Page 1

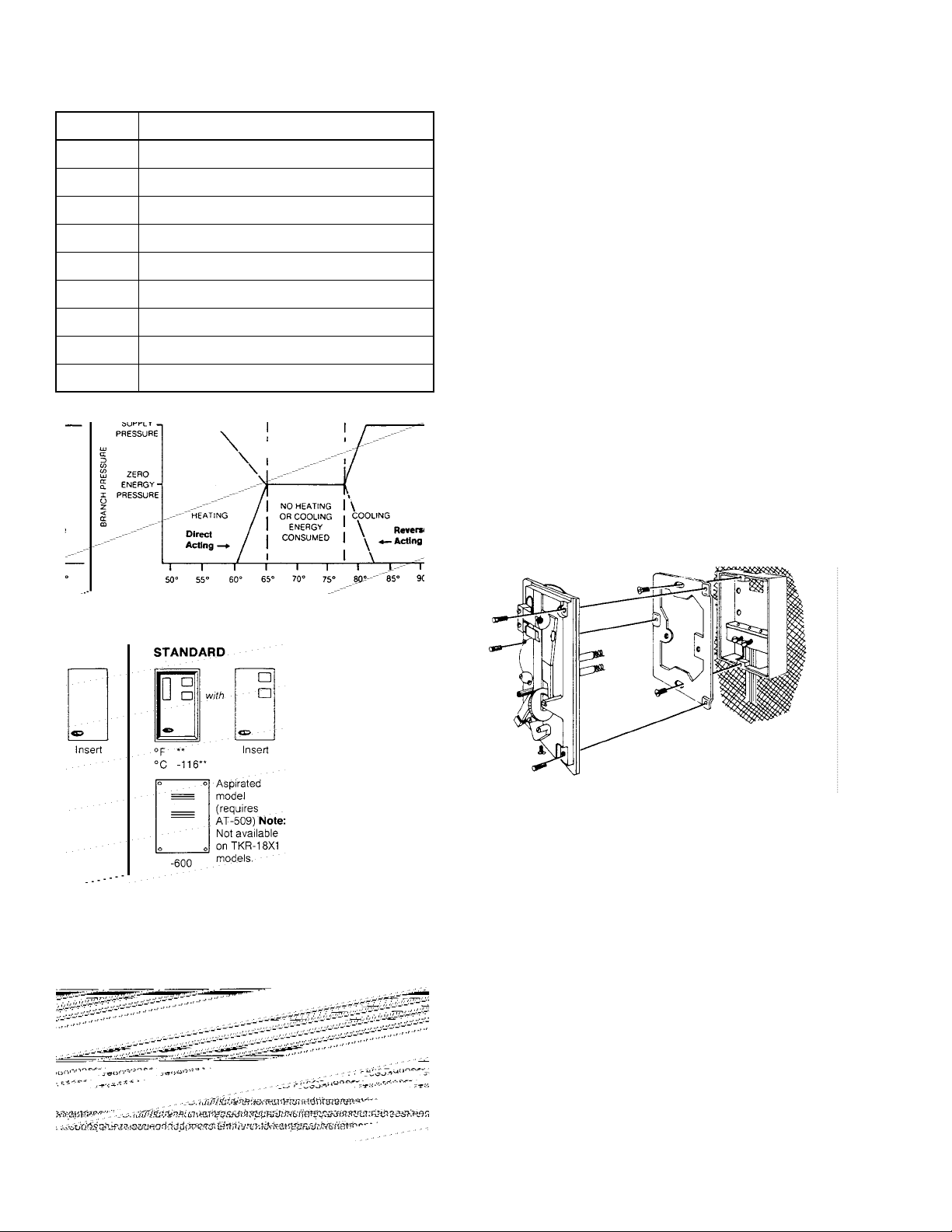

APPLICATION

For proportional control of pneumatically-operated

sequenced heating and cooling valves and/or damper

actuators to maintain room air temperature with a zero

energy band between heating and cooling in heating,

ventilating and air conditioning systems.

SPECIFICATIONS

Thermostat: Proportional two pipe type. Thermostat

maintains constant branch pressure when temperature is

between dial setpoints.

Sensing Elements: Two bimetals.

Control Dial Range: Two independent with stops, see

able 1.

T

Th

rottling Range: Adjustable 2 to 10 °F/10 psi change in

branch pressure when temperature is not between dial

setpoints, factory set at 4 °F/10 psi.

Output Air Signal: 0.5 psig (3.4 kPa) to supply air pressure

-0.5 psig (-3.4 kPa).

ro Energy Band Pressure: Adjustable 5 to 11 psig (34 to

Ze

.

.

sig (55 kPa).

Compressor

x 64 mm).

:

76 kPa) factory set at 8 p

Action: See Table 1.

Ambient Limits:

Shipping, -40 to 150 °F (-40 to 65 °C). 0 to 98% R.H.,

non-condensing

Operating, 20 to 115 °F (-7 to 46 °C). 10 to 98% R.H.,

non-condensing

Supply Air Pressure: Clean, oil free, dry air required

(reference EN-123).

Nominal, 20 psig (138 kPa).

Minimum, 15 psig (103 kPa).

Maximum, 30 psig (207 kPa).

Air Connections:

Main (Black), 5/32" dia. spring reinforced plastic tube.

Branch (white), 5/32" dia. spring reinforced plastic tube.

Air Consumption for Sizing Air

TK-18x1, TKR-18x1, 0.012 scfm (5.7 ml/s).

TK-18x1-600 (Aspirated models), 0.028 scfm (13.2

ml/s).

Air Capacity for Sizing Air Mains:

TK-18x1, TKR-18x1, 16 scim (4.4 ml/s).

TK-18x1-600, 56 scim (15.3 ml/s).

Cover: Beige plastic with brushed bronze metal insert as

andard exce

st

brushed stainless steel covers.

Mounting: Upright position on wall.

Dimensions:

TK-18x1, TKR-18x1, 4-3/8" high x 2-3/4" wide x 1-5/8"

dee

TK18x1-600, Wall box — 5" high x 3-1/2" wide x 2-1/2"

deep (127 mm x 89 mm

Cover — 5-1/2" high x 4" wide (140 mm x 102 mm).

pt aspirated models. Aspirated models have

p (111

mm x 70 mm x 43 mm).

TK-1801, TK-1811

TK-1801, TKR-1811

Pneumatic Zero Energy Band

Room Thermostats

General Instructions

Figure-1

Table-1 SPECIFICATIONS.

55 to 85

TK-1801

TKR-1801

TK-1811

TKR-1811

Part Number

Dial Range**

°F 13 to 29 °C

TK-1801-116

TK-1811-116

Application

N.O. Heat

N.C. Cool

N.C. Heat

N.O. Cool

*Direct Acting (D.A.) - Increase output pressure on

temperature rise.

Reverse

temperature rise.

**Control di

built-in dial stops can limit high and/or low setting of each dial.

Acting (R.A.) - Decrease output pressure on

Control

Action*

Direct

Reverse

al marked °F on one side and °C on the other side;

Printed in U.S.A. 6-10 © Copyright 2010 Schneider Electric All Rights Reserved. F-20007-6

Page 2

Table-2 TKR-18X1 INCLUDES:

Quantity Description

1 TK-18X1 thermostat

1 Blank cover insert

1 Cover insert with setpoint cutout

2 1/4" x 5/32" barbed fitting

2 5/32" x 5/32" barbed fitting

2 1/4" O.D. x 2" Tygon tubing

2 1/4" x 1/4" compression to tubing fitting

1 5/64" Allen head cover screw

1 5/64" Allen head wrench

ACCESSORIES

AT-65 Series Cover inserts

AT-85 Series Digital thermometer cover kit, plastic cover

AT-95 Series Digital thermometer cover kit, metal cover

AT-504 Plaster hole cover

AT-505 Surface mounting base

AT-506 Pneumatic wall box fitting

AT-509 Wall box required for aspirated thermostats

AT-536 Pneumatic wall thermostat conversion kit

AT-546 Auxiliary mounting base

AT-1100 Series Thermostat guards

AT-533-101 Adapter 1/4" plastic to 5/32" plastic

AT-533-127 Adapter 3/16" copper or 1/4" copper with 1/4"

PKG-1093 Digital thermometer battery replacement kit

TOOL-15 Spanner head driver

TOOL-80-1 Changeover/dial

TOOL-95-1 Pneumatic calibration tool kit

coupling (not included)

solder

to 5/32" plastic

PRE-INSTALLATION

The thermostats are shipped with mounting screws. Wall

fittings must be ordered separately.

Before installation, make a visual inspection of the thermostat

carton for obvious signs of damage.

Air Connections:

Two plastic tubes reinforced with a coil spring are coded M

and B. The M (black) designates the supply main and the B

(white) designates the controlled branch line. See Figure 1.

Figure-2

Options (For quantities of 24 or more of same part

number)

Add “dash number” (-XXX) s

uffix to base part number for

desired option. For metal covers, spcify TK2-18X1-XXX.

Figure-3 Typical Mounting Thermostat to AT-506 Wall Box

Fitting.

INSTALLATION

Requirements

Locate the thermostat where it will be exposed to unrestricted

circulation of air which represents the average temperature of

the controlled space. Do not locate the thermostat near

sources of heat or cold such as lamps, motors, sunlight, or

concealed ducts or pipes.

The thermostat fitting is available for either flush or surface

mounting. See Fig

for surface mounting on all wall surfaces and flush mounting

on plastered or stud walls.

ures 3 and 4. Use the AT-506 wall box fitting

2 © Copyright 2010 Schneider Electric All Rights Reserved. F-20007-6

Page 3

Procedure

To mount a thermostat on an AT-506 wall box fitting, refer to

Figure 3.

1. Remove and discard the cardboard cover plate on the wall

box. (The cardboard cover protects the fitting while the wal

is being plastered.)

2. Fasten the mounting plate to the wall box with the two flat

headscrews provided. Make sure it is square with the wall

before tightening the screws.

3. f the thermostat tubing is too long for easy coiling in the

l box, it can be cut to length. Cut the tubing at a 45o

wal

angle for ease of inserting the tubing into the “O” ring

seal. Be sure that the coil spring is cut flush with the

tubing.

4. Remove and discard the short piece of tubing from the

connector head of the

5. Insert the main (black) plastic tubing into the left-hand

hole in the connector head. Insert the branch line (white)

tubing into the right-hand hole in the connector.

Insert tubes at least 1/4". Do not use any lubricant on the

plastic tubing.

6. Fasten the thermostat to the mounting plate with the three

Allen mounting screws provided. Tighten the screws

evenly.

wall box.

Figure-5

For installation of external setpoint, refer

to figure 6

1. Insert the knob through hole in cover. The knob should rest

on the calibration screw with the slots aligned with the dial

clamp screws.

2. Insert screw supplied with the knob into the center of the

knob and tighten, being careful not to disturb the setting

of the calibration screw.

To mount a thermostat on an electrical switch box, refer

to Figure 4

1. Attach the mounting plate to the switch box with the two

flathead screws provided. Be sure the mounting plate is

vertical.

2. Slightly rotate the tubes back and forth, and push firmly

onto the fittings. (See Figure 5)

Fasten the thermostat to the mounting plate with the Allen

3.

head screws provided and tighten evenly.

Figure-4 Typical Mounting Thermostat to Electric Box.

Note: The knob must be removed in order to remove

thermostat cover or recalibrate thermostat.

Figure-6

F-20007-6 © Copyright 2010 Schneider Electric All Rights Reserved. 3

Page 4

CHECKOUT

After installing the thermostat, verify proper operation.

Note: If external setpoint knobs are installed, use

TOOL-80-1 to turn setpoint dials (thermostat cover must be

removed).

1. Measure the ambient temperature near the thermostat

with an accurate thermometer. The ambient should be

stable and between 60 and 80 °F (16 and 27 °C) to

effectively check thermostat operation.

2. Check the Zero Energy Band (ZEB) pressure. Set the

heating dial to 5

(29 °C). Branch pressure should equal the ZEB pressure,

which is factory set at 8 psi. The ZEB pressure should be

between the spring ranges of the actuators being

controlled. If a ZEB pressure other than what is observed

is required, see ADJUSTMENTS.

3. Check thermostat operation. Slowly increase the setting

of the heating dial.

ambient temperature, branch pressure should fall if the

unit is direct acting (TK-1801) or rise if the unit is reverse

acting (TK-1811). Reset the heating dial to 55 °F (13 °C)

slowly lower

and

dial setting falls below the ambient temperature, branch

pressure should rise if the unit is direct acting or fall if the

unit is reverse acting.

Note: The amount of rise or drop in branch pressure may

vary depending on the throttling range setting of the

thermostat and the ambient temperature in the test area. If

the branch pressure is always 0 psig (0kPa), the restriction

may be plugged. If the branch pressure is always equal to

supply or unable to be decreased below 3 psig (21 kPa), the

nozzle may be plugged.

4. Check for active heating thermal element. Set the cooling

dial to 85 °F (29 °C). Vary the setting of the heating dial to

obtain a branch pressure of approximately 3 psig (21

kPa) on a direct acting unit (TK-1801) or 12 psig (82 kPa)

on a reverse acting unit (TK-1811). Slightly warm the

element with your hand or breath. Branch pressure

should increase on a direct acting unit or decrease on a

reverse acting unit.

5 °F (13 °C) and the cooling dial to 85 °F

When the dial setting exceeds the

the setting of the cooling dial. When the

5. Check for active cooling thermal element . Set the heating

ial to 55 °F (29 °C). Vary the setting of the lower cooling

d

dial until a

kPa) on a direct acting unit or 3 psig (21 kPa) on a reverse

acting unit is obtained. Slightly warm the element with

your hand or breath. Branch pressure should increase on

a direct acting unit or decrease on a reverse acting unit.

Refer to CALIBRATION if the thermostat

properly.

branch pressure of approximately 12 psig (82

fails to function

System Checkout

After thermostat operation has been checked, check system

operation as follows:

1. Set the heating dial at 55 °F (13 °C) and the cooling dial at

85 °F (29 °C). The ambient temperature at the thermostat

should be stable an

2. Verify that both the heating and cooling media are off (or

at minimum, depending on system design). If one or both

are energized, contrary to system design, the use of

positive positioners on the heating and/or cooling

actuators can overcome this problem. Alternatively, a 1:2

ratio relay in the branch line to the heating and/or cooling

actuators can be used. Note that this will affect the

system throttling range, and that adjustments of the

thermostat throttling range may be required.

3. Slowly increase the setting of the heating dial. When the

l setting exceeds the a

dia

medium should be energized. Reset the dial at 55 °F (13

°C).

4. Slowly decrease the cooling dial setting. When the dial

setting falls below ambien

medium should be energized.

5. Set the heating and cooling dials to their desired

setpoints.

d between 60 and 80 °F (16 and 27 °C).

mbient temperature, the heating

t temperature, the cooling

Figure-7

4 © Copyright 2010 Schneider Electric All Rights Reserved. F-20007-6

Page 5

ADJUSTMENTS

Zero Energy Band Pressure

The Zero Energy Band (Z.E.B.) pressure (see Figure 7) is

factory set at 8 psig (55 kPa). To check this setting, refer to

Step 1 below. This pressure should be set midway between

the pressure ranges of the heating and cooling actuators in

order to obtain proper sequencing, and the actuator ranges

should be separated by a minimum of 2 psi (more if possible).

If a Z.E.B. pressure other than the factory setting is desired,

proceed as follows:

1. Set the heating dial at 55 °F (13 °C) and the cooling dial at

°F (29 °C). Ambient temperature should be between 60

85

and 80°F (16 and 27 °C). The resulting branch pressure is

the Z.E.B. pressure. To increase this setting, turn the

calibrating screw counterclockwise (see Figure 8).

2. Check the calibration of both dials (see CALIBRATION).

Note: The throttling range of the thermostat is divided

equally between heating and cooling. If the thermostat

throttling range is set at 4 °F, the throttling rang is 2 °F for

heating and 2 °F for cooling (see Figure 7).

To check the throttling range

1. Ambient temperature, as measured by an accurate

thermometer, sh

(16 and 27 °C).

2. Set the up

85 °F (29 °C) and note the Z.E.B. pressure.

3. Slowly increase the setting of the upper dial until the

branch pressure begins to change and note the dial

setting. Continue to increase the setting until branch

pressure reaches 3 psig (21 kPa) on direct acting models

or 13 psig (89 kPa) on reverse acting models. The total

throttling range is:

Difference in Dial Stops, F x 10

Change in Branck Pressure, psi

or ( Difference in Dial Settings, C x 68.5)

Change in Branch Pressure, kPa

To adjust the throttling range

1. Move the throttling range adjustment slider in the required

direction (see Figure 8).

2. Readjust the Z.E.B. pressure (see Zero Energy Band

Pressure).

3. Check the calibration of both dials (see CALIBRATION).

ould be stable and between 60 and 80 °F

per dial at 55 °F (13 °C) and the lower dial at

Figure-8

Throttling Range

Throttling range is factory set at 4 °F per 10 psi (2 °C per 62

kPa) change. If the throttling range setting is too wide,

excessive offset or droop will be encountered and the

throttling range should be decreased. If the throttling range is

too narrow, system cycling or hunting will occur and the

throttling range should be increased. If stable control cannot

be obtained, check system component sizing, sensor location,

and system response time as possible causes. The

thermostat throttling range should be set at the lowest value

which will allow the thermostat to control the system without

cycling under normal load conditions.

Adjustment of Dial Stops

To set the setpoint dial stops, proceed as follows:

1. Using the TOOL-82 5/64" Allen wrench, loosen the two dial

clamp screws approximately

2. Separate the two dial stop tabs if not already separated.

3. Using the TOOL-82 5/64" Allen wrench, turn the setpoint

dial to the desired clockwise dial limit. While holding the

dial with the Allen wrench, slide one stop tab in a

clockwise direction until it touches the top side of the stop

tang.

4. Rotate the setpoint dial to the counterclockwise limit.

While holding

the other stop tab counterclockwise to touch the bottom

of the stop tang.

5. Carefully tighten the dial screws with the TOOL-82 5/64"

Allen wren

6. Rotate setpoint dial from counterclockwise stop to

clockwise stop to check the stop settings. Repeat

adjustment steps if necessary.

Note: Stops can be rotated to lock setpoint dial in one place

if desired.

the dial with the 5/64" Allen wrench, rotate

ch.

1/2 turn.

F-20007-6 © Copyright 2010 Schneider Electric All Rights Reserved. 5

Page 6

Converting Dials to °C

To convert the unit from °F dial reading to °C dial reading,

proceed as follows:

1. Rotate setpoint dial clockwise to end of dial scale.

2. While holding dial, use the TOL-82 5/64" Allen wrench to

remove the dial screws.

3. Carefully remove dial plate and turn over. Make sure stop

tab plates and clamp ring are in place.

4. Align dial plate to read clockwise end of °C scale.

5. Carefully re-install dial screws. Do not tighten.

6. Readjust stop tabs (see Adjustment of Dial Stops).

required.

Procedure

1. Remove the thermostat cover by loosening the cover

screw.

2. Check the Zero Energy Band pressure setting of the

thermostat per CHECKOUT, step 2.

3. Using the TOOL-82 5/64" Allen wrench, unscrew

(counterclockwise rotation) the branch test port one full

turn (see Figure 8).

4. Attach the test gauge rubber seal to the boss. Using a

rotary motion

[1/4"(6mm) minimum]. The tubing will support the test

gauge in a position where it can be easily read.

5. Adjust the dial being calibrated to the measured ambient

temperature. The other dial should be set at the end of its

range (low end for heating, high end for cooling).

6. Using TOOL-80-1 to prevent the dial from rotating, use

the TOOL-82 0.048" six-splin

calibrating screw (see Figure 9) until branch pressure

equals the Z.E.B. pressure (or alternatively the mid-range

pressure of the actuator being controlled).

7. Reset the dial to the end of its range (low end for heating,

high end for cooli

other dial if required.

8. Return both dials to their nominal settings, remove the

test gauge, turn the branch test gauge screw clockwise to

tighten, and replace the cover.

, push the gauge on as far as it will go

e wrench to adjust the dial

ng), and repeat steps 5 and 6 for the

Figure-9

CALIBRATION

As a nominal calibration, the branch line control pressure

should be the Zero Energy Band pressure (factory set at 8.0

psig) when the setpoint is equal to the ambient temperature as

measured by an accurate thermometer. This means that when

space temperature is between the two dial settings, both

heating and cooling are off. It also means that the heating and

cooling throttling ranges are offset above and below their

respective dial settings (see Figure 7). If desired, the

thermostat can be calibrated so the branch pressure equals

the center of the actuator spring ranges when ambient

temperature equals setpoint. Note, however, that in the case

the total thermostat throttling range must be subtracted from

the Zero Energy Band. For example, if the heating setpoint is

65 °F (18 °C), the cooling setpoint is 78 °F (26 °C). and the

rottling range is 6

th

minus 65 °F minus 3 °F or 10 °F (6 °C) total.

When checking or changing the calibration of the heating dial,

set the cooling dial

or changing the ca

dial at 55 °F (13 °C).

Caution: The thermal element of the room thermostat is very

sensitive to temperature change. Do not effect its

temperature by touching the bimetal or breathing on the

thermostat. When calibrating the instrument, observe the wall

box temperature frequently and reset the setpoint dial if

°F (3 °C), the Zero Energy Band is 78 °F

at 85 °F (29 °C). Likewise, when checking

libration of the cooling dial, set the heating

Cover Insert Installation (see Figure 10)

1. Select appropriate cover insert.

2. Remove protective backing and protective skin on face

of cover insert.

3. Press insert uniformly on thermostat with logo in lower

left-hand corner.

Figure-10 Cover Insert Installation.

6 © Copyright 2010 Schneider Electric All Rights Reserved. F-20007-6

Page 7

MAINTENANCE

This is a quality product. Regular maintenance of the total

system is recommended to assure sustained optimum

performance. No routine maintenance of this device is

required if the system is properly maintained.

REPAIR

Field repair of pneumatic thermostats is not recommended.

However, if the thermostat output pressure is 0 and it cannot

be corrected by calibration, the restriction should be checked.

Hold the restriction plate up to the light and check the 0.0045

hole. If the hole is blocked, the restriction plate must be

replaced. The filter should be replaced at the same time. If the

hole is not blocked, then the thermostat should be replaced.

Before replacing a thermostat, check to make sure the

ermostat

th

main air pressure, and check for foreign material (dirt, oil,

water, etc.) in the air supply. If the air supply is contaminated,

remedy this before replacing the thermostat.

Refer to the General Catalog for a complete list of available

replacement part

is piped per the job wiring diagram. Also check

s.

F-20007-6 © Copyright 2010 Schneider Electric All Rights Reserved. 7

Page 8

On Octo be r 1 st, 200 9, TAC bec ame the Build i ngs bus ine ss of its pa ren t company Schn ei d er Ele c tric . This document refle cts the vi sual identity of Schneider Electric,

however there remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be cha nge d to ref lect app ropr iate

corporate brand chan

g

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-20007-6

es.

Loading...

Loading...