Page 1

SERVICE MANUAL

CODE: 00ZMXLCX1/S1E

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM OPTION

LARGE CAPACITY TRAY

MODEL

CONTENTS

[1] PRODUCT OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] UNPACKING AND INSTALLATION

* For how to unpacking and installation, refer to the installation manual (00ZMX2700/I1E).

[4] OUTSIDE VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . . 4-1

[5] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

MX-LCX1

[9] SELF-DIAGNOSIS AND TROUBLE CODES . . . . . . . . . . . . . . . . . 9-1

[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] OTHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

PARTS GUIDE

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[1] PRODUCT OVERVIEW . . . . . . . . . . . . . . . . .1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . .2-1

[3] UNPACKING AND INSTALLATION

* For how to unpacking and installation, refer to the

installation manual (00ZMX2700/I1E).

[4] OUTSIDE VIEW AND INTERNAL STRUCTURE

1. Part Names and Functions . . . . . . . . . . .4-1

[5] OPERATIONAL DESCRIPTIONS

1. Lift Operation . . . . . . . . . . . . . . . . . . . . . .5-1

2. Paper Feed Operation . . . . . . . . . . . . . . .5-1

3. Paper-on-tray Detection. . . . . . . . . . . . . .5-2

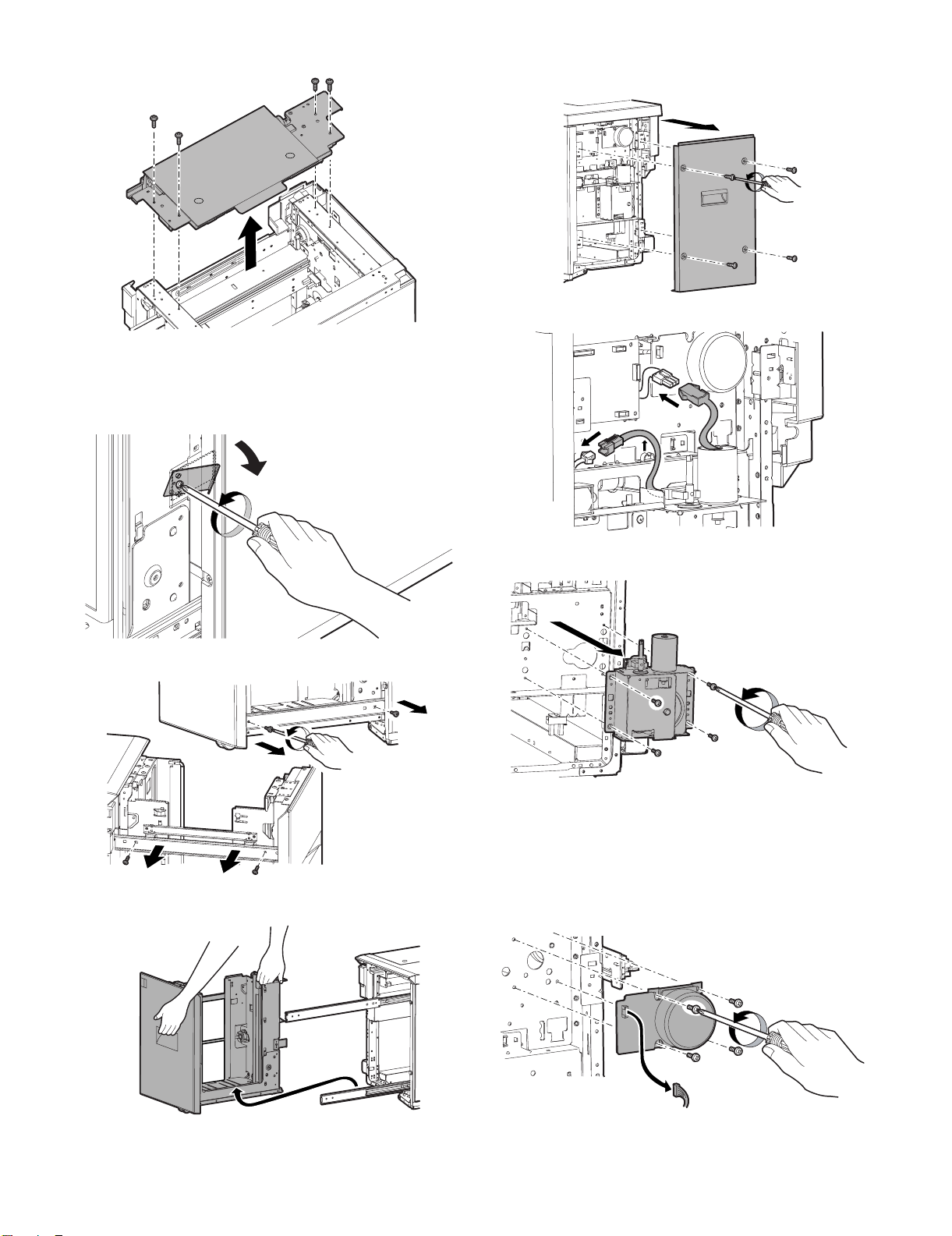

[6] DISASSEMBLY AND ASSEMBLY

1. Maintenance Parts Replacement

Procedures . . . . . . . . . . . . . . . . . . . . . . .6-1

2. Removal of Each Unit . . . . . . . . . . . . . . .6-1

3. Removal of Major Parts . . . . . . . . . . . . . .6-2

[7] MAINTENANCE

1. Maintenance Table. . . . . . . . . . . . . . . . . .7-1

[8] ADJUSTMENT

1. Adjustment Item List. . . . . . . . . . . . . . . . 8-1

2. Detailed Procedures . . . . . . . . . . . . . . . . 8-1

[9] SELF-DIAGNOSIS AND TROUBLE CODES

1. Simulations. . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Self-diagnosis. . . . . . . . . . . . . . . . . . . . . 9-2

3. Trouble Code List . . . . . . . . . . . . . . . . . . 9-3

4. Trouble Code Details . . . . . . . . . . . . . . . 9-3

[10] ELECTRICAL SECTION

1. Electronic/Mechanical Parts

Relationship Diagram . . . . . . . . . . . . . . 10-1

2. Block Diagram . . . . . . . . . . . . . . . . . . . 10-2

3. Wiring Diagram. . . . . . . . . . . . . . . . . . . 10-3

[11] OTHER

1. Note for installation of the heater in a

certain destination . . . . . . . . . . . . . . . . 11-1

PARTS GUID E

Page 3

[1] PRODUCT OVERVIEW

This model is an externally mounted 3500-sheet paper feeder

(large capacity paper feed tray) designed to attach to and work with

compatible digital full-color copier products.

2

It can feed up to 3500 sheets of paper (80 g/m

Service Manual

ing the user to handle large copy jobs without having to refill paper

, 21 lbs), thus allow-

frequently.

The paper feeder has an additional separator mechanism that

ensures long-term reliable paper feed.

Staple cartridge

(Approx. 5000 x 3)

(MX-SCX1)

Punch module

●

2-hole (MX-PNX1A)

●

3-hole (MX-PNX1B)

●

4-hole (MX-PNX1C)

●

4-hole (broad space)

(MX-PNX1D)

Staple cartridge

(Approx. 5000 x 3)

(AR-SC2)

Punch module

●

2-hole (AR-PN1A)

●

3-hole (AR-PN1B)

●

4-hole (AR-PN1C)

●

4-hole (broad space)

(AR-PN1D)

Finisher

(MX-FNX1)

Paper pass unit

(MX-RBX1)

Saddle stitch finisher

(MX-FNX2)

Device Tray with

USB Hub (MX-RKX1)

PCL5c/PCL6

driver

RSPF

Network

scanner

(Sharpdesk 1 license)

HDD

Copier/Printer (PCL)

/Scanner model

(MX-2300N)

(MX-2700N)

Stand/1x500 sheet

paper drawer

(MX-DEX1)

Reversing single pass feeder

(MX-RPX1)

SPLC-c

driver

HDD

Copier/Printer (SPLC-c)

model

(MX-2300G)

(MX-2700G)

Stand/2x500 sheet

paper drawer

(MX-DEX2)

Document cover

(MX-VRX1)

Exit tray unit

(MX-TRX1)

Large capacity tray

(MX-LCX1)

Data security kit

(Including document control)

CC authentication

version

Security

ROM

For document

control PWB

Commercial

version

(MX-FRX1)

256MB expansion memory board

(MX-SMX1)

(For MX-2300G/2700G)

Barcode font kit

CD

ROM

(AR-PF1)

Security

ROM

For document

control PWB

(MX-FRX1U)

Printer expansion

kit (PCL)

CD

(MX-PBX1)

(For MX-2300G/2700G)

Internet Fax

expansion kit

CD

(MX-FWX1)

Application

integration

module

CD

(MX-AMX1)

Network scanner

expansion kit

CD

(MX-NSX1)

Sharpdesk

1 license kit

Sharpdesk

5 license kit

CD

(MX-USX1/

USX5)

Sharpdesk

100 license kit

CD

(MX-USA0)

PS3 expansion

kit

CD ROM

(MX-PKX1)

Sharpdesk

10 license kit

Sharpdesk

50 license kit

CD

(MX-US10/

US50)

Application

communication

module

CD

(MX-AMX2)

Facsimile

expansion kit

(MX-FXX1)

FAX memory (8MB)

(packed together)

External

account module

CD

(MX-AMX3)

MX-LCX1 PRODUCT OVERVIEW 1 – 1

Page 4

[2] SPECIFICATIONS

Type Externally mounted 3500-sheet paper feeder

Transport speed Operable within the speed range of 124 to 360 mm/s (Speed can be selected using a communication command).

Transport reference Center reference

Paper size AB series: A4, 8.5" x 11"

Paper size setting Service engineer support/simulation setup

Factory default paper size setting AB series: A4

Paper type setting Provided

Supported paper types/weight Plain paper, printed paper, recycled paper, letter head, pre-punched paper, color paper: 60 to 105 g/m

Paper capacity 3500 sheets (80 g/m

Paper level detection The paper feeder detects the amount of remaining paper and indicates one of seven levels (100%, 83.3%, 66.7%, 50.0%,

Paper refill method Front loading type; paper can be refilled from the upper part.

Drive mechanism Transport motor (brushless DC motor) controlled by a controller board built in the LCC

Jam processing Can be done by moving the unit to the right or drawing out the tray.

Off-center adjustment ±3 mm (can be adjusted by moving the front and rear regulation plates).

Vertical tray movement time Up: within 15 seconds (with no paper loaded; from tray insertion to "empty" detection).

Power consumption

(except for the heater)

Power supply 5V ± 5% and 24V ± 5% (Supplied from the main unit)

Outside dimensions (W x D x H) 370 x 550 x 520 (mm), 14 9/16 x 21 21/32 x 20 15/32 (inch)

Occupying area (W x D) 370 x 550 (mm) (Clearance from the main unit: 235 mm), 14 9/16 x 21 21/32 (inch) (Clearance from the main unit: 9 1/4 inch)

Weight Approx. 30 kg (66.1 lbs)

Paper feed system Paper pick-up with the aid of a take-up roller; torque limiter reverse rotation separation system

Heater Service parts (kit): When installing, refer to [11].

Installation/maintenance Installed by service personnel

Optional detection Auto detection supported

Packaged items Parts for mounting, installation cautionary note

AB, B5 series: A4, B5, 8.5" x 11”

Inch series: 8.5" x 11", A4

Inch series: 8.5" x 11"

2

(21 lbs)), at effective height of 385 mm

33.3%, 16.7%, and none) on its own panel or on the printer's display.

Down: within 5 seconds

Max. 26.4W

Lift-up: Max. 40.8W

Service Manual

2

(16 to 28 lbs)

MX-LCX1 SPECIFICATIONS 2 – 1

Page 5

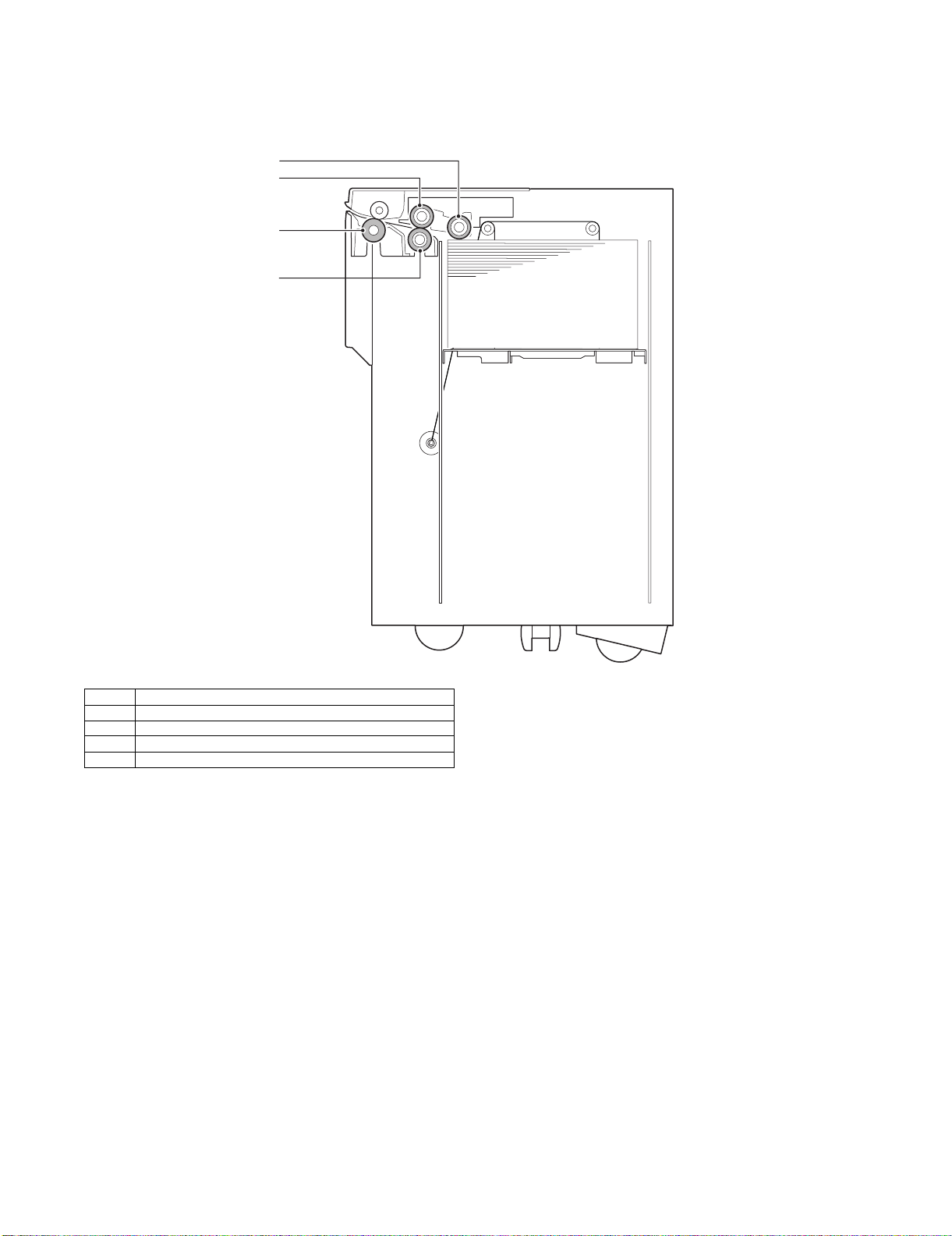

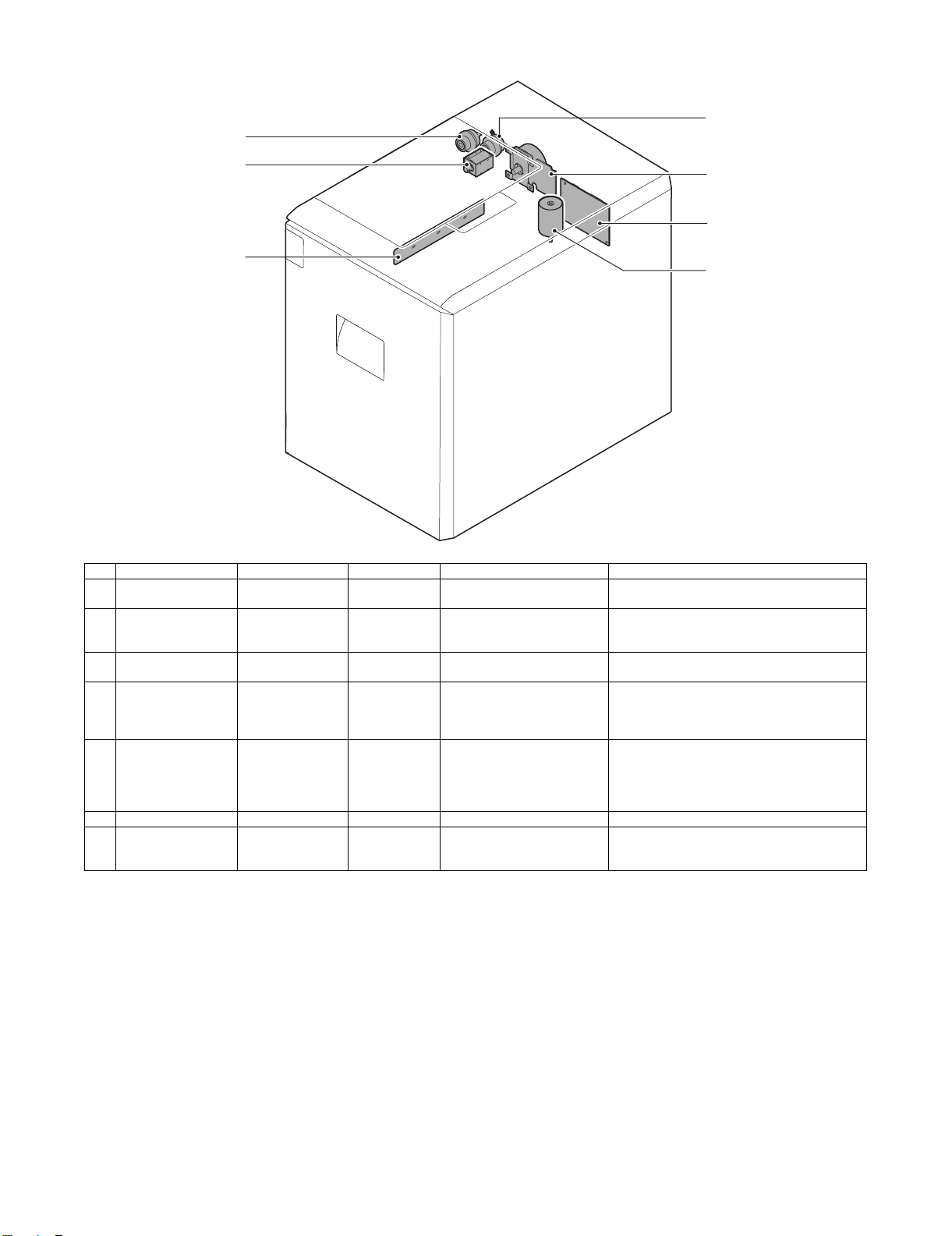

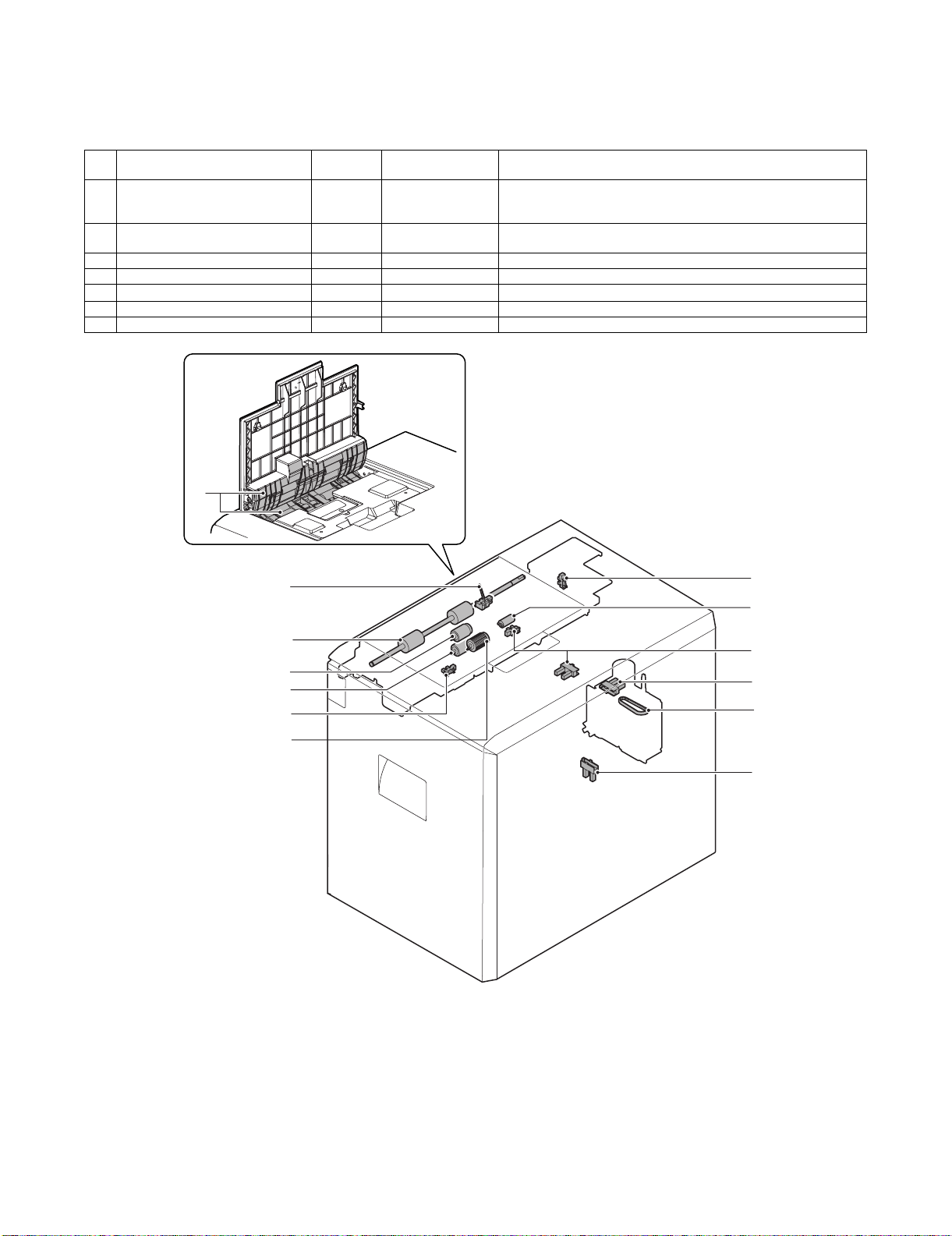

[4] OUTSIDE VIEW AND INTERNAL STRUCTURE

Service Manual

1. Part Names and Functions

A. Internal Structure

1

2

3

4

No. Name

1 Pick-up roller

2 Paper feed roller

3 Transport roller

4 Reverse roller

MX-LCX1 OUTSIDE VIEW AND INTERNAL STRUCTURE 4 – 1

Page 6

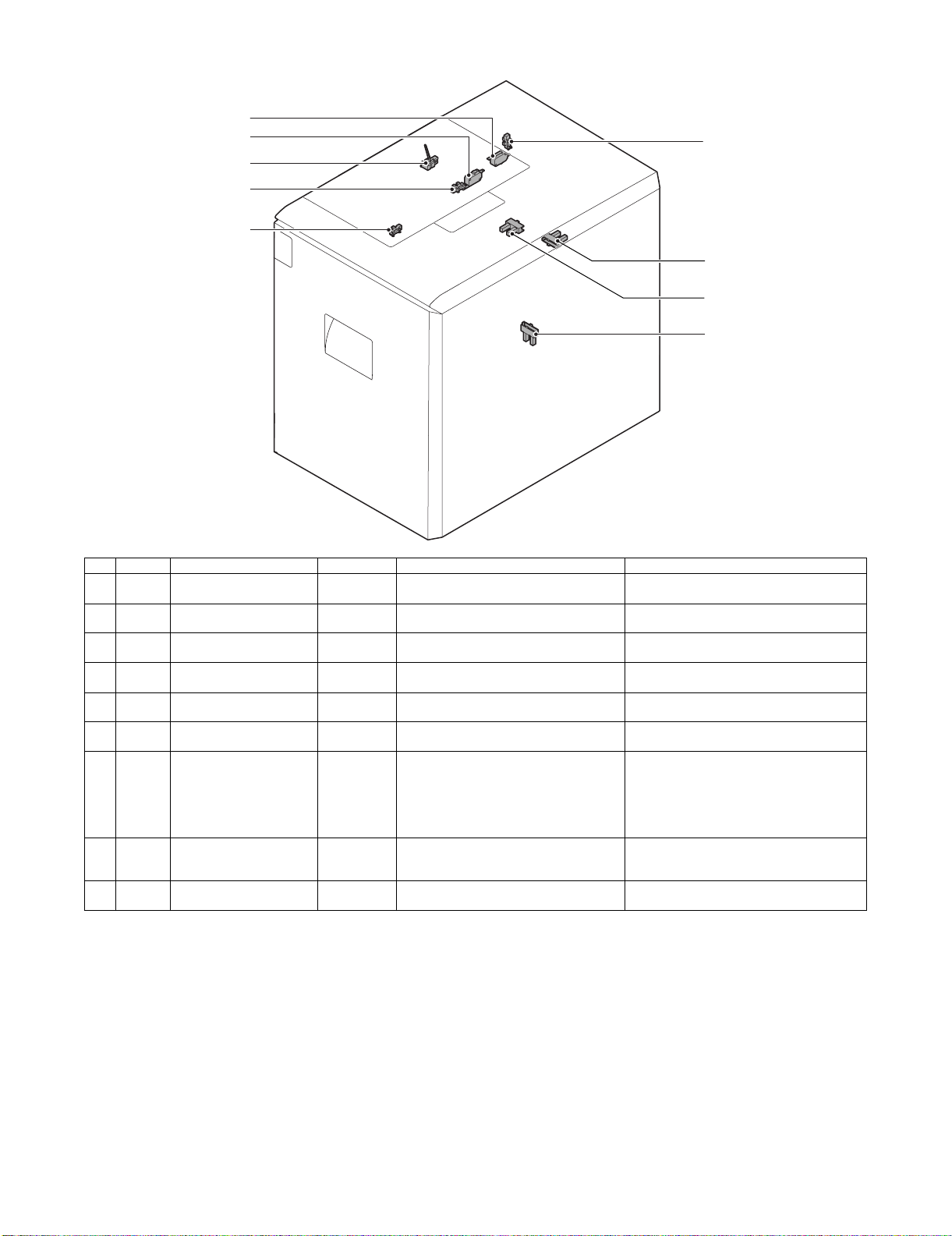

B. Sensors and Switches

9

8

5

6

7

4

2

3

1

No. Signal Name Type Function/operation Activation condition

1 LDD Tray lower limit sensor Transmission

type

2 LRE Lift motor encoder sensor Transmission

type

3 LCD Tray insertion sensor Transmission

type

4 LTOD Main unit connection sensor Transmission

type

5 LPFD Transport sensor Transmission

type

6 LUD Tray upper limit sensor Transmission

type

7 LPED Paper-on-tray sensor Transmission

type

8 LLSW Upper limit switch Microswitch This limit switch is intended to prevent the

9 LDSW Upper door latch switch Microswitch This switch detects when the upper door is

This sensor detects when the tray has

reached its lower limit.

This sensor detects when the lift motor

rotates.

This sensor detects when the tray is

inserted.

This sensor detects when the paper feeder is

connected to the main unit.

This sensor detects when paper is

transported.

This sensor detects when the tray has

reached its upper limit.

This sensor detects whether there is paper in

the tray.

tray from overrunning the upper limit and

breaking the paper feed unit.

opened or closed.

The signal becomes High level when the tray is

at its lower limit.

Pulse signal.

The signal becomes High level when the tray is

inserted.

The signal becomes Low level when connected

to the main unit.

The signal becomes Low level when paper is

transported (when paper exists).

The signal becomes High level when the tray is

at its upper limit (with the lift-up motor stopped).

The signal becomes Low level when paper is in

the tray.

* When the tray is being lifted up and this

signal is at Low level with the LRE signal not

exceeding 800 pulses, the paper feed

solenoid turns ON.

–

–

MX-LCX1 OUTSIDE VIEW AND INTERNAL STRUCTURE 4 – 2

Page 7

C. Drive and Control Components

3

4

5

1

6

7

2

No. Signal Name Type Function/operation Activation condition

1 LPFM LCC transport motor – This motor drives the paper feed

2 LLM LCC lift motor Brush motor This motor raises the paper feed

3 LTRC LCC transport

4 LPFC LCC paper feed

5 LPFS LCC paper feed

6 LCC MAIN PWB CR LCC main board CR – Controls and drives LCC. –

7 DH (S ervice parts (kit):

When installing, refer

to [11].)

clutch

clutch

solenoid

LCC heater – This heater is used to keep

Electromagnetic

clutch

Electromagnetic

clutch

Electromagnetic

solenoid

and transport sections.

table.

This clutch controls the ON/OFF

status of the transport roller.

This clutch controls the ON/OFF

status of the paper feed roller.

This solenoid presses the paper

pick-up roller onto the paper.

warm the LCC tray interior.

The signal becomes High level when paper feed is

started.

The signal is High level when the motor is working;

when the upper limit sensor turns ON, the motor

stops and the signal becomes Low level.

–

The signal becomes High level when paper feed is

started;

the clutch is turned OFF by a timer after transport

is started (with the pick roller turned OFF).

The solenoid is turned OFF after transport is

started and, when the time is up, it is turned ON

again.

The solenoid is ON between lift-up and the

activation of the Paper-on-tray sensor.

–

MX-LCX1 OUTSIDE VIEW AND INTERNAL STRUCTURE 4 – 3

Page 8

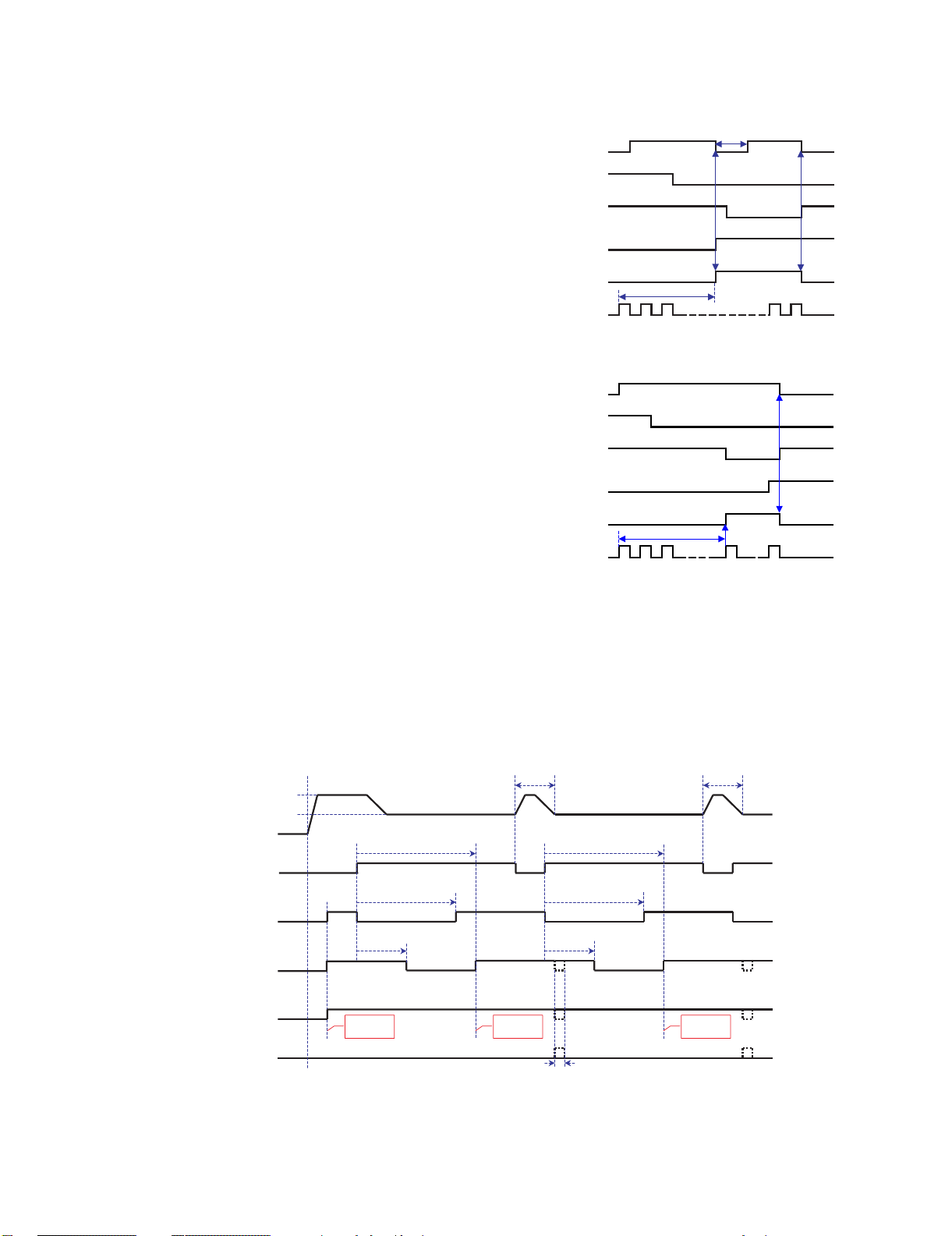

Lift operation (where LPED turns ON within 800 encoder

pulses of the start of lift operation)

(lift motor output)

(lower limit sensor)

(upper limit sensor)

(paper-on-tray sensor)

(solenoid)

(encoder signal)

200 msec

Within 800 pulses

LDD

LLM

LUD

LPED

LPFS

LRE

Lift operation (where LPED does NOT turn ON within 800

encoder pulses of the start of lift operation)

(lift motor output)

(lower limit sensor)

(upper limit sensor)

(paper-on-tray sensor)

(solenoid)

(encoder signal)

LDD

LLM

LUD

LPED

LPFS

LRE

800

[5] OPERATIONAL DESCRIPTIONS

1. Lift Operation

When the power to the main unit is turned ON with the tray at a

midway position (that is, a position where both the upper limit sensor [LUD] and lower limit sensor [LDD] are OFF) or with the tray at

the lower limit position (where the lower limit sensor LDD is ON),

the main unit issues a lift-up request and, in response, the lift motor

is turned ON to lift the tray.

If the Paper-on-tray sensor (LPED) turns ON within 800 encoder

pulses of the start of tray lift, the lift motor is temporarily turned OFF

to stop the tray, and then the paper feed solenoid is turned ON to

lower the pick roller. Subsequently, the lift motor is turned ON, and

the tray is lifted to and stopped at a position where the upper limit

sensor (LUD) is turned ON.

If the Paper-on-tray sensor (LPED) does NOT turn ON within 800

pulses of the start of tray lift, the paper feed solenoid is turned ON

with the lift motor remaining ON, and the pick roller is lowered. The

lift motor stops when the tray reaches a position where the upper

limit sensor (LUD) is turned ON, and subsequently the paper feed

solenoid is turned OFF.

Lift operation is not performed if the power to the main unit is turned

ON with the tray at a position where it can feed paper.

When the tray is drawn out, it lowers by its own weight.

Service Manual

2. Paper Feed Operation

Paper feed operation can be performed if the tray is stationary at a

position where it can feed paper (with the upper limit sensor [LUD]

being ON) and there is paper in the tray.

When paper feed takes place, the transport motor (LPFM), the

transport clutch (LTRC), the paper feed clutch (LPFC), and the

paper feed solenoid (LPFS) operate with the following timings:

Paper feed time chart (with acceleration)

Accelerating speed

Process speed

suspended

on

off

on

off

on

off

on

off

on

off

LPFM

(transport

motor)

LPFD

(transport

sensor)

LPFS

(paper feed

solenoid)

LPFC

(paper feed

clutch)

LTRC

(transport

clutch)

TRC

(main unit

synchronization

signal)

*1:

Operation stops only if the main unit synchronization signal is output.

When operation is stopped, the ON/OFF timing for each load is delayed by the stoppage time because each timer is suspended during the

stoppage.

To ensure efficient job processing, operation is not stopped under normal conditions.

When the transport clutch (LTRC) turns ON with the transport

motor (LPFM) is ON (rotating), the transport roller starts rotating.

When the paper feed clutch (LPFC) turns ON in this state, the

paper feed and take-up rollers start rotating.

When the paper feed solenoid (LPFS) turns ON, the take-up roller

is pushed down to press paper.

Start of job Catch-up control Catch-up control

Clearance-between-papers

control timer

PIC timer

Paper feed clutch

OFF timer

Start of 1st

paper feed

Start of 2nd

paper feed

Clearance-between-papers

control timer

PIC timer

Paper feed clutch

OFF timer

*1

Start of 3rd

paper feed

MX-LCX1 OPERATIONAL DESCRIPTIONS 5 – 1

Page 9

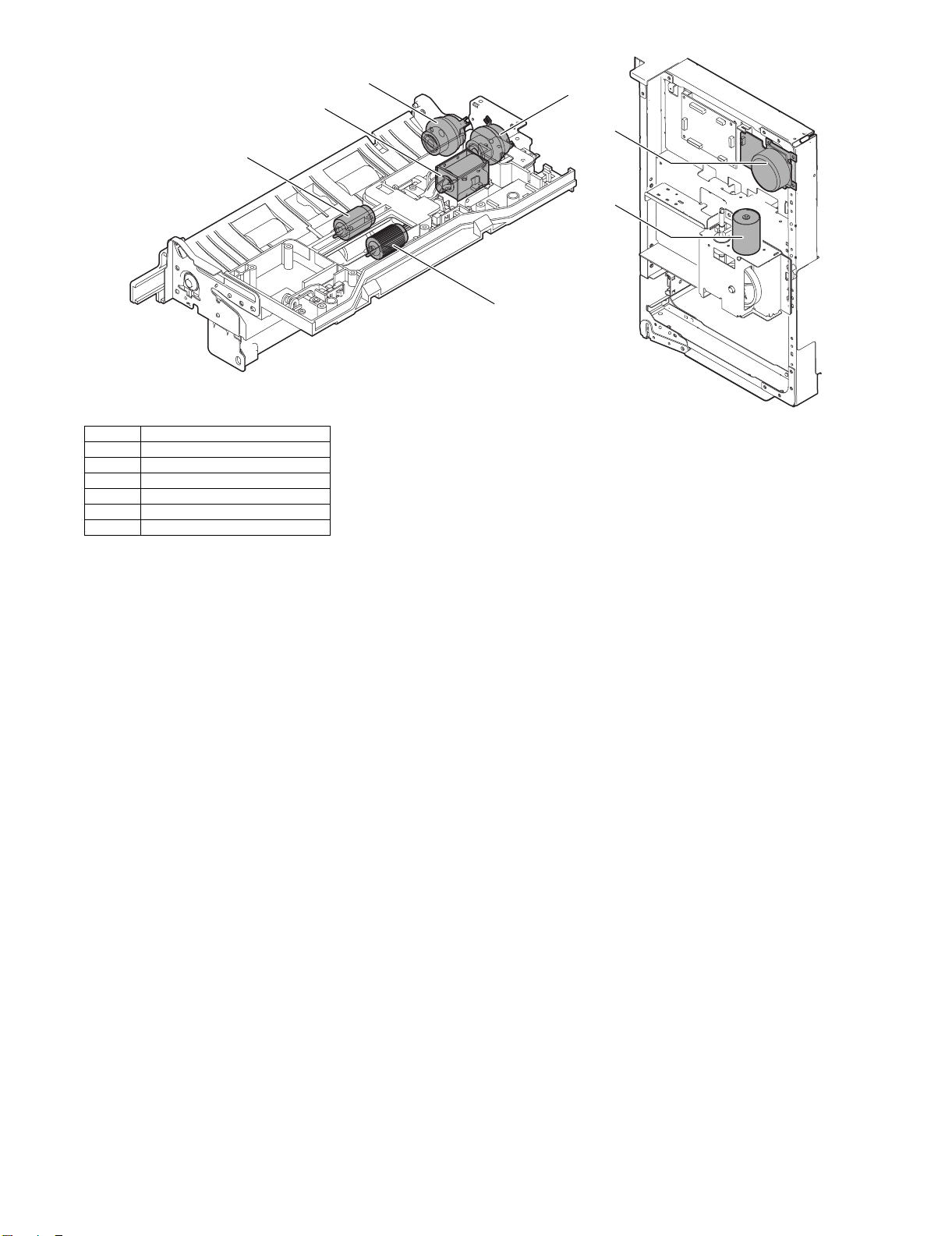

3

1 LCC Paper feed roller clutch

2 Take-up roller

3 Paper feed roller

4 LCC Paper feed solenoid

5 LCC Transport clutch

6 LCC Transport motor

7 LCC Lift-up motor

5

1

4

6

7

2

3. Paper-on-tray Detection

The Paper-on-tray sensor (LPED) checks whether there is paper in

the tray when the tray is lifted and stopped at a position where it

can feed paper, as well as during paper feed operation.

Paper feed operation is stopped if the sensor detects no paper in

the tray during paper feed operation.

MX-LCX1 OPERATIONAL DESCRIPTIONS 5 – 2

Page 10

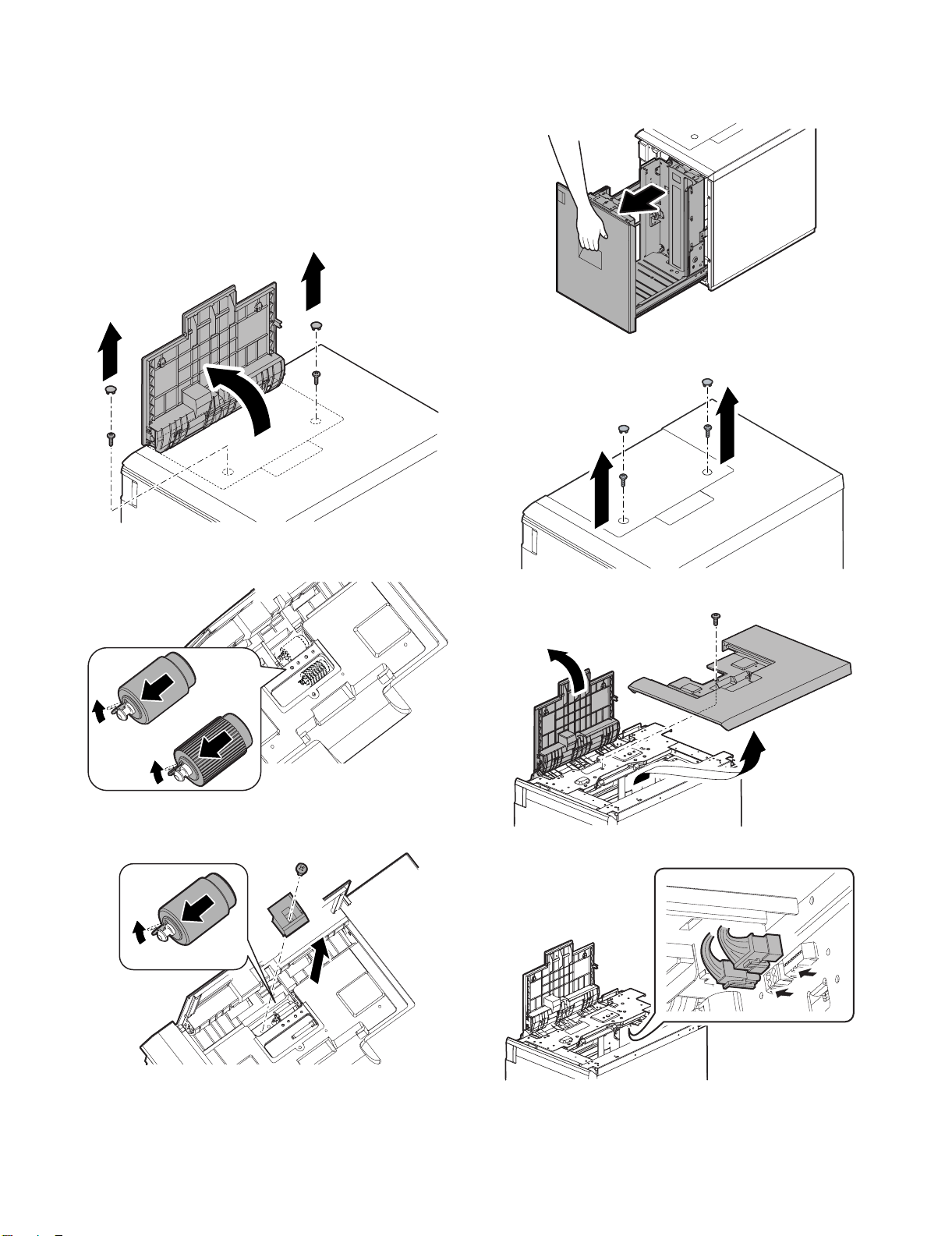

[6] DISASSEMBLY AND

ASSEMBLY

1. Maintenance Parts Replacement Procedures

A. Paper feed roller, pick-up roller,

and reverse roller

1) Remove the screw caps and then remove the screws.

Open the upper cover.

2. Removal of Each Unit

A. Paper feed unit

1) Draw out the tray.

2) Remove the screw caps and then remove the screws.

2) Remove the pick-up and paper feed rollers after releasing their

pawls.

3) Remove the screw and remove the paper guide block.

4) Remove the reverse roller after releasing its pawl.

3) Open the upper cover, and remove the upper cabinet.

4) Disconnect the connectors.

MX-LCX1 DISASSEMBLY AND ASSEMBLY 6 – 1

Page 11

5) Remove the screws and remove the paper feed unit.

B. Paper tray

1) Draw out the tray.

2) Looser the stopper fixing screw (1) on the lower right side of

the paper tray, evacuate the stopper not to function.

C. Drive unit

1) Remove the screws and remove the rear cover.

2) Disconnect the connectors.

3) Remove the screws from the left and right rails.

4) Detach the tray unit from the rails.

3) Remove the screws and remove the drive unit.

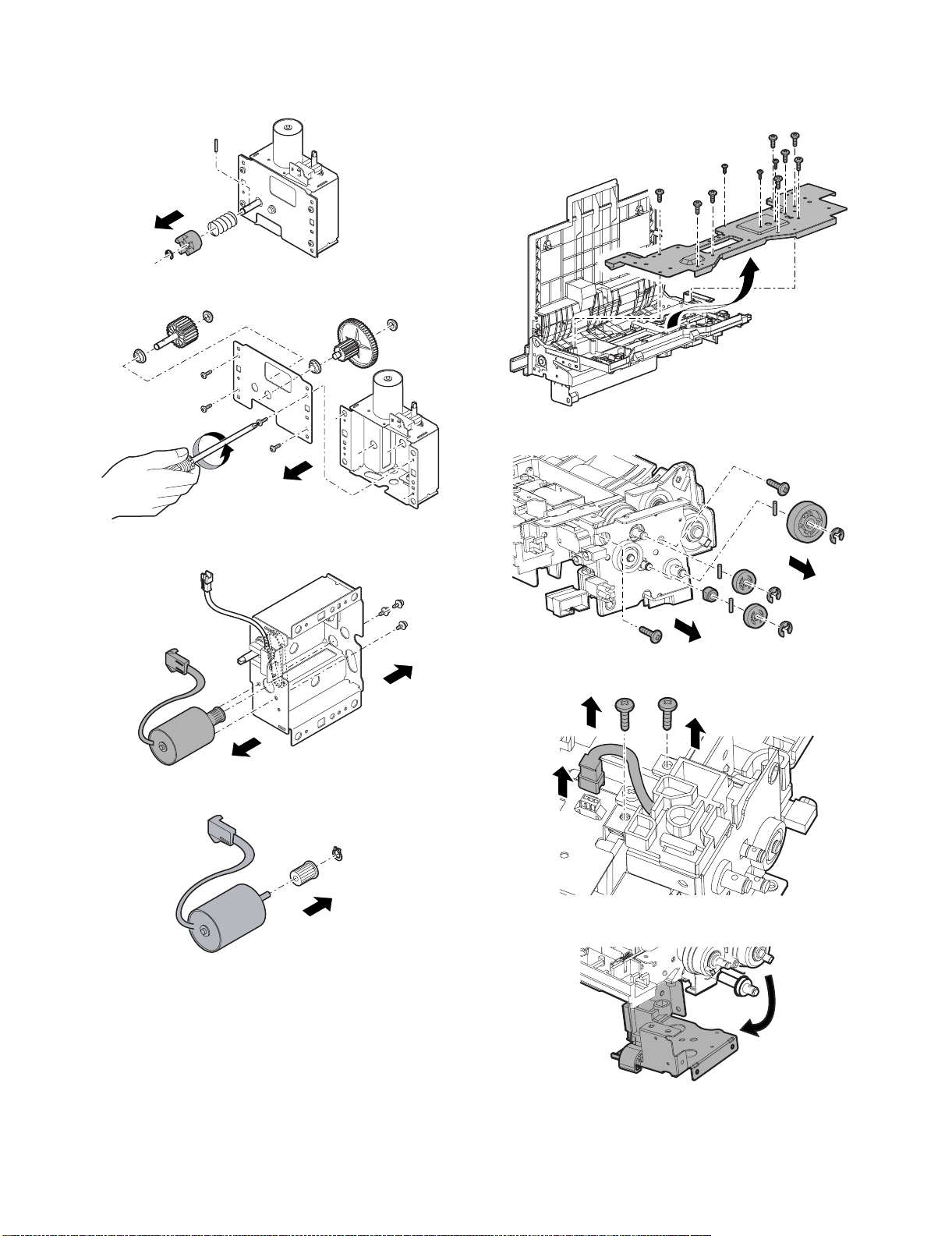

3. Removal of Major Parts

A. Transport motor

1) Remove the screws and remove the rear cover.

2) Disconnect the connectors.

3) Remove the screws and remove the transport motor.

MX-LCX1 DISASSEMBLY AND ASSEMBLY 6 – 2

Page 12

B. Lift motor

1) Remove the drive unit.

2) Remove the E ring and remove each part.

3) Remove the screws and remove the cover.

C. Paper feed clutch and transport clutch

1) Remove the paper feed unit.

(See "2. Removal of Each Unit.")

2) Remove the screws and remove the cover.

3) Remove the E ring and remove each part.

4) Remove the screws and remove the lift motor.

5) Remove the ring and remove the pulley.

4) Disconnect the connector and then remove the screws.

5) Remove the frame.

MX-LCX1 DISASSEMBLY AND ASSEMBLY 6 – 3

Page 13

6) Disconnect the connectors. Remove the E ring and remove the

paper feed clutch and transport clutch.

D. Paper feed solenoid

1) Remove the paper feed unit.

2) Remove the cover.

3) Remove the screws and remove the solenoid unit. Disconnect

the connectors.

4) Lift the shaft, and remove the torque limiter.

F. Transport roller

1) Remove the paper feed unit.

2) Remove the cover.

3) Remove the spring. Remove the screws.

4) Remove the screws and remove the solenoid.

E. Torque limiter

1) Remove the paper feed unit.

2) Remove the cover.

3) Remove the E ring and screws, and remove each part.

4) Remove the plate cover. Remove the lever.

5) Remove the clutch.

6) Remove the screws and E ring, and remove each part.

7) Remove the transport roller.

MX-LCX1 DISASSEMBLY AND ASSEMBLY 6 – 4

Page 14

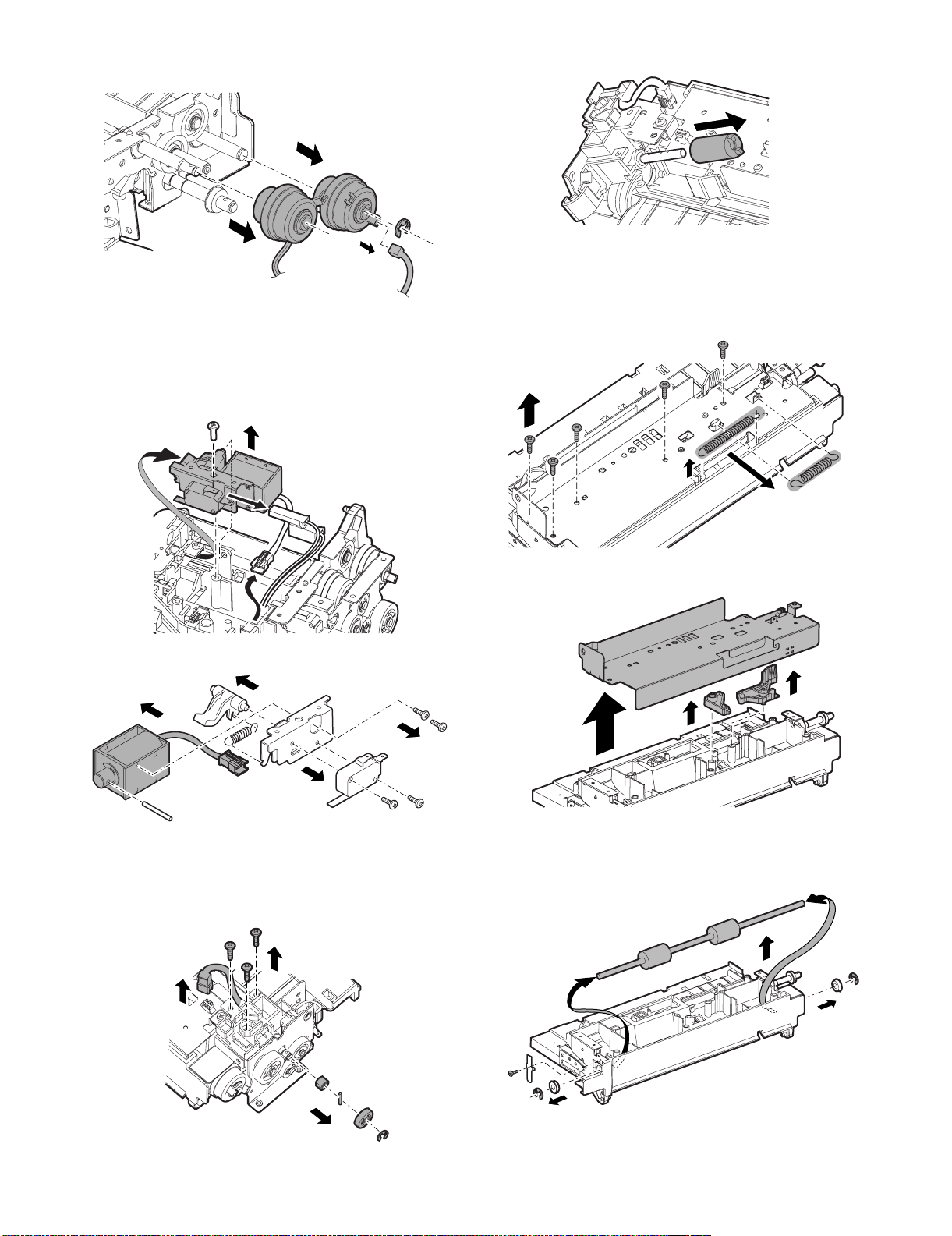

[7] MAINTENANCE

Service Manual

1. Maintenance Table

✕: Check (clean, replace or adjust as required) {: Clean : Replace : Adjust ✩: Lubricate : Relocate

No. Part name

1 Pick-up roller/each paper feed roller ✕ { As a rough guide, these rollers should be replaced when the LCC paper

2 Torque limiter ✕✕As a rough guide, the torque limiter should be replaced when the LCC

3 Each transport rollers ✕ {

4 Each transport paper guides {{

5 Each gears ✕✕

6 Each belts ✕

7 Each sensors ✕✕

When

calling

Main unit

maintenance cycle

Remarks

feed counter reaches a value of 100K (Sim22-9) or when one year has

elapsed since the start of use.

paper feed counter reaches a value of 100K (Sim22-9).

4

7

7

2

3

1

1

7

7

7

6

1

7

MX-LCX1 MAINTENANCE 7 – 1

Page 15

[8] ADJUSTMENT

Each adjustment item in the adjustment item list is indicated with its

JOB number. The adjustment procedures should be performed in

the ascending order of Job numbers.

However, you do not have to always perform all the adjustment

items. Perform only the necessary adjustments according to the

actual conditions.

Skip any unnecessary adjustment items, and perform the next necessary item. Even with some items skipped, the adjustment procedures should be performed in the ascending order of Job numbers.

Failure to perform the adjustment items in the correct order may

result in adjustment errors or some other problems.

To start a simulation:

1) Press the [COPY MODE] key to turn on Copy mode.

2) Press the following keys exactly in this sequence:

[P] (Program), [*] (asterisk), [C] (Copy), [*].

3) This displays the simulation Main Number Entry screen (which

means that the system is waiting for user input).

1. Adjustment Item List

Job number Adjustment Item List Simulation

1 Print off-center adjustment 50-10

2 Regist amount adjustment 51-2

3 Print leading edge adjustment 50-5

2. Detailed Procedures

1 Print off-center adjustment

1) Run SIM 50-10 using the keypad on the main unit.

The following screen appears.

0

EXECUTE

CLOSE

OK

SIMULATION NO.50-10

TEST

PAPER CENTER OFFSET SETUP

100

A:

= 64-140 ]

A:100

; BK-MAG

B:50

; MTF

C:50 ; CS1

D:50 ; CS2

2) This screen allows you to configure the print off-center adjustment value for each paper feed tray.

3) On the touch panel, press [↓] to select "G: 50 :LCC."

4) Enter the desired adjustment value through the numeric keypad.

(This value, which defaults to 50, can be adjusted within the

range of 1 to 99).

• Reducing the adjustment value by 1 causes the main scan/

print position to shift by 0.1 mm toward the rear.

• Increasing the adjustment value by 1 causes the main scan/

print position to shift by 0.1 mm toward the front.

5) After entering the adjustment value, press the [EXECUTE] key

on the touch panel to start printing and save the setting.

6) Check that the adjustment pattern image is printed in the cor-

Service Manual

rect position.

Measure the dimensions of the void areas on the front- and

rear-frame sides of the adjustment pattern image, and make

sure that the following conditions are met:

A

+

A-B = 0 3.0mm

-

B

No adjustment is needed if A - B = 0 ± 3.0 mm.

If the above condition is not met, do the following:

7) Change the adjustment value.

(Enter a new adjustment value and press the [OK] key).

Changing the adjustment value by 1 shifts the position by

approximately 0.1 mm.

Repeat steps 4) to 6) until the condition shown in step 6) is satisfied.

8) After you have completed the adjustment, exit from simulation

mode by pressing the [CA] key.

2 Resist amount adjustment

1) Run SIM 51-2 using the keypad on the main unit.

The following screen appears.

This screen allows you to configure the resist amount adjustment value for each paper feed tray.

0

SIMULATION NO.51-02

TEST

REGIST ROLLER ADJUSTMENT

A:

[1-99]

SIDE1 SIDE2 ENGIN

50

A:50

; NORMAL_PLAIN_HIGH

B:50

; NORMAL_PLAIN_LOW

C:50

; NORMAL_THIN_HIGH

D:50

; NORMAL_THIN_LOW

2) On the touch panel, press [↓] to select "Q: 50 :A4LCC."

3) Enter the desired adjustment value through the numeric keypad.

(This value, which defaults to 50, can be adjusted within the

range of 1 to 99).

• Increasing the adjustment value by 1 causes the resist

amount to increase by 1 msec.

4) After entering the adjustment value, press the [OK] key on the

touch panel to save the setting.

5) After you have completed the adjustment, exit from simulation

mode by pressing the [CA] key.

CLOSE

OK

MX-LCX1 ADJUSTMENT 8 – 1

Page 16

3 Print leading edge adjustment

1) Run SIM 50-5 using the keypad on the main unit.

The following screen appears.

SIMULATION NO.50-05

TEST

LEAD EDGE ADJUSTMENT VALUE(PRINTER)

30

A:

[ 1-99 ]

A:30

; DEN-C

B:20

; DEN-B

C:20 ; FRONT/REAR

D: 1 ; MULTI COUNT

CLOSE

4) Check the adjustment pattern image is printed in the correct

position.

Measure the dimensions of the void areas on the left- and

right-frame sides of the adjustment pattern image, and make

sure that the following conditions are met: A=4.0±2.0 mm

B=4.0±2.0 mm. If these conditions are met, no adjustment is

0

needed.

If the above conditions are not satisfied, proceed to steps 5)

and 6).

A

EXECUTE

OK

2) Press the [EXECUTE] button to highlight it. The main unit

starts printing an adjustment pattern image using the currently

configured values. Upon completion, the [EXECUTE] button

becomes unhighlighted.

* To save the currently configured settings into the EEPROM

and RAM, press any of the following: [↓] or [↑] button, [OK]

button, [EXECUTE] button, [Color] or [Monochrome] key.

* At any time during printing, you can suspend the test print by

pressing any of the following: the [C] key, [CA] key, [SYSTEM SETTING] key, and [EXECUTE] button.

* After being stopped from printing, the main unit resumes the

self-print test when it becomes ready.

3) Select "E: PAPER" and choose the desired paper feed location

(in this example, LCC).

5) Change the adjustment values for adjustment items A (DENC) and B (DEN-B).

* Reducing the adjustment value for item A (DEN-C) by 1

causes the print start point relative to the paper transport

direction to shift toward the paper leading edge by 0.1 mm.

* Reducing the adjustment value for item B (DEN-B) by 1

causes the sub-scan-directional print range, relative to the

paper transport direction, to decrease by 0.1 mm.

6) Repeat steps 2) to 5) until the conditions shown in step 4) are

satisfied.

<< Description of Items >>

Item Display Item Description Valid range Default Remarks

A DEN-C Print leading edge

adjustment

B DEN-B Sub-scan-directional

print range adjustment

1 to 99 30 This adjustment value is intended to adjust the print leading edge for the printer.

Reducing the adjustment value for item A (DEN-C) by 1 causes the print start

point relative to the paper transport direction to shift toward the leading edge by

0.1 mm.

1 to 99 20 This adjust value controls how much void will be created at the trailing edge of the

paper. Reducing the adjustment value for item B (DEN-B) by 1 causes the subscan-directional print range, relative to the paper transport direction, to decrease

by 0.1 mm.

A = 4.0 2.0mm

B = 4.0 2.0mm

B

+

+

-

MX-LCX1 ADJUSTMENT 8 – 2

Page 17

1/1

0

SIMULATION NO.15

TEST

LCC TROUBLE CANCELLATION

CLOSE

EXECUTE

ARE YOU SURE?

YES NO

[9] SELF-DIAGNOSIS AND

TROUBLE CODES

1. Simulations

A. Sensor Check

1) When you run SIM 4-02 using the keypad on the main unit, the

following screen appears and you can monitor changes in sensor status.

0

SIMULATION NO.04-02

TEST

DSK /LCC SENSOR CHECK

DCSI1 DPFD1 DLUD1 DPED1

DCSPD1 DCSS11 DCSS12 DCSS13

DCSS14 DPWD11 DPWD12 DCSI2

DPFD2 DLUD2 DPED2 DCSPD2

DCSS21 DCSS22 DCSS23 DCSS24

* When a sensor turns ON, the corresponding sensor name is

highlighted.

* The [↑] button can be used to move to the previous page.

This button is, however, enabled only when there is one or

more pages that precede the current page.

When there is no page that precedes the current page, the

[↑] button is disabled and grayed out.

The [↓] button can be used to move to the next page. This

button is, however, enabled only when there is one or more

pages that follow the current page.

When there is no page that follows the current page, the [↓]

button is disabled and grayed out.

* You can exit from SIM mode by pressing the [CA] key.

* You can return to the SUB number entry screen by pressing the

[SYSTEM SETTING] key.

< Sensor name list: A4 LCC sensors>

Displayed name Sensor name

LPFD LCC transport sensor

LUD LCC tray upper limit sensor

LDD LCC tray lower limit sensor

LPED LCC paper-on-tray sensor

LCD LCC tray insertion sensor

LDSW LCC upper door latch switch

LRE LCC lift motor encoder sensor

L24VM LCC24V power supply monitor

LLSW LCC upper limit switch

LTOD LCC main unit connection sensor

B. Load Operation Check

1) Run SIM 4-03 using the keypad on the main unit. The following screen appears:

SIMULATION NO.04-03

TEST

DSK/LCC LOAD CHECK

DPFM DLUM1 DPUC1 DLUM2

DPUC2 DTRC

CLOSE

1/2

0

CLOSE

3) Press the [EXECUTE] button to operate the selected load(s).

Service Manual

While the load or loads are operating, the [EXECUTE] button

is highlighted.

* Alternatively, you can press the [EXECUTE] button without

selecting any load; in this case, the [EXECUTE] button is

highlighted to indicate that you are in Execute mode. When,

in this mode, you press the button that corresponds to a load

you want to operate, the load immediately starts operating.

* While one or more loads are operating, you can stop the

operation or add another load.

* Pressing the [EXECUTE] button stops the currently operat-

ing load(s); the [EXECUTE] button then becomes unhighlighted.

* You can return to the SUB number entry screen by pressing the

[SYSTEM SETTING] key.

* You can exit from SIM mode by pressing the [CA] key.

<A4 LCC load item list>

Displayed name Load

LPFM LCC transport motor

LLM LCC lift motor

LPFC LCC paper feed clutch

LPFS LCC paper feed solenoid

LTRC LCC transport clutch

C. Synchronizing Signal Check

1) Run SIM 4-05 using the keypad on the main unit. The following screen appears (initially, both DTRC and LTRC are OFF):

0

SIMULATION NO.04-05

TEST

DESK/LCC SYNCRONIZING SIGNAL CHECK

DTRC

LTRC

: DTRC OFF

: LTRC OFF

2) Select [LTRC] and press the button.

The system starts checking the "turn ON" behavior, and displays the result of the check (the indicator changes to "ON" if

normal, or remains "OFF" if abnormal).

3) Select [LTRC] (now highlighted) and press the button.

The system starts checking the "turn OFF" behavior, and displays the result of the check (the indicator changes to "OFF" if

normal, or remains "ON" if abnormal).

* You can exit from SIM mode by pressing the [CA] key.

* You can return to the SUB number entry screen by pressing the

[SYSTEM SETTING] key.

<Button description>

Button Description

LTRC A4LCC transport clutch

D. LCC Trouble Cancellation

1) Run SIM 15 using the keypad on the main unit.

The following screen appears.

CLOSE

2) Select one or more loads you want to operate (in this example,

[DPFM]). When you select the button that corresponds to a

load, the button is highlighted. The button is unhighlighted

when you press it again.

EXECUTE

1/1

MX-LCX1 SELF-DIAGNOSIS AND TROUBLE CODES 9 – 1

Page 18

2) Press the [EXECUTE] button.

The [EXECUTE] button is highlighted with the [YES] and [NO]

buttons enabled.

3) Press the [YES] button.

Trouble cancellation is executed. The [YES] button is highlighted, and "side LCC lift motor trouble" is cancelled.

* If you press the [NO] or [EXECUTE] button, the [EXECUTE]

button is unhighlighted with the [YES] and [NO] buttons disabled (grayed out).

* When trouble cancellation finishes, the [EXECUTE] button is

unhighlighted with the [YES] and [NO] buttons disabled

(grayed out).

* You can exit from SIM mode by pressing the [CA] key.

* You can return to the Main screen by pressing the [SYSTEM

SETTING] key.

<Cancellable Trouble Codes>

Target Trouble code description

U6-09 Side LCC lift motor trouble

* The above trouble state is preserved even after the power has

been turned OFF.

C. How Self-diagnosis Works

(1) Self-diagnosis and Troubleshooting Workflow

The self-diagnosis program built in the machine is always the monitoring machine function.

When the self-diagnosis program detects a trouble condition, it

stops the machine and displays the appropriate trouble message.

Typically, warning messages are displayed when there is a consumable part whose life is nearly or already expired.

Some warning messages are displayed without machine stoppage,

while other warning messages are displayed at the same time as

machine stoppage.

Trouble and warning messages are displayed on the LCD with one

or more specific indicator lamps lit or flashing.

Some trouble messages are automatically cleared upon recovery

from the trouble, while other trouble messages must be cleared

using the corresponding SIM.

Also, some of warning messages associated with consumable

parts are automatically cleared upon replacement or refill of the

consumable part, while other messages must be cleared using the

corresponding SIM.

2. Self-diagnosis

When a trouble condition occurs in the machine or when there is a

consumable part whose life is nearly or already expired, the

machine's self-diagnosis program detects and analyzes the condition and issues the appropriate notification on the display panel so

that the user and the serviceperson can take suitable action. In the

case of a trouble condition (rather than the expiration of a part's

life), the self-diagnosis program not only issues the appropriate

notification but also stops the machine to minimize damage.

A. Functions and Objectives

1) Ensures safety by stopping the machine as soon as a trouble

condition is detected.

2) Minimizes damage to the machine by stopping the machine as

soon as a trouble condition is detected.

3) Displays the description of the trouble condition so that the

user or serviceperson can quickly and accurately identify the

source of the trouble. This helps the serviceperson to perform

repair work most effectively and efficiently.

4) Issues an alarm when there is a consumable part whose life is

nearly expired so that the user can order the consumable part

before its life is actually expired. This helps prevent machine

outage due to the absence of a consumable part.

B. Types of Self-diagnosis Messages

Self-diagnosis messages can be classified into the following types:

Classification 1User This type includes user-recoverable

trouble or warning conditions (such as

paper jam or consumable part life

expiration).

Service This type includes serviceperson-

recoverable trouble or warning

conditions (such as motor trouble or

maintenance).

Miscellaneous —

Classification 2Warning This type includes those messages that

are primarily intended to warn the user

and not directly related with machine

trouble (such as a warning message

issued when there is a consumable

part whose life is nearly expired).

Trouble This type includes those messages that

are directly related with machine

trouble and issued at the same time as

machine stoppage.

Miscellaneous —

Monitor machine function

Detect and analyze trouble

Trouble/warning

Trouble

Stop the machine

Display the trouble

description

Trouble/warning

Trouble

Identify the cause

Repair

Cancel self-diagnosis

message using "diag"

(test command), etc.

Recovery

Standby

Warning

Warning

Consumable part

life expired?

YES

Replace or refill the

consumable part

NO

MX-LCX1 SELF-DIAGNOSIS AND TROUBLE CODES 9 – 2

Page 19

3. Trouble Code List

No. Main code Sub code Description Section Can occur when Solution Remarks

1 U6 9 LCC lift motor trouble LCC Tray is being lifted. Check connections, etc.

2 20 LCC communication trouble LCC LCC communication is

made.

3 21 LCC transport motor trouble LCC Paper is fed. Check connections, etc.

4 22 LCC 24V power supply abnormal LCC The power is turned ON. Check connections, etc.

5 51 LCC incompatibility trouble LCC The power is turned ON. Check connections, etc.

Turn OFF and back ON

the power.

4. Trouble Code Details

U6-09 LCC lift motor trouble

Content Lift motor trouble

Description LCC lift motor malfunctioning; tray lift failure

Case 1 Cause Defective connection or disconnection of

Check and

Remedy

Case 2 Cause Motor lock, motor rpm abnormality, motor

Check and

Remedy

Case 3 Cause LCC main PWB failure; lift motor

Check and

Remedy

connector and harness

Check the connector and the harness in the

motor line. Connect the connector properly.

Replace the harness.

overcurrent, LRE failure, intrusion of foreign

material

Use SIM 4-2 to select LRE and check the

operation of the single unit. Use SIM 4-3 to

select LLM and check the operation of the

single unit. Check for intrusion of any foreign

material in the drive system.

malfunctioning

Replace the LCC main PWB or the lift motor.

Use SIM.15 to perform trouble cancellation.

U6-20 LCC communication trouble

Content Communication trouble

Description Communication error with LCC; communication line test

Case 1 Cause Defective connection or disconnection of

Case 2 Cause LCC main PWB failure; control PWB (PCU)

Case 3 Cause Malfunction caused by electrical noise

error after turning on the power or canceling an exclusive

simulation.

Check and

Remedy

Check and

Remedy

Check and

Remedy

connector and harness

Check the connector and the harness in the

communication line. Connect the connector

properly. Replace the harness.

failure

Replace the LCC main PWB. Replace the

control PWB (PCU).

Cancel by turning OFF/ON the power.

U6-21 LCC transport motor trouble

U6-22 LCC 24V power supply abnormal

Content LCC 24V power supply abnormal

Description 24V trouble

Case 1 Cause Defective connection or disconnection of

Check and

Remedy

Case 2 Cause Power source fuse blown.

Check and

Remedy

Case 3 Cause Power supply abnormality in the main unit.

Check and

Remedy

connector and harness

Check the connector and the harness which

connect LCC and the main unit. Connect the

connector properly. Replace the harness.

Check for short circuit between 24V and

GND. Check for pinched harness and the

LCC main PWB trouble. Replace the fuse,

the harness, and the LCC main PWB.

Check the 24V output of the main unit side

power supply.

U6-51 LCC incompatibility trouble

Content Incompatibility trouble

Description User attempted to connect an LCC incompatible with MX-

Case 1 Cause User attempted to connect an MX-LCX1 with

LCX1.

Check

and

Remedy

an incompatible device such as AR-LC5.

Connect MX-LCX1.

Content Transport motor trouble

Description LCC transport motor malfunctioning

Case 1 Cause Defective connection or disconnection of

Check and

Remedy

Case 2 Cause Motor lock, motor rpm abnormality, motor

Check and

Remedy

Case 3 Cause LCC main PWB failure; Transport motor

Check and

Remedy

connector and harness

Check the connector and the harness in the

motor line. Connect the connector properly.

Replace the harness.

overcurrent, intrusion of foreign material

Use SIM 4-3 to select LPFM and check the

operation of the single unit. Check for

intrusion of any foreign material in the drive

system.

malfunctioning

Replace the LCC main PWB or the transport

motor.

MX-LCX1 SELF-DIAGNOSIS AND TROUBLE CODES 9 – 3

Page 20

[10] ELECTRICAL SECTION

Service Manual

1. Electronic/Mechanical Parts Relationship Diagram

CN-B

B8B-PH-K-S

1

+5V

+5V

2

3

LRE

LDD

4

GND2

5

6

GND2

7

+24V

(/LTLS)

8

+5V

+5V

+5VR

+5V

+5V

+5V

20

22

23

24

19

21

212

3

212

SMR-03V-N

1

3

1

3

SMP-03V-NC

SMP-03V-NC SMR-03V-N

EXIN2

18

EXIN1

17

/LTOD

16

/LPFD

15

/LPED

14

GND2

GND2

GND2

LUD

10

12

11

13

1

3

1

33

㪣㪚㪚㩷㪤㪘㪠㪥㩷㩷㪧㪮㪙㩷㪚㪩

CN-C

B24B-PHDSS-B

GND1

/LTRC

GND2

GND2

/LPFS

+24V

+24V

GND2

9

LRE

GND22

+5V

LDD

GND22

+5V

/LPFC

1

5

7

4

2

8

3

6

SMP-18V-NC

SMR-03V-N SMP-03V-NC

11

22

33

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

179228-3

+5V1

23/LTOD

GND2

LTRC

CN-E

B14B-PHDSS-B

+5V

LCD

GND2

LLM 5

N.C.

LLM(GND)

N.C.

/LPFM-CLK

LPFM-T 10

/LPFM-EN

GND1 12

GND1 13

+24V(LOSW) 14

+24V(L24VM)

GND2

GND28+24V(LDSW)

GND2

GND2

+24V(LLSW)

+24V(L24VM)

6

7910

LPFC

B10B-PHDSS-B

+24V(LLSW)

GND2

21345

ELR-04NV ELP-04NV

1

2

3GND2

4

6

7

8

9

11

CN-D

SMR-18V-N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

121

434

SMP-03V-NC SMR-03V-N

1

3

2

3

SMP-03V-NC

SMR-03V-N SMP-03V-NC

CZHR-03V-S

1 +24V

2

N.C.

/LTRC3

1

22

3

ELP-03V

PHR-5

1

2

3

4

5

PS-187-3V

FPS-187

1

3

1

232

3

+24V

GND1

/LPFM-EN

LPFM-T

/LPFM-CLK

1COM

2

ON

NC3

1COM

2

ON

NC3

1

2

1

2

212

3

ELR-03V

1

PHR-3

PHR-3

SMR-03V-N

1

2

3

SMR-02V-NSMP-02V-NC

1

2

1

2

1 GND2

2

3

PHR-3

13+5VR

2

1

2

GND2

/LPED

+5V33

LUD

+5V

GND2

/LPFD

1LCD

2

GND2

+5V3

LLM(GND)

LLM

LPED

LPFS

LPFD

LUD

LLSW

LTOD

LDSW

LCD

LPFM

LLM

LRE

LDD

MX-LCX1 ELECTRICAL SECTION 10 – 1

Page 21

2. Block Diagram

+24V

Upper door latch switch

LDSW

24V monitoring circuit

L24VM

Upper door

-

LDSW

monitoring circuit

LPFM

/LPFM

/LPFM-CLK

LPFM-T

LLSW

Upper limit switch

Upper limit

-

LLSW

monitoring circuit

Tray upper limit sensor

LLM

Current control

circuit

+5V

LUD

LCC lift motor

Poly switch 1.1A

Lift motor drive circuit

Tray lower limit sensor

+5V

LDD

Sensor input

circuit

Paper-on-tray sensor

+5V

LPED

Transport sensor

+5V+5V

LPFD

Main unit connection

sensor

+5V

LTOD

Tray insertion sensor

+5V

LCD

Lift motor encoder

sensor

+5V

LRE

LCC paper feed clutch

+24V

LPFC

Transistor array

LCC transport clutch

LCC paper feed solenoid

+24V

+24V

LPFS

LTRC

(TD62003AP)

MX-LCX1

CPU (H8/3687HV)

Xtal

7.37MHz

EEPROM

Input buffer

Input buffer

Input buffer

Output buffer

/DTR-LCC

Input buffer

RES-LCC

/TRC-LCC

+5V

+5V

GND2

GND2

+24V

+24V

GND1

On-board write circuit

Heater

FF

Ground

AC-L

AC-N

Output buffer

LCC MAIN PWB CR

/RXD-LCC

/TXD-LCC

/DSR-LCC

MX-2300/2700

MX-LCX1 ELECTRICAL SECTION 10 – 2

Page 22

3. Wiring Diagram

8765

5678

D

C

B

A

+5V

B8B-PH-K-S

CN-B

GND2

3

1

6

4

8

2

7

5

(/LTLS)

+24V

+5V

GND2

LRE

LDD

LCC

N.C.

LCC MAIN PWB CR

+5V

LLM 5

GND2

6

9

N.C.

7

B14B-PHDSS-B

2

8

3GND2

/LPFM-EN

LCD

4

LPFM-T

10

LLM(GND)

11

/LPFM-CLK

CN-E

1

N.C.

B12B-PHDSS-B

11

/DSR-LCC

RES-LCC

9

GND1

413

+5V

/TRC-LCC

5

2

CN-A

12

N.C.

7

/DTR-LCC6+24V

8

10

/RXD-LCC

GND2

/TXD-LCC

S

10

16

14

1

18

12

5

+5V

GND1

11

17

/LTRC

7

GND2

GND2

/LPFS

+24V

CN-C

+24V

15

+5V

4

13

/LTOD

20

22

9

B24B-PHDSS-B

2

8

/LPED

+5V

23

+5VR

24

3

/LPFD

+5V

19

GND2

/LPFC

21

GND2

21345

6

+24V(L24VM)

+24V(LLSW)

GND2

CN-D

B10B-PHDSS-B

7910

GND2

GND28+24V(LDSW)

GND2

GND2

E

GND2

GND2

+5V

EXIN2

EXIN1

+24V(LLSW)

+24V(L24VM)

GND

B14B-PHDSS-B

11

9

/TXD_LCC

4

3

+5V 5

2

CN-F

7

P85

6

RES_LCC

8

10

/NMI

+5V

/RES_LCC

1

GND1 12

GND1 13

+24V(LOSW) 14

LUD

6

TXD_LCC

RXD_LCC

N.C.

121314

GND

P86

P87

MX-LCX1 ELECTRICAL SECTION 10 – 3

Page 23

1234

SMR-18V-N

SMP-18V-NC

1

1

2

2

3

3

4

4

5

5

6

6

77

8

8

9

9

10

10

11

11

12

12 3

131413

14

15

15

16

16

17

17

18

18

ELR-04NV ELP-04NV

121

2

3

434

SMR-03V-N SMP-03V-NC

11

22

33

SMP-03V-NC

ELP-03V

1

2

3

1

232

3

SMR-03V-N

1

2

3

ELR-03V

1

SMP-03V-NC

SMR-03V-N

1

1

2

2

3

SMR-02V-NSMP-02V-NC

1

1

2

2

SMR-03V-N SMP-03V-NC

1

212

3

3

< Paper feed unit >

PHR-3

1

GND2

LPED

/LPED

2

3

PHR-3

1 GND2

2

3

PHR-3

13+5VR

2

CZHR-03V-S

1+24V

2

PS-187-3V

1COM

2

3

FPS-187

1COM

2

179228-3

1

2

3

1LCD

2

1

2

PHR-5

+24V

1

2

GND1

/LPFM-EN

3

LPFM-T

4

/LPFM-CLK

5

+5V

LUD LUD

+5V

LPFS

LPFC

GND2

/LPFD

N.C.

/LTRC3

NC

NC3

+5V

/LTOD

GND2

+5V3

LLM(GND)

LLM

LPFD

LTRC

LLSWON

LDSWON

LTOD

LCDGND2

LLM

LPFM

Paper-on-tray sensor

Tray upper limit sensor

LCC paper feed solenoid

LCC paper feed clutch

Transport sensor

LCC transport clutch

Upper limit switch

Upper door latch switch

Main unit connection sensor

Tray insertion sensor

LCCliftmotor

LCC transport motor

Main unit

D

C

SMP-03V-NC SMR-03V-N

SMP-03V-NC SMR-03V-N

212

3

212

1

3

1

3

ELP-02V ELR-02V

2112

Ground

Heater

Main unit connection

ELR-12V

ELP-12V

4

4

AC-L(H)

5

5

F.G.

12

12

AC-N(H)

ELP-15V

ELR-15V

1

1

N.C.

2

2

N.C.

3

3

/TXD-LCC

4

4

/RXD-LCC

5

5

/DTR-LCC

6

6

/DSR-LCC

7

7

RES-LCC

8

8

F.G.

9

9

+5V

10

10

GND2

11

11

+24V

12

12

GND1

13

13

/TRC-LCC

14

14

N.C.

15

15

N.C.

1

LRE

GND2

2

3

LRE

+5V

Lift motor encoder sensor

B

A

LDD

1

33

LDD

GND22

+5V

Tray lower limit sensor

4

3

21

MX-LCX1 ELECTRICAL SECTION 10 – 4

Page 24

[11] OTHER

Service Manual

1. Note for installation of the heater in a certain destination

When the heater is installed in Argentine, Philippines, Saudi Arabia (127V only), it does not complies with the safety standards (UL/CE) due to

voltage variation. Therefore, the following work must be performed for the indication label.

When installing the heater in one of the target destinations, be sure to attach the "Blind label" to the nameplate of the safety standards to seal

the safety standard mark.

For Philippines, For Argentine

LARGE CAPACITY TRAY

MX-LCX1

SER.NO.

SHARP CORPORATION

MADE IN CHINA

FABRIQUÉ EN CHINE

U

C

L

ACCESSORY

PE

US LISTED

I.T.E.

E145607

SHARP CORPORATION

For Saudi Arabia of 127V

LARGE CAPACITY TRAY

BANDEJA DE GRAN CAPACIDAD

MX-LCX1

SER.NO.

O

(N

DE SERIE)

MADE IN CHINA

FABRIQUÉ EN CHINE

FABRICADO EN CHINA

Blind label (TLABZ5166FCZZ)

* When the heater is not installed even in a target destination, there is no problem on the safety standards.

* For the other destinations, there is no need to perform this work.

MX-LCX1 OTHER 11 – 1

Page 25

PARTS GUIDE

CODE:00ZMXLCX1/P1/

MODEL MX-LCX1

このパーツガイドに掲載されている表示価格ランクは消費税抜きです。

CONTENTS

1 外装部 (Exteriors)

2 給紙部 1(Paper feeding section 1)

3 給紙部 2(Paper feeding section 2)

4 給紙部 3(Paper feeding section 3)

5 駆動部 (Drive section)

6 フレーム部 (Frame section)

7 トレイ部 (Tray section)

8 後フレーム部 (Rear frame section)

9 梱包&付属品 (Packing material&Accessories)

■ 索引 (Index)

Page 26

補修部品のランク付

市場における補修部品の在庫管理が、適正に運営出来る手助けとなることを、目的とします。

Aランク : メンテナンスパーツ、メンテナンスパーツには入っていないがメンテナンスパーツに近い消耗パーツ。

Bランク : 性能・機能パーツ(センサー、クラッチ等の電気パーツ)、消耗パーツ。

Eランク : 基板含むユニットパーツ。

Dランク : 整備パーツ(外装、パッキング、同梱パーツ)。

Cランク : 上記ランク以外のパーツ(基板の子部品を除いたもの)。

DEFINITION

Rank A : Maintenance parts, and consumable parts which are not included in but closely related to maintenance parts

Rank B : Performance/function parts (sensors, clutches, and other electrical parts), consumable parts

Rank E : Unit parts including PWB

Rank D : Preparation parts (External fitting, packing, parts packed together)

Rank C : Parts other than the above (excluding sub components of PWB)

安全性・信頼性確保のため部品は、必ず正規のものをご使用下さい。

!

印の商品は、安全上重要な部品です。交換をする時は、安全及び性能維持のため必ず指定の部品をご使用下さい。

Because parts marked with "!" is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

F

当モデルのサービス資料には、この資料以外にサービスマニュアル ( 回路図含む ) があります。合わせてご利用下さい。

F Other than this Parts Guide, please refer to documents Service Manual(including Circuit Diagram)of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

1

外装部 (Exteriors)

NO. PARTS CODE

1 GCAB-1060FCWZ BW RJ N D

2 XHBS740P10000 AA DD C

4 GCAB-1059FCWZ BN LE N D

5 0EUHND0401EM1 AM EG N D

6 GCAB-1104FCZZ BV NU N D

7 GCAB-1123FCZZ BT NE N D

8 PCOVP1609FCZ1 AP EQ C

11 0EUCAB0408KM1 BF GN N D

15 LX-BZ0930FCPZ AC DD N C

16 XEBS740P10000 AA DD C

17 MLEVP0977FCZZ AR EQ N C

18 MSPRD3444FCZZ AE DJ N C

19 XEBS730P08000 AC DD C

20 XWSS730-07000 AA DD C

21 PSHEP5435FCZZ AF DS N C

22 LPLTM6354FCZZ AN EG C

23 LX-BZ1055FCZZ AE DJ N C

24 XWHS740-08120 AA DD N C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Upper cabinet 上キャビネット

Screw(4×10) S タイトバインドビス

Rear cabinet 後キャビネット

LCC handle LCC 取手

Right cabinet 右キャビネット

Front cabinet 前キャビネット

Tandem knob cover タンデム取手カバー

3000 tray cabinet left rear CG 3000 トレイキャビネット左後 CG

Screw(4×6) ビス S タイトビス

Screw(4×10) P タイトバインドビス

Lock release front cab lever ロック解除前 CAB レバー

Lock release spring ロック解除復帰スプリング

Screw(3×8) P タイトバインドビス

Washer ワッシャ

Lock release spring cover ロック解除復帰 SP 押エカバー

Rear cabinet fixing plate 後キャビネット取付板

Screw(4×8) 菊ワッシャ付 S タイトビス

Washer ワッシャ

DESCRIPTION

1

外装部 (Exteriors)

17

15

11

14

2

5

2

20

19

21

18

2

19

16

24

2

8

16

2

2

2

22

16

16

2

6

16

16

23

2

7

23

FCP08921

– 1 –

Page 27

2

給紙部 1(Paper feeding section 1)

NO. PARTS CODE

1 RPLU-0339FCPZ AR FG N B

2 NBRGC0632FCZ1 AE DS C

3 LX-WZ0450FCZZ AE DJ C

4 PCLC-0310FCPZ BB GD N B

5 PMLT-1444FCZZ AD DJ N C

6 NGERH1448FCZZ AF DS C

7 LPINS0327FCZZ AC DJ C

9 DHAI-3555FCPZ BA FX N C

11 LPLTP5827FCZZ AF DS C

12 VHPGP1A71L3-1 AG DS B

13 NBRGC0504FCZZ AC DJ C

14 LHLDZ1598FCZZ AP EQ C

15 MSPRT3288FCZZ AK DX C

16 NSFTZ2862FCPZ AT EZ N C

17 NPLYZ0365FCZZ AC DJ C

19 NPLYZ0373FCZZ AH DX C

20 NBLTH0429FCZZ AL EB B

21 NROLR1467FCZ1 AN DX B

22 NROLR1466FCZ1 AN DX B

23 NCPL-0049FCZZ AH DX B

26 PGIDM2090FCZZ BE GN C

27 XHBS730P14000 AA DD C

28 QSW-M0518FCZZ AH DX B

29 LPLTM6353FCZZ AL EB C

30 MSPRT3286FCZZ AH DX C

31 NSFTZ2861FCPZ BA FX N C

32 MLEVP0911FCZZ AL EB C

34 LPLTM6349FCZZ BC GJ C

36 PCOVP1786FCZZ AL EB C

37 XBBS730P04000 AA DD C

38 NBRGC0651FCZZ AD DJ C

39 LBNDJ0013FCZ1 AE DJ C

40 PMLT-1353FCZZ AD DJ C

41 XEBS730P08000 AC DD C

42 XHBS730P08000 AB DD C

43 XHBS740P10000 AA DD C

44 XEBS740P12000 AA DD C

45 XRESP40-06000 AA DD C

46 XRESP50-06000 AA DD C

47 XRESP70-08000 AA DD C

48 VHPGP2A200L-1 AR EQ B

49 PSHEP5257FCZZ AE DS C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Paper fixing solenoid ソレノイド

Bearing 軸受

Washer(4.5×12×0.5) ポリワッシャ

5K clutch(W) 5K クラッチ

Solenoid lever cushion ソレノイドレバー消音モルト

Gear 16T 16T ギヤ

SP pin(2×10)Light SP ピン

Paper feeding harness 給紙ハーネス

Sensor fixing plate マルチセンサー取付板

Photo sensor(GP1A71L) フォトセンサ -

PF bearing(F8×12×5 16X) ベアリング

Paper feeding turn plate LC 給紙回転板 LC

Pick up support spring ピック補助スプリング

Pick up shaft LC 呼込軸 LC

Pick up roller pulley 呼込ローラープーリー

Paper feed roller pulley 給紙ロ - ラープーリー

Belt(B59MXL4.8) ベルト

Pick up roller 呼込ローラー

Paper feeding roller 給紙分離ローラー

Oneway coupling ワンウェイカップリング

Paper feeding upper guide LC 給紙上ガイド LC

Screw(3×14) S タイトバインドビス

Door switch(DSWLU)(AM51612C531) ドアースイッチ

Solenoid fixing plate ソレノイド取付板

SOL arm spring ソレノイドアームスプリング

Paper feeding shaft LC 給紙軸 LC

Solenoid lever LC ソレノイドレバー LC

Paper feeding fixing plate LC 給紙取付板 LC

Solenoid Lower cover ソレノイド下カバー

Screw(3×4) 小ネジバインド

Bearing 焼結軸受

Wire band ワイヤーバンド

Pick up damper cushion 呼込消音モルト

Screw(3×8) P タイトバインドビス

Screw(3×8) S タイトバインドビス

Screw(4×10) S タイトバインドビス

Screw(4×12) P タイトバインドビス

E type ring(E4) E リング

E type ring(E5) E リング

E type ring(E7) E リング

Photo sensor(GP2A200L) フォトセンサー

Sensor cover センサーカバー

DESCRIPTION

2

給紙部 1(Paper feeding section 1)

41

44

40

44

41

41

49

42

48

41

31

43

23

22

44

19

43

21

34

5

32

26

46

20

– 2 –

38

30

17

29

46

37

3

12

47

46

4

6

46

7

44

9

41

39

11

36

47

2

1

44

27

28

45

15

13

13

14

16

FCP08922

Page 28

3

給紙部 2(Paper feeding section 2)

NO. PARTS CODE

1 PCLC-0310FCP1 BA FX N B

2 XRESP50-06000 AA DD C

3 CGERH0406FC01 AE DS C

4 LX-BZ0037QSPZ AB DD N C

5 NBRGC0632FCZ1 AE DS C

6 CFRM-1145FC018 AZ FX N C

8 NGERH1245FCZZ AF DS C

9 NSFTZ2865FCPZ AX FG N C

10 NBRGM0096FCZ1 AC DJ C

11 LPIN-0026MCZZ AA DD C

12 NSFTZ2863FCPZ BA FX N C

15 LPINS0261FCZZ AB DD C

16 NGERH1522FCZ1 AV FG C

18 NGERH1448FCZZ AF DS C

19 LPINS0327FCZZ AC DJ C

20 XHBS730P14000 AA DD C

21 QSW-M0502FCZZ AH DX B

22 CFRM-1146FC01 AZ FQ C

23 LPLTP6361FCZZ AW FG C

24 MLEVP0912FCZZ AP EQ C

25 MARMP0317FCZZ AN EG C

26 MSPRT3287FCZZ AK DX C

27 MSPRT2973FCZZ AD DJ C

28 LPLTM6350FCZZ AX FG C

29 QEARP0124FCZZ AK DX C

30 LHLDZ1581FCZZ AE DS C

31 LFRM-1144FCZZ AT EZ C

32 NSFTZ2864FCPZ AX FG N C

33 NCPL-0067FCZZ AD DJ B

35 DHAI-3566FCPZ AK EB N C

36 PCLC-0334FCZZ AZ FQ B

37 LPINS0339FCZZ AC DJ C

38 PGIDM2089FCZ5 BE GN C

39 NROLR1466FCZ1 AN DX B

40 NROLR1481FCPZ AY FQ N B

41 PGIDM2086FCZZ AQ EQ C

42 NBRGC0531FCZZ AC DJ C

43 PSHEP5133FCZZ AE DS C

44 LX-NZ0103FCPZ AD DD N C

45 LX-BZ4008SCPM AA DD N C

46 XHBS730P08000 AB DD C

47 XHBS740P10000 AA DD C

48 XEBS740P12000 AA DD C

49 XWHS730-08100 AA DD C

50 XRESP70-08000 AA DD C

51 LPINS0334FCZZ AB DJ C

52 PSHEP5272FCZZ AN EQ C

53 LX-WZ5002BCZZ AA DD C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

5K clutch(TMC-5Z-82) 5K クラッチ

E type ring(E5) E リング

DV idle gear(24T) DV アイドラギヤー

Screw ramimeito(4×12) ラミメイトビス

Bearing 軸受

Paper feeding frame R 給紙フレーム R AS

Transport drive gear(28T) 搬送駆動ギヤ

Joint gear shaft 連結ギヤ軸

Bearing 軸受

SP pin(φ2-10) スプリングピン

Reversal roller shaft A LC 逆転ローラー軸 A LC

SP pin(φ3-10) SP ピン

22T Oneway gear 22T ワンウェイギヤ DR

Gear 16T 16T ギヤ

SP pin(2×10)Light SP ピン

Screw(3×14) S タイトバインドビス

Door switch(AM51632C531) ドアスイッチ

Paper feeding sub frame 給紙サブフレーム AS

TL fixing plate TL 取付板

Separate pressure release lever LC 分離圧解レバー LC

Pressure arm 圧接アーム

Separate spring 分離スプリング

Multi separate pressure spring マルチ分離圧解スプリング

Paper feeding support plate 給紙補強板

Delivery earth plate 排紙アース板

Rotation fulcrum holder 回転支点

Paper feeding frame F 給紙フレーム F

Reversal roller shaft B LC 逆転ローラー軸 B LC

Separator coupling 分離カップリング

Sensor harness 2 センサーハーネス 2

Torque limiter 給紙トルクリミッター

SP pin(2×14)Light SP ピン

Paper feeding under guide LC 給紙下ガイド LC

Paper feeding roller 給紙分離ローラー

Transport roller LC 搬送ローラー LC

Separate roller guide 分離ローラーガイド

Bearing(B-S6-4) 軸受

Separate sheet 分離シート

Push nut(M4) プッシュナット

Screw(4×8) ビス

Screw(3×8) S タイトバインドビス

Screw(4×10) S タイトバインドビス

Screw(4×12) P タイトバインドビス

Washer ワッシャ

E type ring(E7) E リング

SP pin(3×14)Light SP ピン

Separate sheet front 分離前シート

Washer(PRW6.2×12×0.5) ワッシャ

DESCRIPTION

4

給紙部 3(Paper feeding section 3)

NO. PARTS CODE

2 GCOV-0252FCZZ AG DS N D

3 XHBS740P12000 AB DD C

4 CPLTM6341FC018 AL EB N C

5 XHBS740P10000 AA DD C

6 XEBS740P10000 AA DD C

7 XRESP50-06000 AA DD C

8 CROLP0945FC01 AF DX C

9 GDOR-0044FCZZ BK HG N D

10 NSFTZ2857FCPZ AY FQ N C

11 MSPRC3284FCZZ AG DX C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Screw cover ビスカバー

Screw(4×12) S タイトバインドビス

Upper open/close fulcrum plate 上開閉支点板 AS

Screw(4×10) S タイトバインドビス

Screw(4×10) P タイトバインドビス

E type ring(E5) E リング

Follow roller 従動ローラー AS

Upper open/close door PA 上開閉ドア PA

Transport follower shaft LC 搬送従動軸 LC

Transport follower spring 搬送従動スプリング

DESCRIPTION

– 3 –

Page 29

3

給紙部 2(Paper feeding section 2)

48

50

40

2

36

47

12

1

50

4

5

26

35

25

11

3

4

10

2

5

47

37

10

6

33

41

44

39

38

32

43

31

52

42

5

53

30

51

2

50

50

9

49

50

23

15

22

46

50

5

8

8

15

16

10

21

45

20

2

2

2

18

19

2

47

29

46

47

4

給紙部 3(Paper feeding section 3)

4

5

28

6

48

27

48

3

11

48

24

47

6

10

2

3

7

4

2

11

7

8

FCP08923

5

8

– 4 –

9

6

6

6

FCP08924

Page 30

5

駆動部 (Drive section)

NO. PARTS CODE

1 NGERH1215FCZZ AF DS C

2 NSFTZ2866FCZZ BF GN C

3 LPINS0263FCZZ AD DJ C

4 NBRGC0504FCZZ AC DJ C

6 RMOTV0904FCPZ BQ LP N B

7 NPLYZ0429FCZZ AM EG C

8 PRNGP0033FCZZ AA DD C

9 XRESP70-08000 AA DD C

10 NBRGY0131FCZZ AM EG C

11 0EUHP543321P4 AT FQ N B

12 NGERW1072FCZ1 BE GN C

13 NBLTH0430FCZZ AM EG B

14 NPLYZ0430FCZZ AN EG C

15 LPINS0096FCZZ AB DD C

16 XBPS730P08KS0 AB DD C

17 NSFTZ2867FCPZ AX FG N C

18 NGERH0933FCZZ AF DX C

19 NGERH0955FCZZ AF DX C

20 LPINS0157FCZZ AB DD C

21 PBOX-0143FCZZ BA FX C

22 XHBS740P10000 AA DD C

23 NCPL-0069FCZZ AY FQ B

25 MSPRC3289FCZZ AL EB C

26 LPLTM6355FCZZ AR EQ C

27 PGUMS0309FCZZ AL EB C

28 XRESP60-08000 AA DD C

29 LX-BZ3008SCPS AA DD C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Gear 30T 30T ギヤ

Lift coupling shaft リフトカップリング軸

T type pin T 型ピン

PF bearing(F8×12×5 16X) ベアリング

Lift motor リフトモーター

Pulley(18P MXL) プーリー

E ring(GTW-4) E リング

E type ring(E7) E リング

Bearing 軸受

Photo sensor(OJ-543321-604) フォトセンサー

Worm gear 3000 DR ウォームギヤー 3000DR

Belt(B70MXL4.8) ベルト

Pulley(36P MXL) プーリー

Pin(φ3-12) 平行ピン

Screw(3×8KS) 3 点ビス

Worm wheel shaft ウォームホイール軸

Worm wheel gear 86T ウォームホイールギヤ 86T

Gear 20T ギヤ 20T

Pin(φ3-14) 平行ピン

Lift drive BOX リフト駆動 BOX

Screw(4×10) S タイトバインドビス

Lift coupling リフトカップリング

Lift coupling spring リフトカップリングスプリング

Lift drive UN fixing plate リフト駆動 UN 取付板

Motor protection rubber モーター防振ゴム

E type ring(E6) E リング

Screw(3×8) カップスクリュー S タイト

DESCRIPTION

5

駆動部 (Drive section)

22

15

23

28

26

25

22

3

3

2

1

9

4

6

4

27

21

7

8

11

9

10

29

12

20

4

9

15

9

17

16

9

14

29

10

18

19

4

9

13

9

FCP08925

– 5 –

Page 31

6

フレーム部 (Frame section)

NO. PARTS CODE

1 CFRM-1147FC04 BM HV C

2 XHBS740P10000 AA DD C

3 LPLTM6547FCZZ BF GN N C

5 LPLTM6549FCZZ AQ EQ N C

6 0EUANG0414EZ2 AU EZ C

7 LRALM0191FCP1 BL HR N C

8 LX-BZ0848FCZZ AC DD C

9 LPLTM6548FCZZ AP EQ N C

10 GLEGP0080FCZZ AR EQ N C

11 NSFTZ2631FCP1 AE DJ N C

12 0EUSFT0415KP/ AN EG N C

14 XRESP50-06000 AA DD C

15 MSPRD3339FCZZ AG DS N C

17 0EUROL0330K// AH DX C

18 CPLTM6545FC01 BB GD N C

21 0EUANG0416E// AK DX C

24 NGERH1602FCZZ AE DS C

26 LX-BZ0940FCPZ AD DD N C

28 XRESP70-08000 AA DD C

29 LX-BZ0989FCP1 AH DX N C

32 XBBS740P08000 AA DD C

34 LHLDZ1414FCZZ AF DS C

35 LX-BZ3008SCPS AA DD C

36 NBRGC0190FCZ1 AD DJ C

37 NBRGY0513FCZZ AK EB C

38 NGERH1601FCZZ AM EG C

39 CGERH1660FC01 BC GD N C

48 PCOVP1792FCZZ AY FQ C

51 XRESP40-06000 AA DD C

52 LSTYM0337FCZ1 AZ FQ N C

53 LX-BZ1055FCZZ AE DJ N C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Drive frame 駆動フレーム AS

Screw(4×10) S タイトバインドビス

Height adjust plate 高サ調整板

Caster movable plate キャスター可動板

Pipe joint stay 3000L 支柱連結ステー 3000L

Slide rail スライドレール

Step screw ACC 固定段ビス N

Height adjust caster plate 高サ調整キャスター板

Caster(φ47) キャスター

T tray lock shaft T カセットロック軸

lock release lever shaft レバー支点軸

E type ring(E5) E リング

Caster spring キャスター可動スプリング

Height adjust roller 高さ調整コロ

LCC joint plate LCC 連結板 AS

Stopper L アキュライドストッパー L

25/33T gear 25/33T ギヤ

Screw(4×6) 偏平 S タイトビス

E type ring(E7) E リング

Step screw スライドレール取付段ビス

Screw(4×8) 小ネジバインド

Holder D ホルダー D

Screw(3×8) カップスクリュー S タイト

F6 bearing F6 軸受

Pressure roller bearing アッチャクローラー軸受

22/39T gear 22/39T ギヤ

30/48T gear AS 30/48T ギヤ AS

Heater cover ヒーターカバー WH2

E type ring(E4) E リング

Lower stay LC 下ステー LC

Screw(4×8) 菊ワッシャ付 S タイトビス

DESCRIPTION

6

フレーム部 (Frame section)

2

48

29

29

32

52

11

2

2

29

28

38

29

7

24

35

34

2

1

51

39

51

21

11

36

37

36

14

26

29

2

29

26

6

29

7

32

18

11

14

15

29

14

12

14

15

3

2

2

17

2

2

2

2

2

5

8

53

14

2

2

17

12

2

10

5

8

14

9

53

11

FCP08926

2

11

9

10

14

– 6 –

Page 32

7

トレイ部 (Tray section)

NO. PARTS CODE

1 PGIDM2087FCZZ AX FG C

4 NSFTZ2860FCZZ BG GT C

6 PCOVP1779FCZZ AF DS C

7 LX-BZ0940FCPZ AD DD N C

8 NPLYZ0431FCZZ AQ EQ C

9 NSFTZ2858FCPZ BG GT N C

12 NSFTZ2631FCP1 AE DJ N C

13 NBRGC0504FCZZ AC DJ C

17 NCPL-0069FCZZ AY FQ B

18 MSPRD3292FCZZ AT EZ C

19 MARMP0270FCZZ AK DX C

20 XRESP50-06000 AA DD C

21 MSPRT3291FCZZ AK EB C

22 MLEVP0913FCZZ AS EZ C

23 0EUPLT0409E// AF DS C

24 NBRGP0690FCZZ AE DJ C

26 XHBS740P10000 AA DD C

27 0EULEG0603KP/ AQ EQ N C

28 LDAIU0684FCZZ BE GN C

29 PGUMS0310FCZZ AD DJ C

30 PGIDM2091FCZZ AM EG C

31 PWIR-0203FCPZ AZ FQ N C

32 PWIR-0204FCPZ AZ FQ N C

34 NPLYZ0400FCZZ AC DJ C

35 PCLR-0381FCZZ AB DJ C

36 PSHEZ3138FCZZ AC DD C

39 CPLTM4094FC018 AL EB N C

40 NGERH0871FCZZ AB DD C

41 PSHEZ5256FCZZ AG DX C

42 LPLTM4096FCZZ AD DJ C

43 MSPRT3295FCZZ AL EB C

44 XWHS740-05100 AD DJ N C

45 CPLTM4097FC018 AF DS N C

46 0EUGER0413L// AT EZ C

48 LPLTM6360FCZZ BE GN C

49 LX-BZ0983FCPZ AD DD N C

50 LPLTM6343FCZZ AN EQ C

51 XBSS730P06000 AA DD C

52 XRESP30-06000 AA DD C

53 TLABZ4453FCZZ AF DS D

54 LX-BZ0714FCPZ AC DD C

55 CCAUH1051FC01 AT EZ D

56 PGUMS0308FCZZ AE DJ C

57 PCOVP1787FCZZ AV FG C

58 NSFTZ2873FCZZ BD GJ C

59 LX-BZ4008SCPM AA DD N C

60 LPINS0096FCZZ AB DD C

61 LPINS0157FCZZ AB DD C

62 XBBS730P04000 AA DD C

63 XBBS740P08000 AA DD C

66 XRESP70-08000 AA DD C

67 0EURNGE040-// AB DJ C

68 XHBS740P06000 AA DD C

70 XRESP60-08000 AA DD C

71 PSHEP5476FCZZ AX FG N C

72 PSHEP5477FCZZ AX FG N C

73 LX-BZ0994FCPZ AE DJ N C

74 PGIDH2100FCZ1 AN EG C

75 TLABZ4937FCZZ AG DX D

78 PSHEZ5346FCZZ AP EQ N C

79 PTPE-0288FCZZ AB DJ N C

80 LPLTM6951FCZZ AK EB N C

81 LPLTM6952FCZZ AD DJ N C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Paper regulation guide 用紙規制ガイド

Winder shaft LC 巻取シャフト LC

Winder pulley cover 巻取プーリーカバー

Screw(4×6) 偏平 S タイトビス

Wire real ワイヤーリール

Rear edge guide [JAPAN and AB series] 後端ガイド

T tray lock shaft T カセットロック軸

PF bearing(F8×12×5 16X) ベアリング

Lift coupling リフトカップリング

D cassette lock arm spring D カセットロックアームスプリング

T cassette lock arm T カセットロックアーム

E type ring(E5) E リング

Lower limit actuator spring 下限アクチェータスプリング

Lower limit actuator 下限アクチェータ

Accuride stopper TRY アキュライドストッパー TRY

Bearing ゲート軸受

Screw(4×10) S タイトバインドビス

Caster(TY40B) キャスター

Paper feed base 給紙台

Paper feeding base soundproof rubber 給紙台防音ゴム

Paper feeding base guide 給紙台ガイド

Wire L ワイヤー L

Wire S ワイヤー S

Wire pulley 2000 ワイヤープーリー 2000

Wire fixing collar ワイヤー押エカラー

Paper feed base sheet 給紙台クラリーノ

Brake plate ブレーキ板 AS

Gear 12 ギヤ 12

Brake pad 遠心ブレーキパット

Centrifugal plate 遠心板

Centrifugal spring 遠心スプリング

Washer ワッシャ

Centrifugal fixing plate 遠心取付板 AS

Gear(78T) ギヤ

Paper size regulation plate サイズ規制板

Screw(4×8) 菊ワッシャー付 S タイト T 赤ビス

Size guide adjust plate サイズガイド調整板

Screw(3×6) サラビス

E type ring(E3) E リング

Label 特殊表示指示線ラベル

Step screw FIN 固定段ビス

Caution label 開梱注意紙 AS

Tray stopper rubber カセットストッパーゴム

Gear cover 遠心ギヤカバー

Cassette position shaft カセット位置決メ軸 R

Screw(4×8) ビス

Pin(φ3-12) 平行ピン

Pin(φ3-14) 平行ピン

Screw(3×4) 小ネジバインド

Screw(3×8) 小ネジバインド

E type ring(E7) E リング

E ring(E4) E リング

Screw(4×6) S タイトバインドビス

E type ring(E6) E リング

Cassette PF sheet F カセット給紙シート F

Cassette PF sheet R カセット給紙シート R

Screw(4×8) 小ネジ扁平 青

Regulation sub guide 規制補助ガイド

Label サイズ指示ラベル

Tray sound poof sheet トレイ消音シート N

Cassette PF tape カセット給紙テープ

Cassette PF plate カセット給紙プレート

Cassette PF plate R カセット給紙プレート R

DESCRIPTION

– 7 –

Page 33

7

トレイ部 (Tray section)

50

48

57

68

41

52

51

49

42

43

66

53

46

44

75

66

52

7

13

45

8

61

42

49

40

51

79

41

6

48

50

39

68

79

81

55

28

7

54

34

35

78

9

8

61

70

32

30

59

78

34

73

31

72

29

74

58

56

FCP08927

12

23

13

60

63

66

67

18

66

17

19

20

22

21

24

71

34

29

62

30

1

6

68

4

34

32

35

70

35

31

36

29

27

1

80

– 8 –

26

Page 34

8

後フレーム部 (Rear frame section)

NO. PARTS CODE

1 0EUHP543321P4 AT FQ N B

2 XHBS740P10000 AA DD C

3 LPLTM5969FCZZ AH DX C

4 LPLTM6354FCZZ AN EG C

5 RHETP0112FCZZ BB GD B

6 MSPRT3301FCZZ AF DS C

7 0EUBZ4015SCPP AF DS N C

8 CPLTM6617FC01 BD GJ N C

9 0EUPLT0427KZ1 AW FG C

12 0EUANG0429K028 BL HL N C

13 VHPGP1A75E/-1 AK EB B

15 DHAI-3554FCPZ AK DX N C

16 XBBS730P04000 AA DD C

17 LPLTM6354FCZ1 AM EG C

18 LFIX-0016FCZZ AD DJ C

19 XBPS740P28KS0 AC DD N C

21 DHAI-3690FCZZ AX FG N C

22 XBPS740P08K00 AA DD C

23 LX-WZ0443FCPZ AB DD C

24 0EUBZ3020SCPB AC DJ N C

25 0EUBZ3008SCPM AG DS N C

26 0EUCOV0419J// AH DX C

27 0EUCOV0418J// AH DX C

28 0EUNZ3024SCPE AB DJ N C

29 DHAI-3691FCZZ AZ FQ N C

33 LHLDW1490FCZZ AD DJ C

37 RMOTP0944FCPZ BP LP N B

38 DHAI-3557FCPZ AR EQ N C

39 DHAI-3552FCPZ AZ FQ N C

40 DHAI-3565FCPZ AS EQ N C

41 CPWBN1653FC31 BS MW N E

42 XBBS730P06000 AC DD C

43 LSUPP0083FCZZ AB DJ C

44 XHBS730P04000 AA DD C

45 LX-BZ0340FCPZ AF DS N C

46 XHBS740P06000 AA DD C

49 0EUHLD0214C// AC DJ C

50 LSUPP1001ACZZ AB DD C

51 LBNDJ0043FCZ1 AA DJ C

52 PFLT-0067FCP1 AS EQ N C

53 MLEVP0976FCZZ AQ EQ N C

54 0EUSFT0415KP/ AN EG N C

55 XRESP50-06000 AA DD C