Schneider Electric E3SUPS10KHB, E3SUPS10KHB1, E3SUPS10KHB2, E3SUPS15KHB, E3SUPS15KHB1 Installation

...Page 1

Easy UPS 3S with Internal Batteries

10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Installation

E3SUPS10KHB, E3SUPS10KHB1, E3SUPS10KHB2, E3SUPS15KHB, E3SUPS15KHB1,

E3SUPS15KHB2,E3SUPS20KHB, E3SUPS20KHB1, E3SUPS20KHB2, E3SUPS30KHB,

E3SUPS30KHB1, E3SUPS30KHB2, E3SUPS40KHB, E3SUPS40KHB1, E3SUPS40KHB2

E3SUPS10KFB1, E3SUPS15KFB1, E3SUPS20KFB1

03/2020

www.schneider-electric.com

Page 2

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Go to http://www.productinfo.schneider-electric.com/portals/ui/easyups3s/ for

translations.

Rendez-vous sur http://www.productinfo.schneider-electric.com/portals/ui/

easyups3s/ pour accéder aux traductions.

Vaya a http://www.productinfo.schneider-electric.com/portals/ui/easyups3s/ para

obtener las traducciones.

Gehe zu http://www.productinfo.schneider-electric.com/portals/ui/easyups3s/ für

Übersetzungen.

Vai a http://www.productinfo.schneider-electric.com/portals/ui/easyups3s/ per le

traduzioni.

Vá para http://www.productinfo.schneider-electric.com/portals/ui/easyups3s/ para

obter as traduções.

Перейдите по ссылке http://www.productinfo.schneider-electric.com/portals/ui/

easyups3s/ для просмотра переводов.

前往 http://www.productinfo.schneider-electric.com/portals/ui/easyups3s/ 查看译文。

前往 http://www.productinfo.schneider-electric.com/portals/ui/easyups3s/ 查看譯文。

Page 3

Table of Contents

Important Safety Instructions — SAVE THESE

10-40 kVA 400 V and 10-20 kVA 208 V 3:3

INSTRUCTIONS

Electromagnetic Compatibility .....................................................................6

Safety Precautions .....................................................................................6

Electrical Safety ....................................................................................8

Battery Safety.......................................................................................9

.........................................................................................5

Specifications for 400 V Systems........................................................... 11

Input Specifications – 3:3 UPSs ................................................................. 11

Bypass Specifications – 3:3 UPSs ............................................................. 11

Output Specifications – 3:3 UPSs .............................................................. 12

Battery Specifications ...............................................................................12

Required Upstream Protection and Cable Sizes – 3:3 UPSs ........................12

UPS Weights and Dimensions – 3:3 UPSs .................................................14

UPS Shipping Weights and Dimensions – 3:3 UPSs....................................14

Specifications for 208 V Systems........................................................... 15

Input Specifications – 3:3 UPSs ................................................................. 15

Bypass Specifications – 3:3 UPSs .............................................................15

Output Specifications – 3:3 UPSs .............................................................. 15

Battery Specifications ...............................................................................16

Required Upstream Protection and Cable Sizes – 3:3 UPSs ........................16

UPS Weights and Dimensions – 3:3 UPSs .................................................17

UPS Shipping Weights and Dimensions – 3:3 UPSs....................................17

Specifications ............................................................................................ 18

Recommended Bolts and Cable Lugs ........................................................ 18

Torque Specifications................................................................................18

Clearance ................................................................................................19

Environmental .......................................................................................... 19

Overview ....................................................................................................20

Overview of Single UPS ............................................................................20

Overview of 1+1 Redundant Parallel System with Common Battery

Bank........................................................................................................ 21

Overview of Parallel System ......................................................................22

Receiving ...................................................................................................23

Remove the UPS from the Pallet................................................................ 23

Connect the Power Cables......................................................................26

Connect the Power Cables in the 10-15 kVA 400 V UPS.............................. 26

Connect the Power Cables in the 20 kVA 400 V / 10 kVA 208 V UPS ............28

Connect the Power Cables in the 30-40 kVA 400 V / 15-20 kVA 208 V

UPS ........................................................................................................ 30

Communication Interfaces.......................................................................32

Input Contacts and Output Relays..............................................................33

Connect the Signal Cables in Parallel Systems ........................................... 34

Backfeed Protection .................................................................................35

Install Batteries in the 400 V UPS ..........................................................38

Install Batteries in the 208 V UPS ..........................................................40

Installation Checklist.................................................................................43

990-5940D-001 3

Page 4

Page 5

Important Safety Instructions — SAVE THESE

INSTRUCTIONS 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Important Safety Instructions — SAVE THESE INSTRUCTIONS

Read these instructions carefully and look at the equipment to become familiar

with it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this symbol

to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

990-5940D-001 5

Page 6

10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Electromagnetic Compatibility

RISK OF ELECTROMAGNETIC DISTURBANCE

This is a product Category C3 according to IEC 62040-2. This is a product for

commercial and industrial applications in the second environment - installation

restrictions or additional measures may be needed to prevent disturbances. The

second environment includes all commercial, light industry, and industrial

locations other than residential, commercial, and light industrial premises

directly connected without intermediate transformer to a public low-voltage

mains supply. The installation and cabling must follow the electromagnetic

compatibility rules, e.g.:

• the segregation of cables,

• the use of shielded or special cables when relevant,

• the use of grounded metallic cable tray and supports.

Failure to follow these instructions can result in equipment damage.

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

NOTICE

Safety Precautions

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

All safety instructions in this document must be read, understood and followed.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Read all instructions in the Installation Manual before installing or working on

this UPS system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not install the UPS system until all construction work has been completed

and the installation room has been cleaned.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• The product must be installed according to the specifications and

requirements as defined by Schneider Electric. It concerns in particular the

external and internal protections (upstream breakers, battery breakers,

cabling, etc.) and environmental requirements. No responsibility is assumed

by Schneider Electric if these requirements are not respected.

• After the UPS system has been electrically wired, do not start up the system.

Start-up must only be performed by Schneider Electric.

Failure to follow these instructions will result in death or serious injury.

6 990-5940D-001

Page 7

Important Safety Instructions — SAVE THESE

INSTRUCTIONS 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The UPS system must be installed according to local and national regulations.

Install the UPS according to:

• IEC 60364 (including 60364–4–41- protection against electric shock, 60364–

4–42 - protection against thermal effect, and 60364–4–43 - protection

against overcurrent), or

• NEC NFPA 70, or

• Canadian Electrical Code (C22.1, Part 1)

depending on which one of the standards apply in your local area.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Install the UPS system in a temperature controlled indoor environment free

of conductive contaminants and humidity.

• Install the UPS system on a non-flammable, level and solid surface (e.g.

concrete) that can support the weight of the system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The UPS is not designed for and must therefore not be installed in the following

unusual operating environments:

• Damaging fumes

• Explosive mixtures of dust or gases, corrosive gases, or conductive or

radiant heat from other sources

• Moisture, abrasive dust, steam or in an excessively damp environment

• Fungus, insects, vermin

• Salt-laden air or contaminated cooling refrigerant

• Pollution degree higher than 2 according to IEC 60664-1

• Exposure to abnormal vibrations, shocks, and tilting

• Exposure to direct sunlight, heat sources, or strong electromagnetic fields

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not drill or cut holes for cables or conduits with the gland plates installed and

do not drill or cut holes in close proximity to the UPS.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD OF ARC FLASH

Do not make mechanical changes to the product (including removal of cabinet

parts or drilling/cutting of holes) that are not described in the Installation Manual.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

990-5940D-001 7

Page 8

10-40 kVA 400 V and 10-20 kVA 208 V 3:3

RISK OF OVERHEATING

Respect the space requirements around the UPS system and do not cover the

product’s ventilation openings when the UPS system is in operation.

Failure to follow these instructions can result in equipment damage.

RISK OF EQUIPMENT DAMAGE

The UPS must use an external regenerative braking kit to dissipate energy

when connected to regenerative loads including photovoltaic systems and

speed drives.

Failure to follow these instructions can result in equipment damage.

Electrical Safety

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

NOTICE

NOTICE

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Electrical equipment must be installed, operated, serviced, and maintained

only by qualified personnel.

• The UPS system must be installed in a room with restricted access (qualified

personnel only).

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• Turn off all power supplying the UPS system before working on or inside the

equipment.

• Before working on the UPS system, check for hazardous voltage between all

terminals including the protective earth.

• The UPS contains an internal energy source. Hazardous voltage can be

present even when disconnected from the utility/mains supply. Before

installing or servicing the UPS system, ensure that the units are OFF and

that utility/mains and batteries are disconnected. Wait five minutes before

opening the UPS to allow the capacitors to discharge.

• A disconnection device (e.g. disconnection circuit breaker or switch) must be

installed to enable isolation of the system from upstream power sources in

accordance with local regulations. This disconnection device must be easily

accessible and visible.

• The UPS must be properly earthed/grounded and due to a high leakage

current, the earthing/grounding conductor must be connected first.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

In systems where backfeed protection is not part of the standard design, an

automatic isolation device (backfeed protection option or other device meeting

the requirements of IEC/EN 62040–1 or UL1778 5th Edition – depending on

which of the two standards apply to your local area) must be installed to prevent

hazardous voltage or energy at the input terminals of the isolation device. The

device must open within 15 seconds after the upstream power supply fails and

must be rated according to the specifications.

Failure to follow these instructions will result in death or serious injury.

8 990-5940D-001

Page 9

Important Safety Instructions — SAVE THESE

INSTRUCTIONS 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

When the UPS input is connected through external isolators that, when opened,

isolate the neutral or when the automatic backfeed isolation is provided external to

the equipment or is connected to an IT power distribution system, a label must be

fitted at the UPS input terminals, and on all primary power isolators installed

remote from the UPS area and on external access points between such isolators

and the UPS, by the user, displaying the following text (or equivalent in a language

which is acceptable in the country in which the UPS system is installed):

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Risk of Voltage Backfeed. Before working on this circuit: Isolate the UPS and

check for hazardous voltage between all terminals including the protective

earth.

Failure to follow these instructions will result in death or serious injury.

Battery Safety

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Battery circuit breakers must be installed according to the specifications and

requirements as defined by Schneider Electric.

• Servicing of batteries must only be performed or supervised by qualified

personnel knowledgeable of batteries and the required precautions. Keep

unqualified personnel away from batteries.

• Disconnect charging source prior to connecting or disconnecting battery

terminals.

• Do not dispose of batteries in a fire as they can explode.

• Do not open, alter, or mutilate batteries. Released electrolyte is harmful to

the skin and eyes. It may be toxic.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Batteries can present a risk of electric shock and high short-circuit current. The

following precautions must be observed when working on batteries

• Remove watches, rings, or other metal objects.

• Use tools with insulated handles.

• Wear protective glasses, gloves and boots.

• Do not lay tools or metal parts on top of batteries.

• Disconnect the charging source prior to connecting or disconnecting battery

terminals.

• Determine if the battery is inadvertently grounded. If inadvertently grounded,

remove source from ground. Contact with any part of a grounded battery can

result in electric shock. The likelihood of such shock can be reduced if such

grounds are removed during installation and maintenance (applicable to

equipment and remote battery supplies not having a grounded supply

circuit).

Failure to follow these instructions will result in death or serious injury.

990-5940D-001 9

Page 10

10-40 kVA 400 V and 10-20 kVA 208 V 3:3

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

When replacing batteries, always replace with the same type and number of

batteries or battery packs.

Failure to follow these instructions will result in death or serious injury.

RISK OF EQUIPMENT DAMAGE

• Wait until the system is ready to be powered up before installing batteries in

the system. The time duration from battery installation until the UPS system

is powered up must not exceed 72 hours or 3 days.

• Batteries must not be stored more than six months due to the requirement of

recharging. If the UPS system remains de-energized for a long period,

Schneider Electric recommends that you energize the UPS system for a

period of 24 hours at least once every month. This charges the batteries,

thus avoiding irreversible damage.

Failure to follow these instructions can result in equipment damage.

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

DANGER

NOTICE

10 990-5940D-001

Page 11

Specifications for 400 V Systems 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Specifications for 400 V Systems

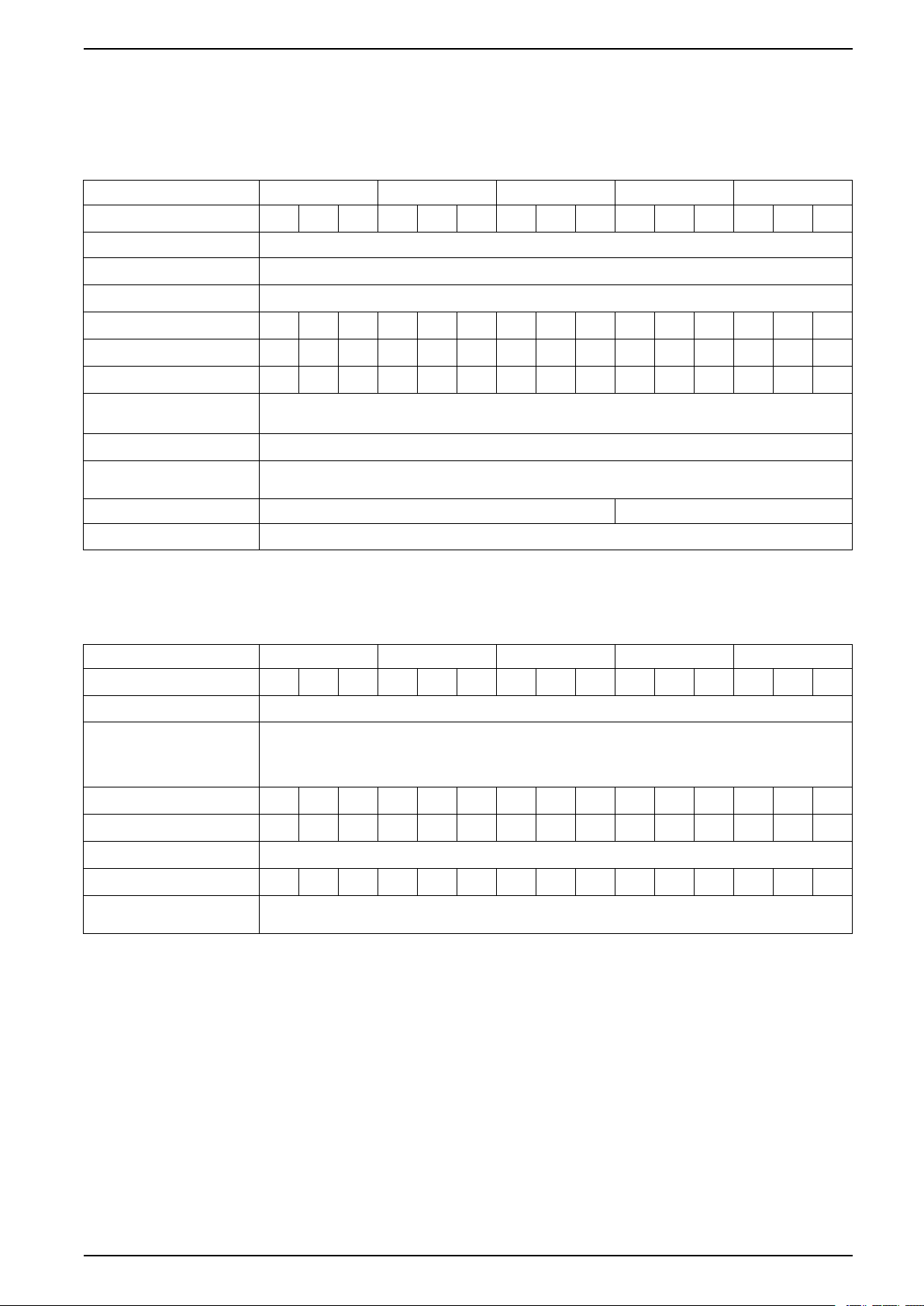

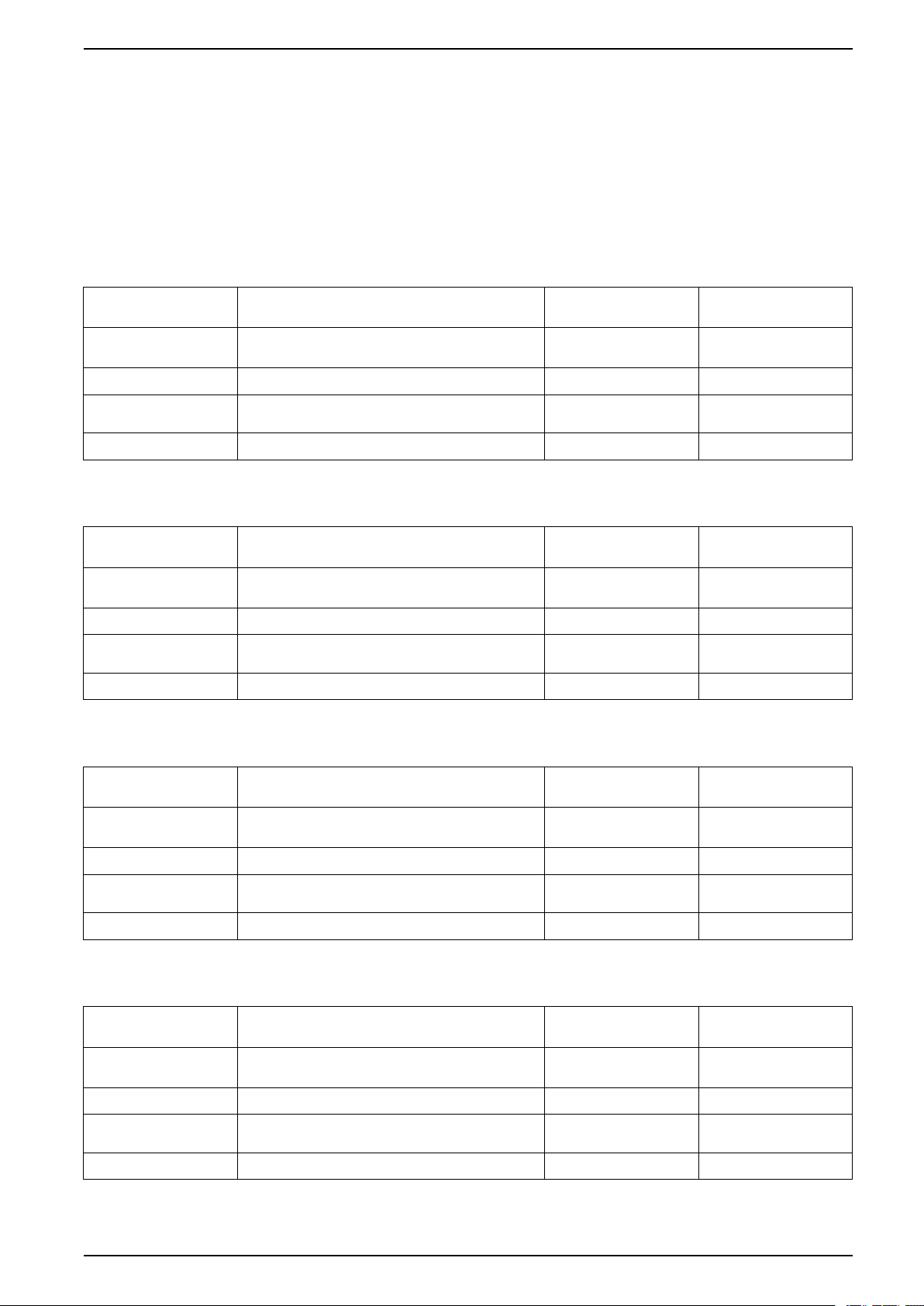

Input Specifications – 3:3 UPSs

10 kVA 15 kVA 20 kVA 30 kVA 40 kVA

Voltage (V) 380 400 415 380 400 415 380 400 415 380 400 415 380 400 415

Connections L1, L2, L3, N, PE

Input voltage range (V) 304–477

Frequency range (Hz) 45–65

Nominal input current (A) 16 15 15 24 23 22 32 31 30 48 46 44 65 61 59

Maximum input current (A) 19 18 18 29 28 26 38 37 36 58 55 53 78 73 71

Input current limitation (A) 22 20 20 33 31 30 44 42 41 65 63 60 89 83 80

Total harmonic distortion

(THDI)

Input power factor > 0.99

Maximum input shortcircuit

withstand

Protection Circuit breaker and fuse Switch and fuse

Ramp-in 15 seconds

<3% for 10 kVA UPS

<4% for 15–40 kVA UPS

Icc=10 kA

Bypass Specifications – 3:3 UPSs

10 kVA 15 kVA 20 kVA 30 kVA 40 kVA

Voltage (V) 380 400 415 380 400 415 380 400 415 380 400 415 380 400 415

Connections L1, L2, L3, N, PE

Overload capacity 125% continuous

Minimum bypass voltage (V) 304 320 332 304 320 332 304 320 332 304 320 332 304 320 332

Maximum bypass voltage (V) 437 460 477 437 460 477 437 460 477 437 460 477 437 460 477

Frequency (Hz) 50 or 60

125–130% for 10 minutes

130–150% for 1 minute

>150% for 300 milliseconds

Nominal bypass current (A) 15 14 14 23 22 21 30 29 28 46 43 42 61 58 56

Maximum input short circuit

withstand

Icc=10 kA

990-5940D-001 11

Page 12

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Specifications for 400 V Systems

Output Specifications – 3:3 UPSs

10 kVA 15 kVA 20 kVA 30 kVA 40 kVA

Voltage (V) 380 400 415 380 400 415 380 400 415 380 400 415 380 400 415

Connections L1, L2, L3, N, PE

Overload capacity 110% for 60 minutes

Output voltage tolerance ± 1%

Dynamic load response 40 milliseconds

Output power factor 1.0 1.0

Nominal output current (A) 15 14 14 23 22 21 30 29 28 46 43 42 61 58 56

125% for 10 minutes

150% for 1 minute

>150% for less than 200 milliseconds

1

Total harmonic distortion

(THDU)

Output frequency (Hz) 50 or 60

Slew rate (Hz/sec) Programmable: 0.1 to 5.0. Default is 2.0.

Output performance

classification (according to

EN62040–3)

<3% at 100% linear load

<5.5% at 100% non-linear load

VFI-SS–111

Battery Specifications

10 kVA 15 kVA 20 kVA 30 kVA 40 kVA

Charging power Programmable from 1% to 20% of UPS capacity. Default is 10%.

Maximum charging power

(W)

Nominal battery voltage

(VDC)

Nominal float voltage (VDC) ± 270

End of discharge voltage (full

load) (VDC)

End of discharge voltage (no

load) (VDC)

2000 3000 4000 6000 8000

± 240

± 192

± 210

Battery current at full load

and nominal battery voltage

(A)

Battery current at full load

and minimum battery voltage

(A)

Temperature compensation

(per cell)

Ripple current < 5% C10

22 33 44 66 89

27 40 54 81 107

Programmable from 0–5 mV. Default is 3 mV.

Required Upstream Protection and Cable Sizes – 3:3 UPSs

NOTE: Overcurrent protection must be provided by others.

Cable sizes in this manual are based on:

• Single core cables type U1000 R02V

1. When ambient temperature is below 30 °C. When the ambient temperature is above 30 °C, the power factor is 0.9.

12 990-5940D-001

Page 13

Specifications for 400 V Systems 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

• Specific to AC cables: Maximum length 70 m with a line voltage drop <3%

installed on perforated cable trays, XLPE-type insulation, single layer trefoil

formation, THDI between 15% and 33%, 35 °C at 400 V grouped in four

touching cables

• Specific to DC cables: Maximum length 15 m with a line voltage drop <1%

NOTE: If neutral conductor is expected to carry a high current, due to lineneutral non-linear load, the circuit breaker must be rated according to

expected neutral current.

10 kVA UPS

Breaker type Cable Size per Phase

Input – single mains

Input – dual mains

Bypass iC65H-C-20A / C60H-C-20A 6 6

Output C65N-B-4P-10A/C60N-B-4P-10A/

Battery Compact NSX100F DC TM50D - 3P 8 6

iC65H-C-20A / C60H-C-20A

iC65H-C-20A / C60H-C-20A

C65N-B-4P-10A /C60N-C-4P-6A

2

(mm

)

6 6

6 6

15 kVA UPS

Breaker type Cable Size per Phase

Input – single mains

Input – dual mains

Bypass iC65H-C-32A / C60H-C-32A 6 6

Output C65N-B-4P-10A/C60N-B-4P-10A/

Battery Compact NSX100F DC TM63D - 3P 8 6

iC65H-C-32A / C60H-C-32A

iC65H-C-32A / C60H-C-32A

C65N-B-4P-10A /C60N-C-4P-6A

2

(mm

)

6 6

6 6

20 kVA UPS

PE Cable Size (mm

PE Cable Size (mm

2

)

2

)

Breaker type Cable Size per Phase

Input – single mains

Input – dual mains

Bypass iC65H-C-40A / C60H-C-40A 10 10

Output C65N-B-4P-10A/C60N-B-4P-10A/

Battery Compact NSX100F DC TM80D - 3P 25 10

iC65H-C-40A / C60H-C-40A

iC65H-C-40A / C60H-C-40A

C65N-B-4P-10A /C60N-C-4P-6A

2

(mm

)

10 10

10 10

30 kVA UPS

Breaker type Cable Size per Phase

Input – single mains

Input – dual mains

Bypass iC65H-C-63A / C60H-C-63A /C120H-C-63A 16 16

Output C65N-B-4P-16A/C60N-B-4P-16A/

Battery Compact NSX160F DC TM125D - 3P 25 16

iC65H-C-63A / C60H-C-63A /C120H-C-63A

iC65H-C-63A / C60H-C-63A /C120H-C-63A

C65N-C-4P-10A /C60N-C-4P-10A

2

(mm

)

16 16

16 16

PE Cable Size (mm

PE Cable Size (mm

2

)

2

)

990-5940D-001 13

Page 14

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Specifications for 400 V Systems

40 kVA UPS

Input – single mains

Input – dual mains

Breaker type Cable Size per Phase

C120H-C-80A / NSX100F TM80C 80A

2

(mm

)

25 16

C120H-C-80A / NSX100F TM80C 80A

PE Cable Size (mm

Bypass C120H-C-80A / NSX100F TM80C 80A 25 16

Output C65N-B-4P-20A/C60N-B-4P-20A/

25 16

C65N-C-4P-10A /C60N-C-4P-10A

Battery Compact NSX160F DC TM160D - 3P 35 16

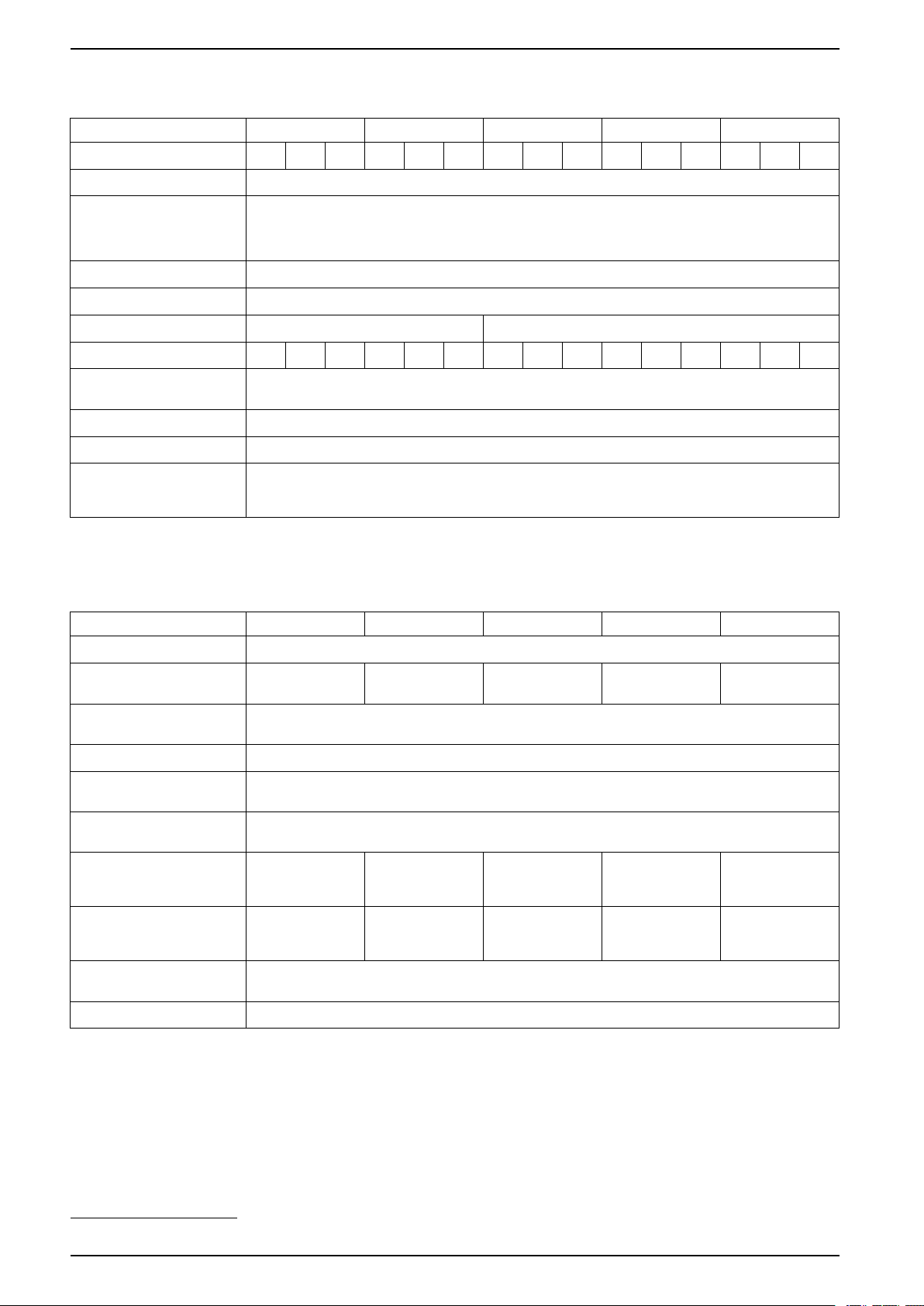

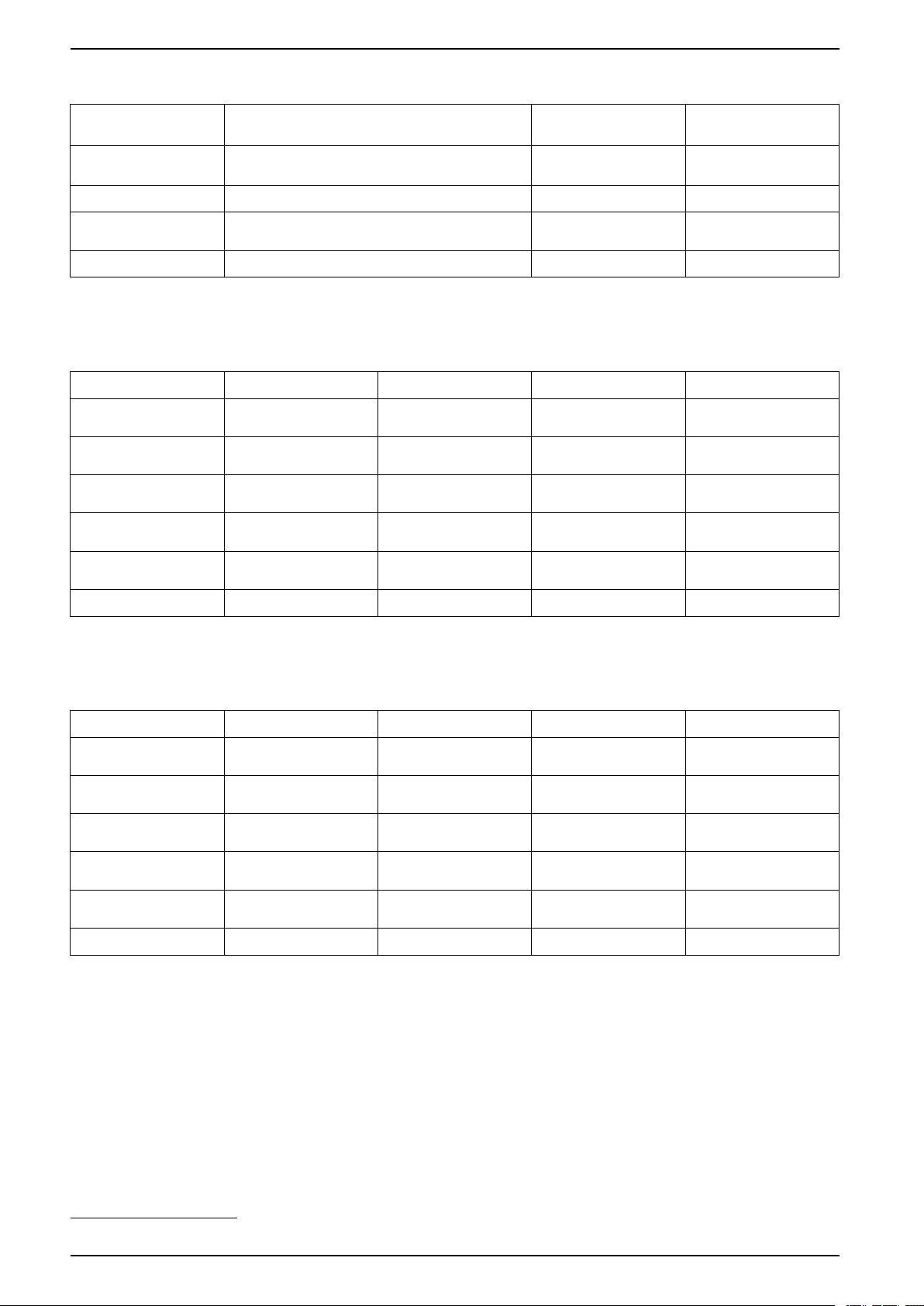

UPS Weights and Dimensions – 3:3 UPSs

UPS Weight kg Height mm Width mm Depth mm

2

10 kVA UPS with internal

112

batteries

2

15 kVA UPS with internal

112

batteries

2

20 kVA UPS with internal

122

batteries

2

30 kVA UPS with internal

152

batteries

2

40 kVA UPS with internal

158

batteries

Battery 27 157 107 760

1400 380 928

1400 380 928

1400 380 928

1400 500 969

1400 500 969

2

)

UPS Shipping Weights and Dimensions – 3:3 UPSs

UPS Weight kg Height mm Width mm Depth mm

2

10 kVA UPS with internal

145

batteries

2

15 kVA UPS with internal

145

batteries

2

20 kVA UPS with internal

158

batteries

2

30 kVA UPS with internal

190

batteries

2

40 kVA UPS with internal

195

batteries

Battery 28 180 140 820

1640 563 1014

1640 563 1014

1640 563 1014

1640 683 1114

1640 683 1114

2. Weight without batteries

14 990-5940D-001

Page 15

Specifications for 208 V Systems 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Specifications for 208 V Systems

Input Specifications – 3:3 UPSs

10 kVA 15 kVA 20 kVA

Voltage (V) 200 208 220 200 208 220 200 208 220

Connections L1, L2, L3, N, PE

Input voltage range (V) 180-253

Frequency range (Hz) 45–65

Nominal input current (A) 32 31 29 48 46 43 63 61 58

Maximum input current (A) 36 34 32 53 51 49 70 68 65

Input current limitation (A) 42 40 38 63 60 57 83 80 76

Total harmonic distortion (THDI) <4%

Input power factor > 0.99

Maximum input shortcircuit withstand Icc=10 kA

Protection Circuit breaker

and fuse

Ramp-in 15 seconds

Switch and fuse

Bypass Specifications – 3:3 UPSs

10 kVA 15 kVA 20 kVA

Voltage (V) 200 208 220 200 208 220 200 208 220

Connections L1, L2, L3, N, PE

Overload capacity 110% continuous

Minimum bypass voltage (V) 180 187 198 180 187 198 180 187 198

Maximum bypass voltage (V) 230 240 253 230 240 253 230 240 253

Frequency (Hz) 50 or 60

Nominal bypass current (A) 29 28 27 44 42 40 58 56 53

Maximum input short circuit withstand Icc=10 kA

110–120% for 10 minutes

120–135% for 1 minute

>135% for 300 milliseconds

Output Specifications – 3:3 UPSs

10 kVA 15 kVA 20 kVA

Voltage (V) 200 208 220 200 208 220 200 208 220

Connections L1, L2, L3, N, PE

Overload capacity 110% for 60 minutes

Output voltage tolerance ± 1%

Dynamic load response 40 milliseconds

Output power factor 1.0

990-5940D-001 15

125% for 10 minutes

150% for 1 minute

>150% for less than 200 milliseconds

Page 16

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Specifications for 208 V Systems

10 kVA 15 kVA 20 kVA

Voltage (V) 200 208 220 200 208 220 200 208 220

Nominal output current (A) 29 28 27 44 42 40 58 56 53

Total harmonic distortion (THDU) <2% at 100% linear load

Output frequency (Hz) 50 or 60

Slew rate (Hz/sec) Programmable: 0.1 to 5.0. Default is 2.0.

Output performance classification (according to EN62040–3) VFI-SS–111

<6% at 100% non-linear load

Battery Specifications

10 kVA 15 kVA 20 kVA

Charging power Programmable from 1% to 20% of UPS capacity. Default is

Maximum charging power (W) 2000 3000 4000

Nominal battery voltage (VDC) ± 120

Nominal float voltage (VDC) ± 135

End of discharge voltage (full load) (VDC) ± 96

End of discharge voltage (no load) (VDC) ± 105

Battery current at full load and nominal battery voltage (A) 46 68 92

Battery current at full load and minimum battery voltage (A) 56 83 111

10%.

Temperature compensation (per cell) Programmable from 0-5 mV. Default is 3 mV.

Ripple current < 5% C10

Required Upstream Protection and Cable Sizes – 3:3 UPSs

NOTE: Overcurrent protection must be provided by others.

Cable sizes in this manual are based on:

• Single core cables type U1000 R02V

• Specific to AC cables: Maximum length 70 m with a line voltage drop <3%

installed on perforated cable trays, XLPE-type insulation, single layer trefoil

formation, THDI between 15% and 33%, 35 °C at 208 V grouped in four

touching cables

• Specific to DC cables: Maximum length 15 m with a line voltage drop <1%

NOTE: If neutral conductor is expected to carry a high current, due to lineneutral non-linear load, the circuit breaker must be rated according to

expected neutral current.

10 kVA UPS

Breaker type Cable Size per Phase

(mm

2

)

PE Cable Size (mm

2

)

Input – single mains

Input – dual mains

Bypass iC65H-C-40A / C60H-C-40A 10 10

Output C65N-B-4P-10A/C60N-B-4P-10A/

Battery Compact NSX100F DC TM80D - 3P 25 10

iC65H-C-40A / C60H-C-40A

iC65H-C-40A / C60H-C-40A

C65N-B-4P-10A /C60N-C-4P-6A

10 10

10 10

16 990-5940D-001

Page 17

Specifications for 208 V Systems 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

15 kVA UPS

Breaker type Cable Size per Phase

Input – single mains

Input – dual mains

Bypass iC65H-C-63A / C60H-C-63A /C120H-C-63A 16 16

Output C65N-B-4P-16A/C60N-B-4P-16A/

Battery Compact NSX160F DC TM125D - 3P 25 16

iC65H-C-63A / C60H-C-63A /C120H-C-63A

iC65H-C-63A / C60H-C-63A /C120H-C-63A

C65N-C-4P-10A /C60N-C-4P-10A

2

(mm

)

16 16

16 16

20 kVA UPS

Breaker type Cable Size per Phase

Input – single mains

Input – dual mains

Bypass C120H-C-80A / NSX100F TM80C 80A 25 16

Output C65N-B-4P-20A/C60N-B-4P-20A/

Battery Compact NSX160F DC TM160D - 3P 35 16

C120H-C-80A / NSX100F TM80C 80A

C120H-C-80A / NSX100F TM80C 80A

C65N-C-4P-10A /C60N-C-4P-10A

2

(mm

)

25 16

25 16

PE Cable Size (mm

PE Cable Size (mm

2

)

2

)

UPS Weights and Dimensions – 3:3 UPSs

UPS Weight kg Height mm Width mm Depth mm

3

10 kVA UPS with internal

batteries

15 kVA UPS with internal

batteries

20 kVA UPS with internal

batteries

Battery 27 157 107 760

122

152

158

3

3

1400 380 928

1400 500 969

1400 500 969

UPS Shipping Weights and Dimensions – 3:3 UPSs

UPS Weight kg Height mm Width mm Depth mm

3

10 kVA UPS with internal

batteries

15 kVA UPS with internal

batteries

20 kVA UPS with internal

batteries

Battery 28 180 140 820

158

190

195

3

3

1640 563 1014

1640 683 1114

1640 683 1114

3. Weight without batteries

990-5940D-001 17

Page 18

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Specifications

Specifications

Recommended Bolts and Cable Lugs

Cable Size (mm²) Bolt Size Cable Lug Type

6 M5 KST TLK6-5

8 M5 KST RNBS8-5

10 M6 KST TLK10-6

16 M6 KST TLK16-6

25 M6 KST DRNB6-25

35 M6 KST TLK35-6

50 M8 KST TLK50-8

Torque Specifications

Bolt Size Torque

M5 4 Nm

M6 5 Nm

M8 12 Nm

18 990-5940D-001

Page 19

Specifications 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Clearance

NOTE: Clearance dimensions are published for airflow and service access

only. Consult with the local safety codes and standards for additional

requirements in your local area.

NOTE: If the UPS is installed without side access, the length of the cables

connected to the UPS must allow for rolling out the UPS.

UPS with Internal Batteries

Option A Option B

Environmental

Operation Storage

Temperature 0 °C to 40 °C

Relative humidity 0–95% non-condensing

Elevation derating according to

IEC 62040–3

Audible noise 10–20 kVA 400 V: <60 dBA at full load

Protection class IP20 (dust filter as standard)

Color RAL 9003

1000 m: 1.000

1500 m: 0.975

2000 m: 0.950

30–40 kVA 400 V: <63 dBA at full load

10–20 kVA 208 V: <63 dBA at full load

4

-15 °C to 40 °C for systems with batteries

-25 °C to 55 °C for systems without batteries

< 15000 m above sea level (or in an

environment with equivalent air pressure)

4. The optimal operation temperature for batteries is 20 °C to 25 °C

990-5940D-001 19

Page 20

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Overview

Overview

Overview of Single UPS

UIB Unit input breaker

SSIB Static switch input breaker

UOB Unit output breaker

MBB Maintenance bypass breaker

BB Battery breaker

20 990-5940D-001

Page 21

Overview 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Overview of 1+1 Redundant Parallel System with Common Battery Bank

NOTE: For UPS with internal batteries, the batteries must be removed and the

internal battery breaker (BB) must be opened.

NOTE: Common battery banks are not supported in systems with internal

batteries.

MIB Mains input breaker

BIB Bypass input breaker

UIB Unit input breaker

SSIB Static switch input breaker

UOB Unit output breaker

Ext. UOB External unit output breaker

MBB Maintenance bypass breaker

Ext. MBB External maintenance bypass breaker

BB1 Battery breaker 1

BB2 Battery breaker 2

990-5940D-001 21

Page 22

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Overview

Overview of Parallel System

NOTE: In parallel systems with an external maintenance bypass breaker Ext.

MBB, the maintenance bypass breakers MBB must be padlocked in the open

position.

UPSs for Internal Batteries

MIB Mains input breaker

BIB Bypass input breaker

UIB Unit input breaker

SSIB Static switch input breaker

UOB Unit output breaker

Ext. UOB External unit output breaker

MBB Maintenance bypass breaker

Ext. MBB External maintenance bypass breaker

SIB System isolation breaker

BB Battery breaker

22 990-5940D-001

Page 23

Receiving 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Receiving

External Inspection

When the shipment arrives, inspect the shipping material for any signs of damage

or mishandling. Do not attempt to install the system if a damage is apparent. If any

damage is noted, contact Schneider Electric and file a damage claim with the

shipping agency within 24 hours.

Compare the components of the shipment with the bill of lading. Report any

missing items to the carrier and to Schneider Electric immediately.

Verify that labelled units match the order confirmation.

Remove the UPS from the Pallet

1. Move the UPS to the final installation area using a forklift.

2. Remove the shipping materials and the ramp from the UPS.

990-5940D-001 23

Page 24

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Receiving

3. Place the ramp on the pallet and fasten with the provided bolts.

4. Loosen the bolts and remove the shipping brackets. Dispose of the shipping

brackets.

5. Roll the UPS down from the pallet.

24 990-5940D-001

Page 25

Receiving 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

6. Move the UPS to its final location and use a wrench to lower the levelling feet.

Ensure that the cabinet is level.

990-5940D-001 25

Page 26

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Connect the Power Cables

Connect the Power Cables

Connect the Power Cables in the 10-15 kVA 400 V UPS

1. Ensure that all breakers are in the OFF (open) position.

2. Remove the conduit box cover.

Rear View

3. In dual mains systems, remove the three single mains brackets.

4. Route the power cables through the bottom of the conduit box.

26 990-5940D-001

Page 27

Connect the Power Cables 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

5. Connect the PE cable to the PE terminal.

6. Connect the input cables, output cables, and bypass cables (if applicable).

7. Connect the battery cables if the UPS should have external batteries for

extended runtime.

NOTE: Ensure that the type and number of blocks are the same as the

internal batteries.

8. Reinstall the conduit box cover.

990-5940D-001 27

Page 28

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Connect the Power Cables

Connect the Power Cables in the 20 kVA 400 V / 10 kVA 208 V UPS

1. Ensure that all breakers are in the OFF (open) position.

2. Remove the conduit box cover.

Rear View

3. In dual mains systems, remove the three single mains brackets.

4. Route the power cables through the bottom of the conduit box.

28 990-5940D-001

Page 29

Connect the Power Cables 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

5. Connect the PE cable to the PE terminal.

6. Connect the input cables, output cables, and bypass cables (if applicable).

7. Connect the battery cables if the UPS should have external batteries for

extended runtime.

NOTE: Ensure that the type and number of blocks are the same as the

internal batteries.

8. Reinstall the conduit box cover.

990-5940D-001 29

Page 30

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Connect the Power Cables

Connect the Power Cables in the 30-40 kVA 400 V / 15-20 kVA 208 V UPS

1. Ensure that all breakers are in the OFF (open) position.

2. Remove the lower plate.

Rear View

3. In dual mains systems, remove the three single mains brackets.

4. Route the power cables through the bottom of the UPS.

30 990-5940D-001

Page 31

Connect the Power Cables 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

5. Connect the PE cable to the PE busbar.

6. Connect the input cables, output cables, and bypass cables (if applicable).

7. Connect the battery cables if the UPS should have external batteries for

extended runtime.

NOTE: Ensure that the type and number of blocks are the same as the

internal batteries.

8. Reinstall the lower plate.

990-5940D-001 31

Page 32

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Communication Interfaces

Communication Interfaces

NOTE: Route the signal cables separately from the power cables.

10-15 kVA 400 V UPS

A. Dry contacts

B. Parallel ports

C. USB (for service)

D. RS485

E. RS232 (for service)

F. Slot for optional SNMP

G. Cold start (optional)

20 kVA 400 V / 10 kVA 208 V UPS

A. Dry contacts

B. Parallel ports

C. USB (for service)

D. RS485

E. RS232 (for service)

F. Slot for optional SNMP

G. Cold start (optional)

32 990-5940D-001

Page 33

Communication Interfaces 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

30-40 kVA 400 V / 15-20 kVA 208 V UPS

A. Dry contacts

B. Parallel ports

C. USB (for service)

D. RS485

E. RS232 (for service)

F. Slot for optional SNMP

G. Cold start (optional)

Input Contacts and Output Relays

Input Contacts

NOTE: J2 is reserved for the internal battery temperature sensor which is

installed from factory.

Input connections are considered Class 2/SELV.

990-5940D-001 33

Page 34

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Communication Interfaces

Input Contacts for UPSs with Batteries

Output Relays

Output relay connection: Maximum 3A/240 VAC.

Connect the Signal Cables in Parallel Systems

1. Connect the optional parallel cables between all the UPSs of the parallel

system.

NOTE: See Communication Interfaces, page 32 for location of parallel

ports.

34 990-5940D-001

Page 35

Backfeed Protection 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Backfeed Protection

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

In systems where backfeed protection is not part of the standard design, an

automatic isolation device (backfeed protection option or other device meeting

the requirements of IEC/EN 62040–1) must be installed to prevent hazardous

voltage or energy at the input terminals of the isolation device. The device must

open within 15 seconds after the upstream power supply fails and must be rated

according to the specifications.

Failure to follow these instructions will result in death or serious injury.

When the UPS input is connected through external isolators that, when opened,

isolate the neutral or when the automatic backfeed isolation is provided external to

the equipment or is connected to an IT power distribution system, a label must be

fitted at the UPS input terminals, and on all primary power isolators installed

remote from the UPS area and on external access points between such isolators

and the UPS, by the user, displaying the following text (or equivalent in a language

which is acceptable in the country in which the UPS system is installed):

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Risk of Voltage Backfeed. Before working on this circuit: Isolate the UPS and

check for hazardous voltage between all terminals including the protective

earth.

Failure to follow these instructions will result in death or serious injury.

An additional external isolation device must be installed in the UPS system. A

magnetic contactor or a circuit breaker with UVR (Under Voltage Release)

functionality can be used for this purpose. In the shown examples, the isolation

device is a magnetic contactor (marked with a MC1 for single mains systems and

marked with a MC1 and MC2 for dual mains systems).

The isolation device must be able to withstand the electrical characteristics as

described in Input Specifications – 3:3 UPSs, page 11.

NOTE: The 24 V source should be generated from the input source in single

mains configurations and from the both the input and bypass source in dual

mains configurations.

990-5940D-001 35

Page 36

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Backfeed Protection

Single Mains UPS and External Isolation Device

Single Mains UPS with Backfeed Box

36 990-5940D-001

Page 37

Backfeed Protection 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Dual Mains UPS and External Isolation Device

Dual Mains with Backfeed Box

990-5940D-001 37

Page 38

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Install Batteries in the 400 V UPS

Install Batteries in the 400 V UPS

1. Remove the plate in front of the battery shelves.

2. Holding the handle, install the battery modules one string at a time from the

bottom and up.

NOTE: For 10–20 kVA UPSs the battery strings are vertical and for 30–40

kVA UPSs the battery strings are horizontal. If the 10–20 kVA UPS

contains one battery string, the batteries should be placed in the middle. If

the 10–20 kVA UPS contains two battery strings, the batteries should be

installed in the left and right sides.

Front View of the 10–20 kVA UPS

Front View of the 30–40 kVA UPS

38 990-5940D-001

Page 39

Install Batteries in the 400 V UPS 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

3. Push down the handle of each battery module and fasten with the provided

screw in front of the battery module.

4. Remove the shrink tubes from the power terminals and connect the power

terminals to the batteries.

5. Reinstall the plate in front of the battery shelves.

990-5940D-001 39

Page 40

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Install Batteries in the 208 V UPS

Install Batteries in the 208 V UPS

NOTE: Each battery string consists of two battery modules and two short

connectors.

• The 10 kVA UPS contains two vertical battery strings installed in the left and

right sides of the UPS.

• The 15 kVA UPS contains two horizontal battery strings.

• The 20 kVA UPS contains three horizontal battery strings.

1. Remove the plate in front of the battery shelves.

40 990-5940D-001

Page 41

Install Batteries in the 208 V UPS 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

2. Holding the handle, install the batteries from the bottom and up in the

indicated positions.

10 kVA UPS

20 kVA UPS

15 kVA UPS

3. Push down the handle of each battery module and fasten with the provided

screw in front of the battery module.

4. Remove the shrink tubes from the power terminals and connect the power

terminals to the batteries.

990-5940D-001 41

Page 42

10-40 kVA 400 V and 10-20 kVA 208 V 3:3 Install Batteries in the 208 V UPS

5. Install the short connectors (from E3SOPT009) in the indicated positions.

10 kVA UPS

15 kVA and 20 kVA UPS

6. Reinstall the plate in front of the battery shelves.

42 990-5940D-001

Page 43

Installation Checklist 10-40 kVA 400 V and 10-20 kVA 208 V 3:3

Installation Checklist

• The UPS and batteries are free of damage.

• The UPS has been installed in a temperature controlled indoor environment

free of conductive contaminants.

• The UPS has been installed on a non-flammable, level and solid surface that

can support the weight of the cabinet.

• Upstream protection is installed according to Required Upstream Protection

and Cable Sizes – 3:3 UPSs, page 12 or Required Upstream Protection and

Cable Sizes – 3:3 UPSs, page 16 and local regulations.

• Power cables have been connected according to the procedures in this

manual.

• Signal cables have been connected according to the procedures in this

manual.

• Battery cables have been connected according to the procedures in this

manual.

• All protection covers have been installed.

990-5940D-001 43

Page 44

Printed in:

Schneider Electric

92500 Rueil Malmaison – France

35 rue Joseph Monier

+ 33 (0) 1 41 29 70 00

Schneider Electric

35 rue Joseph Monier

92500 Rueil Malmaison

France

+ 33 (0) 1 41 29 70 00

*990–5940D-001*

As standards, specifications, and design change from time to time,

please ask for confirmation of the information given in this publication.

© 2018 – 2020 Schneider Electric. All rights reserved.

990-5940D-001

Loading...

Loading...