SEA LEPUS 800,LEPUS Series,LEPUS 2000,LEPUS 1800 Fitting And Connection Instructions

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

LEPUS

FITTING AND CONNECTION INSTRUCTIONS

ENGLISH

LEPUS is an oil-bathed motor-reducer created for sliding

gates automation. The motor-reducer irreversibility allows a

perfect and safe gate closing avoiding the setup of an

electrolock and in case of power supply lacking, the release

device which is in the frontal part of the motor-reducer allows the

manual opening and closing. The operator has a mechanical

adjustable clutch which ensures the control of the gate

pushing. Moreover, the electronic reversing device realized

through an encoder makes the lepus motor-reducer a safe and

reliable operator allowing in a simple way to comply with the

current norms in the countries where this product is set up.

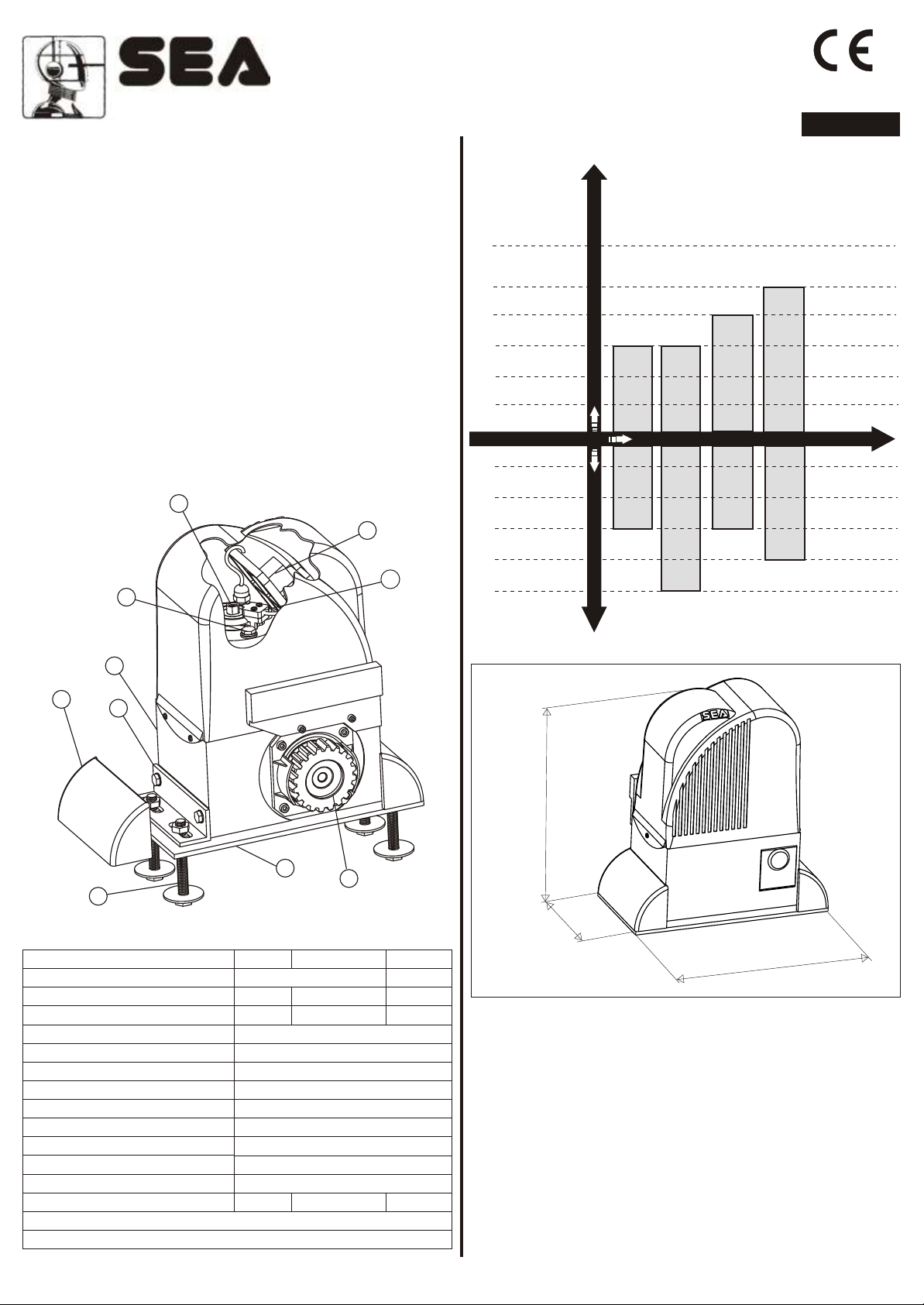

MAIN PARTS NOMENCLATURE

1 Adjustable Foundation plate

2 Anchor bolts

3 Fixing angulars

4 Angular cover

5 Pinion

77

99

6 Lever release reducer

7 Adjusting screw mechanical clutch

8 Electronic control unit

9 Oil filling up cap

10 Magnetic encoder

88

1010

LEPUS MOTOR-REDUCER USING-GRAPHIC

3000 Kg

2000 Kg

1800 Kg

800 Kg

400 Kg

300 Kg

LEPUS 800

LEPUS 800

Oil-bathed motor-reducers

LEPUS 1800

CONTINUO

LEPUS 2000 THREE-PHASE

25%

40%

LEPUS

60%

75%

100%

LEPUS 800

Frequency of use Max gate weight

LEPUS 800 CONTINUO

LEPUS 1800

2000 THREE-PHASE

66

44

TECHNICAL DATA

Power Supply

Power

Absorbed current

Motor rotation speed

Reduction ratio

Room temperature

Thermal protection intervention

Weight of the unit with oil

Oil quantity

Protection rating

Gate speed (pinion Z16)

Gate speed (pinion Z20)

Maximum weight of the gate

Mechanical clutch

Inductive or mechanical limit switch

33

22

230 V (±5%) 50/60 Hz 380V

330W 450W 450W

1,5 A 1,7 A 1,2 A

1/30

15 Kg

800 Kg 1800 Kg 2000Kg

11

800

1400 rpm

-20°C +55°C

130°C

1,75 L.

IP 55

10,5 m/min

12 m/min

1800

DIMENSIONS (mm)

37.54

55

160

2000

325

1. GA TE ARRANGEMENT

The first thing to check is that the gate is in good running order as

follows:

a) The gate is rigid and straight and runs smoothly throughout its

travel.

b) The lower track is in good order , straight and levelled.

c) The lower support wheels have sealed bearings or grease

points.

d) The top guide must be manufactured and installed so that the

gate is perfectly upright.

e) Physical gate stops must be fitted to prevent the gate coming

out of its guides and track.

cod. 67410010

REV 07 - 10/2008

8/40

®

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

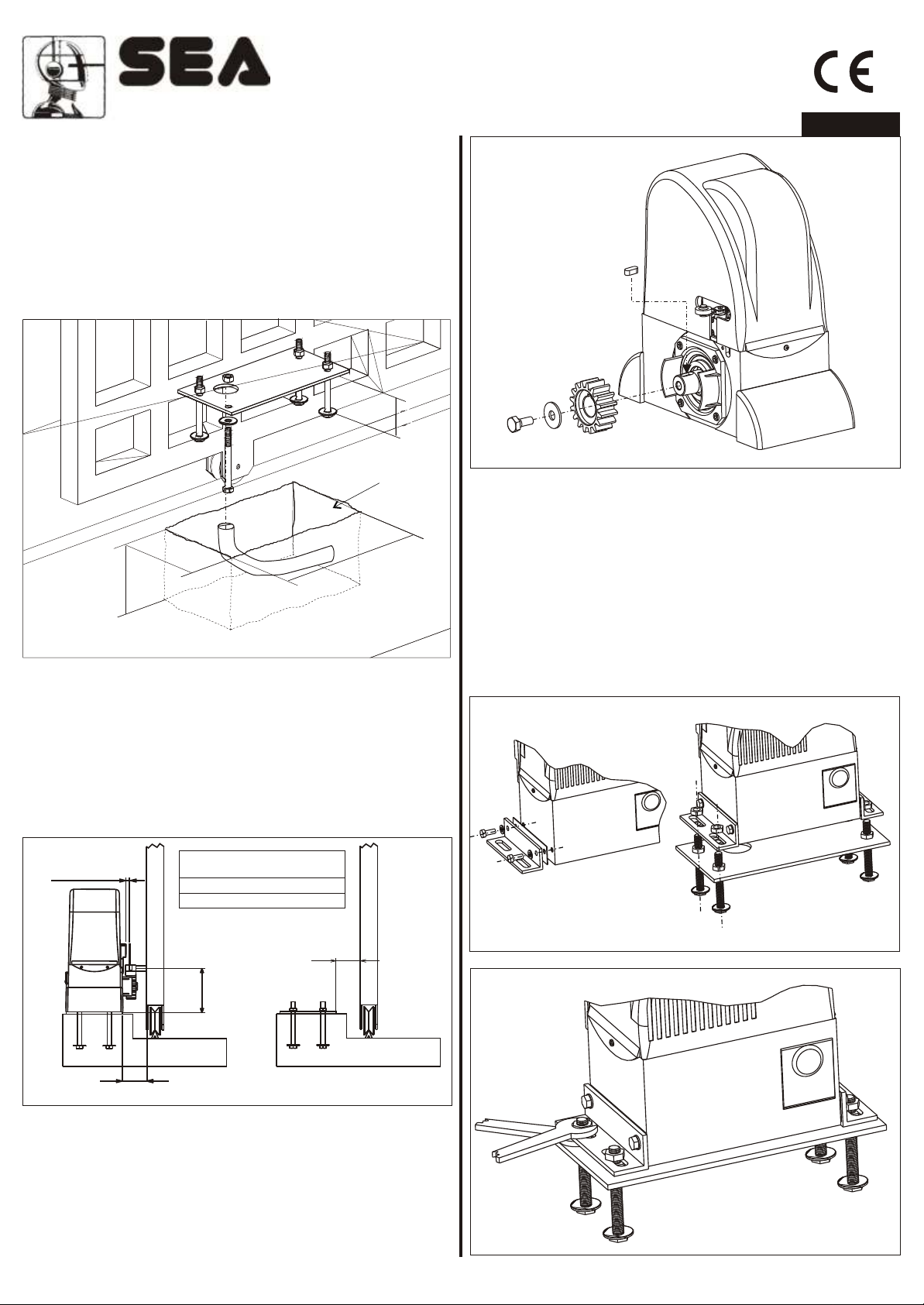

2. MOUNTING PLATE INSTALLATION

T o install the mounting plate it is necessary to:

2.1. Have a mounting plate manufactured to the dimensions

shown in Fig. 1. The plate will require to have concrete holding

into which the foundation plate and the anchor bolts will be

walled up. It is best if the gate structure allows the plate to be

raised up from the finished level by 50 mm. This will stop water

gathering around the operator.

65

Plinth

ENGLISH

Fig. 3

200

350

150

Fig. 1

2.2. When you are concreting in the plate install any necessary

cable ducts (30 mm dia. minimum) and cables in through the

base plate. Cable ducts should have sweep bends not elbow

ones.

2.3. When concreting in the plate check that the plate is perfectly

levelled and that the measurement of 50 - 55 mm given in Fig. 2

is followed.

Max 5 mm

MINIMUM QUOTA Q

Z16

Z20

120 mm

128 mm

50-55

4. FITTING OF THE UNIT

4.1. Fix the side fixing angulars to the motor-reducer with the

provided screws (Fig. 4)

4.2. Fix the motor-reducer to the foundation plate adjusting the

side position and its height (Fig. 4 - Fig. 5) considering the

mentioned measurements in Fig. 2.

4.3. Remove the closing loading oil cap (red) and substitute

it with that supplied apart provided with the airhole (black).

Fig. 4

Q

55-60

Fig. 2

3. PINION ASSEMBLING

3.1. Put the spline into the motor reducer shaft as in Fig. 3.

3.2. Assemble the pinion to the motor reducer fixing it with the

provided bolt (Fig. 3).

cod. 67410010 9/40

REV 07 - 10/2008

Fig. 5

®

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

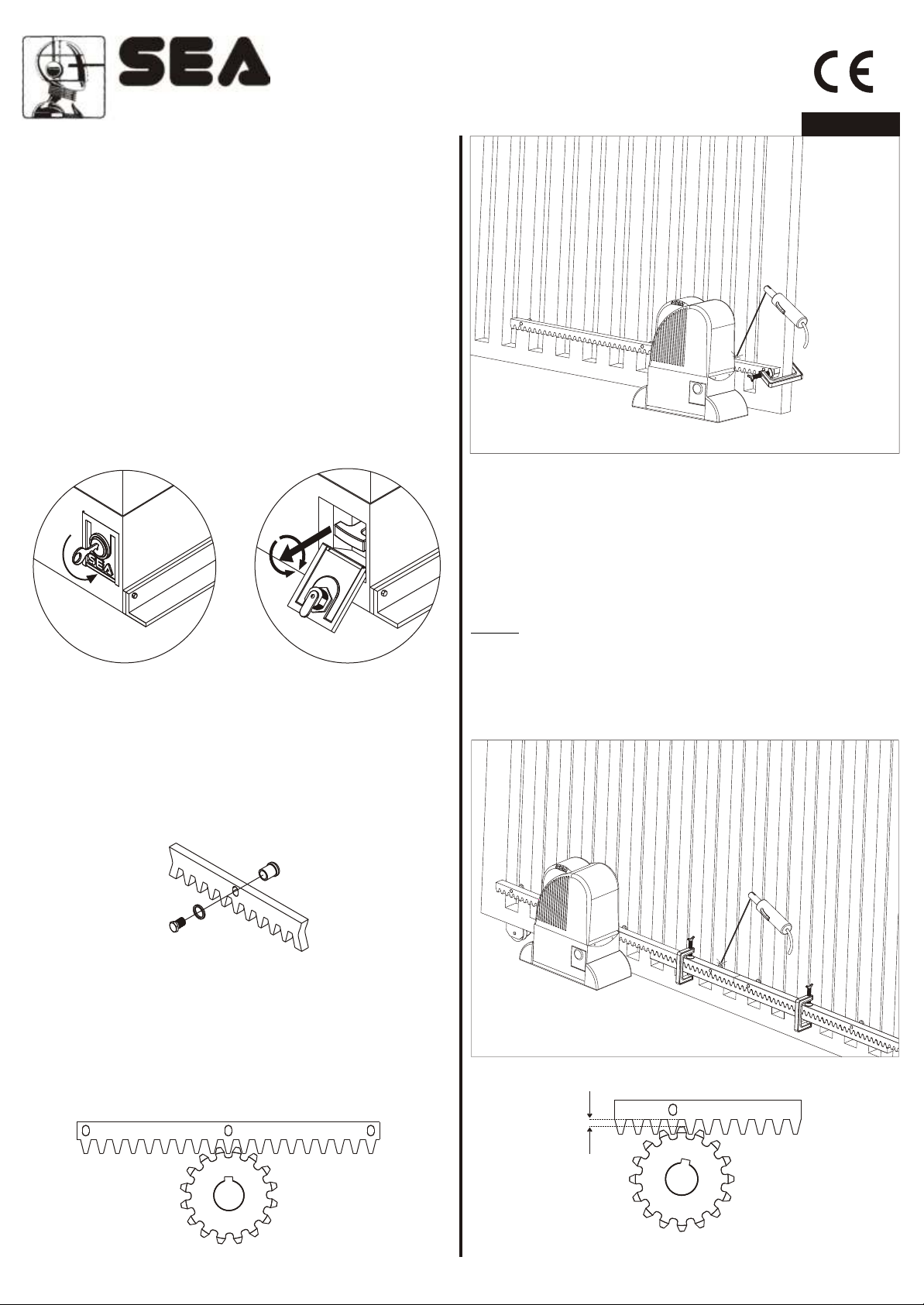

5. RELEASE SYSTEM

5.1. T o release act as follows

- Put the key in and turn it to open the small door which protects

the plastic handle (Fig. 6).

- Grab the handle of the release and pull outward winning the

resistance of the inner spring (Fig. 7).

- Turn the handle of 90° towards left or right and leave it folding it

to 90° to let the small door close.

- Close the small door and take the key away.

5.2. T o stop again act as follows:

- Put the key in and turn it to open the small door which protects

the plastic handle (Fig. 6).

- grab the handle and turn it of 90° towards left or right

- pull it inward until the stop

- move the leaf by hand until the gears are not inserted again,

after this the system is re-established for the automatic use.

ENGLISH

Fig. 10

6.4.Repeat this method for all the pieces of rack that require to

be fitted.

Fig. 6

Fig. 7

6. RACK FITTING

6.1.Release the unit and open the gate completely .

6.2.Fit the bolts to each section of rack using the provided

blocking screw. Make sure the bolt s are placed in the upper part

of the holes (See Fig. 8) ;

Fig. 8

6.5.Check all the rack pieces are perfectly alined and placed

correctely (serrations in phases). When fitting the next section of

rack use a third piece as shown in Fig. 1 1 to ensure a good mesh.

6.6.Set the rack 1.5 mm higher to avoid the gate weight loading

on the pinion (Fig. 12),

Notice: Keep a gap of about 0,5 mm between pinion cog and

gear rack tooth.

6.7.Slide the gate back and forth to check that the rack always

stays in the middle of the pinion. If required adjust the length of

the spacers.

6.3.Lay the section of rack on the pinion of the operator as in Fig.

9 so that it results parallel to the pavement guide of the gate and

tack weld the central bolt B to the gate (Fig. 10).

Manually slide the gate to set the bolt C close to the pinion and

Fig. 11

tack weld them; repeat with bolt A.

A

cod. 67410010 10/40

B

Fig. 9

C

1,5 mm

Fig. 12

REV 07 - 10/2008

Loading...

Loading...