Page 1

SERVICE MANUAL

CODE: 00ZMXLCX3NS1E

DIGITAL

MULTIFUNCTIONAL SYSTEM OPTION

LARGE CAPACITY TRAY

MODEL

CONTENTS

[1] PRODUCT OUTLINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] UNPACKING AND INSTALLATION

* For unpacking and installation, refer to the installation manual( [3] ).

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . . . . . . . . 4-1

[5] OPERATIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

MX-LCX3N

[9] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] SELF DIAG MESSAGE AND TROUBLE CODE . . . . . . . . . . . . . . . . . 10-1

[11] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[1] PRODUCT OUTLINE. . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] UNPACKING AND INSTALLATION

* For unpacking and installation, refer to the installation

manual( [3] ).

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Motor, clutch, solenoid . . . . . . . . . . . . . . . . . . . . 4-1

2. PWB, sensor, switch, heater. . . . . . . . . . . . . . . . 4-2

[5] OPERATIONAL DESCRIPTION

1. Lift operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. Paper feed operation . . . . . . . . . . . . . . . . . . . . . 5-2

3. Paper empty detection . . . . . . . . . . . . . . . . . . . . 5-3

[6] DISASSEMBLY AND ASSEMBLY

1. Maintenance parts replacement procedures. . . . 6-1

2. Each unit removal . . . . . . . . . . . . . . . . . . . . . . . . 6-1

3. Major parts removal . . . . . . . . . . . . . . . . . . . . . . 6-3

[7] MAINTENANCE

1. Maintenance system table . . . . . . . . . . . . . . . . . 7-1

[8] ADJUSTMENTS

1. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] SIMULATION

1. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] SELF DIAG MESSAGE AND TROUBLE CODE

1. Self diag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . 10-2

3. Trouble code details . . . . . . . . . . . . . . . . . . . . . 10-2

[11] ELECTRICAL SECTION

1. Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

2. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

3. Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . .11-5

Page 3

MX-LCX3N

[1] PRODUCT OUTLINE

This model is a large capacity paper feed tray installed to the main unit.

It stores 3,000 sheets, eliminating troublesome paper supply.

* The illustration of the main unit below is intended for the model of MX-5500N series.

Service Manual

MX-LCX3N

Notes

* For the installation to the model of MX-850 series, only MX-M850 is applicable.

* When this model is connected to MX-850, upgrade the firmware of MX-LCX3N.

* If this model is installed to MX-850, it is necessary to install MX-MFX1 sold separately.

MX-LCX3N PRODUCT OUTLINE 1 – 1

Page 4

MX-LCX3N

[2] SPECIFICATIONS

Service Manual

Model Large capacity tray

Transport reference Center reference

Heat reserving heater

Paper capacity

Domestic Normal paper(64g/m

Overseas Normal paper(80g/m

2

,17 lbs bond) 3500 sheets

2

,21 lbs bond) 3000 sheets

Domestic: Heater kit support

Overseas: Service parts support

Paper size/type/weight Refer to Table 1

Paper size detection Not provided (Manually setting from the control panel of the main unit)

Paper type setting Refer to Table 2

Changeover by user Yes (Changeover by manager is allowed)

Paper size change system

Changeover by service man

(Adjustment of guide and entry of size) No

Domestic A3

Factory setting of paper size

Overseas, Inch series 11x17

Overseas, AB series A3

Remaining

paper detection

Tray lift time

Up max. 30 sec.

Down max. 15sec.

Paper empty and 6 steps

(100% ,83.3% ,66.7% ,50% ,33.3% ,16.7% ,Paper empty)

Troubleshooting of paper jam Can be corrected without separating the unit.

Reliability

MCBJ:Conforms to the main unit

MCBF:Conforms to the main unit

Life Conforms to the main unit

Power source Supplied from the main unit

Power consumption Normal operation:50.4W Lift up:40.8W

Dimensions(WxDxH) 670x570x525mm, 26 3/8 x 22 7/16 x 20 21/32 inch

Occupying area(WxD)

670x570mm, 26 3/8 x 22 7/16 inch

* The rear cabin motor restrictor (10mm) is not included.

Weight Approx. 50kg, 110.1 lbs

Installation/Maintenance Implemented by service man

Maintenance parts Paper feed roller

Optional detection Automatic detection

Bundled item Parts for installation

Table 1:Paper size, type, weight

A3W Yes Yes

A3 Yes Yes

B4 Yes Yes

A4 Yes Yes

A4R Yes Yes

B5 Yes Yes

B5R No No

A5R No No

12x18 Yes Yes

11x 17 Yes Yes

Paper size

8.5x14 Yes Yes

8.5x13 Yes Yes

8.5x11 Yes Yes

8.5x11R Yes Yes

7.25x10.5R No No

5.5x8.5R No No

8K * No No

16K * No No

16KR No No

Postcard No No

Envelope No No

Special No No

55-59g/m

15-16- lbs bond

60-105g/m

16-28 lbs bond

106-209g/m

28+-56- lbs bond

210-256g/m

56-68 lbs bond

75-90g/m

20-24 lbs bond

Kind/weight

of

applicable

paper

Thin paper

Normal

paper

Cardboard

1(including

gloss paper)

Cardboard 2

Envelope

OHP paper No

Label paper No

Tab paper No

* : Available for products for China only.

Table2:Paper type setting

AB Series Inch

Normal paper Yes

Printed paper Yes

Recycled paper Yes

Letter head Yes

Perforated paper Yes

Color paper Yes

Paper type

Cardboard 1 Yes

Cardboard 2 No

Thin paper No

Label paper No

OHP No

Tab paper No

Envelope No

Use type 1 to 7 Yes

2

2

2

2

2

No

Yes

Yes

No

No

MX-LCX3N SPECIFICATIONS 2 – 1

Page 5

MX-LCX3N

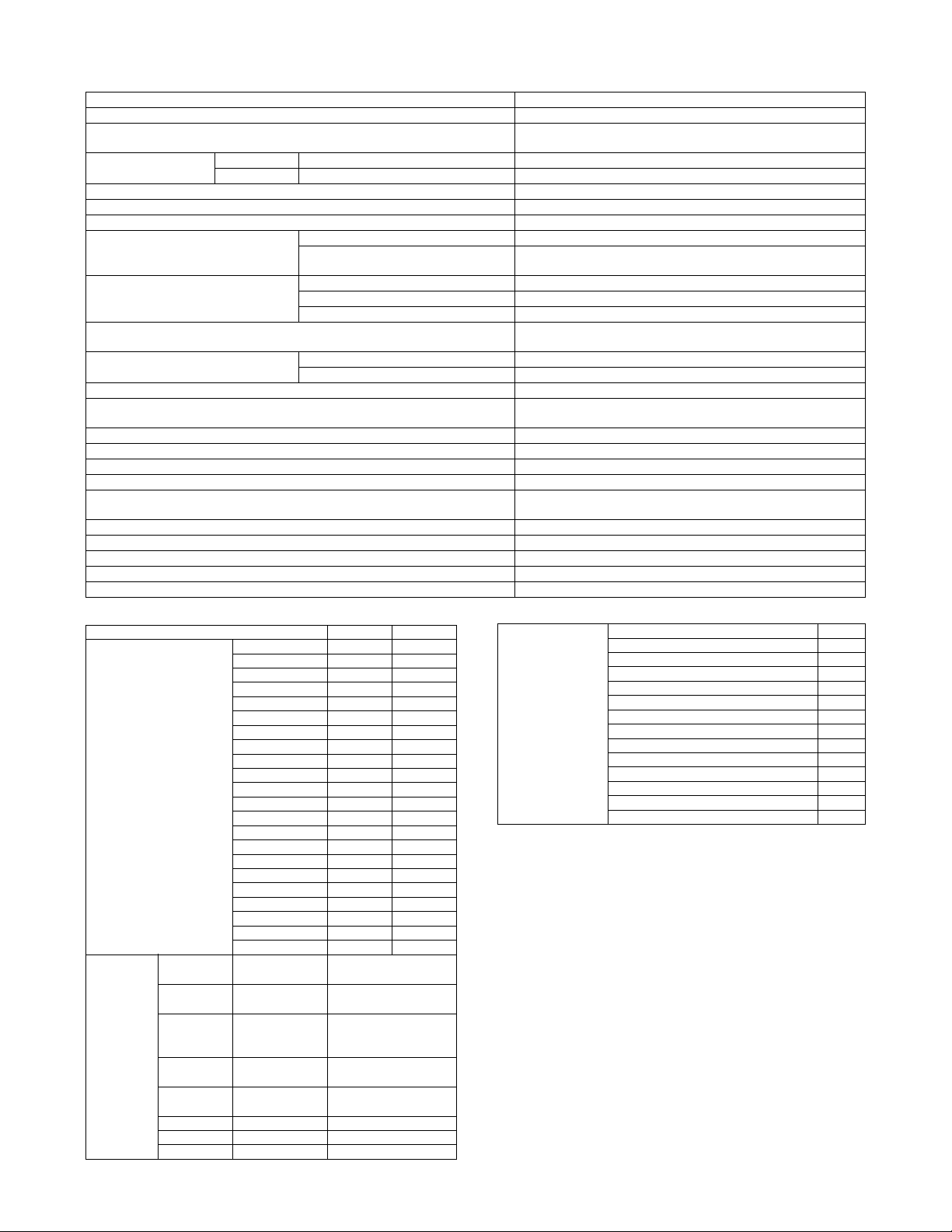

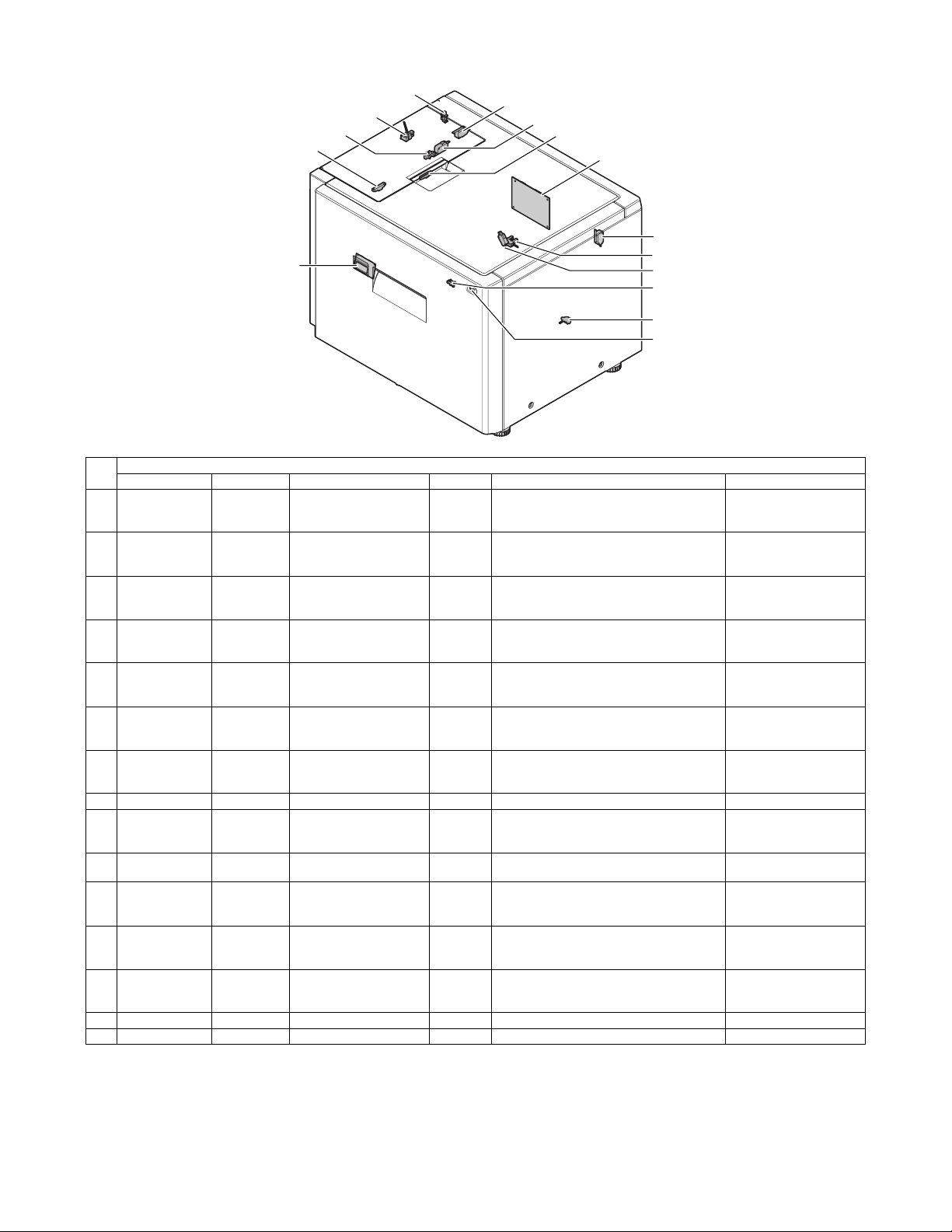

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

Service Manual

1. Motor, clutch, solenoid

No.

Code Signal name Name Type Function/Operation Active condition

1 LPFM LPFM Transport motor Brushless motor Drives the paper feed, and the paper

2 LLM LLM Lift motor Brush motor Lifts or lowers the paper feed table. CN-B

3 LPFS LPFS Paper feed solenoid Presses the paper pickup roller onto paper. CN-E 8pin

4 LTLS LTLS Tray lock solenoid Controls ON/OFF of the tray lock. CN-D

5 LTRC LTRC Transport clutch Controls ON/OFF of the transport roller. CN-F 15pin

6 LPFC LPFC Paper feed clutch Controls ON/OFF of the paper feed roller. CN-F 11pin

7 LFAN LFAN Separation assist

fan

Brushless motor Assists feeding of paper. CN-D 15, 16pin

Parts

transport section.

CN-G

5pin → Motor rotation clock

4pin → Sync signal: Normal HIGH

3pin → Enable signal: LOW when rotating

Lifting: 10pin "24V", 15pin "L"

Lowering: 10pin "L", 15pin "24V"

ON: "L"

OFF: "24V"

Lock: "L" ("24V" after 0.5sec)

Release: "L" ("24V" after 0.5sec)

ON: "L"

OFF: "24V"

ON: "L"

OFF: "24V"

ON: "L"

OFF: "5V"

MX-LCX3N EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 1

Page 6

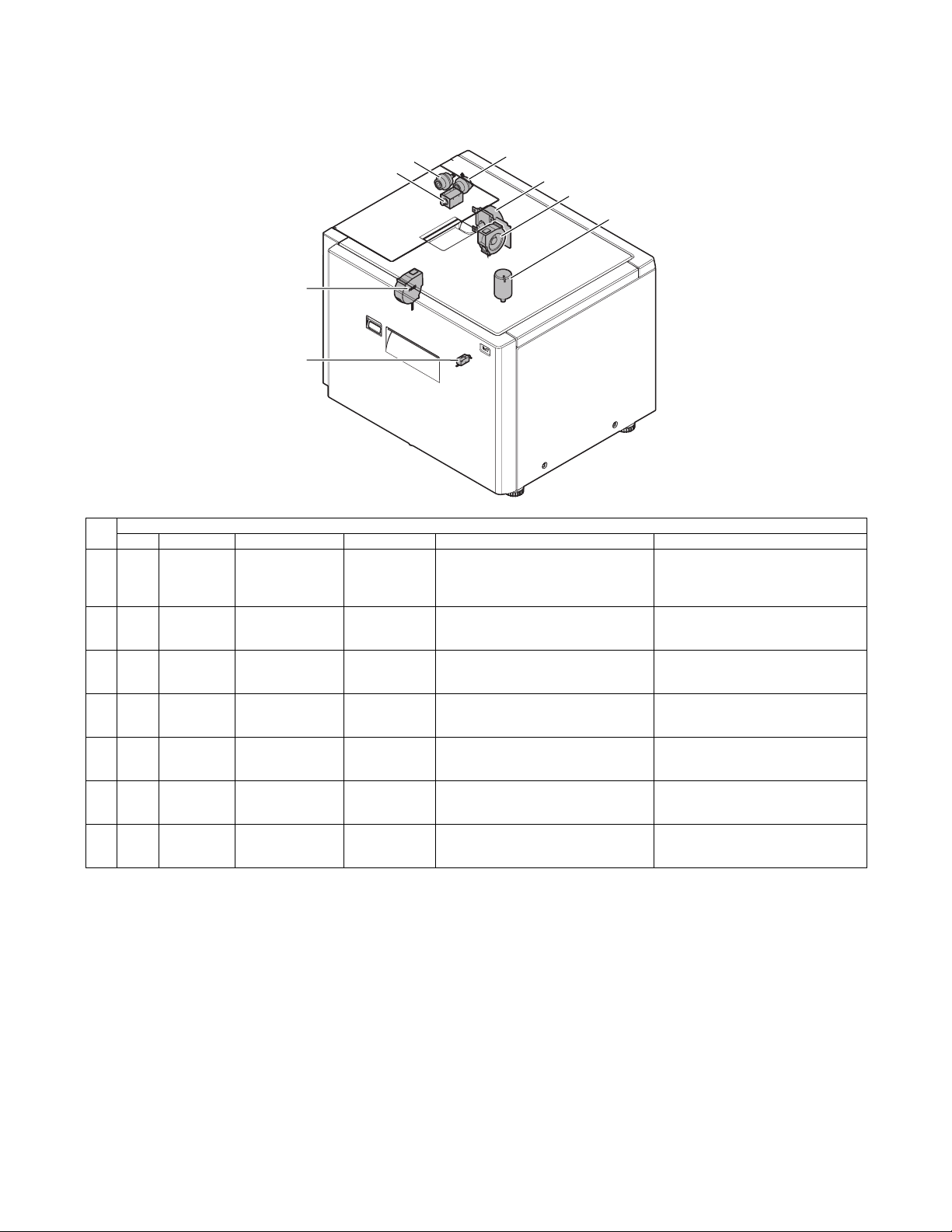

2. PWB, sensor, switch, heater

4

3

2

1

5

6

7

8

9

14

10

11

12

13

15

No.

1 LPUD LPUD LCC paper front surface

2 LUD LUD Upper limit sensor Detects the paper upper limit position. CN-E 5pin

3 LPFD LPFD Transport sensor Detects paper transport. CN-E 11pin

4 LTOD LTOD The main unit connection

5 LDSW LDSW Upper open/close switch Detects open/close of the upper door. CN-F 4pin 6pin

6 LLSW LLSW Upper limit switch Protects the paper feed unit from breakage

7 LPED LPED Paper presence/empty

8 A3-LCC PWB — A3-LCC PWB unit Controls and drives the LCC.

9 LCSW LCSW Cassette detection switch The tray insertion is detected. CN-B 7pin

10 LRE LRE Lift motor encoder The lift motor rotation is detected. CN-C 4pin

11 LWRSW LWRSW LCC reverse-winding

12 LTLD LTLD Tray lock sensor Detects the tray lock CN-C 7pin

13 LDD LDD Lower limit sensor The lower limit of the tray is detected. CN-C 3pin

14 DOWN SW PWB — Lowering SW PWB unit Shifts the tray to the paper supply position.

15 LTLLED LTLLED Tray LED The tray state is displayed with LED.

Code Signal name Name Type Function/Operation Active condition

sensor

sensor

sensor

detection switch

Parts

Detects paper front surface position CN-C 8pin

Detects connection to the main unit. CN-F 19pin

due to lifting the tray too much.

Detects paper presence/empty on the paper

tray.

Detects lift motor reverse-winding CN-B 14pin

Paper detected: "L"

Paper not detected: "H"

Upper limit: "H"

Other than Upper limit: "L"

Paper detected: "L"

Paper not detected: "H"

Connected: "L"

Not connected: "H"

Open: "L"

Close: "24V"

CN-F 7pin

Normal: "24V"

Detection: "L"

CN-E 2pin

Paper present: "L"

Paper empty: "H"

Cassette insertion: "24V"

Cassette puling out: "L"

Pulse

Normal: "24V"

Detection: "L"

Lock: "H"

Release: "L"

Lower limit: "H"

Other than Lower limit: "L"

MX-LCX3N EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 2

Page 7

(

)

(

)

MX-LCX3N

[5] OPERATIONAL DESCRIPTION

Service Manual

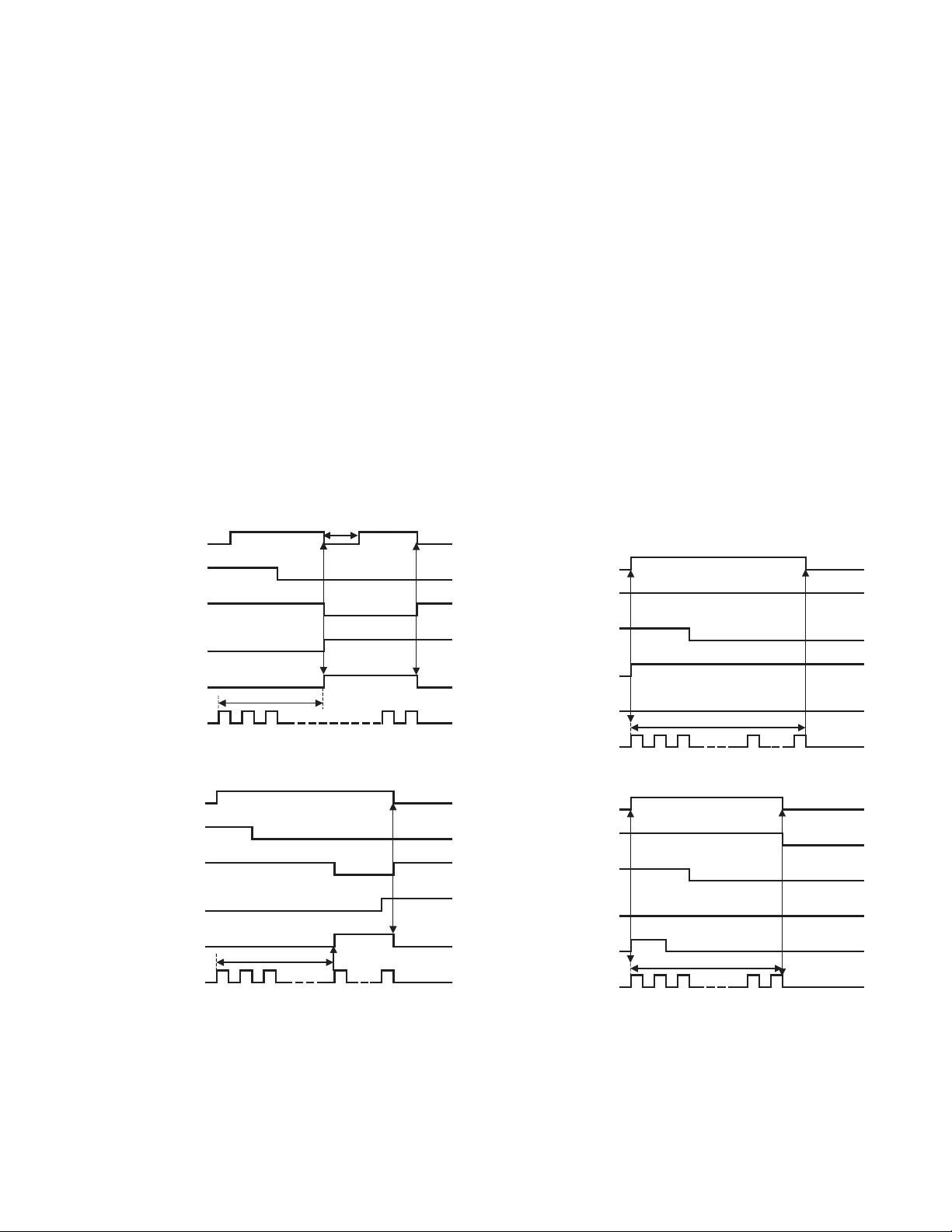

1. Lift operation

A. Lifting by insertion of the tray

When insertion of the tray is detected, the tray is locked by the tray

lock solenoid so that the tray cannot be pulled out.

When tray lock is settled by turning ON the tray lock sensor (LTLD),

the lift motor is turned ON to lift the tray.

When the tray is lifted, the tray LED blinks and stops at the paper

feed position (upper limit) by turning ON the upper limit sensor

(LUD).

When the tray stops at the paper feed position (upper limit), the tray

LED turns on.

When the paper empty sensor (LPED) turns ON within 1097 pulses

of the encoder signal from start of the tray lifting, the lift motor is

turned OFF to stop the tray, and the paper feed solenoid (LPFS) is

turned ON to lower the pick roller.

After that, the lift motor is turned ON again to lift the tray and stop it

at the upper limit sensor (LUD) ON position.

When the paper empty sensor (LPED) does not turn ON within

1097 pulses, the paper feed solenoid (LPFS) is turned ON with the

lift motor ON to lower the pick roller. The lift motor is stopped at the

upper limit sensor (LUD) ON position and the paper feed solenoid

is turned OFF.

Lifting (When LPED turns ON within 1097 pulses during lifting)

(Lift motor output)

(Lower limit sensor)

(Upper limit sensor)

(Paper empty detection)

Encoder signal

LLM

LDD

LUD

LPED

LPSL

(Solenoid)

LRE

Within 1097 pulses

Lifting (When LPED does not turn ON within 1097 pulses during lifting)

(Lift motor output)

(Lower limit sensor)

(Upper limit sensor)

(Paper empty detection)

(Encoder signal)

LLM

LDD

LUD

LPED

LPSL

(Solenoid)

LRE

1097

200msec

B. Lowering operation by paper empty detection

or pressing the tray SW

When the paper empty sensor (LPED) turns OFF with the tray at

the paper feed position (upper limit) or when the tray SW (LTLSW)

is pressed, the tray is lowered by 542 pulses of the encoder signal

and stopped at the paper supply position.

When the lower limit sensor (LDD) turns ON before lowering the

tray by 542 pulses of the encoder signal, the lift motor is turned

OFF to stop the tray.

When the tray is moving down, the tray LED blinks. When the tray

is stopped at the paper supply position, the tray LED turns OFF.

When the tray is stopped at the paper supply position, the tray lock

solenoid releases the lock so that the tray can be pulled out.

When the tray is lowered with the paper empty sensor (LPED) OFF,

the tray remains at the paper supply position and the tray lock is

released.

When the tray is lowered by pressing the tray SW (LTLSW), if the

tray is not pulled out from the paper supply position for 90sec, the

tray lock solenoid locks the tray. When the tray is locked securely,

the lift motor is turned ON to lift the tray.

When the tray is lifting, the tray LED blinks. When the upper limit

sensor (LUD) is turned ON, the tray stops at the paper feed position

(upper limit).

When the tray stop at the paper feed position (upper limit), the tray

LED turns ON.

Lowering operation (when paper empty is detected)

(Lift motor output)

(Lower limit sensor)

(Upper limit sensor)

(Paper empty detection)

Encoder signal

Lowering operation (when tray SW is pressed)

(Lift motor output)

(Lower limit sensor)

(Upper limit sensor)

(Paper empty detection)

(Encoder signal)

LLM

LDD

LUD

LPED

LTLSW

(Tray SW)

LRE

LLM

LDD

LUD

LPED

LTLSW

(Tray SW)

LRE

542

Less than 542

MX-LCX3N OPERATIONAL DESCRIPTION 5 – 1

Page 8

C. Lowering operation by paper supply

If the tray is pulled out when it is at the paper supply position, the

tray lock solenoid keeps the lock open.

When the tray is pulled out, the tray LED turns OFF.

When the paper front surface sensor (LPUD) is turned ON for 2sec

while the tray is pulled out, the lift motor is turned ON to lower the

tray.

When the paper front surface sensor (LPUD) is turned OFF while

the tray is lowered, the lift motor is turned OFF to stop the tray.

When the lower limit sensor (LDD) is turned ON while the tray is

lowered, the lift motor is turned OFF to stop the tray regardless of

the state of the paper front surface sensor (LPUD).

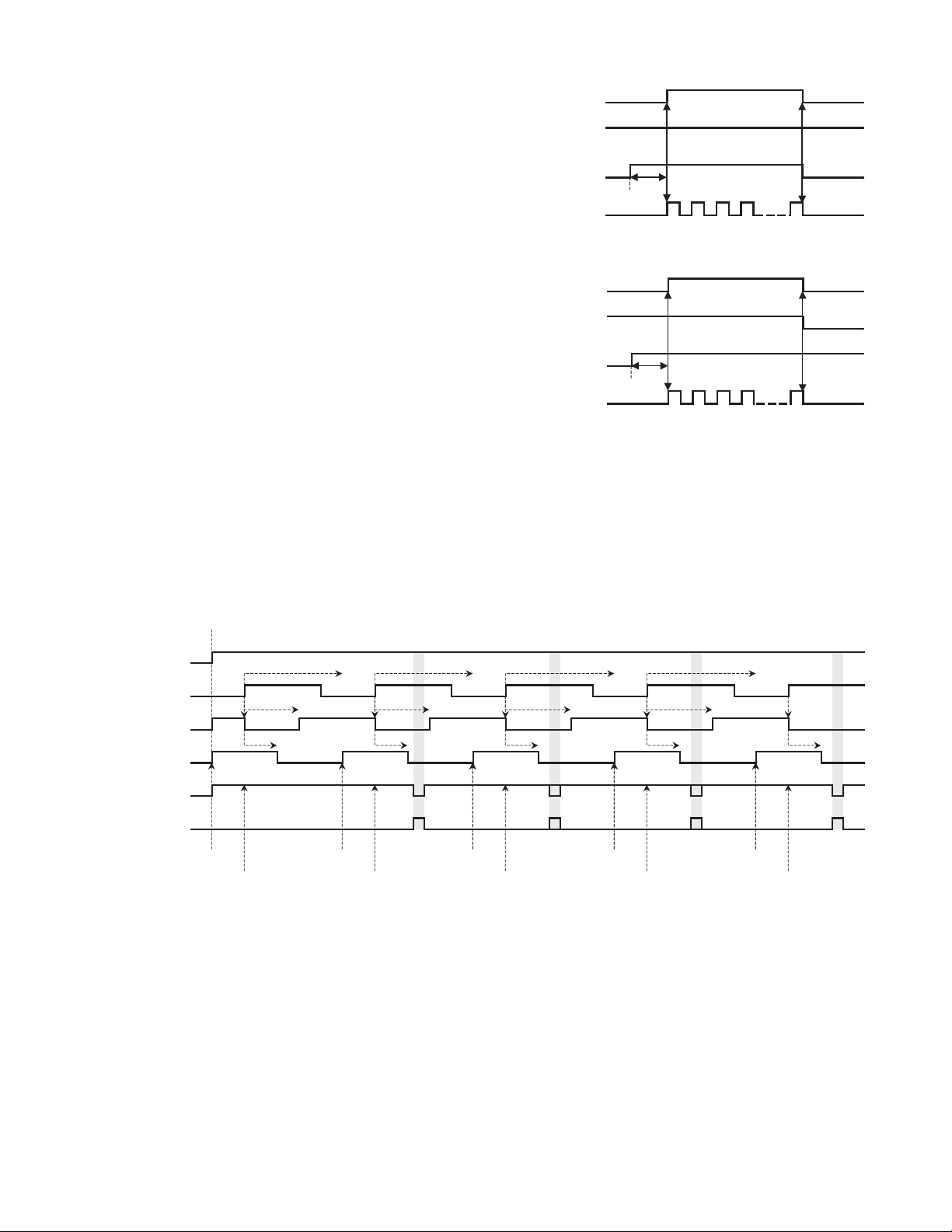

2. Paper feed operation

When the tray is stationary at the paper feed position (upper limit

sensor: LUD ON position) and there is paper on the tray, paper

feed operation can be performed.

Paper feed operation is performed by the transport motor (LPFM),

the transport clutch (LTRC), the paper feed clutch (LPFC), and the

paper feed solenoid (LPFS) at the following timing.

Lowering operation (when paper is supplied or when the paper

front surface sensor is turned ON)

LLM

(Lift motor output)

LDD

(Lower limit sensor)

LPUD

(Paper front surface

sensor)

2 [sec]

LRE

(Encoder signal)

Lowering operation (when paper is supplied or when the lower

limit sensor is turned ON)

(Lift motor output)

(Lower limit sensor)

(Paper front surface

(Encoder signal)

LLM

LDD

LPUD

sensor)

LRE

2 [sec]

When the transport clutch (LTRC) is turned ON with the transport

motor (LPFM) ON (rotating), the transport roller rotates. When the

paper feed clutch (LPFC) is turned on under this state, the paper

feed roller and the take-up roller rotate. When the paper feed solenoid (LPFS) is turned ON, the take-up roller is pushed down to

press paper.

Paper feed time chart

Paper feed start

(Transport motor)

(Transport sensor)

(Paper feed solenoid)

(Paper feed clutch)

(Transport clutch)

synchronous signal)

LPFM

LTD

LPFS

LPFC

LTRC

TRC-LCC

(Main unit

paper feed start

Preliminary

First sheet

Clearance-betweenpapers control timer

PIC drop timer PIC drop timer

Paper feed clutch

OFF timer

Preliminary

paper feed start

Preliminary paper

feed complete

Paper feed start

Second sheet

Clearance-betweenpapers control timer

Paper feed clutch

Resist stop

Preliminary paper

feed complete

Paper feed start

OFF timer

paper feed start

Preliminary

Third sheet

Clearance-betweenpapers control timer

PIC drop timer PIC drop timer

Paper feed clutch

OFF timer

Resist stop Resist stop

Preliminary

paper feed start

Preliminary paper

feed complete

Paper feed start

Fourth sheet

Clearance-betweenpapers control timer

Paper feed clutch

Preliminary paper

feed complete

Paper feed start

OFF timer

Preliminary

paper feed start

Fifth sheet

Paper feed clutch

OFF timer

Resist stop

Preliminary paper

feed complete

Paper feed start

MX-LCX3N OPERATIONAL DESCRIPTION 5 – 2

Page 9

1

5

6

7

32

1 Paper feed roller clutch

2 Take-up roller

3 Paper feed roller

4 Paper feed solenoid

5 Transport clutch

6 Transport motor

7 Lift-up motor

4

3. Paper empty detection

When the tray lifts and stops at the paper feed position and during

paper feed operation, paper presence/empty is detected by the

paper presence/empty sensor (LPED).

When paper empty is detected in the tray during paper feeding,

paper feeding is stopped.

MX-LCX3N OPERATIONAL DESCRIPTION 5 – 3

Page 10

MX-LCX3N

[6] DISASSEMBLY AND ASSEMBLY

Service Manual

1. Maintenance parts replacement procedures

A. Paper feed roller

1) Pull the lever, and open the upper cover.

2) Remove the screw, and remove the sheet.

3) Remove the pawl, and remove the pickup roller and the paper

feed roller.

2. Each unit removal

A. Paper feed unit

1) Pull out the tray.

2) Remove the screw, and remove the left front cabinet.

4) Loosen the screw, and remove the paper guide block.

5) Remove the pawl, and remove the reverse roller.

3) Open the upper cover, and remove the screws.

4) Remove the upper cabinet.

MX-LCX3N DISASSEMBLY AND ASSEMBLY 6 – 1

Page 11

5) Disconnect the connectors.

6) Remove the screws, and remove the paper feed unit.

C. Lift drive unit

1) Check that there is no paper, and lower the paper feed table to

the lower limit with the main unit simulation mode.

2) Remove the screws, and remove the rear cabinet.

B. Paper feed tray

1) Pull out the tray.

2) Remove the upper cabinet. (Refer to "A. Paper feed unit")

3) Remove the left front cabinet. (Refer to "A. Paper feed unit")

4) Remove the harness.

5) Remove the screws from the left and right rail sections, and

remove the tray unit from the rail.

3) Remove the connectors.

4) Remove the screws, and remove the lift drive unit.

MX-LCX3N DISASSEMBLY AND ASSEMBLY 6 – 2

Page 12

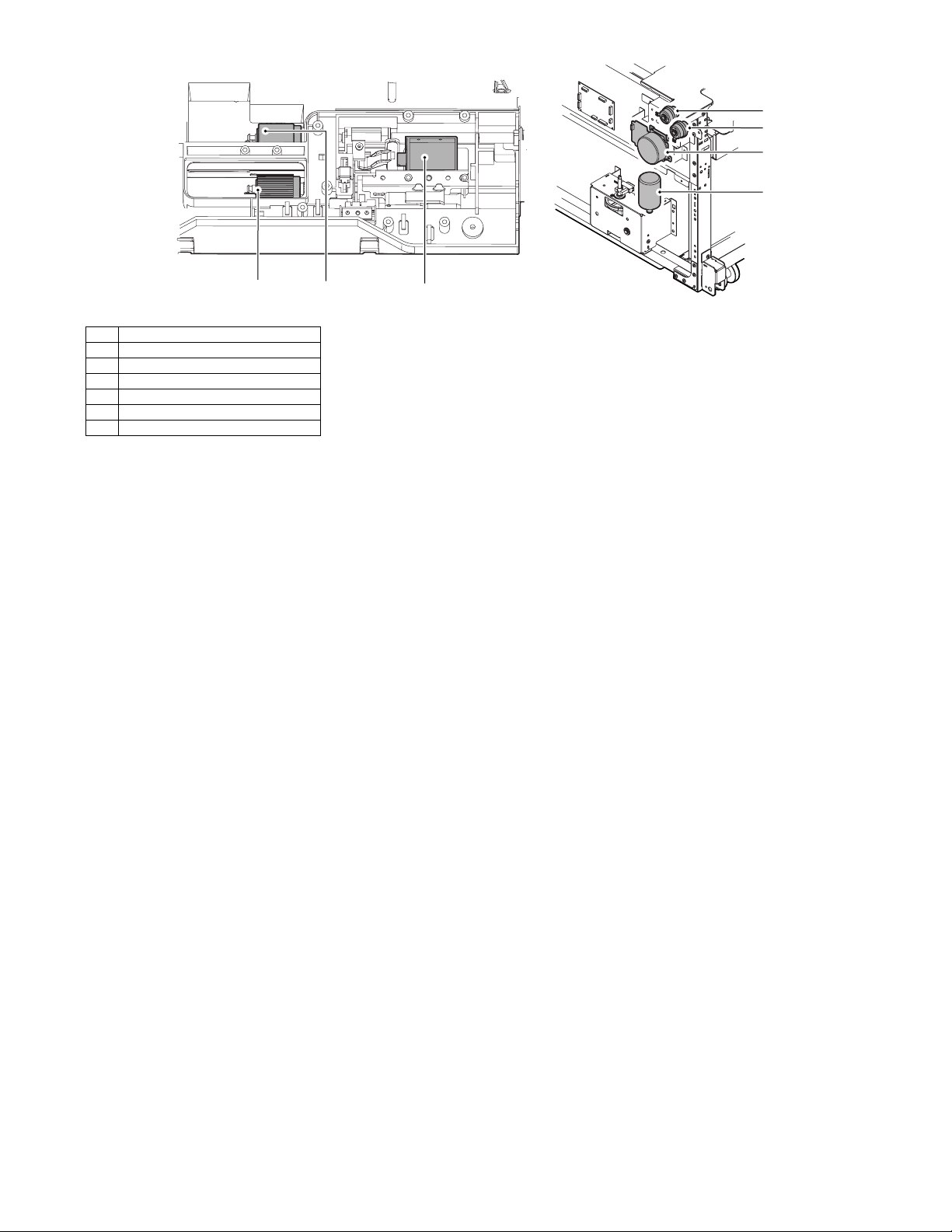

3. Major parts removal

A. Motor (Main)

1) Remove the rear cabinet. (Refer to "2. Each unit removal")

2) Disconnect the connector.

3) Remove the screws, and remove the motor.

B. Lift motor

1) Remove the lift drive unit. (Refer to "2. Each unit removal")

2) Remove the screws, the E-ring, the bearing, and remove the

gear unit.

4) Remove the ring, and remove the pulley.

* Applying grease at maintenance

A: Apply MOLYKOTE (UKOG-0062FCZZ)

B: Apply FLOIL (UKOG-0307FCZZ)

A

A

B

3) Remove the screws, and remove the lift motor.

C. Paper feed solenoid

1) Remove the paper feed unit. (Refer to "2. Each unit removal")

2) Remove the cover.

3) Remove the screw, and remove the unit.

Disconnect the connector.

MX-LCX3N DISASSEMBLY AND ASSEMBLY 6 – 3

Page 13

4) Remove the screws, and remove the solenoid.

D. Torque limiter

1) Remove the paper feed unit. (Refer to "2. Each unit removal")

2) Remove the screw, and remove the paper guide block.

5) Remove the E-ring, and remove the torque limiter.

1

2

3

4

E. Transport roller

1) Remove the paper feed unit. (Refer to "2. Each unit removal")

2) Loosen the screws, and remove the paper guide block.

3) Remove the rear cover, and disconnect the connector. (Refer

to "D. Torque limiter")

4) Remove the screw and the E-ring, and remove the parts.

Remove the transport roller.

3) Remove the screws, and remove the rear cover.

4) Disconnect the connector.

F. Handling solenoid

1) Check that there is no paper, and lower the paper feed table to

the lower limit with the main unit simulation mode.

2) Pull out the tray.

3) Remove the screws.

MX-LCX3N DISASSEMBLY AND ASSEMBLY 6 – 4

Page 14

4) Remove the front cabinet, and disconnect the connector.

5) Remove the connector and the screw.

4) Disconnect the connector, and remove the harness.

Remove the drive frame.

5) Remove the clutch unit.

Remove the E-ring, and remove the clutch.

6) Remove the screws, and remove the solenoid.

2

3

1

G. C lu tch

1) Remove the upper cabinet.

2) Remove the rear cabinet.

3) Remove the left rear cabinet.

MX-LCX3N DISASSEMBLY AND ASSEMBLY 6 – 5

Page 15

MX-LCX3N

[7] MAINTENANCE

Service Manual

1. Maintenance system table

✕ : Checking (clean, replace or adjust as required) { : Cleaning ▲ : Replace ∆ : Adjust ✩ : Lubricate : Position shift

No. Part name

1 Pick-up roller/each paper feed roller ✕ {

2 Torque limiter ✕✕

3 Each transport rollers ✕ {

4 Each transport paper guides {{

5 Each gears ✕✕

6 Each belts ✕

7 Each sensors ✕✕

When

calling

Main unit

maintenance cycle

Remarks

As a rough guide, these rollers should be replaced when the LCC paper feed

counter reaches a value of 100K (Sim22-9) or when one year has elapsed

since the start of use.

As a rough guide, the torque limiter should be replaced when the LCC paper

feed counter reaches a value of 800K (Sim22-9).

MX-LCX3N MAINTENANCE 7 – 1

Page 16

EXECUTE

Printing is finished

EXECUTE

10

Key

A㧦100

㧧 BK-MAG

B㧦 50 㧧 CS1

C㧦 50 㧧 CS2

D㧦 50 㧧 CS3

0

A

:

PAPER CENTER OFFSET SETUP

100

㨇㨉

OK

TEST

CLOSE

E㧦 50 㧧 CS4

F㧦 50 㧧 ADU

G㧦 50 㧧 MFT

H㧦 50 㧧 LCC

I㧦 1 㧧 MULTICOUNT

J㧦 2 㧧 PA PER㧦CS 1

K㧦 1 㧧 DUPLEX㧦 NO

EXECUTE

A㧦 100

㧧 BK-MAG

B㧦 50 㧧 CS1

C㧦 50 㧧 CS2

D㧦 50 㧧 CS3

0

:

PAPER CENTER OFFSET SETUP

60

㨉

OK

TEST

CLOSE

E㧦 50 㧧 CS4

F㧦 50 㧧 ADU

G㧦 50 㧧 MFT

H㧦 60 㧧 LCC

I㧦 1 㧧 MULTICOUNT

J㧦 2 㧧 PA PER㧦CS 1

K㧦 1 㧧 DUPLE X㧦NO

EXECUTE

[Switching of screen]

SIMULATION NO50-10

SIMULATION NO50-10

60㨪140

㨇

1㨪99

MX-LCX3N

[8] ADJUSTMENTS

Service Manual

Each adjustment item in the adjustment item list is indicated with its JOB number. Perform the adjustment procedures in the sequence of Job

numbers from the smallest to the greatest.

However, there is no need to perform all the adjustment items. Perform only the necessary adjustments according to the need.

Unnecessary adjustments can be omitted. Even in this case, however, the sequence from the smallest to the greatest JOB number must be

observed.

If the above precaution should be neglected, the adjustment would not complete normally or an error may occur.

1. List

Job No. Adjustment item list

ADJ 1 Print off-center adjustment 50-10

ADJ 2 Resist amount adjustment ADJ 2A Change in the resist amount adjustment/deflection amount correction value 51-02

2. Details

ADJ 1 Print off-center adjustment

1) Execute SIM.50-10. The displays shown at the right will

appear.

2) The print off-center adjustment value can be set for each tray.

3) Press the [↓] key on the touch panel to select “H:50:LCC”.

4) Then, enter your desired adjustment value with the [10] key.

(Default: 50 Adjustment range: from 1 to 99)

* If the adjustment value is decreased by 1, the main scanning

print position is shifted to the front side by 0.1mm.

* If the adjustment value is increased by 1, the main scanning

print position is shifted to the rear side by 0.1mm.

5) When the [EXECUTE] button is pressed, the [EXECUTE] button is highlighted, currently set value is saved into the

EEPROM and the RAM, and printing for the adjustment pattern image is started. After printing is finished, the [EXECUTE]

button returns to the normal display status.

6) Check the adjustment pattern image position.

Measure the dimensions of the void area in the adjustment

pattern front and rear frame directions, and ensure that they

satisfy the conditions shown below.

Simulation to

be used

ADJ 2B Adjustment of the print lead edge adjustment 50-05

A

+

A-B = 0 3.0mm

-

B

If condition of A - B = 0±3.0mm is satisfied, no adjustment is

necessary.

If it does not satisfy the condition above, execute the procedures shown below.

7) Change the adjustment value. Repeat the steps from 4 thru 6

until the condition described in the step 6) is satisfied.

8) After the adjustment is finished, escape from the simulation

mode with the CA key.

MX-LCX3N ADJUSTMENTS 8 – 1

H

* The screen above is intended for the model of MX-5500N series.

In the installation on other models, standard values are different.

Page 17

A

K

K

ADJ 2 Resist amount adjustment

2-A Changing resist amount adjustment/

deflection amount correction value

1) Execute SIM.51-2 by the key operation of the machine. Then,

the displays shown below appear.

2) Select the [ENGIN] button.

3) Press the [↓] key on the touch panel to select “G:50:LCC”.

4) Then, enter your desired adjustment value with the [10] key.

(Default: 50 Ajustment range: from 1 to 99)

* As the adjustment value is increased, the deflection amount

is also increased. As the adjustment value is decreased, the

deflection amount is also decreased.

(If the adjustment value is changed by “1”, the stop timing is

changed by 0.1mm (1.0msec).)

5) After the adjustment value is entered, press the [OK] key on

the touch panel to save the set value.

6) After the adjustment is finished, escape from the simulation

mode with the CA key.

[Switching of screen]

SIMULATION NO51-02

TEST

REGIST ROLLER ADJUSTMENT

50

:

㨇㨉

REGI1

A: 50 : NORMAL_PLAIN_HIGH

B: 50 : NORMAL_PLAIN_MID

C: 50 : NORMAL_PLAIN_LOW

D: 50 : NORMAL_THIN_HIGH

E: 50 : NORMAL_THIN_MID

F: 50 : NORMAL_THIN_LOW

G: 50 : RANDOM_PLAIN_HIGH

H: 50 : RANDOM_PLAIN_MID

I: 50 : RANDOM_PLAIN_LOW

J: 50 : RANDOM_THIN_HIGH

K: 50 : RANDOM_THIN_MID

L: 50 : RANDOM_THIN_LOW

REGI2 ENGIN

㪈㪇 Key

OK

0

CLOSE

O

2-B Print lead edge adjustment

1) Execute SIM.50-5 by the key operation of the machine. Then,

the displays shown on the next page appear.

2) Press the [↓] key on the touch panel to select “E:PAPER”.

3) Then, enter the adjustment value 6 with the [10] key, and press

the [OK] button.

(Adjustment value 6: LCC)

4) When the [EXECUTE] button is pressed, the [EXECUTE] button is highlighted, and printing for adjustment pattern image is

started with the currently set value. After printing is finished,

the [EXECUTE] button returns to the normal display status.

5) Check the adjustment pattern image position.

Measure the dimensions of the void area in the adjustment

pattern right and left frame directions, and ensure that they satisfy the conditions shown below.

A

+

A = 4.0 2.0mm

+

B = 4.0 2.0mm

-

B

If condition of A=4.0±2.0mm, B=4.0±2.0mm is satisfied, no

adjustment is necessary.

If it does not satisfy the condition above, execute the procedures shown below.

6) Change the adjustment values of the adjustment items

A(DEN-C) and B(DEN-B).

* As the adjustment value of the item A(DEN-C) is decreased

by 1, the print start position is moved to the lead edge side of

paper against the paper feed direction by 0.1mm.

* As the adjustment value of the item B(DEN-B) is decreased

by 1, the print range is increased to the trailing edge side of

paper against the paper feed direction by 0.1mm.

7) Repeat the steps from 4 thru 6 until the condition shown in the

step 5) is satisfied.

8) After the adjustment is finished, escape from the simulation

mode with the CA key.

0

SIMULATION NO51-02

TEST

REGIST ROLLER ADJUSTMENT

60

G:

㨇㨉

REGI1

A: 50 : NORMAL_PLAIN_HIGH

B: 50 : NORMAL_PLAIN_MID

C: 50 : NORMAL_PLAIN_LOW

D: 50 : NORMAL_THIN_HIGH

E: 50 : NORMAL_THIN_MID

F: 50 : NORMAL_THIN_LOW

G: 60 : RANDOM_PLAIN_HIGH

H: 50 : RANDOM_PLAIN_MID

I: 50 : RANDOM_PLAIN_LOW

J: 50 : RANDOM_THIN_HIGH

K: 50 : RANDOM_THIN_MID

L: 50 : RANDOM_THIN_LOW

REGI2 ENGIN

* The screen above is intended for the model of MX-5500N series.

In the installation on other models, standard values are different.

CLOSE

O

MX-LCX3N ADJUSTMENTS 8 – 2

Page 18

[Switching of screen]

A

K

K

SIMULATION NO50-05

TEST

LEAD EDGE ADJUSTMENT VALUE(PRINTER)

:

[1㨪 99 ]

35

A㧦 35

㧧 DE

B㧦 35 㧧 DEN-B

C㧦 35 㧧 FRONT/REAR

D㧦 1 㧧 MULTI COUNT

E㧦 2 㧧 PAPER : CS1

F㧦 1 㧧 DUPLEX : NO

0

CLOSE

N-C

EXECUTE

O

EXECUTE

EXECUTE

Printing is finished

0

SIMULATION NO50-05

TEST

LEAD EDGE ADJUSTMENT VALUE(PRINTER)

E:

㨇 1㨪 6 㨉

A㧦 35

㧧

B㧦 35 㧧

6

C㧦 35 㧧

D㧦 1 㧧

E㧦 6 㧧

F㧦 1 㧧

DEN-C

DEN-B

FRONT/REAR

MULTI COUNT

PAPER : CS1

DUPLEX : NO

* The screen above is intended for the model of MX-5500N series.

In the installation on other models, standard values are different.

EXECUTE

CLOSE

O

MX-LCX3N ADJUSTMENTS 8 – 3

Page 19

MX-LCX3N

[9] SIMULATION

1. List

Service Manual

Code

Main Sub

Used to check the operations of the sensors and detectors in the large capacity tray

2

(LCC) and the control circuit.

4

15 - Used to cancel the self-diag "U6-09 (large capacity paper feed tray)" trouble.

Used to check the operations of the loads in the large capacity tray (LCC) and the

3

control circuit.

5 Used to check the operations of the clutch (LTRC) in the LCC and the monitor. Operation test/Check

Function (purpose) Purpose Section

Operation test/Check

Operation test/Check

Clear/cancel (Trouble

etc.)

Large capacity tray

(LCC)

Large capacity tray

(LCC)

Large capacity tray

(LCC)

LCC

MX-LCX3N SIMULATION 9 – 1

Page 20

Troubleshoot the cause.

YES

NO

Detects/analyzes

the content.

Trouble/Warning

Warning

Trouble

The machine is stopped.

The content is displayed.

Trouble/Warning

Warning

A consumable

part has reached

its lifetime.

Trouble

Replace or supply

the consumable part.

Cancel the self-

diagnostic message with

the diagnostics

(test commands).

Reset

Standby state

Monitors the machine

conditions.

Repair

MX-LCX3N

[10] SELF DIAG MESSAGE AND TROUBLE CODE

Service Manual

1. Self diag

A. General

When an error occurs in the machine or when the life of a consumable part is nearly expired or when the life is expired, the machine

detects and displays it on the display section or notifies to the user

or the serviceman by remote email diagnostics. This allows the

user and the serviceman to take the suitable action. In case of a

failure, this feature notifies the occurrence of a failure and stops the

machine to minimize the damage.

B. Function and purpose

1) Securing safety. (The machine is stopped on detection of a

failure.)

2) The damage to the machine is minimized. (The machine is

stopped on detection of trouble.)

3) By displaying the trouble content, the trouble position can be

quickly identified. (This allows to perform an accurate repair,

improving the repair efficiency.)

4) Preliminary warning of running out of consumable parts allows

to arrange for new parts in advance. (This avoids stopping of

the machine due to running out the a consumable part.)

C. Self diag message kinds

The self diag messages are classified as shown in the table below.

Class 1 User Warning of troubles which can be recovered by

Class 2 Warning Warning to the user, not a machine trouble

D. Self diag operation

(1) Self diag operation and related work flow

The machine always monitors its own state.

When the machine recognizes a trouble, it stops the operation and

displays the trouble message.

A warning message is displayed when a consumable part life is

nearly expired or is expired.

When a warning message is displayed, the machine may or may

not be stopped.

The trouble messages and the warning messages are displayed by

the LCD.

Some error messages are automatically cleared when the trouble

is repaired. Some other error must be cleared by a simulation.

Some warning messages of consumable parts are automatically

cleared when the trouble is replaced. Some other warning messages must be cleared by a simulation.

the user. (Paper jam, consumable part life

Serviceman Warning of troubles which can be recovered only

Other —

Trouble Warning of a machine trouble. The machine is

Other —

expiration, etc.)

by a serviceman. (Motor trouble, maintenance,

etc.)

(Preliminary warning of life expiration of a

consumable part, etc.)

stopped.

MX-LCX3N SELF DIAG MESSAGE AND TROUBLE CODE 10 – 1

Page 21

2. Trouble code list

MAIN

CODE

SUB

CODE

U6 09 Lift motor trouble LCC When the tray is working Check connection.

20 Communication trouble LCC LCC communication Turn OFF/ON the power.

21 Transport motor trouble LCC Paper feed Check connection.

22 24V trouble LCC Power ON Check connection.

23 Tray descending trouble LCC When the tray is working Check connection.

24 Tray lock trouble LCC When the tray is working Check connection.

51 LCC incompatibility trouble LCC Power ON Check connection.

Title (Content) Section Operation mode Countermeasure (Remedy) Note

3. Trouble code details

U6-09 LCC lift motor trouble

Trouble content • The encoder input value is not changed in

Section PCU

Case 1 Cause Sensor trouble, LCC control PWB trouble, gear

Check

and

Remedy

0.2sec (1st time)/0.5sec (2nd time and later)

after rotation of the motor.

• The motor is rotated for 48sec or more.

breakage, lift motor trouble

Use SIM4-2 and 4-3 to check the operation of the

sensor and the lift motor. Use SIM15 to cancel the

trouble.

U6-20 LCC communication trouble

Trouble content LCC communication error. Communication line test

Section PCU

Case 1 Cause Connector and harness connection trouble or

Check

and

Remedy

error after turning ON the power or canceling the

exclusive simulation. LCC and machine model

codes discrepancy error

disconnection, LCC control PWB trouble, control

(PCU) PWB trouble, malfunction due to electrical

noises

Turn OFF/ON the power to cancel the trouble.

Check the connector and the harness of the

communication line.

U6-21 LCC transport motor trouble

Trouble content After passing 1 sec from turning ON the motor, the

Section PCU

Case 1 Cause Motor lock, motor RPM abnormality, an overcurrent

Check

and

Remedy

lock state of the motor lock signal is detected

continuously for 1 sec.

to the motor, LCC control PWB trouble

Use SIM4-3 to check the operation of the transport

motor.

U6-22 LCC 24V power abnormality

Trouble content DC24V power is not supplied to LCC.

Section PCU

Case 1 Cause Connector and harness connection trouble or

Check

and

Remedy

disconnection, LCC control PWB trouble, power

unit trouble

Check the connector and the harness of the power

line. Check that the power unit and the LCC control

PWB is of 24V.

U6-23 LCC tray descending trouble

(reverse winding detection)

Trouble content Reverse winding of the LCC tray wire is detected.

Section PCU

Case 1 Cause Reverse winding of the wire

Check

and

Remedy

Case 2 Cause Connector and harness connection trouble

Check

and

Remedy

Case 3 Cause Reverse winding detection SW-ON, reverse

Check

and

Remedy

Check the wire.

Check connection of the connector and the

harness.

winding detection SW trouble, LCC control PWB

trouble

Replace the reverse winding SW and the LCC

control PWB.

U6-24 LCC tray lock detection trouble

Trouble content Malfunction of the LCC tray lock mechanism is

Section PCU

Case 1 Cause Tray lock mechanism trouble

Check

and

Remedy

Case 2 Cause Connector and harness connection trouble

Check

and

Remedy

Case 3 Cause Tray lock detection sensor trouble, LCC control

Check

and

Remedy

detected.

Check the tray lock mechanism.

Check connection of the connector and the

harness.

PWB trouble

Replace the tray lock detection sensor and the

LCC control PWB.

U6-51 LCC incompatibility trouble

Trouble content Detection of incompatible LCC connection.

Section PCU

Case 1 Cause Connection of incompatible LCC, is detected.

Check

and

Remedy

Install compatible LCC.

MX-LCX3N SELF DIAG MESSAGE AND TROUBLE CODE 10 – 2

Page 22

MMAIN PWB

MX-LCX3N

[11] ELECTRICAL SECTION

1. Wiring diagram

Service Manual

Main unit

Cassete detection

switch

<Cassette unit>

Reverse-winding

detection switch

+24V

ON

LWRSW

LWRSW(24V) 3

+5VR

LDD

LRE

+5V

GND

PHR-4

1

3LTLSW

PHR-3

2LTLD

3

SMP-03V-NC

1

212

33

LLM+

LLM-

Lift motor

Lower limit sensor

LDD

Lift motor encoder input

Paper front surface sensor

LPUD

Lock release PWB

LTLLED

LTLSW

+5VR

LTLLED

GND24

Lowering SW PWB relay harness

Tray lock sensor

LTLD

GND 1

+5V

SMR-03V-N

LTLS

LFAN1

LFAN2

PS-187-3V

1

2

1

2

PHR-3

1

2GND

3

1

2LPUD

3

SMR-04V-N

PHNR-06-H

SMP-03V-NC

Connected

to the main body

179228-3

SMP-04V-NC

11

2

3

1

2

3

4

5

6

1

212

1

212

ELR-12V

AC-L(H)

F.G.

AC-N(H)

ELR-15V

N.C.

N.C.

TXD-LCC

RXD-LCC

/DSR-LCC

RES-LCC

F.G.

+5V

GND

+24V

GND

/TRC-LCC

N.C.

N.C.

ELR-03V

1

232

3

SMP-03V-NC

SMR-03V-N

11

2

2

3

3

2

3

44

6

5

4

3

2

1

PHNR-09-H

SMR-03V-N

33

Cassette unit front harness A3 CD

SMR-03V-NSMP-03V-NC

33

ELP-12V

4

4

5

5

12

12

ELP-15V

1

1

2

2

3

3

4

4

5

5/DTR-LCC

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

LPISW

LCD(24V)LCD

ELP-03V

1

PHNR-09-H

1

9

2

8

7

3

64

55

4

6

7

3

2

8

1

9

Cassette unit side harness A3 CD

PS-187-2V

1

2

3

PHNR-16-H

Safety earth

PHNR-16-H

16

1

15

2

14

3

4

13

5

12

6

11

10

7

9

8

8

9

7

10

6

11

5

12

13

4

14

3

15

2

16

1

Heater harness

ELP-02V

ELR-02V

2112

Main unit relay harness A3

Cassette unit

rear harness A3 CD

SMR-11V-N

4 4

55

6 6

88

11 11

12 12

13 13

16 16

17 17

22

33

44

6

7

8

9

10

Heater

SNP-18V-NCSMR-18V-N

11

22

33

77

99

1010

1414

1515

1818

SMP-11V-NC

11

55

6

7

8

9

10

1111

Cassette relay harness CD

PAP-12V-S

PHDR-16VS-2

PHDR-18VS-2

CN-A

B12B-PASK

1

1

N.C.

2

/TRC-LCC

2

3RES-LCC

3

/DSR-LCC

4

4

/DTR-LCC

5

5

6

RXD-LCC

6

77

TXD-LCC

8

8

GND

9

9

GND

10

10

+5V

11

GND

11

12

+24V

12

CN-B

B16B-PHDSS

LLSW(24V)

1

1

2

2

GND

3

3

GND

LIPSW(24V)

44

5

GND

5

6

LIPSW(24V)

6

LCD(24V)

7

7

8

8

GND

GND

9

9

10

10

LLM(+)

11

+24V(PS)

11

12

GND

12

GND

13

13

LWRSW(24V)

14

14

15

15

LLM(-)

GND

1616

CN-C

B9B-PH-K-S

PHR-9

1

+5VR

1

2

GND

2

LDD

3

3

4

4

LRE

GND

5

5

6

6

+5VR

7

+5V

7

LPUD

8

8

9

9

GND

CN-D

B18B-PHDSS

+5VR

1

1

2

2

LTLLED

LTLSW

3

3

4

GND

4

5

+5V

5

GND

6

6

7

LTLD

7

8

N.C.

8

24V-ICP

9

9

10

10

LTLSL

11

11

N.C.

12

12

LTLSU

13

13

24V

24V

14

14

15

15

LFAN1

16

LFAN2

16

17

17

GND

18

18

GND

MX-LCX3N ELECTRICAL SECTION 11 – 1

Page 23

CN-A

B12B-PASK

1

N.C.

2

/TRC-LCC

RES-LCC

3

4

/DSR-LCC

/DTR-LCC

5

6

RXD-LCC

TXD-LCC

GND

8

GND

9

+5V

10

GND

11

+24V

CN-B

B16B-PHDSS

1

LLSW(24V)

GND

2

3

GND

LIPSW(24V)

4

GND

5

6

LIPSW(24V)

LCD(24V)

7

8

GND

GND

9

10

LLM(+)

+24V(PS)

11

GND

12

GND

13

LWRSW(24V)

14

15

LLM(-)

GND

16

CN-C

B9B-PH-K-S

1

+5VR

2

GND

3

LDD

4

LRE

5

GND

6

+5VR

+5V

7

LPUD

8

9

GND

MAIN PWB

ICP-N15ICP-N15

CN-E

B11B-PH-K-S

/LPED

GND

GND

/LUD

+5V

+24V

LPFS

+5V

GND

/LPFD

CN-F

B20B-PHDSS

+24V(PS)

GND

GND

LDSW(24V)

GND

LDSW(24V)

LLSW(24V)

GND

GND

LDSW(24V)-ICP

LPFC

GND

GND

LDSW(24V)-ICP

LTRC

GND

GND

+5VR

LTOD

GND

CN-G

B5B-PH-K-S

+24V

GND

LPFM

LPFM-T

LPFM-CLK

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

99

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

PHR-11

1+5V

2

3

4

5

6

7

8

9

10

11

PHDR-20VS-2

1

2

3

4

5

6

7

8

Paper feed side

main harness

1010

11

12

13

14

15

16

17

18

19

20

PHR-5

1

2

3

4

5

SMP-18V-NC SMR-18V-N

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

1612

17

17

18

18

Paper feed unit harness A3

SMP-02V-BC SMR-02V-B

131

22

3

SMP-03V-NC

Transport sensor relay harness A3

SMP-03V-NC SMP-04V-NC

SMR-03V-N

SMR-03V-N

Transport sensor relay harness A3 CD

1

3223

179228-3

PHR-3

212

11

FPS-187

PS-187-3V

CZHR-03V-S

CZHR-03V-S

179228-3

1+5V

/LPED

2

GND

3

1GND

/LUD LUD

2

+5V

3

22

3113

SMR-04V-N

1

+24V

1

LDSW(24V)

1 LDSW(24V)

NC

2

LLSW(24V)

3

1 +24V

2

N.C. LPFC

LPFC3

1

+24V

2

N.C. LTRC

LTRC

3

+5VR

1

LTOD

2

3

GND

PHR-5

+24V

1

2

GND1

LPFM

3

4

LPFM-T

LPFM-CLK

5

<Paper feed unit>

Tray paper sensor

LPED

Tray upper limit sensor

LPFS

Transport sensor harness A3 CD

LPFM

Paper feed solenoid

179228-3

2/LPFD

Paper feed sensor

LDSW

Upper open/close switch

LLSW

Upper limit switch

Paper feed clutch

Paper transport clutch

Main unit

LTOD

communication sensor

LCC transport motor

+5V

GND13

LPFD

CN-D

B18B-PHDSS

+5VR

1

2

LTLLED

LTLSW

3

GND

4

+5V

5

GND

6

LTLD

7

N.C.

8

24V-ICP

9

10

LTLSL

11

N.C.

12

LTLSU

13

24V

24V

14

15

LFAN1

16

LFAN2

17

GND

18

GND

MX-LCX3N ELECTRICAL SECTION 11 – 2

Page 24

2. Block diagram

RXD-LCC

DSR-LCC

TXD-LCC

DTR-LCC

RES-LCC

GND2

5V

24V

GND1

F.G.

TRC-LCC

+24V

+24V

LDSW(24V)-ICP

+24V

5V

Communication

buffer circuit

Onboard

writing circuit

Main unit

EEPROM

A3-LCC P

A3-LCC

Xtal

7.37MHz

Communication

writing circuit

LCC tray lock solenoid

Solenoid clutch drive circuit

LCC tray LED(LTLLED)

LCC separation

auxiliary fan(FAN1)

LCC separation

auxiliary fan(FAN2)

LCC paper feed

clutch(LPFC)

LCC paper feed

clutch(LTRC)

LCC paper feed solenoid(LPFS)

Lock release(LTLSU)

Lock(LTLSL)

LED drive

circuit

Input circuit

Sensor

input circuit

Buffer

circuit

LCC tray SW(LTLSW)

DOWN SW PWB

ICP-N15

ICP-N20

ICP-N15

IC protector

IC protector

IC protector

MX-LCX3N ELECTRICAL SECTION 11 – 3

Page 25

CPU(H8/3687)

Calculating section

24V monitor

circuit

Upper door detection

monitor circuit

Upper limit detection

monitor circuit

Illegal paper detection

monitor circuit

Cassete detection

monitor circuit

Reverse-winding detection

monitor circuit

+24V

Poly switch1.1A

LCC transport motor(LPFM)

LCC upper open/close

detection switch(LDSW)

LCC upper limit switch(LLSW)

LCC illegal paper detection switch(LIPSW)

LCC cassette detection switch(LCSW)

LCC reverse-winding

detection switch(LWRSW)

LDSW(24V)-ICP

C

PWB

Rising

circuit

Lift motor drive circuit

Current limt

circuit

Sensor input circuit

Lowering

circuit

LCC lift motor(LLM)

LCC paper front surface sensor(LPUD)

LCC tary upper limit sensor(LUD)

LCC tary lower limit sensor(LDD)

LCC tary paper empty sensor(LPED)

LCC transport sensor(LPFD)

LCC main unit connection sensor(LTOD)

LCC lift motor encoder sensor(LRE)

LCC tray lock sensor(LTLD)

MX-LCX3N ELECTRICAL SECTION 11 – 4

Page 26

3. Circuit diagram

2

V

2

V

Z

Z

X

X

R

/

/

/

/

/

/

6

C27 222Z/50VC27 222Z/50V

R52 4 7KJR52 4 7KJ

5678

D7

D8

D9

NO ASSEMBLY

C1

C1

+

+

47uF/35V

47uF/35V

+5V

+5V

12

34

56

78

910

1112

1314

1516

1718

1SS133D71SS133

1SS133D81SS133

1SS133D91SS133

1

2

3

4

5

6

7

8

1

2

3

4

1

3

5

7

9

11

13

15

ZD1

ZD1

ZD2

ZD2

IC2

IC2

I1

I2

I3

I4

I5

I6

I7

GND

TD62503

TD62503

IC1

IC1

OUT1

-IN1

+IN1

GND

BA10393F

BA10393F

DAP202KD2DAP202K

ICP1

ICP1

ICP-N20

ICP-N20

+

+

LLSW(24V)

GND

GND

LCSW:LC7 , LCD:LCX3

GND

24V(PS)

GND

LLM(-)

R20 10KJR20 10KJ

HZ16BP

HZ16BP

R21 10KJR21 10KJ

HZ16BP

HZ16BP

R22 10KJR22 10KJ

ZD3

ZD3

HZ16BP

HZ16BP

R26

R26

C7

C7

2.4KJ(1/4W)

2.4KJ(1/4W)

47uF/35V

47uF/35V

R24

R24

2.4KJ(1/4W)

2.4KJ(1/4W)

16

O1

15

O2

14

O3

13

O4

12

O5

11

O6

10

O7

TP58TP58

9

N.C.

TP59TP59

+5V

R17 4.7KJR17 4.7KJ

8

Vcc

7

OUT2

TP60TP60

6

-IN2

5

+IN2

C11

C11

683K/50V(2012)

R16 100JR16 100J

TP1TP1

+5V

D1

DAN202KD1DAN202K

D2

R5

4.7KJR54.7KJ

222Z/50V x3

+24V

R8 220J(1/4W)R8 220J(1/4W)

TP54TP54

104Z/16V

104Z/16V

C3C3

VD

R30R30

10KJ x3

Q6

TP4TP4

RT1N141CQ6RT1N141C

TP5TP5

Q7

RT1N141CQ7RT1N141C

R12

R12

1KJ

1KJ

10KJR910KJ

C5

Q15Q15

B

B

R9

Q3

2SB1431Q32SB1431

Q4

2SD2162Q42SD2162

R11

R11

0.22J(1W)

0.22J(1W)

Q20

Q20

RT1N141C

RT1N141C

+5V

RT1N141C x2

Q5

RT1N141CQ5RT1N141C

E

C

C

E

VD

R10

R10

10KJ

10KJ

C6

222Z/50VC6222Z/50V

TP6TP6

R25

R25

2.4KJ(1/4W)

2.4KJ(1/4W)

R23

R23

2.4KJ(1/4W)

2.4KJ(1/4W)

TP53TP53

+5V

R15

R15

R14

R14

1KJ

1KJ

1KJ

1KJ

C10C10

C9C9

+5V

R4

R7

10KJR410KJ

10KJR710KJ

R41 10KJR41 10KJ

R42 10KJR42 10KJ

C2C2

C4C4

+5V

+5V

222Z/50VC5222Z/50V

R3

R2

1KJR21KJ

1KJR31KJ

Q14Q14

R32R32

R31R31

E

C

C

E

1SR153-400 x2

C8

103Z/50VC8103Z/50V

1

2

3

4

R74

R74

4.7KJ

4.7KJ

NO ASSEMBLY

C34

C34

222Z/50V

222Z/50V

R36 10KJR36 10KJ

R73 10KJR73 10KJ

DAN202K

DAN202K

D12

D12

TP49TP49

TP8TP8

TP9TP9

TP7TP7

Q1

2SB1431Q12SB1431

Q2

2SD2162Q22SD2162

R33 10KJR33 10KJ

IC3

IC3

A0

Vcc

A1

WP

A3

SCL

Vss

SDA

CAT24WC04

CAT24WC04

/LRE

Q12Q12

D13

D13

DAN202K

DAN202K

NO ASSEMBLY

R46 10KJR46 10KJ

R47 10KJR47 10KJ

R48 10KJR48 10KJ

C15C15

C17C17

C16C16

222Z/50V x3

+24V

D4D4

B

1SR153-400 x2

D5D5

B

R13

R13

1KJ

1KJ

D6D6

8

7

6

5

D3D3

VD

R38 4.7KJR38 4.7KJ

R39 4.7KJR39 4.7KJ

R400JR40

R37 0JR37 0J

C18

C18

104Z/16V

104Z/16V

LLM(-)

LLM(+)

YOBI_1

YOBI_2

LLUM

LLDM

0J

C19

C19

222Z/50V

222Z/50V

SW1

SW1

T3B-SQ /JM-2W-96

T3B-SQ /JM-2W-96

/RESET_LCC

1

2

3

VD

C20

C20

104Z/16V

104Z/16V

+5V

NO ASSEMBLY

L1

L1

MMZ1608S121AT

MMZ1608S121AT

JP1 +5VJP1 +5V

TP55TP55

TP14TP14

TP15TP15

TP16TP16

TP17TP17

TP10TP10

TP18TP18

TP11TP11

TP12TP12

TP13TP13

R45

R45

R35

R35

R44

R44

CSTLS7M37G53

CSTLS7M37G53

C24

C24

104Z/16V

104Z/16V

LCSW

LWRSW

YOBI_1

N.C._I/O

N.C._I/O

YOBI_2

LLUM

LLDM

/LTLSW

SDA

SCLK

N.C._I/O

/LDD

/LPUD

LTLSU

N.C._I/O

TP40TP40

4.7KJ

4.7KJ

4.7KJ

4.7KJ

4.7KJ

4.7KJ

Q9Q9

RT1N141C x3

RES_LCC

1

/TXD_LCC

2

GND

3

GND

4

+5V

5

+5V

6

/RES_LCC

7

/NMI

8

P85

9

P86

10

P87

11

TXD_LCC

12

RXD_LCC

13

N.C.

14

17

P36

18

P37

19

P52/WKP2

20

P53/WKP3

21

P54/WKP4

22

P55/WKP5/ADTRG

23

P10/TMOW

24

P11

25

P12

26

P56/SDA

27

P57/SCL

28

P74/TMRIV

29

P75/TMCIV

30

P76/TMOV

31

P24

32

P63/FTIOD0

VD

D14

D14

DAN202K

DAN202K

D15

D15

DAP202K

DAP202K

Q11Q11

NO ASSEMBLY

R53

R53

C21

C21

+

+

47uF/16V

47uF/16V

C22

C22

TP50TP50

X1

X1

Q8Q8

TP51TP51

1MJ

1MJ

1

3

2

R550JR55

R540JR54

0J

0J

TP24TP24

TP23TP23

LIPSW

LTRC

LPFS

LPFC

11

9

12

14

16

DSR_LCC

TP19TP19

222Z/50V

222Z/50V

8

Vss

Vcc

P3415P35

OSC210OSC1

P50/WKP013P51/WKP1

IC6

IC6

H8/3687

H8/3687

P62/FTIOC033P61/FTIOB034NMI35P60/FTIOA036P64/FTIOA137P65/FTIOB138P66/FTIOC139P67/FTIOD140P8541P8642P8743P20/SCK344P21/RXD45P22/TXD46P2347P70/SCK3_2

/LED

LPFM-CLK

EM_P85

/NMI

/TRC_LCC

LTLLED

LFAN

DTR_LCC

TP27TP27

TP22TP22

TP20TP20

TP28TP28

TP26TP26

R57 1KJR57 1KJ

R51 10KJR51 10KJ

12345678910

CN-W

CN-W

B14B-PHDSS-B

B14B-PHDSS-B

TP30TP30

IC5

IC5

Xin1VDD

Xout2S0

S13FSOUT

LF4VSS

FS781

FS781

C30

C30

R64

R64

103

103

3.3KJ

3.3KJ

TP29TP29

TP31TP31

R6R

VD

C

C

104Z/16

104Z/16

TP25TP25

L24VM

N.C._IN

5

7

6

3

2

X24X1

Vcl

RES

AVcc

TEST

PB6/AN61PB7/AN7

PB5

PB4

PB0

PB1

PB2

PB3

P17/IRQ3/T

P16/I

P15/I

P14/I

P72/T

P71/R

48

RXD_LCC

EM_P87

EM_P86

TXD_LCC

LTLSL

N.C._I/O

N.C._I/O

10KJ x4

R60R60

R59R59

R58R58

R50R50

TP57TP57

R56 10KJR56 10KJ

R63 4.7KJR63 4.7KJ

R62 4.7KJR62 4.7KJ

R61 1KJR61 1KJ

C29 104Z/16VC29 104Z/16V

VD

1112

1314

2

GND

LIPSW(24V)

4

LIPSW(24V)

6

GND

8

LLM(+)

10

GND

12

LWRSW(24V)

14

GND

16

CN-B

+5VR1

GND

/LDD

LRE

GND

+5V

+5V

/LPUD

GND

2

4

6

8

10

12

14

16

18

R28

R28

/LTLSL

/LTLSU

/LTLLED

GND

N.C.

/LTLSL

/LTLSU

+24V

/FAN2

GND

CN-B

B16B-PHDSS-B

B16B-PHDSS-B

100J

100J

R29

R29

R27 15KFR27 15KF

100J

100J

R34

R34

473K/50V(2012)

473K/50V(2012)

104Z/16V

104Z/16V

12

34

56

78

910

1112

1314

1516

D10

D10

D11

D11

1SS133

1SS133

15KF

15KF

C14

C14

C12

C12

CN-C

CN-C

1

2

3

4

5

6

7

8

9

B9B-PH-K-S

B9B-PH-K-S

1

+5VR

3

/LTLSWGND

+5V

5

7

/LTLD

9

+24V-ICP

11

N.C.

13

+24V

15

/FAN1

17

GND

1SS133

1SS133

+5V

C13

C13

473K/50V(2012)

473K/50V(2012)

R18

R18

2.4KJ

2.4KJ

TP3TP3

R19

R19

510J

510J

220J(1/4W)R1220J(1/4W)

R1

CN-D

CN-D

B18B-PHDSS-B

B18B-PHDSS-B

LLM(-)

TP2TP2

D

LLM(+)

LLUM

LLDM

C

2

3

4

5

6

B

7

8

9

A

87 6 5

MX-LCX3N ELECTRICAL SECTION 11 – 5

Page 27

5

TT

8

9

0

2

3

4

5

6

8

9

0

2

1234

2

GND

4

LDSW(24V)

6

LDSW(24V)

8

/LPFS

220J(1/4W)

220J(1/4W)

C39C39

+24V

R78

R78

R84R84

C40C40

GND

10

LDSW(24V)-ICP

GND

12

LDSW(24V)-ICP

14

GND

16

+5V

18

GND

20

CN-E

CN-E

B11B-PH-K-S

B11B-PH-K-S

10

11

CN-G

CN-G

5

4

3

2

1

B5B-PH-K-S

B5B-PH-K-S

+5V

+24V

NO ASSEMBLY

NO ASSEMBLY

R53

R53

TP50TP50

X1

G53X1G53

4

4

C21

C21

+

+

47uF/16V

47uF/16V

7

P36

P37

P52/WKP2

P53/WKP3

1

P54/WKP4

P55/WKP5/ADTRG

P10/TMOW

7

1

0

0

D

Q11Q11

141C x3

_LCC

_LCC

S_LCC

I

_LCC

_LCC

.

P11

P12

P56/SDA

P57/SCL

P74/TMRIV

P75/TMCIV

P76/TMOV

P24

P63/FTIOD0

D14

D14

DAN202K

DAN202K

D15

D15

C22

C22

DAP202K

DAP202K

TP51TP51

1MJ

1MJ

TP30TP30

1

3

2

R540JR54

0J

TP23TP23

LIPSW

LTRC

LPFS

LPFC

12

13

14

16

P3415P35

P50/WKP0

P51/WKP1

H8/3687

H8/3687

P62/FTIOC033P61/FTIOB034NMI35P60/FTIOA036P64/FTIOA137P65/FTIOB138P66/FTIOC139P67/FTIOD140P8541P8642P8743P20/SCK344P21/RXD45P22/TXD46P2347P70/SCK3_2

/LED

LPFM-CLK

/NMI

DSR_LCC

LTLLED

TP22TP22

TP19TP19

TP20TP20

R51 10KJR51 10KJ

222Z/50V

222Z/50V

Q8Q8

Vcc

LFAN

TP28TP28

11

IC6

IC6

TP24TP24

OSC210OSC1

DTR_LCC

TP26TP26

R550JR55

0J

TP25TP25

5

9

7

8

6

Vcl

Vss

RES

TEST

EM_P87

EM_P86

EM_P85

/TRC_LCC

N.C._I/O

TP27TP27

R57 1KJR57 1KJ

12345678910

CN-W

CN-W

B14B-PHDSS-B

B14B-PHDSS-B

R64

R64

3.3KJ

3.3KJ

VD

X24X1

TXD_LCC

1112

IC5

IC5

Xin1VDD

Xout2S0

S13FSOUT

LF4VSS

FS781

FS781

TP29TP29

TP31TP31

104Z/16V

104Z/16V

L24VM

N.C._IN

2

3

AVcc

PB6/AN61PB7/AN7

P17/IRQ3/TRGV

P16/IRQ2

P15/IRQ1

P14/IRQ0

P72/TXD_2

P71/RXD_2

48

RXD_LCC

LTLSL

N.C._I/O

10KJ x4

R60R60

R59R59

R58R58

R50R50

TP57TP57

R56 10KJR56 10KJ

R63 4.7KJR63 4.7KJ

VD

1314

C30

C30

103Z/50V

103Z/50V

R65

R65

C26

C26

PB5/AN5

PB4/AN4

PB0/AN0

PB1/AN1

PB2/AN2

PB3/AN3

R62 4.7KJR62 4.7KJ

R61 1KJR61 1KJ

C29 104Z/16VC29 104Z/16V

8

7

6

5

TP52TP52

P30

P31

P32

P33

VD

R52 4.7KJR52 4.7KJ

C27 222Z/50VC27 222Z/50V

VD

C25

C25

104Z/16V

104Z/16V

/RESET_LCC

10KJ

10KJ

LDSW

64

LLSW

63

/LUD

62

/LPFD

61

/LPED

60

N.C._IN

59

LPFM

58

/LPFM-T

57

/LPFD1

56

N.C._I/O

55

N.C._I/O

54

/LTLD

53

/LRE

52

/LTOD

51

N.C._I/O

50

N.C._I/O

49

4.7KJ x2

R76R76

R49R49

+5V

D17D17

D19D19

DAN202K x2

D18D18

D20D20

DAP202K x2

TP32TP32

TP33TP33

TP34TP34

TP35TP35

TP36TP36

TP37TP37

TP38TP38

TP39TP39

TP41TP41

TP42TP42

RT1N141C x2

Q16Q16

Q10Q10

CN-A

CN-A

YOBI_1

YOBI_2

DAN202K x2

R66

R66

R67 10KJR67 10KJ

R68 10KJR68 10KJ

R69

R69

R70 10KJR70 10KJ

R71 10KJR71 10KJ

R72

R72

R75

R75

TP21TP21

2341567891011

B12B-PASK

B12B-PASK

10KJ

10KJ

10KJ

10KJ

10KJ

10KJ

10KJ

10KJ

104Z/16V

104Z/16V

TP56TP56

12

VD

1

2

3

4

5

6

7

8

TD62003AP

TD62003AP

D23D23

R43

R43

220J(1/4W)

220J(1/4W)

LED1

LED1

LED

LED

C28

C28

IC4

IC4

I1

I2

I3

I4

I5

I6

I7

GND

VD

C33C33

COM

C31C31

1

2

3

4

5

6

7

8

9

10

11

12

MTZJ20BT

MTZJ20BT

O1

O2

O3

O4

O5

O6

O7

D22D22

N.C.

/TRC_LCC

RES_LCC

/DSR_LCC

/DTR_LCC

/RXD_LCC

/TXD_LCC

GND

GND

+5V

GND

+24V

ZD4

ZD4

16

15

14

13

12

11

10

9

10KJ x3

R83R83

C32C32

222Z/50V x3

/LRE

+5V +24V

C35

C35

+

+

47uF/16V

47uF/16V

/LTLSU

/LPFS

/LTLSL

R79R79

R81R81

C36

C36

223K/50V(1608)

223K/50V(1608)

TP44TP44

R6

10KJR610KJ

C23

C23

222Z/50V

222Z/50V

TP46TP46

TP45TP45

C42

C42

+

+

47uF/35V

47uF/35V

HZ16BP x3

10KJ x3

Q18Q18

DAN202K x2

B20B-PHDSS-B

B20B-PHDSS-B

17 18

19 20

ZD7ZD7

DAP202K x2

CN-F

CN-F

R88R88

Q21Q21

15 16

+24V

13 14

TP48TP48

11 12

D24D24

D25D25

5 6

7 8

9 10

D16D16

ZD6ZD6 ZD5ZD5

R86R86 R87R87

TP47TP47

Q17Q17

Q13Q13

RT1N141C x2

3 4

ICP2

ICP2

ICP-N15

ICP-N15

1 2

D26D26

D27D27

1SS133 x2

D21D21

ICP-N15

ICP-N15

RT1N141C x3

TP43TP43

R80R80

C38C38

ICP3

ICP3

+5V

+5V

Q19Q19

+24V

R89

R89

10KJ

10KJ

C41

C41

222Z/50V

222Z/50V

PS1

PS1

RXE110

RXE110

+24V

+5V

10KJ x4

R77R77 R82R82

C37C37

222Z/50V x4

9

R78

R78

+5V

+5V

+5V

R85

R85

220J(1/4W)

220J(1/4W)

1

2

3

5

64+5V

7

8

9

10

11

578

CN-H

CN-H

3

2

1

B3B-PH-K-S

B3B-PH-K-S

3GND

2

1

4

35/LPFM

2

1

1

+24V(PS)

3

GND

5

GND

7

LLSW(24V)

9

GND

11

/LPFC

13

GND

/LTRC

15

GND

17

/LTOD

19

+5V

/LPED

GND

GND

/LUD

+24V

/LPFS

+5VR

GND

/LPFD

23461

R78

LC7:220J 1/4W

LCX3:JUMPER

NO ASSEMBLY

/LPFD1

5VR

/LPFM-CLK

/LPFM-T

GND

LOSW(24V)

D

C

B

A

5

4

3

21

MX-LCX3N ELECTRICAL SECTION 11 – 6

Page 28

LEAD-FREE SOLDER

The PWB’s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder.

The alphabet following the LF mark shows the kind of lead-free solder.

Example:

<Solder composition code of lead-free solder>

Solder composition

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi

Sn-In-Ag-Bi

Sn-Cu-Ni

Sn-Ag-Sb

Bi-Sn-Ag-P

Bi-Sn-Ag

5mm

Lead-Free

Solder composition

code (Refer to the

table at the right.)

a

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread.

Never use conventional lead solder thread, which may cause a breakdown or an accident.

Since the melting point of lead-free solder thread is about 40°C higher than that of conventional lead solder thread, the use of the

exclusive-use soldering iron is recommended.

Solder composition code

a

b

z

i

n

s

p

(2) NOTE FOR SOLDERING WORK

Since the melting point of lead-free solder is about 220°C, which is about 40°C higher than that of conventional lead solder, and its soldering

capacity is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. This may cause land

separation or may exceed the heat-resistive temperature o f components. Use enough care to separate the soldering iron from the PWB when

completion of soldering is confirmed.

Since lead-free solder includes a greater quantity of tin, the iron tip may corrode easily. Turn ON/OFF the soldering iron power frequently.

If different-kind solder remains on the soldering iron tip, it is melted together with lead-free solder. To avoid this, clean the soldering iron

tip after completion of soldering work.

If the soldering iron tip is discolored black during soldering work, clean and file the tip with steel wool or a fine filer.

COPYRIGHT©XXXX BYSHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

Page 29

* Applicable to battery - operated equipment

* Applicable to battery - operated equipment

Page 30

SHARP CORPORATION

Digital Document System Group

CS Promotion Center

Yamatokoriyama, Nara 639-1186, Japan

2007 May Printed in Japan

Loading...

Loading...