Page 1

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Cardiovit

ECG and

AT-10

Spirometry Unit

Service Handbook

SCHILLER AG

Altgasse 68

CH-6341 Baar, Switzerland

Phone: + 41 41 766 42 42

Fax: + 41 41 761 08 80

Home page: http://www.schiller.ch

April 2002 Article Number: 2. 540 005

i

Page 2

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

AT-10 Service Handbook

Article Number 2. 540005

Issue 1: January 1993

Issue 2: July 1998

Issue c: April 2002

Associated Documents

Guide to SCHILLER Interpretation

and Measurement Program E / D / F Article No. 2.510179

SCHILLER AT-10 USER GUIDE - English Article No. 2.510127

SCHILLER AT-10 USER GUIDE - German Article No. 2.510126

SCHILLER AT-10 USER GUIDE - French Article No. 2.510128

© Copyright 2002 by SCHILLER AG

ii

Page 3

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Where to Obtain Service

WELCH ALLYN SCHILLER Inc., 7420 Carroll Road, San Diego, CA , US-92121-2334

USA

USA / Canada

Asia Pacific

Tel.: +1 858 635 6023 Fax : +1 858 635 6611

Home Page : www.welchallyn.com

SCHILLER Asia Pacific, 10 Jalan SS 3/33, Taman Universiti, 47300 Petaling Jaya, Selangor,

Malaysia

Tel.: + 603 7877 5336 Fax : + 603 7877 5744

Austria

France

Germany (EU

authorized

representative)

India

Italy

Switzerland

All other

countries

SCHILLER HmbH, Kampmüllerweg 24, A-4044 Linz, Austria

Tel.: + 43 732 709 90 Fax : + 43 732 757 000

SCHILLER Medical S.A, BP 50, 19, Avenue de la Gare, F-67162 Wissembourg / Cedex,

France

Tel.: +33 3 88 63 36 00 Fax : +33 3 88 94 12 82

SCHILLER Medizintechnik GmbH, Rudolf-Diesel Strasse 14, D-85521 Ottobrunn, Germany

Tel.: + 4989 629 981 0 Fax : + 4989 609 509 0

SCHILLER Healthcare India Pvt. Ltd.,D.C.Silk Mills Compound, 'A' Wing, 1st floor, 5,

Chunawala Estate, Kondivitta Lane, Andheri - Kurla Road, Andheri (E, Mumbai - 400 059,

India

Tel.: + 9122 826 3520 Fax : + 9122 826 3525

ESAOTE Spa (SCHILLER ), Via di Caciolle 15, I-50127 Firenze, Italy

Tel.: + 39055 4229 201 Fax : + 39055 4229 208

SCHILLER Reomed AG, Riedstrasse 14, CH-8953 Dietikon, Switzerland

Tel.: +411 744 3000 Fax : + 411 740 3710

SCHILLER AG, Altgasse 68, CH-6341 Baar, Switzerland

Tel.: + 4141 766 4242 Fax : + 4141 761 0880

Home Page : www.schiller.ch

iii

Page 4

Warranty

Disclaimer

The Information in this guide has been carefully checked for reliability; however no guarantee is

given as to the correctness of the contents and SCHILLER makes no representations or warranties

regarding the contents of this manual. We reserve the right to revise this document and make

changes in the specification of the product described within at any time without obligation to notify

any person of such revision or change.

Trademarks

SCHILLER and AT-10 are registered trademarks of SCHILLER AG. All trademarks are the

property of their owners.

Copyright Notice

© Copyright 1998 by SCHILLER AG. All rights reserved. You may not reproduce, transmit,

transcribe, store in a retrieval system or translate into any language, in any form or by any means,

electronic, mechanical, magnetic, optical, chemical, manual or otherwise, any part of this

publication without express written permission of SCHILLER AG.

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Terms of Warranty

The SCHILLER AT-10 is warranted against defects in material and manufacture for the duration

of one year (as from date of purchase). Excluded from this guarantee is damage caused by an

accident or as a result of improper handling. The warranty entitles free replacement of the defective

part. Any liability for subsequent damage is excluded. The warranty is void if unauthorized or

unqualified persons attempt to make repairs.

In case of a defect, send the apparatus to your dealer or directly to the manufacturer.

The manufacturer can only be held responsible for the safety, reliability, and performance of the

apparatus if:

° assembly operations, extensions, readjustments, modifications, or repairs are carried out by

persons authorized by him, and

° the unit and approved attached equipment is used in accordance with the manufacturers

instructions.

THERE ARE NO EXPRESS OR IMPLIED WARRANTIES WHICH EXTEND BEYOND THE

WARRANTIES HEREINABOVE SET FORTH. SCHILLER MAKES NO WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO

THE PRODUCT OR PARTS THEREOF.

iv

Page 5

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Safety Notices

TO PREVENT ELECTRIC SHOCK DO NOT DISASSEMBLE THE UNIT. NO SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED PERSONNEL ONLY.

DO NOT USE THIS UNIT IN AREAS WHERE THERE IS ANY DANGER OF EXPLOSION

OR THE PRESENCE OF FLAMMABLE GASES SUCH AS ANAESTHETIC AGENTS.

IF THE DISPLAY IS DAMAGED, A LEAKAGE OF FLUID MAY OCCUR. DO NOT INHALE

THE VAPOUR FROM THIS FLUID AND AVOID CONTACT WITH MOUTH AND SKIN. IF

CONTACT IS MADE, CLEAN CONTAMINATED AREA IMMEDIATELY WITH FRESH

WATER.

THIS PRODUCT IS NOT DESIGNED FOR STERILE USE.

SWITCH THE UNIT OFF BEFORE CLEANING AND DISCONNECT FROM THE MAINS.

DO NOT, UNDER ANY CIRCUMSTANCES, IMMERSE THE UNIT OR CABLE ASSEMBLIES

IN LIQUID.

DO NOT OPERATE THE UNIT IF THE EARTH CONNECTION IS SUSPECT OR IF THE

MAINS LEAD IS DAMAGED OR SUSPECTED OF BEING DAMAGED.

DO NOT USE HIGH TEMPERATURE STERILISATION PROCESSES (SUCH AS

AUTOCLAVING). DO NOT USE E-BEAM OR GAMMA RADIATION STERILISATION.

DO NOT USE SOLVENT CLEANERS

USE ONLY ACCESSORIES AND OTHER PARTS RECOMMENDED OR SUPPLIED BY

SCHILLER AG. USE OF OTHER THAN RECOMMENDED OR SUPPLIED PARTS MAY

RESULT IN INJURY INACCURATE INFORMATION AND/ OR DAMAGE TO THE UNIT.

THE AT-10 COMPLIES WITH EMC REGULATIONS FOR MEDICAL PRODUCTS WHICH

AFFORDS PROTECTION AGAINST EMISSIONS AND ELECTRICAL INTERFERENCE.

HOWEVER SPECIAL CARE MUST BE EXERCISED WHEN THE AT-4 IS USED WITH

HIGH FREQUENCY EQUIPMENT.

IT MUST BE ENSURED THAT NEITHER THE PATIENT NOR THE ELECTRODES

(INCLUDING THE NEUTRAL ELECTRODE) COME INTO CONTACT WITH OTHER

PERSONS OR CONDUCTING OBJECTS (EVEN IF THESE ARE EARTHED).

THERE IS NO DANGER WHEN USING THE ECG UNIT FOR A PACEMAKER PATIENT OR

WITH SIMULTANEOUS USE OF OTHER ELECTRICAL STIMULATION EQUIPMENT.

HOWEVER, THE STIMULATION UNITS SHOULD ONLY BE USED AT A SUFFICIENT

DISTANCE FROM THE ELECTRODES. IN CASE OF DOUBT, THE PATIENT SHOULD BE

DISCONNECTED FROM THE RECORDER.

v

Page 6

Safety Notices

THIS UNIT IS CF CLASSIFIED ACCORDING TO IEC 601-1. THIS MEANS THAT THE

PATIENT CONNECTION IS FULLY ISOLATED AND DEFIBRILLATION PROTECTED.

SCHILLER CAN ONLY GUARANTEE PROTECTION AGAINST DEFIBRILLATION

VOLTAGE, HOWEVER, WHEN THE ORIGINAL SCHILLER PATIENT CABLE IS USED.

WHEN NON-MEDICAL DEVICES ARE CONNECTED TO THE RS-232 INTERFACE ENSURE

THAT BOTH UNITS ARE SECURELY CONNECTED TO THE SAME EARTH POTENTIAL.

WHEN OPERATING THE UNIT ON BATTERY AND SIMULTANEOUSLY USING NONMEDICAL DEVICES, THE RS-232 INTERFACE MUST BE FULLY ISOLATED.

BEFORE USING THE UNIT, ENSURE THAT AN INTRODUCTION REGARDING THE

UNIT FUNCTIONS AND THE SAFETY PRECAUTIONS HAS BEEN PROVIDED BY A

SCHILLER REPRESENTATIVE.

THE GUIDELINES FOR PATIENT ELECTRODE PLACEMENT ARE PROVIDED AS ON

OVERVIEW ONLY. THEY ARE NOT A SUBSTITUTE FOR MEDICAL EXPERTISE.

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

THE AT-10 ECG UNIT IS PROVIDED FOR THE EXCLUSIVE USE OF QUALIFIED

PHYSICIANS OR PERSONNEL UNDER THEIR DIRECT SUPERVISION. THE NUMERICAL

AND GRAPHICAL RESULTS AND ANY INTERPRETATION DERIVED FROM A

RECORDING MUST BE EXAMINED WITH RESPECT TO THE PATIENTS OVERALL

CLINICAL CONDITION. THE RECORDING PREPARATION QUALITY AND THE

GENERAL RECORDED DATA QUALITY, WHICH COULD EFFECT THE REPORT DATA

ACCURACY, MUST ALSO BE TAKEN INTO ACCOUNT.

IT IS THE PHYSICIANS RESPONSIBILITY TO MAKE THE DIAGNOSIS OR TO OBTAIN

EXPERT OPINION ON THE RESULTS, AND TO INSTITUTE CORRECT TREATMENT IF

INDICATED.

vi

Page 7

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

What´s in this Book

THE SERVICE PHILOSOPHY FOR ALL SCHILLER UNITS IS FAULT FINDING TO

MODULE LEVEL. THE PURPOSE OF THIS BOOK IS TO PROVIDE ALL THE INFORMATION NECESSARY TO ENABLE THE SERVICE ENGINEER TO EFFICIENTLY LOCATE

AND REPLACE A FAULTY MODULE. THIS BOOK ASSUMES NO DETAILED KNOWLEDGE OF THE AT-10 BUT DOES REQUIRE THAT THE SERVICE ENGINEER IS FAMILIAR WITH STANDARD WORKSHOP PRACTICES.

The book is divided into the following chapters:

Chapter 1 - Operating Elements

The purpose of this chapter is to provide an easy reference for all the main operator functions and

to give a basic introduction to the AT-10. This chapter gives details of the operator controls with

the operation and function of each key briefly explained. The information in this chapter provides

a background to the operating functions only. Complete operating information is provided in the

SCHILLER AT-10 Operating Manual.

Chapter 2 - Functional Overview

This chapter provides a functional overview of the AT-10 The functional description is supported

by functional block diagrams.

Chapter 3 - Fault Diagnosis

This chapter provides a guide to locate a fault to module level. The diagnostics are presented in a

logical sequence of fault finding algorithms and procedures. Illustrations are provided to support

the text where needed.

Chapter 4 - Physical Overview & Module Replacement

This chapter gives an overview of the physical construction of the AT-10 with the main physical

attributes of the unit briefly described. The physical description is supported by illustrations

showing the internal location of all modules. Removal and Replacement instructions for all

replaceable modules are also provided in this chapter. Each procedure is autonomous with details

of tools, jumper settings, adjustments, and settings or special requirements that are required before

and after replacement. Functional checks that must be carried out after replacing a new module are

also provided.

Chapter 5 - Functional Checks & Adjustments

This chapter provides all adjustments and settings. Also detailed in this chapter are basic functional

test procedures that can be performed to check the functioning of the unit.

Chapter 6 - Spare Parts

This Chapter provides the part numbers and reordering information for all replaceable modules.

Also included in this chapter are details of any special test equipment or special tools required for

adjustment or fault finding procedures.

Chapter 7 - Technical Data

The full technical specification of the AT-10 is given in this chapter.

Chapter 8 - Glossary

This Chapter explains all the acronyms and signal titles used in this book and in the AT-10 circuit

diagrams.

vii

Page 8

What´s in this Book

Circuit Diagrams & Board Layouts

The circuit diagrams and component layouts are provided for all boards. These details are provided

for information only.

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

viii

Page 9

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Introduction 1.2

The Keyboard 1.4

Alpha Numeric Keypad 1.4

General Purpose Keys 1.4

Control Keys 1.6

Function Keys 1.7

Resting ECG Function Keys 1.7

Exercise Function Keys 1.8

Connector Panels 1.9

Side Panel 1.9

Back Panel 1.10

Mains Panel 1.11

Liquid Crystal Display 1.12

Calibration 1.13

Manual Baseline Reset 1.13

System Setup 1.14

Defining Macro Functions 1.14

Save Settings 1.15

ECG Menu 1.16

Filters 1.17

Baseline Filter 1.17

Myogram Filter 1.17

Mains Filter 1.17

Number of Printed Copies 1.18

Lead Sequence 1.19

User-programmable Lead Group 1.20

Programmable channels for Printout 1.21

Chapter 1

Operating Elements

Chapter 1

Operating Elements

Contents

1.7

Page 1.1

Page 10

Chapter 1

Operating Elements

Introduction

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

The Schiller Cardiovit AT-10

The CARDIOVIT AT-10 is a sophisticated compact work-station for cardiological diagnosis. It has

the facility to carry out both resting and exercise ECGs with the test results displayed on the integral

LCD and recorded on the built-in thermal printer.

Three RS-232 interfaces and one RS-422 interface are provided for the connection of digitally

controlled exercise test equipment, blood pressure equipment, and for data transmission/reception.

The unit also has facilities for connection of an external video monitor, experimental DC inputs, and

analog controlled exercise equipment.

With ECG program options, the AT-10 can be upgraded to provide ECG interpretation, exercise

test evaluation, pacemaker measurement and Frank vector loops. A Spirometry option enables

Spirometry tests to be performed and pulmonary function diagnosis to be carried out.

The AT-10 can also be connected to the Schiller PC-based data management program (designated

SEMA-200), for the validation and archiving of recorded data.

Page 1.2

Page 11

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Introduction (cont.)

The main operating and connection modules of the Cardiovit AT-10 are as follows:

l Keyboard The keyboard is divided into three functional areas. The

l LCD Screen The LCD screen displays the real-time ECG traces and

l Thermal Printer The printer provides hard copy of test results.

l Right-hand Side Panel The side panel contains dc input connectors, the ECG

Chapter 1

Operating Elements

top area comprises the unit ON/OFF keys, the paper tray

key and other general function keys. The central area

contains dedicated control and function keys, and the

bottom area contains the alpha-numeric keys and other

general function keys.

certain operating and status information. Under operator

control the display also gives menu options and displays

operator entered data. The display is folded down when not

in use.

patient connector, the Spirometry connector and RS serial

connectors. When the floppy disk storage option is installed,

the disk drive is installed on this side panel.

l Left-hand Side Panel This panel contains the paper tray and (below the paper

tray) the program pack.

l Rear Panel The rear panel contains the data input/output connector,

the external video monitor and the ERGO connector. The

rear panel also contains the mains connector with on/off

switch, voltage selector and mains fuse. When the LAN

option is installed the LAN connector is mounted on the

back panel

Page 1.3

Page 12

Chapter 1

Operating Elements

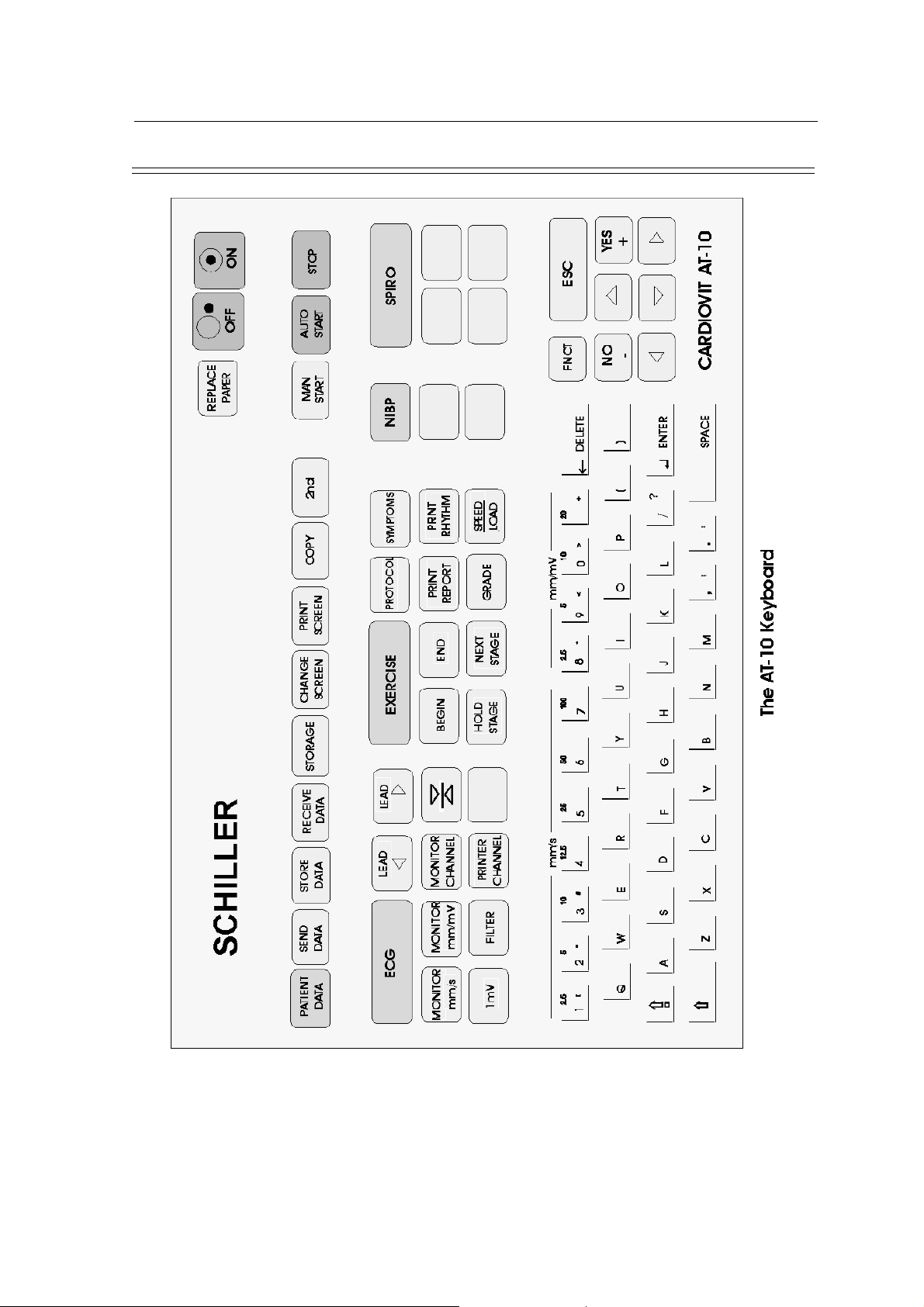

The Keyboard

Alpha Numeric Keypad

The functions of the dual purpose keys on the alphanumeric keyboard are as follows:

KEY FUNCTION

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

DUAL PURPOSE KEYS

'1' to

'7'

Printout Speed Selection 2.5, 5, 10, 12.5, 25, 50, or 100

mm/s

'8' to `_ Printout Sensitivity Selection 2.5, 5, 10, or 20 mm/mV

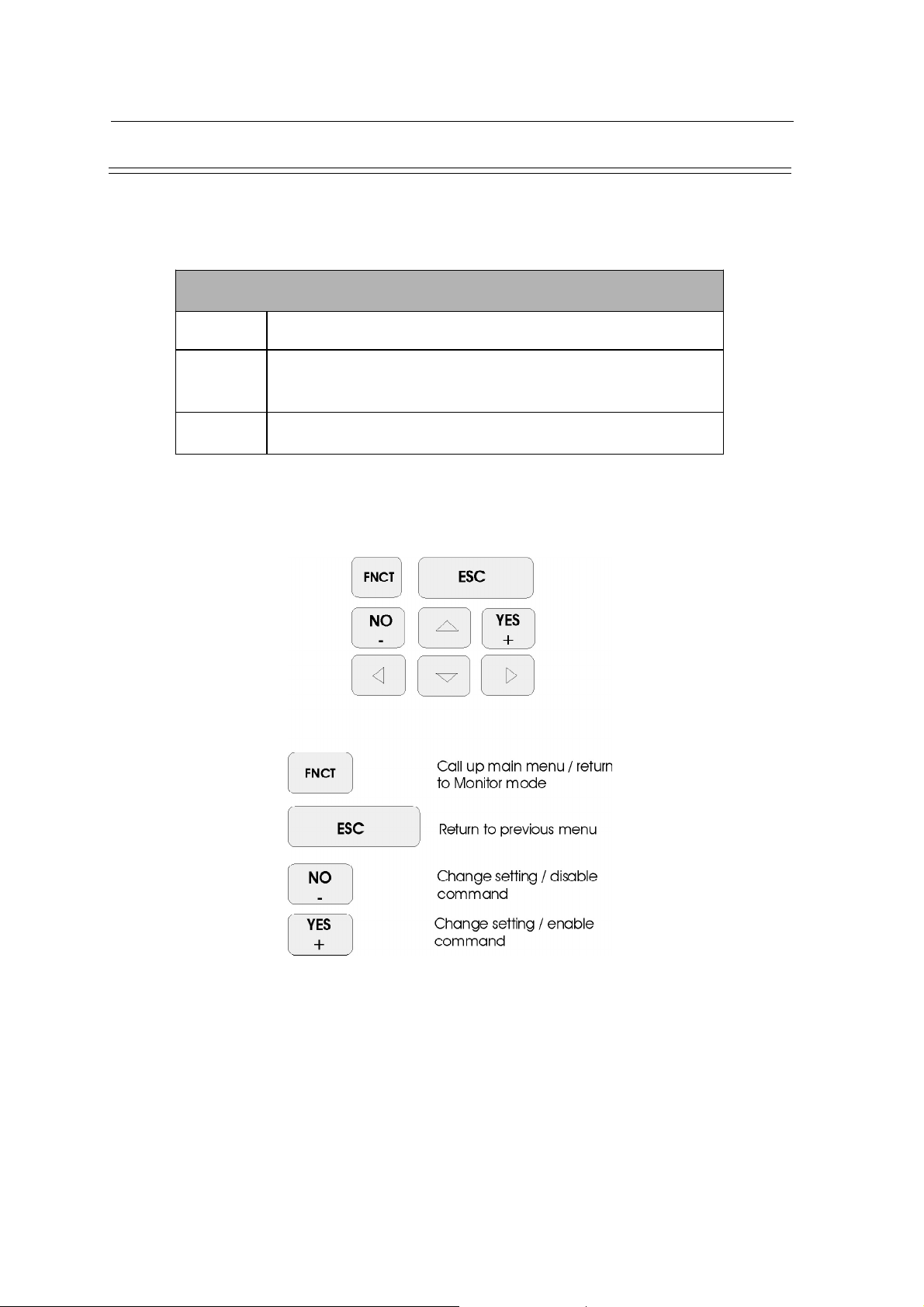

General Purpose Keys

The general purpose keys to the right of the alpha-numeric keypad, are as follows:

Page 1.4

The direction keys are used to move the cursor in order to make menu selections

Page 13

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

The Keyboard (cont.)

Chapter 1

Operating Elements

The top line of the keyboard is dual purpose and when the unit is in the ECG mode, these keys double

as control for the direct setting of speed and sensitivity for manual printout. Otherwise, the

alphanumeric keyboard serves as a normal keyboard for data input.

Page 1.5

Page 14

Chapter 1

Operating Elements

The Keyboard (cont.)

Control Keys

The Control keys are situated at the top of the keyboard and contain the function keys which are

common to all function modules. The control keys are as follows:

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Page 1.6

Note: Slight functional differences may exist in different modes

Page 15

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

The Keyboard (cont.)

Function Keys

The function keys are arranged in a group in the middle of the keyboard. The left part of the group

comprises keys for the resting ECG recording functions. The middle part comprises keys for the

Exercise ECG functions. On the right hand side is the SPIRO key for the optional pulmonary

function testing program. The following is a summary of the keys and their functions:

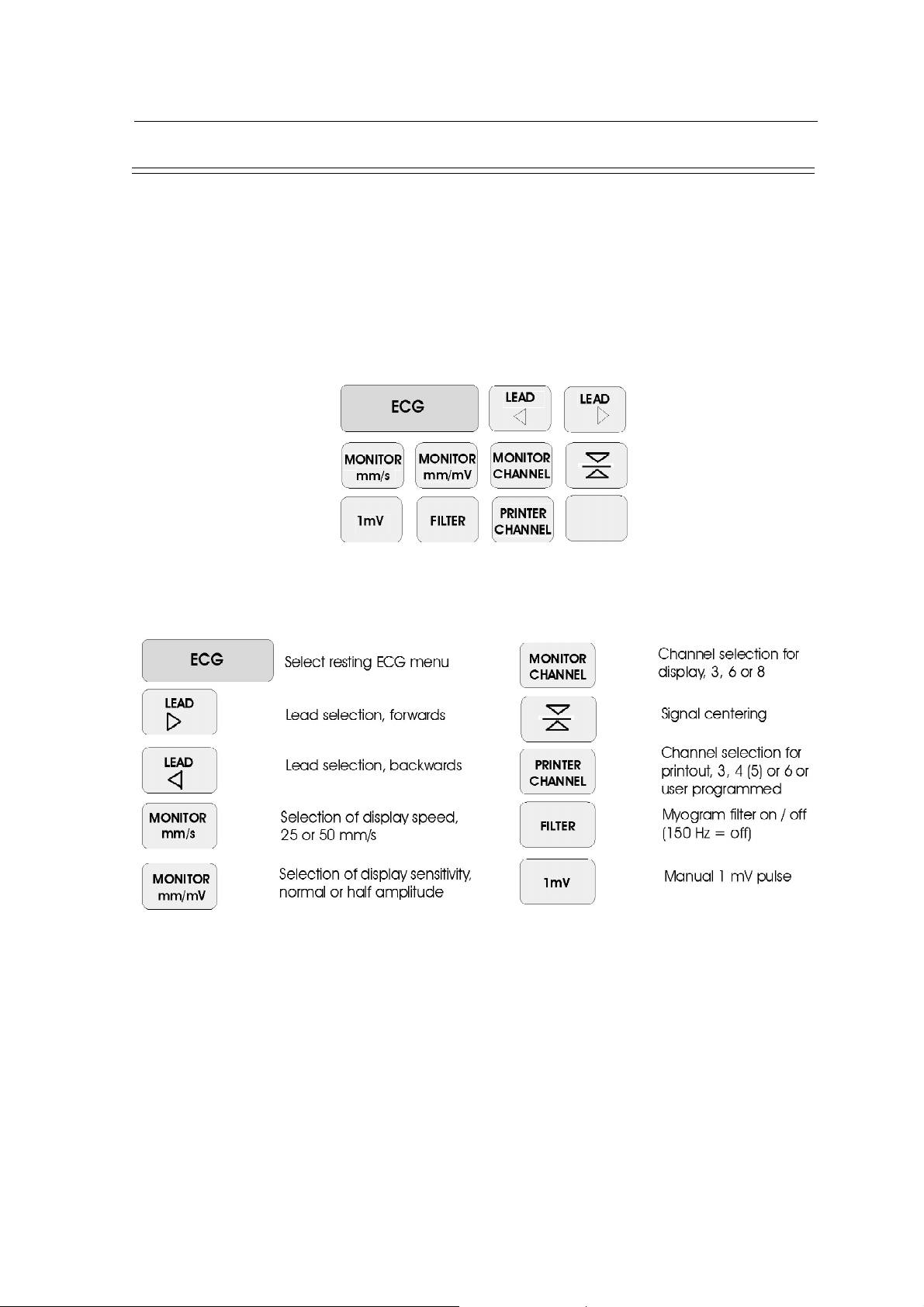

Resting ECG Function Keys

Chapter 1

Operating Elements

Page 1.7

Page 16

Chapter 1

Operating Elements

The Keyboard (cont.)

Exercise Function Keys

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Page 1.8

* The grade increases when pressed in conjunction with the YES (+) key and decreases when

pressed in conjunction with the NO (-) key.

The Speed/Load increases when pressed in conjunction with the YES (+) key and decreases

when pressed in conjunction with the NO (-) key.

Page 17

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Connector Panels

Side Panel

Chapter 1

Operating Elements

The following are located on the side panel:

1. 1 X RS-232C interface for connection of a bicycle with blood pressure measuring device

(Port 1)

2. 1 X RS-232C interface for connection of an ergometer (bicycle or treadmill) (Port 2)

3. 1 X RS-232C interface for data transfer (Port 3)

4. 1 X RS-422 interface for data transfer

5. LCD contrast control

6. DC inputs: DC2 0.5V/cm

7. DC inputs: DC1 0.5V/cm

8. Connection for SP-20, SP-150, SP-110 or SP-110/R flow sensor for lung function

measurements (Option)

9. Test socket for electrode leads with control light

10.EKG / ECG Socket for patient cable

Note: The socket is CF rated ie fully floating and isolated, defibrillation protected, suitable

for intra-cardiac application.

Page 1.9

Page 18

Chapter 1

Operating Elements

Connector Panels (cont.)

Back Panel

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

The following connectors are located on the back panel:

1. Identification Plate

2. Mains Module

3. Connector for external video

4. Exercise (stress) test connection for analogue ergometers (bicycle or treadmill)

5. Data I/O socket for connection of foot-switch, QRS trigger, treadmill elevation control

6. Potential equalisation (ground) connection

7. Local area network Connector (Option)

Page 1.10

Page 19

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Connector Panels (cont.)

Mains Panel

Chapter 1

Operating Elements

The following are located on the mains panel:

1. Mains fuse (200 mA slow) and voltage selector

2. Mains connection

3. Voltage indicator (mains)

4. Power on / off switch

Page 1.11

Page 20

Chapter 1

Operating Elements

Liquid Crystal Display

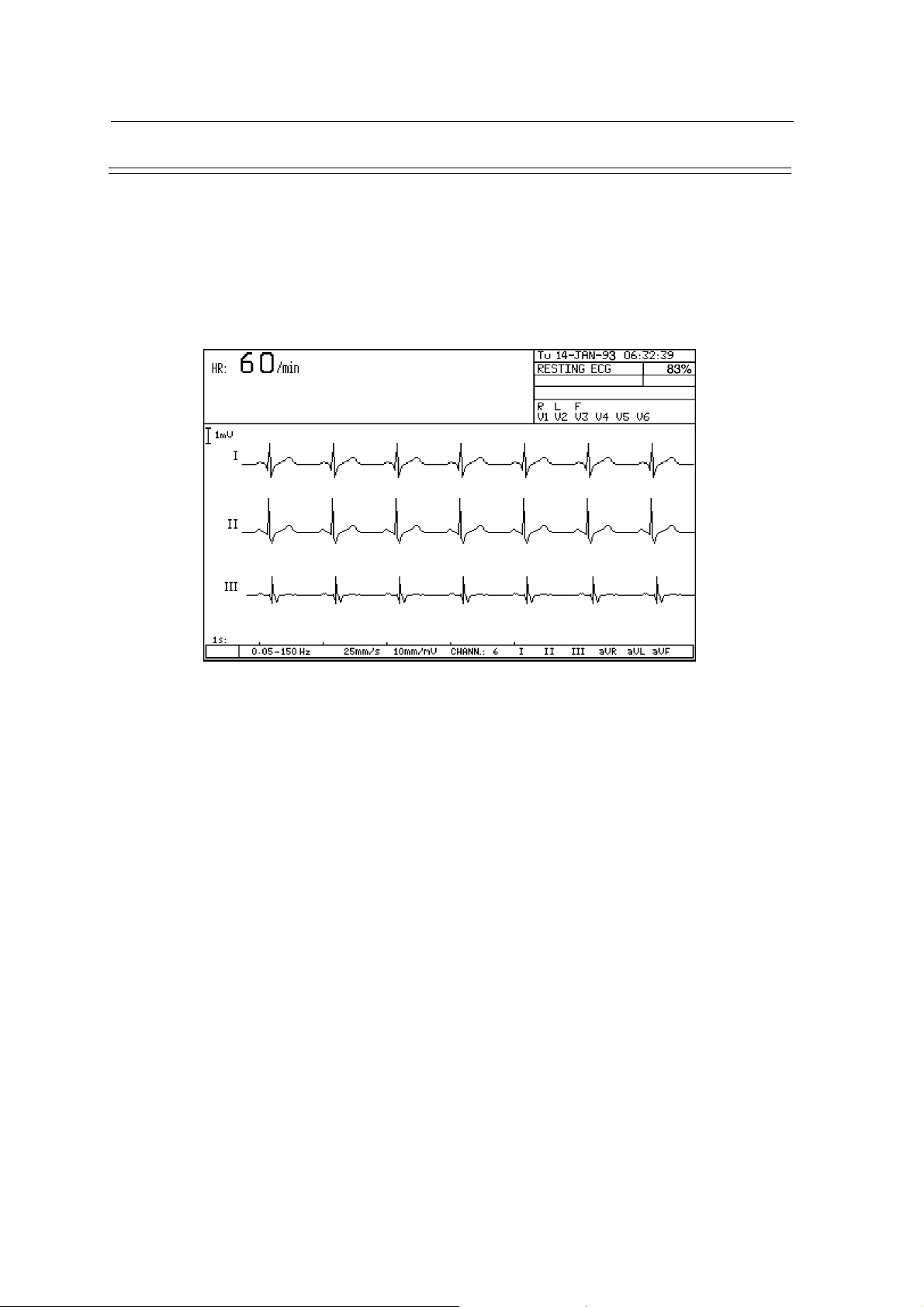

The liquid crystal display (LCD) performs both as a real-time monitor and as an alphanumeric

display for menu selection, data input and the provision of important information.

The display can be folded down when not in use. The contrast can be adjusted by means of the LCD

control located on the side panel of the unit.

A typical display of an ECG recording (with patient simulator connected) is as follows:

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Depending on the function, the displayed information will vary but the screen is normally divided

into three general area as follows:

l The top of the screen gives status and operating information. These are permanently

displayed.

l The central part of the screen is taken up with the measured waveform (ie ECG trace, Lung

function curve, etc) with the lead identifications or measurement units on the left-hand side.

l The bottom of the screen displays the time interval of the recording, indicated in seconds.

The very bottom line gives, from left to right:

• Selected Baseline and Myogram filter settings

• Speed, sensitivity and the number of channels (for direct (manual) print-out)

• The leads that are selected for the printout (for direct (manual) print-out)

Page 1.12

Page 21

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Calibration

At any time during the ECG recording, a 1mV calibration signal can be manually produced by

pressing the <1mV> key on the keyboard. This 1mV square wave signal is indicated both on the

display and on the printout.

Manual Baseline Reset

Pressing the manual baseline recentre key resets the displayed traces to the optimal

position. Use this key to centre the real-time ECG traces, when `drifting´ occurs.

Chapter 1

Operating Elements

Page 1.13

Page 22

Chapter 1

Operating Elements

System Setup

There are several general settings for the AT-10. Press the <FNCT> key to call up the initial menu.

Two options are presented. Option 1 is for entry of the operator information - MTA (Medical

technical Assistant). The second menu item is the set-up option. Press <2> and the System Setup

menu is displayed as follows:

When the menu is entered, the cursor is always located on the first item. There are two ways to select

a particular menu item as follows:

• press the number indicated to the left, or

• use the direction keys to move the cursor to the item required and press the <ENTER> key.

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Most of the options are self explanatory in the set-up menu, however the macro function and the save

setup options are detailed here.

Defining Macro Functions

With the AT-10 you can create your own macro functions and assign them to one of the first six

numerical keys on the alphanumeric keyboard. Up to 30 keystrokes can be stored for one macro

enabling you to call up a particular sub-menu or to carry out a particular programming sequence by

pressing only two keys.

Note: Before starting to program a macro, it is advisable to carry out the sequence making

a note of the order of the key strokes for reference.

In the System Setup menu, press key <1> to call up the Macro function input menu. To start the

programming sequence, press key <I> , then the number key which you wish to program and then

carry out the required sequence.

Once the sequence is completed, press the <2nd> key followed by the <ESC> key and storage of

the keystroke sequence is confirmed by an audible tone.

To initiate a programmed Macro sequence, press the <2nd> key and then the programmed number

key on the alphanumeric keyboard. The sequence will remain stored until a new sequence

overwrites the existing macro programmed for that key.

Page 1.14

Page 23

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

System Setup (cont.)

Save Settings

Programmable parameters can be stored as base settings. These stored settings are not erased when

the unit is switched off. To call up this function, select the last item in the System Setup menu and

the Save Settings menu is displayed as follows:

Chapter 1

Operating Elements

See the AT-10 Operating Manual for full explanation. By pressing <ENTER>, the actual

configuration will be permanently stored and confirmation is given with the message:

*** Settings memorized! ***.

By pressing key "X" the factory default settings are activated. Press <ENTER> and these settings

are stored and confirmed through the message:

*** Settings memorized! ***.

Page 1.15

Page 24

Chapter 1

Operating Elements

ECG Menu

To call up the menu for any of the main functions, simply press the respective function key (eg

<ECG> for resting ECG, <EXERCISE> for exercise ECG, etc). To return from any menu directly

to the Monitor mode, press the <FNCT> key. To return from any menu to the previous menu, press

the ESC key. To call up the main resting ECG menu, press the ECG key.

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Page 1.16

Page 25

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

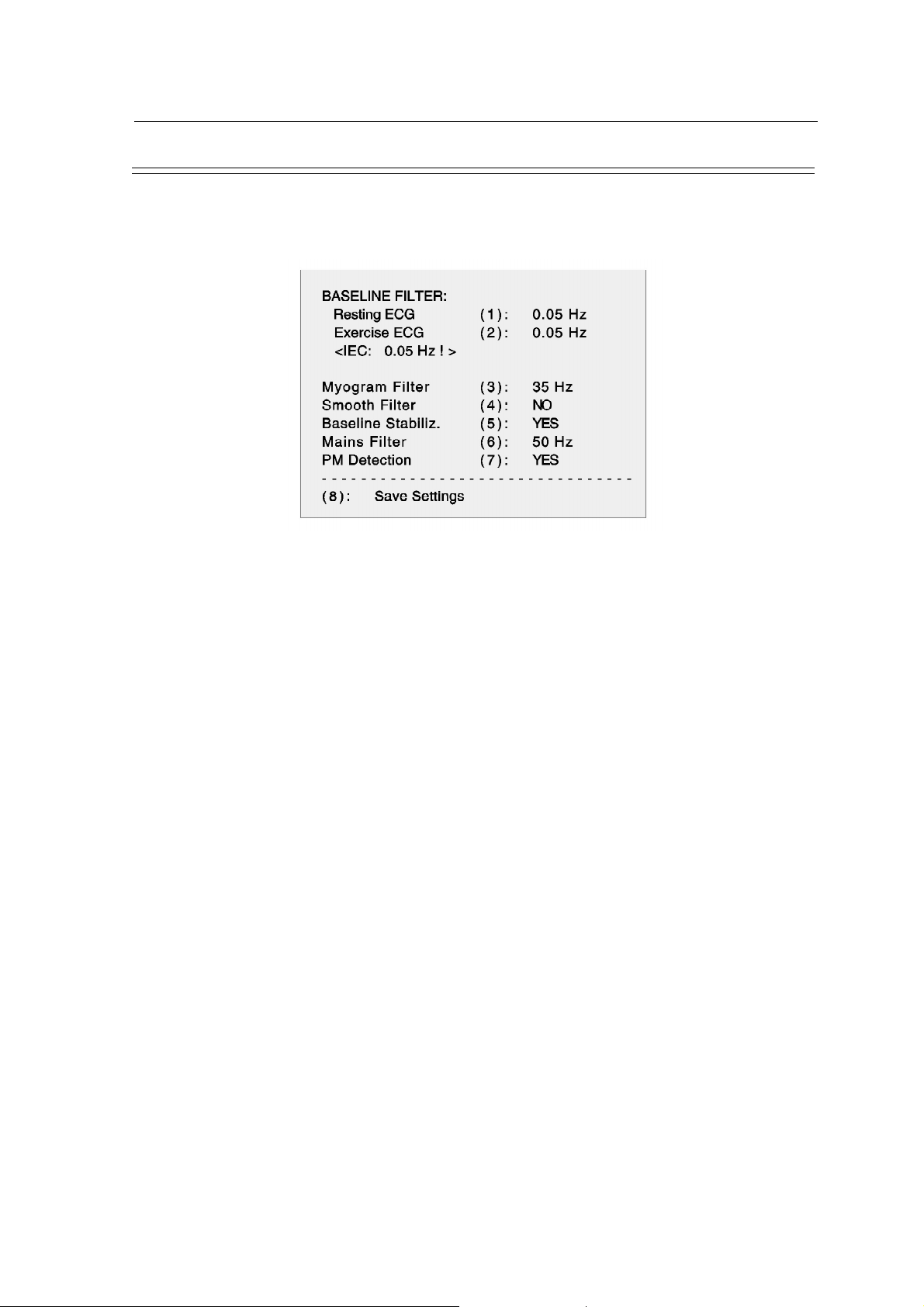

Filters

There are five filters which can be set before starting the recording of an ECG. To call up the menu

for these filters, press the <ECG> key, then select option `ECG Settings´ followed by 'Filters´. The

following menu is displayed:

Chapter 1

Operating Elements

Baseline Filter

A digital baseline filter has been designed in order to suppress excessive baseline drifts. By pressing

key <1> (for resting ECGs) or key <2> (for exercise ECGs), the setting can be altered to one of the

following values: 0.50, 0.25, 0.12 or 0.05 Hz. The value set is the lower limit of the frequency range

and is normally set to 0.05Hz (IEC recommendation), i.e. a frequency range of 0.05 to 150Hz.

The settings 0.12, 0.25 and 0.50Hz should only be used when absolutely necessary as the possibility

exists that they could affect the original ECG signal, especially the ST segments.

Pressing key <4>, <5> or <7> toggles the smooth filter, the baseline stabilisation or the pacemaker

detection circuit on or off.

The current baseline filter setting is indicated at the bottom of the screen. Once the setting has been

changed, firstly press the <FILTER> key in order to reset this indication.

Myogram Filter

The myogram filter suppresses disturbances caused by strong muscle tremor. This filter can be

switched on and off by pressing the <FILTER> key. When set to off, the displayed setting will be

150Hz. When set to on, the selected cut-off frequency (25 or 35Hz) will be indicated.

To alter the setting for the filter, press key <3> and the cut-off frequency can be set to either 25 or

35Hz. The current Myogram filter setting is indicated at the bottom of the screen to the right of the

baseline filter setting. Once the setting has been changed, press the <FILTER> key in order to reset

this indication.

The stored ECG can be printed either with or without passing the myogram filter.

Note: Using the myogram filter causes wave amplitudes on the printout to be reduced by as

much as 20%. Average cycles and measurement values however are not affected by

this filter.

Mains Filter

The mains filter is an adaptive 50Hz / 60Hz digital interference filter designed to suppress ac

interference without attenuating or distorting the ECG. By pressing key <6>, the filter can be set

according to country requirements to either 50Hz (for most European countries) or 60Hz (for the

USA) or switched off.

Page 1.17

Page 26

Chapter 1

Operating Elements

Number of Printed Copies

The number of copies to be printed out can be pre-selected. To do this, press the <ECG> key, select

the ECG Settings / Further Settings menu option and then select ''Number of copies'' (1).

Press key <1> several times to select the required number of copies (either 1, 2, 3, 4 or none).

The unit will now produce the specified number of ECG copies whenever the <AUTO START>

or <COPY> key is pressed.

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Page 1.18

Page 27

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

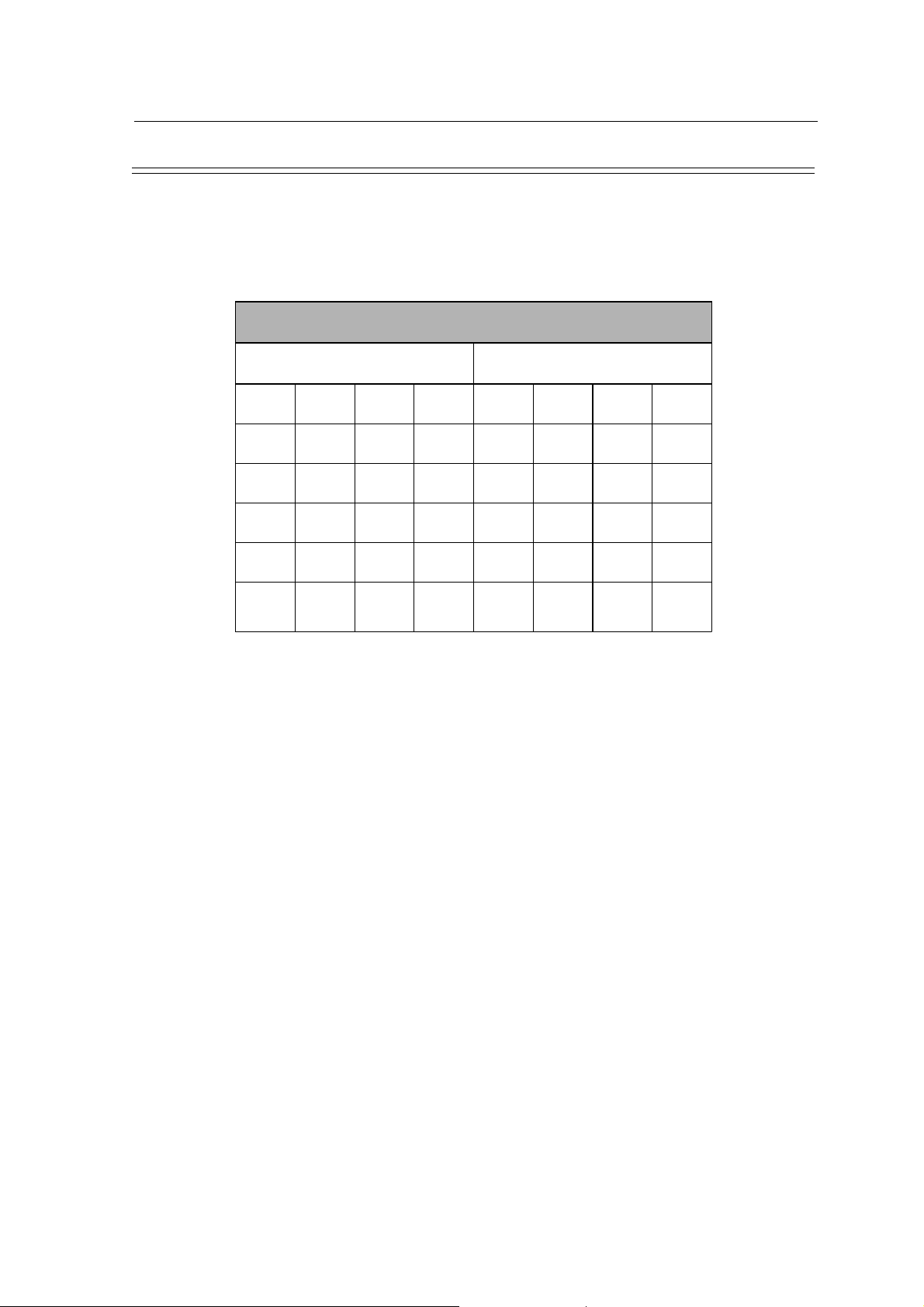

Lead Sequence

The lead sequence can be set to either Standard or Cabrera. The sequence required can be selected

by pressing the <ECG> key, selecting the ECG Settings / Further Settings menu option and then

selecting ''12 Lead Sequence'' (2).

Press key <2> to toggle between Standard and Cabrera leads.

Standard Cabrera

I VI II V4 aVL V1 II V4

II V2 aVF V5 I V2 aVF V5

III V3 III V6 -aVR V3 III V6

aVR V4 V2 V7 II V4 V2 V7

Chapter 1

Operating Elements

Lead Groups

aVL V5 V4 V8 aVF V5 V4 V8

aVF V6 V5 V9 III V6 V5 V9

Page 1.19

Page 28

Chapter 1

Operating Elements

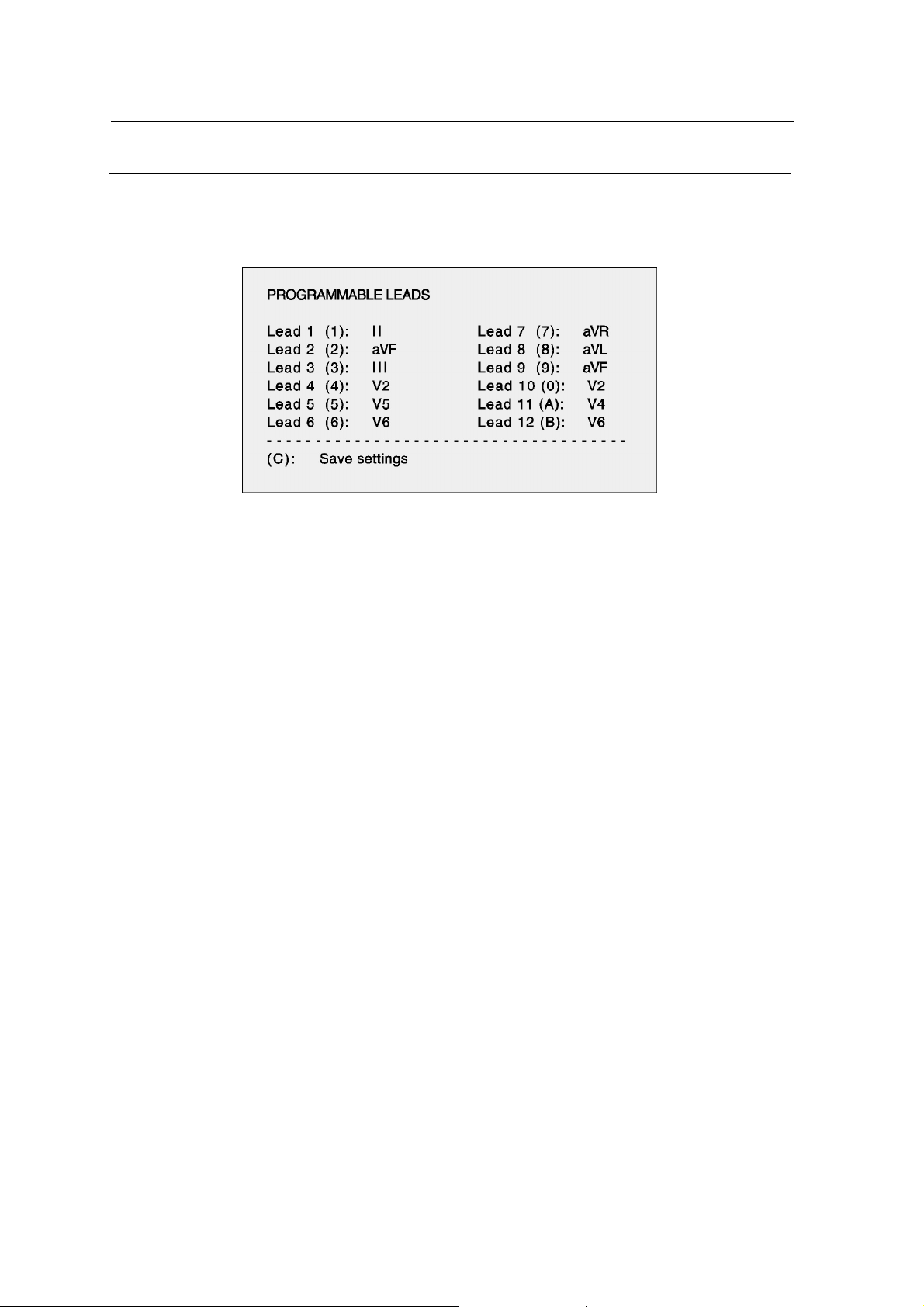

User-programmable Lead Group

The user-programmable group comprises 12 leads which can be individually programmed. To

program these leads, press the <ECG >key, select the ECG Settings menu option and then select

''Programmable Leads'' (5). The following table is then displayed:

The display shows the leads currently programmed. The numbers 1 to 12 symbolise the order of the

leads and the actual lead identifications show which lead is in which position in the group.

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

To program your own lead group, simply enter the code number of the lead you require and press

it several times to select the lead that you want. As an example, to select lead V1 as the first lead,

press key <1> several times until lead V1 is displayed. All leads can be programmed in this way.

Page 1.20

Page 29

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Programmable channels for Printout

The number of channels for the printout can be set to either 3, 4 (5,7), 6 or a user-defined number.

To set this user-defined number, press the <ECG> key, select the ECG Settings / Further Settings

menu option and then select ''Programmable Channels'' (3).

Press key <3>, several times to select the required number of channels (ie, 4, 5 or 7). This setting

is particularly useful when, for example, additional Doppler or Phono waveforms are to be recorded

through the experimental inputs.

Note: Selection of the number of channels (ie, 3, 4 or 6) is performed by pressing the

<PRINTER CHANNEL> key and the current selection is indicated at the bottom of

the screen.

Chapter 1

Operating Elements

Page 1.21

Page 30

Chapter 1

Operating Elements

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Page 1.22

Page 31

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Block Diagram 2.3

Brief Description 2.4

Overall Functional Description 2.7

Power Supply 2.7

Processor and Memory 2.7

ECG 2.7

Keyboard 2.8

Power Supply 2.11

On/Off Control and Low Battery Voltage Monitoring 2.11

Battery Controller 2.12

Processor Board 2.15

CPU 2.15

Program Pack 2.15

Memory 2.15

Communications Controller 2.16

Stress Analog Input/Output 2.17

Thermal Print Head Controller 2.17

Programmable Printer Timer and Beeper 2.17

Power On Reset 2.18

ECG Amplifier 2.20

ECG Isolated Power Supplies 2.20

Pacemaker Trigger 2.21

Cable Tester 2.22

Interface Board 2.23

Thermal Printer Control 2.23

Paper Carriage Control 2.25

Chapter 2

Functional Overview

Chapter 2

Functional Overview

Contents

Page 2.1

Page 32

Chapter 2

Functional Overview

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Page 2.2

Page 33

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Block Diagram

AT-10

P21

PAPER

DC

MOTOR

Chapter 2

Functional Overview

MAINS

DC 1

DC 2

SP-110/R

24 V

BATTERY

PROGRAM

PACK

MK 8-11

P27

POWER SUPPLY

P25

P26

P8

P9

P7

PROCESSOR

MK 8-6

P1

P1

MK 8-1

P20

P12

P2

STEPPER

MOTOR

PAPER

MARK

DETECTION

THERMAL

PRINT

HEAD

KEYBOARD

MK 8-3

LCD

RS-232 (x 3) AND

ONE RS-422

DATA I/O

MK 8-5

BUFFER

MK 8-4

MK 8-7

P22

P24

P23

P29

P13

P14

P15

INTERFACE

P20

LCD/KEYBOARD

P12

RS INTERFACE

P4

ECG

ECG AMPLIFIER

MK 7-20

P4

P3

P6

AT-10 Basic Block and Interconnection Diagram

ERGO

VIDEO

Page 2.3

Page 34

Chapter 2

Functional Overview

Brief Description

The AT-10 comprises the following boards and major functional areas:

Power Supply The power supply rectifies the mains input and generates

Processor Board The Processor Board is the master control for all peripherals

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

all the required voltages for the AT-10 electronics. Two

rechargeable 12V batteries, connected in series, provide

the power for the printer and enable the AT-10 to operate

for about one hour when mains is not present.

and contains the main CPU, system timing circuits and the

unit RAM memory. This board also contains the following:

• Video signal generation circuits and the video/LCD

conversion circuit for the LCD

• Program Pack containing the unit software

• Print control, keyboard timing, and graphics control

circuits

The Processor Board communicates externally over the

following connectors:

• Serial RS-232 and RS-422 interfaces for connection of

RS controlled treadmills and blood pressure measuring

equipment. A port is also available for data transmission

to other ECG equipment or to an external computer for

data evaluation and storage.

• ERGO connector which provides an analog output to

control the speed of a treadmill or the load on a bicycle

ergometer. An analog signal is returned from a treadmill

to indicate the current elevation and speed.

• Data I/O connector which is used for the following:

- a foot-switch input

- QRS trigger output for BP-200

- control signal for treadmill elevation

• Video connector for connection of an external

monochrome VGA standard monitor. The digital video

signal reflects the current LCD display.

• Spirometry connector for connection of a spirometer

(SP-20, SP110, SP-150).

• DC connectors (DC1, DC2) which are used for

experimental analog input signals.

Page 2.4

Page 35

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Brief Description (cont.)

ECG Amplifier Board This board amplifies and carries out some signal processing

Interface Board The Interface board contains the following:

LCD/Keyboard Buffer Board This board buffers the LCD and keyboard data and contains

Chapter 2

Functional Overview

on the incoming ECG signals. To ensure absolute safety of

the patient, all incoming/outgoing data is via opto-isolators.

• Paper mark detection circuit

• Thermal print head data buffers

• Stepper motor control circuit

• Control circuit for the paper tray dc motor

the high voltage circuit for the LCD.

Page 2.5

Page 36

Chapter 2

Functional Overview

+UB

+ 5 V

- 18 V

± 12 V

SUPPLIES

UNIT POWER

(x 3)

RS-422

RS-232

DRIVER

COMMUNICATIONS

ERGO

DATA I/O

STRESS

ANALOG

INPUT / OUTPUT

VIDEO

GRAPHICS

CONTROLLER

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

LCD

BUFFER

VIDEO - LCD

CONVERTER

LCD/KEYBOARD

K/B

BUFFERMK 8-4

BUFFER

DISPLAY

KEYBOARD

VOLTAGE

REGULATION

POWER

CONTROL

ON/OFF

POWER SUPPLY MK 8-6

24V

VOLTAGE

REGULATION

RECTIFICATION

TO CPU

BATTERY CAPACITY

CHARGE

BATTERY

MONITOR

CONTROLLER

COMMUNICATIONS

EEPROM

STATIC AND

DYNAMIC RAM/

PACK

PROGRAM

CPU

MASTER

DATA

ADDRESS

CONTROL

ECG

Multiplexed

TIMER

PRINT HEAD

CONTROLLER

OPTO

ISOLATOR

MK 8-5

INTERFACE

POWER SUPPLY MK 8-6

HEAD BUFFER

THERMAL PRINT

DETECTION

PAPER MARK

MOTOR

DRIVER

PAPER TRAY

MOTOR CONTROL

PRINT HEAD

PHOTODETECTOR

PRINTER MOTOR

MOTOR

PAPER TRAY

AT-10 Functional Block Diagram

Page 2.6

MAINS

ISOLATION

TRANSFORMER

FILTER AND

VOLTAGE SWITCH

MAINS

A /D

CONVERTER

MK 8-1

BOARD

MICROPROCESSOR

DCIN1

DCIN2

SP-100

INTERFACE

SP-100/R

AND

PROCESSOR

MULTIPLEXER

INPUT

AMPLIFIER

ECG AMPLIFIER MK 7-2

ECG

ISOLATION

TRANSFORMER

DC - DC

CONVERTER

CABLE

TESTER

+ 12 V

PAPER

REPLACE

Page 37

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Overall Functional Description

Power Supply

Mains is applied to the power supply via a mains filter, on/off switch and a voltage selection switch.

The voltage selection switch connects the supply to the relevant winding of the mains isolation

transformer. The ac voltage is then rectified to produce a resultant dc voltage of approximately

+27V. This voltage is applied to regulator circuits which generate all of the dc power supplies

required by the AT-10 electronics.

The power on/off control circuit switches the supply voltage to the regulators. The power on/off is

controlled by the following conditions:

• On signal from the keyboard

• Off signal from the Microprocessor (Off key pressed on keyboard, Reset pressed, Batt

Down (5V supply below 4.75V))

• Overcurrent condition on the +12V rail

Two 12V batteries, connected in series, directly provide the power for the thermal printer, and

provide power for the switching regulators when mains is not connected. The charge state of the

battery is monitored by a battery charge monitor circuit.

Chapter 2

Functional Overview

Processor and Memory

The AT-10 is controlled by a high speed, CMOS 68000 processor with a 16-bit data bus and 23bit address bus. The clock speed is 16.7 MHz. The processor works in conjunction with a dedicated

gate array which is custom programmed to perform specific tasks. The working RAM memory

comprises 256 kByte of static RAM and 2MByte of dynamic RAM. The dynamic RAM holds the

ECG (or spirometry) data and other variables and an EEPROM holds the operator selectable

parameters. The unit software comprises 256kBytes of EPROM contained on the program pack. A

digital signal processing chip, also situated on the program pack, is used for real-time processing

of ECG data.

ECG

The ECG signal from the patient is low pass filtered, amplified and applied to the processor and

multiplexer circuit. The ECG Amplifier board carries out the following:

• Analog to digital conversion of the ECG signal at a sampling rate of 4kHz

• Reduction of the sampling rate to 1kHz

• Detection of pacemaker signals and

• Determination of the pulse width of a pacemaker signal

• Transmission of the processed ECG (and PM measurements and status signals) over the

opto-isolators

Page 2.7

Page 38

Chapter 2

Functional Overview

Overall Functional Description (cont.)

The serial input/output is transmitted to the master CPU at 2.5 MBaud and commands are received

from the master CPU at 38.4 kBaud. To ensure absolute patient safety, an isolation transformer

galvanically isolates the AT-10 power supply from the patient.

A cable tester circuit is also incorporated on this board which allows open circuit testing of the

electrode leads. It is automatically activated when a patient lead is connected to the test point.

Keyboard

The keyboard is a matrix style circuit which is periodically scanned by the processor via the

Keyboard Interface circuit. When a key is pressed, the key information is clocked to the Processor

board for interpretation by the master CPU.

Printer Control

The Thermal Print Head is controlled by the print head controller circuit and the timer circuit. The

print head controller serialises the parallel data written by the CPU into a 16-bit FIFO register. The

timer circuit controls how long current is applied to the head, and thus the intensity of the print-out.

The printer motor speed is controlled by the master CPU via the timer circuit.

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Graphics Control

The display data is generated in the graphics processor circuit under the control of the master CPU.

The graphics processor outputs a VGA standard serial video signal. The video signal is converted

to an LCD signal by the Video - LCD circuit.

Miscellaneous Inputs/Outputs

Spirometry

The serial input signal from the spirometer is connected to the interface circuit. The serial data is

clocked into a shift register in the interface circuit and, when enabled the data is presented in parallel

on the data bus for interpretation by the master CPU.

DC Inputs

The dc input connectors allow analog signals, for example from an ultra sound device or a phono

/ pulse recording unit, to be input to the AT-10. The analog inputs are converted to a digital level

and presented on the data bus. The maximum input voltage is 2.5 V p-p.

Video Connector

The video connector outputs the serial video signal generated by the graphics processor. The video

connector reflects the same data as that displayed on the LCD.

Page 2.8

Page 39

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Overall Functional Description (cont.)

ERGO

The analog stress I/O circuit contains a digital to analog converter that converts load or speed

control data to an analog voltage. The elevation and speed of the treadmill is returned as an analog

value and converted to digital data for interpretation by the main CPU. When a bicycle is connected

an analog signal representing the load is sent and received.

Serial Ports

The communications controller contains USARTS which generate serial signals for the transmission and reception of data. The communications driver circuit contains interface circuits to ensure

signal level compatibility with RS-232. The RS-422 connector is used when high data rates are

required or when longer cable lengths are used.

Chapter 2

Functional Overview

Page 2.9

Page 40

Chapter 2

Functional Overview

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

CPU

OFF - FROM

K/B

ON - FROM

+5V

VCC

+5V

SWITCHING

REGULATOR

LOW

BATTERY

VOLTAGE

+US

ON/OFF

CONTROL

-12V

-12V

REGULATOR

12V

SWITCHING

SI2

2AF

-18V

-18V

REGULATOR

REGULATOR

OVER

+12V

CURRENT

+UB

+UBU

+3.5V

REGULATOR

+UB

BATTLC - TO

PROCESSOR

D/A

CONVERTER

UP/DOWN

CURRENT/

FREQUENCY

CONVERSION

BOARD

COUNTER

CURRENT

VOLTAGE/

MONITORING

BOARD MK 8-6

POWER SUPPLY

FILTER

FACTOR

(POWER

SWITCHING

REGULATOR

POWER

RECTIFIER

TRANS-

FORMER

ISOLATION

VOLTAGE

SELECTOR

LINE

FILTER

SWITCH

&ON/OFF

CONTROLLER)

SI1

(2 X 12V)

LEAD-ACID

BATTERIES

RECHARGABLE

10AT

24V

CURRENT

SENSE AND

RECTIFICATION

SENSE

CURRENT

BUFFER MK 8-4

LCD/KEYBOARD

BOARD

PROCESSOR

LEDB - FROM

BATT

MAINS

Power Supply - Functional Block Diagram

AT-10 (PART)

Page 2.10

FUSE

MAINS

200mAT

MAINS MODULE

INPUT

MAINS

STUD

POTENTIAL

EQUALISATION

Page 41

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Power Supply

Mains is applied to the line filter via the on/off switch and two 200 mA, slow-blow fuses. The line

filter incorporates a temperature variable resistor to ensure that the current is limited at initial

switch-on. After a few seconds the resistor warms, the resistance drops and normal power is

supplied. The voltage switch ensures that the correct primary winding of the isolation transformer

is used for the mains voltage applied.

The transformed ac input is full-wave rectified by a bridge rectifier to produce a dc voltage of

approximately +22V. The rectified voltage is used by a switching regulator and filter circuit to

generate the +UB supply .

The switching regulator comprises a power factor controller chip (U1) and associated components.

The switching regulator controls a power MOS FET (Q1) which acts as a switch to regulate the

current flow in loading coil T1. Thus, via diode D4 and output filter (C89, C13 etc), the voltage of

+UB is regulated to +27V.

The pulse width set by U1, is determined by a zero current detection circuit incorporated in U1

(tapping from loading coil T1), the feedback on the current sense (via Q1 power FET), (and the

voltage feedback from +UB (via VR1) when mains is connected (Q3 is switched on). The frequency

of the switching can be between 40kHz and 500kHz.

Chapter 2

Functional Overview

An overvoltage protection circuit monitors +UB when the unit is operating form the mains and cuts

the voltage to the power supply if +UB exceeds +35V. The overvoltage protection circuit is formed

by Q30 and associated components and monitors +UB via Q3 (which is only switched on when

mains is connected to the unit). When an overvoltage is detected, the dc input voltage to the +UB

switching regulator is cut by switching off Q5.

A short circuit protection circuit formed by Q4, C3 and associated components, monitors for

undervoltage which indicates high current and a possible short circuit. If an undervoltage is detected

Q5 is switched off.

On/Off Control and Low Battery Voltage Monitoring

The supply for the +5 and ±12V regulators is controlled by an on/off control circuit. The switch of

the on/off control circuit is Q11. It is initially switched on by the ON signal from the keyboard, and

then latched by the Vcc (+5V) supply. When the OFF signal from the processor goes low, Q11 is

switched off, the power to the switching regulators is cut, and the unit is switched off.

The voltage of the battery is monitored by comparator U6C (monitoring the +US power rail). If the

voltage drops below 18.8V (battery voltage low) Q11 is switched off. In the same manner if an

overcurrent or overvoltage (+12V) is detected, Q11 is switched off via U7B.

Page 2.11

Page 42

Chapter 2

Functional Overview

Power Supply (cont.)

+5V and ±12V Switching Regulators

The 5V and 12V step down switching regulators both function in the same manner. The description

given here is for the 12V regulator.

Power FETs Q9 and Q10 form a push-pull circuit which switches the supply to loading coil T2. The

power FET control circuit is formed by U6A which monitors the ac feedback (via C24) and dc

feedback (via R47) to control the switching oscillator (U5B, C17). A gate booster for the power

FETs is provided by U4 and associated components.

Secondary windings of T2 provide voltages of 13V and 25V. These are used by linear voltage

regulators to produce the regulated -12V and -18V supplies respectively.

The power supply distribution is given on the following table.

POWER SUPPLY DISTRIBUTION

Boards

+ 5 V

(VCC)

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Power Supplies

+ 12 V - 12 V -18V

+UBU

Backup

+ UB

Processor Board 3 3 3 3

LCD/Keyboard Buffer 3 3 3 3

ECG Amplifier 3 3

Interface Board 3 3

Battery Controller

The battery controller circuit measures the charge/discharge current of the battery to enable the

CPU to calculate the capacity of the battery. The battery controller circuit also controls the battery

LED to give a visual indication when the battery is charging and when the unit is using battery power.

The negative side of the battery is connected to a current sense circuit. Operational amplifier U15B

gives an indication to the counter of the current direction ie charging or discharging. Operational

amplifiers U15C and U15A form a current rectification and measurement circuit the output of which

is fed to a current frequency converter circuit. The current/frequency converter provides a

frequency output that is directly proportional to the battery charge or discharge current. The output

of the current/frequency converter clocks an up/down counter which is used to indicate the charge/

discharge current and charge/discharge time of the battery, and thus the actual capacity of the

battery.

Page 2.12

Page 43

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Power Supply (cont.)

The frequency of the current/frequency converter at a charge or discharge rate of 1A is approximately 31.3Hz.

The counter counts up when the battery is discharging and down when the battery is charging. The

count is converted to an analog value by D/A converter U13 for use by the CPU in determining the

charge state of the battery. When the battery is fully charged ie counter all `1´s, the DAC output

is 0V.

The counter is preset when the battery is fully charged. This is carried out by a comparator U14C

which acts as a current sense and goes high when the charging rate of the battery is less than 10mA.

Via Q23, the PRESET signal goes low and the counter is preset to all `1´s. This circuit is also used

(via Q24) to light the battery LED when the battery is charging.

Chapter 2

Functional Overview

Page 2.13

Page 44

Chapter 2

Functional Overview

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

ERGO

LOAD OUT

STRESS

ANALOG

INPUT/OUTPUT

DC 2

I/O

DATA

DC 1

ECGO to ECG Amplifier

RS-232

RS-232

DATA

PORT 2

PORT 1

INTERFACE

COMMUNICATIONS

&

CONTROL

CONTROLLER

COMMUNICATIONS

RS-232

PORT 3

DUAL

PORT

RAM

PORT

RS-422

PRINTER

THERMAL

TPTH

ISYS

THERMAL

MCLK

GATING

ALBEEP

KBBEEP

TIMER

PROGRAMMABLE

PRINTER

PRINTER

THERMAL

AND CONTROL

SERIAL PRINT DATA

PRINT HEAD

CONTROLLER

TPDUR

CONTROL

VIDEO

CONNECTOR

SERIAL VIDEO DATA

SHIFT

REGISTER

LATCH

LIQUID

CRYSTAL

UPPER

LOWER

VIDEO - LCD

CONVERTER

DISPLAY

SIGNALS

CHIP SELECT

MK 8-1

BOARD

MICROPROCESSOR

AT-10 (PART)

DECODER AND

SYSTEM CONTROL LOAD IN, RPM IN

MAIN

PROCESSOR

SHIFT

REGISTER

ECG Amp

ECGI From

DATA BUS

SHIFT

REGISTER

BUS

ADDRESS

BUS

CONTROL

SP-100

CONTROL

CLOCK

REAL TIME

AND

EEPROM

STATIC RAM/

DYNAMIC RAM

PACK

PROGRAM

GRAPHICS

CONTROLLER

SYSEN

VCC

MASTER RESET

POWER ON

RESET AND

VOLTAGE SENSE

Processor - Functional Block Diagram

Page 2.14

SP-100

Page 45

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Processor Board

CPU

Overall control and coordination of all circuits and all peripherals (with the exception of the paper

tray carriage motor), is by the CPU (U46) situated on the Microprocessor Board. The CPU used

is the 68000 and it works in conjunction with a dedicated gate array IC (U47). The main functions

of the gate array circuit are as follows:

• To decode the address bus (A17 to A23) and generate the chip select (CS) signals for the

memory and the peripherals.

• To generate interrupt priority signals (IPL0, IPL1, IPL2) for the main processor - the

highest priority interrupt is `7´ the lowest `1´.

• To generate the row address strobe (RAS), column address strobe (CAS) and address

multiplex control signals for the dynamic RAM.

• To synchronize the clock of the (asynchronous) ECG input signal.

Program Pack

The Program Pack comprises two EPROM chips and a DSP (digital signal processor). The DSP

is used for real time processing of the ECG signal as follows:

• QRS detection

Chapter 2

Functional Overview

• Filtering (Myogram, Mains, Baseline)

• Lead calculation ( I, II .. etc)

A 20 MHz oscillator provides the clock input for the DSP. Communication between the main CPU

and the DSP is via a 16-bit parallel port integral in the DSP.

The EPROM chips contains the AT-10 software. The EPROMs each have 256 or 512 kByte of

memory which is addressed by address lines A0 to A20 and enabled by the EPROM CS signal.

Memory

Dynamic RAM

The Dynamic RAM comprises four 1 Mbyte RAM modules. The RAM control signals are

generated by the gate array (U47). The RAM data is transparently refreshed via CAS before RAS

control protocol at approximately 1kHz. The dynamic RAM stores the following data:

• Printer pixel pattern

• Printer text data

• Stress test ECG data

• Rhythm ECG data

Static RAM and EEPROM

The two 128k RAM chips (U25 & U26) are addressed via address lines A0 to A19; they are enabled

by the CSSRAM signal. The static RAMs use the back-up power supply so that the stored data is

not lost when the unit is switched off.

Page 2.15

Page 46

Chapter 2

Functional Overview

Processor Board (cont.)

The static RAM stores the following:

• Last 10 seconds of ECG data

• Patient data

The AT-10 EEPROM memory stores some user defined parameter settings and comprises a single

64k EEPROM chip (U27). It shares an enable signal (CSRTCC) with the real time clock (U30).

Communications Controller

The Communications Controller carries out the following functions:

• Controls the serial ports

• Converts the incoming analog values from the ERGO connector to digital and vice versa.

• Provides synchronization of the peripheral devices with the CPU

The communications controller comprises a single chip processor (U14) with built in RAM and

ROM to control the serial interfaces and Data I/O ports. Data between the Communications

Controller and the CPU, is via a dual port RAM (U13) which acts as a data buffer. It is selected by

the CSCC signal.

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

The inputs to the A/D converter of the communications controller processor are as follows:

• Speed/load (LOADIN)

• Elevation/RPM (RPMIN)

• Temperature signal from the thermal print head.

Communication over the RS ports is via two dual communication interface controllers. Each of the

controllers monitor two RS ports as follows:

The enable signals for the communication controllers are generated by U14 via a binary to octal

converter (U15).

U14 also outputs the TREADMILL UP and TREADMILL DOWN signals (TMUP, TMDN) to

control treadmill elevation via the Data I/O port.

Page 2.16

Page 47

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Processor Board (cont.)

Stress Analog Input/Output

The analog input/output circuit comprises a digital/analog converter circuit and buffer circuits that

carry out the following functions:

• Converts the control commands for an exercise equipment (ergometer or treadmill), to the

required analog command signal - a 12-bit DAC (U40) produces the LOAD OUT signal

(ERGO 0). The output is 1V per 100 W.

• Buffers and scales the returned analog responses from the ergometer or treadmill. The

returned signals are:

• LOAD IN (ERGO 1) (also used for the treadmill speed input). The load signal is

100W = 1V,

• RPM IN (ERGO 2) (also used for the treadmill elevation input). The RPM signal

scaling is 1V = 100 RPM, the elevation angle scaling is 1V = 12°

These signals, are converted to a digital signal by the A/D converter in the Communications

Controller.

Chapter 2

Functional Overview

Thermal Print Head Controller

The thermal print head controller circuit comprises programmable generic array logic (GAL) chips

and latch buffers. Data to be printed is presented on the data bus and strobed through first in, first

out (FIFO) memories (U60 and U61) in two bytes (lower - D0 to D7, upper D8 to D15). The 10 input,

8 output GALs are programmed to serialise data from the FIFOs memories and send it in the

required format for the printer. To ensure a superior quality print the print head data is `cycled´ so

that each pulse is repeated eight times. This is carried out by FIFO memory U59.

TPD is the print head serial data signal, TPS0 and TPS1 are printer strobes, and TP clock is the 4

MHz serial data clock. The output to the printer is synchronized with the 1.9kHz clock. The

temperature control for the print head is set by the TPDUR signal (thermal print duration from the

programmable timer), which is strobed by signal TGATE (6kHz).

Programmable Printer Timer and Beeper

The timer circuit comprises U28 and U29 which decode the timing instructions from the CPU

encoded on the data bus. The timers are accessed by the CSEE signal. The timing signals produced

are as follows:

• MCLK The printer motor clock. The faster the speed of the motor the

faster the paper feed

• ISYS A general purpose timing clock of 2 kHz, used as system interrupt

(determines sampling rate, printing rate etc.)

• TPDUR The duration that the print head is heated. This is calculated by the

CPU, from the resistance of the print head and the measured

ambient temperature of the print head.

• ALBEEP, KBBEEP Audio signals for the alarm and keyboard beeper.

The timers are addressed by address lines A1 and A2 to select the required timing. The frequency

of the master clock input is 5 MHz.

Page 2.17

Page 48

Chapter 2

Functional Overview

Processor Board (cont.)

Graphics Controller

A VGA standard signal (480 rows with 640 pixels/row with a horizontal sync of approximately 31.8

kHz and a vertical sync of 60 Hz), is generated by a graphics processor chip (U39) and associated

components. The video controller also generates all the necessary protocol signals (HSYNC,

VSYNC etc).

The parallel data output of the video controller is fed to two 8-bit shift registers (U33 and U34)

which together convert the 16-bit parallel output from the video controller to the required serial

video output. Two RAM chips (U31 and U32) form a latch circuit for the pixel memory and allow

picture freeze when required. The video signal to the Video/LCD Converter is gated with signal

SCINV which inverts the screen image (changes the LCD to white on black image), when set.

Certain control and enable signals from the video controller are further decoded by GAL U38.

Video - LCD Converter

The video/LCD converter chip (U74) generates all the timing and strobe signals required by the

LCD and converts the serial video signal into the correct format for display. Four upper and four

lower control and data signals are output to the LCD along with two clock signals. A working

memory for the converter chip is provided (U75).

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Power On Reset

The Power on reset circuit is formed by U54 and associated components. The circuit controls the

master reset of the CPU. This circuit has three functions as follows:

• Provides a delay on initial switch on to ensure that the power supply is fully stabilized and

to give the 200ms reset time required by the 68000 processor

• Ensures that the system is inoperative and in reset mode when the SYSEN indicates that the

Program Pack is not present

• Disables the unit if the +5V rail drops below +4.75V

Page 2.18

Page 49

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Chapter 2

Functional Overview

GALVANIC ISOLATION

AT-10 (PART)

ISOLATION

TRANSFORMER

+ 12 V

DC - AC

28Vpp

POWER

ISOLATED

ECG AMPLIFIER

CONVERTER

7.5Vpp

SUPPLIES

DIGITAL/

ANALOG

CS DADY

CONVERTER

LINK

OPTO

ISOLATION

ECG I

SERIAL

TO CPU

ECG DATA

SI

SERIAL

CONVERTER

PARALLEL TO

D

A

CSGAL

SINGLE CHIP

CS DADY

ADDRESS

COMPUTER

DECODER

ECG O

CONTROL

SO

FROM CPU

- 5 Vi

- 24 Vi

- 12 Vi

+ 12 Vi

SUPPLY RAIL

STABILISATION

RECTIFICATION

28Vpp

ECG AMPLIFIER MK 7-2

GNDi

+ 5 Vi

SUPPLY RAIL

STABILISATION

BRIDGE

RECTIFICATION

7.5Vpp

DC - DC CONVERTER

CABLE

TESTER

-24V

Σ

Σ

ECGMUX

ECG

SIGNAL

MULTIPLEXER

INPUT

AMPLIFIER

FILTER AND

GAIN

SELECT

CHANNEL

CONTROL

BASELINE

DC OFFSET

PMPOS, PMNEG

TRIGGER

PACEMAKER

DETECTION AND

RA

ECG Amplifier - Functional Block Diagram

CABLE

PATIENT

CONNECTOR

Page 2.19

Page 50

Chapter 2

Functional Overview

ECG Amplifier

ECG Isolated Power Supplies

The DC/DC converter circuit produces all the isolated power voltages required by the ECG

Amplifier circuit. The +12V rail from Power Supply MK 8-6 is applied to isolation transformer U2

via a pulsing circuit. The pulsing circuit comprises a 125kHz oscillator divided by two, which via

Schmitt triggers switches MOS FETs Q3 and Q4. This gives a pulsed, 180° phase shifted input on

the two primary windings of the isolation transformer.

The two secondary windings of the isolation transformer produce 28Vpp and 7.5Vpp respectively.

A Schotky diode and capacitor network produce the +12V, -12V and -24V isolated supplies. A

linear regulator (U5) generates the -5V supply from the isolated -12V supply.

The +5V isolated supply is generated from the 7.5Vpp secondary winding. A bridge rectifier

produces approximately +7V which is applied to a FET. The FET is controlled by an operationalamp and transistor circuit so that it acts as a variable resistor to stabilise and produce a +5V supply.

Servicing Note: When taking measurements always ensure that the isolated ground is

ECG Signal

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

used for reference.

The incoming ECG signals RA, LA, and C1 to C9 are 41kHz low-pass filtered and applied to noninverting operational-amps giving a gain of 11. The signals are further low pass filtered (1.6kHz)

and amplified by 3 before being applied to the multiplexer.

The multiplexer enable signal is 4kHz with the output duration of each sampled lead approximately

20 microseconds.

The multiplexed ECG signal is base line compensated. The base line compensation is set by the

ECG processor and converted to an analog signal by a DAC (U20). The maximum compensation

is ± 300 mV. A gain control is also incorporated for the multiplexed ECG signal, and set by the

processor. This gain is selectable to 2.5, 5, or 10.

The signal is then passed to a summing circuit where the last sample value from the D/A converter

(U21) is subtracted from the present sample value. The resultant is the difference of the actual

sample and the previous sample. The resulting voltage is analog to digital converted by the ECG

processor and output to the CPU via a multiplexer and GAL circuit (U23, U26) and opto isolators.

Page 2.20

Page 51

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

ECG Amplifier (cont.)

Pacemaker Trigger

The RA lead is fed, before it is filtered, to the pacemaker detection circuit. The RAPACE signal

from the patient is differentiated and fed to the ECG processor. The negative pulses (PMNEG), and

the positive pulses (PMPOS) indicate the start and end slope of the pacemaker pulse. From the

signals the CPU can calculate the timing of the pacemaker pulse for display (software option).

Chapter 2

Functional Overview

Page 2.21

Page 52

Chapter 2

Functional Overview

ECG Amplifier (cont.)

Cable Tester

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

The cable tester circuit checks the resistance of an individual lead in the patient cable. The resistance

of the lead must be between 10KOhms and 1MOhms.

The cable tester comprises a 3.3kHz oscillator and comparator circuit. The oscillator is connected

to the test point and when a lead is connected to the test point, the potential on the lead (from the

input filter and amplifier circuit) alters the waveform. The waveform is rectified and, via a

comparator (U1B) lights the LED. The comparison voltage at U1B is 1.45V and the generated

waveform is at a base level of approximately -17V with an oscillation of 5V.

Page 2.22

Page 53

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Interface Board

Thermal Printer Control

Chapter 2

Functional Overview

The Thermal Printer stepper motor is controlled by stepper motor controller U1. The MON signal

from the processor is the enable signal for the controller and the MCLK signal sets the speed; 209Hz

gives a paper speed of 2.5 mm/s, 2.09kHz gives a paper speed of 25 mm/s. The driver circuit

incorporates a current sense circuit. The current of the motor is approximately 100mA, depending

on the step rate set.

The printer data, the strobe and the clock signals are buffered by U5. The strobe frequencies (TPS0

and TPS1) are 2kHz, the clock (TPCLCK) is 4MHz, and the latch frequency (TPL) is 2kHz.

Because of the high power peaks drawn by the TPH, reservoir capacitors on the +24V rail ensure

a stable supply to the thermal print head (via the controller).

The paper mark detector is an opto sense circuit. The output from the detector is fed to an operational

amplifier (U4) to set the PM signal when a paper mark is detected. The input from the optocoupler

is 0.4V to 0.6V for white paper and 3.5V to 4V for black paper ie paper mark. The PM output signal

is logic 0 when a paper mark is detected.

Page 2.23

Page 54

Chapter 2

Functional Overview

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Page 2.24

Page 55

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Interface Board (cont.)

Paper Carriage Control

The paper tray carriage motor control circuit works independently from the CPU and has its own

power supply. The power supply is enabled as follows:

• AT-10 switched on Vcc (+5V) latches transistor Q9 on which latches Q7 on to

• AT-10 switched off pressing the REPLACE PAPER key sets signal EJCT to

+Uop is regulated by U4C to generate the +5V supply for the paper carriage motor control circuit

(5Vpd).

Chapter 2

Functional Overview

switch +UB and generate +Uop.

GND and switches transistor Q7 on to generate +Uop from

the +UB supply. Q7 is latched on by Q9 which is switched

on by the DIR.IN signal high. When the tray has returned,

the DIR.IN signal goes to ground which switches Q9 and

Q7 off. This cuts the +Uop rail and switches off the power

supply.

Note that when the AT-10 is switched on the power supply

remains on via Q9 held on from Vcc.

Extend Paper Tray

The 5Vpd voltage initially sets a delay and timing circuit formed by U6C, U6D and associated

components. This sets the ENABLE and INIT signals to flip-flops U7A and U7B so that the circuit

is in a known state. Pressing the REPLACE PAPER key sets the EJECT signal to the flip-flops, via

Q8. The flip-flops enable the motor control chip U8 and set the direction of the 24V dual polarity

motor (GO IN, GO OUT signals). The motor controller incorporates an `H´ bridge current sense

circuit to detect when the paper tray is fully extended. When the paper tray is fully extended the

current increases, the motor controller detects this and sets the sense line which, via comparator

U4D is fed back via a delay circuit, resets the flip-flops and stops the motor. A delay circuit (C34)

prevents the motor being stopped prematurely during the power surge when the motor is initially

activated.

Retract Paper Tray

When the paper tray is extended, pressing the REPLACE PAPER key switches off transistor Q8

and activates the EJECT signal. This produces a clock input to the flip-flops and activates the GO

IN signal to the motor controller. In the same manner as when the paper tray is being extended, the

current sense circuit stops the motor when the paper tray has fully returned.

The flip-flop control circuit monitors the printer motor via the MON signal, and the paper tray motor

via the Stop signal (paper tray motor active). This ensures that the circuit is disabled if the

REPLACE PAPER key is pressed when either the printer motor, or paper tray motors are active.

Page 2.25

Page 56

Chapter 2

Functional Overview

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Page 2.26

Page 57

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Introduction 3.2

Test Equipment 3.3

Fault Diagnosis 3.4

AT-10 Initial Fault Diagnosis Chart (Sheet 1) 3.5

AT-10 Initial Fault Diagnosis Chart (Sheet 2) 3.6

AT-10 Fault Diagnosis Chart (Sheet A - Power Problems) 3.7

AT-10 Fault Diagnosis Chart (Sheet B - Power Problems) 3.8

AT-10 Fault Diagnosis Chart (Sheet C - General Problems) 3.9

AT-10 Fault Diagnosis Chart (Sheet D - Printer Problems) 3.10

AT-10 Fault Diagnosis Chart (Sheet E - Auto Mode Problems) 3.11

AT-10 Fault Diagnosis Chart (Sheet F - Exercise Mode Problems) 3.12

AT-10 Fault Diagnosis Chart (Sheet G - Spirometry Problems) 3.13

AT-10 Fault Diagnosis Chart (Sheet H - Communication Problems) 3.14

Chapter 3

Fault Diagnosis

Chapter 3

Fault Diagnosis

Contents

Page 3.1

Page 58

Chapter 3

Fault Diagnosis

Introduction

The purpose of this chapter is to provide fault-finding procedures that will quickly and efficiently

identify a fault on an AT-10 to a specific module. The fault-finding procedures are designed so that

test equipment is kept to a minimum.

An initial fault diagnosis chart is provided detailing all the general fault indications that may occur.

When this is followed it will indicate the module where the fault lies or specify a further fault-finding

procedure. When more than one module is stated, the first module given is the one most likely to

contain the fault. If the fault is not found on the first module, the other modules should be checked

in the order given.

If the initial fault-finding chart does not indicate the area where the fault exists, re-check all the

settings and parameters that have been entered (for the particular task that fails). If these are correct,

check the software. If this is correct suspect external connections.

If a key operation or menu selection is required when carrying out the functional checks after

replacement, the key sequence required is given in parenthesis ‘<>´. The character(s) given in

parenthesis is the actual character(s) printed on the key. When a key sequence is provided it must

be followed in the order given. For example the key sequence to give the Macro screen is:

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

<FNCT> <2> <ENTER>

This requires that the Function key on the keypad is pressed, followed by the `2´ key followed by

the Return (or Enter) key.

Page 3.2

Page 59

SCHILLER AT-10 ECG and Spirometry Unit

SERVICE HANDBOOK Issue c April 2002

Test Equipment

The following proprietary and dedicated test equipment is the minimum that is required to fault find

and carry out any board checks and adjustments, on the AT-10.

The list of proprietary equipment is not comprehensive. Recommendations of suitable proprietary

test equipment can be obtained from the Schiller Service Department.

Dedicated Test Equipment

• RS Test Cable Assembly required for the RS self test

In addition to the above a Schiller patient cable (Schiller Number 2.400011) is required when

carrying out simulated ECG tests.

Proprietary Test Equipment/Tools

• ECG Emulator, eg Phantom 320*

• Oscilloscope

• Digital Multimeter*

• Stabilised Power Supply

Chapter 3

Fault Diagnosis

• Standard tool kit with a selection of cross-bladed, flat-bladed and posi-drive screwdrivers,

Pliers and general tools*

• Soldering Iron

• VGA Monitor

* Indicates Essential Equipment for basic AT-10 fault finding

Special Tools / Equipment

The following table lists all the special tools and equipment that may be required when fault finding

or carrying out certain maintenance procedures on the AT-10.

Page 3.3

Page 60

Chapter 3

Fault Diagnosis

Fault Diagnosis

Use the fault finding charts and procedures on the following pages to indicate a faulty area or

module. In most cases the fault finding charts should indicate the most likely faulty area.

When a possible faulty module is indicated by the fault finding charts, the module must be replaced.

When a module has been replaced specific test parameters and setting-up of the module may be

applicable. The removal and replacement instructions for all replaceable modules, along with any

set-up or check procedures required, are given in Chapter 4.

MAINS POWER IS PRESENT WHEN THE UNIT COVER IS REMOVED. CERTAIN CHECKS