Page 1

LXM23D and BCH

Servo drive system

Product manual

V2.02, 11.2014

0198441113926, V2.02, 11.2014

www.schneider-electric.com

Page 2

LXM23D and BCH

The information provided in this documentation contains general

descriptions and/or technical characteristics of the performance of the

products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user applications. It is the duty of

any such user or integrator to perform the appropriate and complete

risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric

nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments or have found errors in this

publication, please notify us.

No part of this document may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be

observed when installing and using this product. For reasons of safety

and to help ensure compliance with documented system data, only

the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must be followed.

Failure to use Schneider Electric software or approved software with

our hardware products may result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment

damage.

© 2013 Schneider Electric. All rights reserved.

2 Servo drive system

0198441113926, V2.02, 11.2014

Page 3

LXM23D and BCH Table of contents

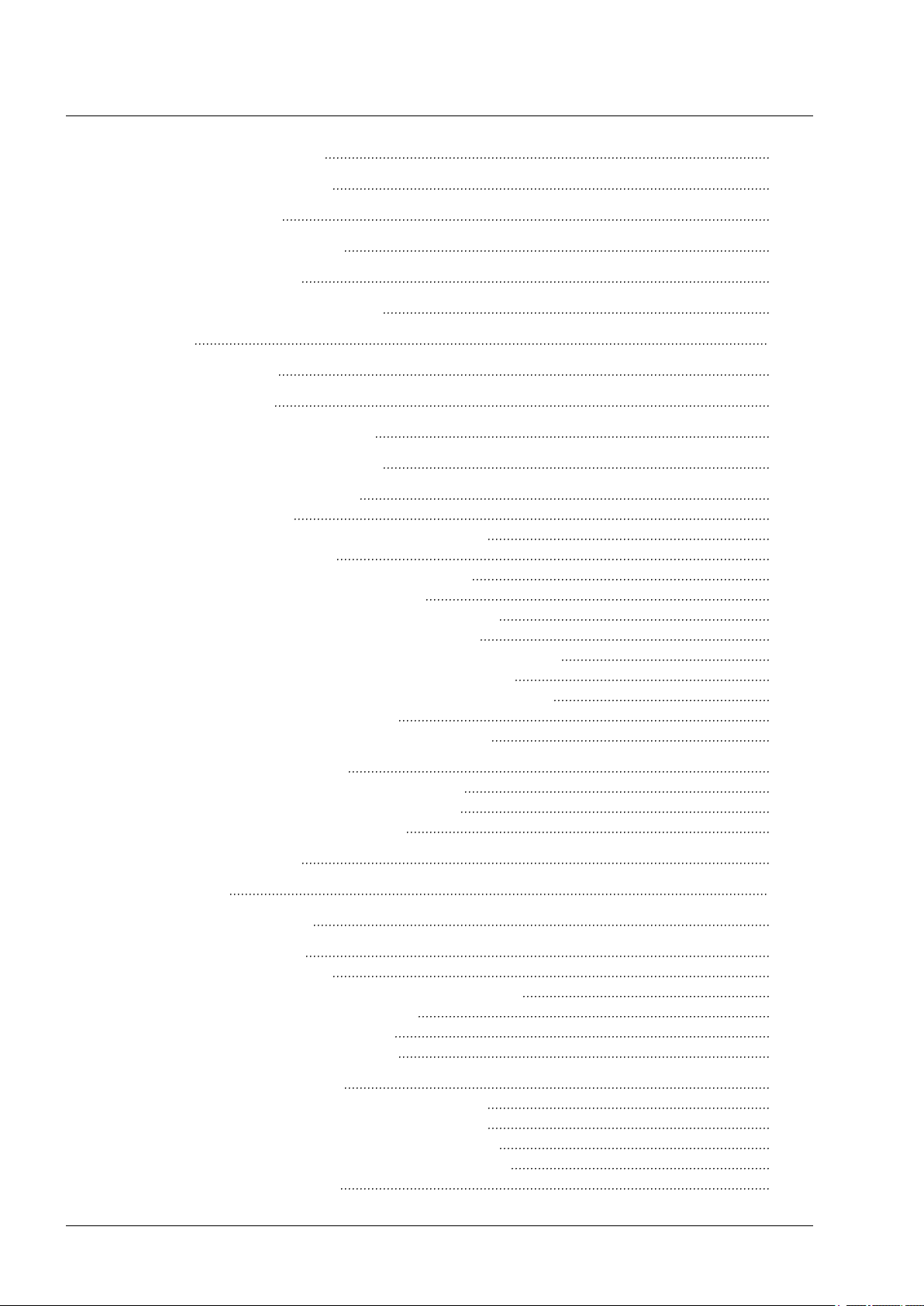

Table of contents

Table of contents 3

Safety Information 9

Hazard categories 9

Qualification of personnel 10

Intended use 10

Basic information 10

DC bus voltage measurement 13

Standards and terminology 13

About the book 15

1 Introduction 17

1.1 Device overview 17

1.2 Components and interfaces 18

1.3 Nameplate 19

1.4 Type code 21

1.5 Servo Drive and Servo Motor Combinations 23

2 Technical Data 25

2.1 Ambient conditions 25

2.1.1 Ambient conditions of drive 25

2.2 Dimensions 27

2.2.1 Dimensions of drive 27

2.2.2 Dimensions of motor 30

2.3 Electrical data of drive 34

2.3.1 Specification of drive 34

2.3.2 DC bus data 36

2.3.3 Additional EMC input filters 36

2.3.4 Upstream circuit breaker, fuse 39

2.4 Motor data 40

2.4.1 Specification of motor 40

2.4.2 Servo Motor Speed-Torque Curves (T-N Curves) 44

2.4.3 Overload Characteristics 49

2.5 Conditions for UL 508C 51

2.6 Certifications 51

2.7 Declaration of conformity 52

3 Engineering 55

0198441113926, V2.02, 11.2014

3.1 Electromagnetic compatibility (EMC) 55

Servo drive system 3

Page 4

Table of contents LXM23D and BCH

3.2 Residual current device 57

3.3 Operation in an IT mains 57

3.4 Common DC bus 57

3.5 Rating the braking resistor 58

3.6 Monitoring functions 65

3.7 Configurable inputs and outputs 66

4 Installation 67

4.1 Before mounting 68

4.2 Scope of supply 69

4.3 Mechanical installation of drive 70

4.4 Mechanical installation of motor 73

4.5 Electrical installation of drive 76

4.5.1 Overview 76

4.5.2 Servo drive connectors and terminals 77

4.5.3 Wiring Methods 80

4.5.4 Cable specifications for servo drive 81

4.5.5 Structure of the drive system 82

4.5.6 Input / Output Interface Connector CN1 83

4.5.6.1 CN1 Terminal Identification 83

4.5.6.2 Signals Explanation of Connector CN1 85

4.5.6.3 User-defined DI and DO signals 97

4.5.6.4 Wiring Diagrams of I/O Signals (CN1) 98

4.5.7 Encoder Connector CN2 106

4.5.8 Serial Communication Connector CN3 107

4.6 Electrical installation motor 108

4.6.1 Connections and pin assignments 108

4.6.2 Connection of motor and encoder 111

4.6.3 Holding brake connection 112

4.7 Verifying installation 114

5 Commissioning 115

5.1 Commissioning steps 116

5.2 Commissioning tools 118

5.2.1 Integrated HMI 119

5.2.1.1 Description of the integrated HMI 119

5.2.1.2 Display Flowchart 120

5.2.1.3 Status Display 121

5.2.2 Commissioning software 125

5.3 Commissioning procedure 126

5.3.1 Commissioning without load (trial run) 127

5.3.1.1 JOG Trial Run without Load 132

5.3.1.2 Speed Trial Run without Load 134

5.3.1.3 Position Trial Run without Load 136

5.3.2 Tuning with load 138

4 Servo drive system

0198441113926, V2.02, 11.2014

Page 5

LXM23D and BCH Table of contents

5.3.2.1 Tuning Flowchart 139

5.3.2.2 Load Inertia Estimation Flowchart 140

5.3.2.3 Auto Mode Tuning Flowchart 140

5.3.2.4 Semi-Auto Mode Tuning Flowchart 142

5.3.2.5 Limit of Load Inertia Estimation 143

5.3.2.6 Mechanical Resonance Suppression Method 145

5.3.2.7 Relationship between Tuning Modes and Parameters 147

5.3.2.8 Gain Adjustment in Manual Mode 148

5.3.3 Forcing the digital outputs 149

6 Operation 151

6.1 Access channels 151

6.2 General Function Operation 152

6.2.1 Displaying alarm codes 152

6.2.2 Jog operation 152

6.3 Control modes 154

6.3.1 Position Control mode 154

6.3.1.1 Command source for Position Conrol (Pt) mode 155

6.3.1.2 Command source for Position Control (Pr) mode 157

6.3.1.3 Structure of Position Control mode 158

6.3.1.4 S-curve filter for Position Control 159

6.3.1.5 Electronic gear ratio 162

6.3.1.6 Low-pass filter 163

6.3.1.7 Timing of Position Control (Pr) mode 164

6.3.1.8 Position loop gain adjustment 165

6.3.1.9 Low-frequency vibration suppression 167

6.3.2 Speed Control Mode 172

6.3.2.1 Command Source of Speed Control Mode 172

6.3.2.2 Structure of Speed Control Mode 173

6.3.2.3 Smoothing Strategy of Speed Control Mode 174

6.3.2.4 Analog Speed Input Scaling 177

6.3.2.5 Timing Chart of Speed Control Mode 179

6.3.2.6 Speed Loop Gain Adjustment 179

6.3.2.7 Resonance Suppression 185

6.3.3 Torque Control Mode 191

6.3.3.1 Command Source of Torque Control Mode 191

6.3.3.2 Structure of Torque Control Mode 191

6.3.3.3 Smoothing Strategy of Torque Control Mode 192

6.3.3.4 Analog Torque Input Scaling 193

6.3.3.5 Timing Chart of Torque Control Mode 194

6.3.4 Control Modes Selection 195

6.3.4.1 Speed / Position Control Mode Selection 195

6.3.4.2 Speed / Torque Control Mode Selection 196

6.3.4.3 Torque / Position Control Mode Selectionn 197

6.4 Other functions 198

6.4.1 Speed Limit 198

6.4.2 Torque Limit 198

6.4.3 Analog Monitor 199

6.4.4 Holding Brake 202

7 Motion Control Function 205

0198441113926, V2.02, 11.2014

Servo drive system 5

Page 6

Table of contents LXM23D and BCH

7.1 Available Motion Control Functions 205

7.2 Servo Drive Information 205

7.2.1 Monitor Variables 206

7.3 Motion Axis 212

7.4 Introduction to Pr mode 212

7.5 Position command unit of Pr mode 213

7.6 Registers of Pr mode 213

7.7 Homing Function of Pr Mode 214

7.8 DI and DO signals of Pr Mode 215

7.9 Parameter settings of Pr mode 216

7.9.1 Path Order 219

7.9.2 Pr Path 219

8 Examples 221

8.1 Position control mode wiring diagram (pulse control) 221

8.2 Position control mode wiring diagram (build-in motion sequence) 222

8.3 Speed control mode wiring diagram 223

8.4 Torque control mode wiring diagram 224

9 Diagnostics and troubleshooting 225

9.1 Status request/status indication 225

9.2 DI Diagnosis Operation 225

9.3 DO Diagnosis Operation 226

9.4 Alarm Messages Table 227

9.5 Potential Cause and Corrective Actions 229

9.6 Clearing alarms 238

10 Parameters 241

10.1 Representation of the parameters 241

10.2 Definition 243

10.3 Parameter Summary 244

10.3.1 Parameters Listed by Group 244

10.3.1.1 Group 0: Monitor Parameters 244

10.3.1.2 Group 1: Basic Parameters 246

10.3.1.3 Group 2: Extension Parameters 249

10.3.1.4 Group 3: Communication Parameters 251

10.3.1.5 Group 4: Diagnosis Parameters 252

10.3.1.6 Group 5: Motion Control Parameters 253

10.3.1.7 Group 6: Pr Path Definition Parameters 256

10.3.2 Parameters Listed by Function 257

10.3.2.1 Monitor and General Use 257

10.3.2.2 Smooth Filter and Resonance Suppression 259

6 Servo drive system

0198441113926, V2.02, 11.2014

Page 7

LXM23D and BCH Table of contents

10.3.2.3 Gain and Switch 260

10.3.2.4 Position Control 261

10.3.2.5 Speed Control 264

10.3.2.6 Torque Control 265

10.3.2.7 Digital I/O and Relative Input Output Setting 266

10.3.2.8 Communication 267

10.3.2.9 Diagnosis 268

10.4 Detailed Parameter Listings 269

10.4.1 Group 0: Monitor Parameters 269

10.4.2 Group 1: Basic Parameters 284

10.4.3 Group 2: Extension Parameters 310

10.4.4 Group 3: Communication Parameters 334

10.4.5 Group 4: Diagnosis Parameters 339

10.4.6 Group 5: Motion Control Parameters 348

10.4.7 Group 6: Pr Path Definition Parameters 366

10.5 Input Function Definition 372

10.6 Output Function Definition 378

11 Accessories and spare parts 385

11.1 Connector and cable 385

11.1.1 Connector 385

11.1.2 Cable 385

11.1.3 Connector for power cable 386

11.1.4 Connector for encoder cable 387

11.1.5 Power cable 388

11.1.6 Encoder cable 391

11.2 Power Connectors 392

11.3 I/O Signal Connector (CN1) 393

11.4 I/O Terminal Block Module 393

11.5 USB to RJ45 connector for CN3 interface 393

11.6 Other Accessories 394

12 Service, maintenance and disposal 397

12.1 Service address 398

12.2 Maintenance 399

12.2.1 Maintenance of drive 399

12.2.2 Maintenance of motor 399

12.3 Replacement of drive 401

12.4 Changing the motor 401

12.5 Shipping, storage, disposal 402

Glossary 403

Units and conversion tables 403

Length 403

Mass 403

Force 403

0198441113926, V2.02, 11.2014

Servo drive system 7

Page 8

Table of contents LXM23D and BCH

Power 403

Rotation 404

Torque 404

Moment of inertia 404

Temperature 404

Conductor cross section 404

Terms and Abbreviations 405

Index 407

0198441113926, V2.02, 11.2014

8

Servo drive system

Page 9

LXM23D and BCH

Safety Information

Safety Information

Read these instructions carefully, and look at the equipment to

become familiar with the device before trying to install, operate, or

maintain it. The following special messages may appear throughout

this documentation or on the equipment to warn of potential hazards

or to call attention to information that clarifies or simplifies a procedure.

The addition of this symbol to a Danger safety label indicates that an electrical hazard exists, which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Hazard categories

Safety instructions to the user are highlighted by safety alert symbols

in the manual. In addition, labels with symbols and/or instructions are

attached to the product that alert you to potential hazards.

Depending on the seriousness of the hazard, the safety instructions

are divided into 4 hazard categories.

DANGER

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not

avoided, can result in death, serious injury, or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not

avoided, can result in injury or equipment damage.

0198441113926, V2.02, 11.2014

Servo drive system

NOTICE

NOTICE indicates a potentially hazardous situation, which, if not

avoided, can result in equipment damage.

9

Page 10

Safety Information

Qualification of personnel

Intended use

LXM23D and BCH

Only appropriately trained persons who are familiar with and understand the contents of this manual and all other pertinent product documentation are authorized to work on and with this product. In addition,

these persons must have received safety training to recognize and

avoid hazards involved. These persons must have sufficient technical

training, knowledge and experience and be able to foresee and detect

potential hazards that may be caused by using the product, by changing the settings and by the mechanical, electrical and electronic equipment of the entire system in which the product is used.

All persons working on and with the product must be fully familiar with

all applicable standards, directives, and accident prevention regulations when performing such work.

This product consists of a drive and a three-phase servo motor; it is

intended for industrial use in this combination according to this manual.

Basic information

The product may only be used in compliance with all applicable safety

regulations and directives, the specified requirements and the technical data.

Prior to using the product, you must perform a risk assessment in view

of the planned application. Based on the results, the appropriate

safety measures must be implemented.

Since the product is used as a component in an entire system, you

must ensure the safety of persons by means of the design of this

entire system (for example, machine design).

Operate the product only with the specified cables and accessories.

Use only genuine accessories and spare parts.

Any use other than the use explicitly permitted is prohibited and can

result in hazards.

Electrical equipment should be installed, operated, serviced, and

maintained only by qualified personnel.

The use and application of the information contained herein require

expertise in the design and programming of automated control systems.

10

Only you, the user, machine builder or integrator, can be aware of all

the conditions and factors present during installation and setup, operation, repair and maintenance of the machine or process.

You must also consider any applicable standards and/or regulations

with respect to grounding of all equipment. Verify compliance with any

safety information, different electrical requirements, and normative

0198441113926, V2.02, 11.2014

Servo drive system

Page 11

LXM23D and BCH

Safety Information

standards that apply to your machine or process in the use of this

equipment.

Many components of the equipment, including the printed circuit

board, operate with mains voltage, or present transformed high currents, and/or high voltages.

The motor itself generates voltage when the motor shaft is rotated.

DANGER

HAZARD DUE TO ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Only qualified personnel may install, adjust, repair and maintain

this equipment.

• Do not touch any connectors, contacts, terminals, unshielded

components or printed circuit boards while the equipment is

under power.

• Use only electrically insulated tools.

• Block the motor shaft to prevent rotation prior to performing any

type of work on the drive system.

• Insulate both ends of unused conductors of the motor cable to

help prevent AC voltage from coupling to unused conductors in

the motor cable.

• Do not short across the DC bus terminals or the DC bus capacitors.

• Before performing work on the drive system:

- Disconnect all power, including external control power that

may be present.

- Place a "Do Not Turn On" label on all power switches.

- Lock all power switches in the open position.

- Wait 10 minutes to allow the DC bus capacitors to discharge.

- Measure the voltage on the DC bus as per chapter "DC bus

voltage measurement" and verify the voltage is <42 Vdc.

- Do not assume that the DC bus is voltage-free when the DC

bus LED is off.

• Refit/replace and secure all covers, accessories, hardware,

cables, and wires and verify that a proper ground connection

exists before applying power to the unit.

Failure to follow these instructions will result in death or serious injury.

This equipment has been designed to operate outside of any hazardous location. Only install this equipment in zones known to be free of

a hazardous atmosphere.

DANGER

POTENTIAL FOR EXPLOSION

Install and use this equipment in non-hazardous locations only.

0198441113926, V2.02, 11.2014

Servo drive system

Failure to follow these instructions will result in death or serious injury.

If the power stage is disabled unintentionally, for example as a result

of power outage, errors or functions, the motor is no longer decelerated in a controlled way. Overload, errors or incorrect use may cause

11

Page 12

Safety Information

LXM23D and BCH

the holding brake to no longer operate properly and may result in premature wear.

WARNING

UNINTENDED EQUIPMENT OPERATION

• Verify that movements without braking effect cannot cause injuries or equipment damage.

• Verify the function of the holding brake at regular intervals.

• Do not use the holding brake as a service brake.

• Do not use the holding brake for safety-related purposes.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

Drive systems may perform unanticipated movements because of

incorrect wiring, incorrect settings, incorrect data or other errors.

WARNING

UNINTENDED EQUIPMENT OPERATION

• Carefully install the wiring in accordance with the EMC requirements.

• Do not operate the product with unknown settings or data.

• Perform a comprehensive commissioning test.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

WARNING

LOSS OF CONTROL

• The designer of any control scheme must consider the potential

failure modes of control paths and, for certain critical functions,

provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are emergency stop,

overtravel stop, power outage and restart.

• Separate or redundant control paths must be provided for critical

functions.

• System control paths may include communication links. Consideration must be given to the implication of unanticipated transmission delays or failures of the link.

• Observe all accident prevention regulations and local safety

guidelines.

• Each implementation of the product must be individually and thoroughly tested for proper operation before being placed into service.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

1)

12

1) For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), “Safety

Guidelines for the Application, Installation, and Maintenance of Solid State Control”

and to NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide

for Selection, Installation and Operation of Adjustable-Speed Drive Systems”.

0198441113926, V2.02, 11.2014

Servo drive system

Page 13

LXM23D and BCH

DC bus voltage measurement

Safety Information

The DC bus voltage can exceed 400 Vdc. The DC bus LED is not an

indicator of the absence of DC bus voltage.

DANGER

ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Disconnect the voltage supply to all connections.

• Wait 10 minutes to allow the DC bus capacitors to discharge.

• Use a properly rated voltage-sensing device for measuring

(>400 Vdc).

• Measure the DC bus voltage between the DC bus terminals (PA/+

and PC/-) to verify that the voltage is less than 42 Vdc.

• Contact your local Schneider Electric representative if the DC bus

capacitors do not discharge to less than 42 Vdc within a period of

10 minutes.

• Do not operate the product if the DC bus capacitors do not discharge properly.

• Do not attempt to repair the product if the DC bus capacitors do

not discharge properly.

• Do not assume that the DC bus is voltage-free when the DC bus

LED is off.

Failure to follow these instructions will result in death or serious injury.

Standards and terminology

Technical terms, terminology and the corresponding descriptions in

this manual are intended to use the terms or definitions of the pertinent standards.

In the area of drive systems, this includes, but is not limited to, terms

such as "safety function", "safe state", "fault", "fault reset", "failure",

"error", "error message", "warning", etc.

Among others, these standards include:

• IEC 61800 series: "Adjustable speed electrical power drive systems"

• IEC 61158 series: "Digital data communications for measurement

and control – Fieldbus for use in industrial control systems"

• IEC 61784 series: "Industrial communication networks – Profiles"

• IEC 61508 series: "Functional safety of electrical/electronic/

programmable electronic safety-related systems"

In addition, the term "zone of operation" is used in conjunction with the

description of specific hazards, and is defined as it is for a "hazard

zone" or "danger zone" in the EC Machinery Directive (2006/42/EC)

and in ISO 12100-1.

0198441113926, V2.02, 11.2014

Servo drive system

Also see the glossary at the end of this manual.

13

Page 14

Safety Information

LXM23D and BCH

14

0198441113926, V2.02, 11.2014

Servo drive system

Page 15

LXM23D and BCH

About the book

Source manuals The latest versions of the manuals can be downloaded from the Inter-

Source CAD data For easier engineering, CAD data (drawings or EPLAN macros) are

About the book

This manual is valid for LXM23D and BCH standard products.

net at:

http://www.schneider-electric.com

available for download from the Internet at:

http://www.schneider-electric.com

Work steps If work steps must be performed consecutively, this sequence of steps

is represented as follows:

■

Special prerequisites for the following work steps

▶

Step 1

◁

Specific response to this work step

▶

Step 2

If a response to a work step is indicated, this allows you to verify that

the work step has been performed correctly.

Unless otherwise stated, the individual steps must be performed in the

specified sequence.

Making work easier Information on making work easier is highlighted by this symbol:

Sections highlighted this way provide supplementary information on

making work easier.

SI units Technical data are specified in SI units. Converted units are shown in

parentheses behind the SI unit; they may be rounded.

Example:

Minimum conductor cross section: 1.5 mm2 (AWG 14)

Glossary Explanations of special technical terms and abbreviations.

Index List of keywords with references to the corresponding page numbers.

0198441113926, V2.02, 11.2014

Servo drive system

15

Page 16

About the book

LXM23D and BCH

16

0198441113926, V2.02, 11.2014

Servo drive system

Page 17

LXM23D and BCH

1 Introduction

1.1 Device overview

1 Introduction

The LXM23 product family consists of two servo drive models that

cover different application areas. Together with Lexium BCH servo

motors as well as a comprehensive range of options and accessories,

the drives are ideally suited to implement compact, high-performance

drive solutions for a wide range of power requirements.

This product manual describes the LXM23D servo drive and the BCH

servo motor.

0198441113926, V2.02, 11.2014

Servo drive system

Overview of some of the features of the servo drive:

• Two analog inputs (+/-10V, pulse/direction) for supplying reference

values.

• The product is commissioned via the integrated HMI or a PC with

commissioning software.

• Operating modes include: Jog, Position Control, Speed Control,

Torque Control, and Dual Mode.

17

Page 18

DANGER

WARNING

C

N

1

C

N

2

C

N

3

PA / +

PBi

PBe

PC/-

U

V

W

R

S

T

L1

L2

C

N

4

ENT

M

S

CN5220V Motor

1 Introduction

LXM23D and BCH

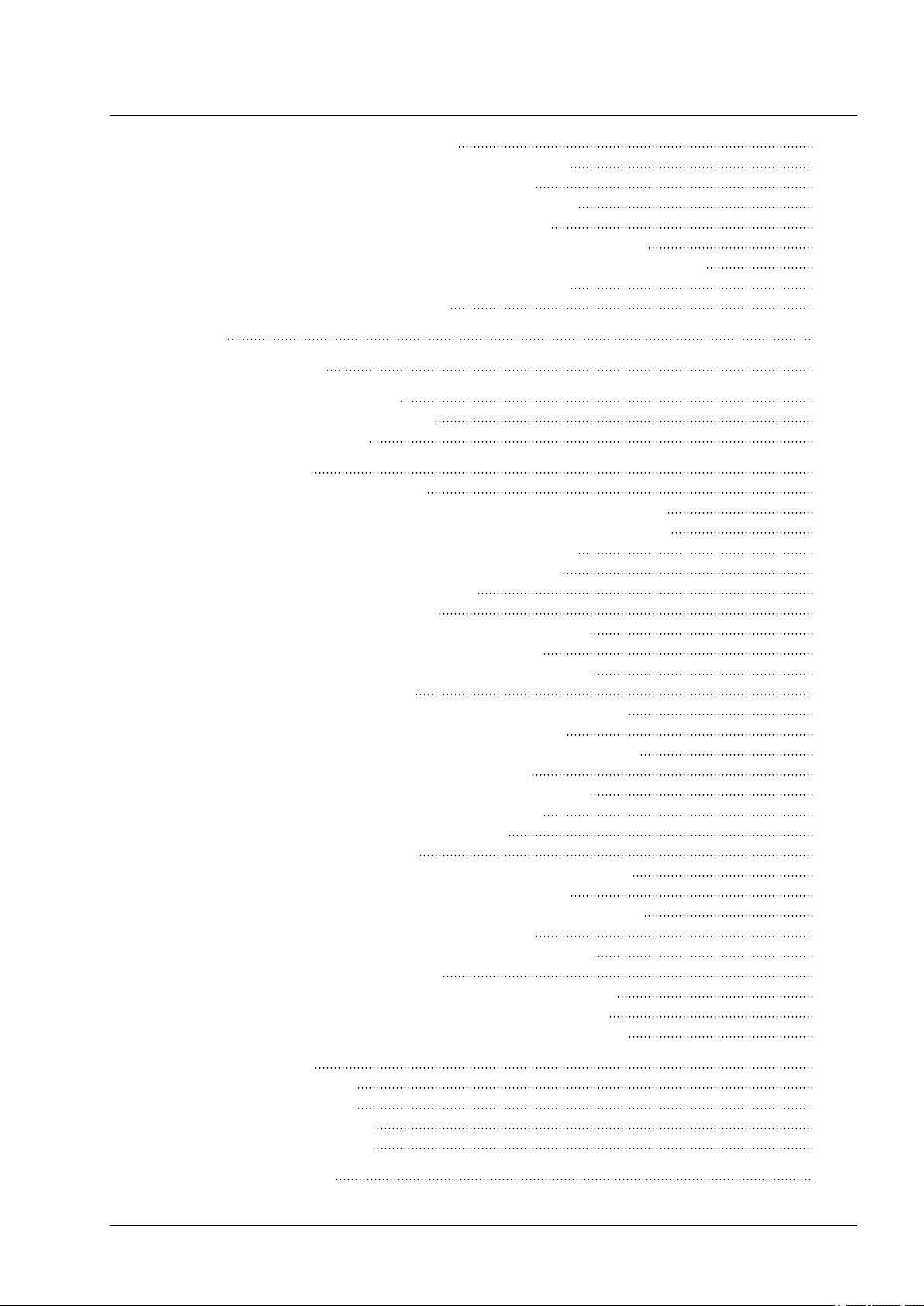

1.2 Components and interfaces

Carefully read and observe all safety instructions and the chapter "Before you begin - safety information".

HMI display

Information: page 119

Alarm codes: page 225

DC bus LED

The LED lights when mains voltage or internal charge are

present. The DC bus LED is not

an indicator of the absence of DC

bus voltage.

Information: page 13

HMI keypad

M: HMI mode

S: Shift (several functions)

UP: Navigate, increase values

DOWN: Navigate, decrease val-

ues

ENT: Confirm, store data

Information: page 119

Controller supply (L1, L2)

Connect to mains circuit.

Information: page 77

Power stage supply (R,S,T)

Connect to mains circuit.

Information: page 77

Servo motor terminals (U,V, W)

Connect output (U, V, W) to the

motor.

Information: page 77

Braking resistor terminal (CN5)

Information: page 77

• Internal braking resistor PA/+

and PBi bridged (PBe not connected)

• External braking resistor PA/+

and PBe (PBi not connected)

Reserved (CN4)

I/O Interface (CN1)

For connecting master controller

(PLC) or I/O signals.

Information: page 77

Encoder Interface (CN2)

For connecting motor encoder.

Information: page 77

Ground terminal

For grounding the drive and the

connected components.

Information: page 77

18

Commissioning interface (CN3)

For connecting PC via converter

VW3M8131

Information: page 77

0198441113926, V2.02, 11.2014

Servo drive system

Page 19

US

C

3

2

1

9

8

7

6

5

4

0000 rpm

BCH ...

UN: 00 VDC

DOM 00-00-00

IP...

USC

Made in China

Brake

Th.-CI B

PN: 0.0 W

2

1

3

5

6

4

9

8

7

10

12

11

Pn:000W

000 V

Sn 0000000000000

Nn:

Imax: 00 A

Un:

Mass: 0.0kg

In: 0.0 A

Mn:0.00 Nm

13

14

15

17

16

LXM23D and BCH

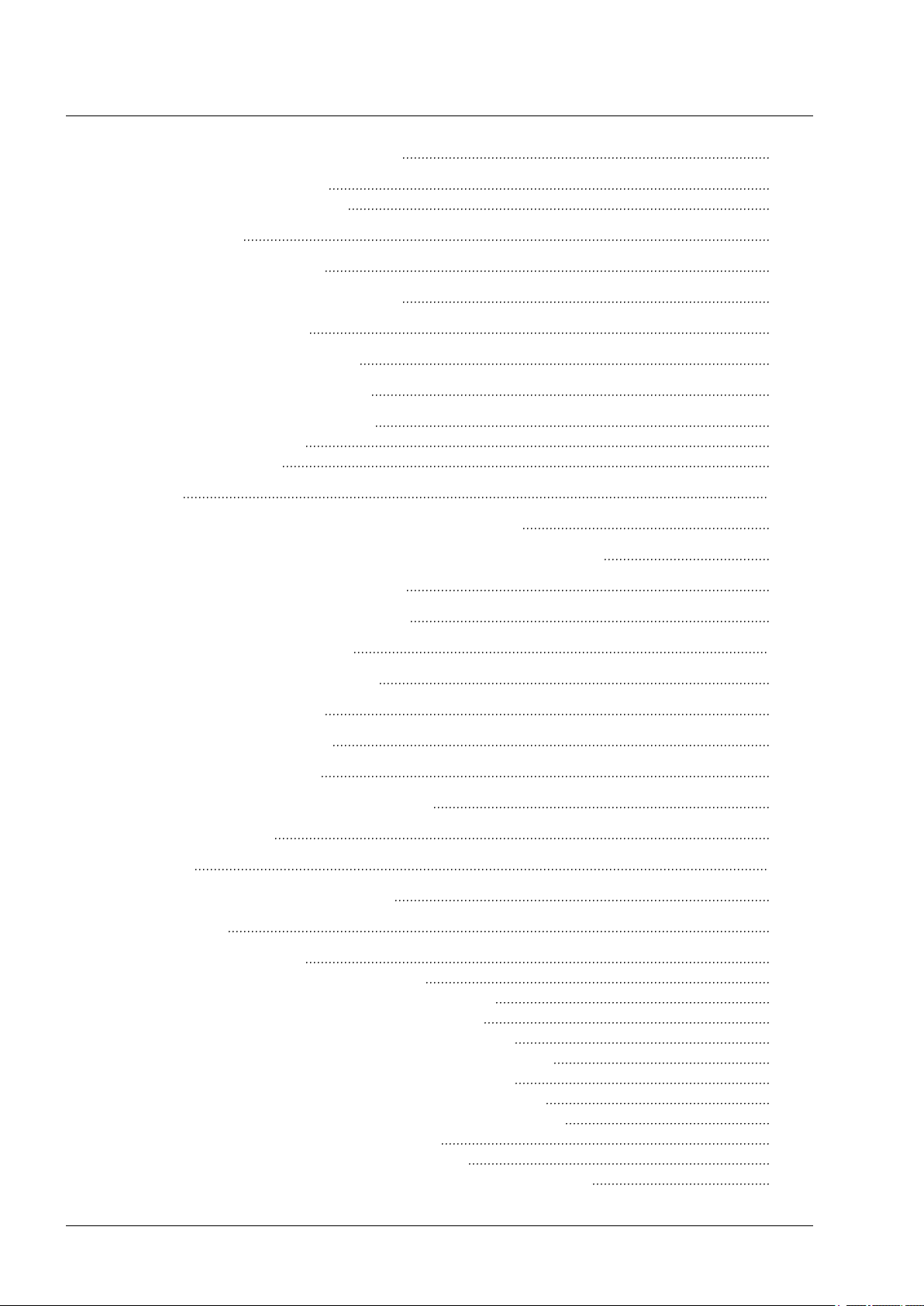

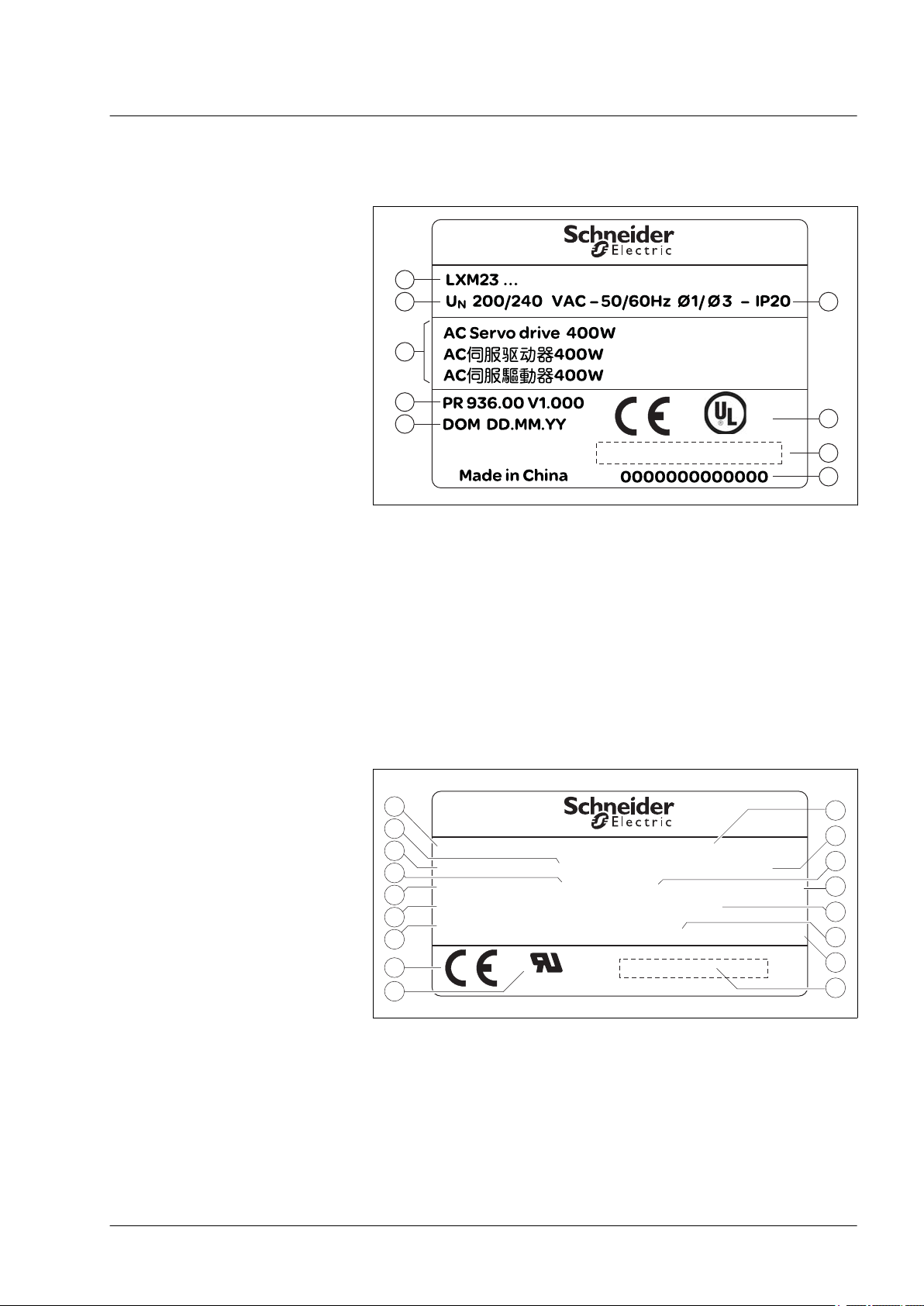

1.3 Nameplate

1 Introduction

Drive The nameplate contains the following data:

Figure 1: Nameplate

(1) Type code

(2) Nominal voltage

(3) Motor type

(4) Firmware version

(5) Date of manufacture DOM, see page 405

(6) Degree of protection

(7) CE marking and UL marking

(8) Barcode

(9) Serial number

Motor The nameplate contains the following data:

Figure 2: Nameplate

0198441113926, V2.02, 11.2014

Servo drive system

19

Page 20

1 Introduction

LXM23D and BCH

(1) Motor type, see type code

(2) Nominal torque

(3) Nominal power

(4) Nominal current

(5) Maximum peak current

(6) Nominal voltage

(7) Nominal speed of rotation

(8) CE marking

(9) UL marking

(10) Date of manufacture DOM, see page 405

(11) Serial number

(12) Degree of protection

(13) Temperature class

(14) Mass

(15) Nominal voltage of the holding brake (optional)

(16) Nominal power of the holding brake (optional)

(17) Barcode

20

0198441113926, V2.02, 11.2014

Servo drive system

Page 21

LXM23D and BCH

1.4 Type code

Product designation

LXM = Lexium

Product type

23 = AC servo drive for one axis

Interfaces

D = I/O

A = Fieldbus CANopen

Continuous power

U01 = 0.1 kW

U02 = 0.2 kW

U04 = 0.4 kW

U07 = 0.75 kW

U10 = 1 kW

U15 = 1.5 kW

U20 = 2 kW

U30 = 3 kW

U45 = 4.5 kW

U55 = 5.5 kW

U75 = 7.5 kW

1 Introduction

Drive

LXM 23 D U07 M3X (∙∙∙∙)

Power stage supply [Vac]

M3X = 3~, 200/240 V

Further options

ac

0198441113926, V2.02, 11.2014

Servo drive system

21

Page 22

1 Introduction

Motor

Product family

BCH = Synchronous motor - medium moment of inertia

Size (housing)

040 = 40 mm flange

060 = 60 mm flange

080 = 80 mm flange

100 = 100 mm flange

130 = 130 mm flange

180 = 180 mm flange

Length

1 = 1 stack

2 = 2 stacks

3 = 3 stacks

4 = 4 stacks

5 = 5 stacks

Winding

M = Optimized in terms of torque (1000 min-1/1500 min-1)

N = Optimized in terms of torque and speed of rotation (2000 min-1)

O = Optimized in terms of speed of rotation (3000 min-1)

Shaft and degree of protection

0 = Smooth shaft; degree of protection: IP40

1 = Parallel key; IP40

2 = Smooth shaft; degree of protection: shaft and housing IP65

3 = Parallel key; degree of protection: shaft and housing IP 65

LXM23D and BCH

BCH 040 1 O 0 2 A 1 C

Encoder system

2 = High-resolution encoder (20 bit)

Holding brake

A = Without holding brake

F = With holding brake

Connection version

1 = Flying leads (for BCH040, BCH060, BCH080); military connector (for BCH100, BCH130, BCH180)

Mechanical interface - mounting

C = Asian standard

22

0198441113926, V2.02, 11.2014

Servo drive system

Page 23

LXM23D and BCH

1.5 Servo Drive and Servo Motor Combinations

1 Introduction

BCH

servo

motor

output

power

kW kgcm

Single phase: 200 ... 255 V ~ 50/60 Hz or three phase : 170 ... 255 V ~50/60 Hz

0.1 0.037 0.32 0.96 5000 3000 LXM23∙U01M3X BCH0401O∙2∙1C ultra low

0.2 0.177 0.64 1.92 5000 3000 LXM23∙U02M3X BCH0601O∙2∙1C ultra low

0.3 8.17 2.86 8.59 2000 1000 LXM23∙U04M3X BCH1301M∙2∙1C medium

0.4 0.277 1.27 3.82 5000 3000 LXM23∙U04M3X BCH0602O∙2∙1C ultra low

0.4 0.68 1.27 3.82 5000 3000 LXM23∙U04M3X BCH0801O∙2∙1C low

0.5 8.17 2.39 7.16 3000 2000 LXM23∙U04M3X BCH1301N∙2∙1C medium

0.6 8.41 5.73 17.19 2000 1000 LXM23∙U07M3X BCH1302M∙2∙1C medium

0.75 1.13 2.39 7.16 5000 3000 LXM23∙U07M3X BCH0802O∙2∙1C low

0.9 11.18 8.59 25.78 2000 1000 LXM23∙U10M3X BCH1303M∙2∙1C medium

1 2.65 3.18 9.54 5000 3000 LXM23∙U10M3X BCH1001O∙2∙1C low

1 11.18 4.77 14.32 3000 2000 LXM23∙U10M3X BCH1302N∙2∙1C medium

1.5 11.18 7.16 21.48 3000 2000 LXM23∙U15M3X BCH1303N∙2∙1C medium

Three phase: 170 ... 255 V ~50/60 Hz

2 4.45 6.37 19.11 5000 3000 LXM23∙U20M3X BCH1002O∙2∙1C low

2 14.59 9.55 26.65 3000 2000 LXM23∙U20M3X BCH1304N∙2∙1C medium

2 34.68 9.55 26.65 3000 2000 LXM23∙U20M3X BCH1801N∙2∙1C high

3 54.95 14.32 42.96 3000 2000 LXM23∙U30M3X BCH1802N∙2∙1C high

3 54.95 19.10 57.29 3000 1500 LXM23∙U30M3X BCH1802M∙2∙1C high

4.5 77.75 28.65 71.62 3000 1500 LXM23∙U45M3X BCH1803M∙2∙1C high

5.5 99.78 35.01 87.53 3000 1500 LXM23∙U55M3X BCH1804M∙2∙1C high

7.5 142.7 47.74 119.36 3000 1500 LXM23∙U75M3X BCH1805M∙2∙1C high

BCH servo

motor inertia

(without

brake)

2

Rated

torque

Nm Nm RPM RPM

Peak

stall torque

Maximum

speed

Rated

speed

Combinations

Servo drive Servo motor Motor

inertia

type

0198441113926, V2.02, 11.2014

Servo drive system

23

Page 24

1 Introduction

LXM23D and BCH

24

0198441113926, V2.02, 11.2014

Servo drive system

Page 25

LXM23D and BCH

2 Technical Data

This chapter contains information on the ambient conditions and on

the mechanical and electrical properties of the product family and the

accessories.

2.1 Ambient conditions

Ambient conditions of motor see chapter "2.4 Motor data".

2.1.1 Ambient conditions of drive

2 Technical Data

Climatic environmental conditions

transportation and storage

Climatic environmental conditions

operation

The environment during transportation and storage must be dry and

free from dust.

Temperature °C

(°F)

-20 ... 65

(-4 ... 149)

The following relative humidity is permissible during transportation and

storage:

Relative humidity (non-condensing)

% 0 ... 90

The maximum permissible ambient temperature during operation

depends on the mounting distances between the devices and on the

required power. Observe the pertinent instructions in the chapter

"4 Installation".

Ambient temperature (no icing,

non-condensing)

Ambient temperature (no icing,

non-condensing) if all of the following conditions are met:

• Installed in a well ventilated

location

• No obstructed airflow for the

cooling fan

°C

(°F)

°C

(°F)

0 ... 45

(32 ... 113)

45 ... 55

(113 ... 131)

0198441113926, V2.02, 11.2014

Servo drive system

The following relative humidity is permissible during operation:

Relative humidity (non-condensing)

Atmospheric pressure kPa

% 5 ... 95

86 ... 106

(psi)

(12.47 ... 15.37)

25

Page 26

2 Technical Data

LXM23D and BCH

Altitude above mean sea level

without derating

Altitude above mean sea level if

all of the following conditions are

met:

• 45 °C (113 °F) maximum

ambient temperature

• Reduction of the continuous

power by 1 % per 100 m

(328 ft) above 1000 m

(3281 ft)

m

(ft)

m

(ft)

<1000

(<3281)

1000 ... 2000

(3281 ... 6562)

Installation site and connection For operation, the device must be mounted in a closed control cabi-

net. The device may only be operated with a permanently installed

connection.

Pollution degree and degree of

protection

Vibration

LXM23∙ U01, U02, U04, U07, U10,

U15

Pollution degree 2

Degree of protection

Vibration resistance

mass <20 kg (<44.1 lb)

Vibration resistance

mass 20 ... 100 kg

(44.1 ... 220.5 lb)

IP20 IP10

Tested as per IEC 60068-2-6

3 mm [2 ... 9 Hz]

10 m/s2 [9 ... 200 Hz]

Tested as per IEC 60068-2-6

1.5 mm [2 ... 13 Hz]

6 m/s2 [13 ... 200 Hz]

U20, U30, U45, U55, U75

26

0198441113926, V2.02, 11.2014

Servo drive system

Page 27

146

60

49

Ø5.5

152

162

5.75

2.36

6.38

5.98

1.93

Ø0.22

mm

in

85

74

Ø5.5

152

162

180

7.09

3.35

6.38

5.98

2.91

Ø0.22

mm

in

LXM23D and BCH

2.2 Dimensions

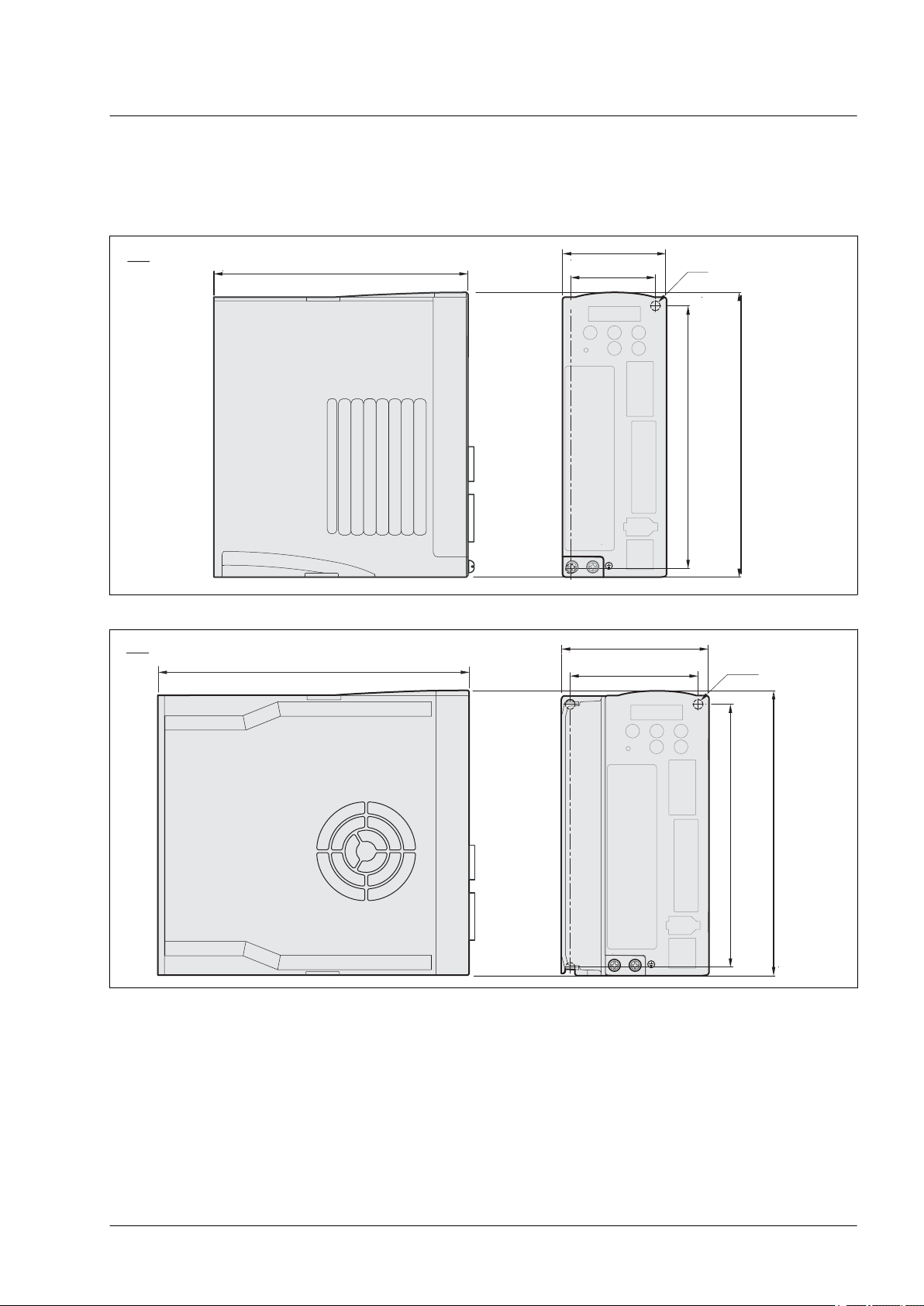

2.2.1 Dimensions of drive

2 Technical Data

Figure 3: Dimensions LXM23∙U01M3X, LXM23∙U02M3X, LXM23∙U04M3X

Figure 4: Dimensions LXM23∙U07M3X, LXM23∙U10M3X, LXM23∙U15M3X

0198441113926, V2.02, 11.2014

Servo drive system

27

Page 28

114

102

Ø5.5

213

225

195

7.68

4.49

8.86

8.39

4.02

Ø0.22

mm

in

110

91.2

230

245

205

Ø5.5

8.07

4.33

9.65

9.06

3.59

Ø0.22

mm

in

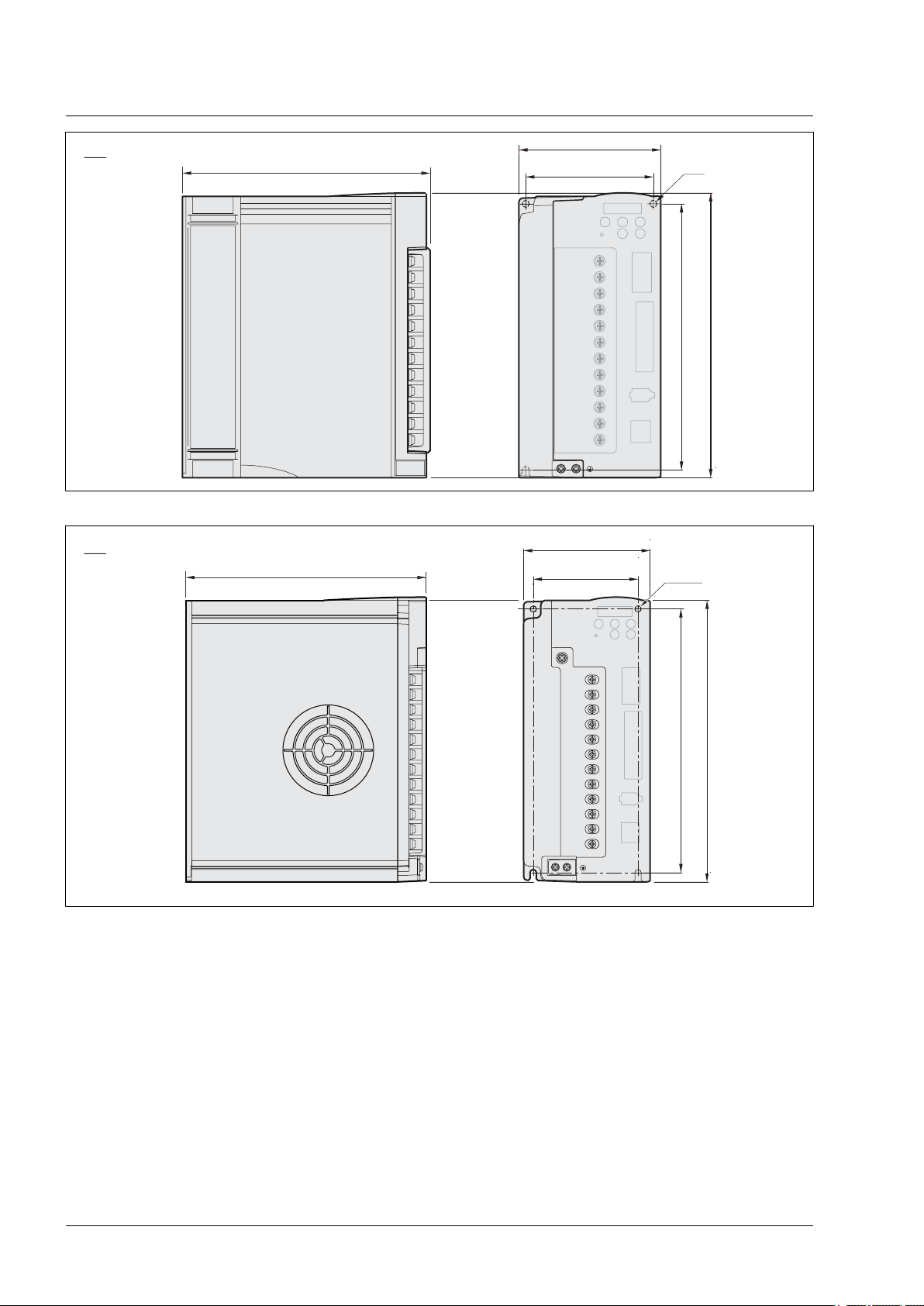

2 Technical Data

Figure 5: Dimensions LXM23∙U20M3X, LXM23∙U30M3X

LXM23D and BCH

Figure 6: Dimensions LXM23∙U45M3X

28

Servo drive system

0198441113926, V2.02, 11.2014

Page 29

123

107

230

245

208.5

Ø6

216.5

8.21

4.84

9.65

9.06

4.21

Ø0.24

8.52

mm

in

136

119.5

230

245

Ø6

107

260

254

208.5

216.5

8.21

5.35

9.65

9.06

4.70

Ø0.24

8.52

10

10.24

4.21

mm

in

LXM23D and BCH

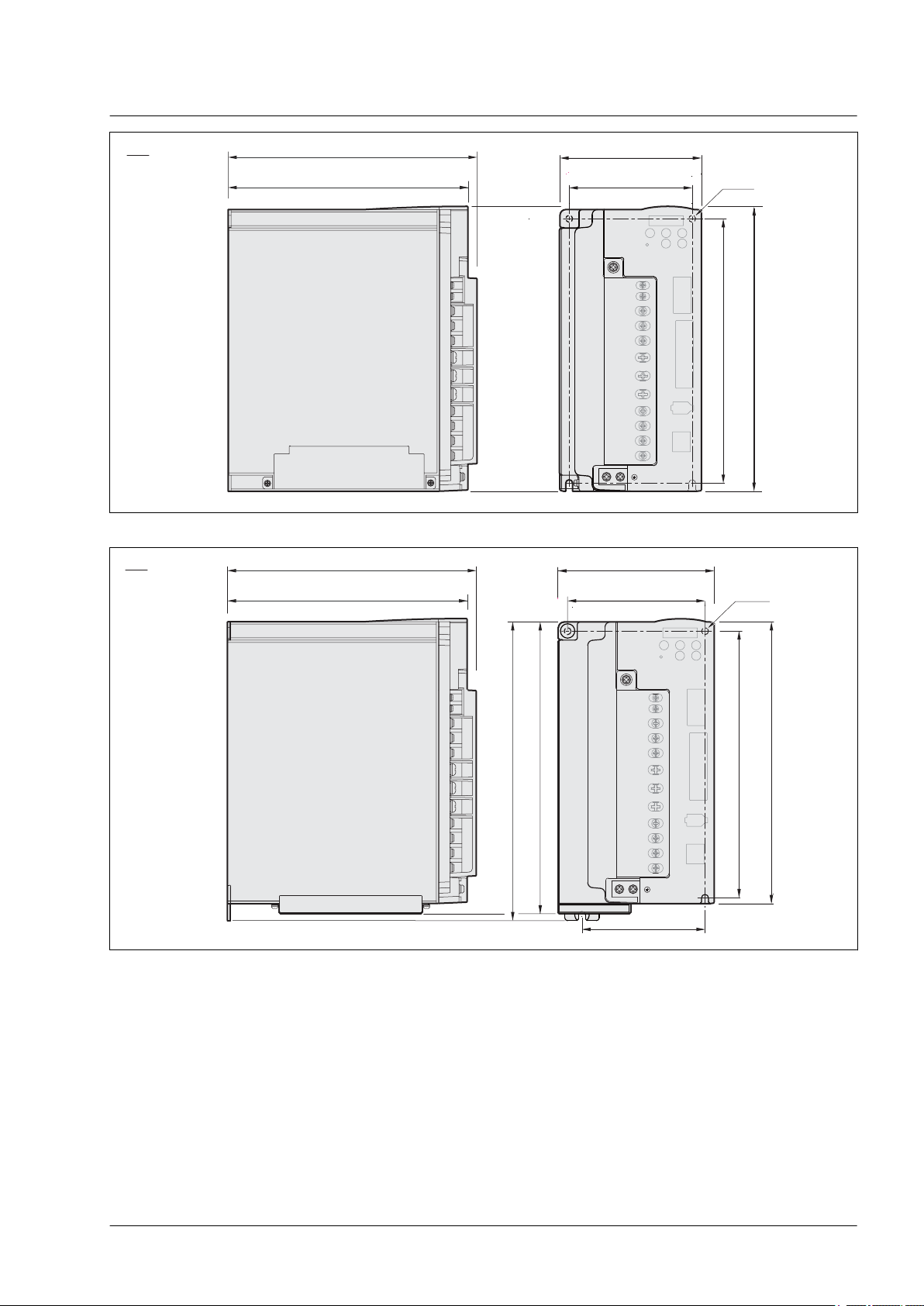

Figure 7: Dimensions LXM23∙U55M3X

2 Technical Data

Figure 8: Dimensions LXM23∙U75M3X

0198441113926, V2.02, 11.2014

Servo drive system

29

Page 30

300±50

11.81±1.97

300±50

11.81±1.97

20

0.79

16

0.63

25

0.98

2.5

0.1

5

0.20

Ø4.5

Ø0.18

4x

Ø46

Ø1.81

Ø30h7

Ø1.18

Ø8h6

Ø0.31

0.12

3

0.12

0.12

6.2

0.24

c

mm

in

40

1.57

3

0

- 0.0 3

3

0

- 0.0 3

300±50

11.81±1.97

300±50

11.81±1.97

24

0.94

20

0.79

30

1.18

3

0.12

7.5

0.30

Ø5.5

Ø0.22

4x

Ø70

Ø2.76

Ø50h7

Ø1.97

Ø14h6

Ø0.55

0.20

5

0.20

0.20

11

0.43

c

60

2.36

5

0

- 0.0 3

5

0

- 0.0 3

mm

in

2 Technical Data

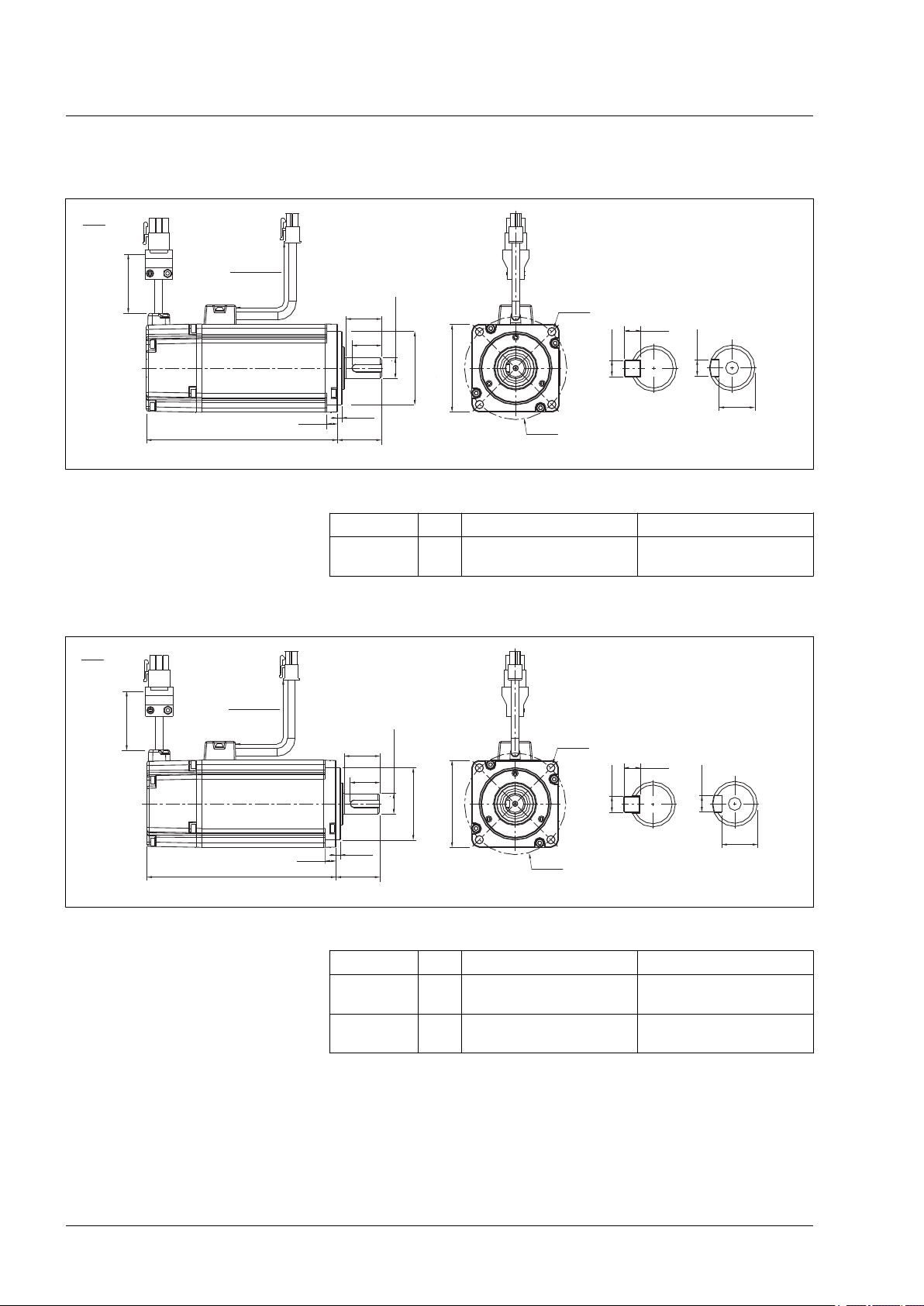

2.2.2 Dimensions of motor

Dimensions BCH040

Figure 9: Dimensions BCH040

BCH040 mm

(in)

LXM23D and BCH

c (without holding brake) c (with holding brake)

100.6

(3.96)

136.6

(5.38)

Dimensions BCH060

Figure 10: Dimensions BCH060

c (without holding brake) c (with holding brake)

BCH0601 mm

BCH0602 mm

(in)

(in)

105.5

(4.15)

130.7

(5.15)

141.6

(5.57)

166.8

(6.57)

30

0198441113926, V2.02, 11.2014

Servo drive system

Page 31

300±50

11.81±1.97

300±50

11.81±1.97

Ø6.6

Ø0.26

Ø90

Ø3.54

80

3.15

c2

c1

LS

3

0.12

8

0.31

c

Ø70h7

Ø2.76

ØSh6

4x

T

RH

W

Wk

0

- 0.0 3

0

- 0.0 3

mm

in

37

1.46

32

1.26

45

1.77

5

0.20

12

0.47

Ø9

Ø0.35

4x

Ø115

Ø4.53

Ø95h7

Ø3.74

Ø22h6

Ø0.87

0.31

7

0.28

0.31

18

0.71

c

100

3.94

8

0

- 0.0 3

8

0

- 0.0 3

mm

in

LXM23D and BCH

Dimensions BCH080

Figure 11: Dimensions BCH080

2 Technical Data

c (without holding

brake)

BCH0801 mm

BCH0802 mm

(in)

(in)

105.5

(4.15)

130.7

(5.15)

Dimensions BCH100

Figure 12: Dimensions BCH100

c (with holding

brake)

141.6

(5.57)

166.8

(6.57)

S c1 c2 LS RH Wk W T

14

(0.55)30(1.18)20(0.79)

19

(0.75)35(1.38)25(0.98)

24.5

(0.96)11(0.43)5(0.2)5(0.2)5(0.2)

29.5

15.5

(1.16)

(0.61)6(0.24)6(0.24)6(0.24)

c (without holding brake) c (with holding brake)

BCH1001 mm

BCH1002 mm

0198441113926, V2.02, 11.2014

Servo drive system

(in)

(in)

153.5

(6.04)

199

(7.83)

192.5

(7.58)

226

(8.9)

31

Page 32

47

1.85

36

1.42

55

2.17

6

0.24

11.5

0.45

Ø9

Ø0.35

4x

Ø145

Ø5.71

Ø110h7

Ø4.33

Ø22h6

Ø0.87

8

0.31

7

0.28

0.31

18

0.71

c

130

5.12

mm

in

0

- 0.0 3

8

0

- 0.0 3

2 Technical Data

Dimensions BCH130

Figure 13: Dimensions BCH130

BCH1301 mm

(in)

BCH1302 mm

(in)

BCH1303M mm

(in)

BCH1303N mm

(in)

BCH1304 mm

(in)

LXM23D and BCH

c (without holding brake) c (with holding brake)

147.5

(5.81)

147.5

(5.81)

163.5

(6.44)

167.5

(6.59)

187.5

(7.38)

183.5

(7.22)

183.5

(7.22)

198

(7.8)

202

(7.95)

216

(8.5)

Servo drive system

0198441113926, V2.02, 11.2014

32

Page 33

Ø13.5

Ø0.53

8

0.31

Ø200

Ø7.87

180

7.09

c2

c1

LS

4

0.16

20

0.79

c

Ø114.3h7

Ø4.5

ØSh6

4x

W

Wk

RH

mm

in

0

- 0.0 3

0

- 0.0 3

LXM23D and BCH

Dimensions BCH180

Figure 14: Dimensions BCH180

2 Technical Data

BCH1801 mm

(in)

BCH1802N mm

(in)

BCH1802M mm

(in)

c (without holding

brake)

169

(6.65)

202.1

(7.96)

202.1

(7.96)

c (with holding brake) S c1 c2 LS RH Wk W

203.1

(8)

235.3

(9.26)

235.3

(9.26)

35

(1.38)79(3.11)63(2.48)73(2.87)30(1.18)10(0.39)10(0.39)

35

(1.38)79(3.11)63(2.48)73(2.87)30(1.18)10(0.39)10(0.39)

35

(1.38)79(3.11)63(2.48)73(2.87)30(1.18)10(0.39)10(0.39)

0198441113926, V2.02, 11.2014

Servo drive system

33

Page 34

2 Technical Data

LXM23D and BCH

2.3 Electrical data of drive

2.3.1 Specification of drive

LXM23∙ U01 U02 U04 U07 U10 U15 U20 U30 U45 U55 U75

Phase / Voltage Three-phase or single-phase: 220 Vac Three-phase: 220 Vac

Permissible Voltage

Range

Continuous output

Power supply

current

Cooling System Natural Air Circulation Fan Cooling

Encoder Resolution /

Feedback Resolution

Control of Main Circuit SVPWM (Space Vector Pulse Width Modulation) Control

Tuning Modes Auto / Manual

Dynamic Brake Internal External

Max. Input Pulse Frequency

Pulse Type Pulse + Direction, A phase + B phase, CCW pulse + CW pulse

Command Source External pulse train (Pt mode) / Internal procedures (Pr mode)

Smoothing Low-pass and P-curve filter

Electronic Gear Electronic gear N/M multiple N: 1 ... 32767, M: 1:32767 (1/50<N/M<25600)

Position Control Mode

Torque Limit Operation

Feed Forward Compensation

Analog

Input

Command

Voltage

Range

Input Resistance

Time Constant

Speed Control Range1)1:5000 1:3000

Speed Control Mode

Three-phase: 170 ... 255 Vac

Three-phase: 170 ... 255 Vac

Single-phase: 200 ... 255 Vac

0.9

A

rms

1.55

A

rms

2.6

A

rms

5.1

A

rms

7.3

A

rms

8.3

A

rms

13.4

A

rms

19.4

A

rms

32.5

A

rms

20-bit (1 280 000 p/rev)

Input PULSE: Max. 500 Kpps (Line driver), Max. 200 Kpps (Open collector)

Input HPULSE: Max. 4 Mpps (Line receiver)

Set by parameters

Set by parameters

±10 Vdc

10 kΩ

2.2 μs

40 A

rms

47.5

A

rms

Command Source External analog signal / Internal parameters

Smoothing Low-pass and S-curve filter

Torque Limit Opera-

Set by parameters or via analog input

tion

Frequency Response

Maximum 1 kHz

Characteristic

Speed Accuracy

(at rated speed of

rotation)

2)

0.01 % or less at 0 ... 100 % load fluctuation

0.01 % or less at ±10% power fluctuation

0.01 % or less at 0 ... 50 °C (32 ... 122 °F)ambient temperature fluctuation xxx

34

0198441113926, V2.02, 11.2014

Servo drive system

Page 35

LXM23D and BCH

LXM23∙ U01 U02 U04 U07 U10 U15 U20 U30 U45 U55 U75

Analog

Input

Command

Command Source External analog signal / Internal parameters

Torque Control Mode

Smoothing Low-pass filter

Speed Limit Operation

Analog Monitor Output

Digital

Inputs/

Outputs

Monitoring functions Overcurrent, Overvoltage, Undervoltage, Motor overheated, Regeneration error, Overload,

Communication Interface RS-232(for PC) / RS-485

Installation Site Indoor location (free from direct sunlight), no corrosive liquid and gas (far away from oil mist,

Power System TN System

Approvals IEC/EN 61800-5-1, UL 508C, C-tick

Environment

Voltage

Range

Input Resistance

Time Constant

Inputs Servo On, Reset, Gain switching, Pulse clear, Zero speed CLAMP, Command input reverse

Outputs Encoder signal output (A, B, Z Line Driver and Z Open Collector )

±10 Vdc

10 kΩ

2.2 μs

Set by parameters or via analog input

Monitor signal can set by parameters (Output voltage range: ±8V)

control, Command triggered, Speed/Torque limit enabled, Position command selection, Motor

stop, Speed Position Selection, Position / Speed mode switching, Speed / Torque mode

switching, Torque / Position mode switching, Pt / Pr command switching, Operational stop,

Forward / Reverse inhibit limit, Reference "Home" sensor, Forward / Reverse operation torque limit, Move to "Home", Forward / Reverse JOG input, Event trigger Pr command, Electronic gear ratio (Numerator) selection and Pulse inhibit input.

Servo ready, Servo On, At Zero speed, At Speed reached, At Positioning completed, At Torques limit, Alarm signal, Holding brake control, Homing completed, Output overload warning,

Warning signal, Position command overflow, Forward / Reverse software limit, Internal position command completed, Capture operation completed output, Motion control completed

output.

Overspeed, Abnormal pulse control command, Excessive deviation, Encoder error, Adjustment error, Operational stop activated, Reverse/ Forward limit switch error, Serial communication error, Input power phase loss, Serial communication timeout, short circuit protection of

U, V, W,

flammable gas, dust)

3)

2 Technical Data

1) During full load, the speed ratio is defined as min. speed (no go and stop) /rated speed

2) When command is rated speed, speed fluctuation rate is defined as (empty load speed - full load speed)/rated speed

3) TN system: A power distribution having one point directly grounded,the exposed conductive parts of the installation being connected

to that points by protective ground conductor; see IEC 60364-1 for additional information.

The products are intended for industrial use and may only be operated

with a permanently installed connection.

0198441113926, V2.02, 11.2014

Servo drive system

35

Page 36

2 Technical Data

LXM23D and BCH

2.3.2 DC bus data

DC bus data for single-phase

drives

LXM23∙ (single-phase) U01 U02 U04 U07 U10 U15

Nominal voltage single-phase Vac 220 220 220 220 220 220

Nominal voltage DC bus Vdc 311 311 311 311 311 311

Undervoltage limit Vdc P4-24 * √2 P4-24 * √2 P4-24 * √2 P4-24 * √2 P4-24 * √2 P4-24 * √2

Voltage limit: activation of error

reaction in drive (quickstop)

Overvoltage limit Vdc 410 410 410 410 410 410

DC bus data for three-phase drives

LXM23∙ (three-phase) U20 U30 U45 U55 U75

Nominal voltage three-phase Vac 220 220 220 220 220

Nominal voltage DC bus Vdc 311 311 311 311 311

Undervoltage limit Vdc P4-24 * √2 P4-24 * √2 P4-24 * √2 P4-24 * √2 P4-24 * √2

Voltage limit:activation of error

reaction in drive (quickstop)

Overvoltage limit Vdc 410 410 410 410 410

Vdc 410 410 410 410 410 410

Vdc 410 410 410 410 410

2.3.3 Additional EMC input filters

Limit values This product meets the EMC requirements according to the standard

IEC 61800-3 if the measures described in this manual are implemented during installation.

If the selected composition (product itself, mains filter, other accessories and measures) does not meet the requirements of category C1,

the following information applies as it appears in IEC 61800-3:

RADIO INTERFERENCE

In a domestic environment this product may cause radio interference

in which case supplementary mitigation measures may be required.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

Applications When combined with LXM23∙U∙ ∙M3X servo drives, additional EMC

filters can be used to meet more stringent requirements and are

designed to reduce conducted emissions on the line supply below the

limits of standard IEC 61800-3, edition 2, categories C2 and C3.

WARNING

36

0198441113926, V2.02, 11.2014

Servo drive system

Page 37

LXM23D and BCH

2 Technical Data

Characteristics of EMC filter

Conforming to standards EN 133200

Degree of protection IP 41 on the upper part

with protective cover in

place

IP 20 after removal of the

protective cover

Relative humidity According to IEC

60721-3-3, class 3K3, 5%

to 85%, without condensation or dripping water

Ambient air temperature See ambient conditions for

the drive.

Altitude above mean sea level without

derating

Altitude above mean sea level if all of the

following conditions are met:

• Max. temperature 40 °C (104 °F)

• Mounting distance between servo

drives >50 mm (1,97 in)

• Protective cover removed

Vibration resistance Conforming to IEC

60068-2-6

Shock resistance Conforming to IEC

60068-2-27

Maximum nominal

voltage

Single-phase 50/60HzV 120 + 10 %

Three-phase 50/60HzV 240 + 10 %

m

<1000

(ft)

(<3281)

m

1000 ... 2000

(ft)

(3281 ... 6562)

10 Hz to 57 Hz: amplitude

0.075 mm

57 Hz to 150 Hz: 1 g

15 gn for 11 ms

240 + 10 %

0198441113926, V2.02, 11.2014

Servo drive system

37

Page 38

2 Technical Data

Additional EMC input filters The specified limit values are complied with if the installation is EMC-

LXM23D and BCH

compliant and if the cables and the external mains filters offered as

accessories are used.

EN 55011 Class A Gr2

IEC/EN 61800-3 Category C3 in environment 2

Additional EMC input filters

For servo drive Ordernumber Weight

kg (lb)

Single-phase supply voltage

LXM23∙U07M3X

LXM23∙U10M3X

LXM23∙U15M3X

LXM23∙U01M3X

LXM23∙U02M3X

LXM23∙U04M3X

Three-phase supply voltage

LXM23∙U07M3X

LXM23∙U10M3X

LXM23∙U15M3X

LXM23∙U20M3X

LXM23∙U30M3X

LXM23∙U45M3X

LXM23∙U55M3X

LXM23∙U75M3X VW3A31407 3.150 (6.94)

VW3A31403 0.775 (1.71)

VW3A31401 0.600 (1.32)

VW3A31404 0.900 (1.98)

VW3A31406 1.350 (2.98)

38

0198441113926, V2.02, 11.2014

Servo drive system

Page 39

LXM23D and BCH

2.3.4 Upstream circuit breaker, fuse

The following tables provide information on the minimum and maximum circuit breaker and fuse ratings for installations as per IEC and

UL. Select fuses with the lowest possible fuse ratings suitable for your

application within the ranges specified in the tables below. The conductors must have a sufficiently large cross section so that the fuses

can trip if required.

Single-phase: 220 Vac The following table shows circuit breaker and fuses to be placed

upstream for single-phase 220 Vac.

2 Technical Data

Input current Circuit breaker

minimum

LXM23∙U01M3X A 0.69 6 6.3 5 5

LXM23∙U02M3X A 1.92 6 6.3 5 5

LXM23∙U04M3X A 4.50 6 10 6 20

LXM23∙U07M3X A 6.78 10 10 10 20

LXM23∙U10M3X A 8.87 13 15 12 25

LXM23∙U15M3X A 10.30 16 25 20 40

1) IEC Circuit: Breaker Characteristic C

2) UL Fuse: Class CC or Class T

1)

Circuit breaker

maximum

)

Fuse minimum2)Fuse maxi-

mum

Three-phase: 170 Vac The following table shows circuit breaker and fuses to be placed

upstream for three-phase 170 Vac.

Input current Circuit breaker

minimum

LXM23∙U01M3X A 0.39 6 6.3 5 5

LXM23∙U02M3X A 1.11 6 6.3 5 5

LXM23∙U04M3X A 1.86 6 10 6 20

LXM23∙U07M3X A 3.66 8 10 8 20

LXM23∙U10M3X A 4.68 10 15 10 25

LXM23∙U15M3X A 5.90 13 25 12 40

LXM23∙U20M3X A 8.70 16 30 15 60

LXM23∙U30M3X A 9.80 20 30 20 80

LXM23∙U45M3X A 17.5 30 60 30 160

LXM23∙U55M3X A 19.7 40 60 40 160

LXM23∙U75M3X A 26.3 50 75 50 200

1) IEC Circuit: Breaker Characteristic C

2) UL Fuse: Class CC or Class T

1)

Circuit breaker

maximum

)

Fuse minimum2)Fuse maxi-

mum

)

)

0198441113926, V2.02, 11.2014

Servo drive system

39

Page 40

2 Technical Data

2.4 Motor data

2.4.1 Specification of motor

Approved drives For permitted combination of motor and drive see chapter

Ultra low/low Inertia Series

LXM23D and BCH

"1.5 Servo Drive and Servo Motor Combinations".

40

0198441113926, V2.02, 11.2014

Servo drive system

Page 41

LXM23D and BCH

BCH... 0401O 0601O 0602O 0801O 0802O 1001O 1002O

Rated output power [kW] 0.1 0.2 0.4 0.4 0.75 1.0 2.0

Rated torque [Nm] 0.32 0.64 1.27 1.27 2.39 3.18 6.37

Maximum torque [Nm] 0.96 1.92 3.82 3.82 7.16 9.54 19.11

Rated speed [RPM] 3000

Maximum speed [RPM] 5000

Rated current [A] 0.9 1.55 2.6 2.6 5.1 7.3 12.05

Maximum current [A] 2.7 4.65 7.8 7.8 15.3 21.9 36.15

Rotor moment of inertia [kg.cm2] (without

brake)

Mechanical time constant [ms] 0.75 0.80 0.53 0.74 0.63 0.74 0.61

Torque constant KT [Nm/A] 0.36 0.41 0.49 0.49 0.47 0.43 0.53

Voltage constant KE [mV/RPM] 13.6 16 17.4 18.5 17.2 16.8 19.2

Winding resistance [Ohm] 9.3 2.79 1.55 0.93 0.42 0.20 0.13

Winding inductance [mH] 24 12.07 6.71 7.39 3.53 1.81 1.50

Electrical time constant [ms] 2.58 4.3 4.3 7.96 8.37 9.3 11.4

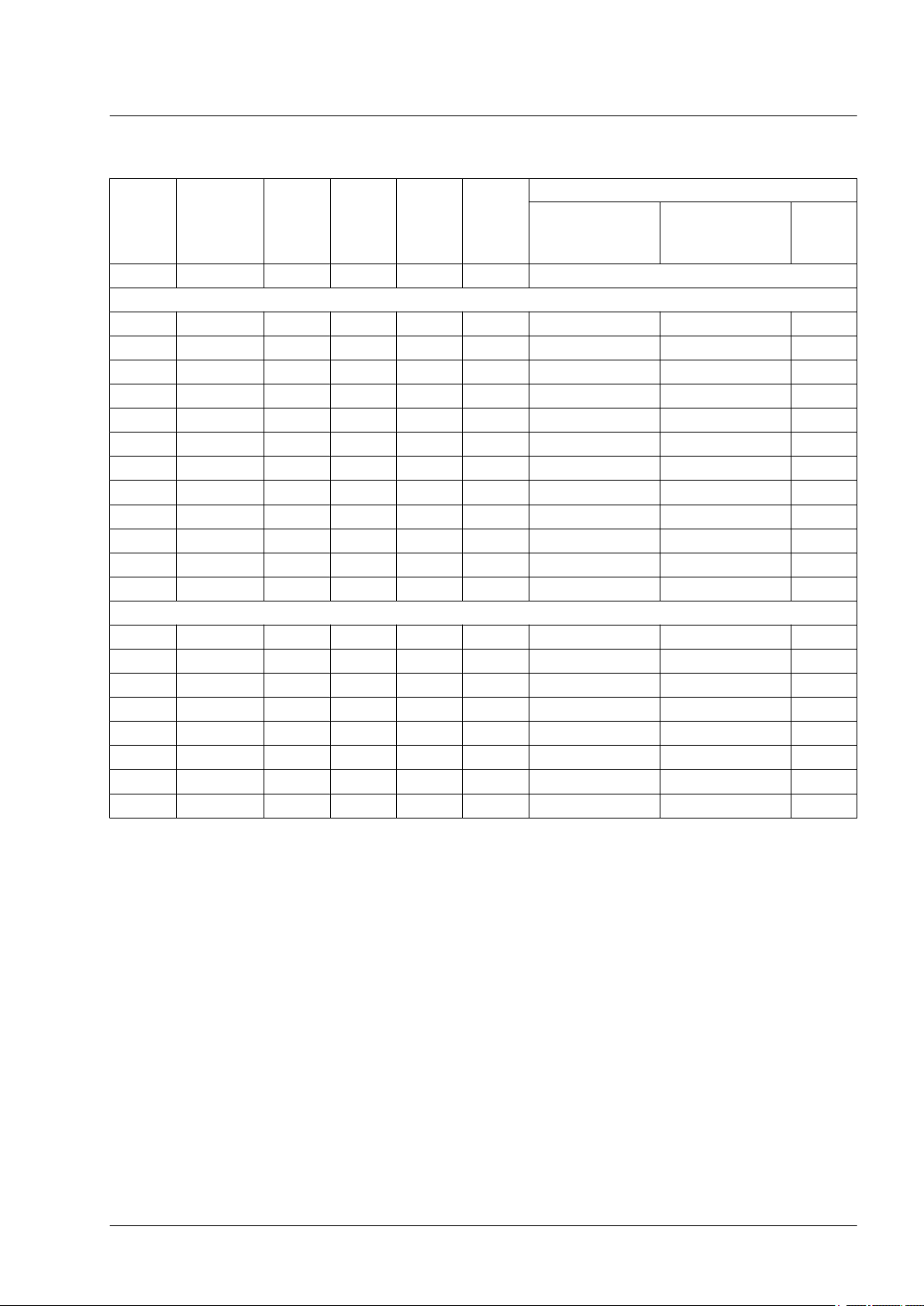

Insulation class Class A (UL), Class B (CE)

Insulation resistance >100MΩ, DC 500V

Insulation strength 1500Vac, 60 seconds

Weight without brake [kg (lb)] 0.5 (1.1) 1.2 (2.6) 1.6 (3.5) 2.1 (4.6) 3.0 (6.6) 4.3 (9.5) 6.2 (13.7)

Weight with brake [kg (lb)] 0.8 (1.8) 1.5 (3.3) 2.0 (4.4) 2.9 (6.4) 3.8 (8.4) 4.7 (10.5) 7.2 (15.9)

Max. radial shaft load [N] 78.4 196 196 245 245 490 490

Max. thrust shaft load [N] 39.2 68 68 98 98 98 98

Rotor moment of inertia [kg.cm2] (with

brake)

Mechanical time constant [ms] (with

brake)

Brake holding torque [Nm] (min) 0.3 1.3 1.3 2.5 2.5 8.0 8.0

Brake power consumption (at 20°C) [W] 7.3 6.5 6.5 8.3 8.2 19.4 19.4

Brake release time [ms] (Max) 5 10 10 10 10 10 10

Brake pull-in time [ms] (Max) 25 70 70 70 70 70 70

Vibration grade [μm] 15

Operating temperature 0 ... 40 °C (32 ... 104 °F)

Storage temperature -10 ... 80 °C (-14 ... 176 °F)

Operating humidity 20 ... 90 % RH (non-condensing)

Storage humidity 20 ... 90 % RH (non-condensing)

Vibration capacity 2.5 m/s

IP Rating IP65 (when IP65 connectors are used, and when an oil seal is fitted to the

Approvals

0.037 0.177 0.277 0.68 1.13 2.65 4.45

0.04 0.192 0.30 0.73 1.18 3.33 4.953

0.81 0.85 0.57 0.78 0.65 0.93 0.66

2

rotating shaft (an oil seal model is used))

2 Technical Data

0198441113926, V2.02, 11.2014

Servo drive system

41

Page 42

2 Technical Data

LXM23D and BCH

Medium / High Inertia Series

BCH... 1301N 1302N 1303N 1304N 1801N 1802N 1803N

Rated output power [kW] 0.5 1.0 1.5 2.0 2.0 3.0

Rated torque [Nm] 2.39 4.77 7.16 9.55 9.55 14.32

Maximum torque [Nm] 7.16 14.3 21.48 28.65 28.65 42.97

Rated speed [RPM] 2000

Maximum speed [RPM] 3000

Rated current (A) 2.9 5.6 8.3 11.01 11.22 16.1

Maximum current (A) 8.7 16.8 24.9 33.03 33.66 48.3

Rotor moment of inertia (kg.cm2) (without

brake)

Mechanical time constant (ms) 1.91 1.51 1.10 0.96 1.62 1.06

Torque constant-KT (Nm/A) 0.83 0.85 0.87 0.87 0.85 0.89

Voltage constant-KE [mV/RPM] 30.9 31.9 31.8 31.8 31.4 32

Winding resistance (Ohm) 0.57 0.47 0.26 0.174 0.119 0.052

Winding inductance (mH) 7.39 5.99 4.01 2.76 2.84 1.38

Electrical time constant (ms) 12.96 12.88 15.31 15.86 23.87 26.39

Insulation class Class A (UL), Class B (CE)

Insulation resistance >100MΩ, DC 500V

Insulation strength 1500Vac, 60 seconds

Weight without brake [kg (lb)] 6.8 (15.0) 7.0 (15.4) 7.5 (16.5) 7.8 (17.2) 13.5

Weight with brake [kg (lb)] 8.2 (18.1) 8.4 (18.5) 8.9 (19.6) 9.2 (20.3) 17.5

Max. radial shaft load [N] 490 490 490 490 1176 1470

Max. thrust shaft load [N] 98 98 98 98 490 490

Rotor moment of inertia [kg.cm2] (with

brake)

Mechanical time constant [ms] (with

brake)

Brake holding torque [Nm] (min) 10 10 10 10 25 25

Brake power consumption (at 20°C) [W] 19 19 19 19 20.4 20.4

Brake release time [ms] (Max) 10 10 10 10 10 10

Brake pull-in time [ms] (Max) 70 70 70 70 70 70

Vibration grade [μm] 15

Operating temperature 0 ... 40 °C (32 ... 104 °F)

Storage temperature -10 ... 80 °C (-14 ... 176 °F)

Operating humidity 20 ... 90 % RH (non-condensing)

Storage humidity 20 ... 90 % RH (non-condensing)

Vibration capacity 2.5m/s

IP Rating IP65 (when IP65 connectors are used, and when an oil seal is fitted to the

Approvals

8.17 8.41 11.18 14.59 34.68 54.95

18.5

(29.8)

(38.6)

8.94 9.14 11.90 15.88 37.86 57.06

2.07 1.64 1.19 1.05 1.77 1.10

2

rotating shaft (an oil seal model is used))

(40.8)

22.5

(49.6)

42

0198441113926, V2.02, 11.2014

Servo drive system

Page 43

LXM23D and BCH

2 Technical Data

Medium / High Inertia Series

BCH... 1301M 1302M 1303M 1802M 1803M 1804M 1805M

Rated output power [kW] 0.3 0.6 0.9 3.0 4.5 5.5 7.5

Rated torque [Nm] 2.86 5.73 8.59 19.10 28.65 35.01 47.74

Maximum torque [Nm] 8.59 17.19 21.48 57.29 71.62 87.53 119.36

Rated speed [RPM] 1000 1500

Maximum speed [RPM] 2000 3000

Rated current (A) 2.5 4.8 7.5 19.4 32.5 40.0 47.5

Maximum current (A) 7.5 14.4 22.5 58.2 81.3 100.0 118.8

Rotor moment of inertia (kg.cm2) (without

brake)

Mechanical time constant (ms) 1.84 1.40 1.06 1.28 0.92 0.96 0.63

Torque constant KT (Nm/A) 1.15 1.19 1.15 0.98 0.88 0.88 1.01

Voltage constant KE [mV/RPM] 42.5 43.8 41.6 35.0 32.0 31.0 35.5

Winding resistance (Ohm) 1.06 0.82 0.43 0.077 0.032 0.025 0.015

Winding inductance (mH) 14.29 11.12 6.97 1.27 0.89 0.60 0.40

Electrical time constant (ms) 13.55 13.50 16.06 16.5 27.8 24.0 26.7

Insulation class Class A (UL), Class B (CE)

Insulation resistance >100MΩ, DC 500V

Insulation strength 1500Vac, 60 seconds

Weight without brake [kg (lb)] 6.8 (15.0) 7.0 (15.4) 7.5 (16.5) 18.5

Weight with brake [kg (lb)] 8.2 (18.1) 8.4 (18.5) 8.9 (19.6) 22.5

Max. radial shaft load [N] 490 490 490 1470 1470 1764 1764

Max. thrust shaft load [N] 98 98 98 490 490 588 588

Rotor moment of inertia [kg.cm2] (with

brake)

Mechanical time constant [ms] (with

brake)

Brake holding torque [Nm] (min) 10 10 10 25.0 25.0 25.0 25.0

Brake power consumption (at 20°C) [W] 19 19 19 20.4 20.4 20.4 20.4

Brake release time [ms] (Max) 10 10 10 10 10 10 10

Brake pull-in time [ms] (Max) 70 70 70 70 70 70 70

Vibration grade [μm] 15

Operating temperature 0 ... 40 °C (32 ... 104 °F)

Storage temperature -10 ... 80 °C (-14 ... 176 °F)

Operating humidity 20 ... 90 % RH (non-condensing)

Storage humidity 20 ... 90 % RH (non-condensing)

Vibration capacity 2.5m/s

IP Rating IP65 (when IP65 connectors are used, and when an oil seal is fitted to the

Approvals

8.17 8.41 11.18 54.95 77.75 99.78 142.7

23.5

(40.8)

(49.6)

8.94 9.14 11.9 57.06 80.65 102.70 145.55

2.0 1.51 1.13 1.33 0.96 0.99 0.64

2

rotating shaft (an oil seal model is used))

(51.8)

29.0

(63.9)

30.5

(67.2)

36.0

(79.4)

37.0

(81.6)

53.0

(116.9)

0198441113926, V2.02, 11.2014

Servo drive system

43

Page 44

0 1000 2000 3000 4000 5000

M

max

M

0

0.2

0.6

1.0

0.8

0

n [1/min]

M [Nm]

1

2

0.4

0 1000 2000 3000 4000 5000

M

max

M

0

0.5

1.0

2.0

1.5

0

1

2

n [1/min]

M [Nm]

0 1000 2000 3000 4000 5000

0.5

1.0

1.5

2.5

2.0

0

4.0

3.5

3.0

M

max

M

0

1

2

n [1/min]

M [Nm]

0 1000 2000 3000 4000 5000

0.5

1.0

1.5

2.5

2.0

0

4.0

3.5

3.0

M

max

M

0

1

2

n [1/min]

M [Nm]

0 1000 2000 3000 4000 5000

1

2

1

2

3

5

4

0

8

6

M

max

M

0

n [1/min]

M [Nm]

2 Technical Data LXM23D and BCH

2.4.2 Servo Motor Speed-Torque Curves (T-N Curves)

Characteristic curves BCH040

Characteristic curves BCH060

BCH0401O + LXM23∙U01M3X

Measurement of the characteristic curves with 220 V single-phase.

(1) Peak current

(2) Continuous torque

BCH0601O + LXM23∙U02M3X BCH0602O + LXM23∙U04M3X

Characteristic curves BCH080

44

Measurement of the characteristic curves with 220 V single-phase.

(1) Peak current

(2) Continuous torque

BCH0801O + LXM23∙U04M3X BCH0802O + LXM23∙U07M3X

Measurement of the characteristic curves with 220 V single-phase.

(1) Peak current

(2) Continuous torque

0198441113926, V2.02, 11.2014

Servo drive system

Page 45

0 1000 2000 3000 4000 5000

1

2

2

4

6

10

8

0

M

max

M

0

n [1/min]

M [Nm]

0 1000 2000 3000 4000 5000

5

10

20

15

0

M

max

M

0

n [1/min]

M [Nm]

1

2

0 1000 2000 3000

1

2

3

5

4

0

8

6

M

max

M

0

n [1/min]

M [Nm]

1

2

0 1000 2000

2

4

6

10

8

0

M

max

M

0

n [1/min]

M [Nm]

1

2

0 1000 2000 3000

5

10

0

20

15

M

max

M

0

n [1/min]

M [Nm]

1

2

0 1000 2000

5

10

20

15

0

M

max

M

0

n [1/min]

M [Nm]

1

2

LXM23D and BCH 2 Technical Data

Characteristic curves BCH100

Characteristic curves BCH1301

BCH1001O + LXM23∙U10M3X BCH1002O + LXM23∙U20M3X

BCH1001O: Measurement of the characteristic curves with 220 V single-phase.

BCH1002O: Measurement of the characteristic curves with 220 V

three-phase.

(1) Peak current

(2) Continuous torque

BCH1301N + LXM23∙U04M3X BCH1301M + LXM23∙U04M3X

Characteristic curves BCH1302

0198441113926, V2.02, 11.2014

Servo drive system

Measurement of the characteristic curves with 220 V single-phase.

(1) Peak current

(2) Continuous torque

BCH1302N + LXM23∙U10M3X BCH1302M + LXM23∙U07M3X

Measurement of the characteristic curves with 220 V single-phase.

(1) Peak current

(2) Continuous torque

45

Page 46

0 1000 2000 3000

5

10

0

25

15

M

max

M

0

n [1/min]

M [Nm]

1

2

20

0 1000 2000

M

max

M

0

n [1/min]

M [Nm]

1

2

5

10

0

25

15

20

30

0 1000 2000 3000

5

10

0

25

15

M

max

M

0

n [1/min]

M [Nm]

20

30

1

2

0 1000 2000 3000

5

0

25

15

M

max

M

0

n [1/min]

M [Nm]

20

30

1

2

10

2 Technical Data LXM23D and BCH

Characteristic curves BCH1303

Characteristic curves BCH1304

BCH1303N + LXM23∙U15M3X BCH1303M + LXM23∙U10M3X

Measurement of the characteristic curves with 220 V single-phase.

(1) Peak current

(2) Continuous torque

BCH1304N + LXM23∙U20M3X

Characteristic curves BCH1801

46

Measurement of the characteristic curves with 220 V three-phase.

(1) Peak current

(2) Continuous torque

BCH1801N + LXM23∙U20M3X

Measurement of the characteristic curves with 220 V three-phase.

(1) Peak current

(2) Continuous torque

0198441113926, V2.02, 11.2014

Servo drive system

Page 47

0 1000 2000 3000

10

0

50

30

M

max

M

0

n [1/min]

M [Nm]

40

60

20

1

2

0 1500 3000

10

0

50

30

M

max

M

0

n [1/min]

M [Nm]

40

60

20

1

2

0 1000 2000 3000

10

0

50

30

M

max

M

0

n [1/min]

M [Nm]

40

60

20

1

2

0 1500 3000

10

20

30

50

40

0

80

60

M

max

M

0

n [1/min]

M [Nm]

1

2

0 1500 2000

20

40

60

100

80

0

M

max

M

0

n [1/min]

M [Nm]

1

2

LXM23D and BCH 2 Technical Data

Characteristic curves BCH1802

Characteristic curves BCH1803

BCH1802N + LXM23∙U30M3X BCH1802M + LXM23∙U30M3X

Measurement of the characteristic curves with 220 V three-phase.

(1) Peak current

(2) Continuous torque

BCH1803N + LXM23∙U45M3X BCH1803M + LXM23∙U45M3X

Characteristic curves BCH1804

0198441113926, V2.02, 11.2014

Servo drive system

Measurement of the characteristic curves with 220 V three-phase.

(1) Peak current

(2) Continuous torque

BCH1804M + LXM23∙U55M3X

Measurement of the characteristic curves with 220 V three-phase.

(1) Peak current

(2) Continuous torque

47

Page 48

0 1500 3000

20

0

100

60

M

max

M

0

n [1/min]

M [Nm]

80

120

40

1

2

2 Technical Data LXM23D and BCH

Characteristic curves BCH1805

BCH1805M + LXM23∙U75M3X

Measurement of the characteristic curves with 220 V three-phase.

(1) Peak current

(2) Continuous torque

48

0198441113926, V2.02, 11.2014

Servo drive system

Page 49

LXM23D and BCH 2 Technical Data

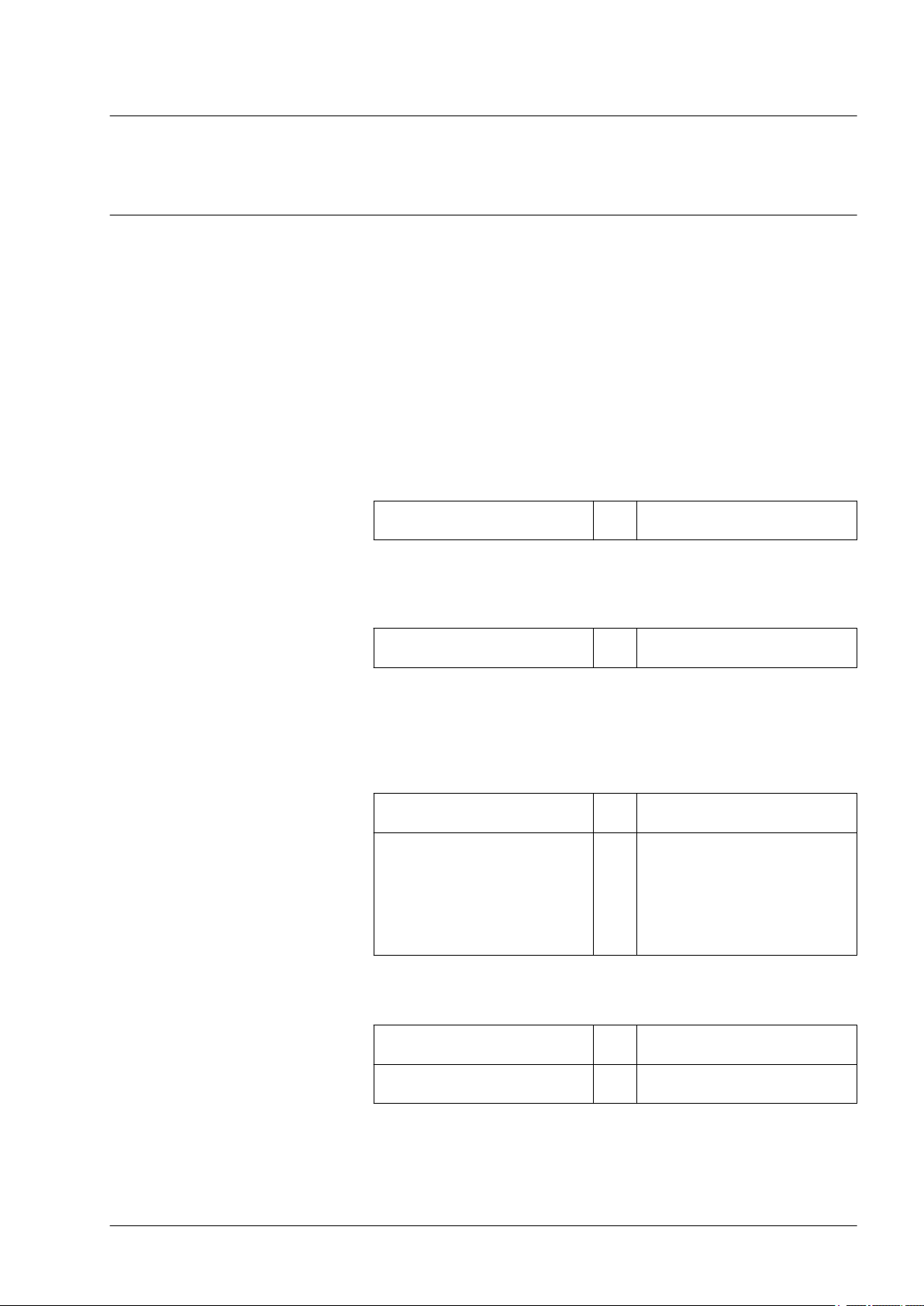

2.4.3 Overload Characteristics

Motor overload monitoring is a function that monitors for excessively

high current in the motor phases.

Motor overload monitoring 1. Motor was operated for several seconds with a torque exceeding

100% torque.

2. Motor had driven high inertia machine and had accelerated and

decelerated at high frequency.

3. Motor cable or encoder cable was not connected correctly.

4. Servo gain was not set properly and caused motor hunting.

5. Motor holding brake was not released.

0198441113926, V2.02, 11.2014

Servo drive system

49

Page 50

240220200180160140140100 300280260

%

10

0

10

4

10

3

10

2

10

1

s

240220200180160140120100 300280260

%

10

0

10

5

10

3

10

2

10

1

s

10

4

2 Technical Data LXM23D and BCH

Chart of load and operating time

Load Operating Time

120 % 263.8 s

140 % 35.2 s

160 % 17.6 s

180 % 11.2 s

200 % 8 s

220 % 6.1 s

240 % 4.8 s

260 % 3.9 s

280 % 3.3 s

300 % 2.8 s

Table 1: Ultra low/low Inertia Series (BCH0401O, BCH0601O, BCH0602O, BCH0801O, BCH0802O, BCH1001O,

BCH1002O)

Load Operating Time

120 % 527.6 s

140 % 70.4 s

160 % 35.2 s

180 % 22.4 s

200 % 16 s

220 % 12.2 s

240 % 9.6 s

260 % 7.8 s

280 % 6.6 s

300 % 5.6 s

Table 2: Medium and Medium-High Inertia Series (BCH1301N, BCH1302N, BCH1303N, BCH1304N, BCH1801N,

BCH1802N, BCH1802M)

50

Servo drive system

0198441113926, V2.02, 11.2014

Page 51

240220200180160140120100 300280260

%

10

0

10

5

10

3

10

2

10

1

s

10

4

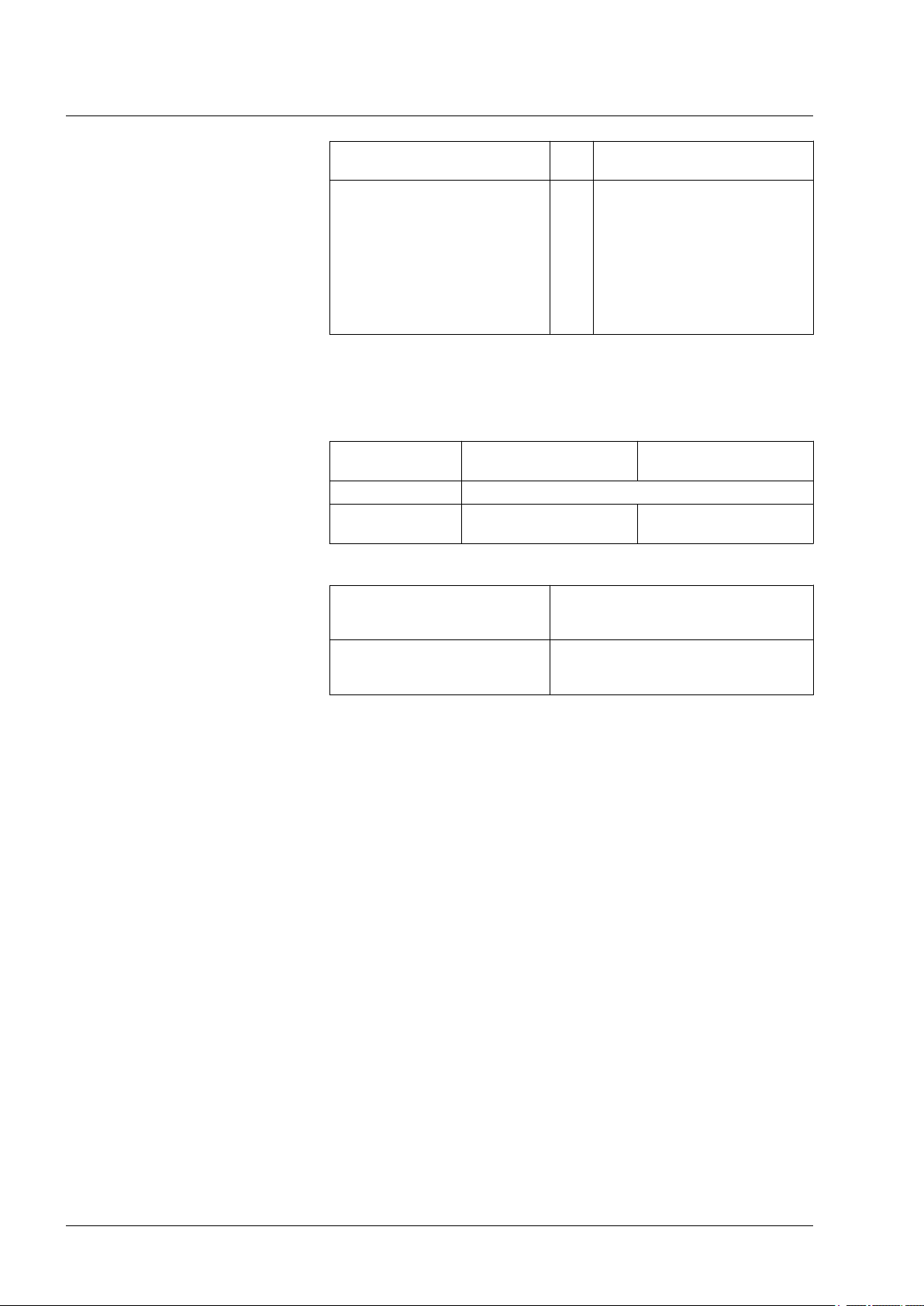

LXM23D and BCH 2 Technical Data

Load Operating Time

120 % 527.6 s

140 % 70.4 s

160 % 35.2 s

180 % 22.4 s

200 % 16 s

220 % 12.2 s

240 % 9.6 s

260 % 7.8 s

280 % 6.6 s

300 % 5.6 s

Table 3: High Inertia Series (BCH1301M, BCH1302M, BCH1303M)

2.5 Conditions for UL 508C

If the product is used to comply with UL 508C, the following conditions

must also be met:

Wiring Use at least 60/75 °C copper conductors.

2.6 Certifications

Product certifications:

Assigned file number Related products Certified by

E153659 LXM23A servo drives,

LXM23D servo drives,

E208613 BCH servo motors UL

UL

0198441113926, V2.02, 11.2014

Servo drive system

51

Page 52

SCHNEIDER ELECTRIC MOTION DEUTSCHLAND GmbH

Breslauer Str. 7 D-77933 Lahr

EC DECLARATION OF CONFORMITY

Y

EAR 2011

according to EC Directive on Machinery 2006/42/EC

according to EC Directive EMC 2004/108/EC

according to EC Directive Low Voltage 2006/95/EC

We hereby declare that the products listed below meet the requirements of the EC

Directives indicated with respect to design, construction and version distributed by us. This

declaration becomes invalid in the case of any modification to the products not authorized

by us.

Designation: AC Servo drive

Type:

Applied

harmonized

standards,

especially:

EN 61800-5-1:2007

EN 61800-3:2004

Applied

national standards

and technical

specifications,

especially:

UL 508C

Product documentation

Company stamp:

Date/Signature: 4 April 2011

Name/Department: Björn Hagemann/Development

LXM23xx

2 Technical Data LXM23D and BCH

2.7 Declaration of conformity

52

0198441113926, V2.02, 11.2014

Servo drive system

Page 53

SCHNEIDER ELECTRIC MOTION DEUTSCHLAND GmbH

Breslauer Str. 7 D-77933 Lahr

EC DECLARATION OF CONFORMITY

Y

EAR 2011

according to EC Directive on Machinery 2006/42/EC

according to EC Directive EMC 2004/108/EC

according to EC Directive Low Voltage 2006/95/EC

We hereby declare that the products listed below meet the requirements of the EC

Directives indicated with respect to design, construction and version distributed by us. This

declaration becomes invalid in the case of any modification to the products not authorized

by us.

Designation: AC Servo motor

Type:

Applied

harmonized

standards,

especially:

EN 61800-5-1:2007

EN 60034-1:2010

EN 60034-5:2001

EN 60034-5/A1:2007

Applied

national standards

and technical

specifications,

especially:

UL 1004

Product documentation

Company stamp:

Date/Signature: 4 April 2011

Name/Department: Björn Hagemann/Development

BCHxx

LXM23D and BCH 2 Technical Data

0198441113926, V2.02, 11.2014

Servo drive system

53

Page 54

2 Technical Data LXM23D and BCH

54

0198441113926, V2.02, 11.2014

Servo drive system

Page 55

LXM23D and BCH

3 Engineering

This chapter contains information on the application of the product

that is vital in the engineering phase.

Subject Page

"3.1 Electromagnetic compatibility (EMC)" 55

"3.2 Residual current device" 57

"3.3 Operation in an IT mains" 57

"3.4 Common DC bus" 57

"3.5 Rating the braking resistor" 58

"3.6 Monitoring functions" 65

"3.7 Configurable inputs and outputs" 66

3.1 Electromagnetic compatibility (EMC)

3 Engineering

Signal interference can cause unexpected responses of the device

and of other equipment in the vicinity of the device.

WARNING

SIGNAL AND DEVICE INTERFERENCE

• Install the wiring in accordance with the EMC requirements

described.

• Verify compliance with the EMC requirements described.

• Verify compliance with all EMC regulations and requirements

applicable in the country in which the product is to be operated

and with all EMC regulations and requirements applicable at the

installation site.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

Limit values This product meets the EMC requirements according to the standard

IEC 61800-3 if the measures described in this manual are implemented during installation.

If the selected composition (product itself, mains filter, other accessories and measures) does not meet the requirements of category C1,

the following information applies as it appears in IEC 61800-3:

0198441113926, V2.02, 11.2014

Servo drive system

WARNING

RADIO INTERFERENCE

In a domestic environment this product may cause radio interference

in which case supplementary mitigation measures may be required.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

55

Page 56

3 Engineering

LXM23D and BCH

An EMC-compliant design is required to meet the specified limit values. Note the following requirements:

Control cabinet design

Additional measures for EMC

improvement

EMC measures Objective

Use mounting plates with good electrical conductivity, connect large surface areas of metal parts,

remove paint from contact areas.

Ground the control cabinet, the control cabinet door

and the mounting plate with ground straps or

ground wires. The conductor cross section must be

at least 10 mm2 (AWG 6).

Install switching devices such as power contactors,

relays or solenoid valves with interference suppression units or arc suppressors (for example, diodes,

varistors, RC circuits).