SEA MARK TANK E 270,MARK TANK E 390 Installation Manual And Security Information

®

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

EnglishEnglish

EspanolEspanol

HYDRAULIC OPERATOR FOR SWING GATE

ACTUADOR OLEODINAMICO PARA CANCELAS ABATIBLES

MARK TANK E

270 - 390

67410019

INSTALLATION MANUAL

and Security Information

MANUAL DE INSTALACIÓN

y informaciones de seguridad

REV 00 - 07/2013

®

MARK TANK E

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

EnglishEnglish

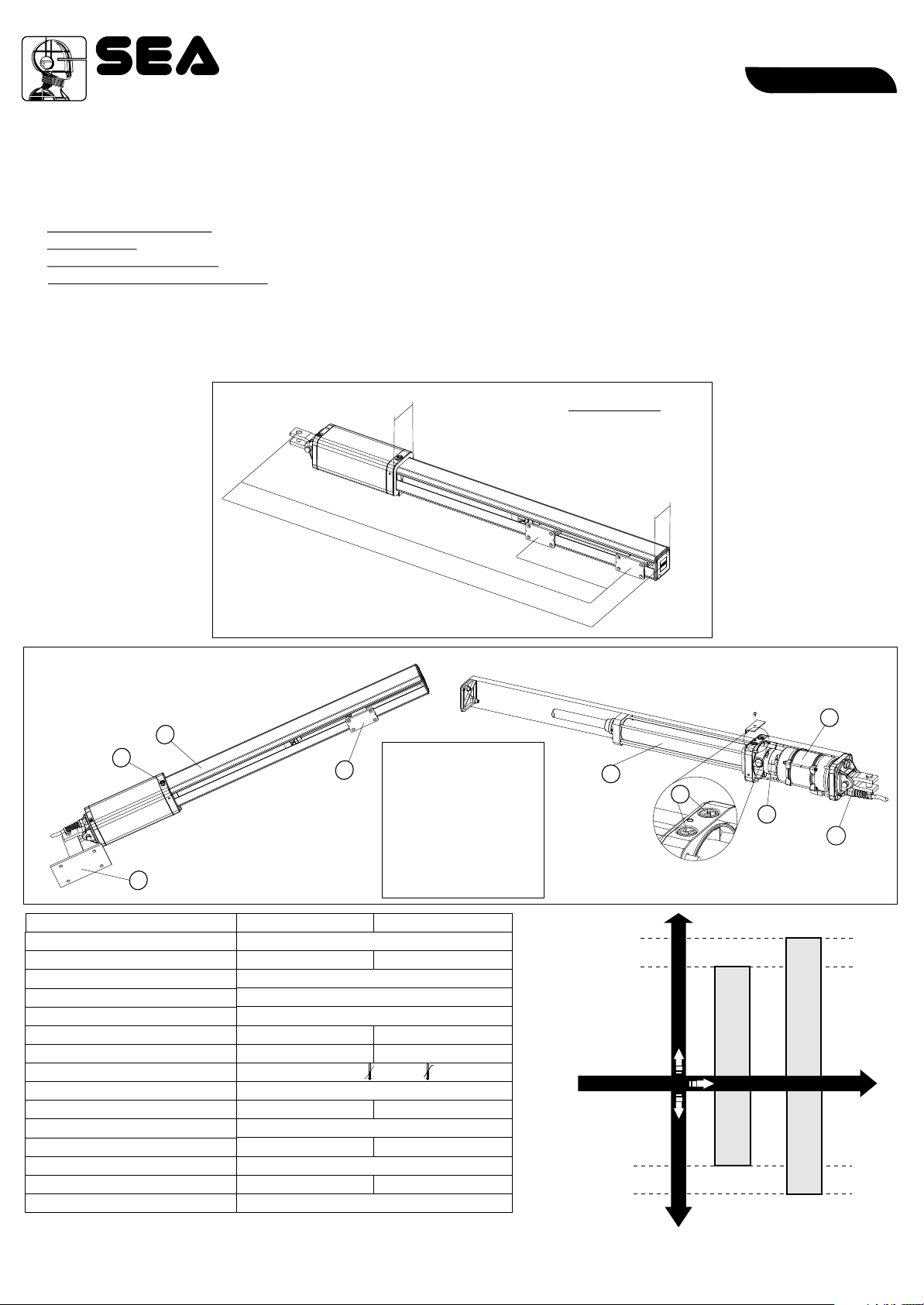

FEATURES AND SPECIFICATIONS

The MARK TANK E 270 and MARK TANK E 390 are two high quality hydraulic operators for residential and condominium use with

leaf length up to respectively 3 and 5 m.

Available in the following versions:

SC (with lock only in closing)

SB (without lock)

SA (with lock only in opening)

AC (with lock in opening and closing)

The lock is guarantied on leaves with lengths under 1,80 m with the MarkTank E 270 operator while for lengths up to 2.20 m use the

Mark Tank E 390. An electric lock should be used for leaves (in all versions) exceeding those lengths.

The Mark Tank E is supplied with by-pass valves for the power regulation in both opening and closing. Electronic adjustable slow

down in opening and closing with electronic control board. For the European laws and directives actually in force it is strongly

recommended to use the Safety Gate (device for the reading of the gate position), for reverse in case of obstacle.

Fig. 1

0 9

Dimensions (mm)

7 0

90 09 / 123

10

/ 129050

Fig. 2

1

2

4

TECHNICAL FEATURES

Power supply

Power

Absorbed current

Stroke

Rod speed

Cycles hour (at a temp. of 20°C)

Max working pressure

Operating temperatures

Thermal protection

ax Thrust

M

Capacitor

Weight

rotection class

P

Max leaf lenght

Opening degree of the leaf

3

MARK TANK E 270 MARK TANK E 390

230 V (±5%) 50/60 Hz

180 W 220 W

40 50

30 bar 40 bar

-40°C +60°C

250 daN 640da N

10,5 kg 12 kg

3 m 5 m

90° - 110°

1. Shaft cover

2. release

3. Front bracket

4. Rear bracket

5. Cylinder

6. By-pass valves

7. Electric motor

8. Hydraulic pump

9. Exit electric cables

1 A

270 mm

1,2 cm/s

130°C

12,5µF

Ip55

Note: The frequency of use is valid only for the first hour at 20°C room

temperature.

2

REV 00 - 07/201367410019

270

/ 390

USING GRAPHIC

OPERATOR MARK TANK E

5

5 m

3 m

40

50

6

Max. leaf length

MARK TANK E 270

OPERATORS

MARK

CICLES/HOUR

8

TANK E 270

7

9

MARK TANK E 390

MARK

TANK E 390

®

MARK TANK E

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

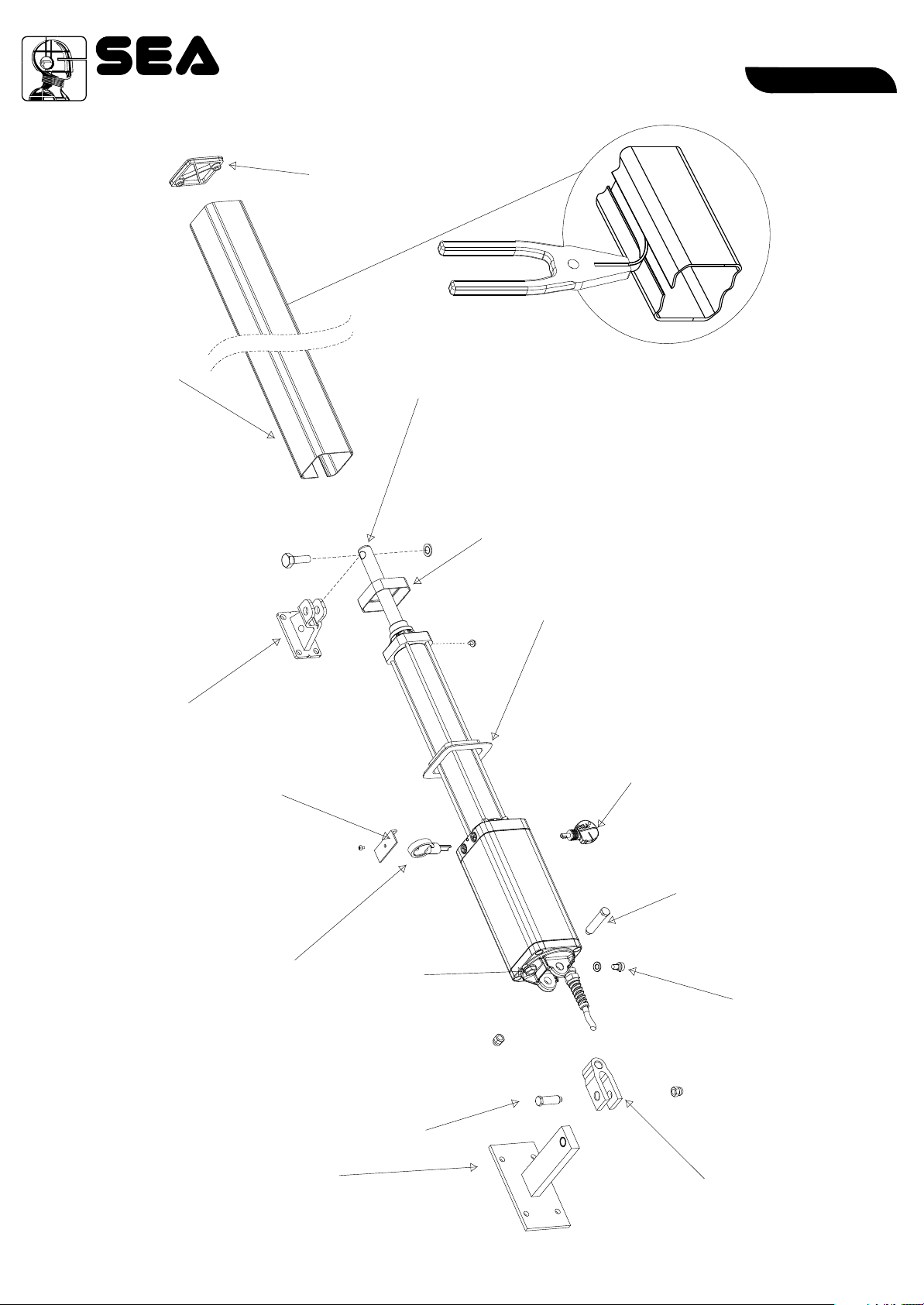

Shaft Cover

EnglishEnglish

End cover

Shaft

Front bracket

By-pass valves

adjustment key

Valve cover

OPTIONAL

(only for installer)

Plastic frame,

Oil fill in cover

anti-vibration (small)

Plastic frame,

anti-vibration (big)

Release key

Brass Pin (long)

Breather screw

Fig. 3

67410019

Rear attachment

Pin rear

attachment

(short)

REV 00 - 07/2013

Clevis Attachment

3

®

MARK TANK E

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

TYPICAL INSTALLATION

11

77

3x1,5

2x1

1010

22

INSIDE

1010

1212

22

3 1 Hx SC .

3x1

11

EnglishEnglish

OUTSIDE

44

58RG

2x1,5

2x1

11

3x1,5

3x1,5

55

2x1

3x1 SCH.

1212

1. MARK TANK E operator

2. Mechanical stop

3. Control board

4. Warning lamp

5. Photocell tx

6. Differential switch 16A-0,03A

7. Photocell rx

8. Key switch start-stop

9. Antenna

10. Column for photocells

11. Warning notice

12. Safety Gate

99

33

66

88

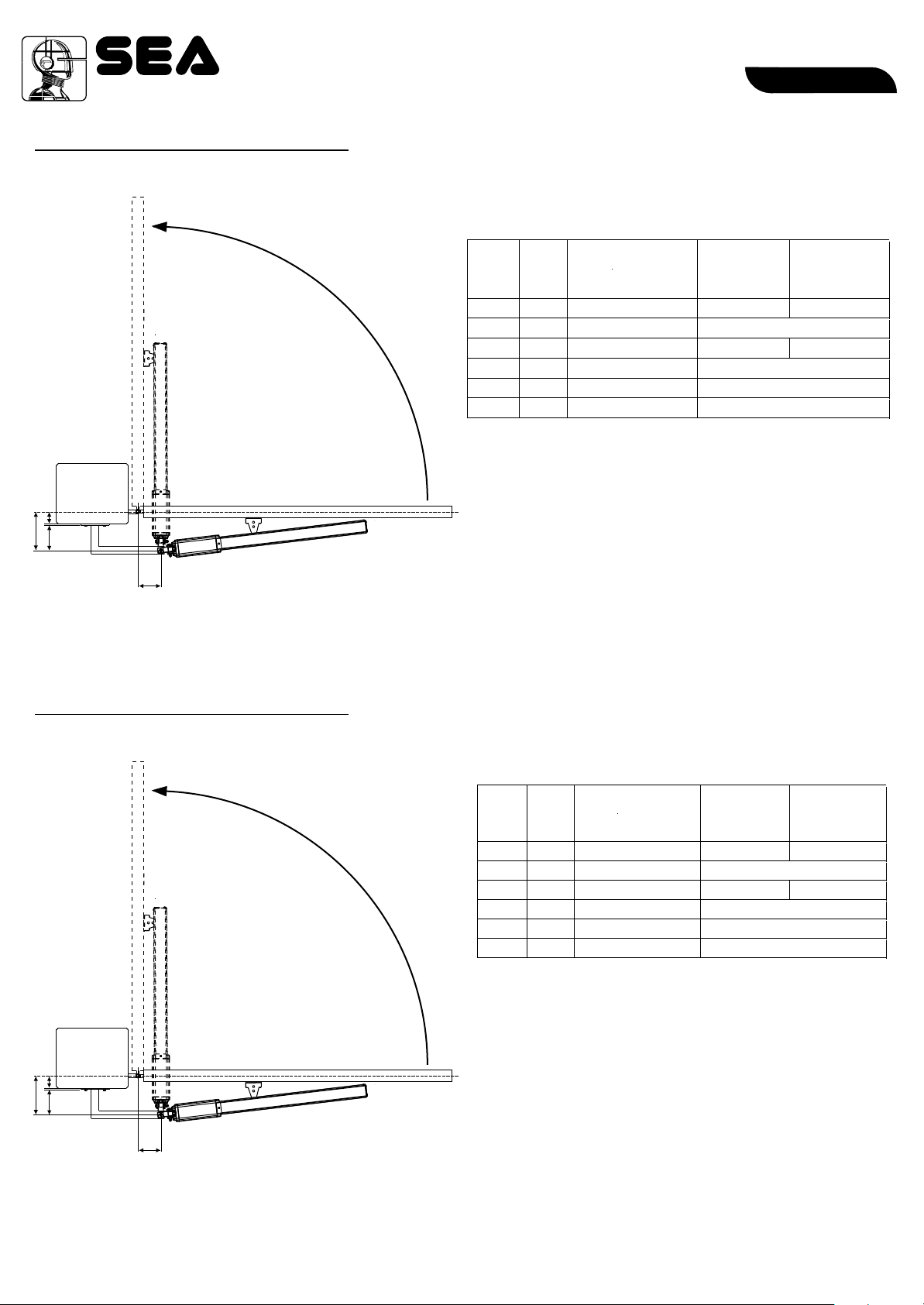

TYPE OF INSTALLATION

It is possible to install the Mark Tank E with opening inside (Fig.4) or opening outside (Fig.5).

Inward installation Outward installation

4

67410019

Outside

inside

Fig. 4

REV 00 - 07/2013

Outside

Install the operator always

inside the property

inside

Fig. 5

®

MARK TANK E

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

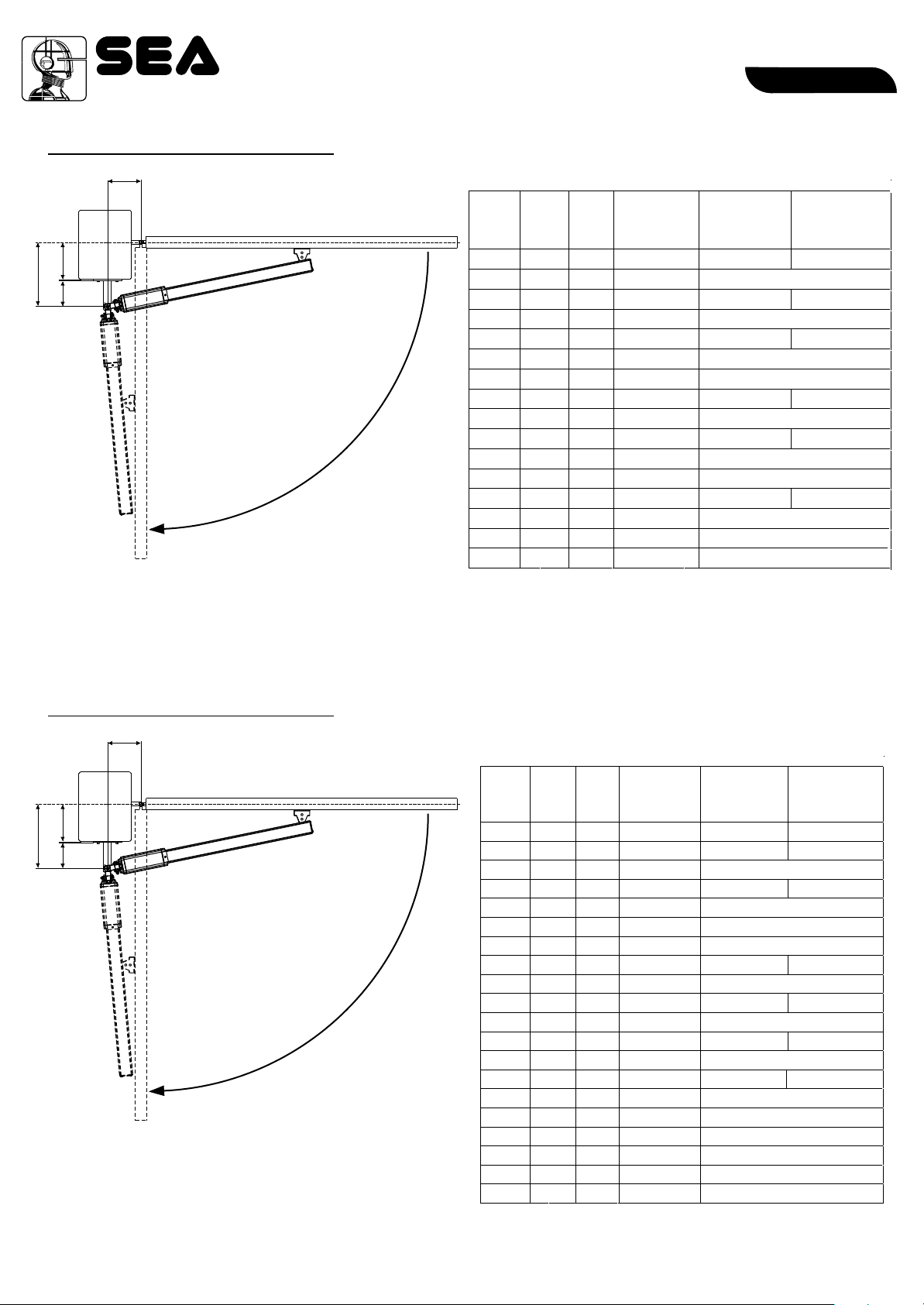

INWARD INSTALLATION

b

outside

d

a

c

Inside

Fig. 6

EnglishEnglish

Total stroke 270 mm - max suggested stroke 250 mm

a b d

(mm)

100

100

105

105

120

120

125

140

140

145

145

150

155

160

170

180

(mm)

115

150

110

145

105

130

125

95

110

95

105

100

85

90

75

65

max

(mm)

50

50

55

55

70

70

75

90

90

95

95

100

105

110

120

130

Opening

Angle

Max

110°

90°

110°

90°

105°

90°

90°

100°

90°

100°

90°

90°

95°

90°

90°

90°

Max stroke

(mm)

250

246

250 235

255 240

249 240

Stroke

for 90°(mm)

215

250

215

250

249 225

250

250

250

250

250

250

248

247

To obtain 110° with d > 55 mm make a recess in the gate.

INWARD INSTALLATION

b

Total stroke 390 mm - max. recommended stroke 370 mm

outside

(mm)

d

a

c

Fig. 6 bis

Inside

To obtain 110° with d > 55 mm make a recess in the gate.

a b d

(mm)

125

130

140

145

145

160

175

185

185

195

195

240

240

250

250

260

260

270

280

295

170

170

235

165

230

210

195

145

190

140

175

110

125

105

115

95

100

90

80

65

max

(mm)

75

80

90

95

95

110

120

130

130

140

140

185

185

195

195

205

205

215

230

245

Opening

Angle

Max

125°

125°

90°

120°

90°

90°

90°

110°

90°

110°

90°

100°

90°

95°

90°

95°

90°

90°

90°

90°

Max stroke

(mm)

368

372

372

370 330

371

370

370

369

for 90°(mm)

370

370

370

370

370

370

370

370

370

370

370

369

Stroke

295

300

310

355

355

360

365

67410019

REV 00 - 07/2013

5

®

MARK TANK E

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

OUTWARD INSTALLATION

outside

d

a

c

Fig. 7

EnglishEnglish

Total stroke 270 mm - max suggested stroke 250 mm

a b

(mm)

150

160

165

175

180

180

(mm)

90

90

80

80

70

65

Max

Opening

Angle

95°

90°

95°

90°

90°

90°

Max stroke

(mm)

250

249

Stroke

for 90°(mm)

240

250

243

250

250

241

b

inside

OUTWARD INSTALLATION

outside

Fig. 7 bis

Total stroke 390 mm - max. recommended stroke 370 mm

a b

(mm)

250

255

265

270

275

275

(mm)

100

95

95

90

90

90

Max

Opening

Angle

100°

95°

95°

90°

90°

90°

Max stroke

(mm)

356

345 336

342

330

325

319

Stroke

for 90°(mm)

342

335

a

6

d

c

67410019

b

inside

REV 00 - 07/2013

®

MARK TANK E

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

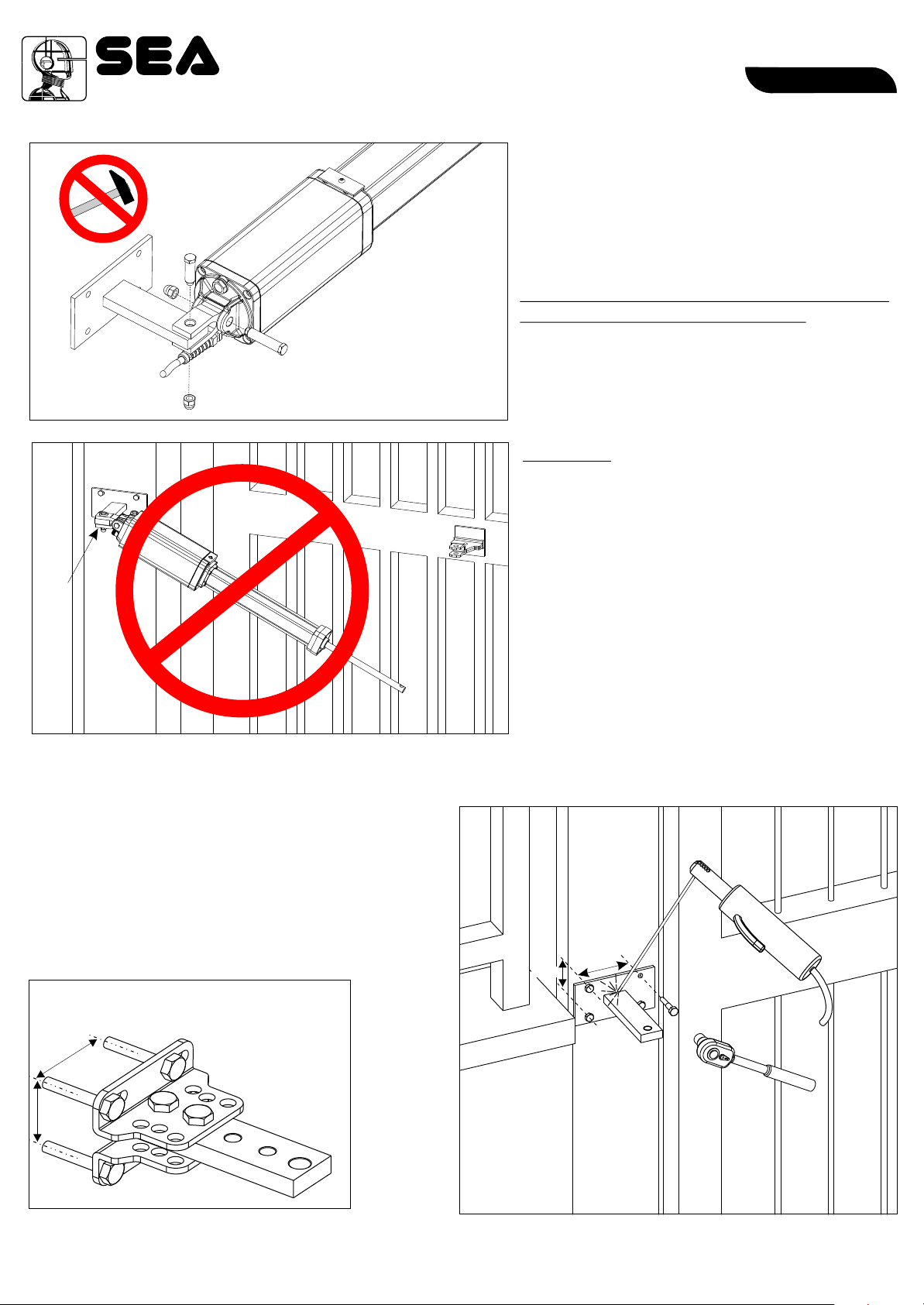

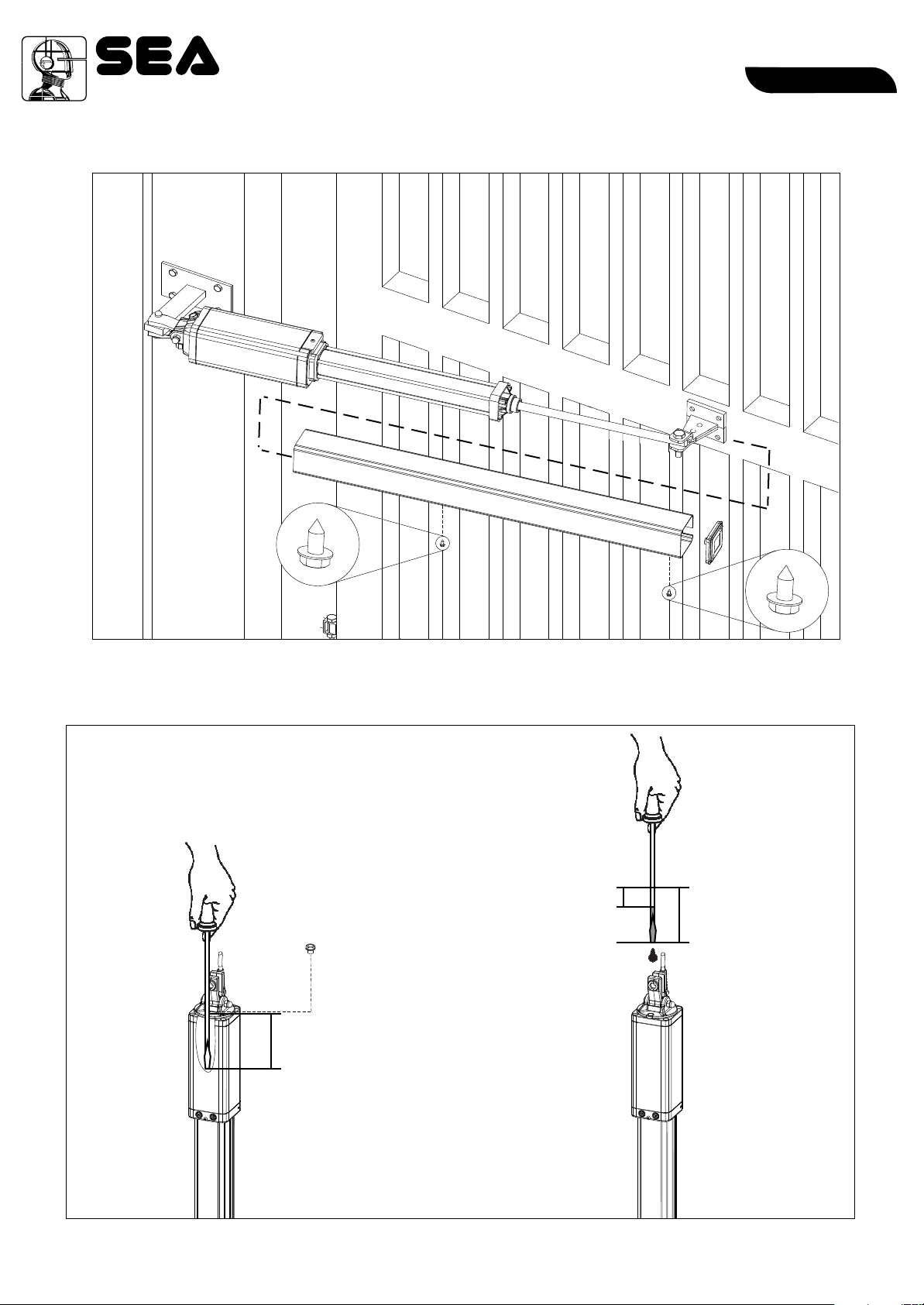

INSTALLATION OF THE OSCILLATING REAR BRACKET

PRELIMINARY

- Open carefully the package, making sure

not to loose parts which are listed in fig. 3

- Attach the rear oscillating bracket as

shown in fig. 9

Attention: Do not use a hammer for the

insertion of the short brass pin; its fitting

into the bracket and clevis attachment must be

done by the simple pressure of the hands.

Fig. 8

Attention: Do not incline the hydraulic

operator further than the allowed angle of the

oscillating bracket (1), risks the possible

braking of it.

EnglishEnglish

(1)

Fig. 9

INSTALLATION OF REAR

BRACKET

According to the type of opening that you have chosen

(inside or outside) and to the chosen leaf rotation (see

page 5-6), the rear bracket must first be cut respecting the

quote “a” on page 5-6 and then welded as in fig. 10.

The support must be positioned so that the operator is

perfectly levelled (Fig. 10, Fig. 12)

Adjustable rear bracket (with screws)

(Accessory on demand)

98 mm

m5 8 m

55 mm

Fig. 11

m65 m

Fig. 10

REV 00 - 07/201367410019

7

®

MARK TANK E

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

EnglishEnglish

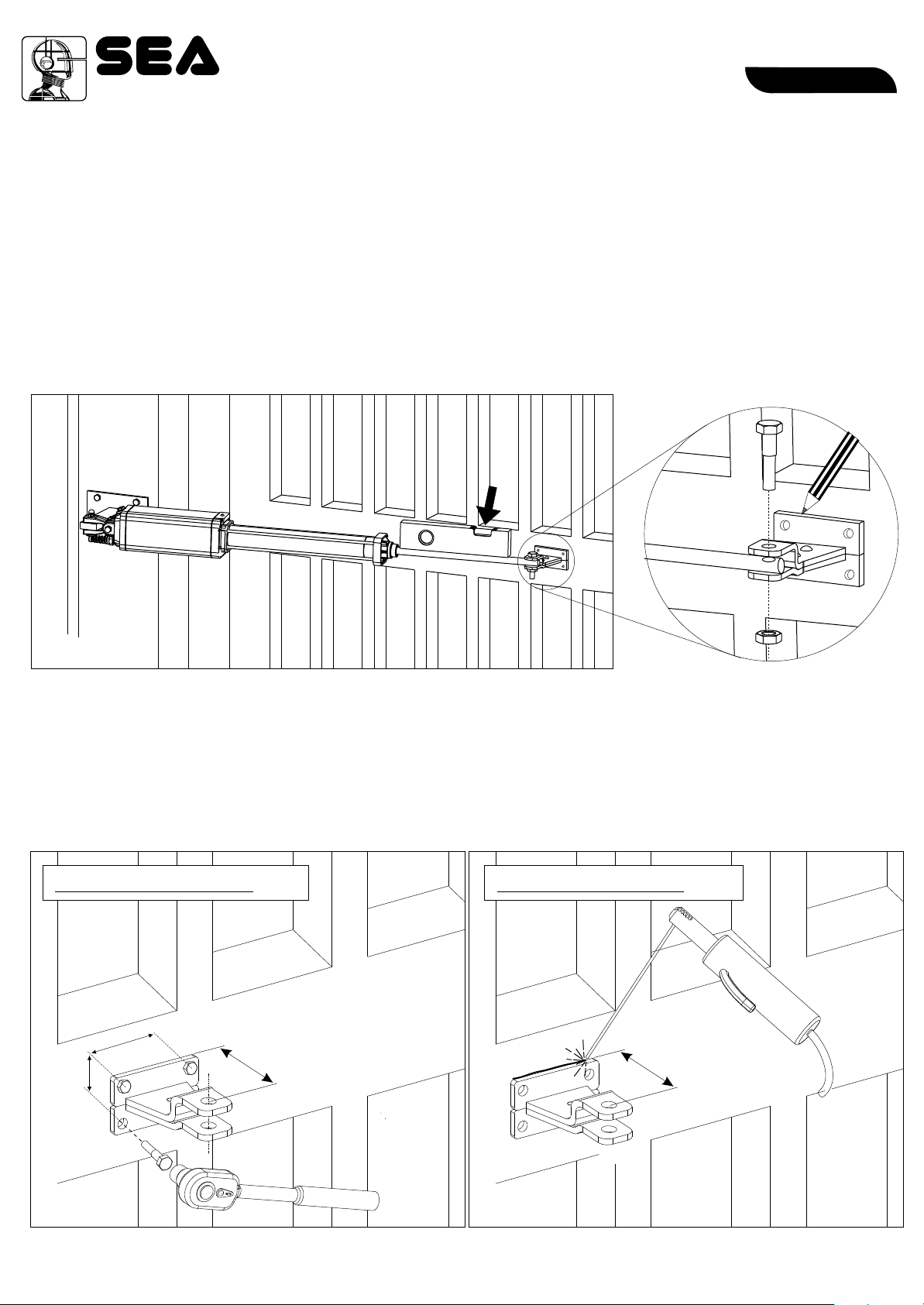

POSITIONING OF THE FRONT BRACKET

Once the operator is attached to the post and the leaf set in the closed position execute the following

operations:

1. Release the operator (as in fig. 25)

2. Pull-out completely the chromate shaft and push it back in 1cm

3. Attach the shaft to the front bracket (Fig. 13)

4. Set the operator perfectly levelled and mark the position of the front bracket (Fig.12)

Attention: avoid the welding of the front bracket to the shaft of the hydraulic operator already attached;

the welding scraps (daps) could ruin the chromium plating of the shaft.

Fig. 12

WELDING OF THE FRONT BRACKET TO THE GATE

The front bracket must be positioned so that the operator is perfectly levelled

According to the nature of the gate the front bracket (wood, steal, Aluminium) can be:

Front bracket welded Front bracket screwed

m

3,5 m

6

46 mm

70 mm

70 mm

Fig. 13

Fig. 14 Fig. 15

8

REV 00 - 07/201367410019

®

MARK TANK E

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

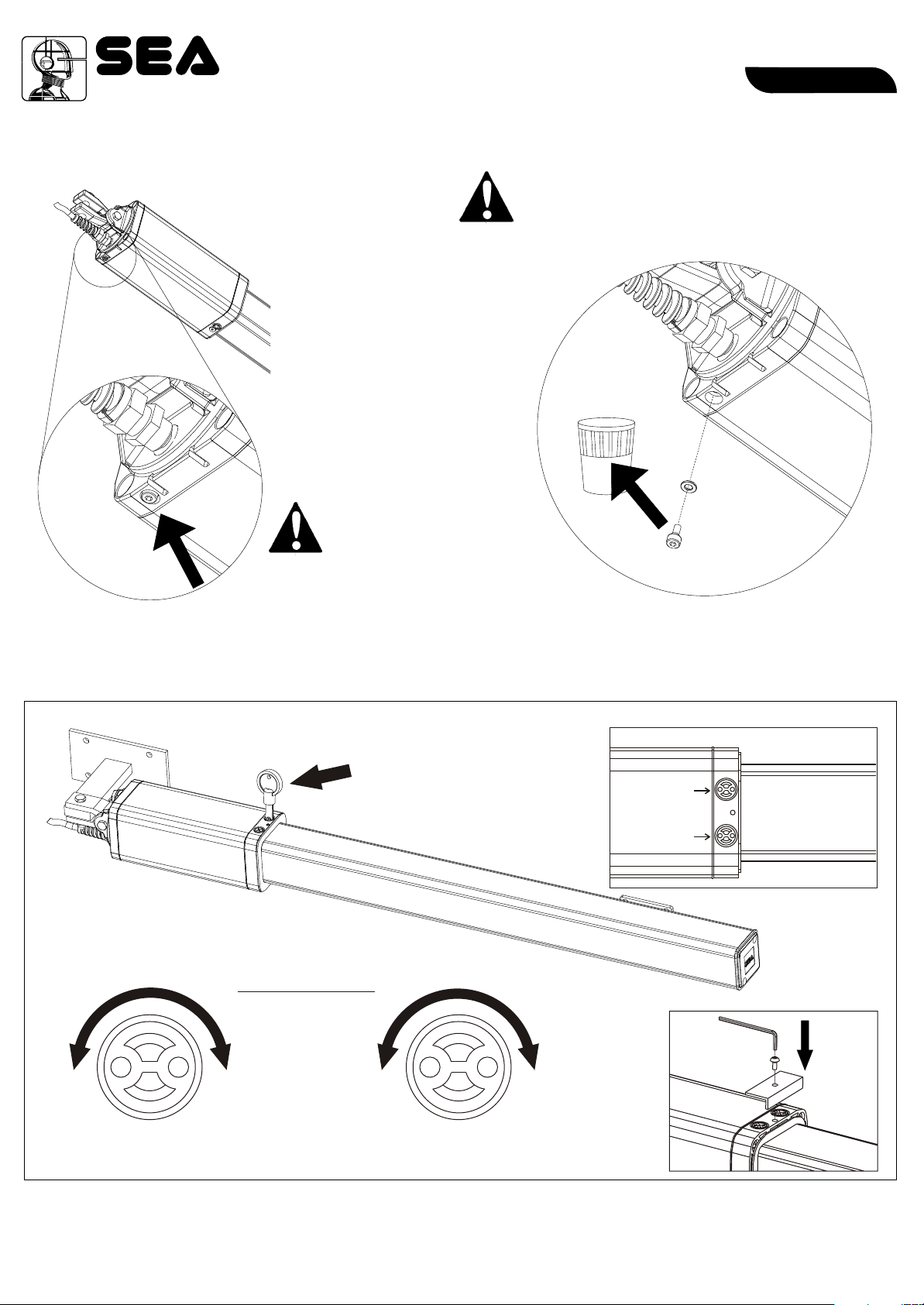

BREATHER SCREW

Fig. 16

ATTENTION

It is obligatory to remove the breather

screw at the end of the installation.

Unscrew and remove

the screw under the

operator at the end

of installation

EnglishEnglish

Fig. 17

TORQUE ADJUSTMENT (by pass valves)

Acting on the by-pas

valves, it is possible to

adjust the operator

pressure in the opening

and closing process.

Fig. 18

Down

s

u

s

r

e

e

r

p

g

n

i

t

a

r

e

p

O

i

n

By-Pass Valves

o

p

e

n

i

n

g

i

t

a

r

e

p

O

s

s

u

e

r

r

p

g

n

e

i

n

c

+-

Grey

Yellow

Up

l

o

s

i

Fig. 19

Grey

Up

Yellow

n

g

Fig. 20

+-

Adjust the opening and closing forces of the gate so that the diagram of the force is respected (present in the regulation

EN 12453); Anyway the max. thrust force should never be superior of 15 KgF.

67410019

REV 00 - 07/2013

9

®

MARK TANK E

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

INSTALLATION OF THE CHROME PLATED SHAFT COVER

EnglishEnglish

Fig. 21

OIL LEVEL MEASUREMENT

8,5

3,5

Insertion into

4,5

the motor (cm)

10

67410019

Fig. 22

REV 00 - 07/2013

Loading...

Loading...