SEA SETRONIK1 Installation And Use Manual

INSTALLATION AND USE

MANUAL

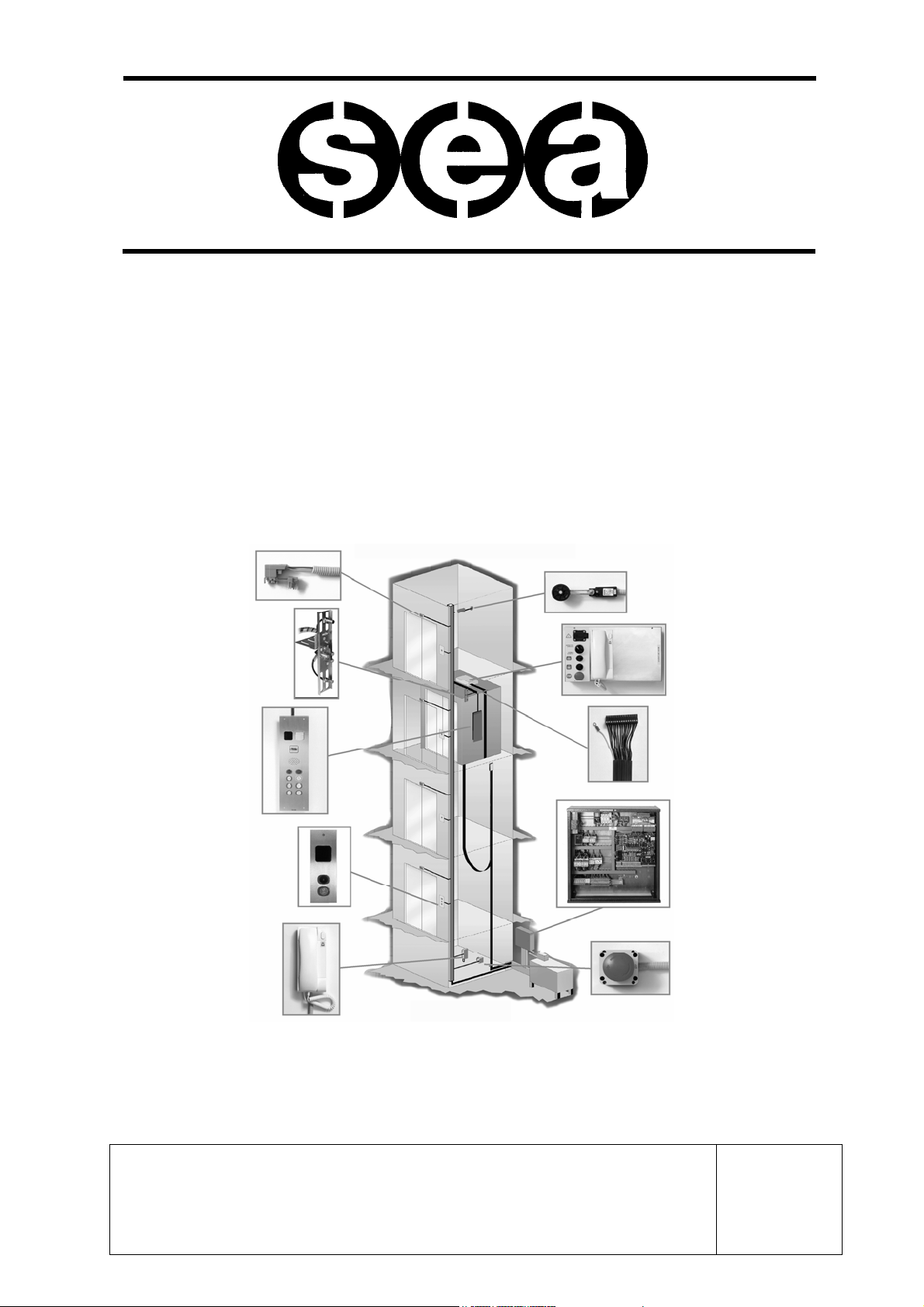

Control Panel and Prewired system

SETRONIK1

For Electric and Hydraulic Lifts

SEA SYSTEMS S.R.L

Control Panels, Push button panels and Prewired systems for lifts

Street San Carlo 13 - 20010 Bareggio - Milano - ITALY

Tel: +39 02 90 36 34 99 - Fax: +39 02 90 36 35 00

Internet: www.seasystems.it - e-mail: sea@seasystems.it

MSTK12-GB

Rev.01

30/12/05

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

INTRODUCTION

Our compliments for choosing the SETRONIK1 controller as the controller for your lift.

Please carefully read this booklet so that you will be able to understand all the qualities of

this device and its potential.

The SETRONIK1 family controllers are microprocessor-controlled controllers specially

designed for the control of 1 Speed, 2 Speeds and Variable Speed, Hydraulic and Rope

Lifts operating in APB, Simplex (up and/or down collective), Duplo and Pick-Up operation.

The STK2-PM programmer allows to set a secret Access Code, know the conditions the lift

is operating in, which and how many times failures and malfunctions have occurred,

control the lift and doors motion and modify the operating characteristics of the lift itself.

Several functions specific to a particular lift can be programmed without having to act on

the Controller wiring.

As far as the operating Diagnostics is concerned, help is provided by the failure and

malfunction indications on the Programmer displays and by the indications

supplied by the board LEDs.

Warning

Since our products are in constant evolution, all information contained in this manual can

be modified by SEA SYSTEMS without notice.

In the case of special lifts, any accessory documentation relating to additional or modified

functions is provided.

SETRONIK1 Pagina 2 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

TABLE OF CONTENTS

1. FUNCTIONAL CHARACTERISTICS ................................................... 5

2. INSTALLATION..................................................................................... 6

2.1. GENERAL NOTES.........................................................................................................7

2.2. SAFETY RULES............................................................................................................8

2.3. GLOSSARY..................................................................................................................8

2.4. PRELIMINARY OPERATIONS...........................................................................................9

2.5. F

2.6. F

2.7. FIXING AND CONNECTION ON THE CAR ROOF ................................................................14

2.8. INSULATION TEST ......................................................................................................23

2.9. SYSTEM COMMISSIONING ...........................................................................................24

3. PROGRAMMING................................................................................. 25

3.1 PROGRAMMER CONNECTION (STK2-PM) ....................................................................25

3.2. EXAMPLE OF PROGRAMMER USE .................................................................................26

3.3. PROGRAMMING THE CUSTOMER SECRET ACCESS CODE...............................................27

3.4. PARAMETERS STORING..............................................................................................28

3.5. PROGRAMMING THE LIFT, OPERATION, SELECTOR........................................................29

3.6. PROGRAMMING THE MAIN FLOOR, PARKING FLOOR, PREFERENTIAL FLOOR, FIREMEN AND

3.7. PROGRAMMING THE OPERATOR..................................................................................31

3.8. PROGRAMMING MAX FLOOR RE-LEVELLINGS, POSITION INDICATIONS. ............................32

3.9. PROGRAMMING OF SPEED AND STOP MODE DURING INSPECTION, MOVABLE PLATFORM,

3.10. PROGRAMMING OF OVERLOAD CONTACT...................................................................34

3.11. P

3.12. S

3.13. P

3.14. I

3.15. OUTPUT PROGRAMMING: .........................................................................................39

IXING AND CONNECTION OF THE CONTROL PANEL ......................................................10

IXING AND CONNECTION IN THE SHAFT.......................................................................11

FIRE-FIGHTING FLOOR, DUPLO VERTICAL RISE FLOORS..................................................30

ADVANCE DOORS OPENING, RE-LEVELLING, GONG .......................................................33

ROGRAMMING OF SERVICES. ..................................................................................35

HAFT PROGRAMMING: ............................................................................................36

ROGRAMMING OF TIMERS:......................................................................................37

NPUT PROGRAMMING: .............................................................................................38

4. DIAGNOSIS......................................................................................... 40

4.1. LIFT STATUS DISPLAY ................................................................................................40

4.2. DISPLAY AND CANCELLATION OF FAILURES / MALFUNCTIONS.........................................41

4.3. C

4.4. C

4.5. LED SIGNALLING LEGEND OF CARDS STK1-B, STK1-E AND AL01................................44

4.6. ERROR CODE LEGEND ...............................................................................................47

SETRONIK1 Pagina 3 di 54

OUNT OF RUNS AND RE-LEVELLINGS PERFORMED. .....................................................42

OMMANDS FOR LIFT OPERATION IN THE MACHINE ROOM: .............................................43

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

5. MAINTENANCE ................................................................................ 50

5.1. BATTERY REPLACEMENT.............................................................................................50

5.2. SHAFT SENSORS........................................................................................................50

5.3. STK1-B BASIC ELECTRONIC BOARD REPLACEMENT .....................................................51

5.4. CS1 SAFETY CIRCUIT REPLACEMENT ..........................................................................52

6. BASIC TROUBLESHOOTING PROCEDURES.................................. 53

6.1. ALARMED CARD (ALL LED ON)....................................................................................53

6.2. ERRONEUS READOUT OF THE SHAFT SENSORS .............................................................53

7. TECHNICAL DATA ............................................................................. 54

SETRONIK1 Pagina 4 di 54

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

SEA SYSTEMS

For Electric and Hydraulic Lifts

1.FUNCTIONAL CHARACTERISTICS

MSTK12-GB

Rev.01

30/12/05

LIFT TYPES

OPERATIONS

NUMBER OF STOPS

DOOR CONTROL

VARIOUS CONTROLS

CAR AND LANDING

SIGNALS ( 24V. )

SHAFT

EMERGENCY

- ROPE 1 - 2 SPEEDS , ACVV , VVVF

- HYDRAULIC : DIRECT , STAR DELTA , SOFT STARTER , SOFT STOP, SCC,

ELECTRONIC VALVES

- APB FOR INDIVIDUAL LIFT

- DOWN COLLECTIVE SIMPLEX

- DOWN-UP COLLECTIVE SIMPLEX

- DUPLO

- PICK UP

- FOR APB AND DOWN COLLECTIVE:

6 BASIC STOPS / 6 SERVICES

EXTENSION OF 6 STOPS \ 6 SERVICES (TOTAL 12 STOPS \ 12 SERVICES)

- FOR UP AND DOWN COLLECTIVE:

4 BASIC STOPS \ 4 SERVICES

EXTENSION 4 STOPS \ 4 SERVICES (TOTAL 8 STOPS \ 8 SERVICES)

- MANUAL ON LANDINGS AND CAR

- MANUAL ON LANDINGS AND WITHOUT DOORS IN THE CAR – BY SAFETY

CELL

- MANUAL ON LANDINGS AND AUTOMATIC IN THE CAR

- AUTOMATIC ON LANDINGS AND IN THE CAR UP TO 2 LIFTS BY ALTERNATE

\SIMULTANEOUS \ SELECTIVE OPENING

- PHOTOCELL, DOOR PRESSURE SWITCH , DOORS OPENING/CLOSING

PUSHBUTTON

- PARKING WITH OPEN/CLOSED DOORS DIFFERENTIATED AT THE VARIOUS

LANDINGS

- TIMED CONTROL OF DOORS MOTORS

- DISPLAY AND CANCELLATION OF FAILURE \ MALFUNCTION CODES

- SAFETY DEVICES CONTROL

- CONTROL OF THE STICKING \ FAILED EXCITATION OF CONTACTORS

- MOBILE PLATFORM \ FULL LOAD \ OVERLOAD

- OIL TEMPERATURE AND PRESSURE

- MOTOR WINDING TEMPERATURE

- SEQUENCE AND PHASE FAILURE

- TIMERS MANAGEMENT (RUN TIME, LOW SPEED TIME)

- 15’ DESPATCH (HYDRAULIC LIFTS)

- MAIN FLOOR PARKING

- LEVELLING SPACE SETTING

- ADVANCE DOORS OPENING

- RESERVED /PREFERENTIAL /FIREMEN / FIRE-FIGHTING OPERATION

- CUSTOMER SECRET ACCESS CODE

- DOOR PROGRAMMING

- AVAILABLE INPUT-OUTPUT PROGRAMMING (SPECIAL OPERATIONS)

- PRESENT / BUSY / COMING (ON LANDINGS)

- OCCUPIED (IN THE CAR / ON LANDINGS)

- POSITION LAMPS AND/OR DISPLAYS BY COMMON NEGATIVE DECODING,

DENIED BCD, GRAY CODE

- NEXT DIRECTION ARROWS (IN THE CAR / ON LANDINGS)

- OVERLOAD

- GONG

- NORMAL, SHORT AND/OR CLOSE FLOORS CONTROL

- ALARM , 12V EMERGENCY LIGHT

- SETTING FOR DEVICE OF DESCENT AND DOOR OPENING IN EMERGENCY

WITH MOTOR 48V FOR HYDRAULIC LIFT (B12E Board)

SETRONIK1 Pagina 5 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

2.INSTALLATION

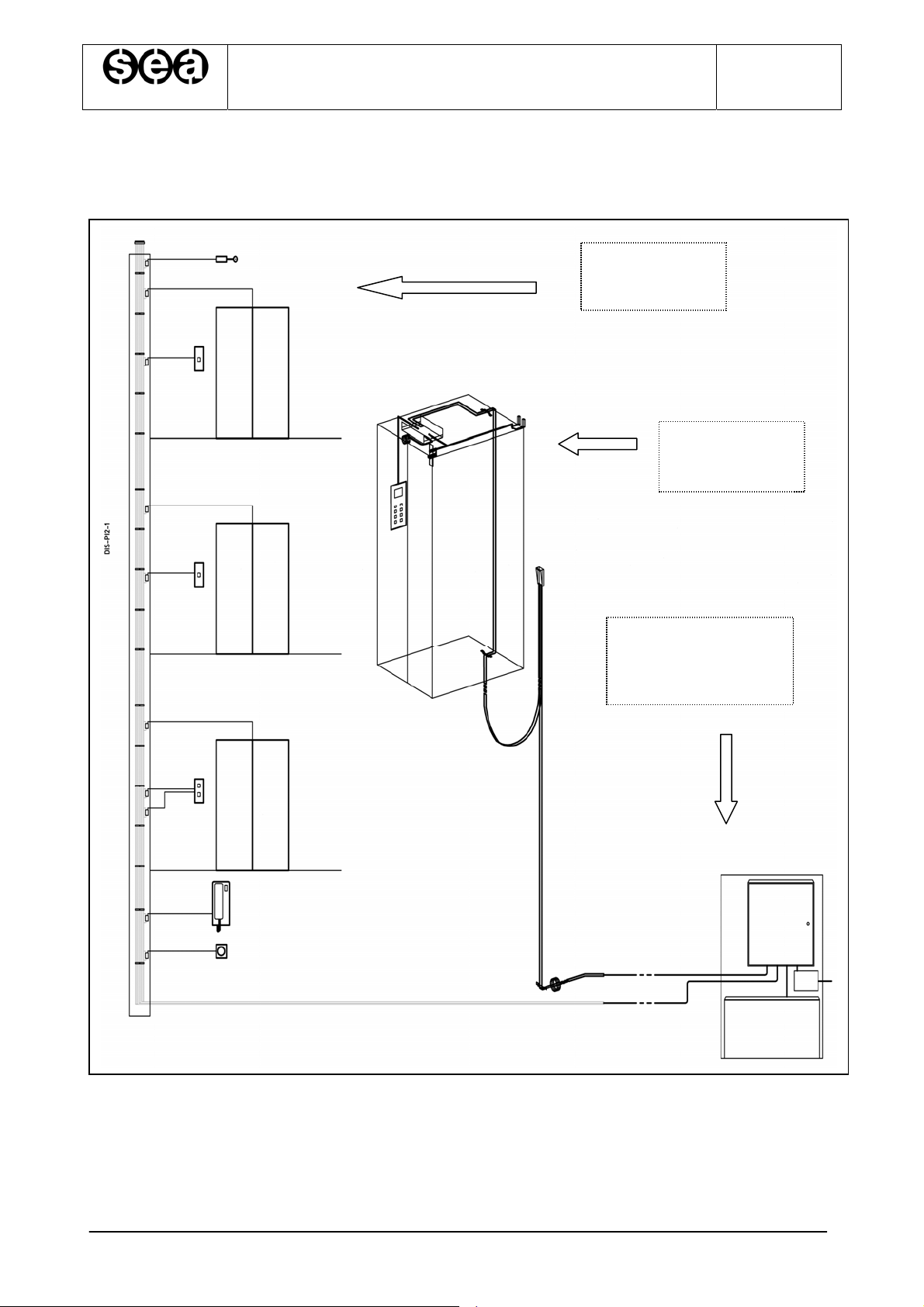

Fig.2.1. Pre-wiring Layout Drawing, including reference paragraphs for installation purposes

SHAFT:

- Par. 2.6

CAR ROOF:

- Par. 2.7

MACHINE ROOM:

- Par. 2.5

SETRONIK1 Pagina 6 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

2.1.GENERAL NOTES

NOTE

Carefully read any warning information in the present operating instructions as

• Installation and service to be carried out in compliance with regulations in force,

according to the manufacturer specifications and by authorised, trained and qualified

personnel only.

• A wrong installation or an improper service could lead to damages to people, animals

or objects, which the manufacturer is not liable for.

• Should the machine be sold or transferred to a different owner, check that the present

operating instructions are always available, as to be duly used by the new owner or

operator.

• Hereby listed documents are to be sued for a correct installation set-up:

-Installation project drawing (not supplied by Sea);

-Control Panel STK1: Installation and Maintenance Manual (this manual);

-Control board programming and troubleshooting operating instructions;

-Control Panel electric wiring;

-Control Panel Installation electric wiring (in this manual).

holding important safety, operating and service instructions.

•The installation manager must store any enclosed documents in a safe place, within

reach, thus providing for a correct lift set-up and service. Operating instructions are an

integral part to the installation and therefore they are not allowed to be damaged. Avoid

tearing pages and when consulted, it is necessary to avoid damaging to provide for any

possible future correct reference.

• Guarantee terms are on the product transportation document back. SEA SYSTEMS

will support its products through the guarantee, in case of defects with a specified time

period. Should the product not be correctly operated or its performance anyhow modified,

differently from factory original specifications, the guarantee no longer applies.

• When necessary, get in touch with the company Service Department always

providing for the installation serial number.

The serial number is specified:

- on the adhesive label on the outside of the control board unit;

- On the first page of the board electric wiring;

- On the Control board programming paper

- On the Board Declaration of Conformity

• The serial number is to be always specified to identify the installation technical

specifications.

The safety department address and telephone number are available on the present

operating instructions cover.

SETRONIK1 Pagina 7 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

2.2.SAFETY RULES

•The unit can only be installed by qualified and authorised personnel, who is liable for the

specific compliance to standards according to the technical best practice available.

•Before any cleaning or serve, cut the unit from the power supply by means of the

installation cut-out switch.

• Always wear the demanded personal protections (fig. 2.1),and more precisely:

- Cask.

- Gloves.

- Overall, closed at the wrist level.

- Protective shoes.

- Safety belts.

- Headphones.

• Never wear loose objects and/or clothing (necklaces, watches, ties), avoid long hair.

• Never store cutting or pointed objects (screwdriver, scissors …) in the shirt pocket.

• Never tamper, wear or hide warning signs or labels. When wore and demanded,

immediately replace the.

• In order to lift heavy loads, always used suitable tools, thus avoiding any damage to the

spine cord depending on the unit manual handling.

Fig. 2.1 – Safety signalling

2.3.GLOSSARY

NOTE

It provides personnel with specific and valuable information.

WARNING

It provides personnel with information which, when not complied with, can lead to

It provides personnel with information on a specific operation, which, if not taken

into account in compliance with safety regulations in force, can lead to possible

light people or installation damages

CAUTION

severe physical damages.

SETRONIK1 Pagina 8 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

2.4.PRELIMINARY OPERATIONS

Before starting the installation, check what follows:

A)INSTALLATION PLACE SET UP

• Check the existing operating lighting.

• Check the unit and pit cleaning

• Check that the mains electric installation is connected to a suitable earthing

(otherwise stop setting the installation up, until a suitable earthing or grounding is

available).

• Check that the unit inlets are perfectly closed.

• A storage area next to the unit is to be available, easily accessible to operators and

protected from any adverse weather condition.

• Check any cable tray and passing holes suitable for electric cabling, always to be

easily inspected and well-refined.

B)MATERIAL UNLOADING AND WAREHOUSING

• Check the Control Panel specifications (Control Panel type, Contactors, Starting,…)

must comply with demanded specifications on the order confirmation.

• Check the availability of any suitable material to be used during assembly, referring

to the checklist accompanying the board documents.

• Check any unit and material condition when delivery to the site, to check possible

damages which arrived during transportation. Immediately prevent SEA SYSTEMS

Srl in the case of missing units or damages

• Store electric and electronic unit in a dry and cold room, in the original packaging.

• Should it not be possible, whatever reason, to immediately install the unit,

periodically check stored units to avoid damages depending on a long storage

under unfavourable conditions.

C)SCAFFOLDING

When setting the unit up, use standard scaffolding, exhibiting operating floors at any stop,

at about 0.5 meter lower than the stop.

CAUTION

Scaffolding completely or partially in metal, to be connected to a suitable

grounding, in compliance with safety regulations in force.

SETRONIK1 Pagina 9 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

2.5.FIXING AND CONNECTION OF THE CONTROL PANEL

1. Drill the wall of the machine room, taking the locating holes of the angle bar

provided as a reference, so that the height at which the panel hangs makes its use

easy and convenient;

2. Anchor the angle bar to the upper section of the panel by means of appropriate

bolts and cage nuts;

3. Fasten the angle bar to the wall of the machine room with corresponding wall plugs.

HIGHLIGHT

Should the control panel be secured on premises other than the standard

machine room (ex: local cabinet, Pit, Shaft,...), the above procedure may be

inappropriate. In this case, follow the instructions specified for the system.

4. Make sure that the QM master switch is set to OFF (DOWN position);

5. Connect the appliances to the control panel as per the installation diagrams

HIGHLIGHT

The control panel has been pre-set with terminal board attachments to allow car

movements with a temporary push-button panel. Attachments to the terminal

board of both the control panel and push-button panel are outlined on the pre-

assembly diagram.

SETRONIK1 Pagina 10 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

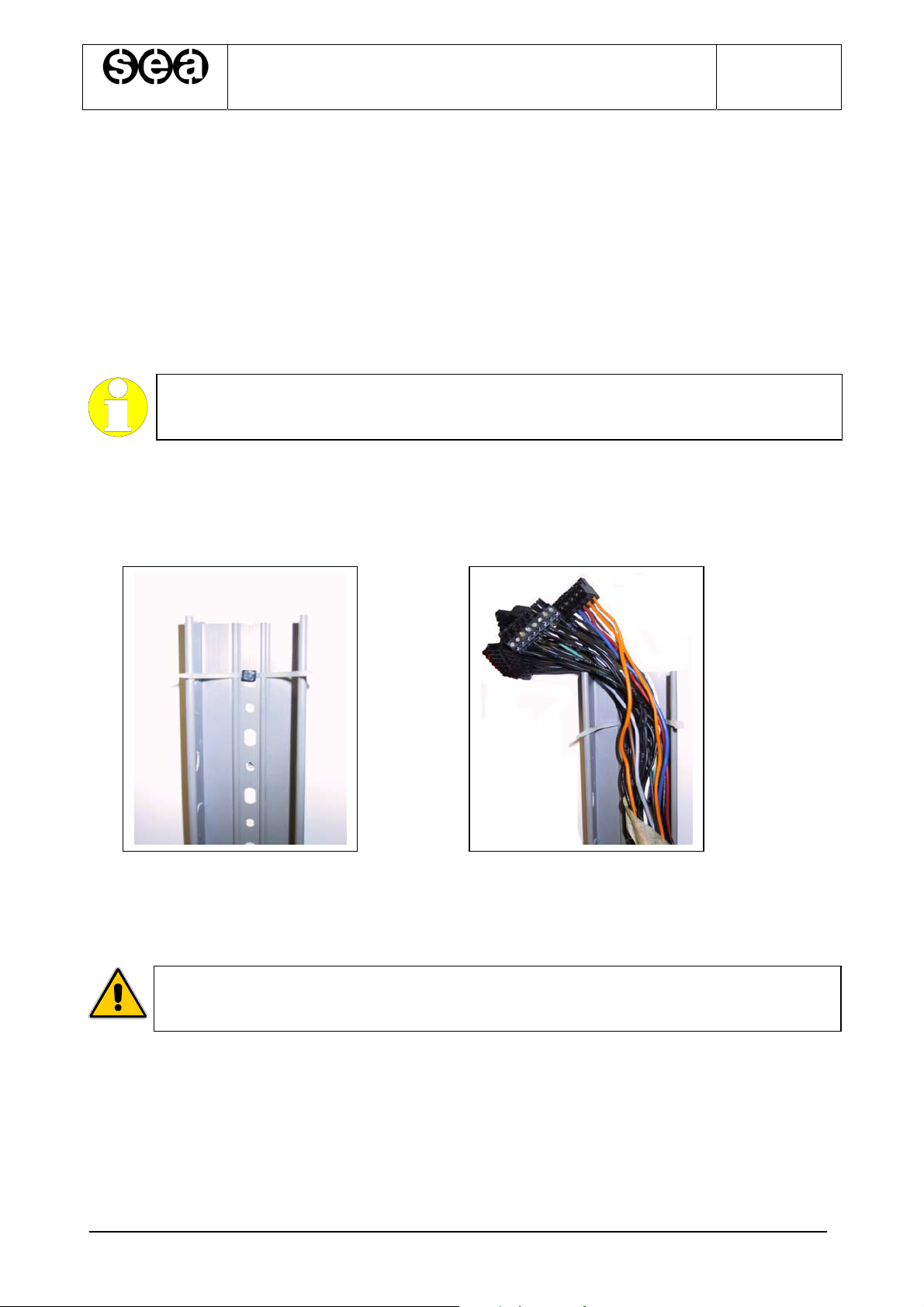

2.6.FIXING AND CONNECTION IN THE SHAFT

2.6.1.SHAFT LINE

1. The shaft line is formed by a taped coil of single-pole, colour-coded and numbered

wires, including plugged-in connectors with labels to the control panel side.

2. Fasten the wireway (P/N P-00060) with appropriate plugs (P/N P-00075) next to the

landing push-button panels, making sure to keep a maximum distance of 1 m from

the doors. If a dual-operator lift has been installed, fit the wireway closer to the most

widely used side

HIGHLIGHT

Set the plug with the clamp (P/N P-00074) already inserted into the eyebolt

3. Temporarily secure the coil on top of the shaft and lower it into the shaft from the

top, letting the side fitted with plugged-in connectors in, to the control panel (Fig.

2.3);

before securing it (Fig. 2.2);

Fig. 2.2. Fig. 2.3

4. Connect the frame connectors to the control panel as per installation diagrams

5. Lay down the coil, starting from the control panel section, using clamps to rivet it to

the retaining plugs of the wireway, all the way to the upper end of the shaft;

WARNING

If cable quantity is too large on the upper side, cut the wires and insulate them

with electric tape or use the previously removed connectors.

SETRONIK1 Pagina 11 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

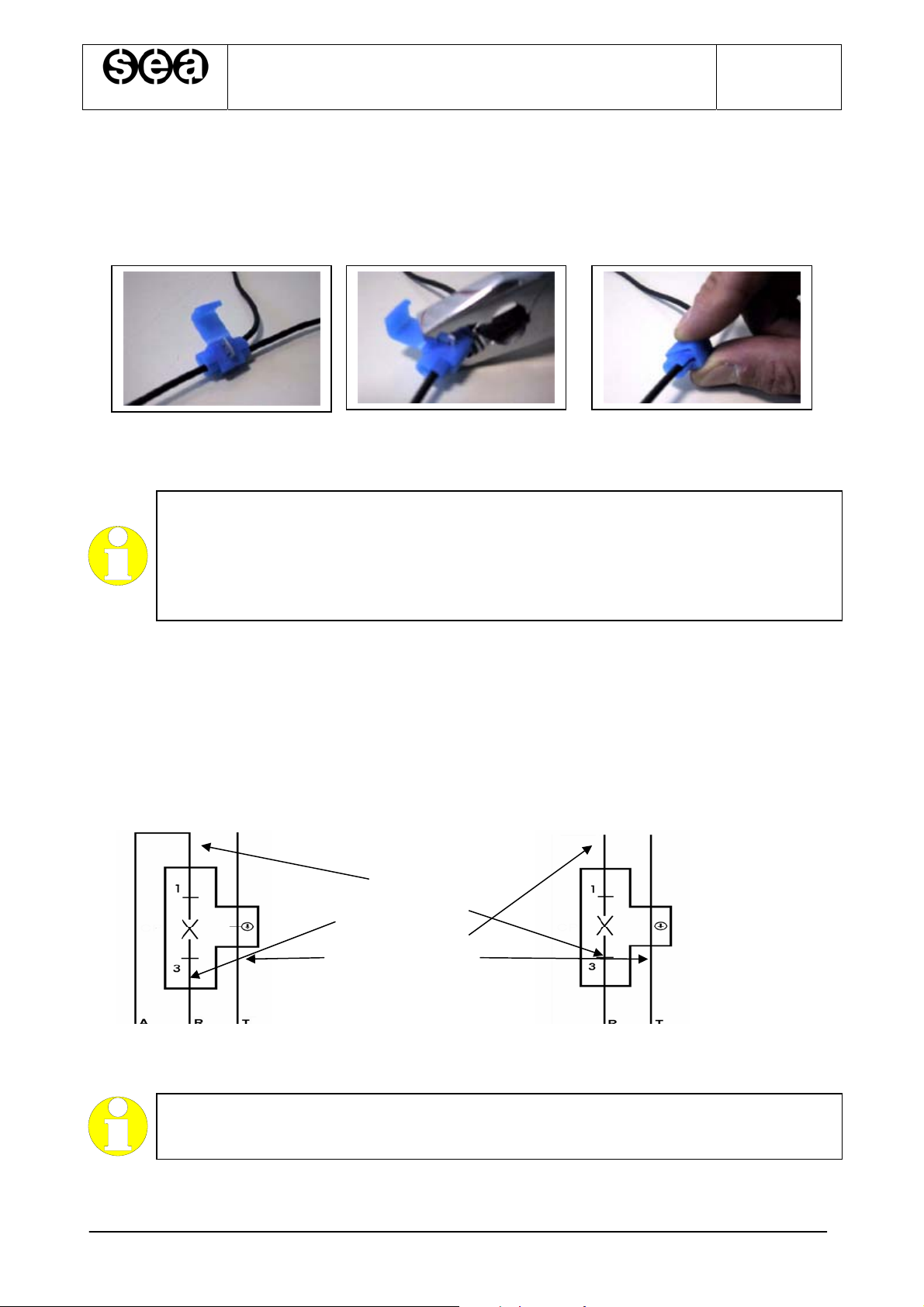

2.6.2.C

ONNECTIONS WITH BRANCH POINT TO THE SHAFT LINE

Use red and blu connectors (Cod. P-00084, P-00085) following the operations in figure 2.4

for the connections with branch point to the shaft line (see installation diagrams).

Fig. 2.4 –Sequence of operations for the connection with branch point

HIGHLIGHT

Generally the devices that need a connection with branch points are:

- Run limit switch;

- Floor push buttons;

- Alarm siren;

- Stop in the pit

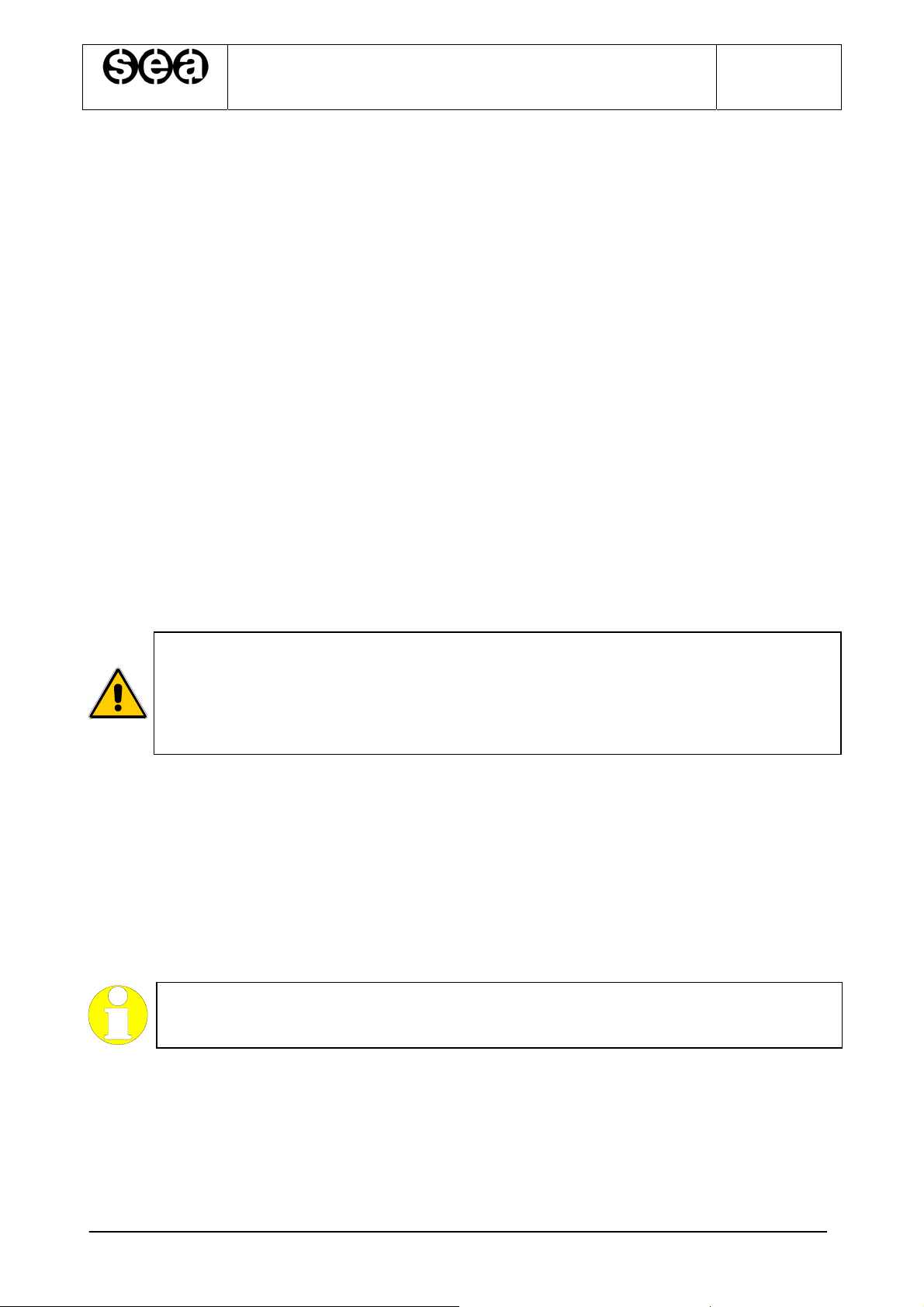

2.6.3.CONNECTIONS IN SERIES TO THE SHAFT LINE

Use orange connectors (BC1 and BC2) following the operations in figure 2.7 for the

connections in series to the shaft line (see installation diagrams).

Connect the last device of the series according to the figure 2.5, and the first devices of

the series according to the figure 2.6

Fig. 6.4.3Fig. 6.4.4

Upper End Landing ConnectorIntermediate Landings Connectors

WIRE COLOURS:

PINK

ORANGE

YELLOW / GREEN

Fig. 2.5 Fig. 2.6

Last connection in the series First connections in the series

HIGHLIGHT

Generally the devices that need a connection in series are:

- Safety contacts for floor door lockings

SETRONIK1 Pagina 12 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

Press the conductors between no-pull,

sealing arms

…. and tighten with a wrench.

Position the upper and lower sections of

the connector…

Male connector plugging into a female

connector

3-pin open female connector:

- 3- cutting blade

4- L cable (phase) cut and contacted, no peeling

5- Contacted ground cable, no peeling

Fig. 2.7 – Sequence of operations to plug in series to the shaft line

SETRONIK1 Pagina 13 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

2.7.FIXING AND CONNECTION ON THE CAR ROOF

2.7.1.JUNCTION BOX FIXING AND FLEXIBLE CABLE CONNECTIONS:

1. Fasten the junction box with appropriate retaining screws;

2. Bring the flexible cables coil into the shaft pit;

3. Connect the flexible cables (ground side, with eyebolts) to the car box connectors as

per installation diagrams and secure them to the box with appropriate clamps (P/N P-

00074);

4. Rivet the flexible cables to the car through the appropriate cable brackets (P/N P-

00089) and plugs (P/N P-00102) on the roof and beneath the car (see fig. 2.1);

5. Connect the flexible cables (ground side, no eyebolts) to the control panel as per

installation diagrams;

6. Fasten the wedge side bracket (P/N P-00086) to the shaft, about halfway, with

appropriate plugs (P/N P-00102);

7. Anchor the flexible cables to the wedge side bracket in such a point that when the car

has been lowered all the way down, the flexible cables box does not touch the

bottom of the pit (see fig.2.1);

WARNING

To solve the issue in connection with too big a box and too many flexible cables in

the pit, shift the wedge side bracket upwards.

Take into account that every time the bracket gets 1 meter higher, the box rises

approximately by ½ meters.

8. Make sure that flexible cables are not entangled in the pit, otherwise, unplug the

connectors from the control panel, pull them straight and reconnect them;

9. Secure one of the cable brackets (P/N P-00089) to the pit wall, where flexible cables

start rising vertically along the shaft.

2.7.2.CAR PUSH BUTTON AND DOOR OPERATOR CONNECTION

Connect the car push button and the operator according to the installation diagrams.

HIGHLIGHT

In case it’s necessary to use the wireway (Cod. P-00087) to fit the cables on the

car roof, fix it at the roof with screws (cod. P-00101)

SETRONIK1 Pagina 14 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

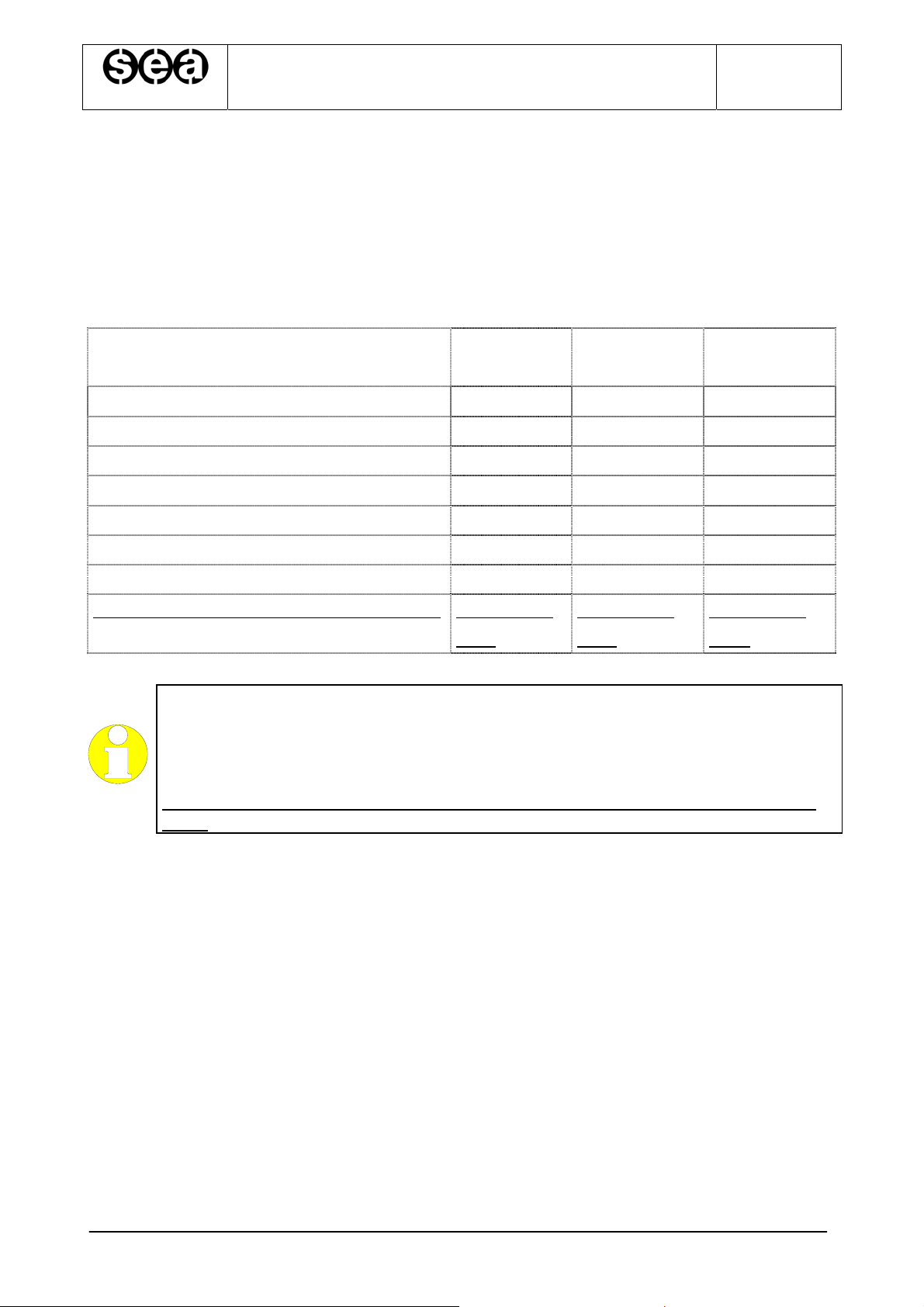

2.7.3.F

IXING AND CONNECTION OF THE SHAFT SENSORS FOR HYDRAULIC LIFTS

The shaft sensor kit can be of tree different type according to the type of brackets used for

sensors and magnets as the following tablet.

The tablet reports also the code of the diagram of the shaft sensor disposition included in

this paragraph.

SENSORS AND MAGNETS A TYPE

KIT BRAKET

Sensors IS, ID, C, D, FCE(optional) CFR CFR G-CFR

Sensors SR, DR, DS CVR SR, DR, DS SR, DR, DS

Magnet bars to command IS, ID, C, D MFR MFR G-MFR

Round magnet couple to command SR MVR-SR No Bracket G-MVR-SR

Round magnet couple to command DR MVR-DR No Bracket G-MVR-DR

Round magnet couple to command DS MVR-DS No Bracket G-MVR-DS

Diagram for sensor and magnet disposition Æ See diagram

B TYPE

KIT BRAKET

See diagram

C TYPE

KIT BRAKET

See diagram

CVIA

CVIA

CVIC

HIGHLIGHT

We recommend that you choose A System or C System for the installation of

magnets. The system ensures tighter fastening of the magnets, a better magnetic

field, less exposure to various bodies (grease, iron fillings….)

With the B System, the magnets without bracket have to be fixed directly on the

guide.

SETRONIK1 Pagina 15 di 54

SEA SYSTEMS

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

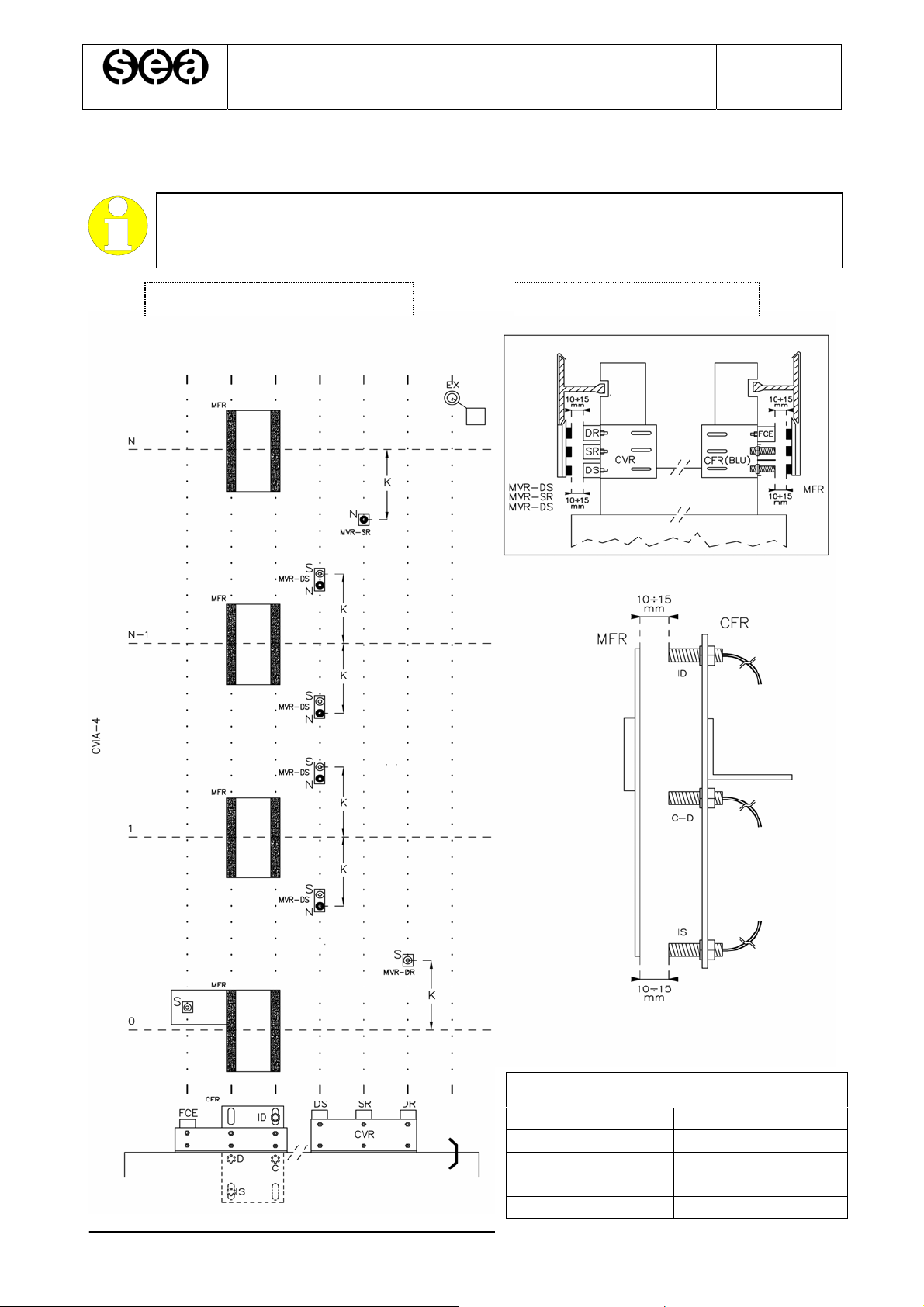

CVIA S

HAFT SENSORS PLACING FOR HYDRAULIC LIFT WITH A OR B SHAFT SENSOR KIT

HIGHLIGHT

With the B System, the magnets without bracket have to be fixed directly on the

guide.

SHAFT FRONTAL VIEW CAR ROOF VIEW

SLOWING DISTANCE K

SPEED K

0.2 m/s 20cm

0.4 m/s 40 cm

0.6 m/s 60 cm

0.8 m/s 80 cm

SETRONIK1 Pagina 16 di 54

SEA SYSTEMS

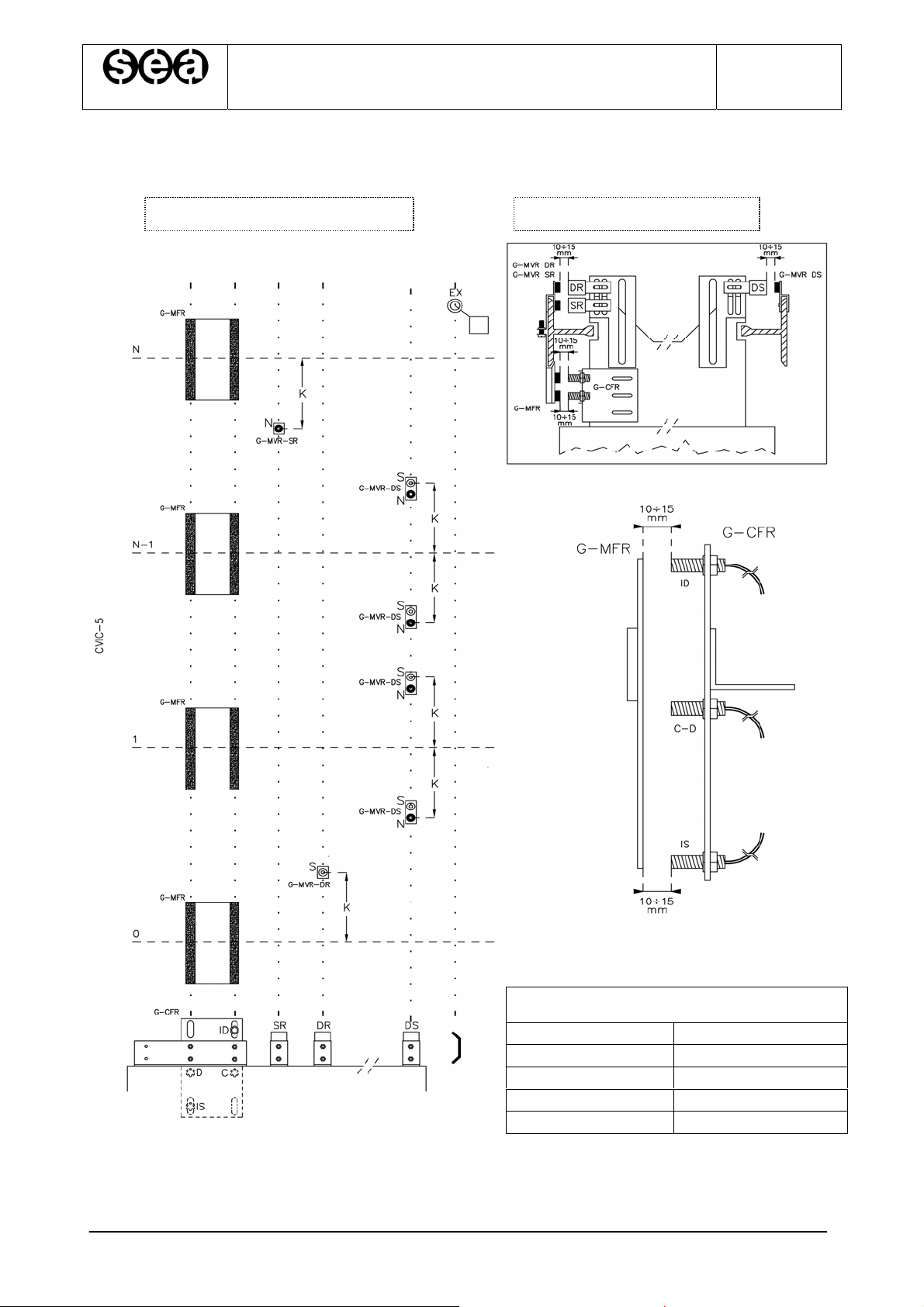

CVIC S

HAFT SENSORS PLACING FOR HYDRAULIC LIFT WITH C SHAFT SENSOR KIT

SHAFT FRONTAL VIEW CAR ROOF VIEW

INSTALLATION AND USE MANUAL

CONTROL PANEL and PREWIRED SYSTEM STK1

For Electric and Hydraulic Lifts

MSTK12-GB

Rev.01

30/12/05

SLOWING DISTANCE K

SPEED K

0.2 m/s 20cm

0.4 m/s 40 cm

0.6 m/s 60 cm

0.8 m/s 80 cm

SETRONIK1 Pagina 17 di 54

Loading...

Loading...