Modicon TM3 Bus Coup ler IO Configurato r

EIO0000004112 08/2020

Modicon TM3 Bus Coupler

IO Configurator

User Guide

08/2020

EIO0000004112.00

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 EIO0000004112 08/2020

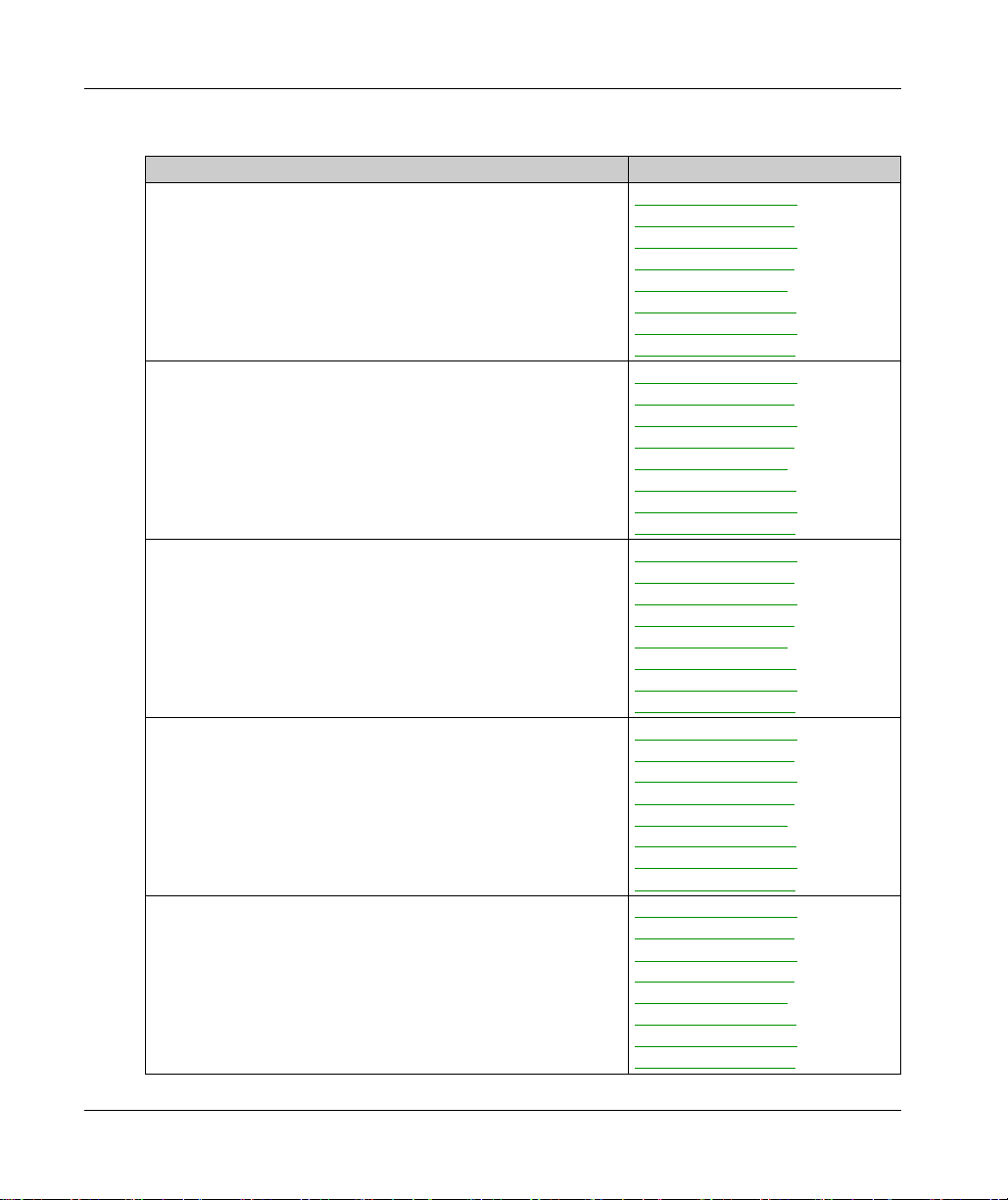

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supported Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Managing Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Use Cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Creating a Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading a Configuration File into a Bus Coupler (TM3BCEIP and

TM3BCSL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exporting Generic Configuration Files . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Configuring Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1 Configuring Bus Couplers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring TM3BCEIP Bus Couplers. . . . . . . . . . . . . . . . . . . . . . . . .

Configuring TM3BCSL Bus Couplers . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring TM3BCCO Bus Couplers . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Configuring TM3 Analog Input Modules . . . . . . . . . . . . . . . . . . . . . . .

TM3AI2H / TM3AI2HG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3AI4 / TM3AI4G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3AI8 / TM3AI8G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3TI4 / TM3TI4G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3TI4D / TM3TI4DG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3TI8T / TM3TI8TG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Configuring TM3 Analog Mixed Modules. . . . . . . . . . . . . . . . . . . . . . .

TM3AM6 / TM3AM6G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3TM3 / TM3TM3G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Configuring TM3 Analog Output Modules . . . . . . . . . . . . . . . . . . . . . .

TM3AQ2 / TM3AQ2G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3AQ4 / TM3AQ4G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Configuring TM3 Digital Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Tab - Configuring TM3 Digital Modules. . . . . . . . . . . . .

14

17

25

29

32

33

34

38

39

40

41

42

43

46

49

53

57

60

65

66

70

74

75

77

79

79

EIO0000004112 08/2020 3

3.6 Configuring TM3 Expert Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3XTYS4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3SAK6R / TM3SAK6RG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3SAFL5R / TM3SAFL5RG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3SAF5R / TM3SAF5RG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3SAC5R / TM3SAC5RG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Configuring CANopen PDO Transmission Mode for Analog Inputs . . .

Configuring CANopen PDO Transmission Mode for Analog Inputs . . .

Chapter 4 Loading Configuration File into a Bus Coupler

(TM3BCEIP and TM3BCSL). . . . . . . . . . . . . . . . . . . . . . . 93

Loading the Configuration File into a Bus Coupler. . . . . . . . . . . . . . . .

Chapter 5 Exporting the Configuration . . . . . . . . . . . . . . . . . . . . . . . 95

Exporting for EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exporting for Modbus TCP / Modbus SL . . . . . . . . . . . . . . . . . . . . . . .

Exporting for CANopen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Memory Mapping Table (TM3BCEIP and TM3BCSL) . . . 101

Memory Mapping Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exporting the Memory Mapping Table . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 Modicon TM3 Bus Coupler Web Server . . . . . . . . . . . . . . 107

7.1 EtherNet/IP (TM3BCEIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Modbus TCP / Modbus SL (TM3BCSL). . . . . . . . . . . . . . . . . . . . . . . .

Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 CANopen (TM3BCCO). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A Use Case Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Use Case 1: TM3BCEIP Bus Coupler, Modicon M251 Logic Controller,

and SoMachine V4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use Case 2: TM3BCSL Bus Coupler, Modicon M251 Logic Controller,

and SoMachine V4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use Case 3: TM3BCEIP Bus Coupler, Modicon M340 Controller, and

EcoStruxure Control Expert V14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use Case 4: TM3BCCO Bus Coupler, Modicon M340 Controller, and

EcoStruxure Control Expert V14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

81

82

84

86

88

90

92

92

93

96

97

99

102

106

108

108

128

128

142

142

155

157

160

164

167

172

177

181

4 EIO0000004112 08/2020

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

EIO0000004112 08/2020 5

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

6 EIO0000004112 08/2020

About the Book

At a Glance

Document Scope

This document describes how to use the TM3 Bus Coupler IO Configurator software.

Validity Note

This document has been updated for the release of the TM3 Bus Coupler IO Configurator V1.0.

The technical characteristics of the devices described in the present document also appear online.

To access the information online, go to the Schneider Electric home page

https://www.se.com/ww/en/download/

The characteristics that are described in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may revise

content over time to improve clarity and accuracy. If you see a difference between the document

and online information, use the online information as your reference.

.

EIO0000004112 08/2020 7

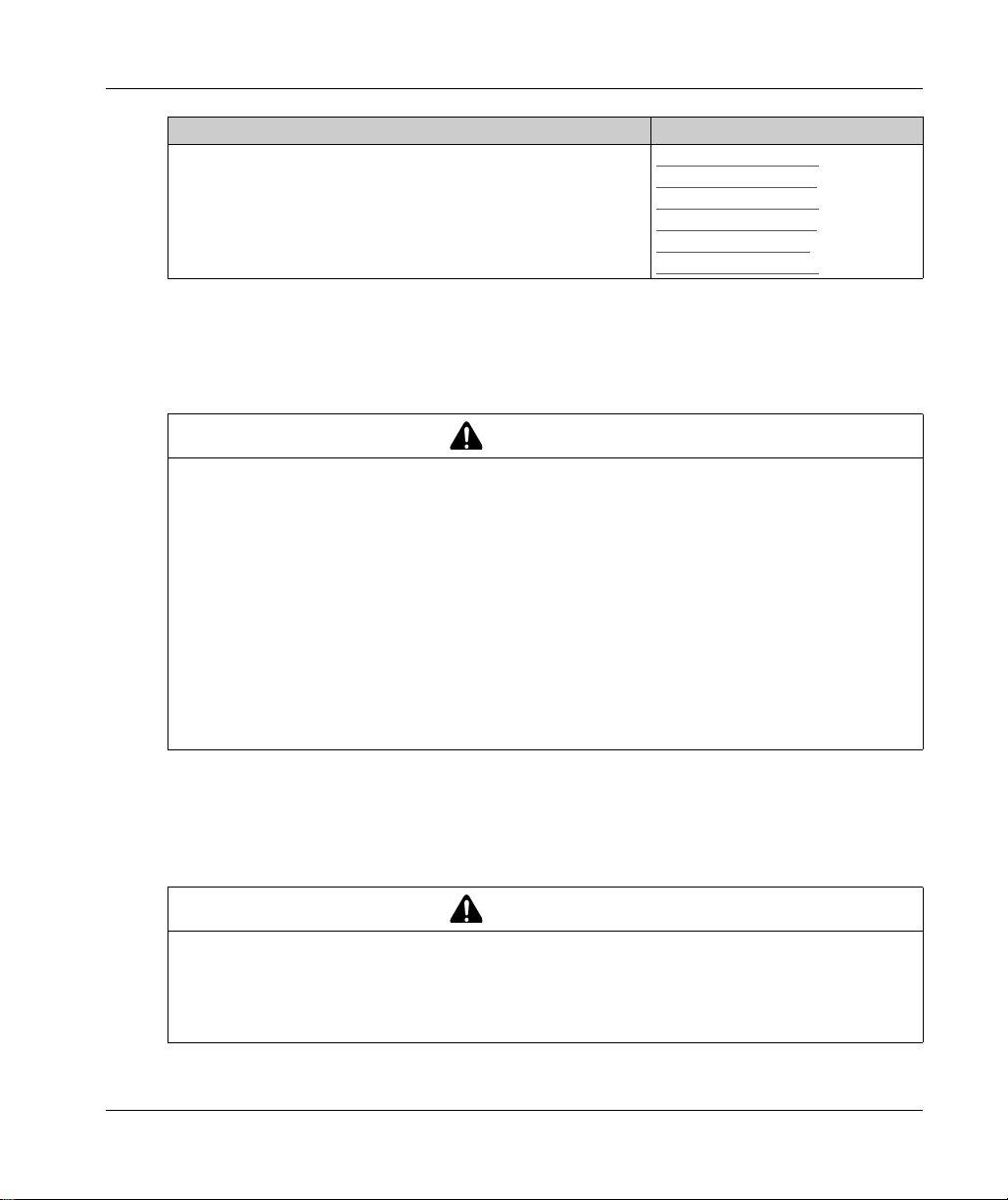

Related Documents

Title of Documentation Reference Number

Modicon TM3 Bus Coupler - Hardware Guide

Modicon TM3 Digital I/0 Modules - Hardware Guide

Modicon TM3 Analog I/0 Modules - Hardware Guide

Modicon TM3 Expert Modules - Hardware Guide

Modicon TM3 Safety Modules - Hardware Guide

EIO0000003635 (ENG)

EIO0000003636 (FRA)

EIO0000003637 (GER)

EIO0000003638 (SPA)

EIO0000003639 (ITA)

EIO0000003640 (CHS)

EIO0000003641 (POR)

EIO0000003642 (TUR)

EIO0000003125 (ENG)

EIO0000003126 (FRA)

EIO0000003127 (GER)

EIO0000003128 (SPA)

EIO0000003129 (ITA)

EIO0000003130 (CHS)

EIO0000003424 (POR)

EIO0000003425 (TUR)

EIO0000003131 (ENG)

EIO0000003132 (FRA)

EIO0000003133 (GER)

EIO0000003134 (SPA)

EIO0000003135 (ITA)

EIO0000003136 (CHS)

EIO0000003426 (POR)

EIO0000003427 (TUR)

EIO0000003137 (ENG)

EIO0000003138 (FRA)

EIO0000003139 (GER)

EIO0000003140 (SPA)

EIO0000003141 (ITA)

EIO0000003142 (CHS)

EIO0000003428 (POR)

EIO0000003429 (TUR)

EIO0000003353 (ENG)

EIO0000003354 (FRA)

EIO0000003355 (GER)

EIO0000003356 (SPA)

EIO0000003357 (ITA)

EIO0000003358 (CHS)

EIO0000003359 (POR)

EIO0000003360 (TUR)

8 EIO0000004112 08/2020

Title of Documentation Reference Number

Modicon TM3 Bus Coupler - Programming Guide (EcoStruxure

Machine Expert)

You can download these technical publications and other technical information from our website

at https://www.se.com/ww/en/download/ .

Product Related Information

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths

and, for certain critical control functions, provide a means to achieve a safe state during and

after a path failure. Examples of critical control functions are emergency stop and overtravel

stop, power outage and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this equipment must be individually and thoroughly tested for proper

operation before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000003643 (ENG)

EIO0000003644 (FRA)

EIO0000003645 (GER)

EIO0000003646 (SPA)

EIO0000003647 (ITA)

EIO0000003648 (CHS)

WARNING

1

1

For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest

edition), "Safety Standards for Construction and Guide for Selection, Installation and Operation of

Adjustable-Speed Drive Systems" or their equivalent governing your particular location.

WARNING

UNINTENDED EQUIPMENT OPERATION

Only use software approved by Schneider Electric for use with this equipment.

Update your application program every time you change the physical hardware configuration.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000004112 08/2020 9

Terminology Derived from Standards

The technical terms, terminology, symbols and the corresponding descriptions in this manual, or

that appear in or on the products themselves, are generally derived from the terms or definitions

of international standards.

In the area of functional safety systems, drives and general automation, this may include, but is not

limited to, terms such as

safety, safety function, safe state, fault, fault reset, malfunction, failure

error, error message, dangerous

Among others, these standards include:

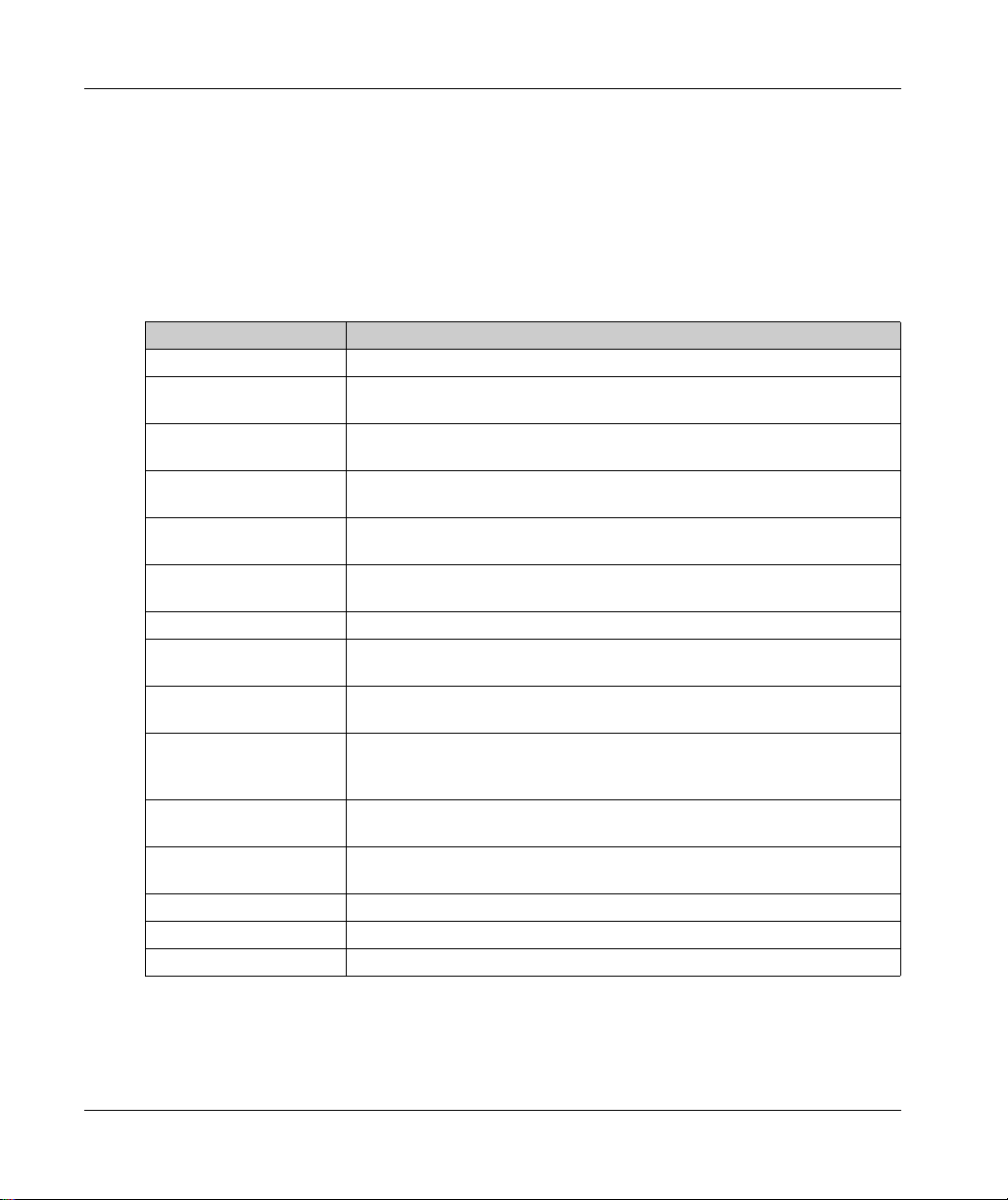

Standard Description

IEC 61131-2:2007 Programmable controllers, part 2: Equipment requirements and tests.

ISO 13849-1:2015 Safety of machinery: Safety related parts of control systems.

EN 61496-1:2013 Safety of machinery: Electro-sensitive protective equipment.

ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

EN 60204-1:2006 Safety of machinery - Electrical equipment of machines - Part 1: General

ISO 14119:2013 Safety of machinery - Interlocking devices associated with guards - Principles

ISO 13850:2015 Safety of machinery - Emergency stop - Principles for design

IEC 62061:2015 Safety of machinery - Functional safety of safety-related electrical, electronic,

IEC 61508-1:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-2:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-3:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61784-3:2016 Industrial communication networks - Profiles - Part 3: Functional safety

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

General principles for design.

Part 1: General requirements and tests.

reduction

requirements

for design and selection

and electronic programmable control systems

related systems: General requirements.

related systems: Requirements for electrical/electronic/programmable

electronic safety-related systems.

related systems: Software requirements.

fieldbuses - General rules and profile definitions.

,

, etc.

10 EIO0000004112 08/2020

In addition, terms used in the present document may tangentially be used as they are derived from

other standards such as:

Standard Description

IEC 60034 series Rotating electrical machines

IEC 61800 series Adjustable speed electrical power drive systems

IEC 61158 series Digital data communications for measurement and control – Fieldbus for use in

industrial control systems

Finally, the term

hazards, and is defined as it is for a

2006/42/EC

(

zone of operation

) and

ISO 12100:2010

may be used in conjunction with the description of specific

hazard zone

or

danger zone

in the

Machinery Directive

.

NOTE: The aforementioned standards may or may not apply to the specific products cited in the

present documentation. For more information concerning the individual standards applicable to the

products described herein, see the characteristics tables for those product references.

EIO0000004112 08/2020 11

12 EIO0000004112 08/2020

Modicon TM3 Bus Coupler IO Configurator

Getting Started

EIO0000004112 08/2020

Getting Started

Chapter 1

Getting Started

Introduction

This chapter provides information to help you get started using the TM3 Bus Coupler IO

Configurator.

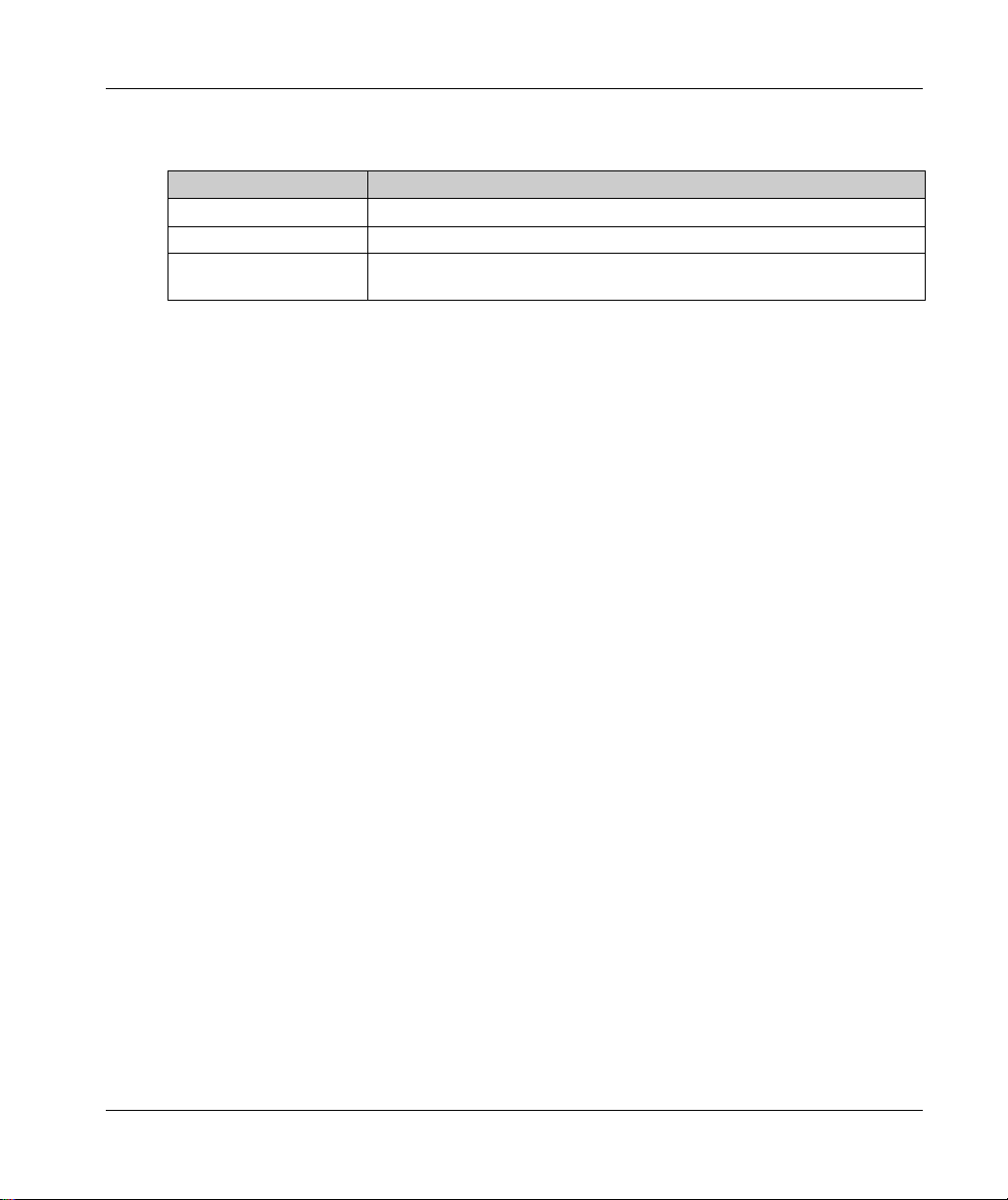

What Is in This Chapter?

This chapter contains the following topics:

System Requirements 14

Supported Devices 17

User Interface 25

Managing Power Consumption 29

Topic Page

EIO0000004112 08/2020 13

Getting Started

System Requirements

PC Configuration

The TM3 Bus Coupler IO Configurator can be installed on any PC that meets the following

minimum hardware and software requirements:

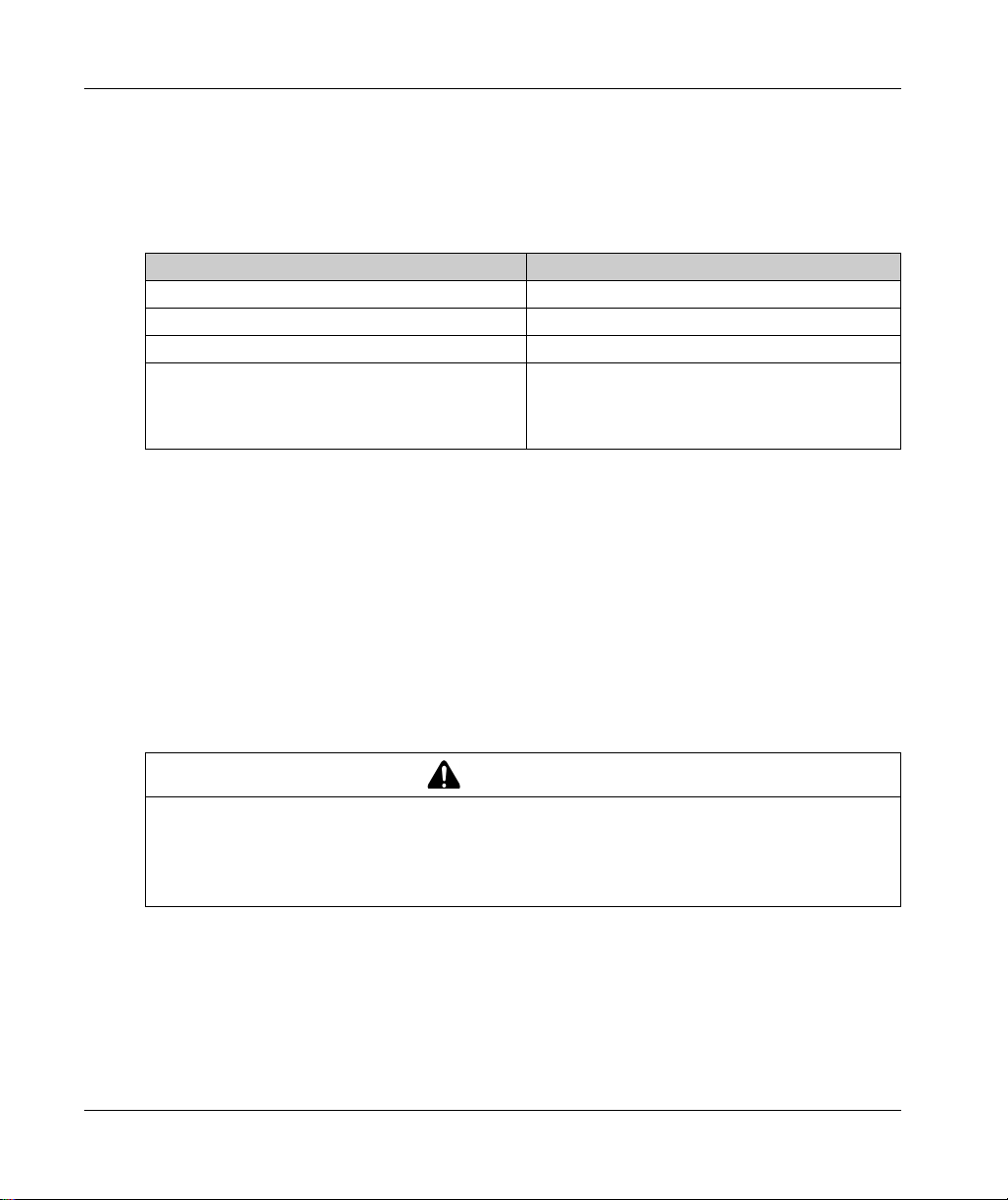

Component Minimum Requirement

Processor Intel Core 2 Duo processor or greater

RAM 1 GB RAM

Display resolution 1280 x 768 pixels or greater

Operating system Microsoft Windows 7 (32-bit or 64-bit processor)

Match Software and Hardware Configuration

Use the TM3 Bus Coupler IO Configurator to build a configuration that matches the physical

configuration of TM3 expansion modules connected to each bus coupler.

The I/O that may be embedded in your controller is independent of the I/O that you may have

added in the form of I/O expansion. It is important that the logical I/O configuration within your

program matches the physical I/O configuration of your installation. If you add or remove any

physical I/O to or from the I/O expansion bus or, depending on the controller reference, to or from

the controller (in the form of cartridges), then you must update your application configuration. This

is also true for any field bus devices you may have in your installation. Otherwise, there is the

potential that the expansion bus or field bus no longer function while the embedded I/O that may

be present in your controller continues to operate.

Microsoft Windows 8 (32-bit or 64-bit processor)

Microsoft Windows 8.1 (32-bit or 64-bit processor)

Microsoft Windows 10 (32-bit or 64-bit processor)

UNINTENDED EQUIPMENT OPERATION

Update the configuration of your program each time you add or delete any type of I/O expansions

on your I/O bus, or you add or delete any devices on your field bus.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Maximum Number of Modules

A maximum of 7 TM3 expansion modules can be added to a bus coupler.

By adding a pair of transmitter/receiver modules, an additional 7 TM3 expansion modules can be

added, for a total of 14 TM3 expansion modules.

14

WARNING

EIO0000004112 08/2020

Optional Modules

TM3 expansion modules can be marked as optional in the TM3 Bus Coupler IO Configurator

configuration. The Optional module feature provides a more flexible configuration by the

acceptance of the definition of modules that are not physically attached to the bus coupler.

Therefore, a single application can support multiple physical configurations of I/O expansion

modules, allowing a greater degree of scalability without the necessity of maintaining multiple

application files for the same application.

Without the Optional module feature, when the bus coupler starts up the I/O expansion bus

(following a power cycle, application download or initialization command), it compares the

configuration defined in the application with the physical I/O modules attached to the I/O bus.

Among other diagnostics made, if the bus coupler determines that there are I/O modules defined

in the configuration that are not physically present on the I/O bus, an error is detected and the I/O

bus does not start.

With the Optional module feature, the bus coupler ignores the absent I/O expansion modules that

you have marked as optional, which then allows the bus coupler to start the I/O expansion bus.

The controller starts the I/O expansion bus at configuration time (following a power cycle,

application download, or initialization command) even if optional expansion modules are not

physically connected to the bus coupler.

NOTE: TM3 Transmitter/Receiver modules (the TM3XTRA1 and the TM3XREC1) cannot be

marked as optional.

You must be fully aware of the implications and impacts of marking I/O modules as optional in your

application, both when those modules are physically absent and present when running your

machine or process. Be sure to include this feature in your risk analysis.

Getting Started

WARNING

UNINTENDED EQUIPMENT OPERATION

Include in your risk analysis each of the variations of I/O configurations that can be realized

marking I/O expansion modules as optional, and in particular the establishment of TM3 Safety

modules (TM3S…) as optional I/O modules, and make a determination whether it is acceptable

as it relates to your application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Marking an I/O Expansion Module as Optional

To add an expansion module and mark it as optional in the TM3 Bus Coupler IO Configurator

configuration:

Step Action

1 Add the expansion module to your TM3 Bus Coupler IO Configurator project.

2 Select the Configuration tab.

3 In the Optional module line, select Yes in the Value column.

EIO0000004112 08/2020 15

Getting Started

Shared Internal ID Codes

Controllers and bus couplers identify expansion modules by an internal ID code. This ID code is

not specific to each reference, but identifies the logical structure of the expansion module.

Therefore, different references can share the same ID code.

You cannot have two modules with the same internal ID code declared as optional without at least

one mandatory module placed between them.

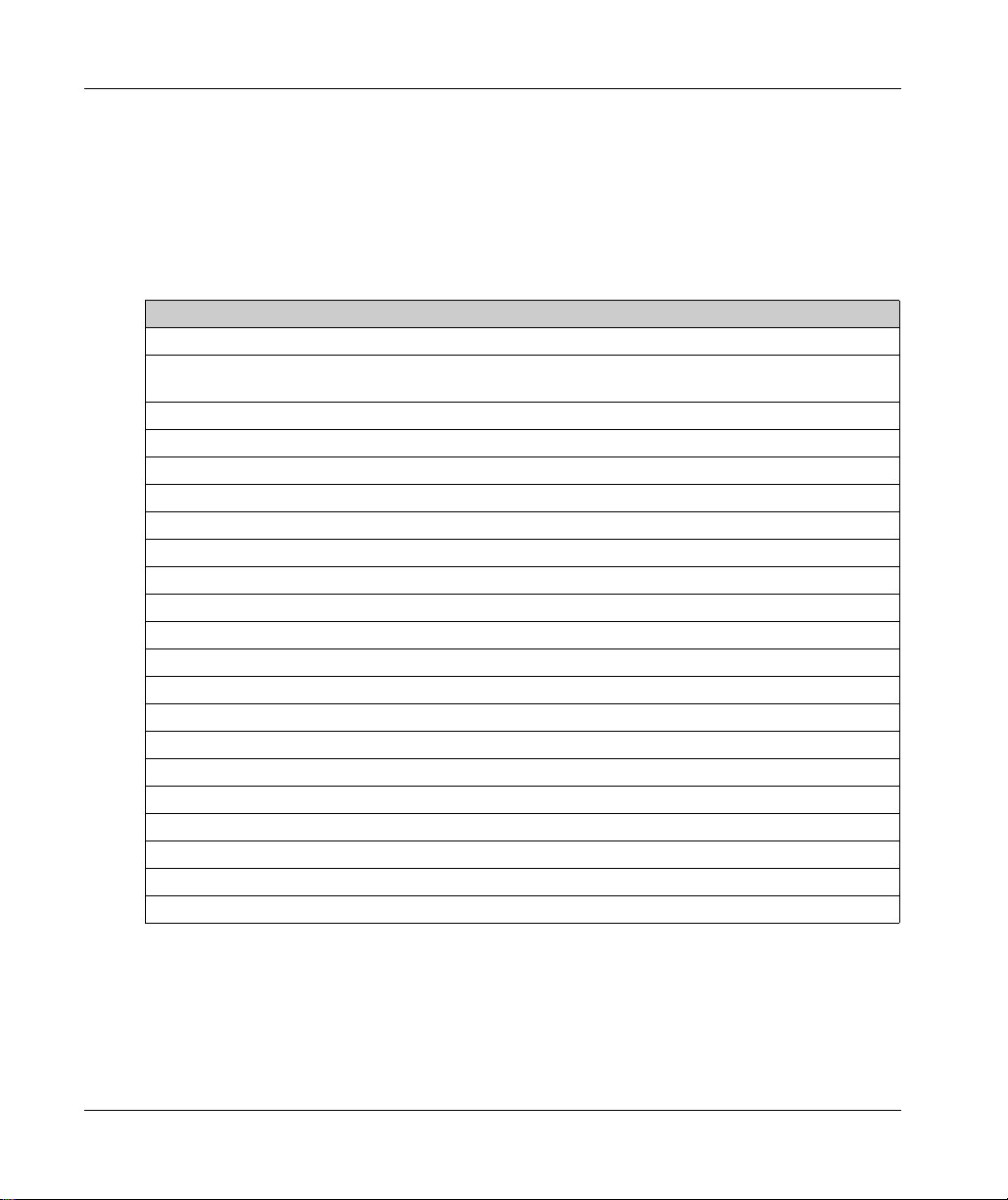

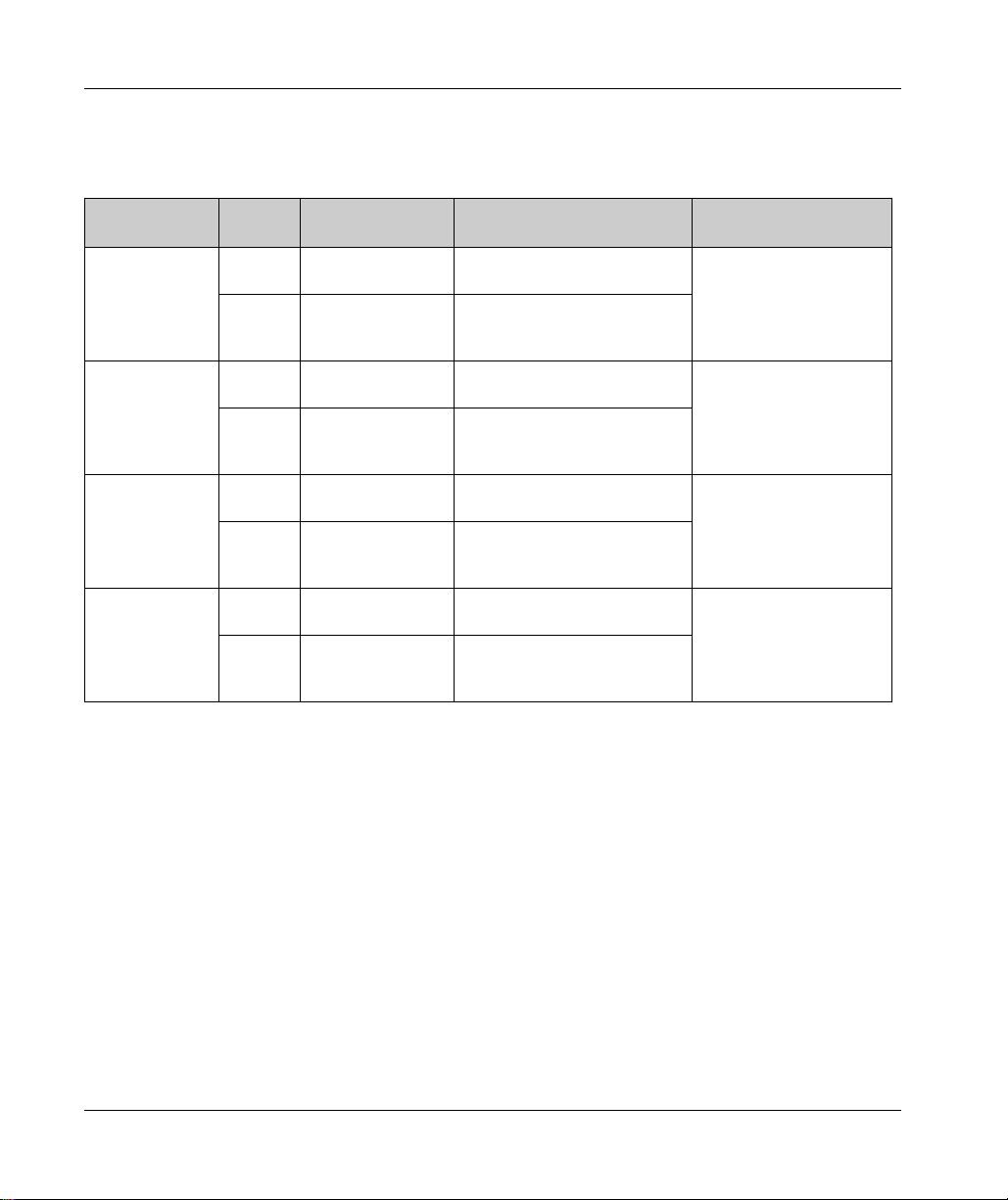

This table groups the module references sharing the same internal ID code:

Modules sharing the same internal ID code

TM3DI16K, TM3DI16, TM3DI16G

TM3DQ16R, TM3DQ16RG, TM3DQ16T, TM3DQ16TG, TM3DQ16TK, TM3DQ16U, TM3DQ16UG,

TM3DQ16UK

TM3DQ32TK, TM3DQ32UK

TM3DI8, TM3DI8G, TM3DI8A

TM3DQ8R, TM3DQ8RG, TM3DQ8T, TM3DQ8TG, TM3DQ8U, TM3DQ8UG

TM3DM8R, TM3DM8RG

TM3DM24R, TM3DM24RG

TM3SAK6R, TM3SAK6RG

TM3SAF5R, TM3SAF5RG

TM3SAC5R, TM3SAC5RG

TM3SAFL5R, TM3SAFL5RG

TM3AI2H, TM3AI2HG

TM3AI4, TM3AI4G

TM3AI8, TM3AI8G

TM3AQ2, TM3AQ2G

TM3AQ4, TM3AQ4G

TM3AM6, TM3AM6G

TM3TM3, TM3TM3G

TM3TI4, TM3TI4G

TM3TI4D, TM3TI4DG

TM3TI8T, TM3TI8TG

16

EIO0000004112 08/2020

Getting Started

Supported Devices

Introduction

The following lists the devices supported by the TM3 Bus Coupler IO Configurator.

NOTE: Modicon TM2 expansion modules are not supported.

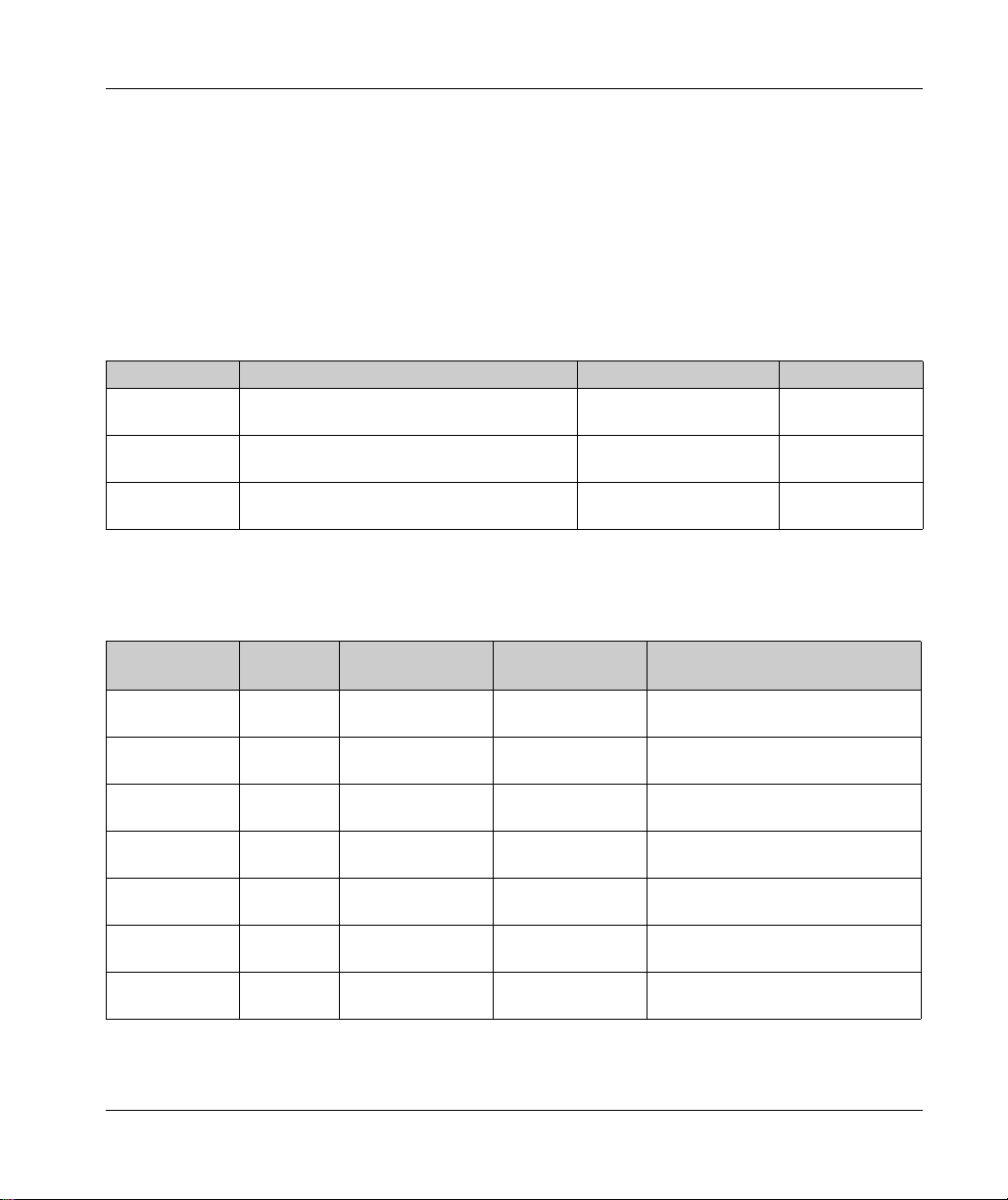

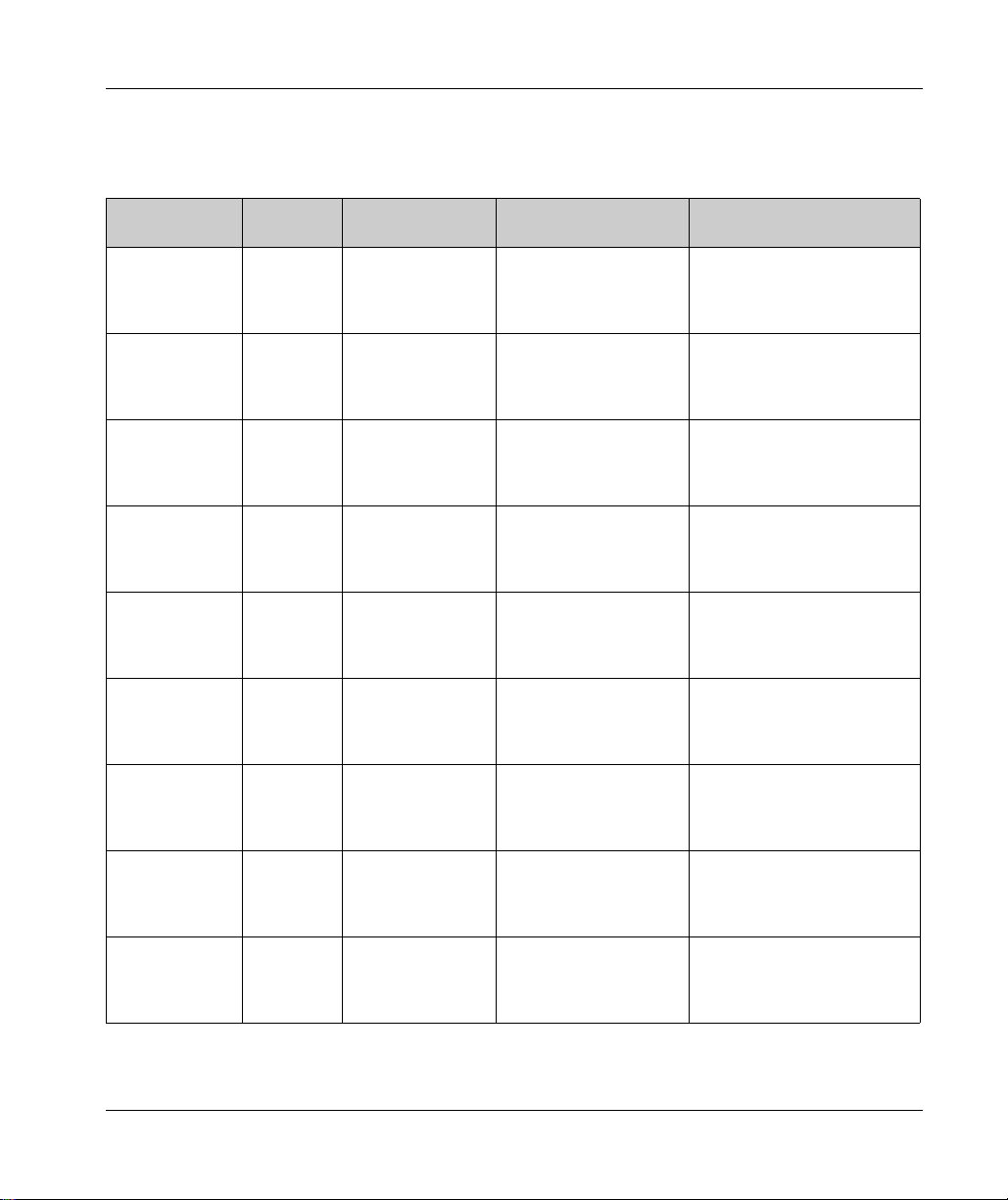

Modicon TM3 Bus Couplers

The following table shows the supported TM3 bus couplers, with port, communication, and terminal

types:

Reference Ports Communication type Terminal Type

TM3BCEIP Isolated switched Ethernet ports: 2

USB mini-B ports: 1

TM3BCSL Isolated RS-485 ports: 2 (daisy-chained)

USB mini-B ports: 1

TM3BCCO Isolated CANopen ports: 2 (daisy-chained)

USB mini-B ports: 1

TM3 Digital Input Modules

The following table shows the TM3 digital input expansion modules, with corresponding channel

type, nominal voltage/current, and terminal type:

EtherNet/IP

Modbus TCP

Modbus Serial line RJ45

CANopen RJ45

RJ45

USB mini-B

USB mini-B

USB mini-B

Reference Channels Channel Type Voltage

Current

TM3DI8A 8 Regular inputs 120 Vac

7.5 mA

TM3DI8 8 Regular inputs 24 Vdc

7mA

TM3DI8G 8 Regular inputs 24 Vdc

7mA

TM3DI16 16 Regular inputs 24 Vdc

7mA

TM3DI16G 16 Regular inputs 24 Vdc

7mA

TM3DI16K 16 Regular inputs 24 Vdc

5mA

TM3DI32K 32 Regular inputs 24 Vdc

5mA

EIO0000004112 08/2020 17

Terminal Type / Pitch

Removable screw terminal block /

5.08 mm

Removable screw terminal block /

5.08 mm

Removable spring terminal block /

5.08 mm

Removable screw terminal blocks /

3.81 mm

Removable spring terminal blocks /

3.81 mm

HE10 (MIL 20) connector

HE10 (MIL 20) connector

Getting Started

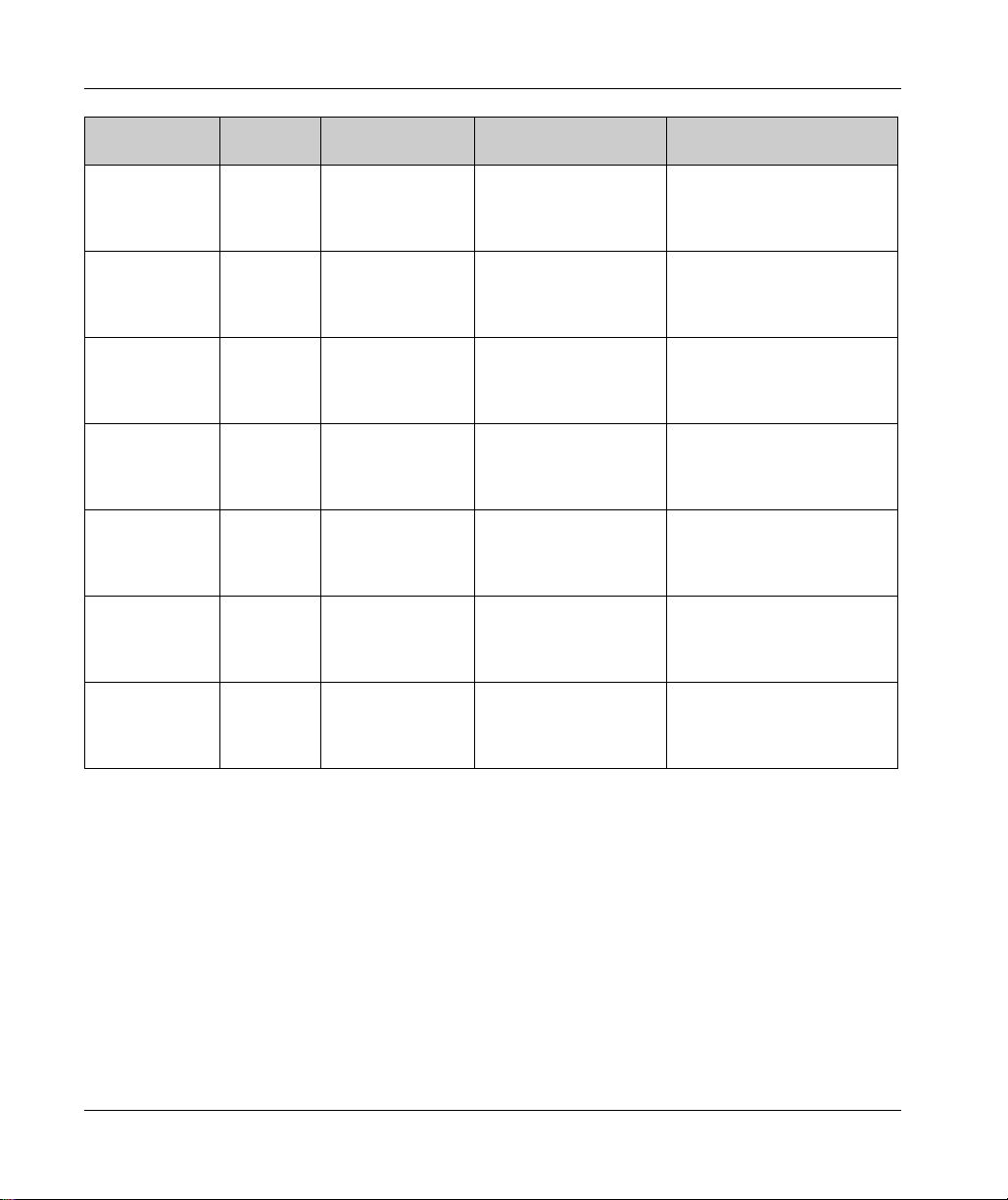

TM3 Digital Mixed Input/Output Modules

This following table shows the TM3 mixed I/O modules, with corresponding channel type, nominal

voltage/current, and terminal type:

Reference Channels Channel Type Voltage

Current

TM3DM8R 4 Regular inputs 24 Vdc

7mA

4 Relay outputs 24 Vdc / 240 Vac

7 A maximum per common line /

2 A maximum per output

TM3DM8RG 4 Regular inputs 24 Vdc

7mA

4 Relay outputs 24 Vdc / 240 Vac

7 A maximum per common line /

2 A maximum per output

TM3DM24R 16 Regular inputs 24 Vdc

7mA

8 Relay outputs 24 Vdc / 240 Vac

7 A maximum per common line /

2 A maximum per output

TM3DM24RG 16 Regular inputs 24 Vdc

7mA

8 Relay outputs 24 Vdc / 240 Vac

7 A maximum per common line /

2 A maximum per output

Terminal Type / Pitch

Removable screw terminal

block / 5.08 mm

Removable spring terminal

block /5.08 mm

Removable screw terminal

blocks / 3.81 mm

Removable spring terminal

blocks / 3.81 mm

18

EIO0000004112 08/2020

TM3 Digital Output Modules

The following table shows the TM3 digital output expansion modules, with corresponding channel

type, nominal voltage/current, and terminal type:

Getting Started

Reference Channels Channel Type Voltage

Current

TM3DQ8R 8 Relay outputs 24 Vdc / 240 Vac

7 A maximum per

common line / 2 A

maximum per output

TM3DQ8RG 8 Relay outputs 24 Vdc / 240 Vac

7 A maximum per

common line / 2 A

maximum per output

TM3DQ8T 8 Regular transistor

outputs (source)

TM3DQ8TG 8 Regular transistor

outputs (source)

TM3DQ8U 8 Regular transistor

outputs (sink)

TM3DQ8UG 8 Regular transistor

outputs (sink)

TM3DQ16R 16 Relay outputs 24 Vdc / 240 Vac

TM3DQ16RG 16 Relay outputs 24 Vdc / 240 Vac

TM3DQ16T 16 Regular transistor

outputs (source)

24 Vdc

4 A maximum per

common line/0.5 A

maximum per output

24 Vdc

4 A maximum per

common line/0.5 A

maximum per output

24 Vdc

4 A maximum per

common line/0.5 A

maximum per output

24 Vdc

4 A maximum per

common line/0.5 A

maximum per output

8 A maximum per

common line / 2 A

maximum per output

8 A maximum per

common line / 2 A

maximum per output

24 Vdc

8 A maximum per

common line / 0.5 A

maximum per output

Terminal Type / Pitch

Removable screw terminal

block / 5.08 mm

Removable spring terminal

block / 5.08 mm

Removable screw terminal

block / 5.08 mm

Removable spring terminal

block / 5.08 mm

Removable screw terminal

block / 5.08 mm

Removable spring terminal

block / 5.08 mm

Removable screw terminal

blocks / 3.81 mm

Removable spring terminal

blocks / 3.81 mm

Removable screw terminal

blocks / 3.81 mm

EIO0000004112 08/2020 19

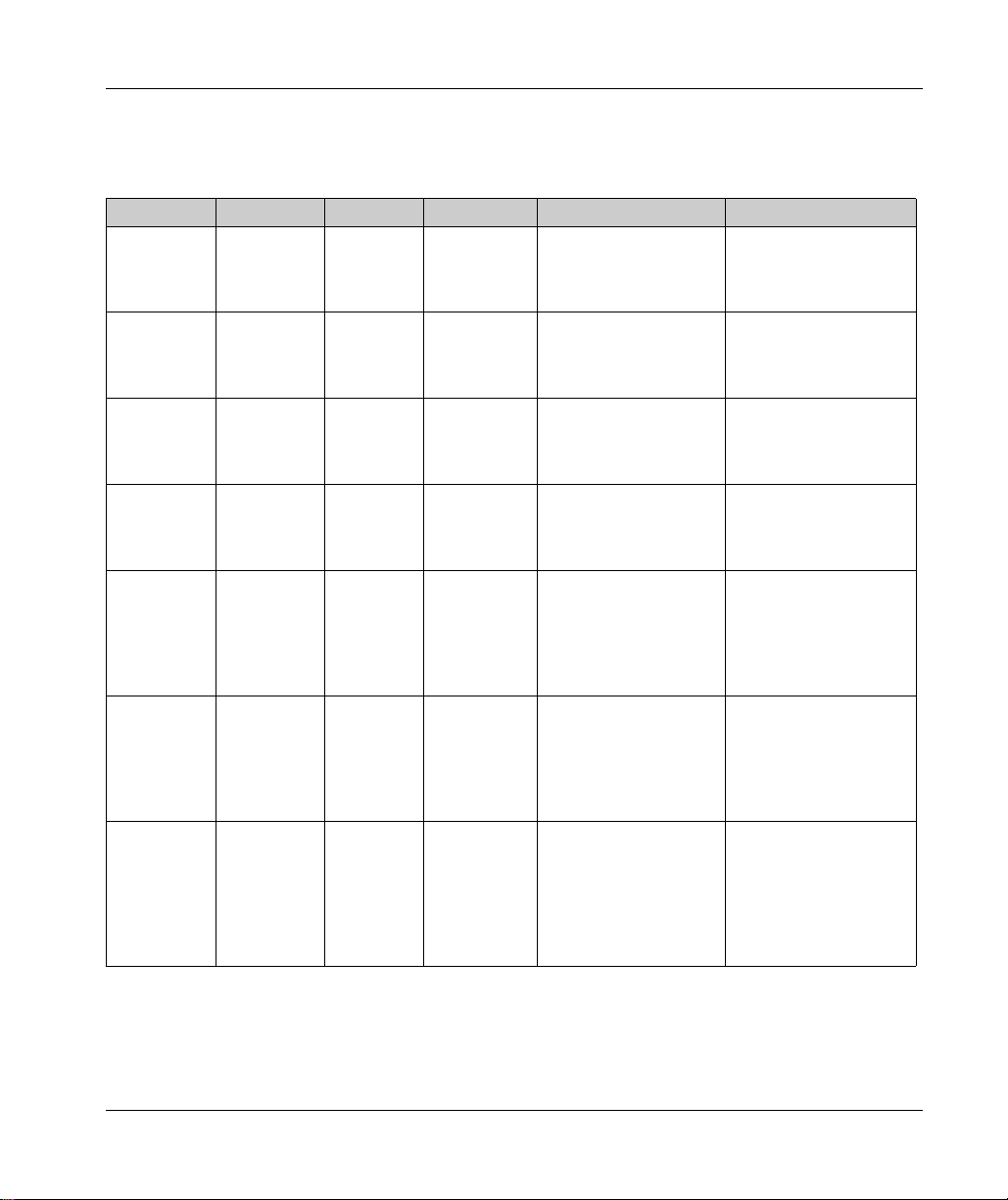

Getting Started

Reference Channels Channel Type Voltage

Current

TM3DQ16TG 16 Regular transistor

outputs (source)

24 Vdc

8 A maximum per

common line / 0.5 A

maximum per output

TM3DQ16U 16 Regular transistor

outputs (sink)

24 Vdc

8 A maximum per

common line / 0.5 A

maximum per output

TM3DQ16UG 16 Regular transistor

outputs (sink)

24 Vdc

8 A maximum per

common line / 0.5 A

maximum per output

TM3DQ16TK 16 Regular transistor

outputs (source)

24 Vdc

2 A maximum per

common line / 0.1 A

maximum per output

TM3DQ16UK 16 Regular transistor

outputs (sink)

24 Vdc

2 A maximum per

common line / 0.1 A

maximum per output

TM3DQ32TK 32 Regular transistor

outputs (source)

24 Vdc

2 A maximum per

common line / 0.1 A

maximum per output

TM3DQ32UK 32 Regular transistor

outputs (sink)

24 Vdc

2 A maximum per

common line / 0.1 A

maximum per output

Terminal Type / Pitch

Removable spring terminal

blocks / 3.81 mm

Removable screw terminal

blocks / 3.81 mm

Removable spring terminal

blocks / 3.81 mm

HE10 (MIL 20) connector

HE10 (MIL 20) connector

HE10 (MIL 20) connectors

HE10 (MIL 20) connectors

20

EIO0000004112 08/2020

Getting Started

TM3 Analog Input Modules

The following table shows the TM3 analog input expansion modules, with corresponding

resolution, channel type, nominal voltage/current, and terminal type:

Reference Resolution Channels Channel Type Supported Modes Terminal Type / Pitch

TM3AI2H 16 bit, or

15 bit + sign

TM3AI2HG 16 bit, or

15 bit + sign

TM3AI4 12 bit, or

11 bit + sign

TM3AI4G 12 bit, or

11 bit + sign

TM3AI8 12 bit, or

11 bit + sign

TM3AI8G 12 bit, or

11 bit + sign

TM3TI4 16 bit, or

15 bit + sign

2 inputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

2 inputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

4 inputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

4 inputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

8 inputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

0...20 mA extended

4...20 mA extended

8 inputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

0...20 mA extended

4...20 mA extended

4 inputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

Thermocouple

PT100/1000

NI100/1000

Removable screw

terminal block / 5.08 mm

Removable spring

terminal block / 5.08 mm

Removable screw

terminal block / 3.81 mm

Removable spring

terminal blocks / 3.81 mm

Removable screw

terminal block / 3.81 mm

Removable spring

terminal blocks / 3.81 mm

Removable screw

terminal block / 3.81 mm

EIO0000004112 08/2020 21

Getting Started

Reference Resolution Channels Channel Type Supported Modes Terminal Type / Pitch

TM3TI4G 16 bit, or

15 bit + sign

TM3TI4D 16 bit, or

15 bit + sign

TM3TI4DG 16 bit, or

15 bit + sign

TM3TI8T 16 bit, or

15 bit + sign

TM3TI8TG 16 bit, or

15 bit + sign

4 inputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

Thermocouple

PT100/1000

NI100/1000

4 inputs Thermocouple Removable screw

4 inputs Thermocouple Removable spring

8 inputs Thermocouple

NTC/PTC

Ohmmeter

8 inputs Thermocouple

NTC/PTC

Ohmmeter

Removable spring

terminal blocks / 3.81 mm

terminal block / 3.81 mm

terminal blocks / 3.81 mm

Removable screw

terminal block / 3.81 mm

Removable spring

terminal blocks / 3.81 mm

TM3 Analog Mixed Input/Output Modules

This following table shows the TM3 analog mixed I/O modules, with corresponding resolution,

channel type, nominal voltage/current, and terminal type:

Reference Resolution Channels Channel Type Mode Terminal Type / Pitch

TM3AM6 12 bit, or

11 bit + sign

TM3AM6G 12 bit, or

11 bit + sign

TM3TM3 16 bit, or

15 bit + sign

12 bit, or

11 bit + sign

22

4 inputs 0...10 Vdc

2 outputs

4 inputs 0...10 Vdc

2 outputs

2 inputs 0...10 Vdc

1 outputs 0...10 Vdc

-10...+10 Vdc

0...20 mA

4...20 mA

-10...+10 Vdc

0...20 mA

4...20 mA

-10...+10 Vdc

0...20 mA

4...20 mA

Thermocouple

PT100/1000

NI100/1000

-10...+10 Vdc

0...20 mA

4...20 mA

Removable screw terminal

block / 3.81 mm

Removable spring terminal

block / 3.81 mm

Removable screw terminal

block / 5.08 mm

EIO0000004112 08/2020

Getting Started

Reference Resolution Channels Channel Type Mode Terminal Type / Pitch

TM3TM3G 16 bit, or

15 bit + sign

12 bit, or

11 bit + sign

2 inputs 0...10 Vdc

-10...+10 Vdc

0...20 mA

4...20 mA

Thermocouple

PT100/1000

NI100/1000

1 outputs 0...10 Vdc

-10...+10 Vdc

0...20 mA

4...20 mA

Removable spring terminal

block / 5.08 mm

TM3 Analog Output Modules

The following table shows the TM3 analog output modules, with corresponding resolution, channel

type, nominal voltage/current, and terminal type:

Reference Resolution Channels Channel Type Mode Terminal Type / Pitch

TM3AQ2 12 bit, or

11 bit + sign

TM3AQ2G 12 bit, or

11 bit + sign

TM3AQ4 12 bit, or

11 bit + sign

TM3AQ4G 12 bit, or

11 bit + sign

2 outputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

2 outputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

4 outputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

4 outputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

Removable screw terminal

block / 5.08 mm

Removable spring terminal

block / 5.08 mm

Removable screw terminal

block / 5.08 mm

Removable spring terminal

block / 5.08 mm

EIO0000004112 08/2020 23

Getting Started

TM3 Expert Modules

The following table shows the TM3 expert expansion modules, with corresponding terminal types:

Reference Description Terminal Type / Pitch

TM3XTYS4 TeSys module 4 front connectors RJ-45

TM3SAC5R/G Safety module, 1 function, CAT3, maximum PL d/SIL2 Removable screw/spring terminal

TM3SAF5R/G Safety module, 1 function, CAT4, maximum PL e/SIL3 Removable screw/spring terminal

TM3SAK6R/G Safety module, 3 functions, CAT4, maximum PL e/SIL3 Removable screw/spring terminal

TM3SAFL5R/G Safety module, 2 functions, CAT3, maximum PL d/SIL2 Removable screw/spring terminal

TM3XTRA1 Data transmitter module for remote I/O 1 front connector RJ-45

TM3XREC1 Data receiver module for remote I/O 1 front connector RJ-45

1 removable power supply

connector / 5.08 mm

block

block

block

block

1 screw for functional ground

connection

1 removable power supply

connector / 5.08 mm

24

EIO0000004112 08/2020

User Interface

Introduction

Use the TM3 Bus Coupler IO Configurator to generate configuration files for Modicon TM3 Bus

Couplers. This can be done

connected to the bus coupler.

A configuration file contains details of the:

Structure and number of expansion modules connected to the bus coupler

Configuration of the bus coupler

Configuration of each of the expansion modules connected to the bus coupler.

Each configuration file created with the TM3 Bus Coupler IO Configurator is specific to one bus

coupler: if your configuration includes more than one bus coupler, create a separate configuration

file for each.

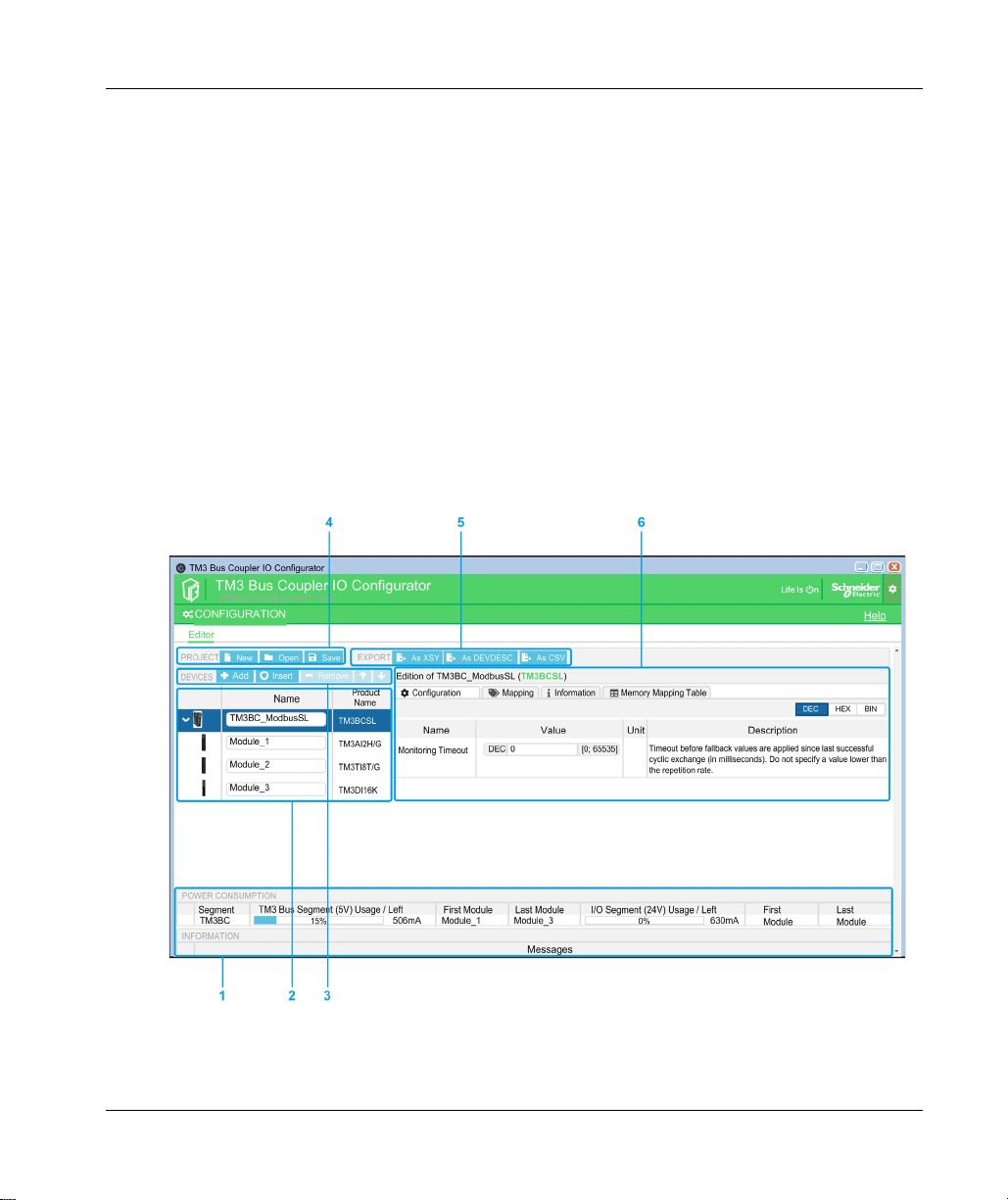

The Configuration Window

The configuration window is displayed when you start the TM3 Bus Coupler IO Configurator:

Getting Started

offline

; that is, the PC running the tool does not need to be physically

EIO0000004112 08/2020 25

Getting Started

1 Power Consumption

2 Structured view of the bus coupler and expansion module configuration

3 DEVICES toolbar

4 PROJECT toolbar

5 EXPORT toolbar

6 Configuration and I/O Mapping tabs to configure the selected module. Information tab to display details of

the selected module. Memory Mapping Table tab for configuration of communication parameters for

EtherNet/IP and Modbus SL/Modbus TCP.

On the Configuration tab, click the DEC (decimal), HEX (hexadecimal) or BIN (binary) button to

display parameter values in the corresponding format.

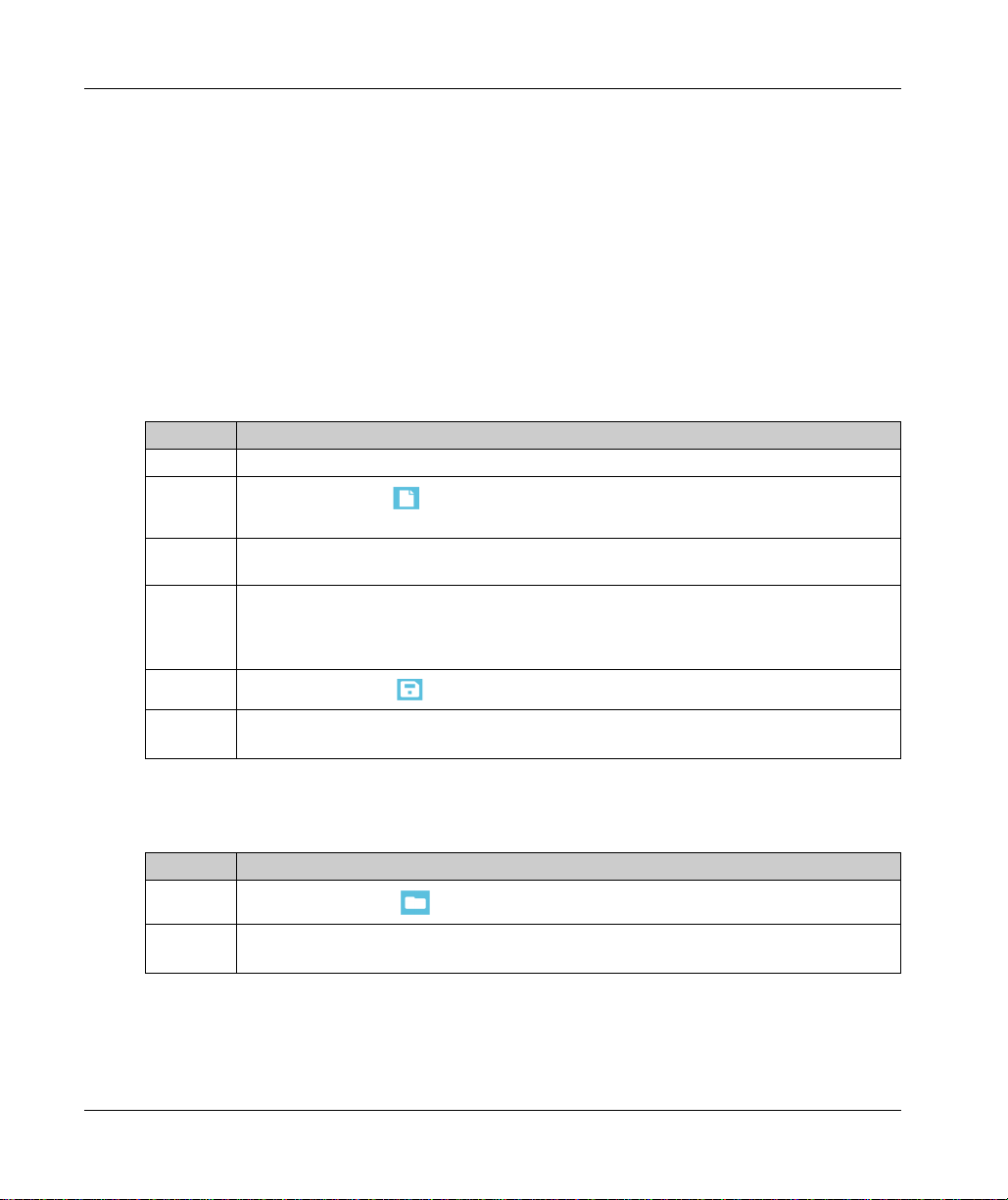

Creating a New Project

To create a new project:

Step Action

1 Start the TM3 Bus Coupler IO Configurator.

2

3 Click the TM3 bus coupler to use.

4 Optionally, click in the text box below Name to edit the default name of the bus coupler.

Click the New button on the PROJECT toolbar.

Result: The New Project window appears showing a list of the supported TM3 bus couplers.

Result: The selected bus coupler appears in the configuration window.

NOTE: Editing the bus coupler name does not automatically change the project file name.

You can now proceed to configure the bus coupler and add modules to the project.

5

6 Type a project name and click Save.

Click the Save button on the PROJECT toolbar.

Result: The project file is saved as a .spf file.

(see page 29)

of the current configuration

Opening an Existing Project

To open an existing project:

Step Action

1

Click the Open button on the PROJECT toolbar.

2 Navigate and select a project file (.spf), then click Open.

Result: The project appears in the configuration window.

26

EIO0000004112 08/2020

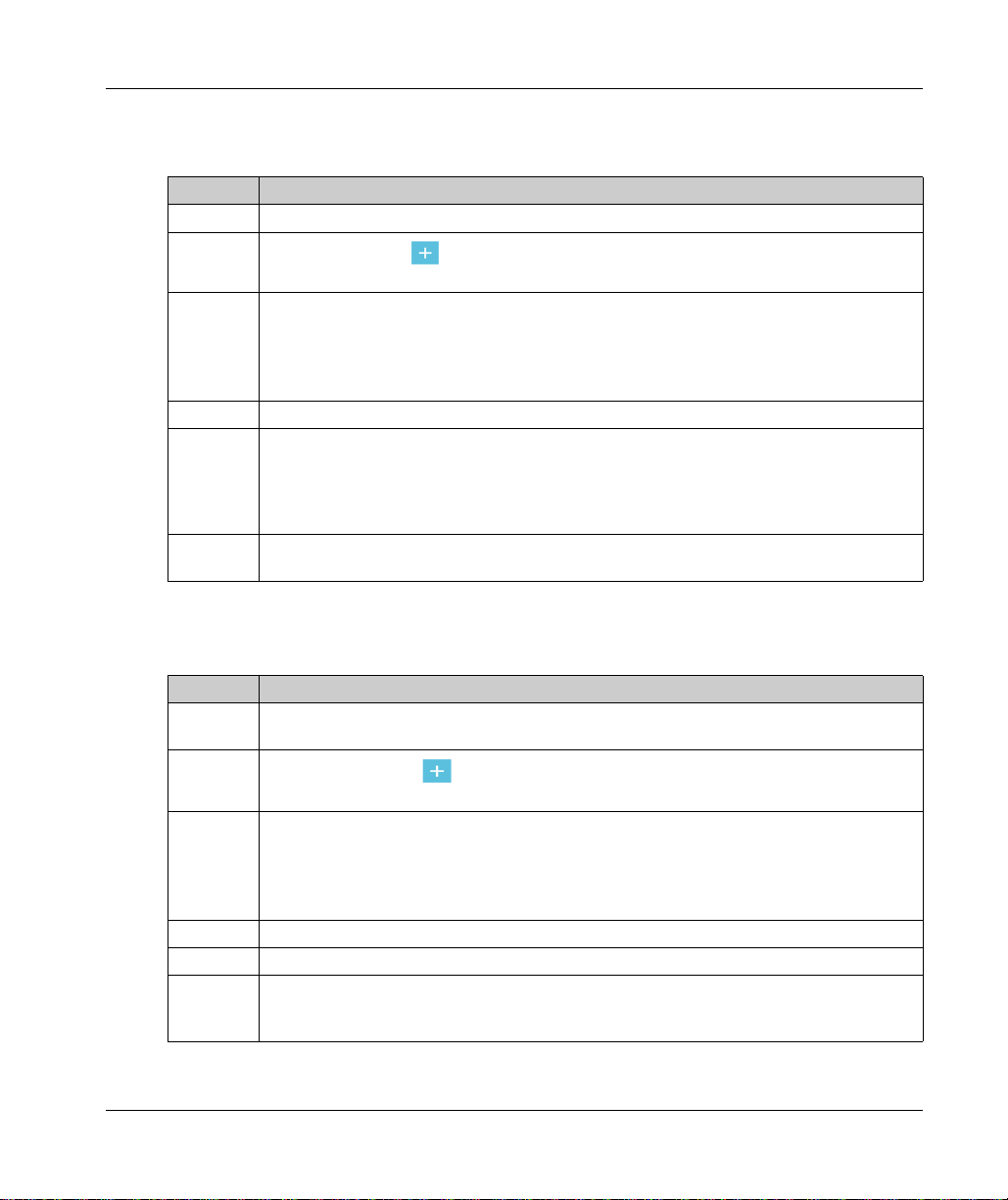

Adding Modules

To add modules to the TM3 bus coupler:

Step Action

1 Select the bus coupler in the configuration window.

2

Click the Add button on the DEVICES toolbar.

Result: The Add or insert a new device window appears.

3Either:

Type the name of a TM3 expansion module in the Search modules text box. When you have

typed 4 characters, a list of all matching modules appears. For example, type “TM3A” to

display all TM3 Analog modules.

Click > to expand the module categories until the module to add appears.

4 Select a module and click the Add button.

5 Repeat the previous two steps to add more modules.

When you have added 7 modules to the bus coupler segment, you are prompted to add a

TM3XTRA1 module. Select the module and click Add to add the Transmitter/Receiver

(TM3XTRA1 and TM3XREC1) modules to the configuration. You can then proceed to add up

to 7 more modules to the transmitter/receiver segment.

6 When all modules have been added, click the Close button.

Result: The new module or modules appear below the bus coupler in the configuration window.

Inserting Modules between Existing Modules

Inserting new modules:

Getting Started

Step Action

1 In the configuration on the left of the configuration window, select the TM3 expansion module

above which to insert a new module.

2

Click the Insert button on the DEVICES toolbar.

Result: The Add or insert a new device window appears.

3Either:

Type the name of a TM3 expansion module in the Search modules text box. When you have

typed 4 characters, a list of all matching modules appears. For example, type “TM3A” to

display all TM3 Analog modules.

Click > to expand the module categories until the module to add appears.

4 Select a module and click Insert.

5 If required, repeat the previous two steps to insert more modules.

6 When all modules have been added, click Close to return to the configuration window.

Result: The new module or modules appear in the configuration window below the module that

was selected.

EIO0000004112 08/2020 27

Getting Started

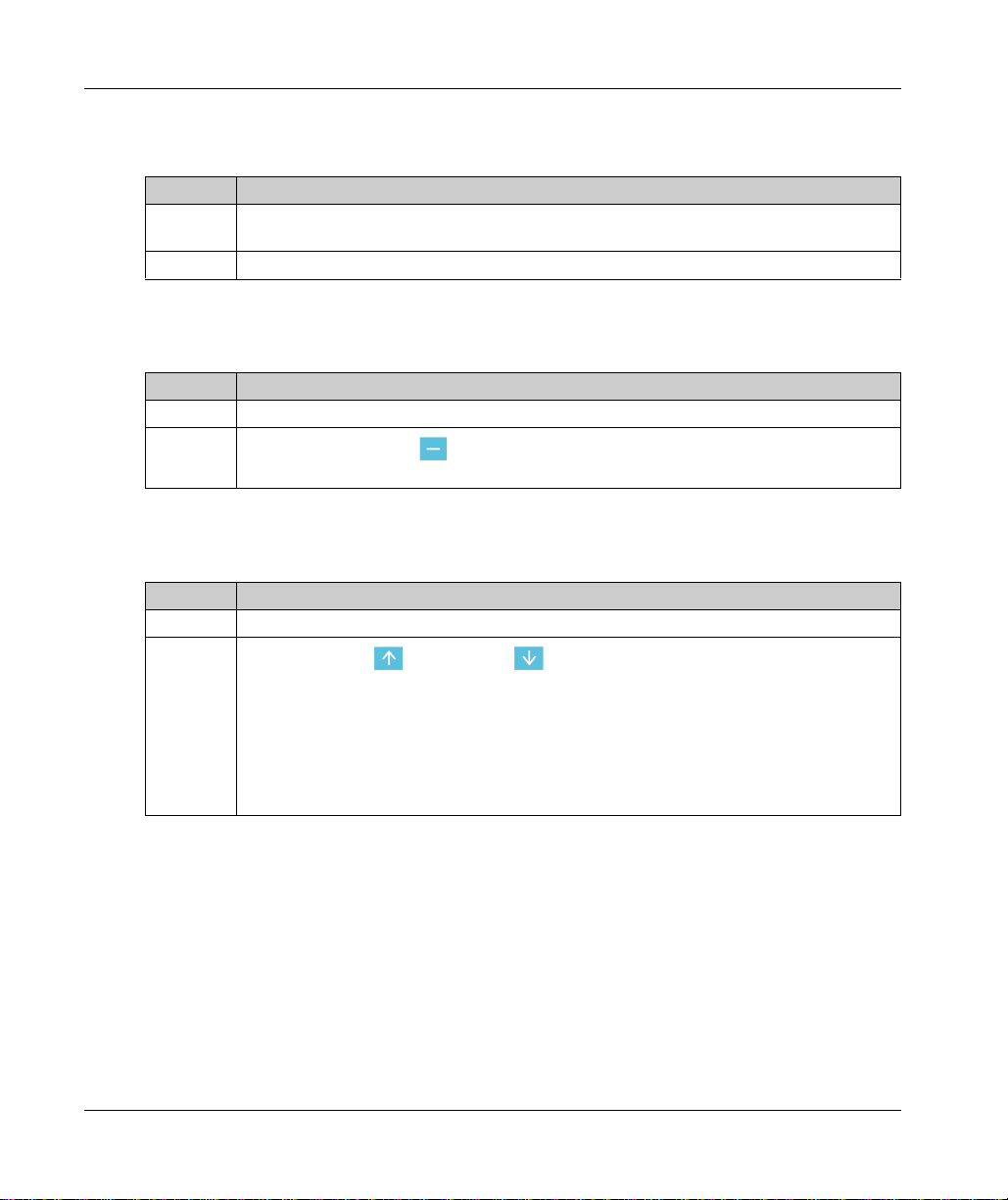

Configuring Modules

To configure a module:

Step Action

1 Select the module in the configuration window.

2 Proceed to configure the module as described in Configuring Modules

Result: The configuration parameters of the module appears.

Removing a Module

To remove a module from the configuration:

Step Action

1 Select the module in the configuration window.

2

Click the Remove button on the DEVICES toolbar.

Result: The module is removed from the configuration.

Changing the Position of Modules

To move a module to a different position in the configuration:

Step Action

1 Select a module in the configuration window.

2

Click the up arrow or down arrow buttons on the DEVICES toolbar until the module

is in the new position.

NOTE: You can only move modules within the bus coupler segment or the transmitter/receiver

segment

module then add it to the other segment. If the segment already contains the maximum number

of modules, you must first remove a module.

(see page 29)

NOTE: You cannot move the Transmitter/Receiver modules up or down in the configuration.

(see page 37)

. To move a module from one segment to another, first remove the

.

28

EIO0000004112 08/2020

Managing Power Consumption

Overview

The TM3 Bus Coupler IO Configurator monitors the number of modules in the configuration and

the power consumed by each module.

TM3 expansion modules consume power on the 5 Vdc TM3 internal bus.

Modules with an independent 24 Vdc power supply may also consume power on the 24 Vdc

internal I/O bus. For example, the TM3XTYS4 modules consumes 37 mA on the 5 Vdc TM3

internal bus and 17 mA on the 24 Vdc internal I/O bus.

Segments

A TM3 Bus Coupler IO Configurator configuration comprises 1 or 2

The bus coupler and the TM3 modules directly connected to it form the

Adding the TM3XTRA1/TM3XREC1 module pair to the end of the bus coupler segment creates

a new

transmitter/receiver segment

TM3XREC1 module.

As the TM3XREC1 module has an independent power supply, it provides the power to the

modules on the transmitter/receiver segment through the 5 Vdc TM3 internal bus.

The total power consumed by the modules on each segment must not exceed 100% of the power

available on the corresponding bus.

Getting Started

segments

:

bus coupler segment

. Additional TM3 modules can then be connected to the

.

Managing Power Consumption of Modules

The Power Consumption window appears at the bottom of the TM3 Bus Coupler IO Configurator

window:

The Power Consumption window shows:

Segment. The segment name: TM3BC (bus coupler) or Transmitter/receiver.

TM3 Bus Segment (5V) Usage / Left. The percentage of 5 V TM3 Bus power being consumed

by the segment and the remaining available power.

NOTE: As the bus coupler provides more power than the TM3XREC1 module, expansion

modules consume a lower percentage of power on the bus coupler segment than on the

transmitter/receiver segment.

First Module. The name of the first expansion module on this segment.

Last Module. The name of the last expansion module on this segment.

EIO0000004112 08/2020 29

Getting Started

I/O Segment (24V) Usage / Left. The percentage of 24 V IO Bus power being consumed by the

segment and the remaining available power.

NOTE: As the bus coupler provides more power than the TM3XREC1 module, expansion

modules consume a lower percentage of power on the bus coupler segment than on the

transmitter/receiver segment.

First Module. The name of the first expansion module on this segment.

Last Module. The name of the last expansion module on this segment.

The TM3 Bus Coupler IO Configurator displays appropriate error or advisory messages in the

Messages area of the Power Consumption window if:

The maximum number of TM3 modules supported by the bus coupler is exceeded.

The total power consumption of all modules in a segment exceeds 100% of available power.

NOTE: The current consumption figures presented by the Power Consumption function are based

on assumed values rather than actual current measurements. The assumed values for the outputs

are based on normal loads. The assumed values for input signals are based on known internal

loads. While the use of the Power Consumption function to test the power budget is required, it is

no substitute for real and complete system testing and commissioning.

30

EIO0000004112 08/2020

Modicon TM3 Bus Coupler IO Configurator

Use Cases

EIO0000004112 08/2020

Use Cases

Chapter 2

Use Cases

Introduction

This chapter describes the main use cases for deployment of the TM3 Bus Coupler IO

Configurator.

For detailed example use cases, refer to Use Case Examples

What Is in This Chapter?

This chapter contains the following topics:

Creating a Configuration File 32

Loading a Configuration File into a Bus Coupler (TM3BCEIP and TM3BCSL) 33

Exporting Generic Configuration Files 34

(see page 159)

.

Topic Page

EIO0000004112 08/2020 31

Use Cases

Creating a Configuration File

Creating a Configuration File

Step Action

1 Use the TM3 Bus Coupler IO Configurator to reproduce the physical configuration of a TM3 bus

coupler and the TM3 expansion modules connected to it:

This is described in User Interface section

2 Configure each of the devices in the configuration.

This is described in the Configuring Devices chapter

3 Save the project, which generates the configuration file.

4 Configure the bus coupler:

For TM3BCEIP and TM3BCSL, directly import the configuration file into the bus coupler

(see page 93)

For TM3BCCO, first export the configuration as a Device Configuration File (DCF), then

import the DCF file into the relevant external software package

.

(see page 25)

(see page 37)

.

.

(see page 99)

.

32

EIO0000004112 08/2020

Loading a Configuration File into a Bus Coupler (TM3BCEIP and TM3BCSL)

Overview

With the TM3BCEIP and TM3BCSL bus couplers, the configuration file can be loaded directly into

the bus coupler using the Web server interface of the bus coupler:

Step Action

1 Save the project in the TM3 Bus Coupler IO Configurator, which generates the configuration as

an SPF file.

2 Load the file into the TM3BCEIP or TM3BCSL bus coupler

(see page 93)

.

Use Cases

EIO0000004112 08/2020 33

Use Cases

Exporting Generic Configuration Files

Overview

A generic configuration file can be exported from the TM3 Bus Coupler IO Configurator in a number

of different formats, which can then be imported into external software packages.

The export process differs depending on the communication protocol being used:

EtherNet/IP

Modbus SL / Modbus TCP

CANopen

EtherNet/IP

A configuration file for an EtherNet/IP bus coupler is exported as an Electronic Data Sheet (EDS)

file. The EDS is a generic file that contains information about assembly instances and their size.

The size of the input (T->O) and output (O->T) assemblies corresponds to the configuration of the

TM3 modules connected to the bus coupler.

A Memory Mapping Table, a file that contains information about communication parameters

(EtherNet/IP assembly instances, inputs and outputs data structures), can also be exported.

This figure shows examples of external software packages and controllers:

(see page 34)

(see page 35)

(see page 36)

34

For details on exporting the EDS file, refer to Exporting for EtherNet/IP

For details on exporting the CSV file, refer to Memory Mapping Table

(see page 96)

(see page 101)

EIO0000004112 08/2020

.

.

Modbus SL / Modbus TCP

This export process depends on the external software package used.

For EcoStruxure Control Expert, a symbol table is exported as an XSY file:

For details on exporting the:

XSY file, refer to Exporting for Modbus SL / Modbus TCP

CSV file, refer to Memory Mapping Table

For SoMachine V4.3 or EcoStruxure Machine Expert, the configuration file is exported as a

devdesc file:

(see page 101)

(see page 97)

.

Use Cases

.

For details on exporting the:

devdesc file, refer to Exporting for Modbus SL / Modbus TCP

CSV file, refer to Memory Mapping Table

EIO0000004112 08/2020 35

(see page 101)

(seepage97)

.

Use Cases

CANopen

A configuration file for a CANopen bus coupler is exported as a Device Configuration File (DCF).

DCF is a standardized file format that can be used by most IEC 61131-compliant software

packages.

This figure shows examples of external software packages and controllers:

For details on exporting the DCF file, refer to Exporting for CANopen

(see page 99)

.

36

EIO0000004112 08/2020

Modicon TM3 Bus Coupler IO Configurator

Configuring Devices

EIO0000004112 08/2020

Configuring Devices

Chapter 3

Configuring Devices

Introduction

This chapter describes how to configure the devices supported by the TM3 Bus Coupler IO

Configurator.

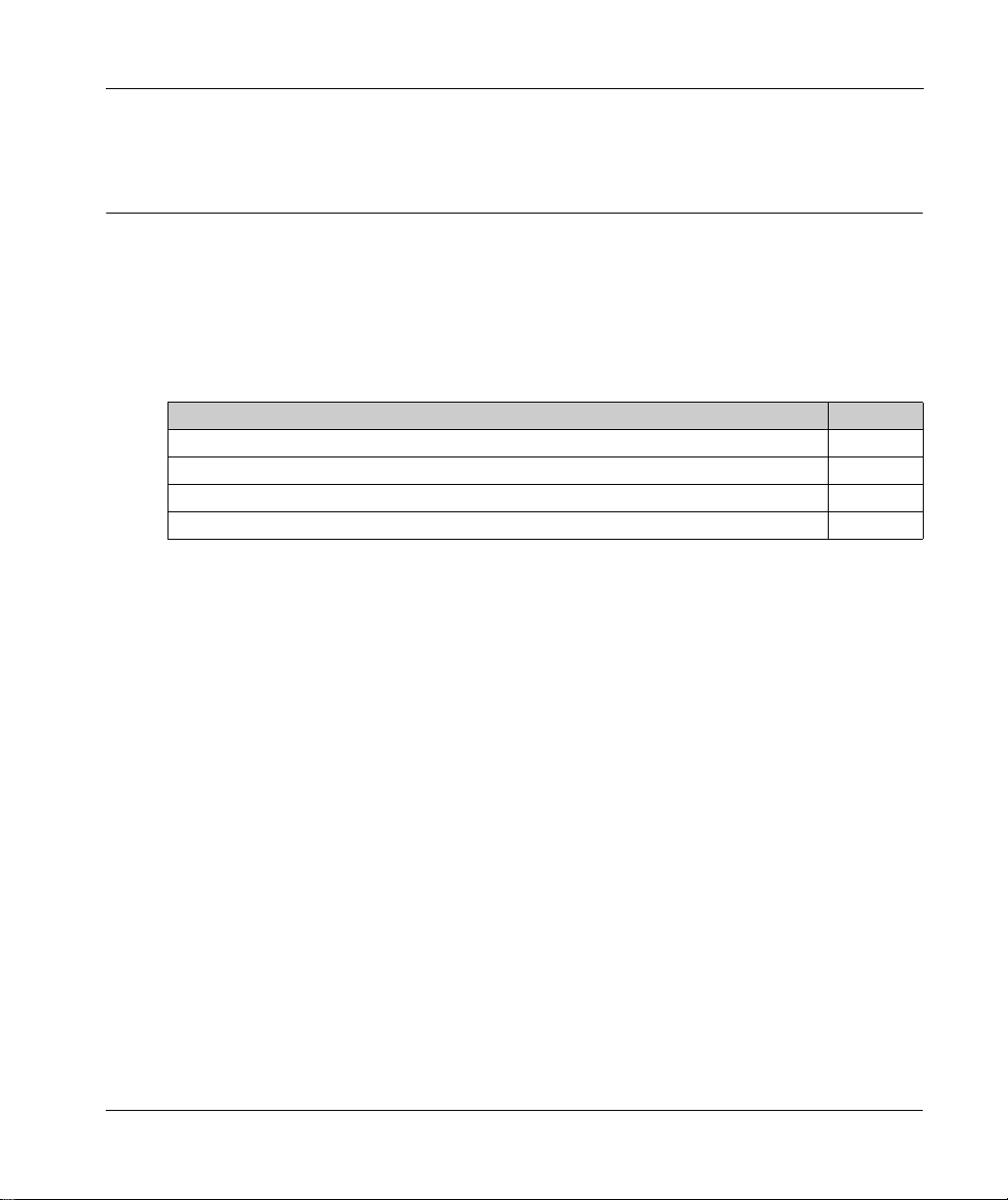

What Is in This Chapter?

This chapter contains the following sections:

Section Topic Page

3.1 Configuring Bus Couplers 38

3.2 Configuring TM3 Analog Input Modules 42

3.3 Configuring TM3 Analog Mixed Modules 65

3.4 Configuring TM3 Analog Output Modules 74

3.5 Configuring TM3 Digital Modules 79

3.6 Configuring TM3 Expert Modules 81

3.7 Configuring CANopen PDO Transmission Mode for Analog Inputs 92

EIO0000004112 08/2020 37

Configuring Devices

Configuring Bus Coupler s

Section 3.1

Configuring Bus Couplers

What Is in This Section?

This section contains the following topics:

Configuring TM3BCEIP Bus Couplers 39

Configuring TM3BCSL Bus Couplers 40

Configuring TM3BCCO Bus Couplers 41

Topic Page

38

EIO0000004112 08/2020

Configuring TM3BCEIP Bus Couplers

Configuring TM3BCEIP for EtherNet/IP

The TM3BCEIP bus coupler for EtherNet/IP does not have any editable parameters.

Configuring TM3BCEIP for Modbus TCP

The TM3BCEIP bus coupler for Modbus TCP has the following configuration parameter:

Name Value Default (DEC) Description

Monitoring Timeout 0...65535 1000 Timeout before fallback values are applied since

NOTE:

Setting Monitoring Timeout to 0 disables:

the monitoring timeout in the bus coupler

fallback management in the bus coupler

the ability to manage the bus coupler using the Web server.

Configuring Devices

last successful cyclic exchange (in milliseconds).

EIO0000004112 08/2020 39

Configuring Devices

Configuring TM3BCSL Bus Couplers

Configuring TM3BCSL

The TM3BCSL bus coupler has the following configuration parameters:

Name Value Default (DEC) Description

Monitoring Timeout 0...65535 0 Timeout (in milliseconds) before the bus coupler goes into

NOTE:

Setting Monitoring Timeout to 0 disables:

the monitoring timeout in the bus coupler

fallback management in the bus coupler

the ability to manage the bus coupler using the Web server.

fallback mode if the communication cable is disconnected

or if the master does not send a request to the bus coupler

within the configured time.

40

EIO0000004112 08/2020

Configuring TM3BCCO Bus Couplers

Configuring the TM3BCCO

The TM3 CANopen bus coupler (TM3BCCO) does not have any editable parameters.

Configuring Devices

EIO0000004112 08/2020 41

Configuring Devices

Configuring TM3 Analog Input Modules

Section 3.2

Configuring TM3 Analog Input Modules

This section describes how to configure TM3 Analog input modules.

What Is in This Section?

This section contains the following topics:

TM3AI2H / TM3AI2HG 43

TM3AI4 / TM3AI4G 46

TM3AI8 / TM3AI8G 49

TM3TI4 / TM3TI4G 53

TM3TI4D / TM3TI4DG 57

TM3TI8T / TM3TI8TG 60

Topic Page

42

EIO0000004112 08/2020

TM3AI2H / TM3AI2HG

Introduction

The TM3AI2H (screw terminal block) / TM3AI2HG (spring terminal block) expansion module

feature 2 analog input channels with 16-bit resolution.

The channel input types are:

0...10 V

-10...+10 V

0...20 mA

4...20 mA

Optional Module

For this module, you can define:

Parameter Value Default Value Description

Optional module Yes

Inputs

For each input channel (IW0, IW1) you can define:

No

Configuring Devices

No Specifies whether this module is optional. When set

to Yes the module must conform to the rules

described in Optional Modules

(see page 15)

.

Parameter Value Default Value Description

Type Not used

0 - 10 V

-10 - +10 V

0 - 20 mA

4 - 20 mA

Minimum 0 - 10 V -32768...32767 0 Specifies the lower measurement limit.

-10 - +10 V -10000

0 - 20 mA 0

4 - 20 mA 4000

Maximum 0 - 10 V -32768...32767 10000 Specifies the upper measurement limit.

-10 - +10 V 10000

0 - 20 mA 20000

4 - 20 mA 20000

EIO0000004112 08/2020 43

Not used Choose the mode of the channel.

Configuring Devices

Parameter Value Default Value Description

Input Filter 0...1000 0 Specifies the first order filter time constant

(0...10 s) in increments of 10 ms.

Sampling 1 1 Specifies the sampling period of the channel

in ms. If an input filter is active, the sampling

period is set internally to 10 ms.

Diagnostic

For this module, you can define:

Parameter Value Default Value Description

Status Enabled Yes

No

Yes Enables the status/diagnostic byte of this input

channel.

If disabled (value = No), status/diagnostic data is not

included in the data structure.

CANopen

For each analog input, you can define:

Parameter Value Default Value Description

Upper limit Yes

No

(1)

Upper limit threshold

Lower limit Yes

Lower limit threshold

Delta interrupt Yes

Delta interrupt

threshold

(1) Depends on the type and the unit of the input.

(1)

0...10000 0 The upper limit threshold value.

No

(1)

0...10000 0 The lower limit threshold value.

No

0...10000 50 The delta interrupt threshold value.

No Enables the upper limit threshold event.

No Enables the lower limit threshold event.

No Enables the delta interrupt event.

44

For details, refer to Configuring CANopen PDO Transmission Mode for Analog Inputs

(see page 92)

.

EIO0000004112 08/2020

I/O Mapping Tab

I/O channels can be mapped to variables in the Mapping tab.

This table describes the Mapping tab:

Variable Channel Symbol

Inputs IW0 Current value of the input 0.

Diagnostic IBStatusIW0 Status of input 0.

Configuring Devices

IW1 Current value of the input 1.

IBStatusIW1 Status of input 1.

EIO0000004112 08/2020 45

Configuring Devices

TM3AI4 / TM3AI4G

Introduction

The TM3AI4 (screw terminal block) / TM3AI4G (spring terminal block) expansion module feature

4 analog input channels with 12-bit resolution.

The channel input types are:

0...10 V

-10...+10 V

0...20 mA

4...20 mA

Optional Module

For this module, you can define:

Parameter Value Default Value Description

Optional module YesNoNo Specifies whether this module is optional. When set

Inputs

For each input channel (IW0...IW3) you can define:

to Yes the module must conform to the rules

described in Optional Modules

(see page 15)

.

Parameter Value Default Value Description

Type Not used

0 - 10 V

-10 - +10 V

0 - 20 mA

4 - 20 mA

Minimum 0 - 10 V -32768...32767 0 Specifies the lower measurement limit.

-10 - +10 V -10000

0 - 20 mA 0

4 - 20 mA 4000

Maximum 0 - 10 V

-10 - +10 V 10000

0 - 20 mA 20000

4 - 20 mA 20000

(1) The 12-bit data (0 to 4095) processed in the analog I/O module can be linear-converted to a value between -32768

and 32767.

46

-32768...32767

Not used Choose the mode of the channel.

(1)

10000 Specifies the upper measurement limit.

EIO0000004112 08/2020

Configuring Devices

Parameter Value Default Value Description

Input Filter 0...1000 0 Specifies the first order filter time constant

(0...10 s) in increments of 10 ms.

Sampling 1

10

(1) The 12-bit data (0 to 4095) processed in the analog I/O module can be linear-converted to a value between -32768

and 32767.

1 Specifies the sampling period of the channel

in ms. If an input filter is active, the sampling

period is set internally to 10 ms.

Diagnostics

For this module, you can define:

Parameter Value Default Value Description

Status Enabled Yes

No

Yes Enables the status/diagnostic byte of this input channel.

If disabled (value = No), status/diagnostic data is not

included in the data structure.

CANopen

For each analog input, you can define:

Parameter Value Default Value Description

Upper limit Yes

Upper limit threshold

Lower limit Yes

Lower limit threshold

Delta interrupt Yes

Delta interrupt

threshold

(1) Depends on the type and the unit of the input.

(1)

No

(1)

0...10000 0 The upper limit threshold value.

No

(1)

0...10000 0 The lower limit threshold value.

No

0...10000 50 The delta interrupt threshold value.

No Enables the upper limit threshold event.

No Enables the lower limit threshold event.

No Enables the delta interrupt event.

For details, refer to Configuring CANopen PDO Transmission Mode for Analog Inputs

(see page 92)

EIO0000004112 08/2020 47

.

Configuring Devices

I/O Mapping Tab

I/O channels can be mapped to variables in the Mapping tab.

This table describes the Mapping tab:

Variable Channel Symbol

Inputs IW0 Current value of the input 0.

Diagnostic IBStatusIW0 Status of input 0.

IW1 Current value of the input 1.

IW2 Current value of the input 2.

IW3 Current value of the input 3.

IBStatusIW1 Status of input 1.

IBStatusIW2 Status of input 2.

IBStatusIW3 Status of input 3.

48

EIO0000004112 08/2020

TM3AI8 / TM3AI8G

Introduction

The TM3AI8 (screw terminal block) / TM3AI8G (spring terminal block) expansion module feature

8 analog input channels with 12-bit resolution.

The channel input types are:

0...10 V

-10...+10 V

0...20 mA

4...20 mA

0...20 mA extended

4...20 mA extended

Optional Module

For this module, you can define:

Parameter Value Default Value Description

Optional module Yes

Inputs

For each input channel (IW0...IW7), you can define:

No

Configuring Devices

No Specifies whether this module is optional. When set

to Yes the module must conform to the rules

described in Optional Modules

(see page 15)

.

Parameter Value Default Value Description

Type Not used

0 - 10 V

Not used Choose the mode of the

channel.

-10 - +10 V

0 - 20 mA

4 - 20 mA

0 - 20 mA extended

4 - 20 mA extended

2

2

Scope Normal Normal The range of values for

a channel.

Minimum 0 - 10 V

-10 - +10 V -10000

-32768...32767

1

0 Specifies the lower

measurement limit.

0 - 20 mA 0

4 - 20 mA 4000

0 - 20 mA extended

4 - 20 mA extended

EIO0000004112 08/2020 49

2

2

0

1200

Configuring Devices

Parameter Value Default Value Description

Maximum 0 - 10 V

Input Filter 0...1000 0 Specifies the first order

Sampling 1

1

The 12-bit data (0 to 4095) processed in the analog I/O module can be linear-converted to a value

between -32768 and 32767.

2

The extended ranges are supported by modules from hardware version (PV) 03, firmware version

(SV) 1.4. The firmware version of the expansion module is displayed on the Information tab.

-32768...32767

1

10000 Specifies the upper

-10 - +10 V 10000

0 - 20 mA 20000

4 - 20 mA 20000

0 - 20 mA extended

4 - 20 mA extended

2

2

23540

23170

1 Specifies the sampling

10

measurement limit.

filter time constant

(0...10 s) in increments

of 10 ms.

period of the channel, in

ms. If an input filter is

active, the sampling

period is set internally

to 10 ms.

Diagnostic

For this module, you can define:

50

Parameter Value Default Value Description

Status Enabled YesNoYes Enables the status/diagnostic byte of this input

channel.

If disabled (value = No), status/diagnostic data is not

included in the data structure.

EIO0000004112 08/2020

CANopen

For each analog input, you can define:

Parameter Value Default Value Description

Upper limit Yes

Upper limit threshold

Lower limit Yes

Lower limit threshold

Delta interrupt Yes

Delta interrupt

threshold

(1) Depends on the type and the unit of the input.

(1)

No

(1)

0...10000 0 The upper limit threshold value.

No

(1)

0...10000 0 The lower limit threshold value.

No

0...10000 50 The delta interrupt threshold value.

No Enables the upper limit threshold event.

No Enables the lower limit threshold event.

No Enables the delta interrupt event.

Configuring Devices

For details, refer to Configuring CANopen PDO Transmission Mode for Analog Inputs

(see page 92)

I/O Mapping Tab

I/O channels can be mapped to variables in the Mapping tab.

This table describes the Mapping tab:

Variable Channel Symbol

Inputs IW0 Current value of the input 0.

.

IW1 Current value of the input 1.

IW2 Current value of the input 2.

IW3 Current value of the input 3.

IW4 Current value of the input 4.

IW5 Current value of the input 5.

IW6 Current value of the input 6.

IW7 Current value of the input 7.

EIO0000004112 08/2020 51

Configuring Devices

Variable Channel Symbol

Diagnostic IBStatusIW0 Status of input 0.

IBStatusIW1 Status of input 1.

IBStatusIW2 Status of input 2.

IBStatusIW3 Status of input 3.

IBStatusIW4 Status of input 4.

IBStatusIW5 Status of input 5.

IBStatusIW6 Status of input 6.

IBStatusIW7 Status of input 7.

52

EIO0000004112 08/2020

TM3TI4 / TM3TI4G

Introduction

The TM3TI4 (screw terminal block) / TM3TI4G (spring terminal block) expansion module feature 4

analog input channels with 16-bit resolution.

The channel input types are:

0...10 V

-10...+10 V

0...20 mA

4...20 mA

K thermocouple

J thermocouple

R thermocouple

S thermocouple

B thermocouple

E thermocouple

T thermocouple

N thermocouple

C thermocouple

PT100

PT1000

NI100

NI1000

Configuring Devices

Optional Module

For this module, you can define:

Parameter Value Default Value Description

Optional module Yes

No

EIO0000004112 08/2020 53

No Specifies whether this module is optional.

When set to Yes the module must conform

to the rules described in Optional Modules

(see page 15)

.

Configuring Devices

Inputs

For each input channel (IW0...IW3), you can define:

Parameter Value Default Value Description

Type Not used

Scope Normal

Min. 0 - 10 V -32768...32767 0 Specifies the lower measurement limit.

Max. 0 - 10 V -32768...32767 10000 Specifies the upper measurement limit.

Input Filter 0...1000 0 Specifies the first order filter time constant

Sampling 10ms/Channel

0 - 10 V

Not used Choose the mode of the channel.

-10 - +10 V

0 - 20 mA

4 - 20 mA

K Thermocouple

J Thermocouple

R Thermocouple

S Thermocouple

B Thermocouple

E Thermocouple

T Thermocouple

N Thermocouple

C Thermocouple

PT100

PT1000

NI100

NI1000

Normal The range of values for a channel.

Celsius (0.1°C)

Fahrenheit (0.1°F)

Fahrenheit (0.2°F)*

-10 - +10 V -10000

0 - 20 mA 0

4 - 20 mA 4000

Temperature See the table below

-10 - +10 V 10000

0 - 20 mA 20000

4 - 20 mA 20000

Temperature See the table below

100ms/Channel Specifies the sampling period of the

100ms/Channel

* Only for B and C thermocouples.

(0...10 s) in increments of 10 ms.

channel. If an input filter is active, the

sampling period is set internally to 10 ms.

54

EIO0000004112 08/2020

Configuring Devices

Type Normal Celsius (0.1 °C) Fahrenheit

Minimum Maximum Minimum Maximum Minimum Maximum Unit

K Thermocouple -32768 32767 -2000 13000 -3280 23720 0.1 °F

J Thermocouple -32768 32767 -2000 10000 -3280 18320 0.1 °F

R Thermocouple -32768 32767 0 17600 320 32000 0.1 °F

S Thermocouple -32768 32767 0 17600 320 32000 0.1 °F

B Thermocouple -32768 32767 0 18200 160 16540 0.2 °F

E Thermocouple -32768 32767 -2000 8000 -3280 14720 0.1 °F

T Thermocouple -32768 32767 -2000 4000 -3280 7520 0.1 °F

N Thermocouple -32768 32767 -2000 13000 -3280 23720 0.1 °F

C Thermocouple -32768 32767 0 23150 160 20995 0.2 °F

PT100 -32768 32767 -2000 8500 -3280 15620 0.1 °F

PT1000 -32768 32767 -2000 6000 -3280 11120 0.1 °F

NI100 -32768 32767 -600 1800 -760 3560 0.1 °F

NI1000 -32768 32767 -600 1800 -760 3560 0.1 °F

Diagnostic

For this module, you can define:

Parameter Value Default Value Description

Status Enabled Yes

No

EIO0000004112 08/2020 55

Yes Enables the status/diagnostic byte of this input channel.

If disabled (value = No), status/diagnostic data is not

included in the data structure.

Configuring Devices

CANopen

For each analog input, you can define:

Parameter Value Default Value Description

Upper limit Yes

Upper limit threshold

Lower limit Yes

Lower limit threshold

Delta interrupt Yes

Delta interrupt threshold

(1) Depends on the type and the unit of the input.

No

(1)

0...10000 0 The upper limit threshold value.

No

(1)

0...10000 0 The lower limit threshold value.

No

(1)

0...10000 50 The delta interrupt threshold value.

No Enables the upper limit threshold event.

No Enables the lower limit threshold event.

No Enables the delta interrupt event.

For details, refer to Configuring CANopen PDO Transmission Mode for Analog Inputs

(see page 92)

I/O Mapping Tab

I/O channels can be mapped to variables in the Mapping tab.

This table describes the Mapping tab:

Variable Channel Symbol

Inputs IW0 Current value of the input 0.

Diagnostic IBStatusIW0 Status of input 0.

.

IW1 Current value of the input 1.

IW2 Current value of the input 2.

IW3 Current value of the input 3.

IBStatusIW1 Status of input 1.

IBStatusIW2 Status of input 2.

IBStatusIW3 Status of input 3.

56

EIO0000004112 08/2020

TM3TI4D / TM3TI4DG

Introduction

The TM3TI4D (screw terminal block) / TM3TI4DG (spring terminal block) expansion module

feature 4 analog input channels with 16-bit resolution.

The channel input types are:

K thermocouple

J thermocouple

R thermocouple

S thermocouple

B thermocouple

E thermocouple

T thermocouple

N thermocouple

C thermocouple

Optional Module

For this module, you can define:

Parameter Value Default Value Description

Optional module Yes

No

Configuring Devices

No Specifies whether this module is optional.

When set to Yes the module must conform

to the rules described in Optional Modules

(see page 15)

.

Inputs

For each input channel (IW0...IW3), you can define:

Parameter Value Default Value Description

Type Not used

K Thermocouple

J Thermocouple

R Thermocouple

S Thermocouple

B Thermocouple

E Thermocouple

T Thermocouple

N Thermocouple

C Thermocouple

Scope Normal

Celsius (0.1°C)

Fahrenheit (0.1°F)

Fahrenheit (0.2°F)*

EIO0000004112 08/2020 57

Not used Choose the mode of the channel.

Normal The range of values for a channel.

* Only for B and C thermocouples.

Configuring Devices

Parameter Value Default Value Description

Minimum See the table below Specifies the lower measurement limit.

Maximum See the table below Specifies the upper measurement limit.

Input Filter 0...1000 0 Specifies the first order filter time constant

Sampling 10

100

Type Normal Celsius (0.1 °C) Fahrenheit

Minimum Maximum Minimum Maximum Minimum Maximum Unit

K Thermocouple -32768 32767 -2000 13000 -3280 23720 0.1 °F

J Thermocouple -32768 32767 -2000 10000 -3280 18320 0.1 °F

R Thermocouple -32768 32767 0 17600 320 32000 0.1 °F

S Thermocouple -32768 32767 0 17600 320 32000 0.1 °F

B Thermocouple -32768 32767 0 18200 160 16540 0.2 °F

E Thermocouple -32768 32767 -2000 8000 -3280 14720 0.1 °F

T Thermocouple -32768 32767 -2000 4000 -3280 7520 0.1 °F

N Thermocouple -32768 32767 -2000 13000 -3280 23720 0.1 °F

C Thermocouple -32768 32767 0 23150 160 20995 0.2 °F

100 Specifies the sampling period of the

(0...10 s) in increments of 10 ms.

channel, in ms. If an input filter is active,

the sampling period is set internally to

10 ms.

Diagnostic

For this module, you can define:

58

Parameter Value Default Value Description

Status Enabled Yes

No

Yes Enables the status/diagnostic byte of this

input channel.

If disabled (value = No), status/diagnostic

data is not included in the data structure.

EIO0000004112 08/2020

CANopen

For each analog input, you can define:

Parameter Value Default Value Description

Upper limit Yes

Upper limit threshold

Lower limit Yes

Lower limit threshold

Delta interrupt Yes

Delta interrupt

threshold

(1) Depends on the type and the unit of the input.

(1)

No

(1)

0...10000 0 The upper limit threshold value.

No

(1)

0...10000 0 The lower limit threshold value.

No

0...10000 50 The delta interrupt threshold value.

No Enables the upper limit threshold event.

No Enables the lower limit threshold event.

No Enables the delta interrupt event.

Configuring Devices

For details, refer to Configuring CANopen PDO Transmission Mode for Analog Inputs

(see page 92)

I/O Mapping Tab

I/O channels can be mapped to variables in the Mapping tab.

This table describes the Mapping tab:

Variable Channel Symbol

Inputs IW0 Current value of the input 0.

Diagnostic IBStatusIW0 Status of input 0.

.

IW1 Current value of the input 1.

IW2 Current value of the input 2.

IW3 Current value of the input 3.

IBStatusIW1 Status of input 1.

IBStatusIW2 Status of input 2.

IBStatusIW3 Status of input 3.

EIO0000004112 08/2020 59

Configuring Devices

TM3TI8T / TM3TI8TG

Introduction

The TM3TI8T (screw terminal block) / TM3TI8TG (spring terminal block) expansion module feature

8 analog input channels with 16-bit resolution.

The channel input types are:

K thermocouple

J thermocouple

R thermocouple

S thermocouple

B thermocouple

E thermocouple

T thermocouple

N thermocouple

C thermocouple

NTC thermistor

PTC thermistor

Ohmmeter

Optional Module

For this module, you can define:

60

Parameter Value Default Value Description

Optional module Yes

No

No Specifies whether this module is optional.

When set to Yes the module must conform

to the rules described in Optional Modules

(see page 15)

.

EIO0000004112 08/2020

Inputs

Configuring Devices

For each input channel (IW0...IW7) you can define the following parameters:

Parameter Value Default Value Description

Type

Not used

Type

K Thermocouple

J Thermocouple

R Thermocouple

S Thermocouple

E Thermocouple

T Thermocouple

N Thermocouple

NTC Thermistor

Type

B Thermocouple

C Thermocouple

Type

PTC Thermistor

Type

Ohmmeter

Minimum See the table below Specifies the low measurement limit.

Maximum See the table below Specifies the high measurement limit.

Rref (used only with

NTC probe)

Tref (used only with

NTC probe)

Beta (used only with

NTC probe)

Input Filter 0...1000 0 Specifies the first order filter time

Sampling 100 100 Specifies the sampling period of the

High Threshold (used

only with PTC probe)

Low Threshold (used

only with PTC probe)

- Not used Choose the parameter type and

scope for the channel.

Scope

Customized

Celsius (0.1 °C)

Fahrenheit (0.1 °F)

Scope

Customized

Celsius (0.1 °C)

Fahrenheit (0.2 °F)

Scope

Customized

Threshold

Scope

Resistance (Ω)

Celsius (0.1 °C)

Celsius (0.1 °C)

Threshold

Resistance

1...65535 330 Reference resistance in Ohm at

temperature Tref.

1...1000 25 Reference temperature value in

Celsius.

1...32767 3569 Sensitivity of NTC probe in Kelvin.

constant (0...10 s) in increments of

10 ms.

channel, in ms.

101...10000 3100 Activation threshold

100...9999 1500 Reactivation threshold

EIO0000004112 08/2020 61

Configuring Devices

The following table indicates the possible range values for the selected type of thermocouple:

Type Customized Range in Celsius Range in Fahrenheit