Page 1

16:07-01

Issue 3 en

Electrical system in P, R, T series

Introduction and general

troubleshooting

©

Scania CV AB 2005, Sweden

Page 2

Contents

Introduction ..................................................................................3

Electrical system in P, R and T

series

DEC system ..................................................................................6

ECU system ..................................................................................7

CAN network Overload on the CAN buses...................................12

..................................................................................4

Activation of the control unit..................................12

Vehicle internal time...............................................13

ECU settings...........................................................14

Cable harness..........................................................15

Power supply..........................................................16

Positive supply........................................................18

Moulded cables.......................................................19

Earthing ..................................................................20

Connectors..............................................................24

User functions ................................................................................26

Wiring Diagrams ................................................................................28

Central electric unit ................................................................................34

Repairing cables ................................................................................35

Troubleshooting ................................................................................40

Communication problems on the

CAN buses

................................................................................55

Abbreviations ................................................................................67

©

2

Scania CV AB 2005, Sweden

16:07-01

Page 3

Introduction

The structure of the electrical system in P, R

and T series vehicles is described here in brief.

In comparison with previous series, the

electrical system is now made up to a greater

extent of a number of control units which

communicate with each other via a network.

This new platform for the electrical system

gives increased reliability and the ability to

more easily re-specify and troubleshoot the

electrical system.

A condition for being able to make use of the

benefits of the new network-based electrical

system is a knowledge of how the Scania

diagnostic tools should be used.

It is important to exercise care and accuracy

when handling connectors, cables and control

units, to ensure that system reliability is

maintained after troubleshooting and respecifying the vehicle.

Note: Always disconnect the battery earth lead

before doing any electric welding on the

vehicle. Connect the earthing cable of the

welding unit to the part to be welded, as close

to the welding area as possible. If the earthing

cable is connected in any other way, items such

as bearings or electronic components may be

damaged.

Note: Do not connect extra equipment to the

CAN cables. Overloading of these cables may

cause malfunctions.

16:07-01

©

Scania CV AB 2005, Sweden

3

Page 4

Electrical system in P, R and T series

The electrical system on vehicles in the PRT

series has here been subdivided into the ECU

system (Electronic Control Unit) and the DEC

system (Discrete Electrical Circuit). The ECU

systems are controlled by an electronic control

unit, and they are connected to the CAN

network. The DEC systems can also be

controlled by an electronic control unit, but they

are not connected to the CAN network. Refer

also to Alternator and Starter motor in Multi and

the section on batteries in 16:06-41

©

4

Scania CV AB 2005, Sweden

16:07-01

Page 5

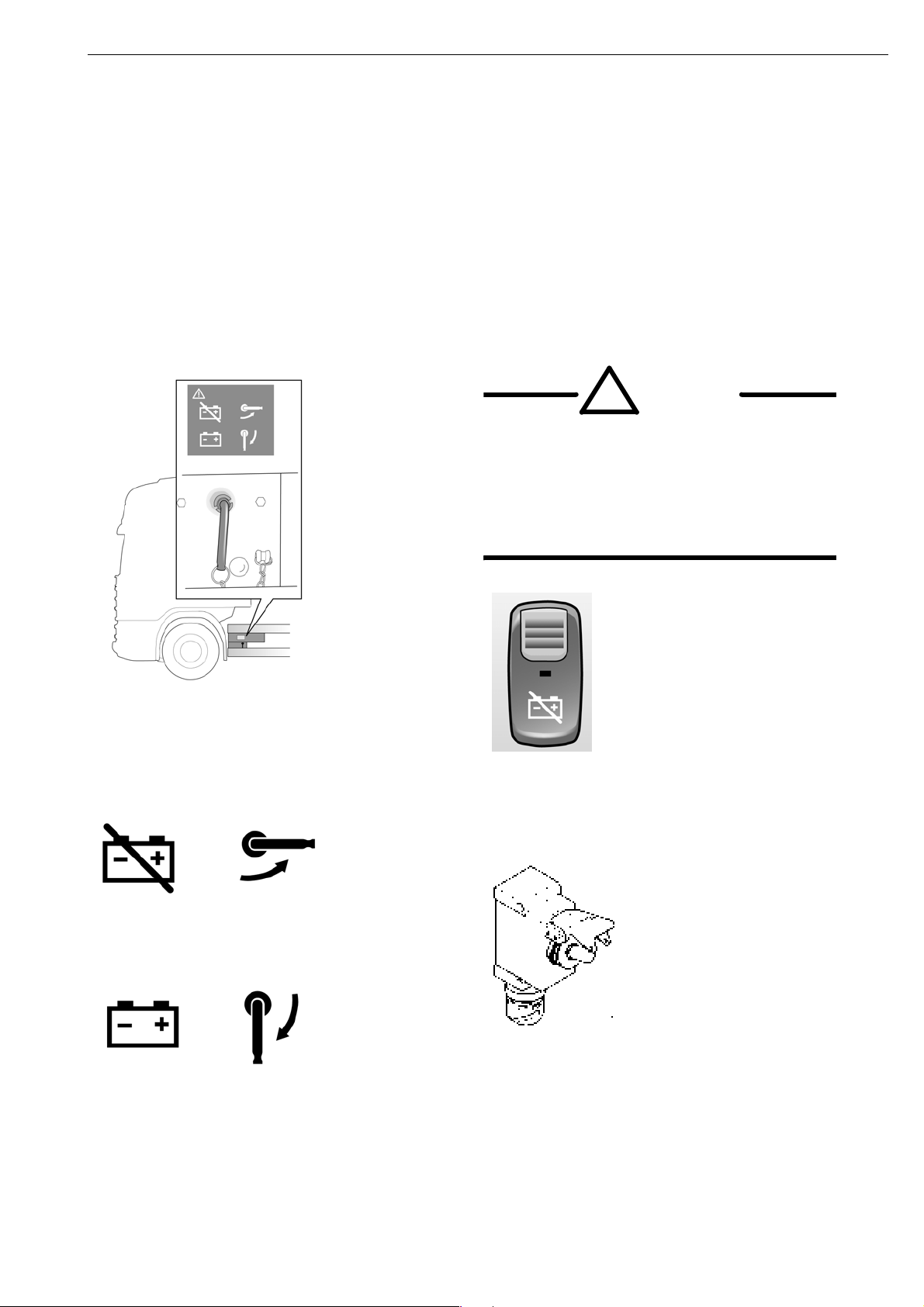

Battery master switch

The service switch is located by the battery box. Switch off the engine before disconnecting the

power. On veh icl es wit h a safet y swi tch the ba ttery ma ster swi tch i s located on the inst rum ent panel.

Some vehicles are also equipped with an exterior safety switch. When the battery master switch is

turned off, power is only supplied to the tachograph. Always disconnect the power in the vehicle

during servicing and work on the electrical system.

WARNING!

!

When the battery master s witch cuts off

the power, the engine stops. The

vehicle becomes difficult to control if

this occurs when moving. Stop the

vehicle, if possible, before cutting off

the power .

The service switch is located by the battery

box. Switch off the engine befor e di sconnecting

the power.

Service switch turned off.

Service switch turned on.

The safety switch for the battery master switch

is located on the instrument panel.

Exterior safety switch.

16:07-01

©

Scania CV AB 2005, Sweden

5

Page 6

DEC system

There are around thirty sub-systems which are

not connected to the CAN network. These

systems are a part of the DEC system group.

Examples of DEC systems are the kitchen

module, seat heating and window winders.

As the DEC system is not connected to the CAN

network, it is not possible to read any fault codes

from them using SDP3. All troubleshooting

should therefore be carried out in the normal

way using a multimeter.

©

6

Scania CV AB 2005, Sweden

16:07-01

Page 7

ECU system

units in the EBS system communicate through

an internal CAN.

The electronic control units in the ECU systems

are programmed to continuously write specific

messages to the CAN network. They are also

programmed to read specific messages which are

written by other control units.

One advantage of connecting together control units

in a network is that both the driver and the

mechanic can obtain significantly more

information on the vehicle status and on any faults.

This makes troubleshooting both simpler and

faster. This is provided you have access to the

Scania diagnosis and programming tool (SDP3).

Furthermore, it enables the mechanic to change

functions in the ECU systems in a simple way by

changing the settings in the control units with

SDP3. If you do not have access to SDP3,

however, it will be more difficult to troubleshoot

compared to earlier vehicle series.

The CAN network on a high specification PRT

series vehicle can contain around 20 ECU systems.

On the simplest vehicles, however, there are only

five ECU systems (EMS, COO, VIS, APS and

ICL).

It should be noted that ICL is connected to the

yellow CAN bus. Problems in this CAN bus

should not stop the vehicle. But if a problem

arises on the yellow CAN bus, this affects ICL

which is then unable to listen to the other CAN

buses and will then prompt the driver to stop

the vehicle.

Several ECU systems in the PRT series were

controlled by an ECU also in the 4-series, and they

were linked together in a CAN network. This

applied to: BMS, EMS, GMS and RTG. Other

systems were controlled by an ECU, but were not

linked together in a CAN network. This applies to:

the radio (now: AUS), the auxiliary heaters with

control unit (ATA/WTA with CTS), the alarm

system (LAS), the air suspension (SMS) and the

tachograph (TCO). Finally, some systems have

been introduced whose functions were previously

controlled using conventional technology such as

relays. This applies to: ACC, APS, BWS, ICL and

VIS.

To reduce the risk of the CAN bus being

overloaded with messages, Scania has chosen to

divide the ECU systems between three CAN buses.

The ECU systems which are most important to

vehicle operation (BMS, COO, EMS and GMS)

are linked together on a CAN bus (red bus). The

other ECU systems are subdivided onto two CAN

buses which Scania calls the yello w and green bus.

Scania Diagnos is connected to the green bus.

In addition to these CAN buses, there can be

additional CAN buses. For example, some of the

©

16:07-01

Scania CV AB 2005, Sweden

7

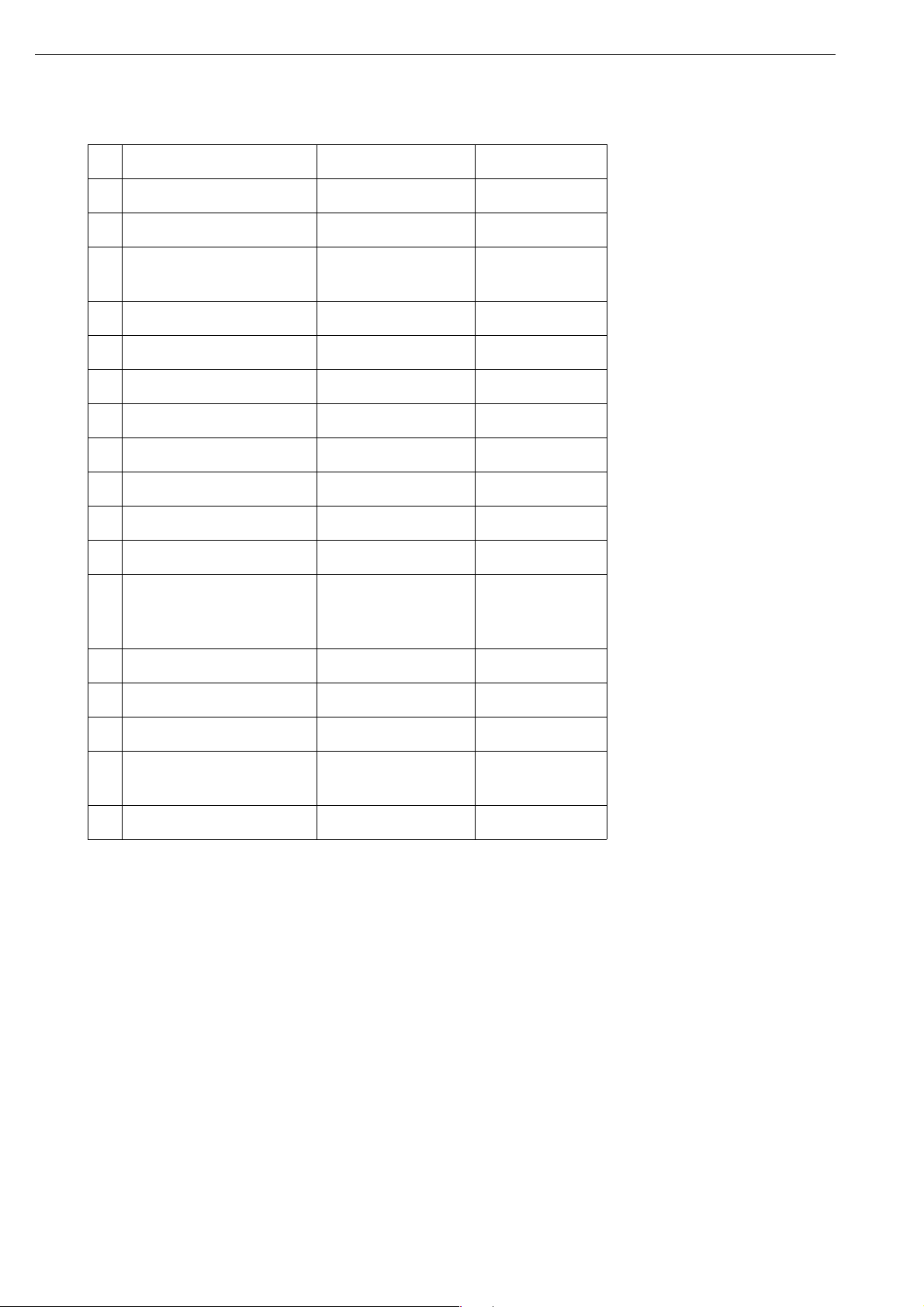

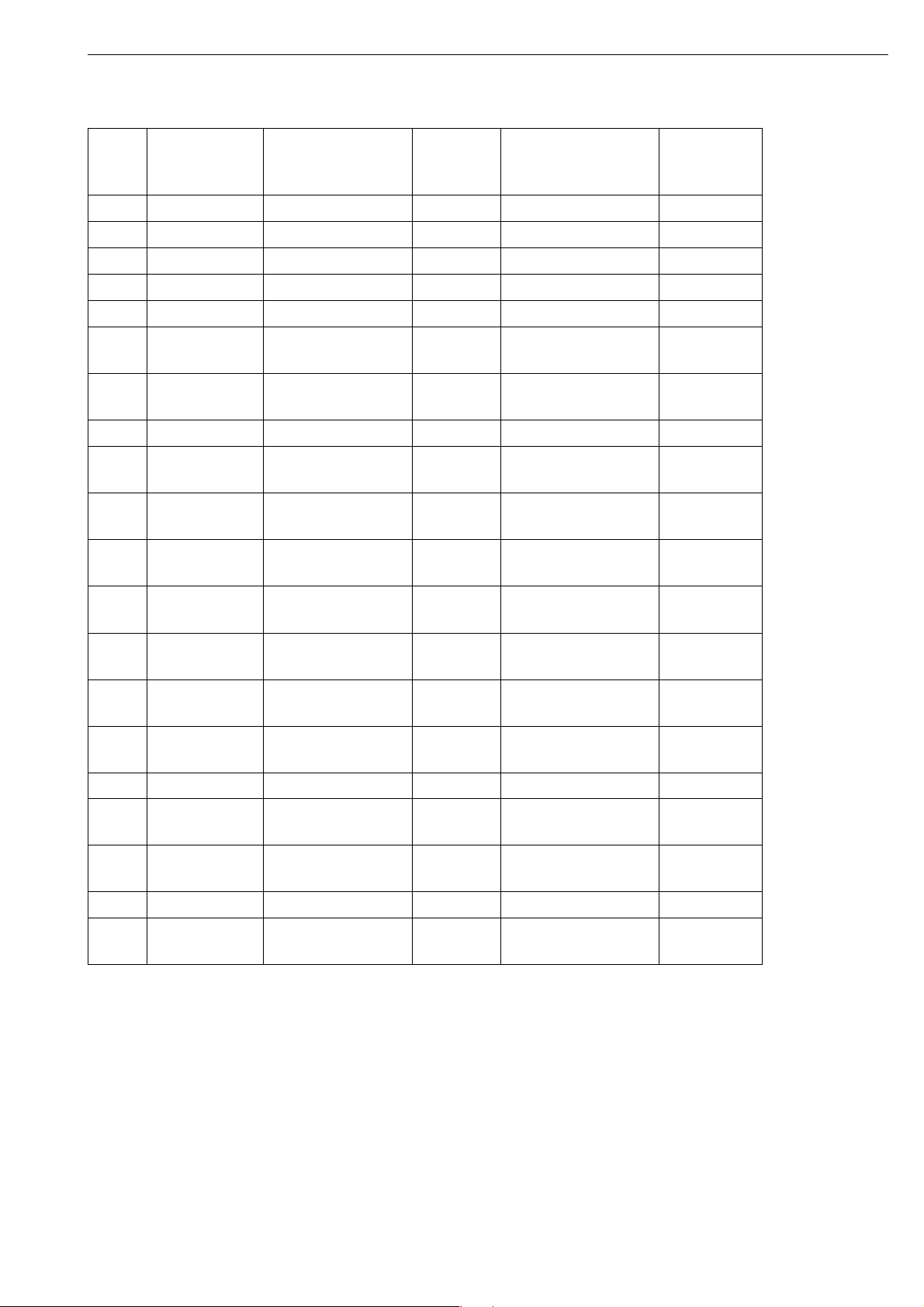

Page 8

Example of functions in the CAN network

Function ECU designation CAN colour

1 Compressed air supply APS Yellow

2 Instrument cluster ICL Yellow

3 Lights, visibility and

VIS Yellow

horn control

4 Locks and alarm LAS Yellow

5 Bodywork interface BWS Yellow

6 Tachograph TCO Yellow

7 Crash safety, airbag CSS Green

8 Climate control ACC Green

9 Radio AUS Green

10 PC RTI Green

11 Vehicle data RTG Green

12,

Auxiliary heater with

13,

control panel

CTS. ATA. WTA Green

14

15 Engine management EMS Red

16 Brake BMS Red

17 Air suspension SMS Red

18 Gearbox and retarder

GMS Red

control

19 Coordinator COO Red

©

8

Scania CV AB 2005, Sweden

16:07-01

Page 9

16:07-01

©

Scania CV AB 2005, Sweden

9

Page 10

CAN network

To be able to troubleshoot in the CAN network,

it is important that you know about a number of

basic factors.

CAN technology has been developed to provide

a reliable transfer of data between different

components in the vehicle. It is based on serial

communication in two cables called CAN High

(CAN H) and CAN Low (CAN L).

The vehicle divides communication between

three CAN buses, red (C480), green (C479) and

yellow (481). This is to ensure good operation

and reliability.

10

©

Scania CV AB 2005, Sweden

16:07-01

Page 11

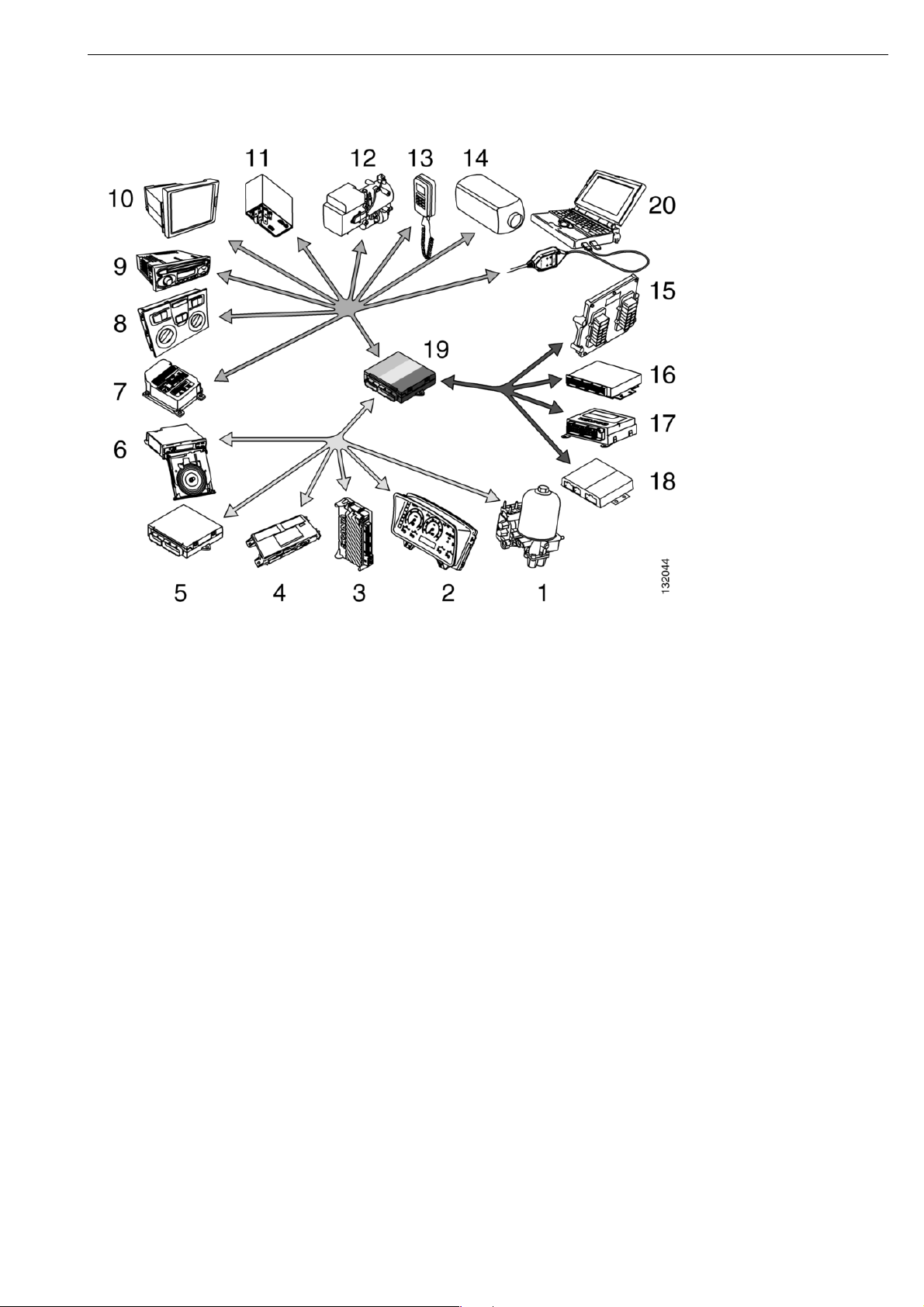

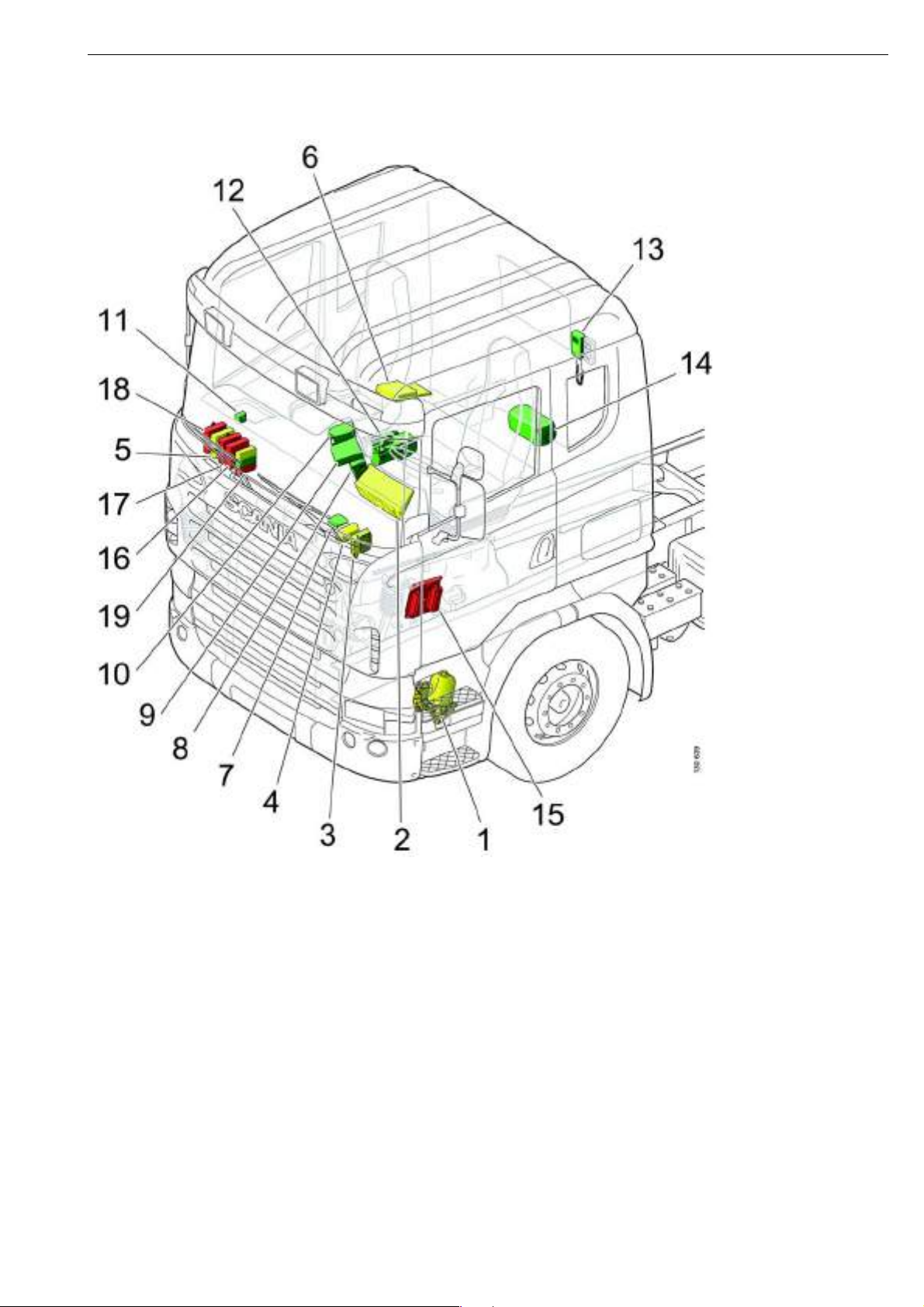

Location of control units in the cab

The illustration shows the basic location of the control units when the P series was introduced.

The control unit location may vary somewhat depending on the cab type and equipment level.

1 APS

2 ICL

3 VIS

4 LAS

5 BWS

6 TCO

7 CSS

8 ACC

9 AUS

11 RTG

12 WTA

13 CTS

14 ATA

15 EMS

16 BMS

17 SMS

18 GMS

19 COO

10 RTI

©

16:07-01

Scania CV AB 2005, Sweden

11

Page 12

Overload on the CAN buses

Faults can arise in ECU systems, resulting in the

systems continuously sending incorrect

messages to the extent that the communication

does not function. This is called overload.

Overload can result in some messages being

transmitted and others not. In turn, this means

that some functions will be missing. If the green

CAN bus is overloaded, this may also mean tha t

SDP3 cannot be used.

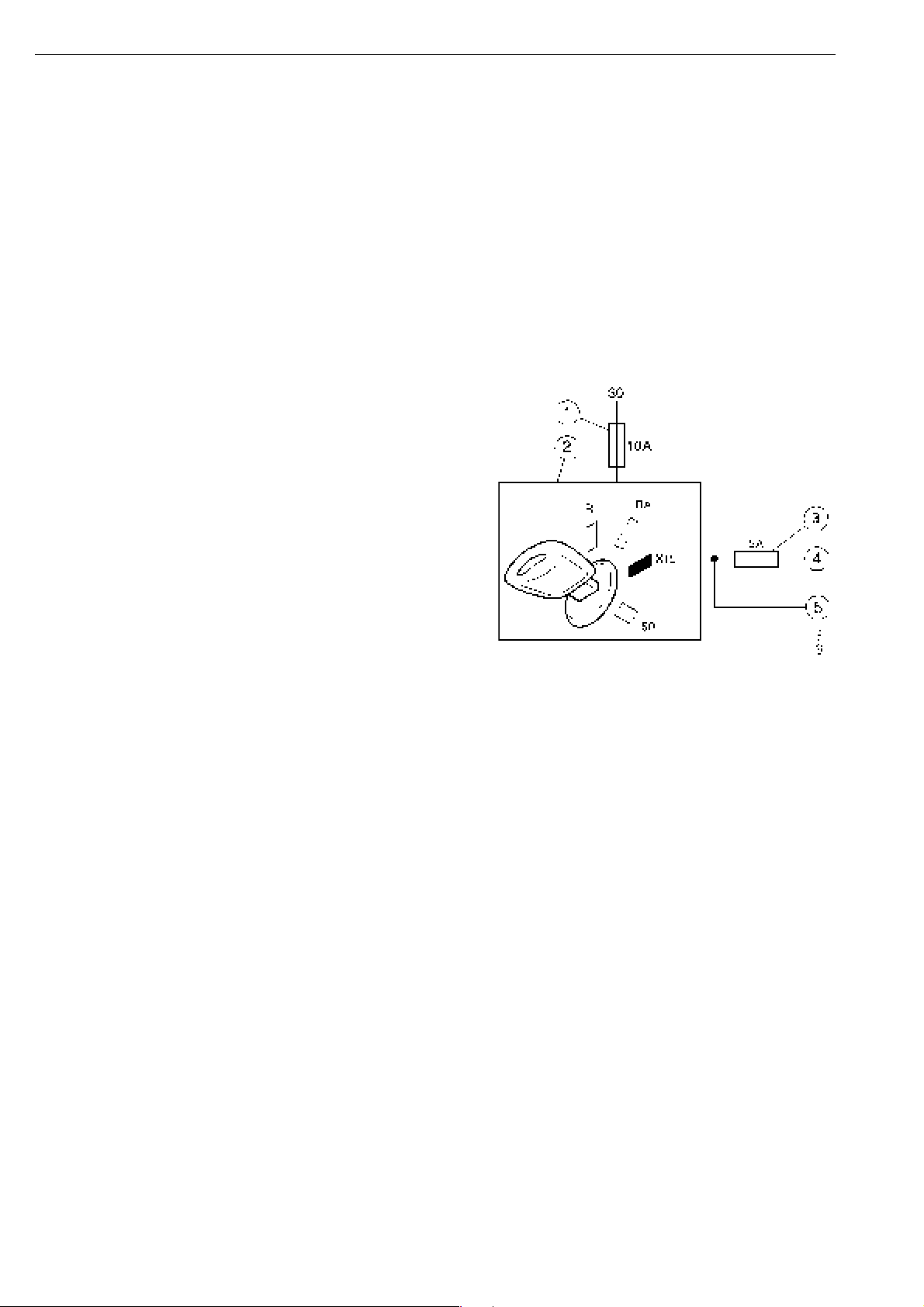

Activation of the control unit

For a control unit (ECU) to be able to receive

CAN messages, it must have a power supply

from the battery (30-supply), and an activation

signal. The control unit is in most cases

activated by the starter key being turned to the

drive position (15-supply).

The starter lock (2) receives voltage from the

30-supply via a 10 amp fuse (1).

An X15-supply runs from the starter lock to the

CAN buses' control units.

To reduce the risk that control units on the red

bus (5) lose the 15-supply due to a fault on the

green or yellow buses (4), the control units on

the latter buses are protected by an additional

fuse (3).

12

©

Scania CV AB 2005, Sweden

16:07-01

Page 13

Connector C483, which supplies the control

units on the yellow and the green buses with

15-supply, is mounted centrally under the

instrument panel (1). Connector C482, which

supplies the red bus with 15-supply , is mounted

under the central electric unit (2).

There are, however, control units which are not

activated by the 15-supply, for example:

- LAS, which is active when the truck is

locked.

- AUS, which is activated as soon as the key is

in radio position.

- ATA/WTA is only activated after a command

from CTS/ACC.

Vehicle internal time

The vehicle internal time is independent from

the time the driver can see and change on the

instrument cluster (ICL).

The vehicle internal time is sent as a message

from the instrument cluster to other control

units. The vehicle internal time is used for

recording times of fault codes which are

generated by the control units. The vehicle

internal time can only be changed using SDP3.

Where a vehicle is equipped with a tachograph

(TCO), the ICL synchronises the vehicle

internal time with TCO internal time. In this

case, the vehicle internal time is set using the

special instrument which is used for setting the

TCO.

16:07-01

©

Scania CV AB 2005, Sweden

13

Page 14

ECU settings

Scania manufactures vehicles with different

specifications. The vehicle model depends on

customer needs and requirements. For the

electrical system in a truck to work correctly,

the control units in the CAN network must be

adjusted so that they correspond to the vehicle

configuration (specification). For e xample, it is

crucial that the brake and suspension systems

are adjusted for the correct number of wheel

axles.

This adjustment is done during manufacture of

the vehicle, by setting a number of parameters

in the control units. These parameters, and

some other information, are written to a file

(the SOPS file), which is stored in COO and

ICL.

For some conversions, the SOPS file must be

changed if the vehicle is to function correctly.

The af fected c ontrol u nits ar e then se t using t he

updated SOPS file. It is possible to make minor

changes to the SOPS file, such as after

changing to a fuel tank with larger volume,

using SDP3. More advanced changes, howe ver ,

may require the SOPS file to be sent to Scania.

COO continuously checks that certain safety

critical control units have not been renewed. If

an ECU is renewed, the new one must be

loaded with the correct parameters from the

SOPS file. This can also be done using SDP3.

14

©

Scania CV AB 2005, Sweden

16:07-01

Page 15

Cable harness

With the introduction of the PRT series, Scania

has also introduced a new concept for earthing

electrical components. This concept will

provide more reliable and clearly arranged

earthing. Scania has also used a more limited

number of connector types for connections,

mainly for those connections located outside

the cab. The marking of the cables has also

been changed to make them more distinct.

Finally , the wiring diagrams hav e been changed

in a number of ways (see "Wiring Diagrams").

16:07-01

©

Scania CV AB 2005, Sweden

15

Page 16

Power supply

The power supply system contains mainly the

components and cables that handle high

currents.

On PRT series vehicles, the electrical path

between the alternator and the batteries is

shorter in comparison with the 4-series. The

main advantage of this is that the total voltage

drop from the alternator to the batteries is less,

which means that more power can be fed to the

batteries.

The power supply system supplies all other

systems with a voltage supply and earth. Thi s is

done via connections 15, 30, 12V/30, 12V/RA,

58 and 61. Each system may have one or more

connections.

The X designation is a new feature on the P, R,

and T series which has been introduced for

different cable functions. If a cable transmits

information, rather than a power supply, it is

marked with the pref ix X. The a cti v ation si gnal

for the CAN bus control units X15 and the

power supply in dri ve position 15 are examples

of this.

16

©

Scania CV AB 2005, Sweden

16:07-01

Page 17

Signal Function Type Direction Functional

source/destination

Physical

source/

destination

X15 Drive position Digital In Coordinator system Starter lock

X58 Relay Digital In Visibility system CUV

X61 Relay Digital In Visibility system CUV

XRA Radio Digital In Coordinator system Starter lock

XB Key inserted Digital In Coordinator system Starter lock

XRAARadio Digital Out Coordinator system Voltage

converter

XBA Key inserted Digital Out Coordinator system Central

electric unit

15 Drive position Voltage supply Out Other system Central

electric unit

30 Battery

voltage

12V/30Battery

voltage

12V/RABattery

voltage

Voltage supply Out Other system Central

electric unit

Voltage supply Out Other system Voltage

converter

Voltage supply Out Other system Voltage

converter

31 System

Earth - Other system

earthing

58 Parking lights Voltage supply Out Other system Central

electric unit

61 Charging

status

Voltage supply Out Other system Central

electric unit

Bodywork Voltage supply Out Bodywork interface

Tag axle lift Voltage supply Out Tag axle lift Junction

block

Visibility

Voltage supply Out Visibility system

system

Tachograph Voltage supply Out Tachograph system

Starter motor Voltage supply Out Starter motor

system

Junction

block

16:07-01

©

Scania CV AB 2005, Sweden

17

Page 18

Positive supply

The power supply system has been simplified in the Scania vehicle range.

The cable from the alternator P3 goes via the starter motor M1 and a junction block C41 to the battery

P1. (A service switch is also f itted before the battery in most cases.) A cable goes from junction block

C41 to junction block C55 which provides a supply for the central electric unit P2 and visibility

system VIS.

18

Schematic diagram of the power supply

©

Scania CV AB 2005, Sweden

16:07-01

Page 19

Moulded cables

Moulded cables are cables comprising several

individual wires with an inner and a common

outer sheath of polymer. The proportion of

moulded cables on the chassis is greater on the

PR T series than on the 4-series. This reduces the

risk of open circuits and short circuits caused by

chafed sheaths. Scania has also produced a new

range of moulded cables with thinner sheaths.

This is to make the cable harness in the frame

member easier to handle.

Note that the colours of the moulded cables do

not always agree with the colours of the

corresponding individual leads inside the cab.

16:07-01

©

Scania CV AB 2005, Sweden

19

Page 20

Earthing

20

The main earthing lines are the left-hand frame member, engine and gearbox block, and the cab

structure. To improve contact with the frame member, Scania has introduced a new earth bolt that is

pressed firmly into the frame member . Scania has also introduced special earthing points on the frame

for bodybuilders (G46 and G47).

Most of the components on and behind the instrument panel are earthed to one of the 21-pole earthing

blocks (G1-G5) that are distributed behind the instrument panel. From each of these blocks a common

cable runs to earthing points in the cab structure (G10, G14, G15). The earth cables are connected to

these earthing points with ring terminals. The most important components and the components

consuming most current are earthed directly to these earthing points. These earthing points can be

found e.g. in the roof and the lower part of the A-pillars.

©

Scania CV AB 2005, Sweden

16:07-01

Page 21

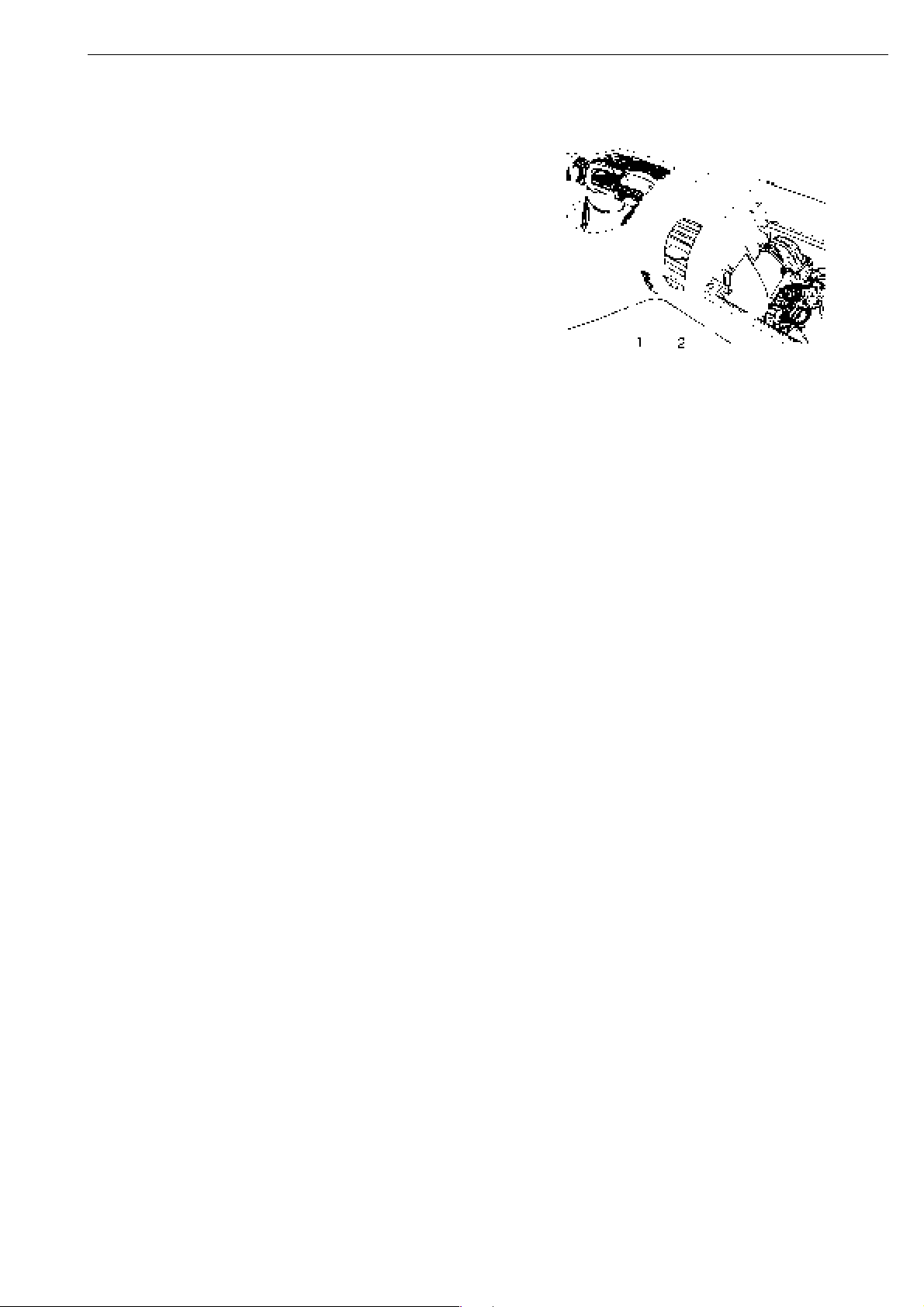

Fitting the frame earth bolt

A maximum of three ring terminals should be

connected to avoid an overload on the earthing

point. If you need to connect more ring

terminals, you must fit more earthing points.

Earth connection nut, part number: 815133

A maximum of three ring terminals may be

connected to each earth bolt. At least 1 turn of

the bolt thread should be visible on the

tightened joint. The earth connection nut is

tightened to 30 Nm using a hand tool.

Fitting the frame earth bolt

If the earth bolt has broken or provides a poor

contact with the vehicle, it must be renewed.

Contact is provided between the grooves in the

bolt and the frame member.

Note that the quality of the hole is crucial for a

good electrical connection. Therefore any rust

or paint in the hole must be removed before a

new earth bolt can be fitted.

The hole must be checked before a new earth

bolt is fitted, regardless of whether you are

using the old hole or drilling a new one. If the

hole is not within the tolerances, 14.2 mm

±0.1 mm, a new hole must be drilled.

If a new hole has to be made, it should be

drilled/reamed in stages up to the final

diameter.

It is important for the hole to be made at right

angles to the frame and for the hole to be as

cylindrical as possible.

16:07-01

©

Scania CV AB 2005, Sweden

21

Page 22

Drilling holes

The pre-drilled holes should be used whenever

possible.

If new holes have to be drilled closer to an

existing hole than the picture shows, the

existing holes should be welded closed, refer to

the Bodywork Manual.

IMPORTANT! It is not permitted to drill holes

in the frame flanges.

B B

A

C

B/2

D

B

D

A. Distance hole - frame flange should be at

least 3 x D and also at least 40 mm.

B. Minimum 4 x D.

C. Minimum 3 x D.

A

B

b129114

b129113

Holes are only to be drilled in the web of the

side members. The strength and service life of

the frame can be drastically affected by an

incorrectly positioned hole. The only

exceptions to this are holes drilled in the front

part of the frame and in the rear overhang in

areas where the loads are low.

22

©

Scania CV AB 2005, Sweden

16:07-01

Page 23

Hole diameter for earth bolt

NB! The hole must be within the tolerance

14.2 mm ±0.1 mm. If the hole is too large, the

contact surface will be too small and this will

result in too poor a connection.

The nut is tightened using a hand tool until the earth

bolt flange is in contact with the frame, but to a

maximum of 50 Nm. If the nut is tightened more than

this, there is a risk of the bolt breaking. If the earth

bolt can be tightened quite easily in the frame, this

indicates that the hole is too large. The grooves on

the earth bolt must be in good contact with the frame.

Frame earth bolt part No: 1743995

Flange nut part No: 815134

Check

The clearance between the earth bolt flange and the

frame should be a maximum of 0.2 mm. If the

clearance is greater than this, the hole is too small.

Tap out the bolt, ream the hole to the corr ect size and

fit a new earth bolt.

16:07-01

©

Scania CV AB 2005, Sweden

23

Page 24

Connectors

0

9

Four types of connectors are used for around 85% of all connections in the vehicles. These types

are:

MCP is used for all switches and most cable

joints in the cab. These have a number of

different codes. This reduces the risk of

2

2 1

1

incorrect connections when connecting cable

joints in the large cable harness in the cab.

DIN and Deutsch connectors. These are used

for most connections outside the cab.

MQS for connecting sensors in the cab

24

©

Scania CV AB 2005, Sweden

16:07-01

Page 25

CAN bus connection block

Some of the CAN bus connection blocks are

fitted with termination resistors. Renew the

connection block if the termination resistor is

faulty.

The middle row on the CAN bus connection

block is inactive. Do not connect any

equipment there.

16:07-01

©

Scania CV AB 2005, Sweden

25

Page 26

User functions

User functions are defined as "An electrical

function on the vehicle which a user, for

example a driver or mechanic, can experience

or affect".

A simple example of a user function is coolant

temperature which is shown in the instrument

cluster.

User functions are partially a new feature, as

we have not talked in terms of these before.

Most user functions are, however, "spread"

across several ECU systems, which differs

from the 4 series.

The ability to communicate between different

control units means that one ECU can use the

information coming from a sensor that is

connected to another ECU.

This, however, means that the cause of a fault

can be more difficult to find. If, for example, a

sensor gives incorrect information, the

information can be transmitted through the

system and generate fault codes in several

systems which use or forward it. To find the

source of a fault, the path of information

through the system should therefore be

examined. The possible information paths in

the system are described in different scenarios

which are called function diagrams.

A function diagram illustrates graphically how

the different systems interact during the event/

task. The horizontal lines illustrate signals and

events. The vertical lines are a time axis which

represents the ECU or component stated at the

top of the line.

Function diagrams are found under the tab with

the same name in the User Function view in

SD3.

26

©

Scania CV AB 2005, Sweden

16:07-01

Page 27

Function diagrams

Coolant temperature display: The engine control unit reads the value on the coolant temperature

sensor. The information is then sent via the coordinator to the instrument cluster.

©

16:07-01

Scania CV AB 2005, Sweden

27

Page 28

Wiring Diagrams

In SDP3, separate circuits are shown for each component connection. These are complemented in the

service literature with more detailed wiring diagrams which instead are shown complete per system.

Subdivision

The table below shows how the wiring diagrams in the service literature are subdivided and which

systems they cover. In general there is one wiring diagram for each defined system in the vehicle,

including the ECU system and the DEC system.

In some cases, one wiring diagram covers several different systems. The systems included are then

grouped under a common designation, known as a syst em family. See example 'AHS' in the table. The

AHS (auxiliary heater) system family includes the A TA (air to air auxiliary heater), WT A (water to air

auxiliary heater), CTS (auxiliary heater control unit) and SSH (short-stop heater) systems.

In many cases, there is not enough space for all the information on one system on one single wiring

diagram. The diagram is then divided into se v eral sheets. The sheet subdivision system can v ary from

system to system, dependent on the solution which is best for that system. Sheets can for example

show different vehicle configurations or different control unit variants for the same system.

Wiring

Diagram

ACL Central lubrication

AHS ATA - Auxiliary heater (Air to Air) SSH, short-stop heater

ALT Scania Alert

APS Compressed air supply

AUS Audio system Radio (Basic)

AWD All-wheel drive

BMS ABS - Anti-lock system

BWS Bodywork interface

CAT Electric cab tilting Crewcab

CBR Comm. broadcasting radio

CCS ACC - automatic climate control MCC, manual climate control

CEH 230 V socket

COO Coordinator

CSS Crash safety

Included in the ECU system Included in the DEC system

WTA - Auxiliary heater (Water to Air)

CTS - auxiliary heater control unit

EBS - Electronic brake system

28

DIS Adaptive cruise control

EEC Emission control

EMS Engine management system

©

Scania CV AB 2005, Sweden

16:07-01

Page 29

Wiring

Included in the ECU system Included in the DEC system

Diagram

FAS Hand-held computer for vehicle analysis

FHS Fuel preheating

GMS OPC - Opticruise

RET - Retarder

HVF Road toll registration

ICL Instrument cluster

INL Interior lamp

KIT Kitchen module

LAS Lock and alarm system MCL Central locking without alarm

MIA Rear view mirror adjustment

MIH Rear view mirror heating

MOP Mobile phone

POW Power supply

RDL Differential lock operation

REF Refrigerator

ROH Roof hatch

RTG Interface for vehicle data

RTI SVIP - Vehicle data

SCS Seat control system

SMS Suspension system

SUA Sun visor adjustment

TAL Tag axle lift

TCO Tachograph

VIS Visibility system - External lighting,

windscreen wipers/washers and horn

Flashing beacon. Headlamp level

adjustment

WIW Window winders

16:07-01

©

Scania CV AB 2005, Sweden

29

Page 30

Type

2

4

3

1

BMS T

ABS1

1 833 768

1/1

1. Information window

In the lower right corner of the wiring diagram there is a window with information which iden tif ies the

diagram. The system designation, the control unit designation (if required), sheet number and whether

the system applies to trucks or buses is stated in the window. At the bottom of the window there is (if

required) a chassis number limit.

Sometimes specific complementary information is required for a wiring diagram. Where required, this

is found translated into the relevant language above the picture of the wiring diagram in the display

tool.

30

©

Scania CV AB 2005, Sweden

16:07-01

Page 31

2. List of components

In the upper right corner of the wiring diagram the electric components shown on the diagram are

listed. Component codes and location in the diagram are specified.

3. Cable marking

PRT series wiring diagrams have all cables drawn.

Example of cable markings:

BMS212.GN-0.75 [P2:A-2]

• BMS: System designation. This is also marked on the physical cable in the vehicle, which means

that it is easy to identify the correct wiring diagram for a cable.

• 212: Serial number for the cable. This is also marked on the physical cable in the vehicle.

• GN: Colour marking, in this case green.

• 0.75: Cable area.

• [P2:A-2]: Address showing where the other end of the cable is connected. In this case: Pin A-2

on the central electric unit. As each cable is drawn in the diagram, address marking is only

provided if the cable is very long and difficult to overview.

Colour markings used:

BK Black

BN Brown

BU Blue

GN Green

GY Grey

OG Orange

PK Pink

RD Red

VT Violet

WH White

YE Yellow

16:07-01

©

Scania CV AB 2005, Sweden

31

Page 32

4. References

References to other diagrams can be given on the wiring diagram. If references apply to a diagram

which cov ers a different s ystem the sys tem name is giv en at the point where the cable ends (i. e. ICL).

If references apply to a different sheet within the same system, the sheet number is specified

alongside the component where it subdivides (i. e. See sheet 2).

In some special cases a longer reference description is considered to be required. Shorter sentences

can then be found on the wiring diagram, always only in English.

32

©

Scania CV AB 2005, Sweden

16:07-01

Page 33

16:07-01

©

Scania CV AB 2005, Sweden

33

Page 34

Central electric unit

The central electric unit (P2) distributes power

to other systems and functions in the vehicle.

Each connection is normally protected by a

fuse and receives power supply via relays in the

central electric unit.

The central electric unit is also numbered

underneath. For connection of accessories,

please refer to the Bodywork Manual.

34

A table showing the location and numbering of

the fuses and relays is pr ovided inside the cover

of the central electric unit.

©

Scania CV AB 2005, Sweden

16:07-01

Page 35

Repairing cables

116952

Tools

Number Description Picture

588 200 Cable stripper

588 207 Crimping tool

588 220 Stripping tool

587 602 Hot air gun

00:1421

You should avoid splicing a cable wherever possible. Each joint is a weak point and possible source

of faults. Damage may however occur on the cable harness and components. In order to avoid

renewing the entire cable harness, it may be necessary to splice a single cable.

1 Use Scania Diagnos to find the defective cable or circuit.

2 Adjust the cable length so that the joints can be positioned where the cables are straight and

protected.

3 Splice on a new cable or component. Use a multimeter and Scania Diagnos to make sure that

there are no open circuits or short circuits in the cable harness.

©

16:07-01

Scania CV AB 2005, Sweden

35

Page 36

Work Description

1 Remove any defective component from the vehicle.

2 Release the cable and clean dirt and grease from it.

3 Mark on the cable where the centre point of the joint should be. It is preferable to place the joint

between two cable retainers.

Note: Remember to add measurement A to the marked centre point so that the cable from the control

unit will not be too short.

4 Cut the new cable as illustrated below. Add measurement B to the marked centre point.

2 wire cable

4-wire cable.

The charge air pressure and temperature sensor and oil pressure sensor have 4 wire cables

36

©

Scania CV AB 2005, Sweden

16:07-01

Page 37

5 Strip the cables using stripping tool 588 220. See illustration. Make sure that you do not damage

the cable insulation.

16:07-01

©

Scania CV AB 2005, Sweden

37

Page 38

6 Cut the cable as illustrated below. The centre line in the illustration is the mark on the cable.

7 Locate the joints on the wires as illustrated below.

8 Strip off 7 mm of the insulation from the ends of the cables with cable stripper 588 200.

2 wire cable

4 wire cable

38

©

Scania CV AB 2005, Sweden

16:07-01

Page 39

IMPORTANT! The joint must be sealed so that no moisture can penetrate.

9 Fit 40 mm long shrinking tubing on each wire.

10 Fit shrinking tubing which is approximately 30 mm longer than the joint on the cable. Two

shrinking tubings are used for 4-wire cable.

11 Clamp on the sleeves using crimping tool 588 207.

12 Heat the sleeves with a hot air gun e. g. 587 602 so that adhesive is forced out from the ends of

the cables.

After the sleeves have been clamped on, the sleeves should be heated until adhesive is forced out.

13 Fit the wire shrinking tubing over the sleeves and heat it so that adhesive is forced out.

14 Fit the wire shrinking tubing over the entire joint and heat it so that adhesive is forced out.

15 Refit the cable. One of the rubber teeth in the cable retainer may have to be cut off if a new

component has been fitted.

16:07-01

©

Scania CV AB 2005, Sweden

39

Page 40

Troubleshooting

Troubleshooting using SDP

A PC-based diagnosis and programming tool is

available for troubleshooting the ECU systems

(SDP3). To be able to use SDP3 on a vehicle, an

interface (VCI) and a hardware key (USB

dongle) are required.

Unlike the 4-series, the VCI is now connected

directly to a CAN bus (the green CAN bus). The

VCI that is needed is called "VCI 2" and will

only work on the PRT series vehicles. Refer also

to the user instructions for SD3.

40

©

Scania CV AB 2005, Sweden

16:07-01

Page 41

Vehicle-based troubleshooting

IVD (In-vehicle Diagnostics) is the designation

of Scania's vehicle-based troubleshooting. To

make it easier for the driver to describe a fault

on the vehicle when he/she speaks with a

workshop or to Scania Assistance, fault codes

can be read in the vehicle display on the

instrument cluster (ICL).

It is only possible to read fault codes when the

vehicle is stationary.

1 The designation on the control system

which generates the fault code for the case

shown in the picture is the EMS.

2 The fault code number is 37 in the example

shown.

3 The part number of the control unit which

generated the fault code is 1120511 in the

example shown.

4 The number of times a fault with the

specified fault code number has occurred is

19 times in the example shown.

5 The snowflake in the bottom right-hand

corner indicates that the fault code was

active when it was retrieved from the

control unit.

16:07-01

©

Scania CV AB 2005, Sweden

41

Page 42

Troubleshooting the CAN cables

CAN communication is well tried and designed

to withstand interference. To reduce the risk of

interference, the CAN cables are twisted. This is

because the system reads voltage differences

between the cables to determine whether it is a

1 or a 0 and if the same interference is affecting

both cables, there will be no difference. The

greater the distance between them, the greater

the risk that one cable will experience more

interference than the other.

Example of a CAN network

42

©

Scania CV AB 2005, Sweden

16:07-01

Page 43

Note: In order to measure resistance in the

CAN cables, the power in the electrical

system must be switched off. No systems

must be disconnected.

As the voltage between CAN H and CAN L

varies continuously depending on whether a

"one" or a "zero" is being sent, the CAN

communication cannot be checked by

measuring with a multimeter. It is, however,

possible to check whether the termination

resistors are intact.

There must be two termination resistors on

each bus for the CAN communication to

function. The termination resistor can either be

"split termination" or a single resistor.

Split termination is a type of termination

resistor which is also a filter that removes high

frequency interference. Split termination

consists of two resistors which are fitted one

after the other on the cable. There is a capacitor

between the resistors which is connected to

earth. The capacitor allows all alternating

currents above a specific frequency to pass

through, which means that these are eliminated.

Connection bl ock with termination re sist or s

The integrity of the termination resistors can be

checked by measuring the resistance between

CAN H and CAN L using a multimeter. The

measurement should be made on the connector

for each CAN bus. One measurement probe is

held against one of the white cables' contact

pins, and the other measurement probe is held

against a contact pin of the other colour. The

resistance on each CAN bus should be

60 ohms. If it is 120 ohms this means that a

termination resistor is missing. If it is 40 ohms

or 30 ohms, this means there are one or two

termination resistors too many on that CAN

bus.

16:07-01

©

Scania CV AB 2005, Sweden

43

Page 44

Things to be considered ...

Note: Always measure on the rear of the

connector.

• Never fit a fuse with a higher amperage than

permitted. The fuse is dimensioned for the

electrical system and its components.

• Avoid changing a fuse when the power

supply is still connected to it. This is to

avoid burns in the fuse holder.

• Always try to carry out voltage tests on a

connector from the rear of the connector.

This avoids damaging the pins and you do

not need to disconnect the connector

unnecessarily. A connector which has been

frequently disconnected can, in time, give

rise to a loose contact.

IMPORTANT! If a connector to a currently

active electronic control system is disconnected,

fault codes are often generated. Therefore

remember to check that no new and misleading

fault codes have been generated after

troubleshooting and repair.

44

©

Scania CV AB 2005, Sweden

16:07-01

Page 45

• When you are searching for an open circuit

between connectors, the following applies:

Never make a hole in a cable which is

located outside the cab to check whether it

is live. Moisture and salt can penetrate even

a very small hole and in time the cable will

form verdigris within the insulation. Such

an open circuit is almost impossible to see.

It is better then to cut the cable and make a

waterproof joint afterwards.

WARNING!

!

Never cut a wire with several internal leads

when it is live. There is a risk of a short

circuit which can result in personal injuries

and costly consequential damage.

16:07-01

©

Scania CV AB 2005, Sweden

45

Page 46

• Do not use a test lamp with an LED to

check whether there is a voltage to

components such as lamps, magnets,

motors, etc which are operated with

24 volts. A bad earth connection to the

circuit concerned is enough to switch on an

LED which then gives an incorrect result.

A test lamp fails to come on or comes on at

a very much reduced output in such a test.

The electrical system and components

should be checked using a multimeter.

46

©

Scania CV AB 2005, Sweden

16:07-01

Page 47

• Troubleshooting in electronic control

systems requires access to a multimeter

and/or PC with the Scania Diagnos

program.

• Electronic control systems generally store

a fault code in their control unit. The fault

code can be read off using Scania Diagnos.

It is generally possible to locate faults and

test various components relatively easily

using Scania Diagnos.

• Control Area Network, CAN

Certain electronic control systems operate

in networks with other control units and

components, CAN communication.

In electronic control systems which use

CAN communication, Scania diagnostic

tools should primarily be used for

troubleshooting.

16:07-01

©

Scania CV AB 2005, Sweden

47

Page 48

Short circuit

There are different types of short circuits:

• Short circuit to earth on live cables.

This often results in a fuse blowing or a

function being absent and a fault code is

generated in an electronic control system.

• Short circuit to earth on an earth circuit.

E.g the cable to the brake lamp switch is

earthed because a screw is screwed through

the cable. Normally that cable is earthed

via the brake lamp switch. The short circuit

does not cause any fuse to blow in this

case, but fault codes can be generated in an

electronic control system. Also different

electronic control systems can lose

functions since several functions are

required at the same time. These faults are

more difficult to find and it is necessary to

understand how the electronic system

operates.

48

©

Scania CV AB 2005, Sweden

16:07-01

Page 49

• Short circuit from one live circuit to

another circuit which is not currently live.

These types of short circuits can occur

because, for example, a screw is screwed

into a cable with several leads, or there is a

contact condition between two pins in a

trailer connection, so that normal lighting

turns on the direction indicator, activates

the tilt function on a connected tipper, etc.

These short circuits do not necessarily

cause any fuse to blow, but fault codes can

be generated in an electronic control

system.

Checking for a short circuit

Live cables

• Switch off the power or remove the

relevant fuse from the vehicle.

• Measure the resistance between the fuse

output and earth. If you touch the cable

harness at the same time as you study the

reading, a circuit in working order should

show a stable and infinite reading on the

multimeter. If the reading on the

multimeter is zero or if low resistance is

measured, this indicates a short circuit.

• To locate where in the cable the fault lies,

move the measuring probe to the next

section of the cable at the same time as you

disconnect the previous section.

Earth circuit

• Proceed in the same way as when checking

live cables, b ut you now kno w that the fault

is after the load (lamp) but before the

control ('make' contact).

16:07-01

©

Scania CV AB 2005, Sweden

49

Page 50

Open circuit

When there are open circuits in cables, the

fuses generally do not blow. What is known as

a current spike may be generated by this if the

cable or lead is loaded just when it is pulled,

torn or cut off. Then a fuse may blo w but when

a new fuse is fitted it will hold, since there is no

longer any load there.

Fault codes are however often generated in

electronic control systems when there is an

open circuit on their cables. This is because

electronic control systems often keep watch

and communicate with their components.

Checking for an open circuit

Measuring the resistance

• Switch off the power in the vehicle

• Measure the resistance, e.g. from the fuse

holder and out towards the load. If the

multimeter shows zero or a low value, the

cable is intact.

Measuring voltage

• On a cable with battery voltage you can

locate the break by starting measuring from

the beginning of the cable, and then

gradually moving "backwards". The cable

always has battery voltage up to the break.

50

©

Scania CV AB 2005, Sweden

16:07-01

Page 51

Voltage dr op

When resistance testing the cable in a currently

load-free circuit, you can obtain a misleading

measurement result which indicates that the

cable and its connections are OK.

Example:

A work lamp is not working. You remove the

bulb and measure directly in the bulb holder

(does not apply to a gas discharge light source).

There you obtain a value of 24 volts and think

that it was the bulb that was defective. But it

still does not work with a new bulb.

You measure the cable resistance and obtain a

value which indicates that the cables and their

connections are OK.

This is a misleading measurement result. With

such a measurement, the load on a cable is so

low that it is suff icient if just one copper wire in

the cable is intact or the connection is quite

poor to obtain a correct measurement result.

Under load, howeve r, the conducti vity becomes

much too poor and the bad cable or connection

then functions as a large resistance and a

voltage drop occurs. The greater the load the

greater the heat released at the voltage drop

point.

In the above case you should measure the

voltage across the lamp, directly on the input to

the bulb holder. If the multimeter shows

24 volts, the contact resistance is located in the

bulb holder. If the measurement shows a low

voltage, this is due to poor earthing or a voltage

drop before the lamp.

Generally, a voltage drop is checked with the

positive cable of the multimeter on the supply

side of the measured component, and the

negative cable closer to the load, across the

load, etc. When the circuit is activated, the

voltage difference is visible. If the circuit is

OK, the voltage drop should be a maximum of

1 Volt.

16:07-01

©

Scania CV AB 2005, Sweden

51

Page 52

Earth fault

Earth faults in the light circuits or circuits with

warning lamps are frequently recognised

because the lamps do not come on at full

output.

Check using the same method as for a voltage

drop.

Good earth connection to the multimeter.

Correct voltage to L1, but the lamp is glowing

faintly.

52

©

Scania CV AB 2005, Sweden

Good earth connection to the multimeter.

Faulty earth connection to L1. The multimeter

shows a low value and the lamp L1 is glowing

faintly.

16:07-01

Page 53

A good earth connection is always dead.

Always make sure that there is a good earth

connection to the test equipment.

Good earth connection to the multimeter and

L2. No multimeter reading.

16:07-01

Faulty earth connection to L1 and multimeter.

L1 glows faintly and the multimeter shows a

low value. This gives a misleading voltage

value for L1.

©

Scania CV AB 2005, Sweden

53

Page 54

Earth faults often result in circuits which have no

common connection apart from the earth

connection quite suddenly having an effect on each

other.

If a common earth point for several different

components comes loose, e.g. from the chassis, the

current will be conducted to the nearest earth

point.

Earth faults in electronic control systems do not

always generate fault codes.

Examples 1 and 2:

Example 1

An earth bolt comes loose but is still held in the

ring cable terminal connectors of other circuits.

Now the current cannot be conducted to earth as

intended but the current is conducted to another

earth point. Then the current is conducted back

into another circuit and in this way circuits are

affected by each other, which they normally are

not.

1. Current via switch, through lamp, to earth

point, faulty earth point, on to motor, back

through the motor, to output on switch, on to lamp

and earths through the lamp and its earth point.

This means that the lamps are glowing and the

motor runs slowly and in the wrong direction.

Example 2

2. Current via switch, through lamp, to earth

point, faulty earth point, on to relay , back thr ough

the relay, to output on switch, on to lamp and

earths through the lamp and its earth point. This

means that the relay operates and the motor is

running at full output, but the lamps are glowing.

54

©

Scania CV AB 2005, Sweden

16:07-01

Page 55

Communication problems on the CAN buses

Most functions in the vehicle are controlled via a network of control units. There are many

advantages with the new electrical system, e.g. performance, safety and a reduced number of cables.

Compared with conventional DEC systems, the use of CAN communication involves to some extent

thinking in new ways when troubleshooting.

It is normally very easy to troubleshoot in the network and rectify the fault using the Scania

diagnostic tool.

In some cases faults may occur which can be difficult to diagnose and rectify using SDP3. You must

then remember that the faults occurring in one function may originate in a component which

according to old ingrained ways of thinking should not have anything to do with the function. The

previous self-evident relationships between fault symptoms and the cause are no longer so selfevident. The symptoms which arise as a result of a specific fault may also vary depending on how

different vehicles are specified.

Examples are provided below of faults which can cause you, the mechanic, a lot of problems and of

ways in which you can carry out troubleshooting on the CAN cables. This is not a comprehensive

guide on how to tackle the obstacles which arise when there are problems with communication. They

do, howev e r, provide examples of how to approach the search for the causes of faults in the electrical

system.

Before you start troubleshooting, you should have determined whether the fault occurred in

connection with some other acti vity, e.g. connecting bodywork, installing accessories, etc. or whether

it just occurred for no apparent reason.

16:07-01

©

Scania CV AB 2005, Sweden

55

Page 56

For tro ubleshootin g you need

• SDP3 + VCI

• Measurement adapter kit 99511

• Multimeter

• Chart of the location of the control units on

the CAN buses (see page 64).

• Fault code descriptions.

If SDP3 has not identified any control units,

you will not obtain any fault code description

in the program. This can be resolved by going

to the SDP3 menu under "view" and "search

for fault codes". There you can obtain a list

with fault code descriptions for each

supplementary number. You can find the

supplementary number via the diagnostics

position (IVD) on the instrument cluster (ICL),

provided that the instrument can establish

contact with the control units and that there are

fault codes present. However, the instrument

cluster always shows which systems it expects

to receive a response from, i.e. which systems

are fitted on the vehicle. If there are no fault

codes, the instrument will respond with "no

errors" and if the instrument cannot establish

contact it will respond with "no contact".

56

In this case, however, it is not the fault codes

that are most important, since it is the

communication we want to test. If the

instrument cluster responds with "no errors",

this means that communication is working.

Systems such as CTS, ATA, WTA and AUS

must be running in order to establish contact

with them

©

Scania CV AB 2005, Sweden

16:07-01

Page 57

No communication on the green CAN bus

Open circuit or short circuit

Result: The diagnostic program is blank.

SDP3 cannot identify a SOPS file (see ECU

settings) when communication with COO is not

running. This means that you cannot see directly

which control units are fitted on the vehicle

either. In order to trace which systems are fitted,

you need to use the vehicle-based troubleshooting

(IVD) in the instrument cluster (ICL).

ICL gives fault code 104 for a communication

fault with the crash safety system (CSS). This is

because CSS is the only control unit on the green

bus for which there are fault codes in ICL. If the

vehicle is not fitted with CSS, ICL will not then

display any fault codes.

In the diagnostics position (IVD) on the

instrument cluster, you can scroll through a list of

the systems which have control units in the CAN

network on the vehicle. If you try to read the fault

codes, the instrument responds with "no contact"

for all control units which are on the green bus,

even if you in this situation do not know which

are included on that bus. W ith the aid of the chart

on page 64 you can see that it is only the control

units located on the green bus which are not

responding. In the instrument cluster it is also

possible to see which fault codes are generated by

the other systems. However, at present ICL

cannot read fault codes from TCO.

16:07-01

©

Scania CV AB 2005, Sweden

57

Page 58

From the information you now have, you can

reach the conclusion that there is no open

circuit on the green bus, e.g. in the diagnostic

socket, nor is there a fault on the cable between

VCI and the diagnostic socket, but that there is

a fault on the bus itself. An open circuit

towards the diagnostic socket would mean that

the instrument cluster (ICL) should be able to

communicate with the green b us whereas SDP3

would not be able to communicate with the

vehicle at all. You can also obtain information

about the status of the communication on the

VCI lamps (see user instructions for SD3). On

low-specification v ehicles without an y systems

on the green bus, ICL will not have any control

unit to communicate with so the chart showing

the location of the control units on the buses

becomes even more important. You will not

always know for certain whether there are any

systems on the green bus. The instrument

cluster always shows which systems the vehicle

is equipped with, and also therefore which are

expected to respond. At the moment, however,

the instrument cluster cannot communicate

with TCO.

• Check that the resistance betwee n the CAN

cables and chassis earth is high enough. It

should be several thousand ohms or more.

• If there is a fault, disconnect the CAN

block for the green bus and measure via it

to find out which section of the bus the

fault is on.

• Disconnect the control unit concerned so

that you can distinguish between faults in

the control unit and cable faults. If there is

a cable fault - carry out troubleshooting on

the cables.

Troubleshooting and remedial action

SDP3 cannot establish contact with the vehicle

• Check VCI - indicator lamps will indicate

its status. Try to start the program again.

• Can ICL communicate with systems on the

green bus - if it ca n, the fault is in VCI or a

fault in the connection to the vehicle or in

the CAN block (C479) for the green bus.

The CAN blocks are concealed on the right

of the central electric unit area.

• On low-specification vehicles, it is not

certain whether there will be any systems

on the green bus. Check with ICL which

systems are available and compare with the

CAN bus chart (page 64).

• Check the voltage level in relation to

chassis earth on the green CAN bus. The

value should be approximately 2.5 V.

58

• Check that the termination resistance on

the CAN cable between CAN H and CAN

L is 60 ohms. All systems must be

connected and the vehicle should not be

supplied with voltage when measuring.

©

Scania CV AB 2005, Sweden

16:07-01

Page 59

Measuring voltage on the CAN bus.

It is not possible to measure the voltage in the

CAN bus and see whether it varies in the circuit!

The multimeter only measures the a verage value

for the CAN bus voltage level and this can

provide enough information to assess the

electrical status of the CAN bus. When it is

active, CAN H rises to approximately 4 V and

CAN L falls to approximately 1 V. This happens

so quickly that you cannot see this on a normal

multimeter. The average value shown on the

multimeter should therefore be approximately

2.5 V relative to chassis earth.

16:07-01

©

Scania CV AB 2005, Sweden

59

Page 60

Coordinator no t supplied with power or malfunctioning

For tro ubleshootin g you need

• SDP3

• Multimeter

• Chart of the location of the control units on

the CAN buses.

• Fault code descriptions.

• Measurement adapter kit 99511. To avoid

damaging the pins on COO and BWS, you

should use the measuring adapter with its

cable. No measurement should be carried

out directly on the pins because they are

very fragile.

60

©

Scania CV AB 2005, Sweden

16:07-01

Page 61

Symptom

If a coordinator is malfunctioning or not

supplied with power, this will result in a

stoppage.

SDP3 only shows the control units which

respond on the green bus. When SDP3 cannot

establish contact with the coordinator or with

ICL, you cannot obtain a SOPS file or see which

control units should have responded, or obtain

any circuits on those that have responded.

CTS, ATA, WTA and AUS must be activated so

that the diagnostic tool can establish contact

with them.

Fault codes in the systems on the green bus can

be read.

You can check which systems it has established

contact with in the diagnostics position (IVD)

on the instrument cluster (ICL). You can also

read fault codes from these systems. In this case,

however, it is not the fault codes that are most

important, since it is the communication we

want to test.

16:07-01

©

Scania CV AB 2005, Sweden

61

Page 62

Troubleshooting and remedial action

SDP3 only establishes contact with systems on

the green bus and ICL only with systems on the

yellow bus.

• Is fuse 19 intact and is there voltage to it?

• Check using measuring adapter 99508

whether the coordinator (COO) is receiving

voltage to pin connection 3 (30-supply), 81

(15-supply) and the earth on pin 5.

• If there is voltage to the control unit,

connect it and test again (there may be a bad

contact in the connector).

• If the fault disappears, inspect the relevant

pin in the connector and renew it if

necessary.

• If the fault remains, test with another control

unit.

62

©

Scania CV AB 2005, Sweden

16:07-01

Page 63

Earthing problems on control units

Systems which appear to be strange, without

showing an y obvious faults durin g simple tests,

which result in inexplicable problems when

driving or using the system in some other way,

can often be assumed to have earthing

problems.

If the vehicle appears strange when used, but

without any evident faults and without

generating fault codes which can be directly

related to the problems, it may be advisable to

check the voltage le vel on the CAN buses. W ith

a normal multimeter, the level should be

approximately 2.5 V. An unreasonably high

voltage indicates that one or more control units

on this bus have problems with the earth

connection. It is difficult to specify what should

be regarded as an unreasonably high voltage,

but if you measure a higher value than 5 V, this

may indicate that there is a defective earth

connection in the circuit.

• Check by measuring the voltage drop on

the control unit earth. Measure from the

control unit to a safe earth, for example,

one of the cab earthing points. Correct

earthing results in no or very little voltage

drop.

Troubleshooting

• If SDP3 is working, check the fault codes.

Special attention should be paid to the

inactive codes which are due to problems

with low voltage. If SDP3 is not working,

try to read the fault codes from ICL.

• If a control unit has a fault code for a low

supply voltage, measure the input voltage

and check its earth connection by, for

example, measuring the voltage drop on

the earth lead.

• If there are no fault codes visible, try to

measure the voltage on the CAN bus. The

multimeter should show approximately

2.5 V.

• If the fault is not currently active, try to

recreate it while the above measurement is

in progress. Use the multimeter memory

function, if applicable.

• If the multimeter shows an unreasonably

high value, more than 5V, this may indicate

earthing problems on one or more ECUs in

the bus being measured.

©

16:07-01

Scania CV AB 2005, Sweden

63

Page 64

With drive position on and the systems active, you can measure as follows.

Diagram 1

This measurement is carried out to make sure that the corr ect volta ge is sup plied to the component. If

it already shows low, you must check the battery voltage. The control units may have fault codes for

low supply voltages.

Measurement 2a

If the result is as abo ve, the pr o blem is in the connection. This is very unusual on contr ol units located

in the cab but occurs in bulb holders. It is easy to see if there is a problem on a lamp but it is very

difficult to measure on a control unit. It is necessary to rely on fault codes. If, however, the

measurement gives, for example, 21V and measurement 1 gives 24V, the fault is in the earth cable.

64

©

Scania CV AB 2005, Sweden

16:07-01

Page 65

Figure 2b

Voltage drop across the earth cable. The cause is often in the connection to the chassis. The

multimeter should, of course, be connected to a safe earth. If the circuit is OK, the voltage drop

should be a maximum of 1 V.

16:07-01

©

Scania CV AB 2005, Sweden

65

Page 66

ECU chart

Location of the control units on the C AN buses

The above figure is an overview of the location of the control units on a basic specification vehicle

when the R series was introduced. The specification and location may vary between vehicles and

development stages.

Termination resistors in the CAN circuits

CAN Red Yellow Green

Termination resistor: 1 COO TCO*COO

Termination resistor: 2 EMS APS CTS*

There should be two termination resistors on each CAN bus. The control units in the table have

integrated termination resistors. *If one of the marked control units is missing in a specific vehicle

configuration, the integrated termination resistors in the control unit are replaced by a termination

resistor located in the CAN bus connector.

66

©

Scania CV AB 2005, Sweden

16:07-01

Page 67

Abbreviations

There are a large number of abbreviations for functions and components in the PRT series

documentation. The most commonly occurring abbreviations and what they stand for in English are

shown below.

• AHS:- Auxiliary Heater System

• AHS (CTS):- Clock and Timer System

• AHS (ATA):- Auxiliary Heater (Air to Air)

• AHS (WTA):- Auxiliary Heater (Water to Air)

• APS:- Air Processing System

• AUS:- Audio System

• BMS:- Brake Management System

• BWS:- Body Work System

• CCS:- Climate Control System

• CCS (ACC):- Automatic Climate Control System

• CSS:- Crash Safety System

• COO:- Coordinator System

• EMS:- Engine Management System

• GMS:- Gearbox Management System

• ICL:- Instrument Cluster System

• LAS:- Locking and Alarm System

• ROH:-Roof Hatch

• RTG:- Road Traffic informatics Gateway (FMS-interface)

• RTI:- Road Transport Informatics (PC on board)

• SMS:- Suspension Management System

• TCO:- Tachograph Systems

• VIS:- Visibility System

• POW:- Power supply

• INL:- Interior Light

• WIW:- Window Winder

• RDL:- Rear Diff Lock

16:07-01

©

Scania CV AB 2005, Sweden

67

Page 68

• ACL:- Automatic Central Lubrication

• MIH:- Mirror Heating

• MIA:- Mirror Adjustment

• ECU System:- A set of components such as sensors, actuators etc which includes an ECU

connected to the CAN bus

• DEC:- Discrete Electrical Circuit ( No ECU, or ECU not connected to the CAN bus)

• FC:- Function Category

• UF:- User Function

• UC:- User Case

• Scenario

• MSC:- Message Sequence Chart

• SIF:- System Internal Function

• (UF requiring no CAN information)

• DF:- Distributed Function

• (UF implemented by several systems)

• DSW:- Direct Signal Wiring

• (Conventional ECU interaction)

• SOPS:-Scania On-board Product Specification

68

©

Scania CV AB 2005, Sweden

16:07-01

Page 69

69

©

Scania CV AB 2005, Sweden

16:07-01

Page 70

70

©

Scania CV AB 2005, Sweden

16:07-01

Page 71

71

©

Scania CV AB 2005, Sweden

16:07-01

Page 72

72

©

Scania CV AB 2005, Sweden

16:07-01

Loading...

Loading...