Seca 769, 799 LC Service Manual

Service Manual

Variants:

769 1321004

769 1321994

780 2321369

7997021099

7997021159

for seca 769 LC / 780 LC gost/ 799 LC

Description:

Colum scale with 4 load cell technology

Content:

Description LC2 electronic 30-34-00-745

Function diagram 25-02-02-281

Adjustment model spezific options 30-34-00-743

Service Manual Number

17-05-01-340-b

Valid as of: 01.12.2010

Description of faults 30-34-00-744

Cableplan 08-02-06-037 a

Spare parts 30-34-00-746 b

Manual number: 17-05-01-340-b

Service Manual Description of the LC2 electronics

Brief description of the LC display module

Introduction

The display module belongs to the LC family of seca’s electronic modules and is used to indicate a

weight value measured with the LC weight module and supplied via the module bus. The display

module also accommodates the operating elements and can process the weight (hold, tare, etc.).

Furthermore, a simple switch/jumper is provided to activate scale service.

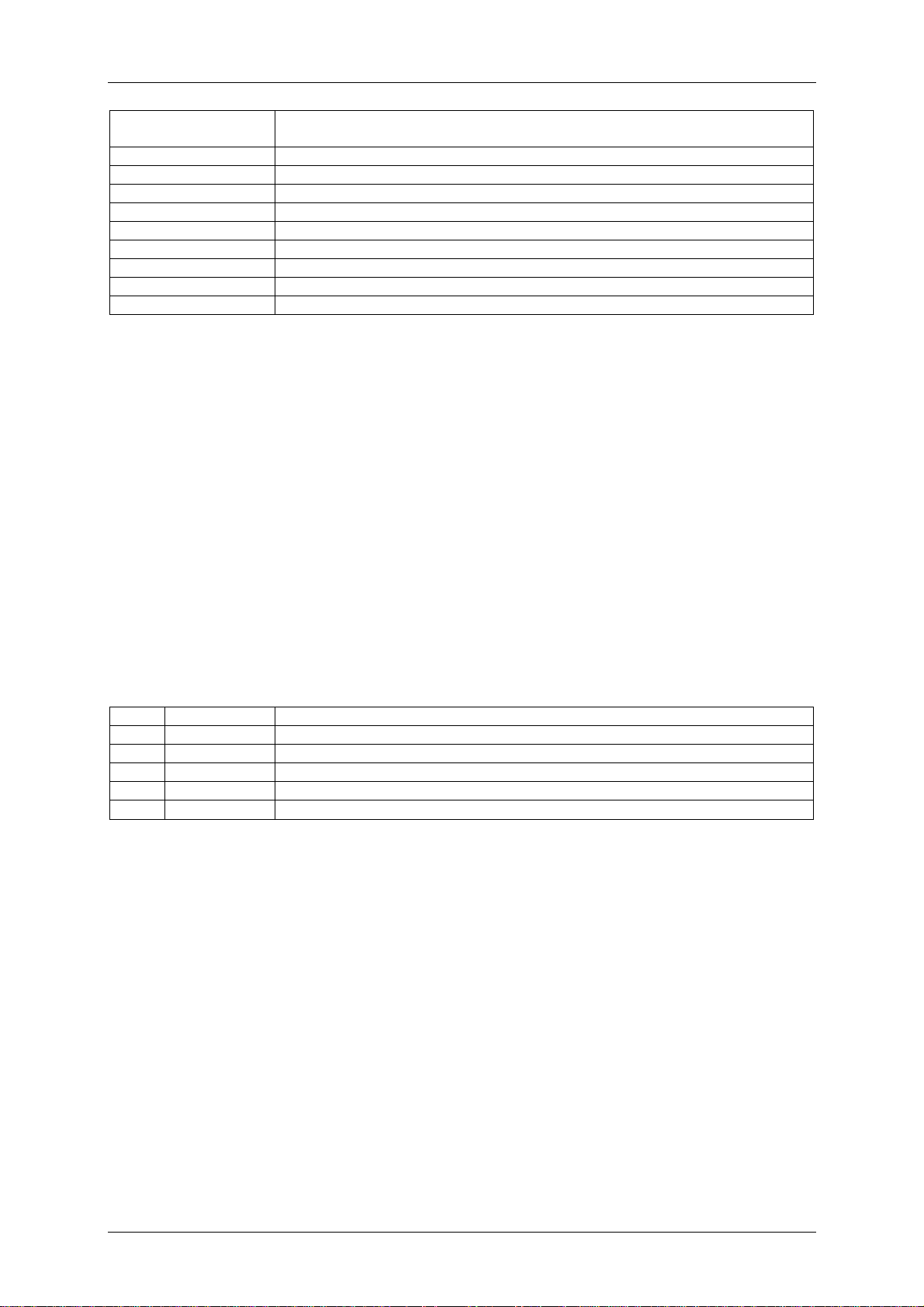

The following block diagram shows the main function blocks of the LC display module:

Programming

interface

uC

Scale

service

LC module bus

Switch

on/off

logics

LCD

Voltage

regulation

Operation

Display representation

A maximum of five digits as well as some special characters can be displayed, which can appear as

shown below:

Explanation of the special characters:

Symbol Meaning

Battery Battery warning, operation of the scale can continue, but the batteries

should be replaced. If the batteries are not replaced and are allowed to

discharge below the next threshold, the ”bAtt“ message is displayed.

Measurements are then no longer possible.

Measuring range 1 Measuring range 1 is active.

Measuring range 2 Measuring range 2 is active.

Power supply unit The scale is operating in power supply unit mode.

PT PT indicates that a weight value previously saved will automatically be

subtracted from the weight value currently measured.

BMI The BMI function is active. Once body height has been entered, the BMI

value is displayed.

23.07.07 Kr/Rei Page 1(6) 30-34-00-745

Service Manual Description of the LC2 electronics

Hold + warning

triangle

TARE, NET Tare or Net show that a weight on the scale has been tared out.

cm The value displayed corresponds to body height in cm. (BMI)

lbs The weight value is displayed in lbs.

kg The weight value is displayed in kg.

sts The weight value is displayed in lbs and sts.

Hold indicates that the weight display has frozen. The warning triangle

signals that the weight displayed on the scale is not verifiable.

Power supply

Power supply is provided via the LC module bus. The power supply for the display module is

connected through the start button. Once the microcontroller on the LC display module has started, it

assumes control of the power supply. When the start button is pressed again, the power supply to the

display is switched off.

Operation

With the exception of the start button (if provided), the connected buttons can be configured as

required for the particular model. These buttons can be pressed just lightly or longer (longer than 1 s).

Scale service

To activate scale service, 2 contact pins on the PCB must be short-circuited by means of a

jumper/switch. Access to these contacts can only be gained by destroying the seal and opening the

display housing. After placing the jumper, switch on the scale to start scale service.

LC module bus

The LC module bus establishes the connection to the LC weight module. The unregulated supply

voltage from the LC weight module is available on the bus. All relevant data is exchanged via a data

line and a clock pulse line.

Pin Function Note

1 SCL Serial Clock TWI

2 GND Ground

3 SDA Serial Data TWI

4 Vin Battery/power supply voltage

Programming interface

The programming interface is a 10-pin interface, which is only accessible after opening the display

housing. The display housing is secured with a seal that must be destroyed to open the housing.

Warning: If the seal is destroyed, verification is no longer valid. A special seca service adapter is

required to access the programming interface.

The service interface can be used to:

- supply the unregulated supply voltage

- measure the regulated voltage for the electronics

- execute the start function

- delete and write new data to the flash memory and the EEPROM of the microcontroller

Programming

The microcontroller contains two types of non-volatile memories that are used for various purposes in

the module.

The following memory types are provided:

23.07.07 Kr/Rei Page 2(6) 30-34-00-745

Service Manual Description of the LC2 electronics

Type of memory Size

Flash memory 8 Kbytes

EEPROM 512 bytes

The flash memory holds the firmware for the microcontroller. During programming, the data is written

to the flash memory via the 10-pin programming interface. The parameters read out by the LC display

module from the LC weight module after being set into operation for the very first time are stored in the

EEPROM. Both memories are protected by an LRC checksum. A data error in either of the two

memories cannot be remedied during the operation and causes a permanent fault indication.

Weighing operations are then no longer possible. Once the scale has been programmed, both

memories are protected against reading out and modifying data via the programming interface. Any

modification of the data first requires that both memories are completely cleared.

Fault handling

If faults occur, they are displayed on the LCD with the relevant fault code. Each fault message

includes the number of the module type on which the fault has occurred.

Module Number

LC weight module 10

LC display module 11

The following fault messages are implemented:

Fault number Fault description

11 Outside value range (positive or negative overload)

12 Switch-on zero point outside the permissible range

13 Zero follow-up outside the permissible range

16 No zero point

40 EEPROM checksum fault

50 Flash memory checksum fault

60 Bus communication fault

Technical data

Supply voltage : 9V – 12V (via LC module bus)

Supply current: typ. 11.8mA

Zero-signal current: typ. < 0.1µA

Operating temperature: approx. 0°C to 50°C

Storage temperature: -10°C to 60°C

Dimensions: 63mm x 42mm x 1.7mm

23.07.07 Kr/Rei Page 3(6) 30-34-00-745

Service Manual Description of the LC2 electronics

Brief description of the LC weight module

Introduction

The LC weight module is used to determine weights using one or several load cell(s) with strain

gauges. The LC module bus supplies the processed measured values to the LC display module.

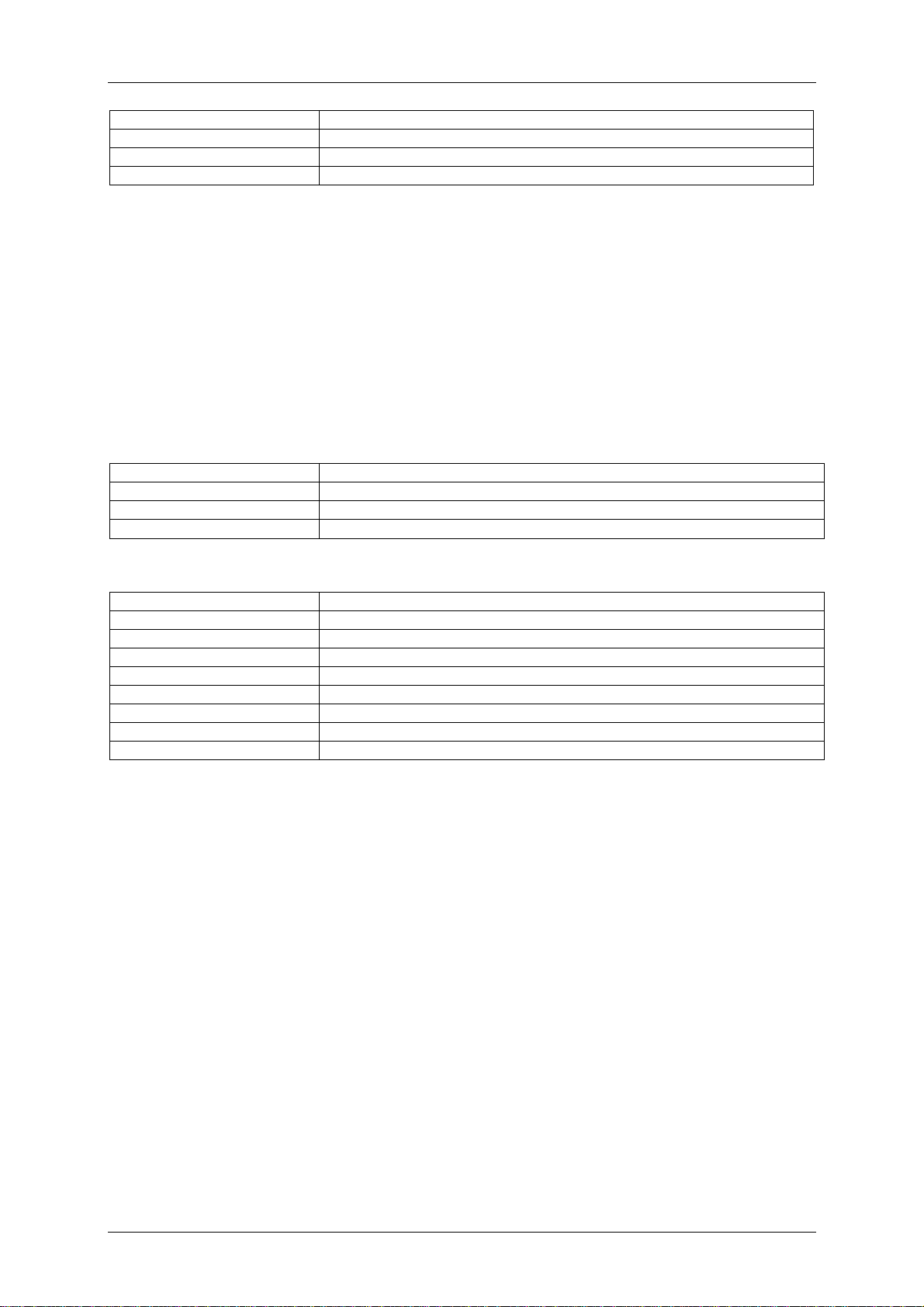

The following block diagram shows the main function blocks of the LC weight module:

Mains

connection

/battery

Load cell(s)

Voltage

measurement

Voltage

regulation

A/D converter

Programming

interface

uC

Switch

on/off

logics

Resonator

LC module bus

Temperature

measurement

Weight measurement

The weight module uses load cells with strain gauges in a double bridge circuit as sensors. The entire

analog part and the load cells, as well as the other peripherals, are supplied with a 5V supply voltage.

At full load, the load cells supply a bridge output voltage of 0.8mV/V. This voltage is measured by a

dual slope A/D converter; the different voltages supplied by the four load cells are multiplexed

accordingly. Every 500 ms, 12 measurements are carried out per load cell and the mean value is then

calculated. Before the mean values for each load cell are merged and converted into the weight value,

an individual corner correction factor is applied to them. A linear function is used to convert the results

into a weight value. The first stable value within the switch-on zero setting range after switching on the

scale is used as zero point. The zero follow-up range is monitoring during the operation of the scale.

Temperature measurement

In order to compensate for the load cell’s temperature drift, the temperature is measured regularly and

the measured value is adjusted accordingly. For this measurement, the voltage is cyclically measured

via an NTC, which forms a voltage divider together with a linearization resistor connected in series. To

reduce measured value fluctuations, a mean value of 8 temperature values is always formed.

Fluctuations are thus reduced to a third compared with individual measurements. The difference

between the current temperature and the temperature measured when the last zero point was

obtained is used to determine a projected zero point. To do so, one assumes that the weight change

per °C is constant. The weight value is then corrected in accordance with the zero point calculated and

in accordance with the difference to the temperature measured when the scale was adjusted.

Power supply

Power supply can be provided by AA size batteries or a power supply unit. The circuit cannot be

operated on rechargeable batteries. The unregulated voltage is connected to a 5V in-phase regulator

via reverse voltage protection diodes. The regulated 5V supply voltage is then available to the entire

circuit. The supply voltage for the analog part can be switched separately from the rest of the PCB via

a switch on/off logic. The digital part is permanently supplied with 5V.

Voltage measurement

To enable power supply unit and battery operation to be distinguished and in order to measure the

current battery voltage, the unregulated voltage is monitored by the microcontroller. Voltage

measurement takes place via a voltage divider and by means of the internal A/D converter.

23.07.07 Kr/Rei Page 4(6) 30-34-00-745

Loading...

Loading...