SEA Sprint Installation Manual

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Italiano

English

Français

SPRINT

Barriera oleodinamica

H barrierydraulic

Barrière oleodynamique

Barrera oleodinámica

Español

67411055-A

SEA S.p.A.

Zona Ind.le S. Atto - 64020 S. Nicolò a Tordino (TE)

Tel. 0861.588341 - Fax 0861.588344

Numero Verde: 800.979.732

www.seateam.com

e-mail: seacom@seateam.com

Rev. 01 - 03/2016

1

®

Sistemi Elettronici

di Apertura Porte e Cancelli

SPRINT BARRIER

INSTALLATION MANUAL

English

Thank you for choosing a SEA product. This choice will give you

the opportunity to understand that our company aims at

combining high-tech and remarkable reliability and safety, thanks

to studies, research and the accurate analysis of our customers'

needs, without undermining the simple use and installation of our

products.

General features

SPRINT is a barrier (2, 3, 4, 5 m) recommended for the hydraulic

automation of access points which require a high opening/closing

speed (parking lots, motorways, airports, etc.) and frequent use

features. The automation includes an anti-crush security system

with adjustable sensitivity, which guarantees a barrier force value

not exceeding 15 kg, thus protecting people and objects from any

accidents. A highly reliable slowdown device guarantees the total

control of the forces of inertia.

The emergency batteries guaranty at least 15 opening cycles

(depending on the installed accessories) in case of power failure

and a release system allows the manual opening in case of

emergency.

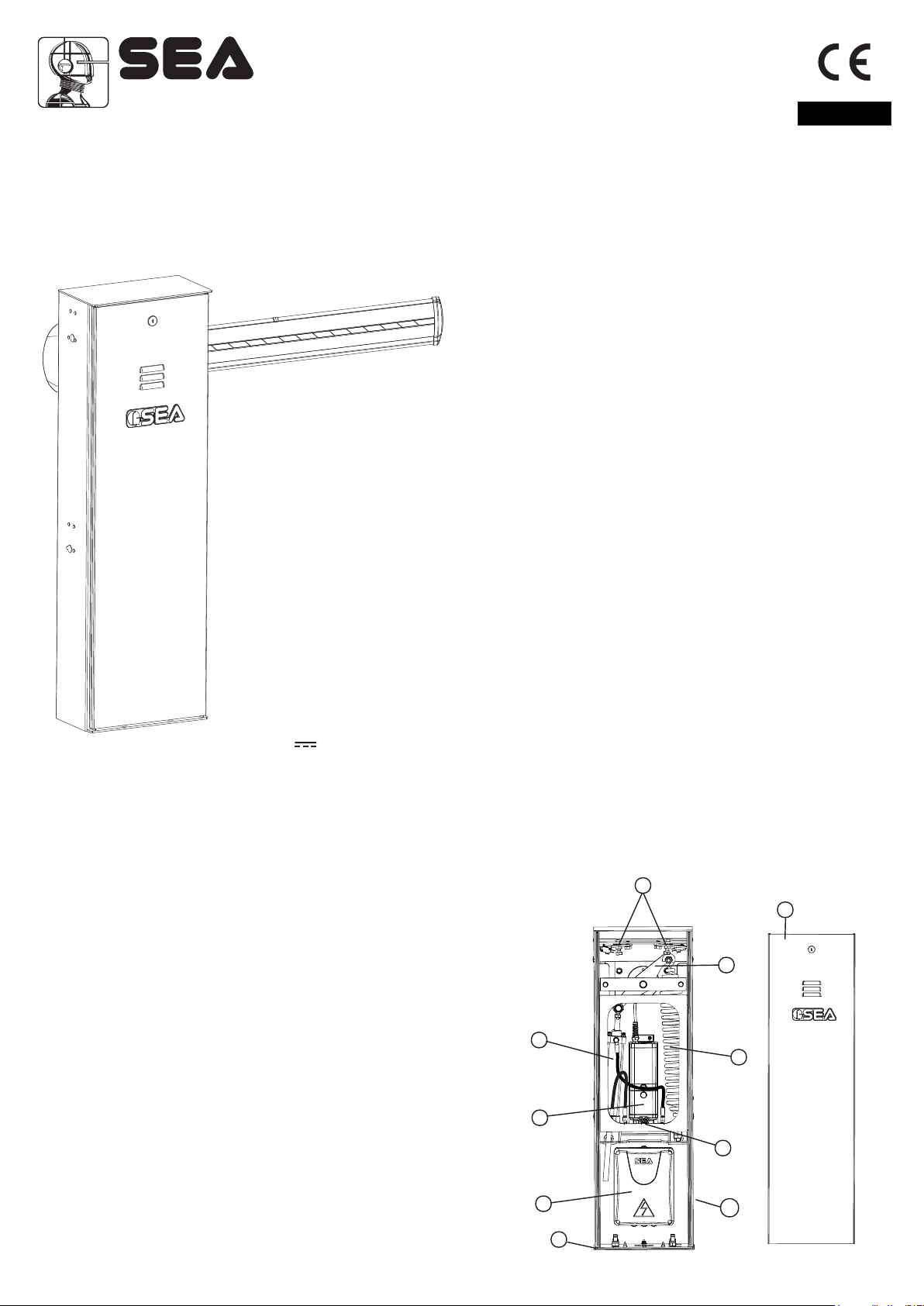

The automation system is composed of the following elements:

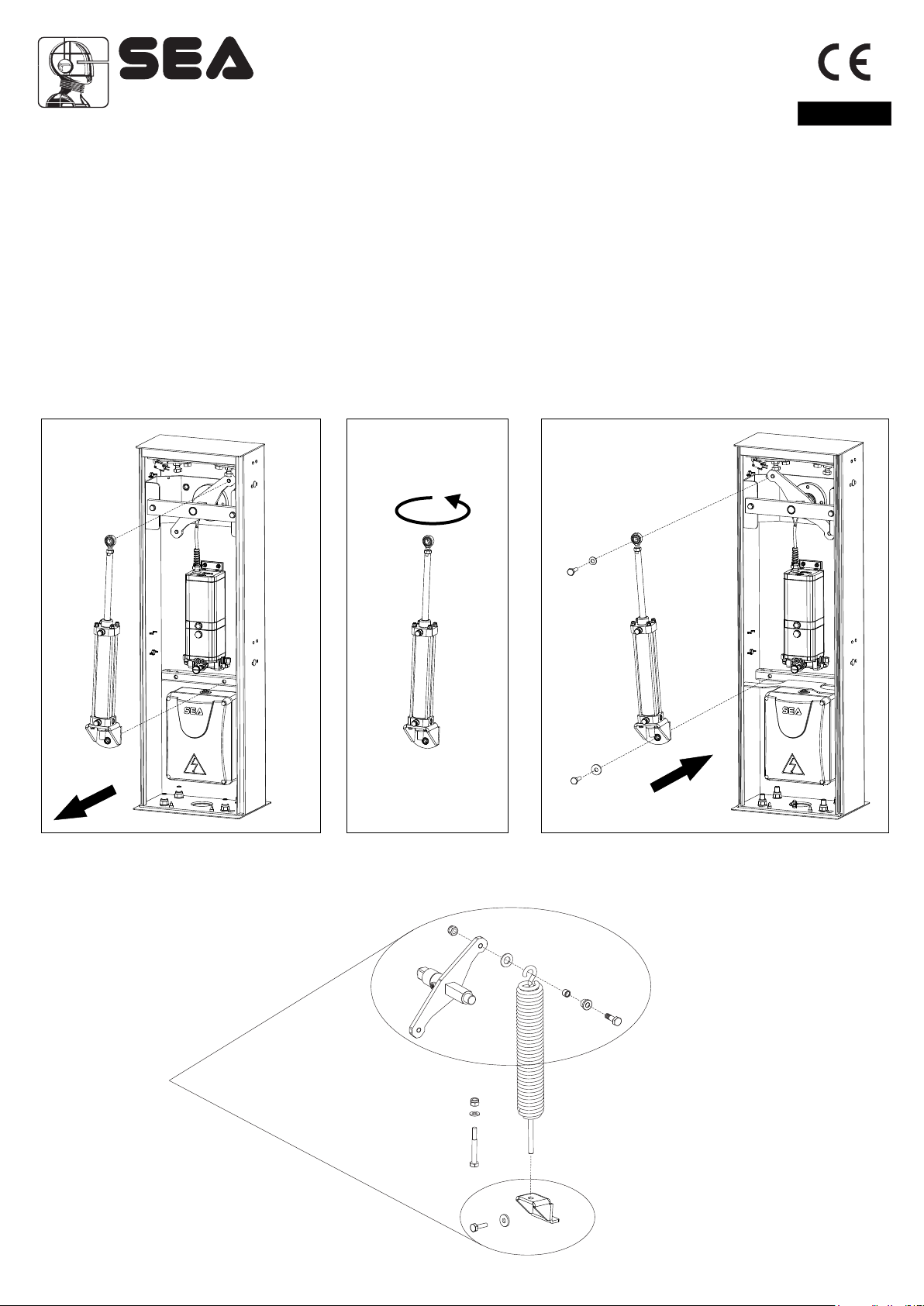

1 Adjustable mechanical and electronic stop with microswitch (where present)

2 Manual release with key

3 Galvanised steel rocker arm.

4 SPRINT, casing cover with lock and DIN key

5 Balancing spring.

6 Electronic control unit, a complex device which can be used to program and manage all the

operation and safety systems.

7 Foundation plate out of galvanized steel

8 24V - 1400 rpm electric motor

9 Cataphoresis-treated and polyester painted SPRINT casing, for outside, protects all included

mechanical and electronic devices from fire, flood, lightning, etc.

Predisposed for the application of photocells, key switch, proximity reader.

Stainless steel casing available on request.

Main components:

1) Adjustable mechanical and electronic stops

2) Release screw

3) Rocker arm

4) SPRINT casing cover

5) Balancing spring

6) Electronic control unit

7) SPRINT anchoring plate (optional)

8) Piston

9) Hydraulic unit

10) SPRINT casing

1

4

3

8

5

9

2

6

7

10

13

®

Sistemi Elettronici

di Apertura Porte e Cancelli

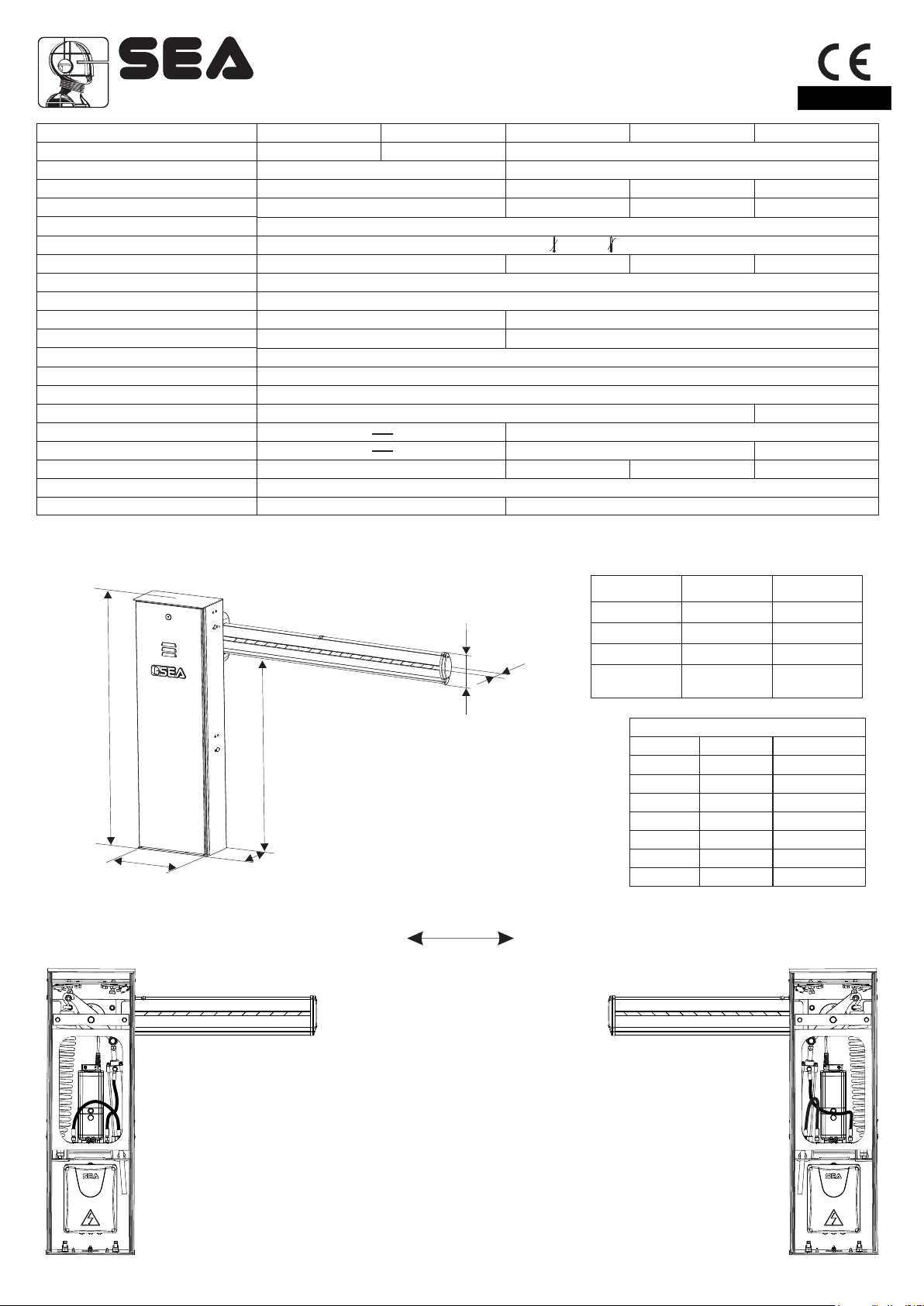

Technical features

Supply voltage

supply voltage Hydraulic unit

Absorbed power

Motor power

Motor speed

Working temperature

Opening/closing time

Protection class

Manual release system

Usage frequency

Anti-crushing device

Holding block

Slowdown

Barrier body treatment

Max. Length

Thermal protection intervention

Starting capacitor

Pump capacity

Weight

Electronic equipment

24V Version 24V Version 230V (1L) Version 230V (2L) Version Fast Version

230 V ± 5% - 50/60 Hz~

115 V ± 5% - 50/60 Hz~

24V

10 A

45 W

Adjustable

90%

A By pass valve mmeter

Cataphoresis treated and polyester painted

2 L

User 1 24V DG R1

1,1 A

220W

1430 rpm

-20° + 55°C

10”

IP55

Yes

Yes

Electronic

5 m

1 L

51 kg

Note: The frequency of use is valid only for the first hour at 20°C room temperature.

230 V ± 5% - 50/60 Hz~

6,3 µF

230V

1,0 A

270W

8”

75%

130°

2 L

Gate 1 DG R1

English

1,2 A

250W

3”

3 m

12,5 µF

3 L

Overall dimensions:

1003

310

1) Spring position

Opening on the left

SPEED BEAMS (For SPRINT 24V only)

Beam Length Opening time

142,5

77

Articulated beam

830

164

INSTALLATION INSTRUCTIONS

Beam 3 m

Beam 4 m

Beam 5 m

3,5 m

Light beam

Beam Length

2 5,5 16400005

2,5 6 16400008

3 6 16400008

3,5 7 16400015

4 7 16400015

4,5 8 16400026

5 8 16400026

6’’

8’’

10’’

10’’

D. Spring Cod. kit beam

Opening on the right

Speed setting

Speed 100%

Speed 80%

Speed 70%

Speed 70%

14

Thanks to its high flexibility, the barrier you are installing can be closed on the

right-hand or left-hand side of the post, according to your needs.

e.g. if the spring is on the right-hand side, the guard opens on the right (see Fig. 2).

Fig.1

Fig.2

®

Sistemi Elettronici

di Apertura Porte e Cancelli

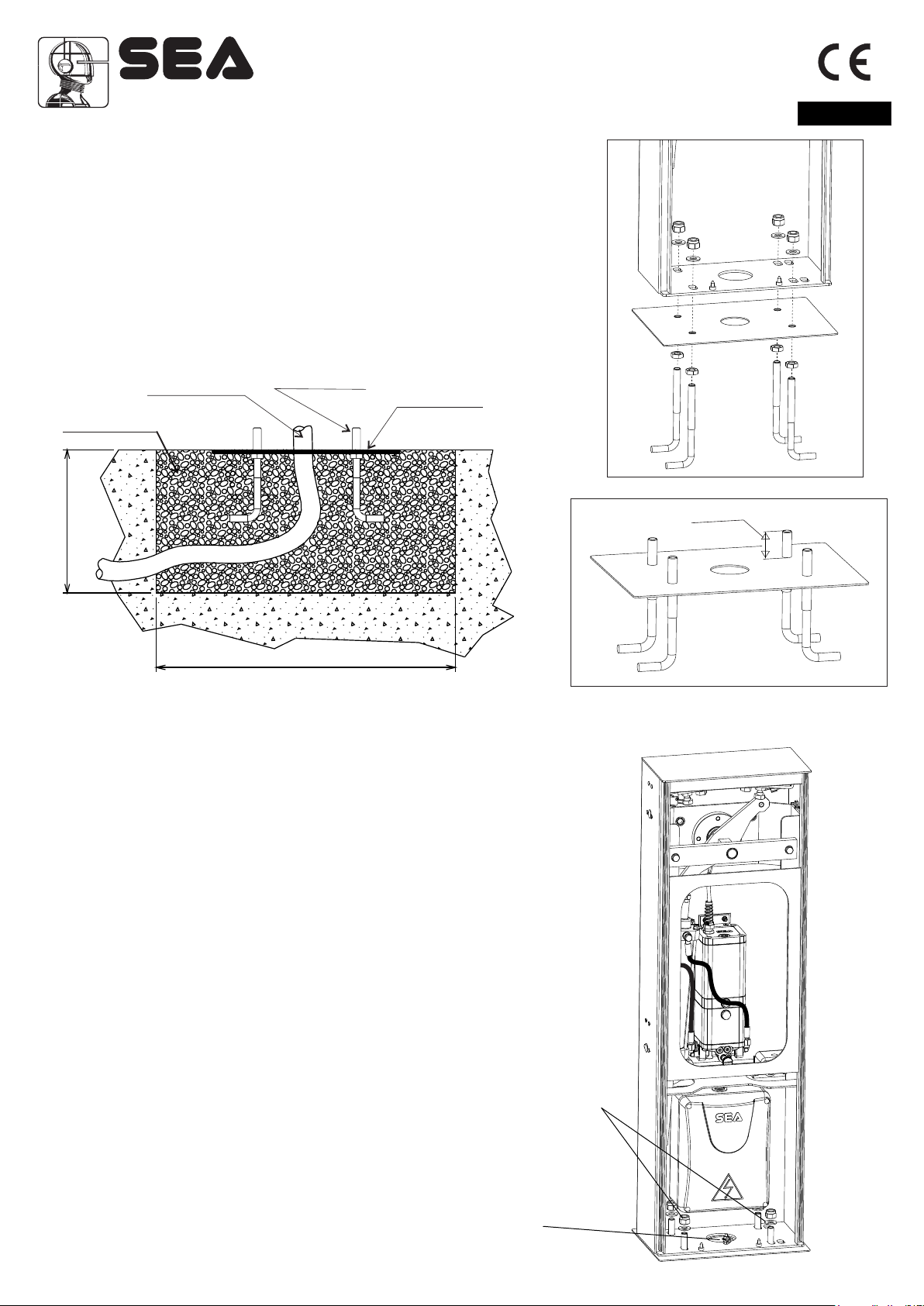

2) Foundation plate anchoring

- Make a 500 x 500 x 300 mm (depth) hole in the ground.

- Fill the hole with R425 concrete and place the foundation plate as shown in

Fig. 3.

- Accurately level the plate.

* The middle hole of the plate must be used for cable routing. Therefore, make

sure that the conduit connected to the hole complies with current regulations,

before filling the hole with concrete.

English

Conduit

Concrete

300

3) Post anchoring on the foundation plate

Ground anchor

500

Foundation plate

to be levelled

Fig.3

- Place the casing so that the holes on the base match the

screws located on the foundation plate.

- Make sure that the conduit for the cables goes through the large

hole of the casing base.

- Fix the casing on the foundation plate, screwing the supplied

nuts and washers carefully.

Fig.4

30 mm

Fig.5

Hole for the conduit

containing the

electrical cables

Anchoring

nuts and

washers

Fig.6

15

®

Sistemi Elettronici

di Apertura Porte e Cancelli

English

4) Mounting of the spring

N.B.: The operator comes as shown in Fig.1 (opening on the left).

Example:

Barrier with opening on the left (Fig.1)

Barrier with opening on the right (Fig. 2)

Before installing the spring check the choice of the barrier, if right or left hand side.

If the barrier is with opening on the right, move the piston from the right to the left hand side as shown in Fig.7 and 9, by rotating the

piston about 360°on itself (Fig.8).

N.B.: Before executing this operation release the motor-reducer as shown in Fig.21.

Note: Before reversing the piston, release about a half turn, the two fittings of the connection pipes between the hydraulic unit

and the hydraulic piston to facilitate the inversion (only on the unit) as shown in Fig.7, being careful not to cause narrowings on

hoses (not visible in the figures).

Once exchanged the piston tighten its fixation screw and lubricate with grease (Use DIN 51502 KP 2 N-20 - K 2 K-20 grease).

360°

Fig.7 Fig.8 Fig.9

Insert the spring in to the carter as shown in Fig.10.

Lubrication

with grease

during mounting

Fig.10

16

®

Sistemi Elettronici

di Apertura Porte e Cancelli

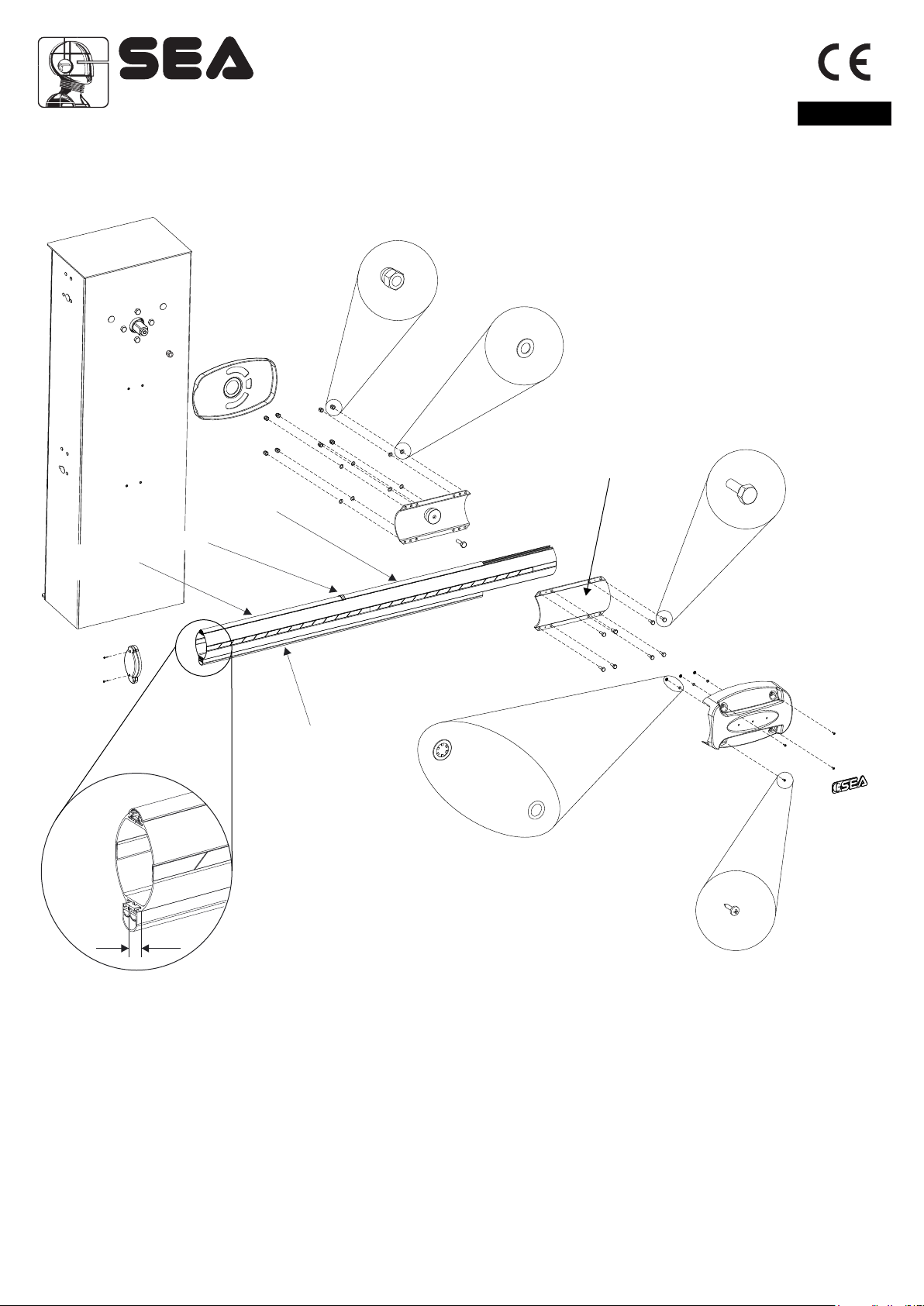

5) Mounting of the Light beam

Note: For 4 and 5 m beams it is recommended to use the fork support or the flexible support.

Fixing

English

Led profile

(B)

Led profile

(A)

Joint

Anti-blunt rubber

5 mm

Fig. 11-a

Fig. 11

Mount the first segment (A) of the LED profile, positioning it in doorstop on the fixing, mount the joint, fit the second segment (B) of

the LED profile and repeat the operation for all segments of the LED profile up to covering the length of the whole beam. The last

profile LED must be cut with a hacksaw at the end of the rod (Fig.11-a). Intersperse each segment of the LED profile with a joint.

Mount the anti-blunt rubber so that it comes out from the beam about 5mm (Fig.11-a).

17

Loading...

Loading...