SEA Mercury Installation And Connection Instructions

MERCURY 400 (230V)

MERCURY 400 (110V)

MERCURY 400 (230V)

MERCURY 400 (110V)

MER. 600 (230V)

MER. 600 (110V)

MERCURY 600 (230V)

MERCURY 600 (110V)

MERCURY 400 24V (230V)

600 kg

400 kg

30%

40%

75%

MERCURY 600 24V (230V)

MER. 400 24V (230V)

MERCURY 600 24V (230V)

MERCURY 600 24V (110V) MERCURY 600 24V (110V)

MERCURY 400 24V (110V)

MER. 400 24V (110V)

MERCURY

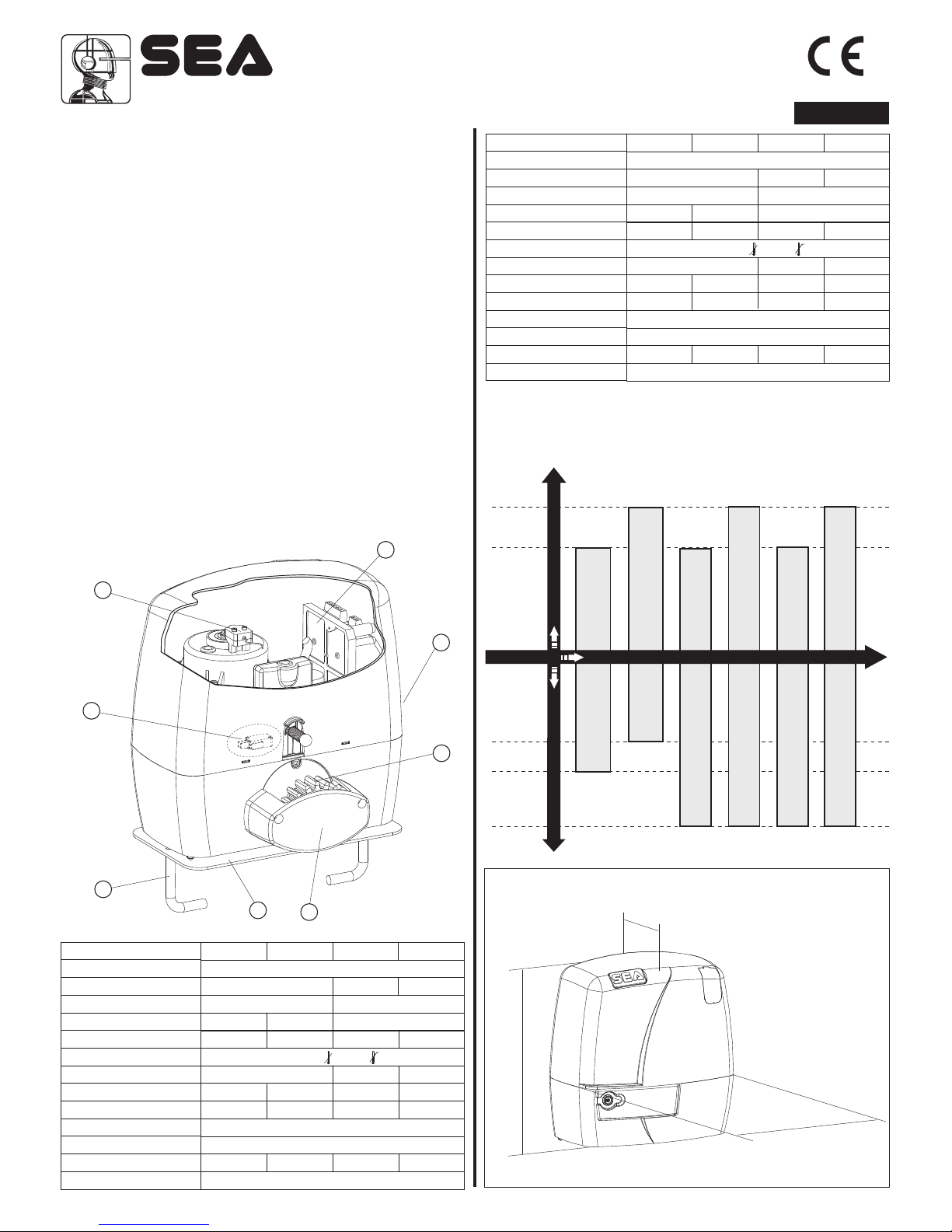

1 Adjustable foundation plate

2 Anchor bolts

3 Pinion protection

4 Pinion

5 Gear release lever

6 Electronic unit

7 Magnetic encoder (If present)

8 Micro switch (If present)

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

2

1

3

4

5

6

7

8

300

106

003

67411230

INSTALLATION AND CONNECTION INSTRUCTIONS

TECHNICAL DATA

Power supply

Absorbed power

Opening speed

Working frequency

Maximum torque

Working Temperature

Thermoprotection

Weight

Gate maximum weight

Anti-crushing clutch

Protection degree

Motor capacitor

Limit switch

230 V~ 50/60 Hz

320 W 80 W 110W

0.15 m/s Adjustable

40% 30% 75%

18 N m 25 N m 0/20 N m 0/30 Nm

-20°C +55°C

130°C - -

6.8 kg 7.2 kg 7.0 kg 7.5 kg

400 kg 600 kg 400 kg 600 kg

Electronic

IP 55

8 µf 10 µf - Mechanical

400 - 230V 600 - 230V 400 - 24V 600 - 24V

115 V~ 50/60 Hz

285 W 80 W 110W

0.15 m/s Adjustable

40% 30% 75%

18 N m 25 N m 0/20 N m 0/30 Nm

-20°C +55°C

130°C - -

6.8 kg 7.2 kg 7.0 kg 7.5 kg

400 kg 600 kg 400 kg 600 kg

Electronic

IP 55

50 µf 60 µf - Mechanical

400 24V-110V

600 24V-110V

400 - 110V 600 - 110V

MERCURY is a sliding gate motor with grease lubricated gear.

The irreversibility of the motor grants a perfect and safe gate

closing, avoiding the need of an elecric lock. In case of electric

power cut, the lock device placed on the front part of the motor

allows the manual opening and closing of the gate. The operator

is equipped with an electronic clutch device providing the thrust

adjustment on the gate. The electronic inversion system

(optional) through encoder makes the Mercury a safe and

reliable operator in compliance with the laws in force in the

country where the product has to be installed.

MAIN PARTS

TECHNICAL DATA

Power supply

Opening speed

Working frequency

Maximum torque

Working Temperature

Thermoprotection

Weight

Gate maximum weight

Anti-crushing clutch

Protection degree

Motor capacitor

Limit switch

Absorbed power

Note: The frequency of use is valid only for the first hour at 20°C

environment temperature.

MERCURY MOTOR FREQUENCY OF USE

Gear Motor

DIMENSIONS (mm)

ENGLISH

7

Use frequency

Gate maximum weight

REV 01 - 05/2012

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

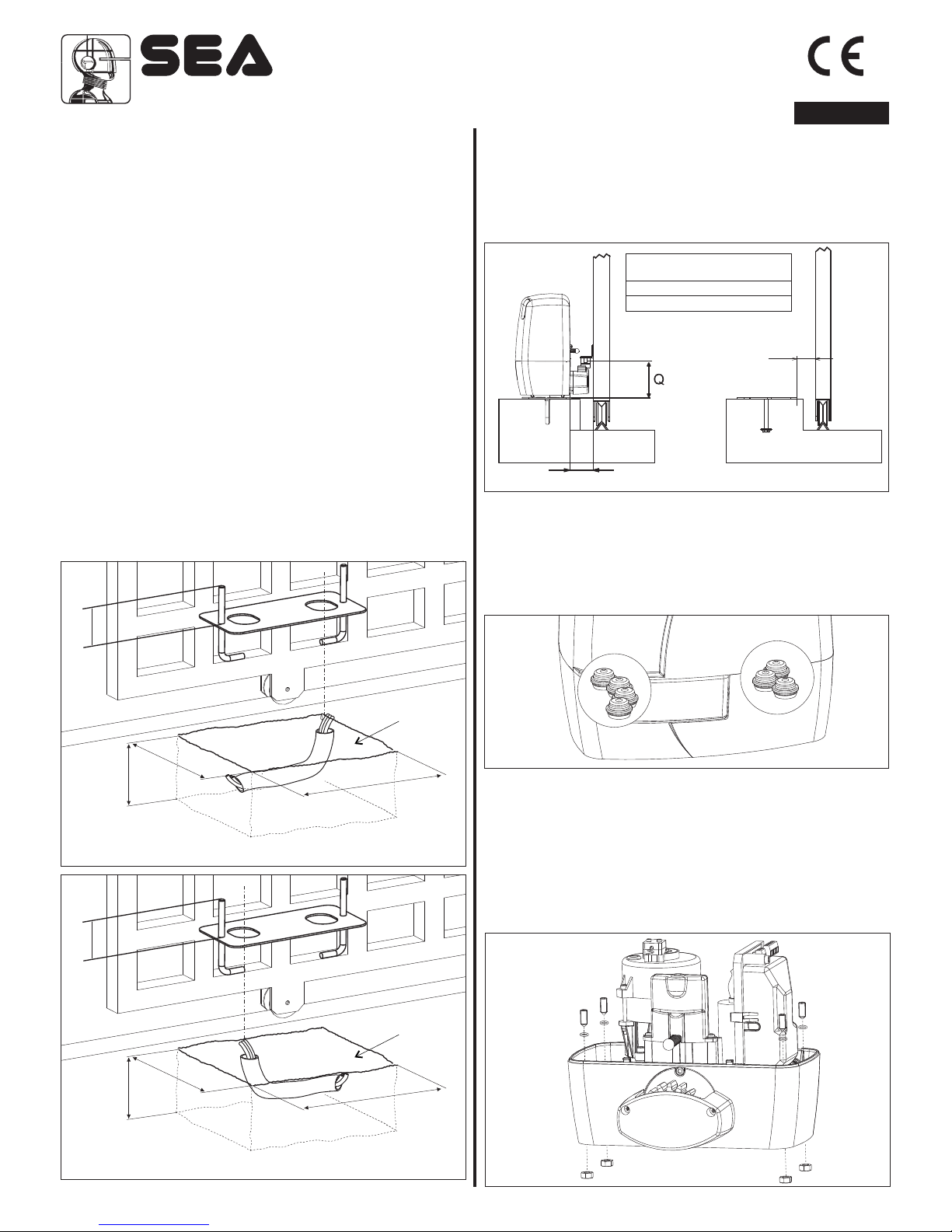

2.2. Before cementing the plate insert a flexible plastic duct of at

least 30mm in diameter into the special hole of the plate.

2.3. Before cementing the plate, make sure that it’s perfectly

leveled and that the distance of 63-68 mm as shown in Fig. 3 is

respected.

Plinth

Fig. 1

DIMENSIONS (mm)ONLY 24V VERSION

Plinth

Fig. 2

DIMENSIONS (mm)ONLY 230V VERSION

4. FITTING OF THE MOTOR

4.1. Insert the 4 grub screws into the special holes for the

adjustment of the motor height on the plate (Fig. 5).

At the end of installation check if the 4 grub screws are well

gripped on the foundation plate.

4.2. Fix the motor on the foundation plate with the 2 included

nuts, adjusting the side position (Fig. 6) so to respect the shown

quota in (Fig. 3).

1. GATE ARRANGEMENT

Before starting the installation check if all the gate parts (fixed

and mobile) have a strong and as less as possible deformable

structure, also make sure that :

a) The leaf is rigid and compact;

b) The inferior slideway is perfectly straight, horizontal and

without any obstacles which could obstruct the gate sliding;

c) The inferior sliding wheels are equipped with greasable or

water tightened bearings;

d) The superior slideway has been produced and placed in the

manner that the gate is in a perfect vertical position;

e) Mechanical stops are always installed in order to avoid

possible derailment of the leaf.

2. FOUNDATION PLATE ANCHORING

For the installation of the foundation plate you have to:

2.1. Prepare a concret basement with the dimensions shown in

Fig. 1 (only Mercury 24V) and Fig. 2 (only Mercury 230V) where

the foundation plate and the anchoring bolts will be cemented.

NOTE: It is recommended (gate structure permitting) to lift the

foundation plate about 50 mm from the ground, in order to avoid

eventual water stagnation.

Fig. 4

67411230

3. CABLES PASSAGE ARRANGEMENT

Mercury is provided with seven holes for electric cables

passage.

Important: Always run mains carrying cables (230V ~) inseparate

holes to low voltage cables ( 24V) Fig. 4.

ENGLISH

8

150

0

4 2

250

150

420

250

Fig. 3

Z16

Z20

100 mm

108 mm

62 mm

63-68 mm

MINIMUN DIMENSION Q

Fig. 5

77

7

7

REV 01 - 05/2012

Loading...

Loading...