3

Page 14

MX-LCX4

[5] OVERALL MECHANICAL

2. Drive layout

Service Manual

INFORMATION

1. Mechanical component layout

11

(1)

10

9

(2)

8

7

(3)

M1

M3

M4

4

M8

M2

M13

M5

5

M7

M6

M12

6

M9

M10

M11

1 4th Paper Feed Unit

2 5th Paper Feed Unit

3 6th Paper Feed Unit

4 4th Tray Drive Belt

5 5th Tray Drive Belt

6 6th Tray Drive Belt

7 Lower Transport Rollers

8 Horizontal Transport Roller

9 LCT Exit roller

10 Upper Transport Rollers

11 Feed Slot (from Bypass Tray)

M1 4th Grip Motor

M2 4th Lift Motor

M3 4th Paper Feed Motor

M4 4th Transport Motor

M5 5th Grip Motor

M6 5th Lift Motor

M7 5th Paper Feed Motor

M8 5th Transport Motor

M9 6th Grip Motor

M10 6th Lift Motor

M11 6th Paper Feed Motor

M12 6th Transport Motor

M13 LCT Exit Motor

MX-LCX4 OVERALL MECHANICAL INFORMATION 5 – 1

Page 15

3. Electrical components

S33

S50

SOL5

S34

S36

S35

SOL6

SW1

S4 4th Paper Height Sensor 1

S5 4th Paper Height Sensor 2

S6 4th Paper Height Sensor 3

S7 4th Paper Height Sensor 4

S12 4th Paper Size Sensors

S15 4th Relay Sensor

S17 4th Transport Sensor

S21 5th Paper Height Sensor 1

S22 5th Paper Height Sensor 2

S23 5th Paper Height Sensor 3

S24 5th Paper Height Sensor 4

S29 5th Paper Size Sensors

S33 5th Transport Sensor

S34 6th Lift Sensor

S35 6th Paper End Sensor

S36 6th Paper Feed Sensor

S37 6th Paper Height Sensor 1

S38 6th Paper Height Sensor 2

S39 6th Paper Height Sensor 3

S40 6th Paper Height Sensor 4

S45 6th Paper Size Sensors

S49 6th Transport Sensor

S50 Exit Sensor

SOL5 6th Pick-up Solenoid

SOL6 6th Separation Solenoid

SW1 Door Safety Switch

NOTE: Items S34, S35, S36, SOL5 and SOL6 are duplicated in

the 4th and 5th units.

S15

S17

M8

M13

M12

M9

1 Main Control Board

2 Anti-Condensation Heaters (Options)

M1 4th Grip Motor

M2 4th Lift Motor

M3 4th Paper Feed Motor

M4 4th Transport Motor

M5 5th Grip Motor

M6 5th Lift Motor

M7 5th Paper Feed Motor

M8 5th Transport Motor

M9 6th Grip Motor

M10 6th Lift Motor

M11 6th Paper Feed Motor

M12 6th Transport Motor

M13 LCT Exit Motor

M4

S7

S49

S12

S24

S45

S40

S39

S38

S37

S6

M1

S5

S4

S29

S23

S22

S21

M3

M5

M7

M2

1

M6

M11

M10

2 (Option:

0PQC4150431//)

MX-LCX4 OVERALL MECHANICAL INFORMATION 5 – 2

Page 16

4. A4/LT LCT MX-LCX4 layout (with bypass)

M3

M4

S8

M1

S17

S3

M4

M5

M8

S15

M13

S33

S50

M1 4th Grip Motor

M1 Paper Feed Motor Bypass (MX-MFX2)

M3 4th Paper Feed Motor

M3 Transport Motor Bypass (MX-MFX2)

M4 4th Transport Motor

M4 Grip Motor Bypass (MX-MFX2)

M5 5th Grip Motor

M7 5th Paper Feed Motor

M8 5th Transport Motor

M9 6th Grip Motor

M11 6th Paper Feed Motor

M12 6th Transport Motor

M13 LCT Exit Motor

S3 4th Paper Feed Sensor

S4 Paper Feed Sensor Bypass (MX-MFX2)

S8 Transport Sensor Bypass (MX-MFX2)

S15 4th Relay Sensor

S17 4th Transport Sensor

S20 5th Paper Feed Sensor

S33 5th Transport Sensor

S36 6th Paper Feed Sensor

S49 6th Transport Sensor

S50 LCT Exit Sensor

S49

M12

S20

M9

S36

M1

S4

M3

Tray 4

M7

Tray 5

M11

Tray 6

5. Electrical component summary

Motors

No.

(Signal)

M1

(L1REVM)

M2

(L1PRM)

M3

(L1PUM)

M4

(L1PFM)

M5

(L2REVM)

M6

(L2PRM)

M7

(L2PUM)

M8

(L2PFM)

M9

(L3REVM)

Name Description

4th Grip Motor Drives the separation roller and the grip

4th Lift Motor Drives the bottom plate of the 4th tray up

4th Paper Feed

Motor

4th Transport

Motor

5th Grip Motor Drives the separation roller and the grip

5th Lift Motor Drives the bottom plate of the 5th tray up

5th Paper Feed

Motor

5th Transport

Motor

6th Grip Motor Drives the separation roller and the grip

roller of the 4th tray.

and down.

Drives the pick-roller and feed roller that

picks up each sheet and starts to feed it

out of the 4th tray.

Drives the rollers in the vertical feed path

that feed the paper from the 4th tray to the

LCT exit motor.

roller of the 5th tray.

and down.

Drives the pick-roller and feed roller that

picks up each sheet and starts to feed it

out of the 5th tray.

Drives the transport rollers in the vertical

feed path that feed the paper from the 4th

tray and the 5th tray to the LCT exit motor.

roller of the 6th tray.

Tray 7

(MX-MFX2)

Motors

No.

(Signal)

M10

(L3PRM)

M11

(L3PUM)

M12

(L3PFM)

M13

(PEM)

PCBs

No. Name Description

PCB1 Main Control

Sensors

No.

(Signal)

S1

(L1ULS)

S2

(L1PES)

S3

(L1PFS)

S4

(L1PVS1)

S5

(L1PVS2)

S6

(L1PVS3)

S7

(L1PVS4)

S12

(L1SIZ1)

S13

(L1SIZ2)

S14

(L1SIZ3)

S15

(L1IDS)

S17

(L1TS)

S18

(L2ULS)

S19

(L2PES)

S20

(L2PFS)

S21

(L2PVS1)

S22

(L2PVS2)

S23

(L2PVS3)

S24

(L2PVS4)

S29

(L2SIZ1)

S30

(L2SIZ2)

S31

(L2SIZ3)

S33

(L2TS)

Name Description

6th Lift Motor Drives the 5th tray up and down.

6th Paper Feed

Motor

6th Transport

Motor

LCT Exit Motor Feeds the paper out the LCT and into the

Board

Name Description

4th Lift Sensor Detects when the paper in the 4th tray is at

4th Paper End

Sensor

4th Paper Feed

Sensor

4th Paper

Height Sensor 1

4th Paper

Height Sensor 2

4th Paper

Height Sensor 3

4th Paper

Height Sensor 4

4th Paper Size

Sensor 1

4th Paper Size

Sensor 2

4th Paper Size

Sensor 3

4th Relay

Sensor

4th Transport

Sensor

5th Lift Sensor Detects when the paper in the 5th tray is at

5th Paper End

Sensor

5th Paper Feed

Sensor

5th Paper

Height Sensor 1

5th Paper

Height Sensor 2

5th Paper

Height Sensor 3

5th Paper

Height Sensor 4

5th Paper Size

Sensor 1

5th Paper Size

Sensor 2

5th Paper Size

Sensor 3

5th Transport

Sensor

Drives the pick-roller and feed roller that

picks up each sheet and starts to feed it

out of the 6th tray.

Drives the rollers in the vertical feed path

that feed the paper from the 6th tray to the

LCT exit motor.

entrance of the copier.

Controls the operation of all motors and

sensors in the LCT unit.

the correct height for paper feed and

switches the 4th lift motor off.

Detects when the last sheet feeds from the

4th tray.

Detects the paper when it arrives at the 4th

paper feed roller and checks for misfeeds.

4th from the bottom of the 4th tray, detects

stack height: 100%

5th from the bottom of the 4th tray, detects

stack height: 75%

6th from the bottom of the 4th tray, detects

stack height: 50%

4th from the bottom of the 4th tray, detects

stack height: 25% and signals near-end.

1 of a set of 3 sensors that detect the width

of the paper in the 4th tray.

1 of a set of 3 sensors that detect the width

of the paper in the 4th tray.

1 of a set of 3 sensors that detect the width

of the paper in the 4th tray.

Detects the leading and trailing edges of

the paper in the paper path near the

bottom of the 4th tray. Checks the timing of

the feed and signals a jam if the paper is

late or lags at this location.

Detects jams in the paper path where the

transport motor feeds the paper from the

4th tray.

the correct height for paper feed and

switches the 4th lift motor off.

Detects when the last sheet feeds from the

5th tray.

Detects the paper when it arrives at the 5th

paper feed roller and checks for misfeeds.

4th from the bottom of the 5th tray, detects

stack height: 100%

5th from the bottom of the 5th tray, detects

stack height: 75%

6th from the bottom of the 5th tray, detects

stack height: 50%

4th from the bottom of the 5th tray, detects

stack height: 25% and signals near-end.

1 of a set of 3 sensors that detect the width

of the paper in the 5th tray.

1 of a set of 3 sensors that detect the width

of the paper in the 5th tray.

1 of a set of 3 sensors that detect the width

of the paper in the 5th tray.

Detects jams in the paper path where the

transport motor feeds the paper from the

5th tray.

MX-LCX4 OVERALL MECHANICAL INFORMATION 5 – 3

Page 17

Sensors

No.

(Signal)

S34

Name Description

6th Lift Sensor Detects when the paper in the 6th tray is at

(L3ULS)

S35

S36

S37

S38

S39

S40

S45

S46

S47

S49

S50

6th Paper End

Sensor

6th Paper Feed

Sensor

6th Paper

Height Sensor 1

6th Paper

Height Sensor 2

6th Paper

Height Sensor 3

6th Paper

Height Sensor 4

6th Paper Size

Sensor 1

6th Paper Size

Sensor 2

6th Paper Size

Sensor 3

6th Transport

Sensor

LCT Exit

Sensor

(L3PES)

(L3PFS)

(L3PVS1)

(L3PVS2)

(L3PVS3)

(L3PVS4)

(L3SIZ1)

(L3SIZ2)

(L3SIZ3)

(L3TS)

(LEXIT)

A. Block diagram

the correct height for paper feed and

switches the 4th lift motor off.

Detects when the last sheet feeds from the

6th tray.

Detects the paper when it arrives at the 6th

paper feed roller and checks for misfeeds.

4th from the bottom of the 6th tray, detects

stack height: 100%

5th from the bottom of the 6th tray, detects

stack height: 75%

6th from the bottom of the 6th tray, detects

stack height: 50%

4th from the bottom of the 6th tray, detects

stack height: 25% and signals near-end.

1 of a set of 3 sensors that detect the width

of the paper in the 6th tray.

1 of a set of 3 sensors that detect the width

of the paper in the 6th tray.

1 of a set of 3 sensors that detect the width

of the paper in the 6th tray.

Detects jams in the paper path where the

transport motor feeds the paper from the

6th tray.

Detects jams at the exit of the LCT unit.

AC POWER LINE

DC POWER LINE

SIGNAL LINE

A4 LCT Multi Bypass Tray

Solenoids

No.

(Signal)

SOL1

(L1PUS)

SOL2

(L1REVS)

SOL3

(L2PUS)

SOL4

(L2REVS)

SOL5

(L3PUS)

SOL6

(L3REVS)

Name Description

4th Pick-up

Solenoid

4th Separation

Solenoid

5th Pick-up

Solenoid

5th Separation

SOL

6th Pick-up

Solenoid

6th Separation

Solenoid

Engages/disengages rotation of the pickup roller in the 4th tray.

Controls up-down movement of the

separation roller in the 4th tray.

Engages/disengages rotation of the pickup roller in the 5th tray.

Controls up-down movement of the

separation roller in the 5th tray.

Engages/disengages rotation of the pickup roller in the 6th tray.

Controls up-down movement of the

separation roller in the 6th tray.

Switches

No.

(Signal)

SW1

(LILSW)

Name Description

Door Safety

Switch

An interlock safety switch that detects

when the front door is opened and closed.

Other

No. Name Description

H1, H2 Anti-Condensation

Heaters

Evaporates moisture around the trays in

the LCT (230V 18W). This is an option

Host

Equipment

Option

Heater

Paper Rise Motor

For 1st Tray

Reverse Motor

For 1st Tray

Pick-Up Motor

For 1st Tray

Paper Rise Motor

For 2nd Tray

Reverse Motor

For 2nd Tray

Pick-Up Motor

For 2nd Tray

Paper Rise Motor

For 3rd Tray

Reverse Motor

For 3rd Tray

Pick-Up Motor

For 3rd Tray

Reverse Solenoid

For 1st Tray

Pick-Up Solenoid

For 1st Tray

Reverse Solenoid

For 2nd Tray

Pick-Up Solenoid

For 2nd Tray

Reverse Solenoid

For 3rd Tray

Pick-Up Solenoid

For 3rd Tray

AC208V-AC240V

or AC85V-AC115V

M1

STM5

STM6

M2

STM7

STM8

M3

STM9

STM10

SOL1

SOL4

SOL2

SOL5

SOL3

SOL6

SIGNAL

DC24V

I/F PWB

14.7456MHz±1.875%

D/D

FU650

CP200

CP201

CP202

D/D

CP650

DC3.3V

SW1

Interlock SW

STM1

Exit Motor

Feed Motor

STM2

For 1st Tray

Feed Motor

For 2nd

STM3

Tray

Feed Motor

STM4

For 3rd Tray

Exit Sensor

Paper Feed Sensor x 3

Paper End Sensor x 3

Upper Limit Sensor x 3

Paper Volume Sensor

For 1st Tray x 4

Paper Volume Sensor

For 2nd Tray x 4

Paper Volume Sensor

For 3rd Tray x 4

Transport Sensor x 3

Intermediate Sensor

For 1st Tray

Connecting Unit Sensor

SIGNAL

DC5V

DC24V

I/F PWB

CP100

DC5V

Paper End Sensor

Length Sensor

Paper Volume Sensor x 2

Upper Limit Sensor

Lower Limit Sensor

Paper Feed Sensor

SOL1

Pick-Up Solenoid

Paper Rise Motor

M1

Reverse Motor

STM1

Pick-Up Motor

STM2

Feed Motor

STM3

MX-LCX4 OVERALL MECHANICAL INFORMATION 5 – 4

Page 18

B. Actual wiring chart

L

C

CN110(MOLEX 3.5)

Main unit

CN100

CN101

A4LCT: C4155350

A3LCT: C4185350

CN111(Mi II) CN112(Mi II)

DSR (Not used)

DTR (Not used)

CN150 MOLEX(W)

When 100V

A4LCT: C4155356

A3LCT: C4185356

When 200V (standard)

A4LCT:C4155351

CN900 CN901

A3LCT:C4185351

4

12

3

5

12 pin

15 pin

Shield

TXD (Main unit)

RXD (Main unit)

A4LCT: C4155355

A3LCT: C4185355

L(200V)

L(200V)

1

1

N

N

3

3

L(100V)

L(100V)

2

2

FG

6T pick-up SOL

SOL SOL

JCN

CN

6T pick-up SOL

4T pick-up SOL

4T reverse SOL

4T paper end sensor

4T paper feed sensor

CN130 (MI II)

6T reverse SOL

JCN

CN

CN CN CN

A4LCT/A3LCT

:B8325311

A4LCT/A3LCT

:B8325311

CN132(Mi II)

6T reverse SOL

4T upper limit sensor

6T paper feed sensor

CN

JCN

CN

6T paper feed sensor

heater

Option

dehumidifying

heater

Option

dehumidifying

6T paper end sensor

6T paper end sensor

2

1

2

1

2

1

2

1

Dehumidifying heater

(230V: 18W)

AX400012 x 2

Dehumidifying heater

(100V: 18W)

AX4000** x 2

A4LCT: B8325302

A3LCT: B8345322

A4LCT: B8325301

A3LCT: B8345320

6T upper limit sensor

6T upper limit sensor

interface harness provided

A4LCT: B8325330

A3LCT: B8345320

4T transport

sensor

5T transport

sensor

CN CN CN

CN CN CN

JCN JCN JCN

CN CN CN

A4LCT: B8325313

A3LCT: B8345305

CN135 (Mi II)

4T transport sensor

5T transport sensor

A4LCT

5T transport sensor

B8325306

CN151 (MOLEX(W)

6T transport

sensor

6T transport sensor

4Tfan1

Not installed

M

JCN

CN

Sensor

For A3LCT

PE sensor 4

Paper feed sensor 4

Remaining quantity sensor 4-1

Remaining quantity sensor 4-2

Size sensor 4-1

Size sensor 4-2

Upper limit sensor 4

4Tfan2

M

JCN

CN

Size sensor 4-3

CN101

JCN

CN CN

Not installed

4T size

detection 1

4T size

detection 2

CN CN CN

CN160 (miniMi II)

Sensor

4T size detection 1

4T size detection 2

5T pick-up SOL

5T reverse SOL

Size sensor 4-4

Size sensor 4-5

Paper length sensor 4

Tray lower limit sensor 4

4T size

detection 3

A3LCT: B8345330

A4LCT: B8325308

A3LCT: B8345302

Drawer not provided

4T size detection 3

5T paper feed sensor

CN131 (Mi Red)

CN101

JCN

CN115CN114

4T length

detection

4T remaining

B8345334(In the tray)

CN CN CN CN

JCN

Drawer CN (39P)

Drawer CN (39P)

JCN

A4LCT:

4T length detection

5T upper limit sensor

5T paper end sensor

Pick-up SOL

Lift M (+)

Lift M (-)

quantity detection 1

4T remaining

CN161 (miniMiII)

4T remaining quantity detection 1

Lift SW

Lift LED

Slide detection

CN100

A4LCT: B8325307

A3LCT: B8345324

CN113

quantity detection 2

4T remaining

quantity detection 3

4T remaining quantity detection 2

4T remaining quantity detection 3

LCT exit port sensor

CN139 (Mi II)

CN

4T remaining

quantity detection 4

CN

4T remaining

quantity detection 4

5T intermediate sensor

LCT exit port sensor

CN800

CN

M

4T reverse

Dotted line : Pulse

A4LCT: B8325300

A3LCT: B8345300

CN

M

4T transport

: Low active

: High active

: Signal flow

A4LCT: B8325312

A3LCT: B8345308

CN

JCN

CN

A4LCT/A3LCT

:B8325311

CN

CN

CN

CN

M

M

4T pick-up M

5T pick-up M

JCN

SOL SOL

4T pick-up SOL

JCN

4T reverse

CN CN CN

4T paper feed sensor

4T paper end sensor

4T upper limit sensor

CN

M

5T reverse

1.A3LCT only

2. Because it is common in A3LCT/A4LCT but the using component is different, the connection, too, is different.

3.˴˴˴˴˴˴˴:A4LCT only. A4LCT doesn't use drawer connector.

A4LCT: B8325300

A3LCT: B8345300

CN

M

5T transport

CN

CN

M

M

Exit port

6T pick-up

CN

JCN

SOL

5T pick-up SOL

A4LCT: B8325312

A3LCT: B8345308

CN

JCN

CN

A4LCT/A3LCT

:B8325311

CN

CN CN CN

JCN

SOL

5T reverse SOL

5T paper feed sensor

5T paper end sensor

A4LCT: B8325318

A3LCT: B8345323

5T upper limit sensor

A4LCT: C4155354

A3LCT: C4185354

CN CN

CN CN

A4LCT: B8325318

A3LCT: B8345322

CN

CN

LCT exit port sensor

5T intermediate sensor

CN

JCNJCN

JCN

CN

A4

:

CN

Interface Unit sensor

MX-LCX4 OVERALL MECHANICAL INFORMATION 5 – 5

Page 19

0

Interface Unit sensor

CN111

Manual feed I/F

Transport sensor

Connection detection

JCN

CN

Manual feed (PAVO)

CN116 (Red)

5Tfan1

Not installed

M

JCN

CN

LCT exit port sensor

0 (MiII)

CN

CN

CN

4LCT/A3LCT

C4155352

CN

5Tfan2

Not installed

M

JCN

CN

CN162 (miniMi II)

Sensor

4T lower tray lift M (+)

A4LCT: B8325310

A3LCT: B8345301

CN

JCN

M

5Tsize

detection 1

CN CN CN

Sensor

5T size detection 1

4T lower tray lift M (-)

5T lower tray lift M (+)

5T lower tray lift M (-)

CN133 (MiII)

CN

JCN

M

5Tsize

detection 2

5Tsize

5T size detection 2

6T lower tray lift M (+)

6T lower tray lift M (-)

Door open/close detection

CN

141

A4LCT: B8325310

A3LCT: B8345303

CN

JCN

M

5Tlength

detection 3

A3LCT: B8345332

B8345334(In the tray)

JCN

Drawer CN (39P)

Drawer CN (39P)

JCN

A3LCT: B8345303

A4LCT:

Drawer not provided

5T size detection 3

CN142

detection

5T remaining

quantity detection 1

5T remaining

quantity detection 2

CN CN CN CN

CN163 (miniMi II)

5T length detection

5T remaining quantity detection 1

5T remaining quantity detection 2

CN154 MOLEX (W)

A4LCT: B8325300

A3LCT: B8345300

CN

CN

M

M

6Treverse

6T transport

5T remaining

quantity detection 3

5T remaining quantity detection 3

5T remaining

quantity detection 4

CN

5T remaining quantity detection 4

PWB

JCN

A4LCT

4T intermediate

lower sensor interface

harness provided

B8325305

Not connected

6Tfan1

6Tfan2

Not installed

Not installed

M

M

JCN

CN

CN

Sensor

Intermediate sensor 4 upper

CN730 (MiRed)CN710(MiII)

A4LCT: C4155354

A3LCT: B8345306

CN CN

JCN JCN

CN CN

A4LCT: B8325302

A3LCT: B8345321

CN CN CN

6Tsize

detection 1

CN CN CN

CN164 (miniMi II)

Sensor

6T size detection 1

Intermediate sensor 4 lower

Intermediate sensor 6T

A4LCT: -

A3LCT: B8345325

6Tsize

detection 2

6Tsize

detection 3

6T length

detection

6T remaining

quantity detection 1

6T remaining

quantity detection 2

6T remaining

quantity detection 3

6T remaining

quantity detection 4

A3LCT: B8345330

B8345334(In the tray)

JCN

Drawer CN (39P)

Drawer CN (39P)

JCN

A4LCT: B8325310

A3LCT: B8345304

CN CN CN CN

CN

CN165 (miniMi II)

A4LCT:

Drawer not provided

6T size detection 2

6T size detection 3

6T length detection

quantity detection 1

quantity detection 2

quantity detection 3

6T remaining

4Tsizedetection3

quantity detection 4

6T remaining

6T remaining

6T remaining

For A4LCT For A4LCT

4T size detection 1

4T size detection 2

CN160 (miniMi II)

A4LCT: B8325308 A4LCT: B8325309

CN

For A4LCT

5T size detection 1

CN162 (miniMiII)

CN164 (miniMiII)

5T size detection 2

CN

6Tsizedetection

CN

A4LCT: B8325310A4LCT: B8325309

6T size detection 1

6T size detection 2

6T size detection 3

5T size detection 3

4T tray lift

6T tray lift

5T tray lift

Door open/close SW

Intermediate sensor 6T

Intermediate sensor 4Tupper

Intermediate sensor 4T lower

4Tsizedetection

5Tsizedetection

MX-LCX4 OVERALL MECHANICAL INFORMATION 5 – 6

Page 20

Memo

Page 21

Memo

Page 22

LEAD-FREE SOLDER

The PWB’s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder.

The alphabet following the LF mark shows the kind of lead-free solder.

Example:

<Solder composition code of lead-free solder>

Solder composition

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi

Sn-In-Ag-Bi

Sn-Cu-Ni

Sn-Ag-Sb

Bi-Sn-Ag-P

Bi-Sn-Ag

5mm

Lead-Free

Solder composition

code (Refer to the

table at the right.)

a

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread.

Never use conventional lead solder thread, which may cause a breakdown or an accident.

Since the melting point of lead-free solder thread is about 40°C higher than that of conventional lead solder thread, the use of the

exclusive-use soldering iron is recommended.

Solder composition code

a

b

z

i

n

s

p

(2) NOTE FOR SOLDERING WORK

Since the melting point of lead-free solder is about 220°C, which is about 40°C higher than that of conventional lead solder, and its soldering

capacity is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. This may cause land

separation or may exceed the heat-resistive temperature of components. Use enough care to separate the soldering iron from the PWB when

completion of soldering is confirmed.

Since lead-free solder includes a greater quantity of tin, the iron tip may corrode easily. Turn ON/OFF the soldering iron power frequently.

If different-kind solder remains on the soldering iron tip, it is melted together with lead-free solder. To avoid this, clean the soldering iron

tip after completion of soldering work.

If the soldering iron tip is discolored black during soldering work, clean and file the tip with steel wool or a fine filer.

COPYRIGHT©XXXX BYSHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

Page 23

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

Mettre au rebut les batteries usagées conformément aux

(Swedish) VARNING

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

Replace only with the same or equivalent type

recommended by the manufacturer.

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

le constructeur.

instructions du fabricant.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

Hersteller angegebenen Anweisungen.

CAUTION FOR BATTERY DISPOSAL

(For USA, CANADA)

THIS PRODUCT CONTAINS A LITHIUM PRIMARY

(MANGANESS DIOXIDE) MEMORY BACK-UP BATTERY

THAT MUST BE DISPOSED OF PROPERLY. REMOVE THE

BATTERY FROM THE PRODUCT AND CONTACT YOUR

LOCAL ENVIRONMENTAL AGENCIES FOR INFORMATION

ON RECYCLING AND DISPOSAL OPTIONS.

CE PRODUIT CONTIENT UNE PILE DE SAUVEGARDE DE

MÉMOIRE LITHIUM PRIMAIRE (DIOXYDE DE MANGANÈSE)

QUI DOIT ÊTRE TRAITÉE CORRECTEMENT. ENLEVEZ LA

PILE DU PRODUIT ET PRENEZ CONTACT AVEC VOTRE

AGENCE ENVIRONNEMENTALE LOCALE POUR DES

INFORMATIONS SUR LES MÉTHODES DE RECYCLAGE ET

“BATTERY DISPOSAL”

“TRAITEMENT DES PILES USAGÉES”

DE TRAITEMENT.

Page 24

COPYRIGHT © 2007 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

Trademark acknowledgements

• Microsoft®, Windows®, Windows®98, Windows®Me, Windows NT®4.0,

Windows

Internet Explorer

Microsoft Corporation in the U.S.A. and other countries.

• PostScript is a registered trademark of Adobe Systems Incorporated.

• Macintosh, Mac OS, AppleTalk, EtherTalk, LaserWriter, and Safari are registered

trademarks or trademarks of Apple Computer, Inc.

• IBM, PC/AT, and PowerPC are trademarks of International Business Machines

Corporation.

• Acrobat

reserved. Adobe, the Adobe logo, Acrobat, and the Acrobat logo are trademarks of

Adobe Systems Incorporated.

• PCL is a registered trademark of the Hewlett-Packard Company.

• All other trademarks and copyrights are the property of their respective owners.

• Sharpdesk is a trademark of Sharp Corporation.

®

2000, Windows®XP, Windows®Vista, Windows®Server 2003 and

®

are registered trademarks or trademarks of

®

Reader Copyright®1987- 2002 Adobe Systems Incorporated. All rights

SHARP CORPORATION

Digital Document System Group

CS Promotion Center

Yamatokoriyama, Nara 639-1186, Japan

2007 May Printed in Japan

Loading...

Loading...