Variants:

6641321108

6641321378

6657021008

6657021198

6657021228

6657021248

6657021288

Service Manual

for seca 664, 665 NEC2

Service Manual Number

17-05-01-375-

Description:

Electronic platform scales with high load-bearing capacity and castors for transport

When servicing or repairing seca devices according to this service manual, always take note of the

instruction manual of th e product. To download the latest version of the ins t ruction manual and EMC

Recommendation go to

www.seca.com

.

Valid as of: 01.02.2013

Contents:

Service description electronic 30-34-00-812 c

Cableplan

Replacement

Spare parts

Spare parts

Spare parts

Spare parts

Spare parts 6657021228

Spare parts

Spare parts 6657021288

Spare parts drawing Frame 30-34-00-844

Spare parts drawing display

EMC Recommendation

08-02-06-058 a

30-34-00-860

664 1321108

6641321378

6657021008

6657021198

6657021248

30-34-00-842

30-34-00-519

Instruction manual 656

Instruction manual 657

Manual number: 17-05-01-375-

17-10-06-385

17-10-07-610

General information seca

Electronics (NEC2) Service

Instructions

ODEL

M

[374|376|378|703|704|264|274|284|285|634|635|644|645|

656|657|664|665|675|676|677|684|685|954|955|957|959|

963]

14.11.12/RLEU/ARI/MRE 1/40 30-34-00-812c

General information seca

Contents

1 General Information

[374|376|378|634|635|644|645|656|657|664|665|674|675|676|677|684|685|70

3|704|264|274|284|285|954|957|959|963]...................................................... 5

1.1 Type Plates

[374|376|378|634|635|644|645|656|657|664|665|674|675|676|677|684|685|70

3|704|264|274|284|285|954|957|959|963]....................................................... 5

1.2 Design and Function of the Scale Part

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|

676|677|684|685|264|274|284|285|954|957|959|963]..................................... 6

1.2.1 Design

[374|376|378|703|704634|635|644|645|656|657|664|665|674|675|676|677|6

84|685|284|285] .......................................................................................... 6

1.2.2 Function

[374|376|378|703|704634|635|644|645|656|657|664|665|674|675|

676|677|684|685|284|285]........................................................................... 6

1.3 Design and Function of the Head Slider [264|274|284|285].................7

2 Maintenance

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|676|677|68

4|685|264|274|284|285|954|957|959|963]...................................................... 8

2.1 Adjustment of Scales

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|

676|677|684|685|264|274|284|285|954|957|959|963]................................... 10

2.1.1

General[374|376|378|703|704|634|635|644|645|656|657|664|665|

674|675|676|677|684|685|264|274|284|285|954|957|959|963].................. 10

2.1.2 Calibration Counter / Number of Adjustments

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|676|677|

684|685||264|274|284|285|954|957|959|963]............................................11

2.1.3 Adjustment Mode and Displaying the Calibration Counter

Contents

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|676|677|

684|685|954|957|959|963]......................................................................... 11

2.1.4 Adjustment Mode and Displaying the Calibration Counter

Contents [284|285]....................................................................................12

2.1.5 Placing Adjustment Weights on the Scale .................................. 12

14.11.12/RLEU/ARI/MRE 2/40 30-34-00-812c

General information seca

2.1.6 Example: Adjusting a Scale with 100g Graduations

[703|704|284|285|634|635|644|645|656|657|664|665|675|676|677 |684|685]

.................................................................................................... 13

2.1.7 Example: Adjusting a Baby Scale with 10g Graduations [374|376].

.................................................................................................... 13

2.1.8 Overview of Adjusting a Scale with 100g Graduations [703|704] 14

2.1.9 Overview of Adjusting a Baby Scale with 10g Graduations

[374|376|378] ............................................................................................ 16

2.2 Adjusting the Head Slider [284|285]................................................... 17

2.2.1 Displaying the Gravity Factor

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|676|677|

684|685|954|957|959|963]......................................................................... 17

2.3 Setting the Gravity Factor

[374|703|634|644|656|664|674|676|684|284|954]:........................................ 18

2.3.1 Example for Gravity Factor Setting

[374|703|634|644|656|664|674|676|684|284|954]..................................... 19

2.3.2 Summary of a Typical Gravity Factor Setting Sequence [374|703].

19

3 Errors

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|676|677|68

4|685|954|957|959|963]................................................................................ 21

3.1 Error Symptoms for Scale

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|

676|677|684|685|954|957|959|963] .............................................................. 21

3.2 Error Symptoms for Head Slider [264|274|284|285]........................... 22

3.3 Radio Error Symptoms

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|

674|675|676|677|684|685|954|957|959|963]................................................. 23

3.4 Scale Error Messages

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|

674|675|676|677|684|685|954|957|959|963]................................................. 24

3.5 Head Slider Error Messages [264|274|284|285] ................................ 25

3.6 Radio Error Message

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|

674|675|676|677|684|685|954|957|959|963]................................................. 26

14.11.12/RLEU/ARI/MRE 3/40 30-34-00-812c

General information seca

4 Measurements

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|674|675|67

6|677|684|685|954|957|959|963].................................................................. 27

4.1 Supply Voltage

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|674|675|67

6|677|684|685|954|957|959|963] .................................................................. 27

4.2 Load Cell

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|674|675|67

6|677|684|685|954|957|959|963] .................................................................. 27

4.2.1 Measurement Using a Multimeter

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|674|675|

676|677|684|685|954|957|959|963]........................................................... 27

5 Software intended Purpose.......................................................................... 30

5.1 Installation and Start .......................................................................... 30

5.2 Updating the Radio Module Software.................................................31

5.3 Set-up Process .................................................................................. 32

5.4 Updating the Radio Module Software.................................................33

5.5 Technical Requirements for Updating................................................34

5.6 Updating the Wireless Printer Software .............................................34

5.7 Updating Old Printers......................................................................... 35

5.8 Problems with Updating..................................................................... 35

Appendixes....................................................................................................... 36

14.11.12/RLEU/ARI/MRE 4/40 30-34-00-812c

General information seca

1 General Information

[

374|376|378|634|635|644|645|656|657|664|665|674|675|676|677

|684|685|703|704|264|274|284|285|954|957|959|963

These service instructions are intended for specialist staff responsible for

maintenance and repair of the devices. These persons must be familiar with all

the relevant electro-technical regulations and must adhere to them any time.

These instructions are not suitable for users without specialist knowledge.

These instructions describe how to service the devices

[374|376|378|634|635|644|645|656|657|664|665|674|675|676|677|684|685|703|

704|264|274|284|285|954|957|959|963]equipped with NEC2 electronic modules.

The device types for which these instructions apply are listed in the section

headings. There are some identical models with NEC1 electronic modules.

These instructions are not valid for those types.

What is the structure of this document and how should you read it? Section 1

provides a short overview of the most important points for service. We

recommend you should read it completely. Section 2 deals with the

maintenance of the devices, i.e. work that may have to be carried out more

frequently. This section can be read as and when required. Troubleshooting is

covered in section 4, where you find detailed descriptions of various

measurements intended to identify specific errors. Starting point for

troubleshooting is section 3, which includes an overview of error descriptions

and the inspection steps required to identify them.

]

1.1 Type Plates

[374|376|378|634|635|644|645|656|657|664|665|674|675|676|677|684|685|703|

704|264|274|284|285|954|957|959|963]

To enable you to identify the device, information about the model and serial

number is found on the underside or on the frame of the device (see Note down

this information so that you have it on hand in case you need to contact us for

queries or spare parts orders.

Figgure 1: Typeplate (left approved, right non approved)

14.11.12/RLEU/ARI/MRE 5/40 30-34-00-812c

General information seca

1.2 Design and Function of the Scale Part

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|

676|677|684|685|264|274|284|285|954|957|959|963]

1.2.1 Design

[374|376|378|703|704634|635|644|645|656|657|664|665|674|675|6

76|677|684|685|284|285]

The scale consists of the following main parts: the frame with up to four load

cells, a display unit, a key panel and a power supply unit.

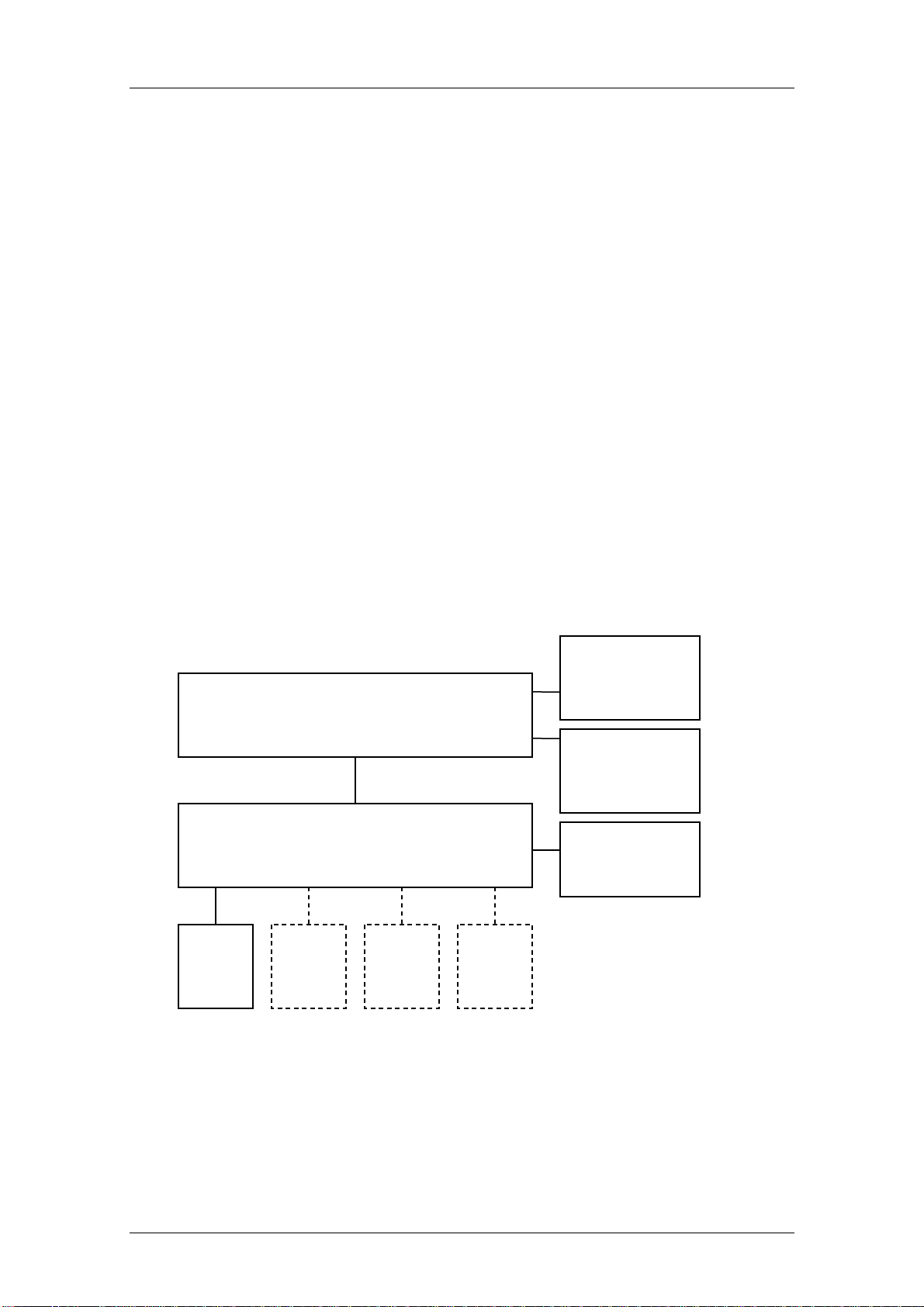

1.2.2 Function

[374|376|378|703|704634|635|644|645|656|657|664|665|674|675|

676|677|684|685|284|285]

The action of a force causes elastic deformation of the load cell. A

corresponding analog signal is supplied, which changes linearly with the force

applied. This signal is measured and evaluated by the scale electronics and

displayed as a weight value. shows the functional diagram for scales with

separated modules for determining and displaying the weight.

Radio module

NEC2 Display module

08-06-18-170 oder -195

NEC2 DMS Module (Weight measurement)

Load

cell

ISIS BUS (Modular cable)

08-06-18-156

Load

cell

Load

cell

Load

cell

08-06-18-172

Keyboard

DC Supply

Figure 1: Functional diagram [704|284|285|634|635|644|645|656|657|664|665|675|677|684|685]

14.11.12/RLEU/ARI/MRE 6/40 30-34-00-812c

General information seca

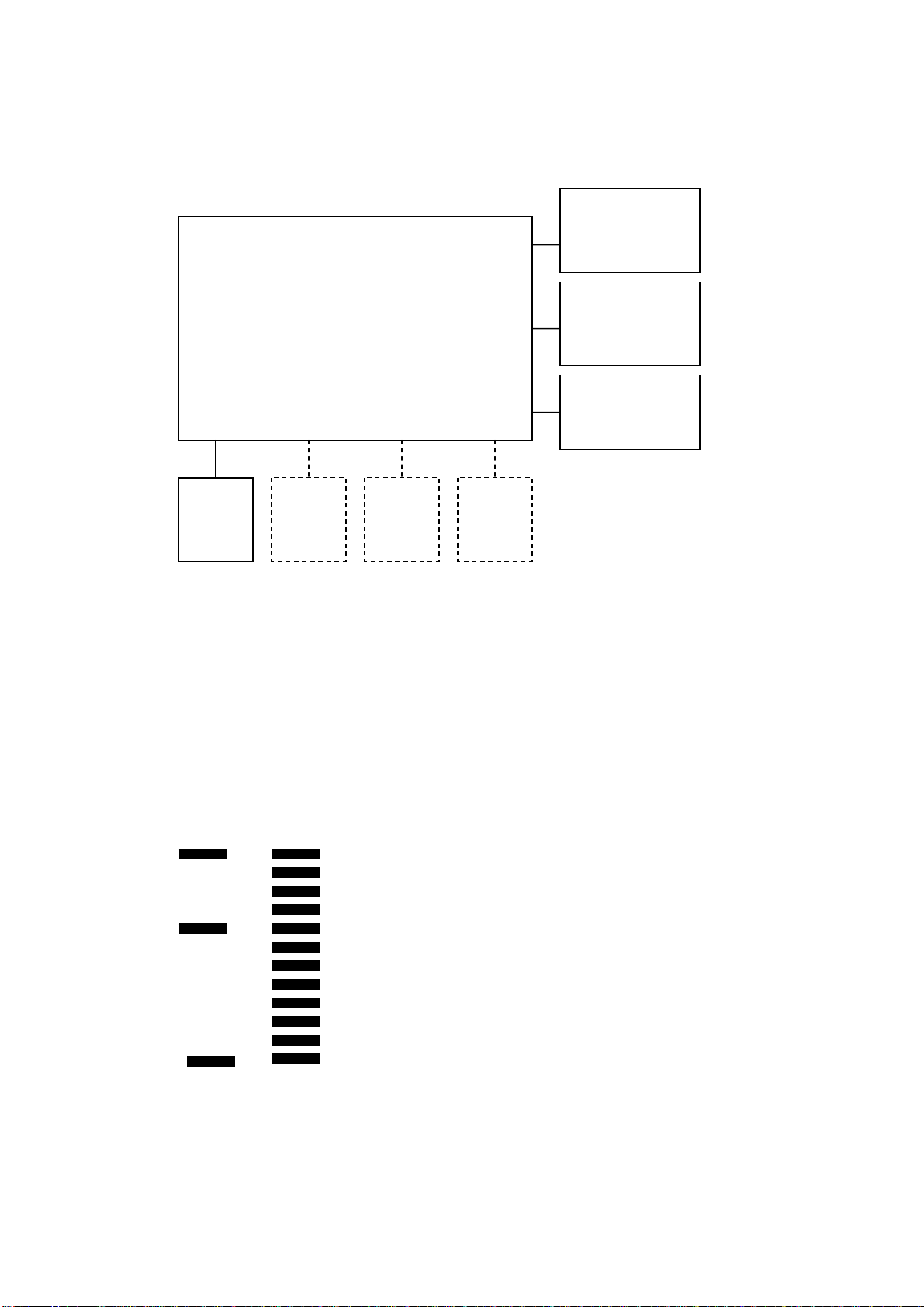

NEC2 Compact module

(Weight measurement and display)

08-06-18-167 oder -163

Figure 3: Functional diagram [374|376|378|703|954|957|959|963]

Load

cell

Load

cell

Load

cell

Load

cell

Radio module

08-06-18-172

Keyboard

DC Supply

1.3 Design and Function of the Head Slider [264|274|284|285]

The head slider uses the measuring method of visual reading off from the insert

scale. Absolute and relative graduation marks are scanned to determine

lengths. Once the slider has moved more than two absolute marks, the absolute

position can be determined and a length is output.

Figure 4: Absolute (left) and relative graduation marks (right) [264|274|284|285]

14.11.12/RLEU/ARI/MRE 7/40 30-34-00-812c

Maintenance seca

2 Maintenance

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675

|676|677|684|685|264|274|284|285|954|957|959|963]

The following section provides an overview of all maintenance jobs which can

be carried out.

To call up the Service Menu, start the scale while pressing another key at the

same time. This causes the content of the calibration counter (i.e. the number of

adjustment operations carried out so far) to be displayed for 24 seconds

(flashing). While the calibration count is displayed, a key must be kept pressed

(for more than 1.5 seconds); the scale then automatically displays the software

identification number and the check digit.

Keypress (any key) and START key simultaneously

- Calibration counter [see 2.1.2]

- Long keypress (any key)

Automatic display for 6 seconds

- XX.YY (software identification)

Then automatic display for 6 seconds

- XXXX (check digit)

Then automatic display

- CAL [see 2.1.5]

Long keypress (any key)

o DEC

Long keypress (any key)

o INC

Short keypress (any key)

- GAL [see1.3]

Long keypress (any key)

o XXXXX (gravity factor)

Short keypress (any key)

- INFO

14.11.12/RLEU/ARI/MRE 8/40 30-34-00-812c

Maintenance seca

Long keypress (any key)

o No: X (module number)

Long keypress (any key)

o XXX.XX (firmware version, e.g. 290.07)

- End

Software identification and check digit:

The existing seca firmware version number is retained and can be called up.

Firmware software identification

Each and every firmware is given its own software identification number.

This software identification number is composed of a version number for the

program part that is subject to verification and a version number for the program

part that is not subject to verification.

Example: 01.08 01 - subject to verification

08 - not subject to verification

Whenever the firmware is changed, the version number for the program part

that is not subject to verification is increased. This is done by analogy with the

firmware index.

When a program part is changed that is subject to verification, the version

number for the program part that is subject to verification is also increased.

Software identification of the device

The overall version number of the program parts which are subject to

verification is the total of the version numbers (subject to verification) of the

individual hardware modules.

The overall version number of the program parts which are not subject to

verification is the total of the version numbers (not subject to verification) of the

individual hardware modules.

14.11.12/RLEU/ARI/MRE 9/40 30-34-00-812c

Maintenance seca

Firmware check digit

Every firmware is given its own check digit.

Device check digit

The overall check digit for the device is the total of the individual check digits.

Representation on display

Hardware module

Firmware version with index / internal seca value

PTB version number

PTB check digit

Weight module

290.08

01.08

1A47

M704

290.08 / 290.08

02.16

348E

Display

290.08

01.08

1A47

Compact

290.08

01.08

1A47

M703

290.08

01.08

1A47

Weight module

290.08

01.08

1A47

Extended display

M285

290.08 / 298.08

02.16

5CAD

2.1 Adjustment of Scales

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|

676|677|684|685|264|274|284|285|954|957|959|963]

298.08

01.08

4266

2.1.1 General[374|376|378|703|704|634|635|644|645|656|657|664|

665|674|675|676|677|684|685|264|274|284|285|954|957|959|963]

To compensate for linear measuring deviations, which occur e.g. as a result of

gravity variations in different gravity zones, the scale offers an adjustment

feature. This adjustment must also be carried out whenever the load cell is

replaced.

14.11.12/RLEU/ARI/MRE 10/40 30-34-00-812c

Maintenance seca

seca scales with modular NEC-G2 electronics are fitted with a softwarecontrolled adjustment device that is controlled using the existing operating

elements. When developing the adjustment device, special attention was paid

to the following requirements:

It must be possible to readjust scales without any additional external

equipment/tools.

The readjustment device must be admissible for verification.

It must be possible to readjust the scales without calibrated test weights.

The readjustment device must be protected against inadvertent use.

Scale adjustment can be carried out manually as described in section 0” or

using seca serva 2.0. Manual adjustment will not correct any corner errors.

2.1.2 Calibration Counter / Number of Adjustments

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|6

76|677|684|685||264|274|284|285|954|957|959|963]

Scales fitted with the new, modular electronics are equipped with a calibration

counter allowing a software adjustment to be carried out in accordance with the

requirements for verified scales. Each completed adjustment procedure is

registered by the calibration counter, i.e. the number is automatically

incremented by 1. Non-approved scales are also fitted with a counter which

counts the number of adjustments.

2.1.3 Adjustment Mode and Displaying the Calibration Counter

Contents

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|6

76|677|684|685|954|957|959|963]

To begin readjustment or to display the calibration counter contents, start the

scale while pressing another key at the same time. The contents of the

calibration counter (i.e. the number of adjustment procedures carried out so far)

are then displayed for 18 seconds (flashing).

While the calibration count is displayed, a key must be kept pressed (for more

than 1.5 seconds) to switch the scale to adjustment mode.

14.11.12/RLEU/ARI/MRE 11/40 30-34-00-812c

Maintenance seca

2.1.4 Adjustment Mode and Displaying the Calibration Counter

Contents [284|285]

To begin readjustment or to display the calibration counter contents, start the

scale and press another key while the display shows seca. The contents of the

calibration counter (i.e. the number of adjustment procedures carried out so far)

are then displayed for 18 seconds (flashing).

While the calibration count is displayed, a key must be kept pressed (for more

than 1.5 seconds) to switch the scale to adjustment mode.

2.1.5 Placing Adjustment Weights on the Scale

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|676|677|684|

685|954|957|959|963]

Once you have switched to adjustment mode as described in section 2.1.3 or

2.1.4, the display shows the text “CAL”. By pressing any key except for the start

key for more than 1.5 seconds, the actual readjustment mode is activated. The

display reads "dec". The weight value currently measured then appears. The

scale is in decrementing state. To switch over from decrementing to

incrementing mode and vice versa press a key for more than 1.5 seconds with a

test weight placed on the scale. The display will read “dec” or “inc” accordingly.

The test weight is at least 25% of the max. load of the scale (we recommend

approx. 66-75%).

Adjustment can now be completed by pressing a key until the display shows

“Sto”. The scale computes and stores a new linearity coefficient and switches

off automatically. Your scale is now adjusted. Remove the test weight.

Note:

Timeout control is not active for the phase of placing and confirming the test weight.

To minimize adjustment errors, readjustment can only be carried out using a test

weight above 25 % and below 100 % of the max. load. Otherwise the error “Er:x:15”

will be displayed.

14.11.12/RLEU/ARI/MRE 12/40 30-34-00-812c

Maintenance seca

2.1.6 Example: Adjusting a Scale with 100g Graduations

[703|704|284|285|634|635|644|645|656|657|664|665|675|676|677

|684|685]

The selected test weight is 200 kg.

The current weight shown on the display is 199.7 kg (max. deviation of 300 g).

In this example, you must switch the scale to incrementing mode to carry out

readjustment. When the tare/hold key has been pressed (for more than 1.5

seconds), "inc" starts flashing.

Now increase the value by the first 10 g (by briefly pressing the tare/hold key).

After this has been repeated x times, the value 200.0 (rounded!) appears on the

display although the internal measured value still is 199.95 kg (not rounded!).

To correct this rounding error, increment the value five times by 10 g to obtain

exactly 200.00 as the calculated value.

Complete the readjustment procedure as described in section 2.1.5.

2.1.7 Example: Adjusting a Baby Scale with 10g Graduations

[374|376]

The selected test weight is 15 kg. The current weight shown on the display is

14.970 kg (max. deviation of 30 g).

In this example, you must switch the scale to incrementing mode to carry out

readjustment. When the tare/hold key has been pressed (for more than 1.5

seconds), "inc" starts flashing.

Now increase the value by the first 1 g (by briefly pressing the tare/hold key).

Each alteration is shown on the display.

Complete the readjustment procedure as described in section 2.1.5.

14.11.12/RLEU/ARI/MRE 13/40 30-34-00-812c

Maintenance seca

A

2.1.8 Overview of Adjusting a Scale with 100g Graduations

[703|704

]

Action carried out by the user

The scale is switched off. No values or characters on the display.

Press the tare/hold key and keep it

pressed while simultaneously pressing

the start key.

Release both keys. The contents of the calibration counter

Press the tare/hold key for more than

1.5seconds within the next 18seconds.

18 seconds have passed and no key has

been pressed.

Result

The contents of the calibration counter

flash on the display for 18 seconds.

flash on the display for 18 seconds.

The system switches to adjustment

selection mode and “CAL” flashes on the

display.

The scale switches off.

Press the tare/hold key for more than 1.5

seconds.

Place the test weight on the scale. The measured weight of the test weight

Decide whether to decrement or to

increment:

Incrementing:

Press the tare/hold key for more than 1.5

seconds.

Decrementing

scale already is in dec mode.

Decrementing or incrementing:

gain briefly press the tare/hold key (for

: No action required as the

"dec" appears on the display (flashing)

and then the current weight (0.0 - also

flashing).

appears on the display (flashing).

Incrementing mode is activated; "inc"

appears on the display.

No output on the display.

The measured weight is decremented or

incremented by 10 g. Please remember

that pressing the key does not always

14.11.12/RLEU/ARI/MRE 14/40 30-34-00-812c

Maintenance seca

less than 1.5 seconds). change the value on the display due to

the low display resolution. Only the

rounded value is output.

Repeat this step until the measured

weight matches the test weight (format:

xxx.0 kg).

To correct this rounding error, decrement

or increment the value five times by 10 g.

Press the tare/hold key until the display

shows “Sto”.

The display indicates the test weight

(format: xxx.0 kg).

The display indicates the exact test

weight (format: xxx.0 kg).

The display reads “Sto” and the scale

switches off automatically.

14.11.12/RLEU/ARI/MRE 15/40 30-34-00-812c

Maintenance seca

2.1.9 Overview of Adjusting a Baby Scale with 10g Graduations

[374|376|378]

Action carried out by the user

The scale is switched off. No values or characters on the display.

Press the tare/hold key and keep it

pressed while simultaneously pressing

the start key.

Release both keys. The contents of the calibration counter

Press the tare/hold key for more than 1.5

seconds.

18 seconds have passed and no key has

been pressed.

Result

The contents of the calibration counter

flash on the display for 18 seconds.

flash on the display for 18 seconds.

The system switches to adjustment

selection mode and “CAL” flashes on the

display.

The scale switches off.

Press the tare/hold key for more than 1.5

seconds.

Place the test weight on the scale. The measured weight of the test weight

Decide whether to decrement or to

increment:

Incrementing:

Press the tare/hold key for more than 1.5

seconds.

Decrementing: No action required as the

scale already is in dec mode.

Decrementing or incrementing: The measured weight is decremented or

"dec" appears on the display (flashing)

and then the current weight (0.000 - also

flashing).

appears on the display (flashing).

Incrementing mode is activated; "inc"

appears on the display.

No output on the display.

14.11.12/RLEU/ARI/MRE 16/40 30-34-00-812c

Maintenance seca

A

gain briefly press the tare/hold key (for

less than 1.5 seconds).

Repeat this step until the measured

weight matches the test weight (format:

xx.000 kg).

Press the tare/hold key until the display

shows “Sto”.

incremented by 1 g.

The display indicates the test weight

(format: xx.000 kg).

The display reads “Sto” and the scale

switches off automatically.

2.2 Adjusting the Head Slider [284|285]

The head slider electronics must be readjusted whenever the electronics are

replaced. Please refer to the instructions in the operating manual.

2.2.1 Displaying the Gravity Factor

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|6

76|677|684|685|954|957|959|963]

To view the gravity factor, the scale must first be switched to adjustment mode

(see section 2.1.3 or 2.1.4).

As soon as the text “CAL” is displayed, press a key briefly (less than 1.5

seconds).

The display shows “GAL”.

Pressing a key for more than 1.5 seconds displays the gravity factor set. The

gravity factor is shown in mm/s².

The scale switches off again automatically after 24 seconds.

Note [376|378|704|285]:

On verified scales, the gravity factor can only be displayed as long as the calibration

count is 1.

14.11.12/RLEU/ARI/MRE 17/40 30-34-00-812c

Maintenance seca

2.3 Setting the Gravity Factor

[374|703|634|644|656|664|674|676|684|284|954]:

The gravity factor can only be set on non-approved models

[374|703|634|644|656|664|674|676|684|284|954].

Before the gravity factor can be set, the scale must first be switched to

adjustment mode (see section 2.1.3 or 2.1.4).

While the calibration count is displayed, a key must be kept pressed (for more

than 1.5 seconds) to switch the scale to adjustment mode.

As soon as the text “CAL” is displayed, press a key briefly (less than 1.5

seconds). The display shows “GAL”.

Then press a key (for more than 1.5 seconds) to switch the scale to the mode

for gravity factor setting. The display shows “dec” and then the gravity factor

currently set. The gravity factor is shown in mm/s².

The scale is in decrementing state.

If the gravity factor displayed matches the target value, no further setting is

required and the menu item can be closed.

If the gravity factor shown on the display needs to be adjusted, it must be

altered by pressing a key until it matches the gravity factor required. Estimate

whether the required gravity factor is easier to reach by decrementing or by

incrementing. To toggle between decrementing mode and incrementing mode,

press a key (for more than 1.5 seconds.) (Display shows dec or inc.)

Press the key for less than 1.5 seconds to increase or decrease the gravity

factor displayed by 5 mm/s². Repeat the procedure until the gravity factor

displayed and the target gravity factor match.

Gravity factor setting can now be completed by pressing a key until the display

shows “Sto”. The scale stores the new gravity factor and switches off

automatically.

14.11.12/RLEU/ARI/MRE 18/40 30-34-00-812c

Maintenance seca

2.3.1 Example for Gravity Factor Setting

[374|703|634|644|656|664|674|676|684|284|954]

The current gravity factor shown on the display is 98135 kg mm/s².

The target gravity factor is 98150 mm/s².

In this example, you must switch the scale to incrementing mode to set the

gravity factor. When the tare/hold key has been pressed (for more than 1.5

seconds), "inc" starts flashing.

Now start to increase the value by 5 mm/s² (by briefly pressing the tare/hold

key). After this has been repeated three times, the value 98150 mm/s² appears

on the display.

Complete the gravity factor setting procedure as described above.

2.3.2 Summary of a Typical Gravity Factor Setting Sequence

[374|703]

Action carried out by the user

The scale is switched off. No values or characters on the display.

Press the tare/hold key and keep it

pressed while simultaneously pressing

the start key.

Release both keys. The contents of the calibration counter

Press the tare/hold key for more than 1.5

seconds.

Result

The contents of the calibration counter

flash on the display for 18 seconds.

flash on the display for 18 seconds.

The system switches to adjustment

selection mode and “CAL” flashes on the

display.

18 seconds have passed and no key has

been pressed.

Briefly press the tare/hold key (for less

than 1.5 seconds).

Press the tare/hold key for more than 1.5 "dec" appears on the display (flashing)

14.11.12/RLEU/ARI/MRE 19/40 30-34-00-812c

The scale switches off.

“GAL” flashes on the display.

Maintenance seca

A

seconds. and then the current gravity factor - also

flashing.

Decide whether to decrement or to

increment:

Incrementing:

Press the tare/hold key for more than 1.5

seconds.

Decrementing

: No action required as the

scale already is in dec mode.

Decrementing or incrementing:

gain briefly press the tare/hold key (for

less than 1.5 seconds).

Repeat this step until the gravity factor

displayed matches the target gravity

factor.

Incrementing mode is activated; "inc"

appears on the display.

No output on the display.

The gravity factor displayed is

decremented or incremented by 5 mm/s².

The display shows the gravity factor

(format: xxxxx mm/s²).

Press the tare/hold key until the scale

switches off.

The display reads “Sto” and the scale

switches off automatically.

14.11.12/RLEU/ARI/MRE 20/40 30-34-00-812c

Errors seca

3 Errors

[374|376|378|703|704|634|635|644|645|656|657|664|665|

674|675|676|677|684|685|954|957|959|963]

The following section provides an overview of possible error symptoms, their

causes and the steps required to remedy the error. In addition, the error

messages generated by the device and ways to eliminate them are explained.

3.1 Error Symptoms for Scale

[374|376|378|703|704|634|635|644|645|656|657|664|665|674|675|

676|677|684|685|954|957|959|963]

Error description

Scale does not

start

Scale shows no

weight or an

incorrect weight

Possible causes Remedy

Battery not inserted or flat

(if provided)

Voltage supply defective See section 4.1

Key panel defective or not

connected

Packaging / transport

locking device not removed

completely

Scale not correctly adjusted See section 2.1

Load cell damaged

Check the batteries

Check cable

connections, check

cable and key panel

for interruptions,

replace if necessary

Check the scale

See replacement

instructions

Force transmission into

load cell interrupted

Measurement

Measured values

electronics/load cell

vary greatly

damaged

14.11.12/RLEU/ARI/MRE 21/40 30-34-00-812c

Check base frame for

damage or incorrect

assembly

See replacement

instructions

Errors seca

3.2 Error Symptoms for Head Slider [264|274|284|285]

Error description

Head slider does

not start

Head slider does

not display a

Possible causes Remedy

Battery not inserted or flat Check the batteries

Voltage supply defective See section 4.1

Check cable

Key panel defective or not

connected

Insert scale defective /

missing / scale top and

bottom reversed

Head slider not adjusted

correctly

connections, check

cable and key panel

for interruptions,

replace if necessary

Check the insert scale

See section 2.2

length or an

incorrect length

Light barriers soiled

Clean the head slider

barriers with a cloth

Key unit not engaged

Check the key unit

correctly

14.11.12/RLEU/ARI/MRE 22/40 30-34-00-812c

Errors seca

3.3 Radio Error Symptoms

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|

674|675|676|677|684|685|954|957|959|963]

Error description

Device does not

transfer any data

when the SEND

or PRINT key is

pressed

Device beeps

twice when

sending and

printing

Possible causes Remedy

Teach-in phase not

completed out successfully

Receiving device not

switched on

Repeat teach-in

phase (see operating

instructions)

Switch on all devices

in the radio network

The device

displays “Wait” at

the end of the

teach-in phase

Two devices are in the

teach-in phase at the same

time

Switch off all devices

within radio

transmission range

and repeat the teachin process

14.11.12/RLEU/ARI/MRE 23/40 30-34-00-812c

Errors seca

3.4 Scale Error Messages

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|

674|675|676|677|684|685|954|957|959|963]

Display: Er:x:nr Electronics detecting a fault.

X : Module number

No Fault number

Scale displays Cause Remedy

seca serva

diagnosis: replace

load cell or

electronics as

required

Er:X:11

Load cell defective,

supply lines damaged or

electronics defective

Er:X:12 Initial load too high

Er:X:15

Er:X:16 Error when determining

Er:X:30

Readjustment error

the switch-on zero point

Data transfer interrupted Check the bus

Replace the

electronics

Check the initial

load

Reference weight

outside the

permitted range or

operating error

Avoid subjecting

the scale to

vibrations during

start-up

connection/

modular cable (if

provided)

14.11.12/RLEU/ARI/MRE 24/40 30-34-00-812c

Errors seca

Er:X:32 Command buffer

overflow error

Er:X:40 EEPROM data faulty

Er:X:41 Incorrect EEPROM

access

Er:X:43 EEPROM defective Replace the

Check the bus

connection/

modular cable (if

provided)

Isolate briefly (60

sec)

Readjust the scale

or upload the scale

adjustment data to

the EEPROM via

seca serva 2.0

Replace the

electronics

electronics

Er:X:44 Calibration counter faulty Replace the

electronics

Er:X:45 EEPROM defective Replace the

electronics

Er:X:57 Quartz does not oscillate Replace the

electronics

3.5 Head Slider Error Messages [264|274|284|285]

Display: Er:x:nr Electronics detecting a fault.

X : Module number

No Fault number

Scale displays Cause Remedy

Er:X:40 EEPROM data faulty Replace the

electronics

Er:X:41 Incorrect EEPROM

access

14.11.12/RLEU/ARI/MRE 25/40 30-34-00-812c

Replace the

electronics

Errors seca

Er:X:43 EEPROM defective Replace the

electronics

Er:X:45 EEPROM defective Replace the

electronics

Er:X:57 Quartz does not oscillate Replace the

electronics

3.6 Radio Error Message

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|

674|675|676|677|684|685|954|957|959|963]

Display: Er:x:nr Electronics detecting a fault.

X : Module number

No Fault number

Scale displays Cause Remedy

Er:X:71

Er:X:72

Radio module is

switched off

Error in teach-in mode Repeat teach-in for

Switch on the radio

module via the

menu (see

operating

instructions)

the devices (see

operating

instructions)

14.11.12/RLEU/ARI/MRE 26/40 30-34-00-812c

Measurements seca

4 Measurements

[374|376|378|703|704|284|285|634|635|644|645|656|657|

664|665|674|675|676|677|684|685|954|957|959|963]

The following section provides an overview of measurements which can be

performed to identify specific errors.

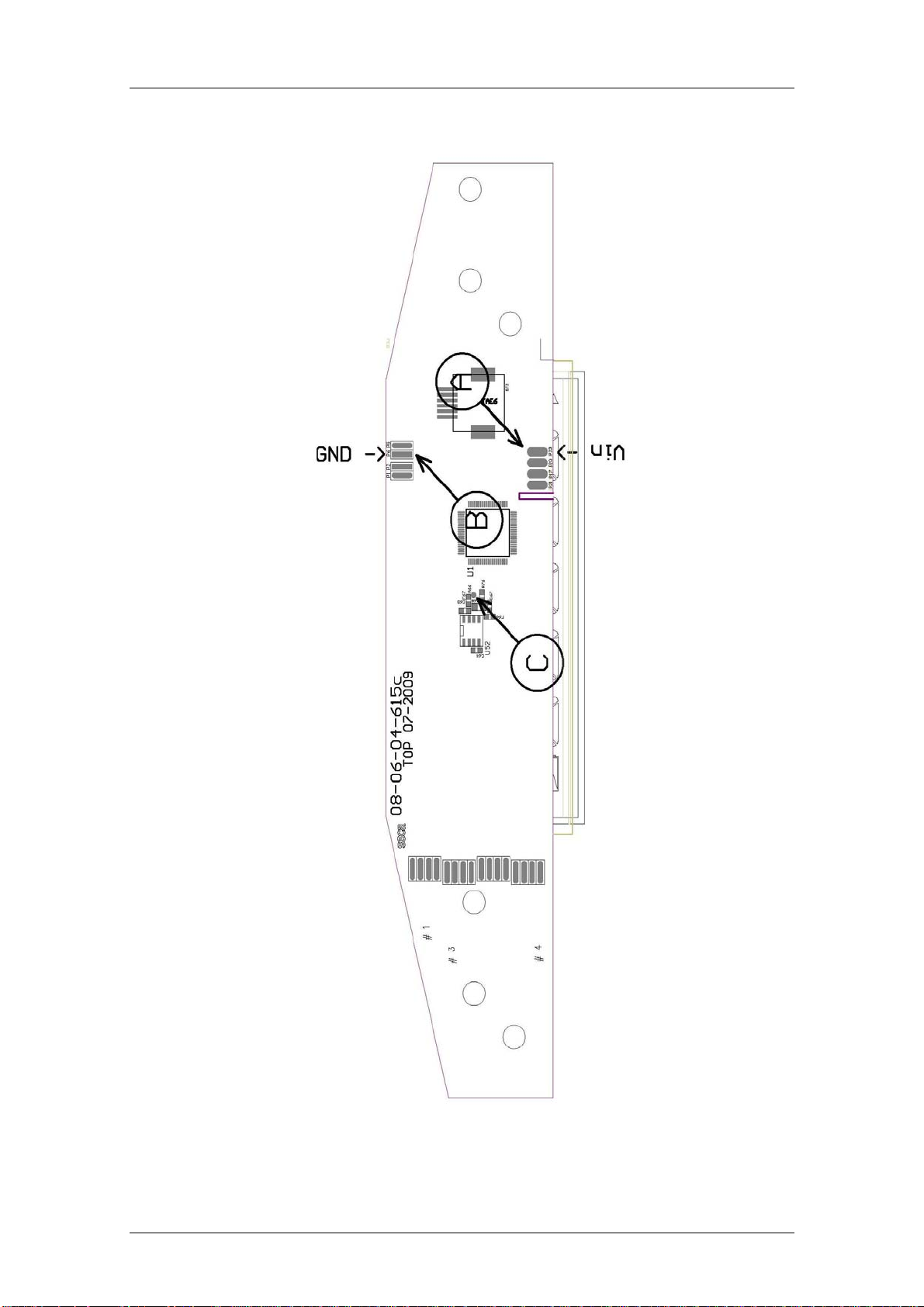

4.1 Supply Voltage

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|6

74|675|676|677|684|685|954|957|959|963]

Measuring the supply voltage at the electronics board provides information on

whether the supply lines to the battery compartment and/or the power supply

unit are OK. Carry out the measurement by connecting a multimeter to

measuring points A and B (see Appendix).

4.2 Load Cell

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|6

74|675|676|677|684|685|954|957|959|963]

The most effective way to identify a defect of the load cell is using the diagnosis

function of seca serva 2.0; if this is not available you can alternatively use a

multimeter (see 4.2.1). A multimeter measurement, however, is less conclusive

so that it should always be second choice.

4.2.1 Measurement Using a Multimeter

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|6

74|675|676|677|684|685|954|957|959|963]

First of all, unsolder the load cell from the electronics and measure the

resistance between the different connecting wires. The tables below show the

values to be expected for the different types of load cells:

14.11.12/RLEU/ARI/MRE 27/40 30-34-00-812c

Measurements seca

Measurement between Ohmic resistance [Ω]

V+ and Sig+ 4 (blue and red) ~250-300

V- and Sig+ (blue and white) ~250-300

V+ and Sig- (red and black) ~250-300

V- and Sig- (white and black)

Sig+/Sig-/V+/V- and aluminium

~250-300

> 1000 M

body of the load cell

Table 1: Resistance of platform load cell type Kogean / HBM [703|704x|954|957|959|963]

Measurement between Ohmic resistance [Ω]

V+ and Sig+ 4 (green and red)

V- and Sig+ (green and white)

V+ and Sig- (red and black)

V- and Sig- (white and black)

Sig+/Sig-/V+/V- and aluminium

~ 800-850

~ 800-850

~ 800-850

~ 800-850

> 500 M

body of the load cell

Table 2: Resistance of Flintec / Kogean Planar Beam / --Wing load cell [376|378|284|285]

The relevant cabling diagram shows the designations and associated cable

colour. The measured values only have a limited informative value, however, as

even a defective load cell can supply absolutely correct values when no load is

placed on it. If the load cell supplies incorrect values when unloaded, it is

definitely defective.

14.11.12/RLEU/ARI/MRE 28/40 30-34-00-812c

Measurements seca

14.11.12/RLEU/ARI/MRE 29/40 30-34-00-812c

Software seca

5 Software intended Purpose

The radio modules of the devices with NEC2 electronics

[374|376|378|703|704|284|285|634|635|644|645|656|657|664|665|674|675|676|

677|684|685|954|957|959|963] as well as the seca 360° wireless USB adapter

[456] contain software to control wireless communications. This software can be

updated using the Windows-based "seca wireless updater" program. Removing

or replacing the radio modules is generally not required.

The Windows program "seca wireless updater" has three functions:

The configuration of the selected wireless group is displayed.

A set-up process can be performed.

The software in the radio modules or in the wireless USB adapter can be

updated.

Updating a wireless USB adapter takes approximately 30 seconds, updating a

radio module in a device can take up to five minutes, depending on the quality

of the wireless transmission, but typically takes 1.5 minutes.

.

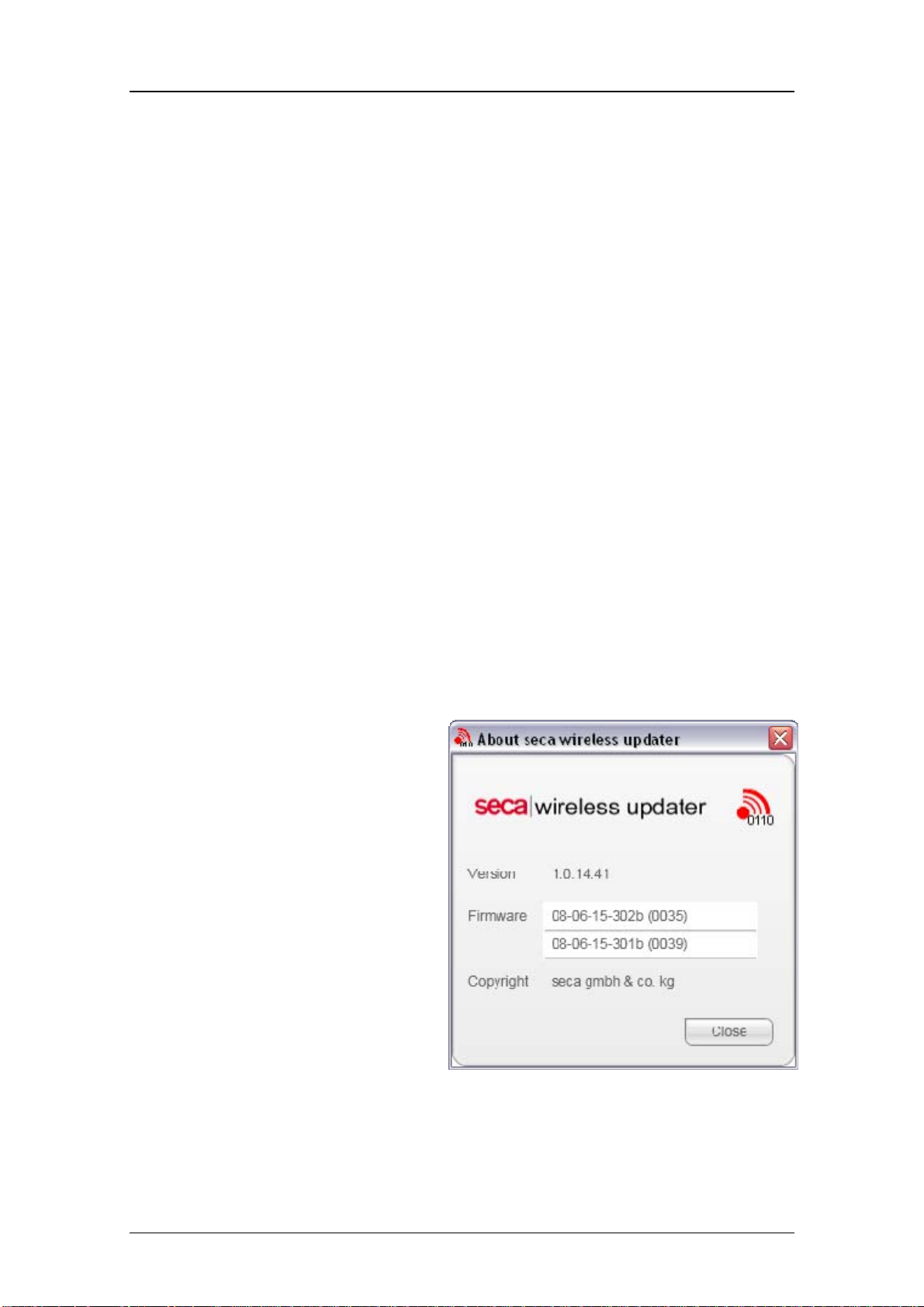

5.1 Installation and Start

The seca wireless updater is

installed on a service PC or

notebook using a Windows

installation program (Setup). The

latest version of the radio module

software is copied to the PC

together with the installation.

You can display the version

numbers of the PC software and the

radio module software installed on

the PC. To do so, select the menu

item “Help” - “About wireless

updater”. Example:

14.11.12/RLEU/ARI/MRE 30/40 30-34-00-812c

Software seca

5.2 Updating the Radio Module Software

Two cases can be distinguished:

1) The customer has a seca 360° wireless USB adapter [456] and has

carried out set-up for his seca devices and this wireless USB adapter.

In this case you should connect the customer's wireless USB adapter to

your service PC and update the entire wireless group from your PC.

2) The customer does not have a wireless USB adapter.

In this case you can use your own wireless USB adapter. Prior to

updating, set-up must be performed for the customer's devices.

Note! The customer's wireless group will be overwritten by the set-up

process. After updating, set-up of the customer's devices must be

repeated – without connecting your wireless USB adapter. Teaching in

again is necessary since otherwise the customer would receive error

messages in future informing him that the wireless USB adapter is not

available.

Information regarding the currently active wireless group is displayed in the

main window of the seca wireless updater. In the example shown, wireless

group 2 is active in which set-up has been performed for a wireless USB

adapter, a baby scale and a wireless printer.

The seca wireless updater attempts to establish a wireless connection to the

individual devices. Responding devices are indicated by a green symbol,

devices in the wireless group which have been taught in but which are currently

not available – e.g. because they are switched off – are indicated by a red

symbol. A blue symbol means that the corresponding device is in updating

14.11.12/RLEU/ARI/MRE 31/40 30-34-00-812c

Software seca

mode (the so-called download kernel). The “Refresh” button refreshes the

display.

5.3 Set-up Process

This function corresponds to the set-up process

carried out for a device. First of all, select the

current wireless group on the left in the main

window. You can now start teaching-in by

pressing the “Set up wireless group” button.

Change the suggested transmission channels if

required and confirm your selection with

“Confirm channels”.

Please switch on the devices to be taught in

one by one. Identification of the devices is

indicated by a series of green symbols. Set-up

is ended by pressing the “Complete login”

button.

14.11.12/RLEU/ARI/MRE 32/40 30-34-00-812c

Software seca

5.4 Updating the Radio Module Software

The lower part of the main window is intended for the actual updating of the

radio modules. The radio modules in the active wireless group are shown in a

list together with a symbol.

Symbol Meaning

“No Action” – updating is not carried out.

“Waiting” – this radio module is going to be updated but is still in

the queue.

“Transmitting” – this radio module is just being updated.

“OK” – this radio module has been updated successfully.

“Error” – an error occurred while updating this radio module.

Use the buttons on the right to activate or deactivate updating of the individual

modules or enable all modules in the list to be updated in succession.

14.11.12/RLEU/ARI/MRE 33/40 30-34-00-812c

Software seca

5.5 Technical Requirements for Updating

Updating by wireless transmission involves transferring large volumes of data.

You should therefore ensure you have a stable wireless connection.

The distance between the wireless USB adapter and the device to be updated

should - if possible - be less than 1.5 metres. For updating, you can connect the

wireless USB adapter to the PC using a standard 5 metre USB extension cable

(type A – type A) and hold or place the wireless USB adapter in the vicinity of

the relevant radio module.

Battery-operated devices are switched off after a certain period of time

[374|376|378|703|704|954|957|959|963]. Updating will only be successful if the

device is prevented from switching off during data transmission. On scales, this

can be achieved by placing a weight on the scale, changing the weight value or

activating the HOLD function. The head sliders of the length measuring rods

[264|274|284|285] must be moved from time to time. When scales and length

measuring rods are being updated, a red bar regularly appears in the main

window of the seca wireless updater to remind you to carry out

activation/moving.

5.6 Updating the Wireless Printer Software

Note: In addition to updating the radio modules, it is essential that new

software is also loaded on the seca wireless printers [465, 466]. If the previous

wireless printer software is used in conjunction with updated radio modules,

printing and teaching in the wireless printer is not possible.

The wireless printer software is updated automatically when an SD card with

the new contents is inserted. The revision contained on the card is given on the

sticker on the SD card. For the seca wireless printer 465, revision code 465d or

more recent is required (or 465dc, 465dj, 465dr for the Chinese, Japanese or

Russian version). The wireless printer 466, accordingly, requires revision code

466d, 466dc, 466dj, 466dr or more recent.

14.11.12/RLEU/ARI/MRE 34/40 30-34-00-812c

Software seca

5.7 Updating Old Printers

The printers of the old generation cannot be updated. This means they cannot

be used in an updated wireless group. Re-programming of the printer at the

seca headquarters in Hamburg is necessary.

The first printout shows whether the printer

already belongs to the new generation. The

new version consists of the download

kernel, i. e. the program core "08-06-15306a (rev. 10)" and the actual printer

software "08-06-15-307b (rev.33)". Updating

the software via SD card is possible if the

kernel number 306a – or a more recent

number (i.e. 306b, 306c, etc.) – is given on

the printout.

5.8 Problems with Updating

If the wireless connection is unstable, the PC program “seca wireless updater”

repeatedly attempts to send the radio module software. If this is unsuccessful

you can try to restart updating.

Remedies if Updating Fails

- Hold the wireless USB adapter closer to the radio module

- Avoid metal surfaces in the vicinity

- Do not stay in the immediate line of sight between the USB wireless adapter

and the radio module

- Wait until interferences from electrical units (e.g. drills) or heavy wireless

traffic (WLAN, bluetooth) have stopped

NEVER repeat set-up of the wireless group if an updating attempt has failed.

Set-up is not possible in updating mode – it would no longer be possible to

identify the corresponding device.

In rare cases, updating will fail entirely. The relevant radio module must then be

reaced. The radio module can be returned to the seca headquarters for repair.

14.11.12/RLEU/ARI/MRE 35/40 30-34-00-812c

Appendixes seca

Appendixes

Appendix 1: Measuring points on SECA module 08-06-18-163 [703]

14.11.12/RLEU/ARI/MRE 36/40 30-34-00-812c

Appendixes seca

Appendix 2: Measuring points on SECA module 08-06-18-165

[704|634|635|644|645|656|657|664|665|674>675|676|677|684|685|284|285]

14.11.12/RLEU/ARI/MRE 37/40 30-34-00-812c

Appendixes seca

Appendix 3: Measuring points on SECA module 08-06-18-167 [374|376|378]

14.11.12/RLEU/ARI/MRE 38/40 30-34-00-812c

Appendixes seca

Appendix 4: Measuring points on SECA module 08-06-18-195a [284|285]

14.11.12/RLEU/ARI/MRE 39/40 30-34-00-812c

Appendixes seca

Appendix 5: Measuring points on SECA module 08-06-18-186a

[264|274|284|285]

14.11.12/RLEU/ARI/MRE 40/40 30-34-00-812c

8

7

6 5

4

3

2

1

OPTIONAL

Akku Anschuß /

RECHARGEABLE BATTERY

CONNECTION

F

+

Rot/RED

F

Grün/ GREEN - VCC

Schwarz /BLACK - GND

-

Weiss / WHITE - HIGH

Blau/BLUE

Rot / RED - DMS

Wägezelle /

LOAD CELL

E

D

C

VCC

GND

HIGH

DMS

Batterie / BATTERY NON RECHA.)

Batterie / BATTERY NON RECHA.)

Akku / BATTERY RECHA.

Akku / BATTERY RECHA.

-

+

-

+

(

(

Netz / MAINS UNIT

Netz / MAINS UNIT

-

+

NEC 2 Gewichtswertmodul /

NEC 2 MODULE

2 x 50-06-79-725 J5,3 DIN 6797

Zahnscheiben montiert auf Ober und Unterseite von Kabelöse/

LOCK WASHER MOUNTED ON BACK AND

UPSIDE FROM CABLE LOCK

-

Blau/BLUE

Kleinspannungsbuchse/

+

DC-socket

Rot/RED

Optional:

Funkmodul / RADIO-MODULE

NEC 2 Anzeigemodul/

NEC 2 DISPLAY MODULE

E

D

C

B

Folientastatur /

MEMBRANE KEYBOARD

Datum/Name:

Änd.Mitteil. / CHANGE:

Index / REVISION:

A

Maßstab / SCALE :

1:1

8

7

6

5

18.09.2012 Schi.

batt. contact (1x)

a

HAMBURG

Werkstoff / MATERIAL :

Erstellt / DRAWN

07.12.2011

Schielmann

Benennung / TITLE :

Geprüft / APPROVED Ver. a

19.11.2012

J. Schmidt

Kabelplan 6xx

CABLEPLAN 6xx

- Batterie/battery, black

OPTIONAL + Batterie/battery, red

a

PROJECTION

ALL RIGHTS CONCERNING THIS DOCUMENT AND ITS

CONTENTS RESERVED. Alle Rechte an und aus diesen

Unterlagen verbleiben

Nr. / NO. :

seca gmbh. & co. kg.

08-02-06-058

Blatt/SHEET 1/1

T:\ARCHIV_DBWORKS\Firma\08-\08-02-\08-02-06-058

B

Montag, 19. November 2012 13:53:25

Replacement Instructions

seca 664, 665

13.02.13 /MRE 1 30-34-00-860_E

Replacement Instructions

seca 664, 665

Contents

I

Safety measures.......................................................................................................................................... 3

II Safety instructions against electrostatic charging (ESD protection measures)........................................... 3

1 Baseframe ................................................................................................................................................... 4

1.1 Replacing the NEC2 weight module................................................................................................... 4

1.2 Replacing the load cells...................................................................................................................... 5

1.3 Setting the overload protection devices.............................................................................................. 7

2 Display ......................................................................................................................................................... 8

2.1 Removing the display.......................................................................................................................... 8

2.2 Replacing the membrane keypad / NEC 2 display / radio module..................................................... 9

13.02.13 /MRE 2 30-34-00-860_E

Replacement Instructions

seca 664, 665

I Safety measures

Before starting any work on the scale, first disconnect the power supply (mains and

batteries).

II Safety instructions against electrostatic charging (ESD protection measures)

ESD protective measures (electrostatic discharge) must be taken whenever work is

performed on electronic components. Please observe the following precautions so that you

can safely repair the scale:

Ground yourself using an antistatic wrist strap

Wear ESD safe shoes

Wear ESD compatible clothing

Only carry out the work to be performed in an electrostatic protective area

Make sure you have static conductive flooring

Only use ESD proof tools

13.02.13 /MRE 3 30-34-00-860_E

Replacement Instructions

seca 684, 685

1 Baseframe

Please be sure to observe the sequence listed below when removing/fitting the parts!

1.1 Replacing the NEC2 weight module

Detach the plug-in connection (A) of the modular cable. Release the four screw

connections (B) on the weight module housing (C) and take off the

cover (D).

Unsolder the connection to the NEC2 weight module (F). Undo the screw connections

(E) of the weight module.

Proceed in the reverse order for reassembling.

When reassembling refer to cabling diagram 08-02-06-058.

B

E

Figure 1: Replacing the weight module

B

D

F

A

C

13.02.13/MRE 4 30-34-00-860_E1

Replacement Instructions

seca 684, 685

1.2 Replacing the load cells

To replace the load cells (G, Fig. 3), first detach the frame from the platform. Remove

the platform mat to do so.

Then undo the four screws (H) that connect the platform with the frame.

You can now take out the frame.

Proceed as described under 1.1 and open the housing for the evaluation electronics

(C, Fig. 1).

Unsolder the connection from the load cell to the NEC2 weight module (F).

Refer to cabling diagram 08-02-06-058.

Unscrew the adjustable feet (I, Fig. 3).

Turn round the frame, undo the 4 screws (J) that secure the load cell to the frame (K)

(Fig. 3).

Carefully pull out the load cell with the load cell cables from the frame tubes.

Proceed in the reverse order for reassembling.

When reassembling refer to cabling diagram 08-02-06-058.

H

H

H

H

13.02.13/MRE 5 30-34-00-860_E1

Replacement Instructions

seca 684, 685

When assembling the load cells (G, Fig. 3), the tightening torque for the four

cheese head screws (J, Fig. 3) of Mt = 12.5 Nm must be observed.

J

G

I

Figure 3: Replacing the load cell

K

13.02.13/MRE 6 30-34-00-860_E1

Replacement Instructions

seca 684, 685

1.3 Setting the overload protection devices

To protect the scale from overload, four overload protection devices are provided.

Set the specified values for the relevant model in accordance with the table (Table 1);

use gauges for this purpose.

The settings must be very accurate to prevent a forced shunt.

Model Dimension x =

634/635/644/645 7 mm

664/665 3.5 mm

674/675 7 mm

676/677 3.5 mm

684/685 7 mm

Table 1: Dimensions to be set for the overload protection device for multi-function scales

Figure 4: Setting the overload protection devices

13.02.13/MRE 7 30-34-00-860_E1

Replacement Instructions

seca 684, 685

2 Display

Please be sure to observe the sequence listed below when removing/fitting the parts!

2.1 Removing the display

First remove the three screws (R) from the handrail tube / display connection

and carefully pull out the display.

Detach the plug-in connection of the modular cable (S).

Figure 7: Connection display handrail tube / plug-in connection modular cable

R

S1

S

13.02.13/MRE 8 30-34-00-860_E1

X

Replacement Instructions

seca 684, 685

2.2 Replacing the membrane keypad / NEC 2 display / radio module

To replace the membrane keypad (U), NEC2 display (V) or radio module (W) you

need to undo the four screw connections (T, Fig. 9) at the bottom of the operating and

display unit first.

Now carefully lift the printed operating and display unit (A1, Fig. 9).

The plug-in connector (X) connects the membrane keyboard (U) with the NEC2

display (V).

Carefully detach this connection! You can now take off the printed operating and

display unit (A1, Fig. 9).

The membrane keyboard (U) is glued in place and must be replaced with a new one.

Detach the plug-in connections between the modular cable and the NEC2 display

(S1).

Unsolder the battery/accumulator battery connections (C1), if applicable.

Unscrew the NEC2 display from the board holder (D1, Fig. 9)

and remove the NEC2 display.

Unscrew the screw (B1, Fig. 9), if fitted, which connects the radio module (W) and the

NEC2 display (V) and carefully remove the module.

Proceed in the reverse order for reassembling.

When aligning the display components refer to cabling diagram 08-02-06-058.

Figure 8: Detail from cabling diagram 08-02-06-058, NEC2 display/radio module/membrane keypad

U

S1

W

V

C1

13.02.13/MRE 9 30-34-00-860_E1

Replacement Instructions

seca 684, 685

Figure 9: Exploded view of display

U

W

D1

B1

T

A1

V

D1

T

13.02.13/MRE 10 30-34-00-860_E1

Spare parts list 664 1321108 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

1 A020203095009 Frame 45

2 A020303091008 Platform 45

3 A020303283009 Platform insert 40

4 A011304345009 Platform mat 28

5 A020303093009 Reinforcing left Platform 26

6 A020303094009 Reinforcing right Platform 26

7 A021103216009 Castor 15

8 A080612264009 Load cell 75 kg 40

9 A080612246009 Rubber buffer 05

10 A011004007009 Levelling device 10

11 A011602257009 Cover load cell 15

12 A011702215009 Holder bubble level 25

13 A011701203009 Bubble level 15

14 A021213048009 Rail for column 40

15 A021213047009 Rail 40

16 A010306207009 Bracket 32

17 A010306208009 Bearing 33

18 A010702256009 Spring 10

19 A011305374009 Slip ring 05

20 A010803357009 Threated axle 27

21 A010803376009 Bold 33

22 A011004223816 Knurled knob 05

23 A040206223009 Column 35

24 A011305375009 Plug

column bottom 05

25 A021217047509 Ramp 40

26 A011601218009 Stop unit

27 A010705301009 Rest spring

13.02.13/USO 1 6641321108_E

ramp 20

ramp 05

Spare parts list 664 1321108 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

28 A011601219009 Terminal plate

ramp left 20

29 A011601220009 Terminal plate ramp right 20

30 A011305474009 Electronic housing NEC2 20

31 A011305483009 Cover

electronic housing 10

32 A080405358009 Cover battery compartment 05

33 A011305484009 Seal 01

34 A011602271009 Fixing bracket 15

35 A080618165009 Electronic module NEC2

measurement 42

36 A663042051009 Clip-holder 01

37 A654210211009 Plug in mains 10

38 A080616436119 Ground harness 05

13.02.13/USO 2 6641321108_E

Spare parts list 664 1321108 Display

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-842

Item Article Designation Price stage

1 A041201009509 Display holder 27

2 A340201210009 Display housing bottom 20

3 A340201029601 Display housing top, printed 20

4 A340201278009 Cap display housing 05

5 A340201277009 Bracket left 05

6 A340201276009 Bracket right 05

7 A080618170009 Display electronic NEC2 40

8 A080618172009 Radio module 35

9 A340204428009 Membrane keyboard

menu 25

10 A080616106119 Modular cable 2,7 mtr. 15

11 A340204339009 Tilt stand 10

14 A340204340009 Wall mountig bracket 10

A683210265009 Power supply international 28

A682212721009 Accu Ni-MH 28

A180107012509 Packaging complete 30

13.02.13/USO 3 6641321108_E

Spare parts list 664 1321378 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

1 A020203095009 Frame 45

2 A020303091008 Platform 45

3 A020303283009 Platform insert 40

4 A011304345009 Platform mat 28

5 A020303093009 Reinforcing left Platform 26

6 A020303094009 Reinforcing right Platform 26

7 A021103216009 Castor 15

8 A080612264009 Load cell 75 kg 40

9 A080612246009 Rubber buffer 05

10 A011004007009 Levelling device 10

11 A011602257009 Cover load cell 15

12 A011702215009 Holder bubble level 25

13 A011701203009 Bubble level 15

14 A021213048009 Rail for column 40

15 A021213047009 Rail 40

16 A010306207009 Bracket 32

17 A010306208009 Bearing 33

18 A010702256009 Spring 10

19 A011305374009 Slip ring 05

20 A010803357009 Threated axle 27

21 A010803376009 Bold 33

22 A011004223816 Knurled knob 05

23 A040206223009 Column 35

24 A011305375009 Plug

column bottom 05

25 A021217047509 Ramp 40

26 A011601218009 Stop unit

27 A010705301009 Rest spring

13.02.13/USO 1 6641321378_E

ramp 20

ramp 05

Spare parts list 664 1321378 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

28 A011601219009 Terminal plate

ramp left 20

29 A011601220009 Terminal plate ramp right 20

30 A011305474009 Electronic housing NEC2 20

31 A011305483009 Cover

electronic housing 10

32 A080405358009 Cover battery compartment 05

33 A011305484009 Seal 01

34 A011602271009 Fixing bracket 15

35 A080618165009 Electronic module NEC2

measurement 42

36 A663042051009 Clip-holder 01

37 A654210211009 Plug in mains 10

38 A080616436119 Ground harness 05

13.02.13/USO 2 6641321378_E

Spare parts list 664 1321378 Display

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-842

Item Article Designation Price stage

1 A041201009509 Display holder 27

2 A340201210009 Display housing bottom 20

3 A340201029601 Display housing top, printed 20

4 A340201278009 Cap display housing 05

5 A340201277009 Bracket left 05

6 A340201276009 Bracket right 05

7 A080618170009 Display electronic NEC2 40

8 A080618172009 Radio module 35

9 A340204428009 Membrane keyboard

menu 25

10 A080616106119 Modular cable 2,7 mtr. 15

11 A340204339009 Tilt stand 10

14 A340204340009 Wall mountig bracket 10

A683210265009 Power supply international 28

A682212721009 Accu Ni-MH 28

A180107012509 Packaging complete 30

13.02.13/USO 3 6641321378_E

Spare parts list 665 7021008 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

1 A020203095009 Frame 45

2 A020303091008 Platform 45

3 A020303283009 Platform insert 40

4 A011304345009 Platform mat 28

5 A020303093009 Reinforcing left

6 A020303094009 Reinforcing right

Platform 26

Platform 26

7 A021103216009 Castor 15

8 A080612264009 Load cell 75 kg 40

9 A080612246009 Rubber buffer 05

10 A011004007009 Levelling device 10

11 A011602257009 Cover load cell 15

12 A011702215009 Holder bubble level 25

13 A011701203009 Bubble level 15

14 A021213048009 Rail for column 40

15 A021213047009 Rail 40

16 A010306207009 Bracket 32

17 A010306208009 Bearing 33

18 A010702256009 Spring 10

19 A011305374009 Slip ring 05

20 A010803357009 Threated axle 27

21 A010803376009 Bold 33

22 A011004223816 Knurled knob 05

23 A040206223009 Column 35

24 A011305375009 Plug

column bottom 05

25 A021217047509 Ramp 40

26 A011601218009 Stop unit

27 A010705301009 Rest spring

13.02.13/USO 1 6657021008_E

ramp 20

ramp 05

Spare parts list 665 7021008 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

28 A011601219009 Terminal plate

ramp left 20

29 A011601220009 Terminal plate ramp right 20

30 A011305474009 Electronic housing NEC2 20

31 A011305483009 Cover

electronic housing 10

32 A080405358009 Cover battery compartment 05

33 A011305484009 Seal 01

34 A011602271009 Fixing bracket 15

35 A080618165009 Electronic module NEC2

measurement 42

36 A663042051009 Clip-holder 01

37 A654210211009 Plug in mains 10

38 A080616436119 Ground harness 05

13.02.13/USO 2 6657021008_E

Spare parts list 665 7021008 Display

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-842

Item Article Designation Price stage

1 A041201009509 Display holder 27

2 A340201210009 Display housing bottom 20

3 A340201029602 Display housing top, printed 20

4 A340201278009 Cap display housing 05

5 A340201277009 Bracket left 05

6 A340201276009 Bracket right 05

7 A080618170009 Display electronic NEC2 40

8 A080618172009 Radio module 35

9 A340204428009 Membrane keyboard

menu 25

10 A080616106119 Modular cable 2,7 mtr. 15

11 A340204339009 Tilt stand 10

14 A340204340009 Wall mountig bracket 10

A683210252009 Power supply 240 V 28

A682212721009 Accu Ni-MH 28

A180107012509 Packaging complete 30

13.02.13/USO 3 6657021008_E

Spare parts list 665 7021198 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

1 A020203095009 Frame 45

2 A020303091008 Platform 45

3 A020303283009 Platform insert 40

4 A011304345009 Platform mat 28

5 A020303093009 Reinforcing left

6 A020303094009 Reinforcing right

Platform 26

Platform 26

7 A021103216009 Castor 15

8 A080612264009 Load cell 75 kg 40

9 A080612246009 Rubber buffer 05

10 A011004007009 Levelling device 10

11 A011602257009 Cover load cell 15

12 A011702215009 Holder bubble level 25

13 A011701203009 Bubble level 15

14 A021213048009 Rail for column 40

15 A021213047009 Rail 40

16 A010306207009 Bracket 32

17 A010306208009 Bearing 33

18 A010702256009 Spring 10

19 A011305374009 Slip ring 05

20 A010803357009 Threated axle 27

21 A010803376009 Bold 33

22 A011004223816 Knurled knob 05

23 A040206223009 Column 35

24 A011305375009 Plug

column bottom 05

25 A021217047509 Ramp 40

26 A011601218009 Stop unit

27 A010705301009 Rest spring

13.02.13/USO 1 6657021198_E

ramp 20

ramp 05

Spare parts list 665 7021198 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

28 A011601219009 Terminal plate

ramp left 20

29 A011601220009 Terminal plate ramp right 20

30 A011305474009 Electronic housing NEC2 20

31 A011305483009 Cover

electronic housing 10

32 A080405358009 Cover battery compartment 05

33 A011305484009 Seal 01

34 A011602271009 Fixing bracket 15

35 A080618165009 Electronic module NEC2

measurement 42

36 A663042051009 Clip-holder 01

37 A654210211009 Plug in mains 10

38 A080616436119 Ground harness 05

13.02.13/USO 2 6657021198_E

Spare parts list 665 7021198 Display

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-842

Item Article Designation Price stage

1 A041201009509 Display holder 27

2 A340201210009 Display housing bottom 20

3 A340201029602 Display housing top, printed 20

4 A340201278009 Cap display housing 05

5 A340201277009 Bracket left 05

6 A340201276009 Bracket right 05

7 A080618170009 Display electronic NEC2 40

8 A080618172009 Radio module 35

9 A340204428009 Membrane keyboard

menu 25

10 A080616106119 Modular cable 2,7 mtr. 15

11 A340204339009 Tilt stand 10

14 A340204340009 Wall mountig bracket 10

A683210265009 Power supply international 28

A682212721009 Accu Ni-MH 28

A180107012509 Packaging complete 30

13.02.13/USO 3 6657021198_E

Spare parts list 665 7021228 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

1 A020203095009 Frame 45

2 A020303091008 Platform 45

3 A020303283009 Platform insert 40

4 A011304345009 Platform mat 28

5 A020303093009 Reinforcing left

6 A020303094009 Reinforcing right

Platform 26

Platform 26

7 A021103216009 Castor 15

8 A080612264009 Load cell 75 kg 40

9 A080612246009 Rubber buffer 05

10 A011004007009 Levelling device 10

11 A011602257009 Cover load cell 15

12 A011702215009 Holder bubble level 25

13 A011701203009 Bubble level 15

14 A021213048009 Rail for column 40

15 A021213047009 Rail 40

16 A010306207009 Bracket 32

17 A010306208009 Bearing 33

18 A010702256009 Spring 10

19 A011305374009 Slip ring 05

20 A010803357009 Threated axle 27

21 A010803376009 Bold 33

22 A011004223816 Knurled knob 05

23 A040206223009 Column 35

24 A011305375009 Plug

column bottom 05

25 A021217047509 Ramp 40

26 A011601218009 Stop unit

27 A010705301009 Rest spring

13.02.13/USO 1 6657021228_E

ramp 20

ramp 05

Spare parts list 665 7021228 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

28 A011601219009 Terminal plate

ramp left 20

29 A011601220009 Terminal plate ramp right 20

30 A011305474009 Electronic housing NEC2 20

31 A011305483009 Cover

electronic housing 10

32 A080405358009 Cover battery compartment 05

33 A011305484009 Seal 01

34 A011602271009 Fixing bracket 15

35 A080618165009 Electronic module NEC2

measurement 42

36 A663042051009 Clip-holder 01

37 A654210211009 Plug in mains 10

38 A080616436119 Ground harness 05

13.02.13/USO 2 6657021228_E

Spare parts list 665 7021228 Display

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-842

Item Article Designation Price stage

1 A041201009509 Display holder 27

2 A340201210009 Display housing bottom 20

3 A340201029602 Display housing top, printed 20

4 A340201278009 Cap display housing 05

5 A340201277009 Bracket left 05

6 A340201276009 Bracket right 05

7 A080618170009 Display electronic NEC2 40

8 A080618172009 Radio module 35

9 A340204428009 Membrane keyboard

menu 25

10 A080616106119 Modular cable 2,7 mtr. 15

11 A340204339009 Tilt stand 10

14 A340204340009 Wall mountig bracket 10

A683210252009 Power supply 240 V 28

A682212721009 Accu Ni-MH 28

A180107012509 Packaging complete 30

13.02.13/USO 3 6657021228_E

Spare parts list 665 7021248 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

1 A020203095009 Frame 45

2 A020303091008 Platform 45

3 A020303283009 Platform insert 40

4 A011304345009 Platform mat 28

5 A020303093009 Reinforcing left

6 A020303094009 Reinforcing right

Platform 26

Platform 26

7 A021103216009 Castor 15

8 A080612264009 Load cell 75 kg 40

9 A080612246009 Rubber buffer 05

10 A011004007009 Levelling device 10

11 A011602257009 Cover load cell 15

12 A011702215009 Holder bubble level 25

13 A011701203009 Bubble level 15

14 A021213048009 Rail for column 40

15 A021213047009 Rail 40

16 A010306207009 Bracket 32

17 A010306208009 Bearing 33

18 A010702256009 Spring 10

19 A011305374009 Slip ring 05

20 A010803357009 Threated axle 27

21 A010803376009 Bold 33

22 A011004223816 Knurled knob 05

23 A040206223009 Column 35

24 A011305375009 Plug

column bottom 05

25 A021217047509 Ramp 40

26 A011601218009 Stop unit

27 A010705301009 Rest spring

13.02.13/USO 1 6657021248_E

ramp 20

ramp 05

Spare parts list 665 7021248 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

28 A011601219009 Terminal plate

ramp left 20

29 A011601220009 Terminal plate ramp right 20

30 A011305474009 Electronic housing NEC2 20

31 A011305483009 Cover

electronic housing 10

32 A080405358009 Cover battery compartment 05

33 A011305484009 Seal 01

34 A011602271009 Fixing bracket 15

35 A080618165009 Electronic module NEC2

measurement 42

36 A663042051009 Clip-holder 01

37 A654210211009 Plug in mains 10

38 A080616436119 Ground harness 05

13.02.13/USO 2 6657021248_E

Spare parts list 665 7021248 Display

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-842

Item Article Designation Price stage

1 A041201009509 Display holder 27

2 A340201210009 Display housing bottom 20

3 A340201029602 Display housing top, printed 20

4 A340201278009 Cap display housing 05

5 A340201277009 Bracket left 05

6 A340201276009 Bracket right 05

7 A080618170009 Display electronic NEC2 40

8 A080618172009 Radio module 35

9 A340204358009 Membrane keyboard

menu, Jp. 25

10 A080616106119 Modular cable 2,7 mtr. 15

11 A340204339009 Tilt stand 10

14 A340204340009 Wall mountig bracket 10

A683210265009 Power supply international 28

A682212721009 Accu Ni-MH 28

A180107012509 Packaging complete 30

13.02.13/USO 3 6657021248_E

Spare parts list 665 7021288 Frame

update April 2012, valid until SN.:

acc. To drawing: 30-34-00-844

Item Article Designation Price stage

1 A020203095009 Frame 45

2 A020303091008 Platform 45

3 A020303283009 Platform insert 40

4 A011304345009 Platform mat 28

5 A020303093009 Reinforcing left

6 A020303094009 Reinforcing right

Platform 26

Platform 26

7 A021103216009 Castor 15

8 A080612264009 Load cell 75 kg 40

9 A080612246009 Rubber buffer 05

10 A011004007009 Levelling device 10

11 A011602257009 Cover load cell 15

12 A011702215009 Holder bubble level 25

13 A011701203009 Bubble level 15