Page 1

SERVICE MANUAL

Parts marked with " " are important for maint aining the safety of the set. Be sur e to rep lace the se parts with

specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

NOTE FOR SERVICING

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] FIRMWARE UPDATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] OPERATIONAL DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

TopPage

CONTENTS

CODE: 00ZMXC250/S4E

MX- C250/C250E

MX- C250F/C250FE

MX- C300F/C300W

MX- C300WE

MODEL

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM

Page 2

CONTENTS

NOTE FOR SERVICING

1. Precautions for servicing . . . . . . . . . . . . . . . . . . . . . . . . . i

2. Warning for servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

3. Note for installing site. . . . . . . . . . . . . . . . . . . . . . . . . . . . i

4. Note for handling PWB and electronic parts . . . . . . . . . .ii

5. Note for repairing/replacing the LSU . . . . . . . . . . . . . . . iii

6. Note for handling the drum unit, the transfer unit,

the developing unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

[1] PRODUCT OUTLINE

1. System diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Product list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

3. Option list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Copy functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

3. Printer function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

4. Scanner/FAX function . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

5. Report/list function. . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

6. Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

7. Dimensions and Weight. . . . . . . . . . . . . . . . . . . . . . . . 2-9

8. Ambient conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

[3] CONSUMABLE PARTS

1. Supply system table. . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

2. Maintenance parts list . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3. Definition of developer/drum life end . . . . . . . . . . . . . .3-2

4. Production number identification . . . . . . . . . . . . . . . . . 3-3

5. Environmental conditions. . . . . . . . . . . . . . . . . . . . . . .3-3

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

A. External view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

B. Document feeder and document glass . . . . . . . . . . . . 4-2

C. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

D. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

E. SPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

F. RSPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

G. Sensor, detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

H. Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

I. Clutches and solenoids . . . . . . . . . . . . . . . . . . . . . . .4-10

J. Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

K. Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

L. Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

M. Fans and filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

N. PWB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

O. Fuses/thermostats . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

[5] ADJUSTMENTS

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

2. Adjustment item list . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3. Details of adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

[6] SIMULATION

1. General and purpose . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

2. List of simulation codes . . . . . . . . . . . . . . . . . . . . . . . .6-3

3. Details of simulation. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

4. Soft switch (Detail of Sim. 66-1). . . . . . . . . . . . . . . . .6-62

[7] TROUBLESHOOTING

1. Error code and troubleshooting . . . . . . . . . . . . . . . . . .7-1

2. JAM and troubleshooting . . . . . . . . . . . . . . . . . . . . . .7-16

3. Image send communication report code . . . . . . . . . .7-17

4. Dial tone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

[8] FIRMWARE UPDATE

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

2. Update procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

[9] MAINTENANCE

1. Necessary work for maintenance. . . . . . . . . . . . . . . . .9-1

2. Maintenance timing display list . . . . . . . . . . . . . . . . . .9-2

3. Maintenance list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

[10] DISASSEMBLY AND ASSEMBLY

1. Disassembly of Units . . . . . . . . . . . . . . . . . . . . . . . . .10-1

2. Disassembly and assembly of each unit . . . . . . . . .10-16

[11] OPERATIONAL DESCRIPTIONS

1. Operation panel section. . . . . . . . . . . . . . . . . . . . . . . 11-1

2. SPF/RSPF section. . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

3. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

4. Manual paper feed section. . . . . . . . . . . . . . . . . . . . . 11-8

5. Paper registration section . . . . . . . . . . . . . . . . . . . . . 11-9

6. Paper feed tray section . . . . . . . . . . . . . . . . . . . . . .11-10

7. Paper exit section. . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

8. Duplex section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

9. LSU section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

10. OPC drum section . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

11. Toner supply section . . . . . . . . . . . . . . . . . . . . . . . . 11-18

12. Developing section. . . . . . . . . . . . . . . . . . . . . . . . . .11-19

13. Transfer section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-21

14. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-23

15. Fan and filter section . . . . . . . . . . . . . . . . . . . . . . . . 11-25

[12] EL E CTR I CAL SEC T IO N

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

2. Power line diagram . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

3. Actual wiring chart . . . . . . . . . . . . . . . . . . . . . . . . . . .12-8

4. Signal list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

[13] OTHERS

1. Necessary works when replacing the PWB,

and the HDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

2. TOOL LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

Page 3

MX-C250 NOTE FOR SERVICING - i

MX-C250

Service Manual

NOTE FOR SERVICING

1. Precautions for servicing

1) When servicing, disconnect the power plug, the printer cable,

the network cable, and the telephone line from the machine,

except when performing the communication test, etc.

It may cause an injury or an electric shock.

2) There is a high temperature area inside the machine. Use

extreme care when servicing.

It may cause a burn.

3) There is a high voltage section inside the machine which may

cause an electric shock. Be careful when servicing.

4) Do not disassemble the laser unit. Do not insert a reflective

material such as a screwdriver in the laser beam path.

It may damage eyes by reflection of laser beams.

5) When servicing with the machine operating, be careful not to

place your hands by belts, gears, chains, and other drive components.

6) Do not leave the machine with the cabinet disassembled.

Do not allow any person other than a serviceman to touch

inside the machine. It may cause an electric shock, a burn, or

an injury.

7) When servicing, do not breathe toner, developer, and ink

excessively. Do not get them in the eyes.

If toner, developer, or ink enters you eyes, wash it away with

water immediately, and consult a doctor if necessary.

8) The machine has got sharp edges inside. Be careful not to

damage fingers when servicing.

9) Do not throw toner or a toner cartridge in a fire. Otherwise,

toner may explode and burn you.

10) When replacing the lithium battery on the PWB, use only the

specified battery.

If a battery of different specification is used, the battery may

cause malfunction or breakdown of the machine.

11) When transporting a PWB, be sure to place the PWB in an

anti-static bag.

It may cause a breakdown or malfunctions.

2. Warning for servicing

1) Be sure to connect the power cord only to a power outlet that

meets the specified voltage and current requirements.

Avoid complex wiring, which may lead to a fire or an electric

shock.

2) If there is any abnormality such as a smoke or an abnormal

smell, interrupt the job and disconnect the power plug.

It may cause a fire or an electric shock.

3) Be sure to connect the grounding wire. If an electric leakage

occurs without grounding, a fire or an electric shock may

result.

For proper machine functionality, the machine must be

grounded.

4) When connecting the grounding wire, never connect it to the

following points.

It may cause an explosion, a fire or an electric shock.

- Gas tube

- Lightning conductor

- A water pipe or a water faucet, which is not recognized as a

grounding object by the authorities.

- Grounding wire for telephone line

5) Do not damage, break, or twist the power cord.

Do not put heavy objects on the power cable. Do not forcefully

bend or pull the power cable.

It may cause a fire or an electric shock.

6) Keep the power cable away from a heat source.

Do not insert the power plug with dust on it into a power outlet.

It may cause a fire or an electric shock.

7) Do not put a metallic object or a container with water in it inside

the machine.

It may cause a fire or an electric shock.

8) With wet or oily hands, do not touch the power plug, do not

perform servicing, touch the power plug, insert a telephone

jack, or operate the machine with wet or oily hands.

It may cause an electric shock.

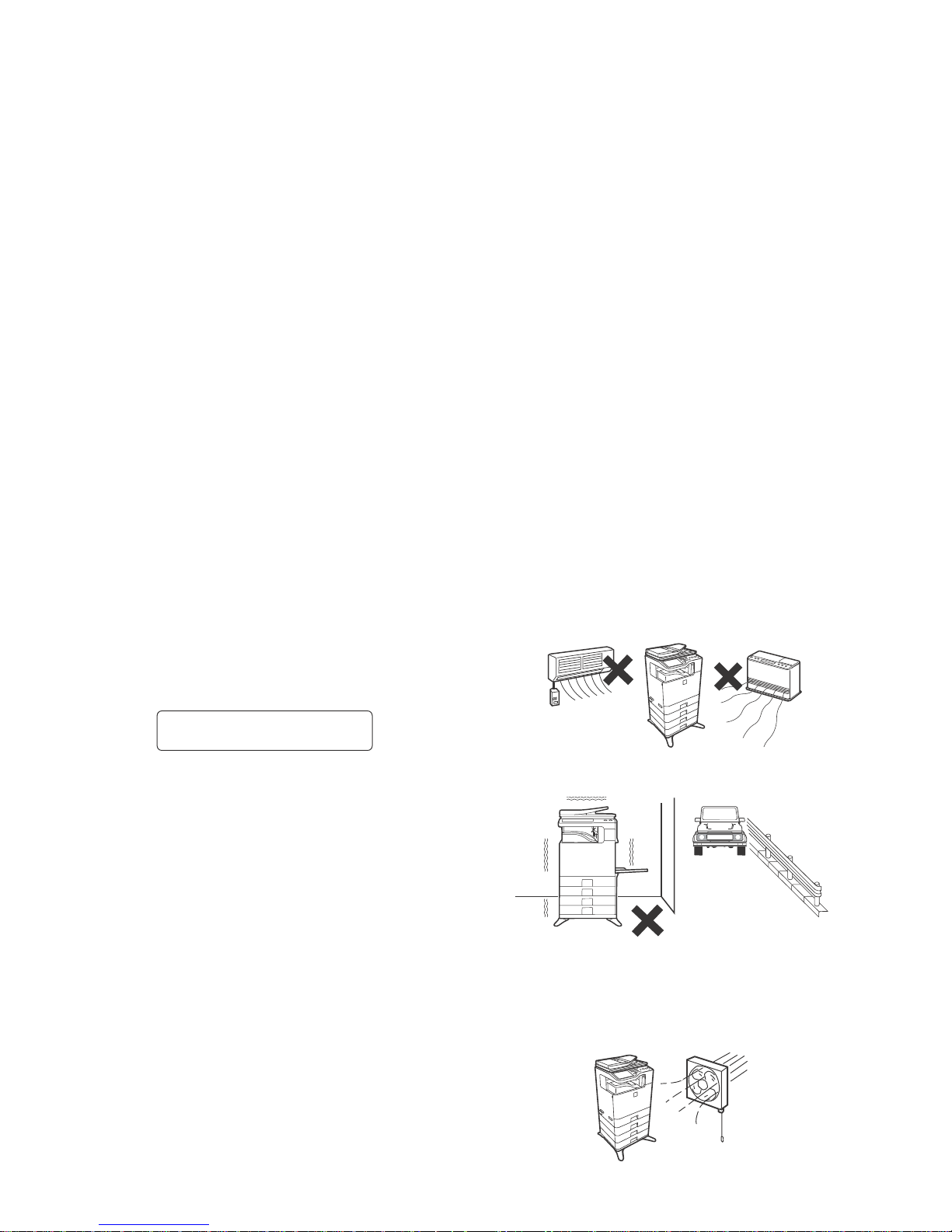

3. Note for installing site

Do not install the machine at the following sites.

1) Place of high temperature, high humidity, low tempera-

ture, low humidity, place under an extreme change in temperature and humidity.

Paper may get damp and form moisture inside the machine,

causing paper jam or copy dirt.

For operating condition, refer to the specifications described

later.

2) Place of much vibration

It may cause a breakdown.

3) Poorly ventilated place

An electro-static type copier will produce ozone inside it.

The quantity of ozone produced is designed to a low level so

as not to affect human bodies. However, continuous use of

such a machine may produce an odor of ozone. Install the

machine in a well ventilated place.

CAUTION

DOUBLE POLE/NEUTRAL FUSING

(200V series only)

Page 4

MX-C250 NOTE FOR SERVICING - ii

4) Place of direct sunlight.

Plastic parts and toner may be deformed, discolored, or may

undergo qualitative change.

It may cause a breakdown or copy quality issues.

5) Place which is full of organic gases such as ammonium

The organic photoconductor (OPC) drum used in the machine

may undergo qualitative change due to organic gases such as

ammonium.

Installation of this machine near a diazo-type copier may result

in copy quality issues.

6) Place of much dust

When dusts enter the machine, it may cause a breakdown or

copy quality issues.

7) Place near a wall

Some machines require intake and exhaust of air.

If intake and exhaust of air are not properly performed, copy

dirt or a breakdown may be a result.

8) Unstable or slant surface

If the machine drops or falls down, it may cause an injury or a

breakdown.

If there are optional paper desks and the copier desks speci-

fied, it is recommendable to use them.

When using the optional desk, be sure to fix the adjuster and

lock the casters.

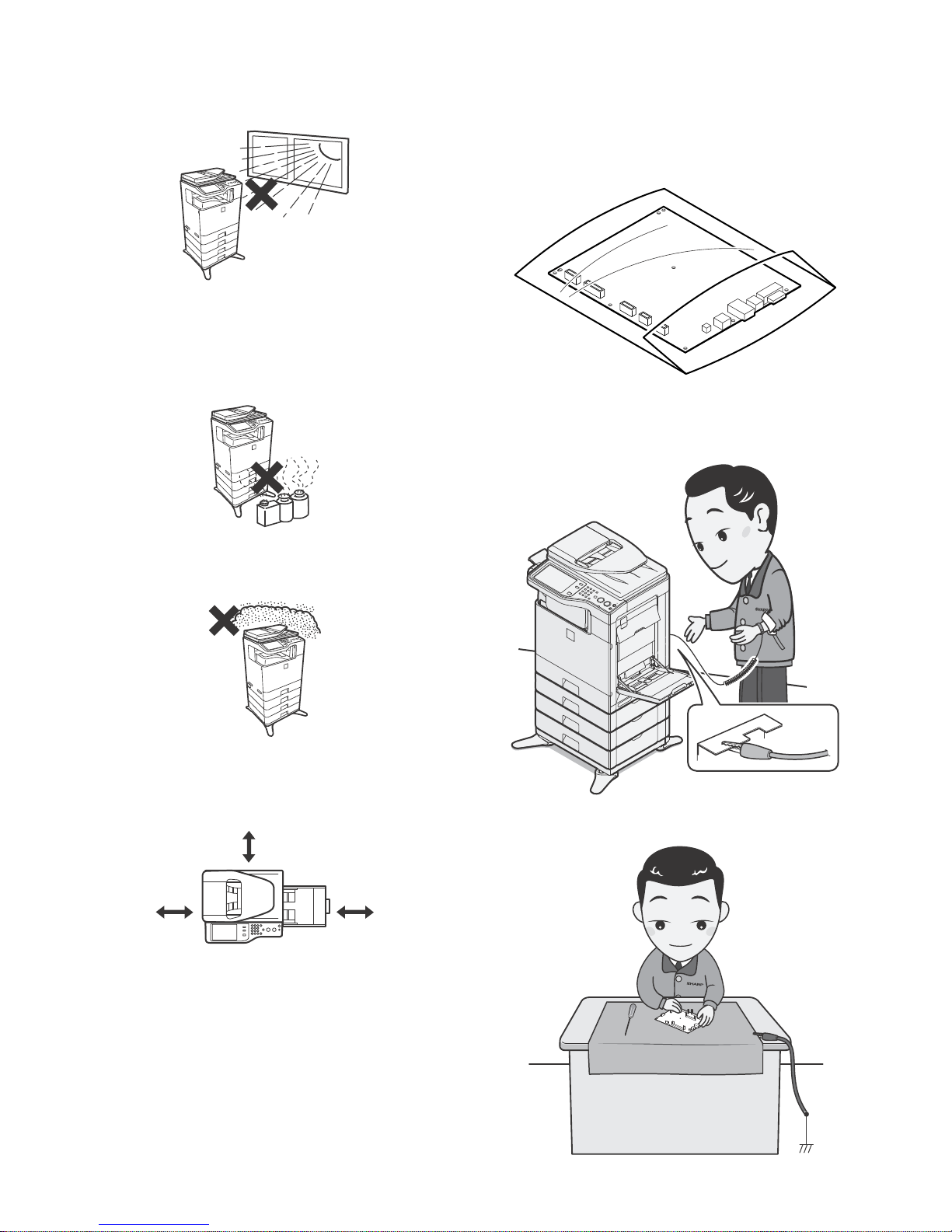

4. Note for handling PWB and electronic

parts

When handling the PWB and the electronic parts, be sure to

observe the following precautions in order to prevent against damage by static electricity.

1) When in transit or storing, put the parts in an anti-static bag or

an anti-static case and do not touch them with bare hands.

2) When and after removing the parts from an anti-static bag

(case), use an earth band as shown below:

- Put an earth band to your arm, and connect it to the

machine.

- When repairing or replacing an electronic part, perform the

procedure on an anti-static mat.

17-23/32"

(45cm)

11-13/16"

(30cm)

11-13/16"

(30cm)

Page 5

MX-C250 NOTE FOR SERVICING - iii

5. Note for replacing the LSU

When replacing, be sure to observe the following items.

1) When replacing the LSU, be sure to disconnect the power plug

from the power outlet.

2) When replacing the LSU, follow the procedures described in

this Service Manual.

3) When checking the operations after repairing the LSU, keep all

the parts including the cover installed and perform the operation check.

4) Do not modify the LSU.

5) When visually checking the inside of the machine for the operation check, be careful not to allow laser beams to enter the

eyes.

If the above precaution is neglected or an undesignated work is

performed, safety may not be assured.

6. Note for handling the OPC drum unit, the

transfer unit, and the developer unit

When handling the OPC drum unit, the transfer unit, and the developer unit, strictly observe the following items.

If these items are neglected, a trouble may be generated in the

copy and print image quality.

(OPC drum)

1) Avoid working at a place with strong lights.

2) Do not expose the OPC drum to lights including interior lights

for a long time.

3) When the OPC drum is removed from the machine, cover it

with light blocking material. (When using paper, use about 10

sheets of paper to cover it.)

4) Be careful not to attach fingerprints, oil, grease, or other foreign material on the OPC drum surface.

(Transfer unit)

1) Be careful not to attach fingerprints, oil, grease, or other foreign material on the transfer belt and the transfer roller.

(Developer unit)

1) Be careful not to attach fingerprints, oil, grease, or other foreign material on the developer unit.

Page 6

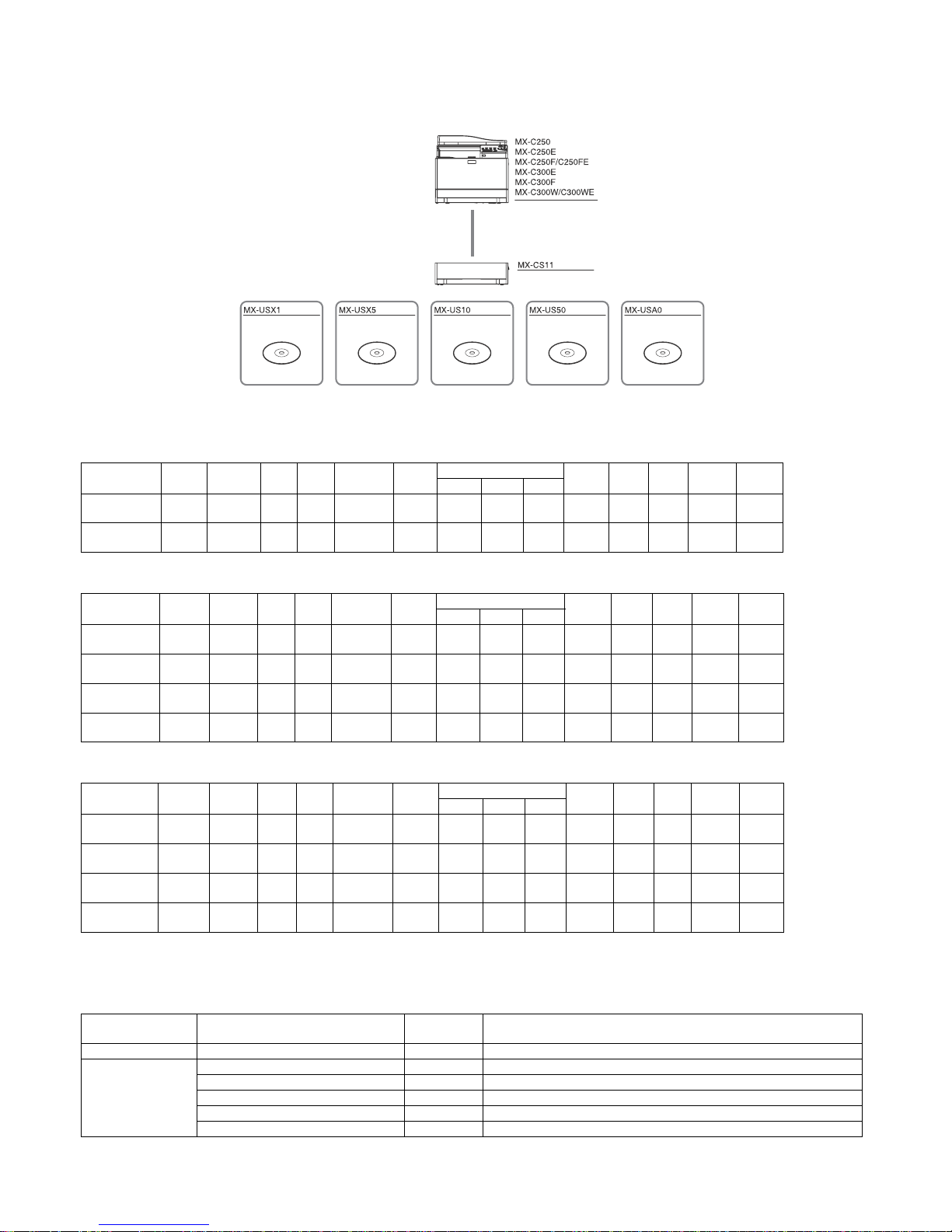

MX-C250 PRODUCT OUTLINE 1 – 1

MX-C250

Service Manual

[1] PRODUCT OUTLINE

1. System configuration

2. Product list

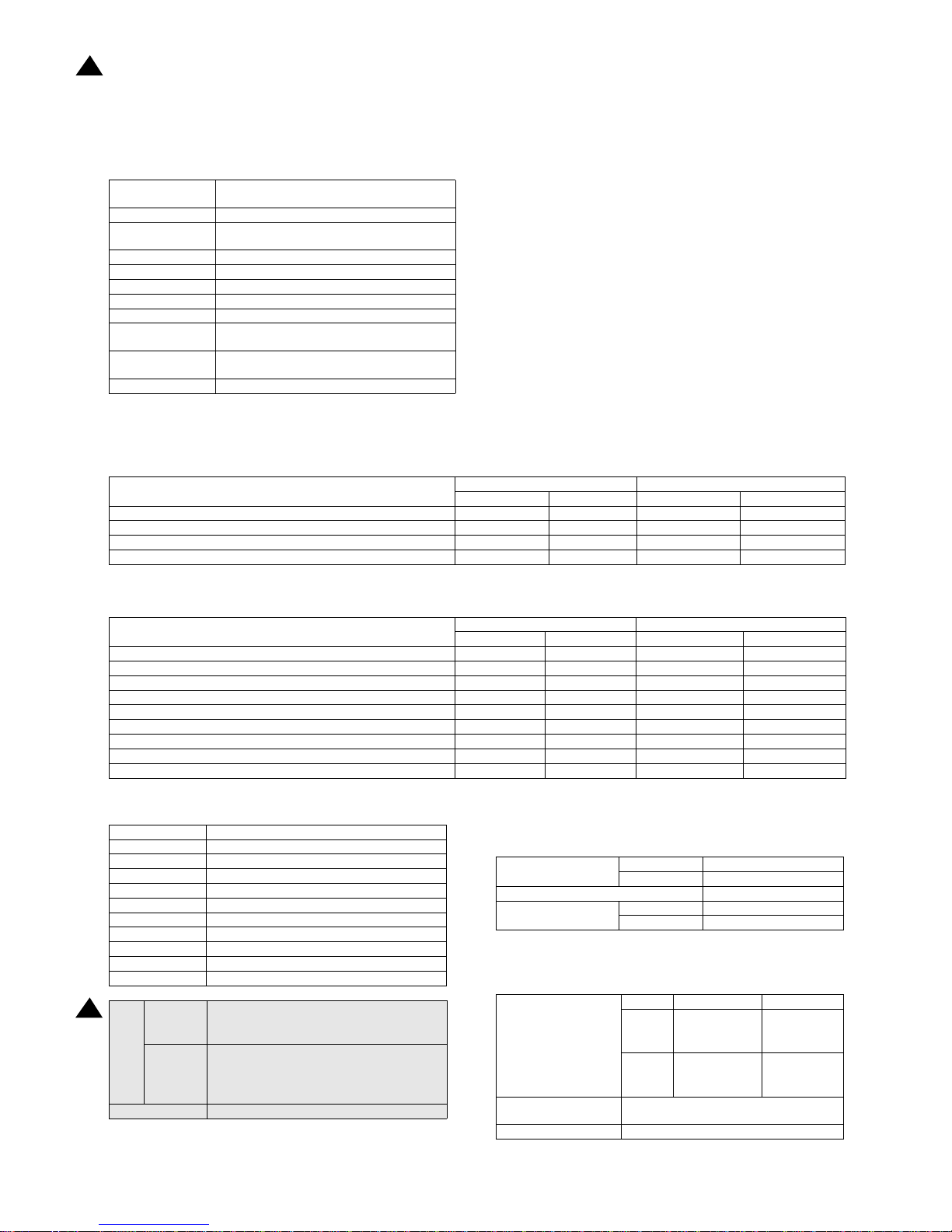

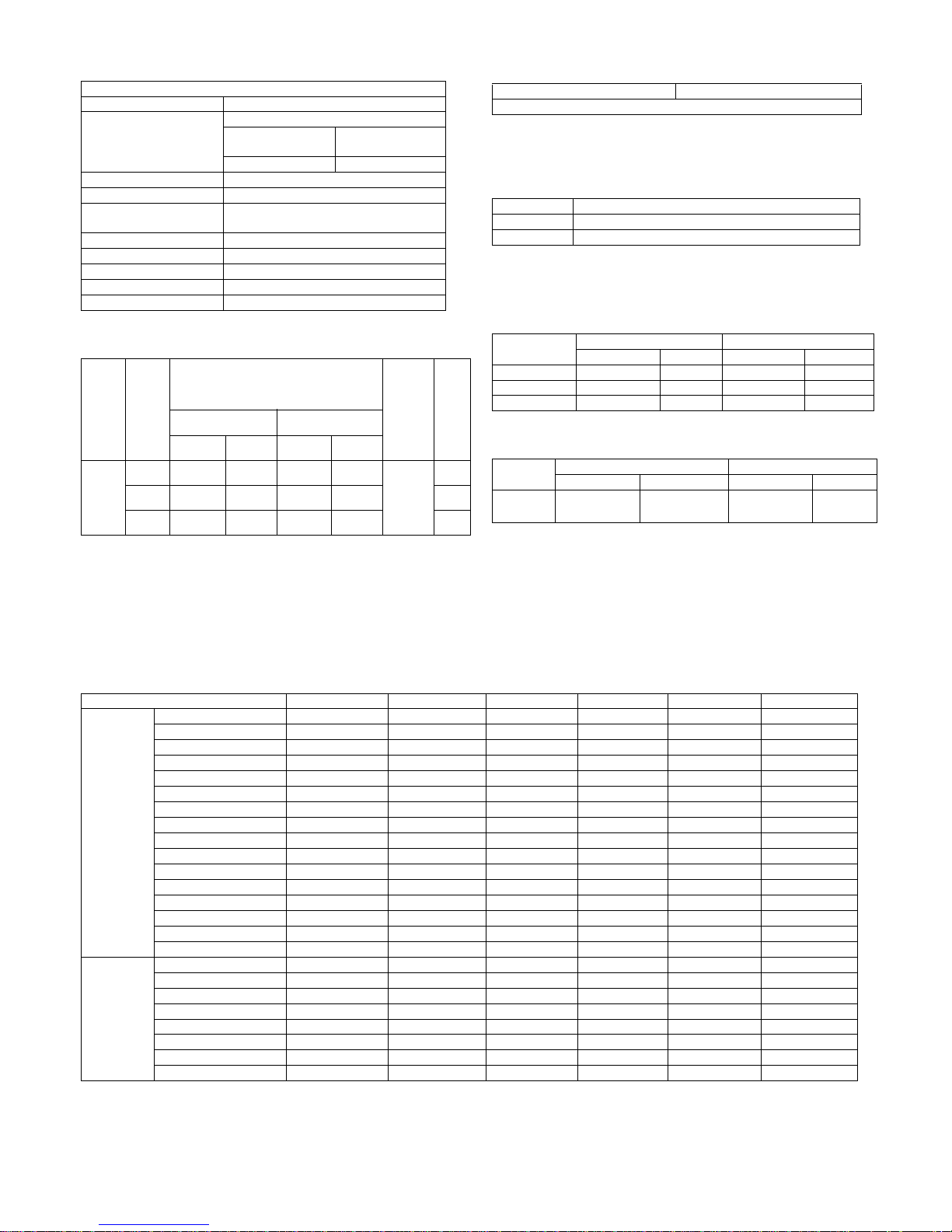

A.North America

B.Europe

C.Other

*The same speed in both Color/Monochrome. The same speed in both A4/LTR.

3. Option list

STD: Standard provision, OPT: Option, - : No setting

Product

Name

cpm* Panel HDD NIC Wireless

LAN

Copy Print NW

Scan

Fax iFAX DF OSA

SAPL PCL PS

MX-C250 25cpm

Mono

CD

No STD No STD No STD STD STD No No

STD

SPF

No

MX-C300W 30cpm

Mono

CD

No STD STD STD No STD STD STD STD No

STD

RSPF

No

Product

Name

cpm* Panel HDD NIC Wireless

LAN

Copy Print NW

Scan

Fax iFAX DF OSA

SAPL PCL PS

MX-C250E 25cpm

Mono

CD

No STD No STD No STD STD STD No No

STD

SPF

No

MX-C250F /

MX-C250FE

25cpm

Mono

CD

No STD No STD No STD STD STD STD No

STD

SPF

No

MX-C300E 30cpm

Mono

CD

No STD No STD No STD STD STD No No

STD

RSPF

No

MX-C300W /

MX-C300WE

30cpm

Mono

CD

No STD STD STD No STD STD STD STD No

STD

RSPF

No

Product

Name

cpm* Panel HDD NIC Wireless

LAN

Copy Print NW

Scan

Fax iFAX DF OSA

SAPL PCL PS

MX-C250 25cpm

Mono

CD

No STD No STD No STD STD STD No No

STD

SPF

No

MX-C250F 25cpm

Mono

CD

No STD No STD No STD STD STD STD No

STD

SPF

No

MX-C300F 30cpm

Mono

CD

No STD No STD No STD STD STD STD No

STD

RSPF

No

MX-C300W 30cpm

Mono

CD

No STD STD STD No STD STD STD STD No

STD

RSPF

No

Model Name Model name MX-C250, MXC250E, MX-C250F, MX-C250FE, MX-C300E, MX-C300F, MX-

C300W, MX-C300WE

Feeding equipment 500-SHEET Paper Feed Unit MX-CS11 OPT

Application

Shar

pdesk

1 License Kit MX-USX1 OPT

Sharpdesk 5 License Kit MX-USX5 OPT

Sharpdesk 10 License Kit MX-US10 OPT

Sharpdesk 50 License Kit MX-US50 OPT

Sharpdesk 100 License Kit MX-USA0 OPT

Digital full color multifunctional system

500 sheet paper feed unit

Sharpdesk 1 license kit Sharpdesk 5 license kit Sharpdesk 10 license kit Sharpdesk 50 license kit Sharpdesk 100 license kit

Page 7

MX-C250 SPECIFICATIONS 2 – 1

MX-C250

Service Manual

[2] SPECIFICATIONS

1. Basic specifications

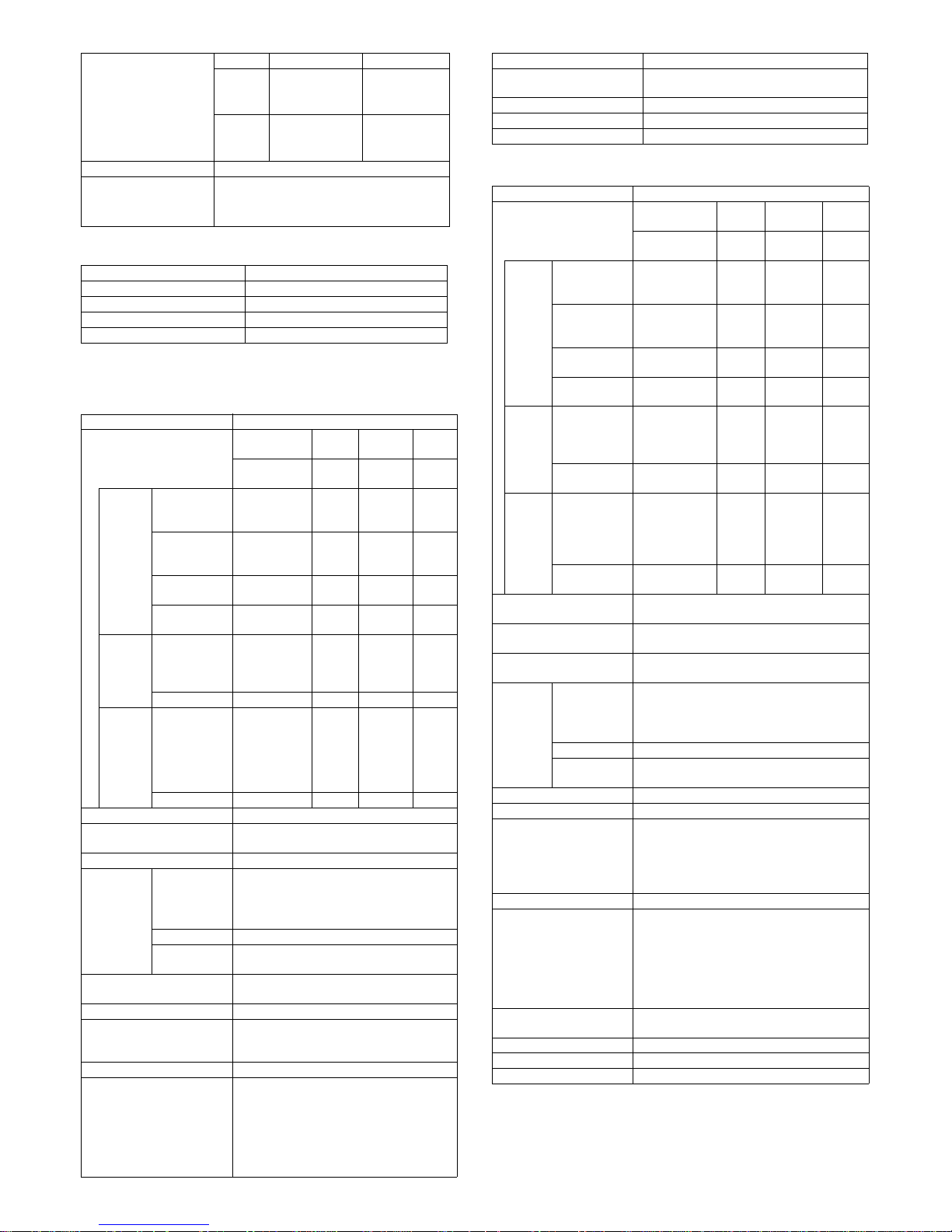

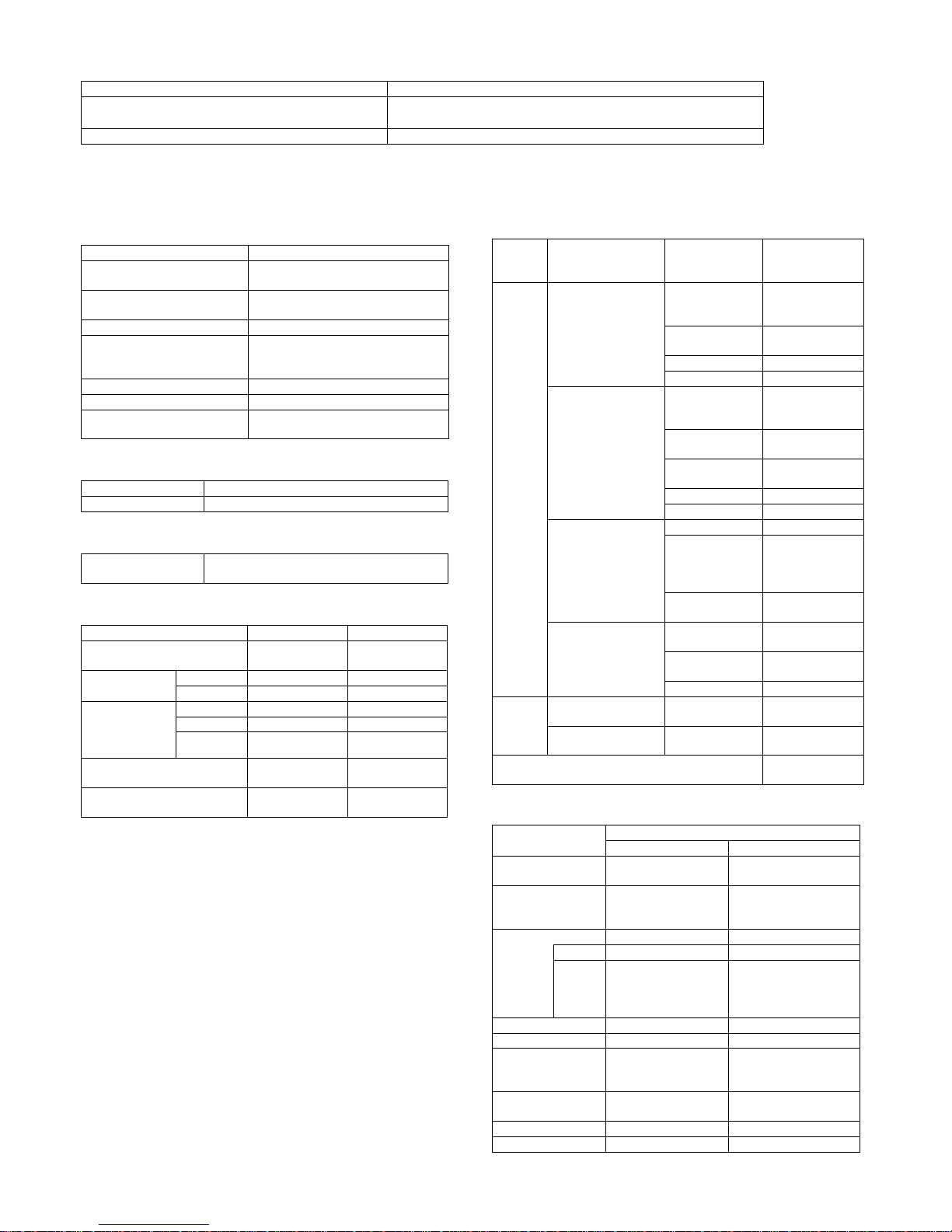

A. Engine Specification

B. Engine speed (ppm)

(1) Tray 1, 2

(2) Bypass tray

C. Printable area

* No margin print function not provided.

D. Engine resolution

E. Scanner section

(1) Resolution/Gradation

Photo Conductor

OPC(Diameter: Black:φ30mm, Color: φ30mmx3

pieces)

Recording Electronic Photo (Laser)

Development

Dry-Type Dual-Component Magnetic Brush

Development

Charging Charged Saw-Tooth Method Roller Charging

First Transfer Mid-Transfer (Belt)

Second Transfer Transfer Roller

Cleaning Counter Blade

Fusing Heat Roller

Waste toner disposal

No toner recycling system/Toner collection

container system

Continuous toner

supply

Not available

Appearance color Neo White

Paper size

MX-C250 MX-C300

Monochrome Color Monochrome Color

8.5x14, 8.5x13, 8.5x13.4, 8.5x13.5 25 25 25 25

A4R 25 25 30 30

8.5x11R, 7.25x10.5R, B5R,16KR 25 25 30 30

A5R, 5.5x8.5R 25 25 30 30

Paper size

MX-C250 MX-C300

Monochrome Color Monochrome Color

8.5x14, 8.5x13, 8.5x13.4, 8.5x13.5 16 16 16 16

A4R 21 21 21 21

8.5x11R, 7.25x10.5R, B5R,16KR 21 21 21 21

A5R, 5.5x8.5R 21 21 21 21

Extra 16 16 16 16

OHP(A4R, 8.5x11R) 9 9 9 9

Envelope (Monarch, Com-10, DL, C5) 9 9 9 9

Heavy paper (A4R,A5R,8.5x11R,8.5x5.5R,16KR) 9 9 9 9

Heavy paper (other than above size) 9 9 9 9

A4R 202x289 mm

B5R 176x249 mm

A5R 140x202 mm

ExecutiveR 176x249 mm

16KR 187x262 mm

8.5x14 208x348 mm

8.5x13.5 208x335 mm

8.5x13.4 208x342 mm

8.5x13 208x322 mm

8.5x11R 208x271 mm

5.5x8.5R 132x208 mm

Void

area

Shipment

Val ue

Top/Rear total: 8mm or less (Lead edge : below

5.5mm)

FR Total: 8mm or less

Authorized

value

Lead edge : below 4.5 - 5.5mm

Rear edge : 2.0 - 3.5mm or less

Lead edge/Rear edge total : 8mm or less

FRONT/REAR total : 8mm or less

Image loss Lead edge/Rear edge/Front/Rear:4mm or less

Resolution

Copy Writing : 600x600dpi

Print Writing : 600x600dpi

Smoothing Function No

To ne

Copy 1bit / 2bit

Print 1bit / 2bit

Scan Resolution for

Copying (dpi)

Monochrome Color

Original

Glass

600x600dpi

600x400dpi

(default)

600x600dpi

600x400dpi

(default)

SPF/

RSPF

600x600dpi

600x300dpi

(default)

600x600dpi

600x300dpi

(default)

Transmission Resolution

(dpi)

Refer to Image Transmission Feature.

Exposure Lamp LED

1

1

13.Aug

Page 8

MX-C250 SPECIFICATIONS 2 – 2

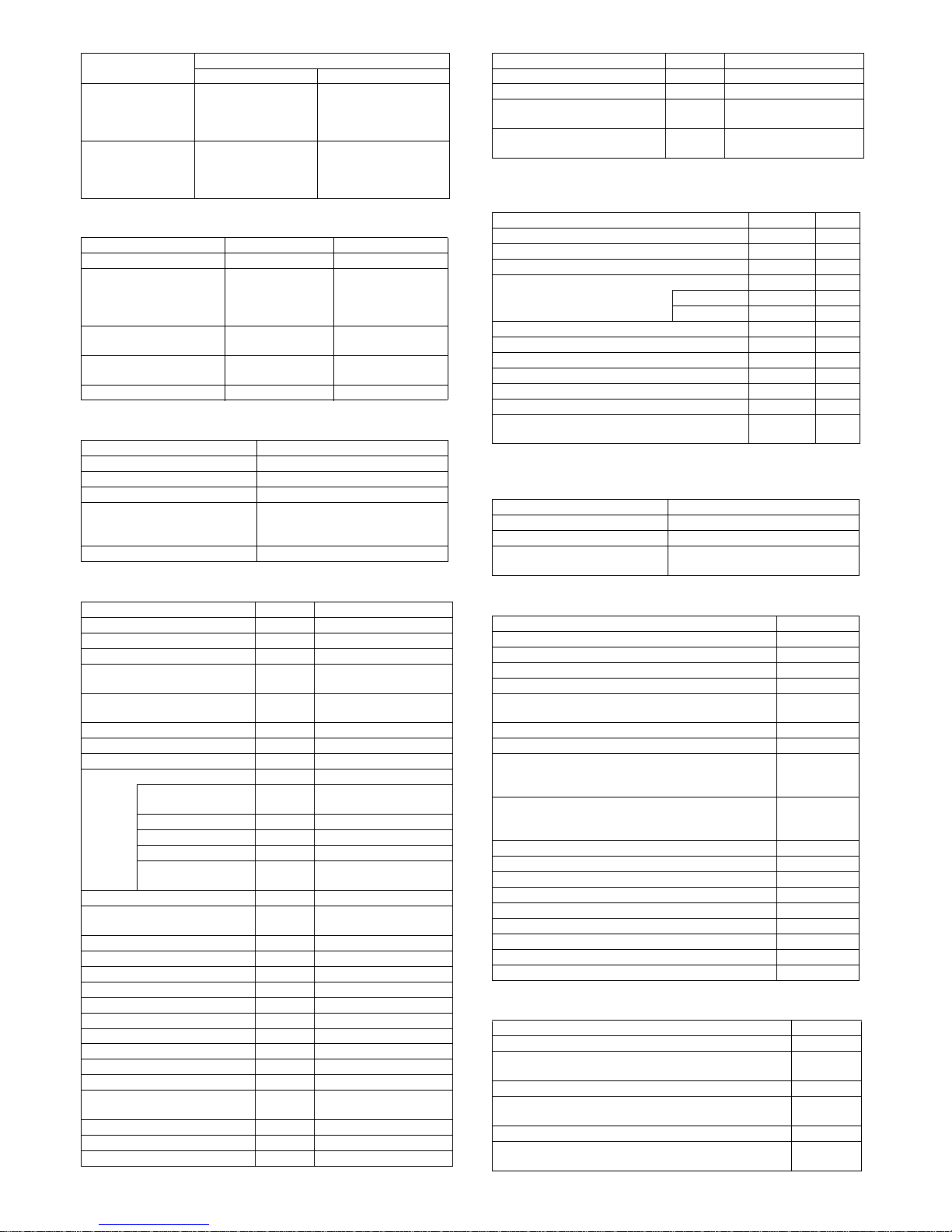

(2) Document table

F. Document feeder

(1) SPF

(2)RSPF

Scan Levels 16 bit

Output Levels

Monochrome : 2bit

Gray scale : 8bit

Full Color : RGB each color 8bit

Form Fixed original glass (Flatbed)

Scan Range 216x297mm(A4/LTR)

Standard Location of Original Rear Left

Original size detection No

Heater (scanner section) No

Type SPF

Scanning speed

Monochrome Color

Monoch

rome

Color

(8.5x11R)

(8.5x1

1R)

(A4R) (A4R)

Copy

Single side

600x300dpi

19page/min

9.5pag

e/min

18 page/

min

9

page/

min

Single side

600x600dpi

9.5page/min

4.5pag

e/min

9 page/

min

4

page/

min

Double side

600x300dpi

No No No No

Double side

600x600dpi

No No No No

Fax(for

nonU.S.

models

only)

Single side

13.5page/min

(200x200dpi)

No

13 page/

min

(200x20

0dpi)

No

Double side No No No No

SCAN

Single side

19page/min

(200x200dpi)

9.5pag

e/min

(200x2

00dpi)

18 page/

min

(200x20

0dpi)

9

page/

min

(200x

200dp

i)

Double side No No No No

Document Setting Direction Face up

Standard Location of

Original Document

Center alignment

Document Feeding Method Sheet through

Document

Size

Standard

Typ e

<Single side> Horizontal scanning :

139.7mm -216mm Vertical scanning :

139.7mm . 356mm

<Double> Not supported

Long Paper Length: Max. 500mm (mono: 1 bit only)

Business

Card*1

Y:51mm-55mm X:89mm-91mm

Mix Paper Feeding

Available for Fax mode (single side send

only)

Random Paper Feeding No

Document Weight

<Single side> Regular paper : 50-105g/m2,

13-28 lb Bond

<Double> Not supported

Document Capacity Max. 35 pages (80g/m2, 21 lbs Bond)

Type of document that may

not be used

OHP, the 2nd original drawing sheet,

Tracing paper, carbon paper, thermal paper,

wrinkled / broken / torn document, document

with cut or paste, document printed with ink

ribbon, and perforated document except for

the document having wide width for 2 holes,

3 holes, or 4 holes

Scan Resolution for

Copying (dpi)

Monochrome Color

Original

Glass

600x600dpi

600x400dpi

(default)

600x600dpi

600x400dpi

(def

ault)

SPF/

RSPF

600x600dpi

600x300dpi

(default)

600x600dpi

600x300dpi

(default)

Standard Location of

Original Document

Center alignment

Document size detection No

Paper Feeding Direction Right hand side paper feeding

Stamp No

Type RSPF

Scanning speed

Monochrome Color

Monochr

ome

Color

(8.5x11R)

(8.5x11

R)

(A4R) (A4R)

Copy

Single side

600x300dpi

19page/min

9.5pag

e/min

18 page/

min

9

page/

min

Single side

600x600dpi

9.5page/min

4.5pag

e/min

9 page/

min

4

page/

min

Double side

600x300dpi

8sheet/min

4.5she

et/min

8sheet/

min

4sheet

/min

Double side

600x600dpi

4.5sheet/min

2sheet/

min

4.5sheet/

min

2sheet

/min

Fax

Single side

13.5page/min

(200x200dpi)

No

13 page/

min

(200x20

0dpi)

No

Double side 7.5sheet/min No

7sheet/

min

No

SCAN

Single side

19page/min

(200x200dpi)

9.5pag

e/min

(200x2

00dpi)

18 page/

min

(200x20

0dpi)

9

page/

min

(200x2

00dpi)

Double side 8sheet/min

4.5she

et/min

8sheet/

min

4.5she

et/min

Document Setting

Direction

Face up

Standard Location of

Original Document

Center alignment

Document Feeding

Method

Sheet through

Documen

t Size

Standard

Type

<Single side> Horizontal scanning : 139.7mm 216mm Vertical scanning : 139.7mm . 356mm

<Double side> Horizontal scanning : 139.7mm

-216mm Vertical scanning : 170mm . 356mm

Long Paper Length: Max. 500mm (mono: 1 bit only)

Business

Card*1

Y:51mm-55mm X:89mm-91mm

Mix Paper Feeding Available for Fax mode

Ra

ndom Paper Feeding No

Document Weight

<Single side> Regular paper : 50-105g/m2,

13-28 lb Bond

<Double side> Regular paper : 50-105g/m2,

13-28 lb Bond

Business Card: Thickness 0.1mm-0.2mm

Document Capacity Max. 50 pages (80g/m2, 21 lbs Bond)

Type of document that

may not be used

OHP, the 2nd original drawing sheet, Tracing

paper, carbon paper, thermal paper, wrinkled /

broken / torn document, document with cut or

paste, document printed with ink ribbon, and

perforated document except for the document

having wide width for 2 holes, 3 holes, or 4

holes

Standard Location of

Original Document

Center alignment

Document size detection No

Paper Feeding Direction Right hand side paper feeding

Stamp No

Type SPF

Page 9

MX-C250 SPECIFICATIONS 2 – 3

G. Paper feed section

(1) Basic specifications

(2) Other paper type capacities

(3) Size of paper which can be fed

Envelope Type

Custom Size

Form

Std: 1-Paper Tray / Multi Bypass Tray

Max: 2-Paper Tray / Multi Bypass Tray

Heater No

Tray Tray 1 Bypass Tray

Paper Capacity Standard paper (80g/m2) 250sheets 50 sheets

Paper Size Detection No

Paper Size Changing Method Changed by Users

Detection of Remaining Paper Only detects if any paper remains or not

Paper Type Bypass Tray

Envelope 10 sheets

OHP 10 sheets

Heavy paper 20 sheets

Tab Paper No

Gloss Paper 1 sheets

Other Special Paper 1 sheet

Paper Feeding Section

Main Unit

Optional

Drawer

Multi Bypass

Paper size

8.5'x14' (Legal) 216x356mm No No Yes

8.5'x13.5' (Asian Legal) 216x343mm No No Yes

8.5'x13.4' (Mexican Legal) 216x340 mm No No Yes

8.5'x13' (Foolscap) 216x330 mm No No Yes

8.5'x11'R (Letter R) 216x279 mm Yes Yes Yes

5.5'x8.5'R (Invoice R) 140x216 mm Yes Yes Yes

ExecutiveR 184x266 mm Yes Yes Yes

A4R 210x297 mm Yes Yes Yes

B5R 182x257 mm Yes Yes Yes

A5R 148x210 mm Yes Yes Yes

A6R 105x148mm No No Yes

16KR 195x270 mm Yes Yes Yes

Envelope No No Yes

Custom No No Yes

Paper Type

Thin Paper 55-59g/m2 13-16lb bond No No Yes

Plain Paper

60-105g/m2 16-28lb bond Yes Yes Yes

Recycled Paper Yes Yes Yes

Color Paper Yes Yes Yes

Letter Head Yes Yes Yes

Pre-Printed Paper Yes Yes Yes

Pre-Punched Paper Yes Yes Yes

Heavy paper

106-220g/m2 28 lb bond -80 lb Cover No No Yes

221 g/mor more 81lb Cover or more No No No

Envelope 75-90g/m2 No No Yes

Transparency No No Yes

Label No No Yes

Tab Paper No No No

Glossy Paper No No Yes

User Setting 1-7 No No No

Type Size

Monarch 98x191

Com10 105x241

DL 110x220

C5 162x229

AB System (mm) Inch System (inch)

Min. Max. Min. Max.

Multi Bypass Tray

X 140 356 5_1/2 14

Y 90 216 3_5/8 8_1/2

Page 10

MX-C250 SPECIFICATIONS 2 – 4

H. Paper exit section

(1) Exit Capacity

(2) Size of paper which can be discharged

Envelope Type

Custom Size

I. Operation panel

Ejection part Center part of the main unit

Ejection method Face-down ejection

Paper capacity for ejection 150 sheets (for A4R, 8.5x11R )

Ejectable paper size and weight Refer to "Size of paper which can be discharged".

Shifter function No

Detection of ejected paper No

Detection of full ejected paper Yes

Duplex Section

Paper Ejection Section

Exit Tray

Paper size

8.5'x14' (Legal) 216x356mm Yes Yes

8.5'x13.5' (Asian Legal) 216x343mm Yes Yes

8.5'x13.4' (Mexican Legal) 216x340 mm Yes Yes

8.5'x13' (Foolscap) 216x330 mm Yes Yes

8.5'x13' (Foolscap) 216x330 mm Yes Yes

8.5'x11'R (Letter R) 216x279 mm Yes Yes

5.5'x8.5'R (Invoice R) 140x216 mm Yes Yes

Executive R 184x266 mm No Yes

A4R 210x297 mm Yes Yes

B5R 182x257 mm Yes Yes

A5R 148x210 mm Yes Yes

A6R 105x148mm No Yes

16KR 195x270 mm Yes Yes

Envelope No Yes

Custom No Yes

Paper Type

Thin Paper 55-59g/m2 13-16lb bond No Yes

Plain Paper

60-105g/m2 16-28lb bond Yes Yes

Recycled Paper Yes Yes

Color Paper Yes Yes

Letter Head Yes Yes

Pre-Printed Paper Yes Yes

Pre-Punched Paper Yes Yes

106-220g/m2 28 lb bond -80 lb Cover No Yes

Heavy paper

106-220g/m2 28 lb bond -80 lb Cover No Yes

221 g/m2 or more 81lb Cover or more No No

Envelope 75-90g/m2 No Yes

Transparency No Yes

Label No Yes

Tab Paper No No

Glossy Paper No Yes

User Setting 1-7 No No

Type Size

Monarch 98x191

Com10 105x241

DL 110x220

C5 162x229

AB System (mm) Inch System (inch)

Min. Max. Min. Max.

Multi Bypass Tray

X 140 356 5_1/2 14

Y 90 216 3_5/8 8_1/2

Form LCD with backlight

Color Monochrome

Number of display dots 192x73 dots

LCD driving display area (WxD) 63 x 65mm

LCD Backlight White LED

LCD Contrast adjustment No

Angle/position adjustment No

Page 11

MX-C250 SPECIFICATIONS 2 – 5

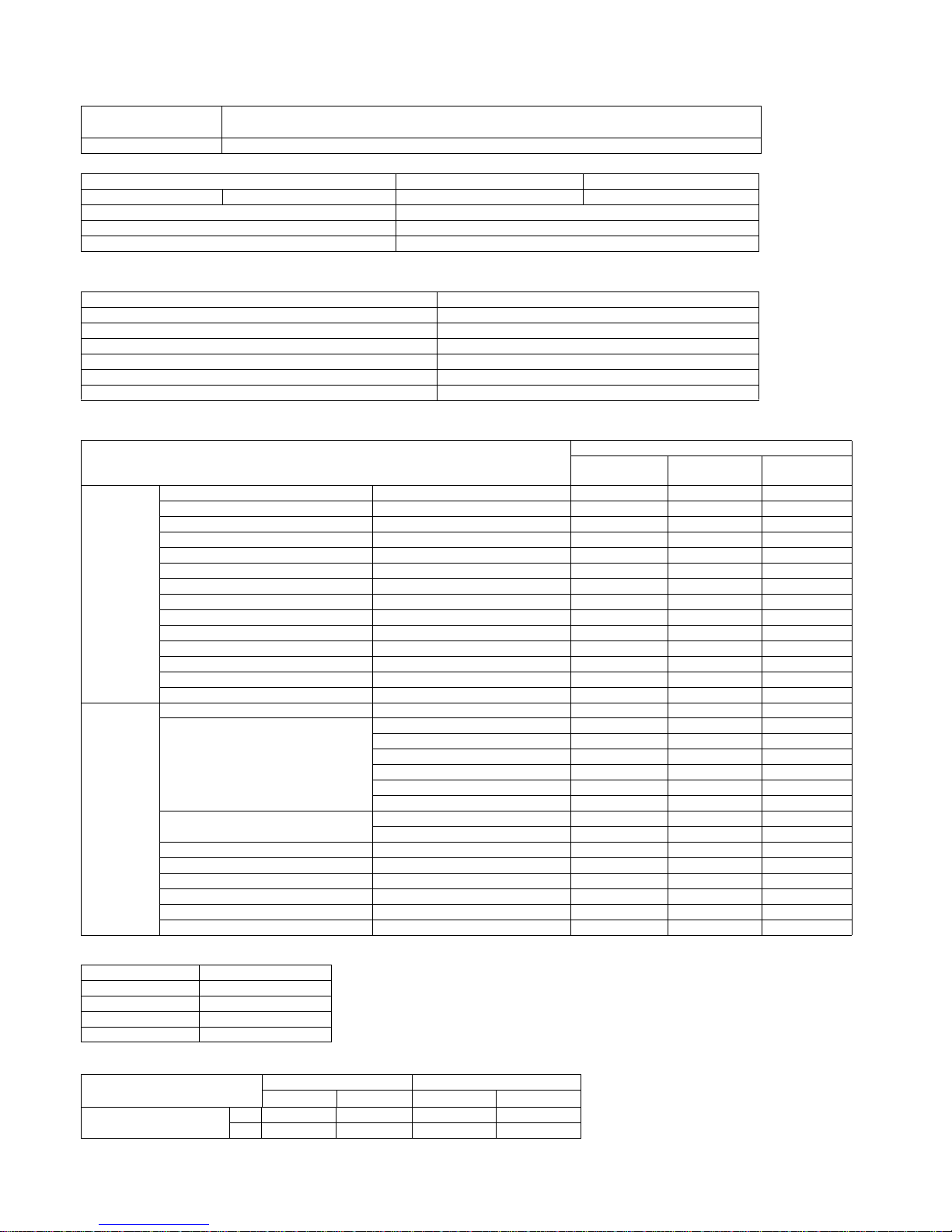

J. Controller board

K. Memory/Hard disk

*1 Fax model only

* For Printing, collate printing is available for every print files.

L. System environment

M. Warm-up time

2. Copy functions

A. First copy time

B. Job Speed

* It regulates copy speed on combination of the main unit and the document

feeder.

* S to S: A4R / 8.5x11R, 11 pages of original, 1 set of copy (not including the

first copy)

* Monochrome: 600x300dpi, Color: 600x300dpi (default).

3. Printer function

A. Printer driver supported OS

*1: For fax model only

*2: Timing is to be determined

Interface

IEEE1284 Parallel No

Ethernet

1 port

Interface

10Base-T, 100BaseTX

Support Protocol TCP/IP(IPv4, IPv6)

USB 2.0 (Host) 1port

USB 2.0 (Device) 1 port

USB authentication

acquisition

No

IrSimple I/F No

Serial I/F (for coin vender) No

Memory Refer to Memory / Hard disc

Memory Slot No

WHQL acquisition Yes

Memor

y

Scan

Resolu

tion

E-sort copy capacity

Fax

Memory

*1

HDD

Monochrome Color

TEST

SHEET D

Greg’s

fruits

TEST

SHEET D

Greg’s

fruits

512MB

600x30

0dpi

Over 50

sheets

Over 50

sheets

Over 50

sheets

13

sheets

8MB

No

600x40

0dpi

Over 50

sheets

41

sheets

Over 50

sheets

12

sheets

No

600x60

0dpi

Over 50

sheets

37

sheets

Over 50

sheets

11

sheets

No

Copier memory (Local memory) Printer memory (System Memory)

512MB (Standard)

Main power SW

Warm up time 29 sec

Preheat Yes

Engine

MX-C250 MX-C300

Monochrome Color Monochrome Color

Original Glass 10sec 18sec 10sec 18sec

SPF 14sec 22sec - RSPF - - 16sec 25sec

Engine

MX-C250 MX-C300

Monochrome Color Monochrome Color

S to S

18 cpm

75.0%

9 cpm

37.5%

18 cpm

64.3%

9 cpm

32.1 %

OS Custom PCL6 Custom PCL5c Custom PS PPD PC-Fax*1 TWAIN

Windows

98 / Me No No No No No No

NT 4.0 SP5 or later No No No No No No

2000 No No No No No No

XP CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

XPx64 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Server 2003 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Server 2003x64 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Server 2008 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Server 2008x64 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Vista CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Vistax64 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Windows7 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Windows7x64 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Windows8 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Windows8x64 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Server 2012 x64 CD-ROM No CD-ROM CD-ROM CD-ROM CD-ROM

Mac

9 No No No No No No

X 10.2 No No No No No No

X 10.3 No No No No No No

X 10.4 No No No CD-ROM No No

X 10.5 No No No CD-ROM Web*2 No

X 10.6 No No No CD-ROM Web*2 No

X 10.7 No No No CD-ROM Web*2 No

X 10.8 No No No CD-ROM Web*2 No

Page 12

MX-C250 SPECIFICATIONS 2 – 6

B. PDL emulation/Font

4. Sanner/Fax function

A. Transmission method

B. Number of Support Line

C. Transmission Mode

D. Image Quality/Image Process

E. Scanner/Fax function

(1) Support image

(2) Specification of Addresses

PDL (command) Font installed

PCL5c compatible /

CL6 compatible

European outline font =80 font types

Line printer font (BMP) =1 font types

Postscrpt3 compatible European outline font =136 font types

Mode Fax

Transmission Time

Less than 2 sec. (Super G3 /JBIG)

Less than 6sec.(G3 ECM)

Modem Speed

33.6 kbps -> 2.4kbps

Auto-fallback

Intercommunication Super G3 / G3

Communication line

Public switched telephone network

(PSTN),

private branch exchange (PBX)

Max. number of lines 1 line

ECM Yes

Support the digital line network

(Sending level)

Yes

Standard 1 line

Expansion Not provided

RSPF/OC

transmission switching

X

Mode Scanner Fax

Halftone reproduction

Equivalent to 256

gradations

Equivalent to 256

gradations

Exposure

Adjustment

Auto Yes Yes

Manual Yes : 5 levels Yes : 5 levels

Original

document type

(Selectable in

manual mode)

Text Yes No

Text / Photo Yes No

Photo Yes No

Magical Scan ( Area division +

Suppress Background )

No No

Selection of Image Quality N/A

Halftone (B&W

only) ON/OFF

Mode Format /

Compression

method

Support

Scanner

File format (Mono 2

gradation)

TIFF

Yes

(1 page to 1 file,

All pages to 1 file)

PDF

Yes

(All page to 1 file)

PDF/A No

Encrypted PDF No

File format ( Color /

Gray scale )

Color TIFF

Yes

(1 page to 1 file,

All pages to 1 file)

JPEG

Yes

(All page to 1 file)

PDF

Yes

(All page to 1 file)

PDF/A No

Encrypted PDF No

Compression method

( Mono 2 gradation )

Non-compression Yes

G3 ( 1dimentional ) =

MH ( Modified

Huffman )

Yes

G4 = MMR

(Modified MR)

Yes

Compression method

( Color / Gray scale )

JPEG ( High /

Middle / Low )

Yes

BK Letter

Emphasis

No

2-Color PDF No

Fax

File format

(Monochrome )

N/A No

Compression method

( Monochrome )

MH / MR / MMR /

JBIG

Yes

File per page ( Setting of the number of pages

available )

No

Mode Support

Scanner Fax

Direct input from 10

keypad , # key, * key

Yes Ye s

Speed Dial (quick

key)

No

Yes

300 addresses (000-

299)

Address Yes Yes

Search No Yes

Tab

Yes

USER / ABCD / EFGHI

/ JKLMN / OPQRST /

UVWXYZ)

No

One-touch key No No

Group dial Yes Yes

Redial No

Yes

Last destination only,

one-address only)

Selection from the

LDAP server

Yes No

USB memory Scan Yes No

Chain Dial No Yes (by the Pause key)

Page 13

MX-C250 SPECIFICATIONS 2 – 7

(3) Specification of Multiple Addresses

(4) Send function

(5) Special Functions of Send function

(6) Other Send Functions

(7) Receive function

(8) Print Functions for Received Data

(9) Inbound Routing of Received Data

Destination

Confirmation

No

Yes (Available when

broadcasting to

destinations including

Individuals.)

Program

Yes (Registered up to

2) Neo MFP has

Program1button and

Program 2 button.

Yes (Registered up to 9)

Mode Scanner Fax

Broadcast Transmission Yes Yes

Number of destinations of

broadcast transmission

Yes(20 addresses)

Yes(100 addresses)

Number of group dial

are up to 50

addresses

Sequential Broadcast

Transmission request

No Yes(100 addresses)

Deleting addresses from

groups

No No

CC/BCC No No

Mode Fax send

Memory transmission Yes

Speaker Yes

Quick online transmission Yes

Direct transmission

(Switching : Memory transmission

<-> Direct transmission)

Yes

Manual transmission setting Yes

Mode Scanner Fax

Job Build No No

Slow Scan Mode No No

Mixed Size Original No Yes Only Single feed.

Original Count (Available to both

DF/OC scanning)

No No

Edge Erase ( Edge/Edge+Center/

Center/Side)

No No

Book Divide No No

Card Shot No No

Time Specified send No Yes

Own Number Sending No Yes

Own Number

Sending

No No

Date Print No Yes

Own Name sending No Yes

Own Number sending N/A Yes

Printing Page

Number at Receiver

N/A Yes

Suppress Background Yes N/A

Blank Page Skip (Available to

both DF/OC scanning)

No N/A

Drop Out Color No N/A

Sharpness Yes N/A

Contrast No N/A

Stamp No N/A

Watermark No No

Filing No No

Quick File No No

Multi shot No No

Verification Stamp No No

Preview No No

Job divide by recognizing blank

pages

No No

Dual Page Scan send No No

Combined pages send No No

Divide send by size limit No No

Mode Support

Scanner Fax

Covers N/A No

Outbound message N/A No

Special Send (Polling / F-code) N/A

Refer to 4.9 Memory box/

Polling / F-code

Memory box N/A

Refer to 4.9 Memory box/

Polling / F-code

Mode Scanner Fax

Auto Reduction Sending Setting No No

Rotation Sending No No

Zoom sending No No

Recall Mode No Yes

Error No Yes

Busy No Yes

Change of the number of pages for each file No No

Restriction on transmission size No No

Reception Report No No

Transmission result notification No No

Deleting the sending history No No

Keeping address for a certain time after sending No No

Retry mode from the transmission error job list

display

No No

Mode Fax

Automatic reception Yes

Manual reception Yes

Switching from manual reception

to auto receptio

Yes

Mode Fax

Auto Receive Reduce Setting Yes

Fixed size reception No

Specified size scaled reception No

Rotated reception No

Setting of received data print condition (Setting of Print

Actual Size or Reduction Print)

Yes

2-sided copy reception Yes

Multi Shot (2in1) reception No

Auto Reduction Sending Setting when A3 size is

received (for only the places of destination of the fax with

the inch system)

No

Auto Reduction Sending Setting when letter size is

received (for only the places of destination of the fax with

the AB system)

Yes

Received data bypass output No

Index printing No

Body Text Print Select Setting No

Output tray setting No

Insert job separators No

Number of copies of received data No

Staple setting of received data No

Color print when empty black toner No

Foot Print No

Format PDF

Destination SMB

Auto create settings of PDF for PC Browsing to the HDD of

the MFP

No

PDF creation for PC Browsing when storing in the HDD No

File name setting when inbound routing (Attached TSI

information)

Yes

The sender name is added to the inbounding file name No

Information about the MFP that transfers the data is added

to the transferred data

No

Mode Scanner Fax

Page 14

MX-C250 SPECIFICATIONS 2 – 8

(10) Other Receive Functions

(11) Reccord Size

(12) Registration-related settings

(13) Sound settings

5. Report/list function

A. User Authority

B. Administrator Authority

C. Other List Print Functions

6. Power consumption

The full configuration can be operated with the rated power source.

Timetable No

Inbound routing by line type No

Alternative mode for destination error Yes

Easy switching destinations of inbound routing No

Forward Table 10 tables

Address (forward)

5

addresses

at one table

Mode Fax

Allowing specified address/domain reception No

Rejecting specified address / domain reception No

Allowing reception from specific numbers No

Rejecting reception from specific numbers Yes

Rejecting reception from fax numbers without a TSI value No

External phone connection remote Yes

Time Specified output Yes

Reception Check Interval Setting No

POP3 Communication Timeout Setting No

Data Forwarding in case of trouble of output Yes

Auto wake up print No

Data Forwarding in case of trouble of output Yes

Alternative reception Yes

NJR transmission after reception (Notifying PC of

reception)

No

Mode Fax

Max. recording width 216mm

Record size A4R . A8.5x11R . 5.5x8.5

Import/export of VCF format No

Import of CSV format No

My address book No

Cloning Address book No

Retrieve local address book Yes (Only Fax)

Fixed mode display No

Linkage with the PC-Fax address book Yes

Import/export of the address book

Yes (by the device cloning

function)

Readout / read-in of data registered in

other models

Yes (by the address book

conversion utility, )

Default color mode registration to

individual

No

Mode Fax

Memory box No

Number of item can be registered in the

memory box

No

Number of characters can be registered

in the memory box

No

Polling Send Yes

Fax Polling Security Yes

Passcode Number Setting Yes

Polling Reception

Yes

Broadcast Polling Reception

Yes

F-code No

Sub-address No

Pass code No

Polling Memory Send No

Polling Memory Reception No

Confidential Send No

Confidential Reception No

Relay Broadcast transmission request No

Relay Broadcast Send No

Format PDF

Mode Item Scanner Fax

Speaker Speaker Volume Setting No Yes

Calling Speaker Volume Setting No Yes

Ring tone Speaker Volume Setting No No

Line monitor Speaker Volume Setting No Yes

Reception Speaker Volume Setting No No

Receive Complete

Signal

Speaker Volume Setting No Yes

Tone Pattern No Yes

Transmission Complete

Sound Time Setting

No Yes

Send/Receive error

signal

Speaker Volume Setting No No

Tone Pattern No No

Transmission Complete

Sound Time Setting

No No

Communication Error

Signal

Speaker Volume Setting No Yes

Setting of Original

Scan Complete Signal

Speaker Volume Setting No Yes

Tone Speaker Volume Setting No Yes

Item Support

Printer SPDL Symbol Set List Yes

SPDL Internal Font List Yes

PS Font List Yes

NIC page Yes

Scanner Sending Address List Yes

Group List Yes

Program List Yes

Fax Sending Address List Yes

Group List Yes

Program List Yes

Transmission Reservation List Yes

Stored Original Check List Yes

Setting List Yes

Item Support

Web Setting List Yes

Fax Setting List Yes

Fax Activity Report Yes

Reject Fax Name List Yes

Inbound Routing List Yes

User List Yes

User Information Print Yes

Item Support

Duplex print Yes

Overseas 100V Overseas 200V

Max. Rated Power 1.1 kW 1.15 kW

Energy consumption efficiency No restriction No restriction

Preheat mode transition time 3min 3min

Recovery time from Pre-heat

mode

10sec 10sec

Sleep mode transition time 15min 15min

Recovery time from Sleep

mode

20sec 20sec

Page 15

MX-C250 SPECIFICATIONS 2 – 9

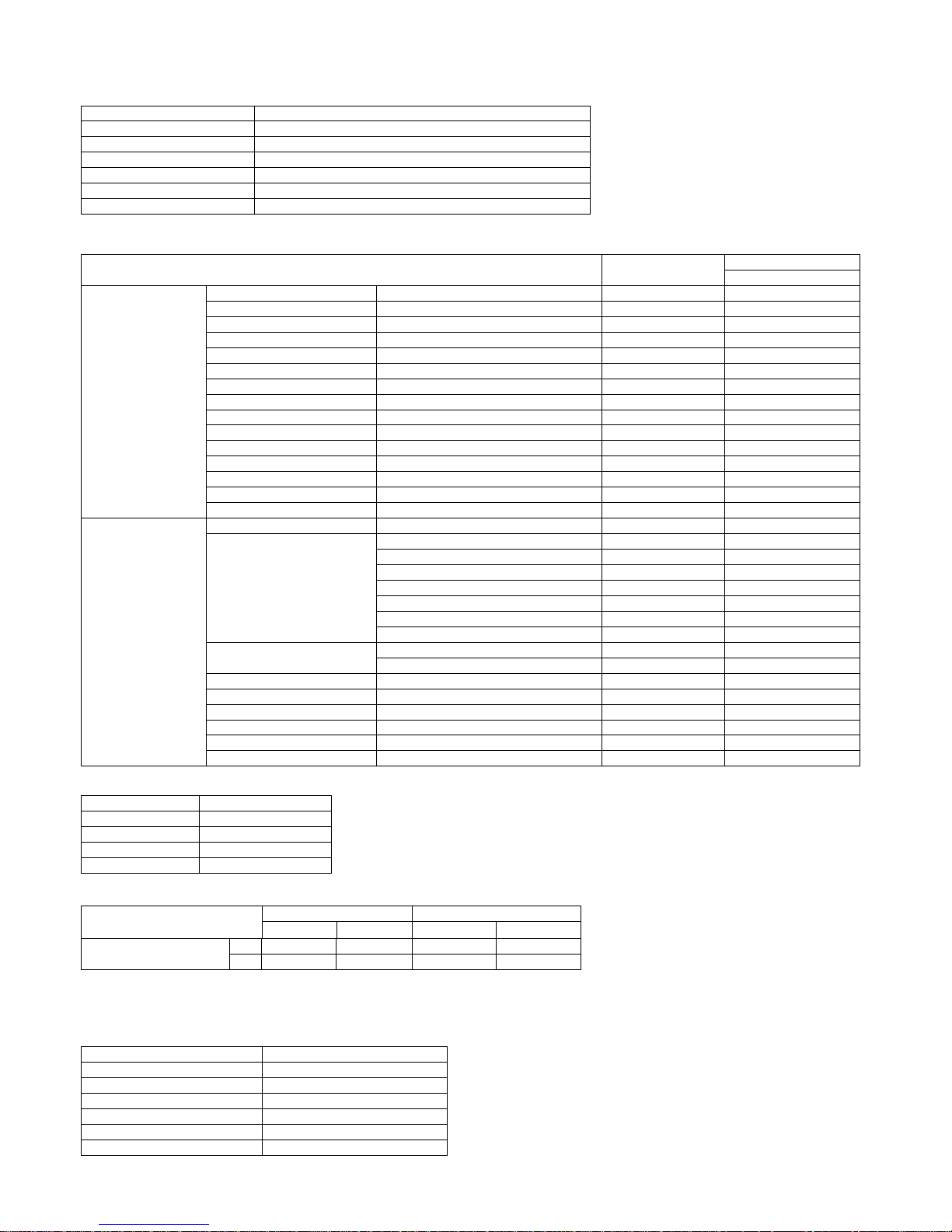

7. Dimensions and Weight

8. Ambient conditions

MX-C250 MX-C300

SPF Model RSPF Model

Outer dimensions (WxDxH)

428mmx509mmx3

98mm

428mmx509mmx

421mm

Full dimensions of the main unit 640mm 640mm

Weight Main unit

(developer and

toner cartridge

included)

MX-C250/

E:27.3kg

MX-C250F/

FE:27.5kg

MX-

C300E:28.1kg

MX-C300F/W/

WE:28.3kg

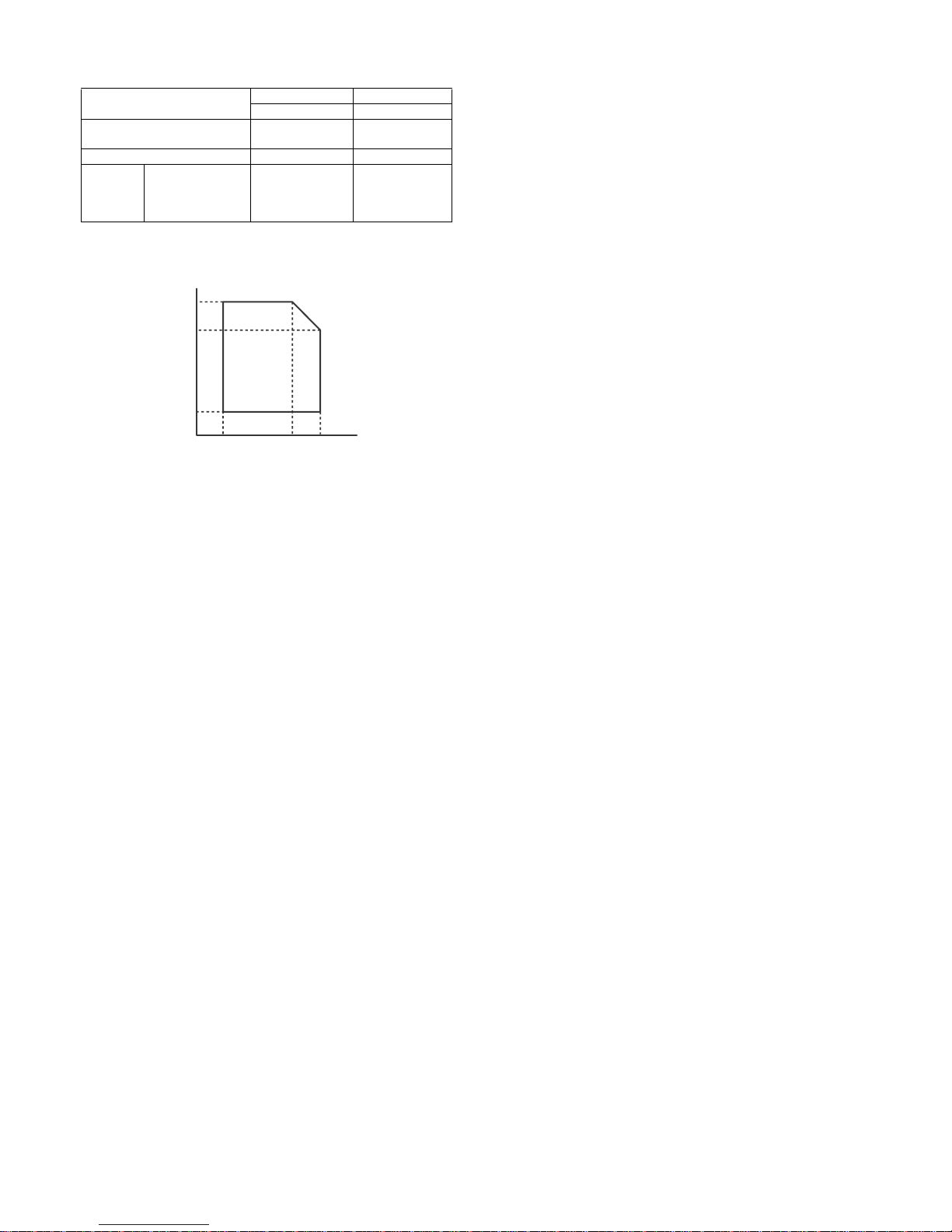

85%

60%

20%

10°C 30°C 35°C

Humidity (RH)

Temperature

Page 16

MX-C250 CONSUMABLE PARTS 3 – 1

MX-C250

Service Manual

[3] CONSUMABLE PARTS

1. Supply system table

A. North America, Middle America, South America

B. Europe, Eastern Europe

C. Australia, New Zealand, Korea

D. Middle East, Taiwan, Africa, Israel, Philippines

E.Asia, Hong Kong

F.China

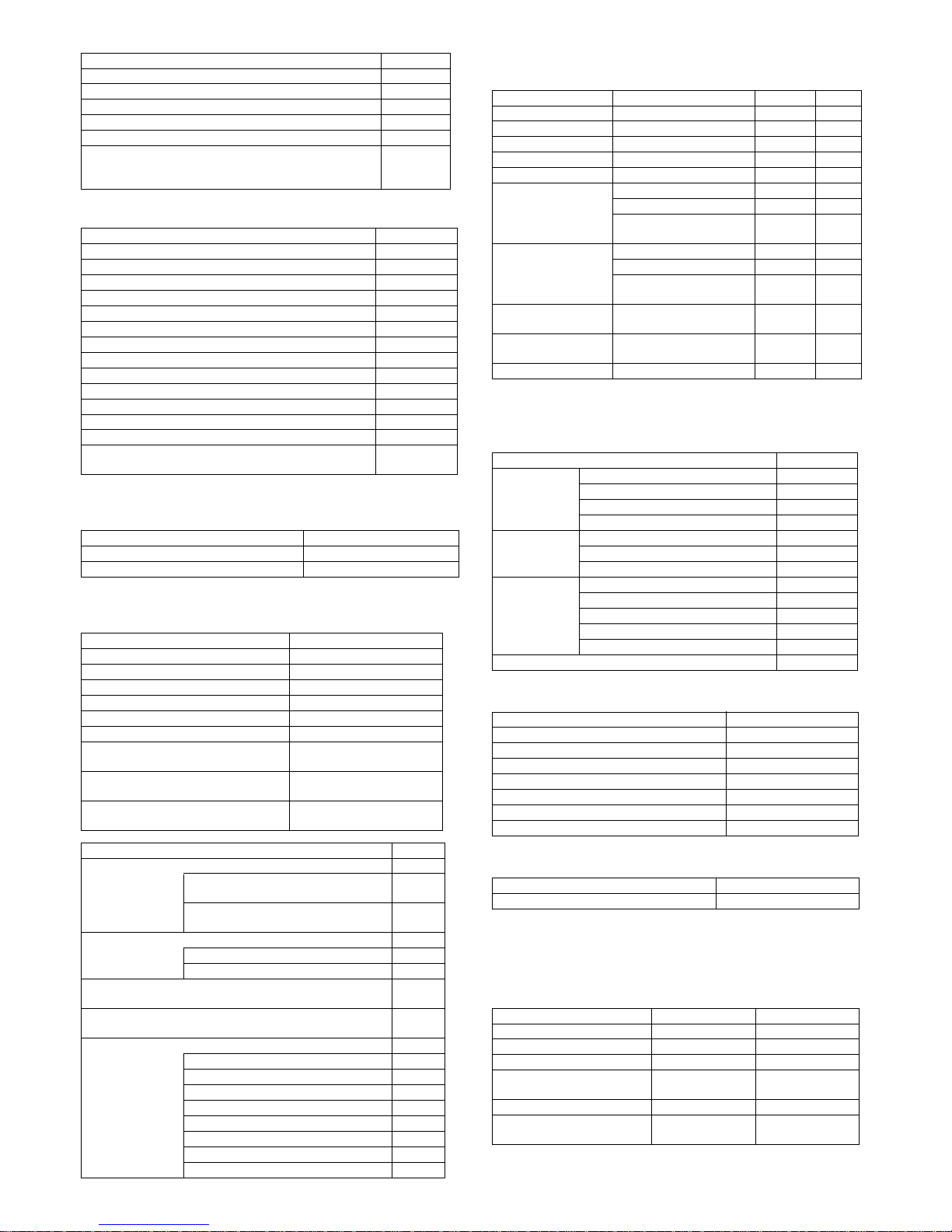

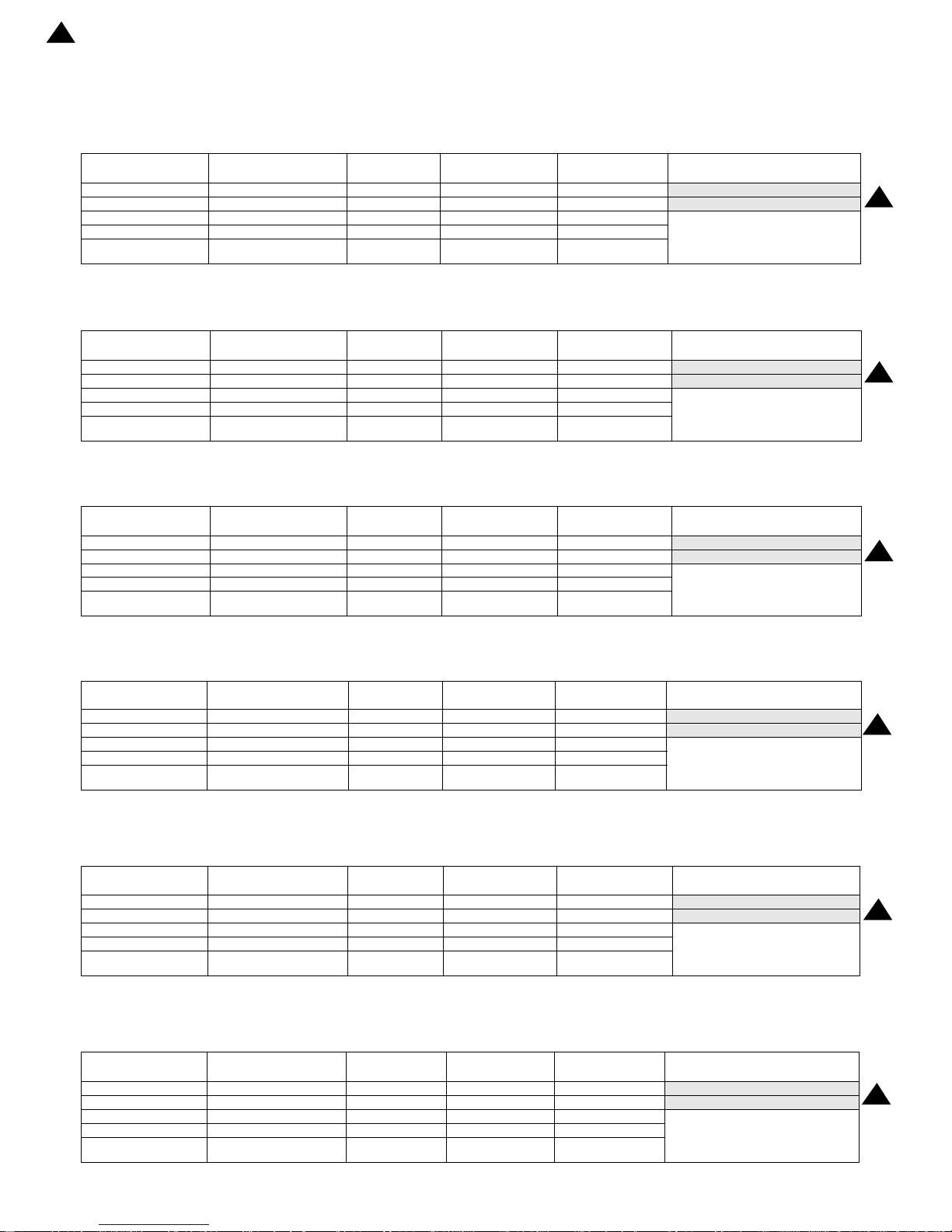

Item Content Life Model name Quantity in

collective package

Remarks

Toner Cartridge (Black) Toner Cartridge (Black) x1 6k MX-C30NT-B 10 Life: A4 5% document

Toner Cartridge (Color) Toner Cartridge (Color) x1 6k MX-C30NT-C/M/Y 10 Life: A4 5% document

Develop Cartridge (Black) Develop Cartridge (Black) x1 75K MX-C30NV-B 10

Develop Cartridge (Col or) Develop Cartridge (Co lor) x1 45K MX-C30NV-C/ M /Y 10

Drum Cartridge Drum Cartridge x1

BK : 75K

CL : 45K

MX-C30DR 10

Item Content Life Model name Quantity in

collective package

Remarks

Toner Cartridge (Black) Toner Cartridge (Black) x1 6k MX-C30GT-B 10 Life: A4 5% document

Toner Cartridge (Color) Toner Cartridge (Color) x1 6k MX-C30GT-C/M/Y 10 Life: A4 5% document

Develop Cartridge (Black) Develop Cartridge (Black) x1 75K MX-C30GV-B 10

Develop Cartridge (Col or) Develop Cartridge (Color) x1 45K MX-C30GV-C/M/Y 10

Drum Cartridge Drum Cartridge x1

BK : 75K

CL : 45K

MX-C30DR 10

Item Content Life Model name Quantity in

collective package

Remarks

Toner Cartridge (Black) Toner Cartridge (Black) x1 6k MX-C30GT-B 10 Life: A4 5% document

Toner Cartridge (Color) Toner Cartridge (Color) x1 6k MX-C30GT-C/M/Y 10 Life: A4 5% document

Develop Cartridge (Black) Develop Cartridge (Black) x1 75K MX-C30GV-B 10

Develop Cartridge (Col or) Develop Cartridge (Color) x1 45K MX-C30GV-C/M/Y 10

Drum Cartridge Drum Cartridge x1

BK : 75K

CL : 45K

MX-C30DR 10

Item Content Life Model name Quantity in

collective package

Remarks

Toner Cartridge (Black) Toner Cartridge (Black) x1 6k MX-C30FT-B 10 Life: A4 5% document

Toner Cartridge (Color) Toner Cartridge (Color) x1 6k MX-C30FT-C/M/Y 10 Life: A4 5% document

Develop Cartridge (Black) Develop Cartridge (Black) x1 75K MX-C30FV-B 10

Develop Cartridge (Color) Develop Cartridge (Color) x1 45K MX-C30FV-C/M/Y 10

Drum Cartridge Drum Cartridge x1

BK : 75K

CL : 45K

MX-C30DR 10

Item Content Life Model name Quantity in

collective package

Remarks

Toner Cartridge (Black) Toner Cartridge (Black) x1 6k MX-C30AT-B 10 Life: A4 5% document

Toner Cartridge (Color) Toner Cartridge (Color) x1 6k MX-C30AT-C/M/Y 10 Life: A4 5% document

Develop Cartridge (Black) Develop Cartridge (Black) x1 75K MX-C30AV-B 10

Develop Cartridge (Col or) Develop Cartridge (Color) x1 45K MX-C30AV-C/M/Y 10

Drum Cartridge Drum Cartridge x1

BK : 75K

CL : 45K

MX-C30DR 10

Item Content Life Model name Quantity in

collective package

Remarks

Toner Cartridge (Black) Toner Cartridge (Black) x1 6k MX-C30CT-B 10 Life: A4 5% document

Toner Cartridge (Color) Toner Cartridge (Color) x1 6k MX-C30CT-C/M/Y 10 Life: A4 5% document

Develop Cartridge (Black) Develop Cartridge (Black) x1 75K MX-C30CV-B 10

Develop Cartridge (Color) Develop Cartridge (Color) x1 45K MX-C30CV-C/M/Y 10

Drum Cartridge Drum Cartridge x1

BK : 75K

CL : 45K

MX-C30DR 10

2

‘13/Oct

2

2

2

2

2

2

Page 17

MX-C250 CONSUMABLE PARTS 3 – 2

2. Maintenance parts list

A. U.S.A/Canada/South and Central America

B. Europe/East Europe/Russia/Australia/New Zealand

C. Asia/Middle East/Africa

D. Hong Kong

*1: Life of each color A4 5% coverage30% color ratio conversion value

(The ratio is a rough reference since it differs depending on print contents, paper seizes, kinds of paper, use environment, the number of

continuous prints.)

3. Definition of developer/drum life end

When the developer/drum counter reaches the specified count.

When the developer/drum rpm reaches the specified count.

When either of the above reach the specified count, it is judged as life end.

In an actual case, the ratio of monochrome output and color output may differ greatly.

When data of mixed documents (monochrome and color) are output, monochrome document data may be output in the color mode in order to

prevent against fall in the job efficiency. (ACS auto color selection).

In addition, when correction or warm-up operation is performed as well as output operation, the developer and the drum rotates.

Therefore, the developer/drum consuming level cannot be determined only by the copy/print quantity. When, therefore, the rpm reaches the

specified amount, it is judged as life end.

To check the developer/drum life, use SIM22-01.

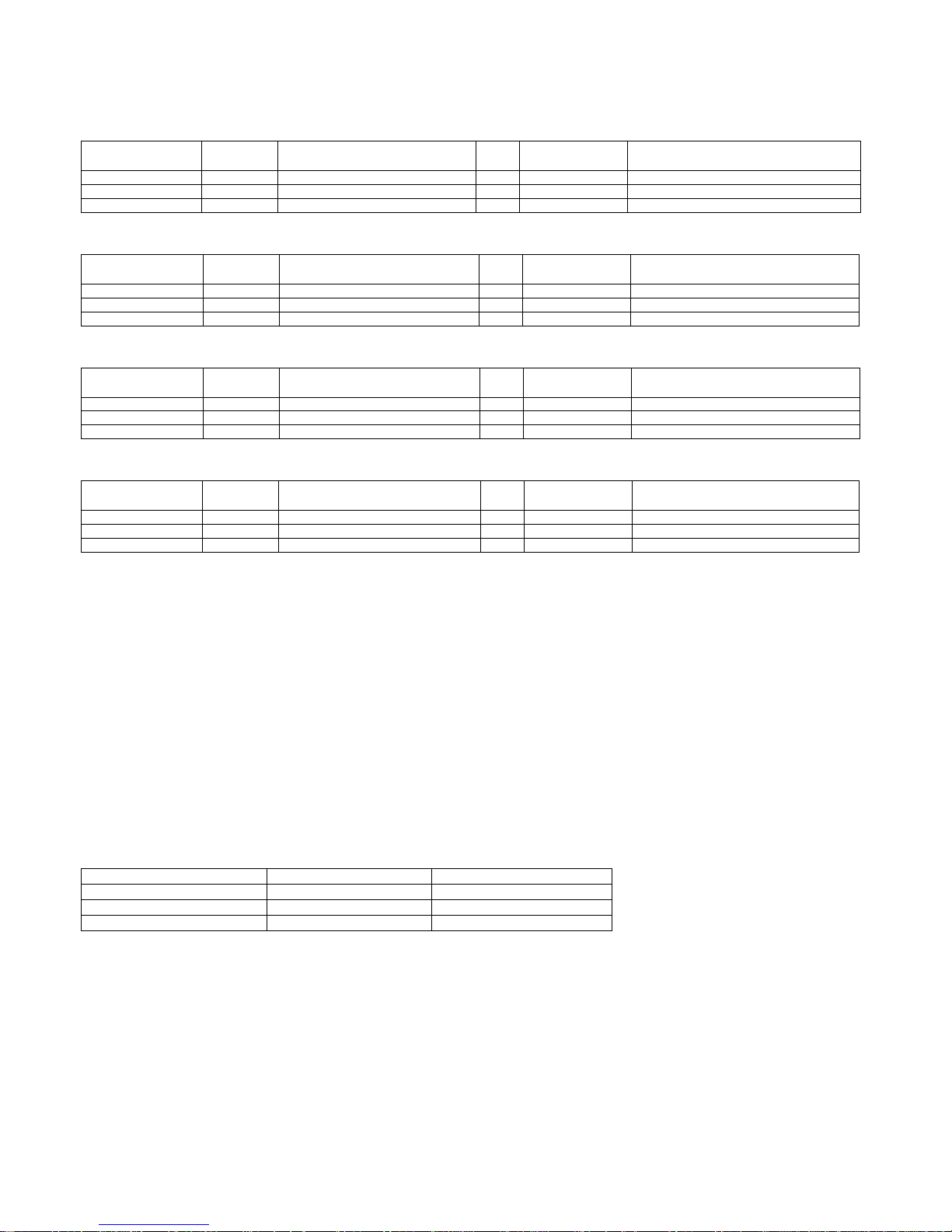

Item Model name Content Life Quantity in

collective package

Remarks

Fusing unit MX-C30FU Fusing unit (Heater lamp 120V) x 1 150K 4

Primary transfer unit MX-C30U1 Primary transfer unit x 1 150K 1

Toner collection container MX-C30HB Toner collection container unit x 1 8K *1 10 Each color A4 5% coverage30% color ratio

Item Model name Content Life Quantity in

collective package

Remarks

Fusing unit MX-C30FU Fusing unit (Heater lamp 230V) x 1 150K 4

Primary transfer unit MX-C30U1 Primary transfer unit x 1 150K 1

Toner collection container MX-C30HB Toner collection container unit x 1 8K *1 10 Each color A4 5% coverage30% color ratio

Item Model name Content Life Quantity in

collective package

Remarks

Fusing unit MX-C30FU Fusing unit (Heater lamp 230V) x 1 150K 4

Primary transfer unit MX-C30U1 Primary transfer unit x 1 150K 1

Toner collection container MX-C30HB Toner collection container unit x 1 8K *1 10 Each color A4 5% coverage30% color ratio

Item Model name Content Life Quantity in

collective package

Remarks

Fusing unit MX-C30FU Fusing unit (Heater lamp 230V) x 1 150K 4

Primary transfer unit MX-C30U1 Primary transfer unit x 1 150K 1

Toner collection container MX-C30HB Toner collection container unit x 1 8K *1 10 Each color A4 5% coverage30% color ratio

Oversea (Except China) China

Rotations 575k 575k

Total Prints (Std) - 75k(BK) / 45k(CL)

Total Prints (Max) 75k(BK) / 45k(CL) -

Page 18

MX-C250 CONSUMABLE PARTS 3 – 3

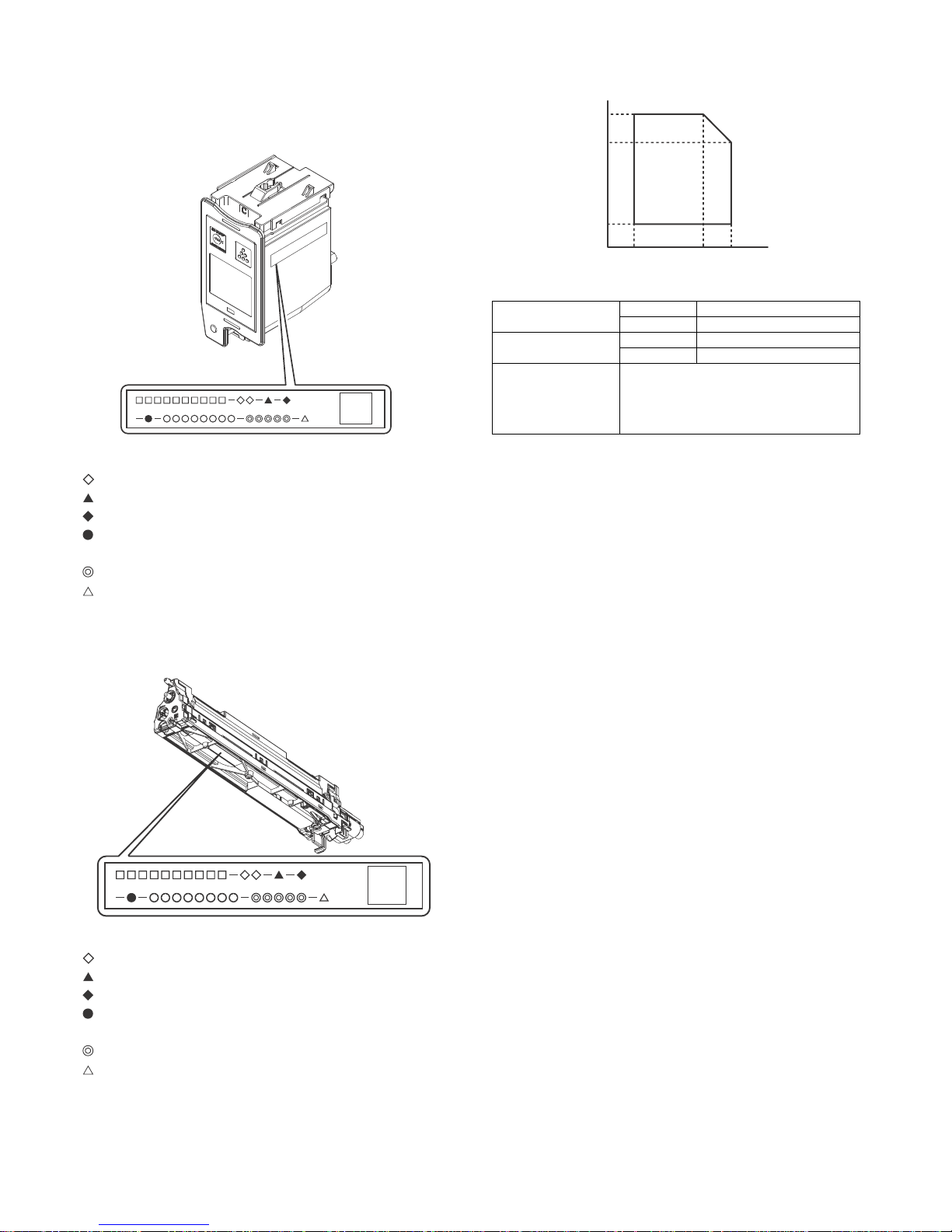

4. Production number identification

A. Toner cartridge

The label indicating the management number is attached to the

bottom of the toner cartridge.

: Unit code/Model name

: Color code (Black: BK /Cyan: CY /Magenta: MA /Yellow: YE)

: Destination

: Skating

: Production place

: Production date (YYYYMMDD)

: Serial number

: Version

B. Developing unit

: Unit code/Model name

: Color code (Black: BK /Cyan: CY /Magenta: MA /Yellow: YE)

: Destination

: Skating

: Production place

: Production date (YYYYMMDD)

: Serial number

: Version

5. Environmental conditions

* Unsealed state is the state that the drum is not exposed. (The

drum is covered by the black paper in packing state.)

Standard environmental

conditions

Temperature 20 - 25 degree C

Humidity 65 +/- 5 %RH

Usage environmental

conditions

Temperature 10 - 35 degree C

Humidity 20 - 85 %RH

Storage period Toner/Developer: 24 months from the

manufactured month (Production lot) under

unsealed state

Drum: 36 months from the manufactured month

under unsealed state

85%

60%

20%

10°C 30°C 35°C

Humidity (RH)

Temperature

Page 19

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 1

MX-C250

Service Manual

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

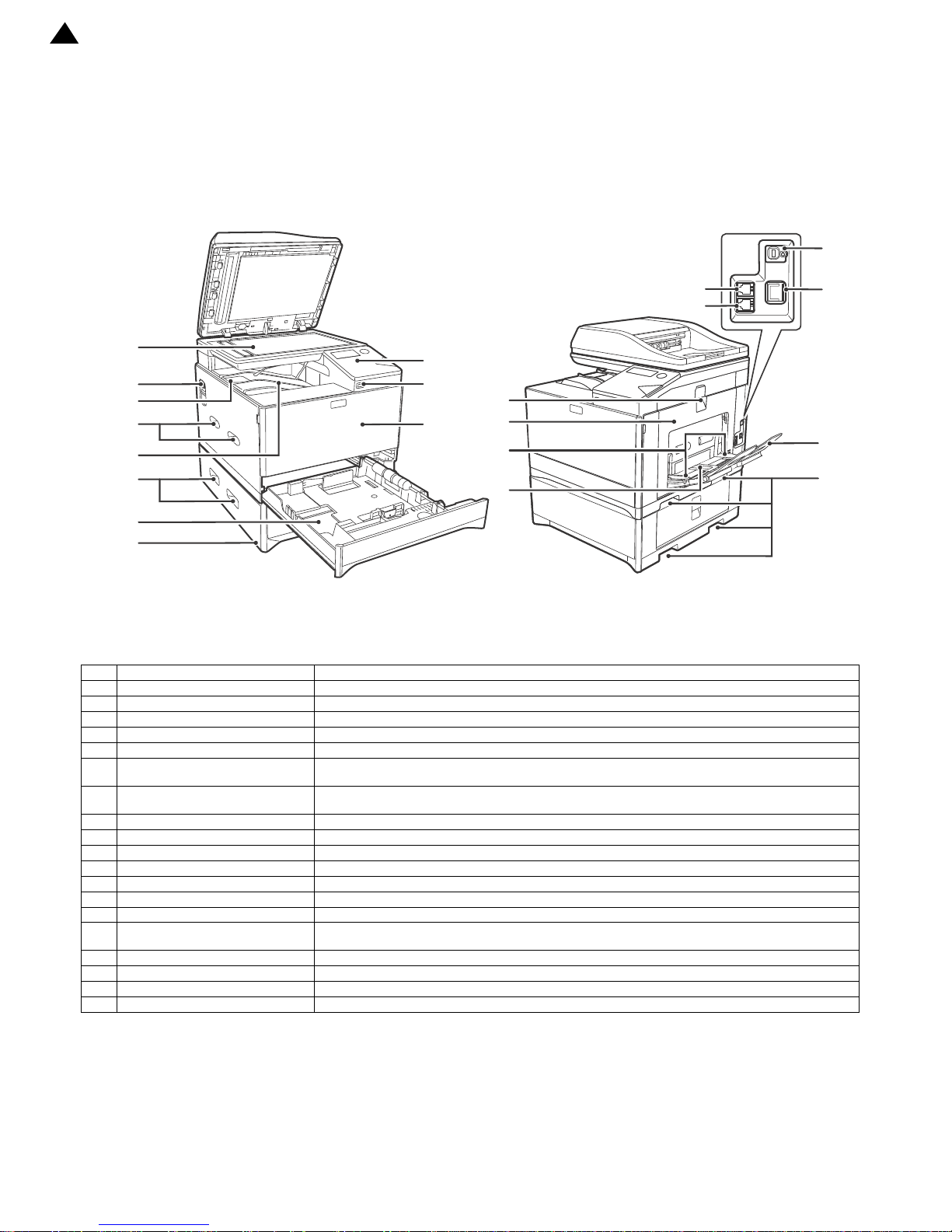

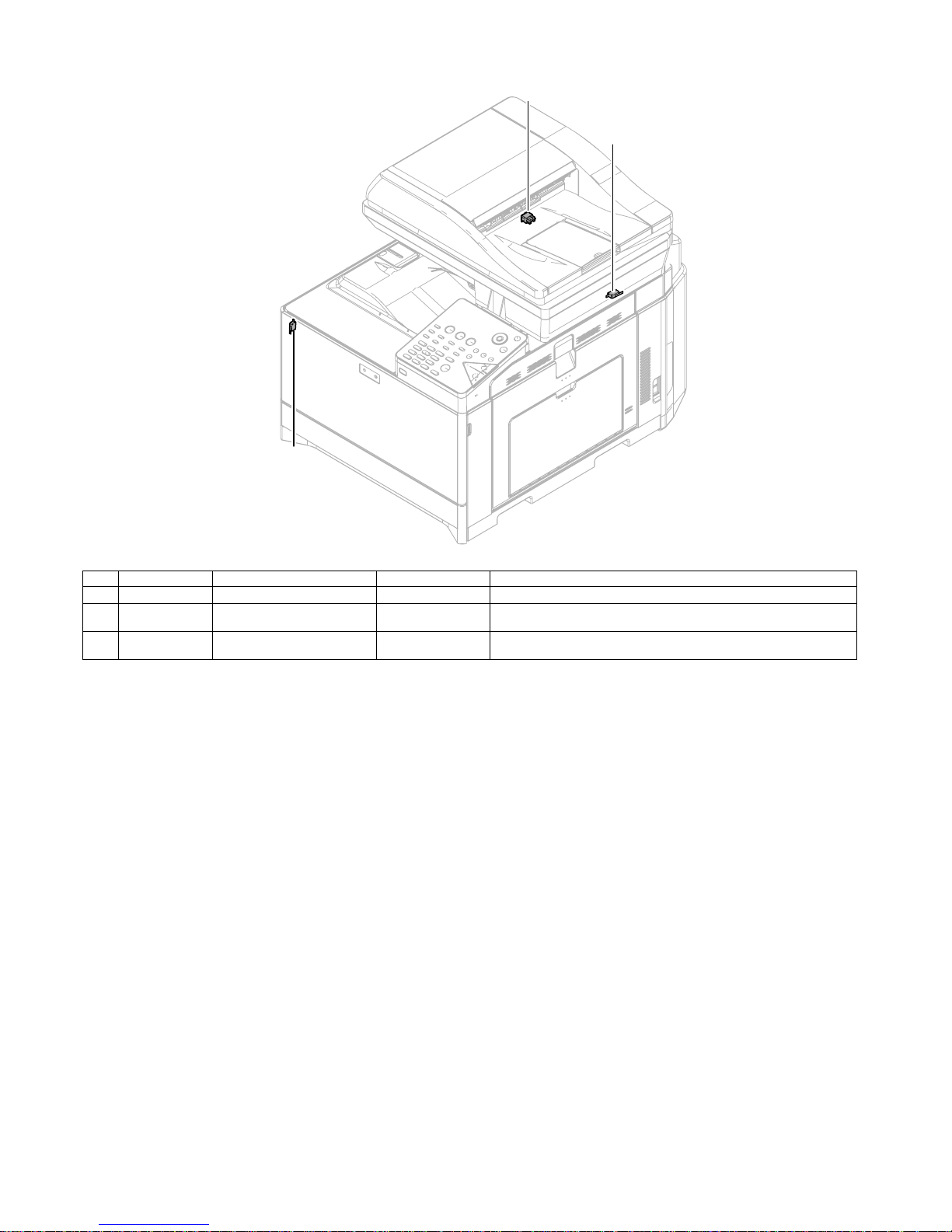

A.External view

No. Name function/Operation

1 Document glass Place an original that you wish to scan face down here.

2 Power switch Press to turn the machine power on and off.

3 Centre tray extensions Flip the extension to the left to eject paper of A4 size or greater.

4 Handles Used to lift and move the machine. When attaching tray 2, use the handle at the bottom.

5 Centre tray Copies and printed pages are output to this tray.

6 Tray 1 Tray 1 can hold approximately 250 sheets of copy paper (64 g/m2 (20 lbs.)). For restrictions on paper types,

sizes, and weights, refer to "PAPER" (p.16).

7 Tray 2 (Option) Tray 2 can hold approximately 550 sheets of copy paper (64 g/m2 (20 lbs.)). For restrictions on paper types,

sizes, and weights, refer to "PAPER" (p.16).

8 Operation panel Contains operation keys and indicator lights.

9 USB 2.0 port (Type A) This is used to connect a USB device such as USB memory to the machine.

10 Front cover Open to remove paper misfeeds or replace the toner cartridge etc.

11 Side cover handle Pull to open the right side cover.

12 Side cover Open to remove misfed paper.

13 Bypass tray guides Adjust to the width of the paper when using the bypass tray.

14 Bypass tray Special paper (heavy paper or transparency film)

15 Extension phone socket The line from an extension phone can be connected t o this socket to use the telephone

function.

16 Telephone line socket When the fax function of the machine is used, the telephone line is connected to this socket.

17 USB 2.0 port (Type B) Connect to your computer to this port to use the printer and scanner functions.

18 LAN connector Connect the LAN cable to this connector when the machine is used on a network.

19 Bypass tray extension Open this tray when loading paper in the bypass tray.

1

‘13/Aug

Page 20

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 2

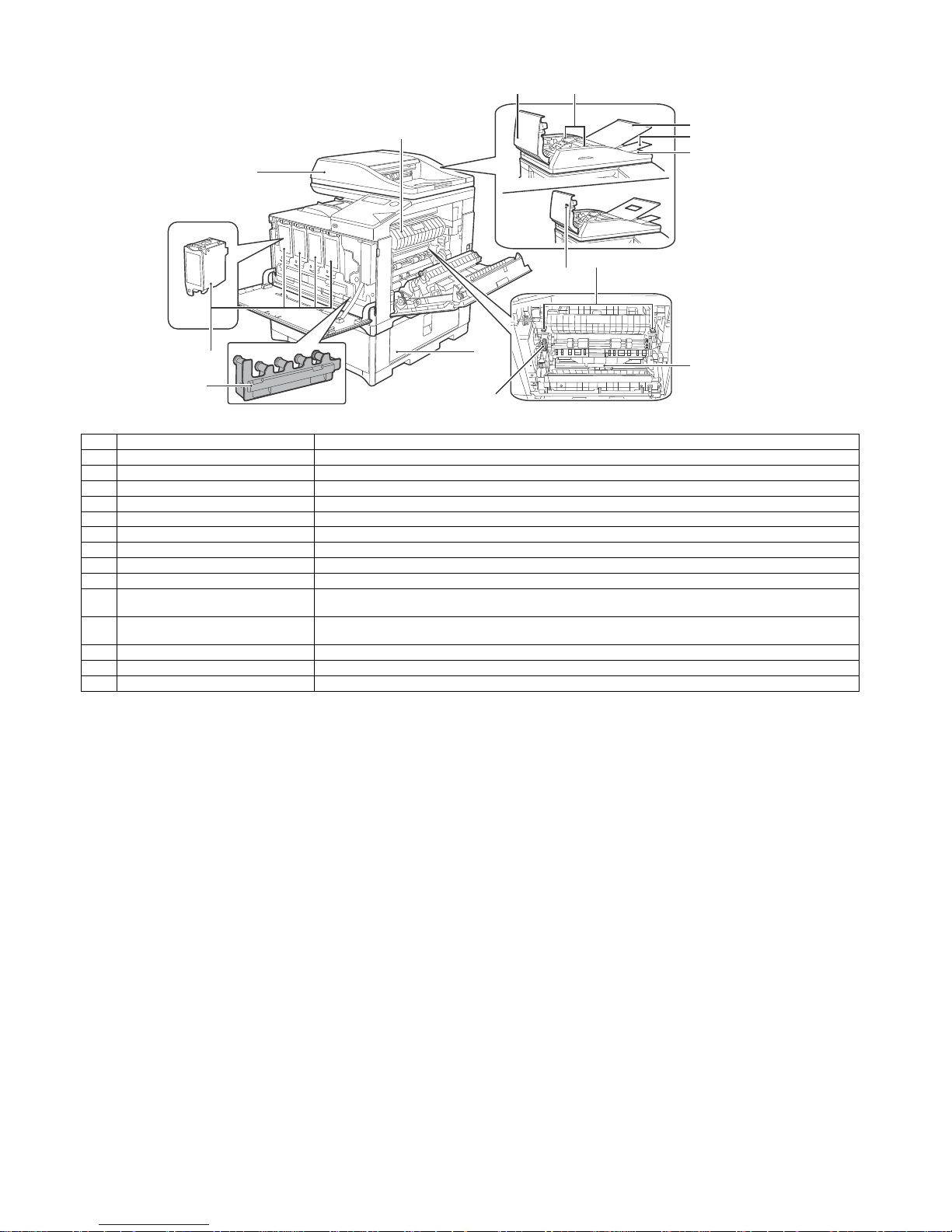

B.Document feeder and document glass

No. Name function/Operation

1 Toner cartridge (Y/M/C/Bk) Contains toner. When the toner runs out in a cartridge, the cartridge of the colour that ran out must be replaced.

2 Document feeder Place the original(s) that you wish to scan face up here. Up to 50 sheets can be placed.

3 Toner collection container This collects excess toner that remains after printing.

4 Feeding roller cover Open to remove misfed originals.

5 Original guides Adjust to the size of the originals.

6 Original feed tray Place original documents for scanning on the original feed tray.

7 Tray extension Open this when you scan a long original.

8 Exit area Exit Tray which stacks original scanned documents.

9 Fusing unit paper guide Open to remove misfed paper.

10 Viewing hole Use the viewing hole (see the illustration at right) to check the position of the original. (Models with the one-

sided scanning function only)

11 Fusing unit release levers Push down these levers to release the pressure when removing misfed paper from inside the

fusing area or when feeding an envelope from the bypass tray.

12 Roller ro tating kn o b Rotate to remove misfed paper.

13 Paper tray right side cover Open this to remove a paper misfeed in trays.

14 Duplex conveyor cover Open this cover to remove a misfeed.

Page 21

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 3

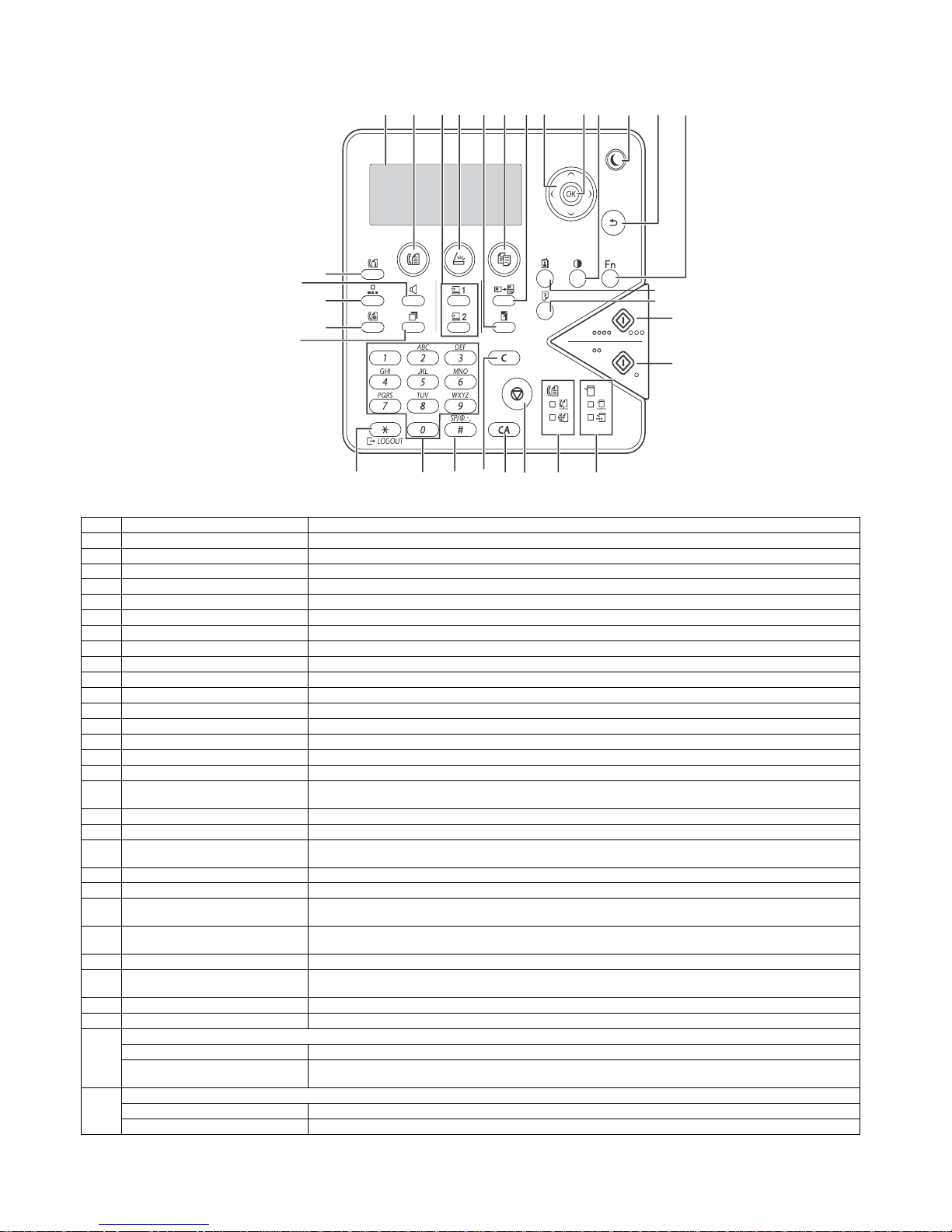

C.Operation panel (Europe, Asia)

No. Name Function/Operation

1 Display Shows various messages.

2 [FAX] key / indicator This key is used to select fax mode.

3 [PROGRAM 1 / PROGRAM 2] key Press to use the program settings of the default scanner.

4 [SCAN] key / indicator Press to select scan mode.

5 [ZOOM] key Press to select a reduction or enlargement copy ratio.

6 [COPY] key / indicator Press to select copy mode. The toner remaining amount is displayed by holding this key.

7 [ID CARD COPY] key Enable ID Card Copy.

8 Arrow keys Press to move the highlighting (which indicates that an item is selected) in the display.

9 [OK] key Press to enter the selected setting.

10 [EXPOSURE] key Use to select the exposure mode.

11 [ENERGY SAVE] key / indicator Press to enter the energy save mode.

12 [BACK] key Press to return the display to the previous screen.

13 [SPECIAL FUNCTION] key Press to select special functions.

14 [C] key Press to clear the set number of copies or stop a copy run.

15 [DUPLEX] key Select the duplex copying and the duplex scanning mode.

16 [ADDRESS] key Used to search for address, numbers and other contact information stored for auto dialling.

17 [COMM. SETTING] key This is used to switch between memory transmission and direct transmission, and to switch between automatic

reception and manual reception. It is also used to enter a space or "-" when entering ch aracters.

18 [SPEED] key This is used to dial by Speed dialling and to enter a symbol when entering characters.

19 [FAX STATUS] key This is used to cancel a fax transmission or a stored fax transmission.

20 [SPEAKER] key This is used to dial without lifting an extension phone connected to the machine and to shift between upper and

lower case when entering characters.

21 [REDIAL/PAUSE] key This is used to redial the last number dialled, and enter a pause when entering a fax number.

22 [COLOUR START] key / indicator Press this key to copy or scan an original in colour. This key cannot be used for fax or Internet fax.

23 [BLACK & WHITE START] key /

indicator

Press this key to copy or scan an original in black and white. This key is also used to send a fax in fax mode.

24 [LOGOUT] key Press this key to log out after yo u have l ogged in and used the machine. When using the fax function, this key

can also be pressed to send tone signals on a pulse dial line.

25 Numeric keys Enter characters/numbers.

26 [READ-END] key When copying in sort mode from the document glass, press this key when you have finish ed scanning the original

pages and are ready to start copying.

27 [CA] key Clears all selected settings and returns the machine to the default settings.

28 [STOP] key Press this key to stop a copy job or scanning of an original.

29 FAX mode indicators

LINE indicator Lights up when a fax is being sent or received.

DATA indicator Blinks when a fax cannot be printed because there is no paper or otherwise. Lights steadily when there is an

unsent fax.

30 Printer mode indicators

ONLINE indicator Print data cannot be received when this lamp is lit.

DATA indicator Blinks when print data is being received. Lights steadily during printing.

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13)

(17)

(18)

(19)

(20)

(21)

(22)

(23)

(14)

(15)

(16)

(28)

(27) (29) (30)(24) (25) (26)

Page 22

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 4

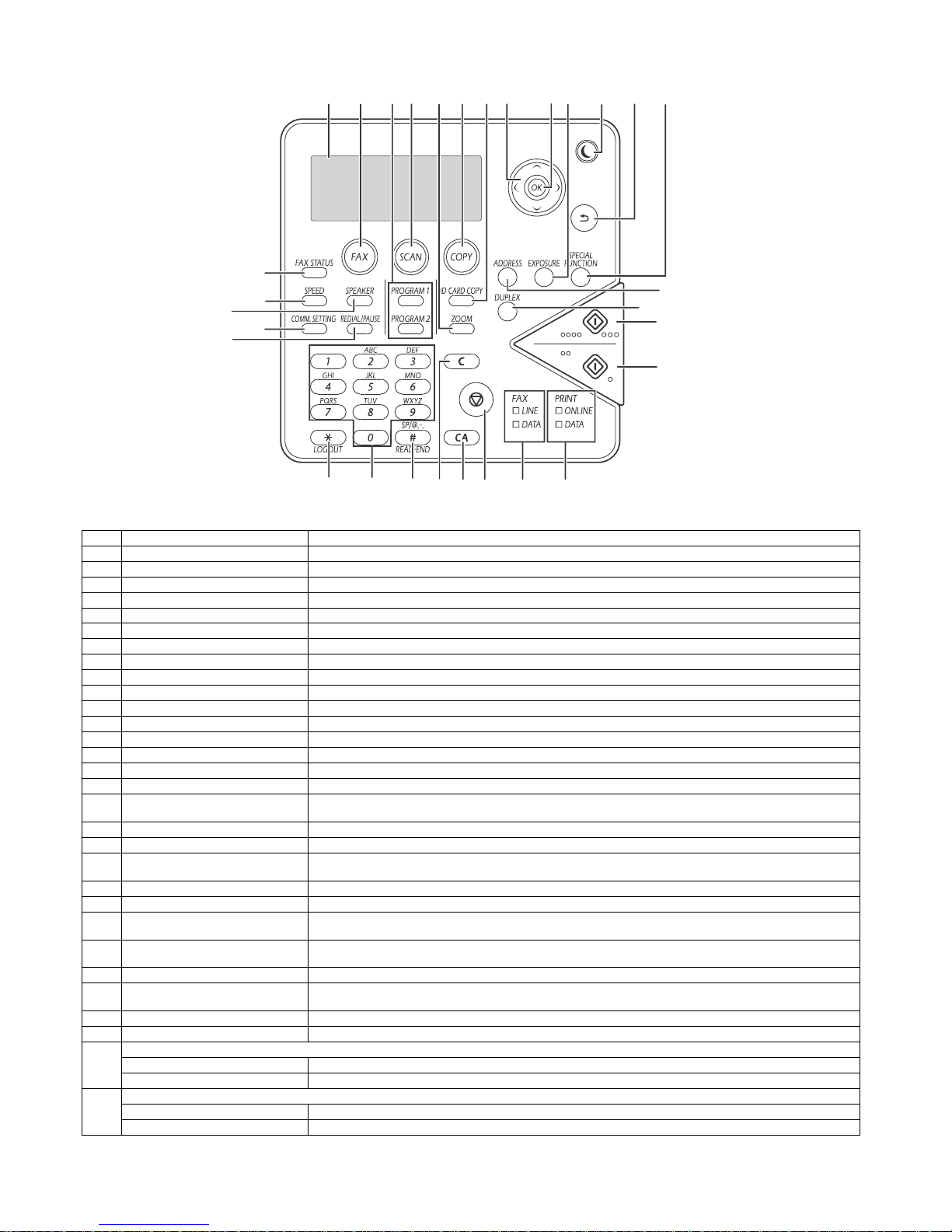

D.Operation panel (USA)

No. Name Function/Operation

1 Display Shows various messages.

2 [FAX] key / indicator This key is used to select fax mode.

3 [PROGRAM 1 / PROGRAM 2] key Press to use the program settings of the default scanner.

4 [SCAN] key / indicator Press to select scan mode.

5 [ZOOM] key Press to select a reduction or enlargement copy ratio.

6 [COPY] key / indicator Press to select copy mode. The toner remaining amount is displayed by holding this key.

7 [ID CARD COPY] key Enable ID Card Copy.

8 Arrow keys Press to move the highlighting (which indicates that an item is selected) in the display.

9 [OK] key Press to enter the selected setting.

10 [EXPOSURE] key Use to select the exposure mode.

11 [ENERGY SAVE] key / indicator Press to enter the energy save mode.

12 [BACK] key Press to return the display to the previous screen.

13 [SPECIAL FUNCTION] key Press to select special functions.

14 [C] key Press to clear the set number of copies or stop a copy run.

15 [DUPLEX] key Select the duplex copying and the duplex scanning mode.

16 [ADDRESS] key Used to search for address, numbers and other contact information stored for auto dialling.

17 [COMM. SETTING] key This is used to switch between memory transmission and direct transmission, and to switch between automatic

reception and manual reception. It is also used to enter a space or "-" when entering ch aracters.

18 [SPEED] key This is used to dial by Speed dialling and to enter a symbol when entering characters.

19 [FAX STATUS] key This is used to cancel a fax transmission or a stored fax transmission.

20 [SPEAKER] key This is used to dial without lifting an extension phone connected to the machine and to shift between upper and

lower case when entering characters.

21 [REDIAL/PAUSE] key This is used to redial the last number dialled, and enter a pause when entering a fax number.

22 [COLOUR START] key / indicator Press this key to copy or scan an original in colour. This key cannot be used for fax or Internet fax.

23 [BLACK & WHITE START] key /

indicator

Press this key to copy or scan an original in black and white. This key is also used to send a fax in fax mode.

24 [LOGOUT] key Press this key to log out after yo u have l ogged in and used the machine. When using the fax function, this key

can also be pressed to send tone signals on a pulse dial line.

25 Numeric keys Enter characters/numbers.

26 [READ-END] key When copying in sort mode from the document glass, press this key when you have finish ed scanning the original

pages and are ready to start copying.

27 [CA] key Clears all selected settings and returns the machine to the default settings.

28 [STOP] key Press this key to stop a copy job or scanning of an original.

29 FAX mode indicators

LINE indicator Lights up when a fax is being sent or received.

DATA indicator Blinks when a fax cannot be printed because there is no paper. Lights steadily when there is an unsent fax.

30 Printer mode indicators

ONLINE indicator Print data cannot be received when this lamp is lit.

DATA indicator Blinks when print data is being received. Lights steadily during printing.

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13)

(17)

(18)

(19)

(20)

(21)

(22)

(23)

(24) (25) (26)

(15)

(16)

(28)

(27) (29) (30)

(14)

Page 23

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 5

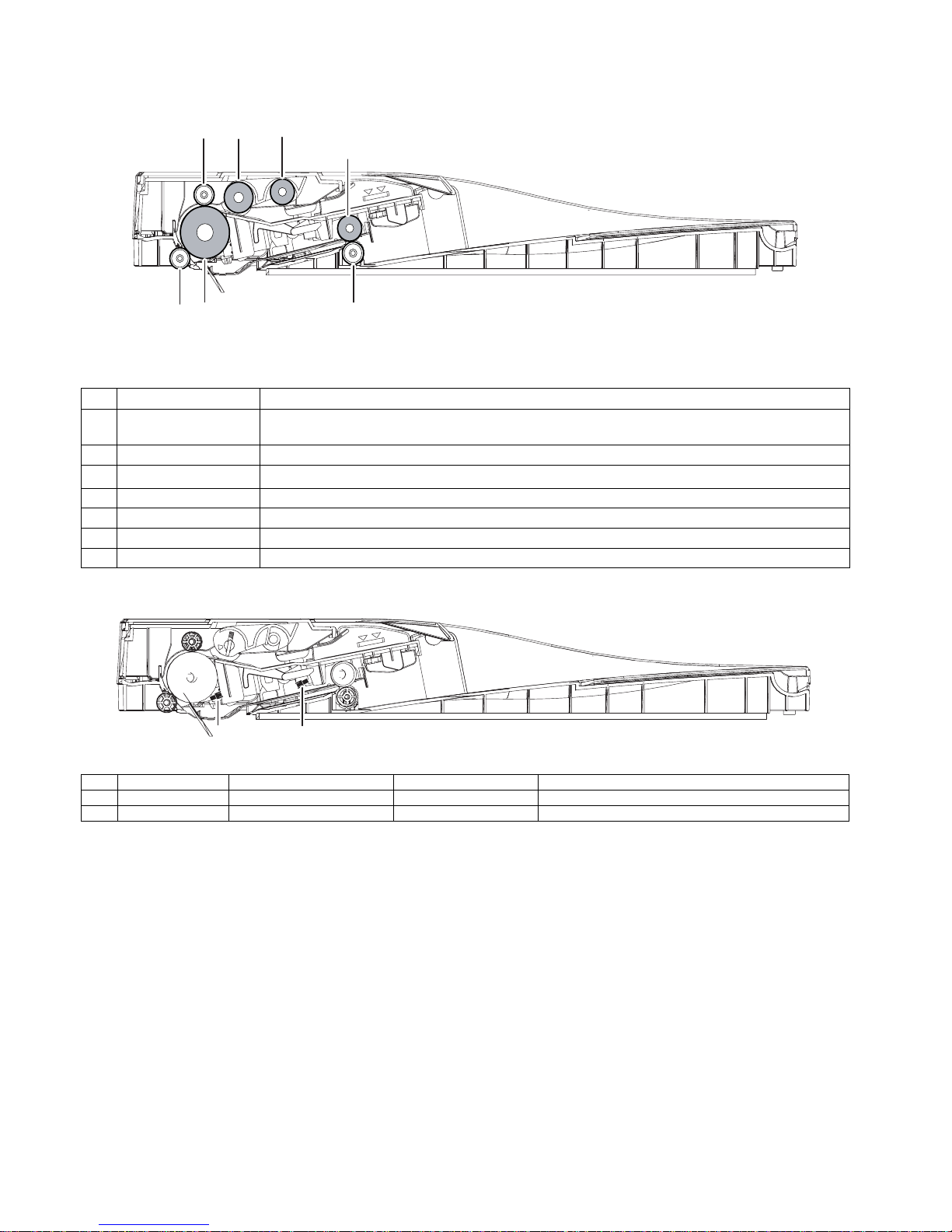

E.SPF

(1)Roller

(2)Detector

No. Name Function/ Operation

1 Paper exit pressure roller Applies pressure to a document and the paper exit drive roller to transport paper into the exit tray.

2 Paper exit roller Exit transport drive roller.

3 Transport pressure roller

Apply a pressure to paper and the transport roller to provide the transport power of the transport roller to

paper.

4 Transport pressure roller Applies pressure to document and drive roller to transport paper.

5 Transport drive roller Transports documents.

6 Pickup roller Picks up an original document and transports the lead edge to the Document Feed Roller.

7 Document Feed Roller Picks up a document and feeds it to the document feed roller.

No. Signal name Name Type Function/Operation

1 SPED Document sensor Light transmission Detects document empty

2 SPPD1 Paper transport detector 1 Light transmission Detects paper pass

1

2

3

4

5

6

7

1

2

Page 24

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 6

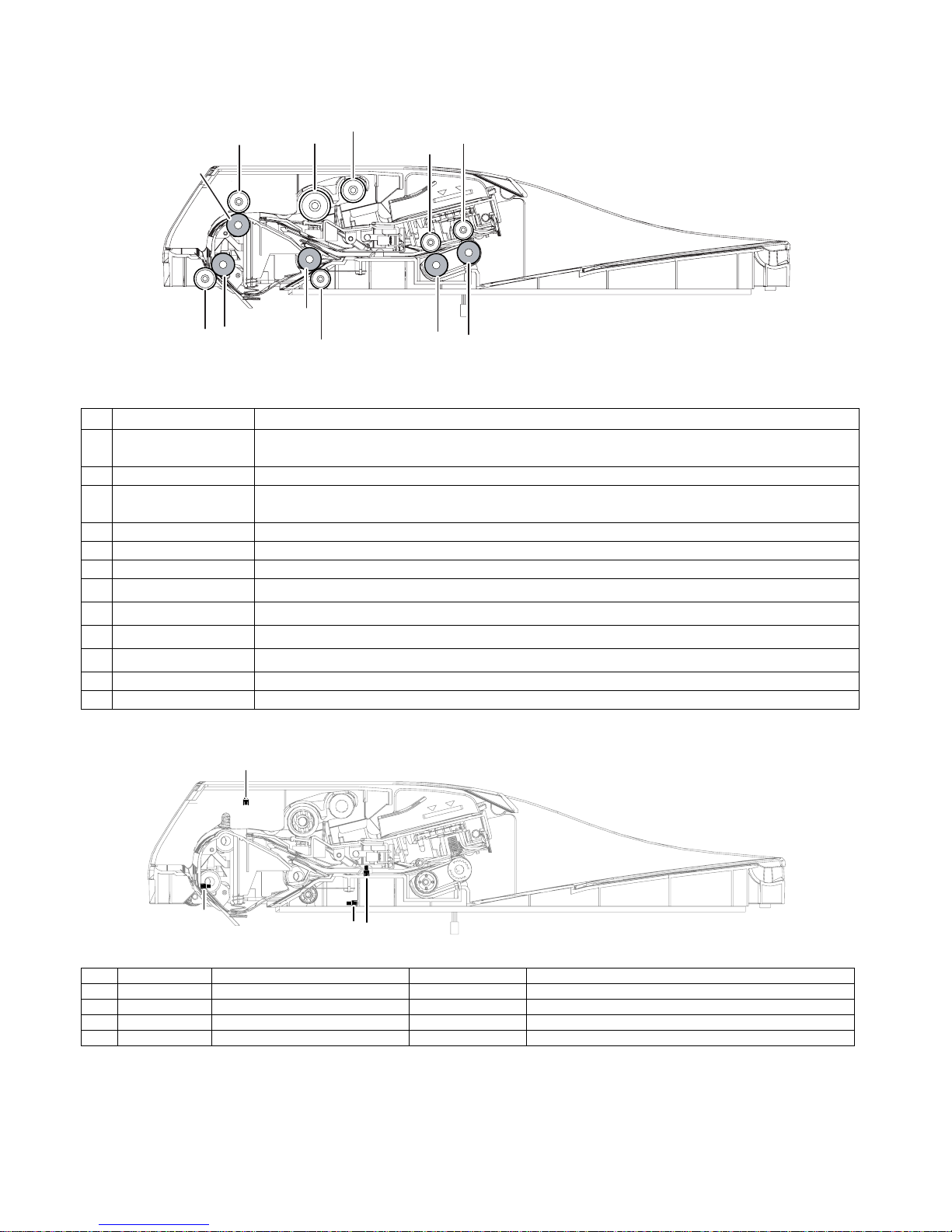

F.RSPF

(1)Roller

(2)Detector

No. Name Function/ Operation

1 Paper exit roller (Idle) Pressure (Idle) roller used in conjunction with the drive roller to move paper in the exit section.

2 Paper exit roller (Drive) Paper Exit Drive Roller used to transport paper into the exit tray or move paper in reverse for duplex scanning.

3 Paper exit roller (Idle) Pressure (Idle) roller used in conjunction with the drive roller to move paper in the exit section.

4 Paper exit roller (Drive) Paper Exit Drive Roller used to transport paper into the exit tray or move paper in reverse for duplex scanning.

5 Upper transport roller (Idle) Pressure Roller used to assist the Drive Roller to transport paper to the PS Roller set.

6 Upper transport roller (Drive) Drive transport Roller used to transport paper to the PS Roller set.

7 PS roller (Idle)

Registration pressure (Idle) roller used to assist PS Drive Roller to transport paper over scanner slit glass and move paper to

the Lower Transport roller set.

8 PS roller (Drive)

Registration Drive roller used to perform paper buckle t iming and transport paper over the scanner slit glass to t he Lower Tra nsport Roller set.

9 Lower transport roller (Idle)

Lower paper transport pressure (idle) roller used to assist in moving paper with the Drive Roller to the the exit section of the

RSPF.

10 Lower transport rol l er (Drive)

Lower Transport Drive Roller used to transport paper to the exit section or move paper to the upper transport rollers when performing a duplex scan.

11 Paper Pickup Roller Picks up the top sheet of paper from the original tray and transports it to the Paper Feed Roller.

12 Paper feed roller (RSPF) Feeds a document to the transport section.

No. Signal name Name Type Function/Operation

1 SCOV RSPF cover open/close detector Transmission type Detects open/close of the RSPF unit.

2 SPPD1 Document transport sensor 1 Transmission type Detects paper pass.

3 SPPD2 Document transport sensor 2 Transmission type Detects paper pass

4 SPED Document sensor Transmission type Detects document empty in the RSPF paper feed tray.

1

2

3

4

5

6

8

7

10

9

11

12

1

3

2

4

Page 25

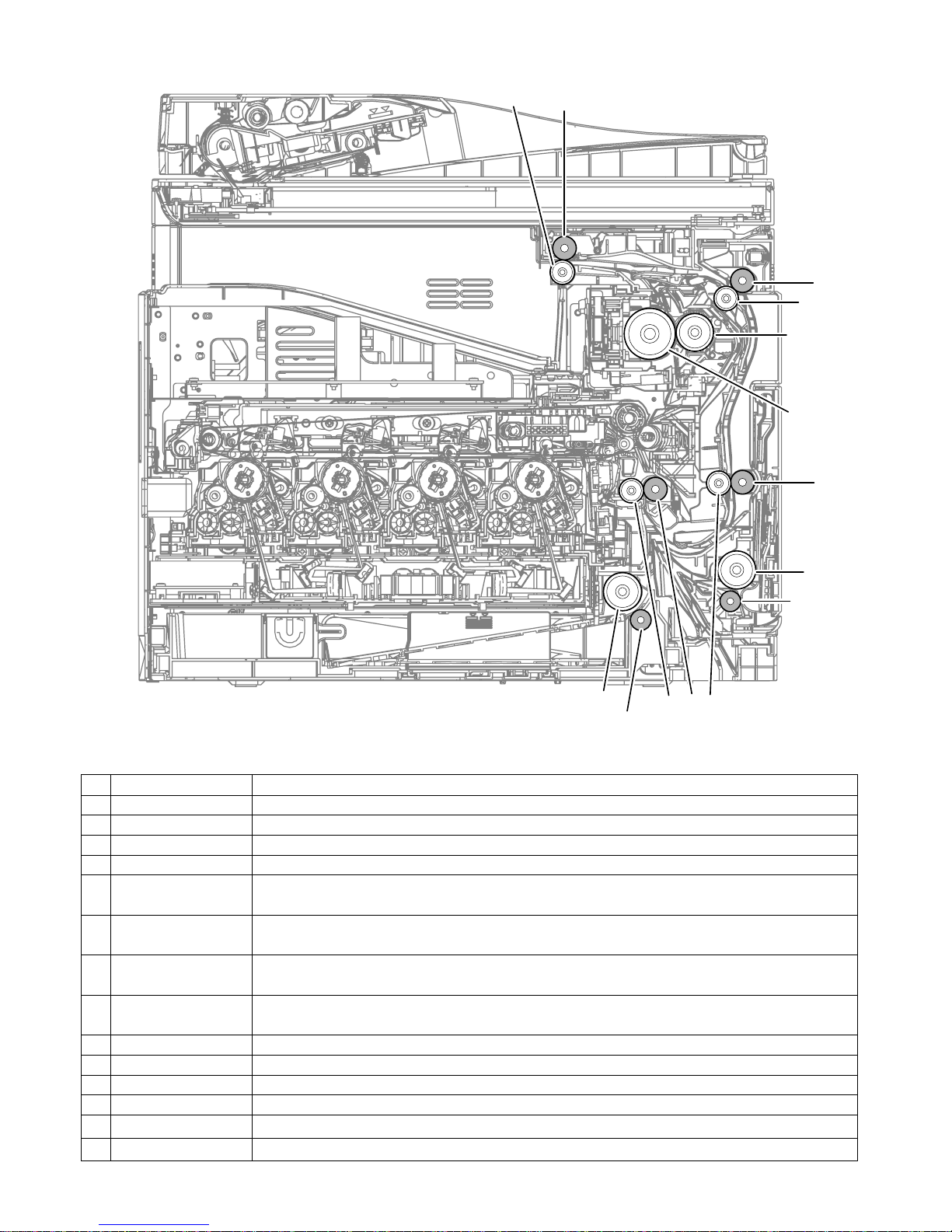

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 7

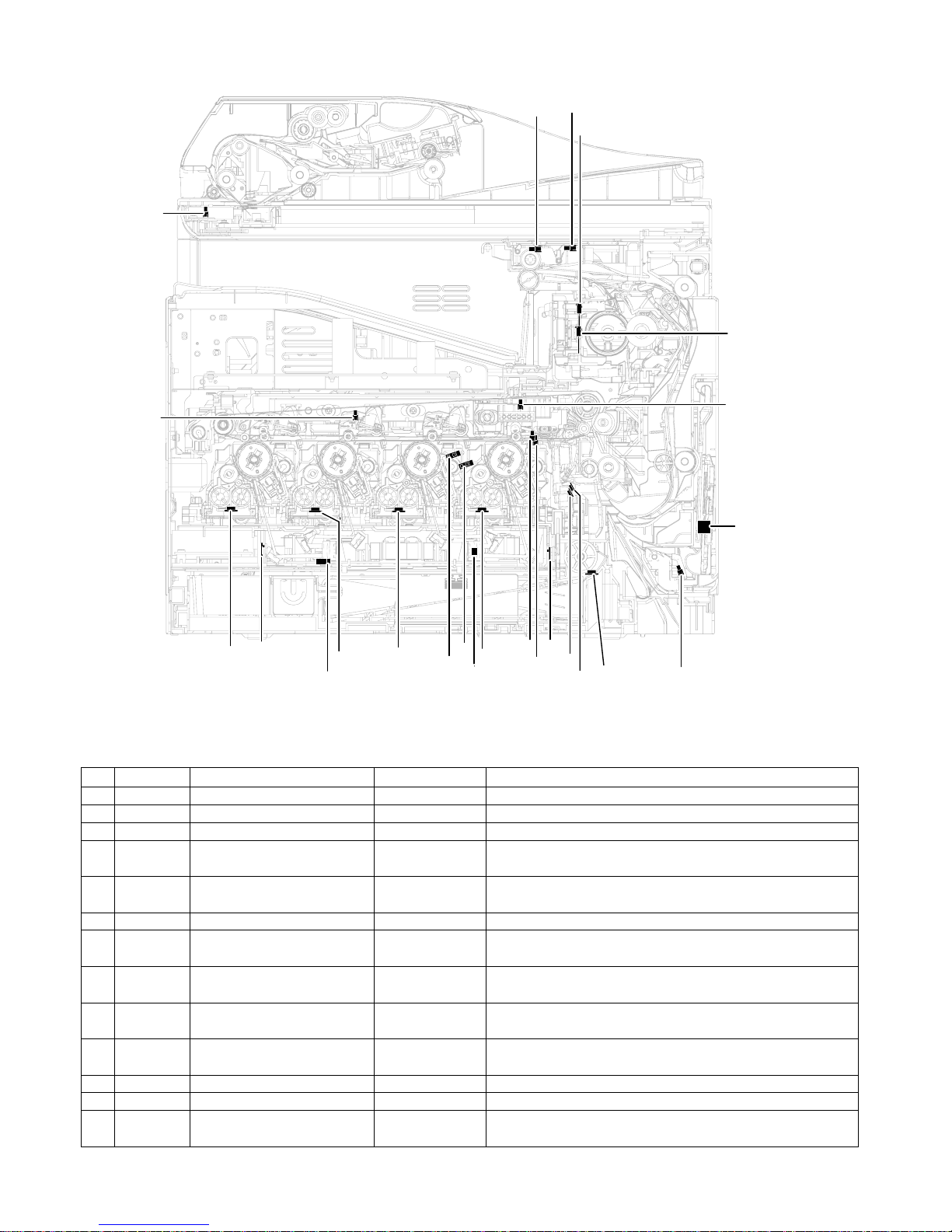

G.Sensor, Detector

No. Signal name Name Type Function/Operation

1 POD1 Fusing paper exit detector Light transmission Detects paper pass in the fusing section.

2 TFD2 Paper exit full detector Light transmission Detects paper full in the paper exit tray.

3 MHPS Scanner home position sensor Light transmission Detects the scanner home position.

4 HUD_M/TH_M Temperature/humidity sensor

Temperature/humidity

sensor

Detects the temperature and the humidity. (For the process control)

5 MPED

Paper empty detector

(Manual paper feed tray)

Light transmission Detects paper empty. (Manual paper feed tray)

6 PPD2 Document transport sensor 2 Light reflection Detects paper pass in front of the resist roller.

7 CPED1

Paper empty sensor

(Paper feed tray 1)

Light transmission Detects paper empty. (Paper feed tray 1)

8

REGS_F/

PCS_F

Registration sensor F

(Image density sensor)

Light reflection Detects color shift. (F side) / Detects the CMY toner patch density.

9REGS_R

Registration sensor R

(Image density sensor)

Light reflection Detects the K toner patch density. (R side)

10 TCS_K Toner sensor (K) Magnetic sensor

Detects toner supply from the toner cartridge.

Detects the toner density (K).

11 DHPD_K OPC drum rotation sensor (K) Light transmission Detects rotation and the phase of the OPC drum (K).

12 DHPD_CL OPC drum rotation sensor (CL) Light reflection Detects rotation and the phase of the OPC drum (CL).

13 TCS_C Toner sensor ( C ) Magnetic sensor

Detects toner supply from the toner cartridge.

Detects the toner density (C).

4

5

6

10

7

11

3

9

12

15

13

8

1

2

14

16

23

24

21

22

18

19

20

17

Page 26

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 8

14 TCS_M Toner sensor (M) Magnetic sensor

Detects toner supply from the toner cartridge.

Detects the toner density (M).

15 TNFD Waste toner full detector Light transmission Detects when waste toner container has become full.

16 TCS_Y Toner sensor (Y) Magnetic sensor

Detects toner supply from the toner cartridge.

Detects the toner density (Y).

17 BD_KC

Laser beam sensor (KC) (on BD

PWB(BC))

Photo diode Detects the timing of the laser beams.

18 BD_MY

Laser beam sensor (MY) (on BD

PWB(MY))

Photo diode Detects the timing of the laser beams.

19 TH_LSU LSU thermistor(on LD PWB) Thermistor Detects the temperature in the LSU. (Used for correction of distortion.)

20 TH_P Ozone duct thermistor Thermistor Detects the temperature in the Ozone duct.

21 1TUD_K Transfer belt separation detector BK Light transmission

Detects position of the transfer belt.

Detects initialization of the transfer unit.

22 1TUD_CL T ransfer belt separation detector CL Light transmission

Detects position of the transfer belt.

Detects initialization of the transfer unit.

23 TH_UM Fusing temperature sensor (Main) Non-contact thermistorDetects the surface temperature at the center section of the fusing roller.

24 TH_US Fusing temperature sensor (Sub) Thermistor Detects the surface temperature at the edge section of the fusing roller.

Page 27

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 9

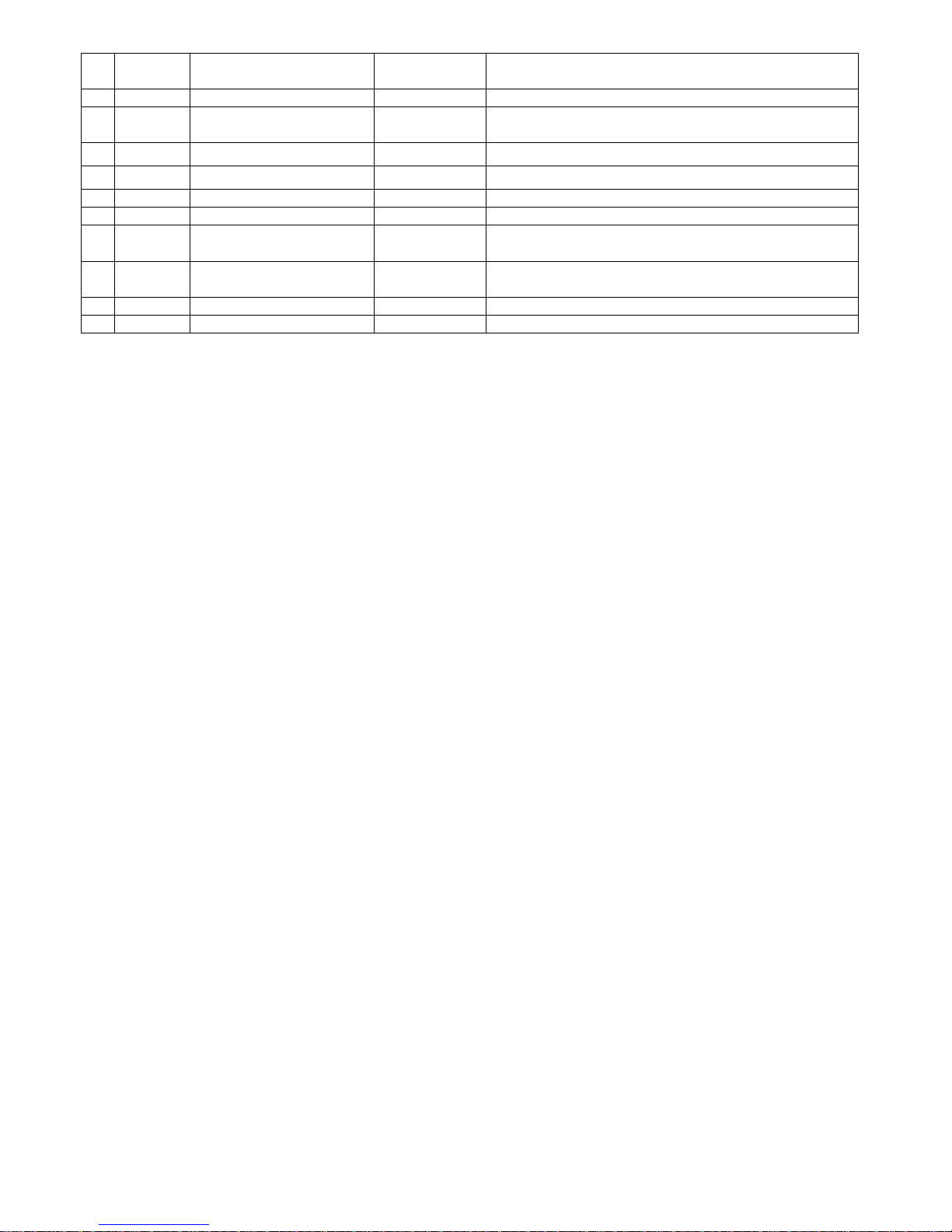

H.Switch

No. Signal name Name Function/Operation Note

1

MSW

Main power switch Seesaw switch Turns ON/OFF the main power.

2 DSW_R Right door open/close switch Micro switch

Detects open/close of the right door. Opens/closes the power lines of the

fusing section, the motors, and the LSU laser.

3 DSW_F Front door open/close switch Micro switch

Detects open/close of the front door. Opens/closes the power lines of the

fusing section, the motors, and the LSU laser.

1

2

3

Page 28

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 10

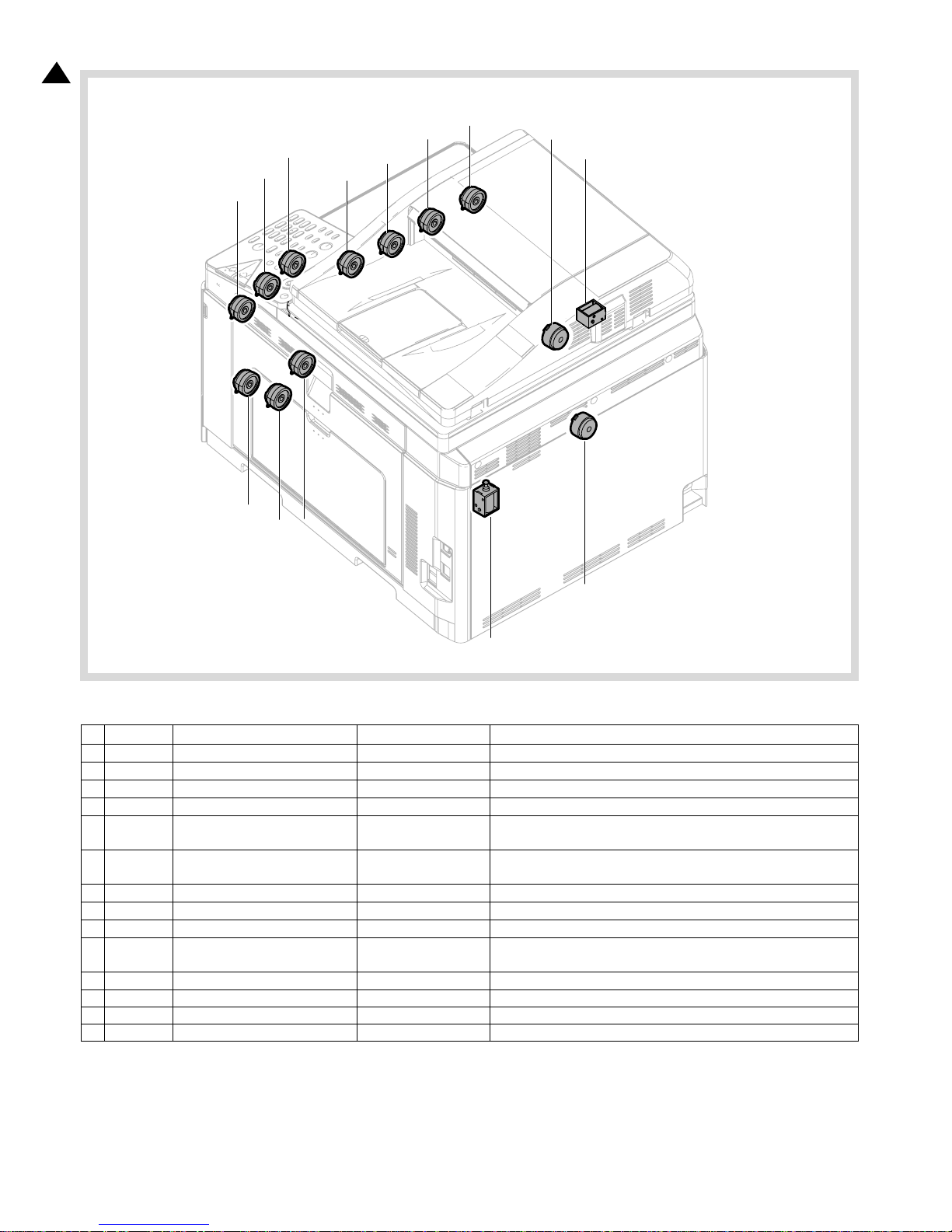

I.Clutches and solenoids

No. Signal name Name Function/Operation Note

1 TNC_Y Toner supply clutch (Y) Electromagnetic clutch Controls the supply of the Y toner cartridge.

2 TNC_M Toner supply clutch (M) Electromagnetic clutch Controls the supply of the M toner cartridge.

3 TNC_C Toner supply clutch (C) Electromagnetic clutch Controls the supply of the C toner cartridge.

4 TNC_K Toner supply clutch (BK) Electromagnetic clutch Controls the supply of the BK toner cartridge.

5 PORC Paper exit clutch Electromagnetic clutch

Controls the operation of the paper exit roller when the the paper exit roller rotates clockwise.

6 POC Paper exit clutch Electromagnetic clutch

Controls the operation of the paper exit roller when the the paper exit roller rotates counter clockwise.

7 ADUC ADU transport clutch Electromagnetic clutch Controls ON/OFF of the roller in the ADU section.

8 CPUC1 Paper feed clutch (Paper feed tray 1) Electromagnetic clutch Controls ON/OFF of the roller in the paper feed tray 1 section.

9 RRC PS clutch Electromagnetic clutch Controls the operation of the PS roller.

10 MFPC Manual paper feed clutch Electromagnetic clutch Controls the operation of the roller of the Manual paper feed clutch.

11 ITURC Primary transfer separation clutch 1 Electromagnetic clutch Controls the primary transfer separation mode.

12 PCSS Process control shutter solenoid Solenoid Controls Open/Close of the Process control shutter solenoid.

13 SRVC Paper exit clutch Electromagnetic clutch Controls Up/Down of the paper exit roller of RSPF.

14 SPUS Paper feed roller solenoid Solenoid Controls Up/Down of the paper feed roller of RSPF.

8

1

2

11

12

3

4

5

6

7

9

10

14

13

1

Page 29

MX-C250 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 11

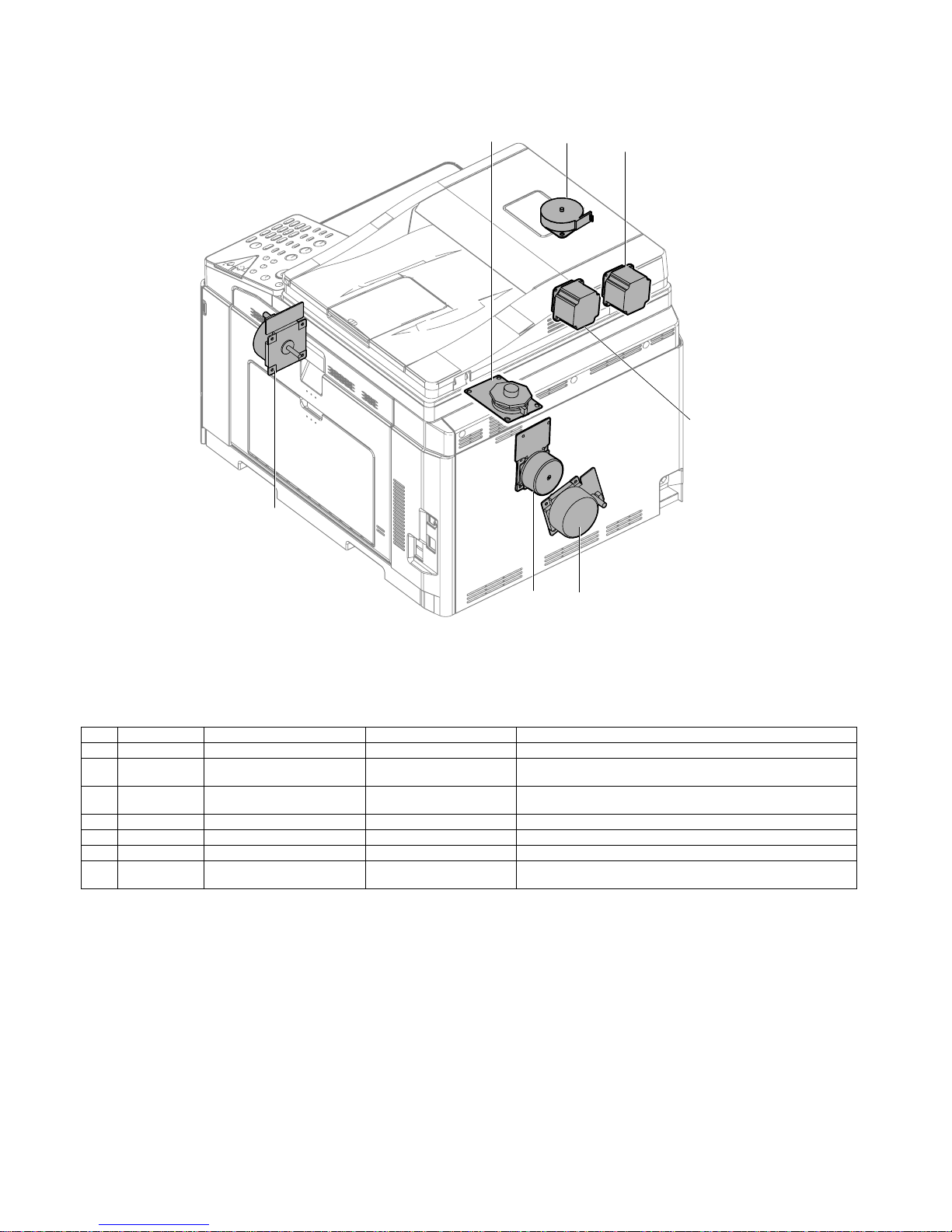

J.Motors

No. Signal name Name Type Function/Operation

1 DVM Developing drive motor DC brush-less motor Drives the developing/OPC drum section (CL).

2DM

Drum Motor, Transfer Belt

Motor, Black OPC Drum Motor