Page 1

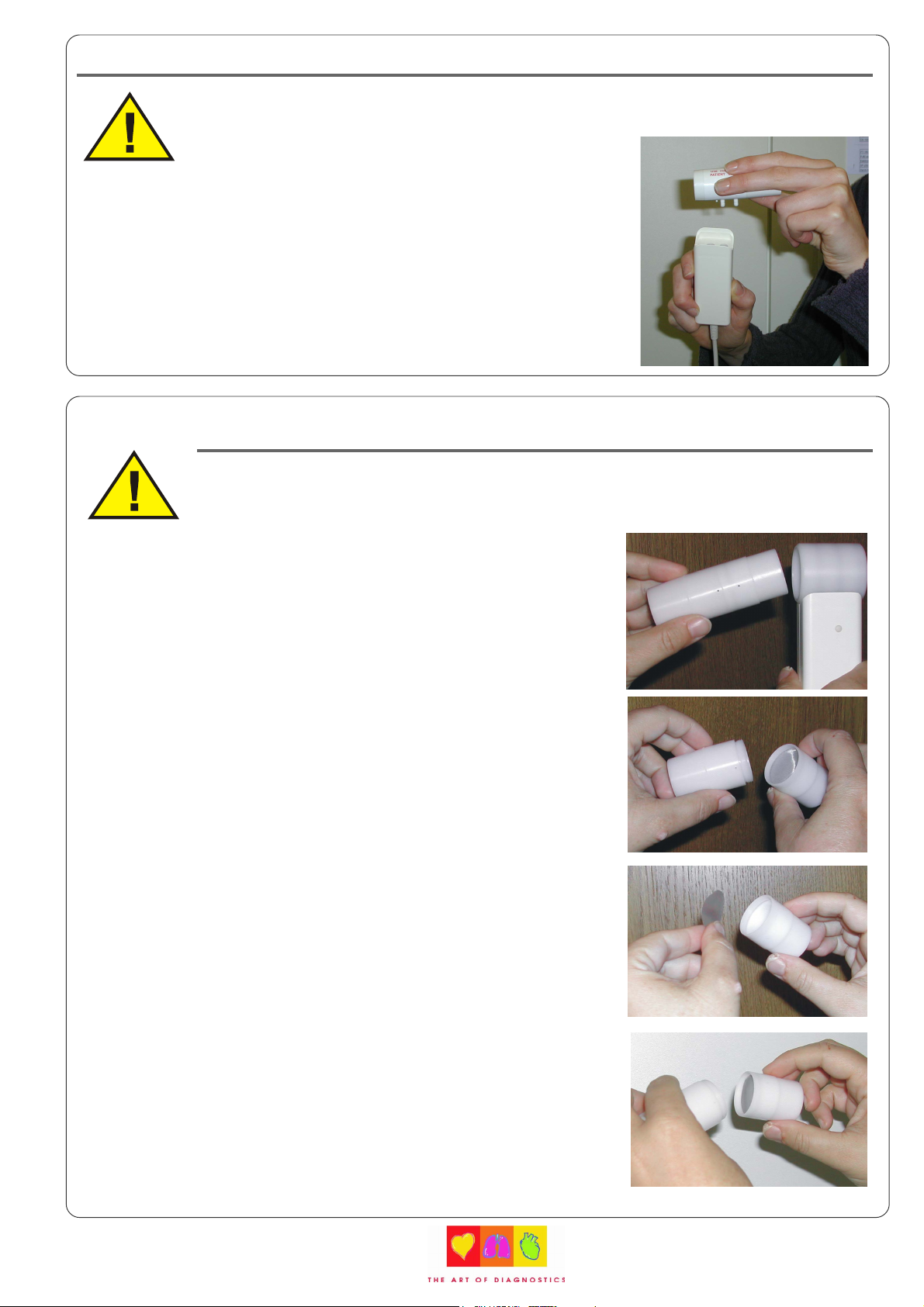

Changing the Mouthpiece on Flow Sensor SP-250

The disposable mouthpiece of the SP-250 is designed for one-time use to eliminate the danger of cross

contamination - do not use the mouthpiece for more than one patient.

1. Remove the disposable mouthpiece by pulling it away from the handle.

2. Discard the complete mouthpiece.

3. Position the new disposable mouthpiece (Part No. 2.100077), and gently but

firmly click it in position.

Note: The disposable mouthpiece can only be positioned in one direction and no force is

necessary to insert it on the handle. Ensure that the orientation is correct by checking

the guide protrusion on the sensor against the guide slot in the handle

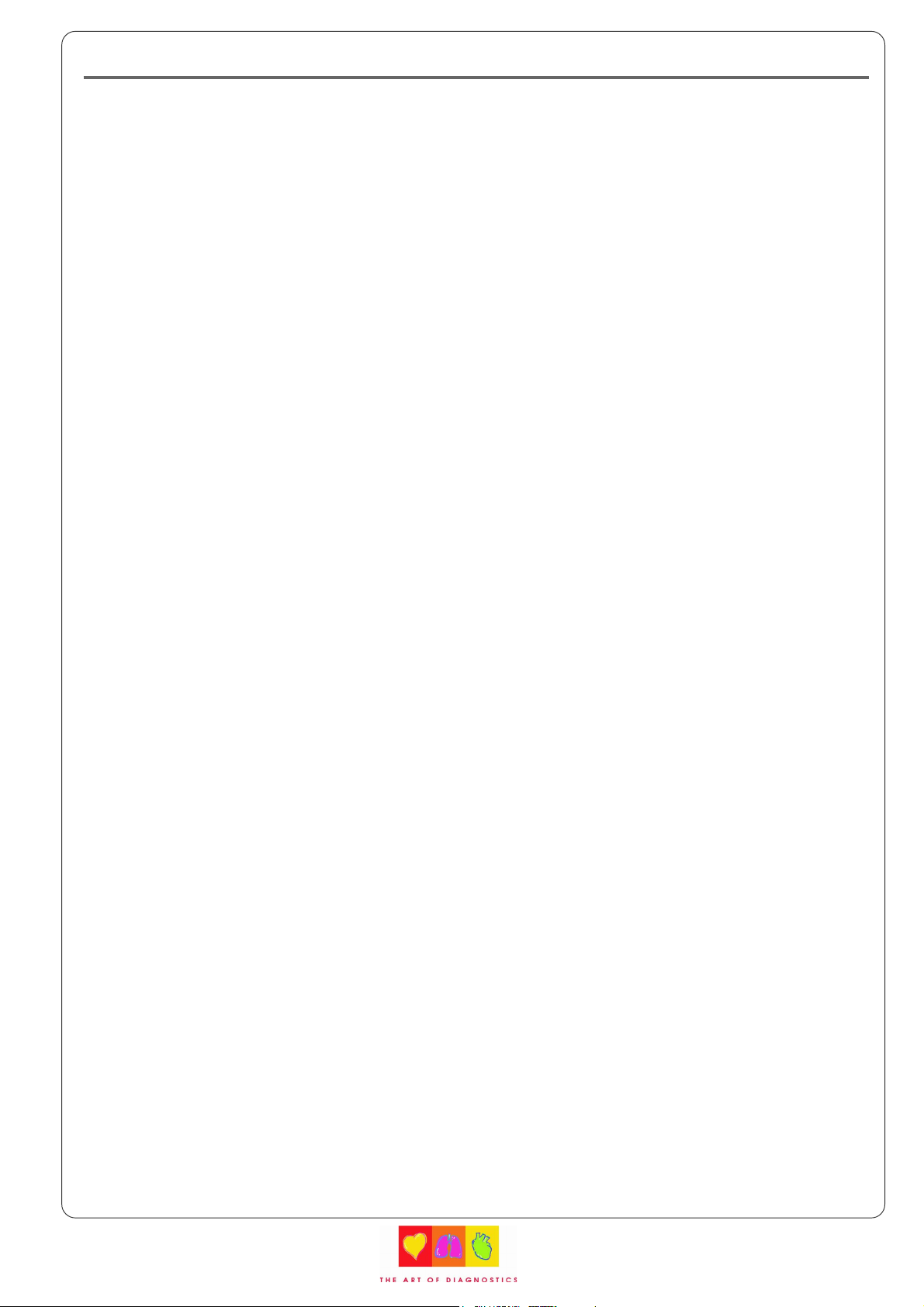

Changing the Filter on Flow Sensor SP-260

Change the filter and sterilise the mouthpiece after every patient to eliminate the danger of cross

contamination - do not use the filter for more than one patient.

1. Remove the mouthpiece by gently twisting and sliding it away from the handle.

The mouthpiece can only be removed in one direction.

2. Unscrew the mouthpiece and discard the filter.

3. Thoroughly disinfect the two halves of the mouthpiece. Use hospital grade

disinfectant for sterilising.

4. Position a new filter (Part No. 2.100123) in the threaded half of the mouthpiece as

shown.

5. Screw the two halves of the mouthpiece together. Ensure the filter is firmly held

with no air gaps.

6. Insert the mouthpiece in the handle.

Note: The mouthpiece can only be positioned in one direction. A moulded lip in the

mouthpiece prevents incorrect insertion.

SP-250/SP260 Instruction and

AT-2plus Spiro and AT-102 calibration

SCHILLER AG 2002; Art. No. 2. 510 338c

Page 2

Maintenance

Cleaning the Sensor Handle.

Disconnect the sensor from the unit before cleaning.

Do not, under any circumstances, immerse the apparatus into a cleaning liquid or sterilize with hot water, steam, or air.

The casing of both sensors and cable assembly can be cleaned with a soft damp cloth on the surface only. Where necessary

a domestic non-caustic cleaner can be used for grease and finger marks. Sterilization, if required, should be done with gas

only and not with steam. To disinfect, wipe with hospital standard disinfectant.

Cable Care

Prevent the possibility of anyone stumbling over the cable; store and use with care.

To ensure cable longevity, prevent damage by people stepping on it or running the wheels of instrument carts over it.

Do not expose the sensor cable to excessive mechanical stress. Whenever disconnecting the cable, hold the plug and not the

cable.

SP-250/SP260 Instruction and

AT-2plus Spiro and AT-102 calibration

SCHILLER AG 2002; Art. No. 2. 510 338c

Page 3

Calibration for AT-2plus Spiro

The unit must be calibrated with the first pulmonary function test of the day and

after every significant temperature change and after changing the sensor assembly.

Select the calibration menu option. The following screen is displayed:

Last calib. : 6.01.00

BTPS Factor : 1.090

Gain Factor : 1.002

ALT

then

25

8

>

Temperature : 70 oF

Measured volume : 0.00 l

Syringe Vol. : 3.00 l

Last Calibration date of last calibration

BTPS Factor calculated Body Temperature, Ambient Pressure, Saturated with water vapor value. This value compensates for the

difference in inhaled and exhaled humidity. The unit is set for measuring exhaled volume (100% humidity, Temp 36.8

this factor is applied when inhaled volume is measured. The unit uses the ambient temperature to calculate the BTPS factor.

This is sufficient for accurate FIVC calculation. The formula used is as follows:

BTPS = 0.033 +

Gain Factor calculated calibration factor between measured volume and actual volume.

Temperature ambient temperature in oF (or oC) dependent on device setting.

Measured Volume air volume measured by the system from the calibration pump.

Syringe Volume reference value of the entered air volume depending on the size of the calibration pump and the number of times

the air was pumped through the sensor; e.g. pumping 2 litres 3 times amounts to 6 litres (the recommended

volume with a 2 litre pump is 4 litres and with a 3 litre pump 3 litres).

Deviation : %

273.15 K + 36.8 °C Where: Tu is the ambient temperature in degrees centigrade

273.15 K + Tu °C 0.033 is the equivalent of 760mmHg at 22oC

273.15 Kelvin = 0o C

o

), and

Calibration Procedure

° Connect the calibration pump to the sensor. Ensure that there are no air leaks.

° In the screen above enter the ambient temperature and press ENTER.

° Press the AUTO PRINT key.

° Wait 1 second.

° Pump 3 to 4 litres of air through the sensor.

Note: Make sure that the flow sensor is kept still during the pumping operation.

While pumping, the unit records the volume being pumped through the flow sensor and indicates it on the display.

° Press the STOP key when finished pumping.

° Enter the reference (syringe) volume of air (dependent on the size of the calibration pump and times of pumping).

° Press the ENTER key to accept.

° The message `Calibration Complete` appears on the display.

° Press the COPY key after calibration to obtain a printout of the calibration report with measurement details and time and

date of calibration.

If the message `EXCESSIVE DEVIATION CHANGE SCREEN` appears on the screen after a calibration, it indicates that the

difference between the measured volume and the entered volume is too great to perform an accurate calibration. Check the

temperature setting and the entered syringe volume. If these are correct change the disposable mouthpiece and recalibrate.

Before recalibrating, the stored calibration values must be reset: to do this press the `ALT` key then the `I` key.

If calibration is still not possible, or for any other questions please contact the SCHILLER service department

SP-250/SP260 Instruction and

AT-2plus Spiro and AT-102 calibration

SCHILLER AG 2002; Art. No. 2. 510 338c

Page 4

Calibration for AT-102 Spiro

The unit must be calibrated with the first pulmonary function test of the day and after

every significant temperature change.

Press the Calibration softkey from the spiro screen

The following screen is displayed:

Last Calibration date of last calibration

BTPS Factor calculated Body Temperature, Ambient Pressure, Saturated with water vapor value. This value compensates for the

difference in inhaled and exhaled humidity. The unit is set for measuring exhaled volume (100% humidity, Temp 36.8o), and

this factor is applied when inhaled volume is measured. The unit uses the ambient temperature to calculate the BTPS factor.

This is sufficient for accurate FIVC calculation. The formula used is as follows:

BTPS = x Where: 273.15 K = 0 °C

Pb - P

Pb - 47 °C 273.15 K + Tu °C

273.15 K + 37 °C

H2O

P

b

P

H2O

= 716mmHg at 500 metres above sea level

= the vapour pressure of water [mmHg]

Tu = the ambient temperature in degrees centigrade

Calibration Factor Calculated value between measured and effective calibration air volume

Temperature Ambient temperature in oC (or oF) dependent on device setting

Measured Volume Air volume measured by the system from the calibration pump

Reference Volume Entered air volume depending on the size of the calibration pump and times the air was pumped

through the sensor; e.g. pumping 2 litres 3 times amounts to 6 litres (the recommended volume with

a 2 litre pump is 4 litres and with a 3 litre pump 6 litres)

Deviation Deviation percentage as a factor calculated between measured and effective calibration air volume

Calibration Procedure

To calibrate the unit proceed as follows:

° Position a new mouthpiece in the sensor

° Connect the calibration pump to the mouthpiece. Ensure that there are no air leaks.

° Press the `NEW CALIB` softkey.

° Enter the ambient temperature.

° Press the enter key to confirm ambient temperature.

° Press the start key. Pump 3 to 6 litres of air through the sensor.

Note: Make sure that the flow sensor is kept still during the pumping operation.

While pumping, the unit records the volume being pumped through the flow sensor and indicates it on the display.

° Press the STOP key when finished pumping .

° Enter the reference volume of air (depending on the size of the calibration pump and times of pumping; e.g. a 2 litre pump

pumped 3 times = 6 litres).

° Press the enter key to confirm.

° The message‚ `Calibration complete` appears on the display

If the message `EXCESSIVE DEVIATION!` or `CHANGE THE FILTER` appears on the screen after a calibration, it indicates thatthe

difference between the measured volume and the entered volume is too great (>12%). Check the temperature setting, the syringe

volume and the entered syringe volume. If these are all correct change the disposable mouthpiece and recalibrate.

SP-250/SP260 Instruction and

AT-2plus Spiro and AT-102 calibration

SCHILLER AG 2002; Art. No. 2. 510 338c

Page 5

Austausch des Sensors SP-250

Um die Gefahr von Kreuzinfektionen auszuschliessen, ist der

austauschbare Sensor nur zum einmaligen Gebrauch bestimmt.

Verwenden Sie für einen neuen Patienten immer einen neuen Sensor.

1. Heben Sie den Einwegsensor aus dem Griff.

2. Entsorgen Sie das gesamte Mundstück.

3. Nehmen Sie einen neuen Sensor (Artikelnr. 2.100077), und stecken Sie ihn auf

den Griff, bis er mit einem deutlichen Klicken einrastet.

Hinweis: Der Einwegsensor kann nur in einer Richtung auf den Griff gesteckt werden.

Es ist keine Gewaltanwendung erforderlich. Orientieren Sie sich an dem

Ministift am Sensor, der mit der Aussparung auf dem Griff beim Aufstecken

übereinstimmen muss.

Filterwechsel für den Sensor SP-260

Um Kreuzinfektionen auszuschliessen, wechseln Sie den Filter nach jedem Patienten, und sterilisieren Sie

das Mundstück jedes Mal. Verwenden Sie einen Filter niemals für mehr als einen Patienten.

1. Entfernen Sie das Mundstück, indem Sie leicht daran drehen und es aus dem

Verankerungsring ziehen. Das Mundstück kann nur in einer Richtung entfernt

werden.

2. Schrauben Sie das Mundstück auseinander, und nehmen Sie den Filter heraus.

3. Desinfizieren Sie beide Hälften des Mundstücks gründlich. Benutzen Sie für die

Sterilisation ein in Krankenhäusern übliches Desinfektionsmittel.

4. Setzen Sie den neuen Filter (Artikelnr. 2.100123) in die Mundstückhälfte, in der

sich das Gewinde befindet (siehe Bild).

5. Schrauben Sie die beiden Mundstückhälften zusammen. Überprüfen Sie, ob der

Filter fest sitzt und rund herum gehalten wird.

6. Setzen Sie das Mundstück wieder auf den Griff.

Hinweis: Das Mundstück kann nur in einer Richtung in den Ring geschoben

werden. Achten Sie auf das schnabelförmige Ende.

Anleitung zu SP-250/SP260 und

Eichung von AT-2plus Spiro und AT-102

SCHILLER AG 2002; Art.-Nr. 2. 510 338c

Page 6

Sensor-Pflege

Reinigung des Sensorgriffs

Trennen Sie den Sensor vor der Reinigung vom Gerät.

Unter keinen Umständen darf der Sensor in eine Reinigungsflüssigkeit eingetaucht oder mit heissem Wasser, Dampf oder

Luft sterilisiert werden.

Der Sensorgriff und die Kabel können mit einem feuchten Tuch abgewischt werden. Sofern erforderlich können Fett- und

Fingerspuren mit einem nicht ätzenden Haushaltsreiniger entfernt werden. Eine Sterilisation darf nur mit Gas und nicht mit

Dampf vorgenommen werden. Zur Desinfektion verwenden Sie ein in Krankenhäusern übliches Desinfektionsmittel.

Umgang mit dem Sensorkabel

Das Sensorkabel ist so zu verlegen, dass niemand darüber stolpert. Bewahren Sie das Kabel sicher auf, und behandeln Sie es

sorgfältig.

Indem das Kabel so verlegt wird, dass niemand darüber stolpert oder mit einem Gerätewagen darüberfährt, werden ausserdem

Beschädigungen vermieden, welche die Lebensdauer des Kabels beeinträchtigen könnten.

Das Kabel darf nicht zu grossen mechanischen Belastungen ausgesetzt werden. Beim Lösen der Steckerverbindungen grundsätzlich

am Stecker und nicht am Kabel ziehen!

Anleitung zu SP-250/SP260 und

Eichung von AT-2plus Spiro und AT-102

SCHILLER AG 2002; Art.-Nr. 2. 510 338c

Page 7

Eichung des AT-2plus Spiro

Vor der ersten Messung des Tages, nach einer signifikanten Temperaturveränderung und nach einem Sensoraustausch ist eine Volumen-Eichung erforderlich.

Drücken Sie die Taste ALT und dann die Taste ´8´. Folgende Anzeige erscheint:

Letzte Eichung : 6.01.00

dann

ALT

Letzte Eichung Datum der letzten Eichung

BTPS Faktor Berechnete BTPS-Korrektur (=> Body Temperature, Ambient Pressure, Saturated with water vapor). Dieser Wert

25

8

kompensiert Unterschiede hinsichtlich der Feuchtigkeitssättigung beim Ein- und Ausatmen. Dieser Faktor wird bei der

Messung des inspiratorischen Volumens verwendet, da das Gerät von der Messung des Exspirationsvolumens

(100% Feuchtigkeit, Temp. 36.8o) ausgeht. Das Gerät berechnet den BTPS-Faktor aufgrund der Umgebungstemperatur.

Diese Ermittlung reicht für die genaue FIVC-Berechnung aus. Die Berechnungsformel lautet wie folgt:

BTPS = 0,033 + 273,15 K + 36,8 °C Wobei: Tu = Umgebungstemperatur in Grad Celsius

>

BTPS Faktor : 1.090

Verst. Faktor : 1.002

Temperatur : 70 oF

Ist-Volumen : 0.00 l

Soll-Volumen : 3.00 l

Abweichung : %

273,15 K + Tu °C 0,033 entspricht 760mmHg bei 22oC

273,15 Kelvin = 0o C

Verst. Faktor Berechneter Wert zum Abgleich zwischen gemessenem und effektivem Luftvolumen.

Temperatur Umgebungstemperatur in oF oder oC, je nach Einstellung.

Ist-Volumen Vom System gemessenes Luftvolumen.

Soll-Volumen Referenzwert für das eingegebene Luftvolumen abhängig von der Volumengrösse der verwendeten Eichpumpe und der

Anzahl Pumpvorgänge. Bei Verwendung einer 2-Liter-Pumpe und dreimaligem Aufpumpen ist der Wert 6 Liter (das

empfohlene Soll-Volumen beträgt bei einer 2-Liter-Pumpe 4 Liter und bei einer 3-Liter-Pumpe 6 Liter).

Ablauf der Eichung

° Verbinden Sie die Eichpumpe mit dem Sensor. Vergewissern Sie sich, dass es keine luftdurchlässigen Stellen gibt.

° Erfassen Sie im obigen Bildschirm die Umgebungstemperatur, und drücken Sie ENTER.

° Drücken Sie die Taste AUTO START.

° Warten Sie 1 Sekunde.

° Pumpen Sie 3 bis 4 Liter Luft durch den Sensor.

Hinweis: Während des Pumpvorgangs darf der Sensor nicht bewegt werden.

Während des Pumpvorgangs zeichnet das Gerät das Volumen auf, das durch den Sensor gepumpt wird, und zeigt den Wert

auf dem Bildschirm an.

° Nach Beendigung des Pumpvorgangs drücken Sie das Taste STOPP.

° Erfassen Sie das Referenz- (Soll-) Luftvolumen (abhängig von der Grösse der Eichpumpe und der Anzahl Pumpvorgänge).

° Bestätigen Sie Ihre Eingabe mit ENTER.

° Am Bildschirm erscheint die Meldung ´Eichung beendet´.

° Drücken Sie nach der Eichung die Taste KOPIE, um einen Bericht mit Messangaben, der Zeit und dem Datum der Eichung

zu drucken.

Falls nach einer Eichung am Bildschirm die Meldung ´ABWEICHUNG ZU GROSS´ oder ´AUSTAUSCH FILTER´ erscheint, ist die

Differenz zwischen dem gemessenen und dem eingegebenen Volumen für eine genaue Eichung zu gross. Überprüfen Sie in

diesem Fall die Temperatur und das erfasste Soll-Volumen. Sofern die Einstellungen korrekt waren, wechseln Sie das austauschbare

Sensorteil und wiederholen den Eichvorgang.

Bevor die Eichung wiederholt wird, müssen die gespeicherten Eichwerte zurückgesetzt werden. Drücken Sie dazu die ALTTaste und die Taste ´I´.

Falls die Eichung danach immer noch nicht möglich ist oder falls Sie andere Fragen haben, wenden Sie sich bitte an die ServiceAbteilung der SCHILLER AG.

Anleitung zu SP-250/SP260 und

Eichung von AT-2plus Spiro und AT-102

SCHILLER AG 2002; Art.-Nr. 2. 510 338c

Page 8

Eichung des AT-102 Spiro

Das Gerät muss vor dem ersten Lungenfunktionstest des Tages und nach jeder grösseren Temperaturveränderung neu geeicht werden.

Drücken Sie im Spirometrie-Bild die

Funktionstaste ´Eichung´.

Das folgende Bild wird aufgerufen:

Letzte Eichung Datum der letzten Eichung

BTPS Faktor Berechnete BTPS-Korrektur (=> Body Temperature, Ambient Pressure, Saturated with water vapor). Dieser Wert

kompensiert Unterschiede hinsichtlich der Feuchtigkeitssättigung beim Ein- und Ausatmen. Dieser Faktor wird bei der

Messung des inspiratorischen Volumens verwendet, da das Gerät von der Messung des Exspirationsvolumens

(100% Feuchtigkeit, Temp. 36.8o) ausgeht. Das Gerät berechnet den BTPS-Faktor aufgrund der Umgebungstemperatur.

Diese Ermittlung reicht für die genaue FIVC-Berechnung aus. Die Berechnungsformel lautet wie folgt:

BTPS = x Wobei: 273,15 K = 0 °C

Pb - P

Pb - 47 °C 273,15 K + Tu °C

273,15 K + 37 °C

H2O

P

b

P

H2O

= 716mmHg auf 500 Meter über Meer

= Dampfdruck von Wasser [mmHg]

Tu = Umgebungstemperatur in °C

Verst. Faktor Berechneter Wert zum Abgleich zwischen gemessenem und effektivem Luftvolumen.

Temperatur Umgebungstemperatur in oC oder oF, je nach Einstellung.

IST-Volumen Vom System gemessenes Luftvolumen.

SOLL-Volumen Erfasstes Luftvolumen, abhängig von der Grösse der Eichpumpe und der Anzahl Pumpvorgänge. Bei

Verwendung einer 2-Liter-Pumpe und 3-maligem Aufpumpen ist der Wert 6 Liter (das empfohlene

Soll-Volumen beträgt bei einer 2-Liter-Pumpe 4 Liter und bei einer 3-Liter-Pumpe 6 Liter).

Abweichung Prozentuale Differenz zwischen IST- und SOLL-Volumen.

Ablauf der Eichung

° Setzen Sie ein neues Mundstück auf den Sensor.

° Schliessen Sie die Eichpumpe an das Mundstück an. Vergewissern Sie sich, dass es keine luftdurchlässigen Stellen gibt.

° Drücken Sie die Funktionstaste ´Eichung´.

° Erfassen Sie die Umgebungstemperatur.

° Bestätigen Sie die erfasste Umgebungstemperatur mit ENTER.

° Drücken Sie die Taste ´START´, und pumpen Sie 3 bis 6 Liter Luft durch den Sensor.

Hinweis: Während des Pumpvorgangs darf der Sensor nicht bewegt werden.

Während der Eichung zeichnet das Gerät das Volumen auf, das durch den Sensor gepumpt wird, und zeigt den Wert auf dem

Bildschirm an.

° Nach Beendigung des Pumpvorgangs drücken Sie die Taste ´STOP´. .

° Geben Sie das Soll-Volumen ein (resultiert aus Eichpumpvolumen x Anzahl Pumpvorgänge; bei einer 2-Liter-Pumpe und

3 Pumpvorgängen ist das Soll-Volumen beispielsweise 6 Liter).

° Bestätigen Sie die Eingabe mit ENTER.

° Die Meldung ´Kalibrierung beendet´ erscheint am Bildschirm.

Wenn nach der Eichung die Meldung ´ABWEICHUNG ZU ROSS´ oder ´AUSTAUSCH FILTER´ erscheint, so ist die Differenz

zwischen dem gemessenen Ist-Volumen und de eingegebenen Soll-Volumen zu gross (>12%). Überprüfen Sie die Temperaturangabe,

das Pumpvolumen der Eichpumpe sowie das eingegebene Soll-Volumen. Sofern die Einstellungenkorrekt waren, wechseln Sie das

austauschbare Mundstück, und wiederholen Sie den Eichvorgang.

Anleitung zu SP-250/SP260 und

Eichung von AT-2plus Spiro und AT-102

SCHILLER AG 2002; Art.-Nr. 2. 510 338c

Loading...

Loading...