SEA LYRA,JACK 400,JACK 800,JACK 1200 Fitting And Connection Instructions

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Italiano

English

Français

Español

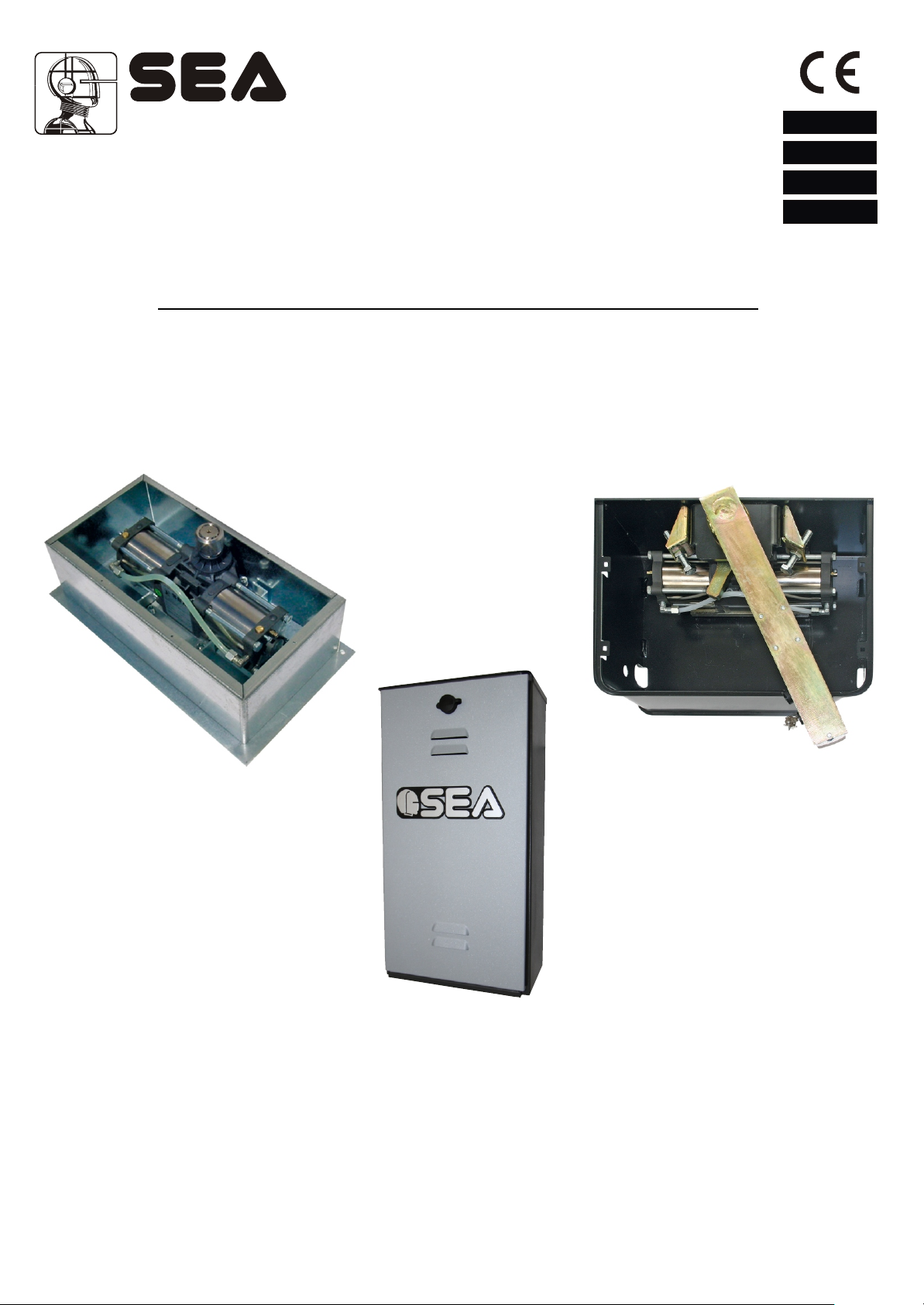

LYRA, JACK 400/800/1200

Operatore oleodinamico interrato

Underground hydraulic operator

Opérateur hydraulique enterré

Actuador oleodinámico enterrado

JACK

JACK

CASSA PORTANTE

CARRYING BOX

LYRA

SEA S.p.A.

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

www.seateam.com

67411740

seacom@seateam.com

REV 01 - 03/2015

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

LYRA

JACK 400 (with and without slowdown)

JACK 800 (with and without slowdown)

JACK 1200 (with and without slowdown)

FITTING AND CONNECTION INSTRUCTIONS

ENGLISH

The LYRA JACK consists of a hydraulic pump and a hydraulic

jack. The jack is placed inside a non carrying or carrying box

(inox only for carrying box).

The pump unit casing, which is used as an oil tank, contains the

electric motor, fluid pump, distributor and hydraulic oil. It is also

provided with an adjustable slowing-down device in the two

stop phases of the leaf (versions with slow-down only).

The wheeling unit is composed by a double piston connected to

a rack which engages with the pinion of the leaf dragging shaft.

Gates up to 2 meters long can be securely locked using the

operators internal hydraulic locking system, thus ensuring

perfect keeping in closing and in opening. For gate in excess of

stated value: A hydraulic non locking operator should be used in

conjunction with a separate electrical locking device to ensure

keeping in closing.

On the operators with hydraulic slow down it is present

only during the last 15° of rotation. The system comes with a

release which allows the manual opening of the leaves in case of

power failure.

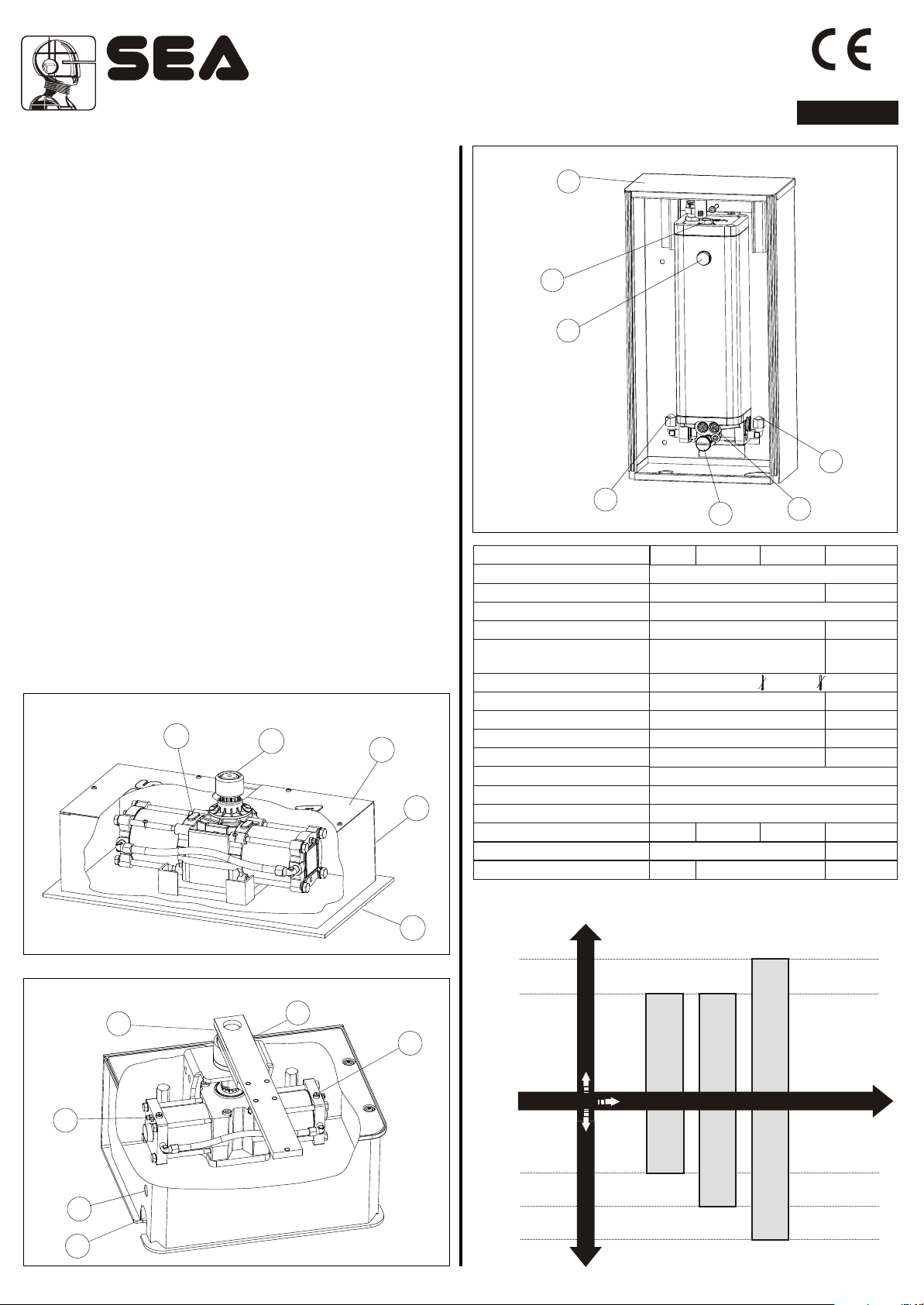

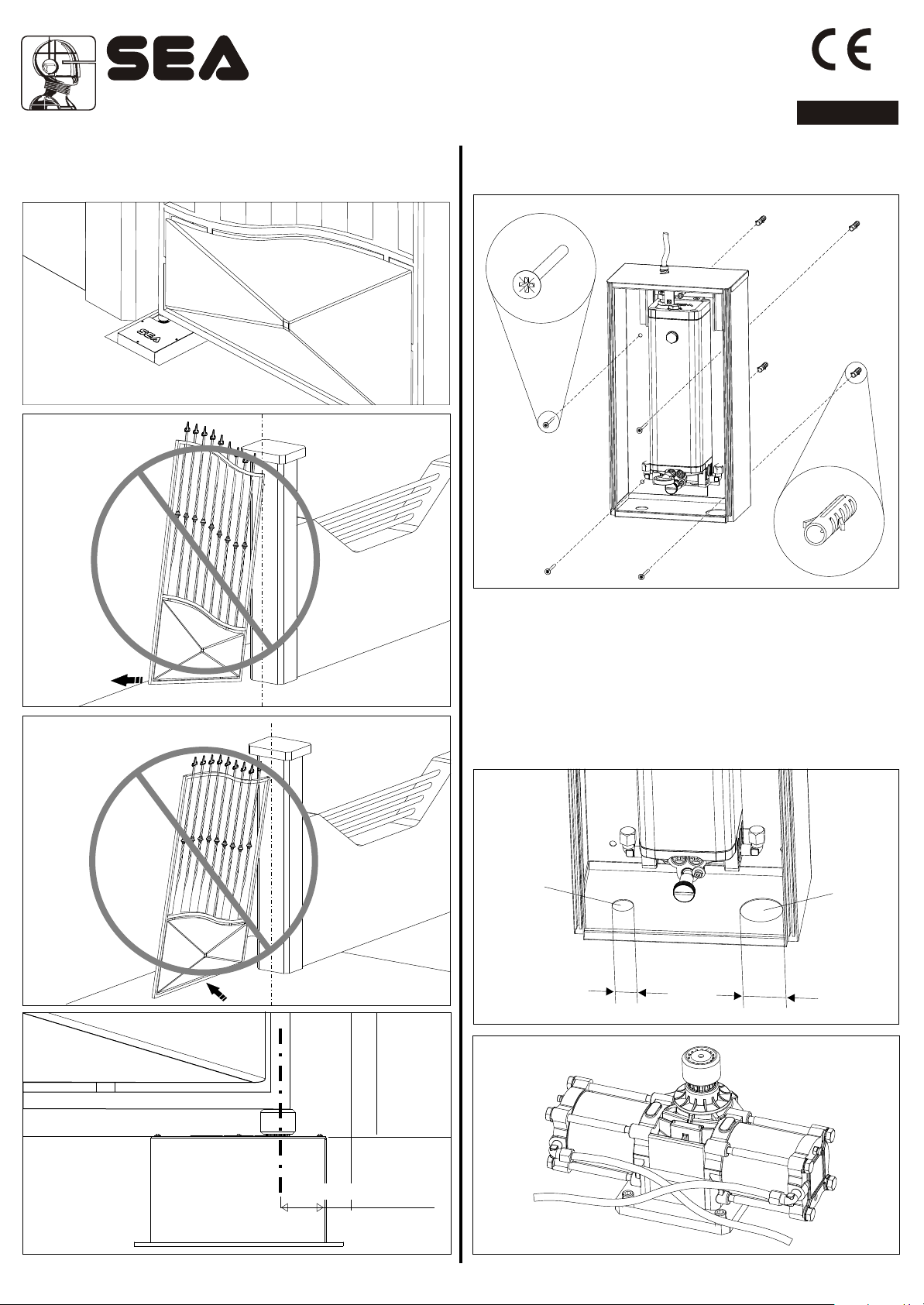

MAIN PARTS NOMENCLATURE

1 Jack

2 Broached bush

3 Box lid

4 Box

5 Foundation base

6 Braking screw

adjusting

(where provided)

7 Exit hole for electric cables

8 Water draining hole

9 Air bleed screw

Greaser

10

Crank

11

12 Hydraulic unit box

13 Oil charge cap

Oil level cap

14

15 Hydraulic plug

16 Release screw

17 By pass valves

NON-CARRYING BOX

1

2

3

4

5

Fig. 1

LYRA HYDRAULIC UNIT

12

13

14

15

15

Fig. 3

TECHNICAL DATA

Power supply

Motor Power

Motor rotation speed

Angular speed

Cycles hour

(with a 20°C temp.)

Operating temperature

Thermal protection intervention

Max torque

Starting capacitor

Pump capacity

Hydro slowdown

Weight

Protection class

Maximum weight of the gate

Max. leaf length

Jack rotation angle

16

Jack 400 Jack 800 Lyra

230 Vac 50/60 Hz

220W

45

-20°C +55°C

130°

56 da N

12,5 µF

0,5 L

SI 15° AP/CH (If present )

-

100° - 140° - 180°

17

1400 rpm

8 Kg

IP67

800 kg400 kg-

Jack 1200

310W

8,2° / s7° / s

60

150°

75 da N

10 µF

1,5 L

1200 kg

5 m4 m

100°

Note: The frequency of use is valid only for the first hour at 20°C

room Temperature.

5 meters

CARRYING BOX

11

9

7

8

10

6

Fig. 2

REV 01 - 03/201567411740

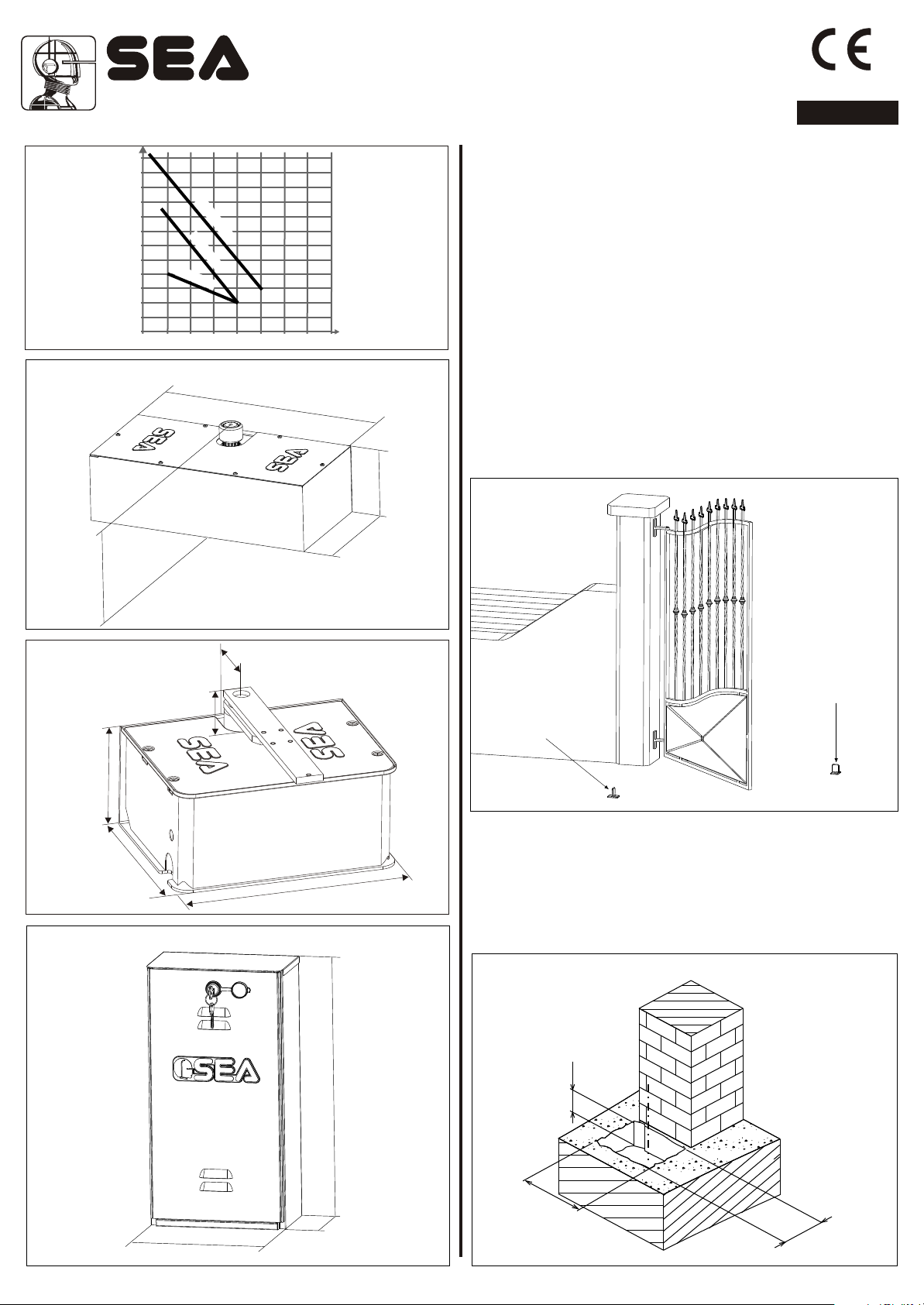

GRAPHIC FOR THE USE OF

4 meters

400 kg

800 kg

JACK 400 - 800 - 1200 OPERATORS

1200 kg

Max leaf width

Max leaf weight

JACK 400

Underground hydraulic operators

JACK 400

JACK 800 JACK 800

JACK 1200 JACK 1200

13

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

ENGLISH

Weight kg

1200

1100

1000

900

800

700

600

500

400

300

200

100

0

0 2 2,5 3

NON-CARRYING BOX

152

Fig. 4

GRAPHIC (A)

A

K 0

1

2

0JC

JACK

800

J

A

CK

40

0

1. GATE ARRANGEMENT

You must do some checks on the gate to see if fitting a LYRA,

JACK system is possible:

A. (Make sure that) the fixed and moving parts of the gate are

strong and non-deformable;

B. the weight of each gate leaf must not exceed 400 kg (Jack

400), 800 kg (Jack 800), 1200 kg (Jack 1200) see the graphic

(A);

C. the hinges and general structure must be in good condition

4 5 6 7 8

Leaf length M

and the gate must move smoothly throughout its travel;

D. the upper hinge alone is sufficient to install the unit; those

which are unnecessary can be eliminated (the lower and that in

the middle if exists);

E. as the limit switches are not provided within the actuator, it is

40

Dimensions (mm)

0

-

44

0

necessary to install mechanical limit switches stops to be fixed to

the ground in closing and in opening (Fig. 7).

121

202

Fig. 7

400 mm ® 100° - 140°

440 mm ® 180°

CARRYING BOX

188

3

2

0

Fig. 5

LYRA HYDRAULIC UNIT

68

55

Dimensions (mm)

14 0

Dimensions (mm)

401

Limit switch stop

in closing

Limit switch stop

in opening

2. NON-CARRYING BOX INSTALLATION

2.1. The excavation which contains the non-carrying box must

have the approximate dimensions mentioned in Fig. 8. For a

correct placing, it is obligatory to closely follow the quote of 55

mm which corresponds to the minimum distance of the rotation

axis from the pillar.

Dimensions (mm)

160

Fig. 8

Fig. 6

14 67411740

210

121

REV 01 - 03/2015

60

0

0

0

3

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

ENGLISH

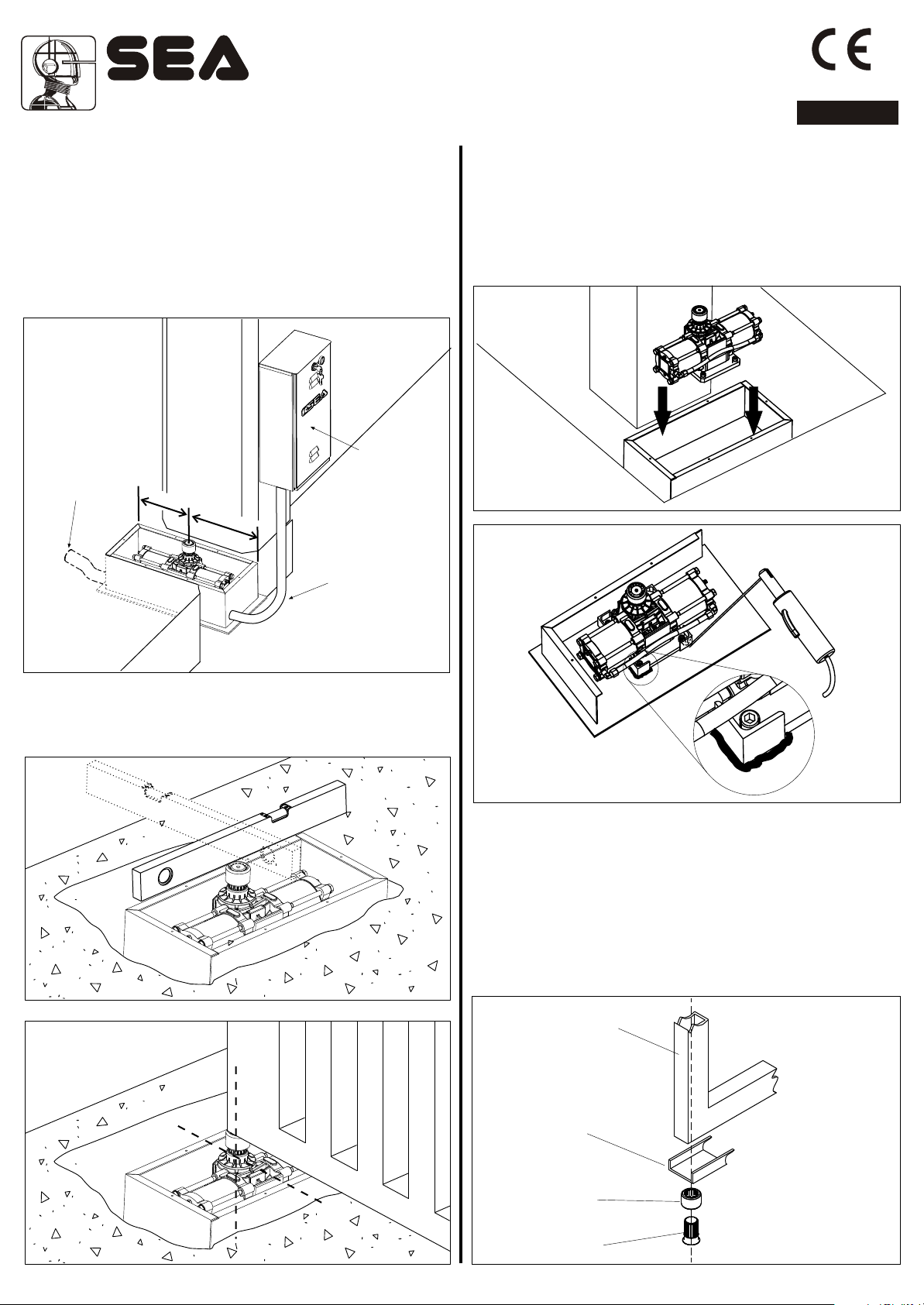

2.2. Inside the excavated pit you have to plan:

- rain water drainage;

- a water waste pipe in flexible plastic of about 40 mm of

diameter to put inside the provided hole of the box before it is

concreted (Fig. 9). It must be brought to the drain of the

sewer line;

- a sheath for the passage of the hydraulic tubes of about 32

mm of diameter which must be brought to the proximity of the

hydraulic unit box (Fig. 9).

Flexible pipe

for water

draining

=

Hydraulic unit

=

Hydraulic tubes

sheath

3. INSTALLATION OF THE OPERATOR

INSIDE THE NON-CARRYING BOX

3.1. Place the jack inside the foundation box (Fig.12)

positioning the axis of the output shaft aligned with the axis of

the hinge of the gate and weld the four angular ends to fix the

same (Fig. 13).

Fig. 12

Fig. 9

2.3. Before concreting the box, use a level to make it perfectly

horizontal to the ground (Fig. 10) and perpendicular to the axis of

the gate (Fig. 11).

Fig. 10

Fig. 11

Fig. 13

4. MOUNTING OF THE LEAF ON NONCARRYING BOX

4.1. Insert the broached bush on the shaft of the jack.

Turn the shaft of the jack toward closing until it stops.

WARNING: For operators with brake make sure that the jack

has reached the stop and not the beginning of the

slowdown.

4.2. Go back about 5° and weld the bush to the U-shaped bar

(not supplied) and to the leaf of the gate (Fig. 14).

Leaf

67411740

REV 01 - 03/2015

U-shaped bar

Bush

Pivot

Fig. 14

15

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

ENGLISH

4.3. Be careful not to place the leaf outside the axis (Fig. 16

and 17) and make sure that the shaft corresponds to the

rotation axis of the jack.

Fig. 15

5. HYDRAULIC UNIT BOX WALL

INSTALLATION (Fig.19)

Fig. 19

Fig. 16

Fig. 17

5.1. Connect the hydraulic tubes with the hydraulic unit and the

jack (Fig.21, Fig.22, Fig.23).

After having installed the box, the gate and the operator, try to

slowly move the gate by hand to make sure that there are no

irregular frictions and that the movement is uniform for the whole

range.

Notice: To do this last operation, release the operator as

described in the related paragraph.

Cable

inlet

Hydraulic

tubes

inlet

Fig. 20

20

40

Fig. 18

16 67411740

55 mm min.

Fig. 21

REV 01 - 03/2015

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

ENGLISH

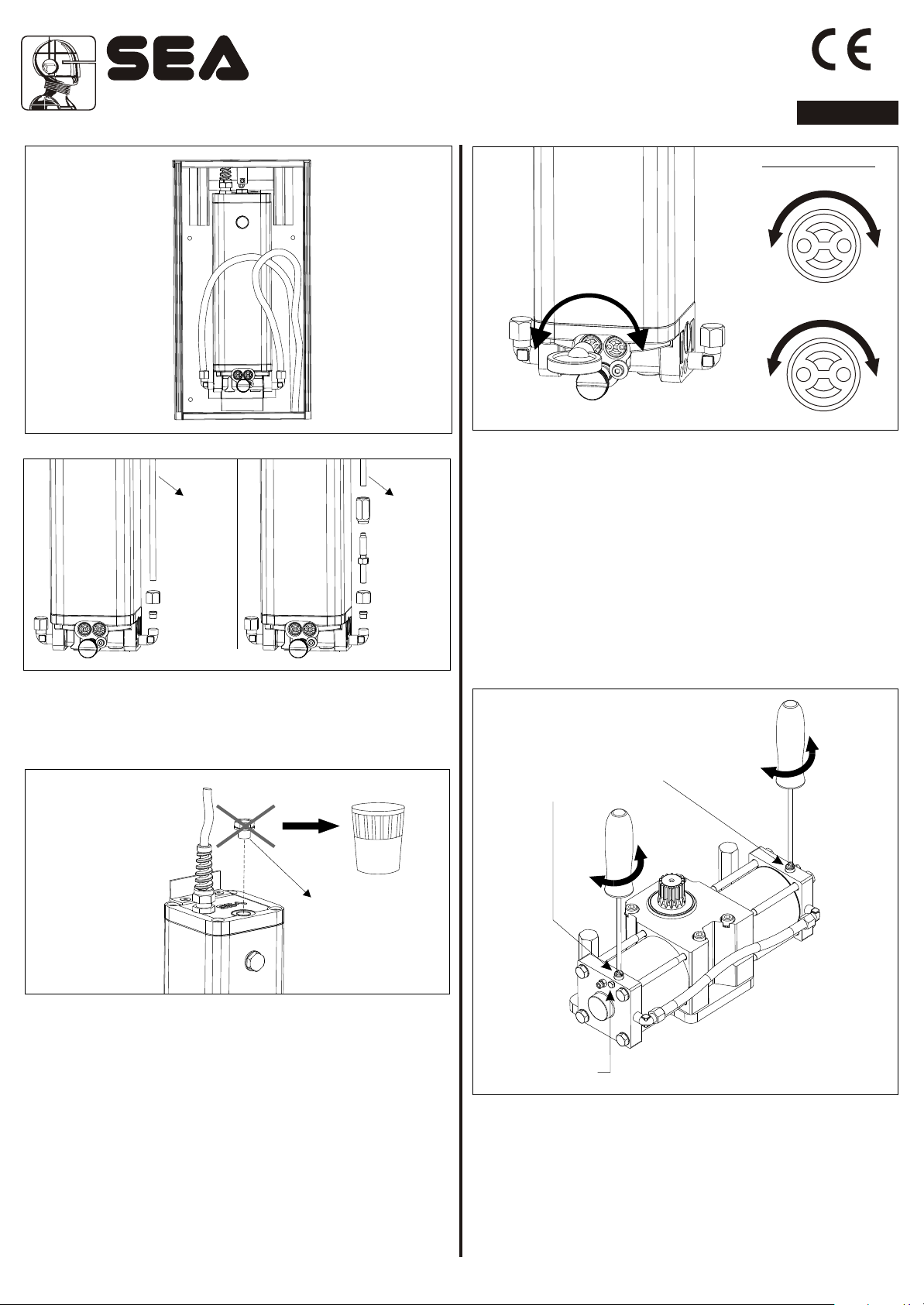

By-Pass Valves

e

n

m

t

t

s

i

u

n

j

d

a

e

c

r

o

F

o

p

e

n

i

n

g

+-

Grey

e

m

t

n

s

t

u

i

j

n

d

a

e

c

r

o

F

c

l

o

s

i

n

g

Fig. 22

Copper

tube

Fig. 23

Flexible

tube

6. BLEED CAP REPLACEMENT (Fig.24)

Remove the red cap and replace it with the supplied black one

after startup.

-

Fig. 25

+

Yellow

+-

8. BRAKING REGULATION (where present)

8.1. It is possible to regulate the leaf slowdown in opening and in

closing, through the braking adjusting screw (Fig. 26).

8.2.To regulate slowdown operate as follow:

- Loosen the blocking screw of braking regulation;

- Act on the adjusting screw clockwise to have a higher braking

and a speed decrease;

- Act on the adjusting screw anti-clockwise to have a lower

braking and a speed increase;

- After the regulation fix the blocking screw of braking regulation.

On the operators with hydraulic slow down it is prensent

only during the last 15° of rotation.

-

Braking regulation screw

Opening/closing

+

Red cap

Fig. 24

7. FORCE ADJUSTMENT

If necessary the thrust force of the leaf can be adjusted by the

two adjusting screws (grey and yellow) placed on the front lower

place of the hydraulic pump unit (Fig. 25).

*The operator is adjusted at 15 Kg force ex works so to

guarantee the anti-crush safety.

We recommend to adjust it only in case of necessity.

67411740

REV 01 - 03/2015

-

+

Blocking screw for

braking regulation

9. BLEEDING OPERATION

During the connection phase between hydraulic unit and jack, air

will inevitably enter into the system and cause an irregular

operation of the operator. The irregular operation shows by an

abnormal movement of the leaf and excessive noise during

operation. To solve this problem it is necessary to proceed as

follows:

Fig. 26

17

Loading...

Loading...