Page 1

ATV 31H

Installation manual

Programming manual

Variable speed drives

for asynchronous motors

V1.7

Page 2

Installation manual ____________________________________________________________________________ A

Programming manual _________________________________________________________________________ B

Page 3

Contents

Drive references ____________________________________________________________________________________________________________ 2

Mounting ___________________________________________________________________________________________________________________ 4

Wiring______________________________________________________________________________________________________________________ 8

NOTE: Please also refer to the Programming Manual.

When the drive is powered up, the power components and some of the control

components are connected to the line supply. It is extremely dangerous to touch them.

The drive cover must be kept closed.

In general, the drive power supply must be disconnected before any operation on

either the electrical or mechanical parts of the installation or machine.

After the ATV has been switched off and the display has disappeared completely, wait

for 10 minutes before working on the equipment. This is the time required for the

capacitors to discharge.

The motor can be stopped during operation by inhibiting start commands or the speed

reference while the drive remains powered up. If personnel safety requires prevention

of sudden restarts, this electronic locking system is not sufficient: fit a cut-off on the

power circuit..

A

The drive is fitted with safety devices which, in the event of a fault, can shut down the

drive and consequently the motor. The motor itself may be stopped by a mechanical

blockage. Finally, voltage variations, especially line supply failures, can also cause

shutdowns.

If the cause of the shutdown disappears, there is a risk of restarting which may

endanger certain machines or installations, especially those which must conform to

safety regulations.

In this case the user must take precautions against the possibility of restarts, in

particular by using a low speed detector to cut off power to the drive if the motor

performs an unprogrammed shutdown.

The drive must be installed and set up in accordance with both international and

national standards. Bringing the device into conformity is the responsibility of the

systems integrator who must observe the EMC directive among others within the

European Union.

The specifications contained in this document must be applied in order to comply with

the essential requirements of the EMC directive.

The ATV 31 must be considered as a component: it is neither a machine nor a device

ready for use in accordance with European directives (machinery directive and

electromagnetic compatibility directive). It is the responsibility of the end user to

ensure that the machine meets these standards.

The drive must not be used as a safety device for machines posing a potential risk of

material damage or personal injury (lifting equipment, for example). In such

applications, overspeed checks and checks to ensure that the trajectory remains under

constant control must be made by separate devices which are independent of the

drive.

The products and equipment described in this document may be changed or modified

at any time, either from a technical point of view or in the way they are operated. Their

description can in no way be considered contractual.

1

Page 4

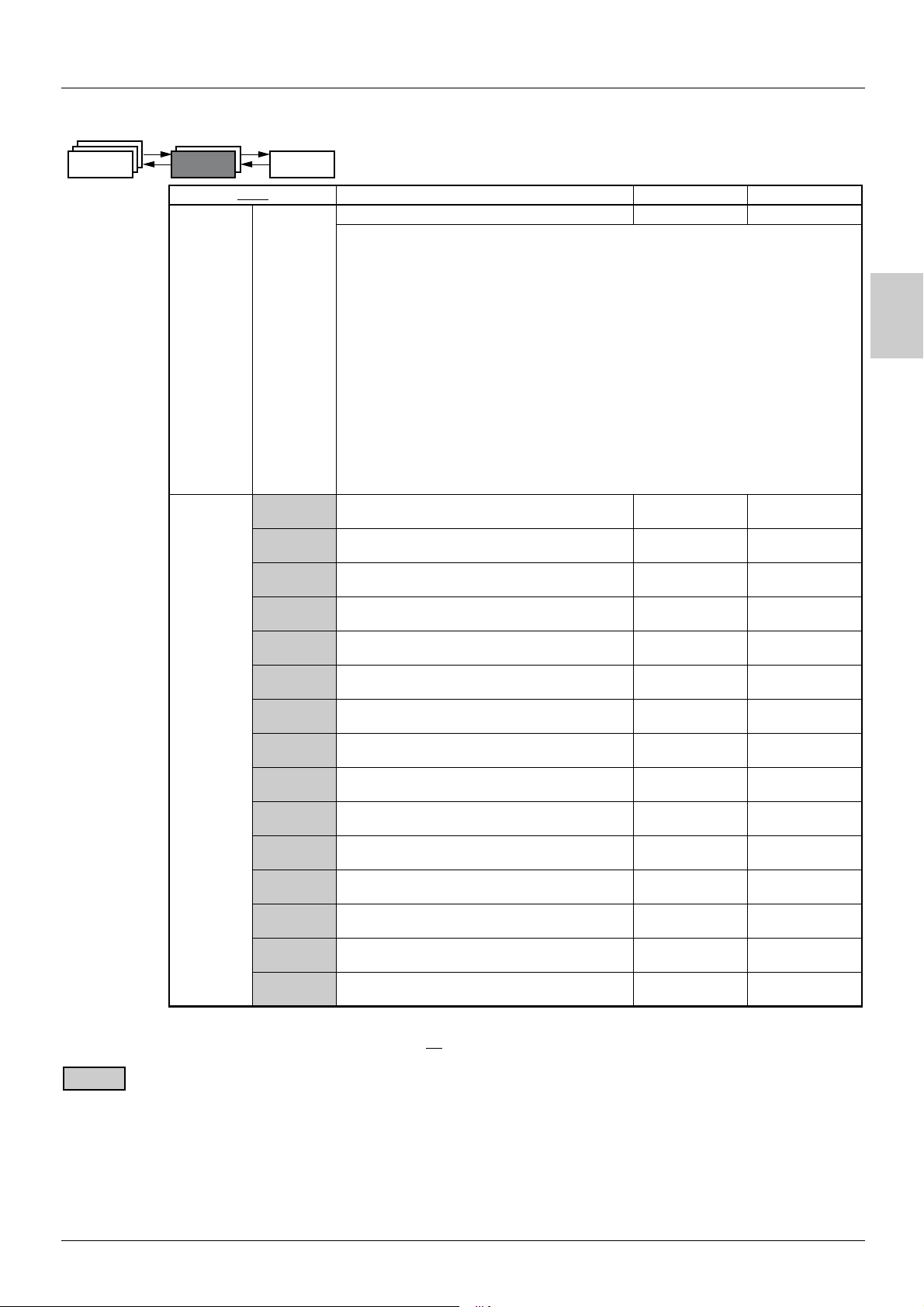

A

Drive references

Single phase supply voltage: 200…240 V 50/60 Hz

3-phase motor 200…240 V

Motor Line supply (input) Drive (output) ATV 31

Power

indicated on

plate (1)

kW/HPAAkAkVAAA A W

0.18/0.25 3.0 2.5 1 0.6 10 1.5 2.3 24 ATV31H018M2

0.37/0.5 5.3 4.4 1 1.0 10 3.3 5.0 41 ATV31H037M2

0.55/0.75 6.8 5.8 1 1.4 10 3.7 5.6 46 ATV31H055M2

0.75/1 8.9 7.5 1 1.8 10 4.8/4.2 (6) 7.2 60 ATV31H075M2

1.1/1.5 12.1 10.2 1 2.4 19 6.9 10.4 74 ATV31HU11M2

1.5/2 15.8 13.3 1 3.2 19 8.0 12.0 90 ATV31HU15M2

2.2/3 21.9 18.4 1 4.4 19 11.0 16.5 123 ATV31HU22M2

Max. line

current (2)

at

200 V

at

240 V

Max.

prospectiv

e line Isc

Apparent

power

Max. inrush

current

(3)

3-phase supply voltage: 200…240 V 50/60 Hz

3-phase motor 200…240 V

Nominal

current In

(1)

Max.

transient

current (1)

(4)

Power

dissipated

at nominal

load

Reference

(5)

Motor Line supply (input) Drive (output) ATV 31

Power

indicated on

plate (1)

kW/HPAAkAkVAAA A W

0.18/0.25 2.1 1.9 5 0.7 10 1.5 2.3 23 ATV31H018M3X

0.37/0.5 3.8 3.3 5 1.3 10 3.3 5.0 38 ATV31H037M3X

0.55/0.75 4.9 4.2 5 1.7 10 3.7 5.6 43 ATV31H055M3X

0.75/1 6.4 5.6 5 2.2 10 4.8 7.2 55 ATV31H075M3X

1.1/1.5 8.5 7.4 5 3.0 10 6.9 10.4 71 ATV31HU11M3X

1.5/2 11.1 9.6 5 3.8 10 8.0 12.0 86 ATV31HU15M3X

2.2/3 14.9 13.0 5 5.2 10 11.0 16.5 114 ATV31HU22M3X

3/3 19.1 16.6 5 6.6 19 13.7 20.6 146 ATV31HU30M3X

4/5 24 21.1 5 8.4 19 17.5 26.3 180 ATV31HU40M3X

5.5/7.5 36.8 32.0 22 12.8 23 27.5 41.3 292 ATV31HU55M3X

7.5/10 46.8 40.9 22 16.2 23 33.0 49.5 388 ATV31HU75M3X

11/15 63.5 55.6 22 22.0 93 54.0 81.0 477 ATV31HD11M3X

15/20 82.1 71.9 22 28.5 93 66.0 99.0 628 ATV31HD15M3X

(1)These power ratings and currents are for a maximum ambient temperature of 50°C and a switching frequency of 4 kHz in continuous

operation.The switching frequency is adjustable from 2 to 16 kHz.

Above 4 kHz, the drive will reduce the switching frequency in the event of excessive temperature rise. The temperature rise is controlled

by a PTC probe in the power module. Nonetheless, the nominal drive current should be derated if operation above 4 kHz needs to be

continuous.

Derating curves are shown on page 6

Max. line

current (2)

at

200 V

at

240 V

Max.

prospectiv

e line Isc

as a function of switching frequency, ambient temperature and mounting conditions.

Apparent

power

Max. inrush

current

(3)

Nominal

current In

(1)

Max.

transient

current (1)

(4)

Power

dissipated

at nominal

load

Reference

(5)

(2)Current on a line supply with the "Max. prospective line Isc" indicated.

(3)Peak current on power-up, for the max. voltage (240 V + 10%).

(4)For 60 seconds.

(5)Reference for a drive with built-in terminal but no control unit. For a drive with control potentiometer and RUN/STOP buttons, add an

A at the end of the reference, e.g.: ATV31H018M2A.

(6)4.8 A at 200 V/4.6 A at 208 V/4.2 A at 230 V and 240 V.

2

Page 5

Drive references

3-phase supply voltage: 380…500 V 50/60 Hz

3-phase motor 380…500 V

Motor Line supply (input) Drive (output) ATV 31

Power

indicated on

plate (1)

kW/HPAAkAkVAAA A W

0.37/0.5 2.2 1.7 5 1.5 10 1.5 2.3 32 ATV31H037N4

0.55/0.75 2.8 2.2 5 1.8 10 1.9 2.9 37 ATV31H055N4

0.75/1 3.6 2.7 5 2.4 10 2.3 3.5 41 ATV31H075N4

1.1/1.5 4.9 3.7 5 3.2 10 3.0 4.5 48 ATV31HU11N4

1.5/2 6.4 4.8 5 4.2 10 4.1 6.2 61 ATV31HU15N4

2.2/3 8.9 6.7 5 5.9 10 5.5 8.3 79 ATV31HU22N4

3/3 10.9 8.3 5 7.1 10 7.1 10.7 125 ATV31HU30N4

4/5 13.9 10.6 5 9.2 10 9.5 14.3 150 ATV31HU40N4

5.5/7.5 21.9 16.5 22 15.0 30 14.3 21.5 232 ATV31HU55N4

7.5/10 27.7 21.0 22 18.0 30 17.0 25.5 269 ATV31HU75N4

11/15 37.2 28.4 22 25.0 97 27.7 41.6 397 ATV31HD11N4

15/20 48.2 36.8 22 32.0 97 33.0 49.5 492 ATV31HD15N4

Max. line

current (2)

at

380 V

at

500 V

Max.

prospectiv

e line Isc

Apparent

power

Max. inrush

current

(3)

Nominal

current In

(1)

Max.

transient

current (1)

(4)

Power

dissipated

at nominal

load

Reference

(5)

A

3-phase supply voltage: 525…600 V 50/60 Hz

3-phase motor 525…600 V

Motor Line supply (input) Drive (output) ATV 31

Power

indicated on

plate (1)

kW/HPAAkAkVAAA A W

0.75/1 2.8 2.4 5 2.5 12 1.7 2.6 36 ATV31H075S6X

1.5/2 4.8 4.2 5 4.4 12 2.7 4.1 48 ATV31HU15S6X

2.2/3 6.4 5.6 5 5.8 12 3.9 5.9 62 ATV31HU22S6X

4/5 10.7 9.3 5 9.7 12 6.1 9.2 94 ATV31HU40S6X

5.5/7.5 16.2 14.1 22 15.0 36 9.0 13.5 133 ATV31HU55S6X

7.5/10 21.3 18.5 22 19.0 36 11.0 16.5 165 ATV31HU75S6X

11/15 27.8 24.4 22 25.0 117 17.0 25.5 257 ATV31HD11S6X

15/20 36.4 31.8 22 33.0 117 22.0 33.0 335 ATV31HD15S6X

(1)These power ratings and currents are for a maximum ambient temperature of 50°C and a switching frequency of 4 kHz in continuous

operation. The switching frequency is adjustable from 2 to 16 kHz.

Above 4 kHz, the drive will reduce the switching frequency in the event of excessive temperature rise. The temperature rise is controlled

by a PTC probe in the power module. Nonetheless, the nominal drive current should be derated if operation above 4 kHz needs to be

continuous.

Derating curves are shown on page 6

Max. line

current (2)

at

525 V

at

600 V

Max.

prospectiv

e line Isc

as a function of switching frequency, ambient temperature and mounting conditions.

Apparent

power

Max. inrush

current

(3)

Nominal

current In

(1)

Max.

transient

current (1)

(4)

Power

dissipated

at

nominal

load

Reference

(2)Current on a line supply with the "Max. prospective line Isc" indicated.

(3)Peak current on power-up, for the max. voltage (500 V + 10%, 600 V + 10%).

(4)For 60 seconds.

(5)Reference for a drive with built-in terminal but no control unit. For a drive with control potentiometer and RUN/STOP buttons, add an

A at the end of the reference, e.g.: ATV31H037N4A.

3

Page 6

A

Mounting

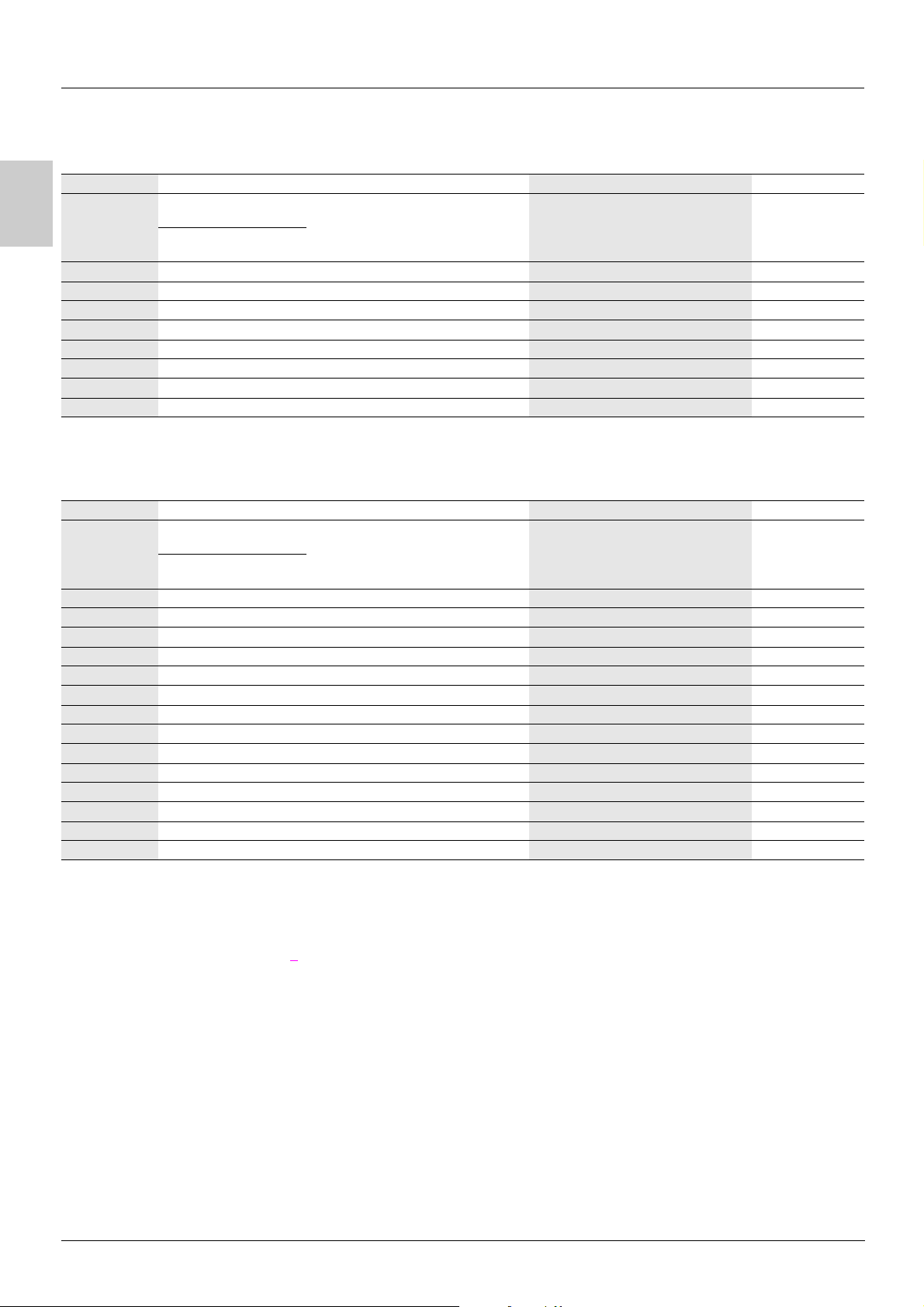

Dimensions and weights

2Ø

b

c G==

a

ATV31 a

H018M3X, H037M3X Size 1 72 145 120 60±1 5 121.5±1 2 x 5 M4 0.9

H055M3X, H075M3X Size 2 72 145 130 60±1 5 121.5±1 2 x 5 M4 0.9

H018M2, H037M2 Size 3 72 145 130 60±1 5 121.5±1 2 x 5 M4 1.05

H055M2, H075M2 Size 4 72 145 140 60±1 5 121.5±1 2 x 5 M4 1.05

HU11M3X, HU15M3X Size 5 105 143 130 93±1 5 121.5±1 2 x 5 M4 1.25

HU11M2, HU15M2,

HU22M3X,

H037N4, H055N4, H075N4,

HU11N4,HU15N4,

H075S6X, HU15S6X

Size 6 105 143 150 93±1 5 121.5±1 2 x 5 M4 1.35

mm

4Ø

Hh

b

mm

c (1)mmG

mm

hr

mm

H

mm

Ø

mm

For

screw

Weight

kg

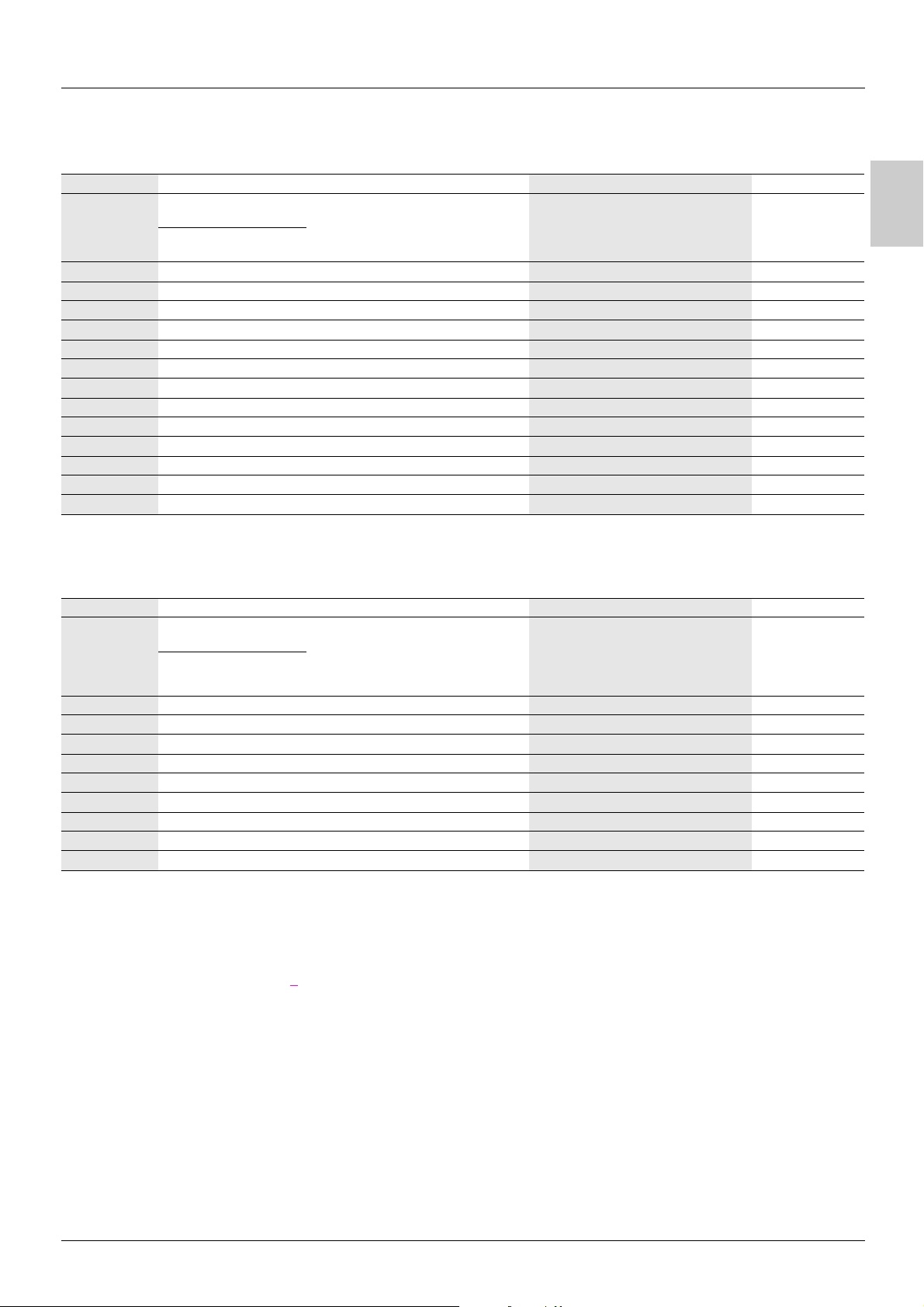

b

c

ATV31 a

HU22M2, HU30M3X, HU40M3X,

HU22N4, HU30N4, HU40N4,

HU22S6X, HU40S6X

HU55M3X, HU75M3X,

HU55N4, HU75N4,

HU55S6X, HU75S6X

HD11M3X, HD15M3X,

HD11N4, HD15N4,

HD11S6X, HD15S6X

(1)For drives in the A range, add 8 mm for the protruding potentiometer button.

Size 7 140 184 150 126±1 6.5 157±1 4 x 5 M4 2.35

Size 8 180 232 170 160±1 5 210±1 4 x 5 M4 4.70

Size 9 245 330 190 225±1 7 295±1 4 x 6 M5 9.0

mm

G==

a

b

mm

Hh

c (1)mmG

mm

hr

mm

H

mm

Ø

mm

For

screw

Weight

kg

4

Page 7

Mounting

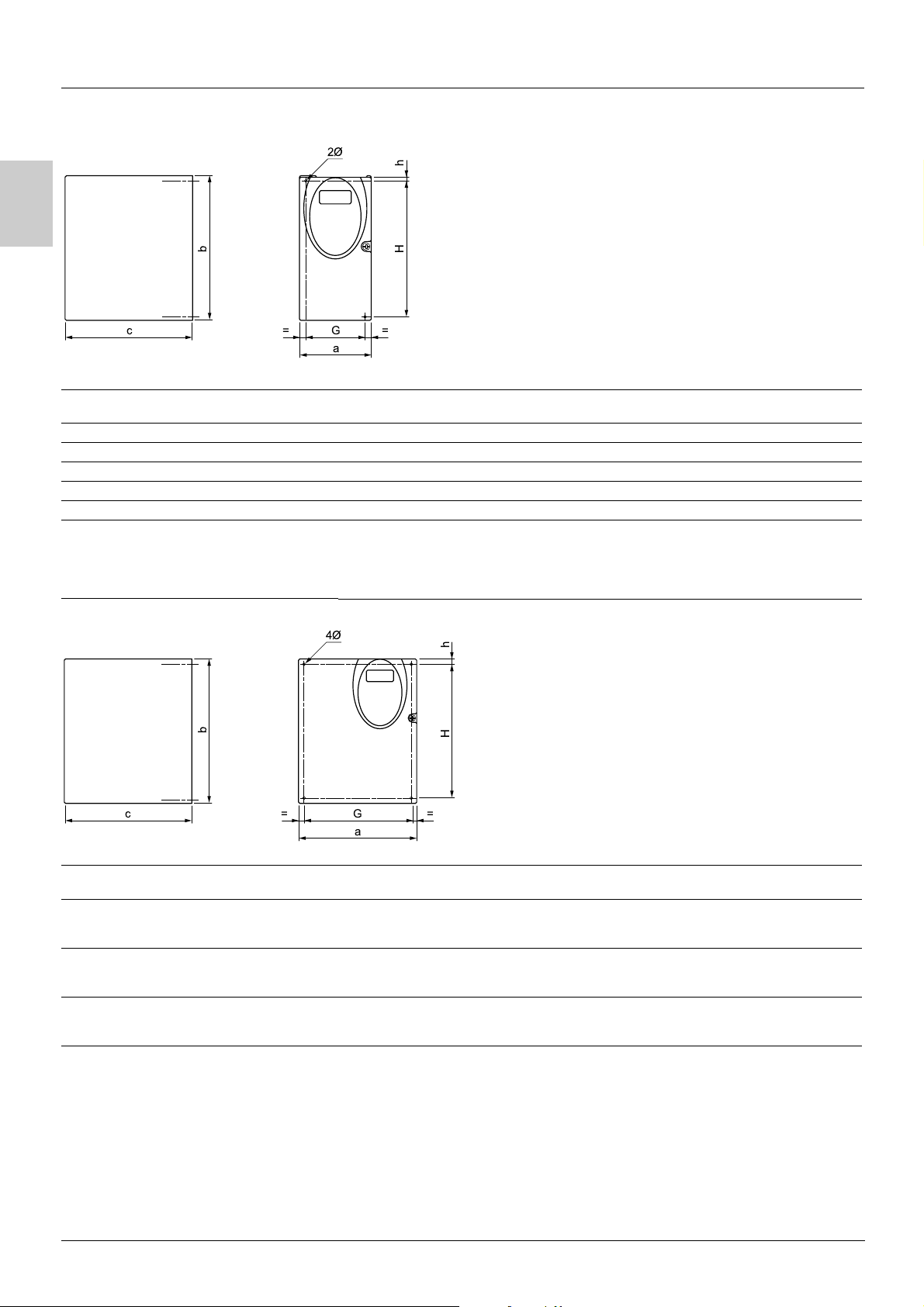

Mounting and temperature conditions

Install the unit vertically, at ± 10°.

Do not place it close to heating elements.

≥ 50 mm

≥ 50 mm

Removing the protective cover

Leave sufficient free space to ensure that the air required for cooling purposes can circulate from the bottom to

the top of the unit.

Free space in front of unit: 10 mm minimum.

When IP20 protection is adequate, we recommend that the protective cover on the top of the drive be removed,

as shown below.

A

3 types of mounting are possible:

Type A

mounting:

Type B

mounting:

Type C

mounting:

Free space

Drives mounted side-by-side, protective cover removed (the degree of protection becomes IP20)

Free space

u 50 mm on each side, with protective cover fitted

u 50 mm u 50 mm

u 50 mm on each side, protective cover removed (the degree of protection becomes IP20)

u 50 mm u 50 mm

Example ATV31HU11M3X

5

Page 8

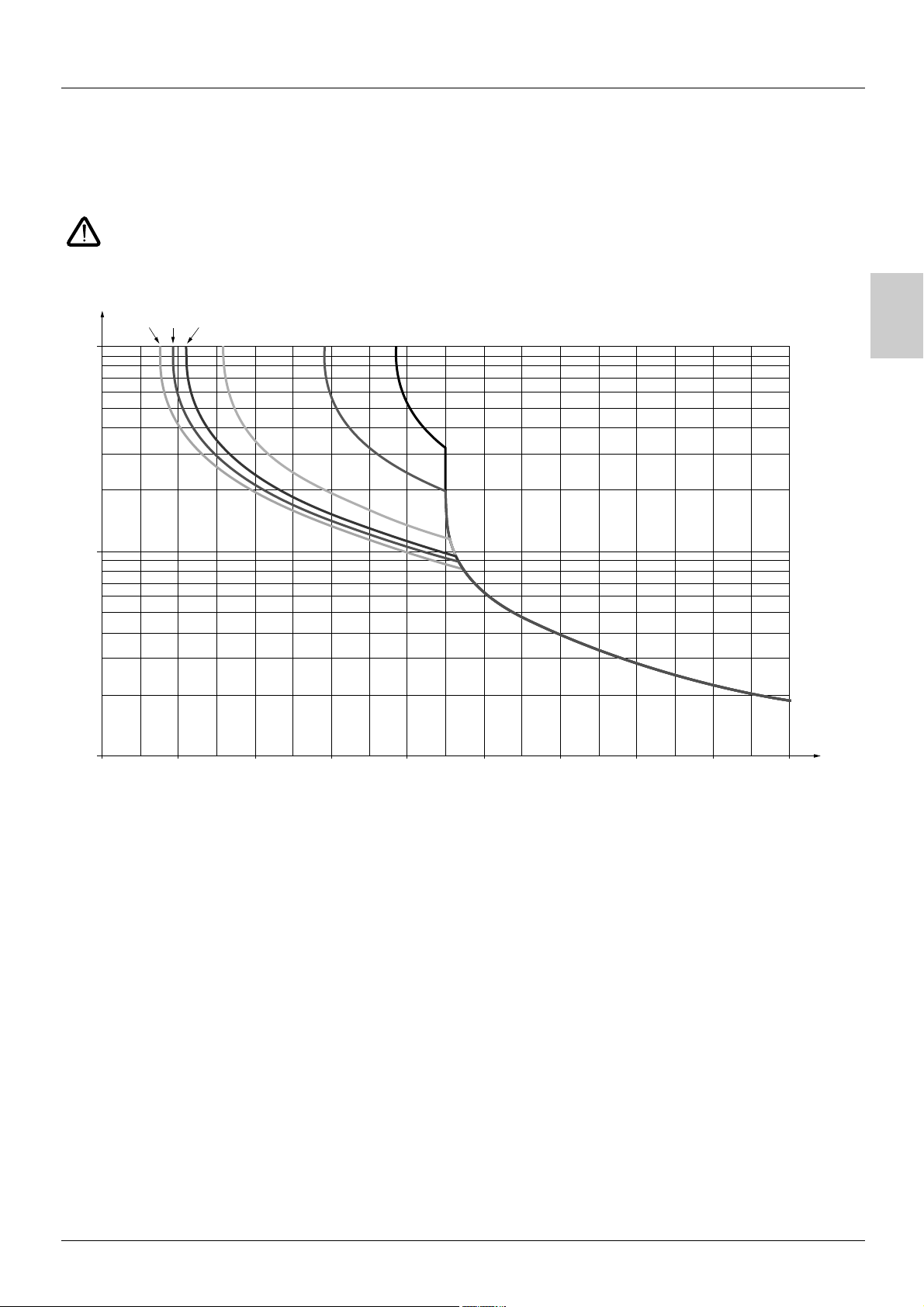

Mounting

Derating curves for the drive current In as a function of the temperature, switching frequency and type of mounting.

I/In

A

In = 100 %

- 5 %

90 %

80 %

70 %

60 %

50 %

40 %

30 %

4 kHz 8 kHz 12 kHz 16 kHz

For intermediate temperatures (e.g. 55°C), interpolate between 2 curves.

- 10 %

- 15 %

- 25 %

- 35 %

- 10 %

- 20 %

- 25 %

- 30 %

- 35 %

- 40 %

- 45 %

- 50 %

- 55 %

- 65 %

40°C mounting types A, B and C

50°C mounting type C

50°C mounting types A and B

60°C mounting type C

60°C mounting types A and B

Switching frequency

If you are installing the drives in enclosures, make provision for a flow of air at least equal to the value given

in the table below for each drive.

ATV31 Flow rate in m3/hour

H018M2, H037M2, H055M2,

H018M3X, H037M3X, H055M3X,

H037N4, H055N4, H075N4, HU11N4

H075S6X, HU15S6X

H075M2, HU11M2, HU15M2

H075M3X, HU11M3X, HU15M3X

HU15N4, HU22N4

HU22S6X, HU40S6X

HU22M2,

HU22M3X, HU30M3X, HU40M3X

HU30N4, HU40N4

HU55S6X, HU75S6X

HU55M3X

HU55N4, HU75N4

HD11S6X

HU75M3X, HD11M3X,

HD11N4, HD15N4

HD15S6X

HD15M3X 216

18

33

93

102

168

6

Page 9

Mounting

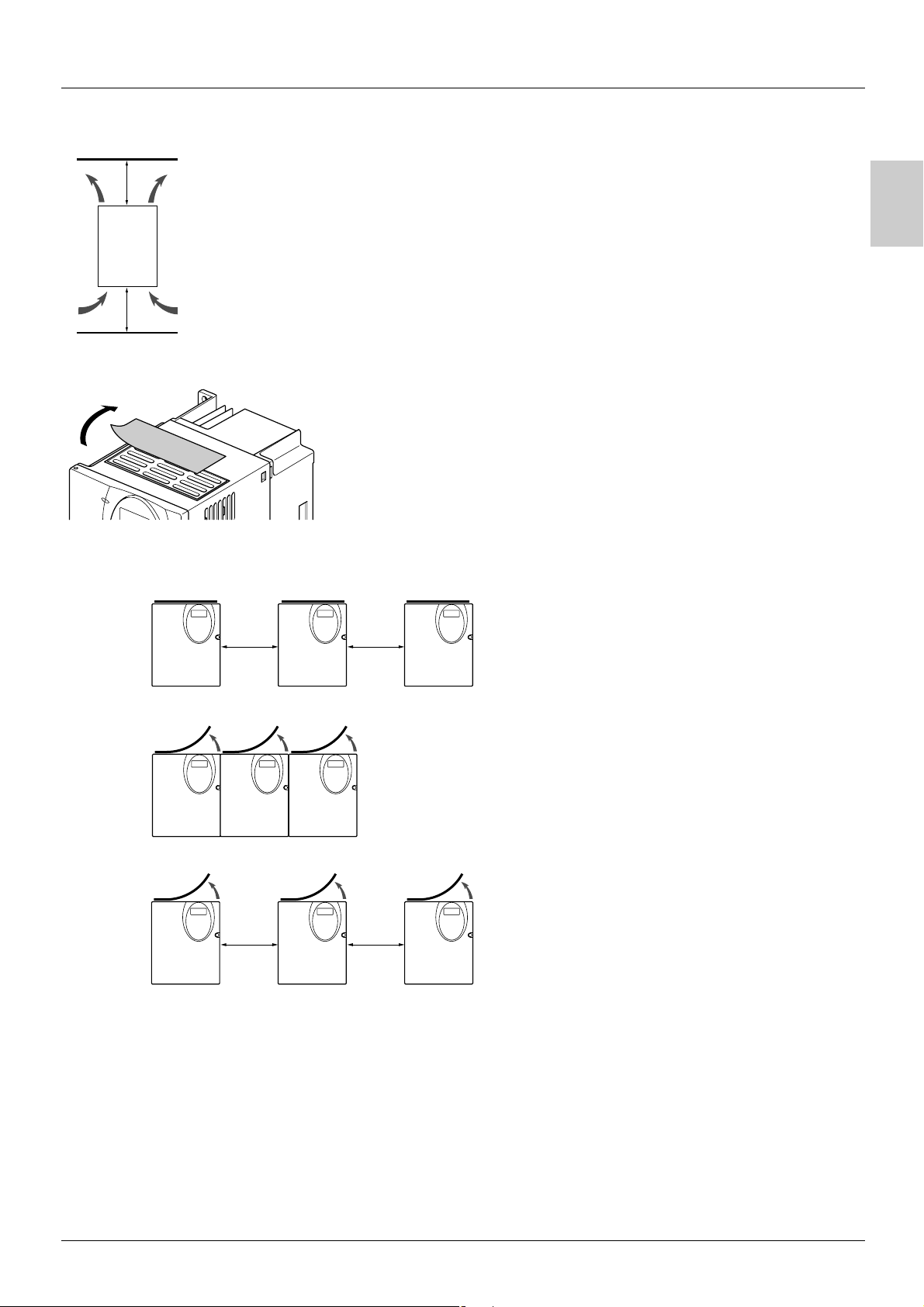

Electromagnetic compatibility

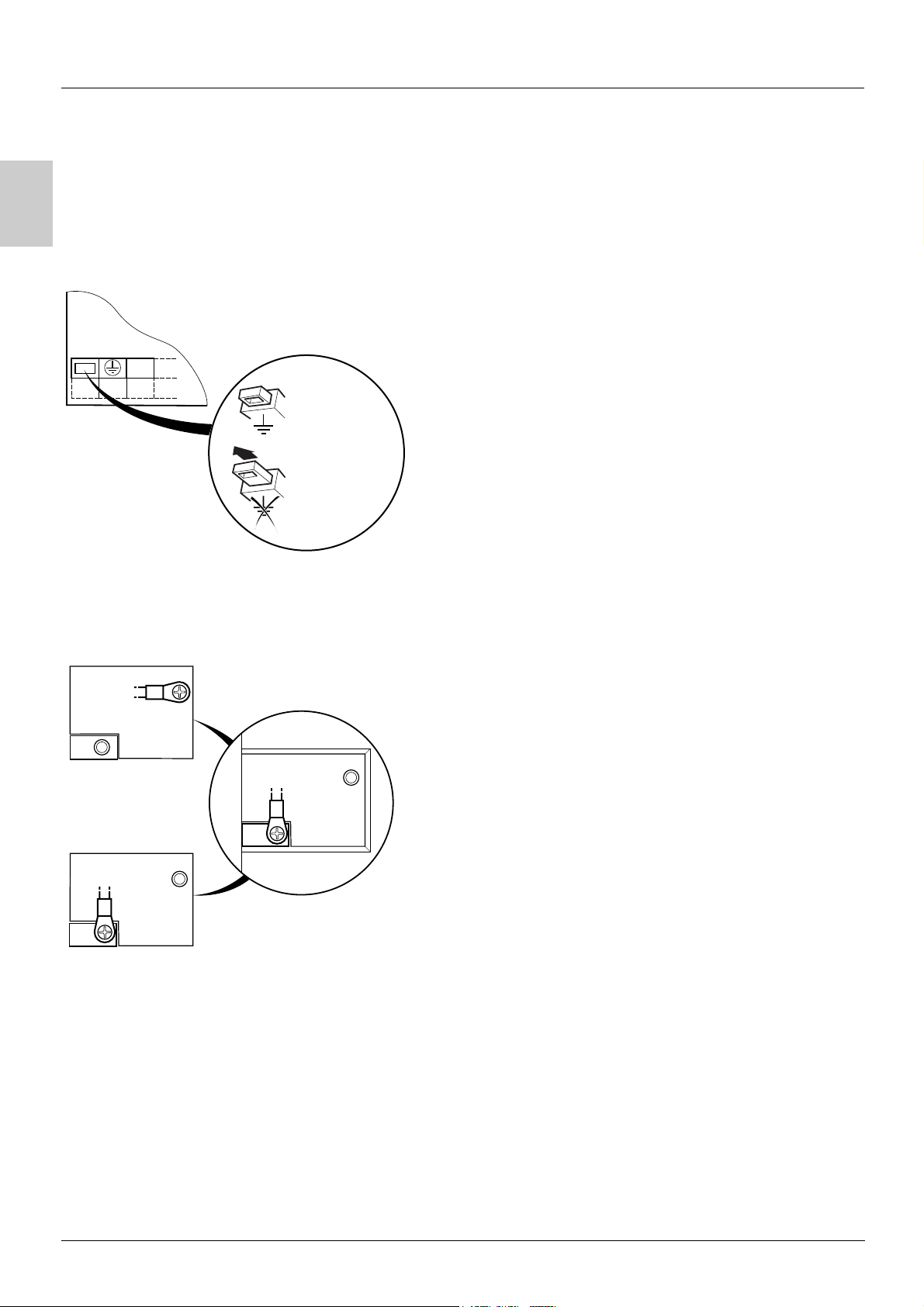

EMC mounting plate: Supplied with the drive

Fix the EMC equipotentiality mounting plate to the holes in the ATV 31 heatsink using the 2 screws supplied, as shown in the drawings

below.

Size 1 - 4 Size 5 -6

Size 7

Size 8 Size 9

A

2

50

Screws supplied:

4 x M4 screws for fixing the EMC clamps (clamps not supplied)

1 x M5 screw for ground

ATV31 ATV31

H018M3X, H037M3X Size 1 HU22M2, HU30M3X, HU40M3X,

H055M3X, H075M3X Size 2

H018M2, H037M2 Size 3 HU55M3X, HU75M3X,

H055M2, H075M2 Size 4

HU11M3X, HU15M3X Size 5 HD11M3X, HD15M3X,

HU11M2, HU15M2, HU22M3X,

H037N4, H055N4, H075N4, HU11N4, HU15N4,

H075S6X, HU15S6X

49

2

2

Size 6

48

HU22N4, HU30N4, HU40N4,

HU22S6X, HU40S6X

HU55N4, HU75N4,

HU55S6X, HU75S6X

HD11N4, HD15N4,

HD11S6X, HD15S6X

2

75

2

75

Size 7

Size 8

Size 9

7

Page 10

A

Wiring

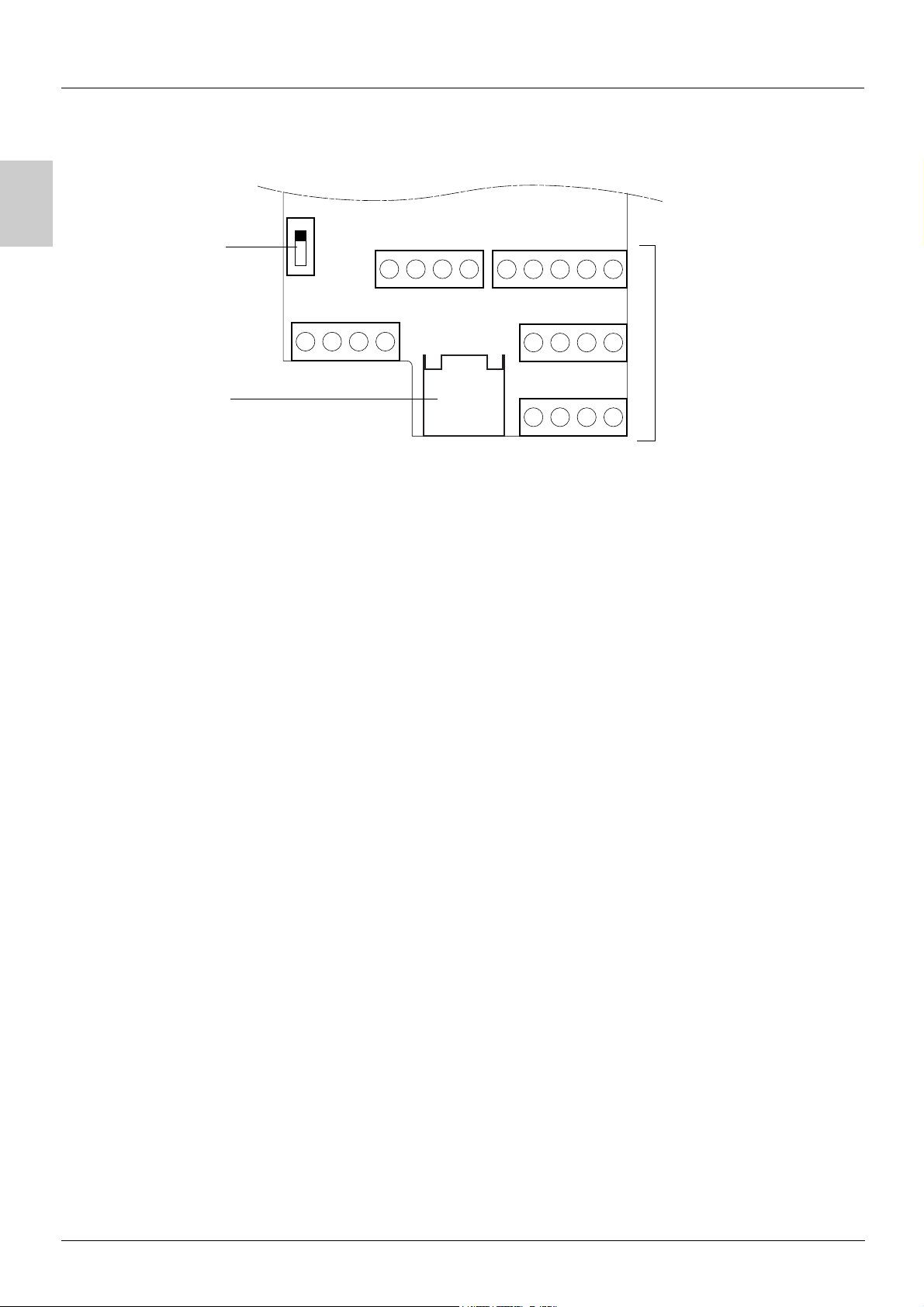

Access to terminals

To access the terminals, open the cover as shown in the example below.

Example ATV31HU11M2

Power terminals

Connect the power terminals before connecting the control terminals.

Power terminal characteristics

ATV 31 Maximum connection capacity Tightening torque

AWG mm

H018M2, H037M2, H055M2, H075M2,

H018M3X, H037M3X, H055M3X, H075M3X, HU11M3X, HU15M3X

HU11M2, HU15M2, HU22M2,

HU22M3X, HU30M3X, HU40M3X,

H037N4, H055N4, H075N4, HU11N4,HU15N4, HU22N4, HU30N4, HU40N4

H075S6X, HU15S6X, HU22S6X, HU40S6X

HU55M3X, HU75M3X,

HU55N4, HU75N4,

HU55S6X, HU75S6X

HD11M3X, HD15M3X,

HD11N4, HD15N4,

HD11S6X, HD15S6X

AWG 14 2.5 0.8

AWG 10 6 1.2

AWG 6 16 2.5

AWG 3 25 4.5

Power terminal functions

Terminal Function For ATV 31

t

R/L1

S/L2

R/L1

S/L2

T/L3

PO DC bus + polarity All ratings

PA/+ Output to braking resistor (+ polarity) All ratings

PB Output to braking resistor All ratings

PC/- DC bus - polarity All ratings

U/T1

V/T2

W/T3

Ground terminal All ratings

ATV31

ATV31

ATV31

ppppM2

ppppM3X

ppppN4

ppppS6X

Power supply ATV31

Outputs to the motor All ratings

2

in Nm

Never remove the commoning link between PO and PA/+. The PO and PA/+ terminal screws must always be fully tightened as a

high current flows through the commoning link.

8

Page 11

Wiring

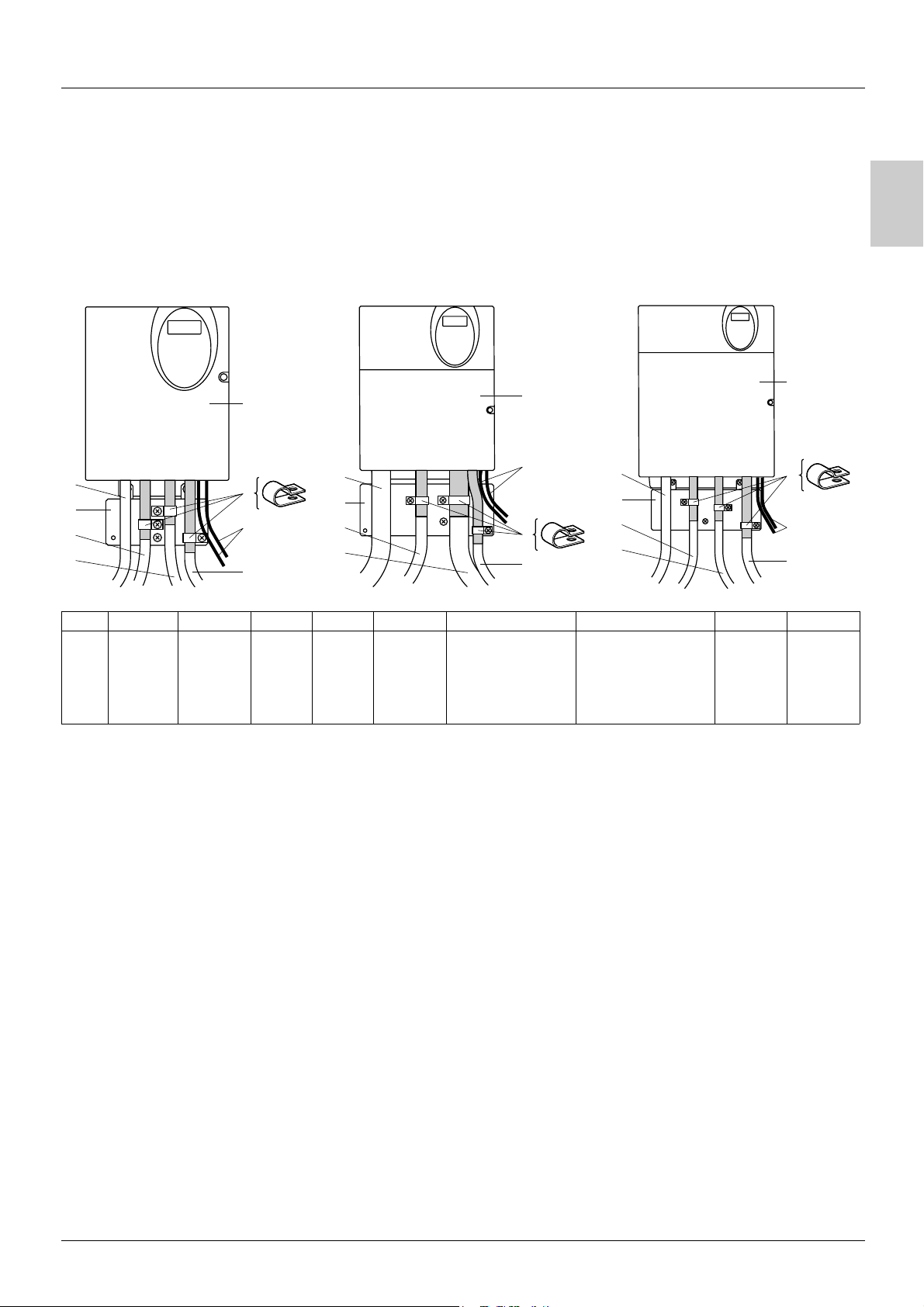

Arrangement of the power terminals

ATV 31H018M3X, H037M3X, H055M3X, H075M3X

T/L3R/L1 S/L2

P0 PA/+ PB PC/- U/T1 V/T2 W/T3

ATV 31HU11M3X, HU15M3X, HU22M3X, HU30M3X, HU40M3X,

H037N4, H055N4, H075N4, HU11N4, HU15N4, HU22N4,

HU30N4, HU40N4, H075S6X, HU15S6X, HU22S6X,

HU40S6X

R/L1 S/L2 T/L3

P0 PA/+ PB PC/- U/T1 V/T2 W/T3

ATV 31H018M2, H037M2, H055M2, H075M2

A

R/L1 S/L2

P0 PA/+ PB PC/- U/T1 V/T2 W/T3

ATV 31HU11M2, HU15M2, HU22M2

R/L1 S/L2

P0 PA/+ PB PC/- U/T1 V/T2 W/T3

ATV 31HU55M3X, HU75M3X, HU55N4, HU75N4, HU55S6X, HU75S6X

R/L1 S/L2 T/L3 P0 PA/+ PB PC/- U/T1 V/T2 W/T3

ATV 31HD11M3X, HD15M3X, HD11N4, HD15N4, HD11S6X, HD15S6X

R/L1 S/L2 T/L3 P0 PA/+ PB PC/- U/T1 V/T2 W/T3

9

Page 12

A

Wiring

Control terminals

Logic input

configuration

switch

Source

CLI

SINK

COM

AI1

10V

AI3

AI2

COM

AOV

AOC

R1A

R1B

LI4

R1C

LI5

R2A

LI6

R2C

CLI

Control

terminals

RJ45

connector

- Maximum connection capacity: 2.5 mm2 - AWG 14

- Max. tightening torque: 0.6 Nm

RJ45

24V

LI1

LI2

LI3

10

Page 13

Wiring

Control terminals

Arrangement, characteristics and functions of the control terminals

Terminal Function Electrical characteristics

R1A

R1B

R1C

R2A

R2C

COM Analog I/O common 0 V

AI1 Analog voltage input Analog input 0 + 10 V (max. safe voltage 30 V)

10 V Power supply for setpoint

AI2 Analog voltage input Bipolar analog input 0 ± 10 V (max. safe voltage ± 30 V)

Common point C/O contact (R1C) of

programmable relay R1

N/O contact of programmable relay R2

potentiometer

1 to 10 k

Ω

• Min. switching capacity: 10 mA for 5 V

• Max. switching capacity on resistive load (cos ϕ = 1 and L/R = 0 ms):

5 A for 250 V

• Max. switching capacity on inductive load (cos ϕ = 0.4 and L/R = 7 ms):

1.5 A for 250 V

• Sampling time 8 ms

• Service life: 100,000 operations at max. switching power

1,000,000 operations at min. switching power

• Impedance 30 k

• Resolution 0.01 V, 10-bit converter

• Precision ± 4.3%, linearity ± 0.2%, of max. value

• Sampling time 8 ms

• Operation with shielded cable 100 m max.

+10 V (+ 8% - 0), 10 mA max, protected against short-circuits and overloads

The + or - polarity of the voltage on AI2 affects the direction of the setpoint and

therefore the direction of operation.

• Impedance 30 k

• Resolution 0.01 V, 10-bit + sign converter

• Precision ± 4.3%, linearity ± 0.2%, of max. value

• Sampling time 8 ms

• Operation with shielded cable 100 m max.

a and 30 V c

a and 30 V c

Ω

Ω

c

A

AI3 Analog current input Analog input X - Y mA. X and Y can be programmed from 0 to 20 mA

COM Analog I/O common 0 V

AOV

AOC

24 V Logic input power supply + 24 V protected against short-circuits and overloads, min. 19 V, max. 30 V

LI1

LI2

LI3

LI4

LI5

LI6

CLI Logic input common See page 12.

Analog voltage output AOV

or

Analog current output AOC

or

Logic voltage output AOC

AOV or AOC can be assigned

(either, but not both)

Logic inputs Programmable logic inputs

Logic inputs Programmable logic inputs

• Impedance 250

• Resolution 0.02 mA, 10-bit converter

• Precision ± 4.3%, linearity ± 0.2%, of max. value

• Sampling time 8 ms

Analog output 0 to 10 V, min. load impedance 470

or

Analog output X - Y mA. X and Y can be programmed from 0 to 20 mA,

max. load impedance 800

• Resolution 8 bits (1)

• Precision ± 1% (1)

• Linearity ± 0.2% (1)

• Sampling time 8 ms

This analog output can be configured as a 24 V logic output on AOC, min. load

impedance 1.2 k

(1) Characteristics of digital/analog converter.

Max. customer current available 100 mA

• + 24 V power supply (max. 30 V)

• Impedance 3.5 k

• State 0 if < 5 V, state 1 if > 11 V (voltage difference between LI- and CLI)

• Sampling time 4 ms

• + 24 V power supply (max. 30 V)

• Impedance 3.5 k

• State 0 if < 5 V, state 1 if > 11 V (voltage difference between LI- and CLI)

• Sampling time 4 ms

Ω

Ω

Ω

Ω.

Ω

Ω

11

Page 14

A

Wiring

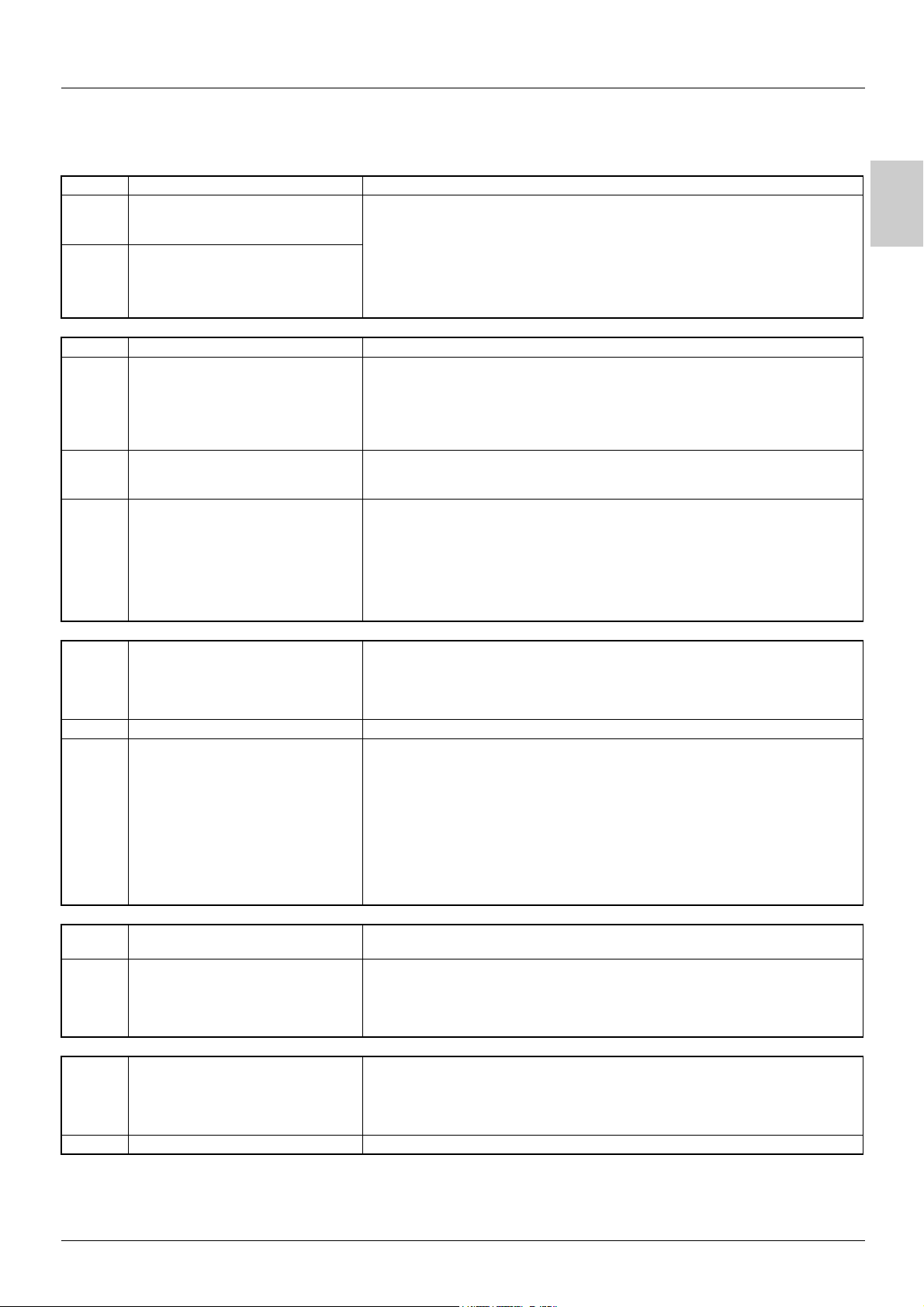

Wiring diagram for factory settings

ATV31ppppM2

Single-phase supply

(1)

S / L2

U1

R / L1

R / L1

U / T1

V1

3 a

M

S / L2

V / T2

(1)

T / L3

W / T3

W1

ATV31

3-phase supply

(2)

R1A

R1B

R1C

P0

Braking resistor,

if used

ppppM3X/N4/S6X

LI1

PB

R2C

PC / -

CLI

+10

Reference

potentiometer

R2A

PA / +

LI2

AI1

LI3

LI4

COM

X - Y mA

0 ± 10 V

LI5

AI3

LI6

AI2

24V

AOV

AOC

Using the analog output as a

logic output

COM

A0C

24 V relay

or

24 V PLC input

or

LED

(1) Line choke, if used (single phase or 3-phase)

(2) Fault relay contacts, for remote indication of the drive status.

Note: Fit interference suppressors to all inductive circuits near the drive or coupled to the same circuit (relays, contactors, solenoid valves,

etc).

Choice of associated components:

Please refer to the catalogue.

Logic input switch

This switch assigns the logic input common link to 0V, 24 V or "floating":

ATV31Hpppp

SOURCE

CLI

SINK

0V

ATV31Hpppp

CLI LI1 LIx

ATV31Hpppp

24V

CLI LI1 LIx

CLI at 0 V (factory setting)

CLI LI1 LIx

CLI "floating"

CLI at 24 V

12

Page 15

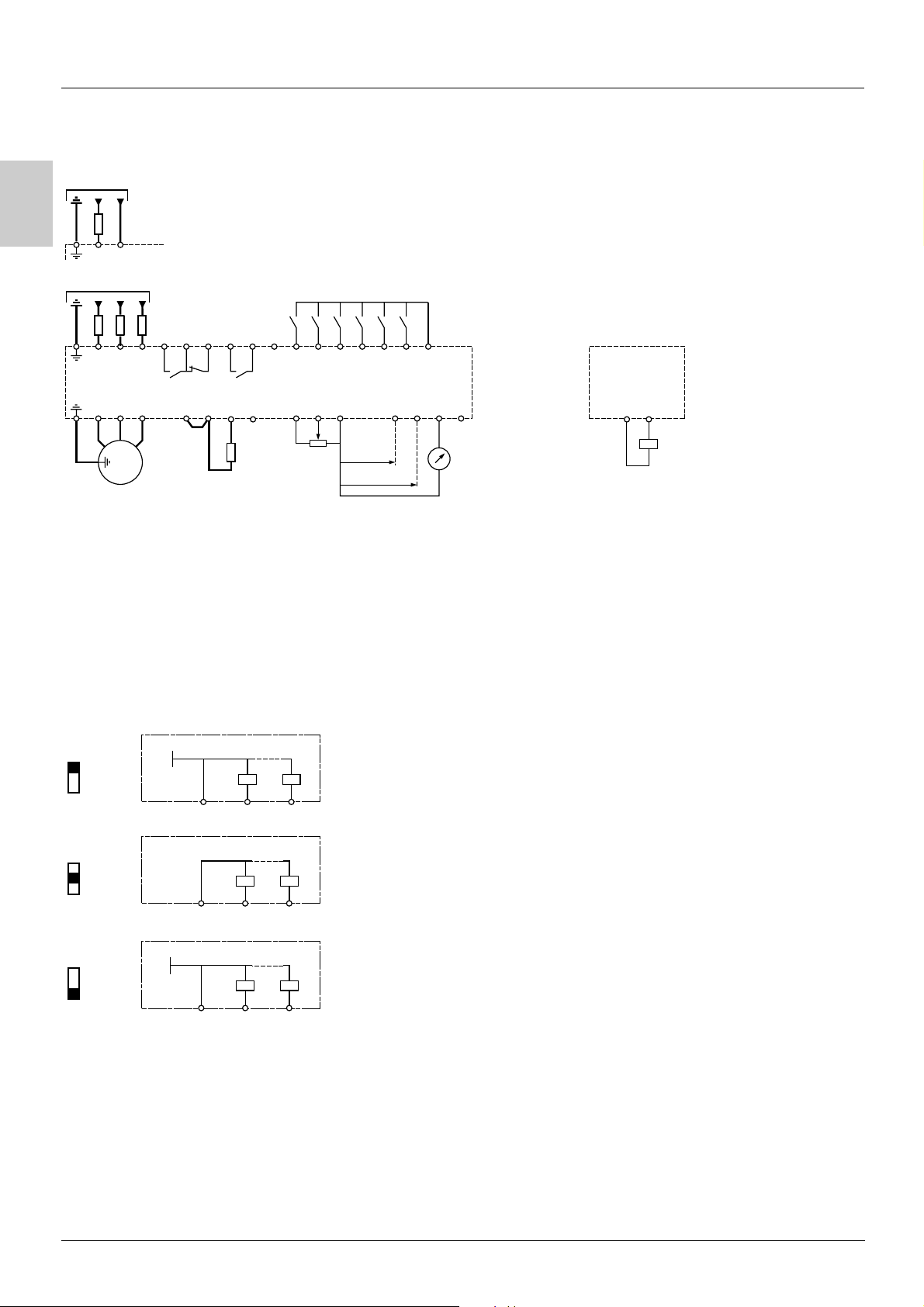

Wiring

Examples of recommended circuit diagrams

Using volt-free contacts

• Switch in "Source" position

(ATV31 factory setting for types other than ATV31

ATV31Hpppp

0V

ppppA)

• Switch in "SINK" position

(factory setting for ATV31ppppA)

A

ATV31Hpppp

24V

LI1

24V

LI1

COM

In this instance, the common must never be connected to

earth or earth ground, as this presents a risk of unintended

equipment operation on the first insulation fault.

Using PLC transistor outputs

• Switch in CLI position • Switch in CLI position

ATV31Hpppp

LI1COM CLI

24V

0V

PLC

ATV31Hpppp

0V

CLI

PLC

LI1COM

24V

Wiring recommendations

Power

The drive must be earthed to conform with the regulations concerning high leakage currents (over 3.5 mA).

When upstream protection by means of a "residual current device" is required by the installation standards, a type A device should be

used for single-phase drives and type B for 3-phase drives. Choose a suitable model incorporating:

• HF current filtering

• A time delay which prevents tripping caused by the load from stray capacitance on power-up. The time delay is not possible for 30 mA

devices. In this case, choose devices with immunity against accidental tripping, for example RCDs with reinforced immunity from the

range (Merlin Gerin brand).

If the installation includes several drives, provide one "residual current device" per drive.

s.i

Keep the power cables separate from circuits in the installation with low-level signals (detectors, PLCs, measuring apparatus, video,

telephone).

If you are using cables > 50 m between the drive and the motor, add output filters (please refer to the catalogue).

Control

Keep the control circuits away from the power cables. For control and speed reference circuits, we recommend using shielded twisted

cables with a pitch of between 25 and 50 mm, connecting the shielding to ground at each end.

13

Page 16

A

Wiring

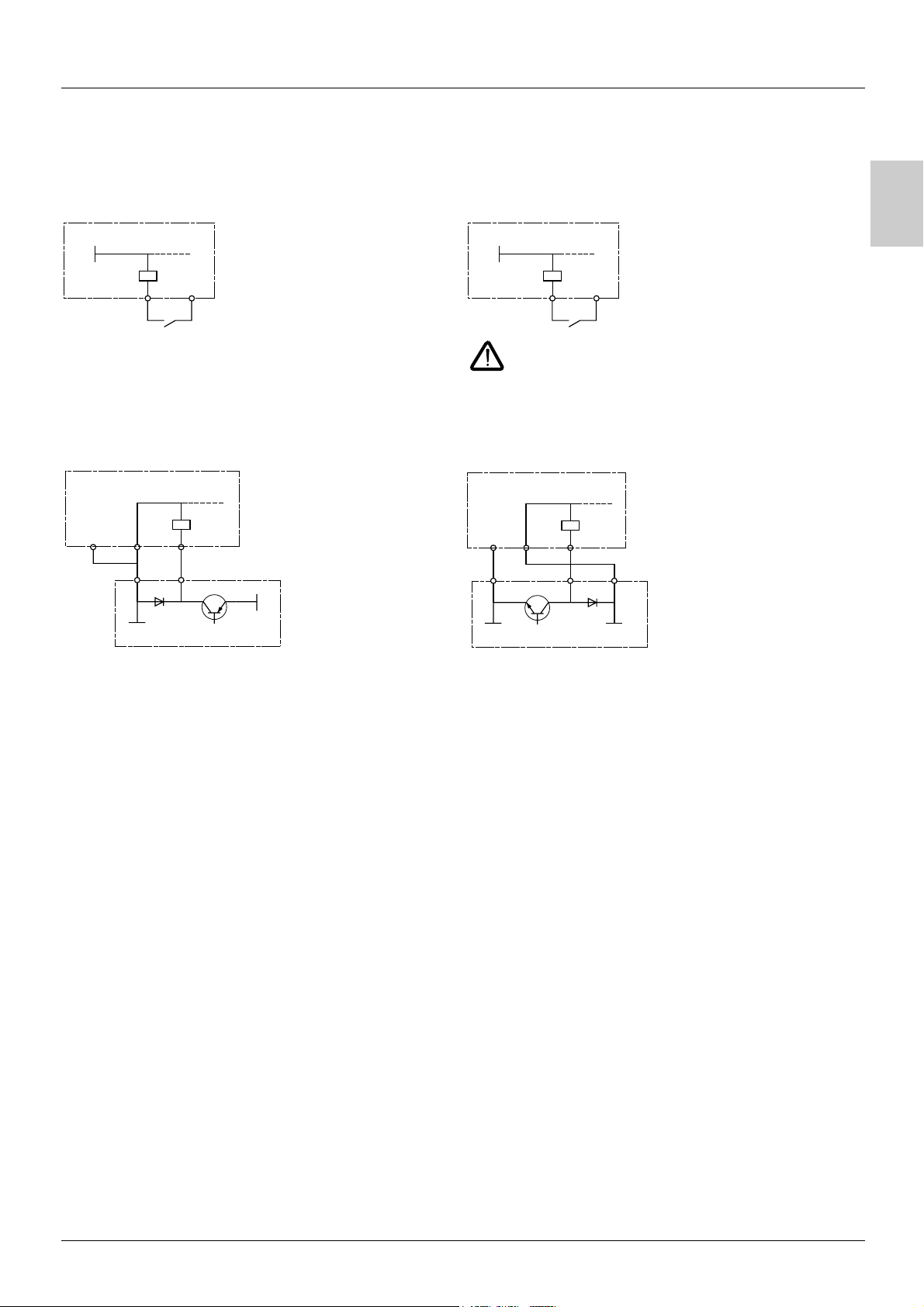

Operation on an IT system

IT system: Isolated or impedance earthed neutral.

Use a permanent insulation monitor compatible with non-linear loads (a Merlin Gerin type XM200, for example).

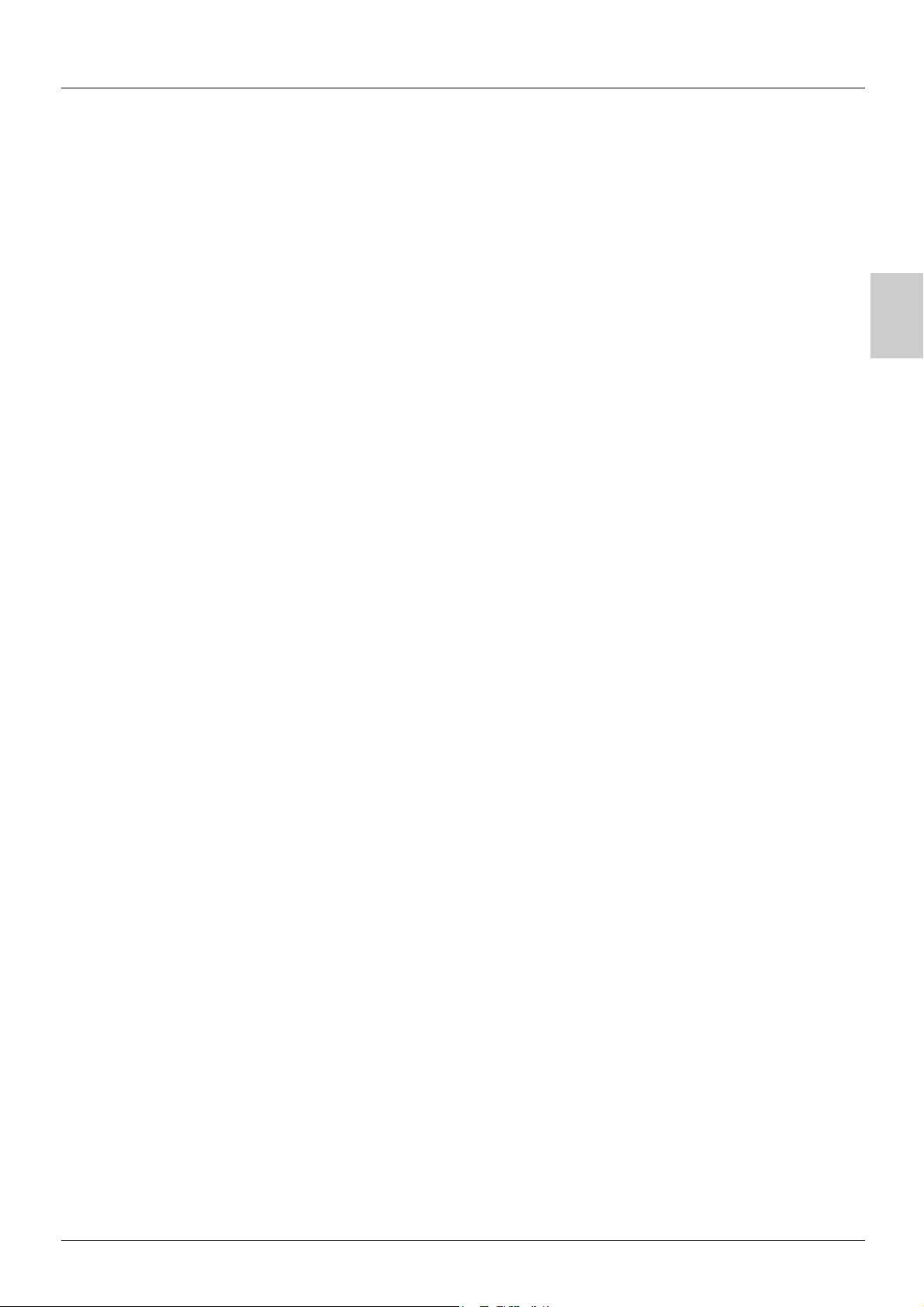

pppM2 and N4 drives feature built-in RFI filters. These filters can be isolated from ground for operation on an IT system as follows:

ATV 31

ATV31H018M2 to U22M2 and ATV31H037N4 to U40N4:

Pull out the jumper on the left of the ground terminal as illustrated below.

Normal

(filter

connected)

IT system

(filter

disconnected)

ATV31HU55N4 to D15N4:

Move the cable tag on the top left of the power terminals as illustrated below (example ATV31HU55N4):

IT system

(filter disconnected)

Normal

(filter connected)

(factory setting)

14

Page 17

Wiring

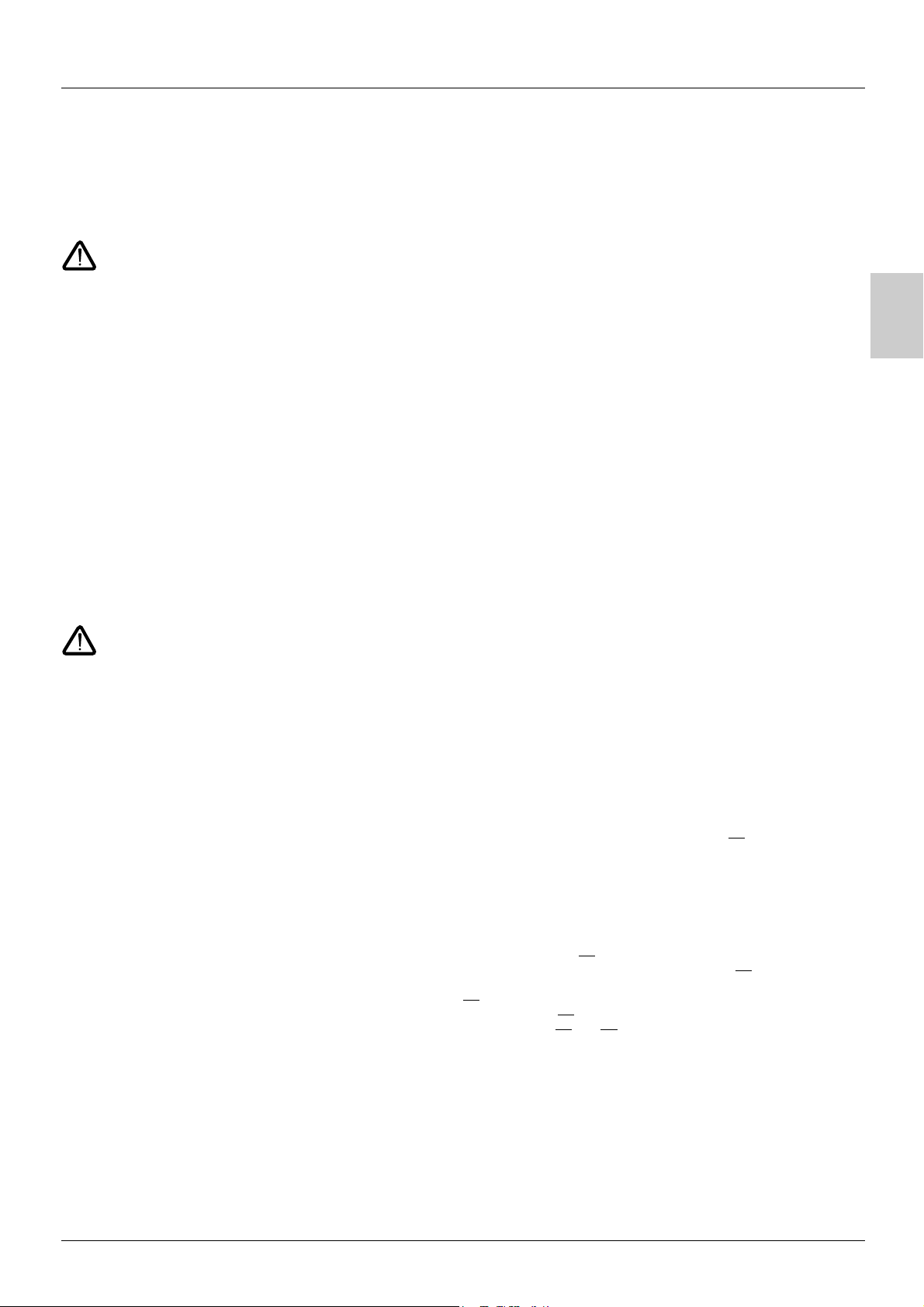

Electromagnetic compatibility

Principle

• Grounds between the drive, motor and cable shielding must have "high frequency" equipotentiality.

• Use shielded cables with shielding connected to ground throughout 360° at both ends for the motor cable 6, braking resistor (if used) 8,

and control-signalling cables 7. Metal ducting or conduit can be used for part of the shielding length provided that there is no break in

continuity.

• Ensure maximum separation between the power supply cable (line supply) and the motor cable.

Installation diagram (examples)

Sizes 1 to 7 Size 8 Size 9

A

2

3

1

8

6

Size 1 Size 2 Size 3 Size 4 Size 5 Size 6 Size 7 Size 8 Size 9

ATV31H018M3X,

H037M3X

1 Sheet steel grounded plate supplied with the drive, to be fitted as indicated on the diagram.

2 ATV 31

3 Non-shielded power supply wires or cable

H055M3X,

H075M3X

5

4

7

H018M2,

H037M2

3

1

8

6

H055M2,

H075M2

HU11M3X,

HU15M3X

HU11M2, HU15M2

HU22M3X

H037N4, H055N4,

H075N4, HU11N4,

HU15N4

H075S6X, HU15S6X

2

4

5

7

HU22M2

HU30M3X, HU40M3X

HU22N4, HU30N4,

HU40N4

HU22S6X, HU40S6X

2

3

1

8

6

HU55M3X,

HU75M3X

HU55N4,

HU75N4

HU55S6X,

HU75S6X

5

4

7

HD11M3X,

HD15M3X

HD11N4,

HD15N4

HD11S6X,

HD15S6X

4 Non-shielded wires for relay contacts

5 Fix and ground the shielding of cables 6, 7 and 8 as close as possible to the drive:

- Strip the shielding.

- Use stainless steel cable clamps of an appropriate size on the parts from which the shielding has been stripped, to attach them to the

plate 1.

The shielding must be clamped tightly enough to the metal plate to ensure correct contact.

6 Shielded cable for motor connection with shielding connected to ground at both ends.

The shielding must be continuous and intermediate terminals must be in EMC shielded metal boxes.

For 0.18 to 1.5 kW drives, if the switching frequency is higher than 12 kHz, use cables with low linear capacitance: max. 130 pF

(picoFarads) per metre.

7 Shielded cable for connecting the control/signalling wiring.

For applications requiring several conductors, use cables with a small cross-section (0.5 mm

The shielding must be connected to ground at both ends. The shielding must be continuous and intermediate terminals must be in EMC

shielded metal boxes.

8 Shielded cable for connecting braking resistor (if fitted).

The shielding must be continuous and intermediate terminals must be in EMC shielded metal boxes.

Note:

• If using an additional input filter, it should be mounted under the drive and connected directly to the line supply via an unshielded cable.

Link 3 on the drive is then via the filter output cable.

• The HF equipotential ground connection between the drive, motor and cable shielding does not remove the need to connect the PE

protective conductors (green-yellow) to the appropriate terminals on each unit.

2

).

15

Page 18

A

16

Page 19

Contents

Warnings ___________________________________________________________________________________________________________________ 2

Steps for setting up the starter _______________________________________________________________________________________________ 3

Factory configuration________________________________________________________________________________________________________ 4

Software enhancements _____________________________________________________________________________________________________ 5

Basic functions______________________________________________________________________________________________________________ 6

Setup - Preliminary recommendations_________________________________________________________________________________________ 8

Functions of the display and the keys _________________________________________________________________________________________ 9

Remote terminal option_____________________________________________________________________________________________________ 11

Programming ______________________________________________________________________________________________________________ 12

Function compatibility ______________________________________________________________________________________________________ 14

List of functions which can be assigned to inputs/outputs______________________________________________________________________ 16

List of functions which can be assigned to the CANopen and Modbus control word bits___________________________________________ 18

Settings menu SEt- _________________________________________________________________________________________________________ 19

Motor control menu drC-____________________________________________________________________________________________________ 23

I/O menu I-O- ______________________________________________________________________________________________________________ 27

Control menu CtL- _________________________________________________________________________________________________________ 31

Application functions menu FUn- ____________________________________________________________________________________________ 42

Fault menu FLt- ____________________________________________________________________________________________________________ 66

Communication menu COM- ________________________________________________________________________________________________ 69

Display menu SUP- _________________________________________________________________________________________________________ 70

Maintenance _______________________________________________________________________________________________________________ 73

Faults - Causes - Remedies__________________________________________________________________________________________________ 74

Configuration/Settings table ________________________________________________________________________________________________ 76

Index of parameter codes ___________________________________________________________________________________________________ 80

Index of functions __________________________________________________________________________________________________________ 81

B

NOTE: Please also refer to the "Installation Guide".

1

Page 20

B

Warnings

When the drive is powered up, the power components and some of the control

components are connected to the line supply. It is extremely dangerous to touch them.

The drive cover must be kept closed.

In general, the drive power supply must be disconnected before any operation on

either the electrical or mechanical parts of the installation or machine.

After the ATV has been switched off and the display has disappeared completely, wait

for 10 minutes before working on the equipment. This is the time required for the

capacitors to discharge.

The motor can be stopped during operation by inhibiting start commands or the speed

reference while the drive remains powered up. If personnel safety requires prevention

of sudden restarts, this electronic locking system is not sufficient: fit a cut-off on the

power circuit.

The drive is fitted with safety devices which, in the event of a fault, can shut down the

drive and consequently the motor. The motor itself may be stopped by a mechanical

blockage. Finally, voltage variations, especially line supply failures, can also cause

shutdowns.

If the cause of the shutdown disappears, there is a risk of restarting which may

endanger certain machines or installations, especially those which must conform to

safety regulations.

In this case the user must take precautions against the possibility of restarts, in

particular by using a low speed detector to cut off power to the drive if the motor

performs an unprogrammed shutdown.

The drive must be installed and set up in accordance with both international and

national standards. Bringing the device into conformity is the responsibility of the

systems integrator who must observe the EMC directive among others within the

European Union.

The specifications contained in this document must be applied in order to comply with

the essential requirements of the EMC directive.

The ATV 31 must be considered as a component: it is neither a machine nor a device

ready for use in accordance with European directives (machinery directive and

electromagnetic compatibility directive). It is the responsibility of the end user to

ensure that the machine meets these standards.

The drive must not be used as a safety device for machines posing a potential risk of

material damage or personal injury (lifting equipment, for example). In such

applications, overspeed checks and checks to ensure that the trajectory remains under

constant control must be made by separate devices which are independent of the

drive.

The products and equipment described in this document may be changed or modified

at any time, either from a technical point of view or in the way they are operated. Their

description can in no way be considered contractual.

2

Page 21

Steps for setting up the starter

1 - Delivery of the drive

• Check that the drive reference printed on the label is the same as that on the delivery note corresponding to the purchase order.

• Remove the ATV 31 from its packaging and check that it has not been damaged in transit.

2 - Check that the line voltage is compatible with the supply voltage range of the drive

(see the ATV 31Installation Manual).

- The drive may be damaged if the line voltage is not compatible.

3 - Fit the drive

4 - Connect the following to the drive:

• The line supply, ensuring that it is:

- compatible with the voltage range of the drive

-switched off

• The motor, ensuring that its coupling corresponds to the line voltage

• The control via the logic inputs

• The speed reference via the logic or analog inputs

5 - Switch on the drive, but do not give a run command

6 - Configure the following:

The nominal frequency (bFr) of the motor, if it is different from 50 Hz.

B

7 - Configure the following in the drC- menu:

The motor parameters, only if the factory configuration of the drive is not suitable.

8 - Configure the following in the I-O-, CtL- and FUn- menus:

The application functions (only if the factory configuration of the drive is not suitable), for example the control mode: 3-wire, or 2-wire

transition detection, or 2-wire level detection, or 2-wire level detection with forward direction priority, or local control for ATV31

The user must ensure that the programmed functions are compatible with the wiring diagram used.

pppA.

9 - Set the following in the SEt- menu:

- The ACC (Acceleration) and dEC (Deceleration) parameters

- The LSP (Low speed when the reference is zero) and HSP (High speed when the reference is maximum) parameters

- The ItH parameter (Motor thermal protection)

10 - Start the drive

Practical recommendations

• Preparations can be made for programming the drive by filling in the configuration and settings tables (see page 76), in particular when

the factory configuration has to be changed.

• It is always possible to return to the factory settings using the FCS parameter in the drC-, I-O-, CtL- and FUn- menus (return to the

configuration selected by the CFG parameter).

The assignment of CFG results directly in a return to the selected configuration.

• For simple applications where the factory settings are suitable, the ATV31 is config ur ed so as to be equ ally robust as the AT V28 factory

settings.

• T o ac hie ve o pti mize d dr ive perf orm anc e in term s of acc urac y an d re spo nse t ime , it is es sen tia l to :

- Enter the values given on the motor rating plate in the Motor control menu drC- (page 23

- Perform an auto-tune operation with the motor cold and connected, using parameter tUn in the drC- menu (page 24

(Aut o- tu ni ng me as ur es th e s ta to r r es is ta nc e o f t he mo to r i n o rd er to op ti mi ze th e c on tr ol al go ri th ms ).

- Adjust parameters FLG and StA in the Settings menu SEt- (page 20

• To locate the description of a function quickly, use the index of functions on page 81

• Before configuring a function, read the "Function compatibility" section on pages 14

).

).

).

.

and 15.

3

Page 22

B

Factory configuration

Factory settings

The ATV 31 is factory-set for the most common operating conditions:

• Display: Drive ready (rdY) with motor stopped, and motor frequency with motor running

• Motor frequency (bFr): 50 Hz

• Constant torque application with sensorless flux vector control (UFt = n)

• Normal stop mode on deceleration ramp (Stt = rMP).

• Stop mode in the event of a fault: Freewheel

• Linear ramps (ACC, dEC): 3 seconds

• Low speed (LSP): 0 Hz

•High speed (HSP): 50 Hz

• Motor thermal current (ItH) = nominal motor current (value depending on drive rating)

• Standstill injection braking current (SdC) = 0.7 x nominal drive current, for 0.5 seconds

• Automatic adaptation of the deceleration ramp in the event of overvoltage on braking

• No automatic restarting after a fault

• Switching frequency 4 kHz

• Logic inputs:

- LI1, LI2 (2 directions of operation): 2-wire transition detection control, LI1 = forward, LI2 = reverse, inactive on ATV 31

(not assigned)

- LI3, LI4: 4 preset speeds (speed 1 = speed reference or LSP, speed 2 = 10 Hz, speed 3 = 15 Hz, speed 4 = 20 Hz).

- LI5 - LI6: Inactive (not assigned)

• Analog inputs:

- AI1: Speed reference 0-10 V, inactive on ATV 31

- AI2: Summed speed reference input 0±10 V

- AI3: 4-20 mA inactive (not assigned)

• Relay R1: The contact opens in the event of a fault (or drive off)

• Relay R2: Inactive (not assigned)

• Analog output AOC: 0-20 mA inactive (not assigned)

ppppppA (not assigned)

ppppppA drives

ATV 31ppppppA range

When they leave the factory, ATV 31ppppppA drives are supplied with local control activated: the RUN, STOP buttons and the drive

potentiometer are active. Logic inputs LI1 and LI2 and analog input AI1 are inactive (not assigned).

If the above values are compatible with the application, the drive can be used without changing the settings.

4

Page 23

Software enhancements

Since it was first marketed, the ATV 31 has been equipped with additional functions. Software version V1.2 has now been updated

to V1.7. This documentation relates to version V1.7.

The software version appears on the rating plate attached to the side of the drive.

Enhancements to version V1.7 compared with V1.2

New parameters

Motor control menu

• /23: Choice of source configuration for the factory settings function (see page 26).

This parameter is also accessible in the I-O-, CtL-, and FUn- menus (pages 29

Application functions menu FUn-

• 5DH: Ramp increment (see page 43)

Fault menu FLt-

• 71I: Configuration of external fault detection (see page 67).

New possible assignments for relays R1 and R2

• Relays R1 and R2 can now be assigned to LI1..LI6. It then returns the value of the selected logic input (see page 28).

, 41 and 65).

B

5

Page 24

B

Basic functions

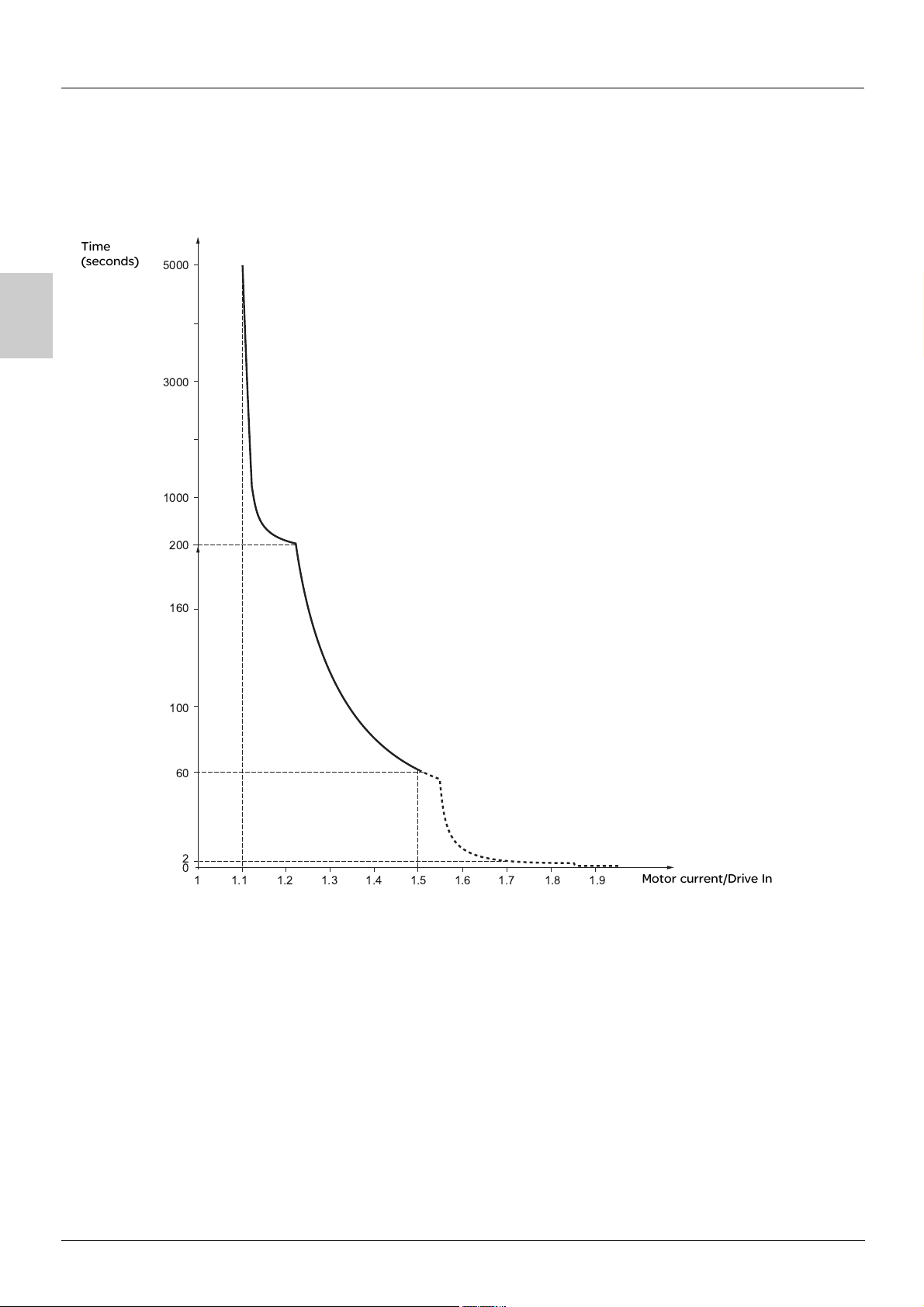

Drive thermal protection

Functions:

Thermal protection by PTC probe fitted on the heatsink or integrated in the power module.

Indirect protection of the drive against overloads by tripping in the event of an overcurrent. Typical tripping points:

- Motor current = 185% of nominal drive current: 2 seconds

- Motor current = 150% of nominal drive current: 60 seconds

Time

(seconds)

5000

3000

1000

200

160

100

60

2

0

1.11

1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9

Motor current/Drive In

Drive ventilation

The fan starts up when the drive is powered up then shuts down after 10 seconds if a run command has not been received.

The fan is powered automatically when the drive is unlocked (operating direction + reference). It is powered down a few seconds after the

drive is locked (motor speed < 0.2 Hz and injection braking completed).

6

Page 25

Basic functions

Motor thermal protection

Function:

Thermal protection by calculating the I2t.

The protection takes account of self-cooled motors.

Caution: The memory of the motor thermal state returns to zero when the drive is disconnected.

Trip time t

in seconds

3 Hz

5 Hz

1 Hz

10 000

50 Hz20 Hz10 Hz

B

1 000

100

0.7 0.8 0.9 1 1.1 1.2 1.3 1.4 1.5 1.6

Motor current/ItH

7

Page 26

Setup - Preliminary recommendations

Prior to switching on and configuring the drive

- Check that the line voltage is compatible with the supply voltage range of the drive (see pages 3 and 4 of the ATV 31

Installation Manual). The drive may be damaged if the line voltage is not compatible.

- Ensure the logic inputs are switched off (state 0) to prevent accidental starting. Otherwise, an input assigned to the run

command may cause the motor to start immediately on exiting the configuration menus.

With power switching via line contactor

- Avoid operating the contactor frequently (premature ageing of the filter capacitors). Use inputs LI1 to LI6 to control the drive.

- These instructions are vital for cycles < 60 s, otherwise the load resistor may be damaged.

B

User adjustment and extension of functions

If necessary, the display and buttons can be used to modify the settings and to extend the functions described in the following pages. It

is very easy to return to the factory settings using the FCS parameter in the drC-, I-O-, CtL- and FUn- menus (set InI to activate the

function, see page 26

There are three types of parameter:

- Display: Values displayed by the drive

- Setting: Can be changed during operation or when stopped

- Configuration: Can only be modified when stopped and no braking is taking place. Can be displayed during operation.

- Check that changes to the current operating settings do not present any danger. Changes should preferably be made with

the drive stopped.

, 30, 41 or 65).

Start up

Important: In factory settings mode on power-up, or in a manual fault reset or after a stop command, the motor can only be powered once

the "forward", "reverse" and "DC injection stop" commands have been reset. If they have not been reset, the drive will display "nSt" but

will not start. If the automatic restart function is configured (parameter Atr in the FLt- menu, see page 66

into account without a reset being necessary.

), these commands are taken

Test on a low power motor or without a motor

• In factory settings mode, "motor phase loss" detection is active (OPL = YES). To check the drive in a test or maintenance environment

without having to switch to a motor with the same rating as the drive (particularly useful in the case of high power drives), deactivate

"motor phase loss" detection (OPL = NO).

•Configure the voltage/frequency ratio: UFt = L (drC- menu on page 24

• Motor thermal protection will not be provided by the drive if the motor current is less than 0.2 times the nominal drive current.

)

Using motors in parallel

•Configure the voltage/frequency ratio: UFt = L (drC- menu on page 24)

• Motor thermal protection is no longer provided by the drive. Provide an alternative means of thermal protection on every

motor.

8

Page 27

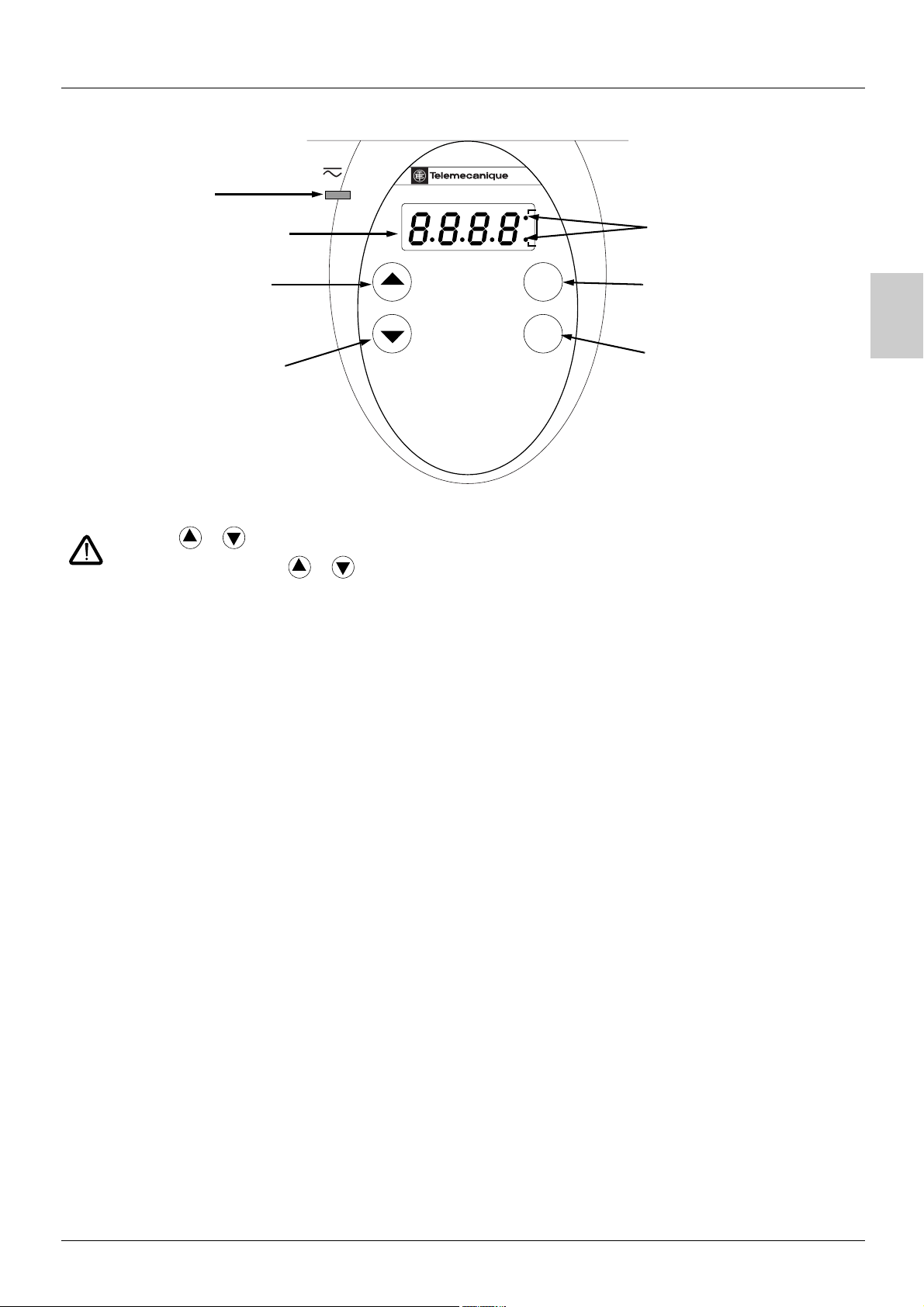

Functions of the display and the keys

•Red LED

"DC bus ON"

• Four 7-segment displays

• Returns to the previous

menu or parameter, or

increases the displayed

value

• Goes to the next menu or

parameter, or decreases

the displayed value

• Pressing or does not store the selection.

• Press and hold down (>2 s) or to scroll through the data quickly.

To save and store the selection: ENT

The display flashes when a value is stored.

ATV 31

RUN

CAN

ERR

ESC

ENT

• 2 CANopen status LEDs

• Exits a menu or parameter, or

clears the displayed value to

return to the previous stored

value

• Enters a menu or a parameter,

or saves the displayed

parameter or value

B

Normal display, with no fault present and no starting:

- 43.0: Display of the parameter selected in the SUP- menu (default selection: motor frequency).

In current limit mode, the display flashes.

- init: Initialization sequence

-rdY: Drive ready

- dcb: DC injection braking in progress

- nSt: Freewheel stop

-FSt: Fast stop

- tUn: Auto-tuning in progress

The display flashes to indicate the presence of a fault.

9

Page 28

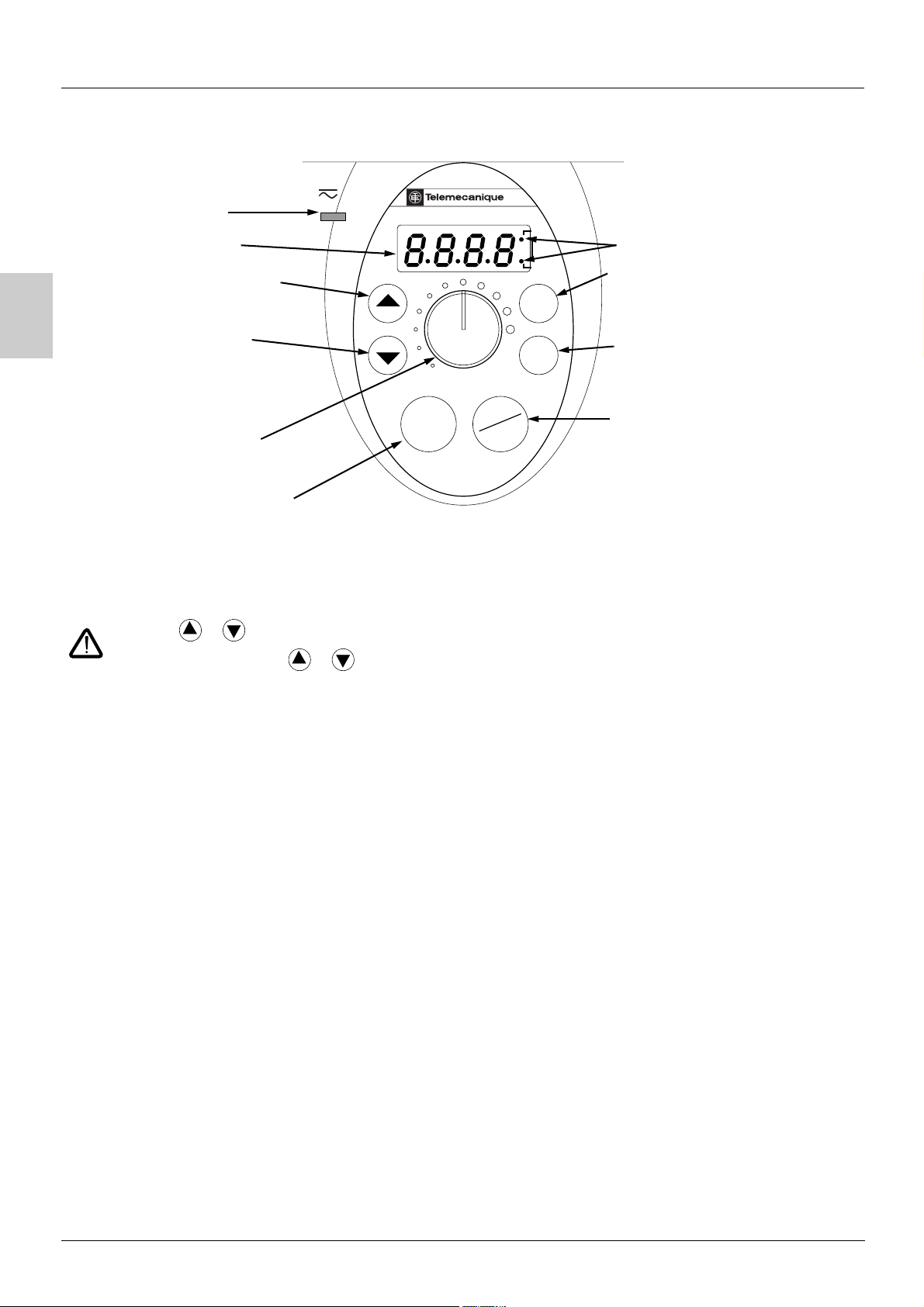

Functions of the display and the keys

ATV31ppppppA:

B

•Red LED

"DC bus ON"

• Four 7-segment displays

• Returns to the previous menu or

parameter, or increases the

displayed value

• Goes to the next menu or

parameter, or decreases the

displayed value

• Reference potentiometer,

active if the Fr1 parameter in the

CtL- menu is configured as AIP

•RUN button: Controls motor

switch-on in forward mode, if

parameter tCC in the I-O- menu is

configured as LOC

• Pressing or does not store the selection.

ATV 31

RUN

STOP

RESET

RUN

CAN

ERR

ESC

ENT

•2 CANopen status LEDs

• Exits a menu or a parameter,

or clears the displayed value to return

to the previous stored value

• Enters a menu or a parameter, or

saves the displayed parameter or

value

STOP/RESET button

• Used to reset faults

•Can be used to control motor

stopping

- If tCC (I-O- menu) is not configured

as LOC, it is a freewheel stop.

- If tCC (I-O- menu) is configured as

LOC, stopping is on a ramp, but if

injection braking is in progress, a

freewheel stop takes place.

• Press and hold down (>2 s) or to scroll through the data quickly.

To save and store the selection: ENT

The display flashes when a value is stored.

Normal display, with no fault present and no starting:

- 43.0: Display of the parameter selected in the SUP- menu (default selection: output frequency applied to the motor).

In current limit mode, the display flashes.

- init: Initialization sequence

-rdY: Drive ready

- dcb: DC injection braking in progress

- nSt: Freewheel stop

-FSt: Fast stop

- tUn: Auto-tuning in progress

The display flashes to indicate the presence of a fault.

10

Page 29

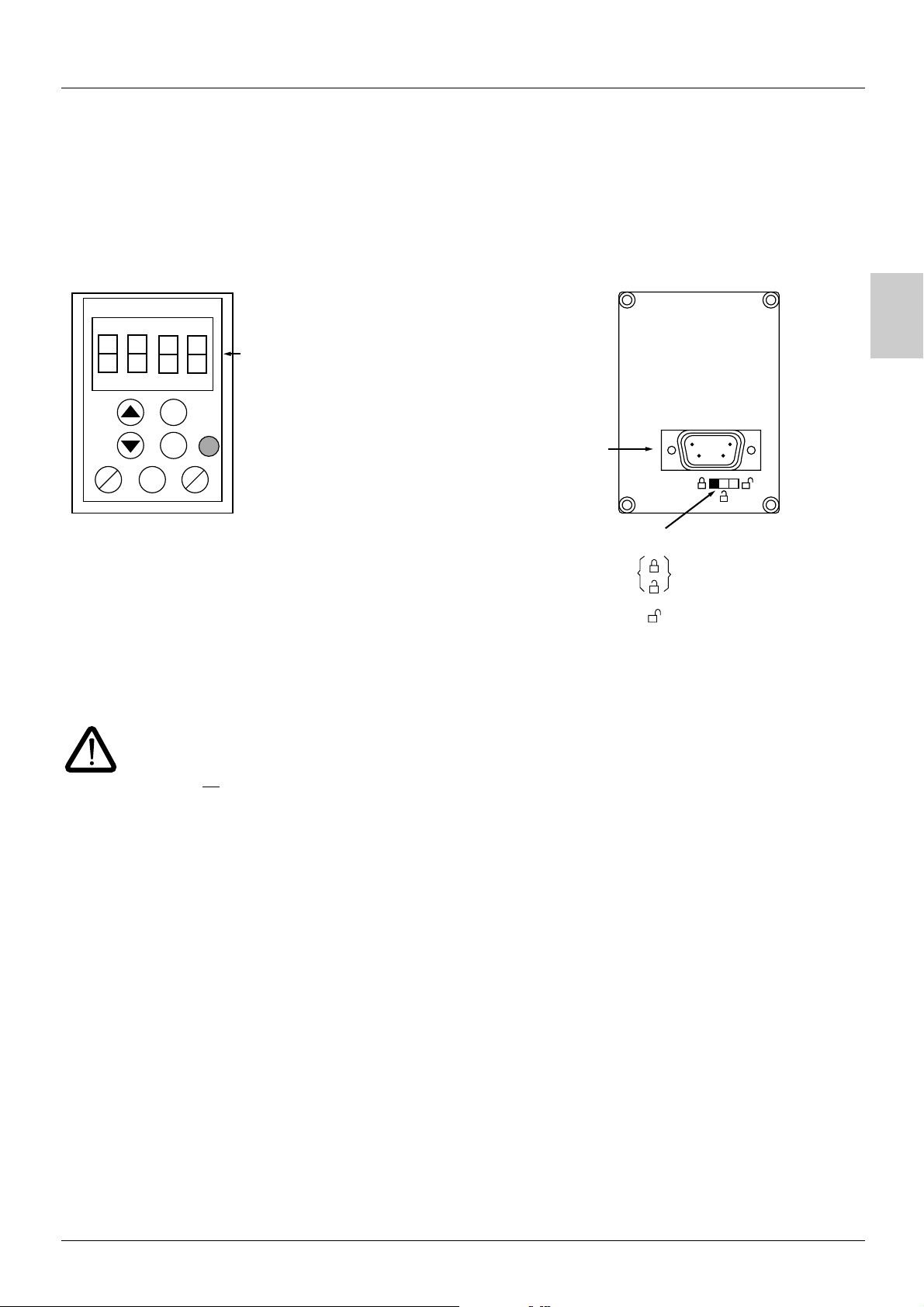

Remote terminal option

This module is a local control unit which can be mounted on the door of the wall-mounted or floor-standing enclosure. It has a cable with

connectors, which is connected to the drive serial link (see the manual supplied with the terminal). It has the same display and the same

programming buttons as the ATV 31 with the addition of a switch to lock access to the menus and three buttons for controlling the drive:

• FWD/REV: reversal of the direction of rotation

• RUN: motor run command

• STOP/RESET: Motor stop command or fault reset

Pressing the button a first time stops the motor, and if DC injection standstill braking is configured, pressing it a second time stops this

braking.

View of the front panel: View of the rear panel:

4-character

display unit

ESC

B

ENT

FWD

REV

Note: Customer password protection has priority on the switch.

• The access locking switch on the remote terminal also prevents the drive settings being accessed via the keypad.

• When the remote terminal is disconnected, if the drive has been locked, the keypad will remain locked.

• In order for the remote terminal to be active, the tbr parameter in the COM- menu must remain in factory settings mode: 19.2

STOP

RUN

(see page 79

RESET

).

Connector

Access locking switch:

• positions: settings and display accessible

(SEt- and SUP- menus)

• position: all menus can be accessed

Saving and loading configurations

Up to four complete configurations for ATV 31 drives can be stored on the remote terminal. These configurations can be saved,

transported and transferred from one drive to another of the same rating. 4 different operations for the same device can also be stored

on the terminal. See the SCS and FCS parameters in the drC-, I-O-, CtL- and FUn- menus.

11

Page 30

B

Programming

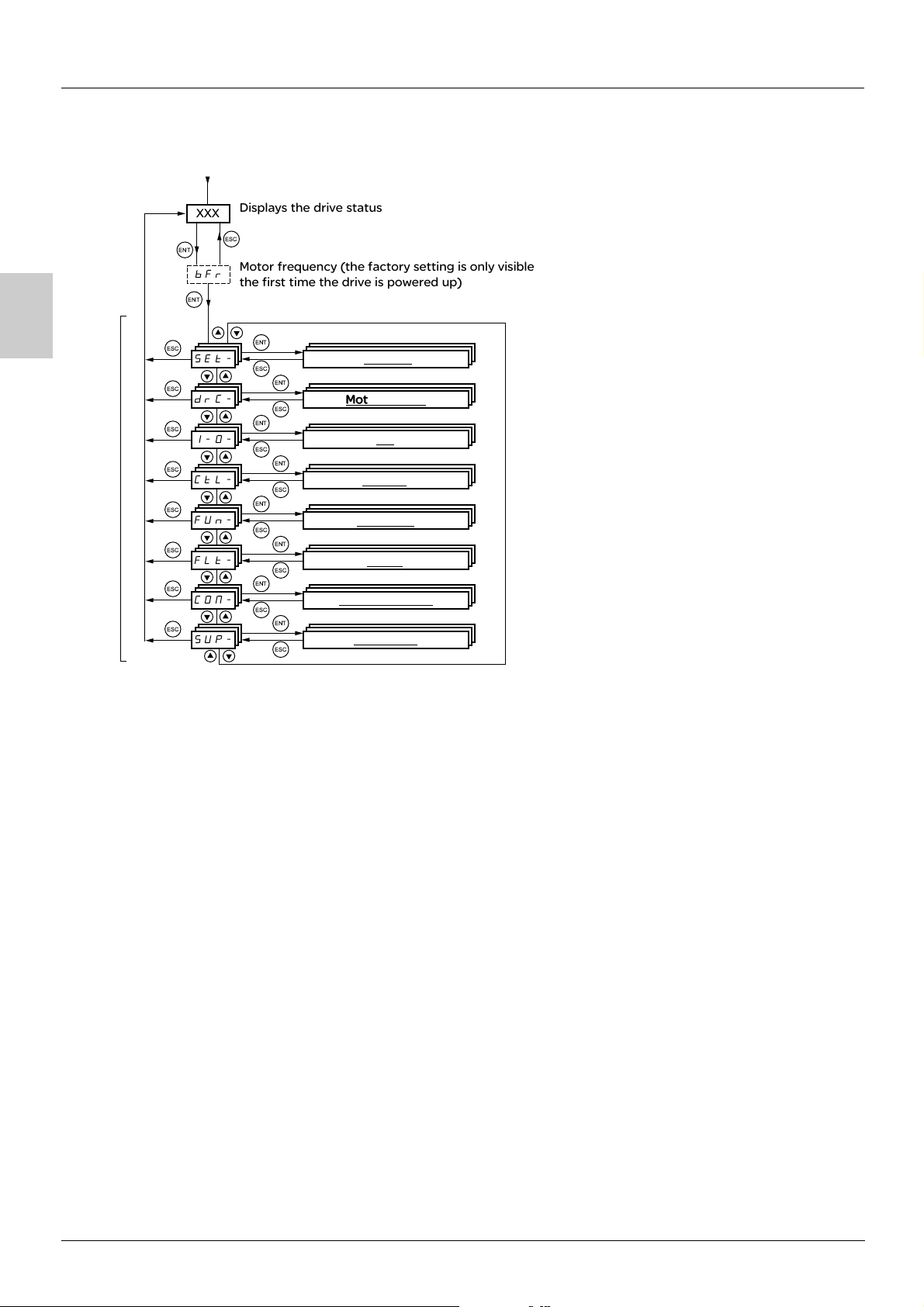

Access to menus

Power-up

XXX

ENT

bFr

ENT

ESC

SEt-

ESC

drC-

ESC

I-O-

ESC

Menus

ESC

ESC

ESC

ESC

CtL-

FUn-

FLt-

CON-

SUP-

Displays the drive status

ESC

Motor frequency (the factory setting is only visible

the first time the drive is powered up)

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

Settings

Motor control

I/O

Control

Functions

Faults

Communication

Monitoring

Some parameters can be accessed in a number of menus for increased user-friendliness:

- Entering settings

- Return to factory settings

- Restoring and saving the configuration

A dash appears after menu and sub-menu codes to differentiate them from parameter codes.

Examples: FUn- menu, ACC parameter.

12

Page 31

Programming

Accessing menu parameters

To save and store the selection:

The display flashes when a value is stored.

Example:

Menu

Parameter

ENT

Value or assignment

ENT

ESC

26.0 26.0

ESC

ENT

1 flash

(save)

SEt-

ENT

ACC 15.0

ESC

dEC

(Next parameter)

All the menus are "drop-down" type menus, which means that after the last parameter, if you continue to press , you will return to the

first parameter and, conversely, you can switch from the first parameter to the last parameter by pressing .

Menu

ENT

ESC

st

1

th

n

last

th

If, after modifying any of the parameters (n

meantime, you will be taken directly to the n

), you quit a menu and return to this menu without having accessed another menu in the

th

parameter (see below). If, in the meantime, you have accessed another menu or have

restarted the system, you will always be taken to the first parameter in the menu (see above).

B

st

1

Menu

ENT

ESC

th

n

last

Configuration of the bFr parameter

This parameter can only be modified in stop mode without a run command.

>.H

Code

bFr Standard motor frequency 50

Description Adjustment range Factory setting

This parameter is only visible the first time the drive is switched on.

It can be modified at any time in the drC- menu.

50 Hz: IEC

60 Hz: NEMA

This parameter modifies the presets of the following parameters: HSP page 19

page 25

.

, Ftd page 22, FrS page 23 and tFr

13

Page 32

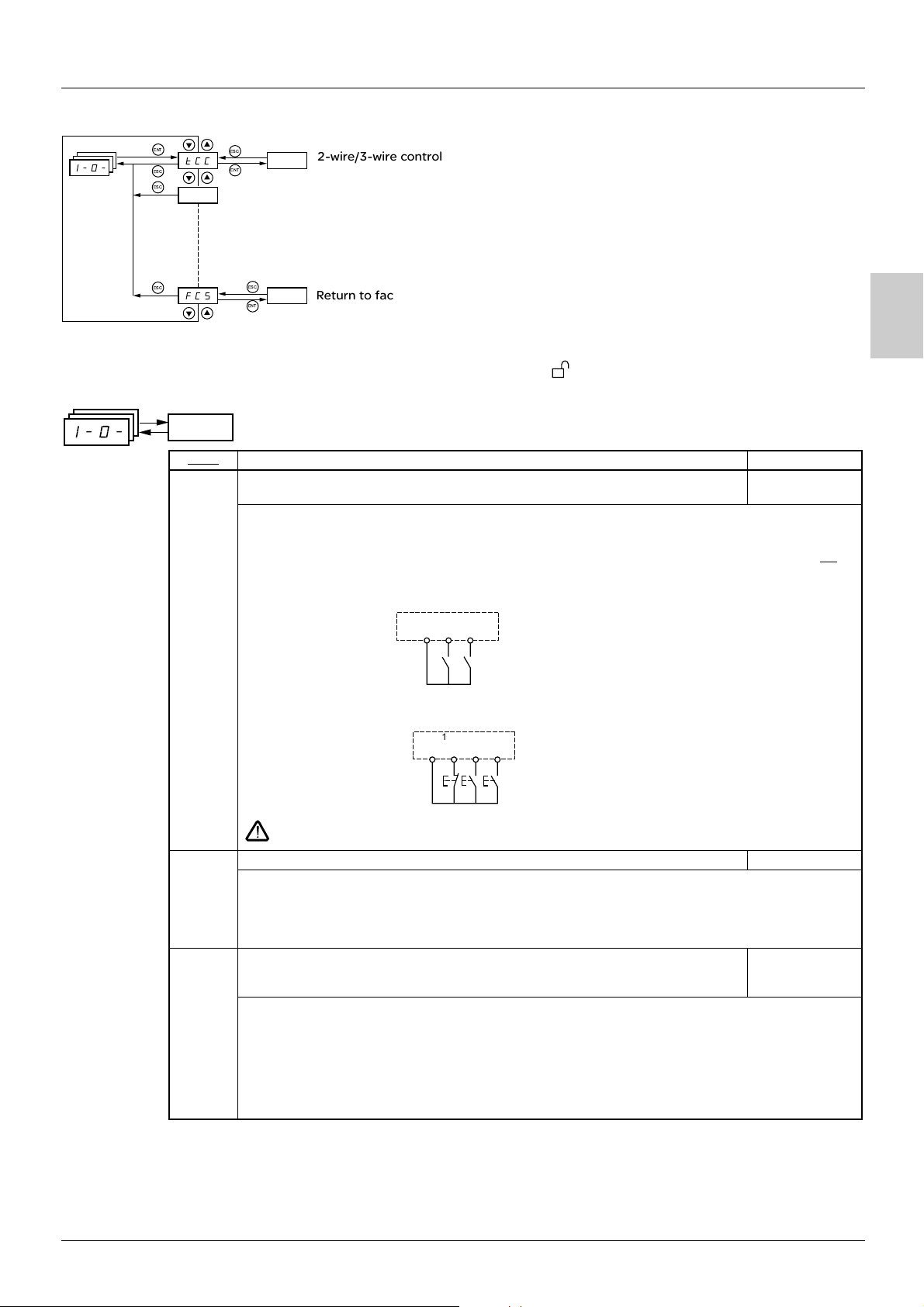

Function compatibility

Incompatible functions

The following functions will be inaccessible or deactivated in the cases described below:

Automatic restart

This is only possible for 2-wire level detection control (tCC = 2C and tCt = LEL or PFO).

Flying restart

This is only possible for 2-wire level detection control (tCC = 2C and tCt = LEL or PFO).

This function is locked if automatic standstill injection is configured as DC (AdC = Ct).

B

Reverse

On the ATV31pppA range only, this function is locked if local control is active (tCC = LOC).

Function compatibility table

The choice of application functions may be limited by the number of I/O and by the fact that some functions are incompatible with one

another. Functions which are not listed in this table are fully compatible.

If there is an incompatibility between functions, the first function configured will prevent the remainder being configured.

To configure a function, first check that functions which are incompatible with it are unassigned, especially those which are

assigned in the factory settings.

Summing inputs (factory setting)

+/- speed (1)

Management of limit switches

Preset speeds (factory setting)

PI regulator

Jog operation

Brake control

DC injection stop

Fast stop

Summing inputs (factory setting)

+/- speed (1)

Management of limit switches

Preset speeds (factory setting)

PI regulator

Jog operation

Brake control

DC injection stop

Fast stop

Freewheel stop

pApA

p ppp

p

Xp pA

pppp pp

Xp Xp p

pp p

p A

XX

Freewheel stop

A

(1)Excluding special application with reference channel Fr2 (see diagrams 33

Incompatible functions Compatible functions Not applicable

p

Priority functions (functions which cannot be active simultaneously):

XA

Stop functions have priority over run commands.

Speed references via logic command have priority over analog references.

14

The function indicated by the arrow has priority over the

other.

and 35)

Page 33

Function compatibility

Logic and analog input application functions

Each of the functions on the following pages can be assigned to one of the inputs.

A single input can activate several functions at the same time (reverse and 2

these functions can be used at the same time.

The SUP- display menu (parameters LIA and AIA on page 72

their compatibility.

Before assigning a reference, a command or a function to a logic or analog input, check that this input has not already been assigned in the

factory settings, and that no other input has been assigned to an incompatible or unwanted function.

• E xam ple of in com pat ibl e fun cti on t o be u nas sig ned: T o

activate "+/- speed", first unassign the preset speeds and summing input 2.

• E xam ple of un wan ted func tio n to be un ass ign ed: To

control an ATV31pppA at the terminals it is advisable to unassign the potentiometer and the RUN button.

The following table indicates the factory-set input assignments and the procedure for unassigning them.

Assigned input Funciton

ppp ATV31pppA

ATV31

LI2 Reverse rrS nO 27

LI3 LI3 2 preset speeds pS2 nO 50

LI4 LI4 4 preset speeds PS4 nO 50

AI1 Reference 1 Fr1 Anything but AI1 38

RUN button Forward tCC 2C or 3C 27

AIP (potentiometer) Reference 1 Fr1 Anything but AIP 38

AI2 AI2 Summing input 2 SA2 nO 48

) can be used to display the functions assigned to each input in order to check

nd

ramp for example). The user must therefore ensure that

Code To unassign, set to: Page

B

15

Page 34

B

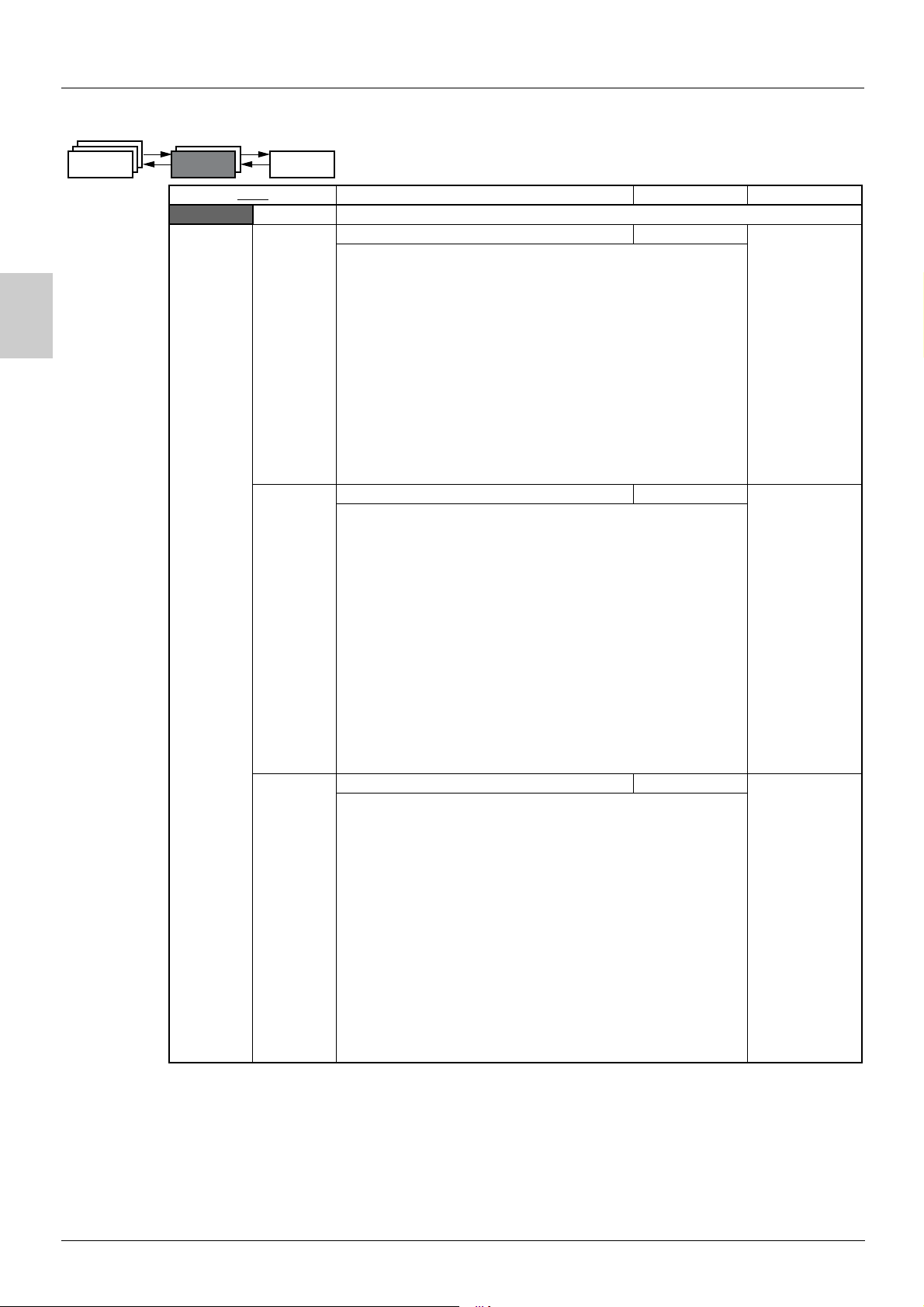

List of functions which can be assigned to inputs/outputs

Logic inputs Page Code Factory setting

ppp ATV31pppA

ATV31

Not assigned -

Forward -

2 preset speeds 50

4 preset speeds 50

8 preset speeds 50

16 preset speeds 51

2 preset PI references 57

4 preset PI references 57

+ speed 54

- speed 54

Jog operation 52

Ramp switching 43

Switching for 2

Fast stop via logic input 45

DC injection via logic input 45

Freewheel stop via logic input 46

Reverse 27

External fault 67

RESET (fault reset) 66

Forced local mode 69

Reference switching 39

Control channel switching 40

Motor switching 62

Forward limit switch 64

Reverse limit switch 64

Fault inhibit 68

nd

current limit 61 LC2

- LI5 - LI6 LI1 - LI2

-LI1

PS2 LI3 LI3

PS4 LI4 LI4

PS8

PS16

Pr2

Pr4

USP

dSP

JOG

rPS

FSt

dCI

nSt

rrS LI2

EtF

rSF

FLO

rFC

CCS

CHP

LAF

LAr

InH

LI5 - LI6

Analog inputs Page

Not assigned -

Reference 1 38

Reference 2 38

Summing input 2 48

Summing input 3 48

PI regulator feedback 57

Analog/logic output Page

Not assigned -

Motor current 28

Motor frequency 28

Motor torque 28

Power supplied by the drive 28

Drive fault (logic data) 28

Drive running (logic data) 28

Frequency threshold reached (logic data) 28

High speed (HSP) reached (logic data) 28

Current threshold reached (logic data) 28

Frequency reference reached (logic data) 28

Motor thermal threshold reached (logic data) 28

Brake sequence (logic data) 60

Code Factory setting

ppp ATV31pppA

ATV31

-AI3AI1 - AI3

Fr1 AI1 AIP

Fr2

SA2 AI2 AI2

SA3

PIF

Code Factory setting

- AOC/AOV

9/H

H2H

979

9:H

27I

H<D

2I27/I;HI;>7/

(potentiometer

)

16

Page 35

List of functions which can be assigned to inputs/outputs

Relay Page Code Factory setting

Not assigned -

Drive fault 28

Drive running 28

Frequency threshold reached 28

High speed (HSP) reached 28

Current threshold reached 28

Frequency reference reached 28

Motor thermal threshold reached 28

Brake sequence 60

Copy of the logic input 28

-R2

27I R1

H<D

2I27/I;HI;>7/

7$ p

B

17

Page 36

B

List of functions that can be assigned to the CANopen and Modbus control

word bits

Relay Page Code

2 preset speeds 50 :;%

4 preset speeds 50

8 preset speeds 50

16 preset speeds 51

2 preset PI references 57

4 preset PI references 57

Ramp switching 43

Switching for 2

Fast stop via logic input 45

DC injection via logic input 45

External fault 67

Reference switching 39

Control channel switching 40

Motor switching 62

nd

current limit 61 7/%

:;'

:;+

:;$)

:H%

:H'

H:(

2;I

@/$

1I2

H2/

CC5

/4:

18

Page 37

Settings menu SEt-

ENT

Speed reference via the terminal

ESC

ENT

ESC

ENT

ESC

ENT

Spd parameter scale factor

ESC

SEt-

ENT

LFr

ESC

ESC

rPI

ESC

ACC

ESC

SdS

The adjustment parameters can be modified with the drive running or stopped.

Check that it is safe to make changes during operation. Changes should preferably be made in stop mode.

These parameter appear regardless of how the other menus have been configured.

These parameters only appear if the corresponding function has been selected in another menu. When the corresponding

function is also accessible and adjustable from within the configuration menu, to aid programming their description is

detailed in these menus, on the pages indicated.

SEt-

B

Code

Description Adjustment range Factory setting

72H Speed reference via the remote terminal 0 to HSP

This parameter appears if LCC = YES (page 40

) or if Fr1/Fr2 = LCC (page 38), and if the remote terminal

is online. In this case, LFr can also be accessed via the drive keypad.

LFr is reset to 0 when the drive is powered down.

H:5 Internal PI regulator reference See page 57 0.0 to 100% 0

-// Acceleration ramp time according to

3 s

parameter Inr

(See page 43

)

Defined as the acceleration time between 0 and the nominal frequency FrS (parameter in the drC- menu).

-/% 2

nd

acceleration ramp time See page 44 according to

5 s

parameter Inr

(See page 43

@1% 2nd deceleration ramp time See page 44 according to

)

5 s

parameter Inr

(See page 43

@1/ Deceleration ramp time according to

)

3 s

parameter Inr

(See page 43

)

Defined as the deceleration time between the nominal frequency FrS (parameter in the drC- menu) and 0.

Check that the value of dEC is not too low in relation to the load to be stopped.

I-$ Start of CUS-type acceleration ramp rounded

See page 42 0 to 100 10%

as % of total ramp time (ACC or AC2)

I-% End of CUS-type acceleration ramp rounded

See page 42 0 to (100-tA1) 10%

as % of total ramp time (ACC or AC2)

I-& Start of CUS-type deceleration ramp rounded

See page 42 0 to 100 10%

as % of total ramp time (dEC or dE2)

I-' End of CUS-type deceleration ramp rounded

See page 42 0 to (100-tA3) 10%

as % of total ramp time (dEC or dE2)

7;: Low speed 0 to HSP 0 Hz

(Motor frequency at min. reference)

4;: High speed LSP to tFr bFr

(Motor frequency to max. reference): Check that this setting is suitable for the motor and the application.

19

Page 38

Settings menu SEt-

SEt-

B

Code

Description Adjustment range Factory setting

5I4 Motor thermal protection - max. thermal current 0.2 to 1.5 In (1) According to drive

rating

Set ItH to the nominal current on the motor rating plate.

Please refer to OLL on page 67

if you wish to suppress thermal protection.

<2H IR compensation/voltage boost 0 to 100% 20

- For UFt (page 24

) = n or nLd: IR compensation

- For UFt = L or P: Voltage boost

Used to optimize the torque at very low speed (increase UFr if the torque is insufficient).

Check that the value of UFr is not too high for when the motor is warm (risk of instability).

Modifying UFt (page 24

) will cause UFr to return to the factory setting (20%).

273 Frequency loop gain 1 to 100% 20

Parameter can only be accessed if UFt (page 24

) = n or nLd.

The FLG parameter adjusts the drive’s ability to follow the speed ramp based on the inertia of the machine

being driven.

Too high a gain may result in operating instability.

Hz

50

40

30

20

10

0

-10

0 0.1 0.2 0.3 0.4 0.5

FLG low

In this case,

increase FLG

Hz

50

40

30

20

10

0

-10

t

0 0.1 0.2 0.3 0.4 0.5

FLG correct

Hz

50

40

30

20

10

0

-10

t

0 0.1 0.2 0.3 0.4 0.5

FLG high

In this case,

reduce FLG

;I- Frequency loop stability 1 to 100% 20

Parameter can only be accessed if UFt (page 24

) = n or nLd.

Used to adapt the return to steady state after a speed transient (acceleration or deceleration), according

to the dynamics of the machine.

Gradually increase the stability to avoid any overspeed.

Hz

50

40

30

20

10

0

-10

0 0.1 0.2 0.3 0.4 0.5 t

StA low

In this case,

increase StA

Hz

50

40

30

20

10

0

-10

0 0.1 0.2 0.3 0.4 0.5 t

StA correct

Hz

50

40

30

20

10

0

-10

0 0.1 0.2 0.3 0.4 0.5 t

StA high

In this case,

reduce StA

;7: Slip compensation 0 to 150% 100

Parameter can only be accessed if UFt (page 24

) = n or nLd.

Used to adjust the slip compensation value fixed by nominal motor speed.

The speeds given on motor rating plates are not necessarily exact.

• If slip setting < actual slip: the motor is not rotating at the correct speed in steady state.

• If slip setting > actual slip: the motor is overcompensated and the speed is unstable.

5@/ Level of DC injection braking current activated via

See page 46 0 to In (1) 0.7 In (1)

logic input or selected as stop mode (2).

I@/ Total DC injection braking time selected as stop

See page 46 0.1 to 30 s 0.5 s

mode (2).

I@/$ Automatic standstill DC injection time See page 47 0.1 to 30 s 0.5 s

;@/$ Level of automatic standstill DC injection current See page 47 0 to 1.2 In (1) 0.7 In (1)

I@/% 2nd automatic standstill DC injection time See page 47 0 to 30 s 0 s

;@/% 2

nd

level of standstill DC injection current See page 47 0 to 1.2 In (1) 0.5 In (1)

t

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the drive rating plate.

(2)Caution: These settings are not related to the "automatic standstill DC injection" function.

These parameters only appear if the corresponding function has been selected in another menu. When the corresponding

function is also accessible and adjustable from within the configuration menu, to aid programming their description is

detailed in these menus, on the pages indicated.

Those which are underlined appear in factory settings mode.

20

Page 39

Settings menu SEt-

SEt-

Code

6:2 Skip frequency 0 to 500 0 Hz

62% 2

632 Jog operating frequency See page 52 0 to 10 Hz 10 Hz

H:3 PI regulator proportional gain See page 57 0.01 to 100 1

H53 PI regulator integral gain See page 57 0.01 to 100/s 1/s

2>; PI feedback multiplication coefficient See page 57 0.1 to 100 1

:5/ Reversal of the direction of correction of the PI

H:% 2

H:& 3

H:' 4

;:% 2nd preset speed See page 51 0 to 500 Hz 10 Hz

;:& 3rd preset speed See page 51 0 to 500 Hz 15 Hz

;:' 4th preset speed See page 51 0 to 500 Hz 20 Hz

;:( 5th preset speed See page 51 0 to 500 Hz 25 Hz

;:) 6th preset speed See page 51 0 to 500 Hz 30 Hz

;:* 7th preset speed See page 51 0 to 500 Hz 35 Hz

;:+ 8th preset speed See page 51 0 to 500 Hz 40 Hz

;:, 9th preset speed See page 51 0 to 500 Hz 45 Hz

;:$# 10th preset speed See page 51 0 to 500 Hz 50 Hz

;:$$ 11th preset speed See page 51 0 to 500 Hz 55 HZ

;:$% 12th preset speed See page 51 0 to 500 Hz 60 Hz

;:$& 13th preset speed See page 51 0 to 500 Hz 70 Hz

;:$' 14th preset speed See page 51 0 to 500 Hz 80 Hz

;:$( 15th preset speed See page 51 0 to 500 Hz 90 Hz

;:$) 16th preset speed See page 51 0 to 500 Hz 100 Hz

/75 Current limit 0.25 to 1.5 In (1) 1.5 In (1)

/7% 2nd current limit See page 61 0.25 to 1.5 In (1) 1.5 In (1)

I7; Low speed operating time 0 to 999.9 s 0 (no time limit)

H;7 Restart error threshold ("wake-up" threshold) See page 58 0 to 100% 0

<2H% IR compensation, motor 2 See page 63 0 to 100% 20

273% Frequency loop gain, motor 2 See page 63 1 to 100% 20

;I-% Stability, motor 2 See page 63 1 to 100% 20

;7:% Slip compensation, motor 2 See page 63 0 to 150% 100%

Description Adjustment range Factory setting

Prevents prolonged operation at a frequency range of ± 1 Hz around JPF. This function prevents a critical

speed which leads to resonance. Setting the function to 0 renders it inactive.

nd

skip frequency 0 to 500 0 Hz

Prevents prolonged operation at a frequency range of ± 1 Hz around JF2. This function prevents a critical

speed which leads to resonance. Setting the function to 0 renders it inactive.

regulator

nd

preset PI reference See page 57 0 to 100% 30%

rd

preset PI reference See page 57 0 to 100% 60%

th

preset PI reference See page 57 0 to 100% 90%

Used to limit the torque and the temperature rise of the motor.

Following operation at LSP for a defined period, a motor stop is requested automatically. The motor

restarts if the frequency reference is greater than LSP and if a run command is still present.

Caution: Value 0 corresponds to an unlimited time

See page 57 nO - YES nO

B

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the drive rating plate.

These parameters only appear if the corresponding function has been selected in another menu. When the corresponding

function is also accessible and adjustable from within the configuration menu, to aid programming their description is

detailed in these menus, on the pages indicated.

Those which are underlined appear in factory settings mode.

21

Page 40

Settings menu SEt-

SEt-

B

Code

2I@ Motor frequency threshold above which the relay contact

II@ Motor thermal state threshold above which the relay contact (R1 or

/I@ Motor current threshold beyond which the relay contact

;@; Scale factor for display parameter SPd1/SPd2/SPd3 (SUP- menu

;2H Switching frequency See page 25

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the drive rating plate.

Description Adjustment range Factory setting

(R1 or R2 = FtA) closes or output AOV = 10 V (dO = StA)

R2 = tSA) closes or output AOV = 10 V (dO = tSA)

(R1 or R2 = CtA) closes or output AOV = 10 V (dO = CtA)

on page 71

Used to scale a value in proportion to the output frequency rFr: the machine speed, the motor speed, etc.

- If SdS

-If 1 < SdS

- If SdS > 10, SPd3 is displayed (possible definition = 1)

- If SdS > 10 and SdS x rFr > 9999:

- If SdS > 10 and SdS x rFr > 65535, display locked at 65.54

Example: Display motor speed for

4-pole motor, 1500 rpm at 50 Hz (synchronous speed):

SdS = 30

SPd3 = 1500 at rFr = 50 Hz

This parameter can also be accessed in the drC- menu.

)

y 1, SPd1 is displayed (possible definition = 0.01)

y 10, SPd2 is displayed (possible definition = 0.1)

Display of Spd3 = to 2 decimal places

Example: For 24 223, display is 24.22

SdS x rFr

1000

0 to 500 Hz bFr

0 to 118% 100%

0 to 1.5 In (1) In (1)

0.1 to 200 30

2.0 to 16 kHz 4 kHz

22

Page 41

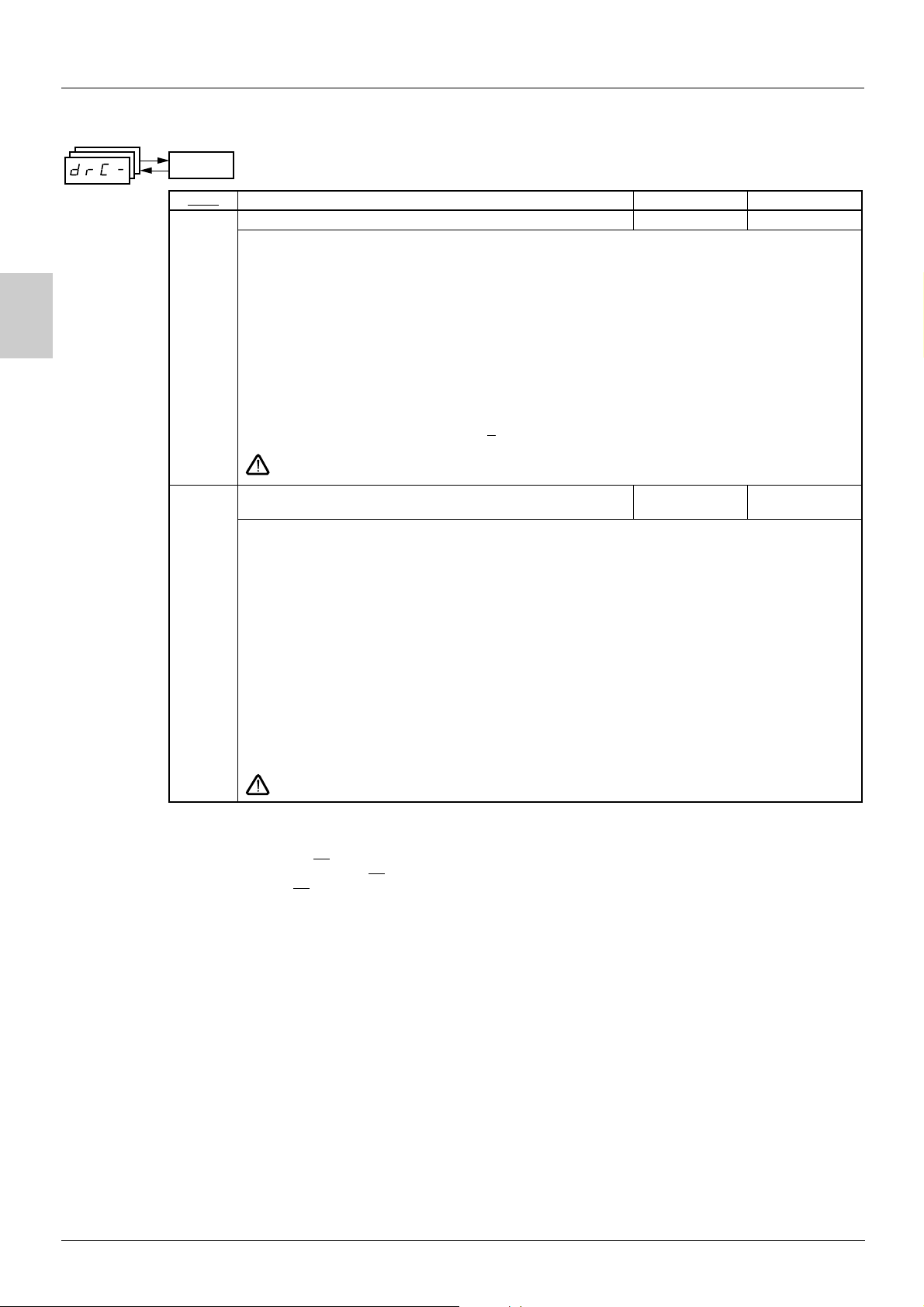

Motor control menu drC-

drC-

ENT

bFr

ESC

ESC

tAI

ESC

FCS

ESC

ENT

ESC

ENT

Standard motor frequency

Return to factory settings/restore configuration

With the exception of tUn, which can power up the motor, parameters can only be modified in stop mode, with no run command present.

On the optional remote terminal, this menu can be accessed with the switch in the position.

Drive performance can be optimized by:

- Entering the values given on the motor rating plate in the drive menu

- Performing an auto-tune operation (on a standard asynchronous motor)

drC-

Code

>2H Standard motor frequency 50

<D; Nominal motor voltage given on the rating plate According to drive

2H; Nominal motor frequency given on the rating plate 10 to 500 Hz 50 Hz

D/H Nominal motor current given on the rating plate 0.25 to 1.5 In (1) According to drive

D;: Nominal motor speed given on the rating plate 0 to 32760 RPM According to drive

Description Adjustment range Factory setting

50 Hz: IEC

60 Hz: NEMA

This parameter modifies the presets of the following parameters: HSP page 19

tFr page 25

.

, Ftd page 22, FrS page 23 and

According to drive

pppM2: 100 to 240 V

ATV31

pppM3X: 100 to 240 V

ATV31

pppN4: 100 to 500 V

ATV31

pppS6X: 100 to 600 V

ATV31

The ratio must not exceed the following values:

ATV31

pppM2: 7 max.

pppM3X: 7 max.

ATV31

pppN4: 14 max.

ATV31

pppS6X: 17 max.

ATV31

rating

UnS (in volts)

FrS (in Hz)

rating

The factory setting is 50 Hz, or preset to 60 Hz if bFr is set to 60 Hz.

rating

rating

0 to 9999 RPM then 10.00 to 32.76 KRPM

If, rather than the nominal speed, the rating plate indicates the synchronous speed and the slip in Hz or as

a %, calculate the nominal speed as follows:

• Nominal speed = Synchronous speed x

or

• Nominal speed = Synchronous speed x (50 Hz motors)

or

• Nominal speed = Synchronous speed x (60 Hz motors)

100 - slip as a %

100

50 - slip in Hz

50

60 - slip in Hz

60

B

/9; Motor Cos Phi given on the rating plate 0.5 to 1 According to drive

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the drive rating plate.

rating

23

Page 42

Motor control menu drC-

drC-

B

Code

H;/ Cold state stator resistance nO

I<D Motor control auto-tuning nO

Description Adjustment range Factory setting

D9: Function inactive. For applications which do not require high performance or do not tolerate

automatic autotuning (passing a current through the motor) each time the drive is powered up.

5D5I: Activates the function. To improve low-speed performance whatever the thermal state of the

motor.

: Value of cold state stator resistance used, in mΩ.

XXXX

Caution:

• It is strongly recommended that this function is activated in Lifting and Handling applications.

• The function should only be activated (InIt) when the motor is in cold state.

• When rSC = InIt, parameter tUn is forced to POn. At the next run command, the stator resistance is

measured with an auto-tune. Parameter rSC then changes to this value (XXXX) and maintains it; tUn

remains forced to POn. Parameter rSC remains at InIt as long as the measurement has not been performed.

• Value XXXX can be forced or modified using the keys(1).

It is essential that all the motor parameters (UnS, FrS, nCr, nSP, COS) are configured correctly before

performing auto-tuning.

D9: Auto-tuning not performed.