Page 1

CD-K4

CP-K4

SHARP

---------------------------------~S92Il'1GDK:455Z1

SERVICE MANUAL

Speaker Unit CP-K455Zisnot included with this productinthe Philippines.

•Inthe

I

interestsofuser-safety

condition

and

only

parts

illJD~@

DIGITAL

AUDIO

CD-K455Z

CP-K455Z

the

set

identicaltothose

shouldberestored

specifiedbeused.

to

its

original

INDEX TO CONTENTS

Page

SPECIFICATIONS 2

VOLTAGE SELECTION 2

NAMES OF PARTS 3-5

DiSASSEMBLy

REMOVING AND REINSTALLING THE MAIN PARTS 8-10

BLOCK DIAGRAM 11-13

NOTES

ADJUSTMENT 15-18

SCHEMATIC DIAGRAM / WIRING SIDE OF P.W.BOARD

WAVEFORMS OF CD CIRCUIT

TROUBLESHOOTING (CD SECTION) 43-47

FUNCTION TABLE OF

LCD SEGMENT

EXPLODED VIEW 56-59

REPLACEMENT PARTS LIST 60-72

ON

SCHEMATIC DIAGRAM/TYPES OF TRANSISTOR AND LED

IC

'"

6,

14

19-41

42

48-55

55

7

SHARP CORPORATION

Page 2

-K455Z

-K455Z

FOR A COMPLETE DESCRIPTION OF THE OPERATION

TO

THE

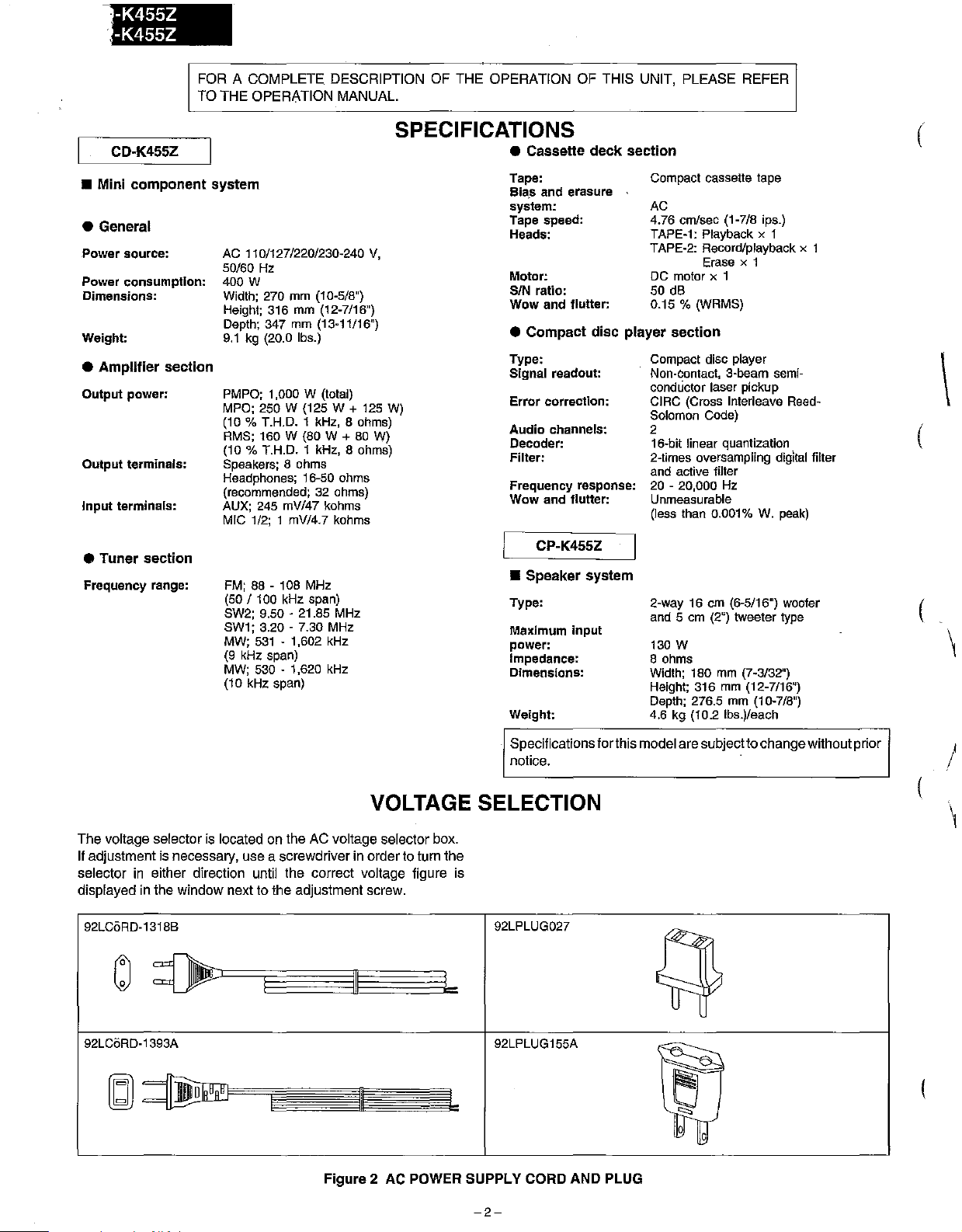

CD-K455Z

• Mini component system

• General

AG

Power

source:

Power consumption:

Dimensions:

Weight:

• Amplifier section

Output power:

Output terminals:

Input terminals:

• Tuner section

Frequency range:

110/127/220/230-240

50/60

400

Width;

Height;

Depth; 347

9.1kg(20.0

PMPO;

MPO;

(10

% T.H.D. 1

RMS;

(10

% T.H.D. 1

Speakers;8ohms

Headphones;

(recommended;32ohms)

AUX;

MIG

FM;88(50/

SW2;

SW1;

MW;

(9

kHz

MW;

(10

kHz

OPERATION MANUAL.

Hz

W

270

mm

316

1,000 W (totai)

250

160 W

245

1/2;

100

9.50 - 21.85 MHz

3.20 - 7.30 MHz

531

span)

530

(10-5/6")

mm

(12-7/16")

mm

(13-11/16")

Ibs.)

W (125 W +

kHz,8ohms)

(80

kHz,8ohms)

16-50

mVl47

1 mVl4.7

108

MHz

kHz

span)

- 1,602

- 1,620

span)

V,

125

W +80W)

ohms

kohms

kohms

kHz

kHz

SPECIFICATIONS

• Cassette deck section

Tape:

Bia.s

and erasure

system:

Tape speed:

Heads:

Motor: DC

SIN

ratio:

Wow and flutter: 0.15 %

• Compact disc player section

Type:

Signal readout:

W)

Error correction:

Audio channels:

Decoder:

Filter:

Frequency response:

Wow and flutter:

CP-K455Z

• Speaker system

Type:

Maximum input

power:

Impedance:

Dimensions:

Weight:

OF

THIS UNIT, PLEASE REFER

Compact

AG

4.76 em/sec (1-7/8 ips.)

TAPE-l: Playback x 1

TAPE-2: Record/playback x 1

50

Compact

Non-contact,

conductor

eIRe

Solomon

2

16-bit

2~tjmes

and

20

Unmeasurable

(less

2-way 16

and5em

130

8

Width;

Height;

Depth;

4.6

cassette

Erase

motor

x 1

dB

(WRMS)

disc

laser

(Cross

Code)

linear

oversampling

active

filter

- 20,000

than

0.001%W.

em

(2")

W

ohms

180mm(7-3/32")

316

276.5

kg

(10.2 Ibs.)/each

3-beam

quantization

Hz

mm

tape

x 1

player

semi-

pickup

Interleave

(6-5/16") wooler

tweeter

mm

Reed~

digital

peak)

type

(12-7116")

(10-7/8")

(

\

(

filter

(

Specifications

notice.

VOLTAGE SELECTION

The

voltage selector is located on the AC voltage selector box.

If adjustment is necessary, use a

seleclor

displayed in the window next to the adjustmenl screw.

92LG6RD·1318B

92LC6RD·1393A 92LPLUG155A

in

either direction untii the correct voltage figure is

screwdriver in order to turn the

92LPLUG027

Figure 2 AC POWER SUPPLY CORD AND PLUG

lor

this modelaresubject10change without prior

o

o

!

-2-

Page 3

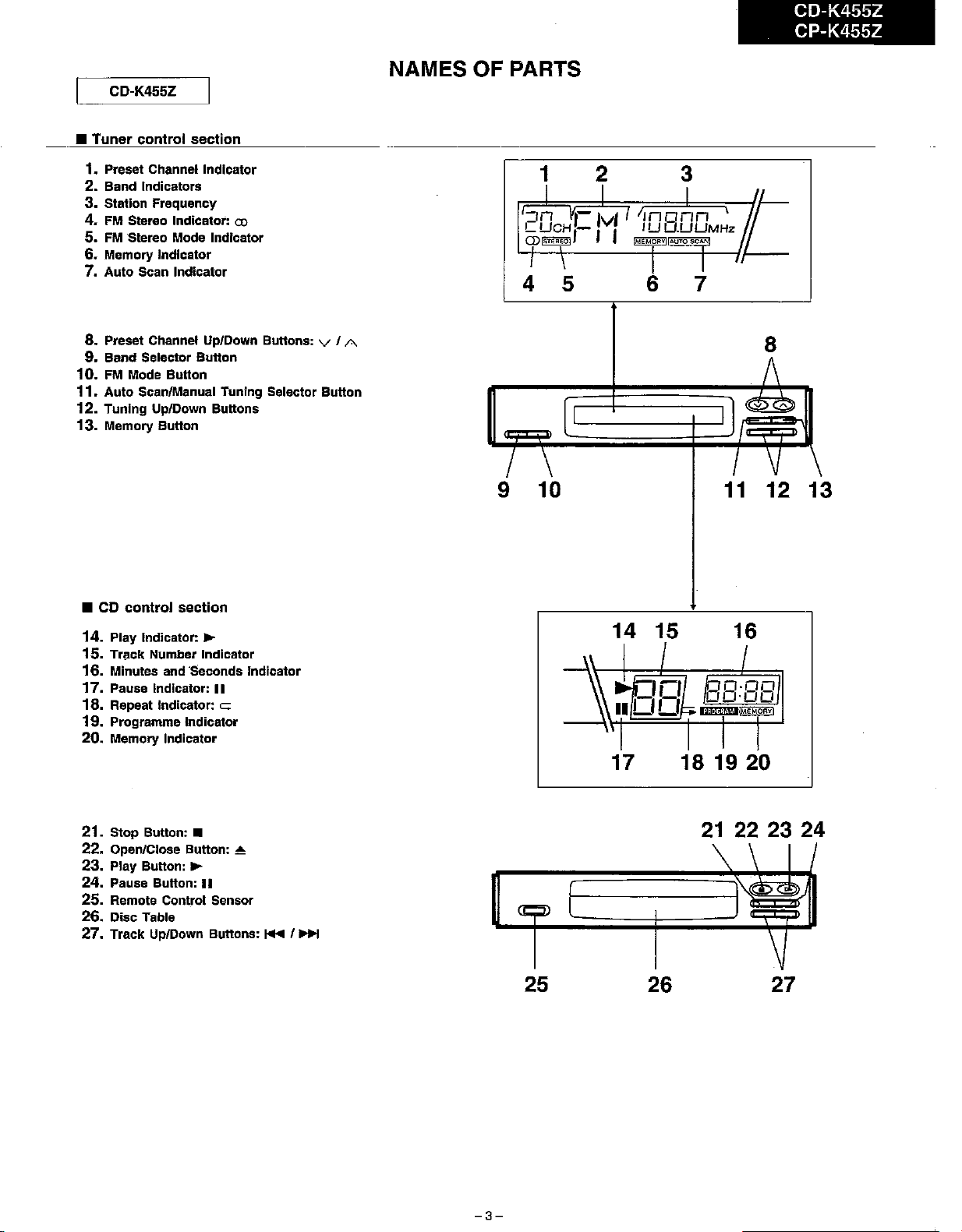

CD-K455Z

•

Tuner

control

1.

Preset Channel Indicator

2.

Band Indicators

3.

Station Frequency

4.

FM Stereo Indicator:

5.FMStereo Mode Indicator

6.

Memory Indicator

7.

Auto Scan

8.

Preset Channel Up/Down Buttons: v / A

9.

Band Selector Button

10.

FM

Mode Button

11.

Auto ScanlManual Tuning Selector Button

12.

Tuning UplDown Buttons

13.

Memory Button

section

CD

Indicator

NAMES OF PARTS

in

CUCH-

cpl[fffiQlf

I \ 1 I

4 5 6 7

[I'--

VII

Ivl"

"~~.

'Ina

IU

nn

.UUMHz

I,

+-_~

t

I

(v::>

CD-K455Z

CP-K455Z

""

•

CD

control

14.

Play Indicator:

15. Track Number Indicator

16.

Minutes and 'Seconds Indicator

17.

Pause Indicator:

18.

Repeat Indicator: c

19.

Programme Indicator

20.

Memory Indicator

21.

Stop Button: •

22.

Open/Close Button:

23.

Play Button:

24.

Pause Button:

25.

Remote Control Sensor

26.

Disc Table

27.

Track Up/Down Bullons:

section

~

II

~

~

II

i+lI/

~

11

12 13

14 15 16

/ I

21

222324

~

-3-

25 26

27

Page 4

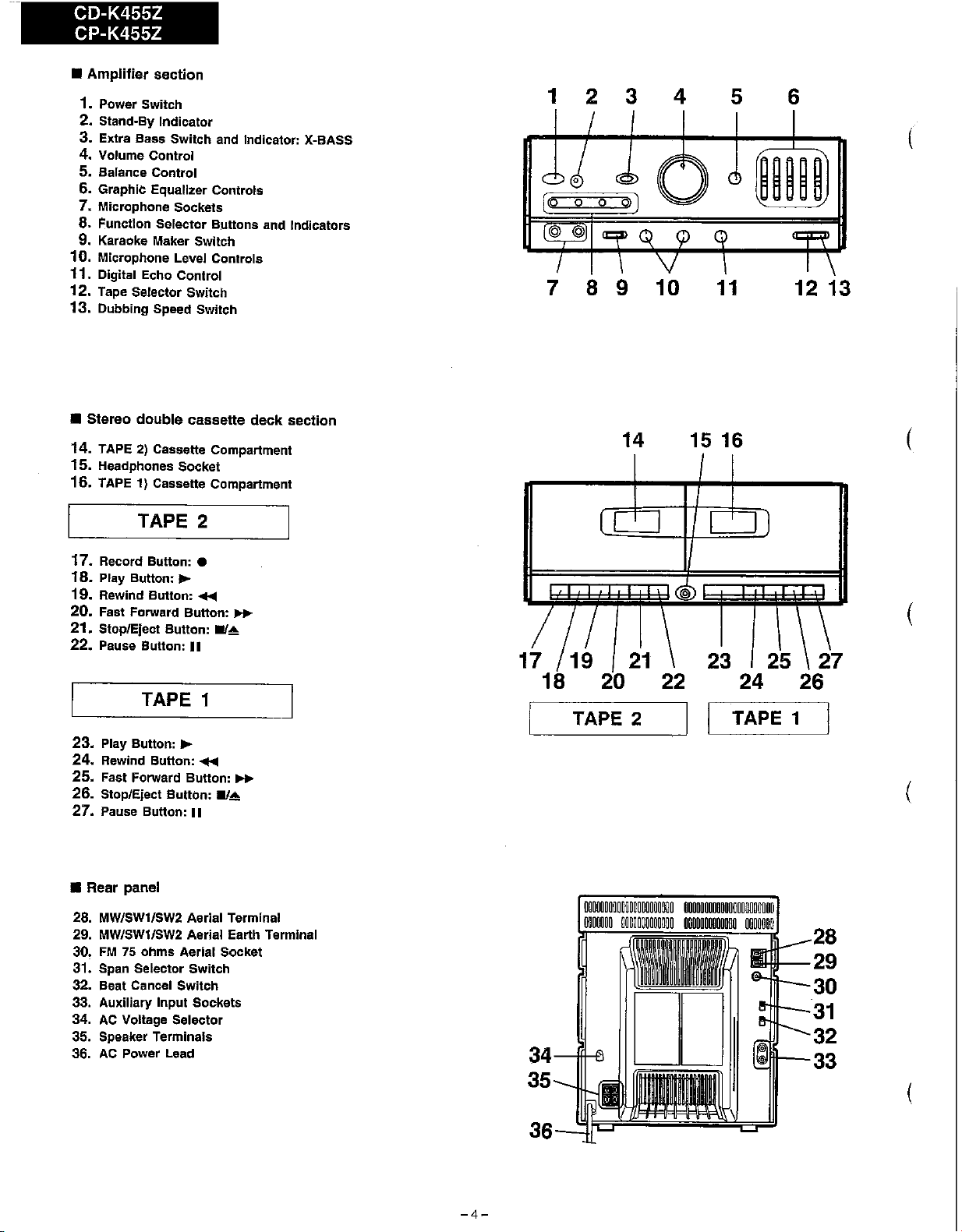

CD-K455Z

CP-K455Z

•

Amplifier

1. Power Switch

2. Stand-By Indicator

3. Extra Bass Switch and Indicator: X-BASS

4. Volume Control

5.

Balance Control

6. Graphic Equalizer Controls

7.

Microphone Sockets

8.

Function Selector Buttons and Indicators

9. Karaoke Maker Switch

10.

Microphone Level Controls

11. Digital Echo Control

12. Tape Selector Switch

13.

Dubbing Speed Switch

section

1 2 3 4

7 8 9 10

5 6

11

(

12 13

•

14.

15.

16.

Stereo

double

TAPE2)Casselle Compartment

Headphones Socket

TAPE 1) Casselle Compartment

cassette

TAPE 2

17.

Record BUllon: •

18.

Play Bullon:

19.

Rewind

20. Fast Forward

21. Stop/Eject

22. Psuse BUllon:

~

Bullon:

Bullon:

...

Bullon:

II/;!;

II

TAPE 1

23.

Play Bullon:

24.

Rewind

25.

Fast Forwsrd

26.

Stop/Eject

27.

Pause Button:

~

Button:

Bullon:

........

Bullon:

II/;!;

II

_

_

deck

seclion

TAPE 2

'-------~

14

15 16

I I TAPE 1

(

(

(

•

Rear

panel

28. MW/SW1/SW2 Aerial Terminal

29. MW/SW1/SW2 Aerial Earth Terminal

30,FM75

31. Span Selector Switch

32. Beat Cancel

33. Auxiliary Input Sockets

34.

35. Speeker Terminels

36.

ohms Aerial Socket

AC

Voltage Selector

AC

Power Lead

Switch

-4-

o~oooooooooooooooooooo

0000000

uoo~ooooooooo

34---tH~

[[]

35

36

ooooooooo~oooooooooooo

0000000000000

0000000

28

1lIl-IH-29

30

31

32

33

(

Page 5

CD-K455Z

CP-K455Z

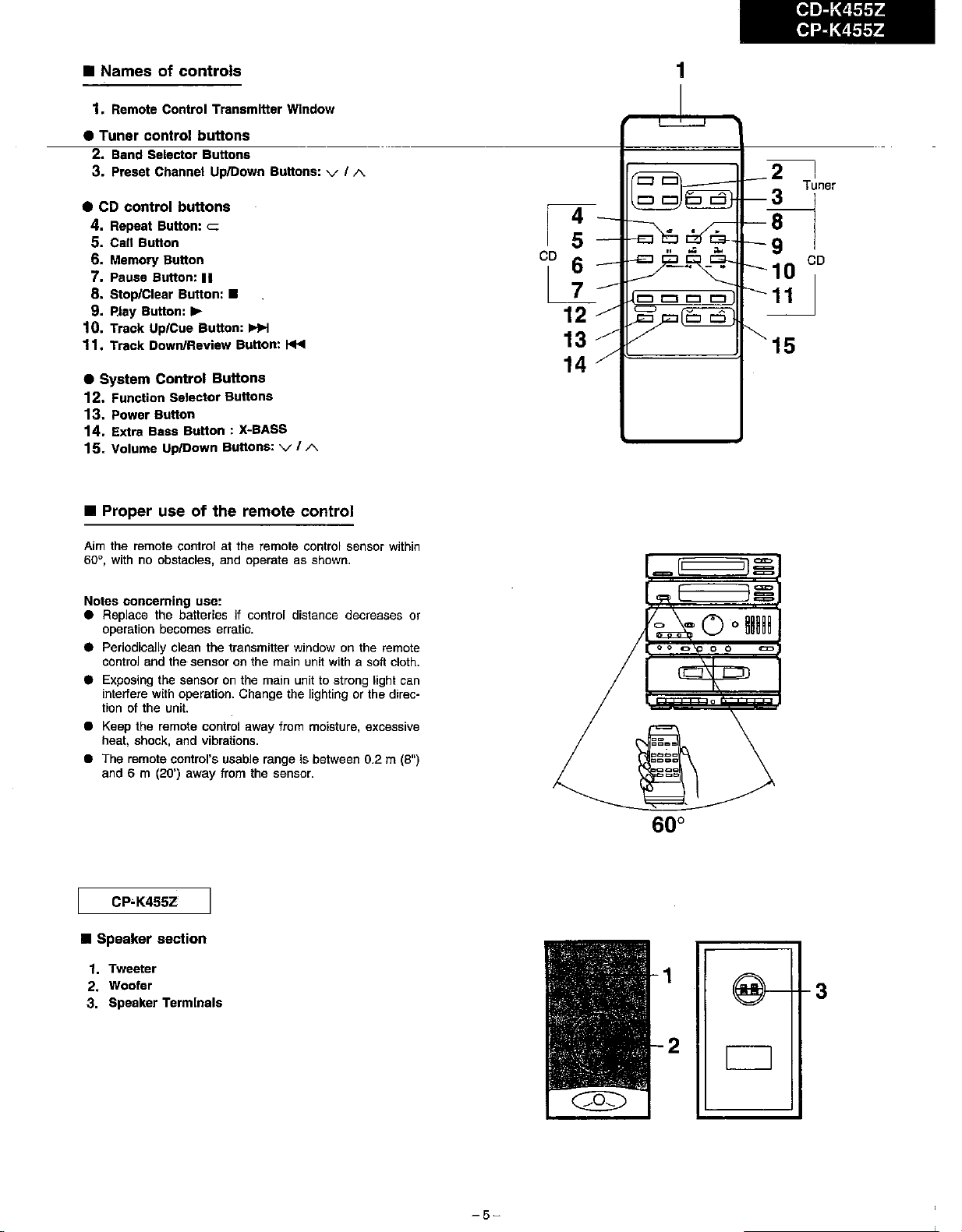

• Namesofcontrols

1.

Remote Control Transmitter Window

• Tuner control buttons

2~

Band Selector Buttons

3.

Preset Channel

•

CD

control buttons

4.

Repeat Bullon: c

5.

Call

Bullon

6.

Memory

7.

Pause Bullon:

8.

Stop/Clear Bullon: •

9.

Play Bullon:

10.

Track

11.

Track DownJReview Button:

• System Control Buttons

12.

Function Selector Buttons

13.

Power Button

14.

Extra Bass Bullon :

15. Volume UpJDown Buttons: v I A

•

Proper

Bullon

Up/Cue

useofthe

UplDown

1\

~

Bullon: _

Bullons: v / A

I'ttolIlI

X-BASS

remote

control

IT

CD 6

LL

12

13

14

1

21

3

Tuner

tI

10 CD

CJ

c:5

iiJ

15

Aim the remote control at the remote control sensor within

60°, with

Notes concerning use:

• Replace the batteriesifcontrol distance decreases or

• Periodically clean the transmitter window on the remote

• Exposing the sensor

• Keep the remote control away from moisture, excessive

• The remote control's usable rangeisbetween 0.2 m (8")

• Speaker section

1. Tweeter

2. Woofer

3. Speaker Terminals

no obstacles, and operate as shown.

operation becomes erratic.

control and the sensor on the main unit with a soft cloth.

on

interfere

tion of the unit.

heat, shock, and vibrations.

and 6 m (20') away from the sensor.

with

operation. Change the lighting or the direc-

the main unit to strong light can

I

..

0

I~

0

iim

00

=

@Jf--I+3

-5-

2

o

Page 6

CD-K455Z

CP-K455Z

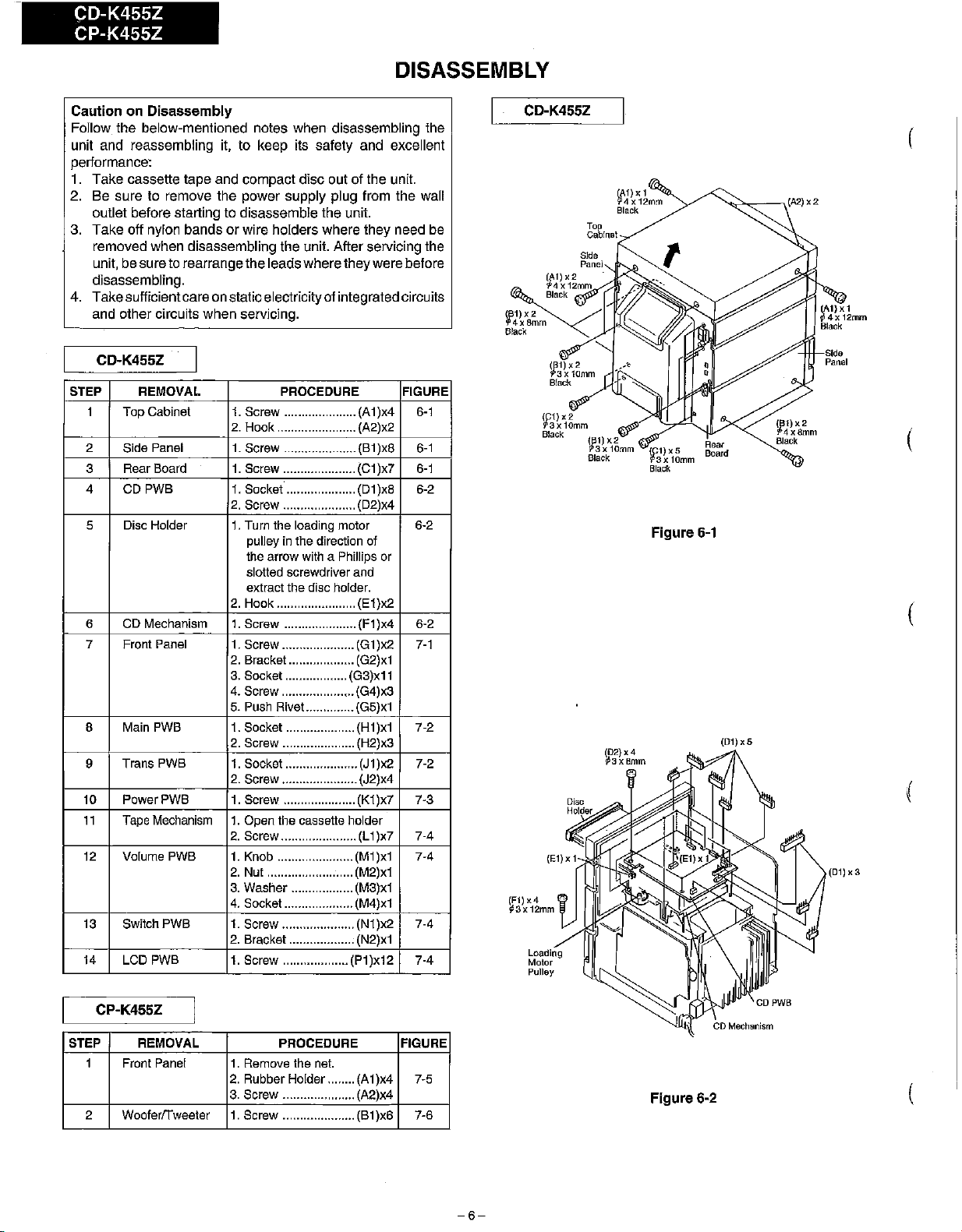

DISASSEMBLY

CautiononDisassembly

Follow the below-mentioned notes when disassembling the

unit and reassembling it, to keep its safety and excellent

pertormance~

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

or

3. Take off nylon bands

wire holders where they need be

removed when disassembling the unit. After servicing the

unit, besure to rearrange the leadswhere theywere before

disassembling.

4. Takesufficientcare on staticelectricityofintegratedcircuits

and other circuits when servicing.

CD-K455Z

STEP

I

2 Side Panel

3 Rear Board

4

5 Disc Holder

REMOVAL

Top Cabinet 1.

CDPWB

PROCEDURE

Screw

2.

1.

1.

I.

2.

1.

.....................(AI )x4

Hook

.......................(A2)x2

Screw .....................(BI )x8 8·1

Screw .....................

Socket ....................

Screw

.....................(D2)x4

Turn the loading

pulley in

the arrow

the

with

(CI

(DI

motor

direction

a Phillips or

)x7

)x8

of

FIGURE

6-1

8-1

6-2

6-2

slotted screwdriver and

extract the disc holder.

2.

Hook

.......................

CD

6

7 Front Panel

8 Main PWB

9

10 PowerPWB 1. Screw .....................

11

12 Volume PWB 1. Knob ......................

13

14

Mechanism

Trans PWB

Tape

Mechanism

SwitchPWB

LCD PWB

I.

Screw

.....................

Screw

1.

2. Bracket ...................

3. Socket ..................

4.

5. Push Rive!.. ............ (G5)x1

I.

2.

1.Socket

2.

1.

2.

2. Nut .........................

3.

4.

1. Screw ..................... (N1)x2

2. Bracket ...................

1. Screw ...................

.....................

Screw

.....................(G4)x3

Socket .................... (HI

Screw

.....................(H2)x3

.....................

Screw

......................(J2)x4

Open

the cassette holder

Screw

......................(LI )x7

Washer

..................(M3)x1

Socket.................... (M4)x1

(EI)x2

(FI

)x4

(GI)x2

(G2)xI

(G3)xl1

)xl

(JI)x2

(KI)x7

(MI

)xl

(M2)xI

(N2)xl

(PI

)x'

6-2

7-1

7-2

7-2

7-3

7·4

7-4

7·4

7-4

2

CD-K455Z

1

W:

)X2

4x8mm

Black

(F1)x4

i63x12mm

Loading

Molor

Pulley

If:'l''

3x10mm

Black

it'l',

Black

Top

Cabinsl

t

'I

"W'"

W3X10mm

Black

(D2}x4

~3xBmm

4 x12mm

1f:'1<5

Black

1

3x

lOmm

Figure

6-1

Rear

Board

(D1)x5

(A2)x2

1

W

)X2

4x8mm

Black

Sida

Panel

(D1)x3

(

(

CP-K455Z

STEP

I

2 Wooferrrweeter

REMOVAL

Front

Panel

1.

Remove the

2.

Rubber

3.

Screw

I.

Screw

PROCEDURE

net.

Holder........

.....................(A2)x4

.....................

(AI)x4

(BI)x6

FIGURE

7-5

7-6

-6-

Figure

6-2

(

Page 7

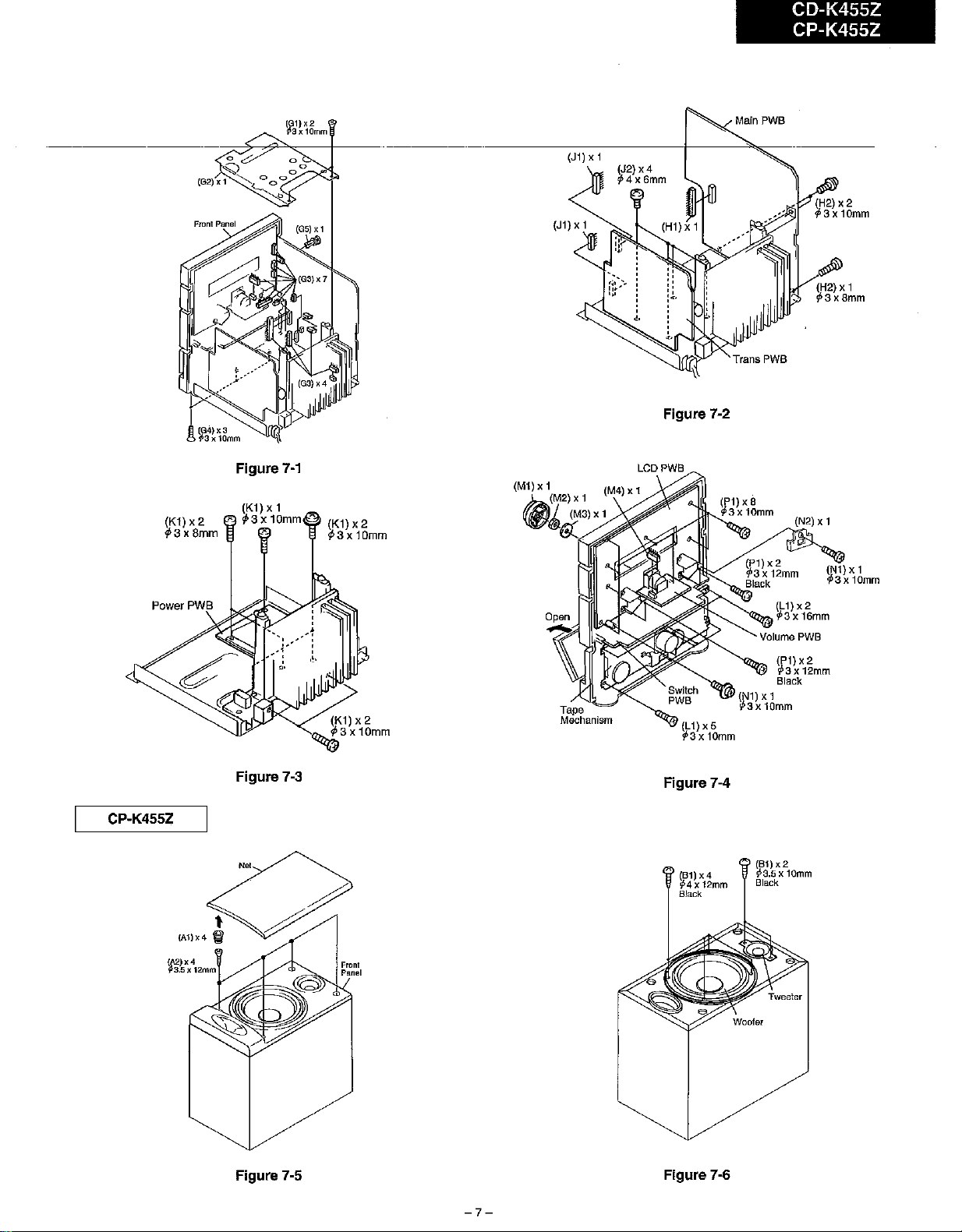

(G1)X2

f3x10mm

.--=~7'-"~-t--

---------------I------"'=--

CD-K455Z

CP-K455Z

(H2)

x2

tp3x

10mm

~

(H2) x 1

¢i3xBmm

CP-K455Z

(G4)x3

P3x10mm

Figure

Figure

No<

7-1

~3X10mm

7-3

(K1) x 2

(M1)x1 (M4)x1

~(M2)X1

f{JfI)4

(M3) x 1

Tape

Mechanism

Figure 7-2

LCDPWB

Figure 7-4

(L1) x 5

13 x

10mm

(B1)x4

914x12mm

Black

(N1) x 1

.p3x

10mm

(B1)x2

913.5x10mm

Black

(N2)

(L1)x2

13 x

16mm

(P1)x2

.p3x12mm

Black

x1

(N1) x1

13x

10mm

(A2)x4

i63.5x12mm

Figure 7-5

Figure 7-6

-7-

Page 8

CD-K455Z

CP-K455Z

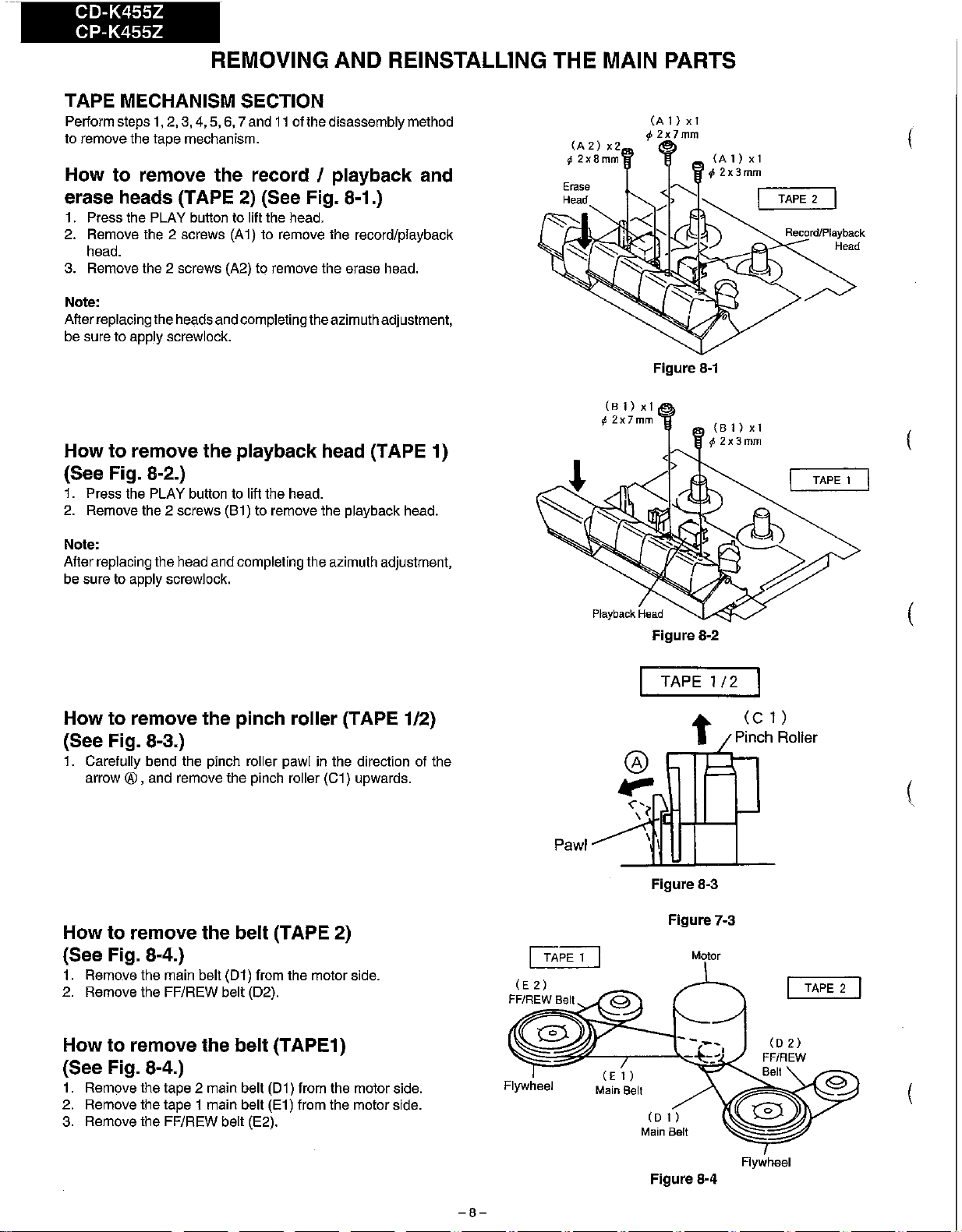

REMOVING AND REINSTALLlNG THE MAIN PARTS

TAPE MECHANISM SECTION

Perform steps

to remove the tape mechanism.

How

erase heads (TAPE 2) (See Fig. 8-1.)

1.

Press the PLAY button to lift the head.

2. Remove the 2 screws (A1) to remove the record/playback

head.

3. Remove the 2 screws (A2) to remove the erase head.

Note:

Afterreplacing theheadsandcompletingtheazimuthadjustment,

be sure to apply screwlock.

Howtoremove the playback head (TAPE 1)

(See Fig. 8-2.)

1.

Press the PLAY button to lift the head.

2.

Remove the 2 screws (81) to remove the playback head.

to

remove

1,2,3,4,5,6,7

the

and11ofthe disassembly method

record I playback and

(A2)x2

If>

2x8mm

(A

1 )

rp2x7mm

Figure

xl

(

(A1)xl

';2x3mm

TAPE 2 I

Record/Playback

Head

8-1

TAPE 1 I

Note:

Afterreplacing the head and completing the azimuth adjustment,

be sure to apply screwlock.

Howtoremove the pinch roller (TAPE 1/2)

(See Fig. 8-3.)

1.

Carefully bend the pinch roller pawlinthe direction of the

arrow

® , and remove the pinch roller

Howtoremove

the

belt (TAPE 2)

(Cl)

upwards.

(See Fig. 8-4.)

1.

Remove the main belt (01) from the motor side.

2. Remove the FF/REW belt (02).

Pawl

[TAPE}]

(E

2)

FFIREW Selt

Figure 8-2

TAPE

t

Figure 8·3

Figure7-3

Motor

1/2

(C

Pinch Roller

(

1)

(

I TAPE 2

Howtoremove the belt (TAPE1)

(See Fig. 8-4.)

1.

Remove the tape 2 main belt (01) from the motor side.

2. Remove the tape 1 main belt

3. Remove the FF/REW belt (E2).

(El)

from the motorside.

-8-

Flywheel

(E

1)

Main Belt

(D

1)

Main Belt

Figure 8-4

Flywheel

Page 9

. CD-K455Z ' CD-K455Z

CP-K455Z CP-K455Z

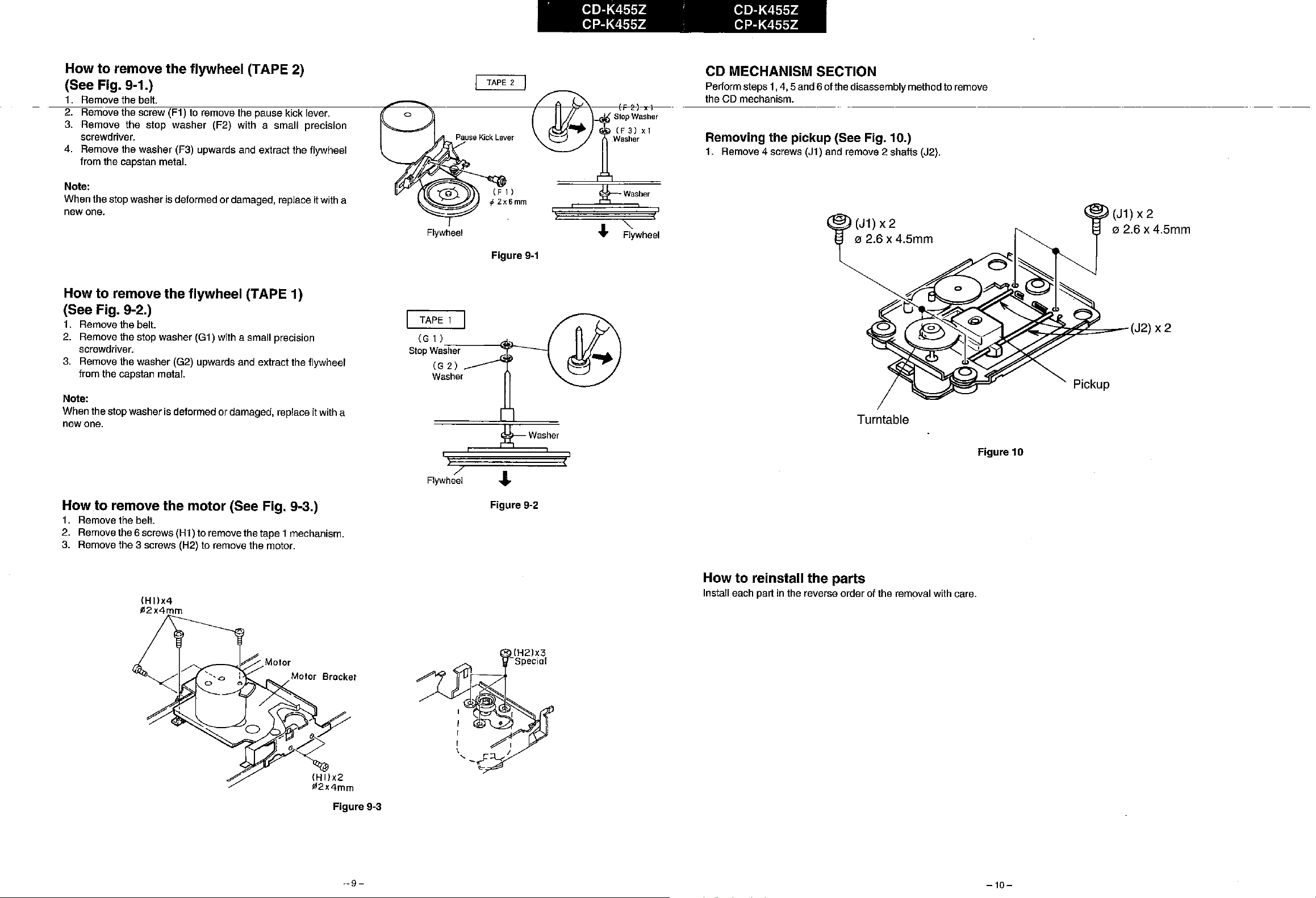

How to remove the flywheel (TAPE 2)

(See Fig. 9-1.)

1.

Remove the belt.

2. Remove the screw (F1) to remove the pause kick lever.

3. Remove the stop washer (F2) with a small precision

screwdriver.

4.

Remove the washer (F3) upwards and extract the flywheel

from the capstan metal.

Note:

When the stop washer

nswans.

is

deformed or damaged, replace itwith a

How to remove the flywheel (TAPE 1)

(See Fig. 9-2.)

1.

Remove the belt.

2. Remove the stop washer (G1) with a small precision

screwdriver.

3.

Remove the washer (G2) upwards and extract the flywheel

from the capstan metal.

Note:

When the stop washer is deformed or damaged, replace It with a

newans.

o

Flywheel

I TAPE 1 I

(G

1)

Stop

Was:;h::e:-r

(G

2)

Washer

)

7

Flywheel

I

TAPE

2 I

Figure

----ll~

__

Ewasher

9-1

CD MECHANISM SECTION

Perform steps

the CD mechanism.

Removing the pickup (See Fig. 10.)

1.

Remove 4 screws (J1) and remove 2 shafts (J2).

Ewasher

"-

Flywheel

1

,

1,4,5

andSofthe disassemblymethod to remove

(J1)

x2

02.6

x 4.5mm

Turntable

~~~~S=-

Figure

10

Pickup

(J1) x 2

02.6

x4.5mm

(J2) x 2

How to remove the motor (See Fig. 9-3.)

1.

Remove the belt.

2. Removethe 6 screws (H1) to removethe tape 1mechanism.

3. Remove the 3 screws (H2) to remove the motor.

(H

Ilx4

¢2x4mm

Figure 9-3

I

,

I

\..,

-?~

.-

r'"

Figure 9-2

How to reinstall the parts

Install each partinthe reverse order of the removal with care.

pP,

/

-9-

-10-

Page 10

KEY

MATRIX

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

€f

----+Il , _ _

CD

Q229

Q230

I

I

INPUT

~~

I-I-_.;;~

~

L

R

: SELIlCTOR.R:ID

i

I R _

'''''''

P.'"'"'

60SS

IAUDIOI

le602

TCH52BP

FUNCTION

,;::,

GRAPIl]

63Hz

250Hz

~"t'

"t'

I L

L

~

L L

'""

_r.

~

..L

4-

RAMP

le6D3

BA4!i5BN

LINE

W r-"Ji

'J)-

I

.~

",.::'

t.v--

R I

C EQUAL I

I'Hz

"t'

ZEn

4-.Hz

l6~Hz

"t'

"t'

~

l.

lC701

8 ...

4558N

GEOIID---+B2

<i!

R

AMP

X-BASS

::::

..

"'"'"'

~

~VR706

1..

~

k..

__

~-B2

RID.

BALANCE

VOLUME

VR707

t t

E§+1l5

V:15~~:

07'

-1.

11:

+Bl

AUDIO

MUTING

ci:~~

l.G

~

L--

! +

6i.

L L

STK42iI5MKIl

R R

~

J901

4-.J

H~i1gb.

:'

-BI

~

I

"'"

'<:Y

PHONES

"eK

·SWITCH

k1--

IC,902

P~~R

~~L.AY

l""

~'"'J":O:'~'

..

.."J

IL

_----t

~~~;,]CONTROL

090

REI-AT

4-

(

-+j

""

IVD202-l!"

MW

~

T202

5W407,,s-'"

Tl

APSS

SOL40

I

~::'-

TI

APSSb

PLAYBACK

"

HEAD

=--"C····~l

'-"~

R-CH

--§.

RECORD/PLAYBACK

HEAD _~L

"

L-CH

-@_-"'.1."·__-----T

R-CH

~~.!'-~l

fil-

I!~E

HEAD ,

SWI ANT

_

SW[TCH[NG

I

I

I

SWITCHING SW[TCHING

,

I

I

L

i

--r-----.--<q;·"'='~=O,_

'

c

~

SW40 I

BEAT

CANSEL

I-

ANT

T206

r

SWI

OSC

-<Q;-;-;-;;;-]~

lIC405~+"

0,0,3101

Q413

sw

I

"'_A,'if

TAPI!

SELECTOR,

__

i!j4LLQ415SWITCHING-G

~.

::::

"''''''~

P·:MpEQ

" I

cl

~

g1~:

Q425

0430

BIAS

L411

FREQ.

Q421

BIAS

Q414

~

-

T"

"'"

R~

~~~~

1- ..

SWU4

T1

MUTING

SWITCHING

SW

ITCHING

(HIGH

SPEEol

",UT[NG

,~'"

Q499

SWITGHING

5W406

IC404

5A4558N

••

O;!'ilD<-1--1-t----;::=:::'-------------":'~~;~:~'~::'~~~======:(,-------------J

,

',~

If If

!.

.,L.

+B4

'"

SW801-SW808

IC80!

RH-IXI846AP

DATA/CLOCK/PRRIOD

IP

REO

SW405

--91

+84

T

'-=.

...

_u_'_'"_'

rf1

I

0402

Q407

Q4QS

~SWITCHING

I '

I i

Q543!

--------------~==I====I

.-_~

1 I

_,

C~~~~~L

loll

CROCOMPUTER

~

+B9

.....fl..

"""-./

LCDSOI

I'

,i

~+:~::::::+::::::::::::::::r~~~========~=F~~~~~~~~~~~~~~~~~~~~~~~===

!I!'

'I

L.-.(jR

II

~~C

,~+B4

0-423

M:;~:G

r.

\l

~539;

SWITCHING

L-----{'Q4101-----+1~~::I-----1

b

L

L

IC403

t<Y

BA3312N

~~~

R~--'"

I

I

+B4

0540

SWITCHING

Q4Q6

Il:::

-"

~

~

L

-

LBA14741:ID----+

_ :

I Q

I,

I

I

I

I I

I

i

1

I

, !

I

SWIM-A

TAPE

4

~

\<J

n

~

RBAI474IR[>

~

MIC

il!

~..!.!:'_---,

'

L L

I

-82

-<1:

ov-+

Lg

r-~~BA:~~8N

Il':f

i J

~

LJ2M VOLTAGE

MIC

SELECTOR

SWITCHING

d

~

__

b,.J

I

2 REGULATOR

I'Q5'3'3l

~1--''--(,,0053y

DUBBING

CONTROL I

...

[C50M

"".'

4

,,,.

,He

5FEED

~

~

,'"

~

~

L W--

'"

"'

T+:

+B2

MIC

h>-

~lh'

~1

,,-'i;;

MIC

LEVEL

SWITCHING

J

I

T'

T"

8 L L

.--~o<;jL

VR1M

I

rif-">J

-"-J'

,-l-;,=.,.,--il't

2

1"f

SPEED

~.

'---==t==------..J

~O'"

't

VR402 VR403

SFEED

CONTROL

~::::6

(j

R ANALOG R [j)

l"R

SW.

,IHi

~":<cr<~~:':;2::==t=~~

SWITCHING

r

~

DIGITAL

M50197F

Q51M Q52M

82

T'

1

-,~r~'~"~'~'~b--_J

BA4558N

7

--;-~~----

tD--_,

'"""

Q\

AMP

ECHO ~~MI-----<+"

IC3M

DIGITAL

ECHO.

Xli-I

tsr

Q"-~

~

1

SWITCHING

SWITCHING

M401

MOTOR

Q535

Q536

't

~"

I~

~br..l-+<--'---'-t+~+"

n~.T529D

I

RMC

L +

~@-@

~==="=.='='=====~

1

WSDl

__}-__

II

I

T'

L

R'"

~

ID--J

~

~

'1'

,'"

L L I I POWER

B~~::~N

BUFPER

"'RA"'P

R

I.t!

SWITCHING

I

SW~NG

~1.---4

I 7,

I'

J'

=__

:Jf-

J<>.

~~~r~KE

'<'>I

~AKER

050101

SWITCH[NG

'

__

,

~

Q531

Q532

SWITCHING

"

.

SW4Q3

T2

MOTOR

...

~.,.--l_

T1

MOTOR

...

~

LAMP 1

0603-0606

--,

~ITCHING

L-I_+

__

=j-1--r-:~

_±+~"~''-I0906

-'""""-i

<

Q603

-,--I

I Q6 04 -

L

l'

,.,,".,

....

·--l.--j----!-Q.;.1'I;';'=

+81

-81

'''l9V

I It:9EVkT911F\ ER{rRL:_O_:

I

<-l-J'-<~--M--

0907

VOLTAGE

'---t---{OQ8(4)--+--t,

RELAY

Q905

CONTROL

t--o'~~

: :

+--.o---ot~

L'=====ll:;-T-,"'","~{L

+a3

~~

-83

~

VOLTAGE VOLTAGE

REGULATOR REGULATOR

+84

+B5

+:~

2V

~:;~

I.--t--+--< { Q • T

~

""'"

,10917

+12VlMIIQ9lS

ILAMP I Q9 19

~

REGULATOR

--

~

VOLTAGE VOLTAGE

RECTIF[ER

D904-D907

'r

Q9l'

0915

R~~tl~~~R

--M--

-;:;.t=<j:J.''.'::-~J--------------'':T;f,

.~

Q920

REGULATOR

+5VlUN

SWITCHING

.f,~"""':'

-{j

FHoNo

S TUNER

TAPE

...

SWITCHING

ON/OFF

S~;~~~~Y

RELAY

[NO.

~+B7

1:

T901

~'="=:~:~:~:::="'='}_-:'~,~.~,-t'-'~~'-~~~~i:~-':v-~~-~~~-~_Rr

::::J

~

1'906

SWITCHeDI

'"

[e702

etE5~:

DM~IW:R

X-BASS

~+~7

Jr-fiI"ST5Z9DITH

~

'0'-_-';;

.;;o""""""-l;>~---<J

l

CS03

""

CONTROLLER

,l!':~,'.'

PiiWiiii

e~~

~

Q805

J.. J.. J..

1:1:~"f:.

LEo80l-LED804

PUNCTION

~

1'903

~.-9-~V--+-~

:

~~

m

SWS09-SWB14

SW901

"'''''

,0,

\{y

J

,II,

~

J.

IND.

220V

_~::~

RXSQI

REMOTE

SENSOR

:)

1'90

[NO

AC

ftx

I

110/127/

22lJ/230-240V

SO/60Hz

i<:?

& R

GND

GND

SPIlAKI!RS

(

(

(

-11

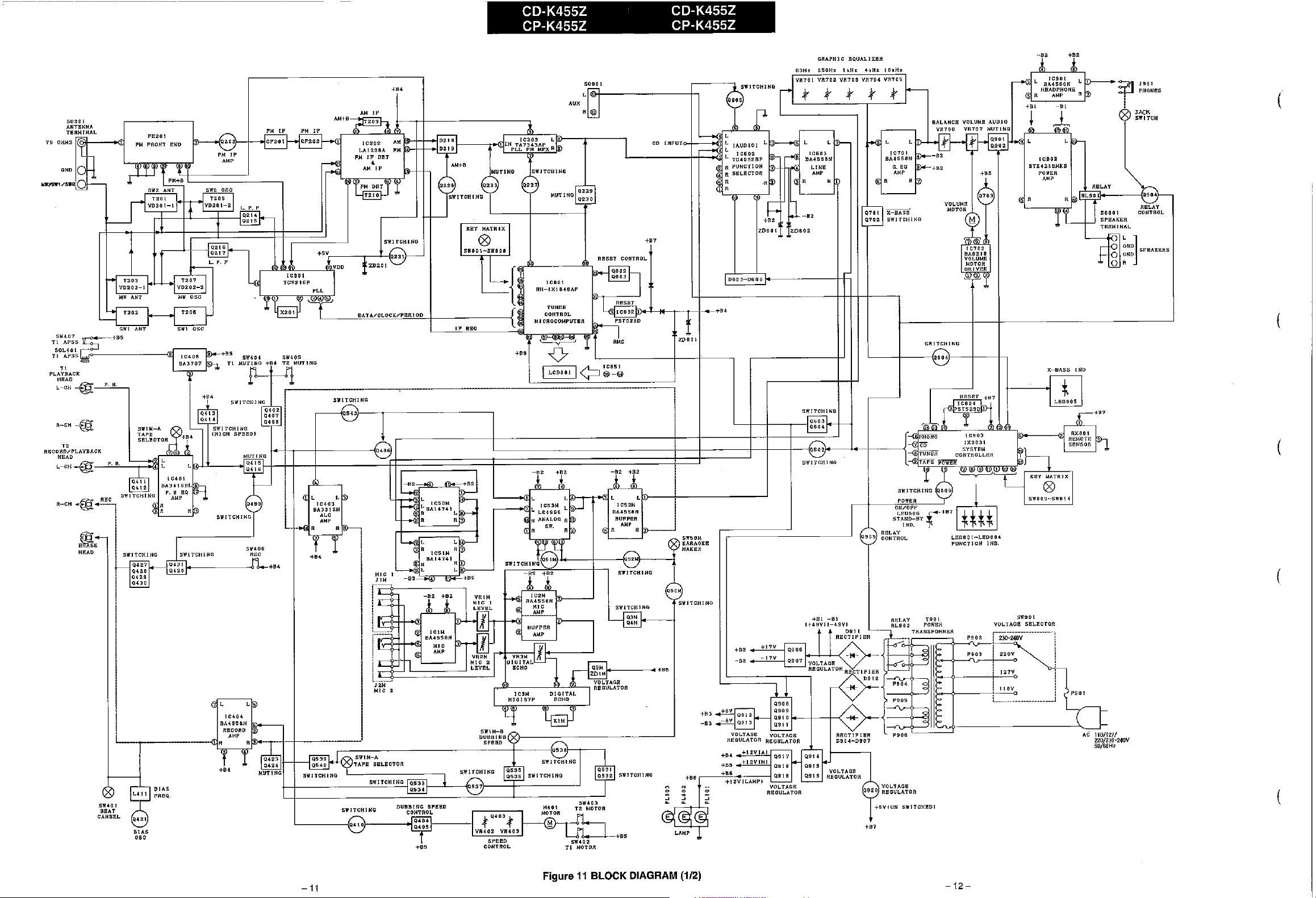

Figure11BLOCK

DIAGRAM (1/2)

-12-

Page 11

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

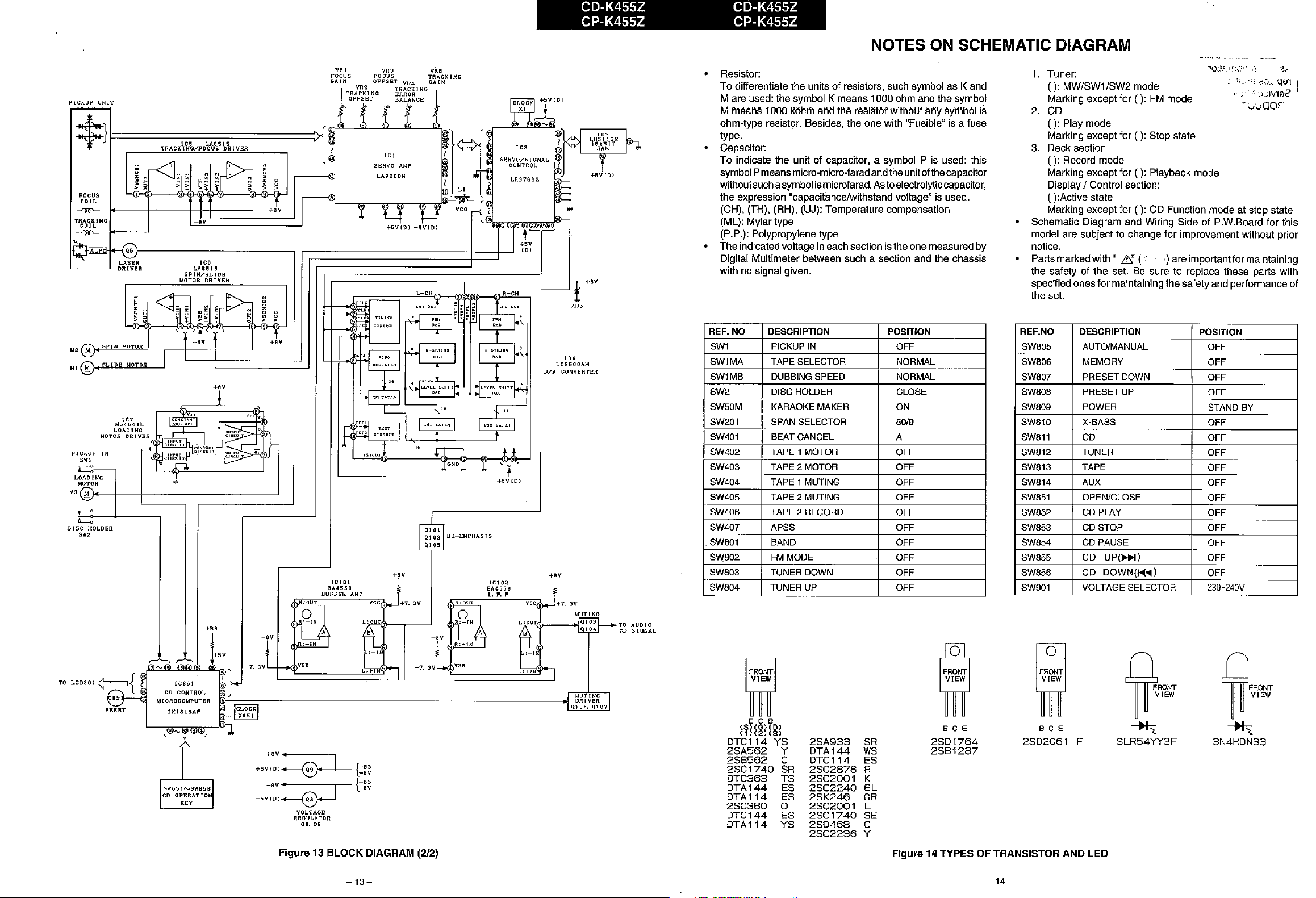

NOTES ON SCHEMATIC DIAGRAM

PICKUP

-------'F~f_-----

UNIT

*}I==='''''=::=WimD==:=~t~'b':==''ve,==:>{

"'C'

T~NGr---I--tJ.J~,v!===~=+~J~"v=~1

~

......

H::Ji;lAjJee"oJ!---{DO

"'

MI

M

PICKUP

SWl

c-

LOADING

MOTOR

M'

MMr--t--+--------~--.J

.......

DISC

m

M

HOLDER

SLID!!

MOTOR

IN

CA'"

DRIVER

MOTOR

'"

M54-64-1I..

CDMING

DRIVER

VRl

FOCUS

GAIN

Vfl2

TRACKING

-------+---<I'--~~.___+----I__x._-.--

OFFS8T

1 i Ie> 1

A1--

f"[i,

}-----------------,

~CNSiA"T

VOLTM"

I,

INPUi

.{(D-ItIJlCU'i~;:umm

I

l(

11:01G,,'i!],~~[[B'lG:.I"""""""l

....'I,

---;:::::::;

L--<~\>-,

.I.

[1'>-

;mr

lDO

LA6515

SPIN/SLIDE

1 V

..

~'-

0

l'

~,"",,"",

~

Jmm

':}

('"

••

0;" 7

---'

I R:DUT vee 8

-8V

n=JA-f

l.

,

!

rFr~~~~~~~~~~~~~~~==I~D~'l-J_r_

Bels

oc,

e

"

---<

'----

" ''"0

•

TSTOUT

ICIO

I

BA4SS'8

BUFFER

AMP

o 0 MUTING

L£UT',7

VR3

POCUS

OPFSE~R~~ilNG

VRS

TRACK

I NG

GAIN

ERROR

BALANCE

')¢=:>{

;

'::::.:'

'tdDI-:t!

Y1~IHO

OOHTOOL

M

H

REGISTE.

..

L,,~JLEYEL

1'1

I

HV

+7.3V

;'f~

VOD

,

0"

I

","

OUT

~~1

,,,

I'"

""

T T

,-,."'"

I

,,,

r r

SHIFT~

DAt

'-

,.

n--l

lOI

,

0102

DE-EMPHASIS

0105"

®D

1 R:DUT vee

8V

Pl:-JU

• Resistor:

To

differentiate the unitsofresistors, such symbolasK and

_~~OVIDI

CLOCK

"'

'"

~

mVD/><

'""

::::;

~

-----

---

l"1~ilI''fJ~~'iJ!t1

11

,

0"

fr:H'

OUT

,

~L£YEL

..-.l

,p

J,:...

,

""

'"

"-STRING

j..\-

",

SH'FT~

OAt

r"

+5"VIDl

I

C1

02

BA45"58

L. P. P

£.X~o"'",rq

10.

LC9600AM

D/A

CONVERTER

HV

+7.3V

,';----I~:~

TO

AUDIO

CO

SIGNAL

M are used: the symboi

--

--M

means 1000 kohm and the resIstor without any symbol

ohm-type resistor. Besides, the one with "Fusible" is a fuse

type.

• Capacitor:

To

indicate the unit of capacitor, a symbol

symbolPmeansmicro-micro-faradand theunit

without suchasymbolismicrofarad.Astoelectrolyticcapacitor,

the expression "capacitancelwithstand voltage" is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Theindicatedvoltage in each section is the

Digitai Multlmeter between such a section and the chassis

with no signal given.

REF.

NO

SW1

SW1MA

SW1MB

SW2

SW50M

SW201

SW401

SW402

SW403

SW404

SW405

SW406

SW407

SW801

SW802

SW803

SW804

DESCRIPTION

PICKUP

TAPE

DUBBING

DISC

KARAOKE

SPAN

BEAT

TAPE1MOTOR

TAPE2MOTOR

TAPE1MUTING

TAPE2MUTING

TAPE2RECORD

APSS

BAND

FMMODE

TUNER

TUNER

K means 1000 ohm and the symboi

one

POSITION

IN

SELECTOR

SPEED

HOLDER

MAKER

SELECTOR

CANCEL

DOWN

UP

OFF

NORMAL

NORMAL

CLOSE

ON

50/9

A

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Pis

used: this

olthe

capacitor

measured by

1.

Tuner:

():

MW/SW1/SW2 mode

():

IS

Marking except for

2.

CD

():

Play mode

Marking except for

3. Deck section

():

Record mode

Marking except for

DisplayI Control section:

( ):Active state

Marking except for

Schematic Diagram and Wiring Side of P

•

model are subject to change

notice.

•

Partsmarkedwith "

the safety of

specifiedones

the set.

REF.NO

SW805

SW806

SW807

SW808

SW809

SW810

SW811

SW812

SW813

SW814

SW851

SW852

SW853

SW854

SW855

SW856

SW901

the

set. Be sure to replace these parts with

for

maintaining the safety and performance of

DESCRIPTION

AUTO/MANUAL

MEMORY

PRESET

PRESET

POWER

X-BASS

CD

TUNER

TAPE

AUX

OPEN/CLOSE

CD

PLAY

CD

STOP

CD

PAUSE

CD

UP(»I)

CD

DOWN(~)

VOLTAGE

FM mode

():

Stop state

():

Playback

():

CD Function

Lt,;'

(

DOWN

UP

SELECTOR

mode

mode

for

improvement without prior

I)

areimportantformaintaining

POSITION

OFF

OFF

OFF

OFF

STAND-BY

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF.

OFF

230-240V

':<

';

~QQr_'

at stop state

W.Board

:':;:,~_

lqtfl

:;-l:JI\/l~2

__

for

this

o

~-~

g/9

TO

LCD80l

~,~.",

,{

"

RES!!T

~

IC851

CD

CONTROL

MICROCOMPUTER

IX1619AP

+5

:;r

-"Itl-+<~'~:~~:~"===='~'

L~~~~-<"!:JI

L:'~'

:,t:.':~~~

":

~~~:~"=I===,~I

,+~:~

L,~~N!:J

I

~

i

OLOCK

X851

J

MUTING

DRIVER

0106.0107

,I

irr

~~~~§~rg~

SR

WS

ES

8

K

8L

OR

L

SE

C

Y

Figure14TYPESOFTRANSISTOR

SW8SI_SW856

CD

OPERATION

K"

HV=BJ-

+5VIDI

-,v

-5VlDJ

09

=-e<=J-

08

VOLTAGE

REGULATOR

08.

09

Figure13BLOCK

{+"

HV

-,v

{-"

DIAGRAM

-13-

(212)

OTC114

2SA562

2S8562

2SC1740

DTC363

DTA144

DTA114

2SC380

OTC144

OTA114

YS

Y

C

SR

TS

ES

ES

0

ES

YS

2SA933

DTA144

DTC114

2SC2878

2SC2001

2SC2240

2SK246

2SC2001

2SC1740

2S0468

2SC2236

FRONT

VIEW

BCE

2S01764

2S81287

-14-

FRONT

VIEW

B C E

2SD2061

AND

~AONT

~ ~

'VIEW

~FAONT

~ ~

VIEW

~ ~

F

SLR54YY3F

LED

3N4HDN33

Page 12

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

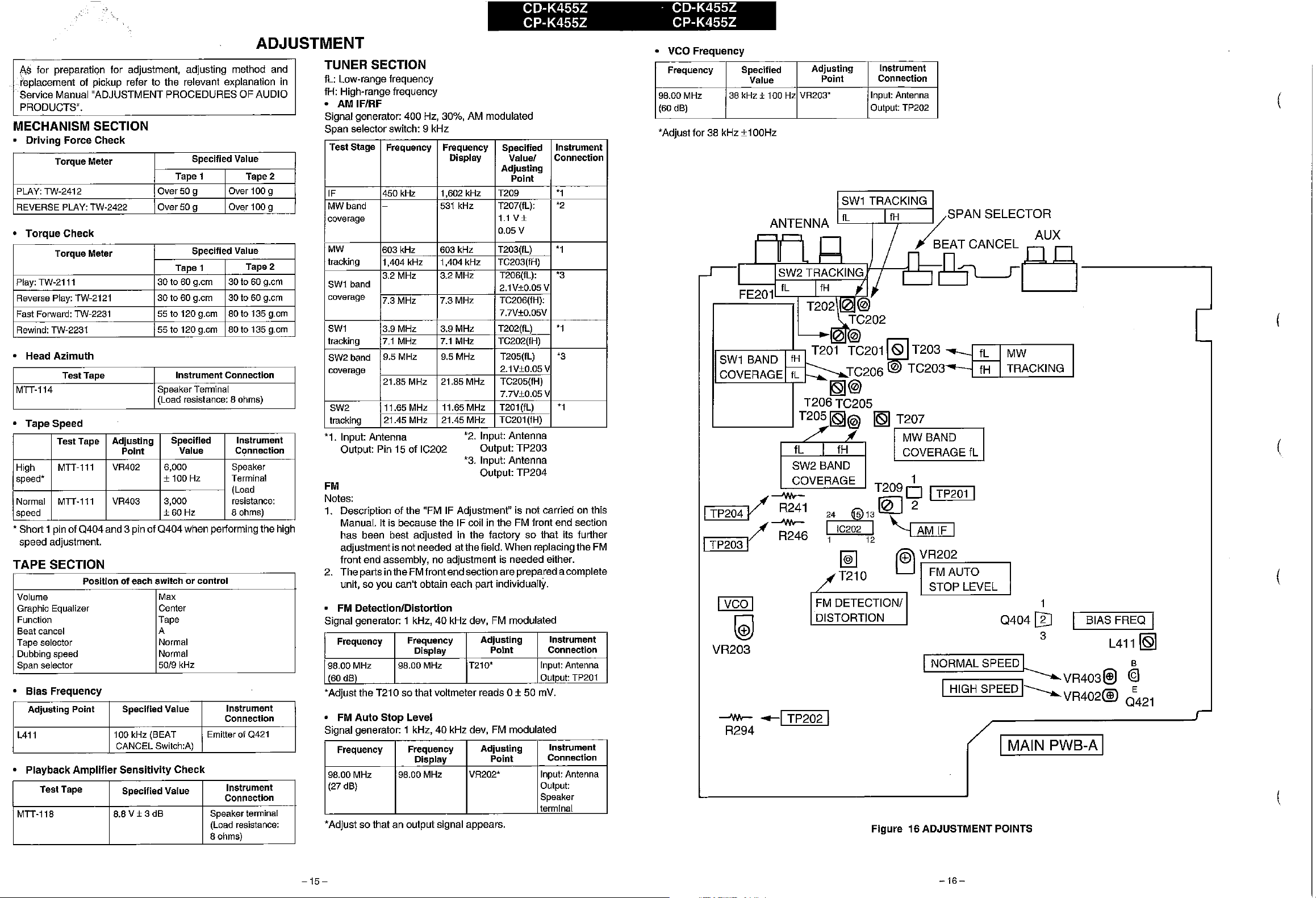

ADJUSTMENT

AS

for preparation for adjustment, adjusting method and

to

replacement of pickup refer

Service Manual "ADJUSTMENT PROCEDURES OF AUDIO

PRODUCTS".

MECHANISM SECTION

•

Driving

PLAY:

REVERSE

•

Torque

Play:

Reverse Play:

Fast Forward: TW-2231

Rewind:

• Head

MIT-114

•

Tape

High

speed*

Normal

speed

, Short1pin of Q404 and Spin of Q404 when performing the high

speed adjustment.

Force

Torque Meter

TW-2412

PLAY:

Check

Torque Meter

TW-2111

TW-2231

Azimuth

Test

Speed

Test Tape

MIT-111

MIT-Ill

Check

TW-2422

TW~2121

Tape

Adjusting

Point

VR402

VR403

TAPE SECTION

Position of each switch or control

Volume

Graphic

Function

Beat cancel

Tape

Dubbing

Span

•

L411

•

MIT-118

Equalizer

selector

speed

selector

Bias

Frequency

Adjusting Point Specified Value

100

CANCEL

Playback

Test

Amplifier

Tape

Sensitivity

Specified Value

8.8

V± 3

the relevant explanation in

Specified Value

Tape 1

Over

50 9 Over 100 9

Over50g

Specified Value

Tape 1

30 to 60 g.cm

30to60

55to120

55to120

Speaker

(Load resistance: 8

kHz

(BEAT

Swilch:A)

dB

g.cm

g.cm

g.cm

Instrument Connection

Terminal

Specified

Value

8,000

±

100

Hz

3,000

±60

Hz

Max

Center

Tape

A

Normal

Normal

50/9

kHz

EmitterofQ421

Check

Speaker

(Load resistance:

8

Tape

Over 100 9

Tape

30to60

30to60

80to135

80to135

ohms)

Instrument

Cc;mnection

Speaker

Terminal

(Load

resistance:

8

ohms)

Instrument

Connection

Instrument

Connection

terminal

ohms)

2

2

g.cm

g.cm

g.cm

g.cm

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• AM IF/RF

Signal generator: 400 Hz,

Span selector switch: 9 kHz

Test

Stage

IF

MWband

coverage

MW

tracking

SWI

band

coverage

SWI

tracking

SW2band

coverage

SW2

tracking

'1.

Input: Antenna

Output: Pin 15

FM

Notes:

1. Description of the "FM

Manual. It is because the IF coil in the FM front end section

has been best adjusted

adjustmentis not needed atthe field. When replacing the FM

front end assembly, no adjustment is needed either.

2. The parts in the FM frontend section arepreparedacomplete

unit, so you can't obtain each part individually.

• FM

Signal generator: 1 kHz, 40 kHz dev,FMmodulated

Frequency

98.00

(60

dB)

'Adjust

• FM

Signal generator: 1 kHz, 40 kHz dev, FM modulated

Frequency

98.00

(27

dB)

'Adjust

Frequency Frequency Specified

450

kHz

-

603

kHz

1,404

kHz

3.2

MHz

7.3

MHz

3.9

MHz

7.1

MHz

9.5

MHz

21.85

MHz

11.65

21.45

Detection/Distortion

Frequency

MHz

the T210 so that voltmeter reads 0 ± 50 mY.

Auto

MHz

so that an output signal appears.

Stop

98.00

Level

Frequency

98.00

MHz

MHz

of

IC202

Display

MHz

Display

MHz

SO%,

AM modulated

Display

1,602

kHz

531

kHz

603

kHz

1,404

kHz

3.2

MHz

7.3

MHz

3.9

MHz

7.1

MHz

9.5

MHz

21.85

MHz

11.65

MHz

21.45

MHz

'2.

'S. Input: Antenna

IF

Adjustmenf' is not carriedonthis

In

the factorysothat its further

T210'

VR202' Input: Antenna

Value/

Adjusting

Point

T209

T207(fL):

1.1

V±

0.05

V

T203(fL)

TC203(fH)

T206(fL):

2.1V+0.05V

TC206(fH);

7.7V+0.05V

T202(fL)

TC202(fH)

T205(fL)

2.1V+0.05 V

TC205(fH)

7.7V+0.05V

T201

(fL)

TC201(fH)

Input: Antenna

Oulpul: TP20S

Output: TP204

Adjusting

Point

Adjusting

Point

Instrument

Connection

'I

'2

'I

'3

'I

'3

'I

Instrument

Connection

Input:

Output:

Instrument

Connection

Oulput:

Speaker

termInal

Antenna

TP201

• VCO

98.00

(60

'AdjustforSBkHz ±100Hz

Frequency

Frequency

MHz

dB)

Specified

38

kHz±

Value

,---I....L-TcS;;;W;;;:2~T:;;R~Ar:C~KI;;;;N;:;G-V-,I--d-t::;

FE201

I.------,..L...,

SW1BAN

COVERAGE

L-

__

ITP204j/'~

I"""T=P2"""0-31

/

Ivcol

~

VR203

--JWv-

R294

__

Adjusting

VR203' Input:

100

Hz

fL

T2020@

L-_I'0o

T201

f_H

-,,-_

D L

fL

T206TC205

---.J

T2051§11@

fL

SW2BAND

COVERAGE

--JWv-

R246

FM

DISTORTION

I

TP202

Point

SW1

fL

fH

TC202

TC201

TC206

~@)

fH

513~

r:--=..,

DETECTIONI

I

Instrument

Connection

Antenna

Output:

TP202

TRACKING

fH

~

~

0

,-T2_0_7

----ySPAN

"

Bp:;ANGE~DAUX

I

T203

::tElL

TC203

__

MWBAND

COVERAGE

-,

L-J

--,

IL

SELECTOR

MW

IH

TRACKING

1

T209

0 I

TP201

I

10'2

~

AM

IF I

@I

VR202

o

FMAUTO

STOP

LEVEL

0404

I

NORMAL

1

HIGH

SPEED

SPEED

IMAIN PWB-A I

Figure16ADJUSTMENT POINTS

--------,

1

[]J

I

S

~

VR403@

1------.....

VR402'EB'

BIAS

L411

~

FREQ

B

©

E

0421

(

(

1

~

-15-

-16-

Page 13

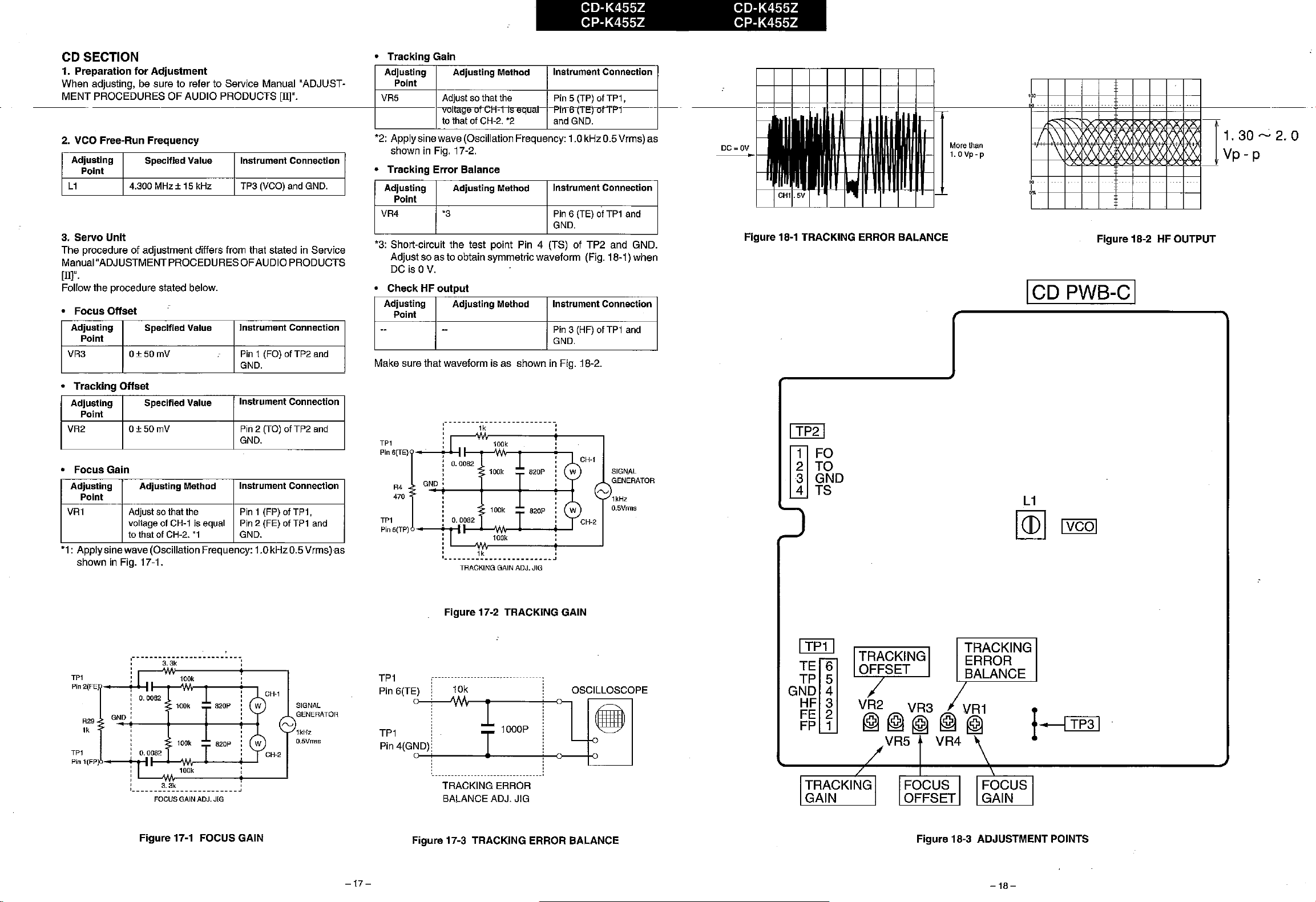

CD SECTION

paration

1. Pre

adjusting, be sure to refer to Service Manual "ADJUST-

When

PROCEDURESOFAUDIO PRODUCTS [Il]".

MENT

2. VCO Free-Run

Adjusting

Point

L1

3.

Servo

The procedure of adjustment differs from that stated in Service

Manual"ADJUSTMENTPROCEDURES OFAUDiOPRODUCTS

[II]"

.

Follow the procedure stated below.

o

Focus

Adjusting

Point

VR3

Unit

Offset

for

Adjustment

Frequency

Specified Value Instrument Connection

4.300

MHz±15

Specified Value

0±50mV

kHz

TP3

(VCO)

and

Instrument Connection

Pin1(FO)

GND.

ofTP2

GND.

and

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

o

Tracking

Adjusting Adjusting Method

Point

VR5

'2:

Applysinewave (Oscillation Frequency: 1.0 kHz 0.5Vrms) as

shown

o

Tracking

Adjusting Adjusting Method

Point

VR4

'3:

Short-circuit the test point Pin 4 (TS) of TP2 and GND.

Adjust so as to obtain symmetric waveform (Fig. 18-1) when

DC

o

CheckHFoutput

Adjusting

Point

--

Make sure that waveform is as shown in Fig. 18-2.

Gain

Adjustsothat

-vultage-otCH1is·"qoaJto

thatofCH-2.

in

Fig. 17-2.

Error

Balance

'3

is

OV.

Adjusting Method Instrument Connection

--

the

Instrument Connection

Pin5(TP)ofTP1,

-PiIT6tfE)-orTP1---

'2

and

GND.

Instrument Connection

Pin6(TE)

GND.

Pin3(HF)

GND.

ofTP1

ofTP1

and

and

'r----j-+-+-+-f-+-+----j-+--i

-

-[

DC=QV

•

Figure

18-1 TRACKING ERROR

BALANCE

More

1.

than

QVp-p

H-~~~~~~

Figure

18-2HFOUTPUT

1. 30~2. 0

Vp - p

ICD PWB-ci

o

Tracking

Adjusting Specified Value

Point

VR2

• Focus Gain

Adjusting Adjusting Method

Point

VRl

.

1: Applysinewave (OsCilialion Frequency: 1.0kHz0.5

shown in Fig. 17-1.

TP1

Pin2(FE~

R29

1k

TP1

Pin 1(FP

Offset

O±50mV

Adjustsothat

voltage of

to

thatofCH-2.

~-----------------------~

:

__

-i,""'"

0.0082

GND:

0.0082

3.3k

CH-1

100k

100k

100k

the

is equal

'1

Instrument Connection

Pin2(TO)ofTP2

GND.

.

Instrument Connection

Pin1(FP)ofTP1.

Pin2(FE)

GND.

,

~

~-'-00-k_--..,..----'

:

~._3~

FOCUS GAIN ADJ. JIG

~

ofTP1

SIGNAL

GENERATOR

1kHz

0.5Vnns

and

and

Vrms)as

TP1

Pin

6{TEl?--'-+Y

R4

470

TP1

Pin

5(TP)b--.....,

TP1

Pin

6(TE) 10k OSCILLOSCOPE

TP1

Pin

4(GND)

,

0.0082

,

GND:

0.0082

.....

:

,------------------------~

Figure

~---''{1fy-.....,.----+--o-,

100k

lOOk

I--<>--Wv-~----+--'

100k

1k

TRACKING GAIN ADJ. JIG

17-2 TRACKING GAIN

10001"

:

~

o--r----T=>---t=----.J

:_--------------------------------_:

TRACKING ERROR

ADJ.

BALANCE

JIG

SIGNAL

GENERATOR

1kHz

O.5Vnns

I

TP21

FO

2 TO

3 GND

4 TS

rn

I

TP11

TE 6

TP 5

GND 4

HF 3

FE

2

FP 1

TRACKING

GAIN

TRACKING

ERROR

BALANCE

VR2 VR3

VR1

@@@@@

VR5 VR4

Figure

17-1 FOCUS GAIN

-17-

Figure

17-3 TRACKING ERROR

BALANCE

Figure

18-3

ADJUSTMENT

POINTS

-18-

Page 14

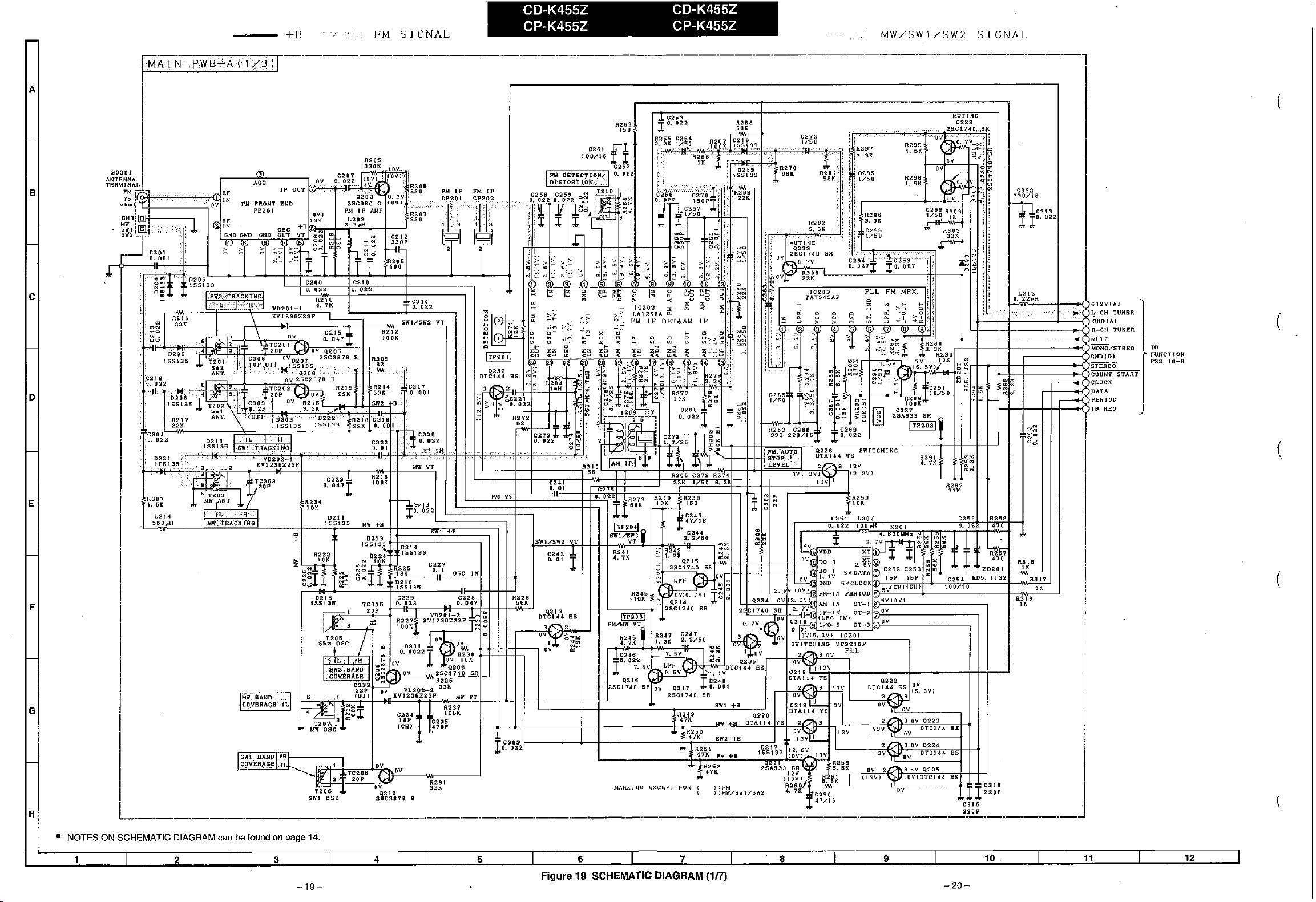

CD-K455Z CD-K455Z

+8

FM

SIGNAL

CP-K455Z CP-K455Z

MW/SWl/SW2

SIGNAL

fATN-PWS"TAlTZiJT·-·-·---·-·-·----·-·-·----·-·-·----.-.-.-.---.-.-.-.---.-.-.----·-·-·-·-·---·-------1

A

(

MUTINC

R263

'"

C272

\/50

R299

I.

5K

Q229

25CI.7:40,5R,

50201

ANIENNA. l

TERMINAL

PM

B

,;*::"~

75:

o

hlllfr"y

i

GNDl

@H

-----

~;II@!-

5WZJ_,-.!

1

..

: RP

_>

-,

.

'V

1 IN

AGG

c

C295

1/50

RZ9B

I.

5K

L212

O.

22",H

(

FUNCTiON

"

P22

10-B

D

(

E

R258

m

(

F

G

'V

'V

Q210

ZSC2878

'V

B

._._._._

R231

'OK

•

TC206

,"p

T206

SWl OSC

L....--

__

H

._.

• NOTES ON SCHEMATIC DIAGRAM can be found on page 14.

2

3 4

-19-

5

Figure 19 SCHEMATIC DIAGRAM

6 7 8

(117)

9

-20-

10

11

12

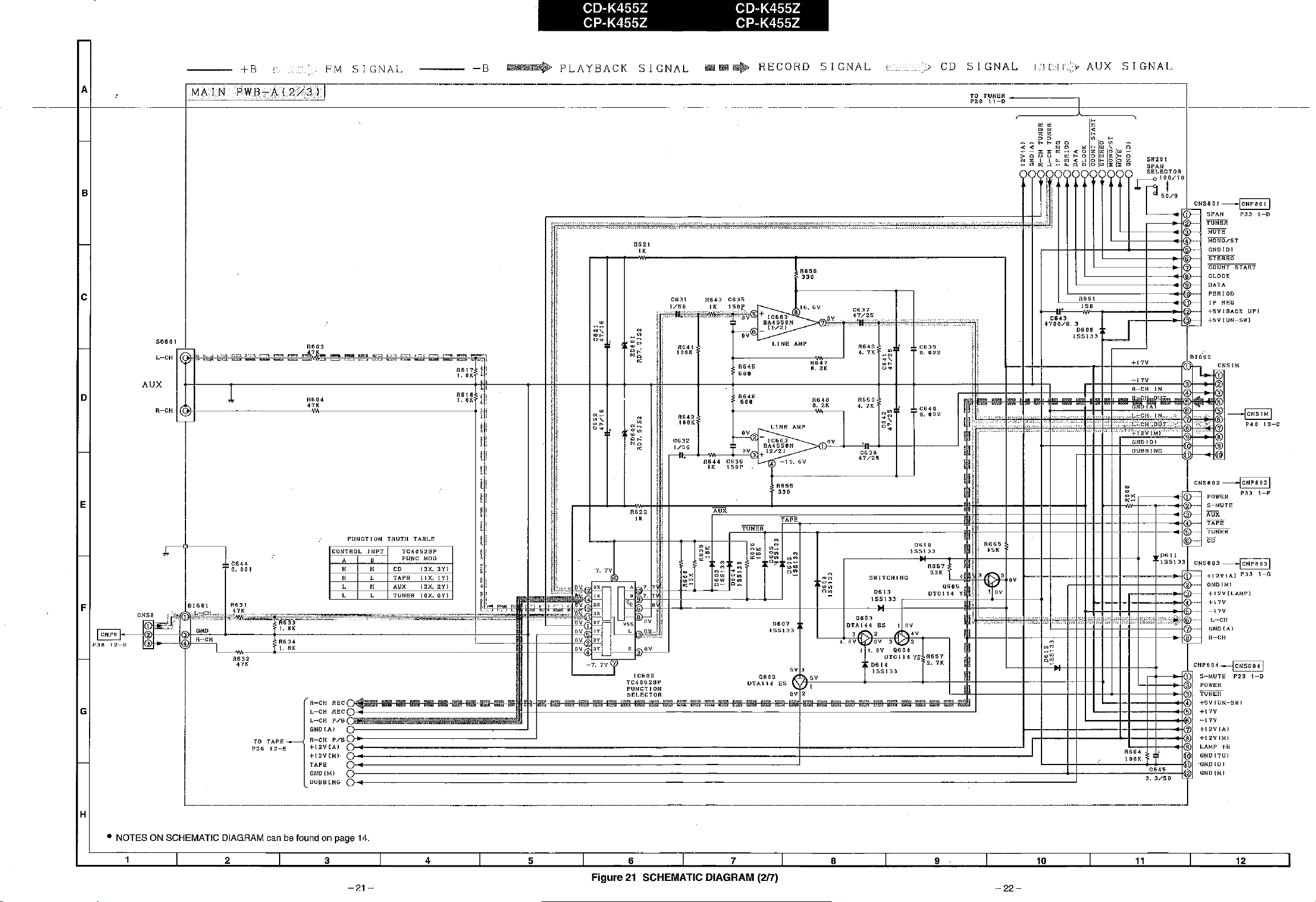

Page 15

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

-·---f----

I--

I--

-

CD

ill!!Ii!J

~

FM

+B

A

B

C

SIGNAL

-B

~

PLAYBACK

SIGNAL

R621

1K

RECORD

R656

".

SIGNAL

SIGNAL

I I [ I

ffi

g;

z z

, ,

......

a 0

• 0

."

o "

.1

~ ~

~ttt1~~~~~~~;;~13~

l

4700/6..3

C643

a661

".

D608

1S5133

SW201

SPAN

SELECTOR

~IOO/10

L

i

~NS801~

I

SPAN

2--TUNER

4

--

MONO/"

5

CNDWI

6

--

S'fEREO

7

COUNT

START

MUTE

8--CLOCK

9

DATA

--

PERIOD

IF

REO

+5VIBACKUPI

+5VlUN-SW)

P33

I-D

AUX

o

R-CH

I-

E

-

F

~:F'

i'JiI

12-E

-

G

-

t!

f'!

•..

1 IK TAPE 3

'

t!

.

[

FUNCTION

CONTROL

A B

O.

~""

eNS

a

~.IE'~~~~~~~::~~~~~[~~~~~~~~~~~~:~:~~::':R~:~:~~::~:~~::;~~~

r:

t1::.J

- 4

BI601

3

~N~H

00 I

RGll

,~7._K"

__•.__

R632

,,"=_~.

T':i~

~~~~

H H CD

H L

lNPT

TRUTH

TC4052BP

FUNG

TAPE

__

~~_~..

TABLE

(3X,3Yl

(IX.

MOD

IY)

tj

[.'1

Vi

l,

""""""

it~·I~il~~~ff~~~~~~'~--~!'i'I~~':}r~,:m9~;~·l'~e=f·~-~=~O=-~~O=-~=~=~_j_l~~~~~l

'T1"';"..,.;,,~~

'"

,~

'"

R-CH

REC

L-CH

REe

L-CH

P/B

GNOIAl

R-CH

P26

TO

TAPE_

12-E

P/B

+12VCAl

+12VCMl

TAPE

GNOIMl

DUBBING

r-t-l_l~Ftlt----r~~~·~~~~·j·~'~~~~~~~~~~~~~~~~~~~~~t~~t~~~~~~~~~~~~~~~~~~j~j~I~[_POWER

'---.-----\-HH-.---.c.-"+-+-,""

7.7V6

.:ox

13X

:~:::

~~~:~

7.7VIJJ

R522

1"'6

0

a

AUX. 2--S-MUTE

TUNER

"'",

:::~

~

......

:g;;;

~~:;:~

":~:.

R.3DV 4.av14.DaV

I -

I

C6:O

2

~~tg~~~

SELECTOR

R655

'"

~;;;~;n..,

0:_

<aUl

",P>

Q:;-

",Ill

Q.~

,~~:i,

:::IV

Q6:O

IHAI14

J

2(\.

LI}~'~V-----l-------l----+--!jJ.!-+-------J.---J.---l--l--l--+-~

ES

~~I

OV

2 3

",::l

SWITCHING

__

~lO~"~"~l'~"'-i===O=T='~~l~',~'"~y~!~=~'f.'~"=VV±_+_i

Q603

O:A~,"

3

v

DTCI14YSR657

D614

155133

06

I 0

155133

fiG67

22K

~

"~V

~~,~,'-'-r-----,

2.7K}._

RoG

6 5

15K

i

41~'~~~'i,:v~~~~,~~~~~~~~~~~~~;'I~.

I.

:~,.;",

H

I~

!!

~=~=~~~tttttttlt~k=::~'C

",::l

~~

I

R664

lOOK

.'>%'

3.

C645

I

CNS802~

AuX

4--TAPE

5

~

D611

ISS!33

eNSU03

4---

~--:~D2~M/LAMP)

5

--

~:-

8,,------

N

P604

1

:-oMw",TRE

:2

r

TUNER

+5VIUN-SWI

4

5

+17V

6

-17V

8

+12VIMI

9 LAMP

+

@I

GND

1 -GND(D1

3/50

GND

P33\-P

TUNER

CD

~

+12V(A)

P33

1-G

+17V

-11V

~;O'~A1

R-CH

~

CNS604

P29

\-0

+B

(lUI

(M)

-----------_._-------

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 14.

I 2

I

-------------_._---------_._-_._--_.

-21

T

4 5

I

6 7 8 I 9

Figure21SCHEMATIC DIAGRAM

-

3

(217)

__

._---

------_._---_.

__

._._--_._---_._._--

I

-22-

10

I

11

12

!

Page 16

CD-K455Z CP-K455Z

- 455Z

A

(

COLOR

TABLE

BROWN

""

RDm)

YL

BL

'L

BY

WI-1{W)

B'

p,

RED

ORANGE

YELLOW

-GREEN

BLUE

VlOLET

GRAY

WHITE

BLACK

PINK

---oe-

B

SOL401

T1

APSS

-

[jbl:==,

SW407

~

TI

c

APSS

~~f

~D-

I

TAPE

q

P.B

HEADI69!

OR

CNS405

~lW

ERASE

o

HEAD(71

W

__

~-

)

,

REC.!

P. 8

HEAD

~""

"

170

!

""""

(

BL

SW40Z

TI

0

MOTOR

B"

YL

M401

MOTOR

E

SW406

TZ

RECORD

B""

F

0

SW405 SW403

TZ

MUTINGTZMOTOR

SW404

TI

MUTING

0

0

,

,

"

W

,

,

W

,,

,

,

B

W

CNS403

(

G

H

2

3

54

Figure

23

:IRING

SIDE OF P.W.BOARD (1/5)

-23-

987

-24-

10

11

12

Page 17

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

W

[j.V

8A3707

IC405

SWUl

i I

APSS

A

B

SOL(OI

TI

APSS

CUSHl

M~~~~

"

(MJ---i,

::

~~;~;::

TI

MUTINe

5'1'05

T2

MUTING

S"'05

72

21111r=~'

sw

SW

/Ille

sw

II

,

~Ii

t--

/1(19

210

lIPSS

•

:;:-

~..

-••Ul:

J

~l

"....

0_

..'" !

~

:=-f~

I-

.~~~1:

~_

-'"

-"'''

----.-

Q(10

liorc,u

ES

ov

5V

112

i 1

~3

DV

/1551

~.5rr----

'"

)'PWBc'AI3/3

/l569

'"

---~-------I

\I

I

c

SWITCHING

o

l.-eH

_

ITAPEIIP.II

E

F

G

IIEAD

/I-eli

_

+B

PLAYBACK

SIGNAL

RECORD

SIGNAL

APSS

SIGNAL

~

;~tr

C(86

'.7/25

TO

PU'lCTlON

P21

/1460

2.7K

/1550

U

85(S

"

/1549

"

0430

155119

..

3-G

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page14.

123

-25-

BIAS

OSC

C4BB

100/16

4

51'1401

B':':':';';;';'A1U59

'rr'

BEAT

CANCEL

"

•

5

.

6 7

Figure25SCHEMATIC DIAGRAM

~_~

__

~ ~

(3")

8 9

+5

J

10

11

12

-26-

Page 18

-K455Z CD-K455Z

CP-K455Z CP-K455Z

A

AC 11OV/127Vj

220V

/230-2411V

J

CORO

50/6OHz

N-r","~""'

R ,

~.:

,

,

CNS702

AC

POWER

SUPPLY

(110

B

c

,

'L

,

"

YL

4

OR

,

RO

,

OR

,

CNS902

(

D

E

PHONES

F

CNS903

RO

OR

YL

OR

,

RO

,

OR

,

YL

•

,

"

,

'L

VL

7

•

WR

,

OK

'0

"

"

'L

"

CNS604

(

(

I

il

I I

I

I

G

~I

,--

-~

( )

L L

H

I'

I I

-.JI

J

COLOR BR

TA8LE

BROWN

RD(Rl

RED

OR

ORANGE YELLOW

YL

OR

GREEN

BL

BLUE

VL

VIOLET

GY

GRAY

WH(W)

WHITE

BK

BLACK

PK

PINK

1

2

3 4

-27-

5

Figure 27 WIRING SIDE OF P.W.BOARD

6 7

(215)

8 9

10

-28-

11

12

Page 19

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

+8

FM

SIGNAL

-8

A

B

MUTING

c

Bigoa

5-MUTB

poweR

TUNER

•

+~Vllln

SWl

...

17V

'"

+12VIAl

+UVIHI

l.AMP

+a

D

GNDlTUl

GNDWI

GKO(MI

~

E

F

I

a906

0902

•.

7/~O

"

R920

0919

",

",

R942

09lo

1/50

;§~~~~"'~~~~··"H·

5.IVI:lV

0972

O.

022

0900

47/25

R994

~

0912

2S1l175~

av

11989

Q9lS

2S02~61

G975

22

....

ISV

",

",

IlV\irfj20V

lJ.!iV

0975

U/25

50

Q920

25D468

C

R990

PJ

5.

7V

"

11.991

f-m

'"

VOLTAGE

REGULATOR

Q917

2902061

P

Q91

S

2SC17H

SR

RS87

."

RDI3152

REGULATOR

Q91e

IlTA1U

R988

20965

13.5V

R908l:~"

220

14V

C9H

10/50

VOLTAGE

...

------.-.---

,-

1

q915

OTAI U I!S

I

20V

2

R994

:v

SVA:"'lo.DV

9 2

,

':fv

Q9U

IlTelUY5

lK

J

20V

/1.985

tOK

liS

~T-,-H",A",N",.,,-S

1199.1

1190.1

Ill-IOU

-,,-PW=8

8.2K

0959

'n;~o

~

~~~~

3

0::'162

5600/63

+

0960

o.

022

L

__

h h

..

--+-~~~·b~'''-'''''-'"''--------·----·----------·-J

,,-,,-8::c.J2

11912

-

54V1I20

~

IT

.I""i'

~

I

CKS902

"""

C982

0.22

IMI.)

CUl

0.22

IMLI

1:958

10/50

I--~"'--l

-lOY

*.,.,tt.'9-,=.-'"'.'J,:"~...j

_17.

"v

nvl

Q907

,.~

259562CR958

~.9n

...

1.2K

~gmS:l

Z0902

RD16JS3

R969

3.

9)(

IPOWER

G

H

• NOTESONSCHEMATIC DIAGRAM can be found on page 14.

1

2 3 4 5 6 7 8 9

-29-

Figure

29 SCHEMATIC DIAGRAM

(4m

-30-

10

11

12

Page 20

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

t

;"'-

(',

~-~i_:-'~

-

A

i~-~

,

·i_~

RD

BK

(

\

B

c

D

CNS601

P24

rr-H

COLOR

BR

RD{R)

OR

YL

GR

BL

VL

GY

WH(W)

BK

PK

TABLE

BROWN

RED

ORANGE

YELLOW

GREEN

BLUE

VIOLET

GRAY

WHITE

BLACK

PINK

(

(

E

I

YQ~UME

F

G

H

2 3

4

-31-

5

Figure31WIRING SIDE OF P.W.BOARD (3/5)

6 7 8

9

-32-

10

PWS-021

11

12

Page 21

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

FM

SIGNAL

----6

LOD80ITUNER/CD

LCD

----I__'L~C::'O"___'P__'W__'B"__~__'O"__l'__l

A

I

R810

ov

OV

"

,.

"

"

C801

!IOOU.10

C802

0.022

0801

155133

SWBD2

rif-.',f-,-,

~+--f---(:O~1l

155133

DB01

RBJH

"""'

I

~~~~~

~

'.

,.

~."~~pH)---'

155133

DBDa

lSSln

C807

":,~.

10/50

5V

SInD

BAllO

."

"

SWBOS

.,~

.~~

I

C80e

330P

_0O!"

,,<'>

....

::::::,"111

SEGl2

SBOIS

SBGH

SeGIS

seCle

B

seOl7

SOllia

SEGIS

BOOZD

SEG21

S8022

58023

SI!G24

SBCZS

SEG26

sec,,?

I

CBO'

RH-IXI846AF

TUNER

CONTROL

MI

CROCOMPUTER

~I~~~

-

~.

~

8

MONO/STBIiIlO

."

IP

Rill!

MUT8

c

P22

12_B

CNSBO I

D

--®

cnpso

•

I

SPAti

TunER

MUTE

MONO/ST

cnOIDl

STEREO

counT

CLOCK

DATA

PERIOD

IF

REO

+5VlBACK

+5V(UN_S'i")

START

UI'I

C810

0.01

CUI

D.

Dl

C813

0.01

R815

R817

"

=:"~~"~===I;r~=-:,'--jfP9i.!,*",.[]."9I-,~-""--j;~"I-;~:"-"1C:~:o!~o_~:ol--+---II~+

~:~~~~~

:~:~~~:~~~:~8gg8

ReSl

1f~==~~'~I~'II"JJ~~~~~~~~~:~~~::~~~~u

'"

,t'

"."'

Down

SW854

R856

>cd

swa53

UP

SW855 SW856

Ra55

10K 10K

m

swa52

O/C)-----++--=

SW851

RS51

10K

0851

lSSIB

....

",-+-'

ISSI33

R858

10K 10K

R859

'"

R860

u

C8s8

ICHI

'"

R869

"

LAMP

.eWB.+O

L.CD

BliCK

I

PLOD

3

LICHT

IL-_~_"~":_'~_":~·_.~"'-<1fi~~·-'~-J'i-I--

llIBOI-A

CBS4

D.

022

CB55

0.01

C856

0.01

C857

'"

lCHi

1S8

RBBB

(1/4)

la51

1 I MUTI!

r-

:f,

4 ---l r

-.II

___

___

8 8 TRAY

___

__

CN55~

TRAY MTR

TRAY MTR

+8V

®t1C

ctlDlDl

PU-IN

TRAYSWOPEti

LANF

lD"

P3B

8-c

OPEN

CLOSE

SW

·SW

CLOSII

E

F

G

H

~:

'"'1"1

PZ212F

CtlS803

TUNER

CU

S1I812

Clf1'802

POWER

S MUTE

,.,

TAPE

TUNER

POWER

SW809 SW811

"

ClfP803

+12V(AI

CNDIMI

+l2YtLAMPI

+17V

'"

L_CH

llNo-(Al

" '"

I

L .

CBI8

47/16

C81S

0.022

RB34

'"

LIlDSOS

3N41101133

STAIID BY

lifO.

LB02

100,Jl

• NOTES ON SCHEMATIC DIAGRAM can be found on page 14.

1

2 3 4 5 6 7

-33-

Figure

33 SCHEMATIC DIAGRAM

(517)

B

9

10

12

"

-34-

Page 22

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

P24

IO-A

9D

A

P2B

Y

12-E

P31

~

4-E

(

B

SR

RD(R)

OR

YL

GR

BL

VL

GY

WHeW)

SK

PK

TABLE

BROWN

REO

ORANGE

YELLOW

GREEN

BLUE

ViOLET

GRAY

WHITE

BLACK

PINK

(

CNS4

,

,

3

4

•

c

D

P31

5-E

-,

I

CNS3

BR

,

,

OR

3

4

BR

RD

OR

YL

GR

o

DISC

CLOSE

sw,

HOLDER

OPEN

.3

LOADING

MOTOR

COLOR

~

I

\.

SPIN

.,

MOTOR

(

---

E

~6~6

:,j-'---P-'-C-K-U-P-U-N-"--'

I

13081

_J

I

I

I

I

I

I

I

I

I

I

I

_J

11

12

F

CNS2A CNS28

-D~~I~~~D-

G

H

•

The

numbers8toCDare

1

waveform

2 3 4

numbers

showninpage

-.35-

42.

5 6 7

Figure 35 WIRING SIDE OF P.W.BOARD (4/5)

CN5lA

,f-__

...,-,-

--iG[!V_--.

,----U~+=l~

~I=::iR=1

•

f~=lb=::;;tr-----"!:-.J

8

GY

9

-36-

10

eNSIS

4

3

,

(

Page 23

CD-K455Z

'CD-K455Z

CP-K455Z CP-K455Z

A

B

eNSIS

-~B

,

,

"!Q'

CNSIA

" _ 4

c

GNP}

l~

~Il.

,'

hi

,

,

--

.

47/lli

"

I~

RI32

'"

Rt.33

HI30

I.

OK

D

PI

CKUP

PNIT

E

"

CI22

47/16

lj

CN52B

F

+8

.,

LOADING

•

NOTES

MOTOR

ON SCHEMATIC DIAGRAM can be found on page 14,

1

2

J

3 4 5 6 7 8 9

Figure 37 SCHEMATIC DIAGRAM

-37-

(617)

G

H

~

PH

12-C

-8

SIGNAL

•

The

numbers 0 to

-38-

G)

are waveform numbers showninpage42.

10

11

12

Page 24

CD-K455Z CD-K455Z

CP-K455Z CP-K455Z

+B

-i

-.-----------------------------------------------------------------------------------------------LECR0

A

I 0

I

II

I

B

C

D

E

I

4-++f-;':;'~K~+r;?~f+;-,

~+~Wr-+-r-<U/

~~~M

C51M

O.

(147

C57M

56~_P_,,_,

C59M

__

56(l_;"T"

~~~M

R52M

68K

68K

C60M

C58M

560P

560P

R58M

,,,

R75M

:27;M

R77M

22K

FM

R54M

C52M

O.

047

IC50M

:'~.""C4~714}'2"t-E~.;·61:·f~"''BrS°.;~j6~07.;IM.:8;4+'lb++2~_@[;:_,8'A

R711M

22K

C65M

tOOP

SIGNAL

~52:';0

"V

R!~8~M

B·

R6IM

5.6K

ov

C56M R68M

0.22/50

ov

7

R62M

5.

6K

I

OV

R79M

'"

MIC

AMP

F'

~i

R65f,f'/

,2?J<;,)

R67M'

27K

27K

R64M

2"

R66M

22K

-B

IC50M.

W1lW1l$'

IC5IM:OPE

~~;{M

R81M

6.

BK

C15

1

:rt.

~4'i-'..c-P":

-8.

GV

RECORD

AMP.

JC51M

B.14741

C"M

~~~M ~~~~

R72M

,,,

C64M

-8.5V

10/50

R74M

1 0 OK

SIGNAL

ANALOG

SWITCH

lC53M

LC4966

7

-B.GY

4-

B';:2M

SWITCHING

D

CIQ1541MyS

DT~5121~

-6.]~3~v

47K

-8.5V

la.6V

MI

C

SIGNAL

-

PWB-F

1

I

(

I

R-CH

IN

BUFFER

R2'29KM

~.,'

~"

D~""

j,

~

AMP.

'.

!

f"

fj

ES

;;;;;; j

tOo

a:~

SW50M

-1

Ie

R9o~.;I:

22K~_,

::>:

~:.:

~~f

,i

~

'''''

1n::N

-j5V

Q5'OM I

DTC114-YS

ov

:73M

47/16

fig 3M:'

4.

7~

15V

g;~6

<I>-..,""=-,-....

Ii*.

R94M;

........

~~4.7K

<:&'''>..''':j!

~

,~

S:J

II

I

I.

I

I'

(

~

~

t'-

•

~

~

_~:~;~:51:~:~~4:':::::J::::l:!:~O~C;7";~~~:~~:W~~~:~~~~:~~~~~~~~~~~::~-:1~::::'::!\11F~~!:r':-j-f-:-{:-~-:-:-:-----:<I--:--"i~~·I-

1

~.

tj~=

f

MIG/BUFFER

AMP.

IC2M

!l~

BA4558N

i;;;;3

-J~;:;

-I

SV

1

'>V

'~;:-+-_++--==~

Rl8M

,

IJ<

'Cd"M"

1

0/50

VR3M

20Kl8J

DIGITAL

ECHO

R~:M

Rl9M

...

JOK

RB4M

1K

t"

u

...

U 0

u...

..

~~~~~~~~~~~~~Hr

R21M

,,,,,~j :"'=~-;

Q4M

DTA114

SWITCH1NG

ES

C14M

~~,:~O;f~!q

5

R25M

22K

C15M

33/10

L-i

H

l1 6

ml, 3

lib~

;[;;;ll!~:l!il~!~]!~~~~l;ll~l~:

~!

,---t--------t_-t_---t<~9)1

.....

~~~~~~~~+~_t~~-.__H])1

R27M

C46M

O.

022

C44M

47/25

C45M

O.

C43M

47/25

" "

022

C16M

lOOP

-11~_t~t_~~~+_+_+~

It

R26M

10K

~

~"l

R28M

""

R-CH

IN

"':

:~~7A~UT

~~

L-CH

L-CH

+12V1MJ

GND

ID I

DUBB I

IN

OUT

NG

P22

7

8

CNSIM

12-D

(

6

~

" =

DIGITAL

ECHO

z z z "

C47M

47/16

._._.

8

LIM

VOLTAGE

REGULATOR

Q5M

2SC200

I L

5.

5V!-cc"WIo-.

~~

R49M

'<1'0

+ 1

00

""

SWlM-A

C

rO

z

0 0

R4BM

dr-

1.

2K

9 10

SELECTOR

---

NORMAL

TAPE

(

CNP804

HI

+B

REC

+8

SWIM-B

H1GH

~

NORMAL

DUB8lNG

SPEED

0

-----------

11

I

2

3

4

6

I

CNS8041

P26

F

"

I

(

12

R7M

tOOK

elM

R'M

_________

J

JIM

MI

C

F

.'

G

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 14.

___________________________________________________

L

[II

r---------~

___

;;_~

MICm

J

4.

R4M

4.7K

i

L2-iT-f,C..,."Hli2""',.,'S:~'P,oS,y~-·

2 3 4

lOOP

7K

C2M

lOOP

R8M

lOOK

k"~G~

:"-'-'Rff'""'~t:160~'~1sv~:

C9"

t/50

C10M

1/50

RlOM

"'0

t-"R

OC

':"-----,

12:CM

120K

~~~p

'V

~51;:<""

VR2M

20K

{Sl

MI

C

[II

LEV

EL

~,:")t'"1,M"6?;'Jif"

!',

,:,4-7K

Cl2M

l'

7<:https://manualmachine.com/~;,--

J

;~~4M

R34M

15K

?;.~

• •

5 6 7

~

U

C34M

O.

,

c

022

XIM

4.

05MHz

C25M

0.0033

R40M

~~

\CJ54~

N

RJ9M

o

R33M

U

2.7K

10K

R4tM

10K

I

C2

0.012

CIOM

0,022

ICJM

R42M

'"

8M

N

N

..

M50197P

~~

Uo

2 3 4 5

C30M C31M

o 01 0 1

o~

Figure 39 SCHEMATIC DIAGRAM (7fT)

-39-

-40-

Page 25

.--A1-------

B

c

VR3M

DIGITAL

ECHO

CD-K455Z

CP-K455Z

o

E

VRIM

F

KARAOKE

MAKER

G

H

2 3 4

5

6

Figure41WIRING SIDE OF P.W.BOARD (5/5)

-41-

Page 26

CD-K455Z

CP-K455Z

HF

o

O.

O.5psec/Dlv(DC)

(When

FRF

O.5V/Dlv

SOm

FE

O.

SQm

STOP--PLAYBACK

tV/Dlv

back

sec/Dlv(DC)

tV/Dlv

sec/Dlv(DC)

p]aylnS

the

disc

WAVEFORMS

II":

0:

l'.'

rg

/

,,\

I

~

I

~

II,

I

W'

I

OF

CD CIRCUIT

FRF

O.5V/Dlv

0.5

sec/D

TRACKING

O.

LV/Dlv

O.5sec/Dlv(OC)

STOP-PLAYBACK

~DATA

."

O.

2V/D

O.

Sp.sllc/Dlv

{When

back

J v

I v

playing

the

(DCI

COIL

discI

*.,

r I

....

I'

(

(

1

FDQ

O.

2V/D

O.

STOP---PLAYBACK

FRF

O.5V/Dlv

O.5sQc/Dlv(DC}

FOCUS

O.

O.

STOP

J v

S",sec/Dlv(DC)

COIL

tV/Dlv

SSGe/DlvIDe)

-PLAYBACK

I

I

II

I

J.

IJ

,j,

.'"

1\

~

Audio

Signal

O.2V/Dlv

O.2m

(''{hen

NOTE:

1.

2.

back

Us

8

Output

sec/Dlv(AC}

playing

the

10:1

e

.•.

dJ

se)

11kHz

probe

to

e.0.8

osclIloscope

~

connect.

Th.

for

~

10..

~

PLAYBACK

Sine

wave

"".,.

measurement.

waS

~

10..

discI

uSed

~

(

(

-42-

Page 27

TROUBLESHOOTING (CD SECTION)·

- 55

CP-K455Z

When the

WhentheCDsectiondoesnotoperateWhen the objective lens oftheopticalpickupisdirty,thissection maynotoperate.Clean the objective

lens,and check the playback operation.When this section does not operate even after the above stepistaken,checkthe following items. u

Remove the cabinet and follow the troubleshooting instructions.

Turn the power switchonthe unit to

Does

CD

does not function

ON.

the LCD or fluorescent character display tubegoon?

'I

Check

the

I

No

does

not

go on."

itemof"The

LCDorfluorescent

character

display

tube

1Yes

Does

the disc tray open?

Does

the disc tray close?

Does the spin

When the discisinitialized, is TOe

Is

TOe

Is there

'-

motor

run?

set to the playback mode?

any

audio output?

~

Yes

~

Yes

~

Yes

---.c-c-

~

Yes

read?

---'I

I

No

I

No

I

No

No

No

Check the item of "The disc tray does not open."

"I

Check the itemof''The disc tray does not close,"

"I

Check the item of ''The spin motor does not run."

"I

Check the item of''The disc does not playback."

Check the audio circuit.

I

I

I

I

I

I

I

OK

I

Turn the

Check

Is the oscillating circuit (X851)ofthe control microcomputer

(ICB51)

Checktosee

(IC851) is operating normally.

[s

tube being output from the control microcomputer (IC851)?

Check

display tube,

power

switchtoON.

the

power

circuit voltage.

operating

the

drive signalofthe

the supply voltageofthe LCDorfluorescent character

normally?

Yes

that the reset circuitofthe control microcomputer

Normal

LCDorfluorescent character display

Yes

No

Check the X851 and peripheral circuits

Check

the reset circuit (085,1) and peripheral circuits and replace

faulty

parts.

The microcomputer (IC851) is defective. Replace it.

The LCD

Replace it.

or

fluorescent character display tube is defective,

and

replace faulty parts.

Are

the

connector

Normal

and

PWB pattern damaged?

-43-

Page 28

CD-K455Z

CP-K455Z

lis

the

open/close

key

signal

being

output?

1Ves

liS

the

tray

close

of

the

control

115

the motor drive output being output from pins 13 and 14 of the I

control

microcomputer

1'5

the motordrive output being output from pins 2 and 7

of

the

motor

detection

microcomputer

driver

IThe loading motor (M3) is defective. Replace

The

loading

mechanismisfaulty.

switch

signal

(l)

being

(IC851)?

~

Yes

(IC851)? I

~

Ves

(Ie?)?

~

Yes

inputtopin

it.

18

The

"I

. I

IIC7

openfcl0S:8

Replace

The

control

Is

there

is defective.

Replace

I

No

No

I

No

No

I

I