Page 1

MODELS:

942297G

FastCat-FX541V KAW W/36 SIDE DISCHARGE

942298G

FastCat-FX600V KAW W/48 SIDE DISCHARGE

942299G

FastCat-FX651V KAW W/52 SIDE DISCHARGE

942302G

FastCat-FX600V KAW W/42 SIDE DISCHARGE

942404G

FastCat-627cc VANGUARD B&S W/61 SIDE DISCHARGE

FastCat-FX691V KAW W/61 SIDE DISCHARGE

REV B 04-2012

MAN 4165951

942405G

PARTS / OPERATOR'S MANUAL

Page 2

CALIFORNIA

Proposition 65 Warning

WARNING

Diesel engine exhaust and some

of its constituents are known to the

State of California to cause cancer,

birth defects and other reproductive

harm.

Californie Proposition 65 Avertissement

Les échappements des moteurs diesel et certains

de leurs composés sont reconnus par l’Etat de

Californie pour être cancérigènes, provoquer

des défauts congénitaux et d’autres dangers en

matière de reproduction.

California Advertencia

de la Proposicion 65

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

AVERTISSEMENT

é

mission du moteur de ce matériel con-

L’

tient des produits chimiques que l’Etat de

Californie consid

provoquer des défauts congénitaux et

d’autres dangers en matière de reproduction.

ADVERTENCIA

è

re être cancérigènes,

El estado de California hace saber que

los gases de escape de los motores diesel

y algunos de sus componentes producen

cáncer, defectos de nacimiento y otros

daños en el proceso de reproducción

humana.

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, wiring

insulation, and related accessories

contain lead and lead compounds,

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

El estado de California hace saber que los

gases de escape de este producto contienen

productos quÍmicos que producen cáncer,

defectos de nacimiento y otros daños en

el proceso de reproducción humana.

Page 3

FastCat Pro

IMPORTANT MESSAGE

Thank you for purchasing this Schiller Grounds Care, Inc.product. You have purchased a world class mowing product, one

of the best designed and built anywhere.

This machine comes with an Operation and Safety Manual. The useful life and good service you receive from this machine

depends to a large extent on how well you read and understand these manuals. Treat your machine properly, lubricate and

adjust it as instructed, and it will give you many years of reliable service.

Your safe use of this Schiller Grounds Care, Inc. product is one of our prime design objectives. Many safety features are

built in, but we also rely on your good sense and care to achieve accident-free operation. For best protection, study the

manual thoroughly. Learn the proper operation of all controls. Observe all safety precautions. Follow all instructions and

warnings. Do not remove or defeat any safety features. Make sure those who operate this machine are as well informed

and careful in its use as you are.

See a Schiller Grounds Care, Inc. dealer for any service or parts needed. Schiller Grounds Care, Inc. service ensures that

you continue to receive the best results possible from Schiller Grounds Care, Inc. products. You can trust Schiller Grounds

Care, Inc. replacement parts because they are manufactured with the same high precision and quality as the original parts.

Schiller Grounds Care, Inc. designs and builds its equipment to serve many years in a safe and productive manner. For

longest life, use this machine only as directed in the manuals, keep it in good repair and follow safety warnings and instructions. You'll always be glad you did.

Schiller Grounds Care, Inc.

One Bob Cat Lane

Johnson Creek, WI 53038-0469

TABLE OF CONTENTS FIGURES PAGE

SAFETY .........................................................................................................................................................2-8

SET-UP INSTRUCTIONS ............................................................................................................................9-10

LABELS .....................................................................................................................................................11-14

CONTROLS ...............................................................................................................................................15-18

PRE-OPERATION CHECKLIST .....................................................................................................................19

OPERATION ..............................................................................................................................................20-22

MAINTENANCE CHART ................................................................................................................................23

MAINTENANCE RECORD .............................................................................................................................24

MAINTENANCE ........................................................................................................................................25-31

ADJUSTMENTS ........................................................................................................................................32-35

BELT REPLACEMENT ..............................................................................................................................36-37

PARTS SECTION ...........................................................................................................................................39

FRAME-ENGINE/CLUTCH ASSY .......................FIGURE 1 ...................................................................40, 41

TRANSAXLE ASSY .............................................FIGURE 2 ...................................................................42, 43

FUEL TANK/BUMPER & CONTROL PANEL.......FIGURE 3 ...................................................................44, 45

FUEL VALVE & COVER PLATE ..........................FIGURE 4 ...................................................................46, 47

DECK LIFT ASSEMBLY ......................................FIGURE 5 ...................................................................48, 49

CASTER ASSEMBL Y ..........................................FIGURE 6 ...................................................................50, 51

KICKPLA TE/SEA T ASSEMBLY ...........................FIGURE 7 ...................................................................52, 53

STEERING ..........................................................FIGURE 8 ...................................................................54, 55

PARKING BRAKE ...............................................FIGURE 9 ...................................................................56, 57

WIRE HARNESS .................................................FIGURE 10 .................................................................58, 59

36" SIDE DISCHARGE .......................................FIGURE 11 .................................................................60, 61

42" SIDE DISCHARGE .......................................FIGURE 12 .................................................................62, 63

48" SIDE DISCHARGE .......................................FIGURE 13 .................................................................64, 65

52" SIDE DISCHARGE .......................................FIGURE 14 .................................................................66, 67

61" SIDE DISCHARGE .......................................FIGURE 15 .................................................................68, 69

BELTS-CUTTERDECK ........................................FIGURE 16 .................................................................70, 71

DECALS-POWERUNIT .......................................FIGURE 17 .................................................................72, 73

04-2012

1

Page 4

SAFETY

FastCat Pro

NOTICE !!!

Unauthorized modications may present extreme

safety hazards to operators and bystanders and

could also result in product damage.

Schiller Grounds Care, Inc. strongly warns against,

rejects and disclaims any modications, add-on

accessories or product alterations that are not

designed, developed, tested and approved by Schiller

Grounds Care, Inc Engineering Department. Any

Schiller Grounds Care, Inc. product that is altered,

modied or changed in any manner not specically

authorized after original manufacture–including the

addition of “aftermarket” accessories or component

parts not specically approved by Schiller Grounds

Care, inc.–will result in the Schiller Grounds Care,

Inc. warranty being voided.

Any and all liability for personal injury and/or property

damage caused by any unauthorized modications,

add-on accessories or products not approved by

Schiller Grounds Care, Inc. will be considered

the responsibility of the individual(s) or company

designing and/or making such changes. Schiller

Grounds Care, Inc. will vigorously pursue full

indemnication and costs from any party responsible

for such unauthorized post-manufacture modications

and/or accessories should personal injury and/or

property damage result.

This symbol means:

ATTENTION!

BECOME ALERT!

Your safety and the safety of others is involved.

Signal word denitions:

The signal words below are used to identify levels

of hazard seriousness. These words appear in this

manual and on the safety labels attached to Schiller

Grounds Care, Inc. machines. For your safety and

the safety of others, read and follow the information

given with these signal words and/or the symbol

shown above.

DANGER indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

CAUTION indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or moderate

injury. It may also be used to alert against unsafe

practices or property damage.

* Serial Plate located on cross member of frame under seat.

2

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, MAY result in property damage

MODEL NUMBER: This number appears on

sales literature, technical manuals and price lists.

SERIAL NUMBER: This number appears only

on your mower. It contains the model number

followed consecutively by the serial number.

Use this number when ordering parts or seeking

warranty information.

Page 5

FastCat Pro

PREPARING FOR SAFE OPERATION

Operator preparation and training

Read the Operation & Safety

Manual

- If an operator or mechanic

cannot read English, it is

the owner's responsibility

to explain this material to

them. If any portion of this

material is unclear, contact

your factory representative for clarication.

- Become familiar with the safe operation of the

equipment, operator controls and safety signs.

Know how to stop the engine and attachments

quickly in an emergency. Do not operate or allow

another person to operate this machine if there

are any questions about safety.

- All operators and mechanics should be trained.

The owner is responsible for training the users.

- Wear appropriate clothing, including long

trousers and safety goggles or safety glasses

with side shields when operating mower. Do not

operate barefoot or wearing open sandals. Long

hair, loose clothing or jewelry may get tangled in

moving parts.

- Wear hearing protection.

- Never allow underage children, unskilled

or improperly trained people operate this

equipment. Local regulations can restrict the age

of the operator.

- Data indicates that those operators age 60 years

and above are involved in a large percentage of

riding mower-related injuries. Those operators

should evaluate their ability to operate the riding

mower safely enough to protect themselves and

others from injury.

- Do not carry passengers, especially small

children. They may fall off and be seriously

injured.

- Keep warning labels and this operator's manual

legible and intact. Replacement labels and

manuals are available from the factory.

- Do not operate machine while under the

inuence of drugs or alcohol.

- The owner/user can prevent and is responsible

for accidents or injuries occurring to themselves,

other people or property.

SAFETY

WARNING

All rotary lawnmowers are potentially

dangerous. They can amputate hands and

feet and throw objects. Failure to follow

these safety and operating instructions

could result in serious injury or death.

Site preparation and circumstances

- Evaluate the terrain to determine what

accessories and attachments are needed to

properly and safely perform the job. Only use

accessories and attachments approved by the

manufacturer.

- Clear the area to be mowed of objects such as

rocks, toys, wire or other debris that may be

picked up or thrown by the mower.

- Be sure the area is clear of pets and people,

especially young children. Never assume they

will remain where you last saw them. Stop the

machine if any enter the area.

- Mow only in daylight or in good articial light.

- Do not mow wet grass as tires may lose traction.

3

Page 6

SAFETY

FastCat Pro

Machine preparation

- Check operator presence interlock system and

brake operation. Adjust or repair any problems

before using.

- Do not tamper with or defeat safety devices.

Keep guards, shields and interlock safety devices

in place and in proper working condition. They

are for your protection.

- Keep all fasteners such as nuts, bolts and pins

well secured.

- Visually inspect blades, blade bolts and the cutter

assembly for wear or damage. Replace worn or

damaged blades and bolts to preserve balance.

- Verify that machine and attachments, if any, are

in good operating condition.

- Do not engage blades until ready to mow.

OPERATING SAFELY

In general

- Use extra care when loading or unloading the

machine into a trailer or truck.

- Slow down and use caution when making turns

and crossing roads and sidewalks. Stop blades if

not mowing.

- Do not run the engine in an enclosed area where

dangerous carbon monoxide fumes can collect.

- Do not place your foot on the ground while

operating the machine.

- Before operating, lower the discharge chute,

install the mulcher or put the entire grass catcher

in place.

- Keep clear of the discharge opening at all times.

Never direct the discharge toward a bystander.

Stop operation if someone approaches.

- Keep washout ports and other mower housing

service openings closed when mowing.

- Use care when pulling loads or using heavy

equipment.

- Use only approved drawbar hitch points.

- Limit loads to those you can safely control.

- Do not turn sharply. Use care when reversing.

- Use counterweight(s) or wheel weights when

suggested in the operator's manual.

- Never leave a machine unattended. Always turn

off blades, set parking brake, stop engine and

remove key before dismounting.

4

Page 7

FastCat Pro

SAFETY

Starting

- Start only according to instructions in this manual

or on the machine.

- Before attempting to start the engine, make sure:

- the parking brake is on;

- the PTO is disengaged;

- the traction drive is in NEUTRAL.

- When starting the engine, make sure hands and

feet are clear of the blades.

- Do not start the machine while standing in front

of the discharge chute or with the chute directed

at someone.

- Do not engage PTO at full throttle. Throttle to

idle or lowest possible engine speed.

- Do not change engine governor settings or

overspeed the engine. Operating the engine

at excessive speed can increase the hazard of

personal injury.

Interrupting operation

- Before leaving the operator's position:

- Park on level ground.

- Disengage the PTO.

- Set the parking brake.

- Shut off the engine and remove the key.

- Disengage the PTO and wait until the blades quit

rotating:

- before raising cutterdeck;

- when not mowing;

- for transport;

- when crossing surfaces other than grass.

- Stop the engine, disengage the PTO, set parking

brake and wait until the blades quit rotating and

lower cutting unit:

- before refueling;

- before removing grass catcher;

- before making height adjustment unless the

adjustment can be made from the operator's

position.

- Stop the engine, disengage the PTO, set parking

brake and disconnect the spark plug wire(s) or

remove the key:

- before clearing blockages or unclogging chute;

- before checking, cleaning or working on the

machine;

- after striking a foreign object. Inspect the

machine for damage and make repairs before

restarting;

- if the machine begins to vibrate abnormally:

shut off machine immediately. Inspect and

make repairs as needed before restarting;

- except for repairs or adjustments as specically

noted, such as for carburetor adjustment,

where the engine must be running. Keep

hands and feet clear of moving parts in these

circumstances.

- Allow the blades to come to a complete stop

when stopping operation to clear blockages,

unclog, inspect the machine, do maintenance or

repair.

- Reduce the throttle setting during engine shutdown and, if the engine is provided with a shutoff valve, turn the fuel off at the conclusion of

mowing.

5

Page 8

SAFETY

MANEUVERING SAFELY

In general

- Slow down before turning.

- Do not mow in reverse unless absolutely

necessary. Always look behind and down

for small children and pets before and during

backing.

- Be aware when approaching blind corners,

shrubs, trees, tall grass or other objects that may

obscure vision.

- If tires lose traction, disengage the blades. If on

a slope, head downhill.

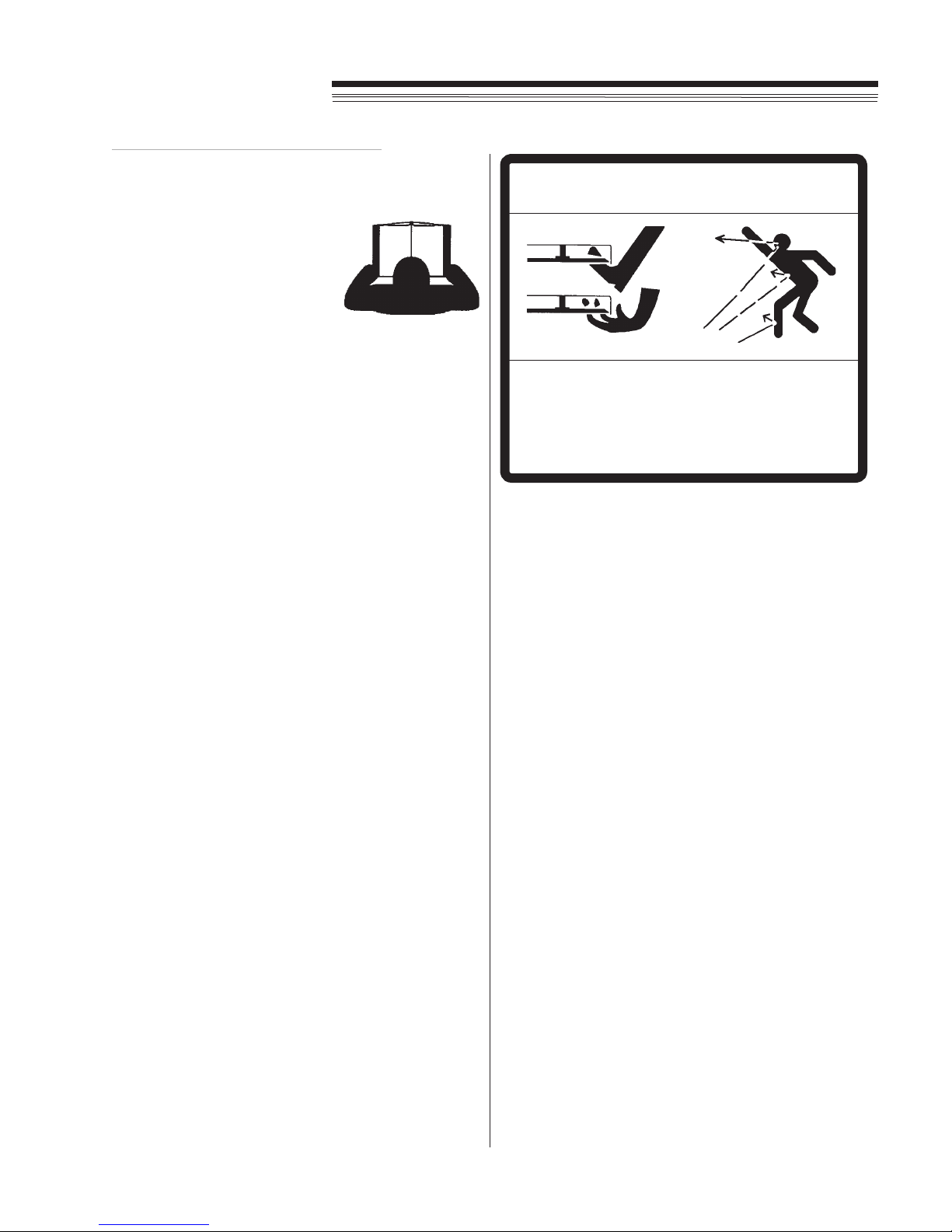

Mowing slopes

Slopes are a major factor in

loss-of-control and tip over

accidents that sometimes lead

to severe injury or death. All

slopes require extra caution.

- Do not mow on slopes if uneasy or uncertain.

Ultimate responsibility for safe operation on

slopes rests with the operator.

- Do not mow excessively steep slopes.

- On zero turn machines, mow across slopes, not

up and down.

- Avoid starting or stopping on a slope. If tires

lose traction, disengage the blades and proceed

slowly straight down the slope.

- With a zero turn machine, if tires lose traction

going down a slope, steering control may be

regained by speeding up.

- Mid-mount zero turns (belly mounted deck) have

much greater traction pointed up slope than

down slope. Be aware that traction may be lost

going down a slope. Do not operate a mid-mount

zero turn on slopes it cannot back up.

- Keep all movement on the slopes slow and

gradual. Do not make sudden changes in speed

or direction.

- Do not turn on slopes unless necessary, and then

turn slowly and downhill when possible.

- Stay away from slopes if the ground is loose or if

caught in the rain during mowing.

- Use lower speeds on a slope to avoid stopping or

shifting.

WARNING

FastCat Pro

- Use extra care with grass catchers or other

attachments. These can change the stability of

the machine.

- Remove obstacles such as rocks, tree limbs etc.

- Avoid driving over obstacles such as ruts, holes,

rocks and roots whenever possible. Be alert to

dips and rises. Uneven terrain can overturn a

mower or cause it to slide. Tall grasses can hide

obstacles.

- Do not mow drop-offs, ditches or embankments.

The machine could suddenly turn over if a wheel

runs over the edge or an edge caves in.

- Follow the manufacturer's recommendations

for wheel weights or counterweights to improve

stability.

- Do not mow slopes when grass is wet. Reduced

traction could cause sliding.

6

Page 9

FastCat Pro

SAFETY

MAINTENANCE SAFETY

In general

- Maintain machine according to manufacturer's

schedule and instructions for maximum safety

and best mowing results.

- Park machine on level ground.

- Never allow untrained personnel to service machine.

- Adjust or repair only after the engine has been

stopped and the blades have quit rotating.

- Inspect grass catcher components regularly. If

worn, damaged or deteriorated, they may expose

moving parts or allow objects to be thrown.

- Replace parts if worn, damaged or faulty.

For best results, always replace with parts

recommended by the manufacturer.

- Disconnect battery or remove spark plug wire(s)

before making any repairs. Disconnect the

negative terminal rst and the positive last. Re-

connect positive rst and negative last.

- Do not dismantle the machine without releasing

or restraining forces which may cause parts to

move suddenly.

- Provide adequate support, e.g. jack stands for

lifted machine or parts if working beneath.

- Do not put hands or feet near or under rotating

parts.

- Clean up spilled oil or fuel thoroughly.

- Replace faulty mufers.

- To reduce re hazards, keep the engine, mufer,

battery compartment and fuel storage area free

of grass, leaves, debris buildup or grease.

- Hydraulic uid can penetrate skin, use paper

to check for leaks. Relieve hydraulic pressure

before disconnecting hoses. Make sure

connections are tight and hoses are in good

condition.

Blades

WARNING

- Mower blades are sharp and

can cut. Use extra caution

when handling. Remove obstructions with care. Wrap the

blade(s) or wear gloves.

- Be aware that rotating one blade on multi blade

mowers can cause other blades to rotate.

- Only replace blades. Never straighten or weld

them.

- Keep other persons away from blades.

WARNING

Fuel

- Gasoline and diesel fuels are

ammable; gasoline vapors

are explosive. Use extra care

when handling.

- Store only in containers specically designed for fuel.

- When refueling or checking fuel level:

- Stop the engine and allow to cool;

- Do not smoke;

- Refuel outdoors only;

- Use a funnel;

- Do not overll;

- If fuel is spilled, do not attempt to start the

engine until the spill is cleaned up and vapors

have cleared.

Sparks from static electricity can start res or cause

explosions. Flowing fuel can generate static

electricity. To prevent static electricity sparks:

- Keep containers electrically grounded. Do not ll

containers in a vehicle or on a truck or trailer bed

with a plastic liner. Fill containers on the ground

away from the vehicle.

- When practical, remove gas powered equipment from the truck or trailer and refuel it on the

ground. If equipment must be refueled on the

truck or trailer, refuel from a portable container

rather than a dispenser nozzle.

- Keep the dispenser nozzle in contact with the rim

of the fuel tank or container opening until fueling

is complete. Do not use a nozzle lock-open

device.

- Replace caps on fuel cans and tanks securely.

7

Page 10

SAFETY

FastCat Pro

BATTERY

Battery acid is caustic and fumes

are explosive and can cause

serious injury or death.

To reduce the risk of personal

injury when working near a battery:

- When working with battery

acid, use protective equipment

such as, but not limited to, goggles, face shield,

rubber gloves and apron.

- Avoid leaning over a battery.

- Do not expose a battery to open ames or

sparks.

- Be sure batteries with ller caps are properly

lled with uid.

- Do not allow battery acid to contact eyes or skin.

Flush any contacted area with water immediately

and get medical help.

- Charge batteries in an open, well ventilated area,

away from sparks and ames. Unplug charger

before connecting or disconnecting from battery.

WARNING

STORAGE AND TRANSPORTATION

- Stop the engine and allow to cool before storing.

- Drain the fuel tank outdoors only.

- Store fuel in an approved container in a cool, dry

place.

- Keep the machine and fuel containers in a locked

storage place to prevent tampering and to keep

children from playing with them.

- When the machine is to be parked, stored or left

unattended, lower the cutterdeck unless a positive mechanical lock is used.

- Do not store the machine or fuel container near

heating appliances with an open ame such as a

water heater or an appliance with a pilot light.

- Keep gasoline storage area free of grass, leaves

and excessive grease to reduce re hazard.

- Clean grass and debris from cutting units, drives,

mufers and engine to help prevent res.

JUMP STARTING

1. Be sure the jumper cables are in good condition.

Turn off the ignition and all electrical accessories

on both machines.

2. Position the machine with a good (charged) battery next to but not touching the machine with the

dead battery so jumper cables will reach.

3. When making cable connections:

- make sure the clamps do not touch anywhere

except to intended metal parts,

- Never connect a positive ("+" or red) terminal

to a negative ("–" or black) terminal.

- Make sure the cables won't get caught in any

parts after the engines are started.

4. Connect one end of the rst jumper cable to the

positive terminal on one battery. Connect the

other end to the positive terminal on the other

battery.

5. Connect one end of the other cable to the

negative terminal of the machine with a good

(charged) battery. Make the nal connection on

the engine of the machine to be started, away

from the battery.

6. Start the vehicle with the good battery, then the

machine with the discharged battery.

7. Remove the cables in the exact reverse order of

installation. When removing each clamp, take

care it does not touch any other metal parts while

the other end remains attached.

8

Page 11

SET UP INSTRUCTIONS

FastCat Pro

TOOLS REQUIRED FOR ASSEMBLY

- Wrecking bar

- Claw hammer

- Sockets: 1/2”, 15/16

- Wrenches: 18mm, 1/2”, 9/16”, 3/4”, 15/16”

- Tire pressure gauge

NOTE: All references below to the “right” or “left” are with respect to an operator at the controls.

1. UNCRATE UNIT

a) Discard packing materials. Loosen the caster wheel axle bolts and bumper bolts to remove the shipping

brackets.

Discard shipping brackets.

b) Re-install and tighten bumper bolts.

c) Tighten caster wheel axle bolts against caster axle spanner bushings to 80 ft/lbs.

2. TIRE PRESSURE

a) Set tire pressures to 14 lbs/in2 (1.0 kg/cm

3. TRACTION LEVERS

a) Tighten bolt A.

b) Sit on the machine. Levers C may be moved to

upper set of holes in bar B for a better operator

t.

2

). Tires are overinated for shipping.

9

Page 12

SETUP INSTRUCTIONS

FastCat Pro

4. FINAL PREPARATIONS

- Check the engine and hydraulic oil levels. Top off with the correct oil if necessary. Use 10W30 motor oil

for the engine. Use fresh, clean 20W50 motor oil for the hydraulic system. See engine operation manual

for specied motor oil viscosity.

- Charge battery and properly connect cables. See steps below.

Battery acid is caustic. Fumes are explosive and can cause serious injury or death.

Use insulated tools, wear protective glasses or goggles and protective clothing when working with batteries.

Read and obey the battery manufacturer’s instructions.

Be certain the ignition switch is OFF and the key has been removed before servicing the battery.

a) Verify battery polarity before connecting or disconnecting the battery cables.

b) When installing the battery, always assemble the RED, positive ( + ) battery cable rst and the

ground, BLACK, negative ( - ) cable last.

c) Tighten cables securely to battery terminals and apply a light coat of silicone dielectric grease to

terminals and cable ends to prevent corrosion. Keep terminal covers in place.

- Read Operation and Safety Manual before starting. Operator Manual is located under the seat/footplate.

Tilt seat forward / footplate up to access manual.

OPERATOR'S MANUAL

IS LOCATED UNDER

THE FOOT PLATE.

OR

4165730

- If deck does not cut level, see deck leveling procedure in the adjustments section of this manual.

- Run engine at full RPM for 5 minutes before engaging blades to allow the engine to be fully lubricated

before load is applied.

- Check the hydro stat neutral adjustment. Neutral is set at the factory but may require readjustment. See

adjustments section of this manual.

- Do not use the machine without an approved grass collector, the grass discharge chute or mulching

plates correctly tted.

10

Page 13

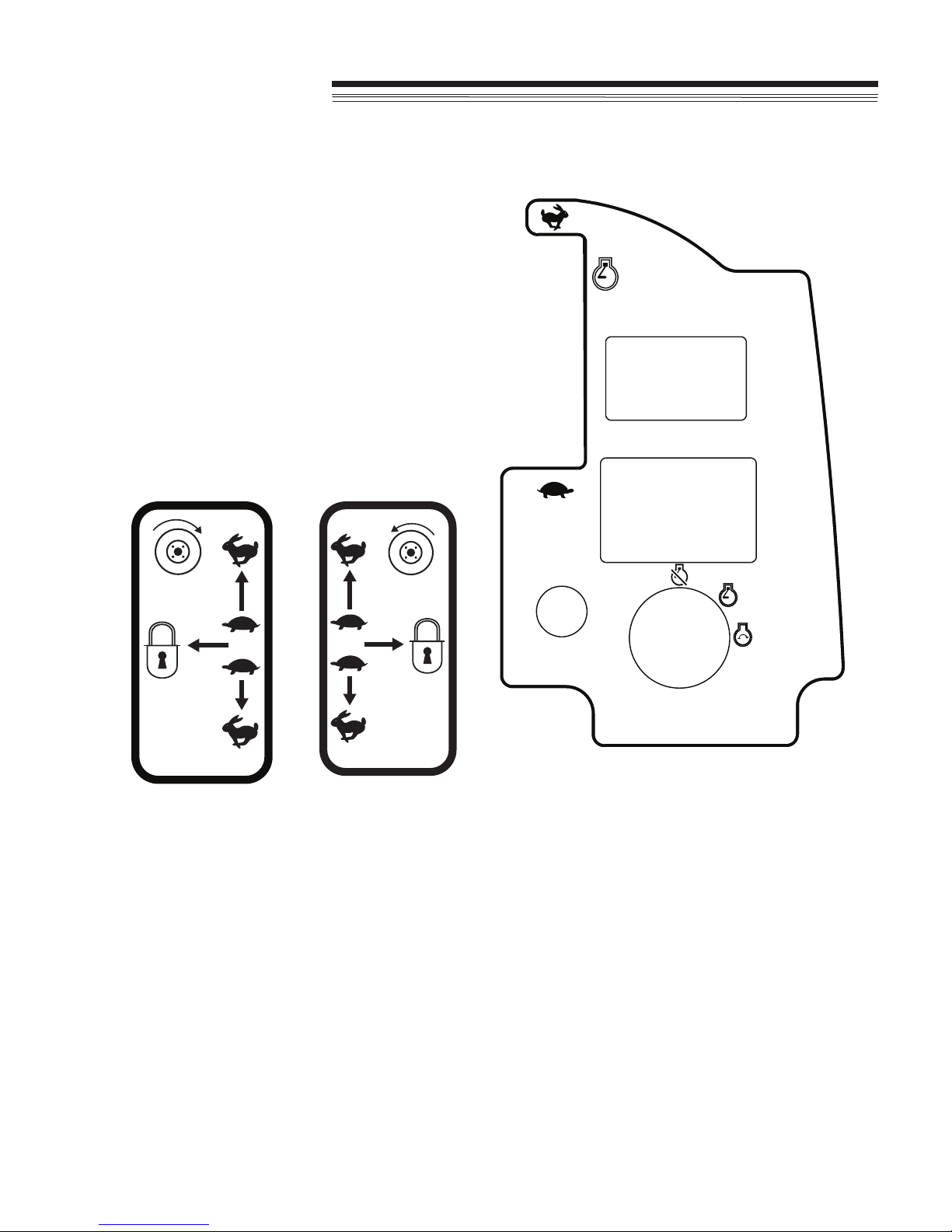

FastCat Pro

bORDER IS NOT BLUE,

BORDER IS WHITE.

LABELS

PTO SWITCH

N

4165616

F

N

R

F

N

R

N

4165662

4165615

11

Page 14

LABELS

FastCat Pro

12

Page 15

FastCat Pro

BEFORE STARTING OR SERVICING:

Read and understand the

Operator's Manual & labels.

LABELS

- Be sure machine is in safe operating condition.

- Move traction levers to neutral lock, parking brake to ON.

- Set PTO switch to OFF.

BEFORE LEAVING SEAT:

- Move traction levers to neutral lock, parking brake to ON.

- Set PTO switch to OFF.

- Turn engine keyswitch to OFF.

- Remove key.

AVOID SERIOUS INJURY OR DEATH:

- Read and obey the Operation & Safety Manual.

- Remove objects that could be thrown by the blades.

- Use caution on slopes. Stay off slopes the machine

cannot back up.

- Stop blades and drive down slowly if machine slides

or stops going on slope.

- Do not mow when children or others are around.

- Do not carry a child or passenger-even with blades off.

- Look down and behind before and while backing.

- Do not operate unless trained.

- Do not operate unless guards, shields and interlocks

are in place and working.

- Replace labels and Operation and Safety Manual if lost

or damaged.

- Remove debris buildup. Debris under belt cover or

near muffler can cause fires.

- Blades continue to rotate for a few seconds after

blades are turned off.

- Blades must be at least 1/8" above bottom of housing.

- All blades must be identical. Check blade bolts daily

for tightness.

- Inspect for damage after striking a foreign object.

Make repairs before restarting operation.

- Find and repair cause of any abnormal vibration.

DECAL IS LOCATED UNDER FOOTPLATE.

- Leer el manual del operador. No permitir que

personas no capacitadas para ello usen la máquina.

- Mantener los protectores en su lugar y sus tornillos

debidamente fijados.

- Antes de limpiar, ajustar o reparar este equipo,

apagar todos los mandos, aplicar el freno de

estacionamiento y apagar el motor.

- Mantener las manos, los pies y la ropa alejados de

las piezas en movimiento.

- No conducir como pasajero ni llavar pasajeros en

máquinas sin asiento para ello.

- Mantener a las demás personas alejadas durante

el funcionamiento de la máquina.

- Si no sabe leer inglés, solicitarie a otra persona

que le lea y explique el contenido de las etiquetas y

del manual de la máquina.

4165610

13

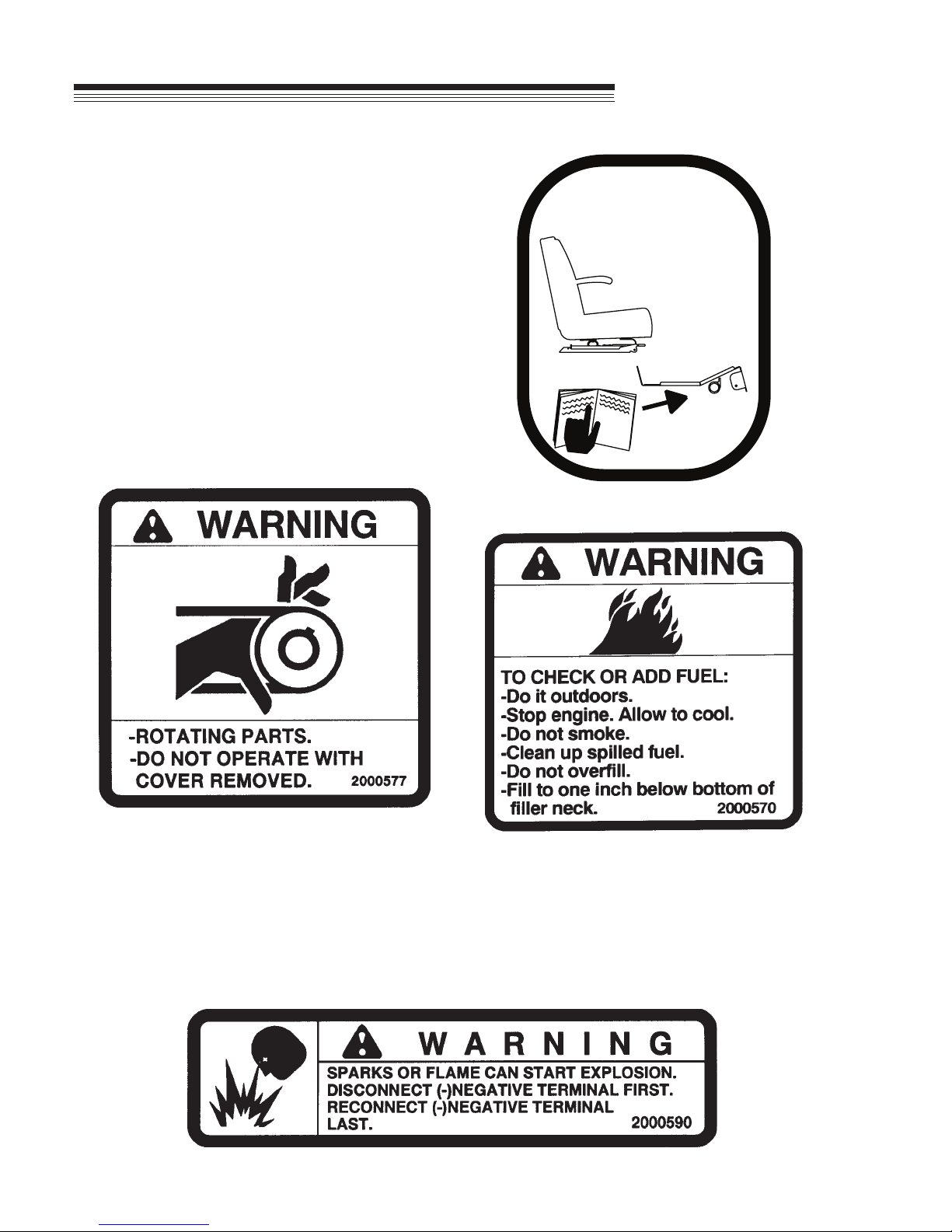

Page 16

LABELS

FastCat Pro

OPERATOR'S MANUAL

IS LOCATED UNDER

THE FOOT PLATE.

4165730

14

Page 17

FastCat Pro

KEYSWITCH (K) - The keyswitch has three

positions: OFF, RUN, and START. Insert the key

and turn it clockwise to move the switch from OFF to

RUN. Turn it further to START and hold to engage

the starter. Release the key and the switch will return

to RUN from START. Turn the key counterclockwise

to OFF to stop the engine.

THROTTLE (T) - Move the throttle lever forward to

increase engine speed until the maximum governed

engine RPM is reached. Move the lever rearward to

decrease engine speed until the engine reaches its

idle speed.

CHOKE (C)

For Kawasaki Engines, pull the choke control out to

set the choke ON. Push it in to set the choke OFF.

POWER TAKE OFF (PTO) SWITCH (P) -

The operator must be in the seat when engaging the

PTO or the engine will kill. Pulling the PTO switch

out engages (turns on) the PTO and starts the blades

or other attachment. Pushing the PTO switch in

disengages (turns off) the PTO and stops the blades

or other attachment.

CONTROLS

At operator's right side

NOTE: The PTO switch does not control

attachments powered by a separate engine.

- Disengage the PTO whenever you stop or leave

the operator’s position

- Shut off engine with the key and remove the

spark plug wires before making adjustments or

unplugging a clogged mower.

- Do not engage the PTO until ready to start

mowing.

HOUR METER (M) - Records accumulated time

the machine is in operation and provides service

alerts. Push and release MODE button to toggle

between functions. Provided service alerts include

change engine oil and lter, change hydraulic oil,

and service air lter. When the service time is

approaching, an alert message will ash temporarily,

interrupting whatever mode the meter is in. This

will continue until the alert is reset. When the

service interval reaches "0" hours, the word "NOW"

replaces the hours remaining. To reset the service

alert, depress and hold down the mode button for 6

seconds while in the alert to be cleared.

Below seat

12 VOLT POWER OUTLET (X) - A 12 volt

power outlet is provided to operate 12 volt personal

accessories.

15

Page 18

CONTROLS

FUEL SELECTOR VALVE (U)

The fuel tank selector valve is located behind the

seat.

The fuel tank selector valve has three positions:

Off: The tank selector is off when the lever points

down. The selector should be off whenever the

machine is transported or stands unused for any

length of time. Shutting off the fuel supply avoids the

possibility of ooding should any dirt get under the

carburetor oat needle. Leaving the tank selector in

either tank position can allow severe ooding, which

may ruin the engine by diluting the oil.

Right Tank: Fuel ows from the right tank when the

selector is turned 1/4 turn toward the right.

Left Tank: Fuel ows from the left tank when the

selector is turned 1/4 turn toward the left.

FastCat Pro

16

Page 19

FastCat Pro

Lift and traction levers

(operator's right side)

CONTROLS

Reverse movement - To move the machine straight

back, pull both traction levers back equally from their

neutral position. Reverse speed increases as the

levers are moved back farther. Maximum reverse

speed is reached when the levers hit the rear of the

forward-reverse slot. When moving in reverse, pushing the levers forward slows the machine, and the

machine stops when the neutral position is reached.

NOTE: Reverse is spring loaded to return to neutral.

This spring resistance may be felt when moving the

traction levers into reverse. When the levers are

released in reverse, spring tension will slowly return

them to the neutral position.

STEERING - To steer, move one lever forward and

one back.

LIFT LEVER (F) - Used to raise the cutterdeck to

maximum height for transport, curb climbing or blade

changing. To return to preset height of cut, lower lift

lever until it contacts height of cut pin A.

TRACTION LEVERS (L) - Each of the two

traction levers controls the drive wheel located on

the same side. They control the forward and reverse

movement of the machine, provide steering and also

provide dynamic braking.

The operator must be in the seat and the parking

brake must be OFF to engage the traction drive.

To engage traction drive, move the traction levers

toward the center of the machine until they are out of

neutral lock slot S.

Forward movement - To move the machine straight

ahead, push both traction levers forward equally from

their neutral position. Forward speed increases as

the levers are moved farther forward from the neutral

position. Maximum forward speed is reached when

the levers hit the front of the forward-reverse slot.

When traveling forward, pulling the traction levers

rearward slows the machine. The machine stops

when the neutral position is reached.

Turns during forward movement:

- Right turn - move the right traction lever back

toward neutral to slow the right drive wheel.

- Left turn - move the left traction lever back to-

ward neutral to slow the left drive wheel.

Turns during reverse movement:

- Reverse right turn - move the right traction lever

forward toward neutral to slow the right drive

wheel.

- Reverse left turn - move the left traction lever

forward toward neutral to slow the left drive

wheel.

Slow, sweeping turns are made with both traction

levers on the same side of neutral and slightly

apart. True zero radius turns about the center of the

machine are made by having one lever in reverse

while the other is in forward. By varying the relative

positions of the two levers, the rate of turn is varied to

suit the mowing situation.

Slow down before making sharp turns. The machine

is capable of turning very rapidly when the levers are

moved further apart from each other. Loss of control

and/or turf damage may result.

17

Page 20

CONTROLS

PARKING BRAKE (R) - Pull the parking brake

lever up and back to put the parking brake ON. Push

it forward and down to put the parking brake OFF.

The parking brake must be ON to start the engine.

It must also be ON to keep the engine running if the

operator leaves the seat. The parking brake must be

OFF to keep the engine running when a traction lever

is moved out of neutral lock.

FastCat Pro

Parking brake in ON position

(operator's left side)

PUSHING THE MACHINE

The machine may be pushed with the engine off, the

parking brake off, and the bypass valves open.

To open the bypass valves, move the parking brake

to the OFF position, then lift and pull bypass control

rod C through the large opening D, until the control

rod stop is past the opening. Drop rod C into the

small opening to lock in place. Repeat for the other

bypass control rod.

To close the bypass valves, lift bypass control rod C

allowing the control rod stop to retract through the

large opening D.

18

Page 21

FastCat Pro

PRE-OPERATION CHECK LIST

(OPERATOR’S RESPONSIBILITY)

PRE-OPERATION CHECK LIST

___ Review and follow all safety rules and safety

decal instructions.

___ Check that all safety decals are installed and in

good condition. Replace if damaged.

___ Check to make sure all shields and guards

are properly installed and in good condition.

Be sure that either the discharge shield or

complete vacuum attachment is installed.

___ Check that all hardware is properly installed.

and secured.

___ Check that equipment is properly and securely

attached to power unit.

___ Check to be sure engine is free of dirt and

debris. Pay particular attention to the cooling

ns, governor parts and mufer. Clean air

intake screen. Check air cleaner; service if

necessary.

___ Never allow riders.

___ Inspect area and remove stones, branches or

other hard objects that might be thrown,

causing injury or damage.

___ Clean area around oil ll dipstick. Remove

dipstick and check to be sure oil is in operating

range (between marks on dipstick). Add oil if

necessary but Do Not Overll. Install dipstick

assembly rmly until cap bottoms out on tube.

Dipstick assembly must always be secured into

ll tube when engine is running.

___ Check all lubrication points and grease as

instructed in manual.

___ Check hydrostatic uid level. Check to be sure

cooling ns on hydro stat are clean.

___ Perform a functional check of the safety

interlock system each time you operate the

unit.

19

Page 22

OPERATION

FastCat Pro

FUELING

- Fill fuel tank with good quality, clean, unleaded

regular gasoline. Do not use hi-test fuel.

- Use a funnel to avoid spilling.

WARNING

TO CHECK OR ADD FUEL:

– Do it outdoors

– Do not smoke

– Stop engine; allow to cool

– Fill to one inch below bottom

of ller neck

– Do not overll

– Clean up spilled fuel

BEFORE STARTING THE ENGINE

- Be familiar with all controls, how each functions

and what each operates.

- Check the engine oil level and add if necessary.

Using the fuel selector valve, select which tank

will supply fuel

- Choke: For cold starts, set the throttle lever to the

half-open position and pull the choke out to the

ON position. For warm starts set the throttle to

the half-open position and the choke to the OFF

position.

OPERATOR PRESENCE

INTERLOCK SYSTEM

To start the engine:

- The PTO switch must be OFF.

- Both traction levers must be in the neutral lock

position.

- The parking brake must be ON.

To operate the machine:

1. The operator must be in the seat or engaging the

PTO will kill the engine.

2. The parking brake must be OFF and the operator must be in the seat, or moving a traction lever

from the neutral lock position will kill the engine.

STARTING THE ENGINE

1. Turn the key to operate the electric starter to start

the engine. Release the key when the engine

starts.

2. If the engine does not start immediately, do not

crank for more than 10 seconds at a time. Allow

60 seconds for the starter motor to cool down

between starting attempts to prevent the starter

motor from burning out.

3. If the choke is ON when the engine starts,

gradually back it off until the engine runs with no

choke at all.

20

Page 23

FastCat Pro

OPERATION

OPERATING NOTES

- Practice at slow engine and travel speeds with the

PTO off until fully familiar with the controls.

- For normal cutting the throttle should be set at the

full open position. By using the traction levers to

speed up or slow down the machine during use,

maximum control and cutting efciency can be

maintained.

- Using the machine at less than full throttle in

heavy conditions will cause the engine to labor

and result in excessive wear and can cause damage to the transaxles.

DRIVING

1. With the PTO disengaged, move the parking

brake to OFF.

2. Move both traction levers out of neutral lock.

3. Push both traction levers forward evenly to drive

forward in a straight line. Pull both traction levers

back evenly to drive backward in a straight line.

4. Steering - Move one lever forward and one back.

Turns during forward movement:

- Right turn - move the right traction lever back

toward neutral to slow the right drive wheel.

- Left turn - move the left traction lever back to-

ward neutral to slow the left drive wheel.

Turns during reverse movement:

- Reverse right turn - move the right traction lever

forward toward neutral to slow the right drive

wheel.

- Reverse left turn - move the left traction lever

forward toward neutral to slow the left drive

wheel.

Use caution when making turns. Slow down before

making sharp turns to help maintain control and to

prevent torn turf from skidding or spinning tires. To

help prevent turf damage, keep both drive tires moving whenever a turn is made.

TIP: The best way to make a sharp "zero" turn is to

come to a stop, get the machine moving in reverse

with both drive wheels and then power the machine

around with the outside wheel. This technique keeps

the drive tires turning and results in less turf damage.

21

Page 24

OPERATION

CUTTING

FastCat Pro

1. Place the discharge chute in the down position or

correctly t a grass collector or mulcher plate.

2. Sit in the seat.

3. Start the engine.

4. Turn the blades on by pulling up on the PTO

switch. Do not start the blades at full throttle.

Instead, use the slowest throttle setting that will allow the engine to pick up the blade load to reduce

the wear on the belts and electric clutch.

5. After the blades are rotating, set the throttle to

maximum. Use the traction levers to obtain the

required cutting speed, to steer around obstacles

and to turn at the end of a cut.

CUTTING TIPS

- When mowing large areas, start by turning to the

right so that clippings will be discharged away

from shrubs, fences, driveways, etc. After two or

three rounds, mow in the opposite direction, left

hand turns, until nished.

- If grass is extremely tall, it should be mowed

twice, the rst cut relatively high, the second cut to

the desired height.

- Use the left side of the mower for trimming.

- Choose cutting directions so that clippings are

thrown onto areas that already have been cut.

This method results in the most even distribution

of clippings and more uniform, better appearing

cuts.

- Use a different mowing pattern each time where

possible. This helps prevent rutting and leads

to a more uniform cut by keeping the grass from

always laying the same way.

DANGER

ROTATING BLADES

–

KEEP HANDS AND FEET AWA Y.

– STOP ENGINE AND LET BLADES STOP

BEFORE REMOVING GRASS COLLECTOR OR UNCLOGGING.

WARNING

THROWN OBJECTS

–

KEEP AREA CLEAR OF PEOPLE

AND PETS.

– REMOVE OBJECTS BLADE MAY

STRIKE AND THROW.

– STOP BLADES TO CROSS GRAVEL

AREAS

– DO NOT OPERATE WITHOUT CHUTE,

MULCHER OR ENTIRE GRASS

CATCHER IN PLACE.

22

Page 25

FastCat Pro

ECNANETNIAM

NOITAREPO

pUpoT/kcehC

leveLliO

skaeLroFkcehCX

MAINTENANCE CHART

neewtebsemitmumixameraslavretniesehT.bojgniognonasiecnanetniaM

.snoitidnocerevesrednunetfoerommrofreP.snoitarepoecnanetniam

5TSRIF

SRUOH

EROFEB

HCAE

ESU

X

YREVE

52

SRUOH

YREVE

05

SRUOH

YREVE

001

SRUOH

YREVE

002

SRUOH

YLRAEY

ENIGNE

snoitcurtsnidnanoitamrofnilanoitiddaroflaunamenigneehttlusnoC

ekatnIriAnaelC

neercS

renaelCriAnaelC

renaelcerP

renaelCriAnaelC

tnemelE

sniFgnilooCnaelC X

dnAliOegnahC

retliF

ecalpeR/kcehC

sgulPkrapS

X

X

X

X

ELXASNART

leveLliOkcehCX

skaeLroFkcehCX

dnAliOegnahC

retliF

X

X

ENIHCAM

kcolretnIkcehC

noitarepO

eriTkcehC

serusserP

pUpoT/kcehC

yrettaB

X

X

alunams'rerutcafunamenigneeeS

X

X

X

L X

stnioPllAetacirbu

23

Page 26

MAINTENANCE RECORD

FastCat Pro

NOTES

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

LARENEG

serusserPeriTkcehC

stnioPllAetacirbuL

stloB&stuNkcehC

ENIGNE

leveLliOkcehC

liOegnahC

naelC

tnemelErenaelCriA

sniFgnilooCnaelC

ecalpeR

tnemelErenaelCriA

ETAD SRH ETAD SRH ETAD SRH ETAD SRH ETAD SRH ETAD SRH

paG&naelC

sgulPkrapS

ELXASNART

retliFdnAliOegnahC

24

.retlifdnalioenigneegnahcnoitarepofosruoh5tsrifretfA:ETON

Page 27

MAINTENANCE

FastCat Pro

CHECK DAILY

Operator Presence Interlock System - Start Operation

For the engine to crank, the parking brake must be on, the PTO (blades) off and traction levers in the neutral

lock position. Sit in the seat and check, one by one, if the engine will crank with the parking brake off, the

blades on, and either traction lever out of neutral lock.

Operator Presence Interlock System - Run Operation

The operator must be in the seat for the engine to run with the parking brake off, the traction levers moved out

of the neutral lock position, or the blades on. To check:

1. Start the engine and run at 1/2 throttle with the operator on the machine but raised off the seat.

2. One by one: move the parking brake to the OFF position, traction levers out of the neutral lock position

(check each independently), and turn the blades on. Each check should kill the engine after 1/2 second.

(A 1/2 second delay is built into the system to prevent engine cutout when traversing rough terrain.)

Repair machine before using if the Operator Presence Interlock System does not operate correctly in start or

run. Contact your authorized Schiller Grounds Care, Inc. dealer.

Hardware

Tighten any nuts and bolts found loose. Replace any broken or missing cotter pins. Repair any other problems before operating.

Tire pressure

Tires should be kept inated to 14 lbs/in

poor traction. Uneven ination can cause uneven cutting. Overination of caster tires can cause casters to

"wobble" on hard surfaces.

2

(1.0 kg/cm

2

). Improper tire ination can cause rapid tire wear and

BATTERY

Battery acid is caustic and fumes

are explosive and can cause serious injury or death.

Use insulated tools, wear protective glasses or

goggles and protective clothing when working with

batteries. Read and obey the battery manufacturer’s

instructions.

Be certain the ignition switch is OFF and the key has

been removed before servicing the battery.

1. Verify battery polarity before connecting or disconnecting the battery cables.

2. When installing the battery, always assemble

the RED, positive ( + ) battery cable rst and the

BLACK ground, negative ( - ) cable last.

4. Check the electrolyte level every 100 hours of

operation or yearly, whichever comes rst. Top

off with distilled water if necessary.

NOTE: Sealed batteries cannot be checked or

topped off.

5. Clean the cable ends and battery posts with steel

wool. Use a solution of baking soda and water

to clean the battery. Do not allow the solution to

enter into the battery cells.

6. Tighten cables securely to battery terminals and

apply a light coat of silicone dielectric grease to

terminals and cable ends to prevent corrosion.

Keep terminal covers in place.

3. When removing the battery, always remove the

BLACK ground, negative ( - ) cable rst and the

red, positive ( + ) cable last.

25

Page 28

MAINTENANCE

FastCat Pro

Every 50 hours of operation, lubricate the following points (1-3) with grease:

1. Deck lift lever (1 point)

2. Deck lift pivots (4 points)

3. Pull arms (2 points located at the front of the cutterdeck)

4. Caster wheel pivots (2 points)

(Lubricate every 500 hours or once a year)

NOTE ON BLADE SPINDLES - The blade spindles on these machines use a

superior sealed bearing that does not require relubrication.

26

LUBRICATION

Page 29

FastCat Pro

ENGINE OIL

Do not perform engine maintenance without the

engine off, spark plug wires disconnected and PTO

disengaged.

AFTER FIRST FIVE (5) HOURS

While the engine is warm:

1. Release the oil drain hose assembly from the

engine clip J. Lay hose assembly over the frame

edge or through the frame cutout, which ever is

most convenient.

2. Remove the rubber cap D from the tip of the

hose assembly and turn the drain valve to allow

oil to drain from the engine. Dispose of used oil

in accordance with local requirements.

3. Clean drain valve and tighten the plastic portion

of the drain valve back into the metal portion of

the valve. Replace rubber cap over the tip of the

valve. Replace hose assembly back into engine

clip.

4. Change oil lter.

5. Fill the crankcase with fresh oil to the full mark.

Do not overll. See engine manual for oil

specications.

MAINTENANCE

DAILY

1. Check oil level with the dipstick.

2. If oil is needed, add fresh oil of proper

viscosity and grade. See engine manual for oil

specications. Do not overll.

3. Replace dipstick before starting engine.

PERIODIC OIL CHANGES

1. See engine manual for oil and lter change intervals after the break-in period.

2. Follow instructions for rst oil change, above.

SPARK PLUGS

Remove each plug and check condition.

- Good operating conditions are indicated if the plug has a light coating of grey or tan deposit.

- A white blistered coating indicates overheating. A black coating indicates an “over rich” fuel mixture. Both

may be caused by a clogged air cleaner or improper carburetor adjustment.

- Do not sandblast, wire brush or otherwise attempt to repair a plug in poor condition. Best results are

obtained with a new plug.

- Set plug gap as specied in engine manual..

FUEL FILTER

An in-line fuel lter is located in the fuel supply line. Inspect at every oil change to make sure it is clean and

unobstructed. Replace if dirty.

27

Page 30

MAINTENANCE

AIR CLEANER

Clean and replace the air cleaner element as speci-

ed in the service chart. Uneven running, lack of

power or black exhaust may indicate a dirty air

cleaner.

1. Unclamp end cover C and remove existing

cleaner element A.

2. Insert new element A and replace cover C.

Ensure breathing port B is pointing down and

towards the front of the tractor.

FastCat Pro

CLEANING MACHINE

Clean the machine after use. The machine will run

cooler and last longer if kept free of clippings and

other debris. A clean machine also reduces the risk

of re due to accumulation of combustible debris and

chaff

Brush or blow clippings and debris off the cutterdeck

and engine deck.

WASHING MACHINE

CAUTION: Improperly washing a machine can cause

water to enter bearings and other components. This

can greatly reduce component life.

– Do not use a pressure washer. Do not direct

water at bearings or seals. High pressure water

can blow past seals ad enter seal bearings.

– Allow the machine to cool down before washing.

Water on a warm machine can be sucked into

sealed bearings as they cool.

– Avoid getting electrical connections wet. Water

can cause electrical faults and corrosion of electrical components.

28

Page 31

FastCat Pro

Lm

Hm

Nm

ENGINE COOLING

Continued operation with a clogged cooling system

will cause severe overheating and can result in engine damage.

- Daily: Clean air intake screen V.

- Every 100 hours: Clean cooling ns beneath

blower housing H with reference to information in

the engine manufacturer's manual.

MAINTENANCE

SPECIFIC TORQUES

PURGING TRANSAXLES

Due to the effects air has on efciency in hydrostatic

drive applications, it is critical that it be purged from

the system.

These purge procedures should be implemented any

time a hydrostatic system has been opened to fa-

cilitate maintenance or any additional uid has been

added to the system.

Purging may be required if the unit shows any of the

following symptoms:

- Noisy operation.

- Lack of power or drive after short term use.

- High operation temperature, excessive oil

expansion.

B

W

E

STLOBEDA

STUNBUHLEE

TLOBTFAHSKNARCENIG

TUNYELLUPELXASNART )mN65-83(SBL-TF6.14-3.82

GULPNIARDELXASNATR mN72-02(SBL-TF02-51

RETLIFELXASNART )mN9.61-6.41(sbl-ni051-031

)

N59(SBL-TF07

)

N302(SBL-TF051

N86(SBL-TF05

)

1. Check the transaxle uid, ll to proper level, if

required.

2. Raise the drive wheels off the ground. Support

unit with jack stands or other suitable means.

3. With the bypass valves open, and the engine

running, slowly move the control levers in both

forward and reverse directions 5 to 6 times. As

air is purged from the unit, the oil level will drop.

4. With the bypass valve closed, and the engine

running, slowly move the control levers in both

forward and reverse directions 5 to 6 times.

5. Stop engine. Check the transaxle uid level, add

uid as required.

6. It may be necessary to repeat steps 3-5 until all

the air is completely purged from the system.

When the transaxle moves forward and reverse

at normal speed, purging is complete.

)

29

Page 32

MAINTENANCE

TRANSAXLES

Inattention to proper safety, operation, or

maintenance procedures could result in personal

injury, or damage to the equipment. Schiller

Grounds Care, Inc. recommends returning the

machine to your authorized Schiller Grounds

Care, Inc. dealer for service or repair.

Perform transaxle maintenance with the engine off,

spark plug wires disconnected and PTO disengaged.

TRANSAXLE FLUID CHANGE

Change the transaxle uid every 200 hours of

operation. It is essential that the exterior of the

transaxle be free of debris, prior to uid maintenance.

1. Remove the three 1/4" lter guard screws and

lter guard A. Remove the oil lter B from the

transaxle and discard. Dispose of used oil in accordance with local requirements.

2. Wipe the lter base surface off and apply a lm

of new oil to the gasket of the new replacement

lter. Install the new lter by hand, turn 3/4 to

one full turn after the lter gasket contacts the

lter base surface.

3. Re-install the lter guard and torque the three

screws to 65 in. lbs. each.

4. Remove cap C, ll the transaxles through the

expansion tank D with approximately 2 quarts of

SAE 20W-50 engine oil PER TRANSAXLE.

FastCat Pro

Do not overll! If you overll the transaxle while the unit

is "cold", it may overow as it reaches normal operating

temperatures. The oil level should not be above the

manufacturer's suggestions. This will allow the space

needed for the oil to expand as it warms up.

5. After starting engine, check the uid level and

continue to add oil to overow tank D to ll line

on tank.

6. Purge the transaxles, following the purging procedures on Page 31.

30

Page 33

FastCat Pro

MAINTENANCE

BLADE REMOVAL

Follow these instructions to prevent injury during

blade removal:

1. Loosen with a box wrench or a socket and long

breaker bar. To gain additional leverage, slip a

long pipe or thick-walled tube over breaker bar or

wrench.

2. Insert wood block A as shown, with grain

perpendicular to blade, to prevent blade from

turning when loosening.

3. Wear thickly padded gloves. Keep hands clear

of blade path. Blades may rotate when bolt

releases.

SHARPENING

BLADE BALANCE

Blade balance must be maintained at 5/8 oz-in (19.4

g-cm) or less. Failure to keep blades balanced

causes excess vibration, wear, and shortened life of

most components of the machine.

To balance a blade:

1. Sharpen blade rst.

2. Balance the blade at the center.

3. Attach a 1/8 oz (3.9 g) weight at a distance 5"

(127 mm) from center on the light end. This

should make the light end the heavy end:

- If it does, the blade is balanced.

- If does not, le or grind the heavy end until

the addition of the weight makes the light end

the heavy end.

BLADE INSTALLATION

1. Wear thickly padded gloves to prevent cuts from

the sharp blade.

2. Insert the blade bolt, in order, through the conical

washer (cup side toward the blade, as shown),

the blade, and the blade spacer.

3. Install assembly on the blade spindle.

4. Torque the blade bolt to 70 ft-lbs.

Blades may be sharpened by ling or grinding.

- Inspect blades before sharpening.

- Replace bent or cracked blades.

- Replace blades when the lift portion has worn

thin.

- Maintain cut angle at 30

o

.

- Do not overheat blades when sharpening.

- Always use Schiller Grounds Care, Inc.blades.

Use of another manufacturer’s blades may be

dangerous.

31

Page 34

ADJUSTMENTS

DECK LEVELING

1. Park the machine on a smooth, level surface.

Raise the deck to the transport position.

2. Lower the deck onto a set of equal height blocks

under the rear corners of the deck. Place another set of blocks under the front of the deck so

that the deck top is pitched forward 1/8".

NOTE: The front and rear of the deck are at different

heights.

3. Measure the height of the blade cutting edge

above the ground. Remove pin B and set the

height of cut lever E to that height

4. Loosen nuts on bolts G. Move bolts in slot to

remove slack in chain. Tighten nuts on bolts G.

FastCat Pro

HEIGHT OF CUT

The height of cut is set by moving height of cut pin B

to the hole designated for the height of cut desired.

To change the height of cut:

1. Lift the deck to the highest position.

2. Move pin B to the selected hole.

3. Lower the deck until the lift lever is stopped by

the pin.

NOTES:

- Height of cut may vary due to the amount of

tread on the tires, tire diameter or ination pressure.

DECK ROLLERS

The deck rollers are adjustable up and down to

provide improved deck otation and scalping protection at various heights of cut. They are not intended

to ride continuously on the ground. Adjust no closer

than 3/8" (10mm) to the ground.

32

Height of cut ranges for roller adjustment

Page 35

FastCat Pro

A

PARKING BRAKE

FOR 61" MODELS

NOTE: There are 2 brakes, 1 on each transaxle.

The parking brake should keep the machine from

moving. To check the parking brake, park the machine on a level surface, open the bypass valves and

set the parking brake to ON. Attempt to move the

machine forward and backward by pushing it. If the

machine moves, adjust the parking brake linkage as

follows:

1. Move the machine to a at horizontal surface.

2. Grip the ats on the brake rod A. Tighten nut

B on the brake rod until you run out of threads.

See Figure 1 for detailed view.

3. Move the parking brake handle to the OFF

position.

4. Loosen nut X.

ADJUSTMENTS

B

X

FIGURE 1

TIGHTEN UNTIL YOU

RUNOUT OF THREADS

5. Hold brake arm in the OFF position as shown in

Figure 2.

6. Adjust linkage rod U until formed end of rod

meets brake arm hole in the OFF position.

7. Insert cotter pin into formed end of linkage rod U.

8. Tighten nut X.

9. Repeat Steps 1-8 on the opposite side.

FIGURE 2

33

Page 36

ADJUSTMENTS

HYDROST ATIC TRANSAXLE ADJUSTMENTS

A turnbuckle style hydro stat neutral adjustment is

provided.

Neutral:

1. Support the machine with the rear wheels off

the ground. Use jack stands or equivalent support. Do not rely only on mechanical or hydraulic

jacks.

2. Move the traction levers out into the neutral lock

position and raise the seat.

3. Disconnect the seat switch wire and temporarily

connect the two terminals with jumper wire J as

shown.

4. Start the engine and run at low speed.

5. Move parking brake to the OFF position.

6. Loosen jam nuts K at both ends of the control

rod L.

7. Rotate the control rod until the corresponding

wheel stops turning. Lock the control rod jam

nuts. Run the engine up to high idle and stroke

the traction levers forward and back to check the

adjustment. Move traction levers back to neutral

and readjust if necessary.

8. Repeat steps 6 and 7 for the opposite side.

9. Remove the jumper wire and reconnect the seat

switch.

FastCat Pro

34

Page 37

FastCat Pro

ARM REST HEIGHT ADJUSTMENTS

1. Remove acorn nuts 1, plastic washers 2, arm

rest 3 and second set of plastic washers 4.

ADJUSTMENTS

2. Adjust carriage bolts 5 to desired height A, B, or

C by pushingg on the carriage bolts 5 until they

are free from the locking slot, adjusting them to

the desired height and then pulling the carriage

bolts 5 into the desired locking slot A, B, or C.

Bolts must be placed into slots a like heights or

arm rest will not t.

3. Re-assemble washers 2 & 4, arm rest 3, and

acorn nuts 1 in reverse order from disassembly.

Hold carriage bolts 5 in lockting slots while tightening acorn nuts 1 to prevent them from falling

out of the locking slots. Tighten nuts 1 until desired resistance in arm rest rotation is acheived.

3

2

1

C

C

B

B

A

A

5

4

SEA T ADJUSTMENT

The seat plate allows from some seat adjustment

either forward or backward.

1. Flip seat up.

2. Use holes 1 or 2 for seat adjustment.

DO NOT USE holes 3 or 4 due to space restric-

tions with the document tube.

12

4

5

35

Page 38

BELT REPLACEMENT

NOTE: Always use Schiller Grounds Care, Inc. replacement belts, not general purpose

belts. Schiller Grounds Care, Inc. belts are specially designed for use on this mower and

will normally last longer.

CUTTERDECK BELT

1. Remove oorplate.

2. Set the cutterdeck in a middle height-of-cut position.

3. Use a 3/8" ratchet and extension to back

tensioning idler off to remove belt from idler.

Remove belt from cutterdeck pulleys.

NOTE: Use the 3/8" ratchet in the square hole A on

the idler.

4. Remove belt from clutch pulley.

5. Install the new belt by performing these steps in

reverse order.

FastCat Pro

2 SPINDLE DECK

NOTE: 61" cutterdeck may require tension spring

adjustment after belt installation. See Belt tension

BELT TENSION FOR 61" DECK

All belts are tensioned by spring loaded idlers and do

not require any adjustment except for the 61"

cutterdeck. Use the eyebolt to adjust the spring

length to be between 6 3/4" - 7 1/2" as pictured.

3 SPINDLE DECK

36

Page 39

FastCat Pro

NOTE: Always use Schiller Grounds Care, Inc. replacement belts, not general purpose

belts. Schiller Grounds Care, Inc. belts are specially designed for use on this mower and

will normally last longer.

HYDRO TRANSAXLE DRIVE BELT

1. Remove cutterdeck belt (see cutterdeck belt

replacement).

2. Disconnect wire I at clutch M. Remove bolts J

and remove torque restraint.

3. Using a ratchet with a 9/16" socket, place over

nut at location P. Use the ratchet to rotate it

enough to remove the transaxle drive belt.

4. Install a new transaxle drive belt by performing

these steps in reverse order.

5. Inspect the fans. Replace if worn or damaged.

Torque transaxle pulley nut to 28.3-41.6 ft-lbs

(38-56 Nm).

6. Reinstall cutterdeck belt (see cutterdeck belt

replacement).

BELT REPLACEMENT

37

Page 40

FastCat Pro

38

Page 41

FastCat Pro

PARTS SECTION

PARTS

SECTION

39

Page 42

FRAME-ENGINE/CLUTCH ASSY

INCLUDED W/ENGINE

FIGURE 1

10

KAW ENGINE

ONLY

16

3

32

B & S ENGINE

ONLY

15

17

16

JUMPER HARNESS

27

21

26

FastCat Pro

1

13

27

24

28

22

11

4

8

19

12

5

7

23

29

2

18

31

14 / 30

40

9

20

25

6

10

Page 43

FastCat Pro

FRAME-ENGINE/CLUTCH ASSY

FIGURE 1

ITM PART NO. DESCRIPTION QTY

1 4164364 ENGINE-FX541V KAW 1

4164366 ENGINE-FX600V KAW 1

38666 FILTER-FUEL

4164537 FILTER-OIL

4164629 FILTER-AIR

(USED ON MODELS 942297G, 942298G &

942302G)

4164366 ENGINE-FX651V KAW 1

4164367 ENGINE-FX691V KAW 1

38666 FILTER-FUEL

4164630 FILTER-AIR

4164631 FILTER-SAFETY

4164537 FILTER-OIL

(USED ON MODELS 942299G & 942405G)

4163987 ENGINE-627cc VANGRD B&S 1

38666 FILTER-FUEL

4164152 ELEMENT-AIR

4164153 FILTER-OIL

(USED ON MODEL 942404F)

2 4164386 MUFFLER-KAW 1

(USED ON MODEL 942297G, 942298G &

942302G)

4164385 MUFFLER -KAW 1

(USED ON MODELS 942299G & 942405G)

4163913 MUFFLER-B&S 1

(USED ON MODEL 942404G)

3 64152-23 1/4-20X3/8 LG SP SCREW 2

4 38665 SOLENOID 1

(ITEMS 3 & 4 USED ON 942299G, 942404G, &

942405G)

5 38304-03 BRG-FLANGED PLASTIC 1

6 2721331.7 WLDMT-CLUTCH STOP 1

7 64265-04 LOCKNUT-M8-1.25 2

8 64164-12 KEY-1/4X1/4X1 SQ END 1

9 64006-06 LOCKWASHER-HEL 7/16 1

10 64205-001 BLT-MET M8-1.25X20 3

11 4164049 S-FRAME W/ LABELS 1

12 4144116 CLUTCH-ENGINE PULLEY 1

13 48412-01 CLAMP 1

14 64197-005 BLT-TDFM 3/8-16X1-1/4 4

ITM PART NO. DESCRIPTION QTY

15 64006-02 LOCKWASHER-HELICAL 5/16 1

(USED ON MODEL 942404G ONLY)

16 64163-55 WSHR .328X.75X14 GA 1

17 64223-11 SCH CAPSCREW M8-1.25X16 1

(USED ON MODEL 942404G ONLY)

18 4144112.7 WLDMT-CLUTCH BRACKET 1

19 4163309 PULLEY-ENGINE 1

20 64123-78 BOLT-HEX 7/16-20X2-1/2 1

(USED ON 942299G, 942404G & 942405G)

21 69053-13 HOSE-HTDRO, 3/8X14" 1

(ITEMS 22-24 USED ON KAW ENGINES ONLY)

22 64266-02 NUT-FL LOCK M8-1.25 2

23 64263-002 BLT-FLG HD M6-1.0 X 16 6

24 4164442.7 BRKT-MUFFLER LH 1

* 4164443.7 BRKT-MUFFLER RH 1

25 64123-55 BLT-HEX 5/16-18X3 1

(USED ON MODEL 942404G & 942405G ONLY)

26 4164251 VAILVE-OIL DRAIN 1

27 88042-03 CLAMP-HOSE 2

28 4164252-001 FITTING-3/8NP TO BARB 1

29 11061-7061 GASKET-MUFFLER 2

(AVAILABLE FROM KAWASAKI DEALER)

806425 GASKET-MUFFLER

(AVAILABLE FROM B&S DEALER)

(ITEMS 30-32 USED ON KAWASAKI UNITS ONLY)

30 64123-70 BLT-HEX 3/8-16X1-1/2 4

31 64006-03 LOCKWSHR-3/8 HELICAL 4

32 4162803.7 DEFLECTOR-AIRFLOW 1

(USED ON 942404G ONLY)

* NOT ILLUSTRATED

41

Page 44

TRANSAXLE ASSY

FIGURE 2

FastCat Pro

42

42

Page 45

FastCat Pro

TRANSAXLE ASSY

FIGURE 2

ITM PART NO. DESCRIPTION QTY

1 4164049 S-FRAME W/LABELS 1

2 4162973 SHAFT-PULLARM MOUNT 1

3 4163957.7 WLDMT-PULL ARM 2

4 4163819 ARM-CONTROL 2

5 4156464 AXLE-LH 1

(INCLUDES ITEMS 4, 25, 26, 27, 32, 39 & 40)

(USED ON 36", 48" AND 52" DECKS ONLY)

6 64163-29 WASHER 2

7 64123-68 BOLT-HEX 5/16-18X1 2

8 64025-02 NUT-HEX 5/16-18 2

9 64270-01 BOLT-MET, HEX M10-1.5x30 1

10 64123-54 BOLT, 5/16-18X3/4 HEX 2

11 64163-55 WASHER .328X.75X14 GA 6

12 4164128 SPRING-TENSION 1

13 64123-67 BLT-HEX 3/8-16 X 2 1

14 4128001 END CAP-24 X 7 1

15 64268-02 NUT-FL NYLON LOCK 5/16-18 10

16 2228016 PULLEY-IDLER PUMP 1

17 64163-31 WASHER, 25/64X1X12 12

18 64123-55 BLT-HEX 5/16-18X3 4

19 64268-03 NUT-FL NYLON LOCK 3/8-16 1

20 4156465 AXLE-RH 1

(INCLUDES ITEMS 4, 25, 26, 27, 32, 39 & 40)

(USED ON 36", 48" AND 52" DECKS ONLY)

21 4143636 BELT-TRANSAXLE 1

22 4163276 ROD-BATTERY CLAMP 2

23 108055 BATTERY 1

24 64123-88 BLT-HEX 3/8-16X2-3/4 4

25* 4142045-06 FILTER-TRANSAXLE 2

26* 4163819 SPRING-CONTROL ARM 2

27 4163820 ARM-BRAKE 2

28 64123-168 BLT-HEX 5/8-11X2-1/2 2

29 64163-93 WSHR-.635 X 1.12 X.062 4

30 85010N ZERK, 1/4-28 4

31 64229-06 LOCKNUT, NYLON 5/8-11 2

32 4164048 KIT-F AN/PULLEY TRANSAXLE 2

(USED ON 36", 48", AND 52" DECKS ONLY)

4164129 KIT-FAN/PULLEY TRANSAXLE 2

(USED ON 61" DECKS ONLY)

ITM PART NO. DESCRIPTION QTY

33 4142752 TIRE-ASSY 20 X 8 - 10 4 PLY 2

4142752-01 20X8-10 4 PLY MULTI TRAC TIRE

4132433-03 WHEEL-10X7

(USED ON 48" DECKS ONLY)

4163731 TIRE-ASSY 20 X 6.50 - 10 2

4163731-01 WHEEL-10X5.375

4163731-02 TIRE-20X6.5-10 GRASSMASTER

(USED ON 36" DECKS ONLY)

4155841 TIRE-ASSY 20 X 10-10 2

4132433-01 TIRE-20X10-10 4PL Y TURFMASTER

4155841-01 WHEEL-10X7

(USED ON 52" DECKS ONLY)

4165552 TIRE-ASSY 23X10.50-12 2

4165552-01 WHEEEL -4-HOLE W/VALVE

(USED ON 61" DECKS ONLY)

34 64187-03 WHEEL NUT 1/2-20 8

35 4133302 S-ASSY-IDLER ARM PUMP 1

(INCLUDES ITEMS 36-38)

36 4128004 BEARING-BALL 10X26X8 2

37 64144-40 SNAP RING-26MM INTERNAL 1

38 4128000 SEAL-16X26X7 1

39 64163-61 WASHER 1

40 4167258.7 TRAY-BATTERY 1

41 64197-022 BLT-TDFM 3/8-16X3/4 3

42 4163264-01 ADAPTER-90 #6 MAORB/#6 FORB 1

43 4163307 ASSY-EXPANSION T ANK 2

44 4142808-01 CAP-HYDRO TANK 2

45 64268-03 NUT-FL NYLON LOCK 3/8-16 4

46 4163772 TRANSAXLE-LH 1

(USED ON 61" DECK ONLY)