Conzerv EM6400NG+

User Manual

NHA2768503-05

01/2021

www.se.com

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Safety information

Important information

Read these instructions carefully and look at the equipment to become familiar

with the device before trying to install, operate, service, or maintain it. The

following special messages may appear throughout this manual or on the

equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label indicates

that an electrical hazard exists which will result in personal injury if the

instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that accompany this symbol to avoid possible

injury or death.

Conzerv EM6400NG+

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury.

Please note

Electrical equipment should be installed, operated, serviced and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material. A qualified person is one who

has skills and knowledge related to the construction, installation, and operation of

electrical equipment and has received safety training to recognize and avoid the

hazards involved.

NHA2768503-05 3

Conzerv EM6400NG+

Notices

FCC

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

his own expense.

The user is cautioned that any changes or modifications not expressly approved

by Schneider Electric could void the user’s authority to operate the equipment.

This digital apparatus complies with CAN ICES-3 (A) /NMB-3(A).

4 NHA2768503-05

Table of Contents

Safety precautions ......................................................................................9

Introduction ................................................................................................10

Meter overview......................................................................................... 10

Meter features..........................................................................................10

Feature summary .....................................................................................10

Measured parameters...............................................................................12

Data display and analysis tools..................................................................13

Meter configuration...................................................................................13

Hardware references................................................................................ 14

Meter types .............................................................................................. 14

Supplemental information..........................................................................14

Panel meter .............................................................................................14

Tamper-resistant cover ............................................................................. 15

Meter mounting ........................................................................................15

Meter wiring .............................................................................................15

Direct connect voltage limits ......................................................................15

Balanced system considerations................................................................17

Serial communications..............................................................................17

Pulse output............................................................................................. 19

Conzerv EM6400NG+

Energy ...............................................................................................12

Demand .............................................................................................12

Instantaneous.....................................................................................12

Power quality...................................................................................... 12

Power Monitoring Expert ..................................................................... 13

Power SCADA Operation .................................................................... 13

RS-485 wiring..................................................................................... 18

Display and meter setup ..........................................................................20

Display overview ......................................................................................20

LED indicators.......................................................................................... 20

Energy pulsing LED ............................................................................21

Heartbeat / serial communications LED ................................................21

Button functions ....................................................................................... 21

Meter screen menus ................................................................................. 22

Display screen menus .........................................................................22

Setup screen menus ........................................................................... 24

Demand .............................................................................................30

Communications setup........................................................................ 32

Setting up the password ......................................................................32

Setting up date and time......................................................................33

Diagnostics (Diag) screen menus......................................................... 33

Clear screen menus ............................................................................35

Lock / Unlock...................................................................................... 37

Remote meter setup ................................................................................. 38

Overview ................................................................................................. 38

ION setup ................................................................................................ 38

RS-485 port setup .................................................................................... 38

Using a serial communications converter to set up RS-485 .................... 38

NHA2768503-05 5

Conzerv EM6400NG+

Meter setup through RS-485 .....................................................................39

Meter configuration using ION setup .......................................................... 39

Viewing meter data ...................................................................................40

Viewing meter data from the display ...........................................................40

Using ION Setup to view or modify configuration data.................................. 41

Using software to view meter data..............................................................41

Power Monitoring Expert ........................................................................... 42

Power SCADA Operation .........................................................................42

Modbus command interface ......................................................................42

Measurements and calculations ............................................................. 43

Meter initialization.....................................................................................43

Real-time readings ................................................................................... 43

Energy measurements..............................................................................43

Quadrant based VARh ..............................................................................43

Min/max values ........................................................................................44

Power demand .........................................................................................44

Power demand calculation methods ..................................................... 44

Block interval demand .........................................................................44

Synchronized demand......................................................................... 45

Thermal demand ................................................................................45

Current demand .......................................................................................46

Predicted demand............................................................................... 46

Peak demand ..................................................................................... 47

Timer.......................................................................................................47

Power quality .............................................................................................48

Harmonics overview ................................................................................. 48

Total harmonic distortion %........................................................................48

Harmonic content calculations ............................................................. 48

THD% calculations..............................................................................48

Displaying harmonics data ........................................................................ 48

Maintenance and upgrades..................................................................... 50

Maintenance overview .............................................................................. 50

Troubleshooting LED indicators .................................................................50

Meter memory..........................................................................................50

Meter battery............................................................................................50

Viewing firmware version, model and serial number ....................................51

Firmware upgrades................................................................................... 51

Firmware upgrade using DLF3000 .......................................................51

Technical assistance .................................................................................52

Verifying accuracy..................................................................................... 53

Overview of meter accuracy ...................................................................... 53

Accuracy test requirements .......................................................................53

Verifying accuracy test ..............................................................................54

Required pulses calculation for accuracy verification testing ........................ 55

Total power calculation for accuracy verification testing ...............................56

Percentage error calculation for accuracy verification testing ....................... 56

Accuracy verification test points.................................................................56

Energy pulsing considerations ...................................................................57

VT and CT considerations..........................................................................57

Example calculations ................................................................................ 58

6 NHA2768503-05

Conzerv EM6400NG+

Typical sources of test errors .....................................................................59

Power and power factor ...........................................................................60

Power and power factor ............................................................................ 60

Current phase shift from voltage ................................................................60

Real, reactive and apparent power (PQS)................................................... 60

Power factor (PF) ..................................................................................... 61

Power factor sign convention ...............................................................61

Power factor min/max convention.........................................................62

Power factor register format................................................................. 63

Specifications ............................................................................................65

NHA2768503-05 7

Safety precautions Conzerv EM6400NG+

Safety precautions

Installation, wiring, testing and service must be performed in accordance with all

local and national electrical codes.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate Personal Protective Equipment (PPE) and follow safe

electrical work practices. See NFPA 70E, CSA Z462 or other local

standards.

• Turn off all power supplying this device and the equipment in which it is

installed before working on or in the equipment.

• Always use a properly rated voltage sensing device to confirm that all power

is off.

• Follow guidelines in the Wiring section of the related Installation Sheet.

• Assume communications and I/O wiring are hazardous live until determined

otherwise.

• Do not exceed the maximum ratings of this device.

• Do not short secondary terminals of Voltage Transformer (VT).

• Do not open secondary terminals of Current Transformer (CT).

• Ground secondary circuit of CTs.

• Do not use the data from the meter to confirm power is off.

• Replace all devices, doors and covers before turning on power to this

equipment.

Failure to follow these instructions will result in death or serious injury.

NOTE: See IEC 60950-1 for more information on communications and I/O

wiring connected to multiple devices.

WARNING

UNINTENDED OPERATION

• Do not use this device for critical control or protection of persons, animals,

property or equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

POTENTIAL COMPROMISE OF SYSTEM AVAILABILITY, INTEGRITY, AND

CONFIDENTIALITY

• Change default passwords/passcodes to help prevent unauthorized access

to device settings and information.

• Disable unused ports/services and default accounts, where possible, to

minimize pathways for malicious attacks.

• Place networked devices behind multiple layers of cyber defenses (such as

firewalls, network segmentation, and network intrusion detection and

protection).

• Use cybersecurity best practices (for example: least privilege, separation of

duties) to help prevent unauthorized exposure, loss, modification of data and

logs, interruption of services, or unintended operation.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NHA2768503-05 9

Conzerv EM6400NG+ Introduction

Introduction

Meter overview

The EM6400NG+ series meters are digital meters that offer comprehensive 3phase electrical instrumentation and load management facilities in a compact and

rugged package.

The EM6400NG+ meters offer value for the demanding needs of your energy

monitoring and cost management applications. All meters in the EM6400NG+

series range comply with Class 1, Class 0.5S, or Class 0.2 accuracy standards

and feature high quality, reliability and affordability in a compact and easy to install

format.

Meter features

The EM6400NG+ meter supports many features, a few of the features are listed

below:

• LED display screen: Intuitive self-guided navigation using three buttons LED

display, with three lines of concurrent values. Two columns of LEDs given on

the either side of the meter’s front panel indicate the parameter name being

displayed.

• Energy accounting and balancing.

• Measurement of both True PF and Displacement PF.

• EM6400NG+ POP (Class 1 and 0.5S) and RS-485 (Class 1, 0.5S, and 0.2)

models.

• THD% and individual harmonics up to 15

• Active, reactive, and apparent energy readings.

• Min/Max values of instantaneous parameters with timestamp.

• Cybersecurity: The meter supports the disabling of RS-485 port through front

panel keys to prevent unauthorized access. Toggle the RTU devices in case

of limited availability of nodes in software system.

• Suppression current: The meter can be configured to disregard the

measurement of induced / auxiliary load current in the circuit (can be set from

5 to 99 mA).

You can use the meter as a stand-alone device, but its extensive capabilities are

fully realized when used as part of an energy management system.

th

order for voltage and current.

For applications, feature details and the most current and complete specifications

of the EM6400NG+ meters, see the EM6400NG+ technical datasheet at www.se.

com.

Feature summary

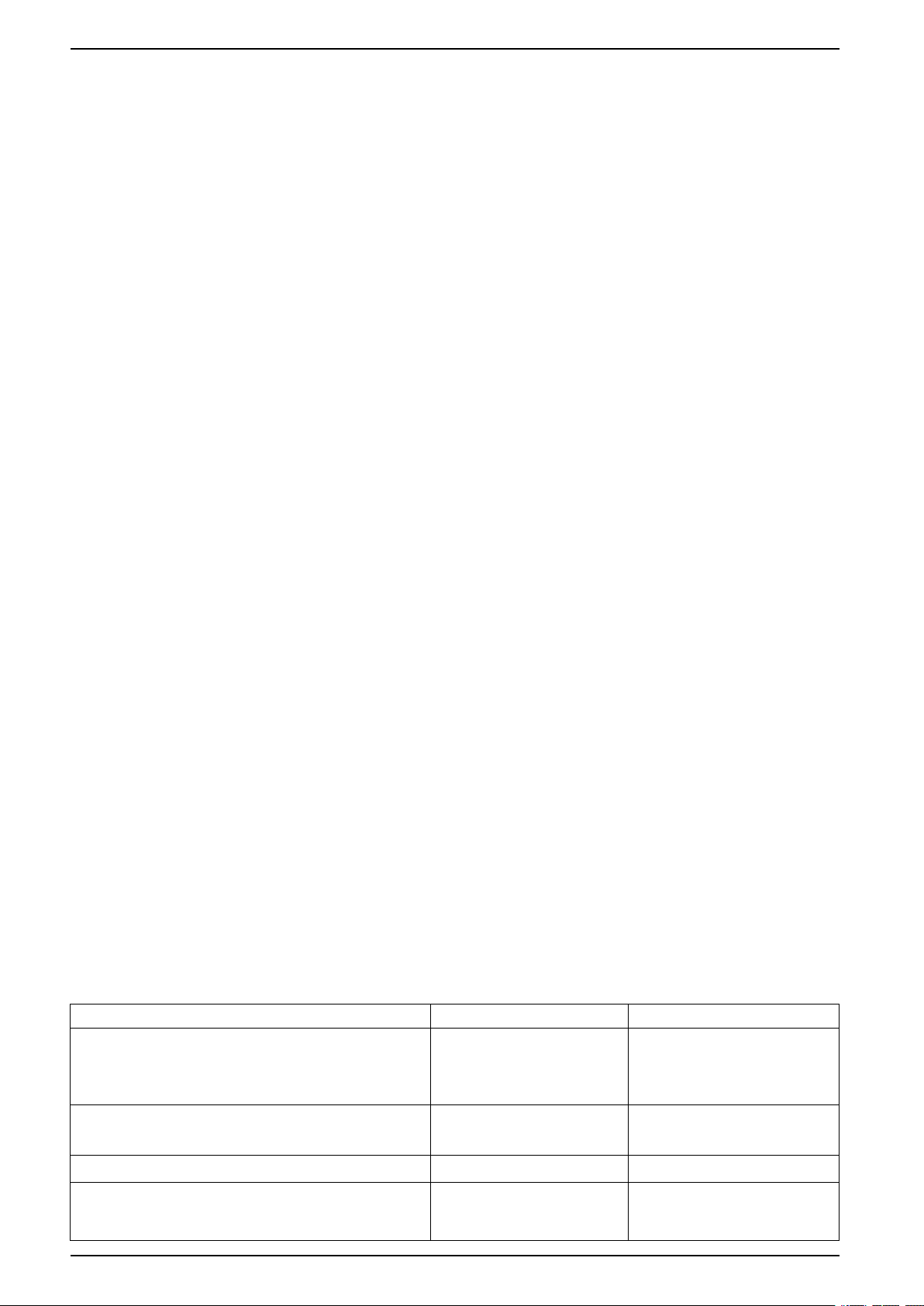

Parameter EM6400NG+ POP EM6400NG+ RS-485

Accuracy Class for Wh Class 1

Class 0.5S

Accuracy Class for VARh 2.0

1.0

Sampling rate per cycle 64 64

Current:

• Per-phase and 3 phase average

• Calculated neutral current

10 NHA2768503-05

✔ ✔

Class 1

Class 0.5S

Class 0.2

2.0

1.0

Introduction Conzerv EM6400NG+

Parameter EM6400NG+ POP EM6400NG+ RS-485

Voltage:

• V L-N - per-phase and 3 phase average

• V L-L - per-phase and 3 phase average

✔ ✔

Power Factor

• Per phase and 3 phase total

Frequency

Power:

True PF True PF

Displacement PF

✔ ✔

✔ ✔

• Active power (kW) - Phase wise and total

• Apparent power (kVA) - Phase wise and total

• Reactive power (kVAR) - Phase wise and total

3 Phase unbalance Current Current

Voltage

Demand parameters (kW, kVA, kVAR, I)

• Last demand

✔

(no timestamp)

✔

• Present demand

• Predictive demand

• Peak demand: Timestamp for peak demand

Energy: kWh, kVAh, kVARh (4 Quadrant)

• Delivered (Import / Forward)

• Received (Export / Reverse)

1

Delivered

Received

Delivered

Received

Total

1

Net

Last cleared (Old)

Meter On hours

—

✔

Load Run hours

Power Interruptions

1

1

1

1

THD:

✔ ✔

• Voltage L-N per phase

• Voltage L-L per phase

• Current per phase

Individual Harmonics

1

Min / Max with timestamp

1

—

—

Up to 15th odd harmonics

✔

• V L-L average

• V L-N average

• Current average

• Frequency

• Active power, Total

• Apparent power, Total

• Reactive power, Total

• Power factor, Total

RTC

—

✔

Communication POP RS-485 Modbus RTU

Retrofit (RtFt)

—

✔

For configuring legacy communication data models

1. Indicates features that can be read through communication only.

NHA2768503-05 11

Conzerv EM6400NG+ Introduction

Measured parameters

Energy

The meter provides bi-directional, 4-quadrant, Class 1 / Class 0.5S / Class 0.2

accurate energy metering.

The meter stores all accumulated active, reactive and apparent energy

parameters in non-volatile memory:

• kWh, kVARh, kVAh (delivered)

• kWh, kVARh, kVAh (received)

• kWh, kVARh, kVAh (delivered + received)

• kWh, kVARh, kVAh (delivered - received)

NOTE: Based on the energy scale selection, when any of energy parameters

overflow at 999999999.999 all energy parameters value resets.

Demand

The meter provides last, present, predicted, and maximum (peak) demand values,

and a timestamp when the maximum (peak) demand occurred.

Instantaneous

The meter supports standard demand calculation methods, including sliding block,

fixed block, rolling block, thermal and synchronized.

Peak demand registers can be reset manually (password protected).

Demand measurements include:

• W, VAR, VA demand total

• Amps demand average

The meter provides highly accurate 1-second measurements, average values,

including true RMS, per phase and total for:

• Per phase and average voltage (line-to-line, line-to-neutral)

• Per phase and average current, and neutral current

NOTE: Neutral current is calculated.

• Per phase and total power (VA, W, Var)

• Per phase and average for true and displacement power factor

• System frequency

• Per phase and maximum of all three for voltage unbalance and current

unbalance

Power quality

The meter provides complete harmonic distortion metering, recording, and realtime reporting, up to the 15

The following power quality measurements are available:

• Individual odd harmonics up to 15

• Total harmonic distortion (THD%) for current and voltage (displays line-to-line

or line-to-neutral, based on selected system configuration)

12 NHA2768503-05

th

harmonic for all voltage and current inputs.

th

order (voltage and current, per phase)

Introduction Conzerv EM6400NG+

Data display and analysis tools

Power Monitoring Expert

EcoStruxure™Power Monitoring Expert is a complete supervisory software

package for power management applications.

The software collects and organizes data gathered from your facility’s electrical

network and presents it as meaningful, actionable information via an intuitive web

interface.

Power Monitoring Expert communicates with devices on the network to provide:

• Real-time monitoring through a multi-user web portal

• Trend graphing and aggregation

• Power quality analysis and compliance monitoring

• Preconfigured and custom reporting

See the EcoStruxure

how to add your device into its system for data collection and analysis.

Power SCADA Operation

™

Power Monitoring Expert online help for instructions on

EcoStruxure™Power SCADA Operation is a complete real-time monitoring and

control solution for large facility and critical infrastructure operations.

It communicates with your device for data acquisition and real-time control. You

can use Power SCADA Operation for:

See the EcoStruxure

how to add your device into its system for data collection and analysis.

Meter configuration

Meter configuration is performed through the display or through ION Setup.

ION Setup is a meter configuration tool that can be downloaded for free at

www.se.com.

See the Conzerv EM6400NG Load Manager topic in the ION Setup online help or

in the ION Setup device configuration guide. To download a copy, go to

www.se.com and search for ION Setup device configuration guide.

• System supervision

• Real-time and historical trending, event logging

• PC-based custom alarms

™

Power SCADA Operation online help for instructions on

NHA2768503-05 13

Conzerv EM6400NG+ Hardware references

Hardware references

Meter types

The EM6400NG+ series is available in one physical form factor.

Commercial Reference Description

METSEEM6400NGPOCL1 Class 1 panel mount meter with pulse output and integrated display.

METSEEM6400NGPOCL5 Class 0.5S panel mount meter with pulse output and integrated

METSEEM6400NGRSCL1 Class 1 panel mount meter with RS-485 and integrated display.

METSEEM6400NGRSCL5 Class 0.5S panel mount meter with RS-485 and integrated display.

METSEEM6400NGRSCL2 Class 0.2 panel mount meter with RS-485 and integrated display.

Supplemental information

This document is intended to be used in conjunction with the installation sheet that

ships in the box with your device and accessories.

See your device’s installation sheet for information related to installation.

See your product’s catalog pages at www.se.com for information about your

device, its options and accessories.

You can download updated documentation from www.se.com or contact your local

Schneider Electric representative for the latest information about your product.

Panel meter

display.

The back of your meter supports various power system connections.

14 NHA2768503-05

Hardware references Conzerv EM6400NG+

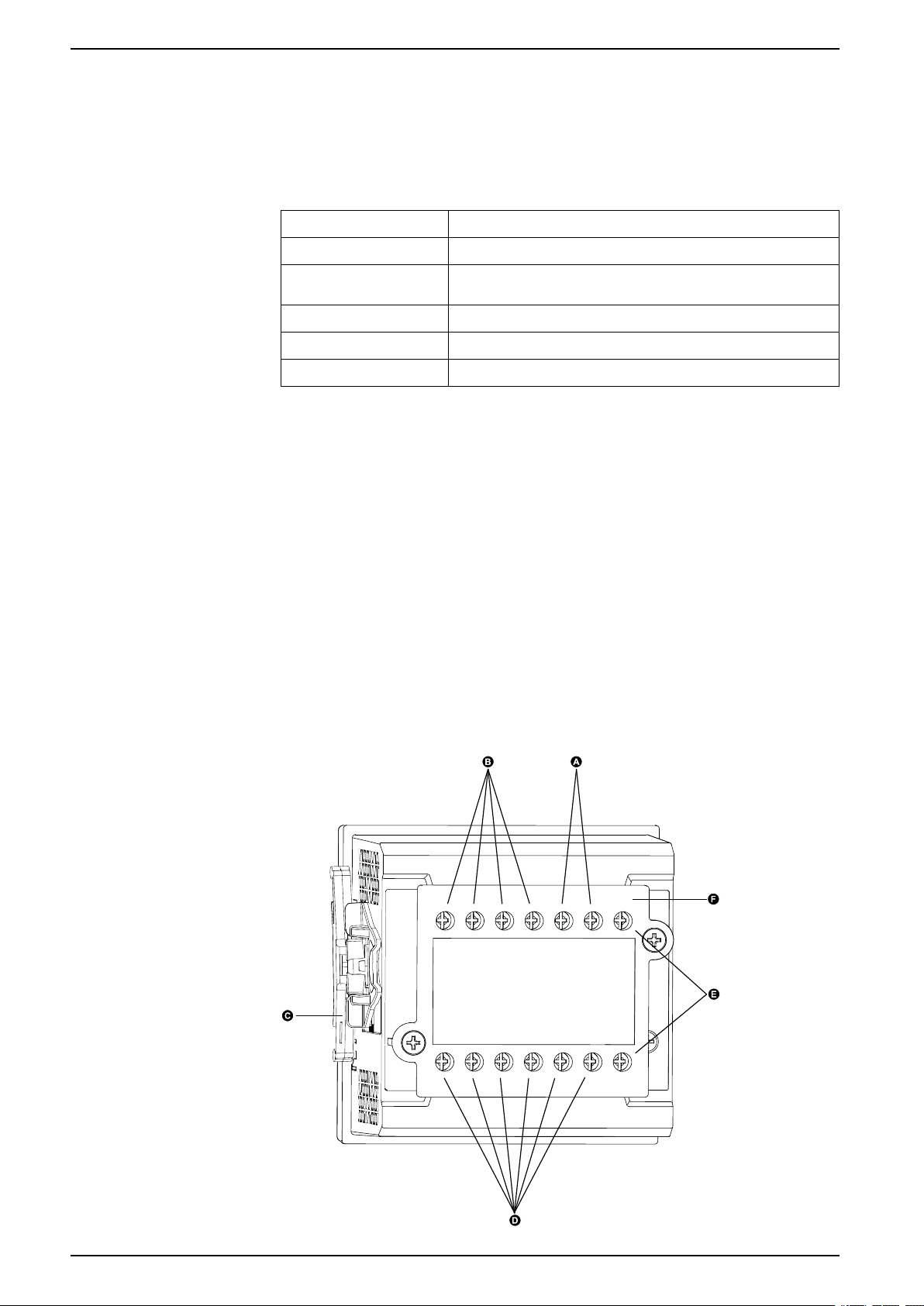

A Auxiliary power supply (control power) terminals (L+, N-)

B Input voltage terminals (V1, V2, V3, VN)

C Retainer clip

D Input current terminals [A1(S1, S2), A2 (S1, S2), A3 (S1, S2)]

E RS-485 communications/POP terminals (D1+, D0-)

F Protective cover

Tamper-resistant cover

The tamper-resistant cover helps prevent tampering with the meter’s voltage and

current measurement inputs.

The tamper-resistant cover encloses the terminals, the conductor fixing screws

and a length of the external conductors and their insulation. The covers are

secured by tamper-resistant meter seals.

The meter’s tamper-resistant cover must be installed by a qualified installer.

Meter mounting

For mounting instructions and safety precautions, see the installation sheet that

was shipped with your device

You can also download the latest copy at www.se.com.

Meter wiring

For wiring instructions and safety precautions, see the meter installation sheet that

was shipped with your meter.

You can also download the latest copy at www.se.com.

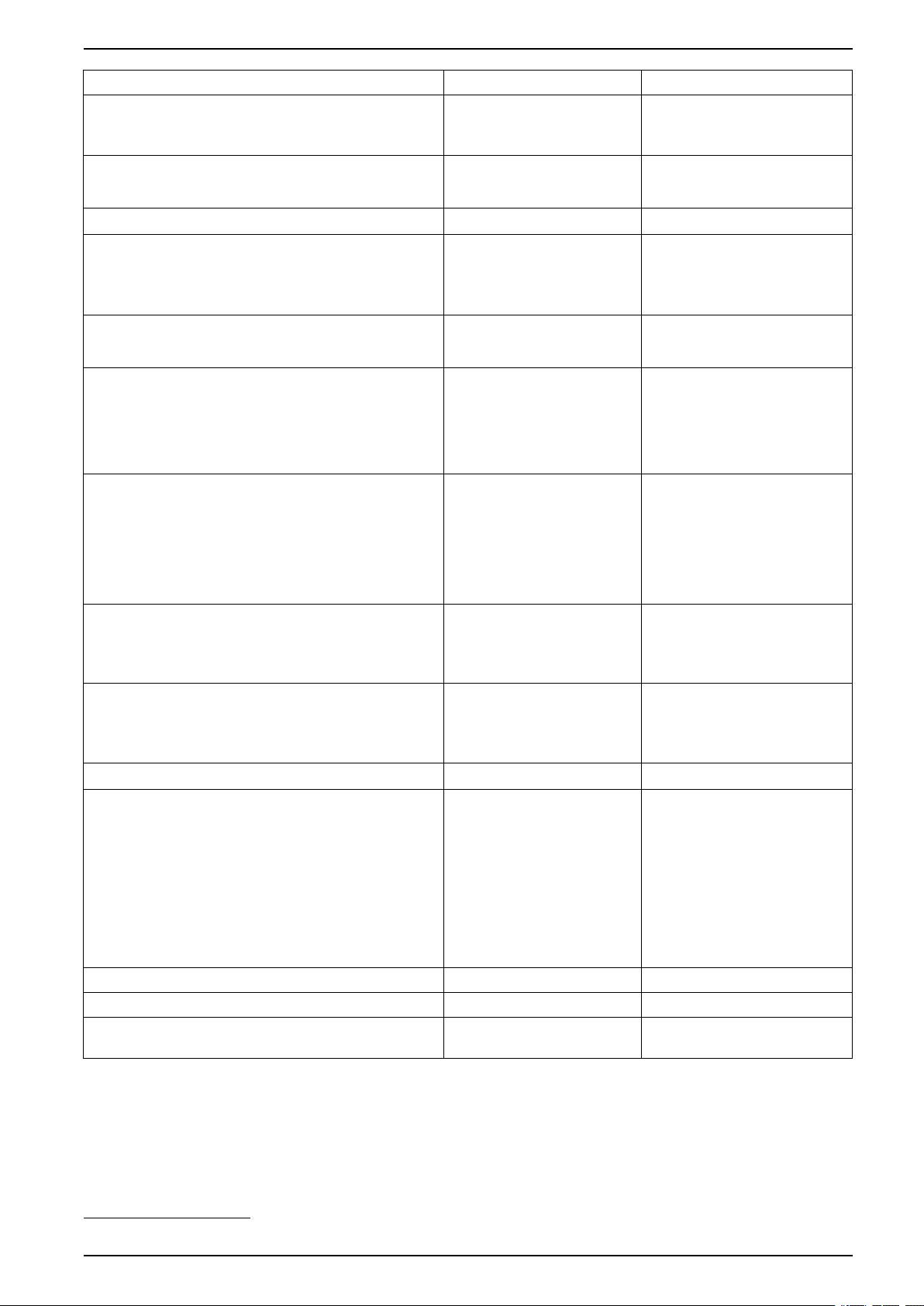

Direct connect voltage limits

You can connect the meter’s voltage inputs directly to the phase voltage lines of

the power system if the power system’s line-to-line or line-to-neutral voltages do

not exceed the meter’s direct connect maximum voltage limits.

The meter's voltage measurement inputs are rated by the manufacturer for up to

277 V L-N / 480 V L-L. However, the maximum voltage allowed for direct

connection may be lower, depending on the local electrical codes and regulations.

As per installation category II / III the maximum voltage on the meter voltage

measurement inputs should not exceed 277 V L-N / 480 V L-L for CAT III and 347

V L-N / 600 V L-L for CAT II.

If your system voltage is greater than the specified direct connect maximum

voltage, you must use VTs (voltage transformers) to step down the voltages.

NHA2768503-05 15

Conzerv EM6400NG+ Hardware references

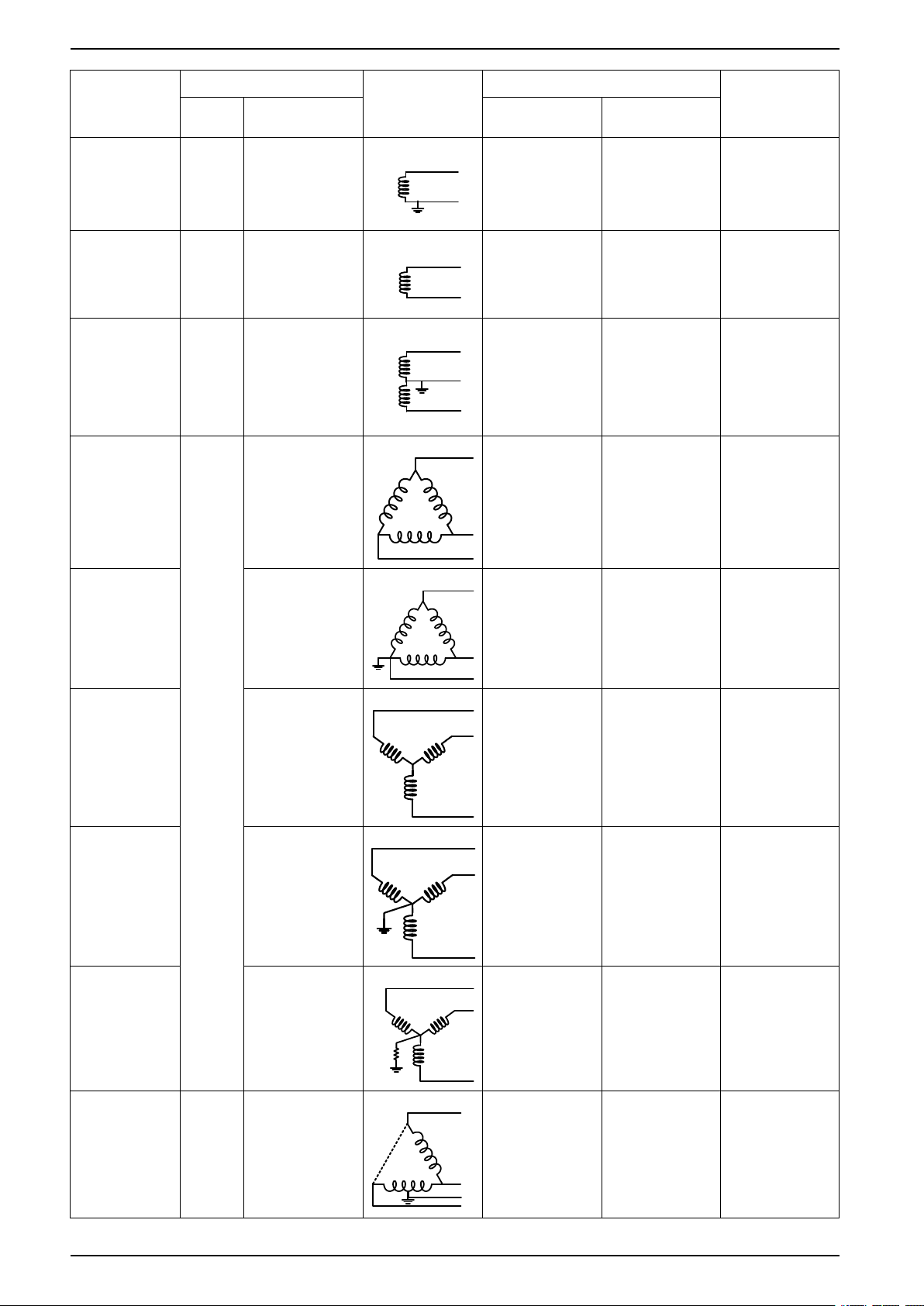

N

Power system

description

Single-phase 2wire line-toneutral

Single-phase 2wire line-to-line

Single-phase 3wire line-to-line

with neutral

3-phase 3-wire

Delta

ungrounded

Meter setting Symbol Direct connect maximum (UL / IEC) # of VTs (if

required)

Display

(meter)

1P.LN 1PH 2Wire L-N

1P.LL 1PH 2Wire L-L

1P.3L 1PH 3Wire L-L

3P.3L 3PH 3Wire

Display

(communication)

with N

Installation

category III

Installation

category II

≤ 277 V L-N ≤ 347 V L-N 1 VT

480 V L-L 600 V L-L 1 VT

≤ 277 V L-N / 480

V L-L

≤ 347 V L-N / 600

V L-L

2 VT

480 V L-L 600 V L-L 2 VT

Ungrounded Delta

3-phase 3-wire

Delta corner

grounded

3-phase 3-wire

Wye ungrounded

3-phase 3-wire

Wye grounded

3-phase 3-wire

Wye resistancegrounded

3PH 3Wire Corner

Grounded Delta

3PH 3Wire

Ungrounded Wye

3PH 3Wire

Grounded Wye

3PH 3Wire

Resistance

Grounded Wye

480 V L-L 600 V L-L 2 VT

480 V L-L 600 V L-L 2 VT

480 V L-L 600 V L-L 2 VT

480 V L-L 600 V L-L 2 VT

3-phase 4-wire

open Delta

center-tapped

3P.4L 3PH 4Wire

Center-Tapped

Open Delta

240 V L-N / 480 V

L-L

240 V L-N / 480 V

L-L

3 VT

16 NHA2768503-05

Hardware references Conzerv EM6400NG+

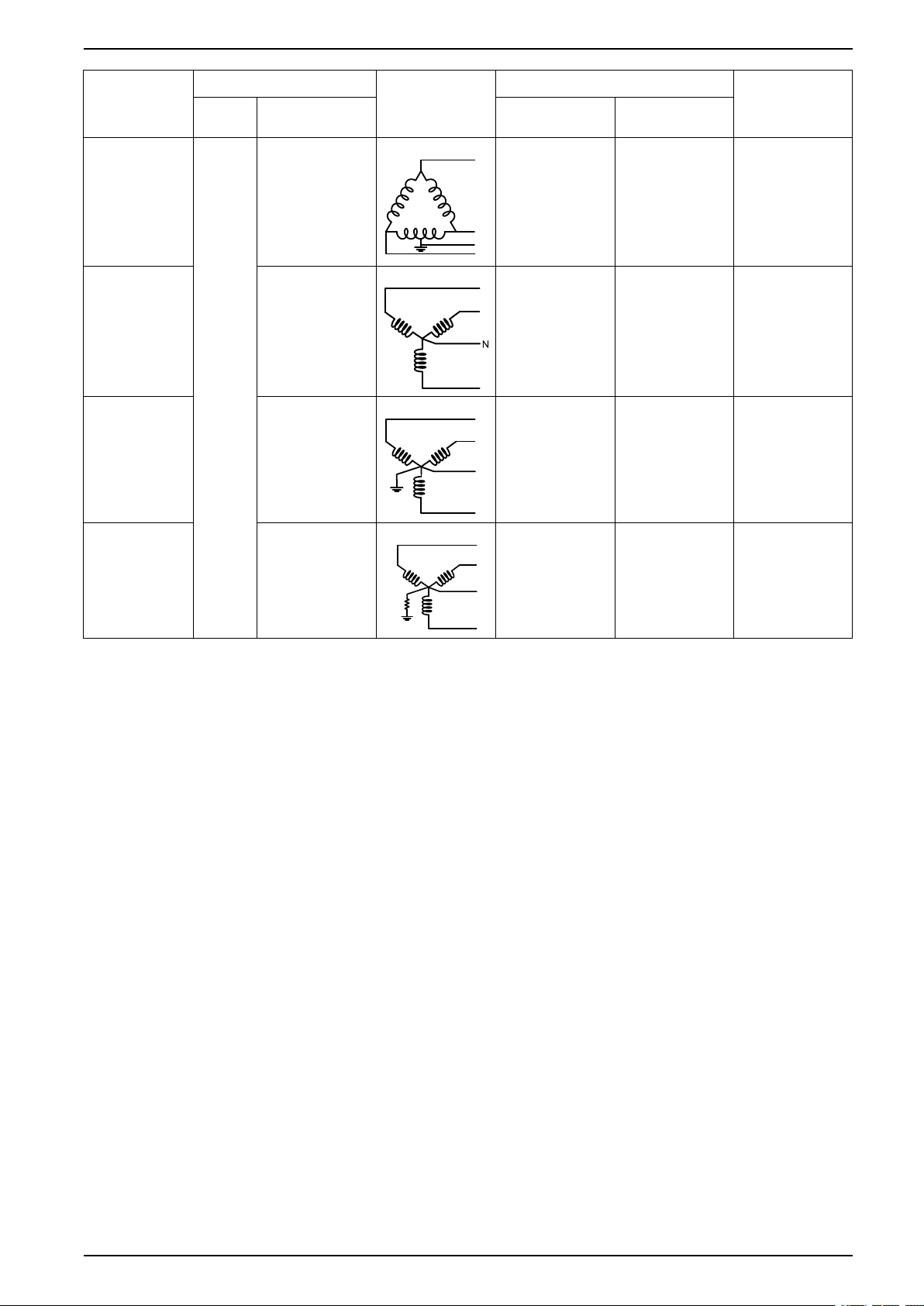

N

N

N

Power system

description

3-phase 4-wire

Delta centertapped

3-phase 4-wire

ungrounded Wye

3-phase 4-wire

grounded Wye

Meter setting Symbol Direct connect maximum (UL / IEC) # of VTs (if

Display

(meter)

Display

(communication)

3PH 4Wire

Center-Tapped

Delta

3PH 4Wire

Ungrounded Wye

3PH 4Wire

Grounded Wye

Installation

category III

240 V L-N / 480 V

L-L

≤ 277 V L-N / 480

V L-L

≤ 277 V L-N / 480

V L-L

Installation

category II

240 V L-N / 480 V

L-L

≤ 347 V L-N / 600

V L-L

≤ 347 V L-N / 600

V L-L

required)

3 VT

3 VT or 2 VT

3 VT or 2 VT

3-phase 4-wire

resistancegrounded Wye

3PH 4Wire

Resistance

Grounded Wye

Balanced system considerations

In situations where you are monitoring a balanced 3-phase load, you may choose

to connect only one or two CTs on the phase(s) you want to measure, and then

configure the meter so it calculates the current on the unconnected current

input(s).

NOTE: For a balanced 4-wire Wye system, the meter’s calculations assume

that there is no current flowing through the neutral conductor.

Balanced 3-phase Wye system with 2 CTs

The current for the unconnected current input is calculated so that the vector sum

for all three phases equal zero.

Balanced 3-phase Wye or Delta system with 1CT

≤ 277 V L-N / 480

V L-L

≤ 347 V L-N / 600

V L-L

3 VT or 2 VT

The currents for the unconnected current inputs are calculated so that their

magnitude and phase angle are identical and equally distributed, and the vector

sum for all three phase currents equal zero.

NOTE: You must always use 3 CTs for 3-phase 4-wire center-tapped Delta or

center-tapped open Delta systems.

Serial communications

The meter supports serial communications through the RS-485 port. Up to 32

devices can be connected on a single RS-485 bus.

NHA2768503-05 17

Conzerv EM6400NG+ Hardware references

+

-

120 Ω

C

+

-

In an RS-485 network, there is one master device, typically an Ethernet to RS-485

gateway. It provides the means for RS-485 communications with multiple slave

devices (for example, meters). For applications that require only one dedicated

computer to communicate with the slave devices, an RS-232 to RS-485 converter

can be used as the master device.

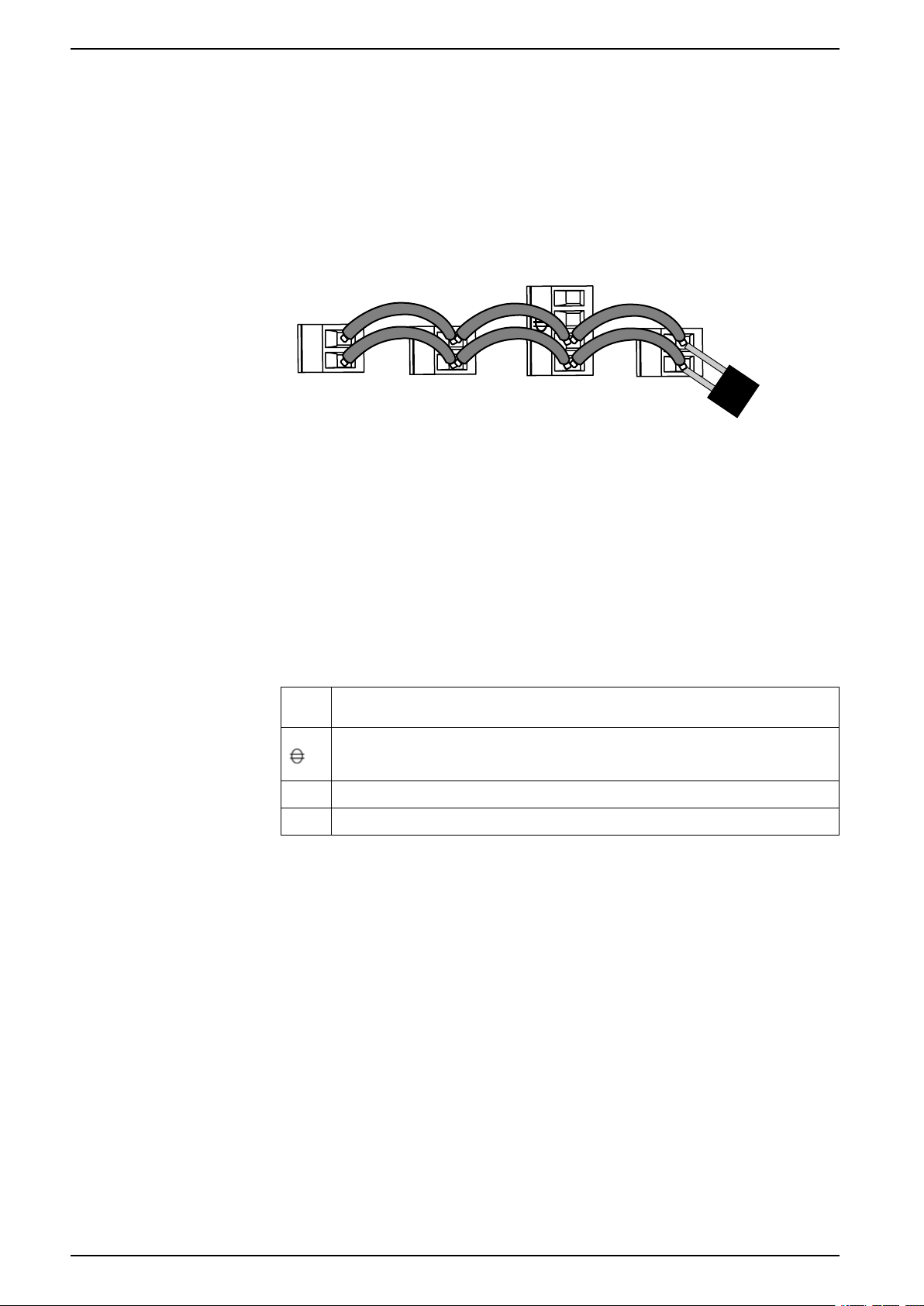

RS-485 wiring

Connect the devices on the RS-485 bus in a point-to-point configuration, with the

(+) and (-) terminals from one device connected to the corresponding (+) and (-)

terminals on the next device.

NOTE:

Straight-line topology only. Loop or ring topology is not supported.

Resistor is an optional accessory that you can order separately. To terminate a

series, it is recommended to use a 120 Ω / 0.5 W resistor.

RS-485 cable

Use a shielded 2 wires or 1 twisted pair RS-485 cable to wire the devices. Use the

twisted pair to connect the (+) and (-) terminals.

RS-485 terminals

C Common. This provides the voltage reference (zero volts) for the data plus and data minus

signals

Shield. Connect the bare wire to this terminal to help suppress signal noise that may be

present. Ground the shield wiring at one end only (either at the master or the last slave

device, but not both.

-

Data minus. This transmits/receives the inverting data signals.

+

Data plus. This transmits/receives the non-inverting data signals.

NOTE: If some devices in your RS-485 network do not have the C terminal,

use the bare wire in the RS-485 cable to connect the C terminal from the

meter to the shield terminal on the devices that do not have the C terminal.

RS-485 maximum cable length

The total distance for devices connected on an RS-485 bus should not exceed

900 m (2953 ft).

RS-485 network configuration

After you have wired the RS-485 port and powered up the meter, you must

configure the serial communications port in order to communicate with the meter.

Each device on the same RS-485 communications bus must have a unique

address and all connected devices must be set to the same protocol, baud rate,

and parity (data format).

NOTE: To communicate with the meter using ION Setup, you must set the

serial site and all connected devices in the RS-485 network to the same parity

setting.

18 NHA2768503-05

Hardware references Conzerv EM6400NG+

D1+

≤40 V

≤20 mA

D1-

(60)

(61)

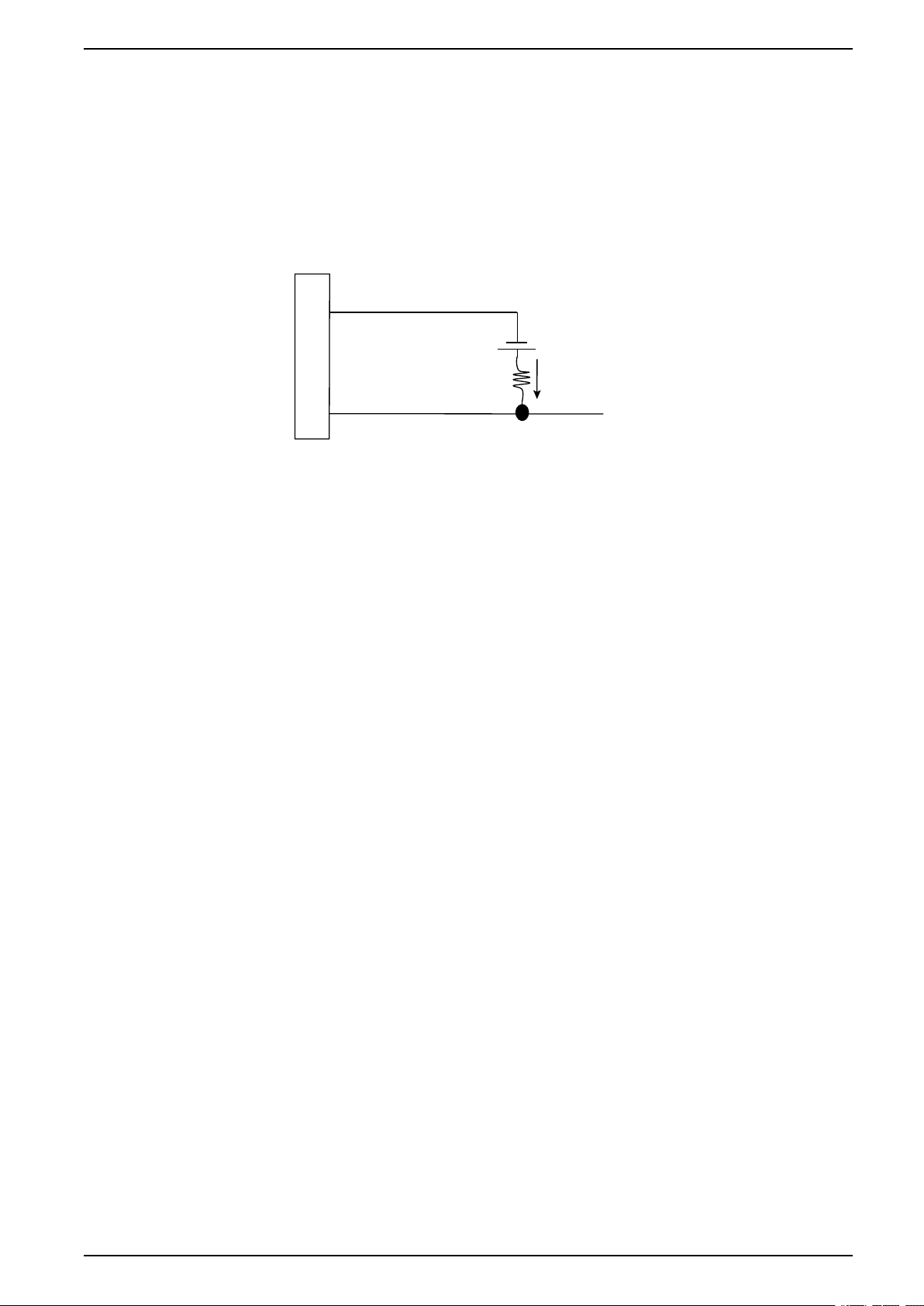

Pulse output

The meter is equipped with one pulse output port (D1+, D0-).

You can configure the pulse outputs for use in the following application:

• Energy pulsing applications, where a receiving device determines energy

usage by counting the k_h pulses coming from the meter’s pulse output port.

One pulse output can handle voltage less than or equal to 40 V DC (20 mA

maximum). For higher voltage applications, use an external relay in the switching

circuit.

NHA2768503-05 19

Conzerv EM6400NG+ Display and meter setup

Conzerv EM6400NG+

%

%

%

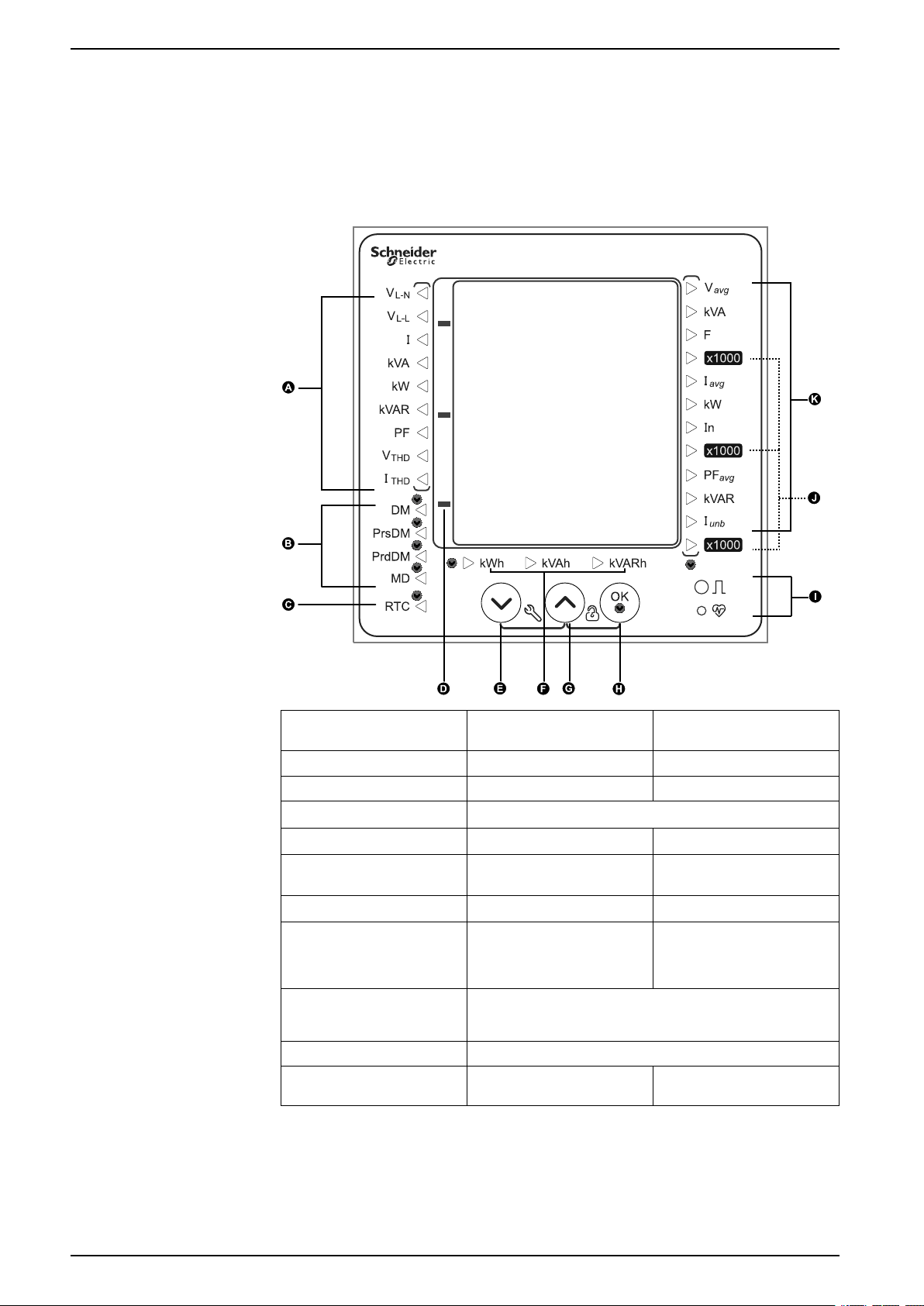

Display and meter setup

Display overview

The display lets you use the meter to perform various tasks such as setting up the

meter, displaying data screens, or performing resets.

LED indicators

A Phase measurements V

B Demand measurements DM, PrsDM, PrdDM, MD

C RTC Date and time

D Negative indicator

E Navigation key To navigate down

F Energy readings Apparent energy, Active

G Navigation key To navigate up

H OK Enter key

I Energy pulsing LED (Red)

J x 1000 indicator

K System measurements V

Heartbeat / communications LED (Green)

, V

, I, kVA, kW, kVAR,

L-N

L-L

THD

, kVA, F, I

avg

unb

, I

THD

, kW, In, PF

avg

PF, V

energy, and Reactive energy

To toggle between

measurement parameters

kVAR, I

avg

,

The LED indicators alert or inform you of meter activity.

20 NHA2768503-05

Display and meter setup Conzerv EM6400NG+

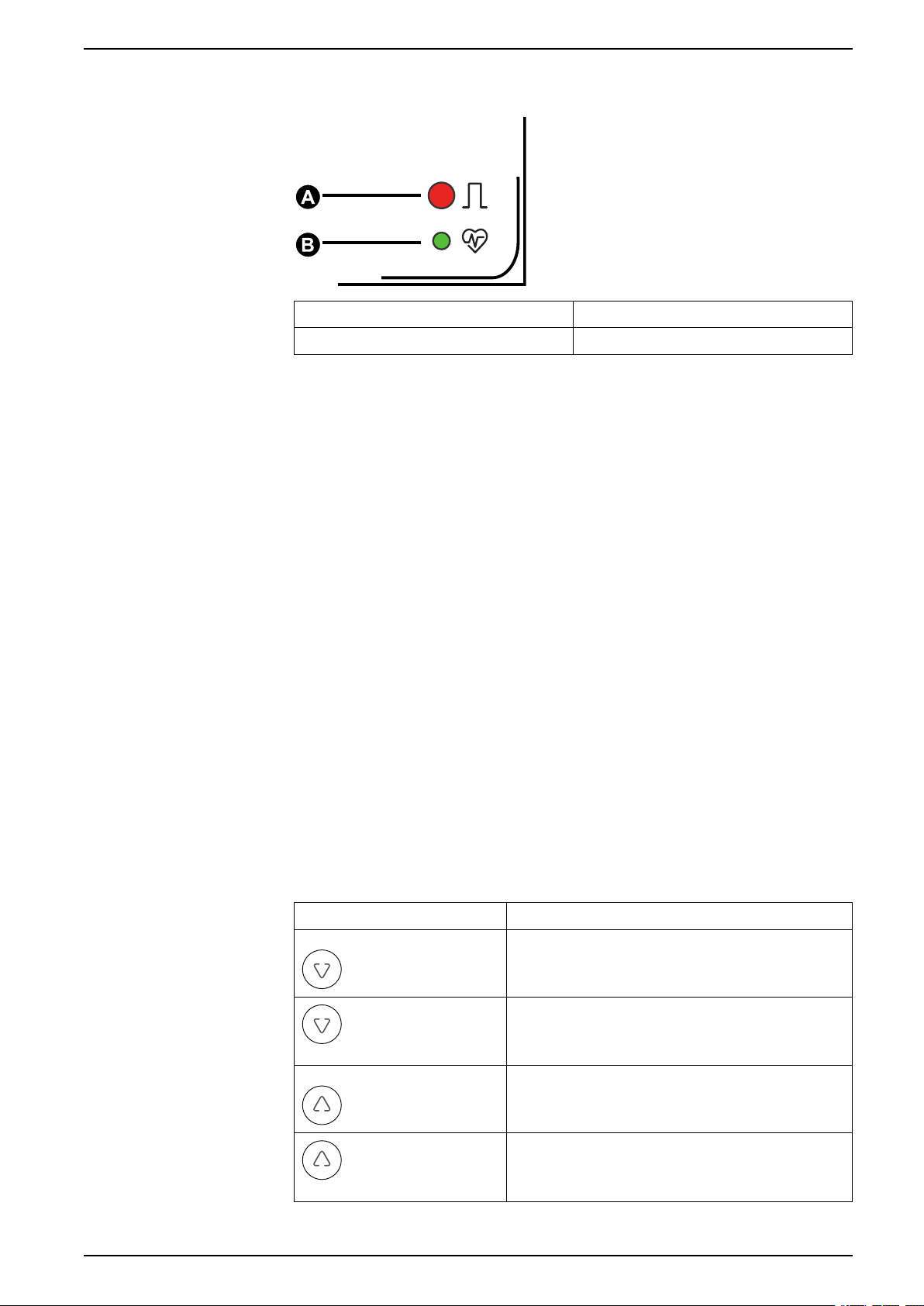

A Alarm / energy pulsing LED (Red)

B Heartbeat / serial communications LED (Green)

Energy pulsing LED

The EM6400NG+ meter has an energy pulsing LED that can be configured for

energy pulsing.

This LED flashes at a rate proportional to the amount of energy consumed. This is

typically used to verify the meter’s accuracy.

NOTE: EM6400NG+ meter does not support alarm function.

Heartbeat / serial communications LED

The heartbeat / serial communications LED blinks to indicate the meter’s

operation and serial Modbus communications status.

The LED blinks at a slow, steady rate to indicate the meter is operational. The LED

flashes at a variable, faster rate when the meter is communicating over a Modbus

serial communications port.

You cannot configure this LED for other purposes.

NOTE: A heartbeat LED that remains lit and does not blink (or flash) can

indicate a problem. In this case, power down the meter and reapply power. If

the LED still does not blink or flash, contact Technical Support.

Button functions

The meter supports single press and combination press functions of the buttons.

Symbol Description

To navigate down the list of items.

To move cursor to the left.

Press and hold for 2

seconds.

To navigate up the list of items.

To move cursor to the right.

Press and hold for 2

seconds.

NHA2768503-05 21

Conzerv EM6400NG+ Display and meter setup

Symbol Description

To select a parameter.

To enter into or exit Clear page.

Press and hold for 2

seconds.

To enter into or exit Setup page.

To enter into or exit Diagnostics page.

To lock or unlock a meter page.

Meter screen menus

Display screen menus

All meter screens are grouped logically, according to their function. You can

access any available meter screen by first selecting the Level 1 (top level) screen

that contains it.

With the meter front panel, you can view parameter values; configure parameters;

perform demand resets; perform LED checks; and view meter information. Each

of these functions can be accomplished by pressing the Up, Down, and OK

buttons on the front panel.

These button actions achieve different results according to the mode that the

meter is in:

• Display mode (default): view parameter measurements

• Setup mode: configure a parameter

• Clear mode: reset measurements

• Lock mode: lock or unlock a screen

This section describes front panel navigation within each mode.

In Display mode, you can view values from the following measurement groups:

• System measurements

• Phase measurements

• Energy measurements

• Demand measurements

• RTC

Viewing display parameters

The meter’s display screen and buttons allow you to view the required

parameters.

1. Press the OK button to navigate to different measurement types.

2. Press the Up or Down button to navigate to the previous or next value under

each measurement type.

22 NHA2768503-05

Display and meter setup Conzerv EM6400NG+

F

System measurement

Vavg

kVA

Iavg

kW

In

PFavg

kVAR

Iunb

%

Phase measurement

V

L-N

V

L-L

I

kVA

kW

kVAR

PF

V

THD%

I

THD%

V1, V2, V3

A1, A2, A3

V12, V23, V31

kVA1, kVA2, kVA3

kW1, kW2, kW3

kVAR1, kVAR2, kVAR3

V1

THD

, V2

THD

, V3

THD

PF1, PF2, PF3

A1

THD

, A2

THD

, A3

THD

Demand measurement

RTC

DM

PrsDM

PrdDM

MD

kW, kVA, kVAR, Iavg

kW, kVA, kVAR, Iavg

kW, kVA, kVAR, Iavg

kW, kVA, kVAR, Iavg

Energy measurement

kWh

kVAh

kVARh Reactive Energy - Import/Export

Active Energy - Import/Export

Apparent energy - Import/Export

RTC

Date and Time

Display screen menu tree

Use the menu tree to navigate to the setting you want to view.

The below image summarizes the available meter screens and parameters:

Display parameters

The meter displays various power system measurements.

Measurement Group Parameters Measured

System measurements V

Phase measurements V

Demand measurements DM, PrsDM, PrdDM, MD

RTC Date and time

Energy readings kWh (Active energy): Delivered / Received

, kVA, F, I

avg

, V

L-N

L-L

, kW, In, PF

avg

, kVAR, I

avg

, I, kVA, kW, kVAR, PF, V

THD

unb

, I

THD

NOTE: RTC is only applicable for meters

with RS-485 communication. Meters with

POP do not support this function.

kVAh (Apparent energy): Delivered / Received

kVARh (Reactive energy): Delivered / Received

NOTE: When the x 1000 LED is lit, multiply the displayed value by 1000 for

the actual value.

NHA2768503-05 23

Conzerv EM6400NG+ Display and meter setup

Button functions in viewing display parameters

Display mode is the default page when you power up the meter.

Mode Button Function

Display Mode

To view the next parameter value.

To view the previous parameter value.

To move from one measurement group to the

next measurement group.

Setup screen menus

Setup screen enables you to configure various setup parameters.

Below is the list of setup parameters and the configurations it supports.

24 NHA2768503-05

Display and meter setup Conzerv EM6400NG+

Ct.SE

Setup parameters

tYPE

Vt.SE

Vt

Ct

FrEq

Vt.Pr

Ct.Pr

Pd

Pd.CY

Pd.ut

Pd.SY

Ad

Ad.CY

Ad.ut

Ad.SY

LED

L.PLS

L.PAr

CoM

Id

bAud

Prty

PASS

YEAr

dAtE

hour

PoP

P.PLS

P.PAr

A.SuP

Ther, t.Sb, t.b, t.rb, CS.b, CS.rb, CL.b, Cl.rb

1 to 60 mins

1 to 60 mins

00:00 - 23:59

Ther, t.Sb, t.b, t.rb, CS.b, CS.rb, CL.b, Cl.rb

1 to 60 mins

00:00 - 23:59

1 to 60 mins

1P.LN, 1P.LL, 1P.3L, 3P.3L, 3P.4L

0100 V to 999000 V

no.Vt, 2.VT, 3.VT, 1.VT

100, 110, 115, 120

A.1, A.2, A.3, A.12, A.23, A.31, A.123

1 A to 32760 A

50 Hz, 60 Hz

1 A, 5 A

5 mA

Off, EnrG, ALM

1 to 9999000(Pulse per k_h)

d.Wh, r.Wh, t.Wh, d.Vrh, r.Vrh, t.Vrh, d.VAh, r.VAh, t.VAh, nonE

ON, OFF

1 to 247

4800, 9600, 19200, 38400

Even, Odd, None

0000 - 9999

YYYY (2000 to 2127)

M(month) - 1 to 12, dd(day) - 1 to 31

HH(hours) - 00 to 23, M(minutes) - 00 to 59

Off, EnrG

1 to 9999000 (k_h)

Wh, Vrh, VAh

Ct.Sq

Ct.rV

nonE, A.1, A.2, A.3, A.12, A.23, A.31, A.123

A.123, A.321, A.312, A.231, A.213, A.132

EM6400NG+ meter setup menus

NHA2768503-05 25

NOTE: The setup parameters CoM, Id, bAud, Prty, YEAr,. dAtE, and hour are

applicable for the commercial references METSEEM6400NGRSCL1,

METSEEM6400NGRSCL5, and METSEEM6400NGRSCL2. The setup

parameters PoP, P.PLS, and P.PAr are available for the commercial

references.METSEEM6400NGPOCL1, and METSEEM6400NGPOCL5.

Entering setup

The meter’s display screen and buttons allow you to navigate to and edit the

required parameters.

1. Press and hold the Up key and Down key simultaneously for 2 seconds.

2. Enter the password. Default password is 0000.

3. Press OK key to enter setup.

4. Press and hold the Up key and Down key simultaneously for 2 seconds to exit

Setup after viewing parameters.

Setup parameters

The meter supports configuration of various measurement parameters.

Conzerv EM6400NG+ Display and meter setup

Name on display Description Input range Default value

tYPE = Power System

Configurations

Vt= VT Connect Input range = no.Vt, 2.VT, 3.VT, 1.

Vt.Pr = Primary Voltage (V L-L) 100 V to 999000 V

Vt.SE = Secondary Voltage (V LL)

Ct = CT Terminal A.1, A.2, A.3, A.12, A.23, A.31,

Input range = 1P.Ln, 1P.LL, 1P.3L,

3P.3L, 3P.4L Default value = 3P4L

NOTE: Other power system

configurations can be set

through ION setup.

VT

NOTE: The VT Connect

parameters are enabled

based on selected power

system configuration.

NOTE: Vt.Pr will not be

enabled if VT Connect is no.

VT.

100, 110, 115, 120 V

NOTE: Vt.SE will not be

enabled if VT Connect is no.

VT.

A.123

NOTE: The Ct terminal

parameters are enabled

based on the selected power

system and VT connect

configuration.

3P.4L

no.Vt

120

120

A.123

Ct.Pr = CT Primary 1 A to 32760 A

NOTE: Ct primary can be set

to 32767 A through

communication.

Ct.SE = CT Secondary 1 A, 5 A 5

FrEq = System Frequency 50 Hz, 60 Hz 50

A.SuP: A.Suppression (Minimum

current at which meter starts

functioning)

Ct.Sq = CT Sequence Input range = A.123, A.321,

Ct.rV = CT Polarity Correction Input range = nonE, A1, A.2, A.3,

5 mA to 99 mA 5

A.312, A.231, A.213, A.132

NOTE: The CT Sequence is

applicable for 3P.3L and

3P.4L configurations and

A.123 CT Terminal value. If

you change the Power

System Configurations or CT

Terminal value, then the CT

sequence resets to the

default value.

A.12, A.23, A.31, A.123

NOTE: The CT Polarity

Correction parameters are

enabled based on selected

Power System

Configurations and CT

100

A.123

nonE

26 NHA2768503-05

Display and meter setup Conzerv EM6400NG+

Name on display Description Input range Default value

Terminal value. If you change

the Power System

Configurations or CT

Terminal value, then the CT

Polarity Correction resets to

the default value.

Pd = Power Demand tHEr, t.Sb, t.b, t.rb, CS.b, CS.rb,

CL.b, CL.rb

t.b

Pd.CY = Power Demand Period 1 to 60 mins

NOTE: The demand update

time is available for rolling

block methods under power

demand.

Pd.ut = Power Demand Update

Time

Pd.SY = Power Demand Clock

Sync Time

Ad = Current Demand tHEr, t.Sb, t.b, t.rb, CS.b, CS.rb,

Ad.CY = Current Demand Period 1 to 60 mins 15

1 to 60 mins

NOTE: The power demand

update time is available for

rolling block methods under

power demand.

00:00 to 23:59

NOTE: The clock sync time

is available only for clock

sync block and clock sync

roll block methods under

power demand.

CL.b, CL.rb

15

15

00.00

t.b

Ad.ut = Current Demand Update

Time

Ad.SY = Current Demand Clock

Sync Time

LEd = LED Off, EnrG Off

L.PLS = LED Pulse Weight 1 to 9999000 (Pulse per k_h)

LPAr = LED Energy Parameter d.Wh, r.Wh, t.Wh, d.Vrh, r.Vrh, t.

1 to 60 mins

NOTE: The current demand

update time is available for

rolling block methods under

current demand.

00:00 to 23:59

NOTE: The clock sync time

is available only for clock

sync block and clock sync

roll block methods under

current demand.

NOTE: Pulse per energy

values cannot be viewed if

LED is off.

Vrh, d.VAh, r.VAh, t.VAh, nonE

NOTE: LED parameter

values cannot be viewed if

LED is off.

15

00.00

1

nonE

NHA2768503-05 27

Conzerv EM6400NG+ Display and meter setup

Name on display Description Input range Default value

PASS = Password 0000 - 9999 0000

CoM = Communication

NOTE: Id, baud rate, and

parity cannot be viewed if

com is off.

Id = Unit Id 1 to 247 1

bAud = Baud Rate 4800, 9600, 19200, 38400 19200

Prty = Parity EVEn, odd, nonE EVEn

YEAr = RTC YYYY ( 2000 to 2127) NA

ON, OFF, RTFT

NOTE: ON / OFF: To enable

/ disable communications

port.

NOTE: Retrofit (RTFT): For

configuring legacy

communication data models

(Applicable only in

EM6400NG+ RS-485 meter

model).

ON

dAtE = Month:Date MM (month) - 1 to 12

dd (day) - 1 to 31

hour = Hours:Minutes HH (hours) - 00 to 23

MM (minutes) - 00 to 59

PoP = Communication Pulse

Output

P.PLS = POP Pulse Weight 1 to 9999000 (pulse per k_h) 200

Off, EnrG

NOTE: Pulse weight and

energy parameter cannot be

viewed if POP is off.

NA

NA

EnrG

28 NHA2768503-05

Display and meter setup Conzerv EM6400NG+

Name on display Description Input range Default value

P.PAr = POP Energy Parameter Wh, VAh, Vrh Wh

Indicates optional setup parameters

Button functions in viewing setup parameters

The meter supports single press and combination press functions of the buttons to

view setup parameters.

Mode Button Function

To navigate to the next parameter

configuration screen.

To navigate to the previous parameter

configuration screen.

Setup Menu

Enter setup mode to configure the displayed

parameter value.

Press and hold the Up and Down buttons

simultaneously for 2 seconds to enter Setup.

Exit setup with the same button sequence.

Button functions in editing setup parameters

The meter supports single press and combination press functions of the buttons to

edit setup parameters.

Mode Button Function

Flashing Digit: To decrease the numeric

value.

Flashing Value: To view the next value from

the list.

Flashing Decimal Point: To move the decimal

point to the left.

Flashing Digit: To increase the numeric value.

Flashing Value: To view the previous value

from the list.

Setup Menu

Press and hold for 2 seconds.

Press and hold for 2 seconds.

Flashing Decimal Point: To move the decimal

point to the right.

Flashing Digit / Flashing Decimal Point: To

move the position of the cursor to left.

Flashing Digit / Flashing Decimal Point: To

move the position of the cursor to right.

NHA2768503-05 29

Conzerv EM6400NG+ Display and meter setup

Mode Button Function

To select a parameter to edit the values.

To select configured parameter values.

To save the changes made to setup

parameter.

Press and hold the Up and Down buttons

simultaneously for 2 seconds to enter Setup.

Exit setup with the same button sequence.

Editing setup parameters

You can edit various measurement parameters as required.

1. Press and hold the Up and Down buttons simultaneously for 2 seconds to

enter Setup.

2. Enter password. Default password is 0000.

3. Press OK.

4. Press the Up or Down button to select a parameter to edit.

The selected parameter flashes the digit, value, or decimal point that is

required to be set (the meter automatically determines which option to flash

for editing, depending on the parameter).

5. Increase or decrease the digit value, move the decimal point, or select a

value from a pre-programmed list using the Up or Down button.

6. Press OK after making the required changes.

7. Press and hold the Up and Down buttons simultaneously for 2 seconds to exit

Setup.

8. Select Yes to save your settings.

Exiting setup parameters

The following steps describe how to exit setup mode without editing any

parameter values.

1. Press and hold the Up and Down buttons simultaneously for 2 seconds to

enter Setup.

2. Enter password. Default password is 0000.

3. Press OK.

4. Press the Up or Down button to view various setup parameters.

5. Press and hold the Up and Down buttons simultaneously for 2 seconds to exit

Setup without making any changes to the parameter values.

Demand

Demand parameters

Demand is a measure of average consumption (typically power or current) over a

fixed programmed time interval.

30 NHA2768503-05

Display and meter setup Conzerv EM6400NG+

Power / current demand setup parameters

Parameter Values Description

Method • Thermal: Ther

• Timed Sliding Block: t.Sb

• Timed Block: t.b

• Timed Rolling Block: t.rb

• Command Sync Block:

CS.b

• Command Sync Rolling

Block: CS.rb

• Clock Sync Block: CL.b

• Clock Sync Rolling Block:

Cl.rb

NOTE: Command sync

and clock sync methods

are applicable for meters

with RS-485

communication only.

Interval 1 – 60 Set the demand interval, in minutes.

Subinterval

(update time)

Clock Sync Time 00:00 – 23:59 Applies only to clock sync methods (these

1 – 60 Applies only to rolling block methods.

Select the appropriate demand calculation

method for your needs.

Define how many subintervals the demand

interval should be equally divided into.

synchronize the demand interval to the

meter’s internal clock).

Define what time of day you want to

synchronize the demand.

Viewing demand values on Display screen

You can view the demand values provided on the display screen by navigation

through display parameters.

1. Press OK to navigate to demand values on display screen.

2. The LED indicates last demand (DM).The values displayed on the screen

indicate kVA, kW, and kVAR.

3. Press the Down button to view I

avg

values.

4. Repeat the steps to view present demand (PrsDM), predictive demand

(PrdDM), and max demand (MD) values.

Viewing demand values in Setup screen

The meter supports editing power and current demand through setup mode.

1. Press and hold the Up and Down buttons simultaneously for 2 seconds to

enter Setup.

2. Enter password. Default password is 0000.

3. Press OK.

4. Press the Down button to select Pd (power demand) or Ad (current demand)

parameter.

5. Press OK.

6. Press the Down button to select required values from the existing list.

7. Press OK.

8. Press and hold the Up and Down buttons simultaneously for 2 seconds to exit

Setup.

NHA2768503-05 31

Conzerv EM6400NG+ Display and meter setup

9. Select Yes to save your settings.

Communications setup

After wiring the meter’s serial communications ports, you can configure these

ports so you can connect to the meter remotely and use device configuration

software such as ION Setup to configure the meter.

The setup screen allows you to configure the meter’s RS-485 communications

port so you can use software to access the meter’s data or configure the meter

remotely.

To turn on communication in setup screen, follow these steps:

1. Press and hold the Up and Down buttons simultaneously for 2 seconds to

enter setup.

2. Enter password. Default password is 0000.

3. Press OK.

4. Press the Down button to select a CoM (communication) parameter.

5. Press OK.

6. Press the Down button to select on from the list.

7. Press OK.

8. Press and hold the Up and Down buttons simultaneously for 2 seconds to exit

Setup.

9. Select Yes to save your settings.

Setting up the password

RS-485 communication parameters

Parameter Values Description

Address 1 to 247 Set the address for this device. The address must be

Baud Rate 4800, 9600, 19200,

Parity –

Number of

stop bits

38400

Even – 1

Odd – 1

None – 2

unique for each device in a communications loop.

Select the speed for data transmission. The baud rate

must be the same for all devices in a communications

loop.

Select None if the parity bit is not used. The parity

setting must be the same for all devices in a

communications loop.

NOTE: Communication parameters display ON / OFF / Retrofit (RTFT).

NOTE: Retrofit provides you an option of configuring legacy data models for

your device to communicate with newer models. (Applicable only in

EM6400NG+ RS-485 meter model).

The meter password can only be configured through the front panel.

The factory-default setting for all passwords is “0000” (zero). Changing the default

password for screens that are password protected prevents unauthorized

personnel from accessing certain screens such as the Setup and Clear screens.

To change the meter password using Setup, follow these steps:

1. Press and hold the Up and Down buttons simultaneously for 2 seconds to

enter Setup.

2. Enter password. Default password is 0000.

3. Press OK.

4. Press the Down button to select PASS (password) parameter.

5. Press OK.

32 NHA2768503-05

Display and meter setup Conzerv EM6400NG+

6. Press the Down button to change the digits.

NOTE: Hold Down button for 2 seconds to move the cursor to the next

digit.

7. Press OK.

8. Press and hold the Up and Down buttons simultaneously for 2 seconds to exit

Setup.

9. Select Yes to save your settings.

Password settings

Parameter Values Description

Setting up date and time

Pass 0000 - 9999 Sets the password for accessing the meter setup

screen.

NOTE: Common password applies across all

parameters.

Lost password

Visit www.se.com for support and assistance with lost passwords or other

technical problems with the meter. Make sure you include your meter’s model,

serial number and firmware version in your email or have it readily available if

calling Technical Support.

The Clock setup allows you to set the meter’s date and time.

1. Press and hold the Up and Down buttons simultaneously for 2 seconds to

enter Setup.

2. Enter password. Default password is 0000.

3. Press OK.

4. Press the Down button to select year, date, and hour parameter.

5. Press OK.

6. Press Down button to change the digits.

NOTE: Hold the Down button for 2 seconds to move the cursor to the next

digit.

7. Press OK.

8. Press and hold the Up and Down buttons simultaneously for 2 seconds to exit

Setup.

9. Select Yes to save your settings.

NOTE: You must always set or sync the meter time to local time.

Clock setup parameters

Parameter Values Description

Year YYYY Set the current year using format displayed on screen.

Date MM:DD Set the current date using the format displayed on

Hour HH:MM Use the 24 hours format to set the current time in local

screen, where date is in MM (month) and DD (date)

format.

time, where the time is in HH (hour) and MM (minutes)

format.

Diagnostics (Diag) screen menus

In Diag, you can verify the front panel LEDs, and view meter information.

Below is the list of Diag parameter that are displayed on the meter screen.

NHA2768503-05 33

Conzerv EM6400NG+ Display and meter setup

Diag parameters

All LEDs on

OS version

Meter Model

RS version

Serial number

Diagnostics error code

Delivered run hours

Received run hours

On hours

Interruptions

RS-485

EM6400NG+ meter diag menus

Viewing Diag

The meter’s display screen and buttons allow you to navigate to the Diag.

1. Press and hold the Down and OK buttons simultaneously for 2 seconds to

view Diag.

2. Press the Down button to navigate to the next screen.

3. Press and hold the Down and OK buttons simultaneously for 2 seconds to

exit Diag.

Diag screens

The meter displays various diagnostics screens.

Screens Description

All LEDs on On entering diag screen, all LEDs on the front panel light up. The display shows four eights (8888), four

Meter Model Displays the meter model number.

Serial number Displays the meter serial number, for example SN.0500005174.

OS version Displays the operating system version number, for example OS 1.00.0.

RS version Displays the reset (boot code) version number, for example RS 1.00.0.

decimal points (....) per line, negative indicators, and parameter LEDs. This indicates that the front panel LEDs

and display are operating correctly.

NOTE: Ensure you have your meter’s serial number information available while contacting Technical

Support for help.

Diagnostics error code Displays the error codes of the meter for diagnostics. The following are the diagnostics error codes.

Run hours

34 NHA2768503-05

• 0003 is the error code for RAM failure.

• 0005 is the error code for NVRAM failure.

• 0009 is the error code for RTC failure.

• 0011 is the error code for Calibration failure.

• 0021 is the error code for Clipping detected.

• 0041 is the error code for Over-Running energy pulse output.

• 0081 is the error code for Backup RAM failure.

• 0101 is the error code for Language file mismatch.

• 0201 is the error code for Language string mismatch.

Delivered / Import Indicates the period the load has been delivered. This counter accumulates as

long as the load is ON.

Display and meter setup Conzerv EM6400NG+

Clear parameters

Energy

MD

DM

Hi Lo

Screens Description

On hours

Interruptions

RS-485

Received / Export Indicates the period the load has been received. This counter accumulates as

Indicates the period for which the power meter's auxiliary supply is ON, regardless of the voltage and current

inputs.

Number of supply outages, means the number of auxiliary supply interruptions. If the power meter auxiliary

supply is from a UPS then the INTR (number of interruptions) will be zero (as long as the UPS stays ON), even

if the voltage signals die out from time to time.

Communication error

code

Communication settings

screen

long as the load is ON.

Displays the communication errors of the meter. The following are the

communication error codes.

• F is the error code for Illegal function error

• A is the error code for Data Address error

• D is the error code for Data value error

• E is the error code for Slave device failure error

• B is the error code for Device busy error

• C is the error code for CRC error

• O is the error code for Over Run error

• U is the error code for Unit ID error

Displays the unit ID, baud rate, and parity values of the meter.

Button functions in viewing Diag screen

The meter supports single press and combination press functions of the buttons to

view Diag screens.

Clear screen menus

Mode Button Function

To navigate to the next screen.

To navigate to the previous screen.

Setup Menu

Press and hold the Down and OK buttons

simultaneously for 2 seconds to view Diag.

Exit Diag screen with the same button

sequence.

Clear screen enables you to reset energy, demand, min / max, or max demand

values.

Below is the list of clear screen parameter that are displayed on the meter screen.

Meter clear screen menus

NHA2768503-05 35

Entering Clear screen

The meter’s display screen and buttons allow you to navigate to Clear.

1. Press and hold the OK button for 2 seconds.

Conzerv EM6400NG+ Display and meter setup

2. Press the Up button to select Yes.

3. Press OK.

4. Enter password. Default password is 0000.

5. Press OK.

6. Press the Down or Up button to navigate to the required parameter for

clearing the values.

7. Press and hold the OK button simultaneously for 2 seconds to exit Clear

screen.

Clear parameters

The meter supports reset of various parameters.

Parameters Description

Energy Resets the energy values. The meter supports reset of the following parameter values:

DM Used for demand synchronization function. The meter supports reset of the following parameter values:

Hi Lo Resets the minimum and maximum (min/max) values. The meter supports reset of the following parameter

MD Resets the maximum demand values.

• Active energy - Import / Export

• Reactive energy - Import / Export

• Apparent energy - Import / Export

• Run Hour

• Last demand

• Present demand

• Predictive demand

values:

• V L-L average

• V L-N average

• Current average

• Frequency

• Active power, Total

• Apparent power, Total

• Reactive power, Total

• Power factor, Total

• W, VA, VAR, and current demand with timestamp

Button functions in editing Clear parameters

The meter supports single press functions of the buttons to enter Clear screens.

Mode Button Function

Press and hold OK button for 2 seconds to

enter Clear.

Press OK button to clear/reset parameter

values.

Press and hold OK button for 2 seconds to

exit Clear.

Clear Screen

36 NHA2768503-05

To navigate to the next parameter.

To navigate to the previous parameter.

Display and meter setup Conzerv EM6400NG+

Lock / Unlock

Lock enables you to set the a meter screen to default screen. You can scroll to

other display screens while a screen has been locked. Once the manual scrolling

is stopped, the meter displays the default (lock) screen after four minutes.

The meter’s display screen and buttons allow you to lock or unlock any screen.

To lock / unlock a meter screen:

• Press and hold the Up and OK buttons simultaneously for 2 seconds to lock

or unlock a meter screen.

NOTE:

You can only lock the display parameters.

You cannot enter the Setup or Clear when a meter screen is locked.

Button functions in locking / unlocking meter screen

The meter supports a combination press function of the buttons to lock or unlock a

screen.

Mode Button Function

Lock / Unlock

Press and hold the Up and OK buttons

simultaneously for 2 seconds to lock or

unlock a meter screen.

NHA2768503-05 37

Conzerv EM6400NG+ Remote meter setup

Remote meter setup

Overview

You can configure the meter’s setup parameters through the meter’s RS-485

communications port.

The meter is factory-configured with default RS-485 communications port settings.

You must modify the default settings before connecting the meter to your RS-485

network. To configure the RS-485 port, you need:

• ION Setup

NOTE: Remote meter setup is applicable only for meter models supporting

RS-485 communication.

ION setup

Go to www.se.com and search for ION Setup to download a copy of the

installation file.

If you already have an existing installation of ION Setup, it is recommended that

you upgrade to the latest version in order to access new features or

enhancements and properly configure features available on your device.

Refer to the online help to learn how to use ION Setup.

RS-485 port setup

The meter is factory-configured with default serial communications settings that

you may need to modify before connecting the meter to the RS-485 bus.

The meter is factory-configured with the following default serial communications

settings:

• Protocol = Modbus RTU

• Address = 1

• Baud rate = 19200

• Parity = Even

You can use a communications converter (USB to RS-485 or RS-232 to RS-485)

device to connect to the meter.

Using a serial communications converter to set up RS-485

You can use a communications converter (USB to RS-485 or RS-232 to RS-485)

to connect to the meter.

NOTE: Configuring the serial communications settings using this method may

cause ION Setup to lose communications when the changes are sent to your

meter. You must reconfigure ION Setup to match the new settings to reestablish communications with your meter.

1. Configure the serial communications converter’s settings to be compatible

with the meter’s default communications settings.

2. Connect the meter’s RS-485 port to the serial communications converter.

3. Connect the communications converter to the computer.

4. Start ION Setup in Network mode.

38 NHA2768503-05

Remote meter setup Conzerv EM6400NG+

5. Add a serial site and set its properties:

• Comm link = Serial

• Comm port = select which serial (or USB) port the communications

converter is attached to

• Baud rate = 19200

• Format = select a format with even parity

6. Add a meter to the site and set its properties:

• Type = EM6400NG series load manager

• Unit ID = 1

7. Use the setup screens to modify the meter’s setup parameters.

8. Use the RS-485 Base Comm setup screen to modify the meter’s serial

communication settings.

9. Click Send to save your changes to the meter. You need to reconfigure ION

Setup to match the changed settings in order to re-establish communications

with your meter.

10. Exit ION Setup.

RS-485 port settings

Parameter Values Description

Protocol Modbus RTU Select the communications format used to

Address 1 to 247 Set the address for this device. The address

Baud rate 4800, 9600, 19200, 38400 Select the speed for data transmission. The

Parity Even, Odd, None Select None if the parity bit is not used. The

Meter setup through RS-485

After the meter’s RS-485 port is configured and connected to the RS-485 network,

you can use ION Setup to configure all other meter setup parameters.

transmit data. The protocol must be the same

for all devices in a communications loop.

ION Setup does not support ASCII 8, ASCII 7 or

JBus protocols.

must be unique for each device in a

communications loop.

baud rate must be the same for all devices in a

communications loop.

parity setting must be the same for all devices in

a communications loop.

Meter configuration using ION setup

Start ION Setup, create a site (or if applicable, use an existing site), then add your

meter to the site.

See the “EM6400NG series” topic in the ION Setup online help or in the ION

Setup device configuration guide. To download a copy, go to www.se.com and

search for ION Setup device configuration guide.

NHA2768503-05 39

Conzerv EM6400NG+ Viewing meter data

Conzerv EM6400NG+

%

%

%

Viewing meter data

Viewing meter data from the display

Voltage average, current average, and power factor average are displayed the

first time a meter is powered up, after which the last viewed screen or locked

(default) screen is displayed every time the meter is powered up.

Meters data screens

Meter data display screens

The meter screens in EM6400NG+ meter is divided as per phase measurements,

system measurements, demand measurements, energy measurements, and

RTC.

The screen menu items are listed below:

System measurements

V

avg

kVA Apparent power total

F Frequency (Hz)

x1000 Multiplication factor

I

avg

kW Active power total

In Neutral current

x1000 Multiplication factor

PF

avg

kVAR Reactive power total

Voltage 3 phase average

Current 3 phase average

Power factor average

40 NHA2768503-05

Viewing meter data Conzerv EM6400NG+

System measurements (Continued)

I

unb

x1000 Multiplication factor

Current unbalance

Phase measurements

V

L-N

V

L-L

I Current A1 A2 A3

kVA Apparent Power kVA1 kVA2 KVA3

kW Active Power kW1 kW2 kW3

kVAR Reactive Power kVAR1 KVAR2 KVAR3

PF Power factor – : Leading PF PF1 PF2 PF3

V

THD

I

THD

Voltage Line to neutral V1 V2 V3

Voltage Line to Line V12 V23 V31

+: Lagging PF

Voltage THD% V1

Current THD% A1

THD

THD

V2

A2

THD

THD

V3

A3

Energy measurements

kWh Active energy - Import / Delivered (+)

Active energy - Export / Received (-)

THD

THD

kVAh Apparent energy - Import / Delivered (+)

Apparent energy - Export / Received (-)

kVARh Reactive energy - Import / Delivered (+)

Reactive energy - Export / Received (-)

Demand measurements

DM Last Demand kVA kVAR kW I

PrsDM Present/

Raising

demand

PrdDM Predictive

demand

MD Max demand kVA kVAR kW I

kVA kVAR kW I

kVA kVAR kW I

RTC

RTC Date and time Year / Date / Hour

Using ION Setup to view or modify configuration data

avg

avg

avg

avg

You can use ION setup to view or modify the meter setup parameters.

Using software to view meter data

There are different software systems and methods you can use to access or

display the meter data. This can range from using a simple Modbus register

interface to read stored values in the meter’s registers, to viewing intelligent

information from the meter through an energy management system.

NHA2768503-05 41

Conzerv EM6400NG+ Viewing meter data

Power Monitoring Expert

EcoStruxure™Power Monitoring Expert is a complete supervisory software

package for power management applications.

The software collects and organizes data gathered from your facility’s electrical

network and presents it as meaningful, actionable information via an intuitive web

interface.

Power Monitoring Expert communicates with devices on the network to provide:

• Real-time monitoring through a multi-user web portal

• Trend graphing and aggregation

• Power quality analysis and compliance monitoring

• Preconfigured and custom reporting

See the EcoStruxure

how to add your device into its system for data collection and analysis.

™

Power Monitoring Expert online help for instructions on

Power SCADA Operation

EcoStruxure™Power SCADA Operation is a complete real-time monitoring and

control solution for large facility and critical infrastructure operations.

It communicates with your device for data acquisition and real-time control. You

can use Power SCADA Operation for:

• System supervision

• Real-time and historical trending, event logging

• PC-based custom alarms

See the EcoStruxure

how to add your device into its system for data collection and analysis.

Modbus command interface

Most of the meter’s real-time and logged data, as well as basic configuration and

setup of meter features, can be accessed and programmed using a Modbus

command interface as published in the meter’s Modbus register list.

This is an advanced procedure that should only be performed by users with

advanced knowledge of Modbus, their meter, and the power system being