Page 1

TopPage

SAFETY PRECAUTION

IMPORTANT SERVICE PRECAUTION .............i

PRECAUTIONS FOR USING LEAD-FREE

SOLDER ...........................................................ii

OUTLINE-MAJOR SERVICE PARTS ..............iii

LCD KIT

1st Addition

SERVICE MANUAL

No. SZ4M67LC-60/70H20T

LED BACKLIGHT TV

MODEL:

LC-60H20T

LC-70H20T

CONTENTS

CHAPTER 8. DESCRIPTION OF SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIA-

GRAM ...........................................................8-1

[2] MAIN UNIT ...................................................8-2

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS ......................................... 1-1

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL .................................. 2-1

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS ............................................... 3-1

CHAPTER 4. REMOVING MAJOR PARTS

[1] REMOVING MAJOR PARTS ........................ 4-1

CHAPTER 5. ADJUSTMENT

[1] ADJUSTMENT .............................................. 5-1

[2] USB CLONE SPECIFICATIONS.................... 5-8

[3] PUBLIC MODE SETTING......................5-8

CHAPTER 6. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE ...................... 6-1

CHAPTER 7. SYSTEM BLOCK DIAGRAM /WIRING

DIAGRAM

[1] SYSTEM BLOCK DIAGRAM ........................ 7-1

[2] WIRING DIAGRAM LC-60H20T .................... 7-2

[3] WIRING DIARAM LC-70H20T ....................... 7-3

Parts Guide

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-60H20T/LC-70H20T

i

SAFETY PRECAUTION

IMPORTANT SERVICE PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

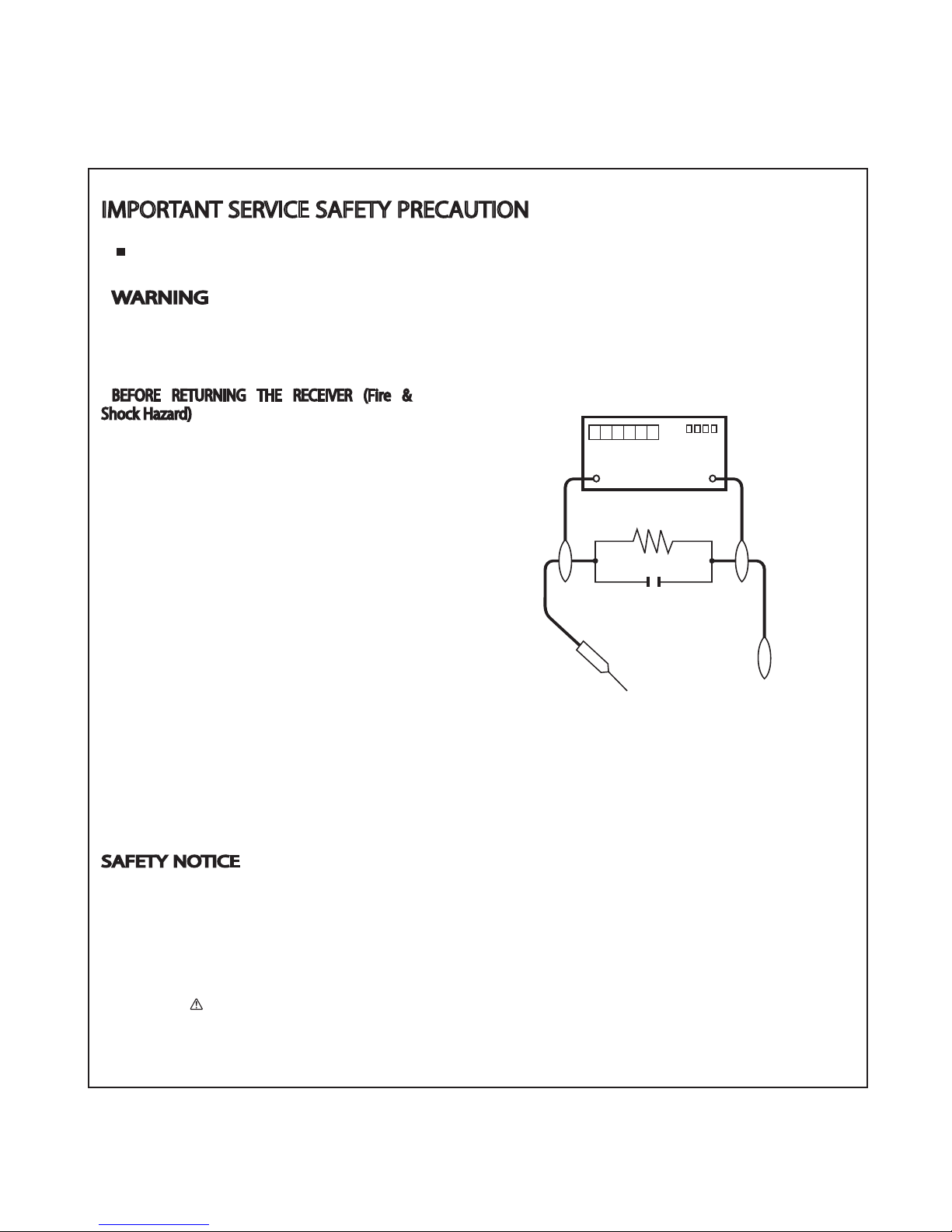

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE RECEIVER (Fire &

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 110-240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15 F capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

• Use an AC voltmeter having

with 5000 ohm per volt, or higher, sen-

sitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.74 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD colour television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

0.15µF

TEST PROBE

Page 3

LC-60H20T/LC-70H20T

ii

PRECAUTIONS FOR USING LEAD-FREE SOLDER

PRECAUTIONS FOR USING LEAD-FREE SOLDER

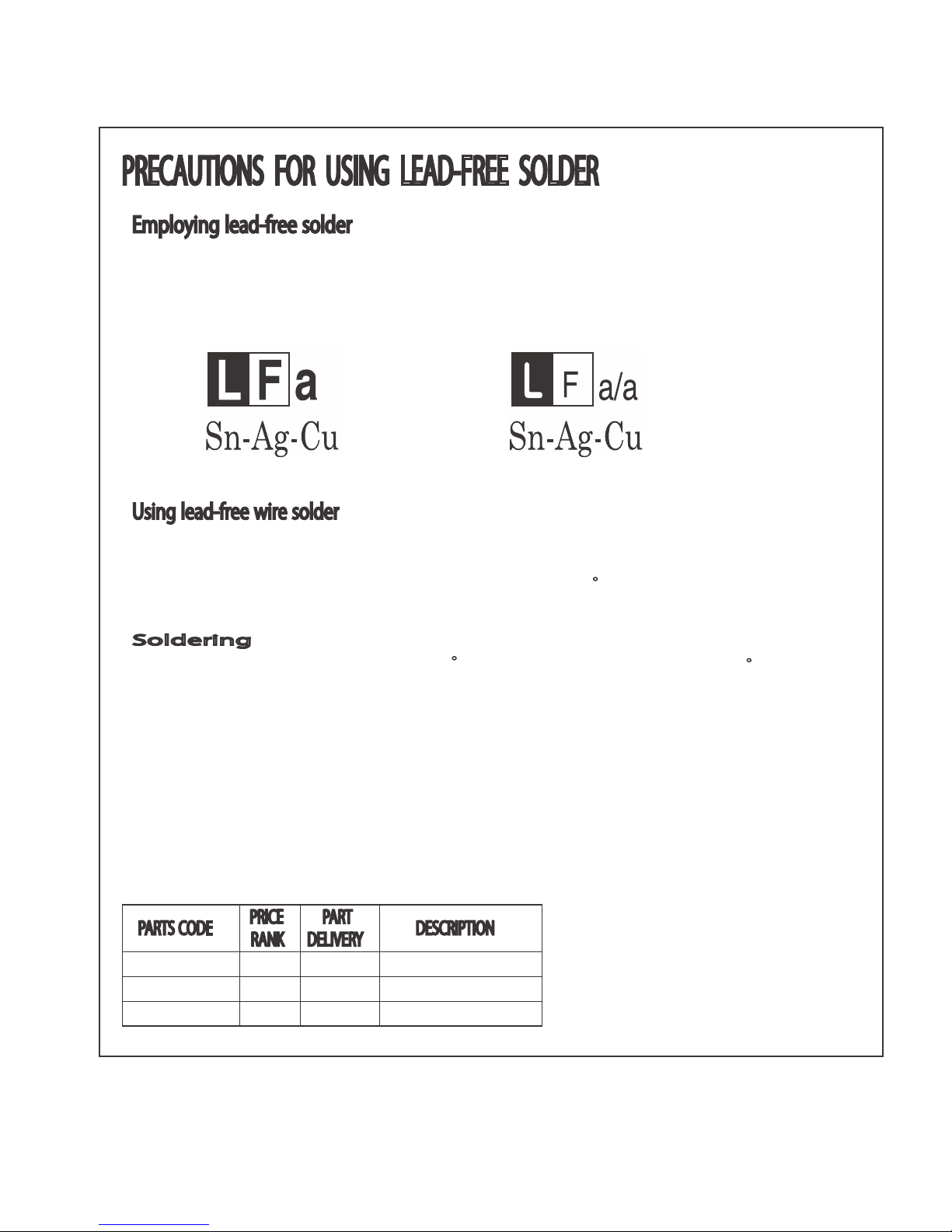

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type oflead-free solder.

Example:

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point oflead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point oflead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead solder by 40 C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use ofit.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

PARTS CODE

PRICE

RANK

PART

DELIVERY

DESCRIPTION

ZHNDAi123250E BL J 0.3mm 250g (1roll)

ZHNDAi126500E BK J 0.6mm 500g (1roll)

ZHNDAi12801KE BM J 1.0mm 1kg (1roll)

Page 4

LC-60H20T/LC-70H20T

iii

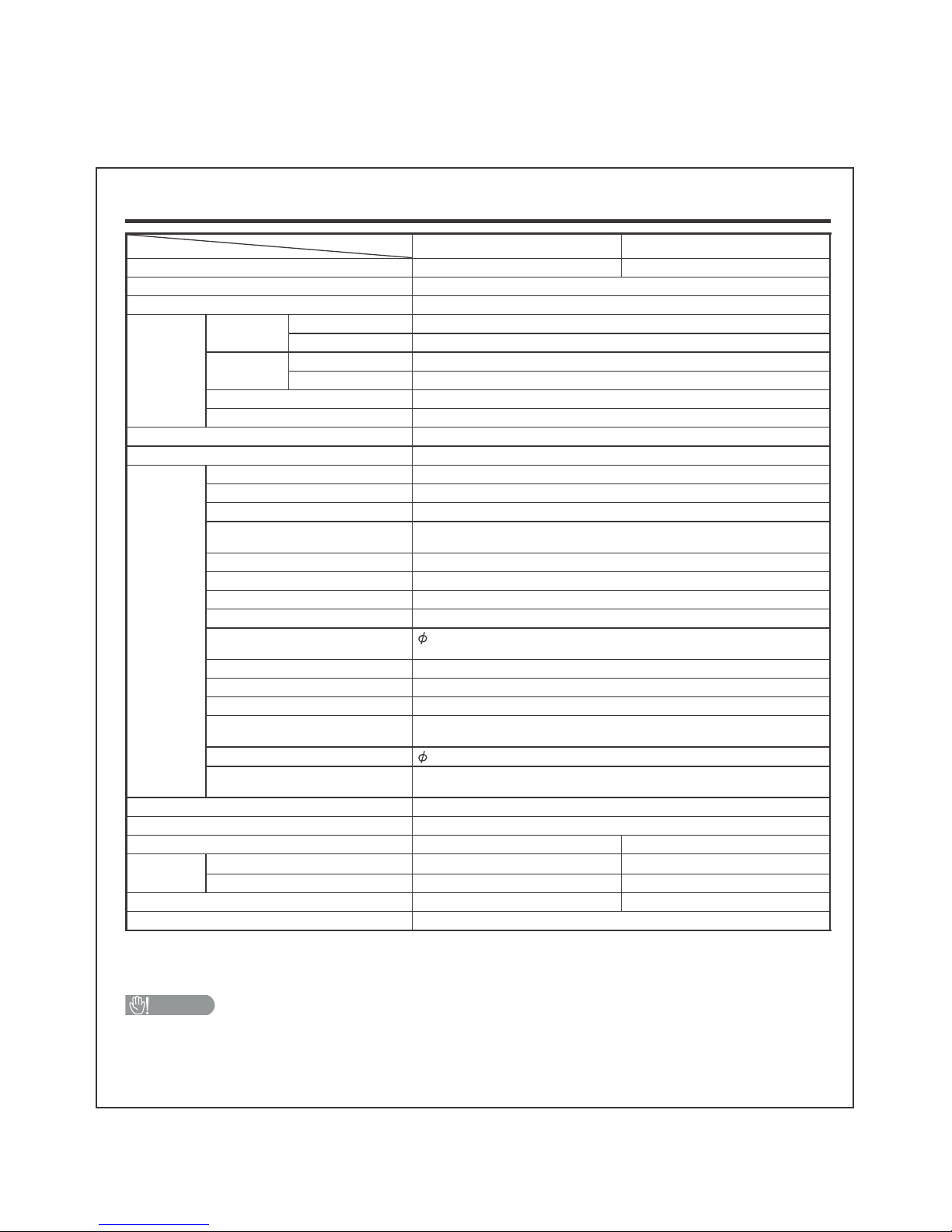

OUTLINE-MAJOR SERVICE PARTS

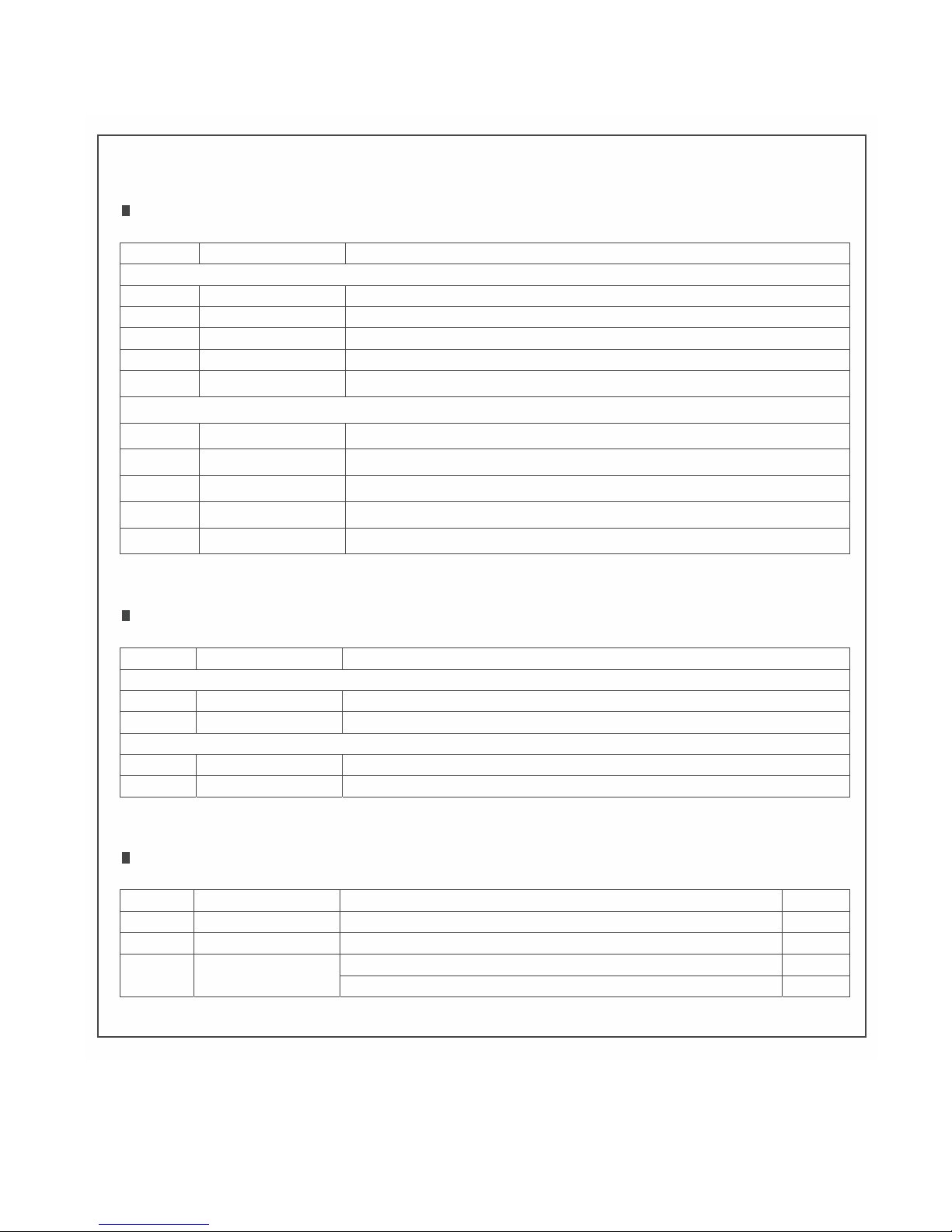

PWBUNIT

cseD.oNtraP.oNfeR

ripti

on

LC-60H20T

N

DKEYMG542FM01

MAINUnit

N DUNTKG505FM01 COCOROEYE

NDUNTKG504FM01

NETBOARD

N RUNTKB285WJQZ POWER Unit

N DUNTKG477FMG1

T-CON

Unit

LC-70H20T

N

DKEYMG542FM02

MAINUnit

N DUNTKG505FM01 COCOROEYE

NDUNTKG504FM01

NETBOARD

N RUNTKB286WJQZ POWERUnit

N DUNTKG477FMG2

T-CON

Unit

OTHERUNIT

cseD.oNtraP.oNfeR

ripti

on

LC-60H20T

N R1JE601D3HA10W

60"TFTLCD OpenCell

N CLCDTA375WEA4

60”PanelAssemblyUnit

LC-70H20T

N R1JE695D3HC50W

70"LCDPanel Module

Unit

N CLCDTA376WEA4

70”PanelAssemblyUnit

SERVICE

JIGS

cseD.oNtraP.oNfeR

ripti

Qno

ʼty

N QCNW-C222WJQZ ConnectingCor 2lenaPDCL-noC-T,d

1)WL(noC-T-niaM,droCgnitcennoCZQJW676F-WNCQN

NQCNW-N846WJPZ

Connectin

g

Cord, Main-T-Con (PL ) 1

ConnectingCord, Main-Power ( PD ) 1

Page 5

LC-60H20T/LC-70H20T

1 – 1

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS

Specifi cations

T02H07-CLT02H06-CLledoM metI

mc 771mc 251lenap DCL

Resolution

2,073,600 pixels (1920 g 1080)

06 LAP/34.4 CSTN/85.3 CSTN/MACES/LAPmetsys ruoloc oediV

TV function TV-standard Analogue NTSC: M

Digital DVB-T

Receiving

channel

VHF/UHF 44.25—863.25 MHz

Digital VHF 470—806 MHz

TV-tuning system Auto Preset 135 ch

STEREO/BILINGUAL BTSC system

º671 :V º671 :Hselgna gniweiV

Audio amplifi er/Speakers

10 W g 2 / 4.5 g 10 cm 2pcs

Terminals

Antenna input

UHF/VHF/CATV 75 q F type

輸入1

(INPUT 1) (HDMI/ARC) HDMI (HDMI input)

輸入2

(INPUT 2) (HDMI/MHL) HDMI (HDMI input)

輸入3

(INPUT 3)/

輸入4

(INPUT 4)/

輸入5

(INPUT 5) (HDMI)

HDMI (HDMI input)

輸入6

(INPUT 6) VIDEO in, AUDIO in, COMPONENT in

輸入7

(INPUT 7)

VIDEO in, AUDIO in

電腦

bus-D inim nip 51)CP(

聲音輸出

(AUDIO OUT) AUDIO out

聲音輸入(

HDMI 5 /

電腦)

AUDIO IN (HDMI 5/PC)

3.5 mm jack*

1

BSU2 BSU/1 BSU

輸出

(OUTPUT) USB

rotcennoc elam bus-D nip 9C232-SR

數位聲音輸出

(DIGITAL AUDIO

OUTPUT)

Optical Digital Audio Output

Headphone

3.5 mm stereo

乙太網路

(ETHERNET)

(10/100 BASE-T)

Network connector

esenihC lanoitidarT/hsilgnEegaugnal DSO

zH 06 ,V 011 CAtnemeriuqer rewoP

)ybdnatS W 5.0( W 902)ybdnatS W 5.0( W 571noitpmusnoc rewoP

Dimensions without stand

1,355 (W) g 817 (H) g 86 (D) mm 1,563 (W) g 934 (H) g 87 (D) mm

with stand

1,355 (W) g 835 (H) g 350 (D) mm 1,563 (W) g 952 (H) g 350 (D) mm

)gk 73( gk 43)gk 72( gk 42)dnats htiw( dnats tuohtiw thgieW

C°04 — C°0erutarepmet gnitarepO

*

1

The HDMI 5 and

電腦

(PC) terminals can both use the same audio input terminal.

• As a part of policy of continuous improvement, SHARP reserves the right to make design and specifi cation changes for

product improvement without prior notice. The performance specifi cation fi gures indicated are nominal values of production

units. There may be some deviations from these values in individual units.

CAUTION

• Installing the Liquid Crystal Television requires special skill that should only be performed by qualifi ed service personnel.

Customers should not attempt to do the work themselves. SHARP bears no responsibility for improper mounting or mounting

that results in accident or injury.

• Carefully read the instructions that come with the bracket before beginning work.

Page 6

LC-60H20T/LC-70H20T

2 – 1

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL

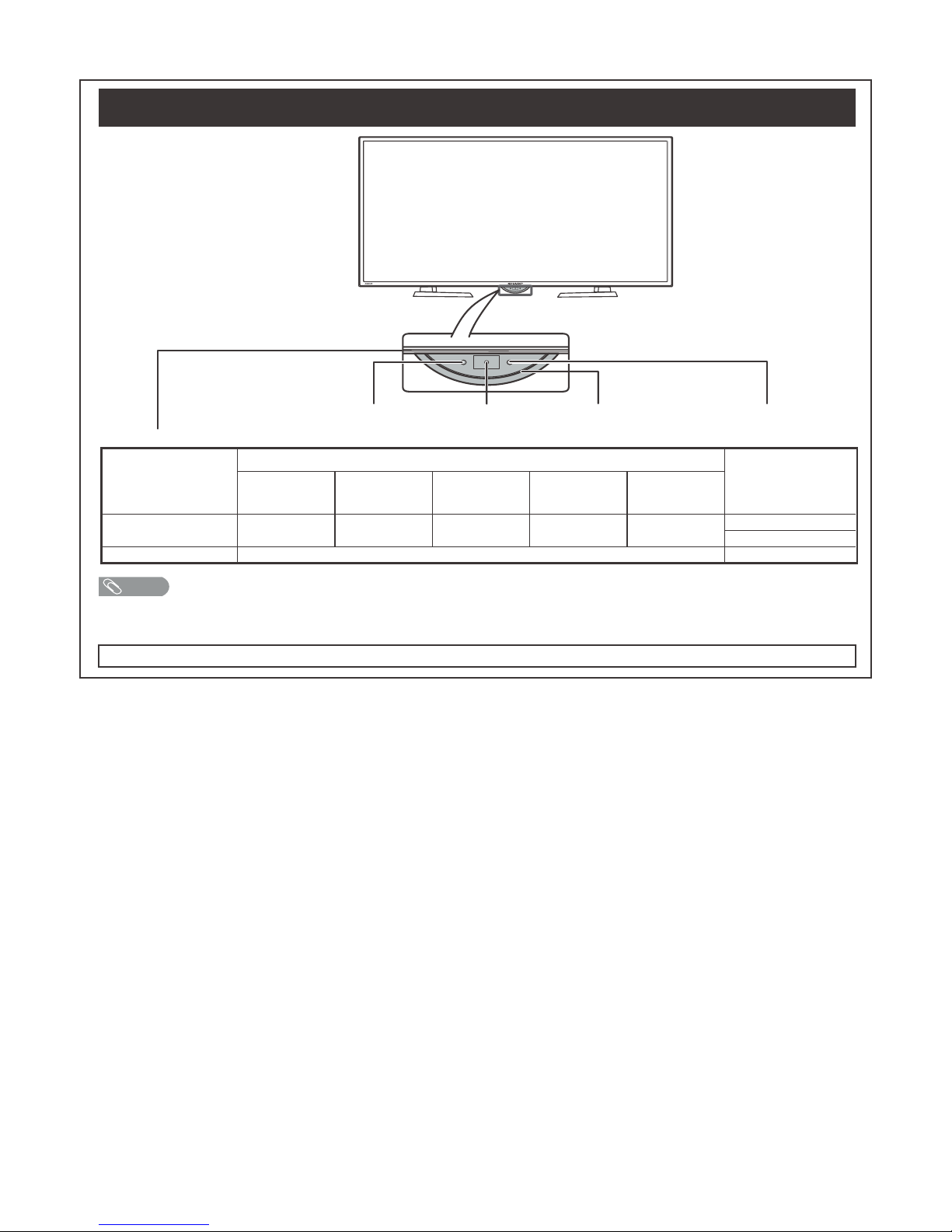

Attaching the stand

• Before attaching (or detaching) the stand, unplug the AC cord from the AC outlet.

• Before performing work spread cushioning over the base area to lay the TV on. This will prevent it from being damaged.

1

Confi rm the screws supplied with the TV.

(Six long screws and four short screws)

2

Insert the support angle into the stand base slot holes. (

1

)

• Please make sure left support angle into the left stand base and right support angle into the right stand base

(left side part engraved “L”, right side part engraved “R”).

3

Push the support angle follow the direction of the arrow mark on the stand base.

Push

Push the support angle follow

the direction of the arrow mark

4

For easily, user can use polystyrene foam as a jig to hold the stand base when fi xing by using the long

screws. (

2

)

2

Example for left side

2

5

Insert the stand into the openings on the bottom of the TV. (

3

)

6

Insert and tighten four short screws into the holes on the rear of the TV. (

4

)

Soft cushion

OUTPU

T

DC

5

V

1

.5A

H

D

MI

4

HDMI

5

U

SB

2

DC5V 0

.5A

AU

DI

O IN

D

IGI

T

AL

AUDIO

OUTPU

T

ANALOGU

E

RGB

(

PC

)

ARC

PC

H

DMI

1

INPUT 6

INPUT 7

AUDIO OUT

R

-

AU

DIO -

L

R -

AUDIO -

L

R

-

AUD

I

O

L

V

I

D

E

O/

Y

P

B

(C

B

)

P

R

(C

R

)

C

OMPO

NEN

T/

A

V

INPU

T

VIDEO

RS-232C IOIOI

US

B

1

D

C

5V

1

.

5A

(D

C5V

90

0

m

A

)

A

UD

I

O

(

L

/

R)

C

.I

.

M

H

L

HDMI 2

HDM

I 3

OUTPUT

3

4

NOTE

• To detach the stand, perform the steps in reverse order.

• Refer “Building the Work Table” in carton box to assemble the TV.

CAUTION

• Do not attach or detach the stand without holding it.

Doing so can cause the stand to fall, resulting in serious personal injuries as well as damage to the stand.

• The illustrations used throughout this manual are based on LC-60LE660X.

Polystyrene foam

Page 7

LC-60H20T/LC-70H20T

2 – 2

TV (Front)

RGB sensorRemote control sensor Motion sensor Power indicator

COCORO EYE LED

COCORO EYE LED

Power On mode (Power indicator lighted)

Standby mode

(Lighted)

Smart Power

Control

Auto Colour

Adjustment

Assist Light

mode

Optical

Picture

Control

Normal

ON

Green*

1

White White White Blue

Red

White (ASL is On)*

2

OFF

deRDEL oN

NOTE

*1 “SMART POWER CONTROL” IS PRIORITY. Power indicator will display Green even if other setting also turn On at the same

time.

*

2

If the “Assist Light mode” is turned On, Power indicator will display weak White during standby mode.

• The illustrations used throughout this manual are based on LC-60H20T.

Page 8

LC-60H20T/LC-70H20T

2 – 3

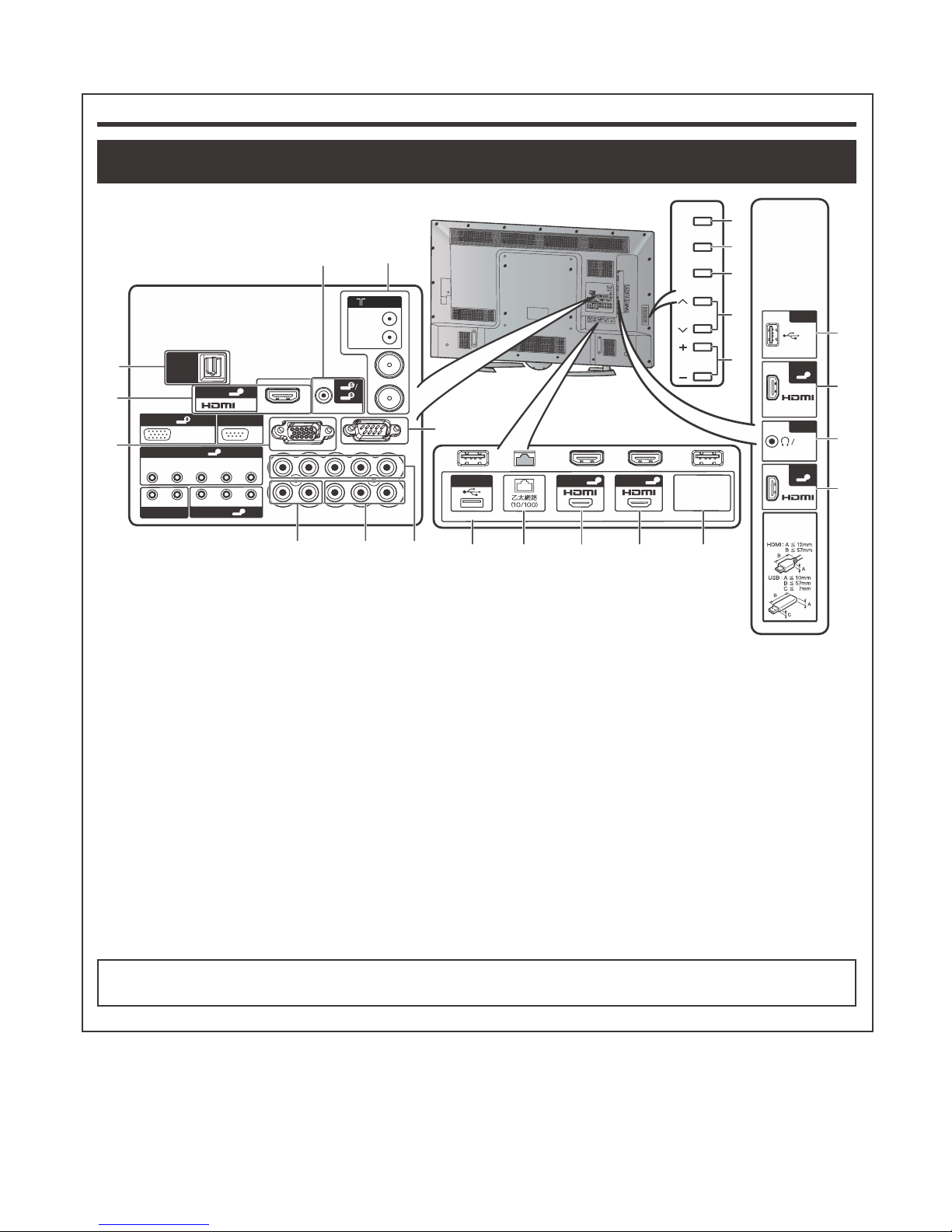

TV (Rear)

ARC

1

3

䴱㞜

2

䕮࠰

DC5V 1.5A

4

5

USB 2

DC5V 0.5A

䕮࠰

DC5V

1.5A

HDMI 5

6

䕮ޛ 6

7

䕮ޛ 7

㚨丩䕮࠰

-

㚨丩

-

ᐜ

-

㚨丩

-

ᐜ

-

㚨丩

-

ᐜ

ᖧ܅Y

P

B

(C

B

)

P

R

(C

R

)

㢨ᐤᖧ܅䕮ޛ

ᖧ܅

ᮮփ㚨丩

䕮࠰

㚨丩䕮ޛ

⌞ᝅ

ᴶ֩Ⲻ䙙ᯯᕅᱥֵ

⭞ޭᴿHDMI/USB

ㄥᆆ䁣ۏҁ⭘Ⱦ

(DC5V 900mA)

㚨丩ᐜ

RS-232C IOIOI

䕮ޛ 1

五∊

RGB

䴱㞜

HDMI 4

HDMI 3

HDMI 2

USB 1

MHL

䴱

Ⓠ

ⴤ

䤺

䕮

ޛ

乱

䚉

丩

䠅

❗㐐䴱㿌

ᴿ㐐䴱㿌

ཟ㐐ㄥᆆ

8

9

7

6

1

2

3

4

5

14 1213 11 10

15

16

17

23

21 2220

1918

1

電源

(POWER) (On/Off) button

2

目錄

(MENU) button

3

輸入

(INPUT) button

4

頻道

r/s

(CH r/s) buttons

5

音量

e/f (VOL e/f) buttons

6 USB 1 terminal

7 HDMI 2 (INPUT 2) (HDMI/MHL) terminal

8

輸出

(Headphones/

聲音(左/右)

) terminal

• The speakers do not output volume when

headphones are plugged in.

9 HDMI 3 (INPUT 3) (HDMI) terminal

10

輸出

(OUTPUT) terminal (For power output only)*

1

11 HDMI 4 (INPUT 4) (HDMI) terminal

12 HDMI 5 (INPUT 5) (HDMI) terminal*

2

13

乙太網路

(ETHERNET) (10/100) terminal

14 USB 2 terminal

15

數位聲音輸出

(DIGITAL AUDIO OUTPUT) terminal

16

輸入1

(INPUT 1) (HDMI/ARC) terminal

17

電腦

(PC) terminal*

2

18

聲音輸入

(AUDIO IN) terminal

19 Antenna terminals

(無線電視 / 有線電視)

20

聲音輸出

(AUDIO OUT) terminals

21

輸入7

(INPUT 7)

(影像 / 聲音(左 / 右))

terminals

22

輸入6

(INPUT 6)

(色差端子 / 聲音(左 / 右))

terminals

23 RS-232C terminal

*

1

This terminal can supply power for dongles. (Availability is depend on the specifi cation of dongle).

*

2

The HDMI 5 and

電腦

(PC) terminals can both use the same analogue audio input terminal. However, the proper item must

be selected in the “Audio select” menu.

• The illustrations in this operation manual are for explanation purposes and may vary slightly from the actual operations.

• The illustrations used throughout this manual are based on LC-60H20T.

Part names and functions

Page 9

LC-60H20T/LC-70H20T

2 – 4

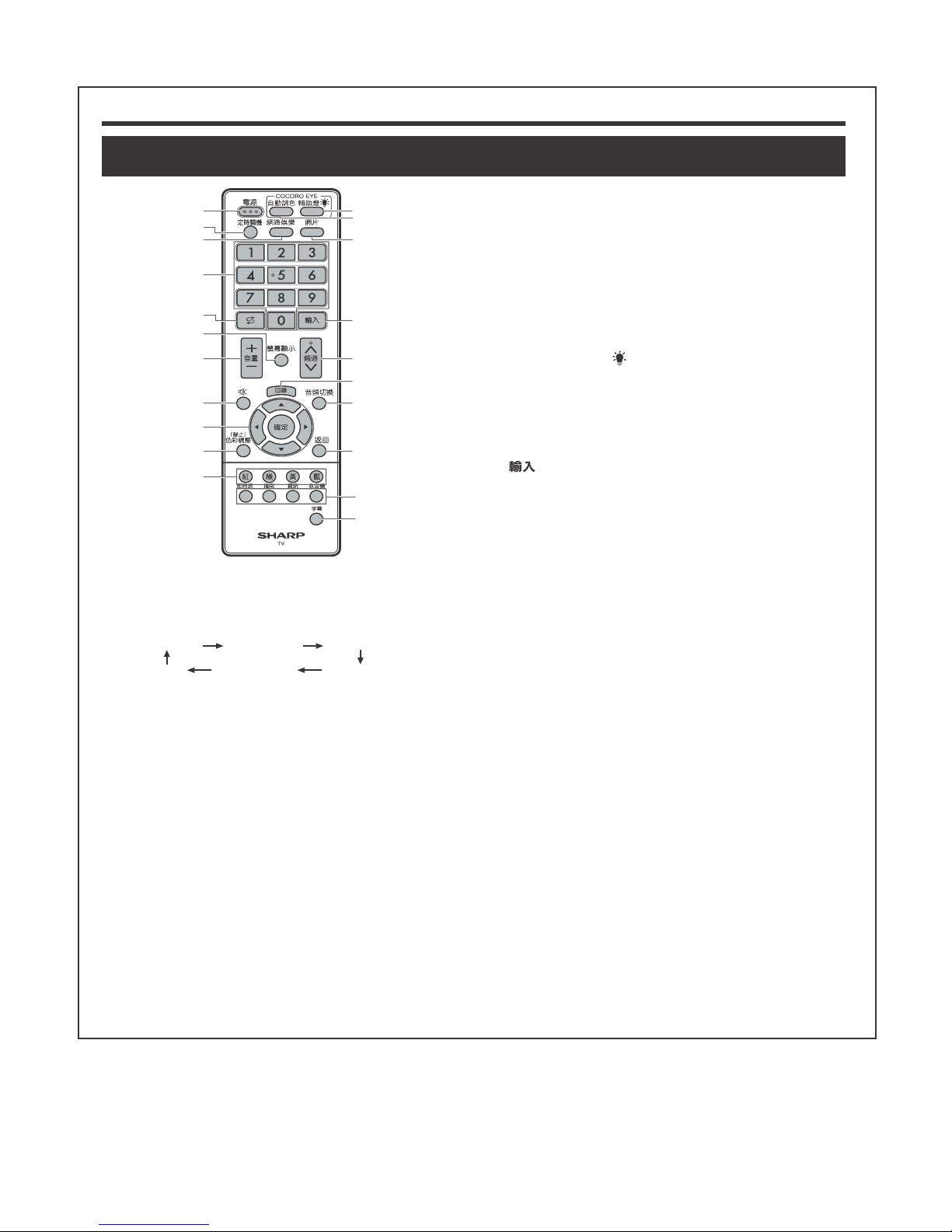

Part names and functions

Remote control unit

1

2

5

7

8

9

11

6

3

4

12

13

14

15

16

17

18

10

19

20

21

9 a/b/c/d (Cursor)

Select a desired item on the setting screen.

確定

(ENTER)

Execute a command.

10

色彩調整 (靜止

) [(COLOUR ADJ.) (FREEZE)]

Freeze a motion picture on the screen and adjust the

colour tone of the still image.

11 紅/綠/黃/藍 (R/G/Y/B) (Colour) buttons

The coloured buttons are correspondingly used to select

the coloured items on the screen.

12

輔助燈

(ASSIST)

To turn on/off Assist Light mode.

13

自動調色

(AUTO COLOUR)

To turn on/off Auto Colour.

14

照片

(PHOTO)

Display your pictures directly on the TV screen.

15

(INPUT) (INPUT SOURCE)

Select an input source.

16

頻道

r/s (CHr/s)

TV input mode: Select the channel.

(

頻道

r

) Increase the channel number.

(

頻道

s

) Decrease the channel number.

17

目錄

(MENU)

Display the menu screen.

18

音頻切換

(MPX)

Select the sound multiplex mode.

19

返回

(RETURN)

MENU mode: Return to the previous menu screen.

20

節目表

(EPG)

DTV mode: To display EPG (Electronic Programme Guide)

screen.

指南

(GUIDE)

DTV mode: Display the programme channel list.

資訊

(INFO)

DTV mode: Display the programme information.

收音機

(RADIO)

Press to access RADIO mode.

21

字幕

(SUBTITLE)

Switch subtitle languages on/off.

1

電源

(POWER) (STANDBY/ON)

To switch the power on and off.

2

定時關機

(SLEEP)

Set the Sleep timer.

0 hr. 30 min. 1 hr. 00 min.

2 hr. 30 min.

1 hr. 30 min.

2 hr. 00 min.

Off

3

網路娛樂

(INTERNET)

Press to select internet link.

4 0 – 9

Set the channel.

5 A (Flashback)

Press A to return to the previous selected channel or

external input mode.

6

螢幕顯示

(DISPLAY)

Display the channel or input information.

7

音量

k/l (VOLk/l)

Set the volume.

(

音量

k

) Increase the volume.

(

音量

l

) Decrease the volume.

8 e (Mute)

Press e s Mutes sound.

Press e again s Restores sound.

Mute will be cancelled after 30 minutes. However, the TV

will not suddenly output loud sound as the volume level

will be set to 0 automatically. Increase the volume level by

pressing

音量

k

(VOLk).

Page 10

LC-60H20T/LC-70H20T

3 – 1

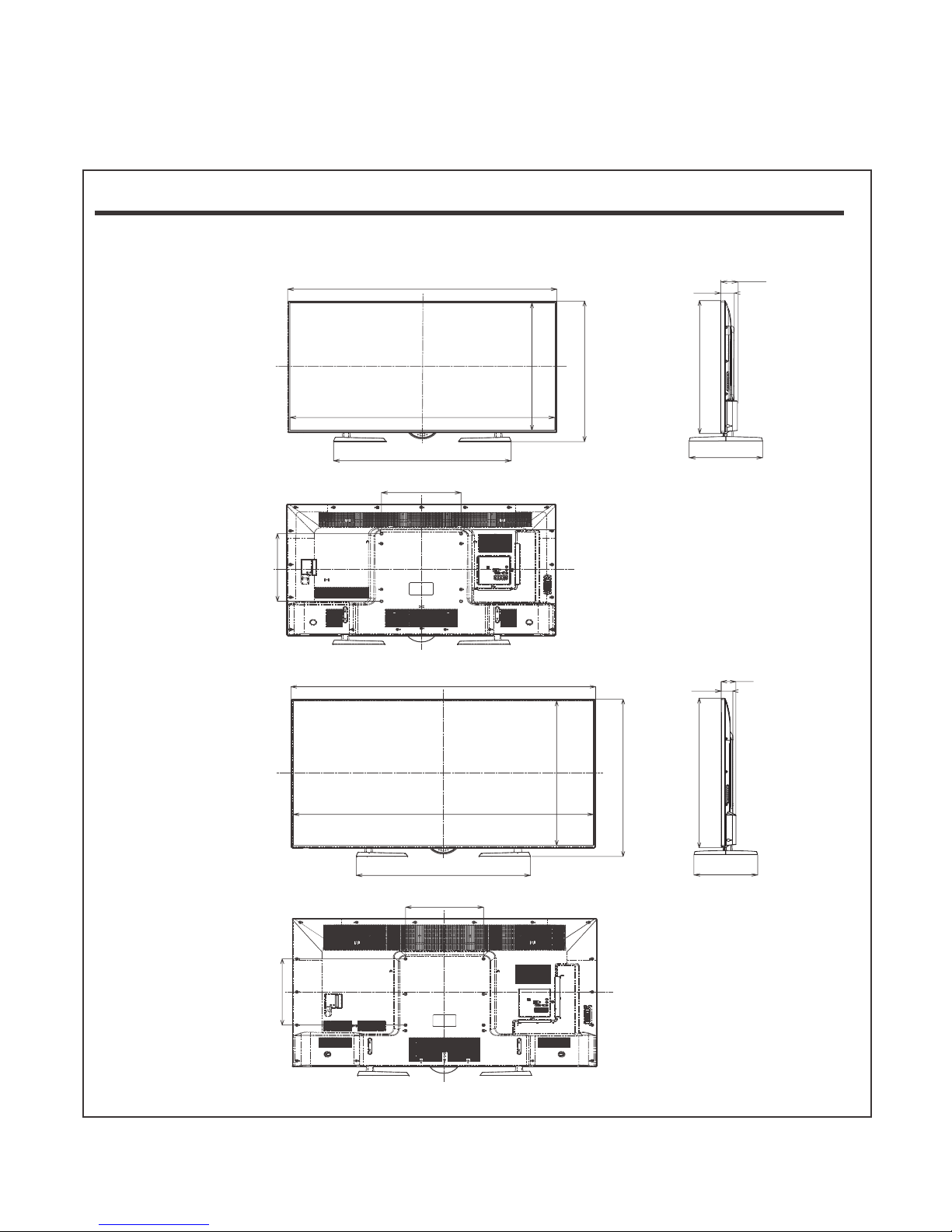

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS

Dimensional drawings

400

400

400

400

86

69

350

817

1355

1332.4

901

835

754.3

1540.6

1563

901

952

871.5

LC-60H20T

LC-70H20T

87

69

350

934

Unit : mm

Page 11

LC-60H20T/LC-70H20T

4 – 1

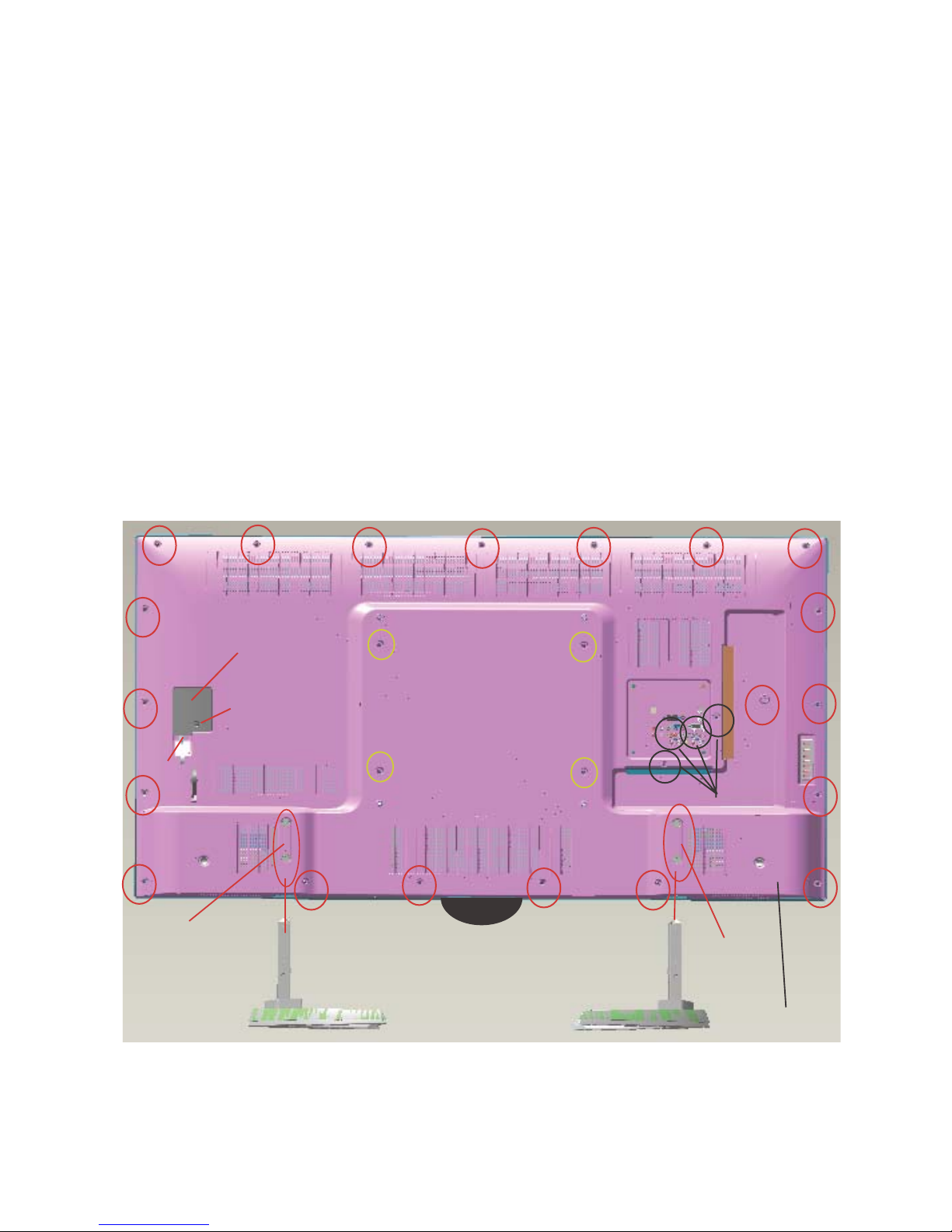

CHAPTER 4. REMOVING MAJOR

PARTS

[1] REMOVING MAJOR PARTS

[1] REMOVING OF MAJOR PARTS

REMOVING OF THE STAND UNIT AND REAR CABINET

1.Remove the 4 lock screw [1] and detech stand unit [2].

2.Remove 1 lock screw [3] and detech the AC cord cover [4].

3.Disconnect AC Cord [5].

4.Remove the 20 lock screws [6],remove 4 screw [7],remove 4 screw [8]. (LC-60LE360X)

Remove the 28 lock screws [6],remove 4 screw [7]. (LC-70LE360X) refer next page.

5.Detech rear cabinet assmbly [9].

[1]

[1]

[2]

[2]

[3]

[4]

[5]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[7]

[7]

[7]

[7]

[6]

[8]

[9]

LC-60LE360X

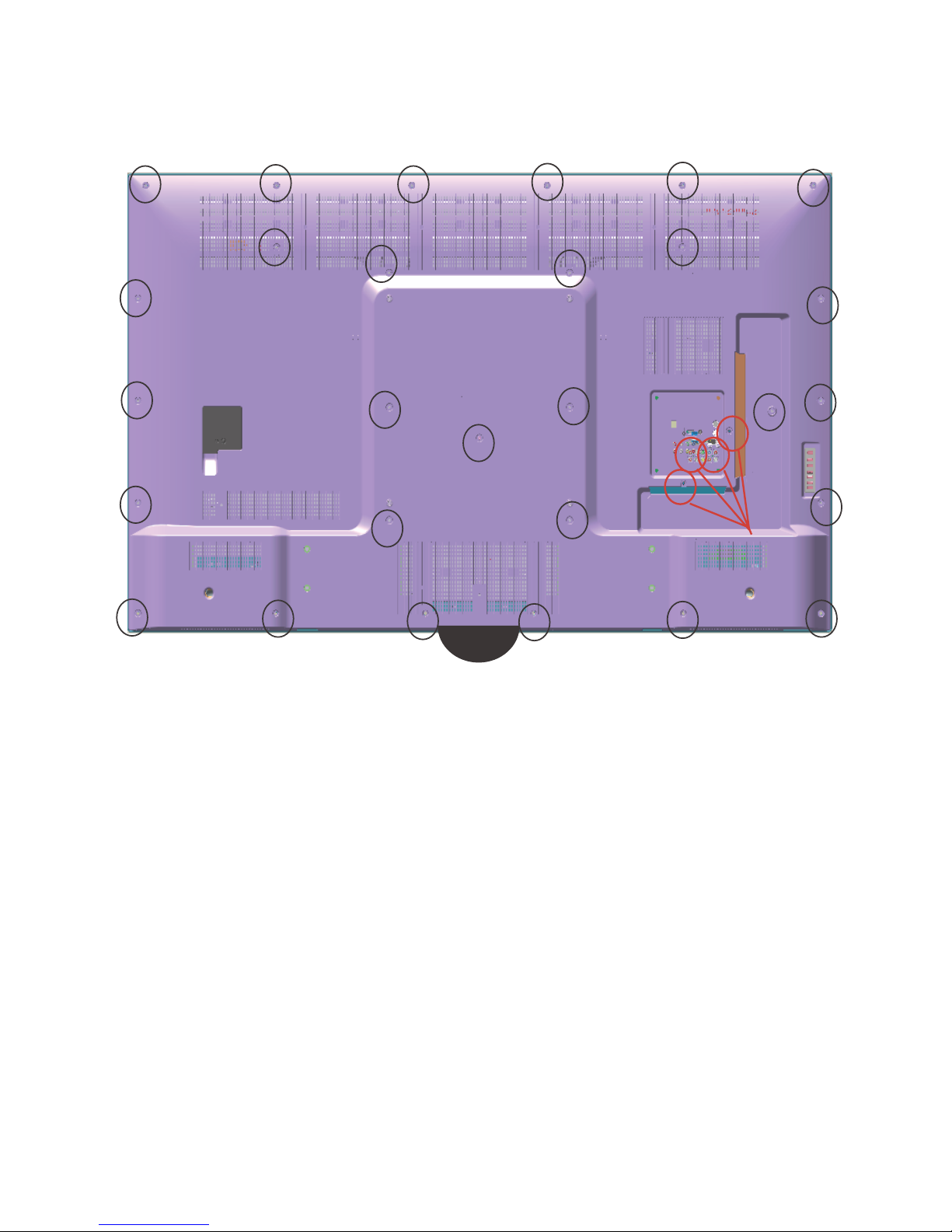

Page 12

LC-60H20T/LC-70H20T

4 – 2

LC-70LE660X

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[6]

[7]

Page 13

LC-60H20T/LC-70H20T

4 – 3

[2] Removing of connectors & PWB

1.Disconnect the following connectors from Main Unit. (SP,RA,KM,LWwires)

2.Disconnect the following connectors from the POWER Unit.(PD,PL,LED wire)

3.Disconnect the following connectors from the LCD CONTROL Unit .(T-Con FFC wayer)

4.Remove 4screws [1]Main Unit ,remove 6 screws [2] Power unit & remove 4 screws [3]

T-CON board,remove 3 screws [4] cocoro eye

[2]

[2]

[2]

[2]

[2]

[2]

LED Wire

[PD]

[PL]

COCORO EYE

[4]

[RB]

[KM]

[T-CON FFC wayer]

[LW]

[LW]

Page 14

LC-60H20T/LC-70H20T

5 – 1

CHAPTER 5. ADJUSTMENT

[1] ADJUSTMENT

1.Enteringandcanceltheadjustmentprocessmode

1) WhileholdingdowntheINPUT andVolumeDOWNkeysatthesametime,plugintheACcordtoturnonthepower.(“K”standingfo rinspectionprocessmodeisdisplayedontheupperleftpositionofthescreen.)

2) PresstheChannelDOWNandVolumeDOWNkeysatthesametime.(Theadjustmentprocessmodescreenappears.)

3) Tocancelit,turnoffthepowerusingthePowerswitchorremotecontrol.

2.Remotecontrollerkey operationanddescriptionofdisplayinadjustment processmode.

1. keyoperation

* Inputmodeisswitchedautomaticallywhenrelevantadjustmentisstartedsofarasthenecessaryinputsignalisavailable.

noitcnuFyektinuniaMyekrellortnocetomeR

CH( / )

CH( / )

Changingchannel(UP/DOWN)

)NWOD/PU(emulovgnignahC)‒/+(LOV)‒/+(LOV

Cursor( / )

)TXEN/SUOIVERP(egapagninruT

Cursor( / )

)01-/01+(gnittesenildetcelesagnignah

C

INPUTbuttononremotecontroller

)gnihctiwselggot(gnihctiwsecruostupnInottubTUPNI

ENTER

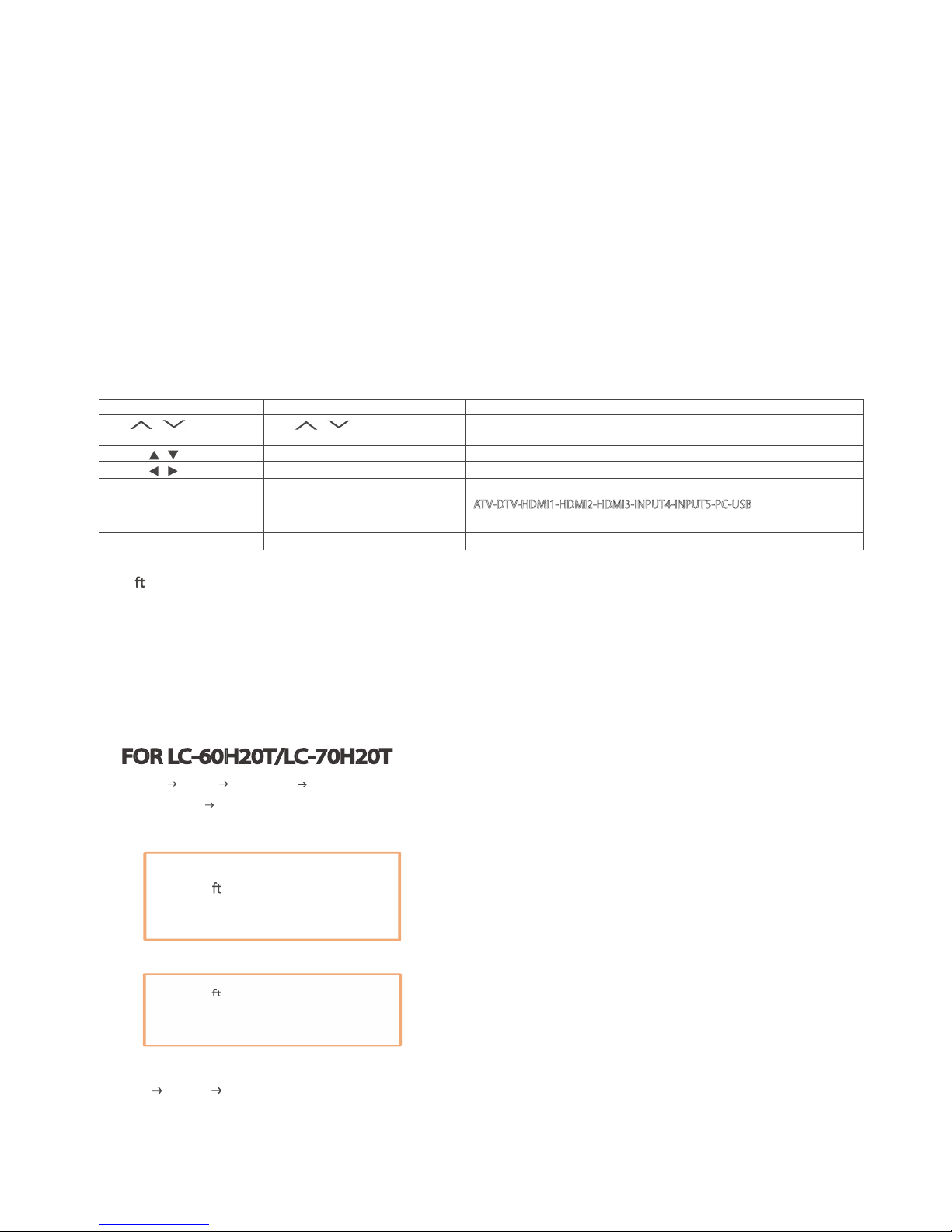

3.So wareupgrading

1)MakesureLCDTVison.

2)InsertUSBdevicetotheUSBterminalattheLCDTV.

(MakesurethelatestsoftwareisinstalledintheUSBdevice.)

3)Usebelowmenuproceduretostartupgradingsoftwareversion:

4)Afewsecondlater,thesoftwareupgradingwillstartautomatically.

So wareUpdate(USB)

1%

ATV-DTV-HDMI1-HDMI2-HDMI3-INPUT4-INPUT5-PC-USB

-Menu

Option

Systemdata

-Areyousure?

Yes

II

I

USBdatatrans

5)Softwareissuccessfullyinstalledwhenthefollowingappearsattheendoftheprocess.

6)Onceupdatingcompleted,LCDTVwillbeautomaticallyoffandagain,afterfewseconds,automaticallyrestart.

7)Menu

S

etup

Identification

So wareUpdate(USB)

100%

FOR LC-60H20T/LC-70H20T

Page 15

LC-60H20T/LC-70H20T

5 – 2

LCD TV ADJUSTMENT ITEM

1. VCOM ADJUSTMENT

i. Enter service mode key and go to VCOM/TEST PATTERN Page

ii. Press “Enter” key (at VCOM)

iii. Adjust the flicker effect by pressing “VOL +/-“ of RC key

iv. Press “Enter” key after get the best value

2. SOFTWARE PACKAGE

i) Main Software

egakcaP erawtfoS ledoM

LC-60H20T

LC-70H20T

Wisteria_Taiwan_Pack15_vXXX.bin

Main Software Filename : XXX is Software version

Please manually change the panel inch setting (60” or 70”) according to the model.

If any changes of software, will be informed by MARUHEN.

ii) Net Software

krameR egakcaP erawtfoS ledoM

LC-60H20T

LC-70H20T

wisteria660_netboot_vXXXX.bin For Bootloader ( write at ISP Flash)

wisteria660_net_vXXXX.bin Net Software ( write at NAND Flash)

Net Software Filename : XXXX is Software version

iii) Sub Software

egakcaP erawtfoS ledoM

LC-60H20T

LC-70H20T

Wisteria660_Sub_VXXX.production.hex

Sub Software Filename : XXX is Software version

Page 16

LC-60H20T/LC-70H20T

5 – 3

3. T-CON ROM DATA INPUT (T-CON PWB : QPWBXG477WJ**)

ERUDECORP NOITIDNOC METI

1 T-CON Data

Input

(T-CON PWB)

Checker

adjustment

Full version

confirmation

1. At checker, connect software jig at CN5801 (TL5801~5807).

2. Input voltage at P4804 (TL4839~TL4880) and ROM start to

input data.

3. Power OFF after finish data input.

[ Caution item ]

If some error happened, ROM data is not written in at all.

Note: Please refer to below for combination of T-Con software

LCD PANEL T-CON UNIT T-CON SOFTWARE

1

R1JE601D3HA10W

(LC-60H20T)

DUNTKG477FMG1

SHARP_71912_FW_(v20140924_60425110)_SPI.bin

2

R1JE695D3HC50W

(LC-70H20T)

DUNTKG477FMG2

SHARP_71912_FW_(v20140924_70425100)_SPI.bin

4. MAC ADDRESS & WMDRM PROGRAMMING

(Key is from Sharp IT department)

One key is for every each unit except the WMDRM key. Please be extra careful in data management so

as NOT to write multiple data. Also, when data writing location parts is broken, please change PWB board

(since the concerned IC is non-exchangeable part).

Note: a) MAC Address is from Sharp IT department

b) WMDRM Key is from SEM Enginering department

5. SIGNAL ADJUSTMENT

A. PICTURE ADJUSTMENT

Confirmation of signal from generator (setting to spec le

vel)

PAL Composite signal 㸸0.7Vp-p s 0.02Vp-p (pedestal to white level)

15K Component signal (50Hz) 㸸Y level 㸸0.7Vp-p s 0.02Vp-p (pedestal to white level)

Pb, Pr level 㸸0.7Vp-p 㸸0.7Vp-p s 0.02Vp-p

33K Component signal 㸸Y level 㸸0.7Vp-p s 0.02Vp-p (pedestal to white level)

Pb, Pr level 㸸0.7Vp-p 㸸0.7Vp-p s 0.02Vp-Com

Page 17

LC-60H20T/LC-70H20T

5 – 4

a) Adjustment Mode

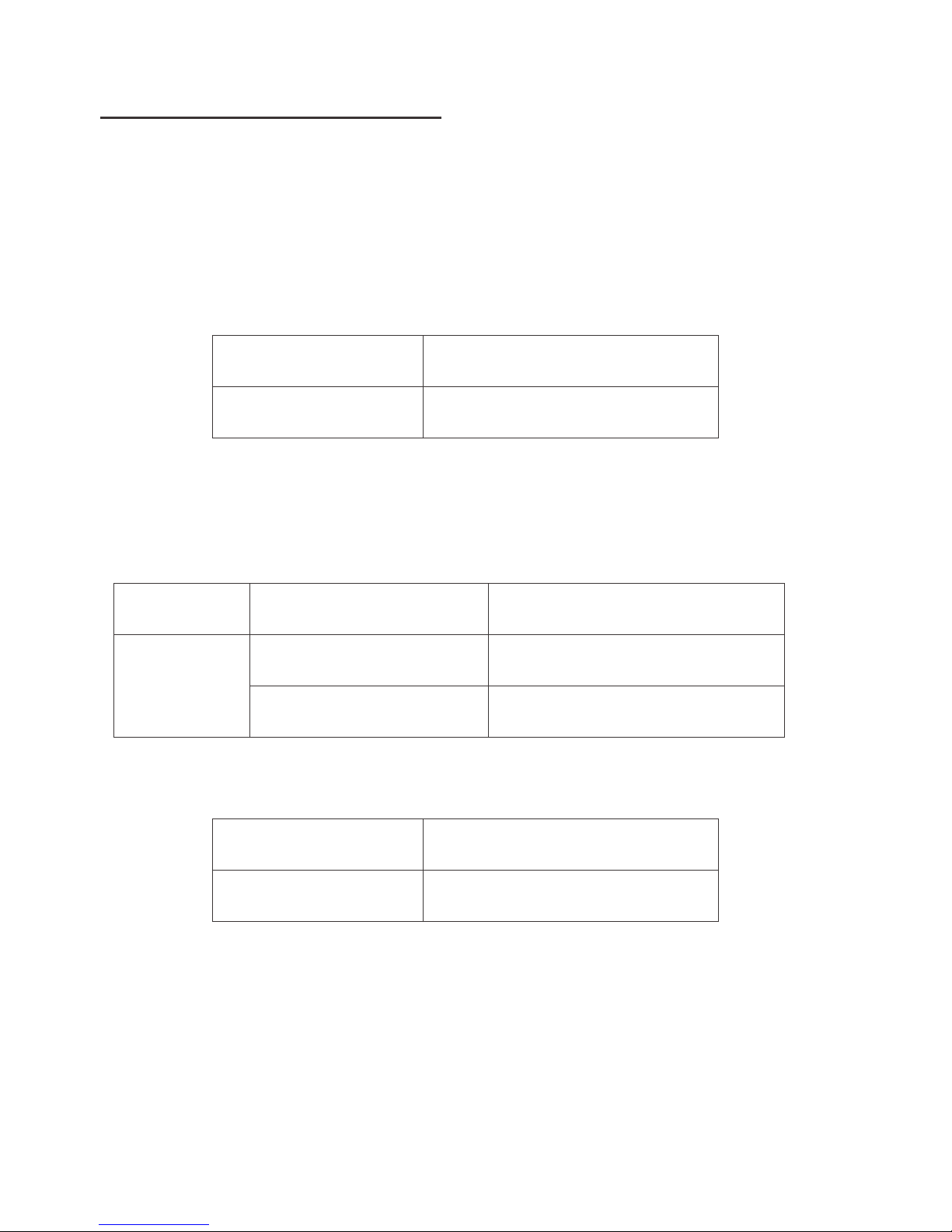

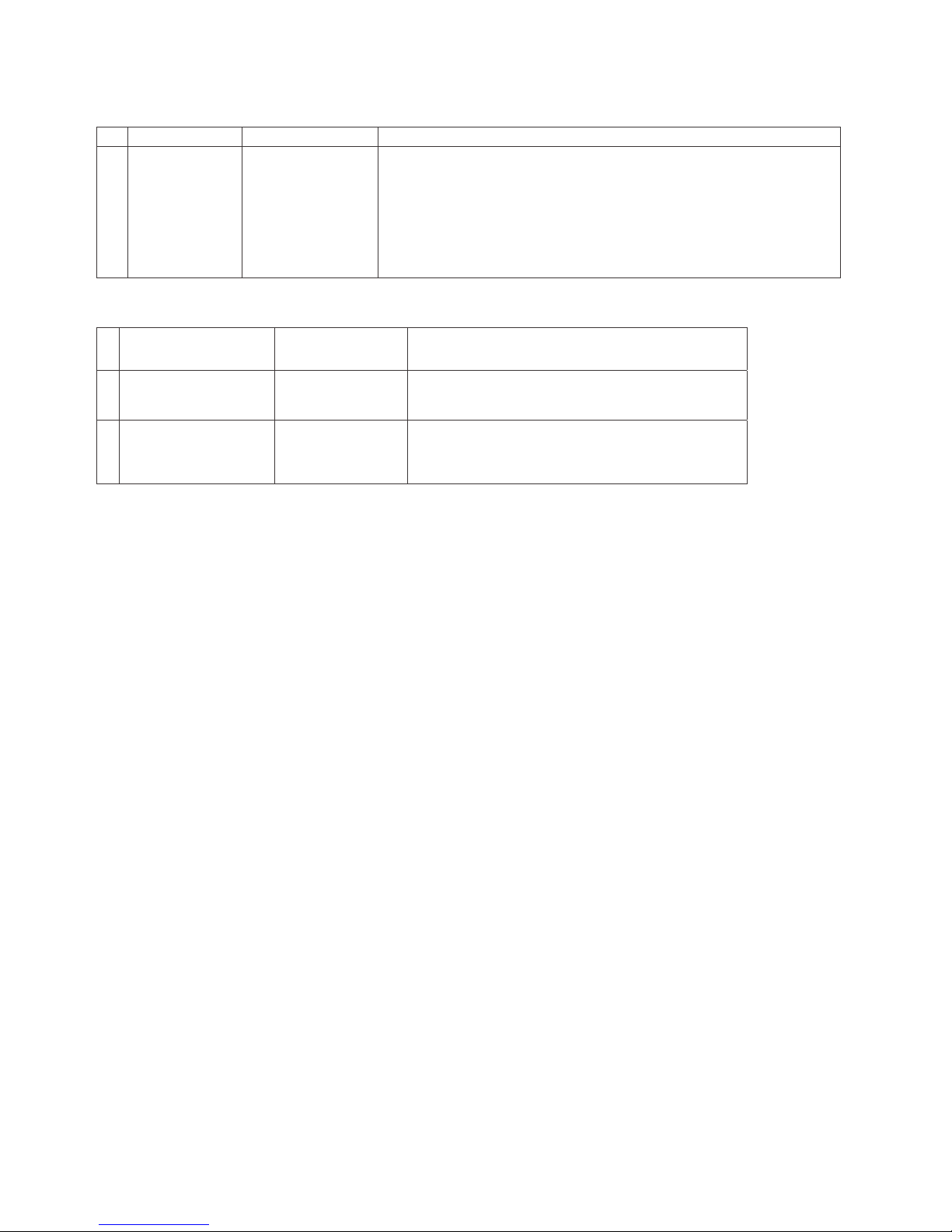

NO. ERUDECORP NOITIDNOC METI

1 Adjustment Mode Press the test key at the test remote control

b) Component 15K 50Hz Signal Adjustment (COMP-SD)

NO. ERUDECORP NOITIDNOC METI

1 Setting [Signal]

COMP 15K 50Hz

(576i)

100% Full-field

Colour Bar

[Terminal]

COMPONENT

INPUT 6

࣭Feed the COMPONENT 15K 50Hz (576i) 100% Full-field

Colour Bar signal(100% colour saturation) to

COMPONENT INPUT 3

2 Auto Adjustment Test Mode page 4

(COMP SD)

At the related page, move cursor to [COMP SD ADJ], press

ENTER.

[OK] appears when finished.

c) Component 33K 60Hz Signal Adjustment (COMP-HD)

NO. ERUDECORP NOITIDNOC METI

1 Setting [Signal]

COMP 33K 60Hz

(1080i)

100% Full-field

Colour Bar

[Terminal]

COMPONENT

INPUT 6

࣭Feed the COMPONENT 33K 60Hz (1080i) 100% Full-field

Colour Bar signal(100% colour saturation) to

COMPONENT INPUT 3

Page 18

LC-60H20T/LC-70H20T

5 – 5

2 Auto Adjustment Test Mode page 5

(COMP HD)

At the related page, move cursor to [COMP HD ADJ], press

ENTER.

[OK] appears when finished.

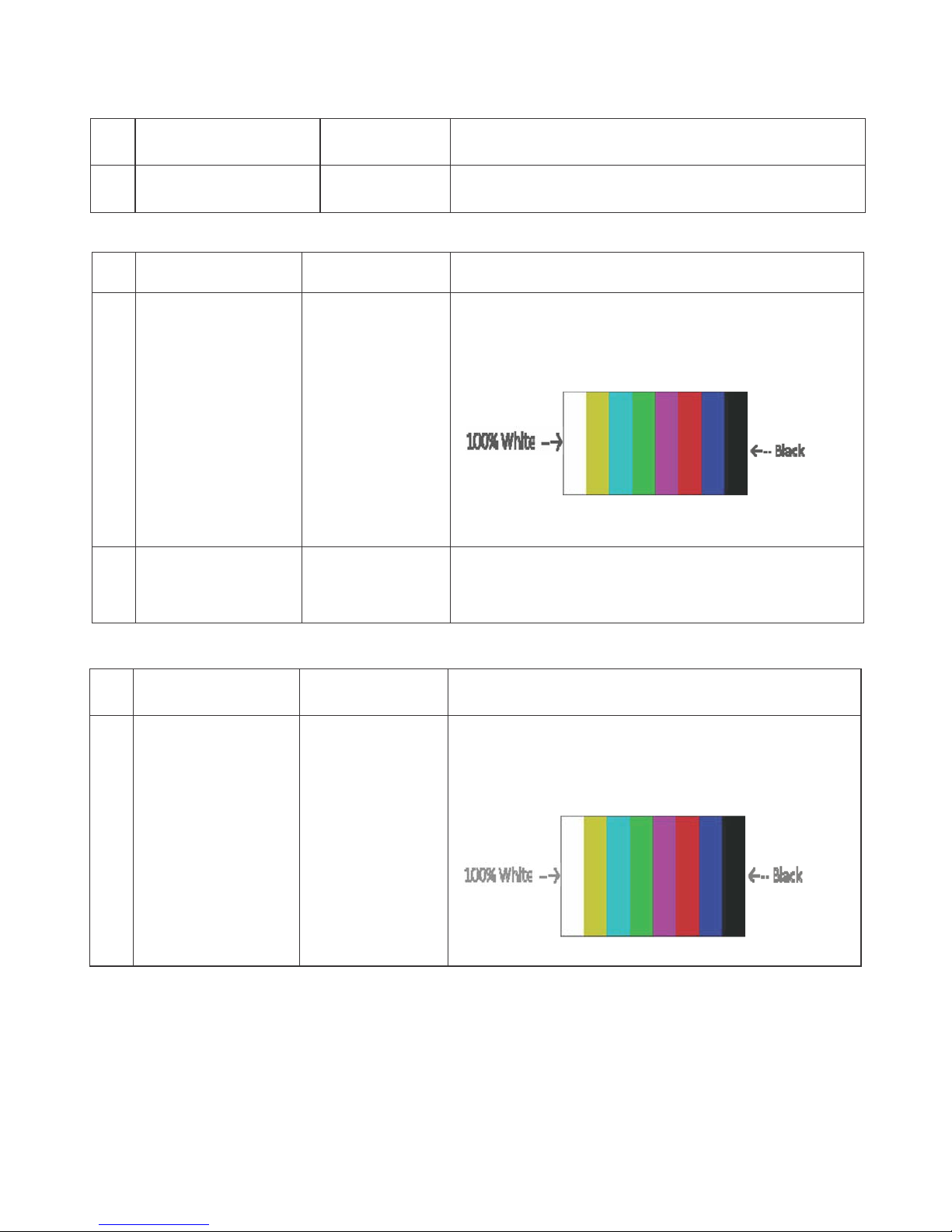

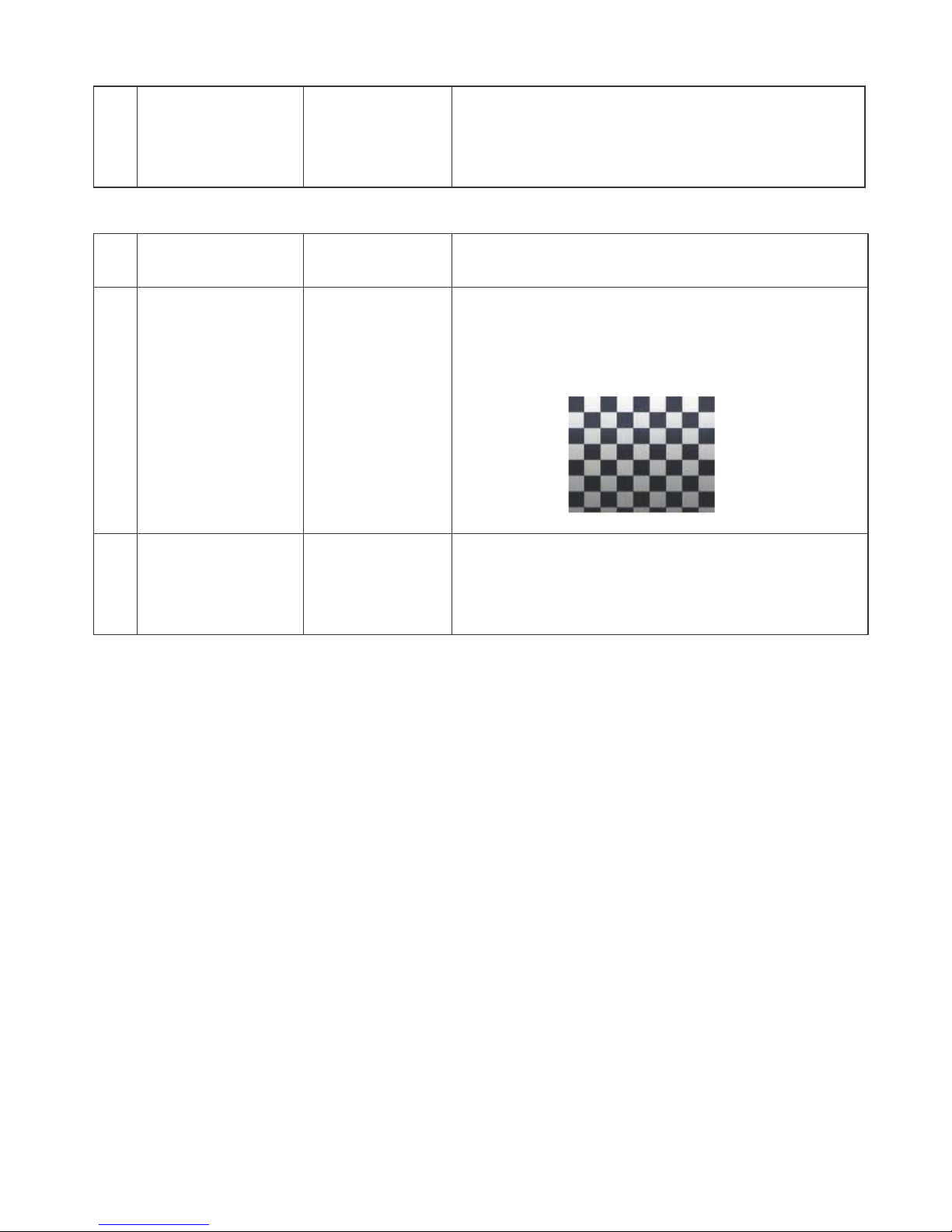

d) PC (ANALOG RGB) Signal Adjustment (PC-RGB)

NO. ERUDECORP NOITIDNOC METI

1 Setting [Signal]

XGA 60Hz

100% Checkered

Pattern

[Terminal]

PC INPUT 8

࣭Feed the XGA 60Hz 100% Checkered pattern signal (100%

colour saturation) to PC INPUT

䈜Please make sure SYNC is OFF.

2 Auto Adjustment Test Mode page 6

(PC-RGB)

At the related page, move cursor to [RGB ADJ], press

ENTER.

[OK] appears when finished.

Page 19

LC-60H20T/LC-70H20T

5 – 6

MGMB**** RB to the reference value of point 1.

(18) Adjusted value is writing at [command]

MSET0003

(19) Set the G of point Max. to the default value

(4080 x G value of point 2 / R2). Set the R,B

Max. value [G

max

– G value of point 2 + (R,B

value of point 2)

(20) Calculate the slope R2

slope,

G2

slope,

B2

slope

between MAX and Point2.

R2

slope =

(R

max

- R

high

)/(4080-3664)

(21) Calculate the correction value

پR

high, پGhigh, پBhigh.

پR

high = R2slope X

(3840-3664)

(22)

Set the reference value R,G,B of point 2

(R2䇻)=R2+پR

high

(23)

Calculate the slope R1

slope,

G1

slope,

B1

slope

between Point2 and Point1.

R1

slope =

(R

high

- R

low

)/(3664-480)

(24)

Calculate the correction value پR

low,

پG

low, پBlow.

پR

low = R1slope X

(538-480)

(25)

Set the reference value R,G,B of point 1

(R1䇻)=R1+پR

low

(26) Shut down the AC power.

䈜Initial value at RGB 2 point : 3664

䈜Initial value at RGB 1 point : 480

[Adjustment value]

ۼTeaching set send by engineering dept is set as

reference.

[Reference values for adjustment reference]

Equipment : Luminance meter [Minolta CA-210]

Level

Spec

Data

Adj. Spec.

Inspection

Spec.

Point

2 ref.

values

229

x=0.2685

y=0.267

0.0010 0.0020

Point

1 ref.

values

30

x=0.2685

y=0.267

0.0045 0.0090

Ref. : For inspection, set the LCD TV as below.

AV MODE : [DYNAMIC] (Reset)

Aging Time : Minimum 30 minutes

RESULT

+

-

+

-

+

-

+

-

Page 20

LC-60H20T/LC-70H20T

5 – 7

6. FACTORY SETTING

AC power is plug off after shipment setting is done.

Caution

: Do not plug on again after shipment setting is done. If do, please re-do the shipment setting. Do not off

with remote control.

Model Name Factory Setting

Key Name

Remote Control

Code

S-System Setting OSD Language

Setting

A3LCRH20T

A3LCTH20T

T-Setting 100000111111110 M

TRADITIONAL

CHINESE/

ENGLISH

ITEM ERUDECORP NOITIDNOC

Factory setting AC power off to exit

the factory setting.

1. Setting is done with test remote control.

2. Press the ‘Factory Setting’ key on the remote control continuously.

3. When Green background appears on screen and ‘K’ mark

disappears, setting is completed.

The followings are initialised to factory setting:

1) User setting

2) Channel data (e.g. broadcast frequencies)

3) Manufacturer’s option settings

4) Password data

5) Setting values are set based on model destination

Page 21

LC-60H20T/LC-70H20T

5 – 8

[2] USB CLONE SPECIFICATIONS

[3] USB CLONE SPECIFICATIONS

[2] USB Clone (Smart Loader)

1. Description

The Smart Loader is a function implemented in the service software to easily replicate the user settings of one TV into another.

These settings include (but not restricted to): picture and audio, turning set-up, language and country selection, PIN, child locked programs etc.

Factory adjustments are not copied as they are different for every TV.

The Smart Loader makes possible the user data to be stored in a memory device connected to the USB terminal of the TV that is used as reference

and later load those data into other TVs by using their respective USB terminal.

2. How it works

1. Enter USB clone menu (Smart Loader)

i) Press panel key [INPUT] and [VOL+] and AC on, it will go to password entry OSD

ii) Enter digit “369” then it will go to Smart Loader Menu

2. Smart Loader function

i) SMLD Store

• To copy all related data fro

m TV -> USB and put under a fixed filename “SHPSMLD.bin” (8kB).

ii) SMLD Restore

• To restore the related data from USB -> TV.

iii) SMLD Store and Restore execution

• To execute SMLD Store or SMLD Restore, highlight at selected item and press Enter.

• After cloning process is done, “OK” is displayed.

If cloning process is not finished due to error (e.g. no pendrive detected), “NG” is displayed.

3. Exit USB Clone menu (Smart Loader)

i) To exit Smart Loader menu, plug off AC Cord.

SMLD Store SMLD Restore

2nd AQUOS TVUSB1st AQUOS TV

Page 22

LC-60H20T/LC-70H20T

5 – 9

[4] PUBLIC MODE SETTING

[5] PUBLIC MODE SETTING

[3] PUBLIC MODE SETTING PROCEDURE

1. How to start Public Mode

• There are the following two ways to get the public mode setup screen displayed.

1) Press the “INPUT” and “VOL (+)” keys on the set at once and turn on the power.

2) Get the password input screen displayed.

3) The 3-digit password is now verified.

The password [0] [2] [7] provides for the public mode screen. (This screen comes on with whatever adjustment process settings.)

With any other passwords, the screen changes to the normal mode.

In the adjustment process mode, turn on “PUBLIC MODE”. Also press the “CH ( )” and “VOL (+)” keys on the set at once and turn on the power.

2. How to exit Public Mode

There are the following ways to quit the public mode setup screen.

• Turn off “PUBLIC MODE” in the adjustment process mode. ( ) This way alone is not for quitting the setup screen, but for quitting the mode by

itself.

• Turn off the powe

r with the “POWER” key. ( )

• Select “EXECUTE”.( )

“PUBLIC MODE” stays on in the adjustment process mode.

The settings will be back to the factory ones.

3. Public Mode Setting Values

• With the factory settings made, the public mode settings get initialized. (The adjustment process remains intact.)

Procedure

• The input starts with the leftmost digit.

• Use the numeric keys [1] thru [9] and [10/0] keys on the remote controller.

The other keys are not acceptable.

• With a numeric-key input,“

“ will change to “ “. The input position will move one digit to the right.

• With all the 3 digits entered, the password will be verified.

Page 23

LC-60H20T/LC-70H20T

5 – 10

4. Public Mode Menu

The guidance is not displayed onscreen.

Setup procedure

• To move the cursor up and down, use the “cursor UP/DOWN” key (remote controller) and “CH ( )/( )” key (remote controller and set).

• To change the settings, use the “cursor RIGHT/LEFT” key (remote controller) and “VOL (+)/(‒)” key (remote controller and set).

• To save new settings, keep the cursor at “Execute” and use the “cursor RIGHT/LEFT” key (remote controller) and “VOL (+)/(‒)” key (remote controller and set).

5. On Setting Items

1. POWER ON FIXED

2. MAX V OLUME

Selection Variable/Fixed

Default Variable

Explanation When set to “Fixed”, the power cannot be turned off with the power key on the remote control or main unit, and the image

reception state is kept (it does not enter the standby state).

The power can be turned off by shutting off power supply from AC.

Limit in setting • Power key on the main unit/

remote control power supply key

• OFF timer/ON timer

Exception None

Remarks • Selection of “FIXED” assumes use of STB, etc.

• When set to “Variable”, if the main power switch is set to off, the power is turned off after a wait of 1 second.

(Push-push switch only)

• Display ON/OFF in the hotel menu is controlled by the adjustment process “HOTEL POWERFIX”.

• When the power button is operated, a caution is displayed (it times out in 5 seconds).

(For the caution, refer to the power on fixed message sheet.)

* The caution is not displayed when in the adjustment process, hotel menu, default setting, MCL operation and auto preset

(Ch search operation).

The OSD display including the menu and this caution have priority over all others.

When “OSD display” (described below) is set to “Variable”, this caution is displayed as a special case.

Selection Adjustment from 1 to 60 (no loop)

Def

ault 060

Explanation Sound volume can not be adjusted higher than the preset value.

Limit in setting • When the sound volume is set lower than 59, only figures are displayed and the sound volume bar is not displayed.

• The maximum sound volume for ON-timer (Wake up timer) is limited also to the preset value.

Exception • In the item “VOLUME” of adjustment process, the sound volume can be set freely irrespective of this setting.

Remarks • Setting is valid only for the speakers of the unit. (As for the headphone, the sound volume can be set up to 60 irrespective

of the limit.)

• In line output (sound volume variable), the sound volume can be adjusted from -60 to 0 irrespective of pre-adjusted value.

• When the sound volume is set higher than the MAX setting by the adjusting process or headphone, the sound volume con-

trol operation is prohibited for turn-up and the sound volume should be tu

rned down to MAX in this state.

<Example ofimage>

Page 24

LC-60H20T/LC-70H20T

5 – 11

3. VOLUME FIXED

4. VOLUME FIXED LEVEL

5. RC BUTTON

6. PANEL BUTTON

7. MENU BUTTON

Selection Selection between “Variable”,''Fixed'' and ''AC/RC CTRL'' ( loop provided ).

Default Variable

Explanation Sound volume is fixed and made invariable.

Limit in setting • The sound volume for the ON-timer (Wake up timer) is fixed also without display of menu. Besides, the setting is made

impossible. (Basically, the menu is not displayed.)

• The following keys become invalid:

1) Sound volume Up/Down (VOL +/-) [for both remote control and the unit]

2) Mute (MUTE)

Exception • In the item “VOLUME” of adjustment process, the sound volume can be set freely irrespective of this setting.

Remarks • In “Variable” setting, the sound volume had been conventionally set at 1 but this operation has been abolished (and follows

the last memory).

•

The sound volume for the ON

-time is not set at 1 either and the sound volume set value of the ON-timer before the hotel

mode is executed.

• Setting is valid only for the speakers of the unit. (As for the headphone, the sound volume can be set up to 60 irrespective

of the limit.)

• In line output (sound volume variable), the sound volume can be adjusted from -60 to 0 irrespective of pre-adjusted value.

• As for sound volume fixing and sound volume MAX level, the sound volume fixing has priority.

• Once the sound volume has been changed by adjustment process or headphone, it should be set back to the sound volume

preset by sound volume fixing level when the adjustment process ends or when the headphone is removed.

Selection Adjustment from 1 to 60 (no loop)

Default 020

Explanation The sound volume to be fixed by “Volume fixed” is determined.

Limit in setting None

Exception None

Rem

arks Setting is valid only when “Volume fixed” is selected for “fixed”.

This must be confirmed actually by changing also the sound volume in accordance with setting.

Selection Selection between “Resp ond”and "No respond"( loop provide ).

Default Respond

Explanation Acceptability of keys by remote control is limited or reception of keys can be prohibited.

Limit in setting

1)

In “No respond” setting, all the keys (including the power key) are not accepted.

Exception • Adjustment process, factory setting, inspection process and hotel only keys are valid irrespective of setting.

• All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

Remarks

Selection Selection between “Respond” and “No respond” (loop provide)

Default Respond

Explanation All the operations by keys (except the power key) of the unit can be invalidated.

Limit in setting

Exception • Inspection mode and hotel menu mode can be started irrespective of setting.

• All the keys ca

n be used in adjustment process, inspection mode and hotel menu irrespective of setting.

Remarks

Selection Selection between “Respond” and “No respond” (loop provide)

Default Respond

Explanation In “No respond” setting, the menu operation by the menu key of the remote control and the menu key of the unit is invalidated.

Limit in setting • ON-timer (Wakeup Timer) is turned OFF.

• The following keys become invalid.

Wake-up timer and clock setting keys and all of the direct change keys to menu display

Exception • Inspection mode and hotel menu mode can be started irrespective of setting.

• All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

Remarks

•

In "AC/RC CTRL" the tv stars at the volume specified in the volume fixed level.The volume can be adjust by remote control

but after OFF.ON ,it will return to the volume fixed level.

Page 25

LC-60H20T/LC-70H20T

5 – 12

8. OSD DISPLAY

9. BLUE SCREEN

10.INPUT MODE START

11.INPUT MODE FIXED

Selection Selection between “Yes”, “No” (loop provide)

Default Yes

Explanation The following OSD displays are made ineffective.

Displays of menu group, channel call, sound volume bar and direct key call

Limit in setting • Set time of the OFF-timer (SLEEP TIMER) is cleared.

• Setting of the no-signal power-OFF (AUTO POWER OFF) is cleared to “OFF”.

• Setting of the no-operation power-OFF is cleared to “OFF”.

• Keys falling under any of the following items become invalid.

1) Appearance of screen changes and the sound changes.

2) Personal functions which are hard to restore.

Ex.) Screen display, menu, OFF-timer, ON-timer, AV MODE, screen size switching, clock setting, treble emphasis, AUDIO

ONLY, sound changeover, LANGUAGE, CLOSED CAPTION

Others • Simple input switching is generated. Those which are restored soon after leaving as they are and

may be requested for

change by customer are not prohibited.

Ex.) Brightness sensor (BACKLIGHT) and PIC. FLIP

Exception • Such a caution which is displayed independently is displayed asitis.

Non-responding signal caution, TELE TEXT caution and power-ON fixing caution

Selection Selection between “Yes”, “No”

Default No

Explanation When no signal inputs, selecting the background color.

Selected to “Yes”---Blue screen

Selected to “No”---No Blue screen

Selection Selection between “Normal”, “ATV (CH~)'HDMI 1,HDMI 2,HDMI 3,COMPONENT,AV,PC,MEDIA (loop provide)

Default Normal

Explanation In power-ON, the input source to be started or channel can be set.

(In standard mode, the operation follows the last memory.)

About options • All the input sources in the model are made selectable.

• When the input/output switchable input source is selected and the input source is set to output, the setting ofinput/output

switching is changed to input at the execution of hotel menu. In addition, the input/output switching

by menu is prohibited.

• In TV mode, the display of all channels is stopped and it is treated as an input source. At this time, the channel to be set follows the last memory and the content of the last memory is included in the notation by options. Ex.) TV (CH2), TV (CH4)

etc.

• The order of appearance of options in the hotel menu should agree with the order of toggles by input switching key.

Limit in setting • The display of channel setting menu and the channel setting operation are prohibited (except for MCL).

Exception None

Remarks • In setting at “Normal”, the setting of “Input mode fixed” is changed to “Variable” and selection should be prohibited.

Selection Selection between “Variable” and “Fixed” (loop provide)

Default ‒ (Variable)

Explanation The input mode is fixed at the input source or the channel set at the “Input mode start” in 10 and other input sources and chan-

nels can be made non-selectable

.

Limit in setting • With the execution of hotel mode, the input source is forced to change to that set by “Input mode start” and the channel

switching and input switching are prohibited thereafter.

• The following keys are invalidated.

CH , direct tuning button, FLASHBACK, input

*However, the keys (input switching and CH , keys) of the unit for menu operation remain valid.

Exception None

Remarks • In the following case, setting is cancelled and mode is changed to “Variable”.

When the setting of “Input mode start” is set to “Standard (Normal)”

Page 26

LC-60H20T/LC-70H20T

5 – 13

12.PRESET CHANNEL PLAN

Selection Selection between "ON" and "OFF"

Default OFF

Explanation [ON] : Display preset channel plan when power on.

[OFF]: Not display preset channel plan. (Default setting)

Remark When hotel mode is ON and PRESET CHANNEL PLAN is [ON],

press power ON (Panel or R/C key), it displays preset channel plan on the screen.

When

user press ENTER key during TV mode ,its shows preset channel plan.

Page 27

LC-60H20T/LC-70H20T

6 – 1

CHAPTER 6. TROUBLESHOOTING

TABLE

[1] TROUBLESHOOTING TABLE

[2] TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE

No power (front LED failure to light up) or no startup (front LED failure to turn from red to blue)

Are the wire harnesses and other cables properly connected in

the set?

NO Reconnect the wire harnesses and other cables properly in the

set.

YES

Is there the PSONand PNLPOWsignal input at pins

(10 ) and (12

) of P9602?

NO Check the

PS-ON signal li ne PNL POWsignal line.

YES

Are the DC/DC converter outputs and the output voltages along

the control lines as specified?

NO Check the DC/DC converters and the control lines. Replace

defective parts as required.

1) M+5.6V (IC9601) 8) BU+3.3V (IC9604)

2) D+1.0V

(IC9612)

3) D+5V (IC9607)

4) BU+5V (D9610)

5) D+3.3V (IC9606)

6)

D+1.5V(IC9608)

7) D+1.15V

(IC9602)

9) D+2.5V (IC9605)

10) M+5.1V(IC9617)

Page 28

LC-60H20T/LC-70H20T

6 – 2

With [RF] signal input No video onscreen (1)

No video in the UHF/VHF reception

Is there IF output from the tuner pin(8),(9)of TU1102asspecified? NO Check TU1102 and its peripheral circuits.

YES

Is there IF input at pin W1 & W2 of IC3301 ? .1033CI&2011UTneewtebtiucricehtkcehCON

YES

NO Check IC3301 and its peripheral circuit to SC3801

YES

Check LVDS cable, LCD controller (incl. panel) and their peripheral circuits.

With <Video> signal input No video onscreen (2)

No external input video onscreen <INPUT 7>

Is INPUT 7 selected on the input select menu screen? NO Select INPUT 7 on the input select menu screen to pick up the

right input signal.

YES

Is there the video signal input at pin (R2) of IC3301? NO Check the line between pin (9) of J502 and pin (R2) of IC3301.

YES

NO Check IC3301 and its peripheral circuits to SC3801

YES

Check LVDS cable, LCD controller (incl. panel) and their peripheral circuits.

Are there the signal output

( P19-P20,R19-R21,T19-T21,V19-V21

W18-W21,Y18-Y21,AA18-AA20)ofIC3301toSC3801?

Are

there

the signal outputs pin ( P19-P20 , R19-R21 ,T19-

T21,U19-U20,V19-V21,W18-W21,Y18-Y21,AA18-AA20 ) of IC3301 to SC3801?

U19-U20

there

Page 29

LC-60H20T/LC-70H20T

6 – 3

With <Component> signal input No video onscreen (3)

No external input video onscreen <INPUT 6>

Is INPUT 6 selected on the input select menu screen? NO Select INPUT 6 on the input select menu screen to pick up the

right input signal.

YES

Are there the Y, Pb and Pr signal inputs at pins (L1), (L3) and

(M1

) of IC 3301 respectively?

NO Check the line between pins (15)/(17)/(19 )of J502 and pins (L1)/

(L3) /(M1) of IC3301.

YES

NO Check IC3301 and its peripheral circuitstoSC3801

YES

Check LVDS cable, LCD controller (incl. panel) and their peripheral circuits.

With <HDMI1/HDMI2 / HDMI3/HDMI4/HDMI5>signal input No video onscreen (4)

No external input video onscreen <INPUT 5/HDMI1/HDMI2/HDMI3/HDMI4>

ON

YES

YES

toSC3801?stiucriclarehpirepstidna1033CIkcehCONstuptuolangisehterehterA

YES

Check LVDS cable, LCD controller (incl. panel) and their peripheral circuits.

Are there the signal outputs

(P19-P20 ,R19-R21,T19-T21,U19-U20,

V19-V21,W18-W21,Y18-Y21,AA18-AA20 ) of IC3301toSC3801

Pin(P19-P20,R19-R21,T19-T21,U19-U20

,V19-V21,W18-W21,Y18-Y21 ,AA18-AA20 ) of IC3301 toSC3801

Select <HDMI1-HDMI5> on the input

select menu screen to pick up the right signal input

Check peripherel circuit between

IS HDMI1/HDMI2/HDMI3/HDMI4/HDMI5 selected on menu

screen ?

NO

Are there signal output from (SC1501/SC1503/SC1504/SC1506/SC1507)

(SC1501/SC1503/SC1504/SC1506/SC1507)

Page 30

LC-60H20T/LC-70H20T

6 – 4

No audio heard (1)

No sound in the UHF/VHF reception.

NO Check TU1102 and its peripheral circuits.

YES

Is there the 12C signal input at pins (W4 ), (W5) of IC3301? NO Check IC3301 and its peripheral circuits.

YES

stidna2071CIdna1033CIneewtebnoitcennockcehCON?2071CIfo)6(niptatuptnilangisoiduaerehtsI

peripheral circuits.

YES

Is the L-ch audio signal output at pin (26),(27)

NO Check IC1702 and its peripheral circuits.

of IC1702 normal?

YES

Are the audio signal L-ch and R-ch output at (3)/(4) and (1)/(2) of

P1701 normal?

NO Check circuit between IC1702 & P1701.

YES

Check speakers and their peripheral circuits.

(30),(31)

of IC1702 normal?

Is the R-ch audio signal output at pin (10

(11), (14) (15),

Is the IF output from the tuner pin(8) & (9)

of TU1102 as specified ?

Page 31

LC-60H20T/LC-70H20T

6 – 5

No audio heard (2)

No external audio heard

<INPUT 7>

Is there the L-ch audio signal input from pin (7) ofinput terminal

J502 to pin (U4) of IC3301?

Is there the R-ch audio signal input from pin (5) ofinput terminal

J502 to pin (V5

)ofI

C3301?

<INPUT 6>

Is there the L-ch audio signal input from pin (13) ofinput terminal

J502 to pin (T6) of IC3301?

Is there the R-ch audio signal input from pin (11) ofinput terminal

J502 to pin (T7) of IC3301?

YES

Is there the I2S signal output at pin ( J19),(J20) of IC3301 ? NO Check IC3301 and its peripheral circuits.

YES

ON?2071CIfo)6(niptatupnilangisoiduaerehtsI Check connection between IC3301 and IC1702 and its periph-

eral circuits.

YES

Is the L-ch audio signal output at pin(26), (27) ,(30),(31) of

IC1702 normal ?

NO Check IC1702 and its peripheral circuits.

Is the R-ch audio signal output at pin(10), (11),(14),(15) of

IC1702 norma

l?

YES

Are the audio signal L-ch and R-ch output at (3)/(4) and (1)/(2) of

P1701 normal?

NO Check circuit between IC1702 & P1701.

YES

Check speakers and their peripheral circuits.

Page 32

LC-60H20T/LC-70H20T

6 – 6

No audio heard (3)

ON?neercsnoraeppaegamiIMDHehtseoD

YES

.tonronettirwsiDIDEfitikcehCON<morftuptuooiduaoN

YES

Are waveforms input in to the pin(C4,D4/C3,D3/W7,V8)

of IC3301 normally?

NO Check peripheral circuits IC3301.

YES

ON?2071CIfo)6(niptatupnilangisoiduaerehtsI Check connection between IC3301 and IC1702 and its periph-

eral circuits.

YES

Is the L-ch audio signal output at pin(26), (27) ,(30), (31) NO Check IC1702 and its peripheral circuits.

of IC1702 normal?

YES

Are the audio signal L-ch and R-ch output at (3)/(4) and (1)/(2) of

P1702 normal?

NO Check circuit between IC1702 & P1701.

YES

Check speakers and their peripheral circuits.

of IC1702 normal?

Is the R-ch audio signal output at pin(10),(11),(14),(15)

No HDMI sound heard

(*INPUT1/INPUT2/INPUT3 is digital audio )

Refer to "(HDMI1/HDMI2/HDMI3/HDMI4/HDMI5)

video onescreen (HDMI)"

HDMI1/HDMI2/HDMI3/HDMI4/HDMI5 >

Page 33

LC-60H20T/LC-70H20T

6 – 7

No audio heard (4)

No sound from the HDMI sound input terminal.

(INPUT 1 analog audio)

YES

Is there the L-ch audio signal input from pin (2) of external input

terminal J506 (HDMI AUDIO IN) to pin (U3 ) of IC3301?

Is there the R-ch audio signal input from pin (3) of external input

terminal J506 (HDMI AUDIO IN) to pin (U1 ) of IC3301?

YES

NO Check peripheral circuits of IC3301.

YES

CON?2071CIfo)6(niptatupnilangisoiduaerehtsI heck connection between IC3301 and IC1702 and its peripheral circuits.

YES

Is the L-ch audio signal outputat pin(26),(27),(30),(31)

NO Check IC1702 and its peripheral circuits.

of IC1702 normal?

YES

Are the audio signal L-ch and R-ch output at (3)/(4) and (1)/(2) of

P1701 normal?

NO Check circuit between IC1702 & P1701.

YES

Check speakers and their peripheral circuits.

of IC1702 normal?

Is the R-ch audio signal output at pin(10),(11),(14),(15)

Are 12S signal output from the pins ( J19 )

,(J20 ) of IC3301 normally

?

Page 34

LC-60H20T/LC-70H20T

7 – 1

CHAPTER 7. SYSTEM BLOCK DIA-

GRAM /WIRING DIAGRAM

[1] SYSTEM BLOCK DIAGRAM

A

C

B

D

E

F

G

H

2 109

8

7

6

54

3

1

NetSOC

External Key( For 60" and 70" model )

Ethernet Jack

TUNER

*Only LE660 for Realtek Net

Digital/Analog Taiwan( PWB pattern)

T

E

R

M

IN

A

L

C

o

C

o

ro

O

P

C

P

IR

S

e

n

s

o

r, Ex

te

rn

a

l R

e

m

o

te

a

nd

L

E

D

unit

L/R

Y

/P

b

/P

r

C

VBS

a

n

d

A

u

d

io

L

/R

L

/

R

USB_DP2

/DN2

USB_DP1

/DN1

USB_DP0

/DN0

*E

x

c

ep

t T

a

iw

a

n

HP Det

*D

2

M

odel o

n

ly

realtek wifi IC

HDMI

INPUT 3

INPUT 1

INPUT 2

INPUT 4

INPUT 5

MA

IN

P

OWER

I

C

1

7

0

2

Y

amaha

A

UDIO

A

M

P

V

H

IY

D

A

1

7

6

D

L

-1

Y

4

p

in

SP_L

IC3301 (MSTAR)

R

H

-

IX

D

619WJ

Q

Z

Q

(M

S

D

8821KT

K

for

X

)

SP_

M

U

T

E

V

D

A

UDIO

_OUT

SPI

SP

I

I/F

SP_R

SP

_

L

SP

_

R

SP R

8

Ω

1

0

W

IC

3

1

0

4

SPI F

L

ASH

W

in

b

o

n

d

V

HI

W

2

5

Q

2

8

FV

-1

Y

SP L

8

Ω

1

0

W

D

R

A

M

IF

I2

S_M

CLK

da

ta

A

(8

)

clkA

(2

)

da

ta

B

(8

)

clkB

(2

)

P

an

e

l

40

:F

U

ll

HD

60

:

F

U

LL

HD

Dou

b

le

sca

n

R1lk600D3G

V0

DF

70

"Full HD

Do

u

b

le

S

c

an

L

VDS

(

8

b

it

)

L

VDS

(8

b

it)

clkA

(2

)

da

ta

B

(8

)

clk

B

(2

)

da

t

a

A

(

8

)

KEY

KEY/SW

KEY

1

/

2

/P

O

W

E

R

I

R

IN

J502

C

o

m

p

A

ud

io

I

N

J502

C

VBS/C

O

M

P

IN

J5

0

2

M

o

n

L/R O

U

T

M

on

itor

A

ud

i

o

M

o

n

A

m

p

c

ircuit

J508 (

1

.5

A

)

U

SB

I

(S

U

PP

L

Y

)

CV

B

S

C

O

M

P

A

UD

IO

P

C

DD

C

S

C

502

P

C

D

S

U

B

15pin

P

C

(R

G

B

)

H

D

J506

P

C

A

ud

io

S

C

501

P

C

D

S

U

B

9p

in

U

SB

IF

J5

0

4

HP

H

P

A

m

p

c

ircuit

H

P

A

ud

io

out

I

2

S

_

S

D

SP

D

IF

O

U

T

D

516

SP

D

IF

O

U

T

Sharp TUNER

RTUNQA073WJQZ

I2

C

IF

+

/

IF

-

Built-in

D

e

m

odula

tor

40"P

o

w

e

runit

60

"

P

o

w

e

rUn

it

7

0

"P

owe

rUn

it

L

ED D

r

iv

er

O

FL

E

R

R

OR

P

NL S

T

B

P

9

6

0

2

1

6

p

in

12

V

SP_

S

T

B

Y

IC3502

Sa

m

s

un

g

D

D

R3 1

G

b

R

H

-

IX

D4

0

6

W

J

Q

ZQ

Sharp TUNER

RTUNQA075WJQZ

IF

+

/

IF

-

I2

C

S

C3

8

0

1

4

1

p

in

X

IN

/X

OUT

X

3

3

0

1

X

T

A

L(24

.

0

M

H

z

)

I2

S

_

S

C

L

K

I

2

S

_

LRC

L

K

P3302

4 pin (External KEY)

-

For 60"/70"

Key1

Key2

STBY_

GND

T

S

S

C

4401

C

I +

PS_ON(6

0

" and

70

"

)

J501 (1

.

5

A

)

J507 (

500

m

A

)

232

C

_TX

232C_

R

X

RC

on

trol

IR

_

P

AS

S

12

V

UART

R

S

-232C

M

o

tio

n

UAR

T

I2

C

_

D

AT

I2

C

_

C

L

K

R

C

o

n

tro

l

M

oti

o

n De

tector

I2C_

C

L

K

I2C_

D

A

T

R

T

D_R

ESE

T

A

C_C

T

RL

WIFI Module

C

E

C

IN

HD

M

I IN1

HDM

I

SC1501

HDMI 1/ARC

da

t

a

(4

clk(

2

)

I2

C

(

H

D

M

HPD0_

IN

/D

5

V

HDM

I I

N

3

HDM

I DDC

3

SC1503

HDMI 2/MHL(900mA)

data

(4

clk

(

2

)

I

2

C

(

H

D

M

I

HPD2_

IN

/D

5

V

M

HL

_

CAL

E_DET

HDM

I I

N

2

HDM

I DDC

2

HDM

I

S

W

IT

C

H

da

t

a

(

clk(

2

)

I2

C

(

H

D

M

HPD1_

IN

/D

5

V

SC1504

HDMI 3

_

Data

clk(2

)

HPD1_IN/D

5

V

I2

C

(

H

D

M

I

SC1507

HDMI 5

_

Data

cl

k

(

2

)

HPD4_

IN/D

5

V

I2

C

(H

D

M

I

SC1508

HDMI 6

_

D

a

ta

clk(2

)

HPD5_IN

/D

5

V

I2

C

(

H

D

M

I

SC1506

HDMI 4

_

Da

t

a

clk(2

)

HPD3_

IN/D

5

V

I2

C

(H

D

M

I

E

T

H_RX

E

T

H_T

X

HDMI6

J9401 8 pin

LED_R

P

3

8

0

2

1

0

p

in

LE

D

G

re

e

n

/ Red

IR

R

ec

e

i

v

er

SC1508 41 pin

USB

WISTERIA SYSTEM BLOCK

Page 35

LC-60H20T/LC-70H20T

7 – 2

[2] WIRING DIAGRAM LC-60H20T

A

C

B

D

E

F

G

H

2 109

8

7

6

54

3

1

[LW]

[PD] Main

POWER [SP]

Q

[

NE]

[RB]

[KM]

D

UNTKG448FM**

RUNTKB316WJQZ

DUNTKG477FM**

DUNTKG505FM**

Cocoro

NetSOC

WIFI

1

16

41 1

USB 1

2

4

1

HDMI1

HDMI2

[KM] 4 1

1 41

1

4

HP

1

4

1

1

0

1

4

HDMI3

HDMI5

HDMI4

USB

2

Ethernet

1

41

USB

OU

T

PU

T

Page 36

LC-60H20T/LC-70H20T

7 – 3

[3] WIRING DIARAM LC-70H20T

A

C

B

D

E

F

G

H

2 109

8

7

6

54

3

1

DUNTKG504FM**

[LW]

[PD] Main

POWER [SP]

R

U

N

T

K

B

2

8

6

W

J

Q

Z

DUNTKG503FM**

[NE]

[RB]

[KM]

D

U

NTKG448FM**

RUNTKB316WJQZ

DUNTKG477

F

M**

DUNTKG505FM**

Cocoro

NetSOC

WIF

I

1

16

41

1

USB 1

24

1

HD

M

I1

HDMI

2

[KM] 4 1

1 41

1 4

HP

1

4

1

10

1

4

HDMI

3

HDMI5

HDMI4

US

B 2

Ethernet

1

41

USB

OUTPUT

Page 37

LC-60H20T/LC-70H20T

8 – 1

CHAPTER 8. DESCRIPTION OF

SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIAGRAM

1. VOLTAGE MEASUREMENT CONDITION:

1) The voltages at test points are measured on exclusive AC adaptor and the stable supply voltage of AC 110-240V. Signals are fed by a colour bar signal

generator for servicing purpose and the above voltages are measured with a 20k ohm/V tester.

2. INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1) The unit of resistance "

" is omitted.

(K=k

=1000

, M=M

).

2) All resistors are ± 5%, unless otherwise noted.

(K= ± 10%, F= ± 1%, D= ± 0.5%)

3) All resistors are 1/16W, unless otherwise noted.

CAPACITOR

1) All capacitors are

F, unless otherwise noted.

(P=pF=

F)

.

2) All capacitors are 50V, unless otherwise noted.

CAUTION:

T

his circuit diagram is original one,

therefore there may b

e

a slight

difference from yours.

SAFETY NOTES:

1) DISCONNECT THE AC PLUG FROM THE AC OUTLET

BEFORE REPLACING

PARTS.

2) SEMICONDUC

TOR HEAT

SINKS SHOU

LD BE REGARDED AS

POTENTIAL SHOCK HAZARDS WHEN THE CHASSIS IS

OPERATING.

IMPORTANT SAFETY NOTICE:

P

A

RTS MARKED WITH " "

()

ARE IMPORTANT

FOR MAINTAINING

THE SAFETY OF THE SET. BE SURE TO

REPLACE THESE PARTS WITH SPECIFIED ONES FOR MAINTAINING THE SAFETY AND PERFORMANCE OF THE SET.

Page 38

LC-60H20T/LC-70H20T

8 – 2

[2] MAIN UNIT

A

C

B

D

E

F

G

H

2 109

8

7

6

54

3

1

(PWB)

(PWB)

IF_IN+

RESETRESET

IF_IN-

IF+

IF-

TAGC

I2C_DAT

I2C_CLK

RESET

IF_IN+

IF_IN-

I2C_CLK

I2C_DAT

I2C_DAT

004

TAGC

004

D+3.3V

010

IF+

004

C1117

0.1u

I2C_CLK

004

FB1101

0253TA

C1115

47P

CCZ

C1148

0.1u

C1105

10u

16V

R1120

0CZR11210CZ

C1103

0.1u

25V

IF-

004

C1147

0.1u

C1120

0.1u

R1117

470

C1116

47P

CCZ

C1113

0.1u

C1118

0.1u

R1102

10K

TUN_RF_RESET

004

C1101

1000P

50V

C1128

10P

C1125

10P

0.47uH

L1101

PMT

0.47uH

L1102

PMT

*TU1103

QA075WJQZ

Taiwan

1

+5V

2

RESET

3

3.3V

4

NC

5

IF_AGC

6

NC

7

NC

8

IF+

9

IF-

10

SCL

11

SDA

R1104

0

R1109

100

R1108 100

TO MAIN4(CPU)

TO MAIN10(POWER)

Use LOW IF

MAIN1 (TUNER)

Page 39

LC-60H20T/LC-70H20T

8 – 3

A

C

B

D

E

F

G

H

2 109

8

7

6

54

3

1

USB_DP1

USB_DN1

PC_HSYNC_IN

PC_VSYNC_IN

PC_R

PC_G

PC_B

USB_DP1

USB_DN1

PC_AUD_L

PC_AUD_R

HP_PLUG

HP_R_OUT

HP_L_OUT

UART_DEBUG_TX

UART_DEBUG_RX

CVBS_AUD_L

COMP_Pr

MON_L_OUT

CVBS

MON_R_OUT

COMP_Y

COMP_AUD_R

COMP_Pb

CVBS_AUD_R

COMP_AUD_L

RControl

IR_PASS

USB_DP0

USB_DN0

USB_DP0

USB_DN0

232C_TX

232C_RX

USB_DN2USB_DN2

USB_DP2USB_DP2

USB_DP2

USB_DN2

OPT_OUT

FB521

A527WJ

FB519

0241TA

R590

12K

C543

56P

CH

PC_B

FB520

0241TA

R611

2.2K

PC_G

PC_HSYNC_IN

PC_AUD_R

FB522

A527WJ

R613

100

PC_R

PC_AUD_L

C560

47P

CH

FB517

0241TA

C561

47P

CH

C544

56P

CH

R614

100

R578

10K J

FB518

0241TA

R608

4.7K

R577

10K

J

FB523

A527WJ

R607

4.7K

R581

12K

R610

2.2K

PC_VSYNC_IN

TL502

TL503

BU+3.3V

IR_PASS

232C_TX

004

UART_DEBUG_RX

UART_DEBUG_TX

COMP_AUD_L

CVBS_AUD_R

CVBS_AUD_L

COMP_AUD_R

D+5V

COMP_Pr

COMP_Pb

CVBS

MON_R_OUT

COMP_Y

MON_L_OUT

USB_DN1

USB_DP1

*TL579

*TL580

M+5.6V

R621

100

R620

100

C504

10P

R502

33K

C502

10P

R503

5.6K

R510

100K

R505

33

R506

100K

R508

33

HP_PLUG

HP_R_OUT

HP_L_OUT

R58375TQ

R584

75

TQ

R58275TQ

R615

0

R616

0

R534

10K

R525

100K

R511

12K

R527

100K

C526

1000P

J502

LA047WJQZ

1

AV_OUT_R

3

AV_OUT_L

5

AV1_R

24

8

10 11

COMP_R

12

13

COMP_L

1415

COMP_Y

1617

COMP_CB

1819

COMP_CR

6

9

AV1_V

7

AV1_L

20

R515

12K

R532

12K

R54975TQ

FB527

0244TA

R54775TQ

C514

56P

C532

56P

FB512

0244TA

C517

56P

R528

100

1/4W

FB528

0244TA

C527

1000P

C530

56P

FB529

0244TA

R535

12K

R536

10K

R516

10K

R53375TQ

C508

0.01u

R54875TQ

R513

10K

R526

100

1/4W

C509

0.01u

SC502

NB037WJQZ

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

C524

0.1u

10V

K

(PWB)

C523

10u

16V

D516

CDL3711F

#Use VHPCDL3711F-1

123

4

5

OPT_OUT

232C_RX

004

RControl

BU+5V

R624

0

FB501

0104TA

FB502

0104TA

FB511

0104TA

FB509

0104TA

FB510

0104TA

FB514

0104TA

FB508

0104TA

FB513

0104TA

C553

1000P

CH

C548

1000P

CH

*R617

0

*R618

0

SC501

NB035WJQZ

1

2

3

4

5

6

7

8

9

10

11

C589

0.1u

25V

C585

0.1u

C582

10u 16V

KZA510WJPZ

R5530CZ

IC511

M3221EIP

RS232

TRANSMITTERS/RECEIVERS

1

EN

2

C1+

3

V+

4

C1-

5

C2+

6

C2-

7

V-

8

R1_in

9

R1_out

10

NC

11

T1_in

12

FORCEON

13

T1_out

14

GND

15

Vcc

16

SHDN

C584

0.1u

R551

100

1/10W

AHT1G08W

123

GND

4

5

VCC

R550

100

1/10W

C586

0.1u

R552

100

1/10W

C588

1000P

CZB

R556

100

R5540CZ

C587

0.1u

J501

ZA319WJQZ

USB Atype Right Angle

1

+5V

2

USB_DN

3

USB_DP

4

GND

J506

JA039WJQZ

123

D519

EXA741WJQZ

RHEX

TL519

TL521

TL518

TL520

J507

ZA319WJQZ

USB Atype Right Angle

1

+5V

2

USB_DN3USB_DP

4

GND

USB_DN0

USB_DP0

R588

27K

R585

10K

C536

10u

16V

KZA510WJPZ

C537

0.1u

CZB

10V

R587

27K

J

C538

10u

16V

KZA510WJPZ

TL569

TL572

TL571

TL573

J508

ZA319WJQZ

USB Atype Right Angle

1

+5V

2

USB_DN

3

USB_DP

4

GND

M+5.1V

BD2242G

1

Vin

2

GND

3

EN

4

FAULTB

5

ILIM

6

Vout

FB530

A373WJQZ

FB532

A373WJQZ

FB533

A374WJQZ

FB531

A374WJQZ

FB507

A374WJQZ

FB503

A373WJQZ

C592

10u

16V

KZA510WJPZ

C590

10u

16V

KZA510WJPZ

R601

1K

S172B50U

1

ON

2

GND

3

N.C.

4

Vin

5

Vout

J504

JA054WJQZ

1236

R573

27K

J

C540

0.1u

CZB

10V

C539

10u

16V

KZA510WJPZ

R570

10K

R574

27K

C541

10u

16V

KZA510WJPZ

BD2242G

1

Vin

2

GND

3

EN

4

FAULTB

5

ILIM

6

Vout

L501

FA424WJ

1

2

3

4

L502

FA424WJ

1

2

3

4

L503

FA424WJ

1

2

3

4

USB_DP2

USB_DN2

TO MAIN9(AUDIO_AMP)

TO MAIN10(POWER)

TO MAIN4(CPU)

USB:1500mA max

USB:500mA max

USB:1500mA min

USB:1500mA max

HP_PLUG

UN-PLUGGED:H

PLUGGED:L

Bottom

TO MAIN16(I/F)

MAIN2(TERMINAL)

S/PDIF

IC512

IC514

IC515

IC513

PC AUDIO

0 6.1 6.2 6.2 3.2 6.1 -5.6 0

3.3

0

3.30

-5.7

03.3

2.8

3.3 3.3 0

2.2

5.0

Page 40

LC-60H20T/LC-70H20T

8 – 4

A

C

B

D

E

F

G

H

2 109

8

7

6

54

3

1

HDMI2__CLKN

HDMI2_D0P

HDMI2__CLKP

HDMI2_D2P

HDMI2_D1N

HDMI2_D1P

HDMI2_D0N

HDMI2_D2N

HDMI0__CLKP

HDMI0_D0P

HDMI0__CLKN

HDMI0_D1P

HDMI0_D0N

HDMI0_D1N

HDMI0_D2N

HDMI0_D2P

HDMI0_D2P

HDMI0_D2N

HDMI0_D0N

MHL_CABLE_DET1

MHL_VBUS_EN1

MHL_OCD1