Page 1

Harmony IIoT Core Box HMIBSC

EIO0000003374 11/2019

Harmony IIoT Core Box

HMIBSC

User Manual

11/2019

EIO0000003374.03

www.schneider-electric.com

Page 2

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2019 Schneider Electric. All rights reserved.

2 EIO0000003374 11/2019

Page 3

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1 Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FCC Radio Frequency Interference Statement for USA.. . . . . . . . . . .

Certifications and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Physical Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Box iPC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the DC Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power Supply Module Description. . . . . . . . . . . . . . . . . . . . . . . . .

AC Power Supply Module Installation . . . . . . . . . . . . . . . . . . . . . . . . .

UPS Module - Description and Installation . . . . . . . . . . . . . . . . . . . . .

Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Hardware Modifications . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1 Before Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Making Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Box iPC and Storage Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . .

SD Card Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Optional Cards and Optional Interfaces . . . . . . . . . . . . . . . . . . . . . . .

Optional Interface Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 x Analog Input Interface Description. . . . . . . . . . . . . . . . . . . . . . . . .

8 x Analog Input Interface Description. . . . . . . . . . . . . . . . . . . . . . . . .

4G Cellular Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cyber Security TPM Module Description. . . . . . . . . . . . . . . . . . . . . . .

14

15

20

22

26

28

29

32

33

38

41

43

46

52

62

68

68

70

70

73

74

81

84

87

90

EIO0000003374 11/2019 3

Page 4

Chapter 7 Configuration Software. . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Node-RED Quick Start Configuration. . . . . . . . . . . . . . . . . . . . . . . . . .

Software Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Utility on the Target Device . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8 IIoT and Cyber Security . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Cyber Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IIoT and Node-RED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Reinstallation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regular Cleaning and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Accessories for the Box iPC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

94

98

117

124

128

132

136

137

139

141

143

4 EIO0000003374 11/2019

Page 5

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

EIO0000003374 11/2019 5

Page 6

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

HAZARD OF ELECTRIC SHOCK

Do not open product.

Product to be serviced by qualified people only.

Failure to follow these instructions will result in death or serious injury.

UNAUTHENTICATED ACCESS AND SUBSEQUENT UNAUTHORIZED MACHINE

OPERATION

Evaluate whether your environment or your machines are connected to your critical

infrastructure and, if so, take appropriate steps in terms of prevention, based on Defense-inDepth, before connecting the automation system to any network.

Limit the number of devices connected to a network to the minimum necessary.

Isolate your industrial network from other networks inside your company.

Protect any network against unintended access by using firewalls, VPN, or other, proven

security measures.

Monitor activities within your systems.

Prevent subject devices from direct access or direct link by unauthorized parties or unauthen-

ticated actions.

Prepare a recovery plan including backup of your system and process information.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

DANGER

WARNING

6 EIO0000003374 11/2019

Page 7

About the Book

At a Glance

Document Scope

This manual describes the configuration and usage of the Box PC IIoT, part of the range of

Harmony Industrial PC, for its cataloged and configured product offers.

The Box PC IIoT are designed to operate in an industrial environment.

1 Cataloged product offer:

HMIBSCEA53D1L0T - IIoT Edge Box Core eMMC DC Linux TPM

12...24 Vdc

ARM-A53 processor

1GB RAM

8 GB eMMC

TPM module

Linux Yocto

mini PCIe and M.2 slots for optional interface

HMIBSCEA53D1L01 - IIoT Edge Box Core eMMC DC Linux

12...24 Vdc

ARM-A53 processor

1GB RAM

8 GB eMMC

Linux Yocto

mini PCIe and M.2 slots for optional interface

HMIBSCEA53D1L0A - IIoT Edge Box Core eMMC DC Linux

12...24 Vdc

ARM-A53 processor

2GB RAM

64 GB eMMC

Linux Yocto

mini PCIe and M.2 slots for optional interface

Conformal coating

NOTE: The part number for your unit may not be included in the user manual. Commercial part

numbers listed in the user manual are for products available when the user manual was published.

New part numbers may be added to the product range.

New and existing cataloged part numbers are always composed of a prefix (HMI), followed by a

serial arrangement of 12 alphanumeric characters. Each one of the twelve characters matches with

one characteristic of the cataloged Box PC IIoT, such as storage device size, storage device type,

memory size, and bundled software.

EIO0000003374 11/2019 7

Page 8

Use the following legend to identify the features that correspond with each character of the part

number:

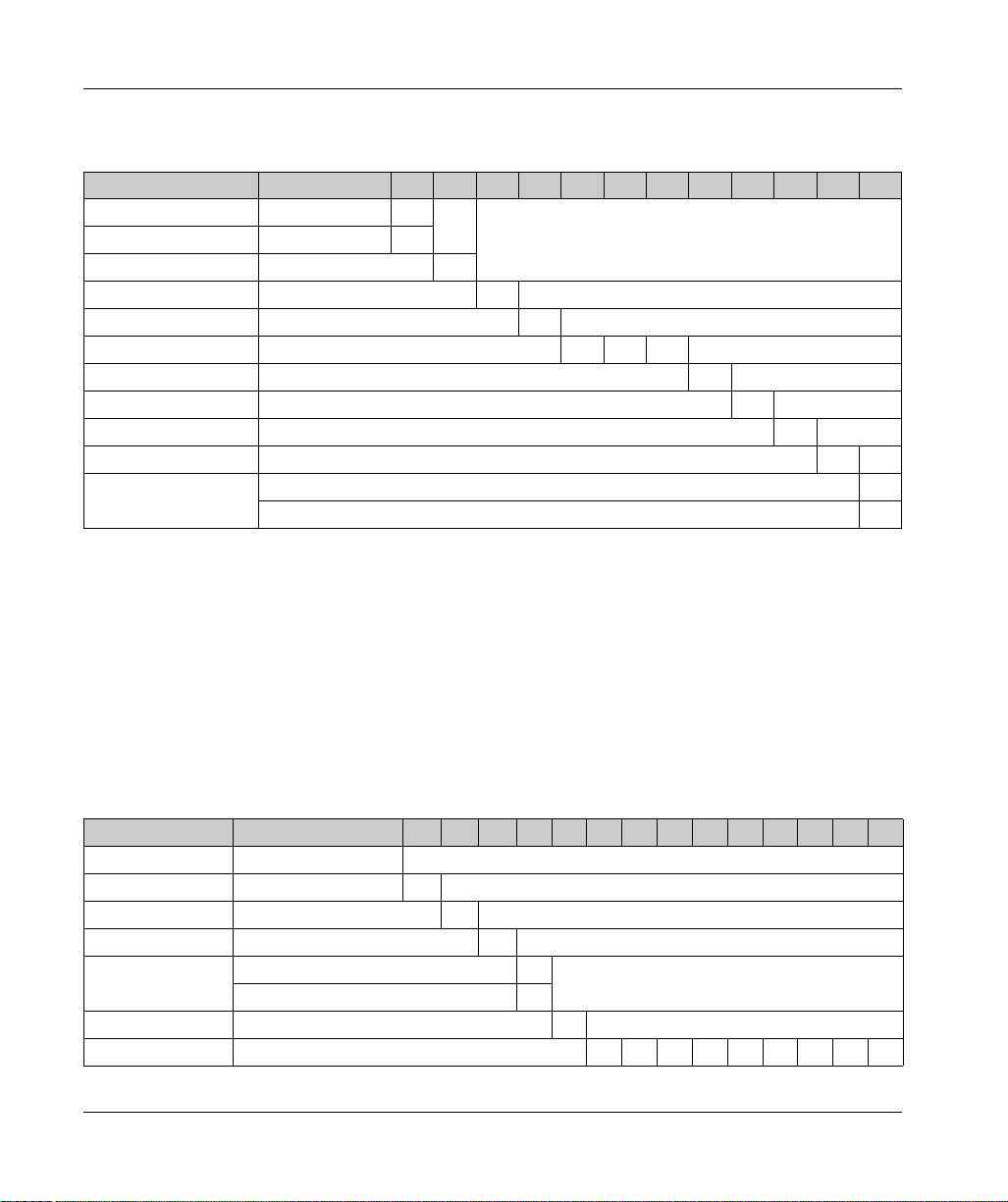

Character number Prefix 1 2 3 4 5 6 7 8 9 10 11 12

Range name HMI

iPC family B

Type S

Version IIoT Edge Box C

Drive eMMC E

CPU type ARM-A53 A 5 3

Power supply DC D

Expansion slots 1 mini PCIe with optional interface 1

Operating system Linux L

Bundled software None 0

Hardware iteration Initial 1

Conformal coating A

2 Configured product offer:

In addition to the catalog offer, other configurations may be available in some countries.

These configured offers use a fixed method of identification. The configured part numbers are

always composed of an arrangement of 20 alphanumeric characters. The first 6 characters are

always HMIPCC. The remaining 14 characters match with one characteristic of the configured Box

PC IIoT, such as storage device size, storage device type, memory size, and bundled software.

The configured offers have similar characteristics and functionalities as the cataloged offer

described in this manual.

In addition to this part number, a configuration number is printed on the product label.

The configuration number format is as follows:

Character number Prefix (1-6) 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Part number HMI PCC

Form factor Edge Box Core A53 X

Product generation Second generation 2

Modular displays None B

Box PC IIoT Box ARM Core DC 1 GB, eMMC 8 GB 7

Box ARM Core DC 2 GB, eMMC 64 GB 8

CPU type ARM-A53 X

Power supply DC D

8 EIO0000003374 11/2019

Page 9

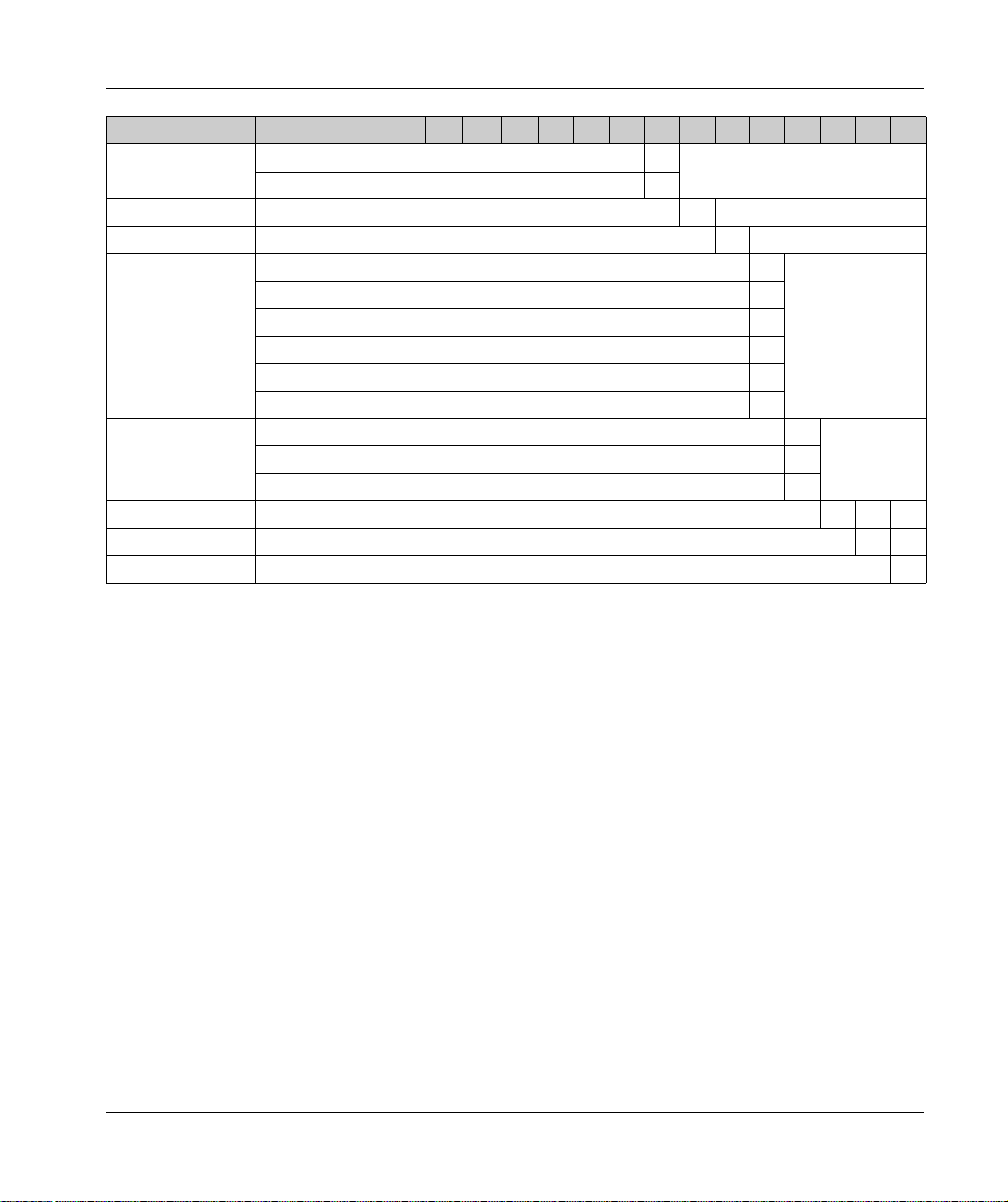

Character number Prefix (1-6) 7 8 9 10 11 12 13 14 15 16 17 18 19 20

RAM 1 GB 1

2GB 2

Operating system Linux Yocto Y

Storage device eMMC (soldered) 4

Optional interfaces None 0

Interface - M.2 2 x analog input Y

Interface - mini PCIe 8 x analog input Z

Cellular 4G for US M

Cellular 4G for EU /ASIA N

TPM module L

Second storage None N

SD Card industrial grade 16 GB 5

SD Card industrial grade 64 GB 6

Software bundle None N

Reserved None 0

Reserved None 0

NOTE: All instructions applicable to the enclosed product and all safety precautions must be

observed.

EIO0000003374 11/2019 9

Page 10

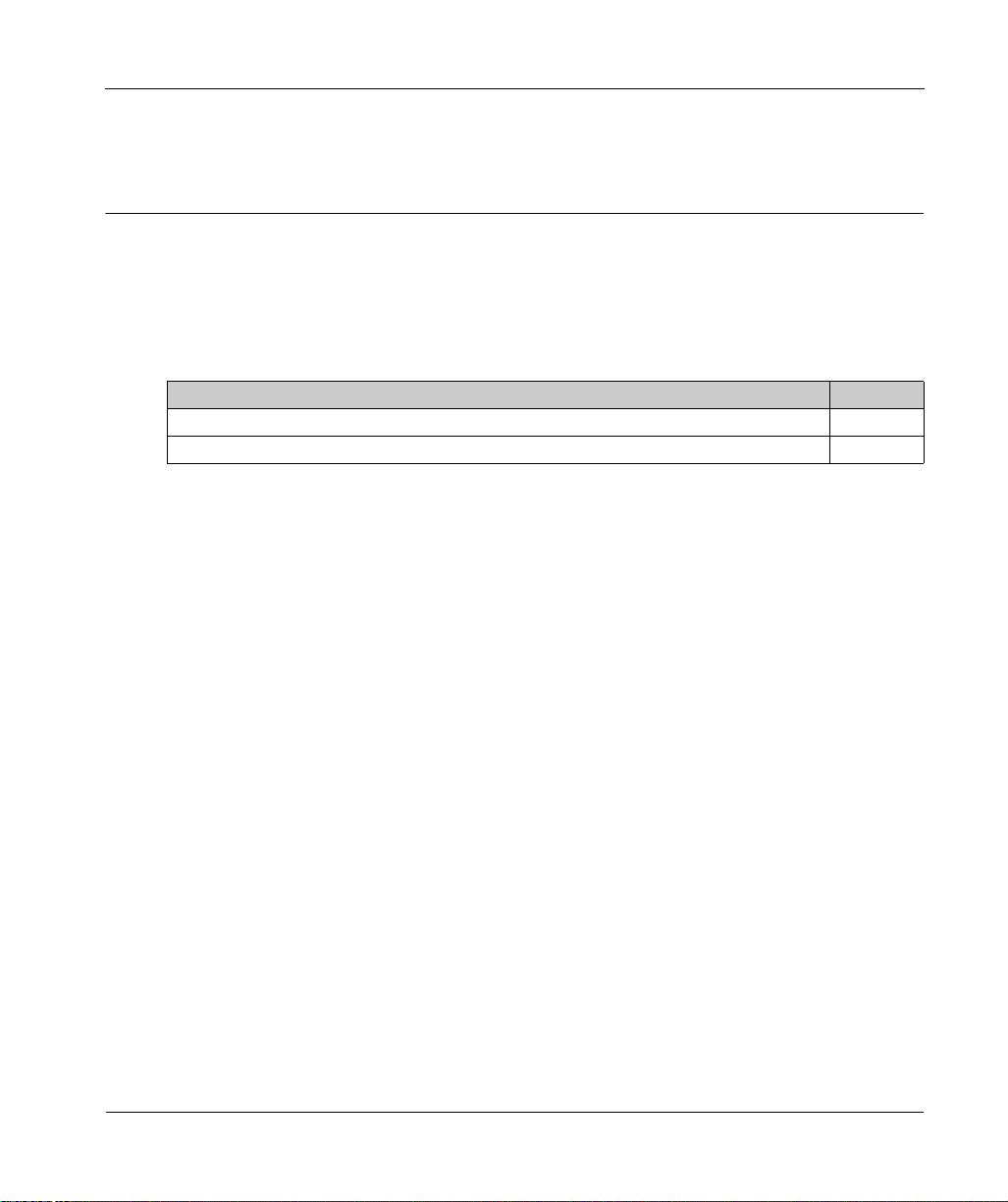

Validity Note

The technical characteristics of the devices described in the present document also appear online.

To access the information online:

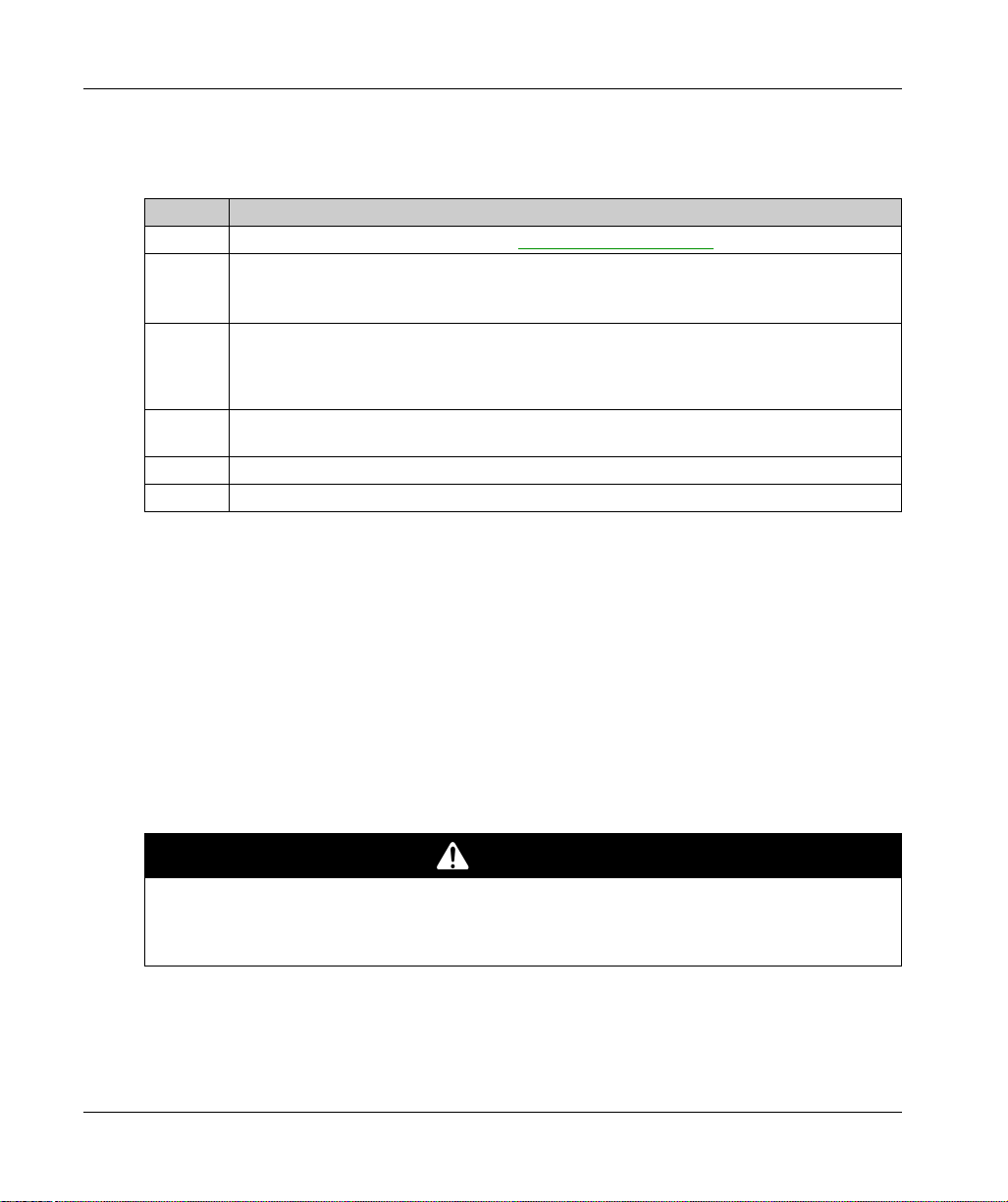

Step Action

The characteristics that are presented in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may revise

content over time to improve clarity and accuracy. If you see a difference between the document

and online information, use the online information as your reference.

Registered trademarks

Linux®, Yocto Project® are registered trademarks of Linux Foundation in the United States and/or

other countries.

Intel®, Cortex®, ARM® are registered trademarks of Intel corporation.

1 Go to the Schneider Electric home page

2 In the Search box type the reference of a product or the name of a product range.

Do not include blank spaces in the reference or product range.

To get information on grouping similar modules, use asterisks (

3 If you entered a reference, go to the Product Datasheets search results and click on the

reference that interests you.

If you entered the name of a product range, go to the Product Ranges search results and click

on the product range that interests you.

4 If more than one reference appears in the Products search results, click on the reference that

interests you.

5 Depending on the size of your screen, you may need to scroll down to see the datasheet.

6 To save or print a datasheet as a .pdf file, click Download XXX product datasheet.

www.schneider-electric.com

.

*

).

Hazardous Location

The Box PC IIoT (HMIBSC) are not classified for used in hazardous locations.

DANGER

POTENTIAL FOR EXPLOSION IN HAZARDOUS LOCATION

Do not use these products in hazardous locations.

Failure to follow these instructions will result in death or serious injury.

10 EIO0000003374 11/2019

Page 11

Product Related Information

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths

and, for certain critical control functions, provide a means to achieve a safe state during and

after a path failure. Examples of critical control functions are emergency stop and overtravel

stop.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Each implementation of a Harmony Industrial PC must be individually and thoroughly tested

for proper operation before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

(1)

For additional information, refer to

Application, Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest

edition),”Safety Standards for Construction and Guide for Selection, Installation and Operation of

Adjustable-Speed Drive Systems” or other applicable standards in your location.

NOTE: The Box PC IIoT are a highly configurable device and is not based on a real-time operating

system. Changes to the software and settings of the following must be considered new implementations as described in the previous warning messages. Examples of such changes include:

Linux system

IIoT

Operating system

Installed hardware

Installed software

NOTE: The Operating System includes security protection for SD card. When using some device,

system may experience issue. Resolution is available here:

electric.com/en/faqs/index?page=content&id=FA290340&actp=search&viewlocale=en_US&sear

chid=1469171130324#__highlight

WARNING

(1)

NEMA ICS 1.1 (latest edition), "Safety Guidelines for the

http://www.schneider-

WARNING

UNINTENDED EQUIPMENT OPERATION

Use only Schneider Electric software with the devices described in this manual.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000003374 11/2019 11

Page 12

EXPLOSION HAZARD

For battery replacement, contact the field services department.

Failure to follow these instructions will result in death or serious injury.

POWER SUPPLY

You must use a Listed Power Adapter or DC power source, rated 12-24Vdc, 1.5A minimum and

Tma 55 degree C with this product. If further assistance is needed, contact Schneider Electric.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Connection for AC mains

Prerequisites

Power installation must be performed with qualified electrician and followed with National

Electrical Code, ANSI/NFPA 70 and Canadian Electrical Code, Part I, CSA C22.1

Use No.14 AWG, 75°C solid copper wire with RHW, THHW, THW, THWN, XHHW, USE or ZW

type pressure terminal connector and 4.5lb-in torque force when connecting to terminal block.

Connected mains shall be built branch circuit breaker which possessed 20 A of current rating.

To connect AC mains

Step Action

1 Turn OFF AC mains by branch circuit breaker of building and the equipment.

2 Ensure AC mains connected earthed cable to the building.

3 Ensure power cable from AC mains to AC IN connector with an earthed cable which is of

AWG14 minimum green-and-yellow wire.

4 Connect signal cables to the equipment.

5 Ensure correct terminals, then connect power cable to the equipment.

6 Connect the power cable to the terminal block of AC mains.

7 Turn ON AC mains by branch circuit breaker of building and the equipment.

DANGER

WARNING

To disconnect AC mains

Step Action

1 Turn OFF AC mains by branch circuit breaker of building and the equipment.

2 Disconnect the power cable from AC mains and the equipment.

3 Remove the signal cables from the connectors.

12 EIO0000003374 11/2019

Page 13

Harmony IIoT Core Box HMIBSC

Important Information

EIO0000003374 11/2019

Important Information

Chapter 1

Important Information

General

This chapter describes specific aspects related to the operation of the Harmony Box iPC.

What Is in This Chapter?

This chapter contains the following topics:

FCC Radio Frequency Interference Statement for USA. 14

Certifications and Standards 15

Topic Page

EIO0000003374 11/2019 13

Page 14

Important Information

FCC Radio Frequency Interference Statement for USA.

Federal Communications Commission (FCC) Radio Interference Information

This equipment has been tested and found to comply with the federal communications commission

(FCC) limits for a Class A digital device, according to Part 15 of the FCC rules. These limits are

designed to provide reasonable protection against harmful interference in a commercial, industrial,

or business environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause or be subject to

interference with radio communications. To minimize the possibility of electromagnetic interference

in your application, observe the following two rules:

Install and operate the Harmony Industrial PC in such a manner that it does not radiate sufficient

electromagnetic energy to cause interference in nearby devices.

Install and test the Harmony Industrial PC to ensure that the electromagnetic energy generated

by nearby devices does not interfere with the Harmony Industrial PC's operation.

Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate this product.

FCC RF Radiation Exposure Statement

This Transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

This equipment complies with RF radiation exposure limits set forth for an uncontrolled

environment.

This equipment should be installed and operated with a minimum distance of 20 cm between

the radiator and your body.

14

WARNING

ELECTROMAGNETIC / INTERFERENCE

Electromagnetic radiation may disrupt the Harmony Industrial PC's operations, leading to

unintended equipment operation. If electromagnetic interference is detected:

Increase the distance between the Harmony Industrial PC and the interfering equipment.

Reorient the Harmony Industrial PC and the interfering equipment.

Reroute power and communication lines to the Harmony Industrial PC and the interfering

equipment.

Connect the Harmony Industrial PC and the interfering equipment to different power supplies.

Always use shielded cables when connecting the Harmony Industrial P C to a perip heral devic e

or another computer.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000003374 11/2019

Page 15

Certifications and Standards

Introduction

Schneider Electric submitted this product for independent testing and qualification by third-party

agencies. These agencies have certified this product as meeting the following standards.

NOTE: Always refer to the markings on the product to confirm the certifications.

Certifications

Underwriters Laboratories Inc., UL 60950, and CSA 60950 (Information Technology

Equipment).

CCC, RCM, and EAC certification. Refer to product markings.

Compliance Standards

Schneider Electric tested this product for compliance with the following compulsory standards:

United States:

Federal Communications Commission, FCC Part 15, Class A

Europe: CE

2014/53/EU RED Directive, based on EN 301 489-1/-17

In complement, the products have been tested according IEC 60950 and EN 61000-6-2 /

EN 61000-6-4

Australia: RCM

Standard AS/NZS CISPR11

Important Information

RF Certifications

Introduction

Schneider Electric submitted this product for independent testing and qualification by third-party

agencies. These agencies have certified this product as meeting the following

countries/geographical zones regulations.

CAUTION

EXPOSURE TO RADIO FREQUENCY RADIATION

This device and its antenna must not be co-located or operating in conjunction with any other

antenna or transmitter.

A separation distance of at least 20 cm (0.79 in) must be maintained between the antenna of

this device and all persons.

Failure to follow these instructions can result in injury or equipment damage.

EIO0000003374 11/2019 15

Page 16

Important Information

RF certifications

RED for Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Poland, Portugal, Romania, Russia, Slovakia, Slovenia, Spain, Sweden,

Switzerland, UK

FCC RF for USA

IC for Canada

SRRC for China

TELEC for Japan

RCM for Australia, New Zealand

The detailed documentation for these certifications can be found

If your country is not in this list, in case of issue, please contact our support to troubleshoot:

https://www.se.com

Qualification Standards

Schneider Electric voluntarily tested this product to additional standards. The additional tests

performed, and the standards under which the tests were conducted, are identified in the

environmental characteristics.

Hazardous Substances

This product is compliant with:

WEEE, Directive 2012/19/EU

RoHS, Directive 2011/65/EU, and 2015/863/EU

RoHS China, Standard GB/T 26572

REACH regulation EC 1907/2006

NOTE: Documentation about sustainable development is available on Schneider Electric website

(Product Environmental Profile and End of Life Instruction, RoHS, and REACH certificates).

@ https://www.se.com

End of Life (Waste Electrical and Electronic Equipment)

The product contains electronic boards. It must be disposed of in specific treatment channels. The

product contains cells and/or storage batteries which must be collected and processed separately,

when they have run out and at the end of product life (European Directive 2012/19/EU).

Refer to the section Maintenance to extract cells and batteries from the product. These batteries

do not contain a weight percentage of heavy metals over the threshold (European Directive

2006/66/CE).

Batteries comply with UN recommendations and IATA requirements.

16

EIO0000003374 11/2019

Page 17

European (CE) Compliance

The products described in this manual comply with the European Directives concerning

Electromagnetic Compatibility and Low Voltage (CE marking) when used as specified in the

relevant documentation, in applications for which they are intended, and in connection with

approved third-party products.

Canadian Notice

This device contains license-exempt transmitter/receiver that comply with Innovation, Science and

Economic Development Canada’s license-exempt RSS. Operation is subject to the following two

conditions:

This device may cause interference.

This device may accept any interference, including interference that may cause undesired

operation of the device.

Important Information

EIO0000003374 11/2019 17

Page 18

Important Information

18

EIO0000003374 11/2019

Page 19

Harmony IIoT Core Box HMIBSC

Physical Overview

EIO0000003374 11/2019

Physical Overview

Chapter 2

Physical Overview

Subject of this Chapter

This chapter provides a physical overview of the Box PC IIoT.

What Is in This Chapter?

This chapter contains the following topics:

Package Contents 20

Description 22

Topic Page

EIO0000003374 11/2019 19

Page 20

Physical Overview

Package Contents

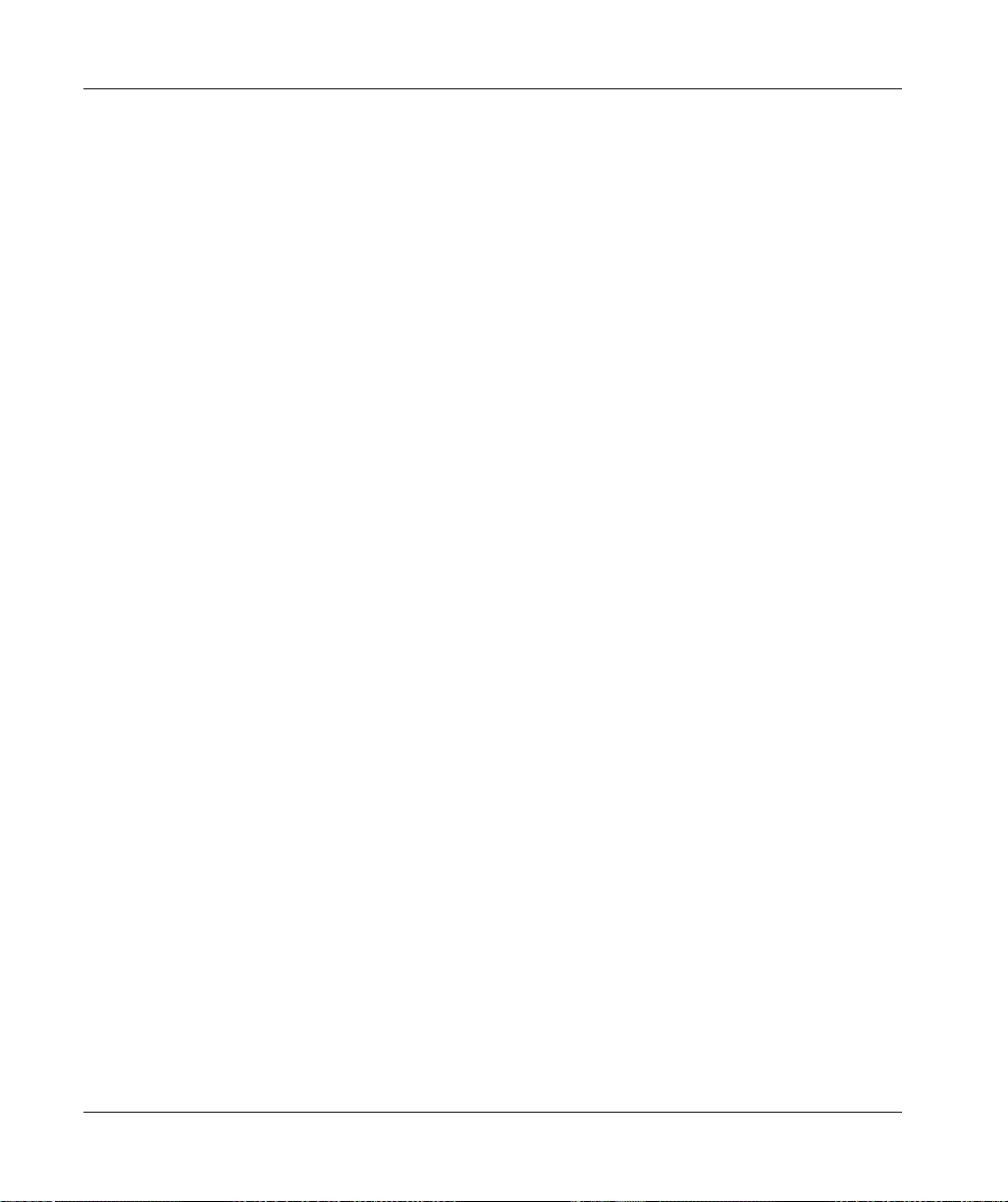

Items of The Box PC IIoT

The following items are included in the package of the Box PC IIoT. Before using the Box PC IIoT,

confirm that all items listed here are present:

Box PC IIoT

20

Recovery media containing the software required

to reinstall the operating system. Additional

drivers are in the recovery media

Chinese user manual

“Before using this product” flyer

Chinese RoHS flyer

EIO0000003374 11/2019

Page 21

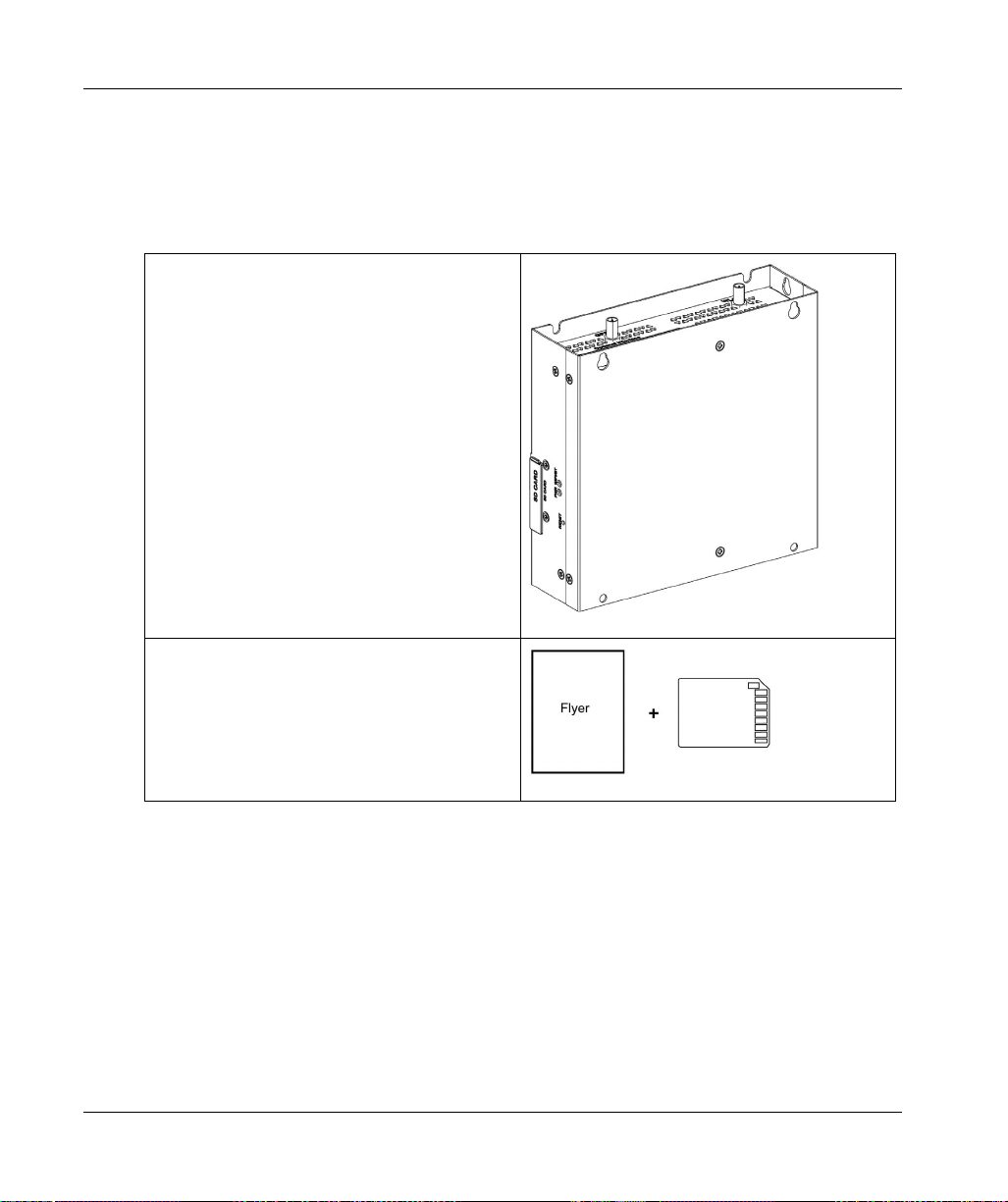

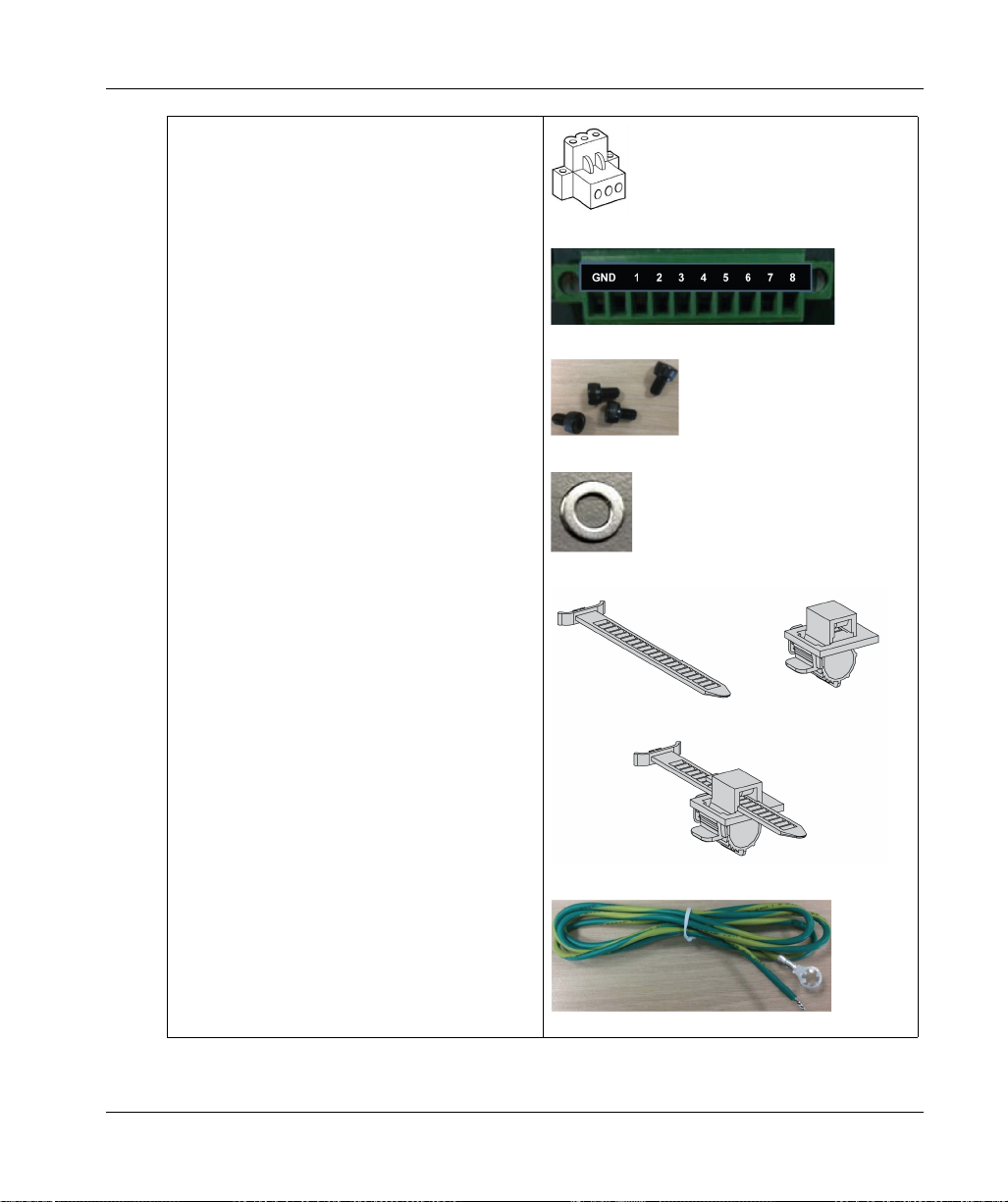

1 x DC terminal block: 3-pin power connector

1 x wire for chassis ground

2 X Flexible HDMI/USB lockers

1 x GPIO terminal block

4 x screws and 4 x washers

Physical Overview

The Box PC IIoT has been carefully packed, with special attention to quality. However, should you

find anything damaged or missing, contact your local distributor immediately.

EIO0000003374 11/2019 21

Page 22

Physical Overview

Description

Introduction

During operation, the surface temperature of the heat sink may exceed 70 °C (158 °F).

RISK OF BURNS

Do not touch the surface of the heat sink during operation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

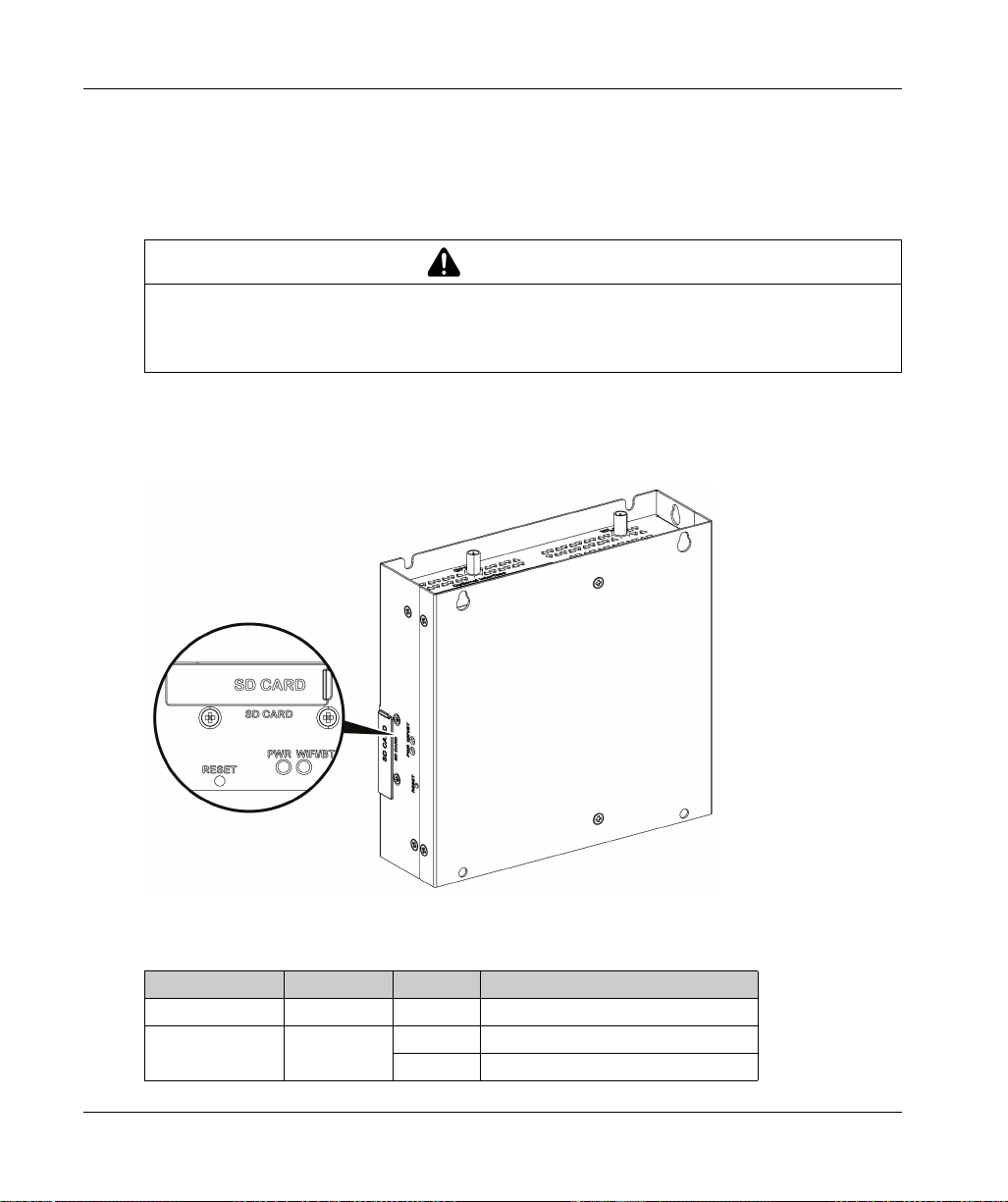

Standard Description

Overview

WARNING

22

Reset button and LEDs

The table describes the meaning of the status LEDs:

Marking Color State Meaning

PWR Green On Active (user operates OS) (state S0).

WiFi/BT Green Off No WiFi/BT data transmission.

On Data transmission.

EIO0000003374 11/2019

Page 23

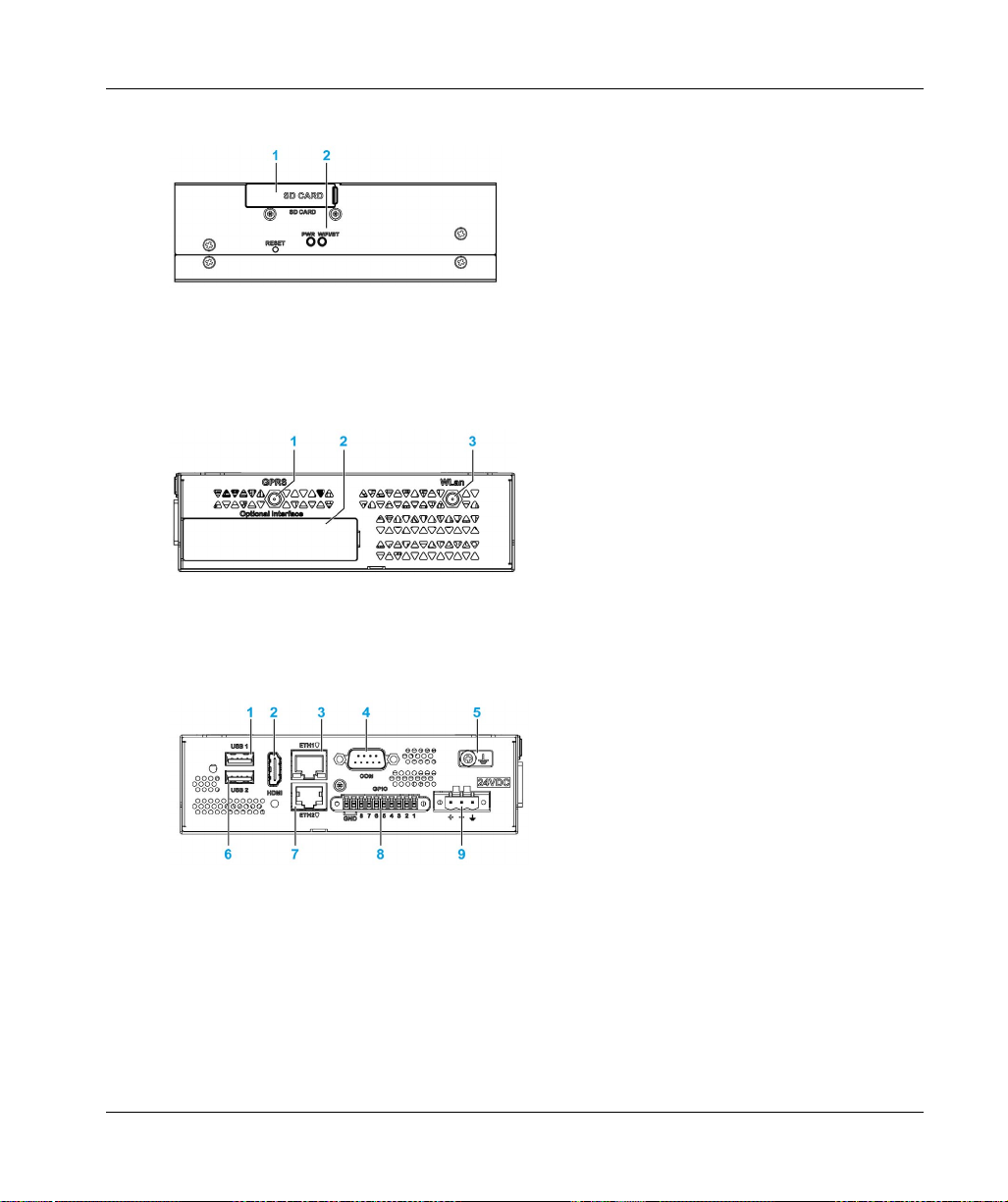

Front View

1 SD card socket

2 LEDs and reset button

NOTE: The regular installation of the default OS has to be made with the SD card.

Top View

1 SMA connector for the GPRS/4G external antenna

2 Optional interface

3 SMA connector for the WLan external antenna

Physical Overview

Bottom View

1 USB1 (USB 2.0)

2 HDMI port

3 ETH1 (10/100/1000 Mb/s)

4 COM port RS-232 (default), RS-232/422/485 (non-isolated)

5 Ground connection pin

6 USB2 (USB 2.0)

7 ETH2 (10/100/1000 Mb/s)

8 GPIO

9 DC power connector

EIO0000003374 11/2019 23

Page 24

Physical Overview

HDMI and USB Locker

1 USB locker

2 HDMI locker

24

EIO0000003374 11/2019

Page 25

Harmony IIoT Core Box HMIBSC

Characteristics

EIO0000003374 11/2019

Characteristics

Chapter 3

Characteristics

Subject of this Chapter

This chapter lists the product characteristics.

What Is in This Chapter?

This chapter contains the following topics:

Box iPC Characteristics 26

Power Supply Characteristics 28

Environmental Characteristics 29

Topic Page

EIO0000003374 11/2019 25

Page 26

Characteristics

Box iPC Characteristics

Characteristics

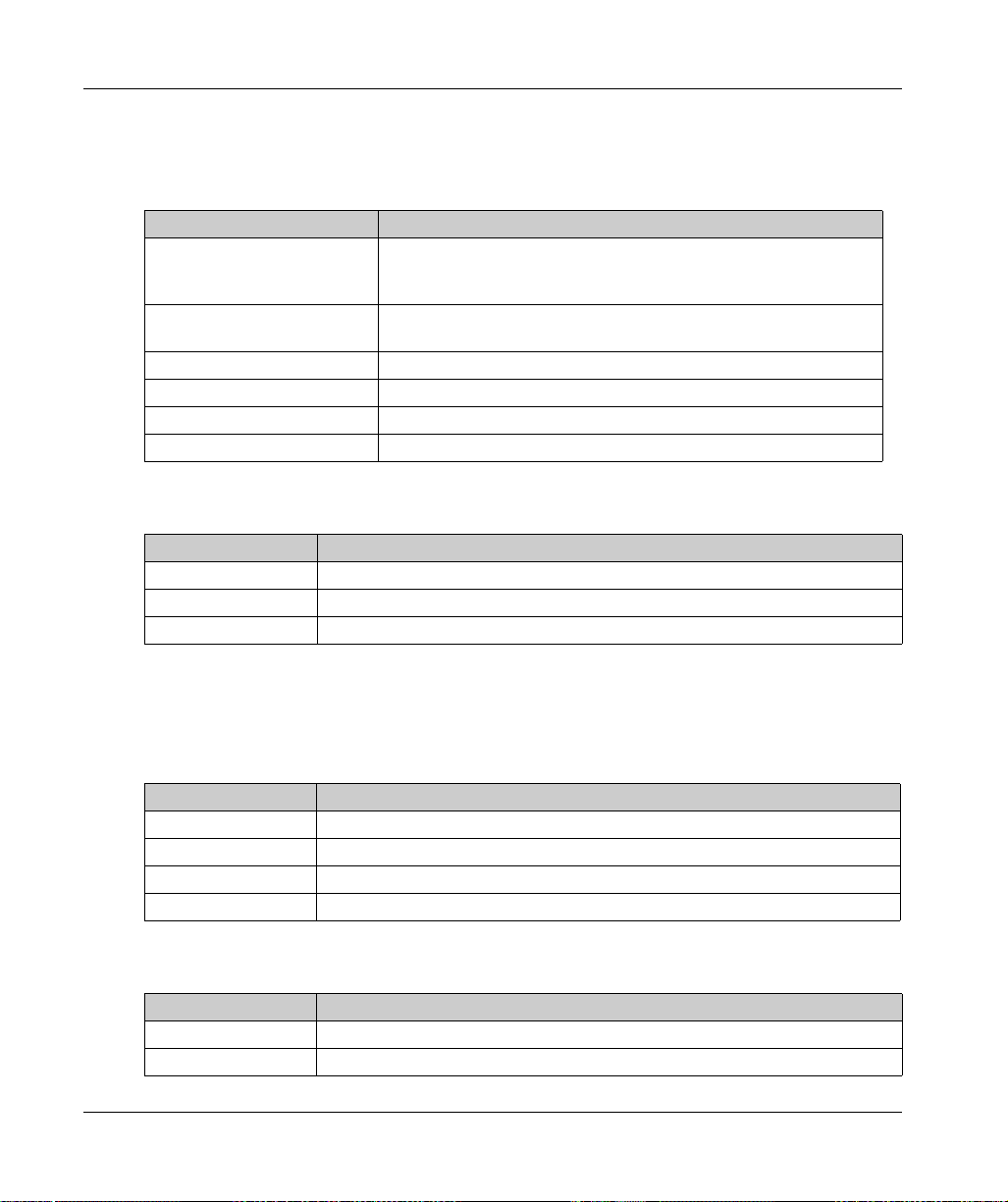

Element Characteristics

Processor ARM-A53

Memory 1 GB or 2 GB, LPDDR3: maximum transfer data rate 533 MHz,

Storage memory 8 GB or 64 GB, eMMC: maximum raw transfer rate 200 MBps

Buzzer No

Cooling method Natural air flow

Weight 1 kg (2.2 lbs)

Serial Interface

Element Characteristics

Type RS-232 (default), RS-422/485 (non-isolated)

Transfer rate Maximum 115.2 kbps

Connection D-Sub 9-pin, plug

Qualcomm ARM® Cortex®-A53 Qualcomm Snapdragon 410

(APQ8016) Quad core up to 1.2 GHz

1066 MTs

NOTE: The serial interface COM port default setting is with RS-232. Refer to the software

configuration

USB Interface

Element Characteristics

Type USB 2.0

Transfer rate Low speed (1.5 Mb/s), full speed (12 Mb/s), high speed (480 Mb/s)

Current load Maximum 0.5 A per connection

Connection Type A

Ethernet Interface

Element Characteristics

Type RJ45

Speed 10/100/1000 Mb/s base-T

26

(see page 117)

to set RS-422 or RS-485.

EIO0000003374 11/2019

Page 27

HDMI Port

Element Characteristics

HDMI 1920 x 1080 at 60 Hz, HDCP 1.3

Encode 30 fps 720 p (H.264 Baseline/MPEG-4) 30 fps 1080 p

Decode 30 fps 1080 p (MPEG-

GPIO

The general-purpose input/output (GPIO) has eight channels with digital input and output (DIO).

The characteristic is 3.3 Vdc TTL.

Wi-Fi

WCN3620 802.11 b/g/n 2.4 GHz.

Bluetooth

WCN3620 Bluetooth 4.1.

SD Socket

SD 3.0, max raw transfer rate 104 MBps, support SD,SDHC,SDXC (Standard SD: 32 x 24 mm).

Characteristics

(MPEG-4/H.264/VP8/H.263)

4/H.264/H.263/DivX/MPEG2/VC1/Soreson/VP8)

mini_PCIe Card

USB 2.0: max raw transfer rate 480 MBps.

M.2 Card

M.2 2230 key.E (cannot support storage), USB 2.0: max raw transfer rate 480 MBps.

Conformal Coating (HMIBSCEA53D100A - IIoT Edge Box iPC - Base Unit)

Conformal coating is used for assembly process on:

Single motherboard

Board coating scope excludes:

connectors

screw holes (standoffs)

chipsets

RTC battery

dip switches

labels

NOTE: The conformal coating is available according to the product configuration

EIO0000003374 11/2019 27

Page 28

Characteristics

Power Supply Characteristics

Box PC IIoT DC Power Supply

Element Characteristics

Rated voltage 24 Vdc (12...24 Vdc)

Inrush current 0.43 A

Power consumption 16 W

28

EIO0000003374 11/2019

Page 29

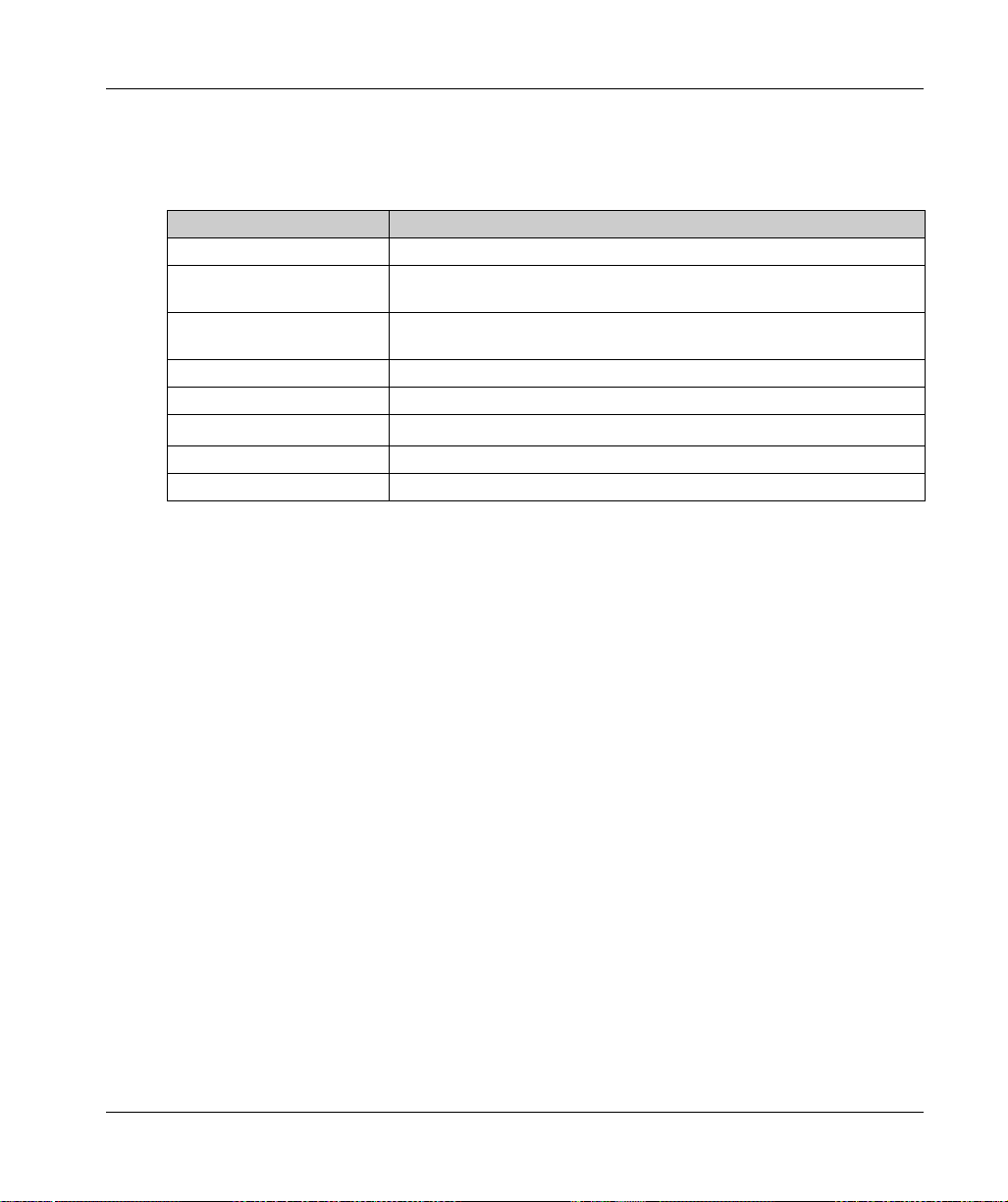

Environmental Characteristics

Characteristics

Characteristics Value

Pollution degree For use in pollution degree 2 environment

Operating temperature 0…50 °C (32...122 °F)

Operating temperature for

horizontal mounting

Storage temperature -20...60 °C (-4...140 °F)

Operating altitude 2,000 m (6,560 ft) max

Random vibration 5...500 Hz: 2 G

Storage humidity 10...95 % RH at 40 °C (104 °F), no condensation

Operating humidity 10...95 % RH at 40 °C (104 °F), no condensation

Characteristics

Optional interface installed: limited to 45 °C (113 °F)

0...50 °C (32...122 °F)

mini PCIe installed: limited to 45 °C (113 °F)

rms

EIO0000003374 11/2019 29

Page 30

Characteristics

30

EIO0000003374 11/2019

Page 31

Harmony IIoT Core Box HMIBSC

Installation

EIO0000003374 11/2019

Installation

Chapter 4

Installation

What Is in This Chapter?

This chapter contains the following topics:

Dimensions 32

Installation 33

Topic Page

EIO0000003374 11/2019 31

Page 32

Installation

Dimensions

Dimensions

Dimensional Tolerances

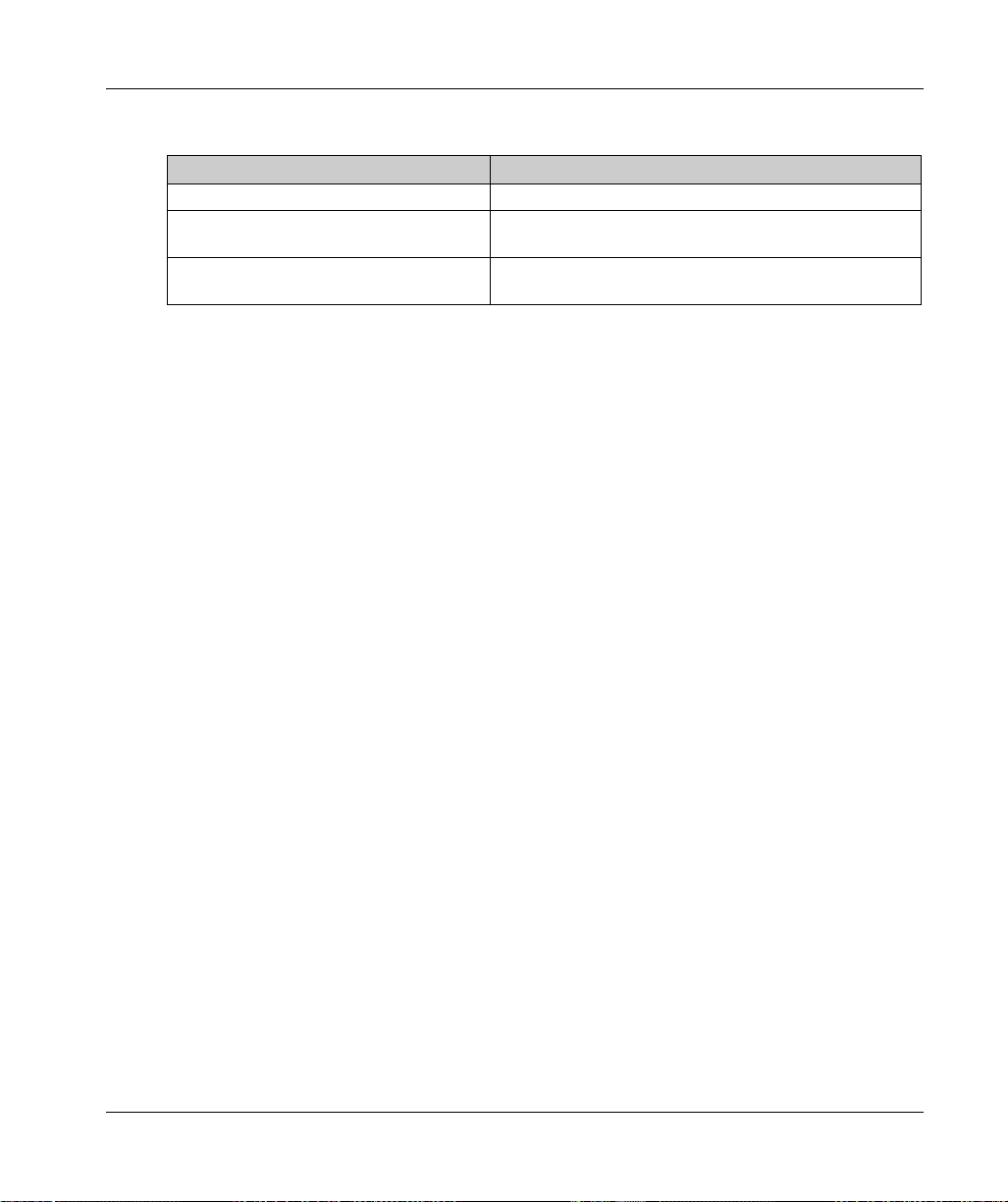

The table indicates the general tolerance for the dimensions:

Nominal measurement range General tolerance acc. DIN ISO 2768 medium

up to 6 mm (up to 0.236 in) ±0.1 mm (±0.004 in)

6...30 mm (0.236...1.181 in) ±0.2 mm (±0.0078 in)

30...80 mm (1.181...3.149 in) ±0.25 mm (±0.0098 in)

80...180 mm (3.149...7.08 in) ±0.3 mm (±0.012 in)

32

EIO0000003374 11/2019

Page 33

Installation

Installation of the Box PC IIoT

Follow these steps for installation:

Step Action

1 Remove the power and confirm that the power supply is disconnected from its power source.

2 Wall mounting: Fasten the Box PC IIoT on the cabinet with four M4 hex screws (8 mm (0.31 in)).

Book mounting: Fasten the Box PC IIoT on the cabinet with two M4 hex screws (8 mm (0.31 in)).

Installation

NOTE: The recommended torque to tighten these screws is 0.5 Nm (4.5 lb-in).

Horizontal mounting: Fasten the Box PC IIoT with four M4 hex screws (8 mm (0.31 in)):

NOTE:

The horizontal mounting is allowed with a temperature derating. See Environmental

Characteristics

For correct heat dissipation when horizontal mounting, the marking is at the bottom.

Use screw driver less than 4.5 mm for Hex socket cap screws provided.

The recommended torque to tighten these screws is 0.5 Nm (4.5 lb-in).

EIO0000003374 11/2019 33

(see page 29)

.

Page 34

Installation

Installation Din-Rail Mounting of the Box PC IIoT

Follow these steps for installation:

Step Action

1 Remove the power and confirm that the power supply is disconnected from its power source.

2 Fasten the Din-rail bracket (HMIYADBMODIN11) to the Box PC IIoT with three M3 screws (6 mm

(0.23 in)):

34

3 Hook the Box PC IIoT with bracket on the mounting rail:

EIO0000003374 11/2019

Page 35

Mounting Orientation

The figure shows the allowed mounting orientation for the Box PC IIoT:

Spacing Requirements

In order to provide sufficient air circulation, mount the Box PC IIoT so that the spacing on the top,

bottom, and side is as follows:

Installation

1 Air out

2 Air in

x1 > 100 mm (3.93 in)

x2 > 50 mm (1.96 in)

EIO0000003374 11/2019 35

Page 36

Installation

x1 > 100 mm (3.93 in)

x2 > 50 mm (1.96 in)

36

EIO0000003374 11/2019

Page 37

Harmony IIoT Core Box HMIBSC

Box iPC Connections

EIO0000003374 11/2019

Connections

Chapter 5

Connections

Subject of This Chapter

This chapter describes the connection of the Box iPC to the main power supply. It also describes

the USB ports and identifies the serial interface pin assignments.

What Is in This Chapter?

This chapter contains the following topics:

Grounding 38

Connecting the DC Power Cord 41

AC Power Supply Module Description 43

AC Power Supply Module Installation 46

UPS Module - Description and Installation 52

Interface Connections 62

Topic Page

EIO0000003374 11/2019 37

Page 38

Box iPC Connections

Grounding

Overview

The grounding resistance between the Box PC IIoT ground wire and the ground must be 100 Ω or

less. When using a long grounding wire, check the resistance and, if required, replace the wire with

a thicker wire and place it in a duct.

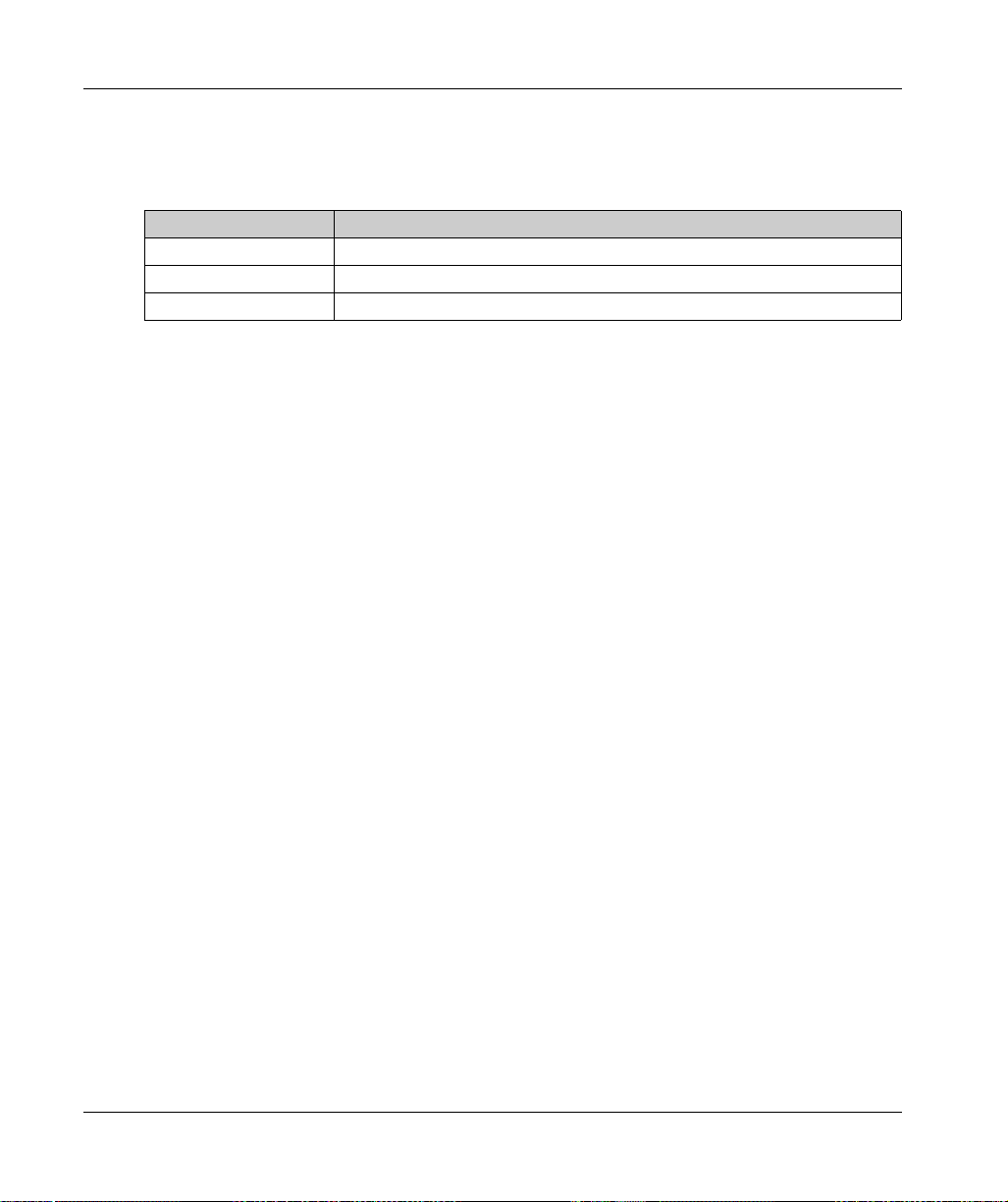

The table shows the maximum length for the wires:

Wire cross-section Maximum line length

2

1.3 mm

Grounding Procedure

UNINTENDED EQUIPMENT OPERATION

Use only the authorized grounding configurations shown below.

Confirm that the grounding resistance is 100 Ω or less.

Test the quality of your ground connection before applying power to the device. Excessive

Failure to follow these instructions can result in death, serious injury, or equipment damage.

(AWG 16)

noise on the ground line can disrupt operations of the Harmony Industrial PC.

30 m (98 ft)

60 m (196 ft) round trip

WARNING

38

The Box PC IIoT ground have 2 connections:

DC Supply voltage

Ground connection pin

EIO0000003374 11/2019

Page 39

The Box PC IIoT connections:

1 Ground connection pin (functional ground connection pin)

2 Switching cabinet

3 Grounding strip

Box iPC Connections

EIO0000003374 11/2019 39

Page 40

Box iPC Connections

When grounding, follow this procedure:

Step Action

1 Ensure all of the following is done for the system wiring:

Connect the cabinet to ground.

Ensure that all cabinets are grounded together.

Connect the ground of the power supply to the cabinet.

Connect the ground pin of the Box PC IIoT to the cabinet.

Connect the I/O to the controller if needed.

Connect the power supply to the Box PC IIoT.

2 Check that the grounding resistance is 100 Ω or less.

3 When connecting the SG line to another device, ensure that the design of the system/connection

does not produce a ground loop.

NOTE: The SG and ground connection screw are connected internally in the Box PC IIoT.

4

Use 1.3 mm

close to the Box PC IIoT as possible and make the wire as short as possible.

Grounding I/O Signal Lines

The Box PC IIoT (HMIBSC) are not classified for use in hazardous locations.

POTENTIAL FOR EXPLOSION IN HAZARDOUS LOCATION

Do not use these products in hazardous locations.

Failure to follow these instructions will result in death or serious injury.

2

(AWG 16) wire to make the ground connection. Create the connection point as

DANGER

40

Electromagnetic radiation may interfere with the control communications of the Box PC IIoT.

WARNING

UNINTENDED EQUIPMENT OPERATION

If wiring of I/O lines near power lines or radio equipment is unavoidable, use shielded cables

and ground one end of the shield to the Harmony Industrial PC ground connection screw.

Do not wire I/O lines in proximity to power cables, radio devices, or other equipment that may

cause electromagnetic interference.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000003374 11/2019

Page 41

Connecting the DC Power Cord

Precaution

When connecting the power cord to the power connector on the Box iPC, first ensure that the

power cord is disconnected from the DC power supply.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Remove all power from the device before removing any covers or elements of the system, and

prior to installing or removing any accessories, hardware, or cables.

Unplug the power cable from both the Harmony Industrial PC and the power supply.

Always use a properly rated voltage sensing device to confirm power is off.

Replace and secure all covers or elements of the system before applying power to the unit.

Use only the specified voltage when operating the Harmony Industrial PC. The DC unit is

designed to use 24 Vdc input.

Failure to follow these instructions will result in death or serious injury.

EQUIPMENT DISCONNECTION OR UNINTENDED EQUIPMENT OPERATION

Ensure that power, communication, and accessory connections do not place excessive stress

on the ports. Consider the vibration in the environment.

Securely attach power, communication, and external accessory cables to the panel or cabinet.

Use only D-Sub 9-pin connector cables with a locking system in good condition.

Use only commercially available USB cables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Box iPC Connections

DANGER

WARNING

EIO0000003374 11/2019 41

Page 42

Box iPC Connections

Wiring and Connecting the Terminal Block of the Box iPC

The table below describes how to connect the power cord to the DC terminal block:

Step Action

1 Remove all power from the Box iPC and confirm that the DC power supply is disconnected from

its power source.

2 Remove the terminal block from the power connector on the Box iPC and connect the power

cord to the terminal block:

42

Use copper wire rated for 75 °C (167 °F) with a section of 0.75 to 2.5 mm

and use 2.5 mm

2

wire to make the ground connection.

3 Place the terminal block in the power connector and tighten the screws:

NOTE: The recommended torque to tighten these screws is 0.5 Nm (4.5 lb-in).

2

(AWG 18 to AWG 14)

EIO0000003374 11/2019

Page 43

AC Power Supply Module Description

Overview

The AC power supply modules HMIYMMAC1 (100 W) or HMIYPSOMAC1 (60 W) can optionally

be used with the Box iPC to be operated with 100...240 Vac.

AC Power Supply Module (HMIYMMAC1) Description

The figure shows the AC power supply module:

Box iPC Connections

The figure shows the DC power cable of the AC power supply module:

EIO0000003374 11/2019 43

Page 44

Box iPC Connections

The figure shows the dimensions of the AC power supply module:

The table gives the technical data of the AC power supply module (PV02):

Features Values

Nominal input voltage 100...240 Vac

Frequency 47...63 Hz

Power switch Yes

Internal fuse 3.15 A

Nominal output voltage 24 Vdc

Output current 5.5 A maximum

Operation temperature -20...55 °C (-4...131 °F)

Weight 0.795 kg (1.75 lb)

44

EIO0000003374 11/2019

Page 45

AC Power Supply Module (HMIYPSOMAC1) Description

This figure shows the AC power supply module:

1 AC power cord

2 Mounting bracket

3 AC power supply

4 DC power cord

The table provides technical data for the AC power supply module:

Element Characteristics

Input 90...260 Vac / 47...63 Hz / 1.6 A at 100 Vac

Output 24 Vdc / 2.62 A maximum

Inrush current 70 A at 230 Vac

Environment

Operation temperature 0...70 °C (32...158 °F), see derating curve

Storage temperature -40...85 °C (-40...185 °F)

Relative humidity: 0...95 %, non-condensing

Box iPC Connections

Operation temperature of the AC power supply derating curve:

EIO0000003374 11/2019 45

Page 46

Box iPC Connections

AC Power Supply Module Installation

Installing the AC Power Supply Module (HMIYMMAC1)

Before installing an AC power supply module (HMIYMMAC1), shut down the operating system in

an orderly fashion and remove all power from the device.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Re move al l power f r om the d e vice before removing any covers or elements of the system, and

prior to installing or removing any accessories, hardware, or cables.

Unplug the power cable from both the Harmony Industrial PC and the power supply.

Always use a properly rated voltage sensing device to confirm that power is off.

Replace and secure all covers or elements of the system before applying power to the unit.

Use only the specified voltage when operating the Harmony Industrial PC. The AC unit is

designed to use 100...240 Vac input.

Failure to follow these instructions will result in death or serious injury.

CAUTION

OVERTORQUE AND LOOSE HARDWARE

Do not exert more than 0.5 Nm (4.5 lb-in) of torque when tightening the installation fastener,

enclosure, accessory, or terminal block screws. Tightening the screws with excessive force

can damage the installation fastener.

When fastening or removing screws, ensure that they do not fall inside the Harmony Industrial

PC chassis.

Failure to follow these instructions can result in injury or equipment damage.

46

EIO0000003374 11/2019

Page 47

Box iPC Connections

Follow these steps when installing the AC power supply module (HMIYMMAC1):

Step Action

1 Remove the power from the Box PC IIoT and confirm that the power adapter has been

disconnected from its power source.

2 Mount the AC power supply module on the cabinet with two screws (the power switch cover and

the AC IN connector have to be removed):

1 Wall mounting

2 Book mounting

NOTE: The recommended torque to tighten these screws is 0.5 Nm (4.5 lb-in).

3 Remove the terminal block from the power connector on the Box PC IIoT and connect one side of

the DC power cable to the terminal block:

EIO0000003374 11/2019 47

Page 48

Box iPC Connections

Step Action

4 Place the terminal block in the power connector of the Box PC IIoT and tighten the screws:

5 Connect the other side of DC power cable with the terminal block attached to 24 V DC OUT of the

NOTE: The recommended torque to tighten these screws is 0.5 Nm (4.5 lb-in).

AC power supply module and tighten the screws:

48

Use copper wire rated for 75 °C (167 °F) with a section of 0.75 to 2.5 mm

2

(AWG 18 to AWG 14).

EIO0000003374 11/2019

Page 49

Box iPC Connections

Step Action

6 Connect the AC power cable with the terminal block attached to AC IN of the AC power supply

module from its power source:

EIO0000003374 11/2019 49

Page 50

Box iPC Connections

Installing the AC Power Supply Module (HMIYPSOMAC1)

Follow these steps when installing the AC power supply module (HMIYPSOMAC1):

Step Action

1 Remove all power from the Box PC IIoT and confirm that the power adapter is disconnected from

its power source.

2 The AC power supply module is mounted to the cabinet with four screws M3 x 6:

50

NOTE: The recommended torque to tighten these screws is 0.5 Nm (4.5 lb-in).

3 Remove the terminal block from the power connector on the Box PC IIoT and connect the power

cord to the terminal block:

Connect the black wire with the 0 V and the red wire with the 24 V of the terminal block. Use

2

2.5 mm

copper wire to make the ground connection of the terminal block.

EIO0000003374 11/2019

Page 51

Step Action

4 Place the terminal block in the power connector and tighten the screws:

NOTE: The recommended torque to tighten these screws is 0.5 Nm (4.5 lb-in).

5 Put on the clip through the mounting bracket and the power cord together:

Box iPC Connections

Press the clip to fasten the power cord:

1 Mounting bracket

6 Connect the AC power cable of the AC power supply module from its power source.

EIO0000003374 11/2019 51

Page 52

Box iPC Connections

UPS Module - Description and Installation

Overview

EXPLOSION, FIRE, OR CHEMICAL HAZARD

Handling and storage:

Store in cool, dry and ventilated rooms with impermeable surfaces and appropriate

containment in case of leakage.

Protect from adverse weather conditions and keep separate from incompatible materials

during storage and transport.

A sufficient supply of water must be located nearby.

Damage to containers where batteries are stored and transported must be prevented.

Keep away from fire, sparks, and excessive heat.

Failure to follow these instructions will result in death or serious injury.

The uninterrupted power supply (UPS) option (HMIYMUPSKT1) includes a battery cell, a charger

circuit, and a power path switch circuit. When battery capacity is not f ull, the char ger c ircu it ch arg es

the battery cell automatically.

NOTE: If the UPS is configured and is activated in IIoT, the UPS is available.

The figure shows the UPS module:

DANGER

52

EIO0000003374 11/2019

Page 53

The figure shows the UPS module cables:

The main features of the UPS option are:

Long-lasting, maintenance-free rechargeable batteries

Communication via integrated interfaces

UPS Principle

With the optional UPS module, the Box PC IIoT completes write operations even when it is turned

off while write operations are being executed. When the UPS module detects a power off, it

switches to battery operation immediately without interruption.

NOTE:

The connected monitor is not handled by the UPS and shut-off when the power is exhausted.

There are two configurations for UPS module:

UPS module: The power source of the UPS module is from DC input power.

UPS and AC power supply modules: The power source of the module is from AC input power.

Box iPC Connections

EIO0000003374 11/2019 53

Page 54

Box iPC Connections

This figure shows the UPS module (HMIYMUPSKT1) with the AC power supply module

(HMIYMMAC1) and the Box PC IIoT with the COM port cable and the DC power cable of the UPS

cable kit (HMIYCABUPS31):

The Box PC IIoT can get battery information from the COM port.

The table describes the additional modules for the UPS:

Input power UPS Additional modules Reference

DC No – –

AC No AC power supply module HMIYMMAC1

Yes UPS module / UPS cables HMIYMUPSKT1 / HMIYCABUPS31

Yes UPS module / UPS cable and

AC power supply module

HMIYMUPSKT1 / HMIYCABUPS31 and

HMIYMMAC1

54

EIO0000003374 11/2019

Page 55

UPS Module Description

The UPS module is subject to wear and should be replaced regularly, depending on the battery

status. This information is displayed by IIoT. The Health status shows when the battery needs to

be changed.

The figure shows the UPS module (HMIYMUPSKT1):

1 LEDs ([DCIN / CHG / RDY/ BAT]) and reset button ([RST])

2 Communication port connector ([COM port / PWR])

3 DC power connector ([DC OUT / 24V DCIN])

4 Ground connection pin

The table describes the meaning of the status indicator:

Box iPC Connections

Marking Color State Meaning

DCIN Green ON The input source is OK.

1Hz

Flashing

OFF DCIN loss.

CHG Green 0.5 Hz

Flashing

1Hz

Flashing

OFF The battery capacity is over 90 % (charging not required).

RDY Blue ON The UPS module is ready.

OFF The UPS module is not functioning.

BAT Yellow ON The battery is ready.

0.5 Hz

Flashing

OFF The battery is not detected.

EIO0000003374 11/2019 55

DCIN loss up to 5 minutes.

The temperature of the battery is > 60 °C (remains flashing until

the temperature is < 55 °C).

The battery is charging.

The temperature of the battery is > 60 °C (remains flashing until

the temperature is < 55 °C) or less than 15 % charge.

Page 56

Box iPC Connections

UPS working flow:

NOTE: The button RST is used to reset the UPS module.

The table shows the technical data of the UPS module:

Features Values

UPS

Input voltage 18...36 Vdc

Output voltage 24 Vdc

Output current 3 A

Communication port COM port / RS-232 (non-Isolated)

Back-up time 10 minutes (battery 70 % fulled)

Operating temperature 0...45 °C (32...113 °F)

Mounting Horizontal mounting

Battery cells

Capacity: 27.5 Wh (2.73 Ah, 4S1P)

Maximum discharger current 9 A (if discharged at high rate and high temperature frequently,

Charging current (max) 1 A

Operating voltage 12...16 Vdc

Cycle life of recharging 300 times

Operating temperature Charge: 0...45 °C (32...113 °F)

Typical recharge time at low battery 4 hours

Weight 1.15 Kg (2.53 lbs)

the battery life will be shortened)

Discharge: 0...60 °C (32...140 °F)

56

EIO0000003374 11/2019

Page 57

The figure shows the dimensions of the UPS module (HMIYMUPSKT1) equipped with the optional

AC power supply module (HMIYMMAC1):

Installing Instructions

Before installing the UPS system, shut down the operating system in an orderly fashion and

remove the power from the device.

Box iPC Connections

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Remove all power from the device before removing any covers or elements of the system, and

prior to installing or removing any accessories, hardware, or cables.

Unplug the power cable from both the Harmony Industrial PC and the power supply.

Always use a properly rated voltage sensing device to confirm that power is off.

Replace and secure all covers or elements of the system before applying power to the unit.

Use only the specified voltage when operating the Harmony Industrial PC. The AC unit is

designed to use 100...240 Vac input. The DC unit is designed to use 24 Vdc input. Always

check whether your device is AC or DC powered before applying power.

Failure to follow these instructions will result in death or serious injury.

EIO0000003374 11/2019 57

Page 58

Box iPC Connections

OVERTORQUE AND LOOSE HARDWARE

Do not exert more than 0.5 Nm (4.5 lb-in) of torque when tightening the installation fastener,

enclosure, accessory, or terminal block screws. Tightening the screws with excessive force

can damage the installation fastener.

When fastening or removing screws, ensure that they do not fall inside the Harmony Industrial

PC chassis.

Failure to follow these instructions can result in injury or equipment damage.

By adding the charging circuit in the Box PC IIoT housing, installation is reduced to merely

attaching the connection cable to the UPS module mounted next to the Box PC IIoT.

NOTE: Due to the construction of these batteries, you can store and operate the UPS module in

any position.

Follow the steps when installing the UPS module equipped with the optional AC power supply

module:

Step Action

1 Disconnect the power supply of the Box PC IIoT.

2 Touch the housing or ground connection (not the power supply) to discharge any electrostatic

3 Mount the AC power supply module on the UPS module with the four screws supplied:

CAUTION

charge from your body.

58

EIO0000003374 11/2019

Page 59

Box iPC Connections

Step Action

4 Install the UPS module (HMIYMUPSKT1). The installation requires four x M5 screws and

four washers:

5 Connect the two UPS cables (HMIYCABUPS31) to the UPS module. Be sure to use the correct

connection terminals.

6 Connect the DC power cable of the UPS module to the DC power connector of the Box PC IIoT

Connect the COM port cable of the UPS module to the [COM] port of the Box PC IIoT:

Tighten the connected cables in the screw clamps.

EIO0000003374 11/2019 59

Page 60

Box iPC Connections

Step Action

7 Connect the AC power supply module ([24V DCOUT]) to the DC power cable ([24V DCIN]) of the

8 Connect the AC power cable ([AC IN]) of the AC power supply module:

UPS module:

60

EIO0000003374 11/2019

Page 61

Box iPC Connections

Follow the steps when installing the UPS module without the optional AC power supply module:

Step Action

1 Disconnect the power supply of the Box PC IIoT.

2 Touch the housing or ground connection (not the power supply) to discharge any electrostatic

charge from your body.

3 Install the UPS module (HMIYMUPSKT1). The installation requires four x M5 screws and

four washers.

Connect the two UPS cables (HMIYCABUPS31) to the UPS module. Connect the DC power cable

to the DC power connector of the Box PC IIoT and connect the communication cable (COM port)

to the COM port RS-232 of the Box PC IIoT:

Tighten the connected cables in the screw clamps.

4 Connect the DC power supply ([24V DCIN]) of the UPS module from its power source:

EIO0000003374 11/2019 61

Page 62

Box iPC Connections

Interface Connections

Introduction

The Box PC IIoT are not classified hazardous locations.

POTENTIAL FOR EXPLOSION IN HAZARDOUS LOCATION

Do not use these products in hazardous locations.

Failure to follow these instructions will result in death or serious injury.

EQUIPMENT DISCONNECTION OR UNINTENDED EQUIPMENT OPERATION

Ensure that power, communication, and accessory connections do not place excessive stress

on the ports. Consider the vibration in the environment.

Securely attach power, communication, and external accessory cables to the panel or cabinet.

Use only D-Sub 9-pin connector cables with a locking system in good condition.

Use only commercially available USB cables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

DANGER

WARNING

62

EIO0000003374 11/2019

Page 63

Serial Interface Connections

This interface is used to connect the Box PC IIoT to remote equipment, via a serial interface cable.

The connector is a D-Sub 9-pin plug connector.

By using a long PLC cable to connect to the Box PC IIoT, it is possible that the cable can be at a

different electrical potential than the panel, even if both are connected to ground.

NOTE: The Box PC IIoT can get UPS information from COM port.

ELECTRIC SHOCK

Make a direct connection between the ground connection screw and ground.

Do not connect other devices to ground through the ground connection screw of this device.

Install all cables according to local codes and requirements. If local codes do not require

grounding, follow a reliable guide such as the US National Electrical Code, Article 800.

Failure to follow these instructions will result in death or serious injury.

The table shows the D-Sub 9-pin assignments (COM):

Pin Assignment D-Sub 9-pin plug connector

RS-232 RS-422 RS-485

1 DCD TxD- Data-

2 RxD TxD+ Data+

3 TxD RxD+ N/A

4 DTR RxD- N/A

5GNDGNDGND

6DSRN/AN/A

7RTSN/AN/A

8CTSN/AN/A

9RIN/AN/A

Box iPC Connections

DANGER

Any excessive weight or stress on communication cables may disconnect the equipment.

EIO0000003374 11/2019 63

Page 64

Box iPC Connections

HDMI Port

The figure shows the HDMI port:

1 HDMI port

Pin number Description Pin number Description HDMI port

Pin1 HDMI_TD2+ Pin11 GND

Pin2 GND Pin12 HDMI_CLK-

Pin3 HDMI_TD2- Pin13 HDMI_CEC

Pin4 HDMI_TD1+ Pin14 NC

Pin5 GND Pin15 HDMI_DDC_SCL

Pin6 HDMI_TD1- Pin16 HDMI_DDC_SDA

Pin7 HDMI_TD0- Pin17 GND

Pin8 GND Pin18 POWER

Pin9 HDMI_TD0- Pin19 HDMI_HPD

Pin10 HDMI_CLK+

GPIO

64

Pin number Description Pin number Description GPIO terminal block

Pin1 GPIO1 Pin6 GPIO6

Pin2 GPIO2 Pin7 GPIO7

Pin3 GPIO3 Pin8 GPIO8

Pin4 GPIO4 GND GND

Pin5 GPIO5 GND GND

EIO0000003374 11/2019

Page 65

Ethernet Interface Connector Status LEDs

The figure shows the RJ45 connector status LEDs:

The table describes the RJ45 connector status LED:

Label Description LED

Color Status Description

IND1 Ethernet link Green/Yellow Off Link at 10 Mb/s

IND2 Ethernet activity Green Off No activity

USB Interface

Pin number Description Pin number Description USB port

Pin1 USB power Pin5 USB power

Pin2 USB_0+ Pin6 USB_1+

Pin3 USB_0- Pin7 USB_1-

Pin4 GND Pin8 GND

Box iPC Connections

Solid yellow Link at 100 Mb/s

Solid green Link at 1000 Mb/s

On Transmitting or receiving data

EIO0000003374 11/2019 65

Page 66

Box iPC Connections

66

EIO0000003374 11/2019

Page 67

Harmony IIoT Core Box HMIBSC

Hardware Modifications

EIO0000003374 11/2019

Hardware Modifications

Chapter 6

Hardware Modifications

Subject of This Chapter

This chapter describes the hardware modifications for the Harmony Box iPC.

What Is in This Chapter?

This chapter contains the following sections:

Section Topic Page

6.1 Before Modifications 68

6.2 Box iPC and Storage Modifications 70

6.3 Optional Cards and Optional Interfaces 73

EIO0000003374 11/2019 67

Page 68

Hardware Modifications

Before Modifications

Section 6.1

Before Modifications

Before Making Modifications

Introduction

For detailed installation procedures for optional units, refer to the OEM (original equipment

manufacturer) Installation guide included with the optional unit.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Re move al l power f r om the d e vice before removing any covers or elements of the system, and

prior to installing or removing any accessories, hardware, or cables.

Unplug the power cable from both the Harmony Industrial PC and the power supply.

Always use a properly rated voltage sensing device to confirm power is off.

Replace and secure all covers or elements of the system before applying power to the unit.

Use only the specified voltage when operating the Harmony Industrial PC. The DC unit is

designed to use 24 Vdc input.

Failure to follow these instructions will result in death or serious injury.

DANGER

68

The Box PC IIoT (HMIBSC) are not classified for use in hazardous locations.

DANGER

POTENTIAL FOR EXPLOSION IN HAZARDOUS LOCATION

Do not use these products in hazardous locations.

Failure to follow these instructions will result in death or serious injury.

During operation, the surface temperature of the heat sink may exceed 70 °C (158 °F).

WARNING

RISK OF BURNS

Do not touch the surface of the heat sink during operation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000003374 11/2019

Page 69

Hardware Modifications

CAUTION

OVERTORQUE AND LOOSE HARDWARE

Do not exert more than 0.5 Nm (4.5 lb-in) of torque when tightening the installation fastener,

enclosure, accessory, or terminal block screws. Tightening the screws with excessive force

can damage the installation fastener.

When fastening or removing screws, ensure that they do not fall inside the Harmony Industrial

PC chassis.

Failure to follow these instructions can result in injury or equipment damage.

CAUTION

STATIC SENSITIVE COMPONENTS

Harmony Industrial PC Internal components, including accessories such as RAM modules and

expansion boards, can be damaged by static electricity.

Keep static-producing materials (plastic, upholstery, carpeting) out of the immediate work

area.

Do not remove ESD-sensitive components from their anti-static bags until you are ready to

install them.

When handling static-sensitive components, wear a properly grounded wrist strap (or

equivalent).

Avoid unnecessary contact with exposed conductors and component leads with skin or

clothing.

Failure to follow these instructions can result in injury or equipment damage.

EIO0000003374 11/2019 69

Page 70

Hardware Modifications

Box iPC and Storage Mo difications

Section 6.2

Box iPC and Storage Modifications

SD Card Installation

Introduction

The Box PC IIoT operating system views the SD card as a hard disk. Proper handling and care of

the SD card helps extend the life of the card. Familiarize yourself with the card before attempting

to insert or remove the card.

Before installing or removing an SD card, shut down the operating system in an orderly fashion and

remove the power from the device.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Re move al l power f r om the d e vice before removing any covers or elements of the system, and

prior to installing or removing any accessories, hardware, or cables.

Unplug the power cable from both the Harmony Industrial PC and the power supply.

Always use a properly rated voltage sensing device to confirm that power is off.

Replace and secure all covers or elements of the system before applying power to the unit.

Use only the specified voltage when operating the Harmony Industrial PC. The AC unit is

designed to use 100...240 Vac input. The DC unit is designed to use 24 Vdc input. Always

check whether your device is AC or DC powered before applying power.

Failure to follow these instructions will result in death or serious injury.

DANGER

70

CAUTION

MEMORY CARD DAMAGE AND DATA LOSS

Remove all power before making any contact with an installed memory card.

Use only memory cards sold by Schneider Electric as accessory for this product. The

performance of the Harmony Industrial PC has not been tested using memory cards from other

manufacturers.

Confirm that the memory card is correctly oriented before insertion.

Do not bend, drop, or strike the memory card.

Do not touch the memory card connectors.

Do not disassemble or modify the memory card.

Keep the memory card dry.

Failure to follow these instructions can result in injury or equipment damage.

EIO0000003374 11/2019

Page 71

ELECTROSTATIC DISCHARGE

Take the necessary protective measures against electrostatic discharge before attempting to

remove the Box PC IIoT cover.

Failure to follow these instructions can result in equipment damage.

Inserting the SD Card

The procedure describes how to insert the SD card.

Step Action

1 Remove the cover of the SD card slot:

Hardware Modifications

NOTICE

EIO0000003374 11/2019 71

Page 72

Hardware Modifications

Step Action

2 Insert the SD card into the card slot. Press the SD card slot firmly into the Box PC IIoT. Replace

the cover:

72

EIO0000003374 11/2019

Page 73

Optional Cards and Optional Interfaces

Section 6.3

Optional Cards and Optional Interfaces

Overview

This section describes the optional cards, optional interfaces, and their installation.

What Is in This Section?

This section contains the following topics:

Optional Interface Installation 74

2 x Analog Input Interface Description 81

8 x Analog Input Interface Description 84

4G Cellular Description 87

Cyber Security TPM Module Description 90

Hardware Modifications

Topic Page

EIO0000003374 11/2019 73

Page 74

Hardware Modifications

Optional Interface Installation

Introduction

Before installing or removing an interface, shut down the operating system in an orderly fashion

and remove the power from the device.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Re move al l power f r om the d e vice before removing any covers or elements of the system, and

prior to installing or removing any accessories, hardware, or cables.

Unplug the power cable from both the Harmony Industrial PC and the power supply.

Always use a properly rated voltage sensing device to confirm that power is off.

Replace and secure all covers or elements of the system before applying power to the unit.

Use only the specified voltage when operating the Harmony Industrial PC. The AC unit is

designed to use 100...240 Vac input. The DC unit is designed to use 24 Vdc input. Always

check whether your device is AC or DC powered before applying power.

Failure to follow these instructions will result in death or serious injury.

Optional Interface Types

The figure shows the interface types (top view):

DANGER

74

EIO0000003374 11/2019

Page 75

The figure shows the available interfaces:

1 2 x AI interface

2 8 x AI interface

3 Optional interface

The table shows the type and the interface part numbers:

Hardware Modifications

Designation Part number Interface mini PCIe

slot

2 AI interface (M.2) HMIYBIN2AIM21 2 x analog input – 1 1 –

8 AI interface (mini PCIe) HMIYMIN8AI1 8 x analog input 1 – 1 –

4G cellular for EU/ASIA HMIYMIN4GEU1 4G cellular for EU/Asia

and antenna

4G cellular for US HMIYMIN4GUS1 4G cellular for US and

antenna

TPM module HMIYBINLTPM201 – – – – 1

1–––

1–––

M.2

slot

Interface

plate

Pin header

from

system

EIO0000003374 11/2019 75

Page 76

Hardware Modifications

Compatibility Table

Configurations 2 AI interface (M.2) 8 AI interface

(mini PCIe)

HMIYBIN2AIM21 HMIYMIN8AI1 HMIYMIN4GEU1/HMIYMIN4GUS1

1Yes No No

2No Yes No

3NoNoYes

4Yes No Yes

4G cellular

NOTE:

The Box PC IIoT only have one M.2 2230 slot and one mini PCIe slot. The mini PCIe slot only

can support either 4G cellular or 8 x AI optional interface module. Therefore, 8 x AI optional

interface module cannot be installed together with 4G cellular.

The 2 x AI optional interface module can be supported together with 4G cellular (with inner

GPRS SMA connector, not through 4G optional interface).

The Box PC IIoT only have one optional interface slot, therefore, 2 x AI optional interface

module cannot be used together with 8 x AI optional interface module.

The 16DI/8DO optional interface module (HMIYMINIO1) is not supported on Box PC IIoT,

because no Linux Yocto driver support.

76

EIO0000003374 11/2019

Page 77

Interface Installation

Before installing or removing a mini PCIe card, shut down the operating system in an orderly

fashion and remove the power from the device.

The Box PC IIoT are not classified for use in hazardous locations.

POTENTIAL FOR EXPLOSION IN HAZARDOUS LOCATION

Do not use these products in hazardous locations.

Failure to follow these instructions will result in death or serious injury.

ELECTROSTATIC DISCHARGE

Take the necessary protective measures against electrostatic discharge before attempting to

remove the Harmony Industrial PC cover.

Failure to follow these instructions can result in equipment damage.

OVERTORQUE AND LOOSE HARDWARE

Do not exert more than 0.5 Nm (4.5 lb-in) of torque when tightening the installation fastener,

enclosure, accessory, or terminal block screws. Tightening the screws with excessive force

can damage the installation fastener.

When fastening or removing screws, ensure that they do not fall inside the Harmony Industrial

PC chassis.

Failure to follow these instructions can result in injury or equipment damage.

Hardware Modifications

DANGER

NOTICE

CAUTION

EIO0000003374 11/2019 77

Page 78

Hardware Modifications

NOTE: Remove the power before attempting this procedure.

The table describes how to install an interface:

Step Action

1 Disconnect the power cord from the Box PC IIoT.

2 Touch the housing or ground connection (not the power supply) to discharge any electrostatic charge

from your body.

3 Unscrew the six screws from the cover and remove it:

78

4 Remove the plate:

EIO0000003374 11/2019

Page 79

Hardware Modifications

Step Action

5 4G cellular or 8 x analog input interface: Insert the mini PCIe card into the expansion card connector

of the Box PC IIoT and fasten it with two screws.

2 x analog input interface: Insert the M.2 card into the expansion card connector of the Box PC IIoT

and fasten it with one screw.

TPM module: Insert the module to the pin header.

1 mini PCIe card with the 4G cellular or 8 x analog input interface

2 M.2 card with the 2 x analog input interface

3 1 x screw size M3 (included in accessory Box PC IIoT)

4 2 x screw size M2 (included in accessory Box PC IIoT)

5 TPM module

NOTE:

When using a mini PCIe card with an external cable attached, install a clamp or other device to

secure the cable.

The requirement of Phillips screw driver is type size 2. The recommended torque to tighten these

screws is 0.5 Nm (4.5 lb-in).

EIO0000003374 11/2019 79

Page 80

Hardware Modifications

Step Action

6 Insert the interface in the slot of the Box iPC and fasten it with two screws:

NOTE: The recommended torque to tighten these screws is 0.5 Nm (4.5 lb-in).

7 Replace the cover and fasten it with six screws:

80

NOTE: The recommended torque to tighten these screws is 0.5 Nm (4.5 lb-in).

EIO0000003374 11/2019

Page 81

2 x Analog Input Interface Description

Introduction

The HMIYBIN2AIM21 is categorized as an analog input module. It is compatible with the M.2 card.

The figure shows the 2 AI interface:

The figure shows the dimensions:

Hardware Modifications

EIO0000003374 11/2019 81

Page 82

Hardware Modifications

The figure shows the 2 AI interface with the M.2 card installation:

1 M.2 card

2 2 x AI interface

NOTE: Connect the cable to M.2 card first.

Characteristics

The table shows technical data:

82

Element Characteristics

Input channel 2 (differential)

Input impedance 100 KΩ (voltage)

120 Ω (current)

Input type 0...10 Vdc

4...20 mA

Accuracy ±0.1% or better (voltage) at 25 °C

Resolution 16 bits

Calibration Auto calibration

Sampling rate 10 sample/second

Isolation 2000 Vdc

Common mode rejection

(CMR) at 50/60 Hz

Normal mode rejection

(NMR) at 50/60 Hz

±0.2% or better (current) at 25 °C

90 dB

67 dB

EIO0000003374 11/2019

Page 83

Element Characteristics

Span drift ±25 ppm

Zero drift ± 6 μV

Common-mode voltage 350 Vdc

Switch Setting

The switch on 2ch-AI module to modify to voltage or current:

For AI0 and AI1, the switch is pushed to:

Off - voltage

On - current

NOTE: By default, the switches are in off state.

Hardware Modifications

Cable Routing

EIO0000003374 11/2019 83

Page 84

Hardware Modifications

8 x Analog Input Interface Description

Introduction

The HMIYMIN8AI1 is categorized as an analog input module. It is compatible with the mini PCIe

card.

The figure shows the 8 analog input interface:

The figure shows the dimensions:

84

EIO0000003374 11/2019

Page 85

Characteristics

The table shows technical data:

Element Characteristics

Input channel 8 (differential)

Input range 0...10 V

Input type 0...10 Vdc

Accuracy ± 0.1% or better (voltage) at 25 °C

Resolution 16 bits

Calibration Auto calibration

Sampling rate 10 sample/second for total channels (when eight channels are activated,